Patents

Literature

42results about How to "Regular and beautiful appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

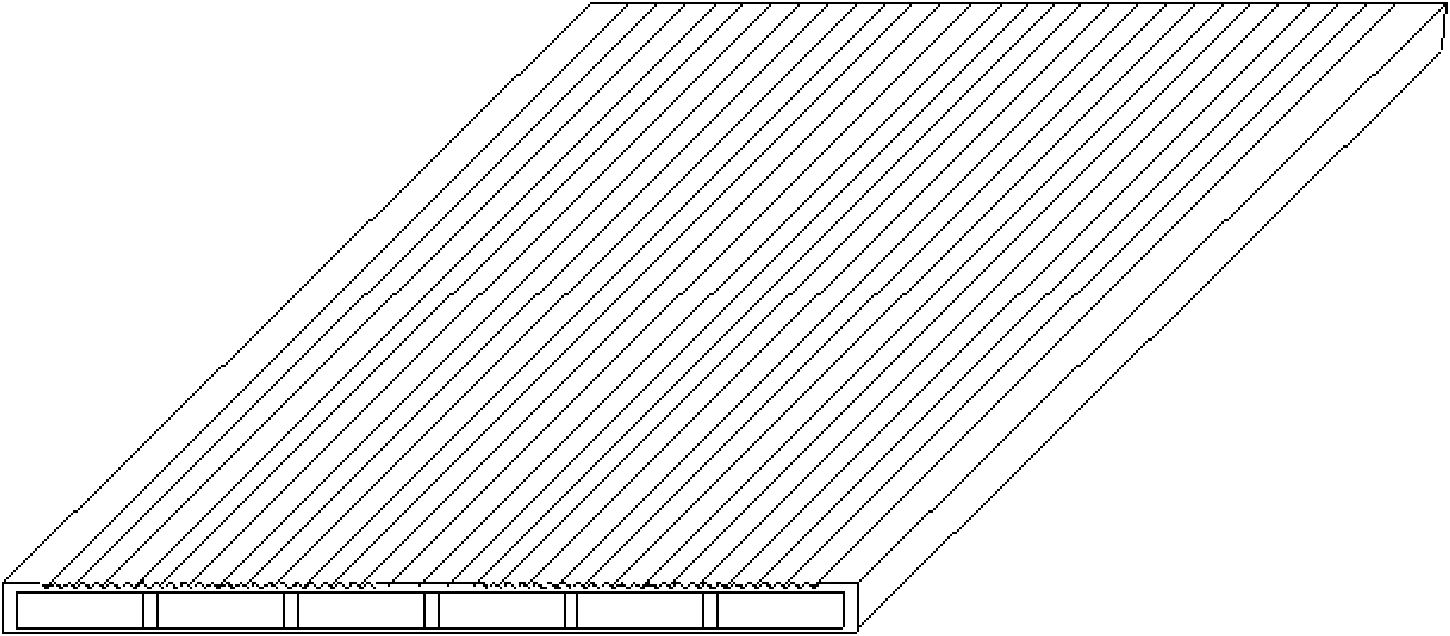

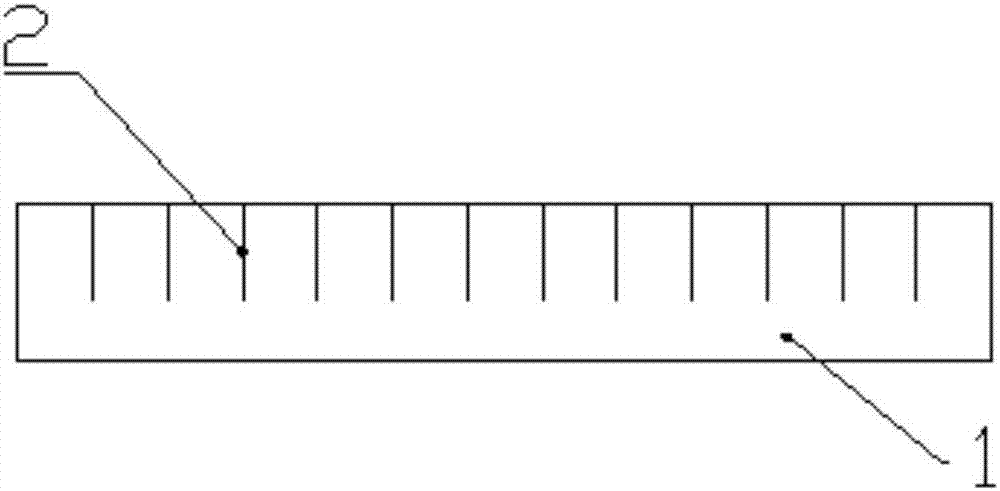

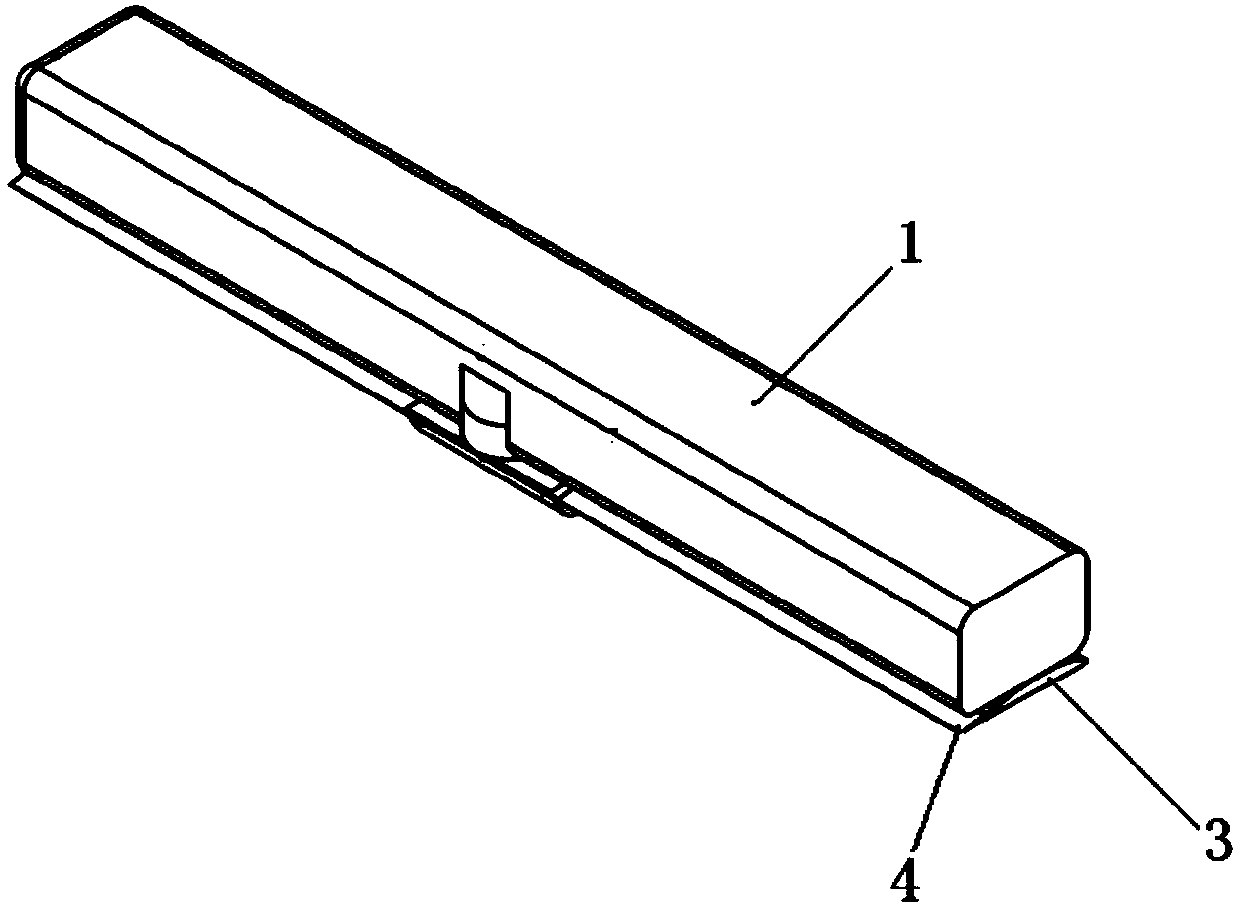

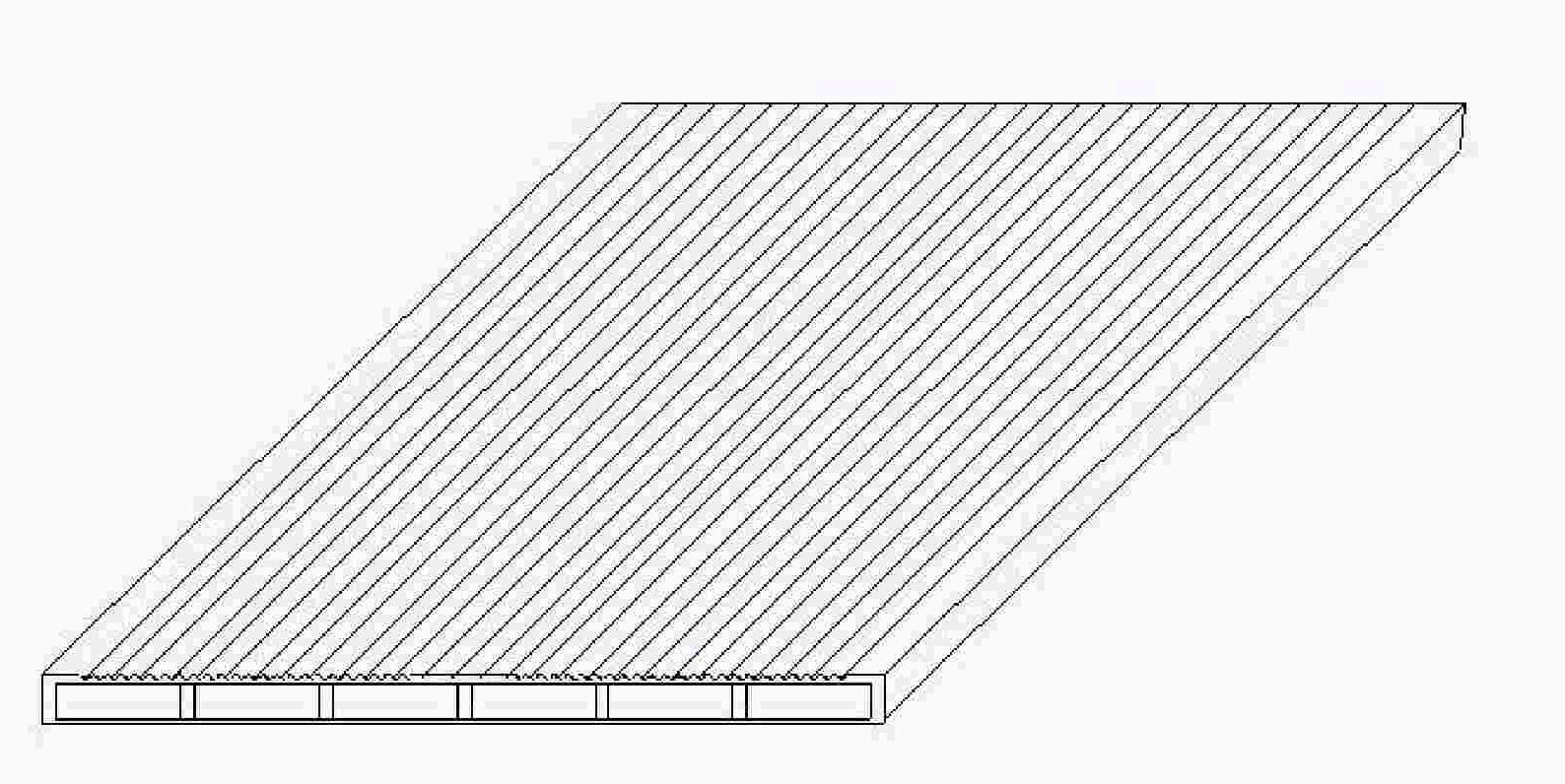

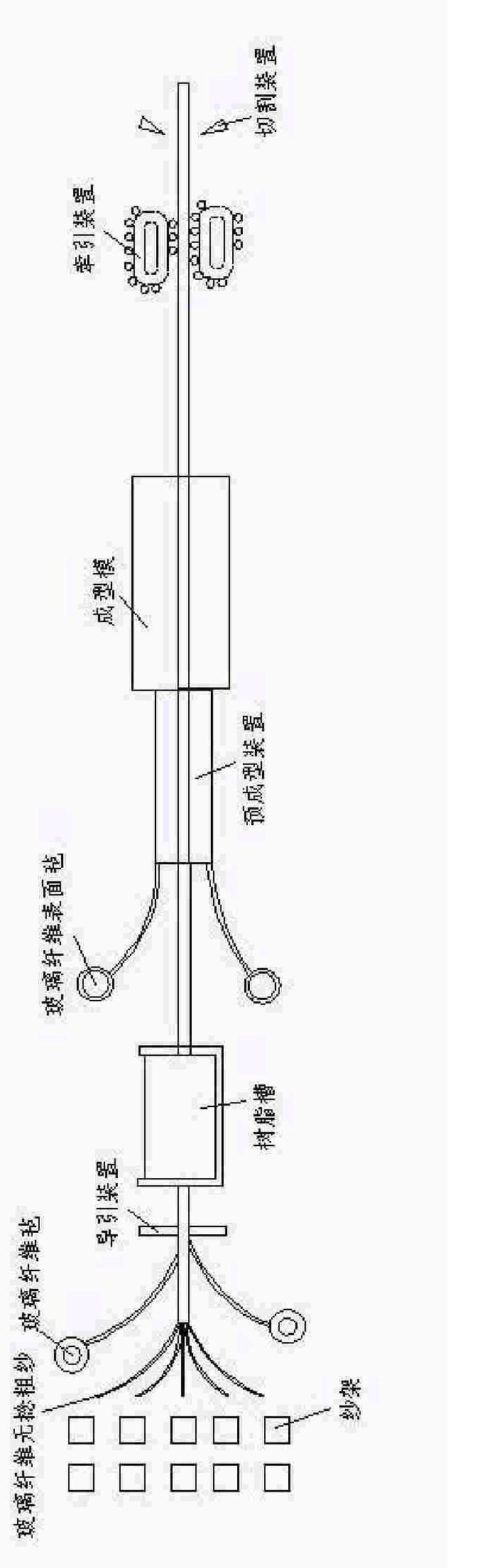

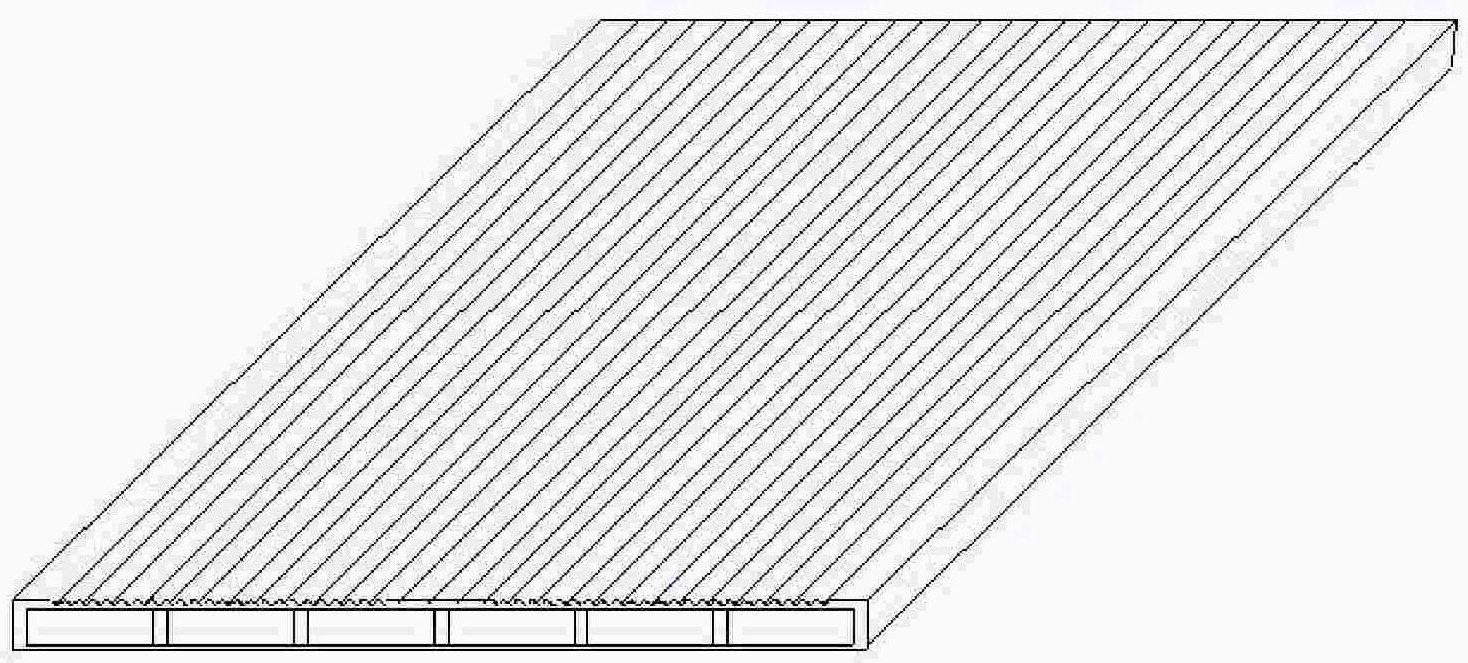

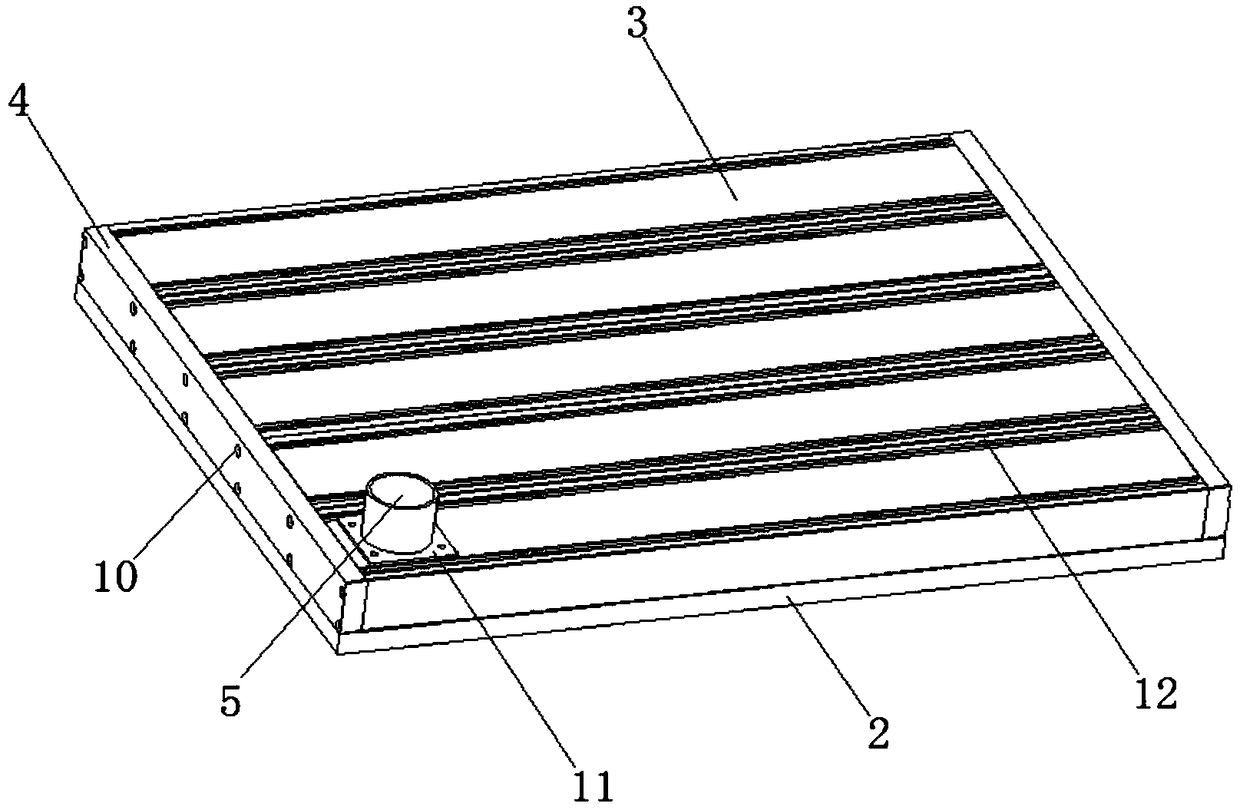

Glass fiber reinforced plastic cable channel cover plate and production method thereof

InactiveCN101672044AImprove corrosion resistanceStrong anti-agingArtificial islandsUnderwater structuresPolyvinyl alcoholEngineering

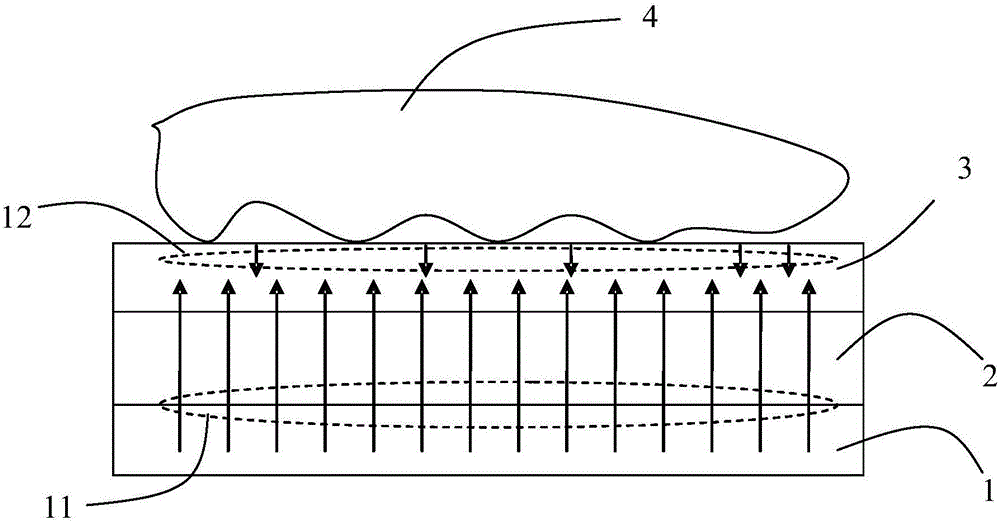

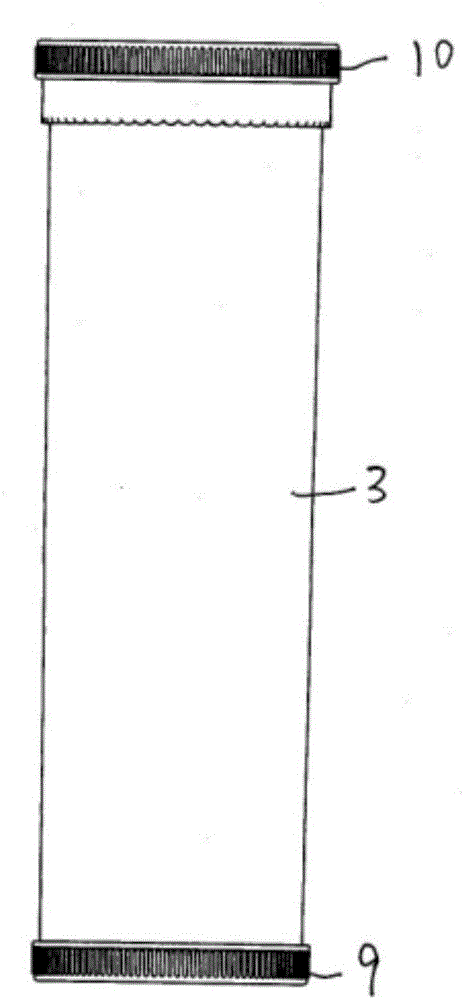

The invention relates to a glass fiber reinforced plastic cable channel cover plate and a production method thereof. The cover plate is a rectangular hollow belly structure, longitudinal stiffening ribs are arranged in the hollow belly of the cover plate and the upper surface of the cover plate is provided with strip-shaped antiskid grains; the invention comprises the following raw materials: unsaturated polyester resin, curing agent, packing, polyvinyl alcohol solution, pigment, fiberglass roving and fiberglass felt; the invention comprises the following steps: (1) arranging a tooling equipment on an extrusion molding machine; (2) mixing and pouring the raw materials in a resin tank; and (3) inducing the fiberglass roving and the fiberglass felt through immersion, a performing device, a forming device, curing and cutting. The cover plate has high strength, smooth surface, neat and beautiful appearance, corrosion resistance of alkali, acid, petrol and the like, aging resistance, long service life without pulverization, discoloration, crack, deformation and the like. The invention ensures the safe operation of cables and prolongs the service life of the cables.

