Patents

Literature

948 results about "Industrial machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

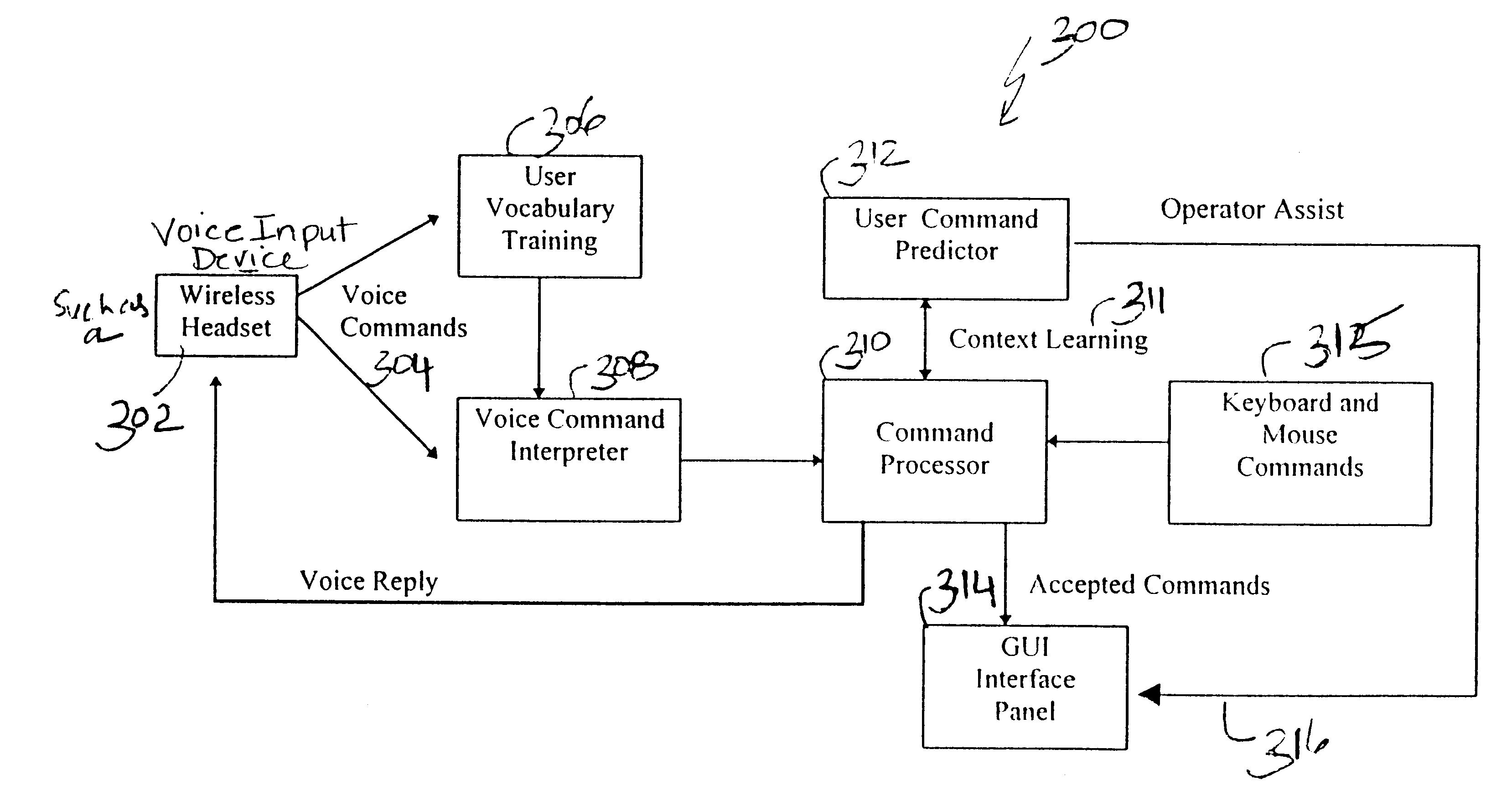

Voice actuation with contextual learning for intelligent machine control

InactiveUS6895380B2Reduce probabilityImprove robustnessFlow propertiesMeasurement arrangements for variableHuman–computer interactionTensile testing

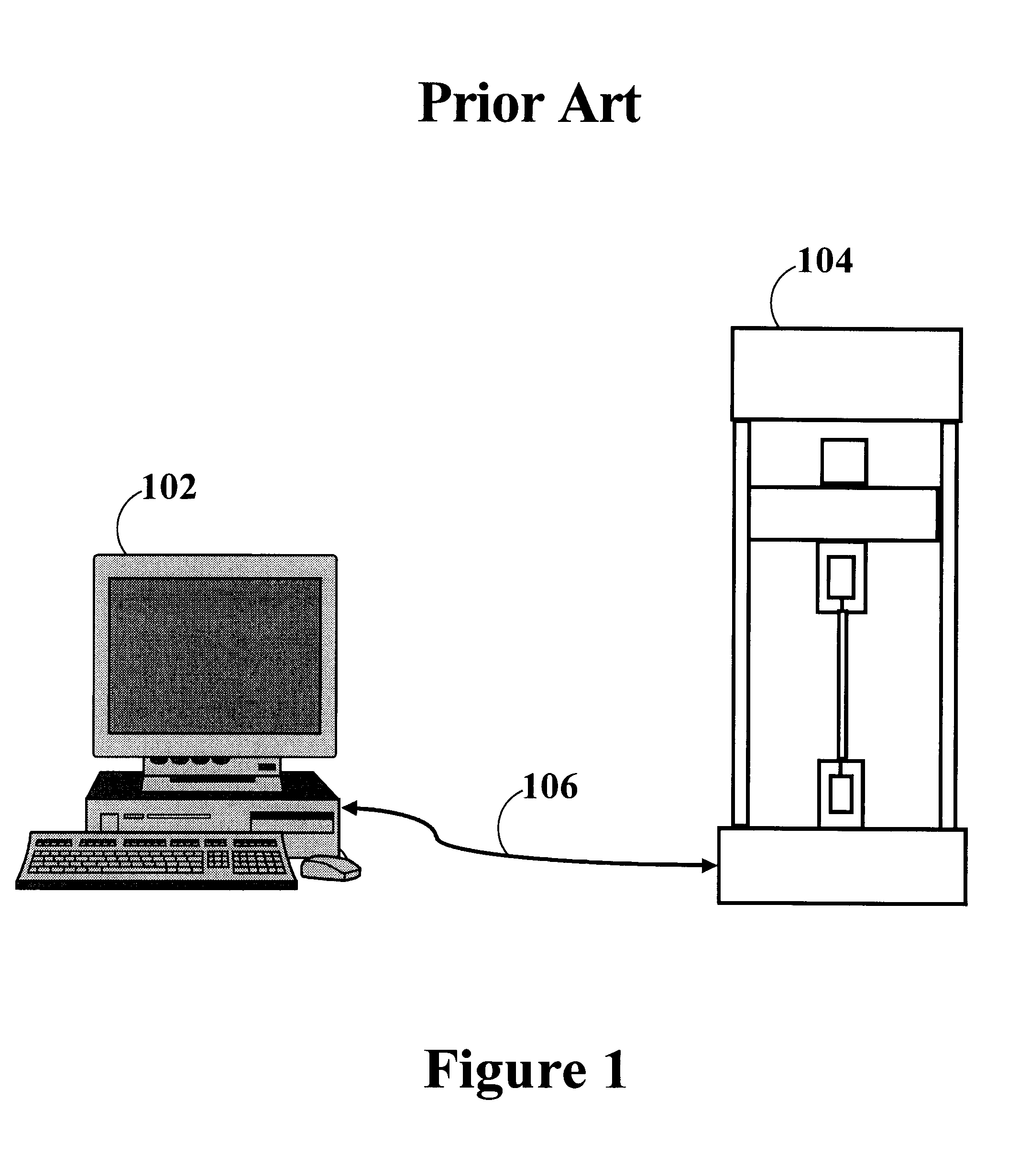

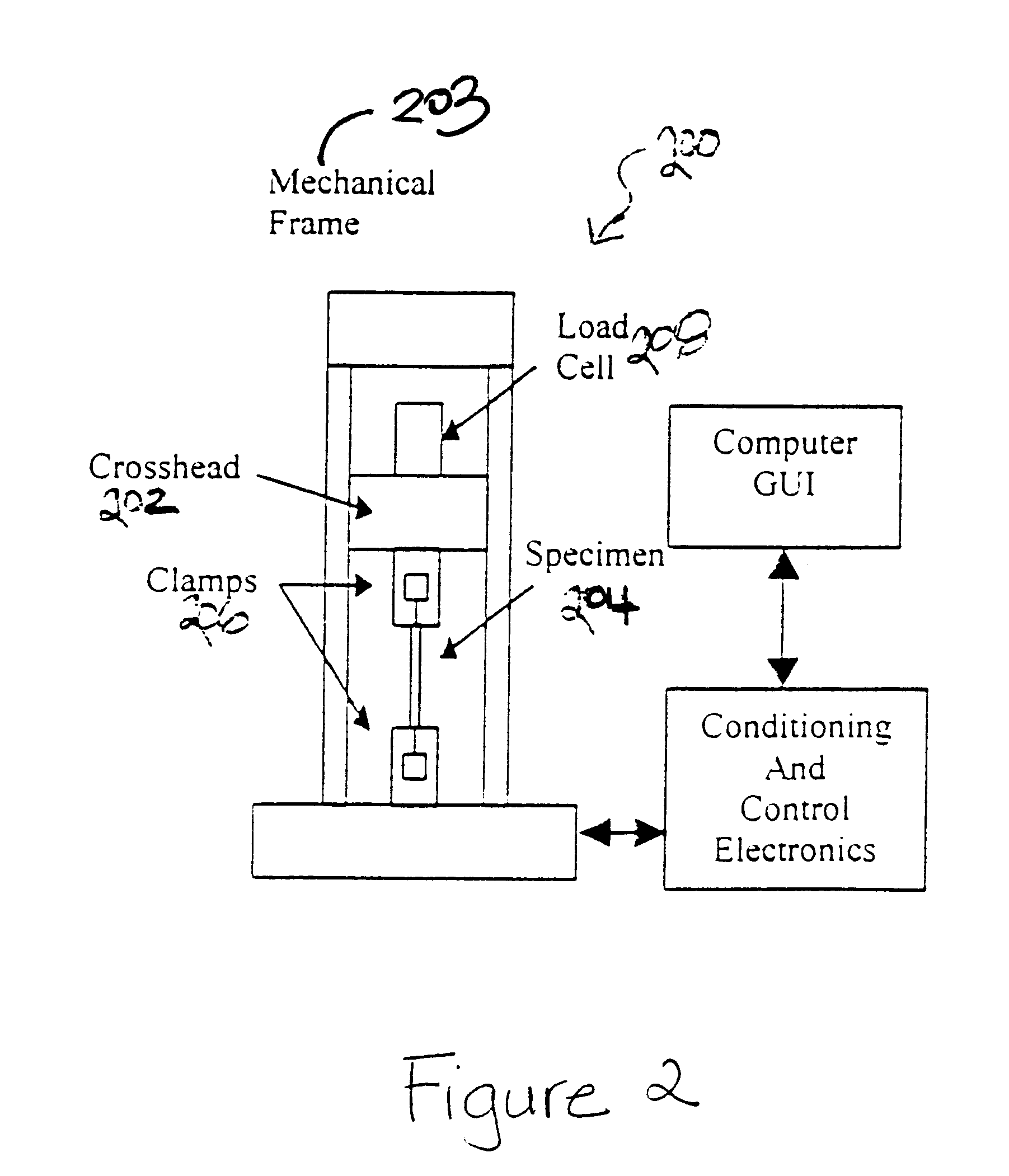

An interactive voice actuated control system for a testing machine such as a tensile testing machine is described. Voice commands are passed through a user-command predictor and integrated with a graphical user interface control panel to allow hands-free operation. The user-command predictor learns operator command patterns on-line and predicts the most likely next action. It assists less experienced operators by recommending the next command, and it adds robustness to the voice command interpreter by verbally asking the operator to repeat unlikely commanded actions. The voice actuated control system applies to industrial machines whose normal operation is characterized by a nonrandom series of commands.

Owner:ELECTRO STANDARDS LAB

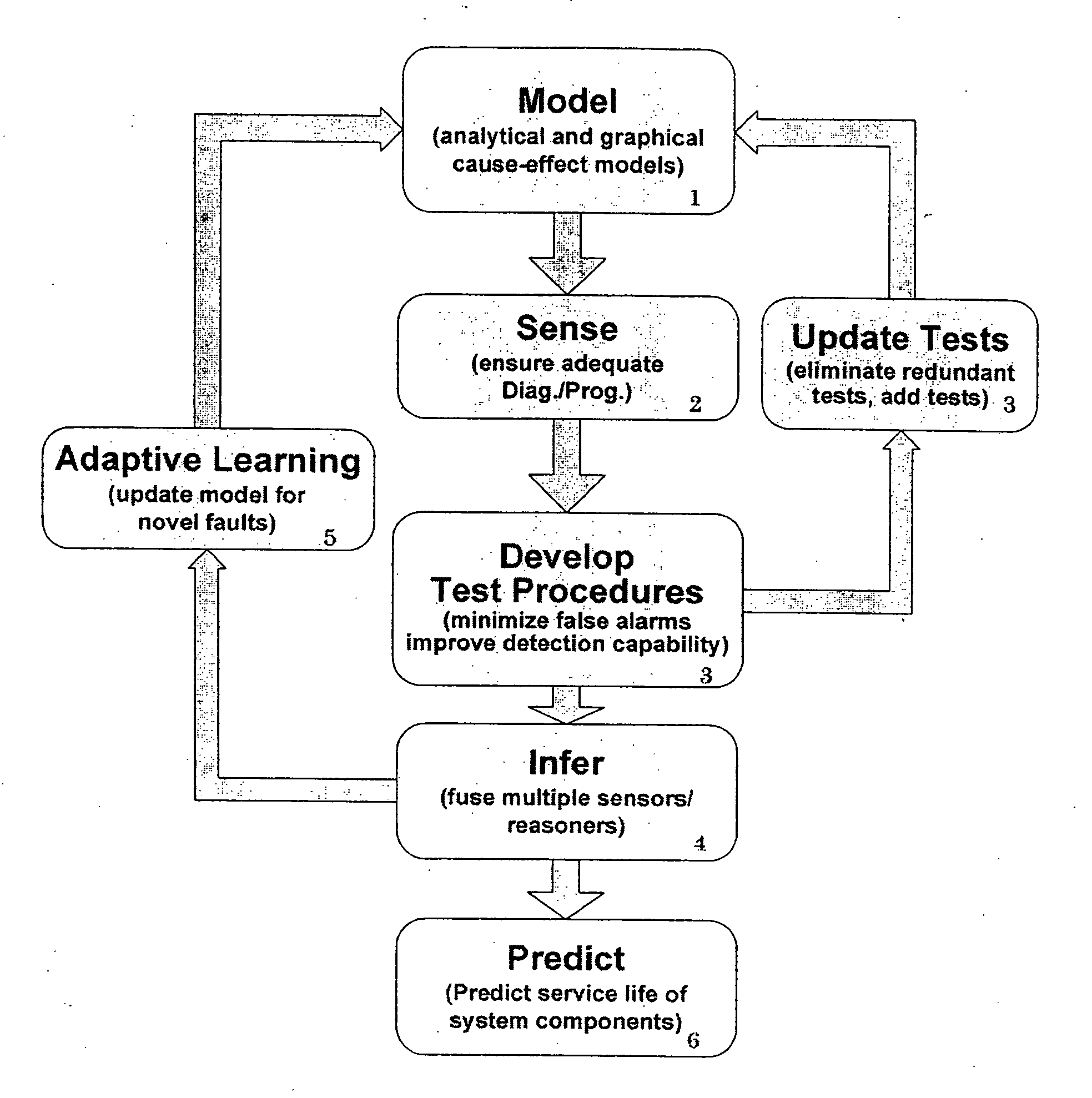

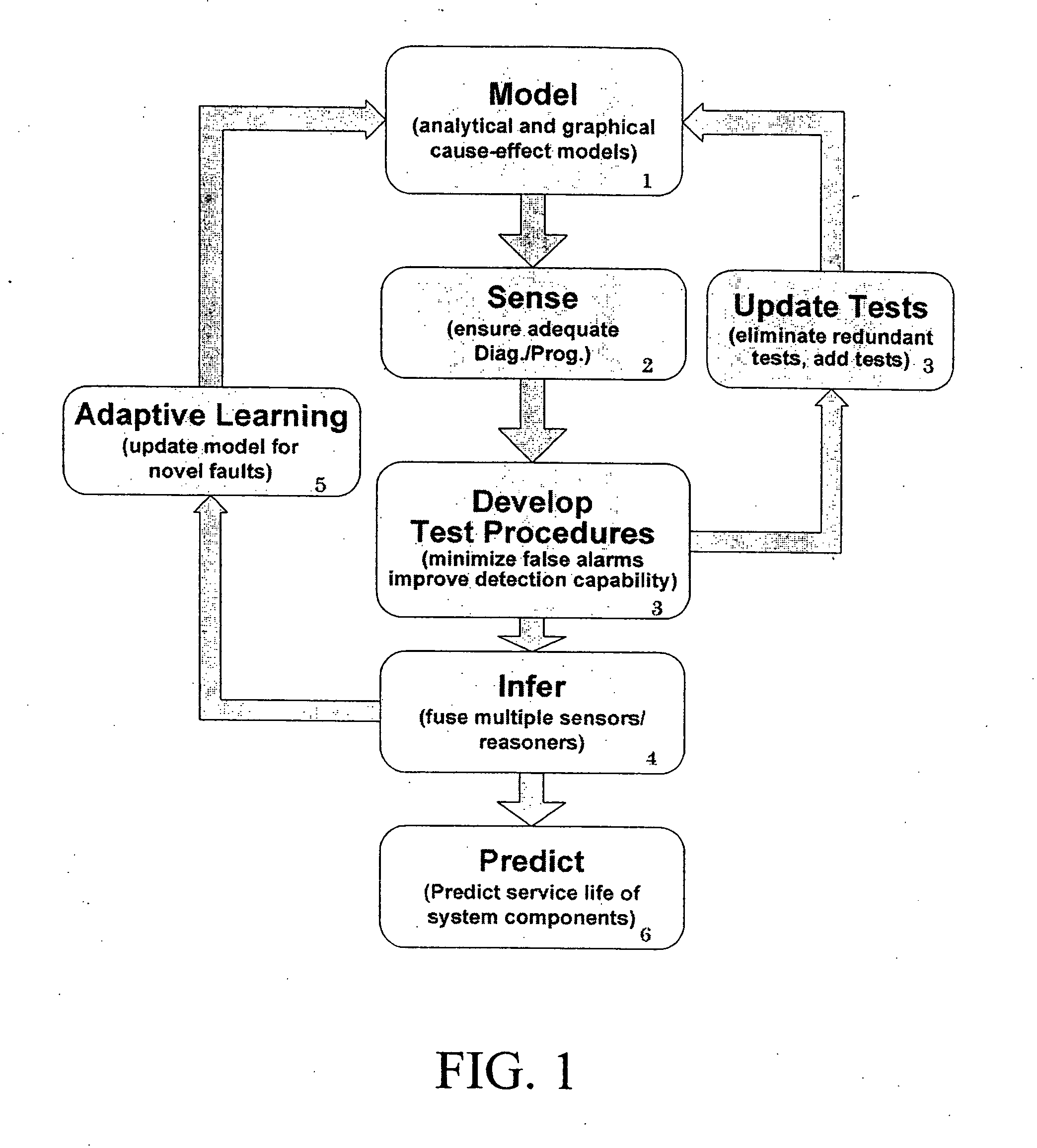

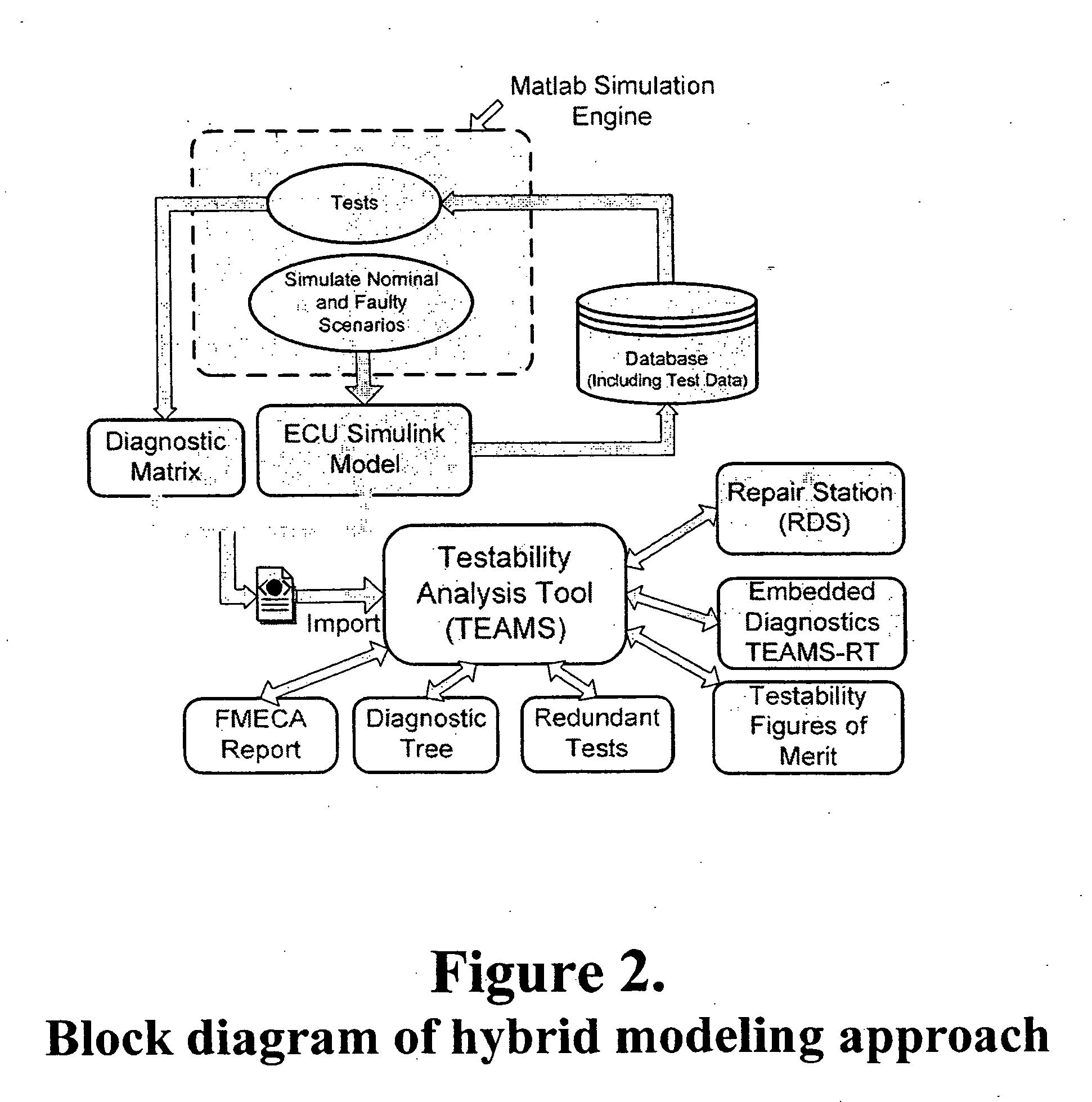

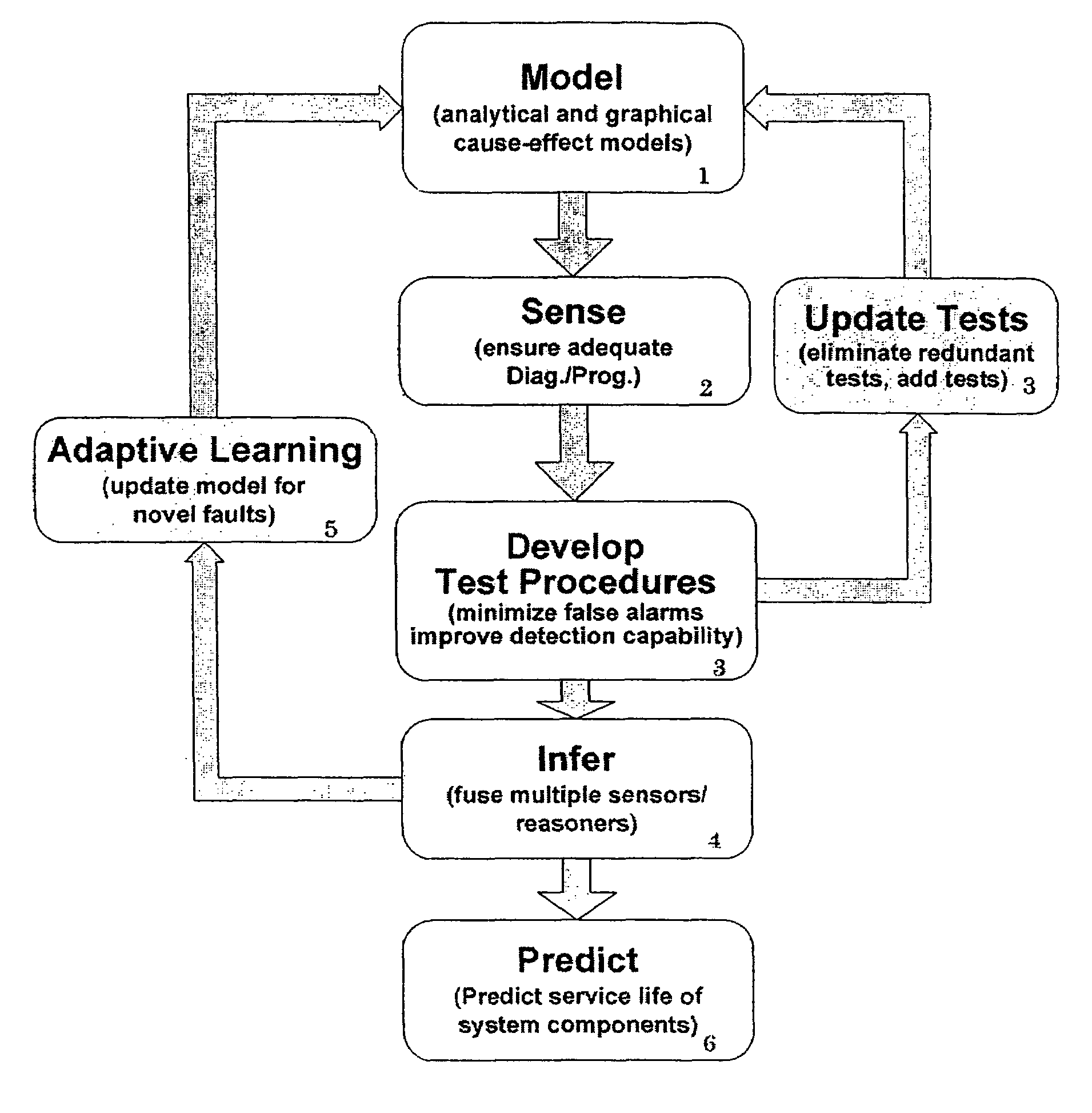

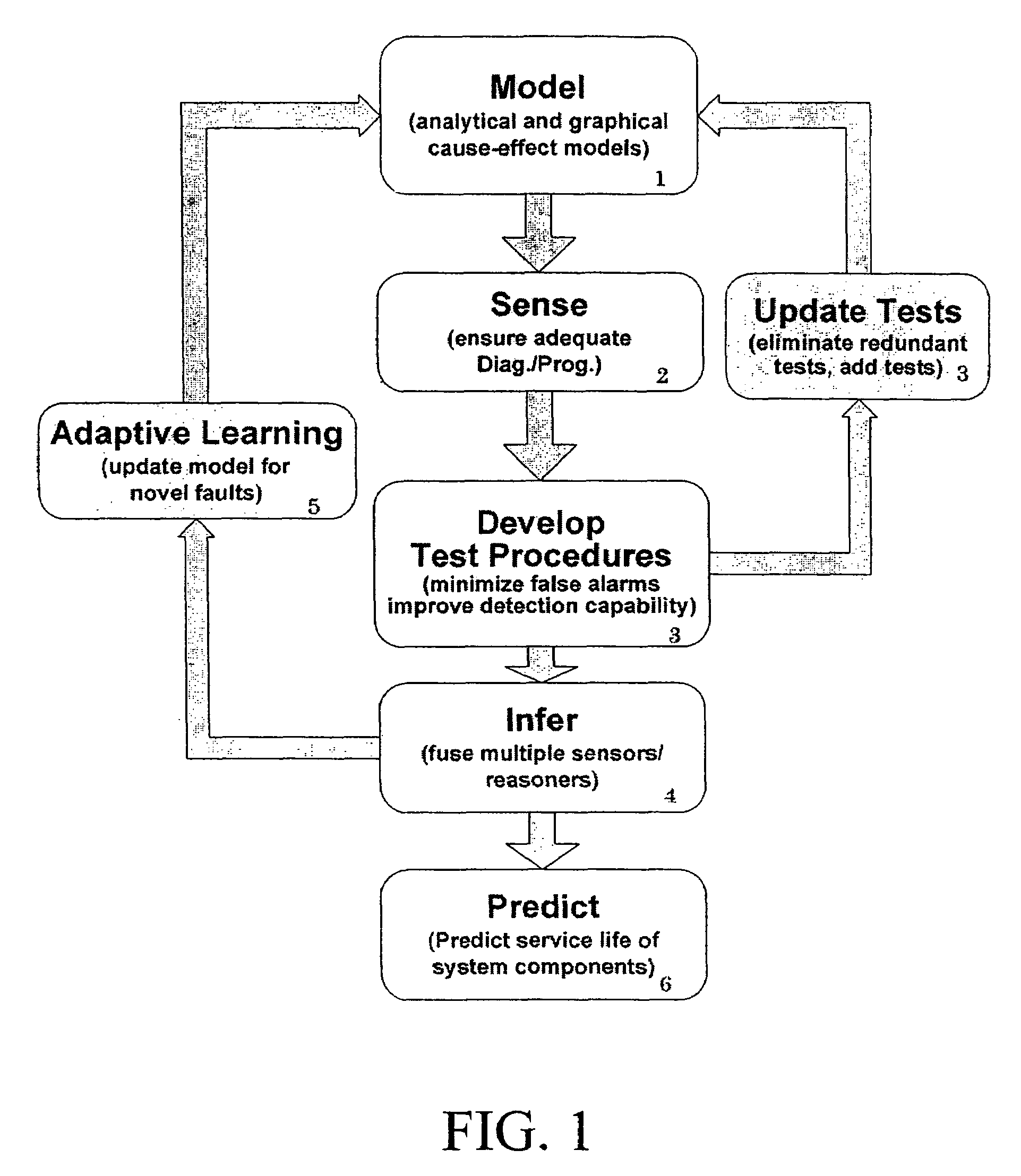

Intelligent model-based diagnostics for system monitoring, diagnosis and maintenance

InactiveUS20060064291A1Improve accuracyImprove consistencyAmplifier modifications to reduce noise influenceTesting/monitoring control systemsElectric power systemCompound (substance)

Systems and methods are provided for monitoring, diagnosis and condition-based maintenance of mechanical systems. The disclosed systems and methods employ intelligent model-based diagnostic methodologies to effectuate such monitoring, diagnosis and maintenance. According to exemplary embodiments of the present disclosure, the intelligent model-based diagnostic methodologies combine or integrate quantitative (analytical) models and graph-based dependency models to enhance diagnostic performance. The disclosed systems and methods may be employed a wide variety of applications, including automotive, aircraft, power systems, manufacturing systems, chemical processes and systems, transportation systems, and industrial machines / equipment.

