Patents

Literature

39results about How to "Solve low manufacturing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

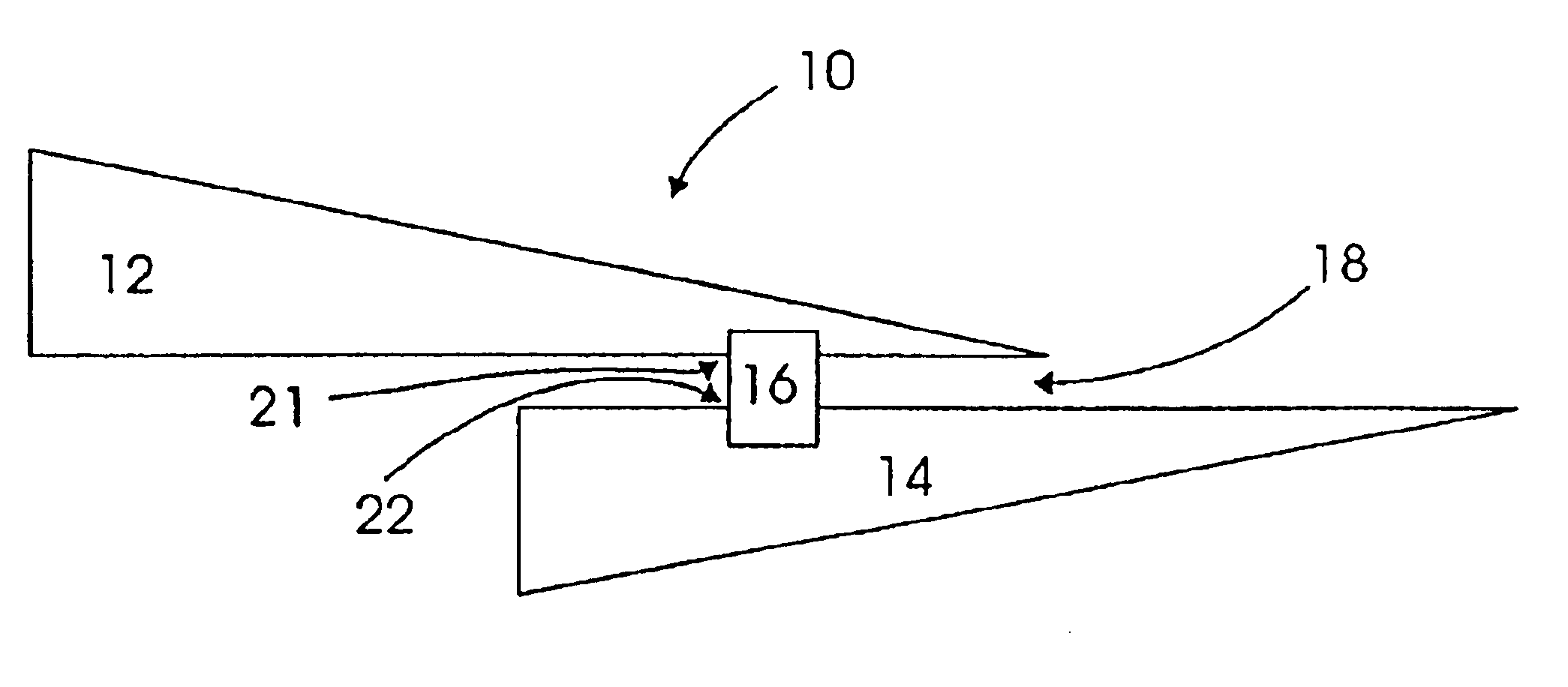

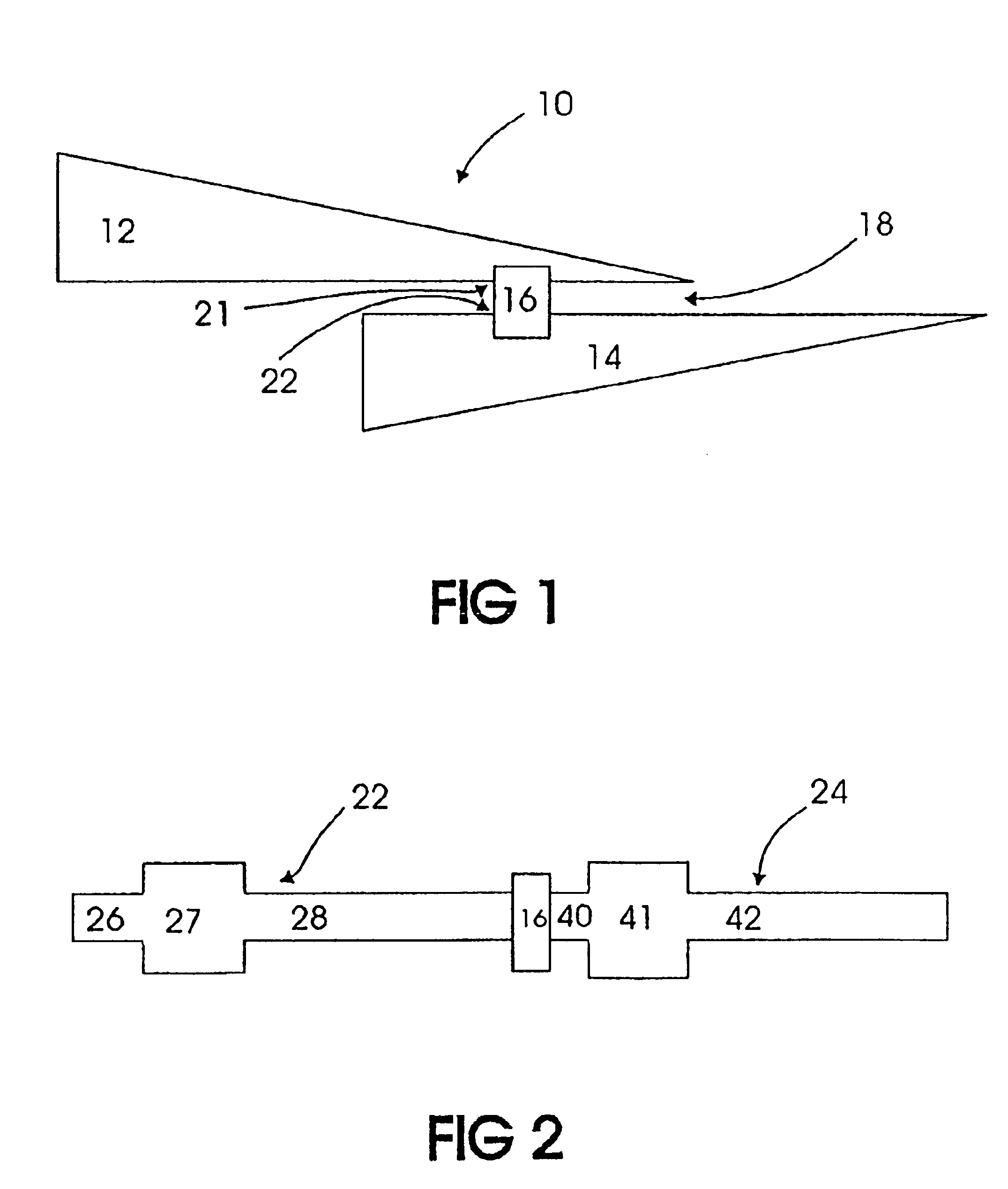

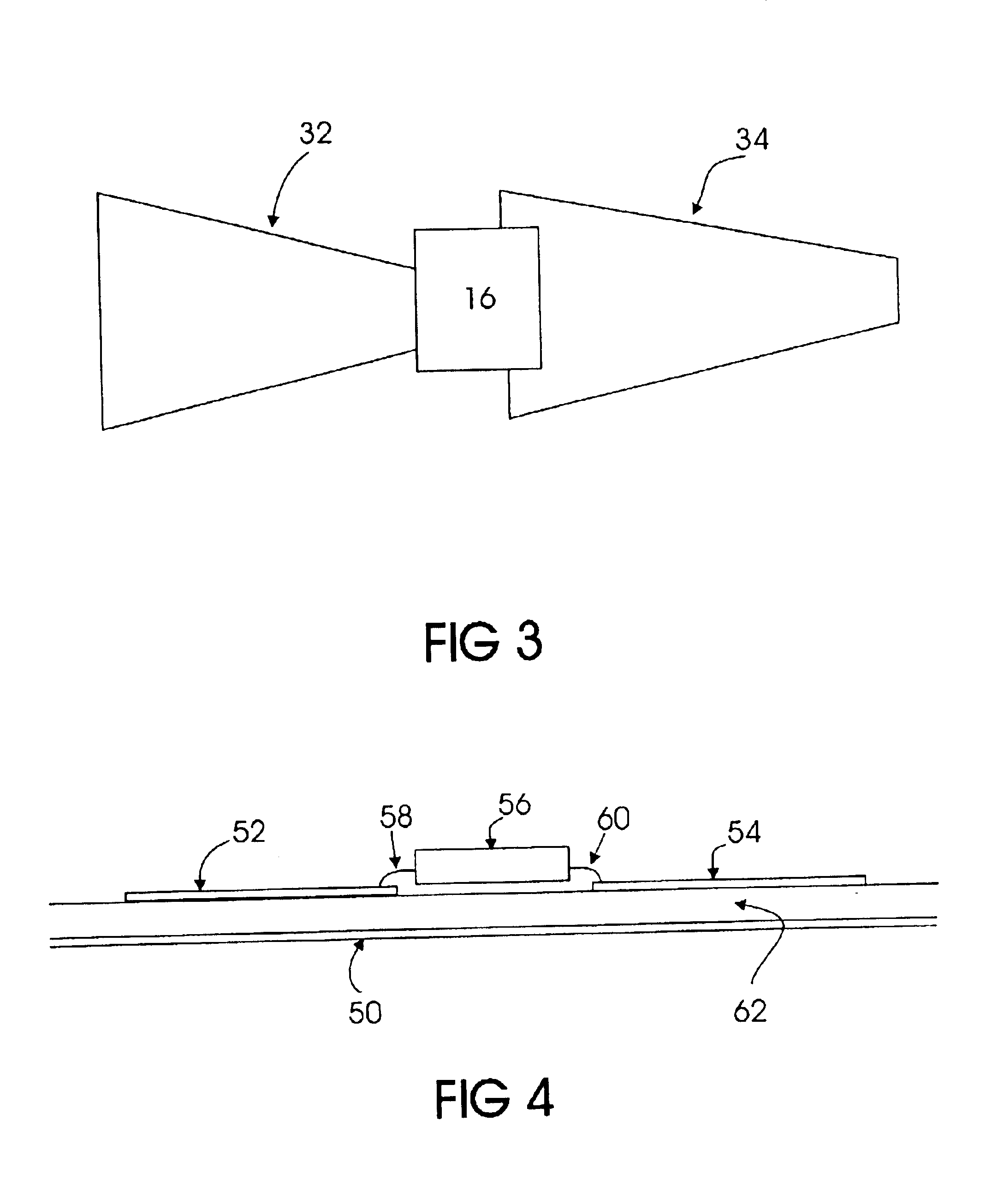

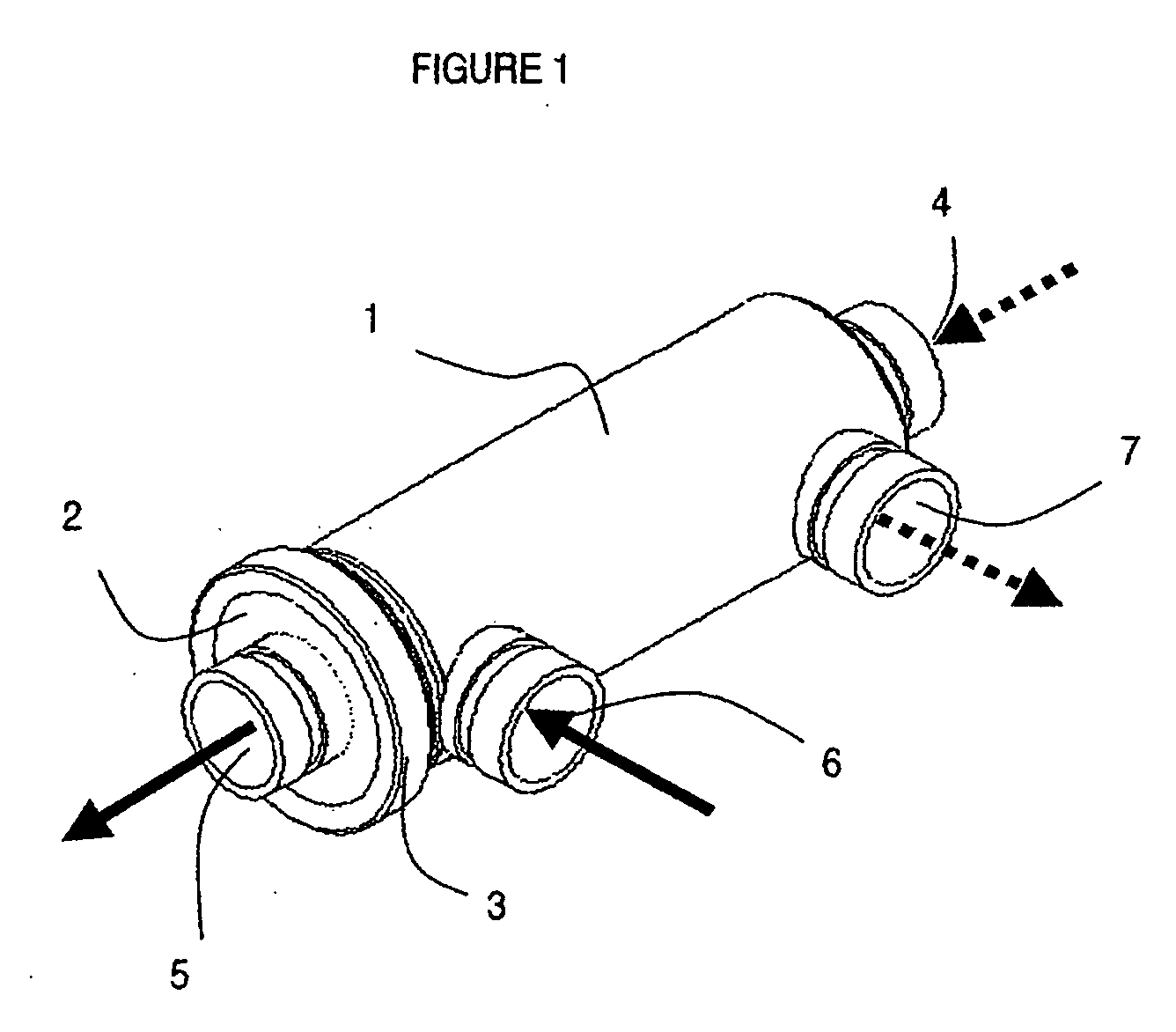

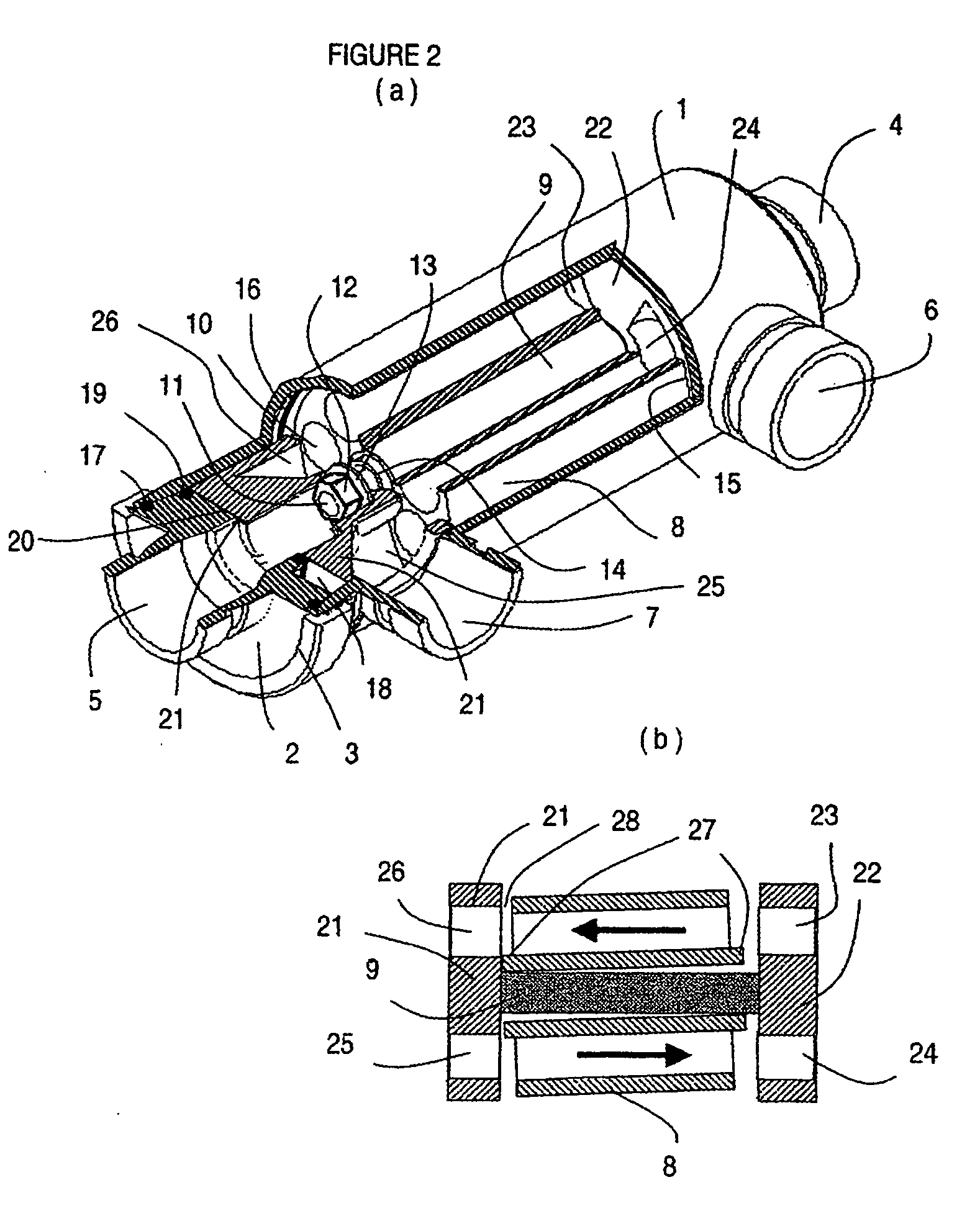

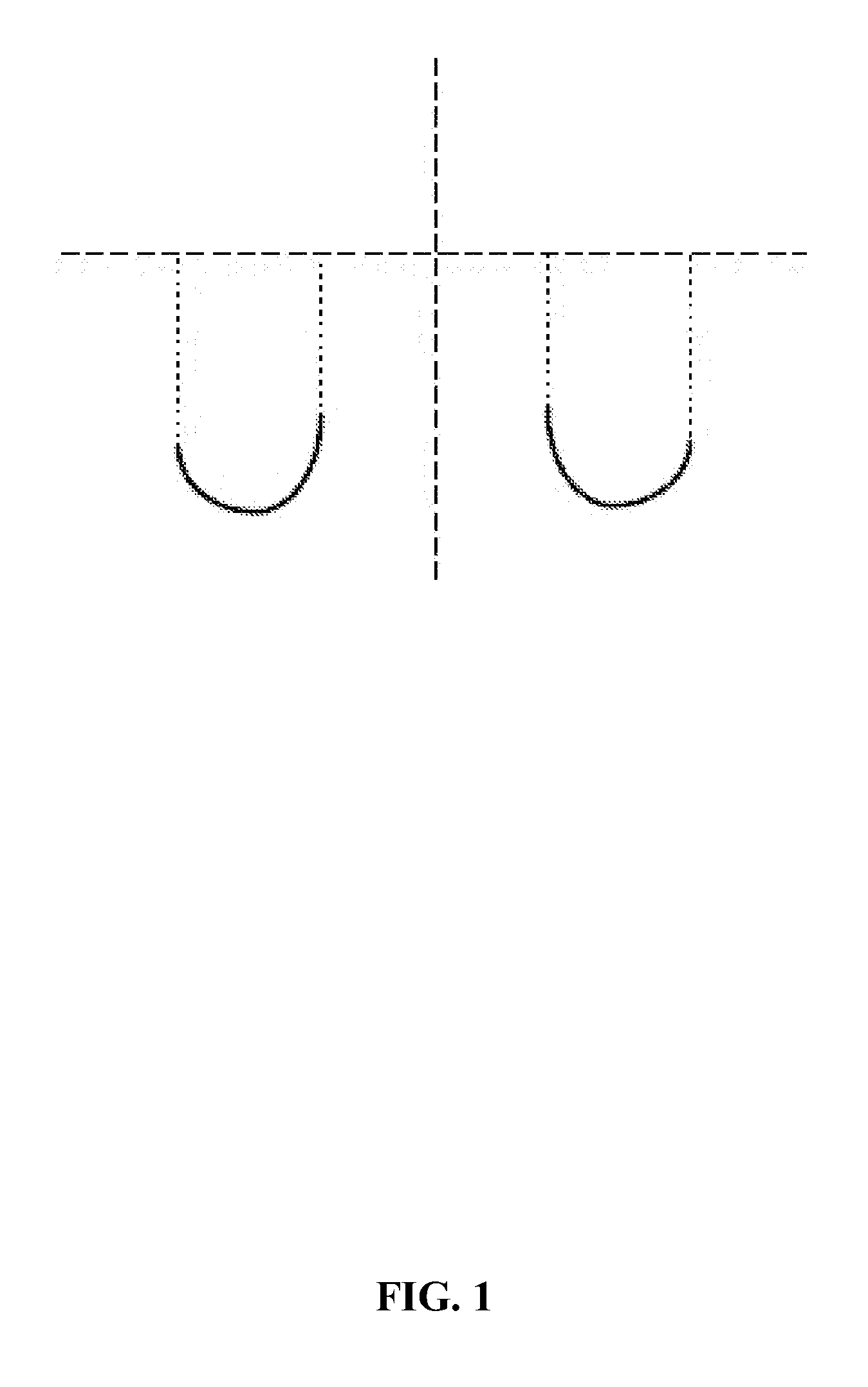

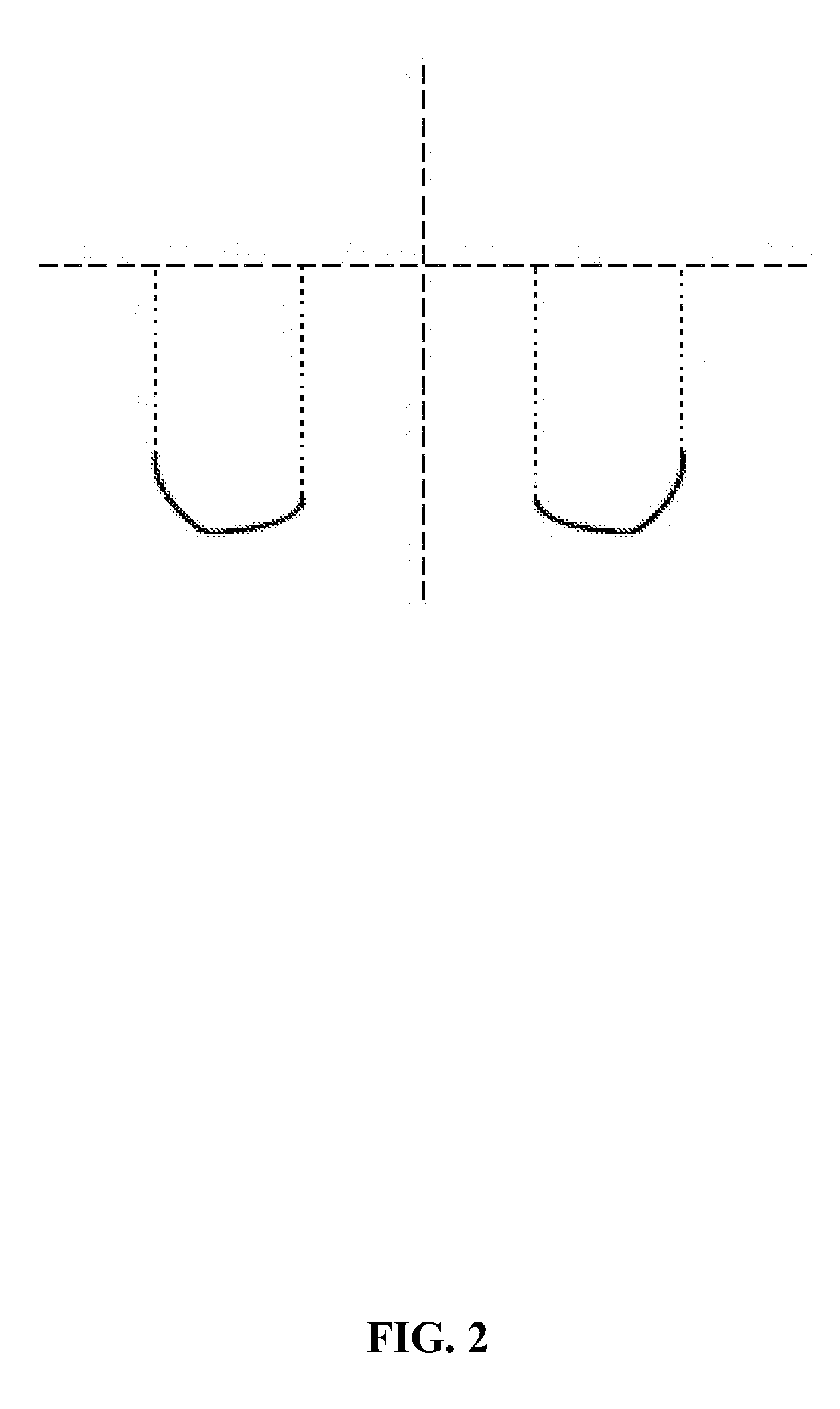

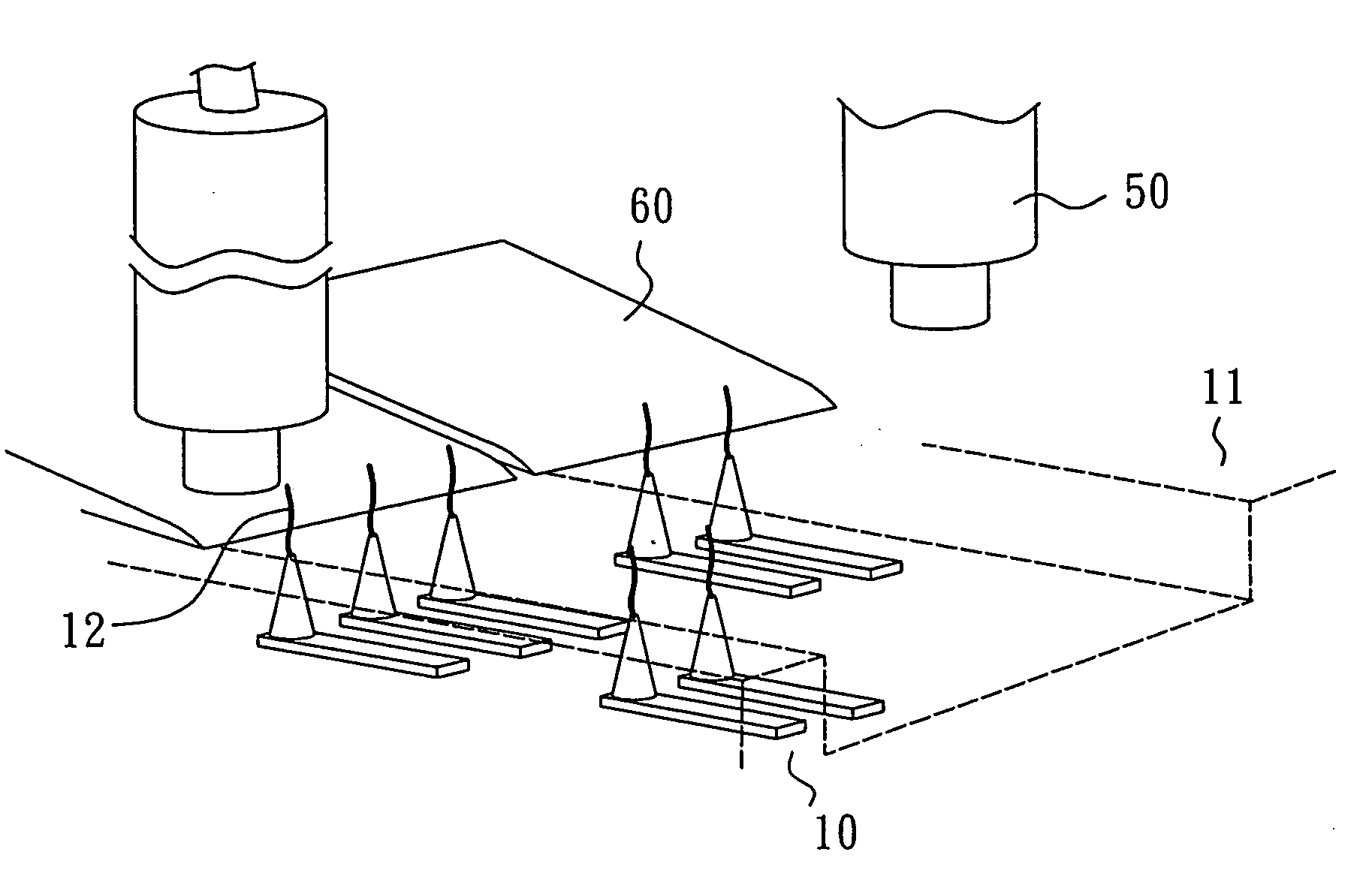

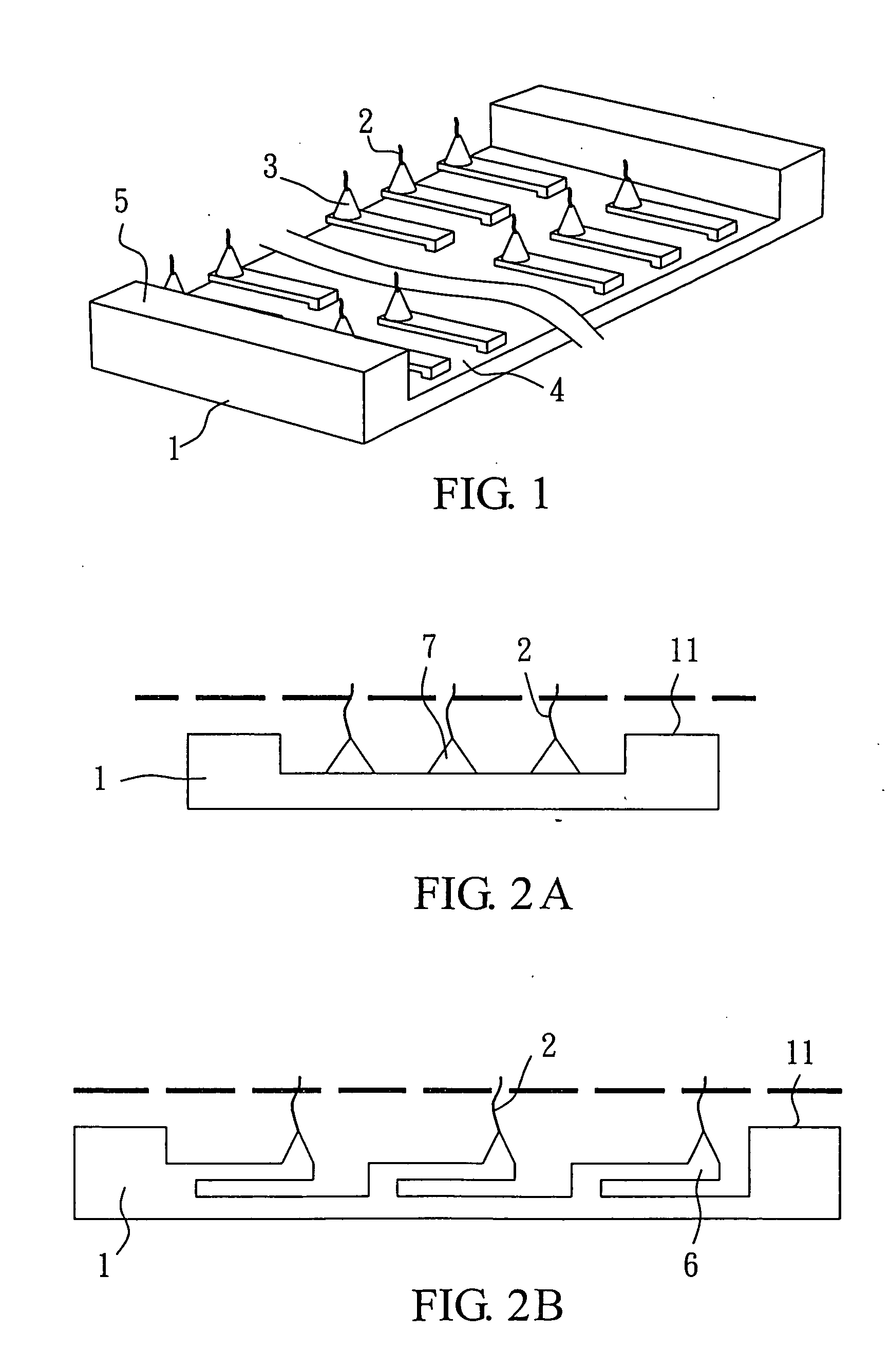

RFID tag using a surface insensitive antenna structure

InactiveUS6914562B2Efficient executionEasy to manufactureSimultaneous aerial operationsAntenna supports/mountingsRadio frequency energyCommunication device

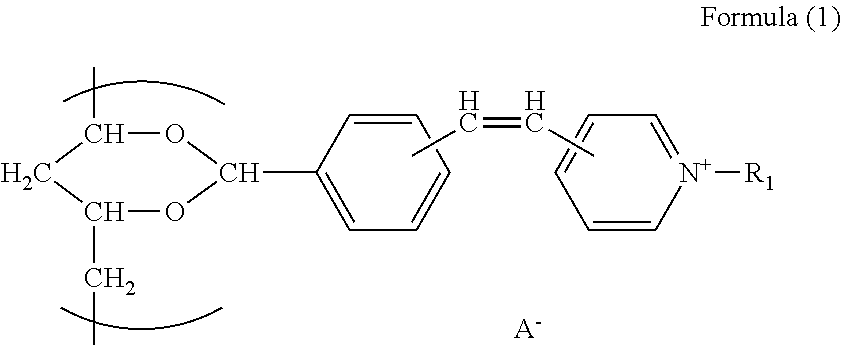

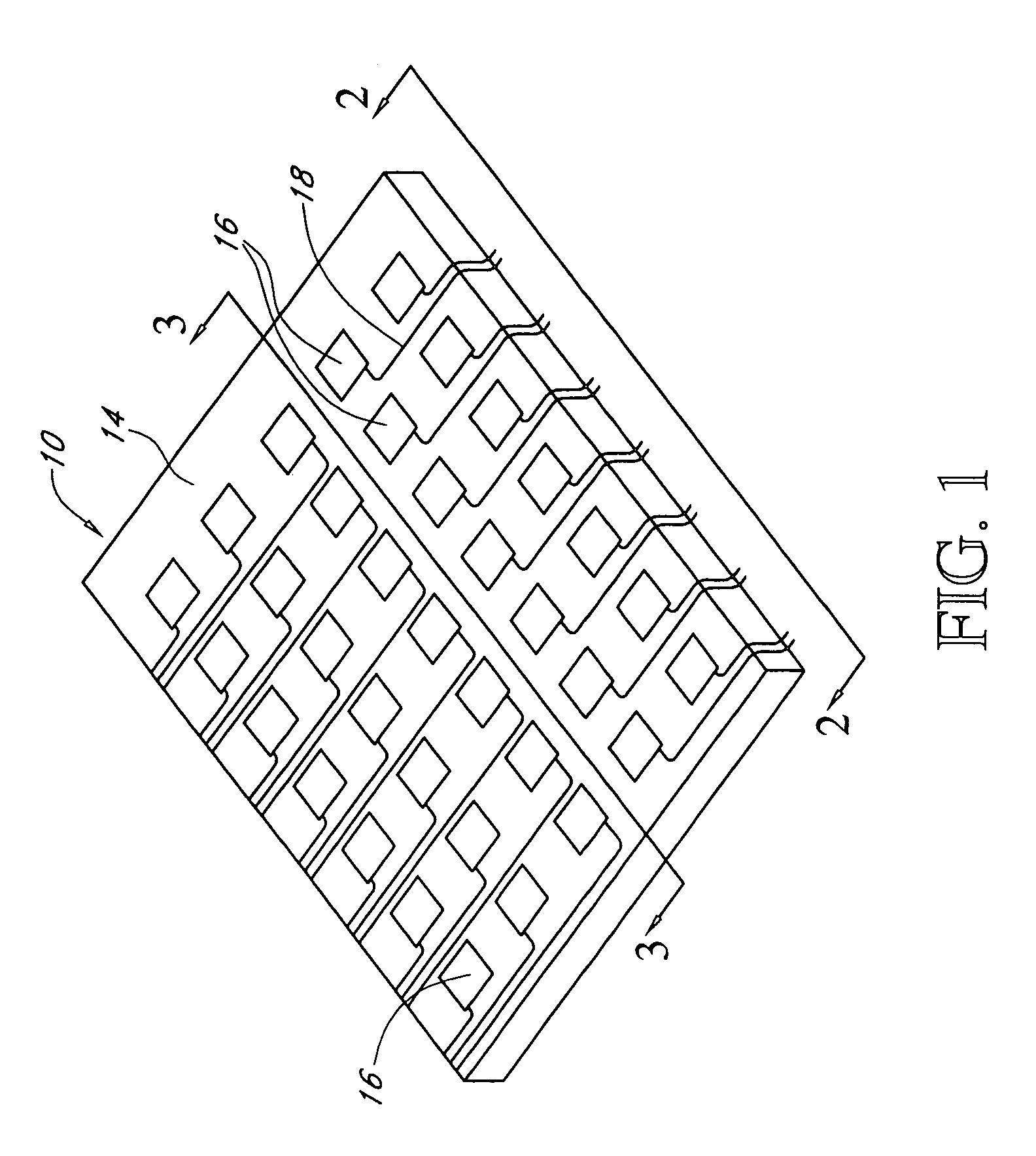

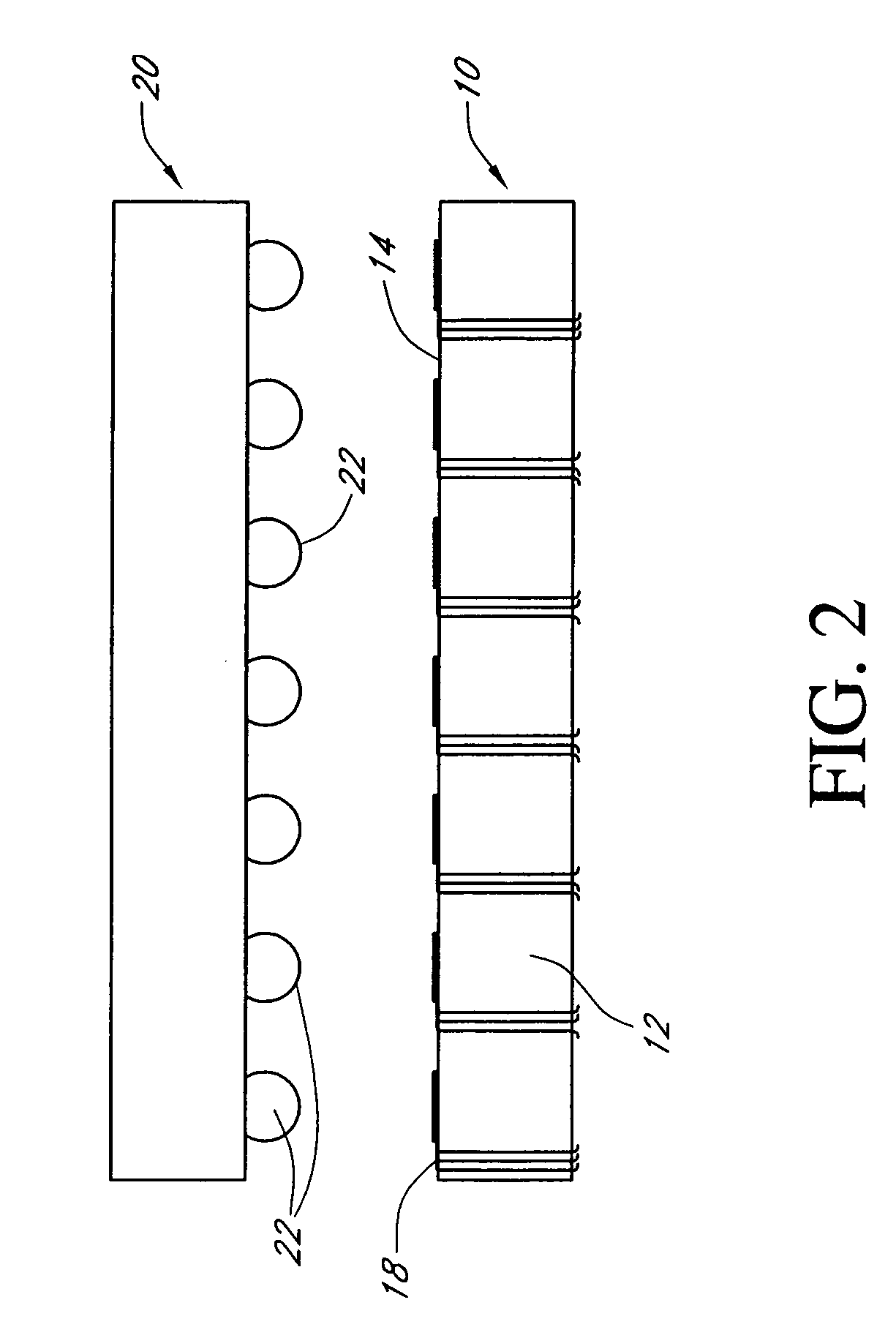

An antenna system that is insensitive to the surface on which it is mounted for use with a RFID tag having a wireless communication device, including a plurality of conductive tabs coupled to the wireless communication device for receiving and radiating radio frequency energy. At least two of the tabs are substantially identical in shape and coupled to the wireless communication device at feedpoint differing in location on each of the two tabs wherein the width of said at least two of said plurality of tabs taken transverse to the longitudinal centerline axis of each tab varies with distance along the longitudinal centerline axis of each of said tabs from its feedpoint. Alternatively, the wireless communication device is coupled to the tab at a feedpoint selected at a location differing on each of the tabs where the conducting area per unit length of the longitudinal centerline axis of each tab varies with distance along the longitudinal centerline axis of each of said tabs from its feedpoint. A radio frequency reflecting structure is coupled to the conductive tabs for reflecting radio frequency energy radiated therefrom. A dielectric material is located intermediate the conductive tabs and the radio frequency reflecting means.

