Method for welding thin-walled cylinder with magnet sleeved inside in seal housing component

A technology of sealed shell and thin-walled cylinder, which is applied in welding equipment, electron beam welding equipment, metal processing equipment, etc., can solve the problems of burn-through, high cost, and small heat capacity, and achieve uniform melting, easy operation, and high quality stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further illustrated in the following examples, which are only used to illustrate the present invention and not to limit the present invention.

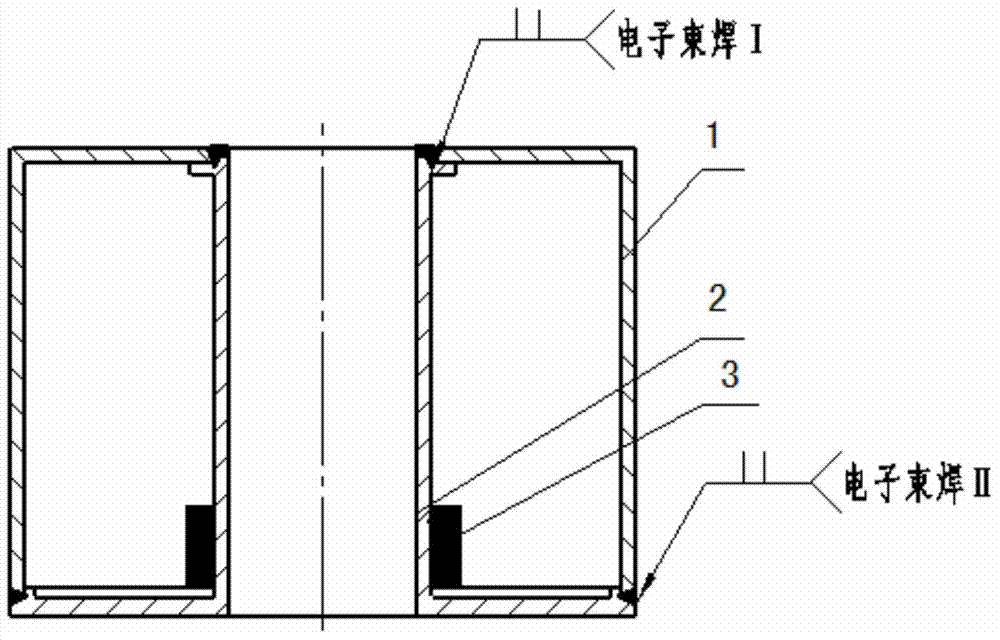

[0014] see figure 1 . The sealed shell assembly has an outer shell 1 of an aluminum alloy hollow thin shell, which has a cylindrical inner shell 2 which can be fixedly connected by electron beam I and electron beam II. The magnet 3 is assembled at the bottom end through the inner casing 2 of the thin-walled cylinder. The outer shell 1 with the inner shell 2 can seal the inner shell 2 and the magnet 3 in the hollow thin shell by electron beam I and electron beam II to form a sealing body. According to the pre-welding preparation of the present invention, conventional chemical methods can be used to remove oxides on the surface of the joints of the sealed shell components, and organic cleaning agents are used to strictly clean the vicinity of the joints to be welded before welding. Then, the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com