Owner:TOYOTA TECHN CENT USA +1

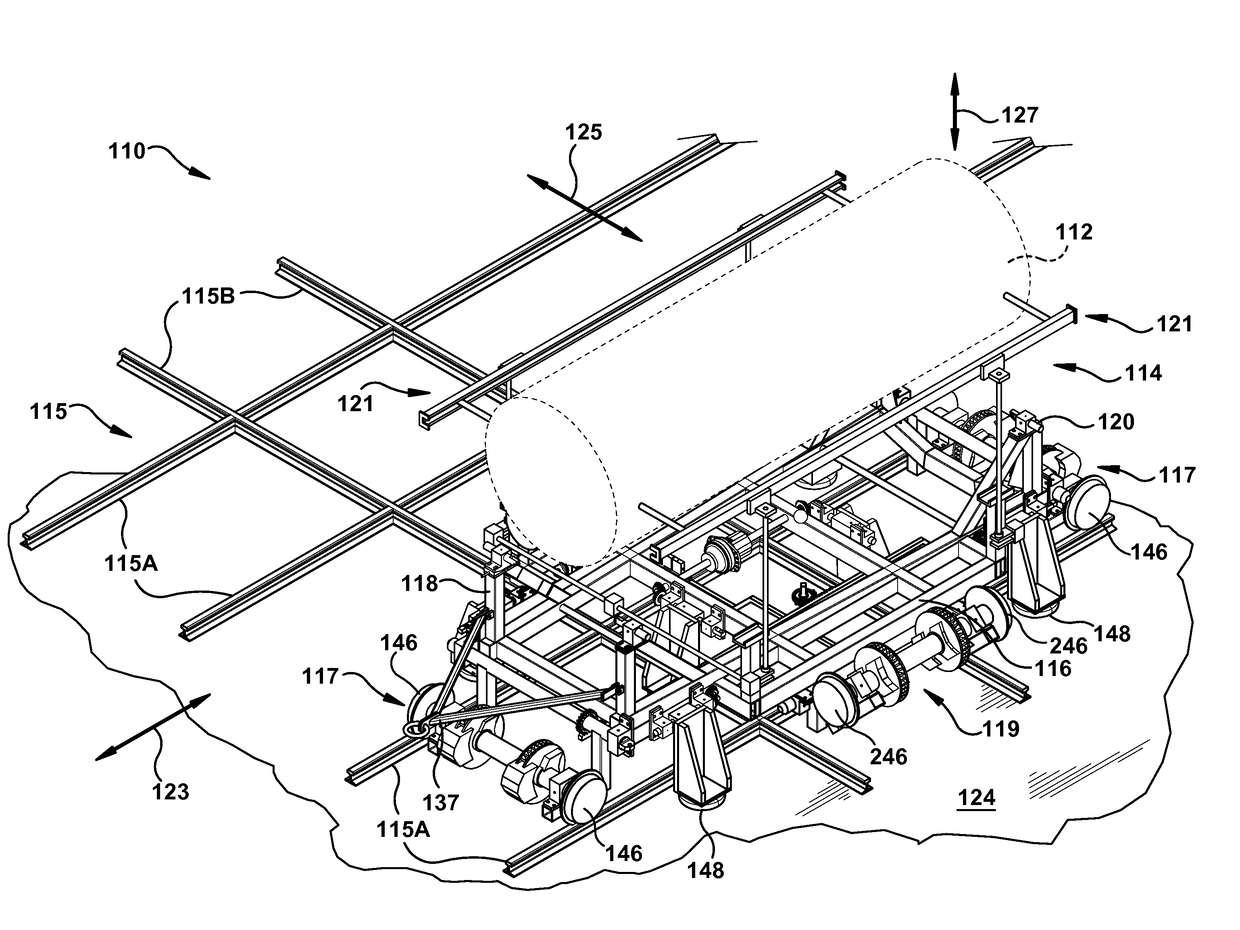

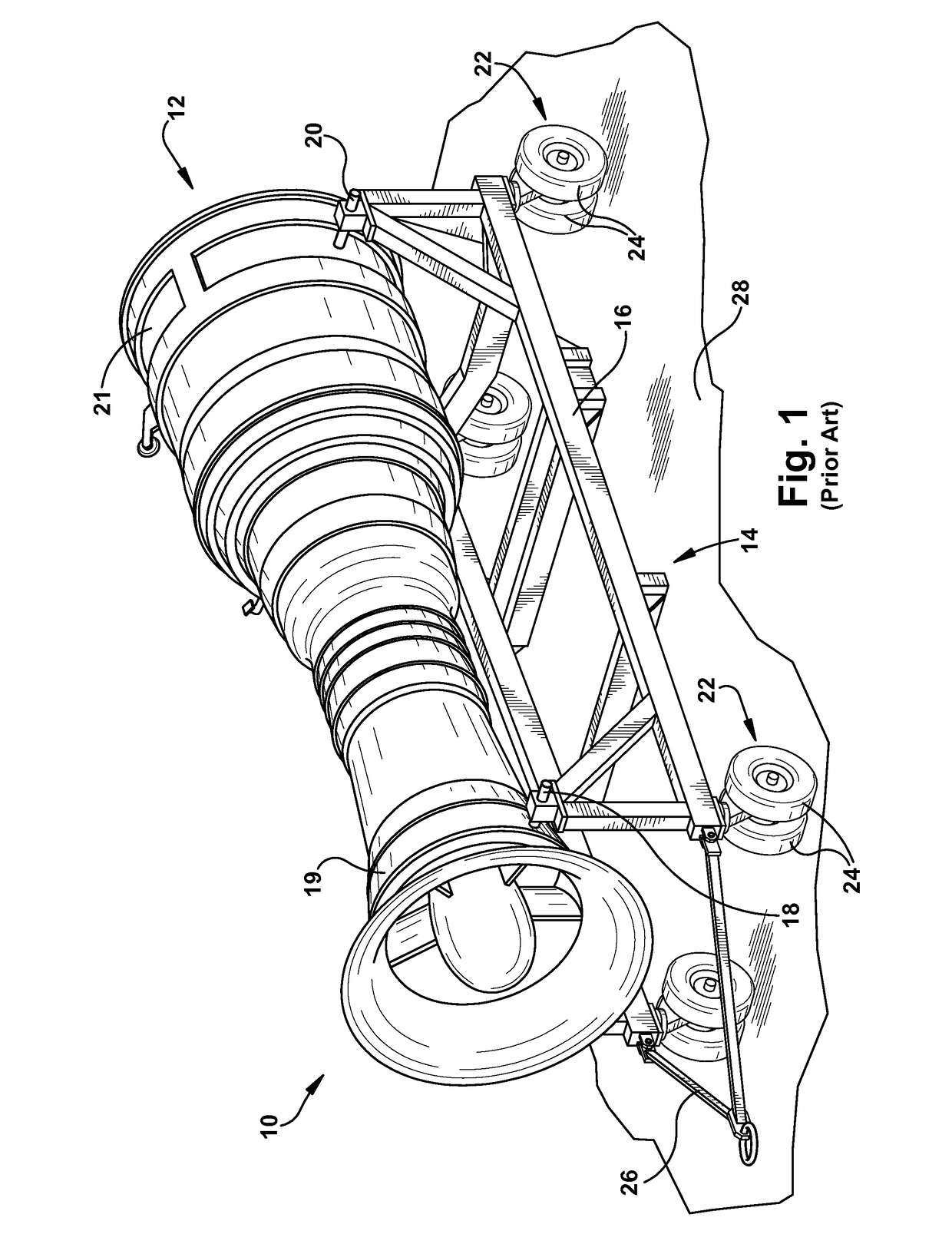

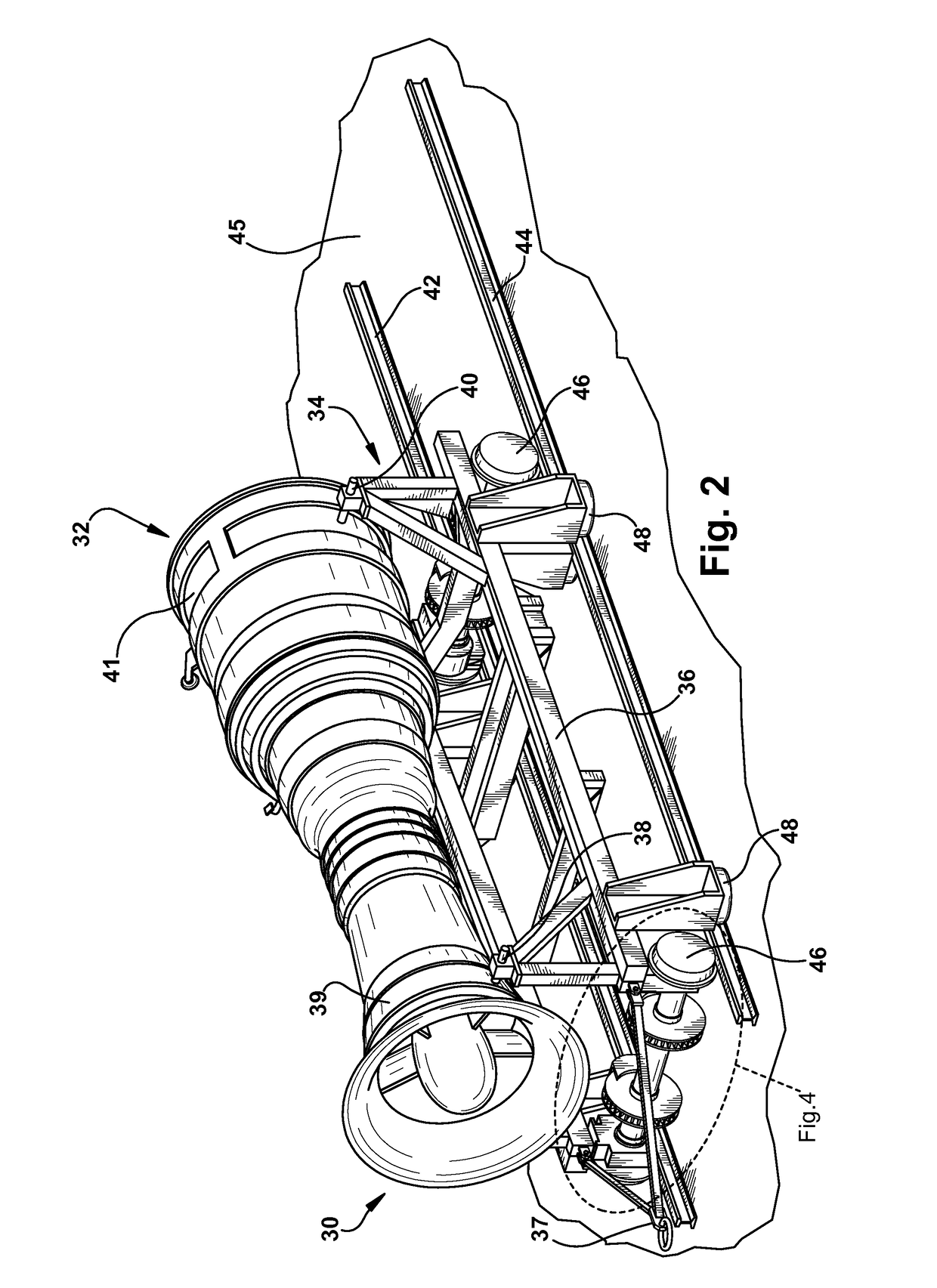

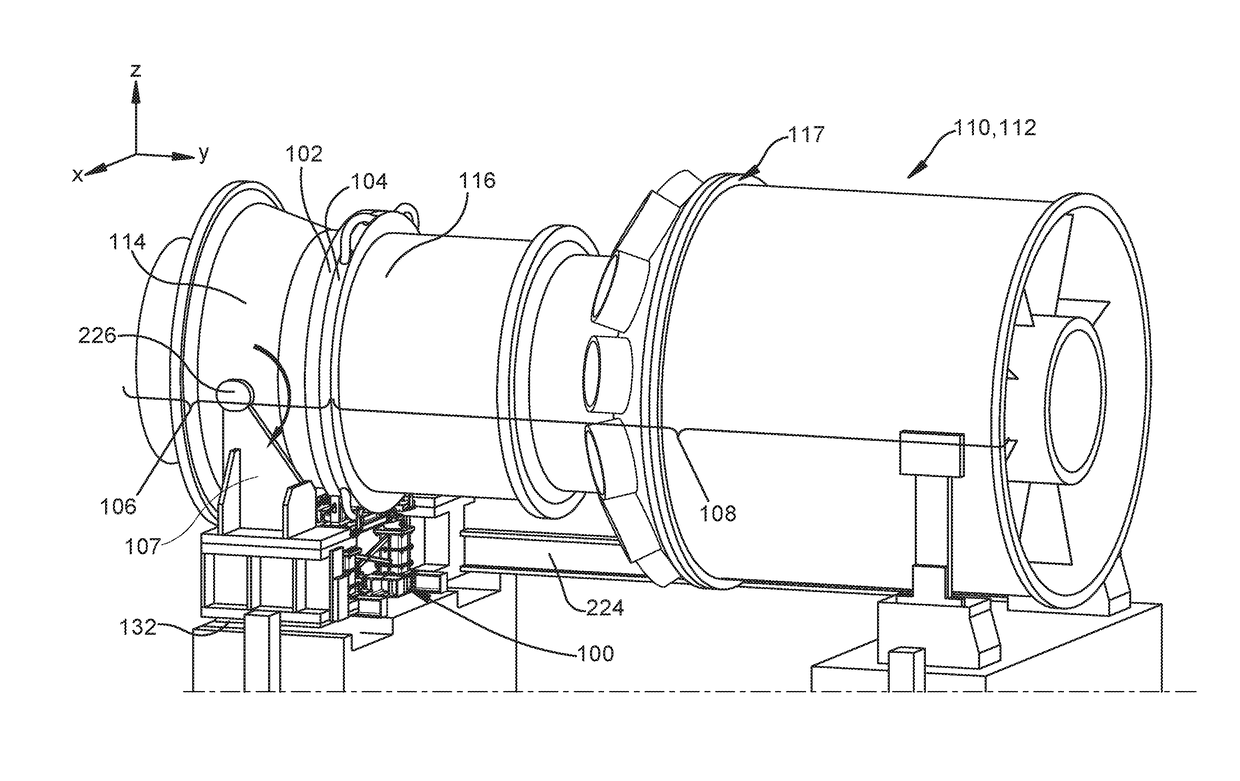

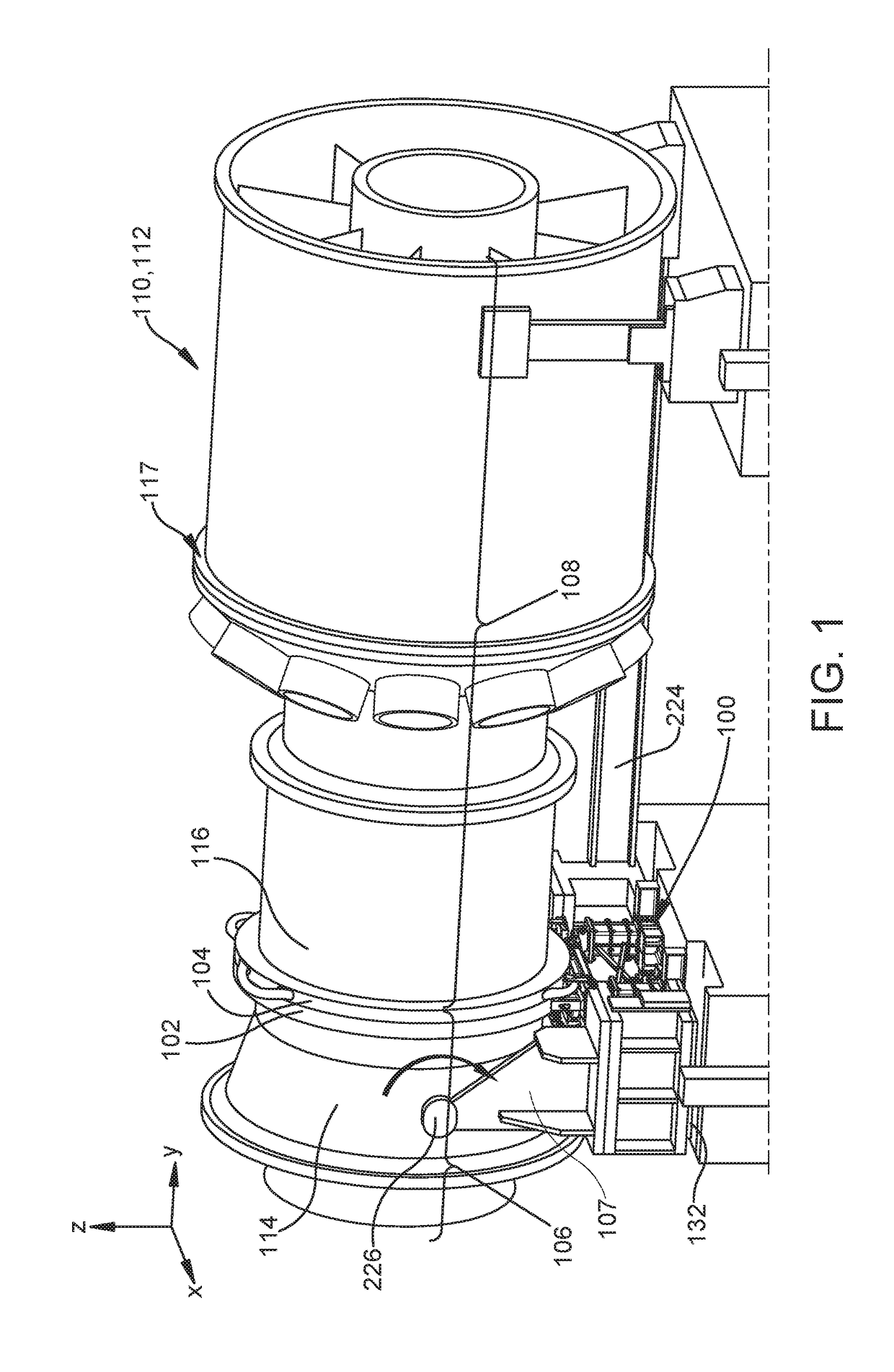

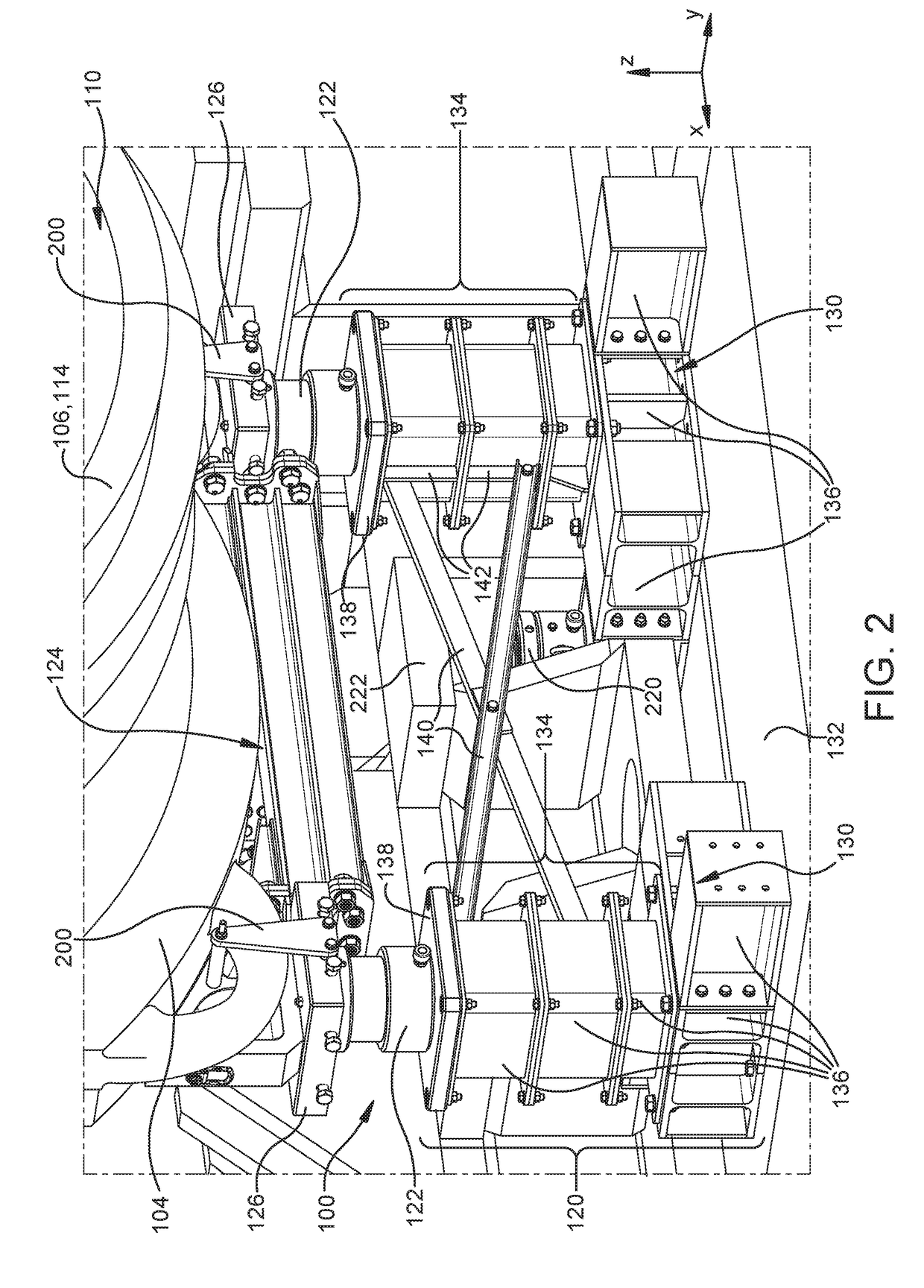

Load transport and restraining devices and methods for restraining loads

ActiveUS9809308B2Efficient transportPrevent disengagementRailway system combinationsElectric locomotivesEngineeringIndustrial machine

Load transport and retraining devices and methods for restraining industrial machines or heavy machinery, such as, turbines, to prevent displacement during adverse environmental conditions, such as, pitching and rolling seas, are provided. The devices include support structures adapted to support loads and having wheels positioned and adapted to engage rails. The wheels include a first set of wheels adapted to ride on top of the rails and a second set of wheels adapted to engage the sides of the rails and thereby retain the support structure to the rails. The devices may also include a third set of wheels adapted to also engage the sides of the rails. The devices may include brake and drive assemblies to facilitate handling. Aspects of the disclosure are uniquely adapted to turbines, but other aspects of the disclosure may restrain any industrial machine that may be exposed to adverse environmental conditions.

Owner:GE INFRASTRUCTURE TECH INT LLC

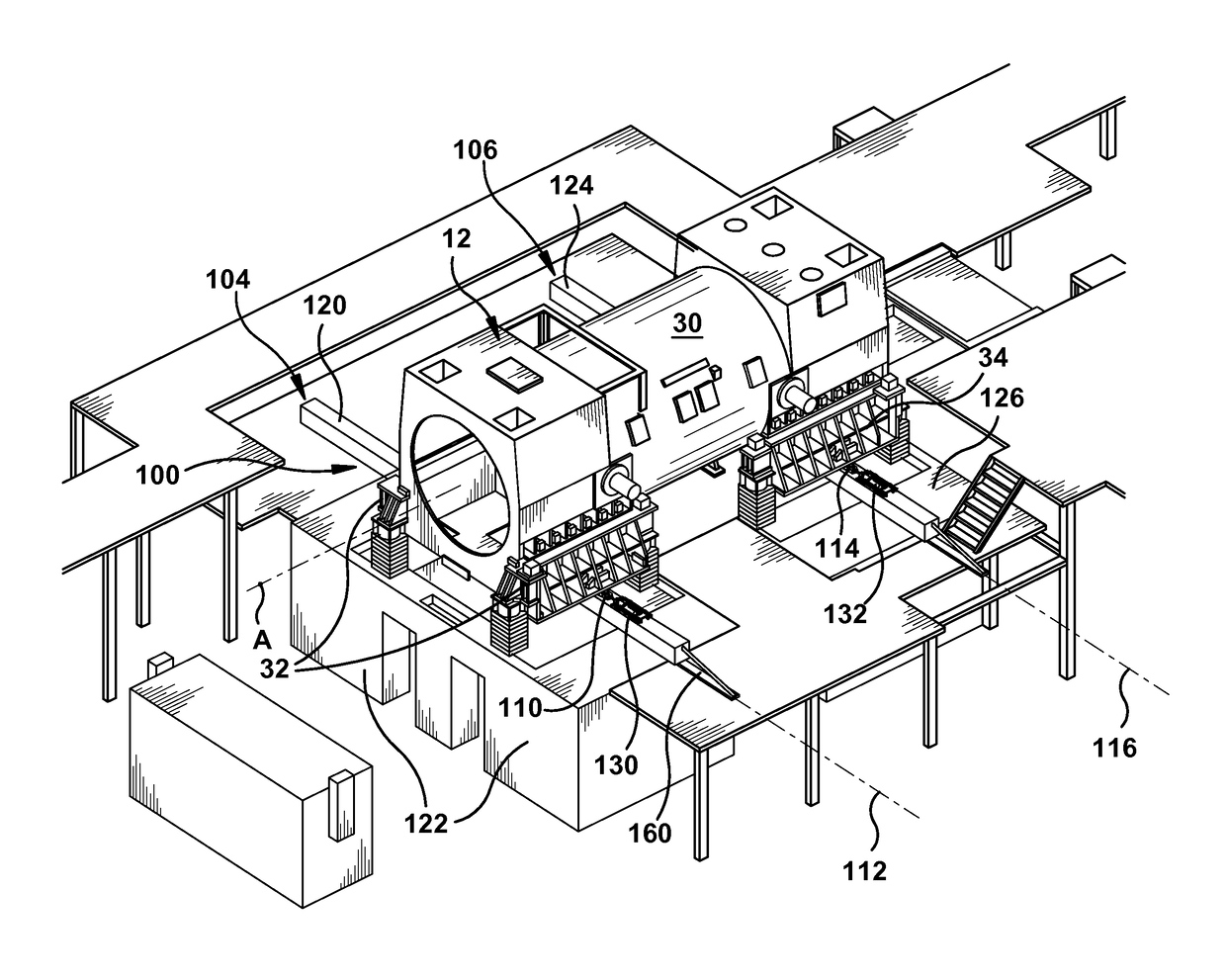

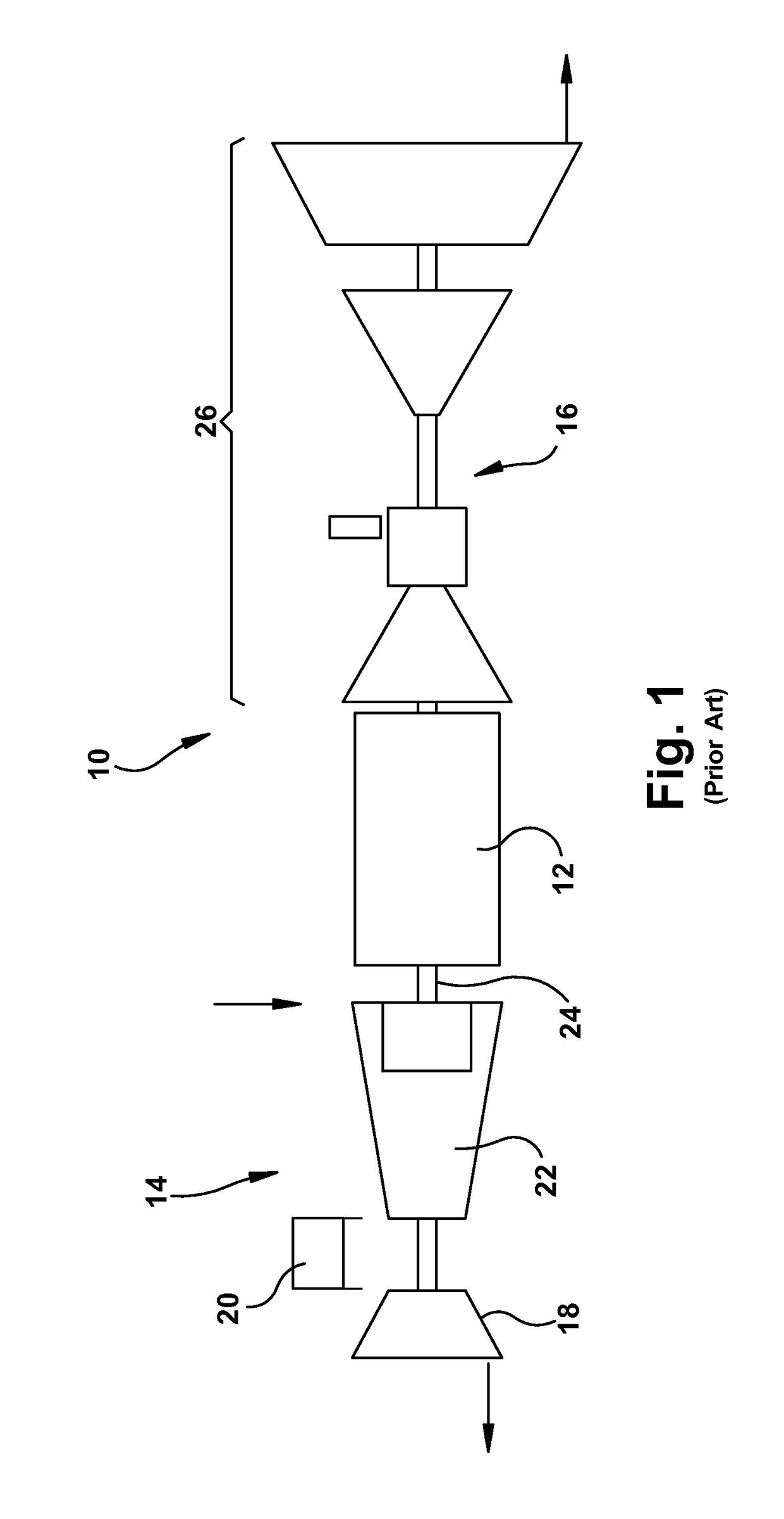

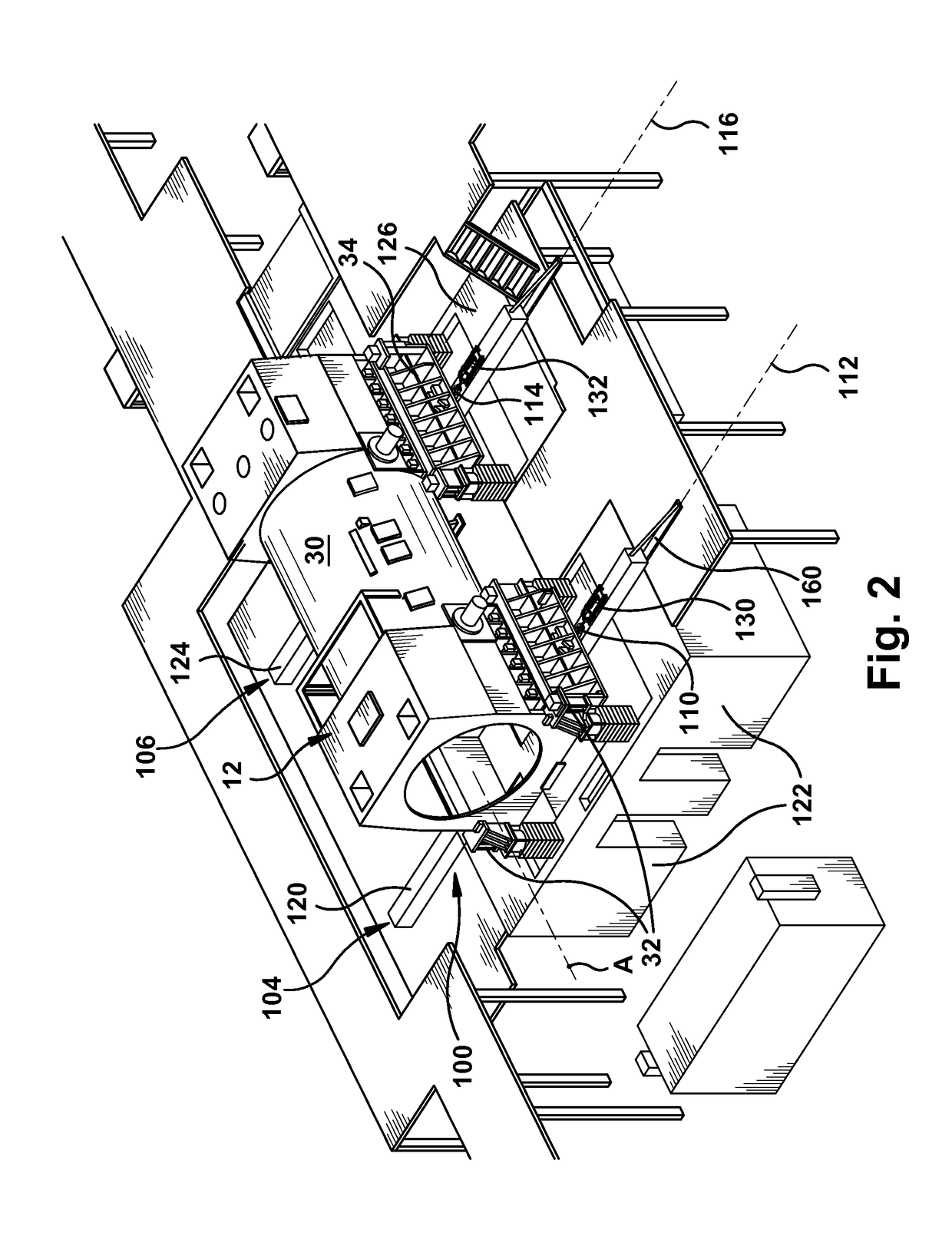

Method for laterally moving industrial machine

A method for laterally moving an industrial machine is provided. The method may include: supporting the industrial machine on a pair of rail elements configured to be positioned laterally below and support the industrial machine, the rail elements allowing the industrial machine to be moved laterally from a first operative position to a second, maintenance position. A pair of linear actuators configured to laterally move the industrial machine from the first, operative position to the second, maintenance position.

Owner:GE INFRASTRUCTURE TECH INT LLC

Intelligent model-based diagnostics for system monitoring, diagnosis and maintenance

InactiveUS7260501B2Improve accuracyImprove consistencyAmplifier modifications to reduce noise influenceTesting/monitoring control systemsTransit systemElectric power system

Owner:TOYOTA TECHN CENT USA +1

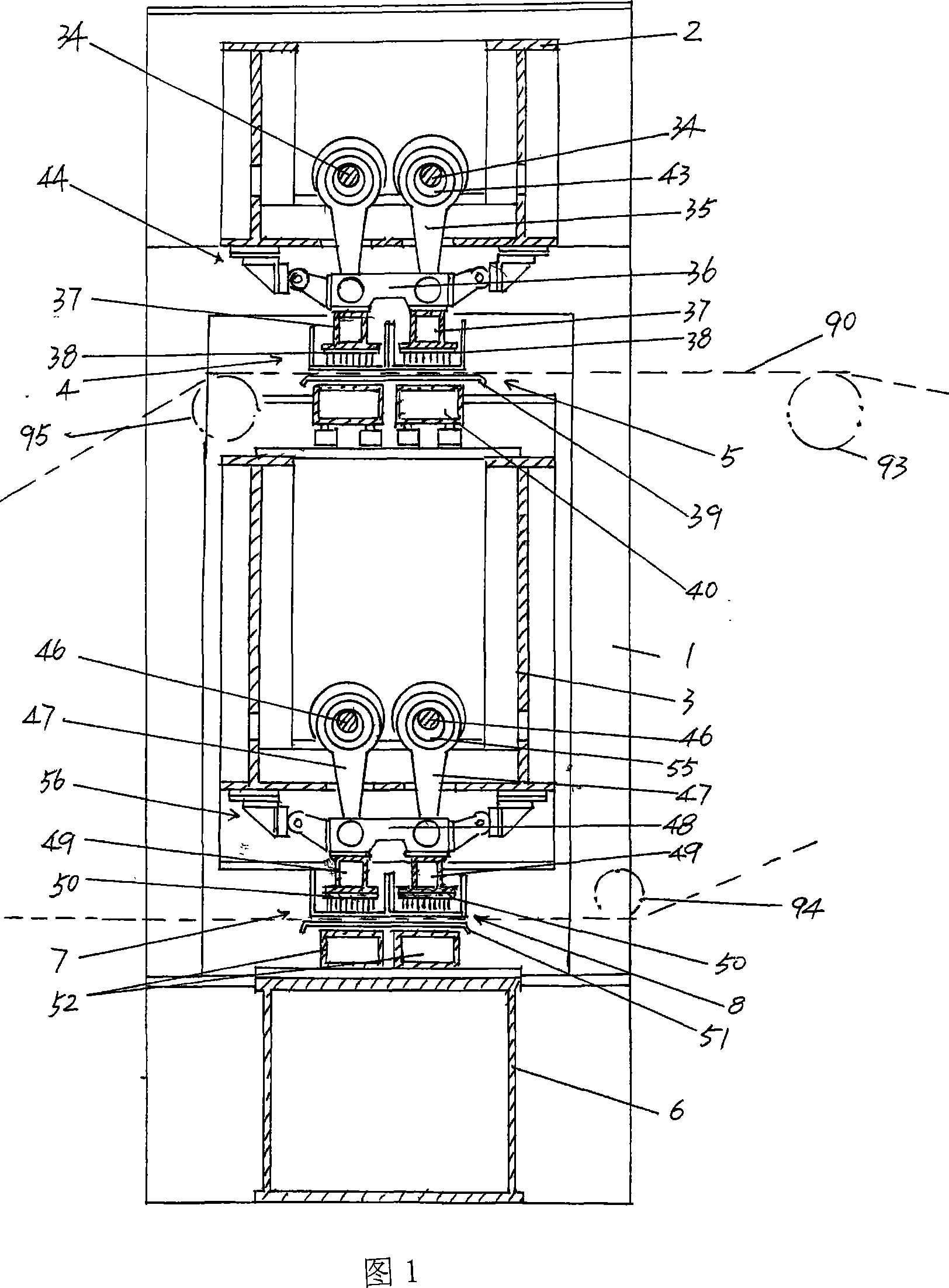

Positioning system for industrial machine coupling elements

A positioning system for aligning first and second coupling elements of adjacent sections of an industrial machine such as a shaft of a turbomachine or generator is provided. The system may include a base, and a pair of lifting jacks supported by the base for adjusting a vertical position of the first coupling element relative to the second coupling element. A coupling element support supports the first coupling element and is supported by the pair of lifting jacks on the base. An adjusting element positioned between each lifting jack and the coupling element support allows adjusting a position of the first coupling element relative to the second coupling element in the axial direction and a lateral direction substantially perpendicular to the axial direction.

