High-power LED multi-hole phase-changing heat sink structure

A porous structure, high-power technology, applied in the field of lighting, can solve the problems of large impact on structural heat transfer efficiency, poor energy consumption and reliability of disturbance system, limited heat transfer capacity, etc., to achieve easy control of volume expansion, good heat dissipation effect, volume The effect of small expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

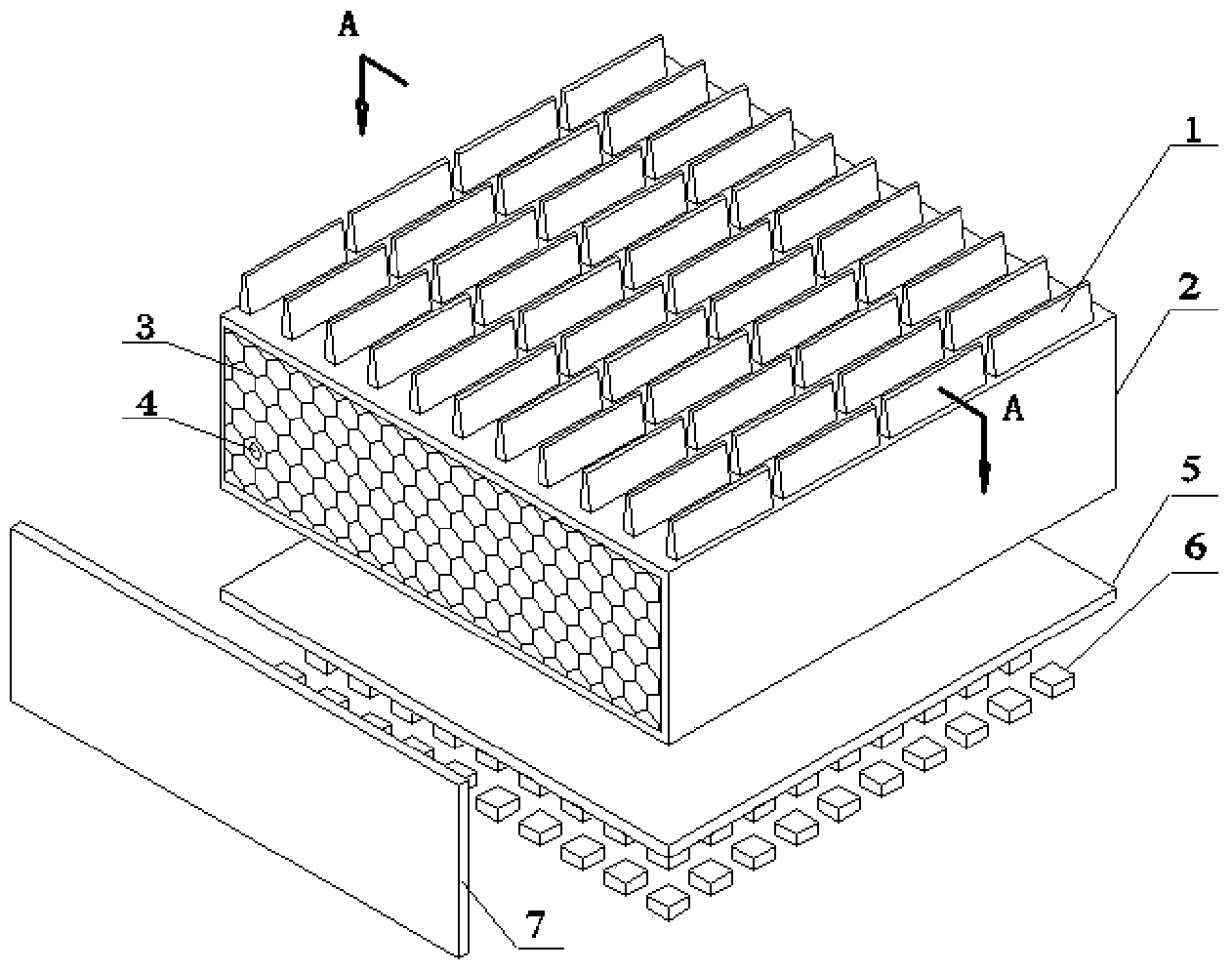

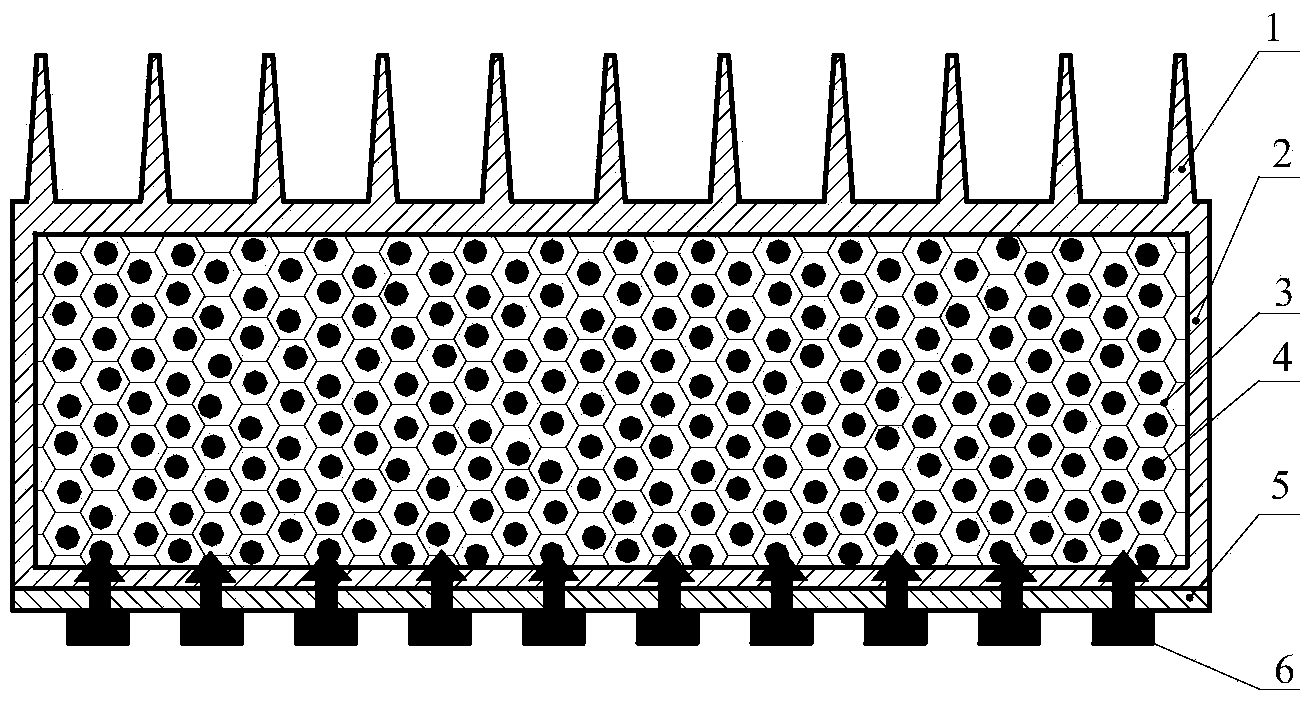

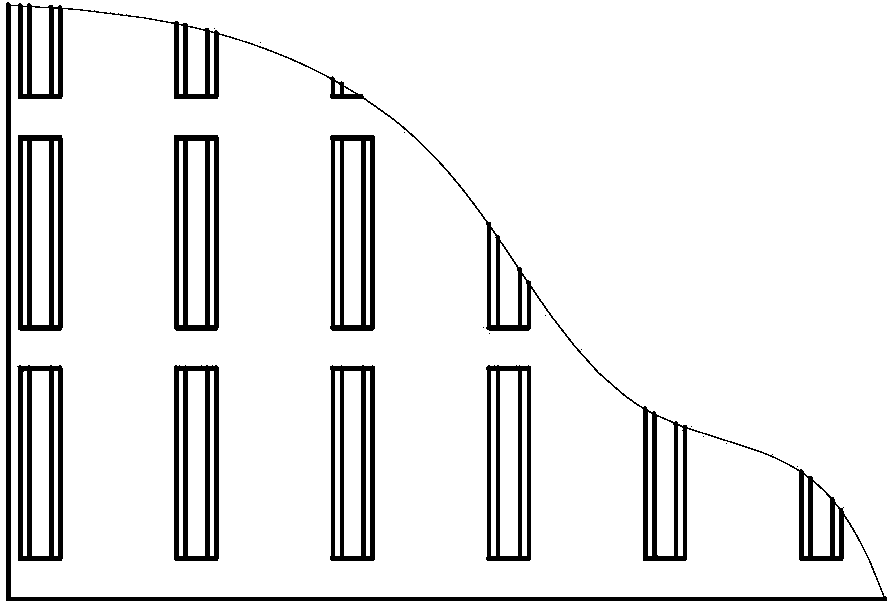

[0024] Such as figure 1 As shown, the present invention includes a radiator cavity 2 with a plurality of radiator fins 1 on the top surface, and a metal porous structure 3 with a porosity ranging from 30% to 99% is sintered in the radiator cavity 2, and the metal porous structure 3 A metal foam porous structure or a metal fiber felt porous structure prepared for high thermal conductivity metal materials such as aluminum or copper; the pores of the metal porous structure 3 are filled with phase change materials 4, and the metal porous structure 3 can improve the effectiveness of the phase change material 4 Thermal conductivity, thereby improving the response rate of phase change latent heat storage; the volume filling rate of the phase change material 4 in the metal porous structure 3 is less than 95%, to consider the volume expansion of the phase change mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com