Owner:AVERY DENNISON CORP

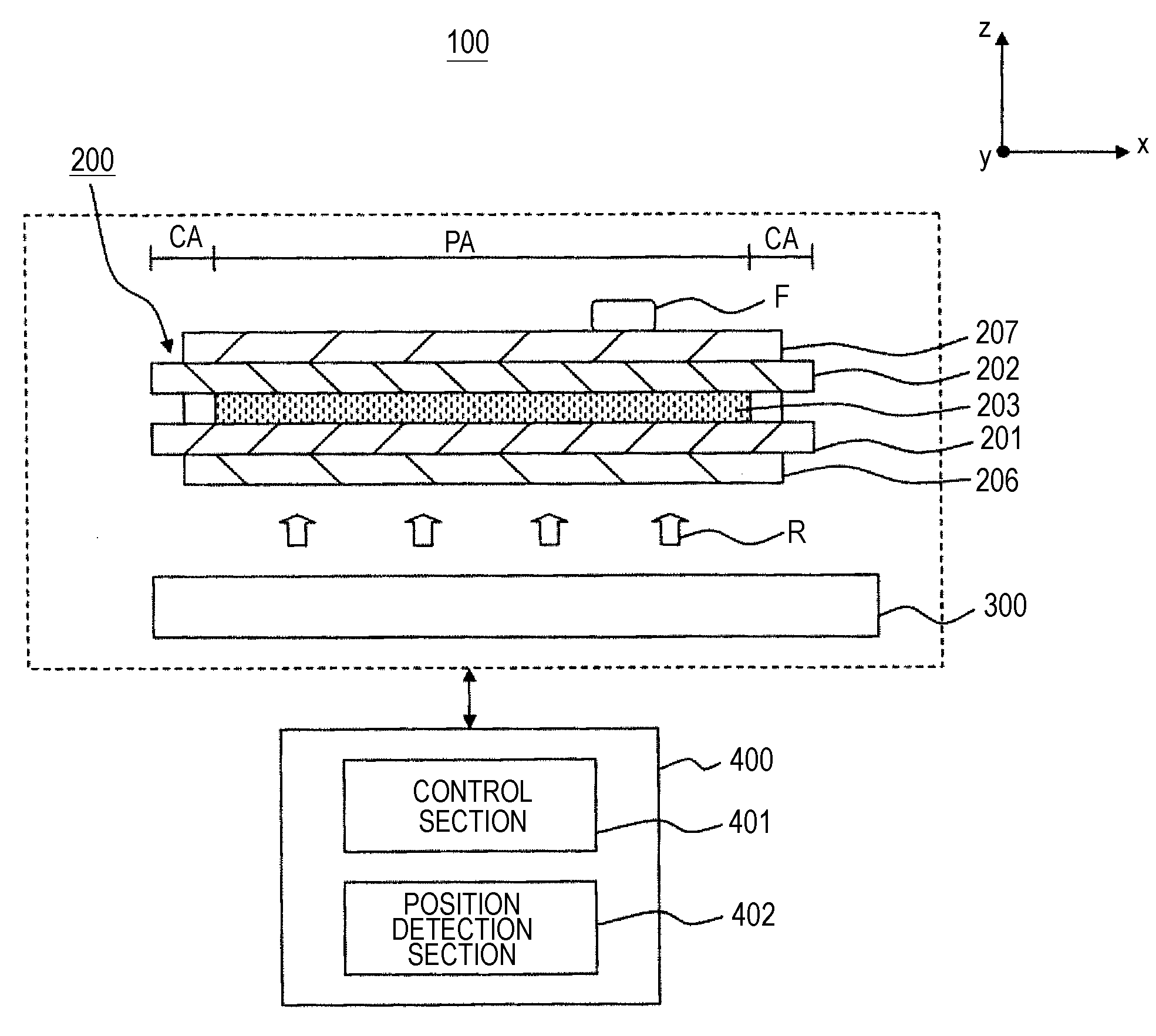

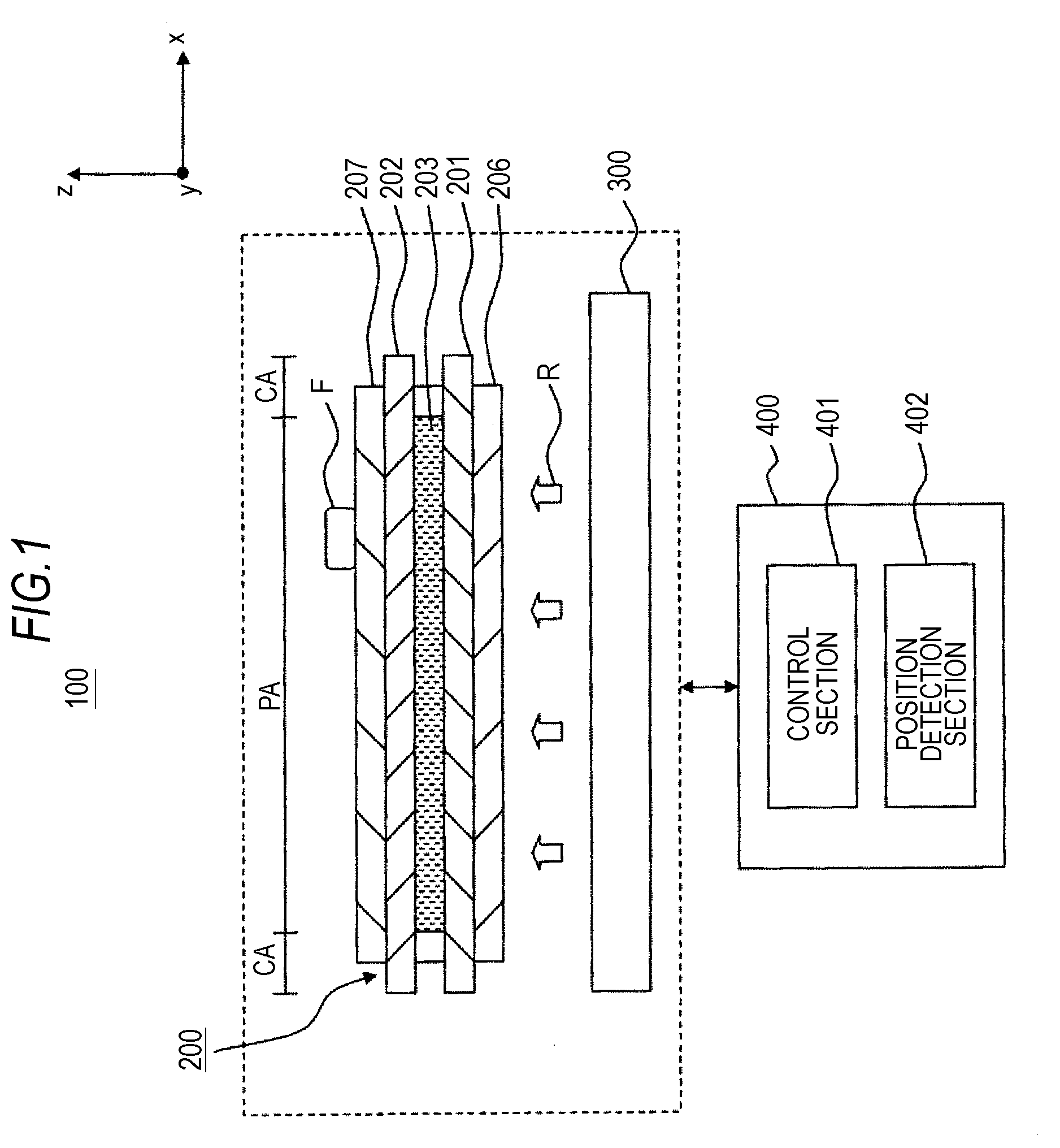

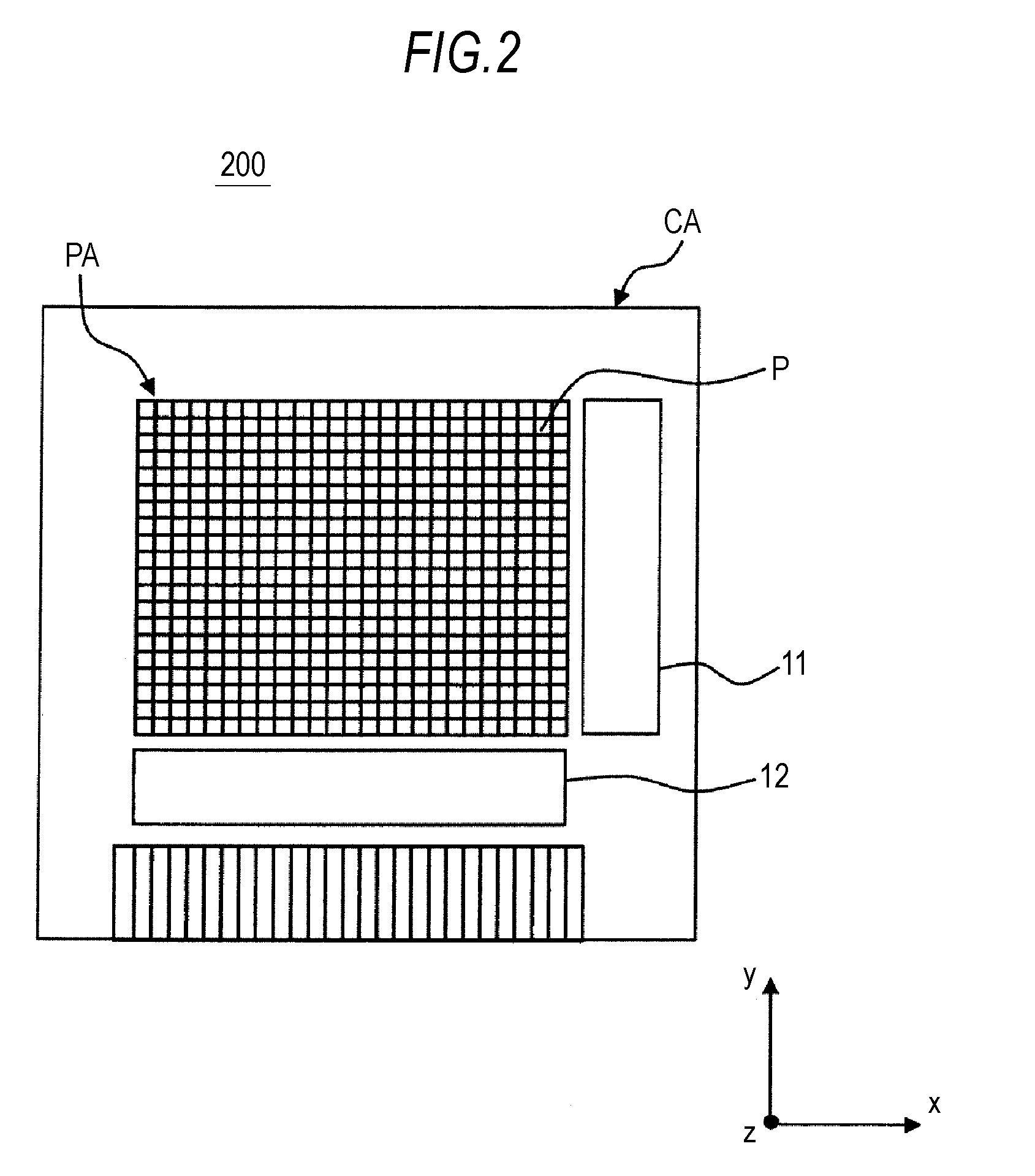

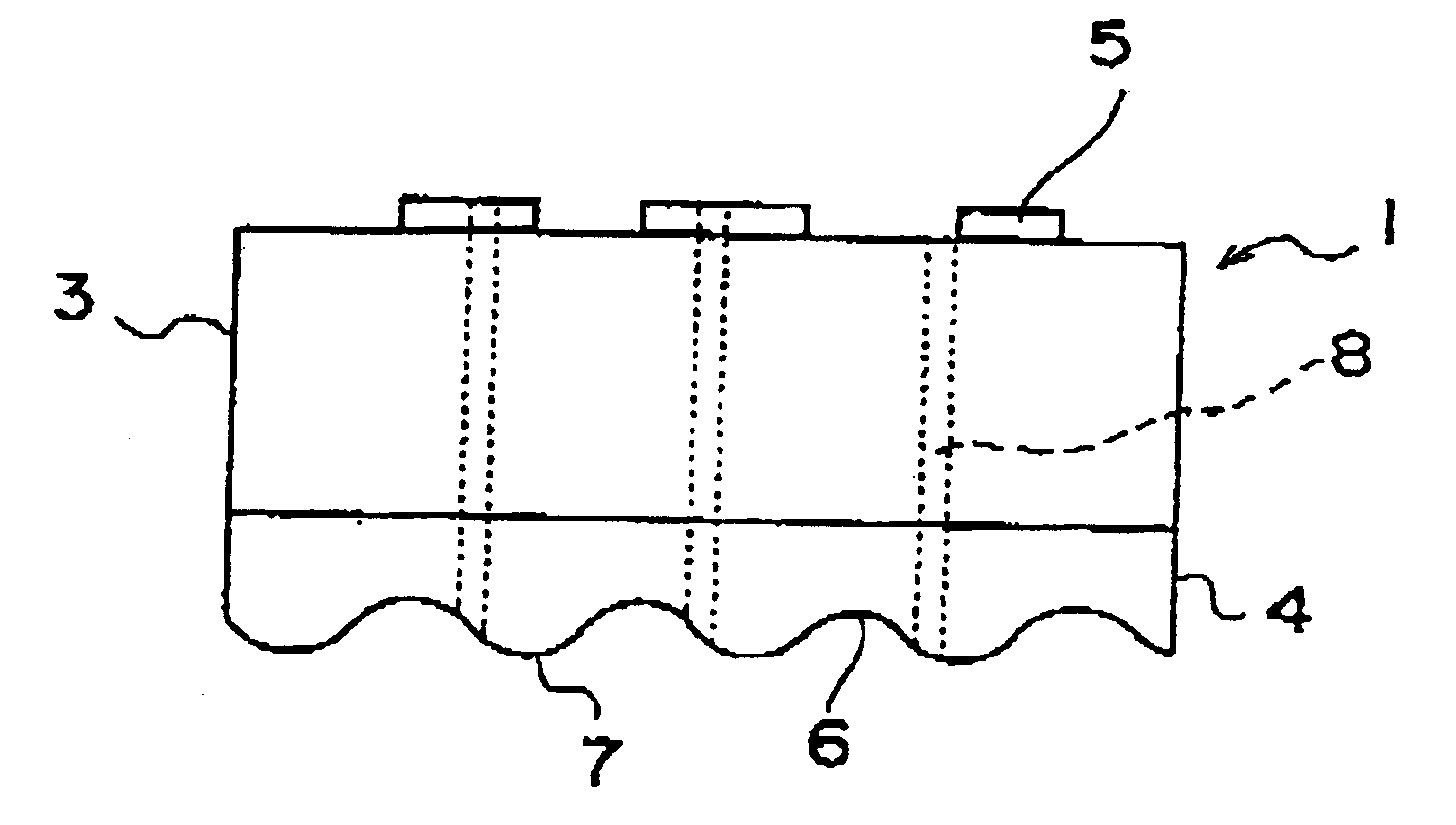

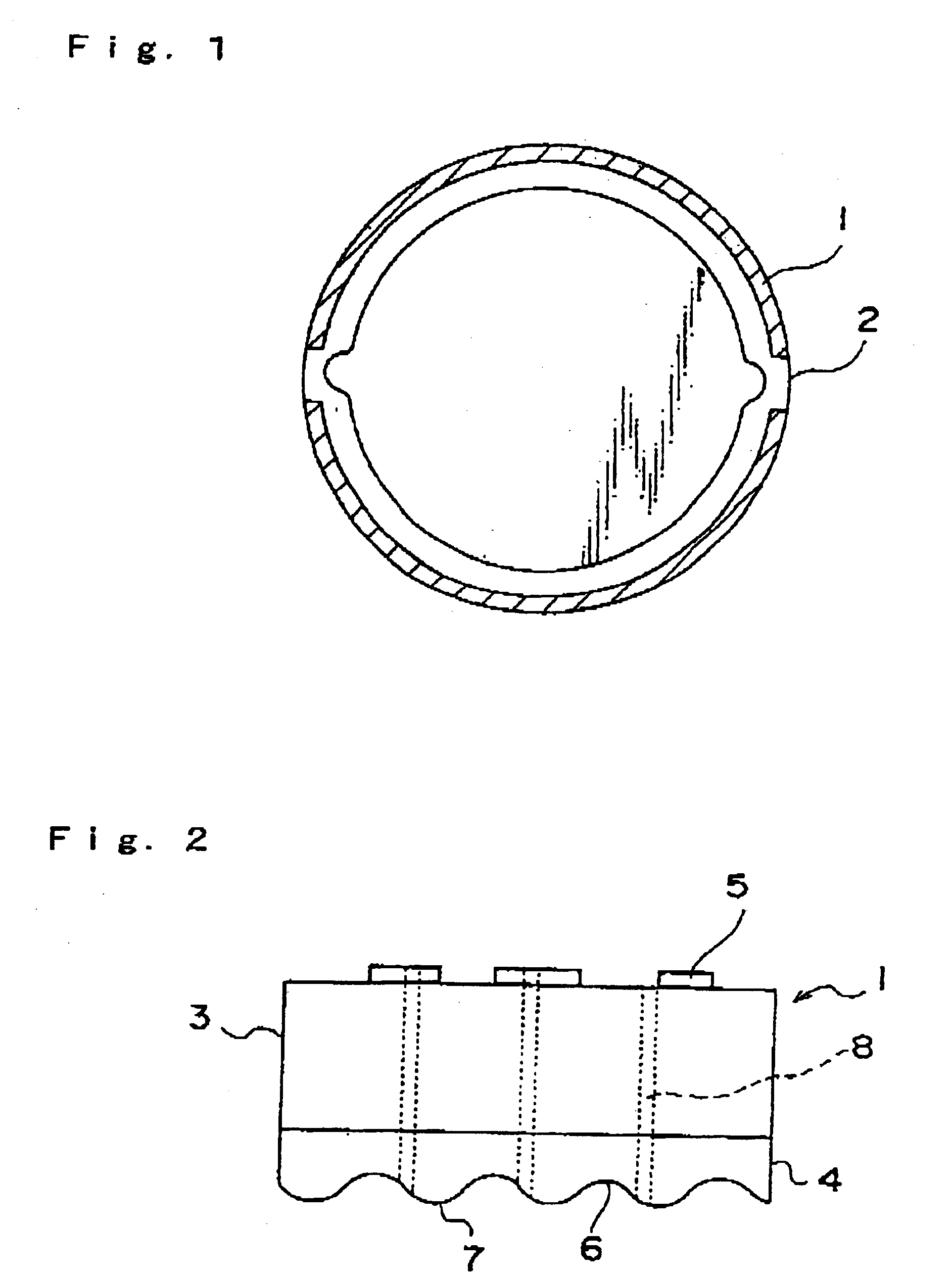

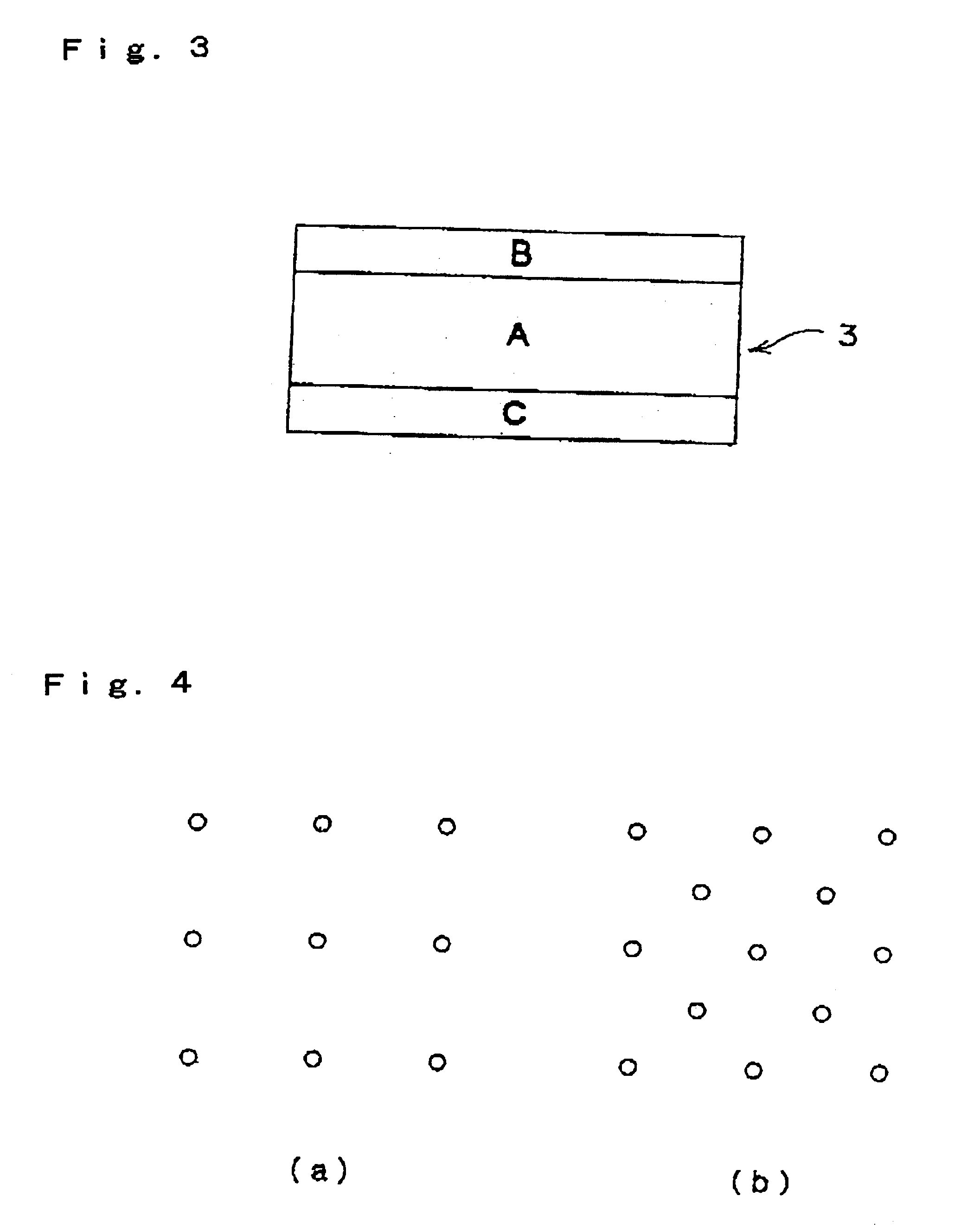

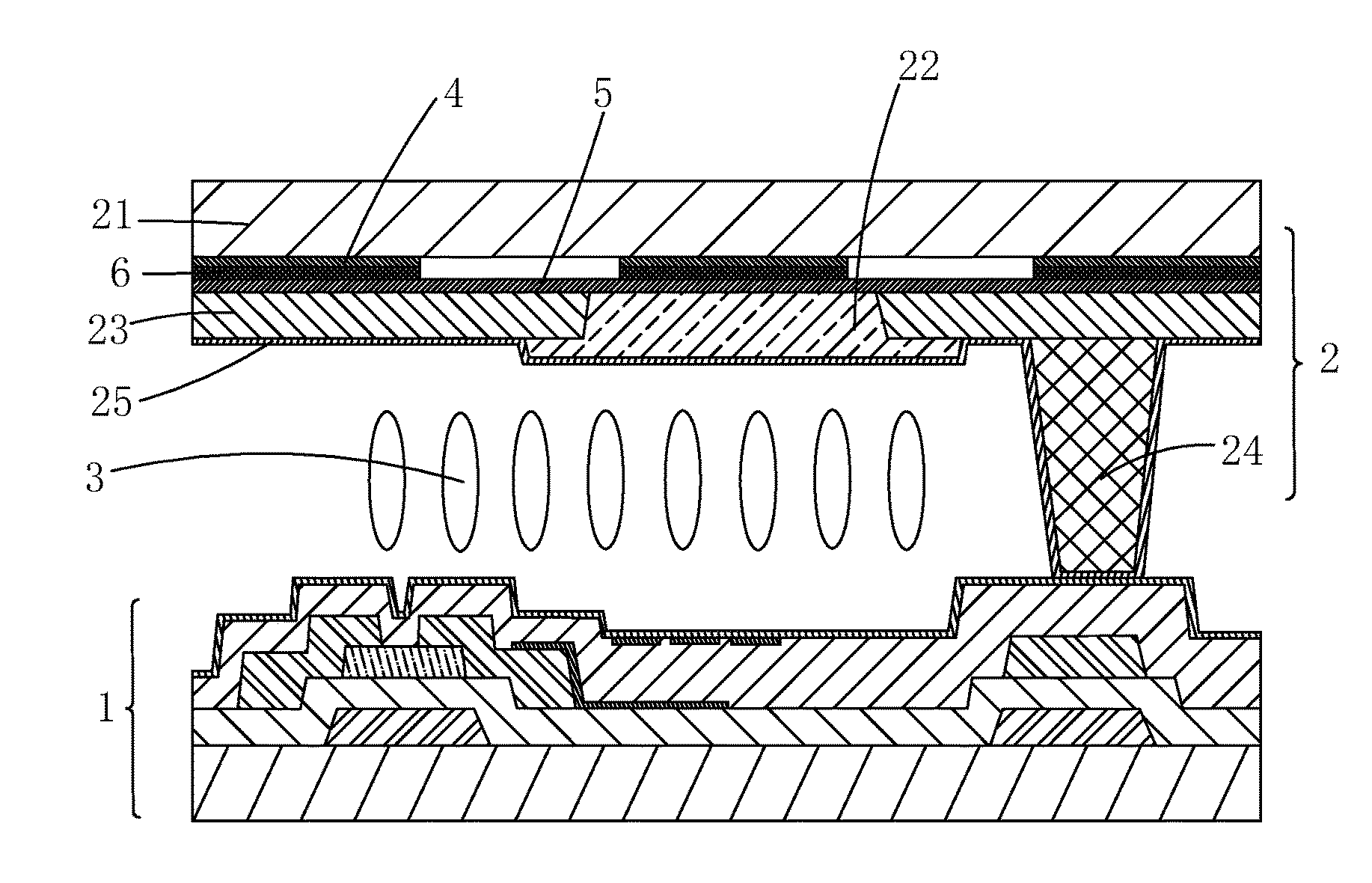

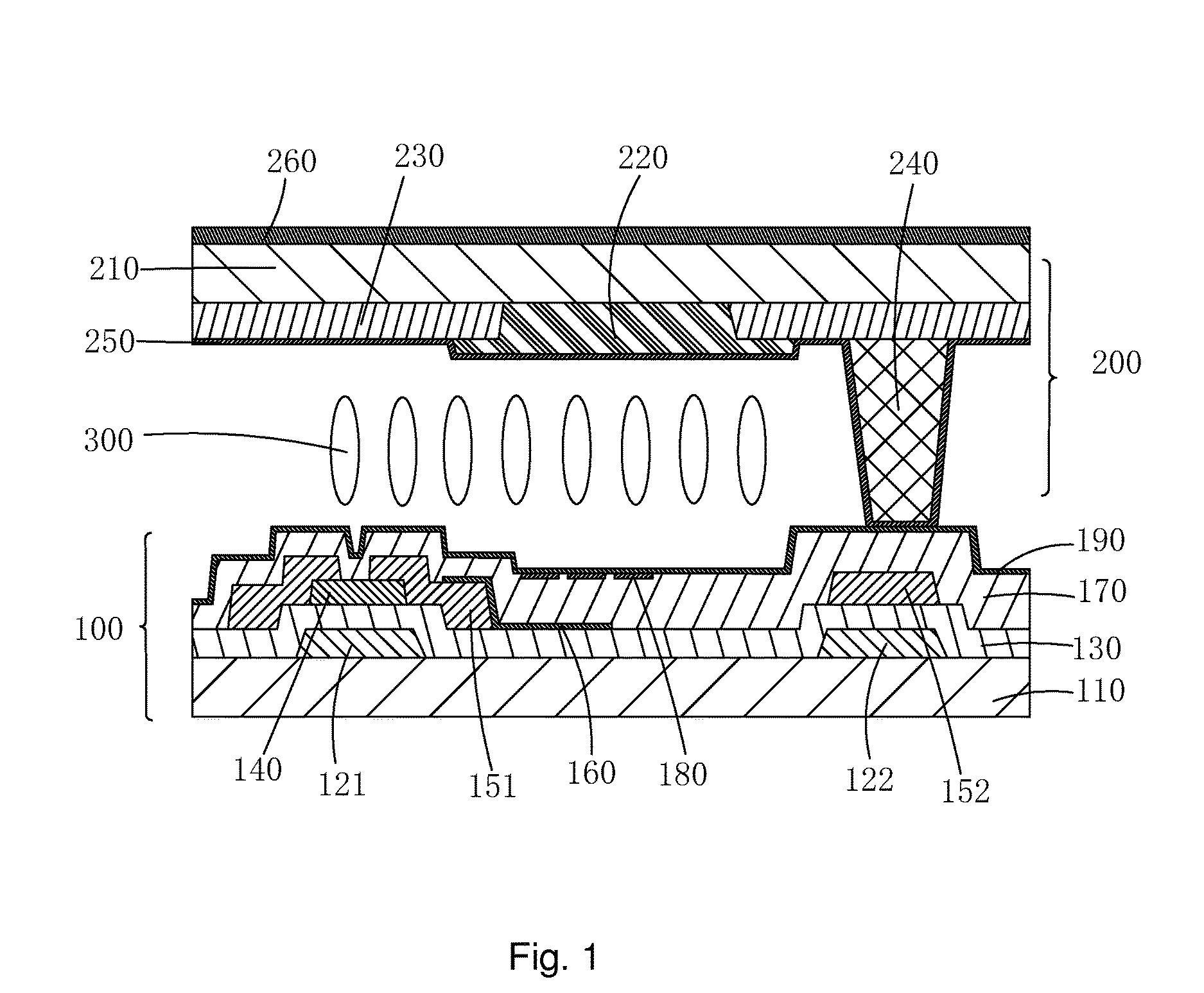

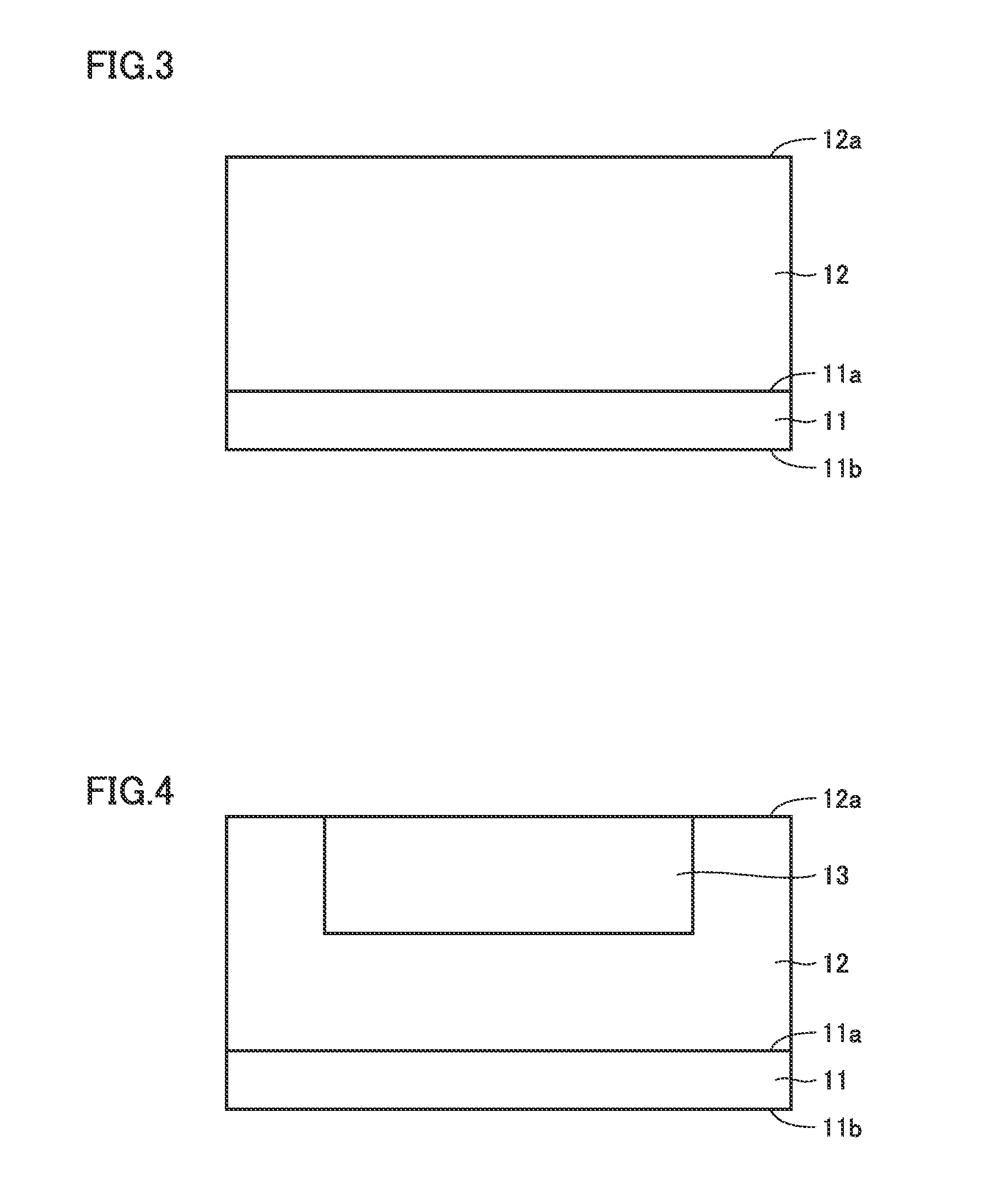

Liquid crystal display device, manufacturing method of liquid crystal display device, display device and information input apparatus

ActiveUS20100194709A1Improve image qualitySolve low manufacturing efficiencyVessels or leading-in conductors manufactureNon-linear opticsLiquid-crystal displayDisplay device

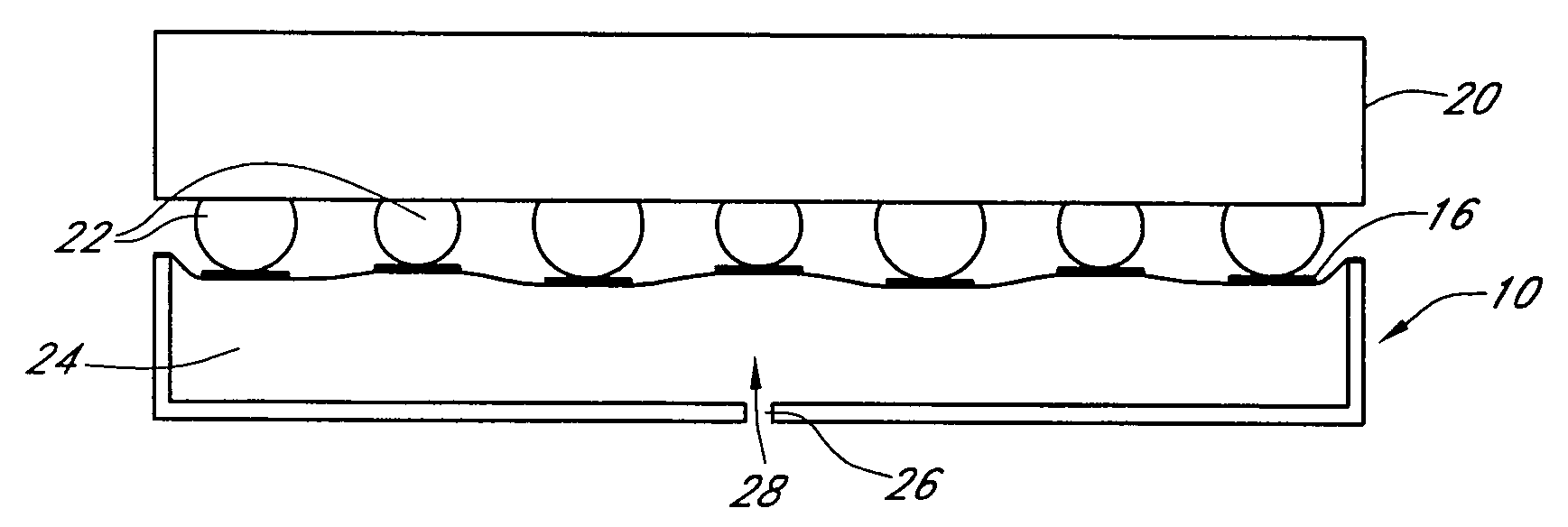

A display device includes: a display panel including first and second substrates spaced from and opposite to each other, and has a touch sensor switch. The touch sensor switch includes a first touch electrode provided on a surface of the first substrate facing the second substrate, and a second touch electrode provided on a surface of the second substrate facing the first substrate and spaced from and faces the first touch electrode. The first and second touch electrodes contact with each other when the touch panel is deformed by an external pressure. The first touch electrode covers a surface of a concave and convex area where grooves are formed to be spaced from each other, and on the surface on which the first touch electrode is provided, an application film is provided to expose a surface of a top face of a convex part of the concave and convex area.