Owner:醴陵市万通新型材料有限公司

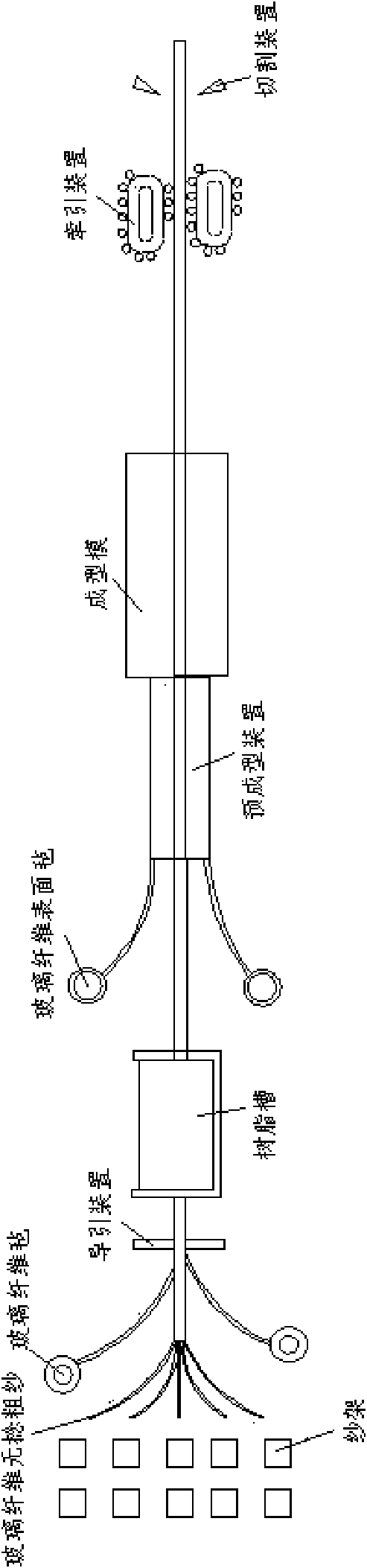

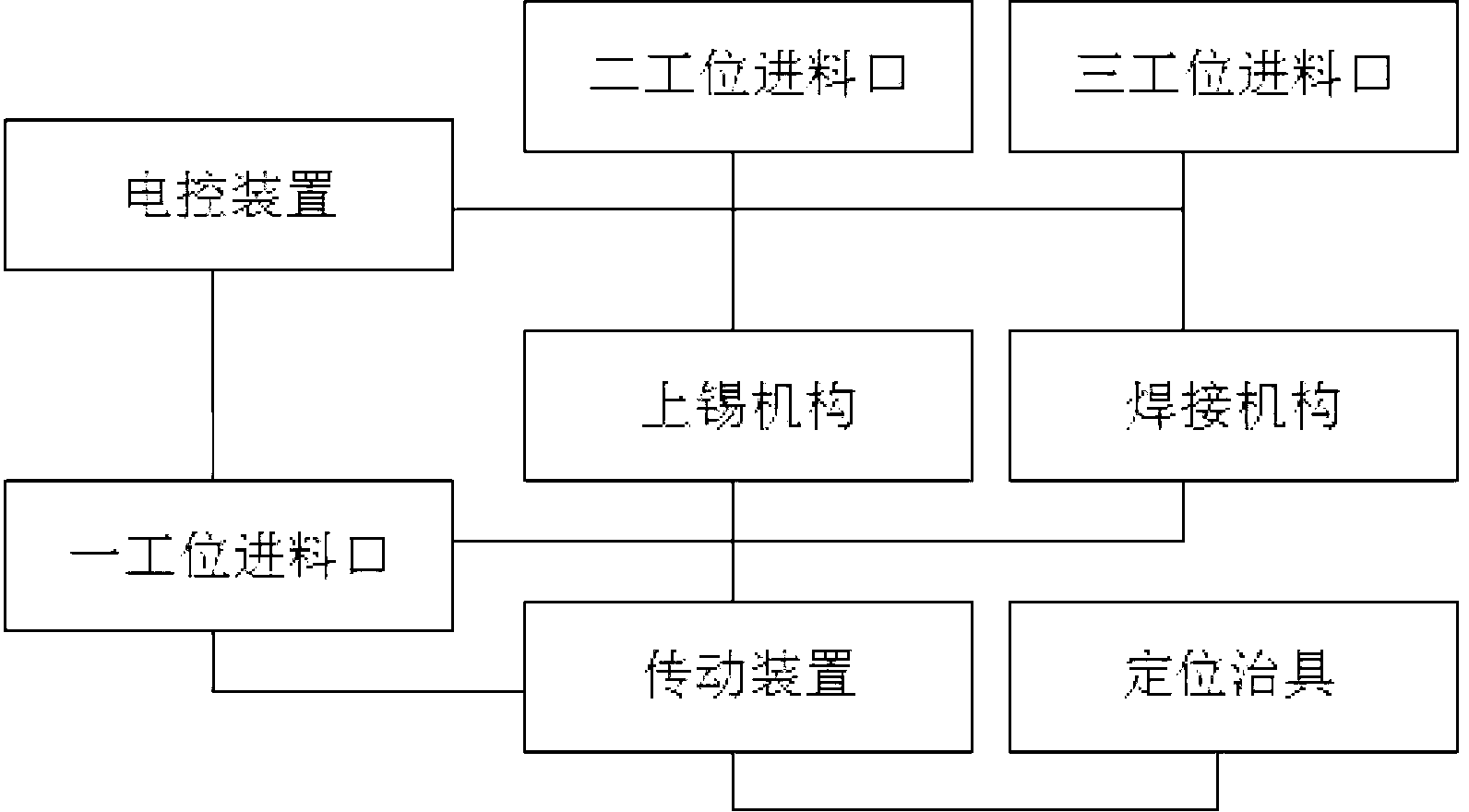

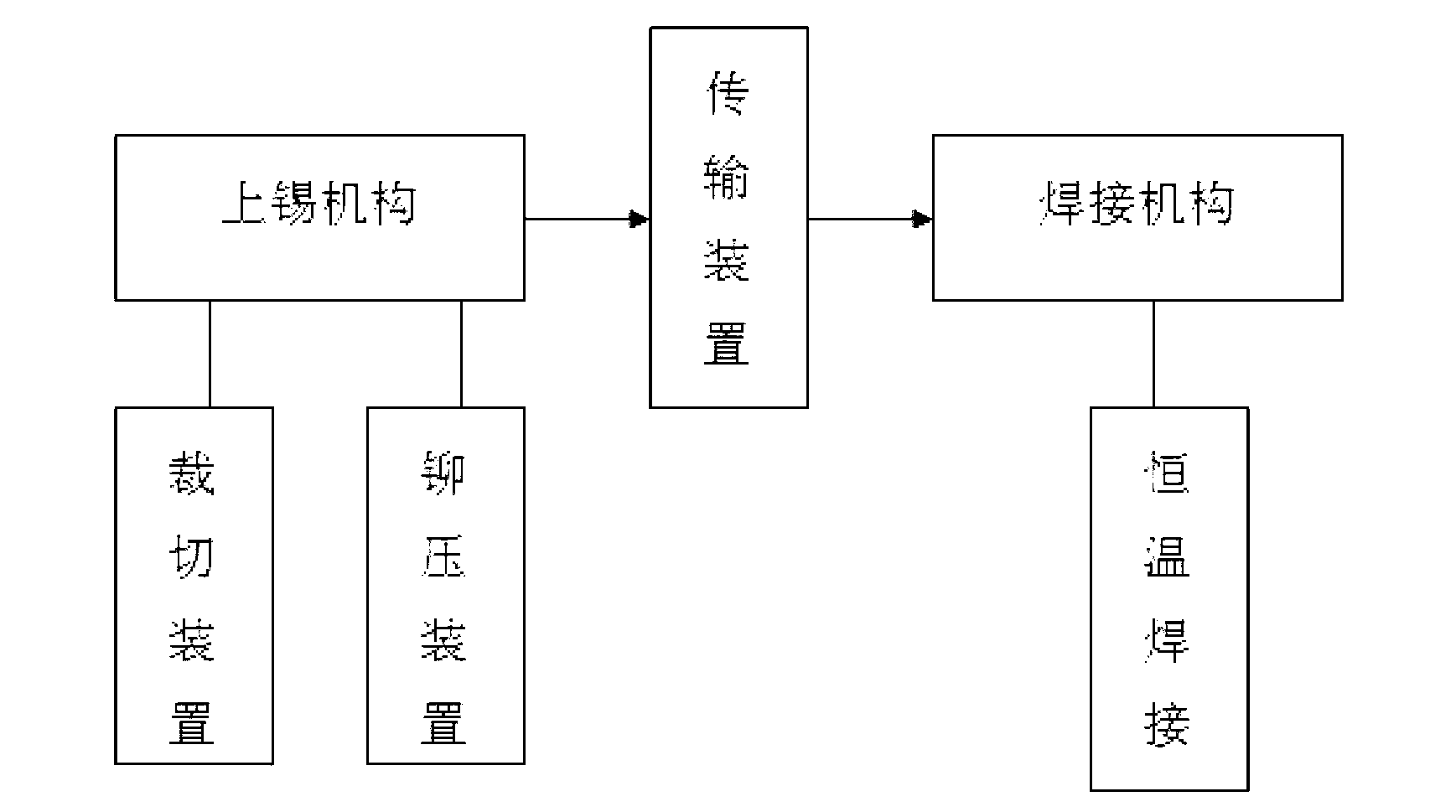

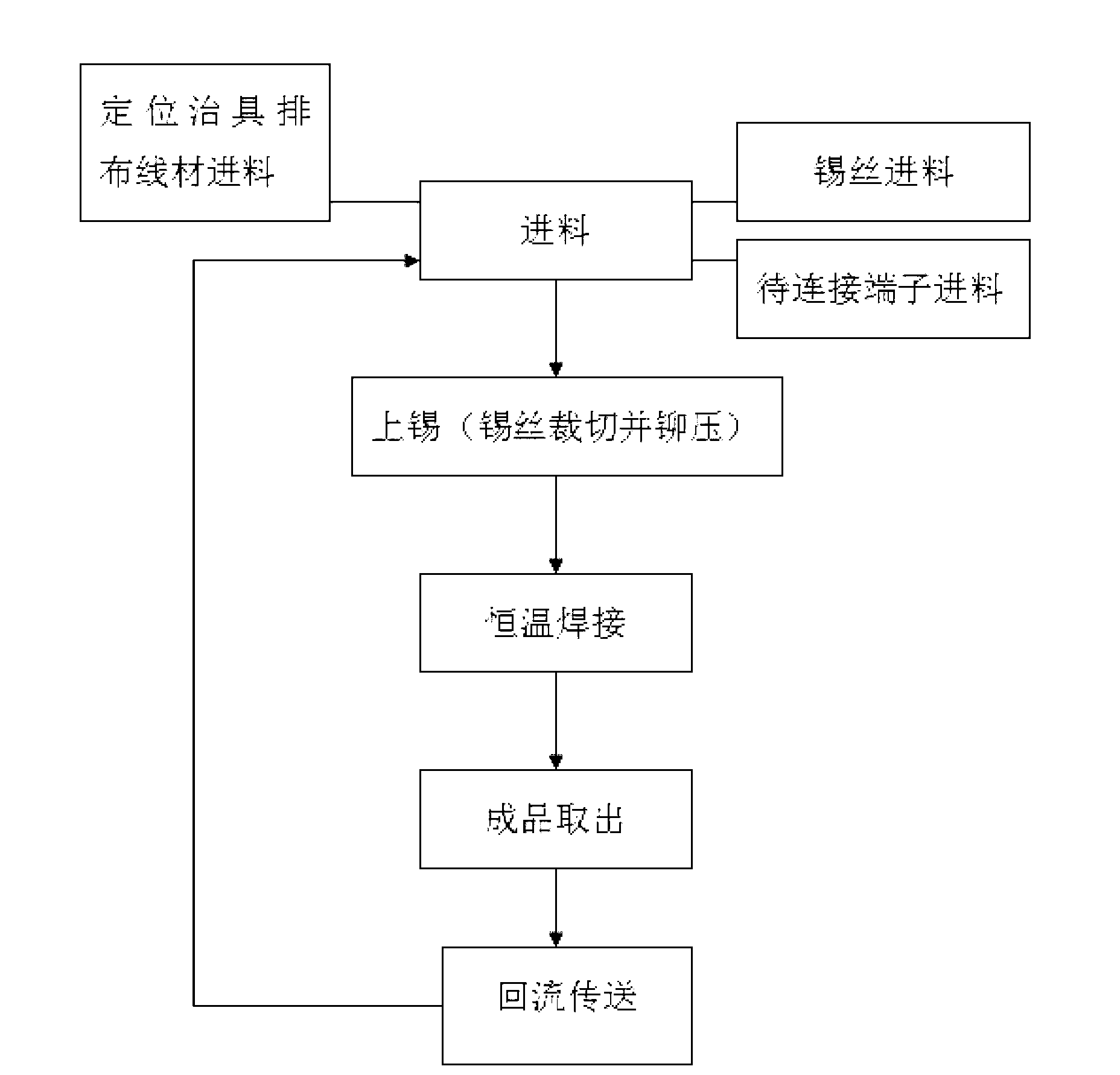

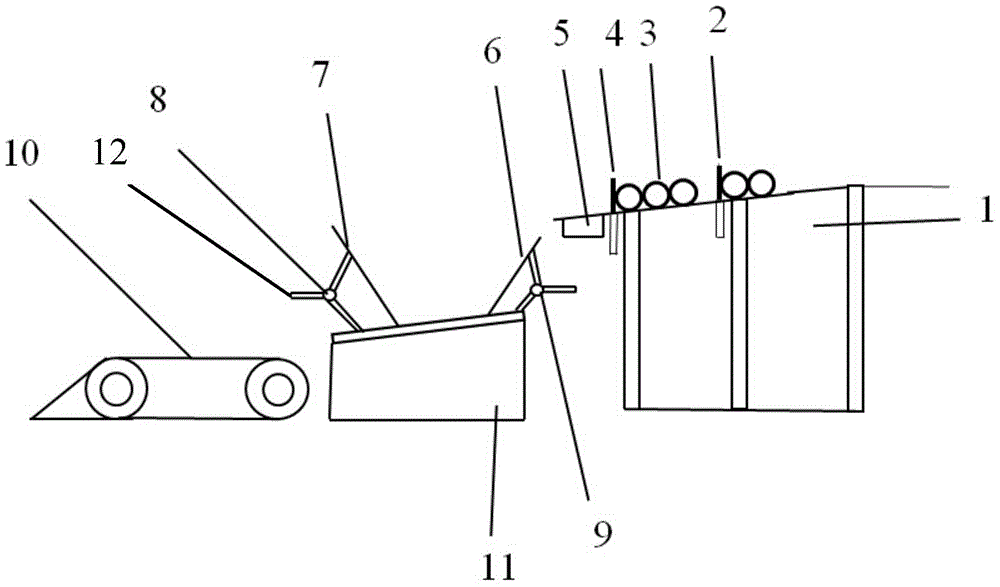

Automatic wire welding process and automatic wire welding machine

ActiveCN103252551AEvenly meltedRegular and beautiful appearanceLine/current collector detailsConductorsEngineeringTin

The invention discloses an automatic wire welding process. A first station feed inlet of a feed processing device guides a to-be-welded wire which is subjected to peeling and cutting at a cutting station into a positioning jig of a transmission device. A second station feed inlet guide a tin wire into a tinning mechanism. A third station feed inlet guide a to-be-connected terminal into a welding structure. The tinning mechanism flattens and cuts the tin wire to form a tin sheet, and the tin sheet is riveted by means of casting and wrapped at the connection of the wire and the terminal. The welding structure guides the positioning jig for fixing the to-be-welded wire to a welding station and performs constant-temperature welding of the wire and the terminal after accurate positioning of the wire and the to-be-connected terminal. By the automatic wire welding process, automatic wire welding is achieved, tin wire welding totally covers wire heads, crack and dropping are less easily, and product service life is prolonged. The invention further provides an automatic wire welding machine for realizing the process.

Owner:东莞市恒仓智能机械设备厂

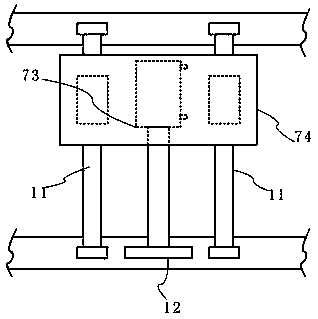

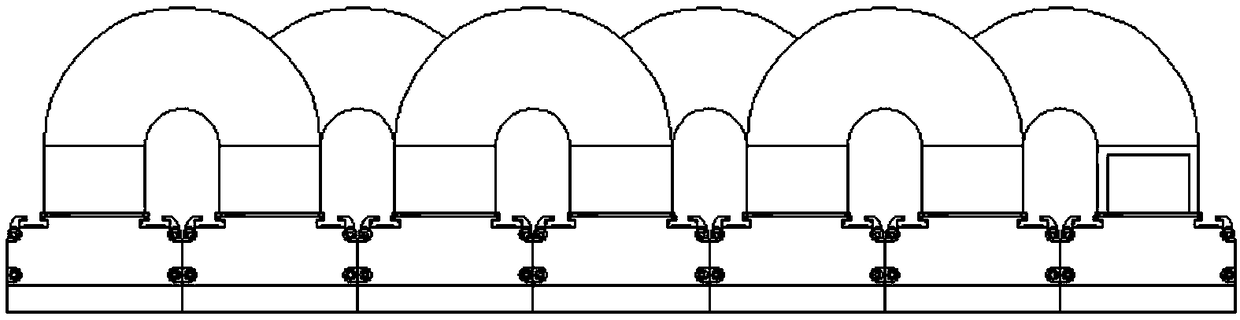

Steel pipe bundling and conveying device

InactiveCN105460315AAccurate countGood degree of automationPackaging automatic controlRod-shaped articlesSteel tubeEngineering

The invention provides a steel pipe bundling and conveying device. The steel pipe bundling and conveying device is characterized by comprising a bearing device, a bundling device and a conveying device. The bearing device comprises a first stopper, a second stopper, steel pipes and an optical grating counter. The bundling device comprises a first baffle, a second baffle, a first angle regulator and a second angle regulator. By means of the technical scheme, during usage, the two stoppers act respectively, the steel pipes of a specific number can be bundled, and the steel pipes can be accurately counted by the aid of the optical grating counter; the manpower cost is reduced; the counting by the bundling and conveying device is more accurate than that by people; the automation degree is good. The steel pipes are bundled and conveyed through the steel pipe bundling and conveying device, the bundling shape is regular so as to facilitate storage and conveying, and moreover the appearance is attractive. The steel pipe bundling and conveying device has the advantages of being simple in structure, easy to operate, high in work efficiency and the like.

