Patents

Literature

230results about How to "Improve reclaiming efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

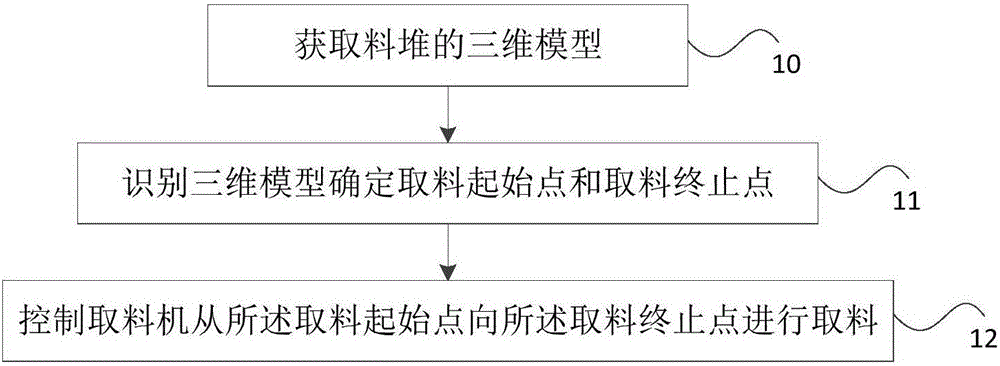

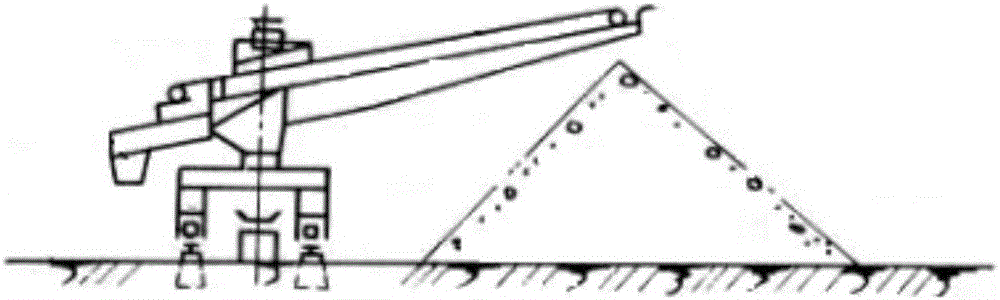

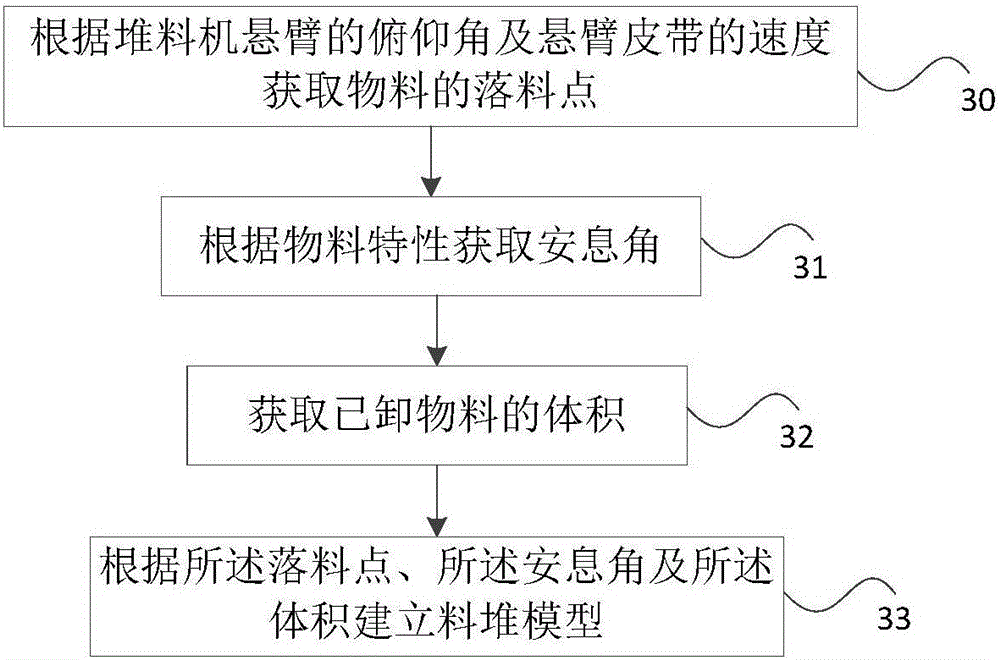

Material taking method

ActiveCN106044253AControl control processReasonable control processConveyorsLoading/unloadingThree dimensional modelInitial point

The invention relates to the field of control engineering and discloses a material taking method. The material taking method comprises the steps that a three-dimensional model of a material pile is obtained; a material taking initial point and a material taking ending point are determined by identifying the three-dimensional model; and a material taking machine is controlled to move from the material taking initial point to the material taking ending point for material taking. In this way, the control process of the material taking machine can be reasonably controlled, the stability and the material taking efficiency of material taking work are improved, and the labor cost is reduced.

Owner:CHINA SHENHUA ENERGY CO LTD +1

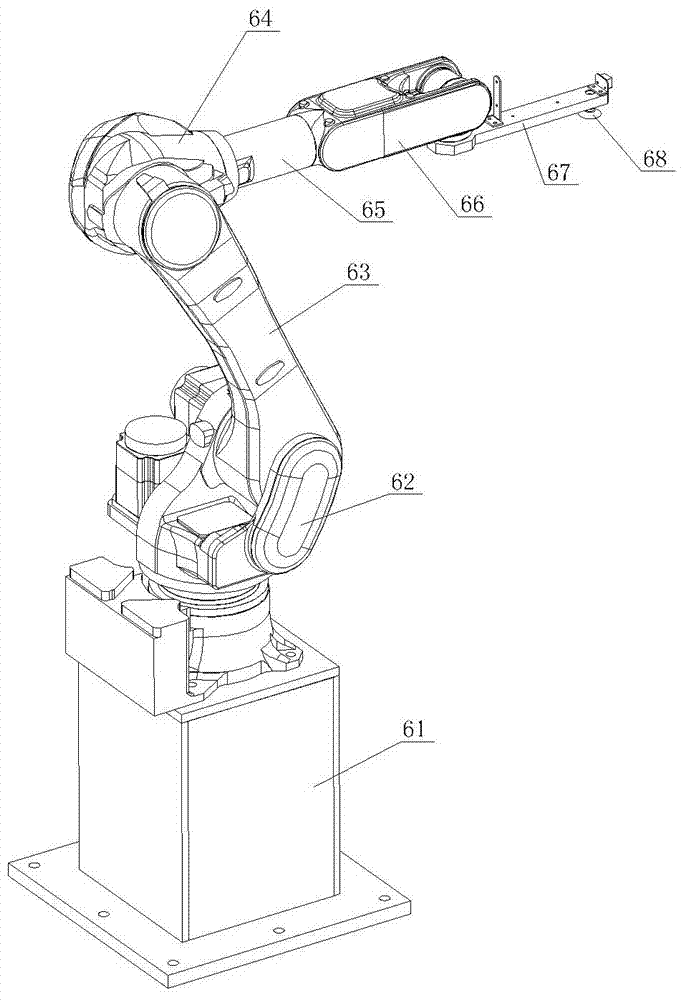

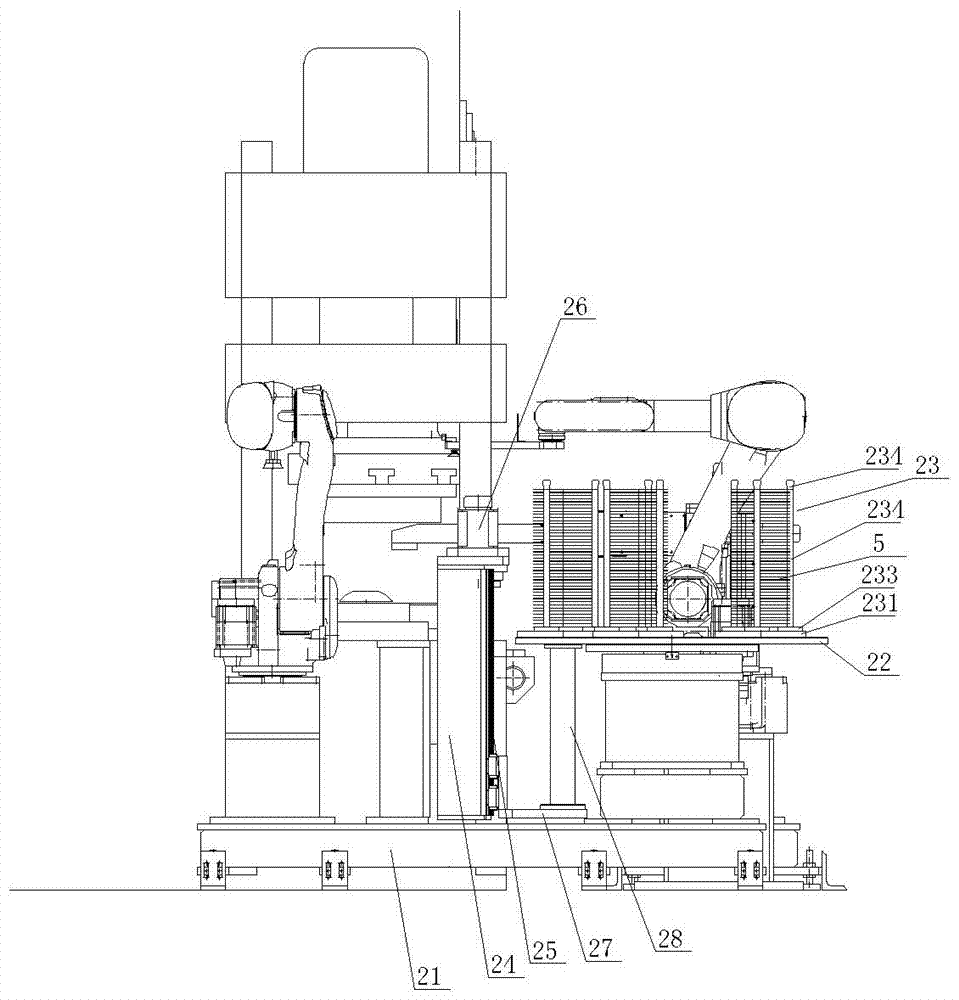

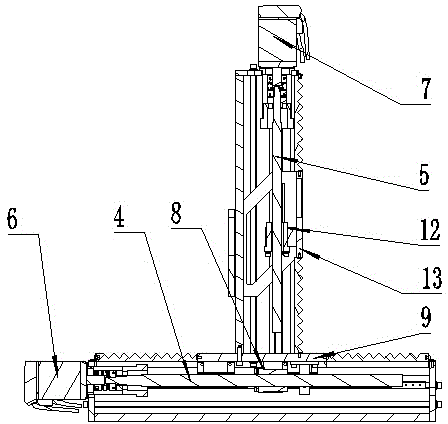

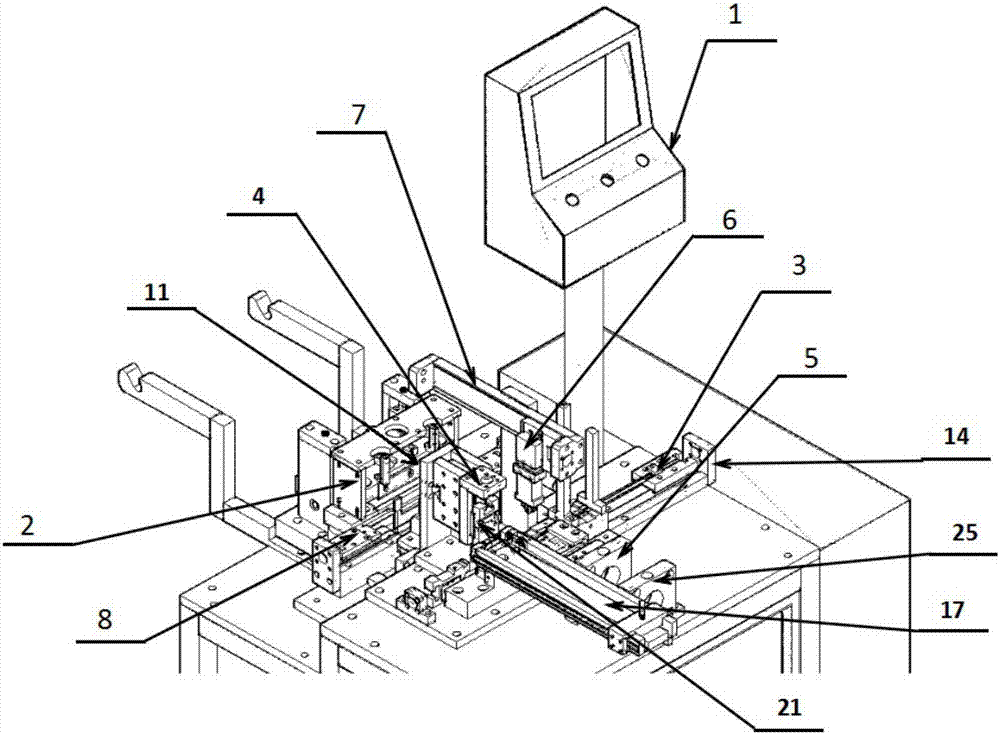

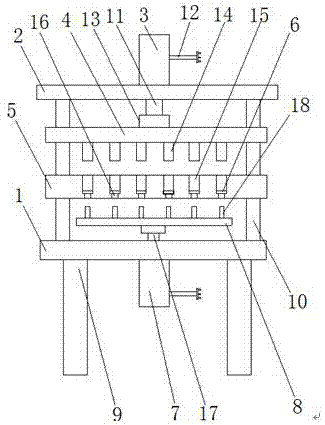

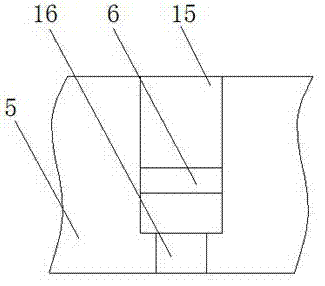

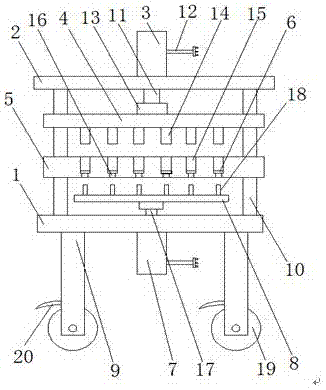

Automatic feed and discharge system of press robot

InactiveCN107159803AConvenient continuous feedingImprove feeding efficiencyMetal-working feeding devicesPositioning devicesNumerical controlAutomatic control

The invention relates to an automatic feed and discharge system of a press robot. The automatic feed and discharge system comprises at least one punch press, an automatic feed device, an automatic discharge device and a computer automatic-control system. The automatic feed device comprises a rotary feeding mechanism and a feed manipulator device, and the computer automatic-control system comprises an integrated chip, a numerical control circuit, a display screen and a control panel; automatic feed, stamping forming and automatic discharge of the punch press, the rotary feeding mechanism, the feed manipulator device and the automatic discharge device are achieved through the computer automatic-control system. By adopting the above structure, the automatic feed and discharge system has the advantages that the machining is quick and accurate, and the machining accuracy is even; the production efficiency is improved, and the manpower cost is reduced; and manual feed and discharge are avoided, and the production safety is improved.