Owner:JAPAN DISPLAY WEST

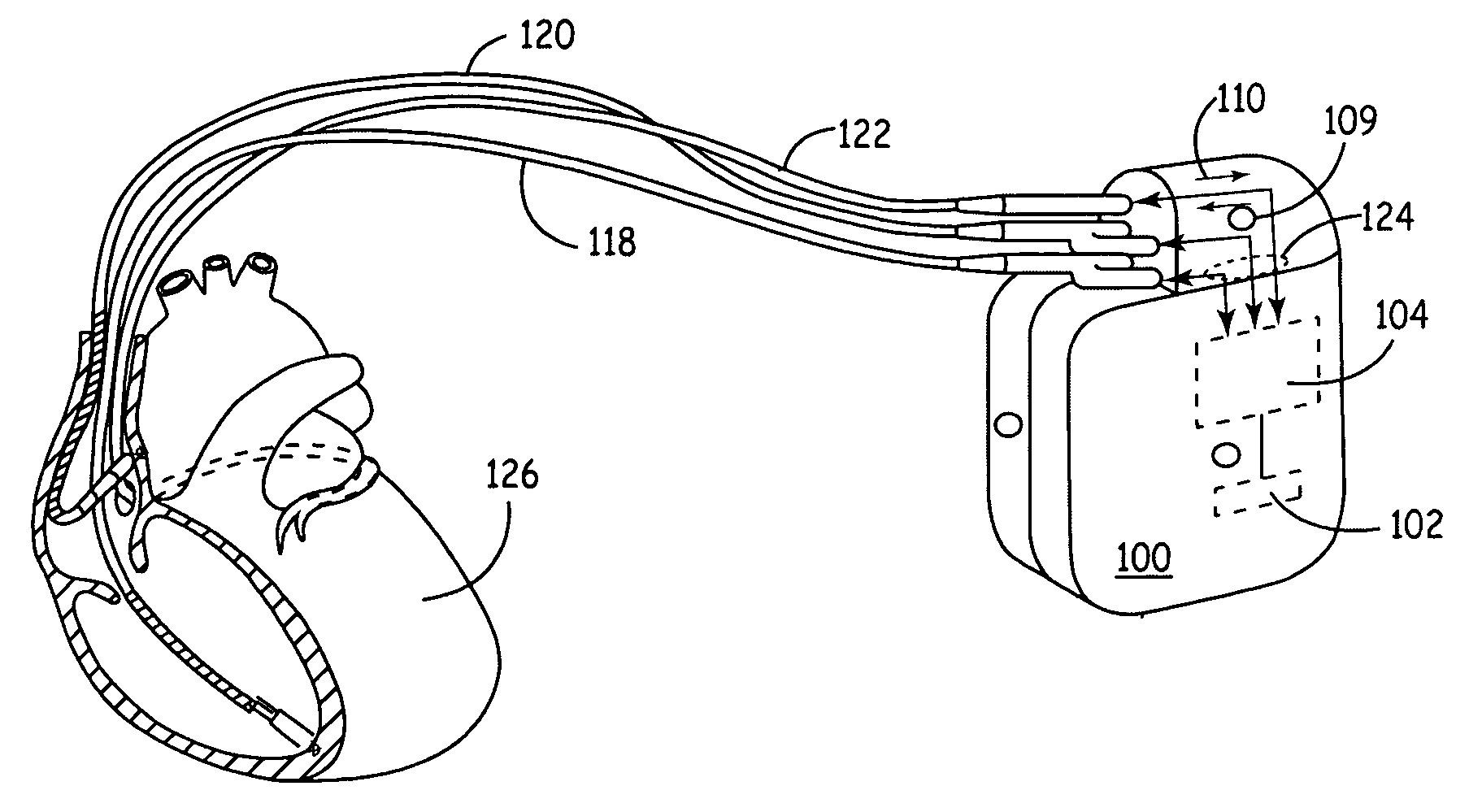

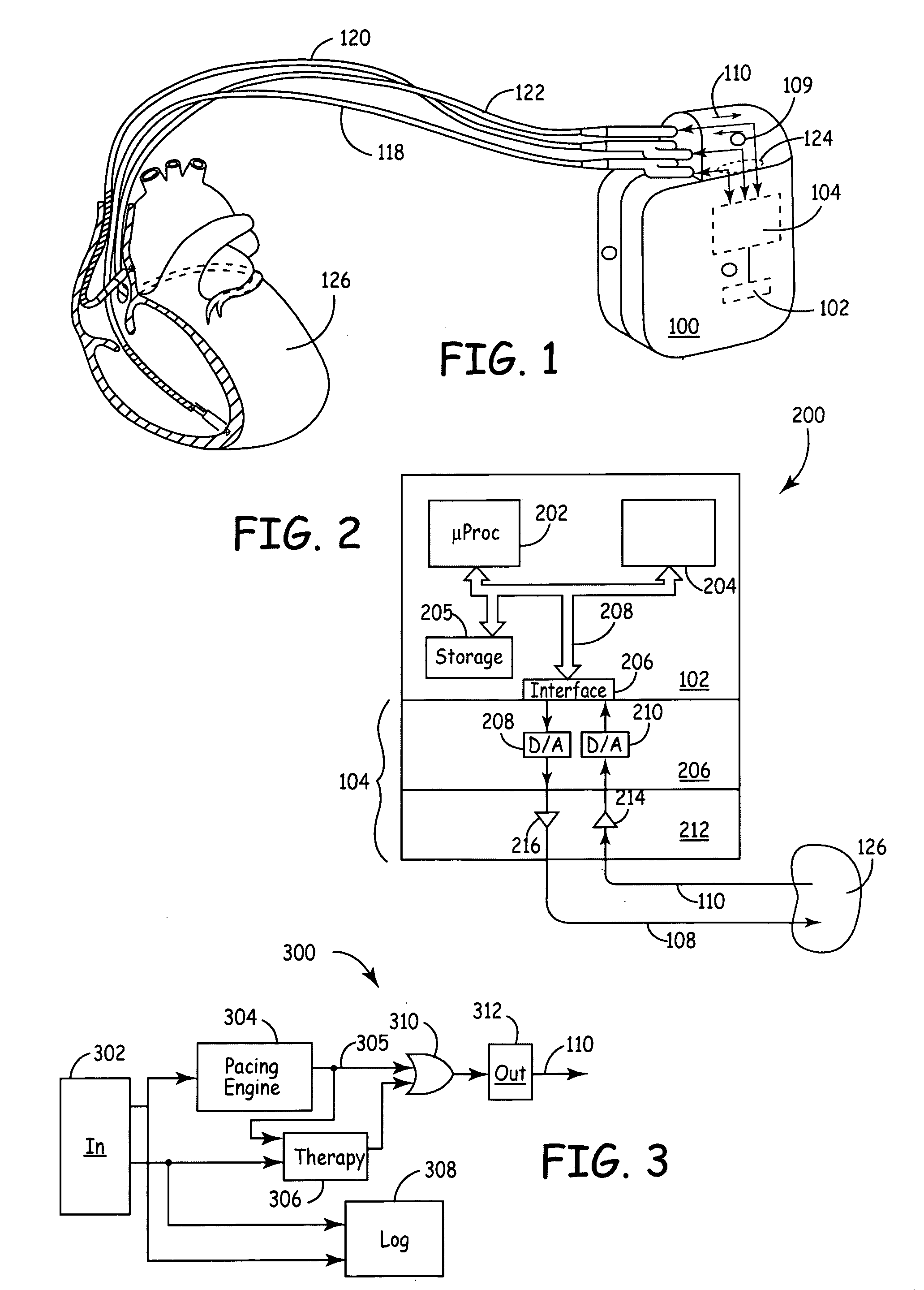

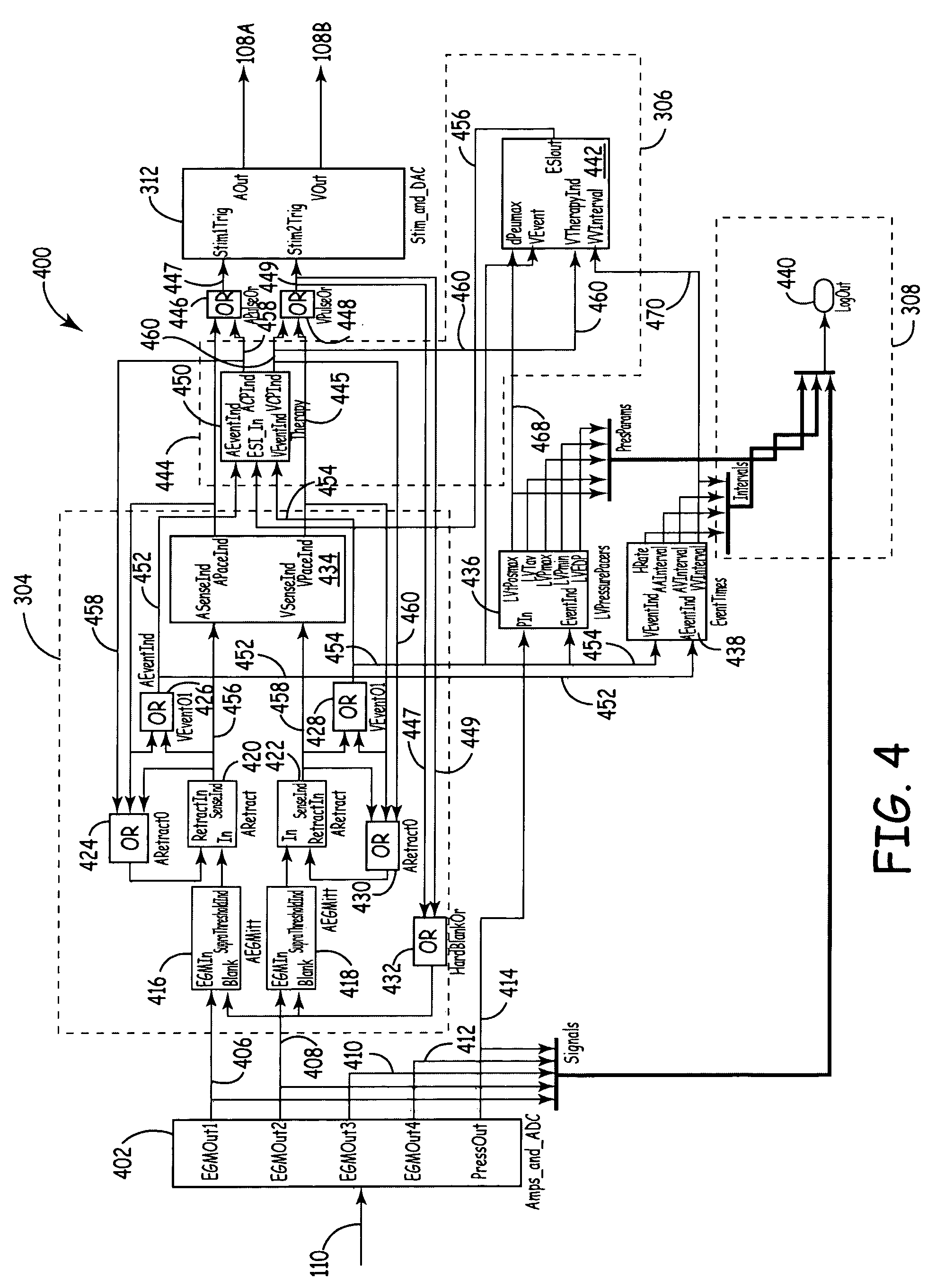

Software configurable medical device platform and associated methods

ActiveUS20060079942A1Simple designSolve low manufacturing efficiencyHeart stimulatorsModularityMultiple therapy

The invention relates to medical devices such as pacemakers, pulse generators, cardioverter-defibrillators and the like and more particularly relates to modular and reconfigurable medical system platforms and methods of designing, testing, controlling and implementing diverse therapies, diagnostics, physiologic sensors and related instrumentation using said medical system platforms. Methods, systems and devices provide a new design platform for implantable and external medical devices such as pacemakers, defibrillators, neurostimulators, heart monitors, etc. A real-time, highly flexible system of software and hardware modules enables both prototypes and products to respond to patient and customer needs with greater design and manufacturing efficiency. Certain embodiments integrate a general-purpose processor with interface circuitry to provide a standard platform for implementing new and conventional therapies with software models rather than custom circuitry. The platform described may be used as a simulation environment, development and test platform and / or may be used as architecture for building new medical devices.

Owner:MEDTRONIC INC

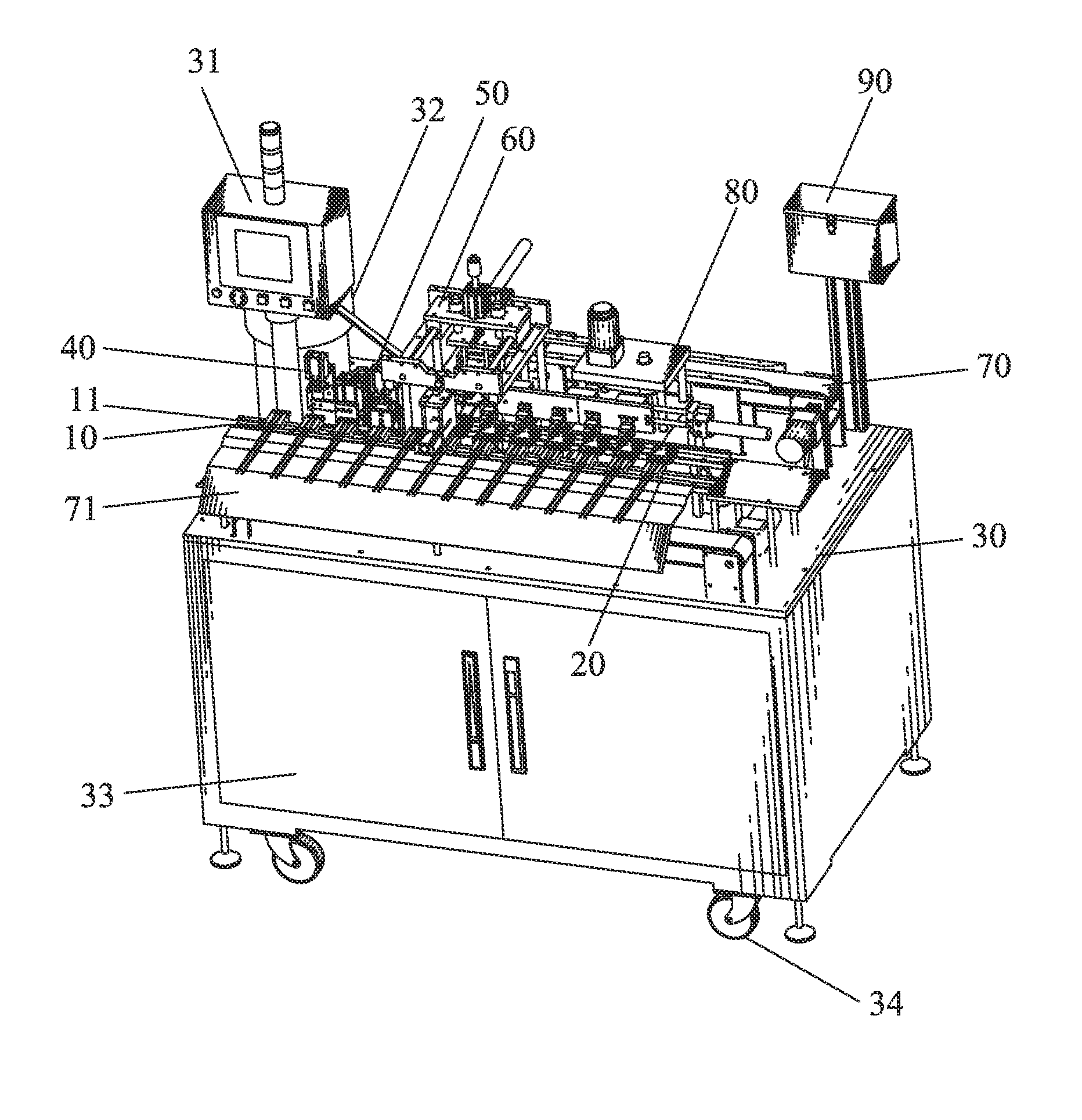

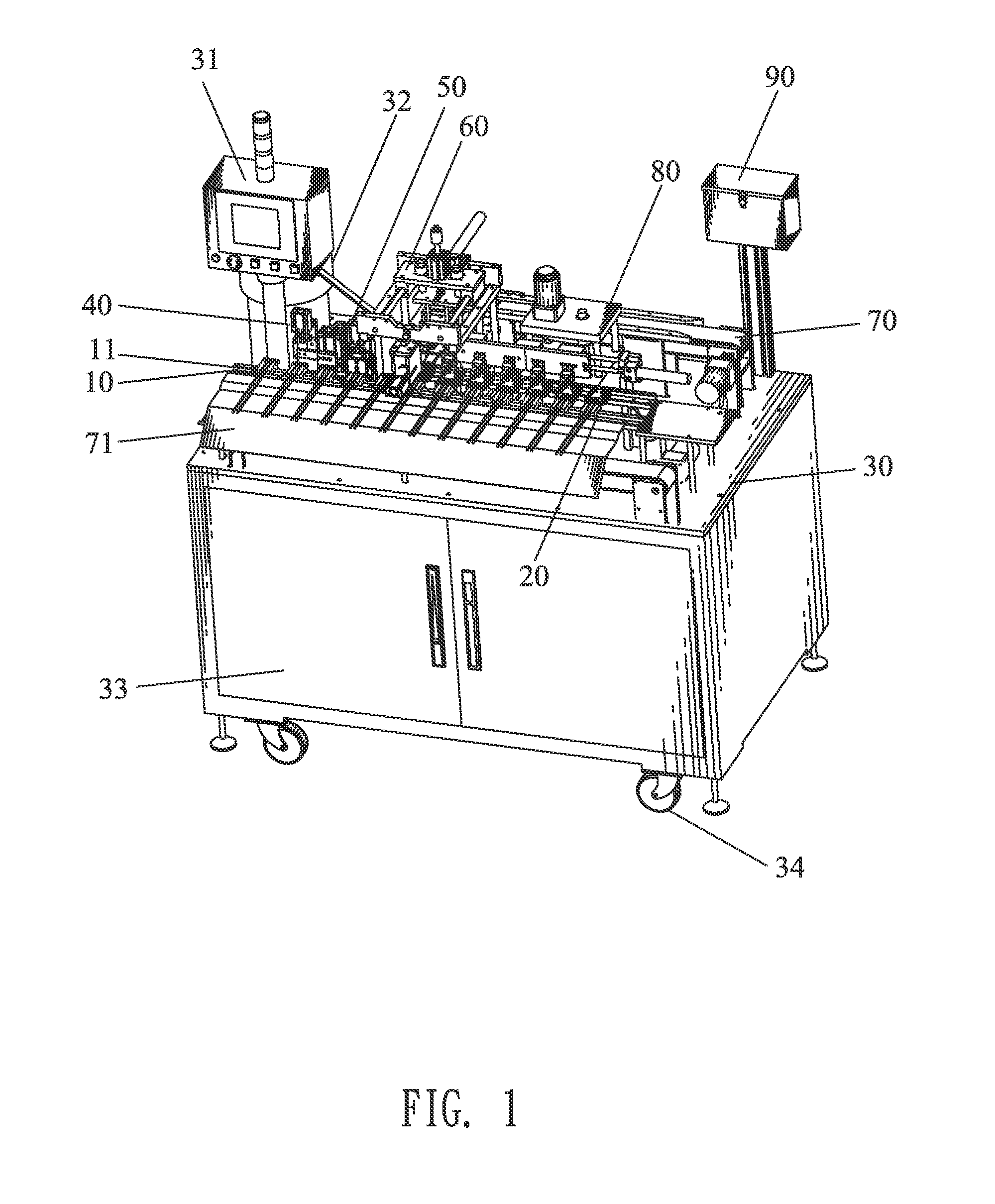

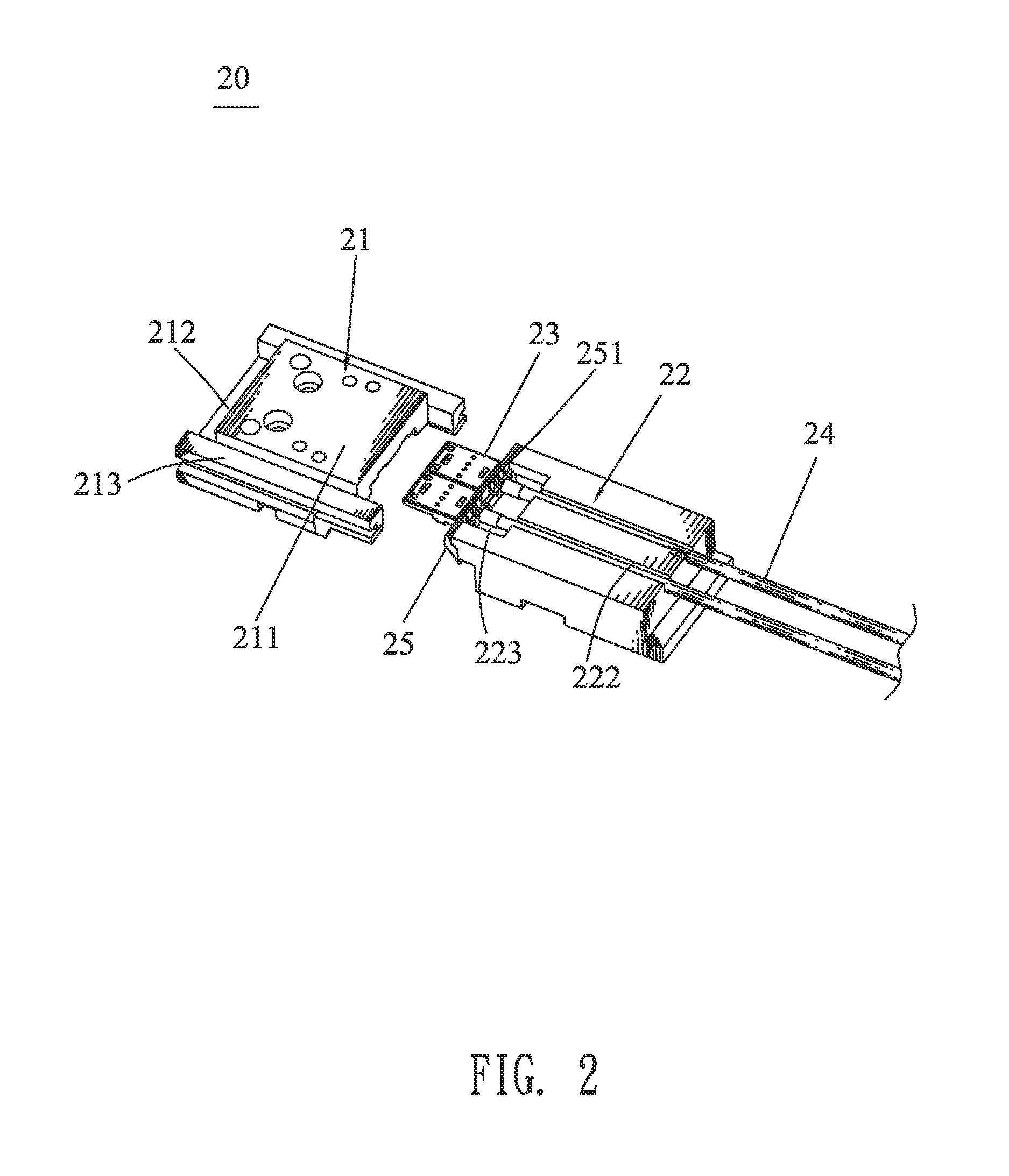

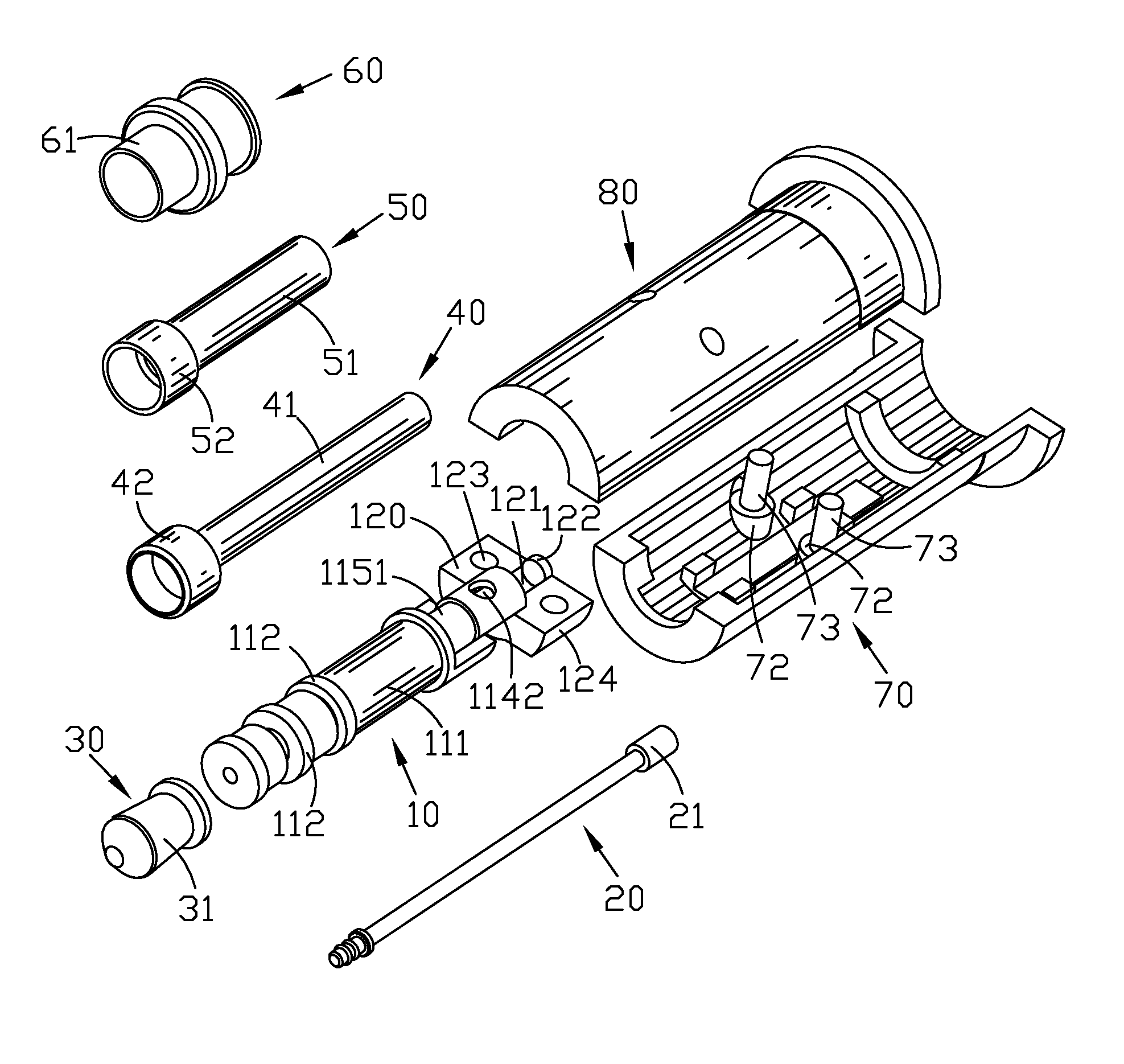

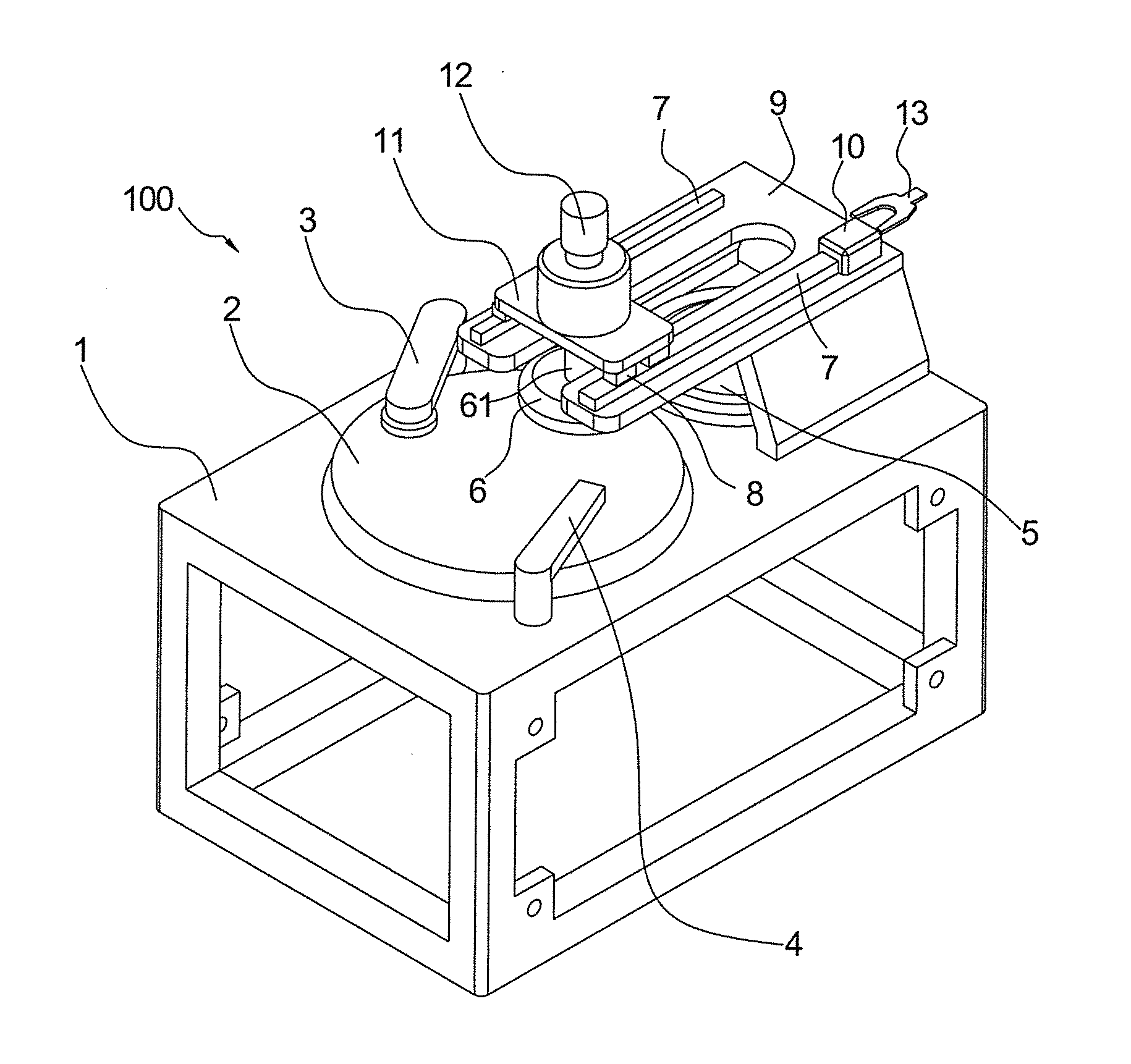

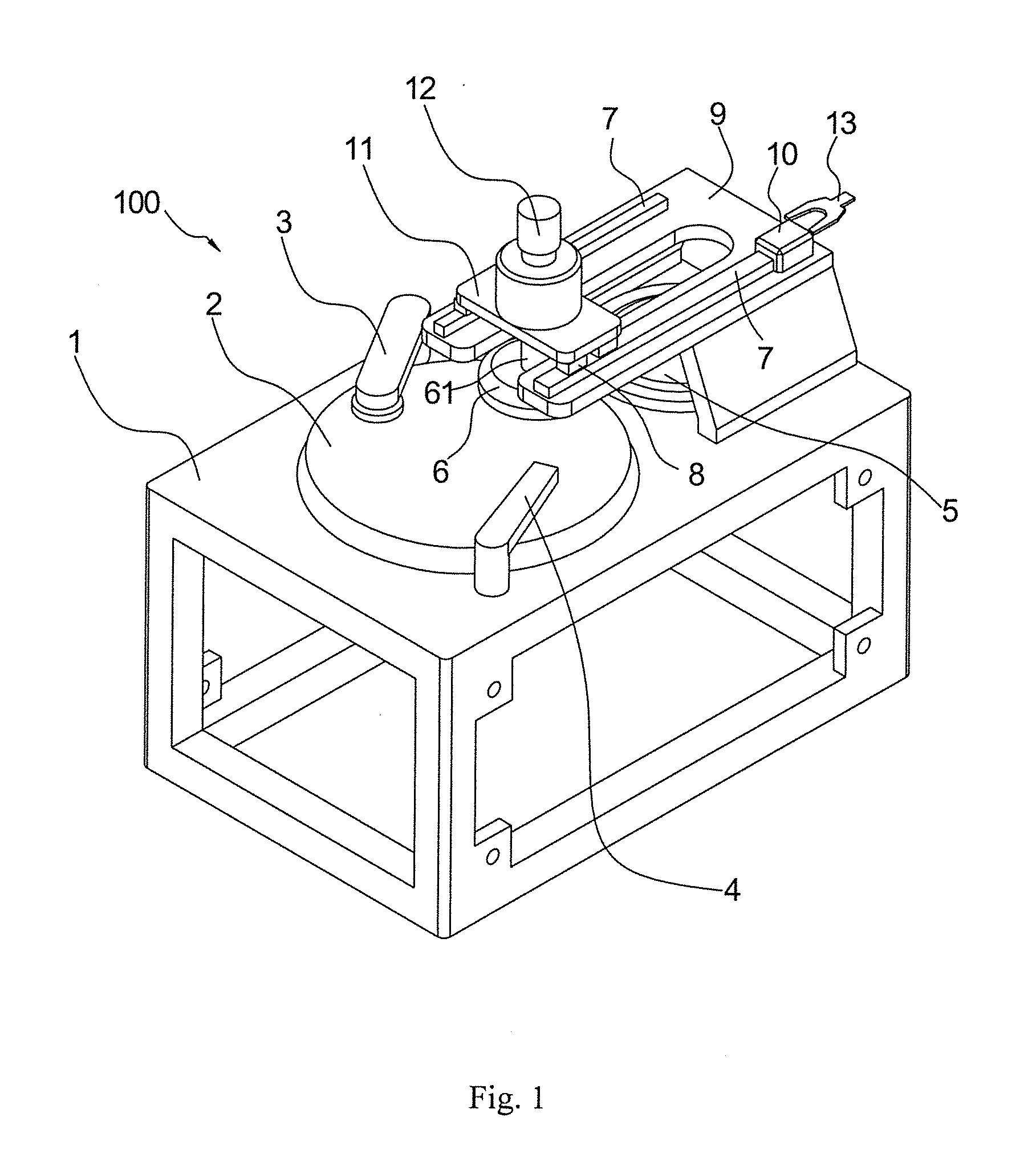

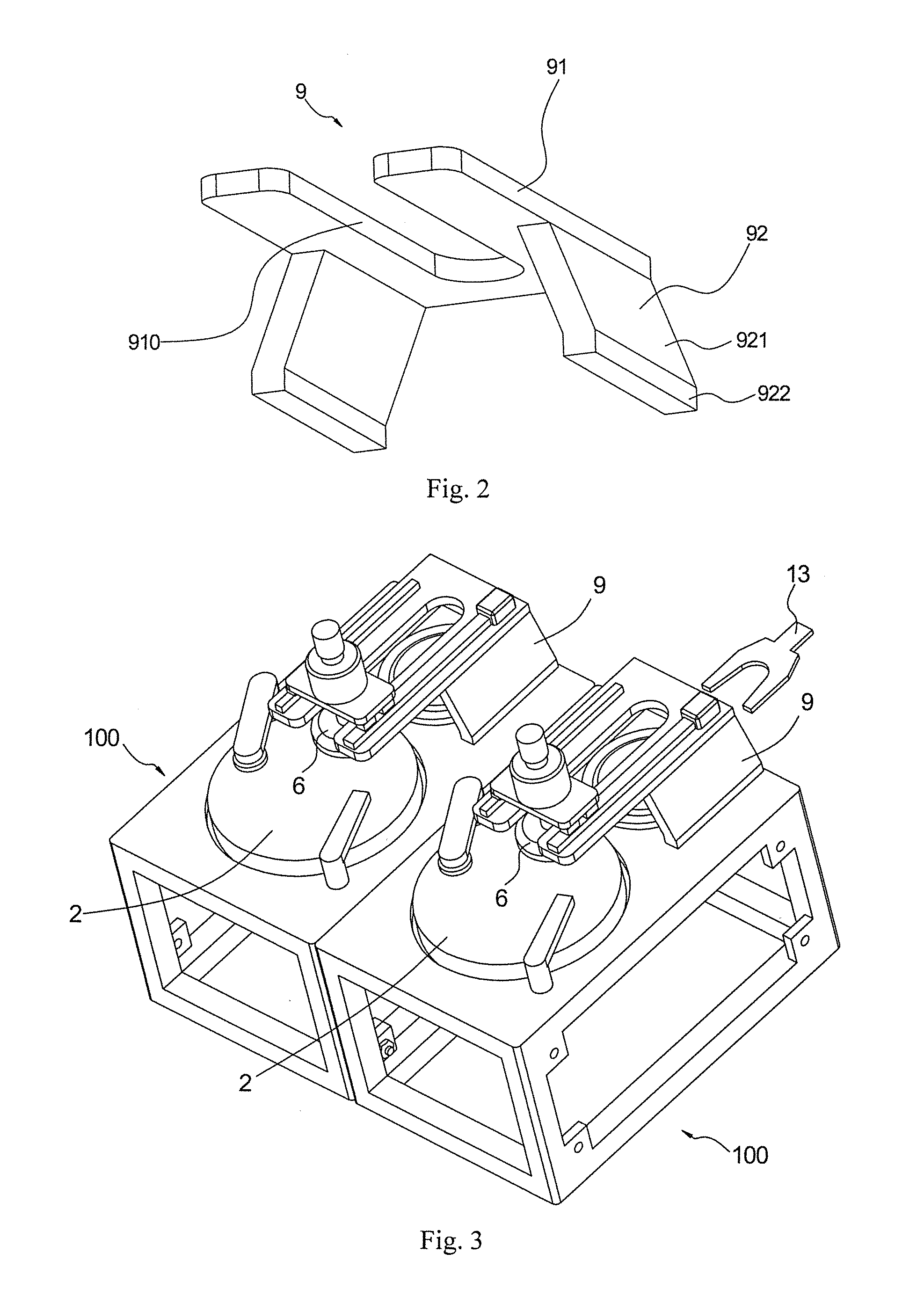

Automatic soldering machine

InactiveUS8517245B1Solve low manufacturing efficiencyQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesMan machineEngineering

An automatic soldering machine adapted for soldering cables with electronic products includes a main frame module, a man-machine control interface, a sliding tray located in front of the man-machine control interface, a loading tool slidably disposed in the sliding tray, a feeding module close to a bottom of the sliding tray, a removing module located between the man-machine control interface and a reforming module, a container, a loading tool combination module located above the sliding tray, a spraying module located in rear of the sliding tray, and a loading tool reflow module mounted on a rear of the main frame module. The man-machine control interface is connected with and controls the loading tool, the feeding module, the removing module, the reforming module, the loading tool combination module, the spraying module and the loading tool reflow module for realizing an automatic soldering process of the electronic products and the cables.

