Circular tube centering flexible clamp for magnetic pulse welding

A flexible fixture and magnetic pulse technology, applied in the field of mechanical processing and manufacturing, can solve the problems of single function, heavy tooling and fixture, and inability to adapt to flexible manufacturing, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

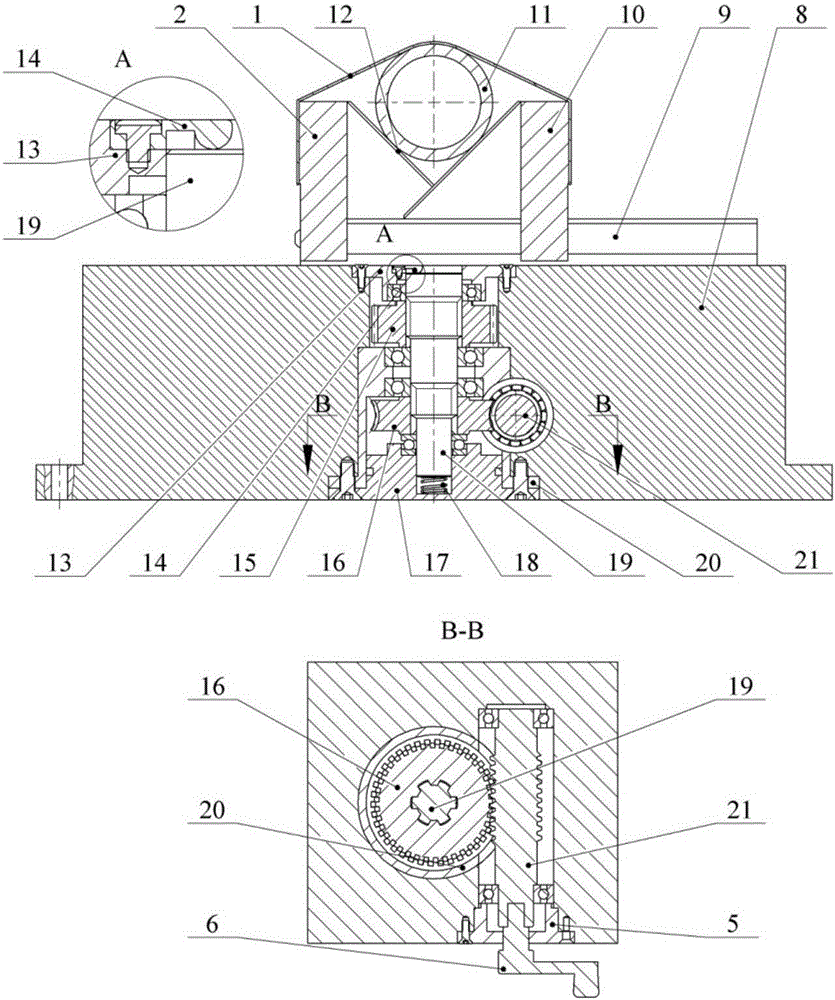

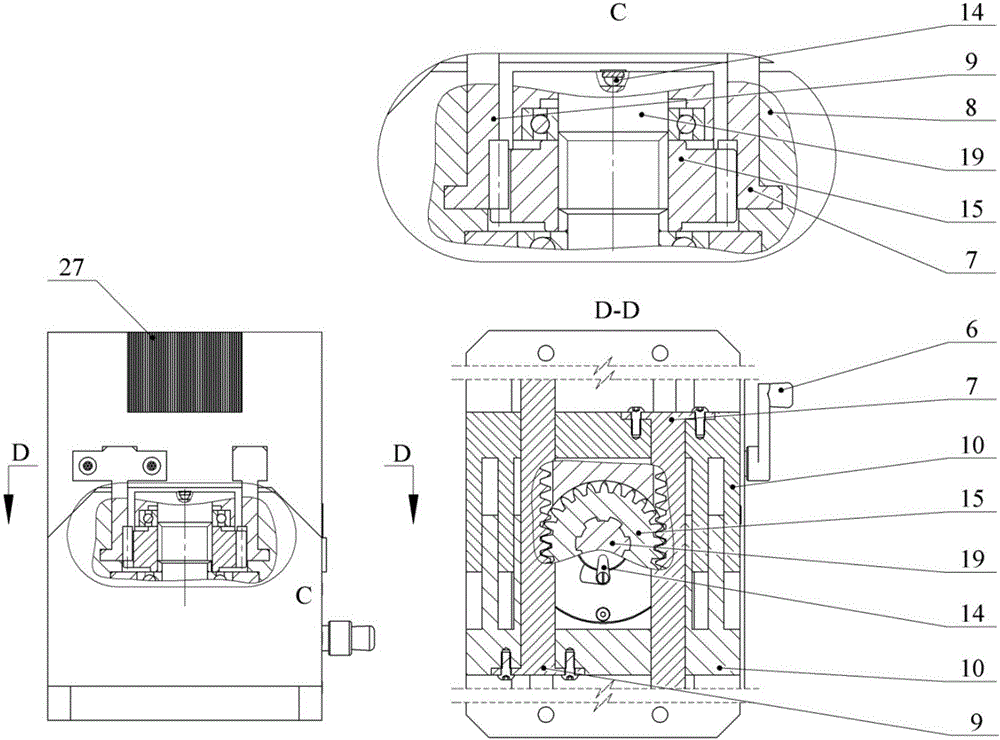

[0014] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. Those skilled in the art can also obtain other drawings based on these drawings without creative work.