Owner:GUANGZHOU ZHENGBAO PRECISION MACHINERY +1

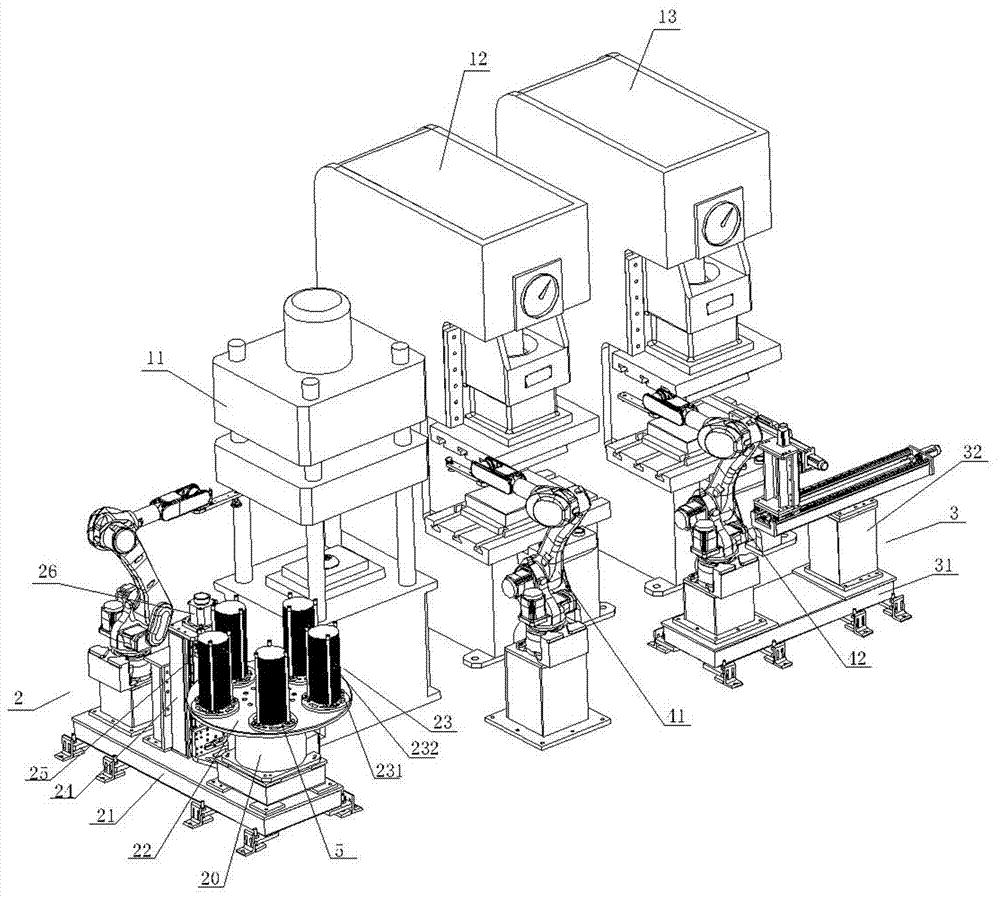

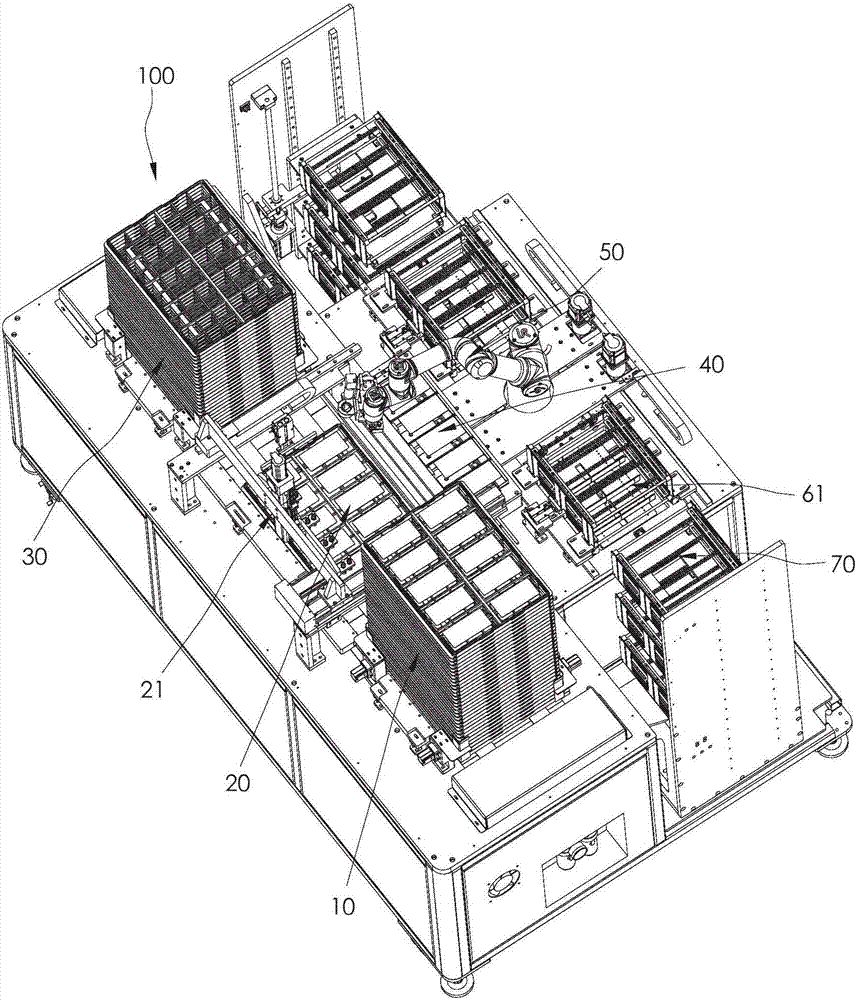

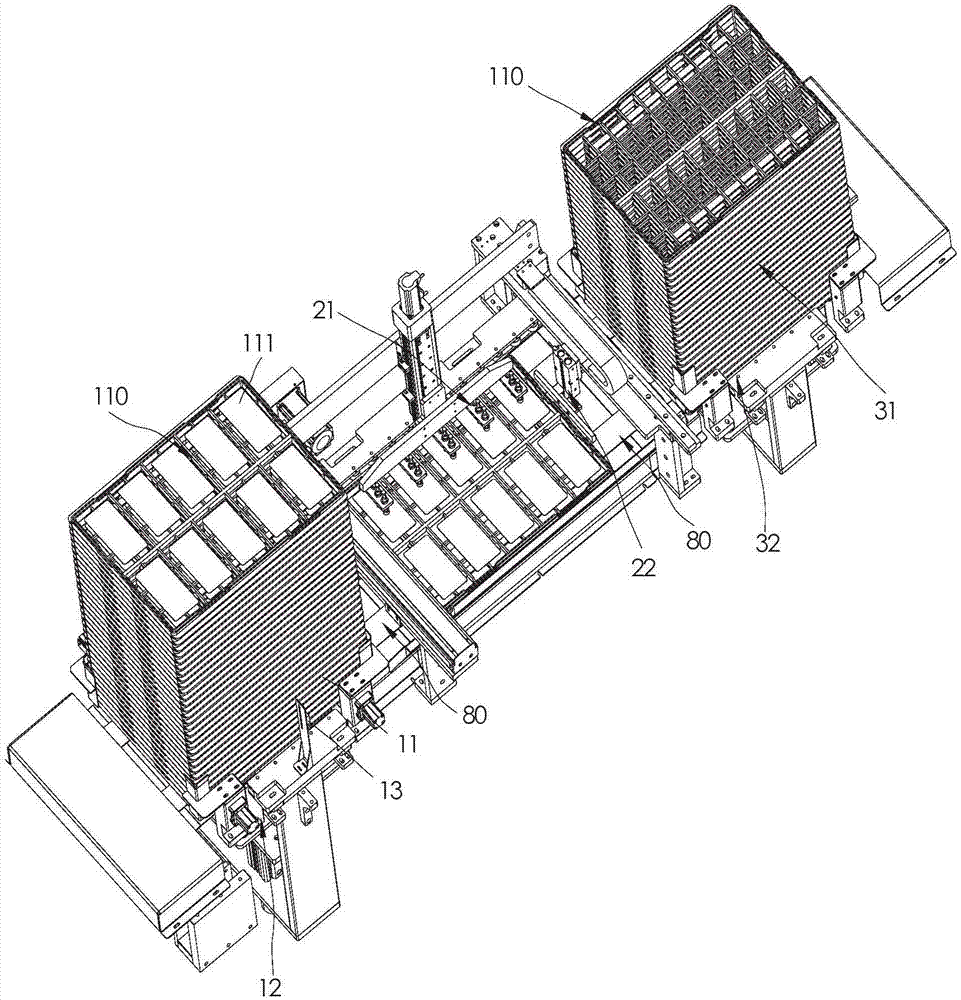

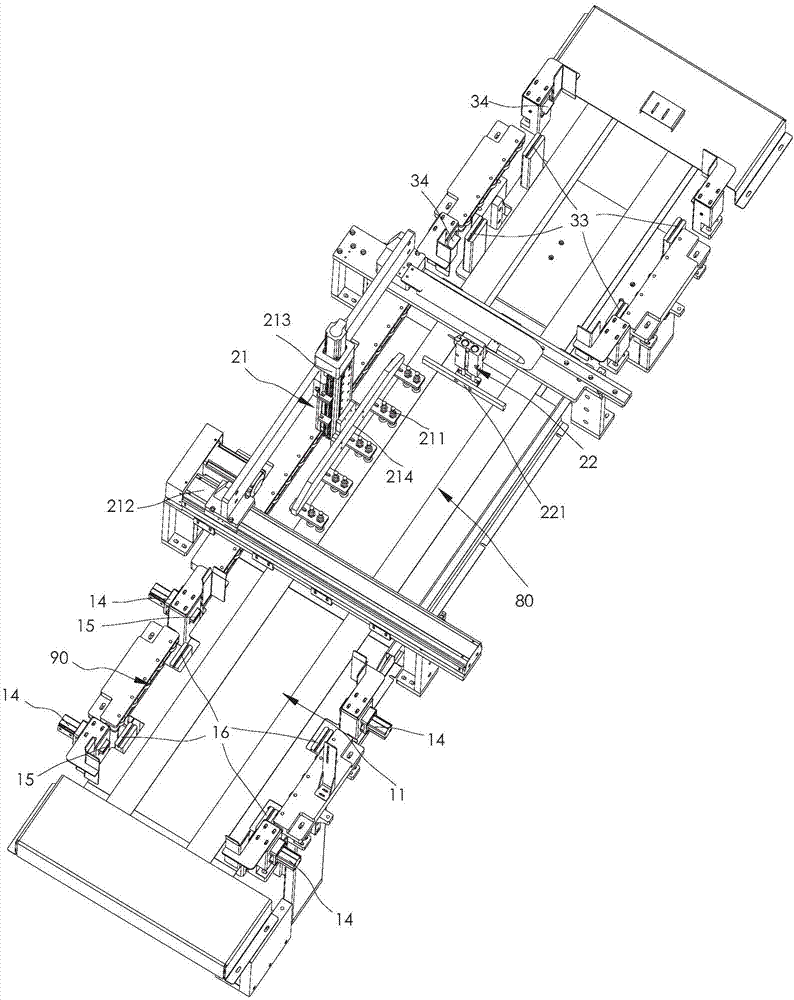

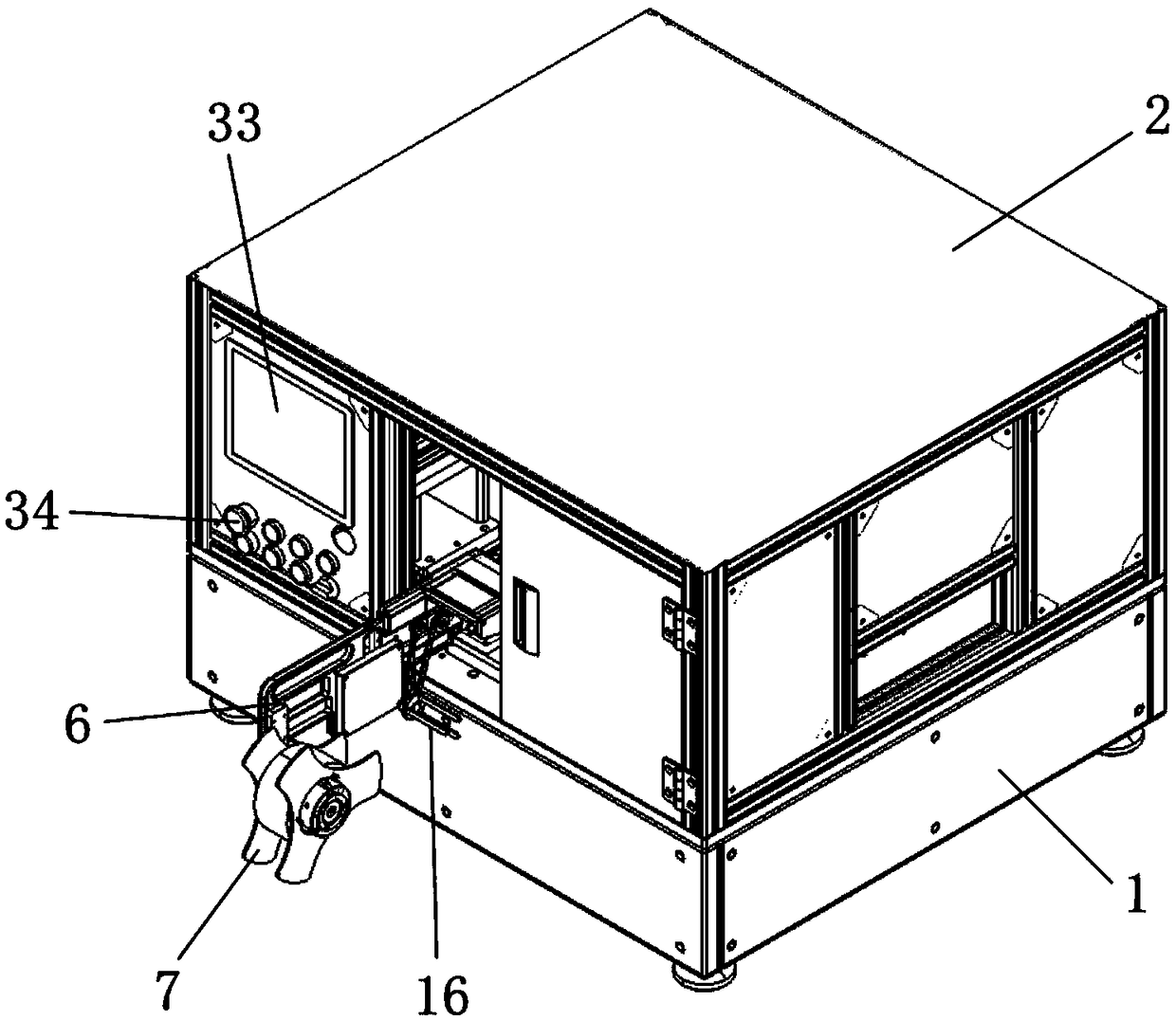

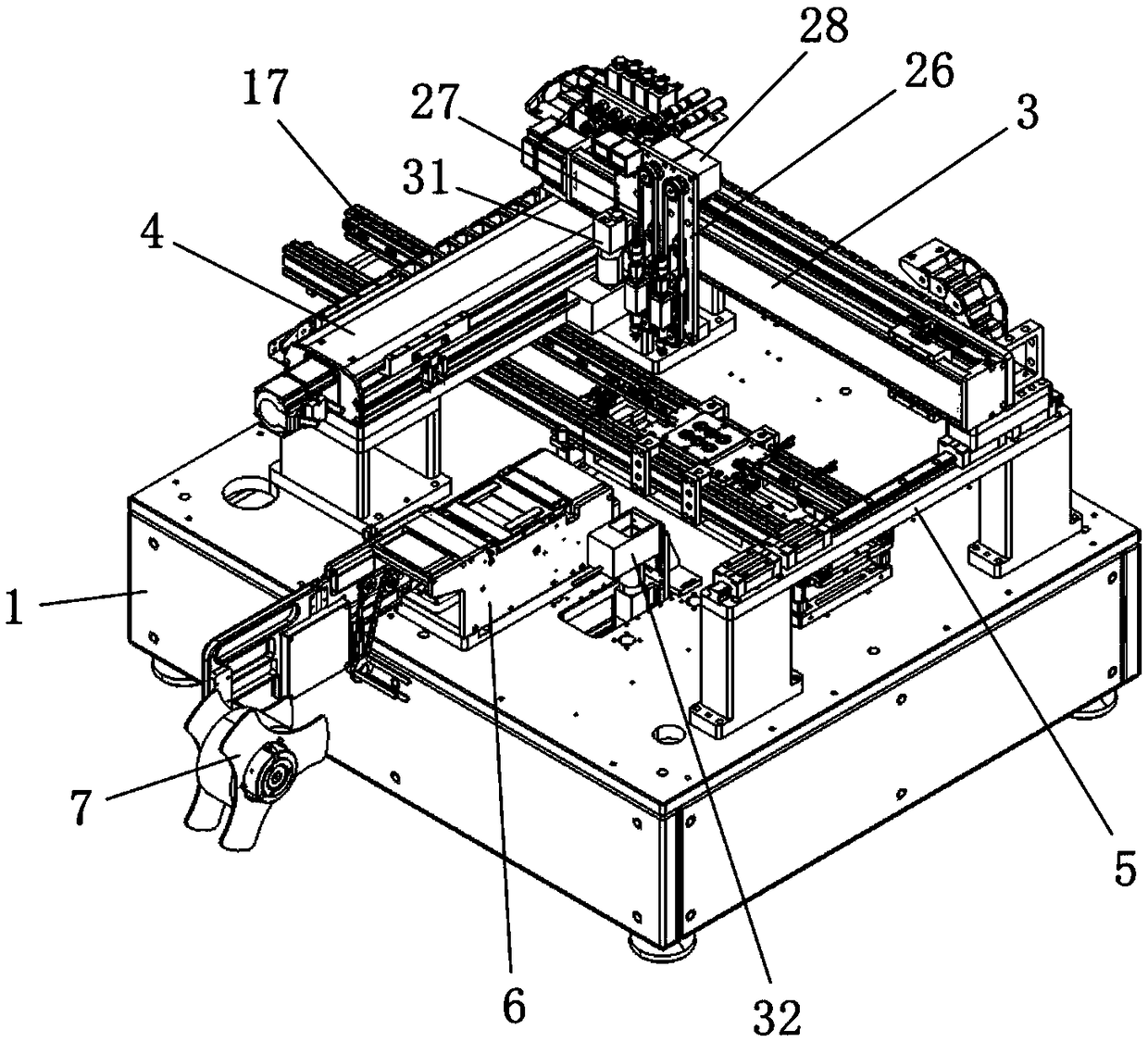

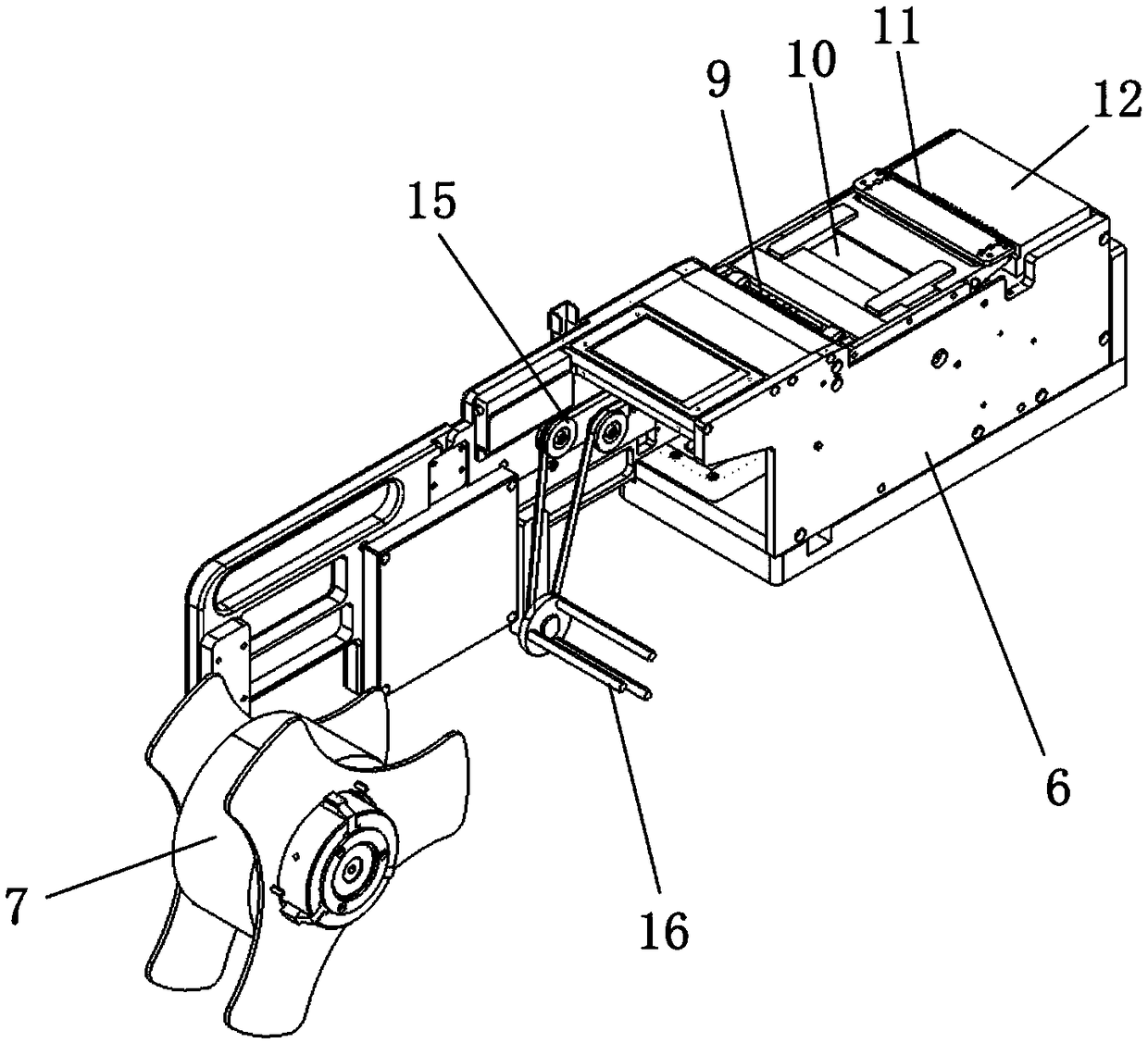

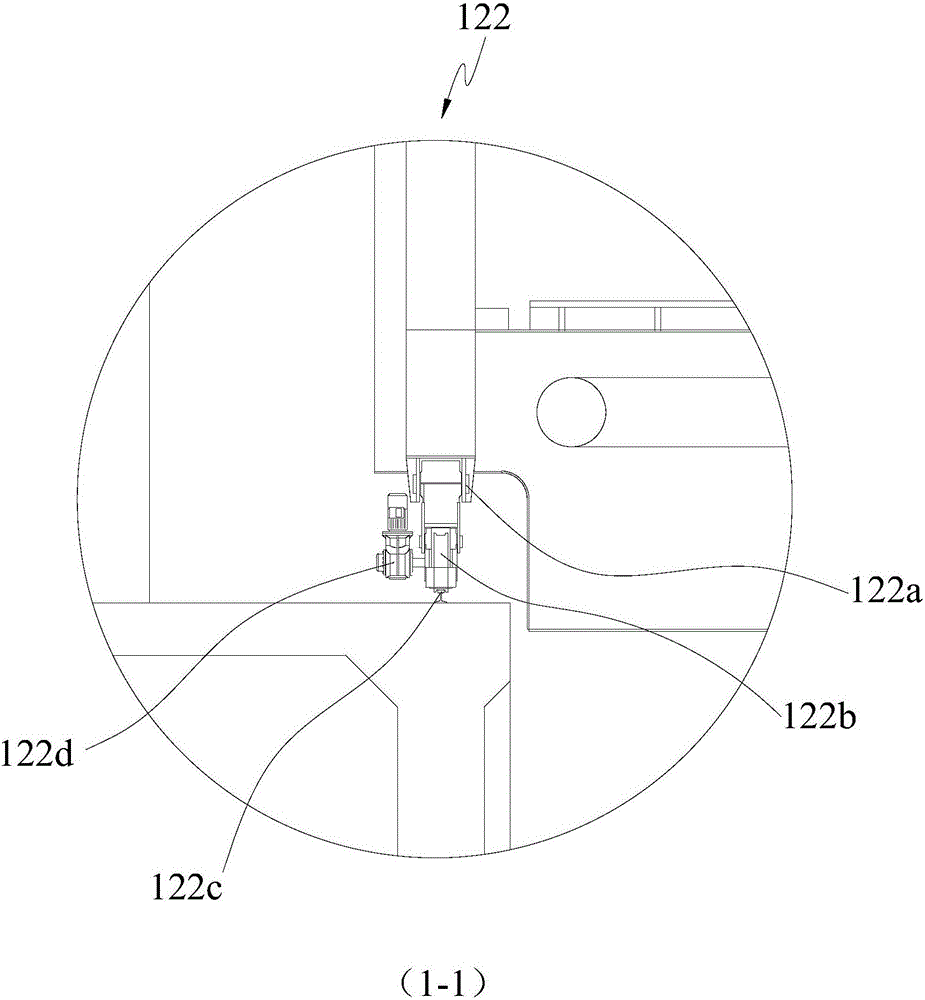

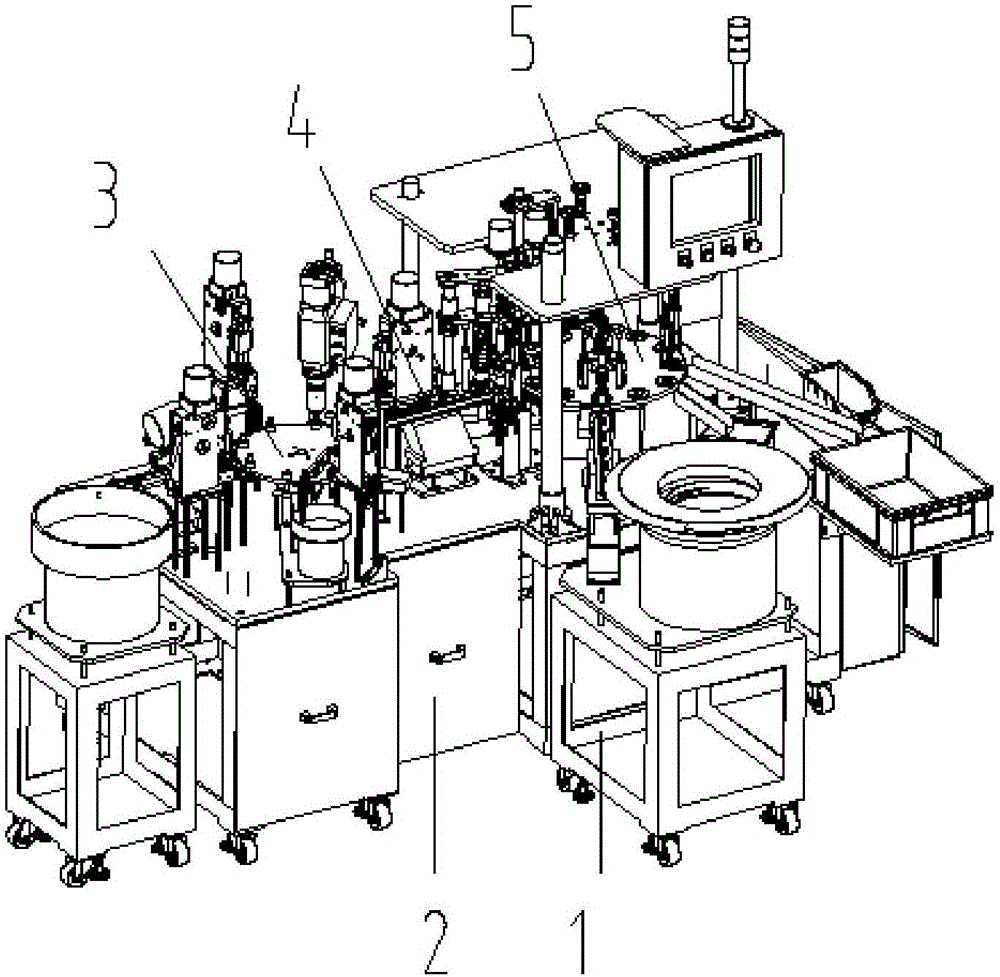

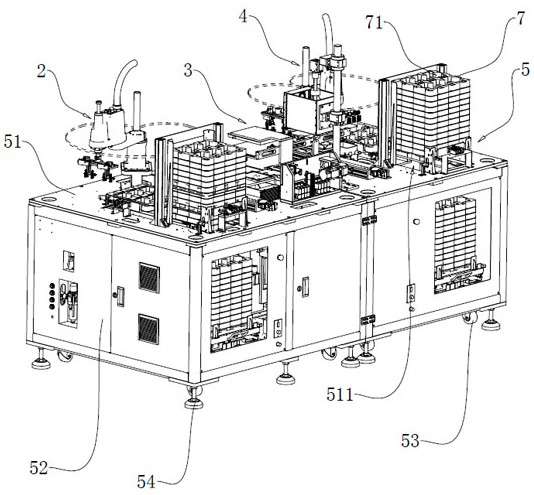

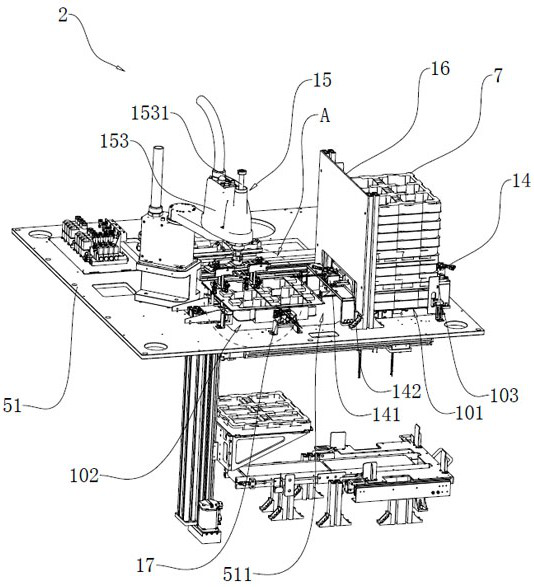

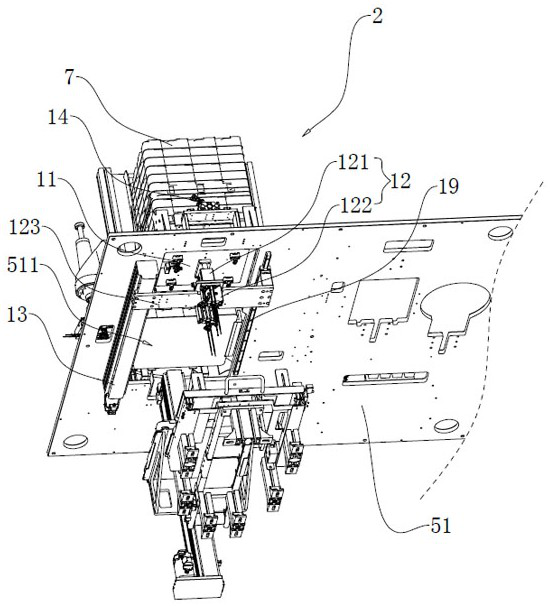

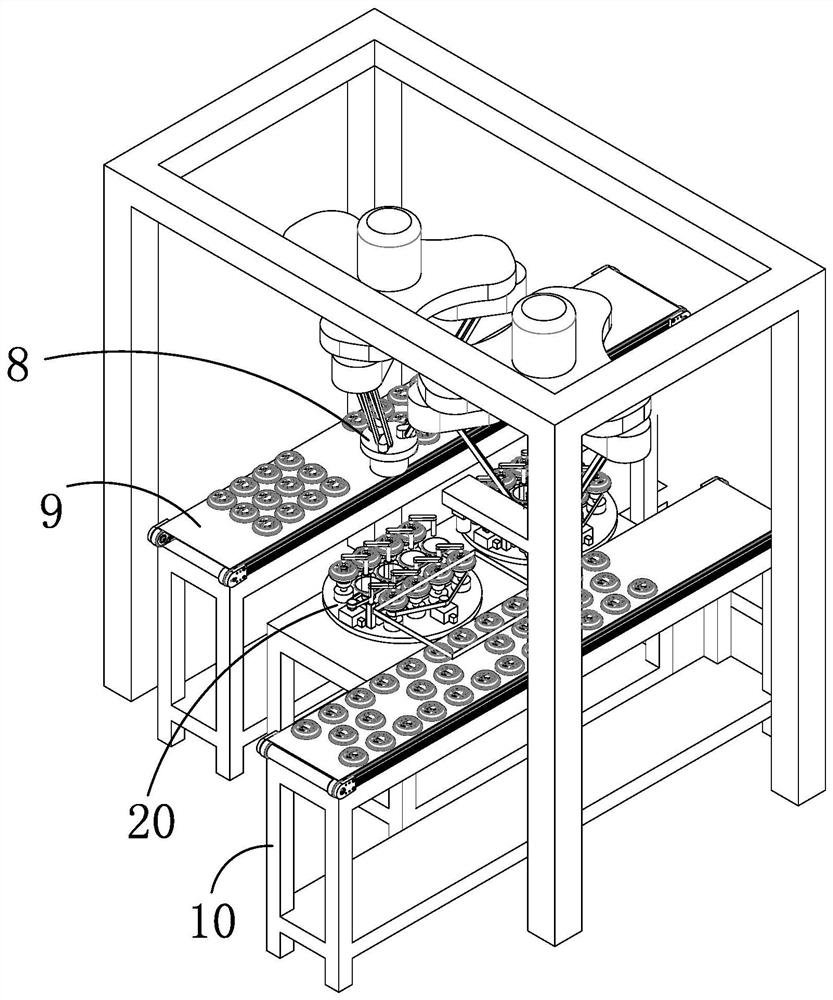

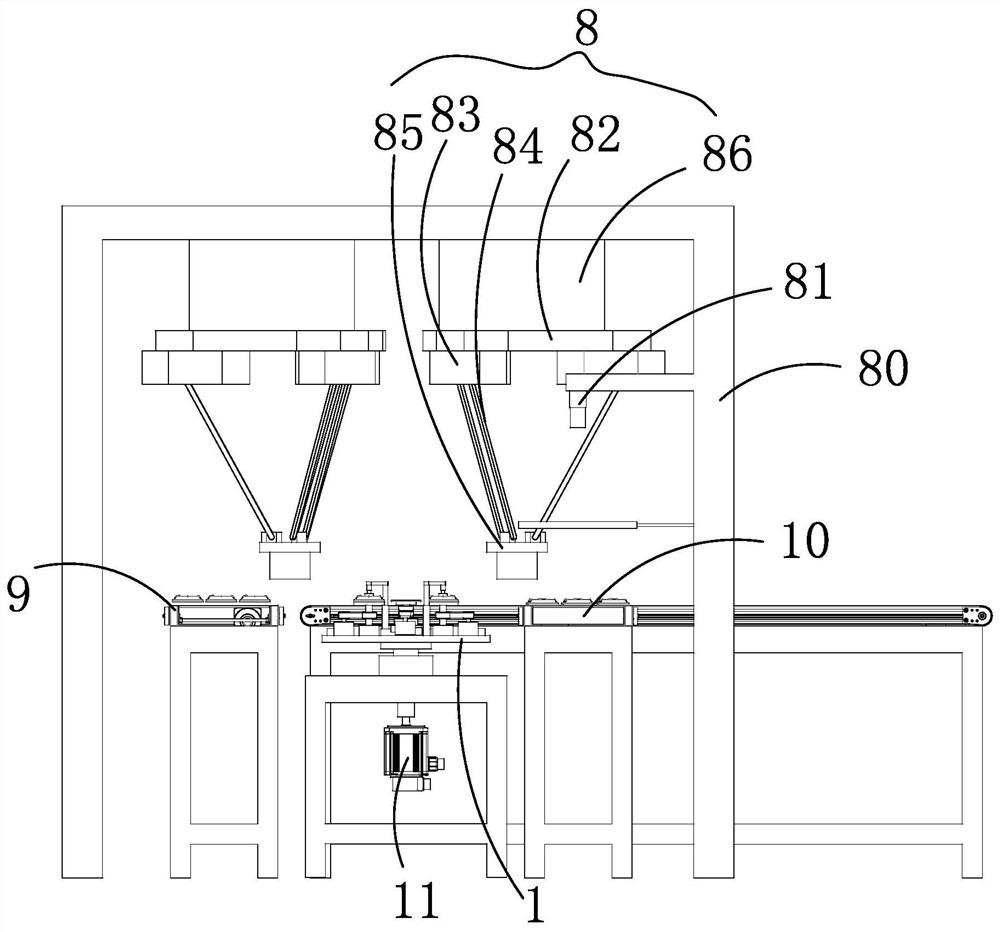

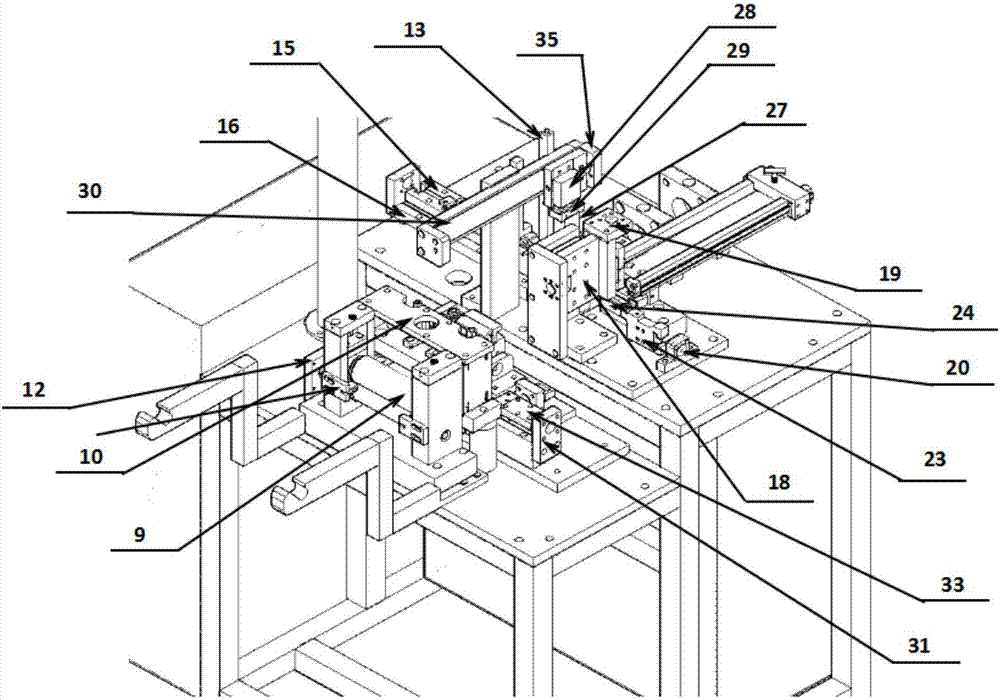

Automatic loading-unloading system

ActiveCN106966167AImprove reclaiming efficiencyFast automatic loadingCharge manipulationConveyor partsManipulatorEngineering

The invention discloses an automatic loading-unloading system. The automatic loading-unloading system comprises a rack, a first conveying mechanism, a loading mechanism, a taking mechanism, an unloading mechanism, a location mechanism and an insertion manipulator, wherein a loading station, a taking station, a location station, an unloading station and an insertion groove station are formed on the rack; the loading mechanism comprises a clamping mechanism and a support mechanism; the taking mechanism is used for clamping workpieces on carrying frames at the taking station to the location station; the location mechanism is used for locating the workpieces; and the insertion manipulator is used for clamping the workpieces at the location station and overturning the workpieces to insert the overturned workpieces into insertion grooves of insertion frames. The automatic loading-unloading system disclosed by the invention automatically completes loading, taking, location, insertion and unloading for the workpieces, and is capable of automatically stacking the empty carrying frames and high in automation degree.