Owner:CHENG UEI PRECISION IND CO LTD

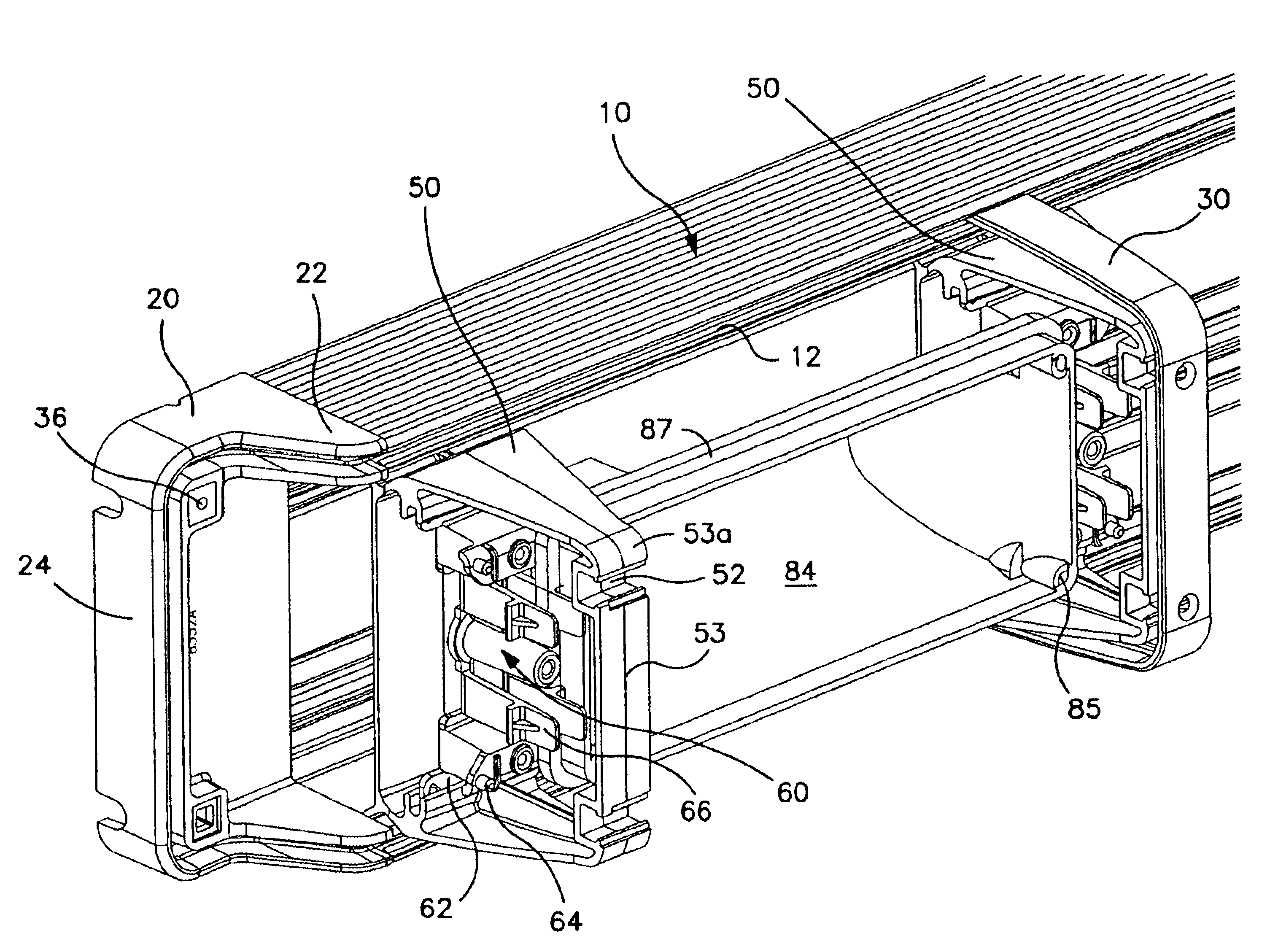

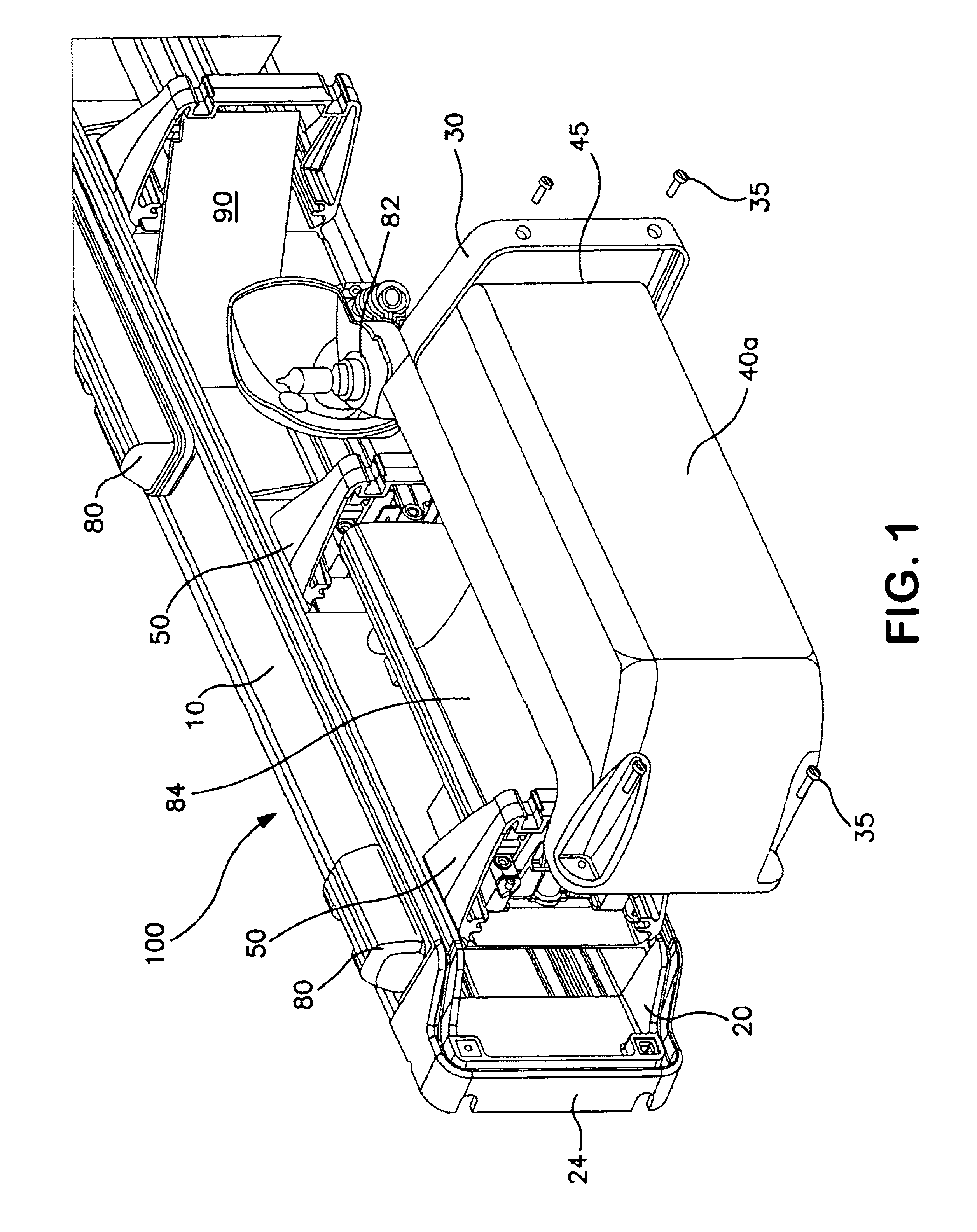

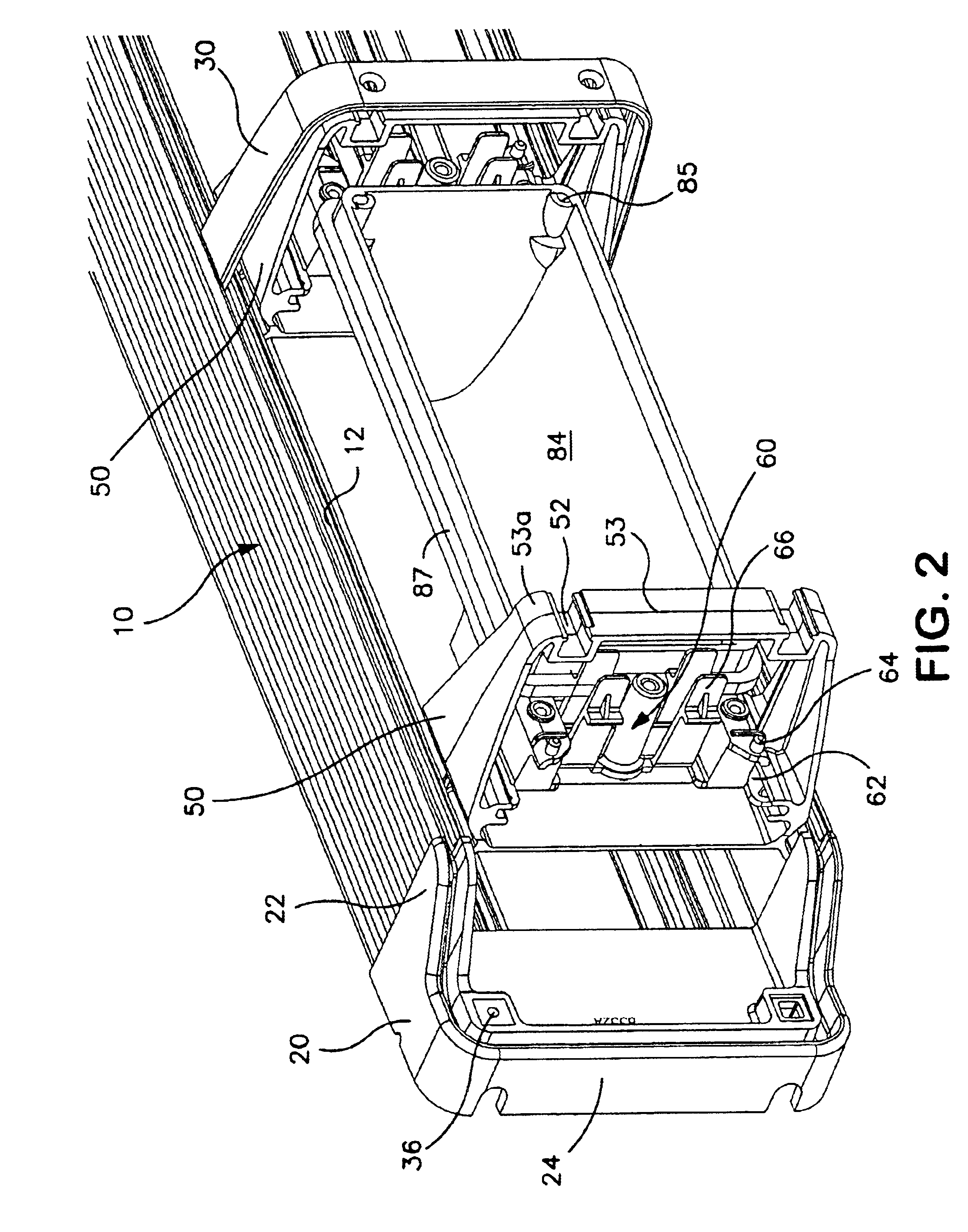

Light bar with integrated warning illumination and lens support structure

InactiveUS6863424B2Good weather resistanceIncrease flexibilityPortable emergency signal deviceNon-electric lightingCamera lensEngineering

Brackets received in an elongated base support both lens portions and internal light bar components. Lens portion longitudinal edges penetrate the outer portion of a gasket channel to engage a gasket member. Lens retainer straps sandwich gasket layers to seal the longitudinal butt ends of lens portions. The lens retainers also penetrate the gasket channel to engage the gasket member. The brackets provide multiple locations for mounting warning light units and related light bar components within the space defined between the base and the lens portions.

Owner:WHELEN ENGINEERING COMPANY

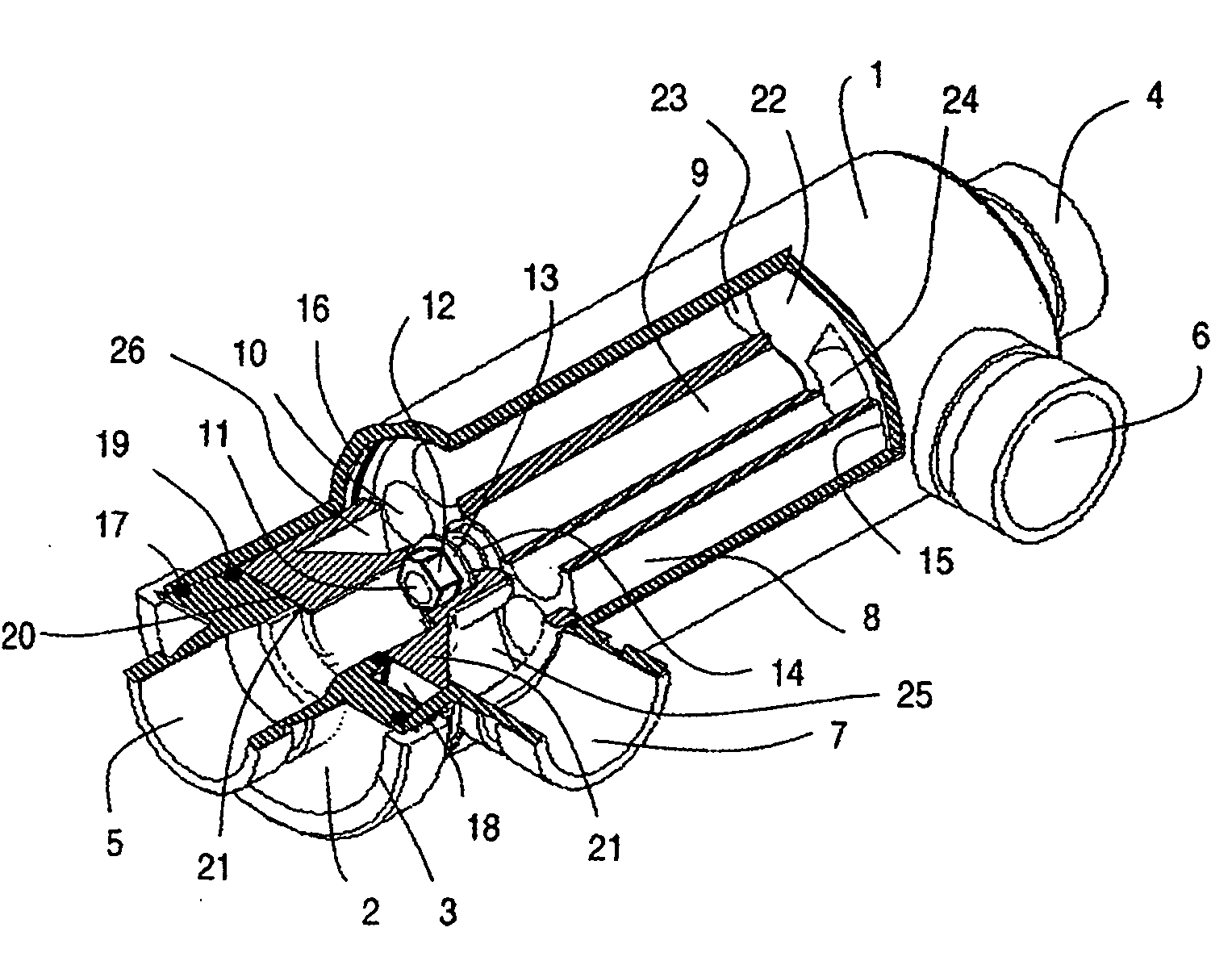

Pressure exchanger

ActiveUS20060032808A1Improve flow capacityIncrease momentumRotary/oscillating piston combinations for elastic fluidsGeneral water supply conservationCavitationMomentum

A pressure exchanger for transferring pressure energy from a relatively high-pressure fluid stream to another relatively low-pressure fluid stream is provided. A ducted rotor is positioned on a central axle between two end covers inside a pressure vessel with a coaxial inlet and outlet pair that is in communication with a pair of low pressure ports having inclination forming an inlet tangential velocity vector in the direction of rotor rotation and an outlet tangential velocity vector in opposite direction imparting a rotational momentum on rotor. A pair of high-pressure ports is adapted for flow without inclination and imparts no momentum to rotor and flow can be varied without impacting the rotor's RPM. The end covers have a sloped surface following a flat sealing area that increases the clearance in the direction of rotation causing increased outflow during depressurization and lower duct pressure before duct is exposed to low pressure port and furthermore causing increased inflow during the pressurization phase before duct is exposed to the high pressure port, which will dissipate pressure energy as opposed to producing cavitation or pressure waves with result wear and noise.

Owner:ISOBARIC STRATEGIES INC

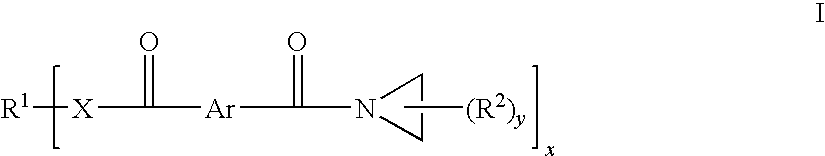

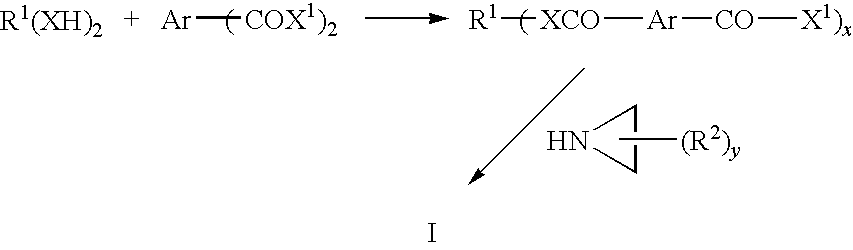

Aziridine crosslinking agents for acrylic adhesives

InactiveUS20100227969A1Reduce sensitivityGood shear propertyOrganic chemistryNon-macromolecular adhesive additivesMeth-Aziridine

Owner:3M INNOVATIVE PROPERTIES CO

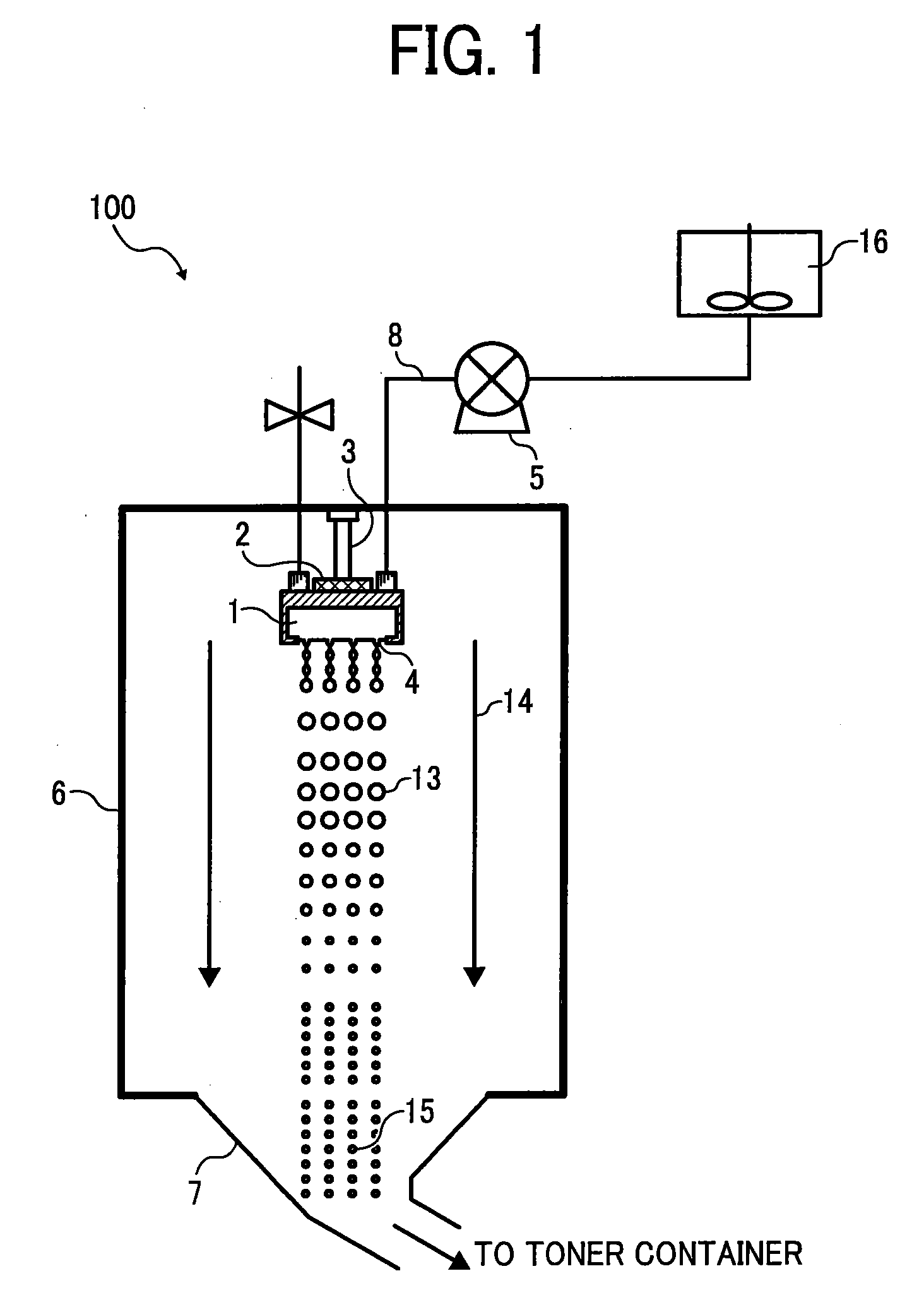

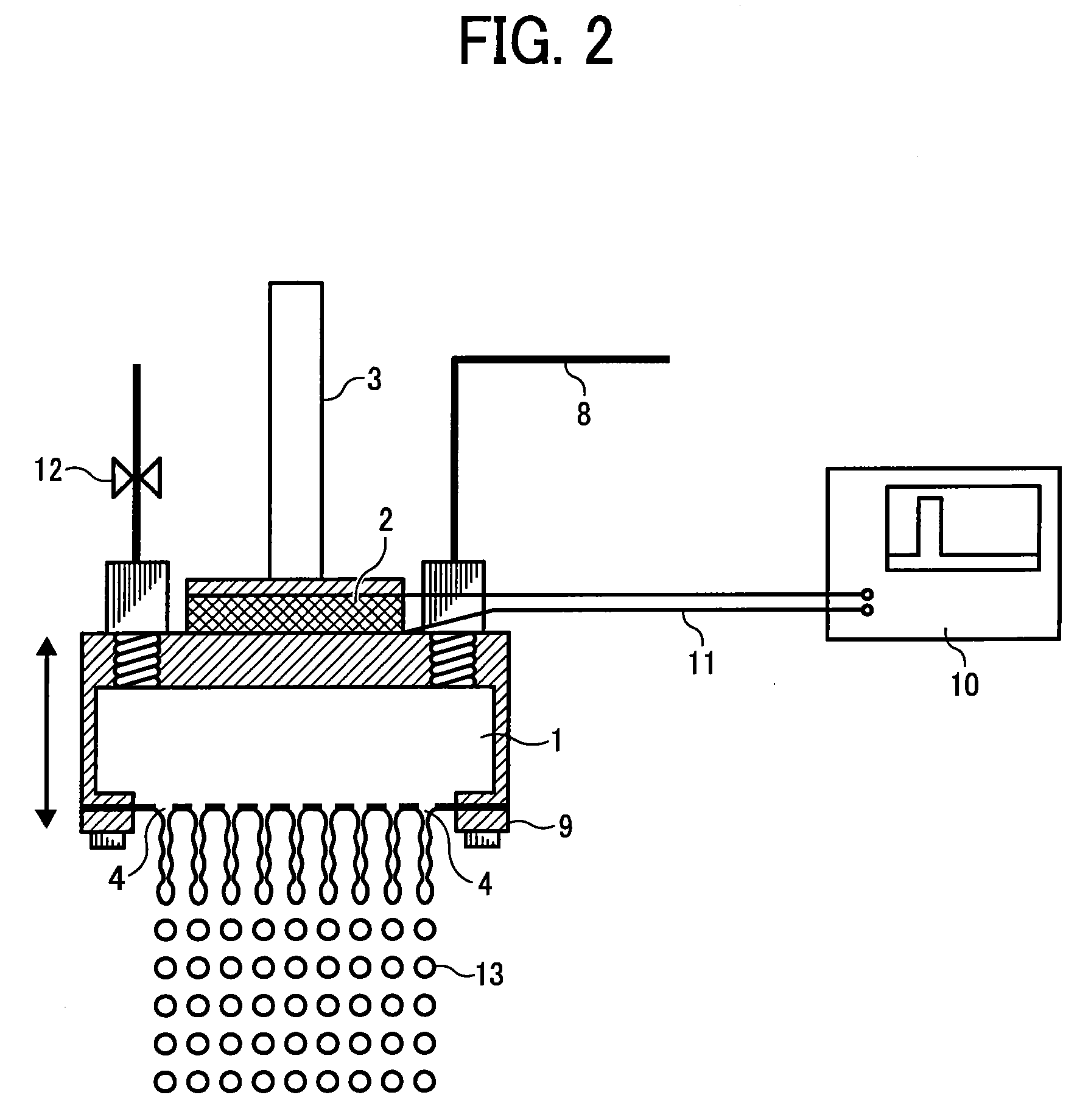

Toner, developer, and image forming apparatus

InactiveUS20080227011A1Good transferabilityImprove cleanabilityElectrographic process apparatusDevelopersEngineeringMechanical engineering

A toner including a binder resin, a colorant, and a silicon-containing polymer, which is manufactured by a method including: discharging a toner constituent liquid including toner constituents including the binder resin, the colorant, and the silicon-containing polymer, from at least one discharge opening to form liquid droplets thereof; and converting the liquid droplets into solid toner particles in a granulation space.

Owner:RICOH KK

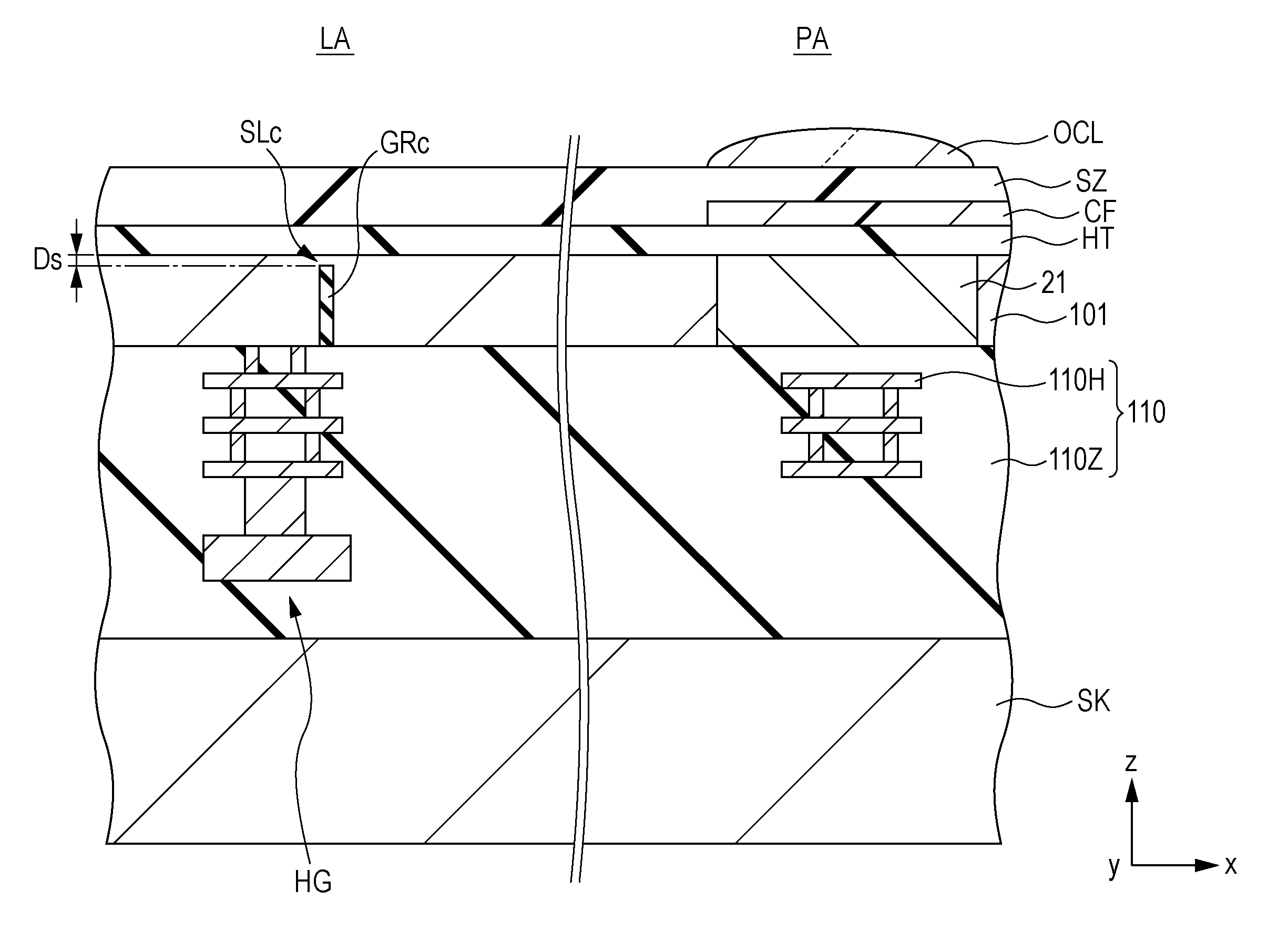

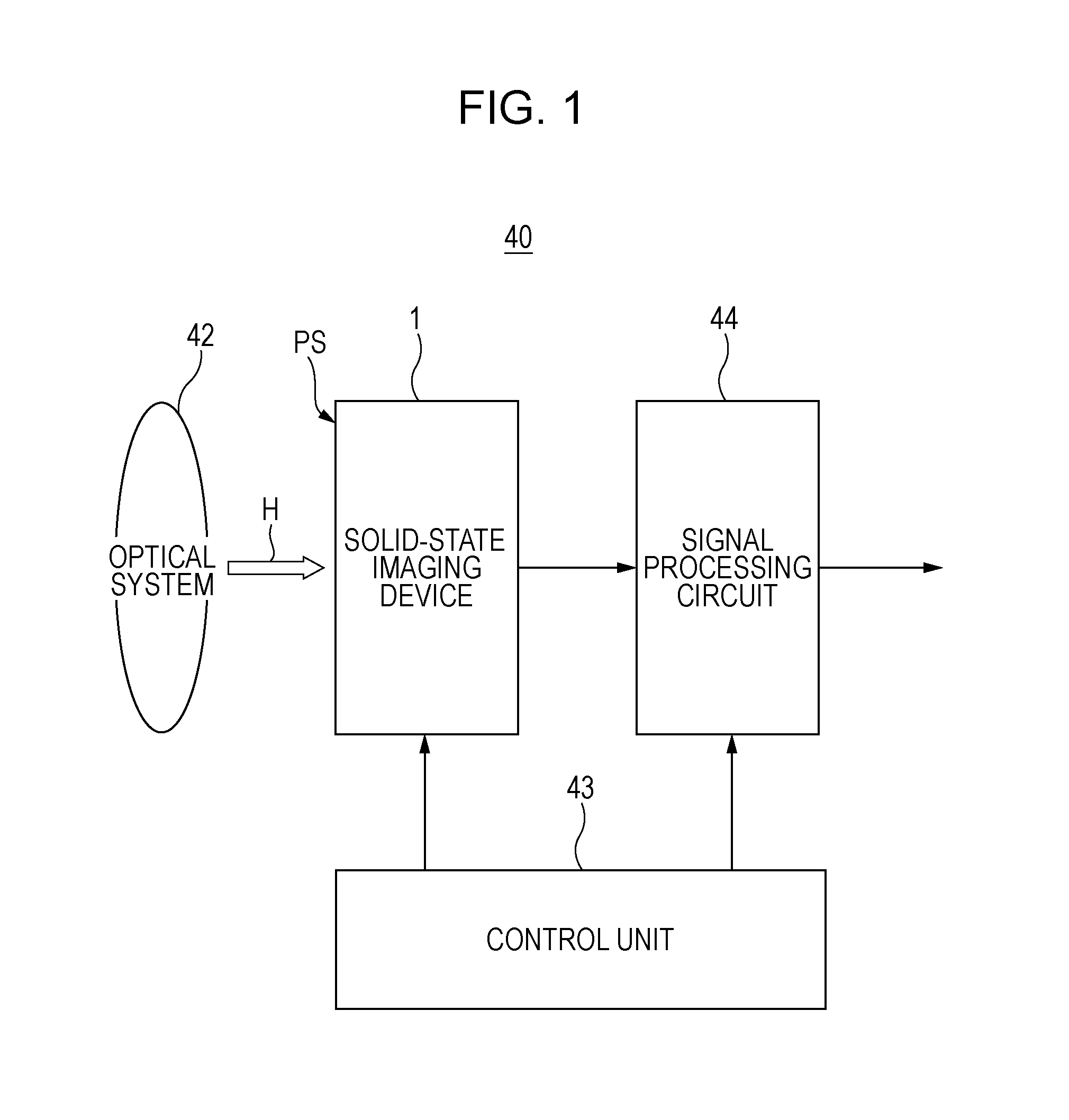

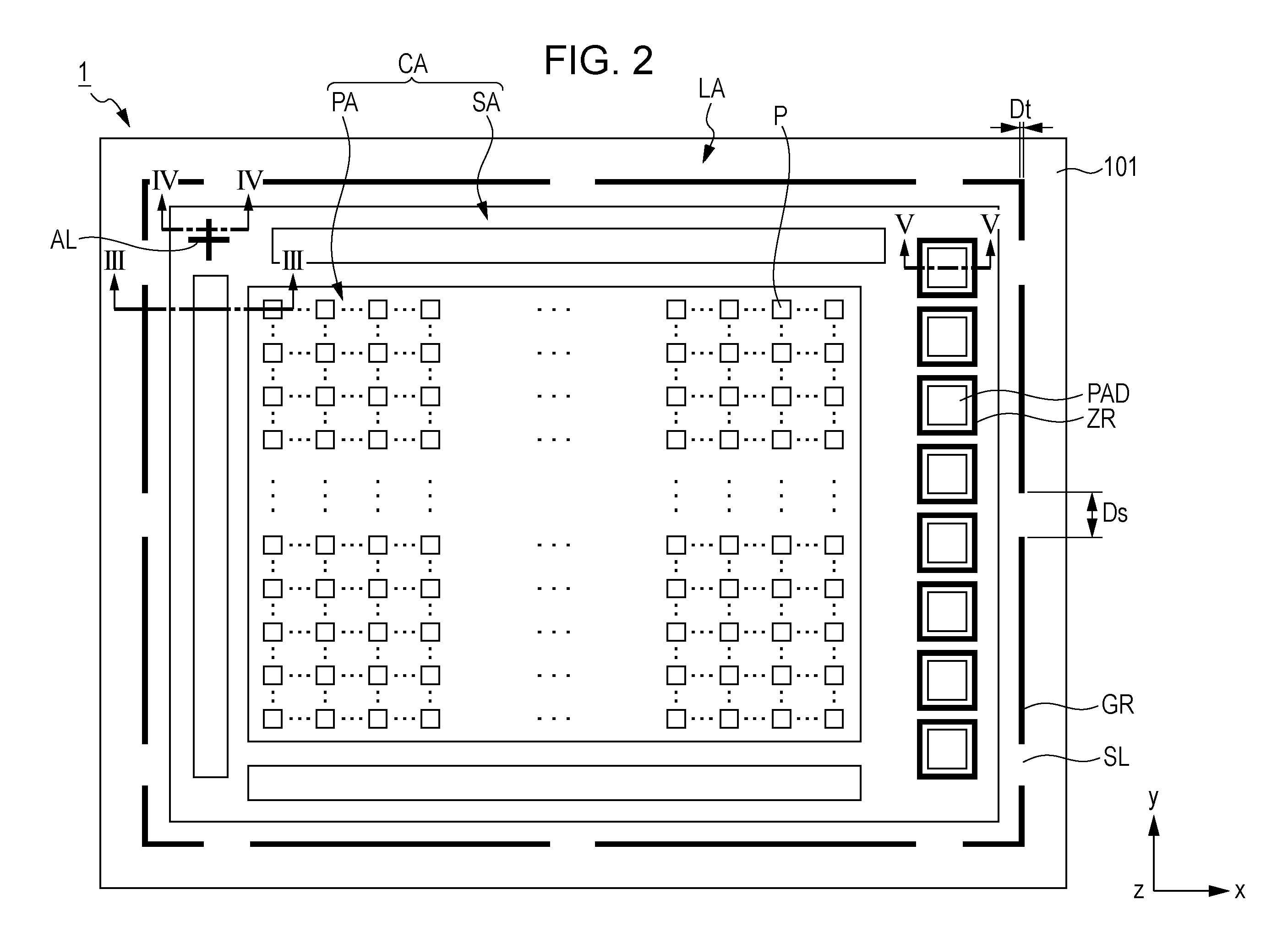

Solid-state imaging device, manufacturing method thereof, electronic apparatus, and semiconductor device

ActiveUS20110186917A1Improve production yieldSolve low manufacturing efficiencyFinal product manufactureSemiconductor/solid-state device detailsEngineeringGuard ring

A semiconductor device includes a substrate, a region including a semiconductor element on the substrate, and at least one guard ring structure provided around the region. The guard ring structure includes a guard ring and at least one portion comprised of the substrate.

