Patents

Literature

150results about How to "Improve suction performance" patented technology

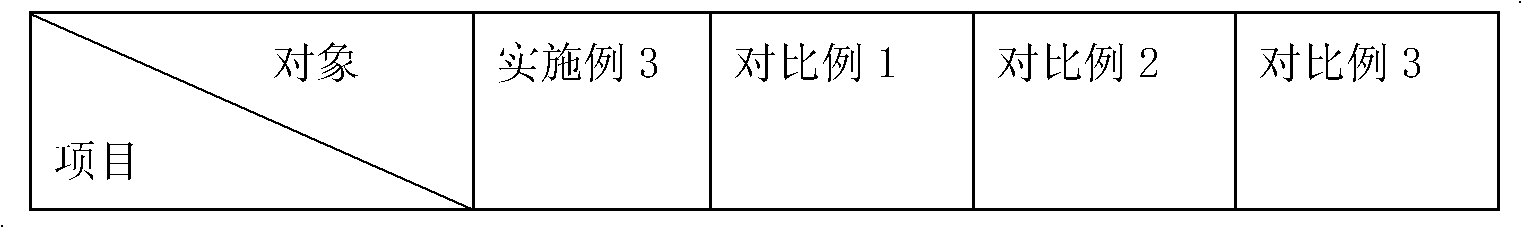

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

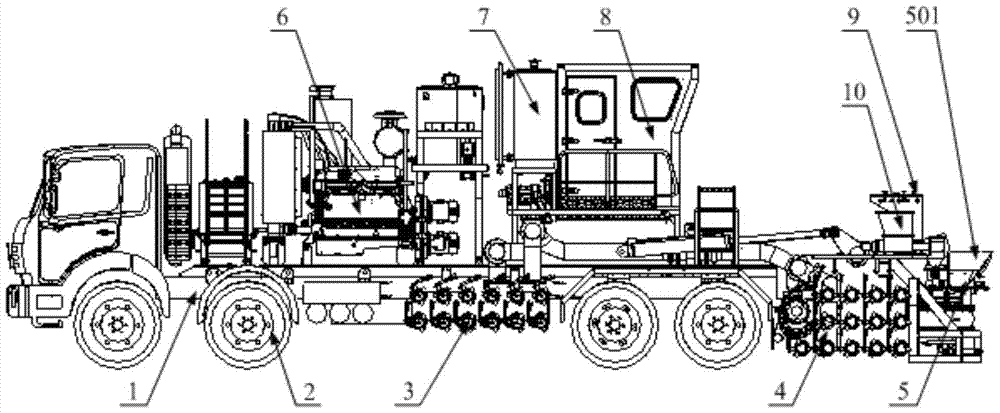

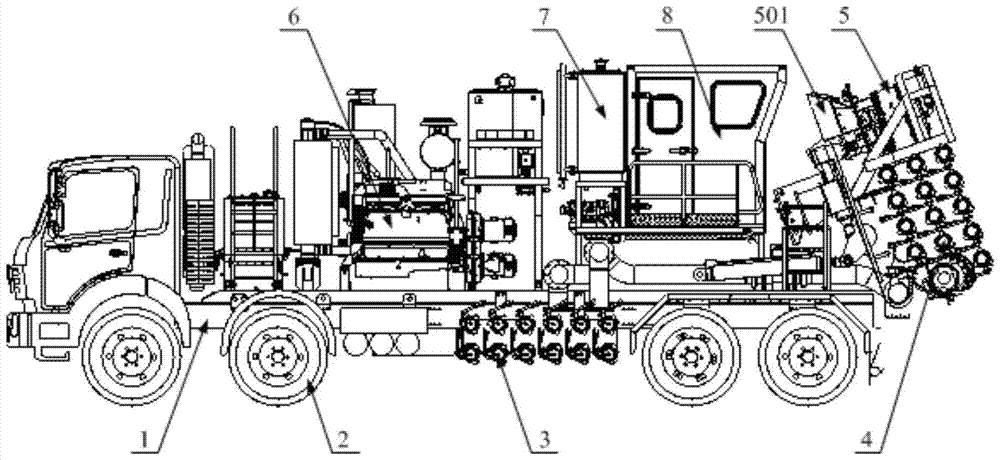

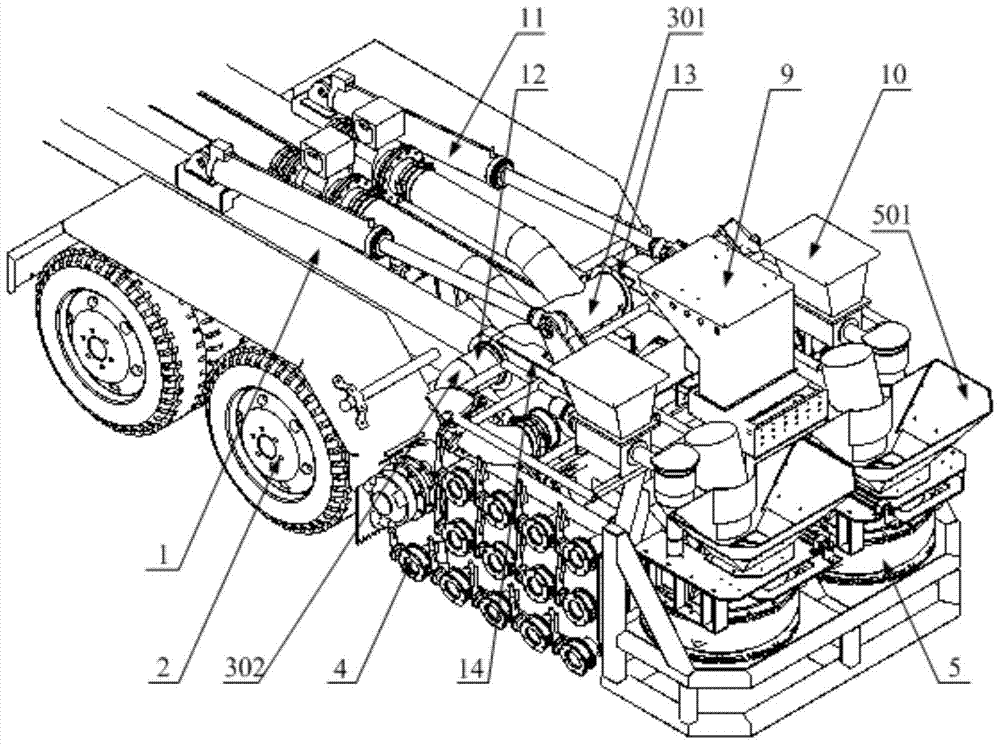

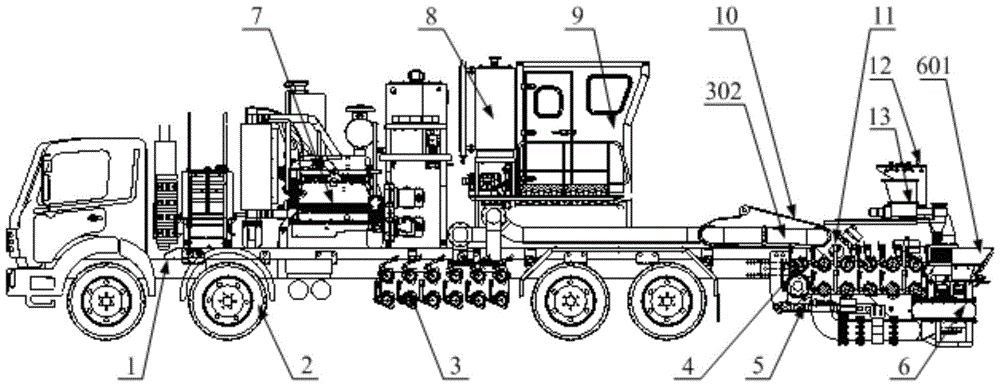

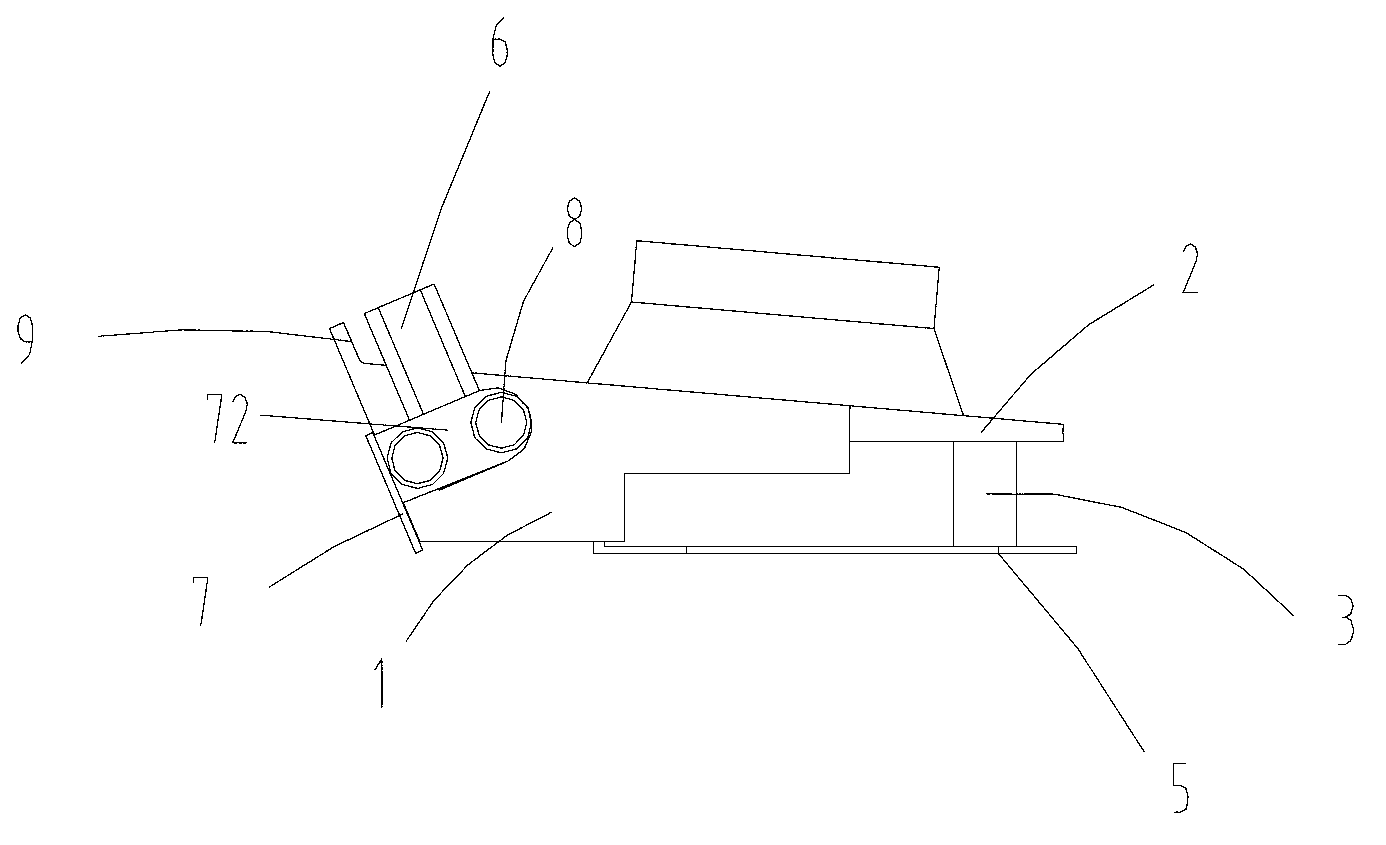

A fracturing sand mixed car

ActiveCN104563995BIncrease displacementLower the altitudeFluid removalItem transportation vehiclesFracturing fluidEngineering