Owner:天津腾飞钢管有限公司

Electroslag ignition agent and preparation method thereof

InactiveCN104726721AGood arc starting effectReduce manufacturing costCarrying capacityGraphite electrode

The invention discloses an electroslag ignition agent and a preparation method thereof. The electroslag ignition agent is used for igniting and remelting slag material in an electroslag remelting technology to establish electroslag. The ignition agent comprises the following raw material components in percentage by weight: 25-35% of fluorite powder, 2-12% of silica powder, 30-40% of graphite electrode powder, 1-11% of quicklime powder and 18-28% of water glass. The preparation method comprises the following process steps: preparing mixed dry powder: uniformly mixing the raw materials according to the content in percentage by weight of each raw material and the carrying capacity of a mold to obtain the mixed dry powder; mixing with sludge, loading into the mold, adding the water glass into the mixed dry powder, stirring till no dry powder exists, loading a mixture which is uniformly stirred into the mold, tamping and compacting; blowing gas, demolding, blowing CO2 into the mold, and demolding after stopping gas blowing to obtain an ignition agent block; and drying at low temperature. The ignition agent disclosed by the invention has a good arc starting effect in the using process and can avoid a titanium-increasing effect, and high-temperature smelting is not required in the manufacturing process of the ignition agent.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

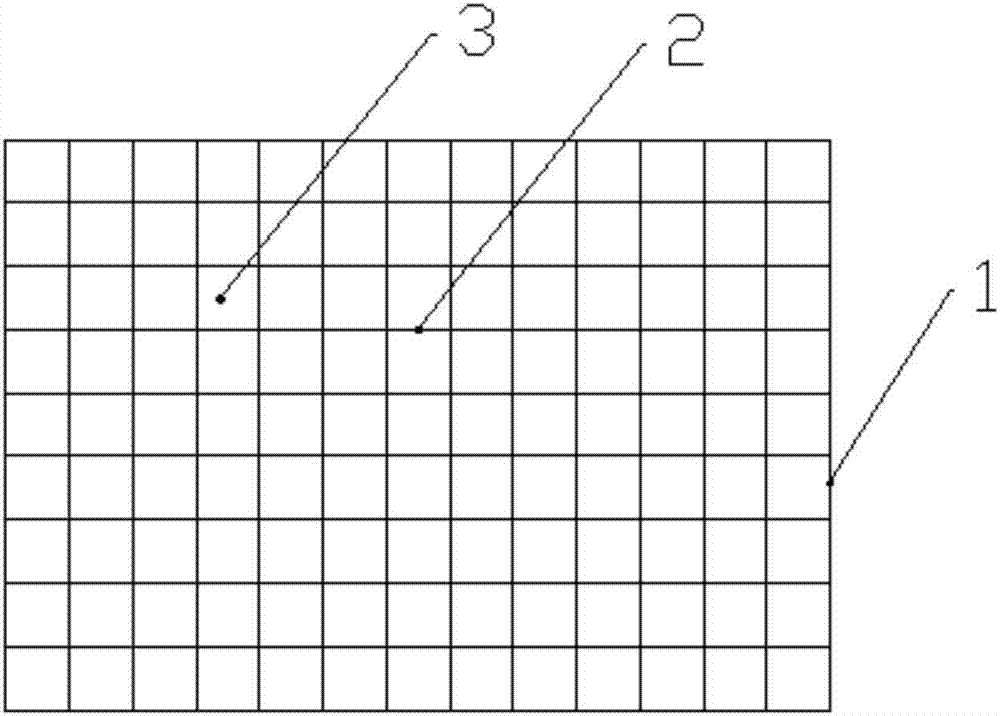

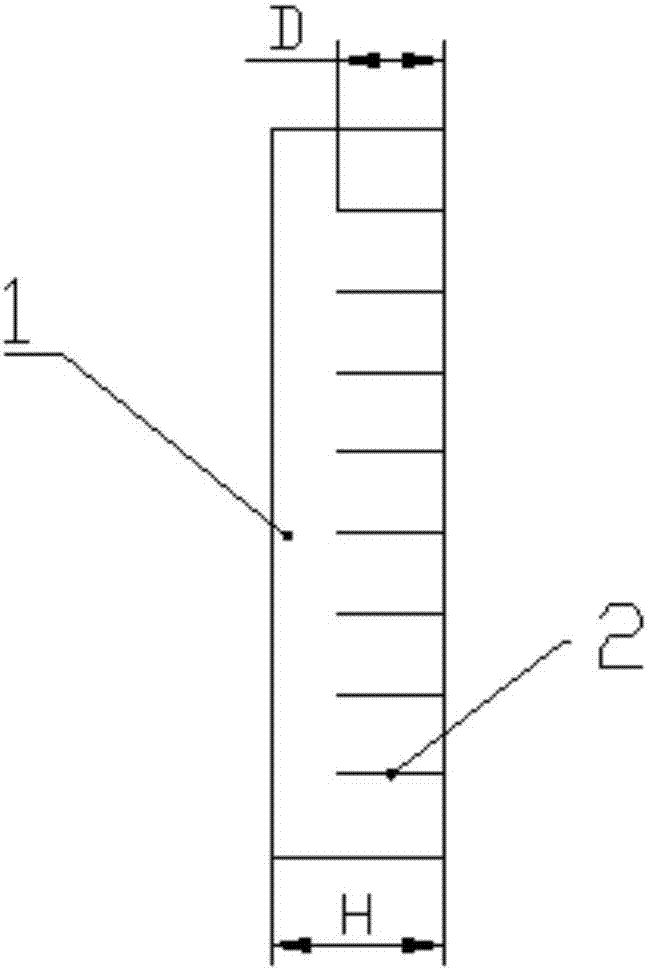

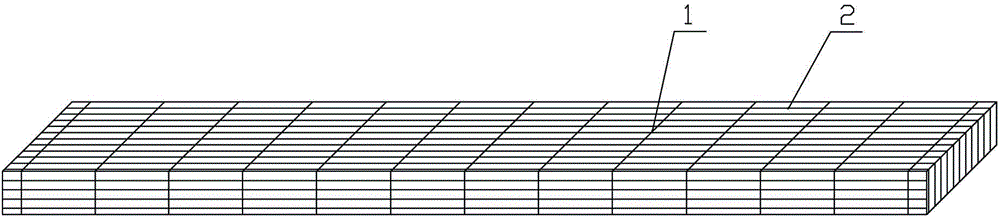

Fragile product packaging device, assembly and method

The invention provides a fragile product packaging device, assembly and method, and belongs to the technical field of packaging. The fragile product packaging device comprises a body, wherein the body is made of flexible cushioning materials. Body cutting marks are formed in one side of the body and distributed in a grid mode, and therefore the side of the body is divided into a plurality of grid units. The body cutting marks extend to the interior of the body in the thickness direction of the body, the depth of each body cutting mark is D, the thickness of each body cutting mark is H, H is larger than D and larger than zero, and D is larger than zero. The invention further provides the fragile product packaging assembly with the fragile product packaging device and the method for packaging fragile products by utilizing the fragile product packaging device. The fragile product packaging device, assembly and method are suitable for packaging the fragile products, time and labor are saved in the packaging process, the cost is saved, and the fragile products can be protected to be intact under the normal transporting and warehouse stacking conditions.

Owner:SF EXPRESS

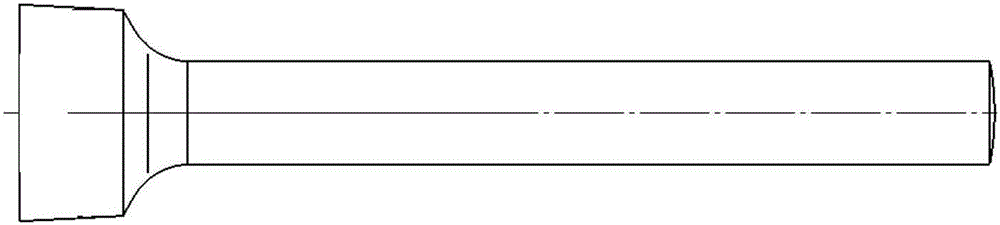

Integral die forging method for large-scale GH4169 turbine shaft

The invention relates to an integral die forging method for a large-scale GH4169 alloy turbine shaft (the length of the shaft is 1520 mm). In general, two forging methods are adopted for large-scale shaft type forge pieces, and include the axial drawing-out free forging method and the comprehensive forging method combining rod portion local free drawing-out with flange local (forming) die forging. A shaft forging piece manufactured through the axial drawing-out free forging method is generally characterized by being uneven in deformation, large, poor in coaxiality and cylindricity, serious in warping, and low in production efficiency; compared with the shaft forging piece manufactured through the axial drawing-out free forging method, a shaft forging piece manufactured through the comprehensive forging method combining rod portion local free drawing-out with flange local (forming) die forging has similar characteristics, flange part forming is slightly superior, however, a transitional structure is inevitably generated in partial forging, and thus the whole performance of a forging piece of the turbine shaft is greatly lowered. According to the integral die forging method for the large-scale GH4169 turbine shaft, the technology thinking of partial crude manufacturing and whole die forging forming is adopted, the structure homogeneity, integrality and product stability of the shaft forging piece of the GH4169 alloy turbine shaft can be effectively improved, and production efficiency is greatly improved.

