3D modeling system of coal pile

A technology of 3D modeling and coal pile, which is applied in the field of 3D modeling system of coal pile, can solve the problems of low operation accuracy and low material retrieving efficiency, and achieve the effect of reducing repeated determination of operation positions and efficient unmanned automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

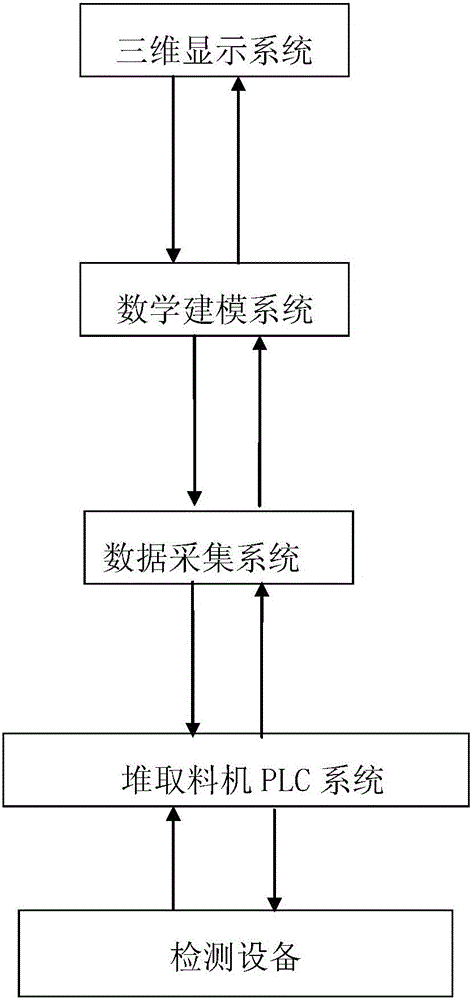

[0008] A three-dimensional modeling system for coal piles, which is characterized in that it includes a three-dimensional display system, a mathematical modeling system, a data acquisition system, a stacker-reclaimer PLC system, and a detection device. The three-dimensional display system is bidirectionally connected with the data modeling system. The mathematical modeling system is bidirectionally connected with the data acquisition system, the data acquisition system is bidirectionally connected with the stacker and reclaimer PLC system, and the stacker and reclaimer PLC system is bidirectionally connected with the detection equipment. The three-dimensional display system is connected to the stacker and reclaimer PLC system through OPC. The detection equipment includes one or more of radar, pressure, speed measuring gear, GPS and walking encoder.

[0009] The detection equipment is installed at the front end of the stacker and the reclaimer cantilever to measure the stacking he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com