Patents

Literature

434results about "Support wheels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

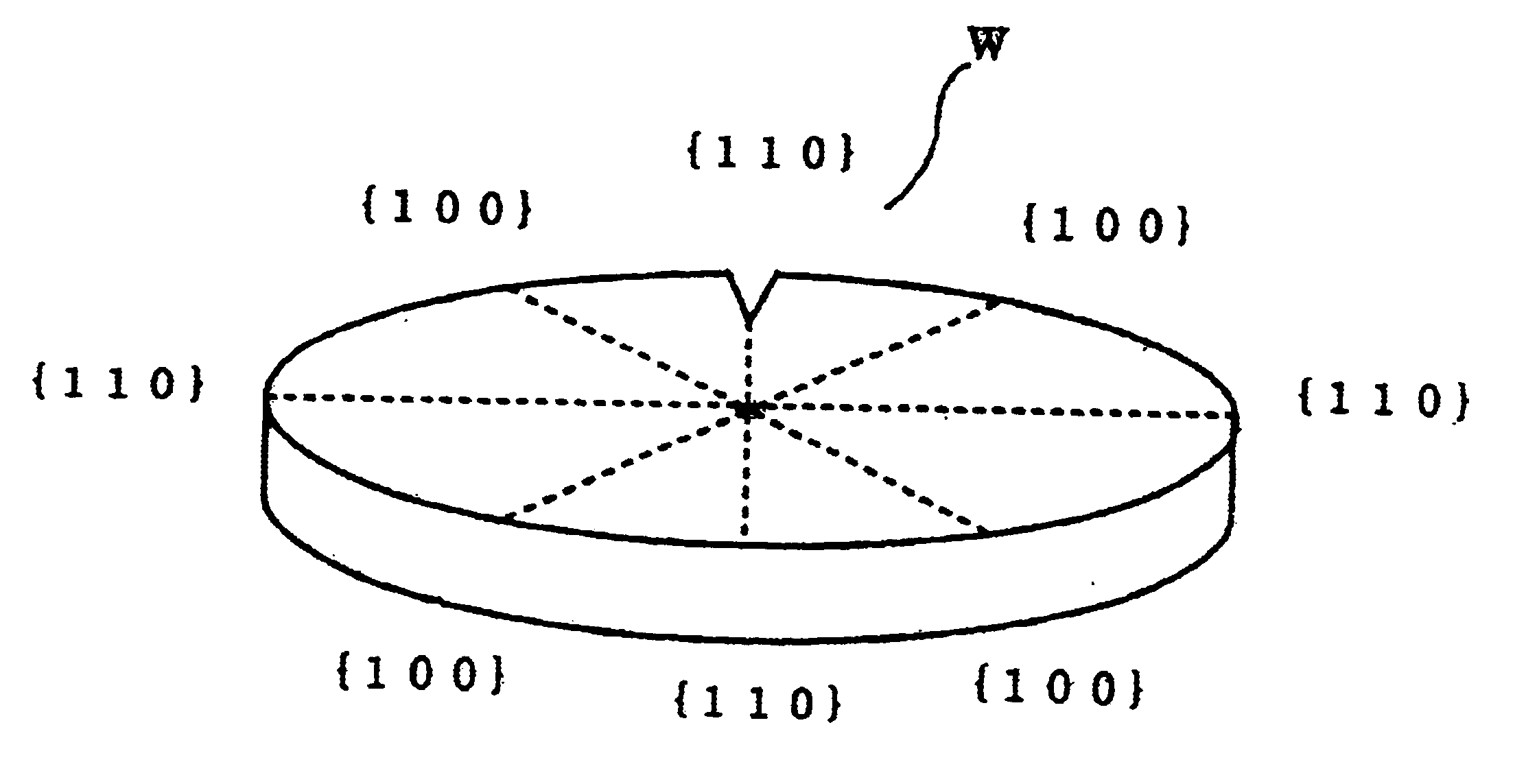

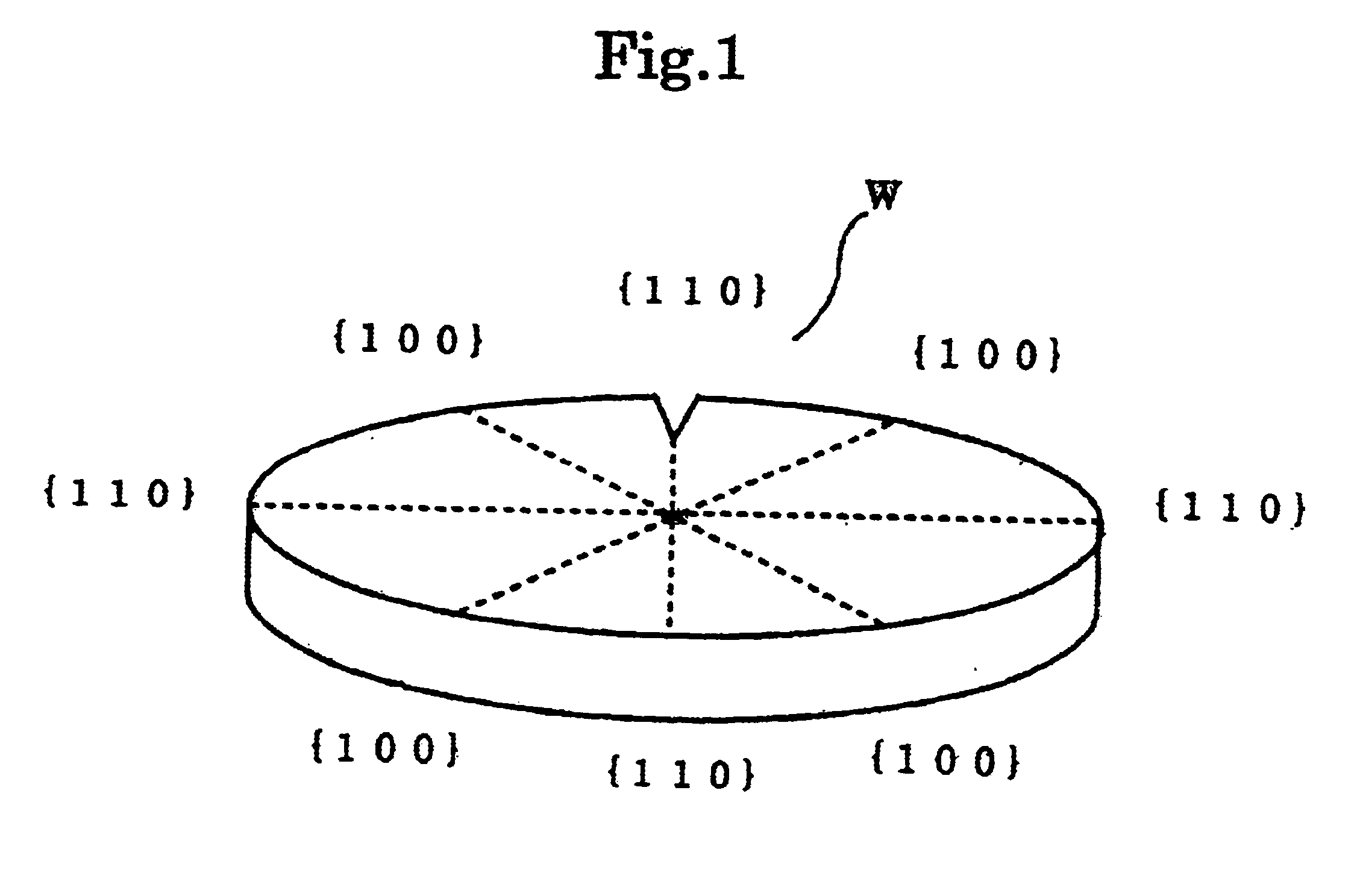

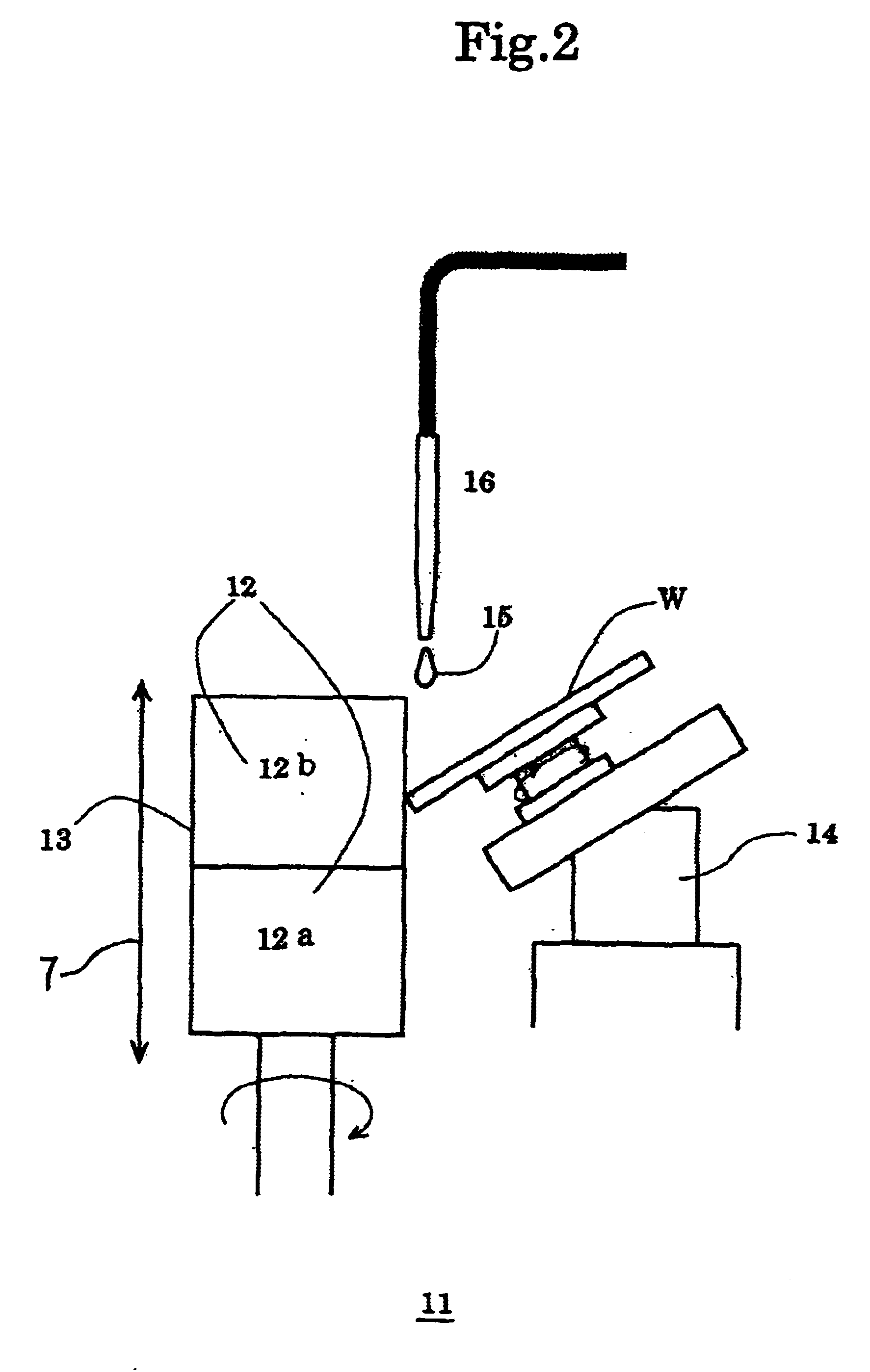

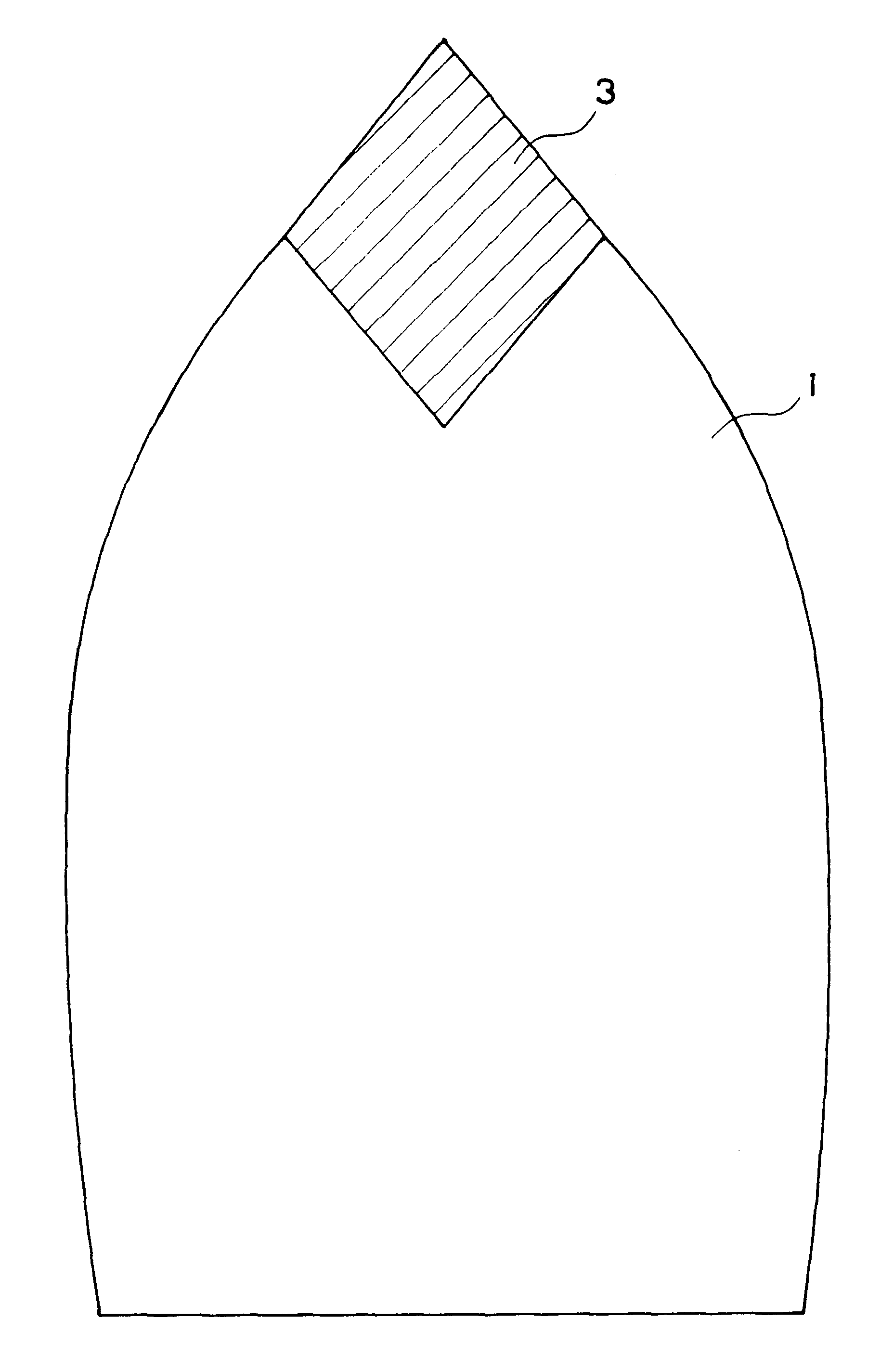

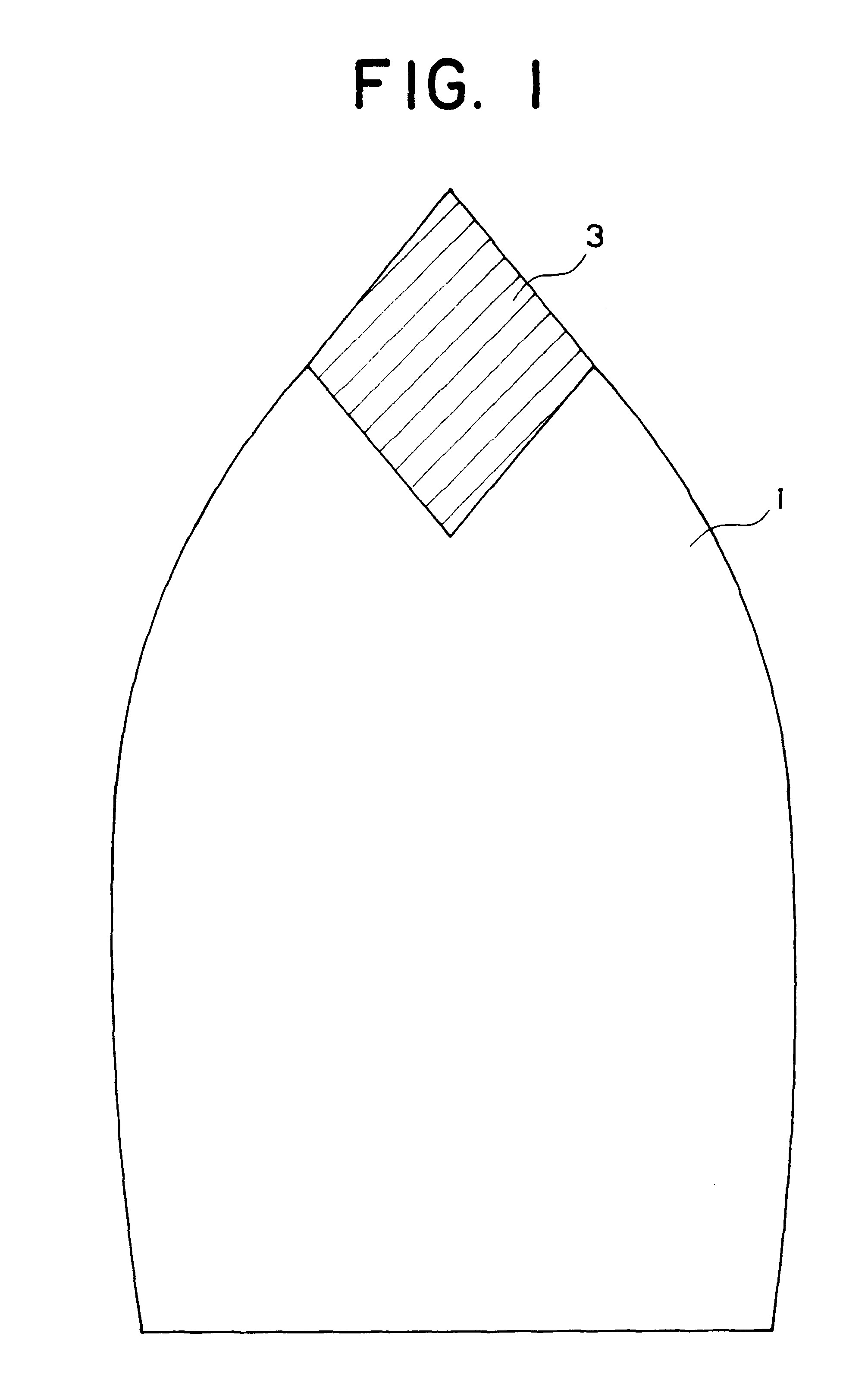

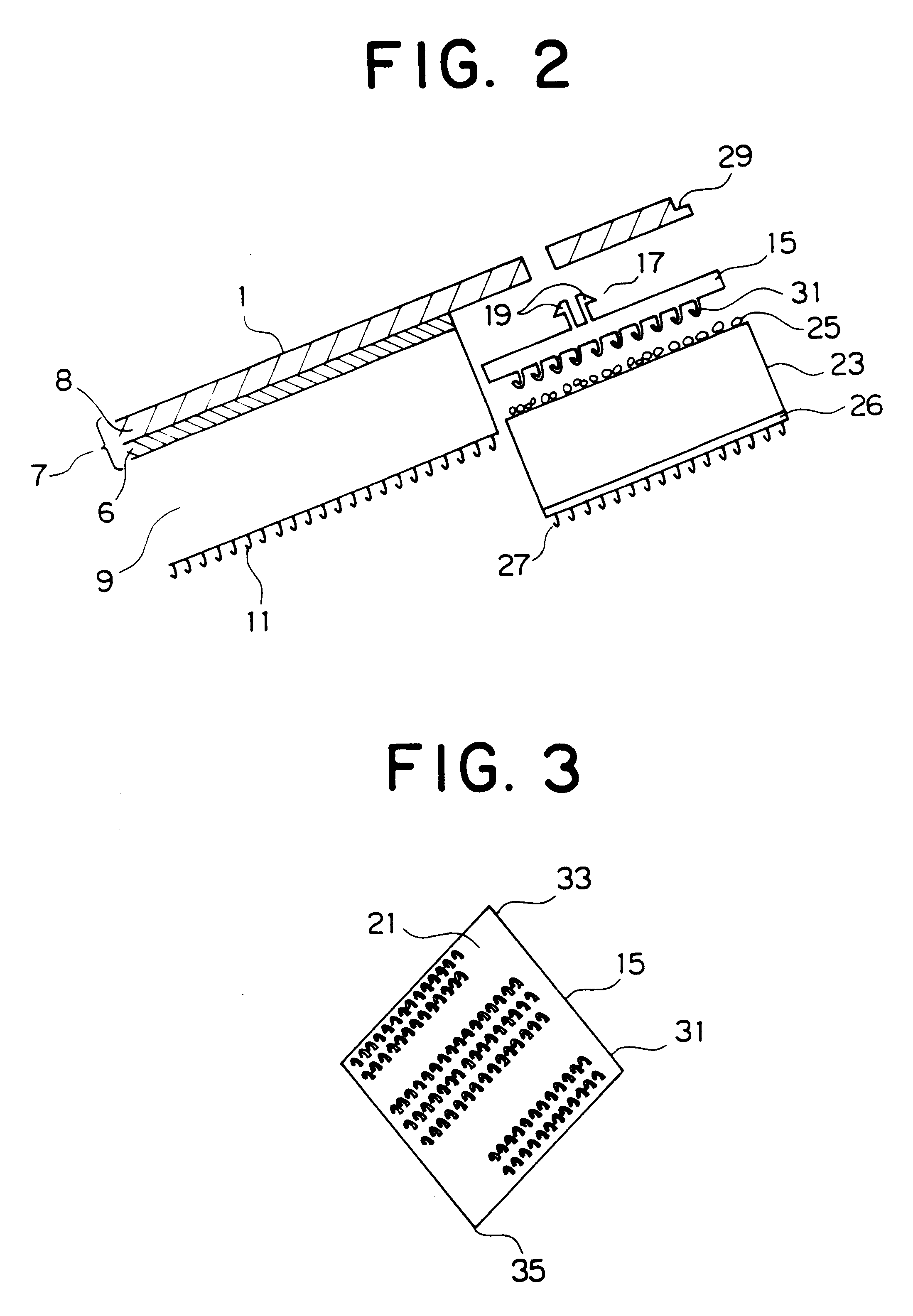

Method for apparatus for polishing outer peripheral chamfered part of wafer

InactiveUS6884154B2Improve productivityShorten polishing timeEdge grinding machinesPolishing machinesProduction rateHardness

In a process for polishing the chamfered peripheral part of a wafer using a polishing cloth while supplying a polishing slurry in order to improve productivity of the process by reducing a polishing time, at least two steps of polishing processes are performed in sequence. The process comprises a first polishing process to polish a particular part, e.g. the part corresponding to the {110} plane of a peripheral part of the wafer and a second polishing process in which the whole part of a peripheral part of the wafer is polished for finishing by means of varying a hardness of the polishing clothes and / or a particle size of abrasives in the slurry such as the hardness of the polishing cloth in the second polishing process being softer than that of in the first polishing process and a particle size of abrasives in the slurry in the second polishing process being finer than that of in the first polishing process.

Owner:SHIN-ETSU HANDOTAI CO LTD

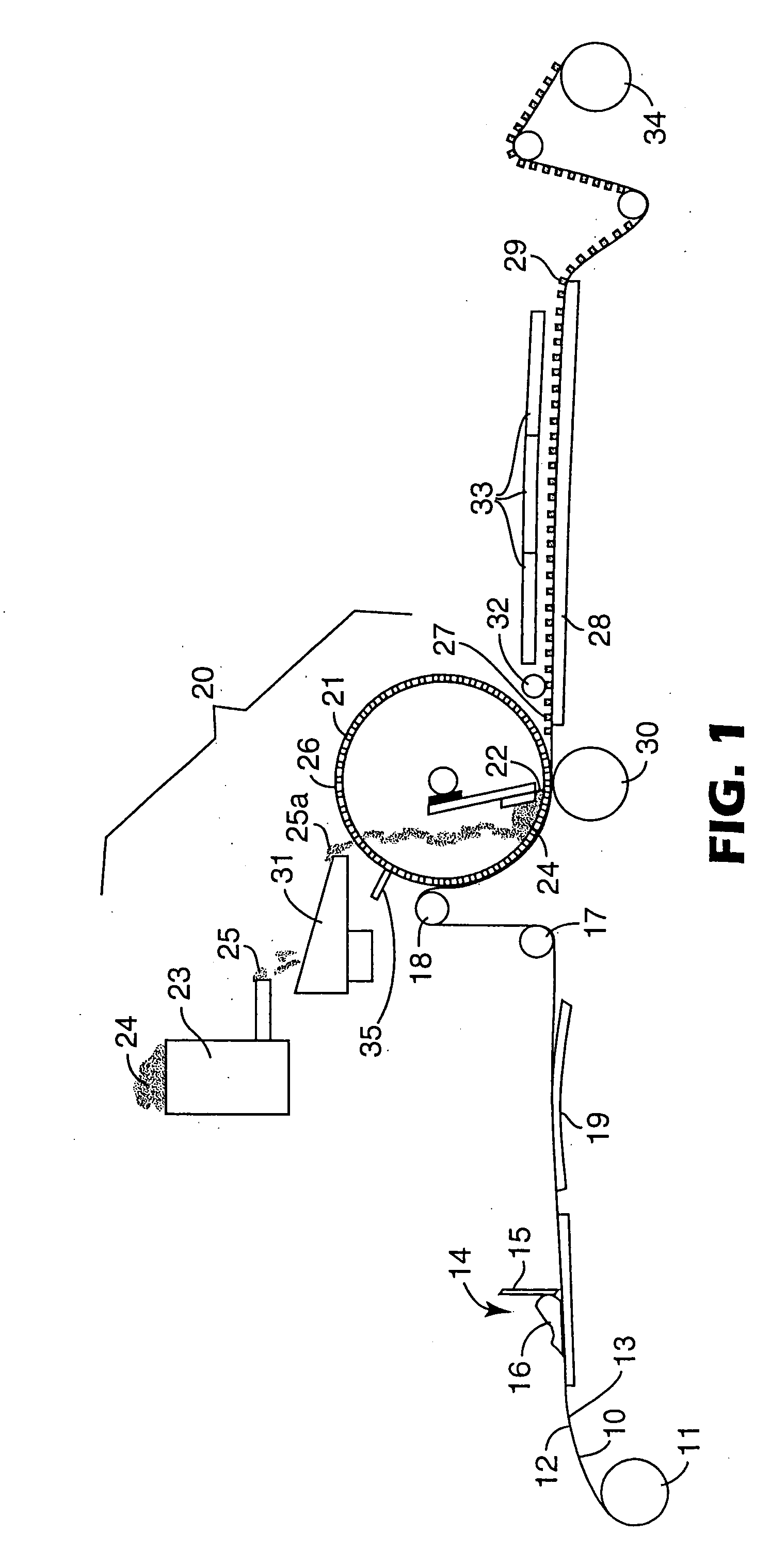

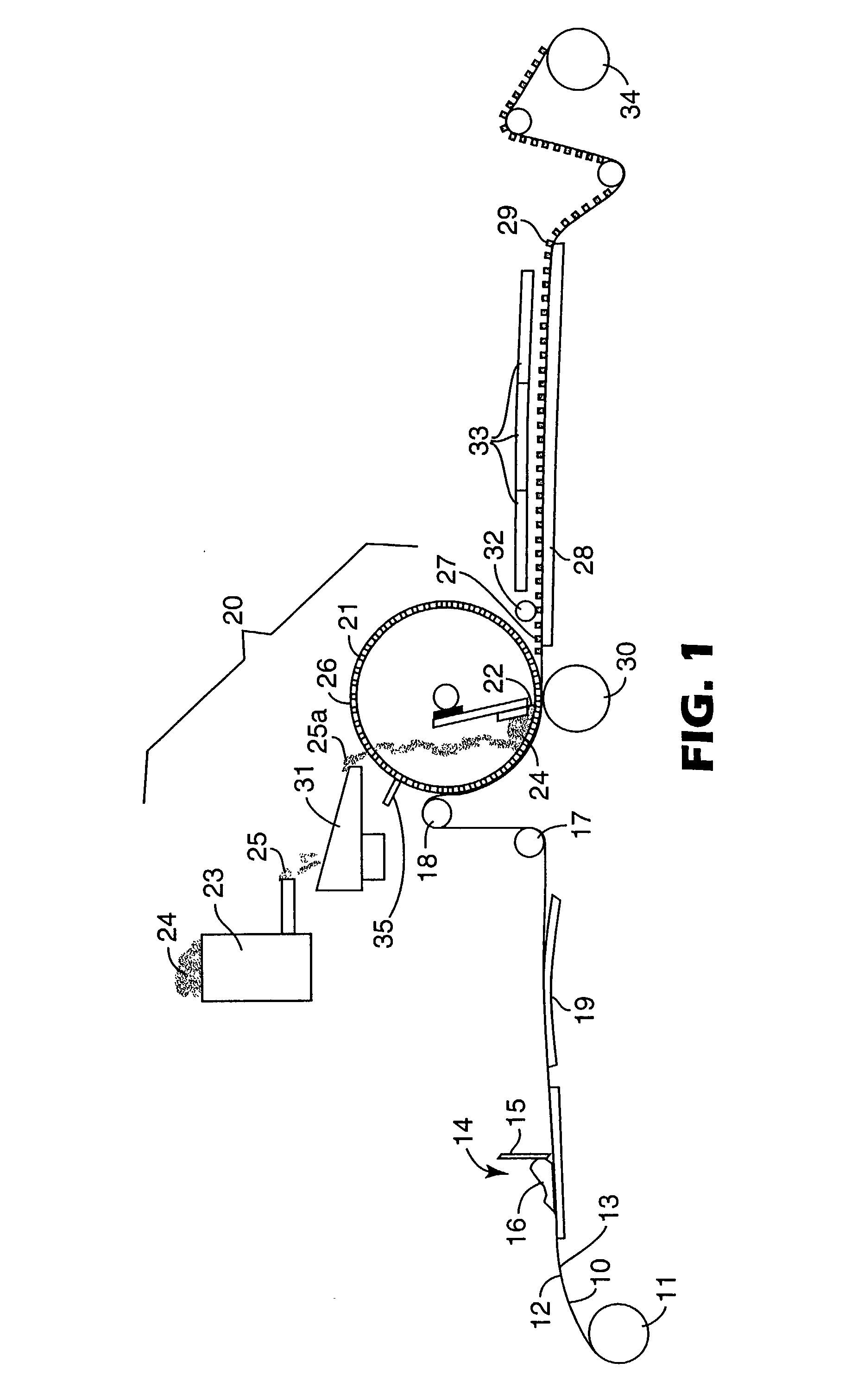

Abrasive product, method of making and using the same, and apparatus for making the same

The invention provides a method and apparatus for making an abrasive product comprising providing a substantially horizontally deployed flexible backing having a first surface bearing an at least partially cured primer coating and an opposite second surface; providing a dry flowable particle mixture comprising abrasive particles and particulate curable binder material; depositing a plurality of temporary shaped structures comprised of said particle mixture on the at least partially cured primer coating of the first surface of the backing; softening said particulate curable binder material to provide adhesion between adjacent abrasive particles; and curing the softened particulate curable binder material to convert said temporary shaped structures into permanent shaped structures and cure the at least partially cured primer coating on the first surface of the backing. The invention also provides an abrasive product made by the method.