Owner:SHAANXI HONGYUAN AVIATION FORGING

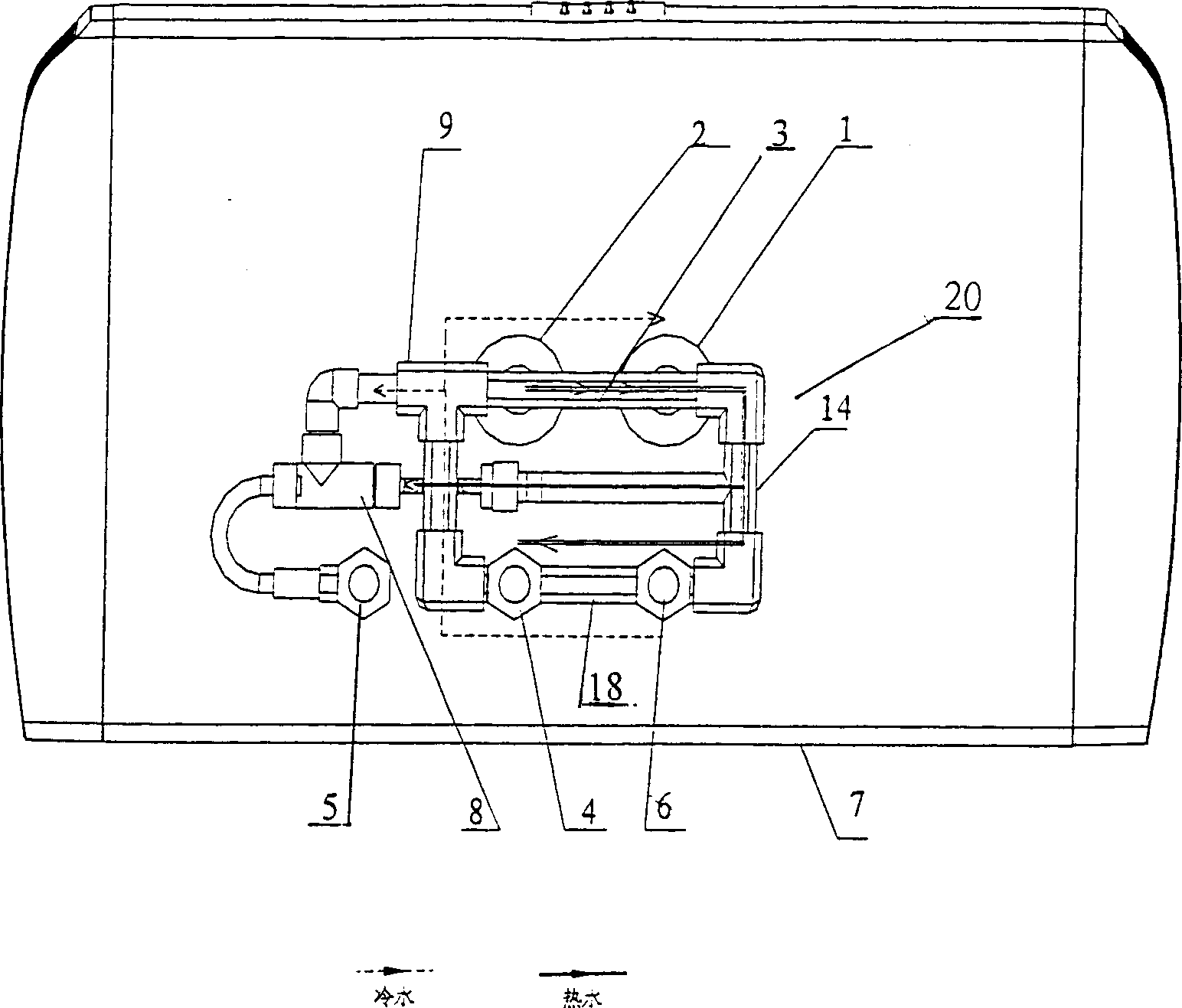

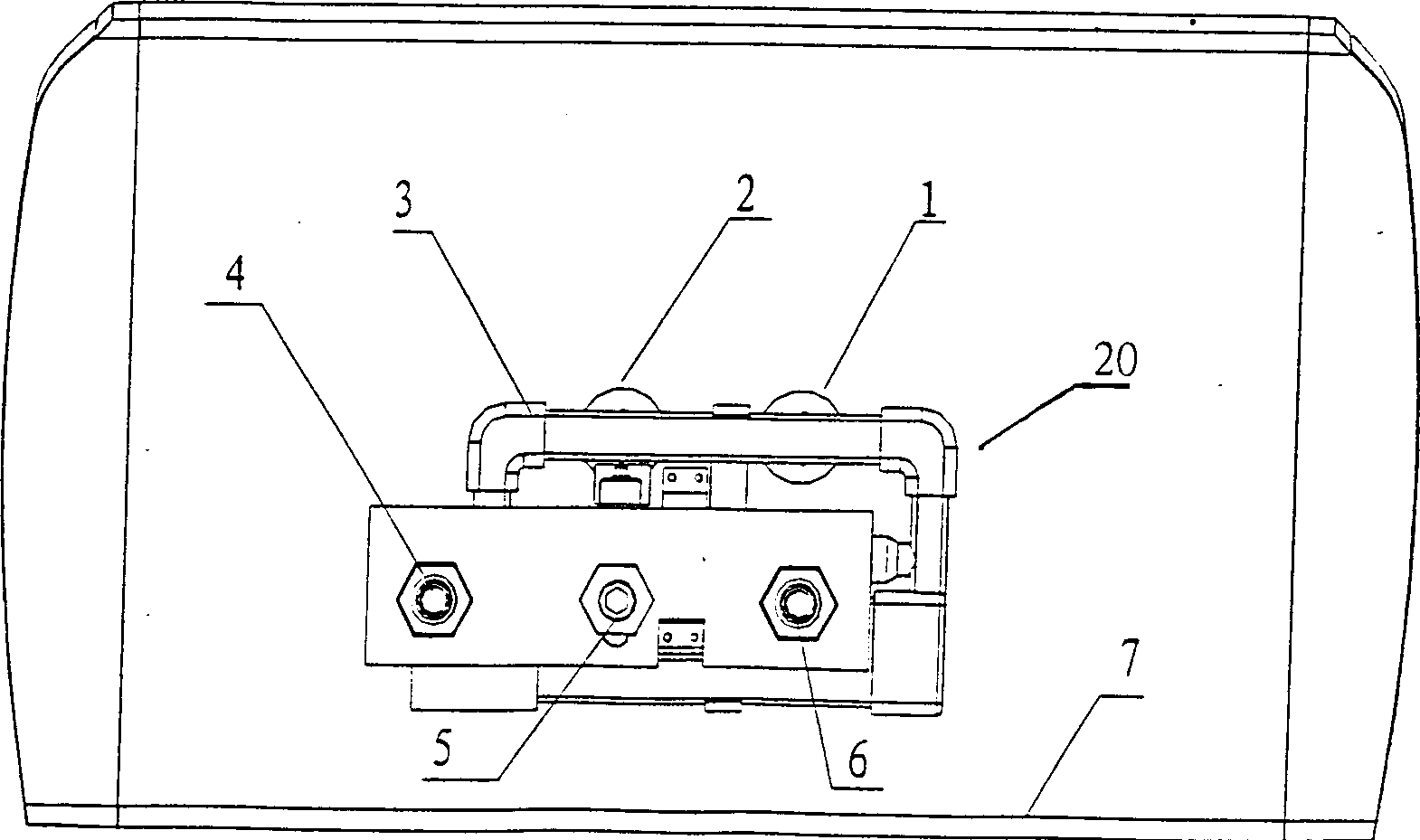

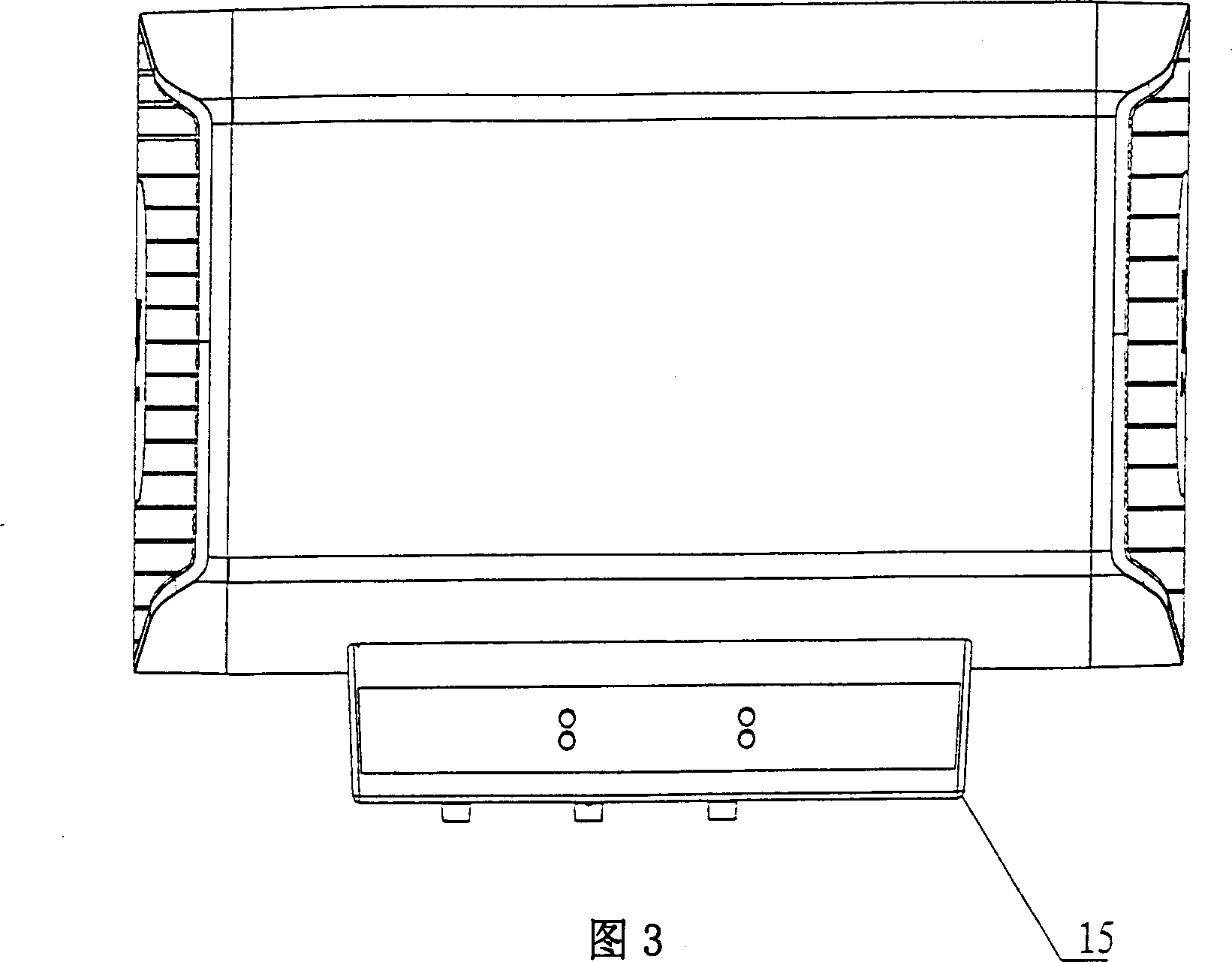

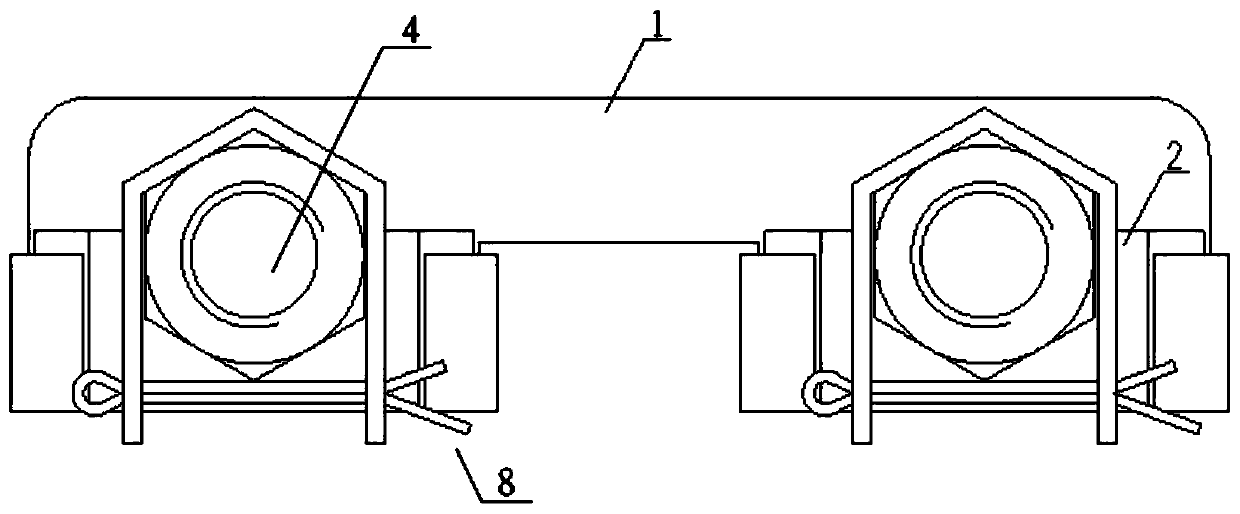

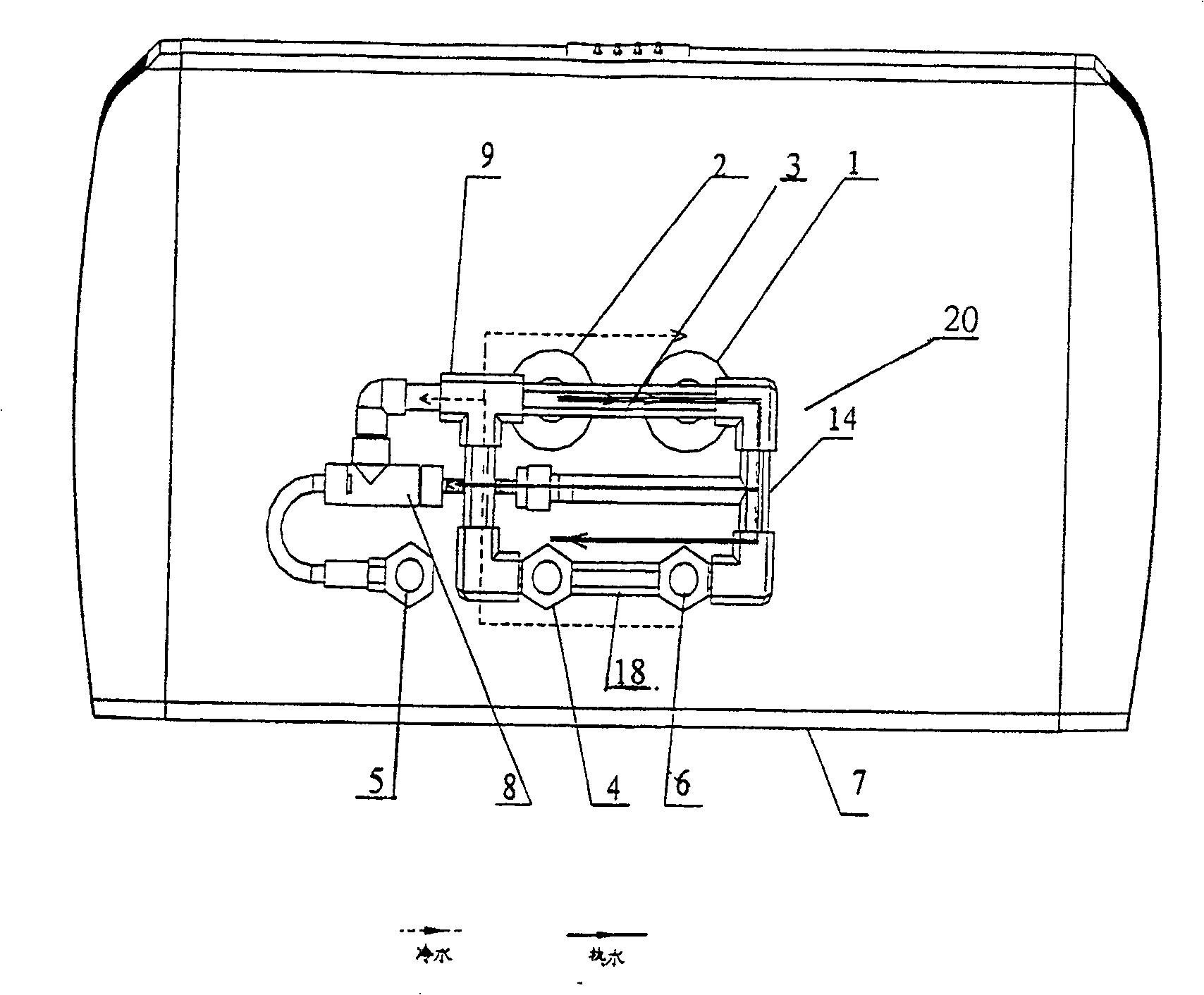

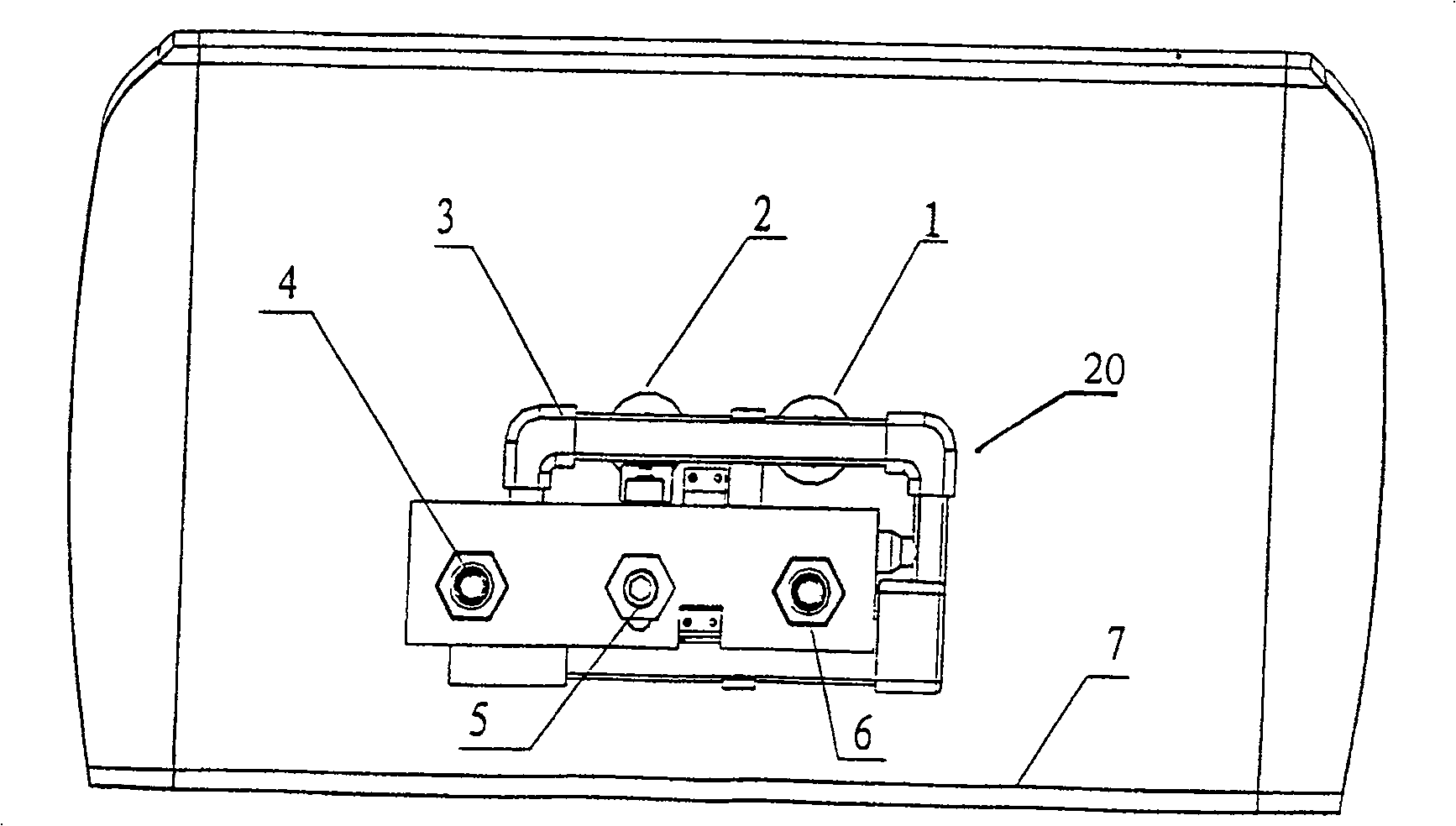

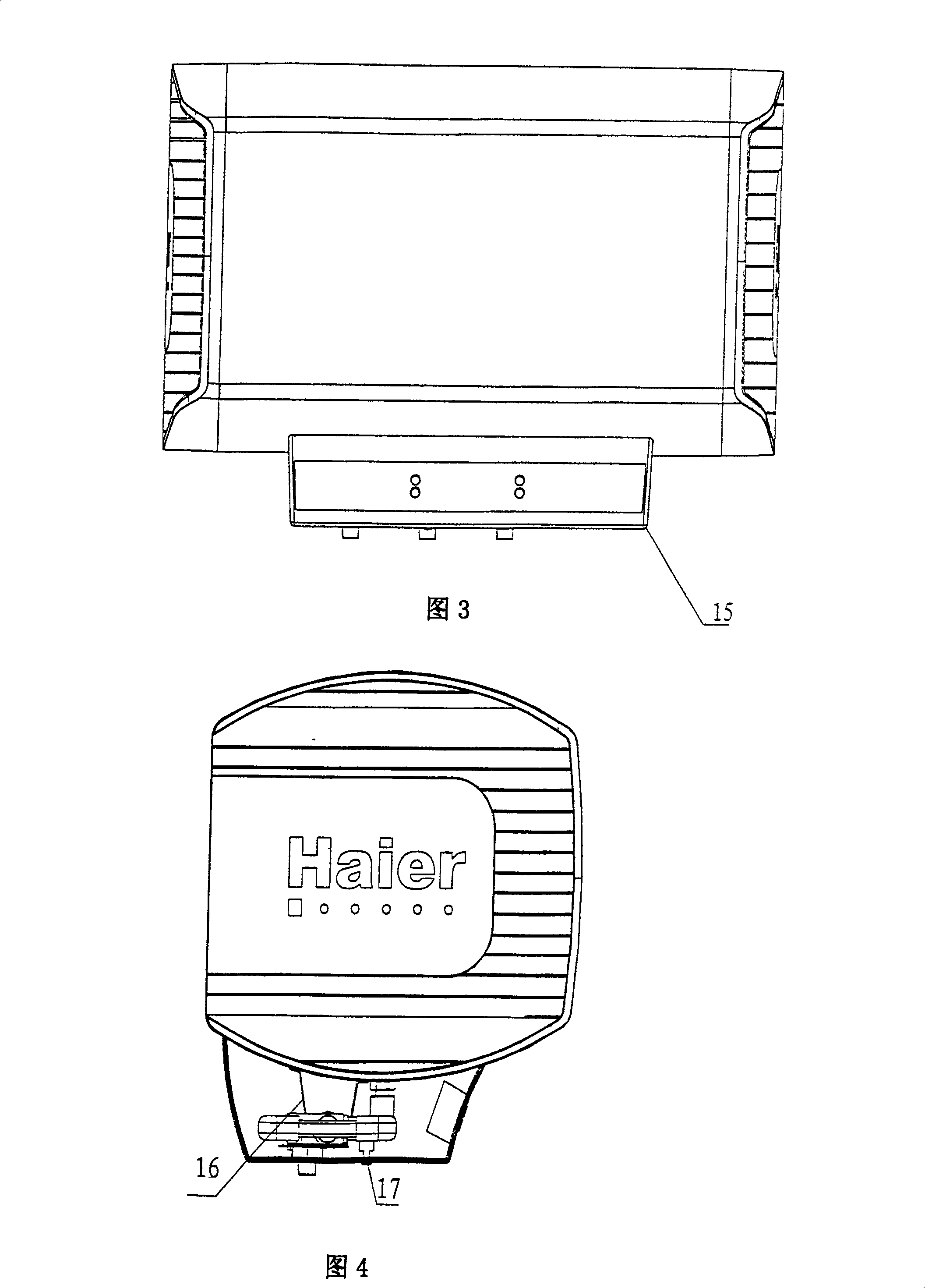

Constant temperature water heater

Thermostatic water blender in shape of framework composed of two pieces of composite insulating tube and elbow, tee joint and thermo valve is connected to water inlet and water outlet on main body of water heater. The thermo valve is positioned at a framework composed of two pieces of composite insulating tube and tee joint for hot water. Hot water pipe or cold water pipe in the composite insulating tube is composition piece of coil pipe and dual waterway pipe. The compact structure reduces space needed, lowers cost and provides good appearance. An attemperator is added to the water blender. Thus, temperature of water is adjustable so as to meet usersí» requirement for adjusting fine difference of temperature in range of specific temperature.

Owner:HAIER GRP CORP +1

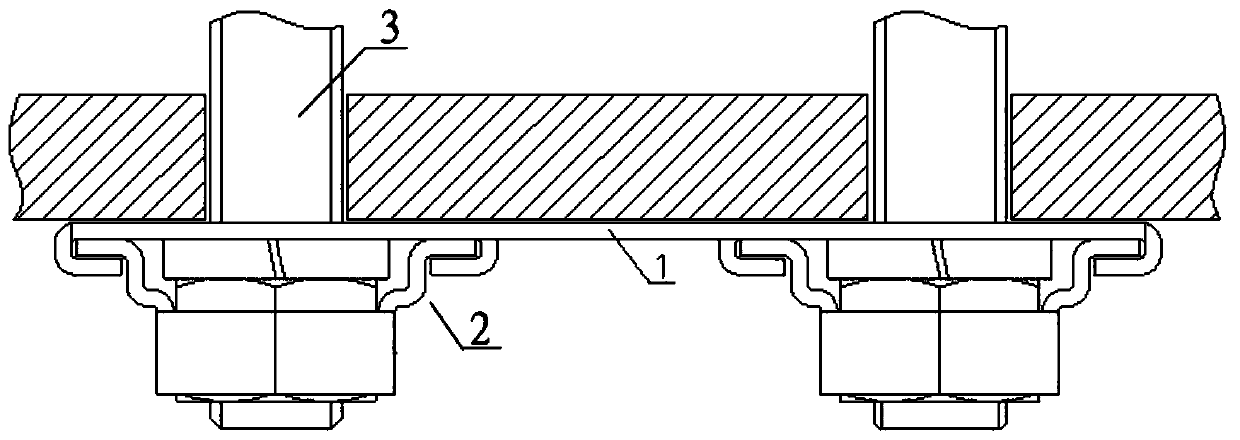

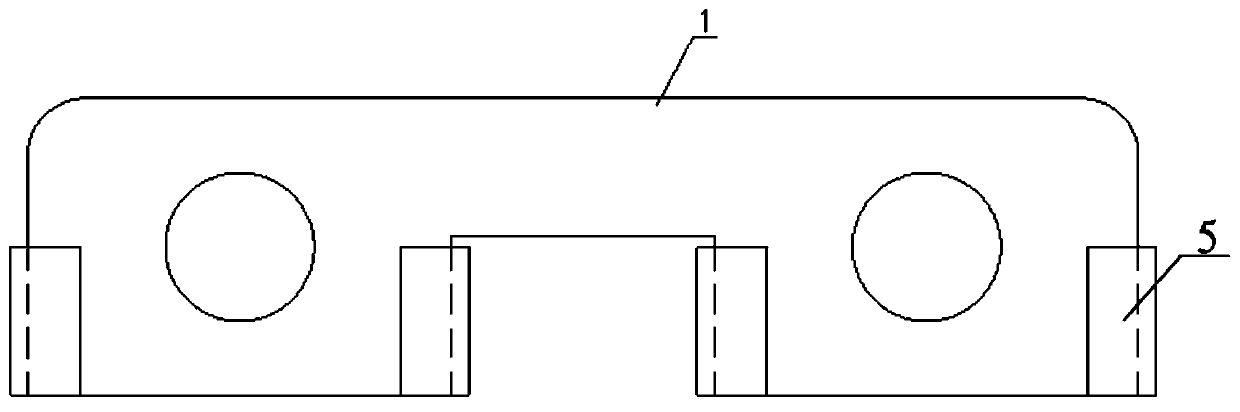

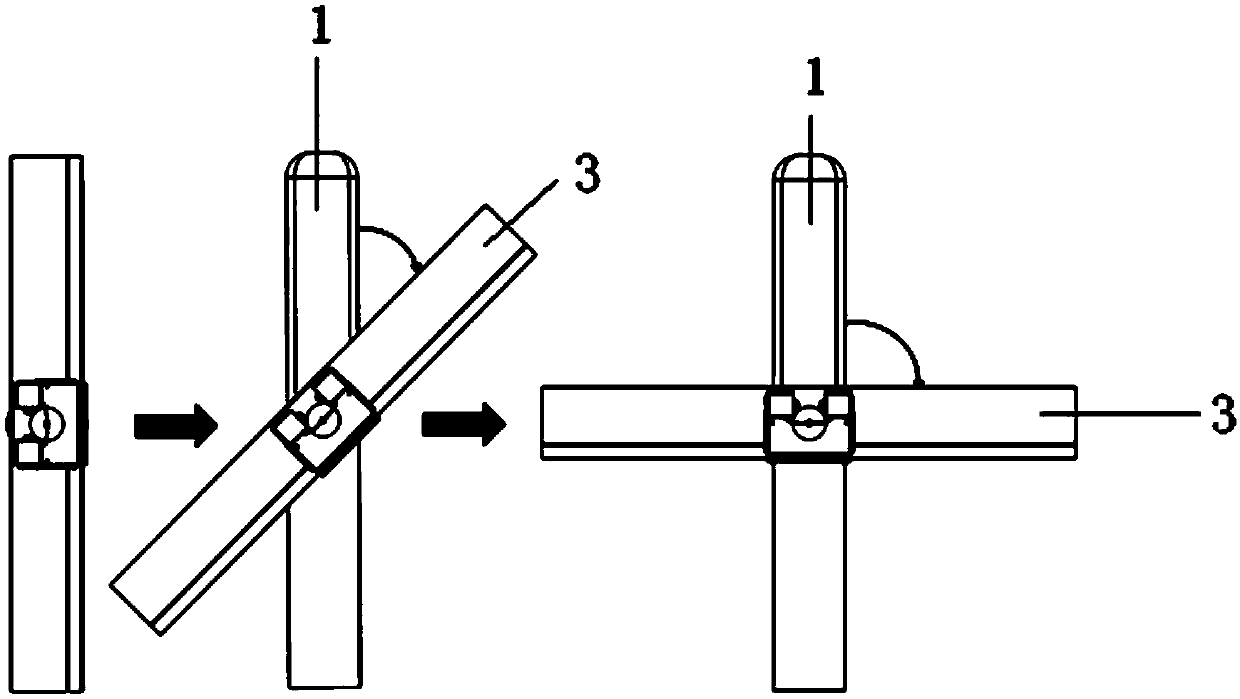

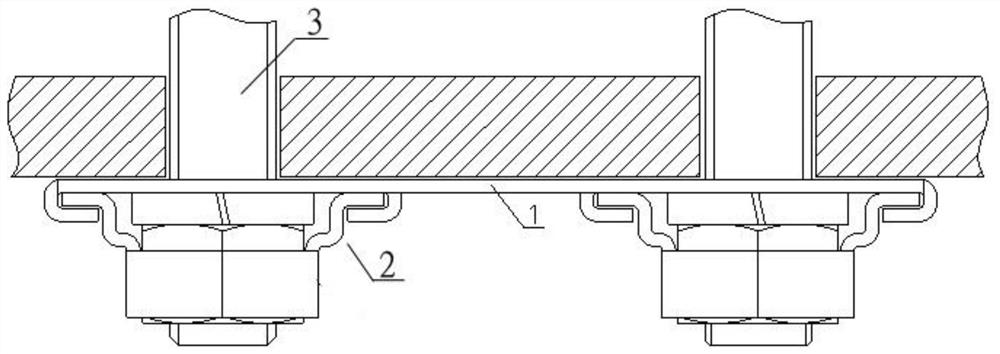

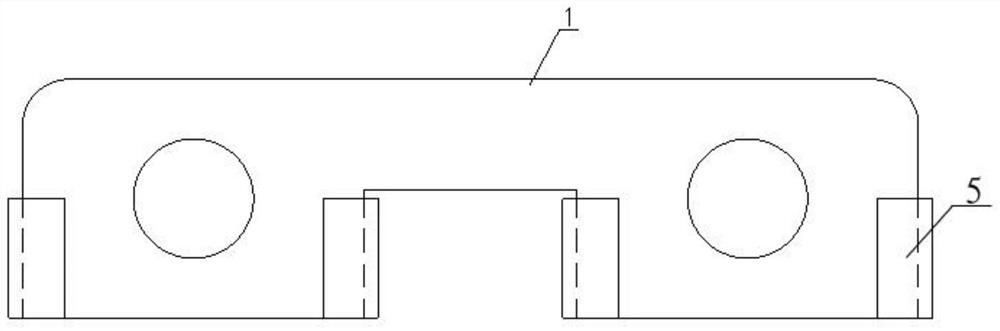

Turnout fastener mechanical anti-loosening structure

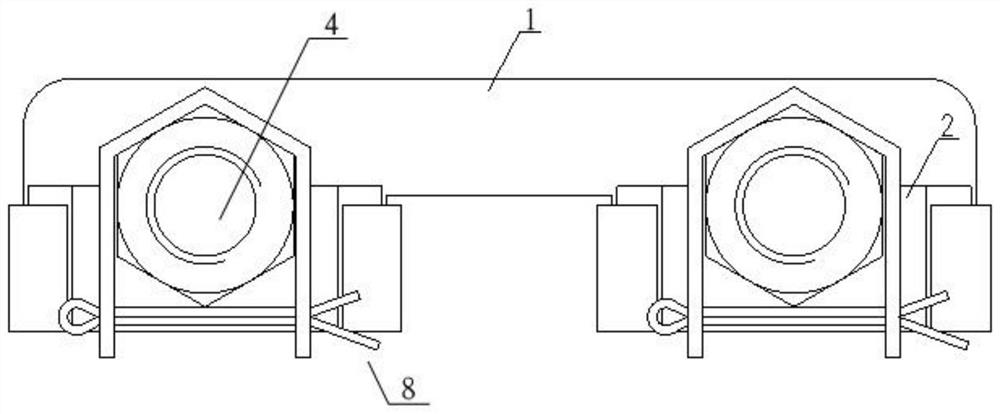

ActiveCN110904743ASmall space required for installationAnti-loose effect is firmRail fastenersSplit pinFastener

The invention provides a turnout fastener mechanical anti-loosening structure which comprises an anti-rotating support and anti-loosening pieces, the anti-rotating support is installed on the oppositeside rail web of a turnout assembly part, the two sides of the anti-rotating support are fastened to the rail web of a steel rail part and the turnout assembly part through bolts and nuts respectively, and inserting grooves are symmetrically formed in the side, back on to the rail web, of the anti-rotating support; each anti-loosening piece comprises a clamping part attached to the outer side face of the nut and provided with an opening in the bottom and an inserting part matched with the corresponding inserting groove, and each inserting part is fixed to the corresponding clamping part. In afastened state, the clamping parts are arranged above the nuts in a sleeving mode from top to bottom and attached to the nuts, meanwhile, the inserting parts are inserted into the inserting grooves,and the bottoms of the clamping parts are fixed through cotter pins. The anti-loosening structure is firm in anti-loosening effect, the anti-rotating support does not need to abut against the upper inclined face and the lower inclined face of the rail web space, the space needed for installation of the anti-loosening pieces is small, and therefore the anti-loosening structure can be universally suitable for different rail types and bolt hole center heights and is high in universality.