Owner:SONY SEMICON SOLUTIONS CORP

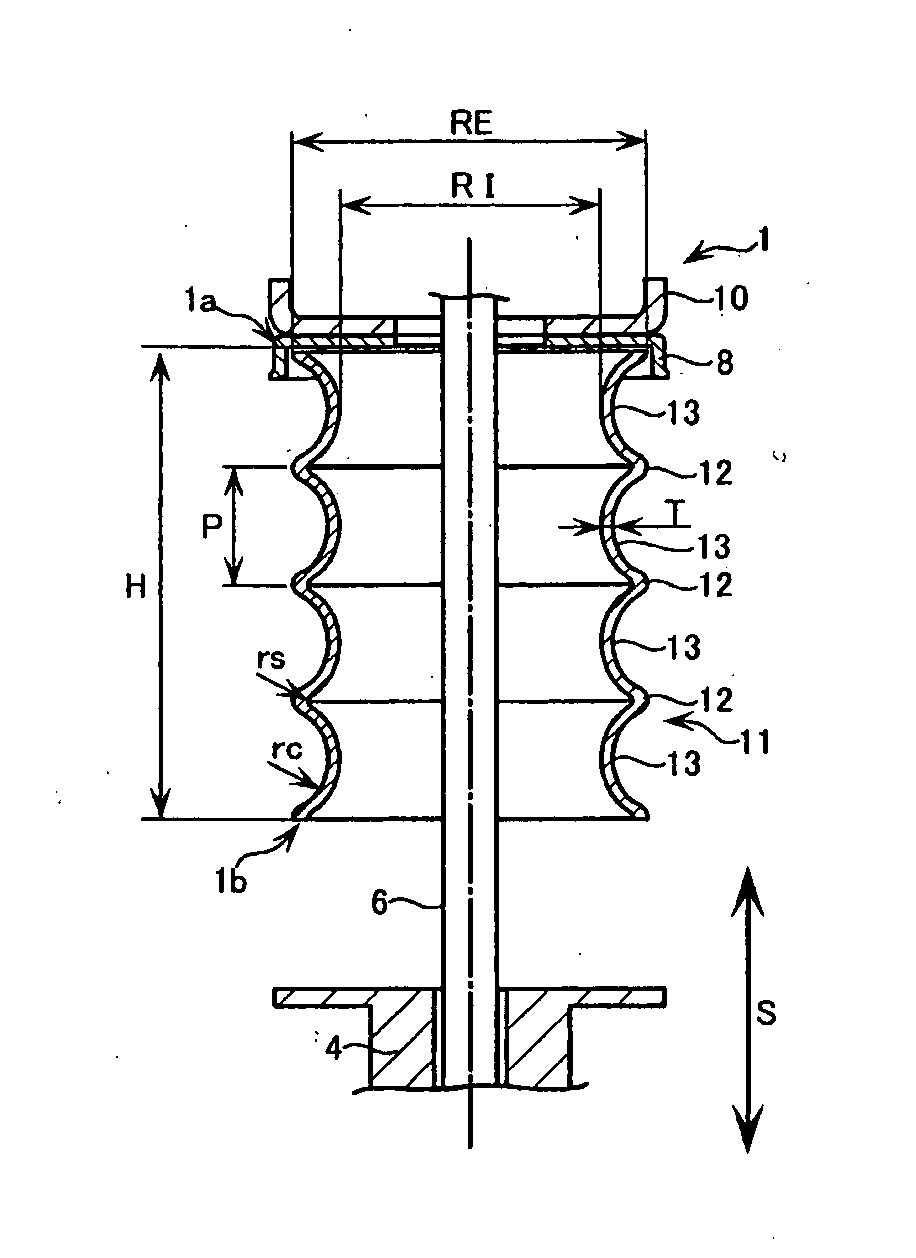

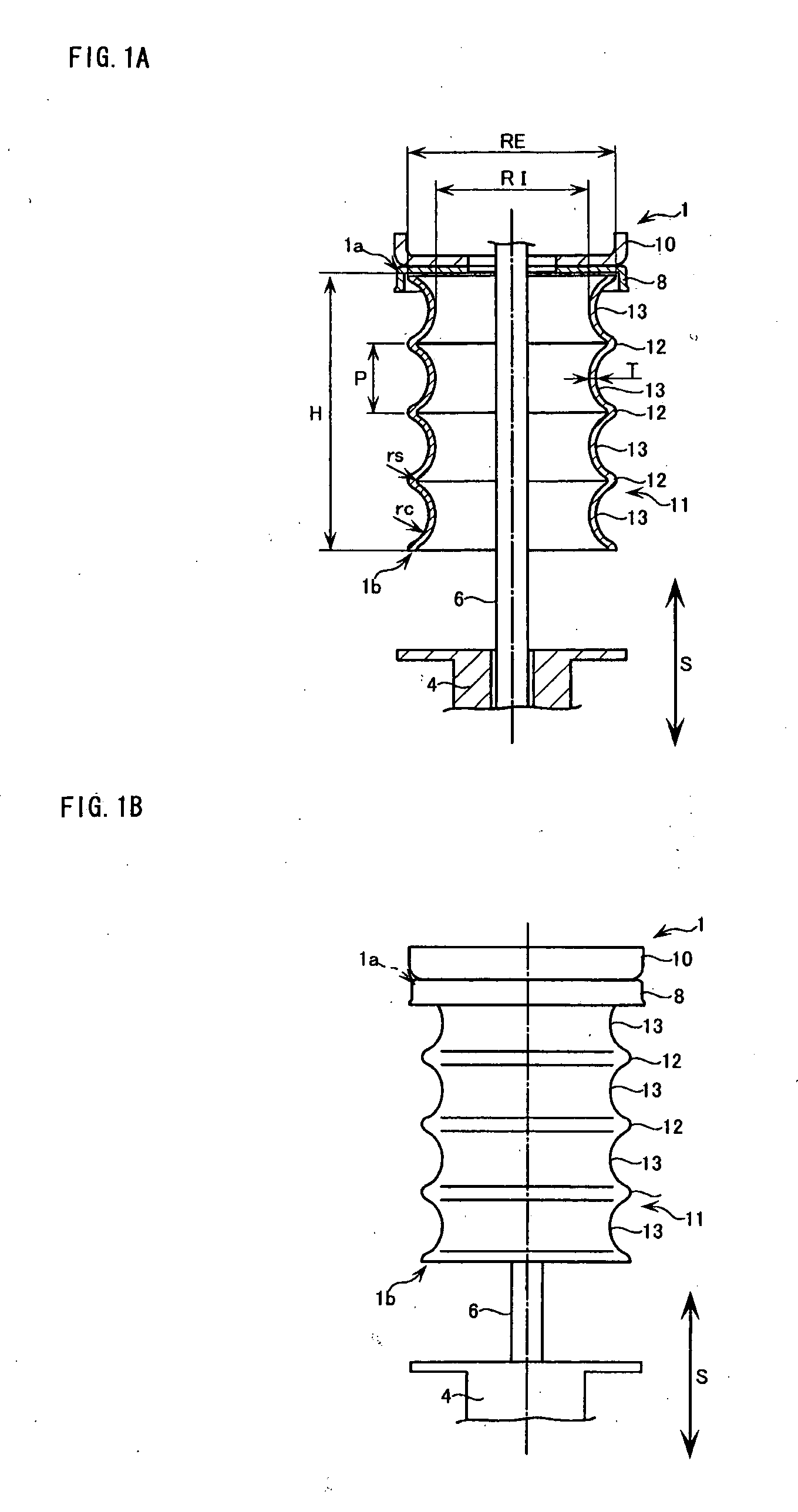

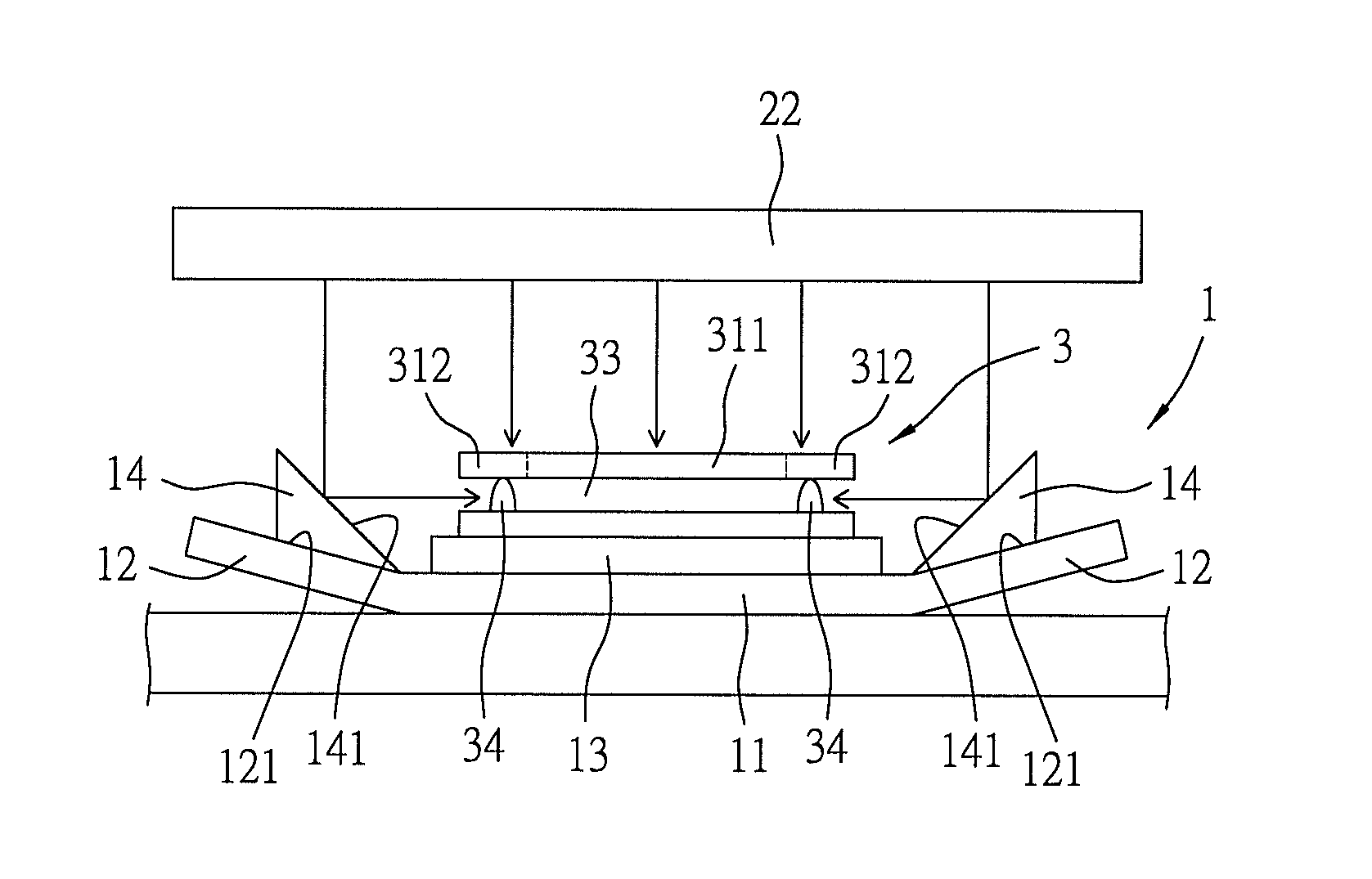

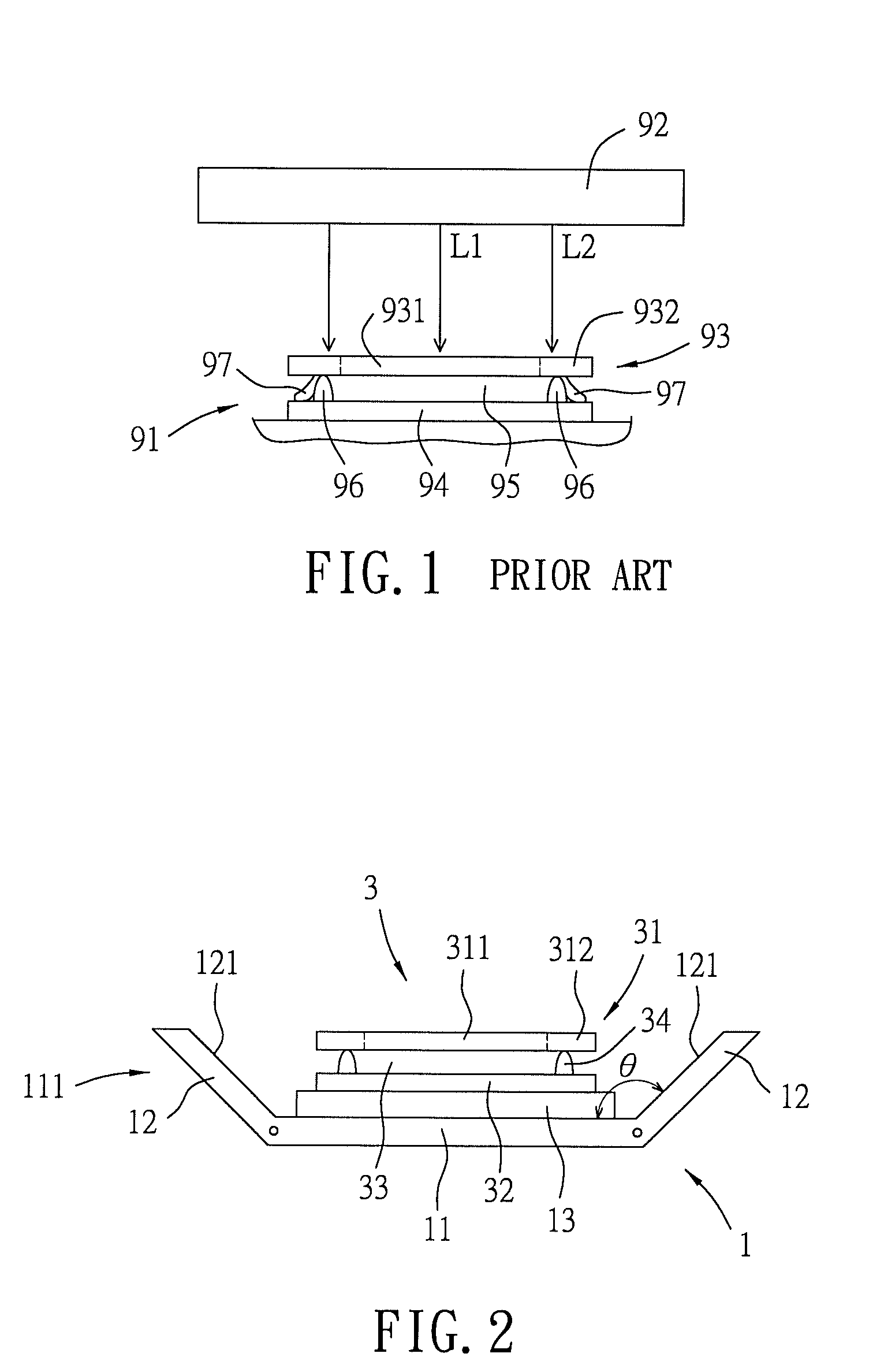

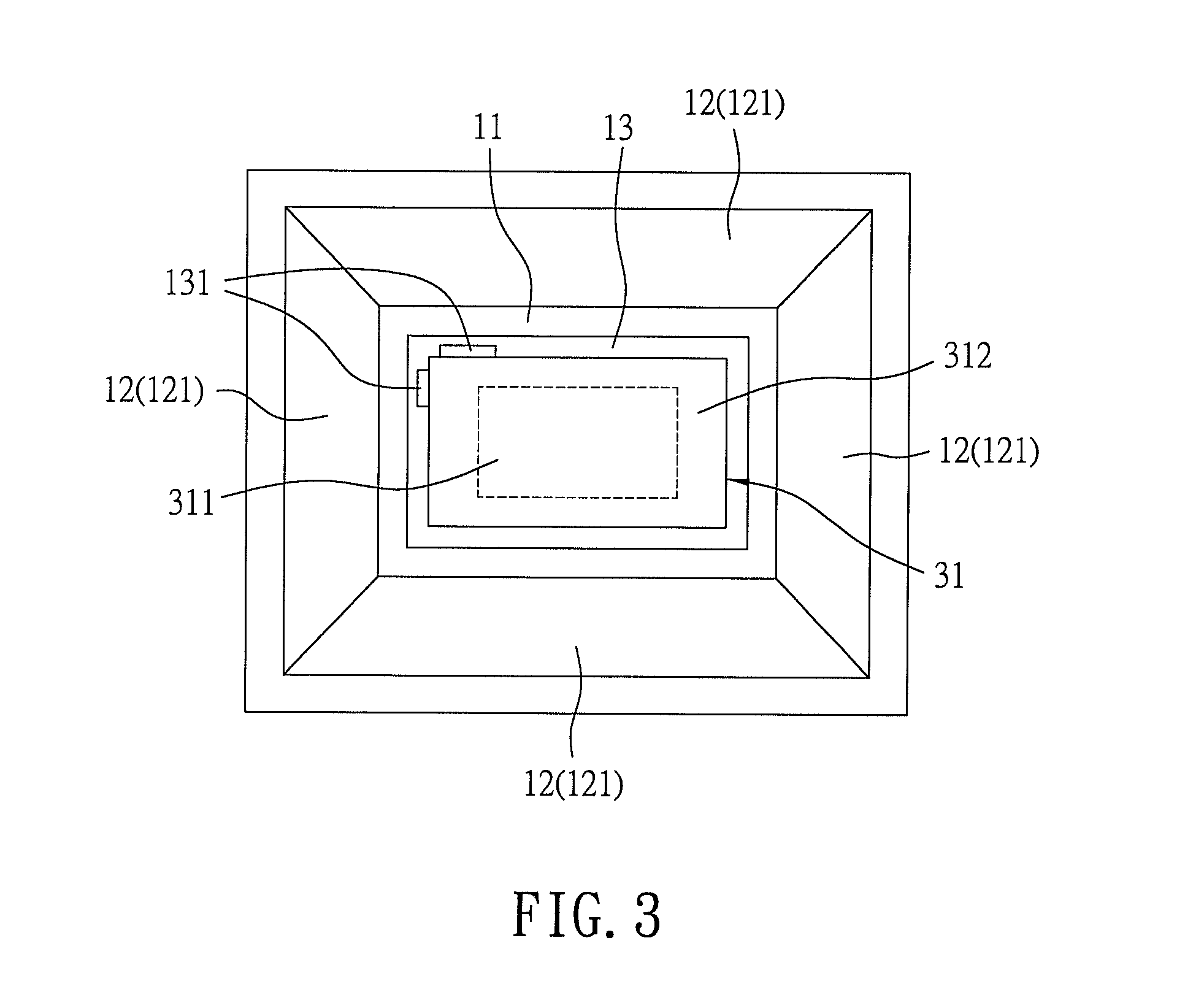

Bump stopper and manufacturing method therefor

InactiveUS20110156327A1Excellent in material yield rateSolve low manufacturing efficiencyResilient suspensionsPivoted suspension armsEngineeringShock absorber

Disclosed are a bump stopper and a manufacturing method therefor which can maintain the shock-absorbing characteristics and durability performance constantly for a prolonged period of time regardless of the temperature or humidity of the usage environment, which can maintain a constant dimensional precision for a finished product, which is excellent in material yield rate and manufacturing efficiency, and which is low-cost, lightweight, recyclable, and ecological. A bump stopper (1) is provided in the vicinity of a rod of a shock absorber to elastically limit the stroke of the shock absorber at the time of the contraction thereof and to absorb the shock generated at that time. The bump stopper includes a hollow cylindrical bellows part (11) which extends along a stroke direction S of the shock absorber. The bellows part is formed by thinning thermoplastic resin and is constructed such that first parts (12) which are bulged outward and second parts (13) which are recessed inward are provided alternately and repeatedly in the stroke direction S.

Owner:FUKOKU CO LTD

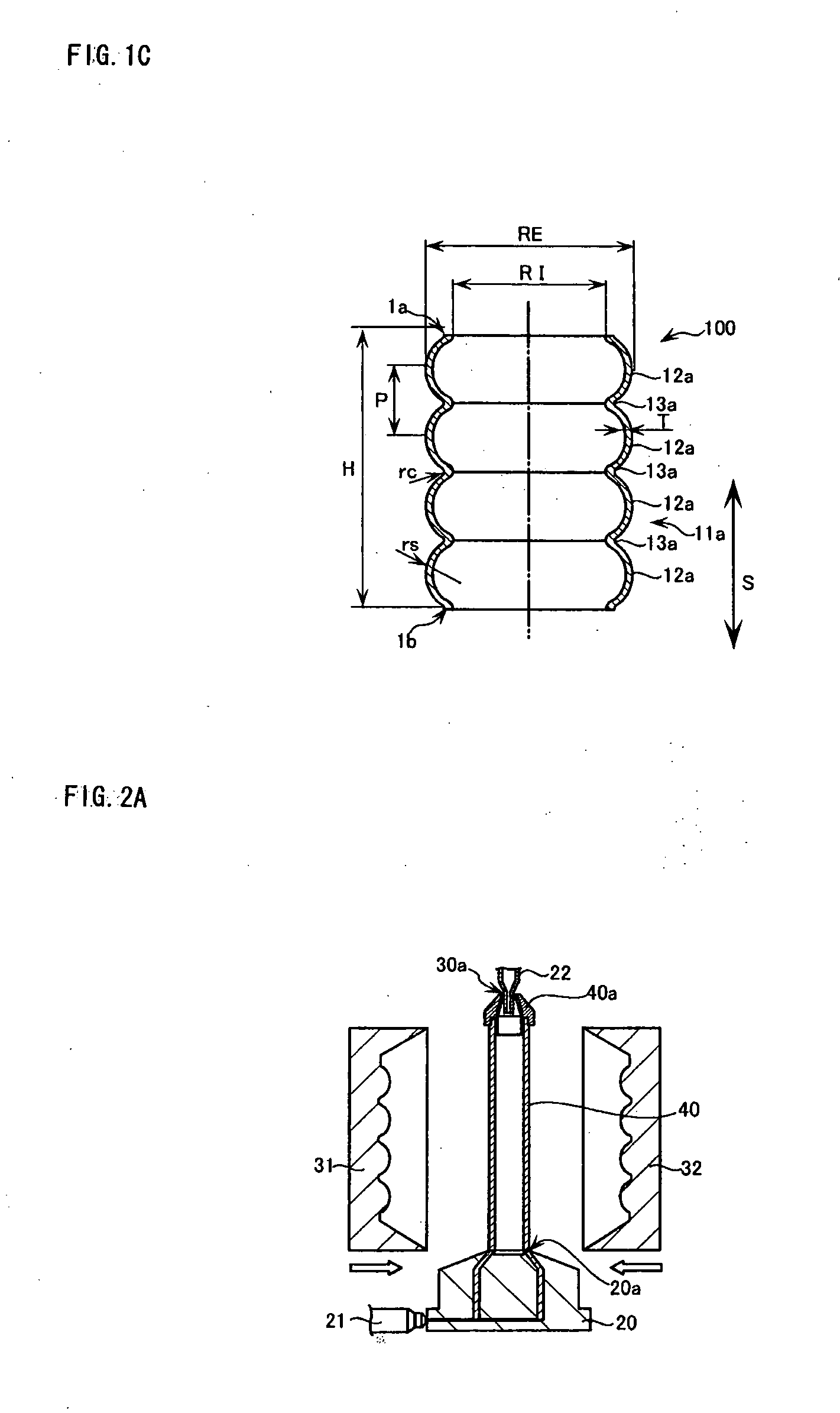

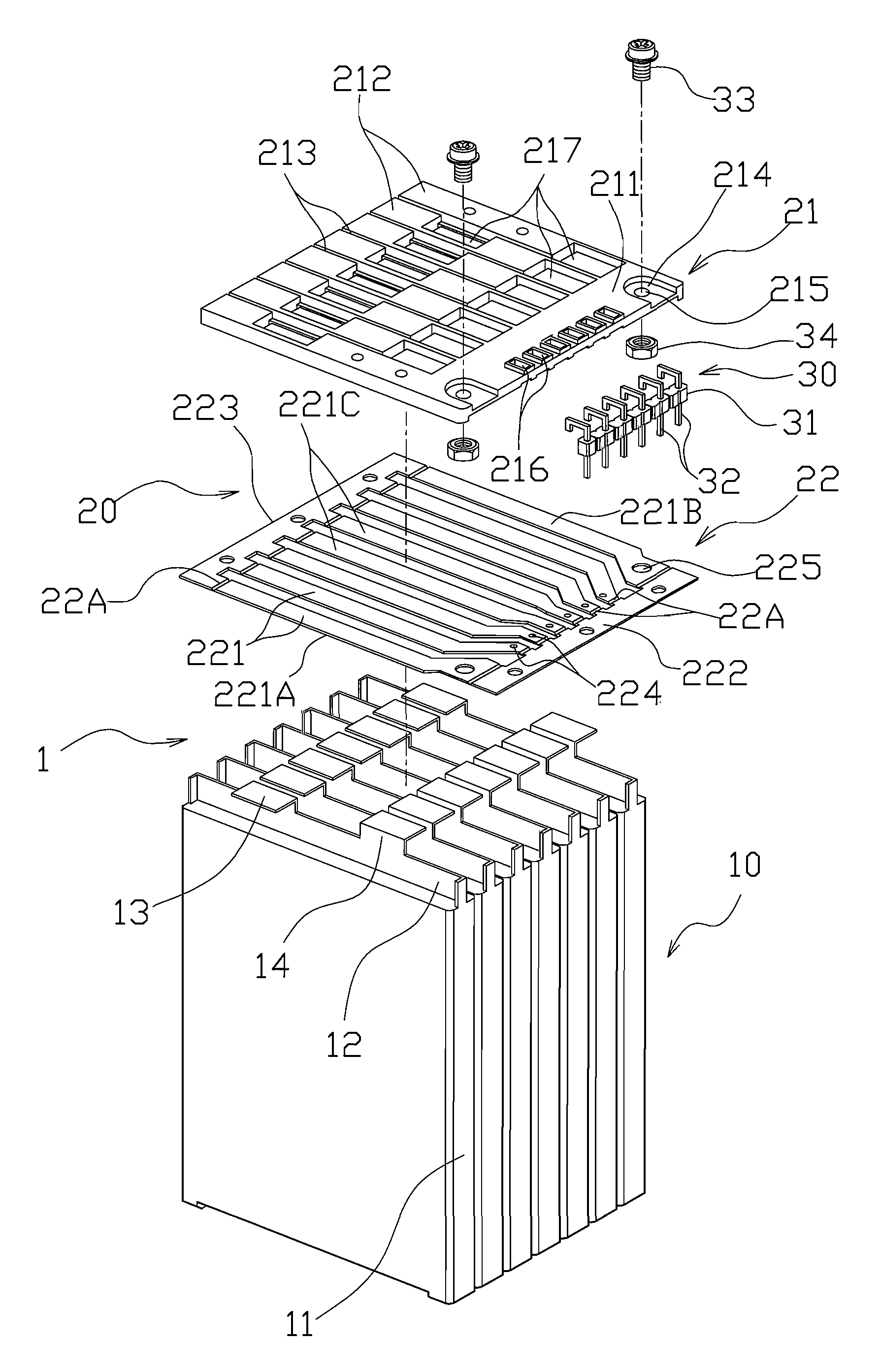

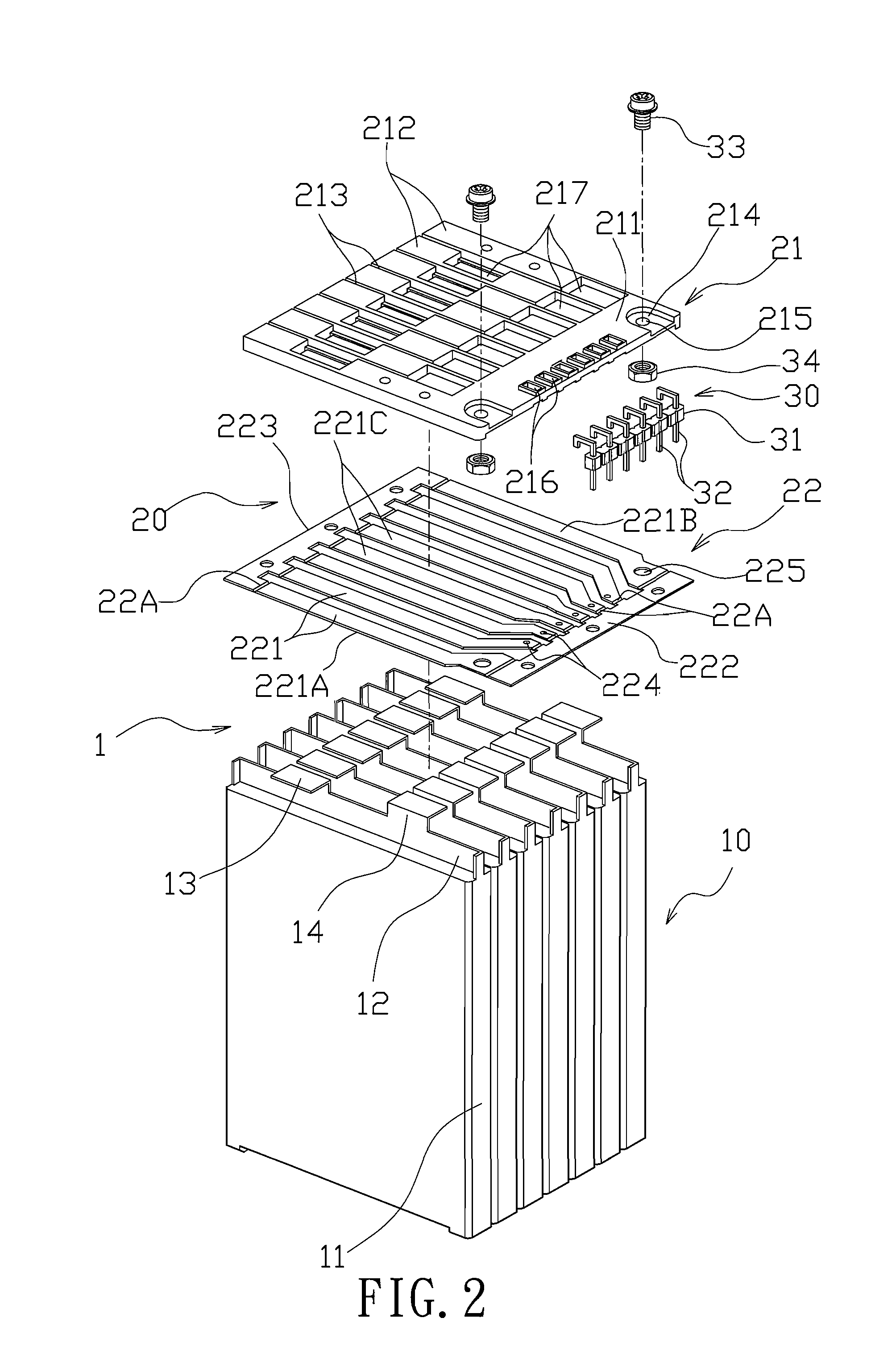

Multi-cells connection board (MCB) assembly and its fabrication method

InactiveUS20080131761A1Easy to manufactureSolve low manufacturing efficiencyPrimary cellsElectrode carriers/collectorsBattery cellMetal

A MCB assembly is disclosed to include an electrically insulative mounting board, which has an end plate and cell compartments extending from the end plate in a parallel manner and spaced from one another by a respective narrow crevice for dividing a plurality of battery cells, a metal conducting strip bar, which is joined to the electrically insulative mounting board by means of injection molding, having a plurality of metal conducting strips and two connecting strips respectively formed integral with the opposite ends of the metal conducting strips that are separated from the metal conducting strips after joining of the metal conducting strip bar to the mounting board, and a sensor connector mounted in through holes on the end plate of the mounting board and bonded with metal terminals thereof to a respective conducting bonding hole on each of the metal conducting strips.

Owner:HITECH ENERGY

Methods for manufacturing optical fiber preform and methods for manufacturing optical fiber

ActiveUS20120324958A1Solve low manufacturing efficiencySmall additional bending lossGlass optical fibreGlass fibre drawing apparatusMicrowaveOxygen

A method for manufacturing an optical fiber preform, including: a) providing a lining tube as a substrate tube, and doping and depositing by a PCVD or an MCVD process; b) in the reacting gas of silicon tetrachloride and oxygen, introducing a fluorine-containing gas for fluorine doping, introducing germanium tetrachioride for germanium doping, ionizing the reacting gas in the lining tube through microwaves to form plasma, depositing the plasma on the inner wall of the lining tube in the form of glass; c) after the completion of deposition, processing the deposited lining tube into a solid core rod by melting contraction through an electric heating furnace; d) sleeving the solid core rod into a pure quartz glass jacketing tube and manufacturing the two into an optical fiber preform; and e) allowing the effective diameter d of the optical fiber preform to become between 95 and 205 mm.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Labels for in-mold forming and molded resin products having the same

InactiveUS6858283B2Reliably securedSolve low manufacturing efficiencyStampsDecorative surface effectsMicrometerFilm base

Disclosed is a label for in-mold forming comprising a thermoplastic resin film base layer and a heat-seal resin layer, wherein a surface of the heat-seal resin layer has a centerline average roughness of 0.5 to 5 micrometers and the label has an air permeability of 10 to 20,000 seconds. When in-mold forming is conducted with the label of the present invention, labeled molded resin articles of various shapes can be manufactured while effectively inhibiting blistering.