Owner:GENERAL ELECTRIC CO

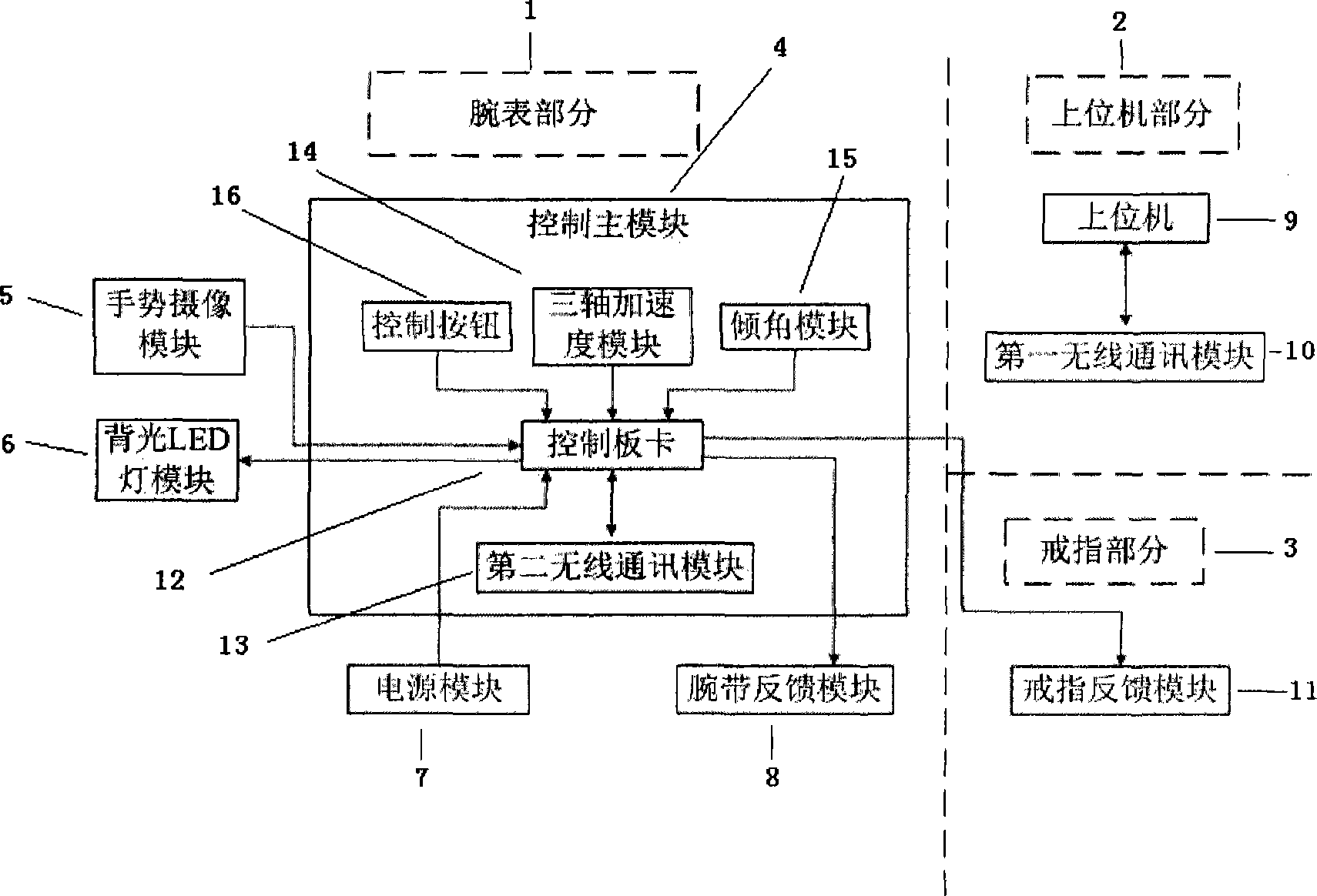

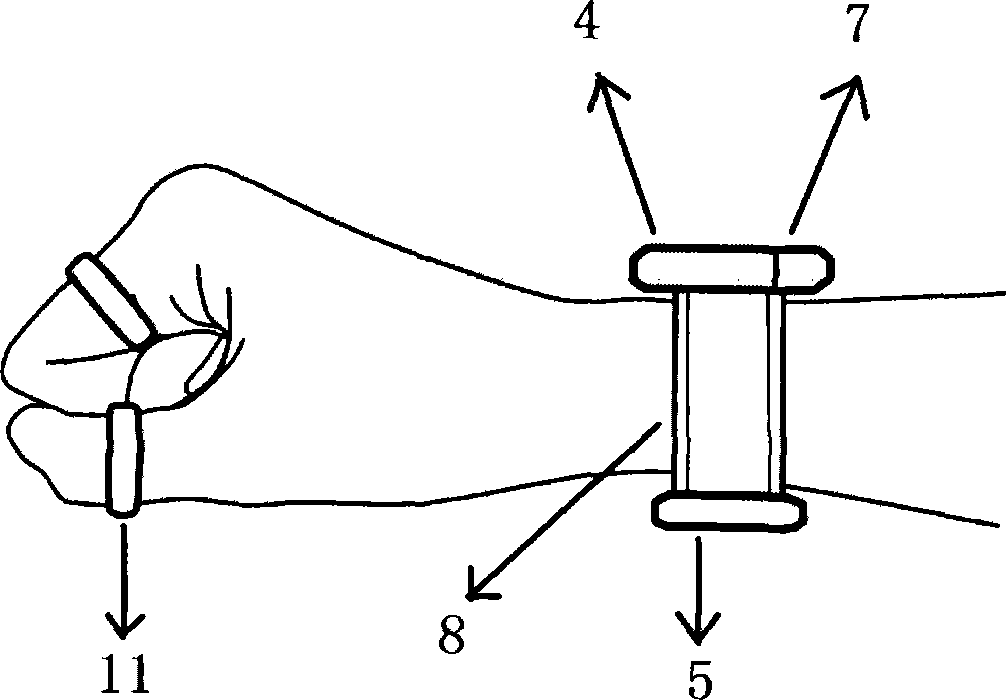

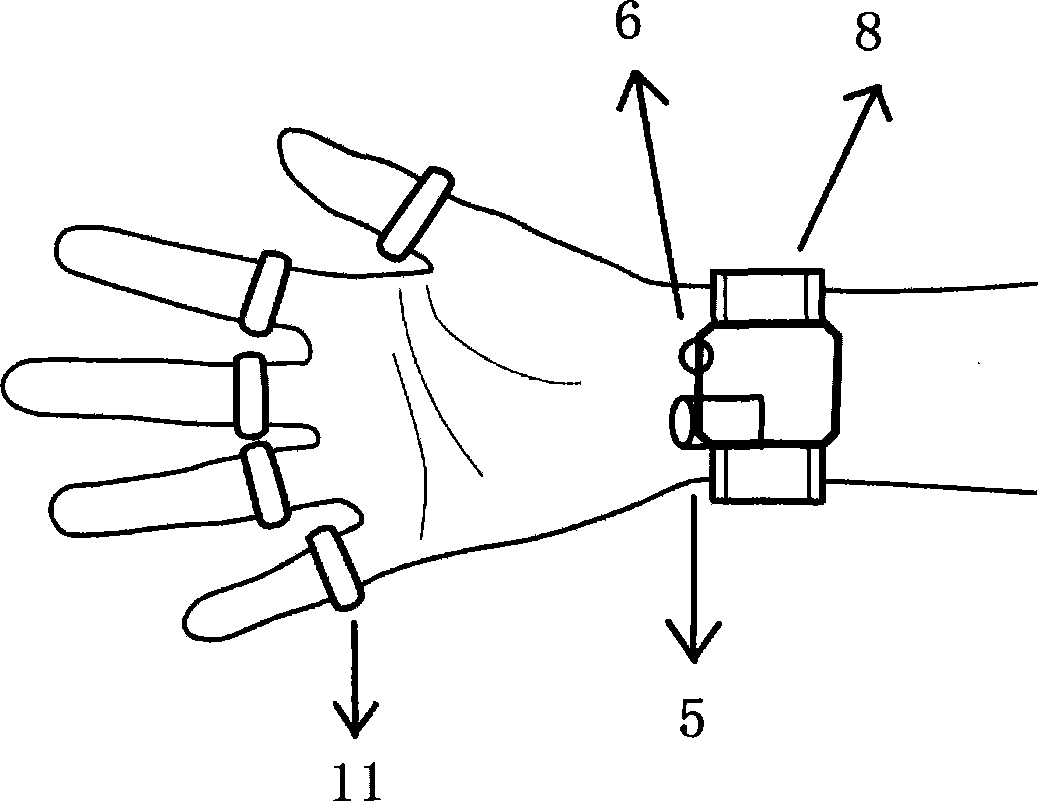

Wrist gesture control system and method

ActiveCN102915111AMiniaturizationEasy to moveInput/output for user-computer interactionGraph readingVirtual controlHuman–computer interaction

The invention relates to a wrist gesture control system and a wrist gesture control method, particularly relates to a wrist watch type gesture identifying system for controlling electronic products such as mobile phones and computers, and the system can further be used for the remote control and the virtual control of various electromechanical devices such as household appliances, vehicles, industrial machines, game and entertainment devices, teaching and scientific research devices, medical apparatus and instruments, and voice control devices. Each set of the system comprises a left hand system and a right hand system or a system only used by one hand, the wrist gesture control system comprises a wrist watch part 1 which cooperatively works with an upper computer part 2 to control an upper computer as well as a selectively-worn ring part 3, wherein the wrist watch part 1 comprises a control main module 4, a gesture photographing part 5, a backlight LED (Light Emitting Diode) lamp module 6, a power supply module 7 and a waistband feedback module 8; and the upper computer part 2 comprises the upper computer 9 and a first wireless communication module 10; the ring part 3 comprises a ring feedback module 11; the control main module 4 further comprises a control board clamp 12, a second wireless communication module 13, a three-shaft acceleration module 14, a dip angle module 15 and a control button 16.

Owner:寇传阳

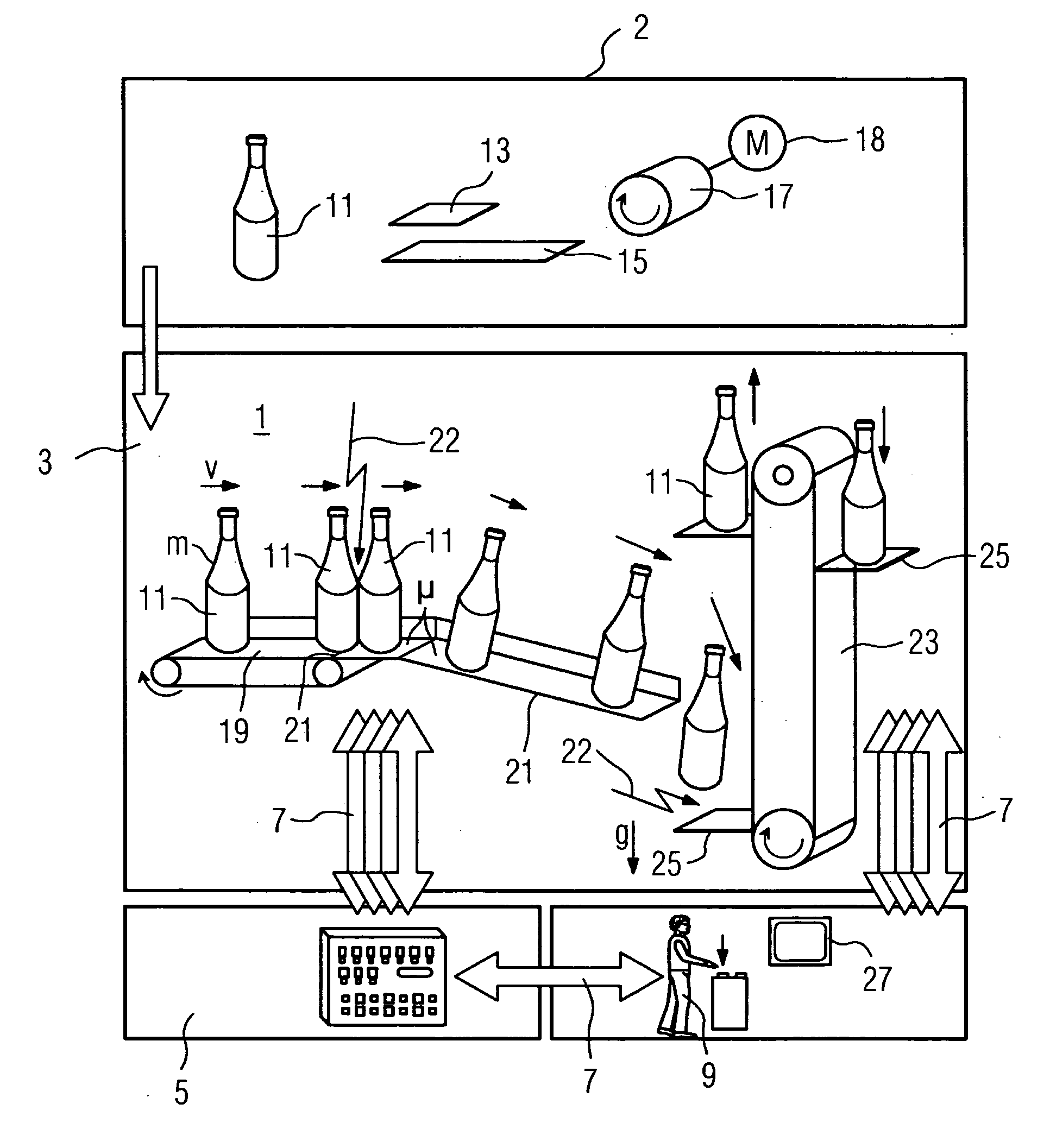

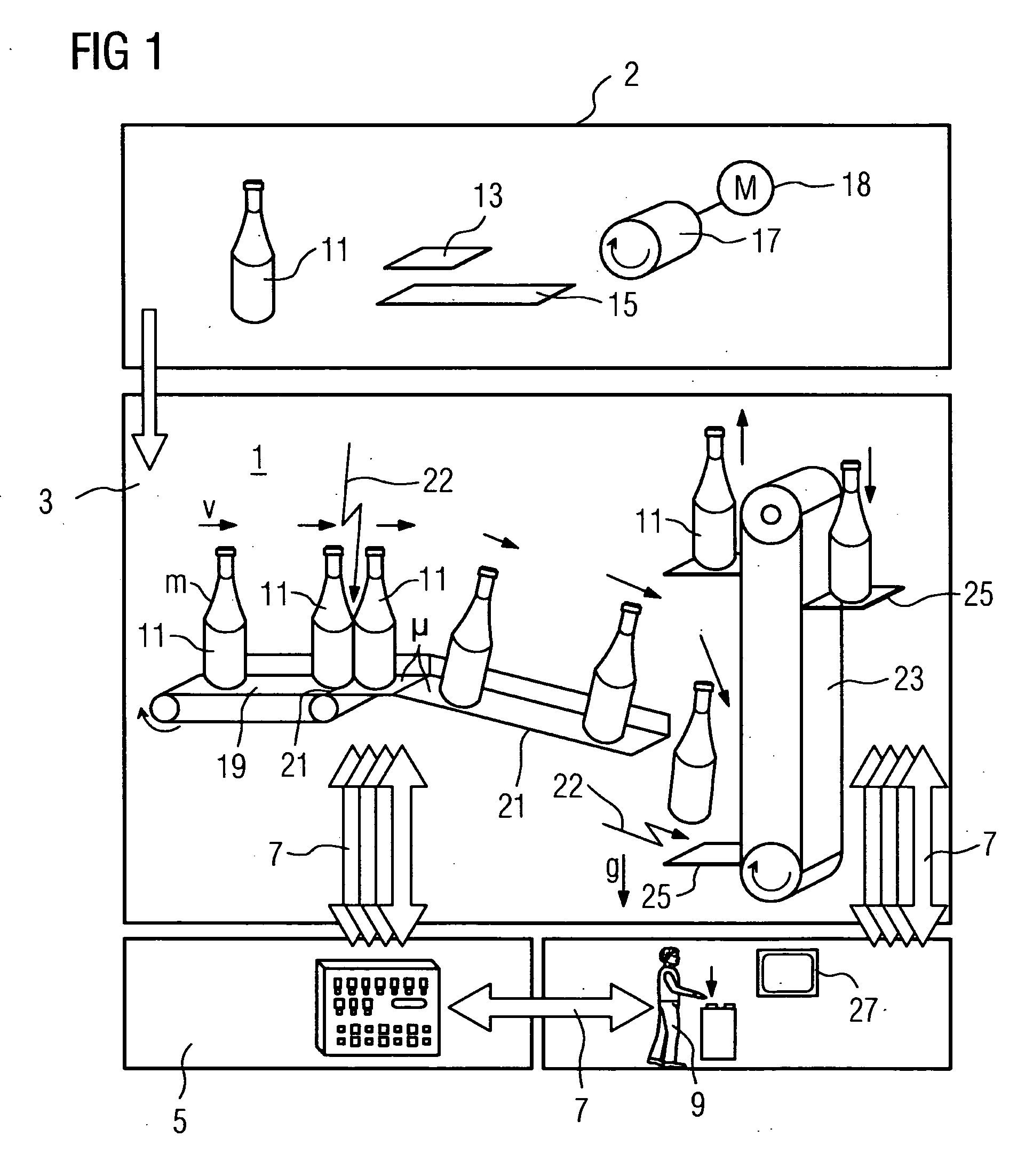

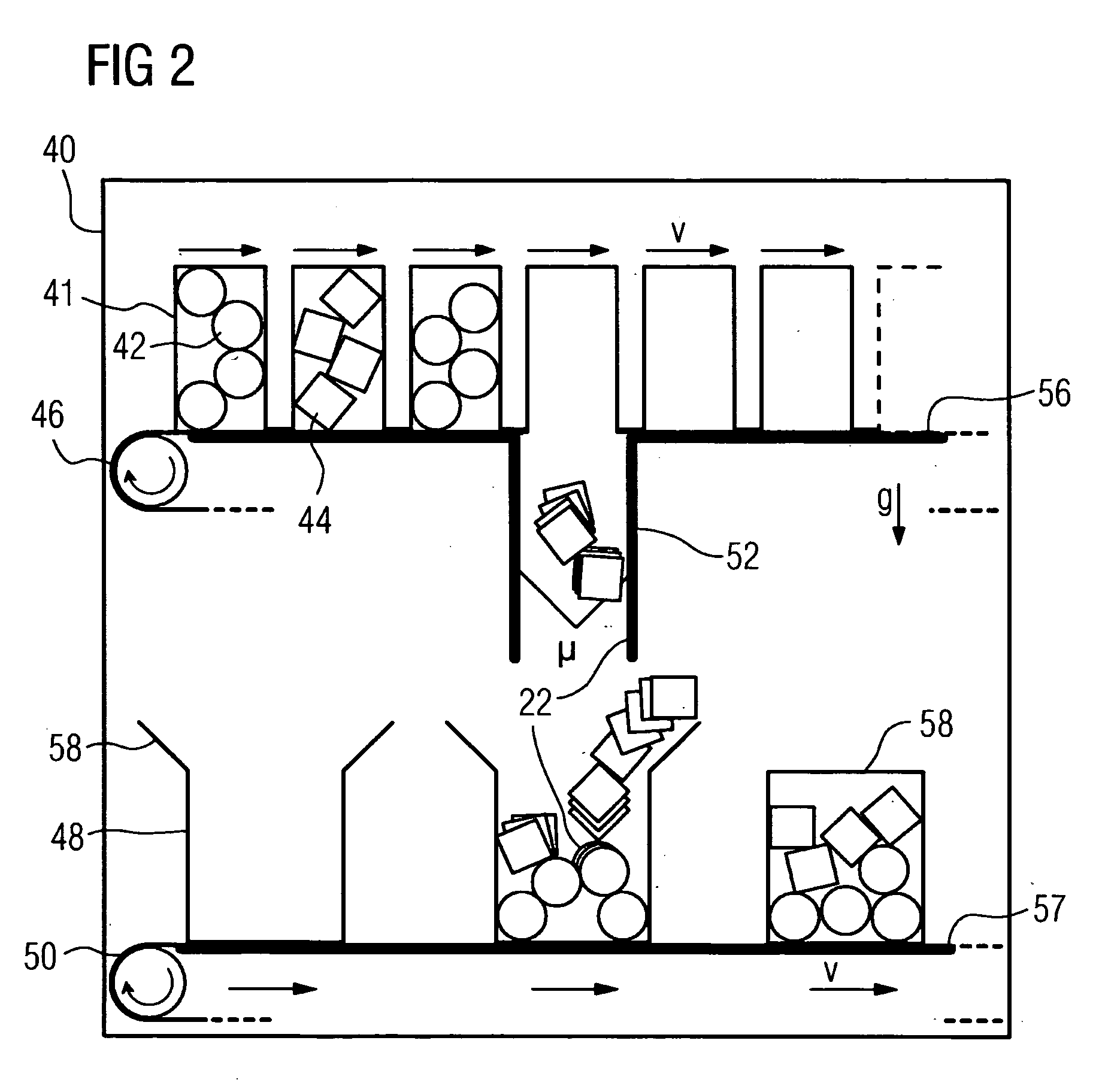

Method and/or device for controlling and/or monitoring the movement of industrial machines

InactiveUS20090259444A1High simulationEasy to useProgramme controlAnalogue computers for control systemsIndustrial machineActuator

There is described a method for controlling and / or monitoring a movement of a free body in an industrial machine, wherein the industrial machine comprises an actuator for carrying out a movement, wherein the movement of at least one free body is either mechanically coupled to the movement of the actuator and / or is decoupled from the movement of the actuator. At least one of the following physical variables of the free body: weight, density, frictional parameters, geometric form and / or center of gravity is input into a simulation program, whereupon with the aid of at least one of these physical variables, the movement of the free body is simulated, wherein the simulation takes place, in particular, in real time. This enables a better simulation of dynamic and / or static processes in an industrial machine.

Owner:SIEMENS AG

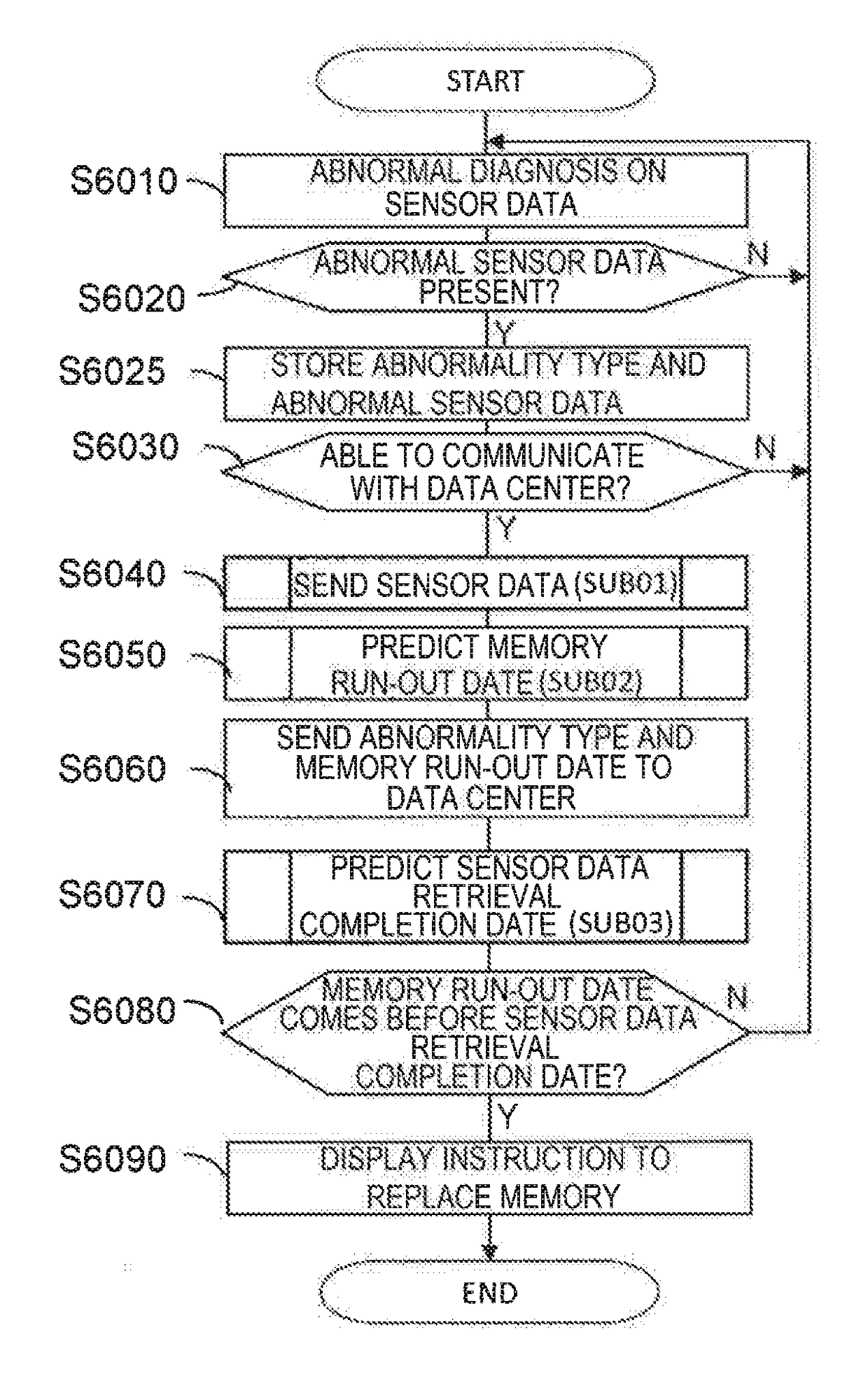

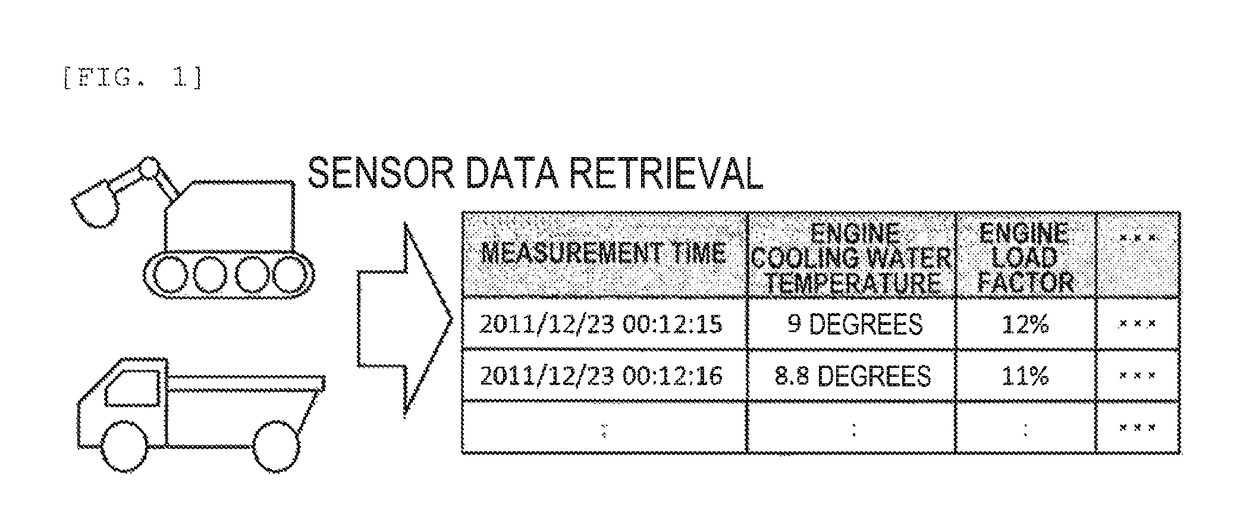

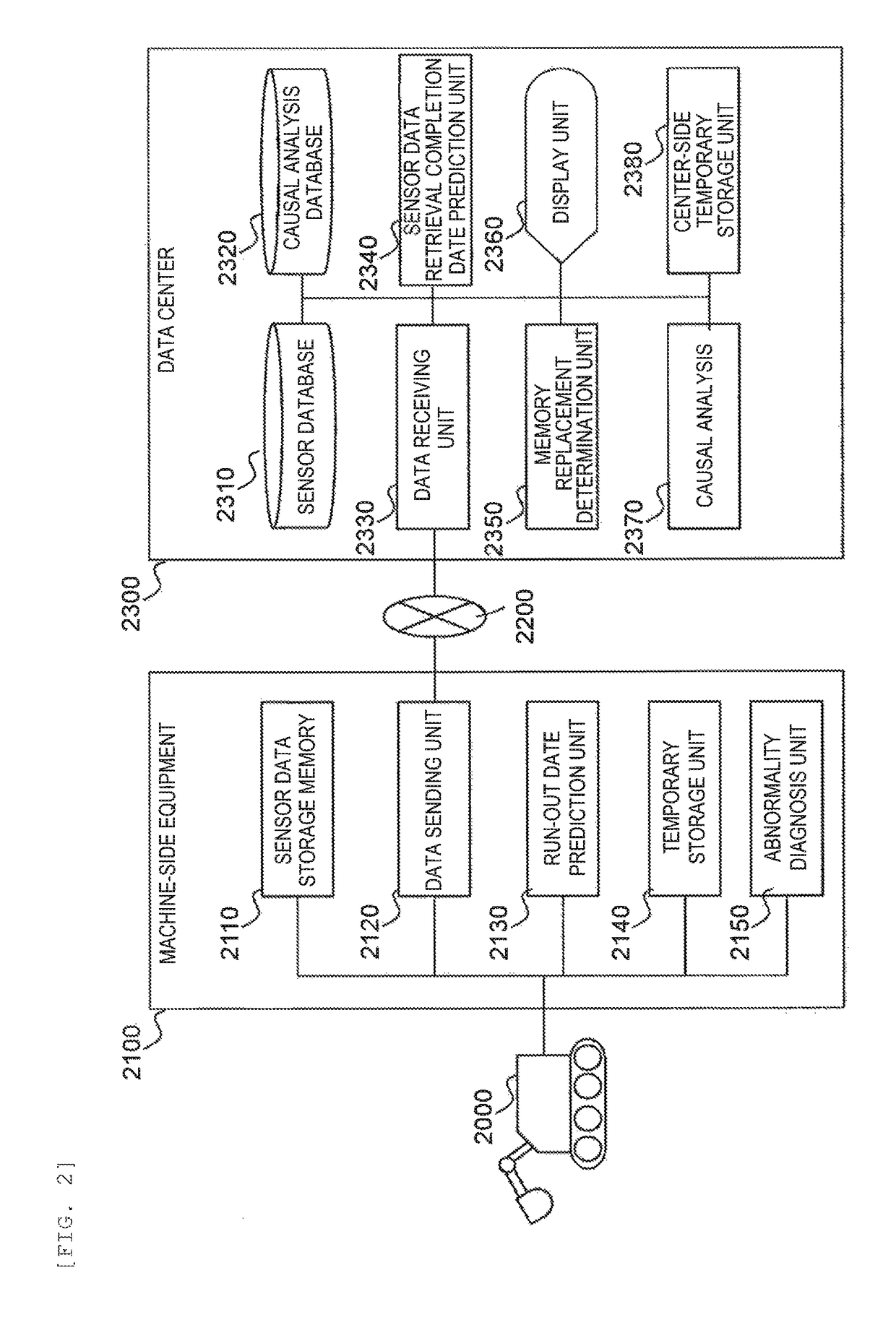

Abnormality diagnosis method and device therefor

ActiveUS10073447B2Detected as abnormalityProgramme controlRegistering/indicating working of vehiclesMechanical AbnormalityDiagnosis methods

In industrial machine abnormality diagnosis, if the machine is diagnosed to have abnormality, then sensor data from the machine needs to be sent to a management center for causal analysis. However, since machines operated at a remote site cannot always communicate with a management center, it has been found that, in some cases, sensor data that has failed to be sent from a machine remains in the memory of the machine, resulting in lack of available memory capacity. In view of this, the present invention determines beforehand whether the diagnosed machine will run out of available memory capacity before the completion of sending the amount of sensor data required for causal analysis for the machine, and instructs a maintenance person to recover memory. This determination as to whether the machine will run out of available memory capacity before the completion of sending the amount of sensor data required for the causal analysis for the machine, is made as follows: (1) first, the machine predicts the run-out date on which the machine will run out of memory capacity for storing sensor data generated in the machine, and sends a notification of the predicted run-out date to the management center for the machine; and (2) next, from the amount of sensor data required for the causal analysis and the reception rate of sensor data, the management center calculates the number of days required to retrieve the necessary data for the causal analysis and determines whether the management center can retrieve the data by the predicted run-out date.

Owner:HITACHI LTD

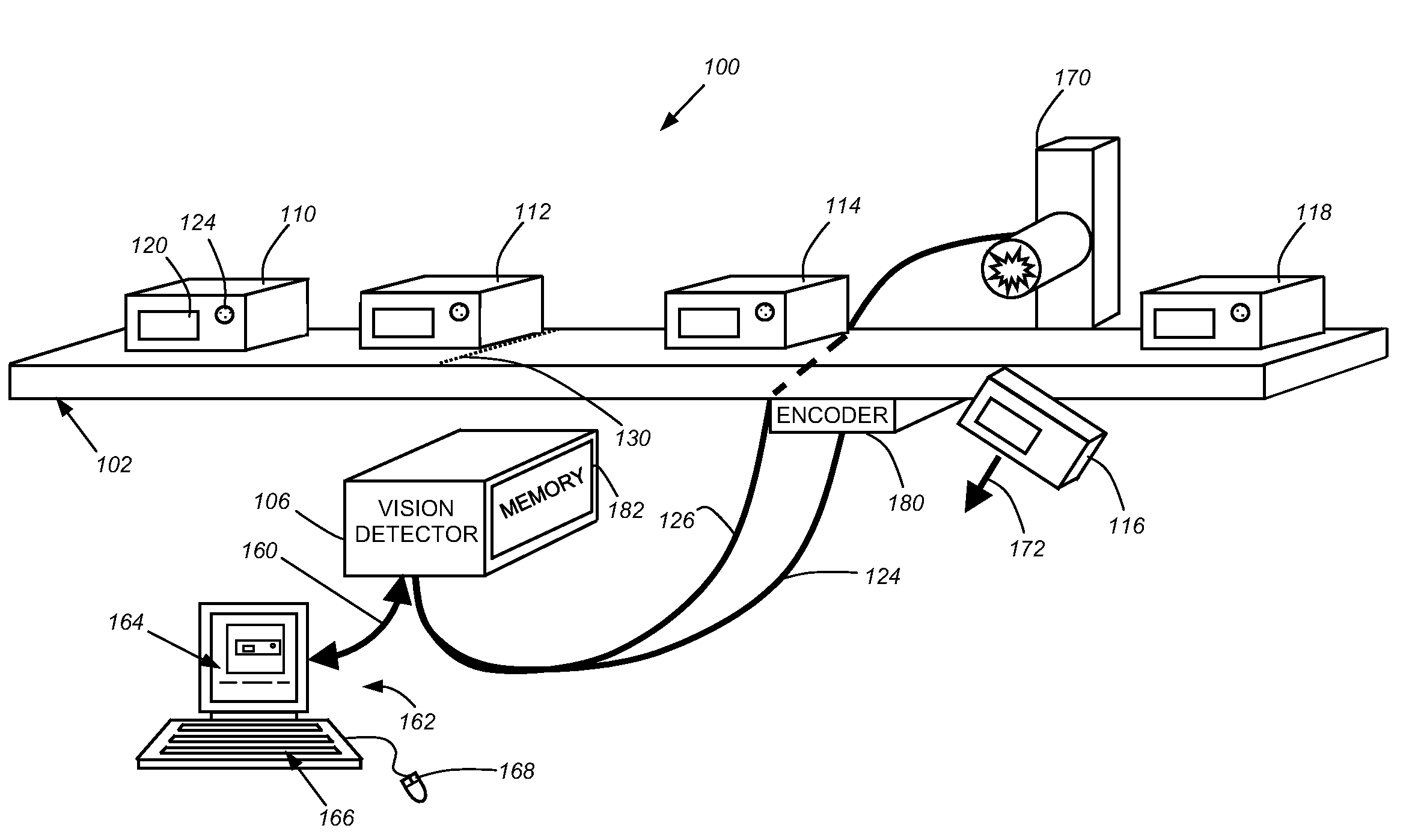

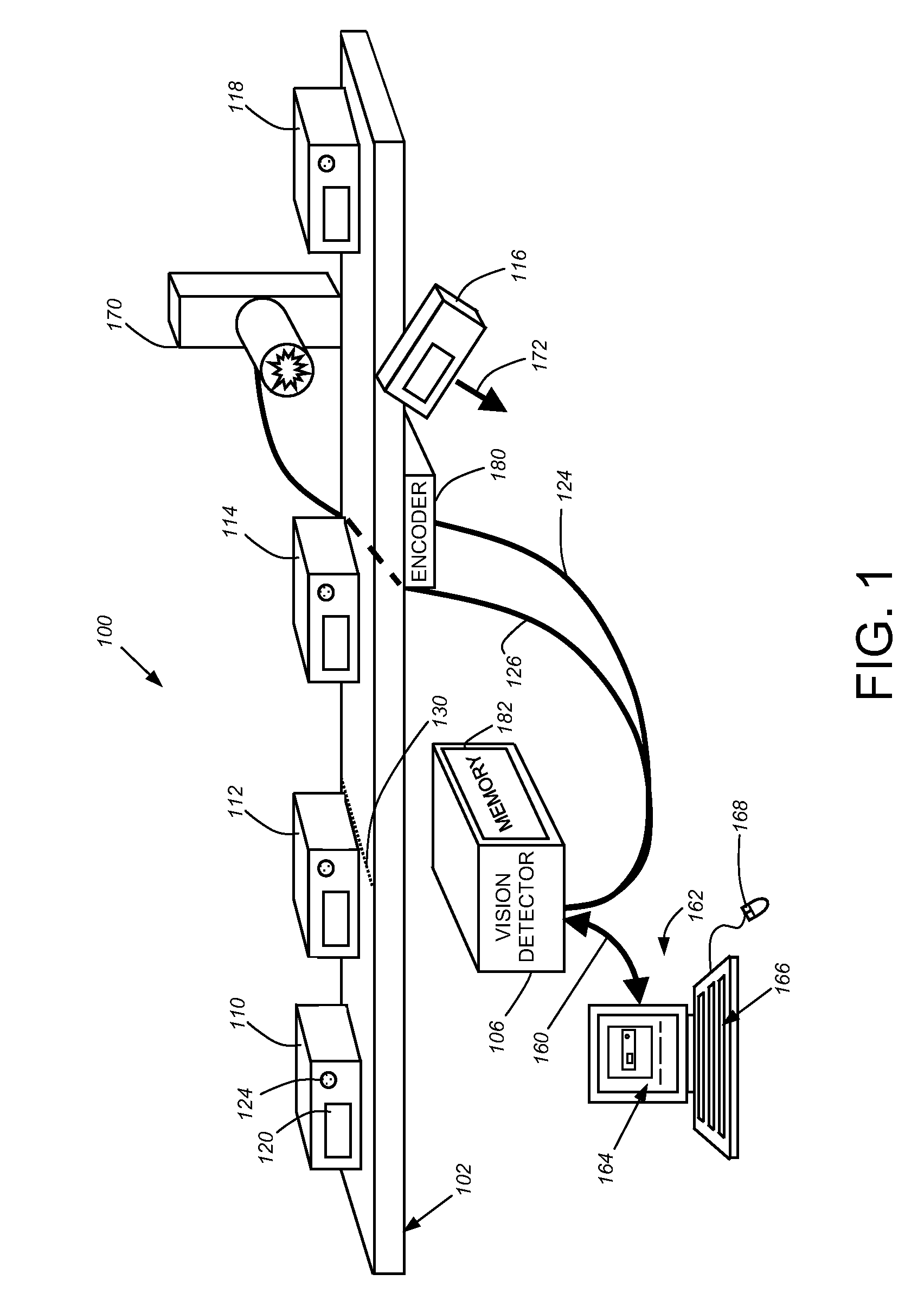

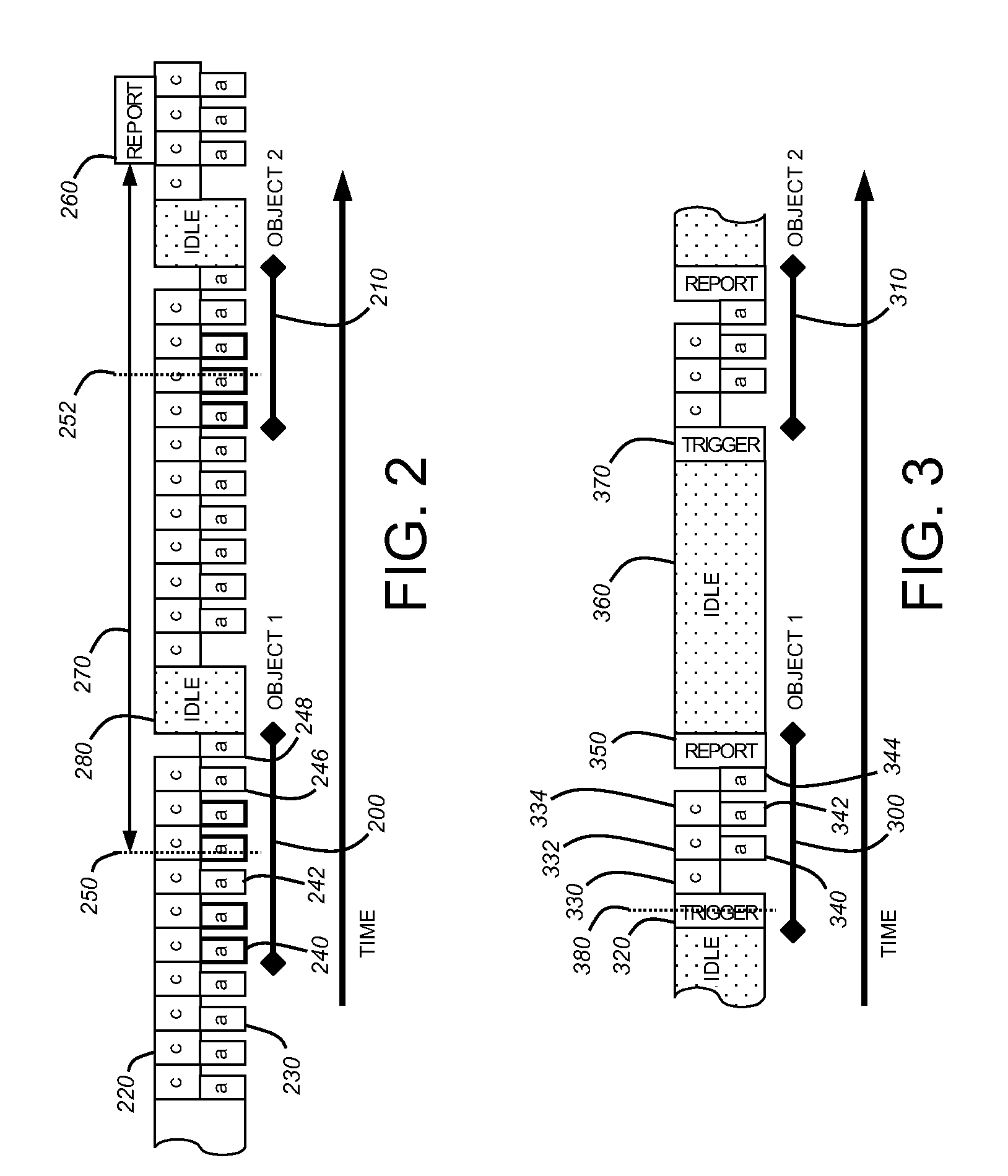

Human-machine-interface and method for manipulating data in a machine vision system

InactiveUS20070146491A1Easy to set upIncrease speedTelevision system detailsImage analysisHuman–machine interfaceThumbnail

This invention provides a Graphical User Interface (GUI) that operates in connection with a machine vision detector or other machine vision system, which provides a highly intuitive and industrial machine-like appearance and layout. The GUI includes a centralized image frame window surrounded by panes having buttons and specific interface components that the user employs in each step of a machine vision system set up and run procedure. One pane allows the user to view and manipulate a recorded filmstrip of image thumbnails taken in a sequence, and provides the filmstrip with specialized highlighting (colors or patterns) that indicate useful information about the underlying images. The system is set up and run are using a sequential series of buttons or switches that are activated by the user in turn to perform each of the steps needed to connect to a vision system, train the system to recognize or detect objects / parts, configure the logic that is used to handle recognition / detection signals, set up system outputs from the system based upon the logical results, and finally, run the programmed system in real time. The programming of logic is performed using a programming window that includes a ladder logic arrangement. A thumbnail window is provided on the programming window in which an image from a filmstrip is displayed, focusing upon the locations of the image (and underlying viewed object / part) in which the selected contact element is provided.

