Patents

Literature

36results about How to "Dense weld" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for welding thin-walled cylinder with magnet sleeved inside in seal housing component

ActiveCN103537788ASimple and fast operationQuality improvementElectron beam welding apparatusSteam pressureEngineering

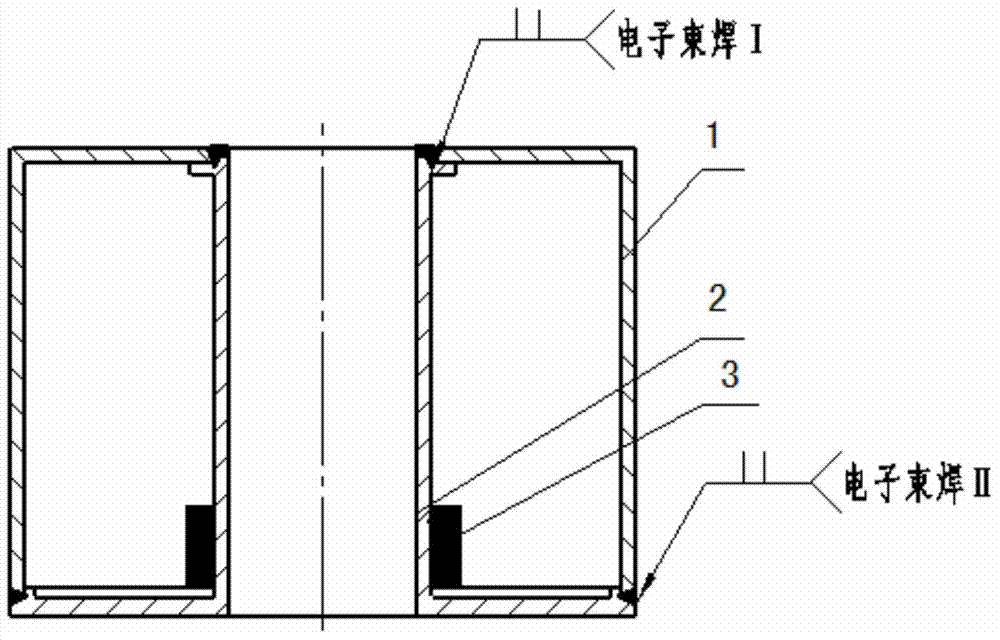

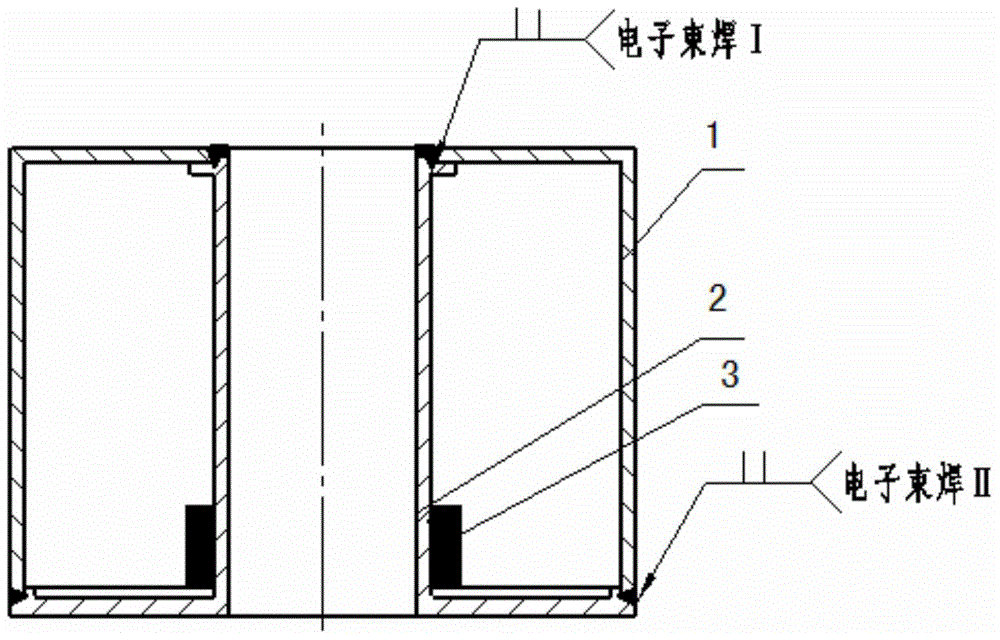

The invention provides a method for welding a thin-walled cylinder with a magnet sleeved inside in a seal housing component. The welding efficiency of the aluminum alloy thin-walled seal housing component can be obviously improved through the method, quality is stable, a connector is bright, fusion is even, and continuous and compact welding beads can be formed. According to the technical scheme, the method comprises the following steps that the butt joint positions of inner and outer housing welding joints are closely attached through a clamp, and annular welding joint pulse electron beam tack welding is carried out on the circumferential seam crossing of an assembled component; a deflection distance occurring to an electron beam caused by Lorentz force is compensated by an electron beam deflection angle; the total heat input amount of the electron beam is controlled with the impulse waveform of the pulse electron beam, the impulse waveform is steep in the front and gentle in the back, and welding is carried out through heat generated when beam flow ascends and descends; under the condition that small pulse power is set and steam pressure is reduced, a pulse back edge is prolonged by 3-5s, slow reduction is carried out, the focal position of the electron beam is adjusted to be within the range 0.55mm below the surface of a workpiece, the surface of a connector to be welded is melted and integrally welded, and the continuous welding beads are formed.

Owner:四川泛华航空仪表电器有限公司

Cadmium-free silver solder containing indium and silicon

InactiveCN101279407AReduce dosageSave resourcesWelding/cutting media/materialsSoldering mediaIndiumCadmium Cation

The invention relates to an indium and silicon-contained cadmium-free silver filler metal, which belongs to the field of medium-temperature brazing materials. The cadmium-free silver filler metal consists of chemical components accounting by weight percentage: 36 percent to 40 percent of copper, 25 percent to 35 percent of zinc, 0.5 percent to 4.5 percent of indium, 0.01 percent to 0.5 percent of silicon and 0.001 percent to 0.1 percent of microalloy elements and the allowance is silver; wherein, the microalloy elements are one or more of the alloying elements such as Ni, Mn, Sb, Zr, B, Ce, La, etc. The components are smelted and cast by adopting a conventional medium-frequency induction furnace, and then the required filler metal can be obtained by extruding, drawing, forming and washing the processed components. The temperature at which the indium and silicon-contained cadmium-free silver filler metal of the invention is melted ranges from 640 to 760 DEG C. By removing the hazardous element-cadmium, the alloy filler metal completely meets the requirement of the RoHS directive by European Union, removes the hazard caused to the health of the bodies of the operation employees and contaminations caused to the environment. By matching the FB102 flux and the silver filler metal of the invention for use, the invention can be applied to the brazing between the copper and workpieces such as copper alloy, hard alloy, stainless steel fitting, etc., and has the advantages of favorable wettability and fluidity, high mechanical strength of the brazed joint, good brazing process performance, etc. The mechanical property of the weld is equal to that of the silver filler metals such as BAg40CuZnCd, BAG45CuZnCd, BAG45CuZn, etc. The silver filler metal of the invention can be widely applied to the brazing in the industries such as refrigeration, machinery, electric machinery, electric apparatuses, instruments and meters, valves and pipe fittings, etc.