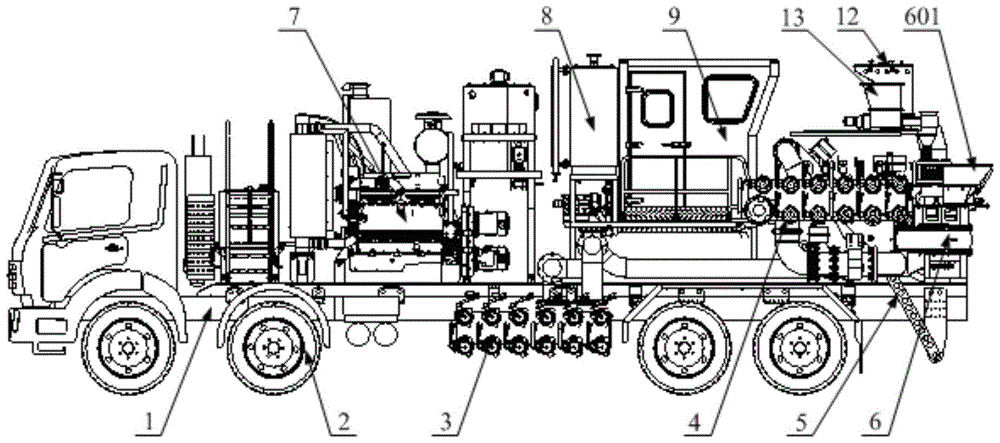

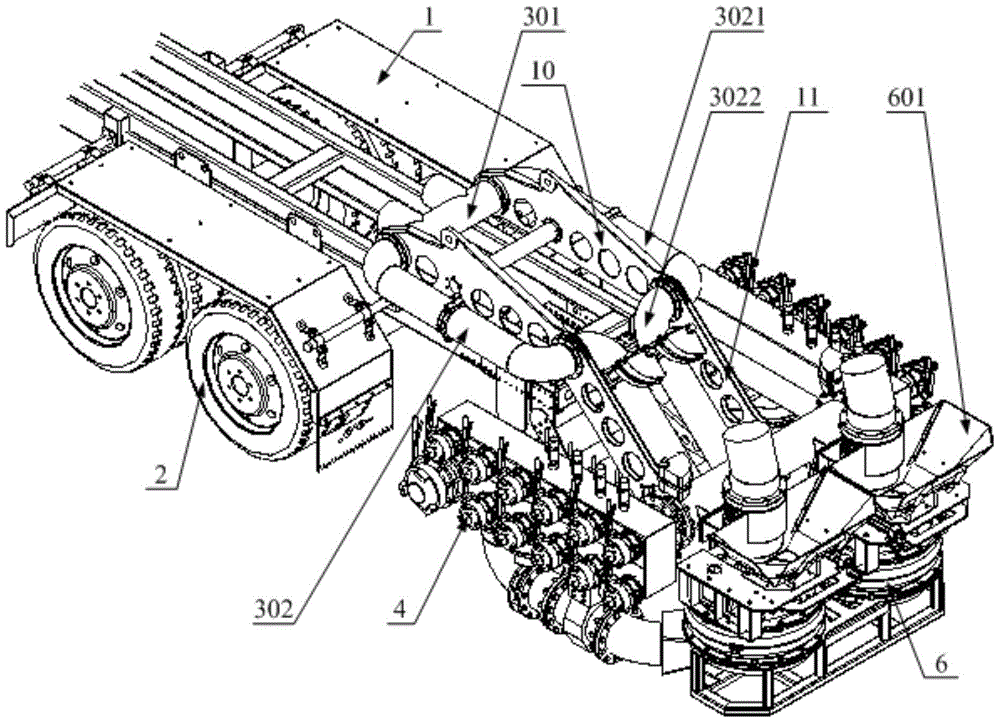

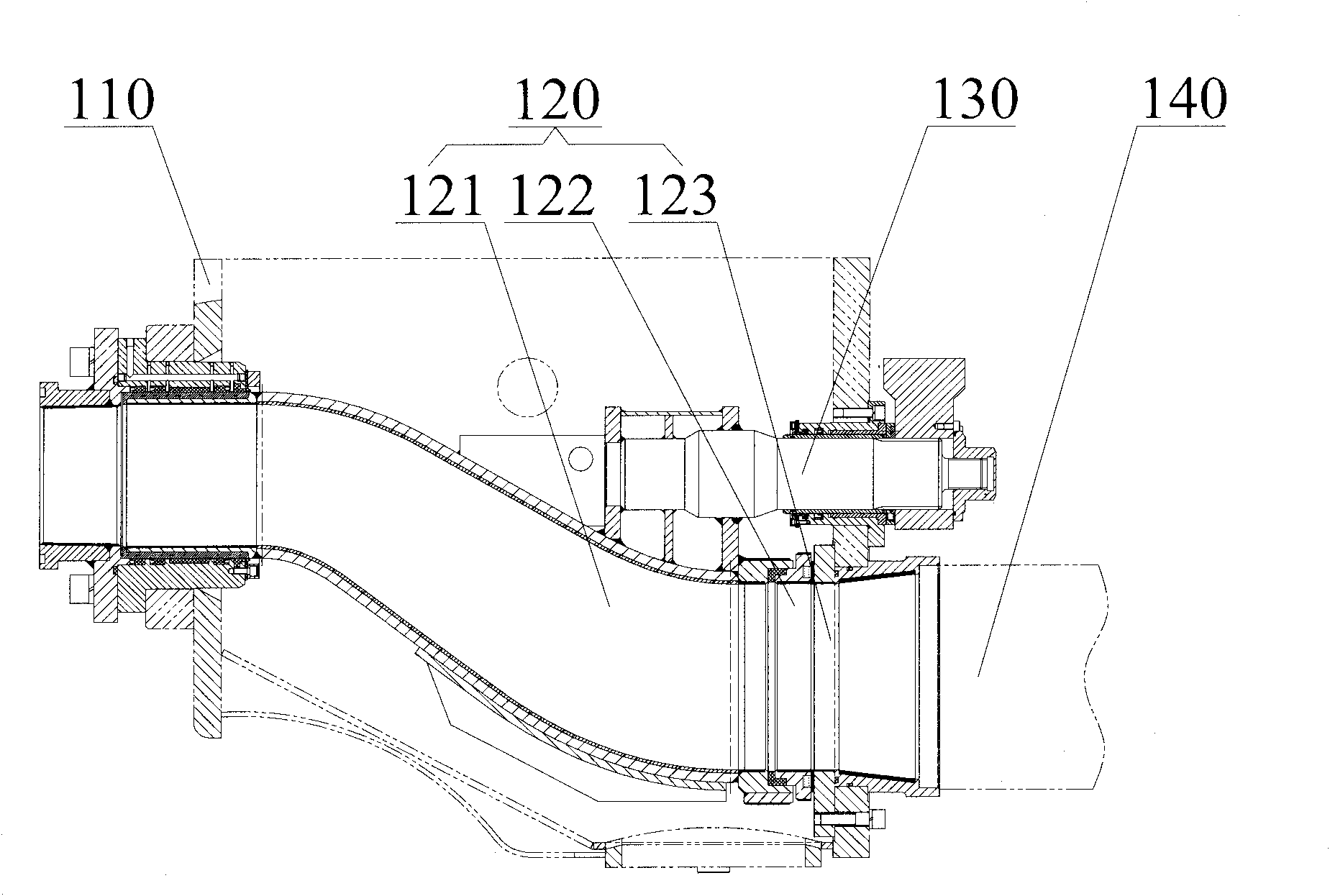

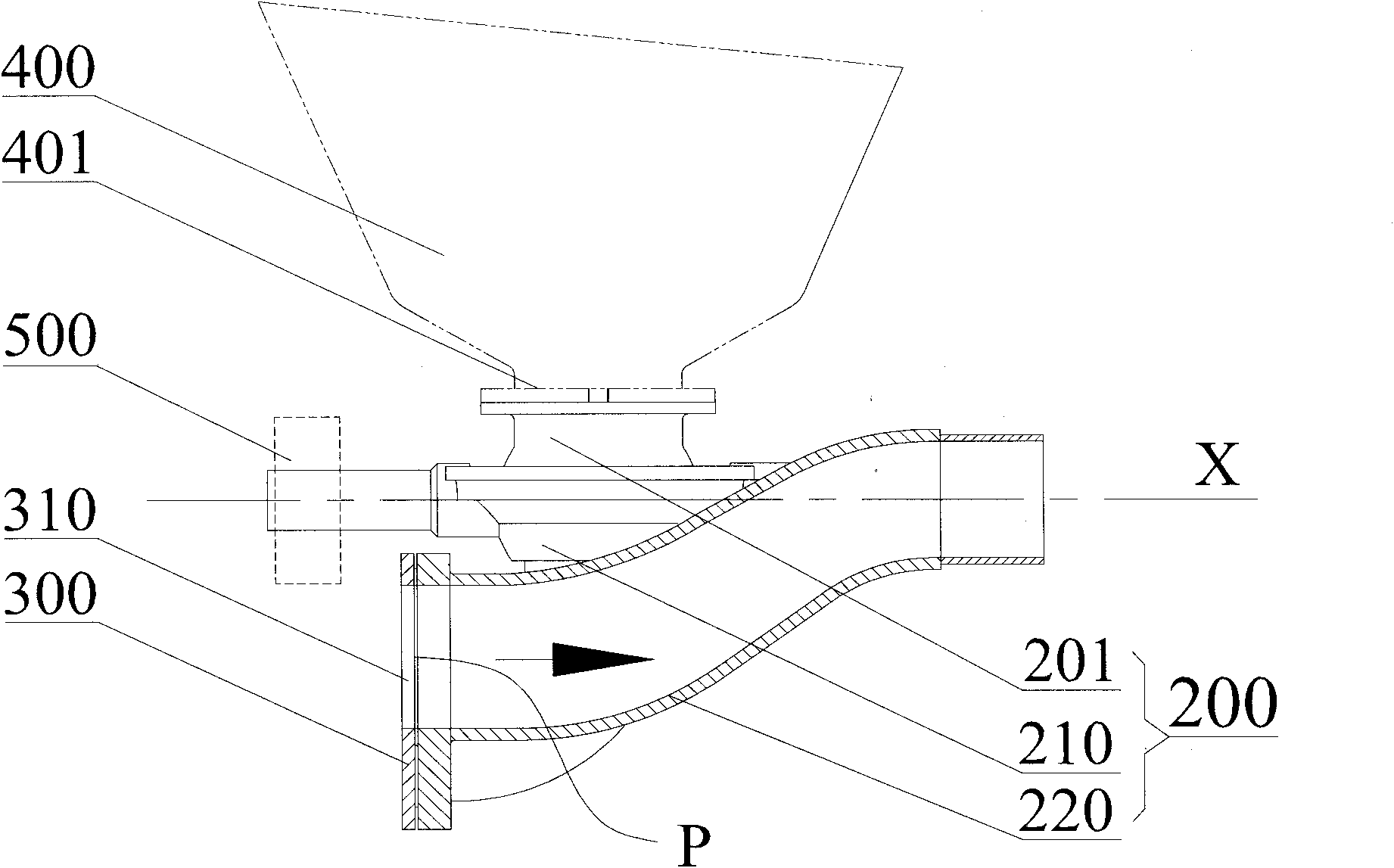

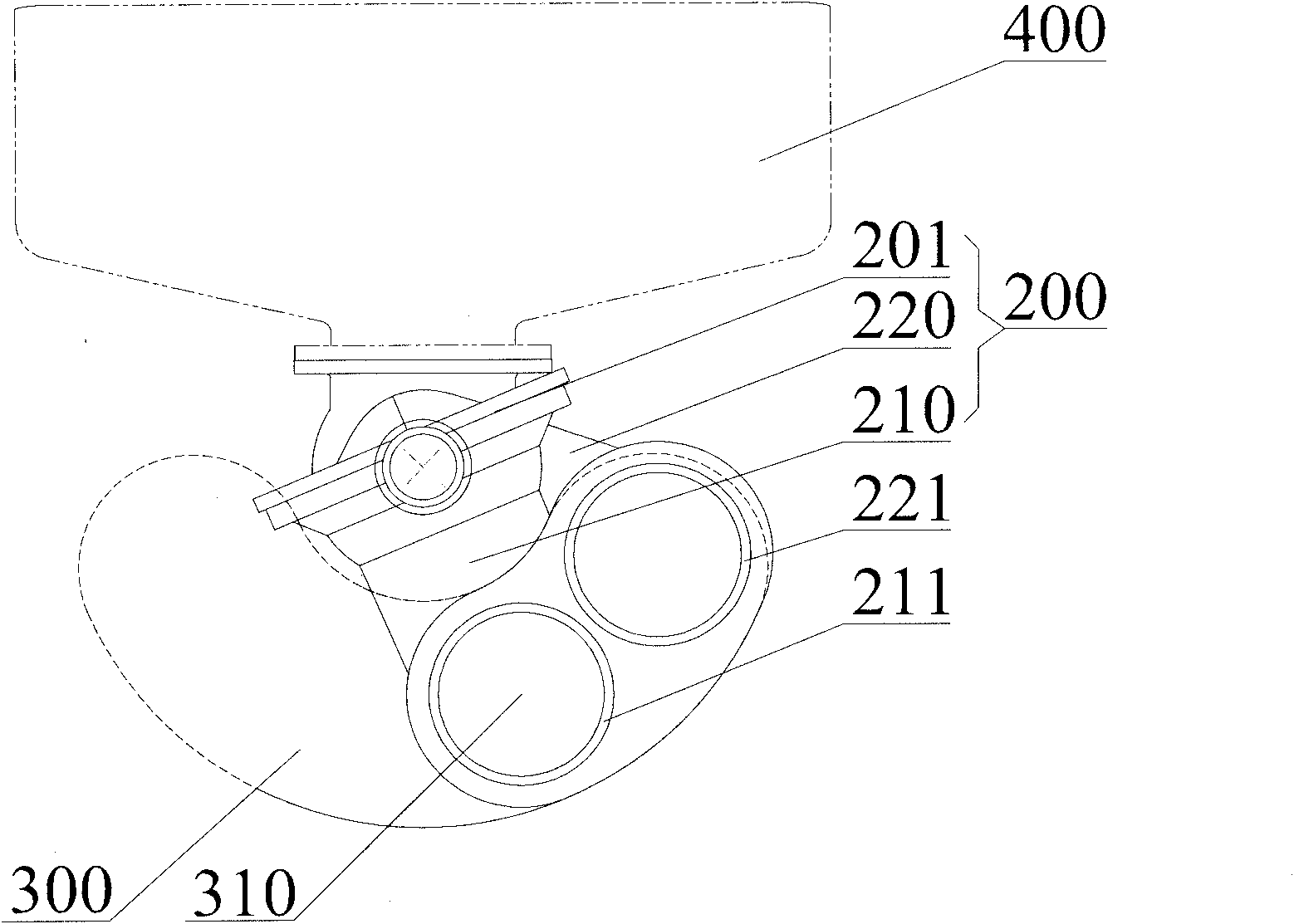

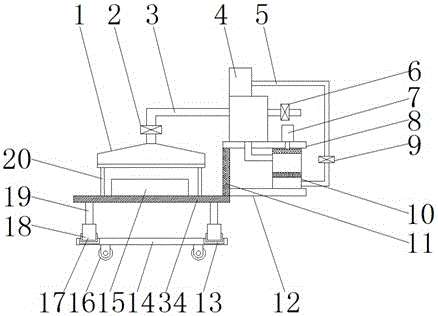

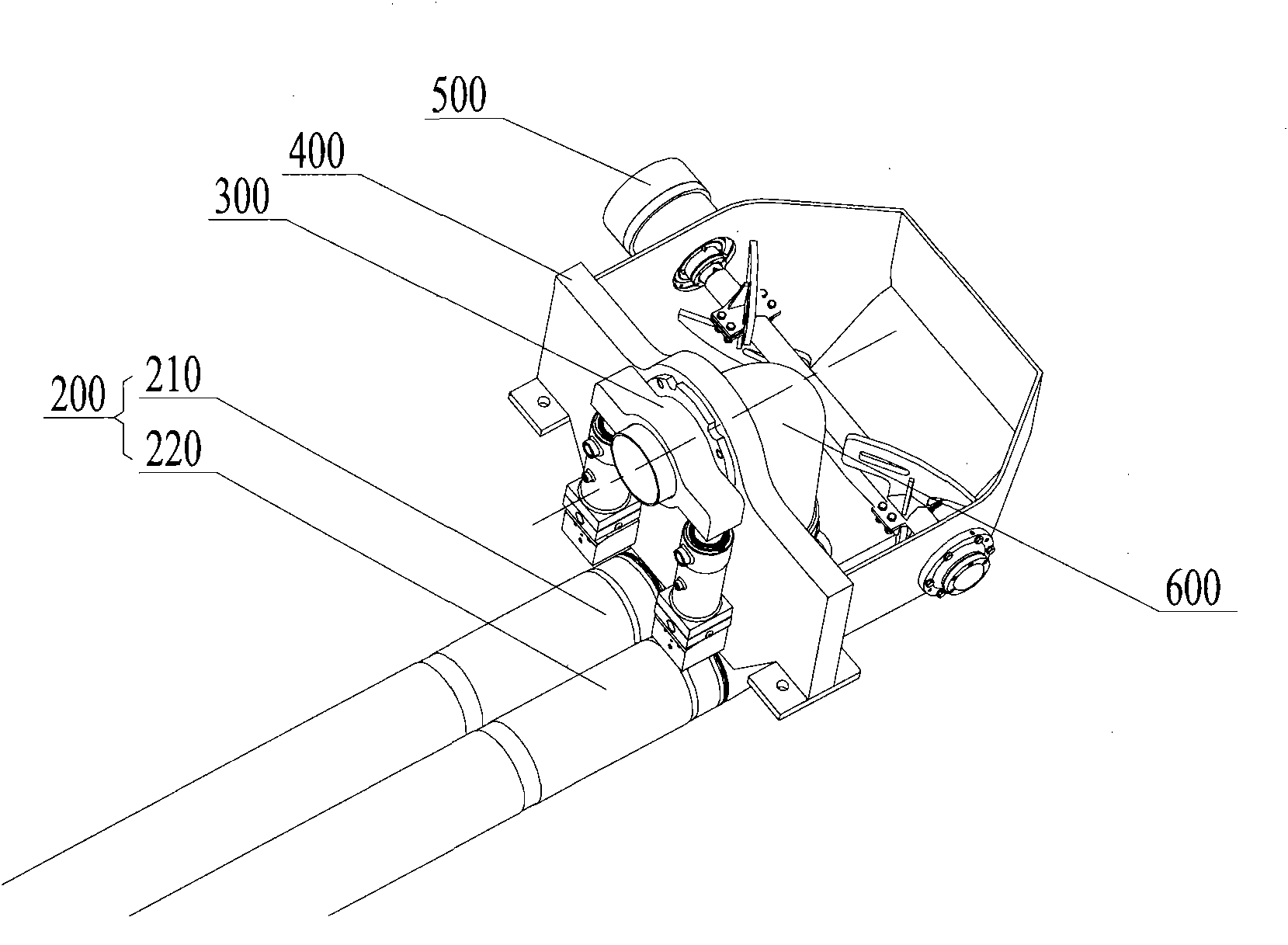

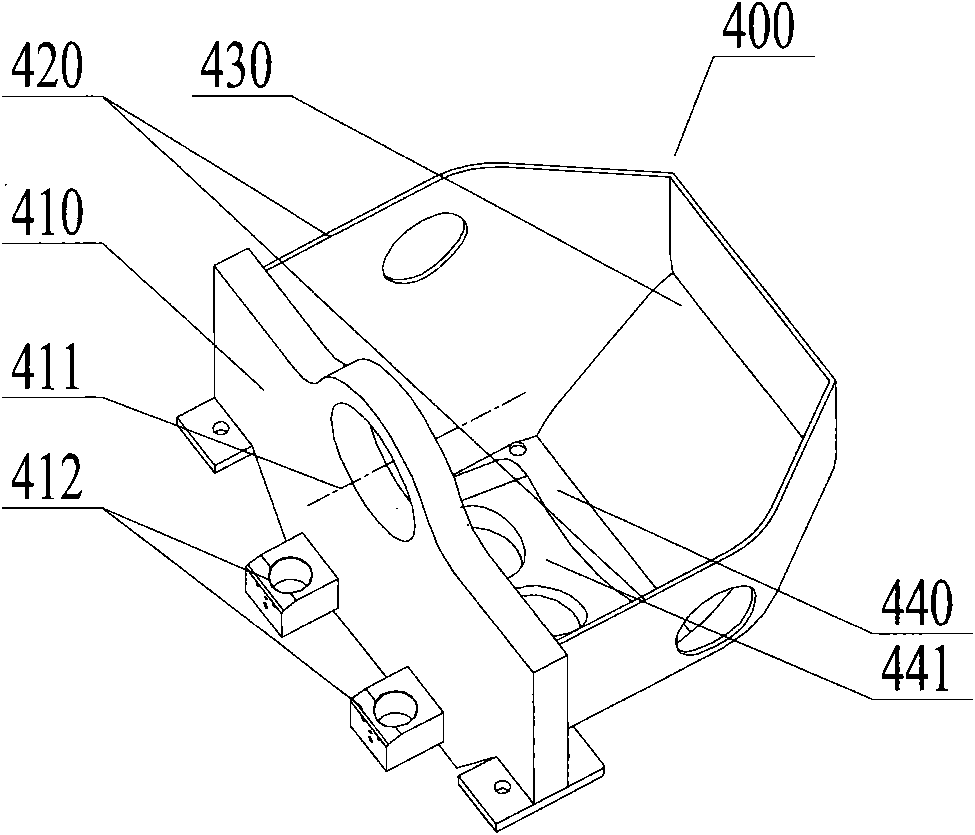

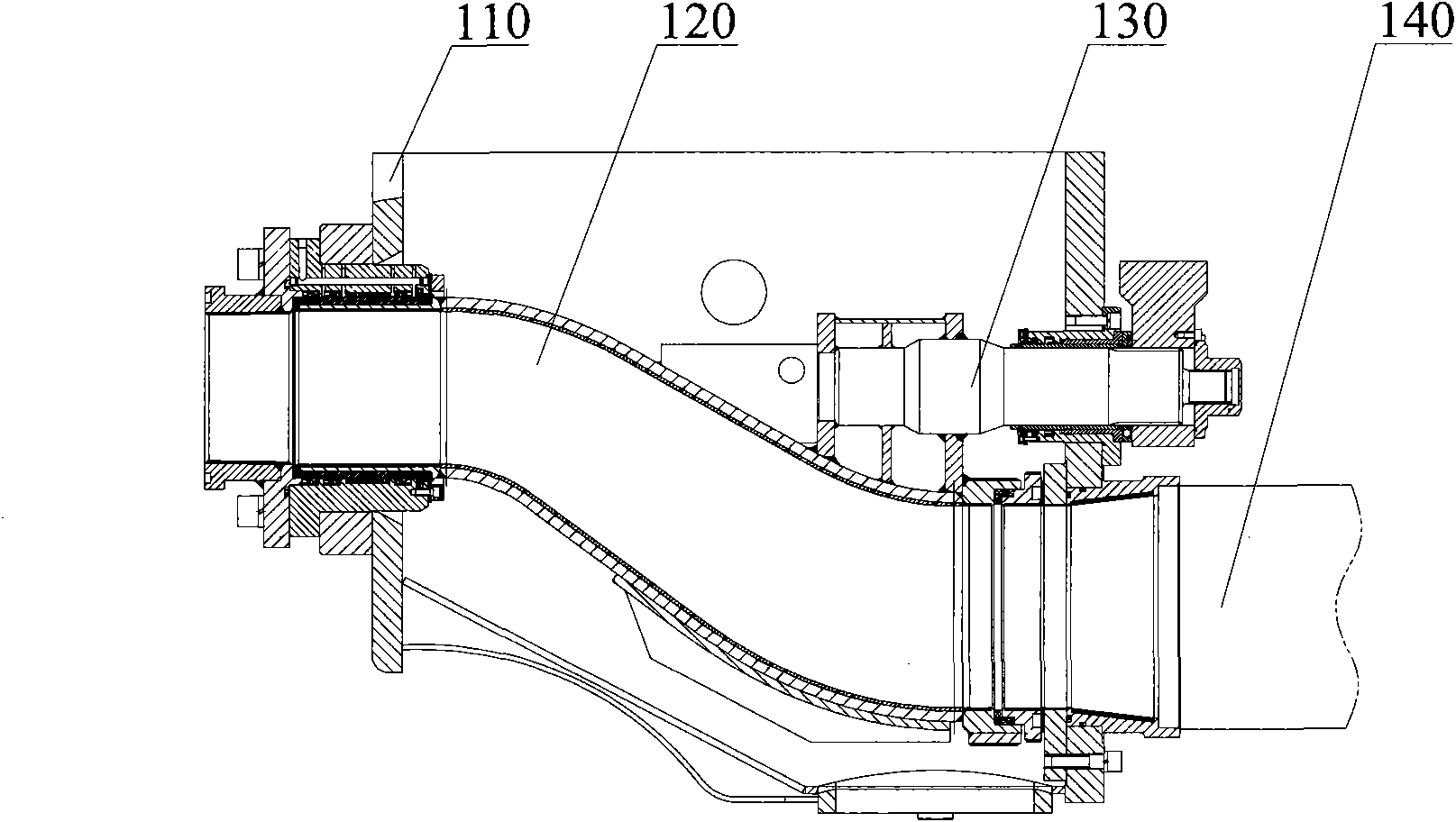

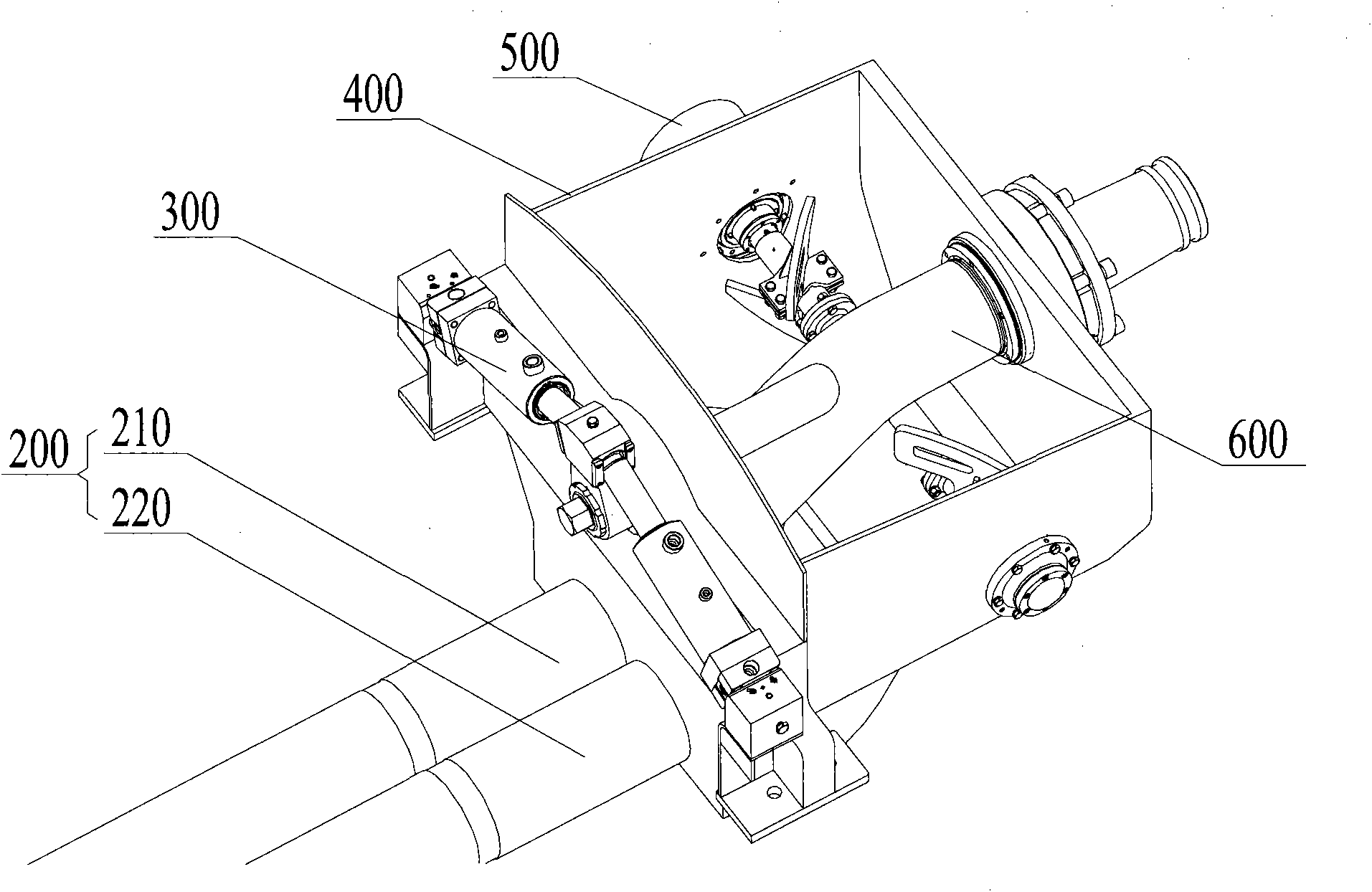

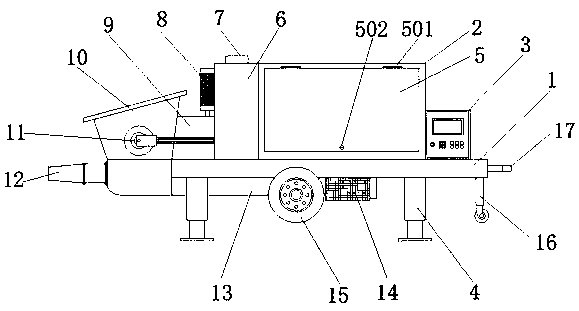

The invention provides a fracturing blender truck. The fracturing blender truck comprises a chassis and a sand blending device arranged above the chassis. The sand blending device comprises a sand blender provided with a fracturing sand inlet, a base fluid inlet and a fracturing fluid outlet, and a closed-type mixing pump serves as the sand blender. The fracturing blender truck further comprises an overturning support and a power system, wherein the overturning support arranged on the chassis is capable of achieving reciprocating rotation and used for bearing the sand blending device, and the power system arranged on the chassis is connected with the overturning support and drives the overturning support to rotate to enable a base of the closed-type mixing pump to be capable of contacting with the ground. The fracturing blender truck has the advantages that the closed-type mixing pump serves as the sand blender, and the rotatable overturning support is used for bearing the sand blending device to enable the base of the closed-type mixing pump to be capable of contacting with the ground, so that suction capacity of the closed-type mixing pump is improved, delivery capacity of the closed-type mixing pump is increased, delivery capacity of the fracturing blender truck is increased without changing the occupied area of the fracturing blender truck, and the requirements on large-scale fracturing operation can be met.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP

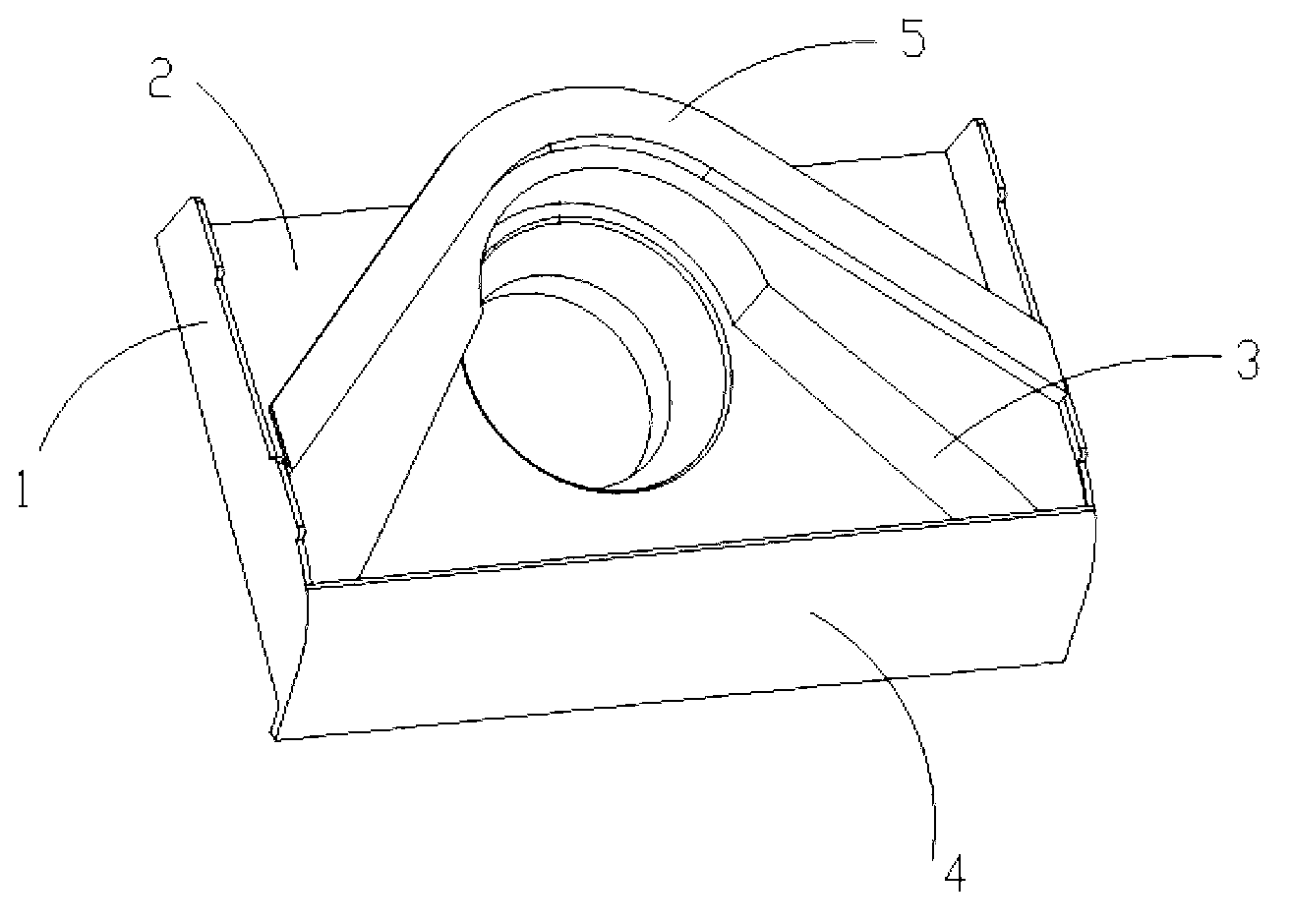

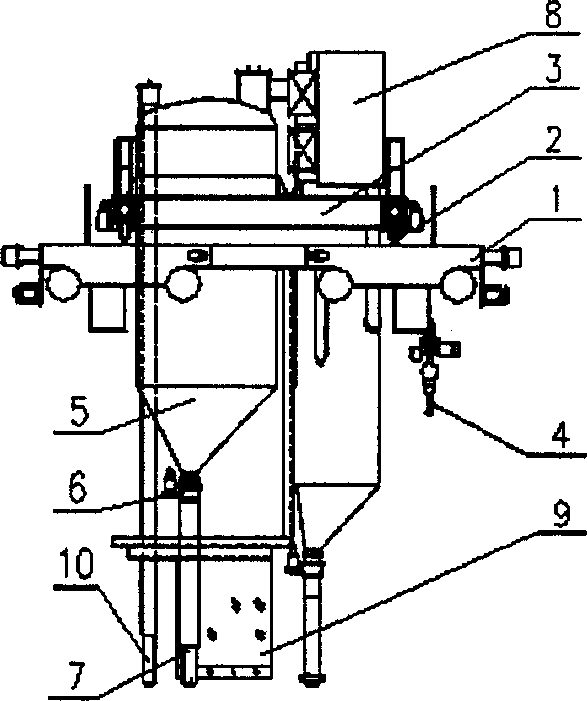

A kind of fracturing sand mixer

ActiveCN104563994BLower the altitudeReduce the overall heightFluid removalGround contactFracturing fluid

The invention provides a fracturing blender truck. The fracturing blender truck comprises a chassis, a sand blending device, a four-connecting-rod mechanism and a power system. The sand blending device is arranged above the chassis and provided with a sand blender, and a closed-type mixing pump serves as the sand blender. The four-connecting-rod mechanism is capable of driving the sand blending device to move to enable a base of the closed-type mixing pump to contact with the ground, a first connecting rod and a third connecting rod of the four-connecting-rod mechanism are arranged on the chassis rotatably, and the sand blending device is arranged on a second connecting rod of the four-connecting-rod mechanism. The power system arranged on the chassis is connected with the first connecting rod and drives the four-connecting-rod mechanism to rotate to enable the closed-type mixing pump to contact with the ground. The fracturing blender truck has the advantages that the closed-type mixing pump serves as the sand blender, and the second connecting rod of the four-connecting-rod mechanism is used for bearing the sand blending device to enable the base of the closed-type mixing pump to be capable of contacting with the ground, so that the height of the closed-type mixing pump is decreased, suction capacity of the closed-type mixing pump is improved, a great quantity of fracturing fluid can be guided out, delivery capacity of the fracturing blender truck is increased, and the requirements on large-scale fracturing operation can be met.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP

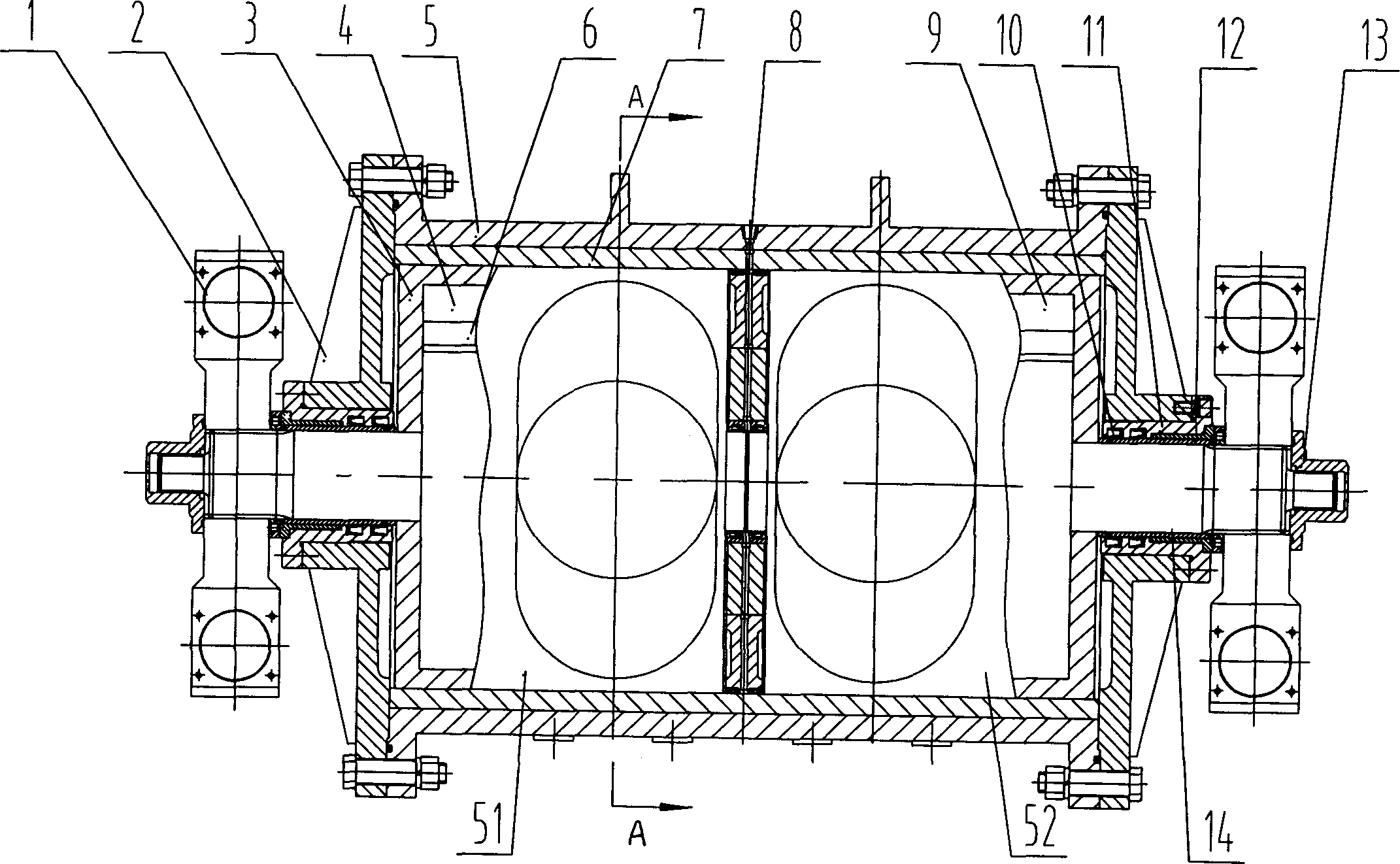

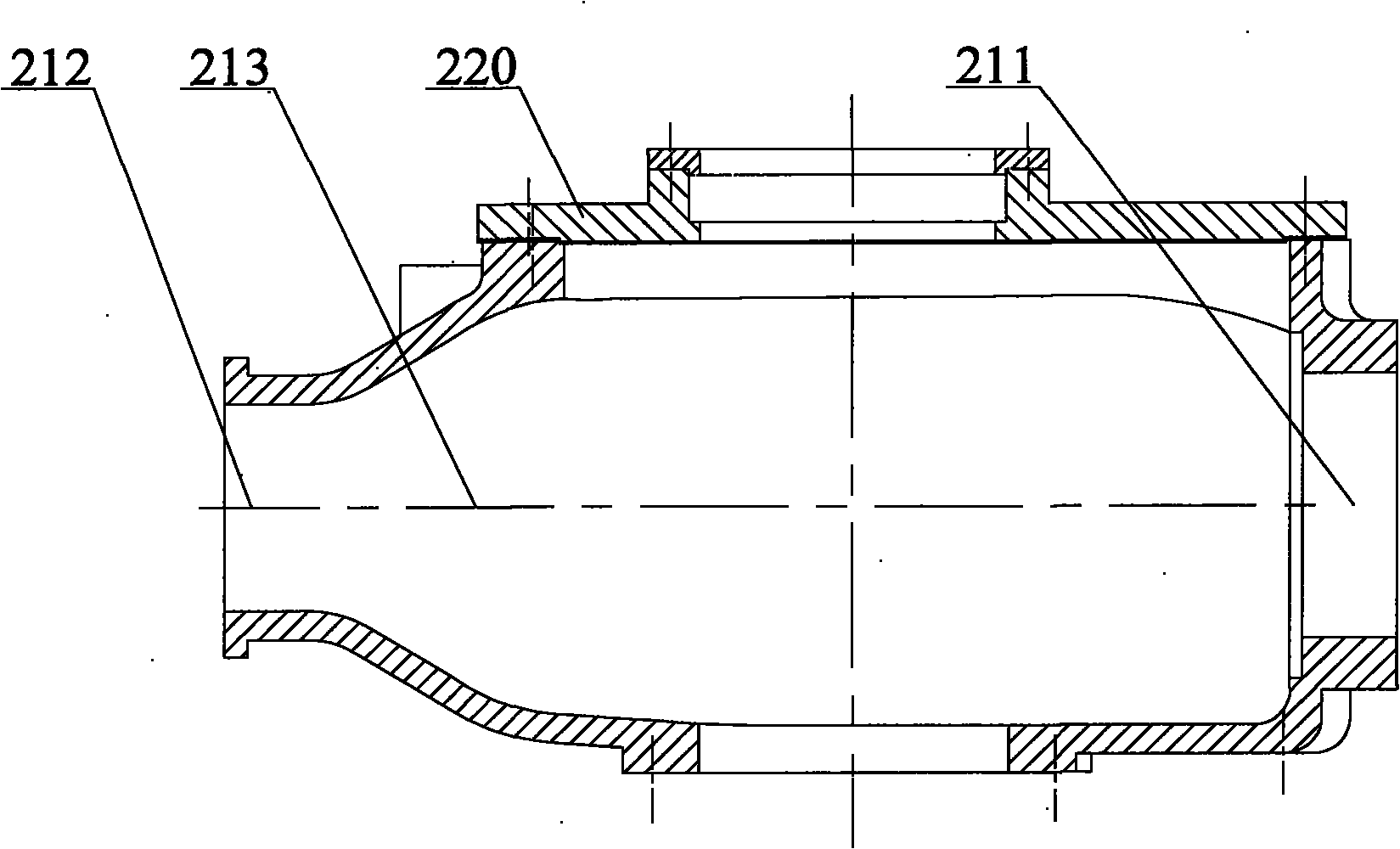

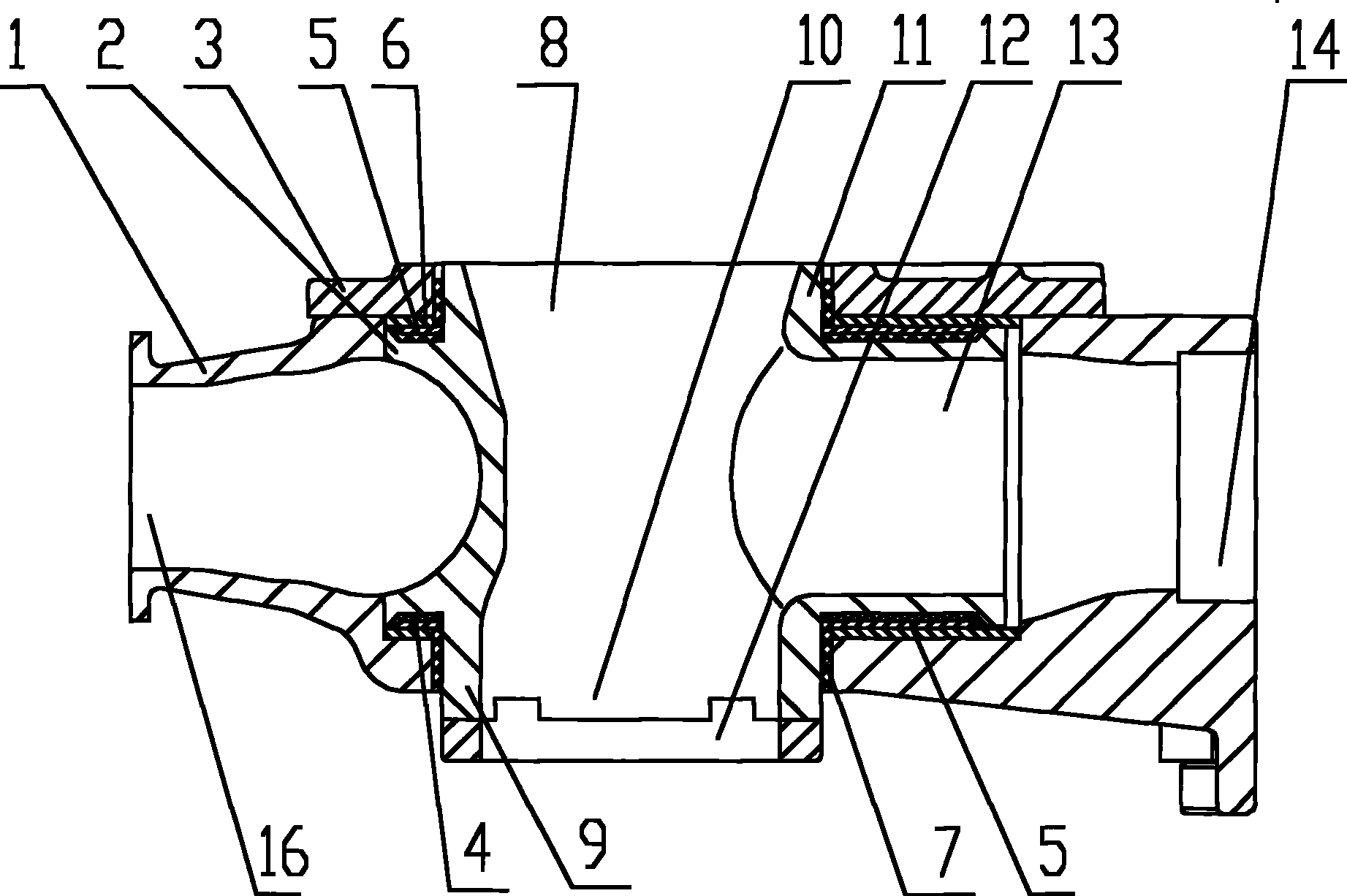

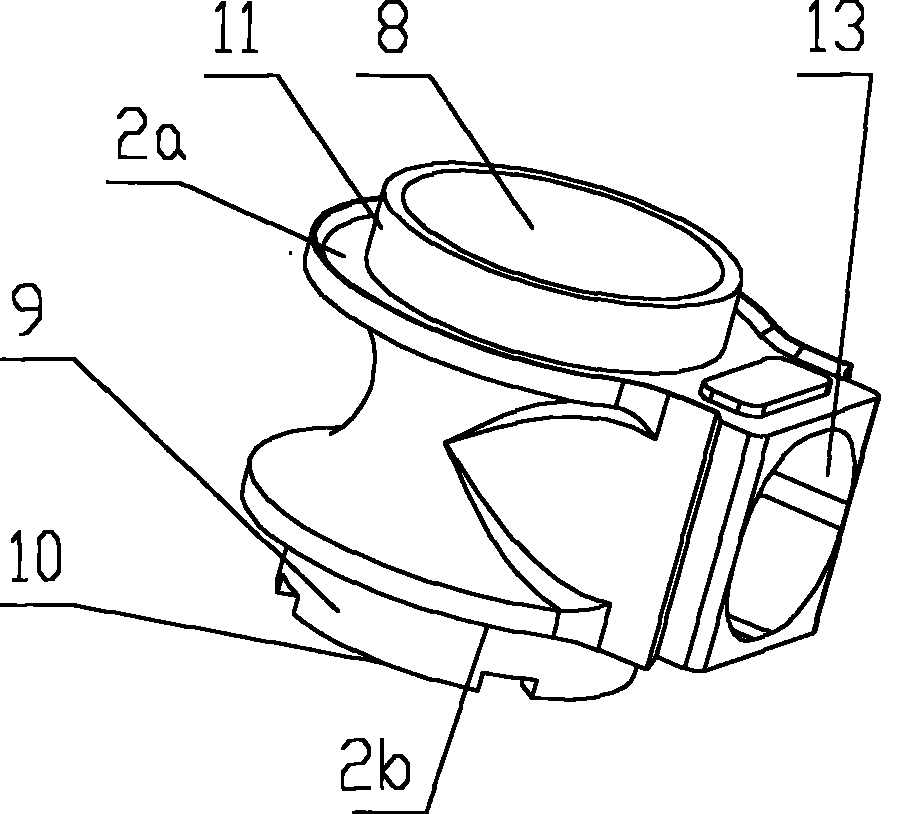

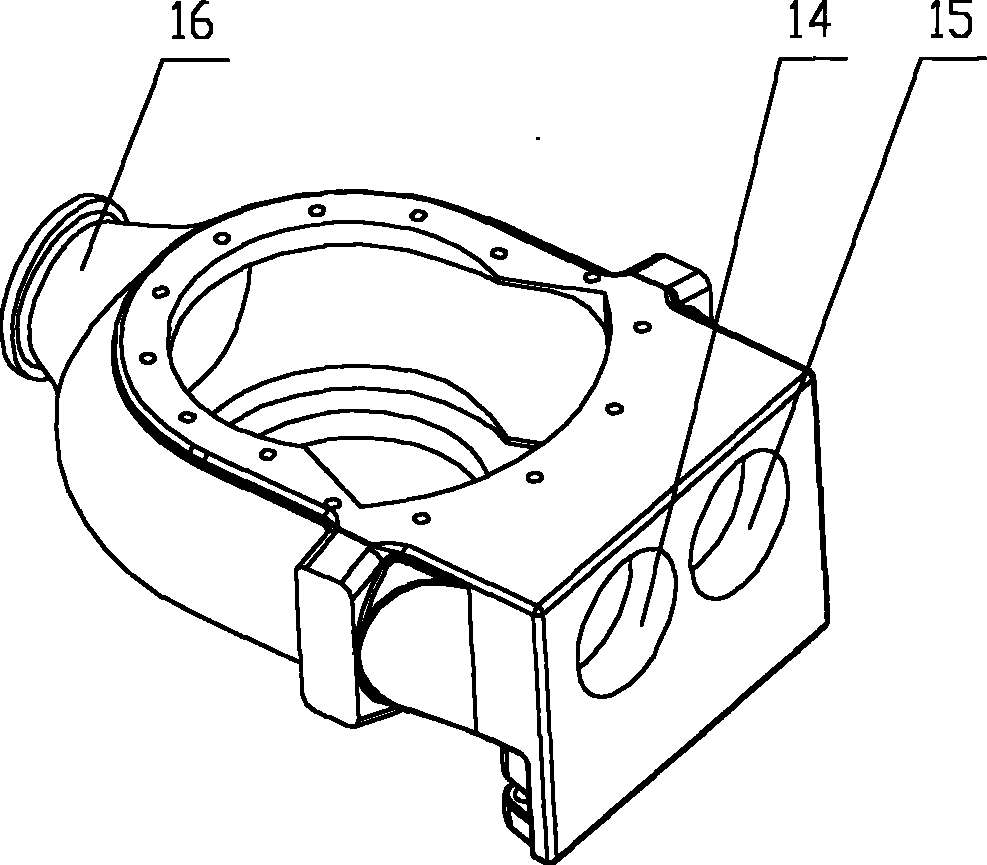

Distributing valve for concrete pump, concrete pump, control method thereof and concrete pump truck

InactiveCN101787973AReduce wear rateImprove suction performancePositive displacement pump componentsPump controlSlurryHigh pressure

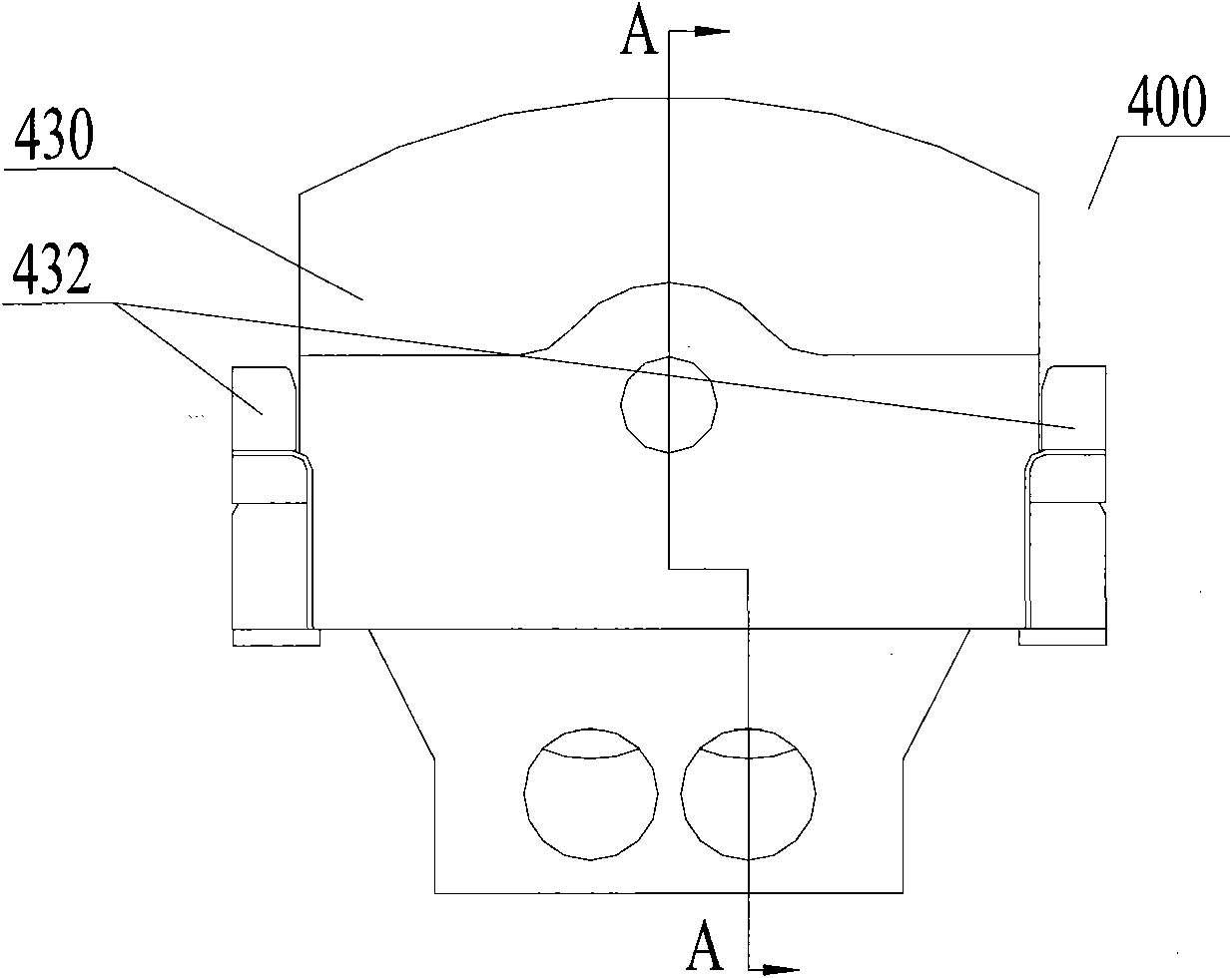

The invention discloses a distributing valve for a concrete pump, the concrete pump, a control method thereof and a concrete pump truck. The distributing valve for the concrete pump comprises a valve body and a wear-resisting plate. The valve body comprises a first suction pipe and a first pumping pipe, wherein the back end of the first suction pipe is communicated with an outlet of a hopper so as to communicate the hopper and a delivery cylinder, and the back end of the first pumping pipe is rotatably connected with a delivery pipe of the concrete pump so as to communicate the delivery cylinder and the delivery pipe. The valve body can be switched between a first state and a second state under the driving of a drive mechanism, in the first state, concrete slurry is sucked into the delivery cylinder through the first suction pipe, and in the second state, the delivery cylinder pumps over the concrete slurry through the first pumping pipe. Because of the distributing valve with the structure, the concrete pump can thoroughly employ the self-flowing capacity of the concrete slurry in order to increase the suction performance of the concrete pump. The distributing valve has higher pressure bearing capacity, and the concrete pump can ensure that the concrete slurry has higher pressure through the delivery cylinder, thereby meeting the needs of high-pressure pumps to pump over the concrete slurry.

