Patents

Literature

121results about How to "Reduce idle travel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

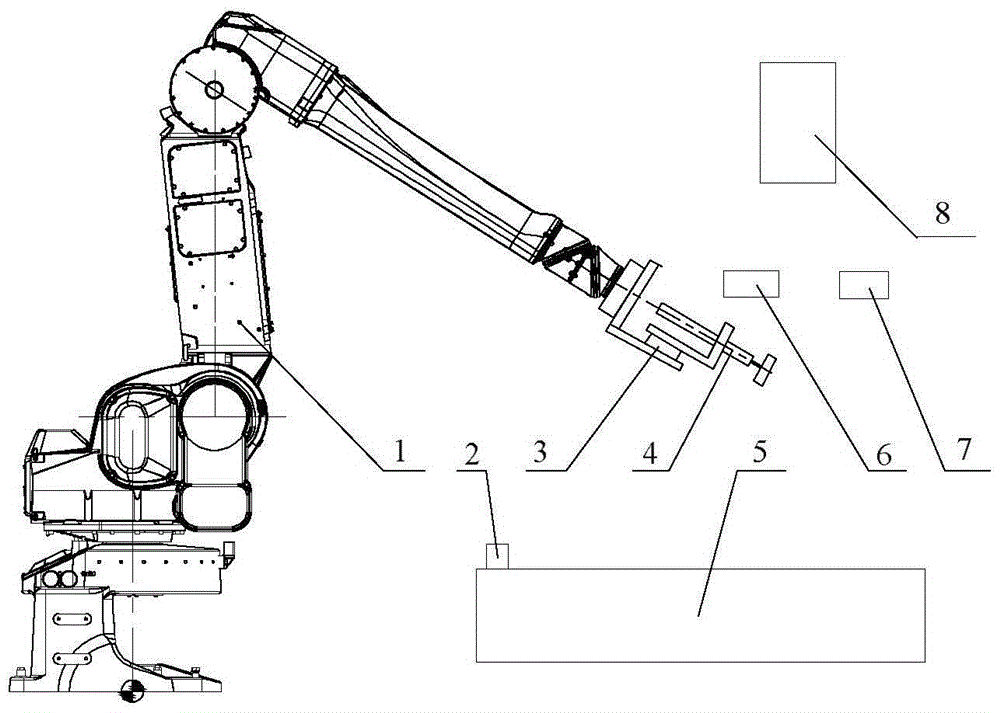

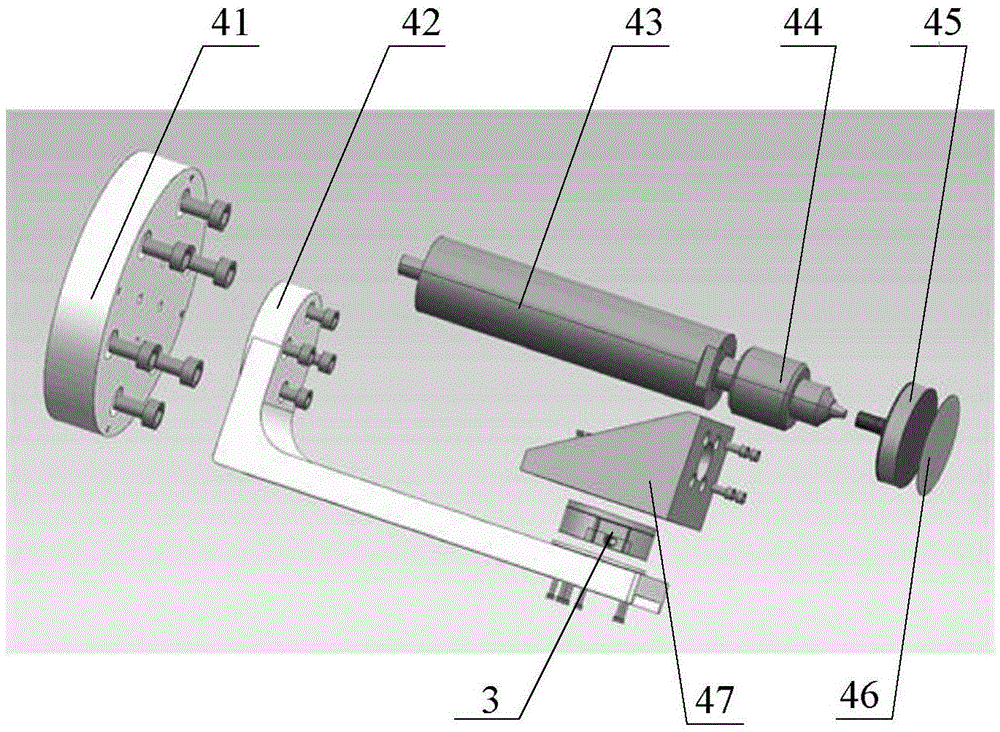

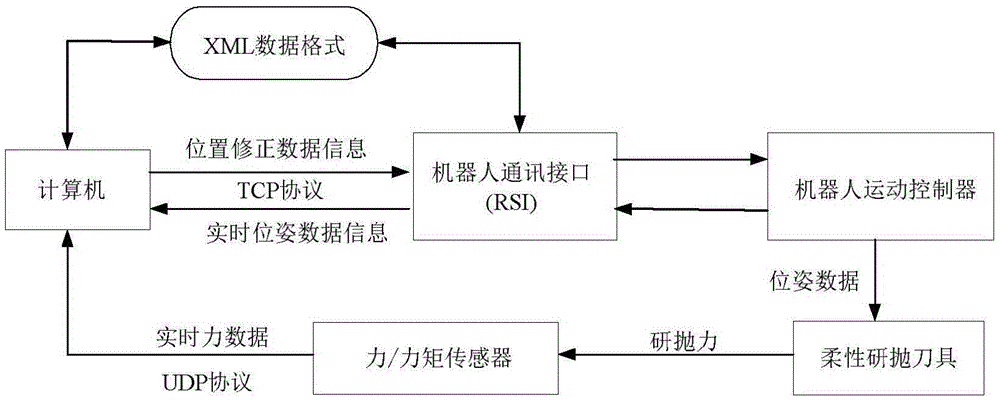

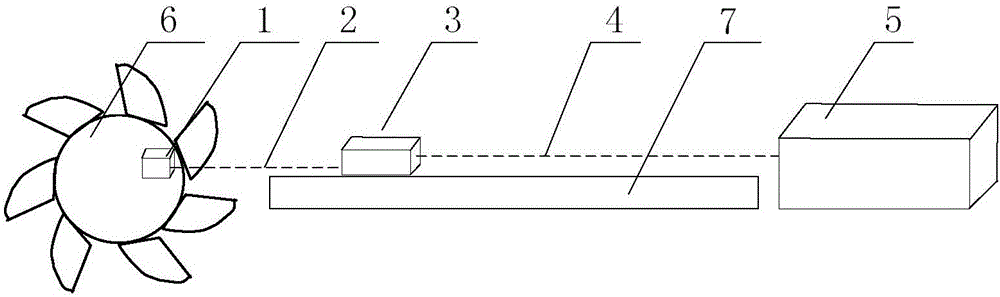

Automatic lapping and polishing system for complex surface of compliant control-based robot and machining method

InactiveCN105643399AReduce manual labor intensityReduce processing costsGrinding wheel securing apparatusGrinding drivesProcess systemsAudio power amplifier

The invention relates to an automatic lapping and polishing system for a complex surface of a compliant control-based robot and a machining method. The automatic lapping and polishing system comprises an industrial robot, a worktable, a force sensor, a flexible lapping and polishing cutter, a signal conversion amplifier, a computer and a robot controller; the method comprises the following steps: performing machining trace planning before lapping and polishing a complex surface workpiece to obtain cutter contact point trace of the lapping and polishing cutter to obtain a surface machining cutter location point trace; converting the surface machining cutter location point trace into a code format program file which can be identified by the robot controller, and inputting the code format program file into the robot controller; positioning and clamping the workpiece to complete coordinate labeling and unification of a process system; and driving the robot to move according to a machining trace planning program file to drive the lapping and polishing cutter arranged on an end executor of the robot to perform contact machining on a machined surface. According to the automatic lapping and polishing system and the machining method disclosed by the invention, manual operation at a finish machining stage of the complex surface workpiece, especially a large-sized complex surface workpiece, can be replaced; labor strength and machining cost are reduced; and quality stability and quality consistency of a machined molded surface are increased.

Owner:SHENYANG LIGONG UNIV

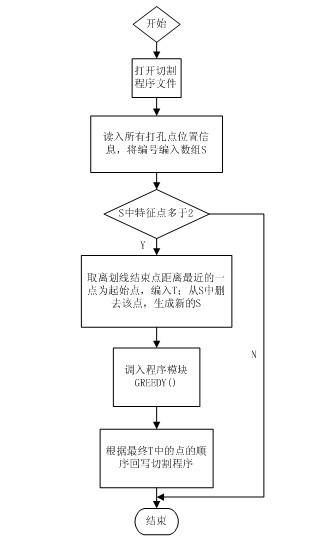

Seeking route plan optimizing method of laser cutting machine

InactiveCN102023611AHigh degree of automationPrecise positioningLaser beam welding apparatusNumerical controlPunchingArray data structure

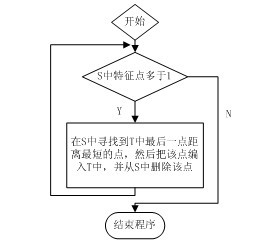

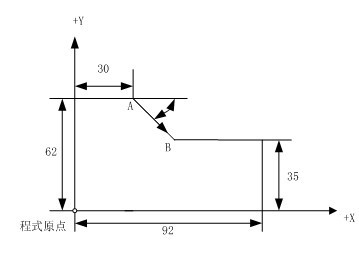

The invention provides a seeking route plan optimizing method of a laser cutting machine. The method comprises the following steps that: 1, a program writes the information of all the 'punching points' into an array S according to sequence; 2, the points in S are judged and optimally sequenced, if the points are less than 2, the program is terminated, and if the points are more than 2, the program is continued; 3, the point closest to a ruling end point is taken as a start point, is written into an array T and is then deleted from the array S to generate a new array S; 4, a greedy program module GREEDY () is called until all the points are processed by the greedy method to generate a new route point array T; and 5, a cutting program is written back according to the sequence of the punching point optimized in the array T to acquire the optimized cutting program. By the method provided by the invention, the automation degree of the laser cutting machine can be improved; the positioning is accurate; the idle stroke is shortened to the largest extent; the cutting time is shortened; and the working efficiency is improved.

Owner:GUANGDONG UNIV OF TECH

Track generating method facing toward complex curved surface processing and track generating system thereof

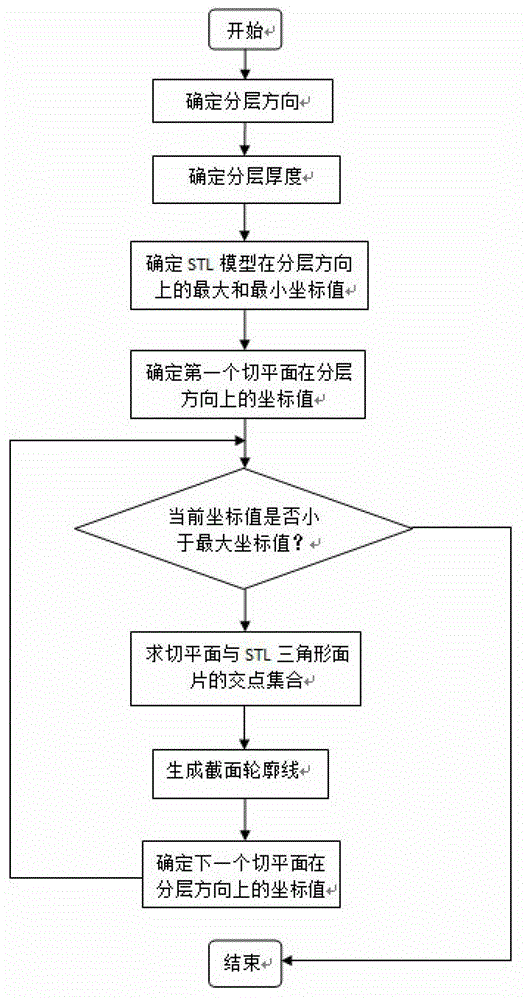

InactiveCN103064343AOvercoming the inability to resolve model voidsReduce the number of timesProgramme controlComputer controlIntersection of a polyhedron with a lineMotion controller

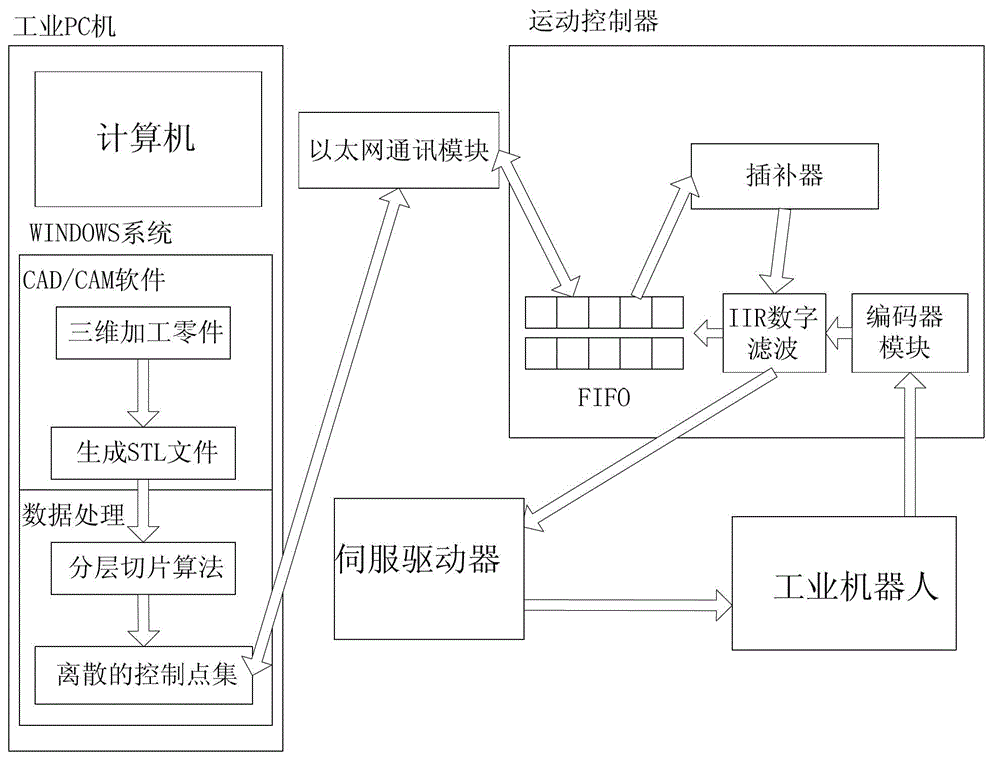

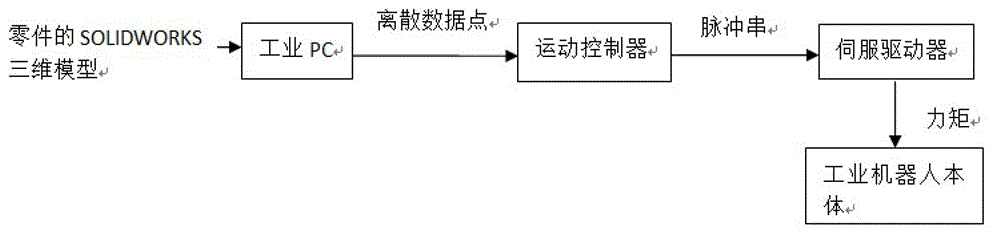

The invention discloses a track generating method facing toward complex curved surface processing and a track generating system thereof. The track generating method includes that a to-be-processed complex curved surface is chosen and a standard template library (STL) file is generated; layer dividing direction and layer dividing thickness are determined; group dividing is conducted on a triangular patch; the point of intersection is obtained by an incremental method; a coordinate minimum value point of each section point of intersection gather in the direction of being vertical to the layer dividing direction is found out, another point of intersection of the same triangular patch is searched and connected with the minimum value point, and the process continues until the outline of each tangent plane is obtained and eventually the generating route track is obtained. The track generating system comprises an industrial personal computer (PC), a motion controller, a servo driver and an industrial robot body. The industrial PC generates three-dimensional to-be-processed components into a scattered control point set and transmits the control point set to the motion controller. The motion controller conducts an interpolation calculation on the control point set and outputs pulse trains to the servo driver, and drives the industrial robot body to conduct coordinated movement in a torque control mode. The track generating method facing toward complex curved surface processing and the track generating system thereof have the advantages of small calculation quantity, short calculation time, and high calculation efficiency.

Owner:SOUTH CHINA UNIV OF TECH

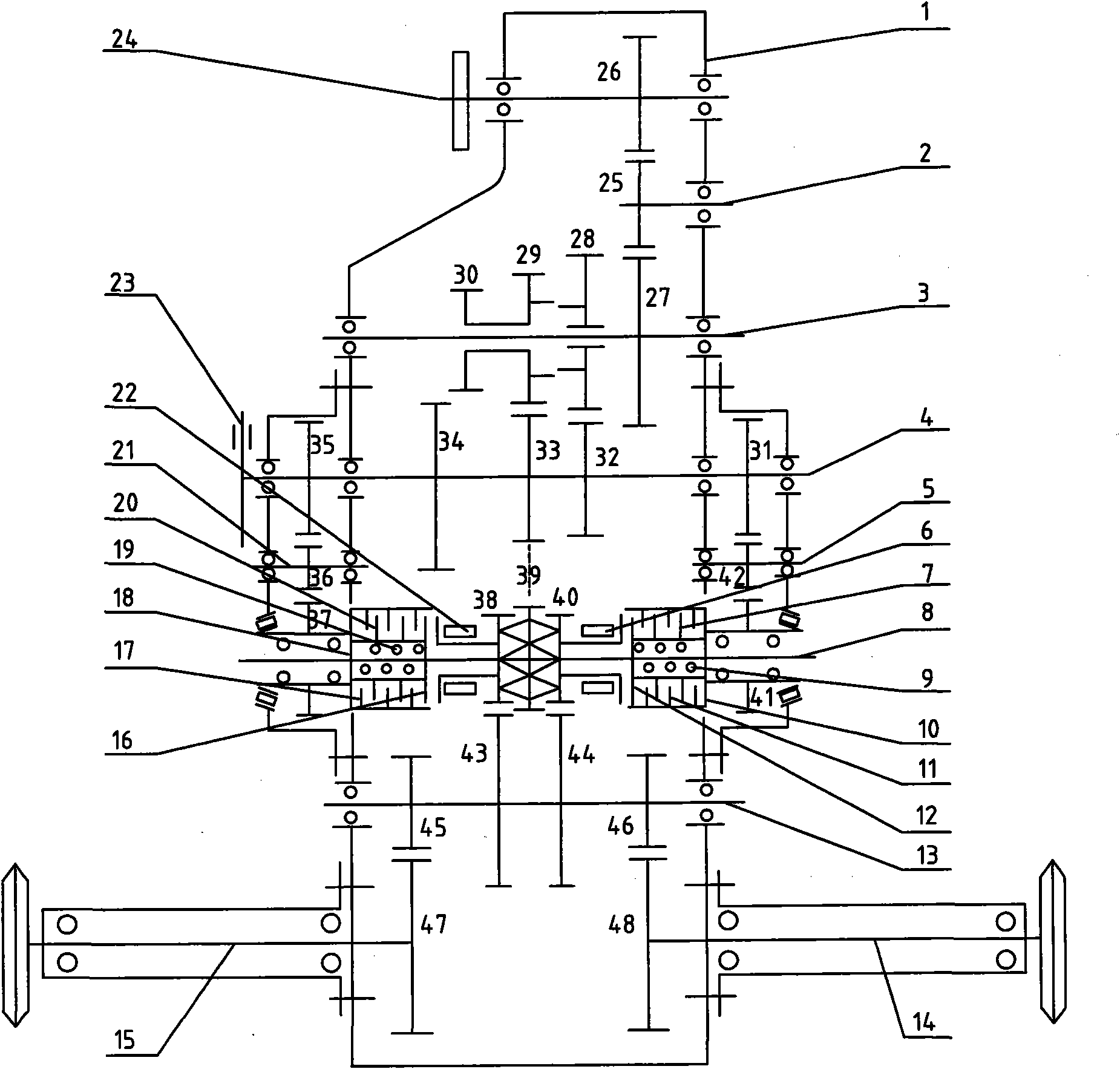

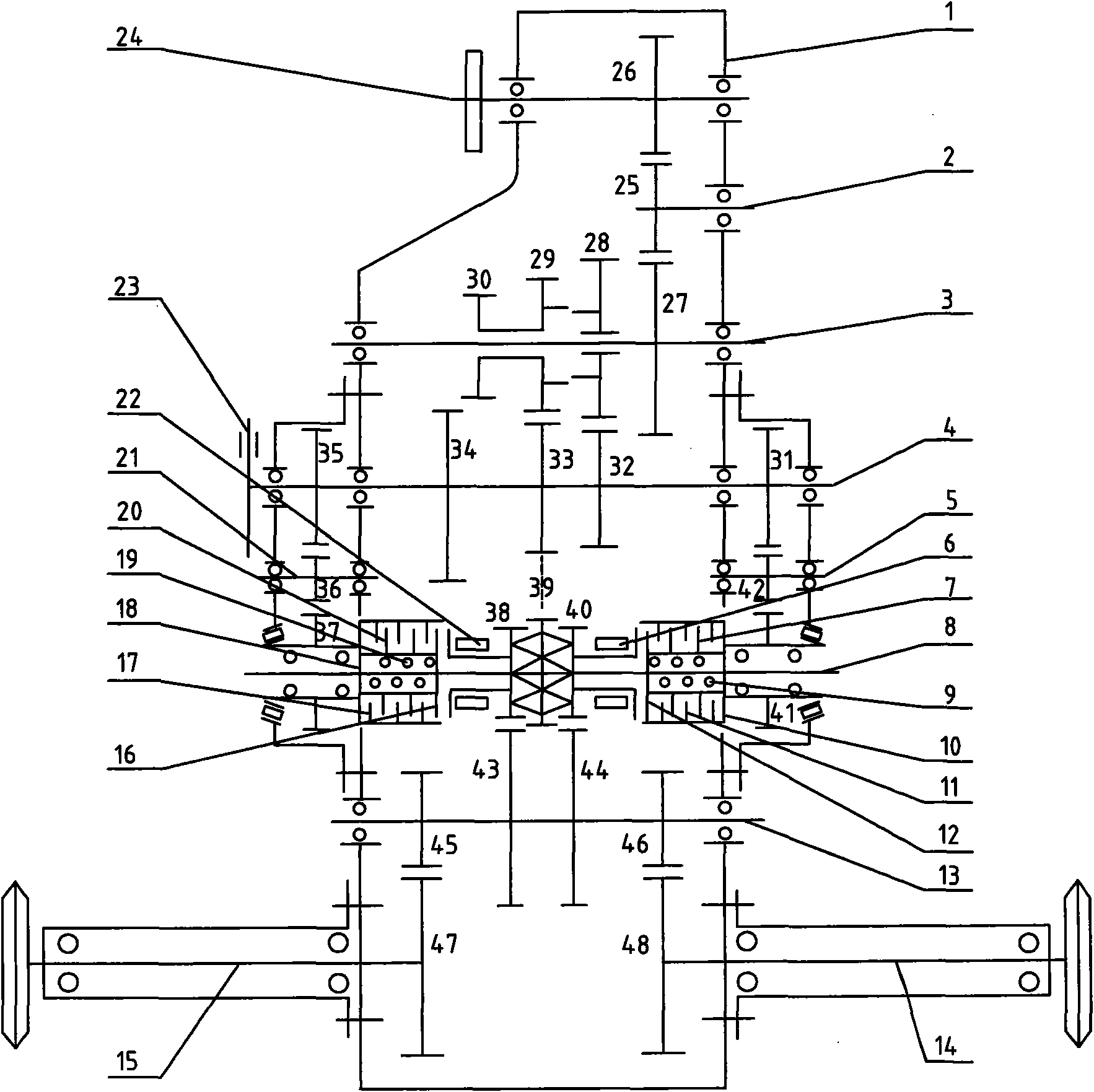

Zero-radius steering walking speed change box for combine harvester

ActiveCN102077741AImprove mobilityReduce idle travelHarvestersToothed gearingsGear driveControl theory

The invention discloses a zero-radius steering walking speed change box for a combine harvester, comprising a speed change mechanism, a steering mechanism and a speed reduction mechanism, wherein the speed change mechanism, the steering mechanism and the speed reduction mechanism are arranged in the speed change box body; the speed change mechanism drives the steering mechanism; the steering mechanism drives the combine harvester to walk via the speed reduction mechanism, and comprises a steering shaft; the steering shaft is provided with a central transmission gear with clutches at two sides; the left and right sides of the central transmission gear with clutches at two sides are respectively provided with symmetrical clutch gears, shift forks, pressure plates, tensioning springs, steering clutches and steering clutch gears; the clutch gears are movably connected with the central transmission gear under the driving of the shift forks; the shift forks push the pressure plates so that the steering clutches are combined with each other to realize power transmission; one end of each of the tensioning springs butts against the pressure plates, and the other end of each of the tensioning springs butts against the steering clutches; and the steering clutch gears drive the clutch gears via the combination of the steering clutches. The zero-radius steering walking speed change box in the invention realizes zero-radius steering of the combine harvester, improves the maneuverability of the combine harvester and reduces idle strokes and energy consumption.