Owner:金李梅

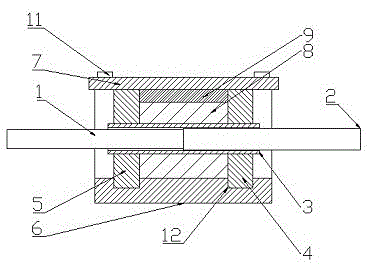

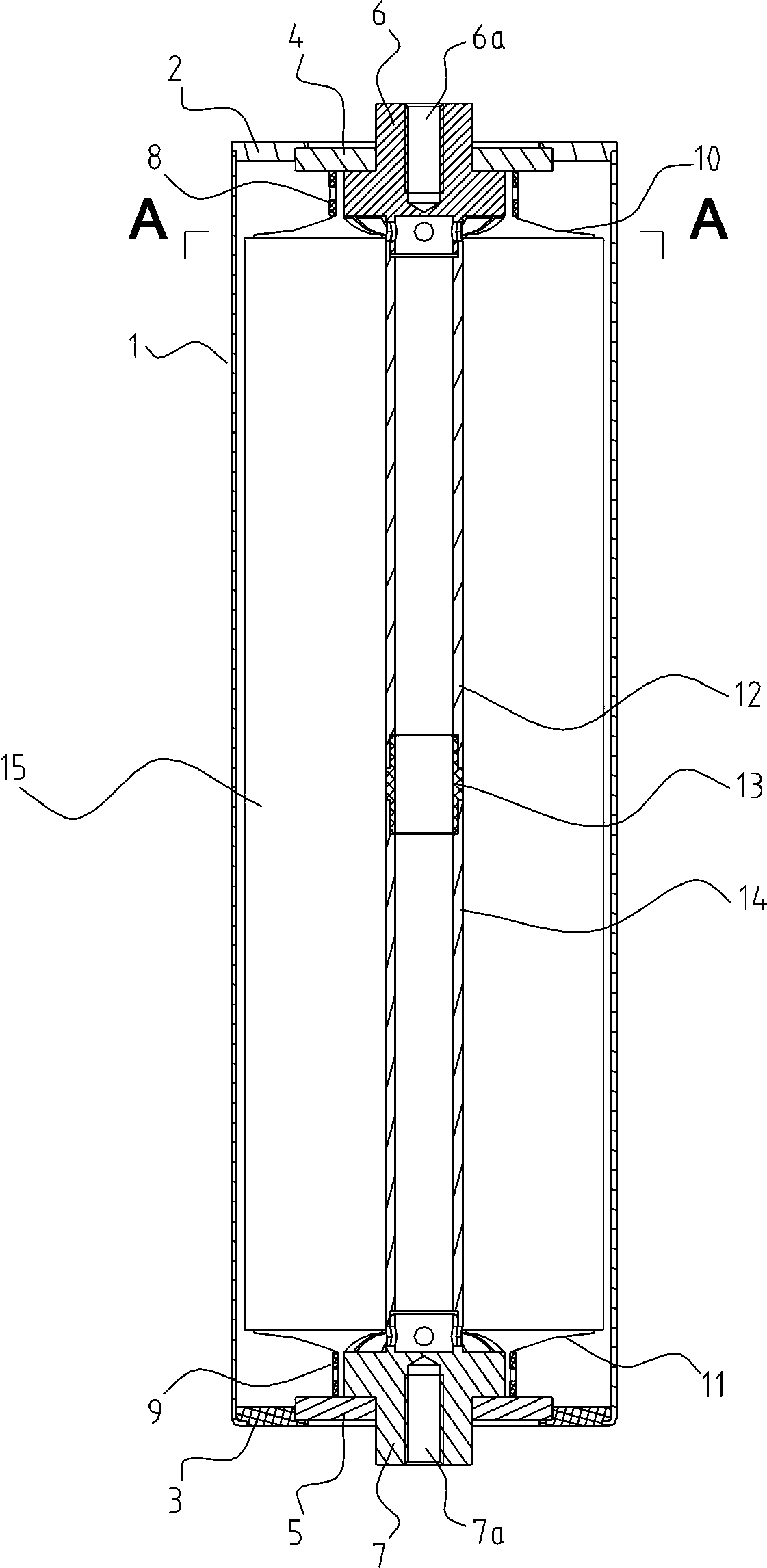

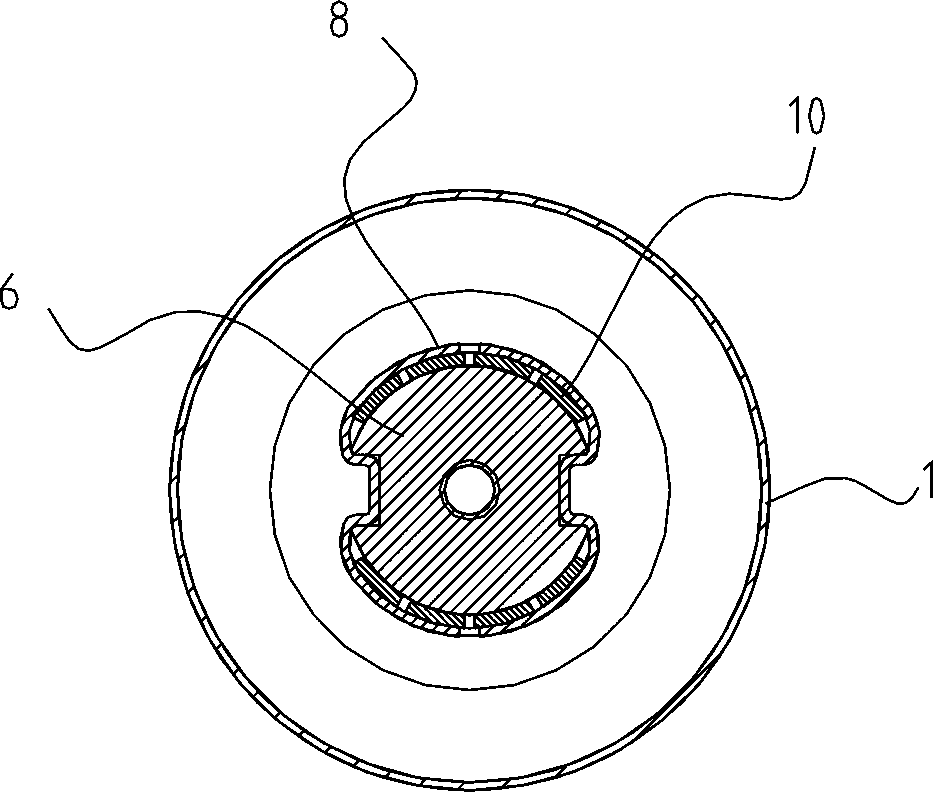

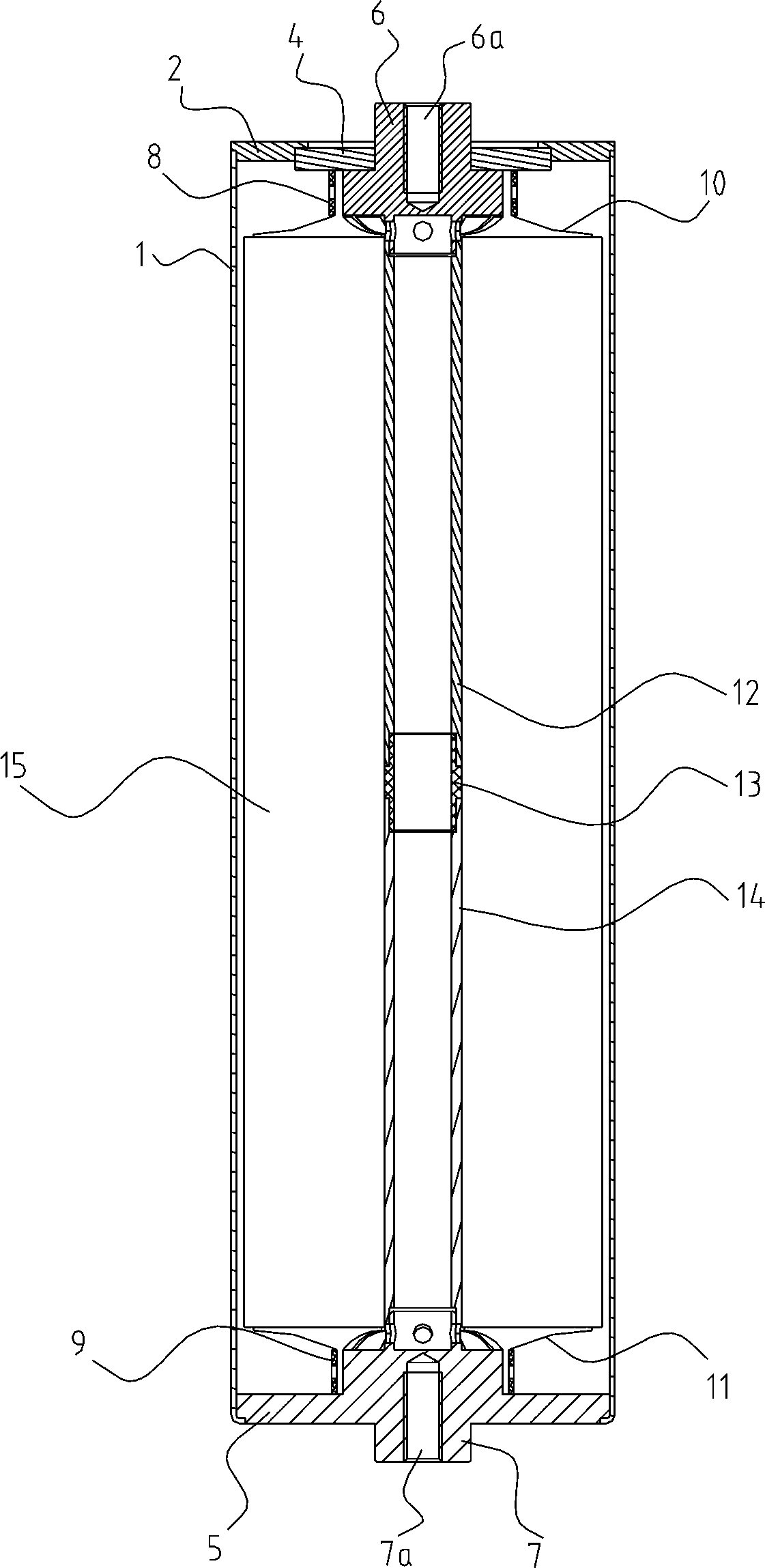

A cylindrical lithium-ion power battery

ActiveCN102299271APrevent leakageImprove high temperature resistanceFinal product manufactureSmall-sized cells cases/jacketsElectrical batteryEngineering