Owner:COGNEX CORP

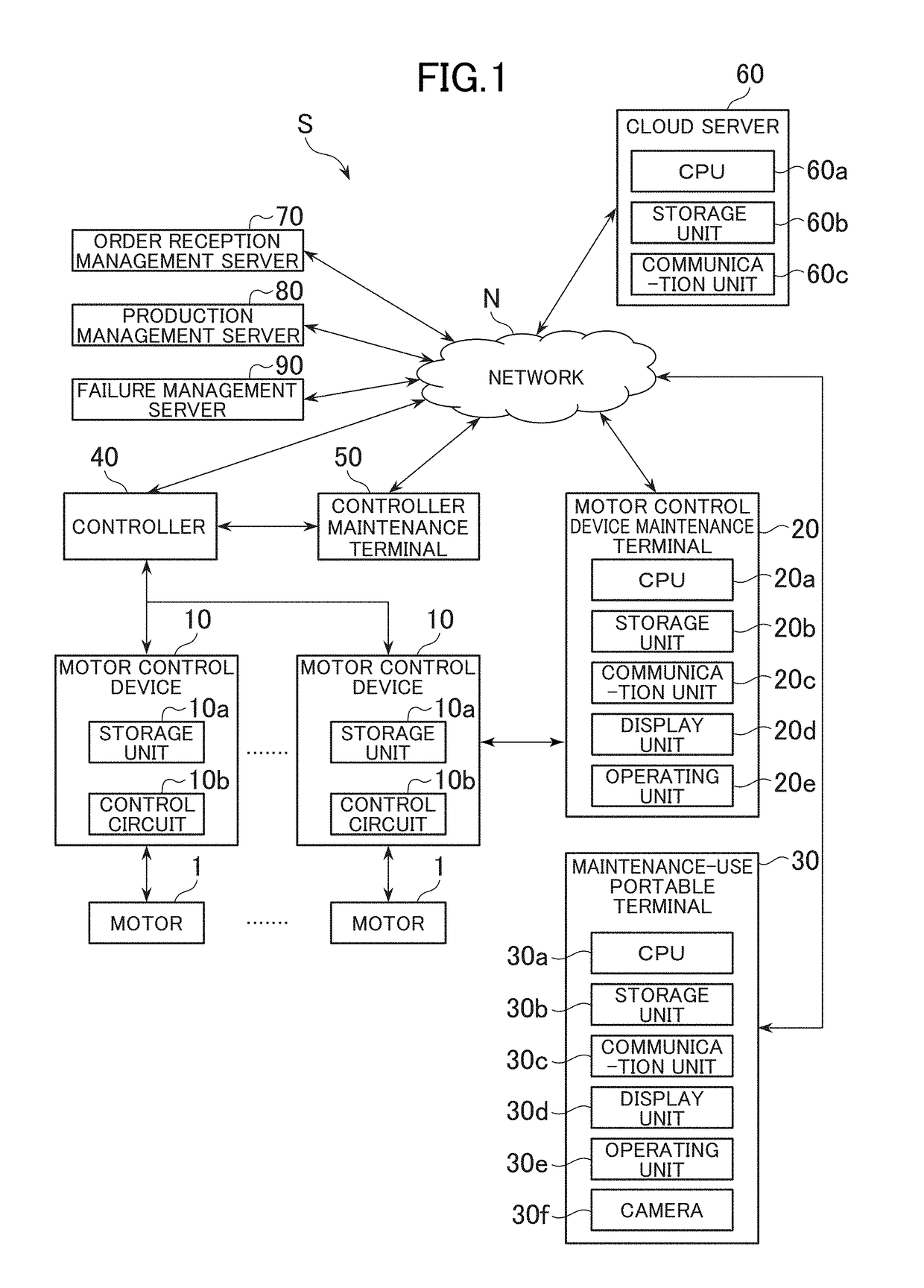

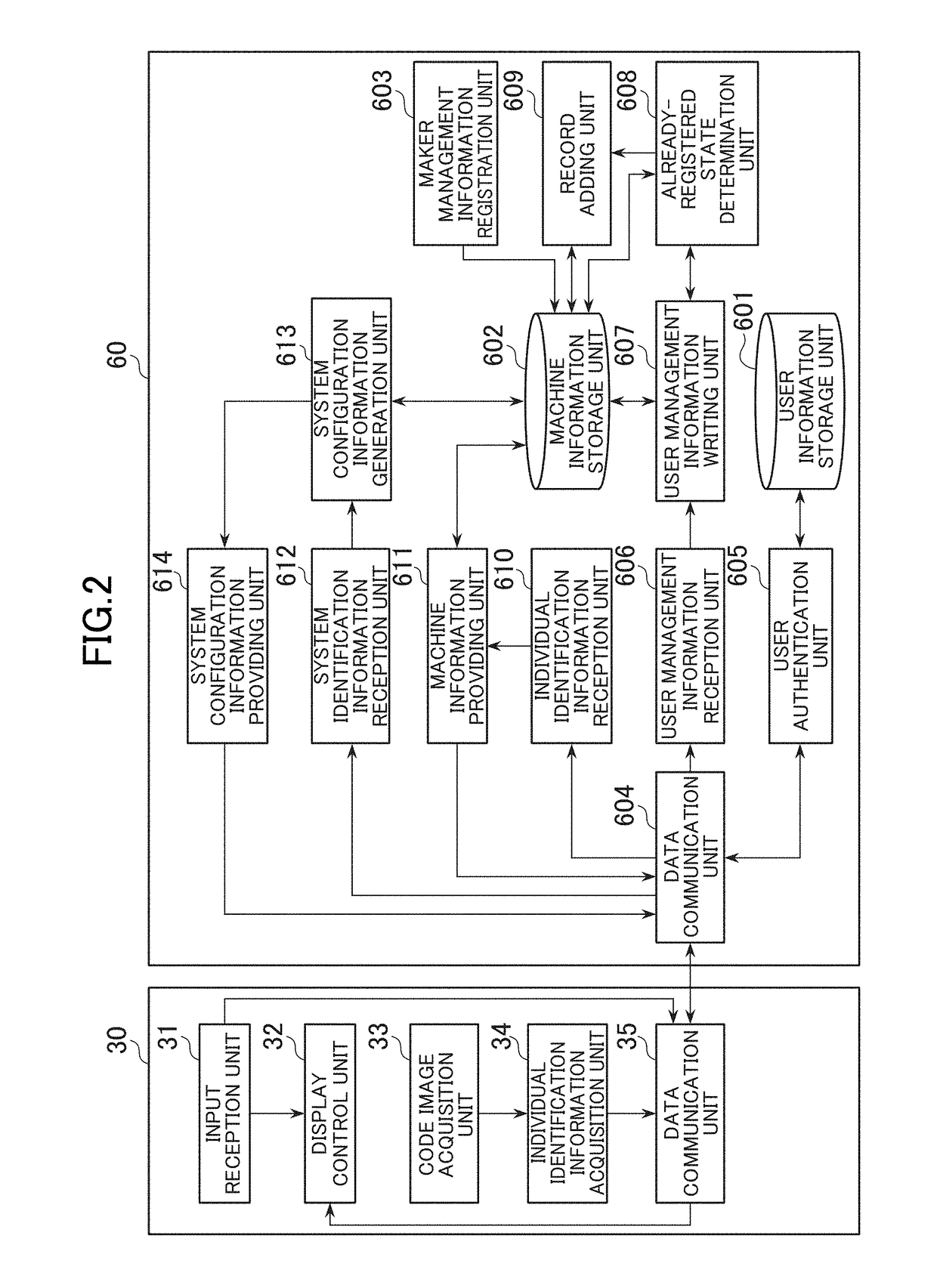

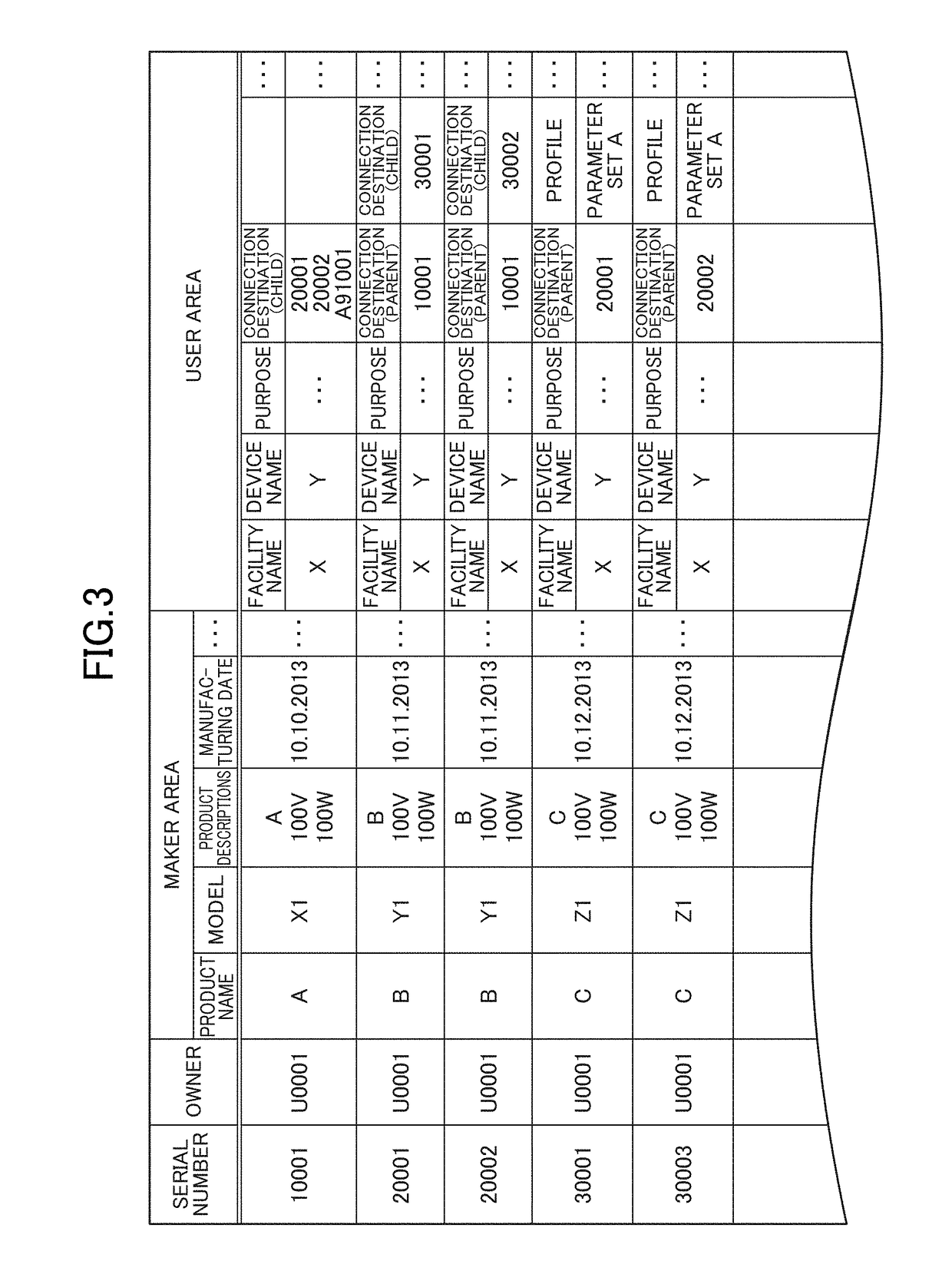

Industrial machine management system, industrial machine management device, industrial machine management method, and information storage medium

An industrial machine management system includes a maintenance-use portable terminal and a cloud server. The maintenance-use portable terminal includes a data communication unit for transmitting management information for a user, which is set in accordance with an input from the user in regard to an industrial machine to be managed. The cloud server includes a data communication unit for receiving the management information for the user transmitted by the data communication unit, and a machine information storage for storing the management information for the user received by the data communication unit in association with individual identification information on the industrial machine to be managed.

Owner:YASKAWA DENKI KK

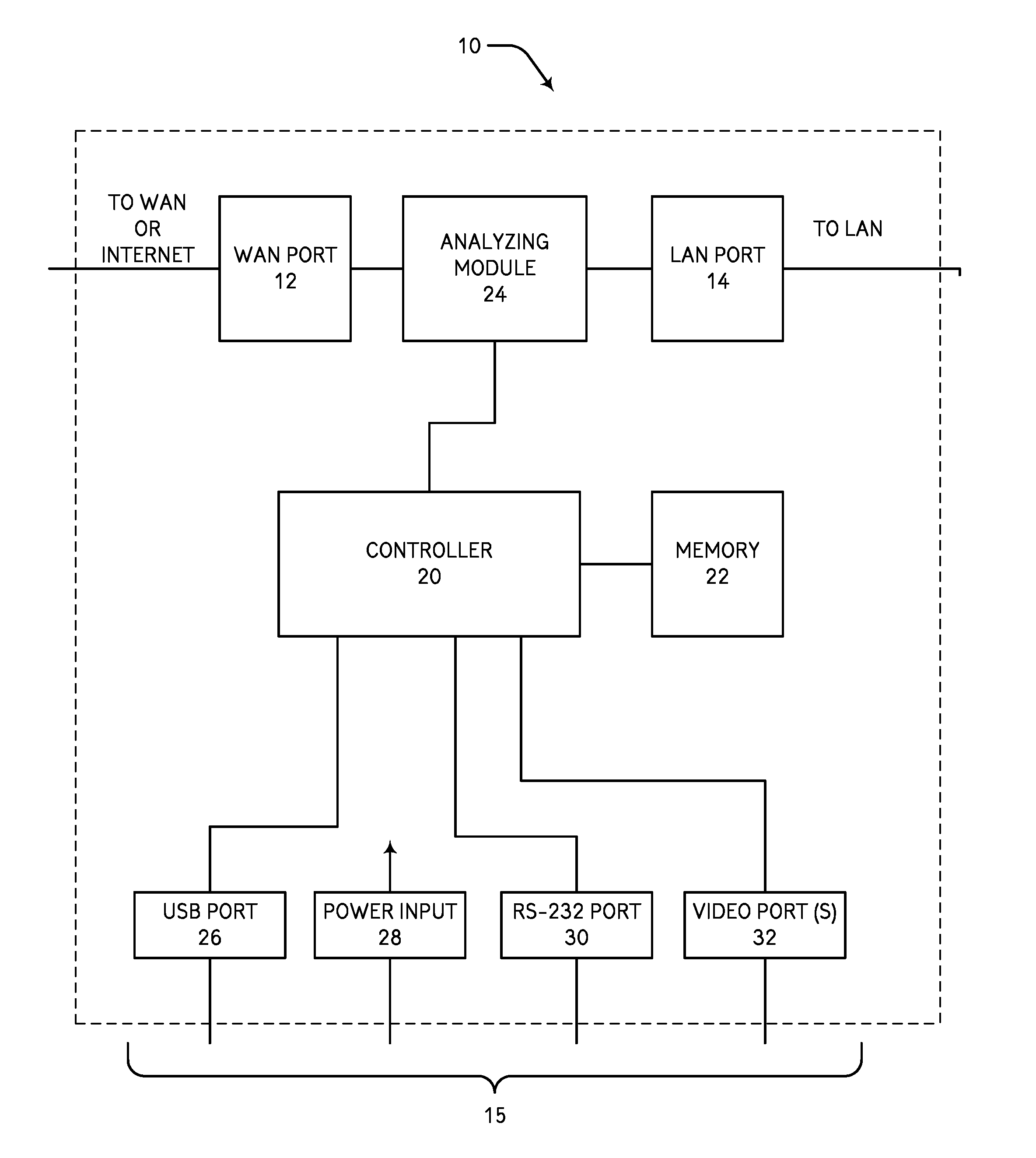

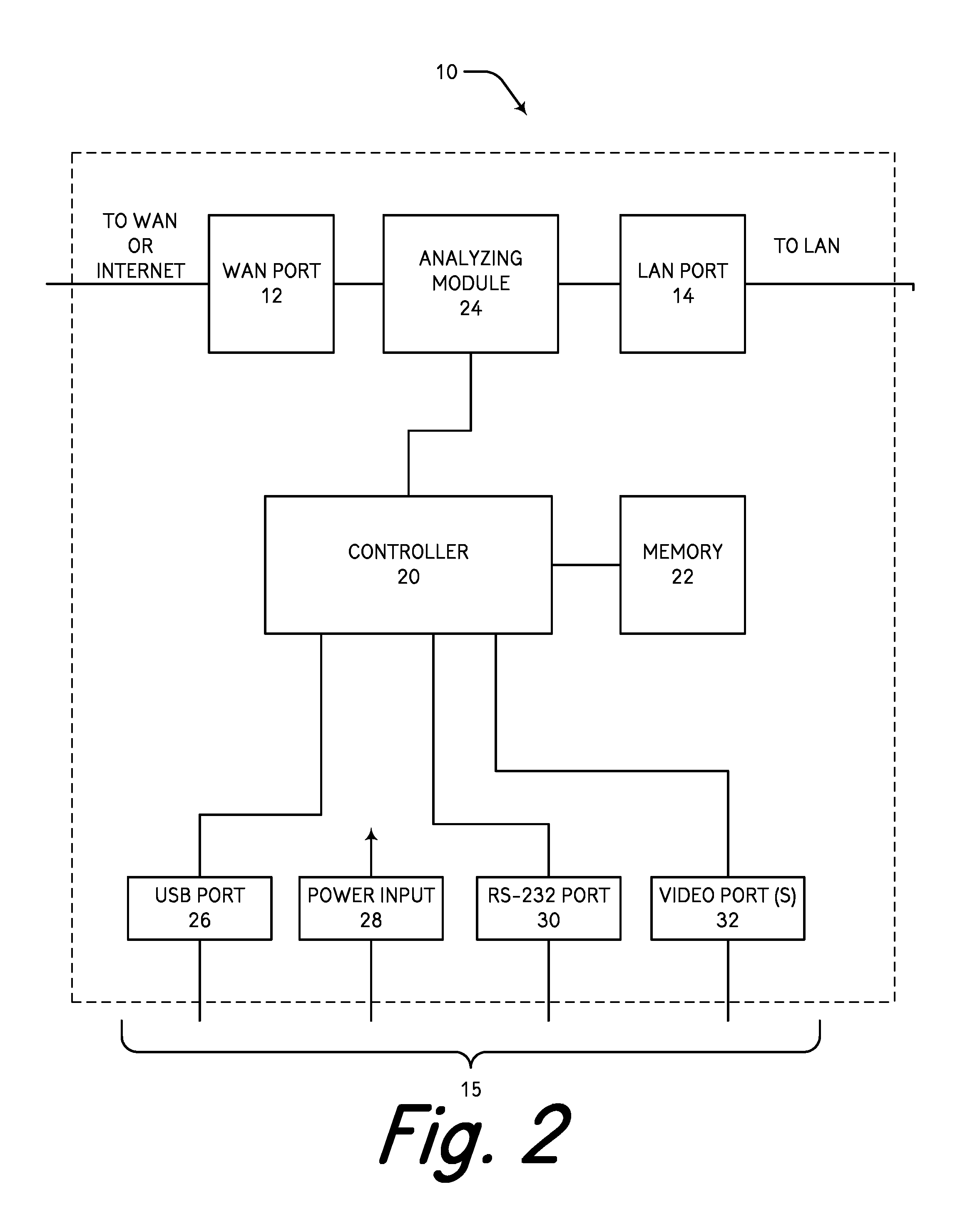

Network protocol analyzer apparatus and method

ActiveUS20130094376A1Improve securityError preventionTransmission systemsReal-time computingIndustrial machine

In one embodiment, a method for electronically analyzing packets using a packet analyzing apparatus includes receiving one or more data packets via a first interface port, wherein the one or more data packets comprises a full packet that may include a payload, determining whether the full packet is part of an existing permitted connection, and if so, determining whether the full packet contains a payload, and if the full packet of the existing permitted connection does not contain a payload, transmitting data indicative of the full packet via the second interface port to an industrial machine control.

Owner:SECURE CROSSING RES & DEV +1

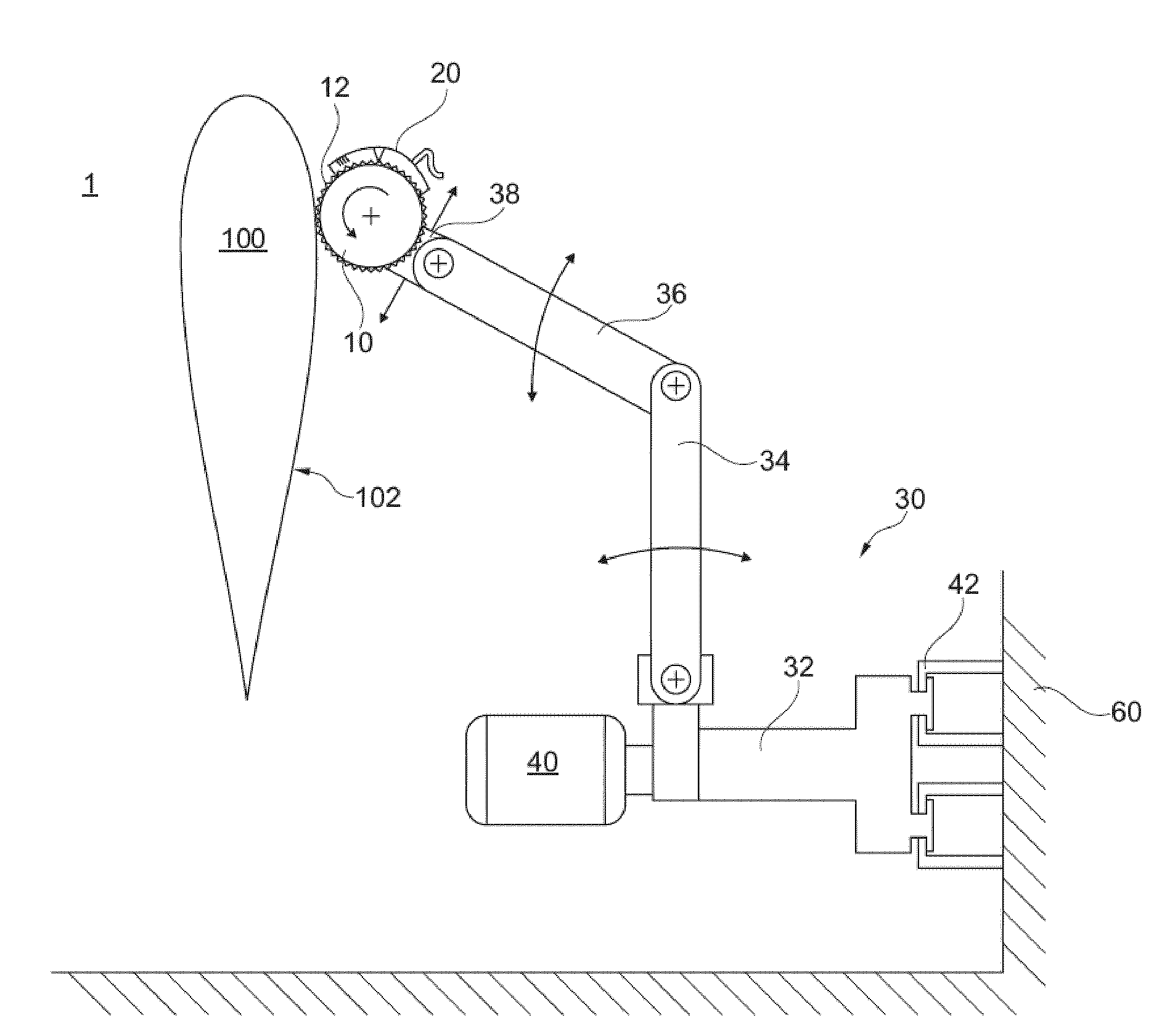

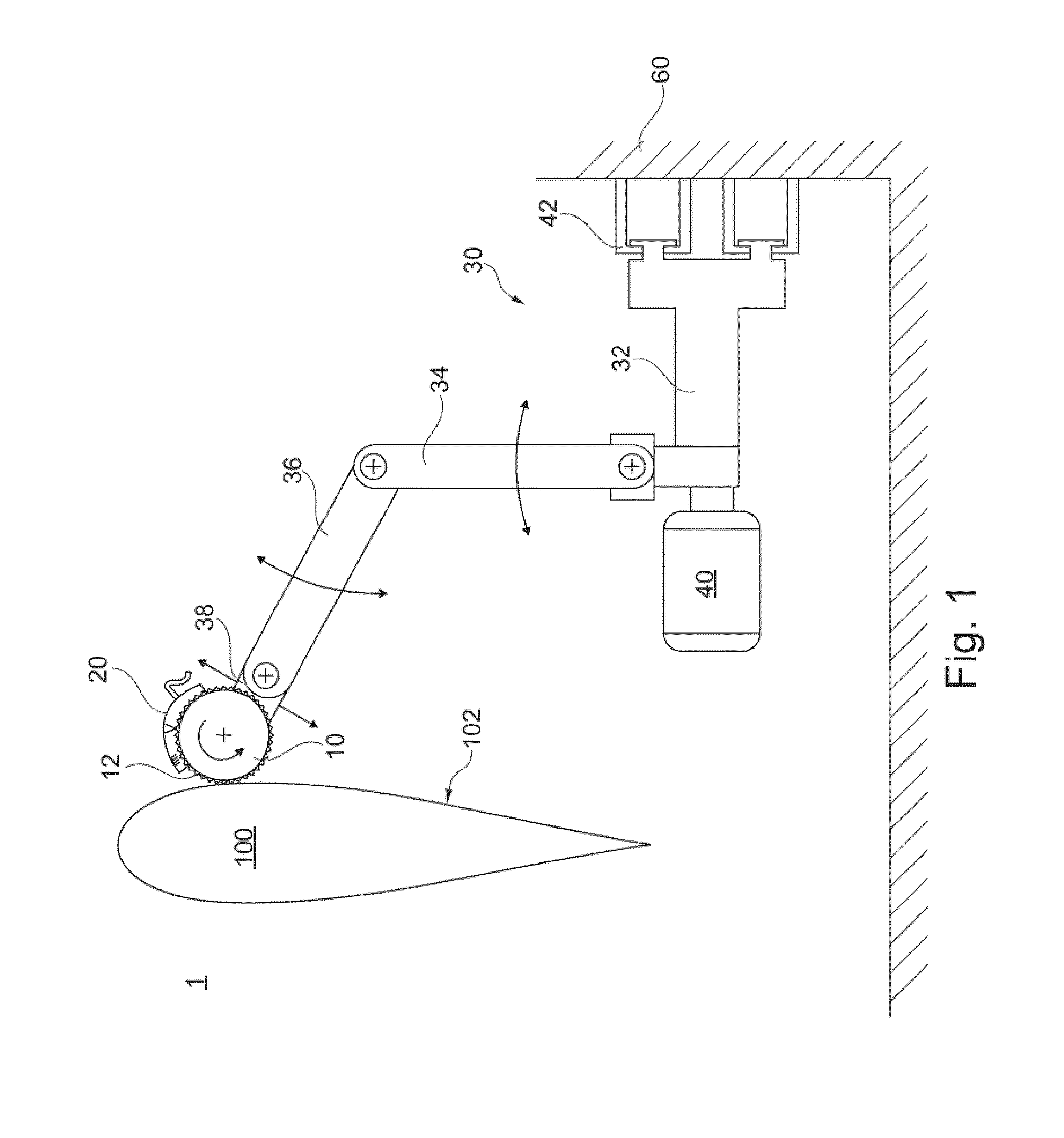

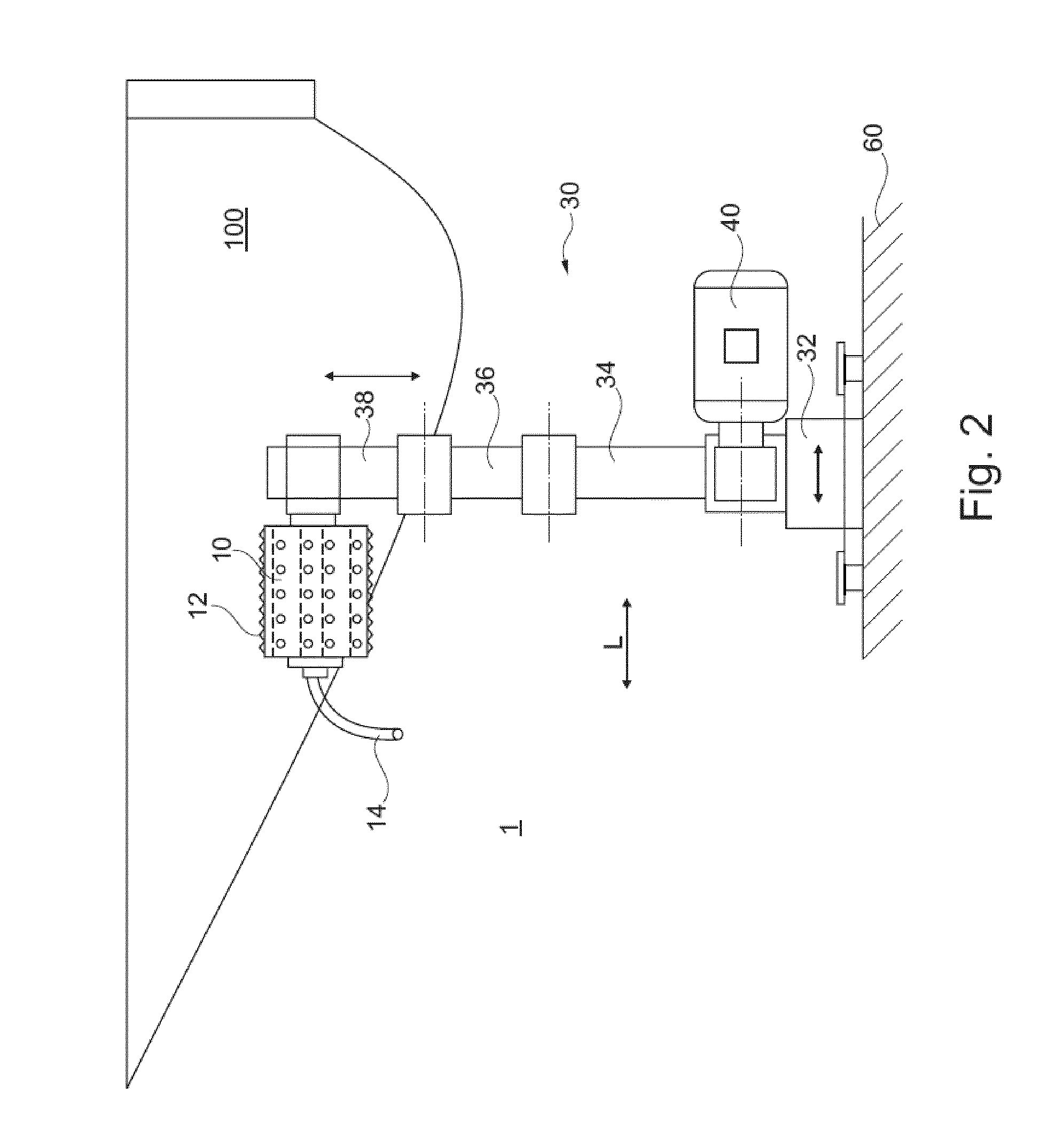

Grinding device for machine based grinding of rotor blades for wind energy systems

InactiveUS20120322349A1Life time of the grinding means is increasedLow investment costEdge grinding machinesSupport wheelsIndustrial machinePulp and paper industry

Grinding device 1 for machine-based grinding of rotor blades 100 for wind energy systems, comprising at least one industrial robot 30 and a grinding unit 10, 50, 70 that is guided by the industrial robot 30, wherein the grinding unit 10, 50, 70 comprises a grinding means, 12, 52 and a cleaning device 20, that cleans the grinding means 12, 52 at its grinding surface 64, 53.