Owner:3M INNOVATIVE PROPERTIES CO

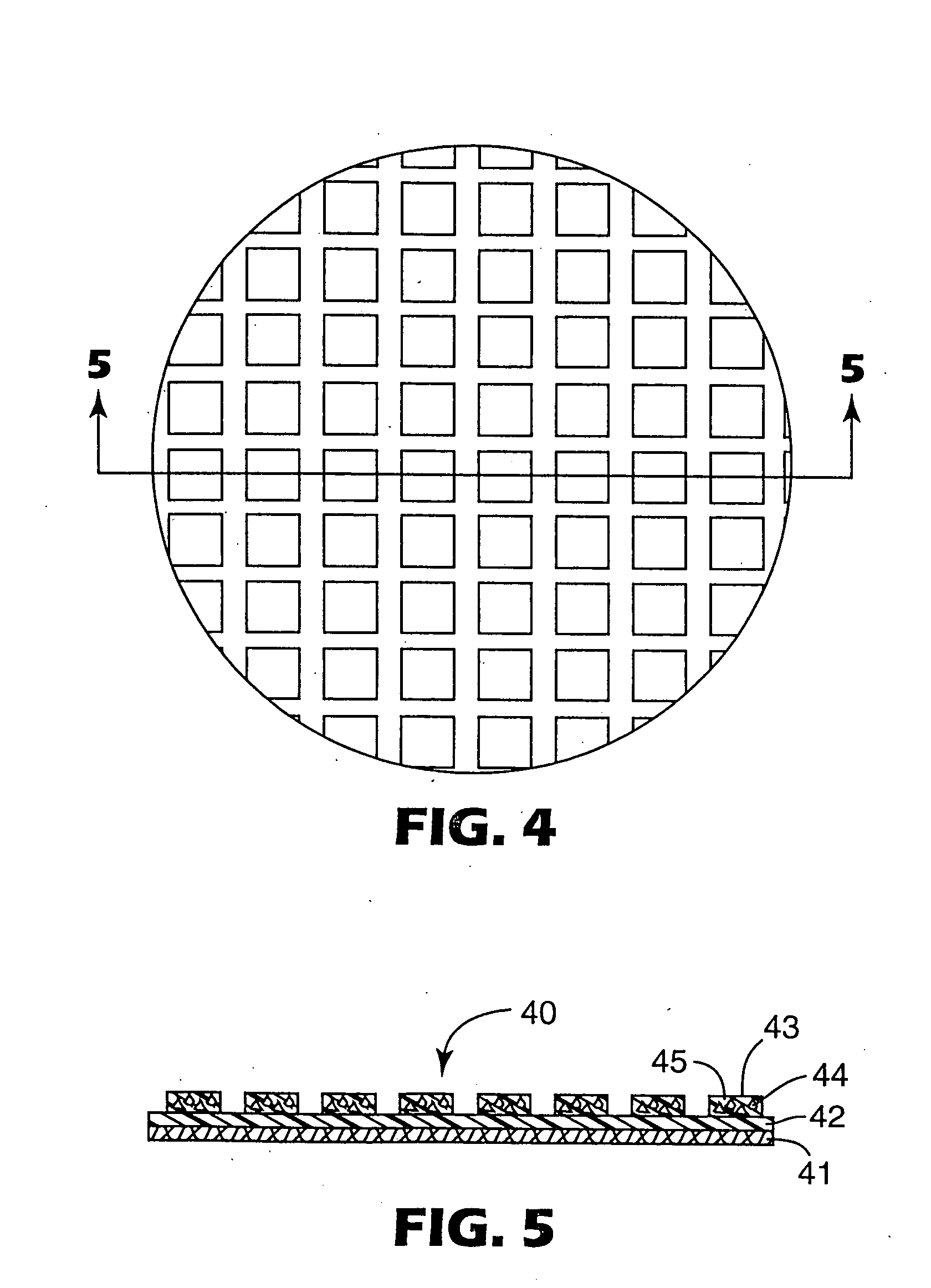

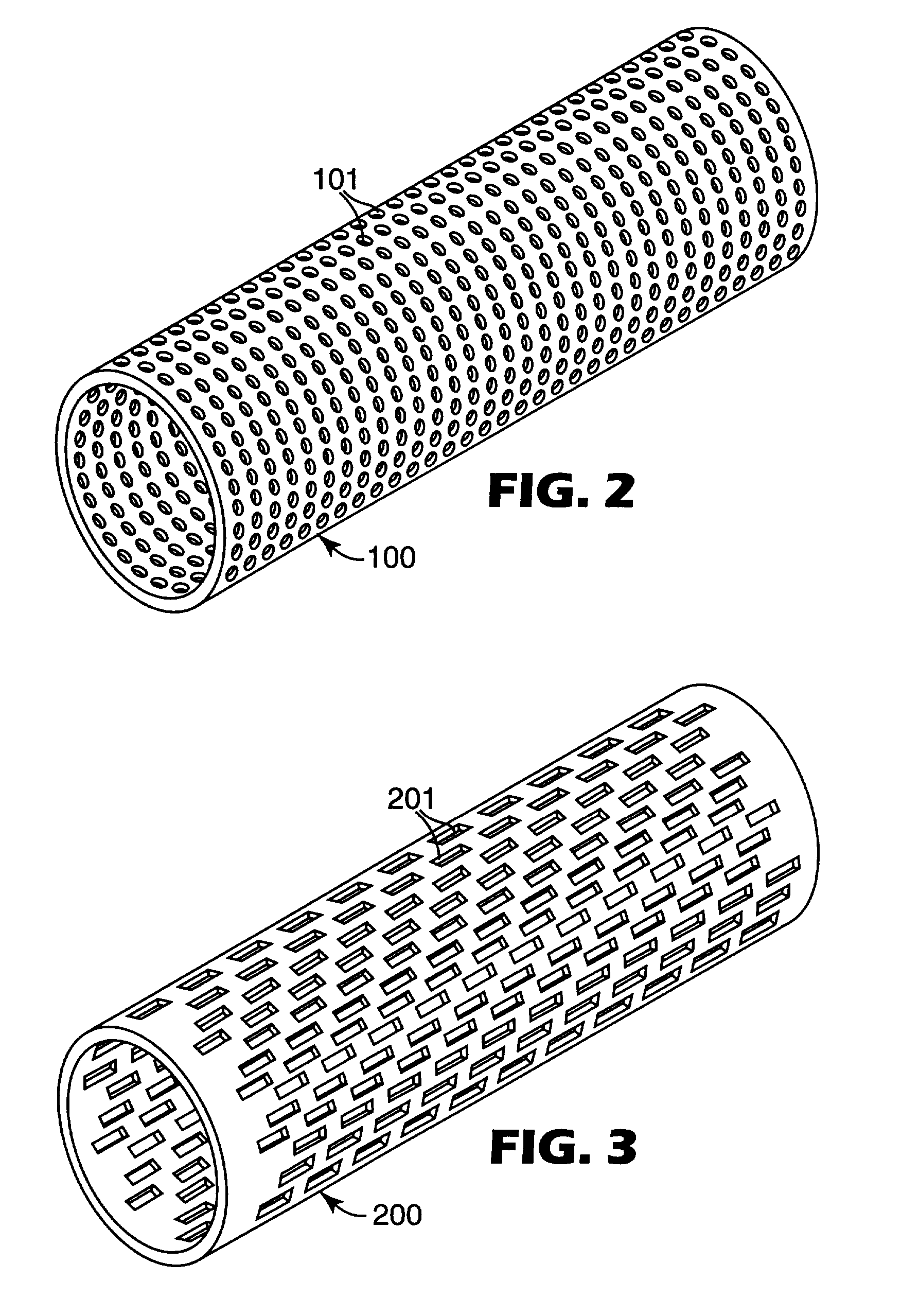

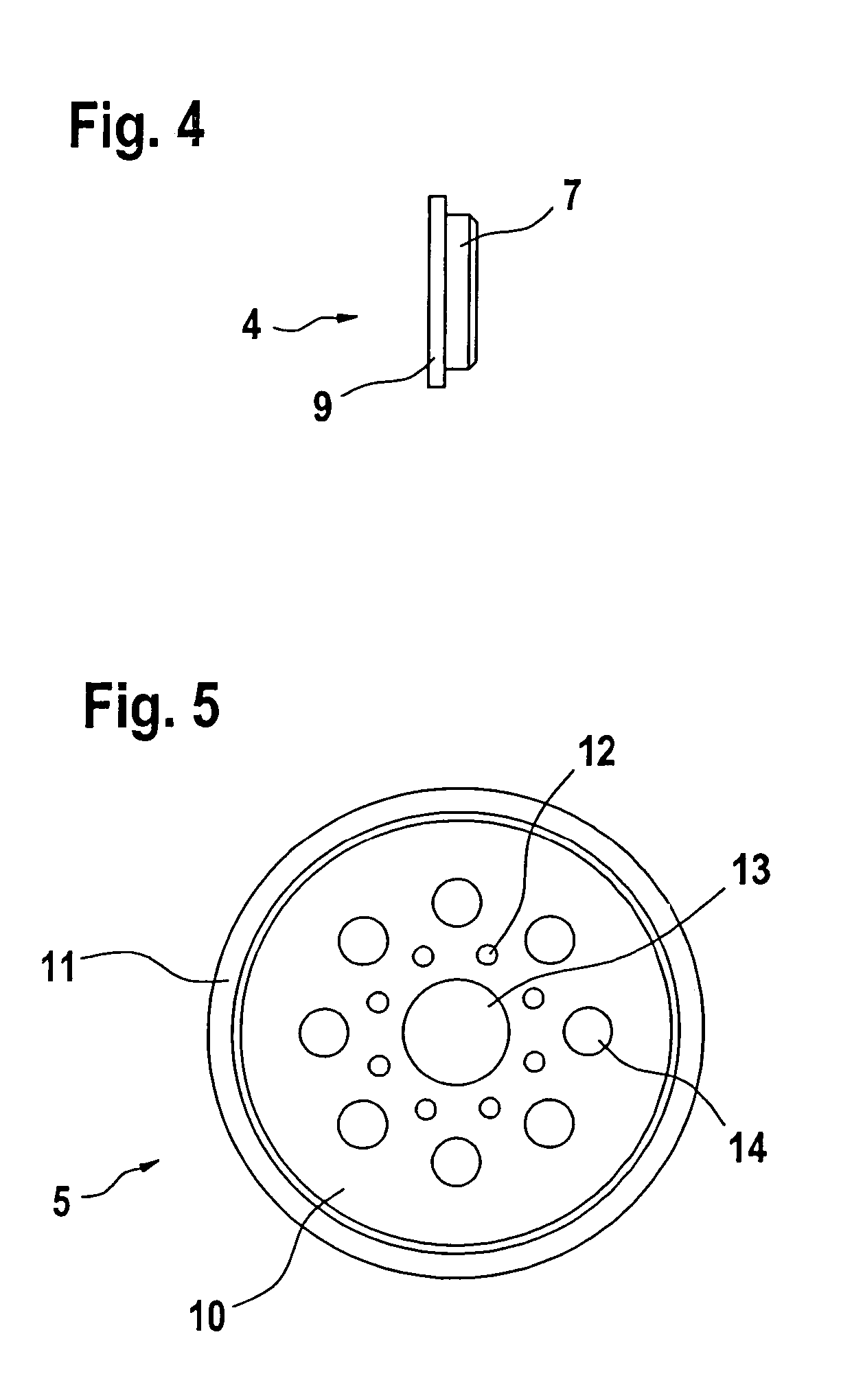

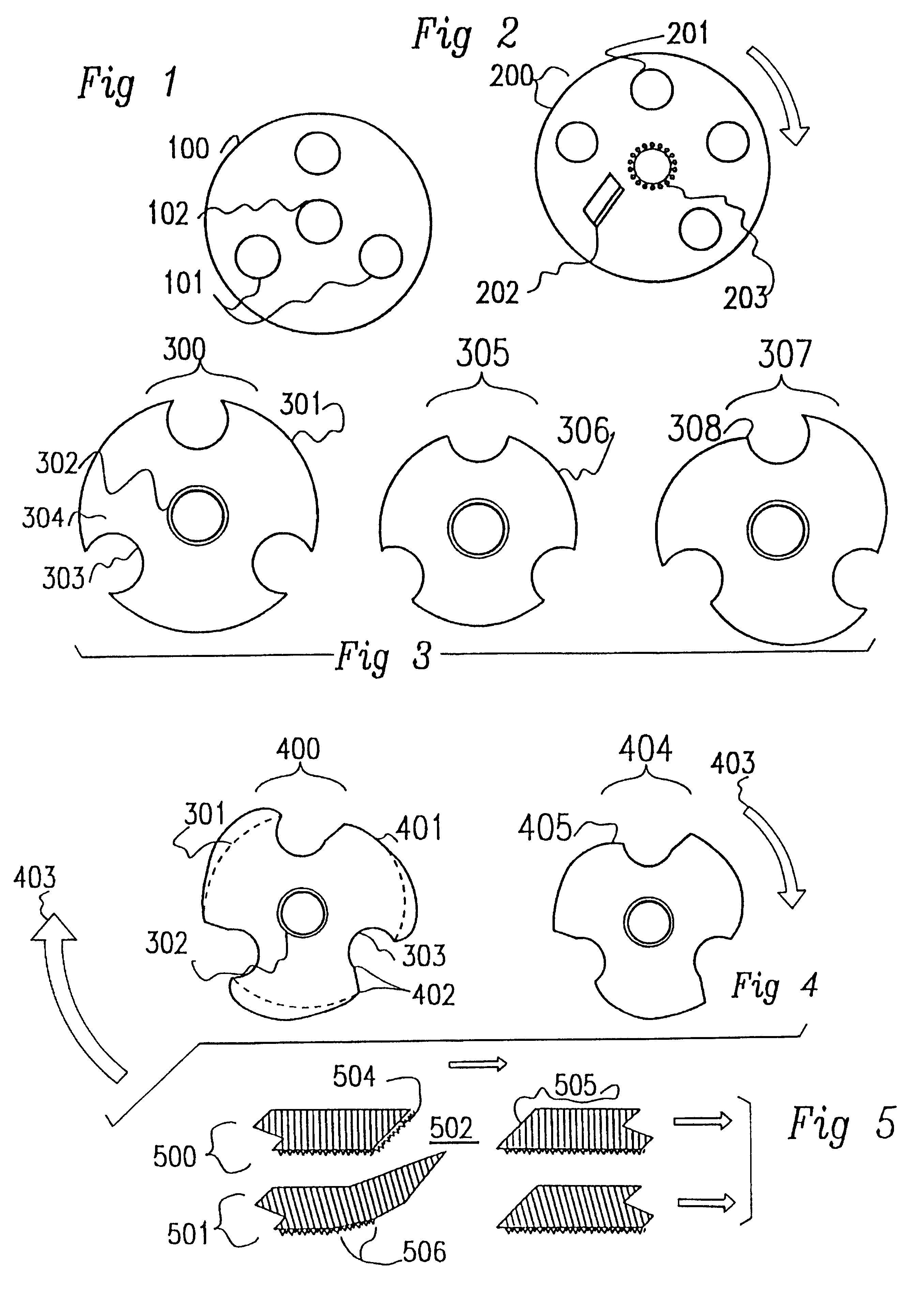

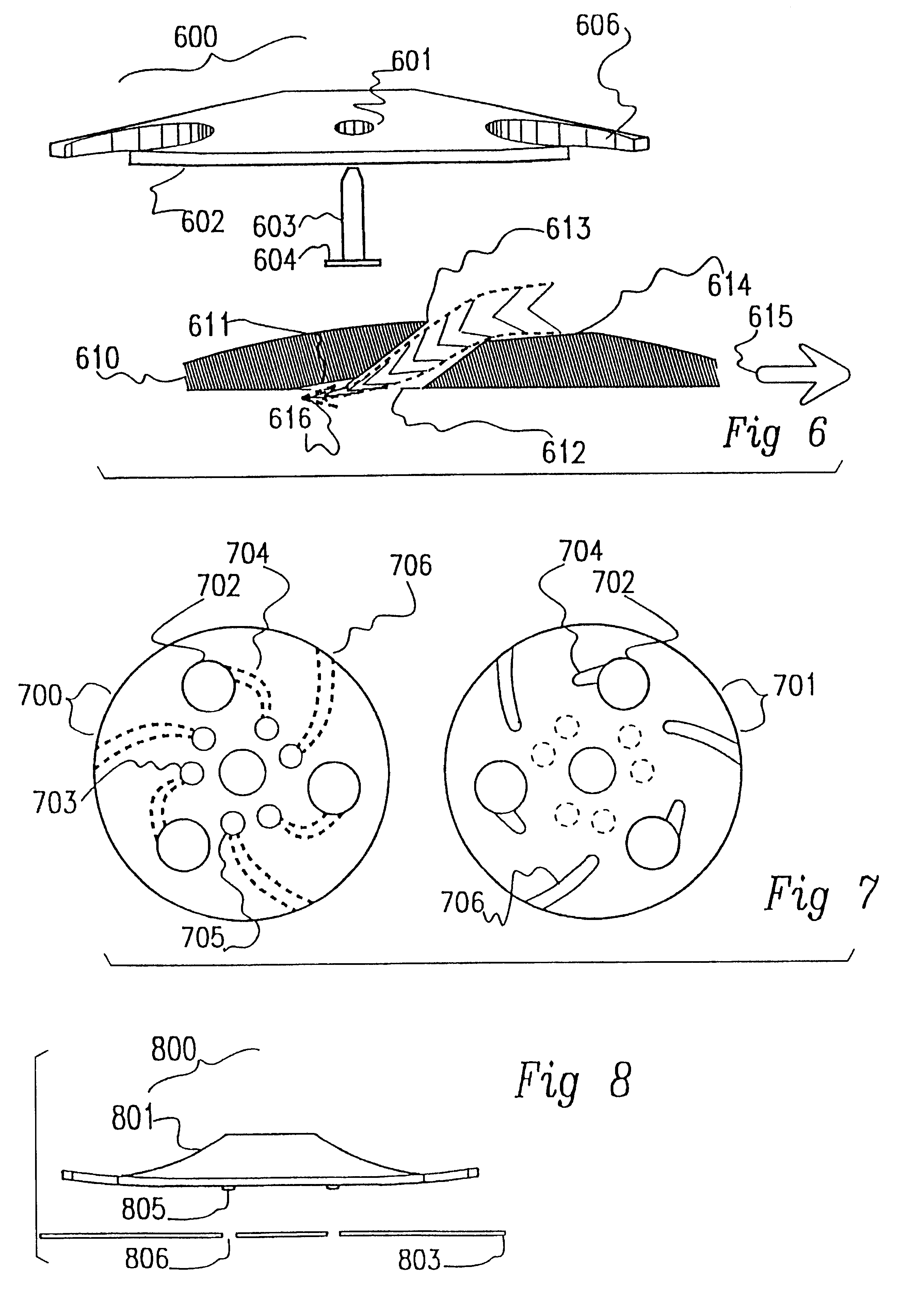

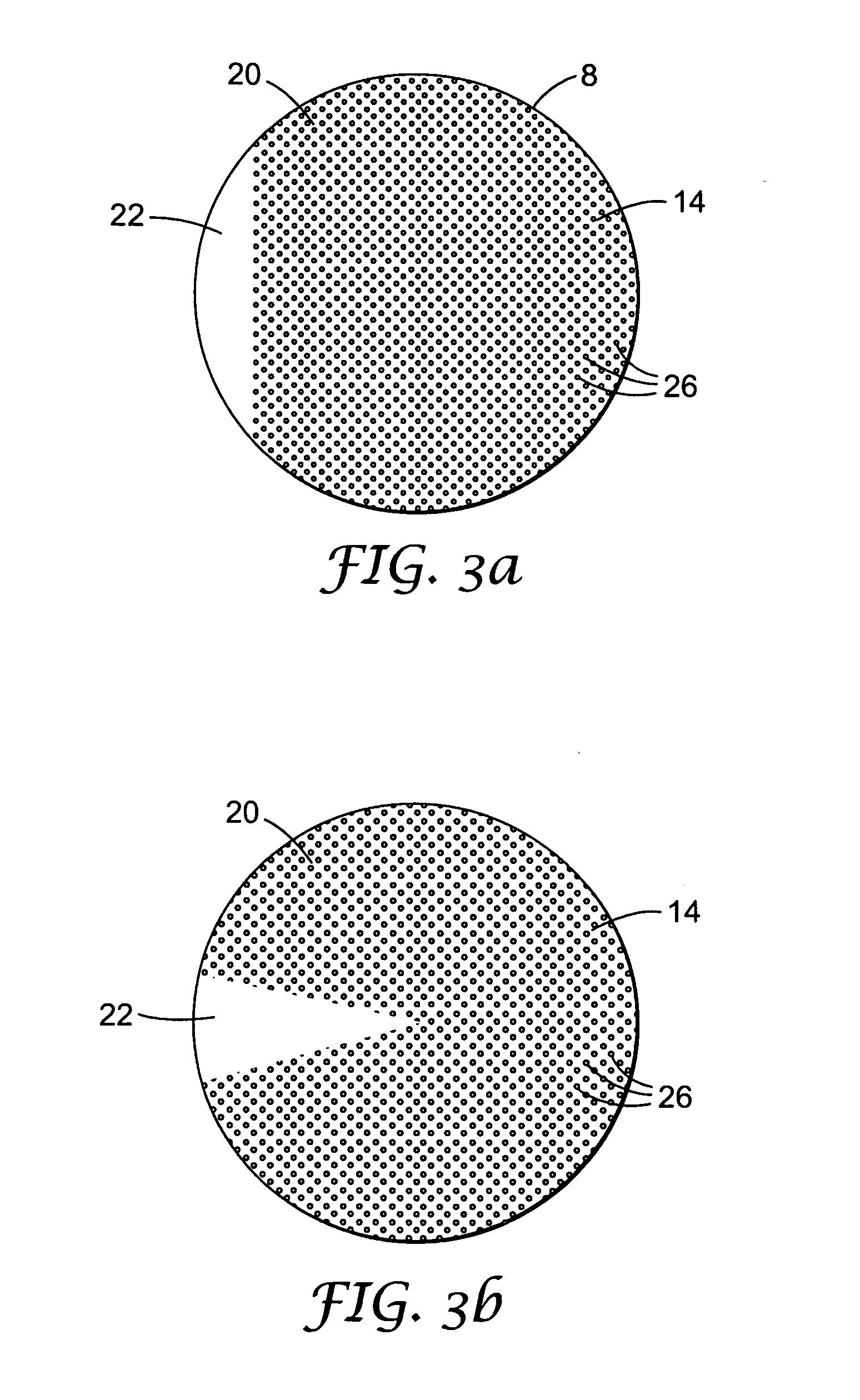

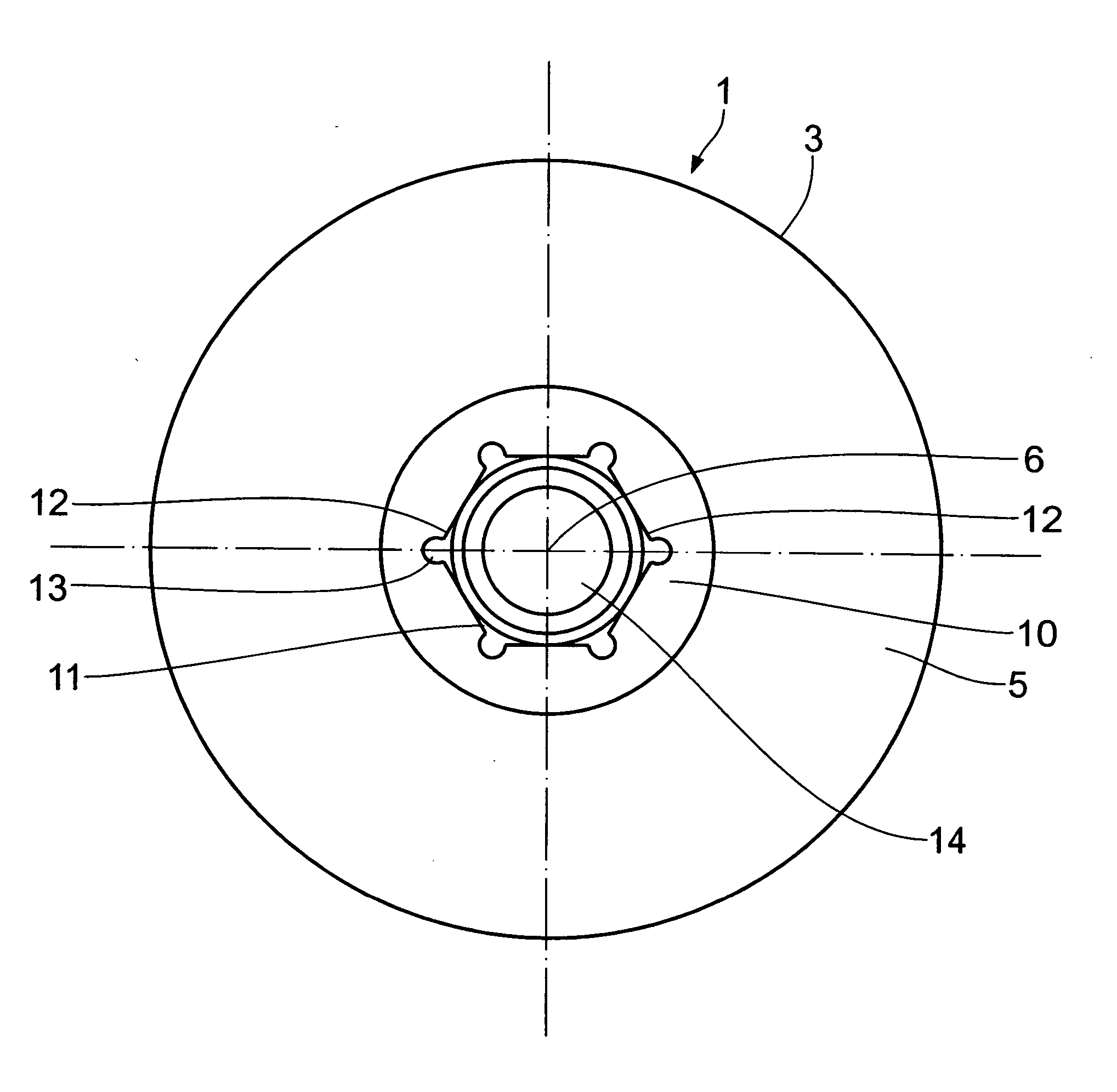

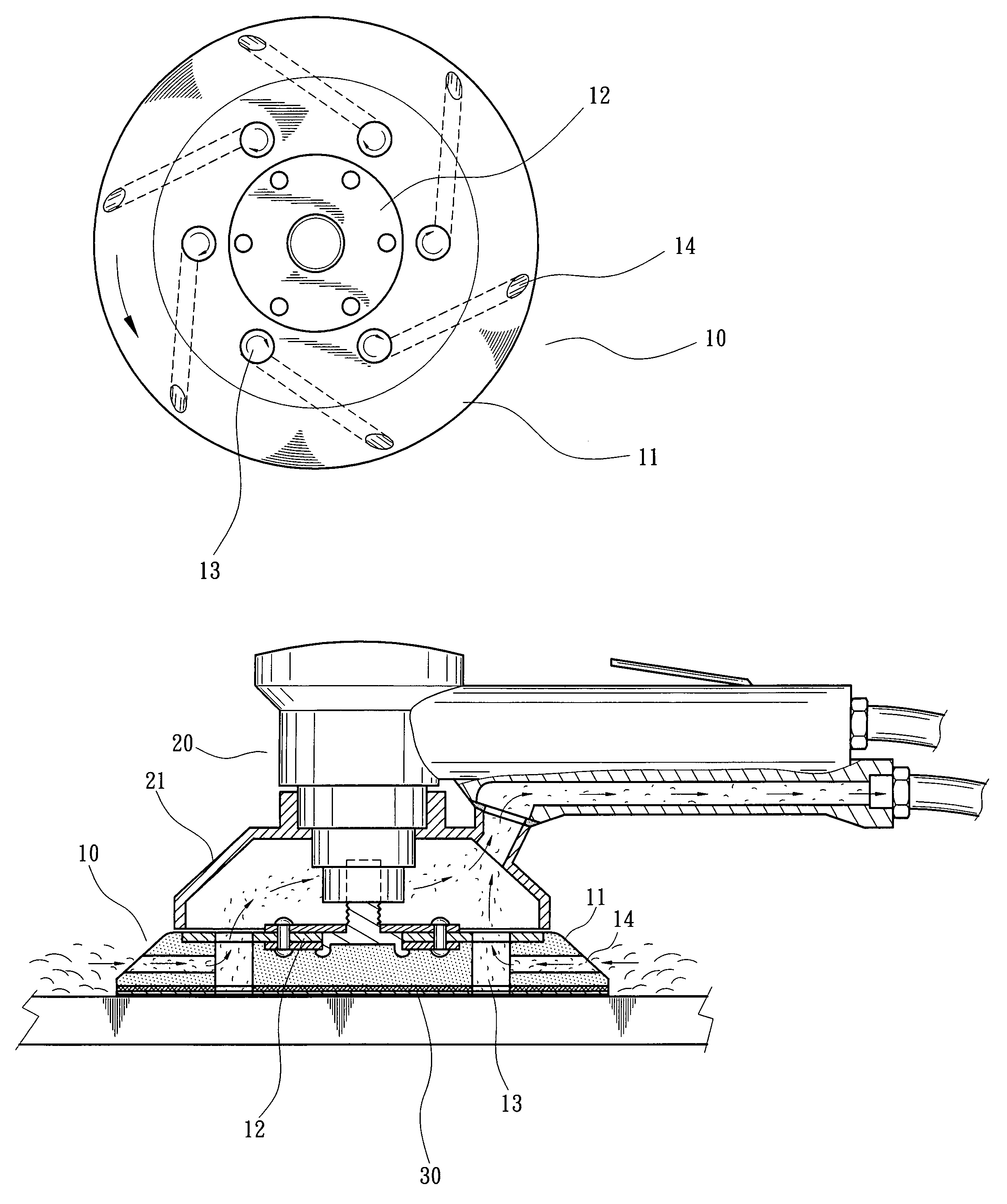

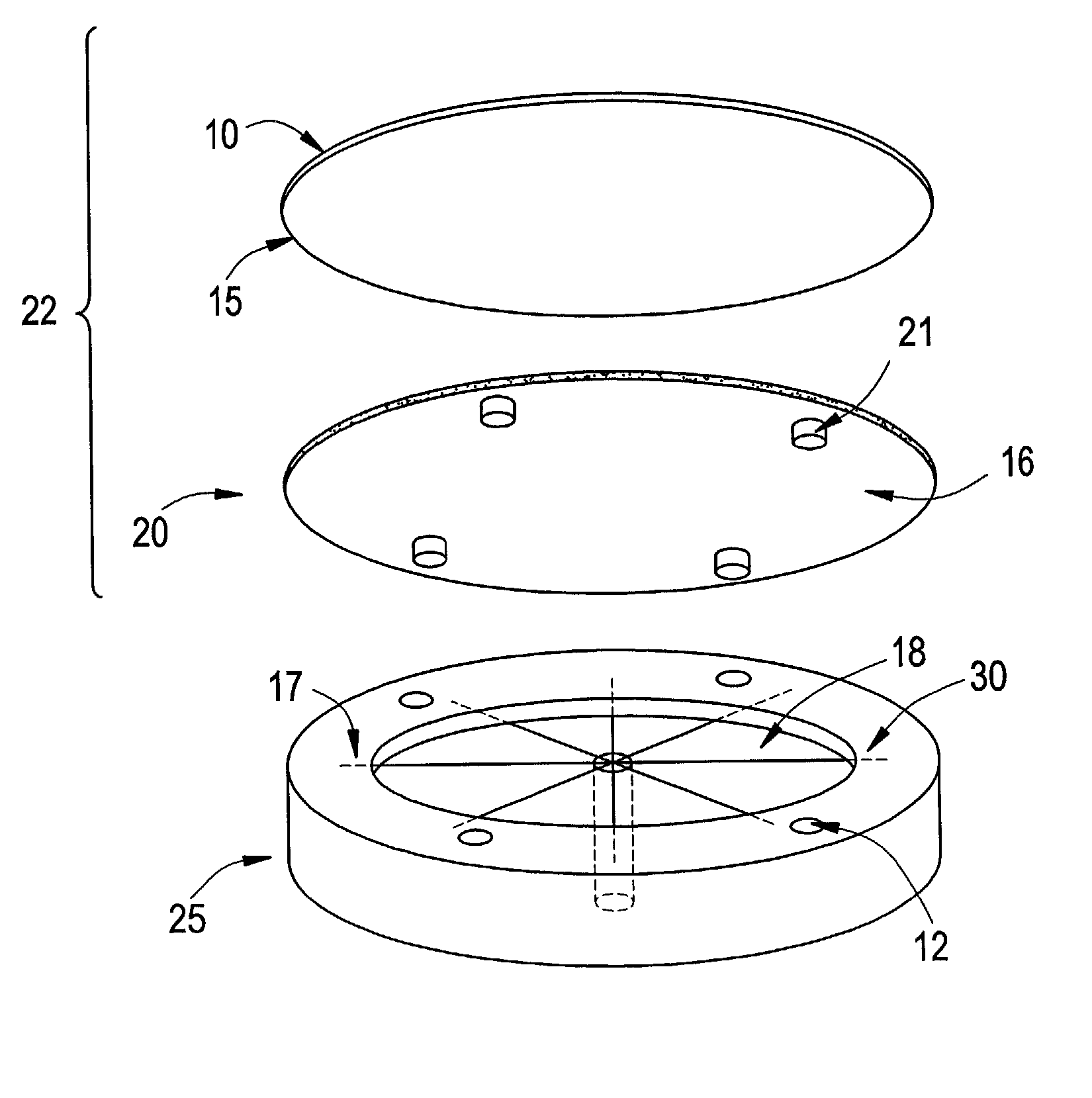

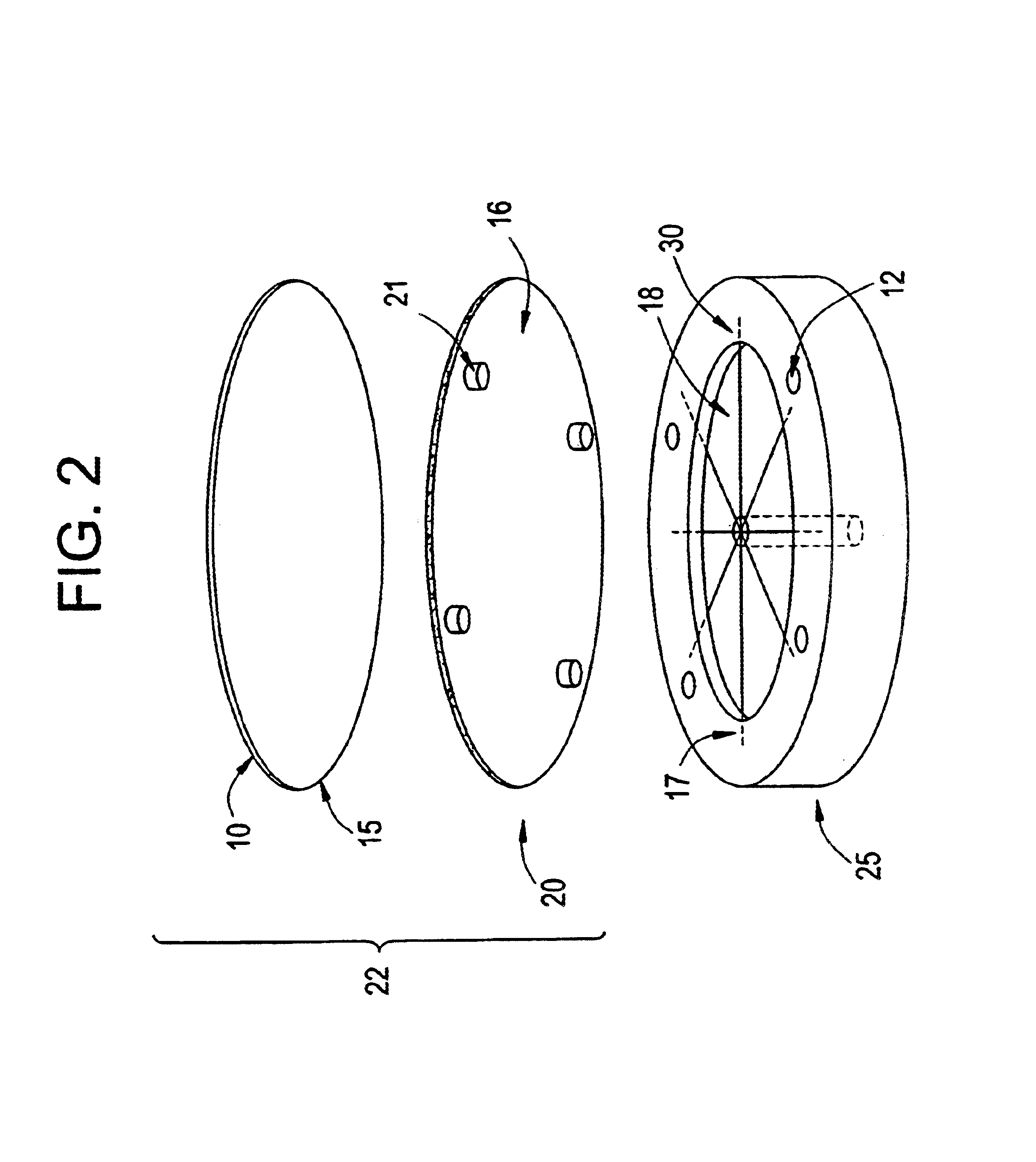

Sanding disks

InactiveUS6312325B1Risk minimizationProtect from harmRevolution surface grinding machinesSupport wheelsAngle grinderEngineering

Accessories for an angle grinder include a disposable rotary sanding disk having quite large shaped ventilating / viewing apertures, for use with a resilient backing plate also having shaped ventilating apertures. The apertures of one or both parts are shaped so that snagging of the apertures on projections from the work surface is minimized and to facilitate air flow across the work surface during use. This air flow helps in cooling the work and ejecting detritus, so minimising clogging effects. The ventilating apertures also facilitate viewing the work to be sanded through the spinning disk during the abrasion process, so that operator feedback is immediate. The holes also give the sanding disk more resilience so that a greater area comes in contact with the work and the disk wears more evenly over its abrasive surface.

Owner:MORTON CO

Abrasive product, method of making and using the same, and apparatus for making the same

The invention provides a method and apparatus for making an abrasive product comprising providing a substantially horizontally deployed flexible backing having a first surface bearing an at least partially cured primer coating and an opposite second surface; providing a dry flowable particle mixture comprising abrasive particles and particulate curable binder material; depositing a plurality of temporary shaped structures comprised of said particle mixture on the at least partially cured primer coating of the first surface of the backing; softening said particulate curable binder material to provide adhesion between adjacent abrasive particles; and curing the softened particulate curable binder material to convert said temporary shaped structures into permanent shaped structures and cure the at least partially cured primer coating on the first surface of the backing. The invention also provides an abrasive product made by the method.

Owner:3M INNOVATIVE PROPERTIES CO

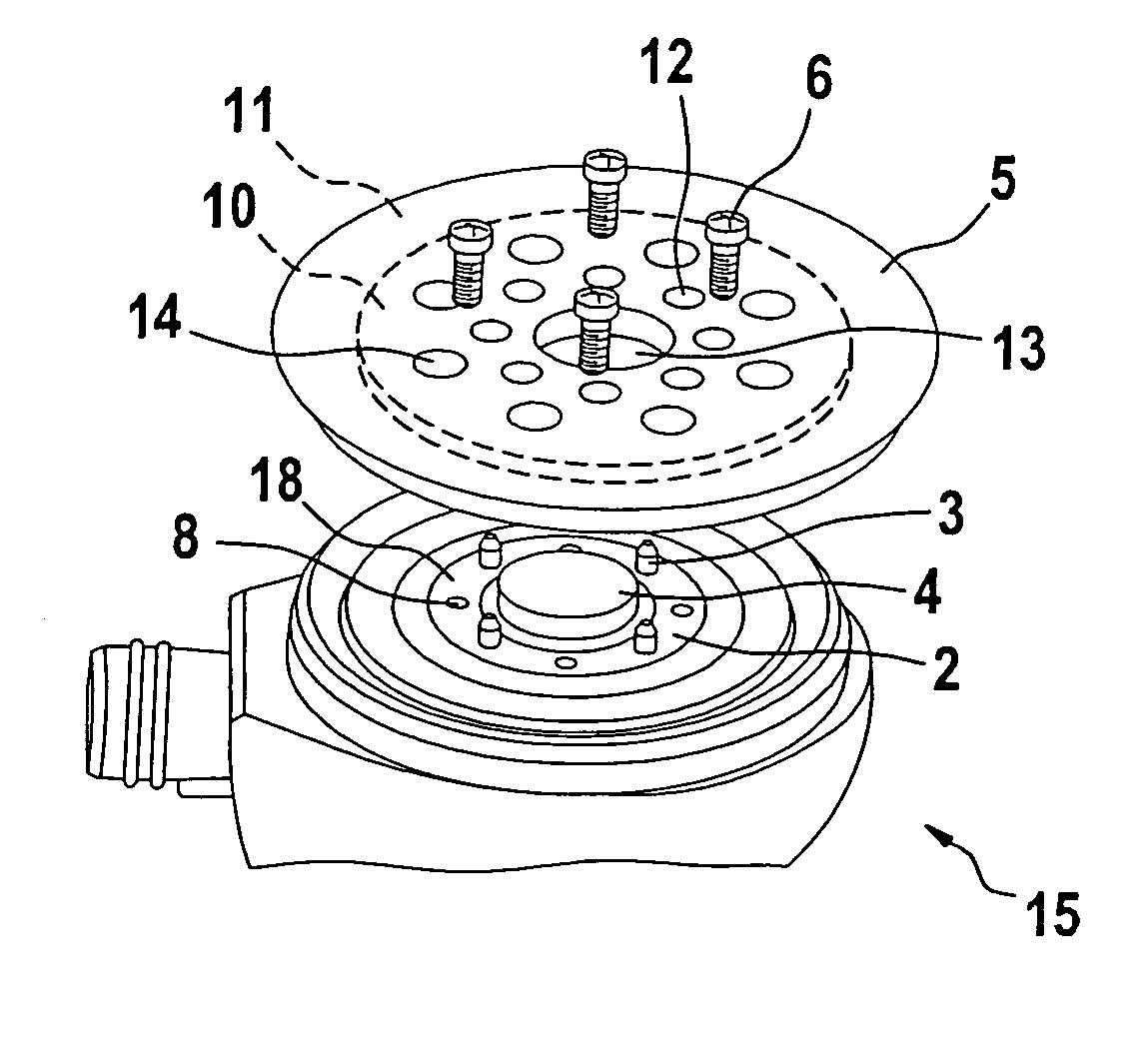

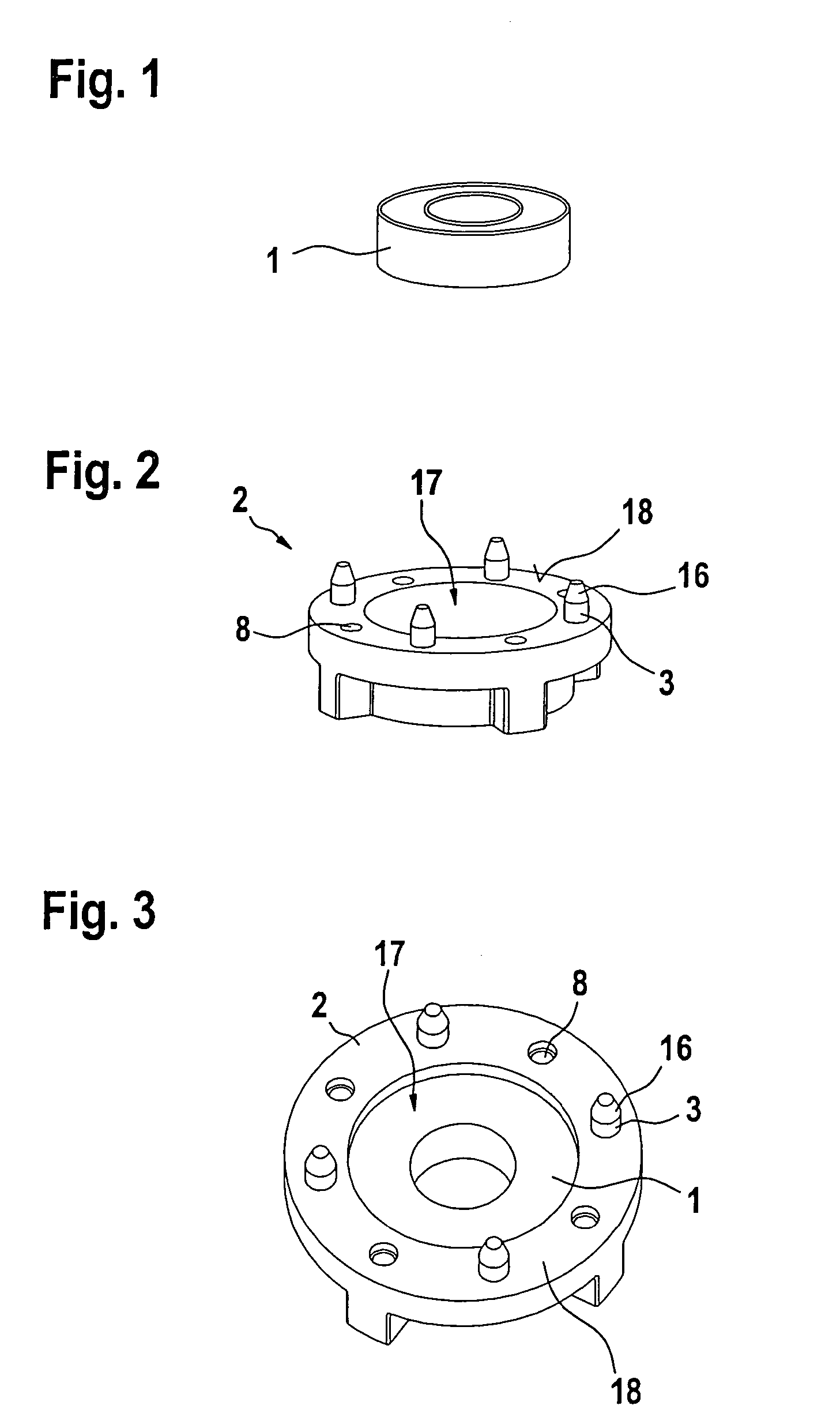

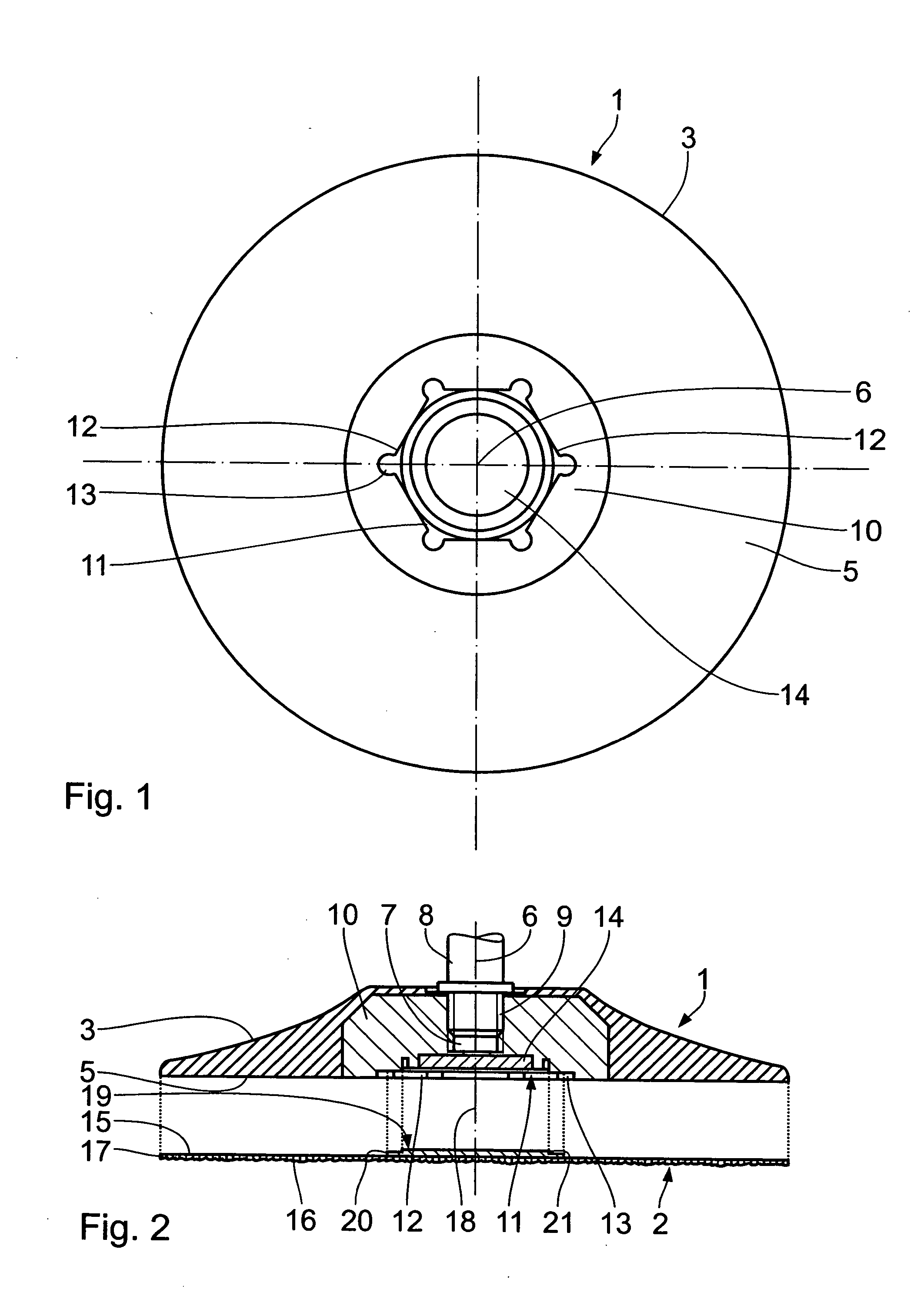

Grinding-disk receiving element especially for a hand-guided electric grinding tool

ActiveUS7217177B2Easy to installEasy to driveGrinding wheel securing apparatusSupport wheelsSanderEngineering

Owner:ROBERT BOSCH GMBH

Backing plates for abrasive disks

Backing plates are provided for use with abrasive disks designed to permit a view of the surface while abrading is occurring. This is achieved by the removal of portions of the circumference of the plate and preferably also viewing apertures in the body of the plate.