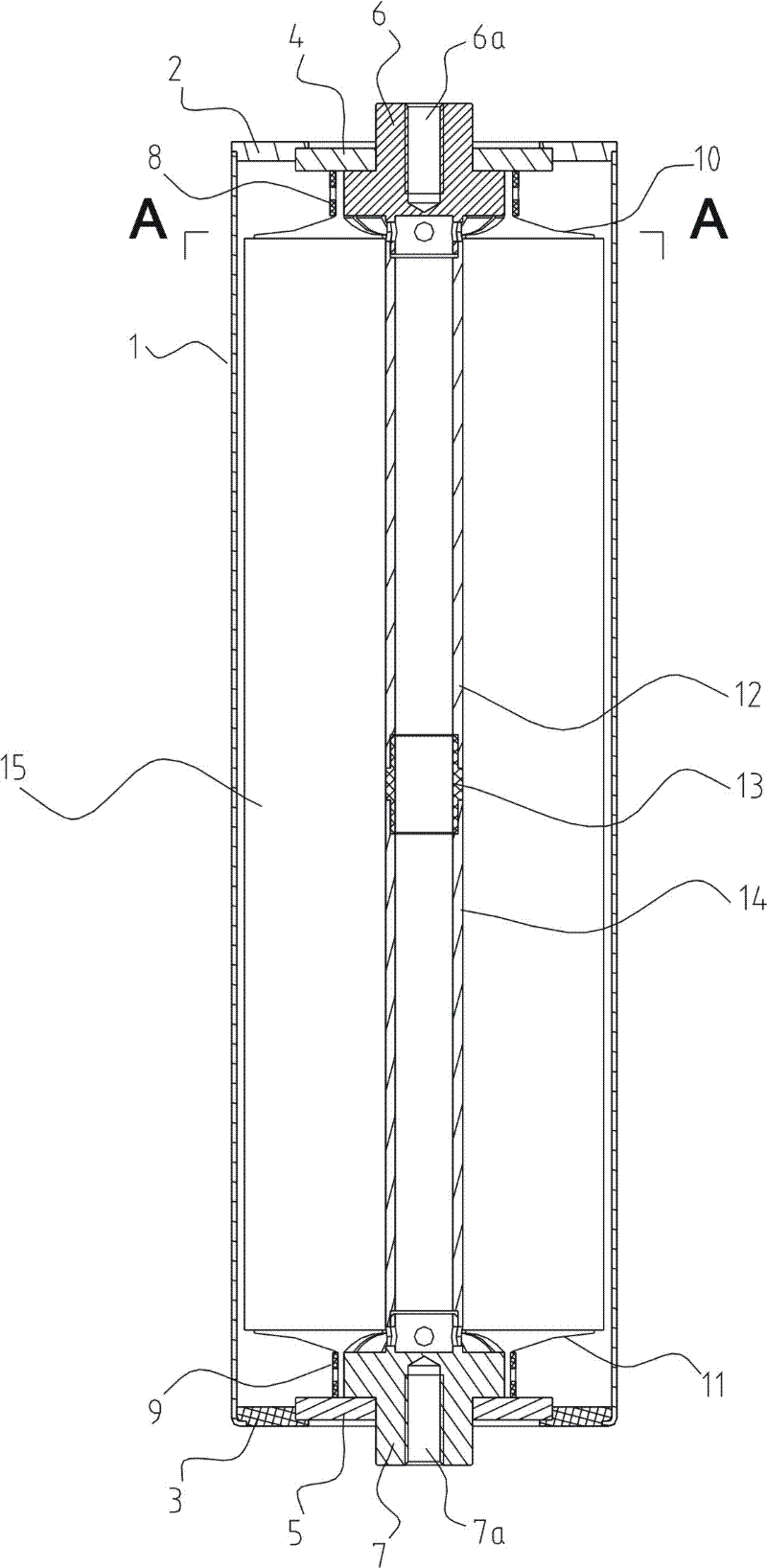

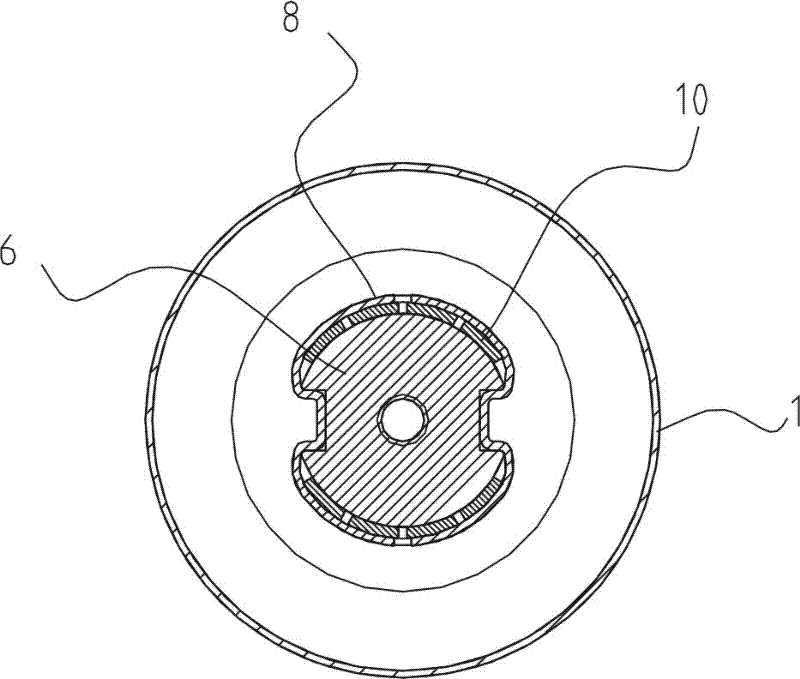

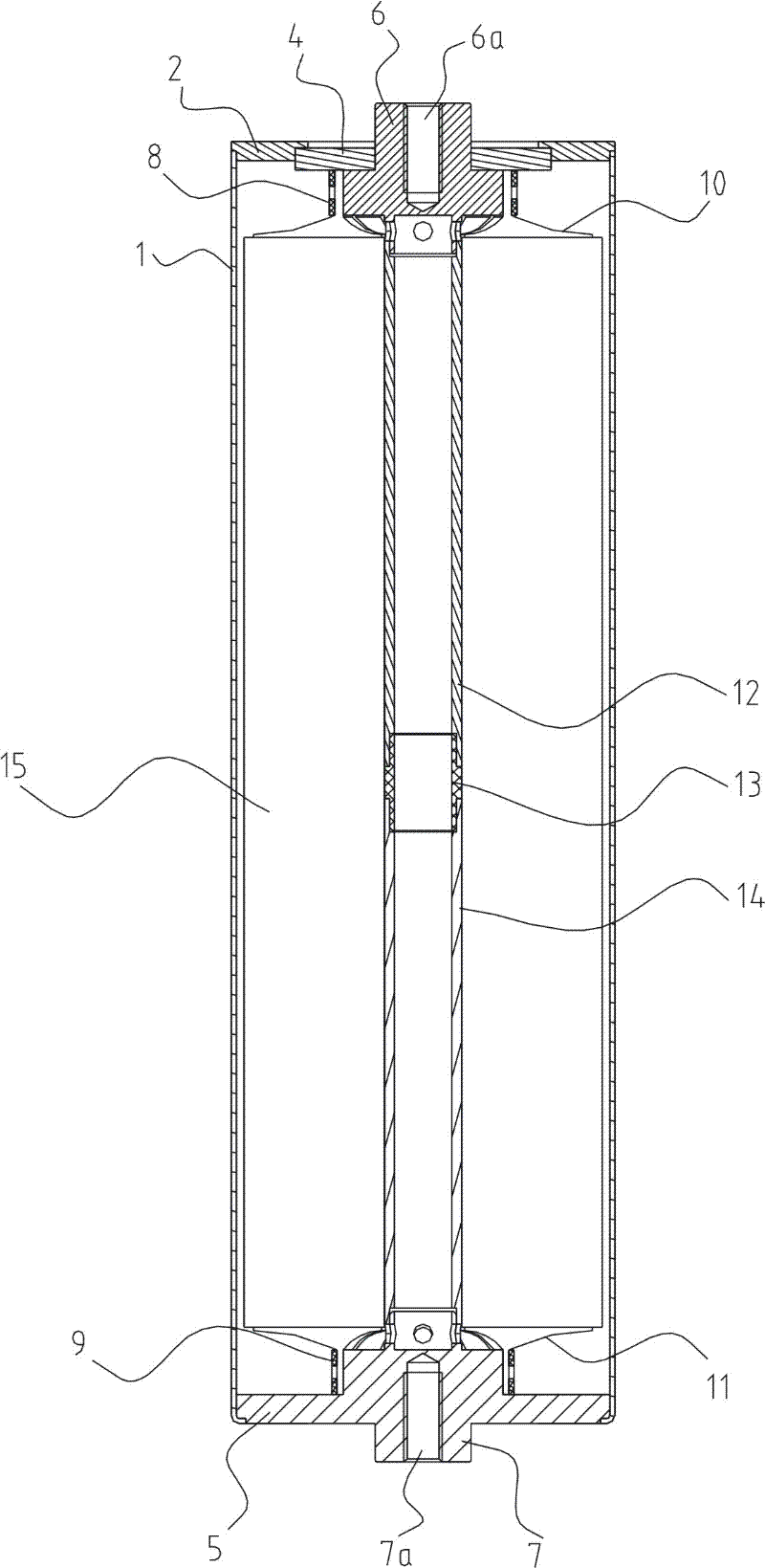

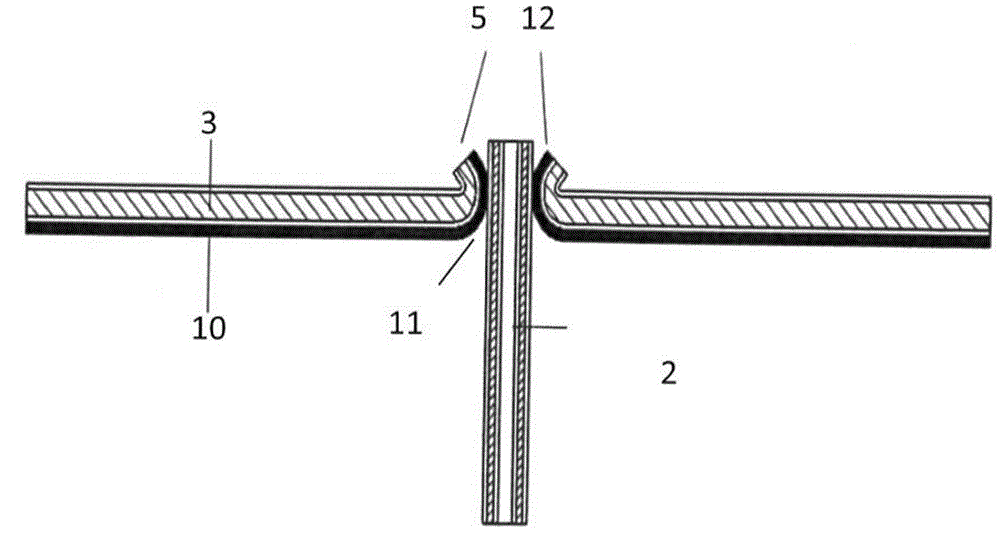

The invention discloses a cylindrical lithium ion power cell, which comprises a cylindrical housing, a positive electrode cover plate, a negative electrode cover plate, a positive electrode post, a negative electrode post, a center tube and an electrical core, and is characterized in that the positive electrode cover plate and the negative electrode cover plate are respectively fixed on two ends of the housing; the positive electrode post and the negative electrode post are respectively disposed on the positive electrode cover plate and the negative electrode cover plate; the center tube is positioned inside the housing; the two ends of the center tube are respectively connected with the positive electrode post and the negative electrode post; and the electrical core contains a negative electrode piece, an isolated film and a positive electrode piece, wherein the negative electrode piece, the isolated film and the positive electrode piece successively wind on the center tube; the negative electrode cover plate is equipped with a through hole; a negative electrode ceramic ring is seal welded inside the through hole; and the negative electrode post is disposed through the central hole of the negative electrode ceramic ring and seal welded with the negative electrode ceramic ring. According to the invention, the ceramic ring is used to separate the negative electrode cover plate from the negative electrode post, and vacuum sealing can be achieved after the ceramic ring is welded, thus greatly raising the reliability of the cell sealing and guaranteeing the security of the cell used for a long time; in addition, the cell provided by the invention has a long service life.

Owner:YINLONG ENERGY CO LTD

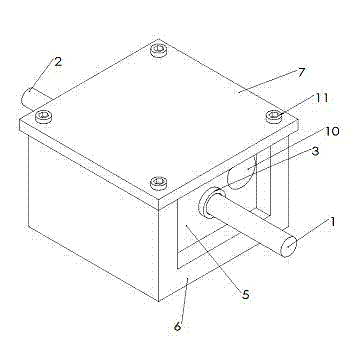

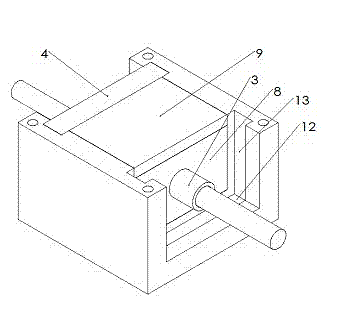

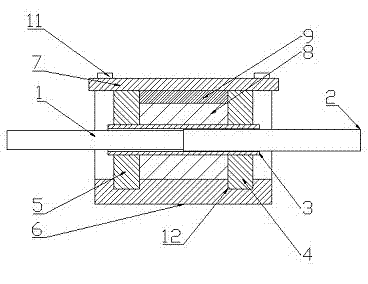

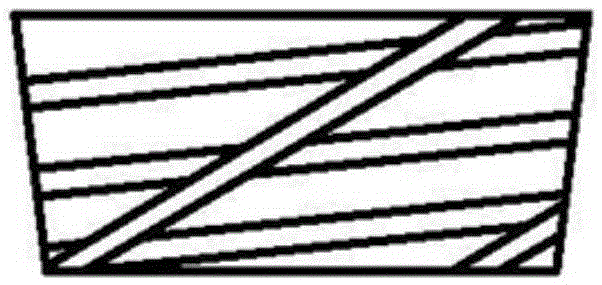

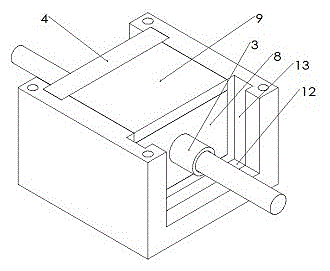

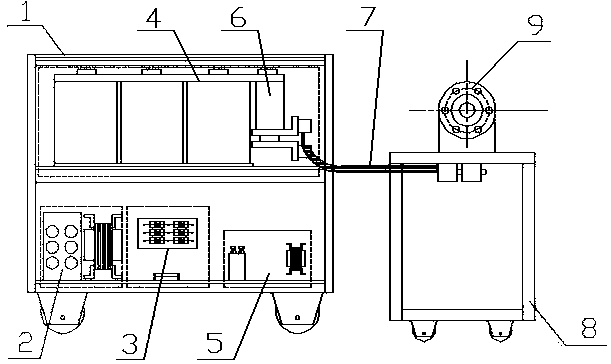

Device used for welding copper tube and aluminum tube in refrigeration equipment and welding method thereof

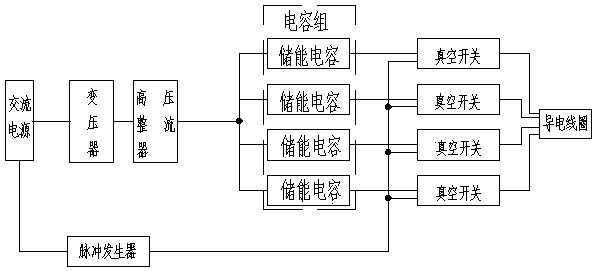

ActiveCN104191081ANo consumptionNice appearanceHigh frequency current welding apparatusWelding/soldering/cutting articlesMagnetic tension forceTransformer

The invention discloses a device used for welding a copper tube and an aluminum tube in refrigeration equipment and a welding method of the device. The device comprises a main device body and a working table, wherein the main device body comprises a main box, an alternating-current power source, a transformer, a high-voltage rectifier, a capacitor set, vacuum switches and a triggering device; the working table comprises a rack and a welding head, the welding head comprises an electric conducting coil and a magnetic flux concentrator, and the electric conduction coil is connected with all the vacuum switches through coaxial cables. The welding method includes the following steps that (1), one end of an outer tube is inserted in the magnetic flux concentrator, and one end of an inner tube is inserted into the magnetic flux concentrator; (2), a pulser is started, when a charging voltage reaches a set value, the system control triggering device turns on a discharging switch, and the outer tube and the inner tube are welded through magnetic force in the magnetic flux concentrator. The device used for welding the copper tube and the aluminum tube in the refrigeration equipment achieves normal-temperature welding, and is more convenient and faster to use, more environmentally friendly and lower in welding cost.

Owner:CHONGQING PULSAR TECH

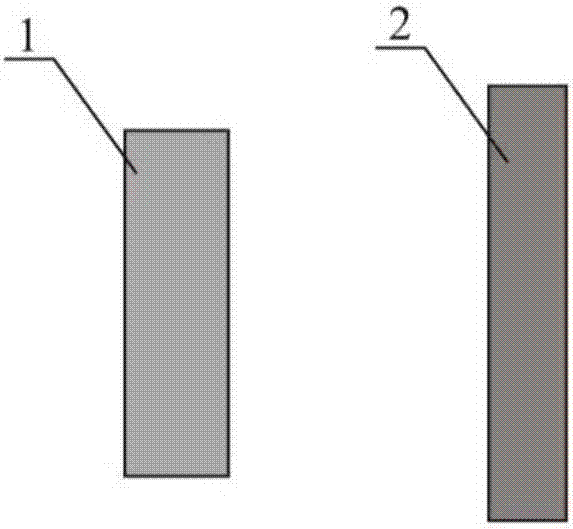

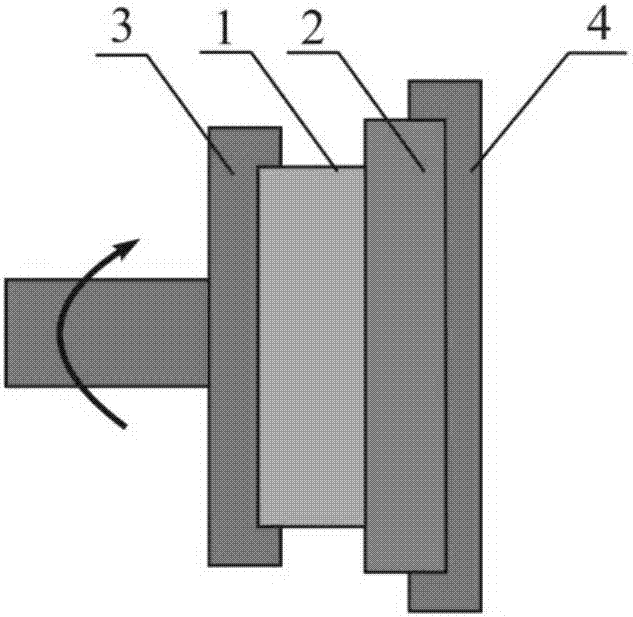

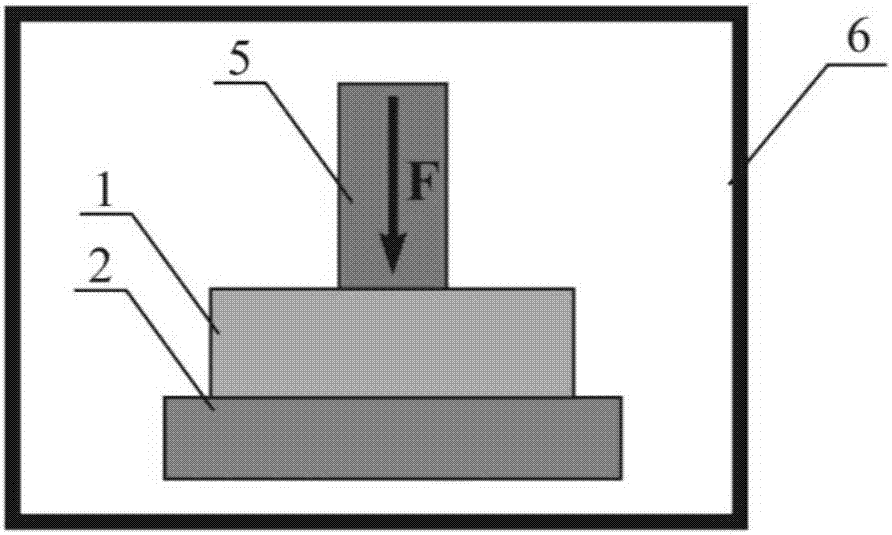

Frictional diffusion welding method for aluminum target assembly

ActiveCN107984075AEfficient removalHigh strengthWelding/soldering/cutting articlesNon-electric welding apparatusFriction weldingDiffusion welding