Owner:CHINA RAILWAY SHANQIAO GRP CO LTD

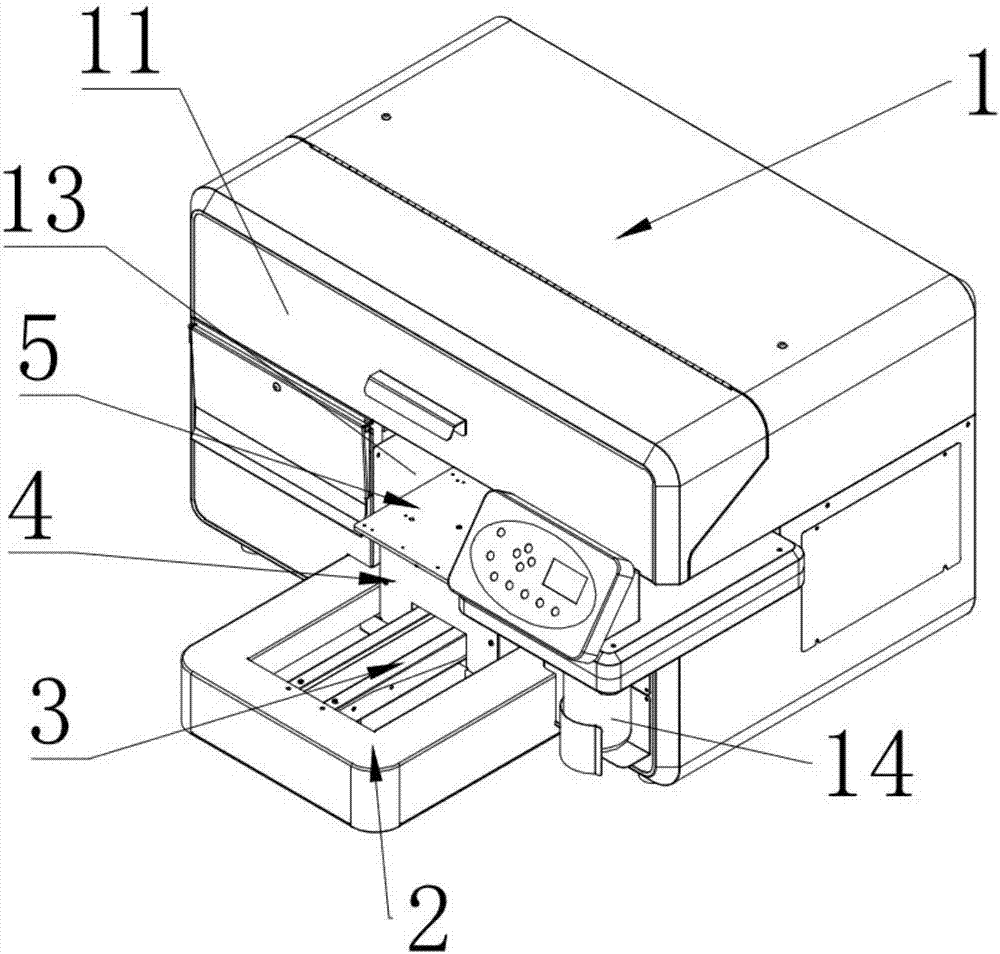

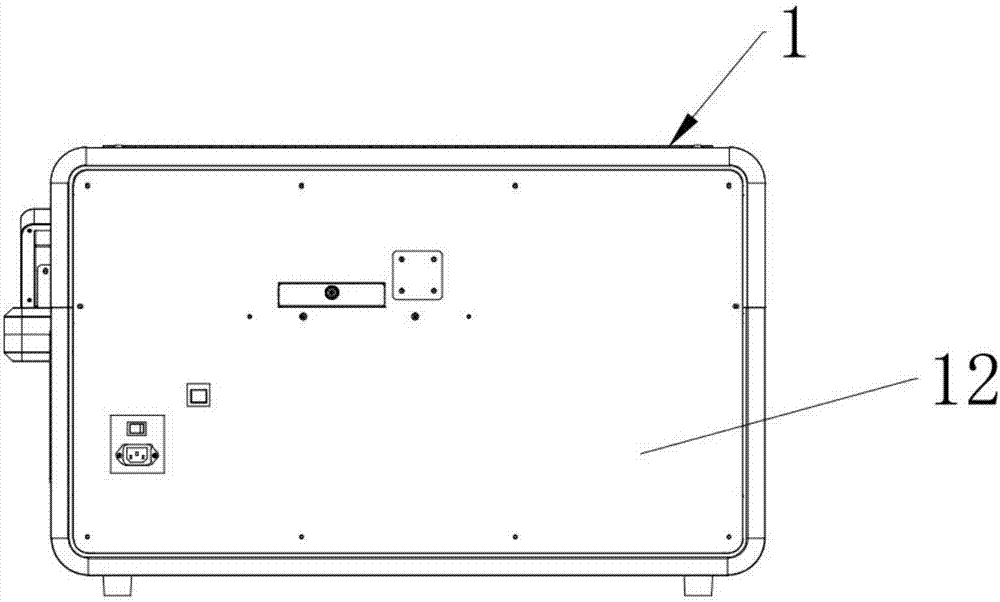

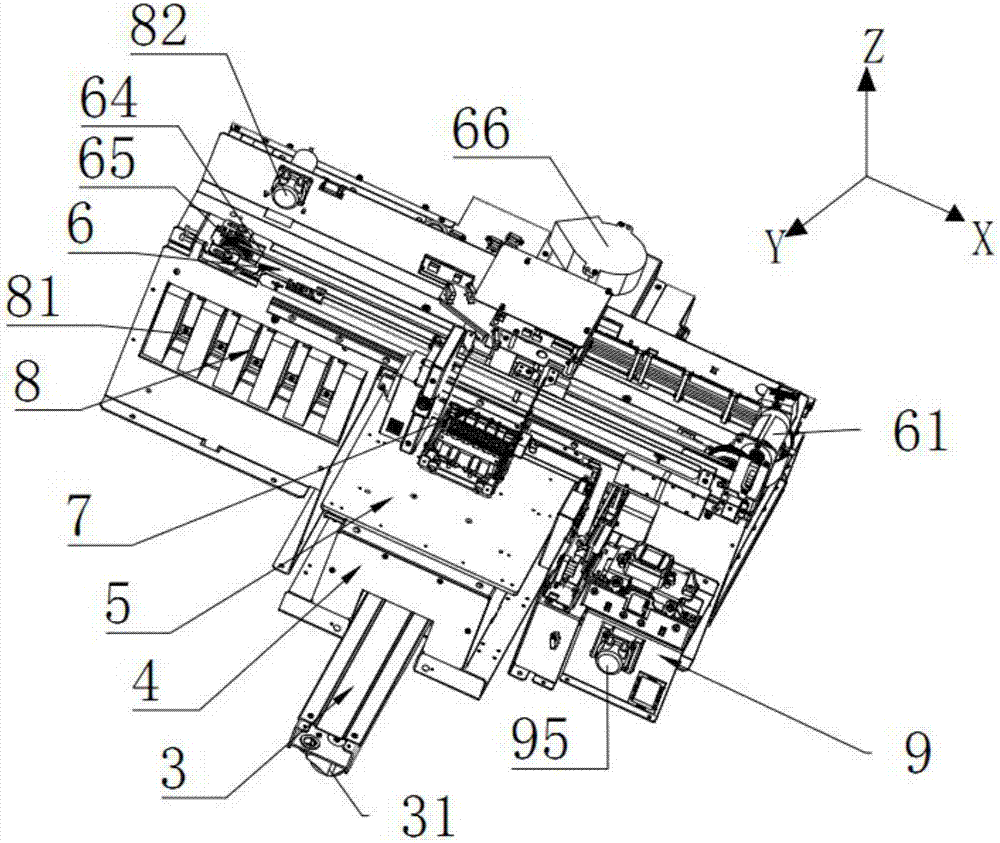

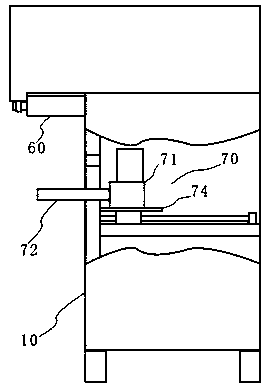

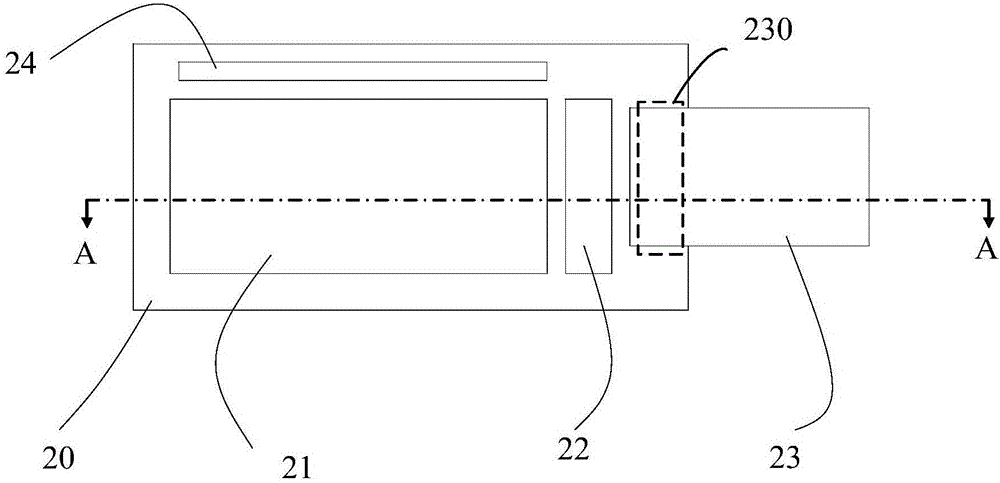

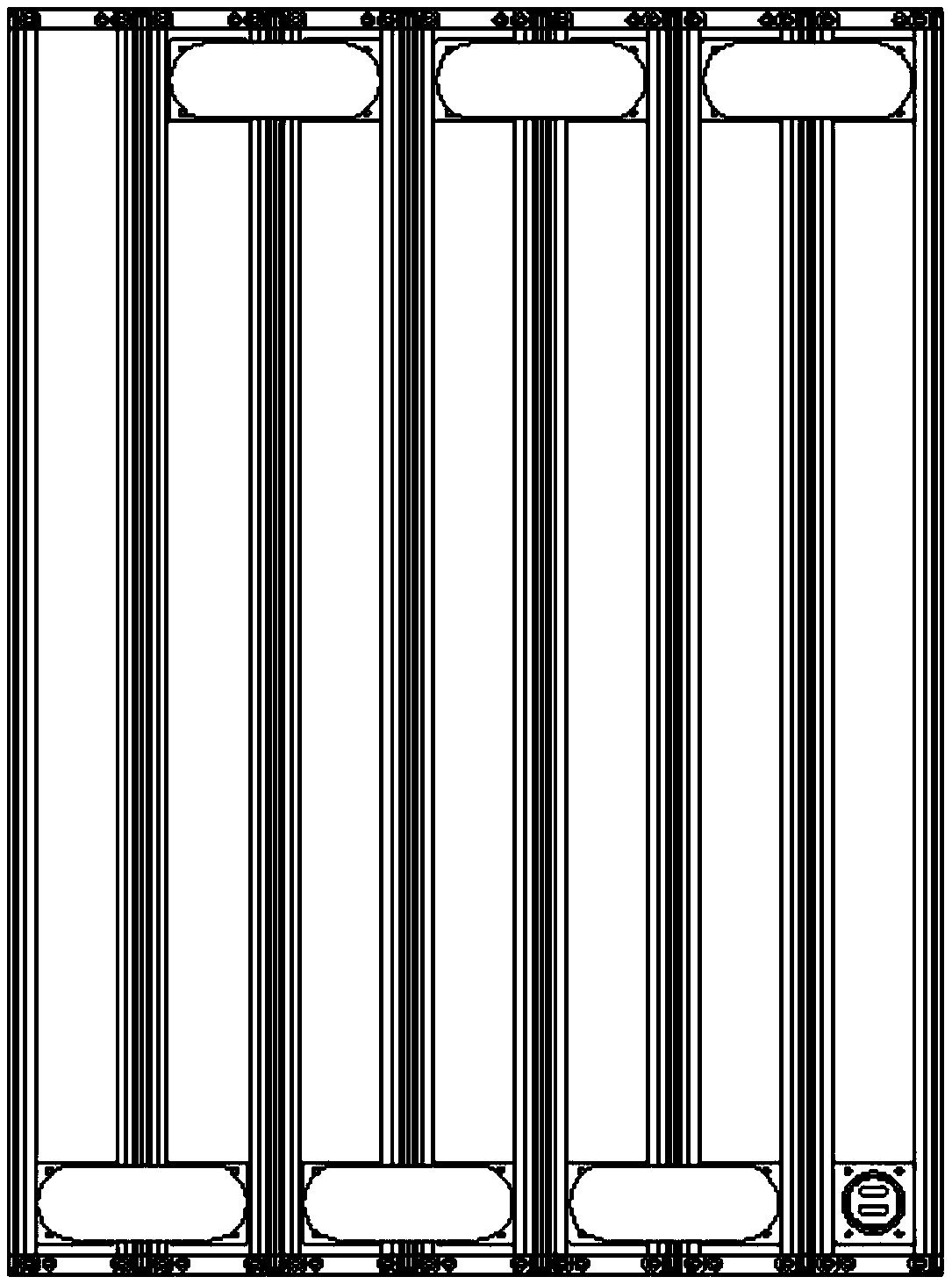

Flatbed printer

PendingCN107499005ARegular and beautiful appearanceSmall footprintTypewritersOther printing apparatusEngineeringMoisture

The invention discloses a flatbed printer. The flatbed printer comprises a machine shell, a bottom plate framework, an underframe transmission assembly, an underframe lifting assembly, a working platform, a machine body transmission assembly, an ink vehicle, an ink box and a moisture preservation cleaning part. The machine shell is provided with a front end face, a rear end face and a sliding cavity, wherein the front end face and the rear end face are opposite to each other. The sliding cavity extends to the rear end face from the front end face. One end of the bottom plate framework is arranged on the rear end face, and the other end of the bottom plate framework extends in the direction far away from the front end face along the sliding cavity. The underframe transmission assembly is arranged inside the bottom plate framework. The underframe lifting assembly is arranged on the underframe transmission assembly. The working platform is arranged on the underframe lifting assembly. The machine body transmission assembly, the ink vehicle, the ink box and the moisture preservation cleaning part are arranged inside the machine shell. The machine body transmission assembly is transversely arranged above the working platform and is further parallel to the working platform. The ink vehicle is arranged on the machine body transmission assembly. The ink box and the moisture preservation cleaning part are located below the two ends of the machine body transmission assembly correspondingly and are further fixed to the inner wall of the shell. The flatbed printer disclosed by the invention is compact in structure, small in space occupation, regular and attractive in appearance and easy to carry and use.

Owner:GUANGZHOU NUOCAI DIGITAL PROD CO LTD

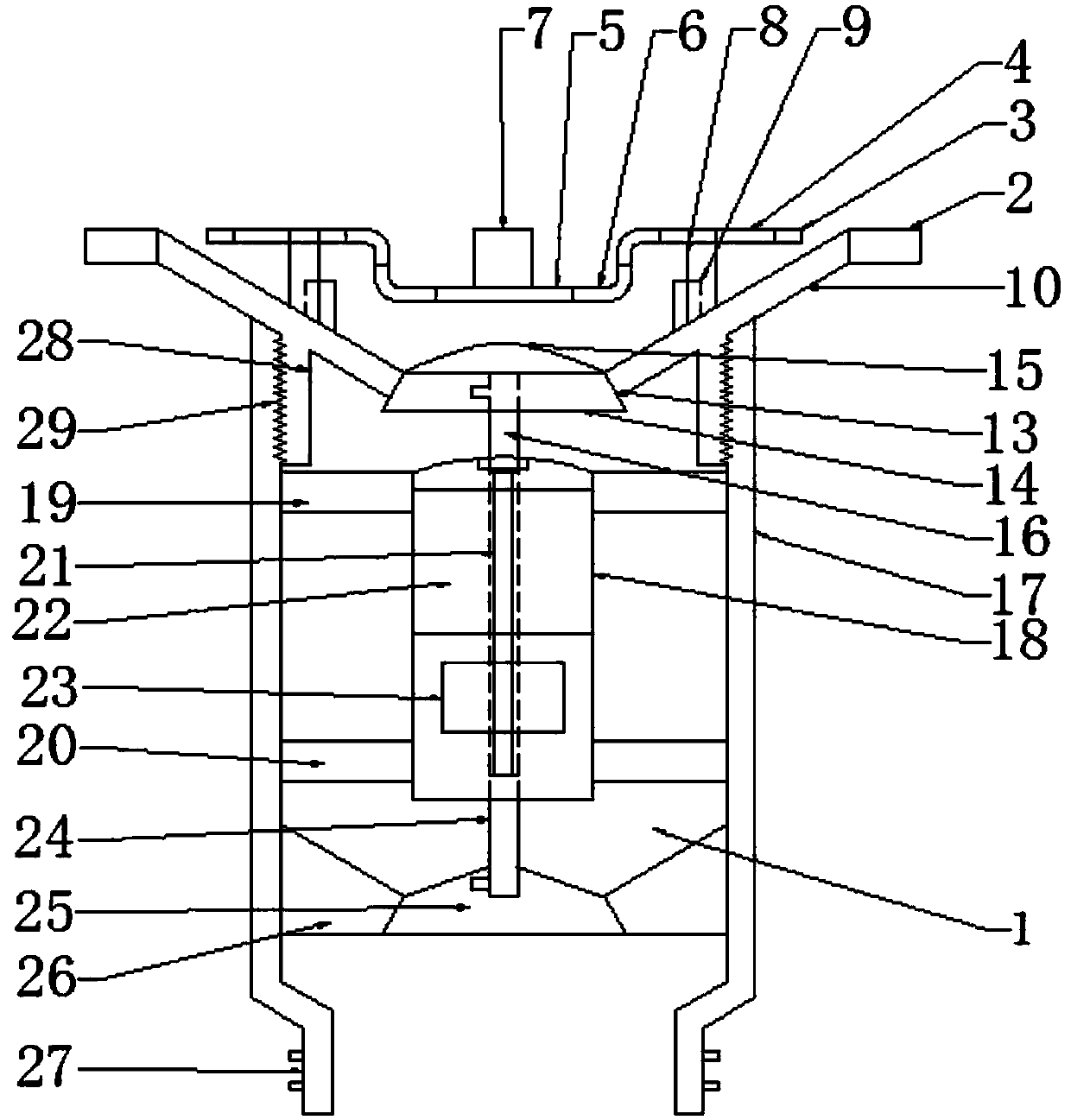

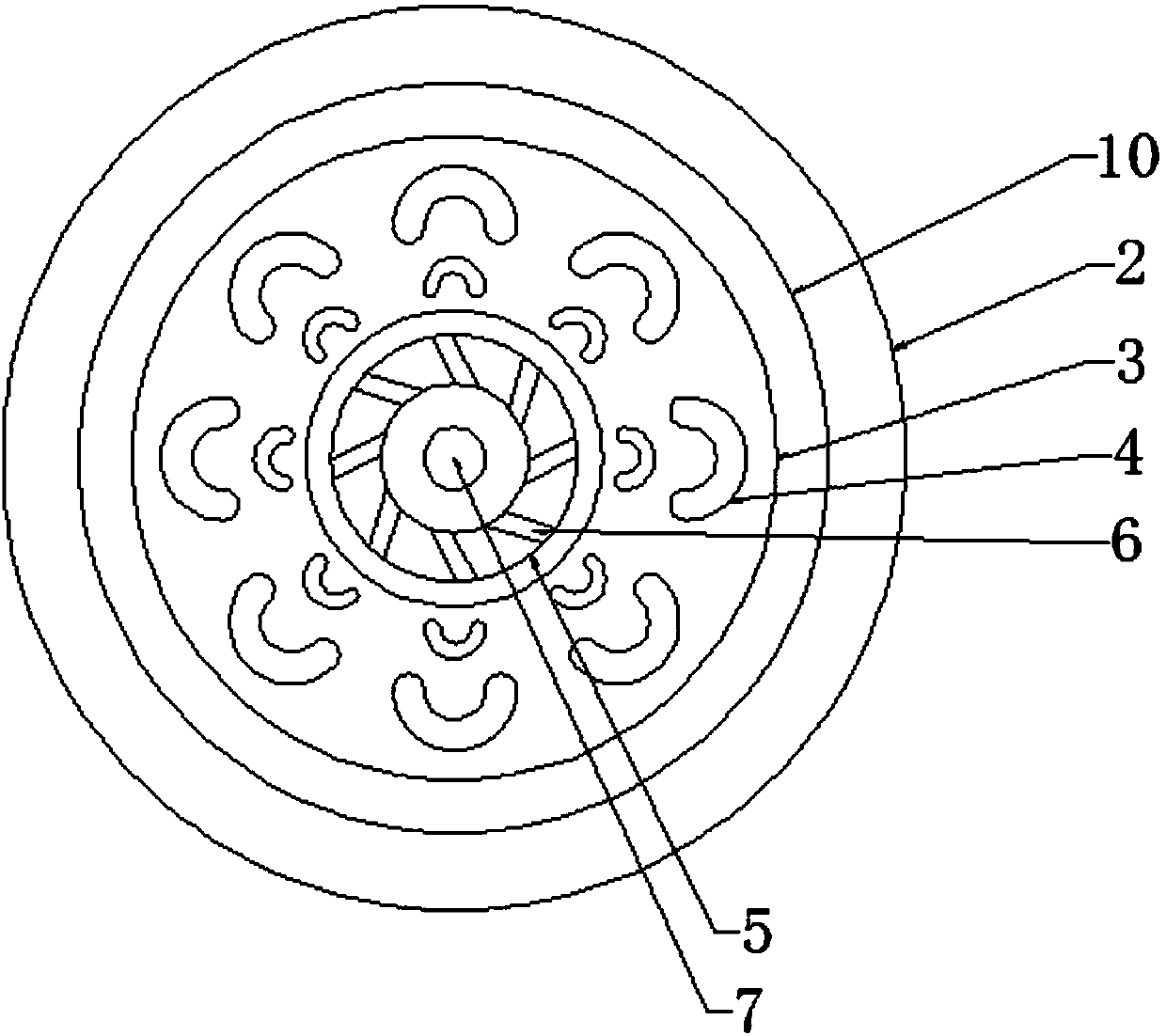

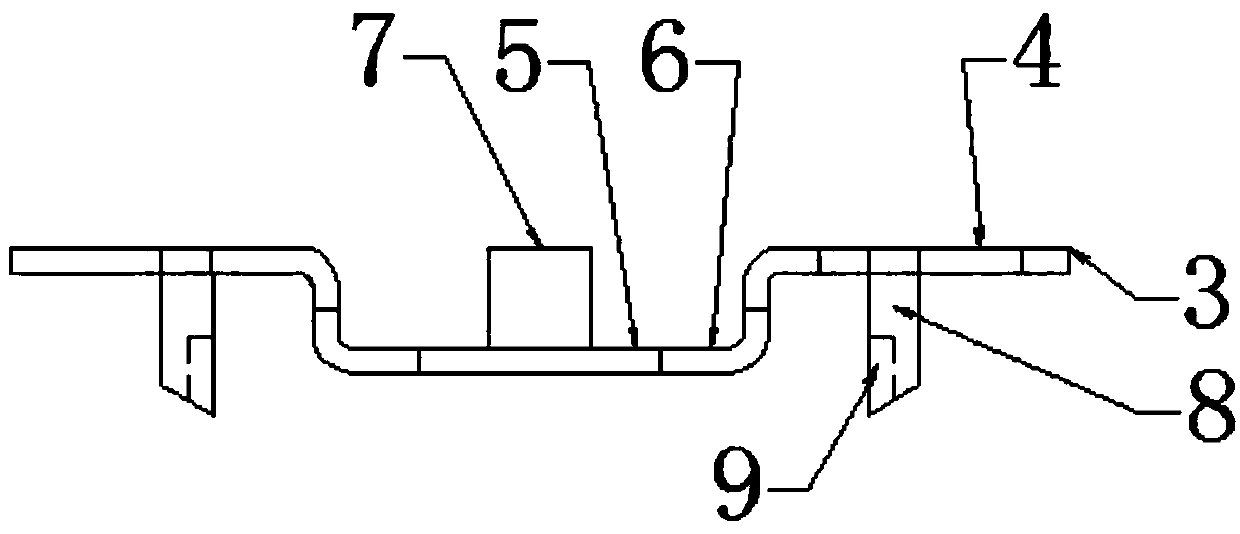

Toilet floor drain device

InactiveCN107829485AEasy to clean and maintainEasy to useSewerage structuresIndoor air qualityArchitectural engineering

The invention discloses a floor drain device for toilet, which comprises a floor drain body, wherein, a panel is arranged on the top of the floor drain body, a cover plate is arranged on the top of the panel, and several water leakage holes are arranged on the top of the cover plate. , the inside of the cover is provided with a groove, the groove is provided with a number of leakage holes 2, the top of the inner bottom of the groove is provided with a handle, and the bottom of the cover is provided with several support plates, The inner side of the support plate is provided with a card slot, the inner side of the panel is provided with a water leak, the inner side of the water leak is provided with a card plate, the card plate matches the card slot, and the bottom of the water leak is provided There is a water leakage port, and the water leakage port is matched with a sealing plug one, a switch is arranged on the top of the sealing plug one, and a rotating shaft one is arranged inside the sealing plug one. Beneficial effects: ensure that the indoor air quality will not be affected, and it is easy to clean and maintain, and can be used effectively for a long time.