Owner:MORTON CO

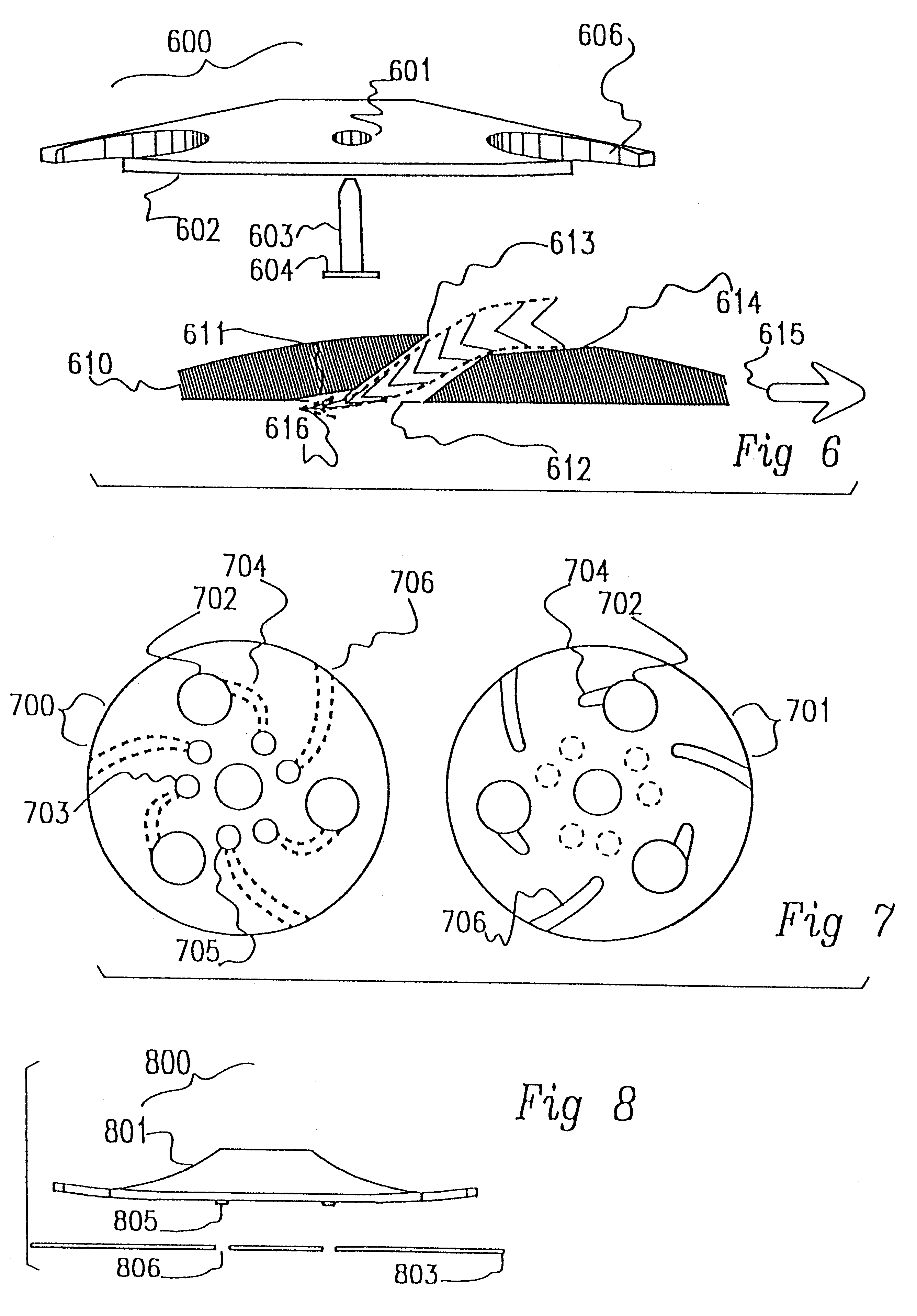

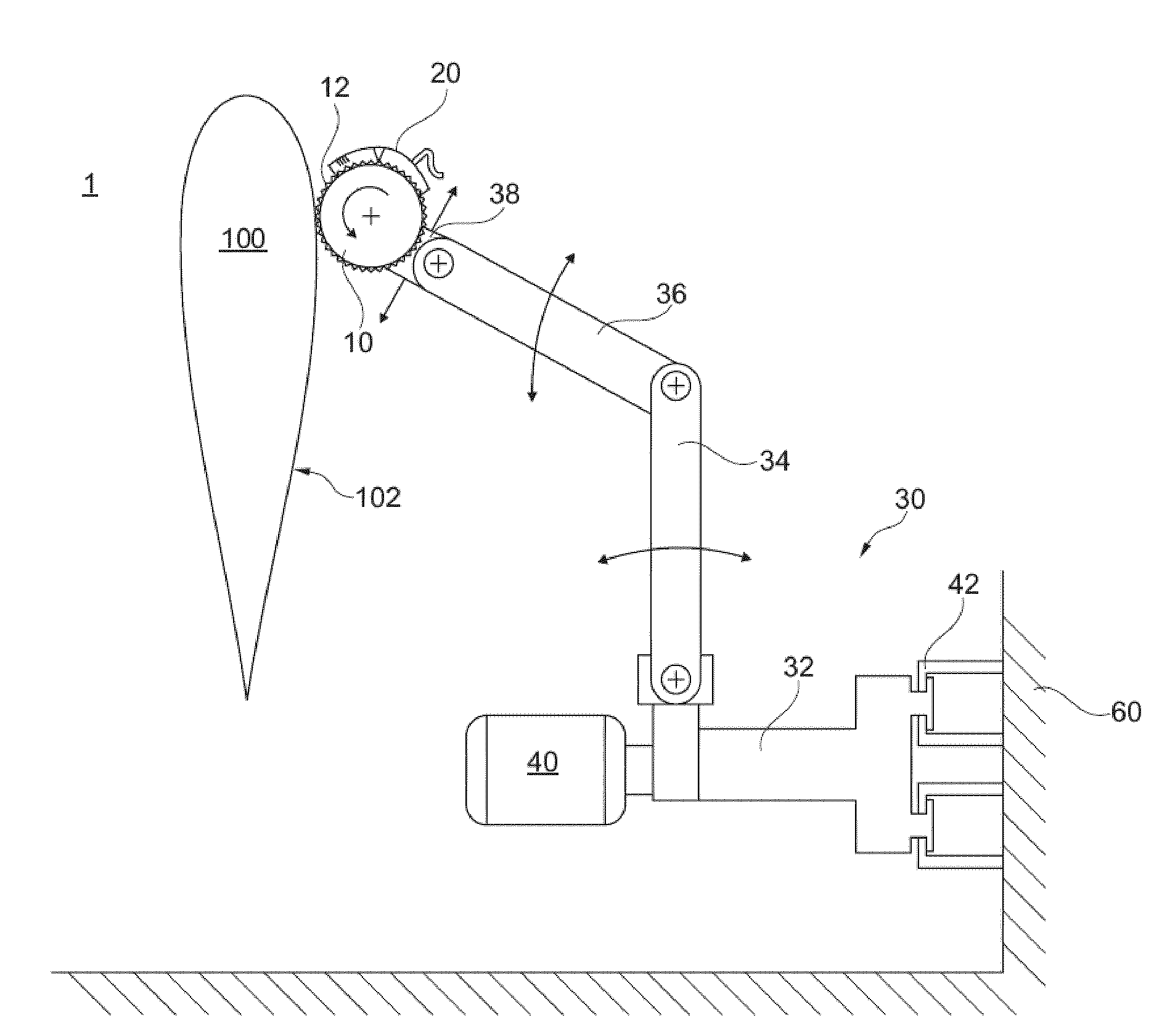

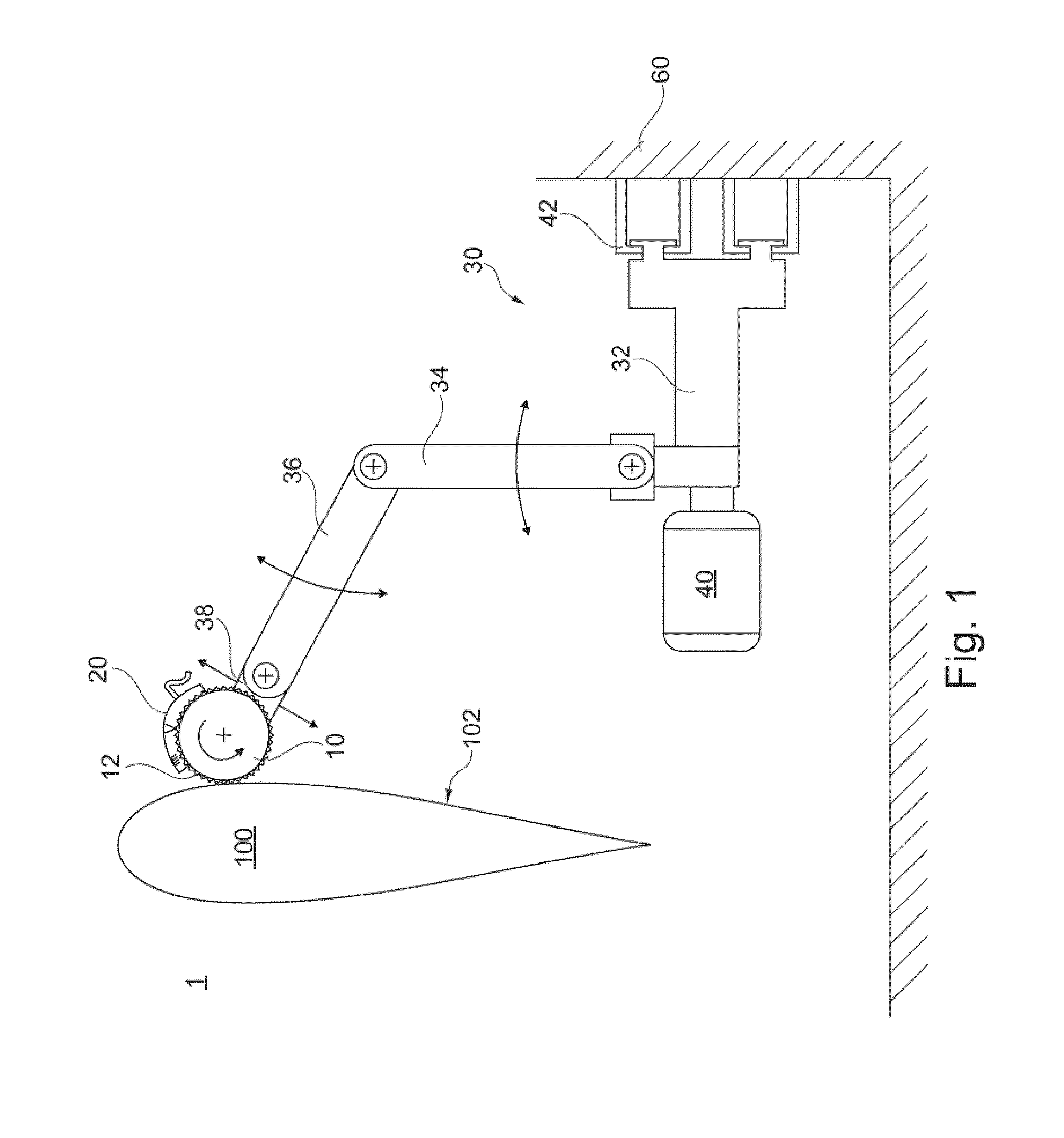

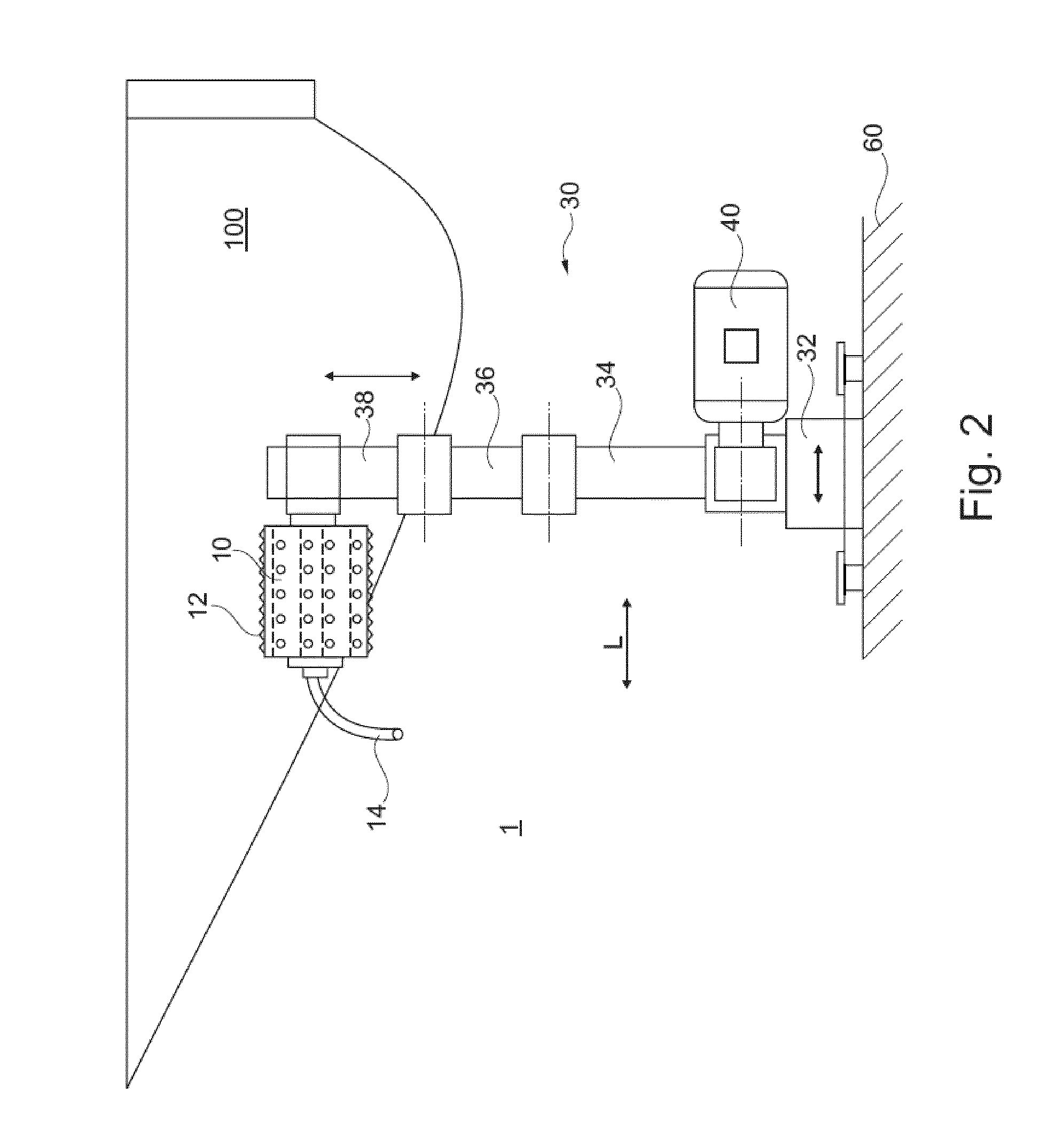

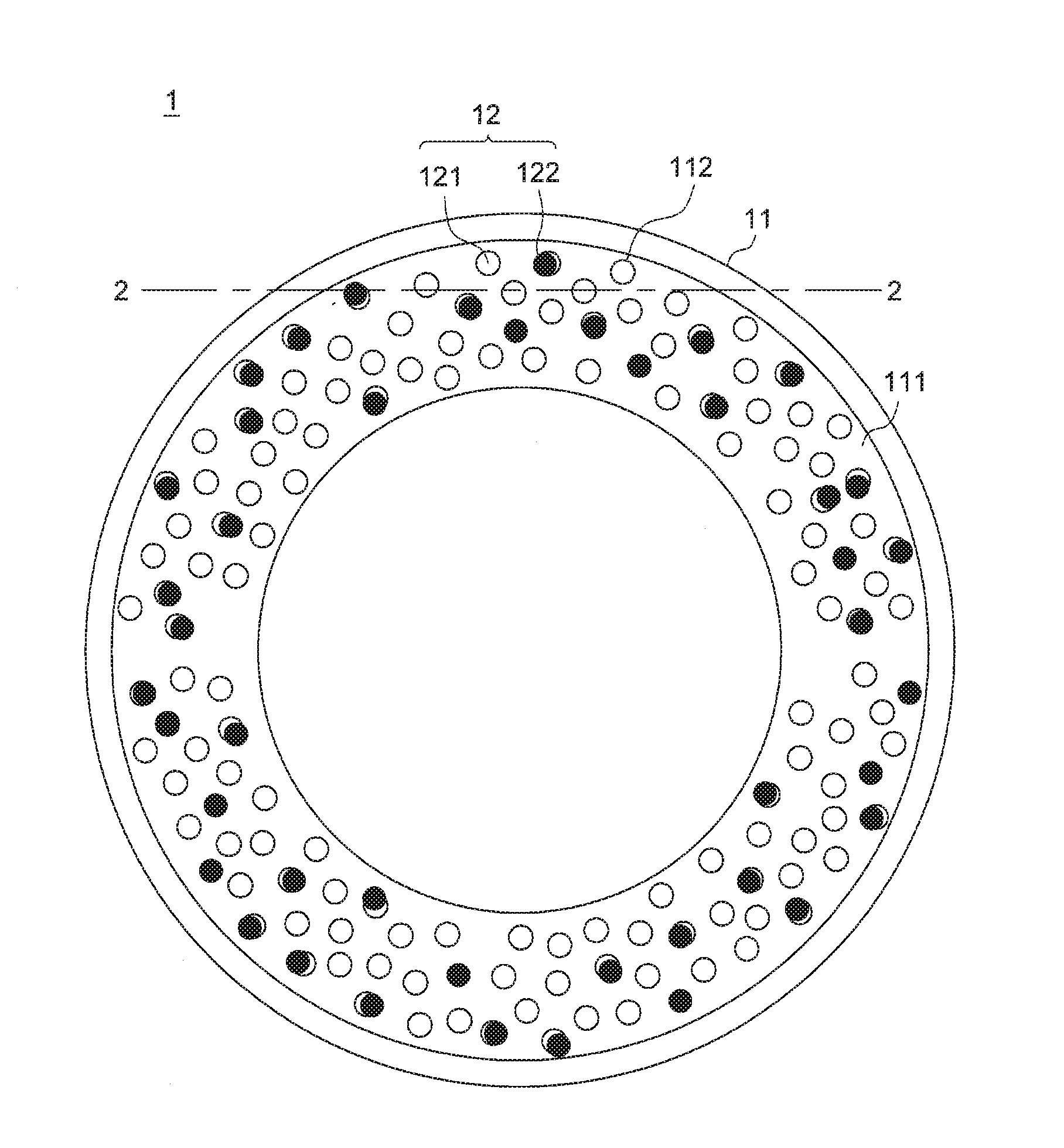

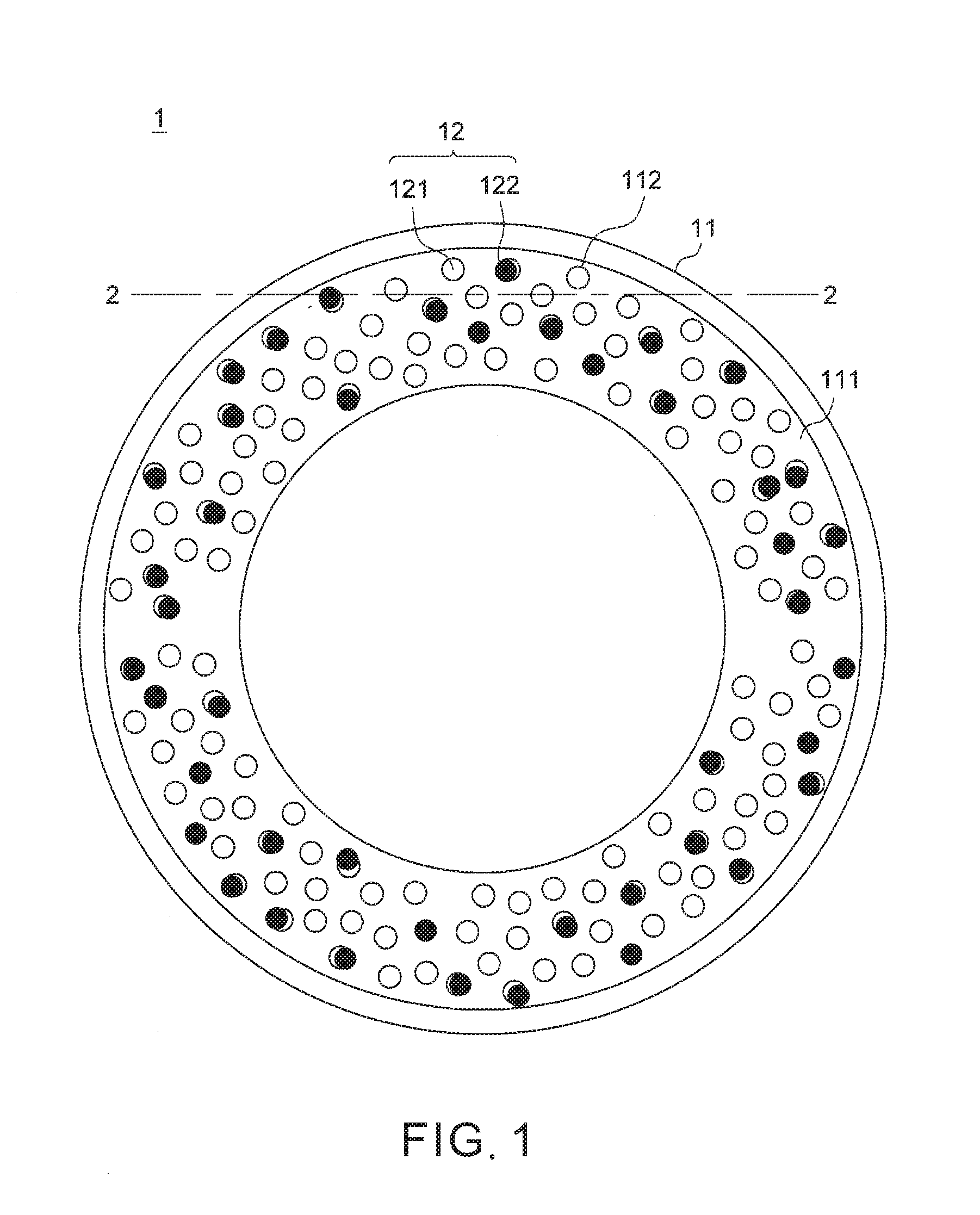

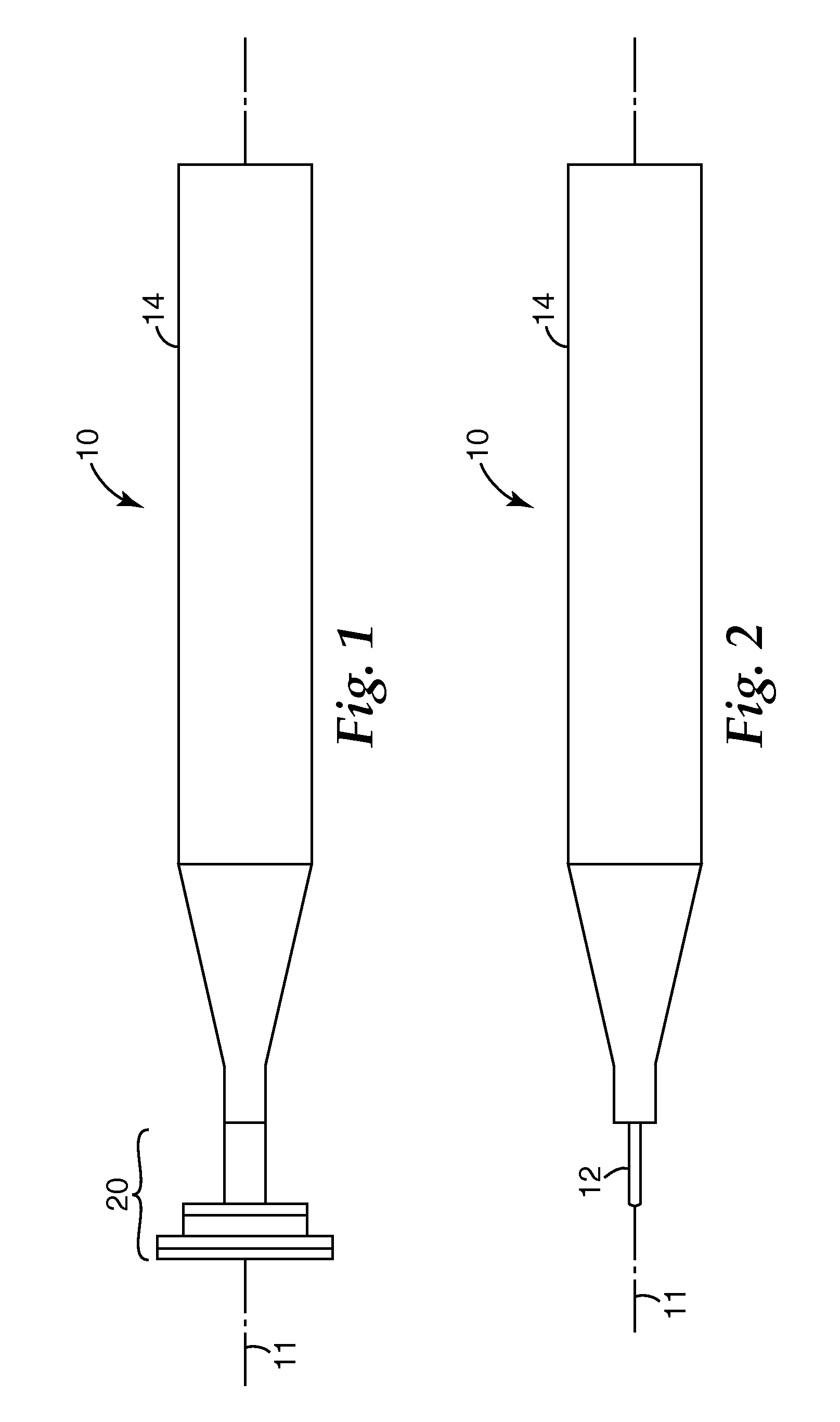

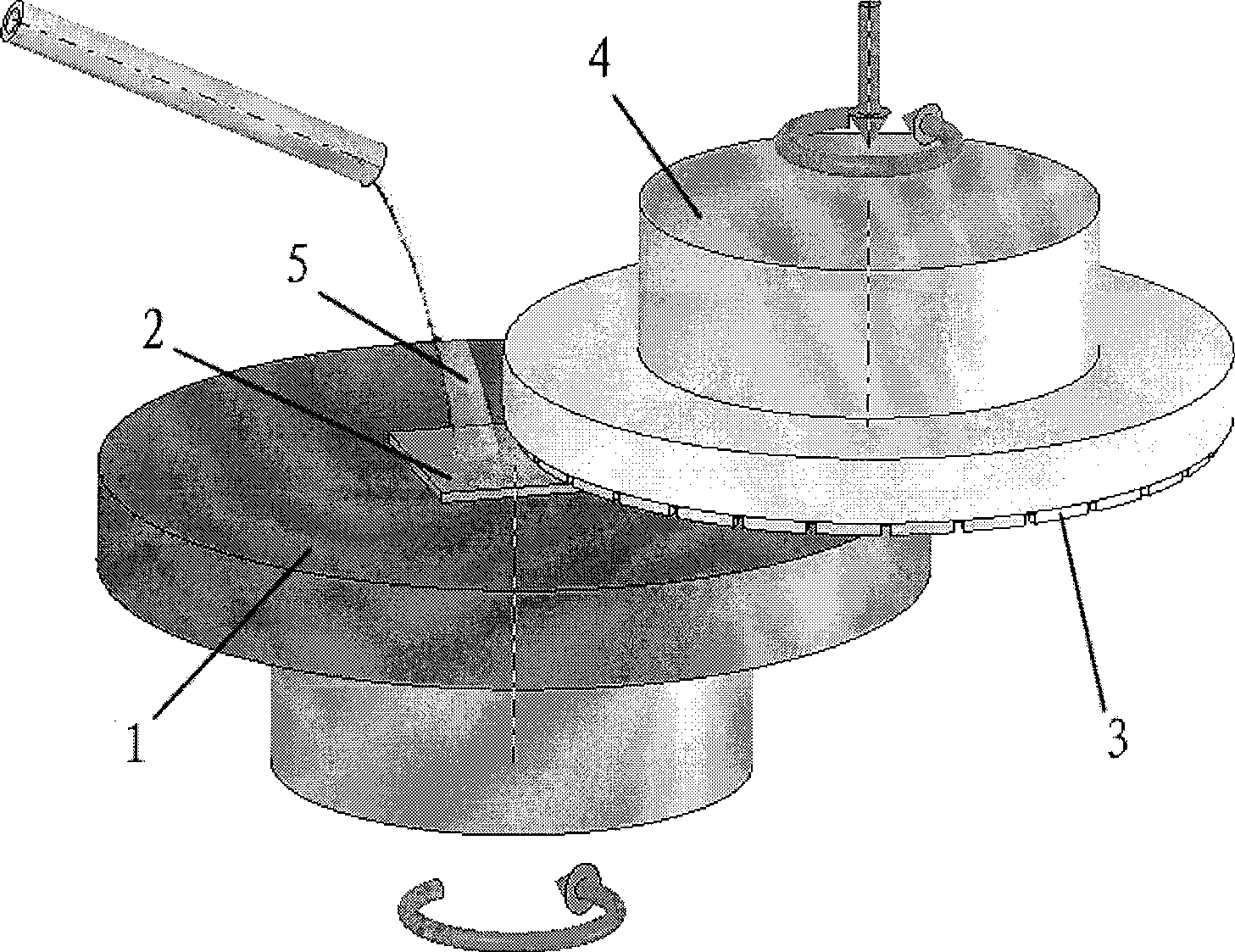

Grinding device for machine based grinding of rotor blades for wind energy systems

InactiveUS20120322349A1Life time of the grinding means is increasedLow investment costEdge grinding machinesSupport wheelsIndustrial machinePulp and paper industry

Grinding device 1 for machine-based grinding of rotor blades 100 for wind energy systems, comprising at least one industrial robot 30 and a grinding unit 10, 50, 70 that is guided by the industrial robot 30, wherein the grinding unit 10, 50, 70 comprises a grinding means, 12, 52 and a cleaning device 20, that cleans the grinding means 12, 52 at its grinding surface 64, 53.

Owner:JOST GMBH & CO KG

Grinding Tool and Method of Manufacturing the Same

A grinding tool includes a substrate having a working surface, and a plurality of abrasive particles distributed over the working surface and protruding outward from the working surface, wherein at least some of the abrasive particles are machined to form abrasive particles respectively having an obliquely truncated pyramid shape. Some embodiments described herein also include a method of manufacturing the grinding tool.

Owner:KINIK

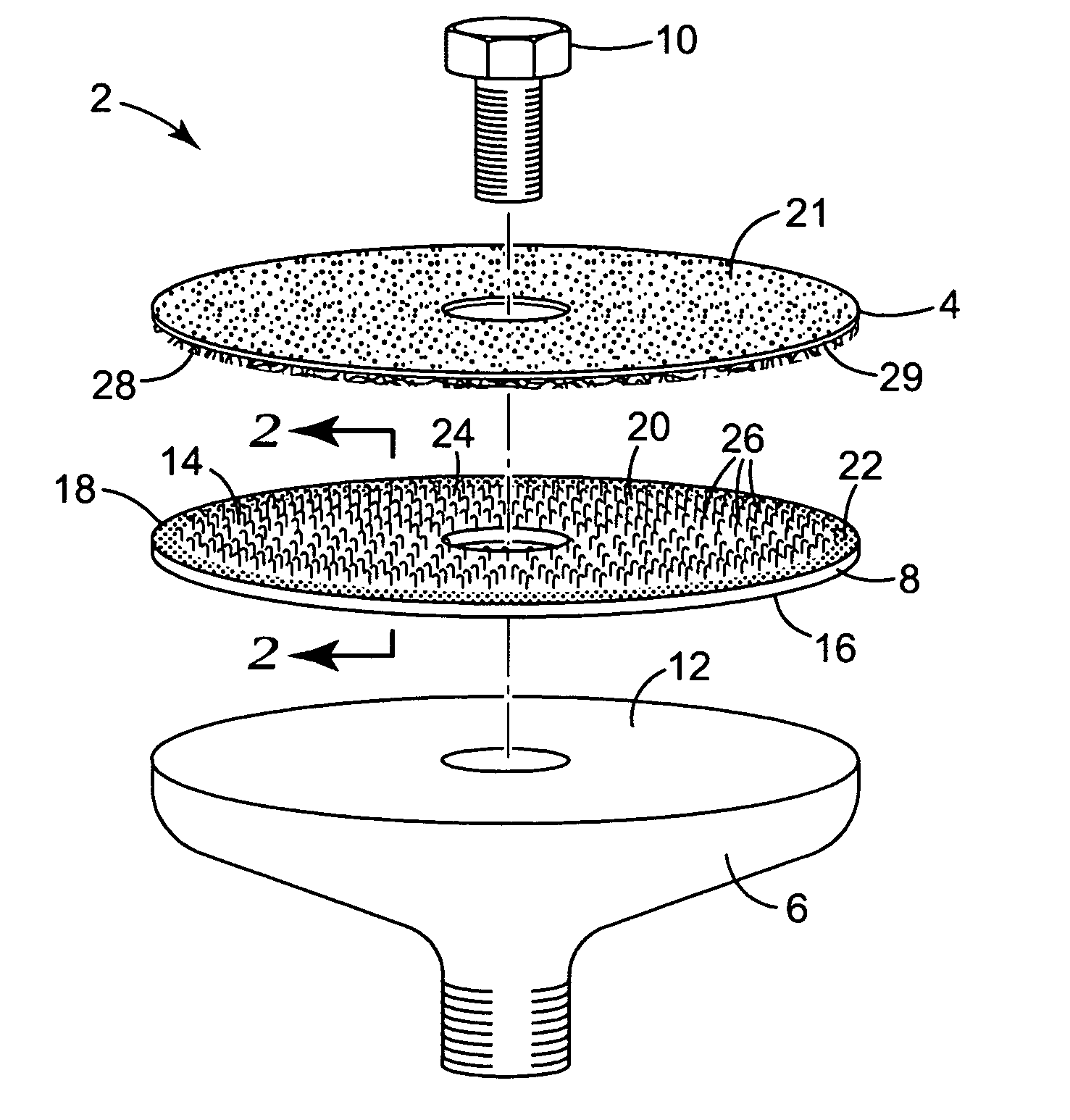

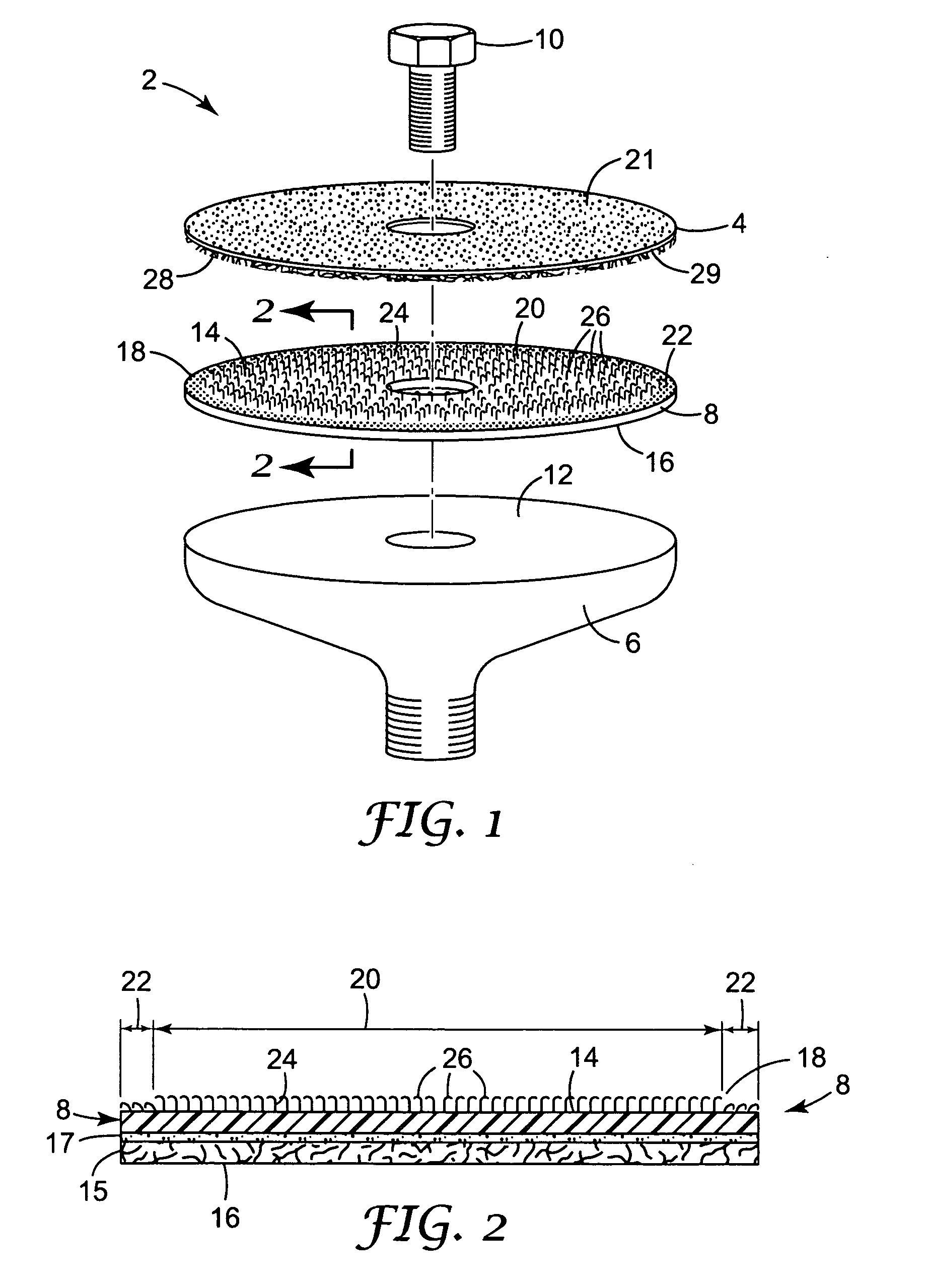

Attachment system for a sanding tool

ActiveUS20050227600A1Easy to separateUniform supportSupport wheelsGrinding/polishing hand toolsEngineeringMechanical engineering

An attachment system for attaching an abrasive article, such as an abrasive sheet or disc, to a sanding tool includes an article having a first major surface including an attachment region with attachment material for attachment with an associated mating surface on the sanding tool, and a non-attachment region along at least a portion of an edge of the first major surface forming a sufficiently weak attachment with the associated mating surface to allow a user to grasp the abrasive article and separate the abrasive article from the sanding tool.