Owner:JOST GMBH & CO KG

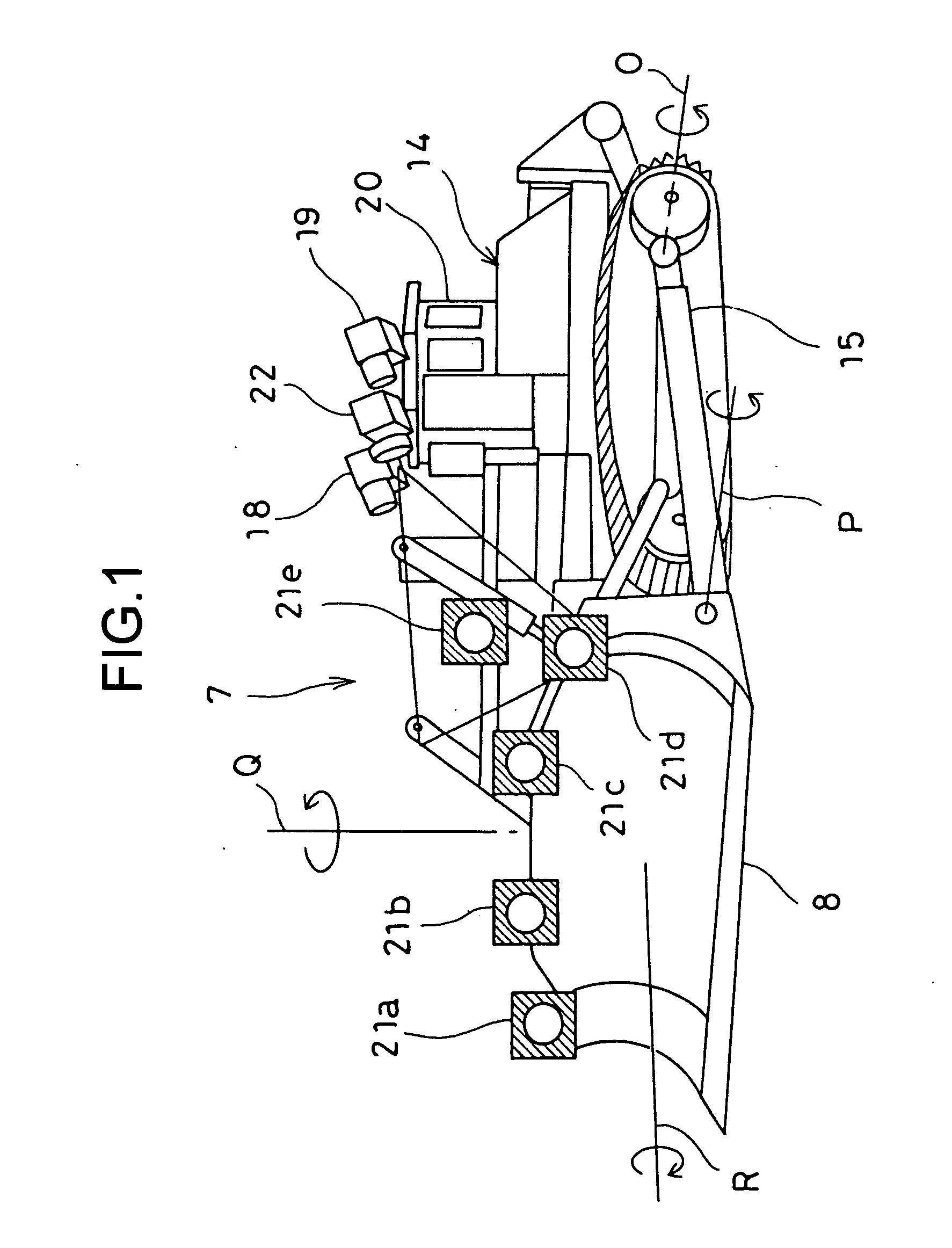

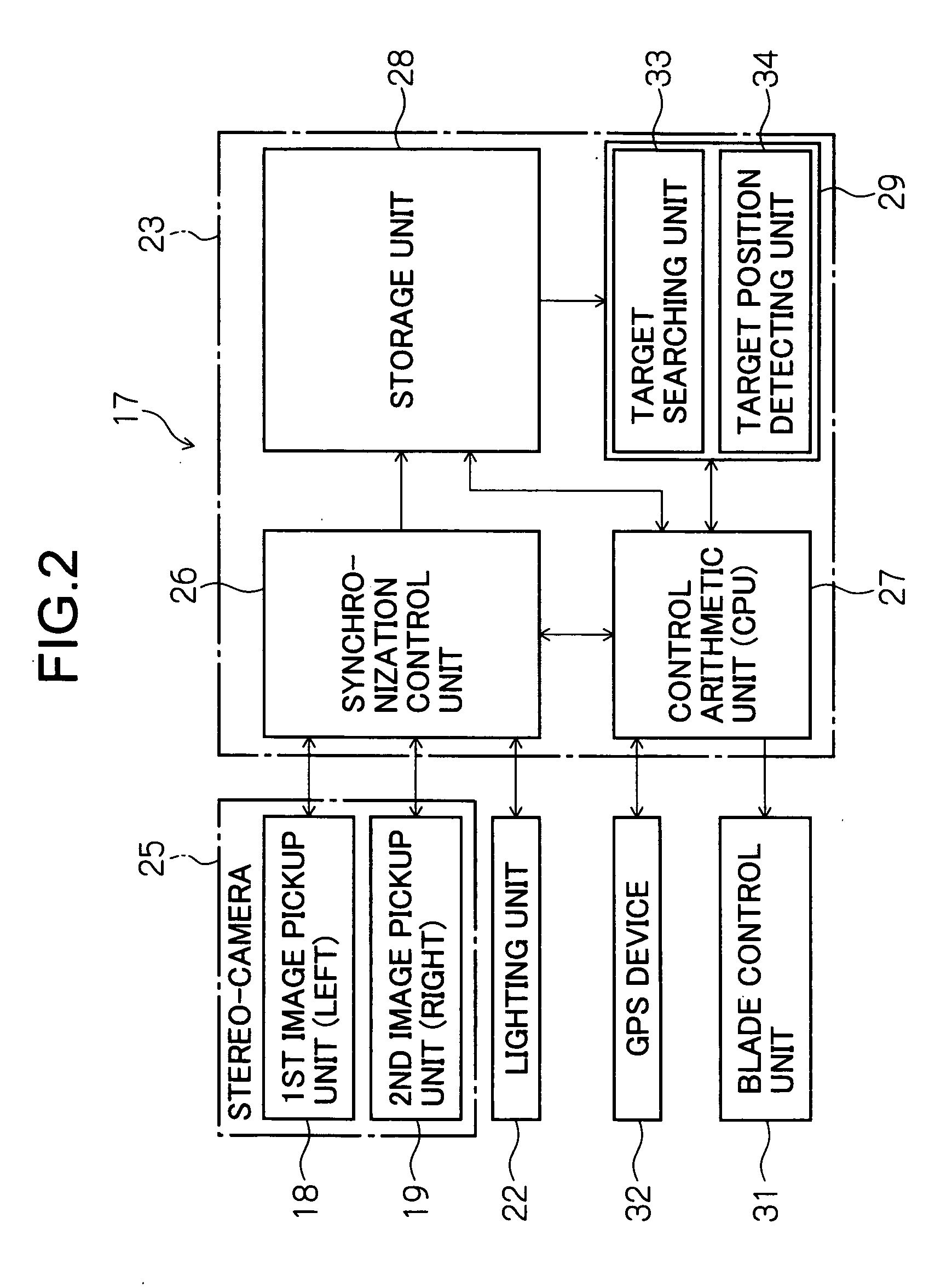

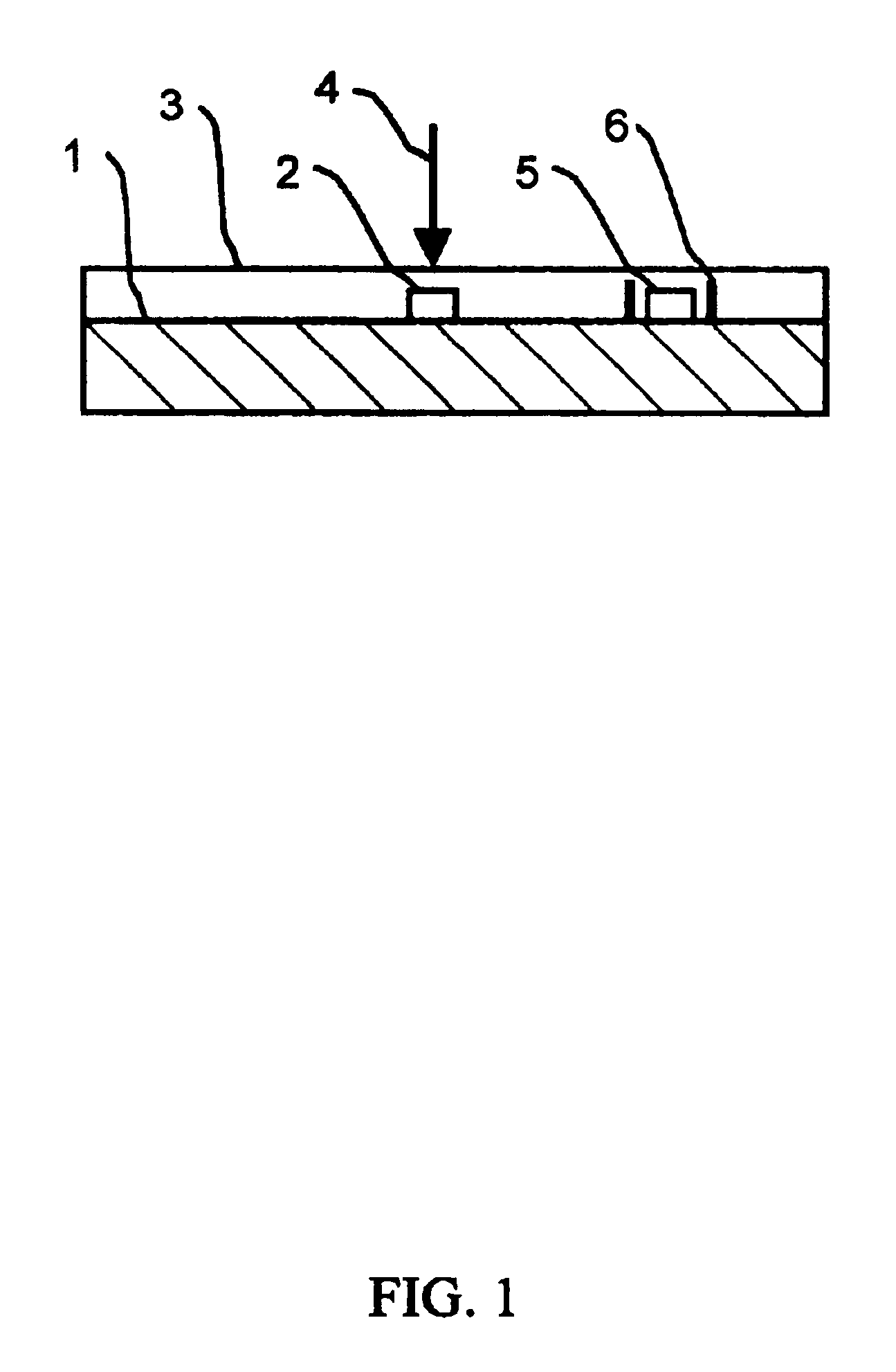

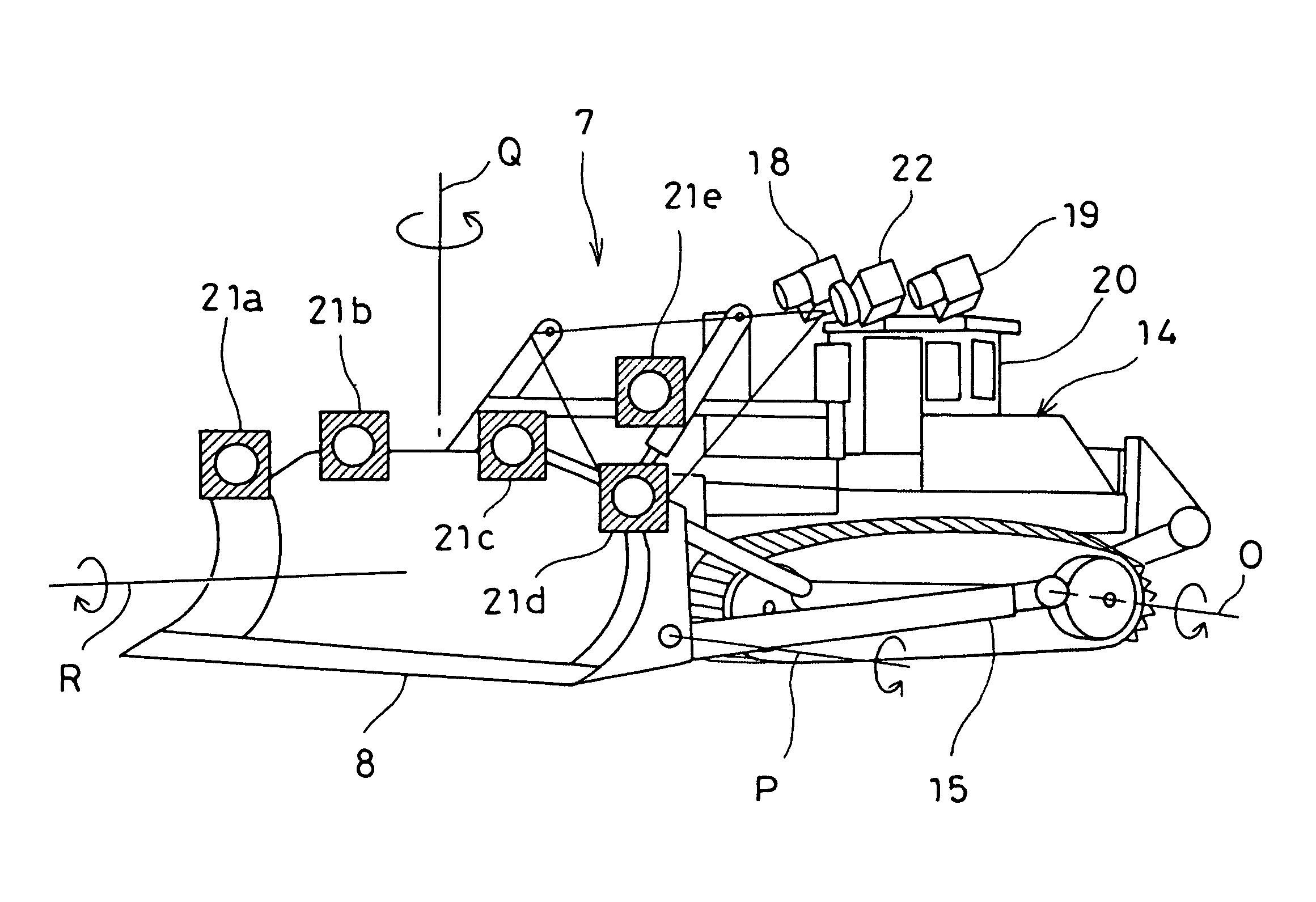

Industrial machine

ActiveUS20100121540A1Easy extractionAccurate detectionAnalogue computers for trafficPosition fixationVisual field lossIndustrial machine

Owner:KK TOPCON

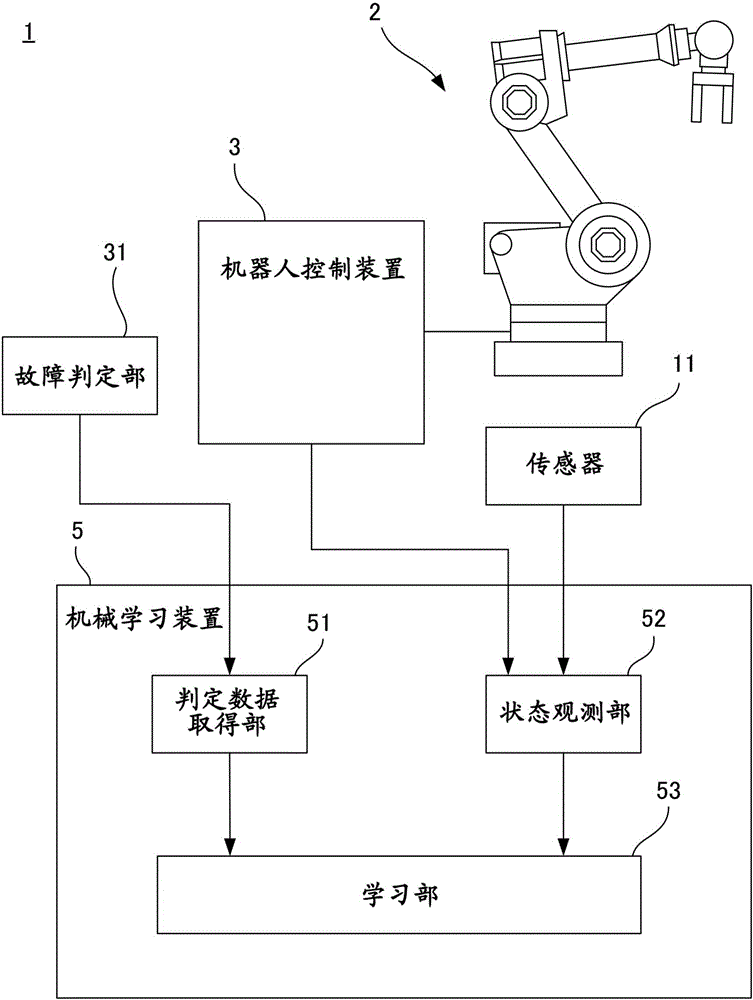

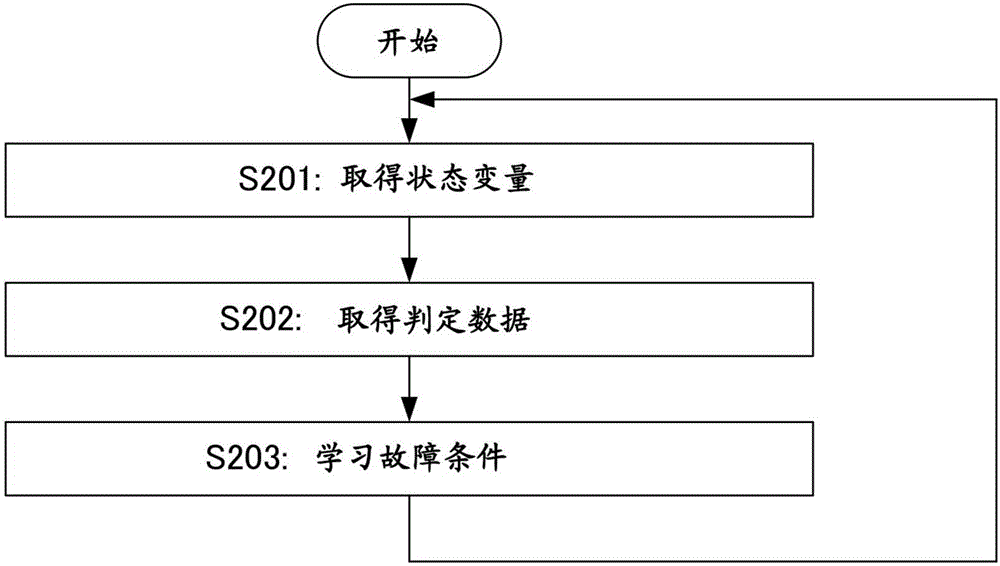

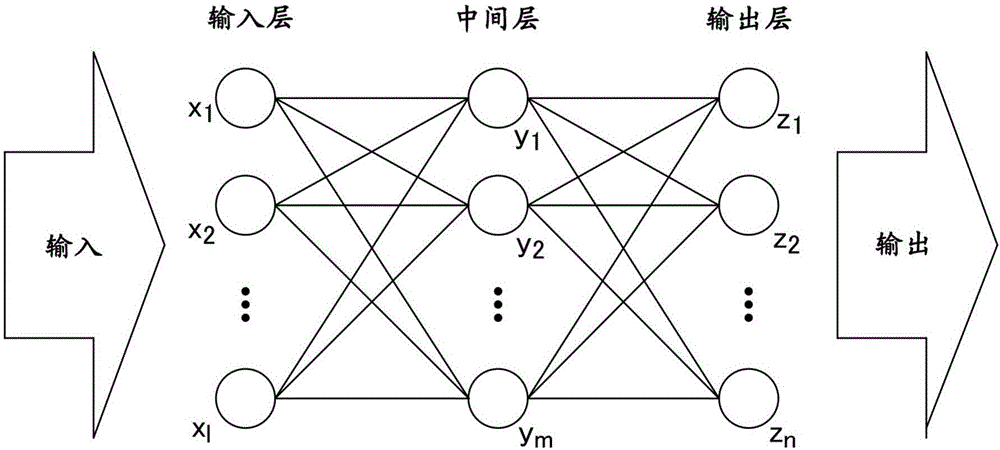

Machine learning method and machine learning device, and fault prediction device and fault prediction system

A machine learning method and a machine learning device, and a fault prediction device and a fault prediction system. fault prediction system includes a machine learning device that learns conditions associated with a fault of an industrial machine. The machine learning device includes a state observation unit that, while the industrial machine is in operation or at rest, observes a state variable including, e.g., data output from a sensor, internal data of control software, or computational data obtained based on these data, a determination data obtaining unit that obtains determination data used to determine whether a fault has occurred in the industrial machine or the degree of fault, and a learning unit that learns the conditions associated with the fault of the industrial machine in accordance with a training data set generated based on a combination of the state variable and the determination data.

Owner:FANUC LTD

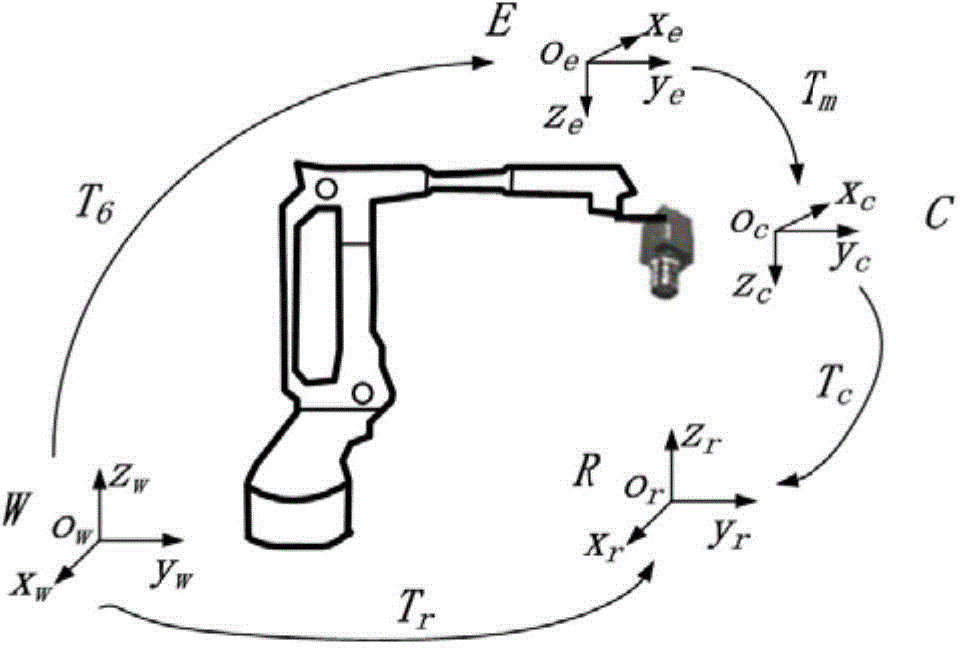

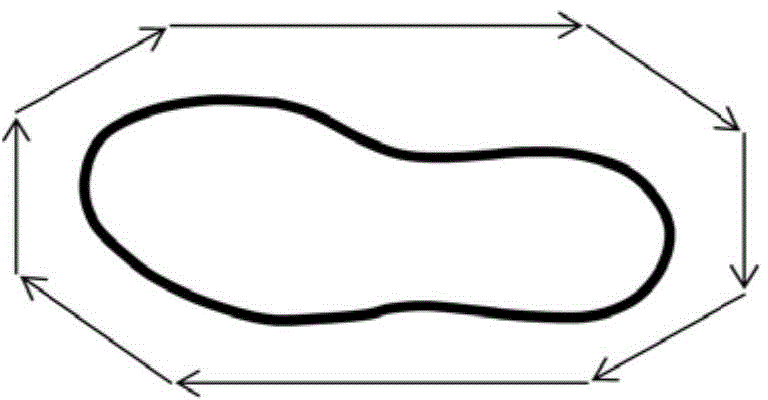

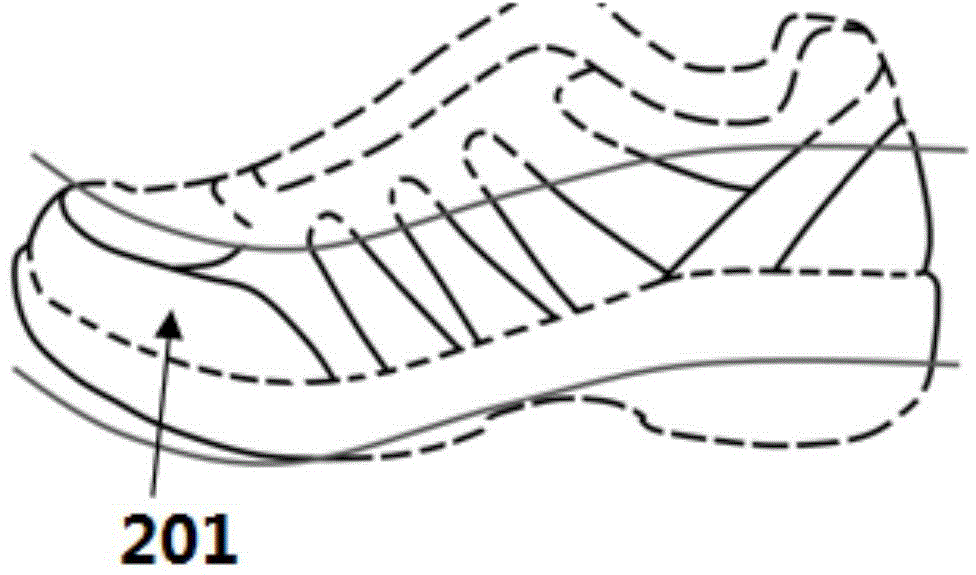

Automatic shoe sole edge line tracking method based on robot

InactiveCN104463851ASave human effortQuick scanImage enhancementImage analysisThree levelGeneration process

The invention provides an automatic shoe sole edge line tracking method based on a robot. The method includes the steps that firstly, a shoe with a shoe sole bound is scanned, after point cloud data are acquired, point cloud feature points are acquired through a weighted PCA three-level-set total least square method, the feature points are divided into blocks and projected to a two-dimensional region, a longest feature line in a two-dimensional image is acquired through a two-dimensional line segment splicing method, the feature line is back projected to three-dimensional space, a closed three-dimensional curve of the edge of the shoe sole is thinned through a space linear projection method, a new curve is generated through a scanned current vamp and the three-dimensional closed curve generated previously in the generation process, the curve is tracked through the industrial robot, and then automatic grinding, liquid medicine coating and glue spraying operation and the like can be achieved. The method can be widely applied to an automatic shoe-making system, and the production efficiency and product quality are improved.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Light ground mass industrial machine-shaping process technology

InactiveCN101253845AReduce labor intensityProtect environmentBio-organic fraction processingBiofuelsEcological environmentEngineering

A technology for industrialized processing and molding of a light matrix includes the steps of crushing agricultural and forest waste first, composting the waste with beneficial microbes, namely EM bacteria for fermentation, conducting rational sifting and matrix matching, using a light-matrix processing and molding machine to process the scattered matrix into an enteroid matrix container with a diameter of 35mm to 50mm, and then cutting the matrix container into small sections, namely matrix sections in the length of 80mm to 100mm, thereby suiting both the cultivation of eucalyptus grafts and the upper bag of the seedling container for tissue-culture rooting. The technology, which can be used for industrialized matrix production, greatly reduces labor intensity and protects ecological environment. The matrix, belonging to composite matrix, can be used for seeding, cuttage and transplant of plants and for the cultivation of other seedlings for greening purpose, with a high survival rate and robust root systems.

Owner:CHINA EUCALYPT RES CENT

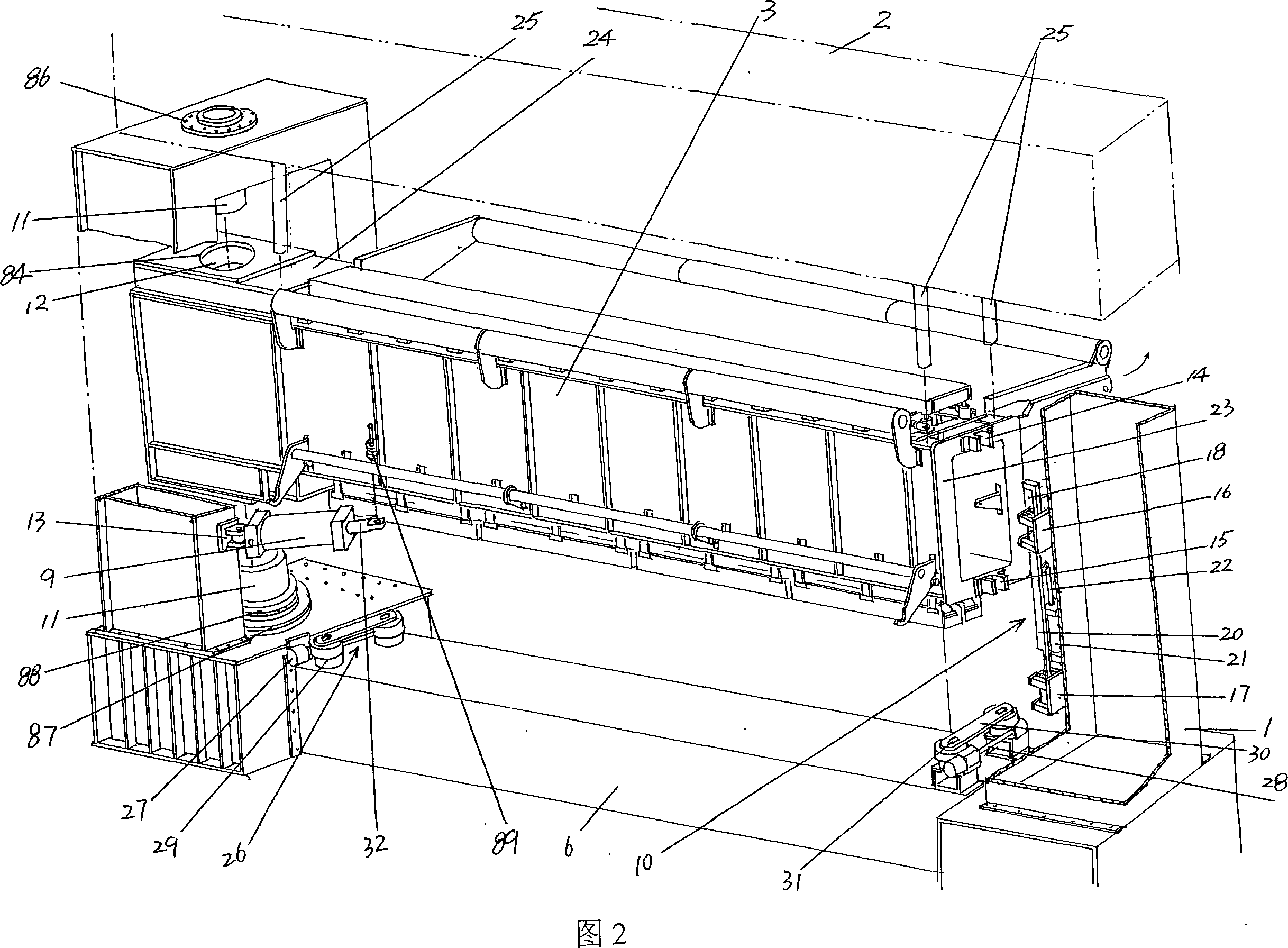

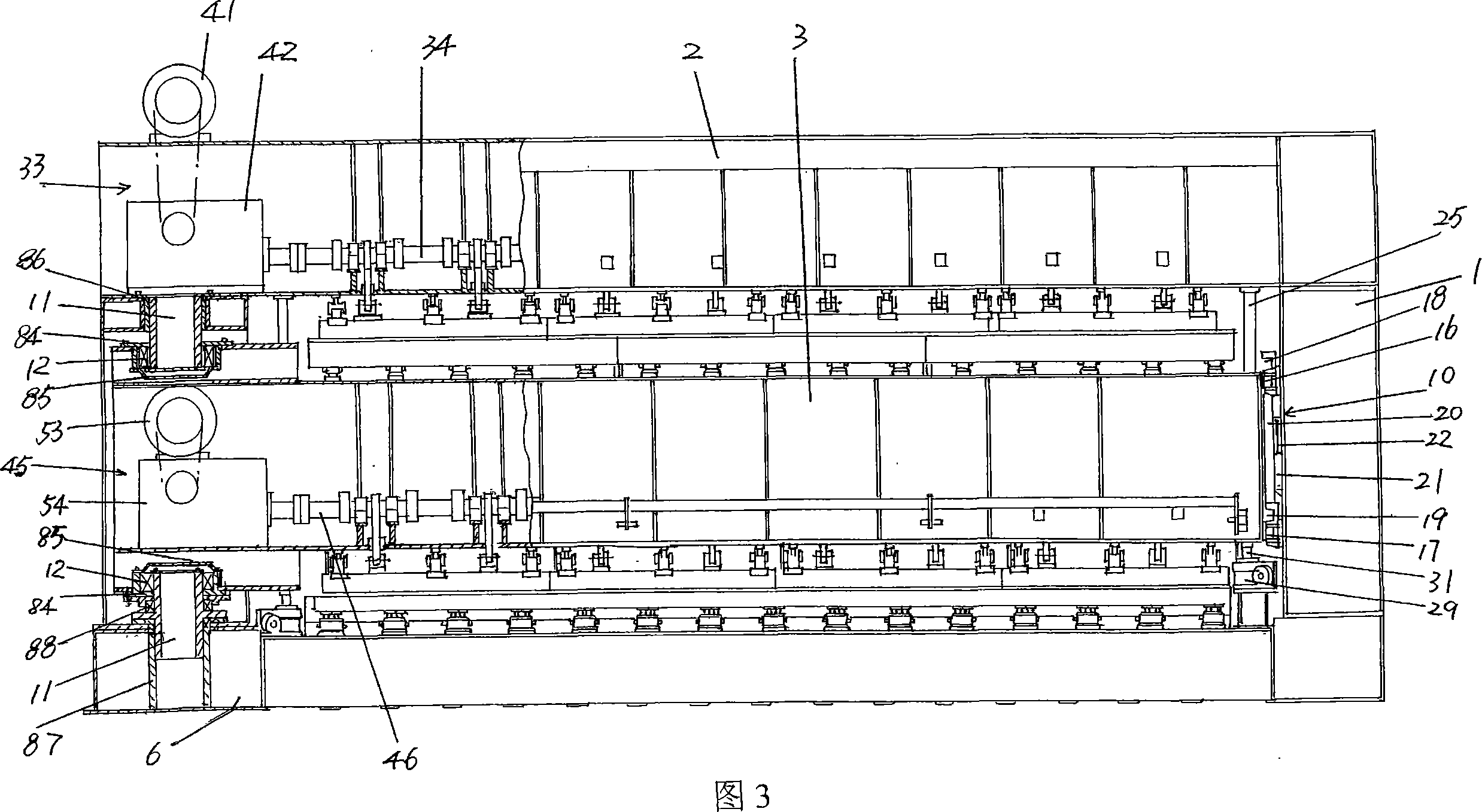

Joint-free industrial felt needle machine with four needle regions needle prick

InactiveCN101122068AReduce labor intensityMeet processing requirementsNeedling machinesIndustrial machineNonwoven fabric

The utility model relates to a non-joint industrial wool needle loom with four needle zones, which belongs to the technical field of non-woven machinery. It includes a frame with a bottom beam, an outer needle punching mechanism for needle punching the outside of the non-woven fiber base cloth on the first beam of the frame, and an openable second needle punching mechanism on the frame. On the beam and corresponding to the inner needling mechanism for needling the inner side of the non-woven fiber base cloth under the outer needling mechanism, the outer needling mechanism constitutes a first and a second outer needling area, The inner needling mechanism is composed of first and second inner needling areas. Advantages: Since the outer and inner needling mechanisms respectively used to simultaneously needling the outer side and inner side of the non-woven fiber base fabric each constitute a pair of needling areas, it is possible to perform needling in four needling areas simultaneously, which has the advantages of Excellent processing efficiency, during the acupuncture process, there is no need to turn over the base fabric, which can reduce the labor intensity of workers; the second beam can be opened and closed, which can meet the processing requirements for wide-width blankets and belts.

