3D printing forming method based on skeleton line contour recognition and area segmentation

A 3D printing and area segmentation technology, applied in 3D printing related fields to achieve the effect of high forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

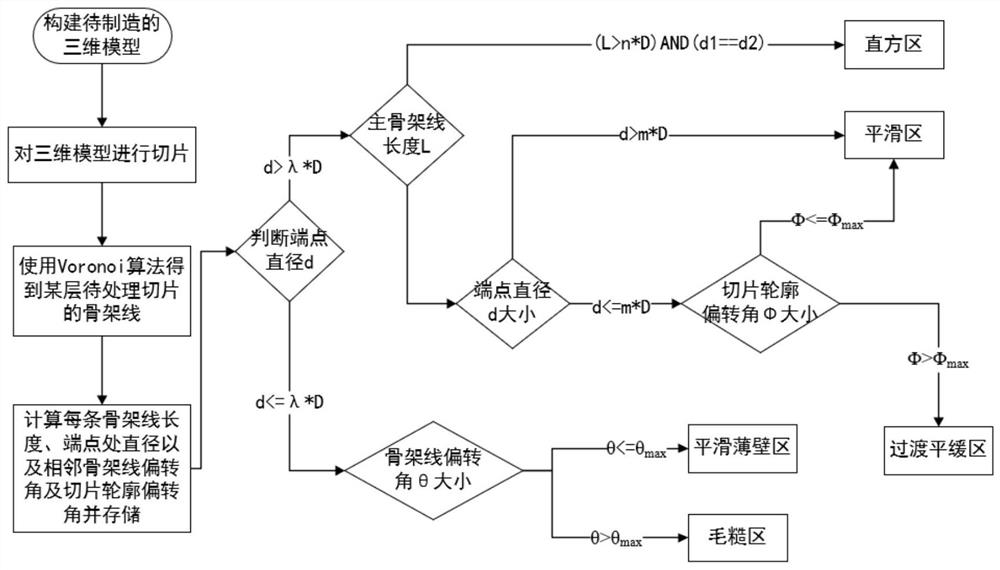

[0051] For this example, the calculation method is: (1) the length of the skeleton line is the distance between the two endpoints; (2) the diameter at the endpoint is the minimum distance between the endpoint and the slice contour. For the center circle, the diameter of the circle is incremented. When the outline segment appears in the circle for the first time, the straight-line distance between the calculated line segment and the end point is the diameter d of the end point; (3) The deflection angle between the two skeleton lines The calculation method is: find two skeleton lines L1 and L2 with the same end point, the end point is P, the other end point of L1 is P1, and the other end point of L2 is P2, then the supplementary angle of ∠P1PP2 on the extension line of P1P That is the deflection angle; (4) The deflection angle between two adjacent sides of a certain point on the original contour is the same as the calculation method of (3) above.

[0052] (e) Identify each regio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com