Owner:3M INNOVATIVE PROPERTIES CO

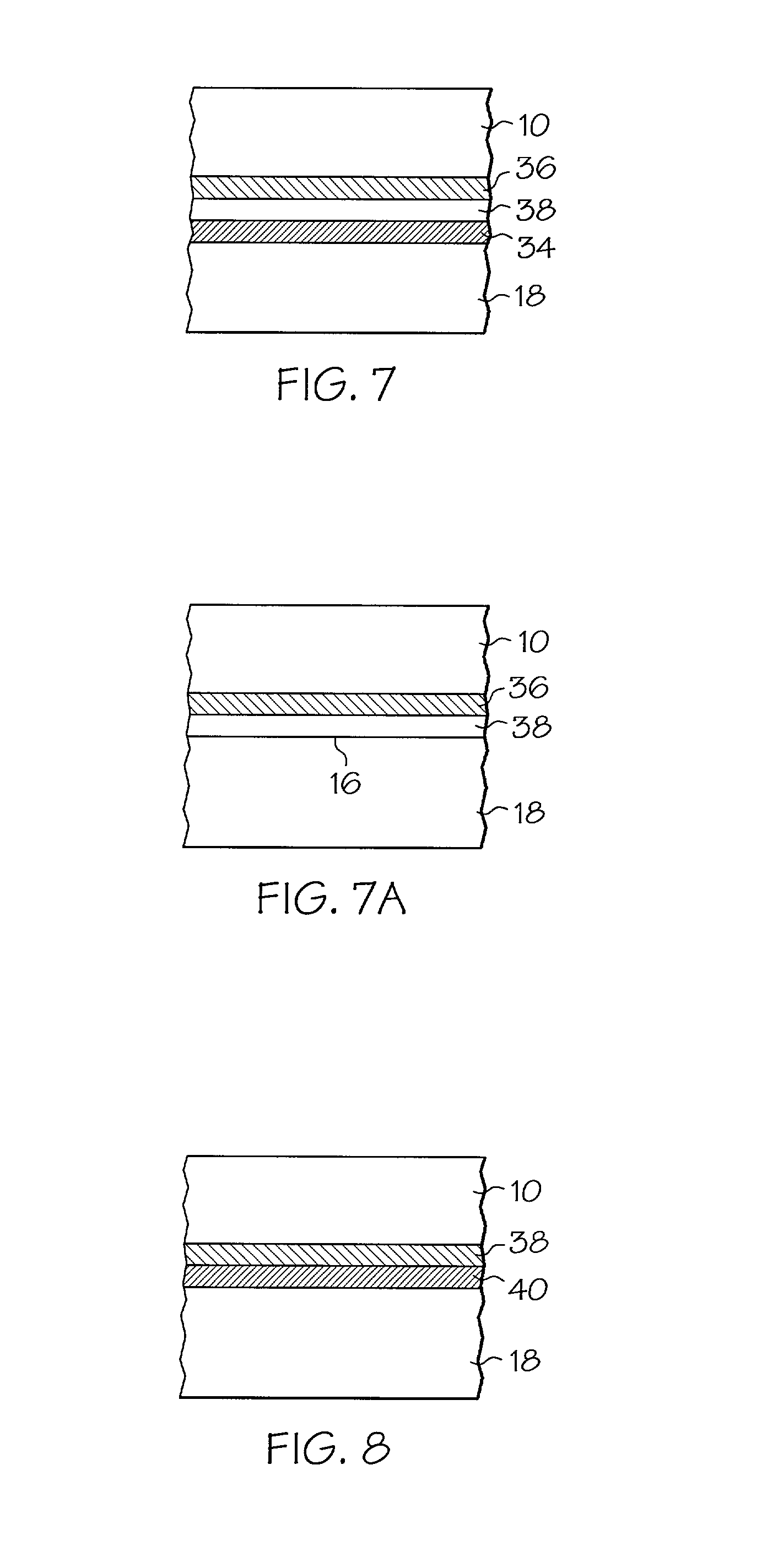

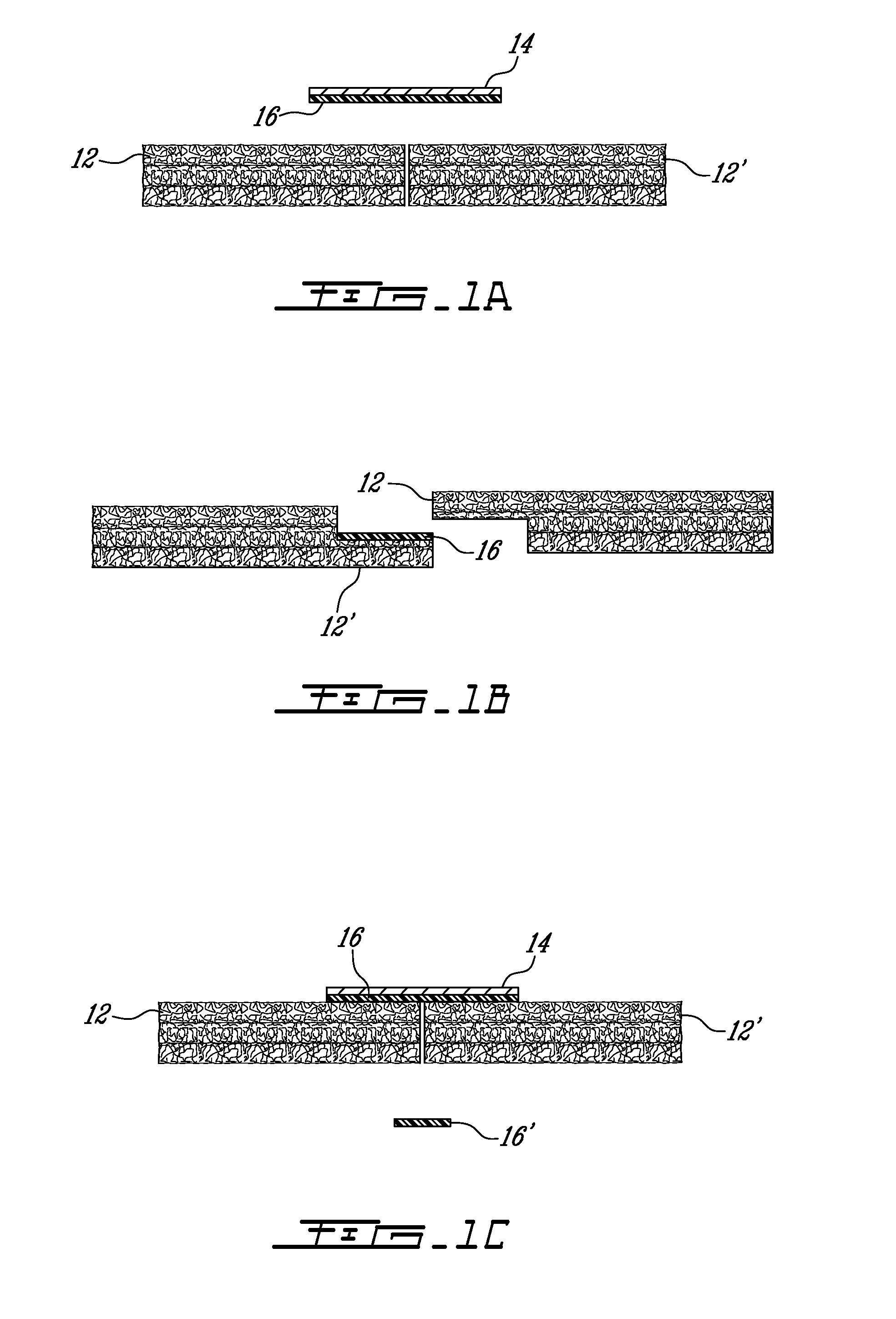

Eliminating air pockets under a polishing pad

InactiveUS6561891B2Polishing machinesRevolution surface grinding machinesElectrical devicesEngineering

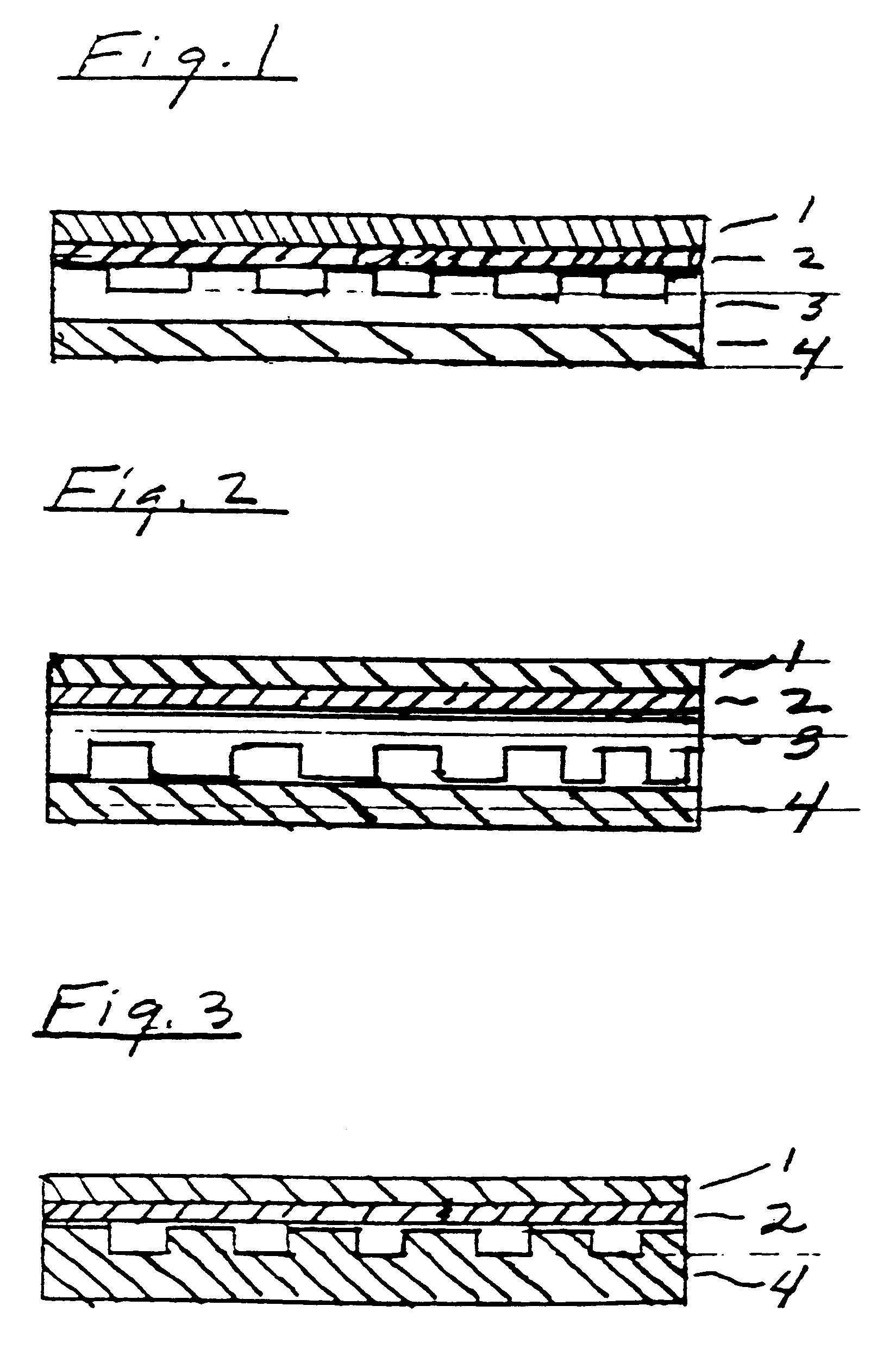

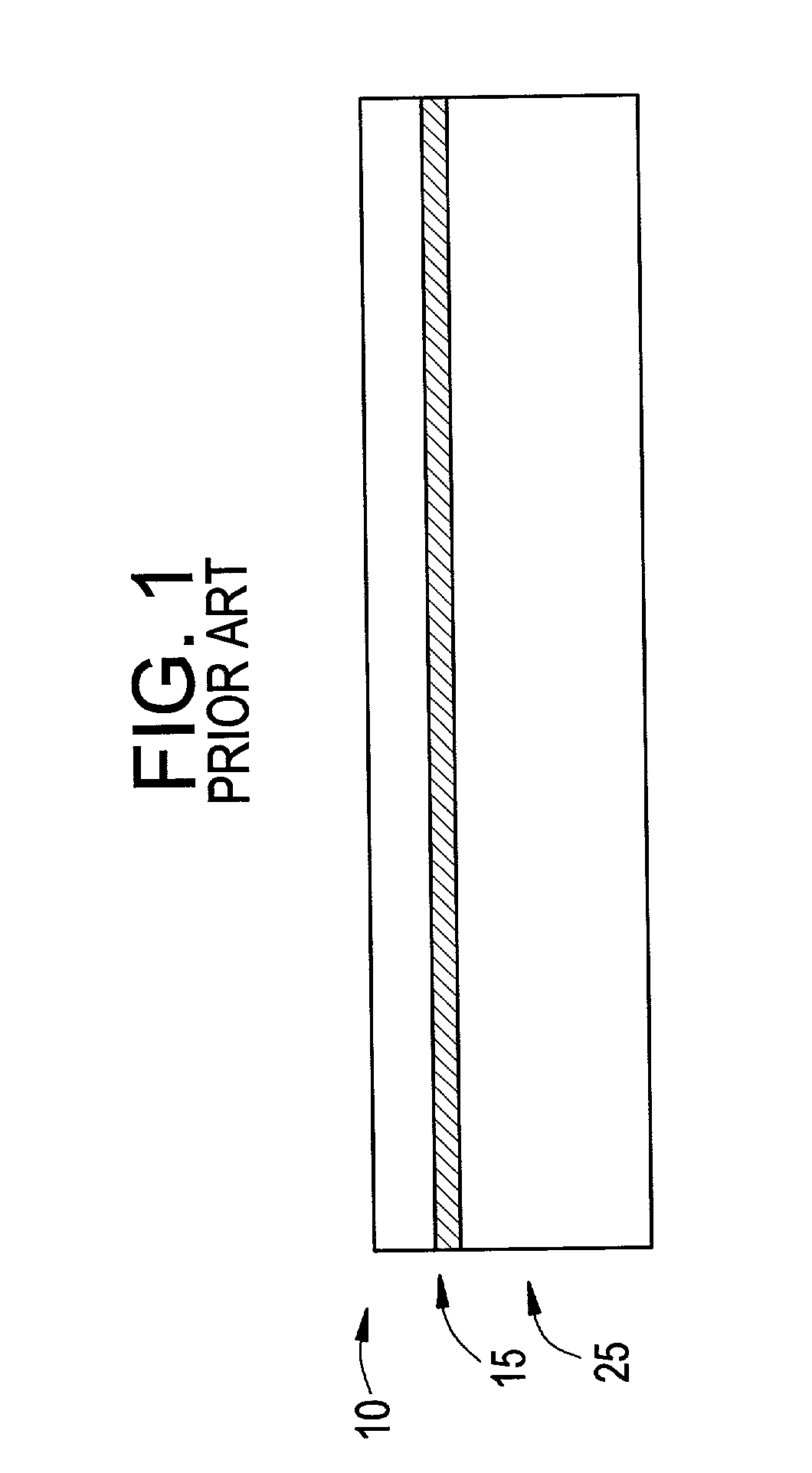

A polishing pad assembly is provided that is useful for the chemical mechanical polishing of glass and electrical devices such as semiconductor wafers that comprises a polish pad and a semi-rigid base material firmly adhered to the polishing pad for positioning on a polishing platen of a polishing machine; wherein the semi-rigid base material has a modulus of rigidity of 0.01-50 GPa (GigaPascals) determined according to ASTM D 790, a thickness of 0.25-15.0 mm, and a grooved surface having a pitch of 5-100 mm and the grooves have a width of 0.025-2.5 mm and a depth of 0.1-2.5 mm.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

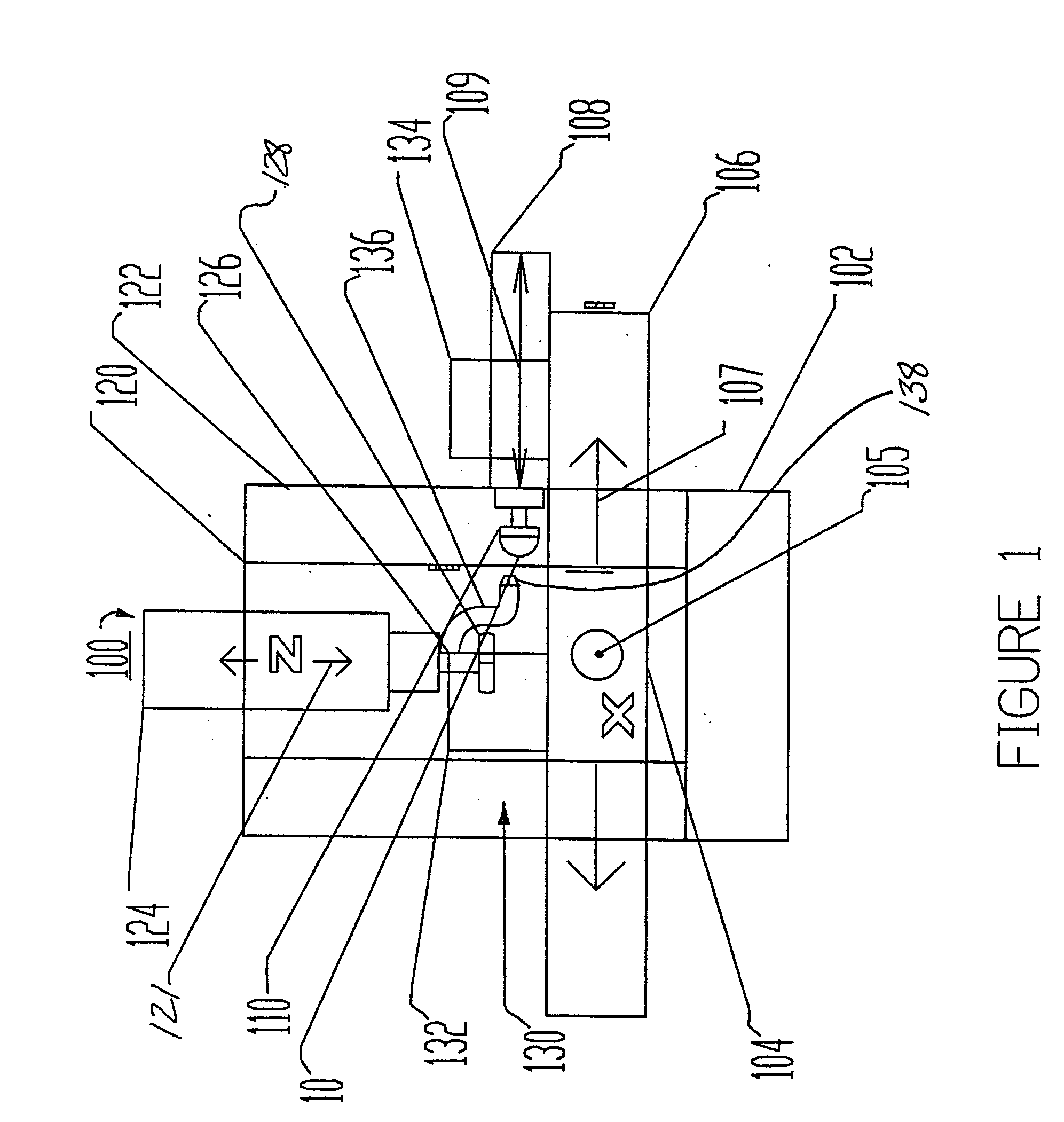

Tool, apparatus, and method for precision polishing of lenses and lens molds

InactiveUS20050079812A1Low costImprove accuracyOptical surface grinding machinesSupport wheelsParallel plateEngineering

A tool for polishing objects having a wide variety of materials and shapes including precision optical surfaces, injection mold inserts, and thin film coating dies. The tool has an elastic solid bladder with a curved surface, upon which is disposed an abrasive band. The curved bladder surface is produced by compressing the bladder between two parallel plates. The apparatus comprises a multi-axis computer controlled machine to which the tool is attached.

Owner:OPTIPRO SYST

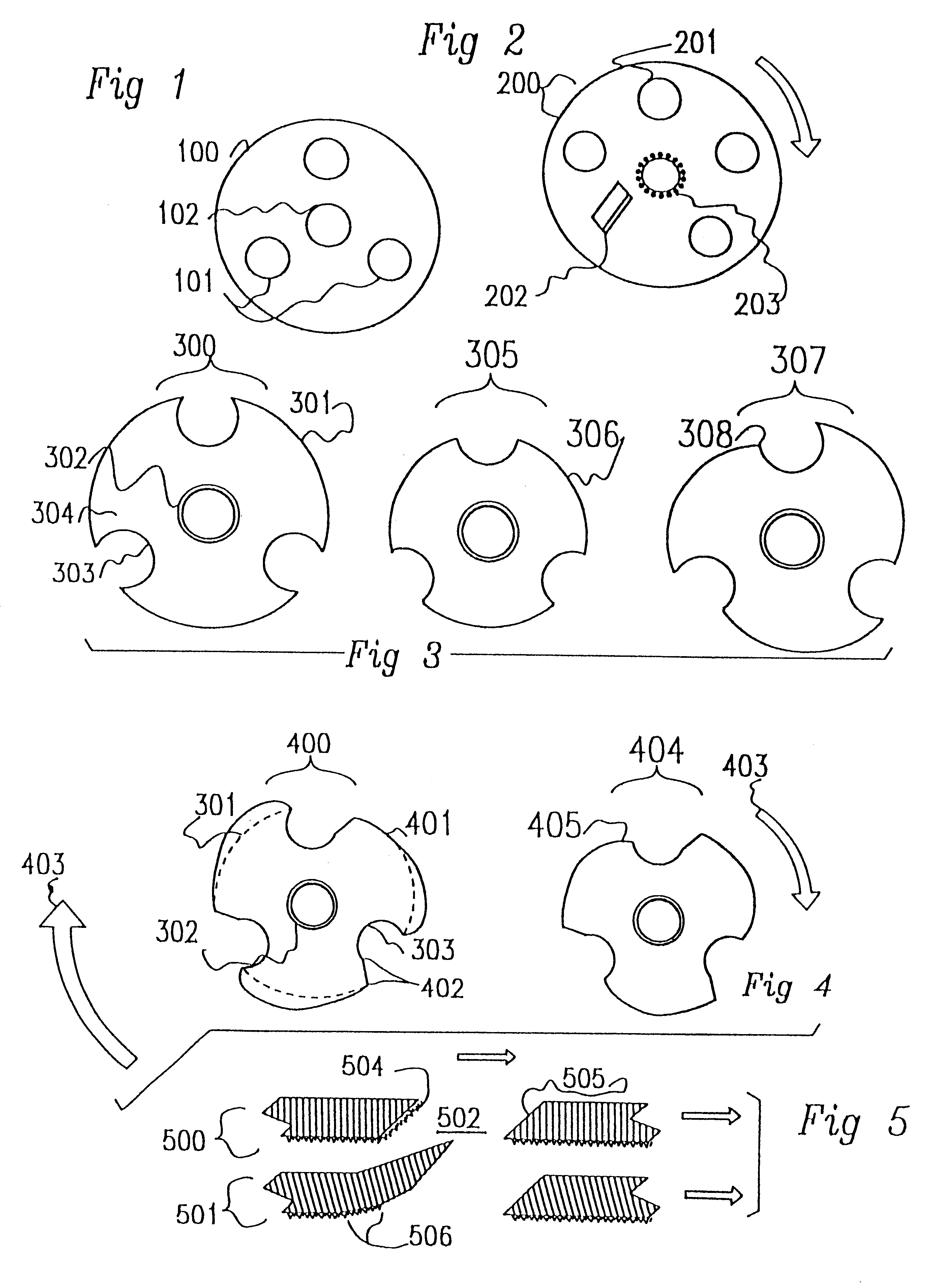

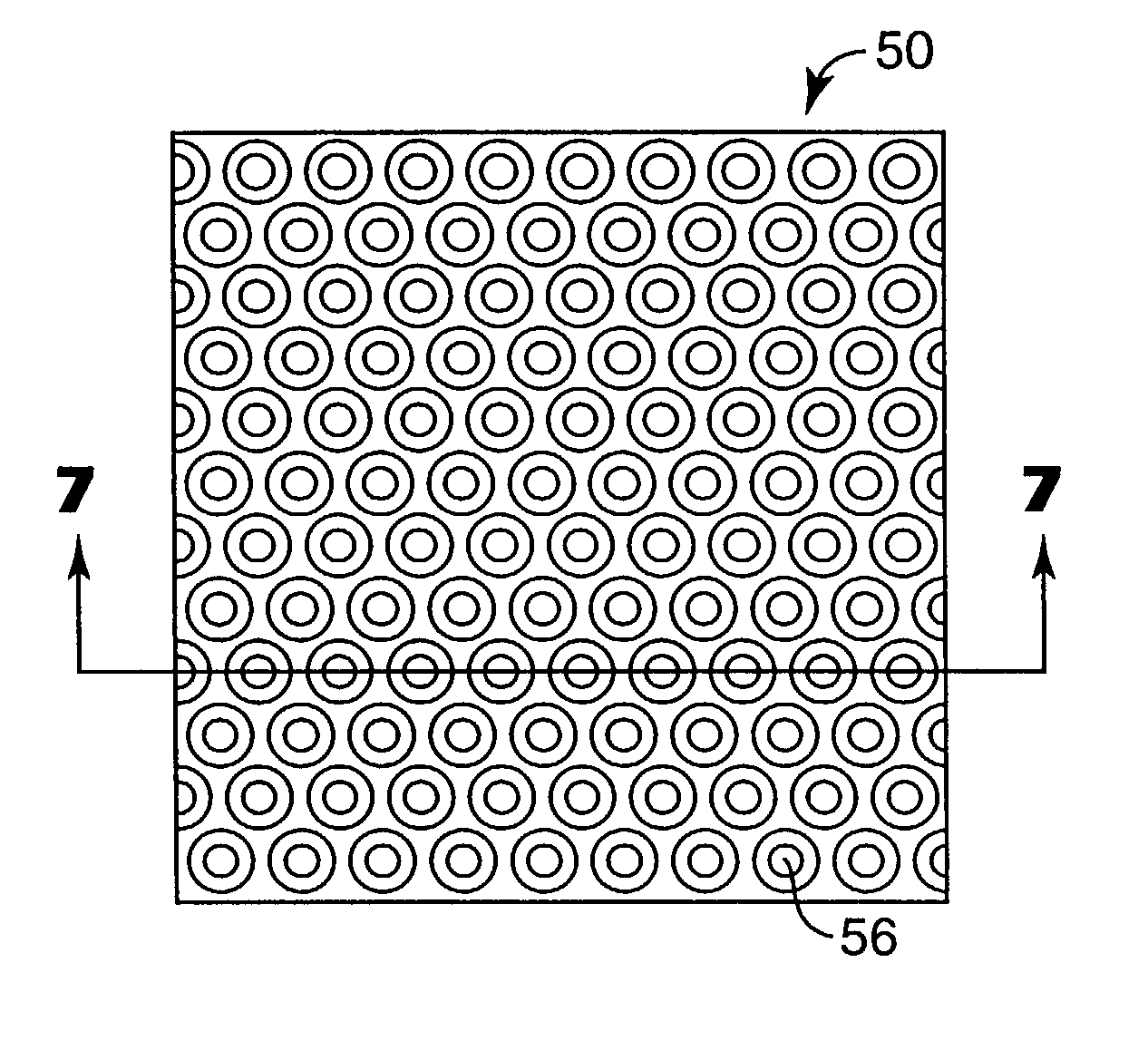

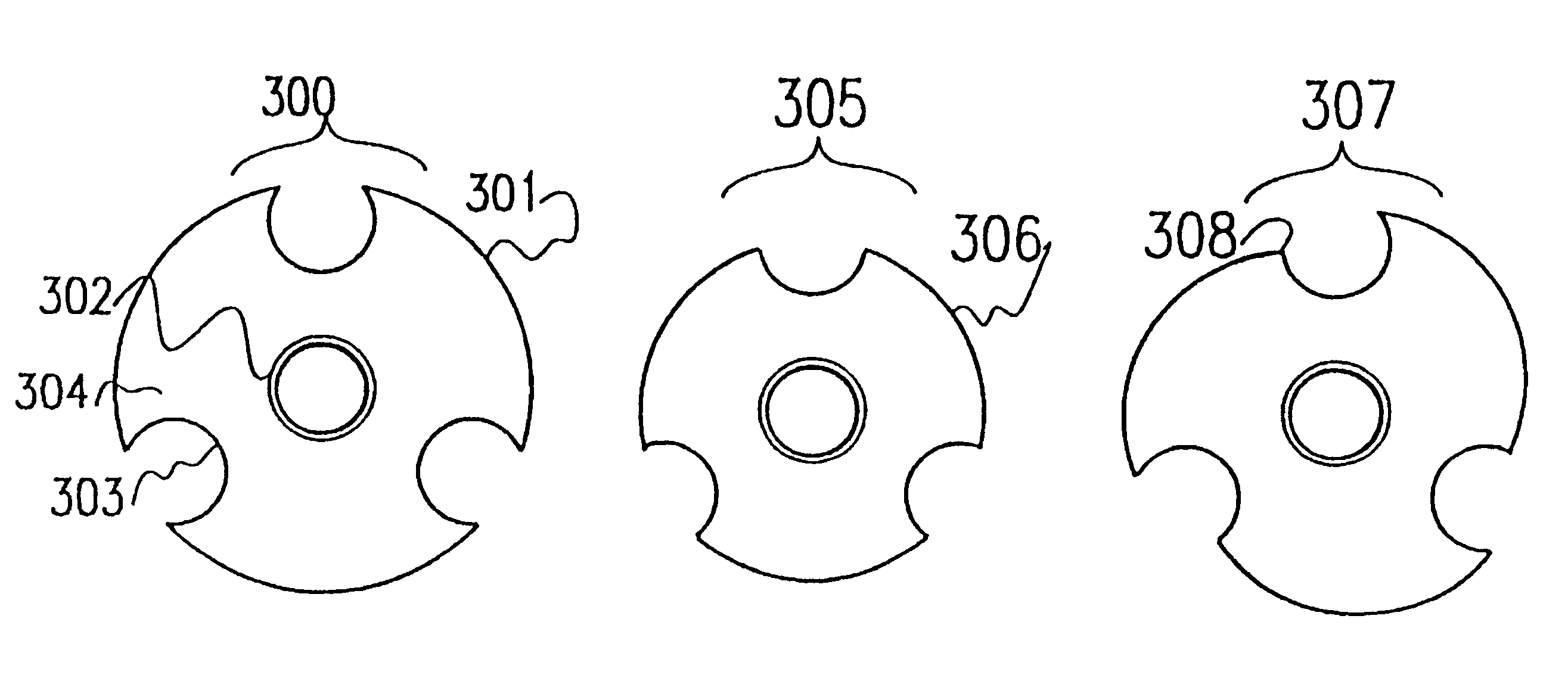

Abrasive articles, rotationally reciprocating tools, and methods

InactiveUS20080233845A1Surface defectControl impactEdge grinding machinesSupport wheelsMaterials sciencePolishing

Methods of abrading surfaces by rotationally reciprocating abrasive surfaces in contact with the surfaces, abrasive articles for use in rotationally reciprocating tools, and methods of removing defects in a surface, where the methods include sanding using a rotationally reciprocating abrasive surface followed by one or more polishing operations are disclosed.