Owner:深圳市宇瀚智慧装备科技有限公司

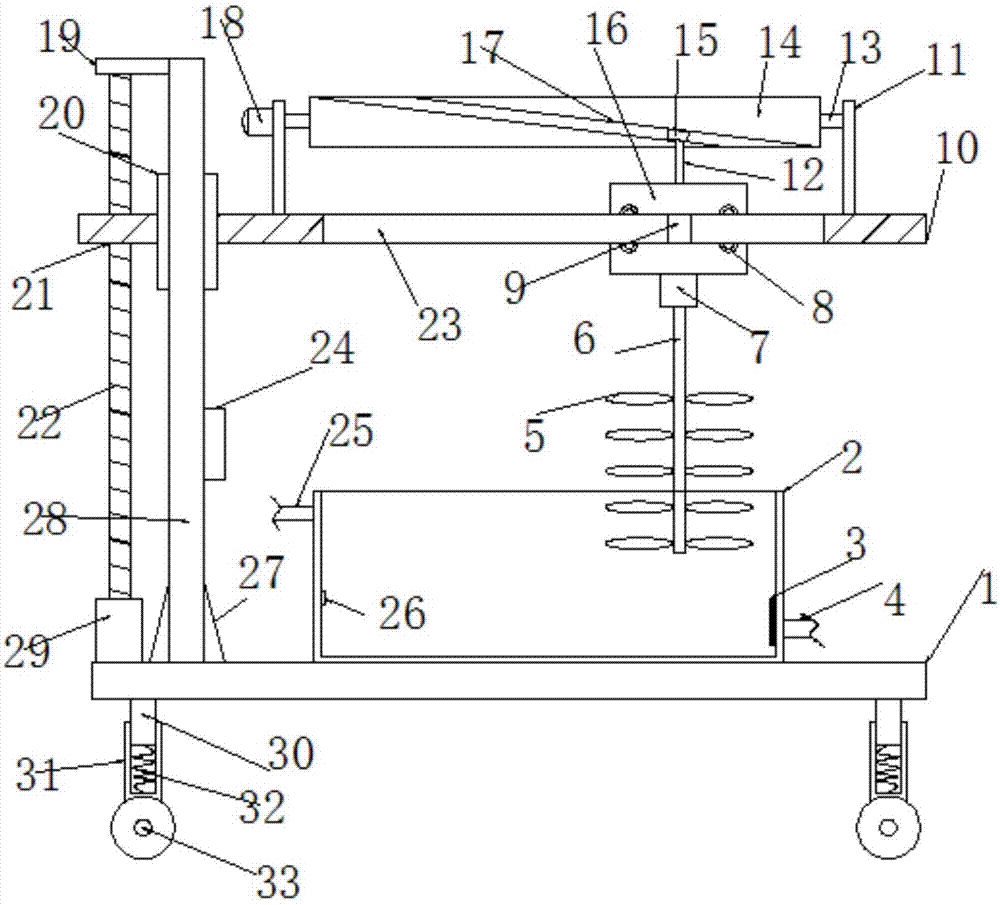

Wool cleaning device for animal husbandry

PendingCN107385519ASimple structureReasonable structureWool fibre washing/scouringClimate change adaptationAnimal scienceAnimal husbandry

The invention discloses a wool cleaning device for the animal husbandry. The wool cleaning device comprises a base. A cleaning box is fixed to the upper end of the base, an opening is formed in the upper end of the cleaning box, a water inlet pipe is arranged on the left upper side of the cleaning box, a drain pipe is arranged on the right lower side of the cleaning box, a filter plate is arranged at an inner port of the drain pipe, a lifting support column is vertically arranged at the left upper end of the base, and a plurality of reinforcing ribs are arranged between the outer side of the lower end of the lifting support column and the base, so that the mechanical properties of the lifting support column can be improved; the lifting support column is provided with a rectangular cross section, a lifting plate is penetratingly arranged on the lifting support column, and a lifting sleeve with a rectangular cross section is arranged on the lifting plate and is arranged on the lifting support column in a slide fit manner. The wool cleaning device has the advantages that the wool cleaning device is simple and reasonable in structure and convenient to carry, a stirring shaft and stirring blades can move in the left-right directions during cleaning, and accordingly cleaning effects can be improved; the lifting plate can be lifted when materials are fetched in late periods, the stirring shaft and the stirring blades can be taken out of the cleaning box, and accordingly the wool cleaning device is beneficial to improving the material fetching efficiency and high in practicability.

Owner:内蒙古沃尔绒业有限公司

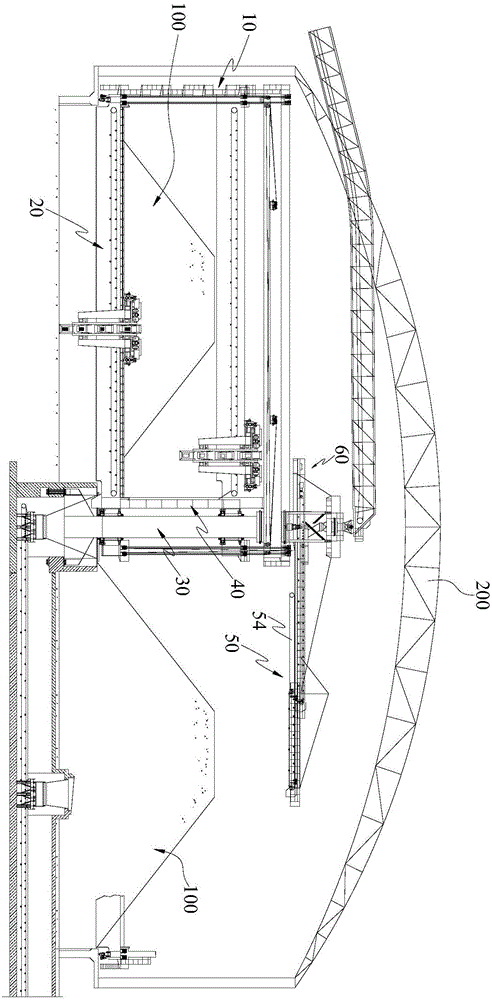

Round stockyard stacking and fetching machine

ActiveCN106219258ASolve the realization of stacking and reclaimingStacking adjustableLoading/unloadingEngineeringBelt conveyor

The invention discloses a round stockyard stacking and fetching machine which comprises a rotating portal portion, a bucket wheel fetching portion, a conveying portion and a centering swinging mechanism. The rotating portal portion rotates around the centering swinging mechanism by taking span of the rotating portal portion as a radius, the bucket wheel fetching portion and the conveying portion are connected with the rotating portal portion, and the conveying portion is composed of multiple belt conveyors and cooperates with the bucket wheel fetching portion to form a fetching logistics channel and / or a stacking logistics channel. Different from existing equipment, the round stockyard stacking and fetching machine takes the span of a portal as actual working range radius, and application of the stacking and fetching machine in a round stockyard is realized for the first time.

Owner:TIDFORE HEAVY IND

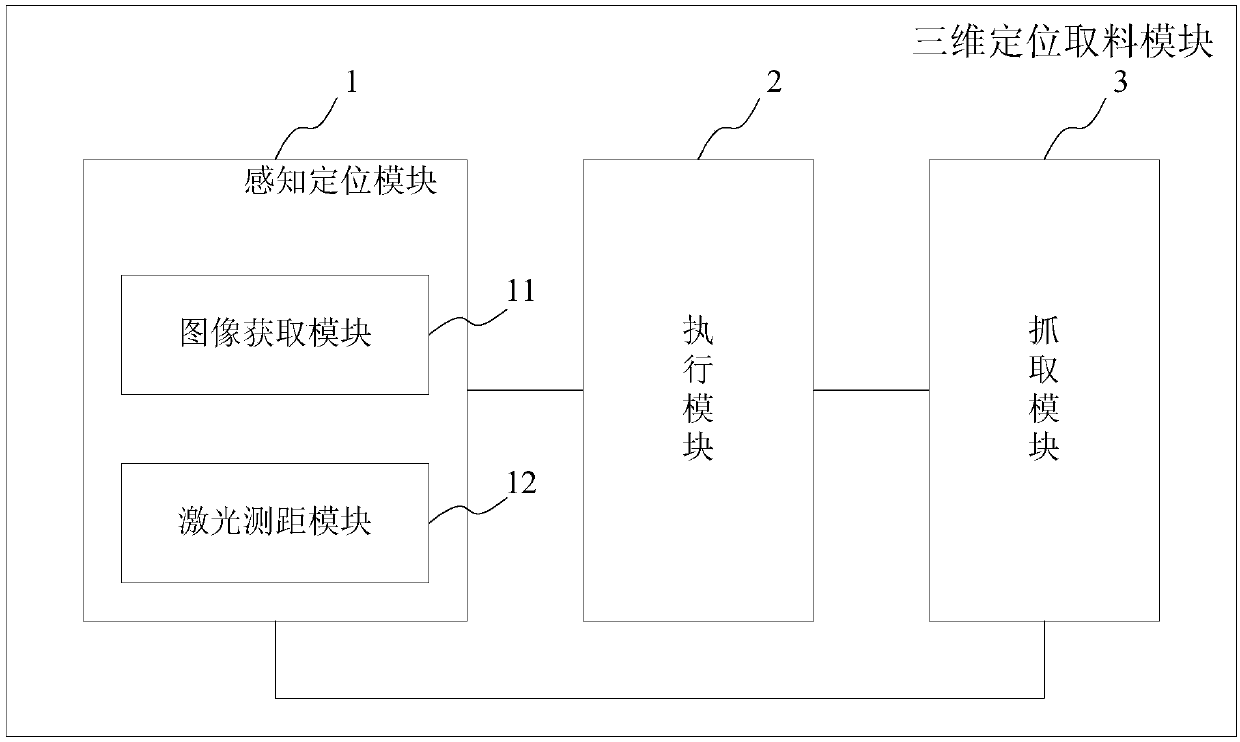

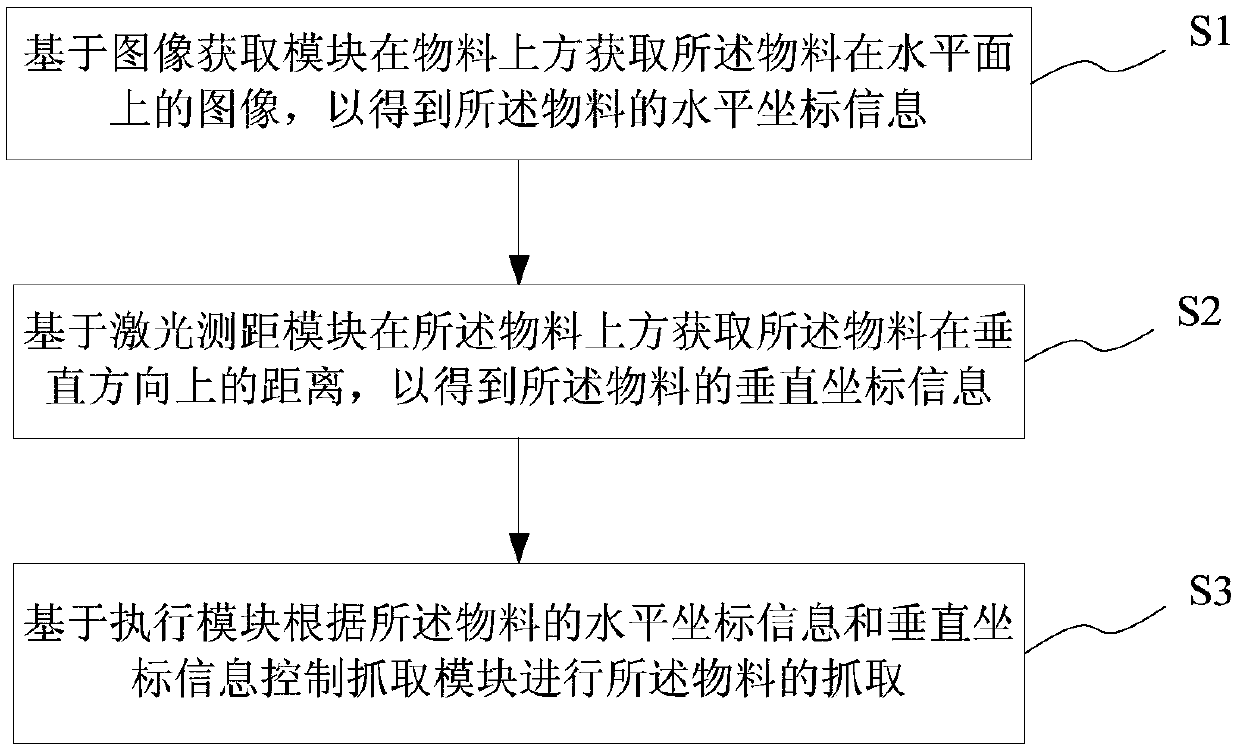

Two-dimensional positional fetching system and method

InactiveCN109605381AAccurate captureHigh accuracy of motion positioningProgramme-controlled manipulatorLaser rangingComputer science

The invention provides a two-dimensional positional fetching system and method. The two-dimensional positional fetching system comprises an induction positioning module, an execution module and a grabbing module. The induction positioning module comprises an image acquisition module and a laser ranging module. The image acquisition module is used for acquiring an image of a material on the horizontal plane at a position above the material under the control of the execution module, so that horizontal coordinate information of the material is obtained. The laser ranging module is used for acquiring the distance of the material in the vertical position at a position above the material under the control of the execution module, so that vertical coordinate information of the material is obtained. The execution module is used for grabbing the material according to the horizontal coordinate information of the material and the vertical coordinate information of the material. By adoption of thetwo-dimensional positional fetching system and method, materials of different batches and specifications and at non-fixed positions can be grabbed.

Owner:欧米瑞(广东)智能制造有限公司

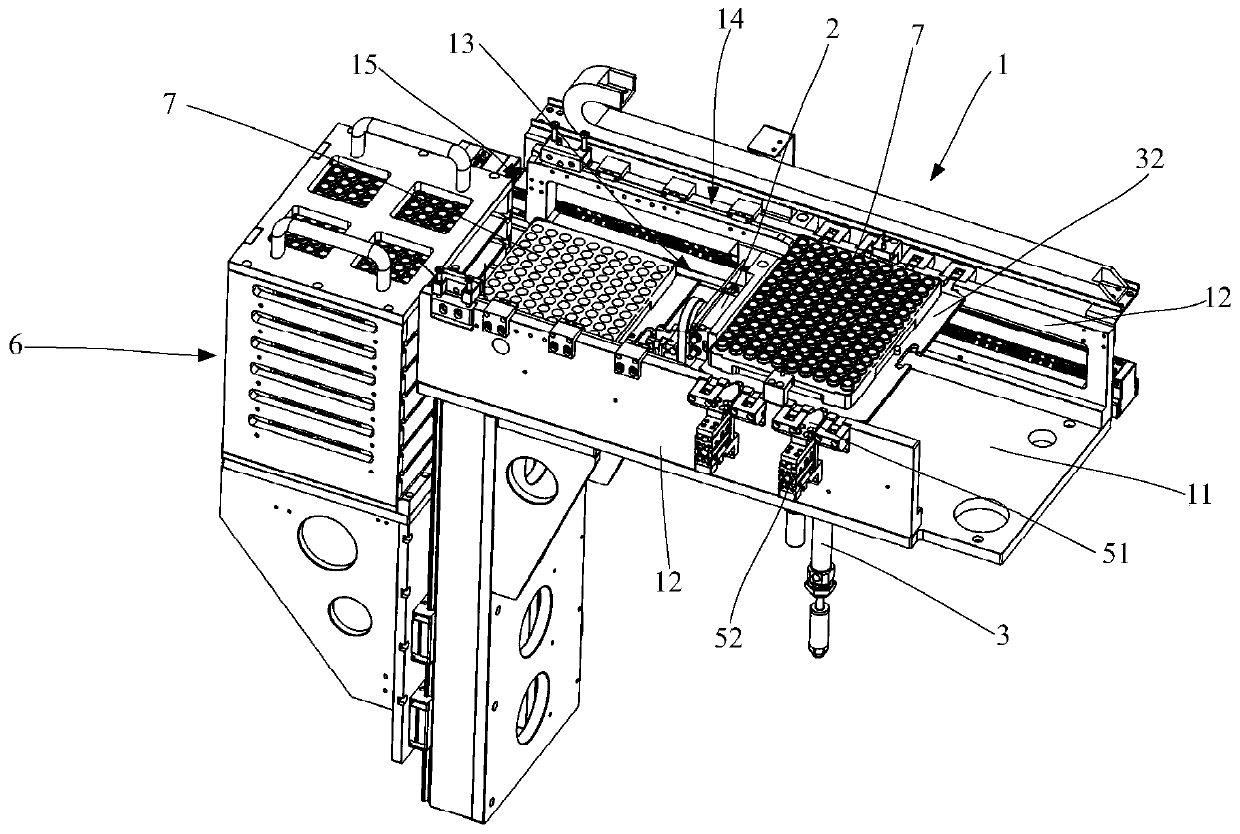

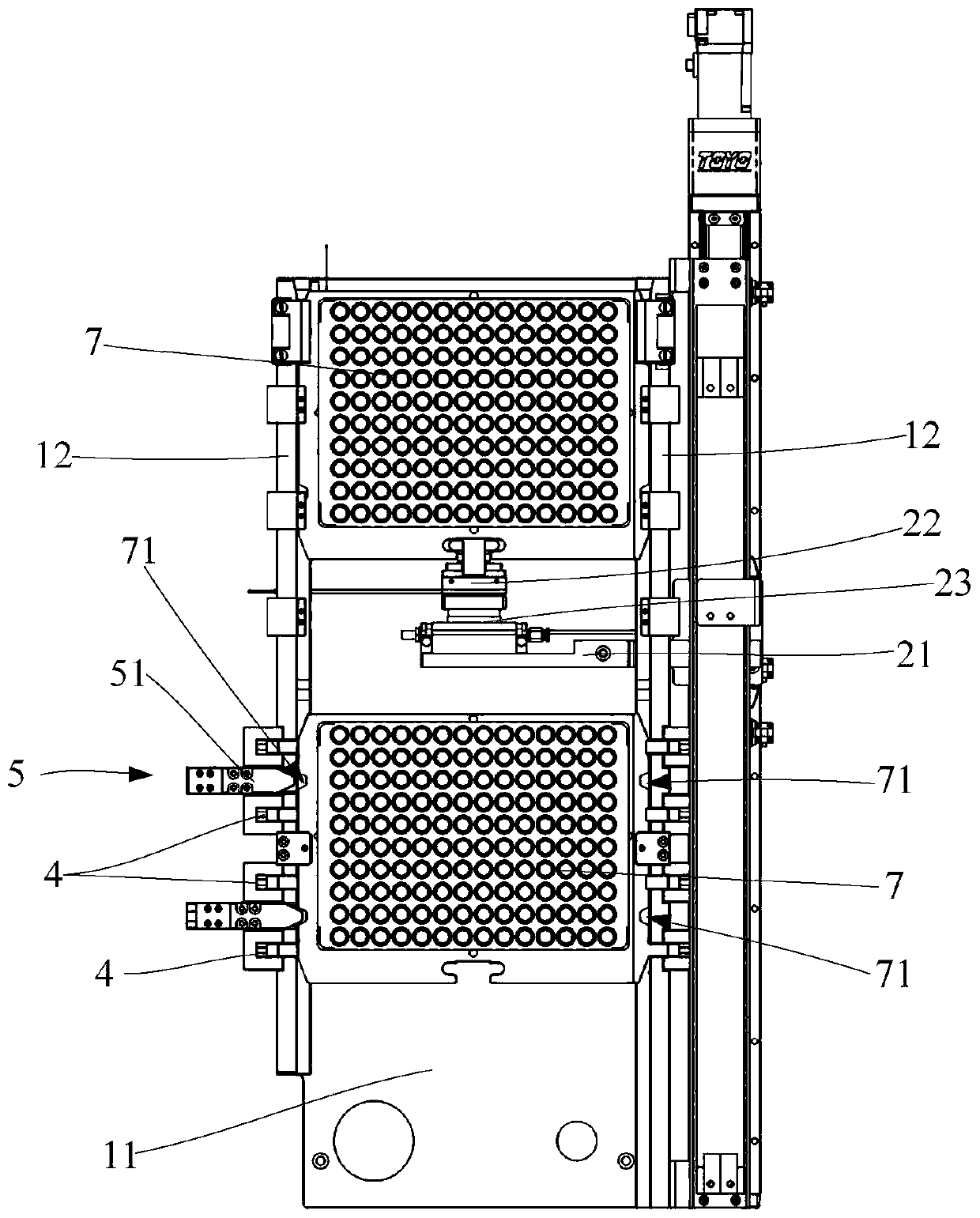

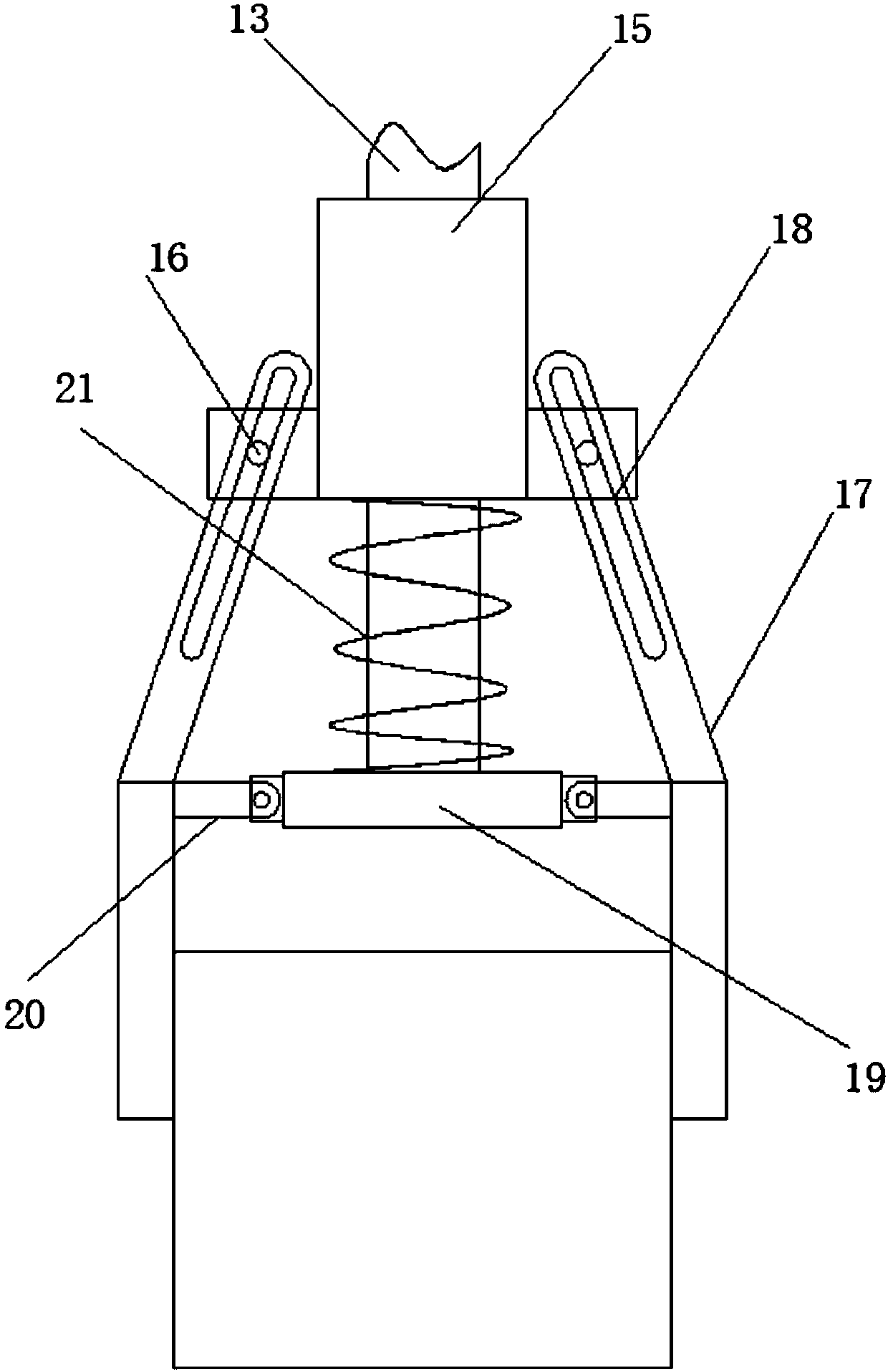

Material tray processing device and material tray processing method

ActiveCN110937391AImprove reclaiming efficiencyConveyor partsStructural engineeringManufacturing engineering

The invention discloses a material tray processing device and a material tray processing method. The material tray processing device and the material tray processing method are used for improving theefficiency of taking materials from material trays. The material tray processing device comprises a main body, a pulling mechanism, a jacking mechanism and a vertical positioning mechanism. The main body comprises a bottom plate and two side plates, wherein a first rail and a second rail are arranged on the two side plates; the first rail comprises a jacking position; and the second rail comprisesa material taking position. The pulling mechanism comprises a mounting rod and a clamping jaw, wherein the clamping jaw is arranged on the mounting rod, the mounting rod is slidably connected with one side plate, the clamping jaw is used for grabbing the material tray, and the pulling mechanism is used for controlling the mounting rod to move so as to move the clamping jaw. The jacking mechanismcomprises a jacking device and a supporting plate, wherein the supporting plate is arranged on the jacking device, and the jacking device is used for lifting and moving the supporting plate so as to enable the supporting plate to jack the material tray on the jacking position to the material taking position. The vertical positioning mechanism is used for fixing the material tray on the material taking position in the vertical direction. The material taking efficiency is improved by automatically taking materials from the material tray.