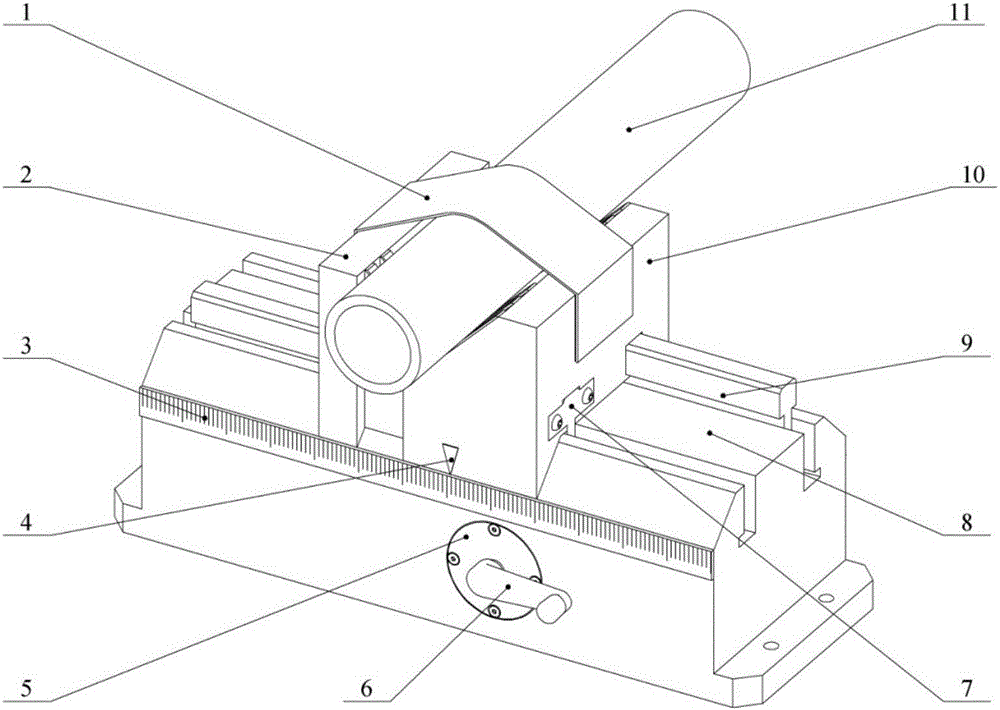

[0015] Such as figure 1 As shown, a round tube centering flexible fixture for magnetic pulse welding of the present invention includes an adjustment mechanism and a workpiece fixing mechanism.

[0016] Wherein: the adjustment mechanism includes three parts: the base 8, the worm shaft system and the central shaft system.

[0017] which, combined with figure 1 , base 8 as the basis for assembly. Along the width direction of the base 8, install the scale 3 on the front of the base 8, and at the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com