Owner:三一西北重工有限公司

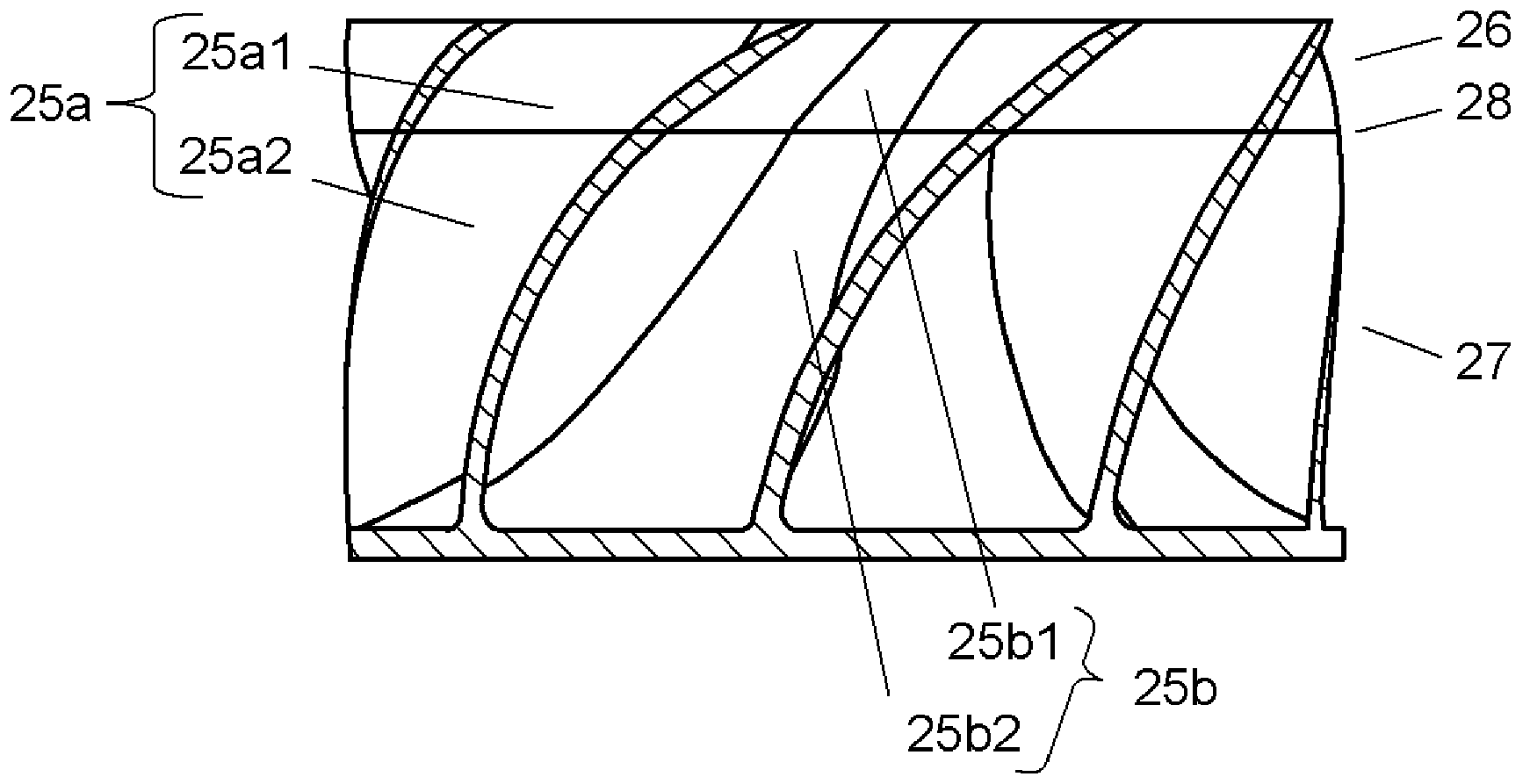

Inflation tire

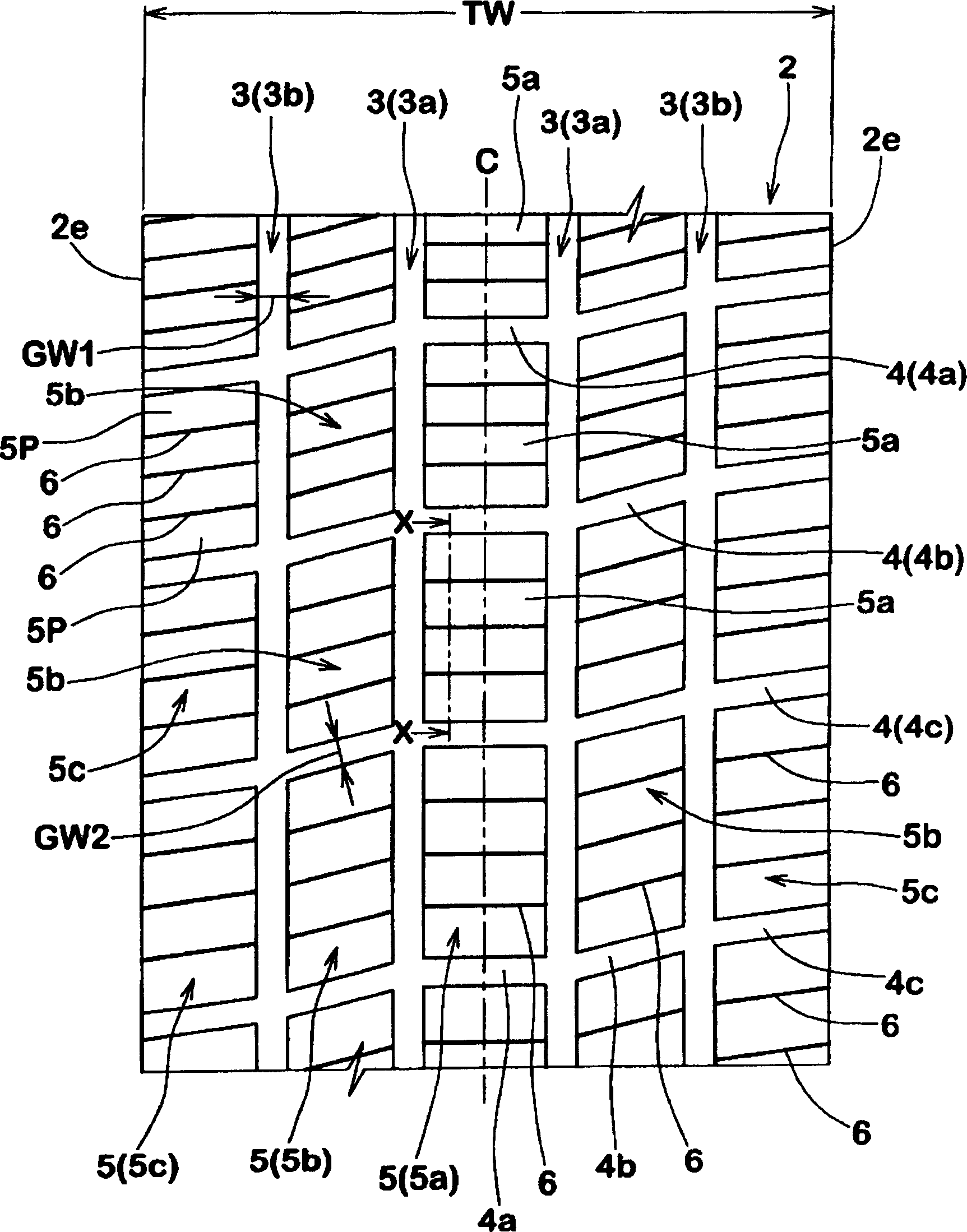

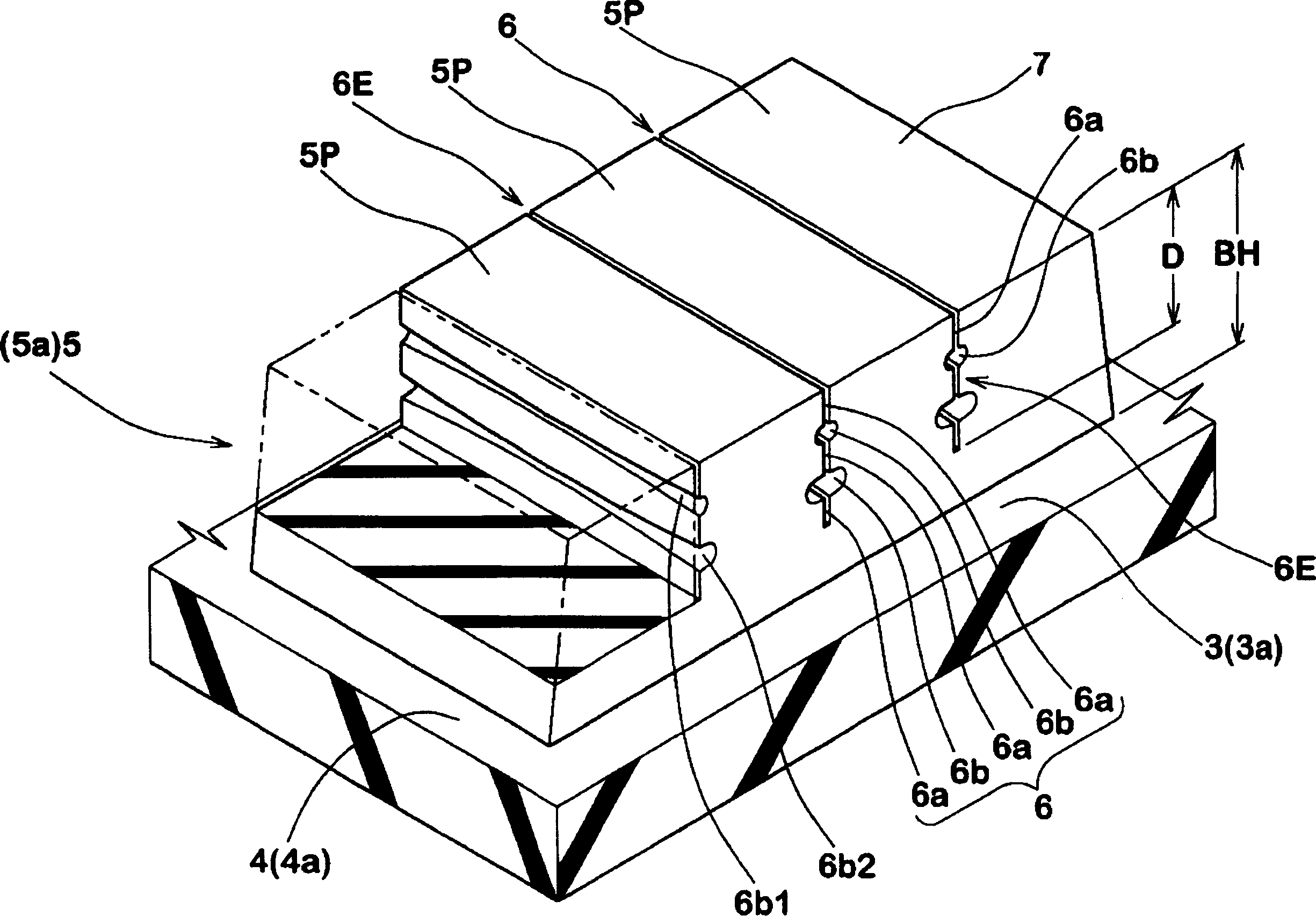

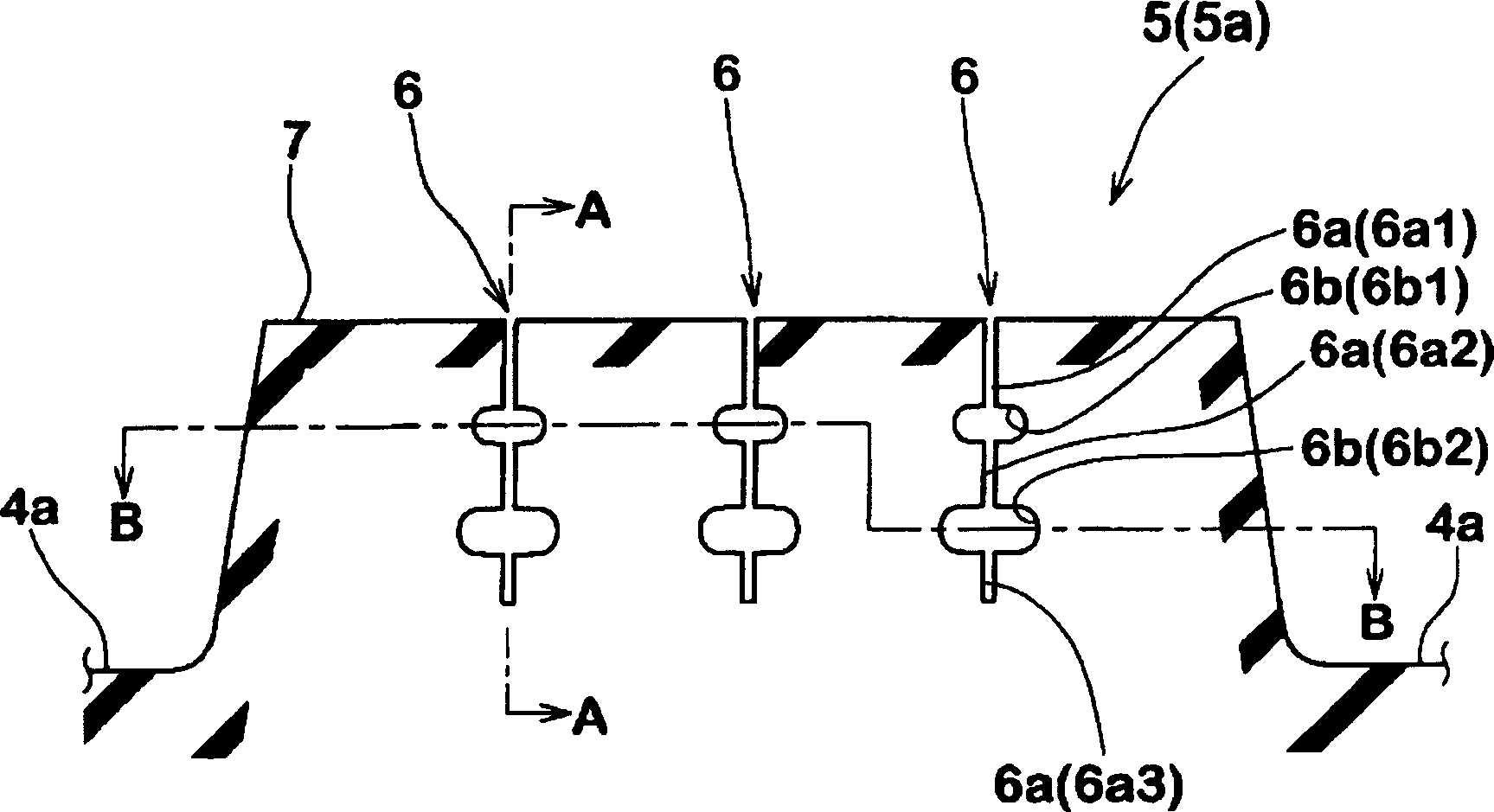

InactiveCN1853965APrevent occlusionImprove inhalation effectTyre tread bands/patternsStructural engineeringMaximum depth

PROBLEM TO BE SOLVED: To provide a pneumatic tire capable of enhancing water-absorbing effect on an ice road and improving traveling performance. ŽSOLUTION: The pneumatic tire is provided with a plurality of longitudinal grooves 3 extending to the tire circumferential direction on a tread part. The pneumatic tire has land parts 5 between adjacent longitudinal grooves 3, 3 or between the longitudinal groove 3 and the tread end. The land part 5 is provided with a siping shape narrow groove 6 which extends to the direction crossing the land part 5, at least one end 6E is communicated to the longitudinal groove 3 or the tread end, and opens at the ground surface 7. The siping shape narrow groove 6 comprises a sipe part 6a having an incised shape groove width of 2.0 mm or less, and an expanded width part 6b which is continued to the inward radial direction of the sipe part 6a and has the groove width of more than 2.0 mm. The expanded width 6b is provided at the area Y where the maximum depth D of the siping shape narrow groove from the ground surface 7 is not less than 20% and not more than 90%. ŽCOPYRIGHT: (C)2007,JPO&INPIT Ž

Owner:SUMITOMO RUBBER IND LTD

Concrete distributing valve and concrete pumping mechanism

InactiveCN101245866AImprove suction performancePositive displacement pump componentsMultiple way valvesConcrete pumpMechanical engineering

Owner:SANY AUTOMOBILE MFG CO LTD

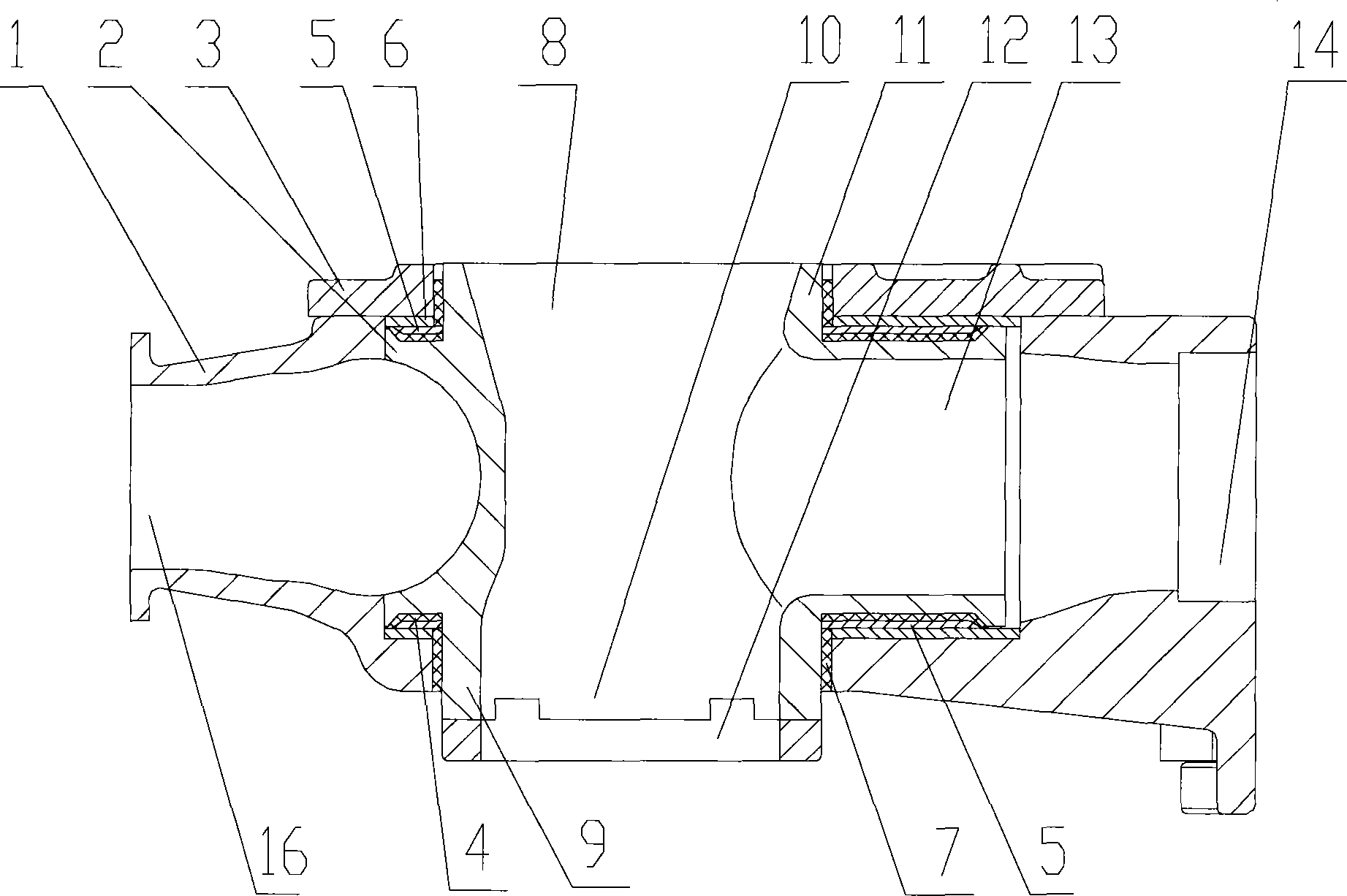

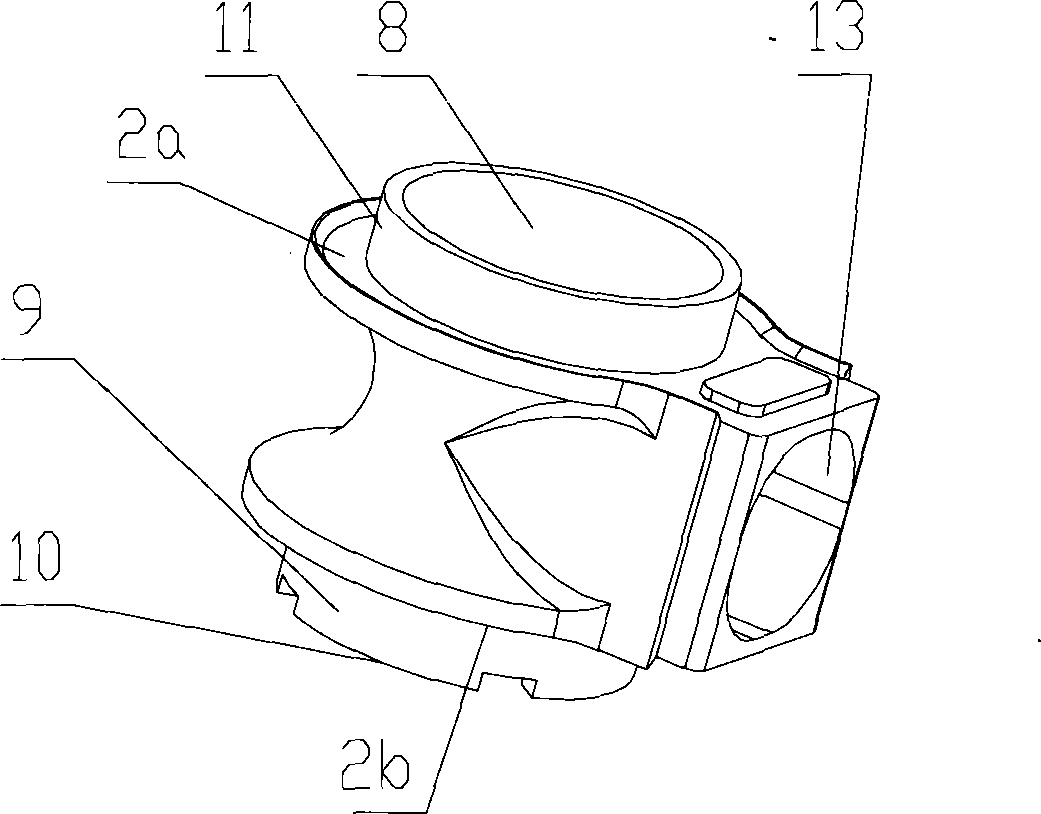

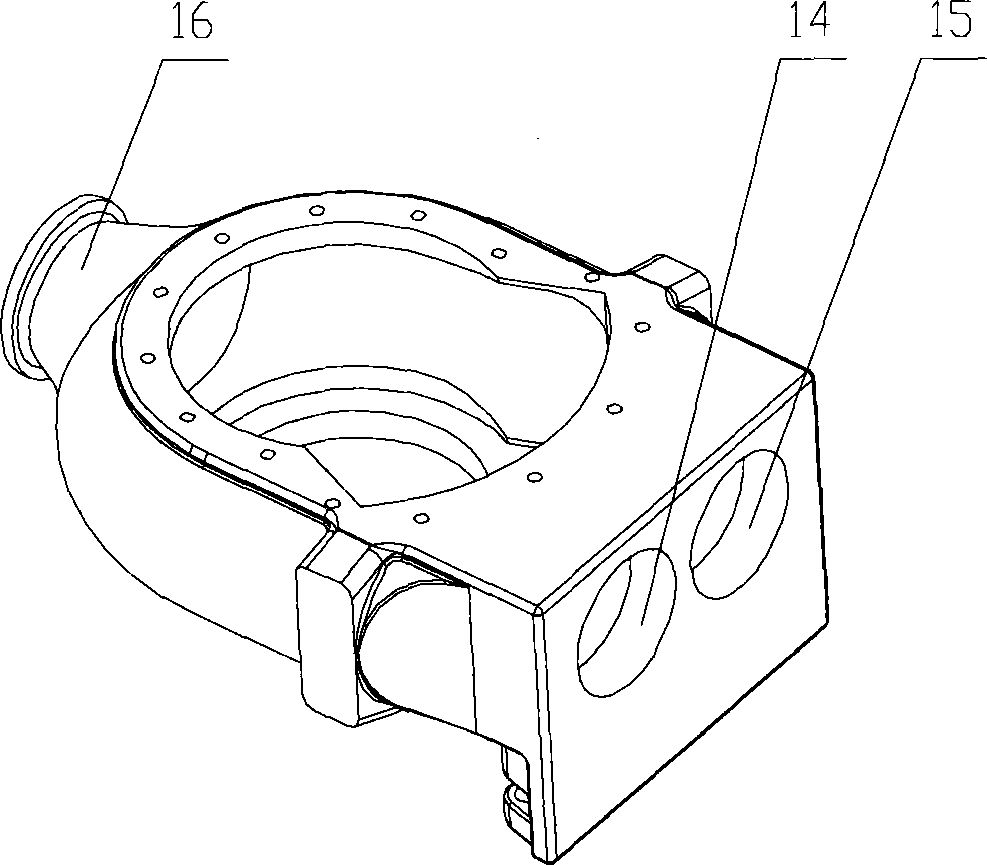

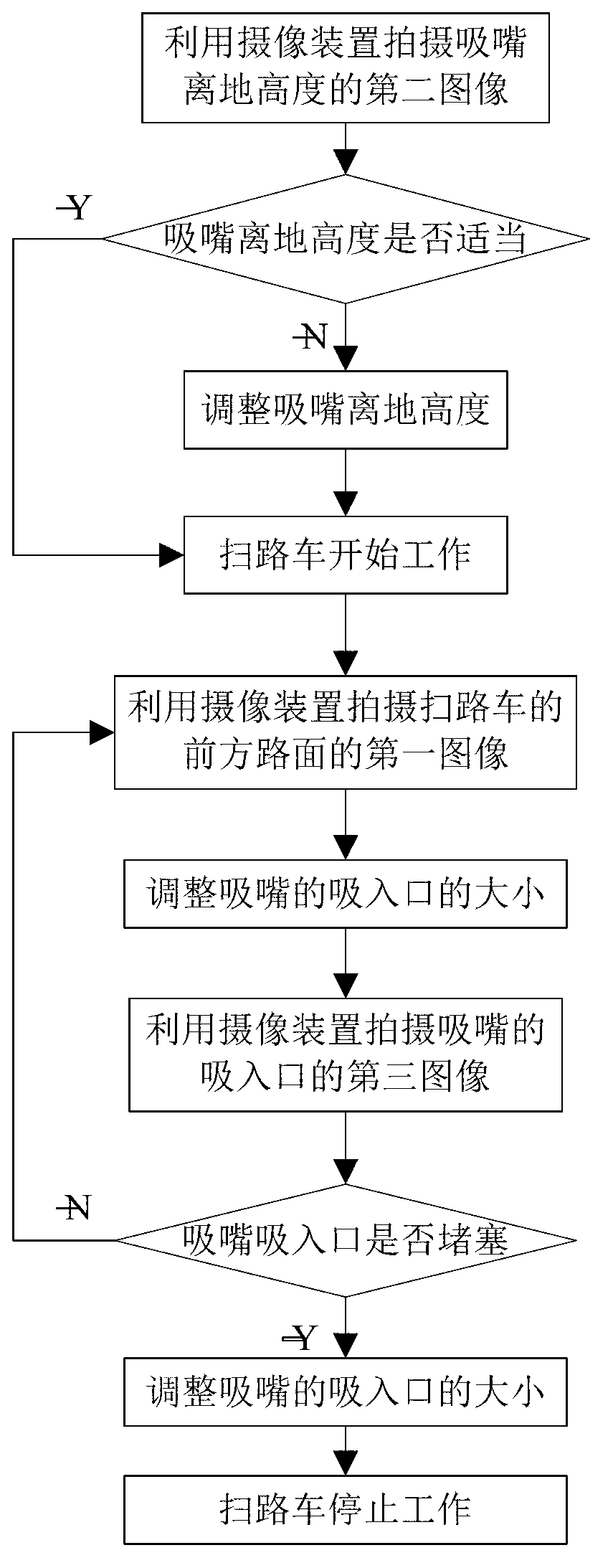

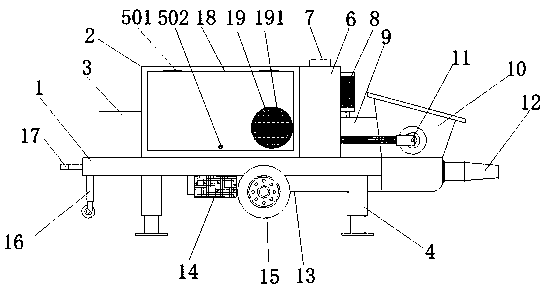

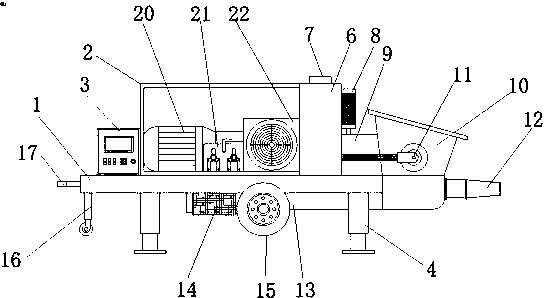

Sweeping machine and visual control method, controller and control system for suction nozzle of sweeping machine

ActiveCN103064317AImprove trash suctionGood cleaning effectRoad cleaningProgramme control in sequence/logic controllersVisual controlNozzle

The invention discloses a visual control method for a suction nozzle of a sweeping machine. The visual control method for the suction nozzle of the sweeping machine is characterized by comprising the following steps: a camera device is used for shooting an image of a road surface in front of the sweeping machine, and a condition of rubbish of the image is judged to accordingly adjust the size of a suction inlet of the suction nozzle. The invention further provides a visual controller and a control system for the suction nozzle of the sweeping machine. Through the technical scheme, the camera device is used for monitoring the road surface in front of the sweeping machine to accordingly adjust the suction nozzle according to monitoring information of the rubbish condition in the image, so that the size of the suction inlet is adjusted reasonably, the rubbish suction capacity of the suction nozzle is improved, and the sweeping machine is enabled to response to different road conditions to achieve good a sweeping effect.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

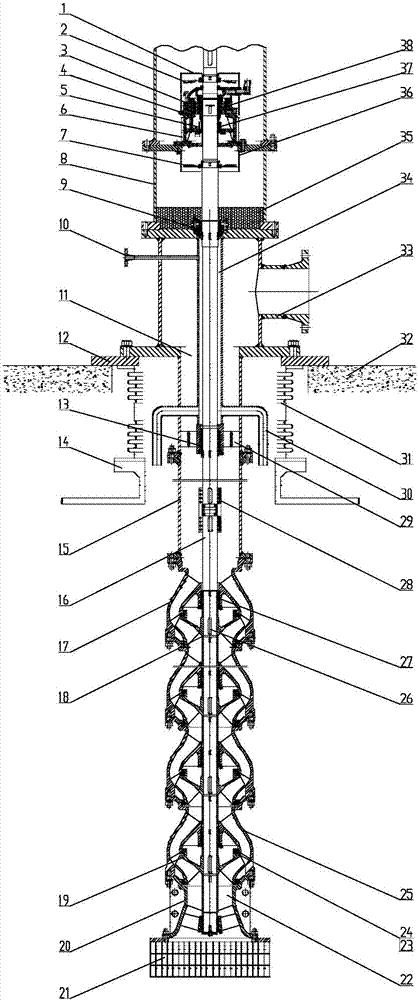

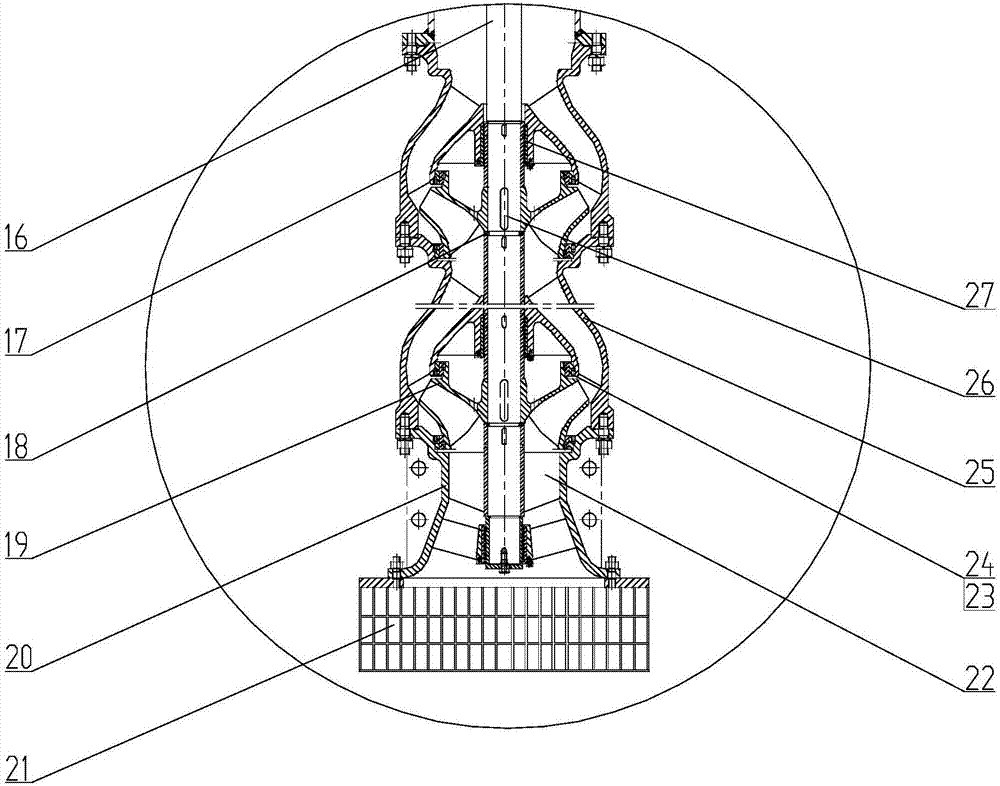

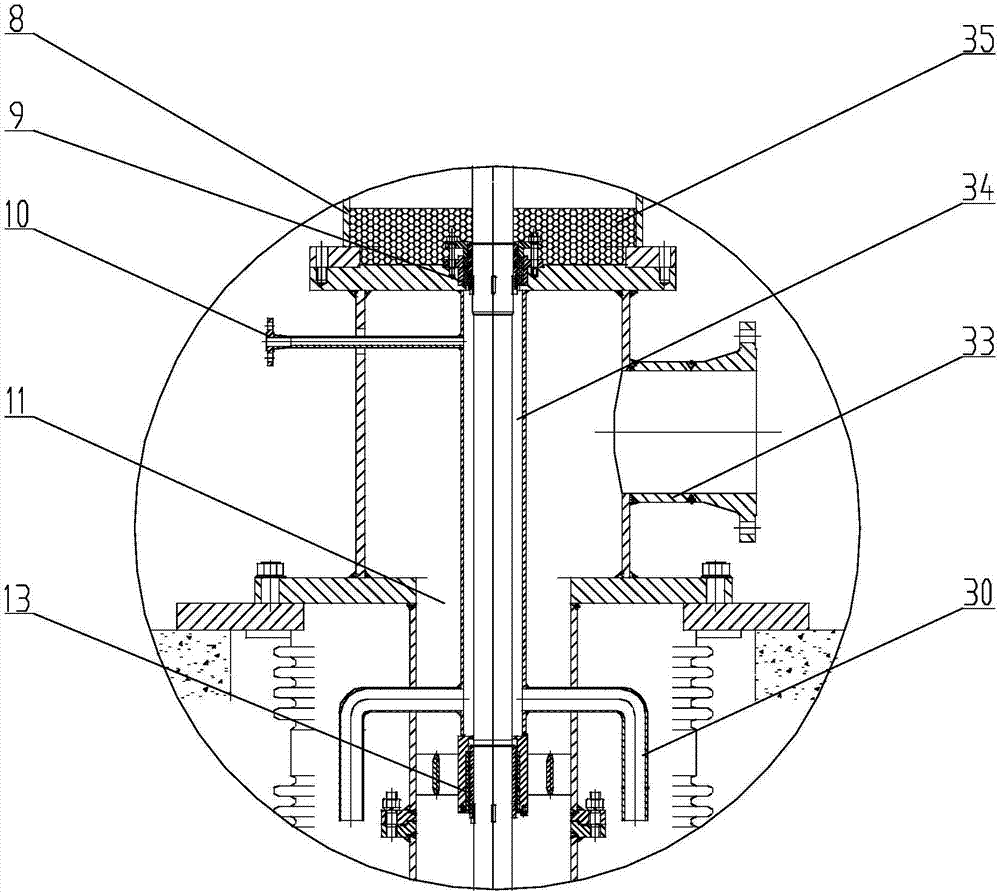

Solar thermal power high-temperature long shaft molten salt pump

PendingCN107355389AFlow state is stableMaximize power generationSpecific fluid pumpsPump componentsThermal dilatationMolten salt

The invention discloses a solar thermal power high-temperature long shaft molten salt pump. The solar thermal power high-temperature long shaft molten salt pump comprises a pump shaft, a hydraulic part, a supporting vibration reduction structure, a fluid seal structure and a bearing cooling device are sequentially arranged on the pump shaft from bottom to top, a suction segment is arranged at the front end of the hydraulic part, a blade grid type filter is arranged on the front end of the suction segment, a tail stage flow guide shell is arranged at the tail end of the hydraulic part, the tail end of the tail stage flow guide shell and the front end of a supporting pipe of the supporting vibration reduction structure are fixedly connected, and the tail end of the supporting pipe of the supporting vibration reduction structure is fixedly connected with the bottom of the outlet segment of the fluid seal structure through a flange plate. The solar thermal power high-temperature long shaft molten salt pump is designed to be in the center flow-out manner, thermal expansion uniformity under the high-temperature state can be ensured, through solution schemes of reliable fluid seal design, reasonable cooling structures, flange type expansion joint vibration reduction configuration and the like, safe, reliable and efficient running of the solar thermal power high-temperature long shaft molten salt pump is ensured, and meanwhile, various property indexes are met.