Owner:广东金龙东创智能装备有限公司

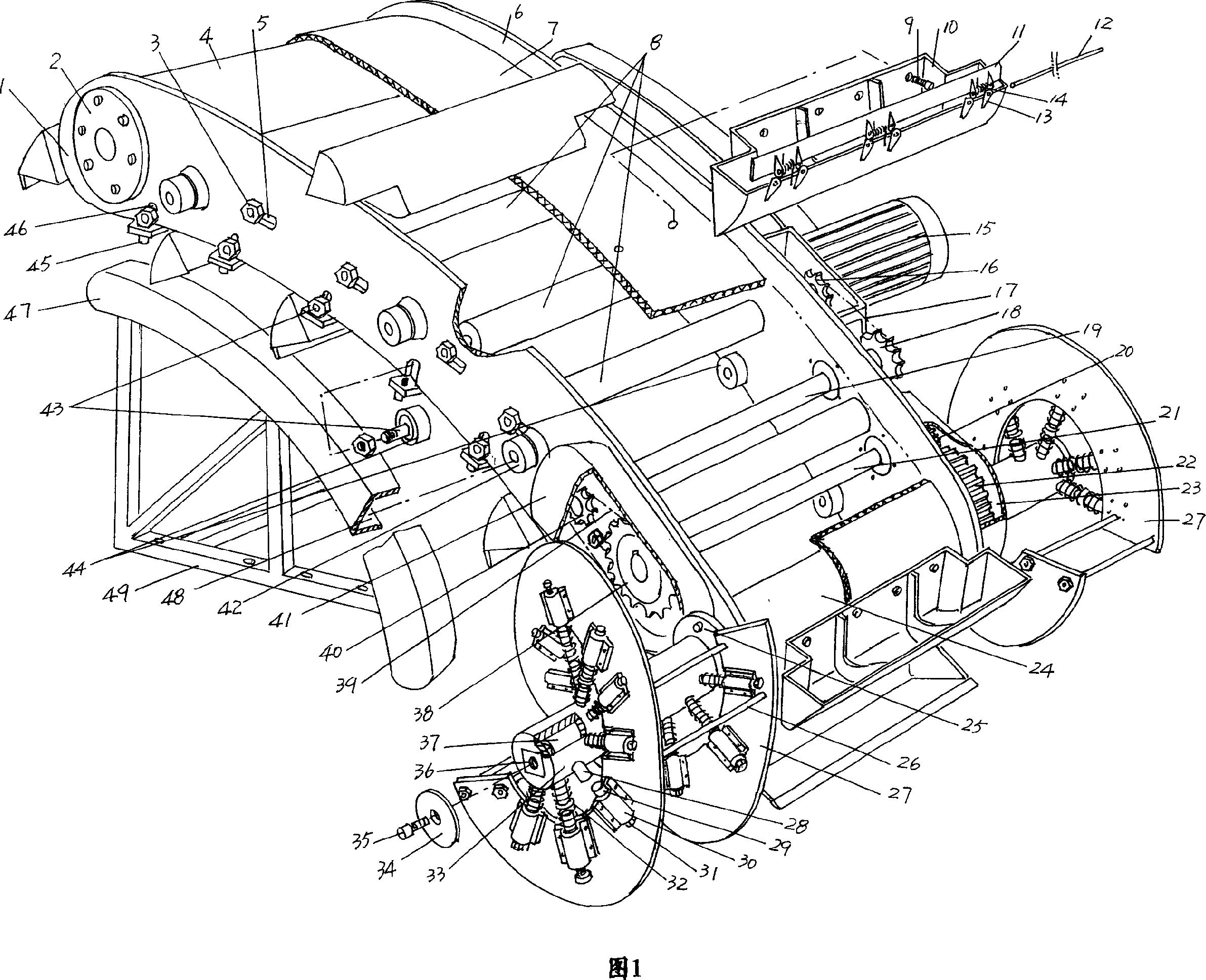

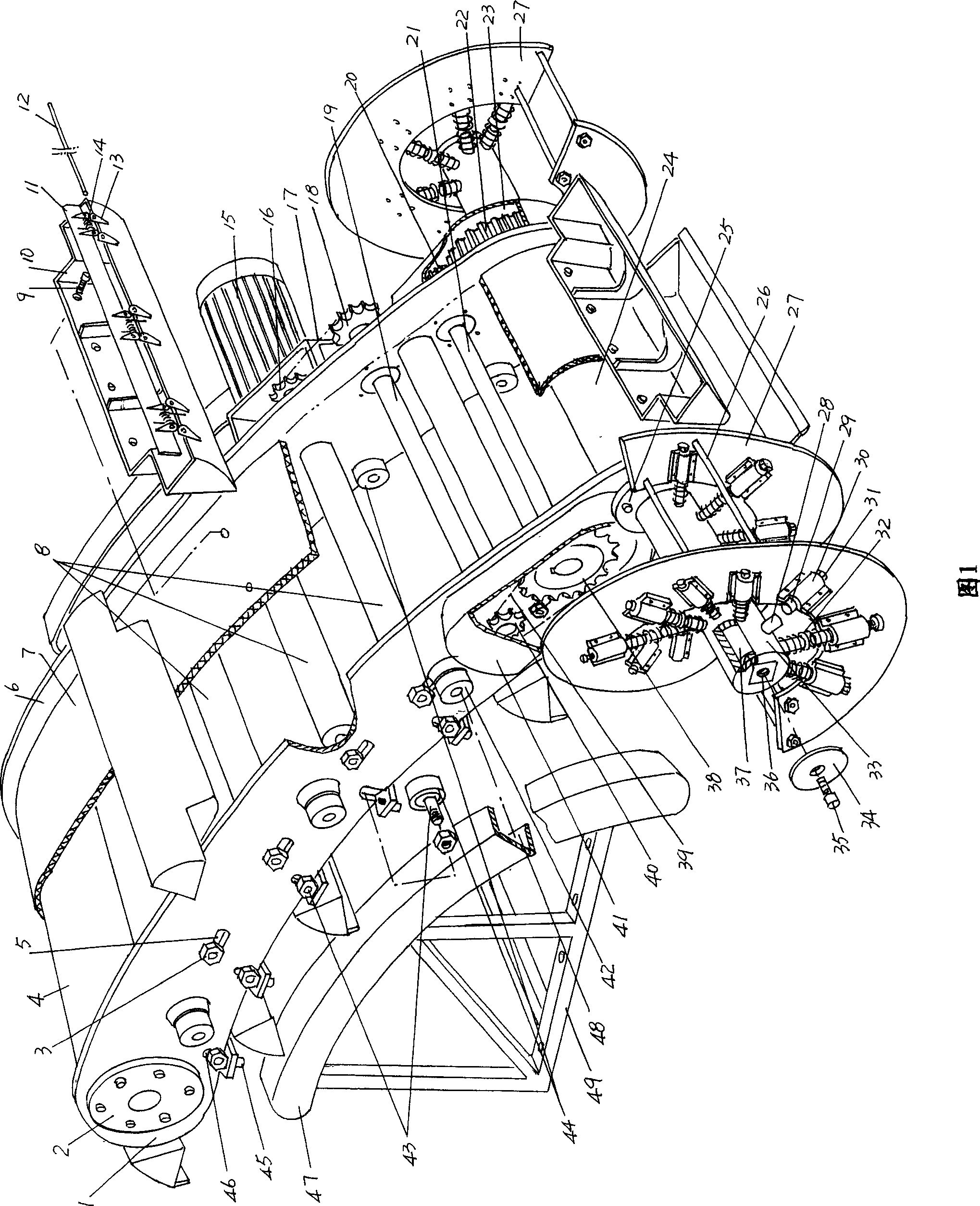

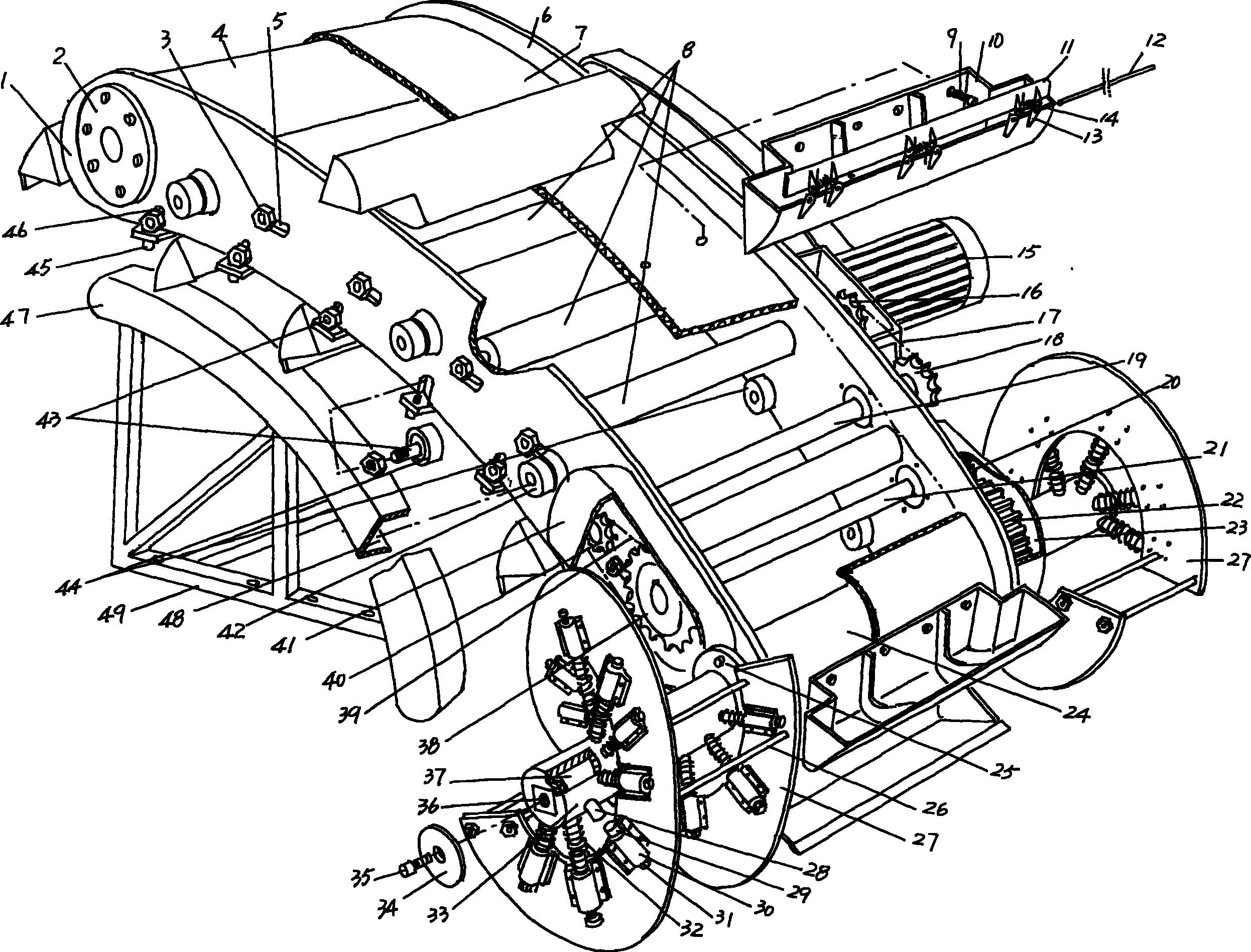

Material fetching mechanism for full-automatic cabin cleaning vehicle

InactiveCN101016124AMeet miniaturization configuration requirementsThe structure is simple but not complicatedToothed gearingsLoading/unloadingEngineeringTransmitter

A material feeder of full-automatic chamber cleaner comprises a couple of left and right wall plates, a rotary drum and an active drum axially arranged at two ends of the wall plates, a couple of support rollers distantly distributed between the rotary drum and the active drum, two support wheel groups, a transmission band contacted with the support roller and the support wheel, a hopper group distributed on the transmission band, a transmitter linked with the drum axle of the active drum, a couple of pushing plates at two ends of the drum axle, two wheel groups axially arranged at outer side and near the middle of left and right wall plates, a couple of tracks covering the roller groups. The invention has the advantages in simple structure and simple connection with the chassis of walking device, high feeding efficiency, or the like.

Owner:常熟市诚达港务机械设备厂

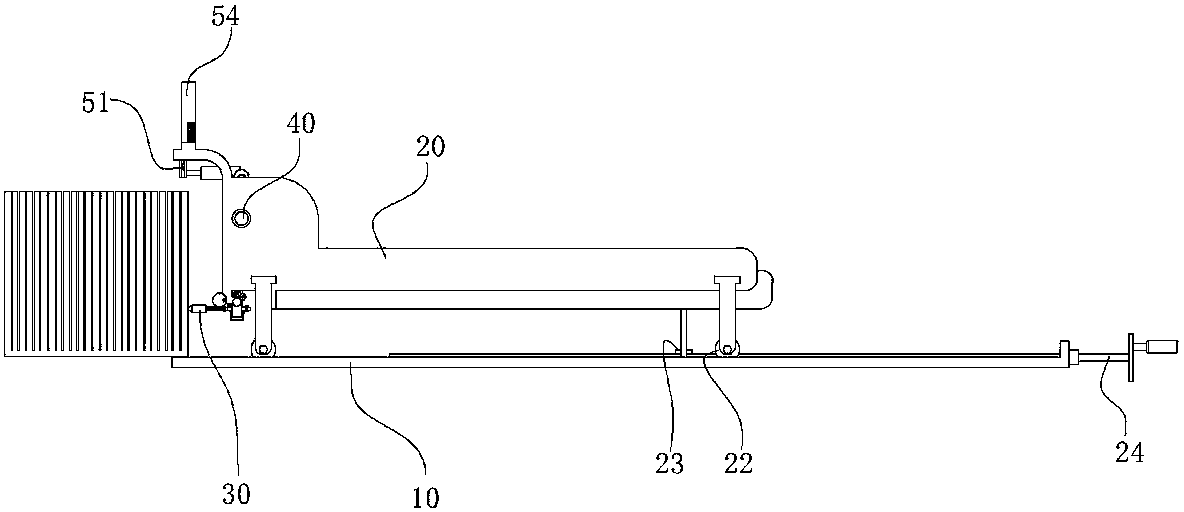

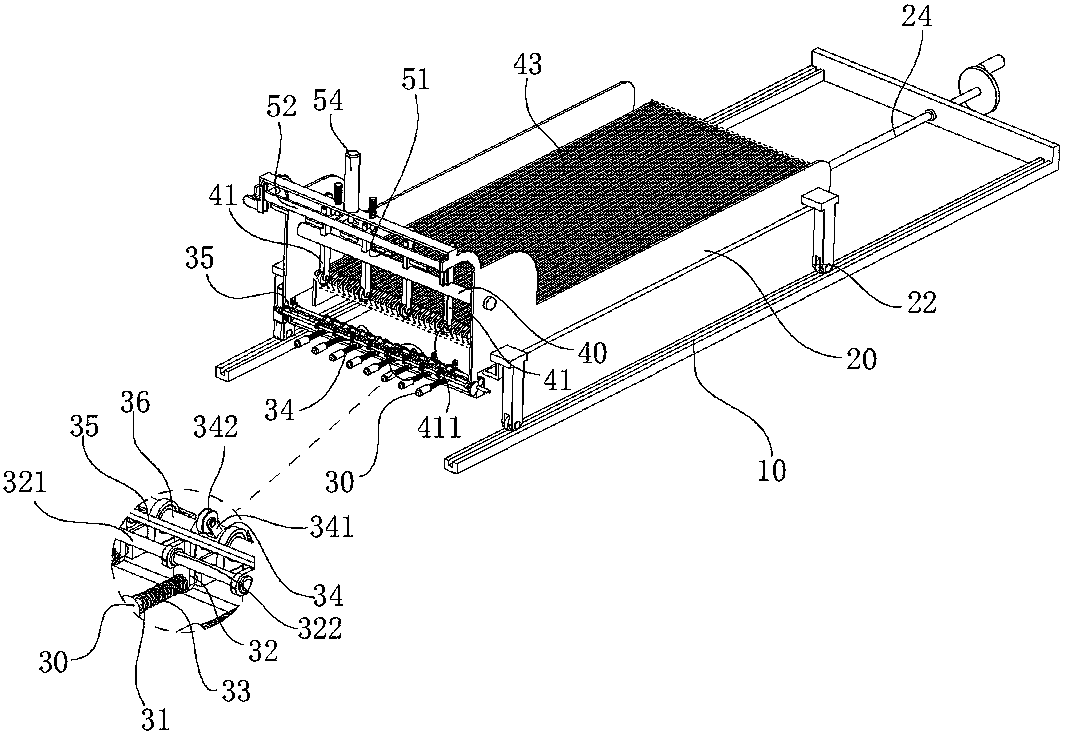

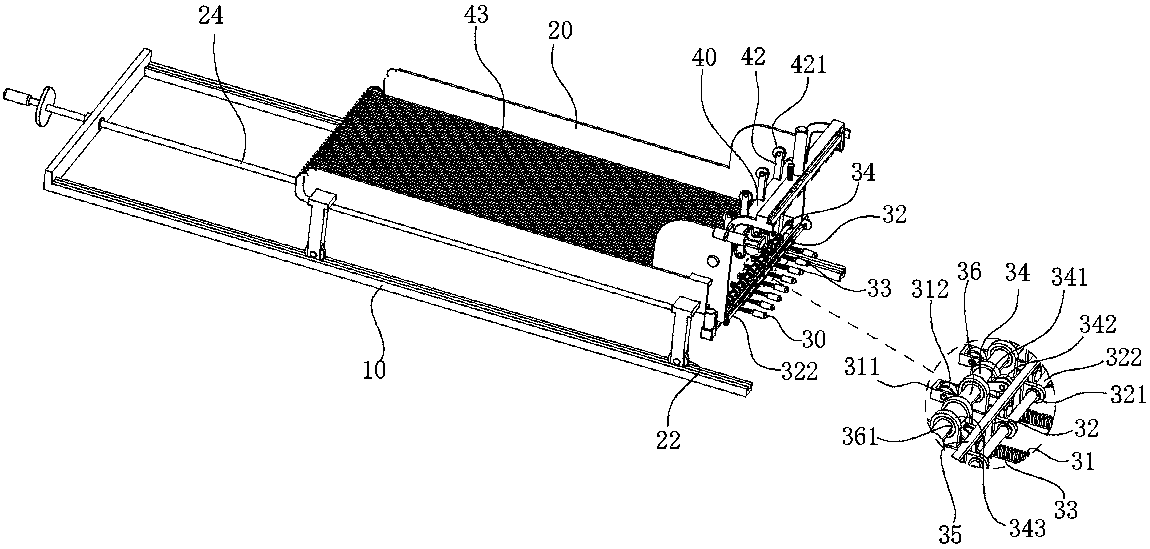

Vision-guided automatic mounting machine and using method thereof

PendingCN108882674AChange positionImprove placement accuracyElectrical componentsControl systemCcd camera

The invention discloses a vision-guided automatic mounting machine and a using method thereof. The vision-guided automatic mounting machine comprises a displacement mechanism, a feeding mechanism, a fixture conveying mechanism, a mounting mechanism, a first CCD camera mechanism, a second CCD camera mechanism and a control system. The displacement mechanism can change the position of the mounting mechanism more quickly, so the mounting accuracy is improved. The feeding mechanism can continuously scrape materials on a material belt, so the material fetching efficiency is improved. The fixture conveying mechanism can quickly convey mounted products to corresponding positions, so the processing efficiency is improved. The mounting mechanism can quickly obtain the materials and then carries outmounting operations, so the mounting efficiency is improved. The first CCD camera mechanism and the second CCD camera mechanism can take photos and record the positions of the materials and the mounted products, thereby ensuring the mounting accuracy. The control system can stably control the whole machine. The vision-guided automatic mounting machine can carry out mounting operations on a plurality of products, is improved in universality, and improves the mounting efficiency and accuracy at the same time.