Owner:3M INNOVATIVE PROPERTIES CO

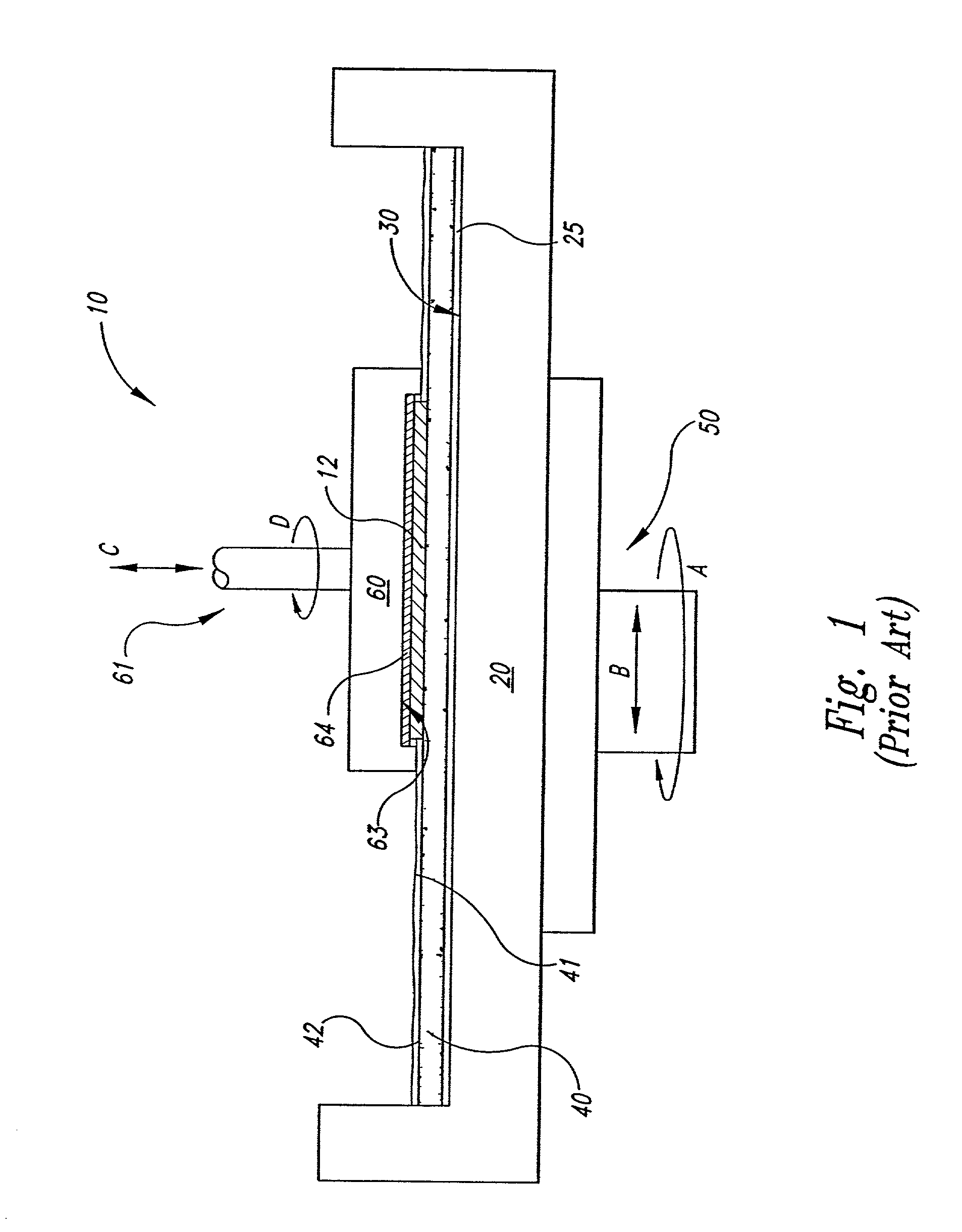

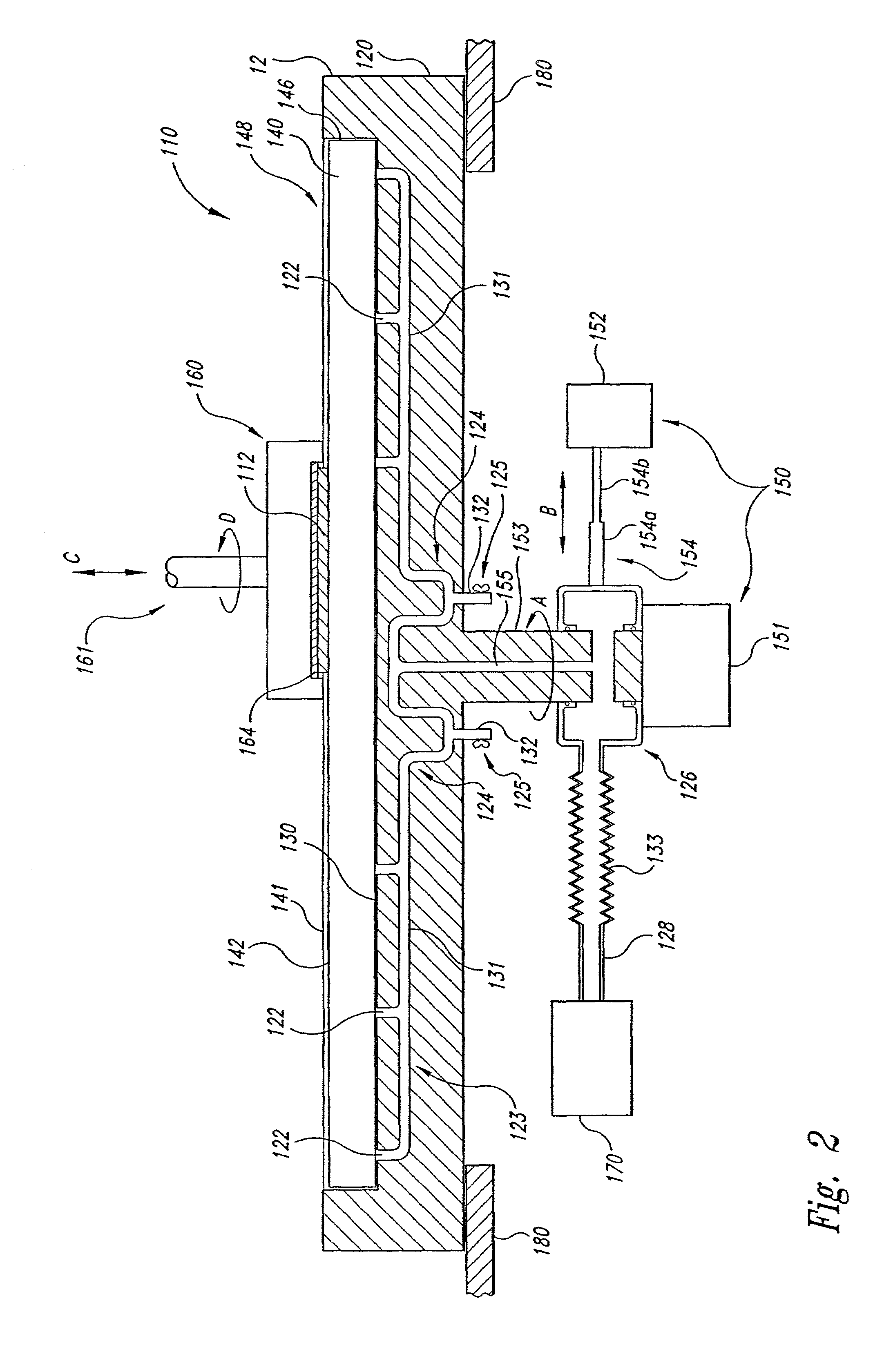

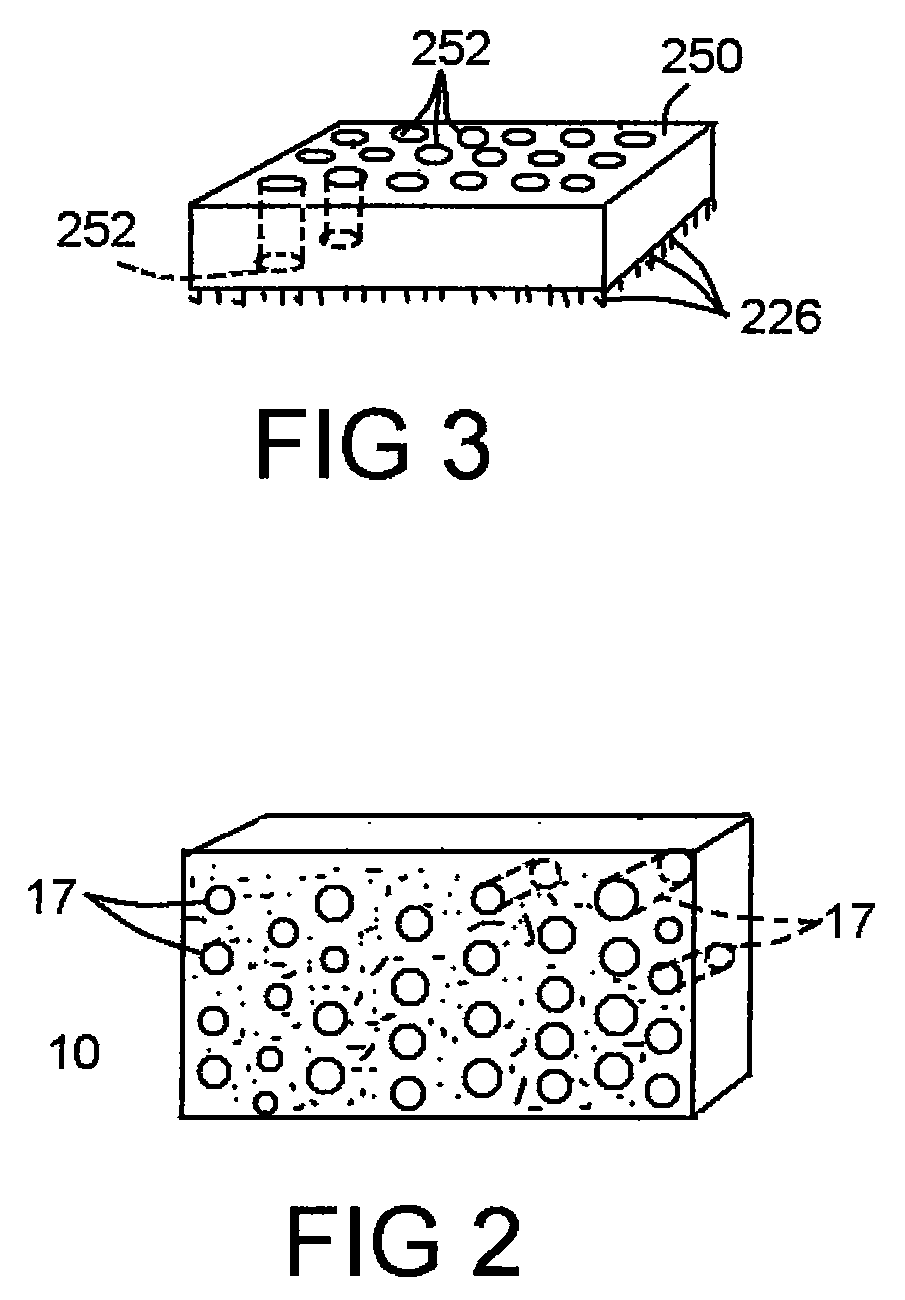

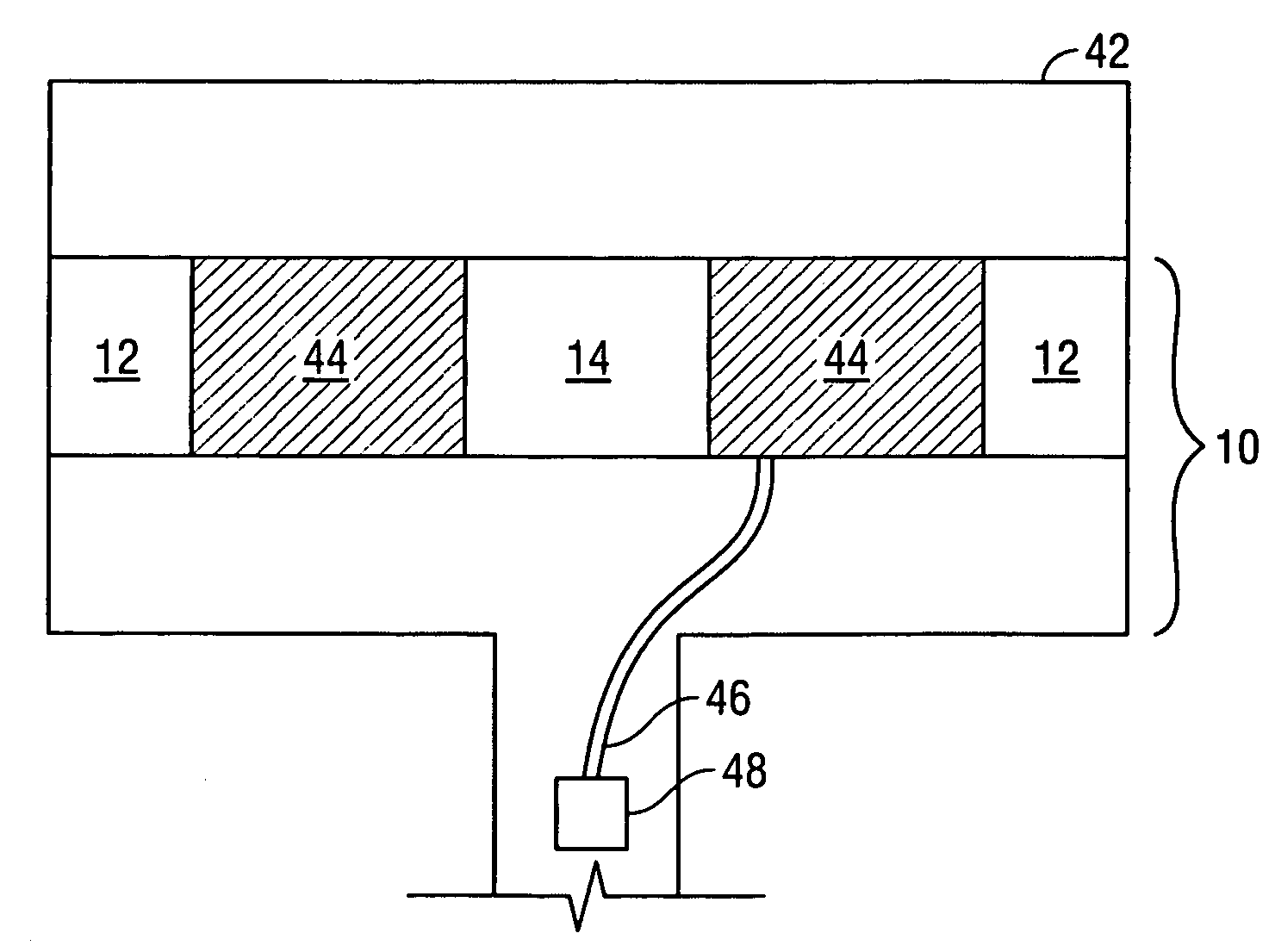

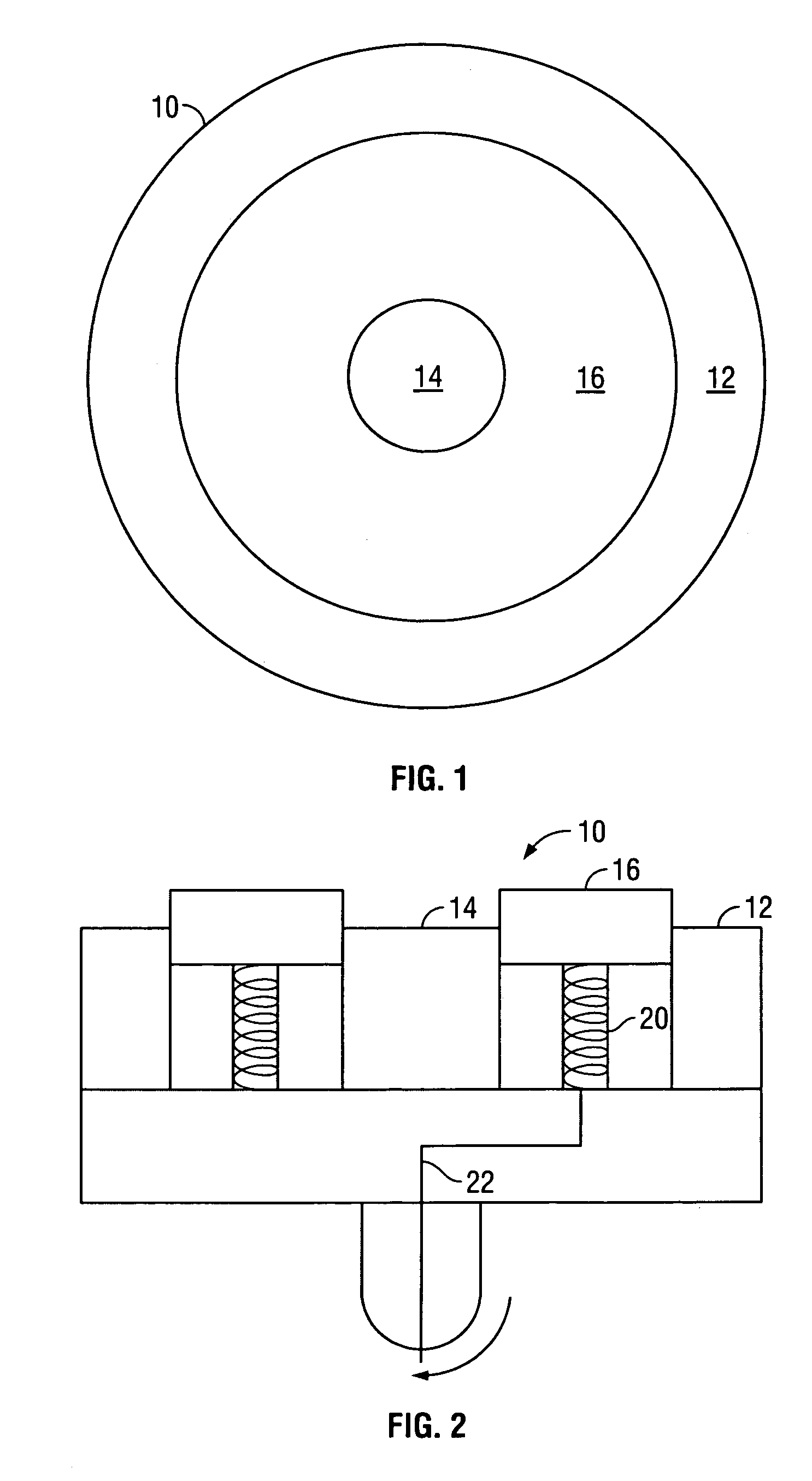

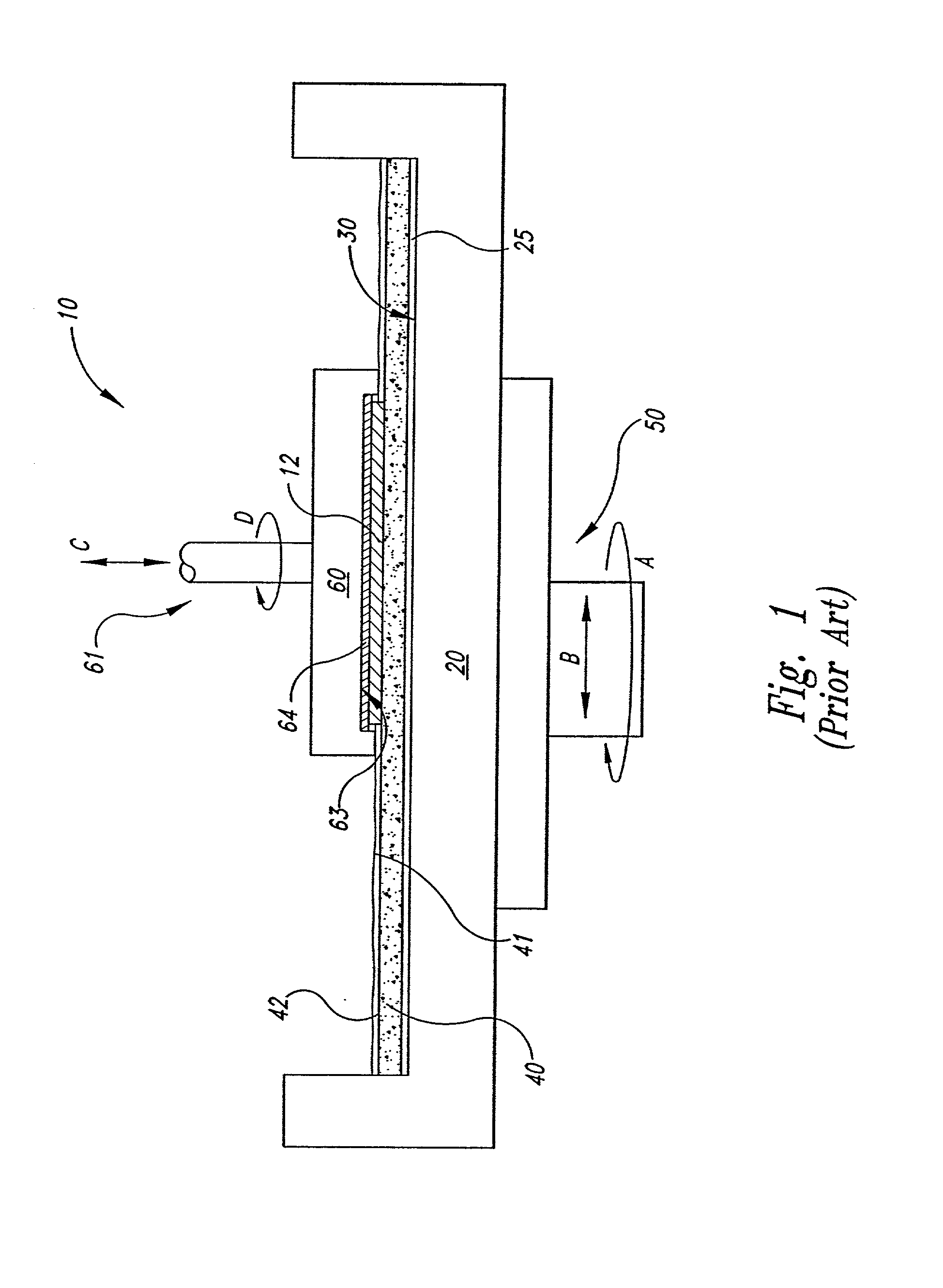

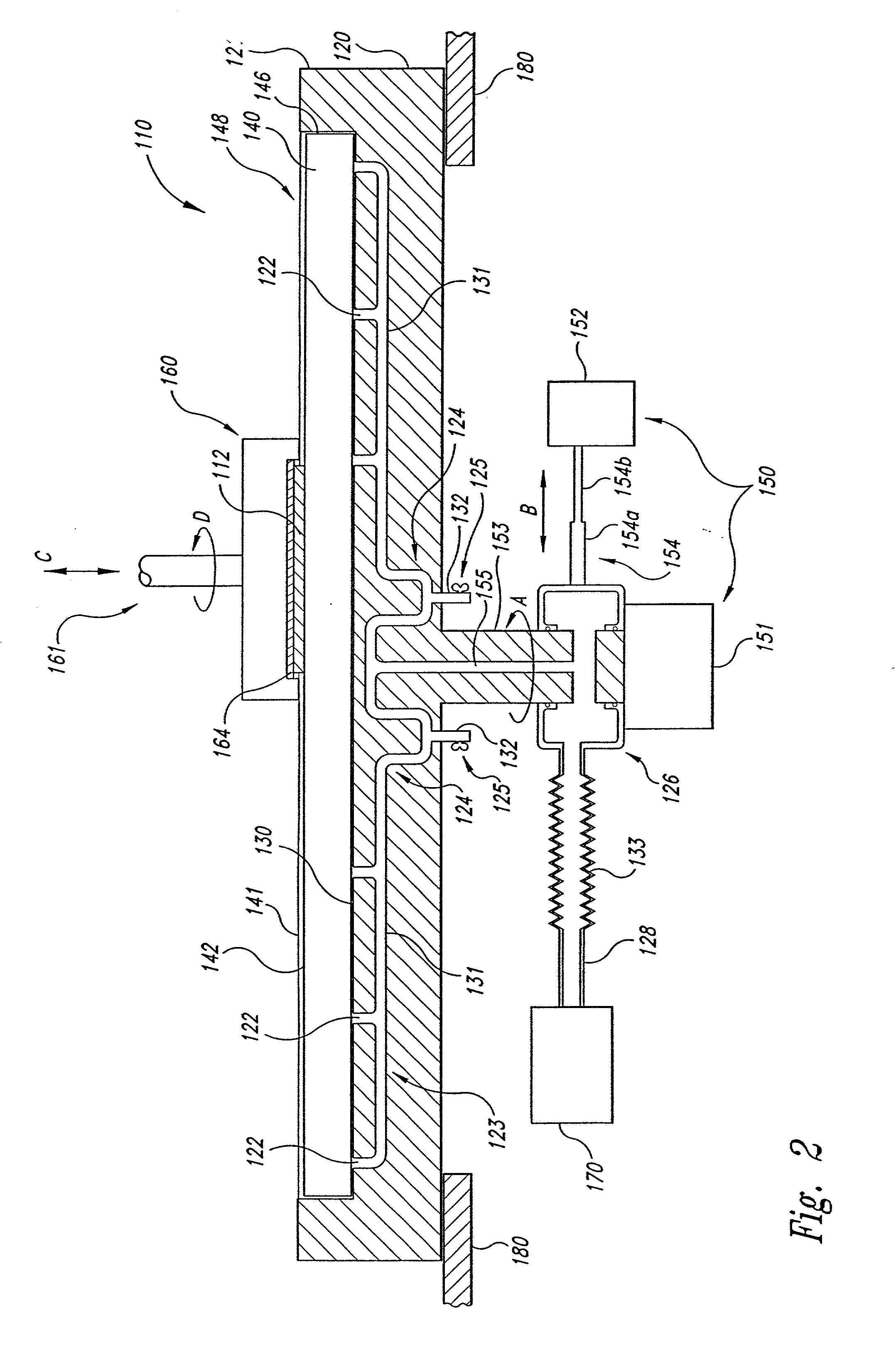

Method and apparatus for releasably attaching a polishing pad to a chemical-mechanical planarization machine

A method and apparatus for releasably attaching a planarizing medium, such as a polishing pad, to the platen of a chemical-mechanical planarization machine. In one embodiment, the apparatus can include several apertures in the upper surface of the platen that are coupled to a vacuum source. When a vacuum is drawn through the apertures in the platen, the polishing pad is drawn tightly against the platen and may therefore be less likely to wrinkle when a semiconductor substrate is engaged with the polishing pad during planarization. When the vacuum is released, the polishing pad can be easily separated from the platen. The apparatus can further include a liquid trap to separate liquid from the fluid drawn by the vacuum source through the apertures, and can also include a releasable stop to prevent the polishing pad from separating from the platen should the vacuum source be deactivated while the platen is in motion. In another embodiment, a signal can be applied to the platen to draw the polishing pad toward the platen via electrostatic or electromagnetic forces. In still another embodiment, the polishing pad can be attached to a pad support and conditioned on a separate jig.

Owner:MICRON TECH INC

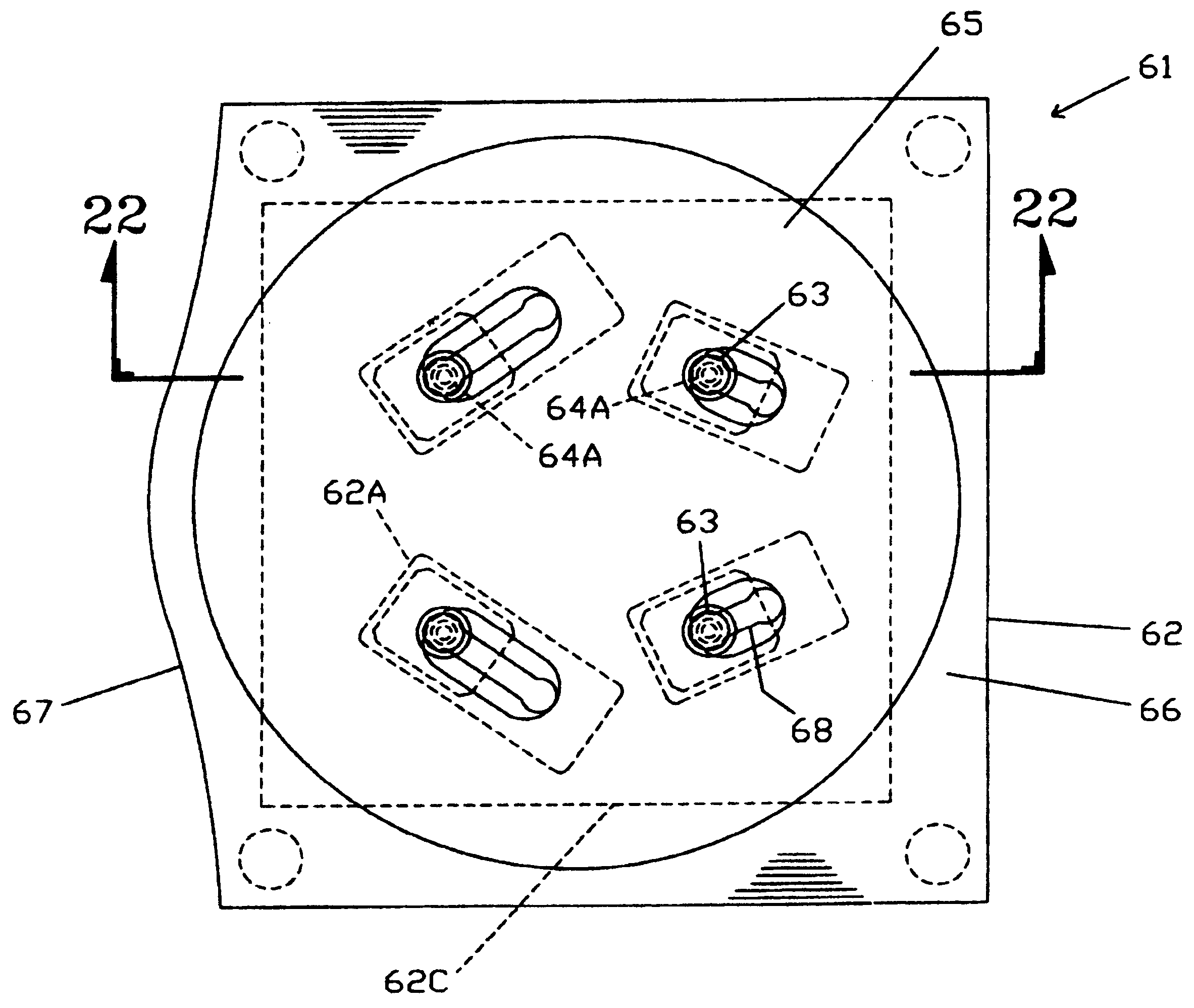

Tool

InactiveUS20050153640A1Releasing connectionProducing releasingGrinding wheel securing apparatusSupport wheelsEngineeringMagnet

In a tool comprising a supporting part and a disk-shaped working part for machining operation, the supporting part comprises a supporting face for the working part and a permanent magnet within the supporting face. The working part comprises a coupling member of ferromagnetic material which is movable into magnetically clinging connection with the permanent magnet upon application of a counterpart supporting face to the supporting face.