Owner:海宁市钱江兴业投资开发有限公司

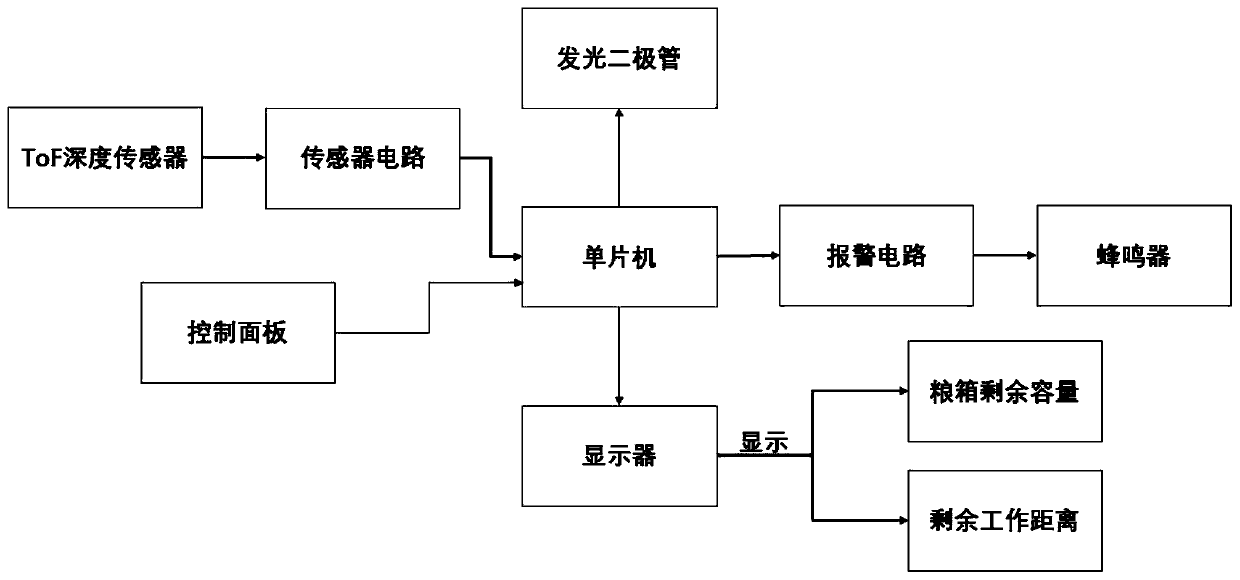

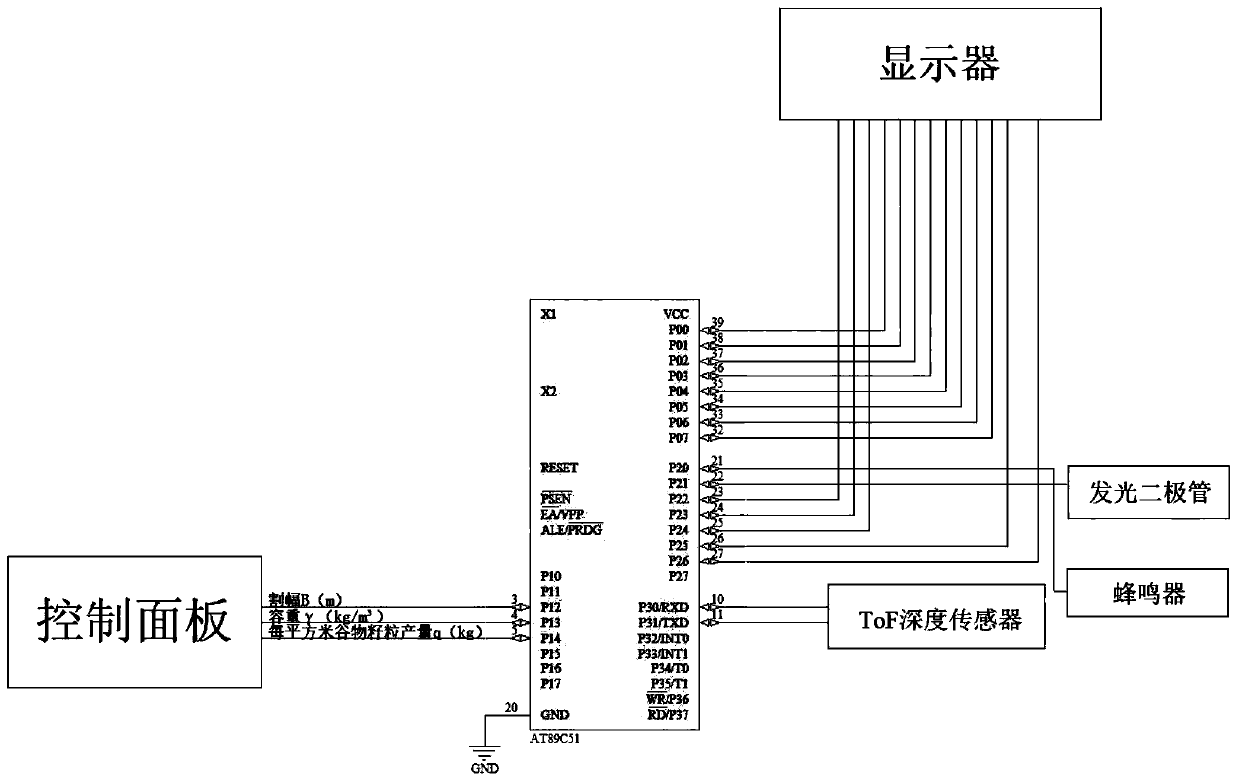

Device and method for monitoring residual capacity of grain tank and residual walking distance of combine harvester

PendingCN111406505AGrasp the accumulation status in real timePrevent leakageProgramme controlComputer controlAgricultural engineeringControl cell

The invention provides a device and method for monitoring the residual capacity of a grain tank and the residual walking distance of a combine harvester. The device comprises the grain tank, a detection device, a control panel, a control unit and a warning device, wherein the detection device is used for detecting average distance information from the stacking surface of grains in the grain tank to the top of the grain tank and transferring the average distance information to the control unit; and the control panel is used for at least inputting information including a cross section area of the grain tank, the height of the grain tank, the cutting width of the harvester, the grain yield per square meter and the unit weight of cereal grains and transferring the information to the control unit. By monitoring the residual space in the grain tank in real time, the residual walking distance of the combine harvester during harvesting working is calculated and is displayed in a display in a cab in real time, so that a tractor driver can be assisted to plan a harvesting route and an unloading route, the idle stroke of the combine harvester during field walking is shortened, and the harvesting working efficiency is improved; and when the capacity of the grain tank is about to be used up, a light-emitting diode cooperates with a buzzer to raise the alarm to remind the tractor driver to timely unload the grains, so that the loss caused due to leakage of the grains is avoided.

Owner:JIANGSU UNIV

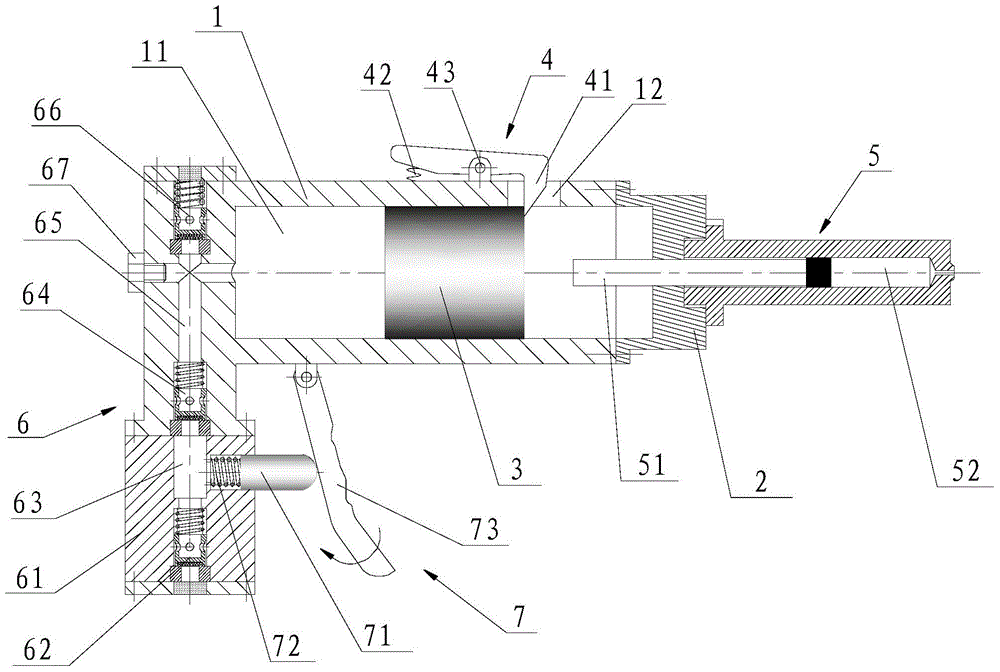

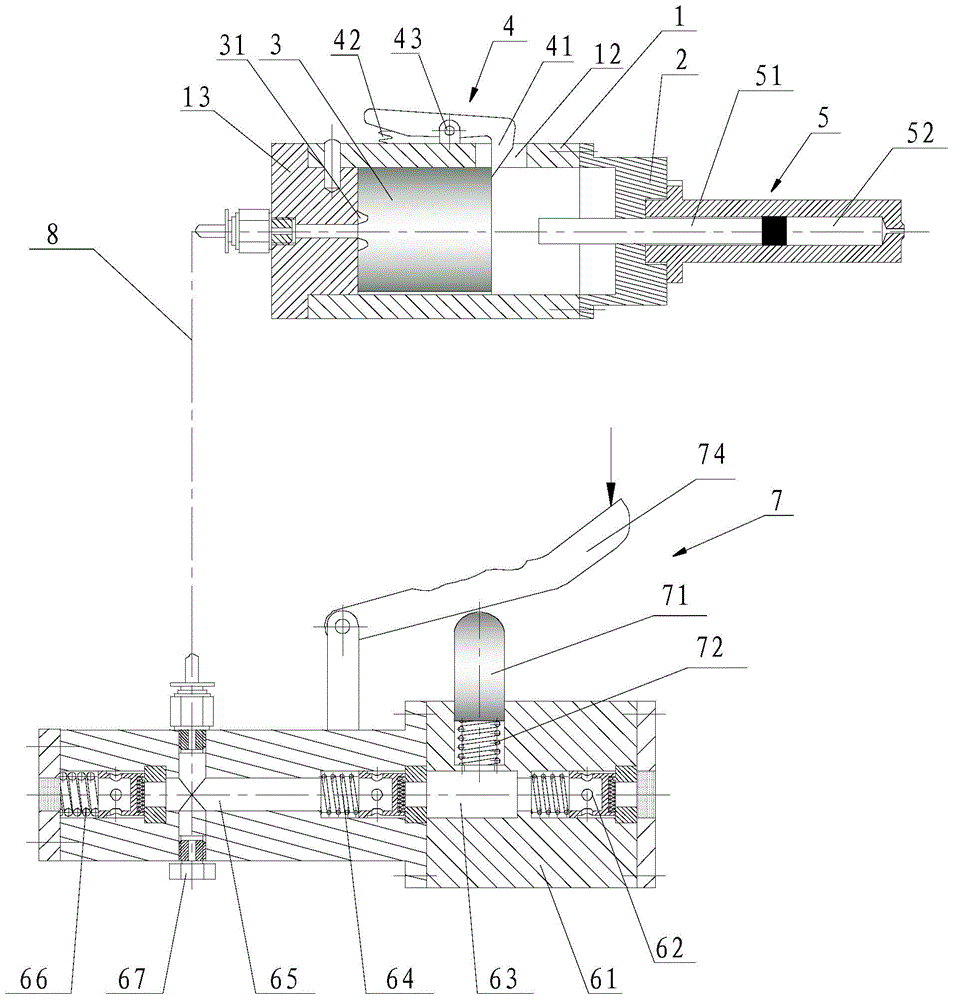

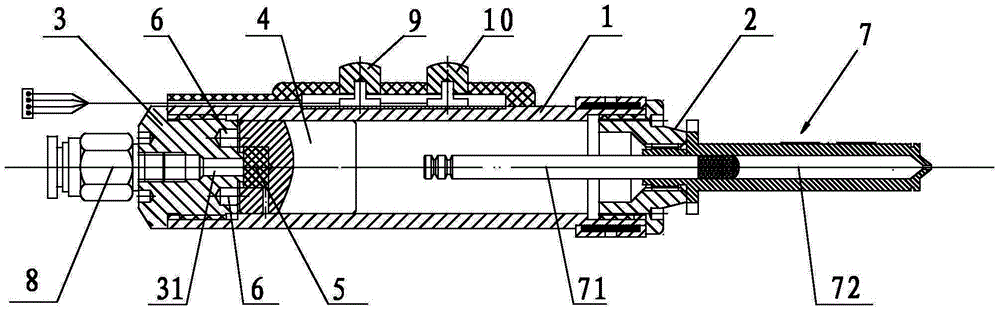

Manpower-driven energy storage needleless syringe

ActiveCN103977480AReduce volumeSimple structureJet injection syringesIntravenous devicesNeedle Free InjectionNeedle free

The invention discloses a manpower-driven energy storage needleless syringe. The needleless syringe comprises a cylinder barrel with an inner cavity, a front end cover fixedly arranged at the front end of the cylinder barrel, a needleless ampoule assembly arranged on the front end cover and an impact part movably arranged in the cylinder barrel along the front and back direction; a closed chamber is formed between the impact part and the rear part of the cylinder barrel in the cylinder barrel; the needleless syringe also comprises a manpower-driven air supplier for charging compressed air into the chamber; the needleless ampoule assembly at least comprises a piston rod capable of moving along the front and back direction; the cylinder barrel is provided with a control mechanism for switching work states of the impact part. The impact is realized in a mode of storing certain potential energy for the impact part and then releasing the potential energy, so the piston rod of the needleless ampoule assembly is driven to move to realize the injection of medicine liquid; the initial acceleration speed of the impact part is larger during the impacting, so the idle stroke is greatly shortened, and the size of the needleless syringe is greatly reduced.

Owner:SUZHOU UNIV

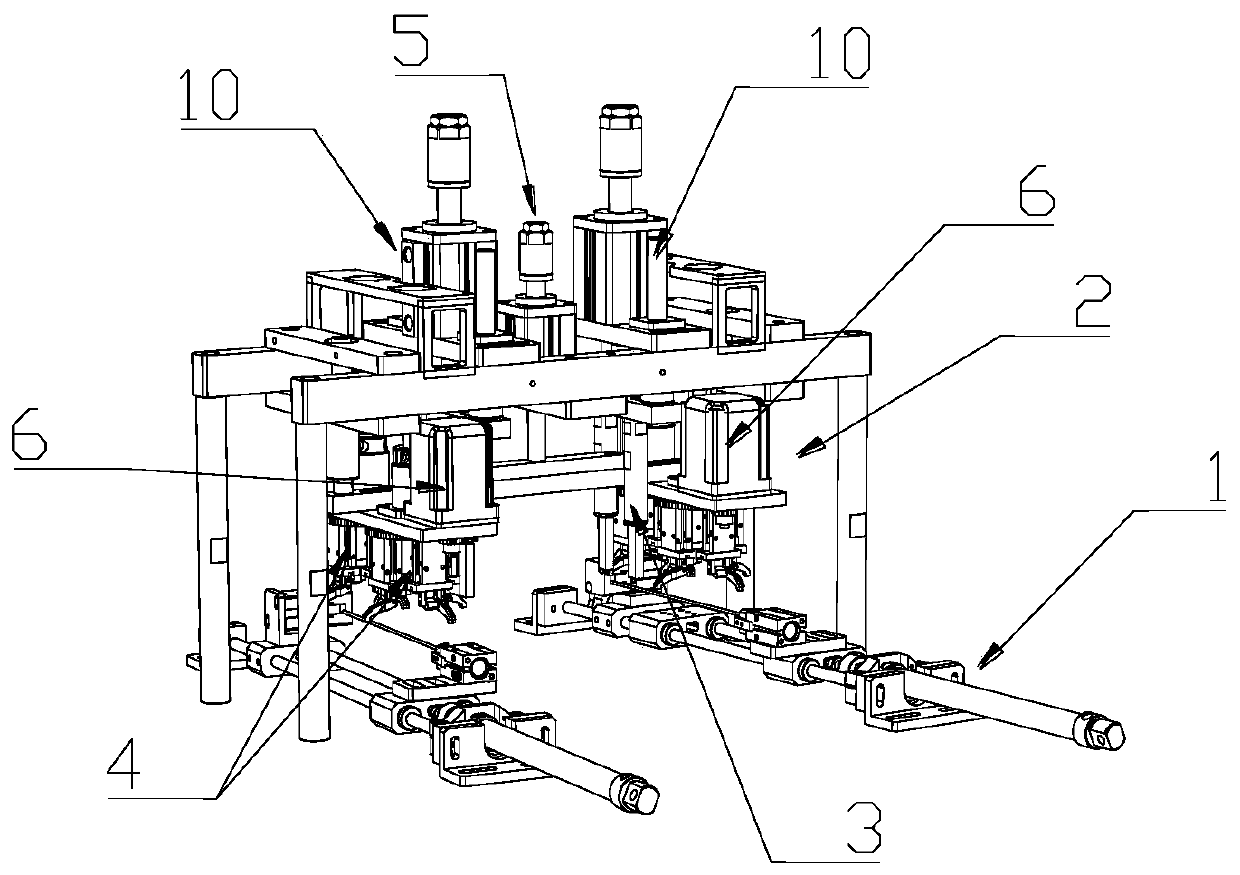

Intermittent ear line welding equipment for mask production

PendingCN111284030AReduce idle travelEar wire welding speed increasedDomestic articlesWeldingEngineering

The invention discloses intermittent ear line welding equipment for mask production. The intermittent ear line welding equipment comprises a mask conveying device, an ear line conveying device, an earline clamping and conveying device and an ear line welding device. The ear line clamping and conveying device comprises two clamping modules, a vertical driving mechanism and a rotary driving mechanism. The two clamping modules are sequentially arranged in the conveying direction of mask bodies. Each clamping module comprises at least two clamping mechanisms and a clamping driving mechanism. Therotary driving mechanism is used for driving the two clamping modules to rotate in the opposite directions and driving the clamping mechanisms in each clamping module to rotate from an ear line clamping station to an ear line welding station. When the first clamping mechanism reaches the ear line welding station, the next clamping mechanism is located at the ear line clamping station. The ear lineconveying mechanism is used for conveying ear lines to the ear line clamping station. By the intermittent ear line welding equipment, ear line carrying time can be greatly shortened, and the production efficiency is improved in multiples.

Owner:GUANGZHOU MINGSEN TECH CO LTD

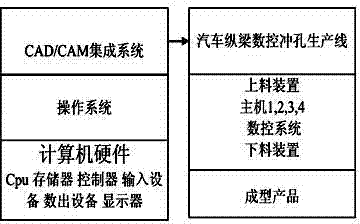

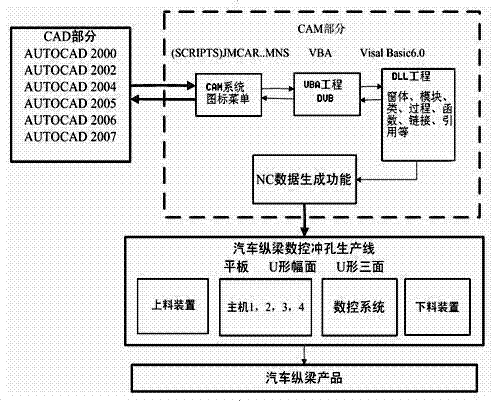

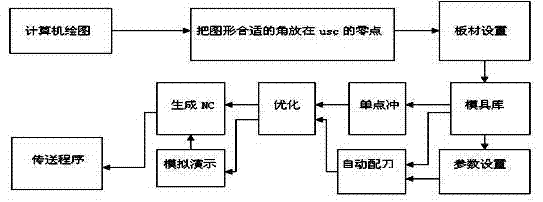

Method for constructing CAM (computer-aided manufacturing) system for punching for automobile girders

ActiveCN102707669ARealize integrationAvoid reducing service lifeProgramme controlComputer controlNumerical controlVisual Basic

A method for constructing a CAM (computer-aided manufacturing) system for punching for automobile girders is characterized by including selecting the types of used numerical-control punching production lines for the automobile girders; creating projects corresponding to the types of the numerical-control punching production lines for the automobile girders, building mathematical models of algorithms, and building generic modules; determining the types of the projects as Activex DII and compiling the types of the projects into types of dynamic linking libraries; writing and compiling interface programs connected with the dynamic linking libraries by VBA (visual basic for application); writing scripts for the various types of numerical-control punching production lines, and creating a CAM icon menu file and icons corresponding to various items; packaging various documents such as the CAM icon menu file, the interface programs written by the VBA, each class-generation DLL (dynamic linking library) compiled by VB (visual basic), development interfaces provided in the form of VB types, windows, the modules, the projects, an encryption method and instructions in a SETUP to form installation programs of the various types of numerical-control punching production lines for the automobile girders; and adding a CAM menu into a menu self-defining term in a CAD (computer-aided design).

Owner:广州市力鼎汽车零部件有限公司

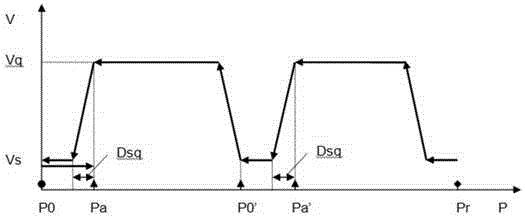

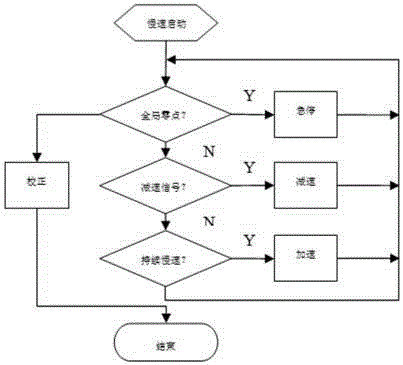

Self-check zero returning method for stepping motor motion system

ActiveCN106788010AFast and reliable self-test return to zeroFast and reliable self-checking and zeroing processDynamo-electric converter controlEngineeringMotion system

The invention provides a self-check zero returning method for a stepping motor motion system. According to the method, a stepping motor starts at any zero returning initial position Pr, through slow-speed and rapid-speed combination and switching, the stepping motor moves in only one direction, a global zero point P0 is found out, after the global zero point P0 is found out, correction to an actual zero point Pa is carried out, and a self-check zero returning method is accomplished. The self-check zero returning method is advantaged in that the time of a self-check zero returning process, bumping and debugging of the stepping motor motion system can be reduced, rapid and reliable self-check zero returning of the stepping motor motion system can be realized, the self-check zero returning process is rapid and reliable, noise generated in the self-check zero returning process can be effectively reduced, moreover, a debugging process and a debugging program can be further simplified, and diagnosis of possible faults of hardware and the structure of the stepping motor can be facilitated.

Owner:HUNAN MINGHE OPTO TECH

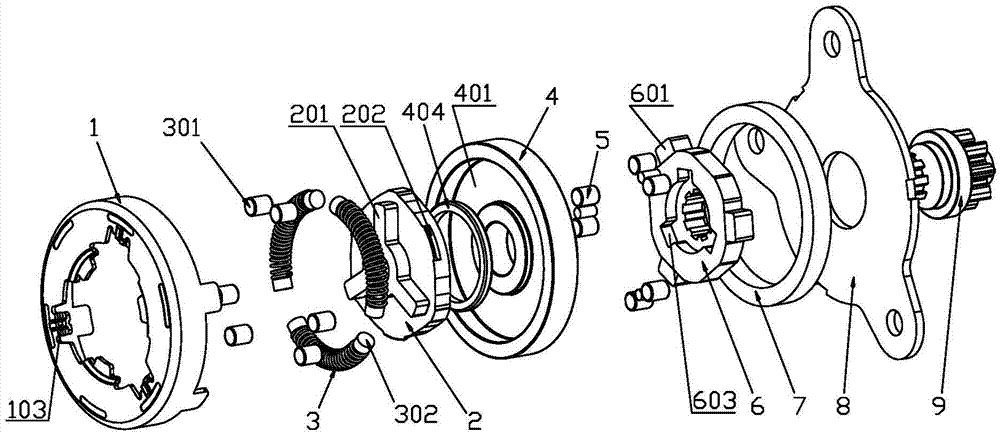

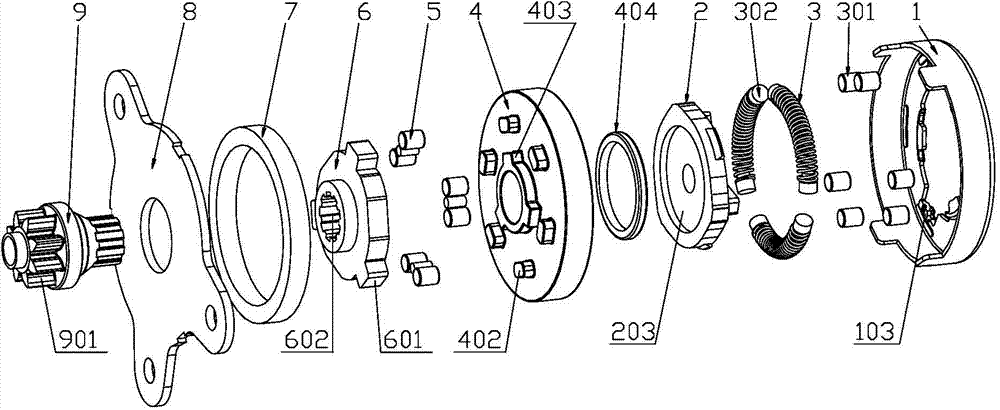

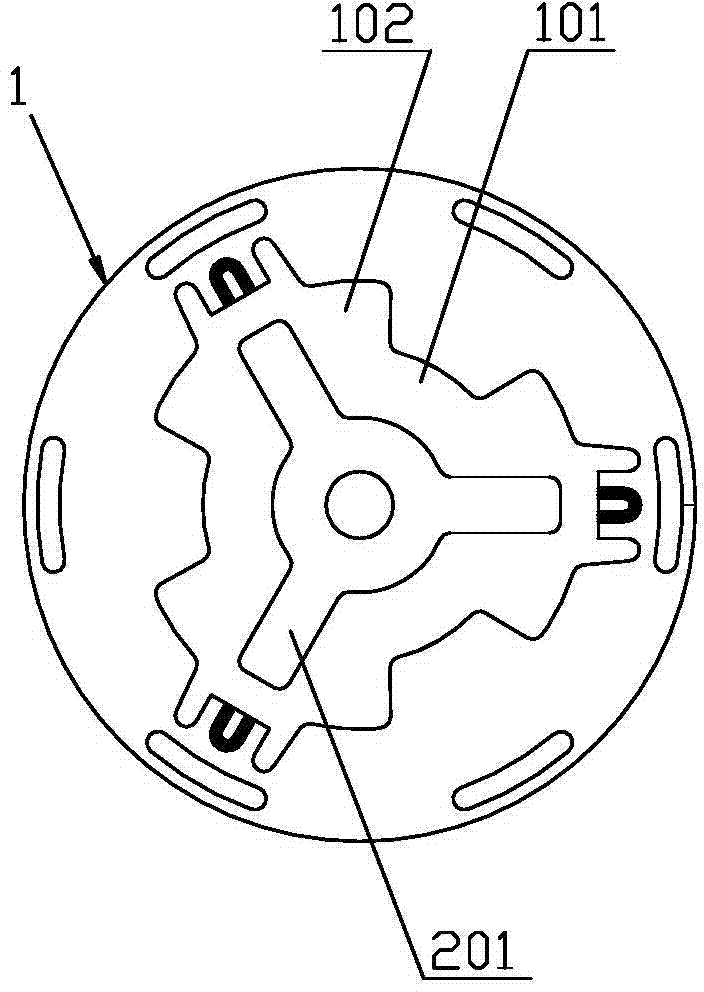

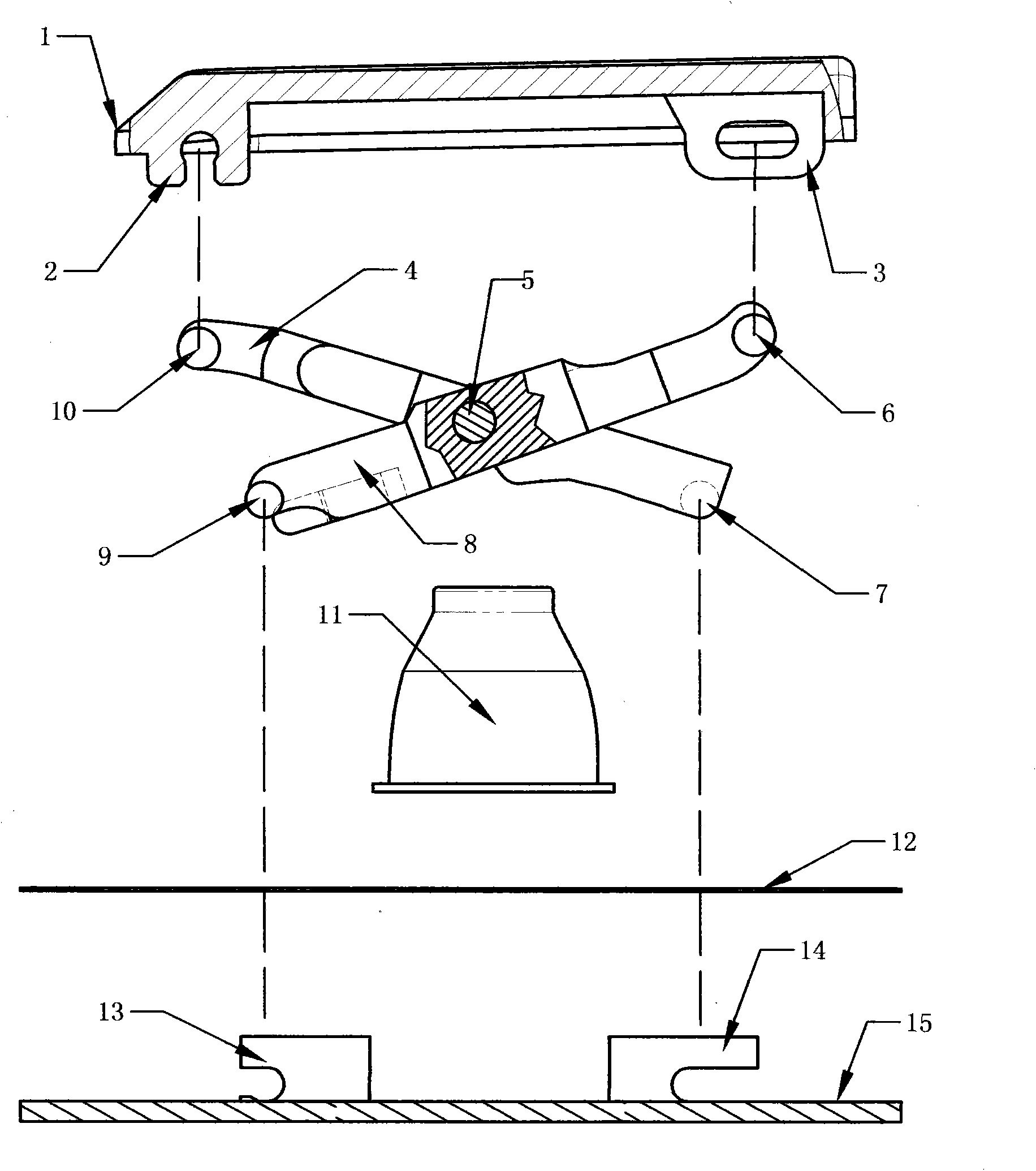

Height-regulating mechanism of vehicle seat

InactiveCN104723910AEasy to unlockReliable two-way self-lockingMovable seatsWork performanceSelf locking

The invention provides a height-regulating mechanism of a vehicle seat. The height-regulating mechanism of the vehicle seat comprises a first bidirectional overrunning clutch and a second bidirectional overrunning clutch which use a pusher dog disc in common. The first bidirectional overrunning clutch comprises a first transmission star wheel, the outer side surface of the first transmission star wheel comprises three sections of first arc surfaces and three sections of second arc surfaces which are arranged circumferentially at intervals, and one first arc surface and one second arc surface are connected through a first arc wedge surface. Springs are respectively arranged between one first arc surface and a circular groove wheel of the pusher dog disc, and two ends of each spring is provided with a roller which is clamped between the first arc wedge surface and the circular groove wheel. The second bidirectional overrunning clutch comprises a second transmission star wheel, the outer side surface of the second transmission star wheel comprises three sections of third arc surfaces and three sections of planes which are arranged circumferentially at intervals, and a third arc surface is connected with the planes through a second arc wedge surface. A pin roller which is clamped between the second arc wedge surface and the inner side surface of the output end shell under the function of an elastic element is arranged between each pusher dog of the pusher dog disc. The height-regulating mechanism of the vehicle is good in self-locking performance, stable in working performance, and high in control precision.