The invention discloses a frictional diffusion welding method for an aluminum target assembly. The frictional diffusion welding method for the aluminum target assembly comprises the following steps that firstly, to-be-welded faces of an aluminum target and an aluminum back plate are mechanically polished and cleaned; secondly, the aluminum target and the aluminum back plate which are treated in the first step are fixed through a clamp so that the to-be-welded faces of the aluminum target and the aluminum back plate can be arranged oppositely, the to-be-welded faces of the aluminum target and the aluminum back plate are made to draw close to each other through a driving clamp, at least one of the aluminum target and the aluminum back plate is rotated in the process of drawing close to eachother, and after the aluminum back plate and the aluminum target are in contact, the pressure is increased to 0.5 MPa-2.0 MPa and is maintained for 5 s-25 s to complete primary frictional welding; thirdly, the aluminum target assembly subjected to primary frictional welding in the second step is placed in an axial pressurizing diffusion welding furnace, vacuumizing is conducted, and heating and pressurization in the axial direction are conducted till welding is completed; and fourthly, the aluminum target assembly treated in the third step is cooled. By adoption of the frictional diffusion method for the aluminum target assembly, the problems that when an aluminum target assembly is subjected to diffusion welding directly, the requirement for the environment condition is high, and defectsof weld joints are likely to be caused are solved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Flux-cored welding wire for downward vertically

InactiveCN1338352AEasy to controlBeautiful shapeWelding/cutting media/materialsSoldering mediaCarbon steelCorex

A flux-corex welding wire fed downward vertically for gas shielded welding is composed of skin made of low-carbon steel and flux core containing TiO2 (20-40 wt%), Al2O3 (1.2-7), ZrO2 (3-8.5), MgO (0.5-3), NaF+K2SiF6 (1.2-4), deoxidizing agent which is one or more of Si, Mn, Ti, Al and Mg (11-20), alloying agent which is one or more of Ni, Cr, MO, Cu and V (less than 5) and Fe (rest).

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

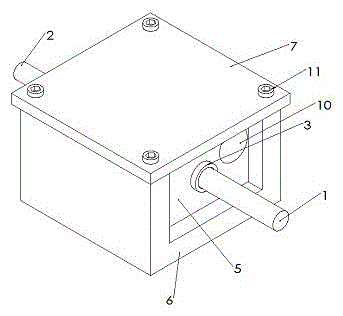

Fine wire resistance socket welding method and socket welding mould

InactiveCN103658953AImprove welding strengthIncrease productivityResistance electrode holdersPre stressMetal

The invention provides a fine wire resistance socket welding method and a socket welding mould. Expansion cement is used for wrapping a sleeve-connection thin-wall sleeve pipe in a clamp provided with the fine wire resistance socket welding mould, pre-stress is formed in the sleeve pipe through the mould, the sleeve pipe is prevented from expanding in the welding process, and therefore a perfect welding connector with the unchanged appearance size of the sleeve pipe for welding wires and welding a wire and the sleeve pipe is obtained. A fixing insulation block is formed by utilizing the expansion cement, the expansion of the sleeve pipe is limited, current is concentrated to heat the welding position, and the connector and the mould are simple in structure, convenient to install and easy to operate. After welding is finished, the welded metal wire can be taken out only by breaking the cement block to pieces, and the whole mould is low in manufacturing cost and can be produced in a batch mode.

Owner:WUHAN UNIV

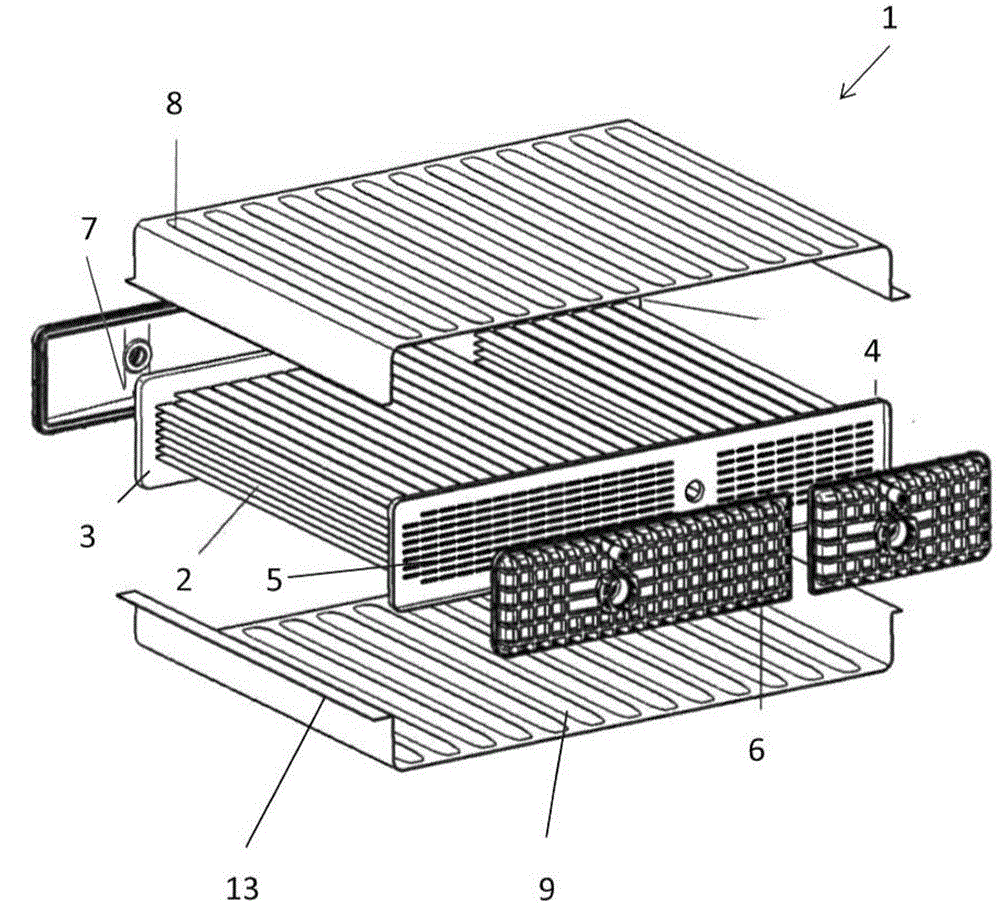

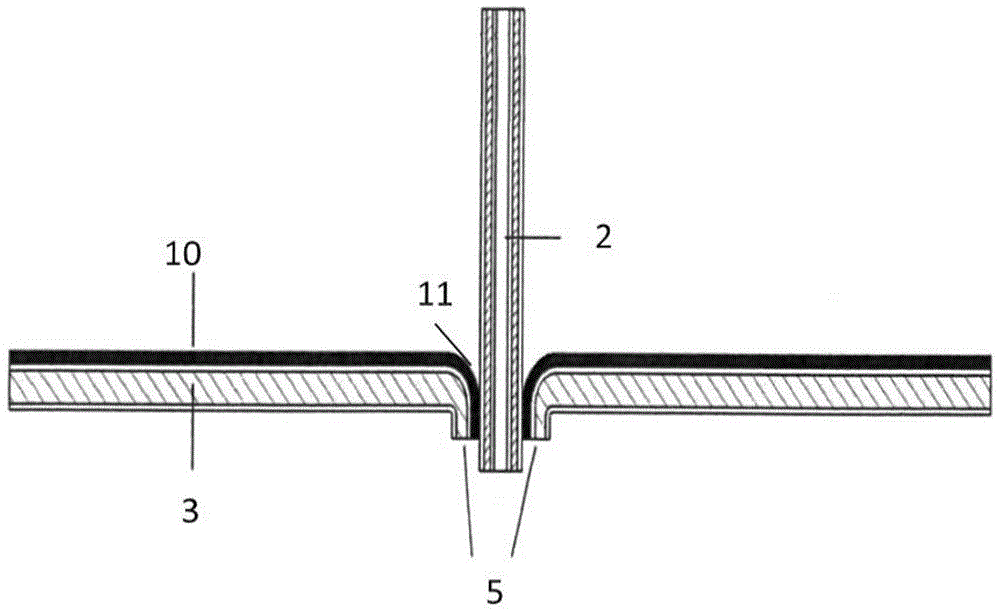

Heat exchanger, and especially manufacturing method of adsorption type heat exchanger

InactiveCN104588895AReliable closureAvoid erosionHeat pumpsBoiler absorbersEngineeringLow melting point

The invention relates to a heat exchanger, and especially a manufacturing method of an adsorption type heat exchanger. A plurality of composition parts of the heat exchanger are composed of iron-based material, such as pipes, a housing part enclosing the bottoms of the pipes and surrounding the bottoms and the pipes are assembled and then brazing is subsequently performed. The method can reliably braze joint welding lines in different widths. When the composition parts, made of steel or stainless steel, of the heat exchanger are assembled, welding films are disposed between the joint welding lines of the composition parts of the heat exchanger, the joint welding lines are then filled with low-melting-point welding materials, and the brazing without a welding flux is then performed.

