Continuous casting mold powder for ferrite stainless steel and preparation method thereof

A technology for continuous casting mold flux and stainless steel, which is applied in the field of continuous casting mold flux for ferritic stainless steel and its preparation, can solve the problems of agglomeration, mold formation and difficulty in continuous casting, and achieves simple process and low melting temperature. , the effect of suitable crystallization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

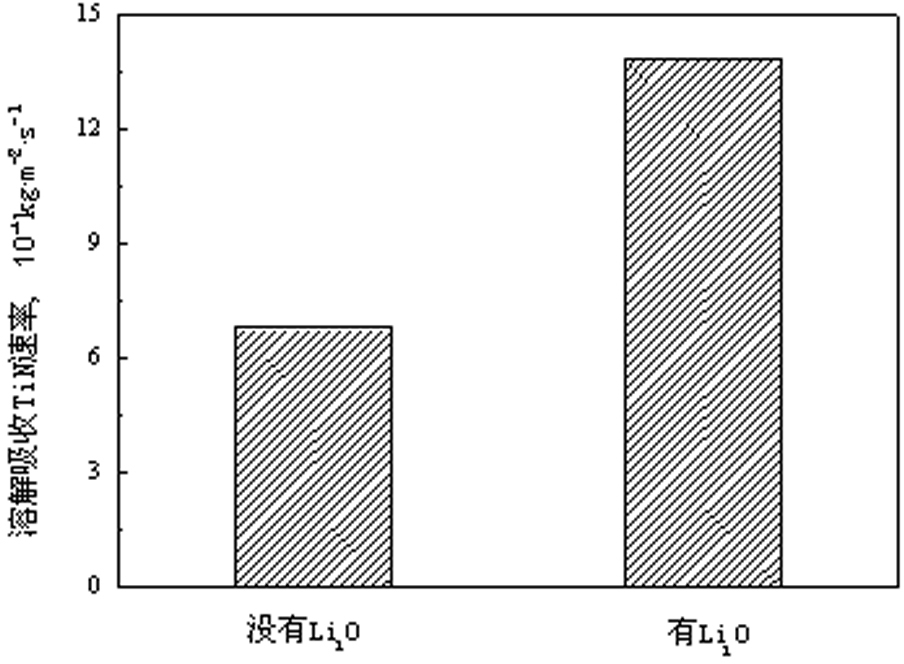

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 The carbonaceous material, wollastonite, power plant ash, limestone, soda ash and cryolite are pulverized to 0.1~1mm and mixed uniformly, the mixing ratio is carbonaceous material 2%, wollastonite 60%, power plant ash 20%, limestone 2%, soda ash 10%, cryolite 6%, make mixed material, then add lithium hydroxide, obtain lithium doped material, the addition of lithium hydroxide accounts for 2.5% of mixed material; The raw material is carbon black; add water to the lithium-doped material and stir to form a slurry, wherein water accounts for 15% of the total weight of the slurry; dry the slurry at 500°C for 1 hour to make powdered iron The continuous casting mold flux for ferritic stainless steel has a particle size of 0.5-1.5mm; the chemical composition of continuous casting mold flux for ferritic stainless steel is CaO20%, SiO 2 50%, Al 2 o 3 5%, MgO5%, Na 2 O15%, CaF 2 2%, Li 2 O1%, C2%; the basicity is 0.4; the above continuous casting mold slag is used...

Embodiment 2

[0026] Crush the carbonaceous material, wollastonite, power plant ash, limestone, soda ash and cryolite to 0.1~1mm and mix them evenly. The mixing ratio is 6% by weight of carbonaceous material, 29% wollastonite, and 25% power plant ash. Limestone 15%, soda ash 20%, cryolite 5%, make mixed material, then add lithium hydroxide, obtain lithium doping material, the addition of lithium hydroxide accounts for 3% of mixed material; Described carbonaceous material is graphite;

[0027] Adding water to the lithium-doped material and stirring to form a slurry, wherein water accounts for 20% of the total weight of the slurry;

[0028] Dry the slurry at 400°C for 2 hours to make powdered ferritic stainless steel continuous casting mold flux with a particle size of 0.5~1.5mm;

[0029] The chemical composition of continuous casting mold flux for ferritic stainless steel is CaO30% by weight, SiO 2 45%, Al 2 o 3 10%, MgO1%, Na 2 O1%, CaF 2 10%, Li 2 O5%, C8%; alkalinity is 0.67;

[0...

Embodiment 3

[0032] Crush the carbonaceous material, wollastonite, power plant ash, limestone, soda ash and cryolite to 0.1~1mm and mix them uniformly. The mixing ratio is 8% by weight of carbonaceous material, 33% wollastonite, and 30% power plant ash. Limestone 4%, soda ash 15%, cryolite 10%, make mixed material, then add lithium hydroxide, obtain lithium doped material, the addition of lithium hydroxide accounts for 3.5% of mixed material; Described carbonaceous material is activated carbon;

[0033] Adding water to the lithium-doped material and stirring it into a slurry, wherein water accounts for 25% of the total weight of the slurry;

[0034] Dry the slurry at 400°C for 1 hour to make powdered ferritic stainless steel continuous casting mold flux with a particle size of 0.5-1.5mm;

[0035] The chemical composition of continuous casting mold flux for ferritic stainless steel is CaO40% by weight, SiO2 30%, Al 2 o 3 6%, MgO3%, Na 2 O9%, CaF 2 4%, Li 2 O2%, C6%; alkalinity is 1.3;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com