Owner:上海交运汽车精密冲压件有限公司

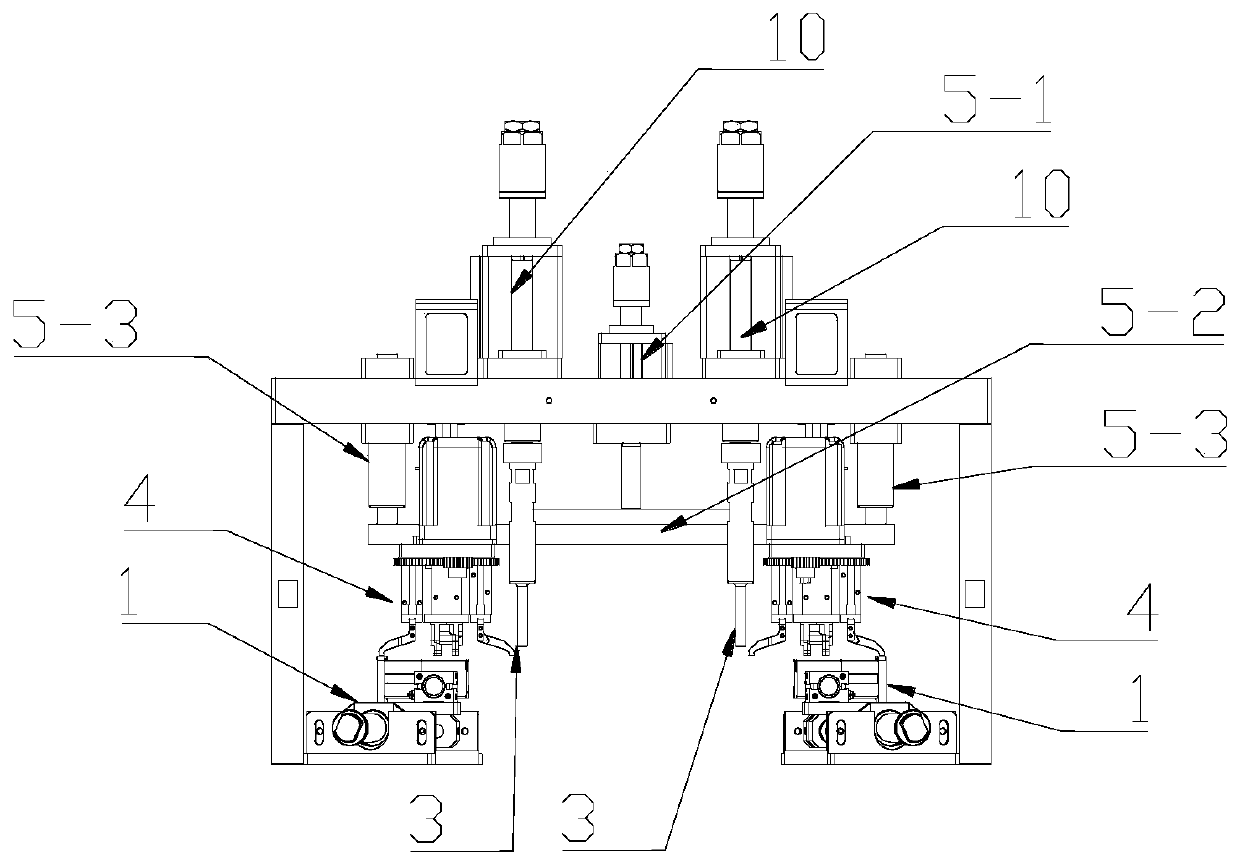

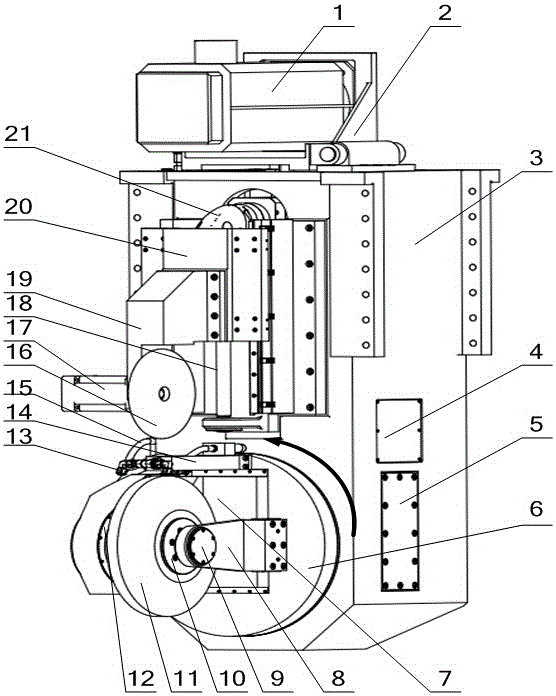

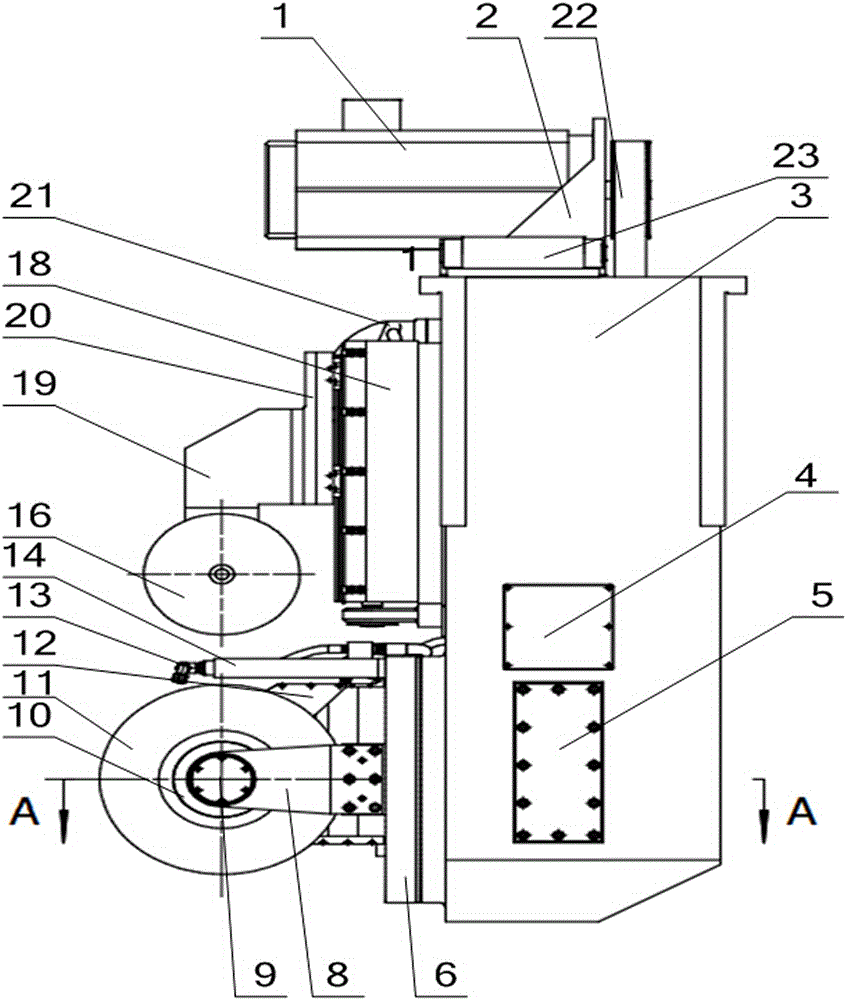

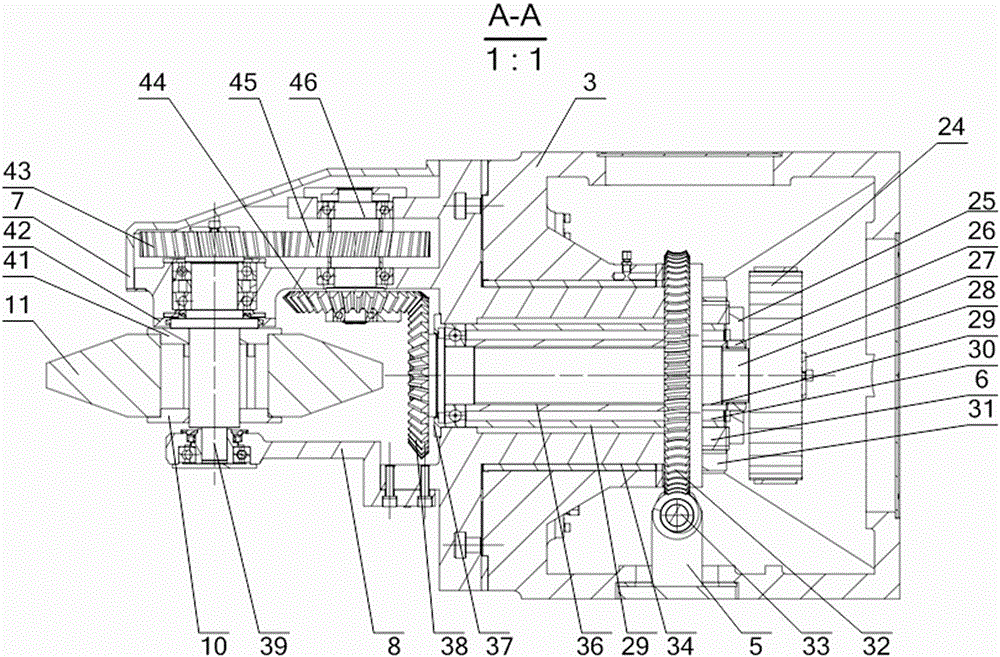

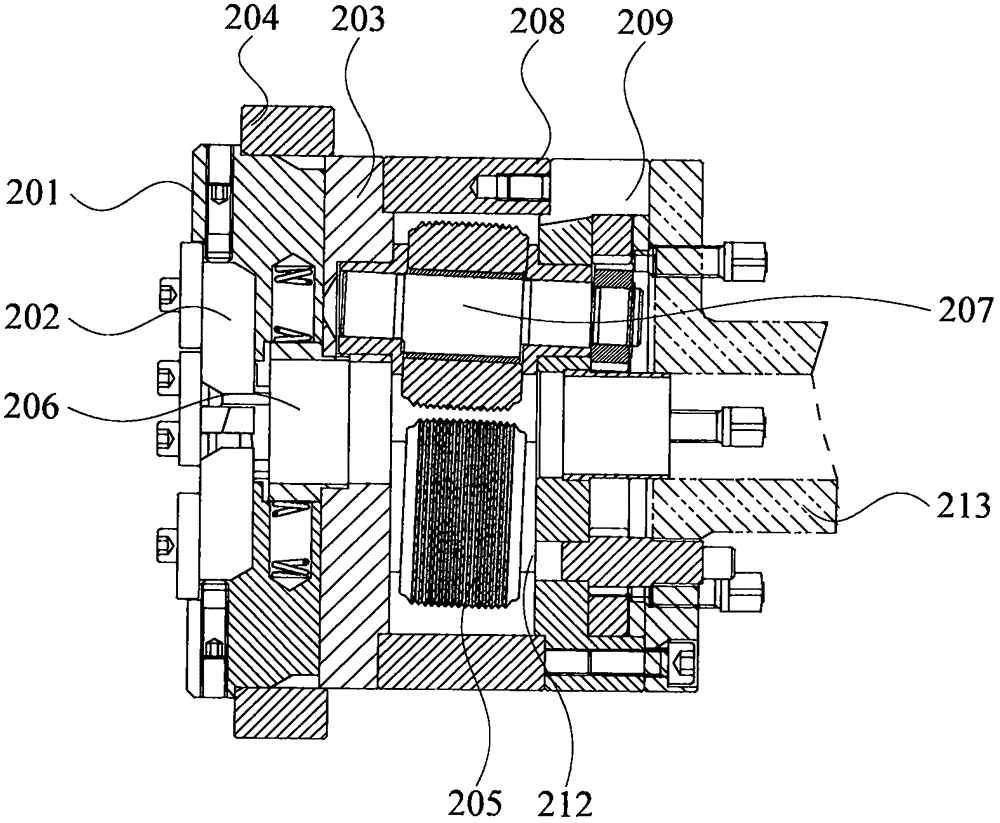

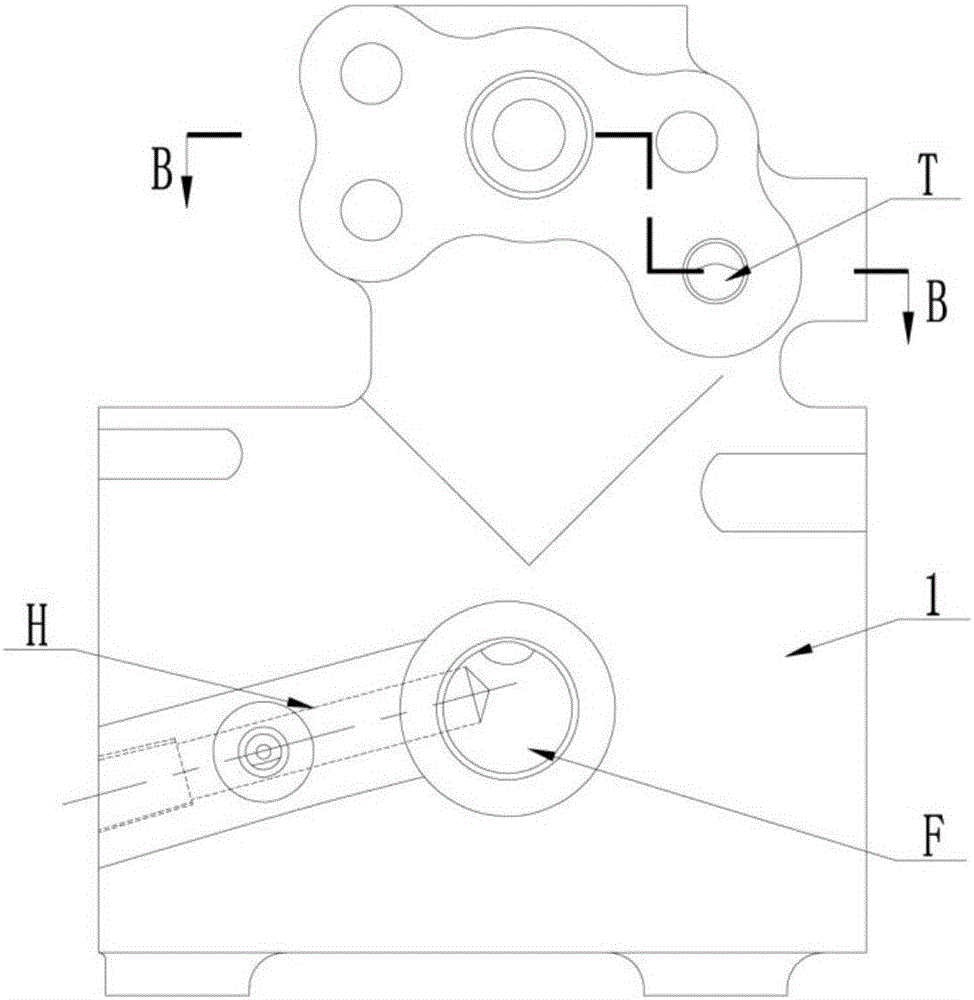

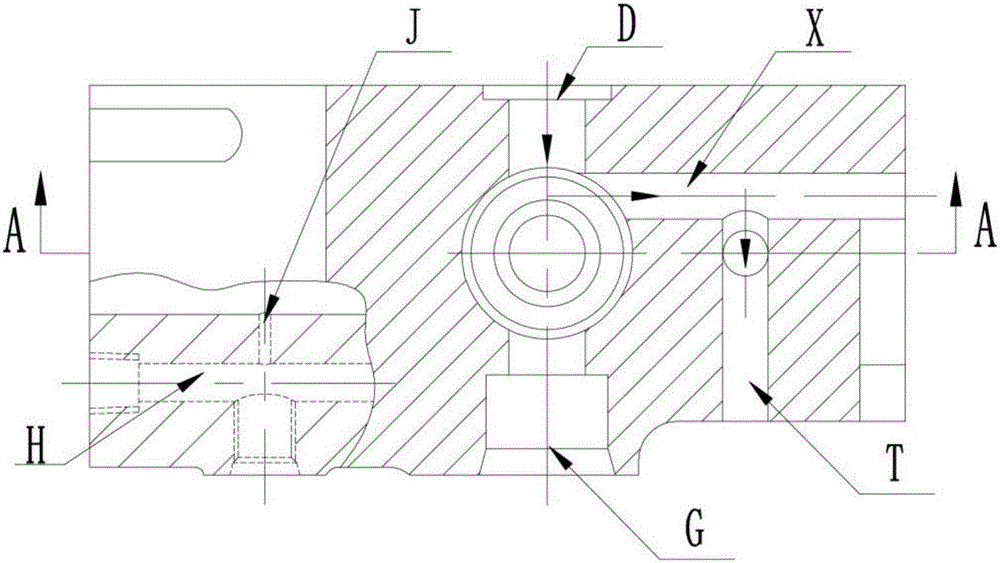

Gear form-grinding mechanism

InactiveCN104985261AEasy to trimReduce idle travelAbrasive surface conditioning devicesGear-cutting machinesVertical planeGear wheel

The invention relates to a gear form-grinding mechanism. The mechanism comprises a box, a main motor, a grinding component, a rotating component, a grinding wheel dressing component and a cooling component. When a grinding wheel needs to be dressed, it is only needed to rotate the grinding wheel in the vertical plane by 180 degrees through the rotating component so as to avoid a cooling liquid nozzle. The vertical movement of a diamond wheel and the rotation of the grinding wheel are linked according to a certain rule, so that the section of a grinding wheel spindle is dressed. Grinding wheel dressing is convenient, the idle stroke of a machine tool is short, and machining efficiency is high. A bevel gear can be ground simply by driving a worm and gear mechanism through a servo motor and adjusting the angle of the grinding wheel. The box is provided with two different positions connected with the machine tool to be used for machining of an external gear or machining of an internal gear respectively. The mechanism is convenient to use and adjust and wide in process range.

Owner:HENAN UNIV OF SCI & TECH

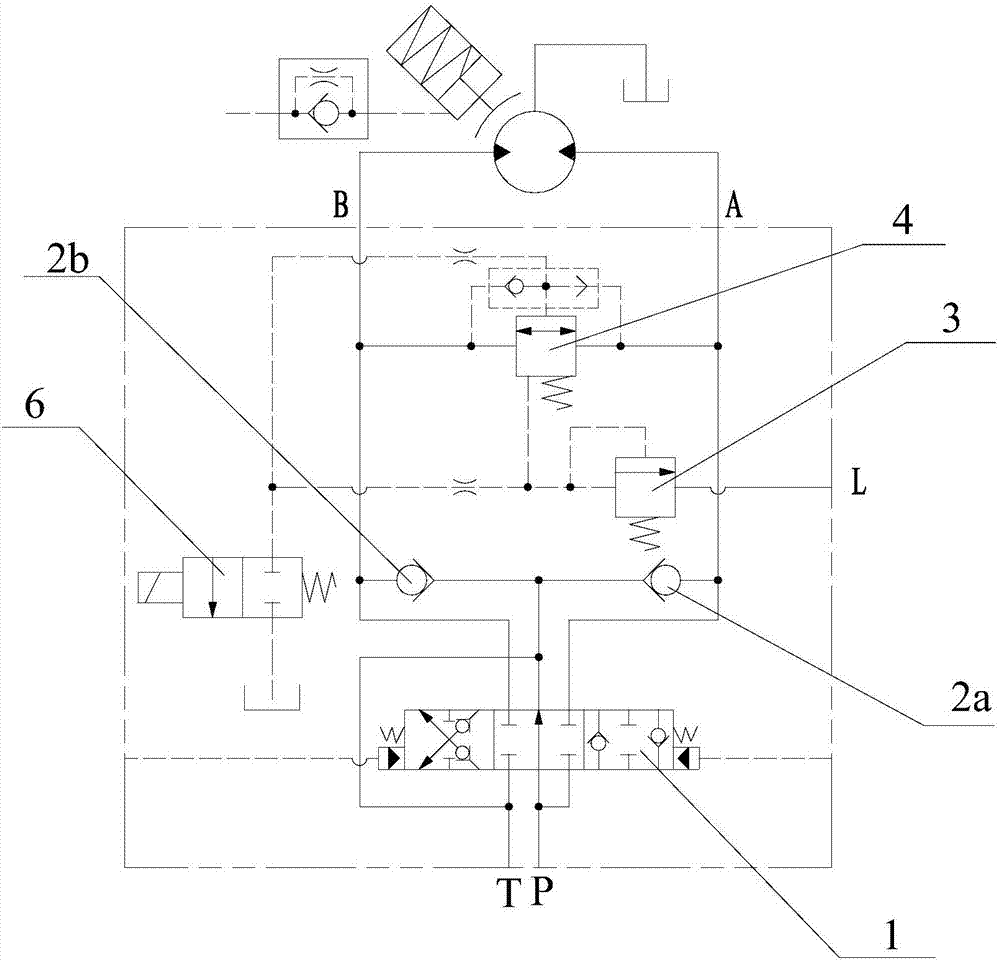

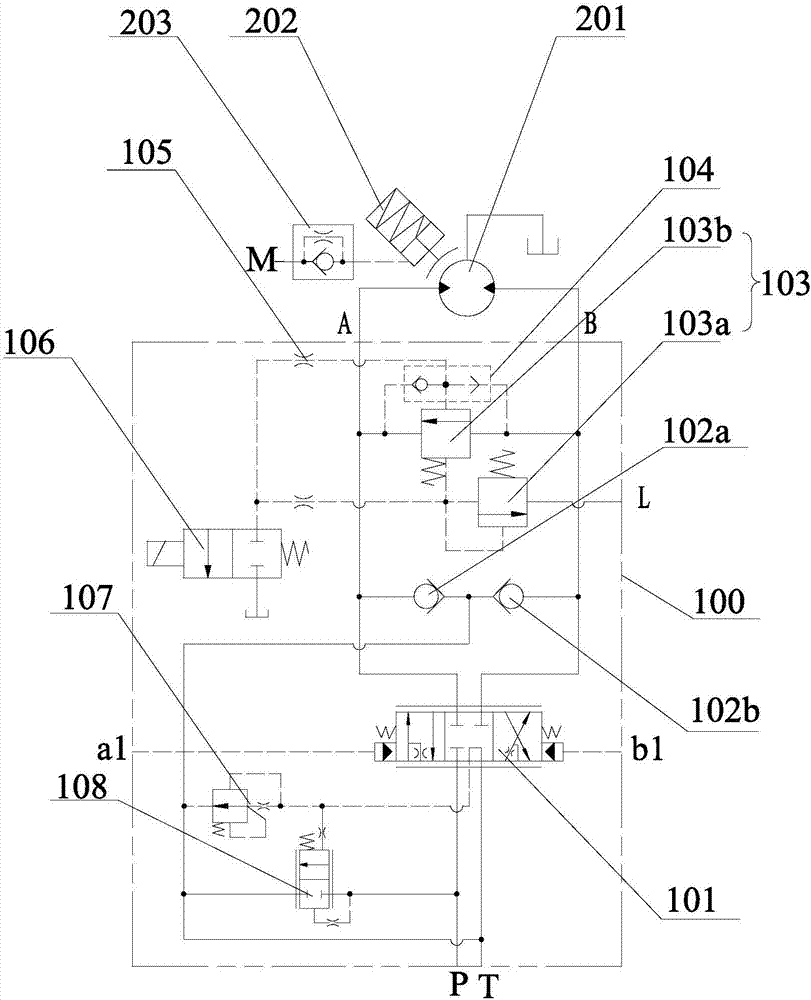

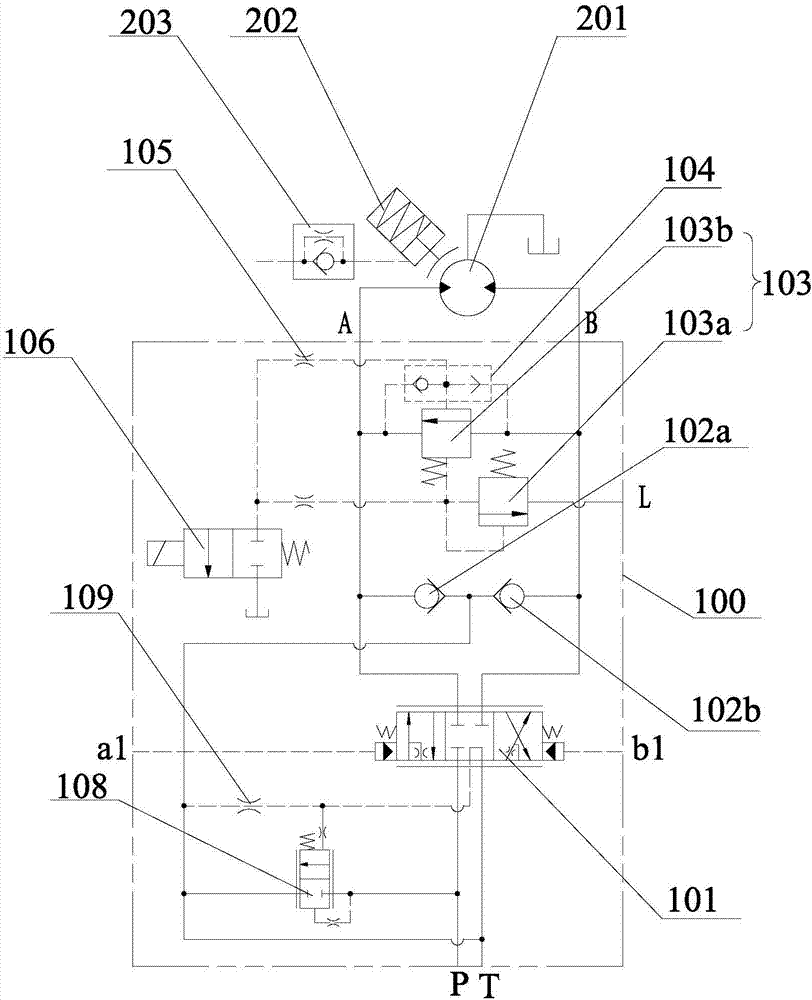

Load-sensitive rotation buffer valve and crane rotation hydraulic system

ActiveCN107355437ALarge operating rangeSwing open smoothlyServomotor componentsCranesMarine engineeringOil intake

The invention discloses a load-sensitive rotation buffer valve and a crane rotation hydraulic system. A middle path of a rotation reversing valve is sequentially connected with a guide oil port of a three-way pressure compensation valve and an oil inlet of a constant flow valve through an LS feedback oil path, an oil inlet of the three-way pressure compensation valve is communicated with an oil inlet of a valve body, an oil outlet of the three-way pressure compensation valve is communicated with an oil returning opening of the valve body, an oil outlet of the constant flow valve is divided into two paths, one path is directly connected with the oil returning opening of the valve body, the other path is communicated with an oil inlet of a first one-way valve and an oil inlet of a second one-way valve at the same time, a speed adjusting valve is formed by the three-way pressure compensation valve and the rotation reversing valve, flow adjustment of a work oil port A and a work oil port B is achieved, flow is output proportionally, influences of the load are avoided, in the whole operation process, action is stable, fast and slow action is avoided, stable opening is achieved, during stopping, pressure impact is small, and a crane cannot rotate and swing.