Owner:FA AUGUST RUGGEBRERG

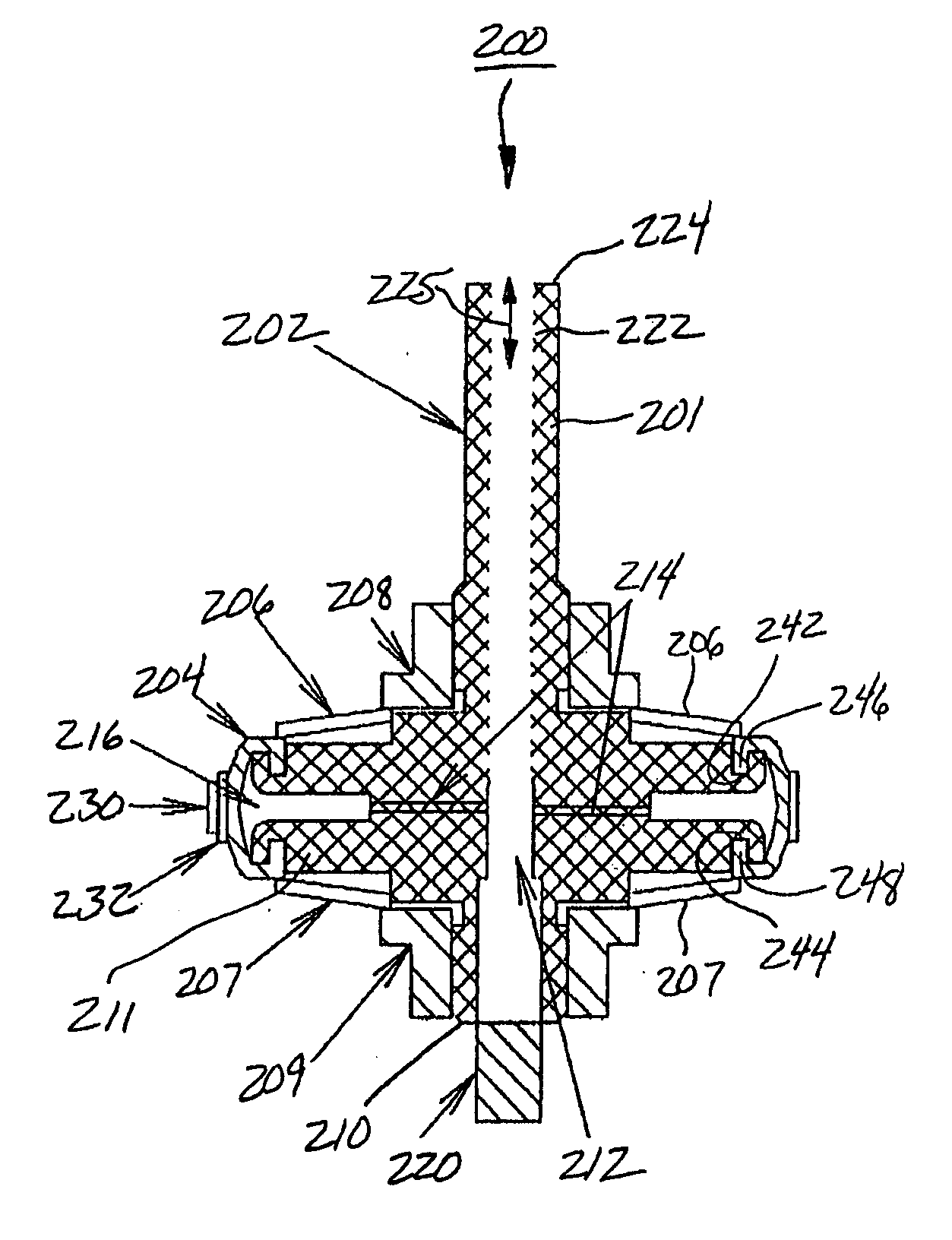

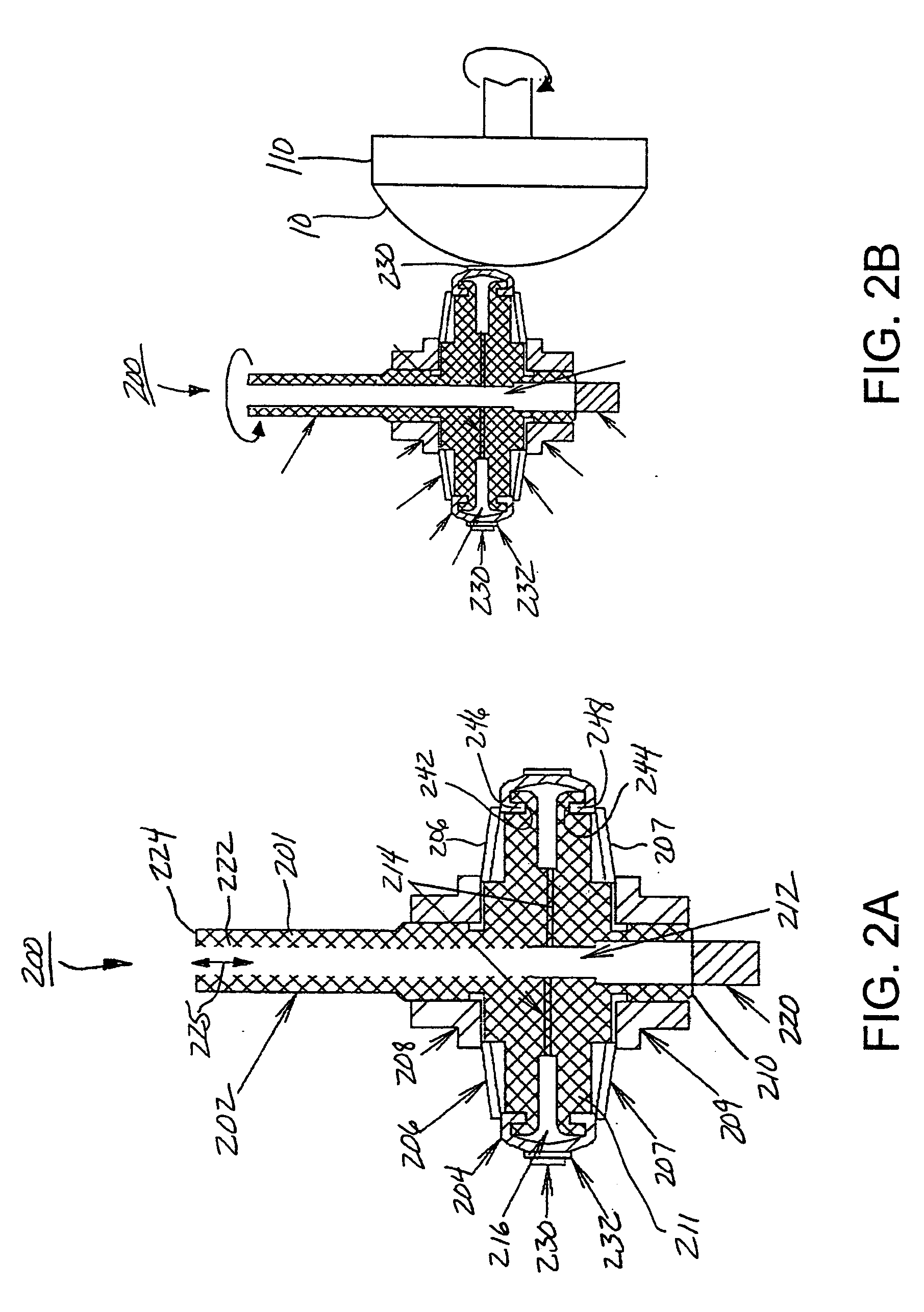

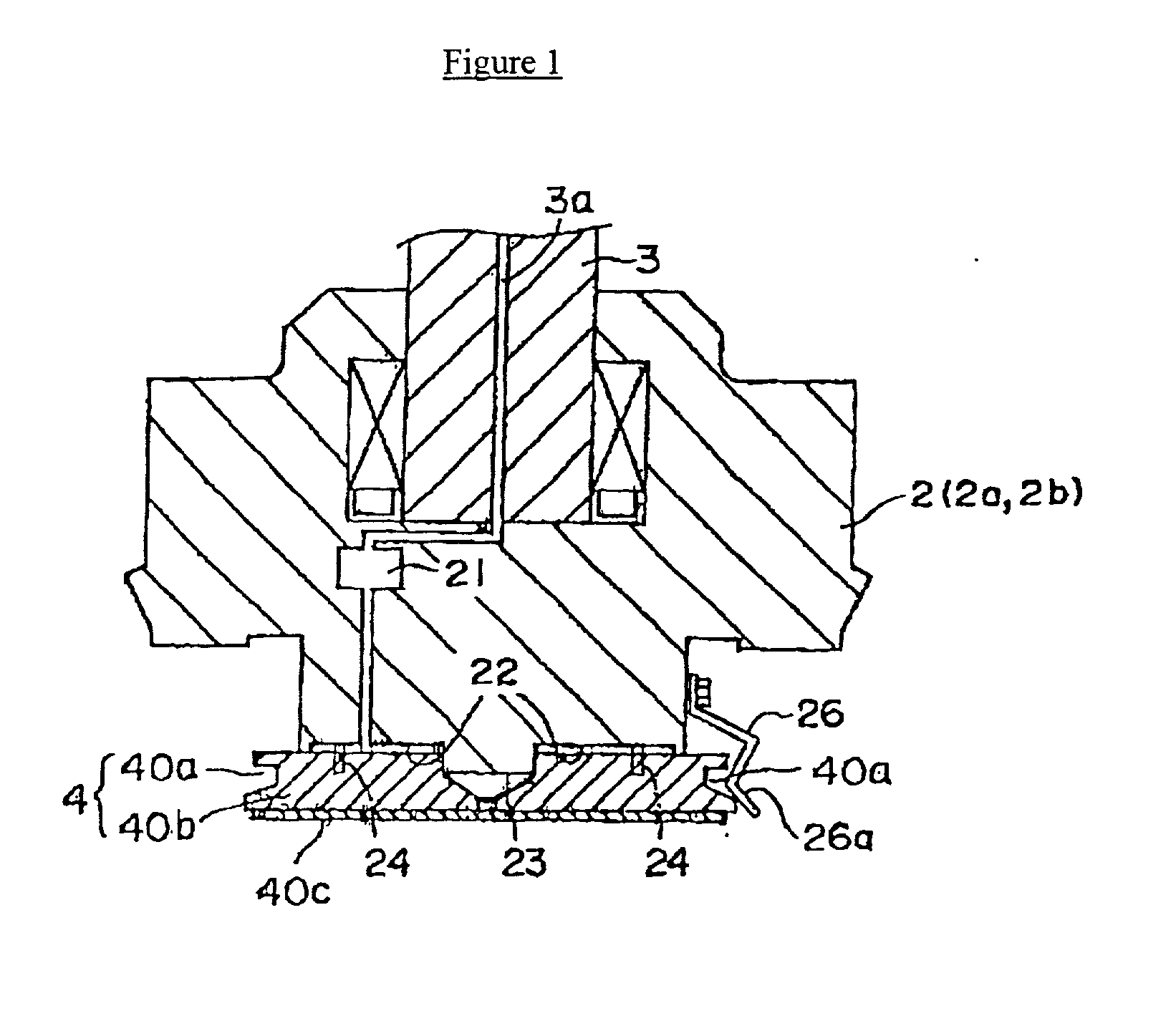

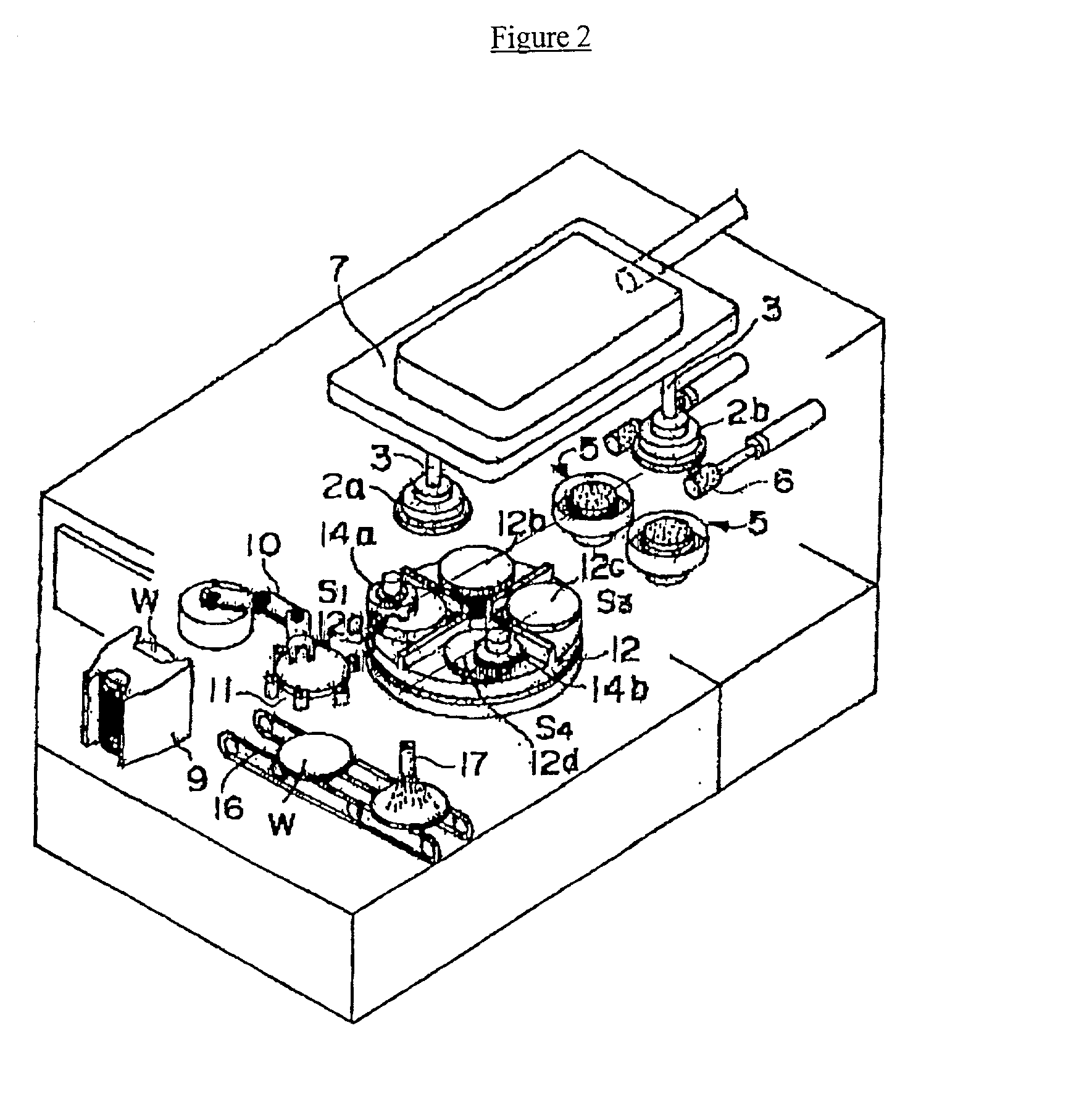

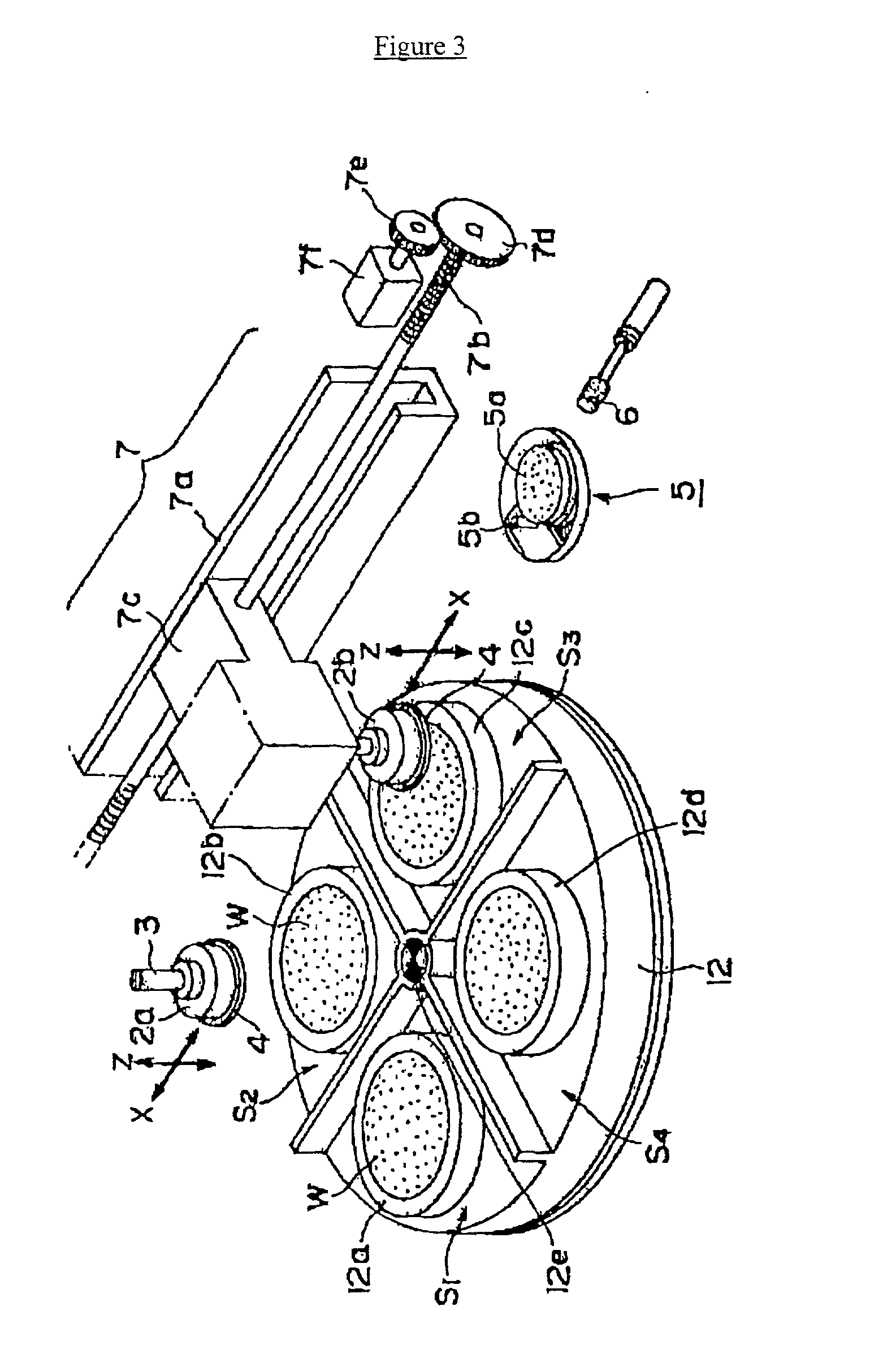

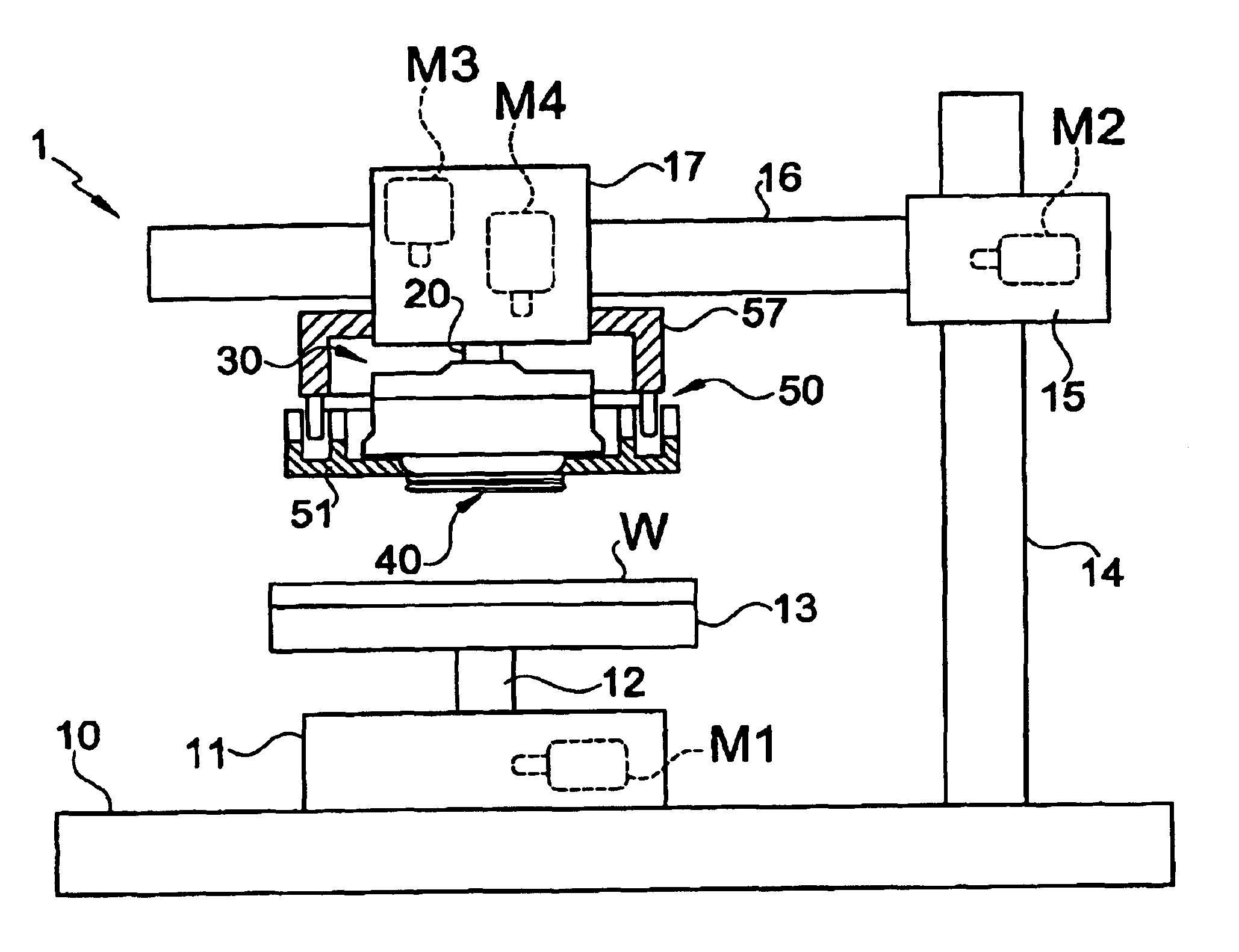

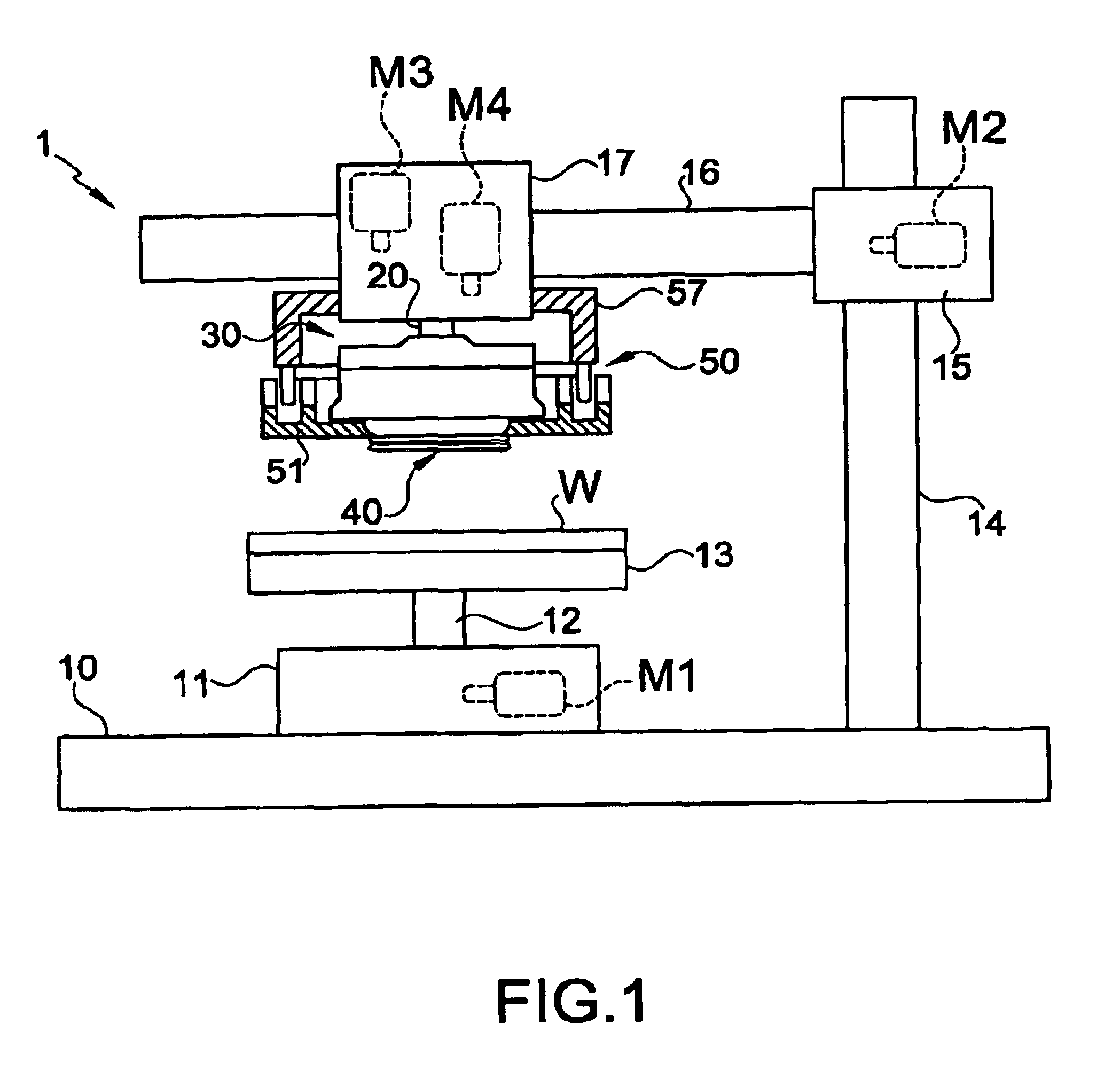

Polishing device and polishing pad component exchange device and method

InactiveUS20010041650A1High frequencyEasy to operateGrinding wheel securing apparatusSupport wheelsRelative displacementMechanical engineering

A polishing device includes a wafer chuck mechanism which retains a wafer while its plane to be polished faces upward, a polishing pad component which possesses a polishing plane which polishes the wafer, a polishing head, and a shift mechanism which enables a relative displacement of said polishing pad component in relation to the wafer. A fixation and retention mechanism fixes and retains said polishing pad component to the polishing head in a detachable fashion while its polishing plane faces downward. The displacement distance of the shift mechanism ranges from the polishing position of the wafer to the exchange position of the polishing pad component, so that the polishing pad component is automatically exchanged.

Owner:NIKON CORP

Method for grinding soft crisp functional crystal

InactiveCN101376228AAvoid scratchesPrevent embeddingSupport wheelsAqueous dispersionsHigh surfaceGrinding wheel

A soft brittle functional crystal grinding and machining method belongs to the technical field of soft brittle functional crystal machining, and particularly relates to a soft brittle functional crystal ultra-precision grinding and machining method for a semiconductor and a photoelectric crystal. The method is characterized in that a micro-powder diamond segmental variable speed feed and a soft abrasion grinding wheel chemical mechanical grinding method are adopted to machine the soft brittle function crystal. During the crude grinding period and the accurate grinding period, the feeding speed of the grinding wheel is firstly high and then low. A grinding fluid is de-ionized water. A soft abrasive agent grinding wheel is adopted to conduct the chemical mechanical grinding. The soft abrasive agent is a macromolecule polymer or waterproof resin. A filler is NaHCO3 or a refined naphthalene foaming agent. The chemical and mechanical grinding fluid is adopted as a reaction fluid and a cooling fluid. The grinding fluid mainly contains lactic acid, acetic acid and de-ionized water. The pH value of the grinding fluid is 2-4. The invention has the advantages of high grinding and machining efficiency, low machining cost and high surface precision. In addition, no surface / sub-surface damage is caused to the surface of a workpiece, such as small scratches, embedment of free abrasive agent, plastic deformation, residual stress, and the like.

Owner:DALIAN UNIV OF TECH

Abrasive sheet alignment dispenser

An abrasive sheet dispenser for aligning and attaching hook and loop backed abrasive sheets onto abrading tools, which utilize vacuum holes incorporated into the backup pad and into its corresponding abrasive sheet. In a preferred embodiment, the dispenser has an injection molded universal base having a plurality of guide hole locations. Each group of guide hole locations is connected by a guide screw channel. The dispenser has a plurality of injection mold guides and a plurality of guide screws. The guides are of a height as to support a plurality of abrasive sheets and fastened onto the universal base by inserting the guide screws through the guide holes in the universal base from underneath and screwing into the bottom center of guides. The guides are adjustable allowing them to be aligned with various vacuum hole patterns and sizes of abrasive sheets by sliding each guide along the guide screw channel to another guide hole location within that group. The dispenser also has an injection molded clear acrylic universal cover plate, which is placed over the stack of abrasive sheets as a protective dust and moisture cover.

Owner:GREENWOOD TIM R

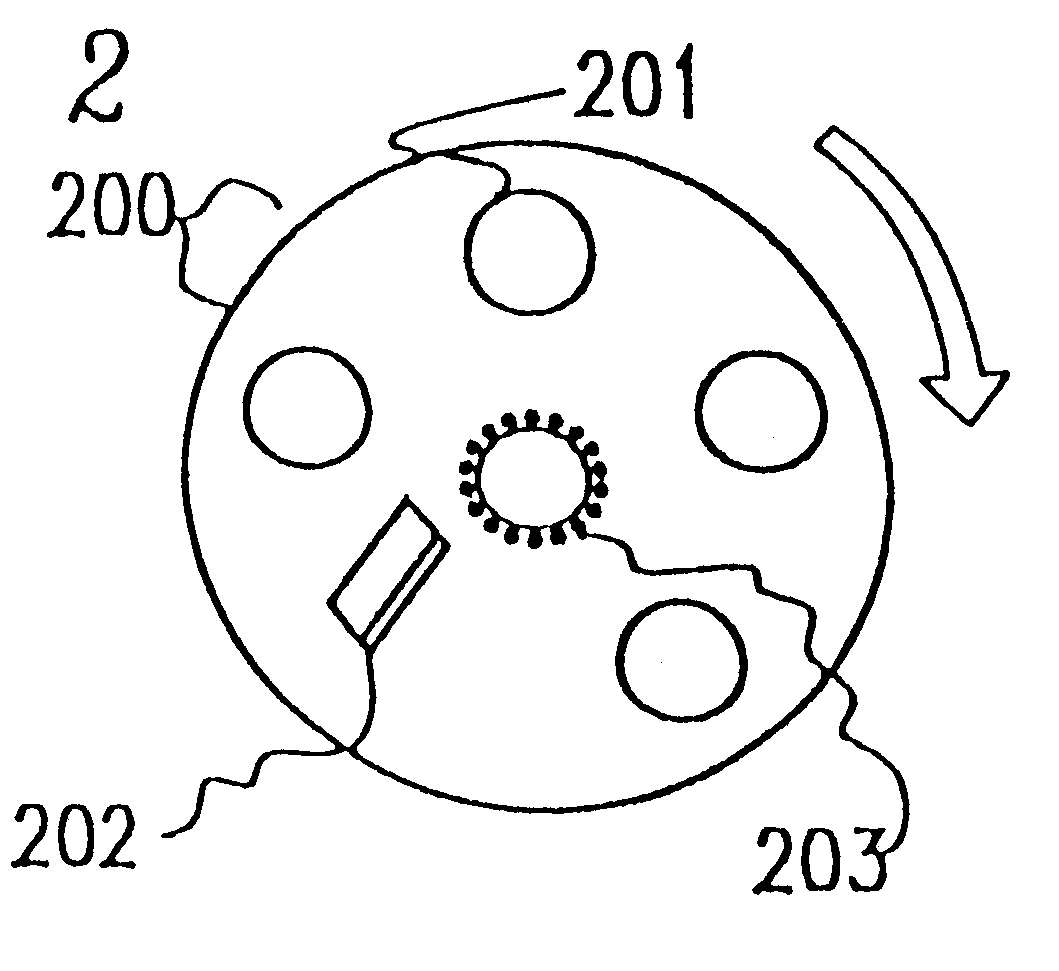

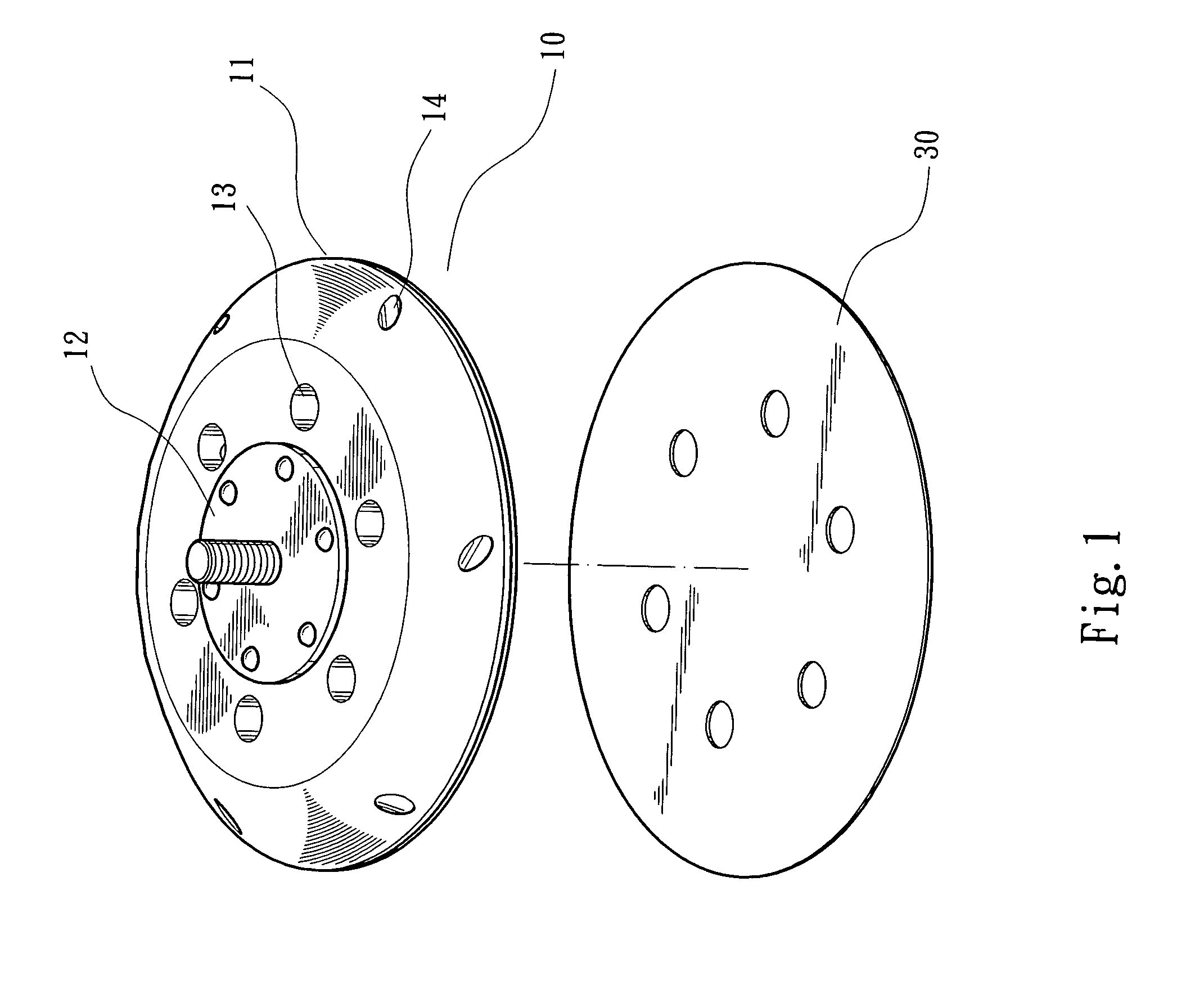

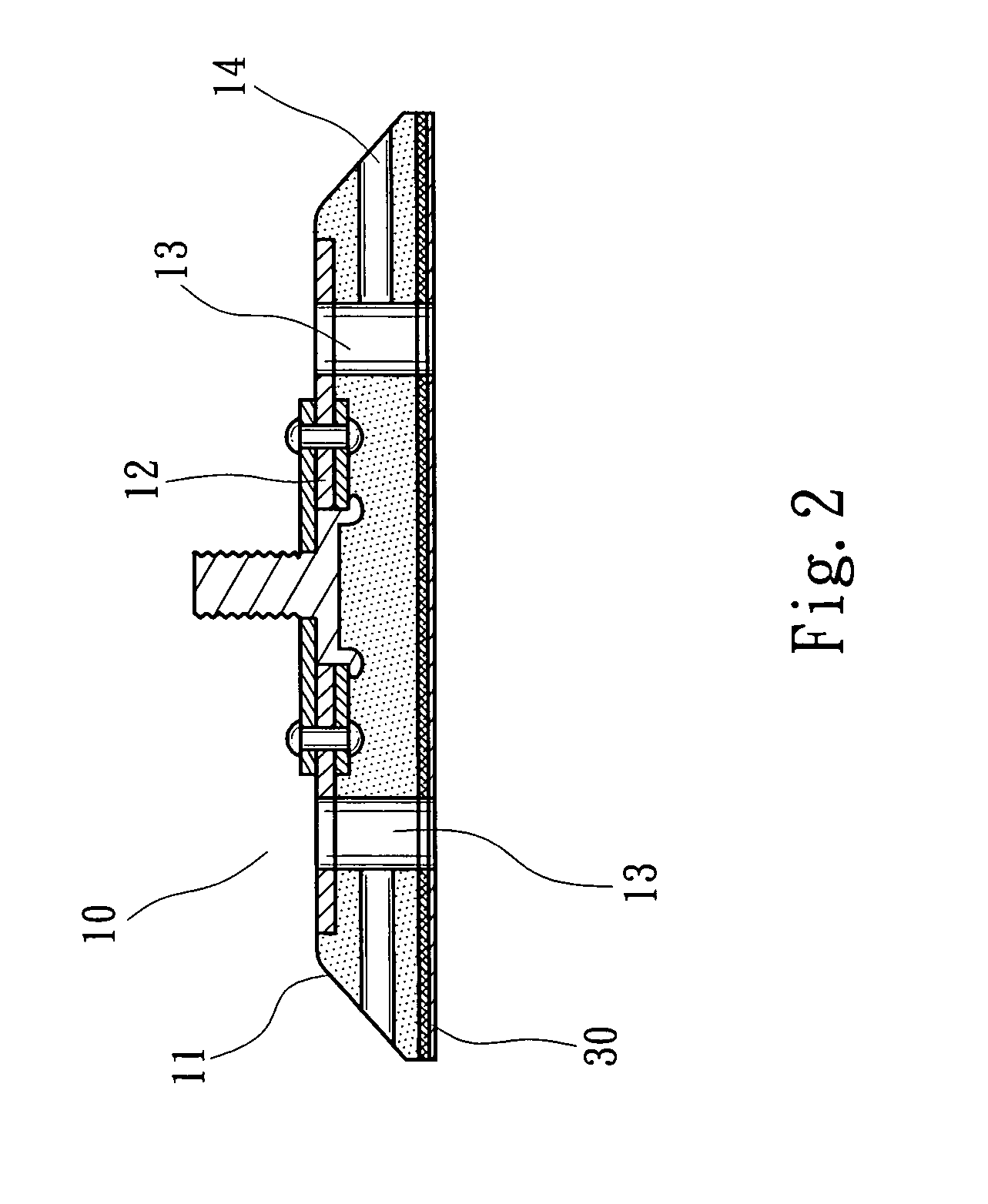

Grinding disc structure

InactiveUS7094138B2Revolution surface grinding machinesSupport wheelsEngineeringMechanical engineering

A grinding disc structure including an integrally formed main disc adapted to a dust-sucking cover body of a grinder. The main disc has multiple through holes nearly in parallel to an axis of the main disc. The main disc is further formed with multiple internal passages which are horizontally formed in the main disc corresponding to the through holes and nearly perpendicular to the axis of the main disc. The passages are tangential to the through holes. Two ends of each passage respectively communicate with the through hole and outer side around the main disc. The main disc has a complete bottom face to which a grinding layer can be fully adhered.

Owner:CHANG JEN PEN

Polishing apparatus, semiconductor device manufacturing method using the polishing apparatus, and semiconductor device manufactured by the manufacturing method

InactiveUS6857950B2Increase ratingsReduce manufacturing costGrinding drivesSemiconductor/solid-state device detailsContact pressureEngineering

The present invention provides a polishing apparatus with a construction which makes it possible to prevent the peripheral portions of a substrate from sloping downward as a result of the polishing member tilting at the peripheral portions of the substrate during the polishing of the substrate, and which makes it possible to adjust the contact pressure quickly in accordance with changes in the contact area between the polishing surface and the substrate surface.

Owner:NIKON CORP

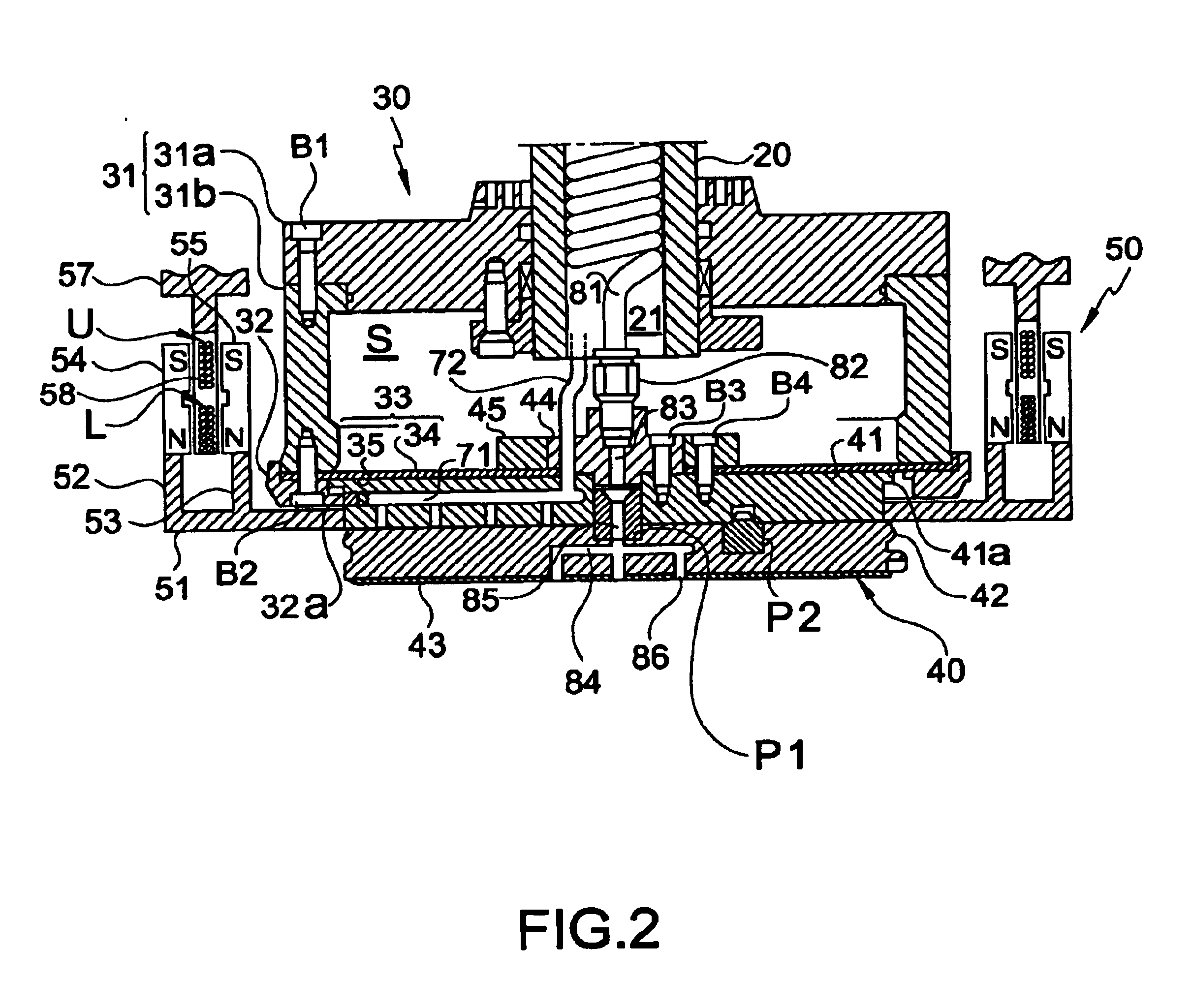

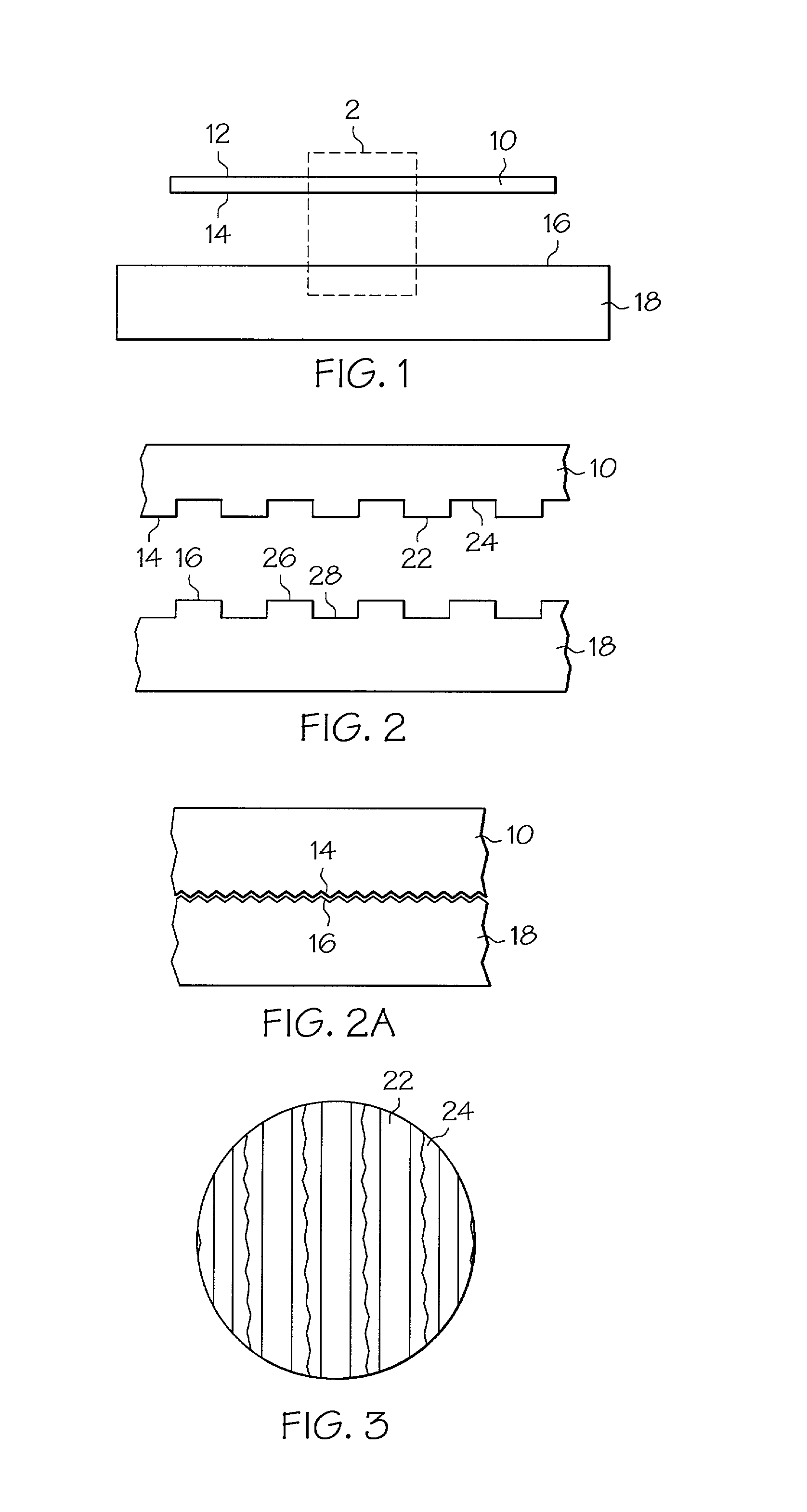

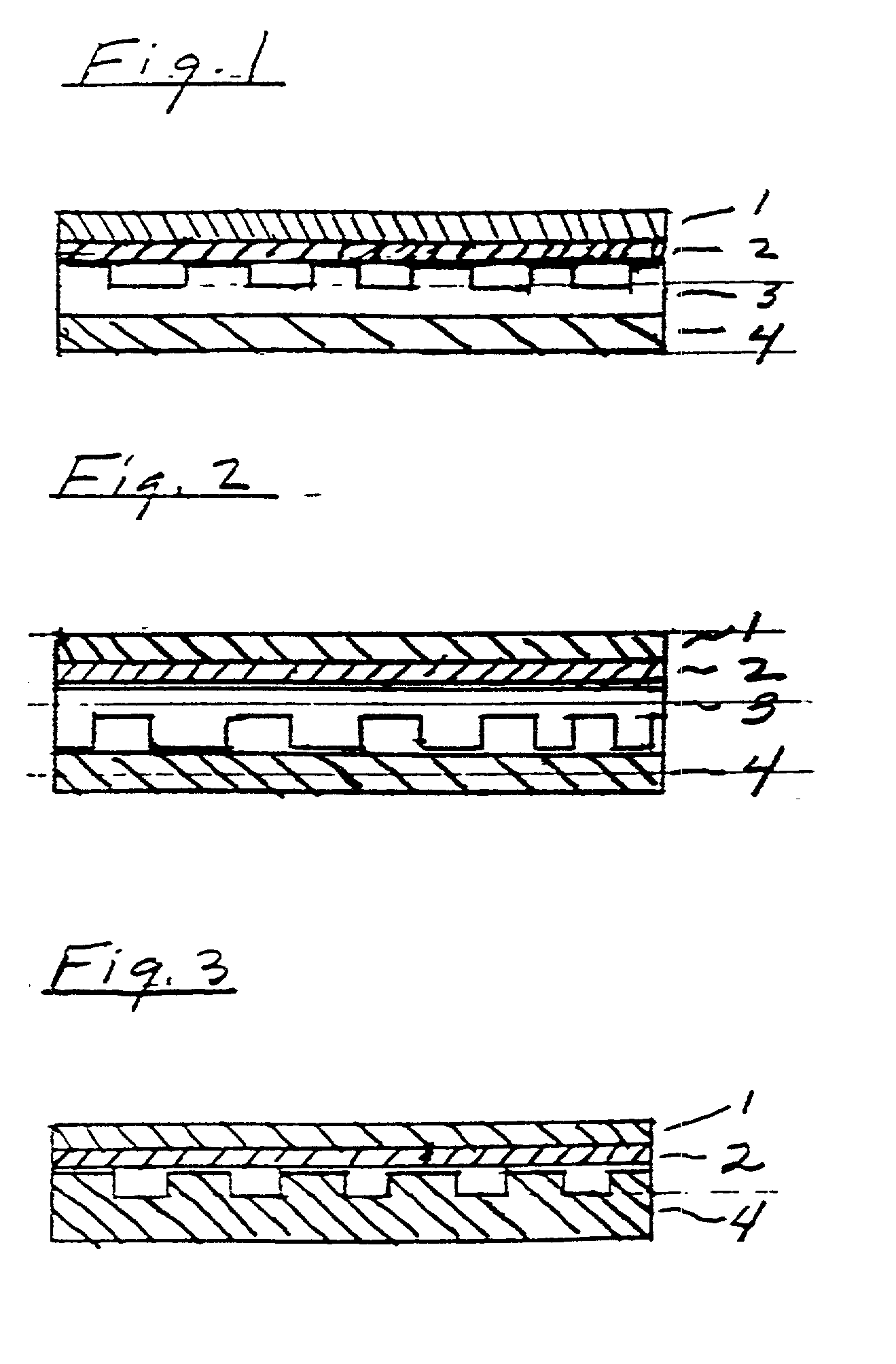

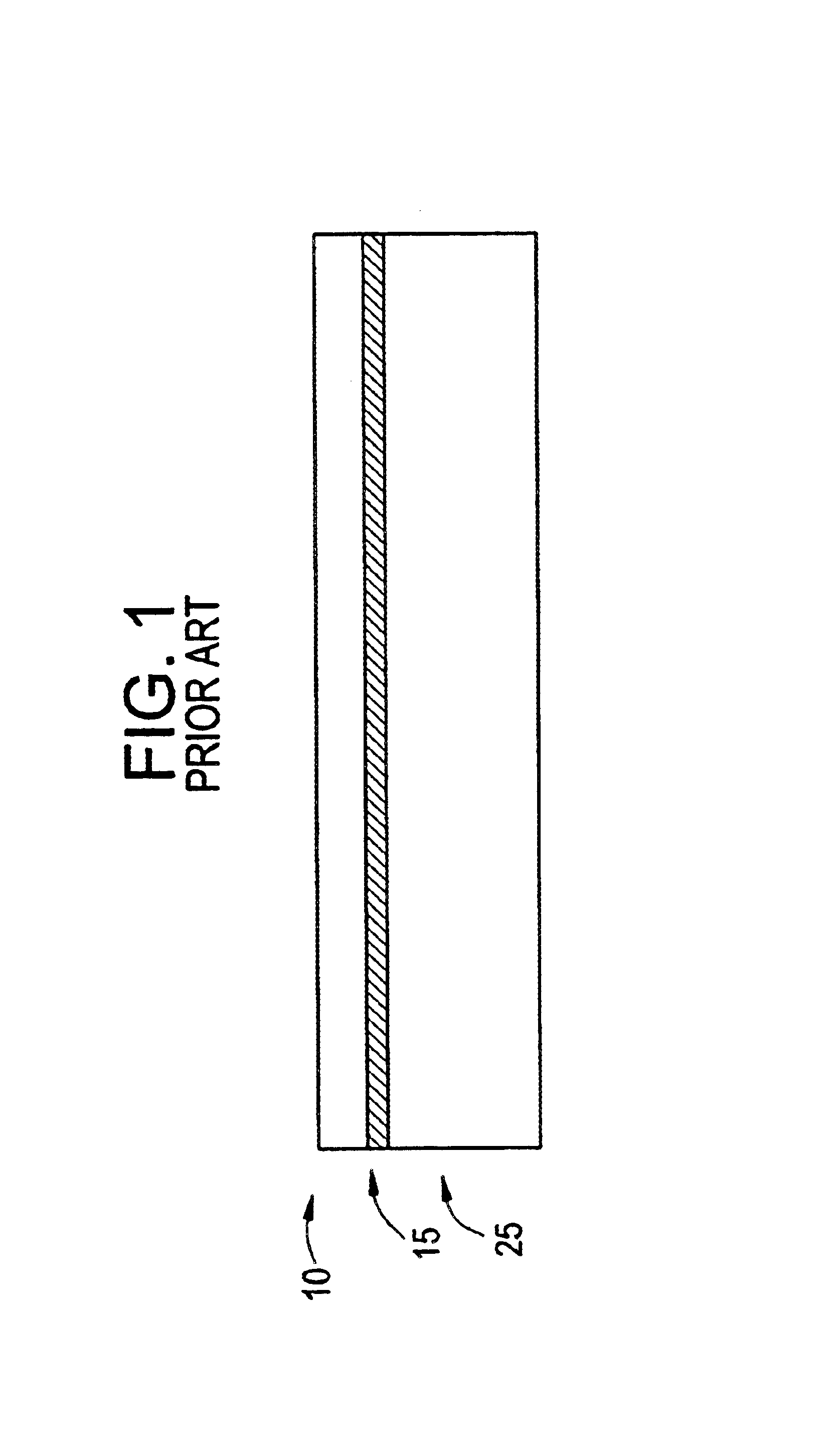

Retention of a polishing pad on a platen

A polishing pad is retained on a platen by structures which do not require adhesive. In one embodiment, a polishing pad has a top polishing surface and an undersurface. The undersurface has a surface profile which is configured to interfit with a complementary surface profile on a platen. The surface profile of the undersurface may comprise an array of parallel ridges and grooves.