Owner:昆山晨鼎嘉电子科技有限公司

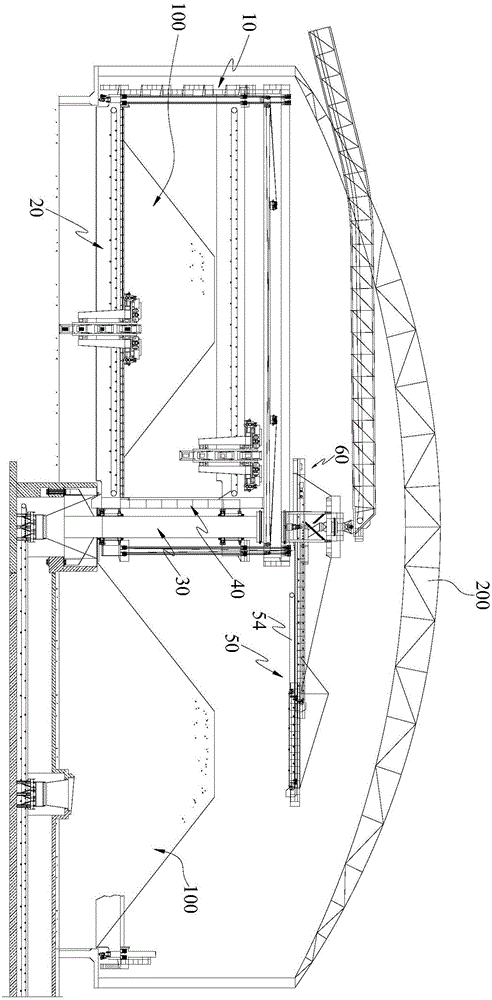

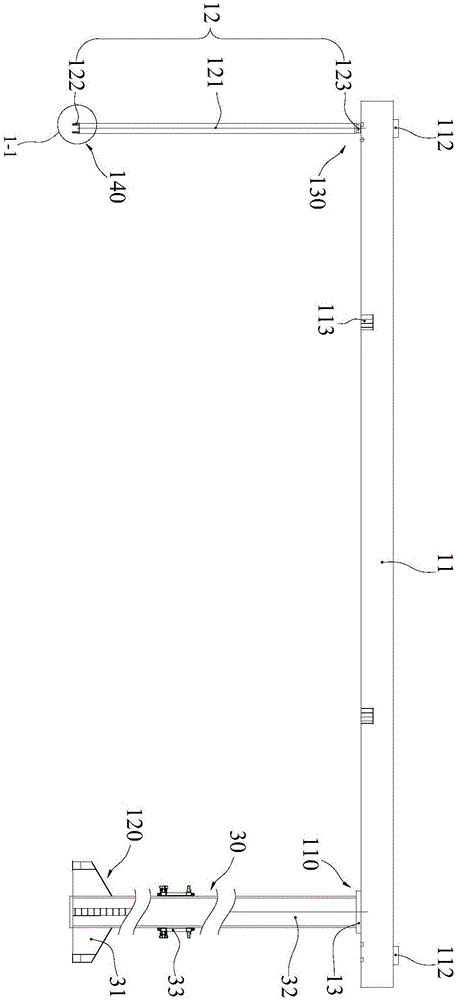

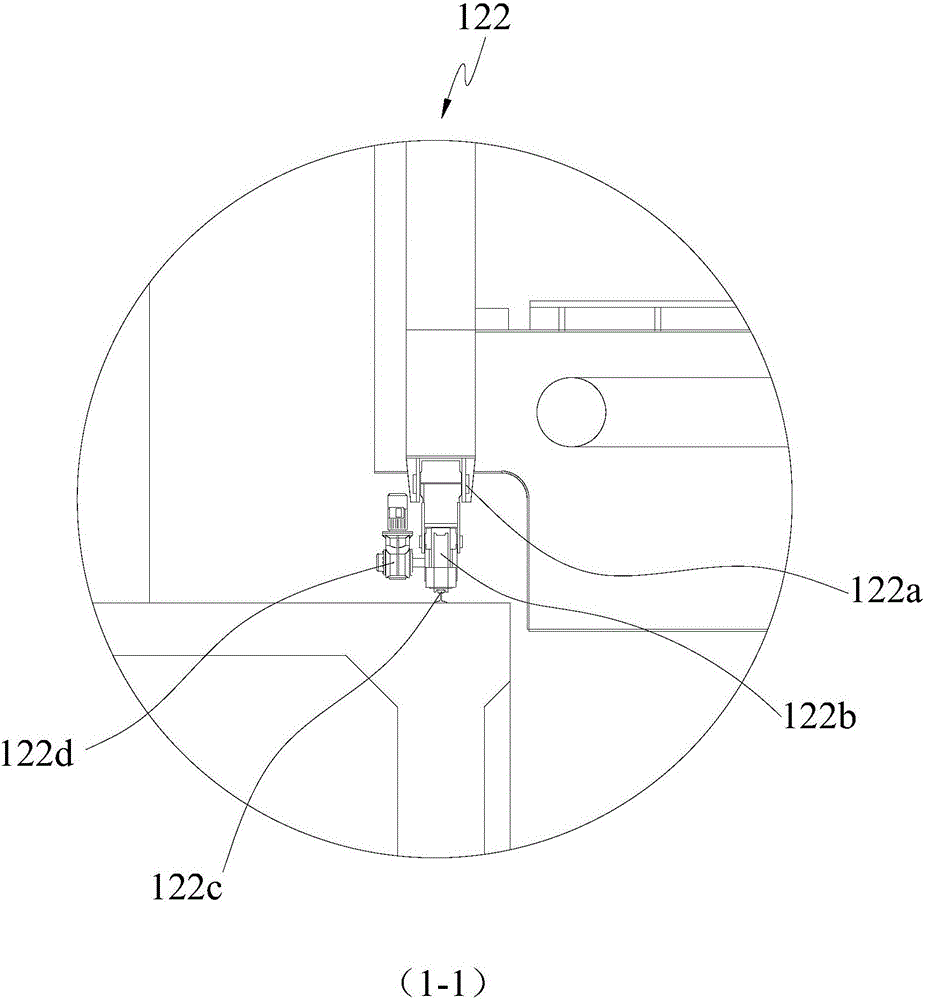

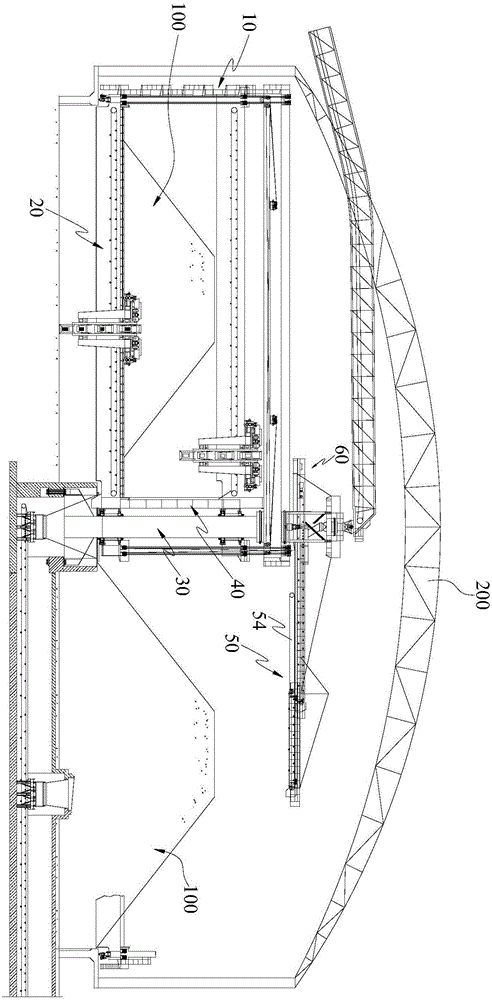

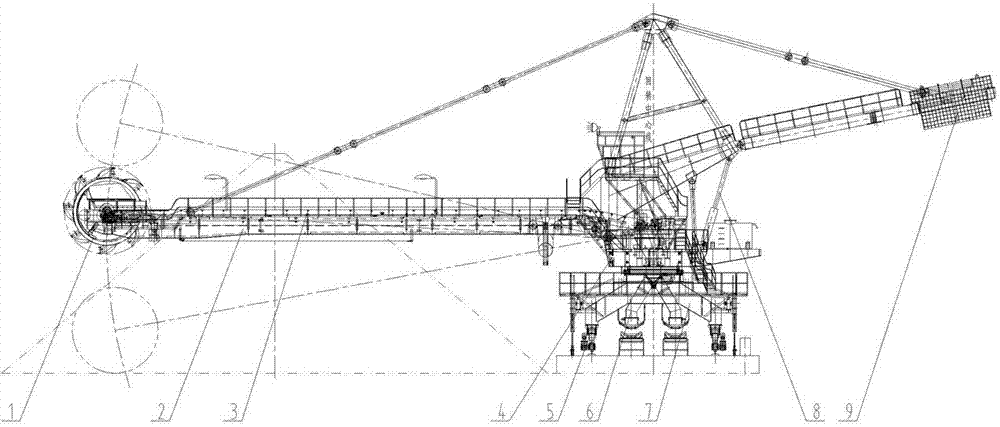

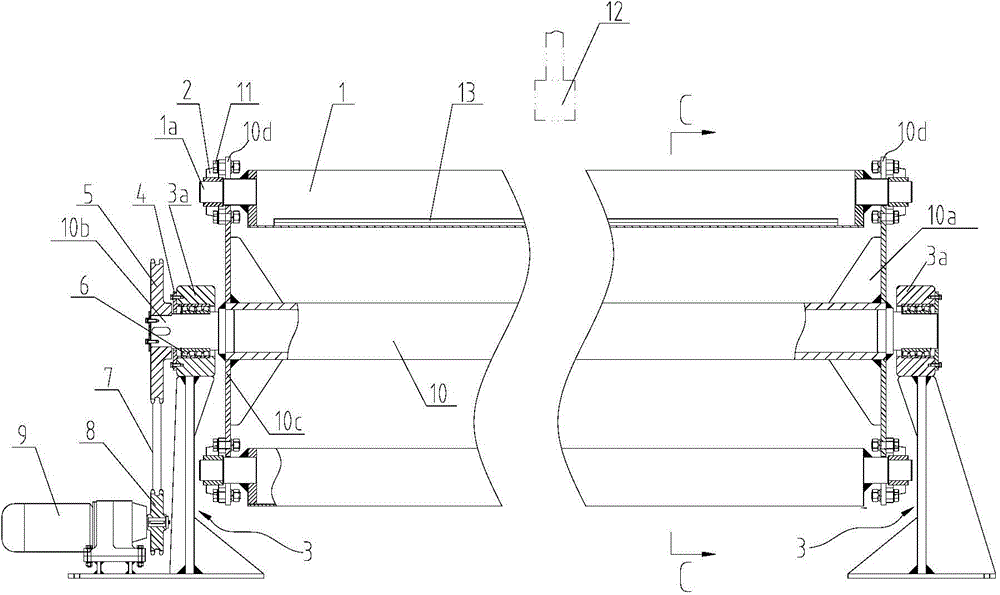

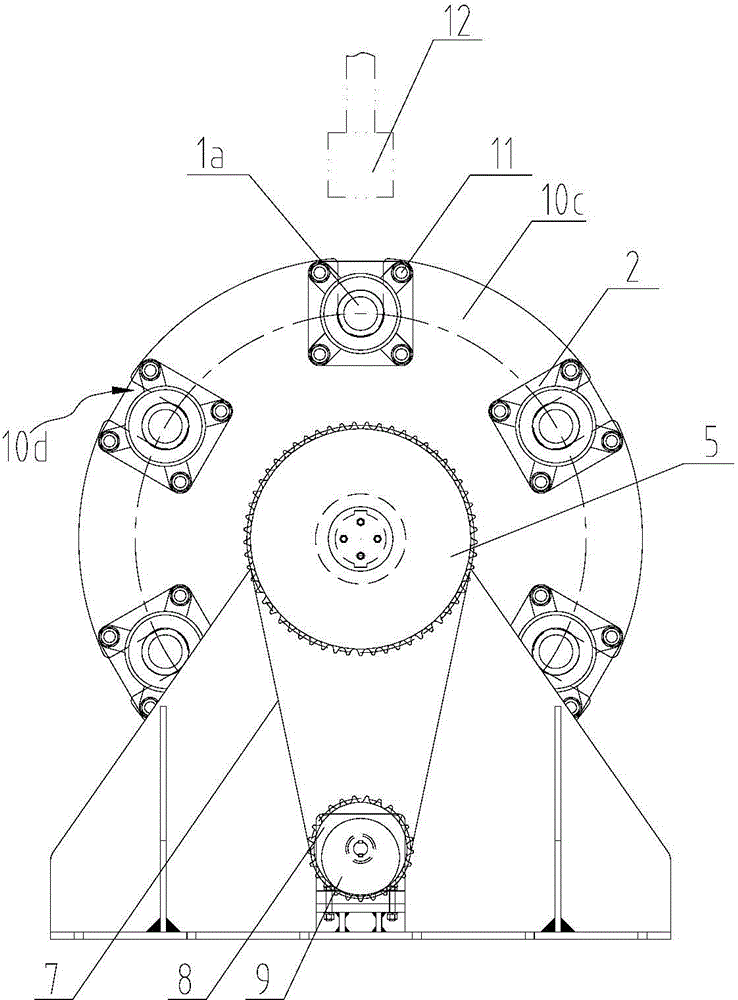

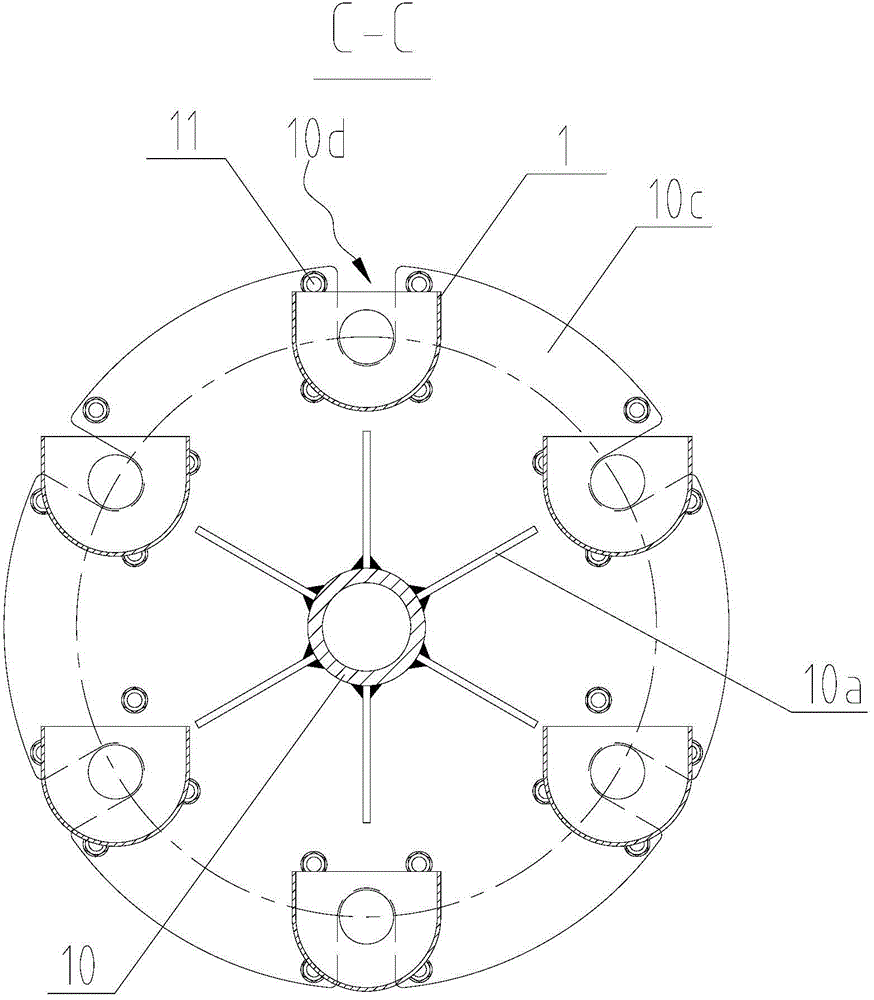

Door type bucket-wheel stacker-reclaimer

ActiveCN106219259ASolve the realization of stacking and reclaimingStacking adjustableLoading/unloadingEngineeringYard

The invention discloses a door type bucket-wheel stacker-reclaimer. The door type bucket-wheel stacker-reclaimer comprises a rotary door frame part, a bucket-wheel reclaiming part, a conveying part and a centered rotating mechanism, wherein the rotary door frame part rotates around the centered rotating mechanism with the span of the rotary door frame part as the radius, and the bucket-wheel reclaiming part and the conveying part are connected to the rotary door frame part. The conveying part is composed of a plurality of belt conveyers and forms a reclaiming logistics channel and / or a stacking logistics channel with the bucket-wheel reclaiming part. Different from existing equipment, the stacker-reclaimer can be applied to a round stock yard innovatively with the span of a door frame as the actual working range radius.

Owner:TIDFORE HEAVY IND

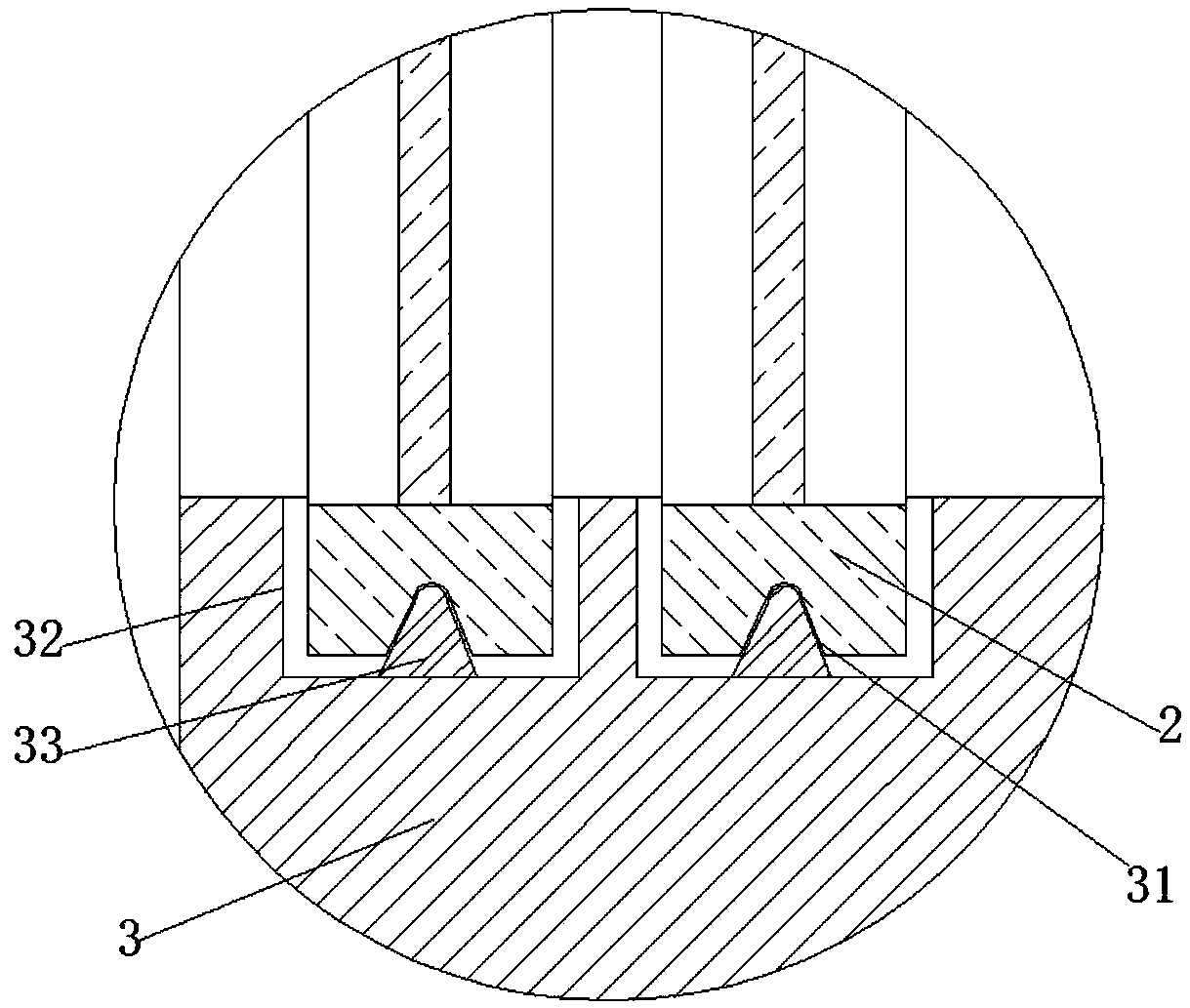

Splitting and fast taking device for soft magnetic ferrite cores

InactiveCN109727762AEasy to splitEasy to take outInductances/transformers/magnets manufactureBatch operationFerrite core

The invention discloses a splitting and fast taking device for soft magnetic ferrite cores, which comprises a base plate. A push plate parallel to the base plate is installed at the bottom of the baseplate. Ejector pins are welded in an array on one side of the push plate near the base plate. A bearing plate fixedly connected with the top of the base plate is installed at one end of the ejector pins extending out of the top of the base plate. The bearing plate is provided with through holes which sleeve the ejector pins in a sliding manner. A sintering plate is placed on the top of the base plate. A bracket is installed on the top of the base plate. A driving mechanism is installed along the length direction of the base plate on one side of the bracket near the base plate. A first cylinder is installed vertically on one side of the driving mechanism near the base plate. A rectangular cover is welded vertically to one end of the first cylinder near the base plate. The device of the invention is simple in structure and convenient to operate. By using the device, sintered soft magnetic ferrite cores can be conveniently split and taken, batch operation on soft magnetic ferrite cores is realized, the efficiency of soft magnetic ferrite core splitting and taking after sintering is improved, and the production efficiency of soft magnetic ferrite cores is improved.

Owner:中山市天文电子有限公司

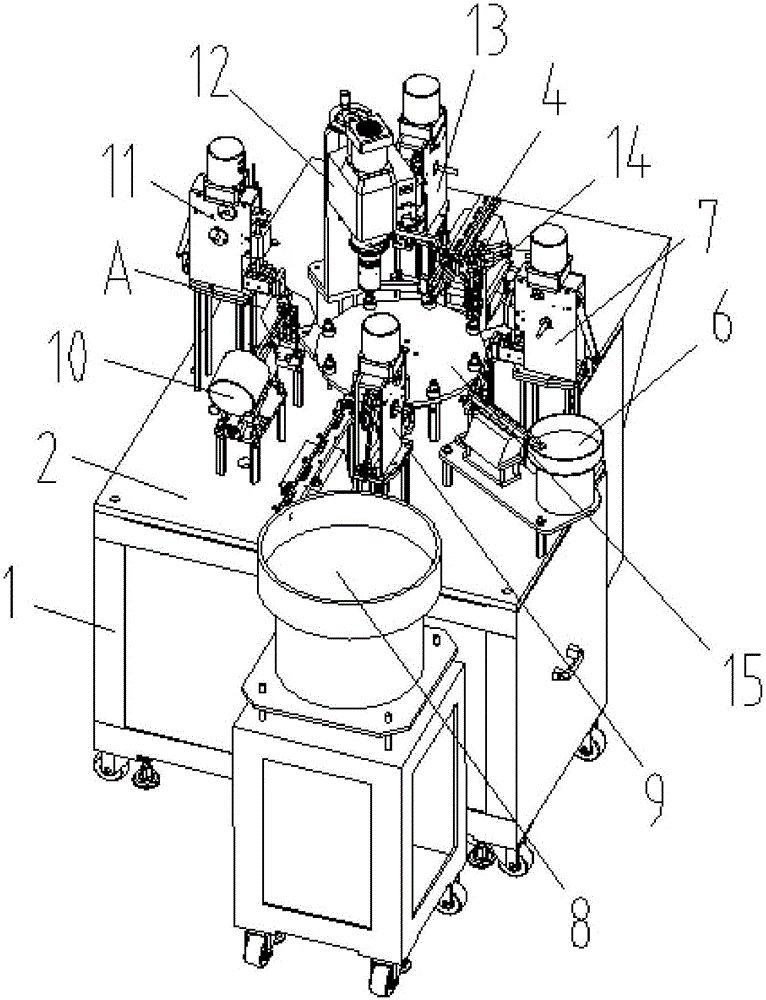

Full-automatic assembly machine of mechanical shaft

ActiveCN106736505AImprove installation efficiencyImprove the efficiency of installation, but also improve the utilization of equipmentAssembly machinesMetal working apparatusDistribution controlGear wheel

The invention relates to a full-automatic assembly machine of a mechanical shaft. The machine comprises a frame and a power distribution control box; the frame is provided with a shaft sleeve mounting mechanism and a gear mounting mechanism connected through a product conveying groove; a shaft sleeve mounting turntable is uniformly provided with loading holes matched with the shaft, and the outer side is provided with a shaft loading device, a shaft sleeve loading device, a screw rod loading device, a shaft sleeve pressing device and a shaft sleeve unloading device matched with the loading holes and connected to the power distribution control box in sequence; the gear mounting mechanism includes a gear mounting turntable arranged on the frame; the gear mounting turntable is uniformly provided with emptying holes matched with the shaft; and the outer side of the gear mounting turntable is provided with a gear loading device, a product loading device, a gear tightening device and a product unloading device matched with the emptying holes or a gear mounting carrier in sequence. The shaft sleeve mounting mechanism and the gear mounting mechanism are connected through the product conveying groove, so that the integral automatic installation is realized, and the mounting efficiency is greatly improved.

Owner:DONGGUAN UNIV OF TECH

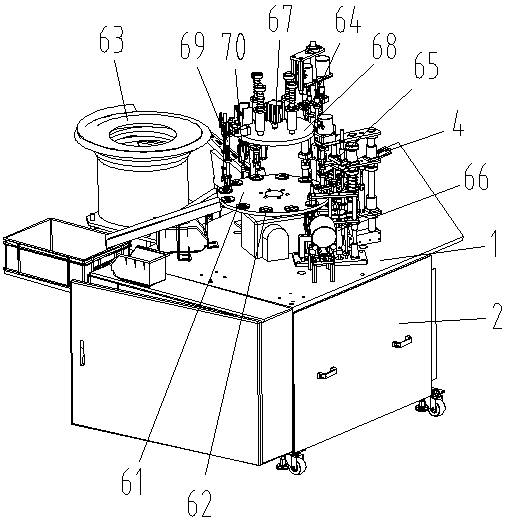

Automatic shaft gear assembling machine convenient for picking materials

ActiveCN108637684AImprove installation efficiencyIncrease profitAssembly machinesMetal working apparatusDistribution controlGear wheel

Owner:双环传动(嘉兴)精密制造有限公司

Displaying cabinet used for selling wooden packaging box and facilitating material taking

The invention belongs to the technical field of displaying cabinets, and particularly relates to a displaying cabinet for selling wooden packaging boxes and facilitating material taking. In order to solve the problems that when packaging boxes are stacked for displaying, the displaying effect of the bottom is blocked, and materials are not convenient to take, the following scheme is provided. Thedisplaying cabinet comprises a supporting frame and packaging box bodies, wherein a displaying cabinet body is fixed to the top end of the supporting frame through bolts, two rectangular sliding chutes are formed in the inner wall at the top end and the inner wall at the bottom end, near an opening, of the displaying cabinet body, three moving doors are in sliding connection between the rectangular sliding chutes between the top end and the bottom end of the displaying cabinet body, and a first separating plate and a second separating plate, which are mutually arranged in parallel, are fixed to the inner wall of the back of the displaying cabinet body through bolts. According to the displaying cabinet disclosed by the invention, when the situation that people watch the packaging boxes is detected, a driving motor is controlled to be started, so that each packaging box body at the top end of a thrust ball is driven to display while rotating, and the displaying effect is improved.

Owner:蒙城县信德木业有限公司

Detection equipment based on visual detection system and use method

The invention relates to the field of visual detection, in particular to detection equipment based on a visual detection system and a use method. The detection equipment based on the visual detection system comprises a working table plate, and a feeding area, a detection area and a receiving area which are arranged on the working table plate, and the feeding area and the receiving area are each provided with a bearing piece, an up-down driving piece, a linear driving piece, a tray supporting mechanism and a mechanical arm. The detection area is provided with a carrying mechanism, a first detection mechanism, a second detection mechanism, a third detection mechanism, a first transfer mechanism and a second transfer mechanism. The use method of the detection equipment based on the visual detection system comprises the steps of feeding, detecting and receiving. Through the arrangement of the feeding area, the detection area and the material receiving area, detection of all detection items of materials can be completed through a one-time continuous detection process; and comprehensive detection results of the materials can be quickly obtained, and unqualified materials can be screened out. During detection, the automation degree is high, circulation steps are few, and the detection efficiency can be improved.

Owner:荣旗工业科技(苏州)股份有限公司

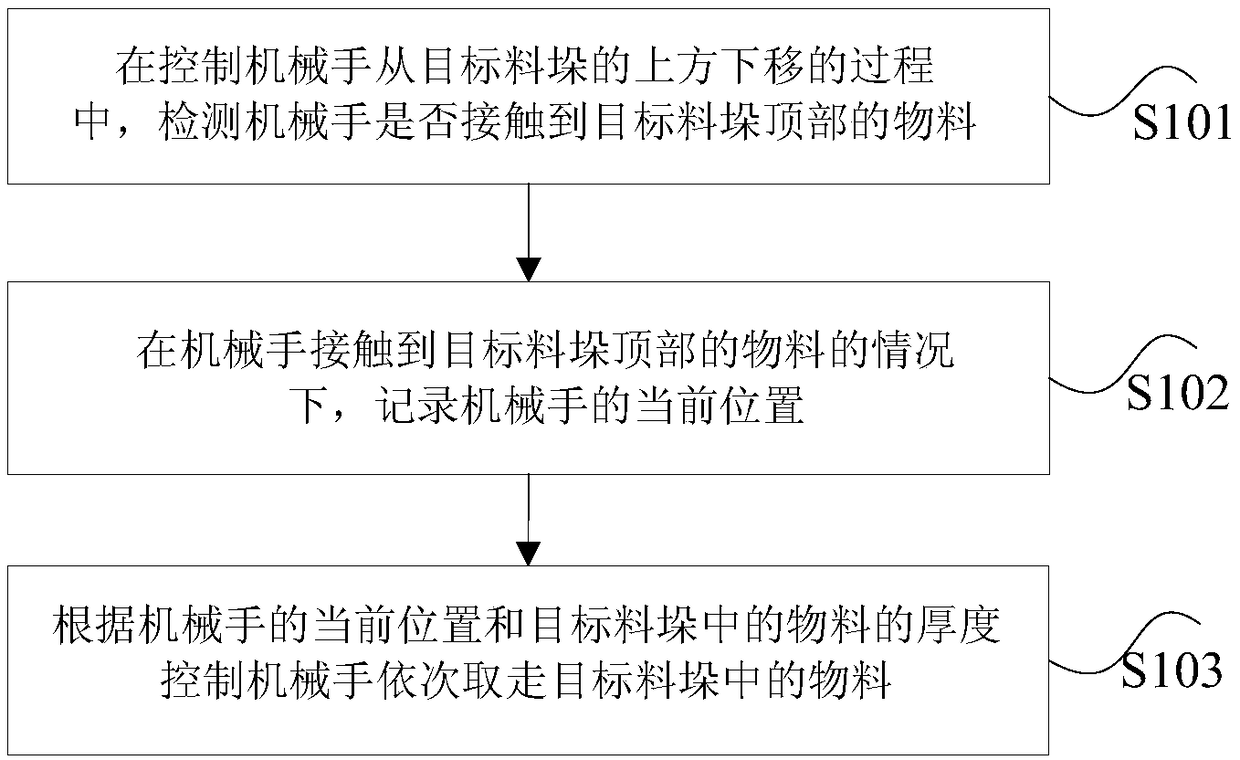

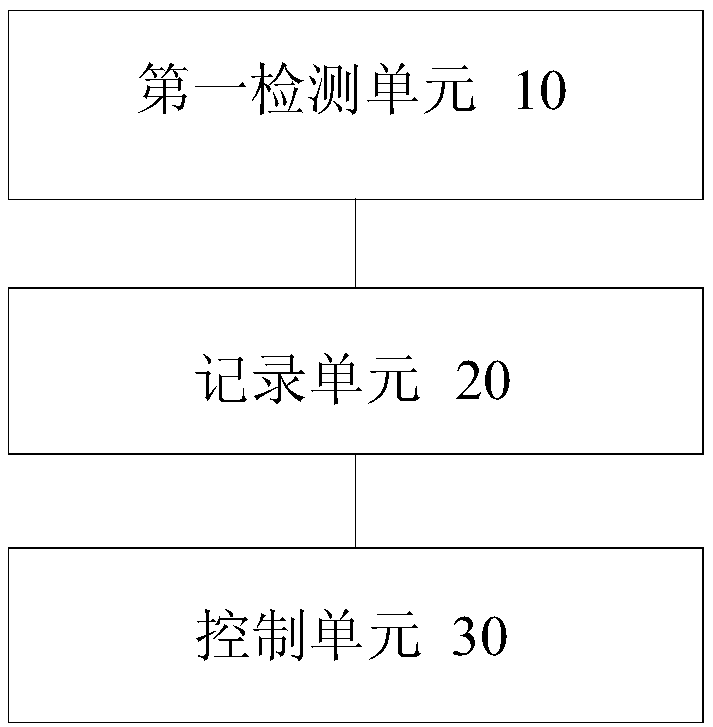

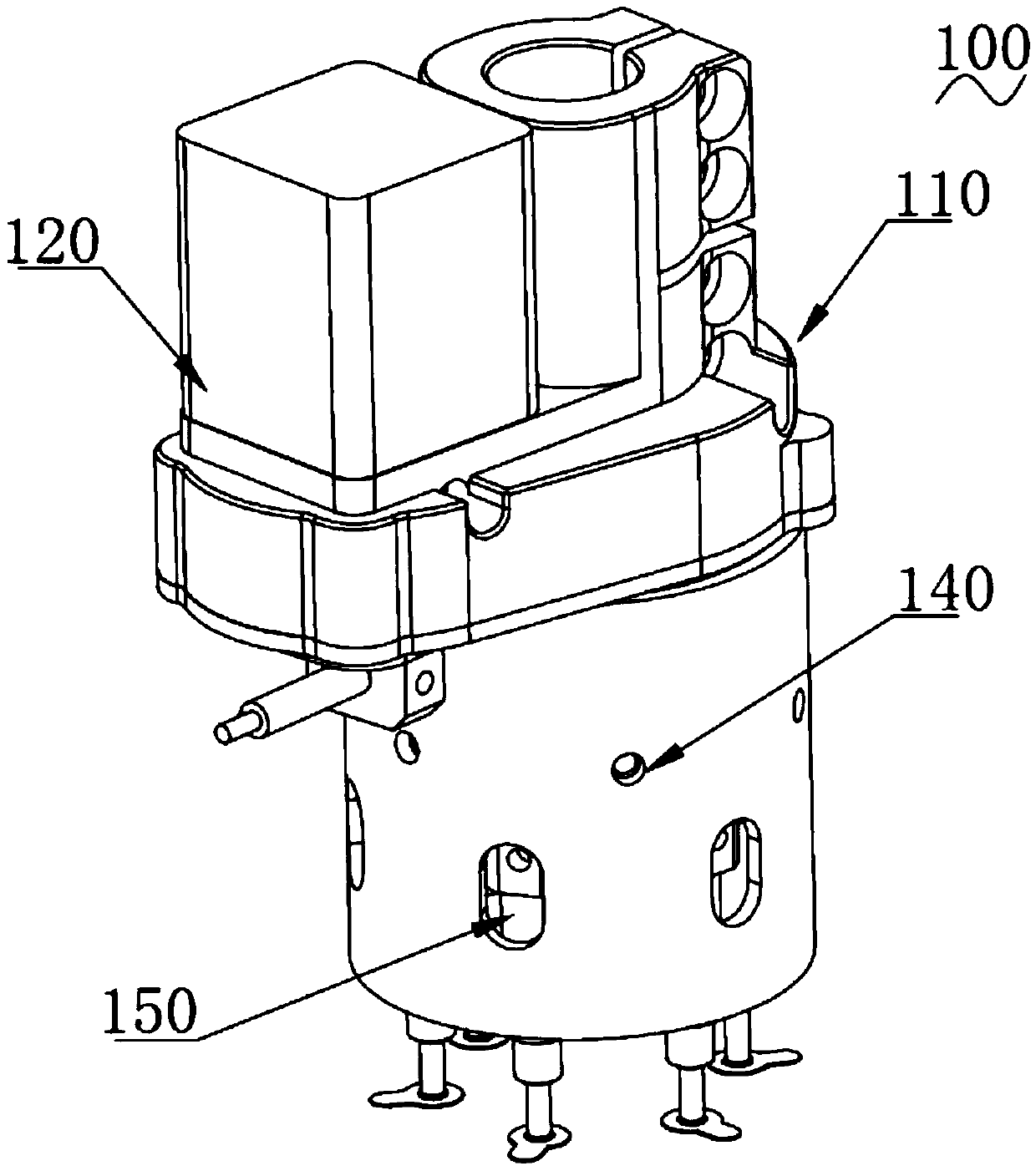

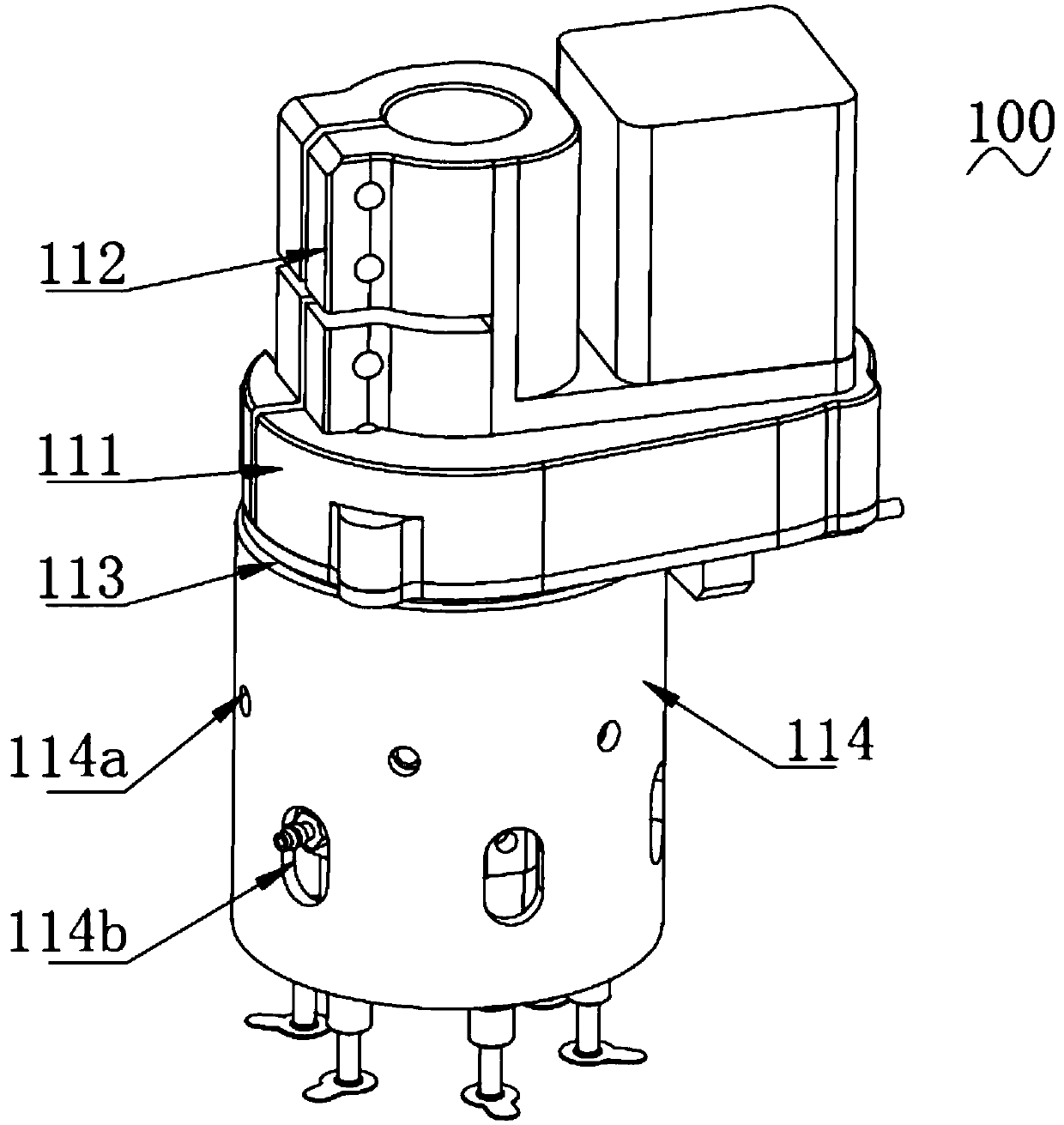

Fetching control method and device

InactiveCN108820905ASolve the problem of low material retrieval efficiencyImprove reclaiming efficiencyStacking articlesDe-stacking articlesEngineeringManipulator

