Vacuum cleaner

A technology for vacuum cleaners and components, which is applied in the direction of vacuum cleaners, DC motor speed/torque control, and installation of electrical equipment. It can solve problems such as loss, work related to boost conversion circuits in the state of no open load, and power loss. Use time, effect of improving dust suction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Next, a first embodiment of the present invention will be described with reference to FIGS. 1 to 17. FIG.

[0033] [structure appearance]

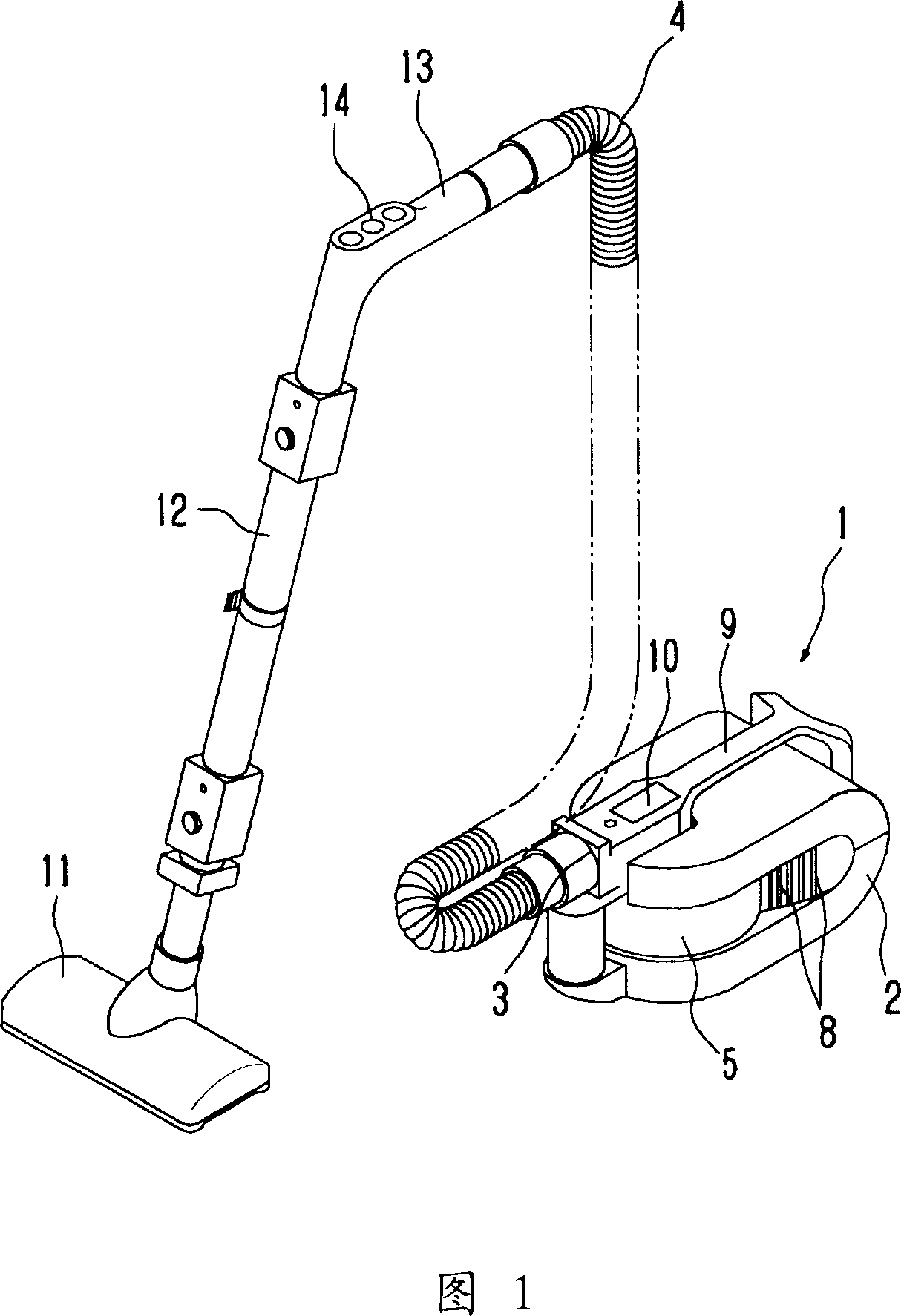

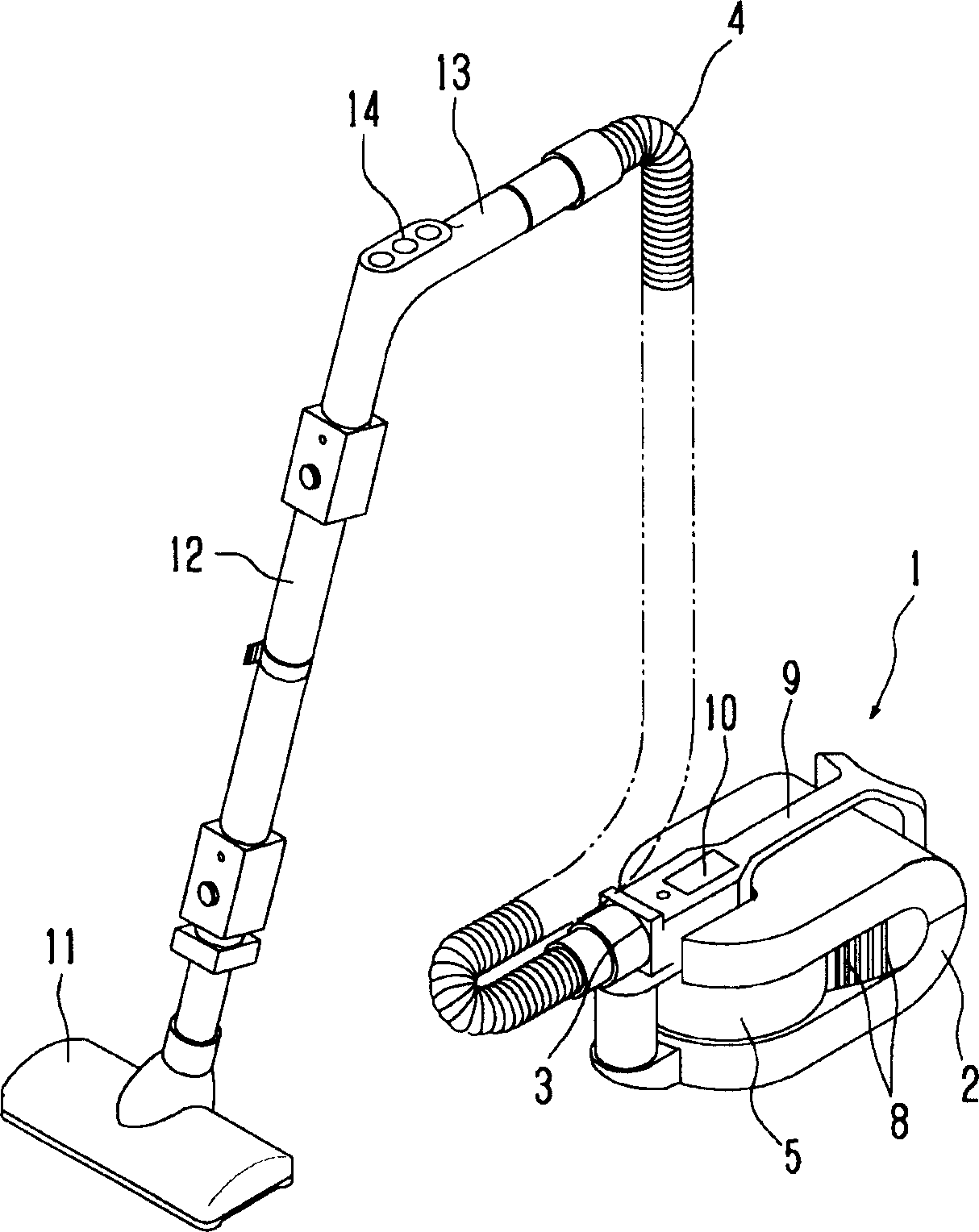

[0034] Fig. 1 is a perspective view showing the appearance structure of a vacuum cleaner according to an embodiment of the present invention. As shown in FIG. 1 , the vacuum cleaner 1 of this embodiment is provided with a detachable hose body 4 facing the suction port 3 provided on the body 2 .