Owner:MAHLE BEHR GMBH & CO

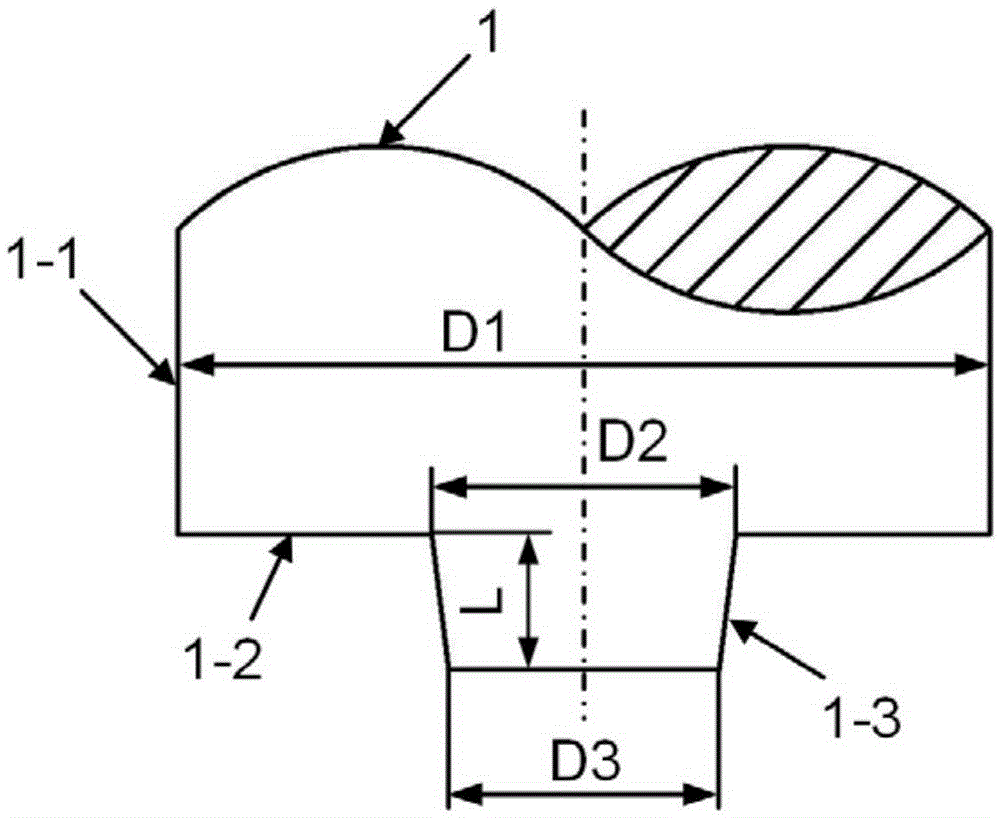

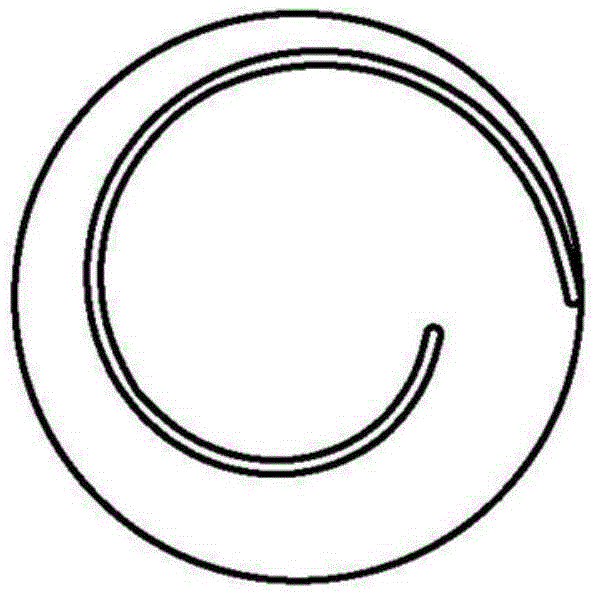

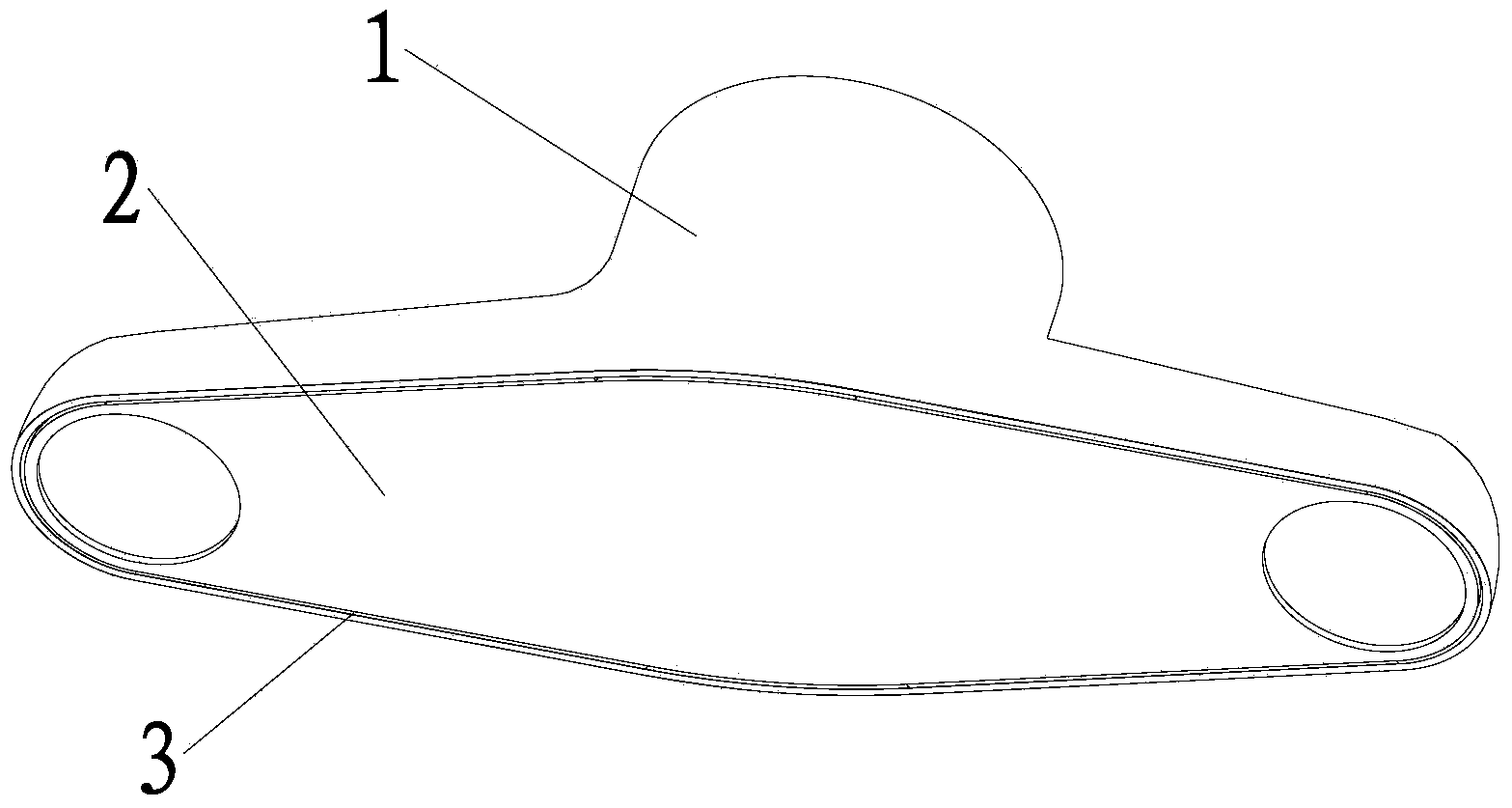

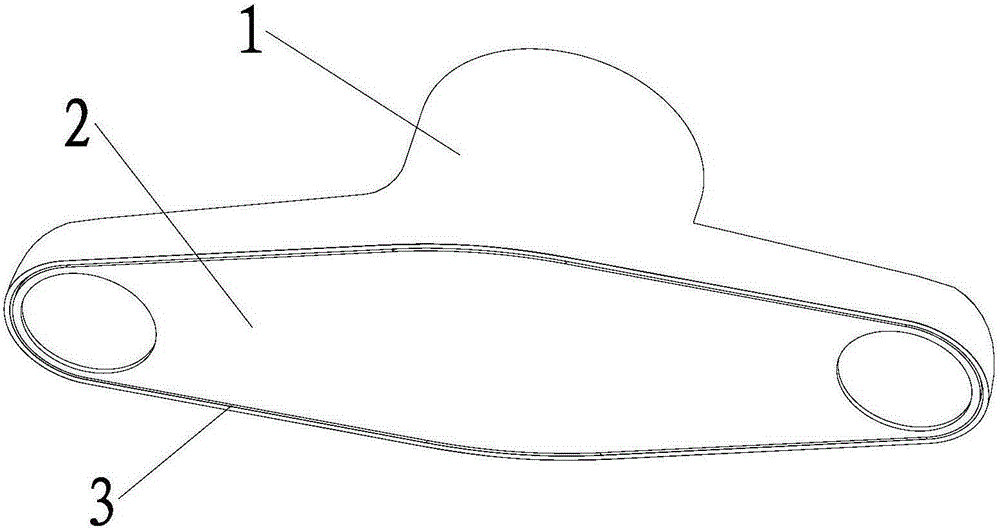

Large-shaft-shoulder stirring head suitable for high-speed friction-stir welding, and welding method

InactiveCN105397278AImprove flow uniformityImprove liquidityNon-electric welding apparatusFriction weldingFriction stir welding

The invention discloses a large-shaft-shoulder stirring head suitable for high-speed friction-stir welding, and a welding method, and relates to a large-shaft-shoulder stirring head and a welding method. The invention aims at solving the problem that the present conventional shaft-shoulder stirring head is difficult to realize high-speed friction-stir welding for a medium-thickness plate. The stirring head is composed of three parts, that is, a clamping area, a shaft shoulder and a stirring needle, wherein the centre of the clamping area, the circle centre of the shaft shoulder and the centre of the stirring needle are coaxially arranged; and a large shaft shoulder with a diameter which is 5 times greater than a plate thickness is used as the shaft shoulder, an Archimedes spiral groove with a variable groove depth is machined in the plane of the shaft shoulder, a conical stirring needle is used as the stirring needle, and two conical threads with different leads are machined on the side surface. The method comprises the following steps: step 1, determination for each dimension of the large-shaft-shoulder stirring head; step 2, clamping for welded workpieces; step 3, location for the stirring head; step 4, determination for penetrating parameters; and step 5, determination for advancing parameters. The stirring head and the welding method, which are disclosed by the invention, are suitable for high-speed friction-stir welding (with a speed of not less than 1500mm / min) for an aluminium alloy medium-thickness plate (with a thickness of not less than 3mm).

Owner:HARBIN INST OF TECH

Stainless steel water faucet shell welding technology

ActiveCN104043901AImprove welding strengthDense weldWelding/soldering/cutting articlesLaser beam welding apparatusWeld strengthFusion welding

The invention relates to a water faucet shell production technology, in particular to a stainless steel water faucet shell welding technology. The stainless steel water faucet shell welding technology comprises the following steps of material selection, part preparation, cleaning before welding, part clamping, part welding and post-welding checking. In the part clamping process, a welding clamp needs to be adjusted so that a welding position of a base plate can be embedded in a welding position of a body. A laser penetration fusion welding method is adopted for part welding. Due to the facts that the welding position of the base plate is embedded in the welding position of the body, and the body and the base plate are welded together through the laser penetration fusion welding method which is highly centralized in energy density, weld strength of weld joints is high, and the weld joints are compact and beautiful in appearance.

Owner:HUAQIAO UNIVERSITY

Large-area sealing resistance welding process for circumferences of tank body and sealing end cover

The invention provides a large-area sealing resistance welding process for circumferences of a tank body and a sealing end cover. By the adoption of the process, a large current can be output within ashort time, and the short time means time shorter than 20-30 milliseconds, the large current refers to the current of 1 million amps or more, and few grids are required; and the joint between the tank body and the sealing end cover which are welded has the beneficial effects of the tight weld seam, good sealing and good pressure resistance. The base material can be directly melted without the help of or use of welding materials in the whole process of welding, no fume polluting the environment and irritating gases are generated, the floor space of the equipment can be reduced and the requirement for the welding materials can be reduced compared to furnace brazing, the energy-saving and environmentally friendly use is realized, and the yield is high.

Owner:HERON INTELLIGENT EQUIP CO LTD

Flux-cored welding wire for downward vertically

InactiveCN1131123CEasy to controlBeautiful shapeWelding/cutting media/materialsSoldering mediaCarbon steelMaterials science

A flux-corex welding wire fed downward vertically for gas shielded welding is composed of skin made of low-carbon steel and flux core containing TiO2 (20-40 wt%), Al2O3 (1.2-7), ZrO2 (3-8.5), MgO (0.5-3), NaF+K2SiF6 (1.2-4), deoxidizing agent which is one or more of Si, Mn, Ti, Al and Mg (11-20), alloying agent which is one or more of Ni, Cr, MO, Cu and V (less than 5) and Fe (rest).

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Corrosion-resistant stainless steel kettle material used for zinc-aluminum alloy hot dipping and process thereof

InactiveCN108707841AReduce dissolutionReduce corrosion and dissolutionHot-dipping/immersion processesHot-dip galvanizationCorrosion resistant

The invention discloses a corrosion-resistant stainless steel kettle material used for zinc-aluminum alloy hot dipping and a processing process thereof. An alloy includes 1.0 wt.%-1.2 wt.% of Li, 0.2wt.%-0.3 wt.% of Mo, 0.1 wt.%-0.2 wt.% of Ca, 8.0 wt.%-9.5 wt.% of Cr, 6.2 wt.%-7.5 wt.% of Ni, 4.0 wt.%-8.0 wt.% of Si, 1.5 wt.%-1.8 wt.% of Co, 0.2 wt.%-0.5 wt.% of B and the balance iron. By meansof development and industrialization of the material, a solution of material science is provided for the current situation that an existing iron kettle in hot-dip galvanizing zinc-aluminum alloy production is extremely short in service life and reloading is not convenient. Implementation and industrialization of the material have important significance in solving the current industry situation ofChina and improving the international competitiveness of products of the metallurgical industry in China.