Owner:HUAIAN JUNRUI CHUANGZHI IND DESIGN CO LTD

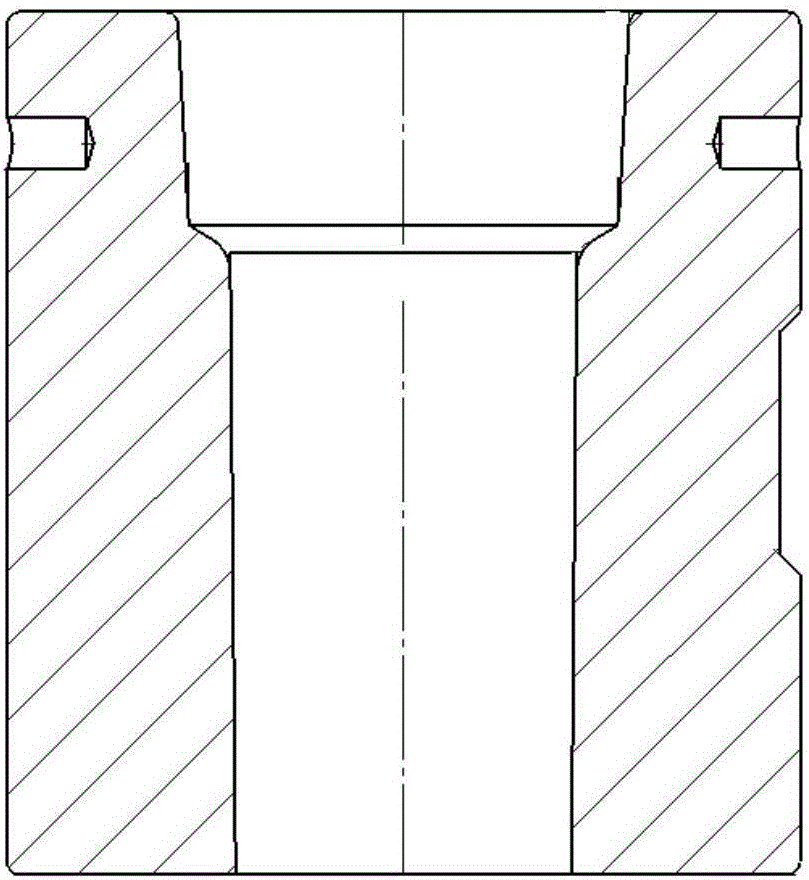

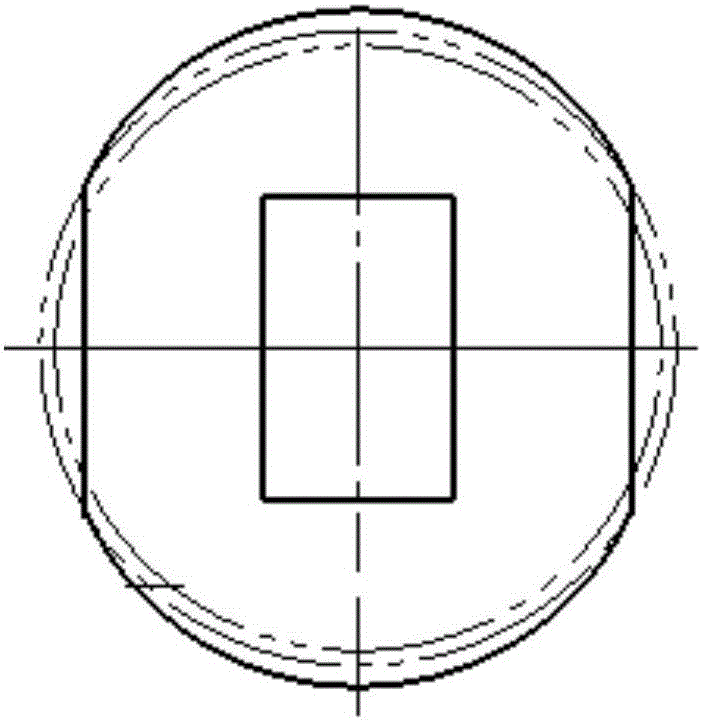

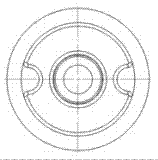

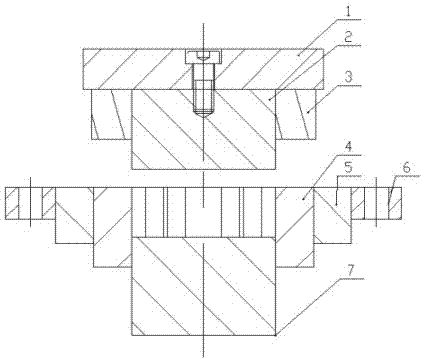

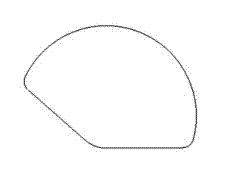

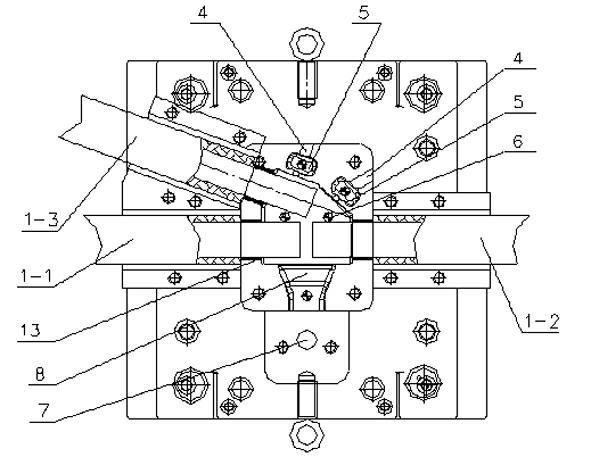

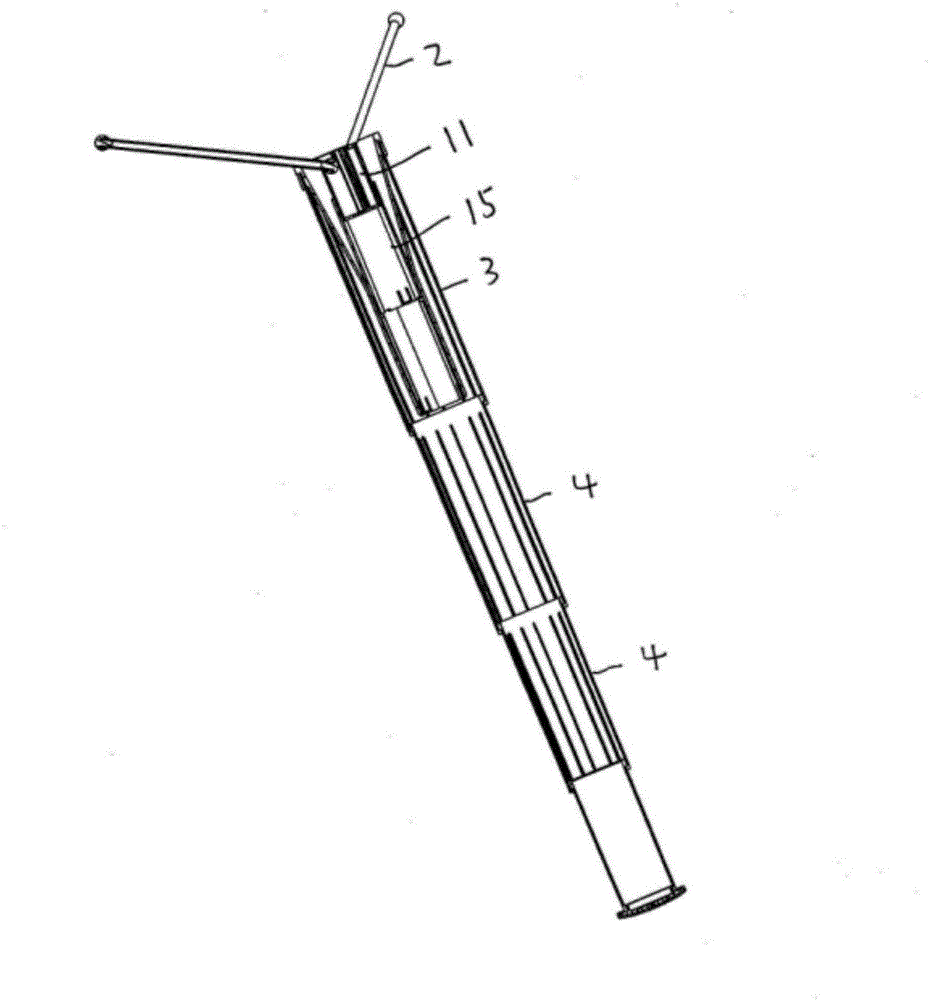

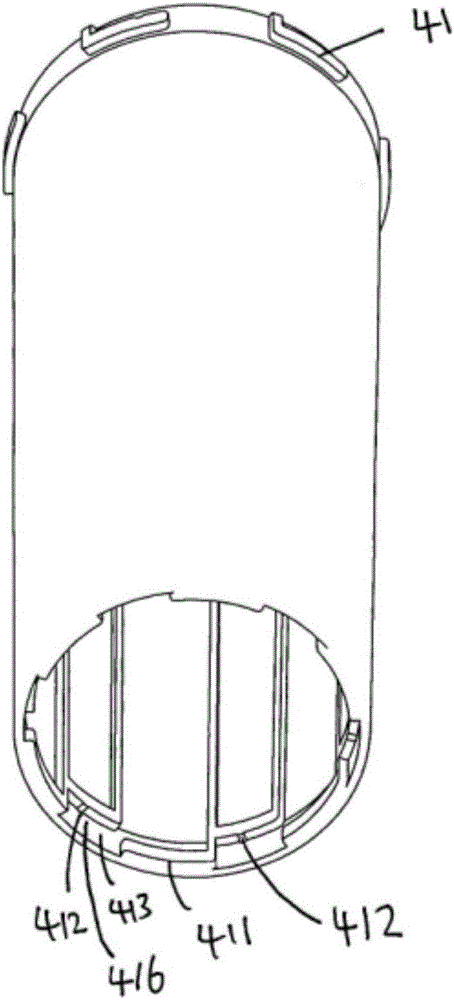

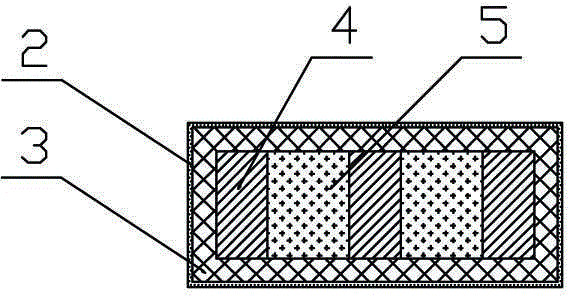

Preforming forging die of sector-shaped forge piece

InactiveCN103084527AHigh densityRegular and beautiful appearanceForging/hammering/pressing machinesEngineeringHigh pressure

The invention discloses a preforming forging die of a sector-shaped forge piece. The sector-shaped forge piece is a sector-shaped worm wheel which is one of the parts of a high-pressure on-off operating mechanism. The preforming forging die of the sector-shaped forge piece comprises a convex die (2) and a concave die (4) and is characterized in that a convex die sleeve (3) is arranged outside the convex die (2), a prestressing ring (5) is arranged outside the concave die (4), the convex die (2) protrudes into an inner cavity of the concave die, an ejector (7) is arranged in the inner cavity of the concave die, and the residual space of the inner cavity of the concave die is a flowing space of blanks. Bars are arranged in the preforming forging die to form sector-shaped preforming blanks with a certain thickness. Products forged by the forging die is high in material density, regular and beautiful in appearance, free of overlaps and burrs, small in machining allowance, and not only material-saving but also favorable for machining.

Owner:QINHAN PRECISION IND CO LTD

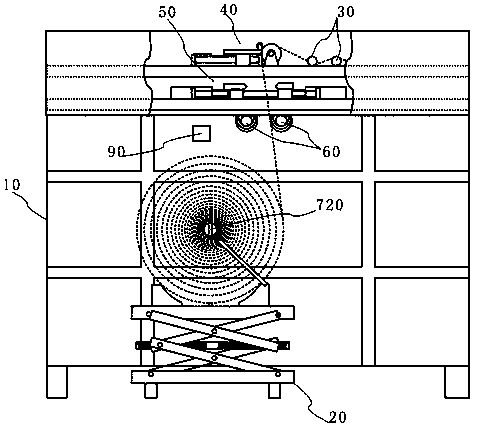

Automatic counting winding and cutting machine and braid winding and cutting method

PendingCN108689211AAppropriate tensionDecrease the tilt angleArticle deliveryElectronic control systemEngineering

The invention relates to an automatic counting winding and cutting machine which comprises an electronic control system, a braid winding mechanism, a receiving disc lifting table, a braid guide rollerset, a fusing mechanism, a limiting assembly and a traction mechanism, the braid guide roller set, the fusing mechanism, the limiting assembly and the traction mechanism are sequentially arranged inthe braid running direction, the center of a braid winding station of the braid winding mechanism is located on any one of the left and right sides of a fusing station, the limiting assembly is located under the fusing station and is provided with a braid walking space, the receiving disc lifting table is correspondingly arranged under the braid winding station, a meter counting wheel and a photoelectric detector are electrically connected with the signal input end of the electronic control system. By means of the automatic counting winding and cutting machine, the inclined angle between a braid and the vertical line can be smaller during full winding, fusion is facilitated, the braid descending angle is limited, and accidental fusion is avoided; and a pneumatic rolling shaft is tightly attached to a traction roller to enable the braid to keep appropriate tension force without corrugation or displacement, and the smooth implementation of braid winding and orderly and attractive braid discs are guaranteed. According to the automatic counting winding and cutting machine, the braid can be automatically cut off and rolled into a disc cake shape according to the set length, the accuracyis high, and the load weight is large.

Owner:福建锦特新材料科技有限公司

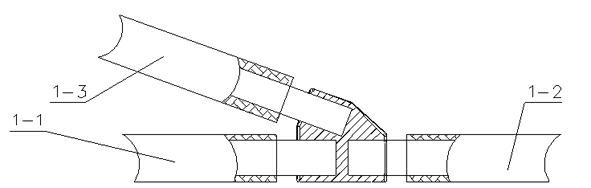

Die-casting connecting method and tool for cable connector

ActiveCN102496829ALow resistivityReduce electrical power lossLine/current collector detailsSlagCopper

The invention relates to a die-casting connecting method and a die-casting connecting tool for a cable connector. The die-casting connecting method for the cable connector comprises the following steps of: 1, processing a die-casting connecting position; 2, putting two or more cables to be connected into an upper mould of a die-casting mould after being tinned; 3, pressing a lower mould of the die-casting mould on the upper mould of the die-casting mould and firmly fixing the lower mould; 4, pressing molten copper liquid into the die-casting mould by a die-casting machine quickly; 5, exhausting air inside the die-casting mould by an external force of a die-casting head and the molten copper liquid in the die-casting process, and absorbing oxidized slag and surplus copper liquid which are generated in the die-casting process by using a residue bag; and 6, ejecting out the cable connector. The connector which is moulded by the die-casting method is high in tensile strength and attractive in appearance. The die-casting connecting tool fixes the cable required to be connected together and a circular hole formed by closing an upper mould core and a lower mould core is in interference fit with the cables, so that gas generated in the die-casting process can be effectively prevented from being exhausted from the circular hole.

Owner:湖南湘电动力有限公司

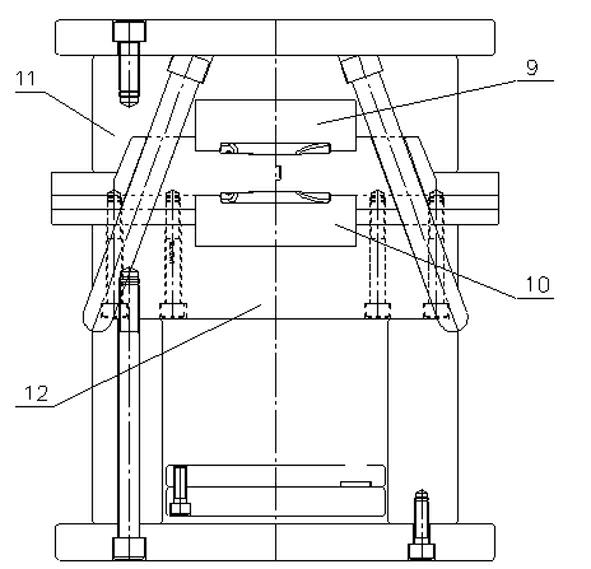

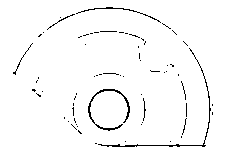

Final-forming forging mold of fan-shaped forging

InactiveCN103230999AHigh densityRegular and beautiful appearanceForging/hammering/pressing machinesEngineeringMaterial density

The invention discloses a final-forming forging mold which comprises a punch (2) and a matrix (4), wherein a punch sleeve (3) is arranged outside the punch (2); a prestressed ring (5) is arranged outside the matrix (4); the punch (2) extends into an inner chamber of the matrix; a knockout (7) is arranged in the inner chamber of the matrix; the lower end of the punch, the upper end of the knockout, and the inner chamber of the matrix form flow space for blank; and preformed blank is placed in a final-forming mold to form an outer ring lug and a central hole of a final-forming blank of a worm sector. A product forged by the forging mold has the advantages of high material density, orderly and attractive appearance without flash burrs and small machining allowance, not only are materials saved, but also machining is facilitated.

Owner:QINHAN PRECISION IND CO LTD

Optical fingerprint sensor

PendingCN106339660AImprove reliabilityReduce design difficultyPrint image acquisitionEngineeringFlexible electronics

The invention discloses an optical fingerprint sensor, which comprises a substrate, a pixel array on the surface of the substrate, a chip on the surface of the substrate, and a flexible printed circuit board bonding region on the surface of the substrate, wherein the pixel array is arranged between the chip and the flexible printed circuit board bonding region. The structural performance of the optical fingerprint sensor is improved.

Owner:SHANGHAI OXI TECH

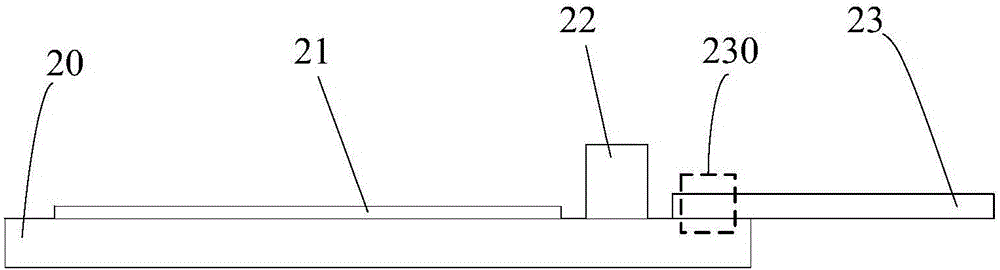

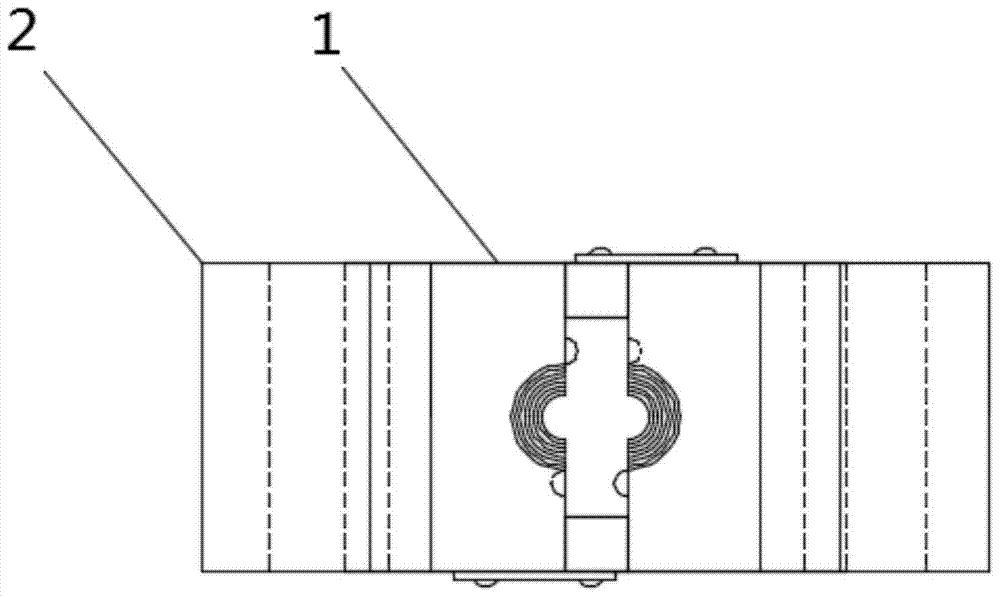

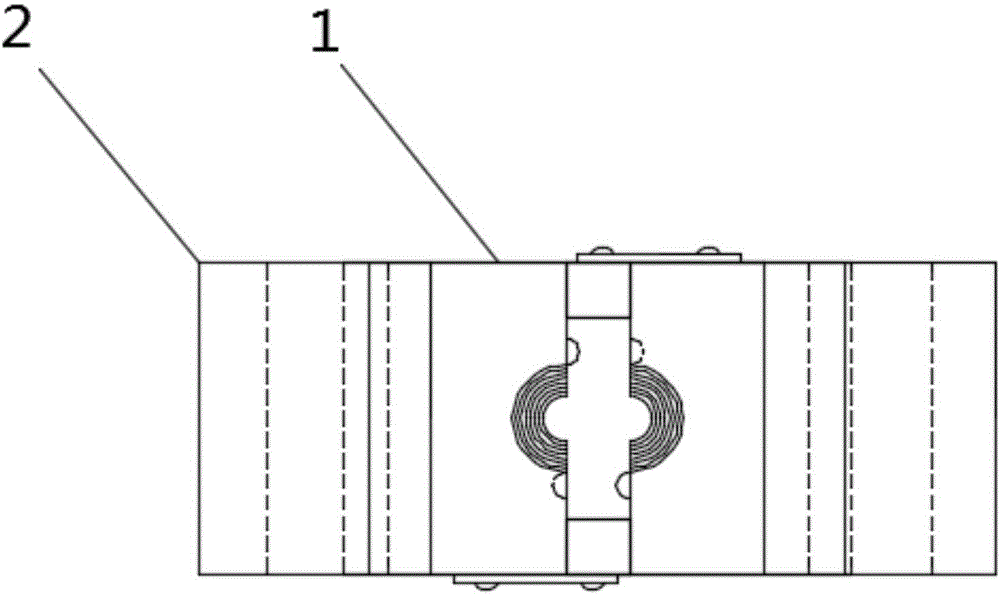

Missile wing single-axis rotating unfolding system considering aileron drive and unfolding method thereof

The invention provides a missile wing single-axis rotating unfolding system considering aileron drive and an unfolding method thereof. The missile wing single-axis rotating unfolding system considering aileron drive comprises a missile body, a missile wing, a folding driving mechanism and a locking mechanism; the folding driving mechanism comprises: after a main shaft passes through a main shaft hole, the top surface of the main shaft is fixed to the bottom surface of the missile body, thus the missile body and the missile wing are assembled together, and the missile wing can rotate around themain shaft; and the center position of a scroll spring sleeves the main shaft, so that the inner end of the scroll spring is clamped in a main shaft scroll spring clamping groove, and the outer end of the scroll spring is clamped in a missile wing scroll spring clamping groove. The missile wing single-axis rotating unfolding system has the advantages that rapid unfolding, accurate positioning andreliable locking of the folded missile wing can be realized, and the missile wing single-axis rotating unfolding system has the characteristics of reasonable design, easy implementation, simple and rapid unfolding mode, regular and beautiful appearance, convenience in carrying and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