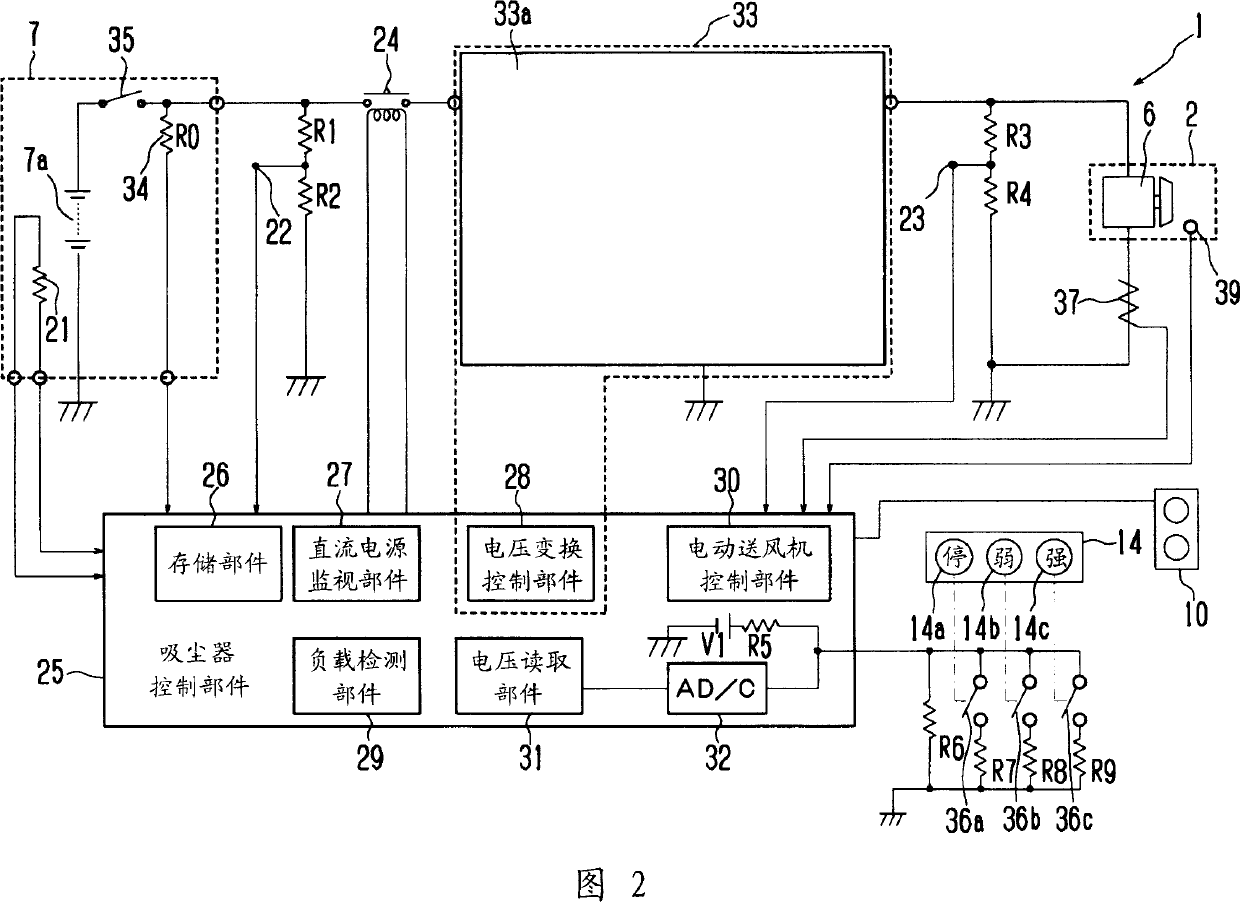

[0035] Inside the body 2, a dust cup 5 serving as a dust collection chamber, an electric blower 6, and a DC power supply 7 are provided (see FIG. 2 ). On the side plate portion of the body 2 , a plurality of exhaust ports 8 opening substantially facing the front side of the communicating electric blower 6 are penetratingly provided. In the upper surface of the body 2, a handle 9 as a handle member is provided. The handle 9 is a slightly Y-shaped structure viewed from a plane. In the vicinity of the handle 9, a display unit 10 including ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com