Owner:RODEL HLDG INC

Resilient abrasive article and method of manufacture

The present invention provides a resilient hand-held abrasive article comprising a flexible and / or conformable grip comprising a top surface, a bottom surface and individual small high-grip pads attached to each other in a pattern that leaves voids therebetween, the individual small high-grip pads comprising a top and a bottom. The top surface of a sanding article is attached, and in certain embodiments removably attached, to the bottom of the high-grip pads and a bottom surface having abrasive particles coated thereon. In certain embodiments, the flexible and / or conformable grip may not comprise voids.

Owner:BROWN JOHN E

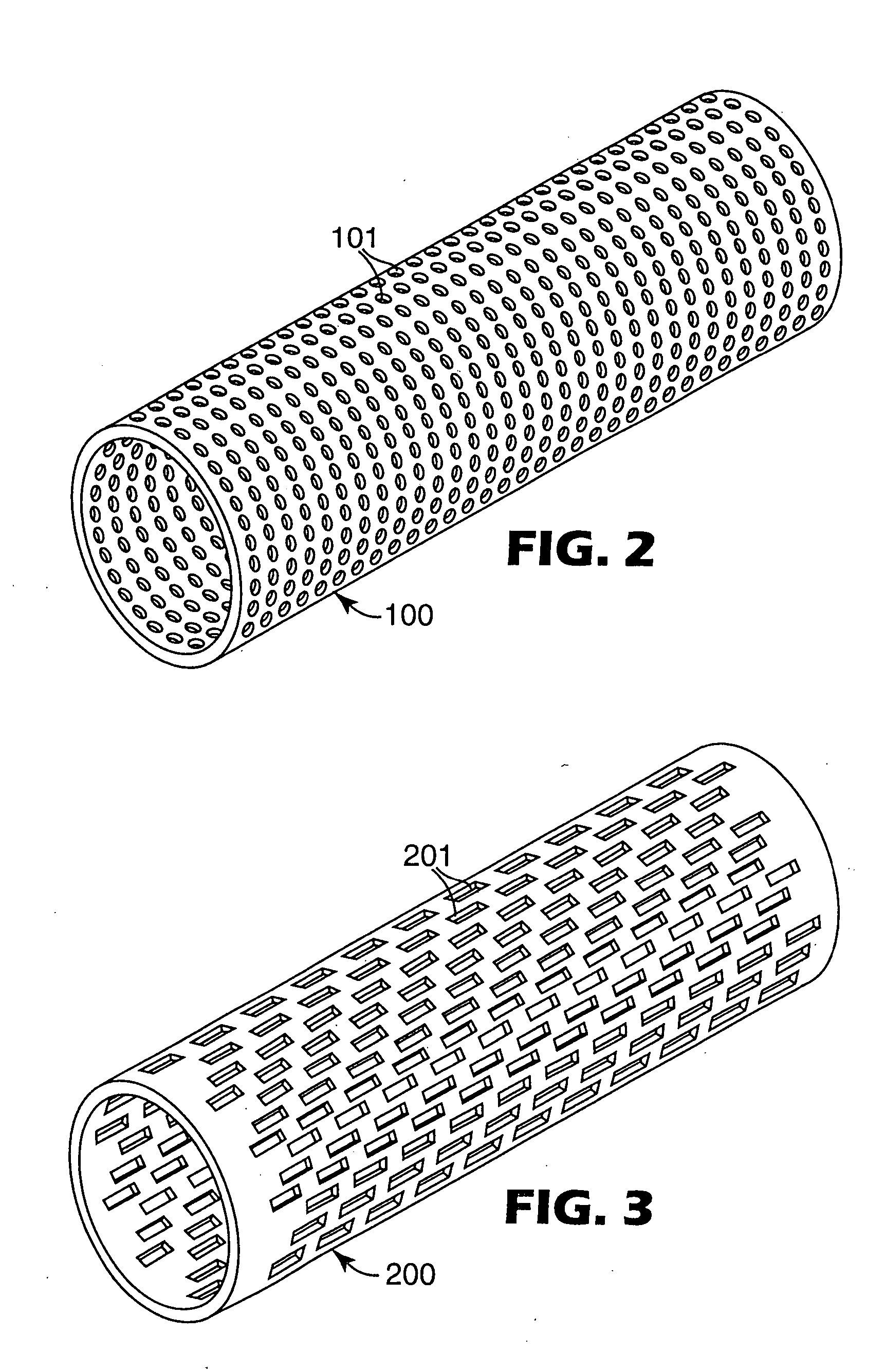

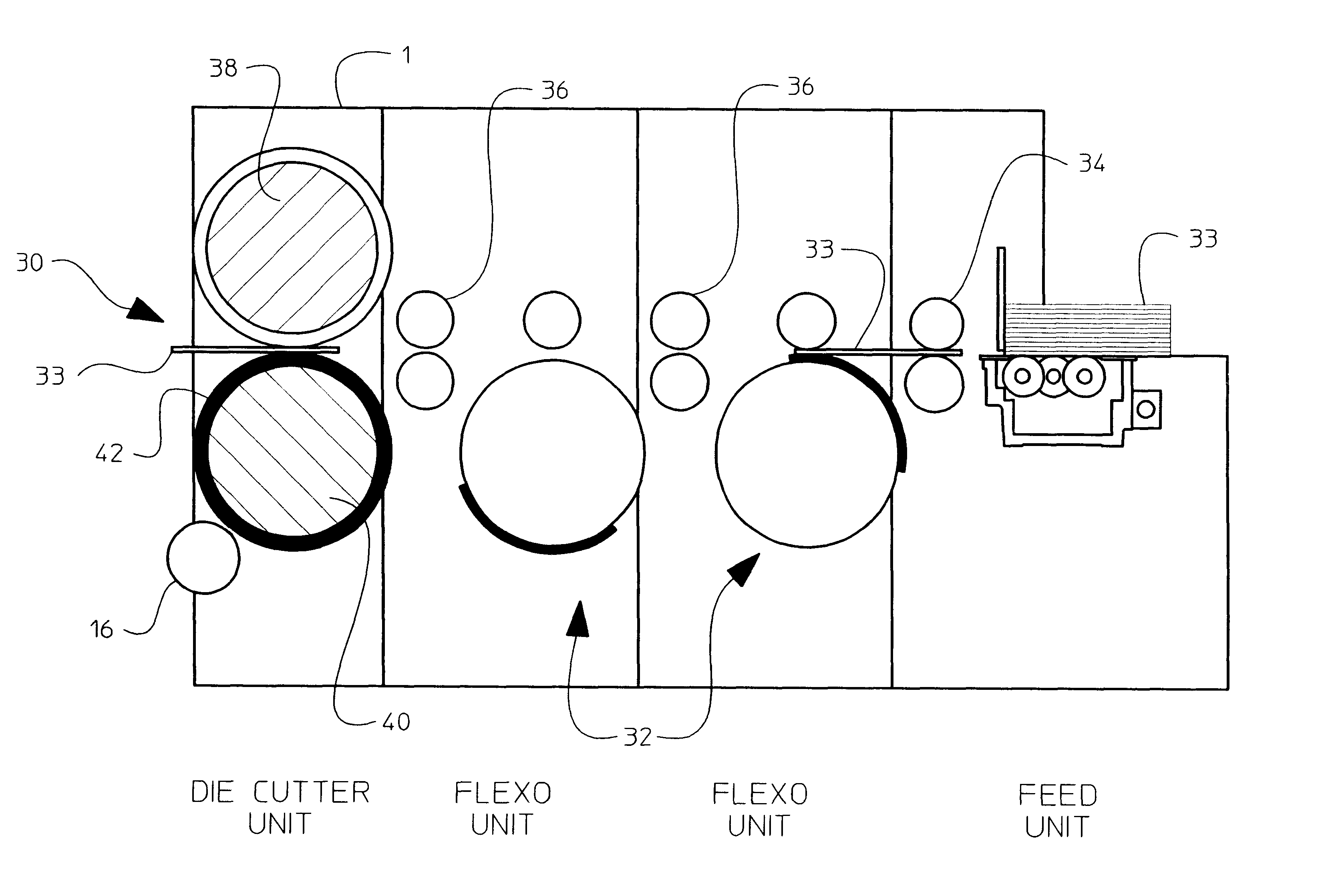

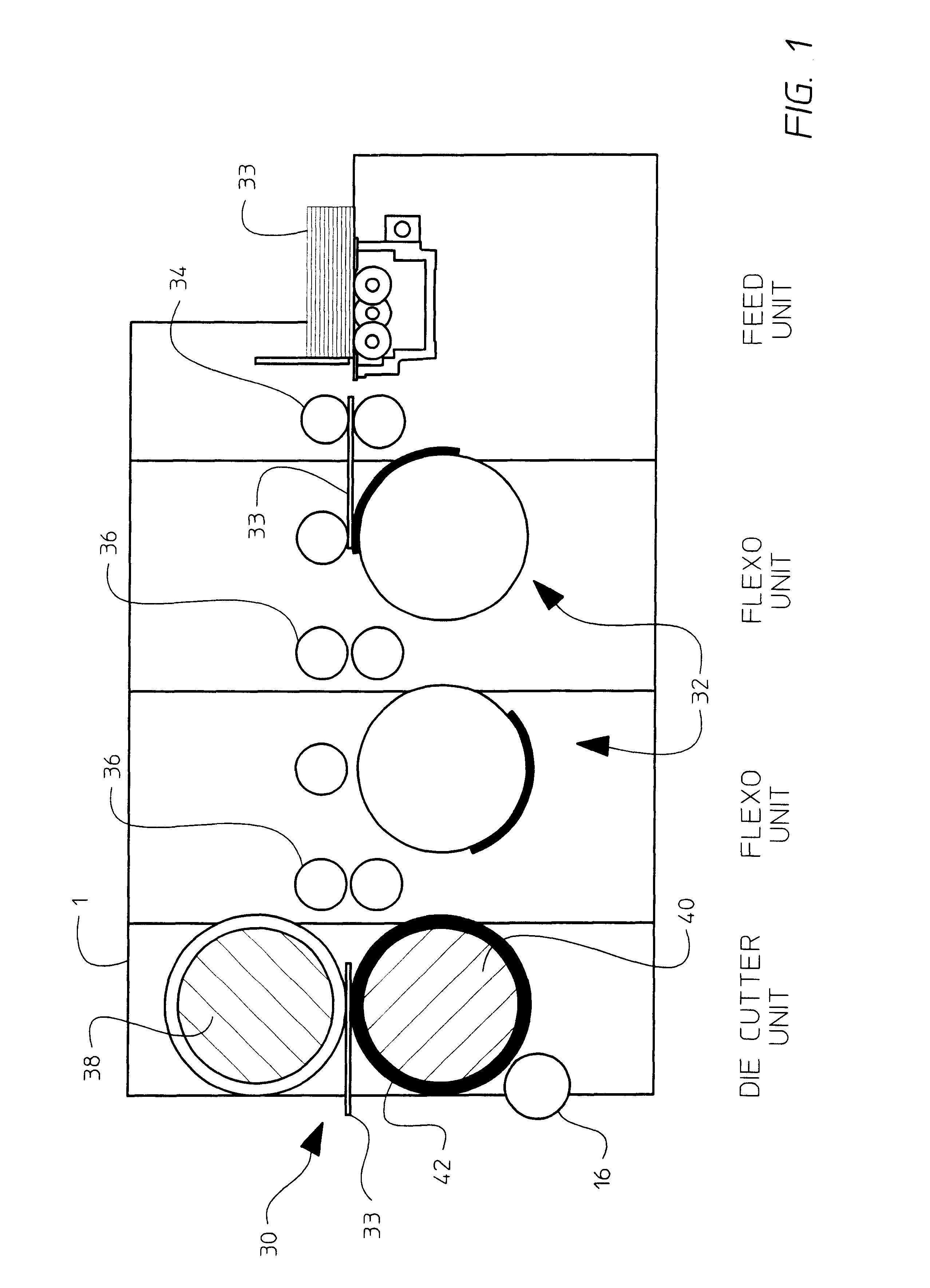

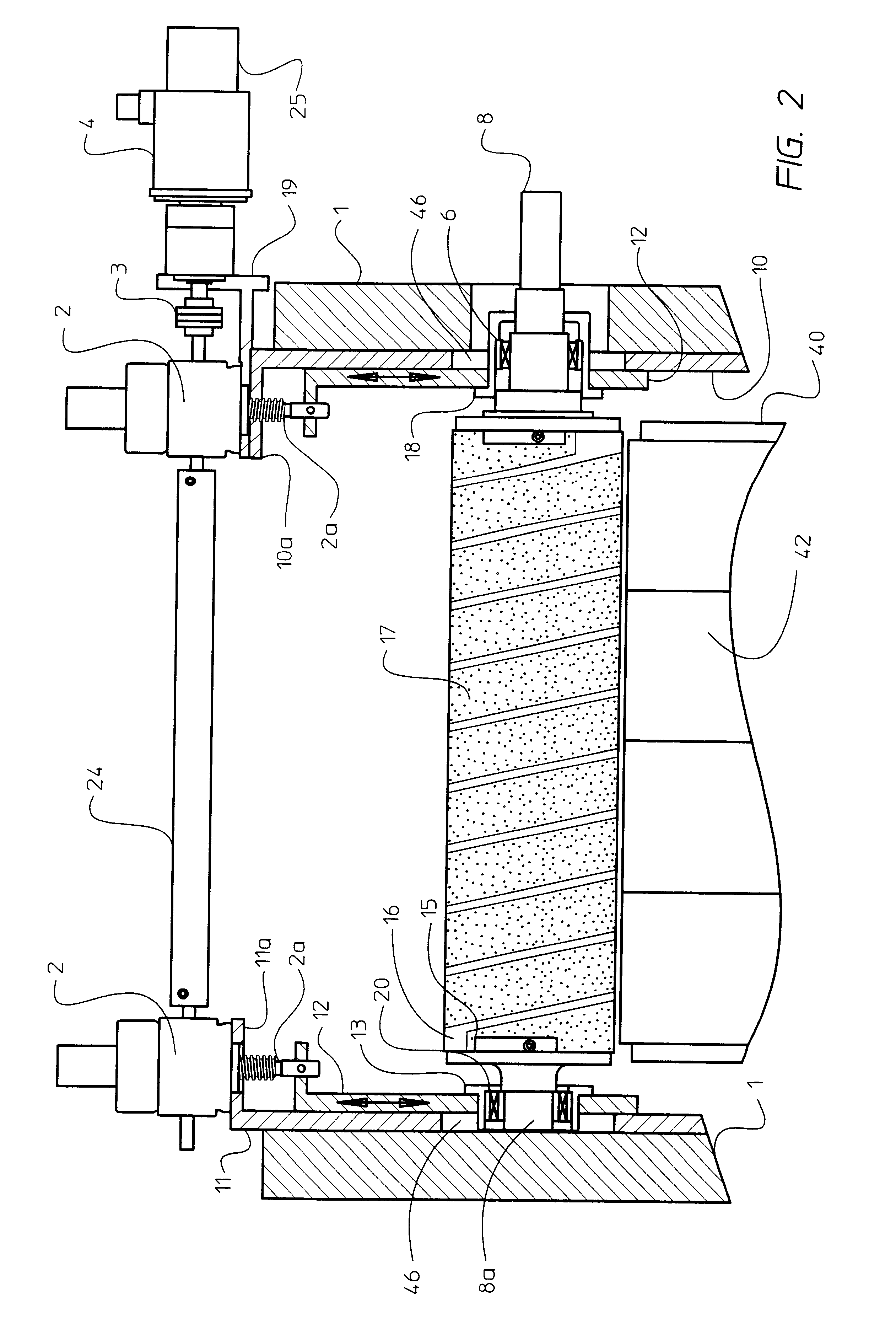

Method and apparatus for resurfacing anvil blanket of a rotary diecutter for box making machine

InactiveUS6609997B1Lower Consistency RequirementsImprovement accuracy is not highEdge grinding machinesMechanical working/deformationAdhesive materialsMechanical engineering

A rotary die cuter for a box making machine has an abrading cylinder mounted for rotation alongside the anvil for engaging and resurfacing the blanket of the anvil on a virtually continuous basis to smooth, level and even the surface of the blanket. This resurfacing occurs during normal operation of the rotary die cutter so no production is lost. The abrading cylinder has a sheet layer of abrasive material spirally wrapped on the surface of the cylinder and bonded thereto with adhesive material on the backside of the sheet layer. The abrading cylinder is movable towards or away from the anvil by a servo motor and gearbox. The position of the abrading cylinder relative to the anvil is determined by an encoder which sends the information to a computer or programmable controller which calculates the changing diameter of the blanket and the amount of speed change that must be imparted to the anvil to compensate for its changing diameter. The computer or programmable controller is connected to a drive system of the anvil to effect the speed change.

Owner:SUN AUTOMATION

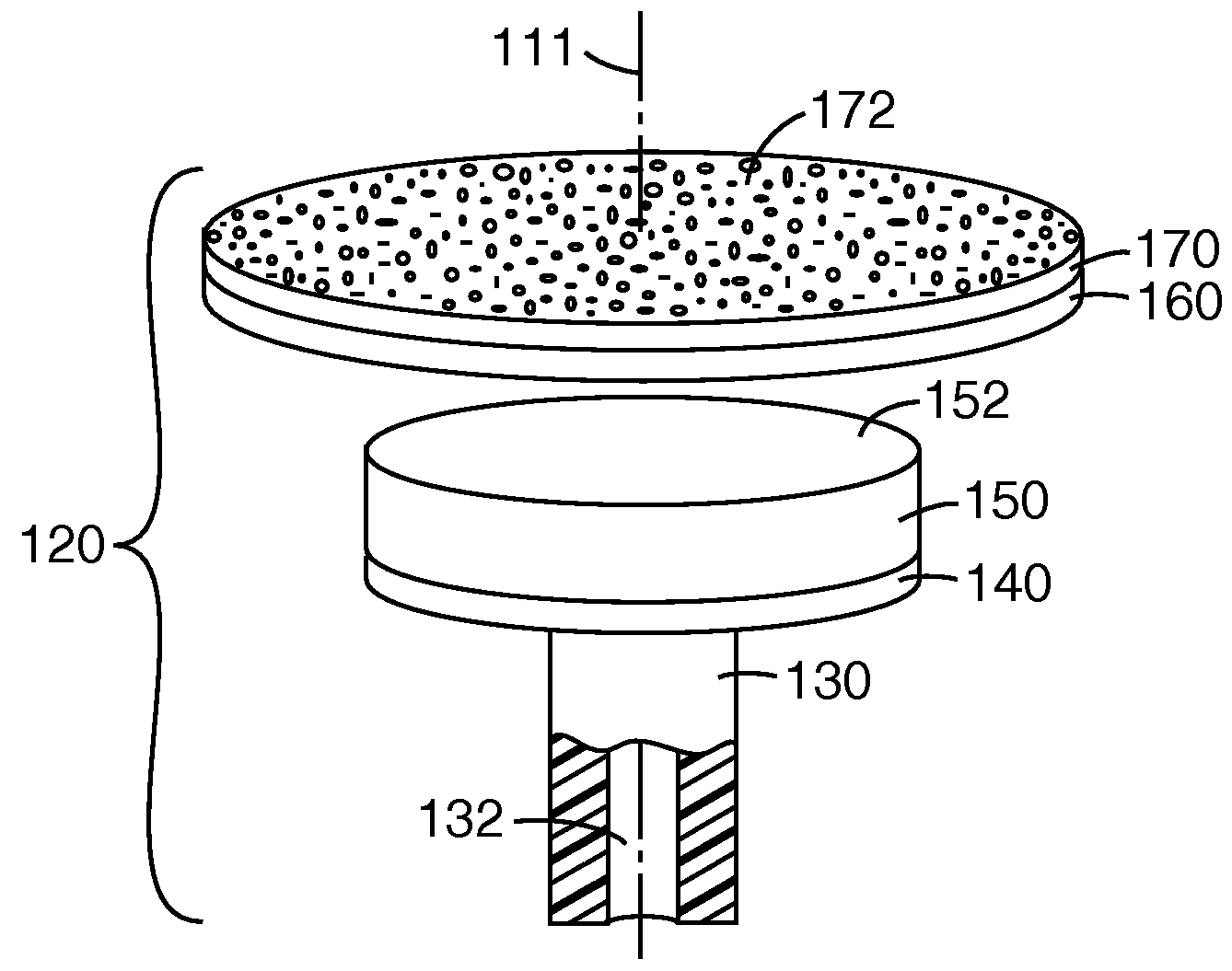

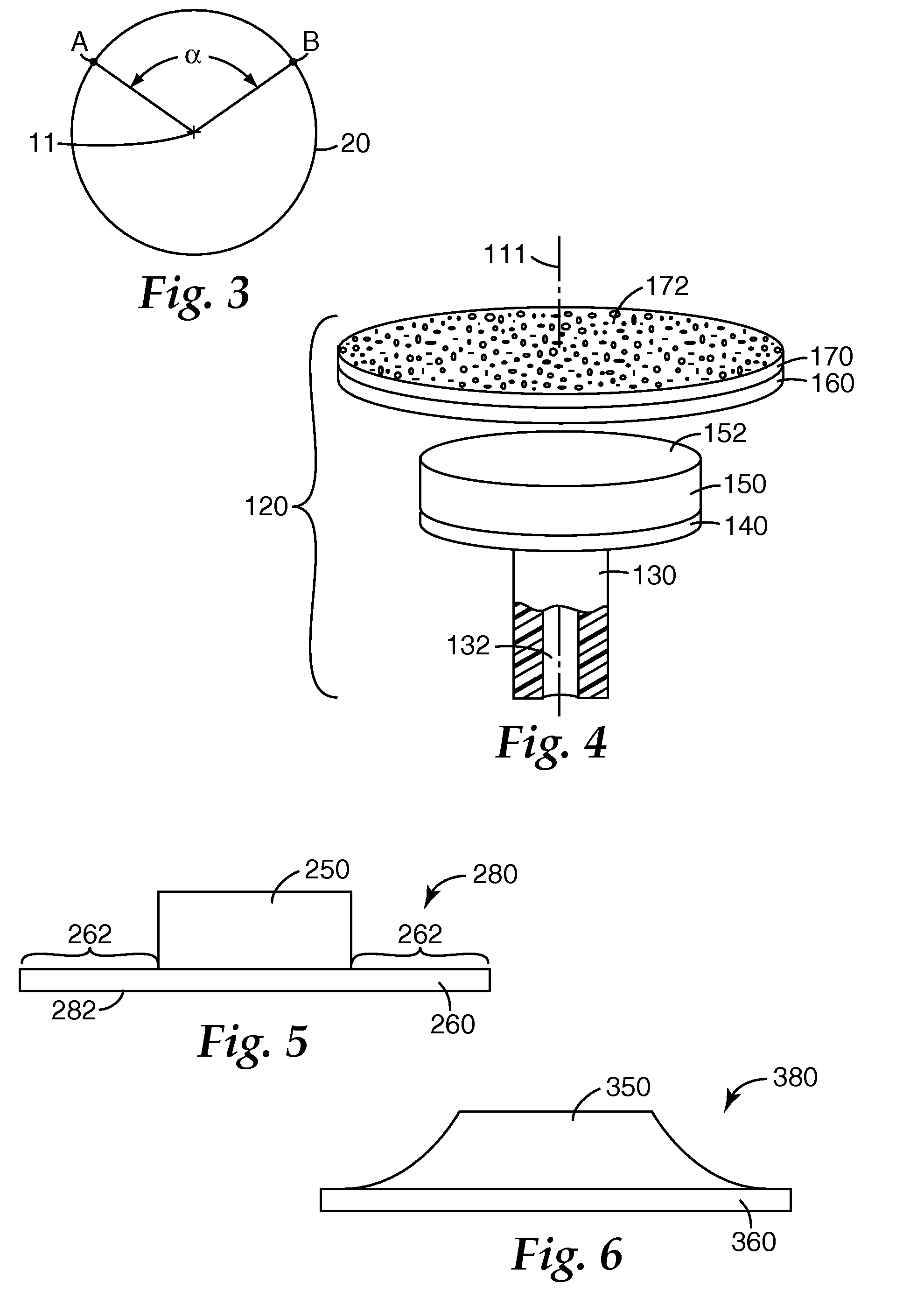

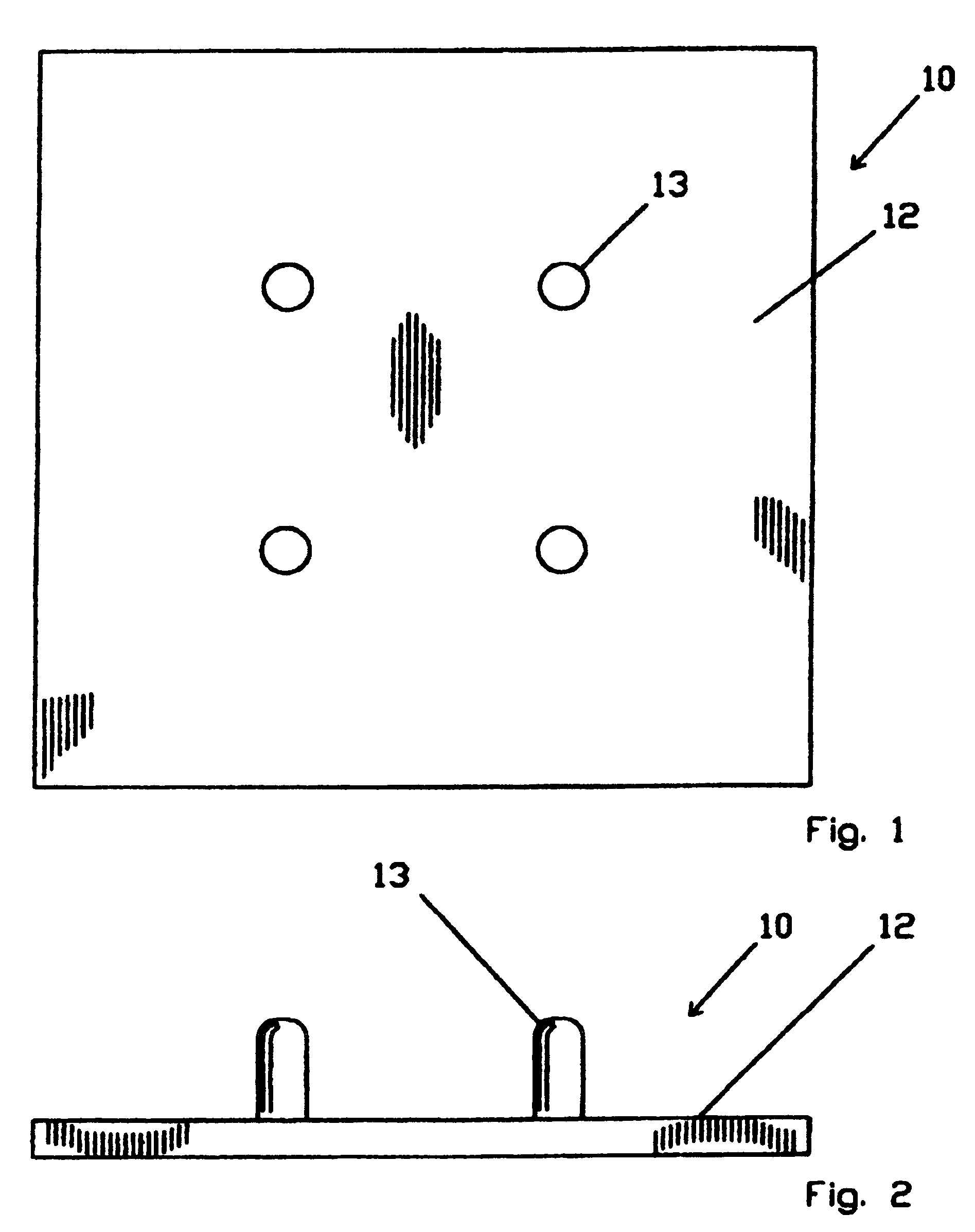

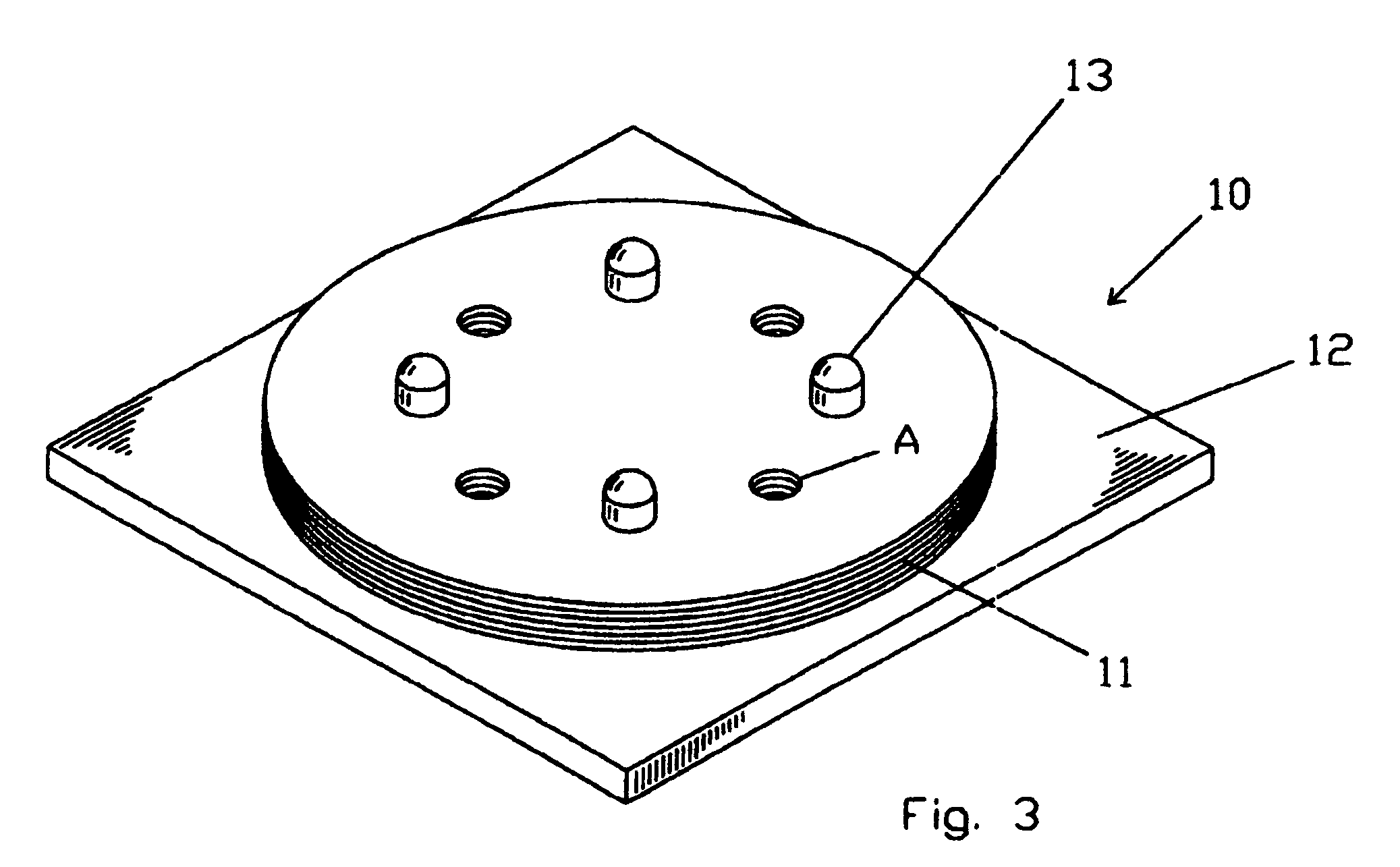

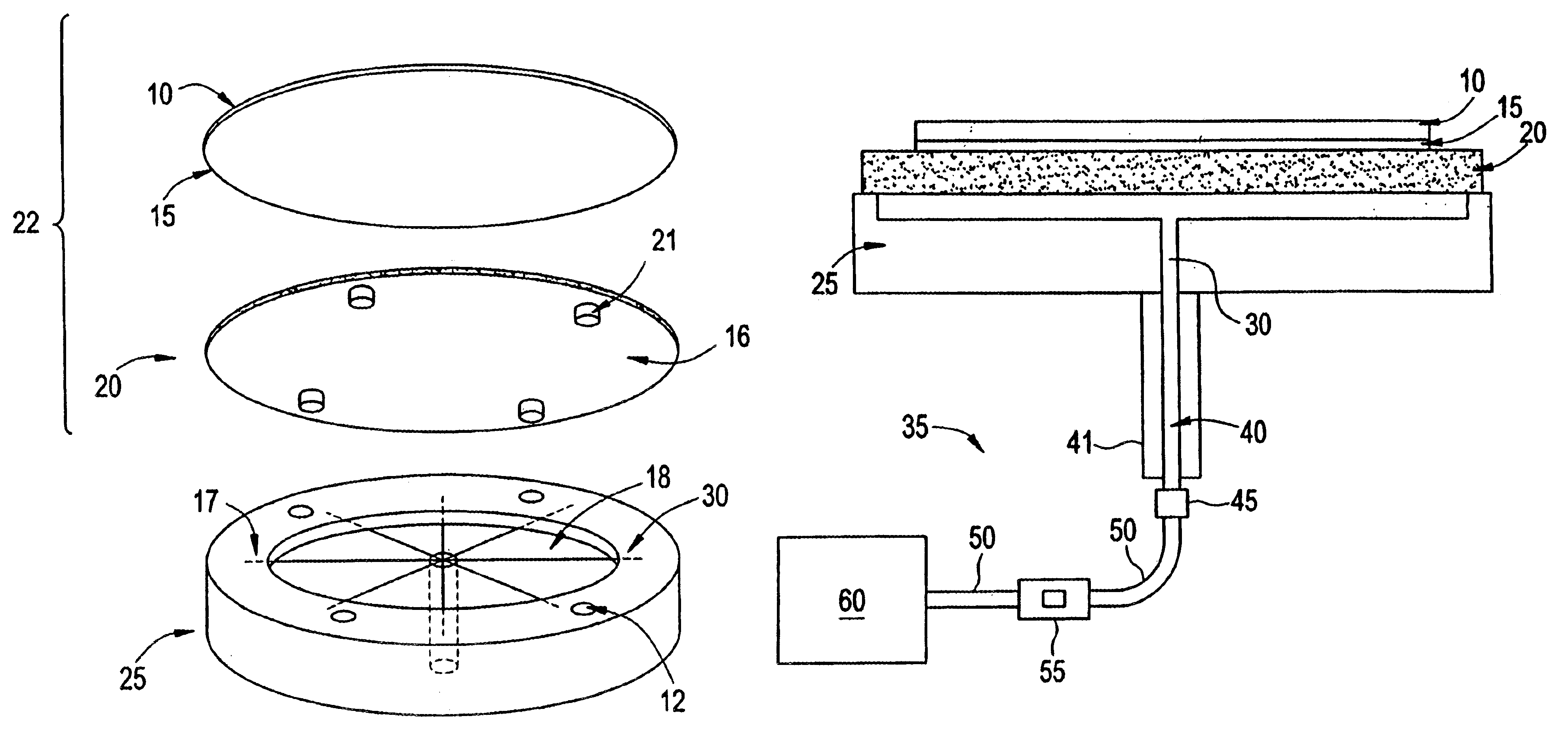

Rigid plate assembly with polishing pad and method of using

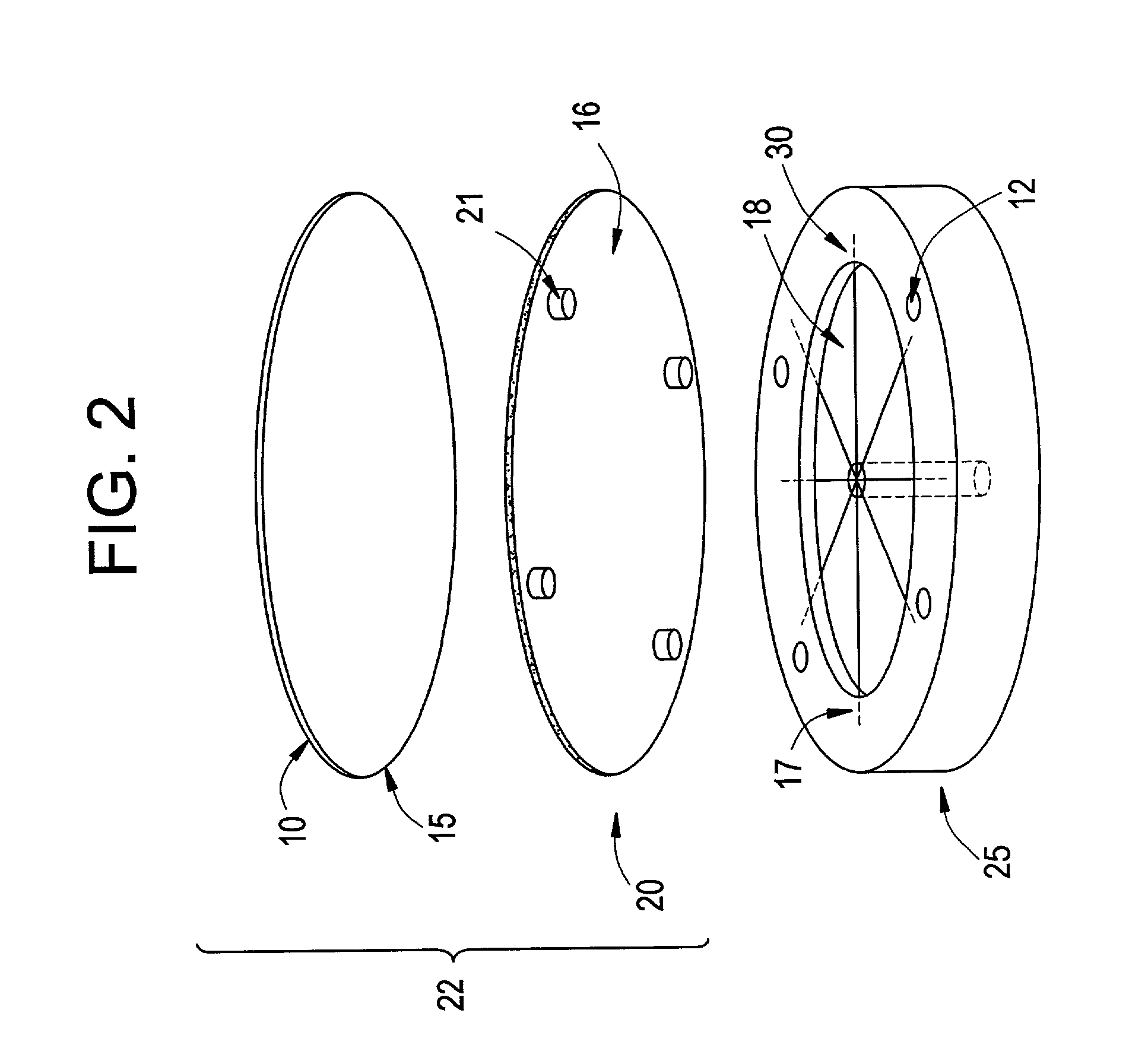

An apparatus according to the principles of the present invention includes a rotatable platen, a rigid plate member with a top surface and a bottom surface, includes pin members coupled to the rigid plate member which can be inserted into guide openings positioned within the rotatable platen, and a vacuum channel formed within the platen that enables removable mounting the rigid plate member to a top surface of the rotatable platen. The vacuum channel includes a cavity in the top surface of the platen. The rigid plate member adhesively holds the polishing pad to form a rigid plate assembly. A vacuum source coupled to the vacuum channel can be activated to create a vacuum within the vacuum channel to attract the rigid plate member to the platen. The platen can then used to polish work pieces contacting the polishing pad on the top surface of the rigid plate member. PATENT

