Magnetic pulse asymmetric magnetic collection device for special-shaped pipe fitting

A special shape, asymmetric technology, used in non-electric welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of inability to implement effective welding, increase in impact speed, etc., to reduce mechanical stress and thermal stress, improve durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention will be further described below in conjunction with the accompanying drawings

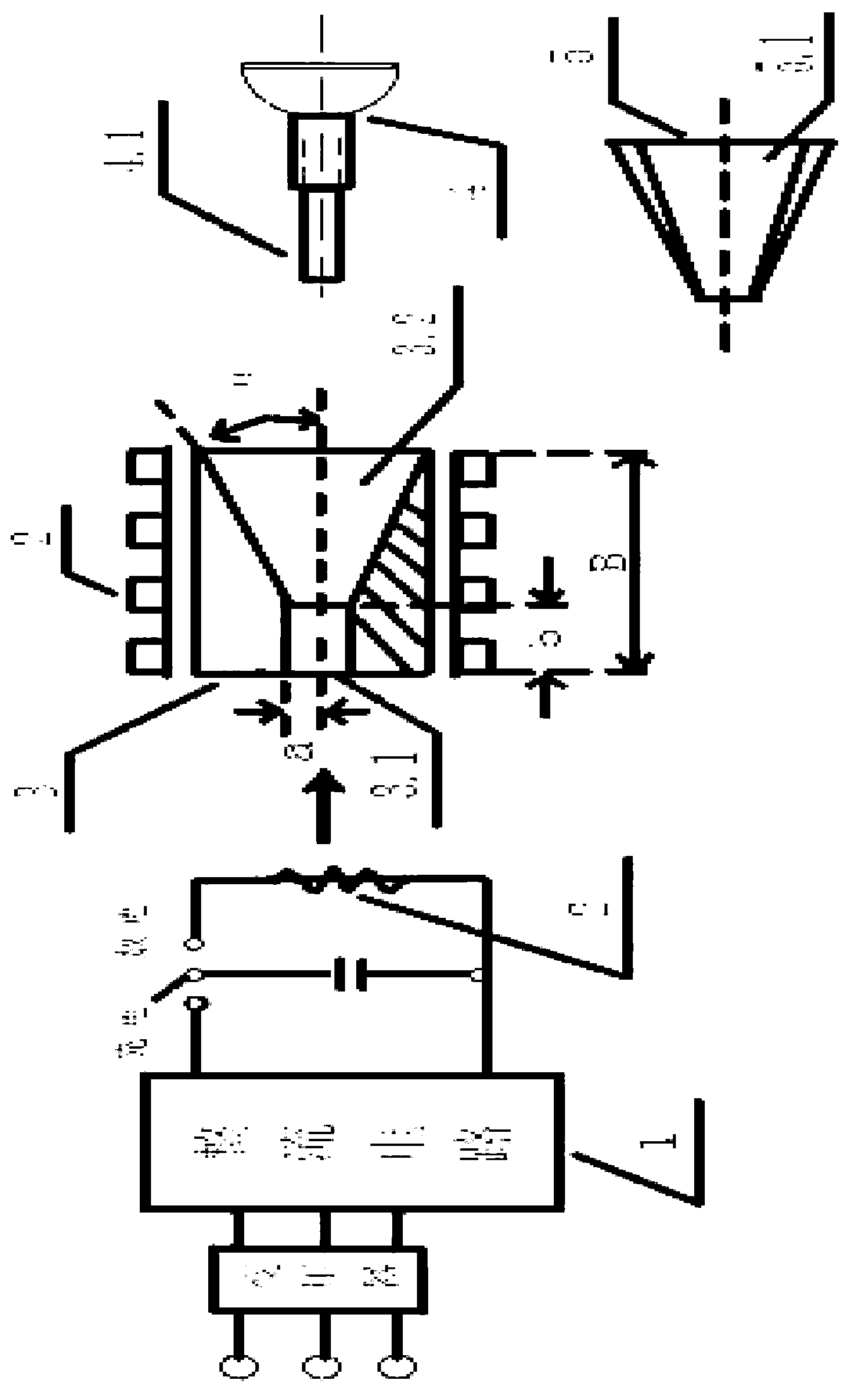

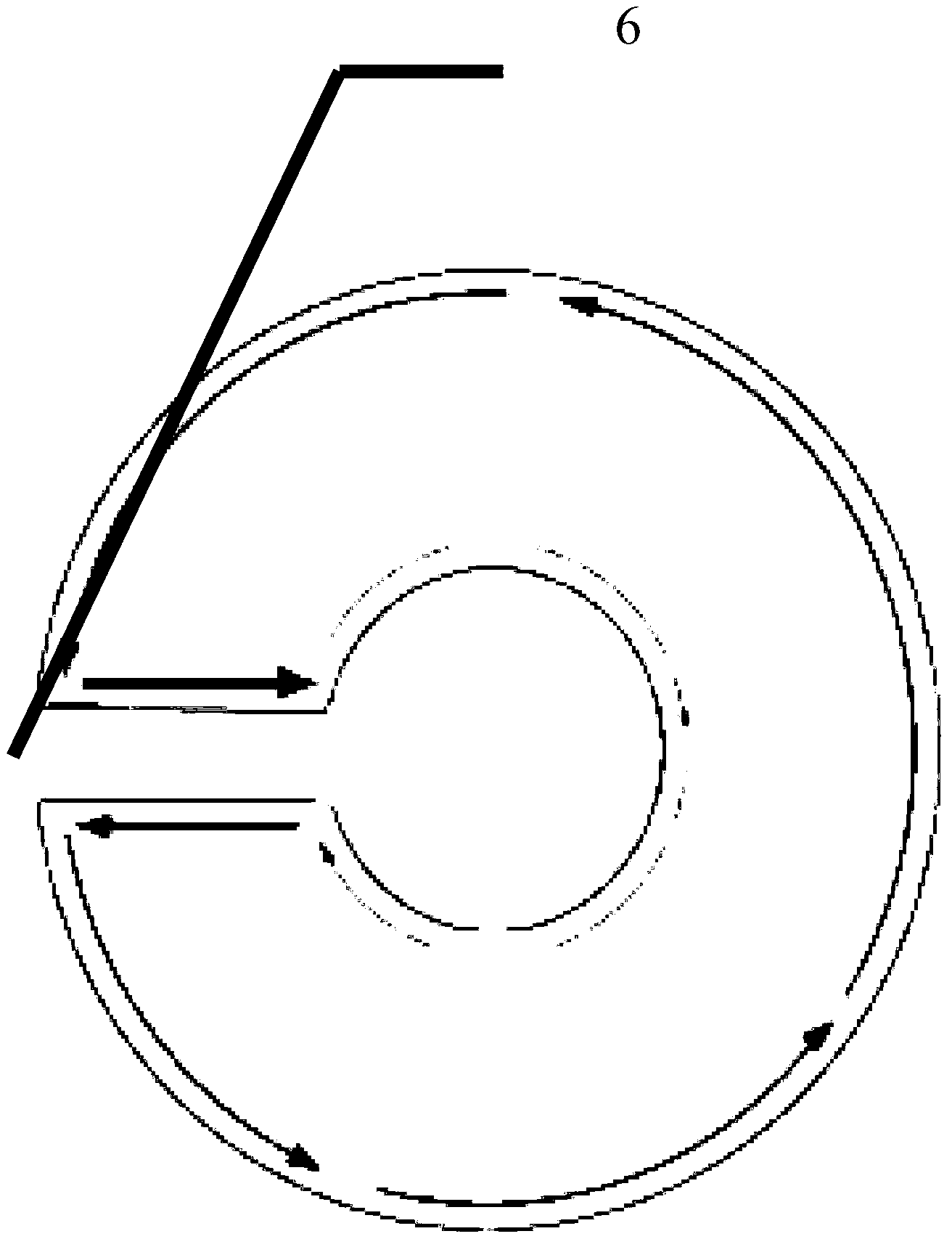

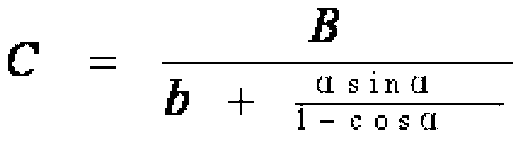

[0021] refer to figure 1 , the shape of the special-shaped pipe fittings is a whole of cylindrical pipe fittings connected to an umbrella-shaped structure. The characteristic of the asymmetric magnetic collector is that it is different from the symmetrical magnetic collector whose working area is located in the middle. The working area 3.1 of the asymmetric magnetic collector is located in the magnetic collector. left side. The asymmetrical magnet collector uses a copper column with a length of B as the material. A cylinder with a radius a and a length b is taken out from the left side, and a frustum-shaped inner cavity 3.2 is taken out from the right side. Finally, a guide needs to be opened on the copper column. The flow groove 6 and the flow guide groove 6 are grooves formed after cutting from the outer surface of the copper pillar to the axis of the copper pillar along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com