Owner:GUANGZHOU YUZHI TECH CO LTD

A stainless steel faucet shell welding process

ActiveCN104043901BImprove welding strengthDense weldWelding/soldering/cutting articlesLaser beam welding apparatusEngineeringWeld strength

The invention relates to a water faucet shell production technology, in particular to a stainless steel water faucet shell welding technology. The stainless steel water faucet shell welding technology comprises the following steps of material selection, part preparation, cleaning before welding, part clamping, part welding and post-welding checking. In the part clamping process, a welding clamp needs to be adjusted so that a welding position of a base plate can be embedded in a welding position of a body. A laser penetration fusion welding method is adopted for part welding. Due to the facts that the welding position of the base plate is embedded in the welding position of the body, and the body and the base plate are welded together through the laser penetration fusion welding method which is highly centralized in energy density, weld strength of weld joints is high, and the weld joints are compact and beautiful in appearance.

Owner:HUAQIAO UNIVERSITY

Y and Sr-containing iron alloy for hot-dip galvanized high-thermal-conductivity iron crucible

InactiveCN108588575AGood welding performanceAccelerated corrosionHot-dipping/immersion processesSheet steelCrucible

The invention discloses a Y and Sr-containing iron alloy for a hot-dip galvanized high-thermal-conductivity iron crucible and a processing technology thereof. The alloy comprises 0.2-0.4 wt.% of Ca,0.2-0.3 wt.% of Sr, 0.4-0.6 wt.% of Re, 0.2-0.4 wt.% of Y, 0.8-1.5 wt.% of V, 0.4-0.5 wt.% of Hf and the balance iron. According to the alloy and the processing technology thereof, the alloy is cast and hot-rolled into a steel plate to form the hot-dip galvanized iron crucibl so that the heat transfer capability of the iron crucible and the uniformity of the thickness of a galvanized layer can begreatly improved; and the service life of the iron crucible is prolonged from 7-10 years to 20 years and longer, and the effects of improving the production efficiency and saving the cost are achieved.

Owner:GUANGZHOU YUZHI TECH CO LTD

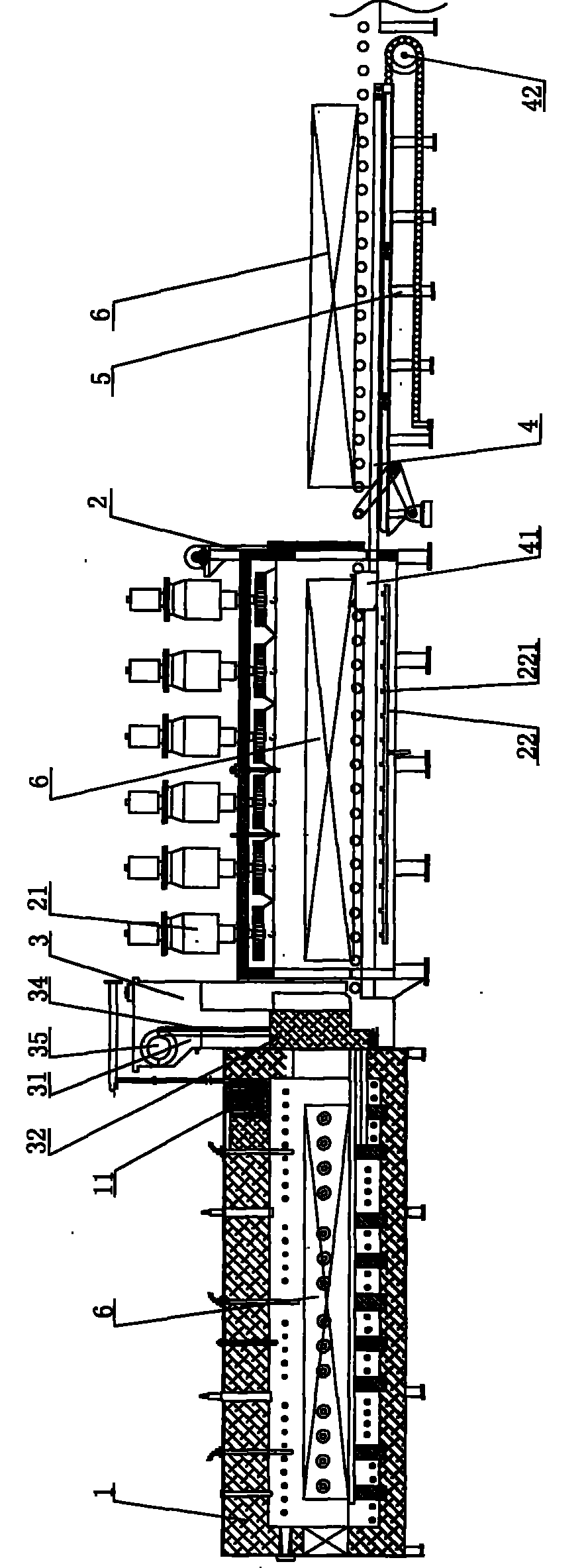

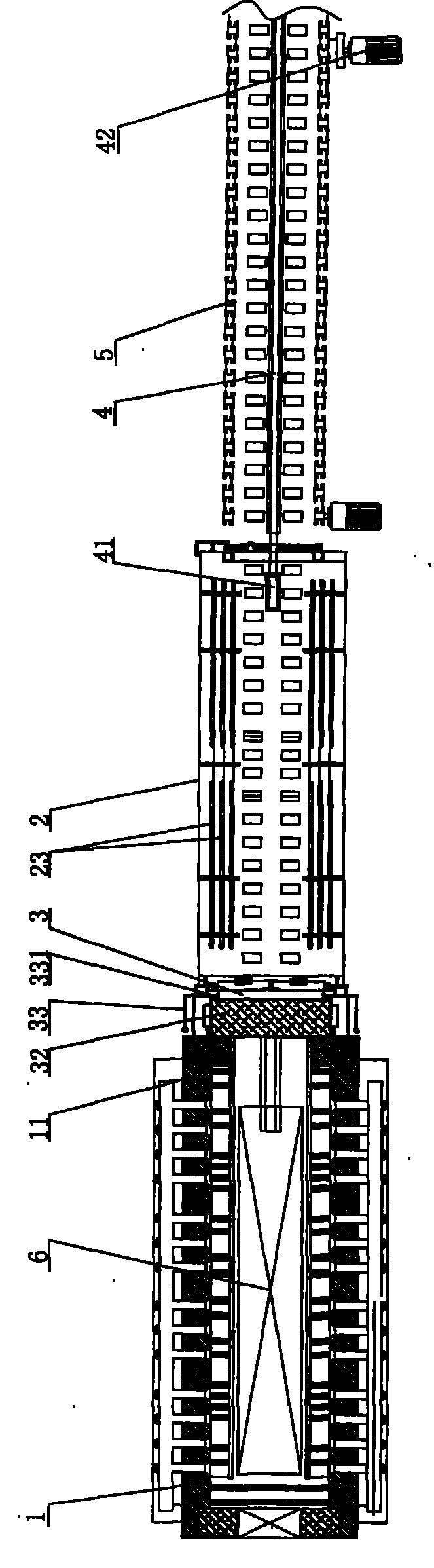

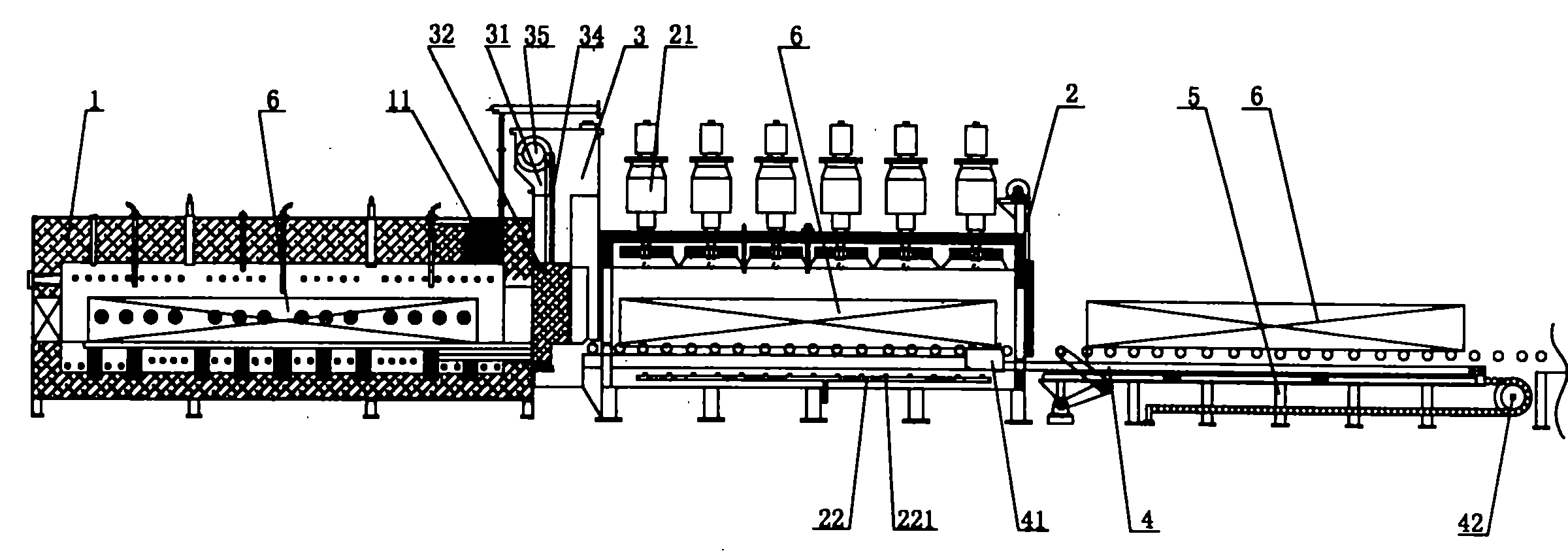

Brazing procedure integration device

InactiveCN101380687BDense weldUniform weldingMetal working apparatusQuenching devicesProcess engineeringWeld line

The invention discloses an integral device for a braze welding technique, which includes a braze welding furnace and a quenching furnace; the discharge opening of the braze welding furnace and the feed opening of the quenching furnace are connected by a seal connection part which is provided with a strobe mechanism. In the invention, based on the existing braze welding furnace, the quenching furnace is combined with the braze welding furnace, thus realizing that the whole technical processes of braze welding, quenching and cooling are carried out in an closed environment with protection atmosphere; the welding lines of workpieces are tight and uniform with a smooth surface, thus not only simplifying the production technique, saving the working time, improving the production efficiency, but also reducing the manual working intensity and saving a workshop space. The integral device has the advantages of novel structure, high automatization degree, simple operation and wide application range.

Owner:浙江华虹电炉有限公司

A kind of thin wire resistance sleeve welding method and sleeve welding die

InactiveCN103658953BImprove welding strengthIncrease productivityResistance electrode holdersElectrical resistance and conductancePre stress

The invention provides a fine wire resistance socket welding method and a socket welding mould. Expansion cement is used for wrapping a sleeve-connection thin-wall sleeve pipe in a clamp provided with the fine wire resistance socket welding mould, pre-stress is formed in the sleeve pipe through the mould, the sleeve pipe is prevented from expanding in the welding process, and therefore a perfect welding connector with the unchanged appearance size of the sleeve pipe for welding wires and welding a wire and the sleeve pipe is obtained. A fixing insulation block is formed by utilizing the expansion cement, the expansion of the sleeve pipe is limited, current is concentrated to heat the welding position, and the connector and the mould are simple in structure, convenient to install and easy to operate. After welding is finished, the welded metal wire can be taken out only by breaking the cement block to pieces, and the whole mould is low in manufacturing cost and can be produced in a batch mode.

Owner:WUHAN UNIV

Zinc corrosion-resistant Te and Mo-containing iron pan material for hot-dip galvanizing

InactiveCN108441787AGood welding performanceAccelerated corrosionHot-dipping/immersion processesCrucibleAlloy

The invention discloses a zinc corrosion-resistant Te and Mo-containing iron pan material for hot-dip galvanizing and a processing technology thereof. By weight percentage, the alloy comprises: 0.2-0.5wt.% of Ca, 0.3-0.8wt.% Ge, 0.2-0.4wt.% of Mo, 0.1-0.2wt.% of Te, 1.8-2.4wt.% of Ni, 0.2-0.4wt.% of W, and the balance iron. The material can be made into iron crucibles for hot-dip galvanizing aftercasting and hot rolling into steel plate, and can greatly improve the corrosion resistance to zinc liquid. The service life of iron crucibles can be increased from 7-10 years to 20 years or more. Therefore, the material provided by the invention has the effects of improving production efficiency and saving cost.