Owner:DALIAN DEEP BLUE PUMP CO LTD

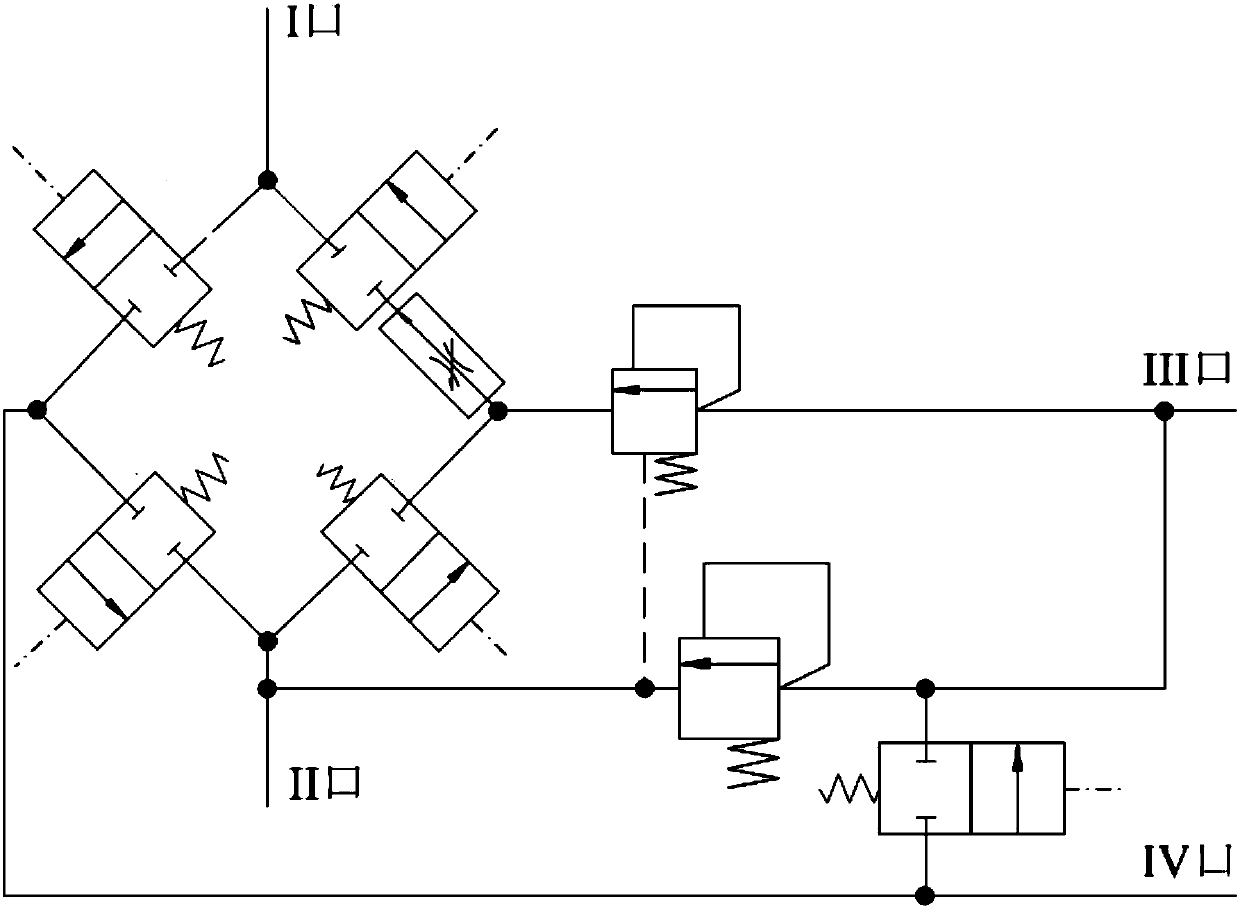

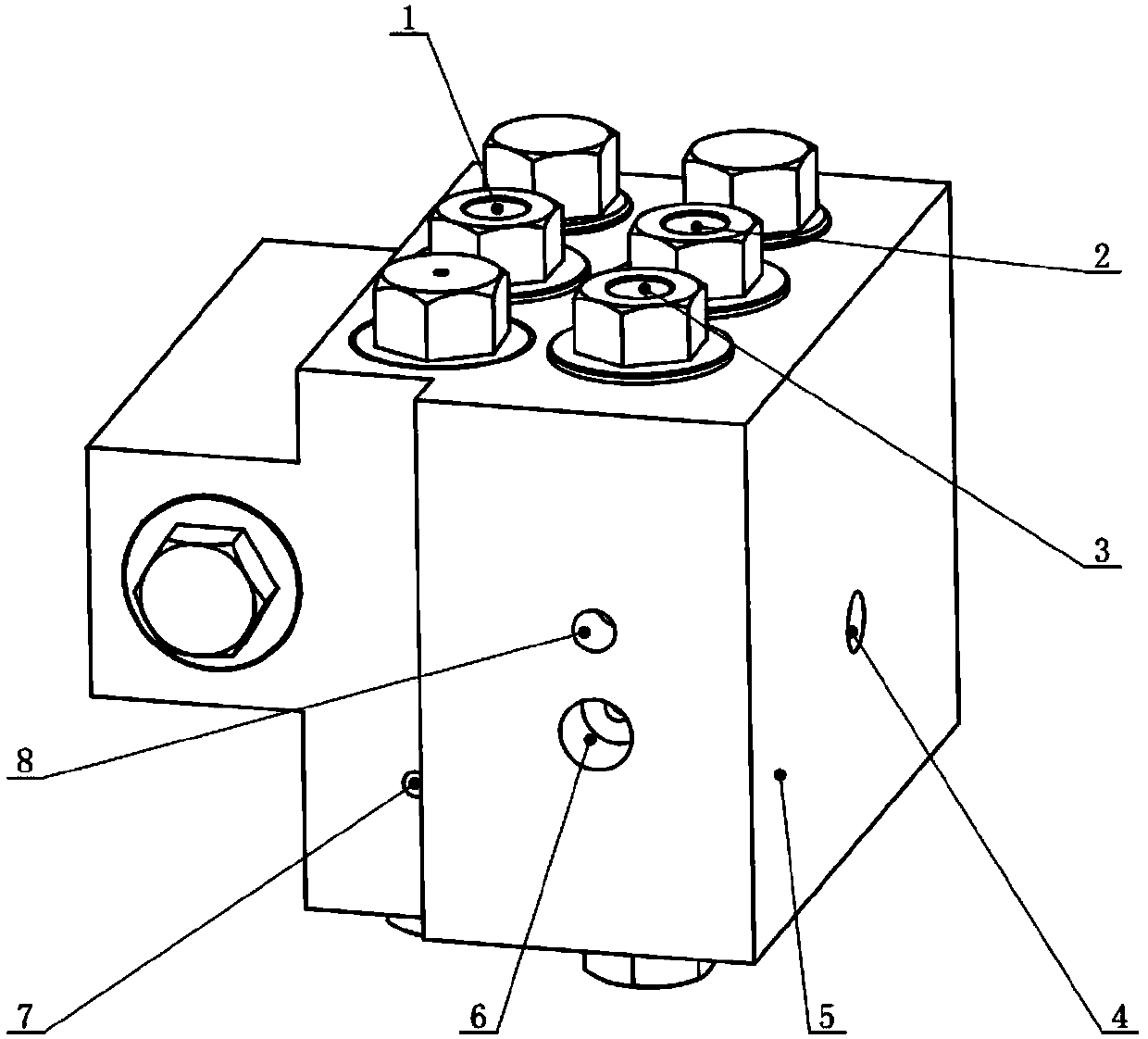

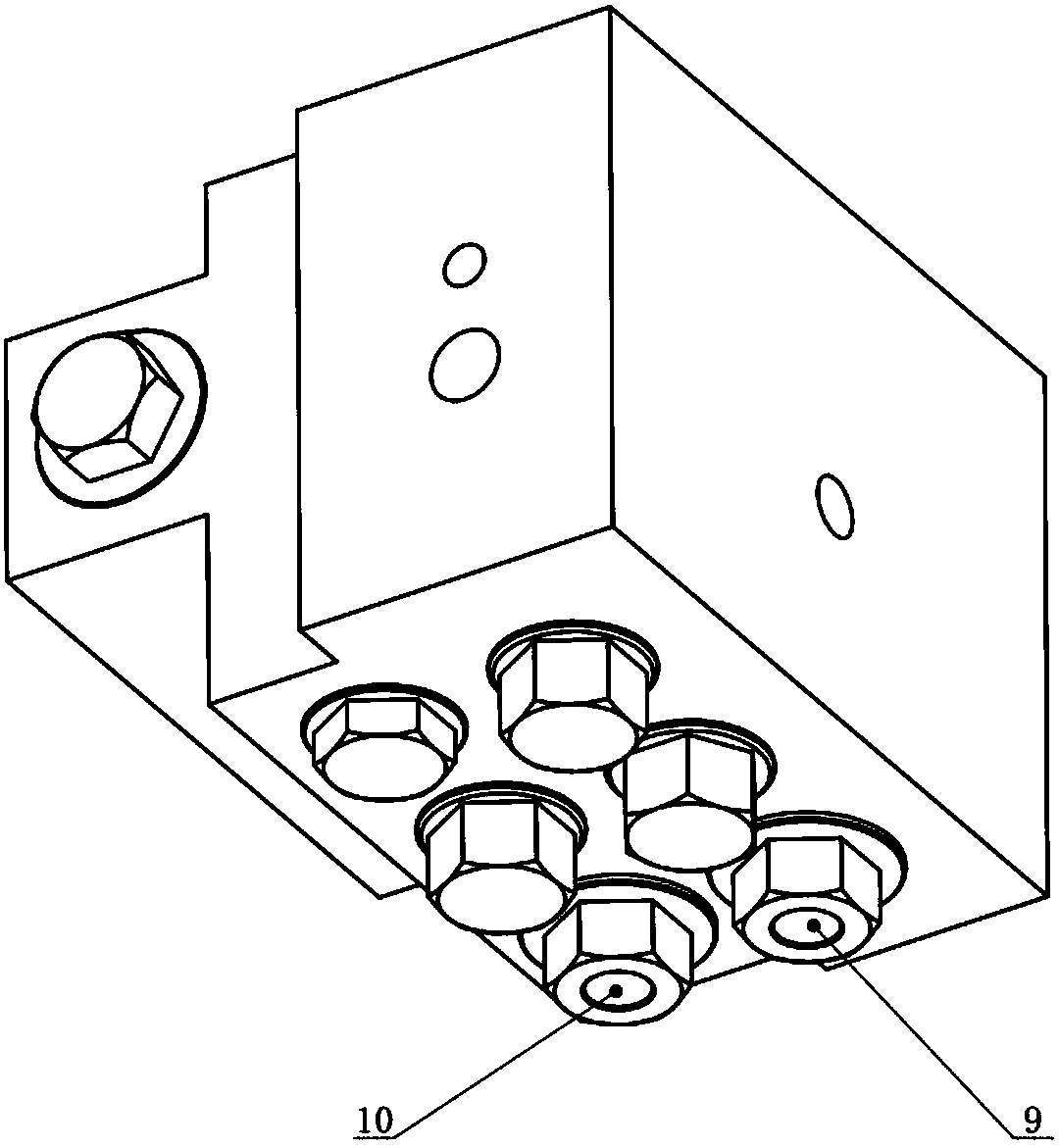

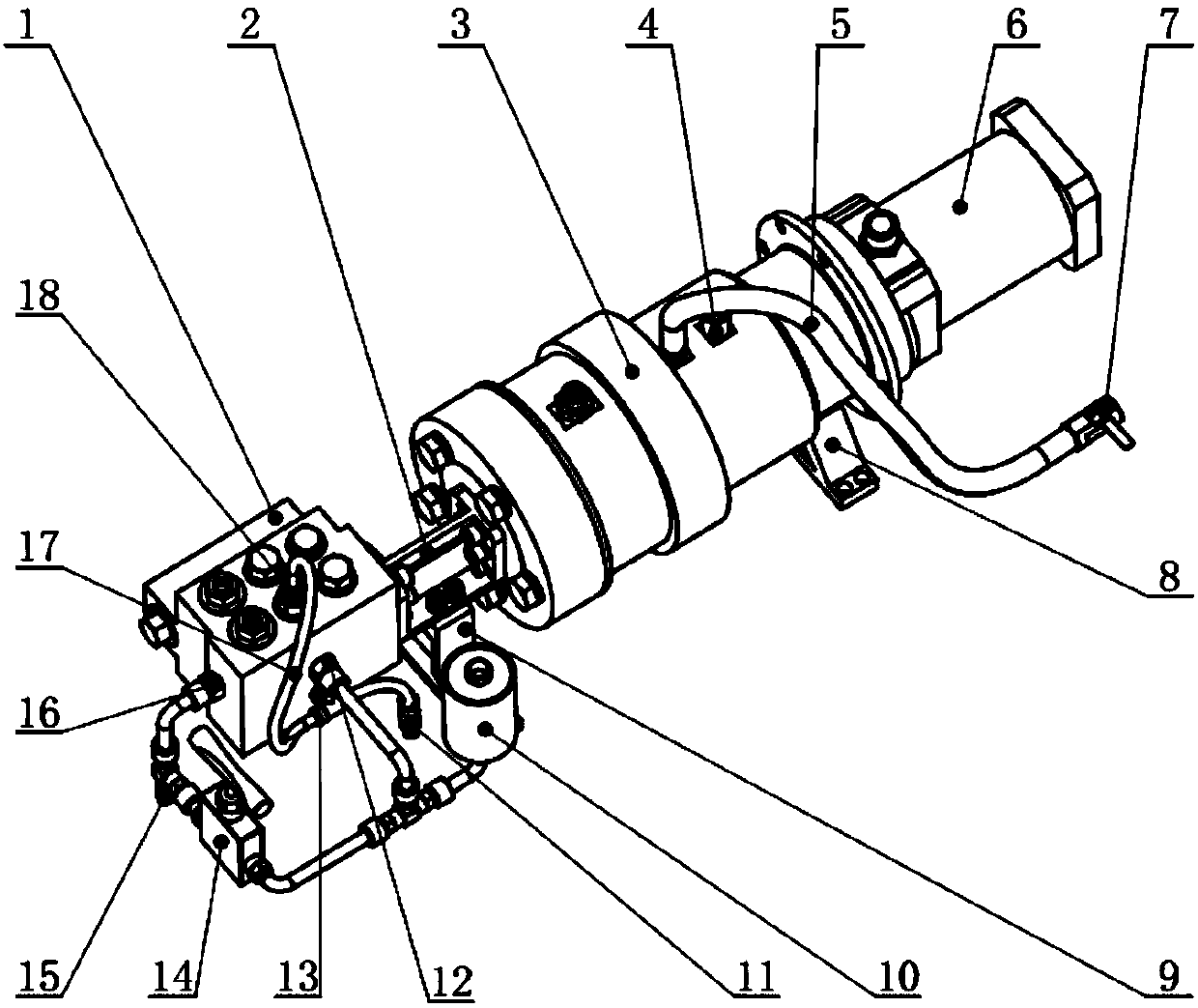

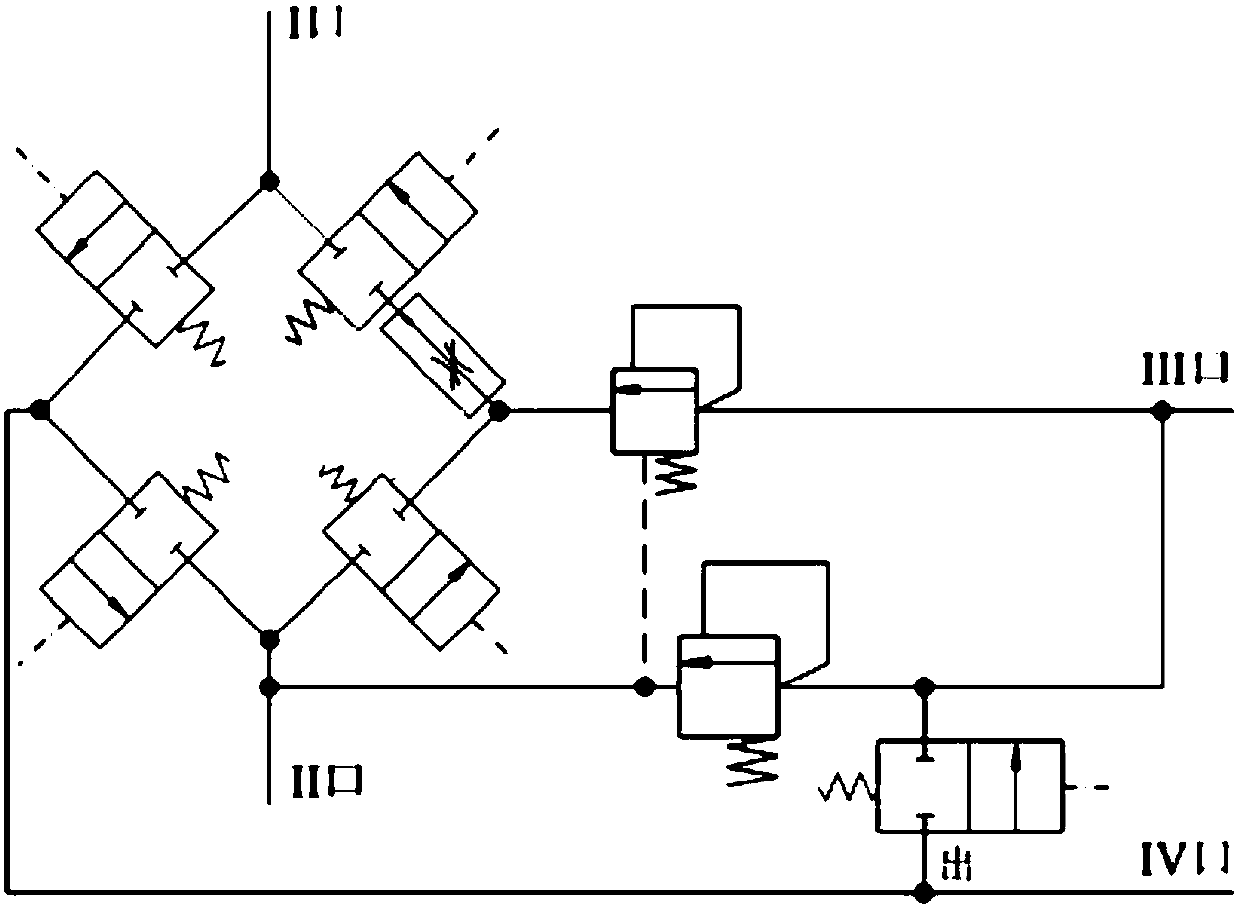

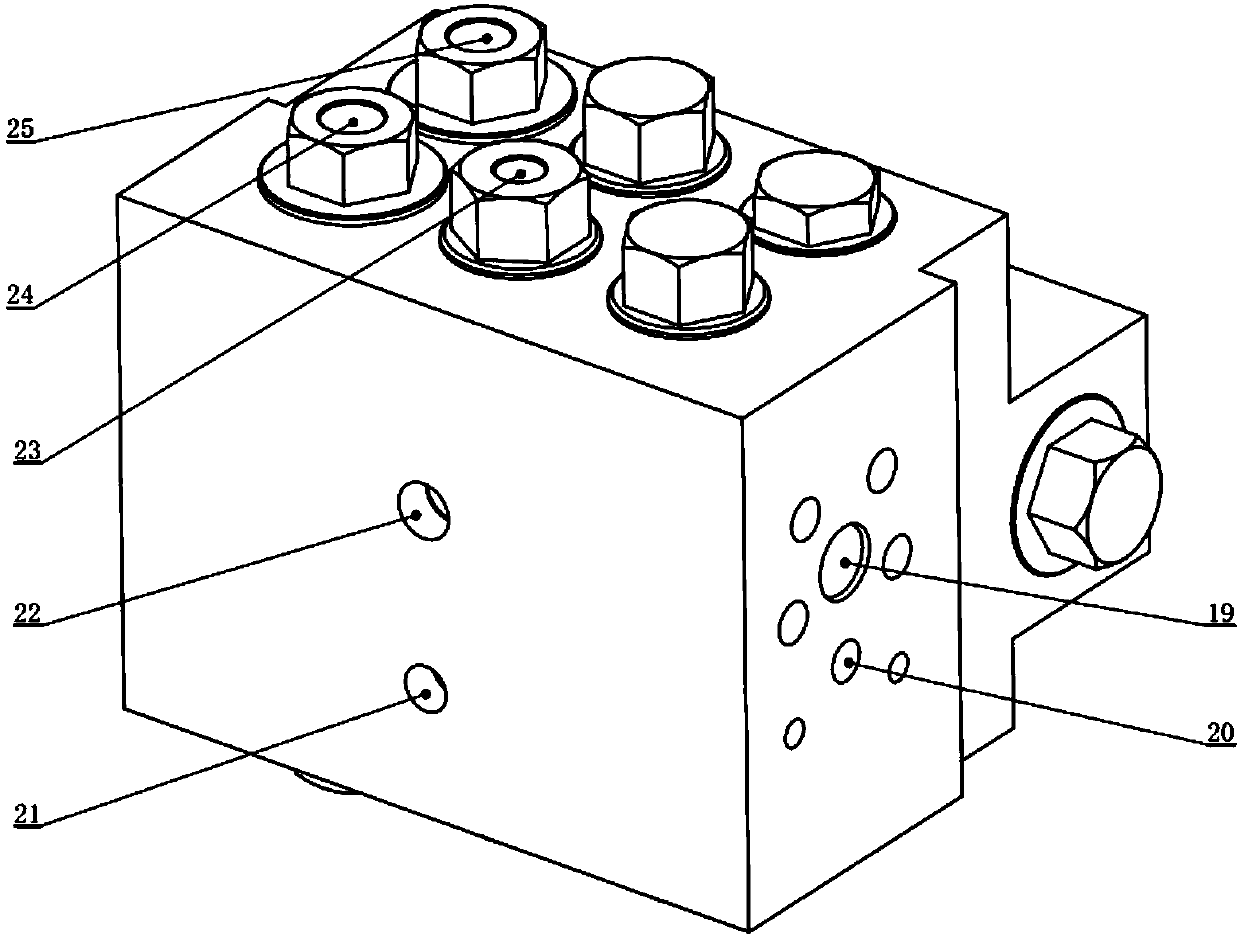

Total-sea-depth buoyancy force adjusting integrated valve set

PendingCN107676315AImprove interchangeabilityCompact structureServomotor componentsServomotorsStart stopBridge type

The invention belongs to the field of submersible buoyancy force adjusting correlation techniques, and discloses a total-sea-depth buoyancy force adjusting integrated valve set. The total-sea-depth buoyancy force adjusting integrated valve set is of a plug-in mounting structure and comprises a first stop valve, a second stop valve, a third stop valve, a fourth stop valve, a speed adjusting valve and a valve body. The first stop valve, the second stop valve, the third stop valve and the fourth stop valve are mounted in the valve body in a plug-in mounting manner and are sequentially connected end to end to form a bridge type loop. Switching of water injection and drainage working conditions of water ballast space is achieved by controlling the start-stop combination among the first stop valve, the second stop valve, the third stop valve and the fourth stop valve. The speed adjusting valve is additionally mounted in the integrated valve set, and therefore the working conditions of the integrated valve set comprise the seawater pump water injection and drainage working condition and the dump injection working condition at the same time. According to the total-sea-depth buoyancy forceadjusting integrated valve set, interchangeability of the valves is good, the overall structure is compact, and mounting and maintaining are convenient.

Owner:HUAZHONG UNIV OF SCI & TECH

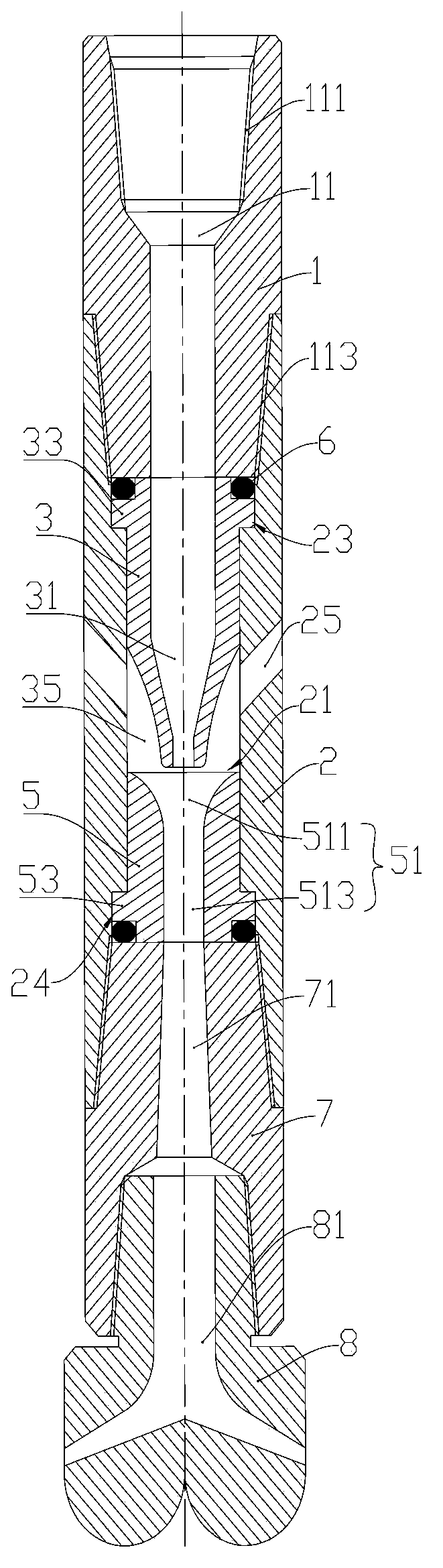

Shaft bottom particle injection drilling speed increasing tool

The invention discloses a shaft bottom particle injection drilling speed increasing tool and belongs to the field of matched devices of petroleum and natural gas drilling. The tool comprises an upper connector, a contracting nozzle, a casing and a lower connector. The lower connector is connected with a drill bit provided with a water hole. The contacting nozzle is provided with a nozzle channel, an annular space is formed between the contacting nozzle and the casing, the nozzle channel is communicated with the annular space, the casing is provided with a particle suction port, a conical diffusion flowing channel is arranged on the lower connector, and the diameter of the inlet position where the diffusion flowing channel is communicated with the annular space is smaller than the diameter of the outlet position where the diffusion flowing channel is communicated with the water hole. In the drilling process, drilling liquid forms high speed injection flow through the contacting nozzle to be sprayed, a low pressure area is formed in the annular space under the injection effect of the injection flow, steelmaking particles in the annular space is sucked into the annular space through pressure difference of high pressure and low pressure, and the particle suction effect is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Distributing valve for concrete pump

InactiveCN1804398AIncrease the use volumeStir wellPositive displacement pump componentsPiston pumpsEngineeringHigh pressure

The invention discloses a distribution valve of concrete pump, which comprises a valve body, swing arms, two end caps, a left rotational valve and right rotational valve. Wherein, the end caps are arranged at the two ends of valve body; the valve body is divided into left valve chamber and right valve chamber; the left and right rotational valves are individually arranged inside the left and right valve chambers; the parts of valve relative to the left and right valve chambers have inlets, material adsorption inlets and outlets; the left and right rotational valves are individually connected to the swing arms at the outer side of two ends of valve body via the rotational axle; and said left and right rotational valves are cylinder which have through holes to connect the inlet and material adsorption inlet or material adsorption inlet and outlet. The invention has better material adsorption property which can meet the demand of high pressure pump.

Owner:SANY HEAVY IND CO LTD (CN)

Textile equipment with dedusting and humidifying functions

InactiveCN107520216AMeet needsImprove suction performanceCombination devicesLighting and heating apparatusYarnWater storage tank

The invention discloses textile equipment with dedusting and humidifying functions. The textile equipment comprises hydraulic telescopic rods, a water-permeable thin film, a second exhaust fan, a first booster pump and a mounting plate. The hydraulic telescopic rods are arranged to be used for adjusting the height of a base so that the height of a textile machine body can be adjusted, and hence the requirements of operators of different heights are met. The water-permeable thin film is arranged to be used for adsorbing cotton thread scraps and dust entering a dedusting and humidifying box and meanwhile humidifying the air. The humidified air in the dedusting and humidifying box can be exhausted out of an air outlet pipe through the second exhaust fan so that the air in a workshop can be humidified, and the phenomenon that the air in the workshop is excessively dried and thus yarns can be broken easily in the spinning process is avoided. Filtered sewage in a filtering tank can enter a water storage tank through a first water guide pipe with the first booster pump, and therefore water resources can be recycled. The environmental protection property of the equipment is improved, dedusting and humidifying cost of the workshop is reduced, and equipment practicability is improved.