Owner:CHANGSHU FEILONG NON WOVEN MACHINERY

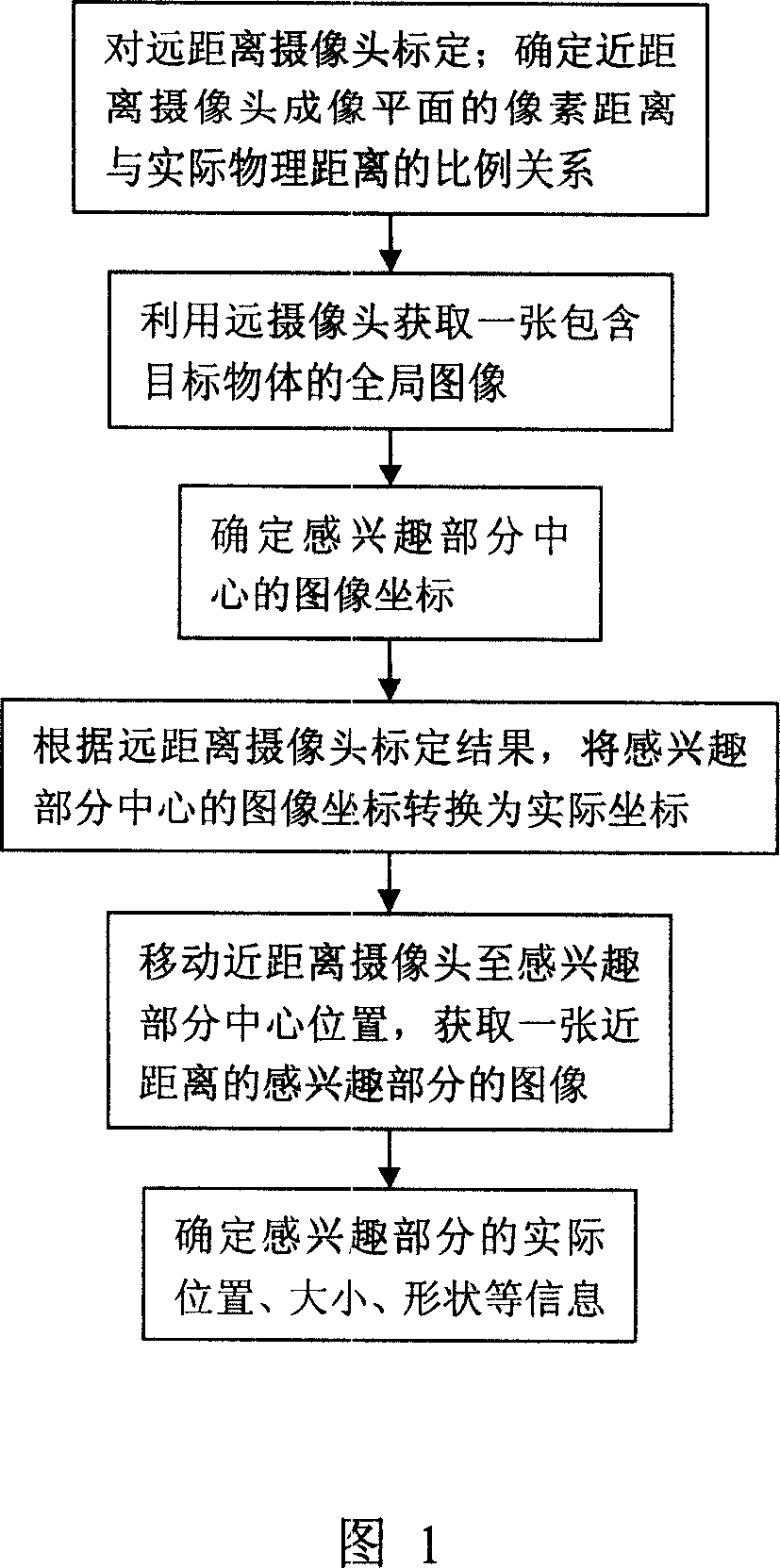

Mechanical vision locating method

InactiveCN101033958AEliminate Radial DistortionRemove tangential distortionPhotogrammetry/videogrammetryMachine visionShortest distance

This invention discloses a machine vision positioning method. It completes the detected mission by using two ordinary cameras includes remote camera used for shooting the whole image of the target object and the close camera used for shooting the interested site in short distance. Firstly calibrate remote camera and then determine the proportion relations between the distance of the actual physical distance and the close camera imaging plane pixel. By using the remote camera shoot target object image and then determine the imaged and the actual coordinates of interested center site. Move the close camera to the interested center site by using the manipulator, acquire the image and determine its imaged coordinates and the actual coordinates, get the information of actual location, shape, size in this site. This invention uses two ordinary camera to obtain with high-precision the detail information on the partial interested site of the target objects, satisfies the high precision demand on the industrial machine vision applications with low cost.

Owner:HUAZHONG UNIV OF SCI & TECH

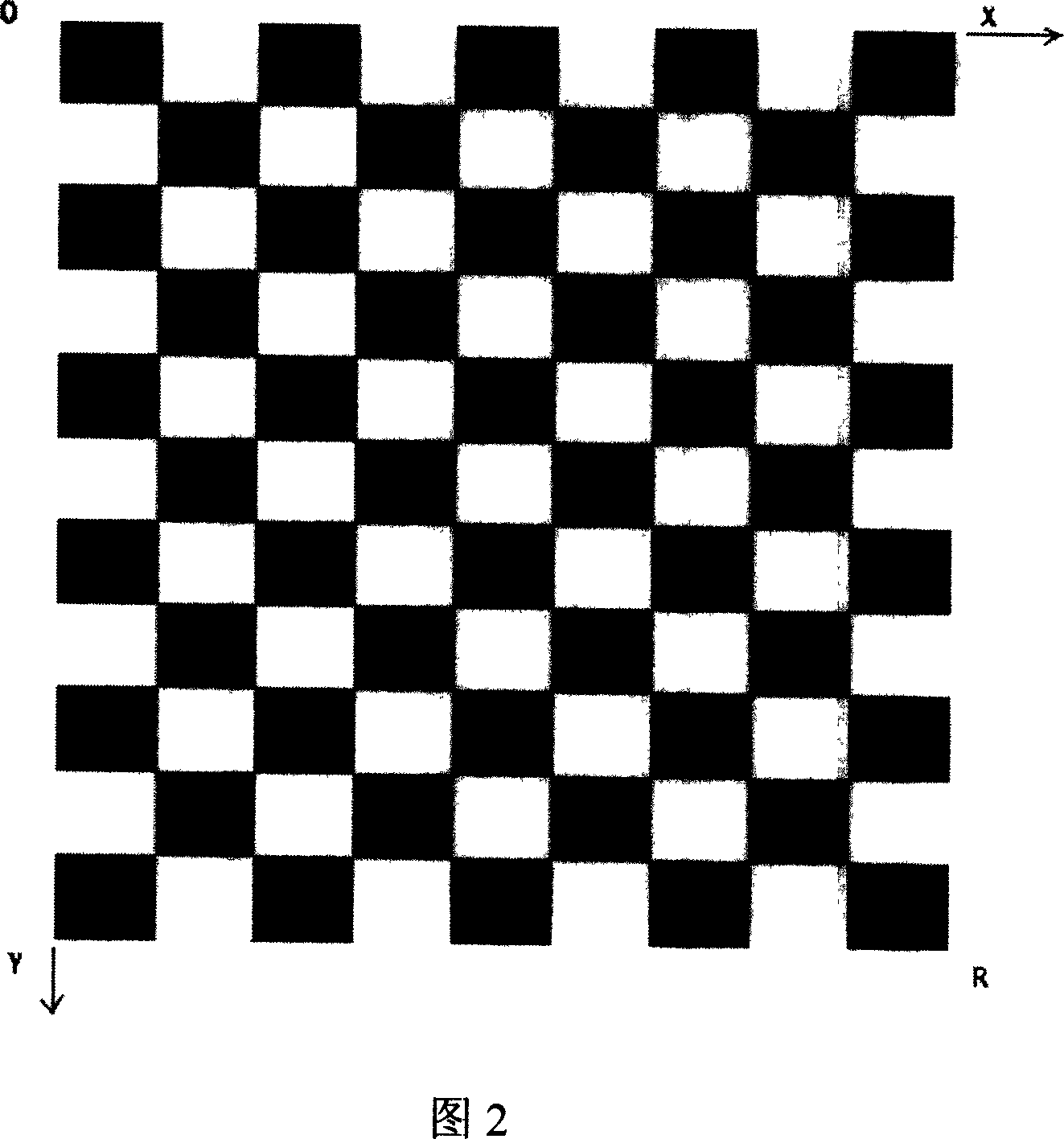

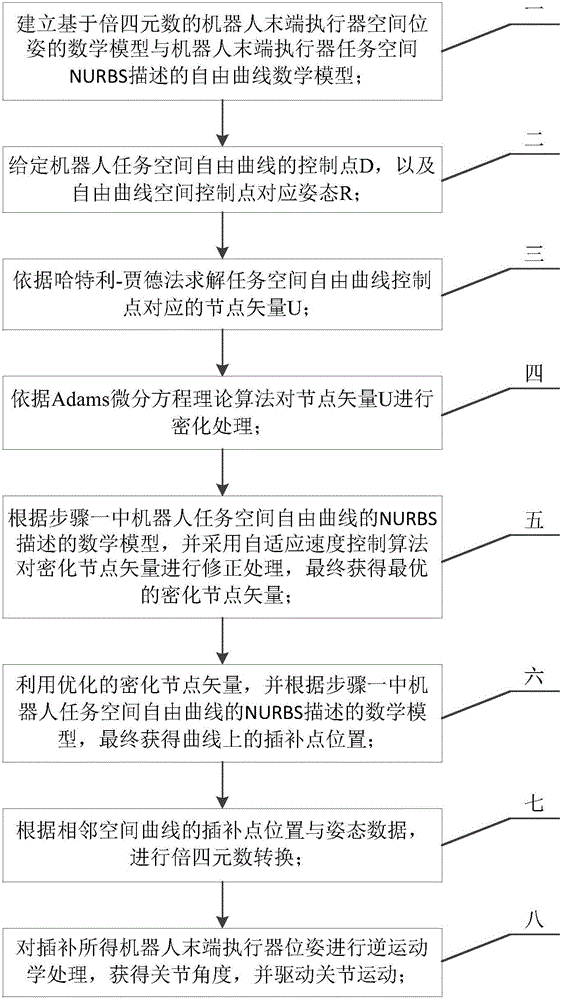

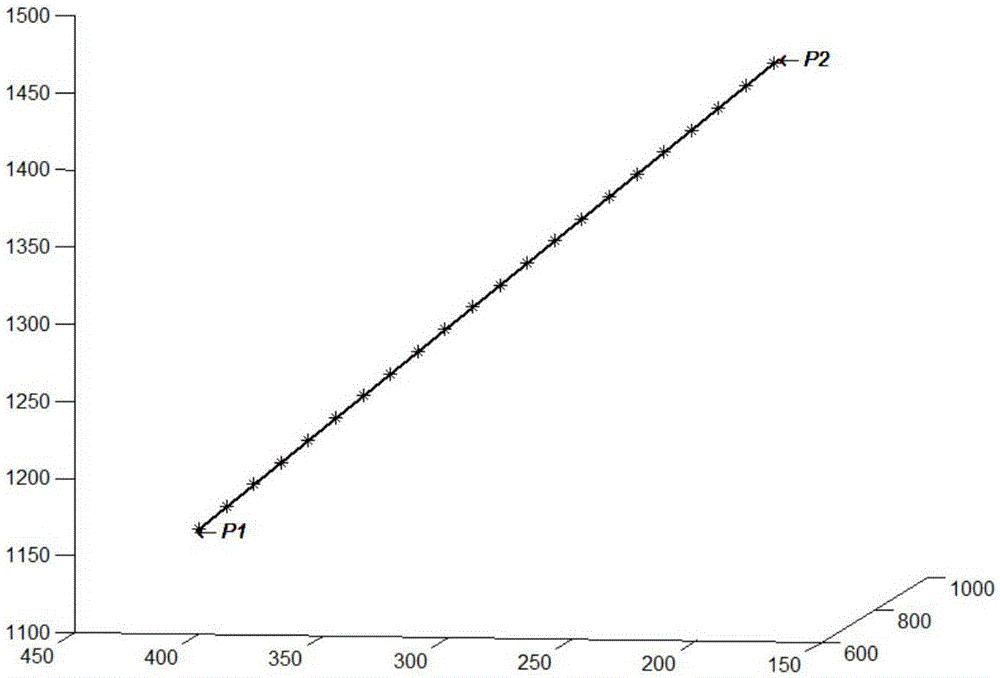

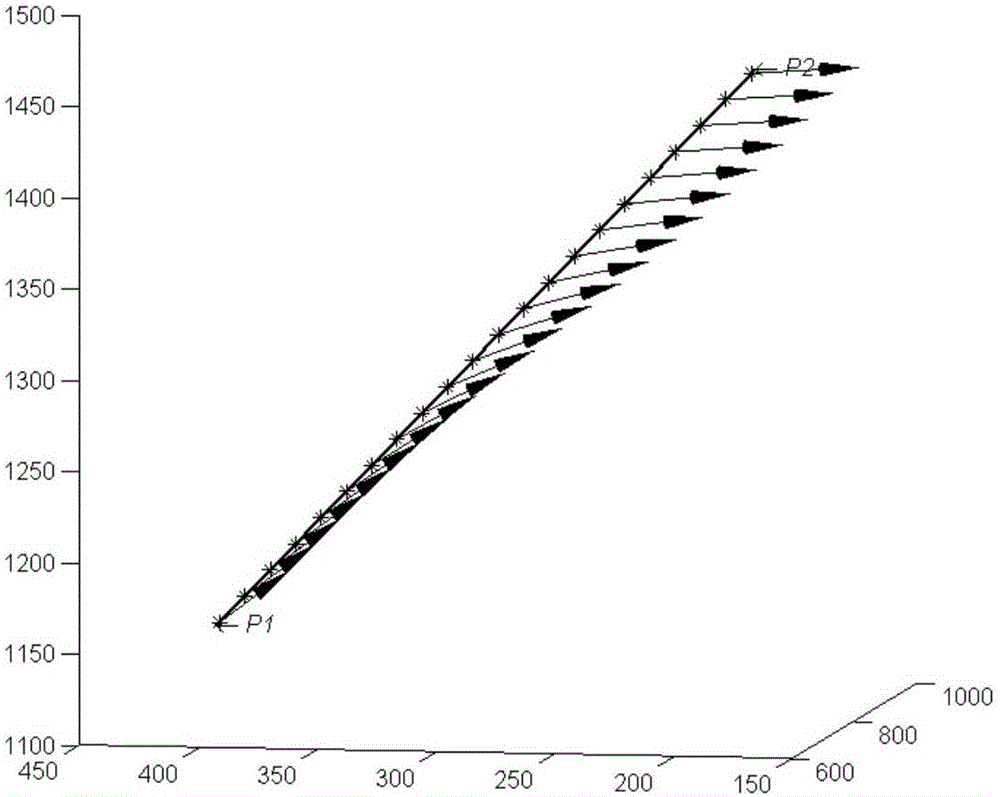

Track planning and control method of free curve of industrial robot based on double quaternions

InactiveCN105773620AImprove work efficiencyImprove the quality of workProgramme-controlled manipulatorQuaternionRobot position

The invention discloses a track planning and control method of a free curve of an industrial robot based on double quaternions. Control point data of the Cartesian space are adopted for describing the contour of the space free curve, and meanwhile an Adams differential equation is adopted for NURBS interpolation compacting calculation, and interpolation speed is adjusted in a self-adaption manner with the maximum contour error and maximum acceleration as constraint conditions; and then the position and posture of the robot in the Cartesian space are converted to a four-dimensional space through a short linear segment obtained through interpolation by adopting the double quaternions, the motion trail of the robot is subjected to spherical linear interpolation through hyperspherical rotation, and finally the track of the NURBS free curve of the industrial robot is planned.

Owner:NANJING INST OF TECH

Measuring pressure exerted by a rigid surface

InactiveUS6931938B2High special resolutionAccurate pressure measurementFluid pressure measurement by electric/magnetic elementsForce measurementElastomerMachine control

A means to accurately measure the pressure distribution across a rigid or semi-rigid surface, or between two rigid or semi-rigid surfaces with high special resolution is disclosed. The present invention relates to measuring a pressure distribution. The present invention would be ideal for use in various types of manufacturing tooling and various in situ industrial machine controls. The present invention uses an array of commercial micro-machined silicon pressure sensing die attached to a substrate and encapsulated in an elastomer.

Owner:KNIRCK JEFFREY G +1

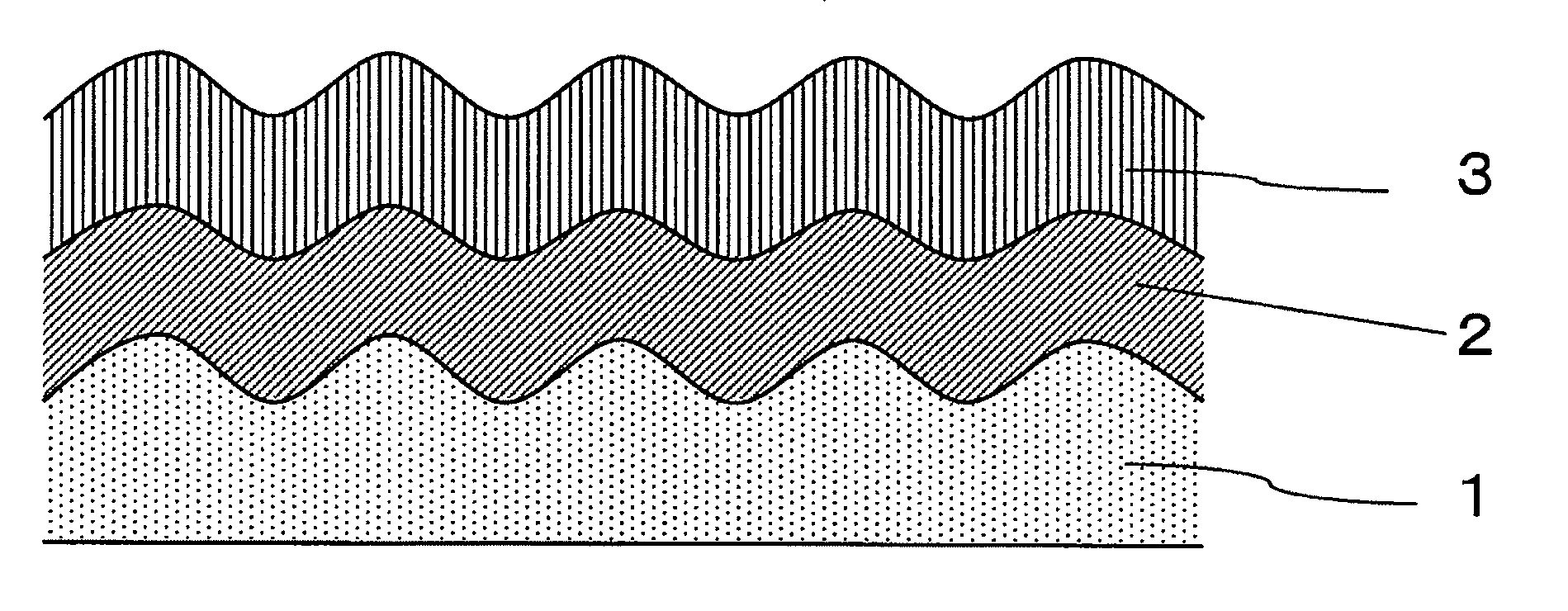

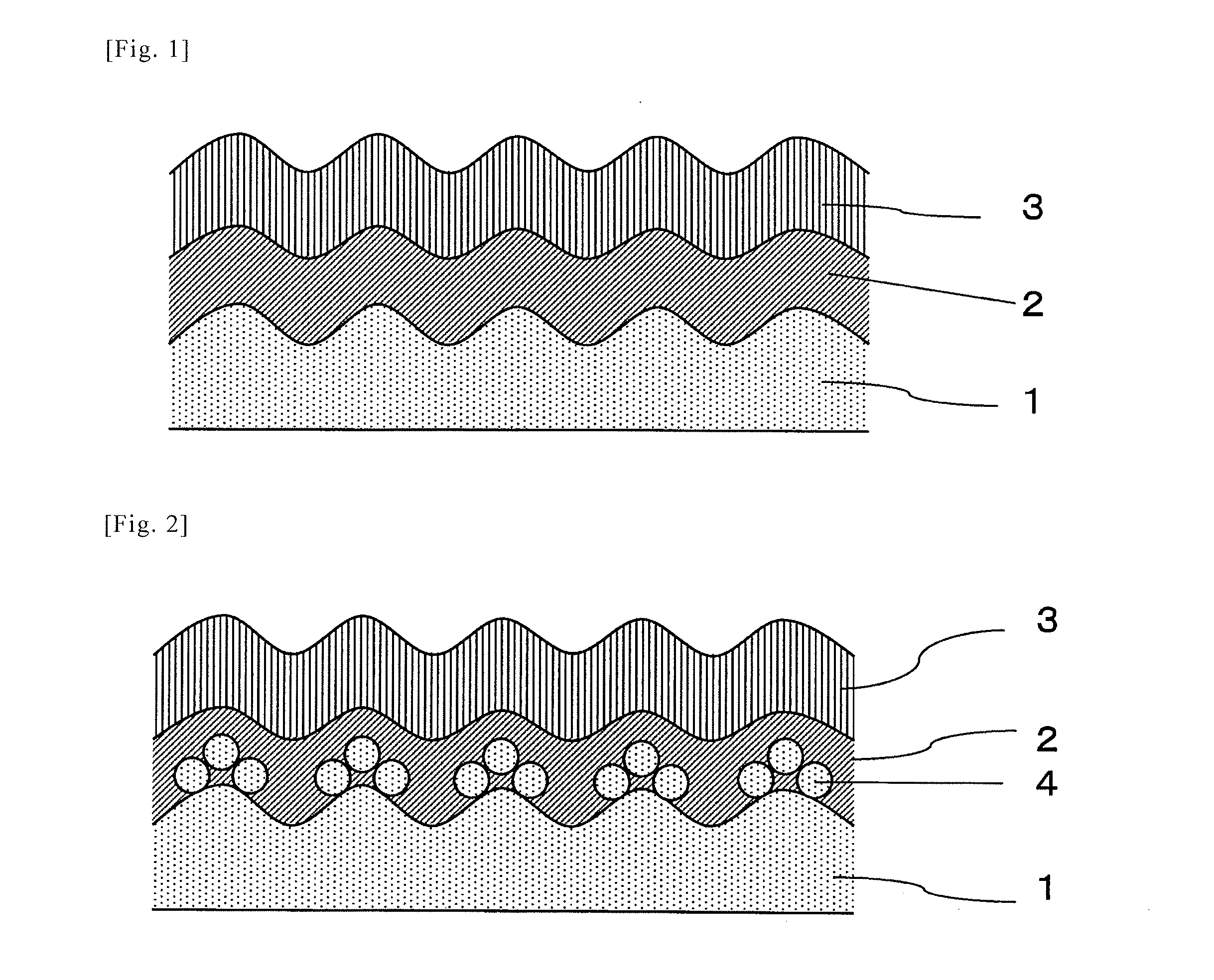

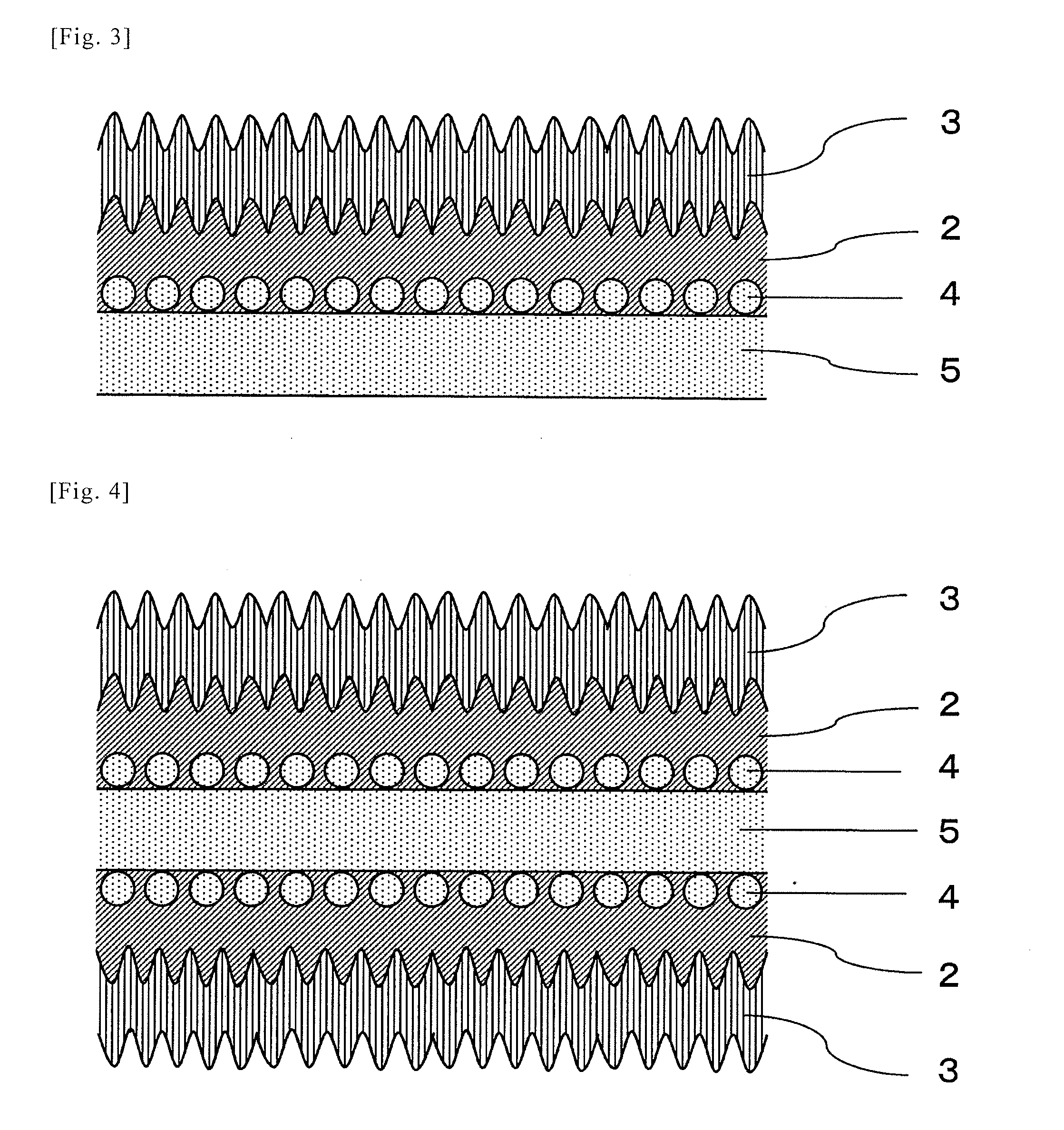

Anode for secondary battery, anode current collector, production method thereof, and secondary battery

ActiveUS20130115510A1Easily be inserted alloyingIncrease capacityElectrolysis componentsFinal product manufactureSurface roughnessCopper foil

A chargeable and dischargeable secondary battery for use in electronic devices, industrial machines, electric-powered vehicles, is provided, along with an anodic electrode and a copper foil for anode current collector. It is an anode for secondary battery that utilizes non-aqueous electrolyte, which comprises a silicon-type active material film formed on one side or both sides of a current collector made of copper foil or copper alloy foil, wherein 1 g / m2 to 14 g / m2 of silicon-type active material film is formed on said current collector, and the lightness Y value in a XYZ colorimetric system (CIE 1931 standard colorimetric system) for the surface of said anode, onto which said silicon-type active material film is formed, is 15 to 50, and the surface roughness (ten point average roughness) Rz specified by the Japanese Industrial Standards (JIS B0601-1994 ten point average roughness) is 1.0 μm or more and 4.5 μm or less.

Owner:FURUKAWA ELECTRIC CO LTD

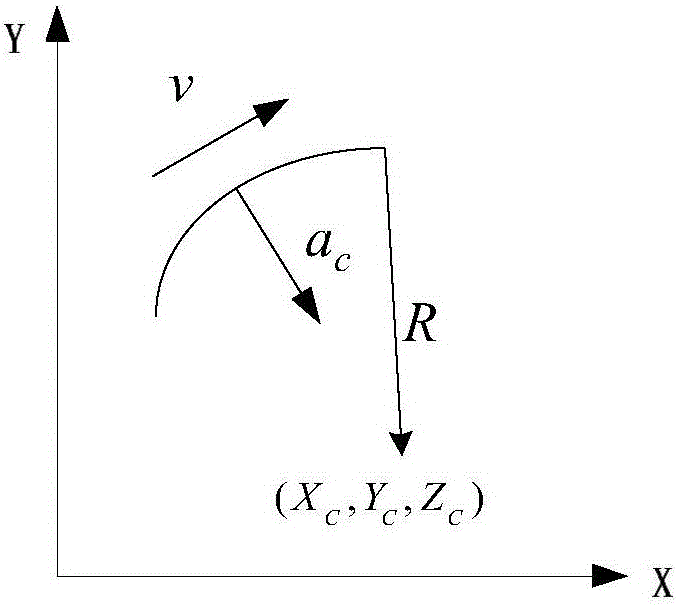

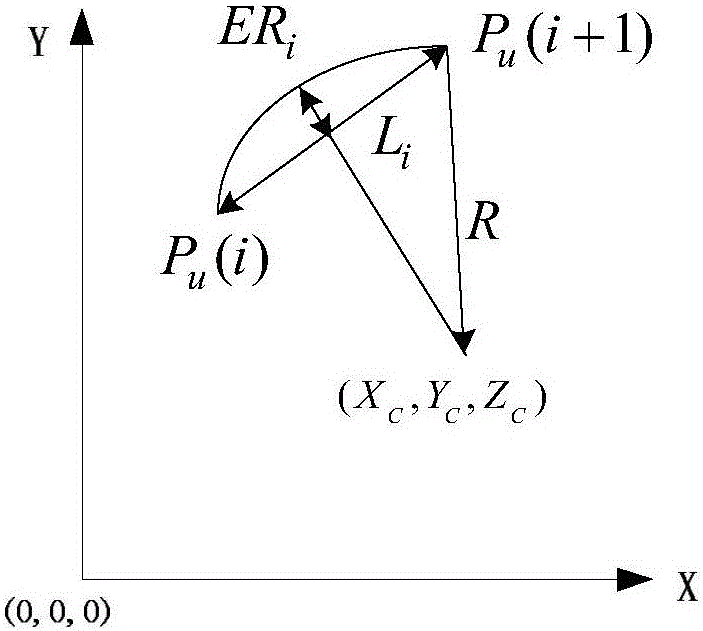

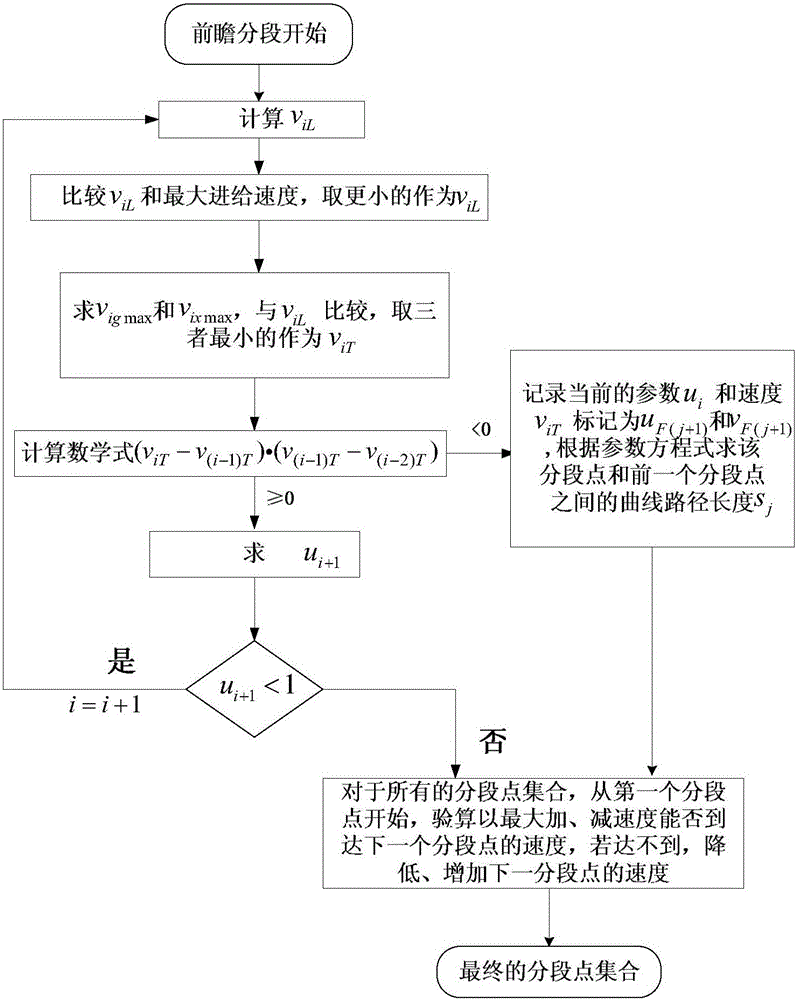

Speed planning method during NURBS curve interpolation of industrial robot

The invention relates to a speed planning method during NURBS curve interpolation of an industrial robot. The method comprises that (1) a characteristic equation, based on a parameter u and a feed velocity v, of an NURBS curve is established; (2) a velocity constraint relation, based on the geometrical constraints as centripetal acceleration and chord-height error, of the NURBS curve is established; and (3) according to the fact that the feed speed in the robot end changes monotonously, predictive speed segmentation is carried out on the NURBS curve to obtain a segment point interpolation parameter set, and a speed planning process is completed. The speed planning method is especially suitable for the NURBS curve in which multiple teaching points are known, a movement track of the robot end needs to be smooth, and the movement speed and acceleration of the robot end cannot change abruptly; the geometric characteristics of the NURBS curve are taken into consideration when speed limitation is established; the curve is segmented predictively according to the monotonicity of speed change; and impact on the robot during NURBS curve interpolation is greatly reduced.

Owner:SOUTH CHINA UNIV OF TECH

Split serial-parallel hybrid dual-power drive system

A split serial-parallel hybrid dual-power drive system, comprised of two or more than two separation drive systems allowing independent operation to respectively drive the load, or all loads driven individually are incorporated in a common frame to drive land, surface, underwater transportation means or aircraft, industrial machines and equipment or any other load drive by rotational kinetic energy.