Owner:ANHUI LIUGONG CRANE

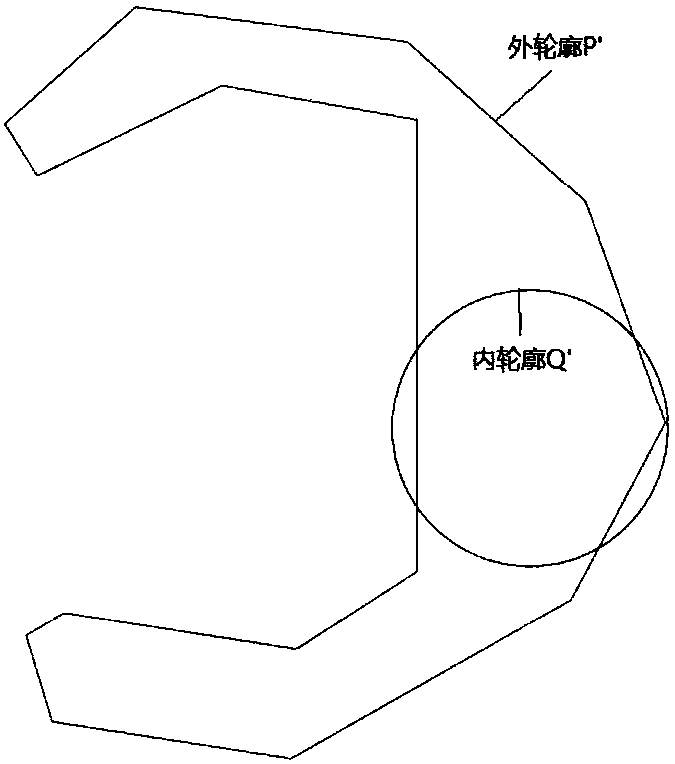

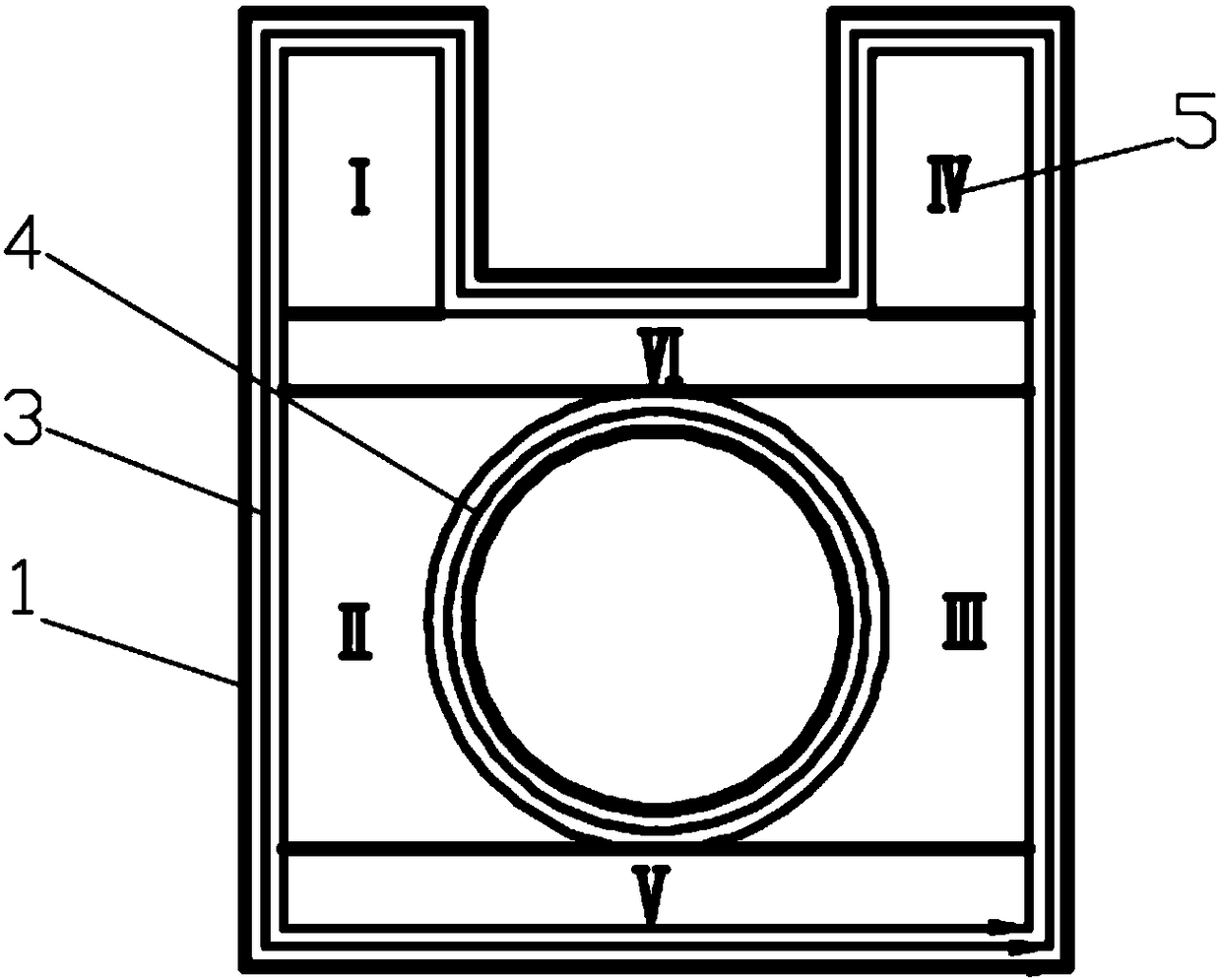

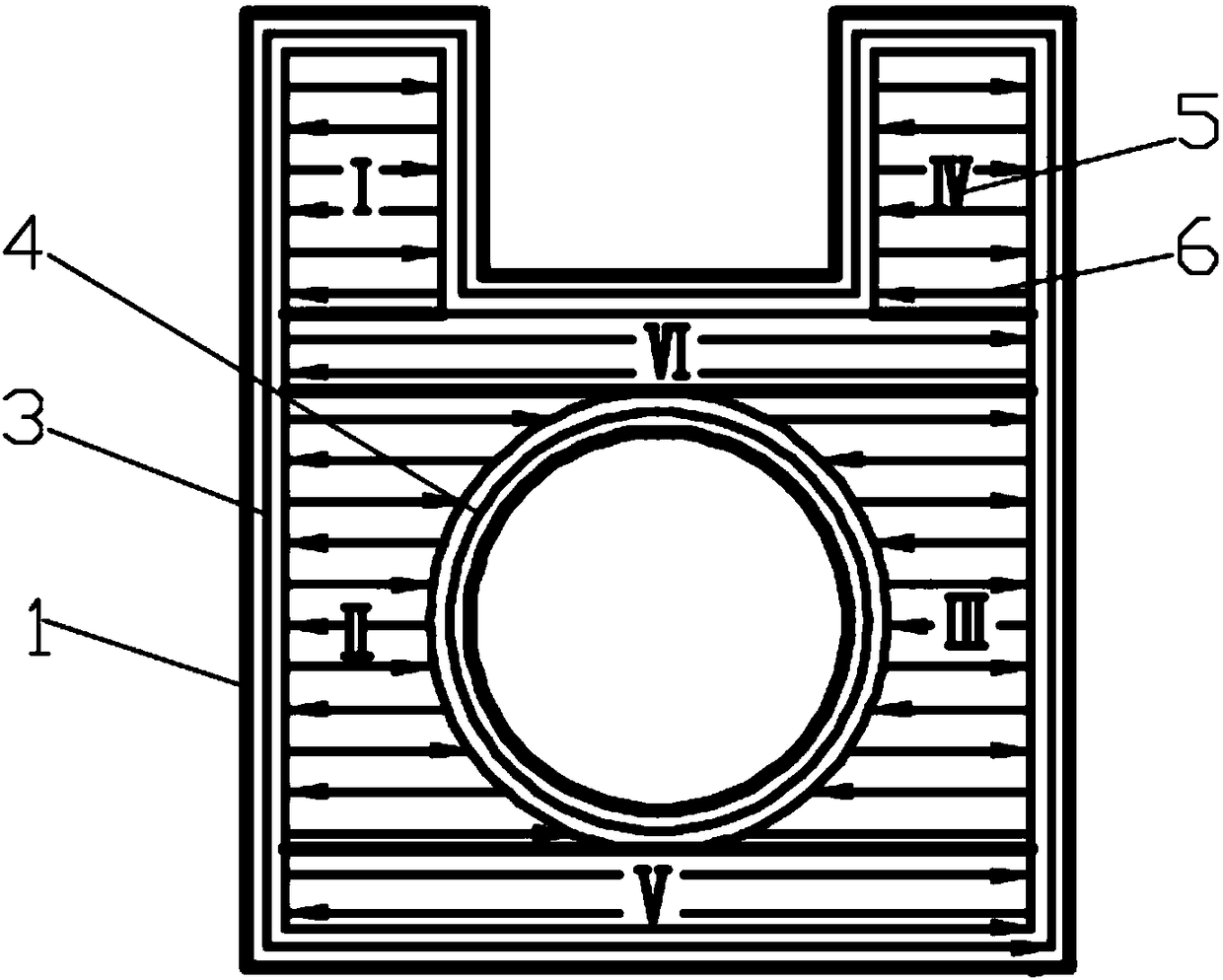

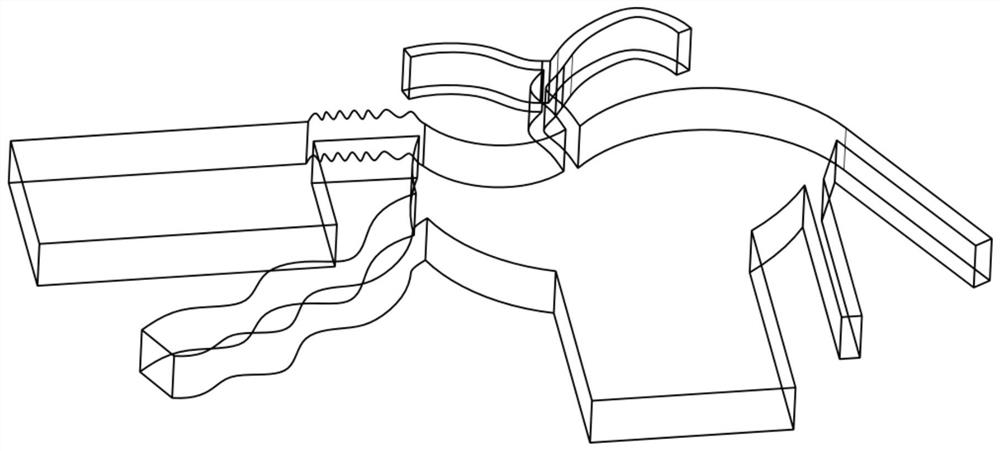

Mixed fill path generation method in arc fuse additive manufacturing technology

InactiveCN108460174AGuarantee the quality of the outer surfaceImprove execution efficiencyGeometric CADSpecial data processing applicationsManufacturing technologyPath generation

The invention relates to a mixed fill path generation method in an arc fuse additive manufacturing technology. The method comprises the following steps of: traversing data points of a section edge profile and a cavity area edge profile, and deleting collinear points on the profiles; sorting the data points on the profiles in a clockwise or counter-clockwise direction; setting a distance of profileoffset; taking a section edge as an outer profile and taking a cavity area edge as an inner profile; distinguishing and judging the inner profile and the outer profile; gradually offsetting the outerprofile inwards and gradually offsetting the inner profile outwards, and stopping the offset when the two profiles are intersected; solving a blank area between the innermost outer profile and the outermost inner profile according to the intersection point; and filling the blank area by using a reciprocating straight line. According to the method, a mixed fill path is adopted, so that complex areas with cavities can be filled, outer surface quality of parts is ensured, the frequencies of arcing and arc striking and idle strokes of welding guns are decreased, and the algorithm execution efficiency is improved.

Owner:WUHAN UNIV OF TECH

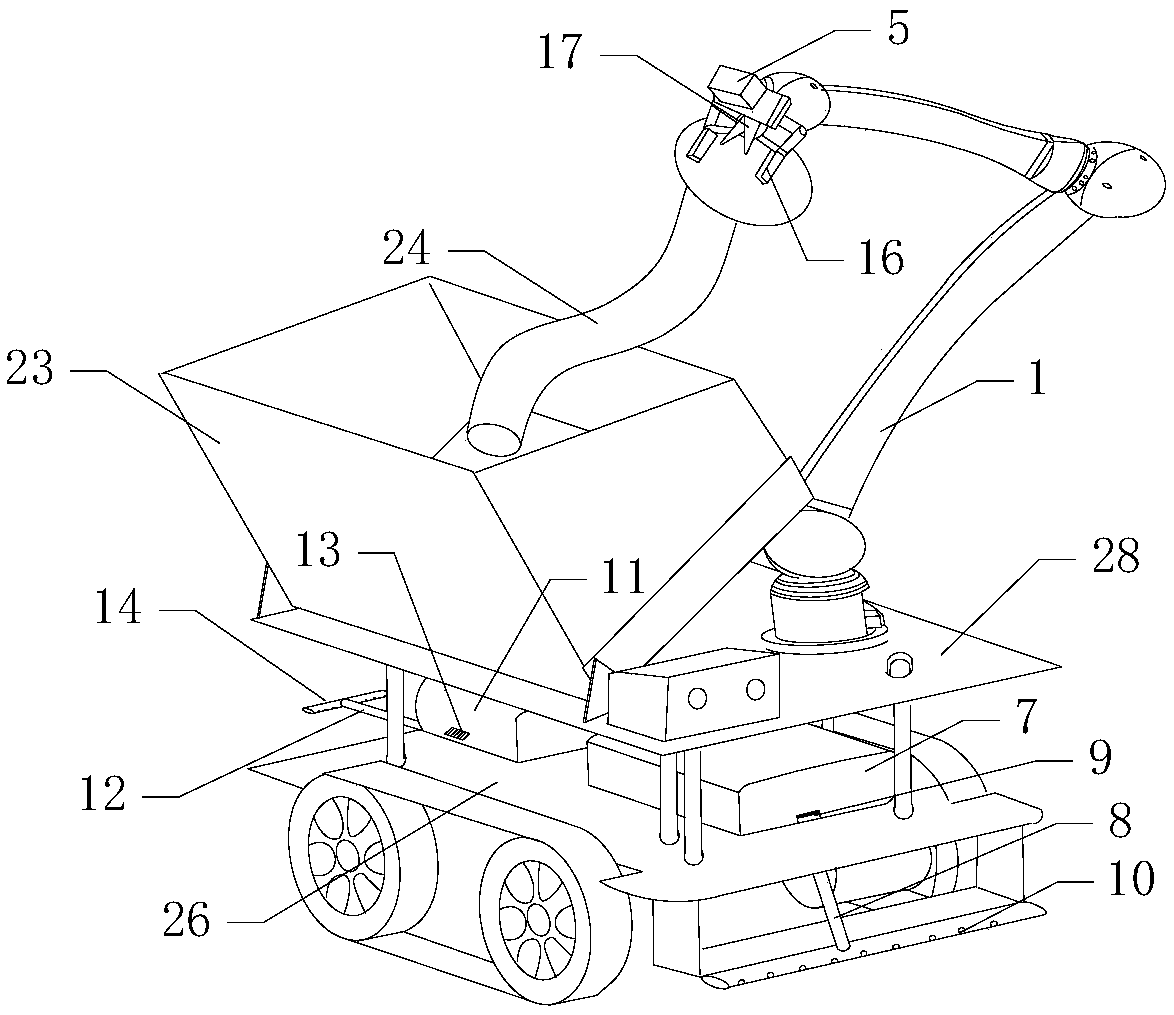

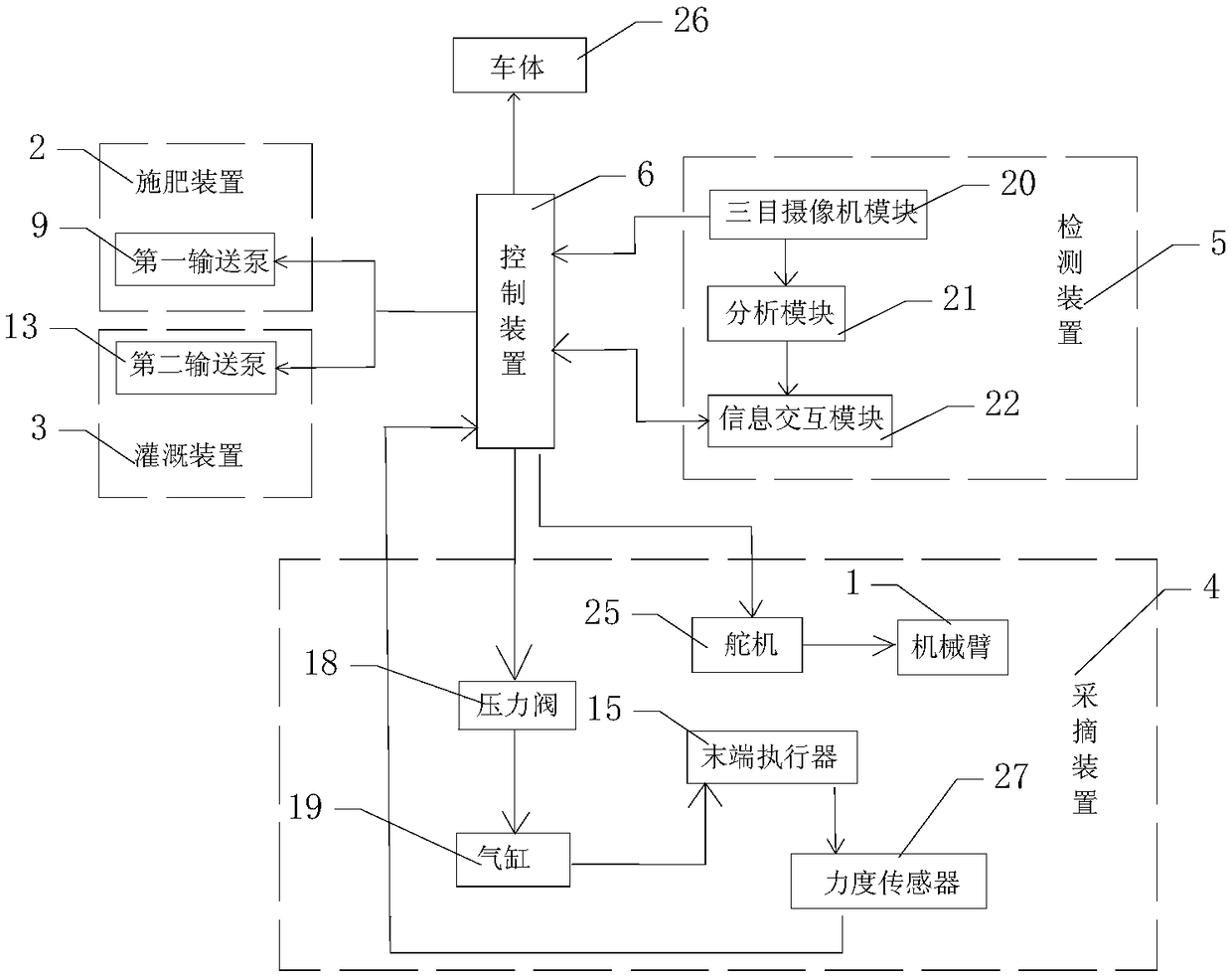

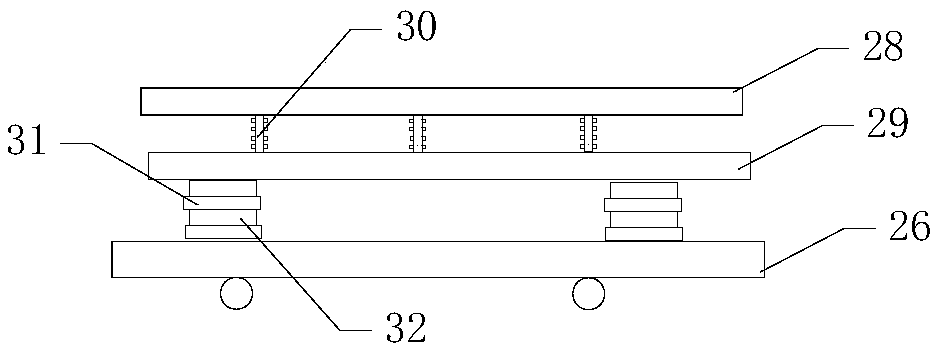

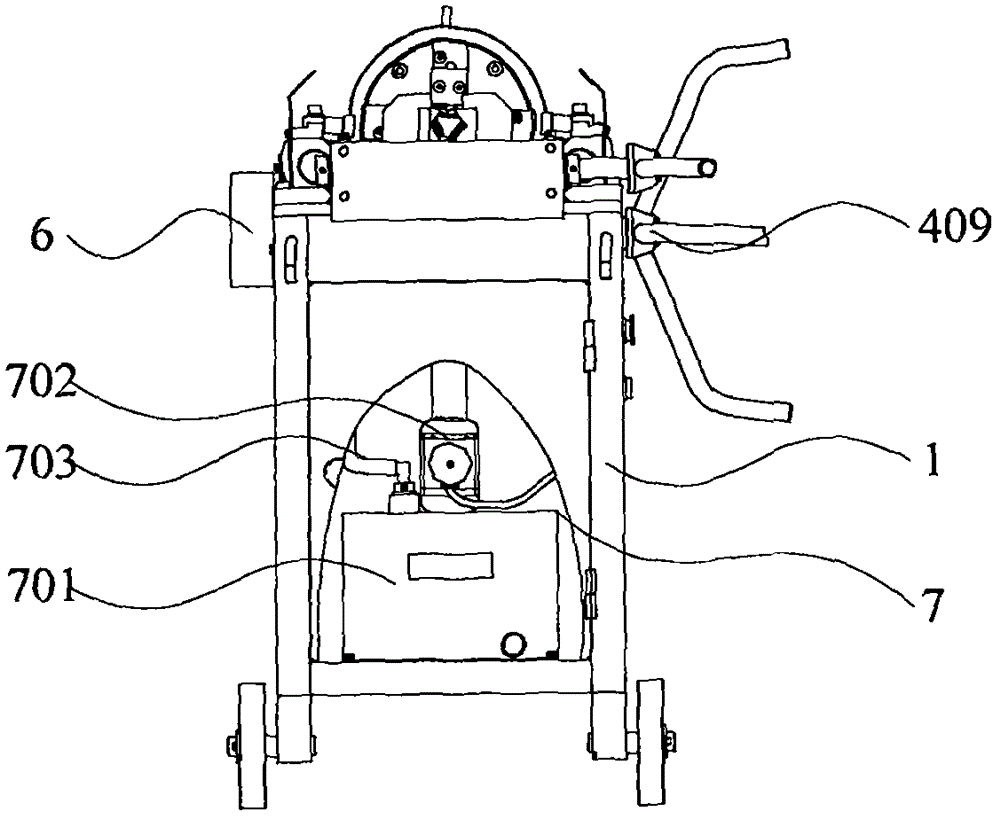

Fertilizing, irrigating and picking integrated system for citrus reiculata Blanco planting

InactiveCN109168529AReasonable designCompact structureWatering devicesLiquid fertiliser regulation systemsEngineeringActuator

The invention belongs to the field of agricultural robots, and provides a fertilizing, irrigating and picking integrated system for citrus reiculata Blanco planting. The system comprises a cart body,wherein a workbench is arranged on the cart body; a fertilizing device, an irrigating device and a control device are arranged between the cart body and the workbench; a mechanical arm, a picking device and a detection device are arranged on the workbench; the detection device is used for collecting a front image, identifying and processing the image, determining information of location areas of fertilizing, irrigating and picking, and transmitting the information to the control device; the control device is used for controlling the cart body to move, a first transfer pump is started to perform atomized spraying operation, a second transfer pump is started to perform spray irrigation operation, and an actuator at the tail end of the picking device is started to perform picking operation; and a clamping claw and a shearing knife are arranged at the tail end of the mechanical arm, fruits are clamped by the clamping claw and sheared through the shearing knife to separate citrus reiculataBlanco from stems. The system can be used for efficiently completing field management including fertilizing, irrigating, picking and the like in the citrus reiculata Blanco planting process, and the work efficiency is improved.