The invention discloses a fetching control method and device. The fetching control method comprises the steps that when a manipulator is controlled to move downwards from a position above a target material stack, whether or not the manipulator touches a material at the top of the target material stack is detected, wherein the target material stack is formed by stacking a plurality of materials ofthe same type from top to bottom; under the condition that the manipulator touches the material at the top of the target material stack, the current position of the manipulator is recorded; and the manipulator is controlled to sequentially take the materials from the target material stack according to the current position of the manipulator and the thickness of the materials in the target materialstack. By adoption of the fetching control method and device, the problem that in the prior art, when a manipulator is used for fetching materials, the positions of the materials in a material stackneed to be obtained manually, and consequentially, the fetching efficiency is low is solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

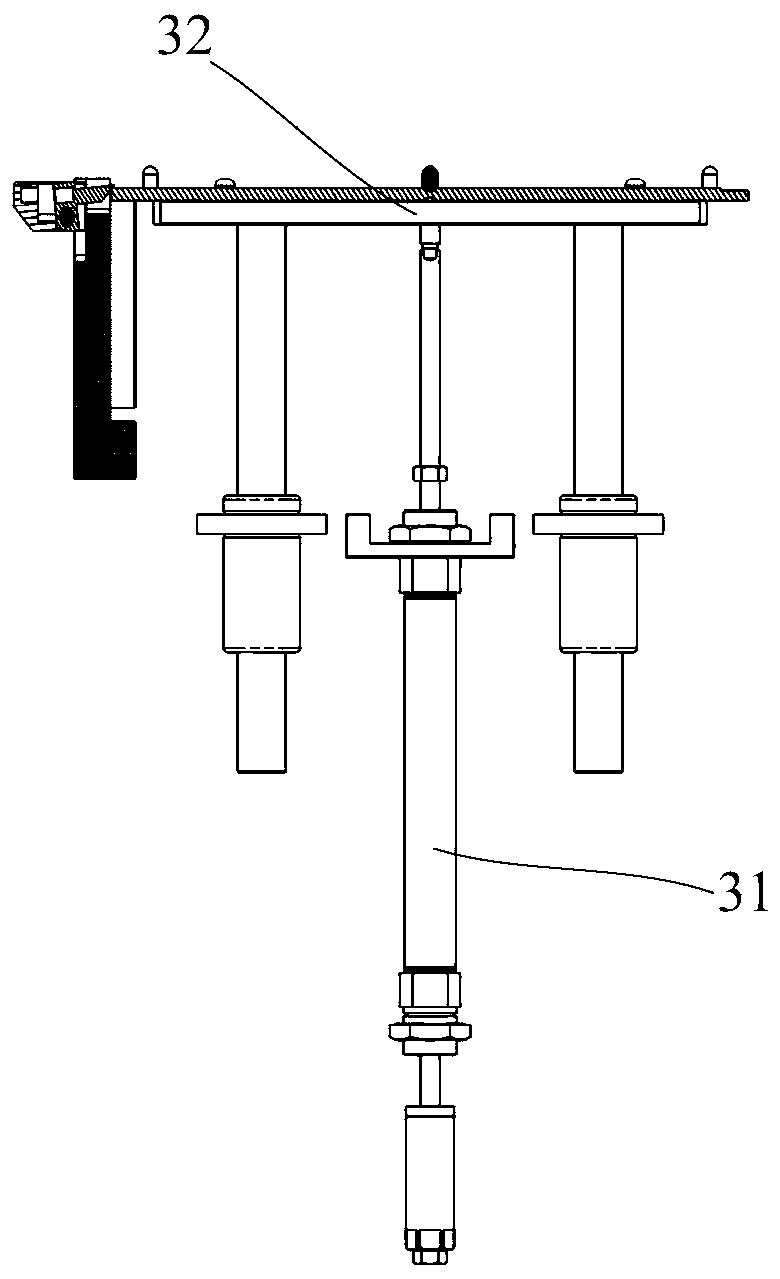

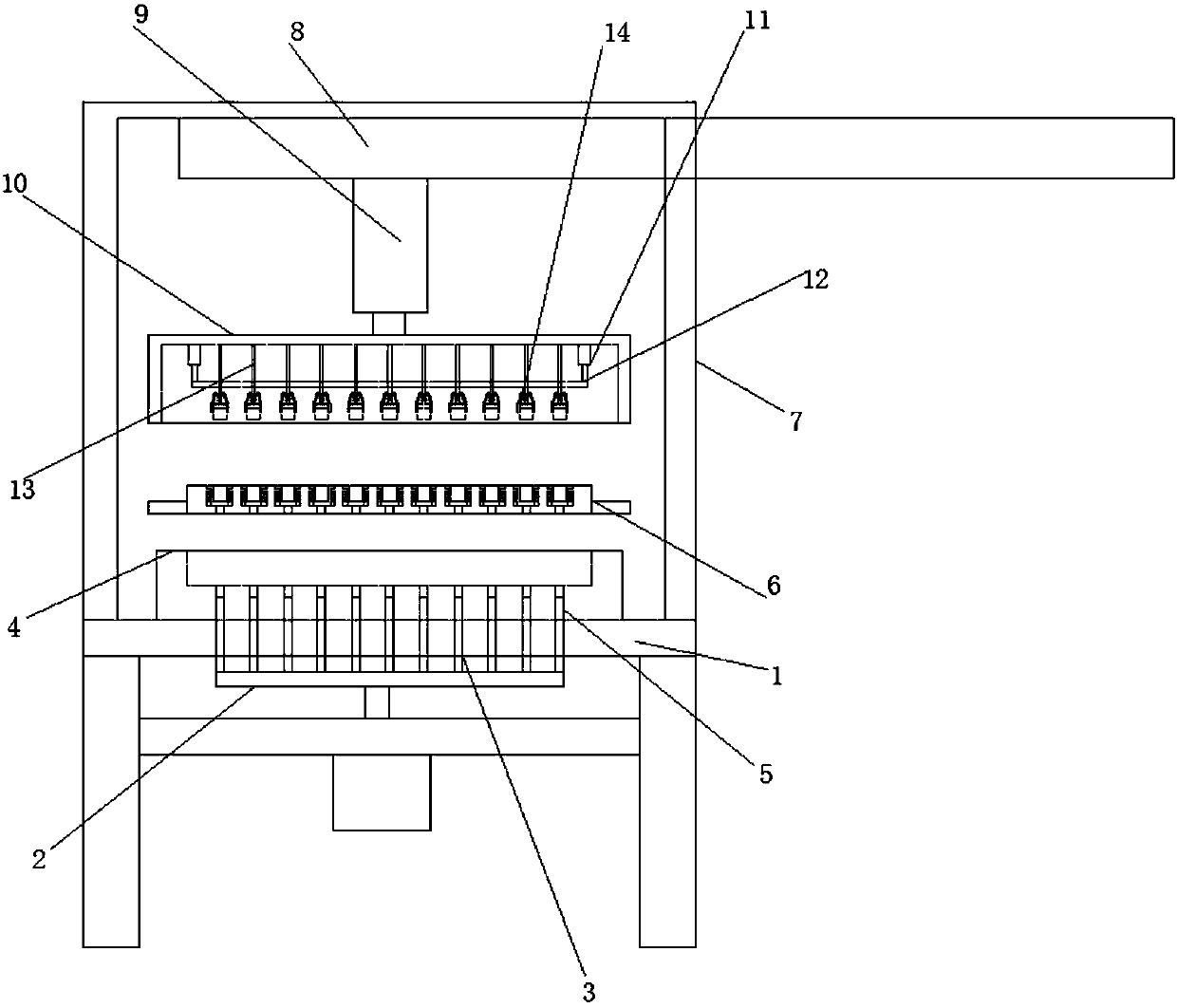

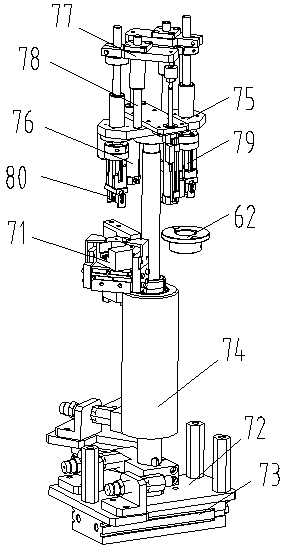

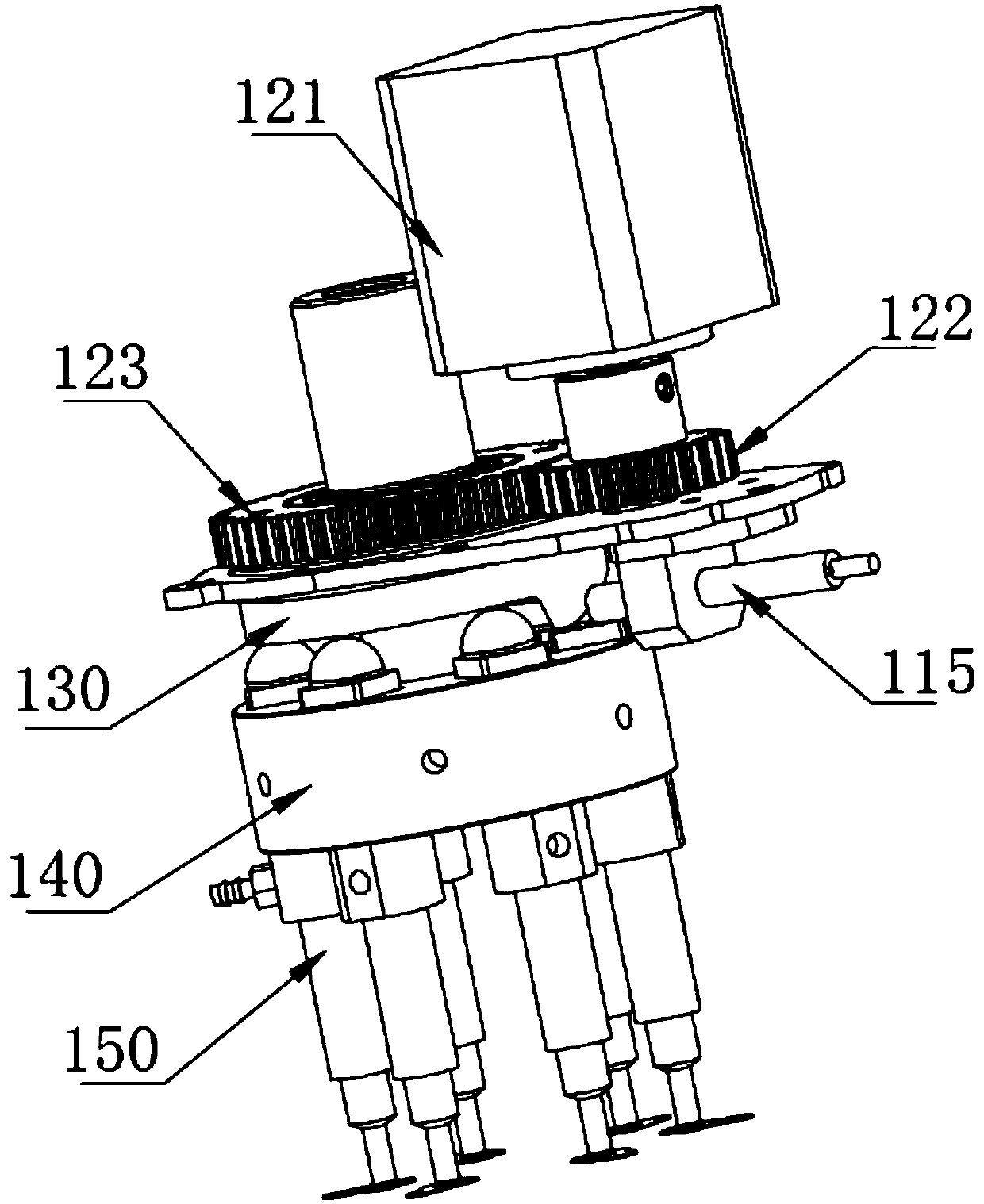

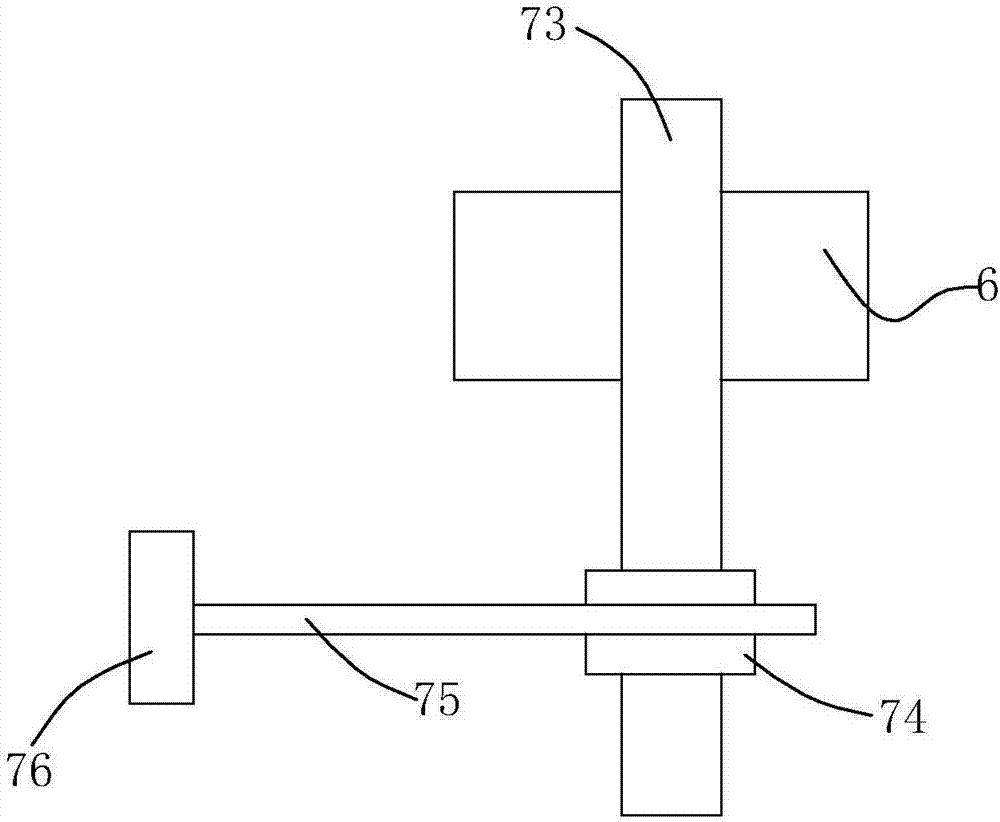

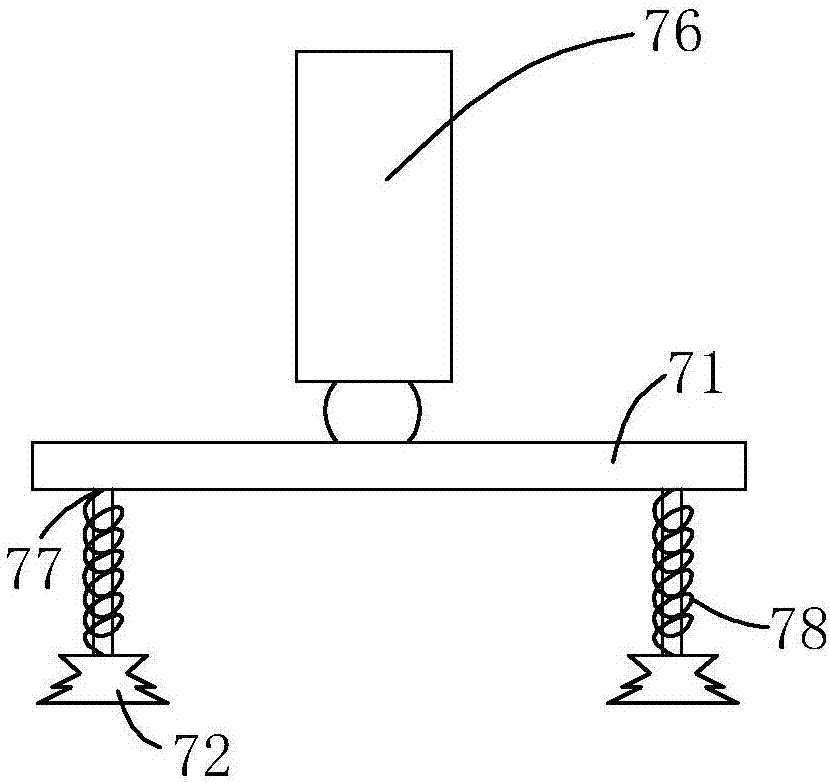

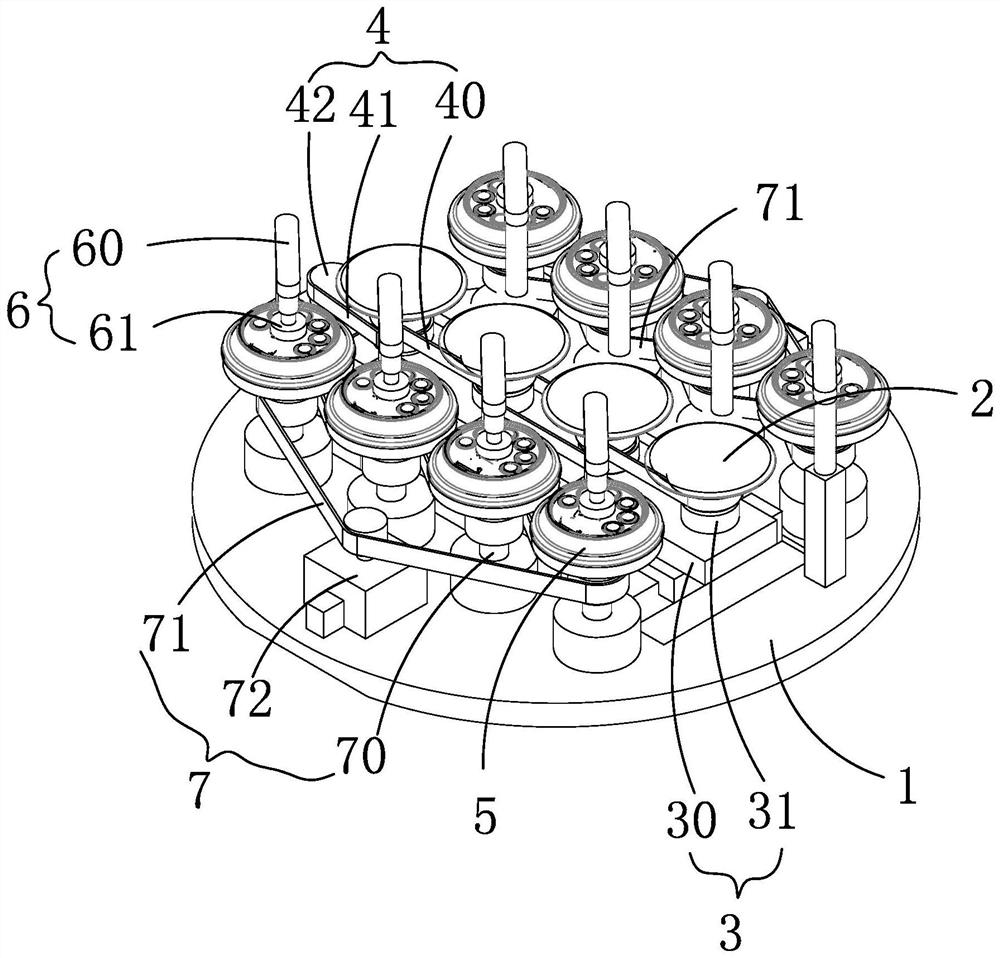

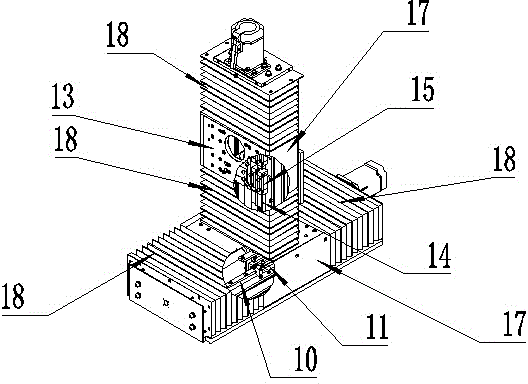

Multi-head material taking device based on cam driving lifting

ActiveCN109650059AImprove suction performanceImprove reclaiming efficiencyConveyor partsCamRotating disc

The invention relates to the technical field of automatic material taking, in particular to a multi-head material taking device based on cam driving lifting. The multi-head material taking device comprises a mounting bracket, a driving part, a cam rotating disc and a material sucking disc. The driving part is arranged on the mounting bracket. The cam rotating disc is in transmission connection with the driving part. The material sucking disc is arranged on the mounting bracket. A plurality of suction nozzles are uniformly distributed on the material sucking disc in the circumferential direction and are telescopically arranged on the material sucking disc. The cam rotating disc is driven by the driving part to drive the suction nozzles to stretch and suck materials. Compared with a transmission material suction structure, the multi-head material taking device is low in cost. Due to the arrangement of the plurality of groups of suction nozzles, the material sucking efficiency and the automation degree are high.

Owner:东莞市威耐科智能装备有限公司

Material fetching mechanism for full-automatic cabin cleaning vehicle

InactiveCN101016124BMeet miniaturization configuration requirementsThe structure is simple but not complicatedToothed gearingsLoading/unloadingEngineeringTransmitter

A material feeder of full-automatic chamber cleaner comprises a couple of left and right wall plates, a rotary drum and an active drum axially arranged at two ends of the wall plates, a couple of support rollers distantly distributed between the rotary drum and the active drum, two support wheel groups, a transmission band contacted with the support roller and the support wheel, a hopper group distributed on the transmission band, a transmitter linked with the drum axle of the active drum, a couple of pushing plates at two ends of the drum axle, two wheel groups axially arranged at outer sideand near the middle of left and right wall plates, a couple of tracks covering the roller groups. The invention has the advantages in simple structure and simple connection with the chassis of walking device, high feeding efficiency, or the like.