Owner:YANG TAI HER

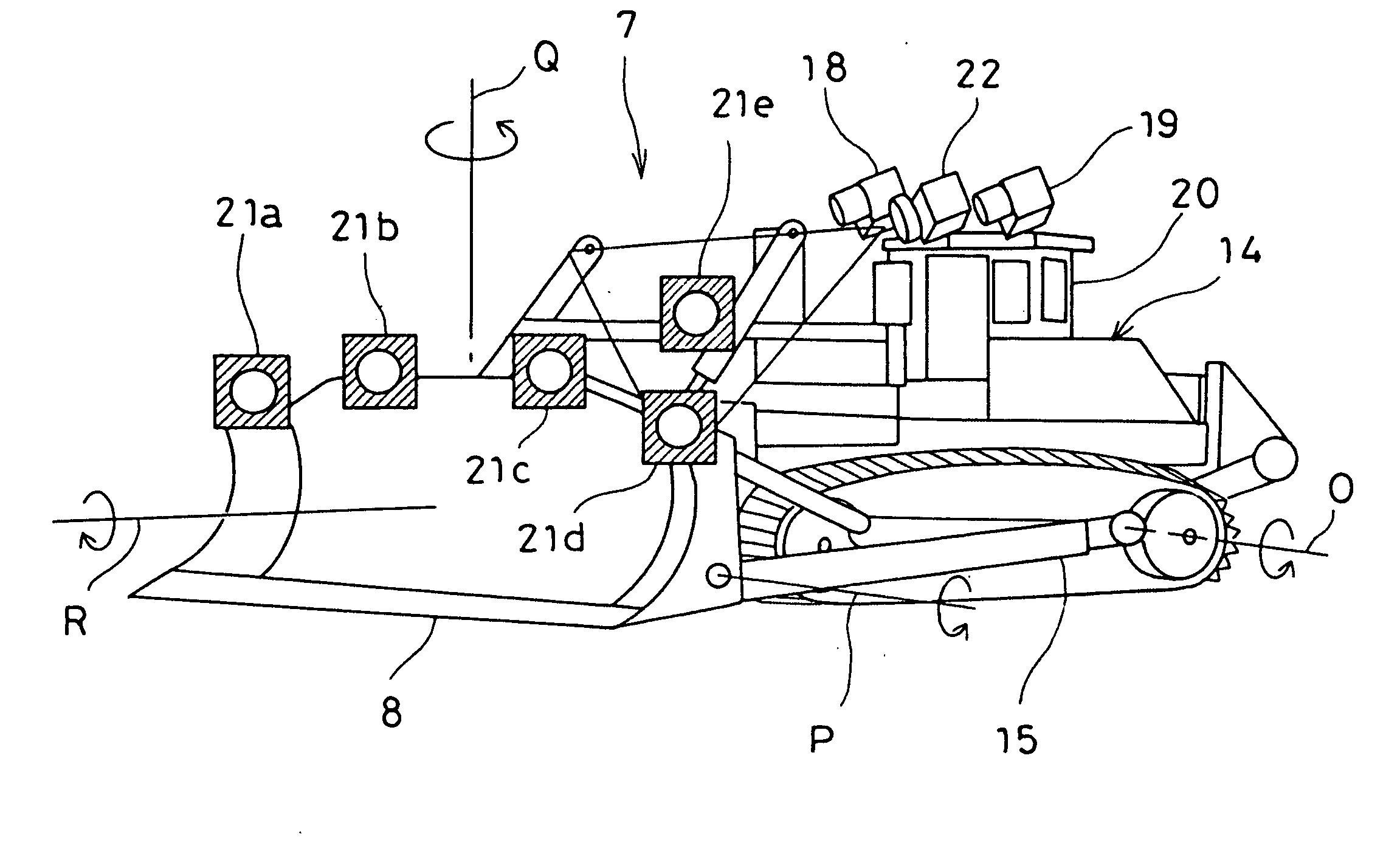

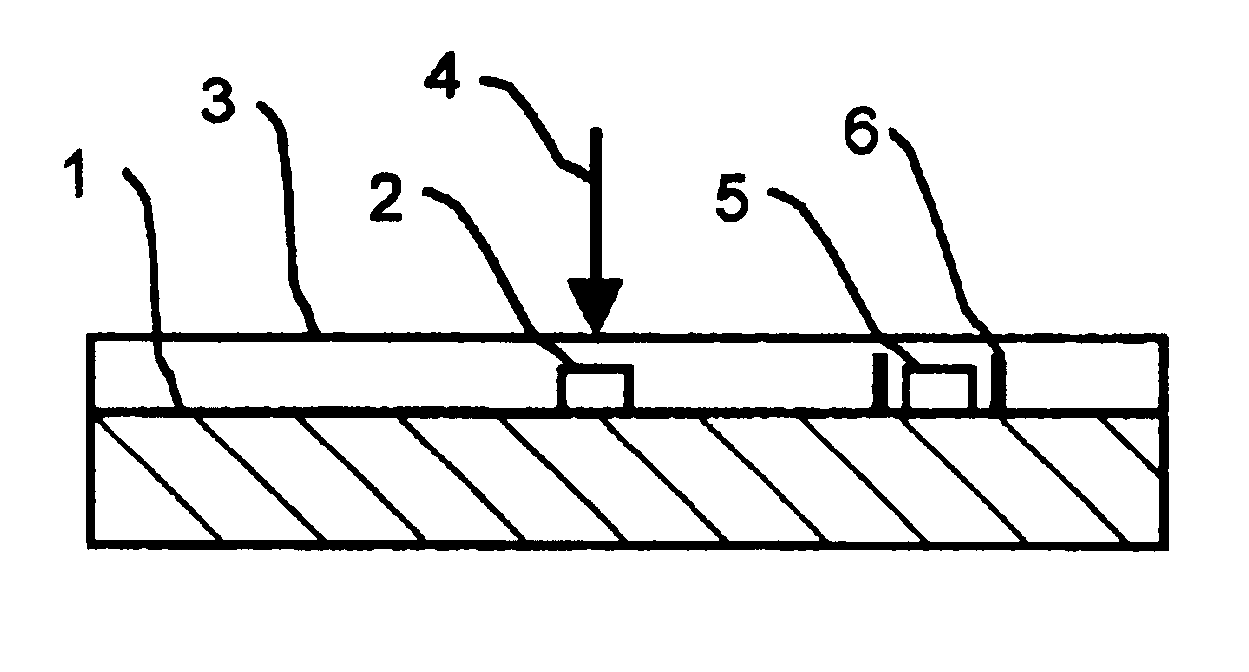

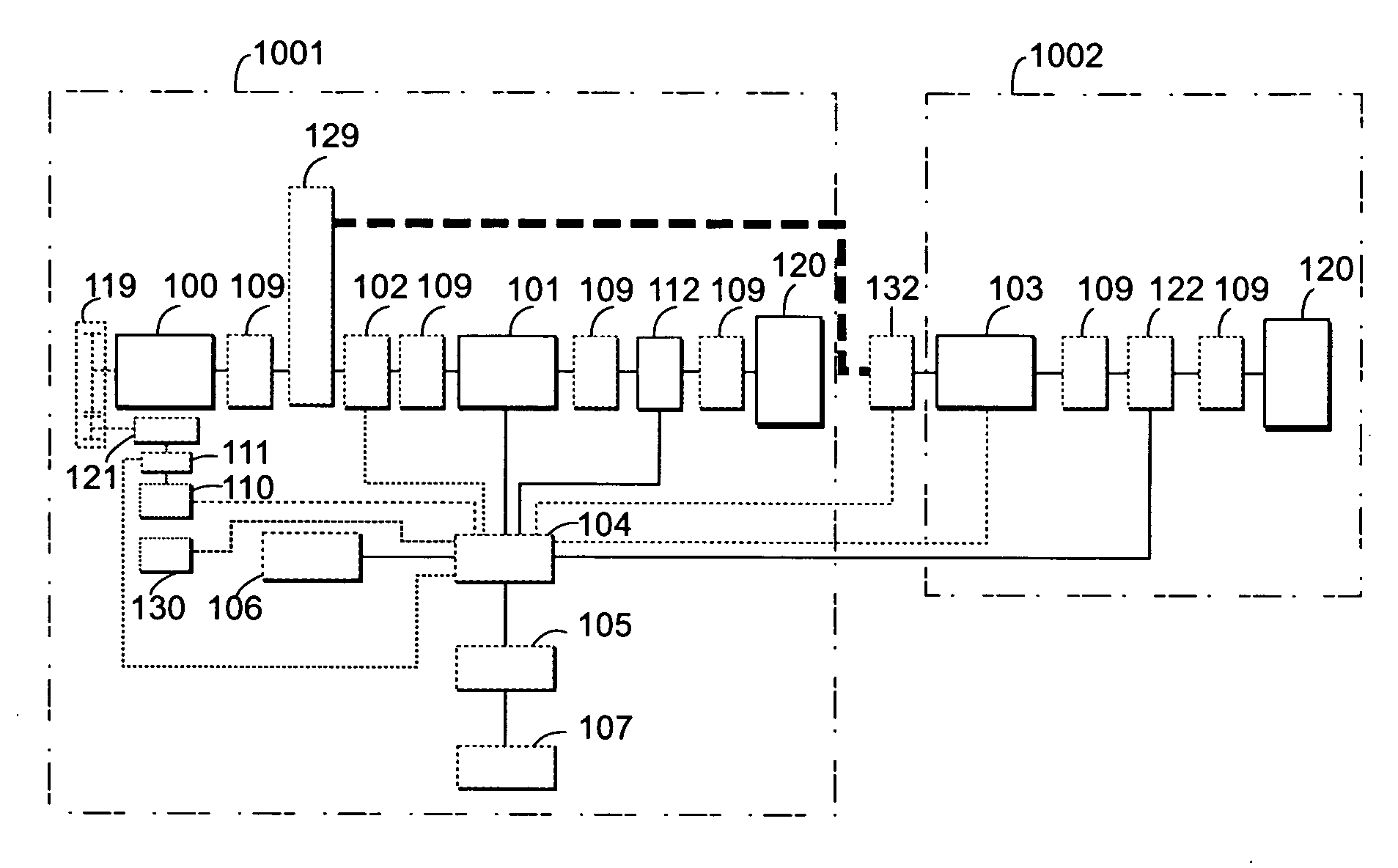

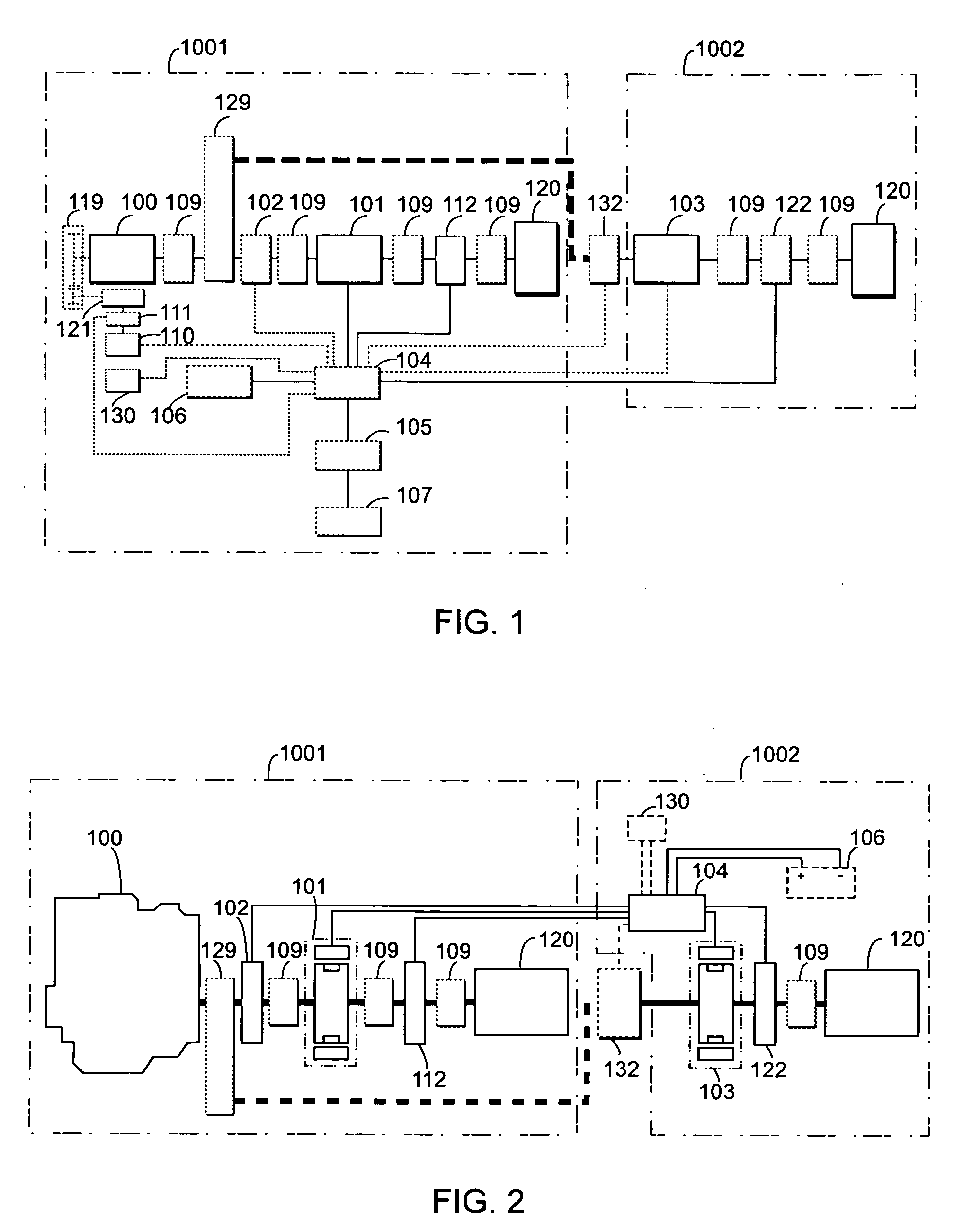

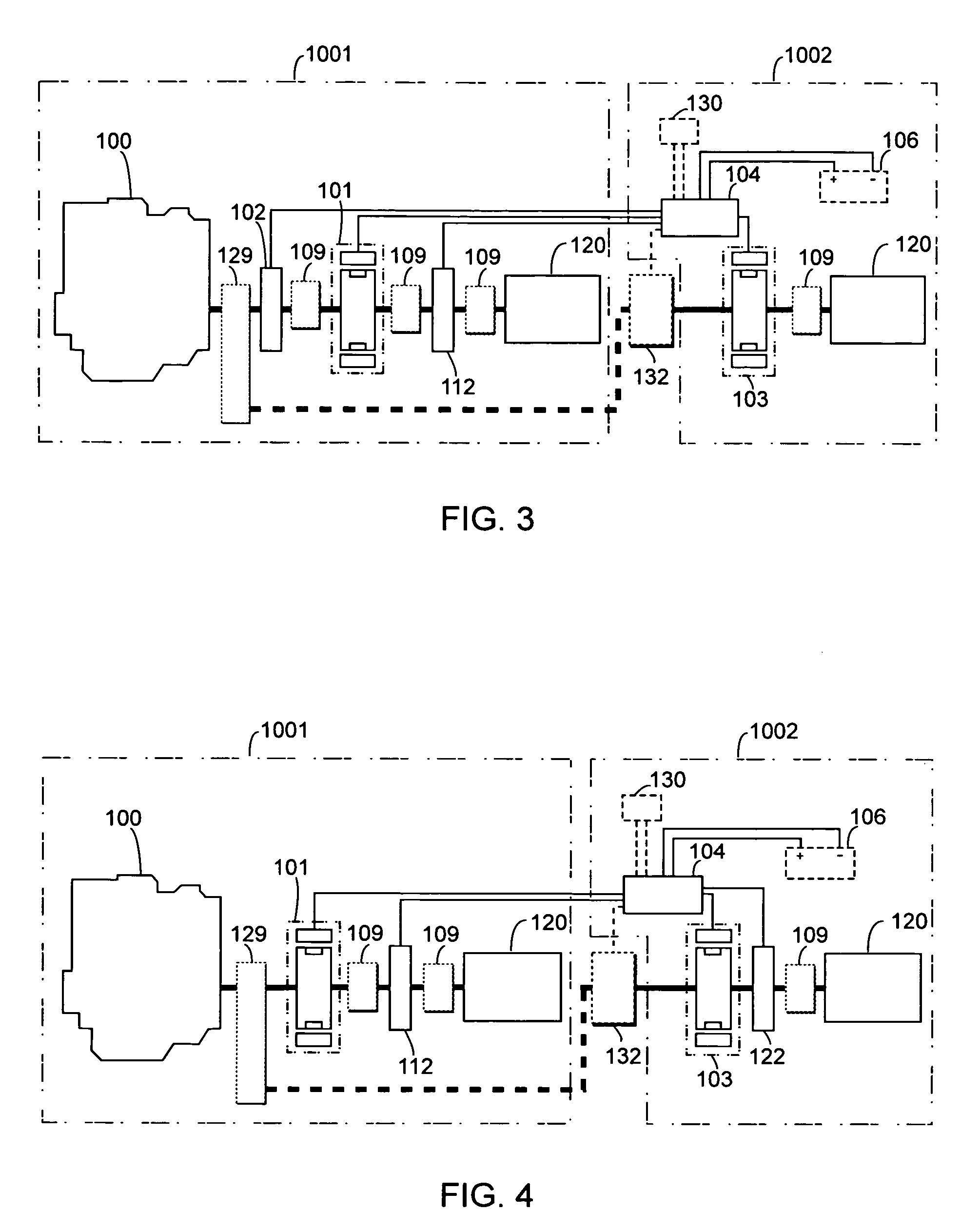

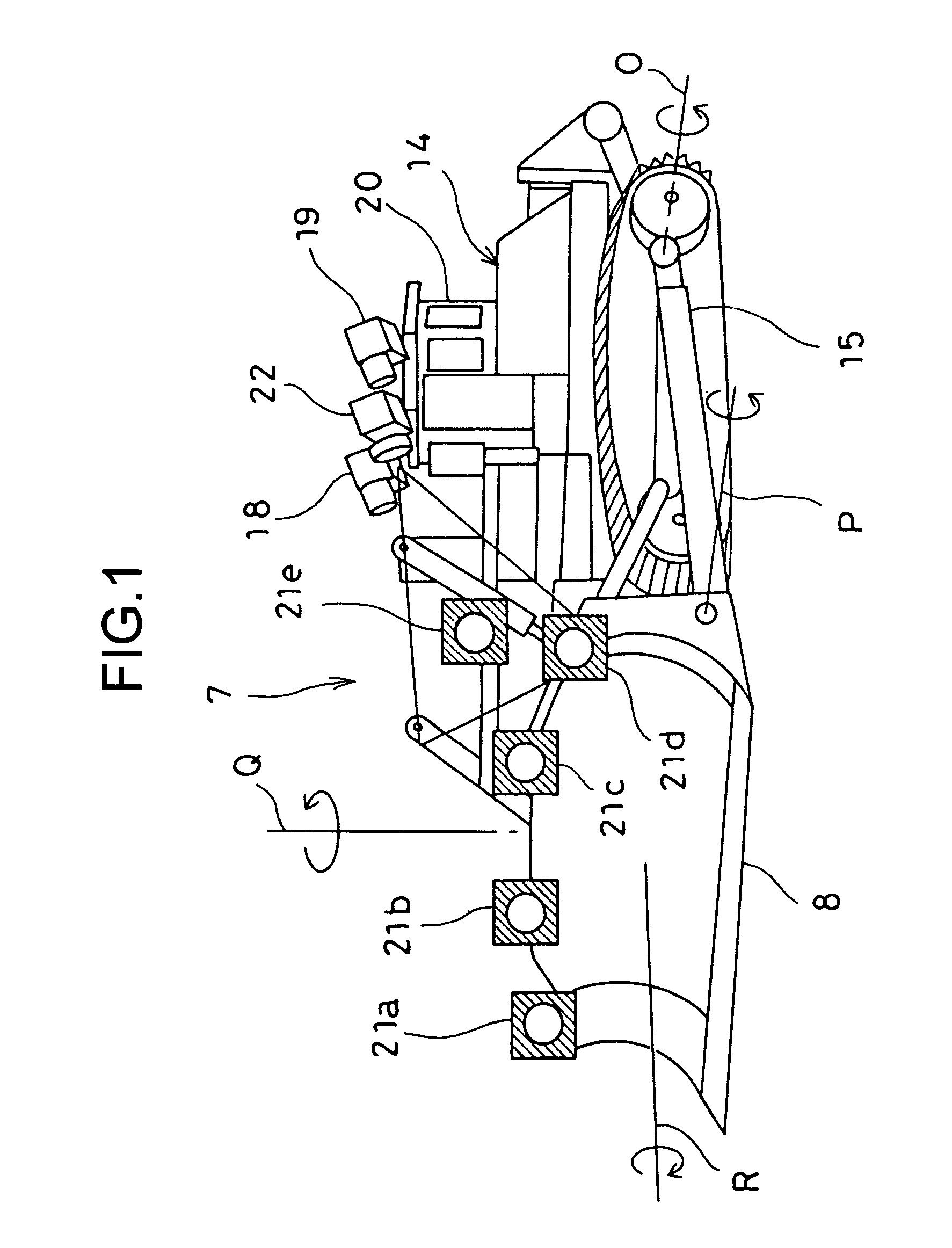

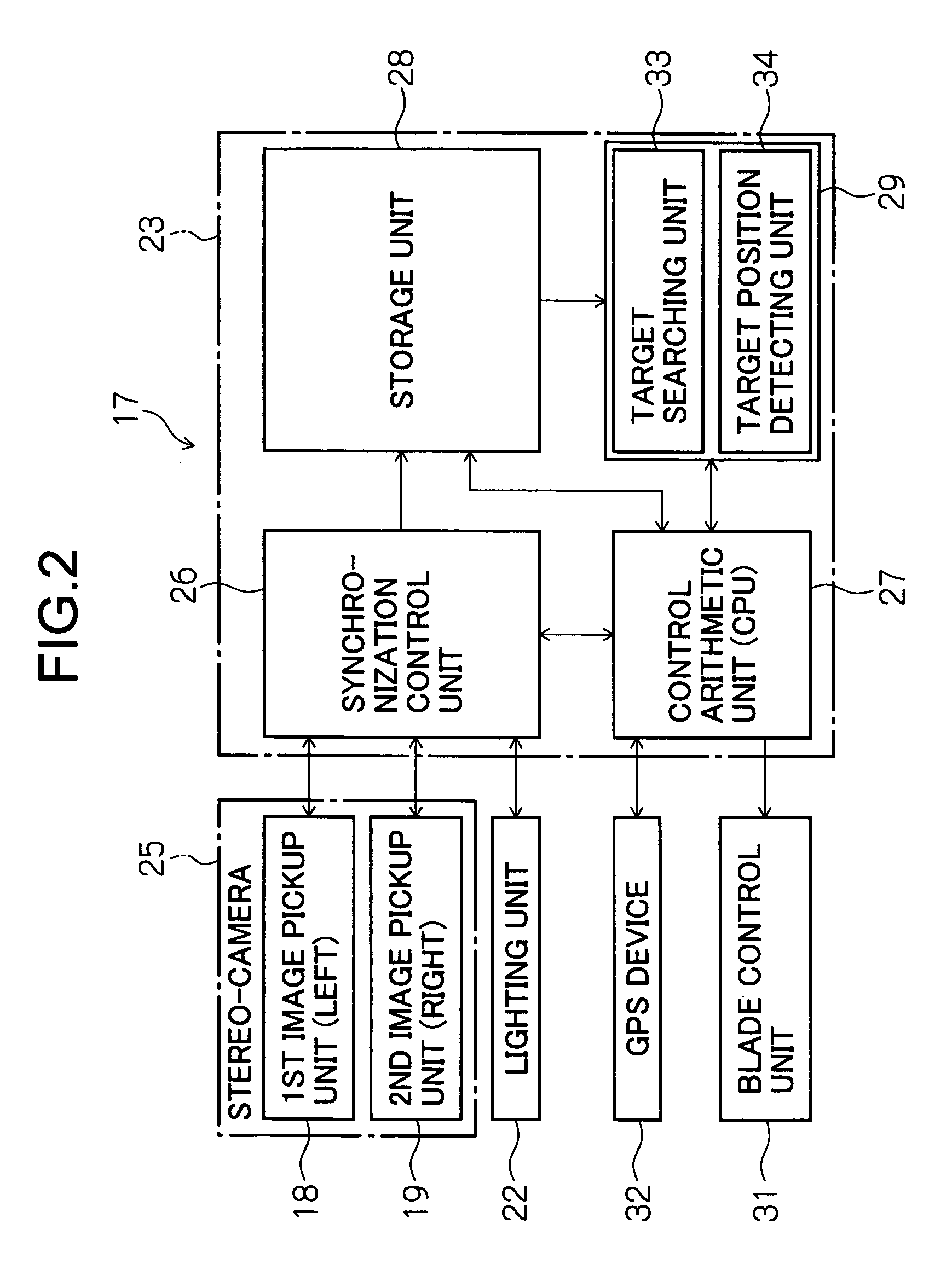

Industrial machine

ActiveUS8412418B2Easy constructionImprove accuracyAnalogue computers for trafficPosition fixationVisual field lossIndustrial machine

An industrial machine comprises an industrial machine main unit, a construction working implement installed on the industrial machine main unit, two cameras each mounted at a known position with respect to a machine center of the industrial machine main unit, at least three targets being installed on the working implement so that the targets are within visual field of each of the two cameras, and an arithmetic processing device. The arithmetic processing device is used for extracting the images of at least three targets in common to the images from stereo-images taken by the two cameras, for obtaining a three-dimensional position of each target image, and for calculating a position and a posture of the working implement with respect to the industrial machine main unit based on the three-dimensional position obtained.

Owner:KK TOPCON

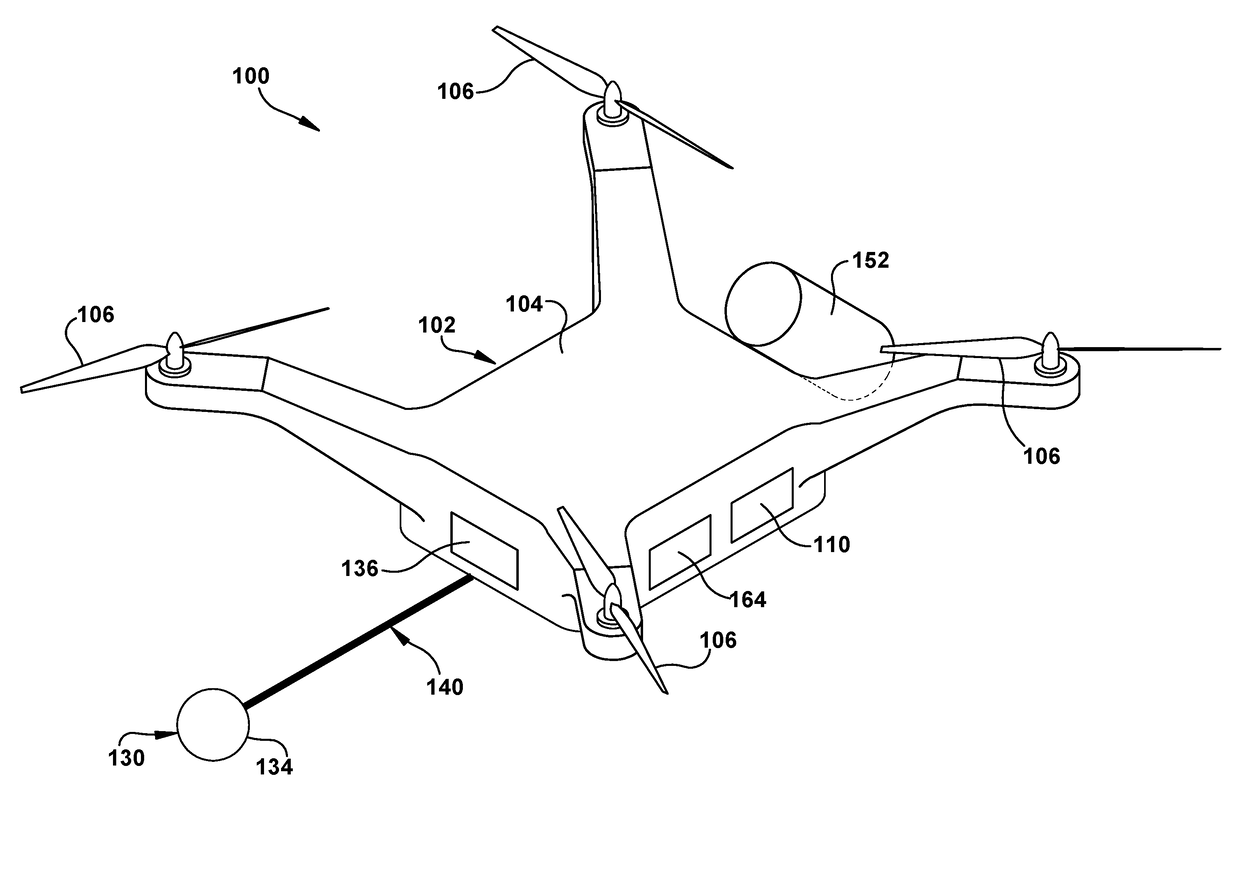

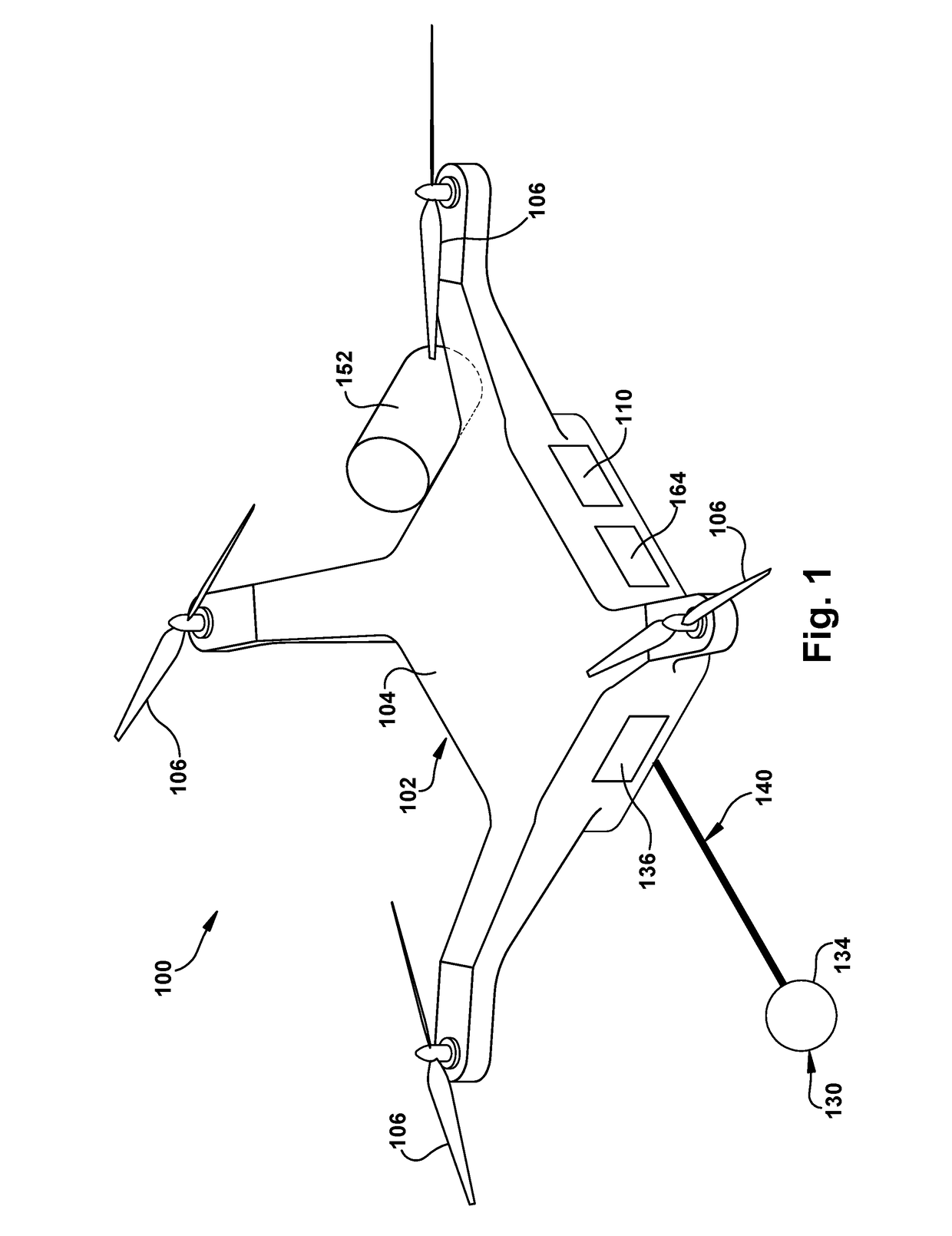

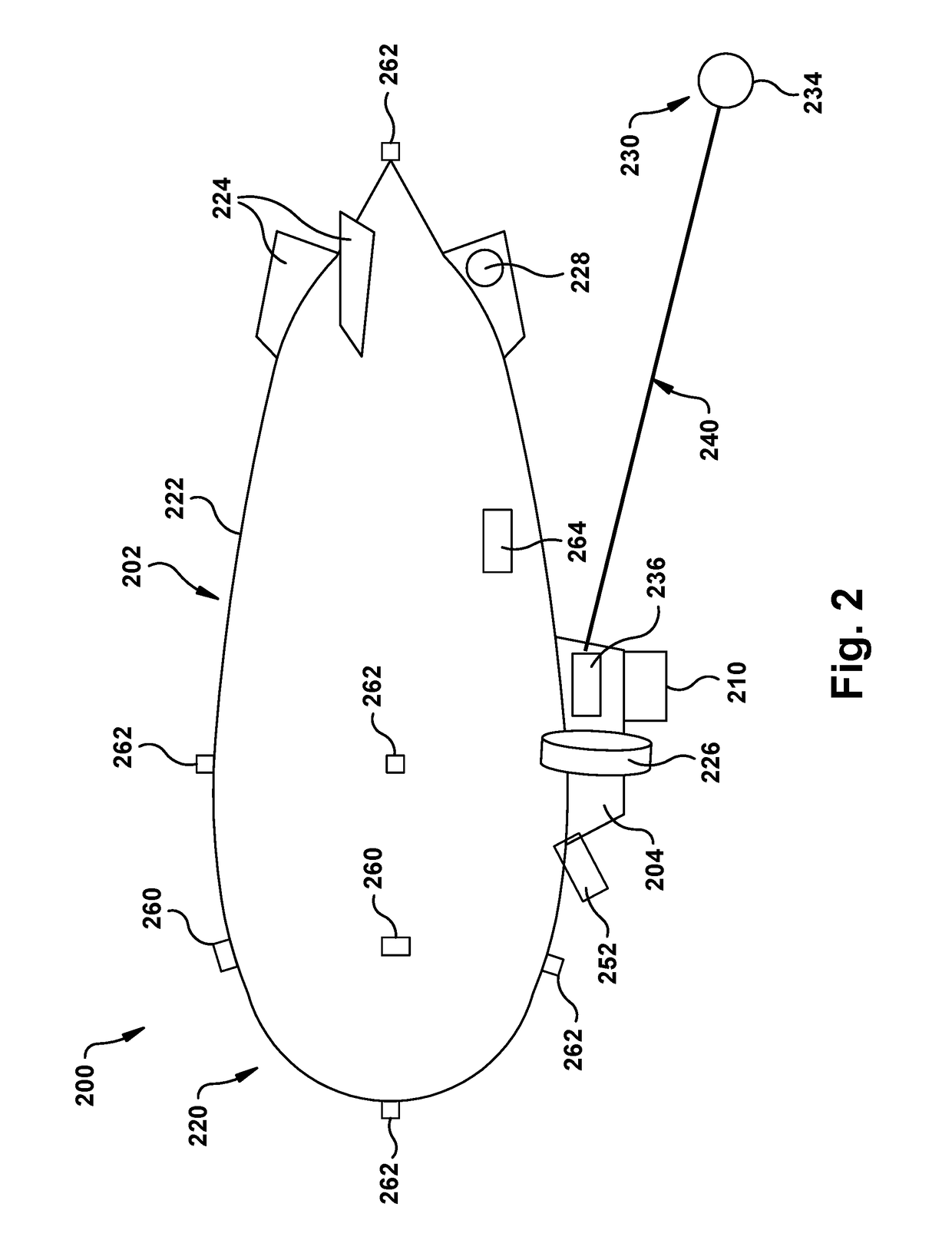

Industrial machine acoustic inspection using unmanned aerial vehicle

A method for collecting acoustic data from an industrial machine is disclosed. The method may include: providing an unmanned aerial vehicle (UAV) having an acoustic receiver attached thereto; and positioning the unmanned aerial vehicle at a specific location so that the acoustic receiver collects acoustic data from the industrial machine at the specific location. An acoustic receiver is attached to the UAV for collecting acoustic data from the industrial machine. An acoustic filter is attached to the acoustic receiver and the UAV for filtering unwanted sound from the acoustic data. Acoustic data can be used by a flight control system to identify a specific location relative to the industrial machine that is a source a specific acoustic signature emanating from the industrial machine.

