Multi-head material taking device based on cam driving lifting

A technology of picking device and cam, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems that multiple sets of suction nozzles cannot be lifted and lowered synchronously, the suction nozzles cannot grasp materials one by one, and the materials cannot be lifted and picked up independently. Achieve the effects of low cost, good suction effect and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

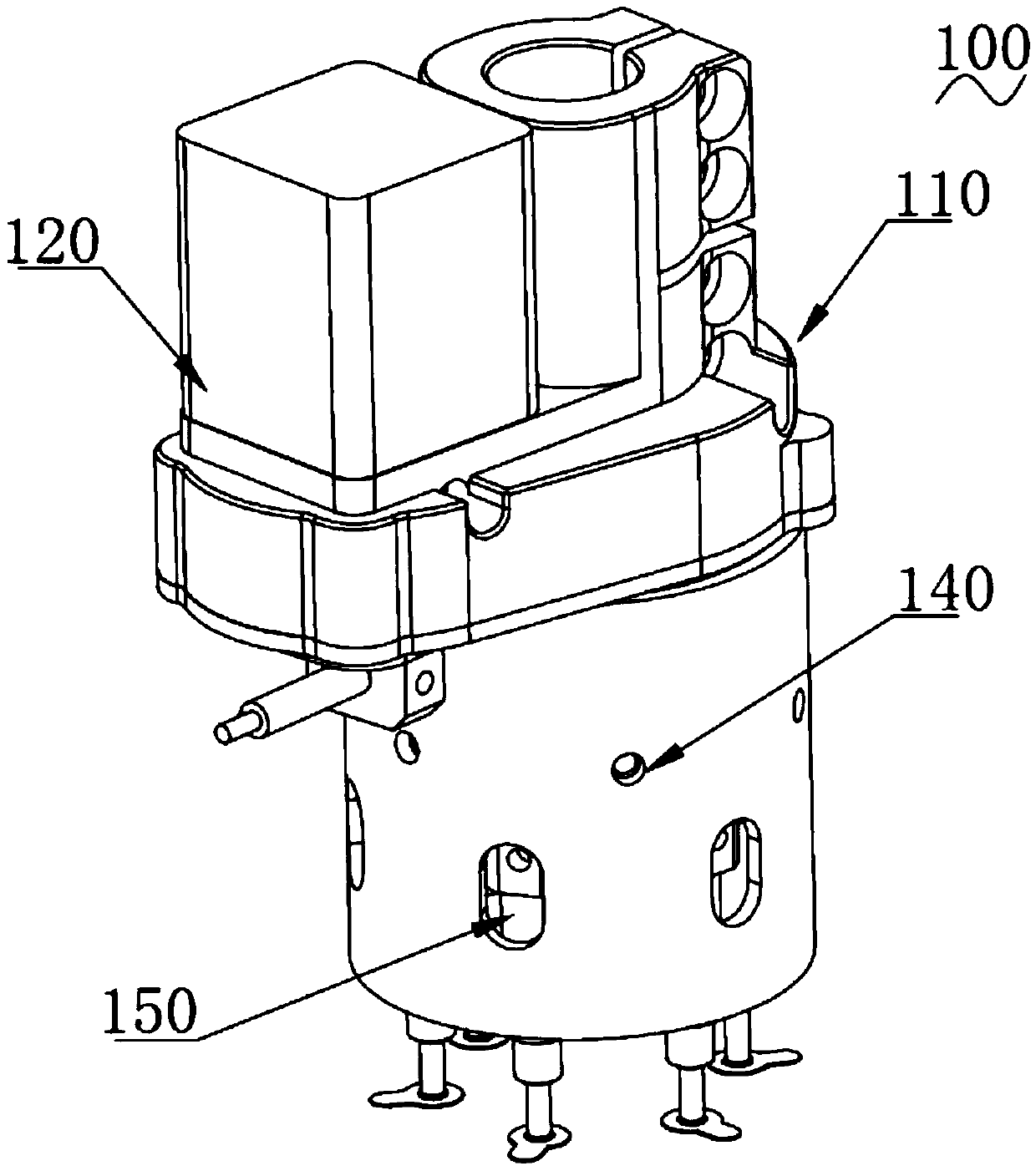