Owner:靖西海越农业有限公司

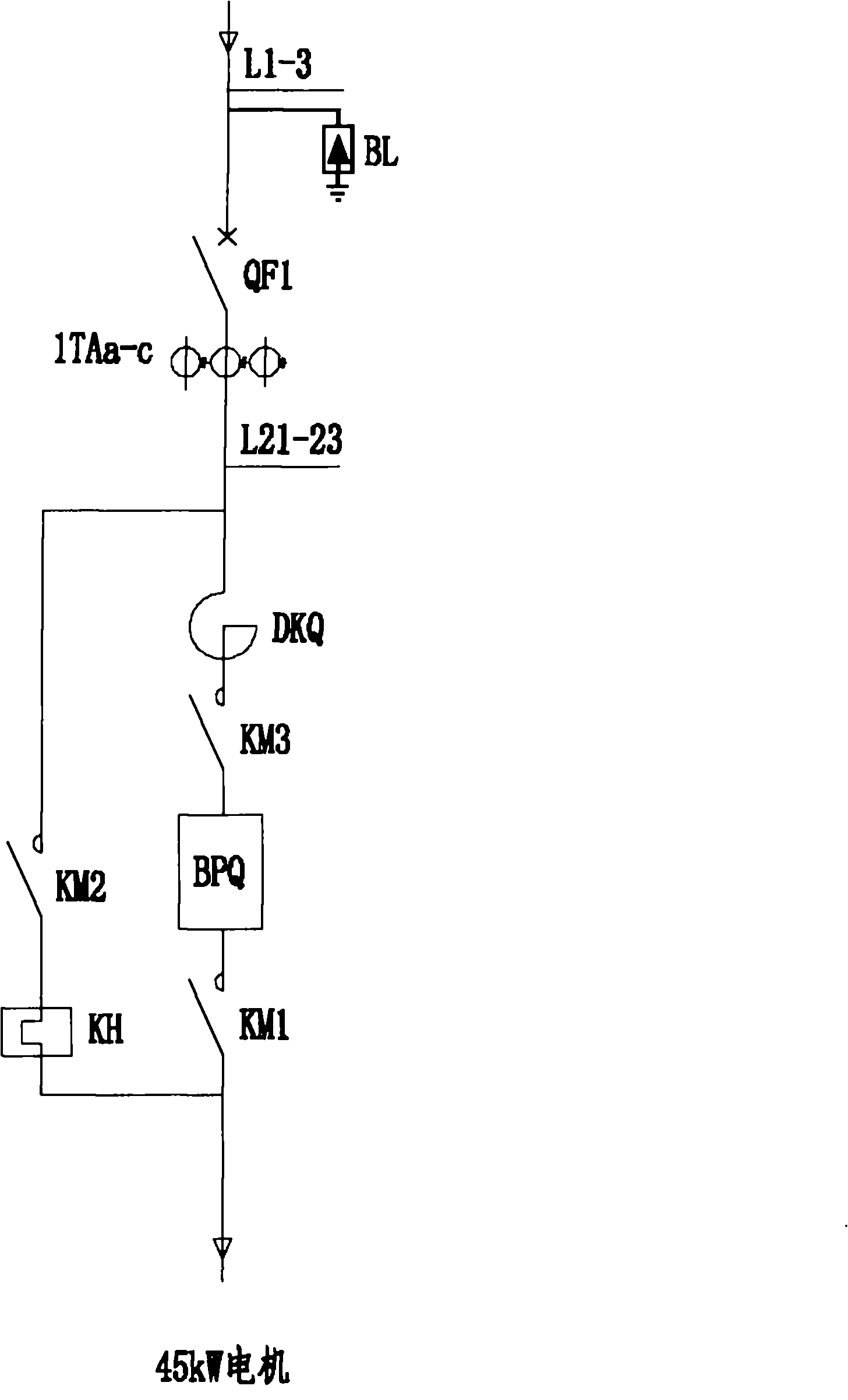

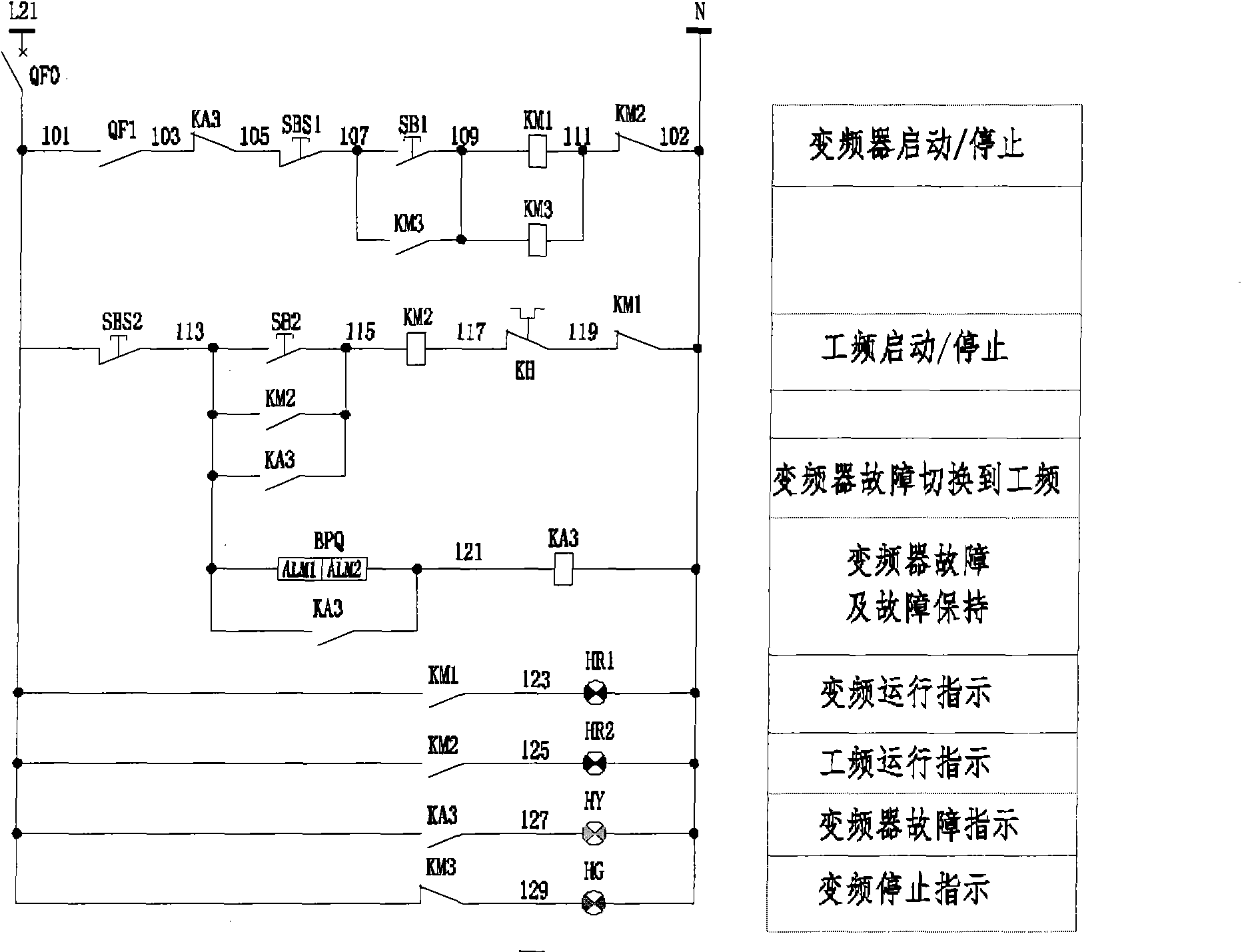

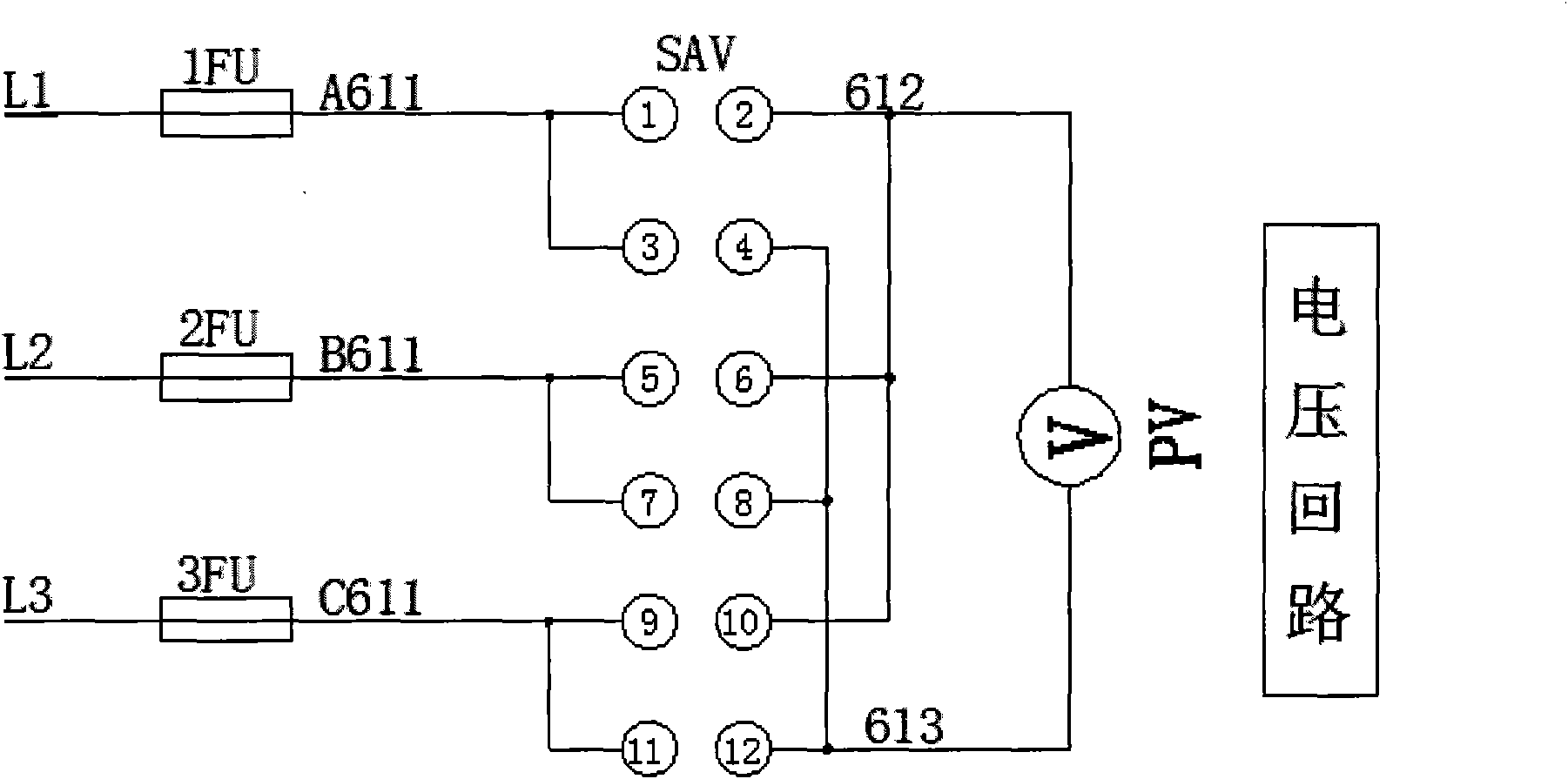

Frequency converting and energy saving device of oil pumping machine

InactiveCN101777762AIncrease productionImprove pump efficiencyReactive power adjustment/elimination/compensationReactive power compensationFrequency changerPower factor

The invention relates to a frequency converting and energy saving device of an oil pumping machine in the technical field of electronic control. The device comprises a breaker, a frequency converter, a current transformer, an input reactor, a first contactor, a second contactor, a third contactor and a thermal relay, wherein an external power supply is connected with the breaker, after the external power supply is controlled by the breaker, the external power supply is divided into two paths of circuits through the current transformer, and one path of the circuit is a frequency conversion loop, while the other path of the circuit is a power frequency loop; the frequency conversion loop firstly passes through the input reactor and then enters the frequency converter through the third contactor, and after the frequency conversion loop is subjected to frequency conversion through the frequency converter, the frequency conversion loop enters the first contactor; the power frequency loop comprises the second contactor and the thermal relay which are connected in series; and the whole power frequency loop and the frequency conversion loop are connected in parallel. The frequency converter is added in a control cabinet of the oil pumping machine so as to improve the output and the pump efficiency of an oil well, compensate the power factor, avoid impacts to power grid equipment when a motor is started and realize arbitrary jig frequency regulation and segmental rotating speed control.

Owner:上海德力西集团有限公司

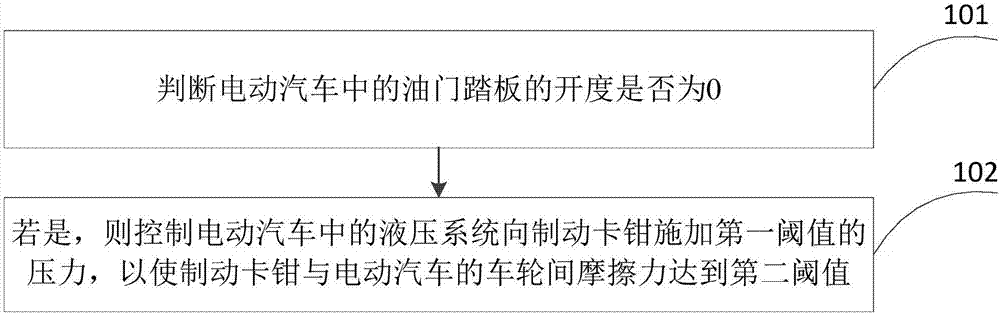

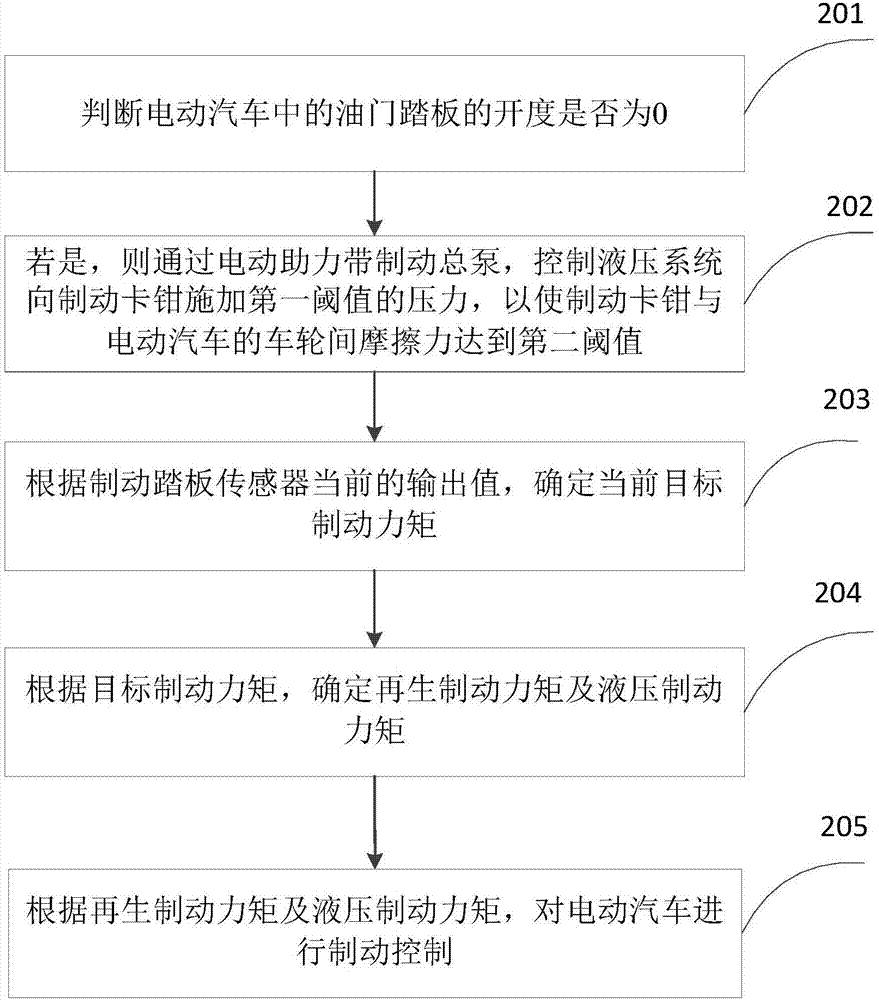

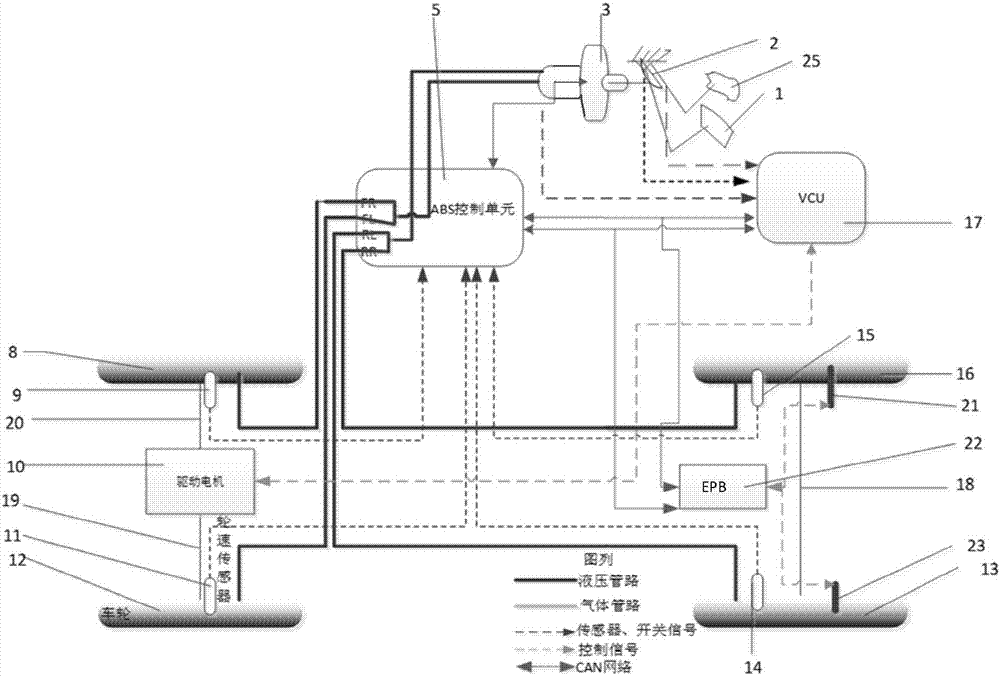

Braking method and device of electric vehicle and electric vehicle

ActiveCN107225978AImprove securityReduce idle travelElectrodynamic brake systemsBrake control systemsDrag torqueElectric cars

The invention provides a braking method and device of an electric vehicle and the electric vehicle. The braking method is applied to the electric vehicle. A braking system of the electric vehicle comprises braking callipers of which the dragging torque is zero. The braking method comprises the following steps of judging whether opening degree of an accelerator pedal in the electric vehicle is 0 or not, and if yes, controlling a hydraulic system in the electric vehicle to exert pressure of a first threshold to the braking callipers, so as to enable the friction between the braking callipers and wheels of the electric vehicle to achieve a second threshold. According to the braking method disclosed by the invention, the braking callipers of which the dragging torque is zero are adopted, so that in the rotating process, the frictional resistance of the wheels is reduced, the life of a braking friction piece is prolonged, the energy sources are saved, and the endurance mileage of the battery is increased; and the safety of the electric vehicle is improved; and when the opening degree of the accelerator pedal is 0, the braking callipers are prepressed, so that the idle stroke of a braking pedal, the reacting time and the braking distance of the braking system are shortened, the feeling of a driver braking the pedal is improved, and the user experience is improved.

Owner:BEIJING ELECTRIC VEHICLE

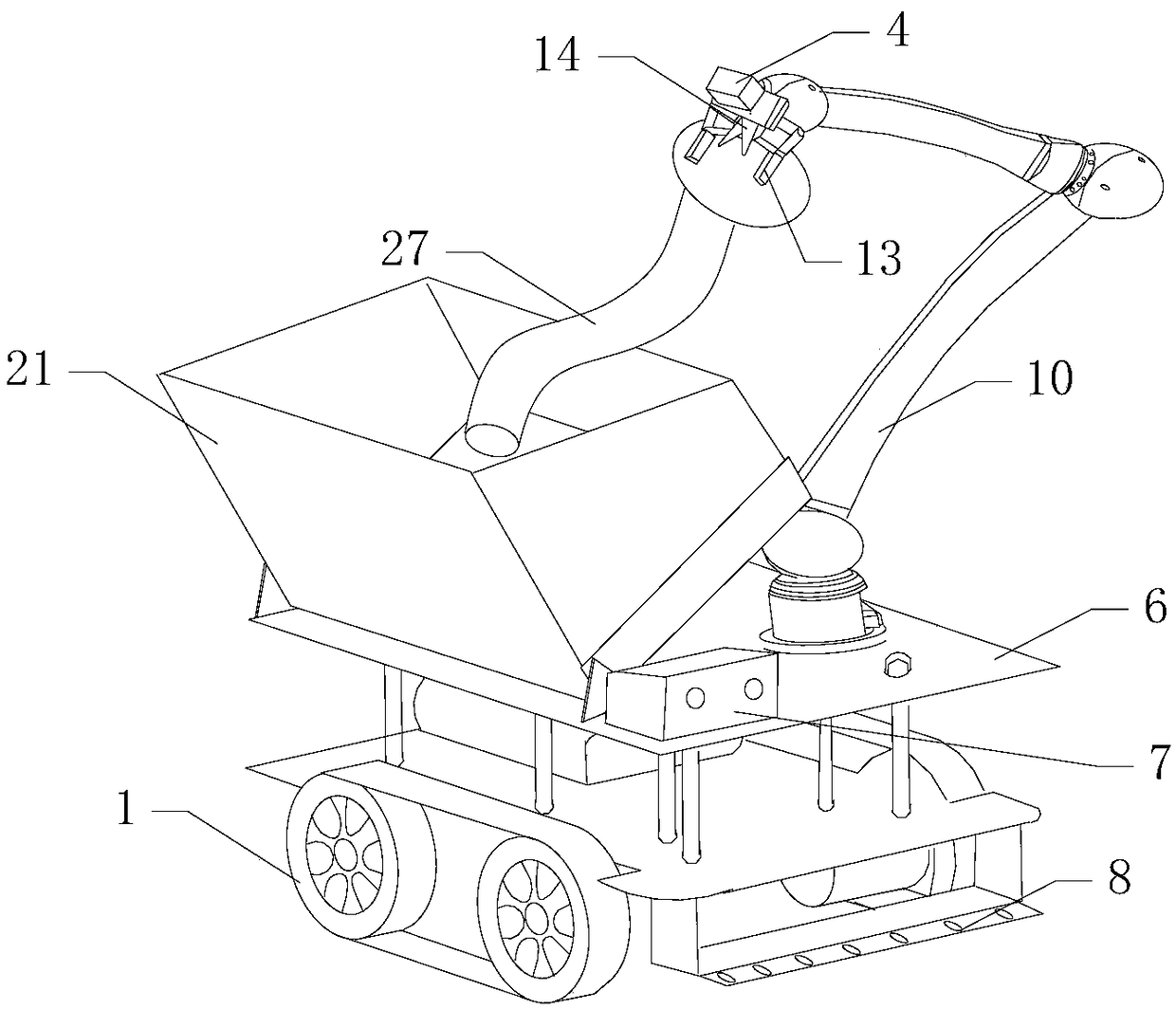

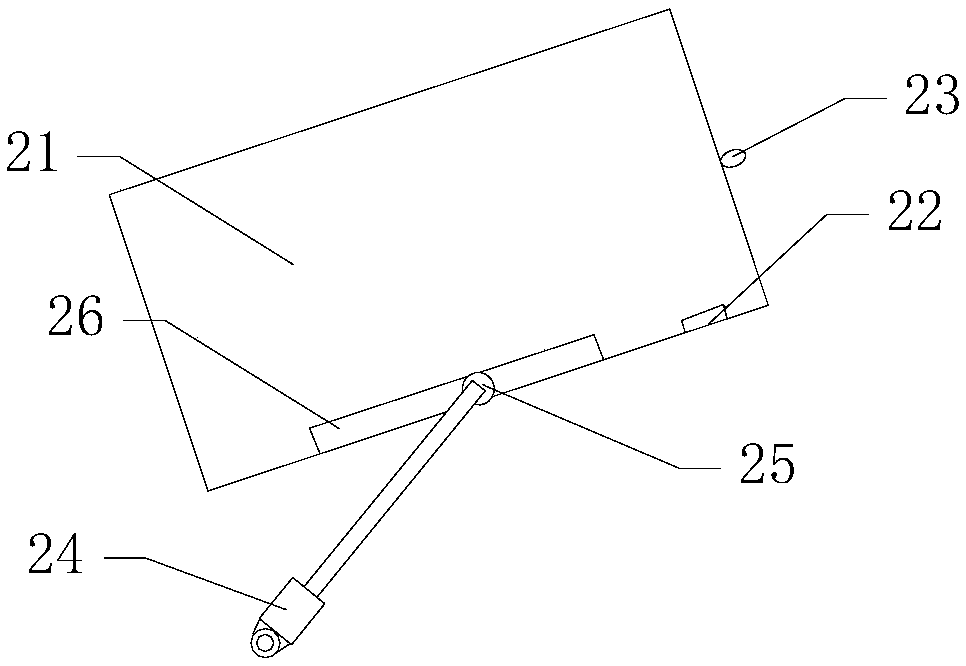

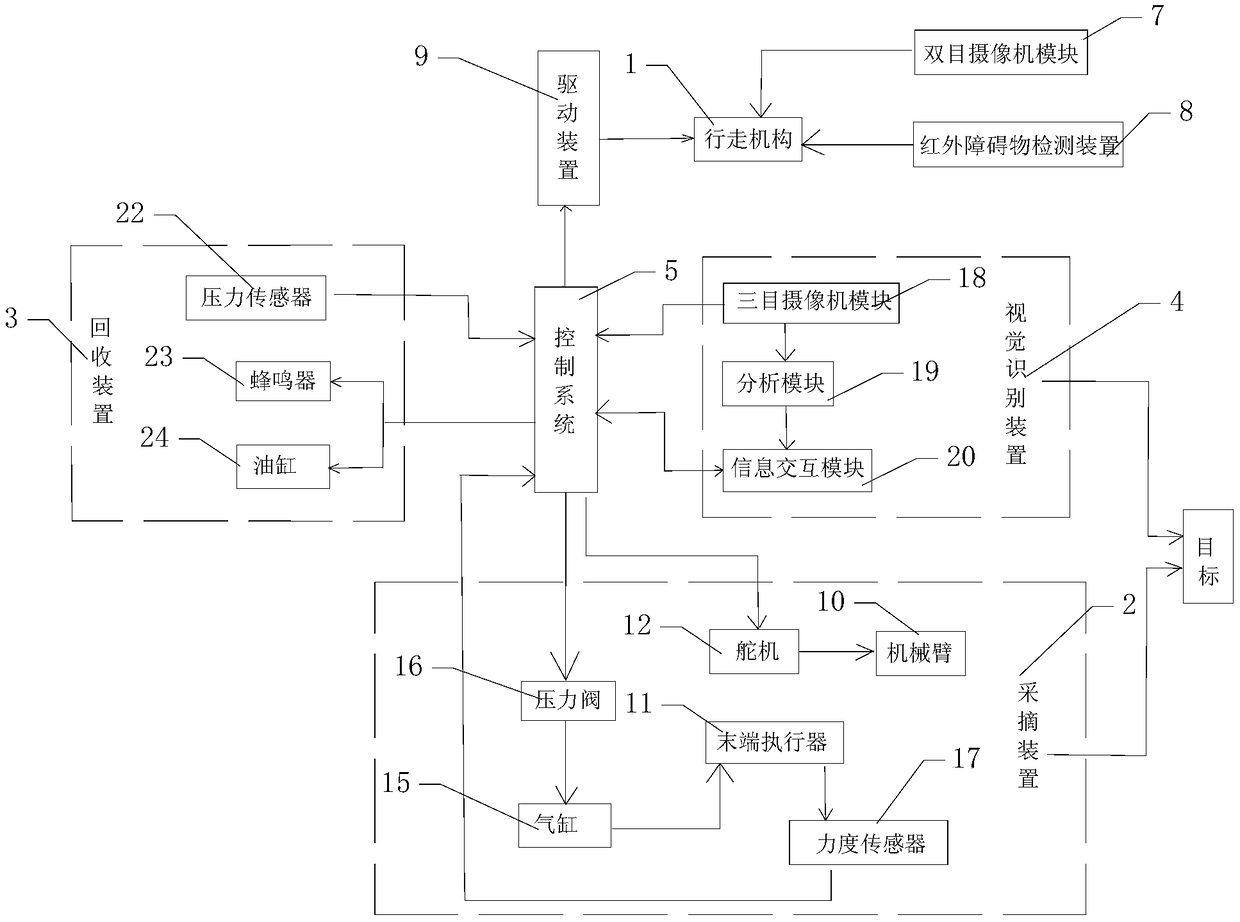

Intelligent Orah orange picking robot

InactiveCN109156161AReduce idle travelImprove work efficiencyNon-rotating vibration suppressionManipulatorOrange TreeAgricultural engineering

The invention belongs to the field of agricultural robots. An intelligent Orah orange picking robot comprises a walking mechanism, a picking device, a recycling device, a visual identification device,a control system and a work table. A binocular camera module arranged on the walking mechanism is capable of collecting images of different time periods and conducting comparing to judge whether there are Orah orange trees to be picked in the image capturing range, and the positions of obstacles can be obtained through an infrared obstacle detection device, so that the robot can automatically walk according to a picking route and intelligently avoid the obstacles; and the visual identification device realizes non-contact measurement between the picking device and oranges. The end of a robot arm is provided with a gripping jaw and a shearing knife, the gripping jaw grips one orange, and then the orange is separated from a fruit stem through cutting by the shearing knife. The intelligent Orah orange picking robot disclosed by the invention can realize automatic picking and collecting, and improve picking efficiency and picking quality.