Owner:HUZHOU DONGKAI TEXTILE CO LTD

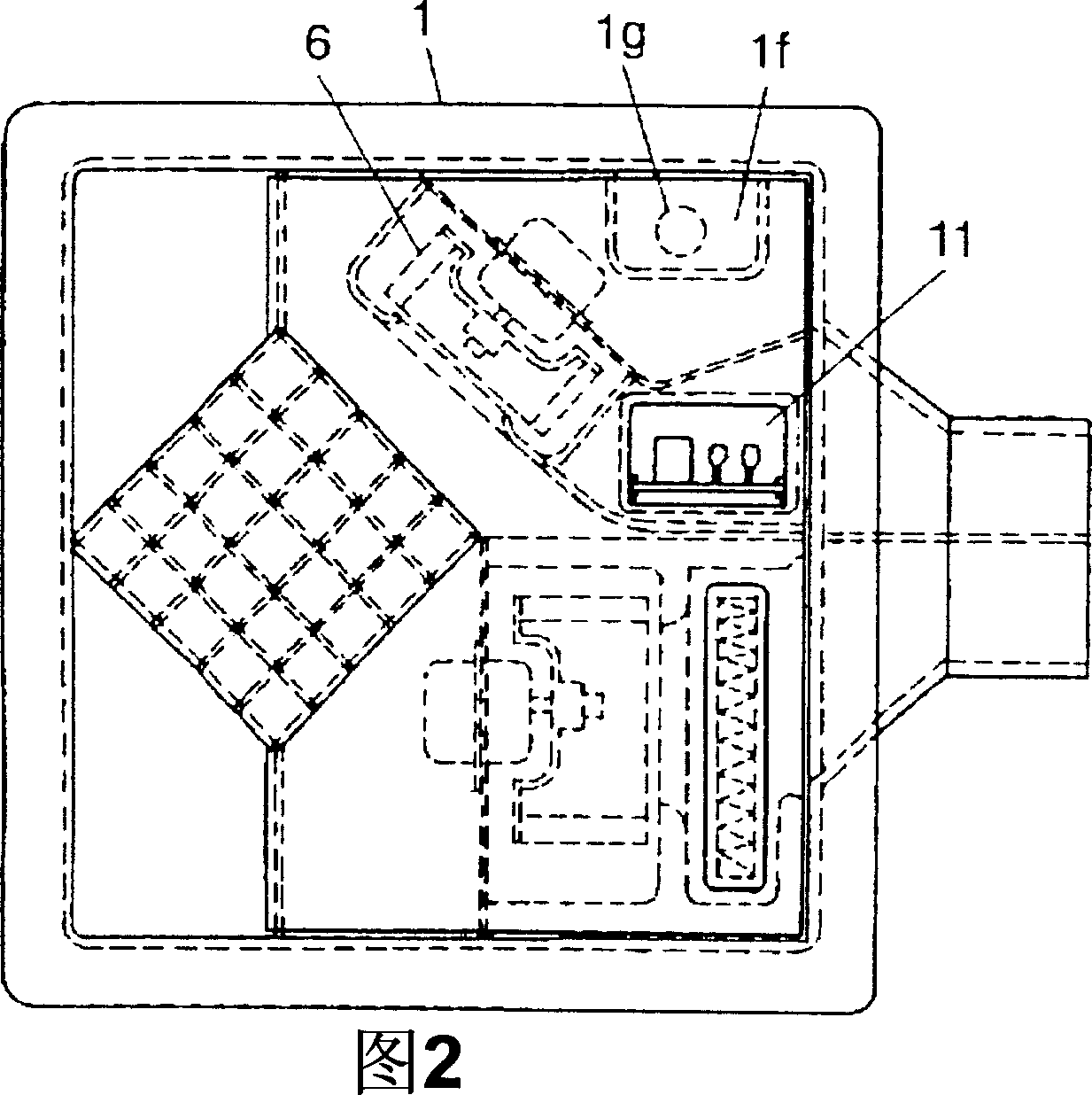

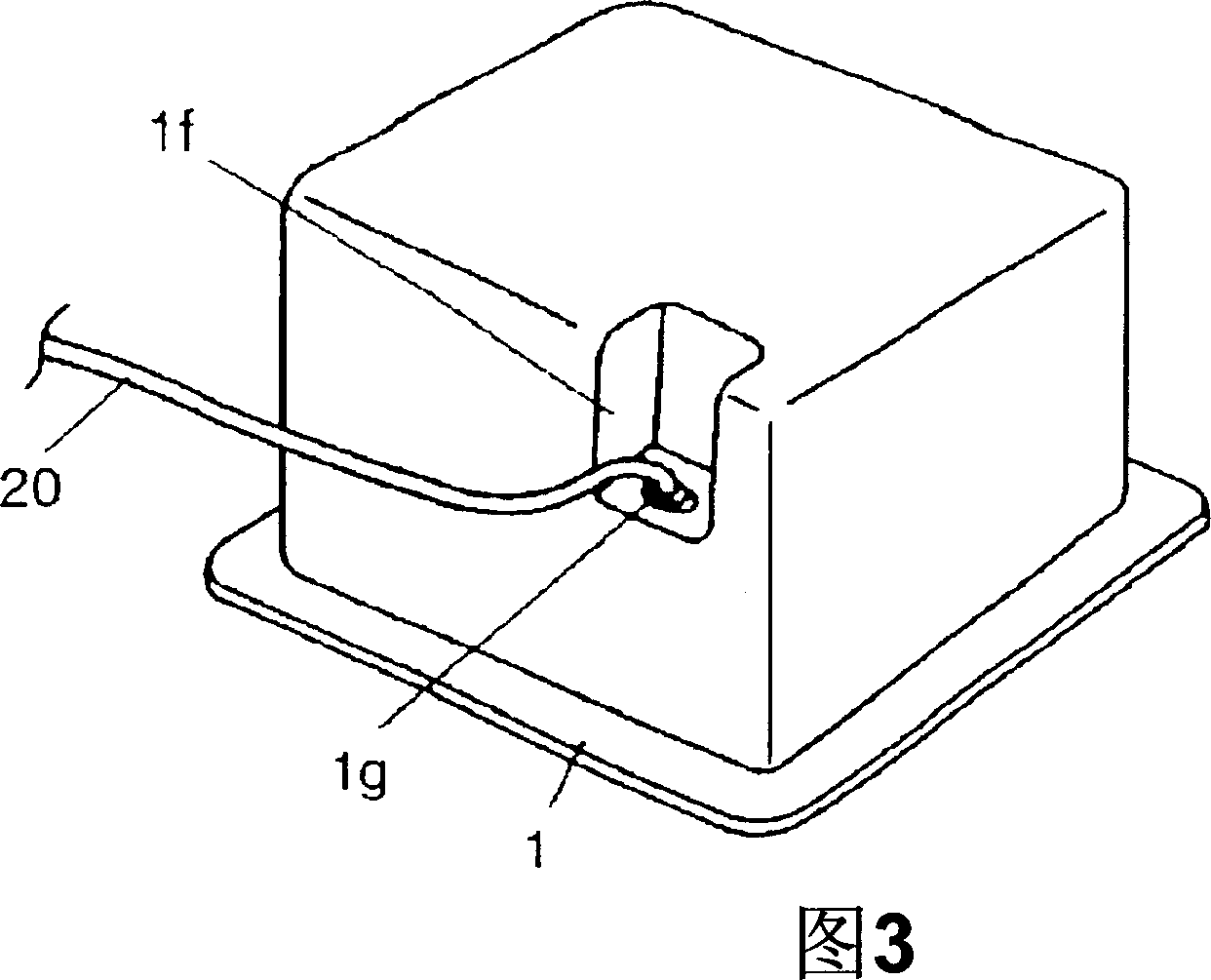

Heat exchange type ventilator

InactiveCN1969152AImprove gas supply capacityEliminate spaceEnergy recovery in ventilation and heatingHeat recovery systemsDouble-walled pipeEngineering

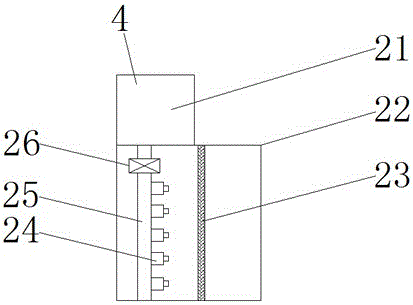

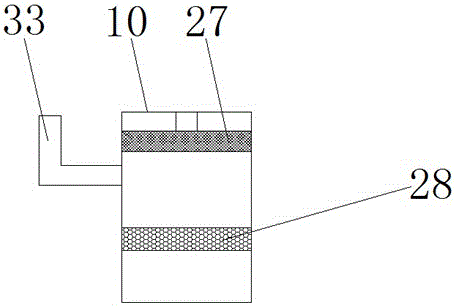

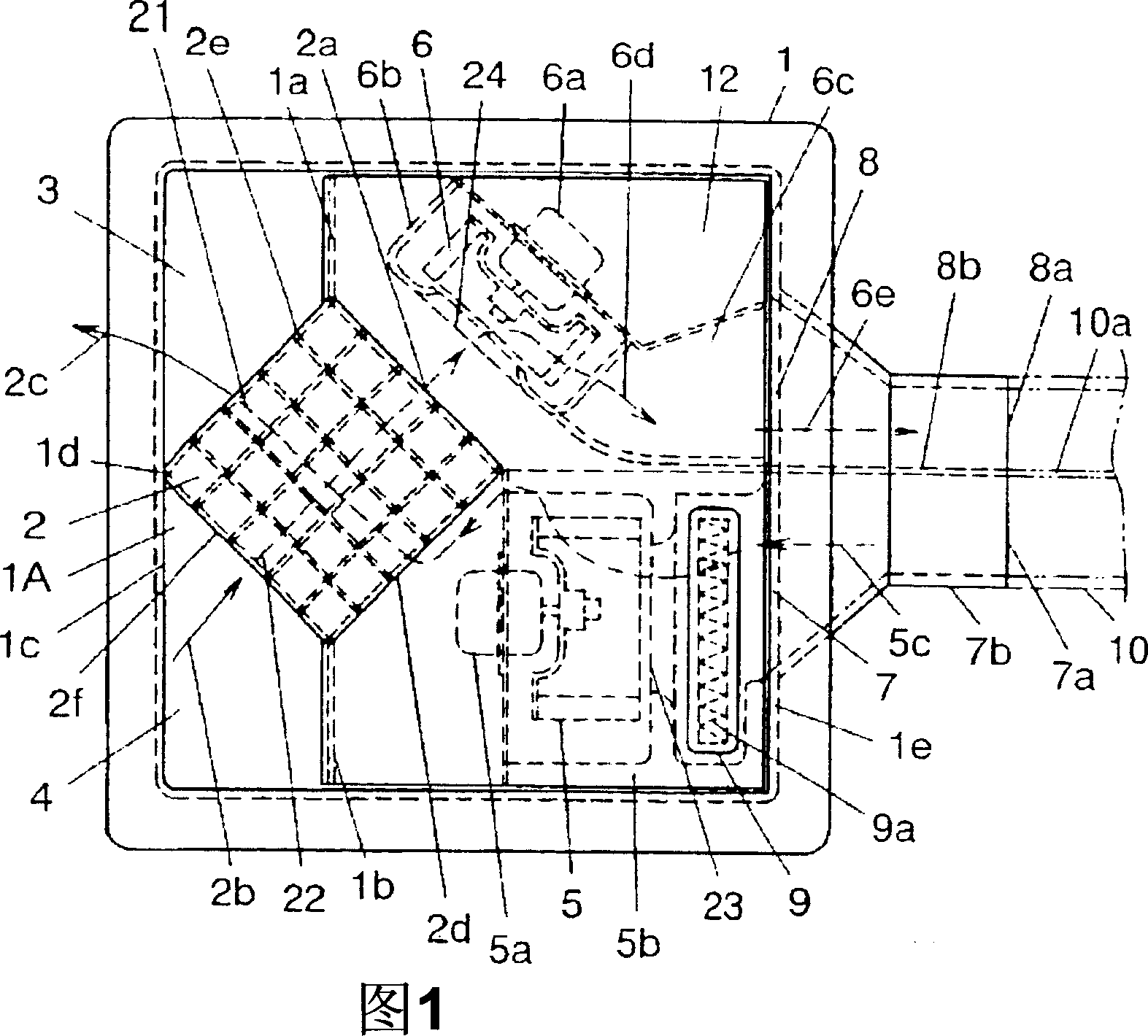

A heat exchange type ventilator enabling a reduction in the size of a device body, comprising a box (1) installed on the surface of a ceiling, having an opening part (1A) in the lower surface thereof, and having a cross section of square shape. A large number of exhaust flow passages (22) and intake flow passages (21) are alternately stacked on each other in the depth direction of the box body (1) so that the exhaust flow passages (22) and the intake flow passages (21) are allowed to cross each other through heat exchange boards. The box also comprises a heat exchange element (2) exchanging heat between an intake flow and an exhaust flow and an intake blower (5) communicating with the intake flow inflow surface (2d) of the heat exchange element (2). The box further comprises an exhaust blower (6) communicating with the exhaust flow outflow surface (2a) of the heat exchange element (2) and an outdoor side intake flow passage inlet (7) formed in the side face of the box on the opposite side of an indoor side intake flow passage outlet (3) on the upstream side of the intake blower (5). In addition, the box comprises, on the downstream side of the exhaust blower (6), an indoor side exhaust flow passage inlet (4) and an outdoor side exhaust flow passage outlet (8) formed in the side face of the box on the opposite side of the indoor side exhaust flow passage inlet, and the outdoor side intake flow passage inlet (7) and the outdoor side exhaust flow passage outlet (8) are positioned adjacent to each other and allowed to communicate with the inside of a bimetallic tube (10) formed by dividing the inside of the tube into two flow passages.

Owner:PANASONIC CORP

Modularized integrated full-sea deep diving submersible adjustable ballast device

ActiveCN107839861ACompact structureEasy to installUnderwater vesselsUnderwater equipmentMotor driveBridge type

The invention belongs to the field of related technologies of submersible buoyancy adjustment, and discloses a modularized integrated full-sea deep diving submersible adjustable ballast device. The modularized integrated full-sea deep diving submersible adjustable ballast device comprises a motor driving module, a sea water driving module and a valve set control module, and the motor driving module, the sea water driving module and the valve set control module are connected in sequence; the valve set control module comprises a valve body, a first stop valve, a second stop valve, a third stop valve and a fourth stop valve, wherein the first stop valve, the second stop valve, the third stop valve and the fourth stop valve are inserted in the valve body, the first stop valve, the third stop valve, the fourth stop valve and the second stop valve are connected from head to tail in sequence to form a bridge type loop, and by controlling the starting-closing combination of the first stop valve, the second stop valve, the third stop valve and the fourth stop valve, the working mode of the modularized integrated full-sea deep diving submersible adjustable ballast device is achieved. The modularized connecting mode facilitates installation, repair and detaching, and the overall structure is compact.

Owner:HUAZHONG UNIV OF SCI & TECH

Distributing valve for concrete pump and concrete pump

ActiveCN101832259ASimple structureEasy to manufacturePositive displacement pump componentsPiston pumpsSlurryHigh pressure

The invention discloses a distributing valve for a concrete pump and a concrete pump. The distributing valve for the concrete pump comprises a valve body and a valve core; a pumping cavity is internally shaped in the valve body and is provided with a discharge hole and a suction hole; wherein the discharge hole is communicated with a delivery pipe and the suction hole is communicated with a delivery tank; a valve core is a L-shaped pipe formed by a first pipe section and a second pipe section, one end of the L-shaped pipe is connected with a hopper and a revolution fitting surface is formed between the end face of the other end of the L-shaped pipe and the internal face and driven by a driving mechanism, the valve core can be switched between a first position and a second position. Compared with the prior art, the distributing valve enjoys the technical effects of simple structure, high reliability, long service life and low manufacturing cost and can meet the demand of delivering concrete slurry under high pressure while reducing power consumption and retaining fine casing capability.

Owner:SANY AUTOMOBILE MFG CO LTD

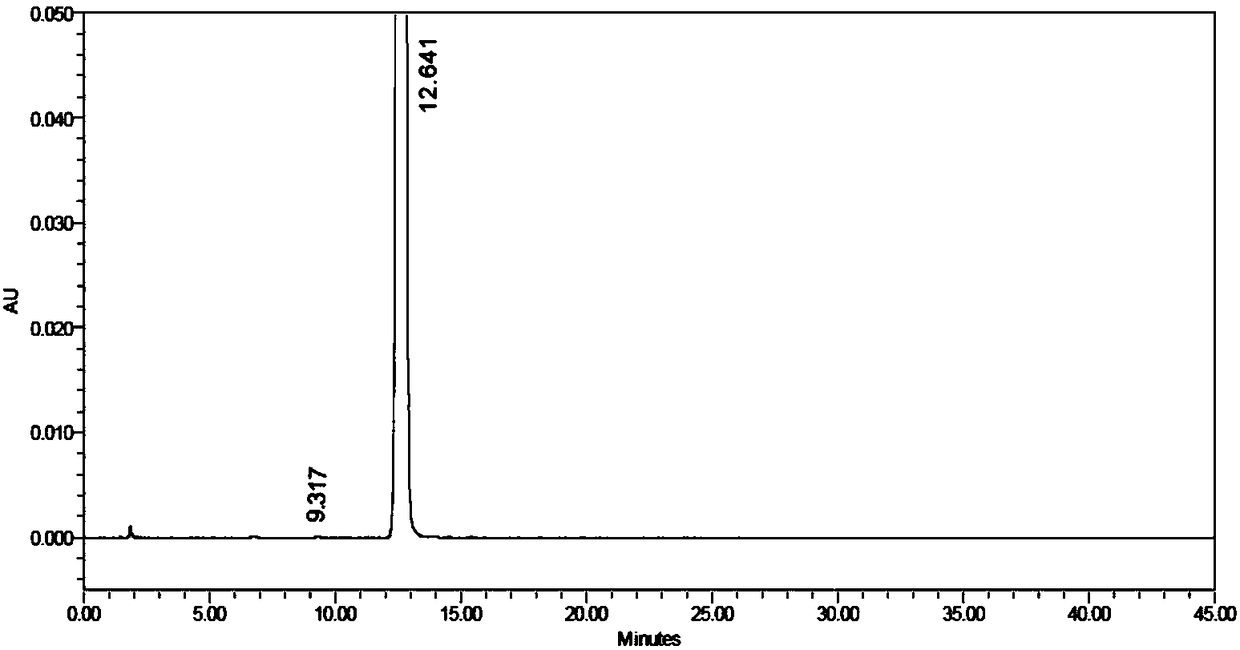

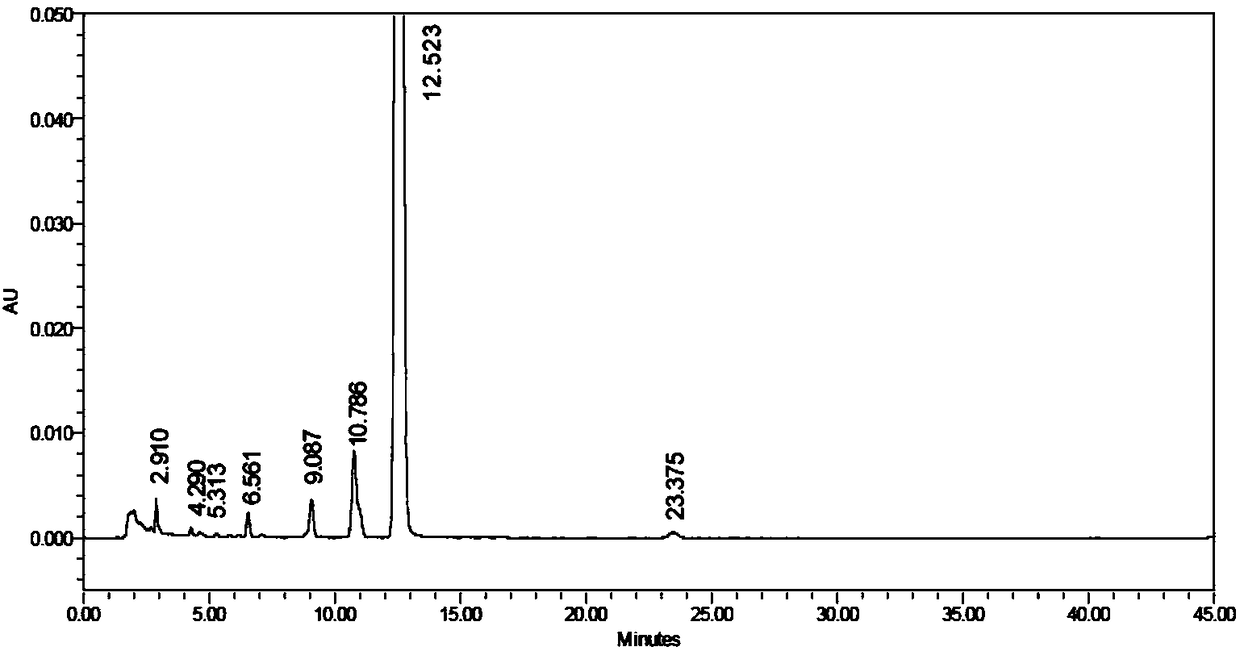

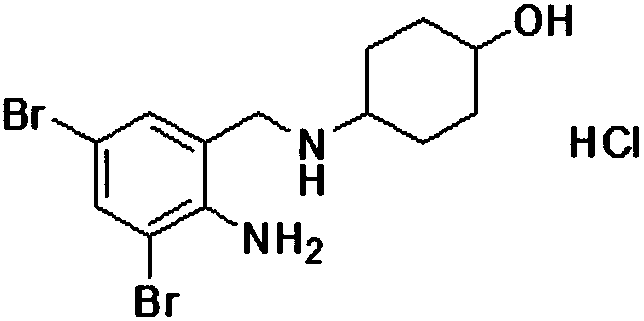

Stable inhalation ambroxol hydrochloride solution and preparation method thereof

ActiveCN108159026AImprove portabilityImprove photostabilityOrganic active ingredientsDispersion deliveryMedicineInhalation

The invention discloses a stable inhalation ambroxol hydrochloride solution and a preparation method thereof. The solution comprises 0.5-0.9%(w / v) of ambroxol hydrochloride, 0.5-0.8%(w / v) of an isotonic agent, 0.001-0.003%(w / v) of a metal ion complex as a stabilizer, a pH adjusting agent and a solvent. The stable inhalation ambroxol hydrochloride solution disclosed by the invention is relatively good in portability, remarkably improved in light stability and inhalation performance, capable of greatly improving stability of medicines in the storage process and relatively well applicable to clinical application requirements.

Owner:SHANGHAI FANGYU HEALTH PHARMA TECH CO LTD +1

Method for preparing getter film

InactiveCN109136867AImprove suction performanceSave spaceVacuum evaporation coatingSputtering coatingCoating systemPre treatment

Owner:李志平

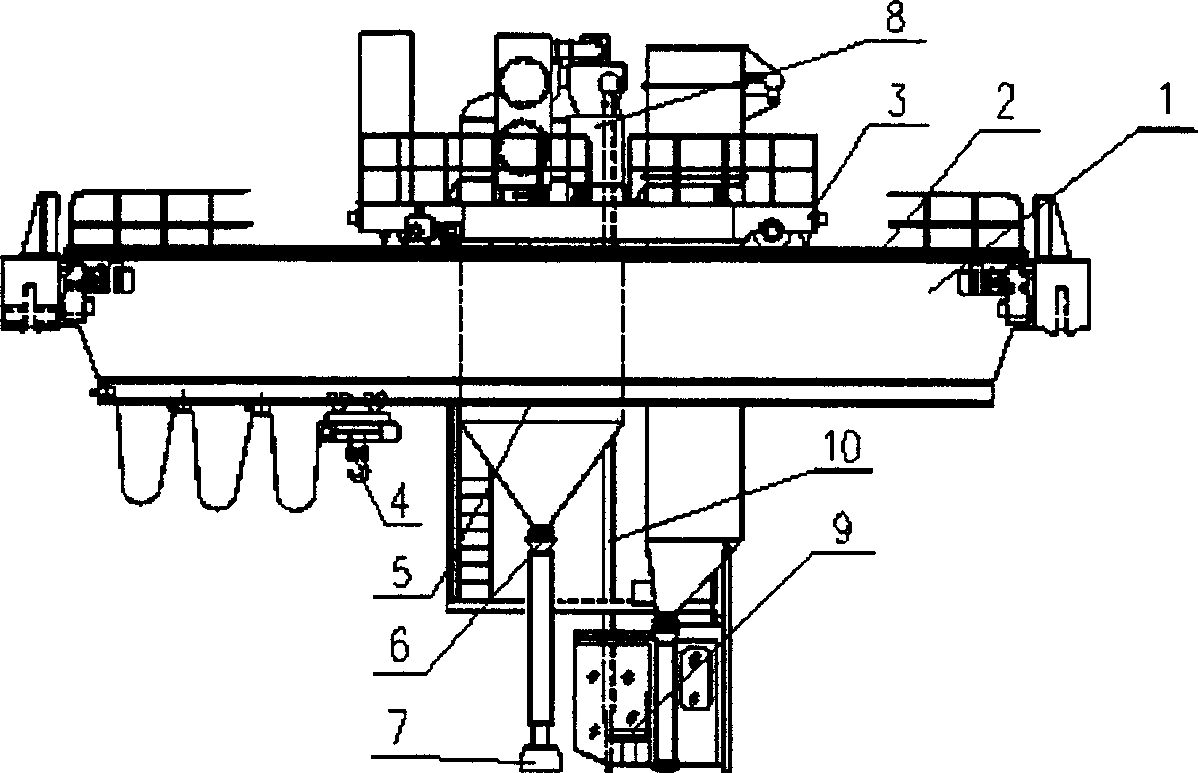

Carbon baking operation crown block

InactiveCN1789872AImprove sound insulationImprove insulation performanceCharge manipulationAir cargoEngineering

This invention discloses one carbon burst operation air cargo, which comprises move cargo fixed on the factory track with trails and operation cargo, wherein, the move air cargo down end is located with lift device; the operation cargo is located with materials storage barrel with materials laid valve on bottom; the materials valve is connected with distribution device connected with vacuum device with absorptive tube stretching out to operation cargo down part.