Owner:GENERAL ELECTRIC CO

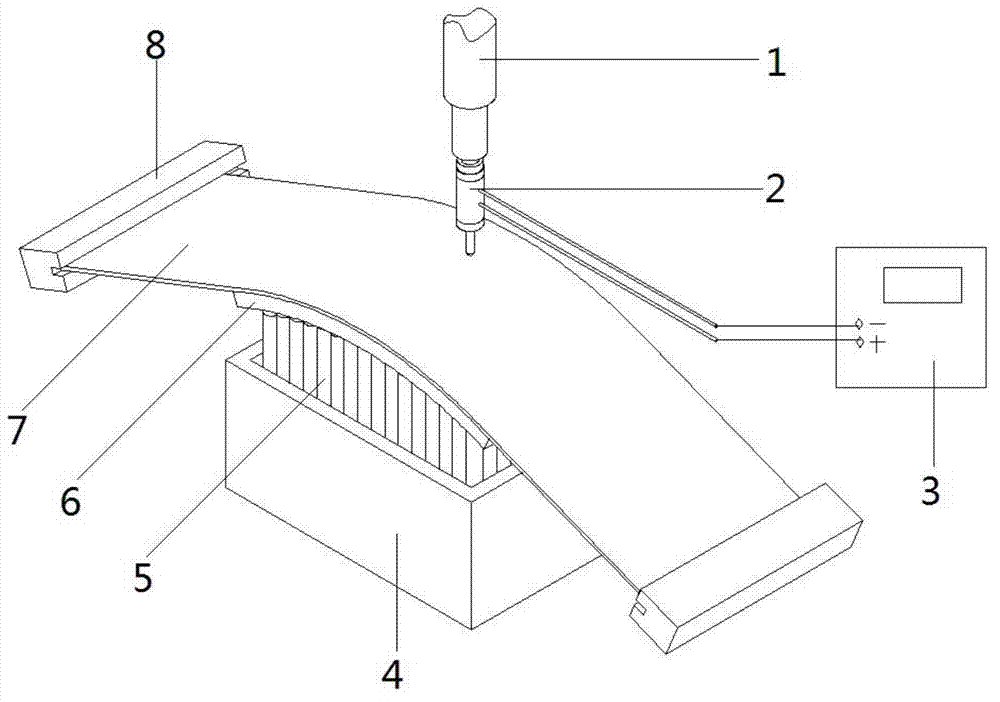

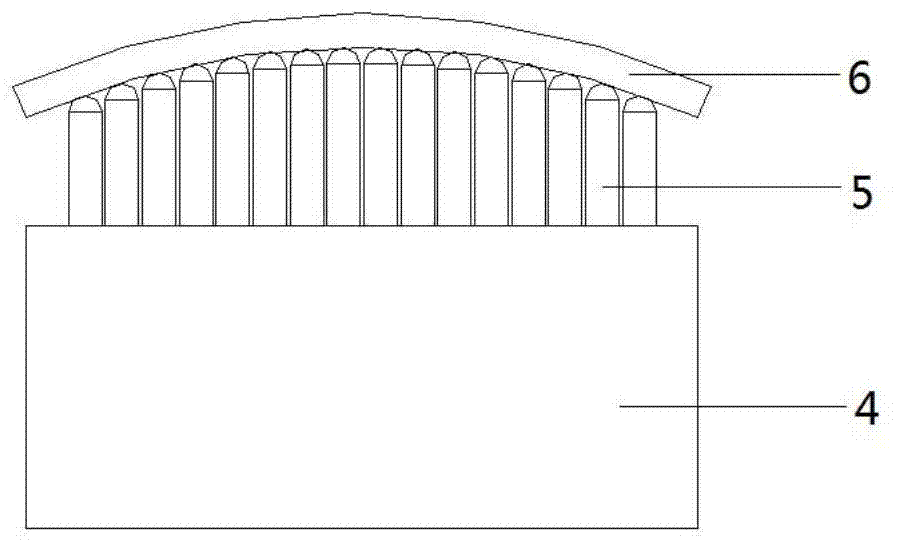

Flexible stretch-forming device and method for carrying out stretch-forming on plate by utilizing same

InactiveCN103480713AReduce deformation resistanceHigh forming precisionShaping toolsIndustrial machineIndustrial manipulator

The invention discloses a flexible stretch-forming device and a method for carrying out stretch-forming on a plate by utilizing the flexible stretch-forming device and solves the technical problem that the stretch-forming accuracy of a flexible stretch-forming device for the molded surface of a reconfigurable unidirectional continuous die is low. The technical scheme includes that the flexible stretch-forming device comprises an industrial manipulator, a heating forming head, a power supply, a multipoint die, a nail post and a polyurethane elastic cushion. The nail post is mounted on the base of the multipoint die, the polyurethane elastic cushion is positioned above the nail post, the lower surface of the polyurethane elastic cushion is attached to the discrete surface formed by the nail head of the nail post, the plate is positioned above the polyurethane elastic cushion, the lower surface of the plate is attached to the upper surface of the polyurethane elastic cushion, the heating forming head is positioned above the plate, and the spherical head surface of the heating forming head is contacted with the upper surface of the plate. According to the flexible stretch-forming device and the method for carrying out stretch-forming on the plate by utilizing the flexible stretch-forming device, the electromagnetic induction heating forming head is adopted to locally heat the plate in the stretch-forming process, the local heat effect of the region can reduce the deformation resistance of the plate, the plasticity is improved, the resilience value is reduced, and the forming accuracy of the plate is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

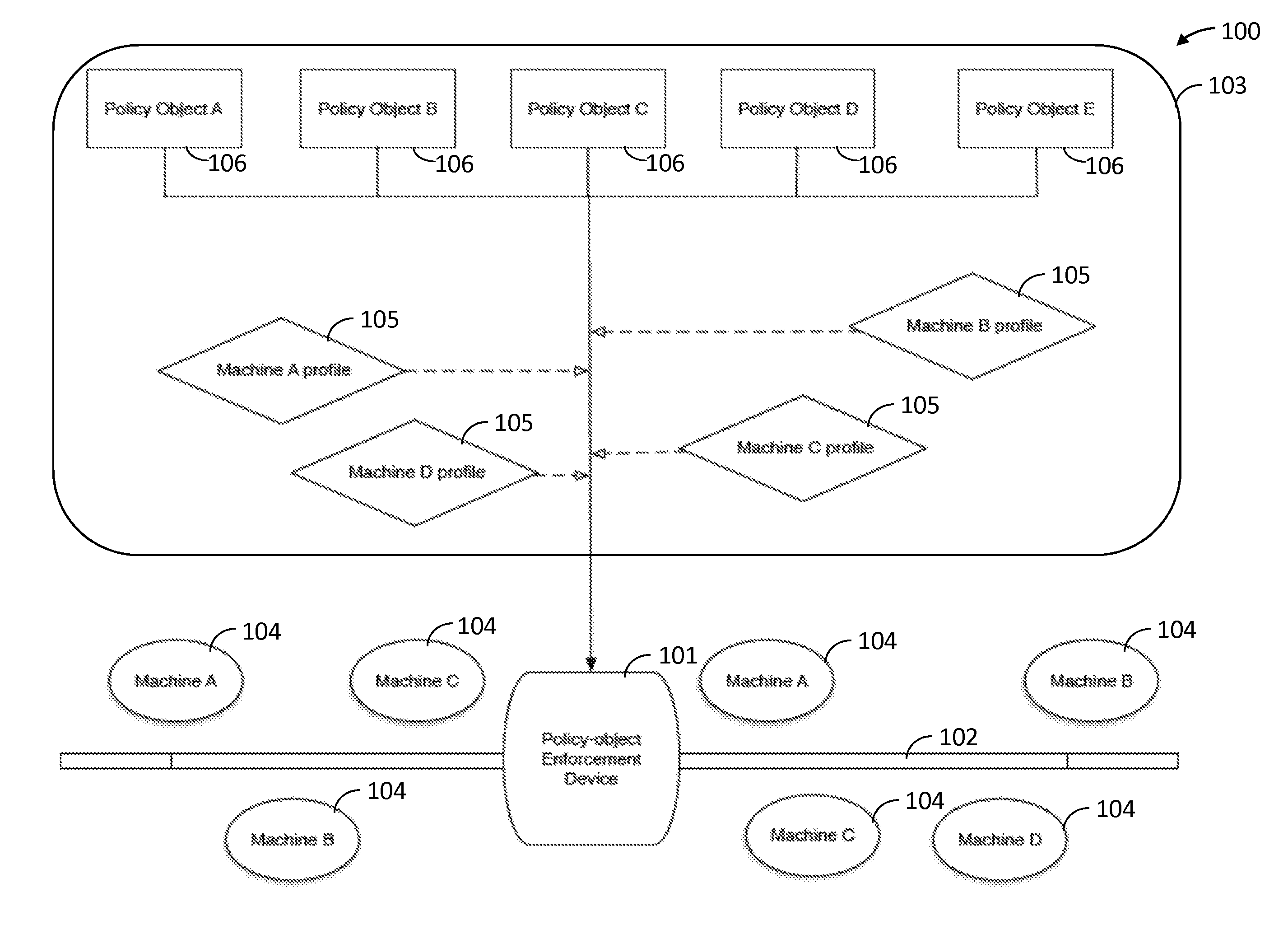

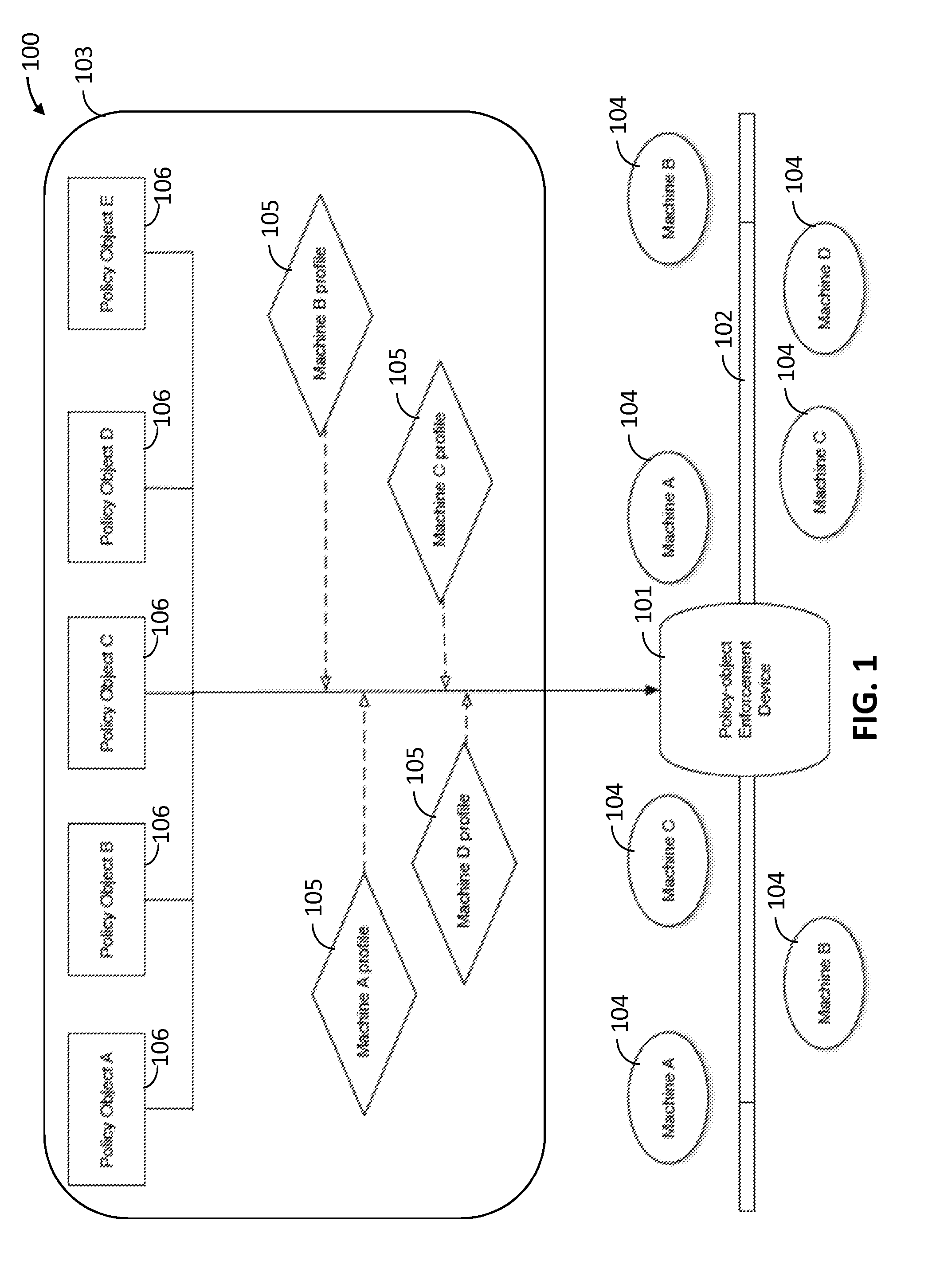

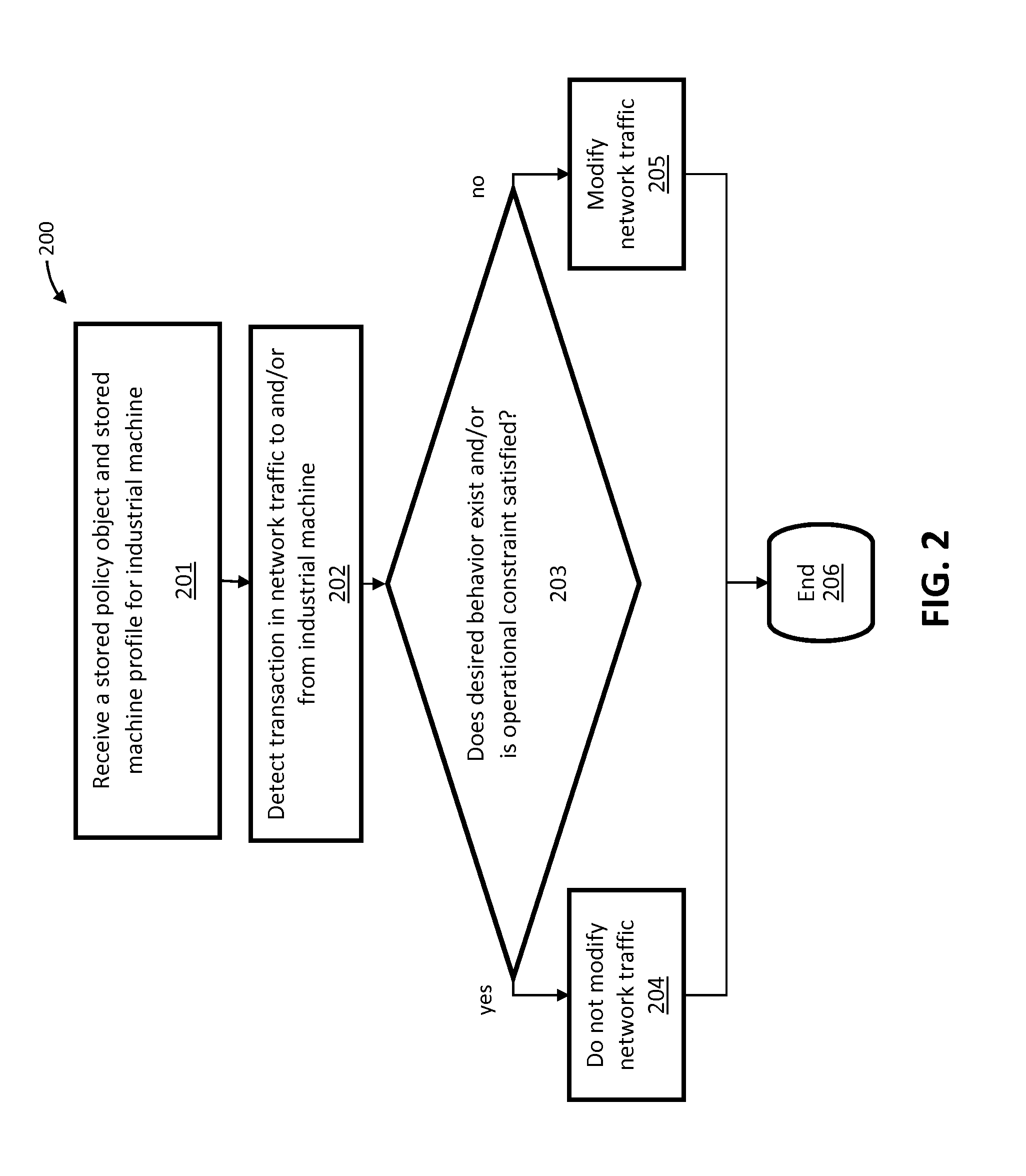

Content-Aware Firewalling, Policy Regulation, and Policy Management for Industrial Automation, Machine To Machine Communications, and Embedded Devices

InactiveUS20160080425A1Operational constraintTransmissionSpecial data processing applicationsControl signalFinancial transaction

In one embodiment, a processor-implemented method for controlling network traffic to and / or from at least one industrial machine, including: (a) receiving, as input, (i) a stored policy object in language form defining at least one desired behavior and / or operational constraint for the at least one industrial machine, and (ii) a stored machine profile defining an association between the language of the stored policy object and at least one control signal or instruction for the at least one industrial machine; (b) detecting, in network traffic to and / or from the at least one industrial machine, a transaction; (c) applying the received policy object and machine profile to the detected transaction to determine whether a desired behavior exists and / or whether an operational constraint is satisfied; and (d) modifying network traffic to and / or from the at least one industrial machine based on the determination in step (c). This permits expression and enforcement of constraints on actual industrial machine behaviors by filtering, modifying or blocking network communications (e.g., control signals and telemetry) that violate constraints or could cause unsafe or inefficient operation.

Owner:OPSWAT

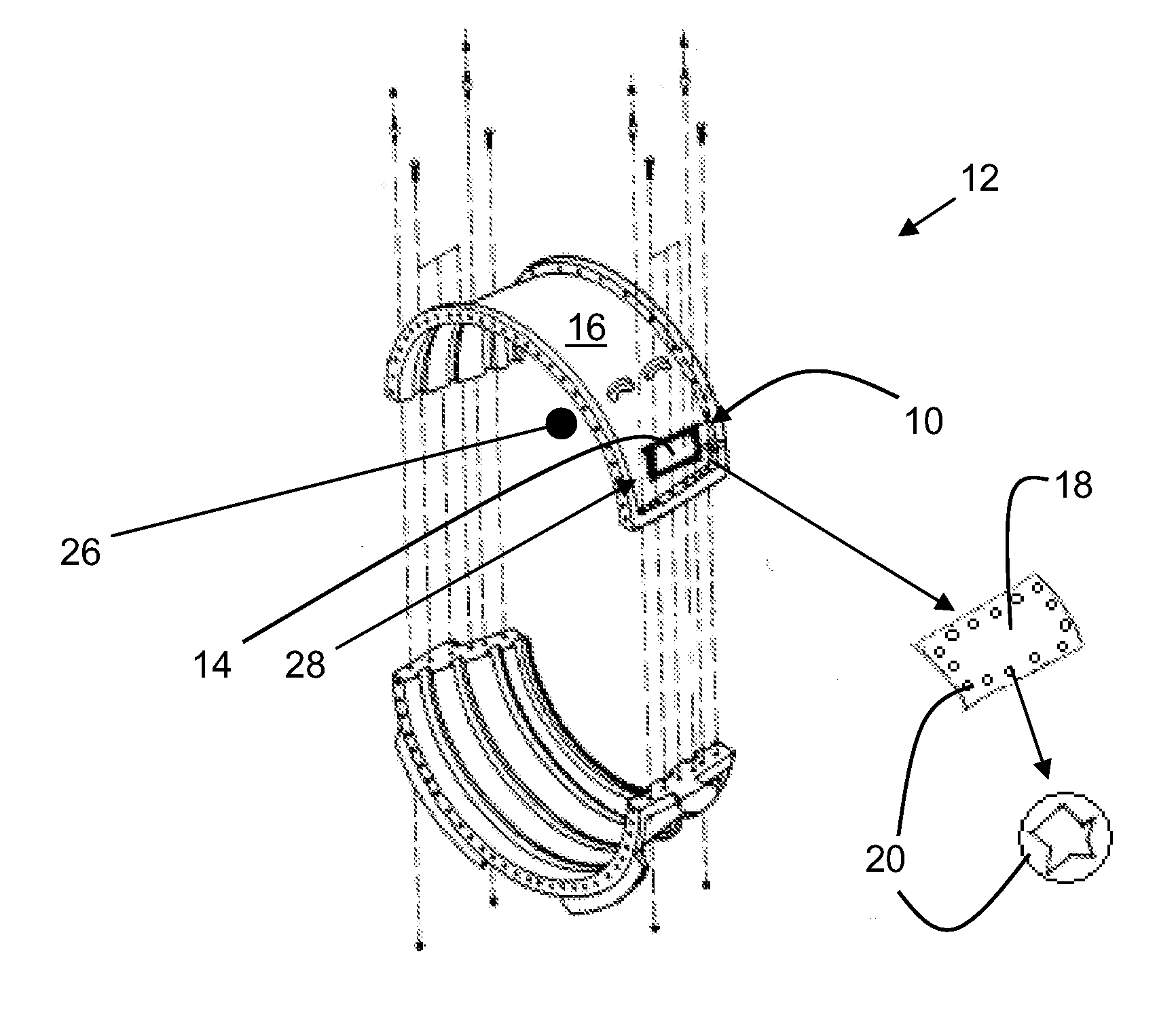

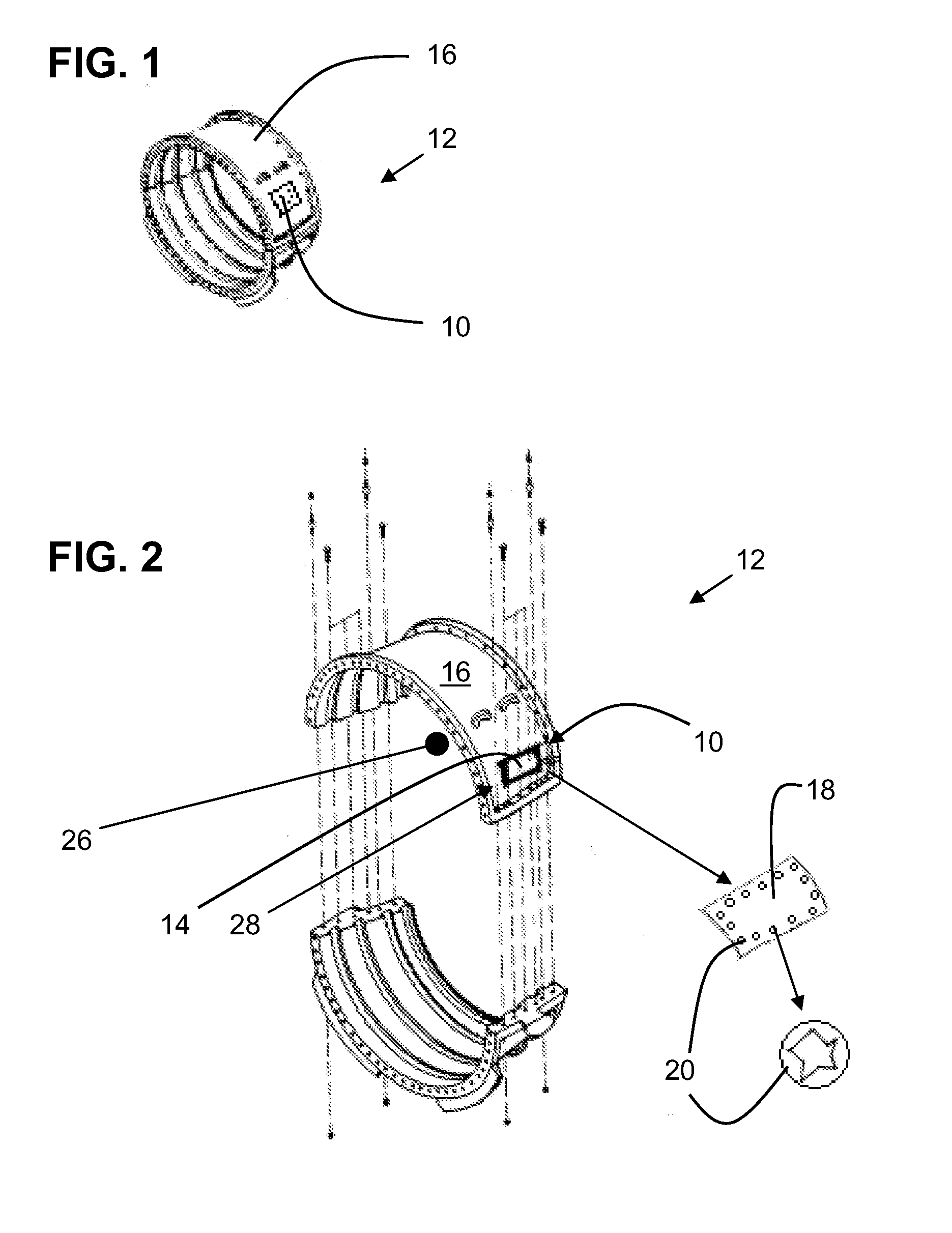

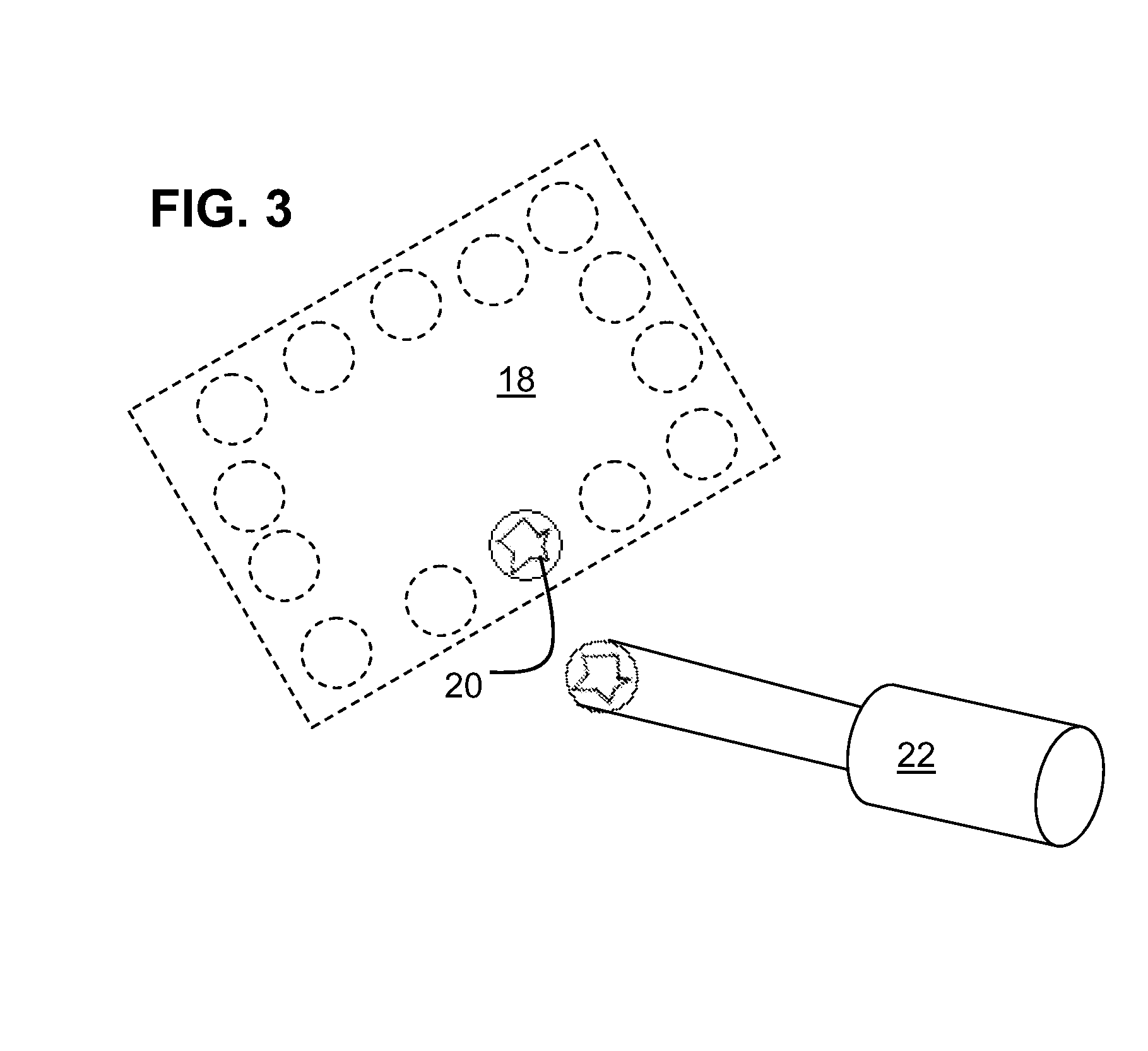

External casing functional access port

A functional access port in a machine casing, a machine having a functional access port, and a method of monitoring a machine via a functional access port are disclosed herein. In an embodiment, an access port is provided in the external casing of an industrial machine. The access port comprises a passageway through the external casing of the machine, providing access to an interior of the machine. The access port further includes a removable passageway cover for removably occluding the passageway. A location, a size, a shape, and an orientation of the passageway relative to the external casing are strategically selected in accordance with engineering and design requirements to provide access through the passageway to a desired location on the interior of the machine while the external casing is in place, with minimal to no disassembly of the casing.

Owner:GENERAL ELECTRIC CO

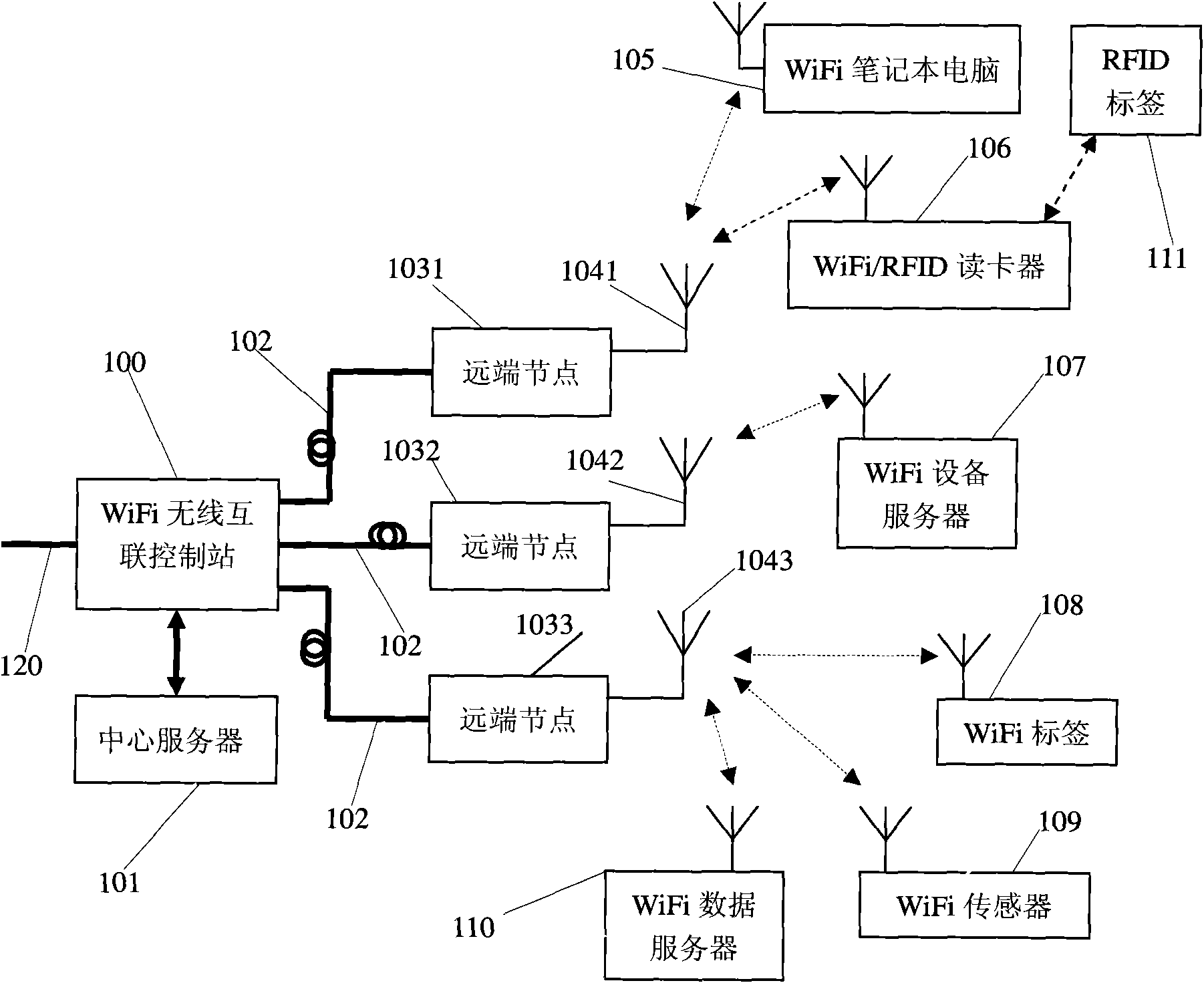

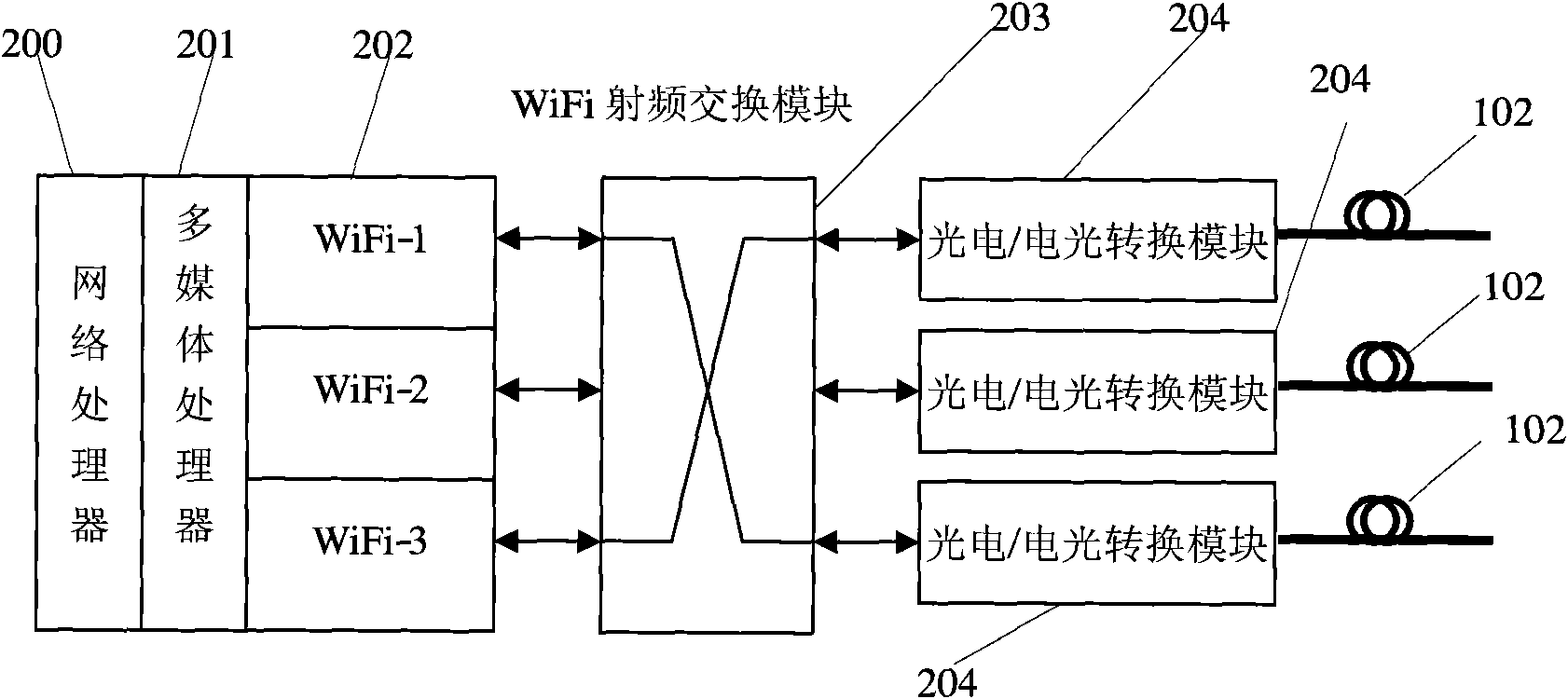

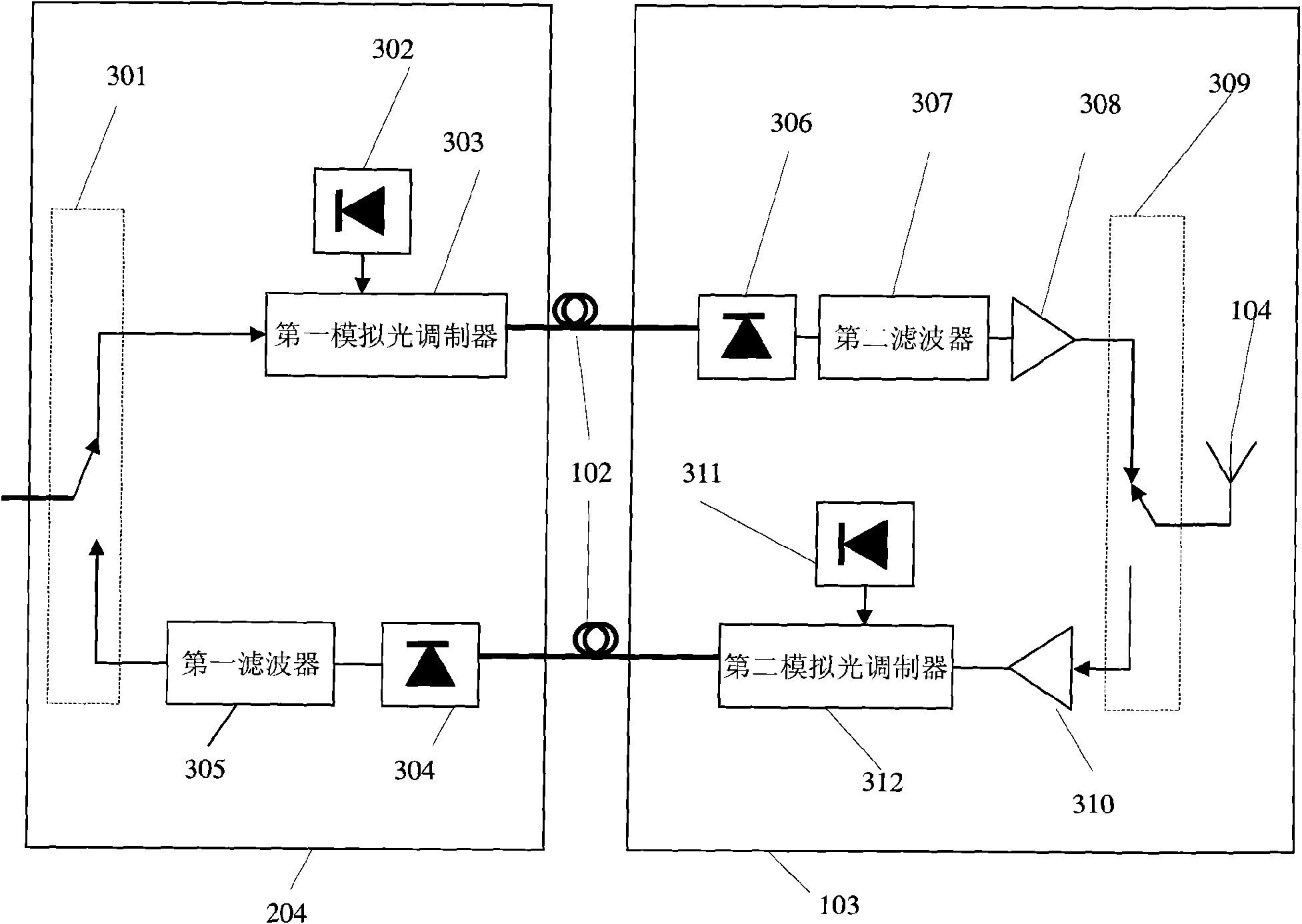

Machine interconnection wireless network system

ActiveCN101626629ALow costRealize automatic controlNetwork topologiesTransmissionRadio over fiberRadio frequency signal

The invention discloses a interconnection wireless network system comprising a central server, a WiFi wireless interconnection control station, a far-end node and a WiFi terminal, wherein, the WiFi wireless interconnection control station is used for providing access connection of the WiFi terminal and distributing the network address of the WiFi terminal accessed in a WiFi LAN and route forwarding network data; the WiFi wireless interconnection control station is wirelessly communicated with the WiFi terminal via optical fiber and the far-end node and forms the WiFi LAN with the WiFi terminal by taking the WiFi wireless interconnection control station as the center; the WiFi terminal comprises a WiFi device server but is not limited to the WiFi device server, and the WiFi device server is connected with an industrial machine device via the standard industrial data interface. The invention adopts an optical fiber radio distribution system to realize low cost, long distance and large-range distribution of WiFi radio-frequency signal and can be applied to places such as factories, office buildings and the like with large range, various devices and complex control.

Owner:广州飞瑞敖电子科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com