Owner:靖西海越农业有限公司

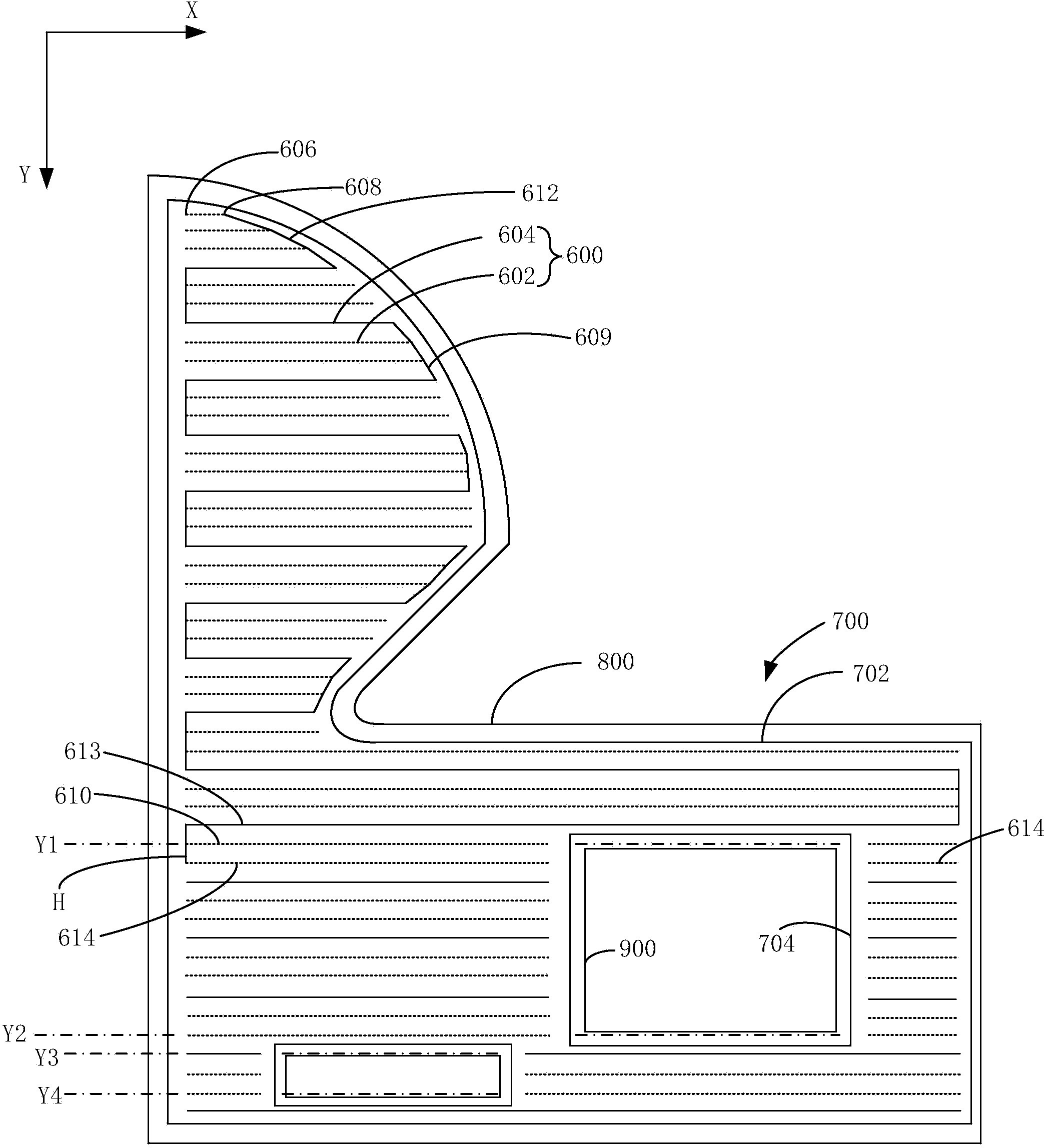

High-energy beam scanning path planning method for manufacturing of addition materials

InactiveCN109420760AEnsure dimensional accuracyQuality assuranceAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringPlanning method

The invention relates to a high-energy beam scanning method capable of improving shaping quality and efficiency of members and for manufacturing of addition materials. Different scanning paths have important influence on the respects of precision, intensity, buckling deformation and processing efficiency of shaped members. The invention provides the high-energy beam scanning path planning method based on combination of inner outline and outer outline deflexion scanning and interval partition straight line return scanning. The high-energy beam scanning path planning method comprises the following steps of under optimized condition of technological parameters ( including the high-energy beam power, the scanning speed, the overlapping rate and the like ), according to two-dimensional sectioninformation of a digital model to be scanned, firstly performing deflexion scanning along the inner outline and the outer outline of a section for some times, then performing partition on remaining region surrounded by outline deflexion lines, and finally, according to a specific logic sequence, performing return scanning on each partition along parallel straight lines. The high-energy beam scanning path planning method disclosed by the invention has the beneficial effects that thermal stress accumulating is avoided, so that deformation is reduced; idle stroke is reduced, so that efficiency isimproved, and the service life of the high-energy beam device is prolonged; and the dimension precision and surface quality of the shaped members can also be guaranteed, so that the performances of the members are improved.

Owner:HUNAN UNIV

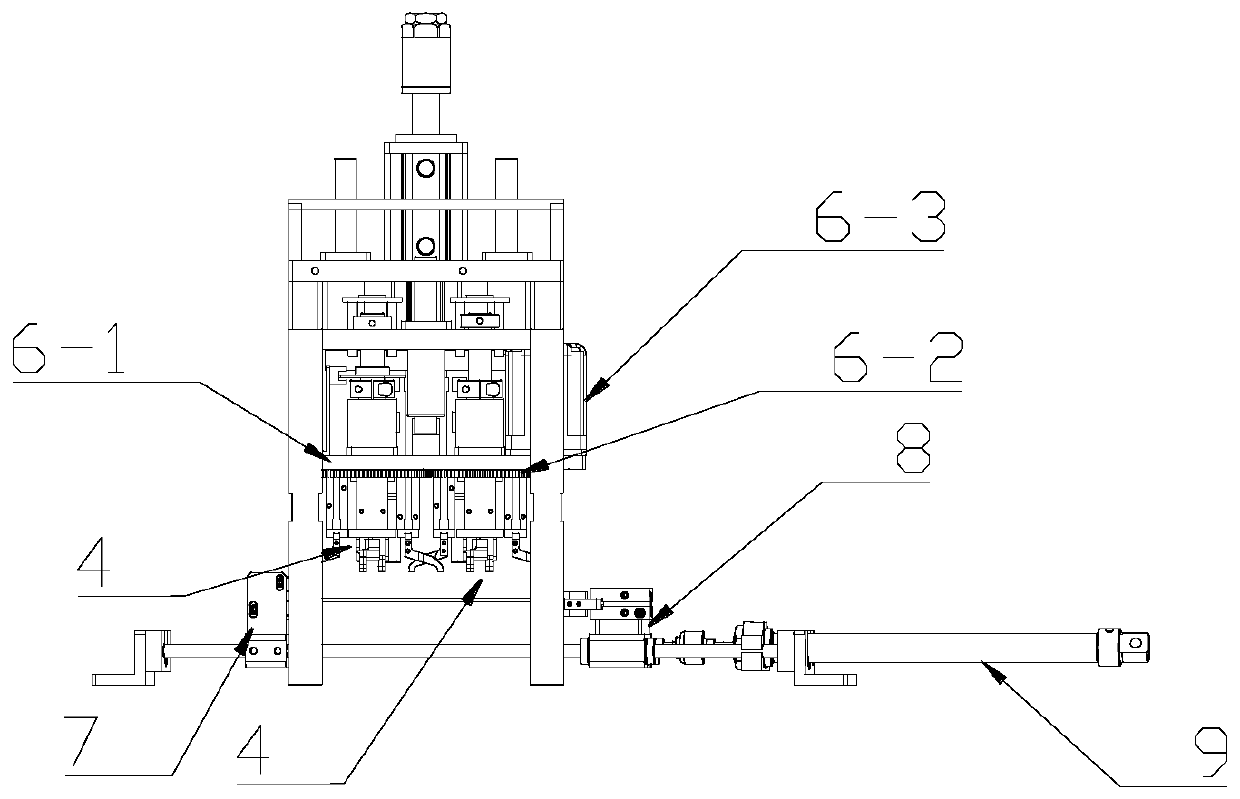

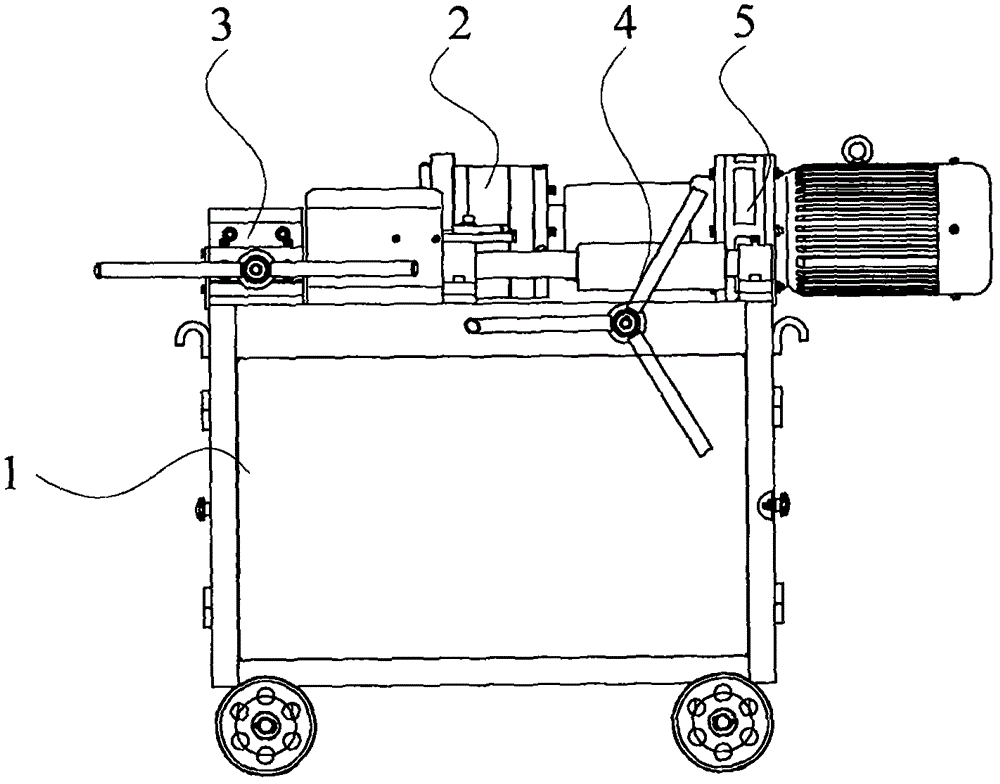

Novel steel bar rib stripping and rolling thread machine tool and machining method thereof

InactiveCN106181410AExtended service lifeLow additional costOther manufacturing equipments/toolsScrew-threads articlesControl systemEngineering

The invention discloses a novel steel bar rib stripping and rolling thread machine tool. The novel steel bar rib stripping and rolling thread machine tool comprises a rack, a rib stripping and thread rolling mechanism, a clamp mechanism, a feeding mechanism, a reducer, an electric appliance control system and a cooling system. The rib stripping and thread rolling mechanism comprises a rib stripping assembly and a thread rolling assembly. The rib stripping assembly comprises a tool body, turning tools and a cutting head body. The turning tools are equidistantly fixed to the tool body in an external fixation mode. The tool body is connected with the cutting head body. The cutting head body is connected with the thread rolling assembly. The clamp mechanism comprises a screw rod, a clamp base, a clamp body and a clamping hand wheel assembly. The clamp body is provided with a clamp opening. The outer side of the screw rod is provided with a left-hand thread and a right-hand thread. According to the novel steel bar rib stripping and rolling thread machine tool of the structure and a machining method of the novel steel bar rib stripping and rolling thread machine tool, one-time axial feeding of the ends of steel bars can be achieved, so that the service life of blades and the service life of a thread rolling wheel are prolonged, the additional cost of connectors is greatly reduced, idle strokes in the steel bar machining process is decreased, the machining speed is increased, meanwhile, the appearance is beautiful, adjustment is convenient, and the automation degree is high.

Owner:保定巨典机械有限公司

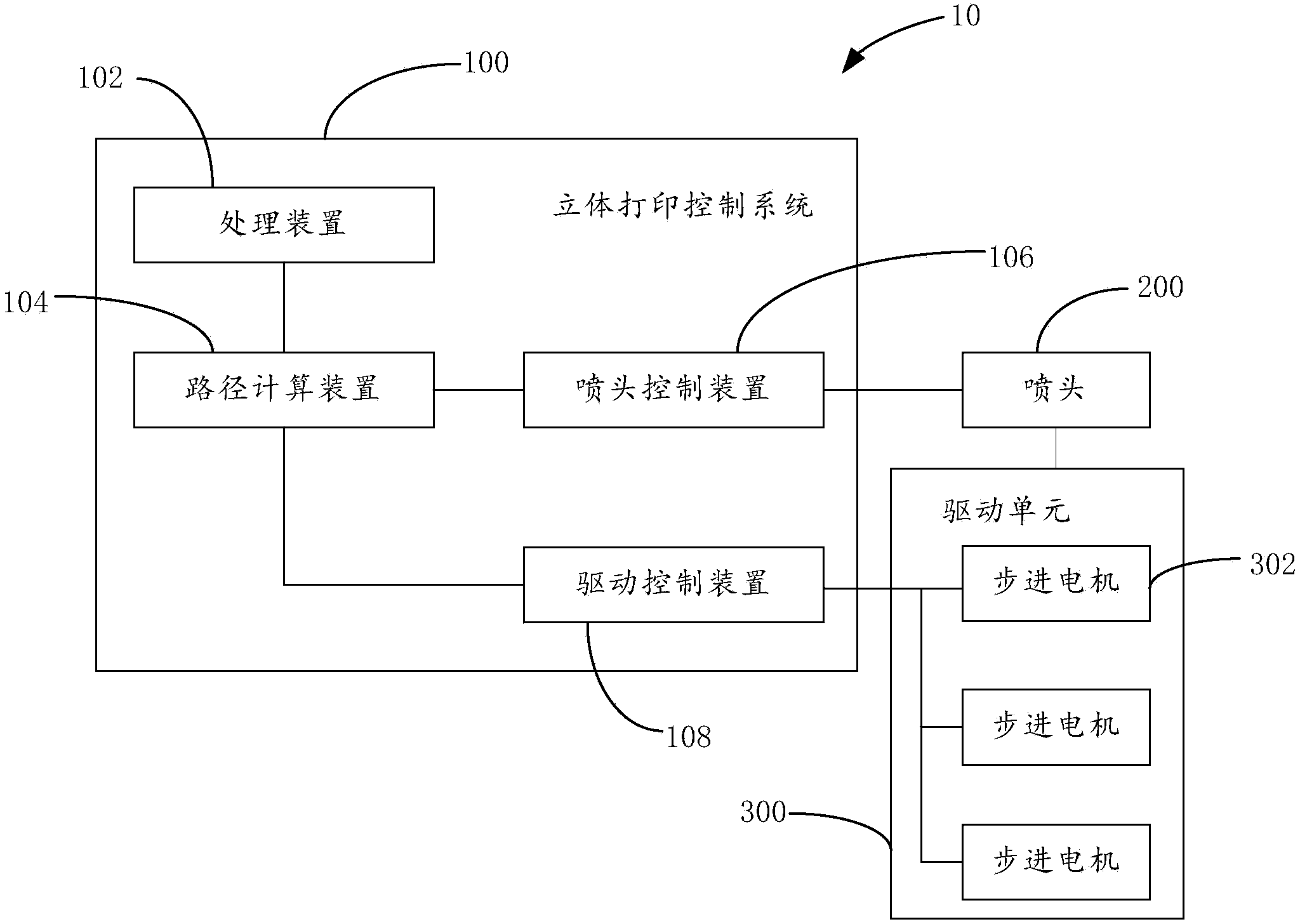

Three-dimensional printing control system and three-dimensional printer

ActiveCN103722898AImprove continuityHigh strengthTypewritersOther printing apparatusControl systemSpray nozzle

A three-dimensional printing control system comprises a processing device, a path generating device, a driving control device and a spraying nozzle control device. The processing device generates a contour line and a plurality of scanning lines, determines the first side end points and the second side end points of the scanning lines inside the contour line and determines the scanning line serving as an alarming line; the path generating device searches for the scanning lines to determine whether a current scanning line is the alarming line and determine whether the current scanning line is a filling scanning line or an auxiliary scanning line to obtain the determining results, according to the results, generates the current scanning line as a filling subpath, or generates the first side end point of the current scanning line into a filling connecting point, or generates the first side end point as a filling dividing point and generates the filling subpath and the connecting paths of all the filling connecting points of two neighboring filling subpaths into a filling path; the driving control device driving spraying nozzles to move according to the filling path; the spraying nozzle control device controls the spraying nozzles to spray out materials according to the filling path and to stop spraying according to the filling dividing points.

Owner:SHINING 3D TECH CO LTD

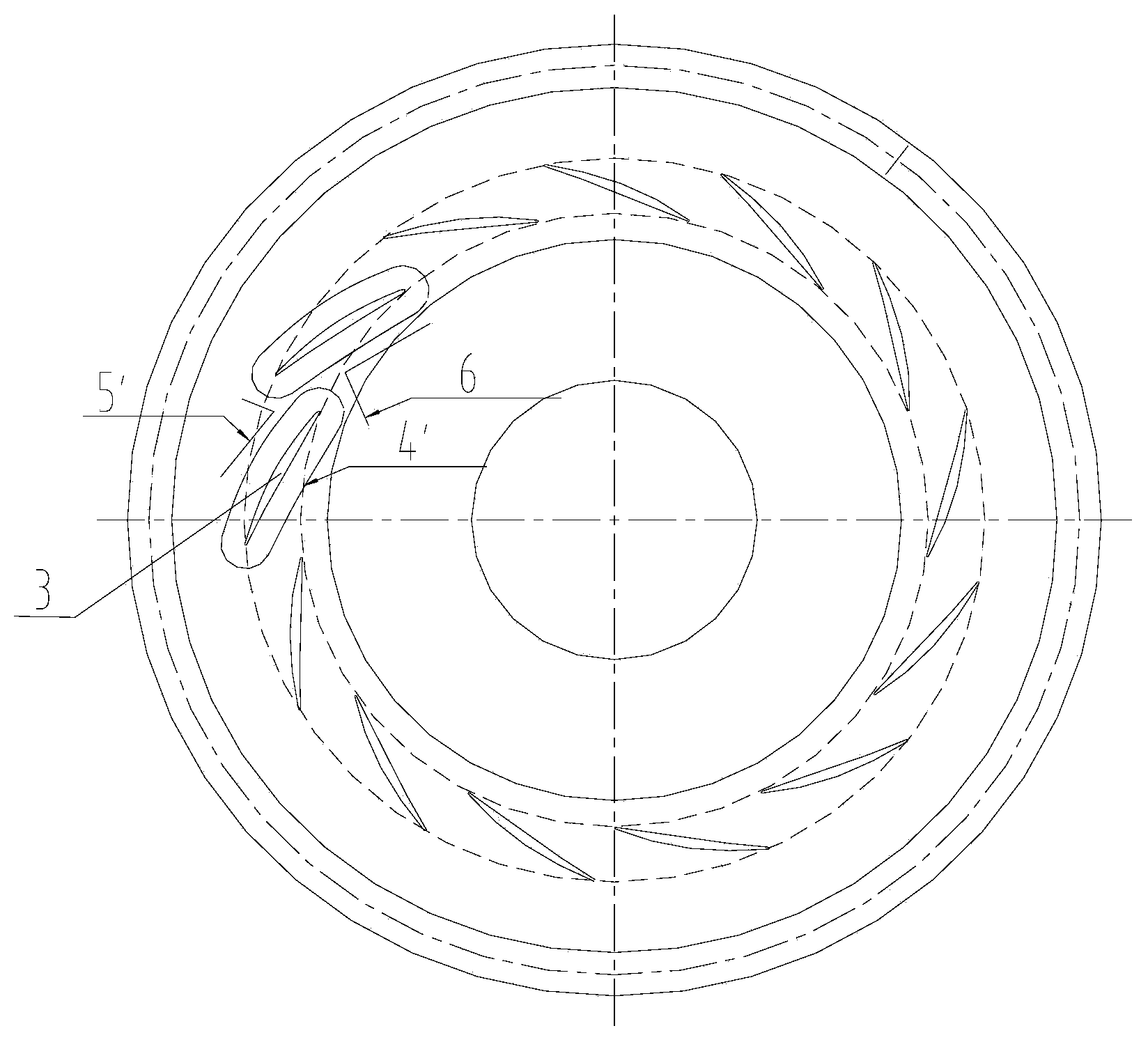

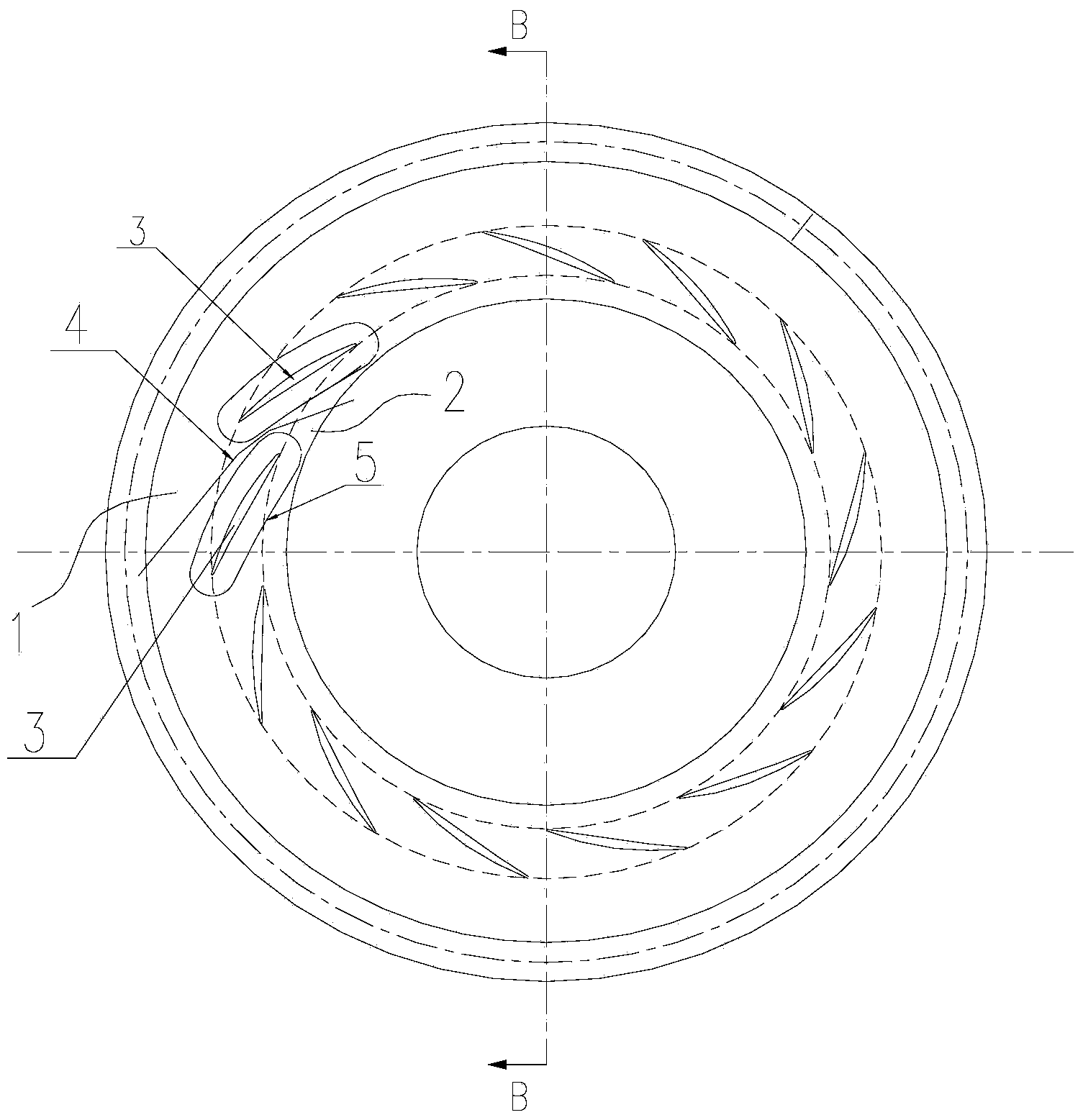

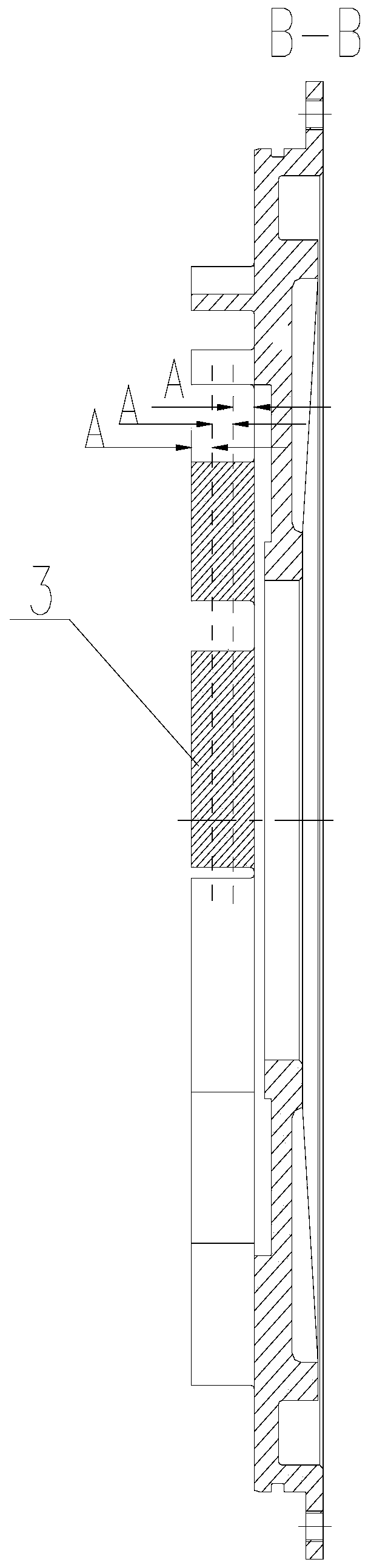

Milling method of diffuser

InactiveCN104227098AExtend your lifeLow costMilling equipment detailsEngineeringMechanical engineering

The invention relates to a milling method of a diffuser. The milling method comprises the following steps: a. with a route from an outlet blade-less section to an inlet blade-less section between two adjacent blades as a first milling route, roughly milling the blades in a layering manner according to the first milling route, and sequentially milling the outlet blade-less sections and the inlet blade-less sections between every two adjacent blades; and b. with a route at the periphery of the blades as a second milling route, milling the margins of the blades in one step according to the second milling route, thus sequentially milling all the blades. By adopting the milling method, the milling quality and milling efficiency of the diffuser can be improved.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