Owner:GUIYANG AL-MG DESIGN & RES INST

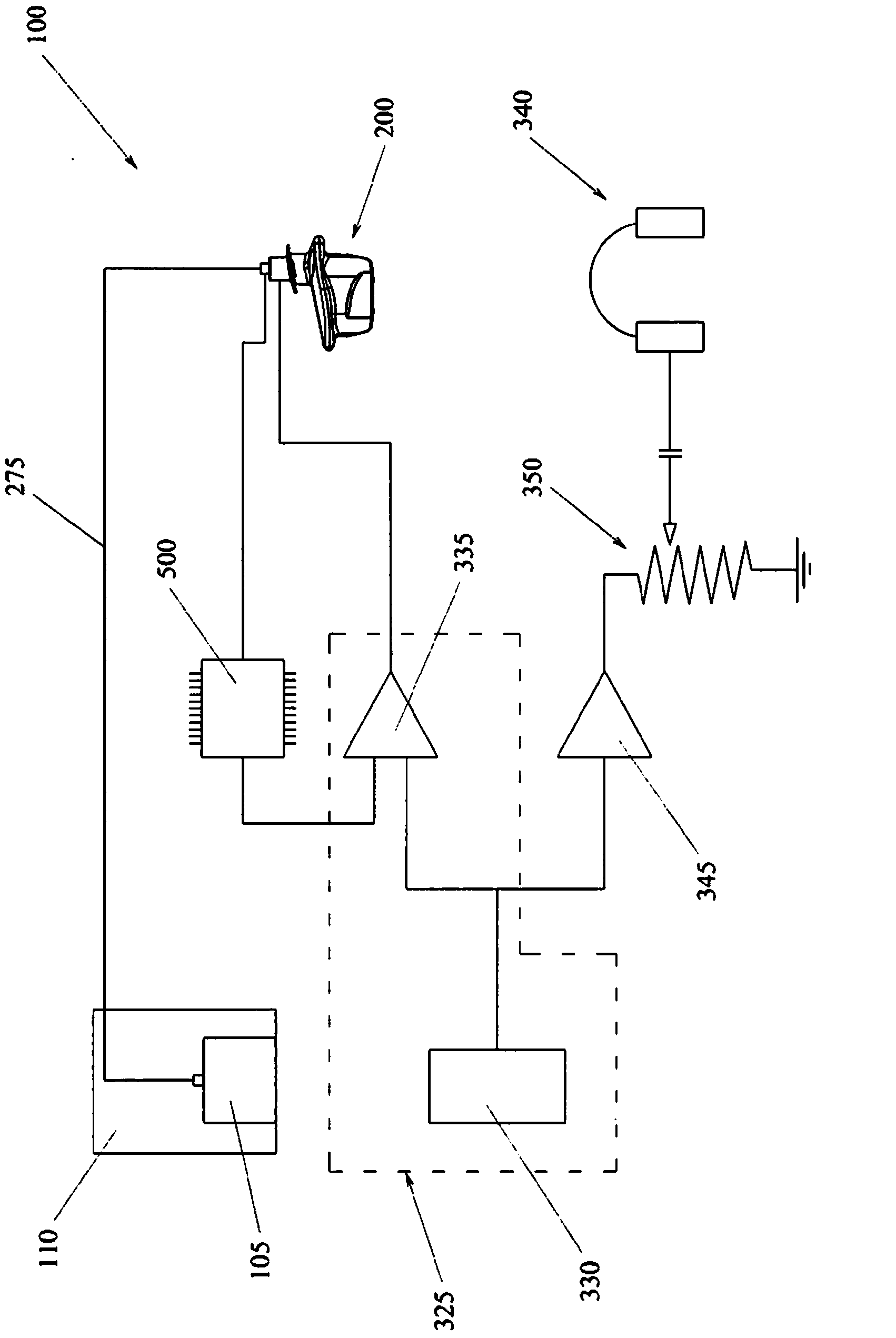

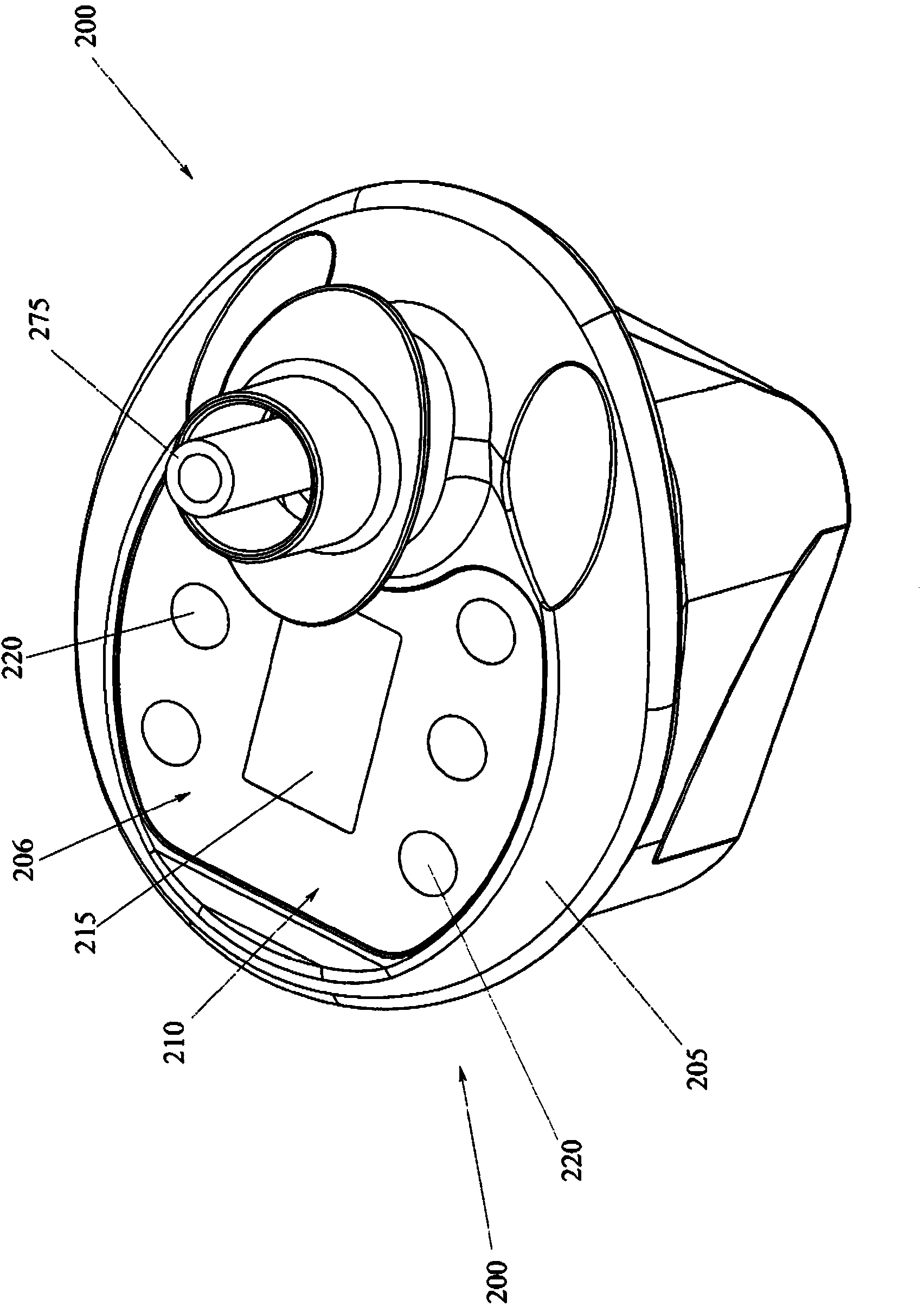

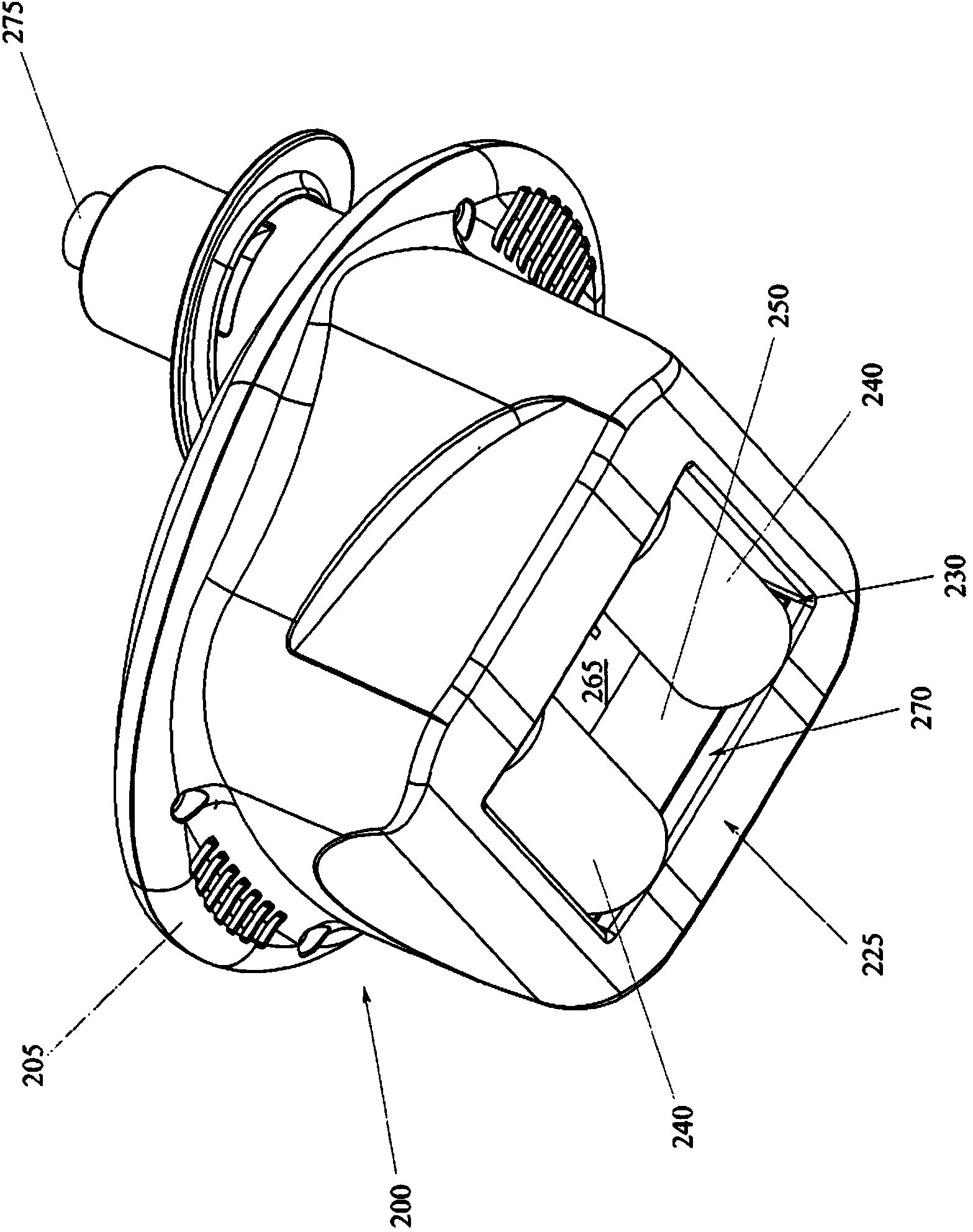

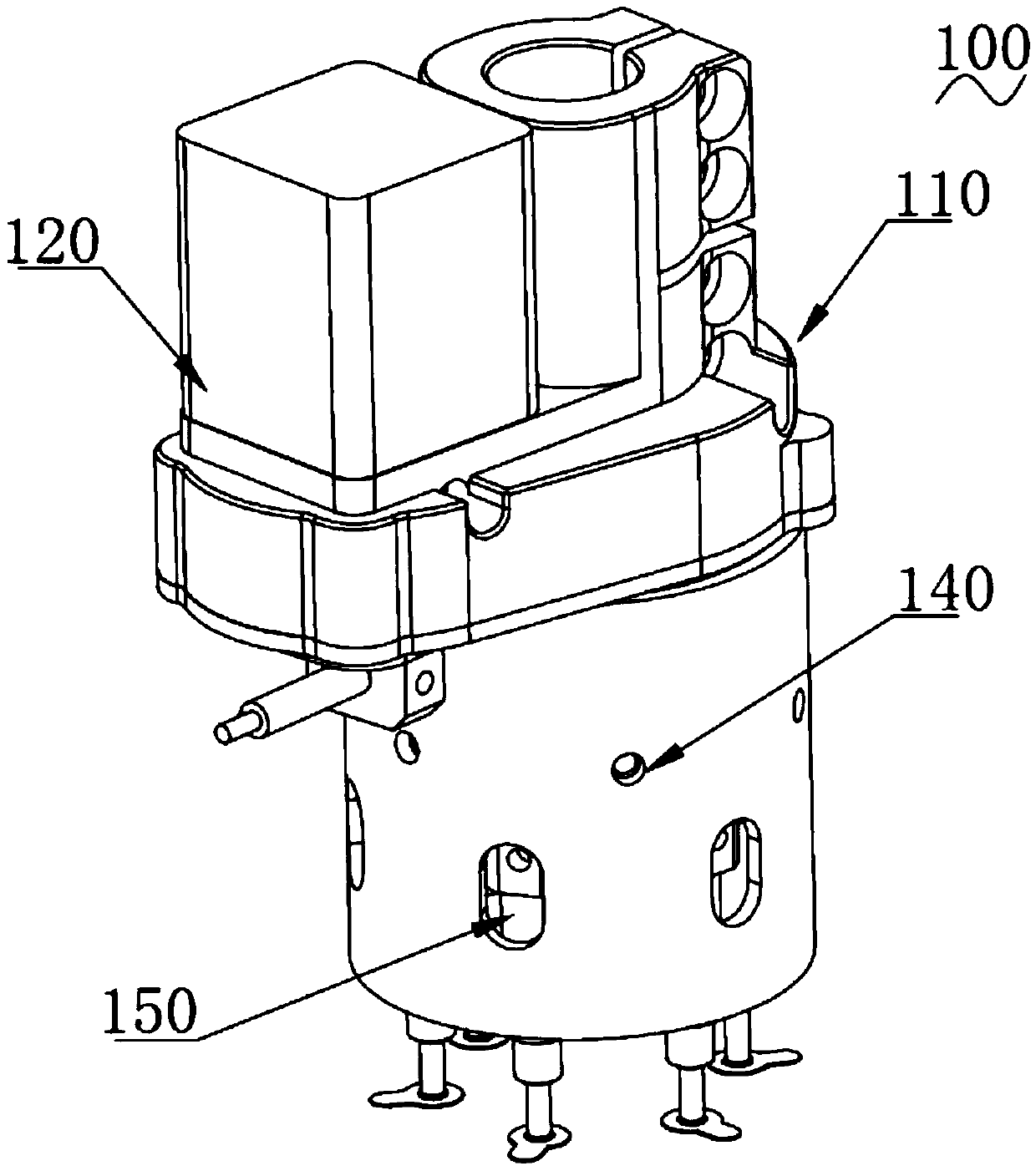

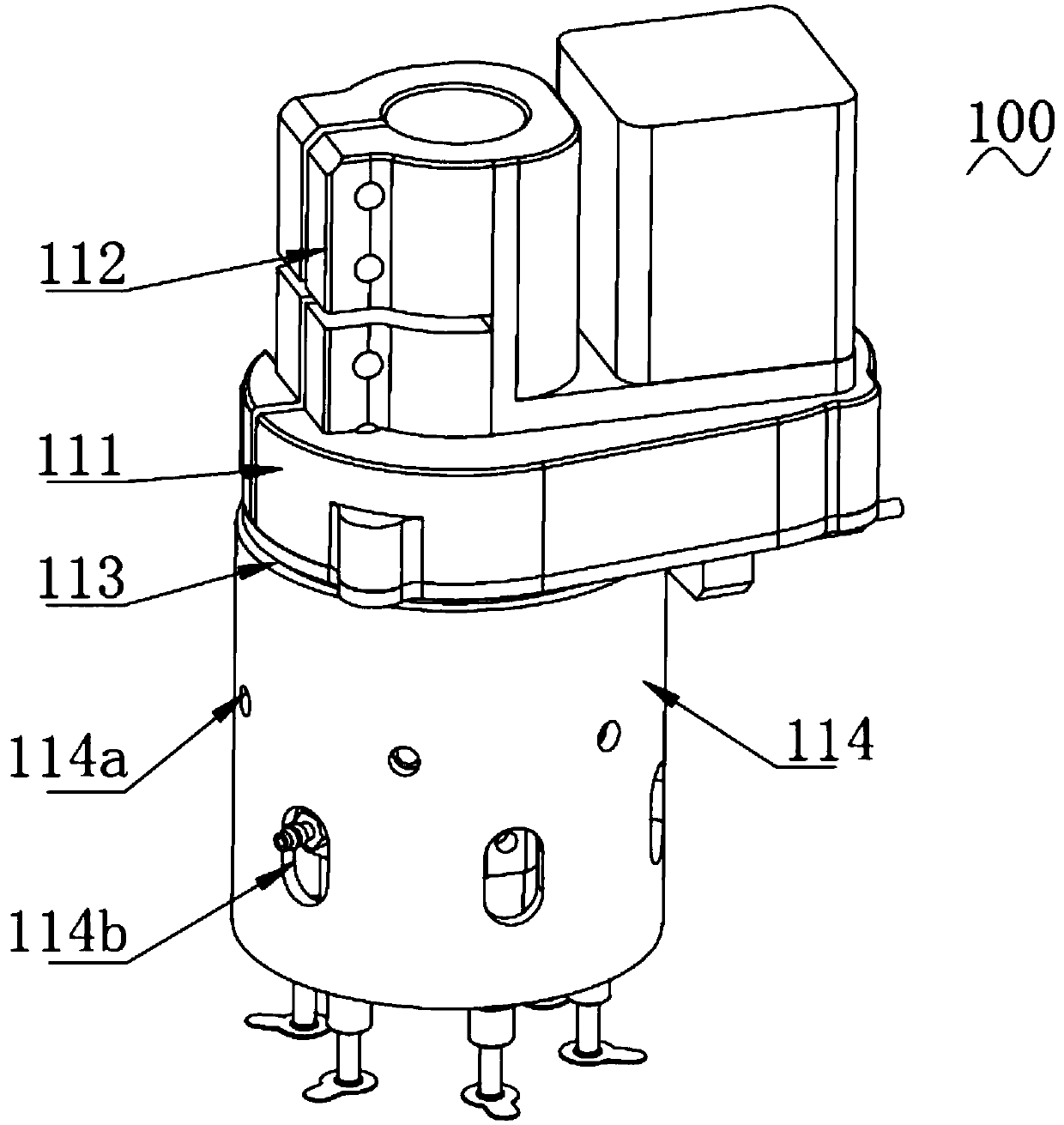

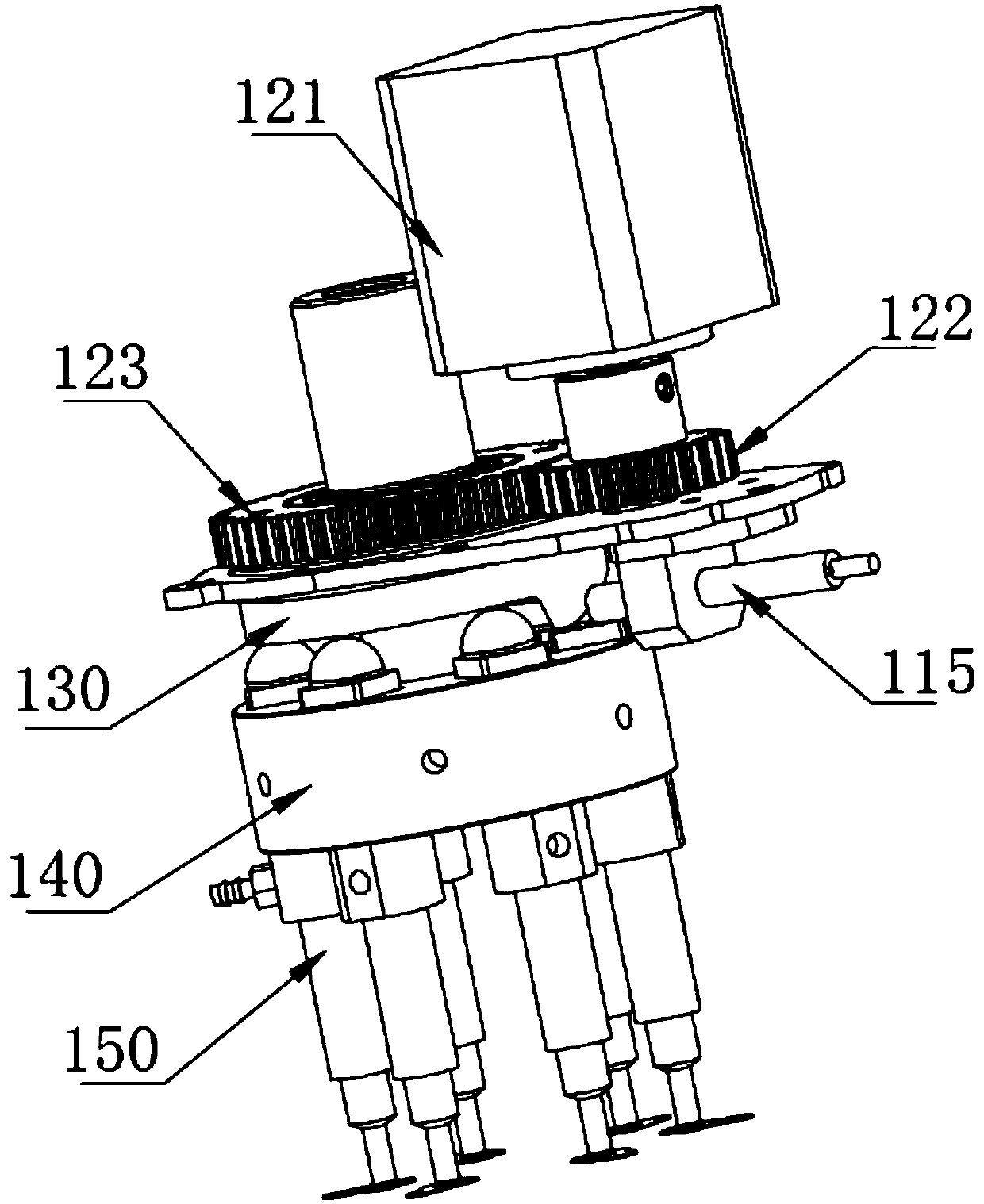

Electromedical device

ActiveCN104144671APromote sportsImprove suction performancePneumatic massageMagnetotherapy using coils/electromagnetsMagnetic transducersMechanical engineering

An electromedical device (100), comprising: a depression chamber (265) provided with an opening (270); aspirating means (105) connected to the depression chamber (265); a pair of rollers (240) suitable for at least partly delimiting the opening (270) of the depression chamber (265); motor means (285) suitable for rotating the rollers (240); a generator (325) of pulsed electric current; and an electromagnetic transducer (320) connected to the generator (325) such as to transform the pulsed electric current into a pulsed magnetic field, the electromagnetic current (320) being configured such that the flow of the pulsed magnetic field crosses the opening (270) of the depression chamber (265).

Owner:MANTIS

Concrete distributing valve and concrete pumping mechanism

InactiveCN101245866BImprove suction performancePositive displacement pump componentsMultiple way valvesStructural engineeringMechanical engineering

Owner:SANY AUTOMOBILE MFG CO LTD

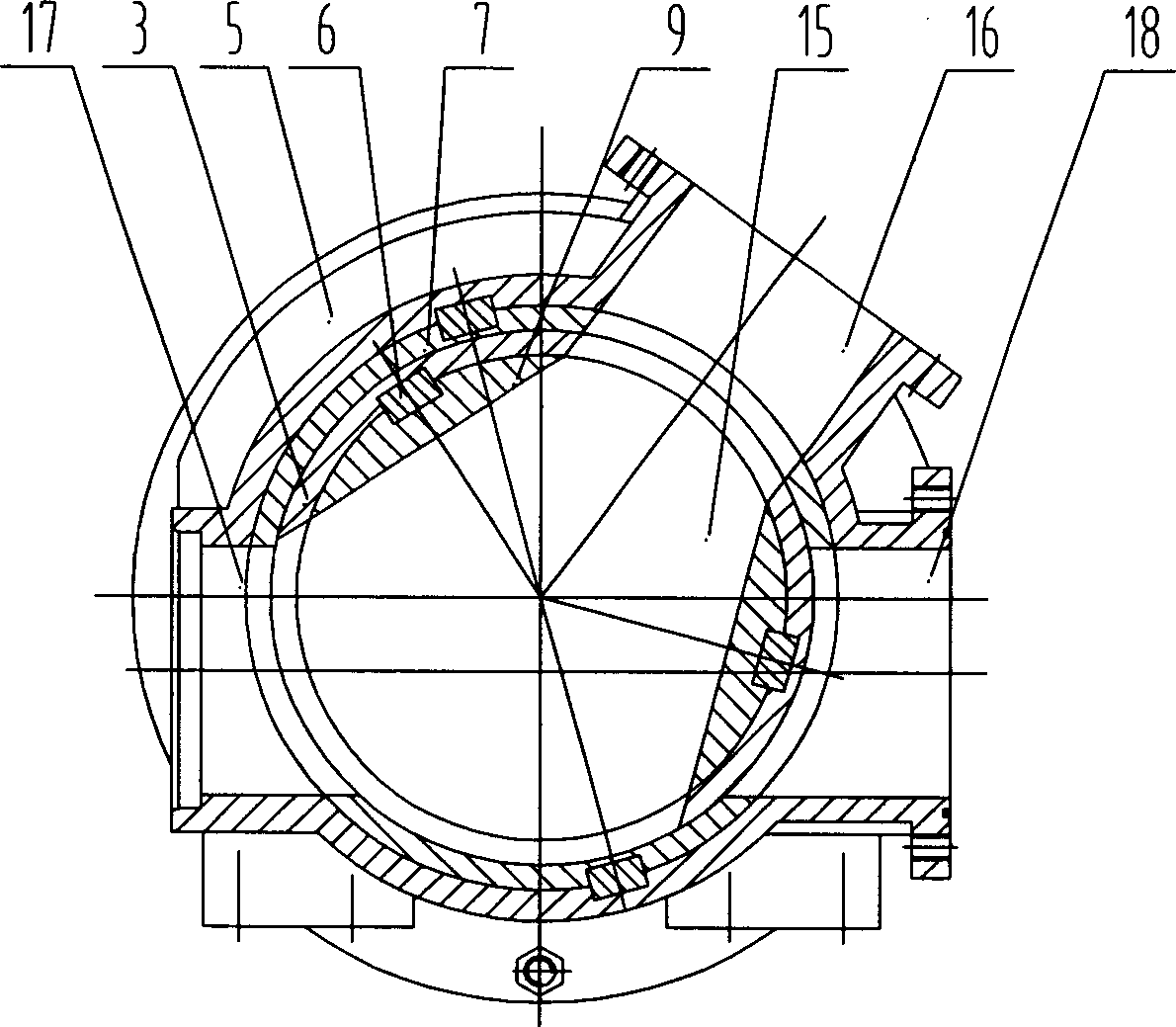

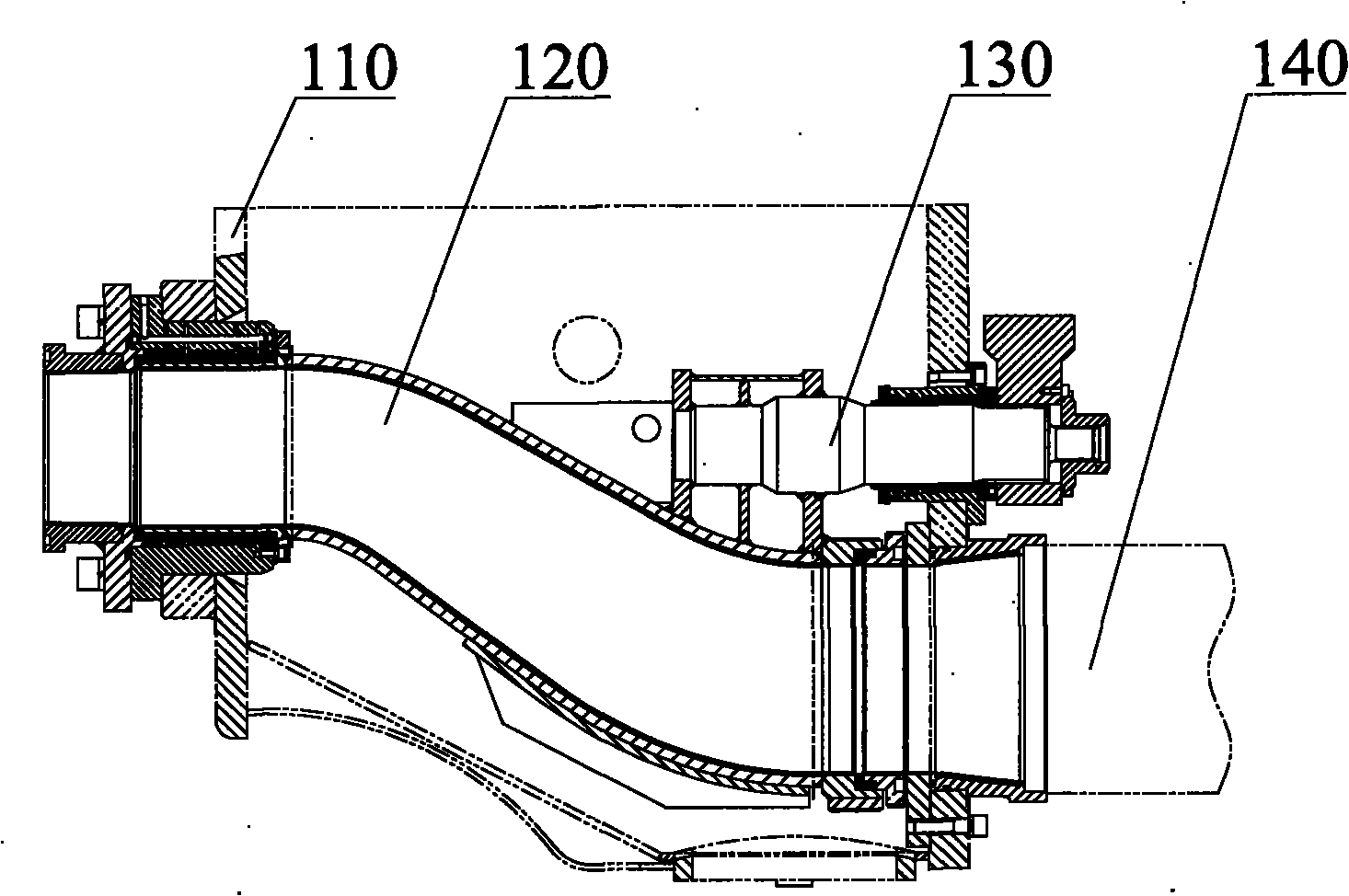

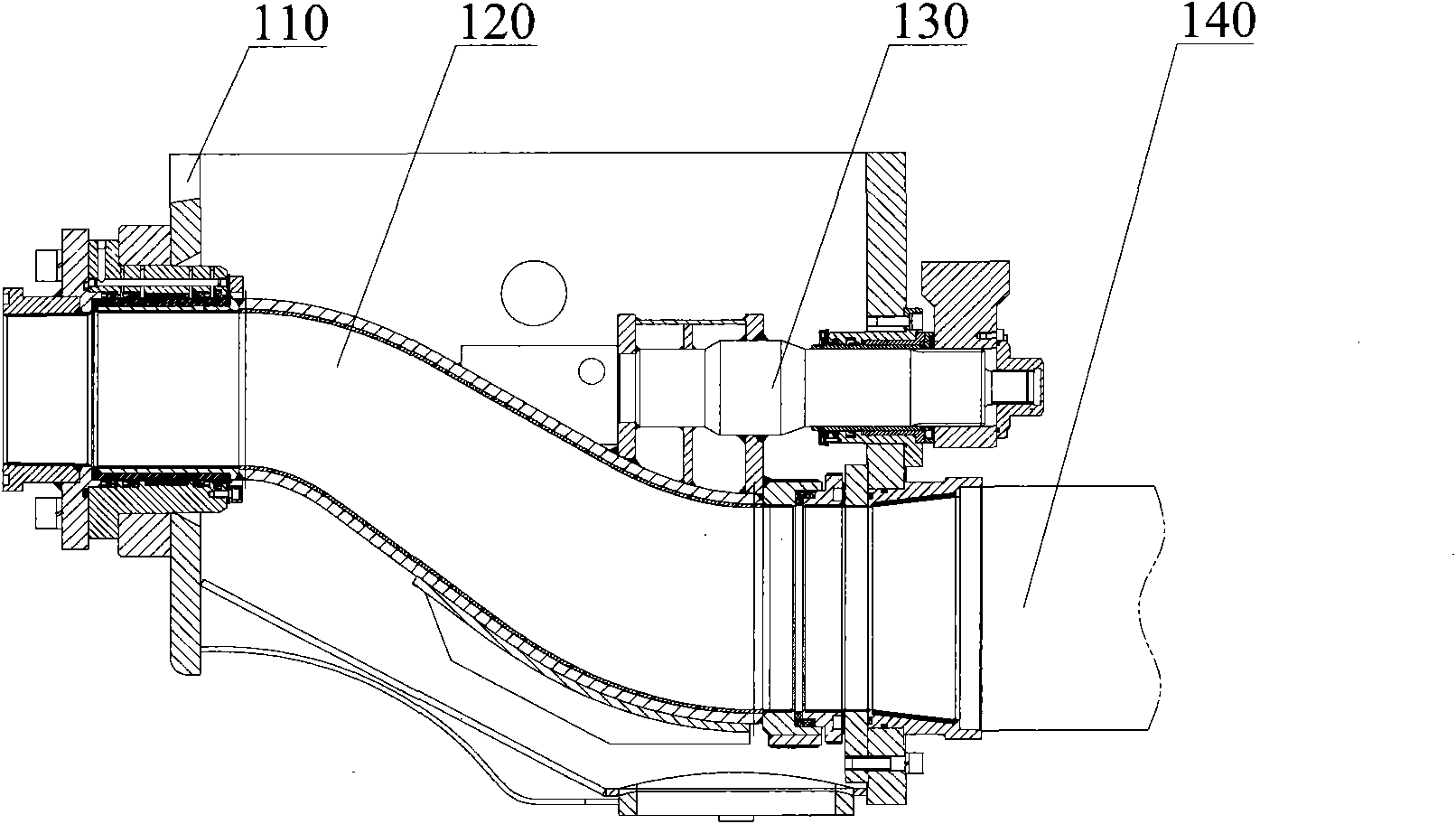

Pumping system and concrete pump truck having the same

ActiveCN101881262AImprove suction performanceStable flowPumpsBuilding material handlingEngineeringMechanical engineering

The invention discloses a pumping system and a concrete pump truck. The pumping system comprises a pumping power mechanism, a hopper and a distribution valve, wherein the distribution valve comprises a first tube section and a second tube section, the central line of the second tube section is vertical to that of the first tube section, and the first tube section can be mounted on the hopper in a rotation way; the lower end surface of the second tube section is matched with a sealing surface of a bottom wall board of the hopper, and the bottom wall board is provided with a delivery hole; and on a first position, the second tube section is communicated with a delivery cylinder of the pumping power mechanism through a delivery hole, and on a second position, the delivery cylinder is communicated with an accommodating space of the hopper through the delivery hole. In the disclosed pumping system and the concrete pump truck, dope inside the hopper can automatically flow into the first delivery cylinder through the delivery hole under the gravity effect, so the delivery cylinder can smoothly absorb the dope of a pre-determined quantity; therefore, the self flowing performance of the dope can be adequately utilized to improve the absorption performance of the pumping system.

Owner:SANY AUTOMOBILE MFG CO LTD

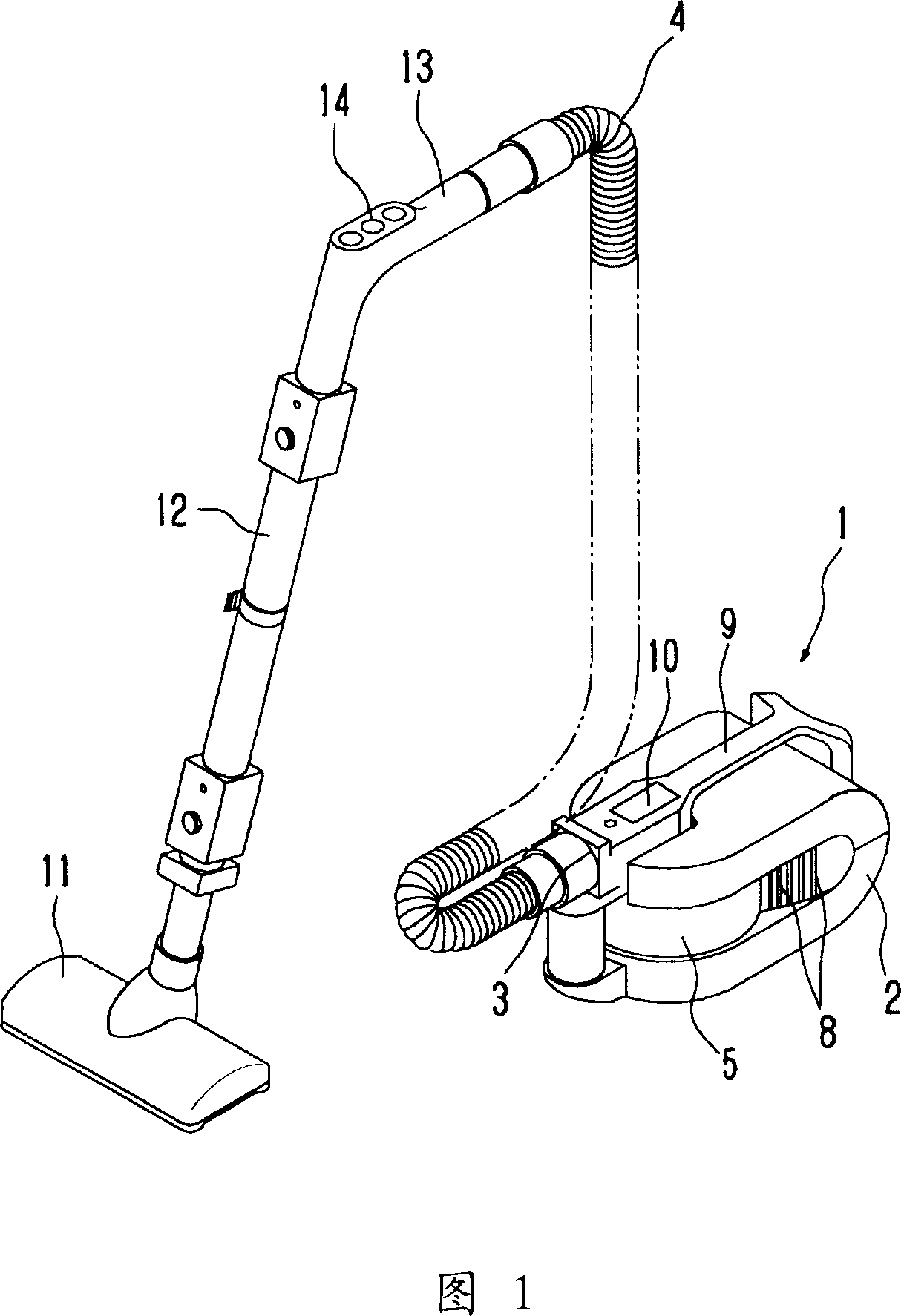

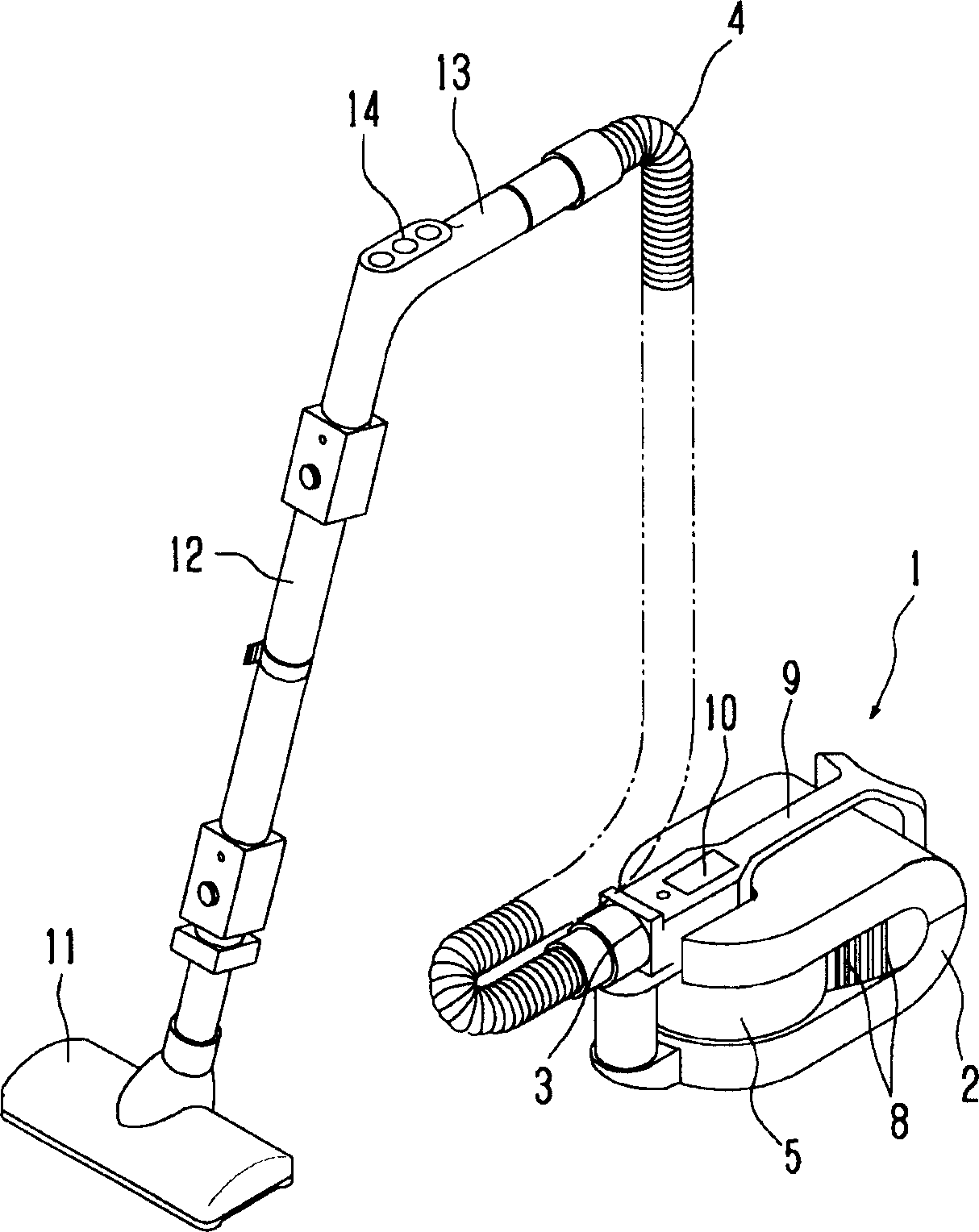

Impeller, electric air blower using same, and electric cleaner using electric air blower

