Material taking rotation boundary judgment and control system and method for bucket wheel machine

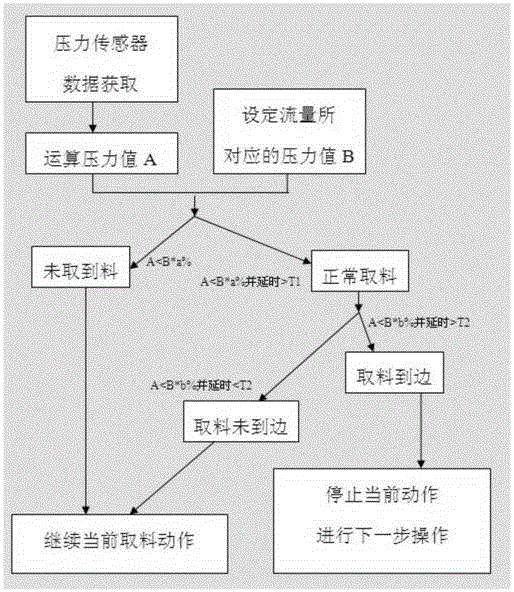

A technology of control system and bucket wheel machine, applied in the direction of conveyor control device, conveyor objects, transportation and packaging, etc., can solve the problems of low accuracy of reclaiming border control and low reclaiming efficiency, and achieve efficient unmanned automatic operation , Improve the efficiency of reclaiming and reduce the effect of empty travel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will be described in detail in conjunction with the embodiments of the present invention with reference to the accompanying drawings.

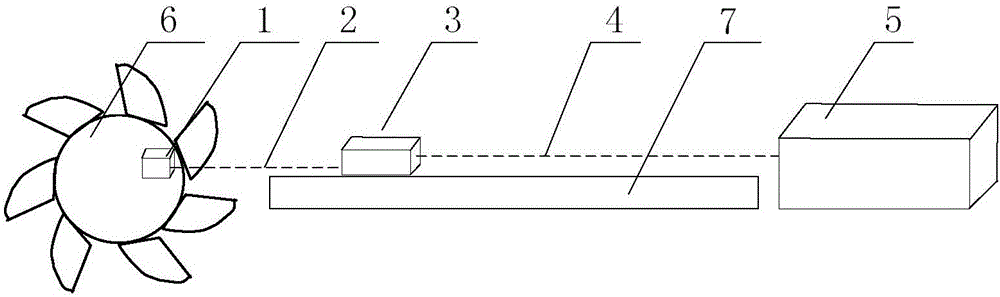

[0017] The control system for judging the boundary of bucket wheel reclaiming and turning includes pressure sensor 1, signal acquisition remote station 3 and stand-alone controller 5. Pressure sensor 1 is connected to signal acquisition remote station 3 through signal cable 2, and signal acquisition remote station 3 is connected to signal acquisition remote station 4 through communication cable 4. Stand-alone controller 5;

[0018] The pressure sensor 1 is arranged on the bucket wheel hydraulic motor 6 of the reclaimer, the signal acquisition remote station 3 is arranged on the cantilever 7 of the reclaimer, and the pressure sensor 1 is used to detect the pressure data of the bucket wheel hydraulic motor 6 of the reclaimer , the signal acquisition remote station 3 is used to acquire pressure data, and transmit the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com