Owner:GUANGZHOU YUZHI TECH CO LTD

Cylindrical lithium ion power cell

ActiveCN102299271BPrevent leakageImprove high temperature resistanceFinal product manufactureSmall-sized cells cases/jacketsPower batteryLithium

Owner:YINLONG ENERGY CO LTD

Zinc corrosion-resistant S and Nb-containing iron pan material for hot-dip galvanizing

InactiveCN108441788AGood welding performanceAccelerated corrosionHot-dipping/immersion processesCrucibleAlloy

The invention discloses a zinc corrosion-resistant S and Nb-containing iron pan material for hot-dip galvanizing and a processing technology thereof. By weight percentage, the alloy comprises: 0.3-0.8wt.% of Ca, 0.5-0.8wt.% of Ge, 0.2-0.4wt.% of In, 0.1-0.2wt.% of S, 1.2-1.4wt.% of Nb, 0.3-0.4wt.% of W, and the balance iron. The material can be made into iron crucibles for hot-dip galvanizing after casting and hot rolling into steel plate, and can greatly improve the corrosion resistance to zinc liquid. The service life of iron crucibles can be increased from 7-10 years to 20 years or more. Therefore, the material provided by the invention has the effects of improving production efficiency and saving cost.

Owner:GUANGZHOU YUZHI TECH CO LTD

Solder without cadmium and silver

ActiveCN100558499CReduce dosageSave resourcesWelding/cutting media/materialsSoldering mediaRare-earth elementIntermediate frequency

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

Anti-vibration W-In-containing stainless steel kettle material for hot dip aluminum plating

InactiveCN108411215AGood welding performanceImprove interactivityHot-dipping/immersion processesSheet steelSS - Stainless steel

The invention discloses an anti-vibration W-In-containing stainless steel kettle material for hot dip aluminum plating. The anti-vibration W-In-containing stainless steel kettle material comprises, byweight, 0.3-0.5 wt.% of Rb, 0.5-0.8 wt.% of W, 6.0-8.0 wt.% of Cr, 5.0-6.0 wt.% of Al, 1.5-3.0 wt.% of Co, 1.0-1.5 wt.% of In, 0.1-0.2 wt.% of S, and the balance Fe. According to the anti-vibration W-In-containing stainless steel kettle material for hot dip aluminum plating, the current situation that at present, technologies of materials for iron kettles in the hot dip aluminum plating field inChina is changed, through innovation and optimization of the material science, the development bottleneck of the production technology and equipment for hot dip aluminum plating steel plates in the high-end field in China is broken through, and in the near future, the iron kettle material is widely applied to the greatest extent.

Owner:GUANGZHOU YUZHI TECH CO LTD

Apparatus for welding copper tubes and aluminum tubes in refrigeration equipment and its welding method

ActiveCN104191081BNo consumptionNice appearanceHigh frequency current welding apparatusWelding/soldering/cutting articlesTransformerEngineering

The invention discloses a device used for welding a copper tube and an aluminum tube in refrigeration equipment and a welding method of the device. The device comprises a main device body and a working table, wherein the main device body comprises a main box, an alternating-current power source, a transformer, a high-voltage rectifier, a capacitor set, vacuum switches and a triggering device; the working table comprises a rack and a welding head, the welding head comprises an electric conducting coil and a magnetic flux concentrator, and the electric conduction coil is connected with all the vacuum switches through coaxial cables. The welding method includes the following steps that (1), one end of an outer tube is inserted in the magnetic flux concentrator, and one end of an inner tube is inserted into the magnetic flux concentrator; (2), a pulser is started, when a charging voltage reaches a set value, the system control triggering device turns on a discharging switch, and the outer tube and the inner tube are welded through magnetic force in the magnetic flux concentrator. The device used for welding the copper tube and the aluminum tube in the refrigeration equipment achieves normal-temperature welding, and is more convenient and faster to use, more environmentally friendly and lower in welding cost.

Owner:CHONGQING PULSAR TECH

Sc and Hf-contained iron alloy for hot-dip galvanizing anti-vibration iron crucible

InactiveCN108588574AGood welding performanceAccelerated corrosionHot-dipping/immersion processesCrucibleAlloy

The invention discloses a Sc and Hf-contained iron alloy for a hot-dip galvanizing anti-vibration iron crucible and a machining process of the Sc and Hf-contained iron alloy. The alloy comprises the ingredients of, in percentage by weight, 0.3-0.5% of Ca, 0.6-0.8% of Bi, 0.2-0.5% of Ge, 0.2-0.3% of Sc, 0.2-0.5% of Hf, 0.3-0.5% of W and the balance iron. The iron alloy is made into the iron crucible for hot-dip galvanizing after being made into a steel plate through casting and hot rolling, the anti-vibration falling capacity of the iron crucible to a transition layer of liquid zinc can be greatly improved, the service life of the iron crucible is prolonged to 20 years or above from 7-10 years, and the functions of improving production efficiency and saving the cost are achieved.

Owner:GUANGZHOU YUZHI TECH CO LTD

Welding method of magnet thin-walled cylinder body in sealed housing assembly

ActiveCN103537788BReduce distortionRemove completelyElectron beam welding apparatusSteam pressureEngineering

The invention provides a method for welding a thin-walled cylinder with a magnet sleeved inside in a seal housing component. The welding efficiency of the aluminum alloy thin-walled seal housing component can be obviously improved through the method, quality is stable, a connector is bright, fusion is even, and continuous and compact welding beads can be formed. According to the technical scheme, the method comprises the following steps that the butt joint positions of inner and outer housing welding joints are closely attached through a clamp, and annular welding joint pulse electron beam tack welding is carried out on the circumferential seam crossing of an assembled component; a deflection distance occurring to an electron beam caused by Lorentz force is compensated by an electron beam deflection angle; the total heat input amount of the electron beam is controlled with the impulse waveform of the pulse electron beam, the impulse waveform is steep in the front and gentle in the back, and welding is carried out through heat generated when beam flow ascends and descends; under the condition that small pulse power is set and steam pressure is reduced, a pulse back edge is prolonged by 3-5s, slow reduction is carried out, the focal position of the electron beam is adjusted to be within the range 0.55mm below the surface of a workpiece, the surface of a connector to be welded is melted and integrally welded, and the continuous welding beads are formed.

Owner:四川泛华航空仪表电器有限公司

High-thermal-conductivity and high-temperature-resistance pan material for zinc-aluminum alloy hot dip coating and process of high-thermal-conductivity and high-temperature-resistance pot material

InactiveCN108728776AReduced service lifeShort lifeHot-dipping/immersion processesDip-coatingMachining process

The invention discloses a high-thermal-conductivity and high-temperature-resistance pan material for zinc-aluminum alloy hot dip coating and a machining process of the high-thermal-conductivity and high-temperature-resistance pan material. The high-thermal-conductivity and high-temperature-resistance pan material comprises, by weight, 1.2-1.5% of Li, 0.2-0.4% of Ti, 0.3-0.5% of Ba, 9.0-10.5% of Cr, 5.0-8.0% of Ni, 2.0-4.0% of Mn, 2.0-3.0% of Sn, 0.2-0.4% of B, and the balance Fe. The development and industrialization of the material provides a solution of material science for solving the current problems that existing iron pans are too short in service life and inconvenient to replace and mount in hot dip coating zinc-aluminum alloy production. The implementation and industrialization of the material is of great importance in solving the current industry status in China and improving the product international competitiveness of the metallurgical industry in China.

Owner:GUANGZHOU YUZHI TECH CO LTD

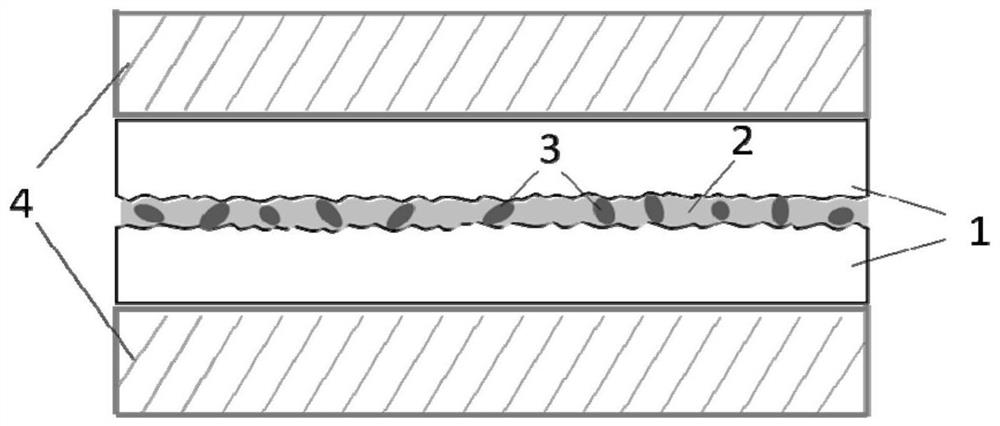

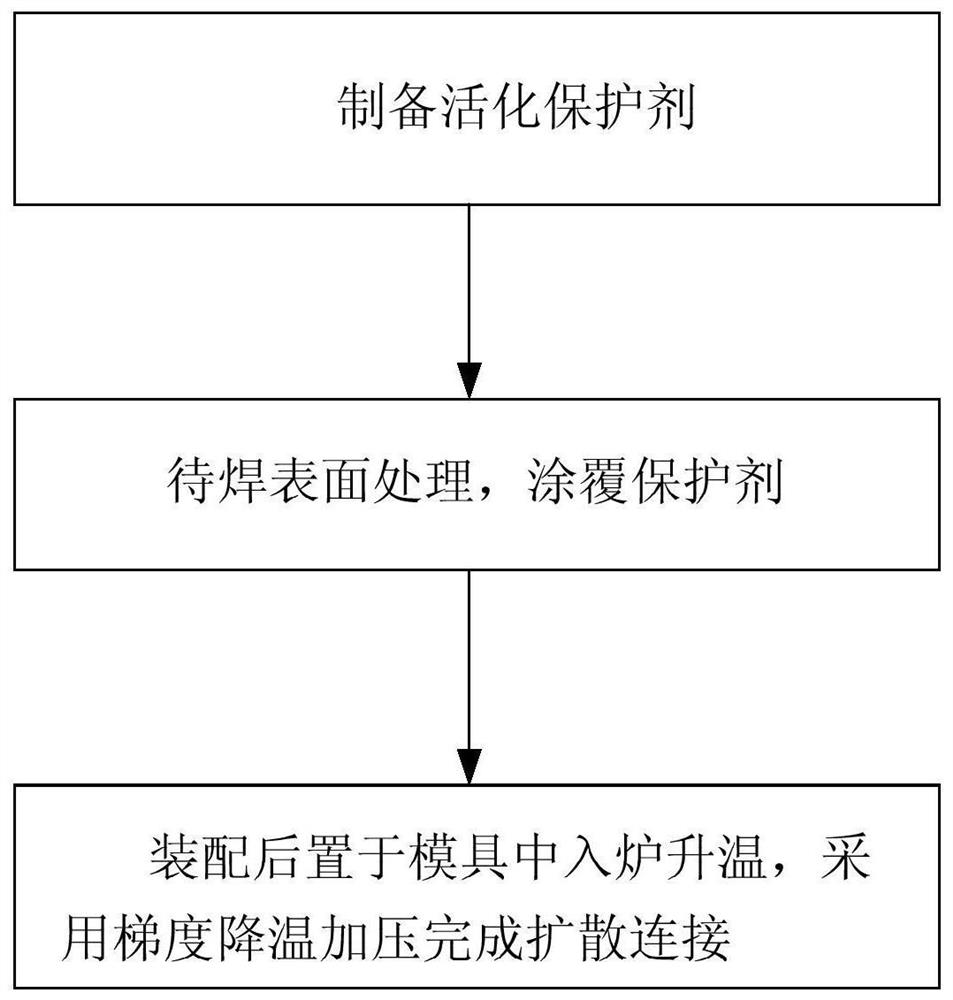

A kind of aluminum alloy diffusion bonding method without intermediate layer

ActiveCN111468815BEasy to keepIncrease the degree of deformation and fragmentationWelding/soldering/cutting articlesNon-electric welding apparatusUltimate tensile strengthWelding deformation

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

Y-and-Mg-containing iron alloy for hot dip galvanized high-heat conduction iron pan

InactiveCN108441789AGood welding performanceAccelerated corrosionHot-dipping/immersion processesAlloyFerric

The invention discloses a Y-and-Mg-containing iron alloy for a hot dip galvanized high-heat conduction iron pan, and a processing technology thereof. The iron alloy contains, by weight, 0.4-0.5% of Ca, 0.2-0.6% of Sb, 0.4-0.6% of In, 0.2-0.4% of Y, 0.8-1.5% of Mg, 0.4-0.5% of Ta, and the balance of iron. The heat conduction ability of the iron pan made of a steel plate formed through casting and hot-rolling of the iron alloy and the uniformity of the thickness of a galvanizing layer are greatly improved. The service life of the iron pan is prolonged to 20 years or more from 7-10 years. The iron alloy can improve the production efficiency and save the cost.