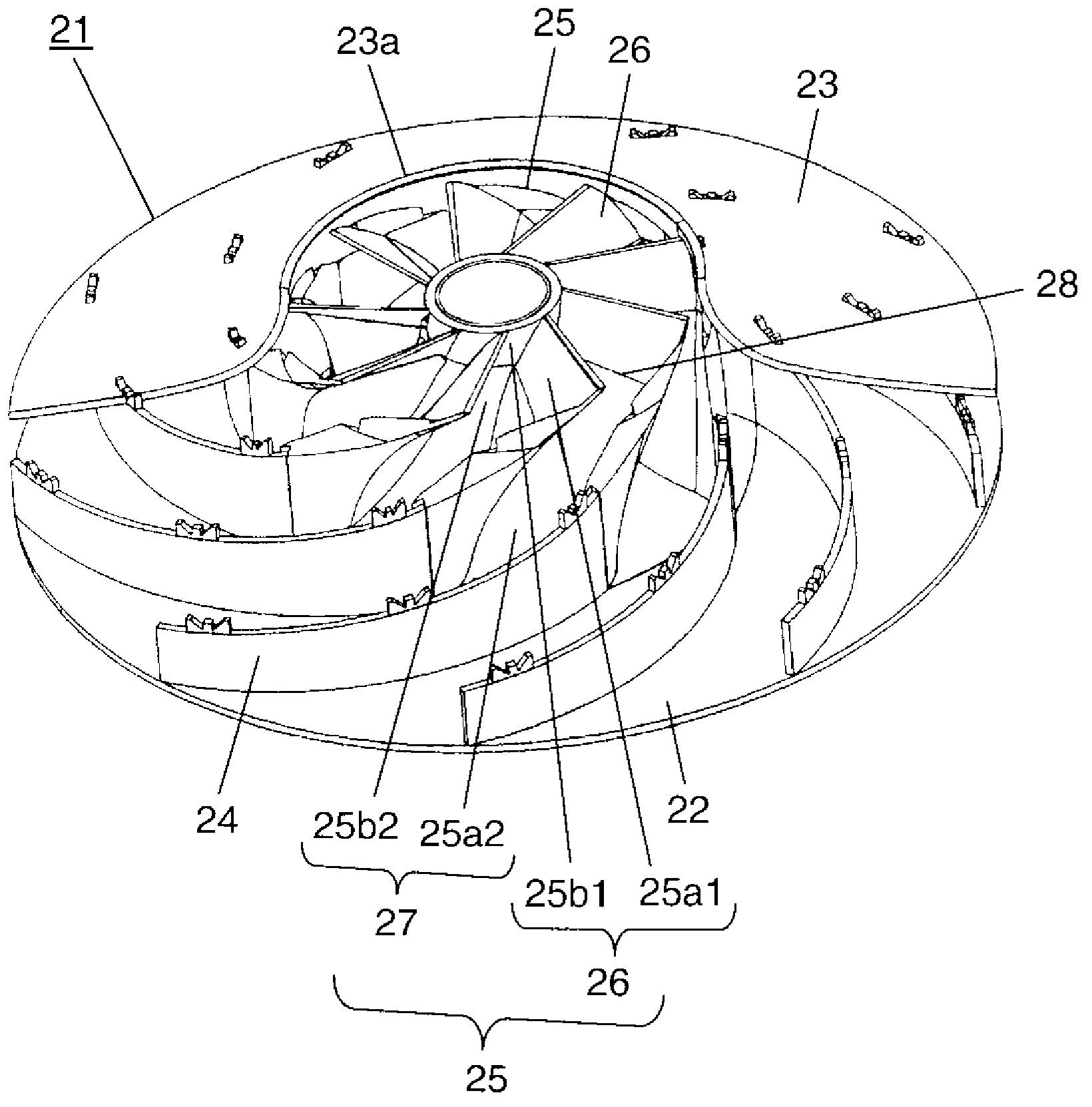

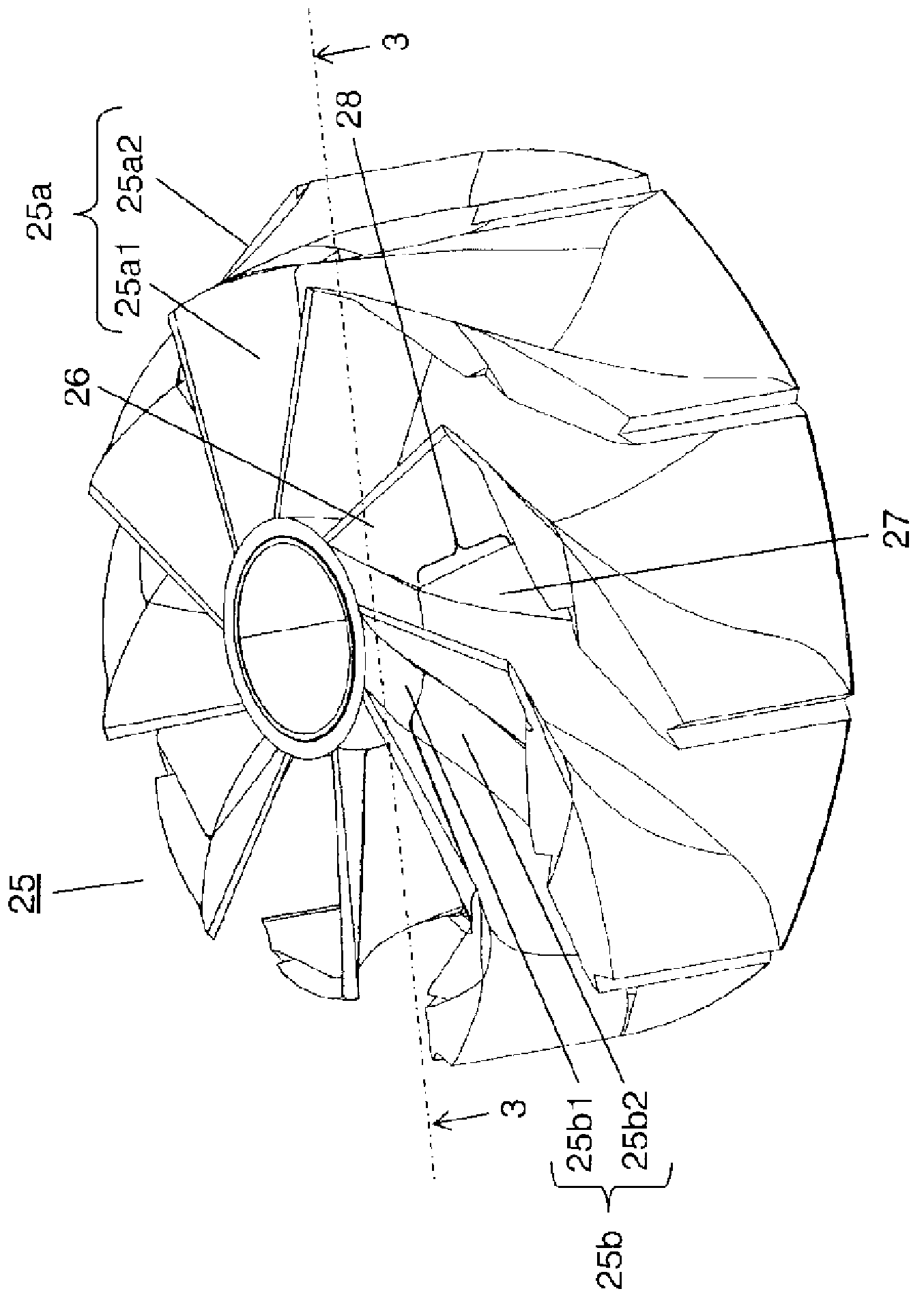

InactiveCN102762873AImprove suction performanceReduce noisePump componentsSuction cleanersImpellerLow noise

The invention provides an impeller, an electric air blower using same and an electric cleaner using the electric air blower. The disclosed impeller is provided with: a front-surface shroud having an air intake port; a back-surface shroud provided facing the front-surface shroud; a first inducer that has a plurality of first fin sections provided to the perimeter of a first hub section provided between the front-surface shroud and the back-surface shroud; a second inducer that has a plurality of second fin sections provided to the perimeter of a second hub section and that is connected to the first fin sections of the first inducer; and a plurality of blades connected to the second fin sections of the second inducer. As a result, it is possible to increase the number of inducer blades, and to provide a high-performance, low-noise impeller.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Multi-head material taking device based on cam driving lifting

ActiveCN109650059AImprove suction performanceImprove reclaiming efficiencyConveyor partsCamRotating disc

The invention relates to the technical field of automatic material taking, in particular to a multi-head material taking device based on cam driving lifting. The multi-head material taking device comprises a mounting bracket, a driving part, a cam rotating disc and a material sucking disc. The driving part is arranged on the mounting bracket. The cam rotating disc is in transmission connection with the driving part. The material sucking disc is arranged on the mounting bracket. A plurality of suction nozzles are uniformly distributed on the material sucking disc in the circumferential direction and are telescopically arranged on the material sucking disc. The cam rotating disc is driven by the driving part to drive the suction nozzles to stretch and suck materials. Compared with a transmission material suction structure, the multi-head material taking device is low in cost. Due to the arrangement of the plurality of groups of suction nozzles, the material sucking efficiency and the automation degree are high.

Owner:东莞市威耐科智能装备有限公司

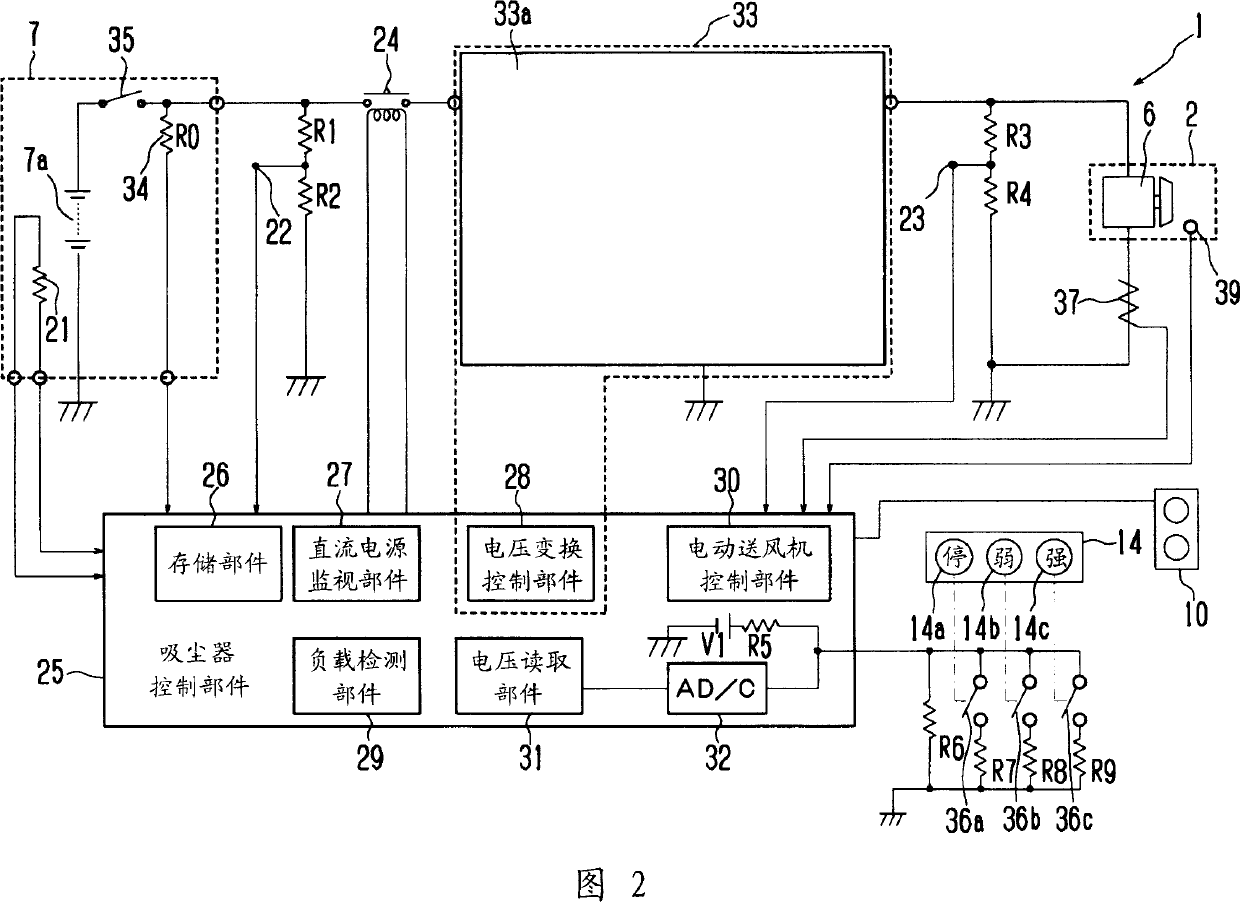

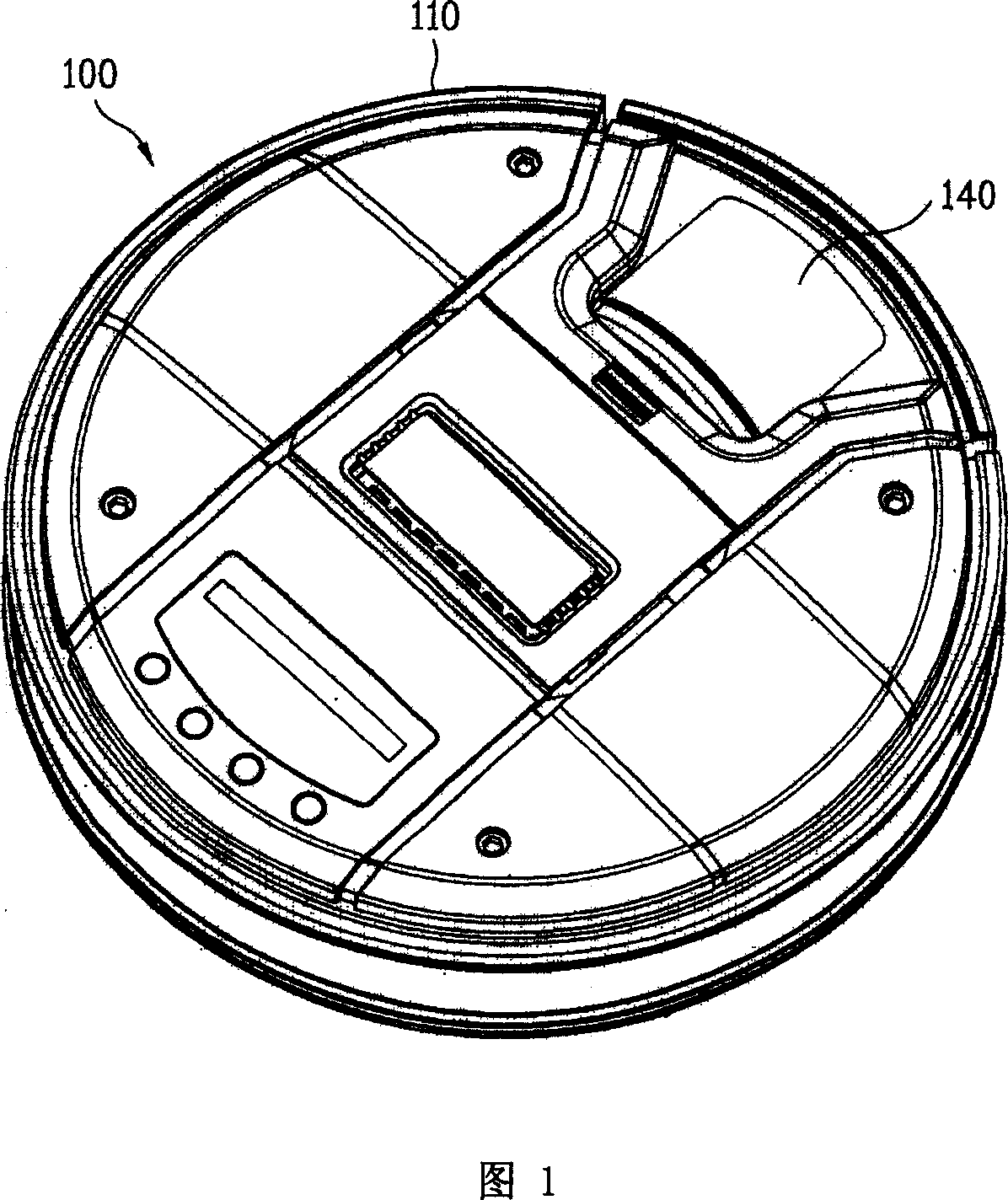

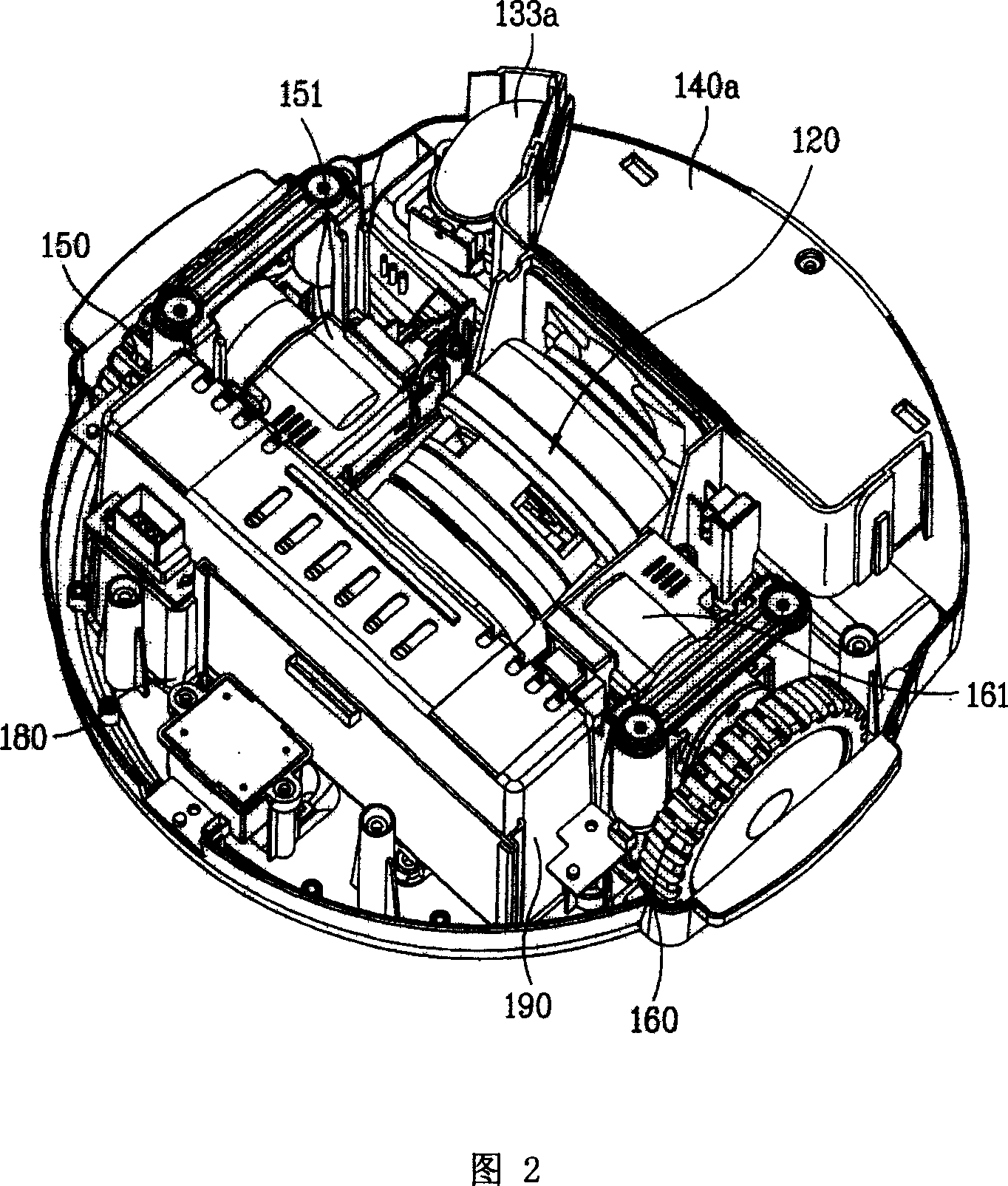

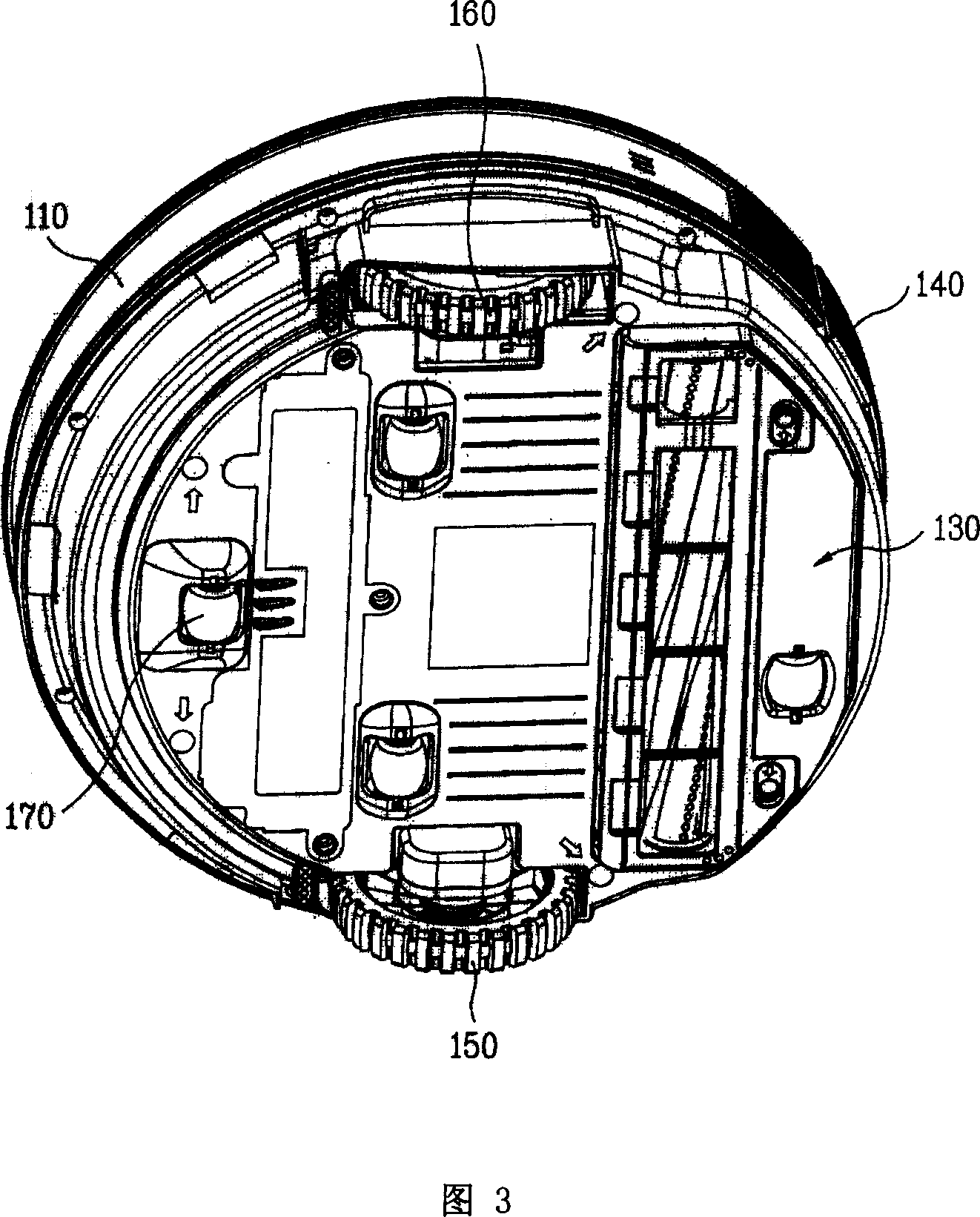

Vacuum cleaner

InactiveCN1496701AGuaranteed to workImprove suction performanceDC motor speed/torque controlElectric equipment installationMotor driveEngineering

Owner:TOSHIBA TEC KK

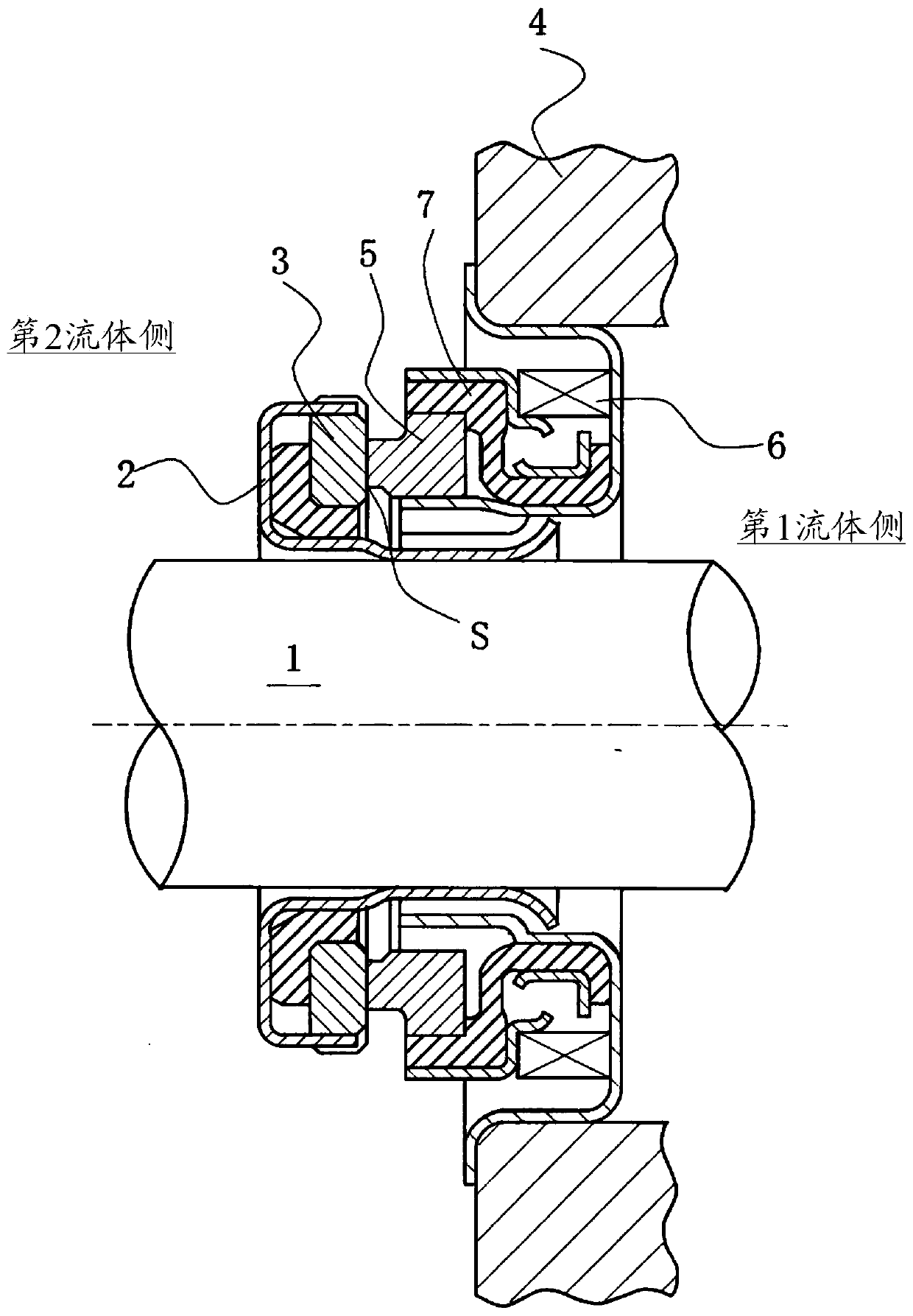

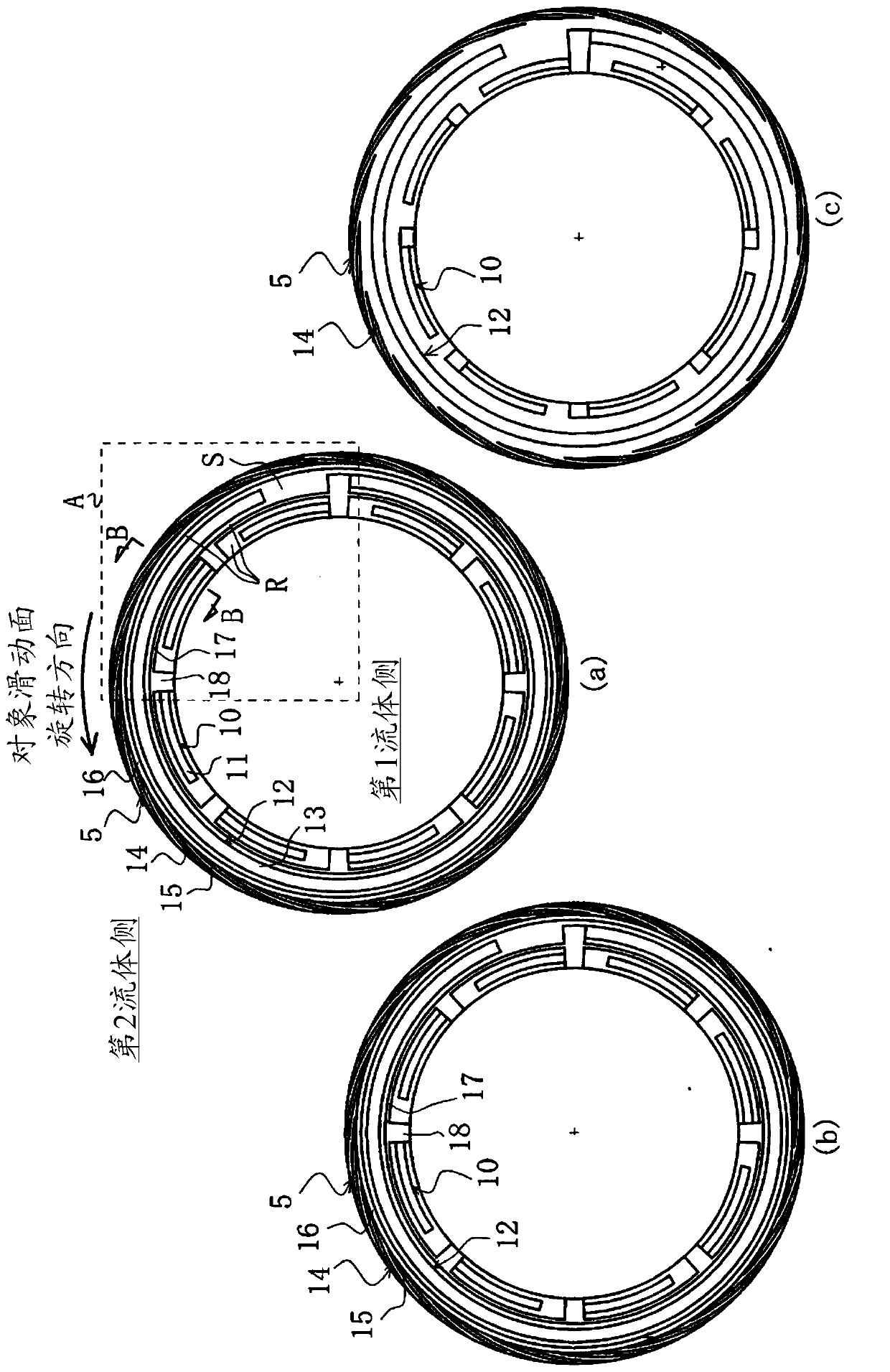

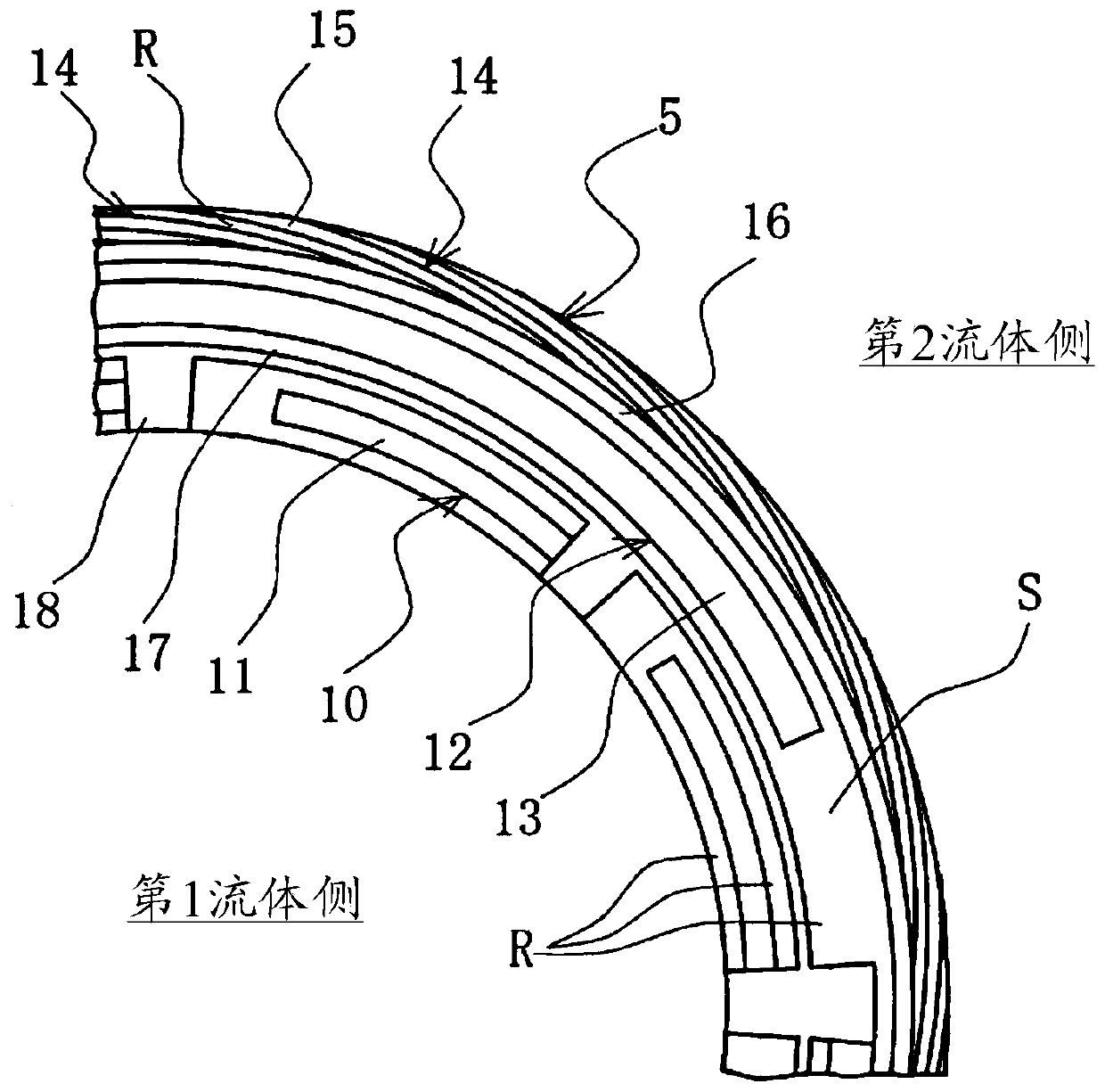

Sliding component

ActiveCN109923340AAvoid mixingAvoid interferenceEngine sealsBearing componentsPressure generationEngineering

Provided is a sliding component with which it is possible to prevent the mixing of different liquids on both sides thereof. The present invention is characterized in that: a sliding surface (S) is provided with a first-fluid-side negative pressure generation mechanism (12) comprising a first negative pressure generation groove (13), a second-fluid-side negative pressure generation mechanism (14) comprising a second negative pressure generation groove (15) and positioned closer to the second-fluid side than the first-fluid-side negative pressure generation mechanism (12), and a dynamic pressuregeneration mechanism (10) comprising dynamic pressure generation grooves (11) positioned closer to the first-fluid side and / or the second-fluid side than the first-fluid-side negative pressure generation mechanism (12) and the second-fluid-side negative pressure generation mechanism (14); the first negative pressure generation groove (13) is separated from the second-fluid side by land sections (R); and the second negative pressure generation groove (15) is separated from the first-fluid side by means of the land sections (R).