Owner:常熟市诚达港务机械设备厂

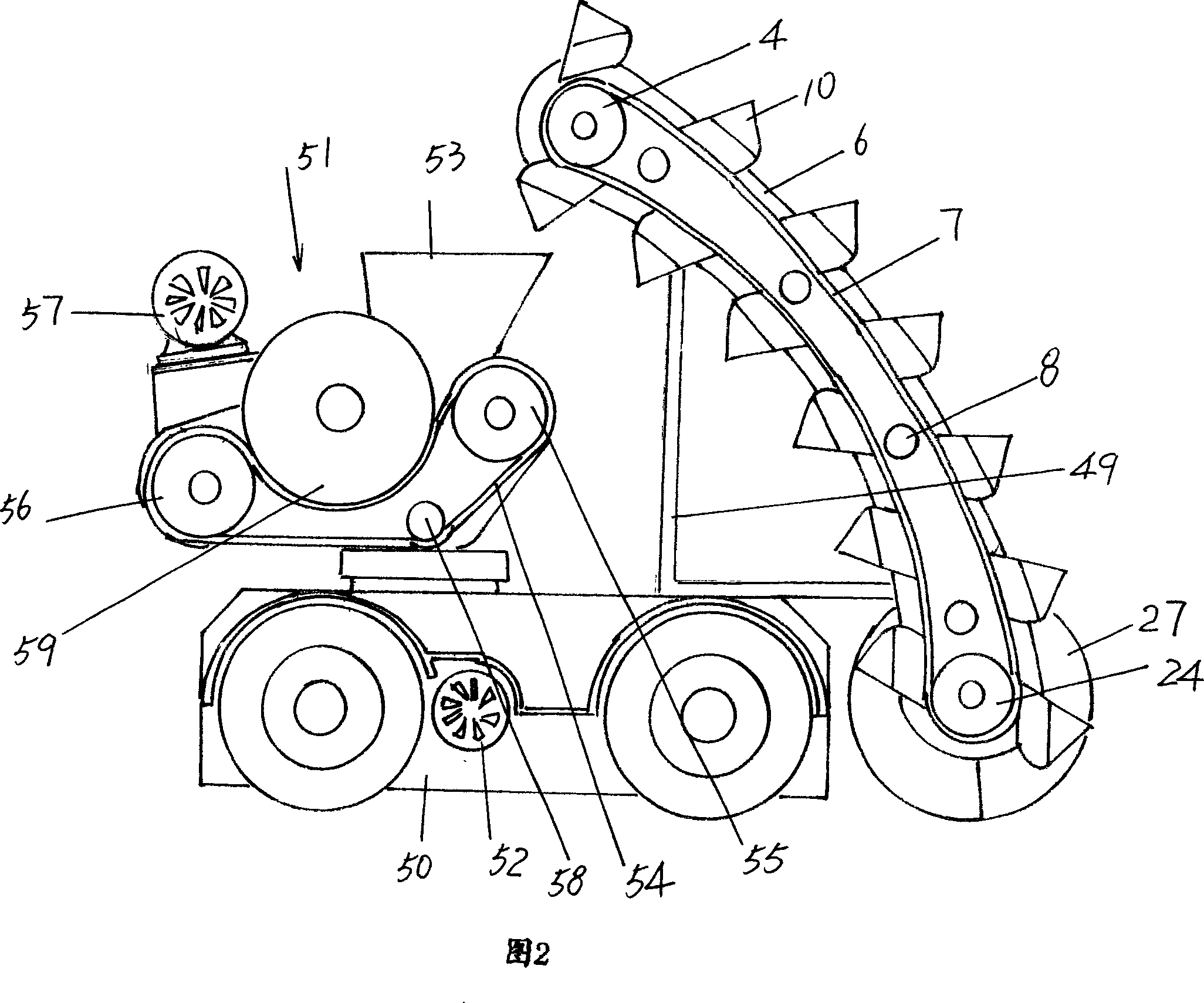

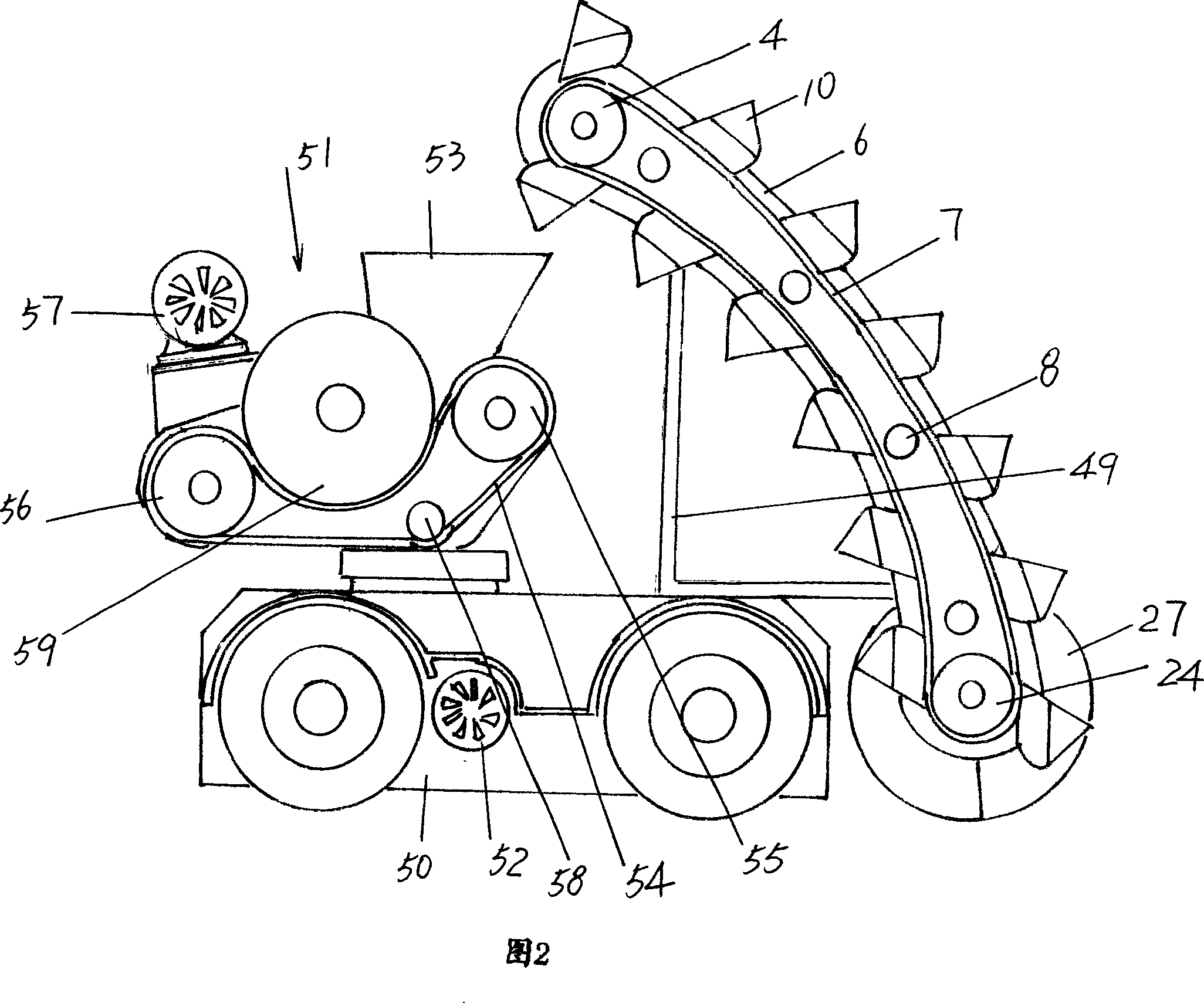

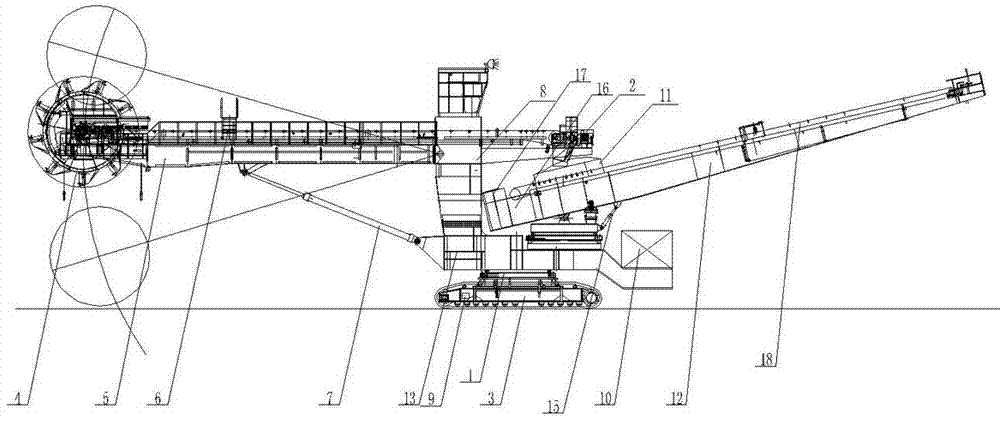

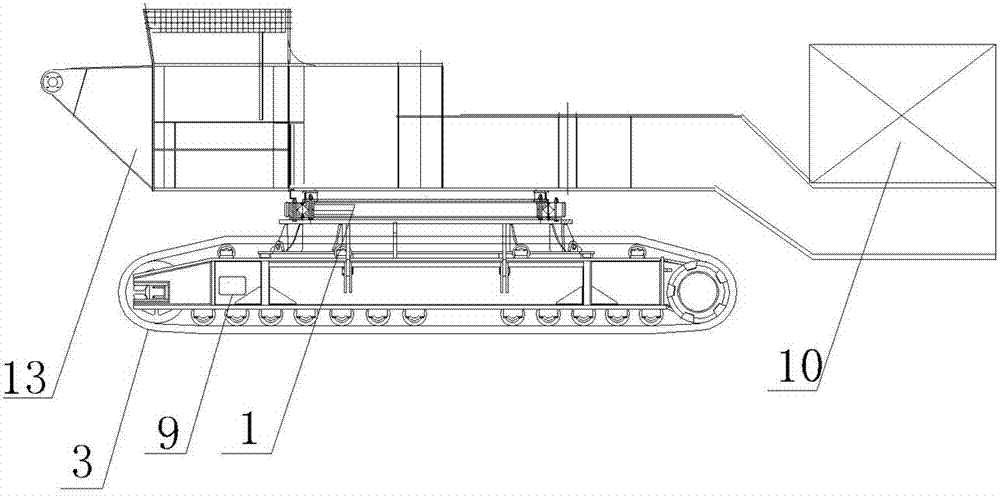

Crawler bucket-wheel reclaimer and reclaiming method thereof

The invention discloses a crawler bucket-wheel reclaimer, which comprises a chassis, a supporting pillar, a central hopper, a traveling mechanism, a bucket-wheel mechanism, a cantilever structure, a belt conveyer, a luffing mechanism, a generator and a power distribution room, the cantilever structure is arranged on the supporting pillar, the central hopper is arranged at the end of the belt conveyer, the traveling mechanism is arranged at the bottom of the chassis, the bucket-wheel mechanism is connected with the central hopper through the cantilever structure, the belt conveyer is arranged on the cantilever structure, the feed inlet of the belt conveyer is connected with the discharge outlet of the bucket-wheel mechanism, the discharge outlet of the belt conveyer is connected with the feed inlet of the central hopper, a piling tray is also arranged on the chassis, the piling tray is connected with the chassis through a piling arm, a piling belt conveyer is arranged on the piling arm, and the feed inlet of the piling belt conveyer is connected with the discharge outlet of the central hopper. The crawler bucket-wheel reclaimer can conveniently pile and load material, a cantilever and the piling arm can be rotated for work by 360 degrees by means of a turntable structure, and the crawler bucket-wheel reclaimer can increase reclaiming efficiency and can be used at more places.

Owner:浙江华电智能电站设备股份有限公司

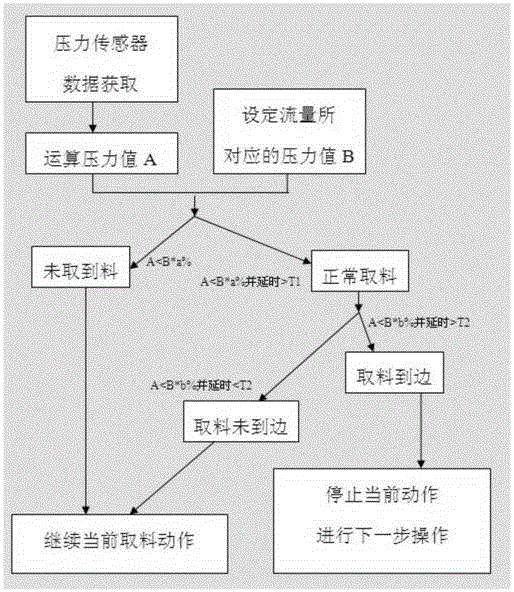

Material taking rotation boundary judgment and control system and method for bucket wheel machine

PendingCN105836419ASafe unmanned automatic operationAccurate unmanned automatic operationControl devices for conveyorsTotal factory controlInternal pressureControl system

The invention relates to a material taking rotation boundary judgment and control system and method for a bucket wheel machine. The system comprises a pressure sensor, a signal collection remote station and a single-machine controller. The pressure sensor is connected with the signal collection remote station through a signal cable, and the signal collection remote station is connected with the single-machine controller through a communication cable. The method comprises the steps that firstly, the internal pressure of a bucket wheel hydraulic pressure of a material taking machine is acquired by the pressure sensor; secondly, pressure data are acquired by the signal collection remote station and transmitted to the single-machine controller; and thirdly, the pressure data are converted by the single-machine controller into a pressure value, the pressure value is compared with a preset pressure value, and whether the actual material stacking boundary is achieved or not is judged. According to the material taking rotation boundary judgment and control system and method, the material taking machine can carry out unmanned automatic operation safely, accurately and efficiently, meanwhile, idle running of the material taking machine in the operation process is reduced, and the material taking efficiency is improved.

Owner:INSTALLATION ENG CO LTD OF CCCC FIRST HARBOR ENG

Stacker-reclaimer

ActiveCN106315247ASolve the realization of stacking and reclaimingStacking adjustableLoading/unloadingEngineeringReclaimer

The invention discloses a stacker-reclaimer. The stacker-reclaimer comprises a rotary portal frame part, a bucket-wheel material taking part, a conveying part and a centering rotating mechanism, wherein the rotary portal frame part rotates around the centering rotating mechanism by taking a span of the rotating portal frame as the radius, and the bucket-wheel material taking part and the conveying part are connected to the rotating portal frame. The conveying part is composed of a plurality of belt conveyors and is matched with the bucket-wheel material taking part to form a material taking material flow channel and / or a material stacking material flow channel. Different from existing equipment, the stacker-reclaimer, taking the span of the portal frame as the actual working range radius, is applied to a round stockyard initiatively.

Owner:TIDFORE HEAVY IND

Rotating type raw material bar storing device

ActiveCN104608104AReduce labor intensityOccupies a small floor spaceWork tools storageAutomatic controlMechanical engineering

The invention discloses a rotating type raw material bar storing device. According to the structure of the rotating type raw material bar storing device, rotating plates are fixed to the two sides of a rotating main shaft, the two ends of the rotating main shaft are hinged into bearing pedestals, one end of the rotating main shaft is connected with a rotating drive device which drives the rotating main shaft and the two rotating plates to rotate, a plurality of storing baskets are hinged between the two rotating plates in a supported mode, storing basket supporting shafts are fixed to the two ends of each storing basket, the storing basket supporting shafts penetrate through supporting grooves in the two rotating plates in a sliding fit mode, then the rear ends of the storing basket supporting shafts are hinged into bearings, the bearings are fixed to the side faces of the two rotating plates, and the axes of the multiple storing basket supporting shafts are located on the concentric circle in the mode of equally distancing from the axis of the rotating main shaft. The storing device has the advantages that the occupied area of placing and storing raw material bars is reduced, the rotating drive device controlled automatically is utilized for finishing automatic replacing of positions of the raw material bar storing basket, automatic taking is facilitated through automatic rotating, the structure is simple, and work is stable; manual replacing of the raw material bars is substituted, and the storing device has the advantage of being high in storing and taking efficiency.

Owner:TJK MACHINERY TIANJIN

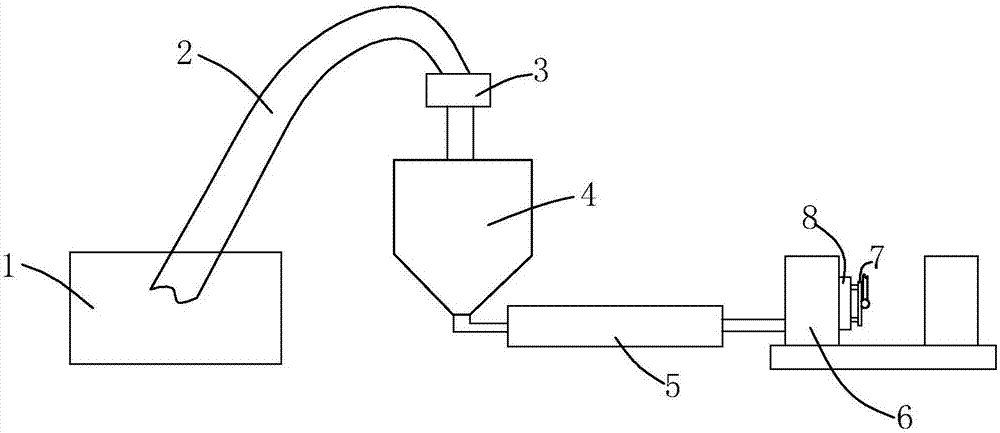

Machine case injection moulding production line

PendingCN107486968ARealize automatic feedingImprove feeding efficiencyCoatingsMachineInjection moulding

The invention discloses a machine case injection moulding production line. A raw material bin is connected with a feeding hopper through a feeding channel, automatic raw material feeding is achieved under the effect of a material sucking device, and the feeding efficiency is improved; an injection moulding machine is provided with a material taking mechanical arm, after machine case injection moulding machining is completed, motions of a movement block, a vertical rail and a horizontal rail are controlled through a PLC control system, an installing disc is fed to the target setting position, a sucker vertically abuts against the surface of a machine case, an air extractor is then controlled to exhaust air, the machine case is taken out by means of the negative pressure, and the material taking efficiency is greatly improved; and meanwhile, an operator does not need to be in contact with a injection moulding machine in a close-range manner, and accidents such as scalding are avoided; a conveying belt is further arranged, the taken-down machine case can be conveyed to the conveying belt through the material taking mechanical arm, automatic production of the overall process from feeding to machining to taking to feeding is achieved, and the machining efficiency is greatly improved.

Owner:江门市华日摩托车配件有限公司

Machining equipment and method for molded pulp product

ActiveCN112144320AReduce manufacturing costImprove feeding efficiencyTextiles and paperMolded pulpMechanical engineering

The invention discloses machining equipment for a molded pulp product. The equipment comprises a feeding unit, a rolling / rotary cutting unit which comprises a horizontal rotary disc, wherein at leastone translation rolling / rotary cutting wheel is horizontally connected to the upper surface of the horizontal rotary disc in a sliding mode, the translation rolling / rotary cutting wheel is connected with a translation driving mechanism, and the translation rolling / rotary cutting wheel is connected with a rotary driving mechanism, the upper surface of the horizontal rotary disc is rotationally connected with two rolling / rotary cutting movable dies which are located on the periphery of each horizontal rolling / rotary cutting wheel and symmetrically distributed with the horizontal rolling / rotary cutting wheel as the center, and each rolling / rotary cutting movable die corresponds to one rotary downward pressing assembly, each rolling / rotary cutting movable die corresponds to one rotary drivingmechanism, and the rotary driving mechanisms drive the rolling / rotary cutting movable dies to rotate, and a material taking and placing unit which is used for placing non-rolled / rotary-cut pulp moldedproducts conveyed by the feeding unit on the rolling / rotary cutting movable dies and taking and transferring the rolled / rotary-cut pulp molded products to the outside of the rolling / rotary cutting unit.

Owner:ZHEJIANG SHURCON MFG

Stone slab machining hammering equipment

ActiveCN110893652AFully automatedImprove reclaiming efficiencyWorking accessoriesStone-like material working toolsWire cuttingStructural engineering

The invention relates to stone slab machining hammering equipment, which comprises a moving frame. The moving frame is movably provided with a material taking rack; a plurality of hammer heads are arranged on the material taking rack at intervals; a connecting line of the plurality of hammer heads is horizontal and is connected with a hammering mechanism; the hammering mechanism drives the hammerhead (30) and the stone slab to form a hammering action; after the blank is cut by wire cutting equipment, the moving frame is arranged on the two sides of the blank; through adjusting the material taking rack, the hammer head on the material taking rack abuts against one side face of the stone slab to be taken; the hammering mechanism is used for hammering the side face of the bottom of the stoneslab and the blank base, so that a certain gap is formed between the stone slab and the blank base, the separated stone slab is guided out through a stone slab guide-out mechanism, automation of stone slab taking is achieved, and the stone slab taking efficiency is improved.

Owner:山东火炬中原技术市场管理有限公司

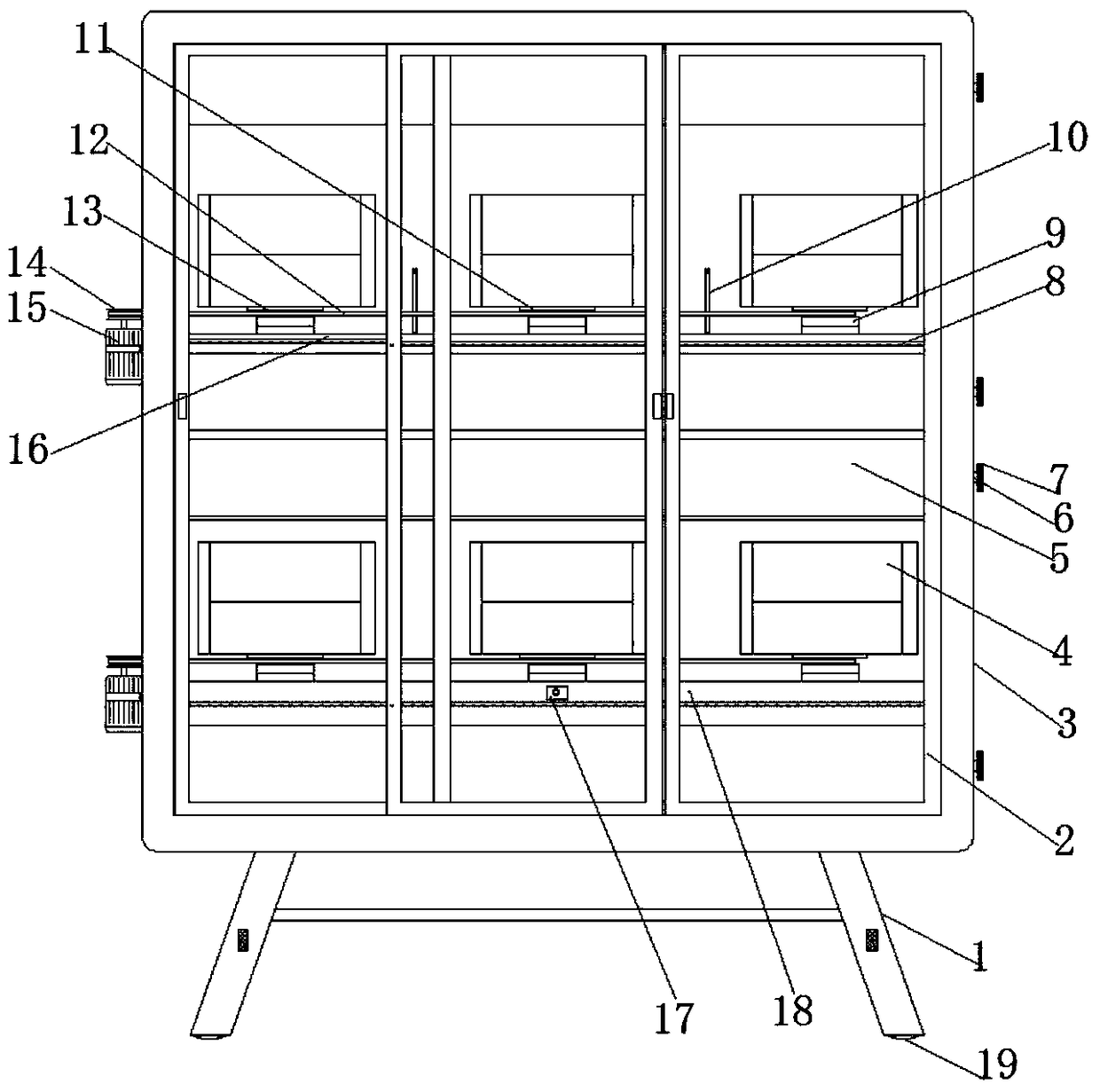

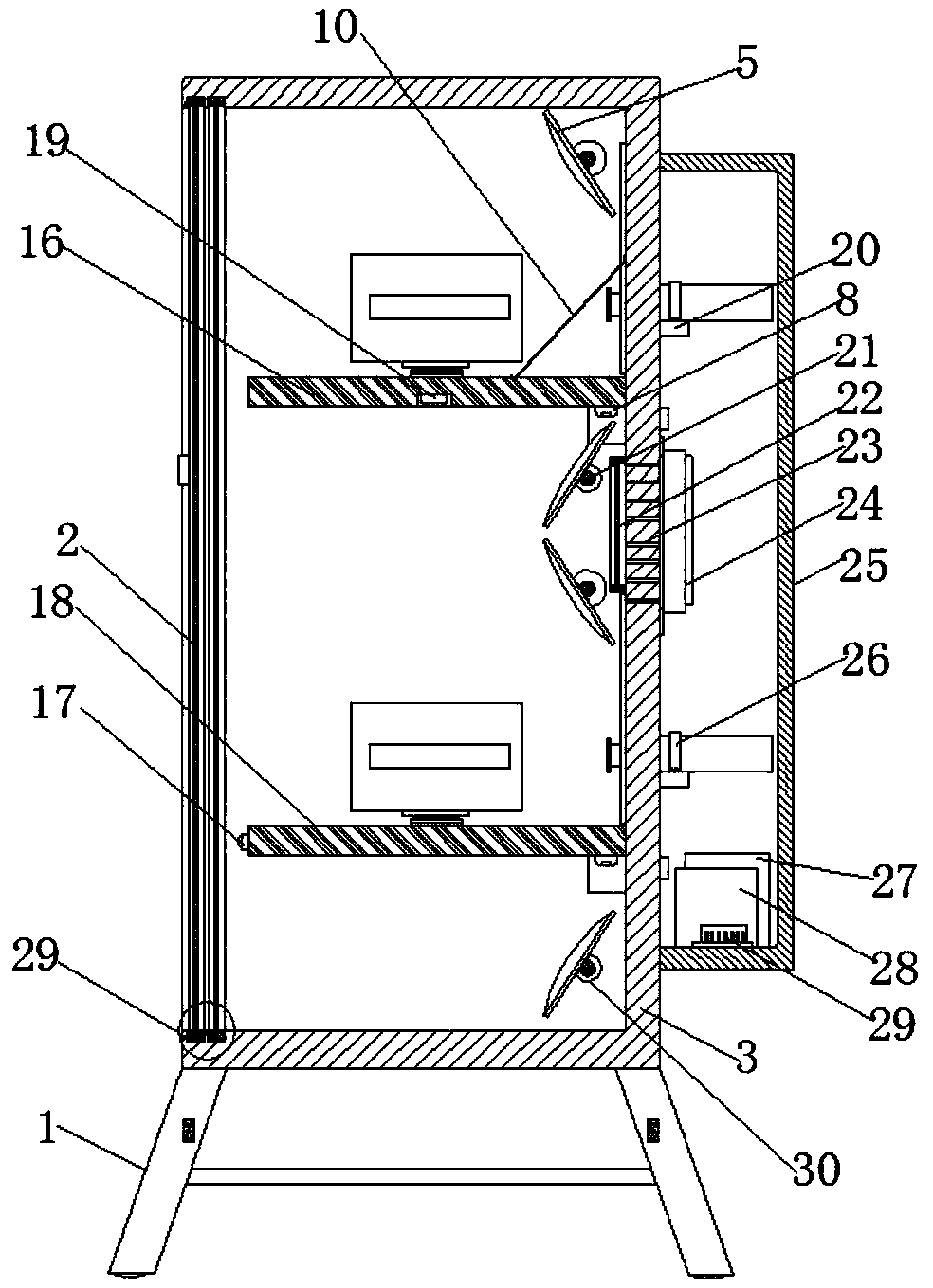

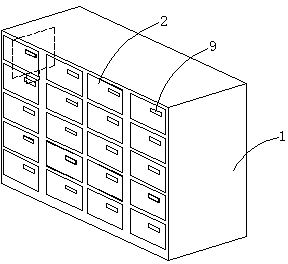

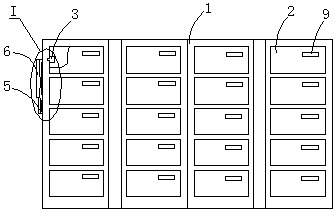

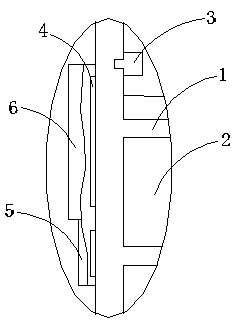

Self-service material taking device based on radio frequency identification device (RFID) and using method thereof

InactiveCN103824040ALower quality requirementsEasy to useSensing record carriersLogisticsElectromagnetic lockEngineering

The invention discloses a self-service material taking device based on a radio frequency identification device (RFID). The self-service material taking device comprises an element box body, wherein element boxes which can be locked are arranged on the element box body, and each element box is correspondingly provided with an electromagnetic lock; a main control circuit board, an RFID card reader and a touch display screen are arranged on the element box body; the main control circuit board is provided with a main control chip and a memory card for storing element information; the main control chip is respectively in signal connection to the RFID card reader, the electromagnetic locks, the touch display screen and the memory card. The self-service material taking device disclosed by the invention has the advantages of being simple in structure and convenient to use; information of a material taking person can be identified through the RFID card reader simply and conveniently; the corresponding element boxes can be automatically opened depending on an inputted material taking list, thus avoiding the trouble of searching elements through manpower and improving the material taking efficiency; by displaying and inputting information through the touch display screen, the information input is simple and clear, and the self-service material taking device is convenient to use.

