Steel pipe bundling and conveying device

A technology of a baling device and a transportation device, which is applied in the directions of transportation and packaging, packaging, packaging machines, etc., can solve the problems of slow baling efficiency, large space occupation, time-consuming and laborious, etc., achieving a good degree of automation, saving labor costs, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

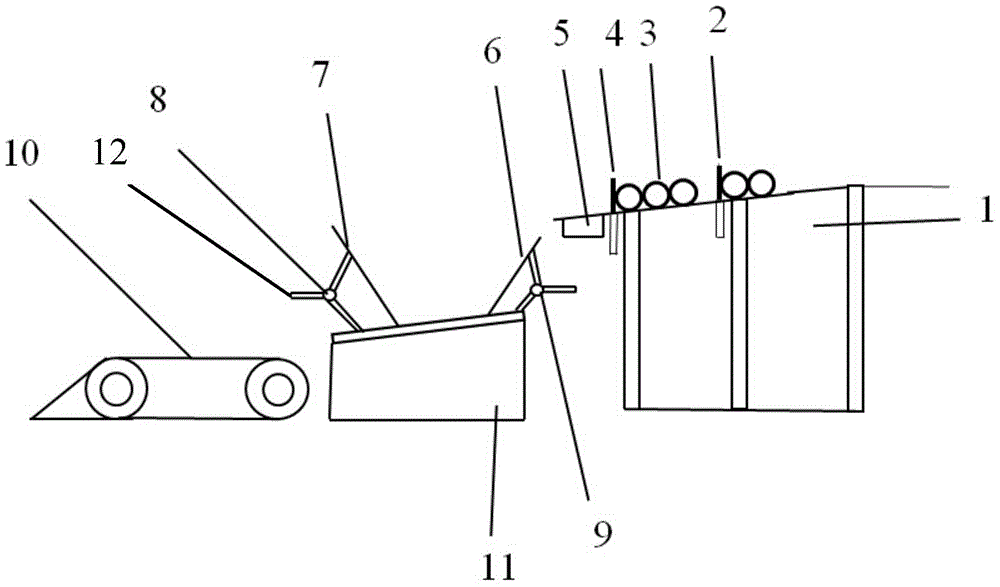

[0020] A steel pipe bundling transport device, comprising a carrying device 1 , a bundling device 11 and a conveying device 10 . The carrying device 1 includes a first stopper 2, a second stopper 4, a steel pipe 3 and a grating counter 5. The steel pipe 3 is placed on the inclined surface of the carrying device 1 and is blocked by the first stopper 2 and the second stopper 4 , the first stopper 2 and the second stopper 4 are placed on the inclined surface of the carrying device, and the second stopper 4 is located below the first stopper 2, and the first stopper 2 and the second stopper 4 include stoppers plate, a baffle slot and a control switch, the baffle slot is placed inside the carrying device, and is fixedly connected with the inclined surface of the carrying device 1, and the grating counter 5 is located under the inclined surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com