Owner:EAGLE INDS

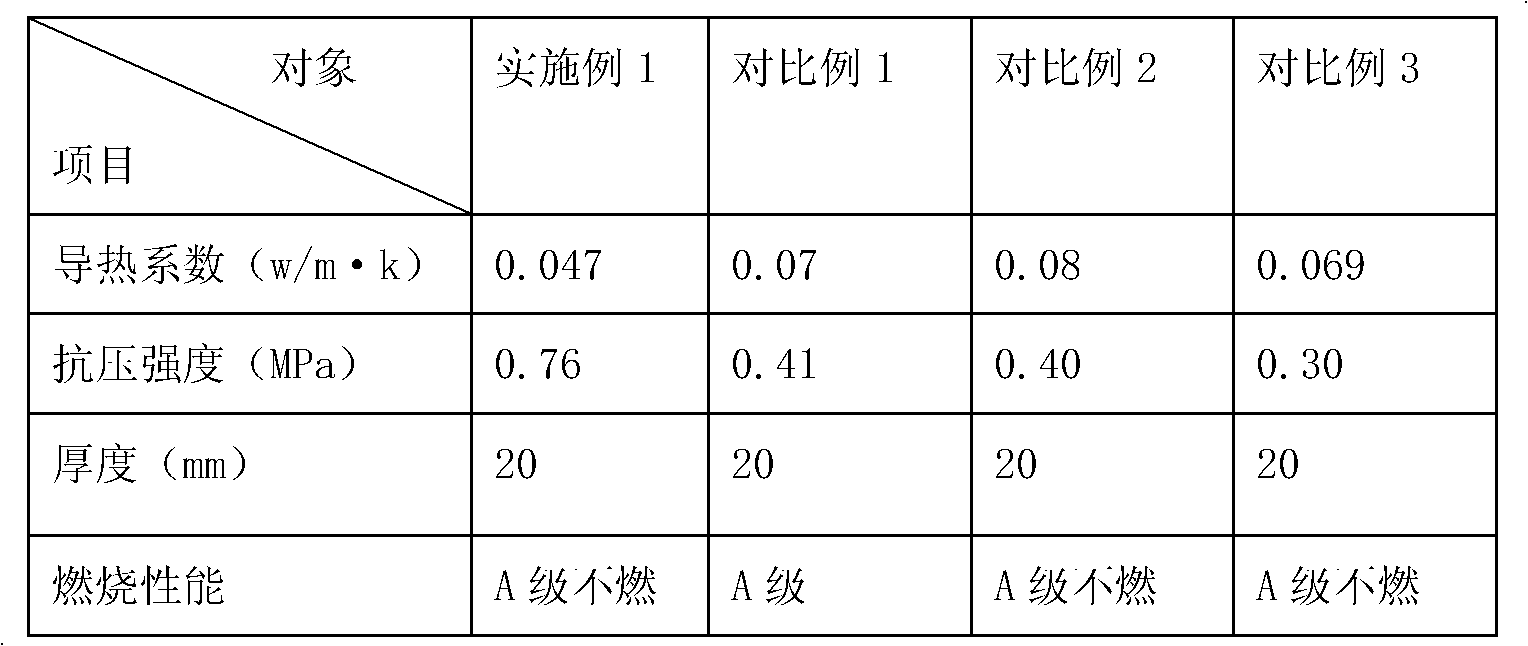

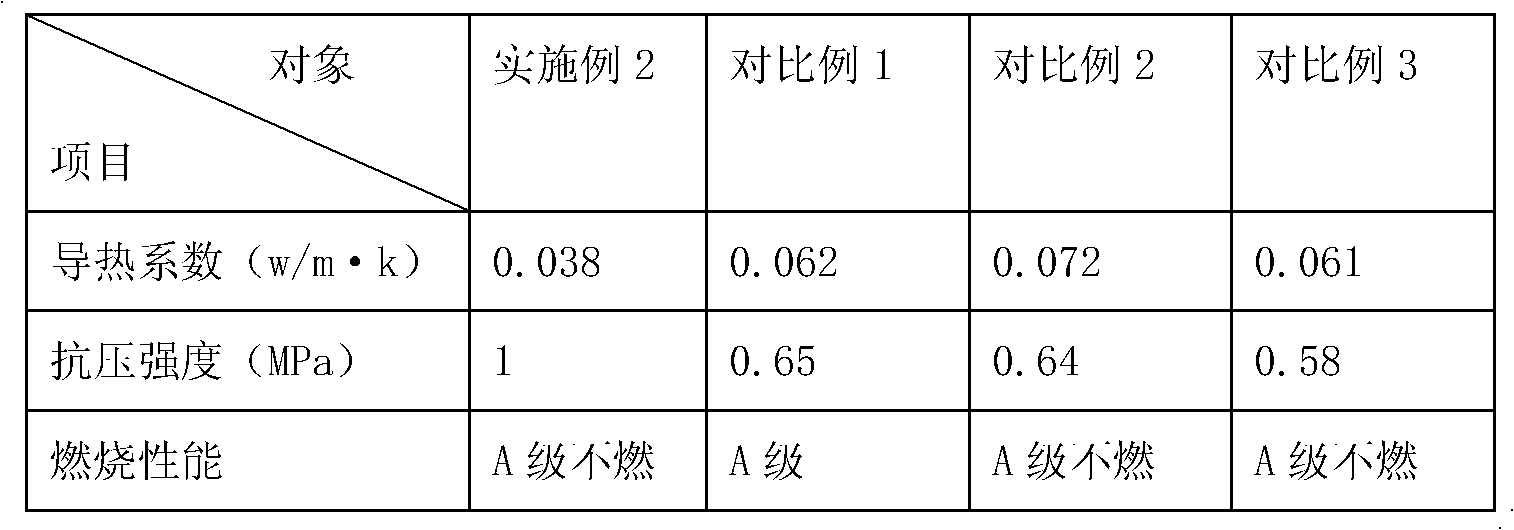

Fireproof thermal insulation material

The invention relates to a building material, and concretely relates to a fireproof thermal insulation material for walls. The fireproof thermal insulation material comprises the following raw materials, by weight, 24-44% of a waste high temperature resistant glass fiber composite filter bag, 28-20% of a scrap obtained by cutting when the filter bag is produced from high temperature resistant glass fiber composite felts, 28-36% of coal ash, 4-6% of a flocculating agent and 4-6% of cationic starch, wherein base clothes of the waste high temperature resistant glass fiber composite filter bag and the scrap obtained by cutting when the filter bag is produced from the high temperature resistant glass fiber composite felts are glass fiber base clothes, and surface layers of the composite filter bag and the scrap are glass fiber composite surface layers. Main raw materials of the invention are waste raw materials, so the recycle of the waste raw materials makes the cost and the land resource be saved; and no harmful gases are discharged, and the fireproof thermal insulation material has the advantages of good high temperature resistance and corrosion resistance, low water absorbability, light weight, small conduction coefficient, good productivity, no combustion and good chemical stability.

Owner:SHANDONG XINLI ENVIRONMENTAL PROTECTION MATERIAL

Suction device of dust collector

The invention relates to a dust collector. Wherein, it comprises a bottom with inlet for absorbing foreign material, rotator at the inlet, blade at the circumference of rotator, and saw part at the outer end of blade. The invention can adsorb the foreign material with low weight and large volume.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

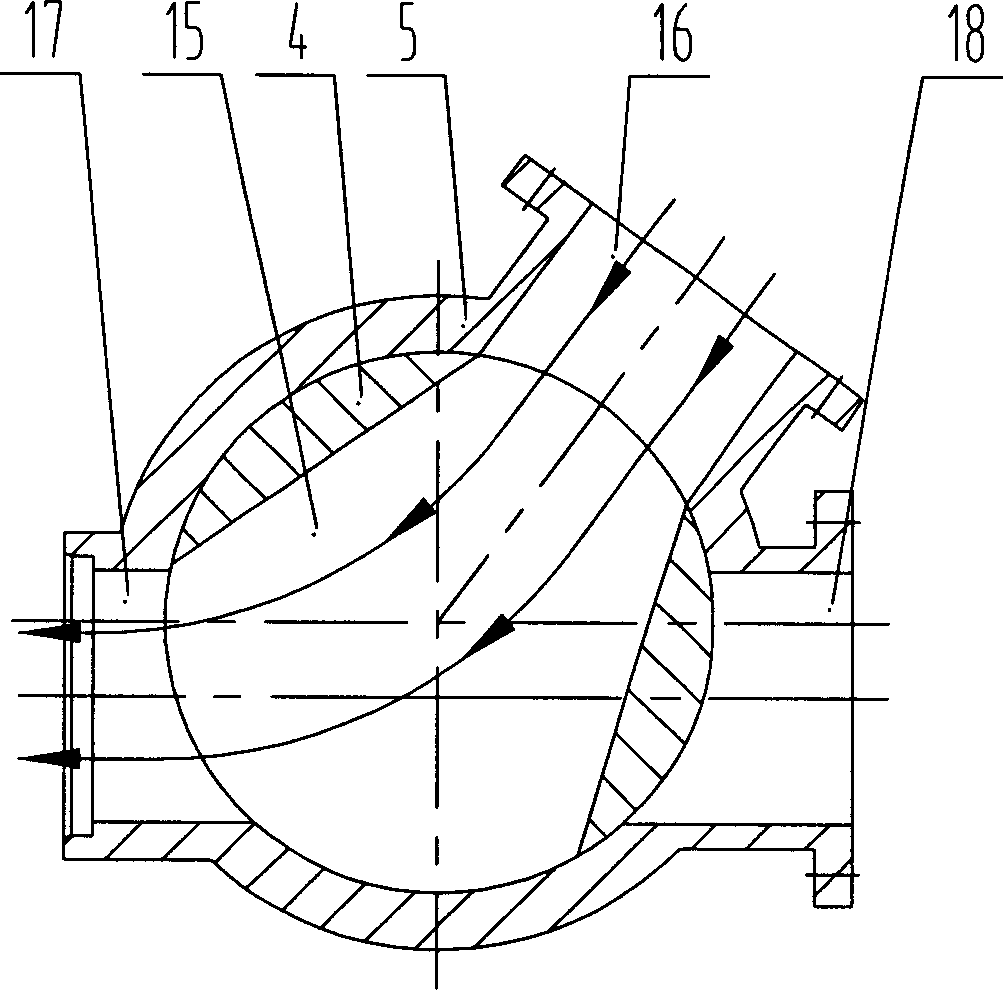

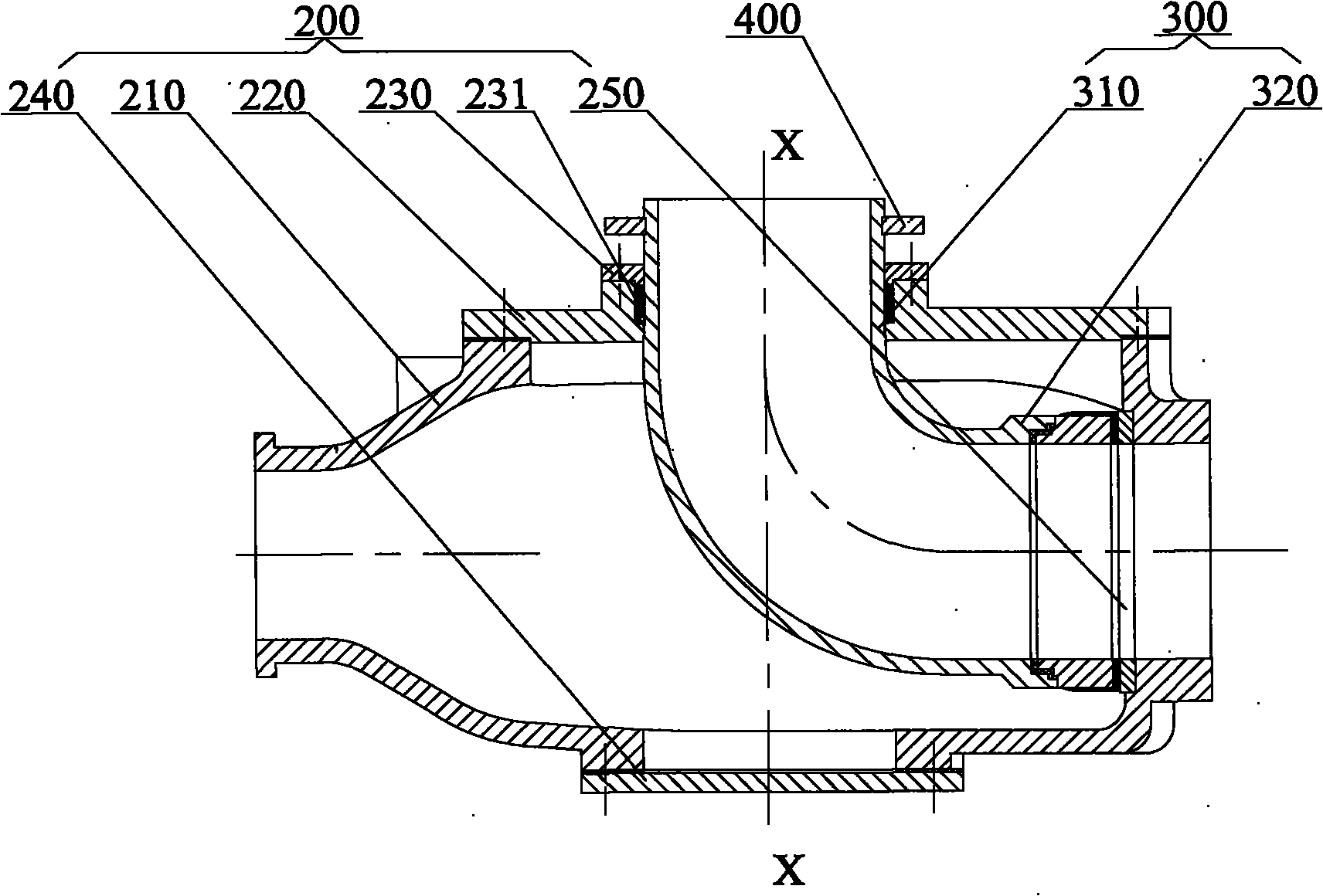

Pumping system and concrete pump truck having the same

ActiveCN101881263AImprove suction performanceIncrease stiffnessPumpsBuilding material handlingMiddle lineEngineering

The invention discloses a pumping system and a concrete pump truck. The pumping system comprises a pumping power mechanism, a hopper and a distribution valve, wherein the distribution valve comprises a first tube section, a second tube section and a rotation shaft, the second tube section is connected with the first tube section, an angle between the middle line of the first and the second tube sections is more than 90 degrees and less than 180 degrees, and the first tube section can be installed on the hopper in a rotation way; the lower end surface of the second tube section is matched with a sealing surface of a bottom wall board of the hopper; the rotation shaft is installed on the hopper in a rotation way, the front end of the rotation shaft is fixed with the first tube section, and the axis of the rotation shaft is overlapped with the central line of the first tube section; the second tube section is communicated with a delivery cylinder through a delivery hole on the bottom wall board on a first position, and the delivery cylinder is communicated with an accommodating space of the hopper through the delivery hole on a second position. In the pumping system and the concrete pump truck, dope inside the hopper can automatically flow into the first delivery cylinder through the delivery hole under the gravity effect, so the self flowing performance of the dope can be adequately used to improve the absorption performance of the pumping system.

Owner:SANY AUTOMOBILE MFG CO LTD

Hydraulic concrete delivery pump

InactiveCN108868145AControl normal operationGuaranteed uptimeUnderground chambersPiston pumpsPulp and paper industryElectric control

The invention relates to the technical field of concrete delivery pumps, in particular to a hydraulic concrete delivery pump, which comprises a rack and a hood as well as an electric control box, wherein support legs are fixedly arranged at the bottom of the rack, and a carrying wheel is arranged at the center of the bottom of the rack; a supporting wheel is fixedly arranged at the right side of the bottom of the rack, and a traction rack is fixedly arranged at the right side of the rack; an anti-overflow hopper is fixedly arranged at the left side of the rack, and a washing tank is fixedly arranged at the bottom of the rack; the left side of the washing tank is connected with a pumping mechanism, and the other end of the pumping mechanism is fixedly connected with the anti-overflow hopper; a stirring mechanism is arranged at both sides of the anti-overflow hopper, and a discharge pipe is arranged at the left side of the anti-overflow hopper; the hood is fixedly arranged at the top ofthe rack, and the right side, close to the anti-overflow hopper, of the hood is provided with a steel swinging mechanism. The overall device has high delivery efficiency and intelligent control, higher stability and practicability and certain promotion value.

Owner:周华梅

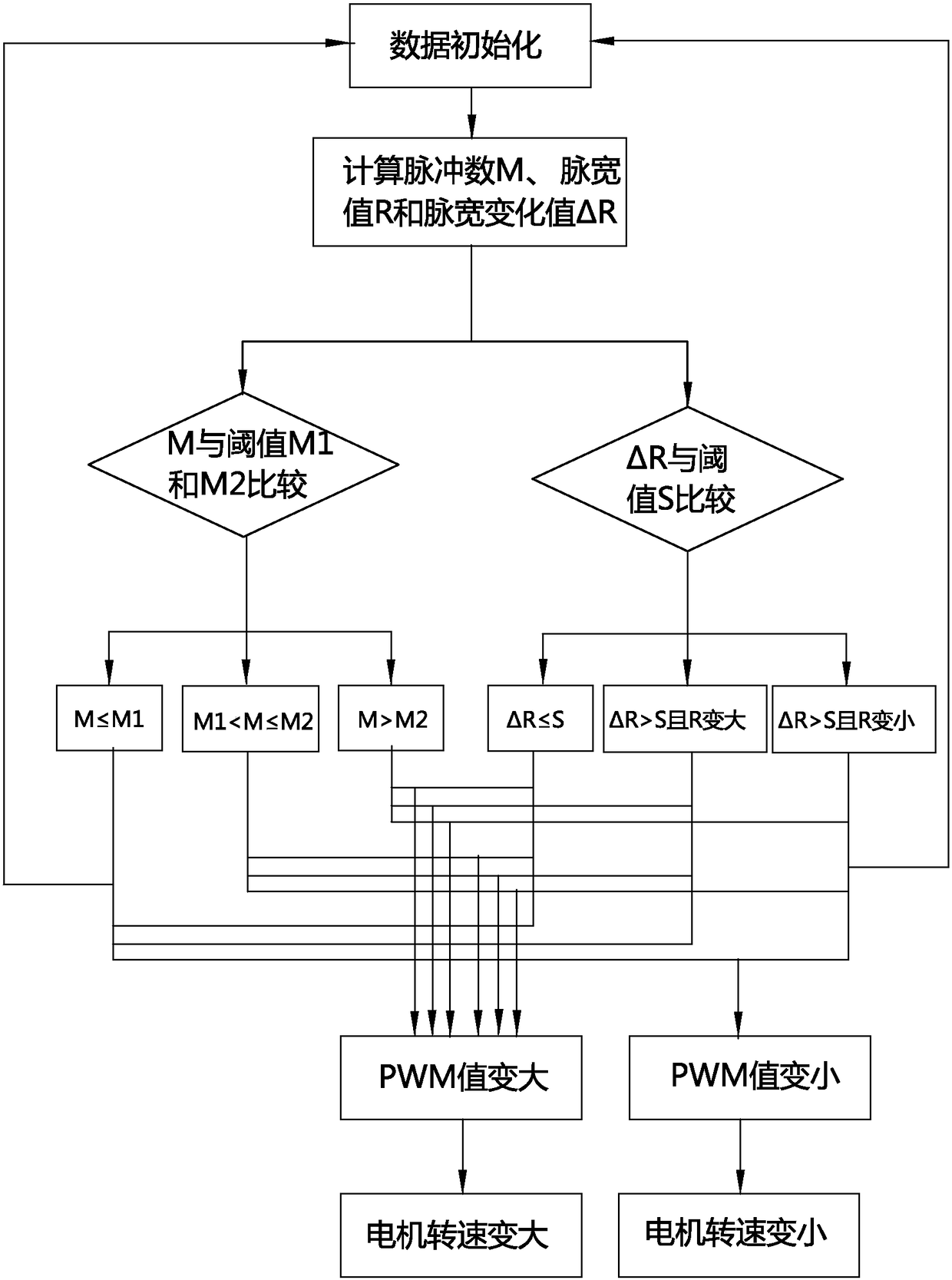

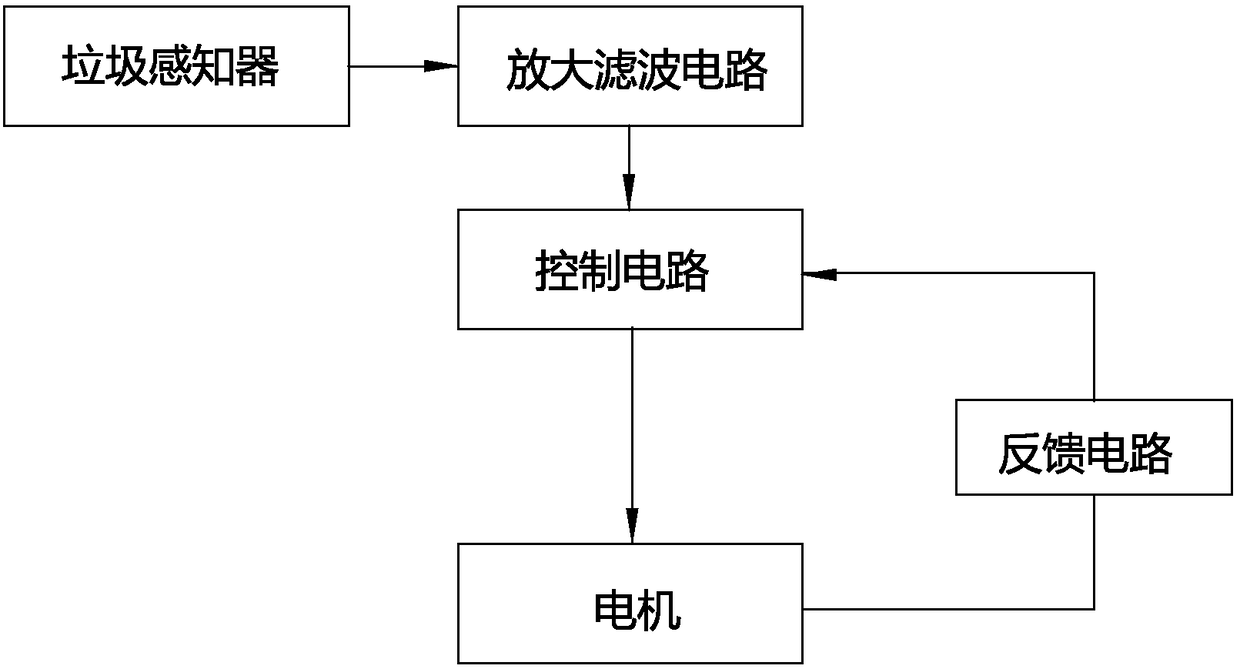

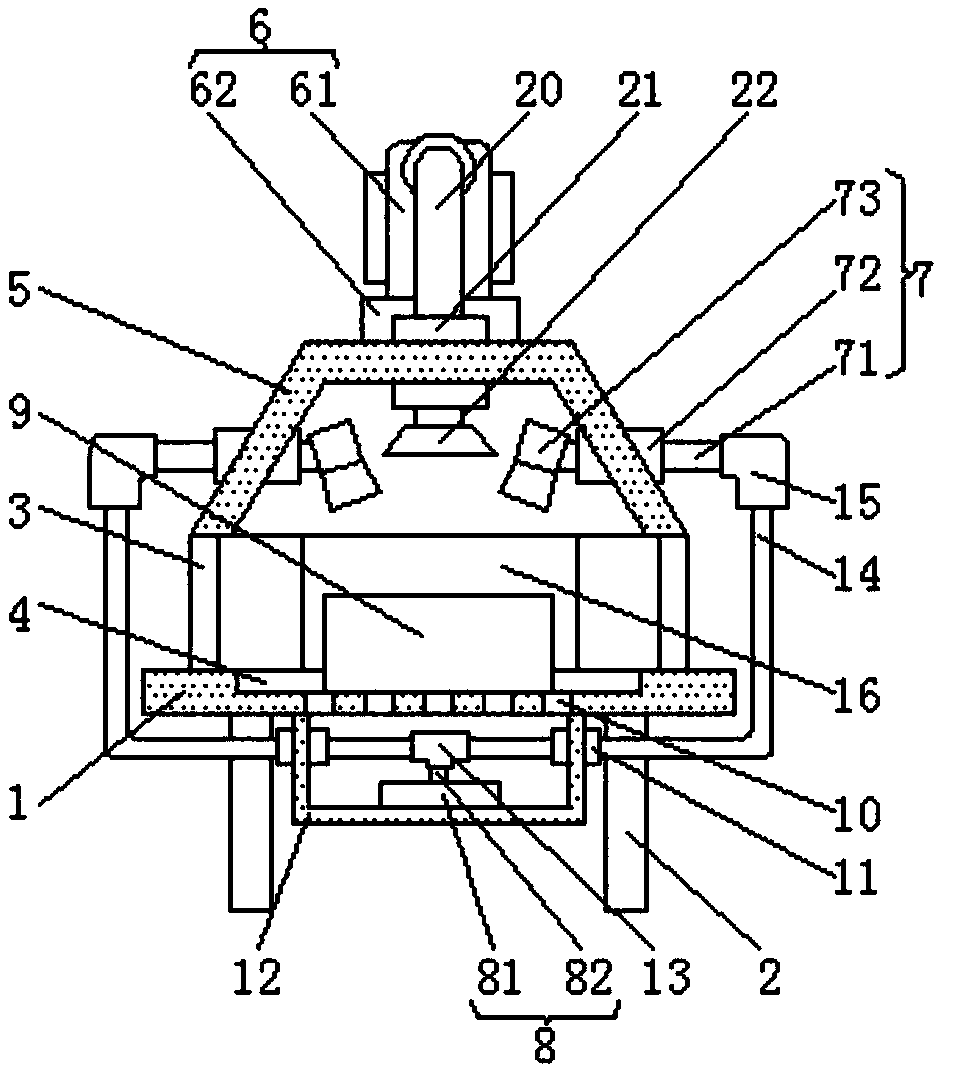

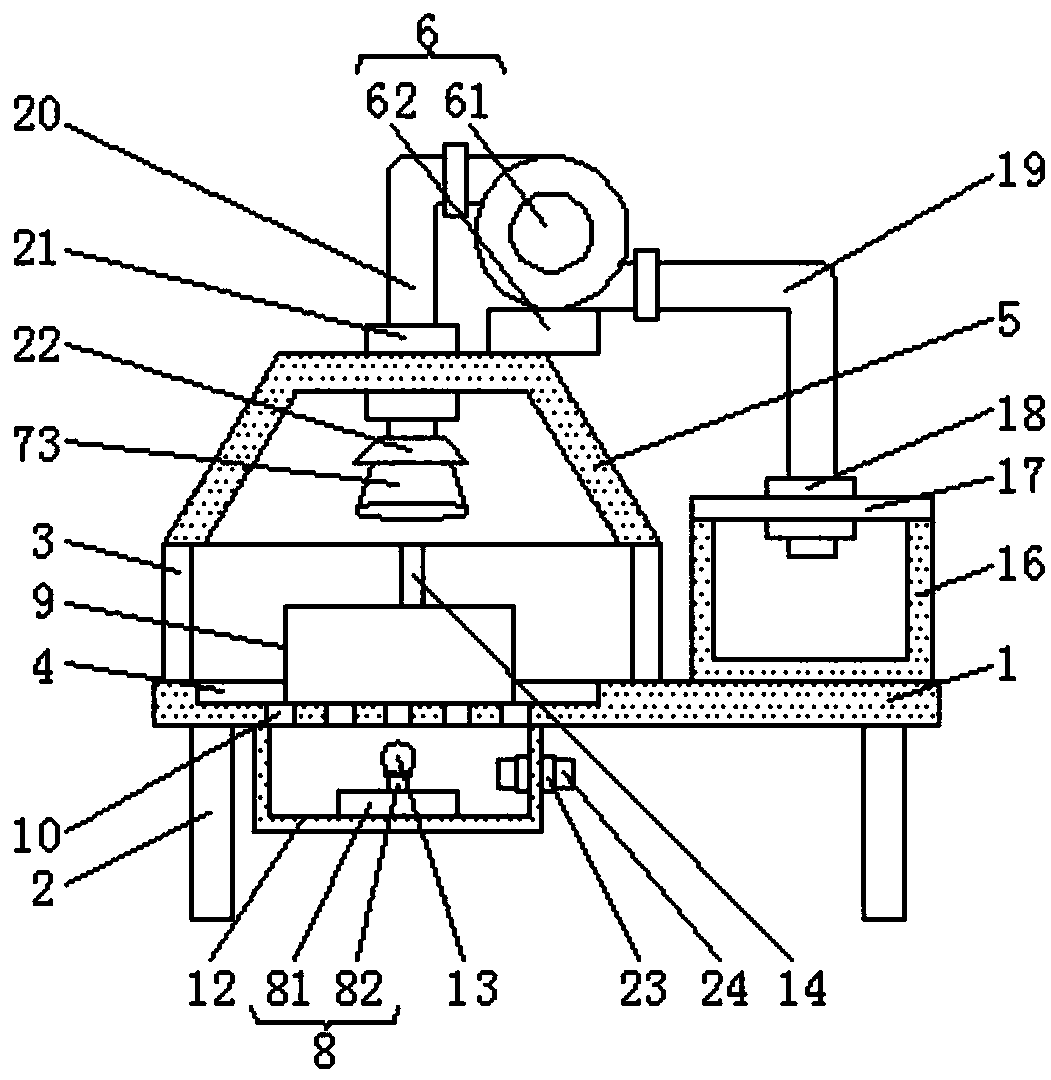

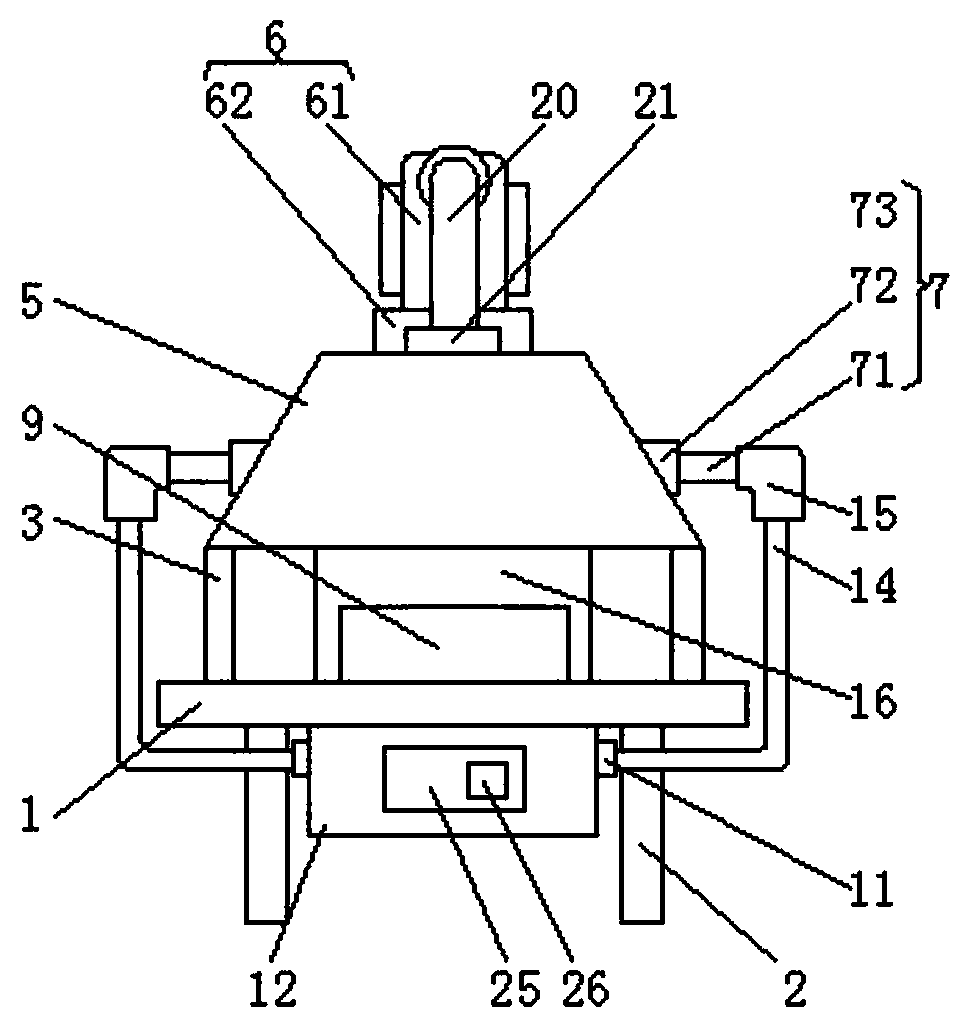

Dust collection device

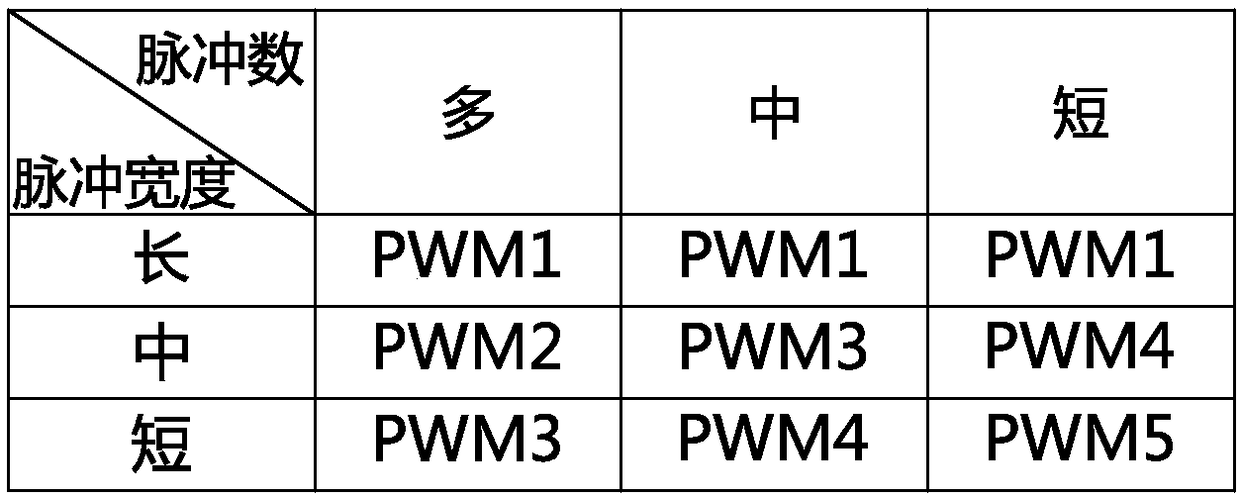

ActiveCN108283460AImprove suction performanceAutomatic speed adjustmentMechanical suction controlFluid pressure control using electric meansElectricityPulse number

The invention discloses a dust collection device. The problems of poor collection effect and high electricity consumption amount of a dust collection device in the prior art are solved. A method adopted by the dust collection device for controlling an air suction motor to work comprises the following steps that 1, data is initialized; 2, when a waste sensor senses waste, a pulse number M, a pulsewidth value R and a pulse width change value delta R start to be calculated; 3, the pulse number M at the moment when preset time T is up is recorded, and a first pulse threshold value M1, a second pulse threshold value M2 and a pulse width change threshold value S are preset in a control circuit, wherein M1 is smaller than or equal to M2, and if the pulse number value M is smaller than or equal to M1 and the pulse width change value delta R is smaller than or equal to S, the first step is returned to; if M is larger than or equal to M1 and smaller than or equal to M2, the pulse width change value delta R is smaller than or equal to S, and the pulse width value R is decreased, the firs step is returned to; if the pulse number value M is smaller than or equal to M1, the pulse width change value delta R is smaller than or equal to S, and the pulse width value R is decreased, a PWM value output by the control circuit is decreased, and the rotation speed of the air suction motor is lowered; otherwise, the PWM value output by the control circuit is increased, and the rotation speed of the air suction motor is increased.

Owner:PANASONIC APPLIANCES CHINA CO LTD

Textile equipment with dust removal and humidification functions

InactiveCN109092836AQuality assuranceGuaranteed production efficiencyTextile treatment machine arrangementsDirt cleaningWater pipeYarn

The invention discloses textile equipment with dust removal and humidification functions. The textile equipment comprises a bottom plate and a dust collecting box, the upper surface of the bottom plate is fixedly connected with the lower surface of a dust collecting cover by four brackets, and the four brackets are correspondingly located at the four corners of the lower surface of the dust collecting cover. The lower surface of the bottom plate is fixedly connected with four supporting legs, and the four supporting legs are correspondingly located at the four corners of the lower surface of the bottom plate. A groove is formed in the upper surface of the bottom plate, and the groove is located between the four brackets. A textile machine is arranged on the lower surface of the inner wallof the groove, and a plurality of through holes are formed in the lower surface of the inner wall of the groove. According to the textile equipment with the dust removal and humidification functions,through the cooperation between an exhaust fan, a suction nozzle, the dust collecting box, a water pump, a first water pipe, a diverting joint, second water pipes and atomizing nozzles, the dust removal and humidification operation is realized in the textile process, it is ensure that the textile operation can be carried out normally, the quality of yarns is ensured, and production efficiency of people is ensured.

Owner:徐州鼎源纺织股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com