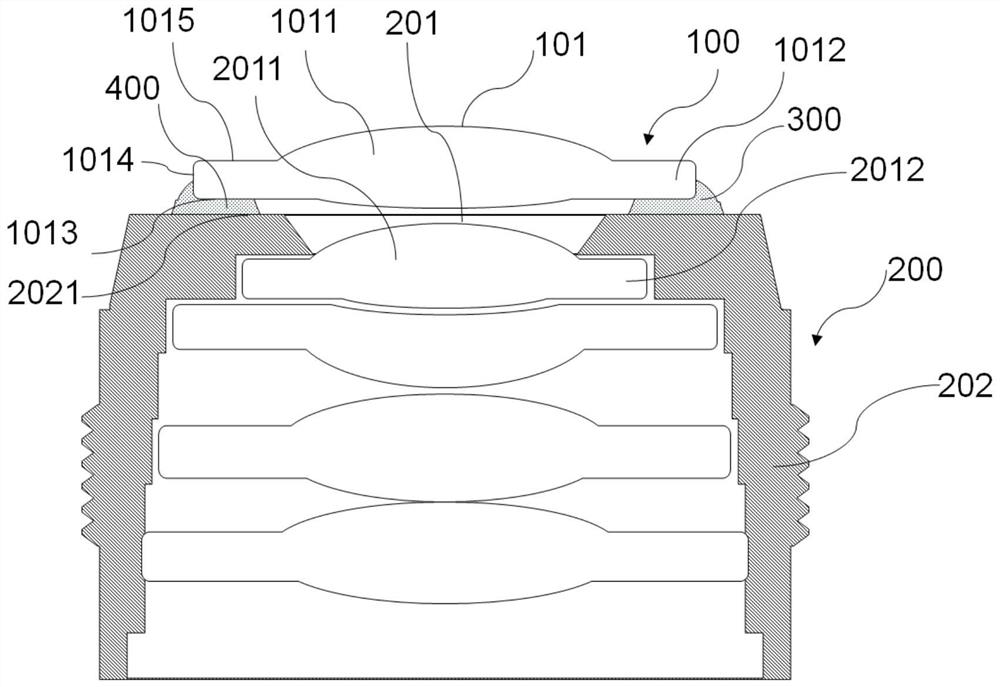

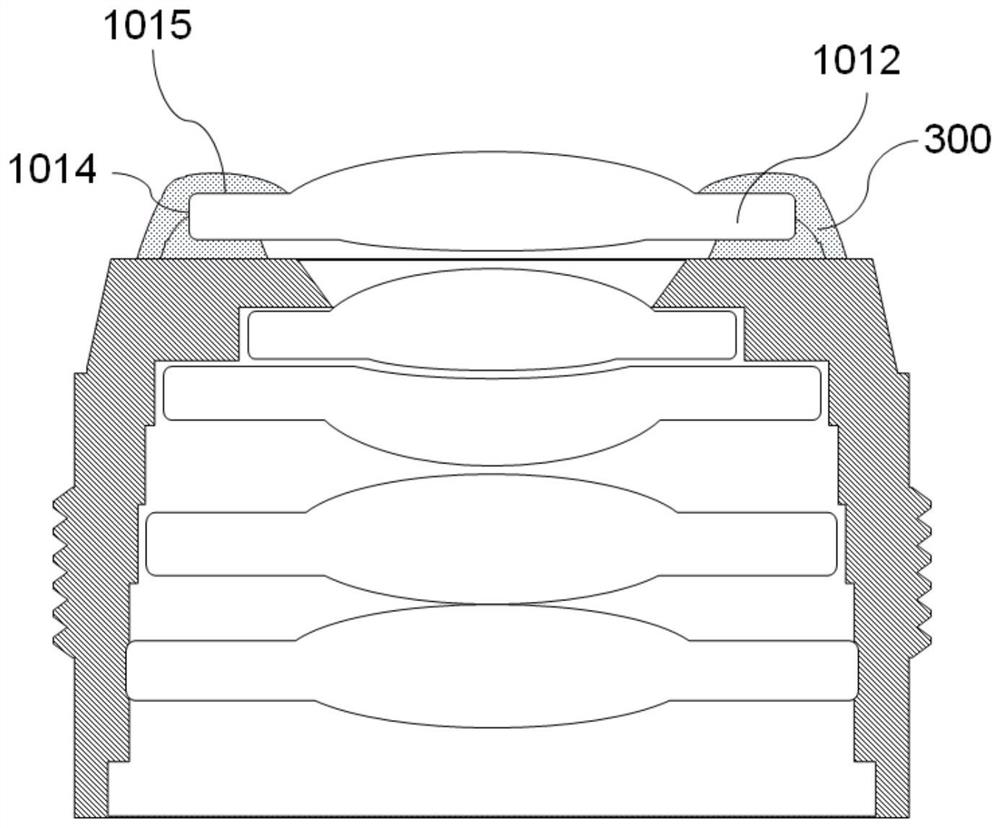

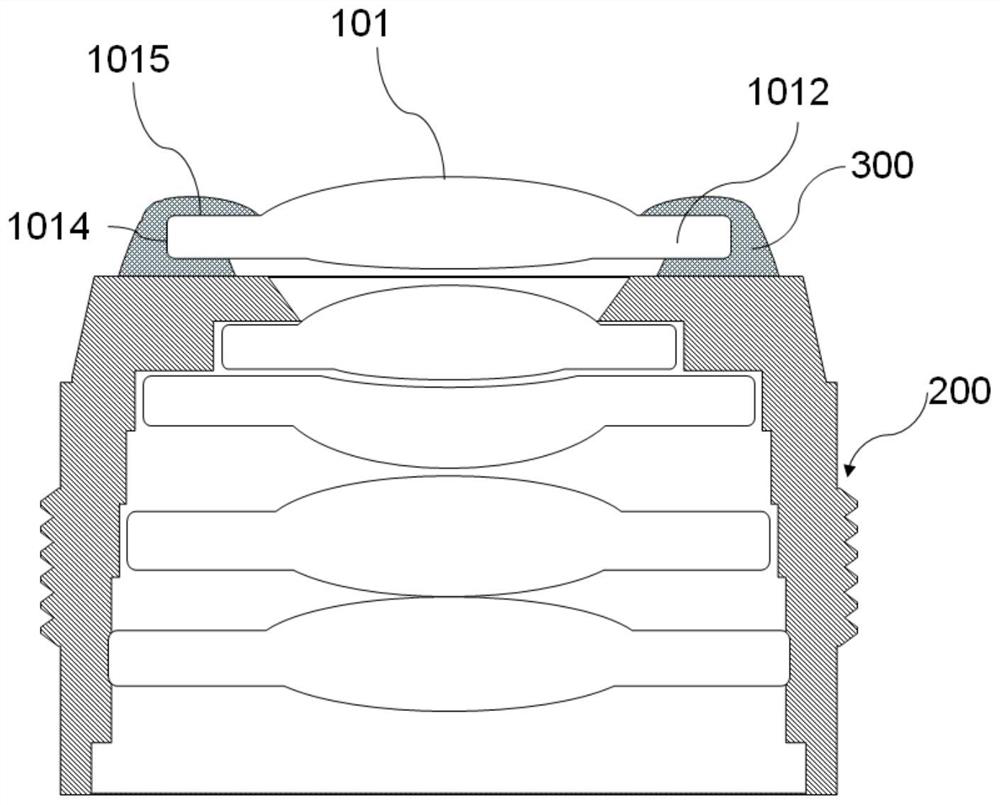

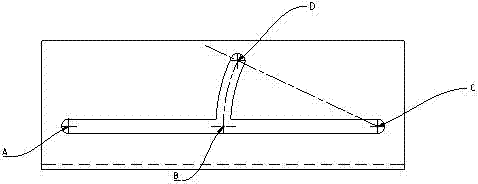

Optical lens, camera module and assembling method thereof

Owner:NINGBO SUNNY OPOTECH CO LTD

Inclined drawer

Owner:苏州托克斯冲压设备有限公司

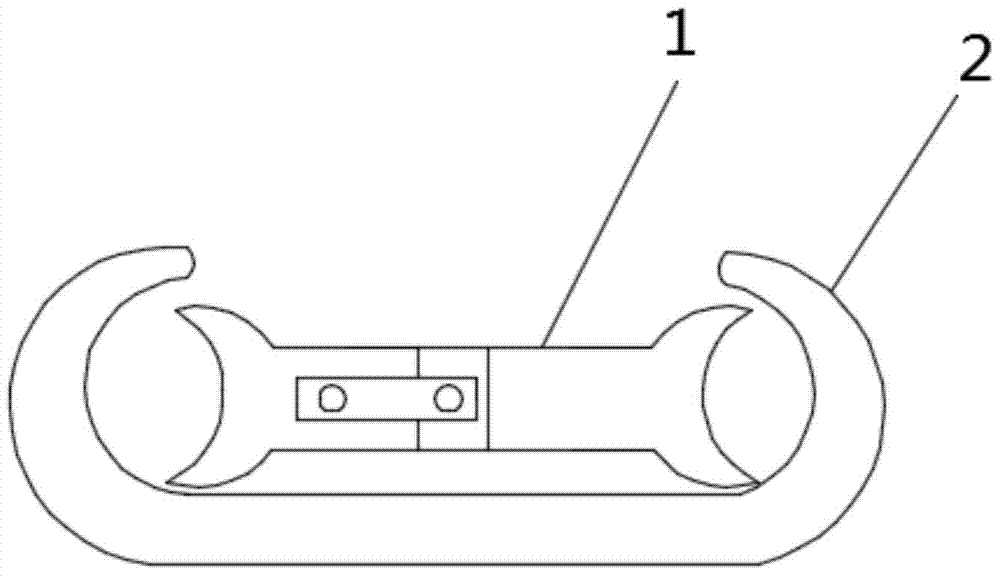

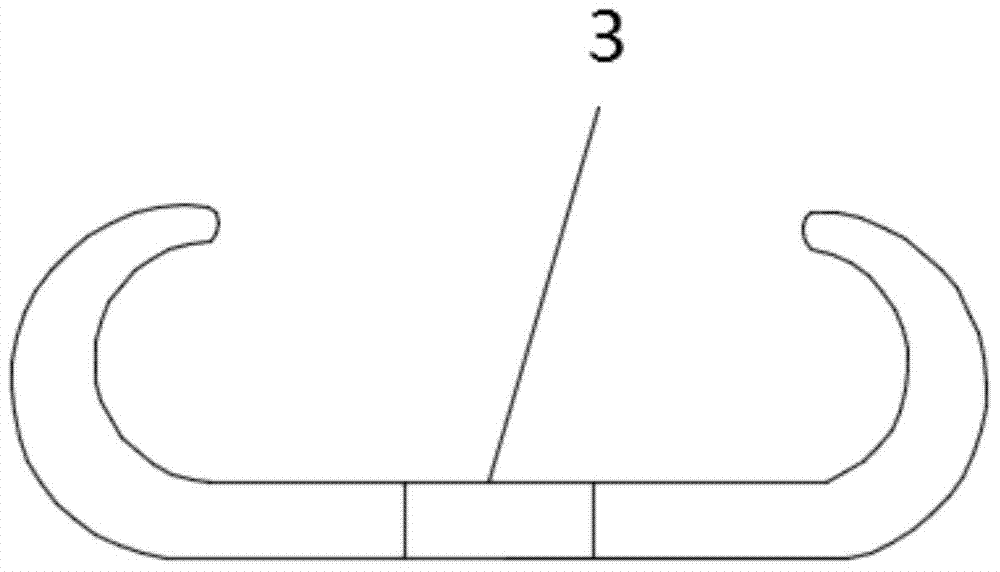

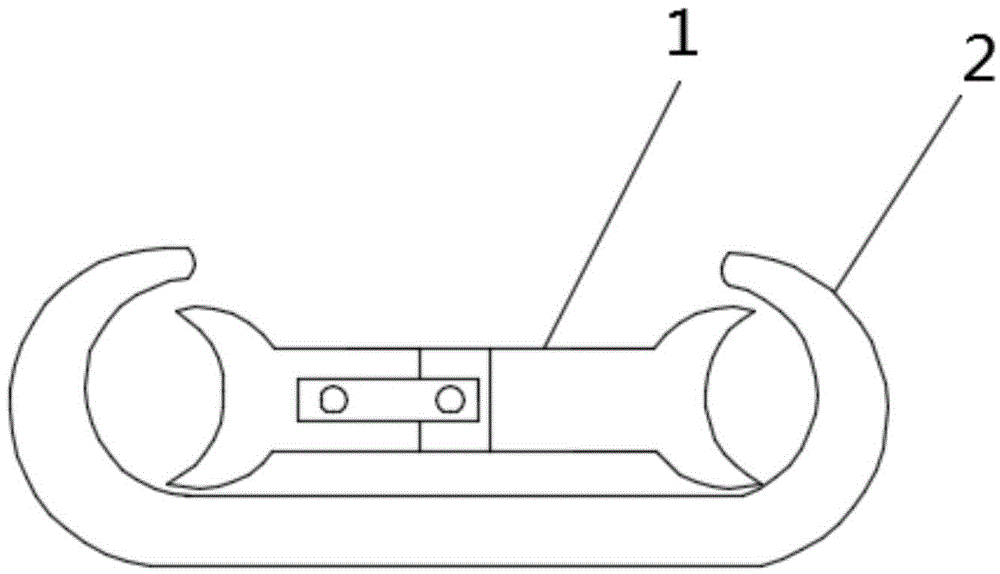

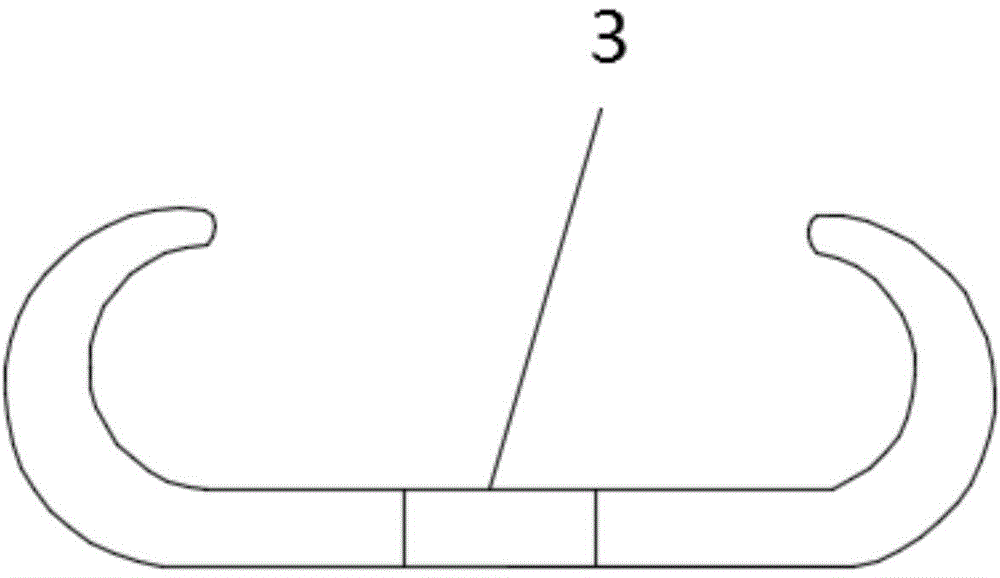

A screwless C-type wire clamp

ActiveCN104966914BRegular and beautiful appearanceReduce water intakeElectric connection structural associationsClamped/spring connectionsElectrical performanceEngineering

The invention discloses a screwless C type wire clamp which comprises a compact block and a C-shaped element. The compact block is composed of two compact bodies. One end of each compact body is provided with a crescent-shaped projection cooperating with the C-shaped element. The side surface of the other end of each compact body is connected with a pressing-in block through a spring piece. The central parts of the upper end face splicing parts of the two compact bodies are provided with one conical screw hole. The two sides of the conical screw hole are respectively provided with a protruding contraposition point and a recessed contraposition point which cooperate with each other. The manufacturing cost of the screwless C type wire clamp is not high. Compared with conventional C type wire clamps, the wire clamp with no screws brings greater convenience when insulating or waterproof processing is performed on the outer side of the wire clamp. The overall appearance of the wire clamp is regular and attractive. Meanwhile, the wire clamp can be used for arranging glue pouring type joints overhead and providing possibilities of better reducing phenomena of water entries into insulation wires on the premise that great electrical performance is maintained.