Owner:YUPO CORP

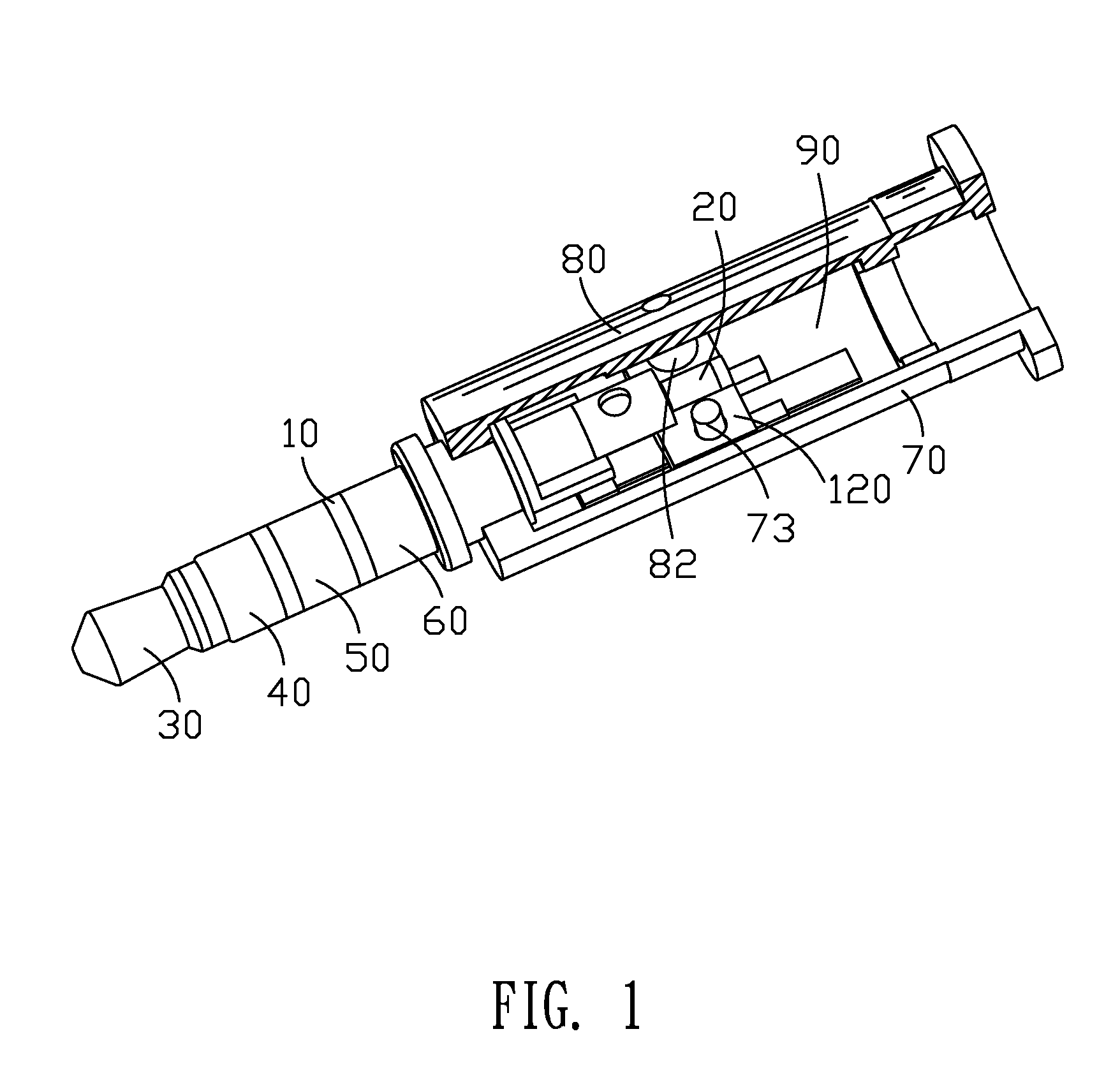

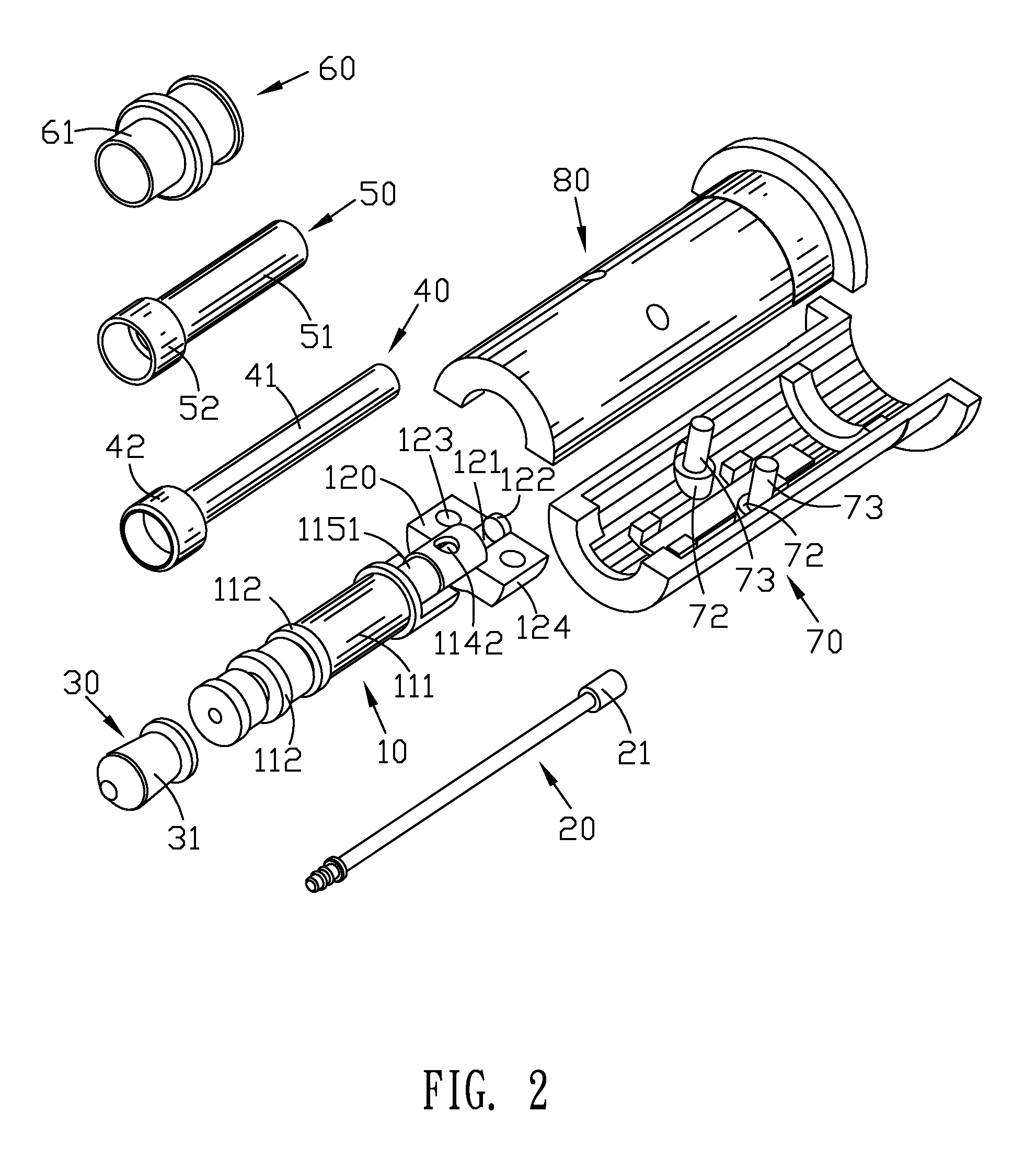

Audio plug connector

InactiveUS7699665B1Solve low manufacturing efficiencyQuality improvementCoupling device detailsTwo-part coupling devicesEngineeringMechanical engineering

Owner:CHENG UEI PRECISION IND CO LTD

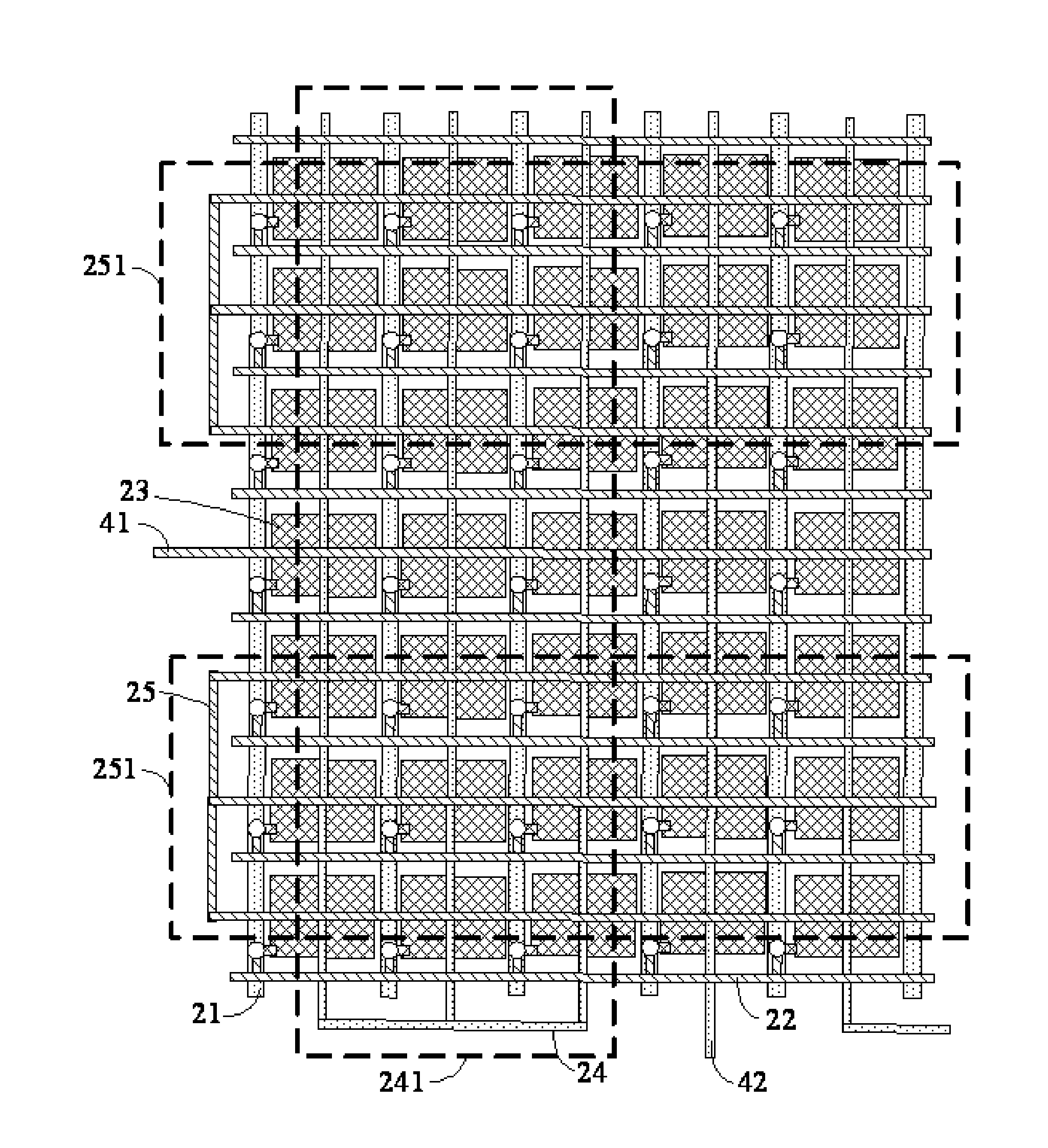

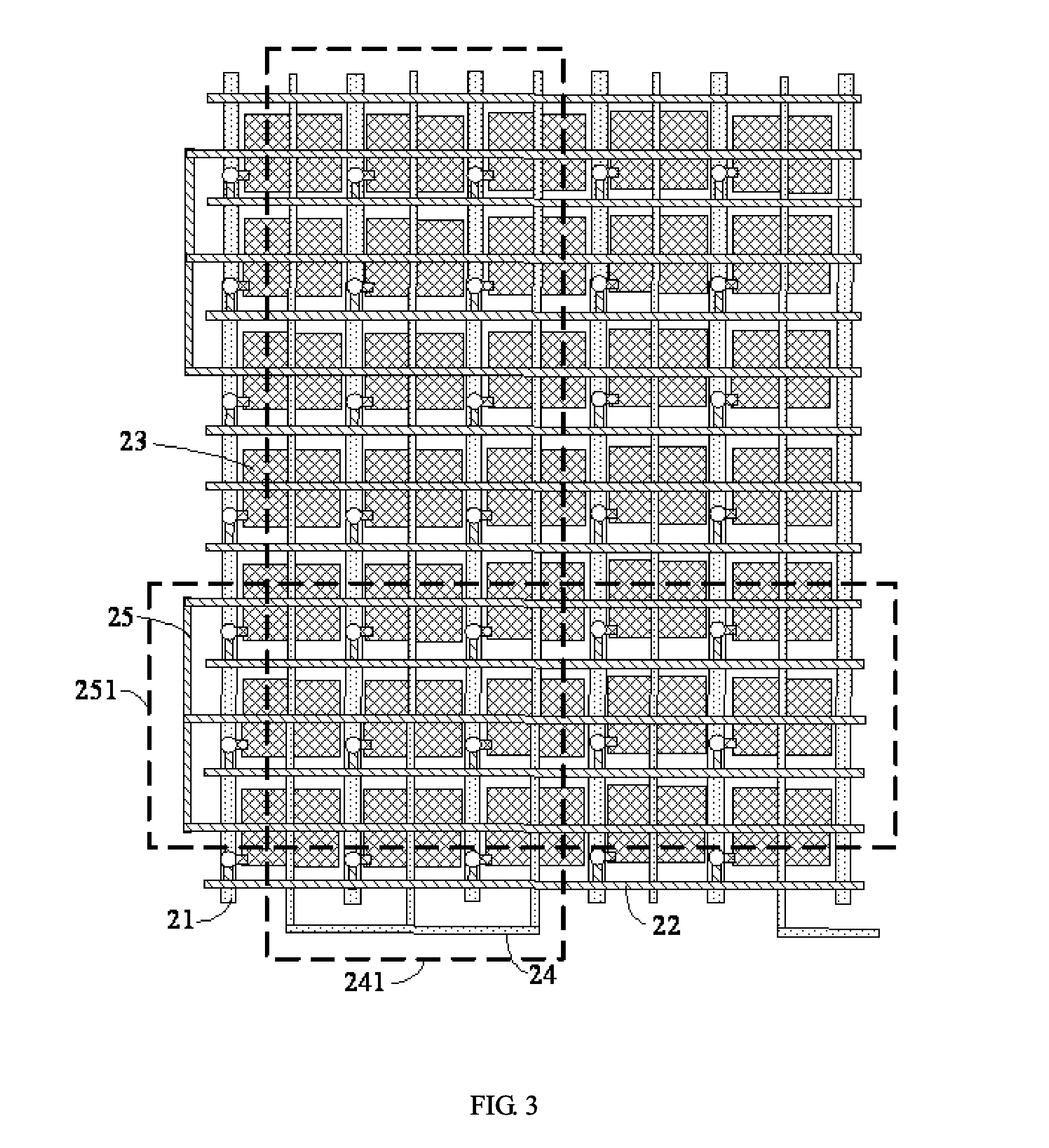

Touch-controlled display panel and touch-controlled display device

ActiveUS20150234510A1Solve low manufacturing efficiencyReduce manufacturing costStatic indicating devicesNon-linear opticsScan lineDisplay device

The present invention provides a touch-controlled display panel, which comprises an array substrate, a color filter substrate, and a liquid crystal layer disposed between the array substrate and the color filter substrate. The array substrate comprises a scan line, a data line, a pixel electrode, a first touch-controlled driving line, and a touch-controlled sensing line. The present invention further provides a touch-controlled display device. The present invention integrates the common line with the touch-controlled driving line and the touch-controlled sensing line, thereby improving the efficiency in manufacturing the touch-controlled display panel and reducing the manufacture cost thereof.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

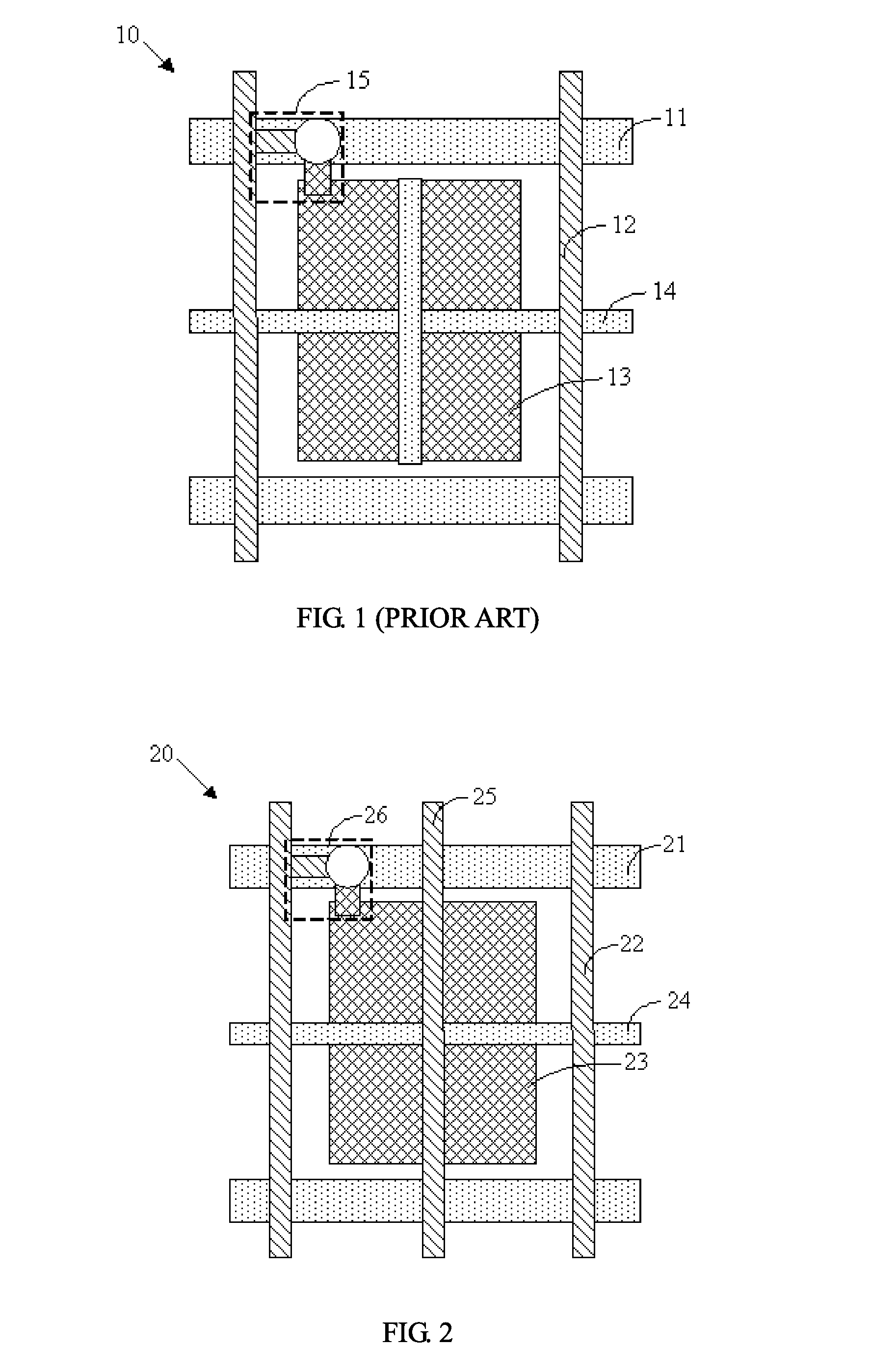

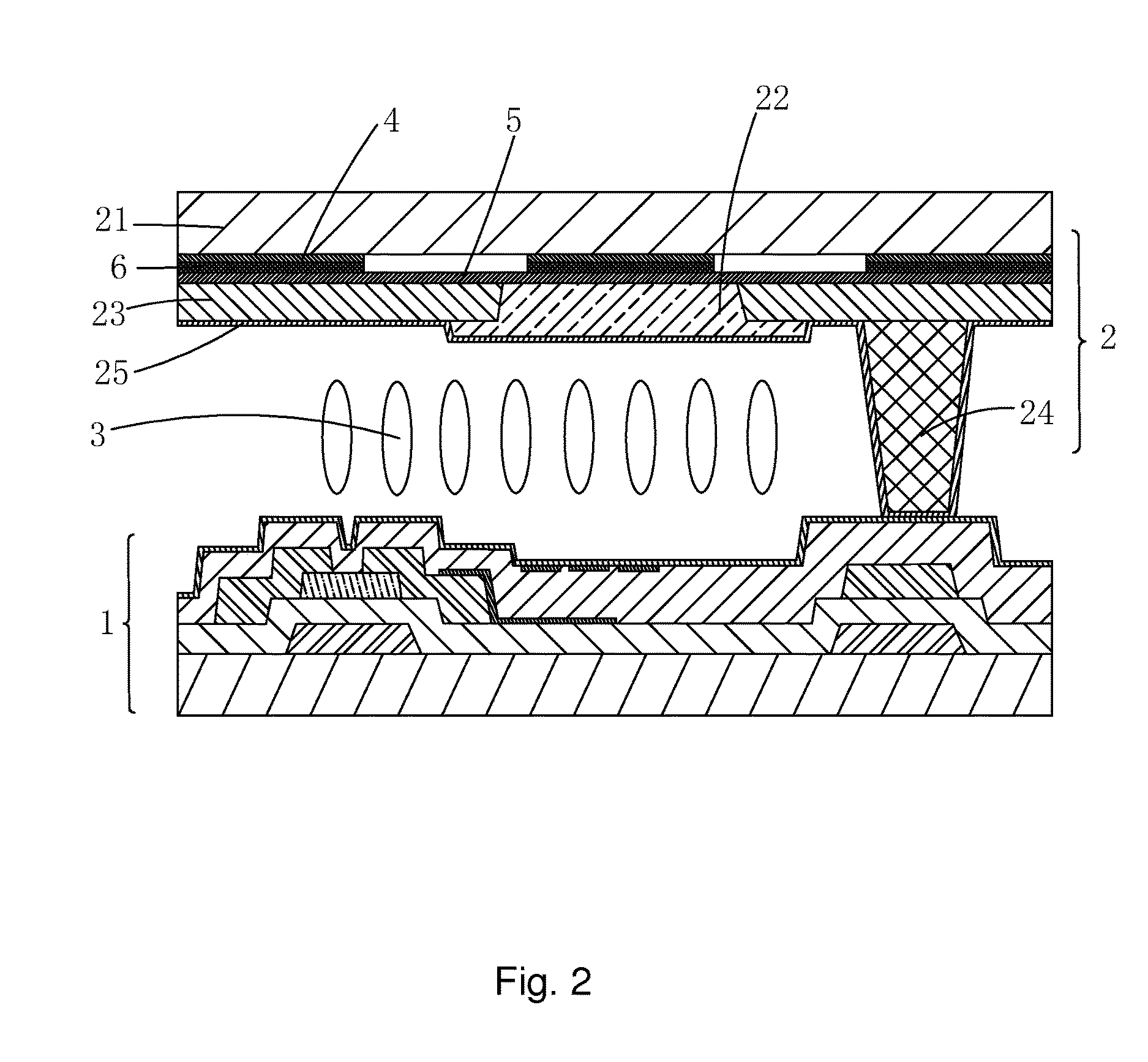

Ips in-cell touch display panel and manufacturing method thereof

InactiveUS20160377898A1Easy to operateReduce manufacturing costNon-linear opticsInput/output processes for data processingCapacitanceManufacturing cost reduction

The present invention provides an IPS in-cell touch display panel and a manufacturing method thereof. The IPS in-cell touch display panel includes insulating photoresist blocks (6) arranged at intersections between touch transmission electrodes (4) and touch receiving electrodes (5) for insulation. The method applies a grey-tone mask and etching operation to form touch transmission electrodes (4) and preserves portions of an organic photoresist that correspond to intersections in perpendicularity between the touch transmission electrodes (4) and touch receiving electrodes (5) to form insulating photoresist blocks (6) to allow insulation to be achieved between the touch transmission electrodes (4) and the touch receiving electrodes (5) with the insulating photoresist blocks (6) so that coating and masking and etching operations specifically for making an insulation layer can be eliminated to thereby simplify the manufacturing operation of a touch display panel, reduce the manufacturing cost, and increase the manufacturing efficiency; and in addition, the touch transmission electrodes (4) and the touch receiving electrodes (5) provide an effect of electromagnetic shielding to capacitance of the liquid crystal layer so that there is no need to specifically form a protection electrode.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

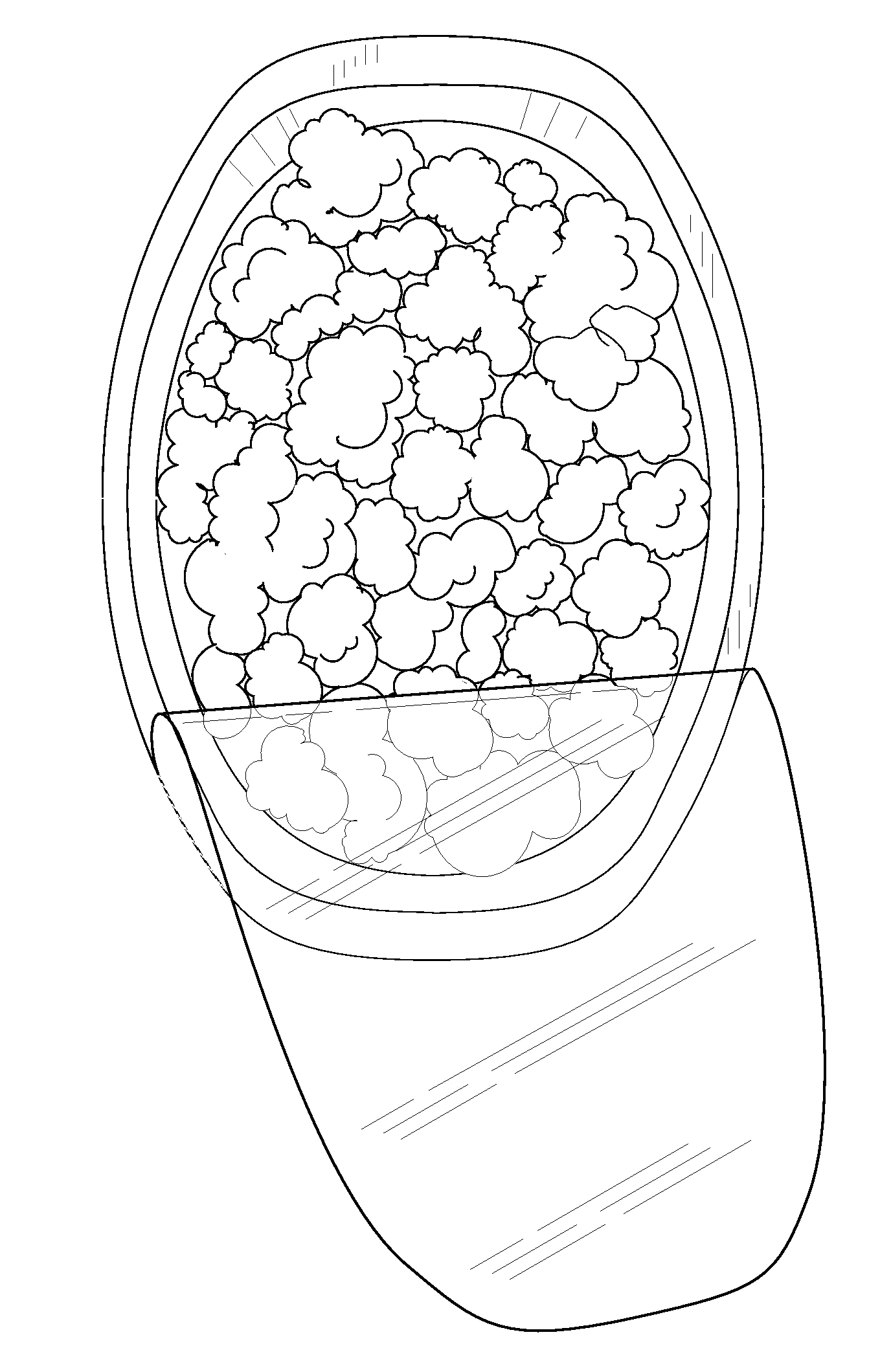

Microwavable refrigerated scrambled eggs and process

ActiveUS20110250323A1Solve low manufacturing efficiencySatisfying eating experienceReady-for-oven doughsEggs preservation using chemicalsAnimal scienceSlurry

A microwavable, refrigerated scrambled egg composition. The composition comprises a first component that is frozen precooked egg portions. At least about 50% by weight of the frozen egg portions are pieces that are at least about ½ inch in one dimension. The second component is a slurry comprising pasteurized liquid egg and pregelatinized modified food starch. The precooked egg portions are from about 50% to about 85% by weight of the total scrambled egg composition and the slurry is from about 15% to about 50% by weight of the total scrambled egg composition. Processes for making and methods of using the microwavable, refrigerated scrambled egg composition are also provided.

Owner:CARGILL INC

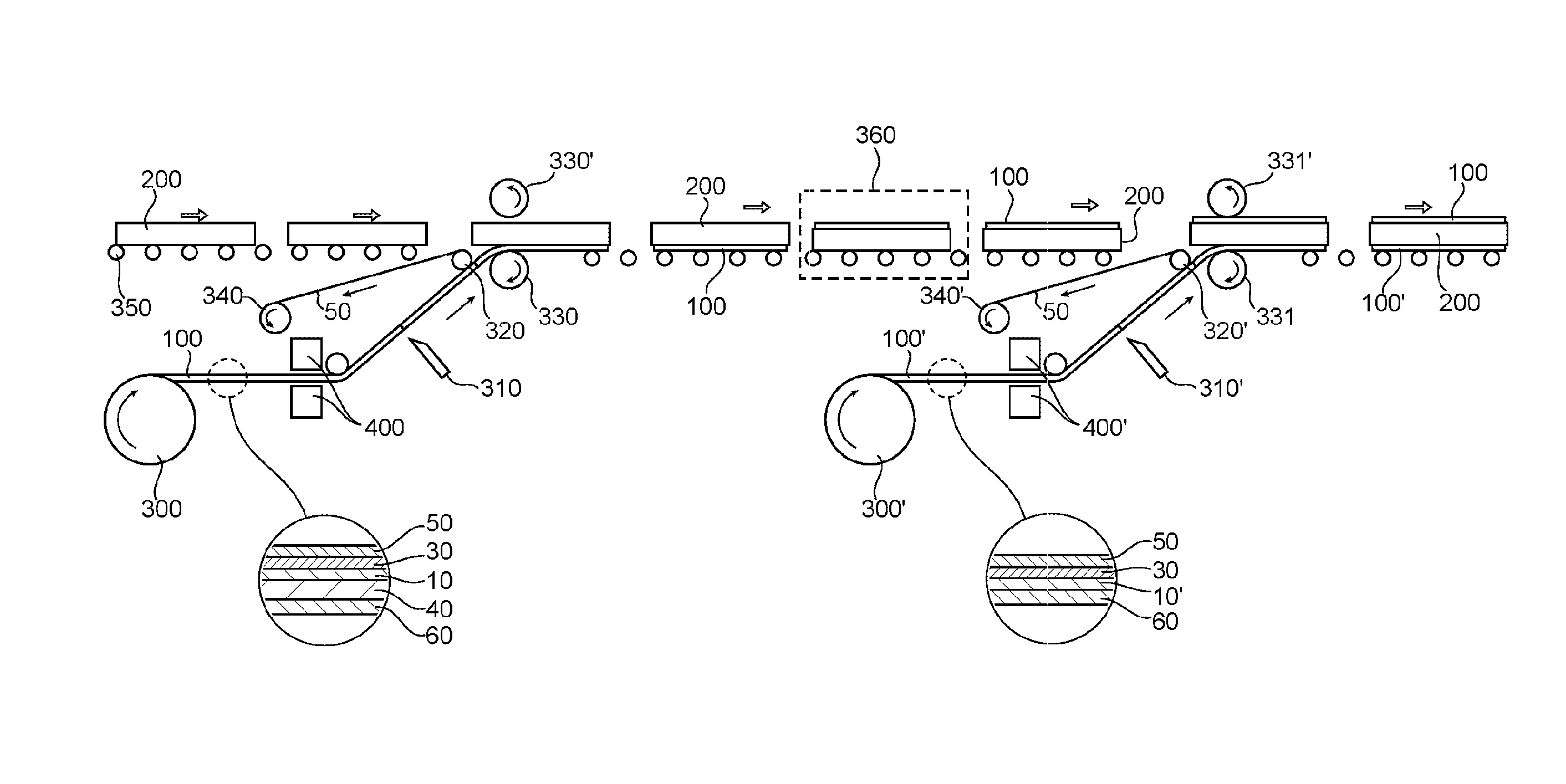

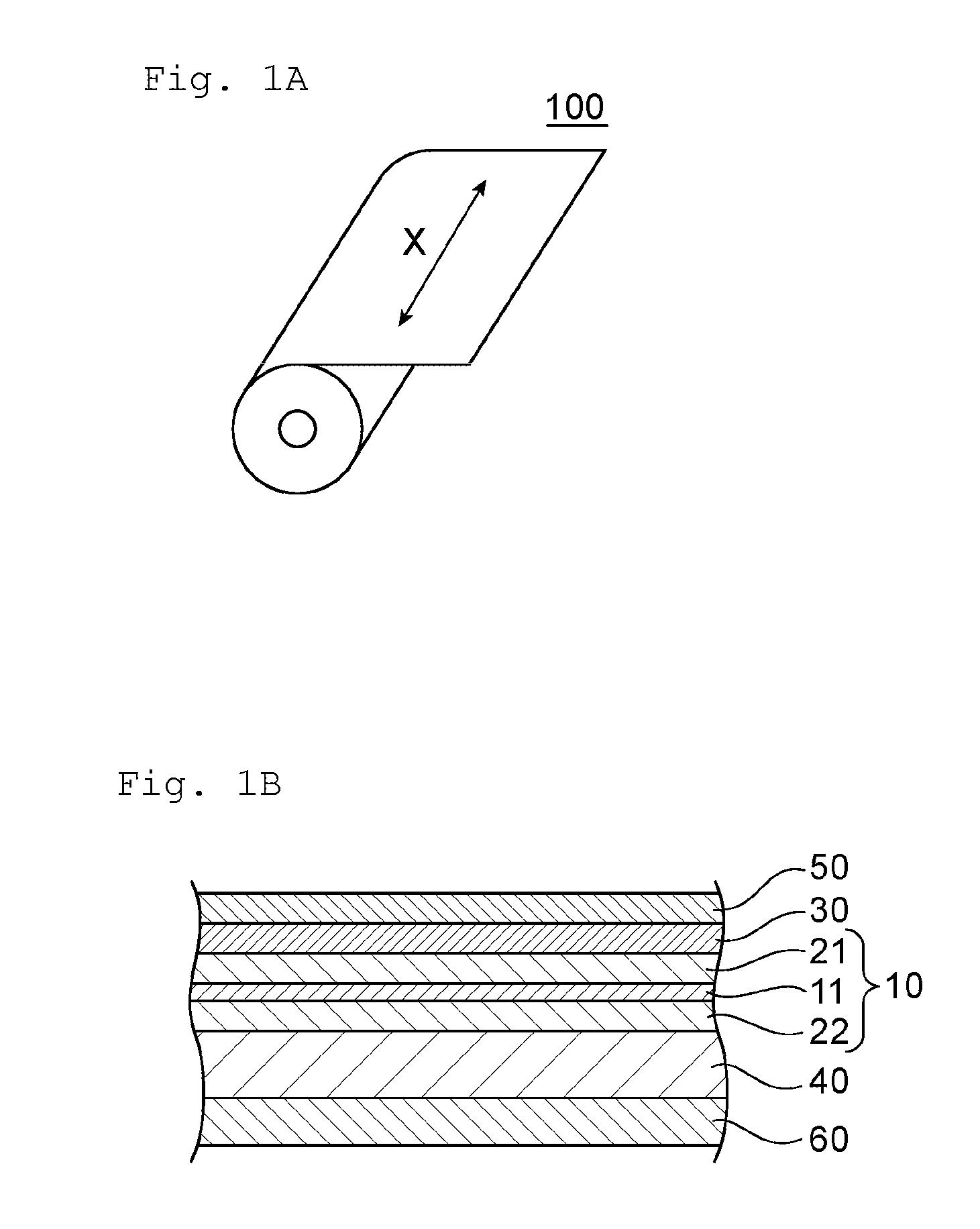

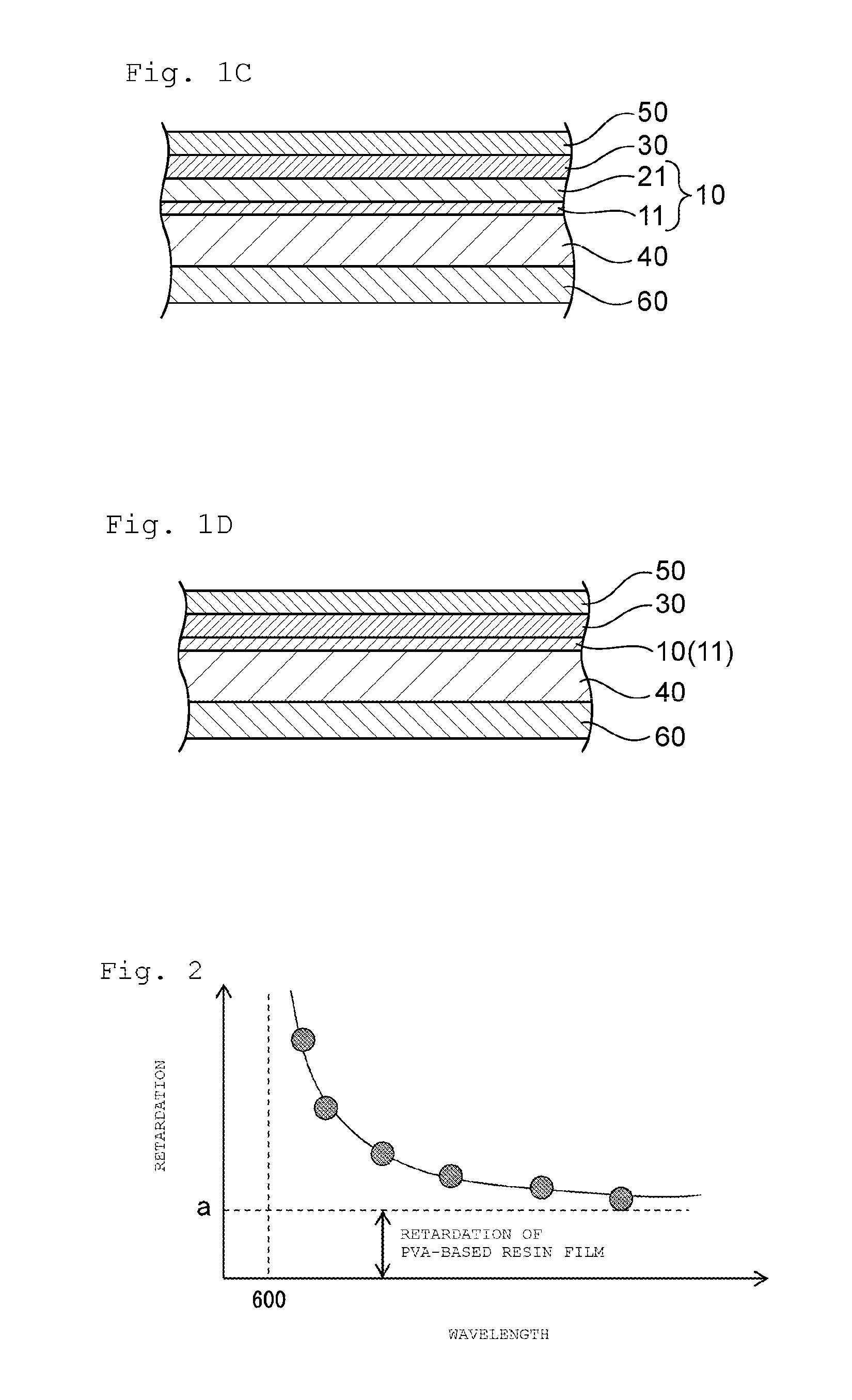

Manufacturing method for liquid crystal display

InactiveUS20150027626A1Solve low manufacturing efficiencyImprove display characteristicsLamination ancillary operationsLayered product treatmentEngineeringLiquid crystal cell

A manufacturing method for a liquid crystal display panel includes slitting a first optical film having an elongate shape, to have a width corresponding to a pair of opposing sides of a liquid crystal cell, and by rolling the slit first optical film in its width direction to have a length corresponding to another pair of opposing sides of the liquid crystal cell; slitting a second optical film having an elongate shape, to have a width corresponding to a pair of opposing sides of the liquid crystal cell, and by rolling the slit second optical film in its width direction to have a length corresponding to another pair of opposing sides of the liquid crystal cell; bonding the cut first optical film onto one surface of the liquid crystal cell; and bonding the cut second optical film onto another surface of the liquid crystal cell.

Owner:NITTO DENKO CORP

Method and apparatus for controlling the length of a carbon nanotube

InactiveUS20070119372A1Solve low manufacturing efficiencyQuality improvementMaterial nanotechnologyLiquid surface applicatorsVoltage pulsePiezoelectric actuators

This invention relates to a method and apparatus for controlling the length of a carbon nanotube, in cooperation with a substrate having at least one reference level on a surface of the substrate on which at least one carbon nanotube is formed, comprising at least one positioning platform for mounting and calibrating the substrate; a discharging electrode mounted on one side of the positioning platform to cut the carbon nanotube wherein the position of the discharging electrode can be calibrated with the positioning platform; a piezoelectric actuator for calibrating the position of the discharging electrode or the height of the discharging electrode relative to the substrate reference level; a position sensor for detection of the height of the substrate; and a voltage pulse supplying means for applying a voltage pulse to the discharging electrode to cut the carbon nanotube.