Owner:GUANGZHOU YUZHI TECH CO LTD

Novel welding method

The invention discloses a novel welding method. The method includes: by the clamping air cylinder of a traction mechanism, clamping a first to-be-welded workpiece, and moving forwards to move the first to-be-welded workpiece to a cutter position; cutting the first to-be-welded workpiece; by the clamping air cylinder of the traction mechanism, clamping the first to-be-welded workpiece, and returning to the original position; by the traction mechanism, moving forwards to move a second to-be-welded workpiece to the cutter position; cutting the second to-be-welded workpiece; retracting the cutter, and lifting a welding desk top; by the clamping air cylinder of the traction mechanism, clamping the first to-be-welded workpiece, and moving forwards to the position of the second to-be-welded workpiece until the first to-be-welded workpiece aligns with the second to-be-welded workpiece; allowing a welding head to weld a first weld joint; allowing the welding head to weld a second weld joint, wherein the to-be-welded workpieces are 16-70mm in width and 0.10-0.2mm in material thickness, the first to-be-welded workpiece and the second to-be-welded workpiece are not coated and are 2m in length, the welding temperature of the welding head can be adjusted, and spot welding is used. The novel welding method is intelligent, convenient to operate, time saving, labor saving, safe, reliable, high in accuracy, simple in welding manner and attractive in welding.

Owner:JIANGSU ZUNSION AUTOMOBILE TECH CO LTD

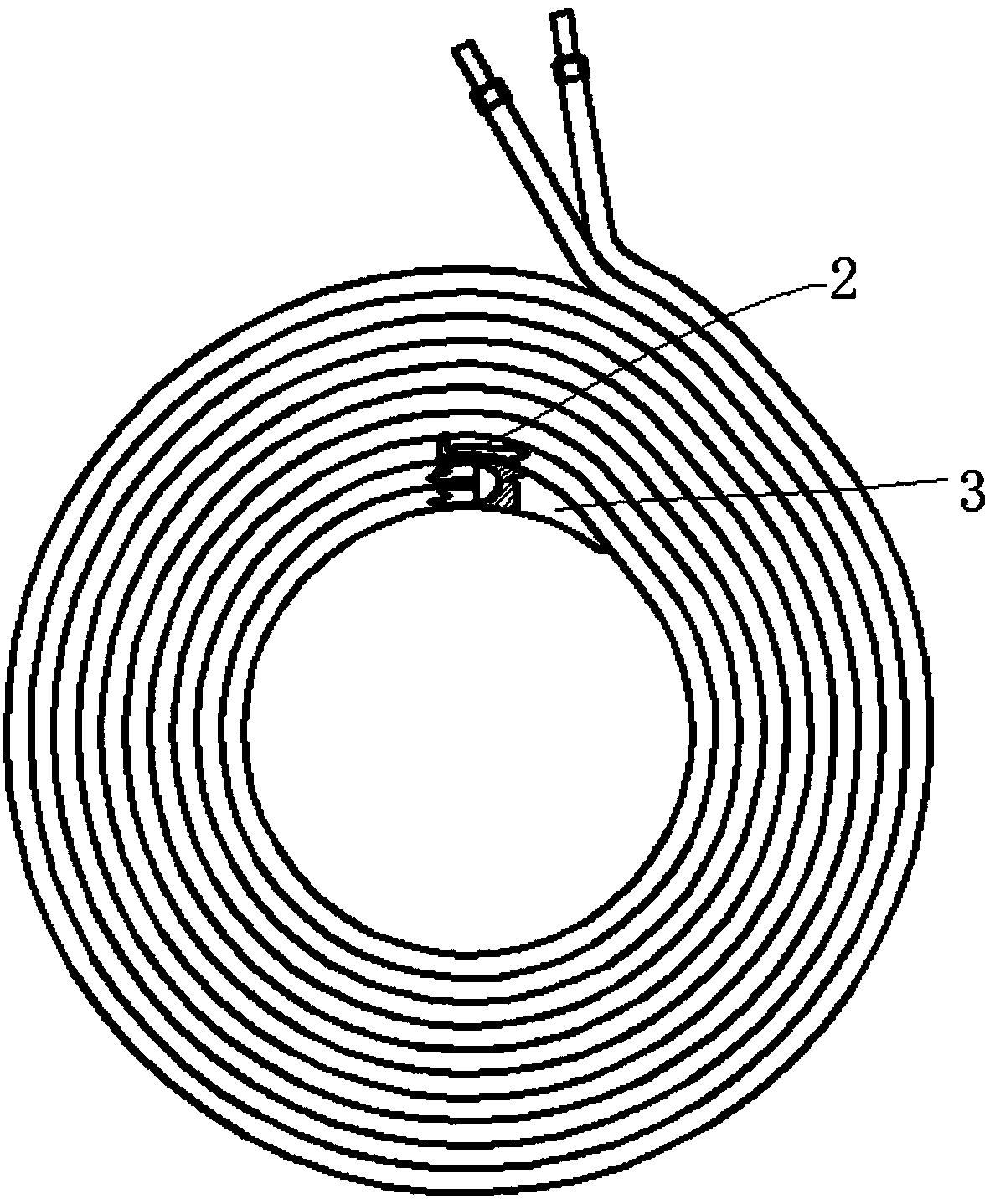

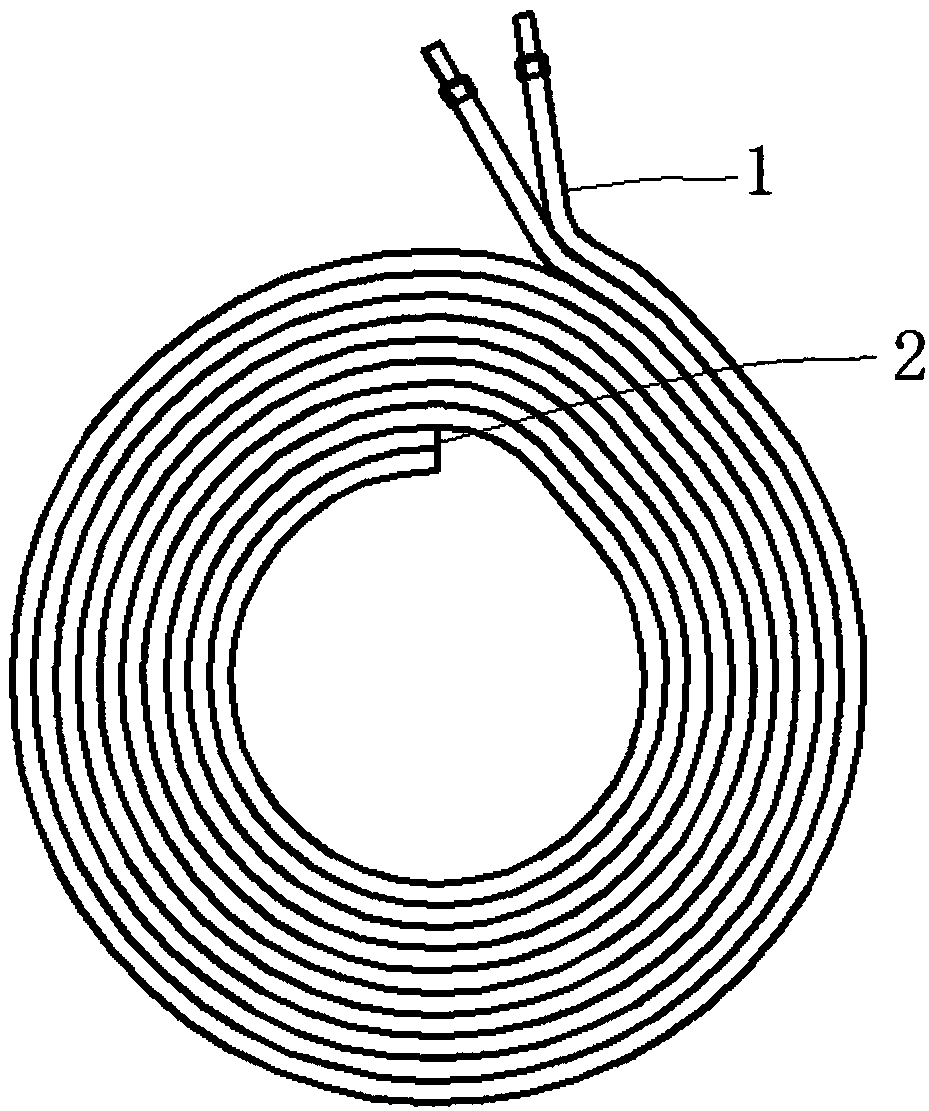

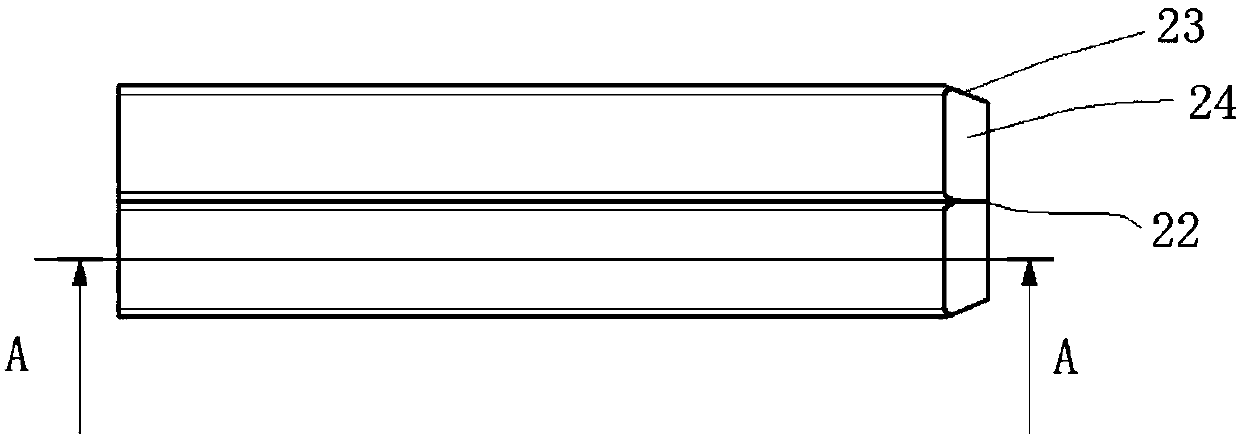

Double-rectangular copper pipe coiling water-cooling disk

PendingCN107941073AIncrease the lengthCompact assemblyHeat exchanger casingsHeat exchanger fasteningEngineeringMachining

The invention relates to the technical field of water-cooling disks, in particular to a double-rectangular copper pipe coiling water-cooling disk. A connection end opening comprises two parallel copper pipe end openings, and two shrinking openings in shrinking states are defined by vertical side walls and oblique side walls. A connector body comprises a body which is in a tapered shape in whole, the end with relatively large sectional area of the connector body is provided with a hollow circular arc-shaped cavity, a joint of the connector body and copper pipes is provided with an oblique faceend opening in a boss shape in whole, the oblique face end opening coordinates with the shrinking openings, the shrinking openings are embedded into the oblique face end opening and communicate with the oblique face end opening through the circular arc-shaped cavity, in this way, fitting surfaces of the connection end opening and the connector body are both designed into oblique faces, assemblingtightness is facilitated, a weld joint is tight after braze welding, the length of a junction surface can be increased through the oblique faces, and the weld joint is firm and reliable; and the connection end opening is completely wrapped in the connector body, and after braze welding, finish machining is carried out on an upper plane and a lower plane, and the weld joint of braze welding cannotbe damaged.

Owner:合肥科烨电物理设备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com