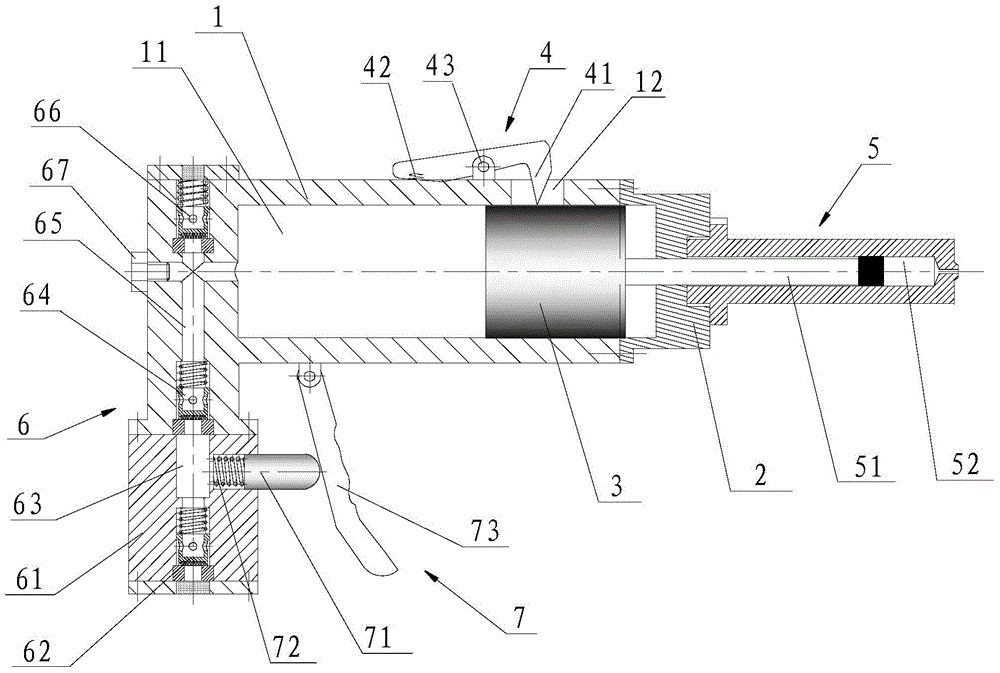

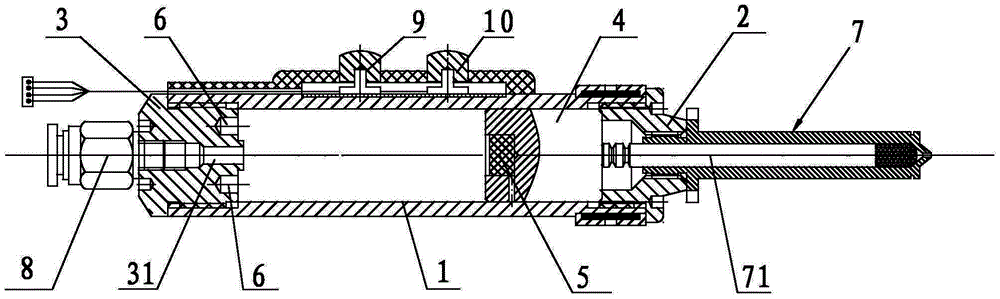

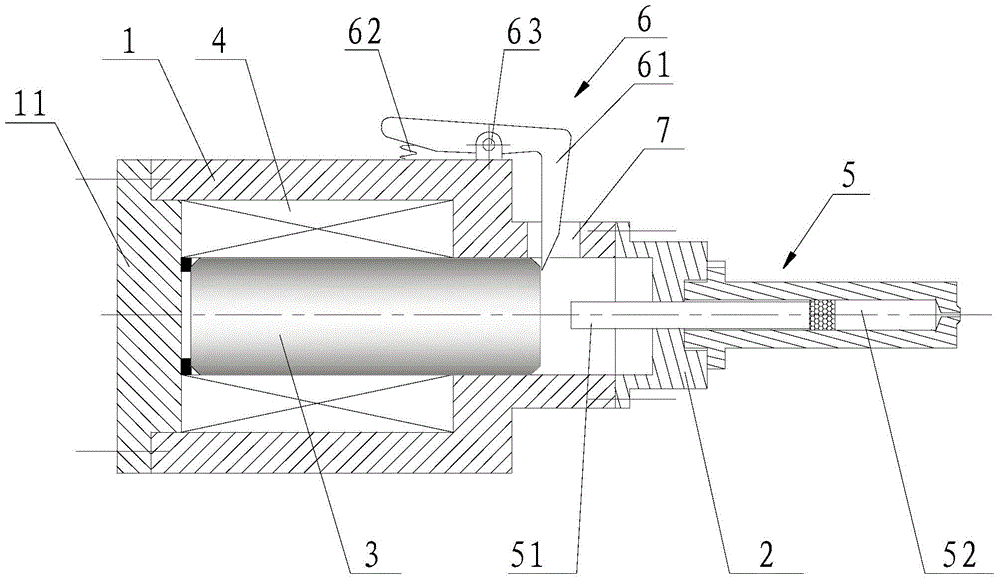

Pneumatic magnetic energy storage needleless syringe

InactiveCN103977484AReduce volumeSimple structureInfusion syringesIntravenous devicesNeedle Free InjectionNeedle free

The invention discloses a pneumatic magnetic energy storage needleless syringe. The syringe comprises a cylinder barrel with an inner cavity, a front end cover fixedly arranged at the front end of the cylinder barrel, a rear end cover fixedly arranged at the rear end of the cylinder barrel, a needleless ampoule assembly arranged on the front end cover and an impact part movably arranged in the inner cavity of the cylinder barrel along the front and back direction; the rear end cover is fixedly provided with a magnet capable of magnetically attracting the impact part; the rear end cover is also provided with an air flow passage communicated with the inner cavity of the cylinder barrel; a seal part capable of plugging the air flow passage is fixedly arranged at the rear part of the impact part; the needleless syringe also comprises an air source device for charging compressed air into the air flow passage; the needleless ampoule assembly at least comprises a piston rod capable of moving front and back. The compressed air is charged into the air flow passage by the air source device, and when the air pressure value in the air flow passage achieves a certain value, the impact part overcomes the magnetic force of the magnet to forwards impact to realize the injection process. The needleless syringe is simple in structure and excellent in manufacturing process and has well use performances.

Owner:ZHANGJIAGANG INST OF IND TECH SOOCHOW UNIV

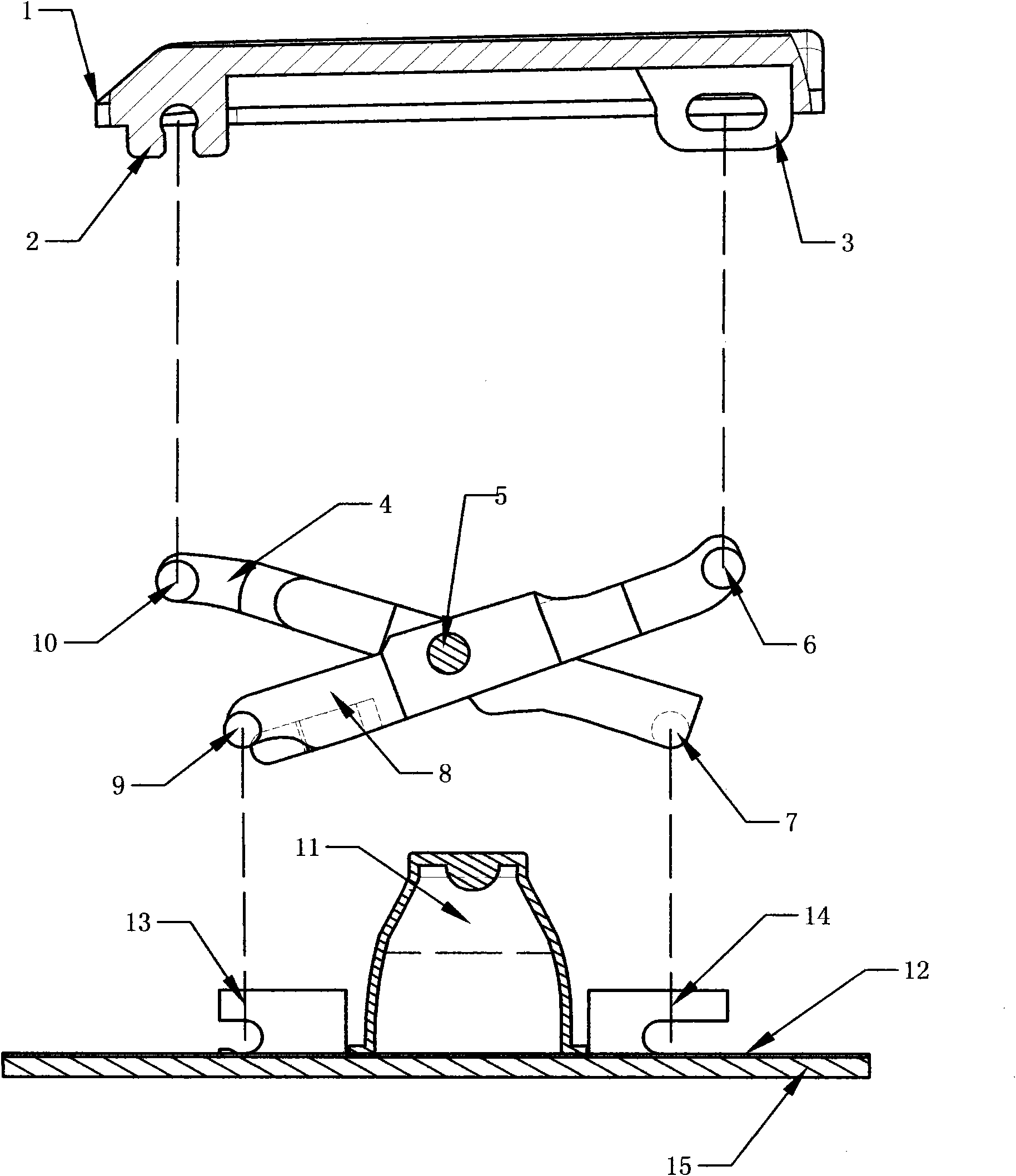

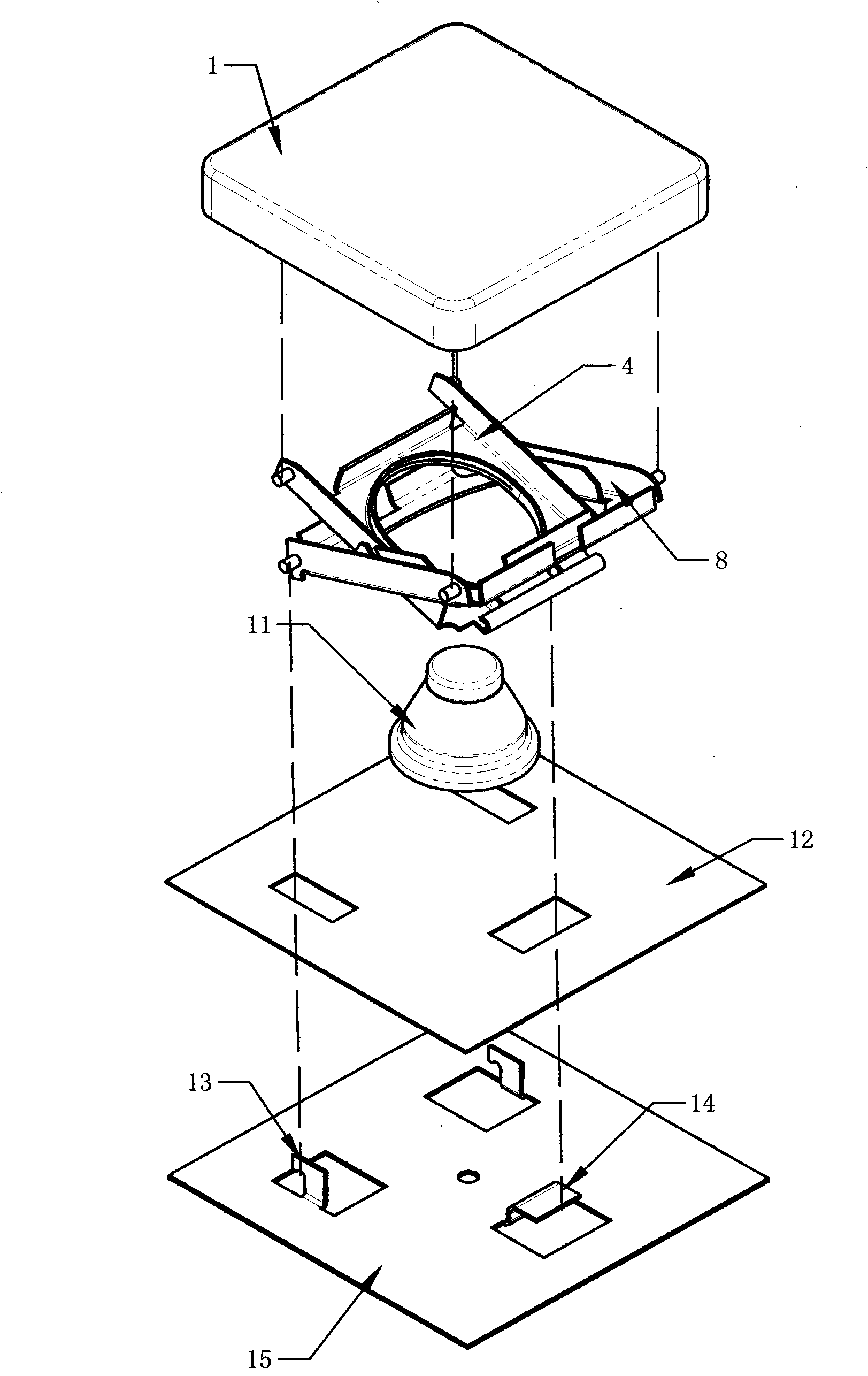

Sheet metal rigid link structure

InactiveCN102856088AIncrease stiffnessHigh strengthContact operating partsEngineeringUltimate tensile strength

The invention discloses a sheet metal rigid link structure which comprises a keycap (1), a rubber elastic ring (11) located between the keycap (1) and a thin film switch piece (12), the thin film switch piece (12) connected with the surface of a support plate (15), the support plate (15), connecting parts through which an inside connecting rod (4) and an outside connecting rod (8) are respectively connected with the keycap (1) and the support plate (15), connecting rod supports respectively formed by linkage between the outside connecting rod (8) and the inside connecting rod (4), and a linkage part which keeps synchronous linkage of the outside connecting rod (8) and the inside connecting rod (4). The sheet metal rigid link structure is characterized in that the structures of the outside connecting rod (8) and the inside connecting rod (4) are respectively that the outside connecting rod face (22) and the inside connecting rod face (18) are respectively connected with two left and right outside connecting rod outward bending edges (25) and two inside connecting rod bending edges (19). The sheet metal rigid link structure is high in structural strength, durable in use, better in hand feeling, high in production efficiency, low in material cost, low in process cost, and low in production energy consumption, and can be widely applied to computer keyboards, and various embedded keyboards.

Owner:陈峰 +1

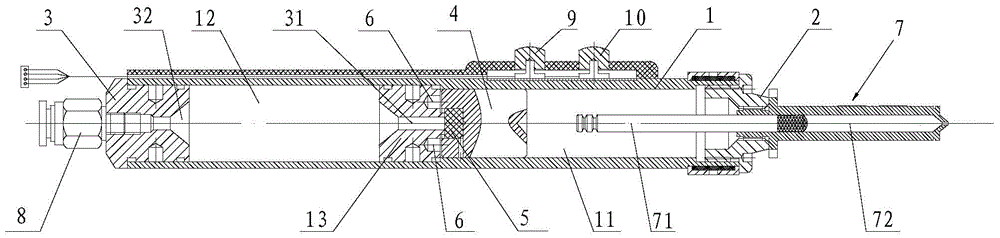

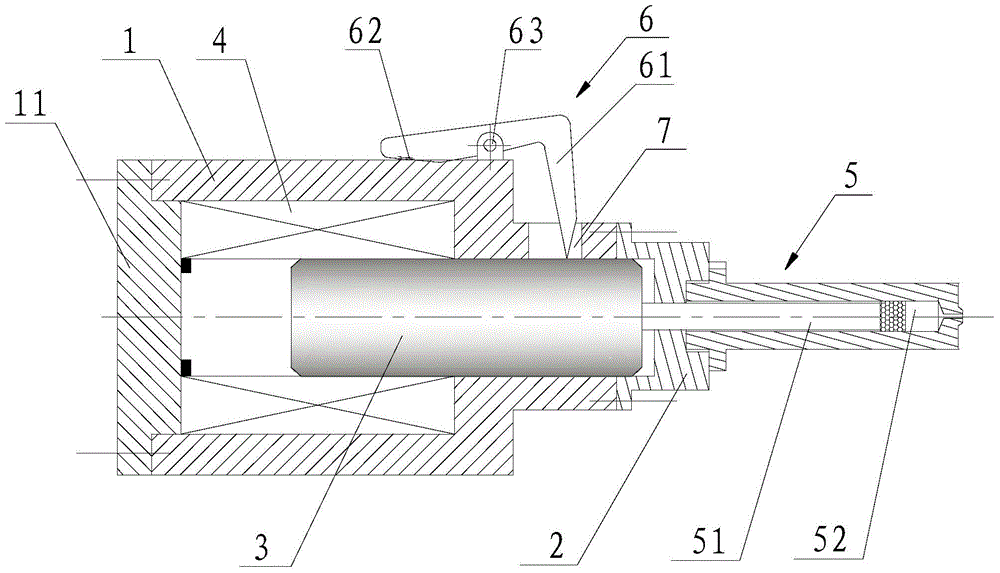

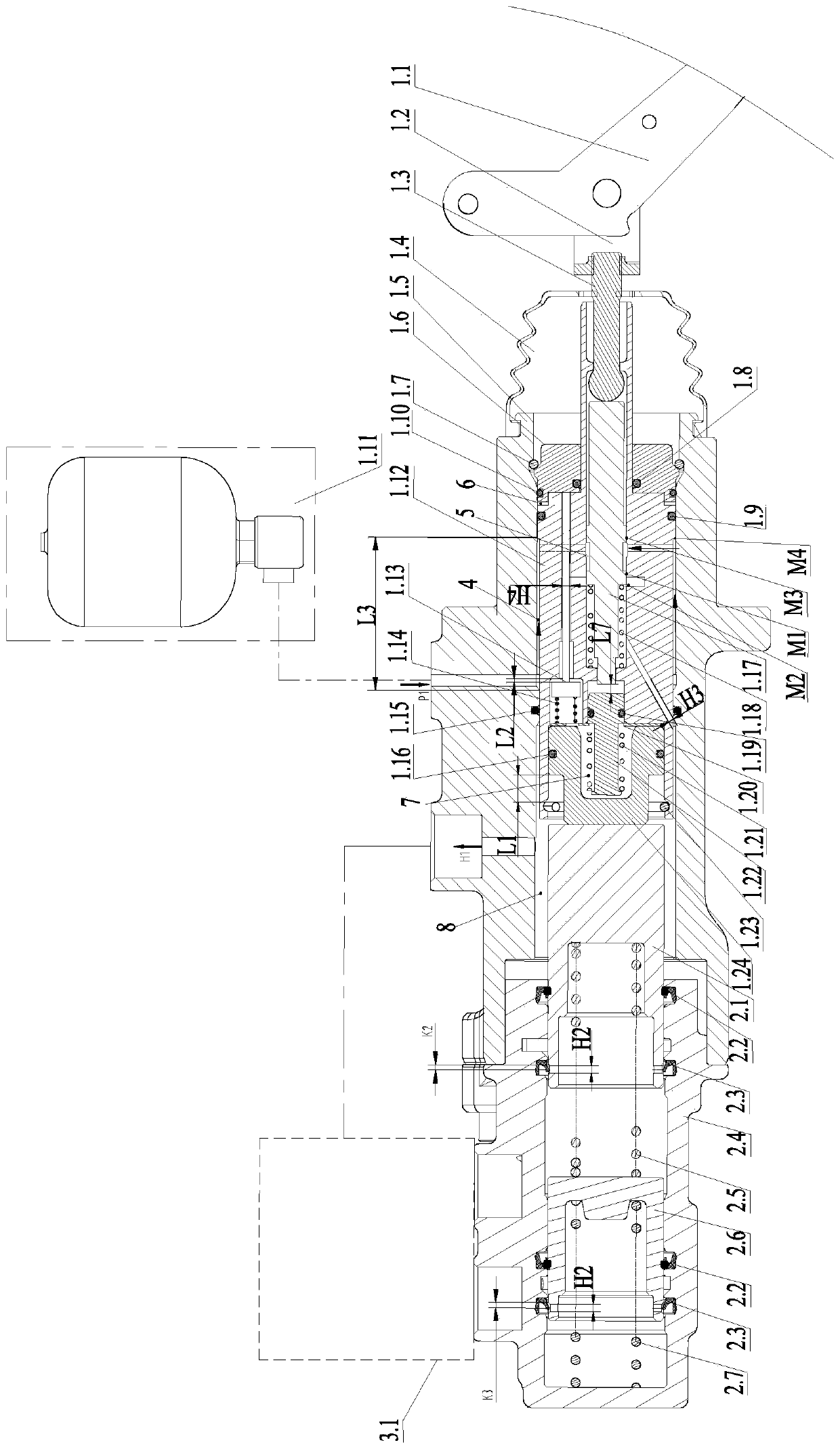

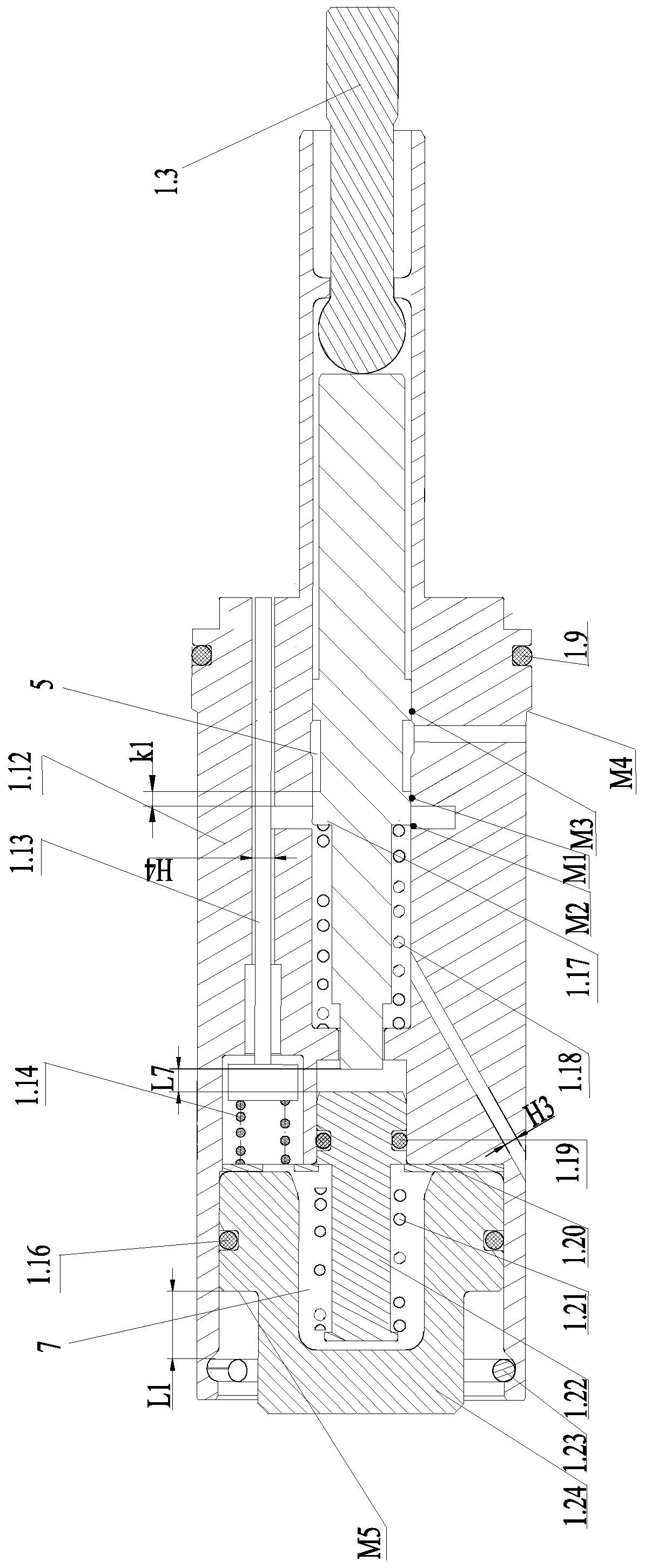

Electromagnetic energy storage type needleless injector

ActiveCN103977483AReduce volumeSimple structureInfusion syringesIntravenous devicesNeedle Free InjectionElectrical control

The invention discloses an electromagnetic energy storage type needleless injector, which comprises an electric control device and an impact injection device, wherein the impact injection device comprises a cylinder barrel with an inner cavity, a front end cover fixedly arranged at the front end of the cylinder barrel, an impact armature movably arranged in the cylinder barrel along the front and back direction of the cylinder barrel, and an electromagnetic coil arranged in the cylinder barrel and used for driving the impact armature to move front and back when being electrified. The impact armature is subjected to energy storage of electricity, after the energy storage is carried out to a certain degree, the impact armature is instantly triggered, the initial acceleration is large, the idle stroke is greatly shortened, and the size of the needleless injector is reduced, and meanwhile, direct current is adopted in the needleless injector, so that safety voltage can be used, and the use is more convenient and safer. The needleless injector is simple in structure, small in size, light in weight and low in manufacturing cost, and can be widely popularized and applied.