Owner:IND TECH RES INST

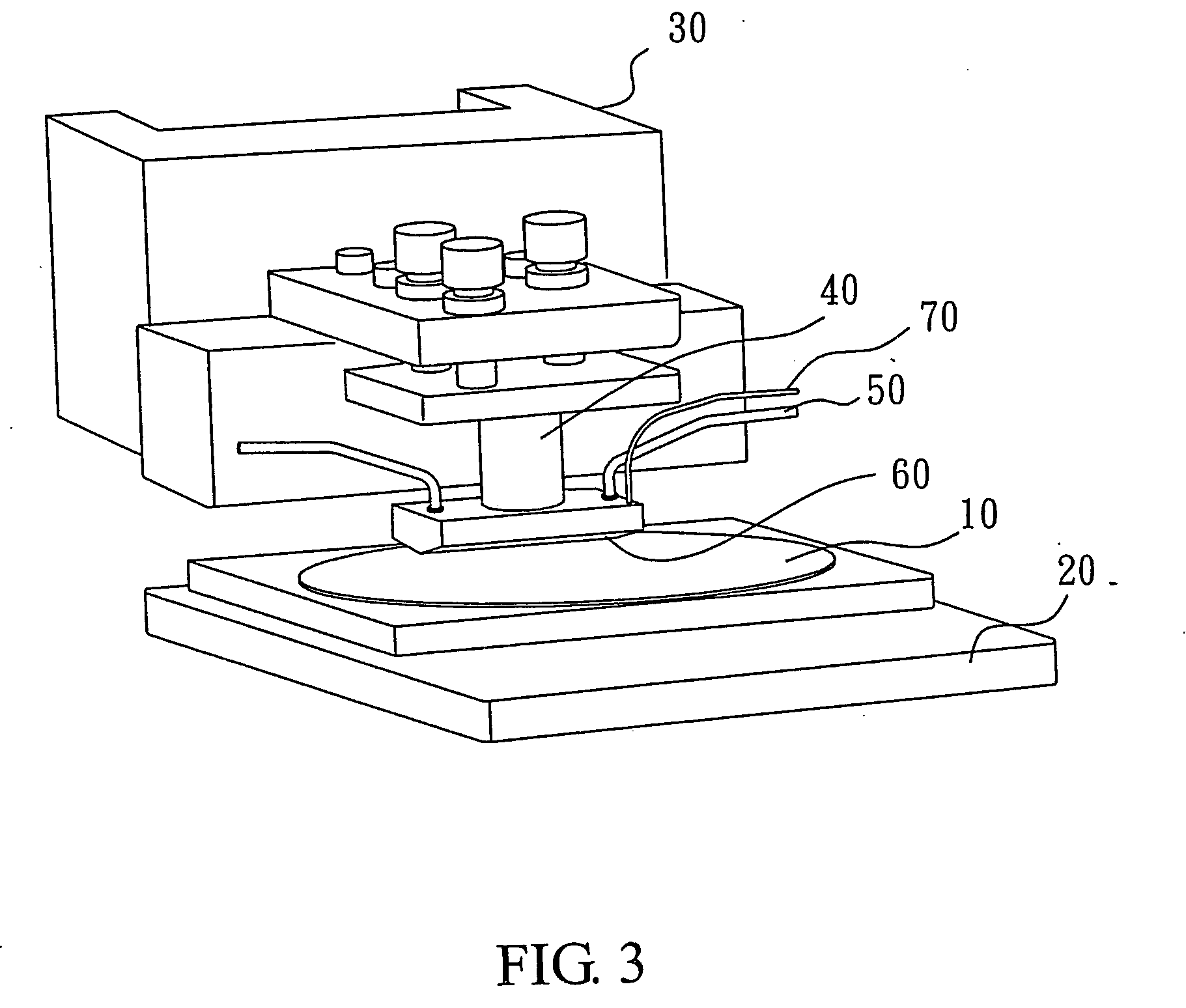

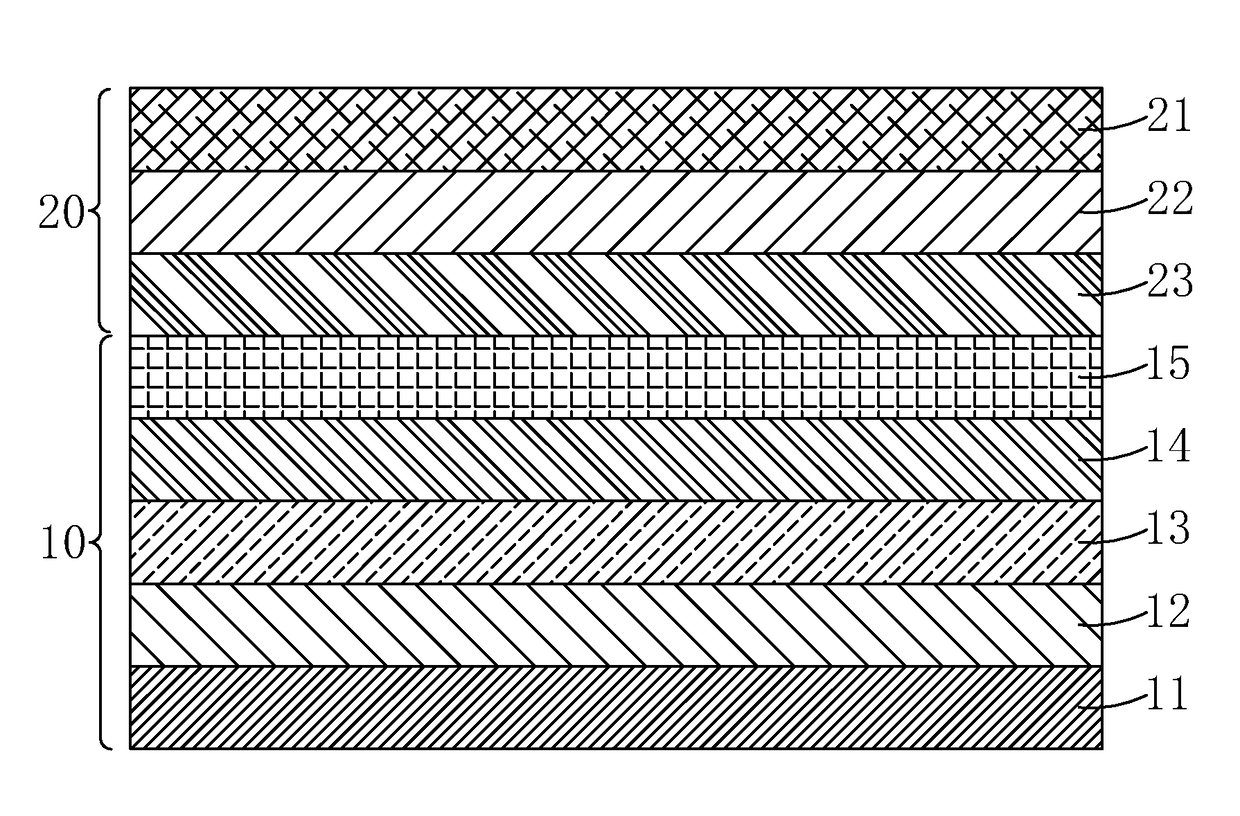

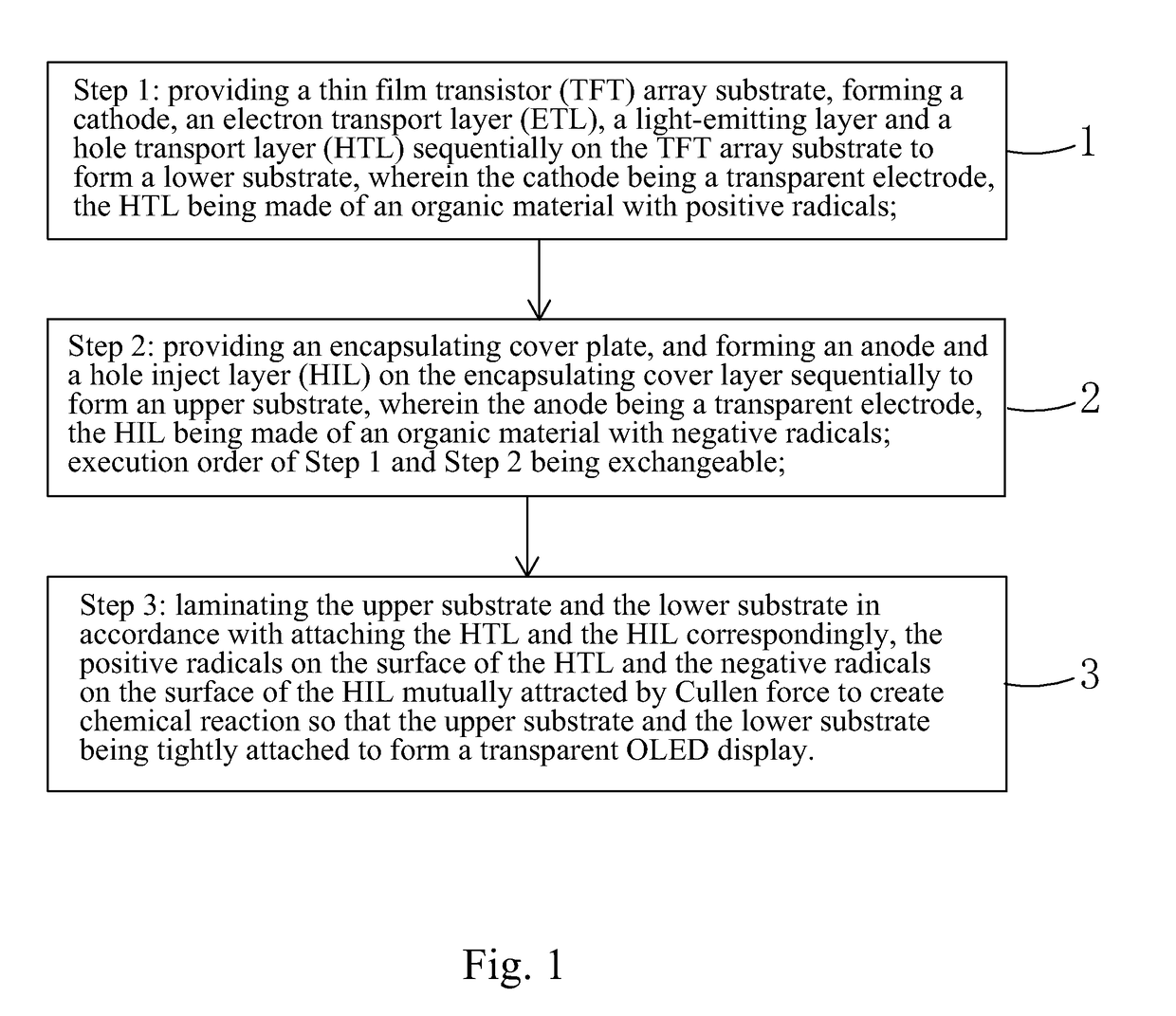

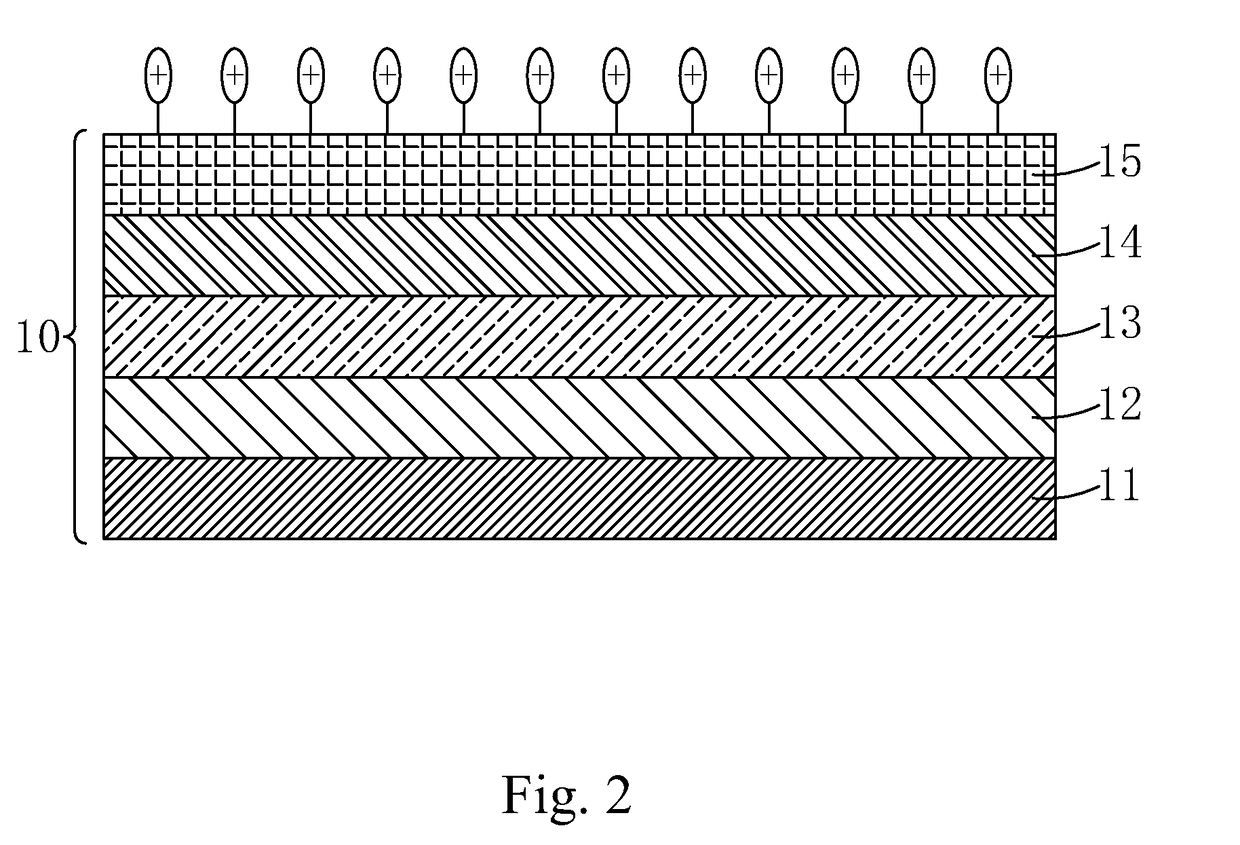

Transparent OLED display and manufacturing method thereof

ActiveUS20180337336A1Improve yieldImprove conductivityFinal product manufactureSolid-state devicesDisplay deviceMaterials science

The invention discloses a transparent OLED display and manufacturing method thereof. The present invention provides a manufacturing method of transparent OLED display, by preparing the cathode and the anode on two different substrates to effectively avoid the destruction of the light-emitting layer made of the organic light-emitting material caused by sputtering the anode at the top of OLED to improve yield rate. The use of the transparent conductive metal oxide to manufacture the cathode and the anode of the OLED display provides an effective solution to the manufacturing of transparent OLED display which requires high conductivity and high transparency for the electrode material. In addition, the two substrates can be manufactured the same time and then pressed to attach to achieve high manufacturing efficiency. The OLED display provided by the present invention is easy to manufacture and provides good performance.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

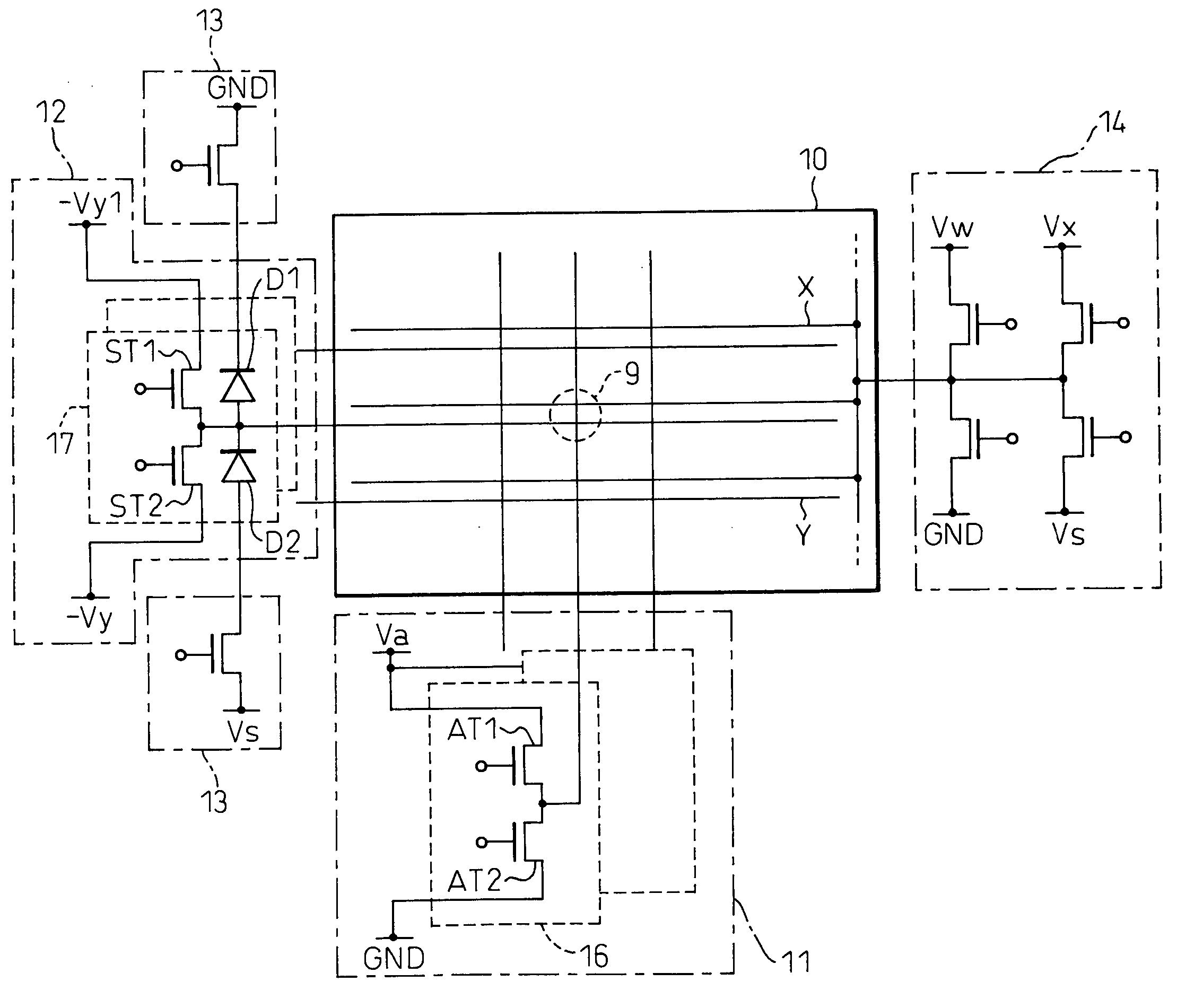

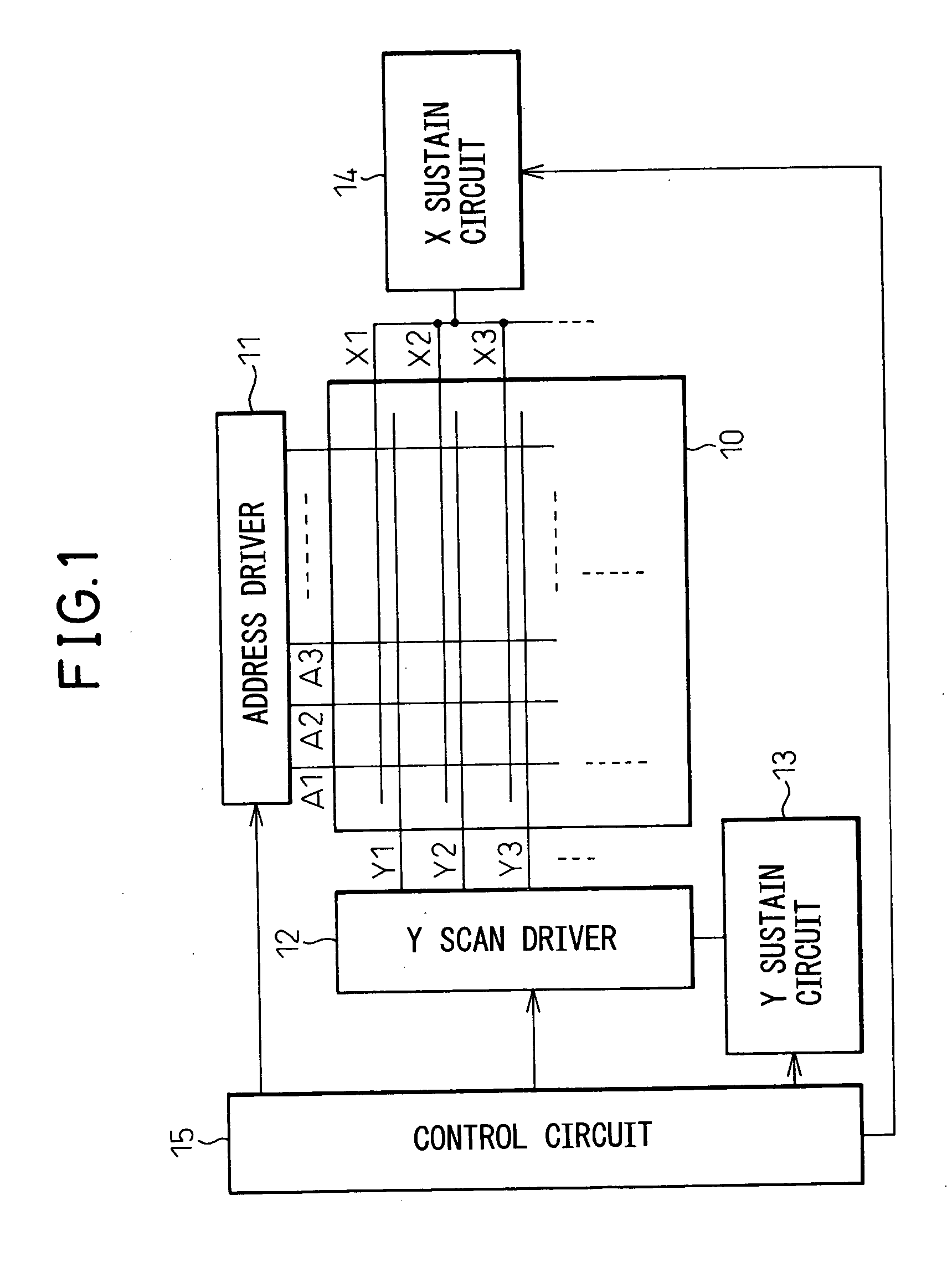

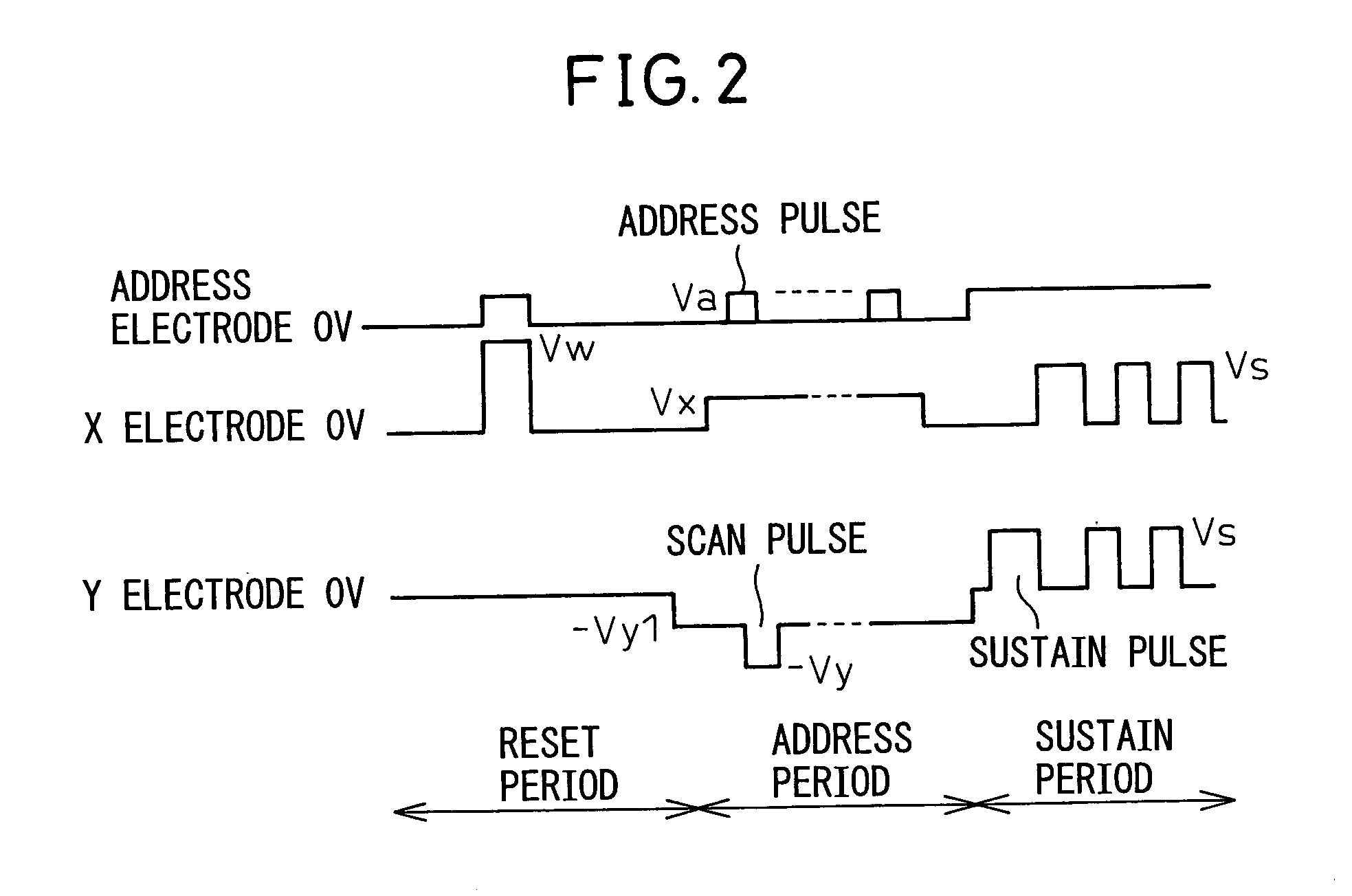

Plasma display apparatus

InactiveUS20050077834A1Drive capacityImprove performanceGas-filled discharge tubesStatic indicating devicesEngineeringPlasma display

A PDP apparatus in which a large-sized plasma display panel, whose electrodes have large drive requirements, is driven by using already existing driver ICs, and a PDP apparatus in which the operating conditions when a plasma display panel is driven by using a plurality of driver ICs have been improved, are disclosed. According to a first aspect, one electrode of the plasma display panel is driven by combining a plurality of drive signals output from the driver IC and, according to a second aspect, in a configuration in which a plurality of electrodes are driven by a plurality of identical driver ICs, when some of a plurality of outputs of the driver ICs are not connected to the electrodes and not used, the unused outputs are distributed in each driver IC as evenly as possible.

Owner:HITACHI LTD

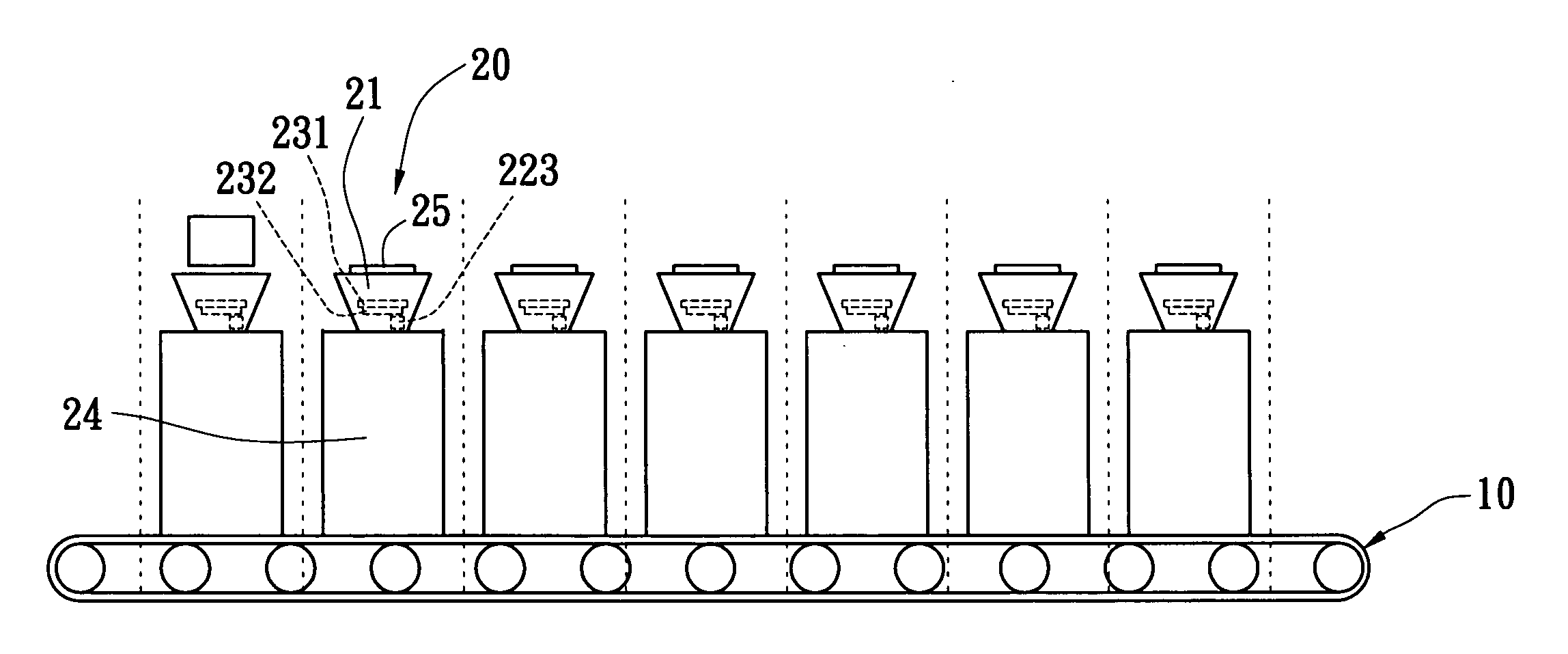

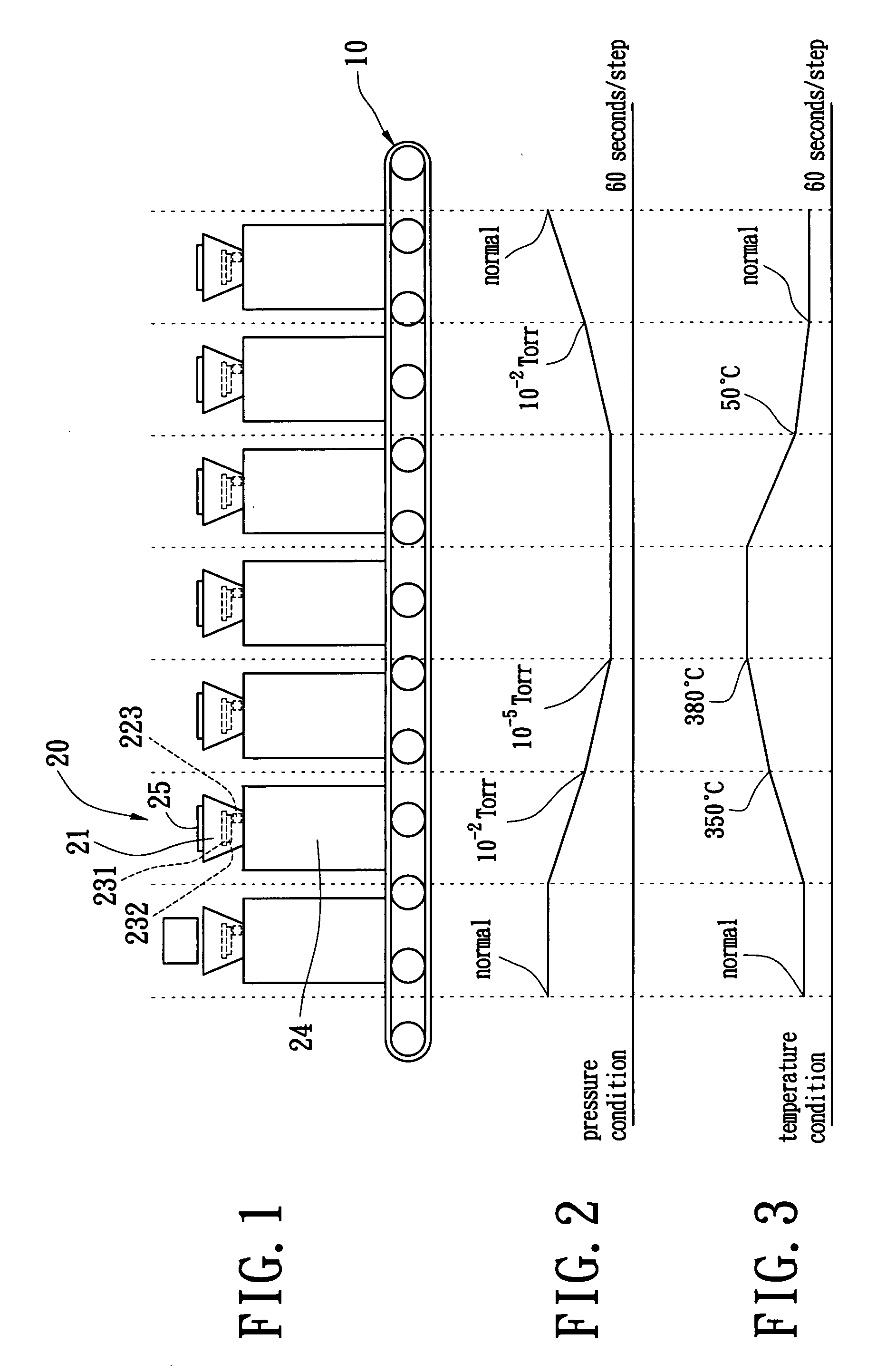

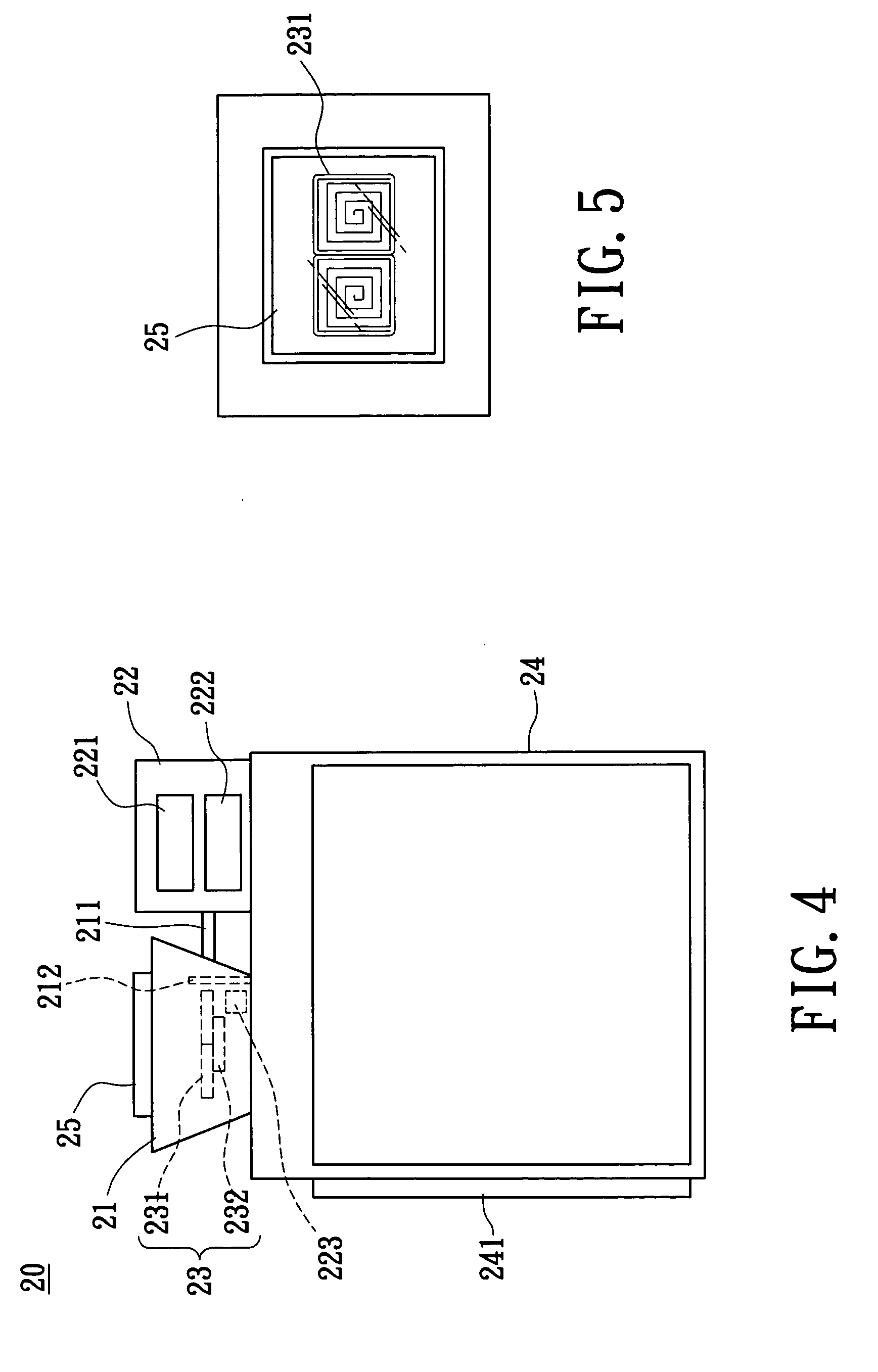

Continuous production vacuum sintering apparatus and vacuum sintering system adopted to the same

InactiveUS6887074B1Extended service lifeImprove heating efficiencyFurnace typesTemperature controlElectricity

A continuous production vacuum sintering apparatus has a conveyer unit and a plurality of vacuum sintering systems individually transferred by the conveyer unit. Each of the vacuum sintering systems includes a sintering furnace, a vacuum control unit communicating with the sintering furnace via an exhaustion valve, a temperature control unit electrically connecting the sintering furnace, and a partition disposed in the sintering furnace and adjacent to the exhaustion valve. The vacuum sintering systems correspond to respective sintering steps, each of which continues from a previous one with a predetermined period. The vacuum sintering systems are separate from one another. The respective pressure and temperature conditions provided by the corresponding vacuum sintering systems do not interfere with one another.