Owner:STATE GRID CORP OF CHINA +3

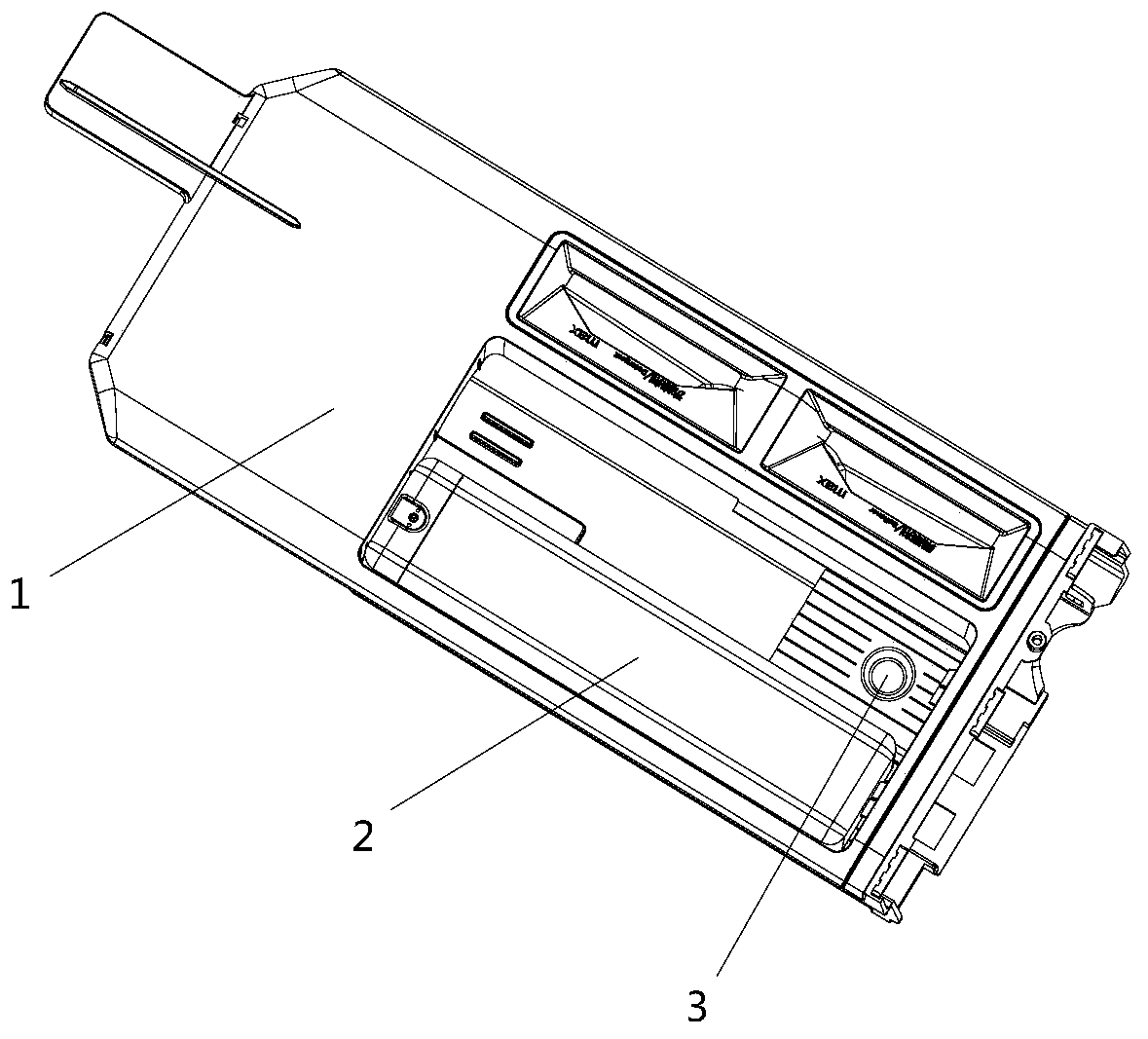

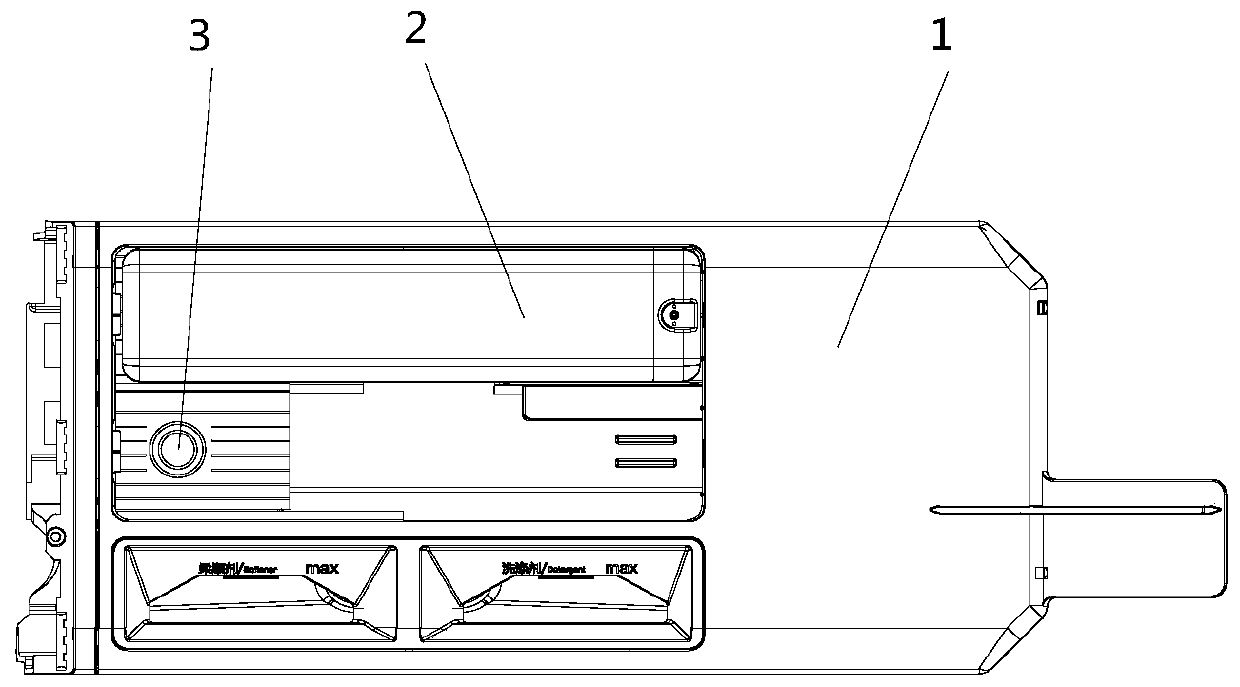

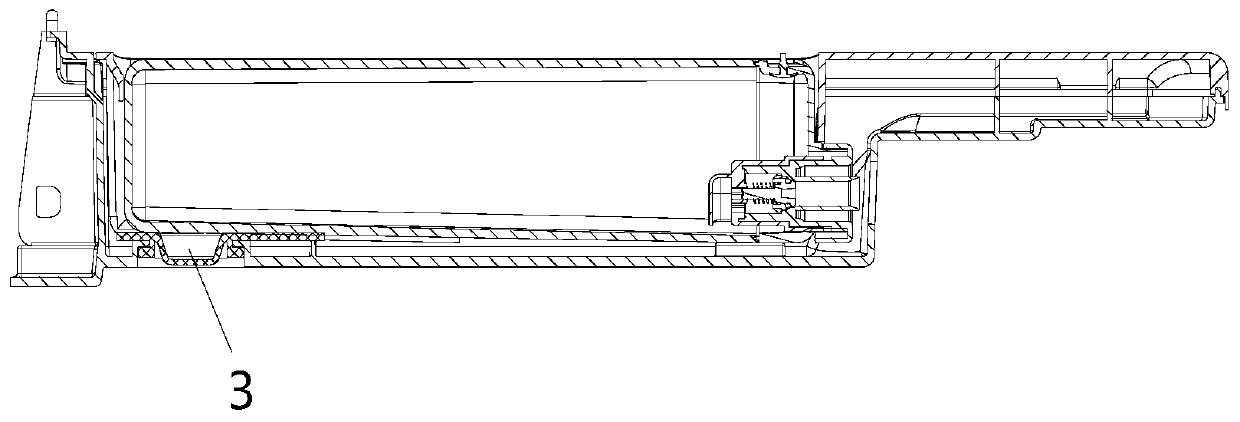

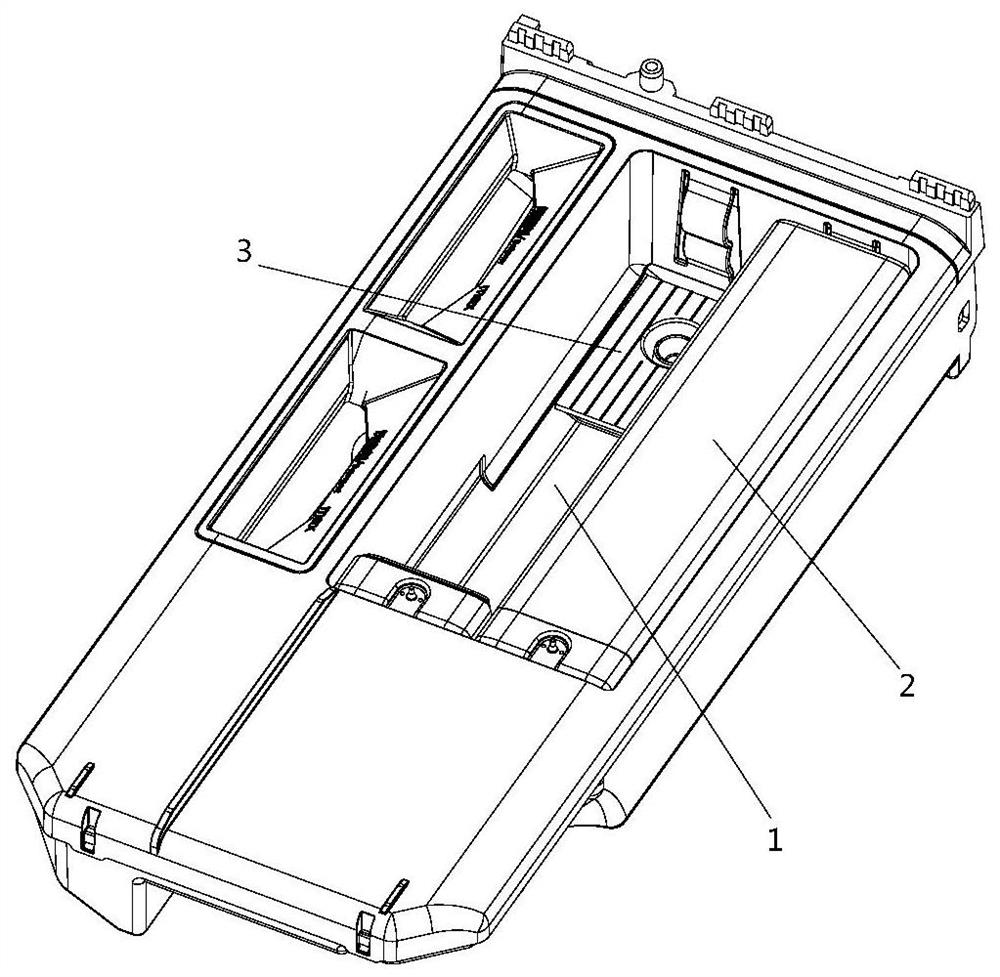

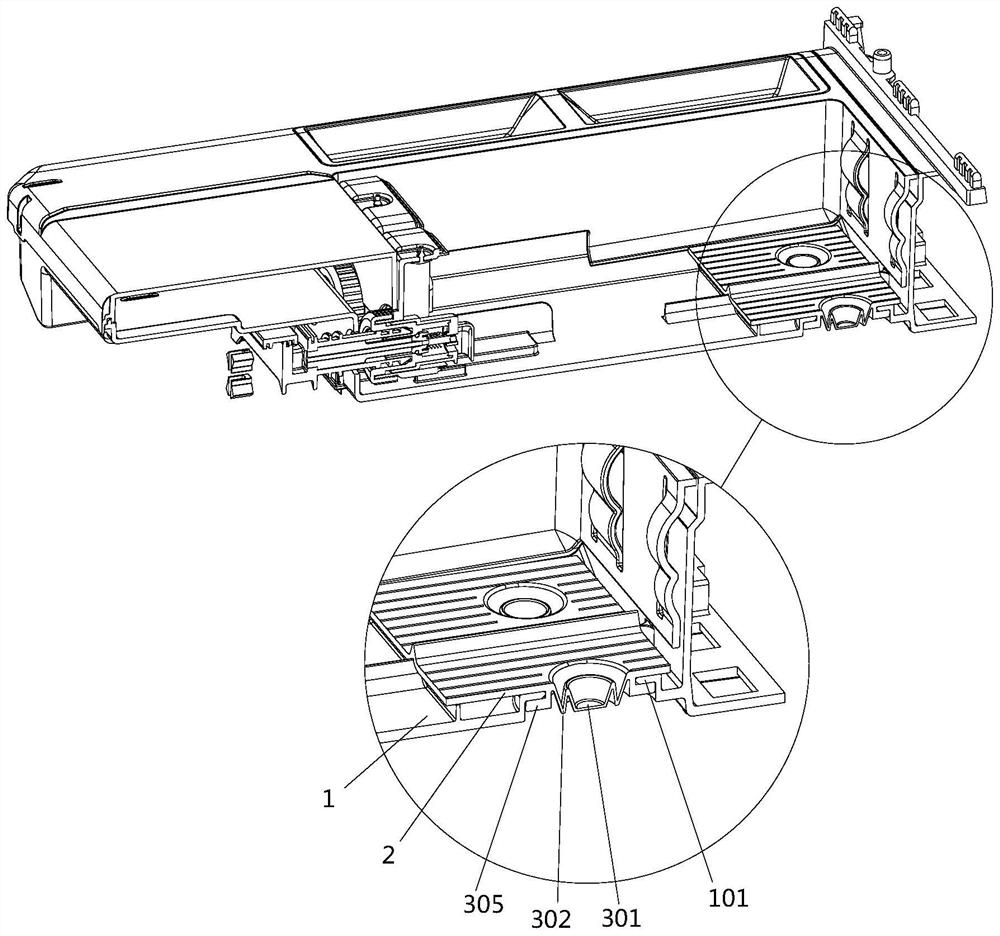

Automatic feeding device of washing machine and using method of automatic feeding device

ActiveCN111485381AReliable structureRegular and beautiful appearanceOther washing machinesTextiles and paperAgricultural engineeringMechanical engineering

The invention discloses an automatic feeding device of a washing machine and a using method of the automatic feeding device. The automatic feeding device comprises an accommodating chamber which movesbetween an open position and a closed position; an additive box used for storing additives is arranged in the accommodating chamber; an ejection structure which applies force from the outer side of the bottom of the accommodating chamber to eject the additive box out of the accommodating chamber is arranged in the position, corresponding to the additive box, of the bottom of the accommodating chamber; the ejection structure is arranged close to one side of the front end of the accommodating chamber; and the distance from the ejection structure to the front end of the accommodating chamber iscalculated from the shape center of the ejection structure or the edge of the side close to the front end of the accommodating chamber. According to the automatic feeding device of the washing machineand the using method of the automatic feeding device, the ejection structure is arranged at the bottom of the accommodating chamber, so that a user can detach the additive box by hands at the bottom,the ejection structure is simple and reliable, and hidden in position, it is ensured that the appearance of the accommodating chamber is regular, square and attractive, the volume of the accommodating chamber is maximized, and replacement is easy.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

Constant temperature water heater

Owner:HAIER GRP CORP +1

Glass fiber reinforced plastic cable channel cover plate and production method thereof

InactiveCN101672044BImprove corrosion resistanceStrong anti-agingArtificial islandsUnderwater structuresPolyvinyl alcoholInjection molding machine

The invention relates to a glass fiber reinforced plastic cable channel cover plate and a production method thereof. The cover plate is prepared by the following materials and steps: unsaturated polyester resin, curing agent, packing, polyvinyl alcohol solution, pigment, fiberglass roving and fiberglass felt; the invention comprises the following steps: (1) arranging a tooling equipment on an extrusion molding machine; (2) mixing evenly the raw materials in the components and pouring in a resin tank; and (3) inducing the fiberglass roving and the fiberglass felt through immersion, a performing device, a forming device, curing and cutting. The cover plate has high strength, smooth surface, neat and beautiful appearance, corrosion resistance of alkali, acid, petrol and the like, aging resistance, long service life without pulverization, discoloration, crack, deformation and the like. The invention ensures the safe operation of cables and prolongs the service life of the cables.

Owner:醴陵市万通新型材料有限公司

Novel profile combined sponge suction cup

PendingCN108942999ARegular and beautiful appearanceReduce processing difficultyGripping headsEngineeringMachining

The invention discloses a novel profile combined sponge suction cup. The novel profile combined sponge suction cup adopts a whole sponge and an aluminum profile main body to replace sponge arranged inblocks and a body formed by machining a whole aluminum profile, thus the machining difficulty is greatly lowered, an upper end cover of the aluminum profile main body is arranged integrally, and theappearance is attractive and regular; cooperation with an S-shaped air circuit formed by partition plates in the aluminum profile main body, an original structure that all air pipes are externally connected for separated air supplying is changed, thus when the sponge suction cup works, all parts of an adsorbing sponge layer deform more evenly, the overall production cost is low, the structure is simple, using is convenient, the adsorbing effect is good, working stability is high, the service life is long, and the novel profile combined sponge suction cup is suitable for a vacuum suction cup.

Owner:YAMILA AUTOMATION TECH (SUZHOU) CO LTD

A kind of preparation method of granule for ternary cavity filter rod

ActiveCN112642221BLow costImprove suction performanceOther chemical processesTobacco smoke filtersCrystallographyPhysical chemistry

The invention discloses a preparation method of granules for ternary cavity filter rods, comprising: mixing denatured tapioca starch and porous starch uniformly according to the mass ratio (10-60): 1, and then performing a flavoring treatment to obtain the first mixed Material; According to mass ratio (20-1): 1, the first compound material and tangerine peel powder are mixed uniformly, obtain the second compound material; Carry out shot blasting after the second compound material is granulated, obtain pellets; Carry out secondary flavoring treatment to obtain flavoring granules, the mass percentage content of secondary flavoring spices is 3% - 8% of the flavoring granules; carry out coating treatment to the flavoring granules, obtain the three-way cavity filter Granules for sticks. The method of the present disclosure embeds the limonene-like essence in the modified starch to form a small fragrance group by adding fragrance twice, and after granulation, the escape of the limonene-like ingredients is blocked by coating, thereby solving the problem of bursting during the preparation of the filter stick. Mouth problems, and the problem of reduced smoking quality caused by the leakage of limonene components.

Owner:CHINA TOBACCO YUNAN NEW MATERIAL

Automatic putting device of washing machine, washing machine and using method of washing machine

PendingCN112227017ARegular and beautiful appearanceMaximize the use of volumeEngine sealsOther washing machinesProcess engineeringMechanical engineering

The invention discloses an automatic putting device of a washing machine, the washing machine and a using method of the washing machine. The automatic putting device comprises a containing cavity, anadditive box arranged in the containing cavity and a sealing structuresealing structure, wherein the sealing structure is positioned below the additive box and is matched and sealed with the bottom wall of the containing chamber, and the sealing structure is provided with a supporting unit which is stressed to jack up the additive box. According to the automatic putting device of the washing machine, the washing machine and the using method of the washing machine, the sealing structure is arranged at the bottom of the containing cavity, a user can detach an ink box with hands at the bottom, the sealing structure is arranged on a drawer below the containing cavity, the structure is simple and reliable, and the position is hidden; the regular, square and attractive appearance of the containing cavity can be ensured; and the sealing structure comprises an ejection part and a sealing part, through cooperation of the sealing part and the bottom of the containing cavity, sealing of the containing cavity is guaranteed, and liquid is prevented from flowing out of the containing cavity when the ink box is used or detached.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

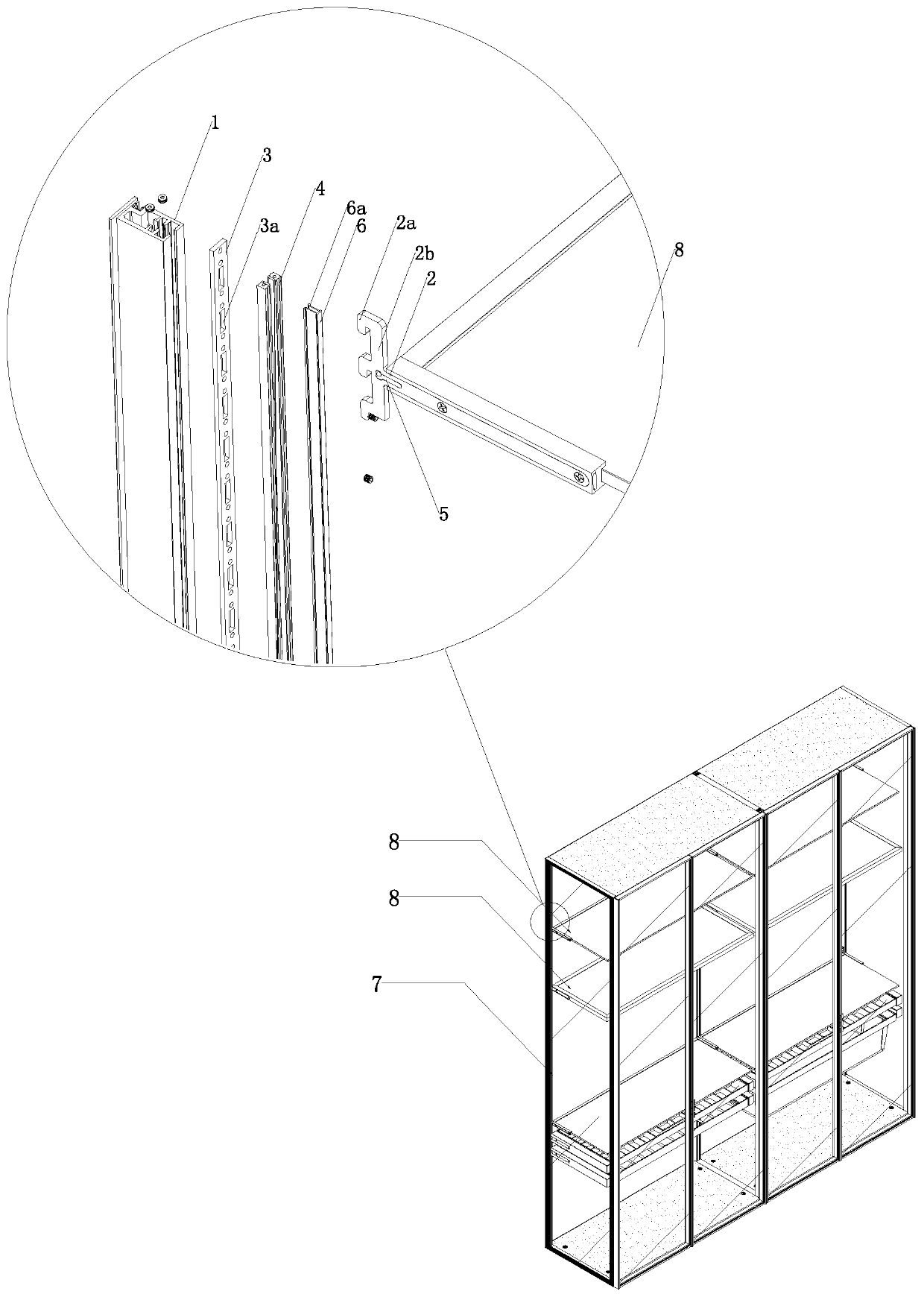

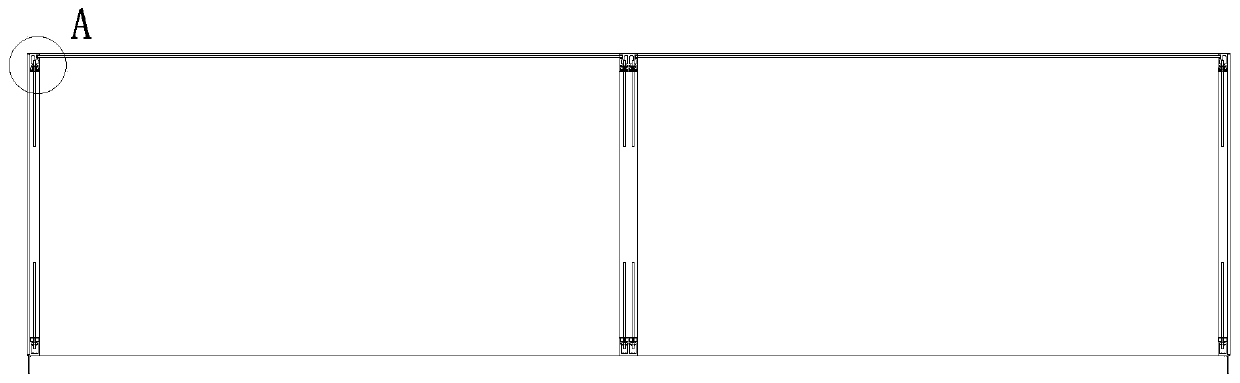

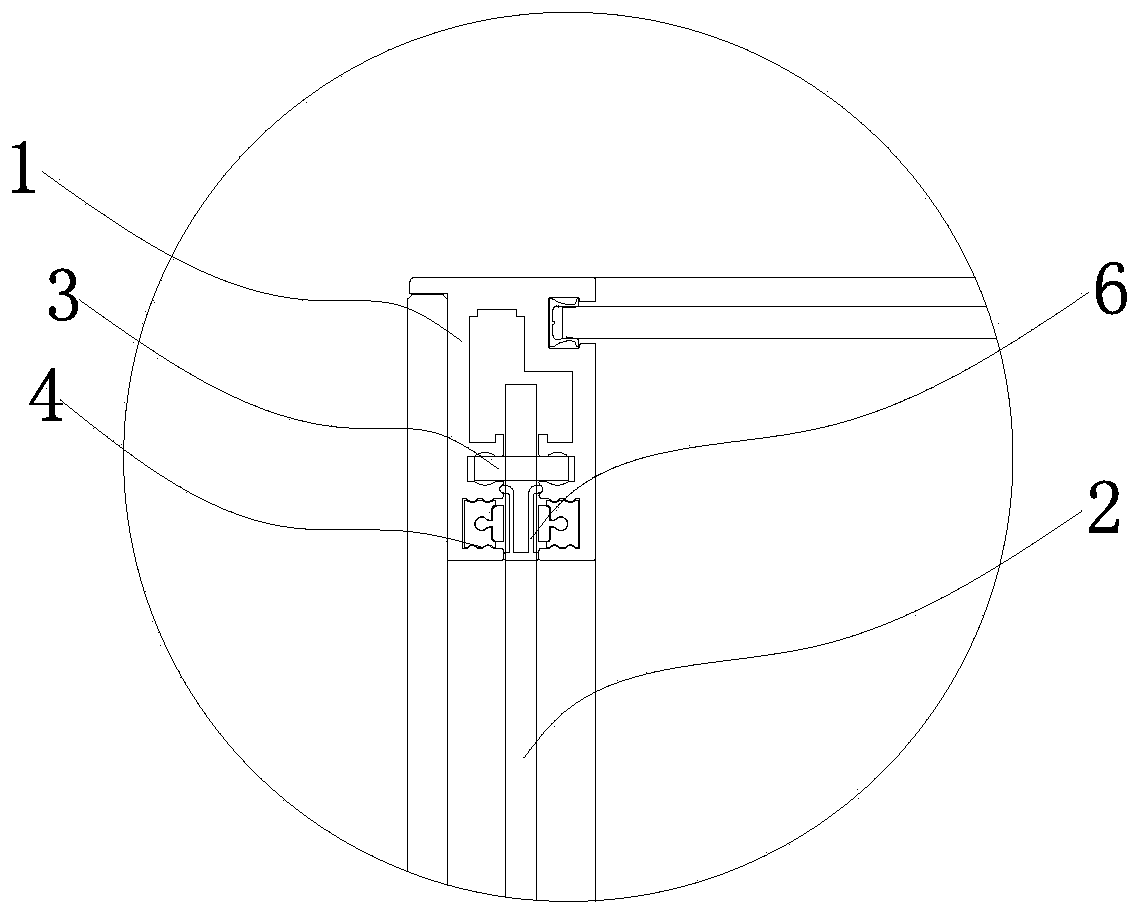

Cabinet

PendingCN111067286AThe overall appearance is regular and beautifulImprove convenienceWing accessoriesHingesStructural engineeringMechanical engineering

Owner:浙江斑马家居有限公司

Single-leg supporting portable folding stool

PendingCN106073262AFree height adjustmentReduce volumeDismountable chairsFoldable chairsEngineeringMechanical engineering

Owner:苏州曼妙环保科技有限公司

Mechanical anti-loosening structure of turnout fasteners

ActiveCN110904743BSmall space required for installationAnti-loose effect is firmRail fastenersSplit pinFastener

The invention provides a mechanical anti-loosening structure of a turnout fastener, which includes an anti-rotation support and an anti-loosening piece. The rail waist and turnout component parts are fastened together, and the anti-rotation support is provided with slots symmetrically on the side facing away from the rail waist; the anti-loosening piece includes an engaging part that fits the outer surface of the nut and has an opening at the bottom , and an inserting part that matches with the slot, the inserting part is fixed on the engaging part; when it is in a fastened state, the engaging part is set over the nut from top to bottom and is in contact with the nut At the same time, the inserting part is inserted into the slot, and the bottom of the engaging part is fixed by a cotter pin. The anti-loosening effect of the present invention is strong, and the anti-rotation support does not need to be against the upper and lower slopes of the rail waist space, and the space required for the installation of the anti-loosening piece is small, so that the anti-loosening structure can be universally adapted to different rail types and bolt hole center heights, and is universal Strong.

Owner:CHINA RAILWAY SHANQIAO GRP CO LTD

Structured grass supporting cushion

InactiveCN104787471ARegular and beautiful appearanceSize standard specificationExternal framesEngineeringCushion

The invention relates to tool types, in particular to a structured grass supporting cushion for supporting goods to be stored. The supporting cushion is provided with a rectangular inner cushion body and is characterized in that the inner cushion body comprises three foam plastic bearing plates which are arranged at intervals, and the position between every two foam plastic supporting plates is filled with cotton stalks; hemp ropes are bound on the periphery of the inner cushion body, and weed layers and neat grass layers are laid on the periphery of the inner cushion body from inside to outside; and a plurality of fastening hoops are arranged on the peripheries of the neat grass layers. The defects that a traditional grass supporting cushion is unstructured in appearance, the size is quite unstructured, weed is prone to being scattered to pollute environment, and deformation is likely to happen are overcome, and the structured grass supporting cushion is widely used for carrying and storing of the goods.

Owner:黄石市捷业设备安装工程有限公司

Screwless C type wire clamp

ActiveCN104966914ARegular and beautiful appearanceReduce water intakeElectric connection structural associationsClamped/spring connectionsEngineeringElectrical performance

The invention discloses a screwless C type wire clamp which comprises a compact block and a C-shaped element. The compact block is composed of two compact bodies. One end of each compact body is provided with a crescent-shaped projection cooperating with the C-shaped element. The side surface of the other end of each compact body is connected with a pressing-in block through a spring piece. The central parts of the upper end face splicing parts of the two compact bodies are provided with one conical screw hole. The two sides of the conical screw hole are respectively provided with a protruding contraposition point and a recessed contraposition point which cooperate with each other. The manufacturing cost of the screwless C type wire clamp is not high. Compared with conventional C type wire clamps, the wire clamp with no screws brings greater convenience when insulating or waterproof processing is performed on the outer side of the wire clamp. The overall appearance of the wire clamp is regular and attractive. Meanwhile, the wire clamp can be used for arranging glue pouring type joints overhead and providing possibilities of better reducing phenomena of water entries into insulation wires on the premise that great electrical performance is maintained.

Owner:STATE GRID CORP OF CHINA +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com