Owner:SUZHOU UNIV

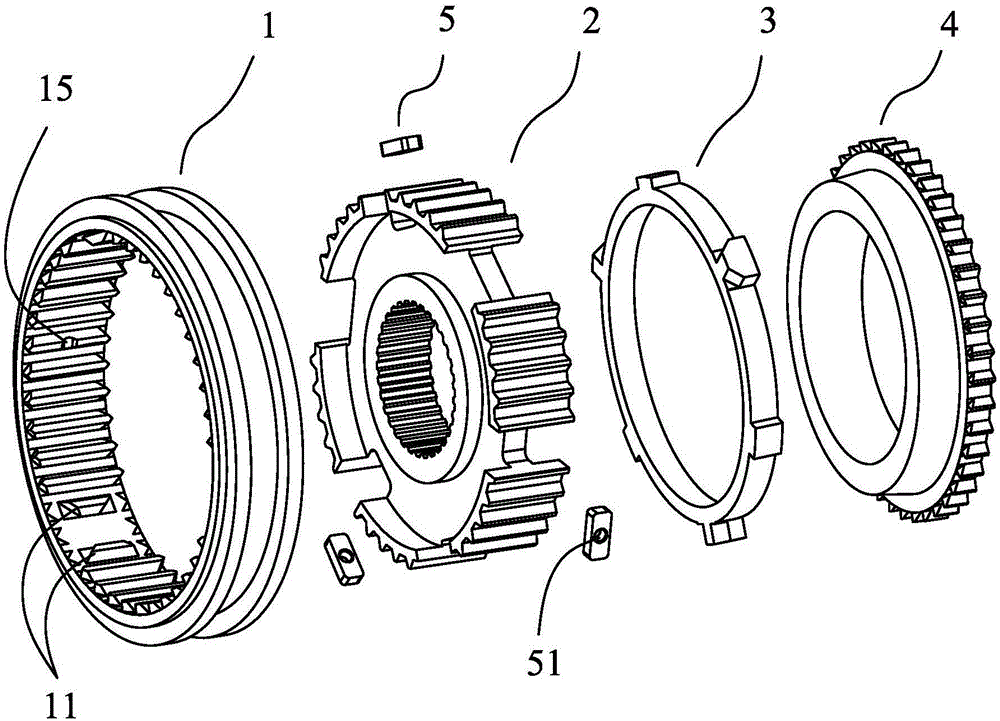

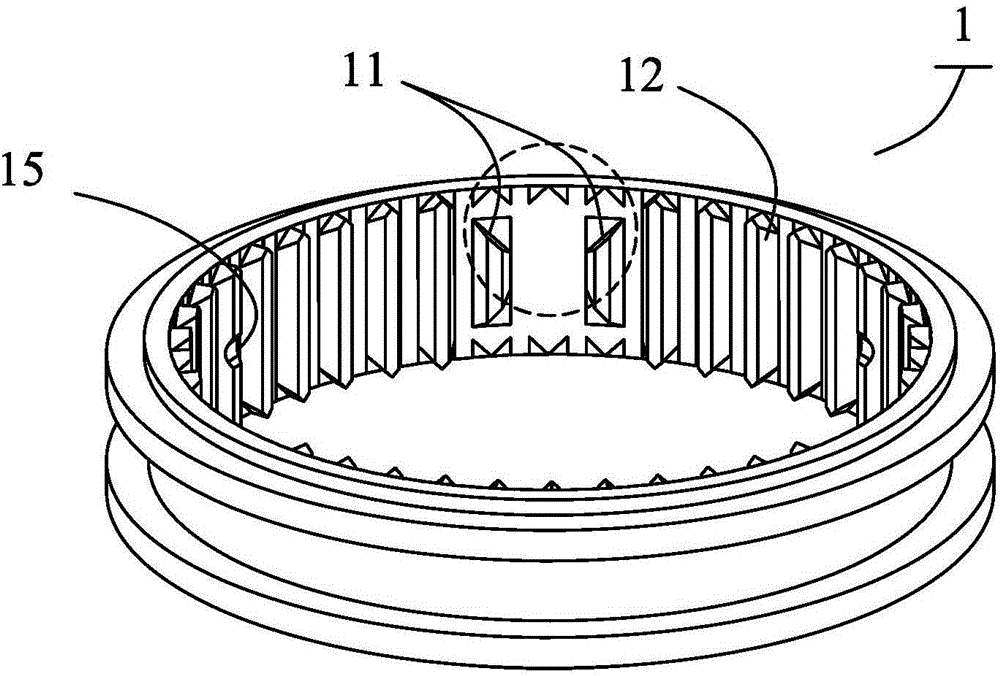

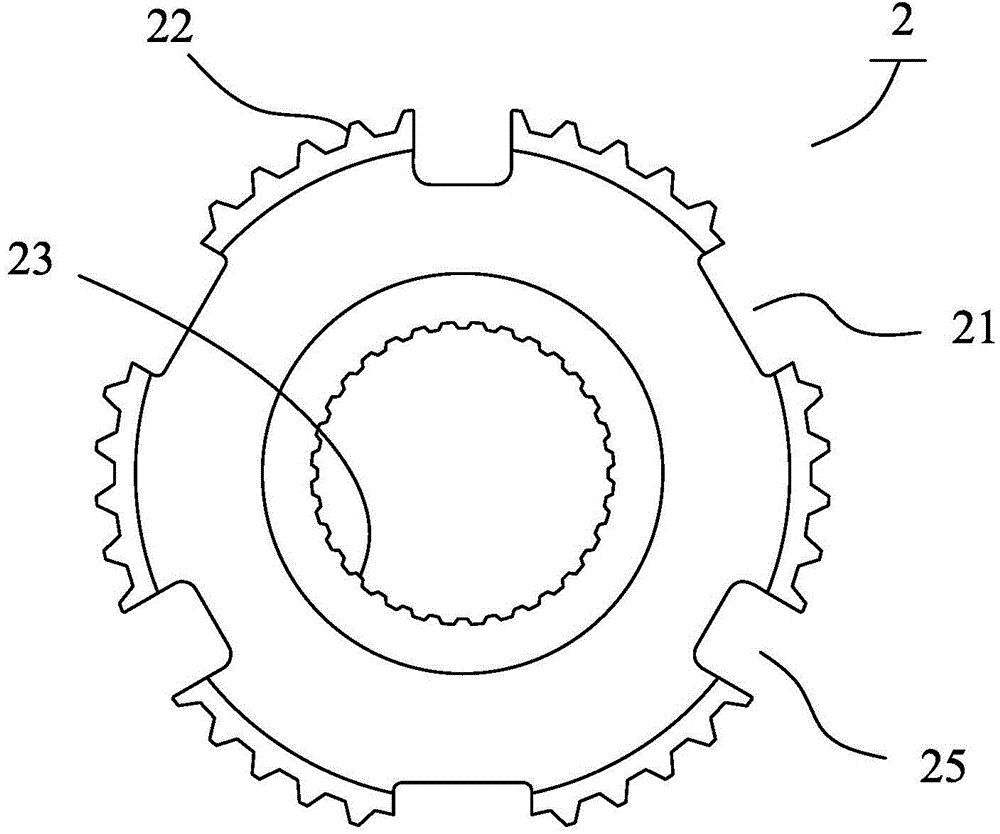

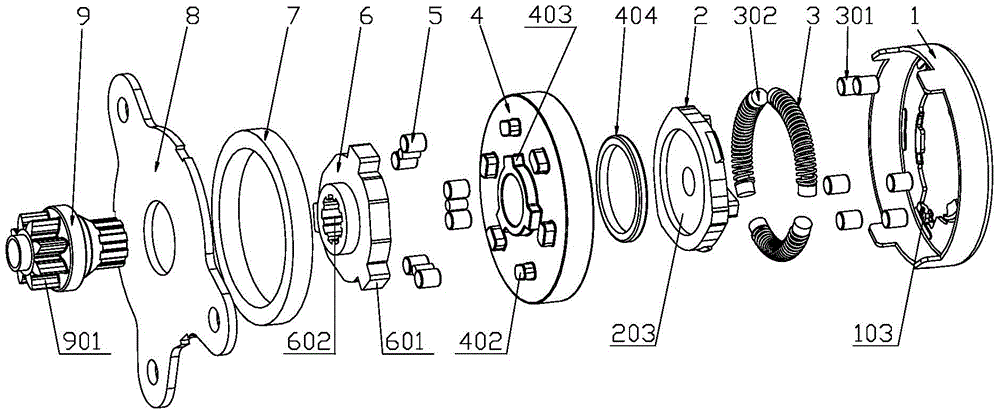

Synchronizer and speed changer

ActiveCN104895950AReduce intensityReduce manufacturing difficultyMechanical actuated clutchesAxial displacementCost Controls

In order to solve the technical problems of longer gear shifting idle stroke, second impact and the like in the prior art, the invention provides a synchronizer and a speed changer. The synchronizer comprises a synchronizer gear sleeve, a synchronizer gear hub, synchronizing rings and combining gears, wherein each synchronizing ring comprises a circular ring body; a locking lug boss is arranged on the outer ring surface of each circular ring body; an axially communicated position avoiding groove is formed in the outer peripheral surface of the synchronizer gear hub; the locking lug boss can move in the axial direction in the corresponding position avoiding groove; one end of the locking lug boss near one side of the synchronizer gear hub is provided with two first locking surfaces; an included angle is formed between the first locking surfaces; the inner peripheral surface of the synchronizer gear sleeve is provided with locking opposite teeth used for locking the locking lug boss; and two second locking surfaces corresponding to the two first locking surfaces are arranged on the end surfaces of the locking opposite teeth. The synchronizer is favorable for cost control; meanwhile, the axial arrangement space of the synchronizer is reduced; the gear shifting secondary impact and the gear shifting noise are reduced; and the scheme is favorable for integral arrangement structure compactness of the speed changer.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

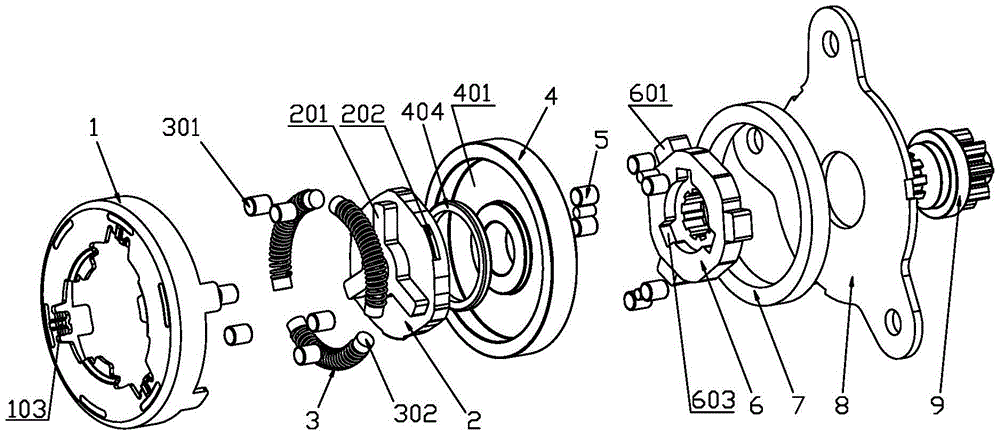

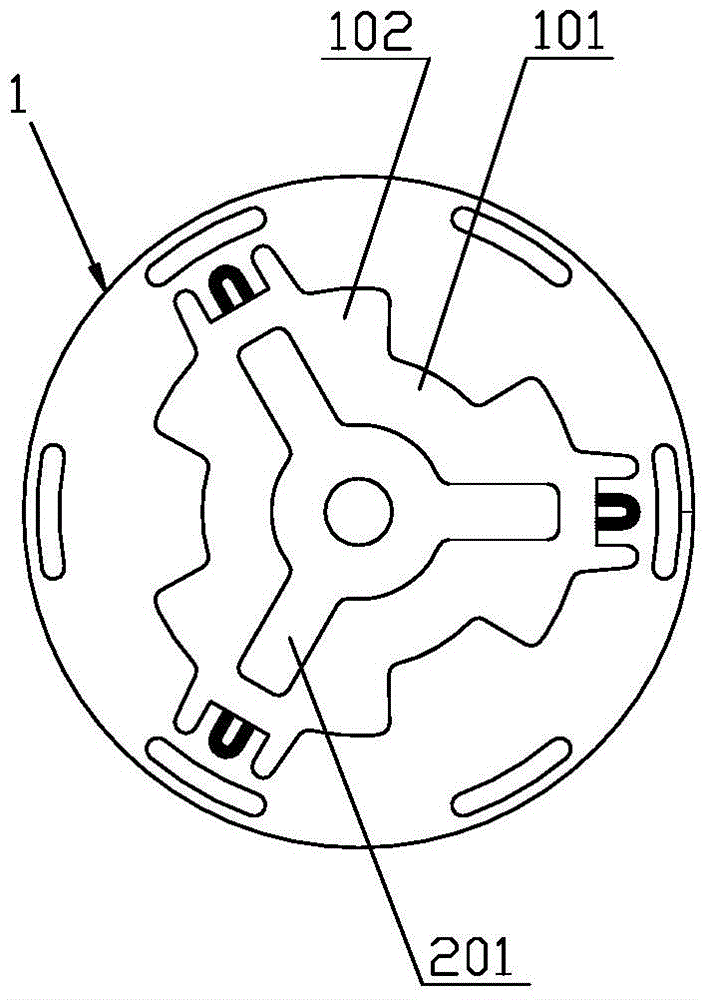

car seat height adjustment mechanism

InactiveCN104723910BEasy to unlockReliable two-way self-lockingMovable seatsWork performanceEngineering

The invention provides a height-regulating mechanism of a vehicle seat. The height-regulating mechanism of the vehicle seat comprises a first bidirectional overrunning clutch and a second bidirectional overrunning clutch which use a pusher dog disc in common. The first bidirectional overrunning clutch comprises a first transmission star wheel, the outer side surface of the first transmission star wheel comprises three sections of first arc surfaces and three sections of second arc surfaces which are arranged circumferentially at intervals, and one first arc surface and one second arc surface are connected through a first arc wedge surface. Springs are respectively arranged between one first arc surface and a circular groove wheel of the pusher dog disc, and two ends of each spring is provided with a roller which is clamped between the first arc wedge surface and the circular groove wheel. The second bidirectional overrunning clutch comprises a second transmission star wheel, the outer side surface of the second transmission star wheel comprises three sections of third arc surfaces and three sections of planes which are arranged circumferentially at intervals, and a third arc surface is connected with the planes through a second arc wedge surface. A pin roller which is clamped between the second arc wedge surface and the inner side surface of the output end shell under the function of an elastic element is arranged between each pusher dog of the pusher dog disc. The height-regulating mechanism of the vehicle is good in self-locking performance, stable in working performance, and high in control precision.

Owner:上海交运汽车精密冲压件有限公司

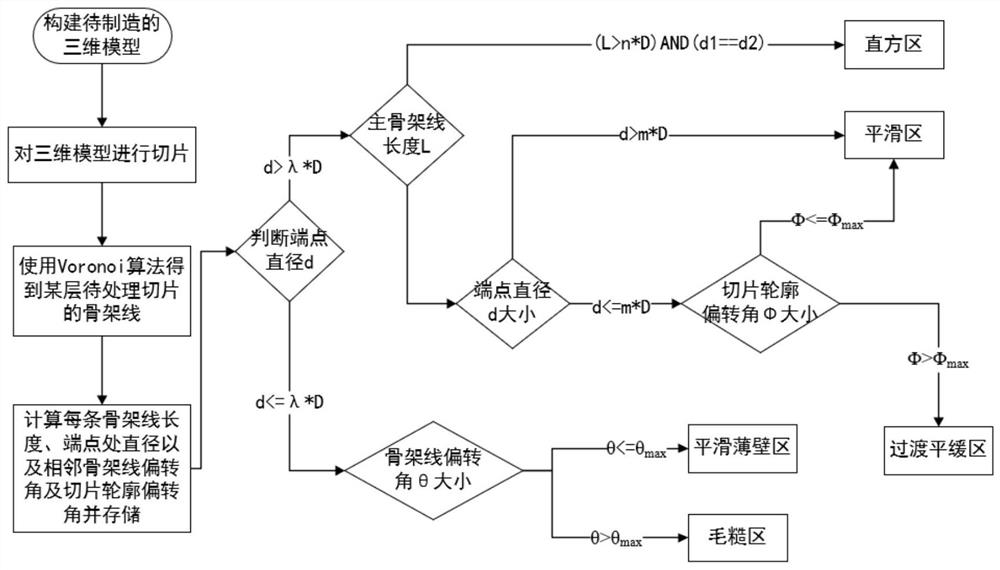

3D printing forming method based on skeleton line contour recognition and area segmentation

ActiveCN113478833AHigh forming precisionTo achieve the effect of adapting measures to "area" conditionsAdditive manufacturing apparatusIncreasing energy efficiencyComputer visionDeflection angle

The invention belongs to the technical field related to 3D printing, and discloses a 3D printing forming method based on skeleton line contour recognition and area segmentation. The method comprises the following steps: S1, calculating a skeleton line in each slice layer forming contour; S2, calculating and solving the length of the main skeleton line, the diameter of the end point of each skeleton line, the deflection angle between every two adjacent skeleton lines and the deflection angle between every two adjacent edges in each forming contour; S3, dividing the area types in each forming contour into a straight square area, a smooth area, a transition smooth area, a smooth thin-wall area and a rough area, establishing an area division standard by multiple parameter values obtained through calculation in the step S2, and dividing the areas in each forming contour; and S4, planning a forming path of each area for 3D printing forming. According to the method, the problems of contour recognition and segmentation of complex contour parts are solved, and a complex path planning method with high efficiency and high robustness is provided.

Owner:HUAZHONG UNIV OF SCI & TECH

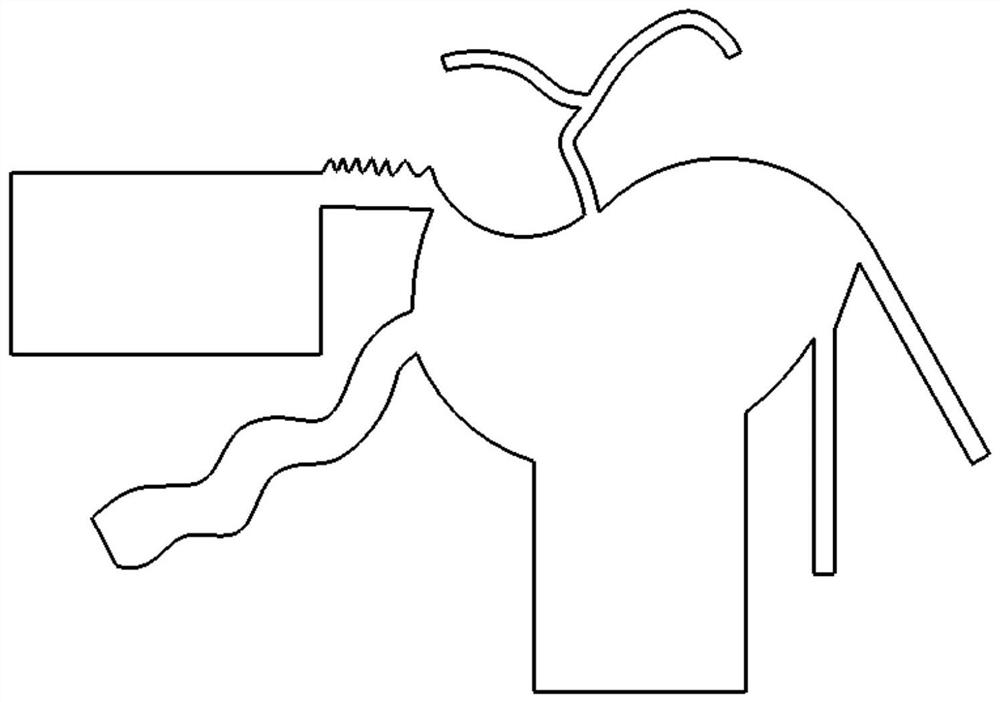

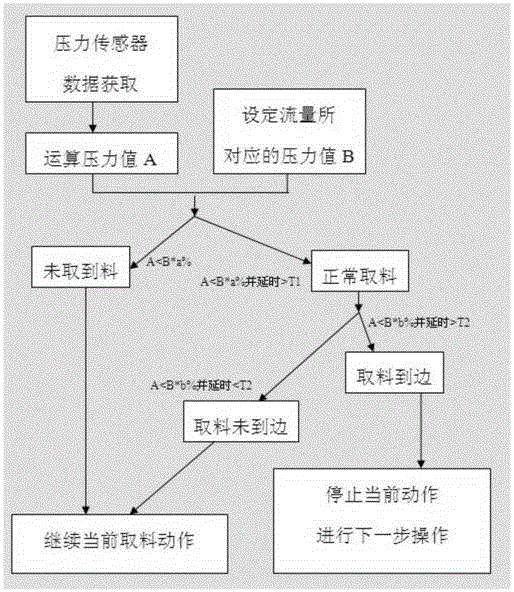

Material taking rotation boundary judgment and control system and method for bucket wheel machine

PendingCN105836419ASafe unmanned automatic operationAccurate unmanned automatic operationControl devices for conveyorsTotal factory controlInternal pressureControl system

The invention relates to a material taking rotation boundary judgment and control system and method for a bucket wheel machine. The system comprises a pressure sensor, a signal collection remote station and a single-machine controller. The pressure sensor is connected with the signal collection remote station through a signal cable, and the signal collection remote station is connected with the single-machine controller through a communication cable. The method comprises the steps that firstly, the internal pressure of a bucket wheel hydraulic pressure of a material taking machine is acquired by the pressure sensor; secondly, pressure data are acquired by the signal collection remote station and transmitted to the single-machine controller; and thirdly, the pressure data are converted by the single-machine controller into a pressure value, the pressure value is compared with a preset pressure value, and whether the actual material stacking boundary is achieved or not is judged. According to the material taking rotation boundary judgment and control system and method, the material taking machine can carry out unmanned automatic operation safely, accurately and efficiently, meanwhile, idle running of the material taking machine in the operation process is reduced, and the material taking efficiency is improved.

Owner:INSTALLATION ENG CO LTD OF CCCC FIRST HARBOR ENG

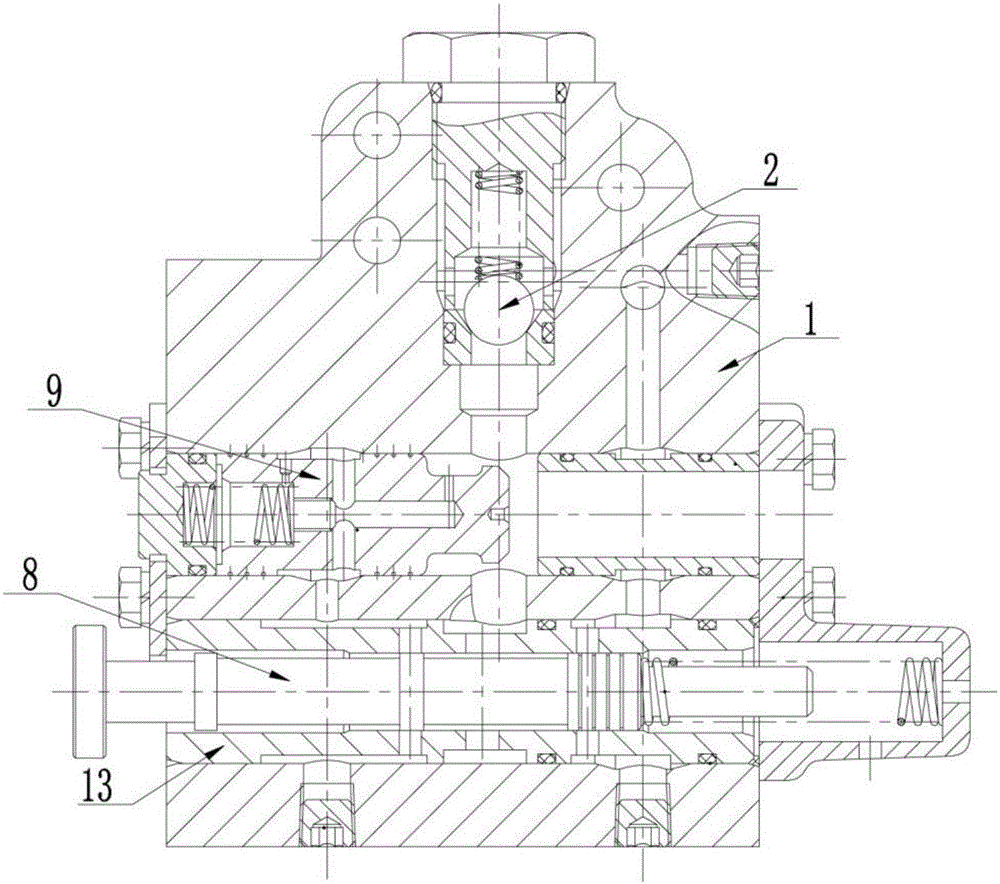

Built-in hydraulic distributor

ActiveCN106015146AReduce idle travelHigh sensitivityServomotor componentsServometer circuitsEngineeringCheck valve

The invention discloses a built-in hydraulic distributor which comprises a distributor shell and a main control valve, an oil return valve and a check valve which are arranged in the shell; an oil inlet, an oil cylinder oil inlet and an oil return opening are formed in the distributor shell; a lowering valve is arranged in a main control valve hole; a lowering valve compressing sleeve and a lowering valve adjusting bolt are arranged at the right side of the lowering valve; the lowering valve is arranged at the right side of the main control valve; the oil cylinder oil inlet communicates with the oil inlet chamber of the lowering valve by an oil cylinder oil drainage oil line; the oil outlet chamber of the lowering valve communicates with the oil return opening; the lowering valve comprises a lowering valve core and a lowering valve seat; the lowering valve compressing sleeve compresses the lowering valve seat; and the lowering valve adjusting bolt compresses on the lowering valve compressing sleeve. The built-in hydraulic distributor can improve the lowering and lifting sensitivity, and the hydrostatic sedimentation value of a hydraulic lifter is ensured by the sealing state of the lowering valve and the check valve, thus being more reliable, good in airtightness, steady in use performances, high in reliability, and convenient to dismantling and maintenance.

Owner:SHANDONG HONGYU AGRI MACHINERY

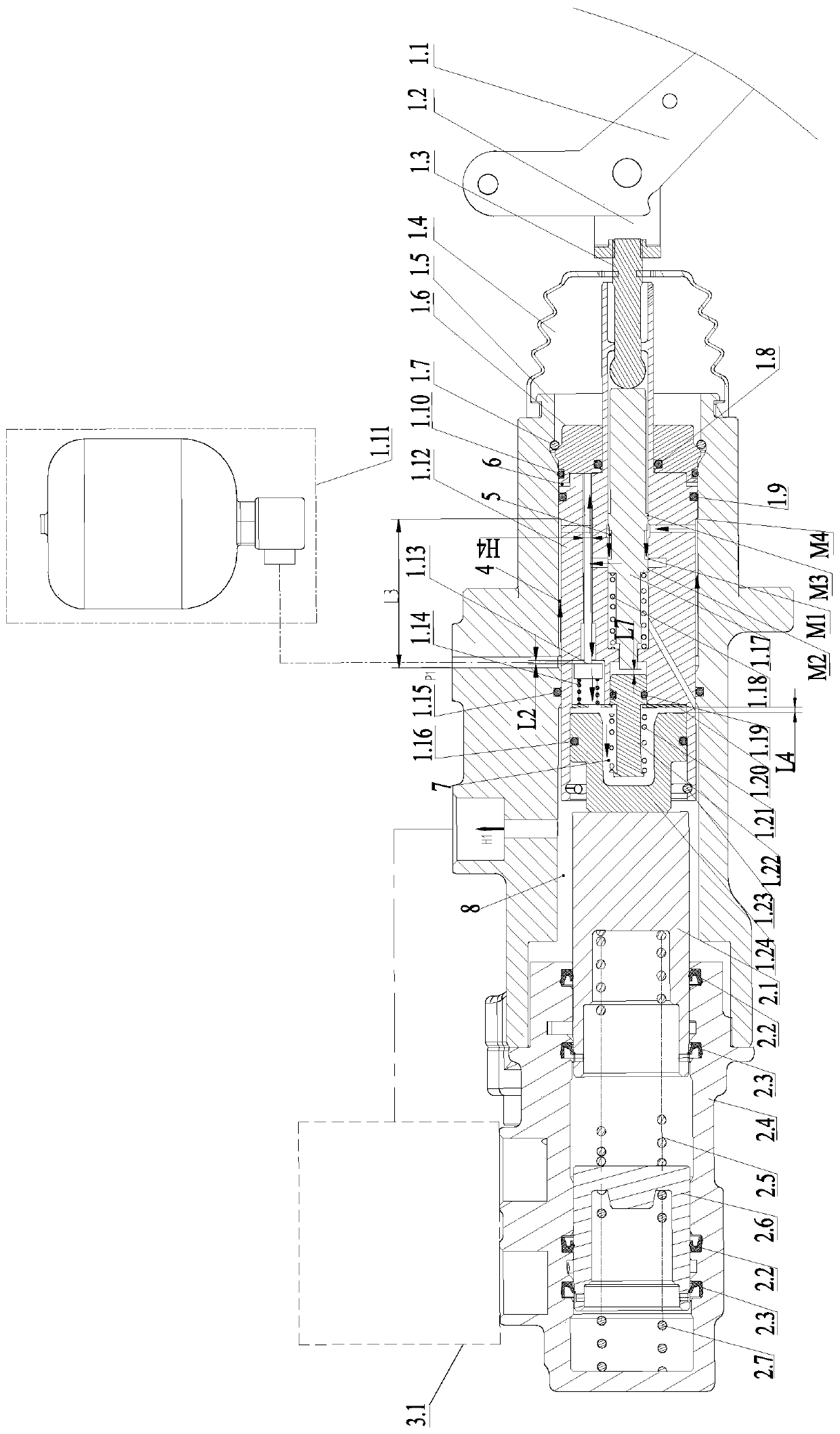

Hydraulic booster assembly device with pre-filling function

PendingCN110171407ACompact structureIncrease empty travelBraking action transmissionMaster cylinderEngineering

The invention relates to the technical field of booster devices applied to an automobile braking system, in particular to a hydraulic booster assembly device with a pre-filling function. A pre-fillingmechanism with the pre-filling function is added on the basis of a traditional hydraulic booster assembly device, the pre-filling mechanism includes a pre-filling piston, high hydraulic pressure doesnot directly push a power assisting piston to move to achieve power assistance, but firstly pressure is prefilled to the pre-filling piston to push a braking main cylinder, and empty travel of the braking main cylinder is eliminated; after the pre-filling piston moves to the pre-filled travel, the booster piston assembly starts to move to ensure continuous pressure of the braking main cylinder. According to the hydraulic booster assembly device with the pre-filling function, the empty travel of the hydraulic booster assembly is effectively reduced, the brake foot sense is greatly improved; available power assisting travel is increased, the structure is more compact and the requirements of different travel can be met to be matched with the braking main cylinder; and at the same time, basicbraking characteristics remain unchanged and can be applied to braking power assistance of the whole system.

Owner:广州电通博华汽车制动系统有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com