Owner:TECO NANOTECH CO LTD

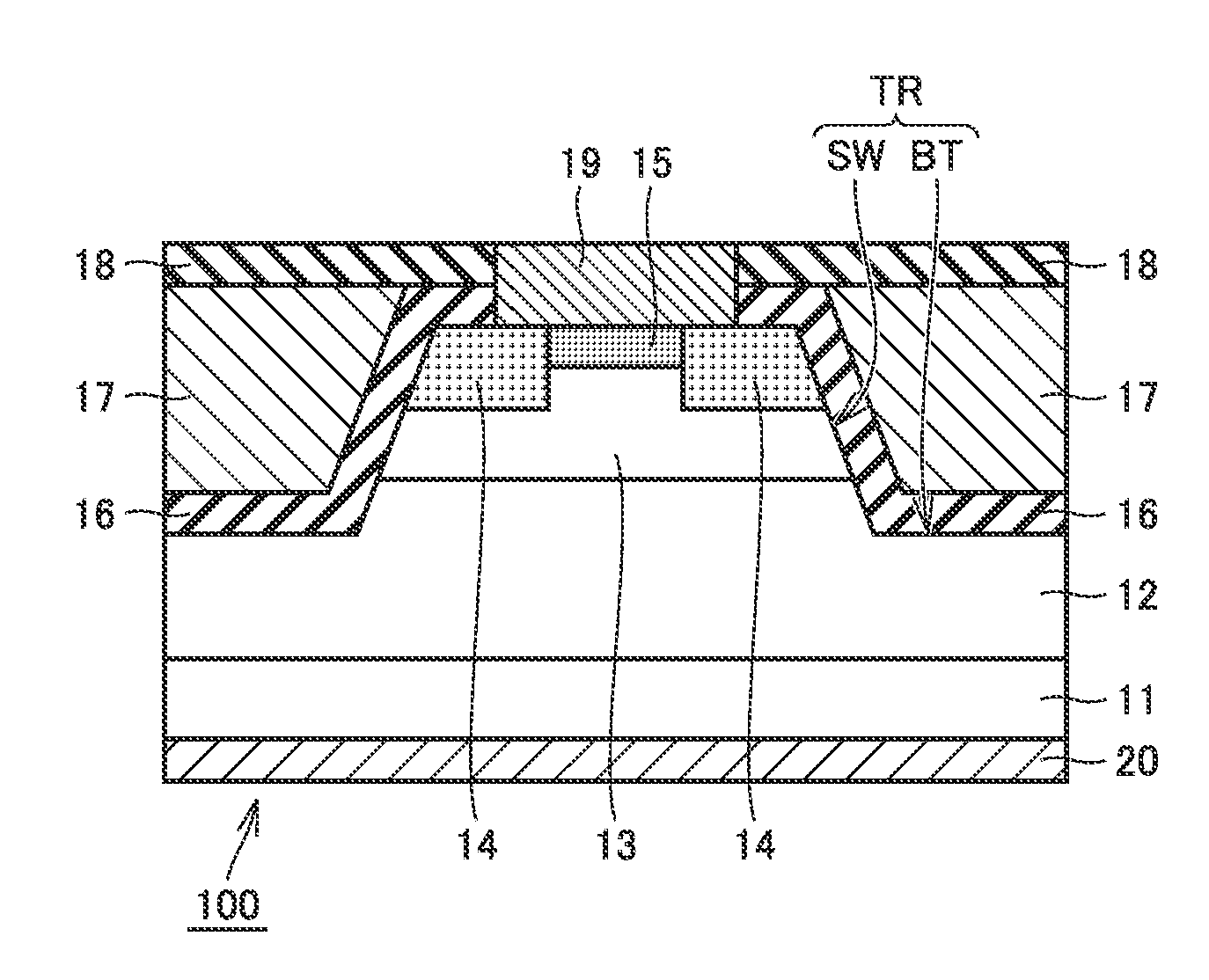

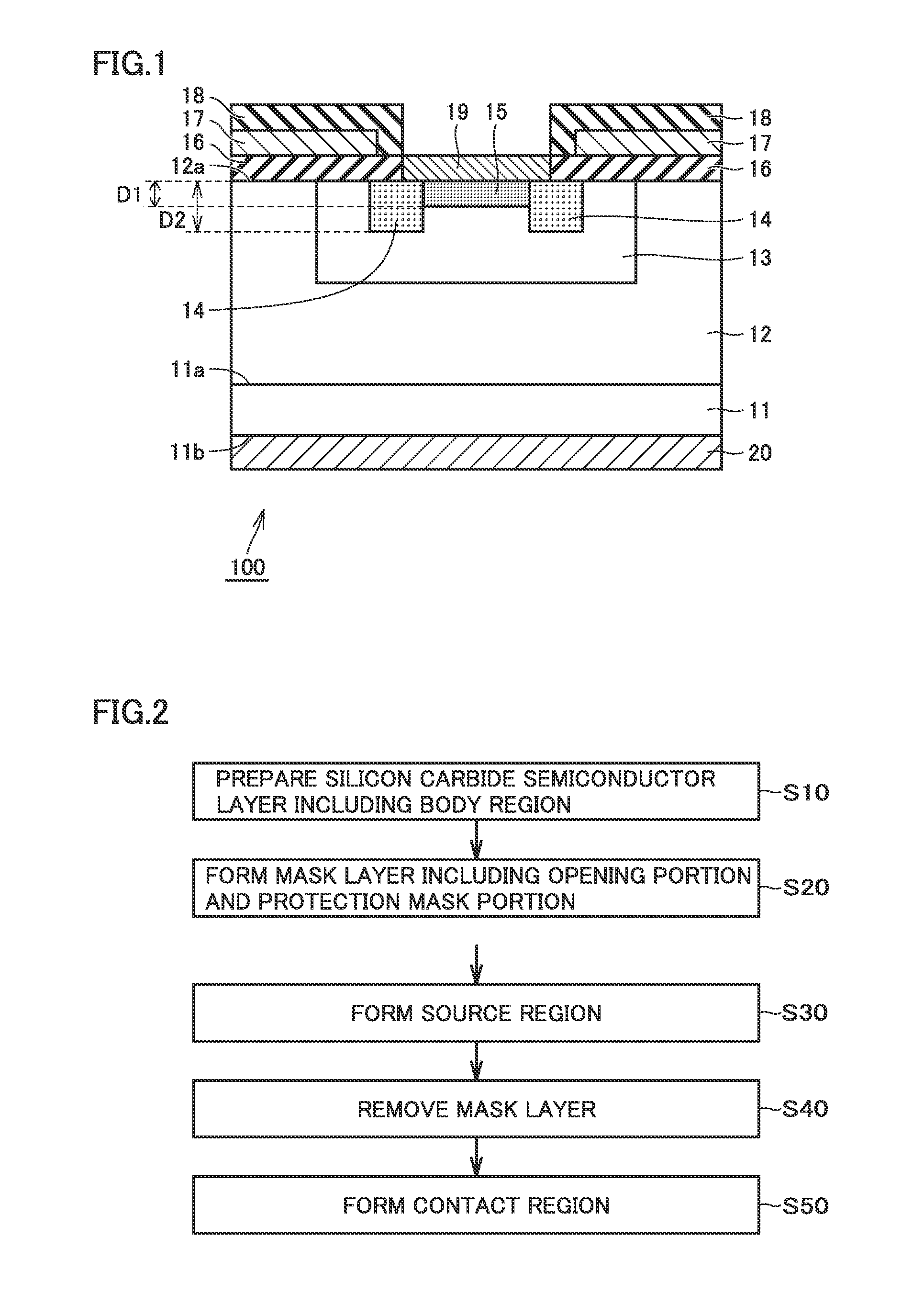

Silicon carbide semiconductor device and method of manufacturing the same

ActiveUS20160218186A1Solve low manufacturing efficiencyHigh manufacturing requirementsTransistorSemiconductor/solid-state device manufacturingSemiconductorImpurity

The silicon carbide semiconductor layer includes a first impurity region, a second impurity region, and a third impurity region. Turning to a first position at which an impurity concentration 1 / 10 as high as a highest impurity concentration is exhibited in a concentration profile of an impurity having the first conductivity type in a direction perpendicular to the main surface in the third impurity region and a second position at which an impurity concentration 1 / 10 as high as a highest impurity concentration is exhibited in a concentration profile of an impurity having the second conductivity type in the direction perpendicular to the main surface in the second impurity region, a first depth from the main surface to the first position is shallower than a second depth from the main surface to the second position. The electrode is electrically connected to the second impurity region and the third impurity region.

Owner:SUMITOMO ELECTRIC IND LTD

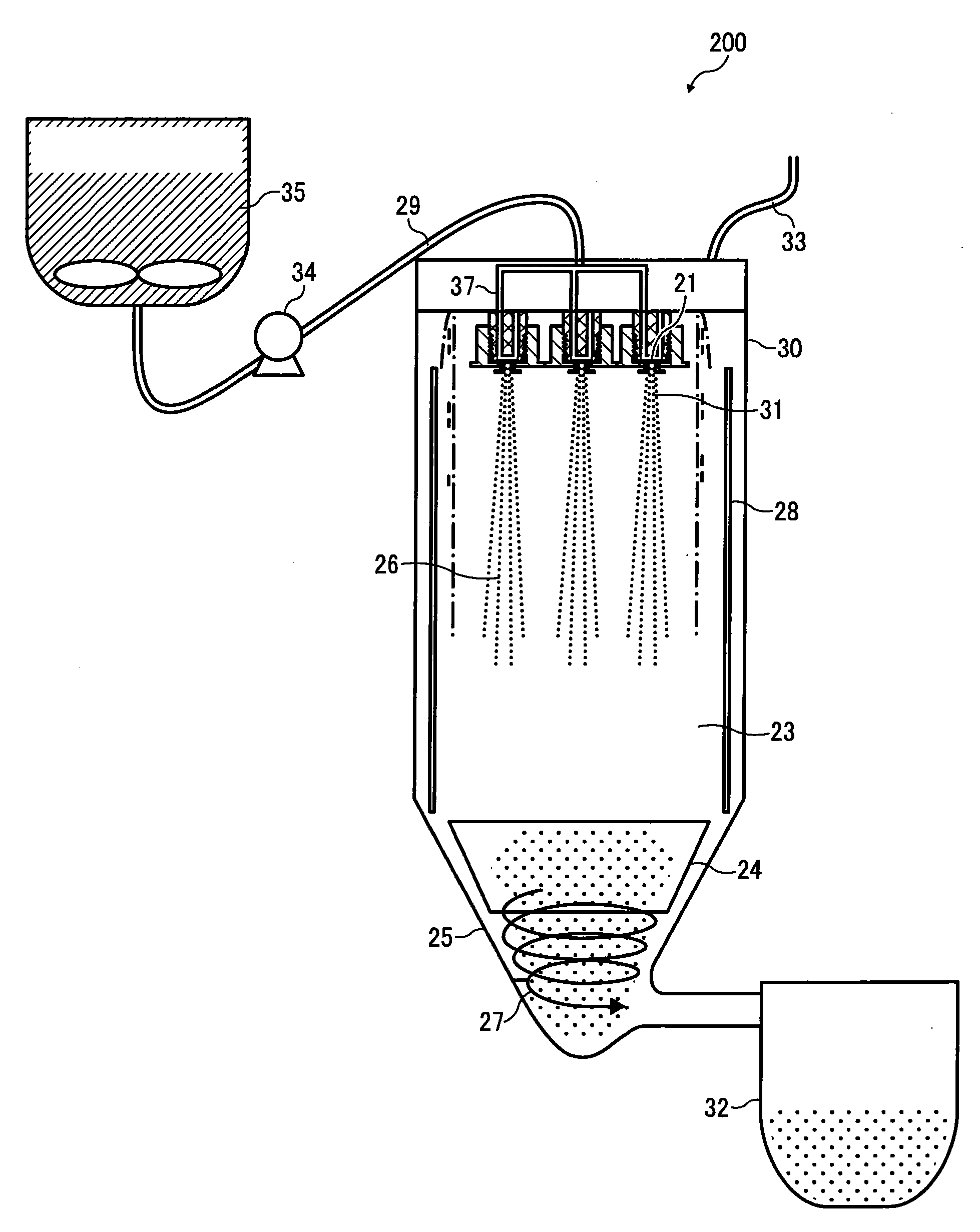

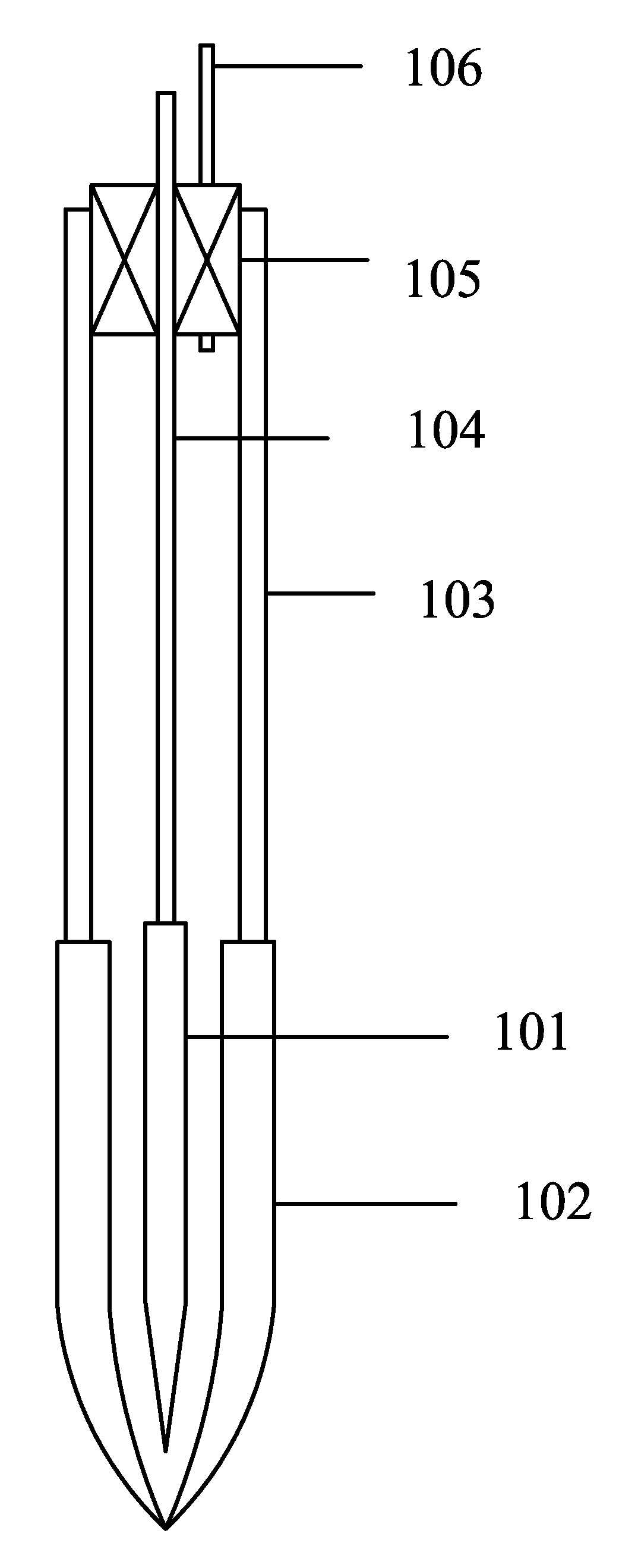

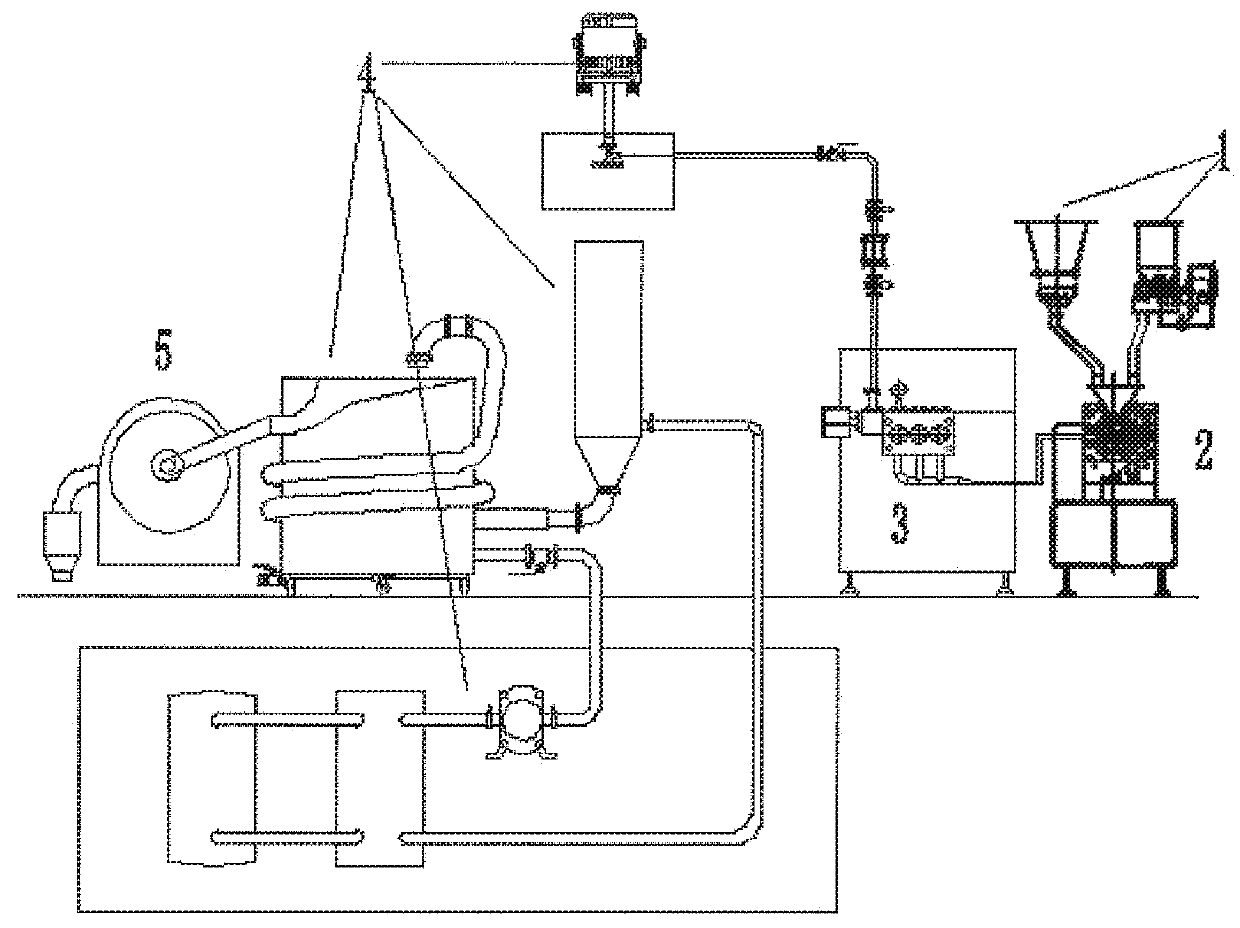

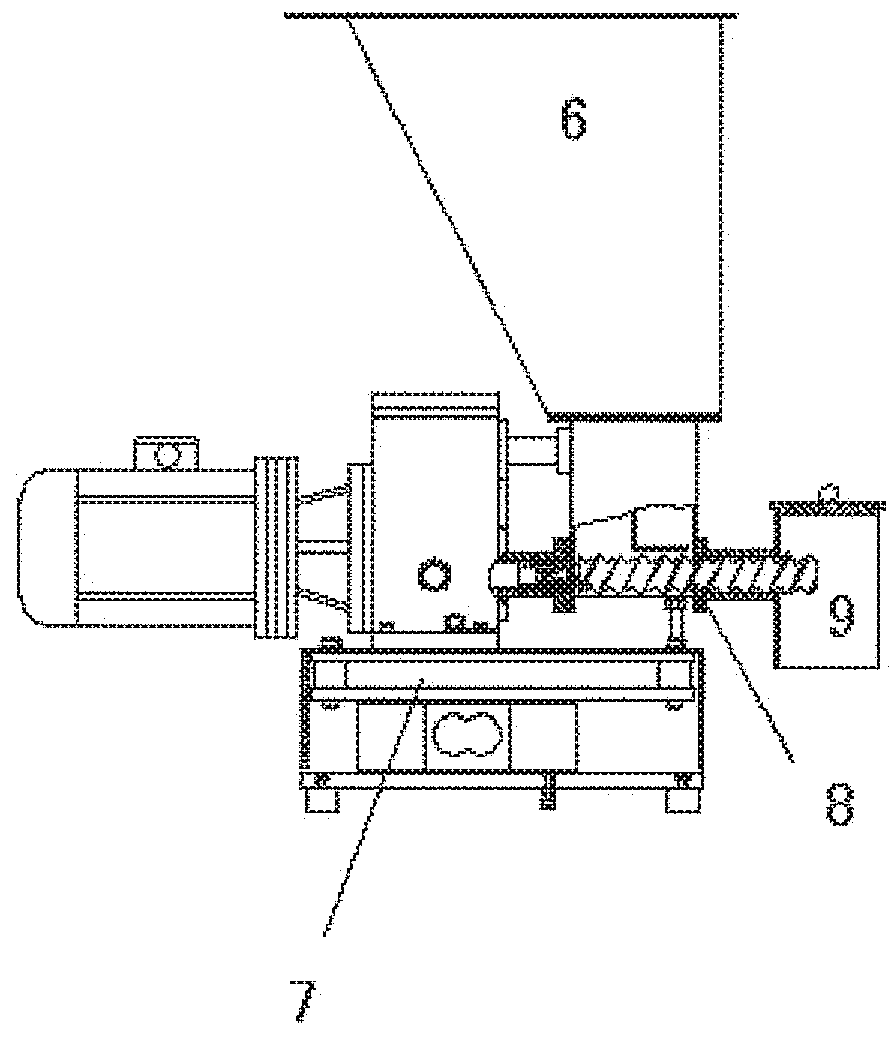

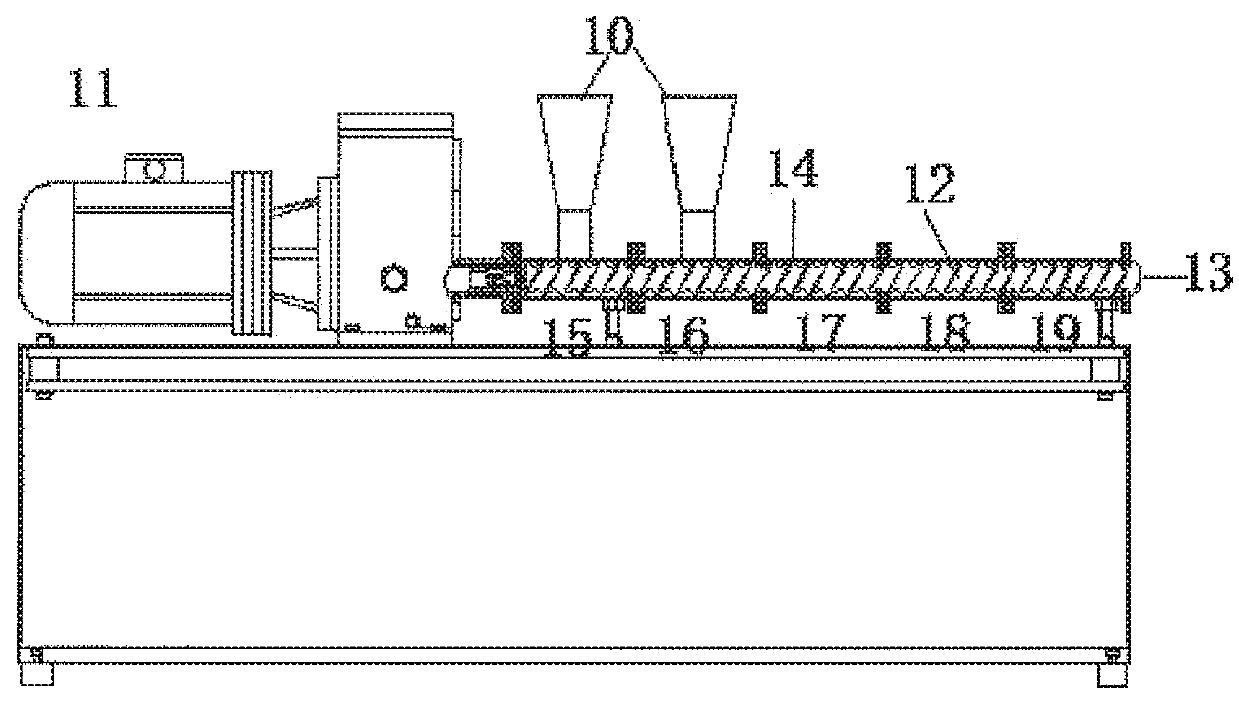

Intelligent dripping pill machine for continuous liquid solidification

ActiveUS20180263851A1Good oil-water separation effectSolve low manufacturing efficiencyTransportation and packagingPharmaceutical product form changeCentrifugationTransmission channel

An intelligent dripping pill machine for continuous liquid solidification comprises: a feeding device (1), a material combining device (2), a homogenizing device (3), a dripping device (4) and a de-oiling device (5) sequentially connected via a transmission channel. The intelligent dripping pill machine removes, via high-speed centrifugation, a cooling liquid attached to dripping pills, and each component device is connected compactly, thereby achieving a continuous manufacturing operation, and reducing an occupied space of the devices as a whole while ensuring the yield of the dripping pills.

Owner:TIANJIN TASLY PHARMA CO LTD

Lamination carrier and lamination method using the same

InactiveUS20150185526A1Solve low manufacturing efficiencyHigh yieldMechanical working/deformationLamination ancillary operationsEngineeringLight guide

A lamination carrier is used in a lamination method of a display device. The display device includes a first component, a second component and an adhesive layer. The first component includes a transparent portion and an opaque portion surrounding the transparent portion. The adhesive layer is disposed between the first component and the second component, and is distributed on the transparent portion and the opaque portion. The lamination carrier includes a base plate and a light-guiding structure having a reflecting surface that extends upwardly and outwardly from the base plate and that is disposed to reflect light to the adhesive layer distributed on the opaque portion of the first component. A lamination method is also disclosed.

Owner:WISTRON CORP

Manufacturing method of honeycomb structure

ActiveUS20090243167A1Good molding effectSolve low manufacturing efficiencyCeramic shaping apparatusCeramicwareMagnificationCordierite

There is provided a manufacturing method of a honeycomb structure, comprising: forming kneaded clay containing a cordierite forming raw material formed by mixing talc having an average particle diameter of 0.1 to 40 μm, kaolin having an average particle diameter of 0.1 to 20 μm, an alumina source raw material having an average particle diameter of 0.05 to 10 μm, and a silica having an average particle diameter of 0.1 to 20 μm, a binder, a surface active agent, water, and a hygroscopic resin having an average particle diameter of two to 200 μm after water absorption and a water absorption magnification of two to 100 magnifications into honeycomb shape to fabricate a honeycomb formed body; and firing the honeycomb formed body to obtain a honeycomb structure whose porosity is less than 40%.

Owner:NGK INSULATORS LTD

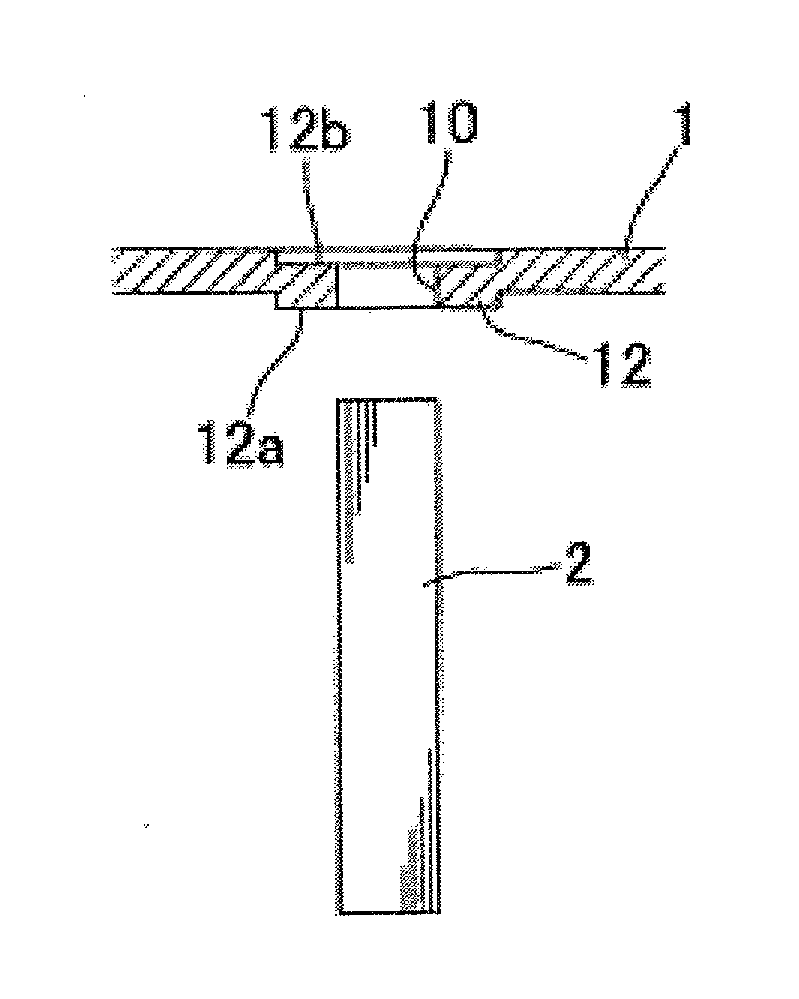

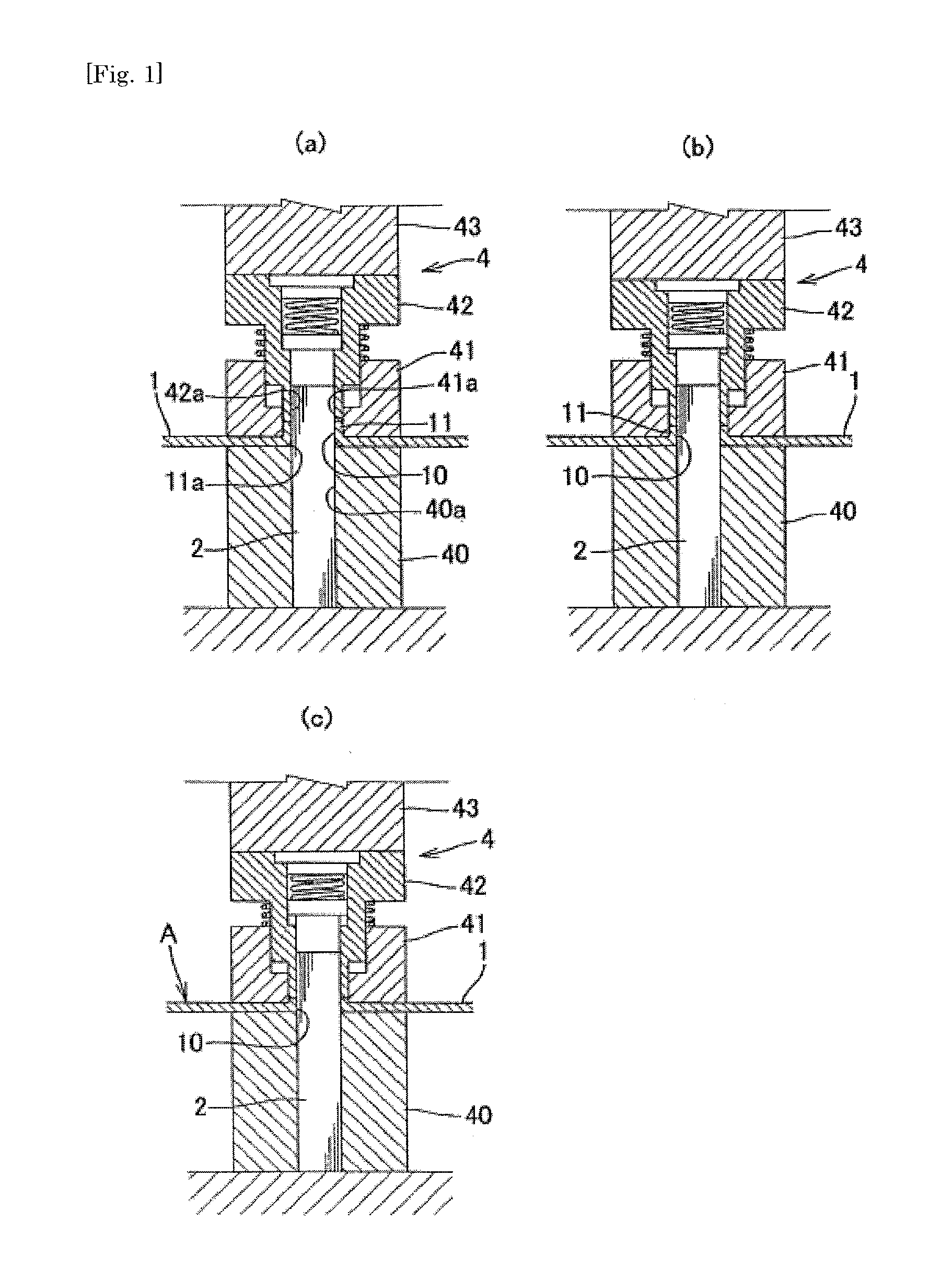

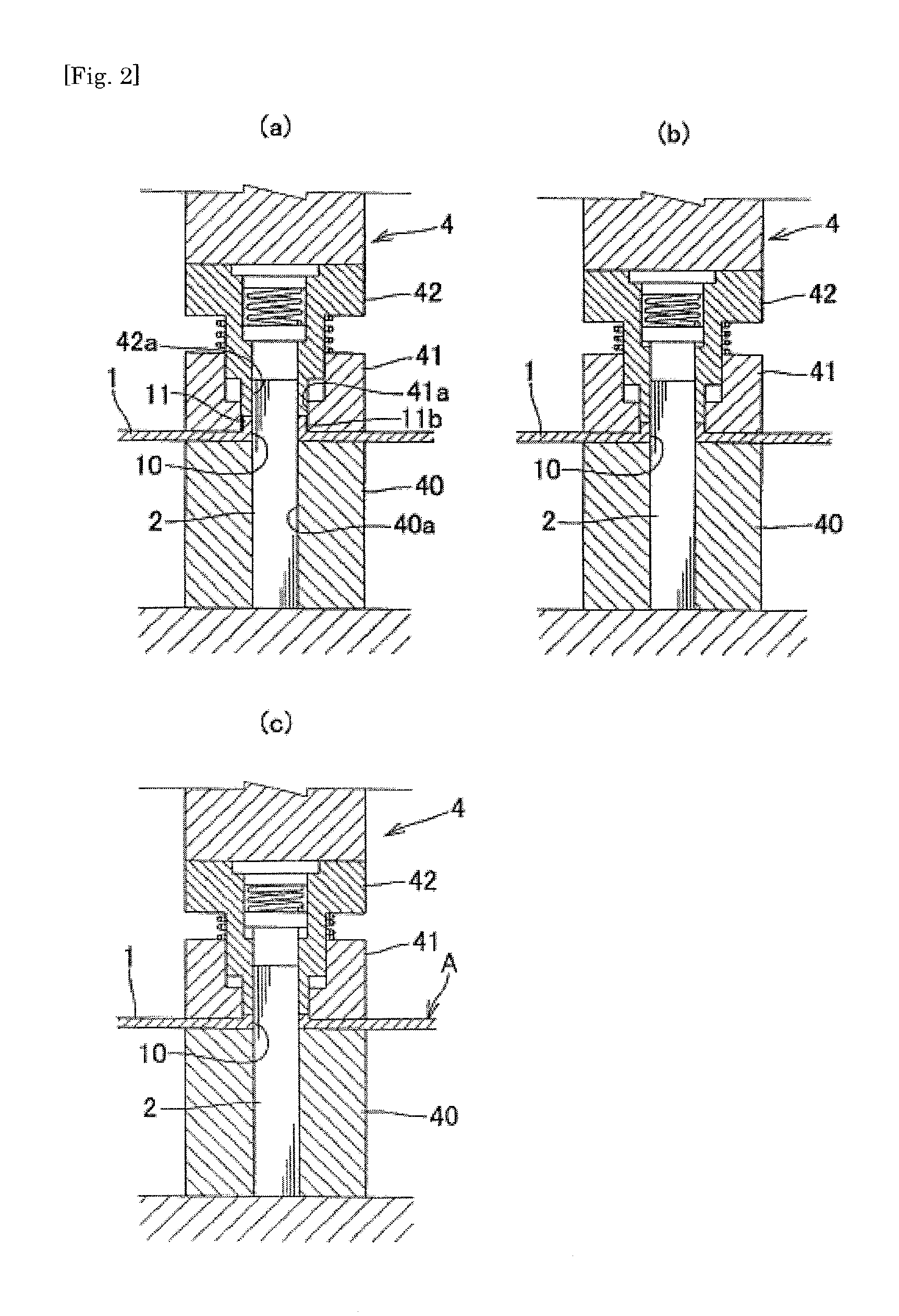

Method for manufacturing a caulked assembly

ActiveUS20130192048A1Low costAvoid deformationSolid-state devicesMetal working apparatusBiomedical engineering

Provided is a method for manufacturing a caulked assembly that is capable of manufacturing the caulked assembly at a low cost, preventing reduction of the strength of a columnar body caused by a circumferential groove, preventing deformation of the columnar body, and assembling a slimmer columnar body with a plate-like body. A mounting hole 10 for inserting and assembling a columnar body 2 is provided in a metallic plate-like body 1, and a thick portion 11 is formed along an inner circumferential edge of the mounting hole 10. Thereafter, as shown in FIG. 1(a), the columnar body 2 is inserted into the mounting hole 10 of the plate-like body 1 so that the plate-like body 1 is set in an assembly position on an outer circumferential surface of the columnar body 2. Further, the thick portion 11 is compressively pressed from an axial direction of the columnar body so as to be plastically deformed toward the center of the mounting hole 10 to thereby tighten and fix the thick portion 11 to the outer circumferential surface of the columnar body 2.

Owner:JAPAN

Ink-jet platemaking method

InactiveUS20110139026A1Improved ink gatheringSolve low manufacturing efficiencyPhotomechanical apparatusInksProduction rateOrganic solvent

An ink-jet platemaking method is provided which takes advantage of the high convenience and high productivity characteristic of platemaking by ink-jet printing and which mitigates or improves the liquid gathering caused by droplet coalescence and printing durability, which have been problematic in platemaking by ink-jet printing. The ink-jet platemaking method comprises: using an ink for platemaking comprising water, one or more water-soluble organic solvents, and fine resin particles; adhering the ink for platemaking to a heated printing plate material; and volatilizing the solvent contained in the platemaking ink to dry the ink and thereby form an image. The ink-jet platemaking method is characterized in that the fine resin particles have a minimum film-forming temperature (MFT (water)) of 40° C. or higher, the ink for platemaking contains a water-soluble organic solvent (A) which lowers the MFT of the fine resin particles by 5° C. or more, the water-soluble organic solvent (A) accounts for 20% or more of all water-soluble organic solvents contained in the ink, and the water-soluble organic solvent (A) has a boiling point of 180-300° C.

Owner:KONICA MINOLTA INC

Air socket for testing integrated circuits

InactiveUS7069638B2Easy to optimizeSolve low manufacturing efficiencyLine/current collector detailsElectrically conductive connectionsElectricityElectrical connection

An electrical component testing device comprising a housing having at least one recess covered by a flexible membrane so as to form a chamber. A fluid passage extends through a portion of the housing and connects to the chamber thus permitting passage of a fluid material into the chamber. At least one contact member is positioned on the flexible membrane so as to provide an electrical connection to an electrical contact on a device to be tested.

Owner:MICRON TECH INC

Chemical mechanical polishing machine and chemical mechanical polishing apparatus comprising the same

ActiveUS20130130601A1Simple structureEasy to manufactureEdge grinding machinesLapping machinesWaferingPolishing

A chemical-mechanical polishing machine includes a work table, polishing platen mounted onto the work table, pad conditioner and slurry-delivery device mounted on the work table and disposed near the polishing platen, and polishing-head support mounted on the work table and including a base plate and supporting side plates. The base plate is formed with a groove in a “thickness” direction. A loading and unloading table is mounted on the work table, disposed below the base plate, and opposed to the polishing platen. A polishing head is rotatably disposed on the polishing-head support, movable in the longitudinal direction, and passes through the groove to extend downwardly. A robotic manipulator is disposed near the work table for placing a wafer on the loading and unloading table and taking the wafer away from it. A chemical-mechanical polishing apparatus includes an array of a plurality of the machine.

Owner:HWATSING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com