Owner:ZHEJIANG TEXTILE & FASHION COLLEGE

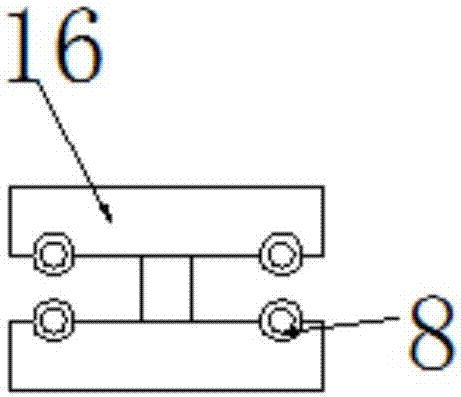

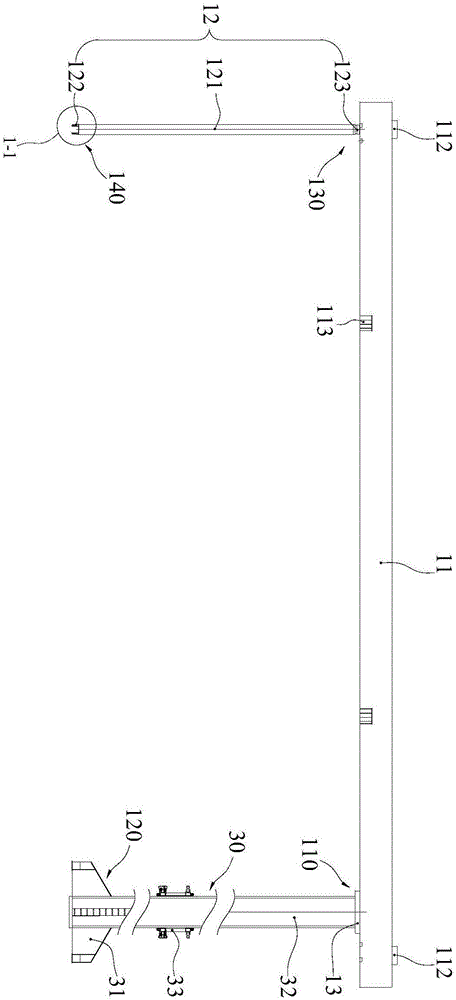

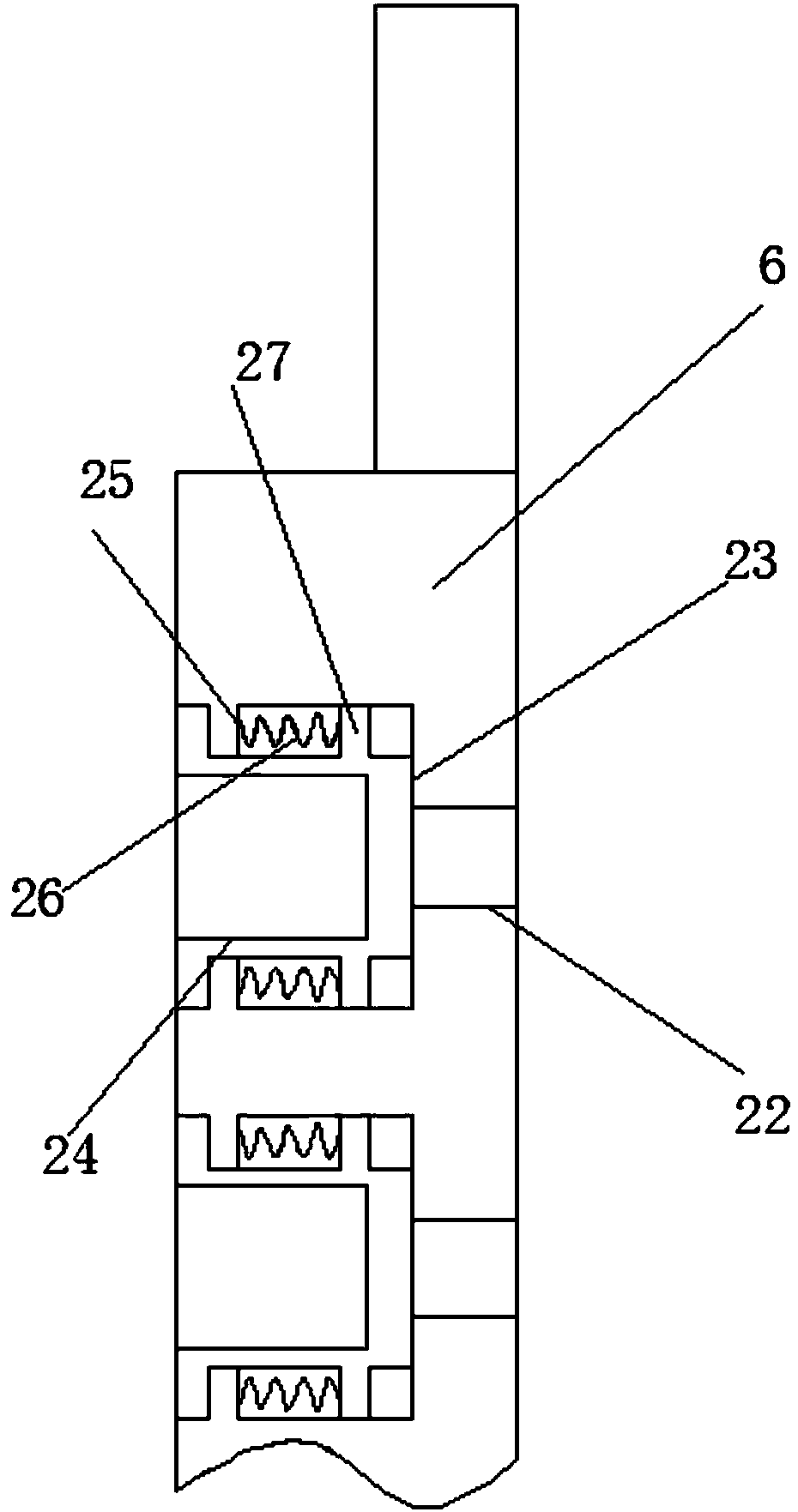

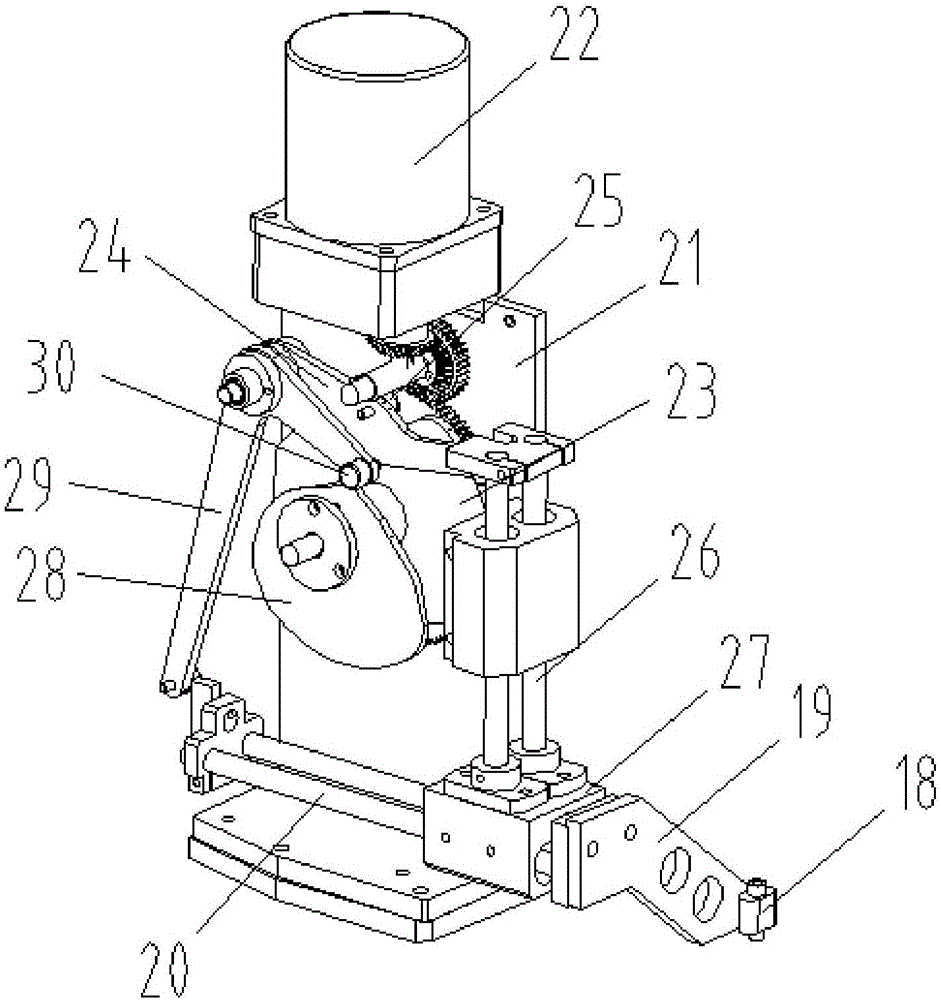

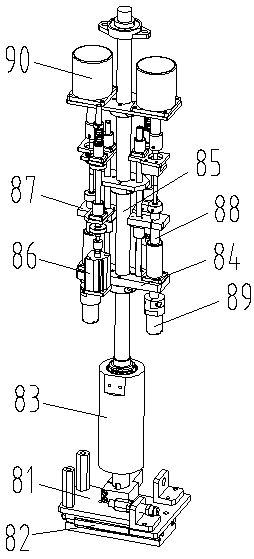

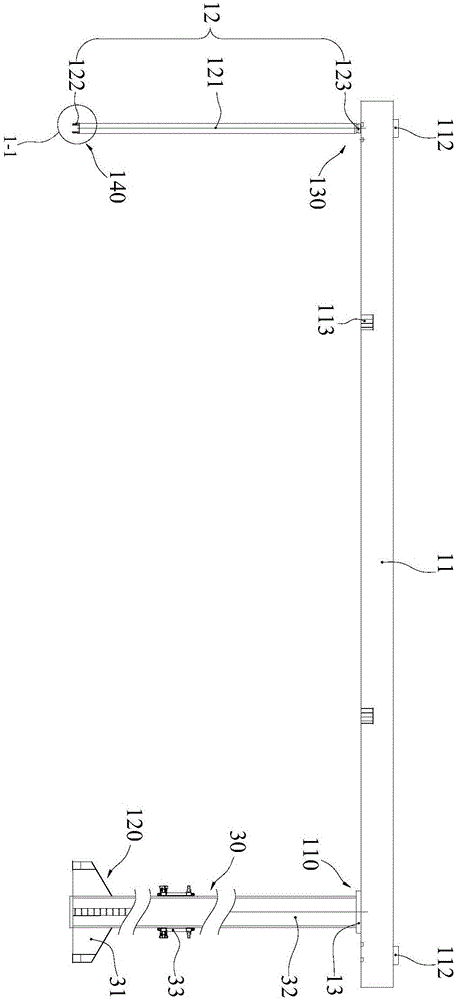

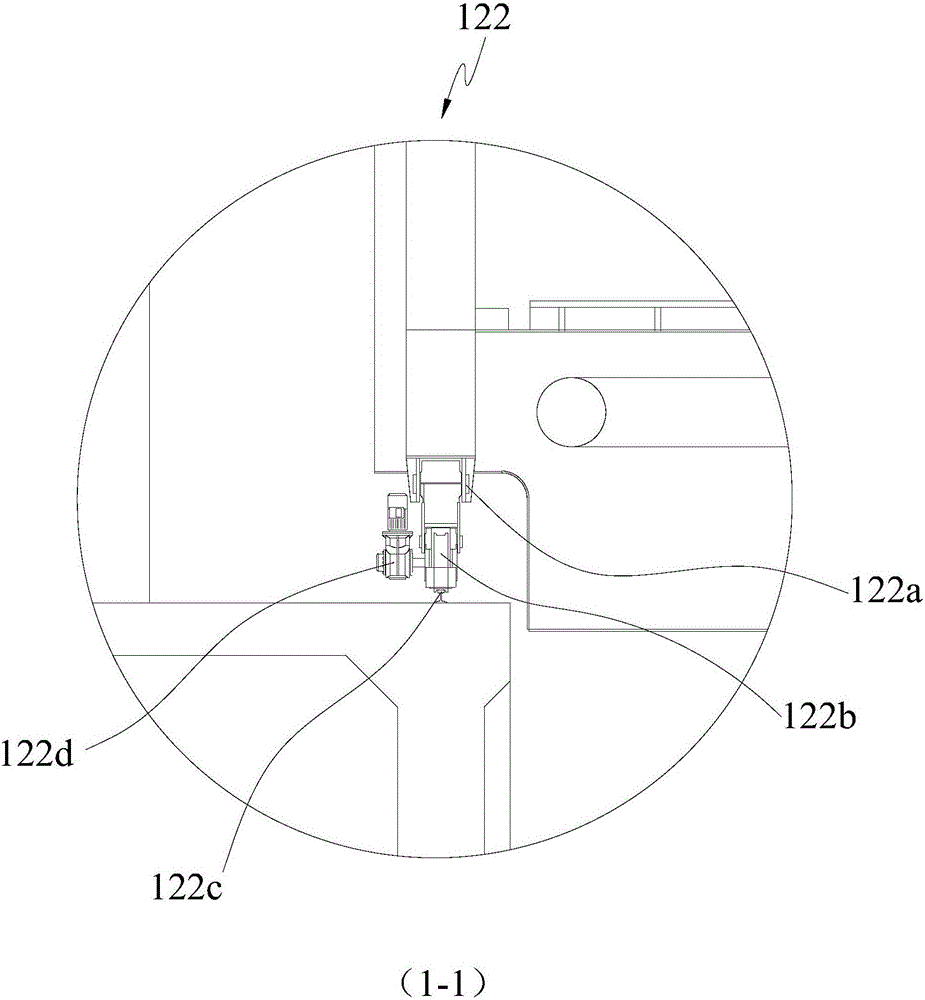

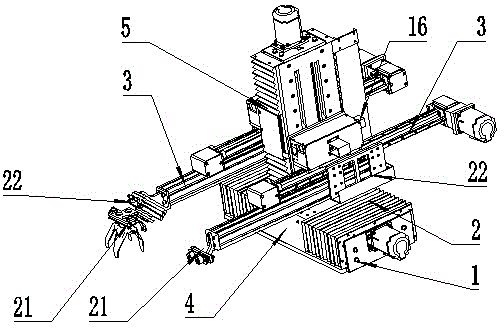

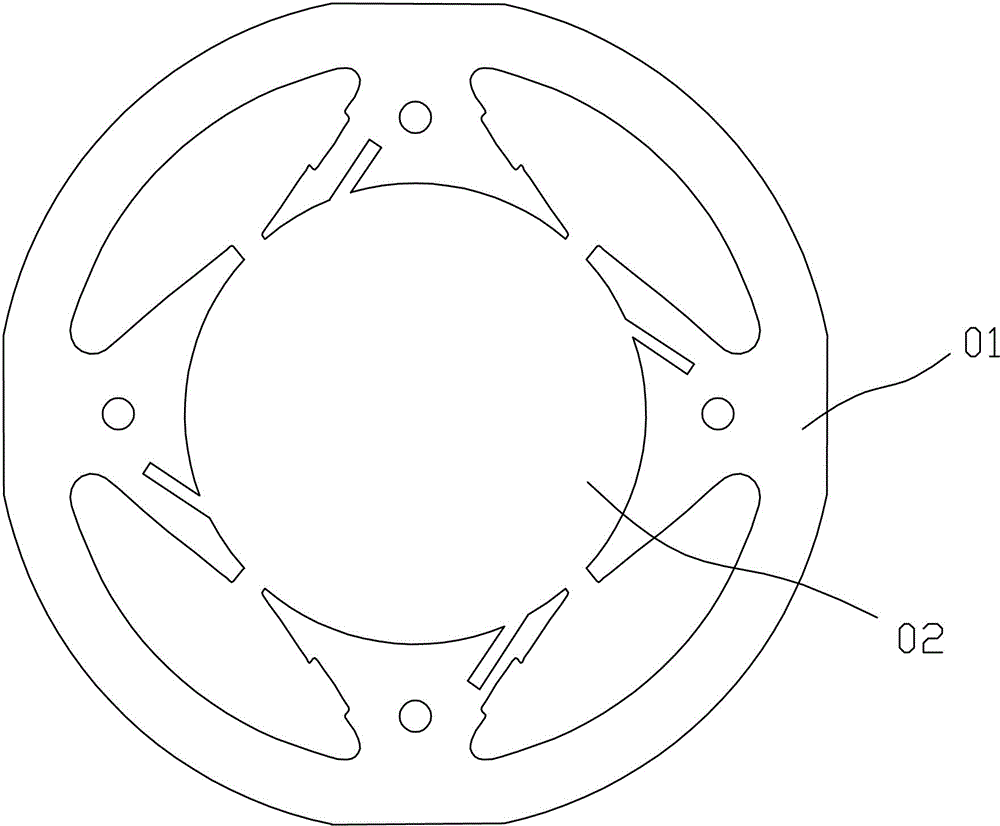

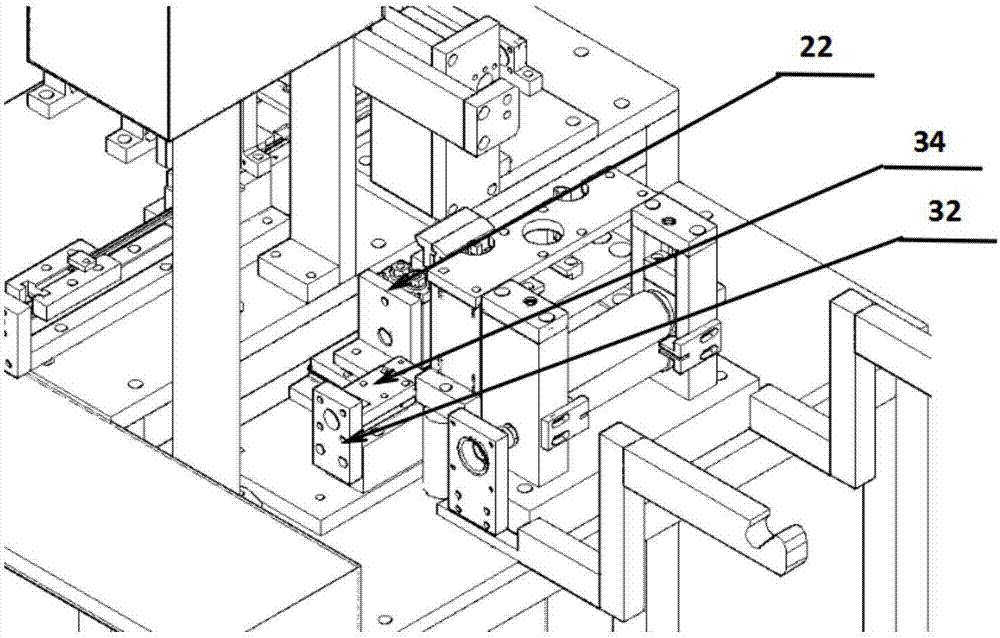

Take-out device for riveting machine

InactiveCN104440894AFully automatedImprove reclaiming efficiencyProgramme-controlled manipulatorRobot handMachine

The invention discloses a take-out device for a riveting machine. The take-out device is a three-coordinate manipulator (1), the three-coordinate manipulator (1) comprises an XZ axis manipulator (2) and a telescopic manipulator (3), and the telescopic manipulator (3) is mounted on the XZ axis manipulator (2). In the riveting process, the take-out device takes out materials without manual work and places the materials on a special location, so that automation of the take-out process is realized, and the take-out efficiency is improved. In addition, the take-out device can also reduce the labor cost.

Owner:CHONGQING LANGZHENG TECH

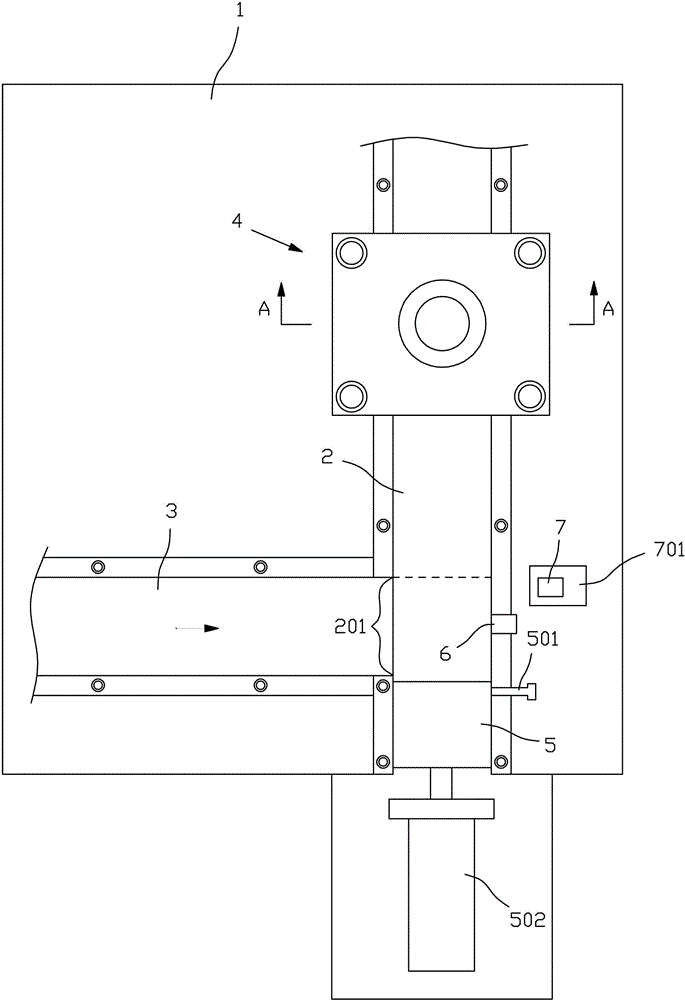

Motor stator reshaping device

InactiveCN104104194AImprove feeding efficiencyImprove reclaiming efficiencyManufacturing stator/rotor bodiesReciprocating motionEngineering

The invention discloses a motor stator reshaping device which comprises a working table. A slide way and an intermittent moving conveying belt for conveying a stator are arranged on the working table, the slide way comprises a stator starting section, a stamping reshaping mechanism, a push block and a drive part for driving the push block to perform reciprocating motion on along the slide way are arranged on the slide way, the push block is located at the front end of the stator starting section, the stamping reshaping mechanism is located at the rear end of the stator starting section, the tail end of the conveying belt is vertically connected with one side of the stator starting section, a first proximity switch and a second proximity switch are arranged at the position of the working table located in the stator starting section, the first proximity switch is used for detecting whether the stator enters the stator starting section, and the second proximity switch is used for limiting a stroke of the push block so as to enable the stable to be located right under the stamping reshaping mechanism when the push block performs the reciprocating motion. The motor stator reshaping device enables the machining efficiency to be high and enables the dangerousness to be low.

Owner:NINGBO LIONBALL VENTILATOR

Eye-brow shaping corrugated blade automatic assembly production equipment and eye-brow shaping corrugated blade automatic assembly method

ActiveCN107098016AIncrease productivityNovel structureWrapper folding/bending apparatusMetal working apparatusEngineeringUltimate tensile strength

The invention discloses eye-brow shaping corrugated blade automatic assembly production equipment and an eye-brow shaping corrugated blade automatic assembly method. The eye-brow shaping corrugated blade automatic assembly production equipment comprises a control unit, a packaging paper cut-off mechanism, a corrugated blade clamp feeding mechanism, a corrugated blade feeding mechanism, a corrugated blade clamp buckling mechanism, a clamping and conveying mechanism, a dispenser and a packaging mechanism. A control path of the control unit is connected with the packaging paper cut-off mechanism, the corrugated blade clamp feeding mechanism, the corrugated blade feeding mechanism, the corrugated blade clamp buckling mechanism, a clamping and conveying mechanism, the dispenser and the packaging mechanism. The disclosed eye-brow shaping corrugated blade automatic assembly production equipment is novel in structure and practical in function, automatic equipment is adopted for replacing manual operation, and compared with manual assembly, the equipment has the beneficial effects that product consistency is high, and the yield is high; the production efficiency is high; the work intensity of production personnel is greatly reduced; and in addition, a taking block is machined through magnetic materials, a strip gap is arranged, the operation that the taking block takes blades away from the blade piles can be smoother, and the equipment reliability is improved.

Owner:江西犀瑞制造有限公司

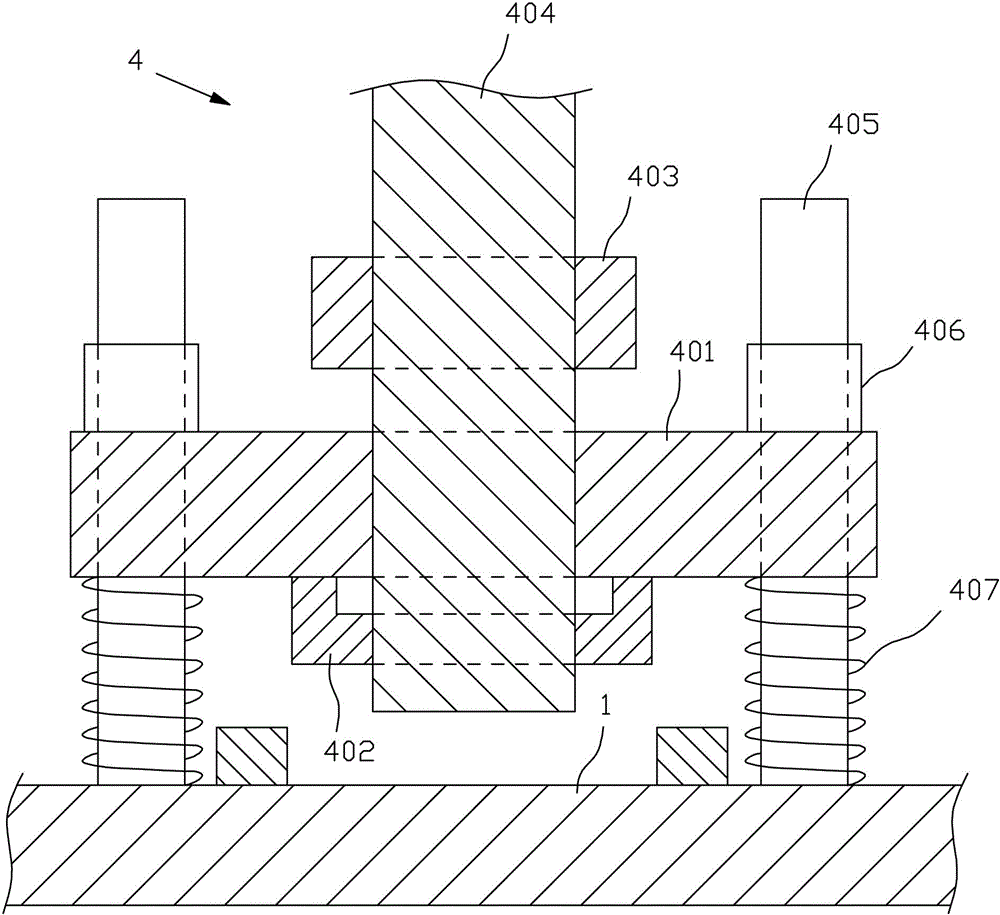

Pressing device of traditional Chinese medicine decoction pieces

InactiveCN107415309AHigh suppression efficiencyImprove reclaiming efficiencyPharmaceutical product form changePress ramBiochemical engineeringPiston rod

The invention provides a pressing device of traditional Chinese medicine decoction pieces. The pressing device comprises an operation table, a fixing plate, a first air cylinder, an upper mold block, a lower mold block, a base plate, a second air cylinder and a push plate and is characterized in that the operation table is arranged on a support, the fixing plate is arranged on a stand column, the first air cylinder is arranged on the fixing plate, the upper mold block is arranged on the stand column, the lower mold block is arranged on the stand column, the base plate is arranged in a lower mold groove, the second air cylinder is arranged on the operation table, and the push plate is arranged on a second piston rod. The upper mold block and the lower mold block are arranged on the stand column, upper mold columns are arranged on the upper mold block, lower mold grooves and through holes are formed in the lower mold block, base plates capable of vertically moving are arranged in the lower mold grooves, the first air cylinder and the first piston rod push the upper mold block downwards, the upper mold columns on the upper mold block press traditional Chinese medicine decoction piece raw materials in the lower mold grooves, and the pressing efficiency and the product quality of the traditional Chinese medicine decoction pieces can be improved.

Owner:芜湖振龙齐欣药业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com