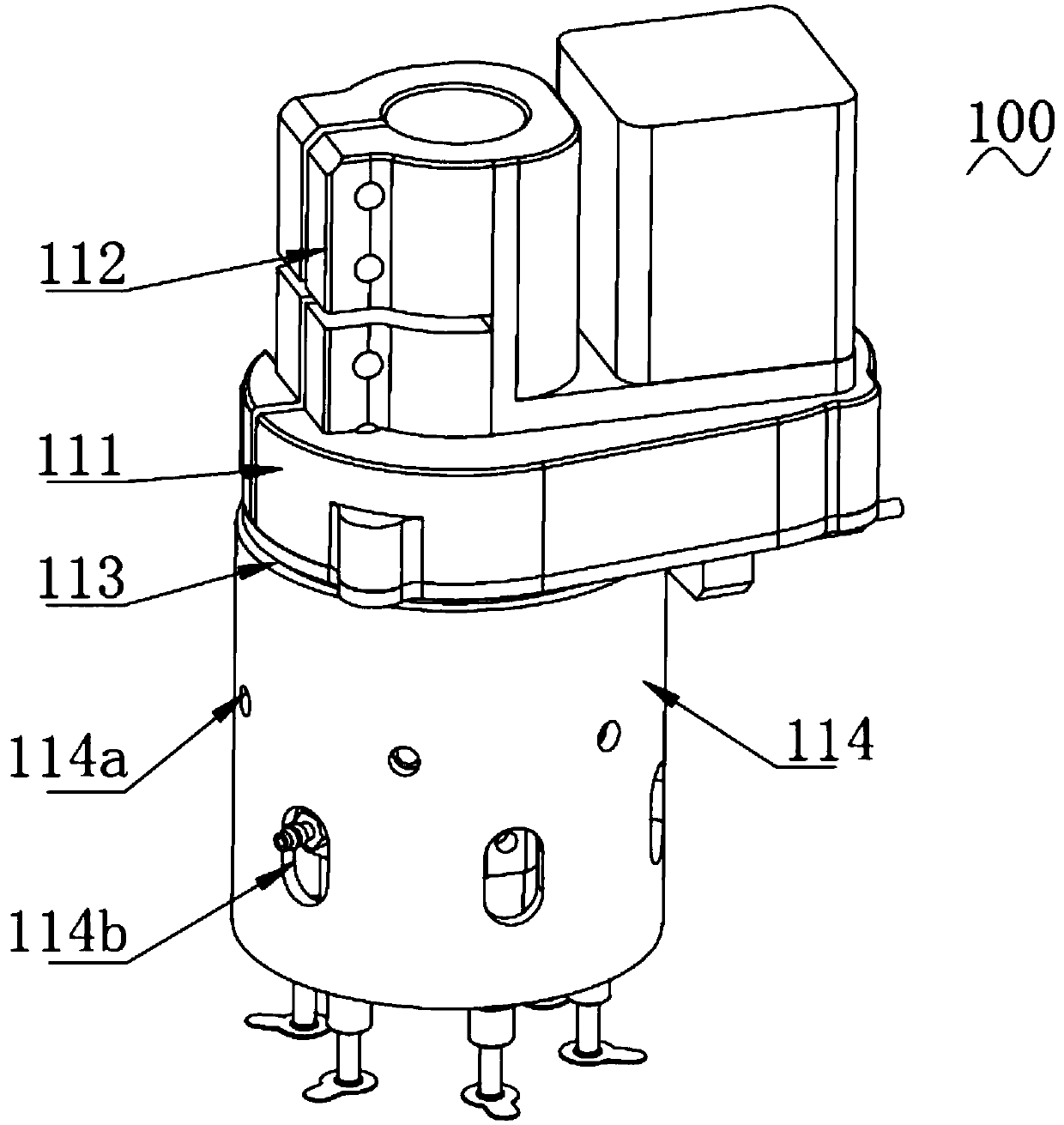

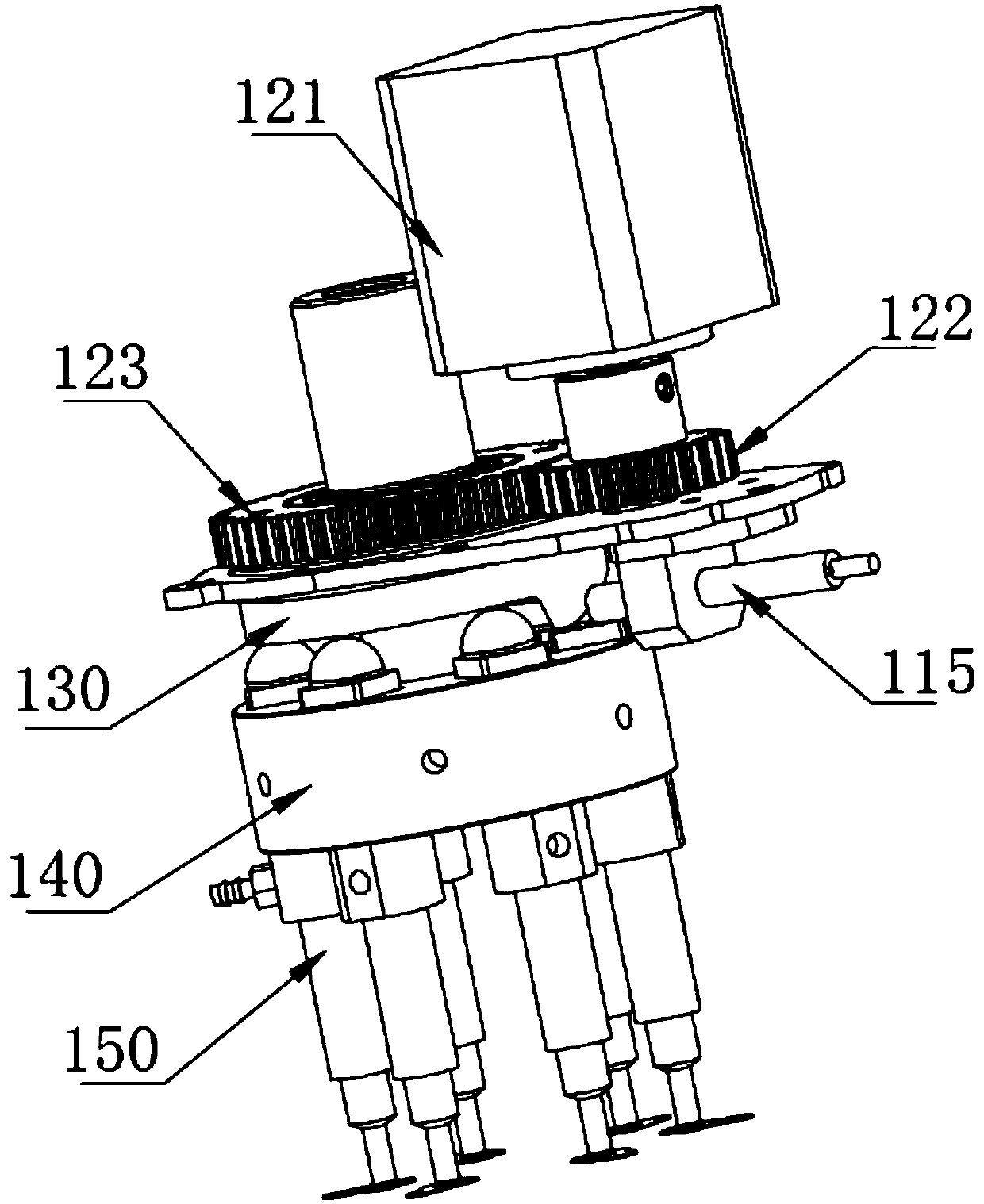

[0023] like Figure 1 ~ Figure 4 As shown, the multi-head reclaimer 100 based on the cam-driven lifting includes a mounting bracket 110, a driving component 120 disposed on the mounting bracket 110, a cam turntable 130 connected to the driving component 120, and a suction plate 140 disposed on the mounting bracket 110. A plurality of suction nozzles 150 are evenly distributed in the circumferential direction of the suction pan 140, and the suction nozzles 150 are telescopically installed on the suction pan 140, and the driving part 120 drives the cam turntable 130 to drive the suction nozzles 150 to stretch and suck materials.

[0024] The mounting bracket 110 includes a fixed cavity 111, a connecting seat 112 connected to the fixed cavity 111, the drive component 120 is installed in the fixed cavity 111, and is used for fixing the installation of the drive component 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com