Owner:ORIOL

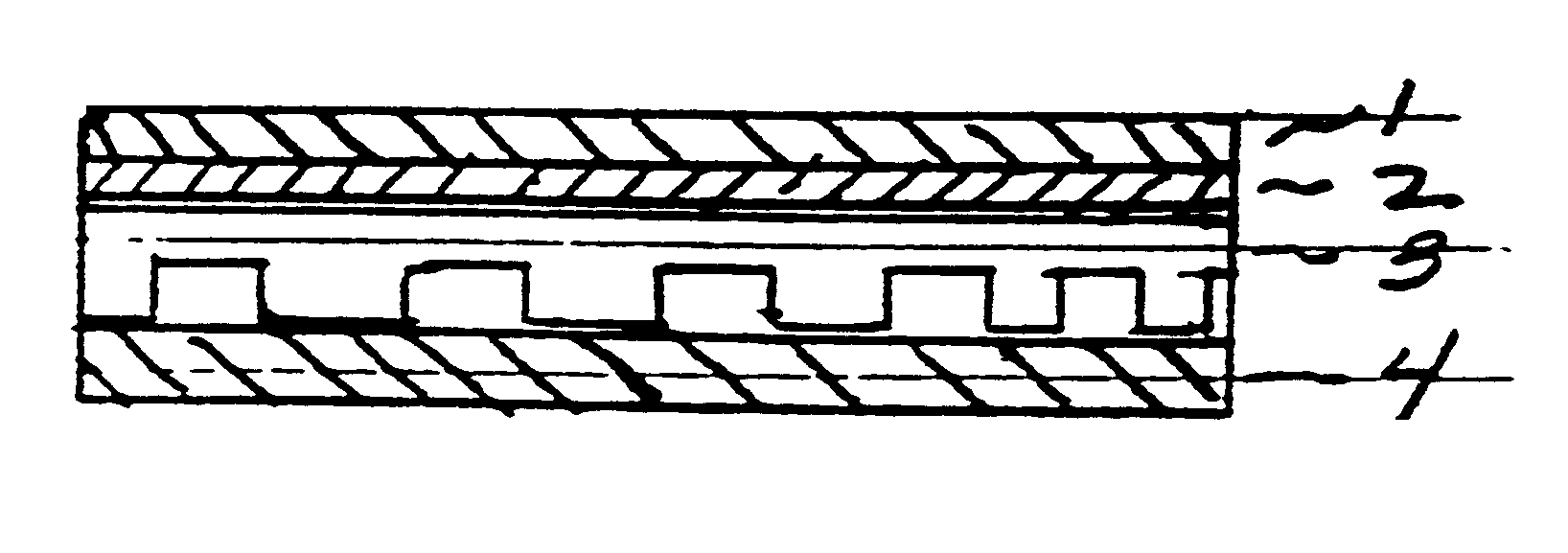

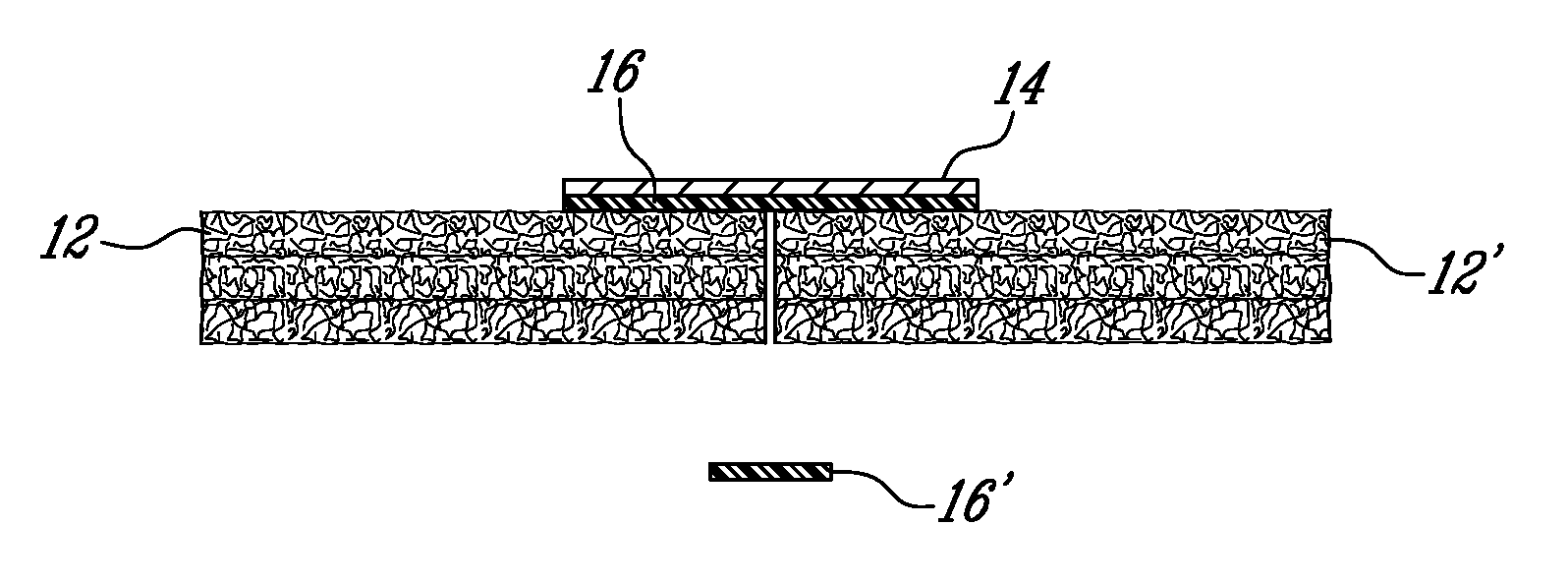

Eliminating air pockets under a polishing pad

InactiveUS20020002027A1Polishing machinesRevolution surface grinding machinesEngineeringSemiconductor

A polishing pad assembly is provided that is useful for the chemical mechanical polishing of glass and electrical devices such as semiconductor wafers that comprises a polish pad and a semi-rigid base material firmly adhered to the polishing pad for positioning on a polishing platen of a polishing machine; wherein the semi-rigid base material has a modulus of rigidity of 0.01-50 GPa (GigaPascals) determined according to ASTM D 790, a thickness of 0.25-15.0 mm, and a grooved surface having a pitch of 5-100 mm and the grooves have a width of 0.025-2.5 mm and a depth of 0.1-2.5 mm.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

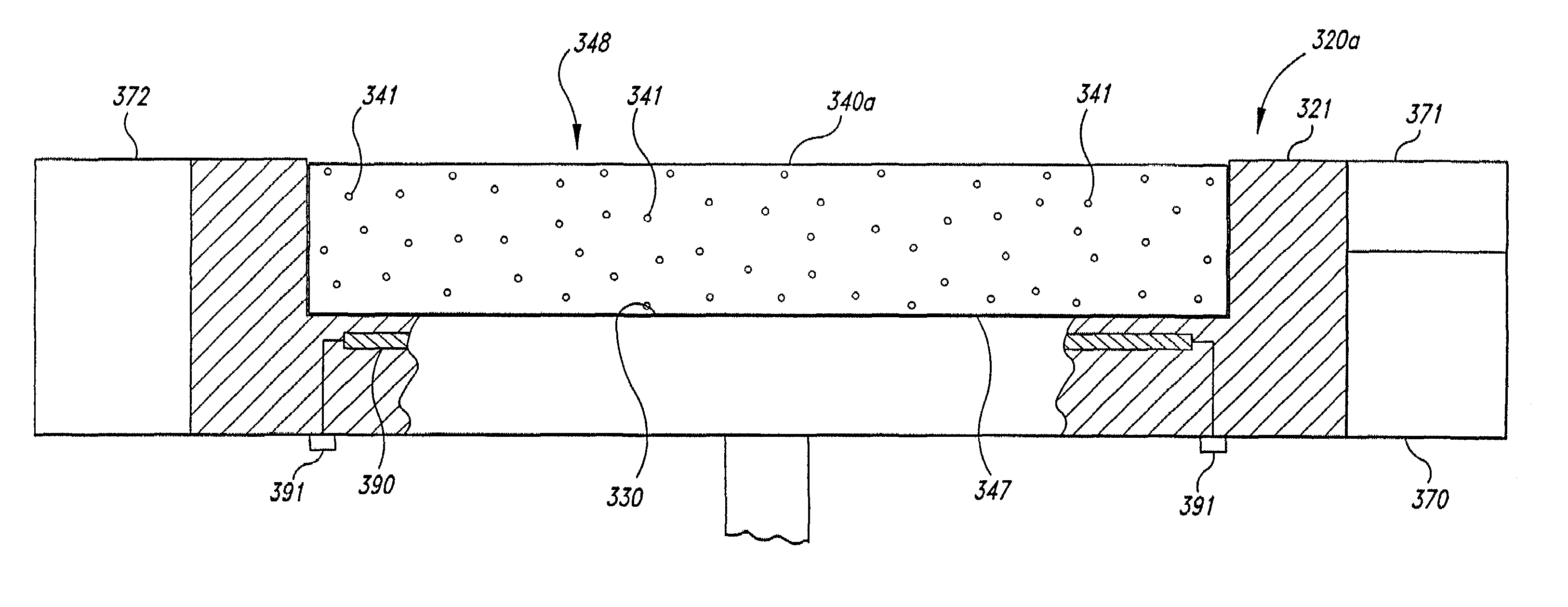

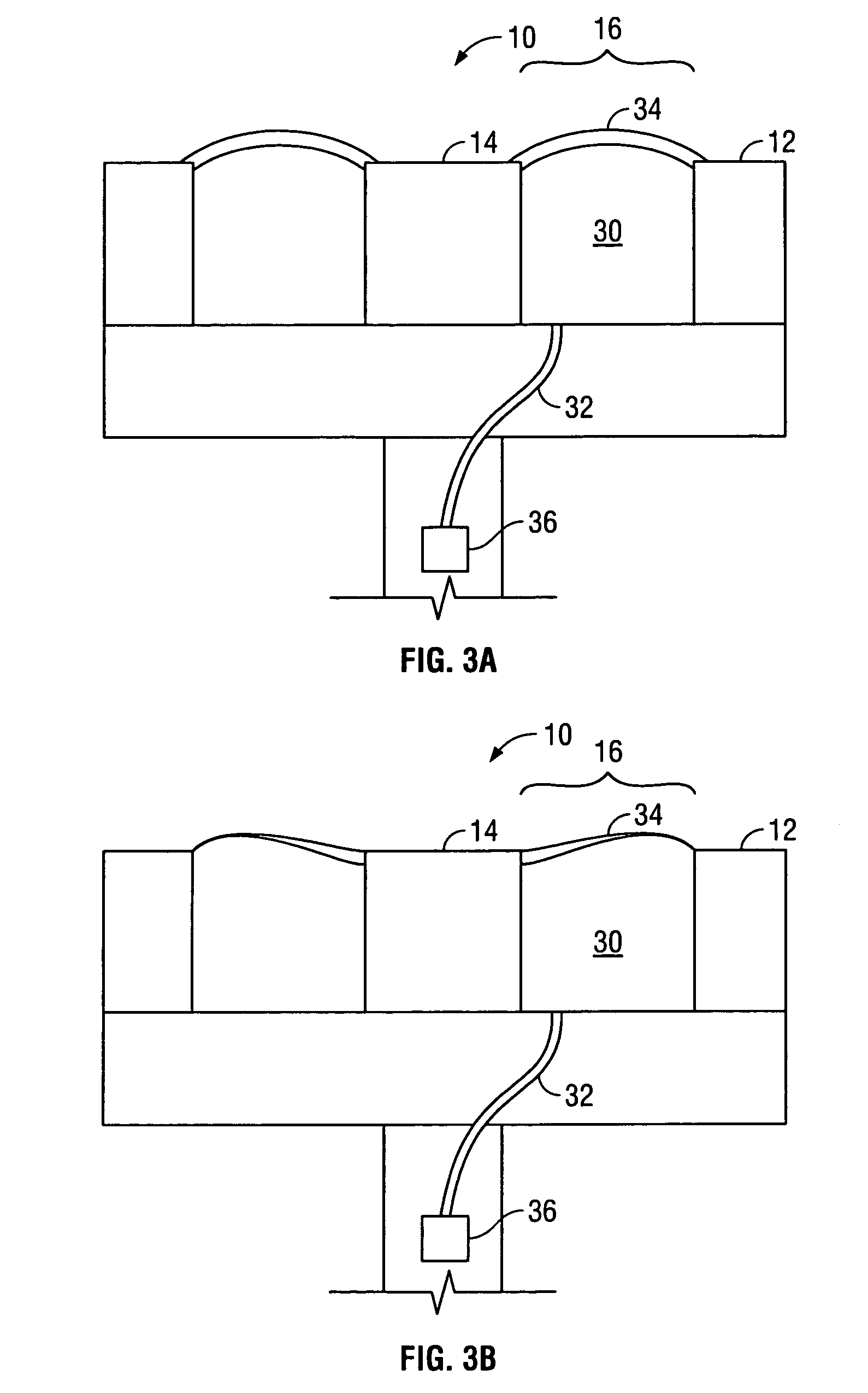

Profile control platen

InactiveUS6913518B2Easy to controlLow polishing rateSupport wheelsLapping machinesEngineeringMechanical engineering

A platen for chemical mechanical polishing of a substrate includes a surface upon which a polishing pad can be placed, a support structure, and a controller. The surface has a first region and a second region and is operable to exert force against the polishing pad during polishing. The support structure is located beneath the second region and is operable to cause the second region to exert more force than the first region. The controller is operable to adjust the amount of force that is exerted by the second region.

Owner:APPLIED MATERIALS INC

Apparatus relating to sanders

A fixing member is provided for fixing a front end section to the rest of a base plate. The fixing member is provided with a surface fastener which is integrally molded with the fixing member.

Owner:YKK CORP

Method for ultrasonic welding and ultrasonic welding fastener and joining systems

There is provided a method for forming joints between components, comprising selecting the components; selecting an ultrasound emitting source; and exposing a region of contact between the components to ultrasounds emitted by the ultrasound emitting source, to form a melted phase, a structural interface at the region of the joint being formed by engagement of the melted phase with the components. The two components may be of similar or dissimilar materials.

Owner:ABRAFAB

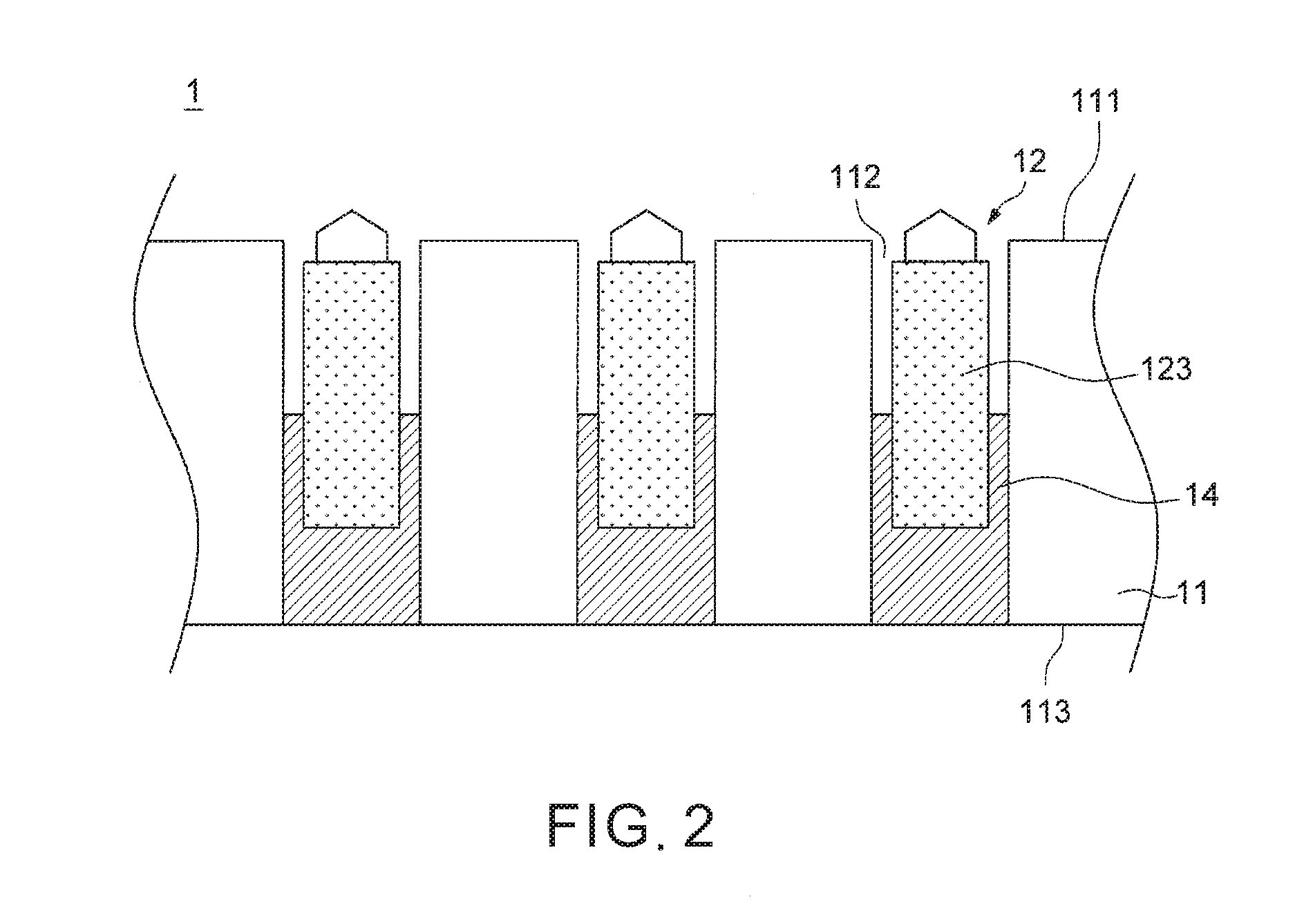

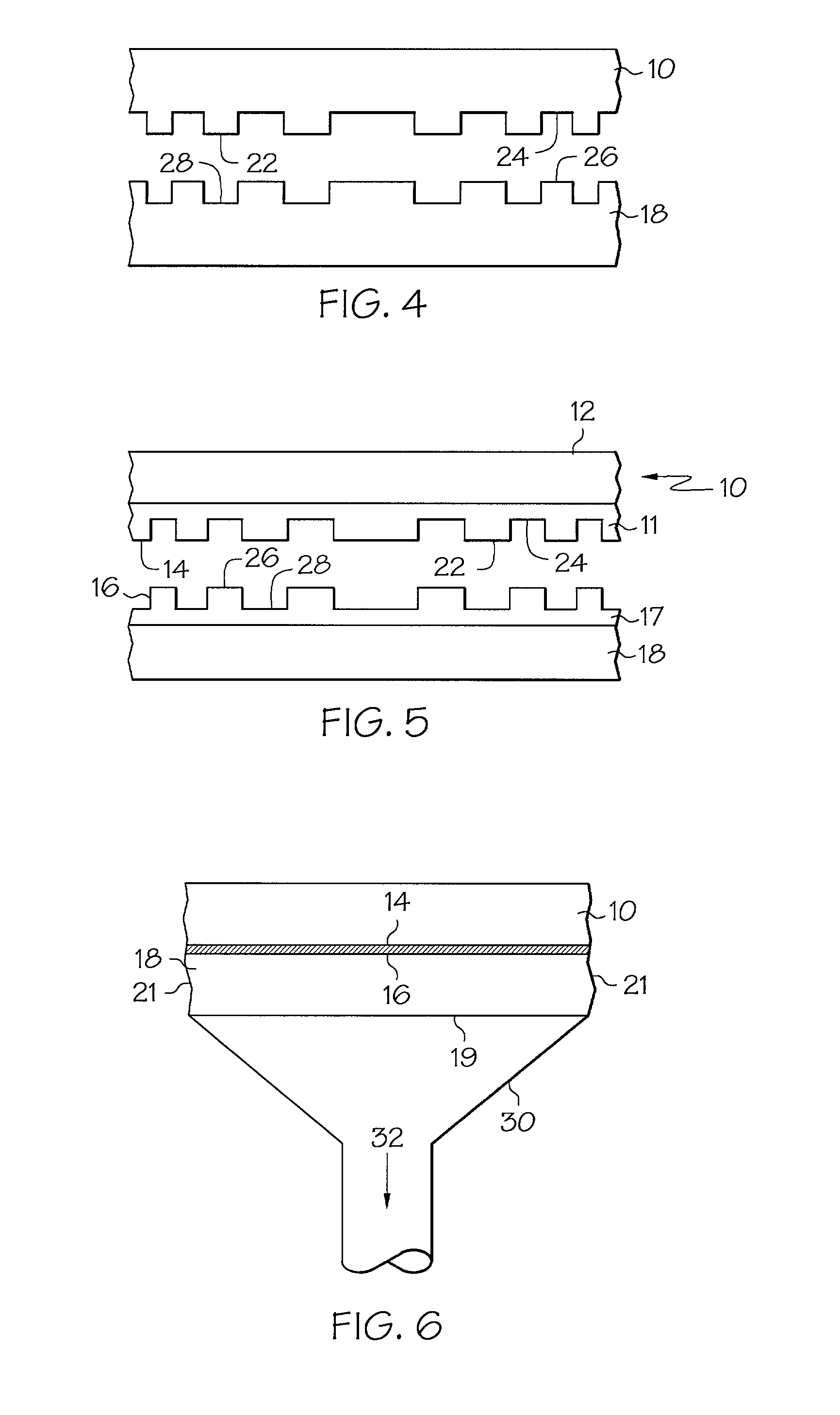

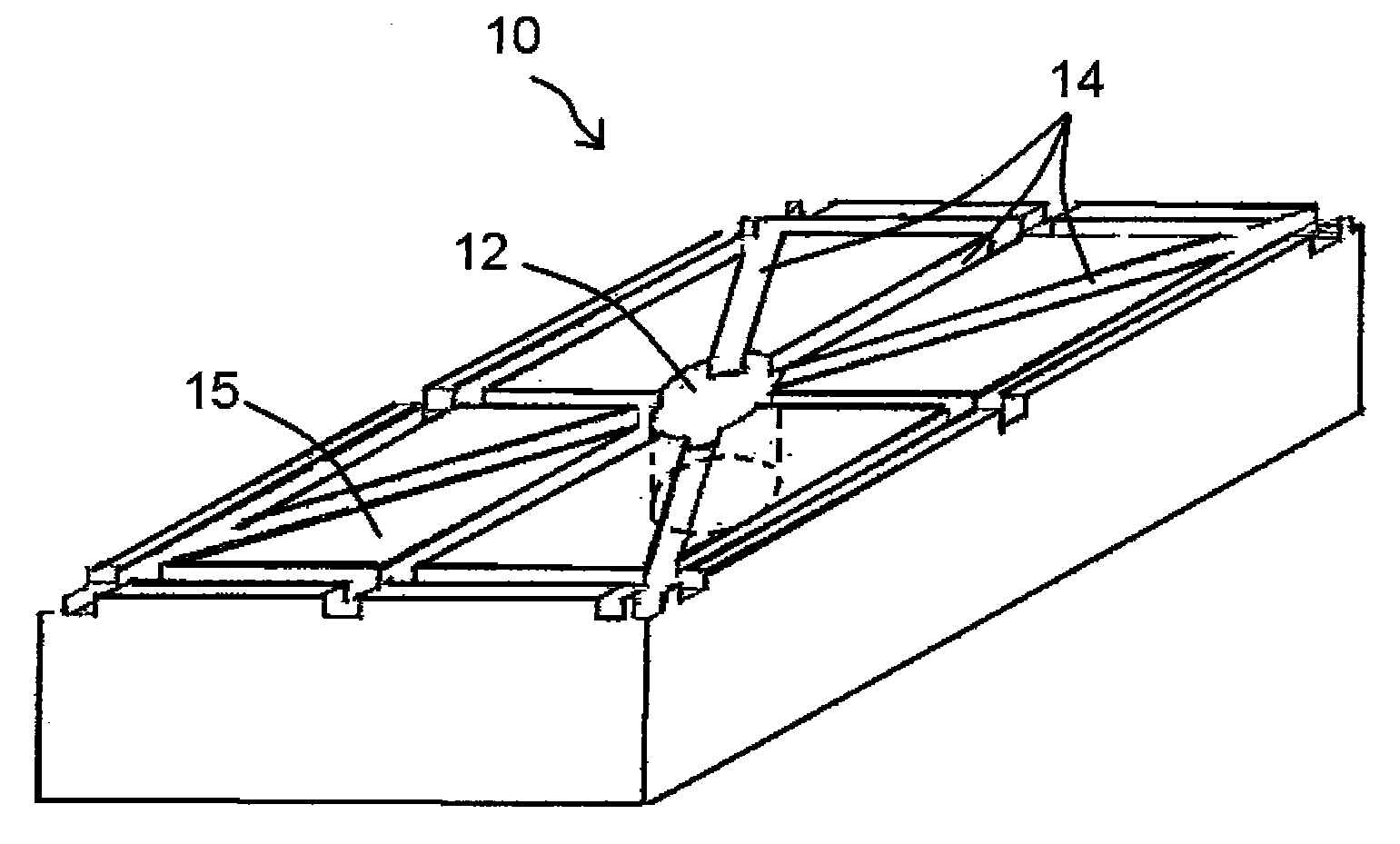

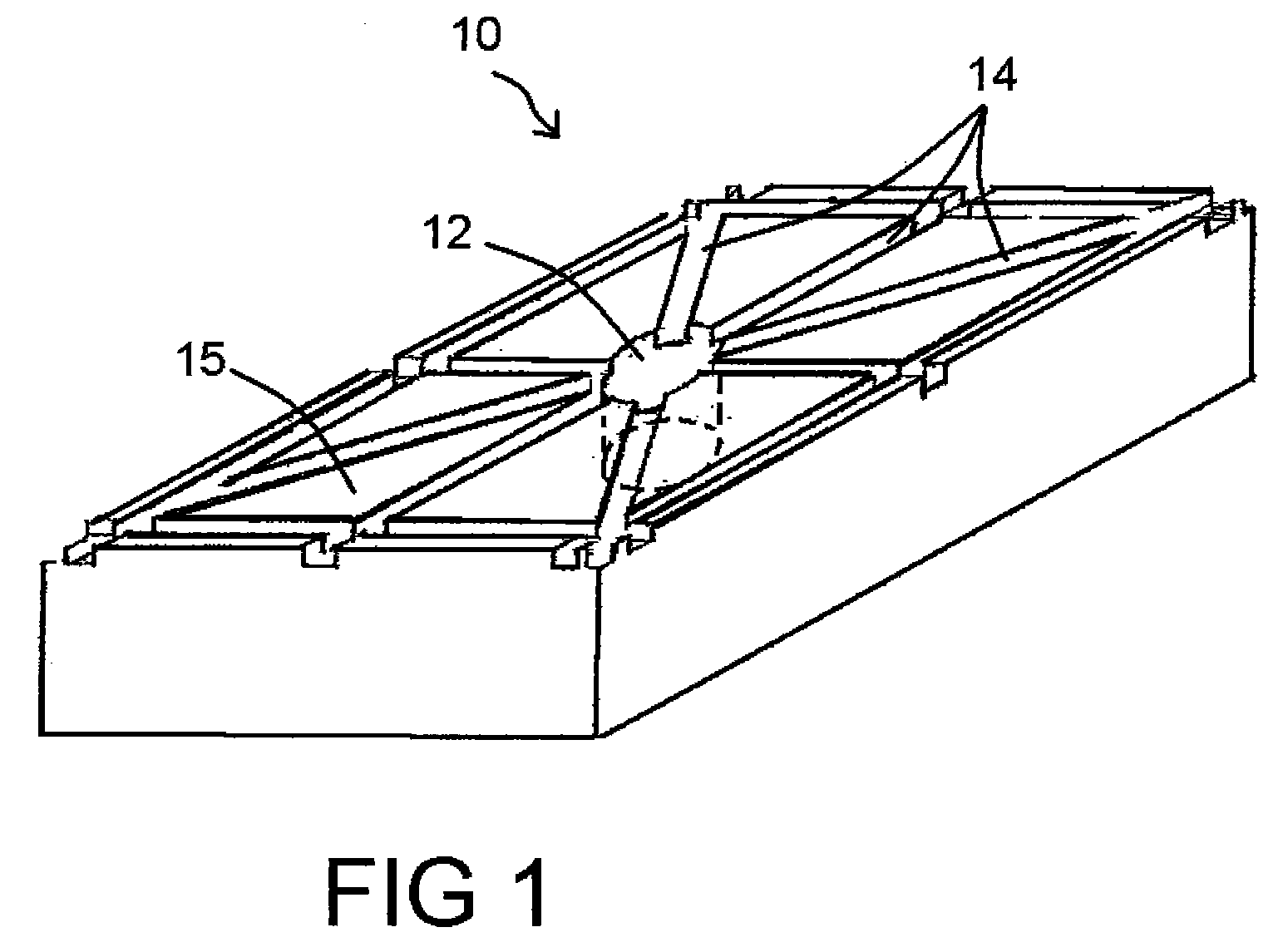

Optical grade surfacing tool

ActiveUS20110136416A1Improve performanceQuality improvementGrinding carriagesOptical surface grinding machinesDistal portionSurface finishing

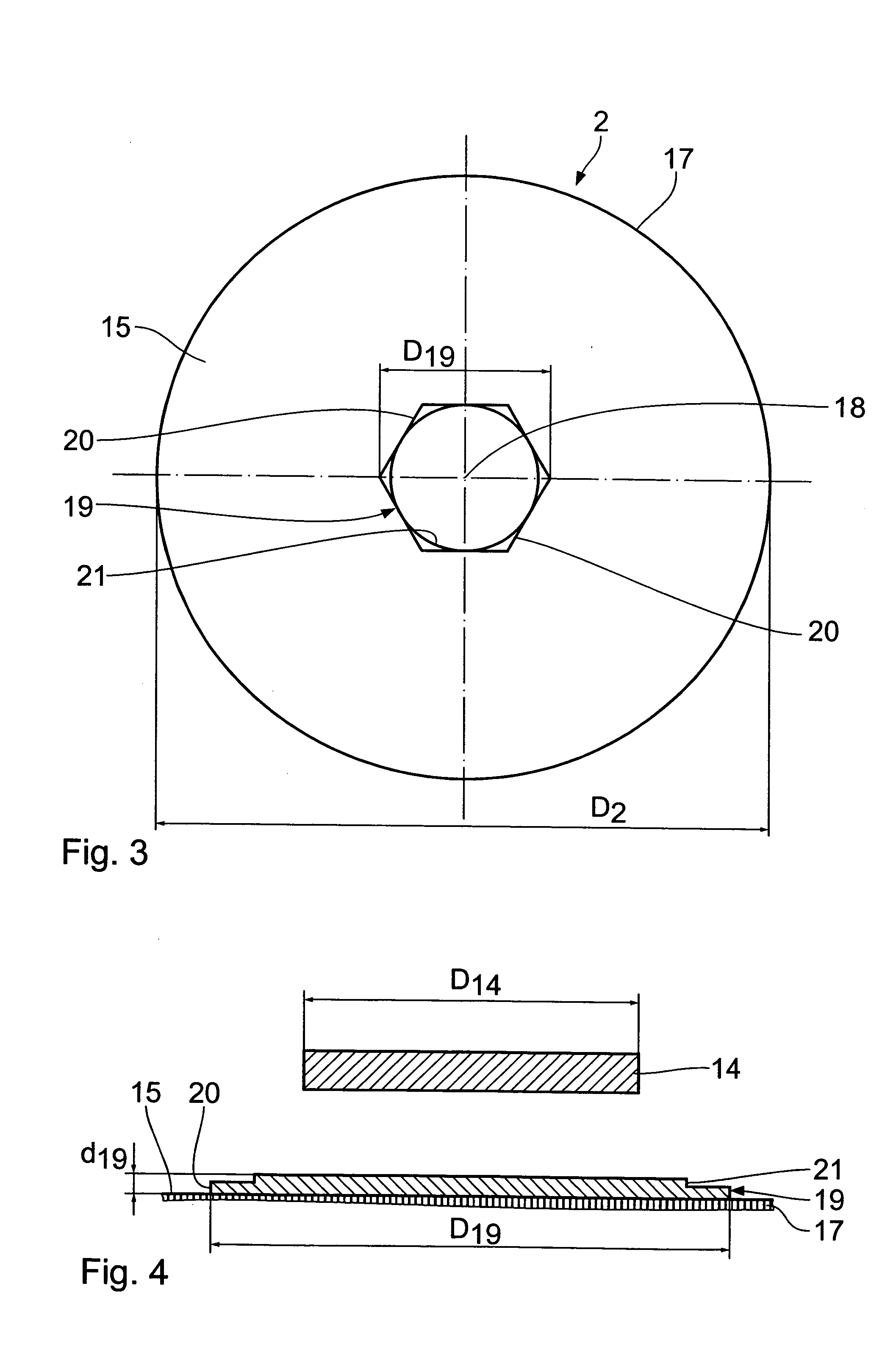

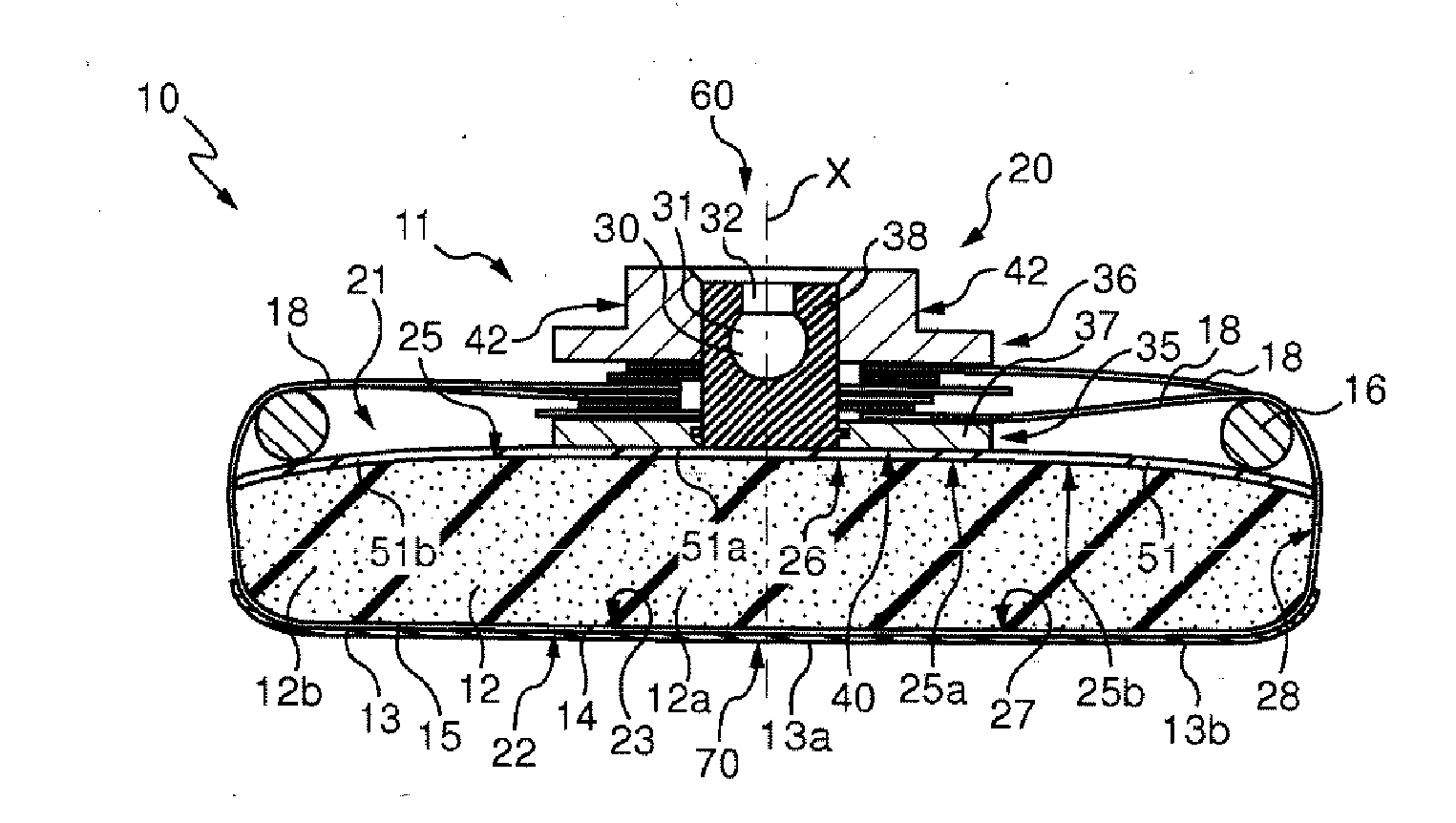

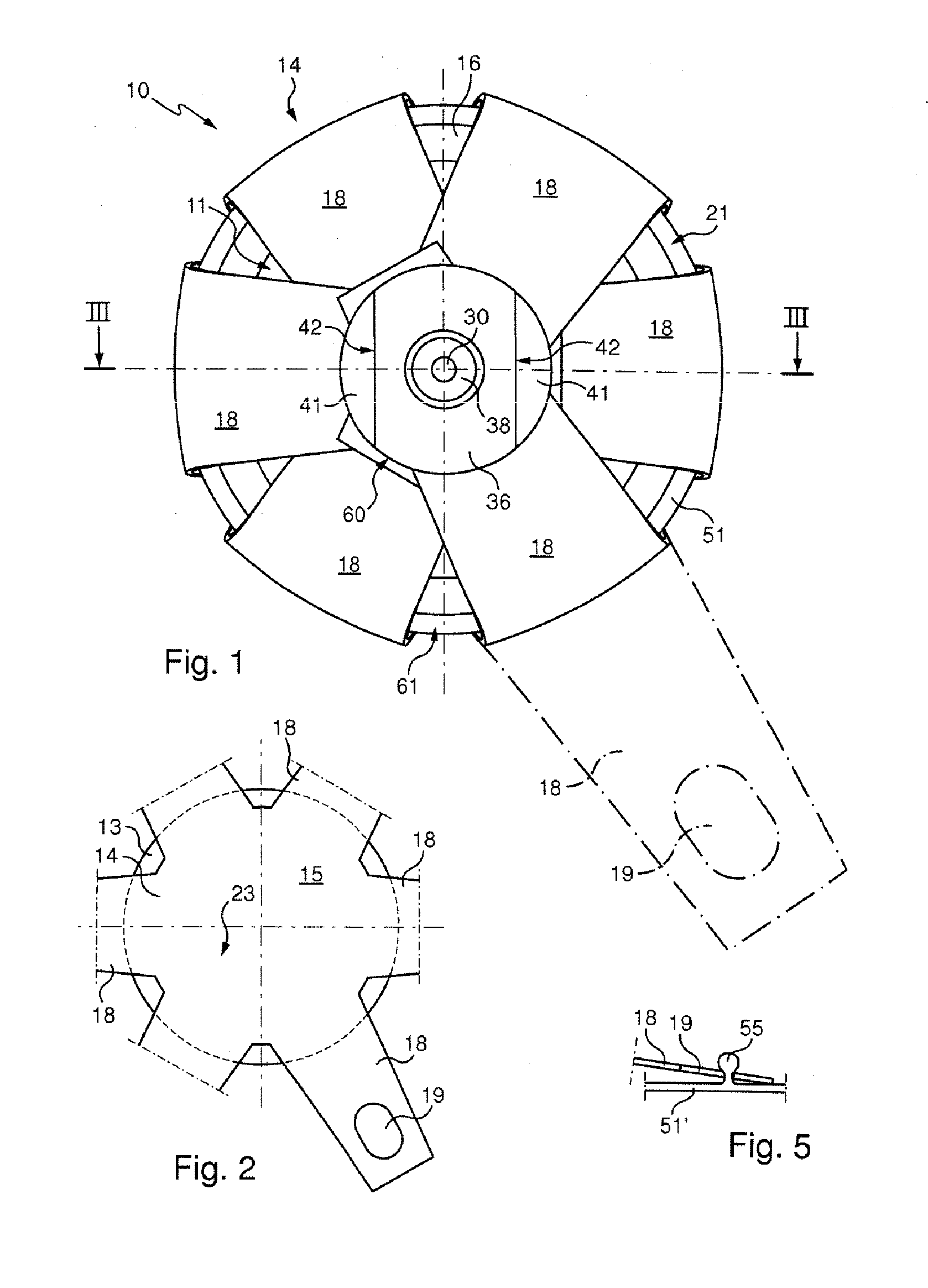

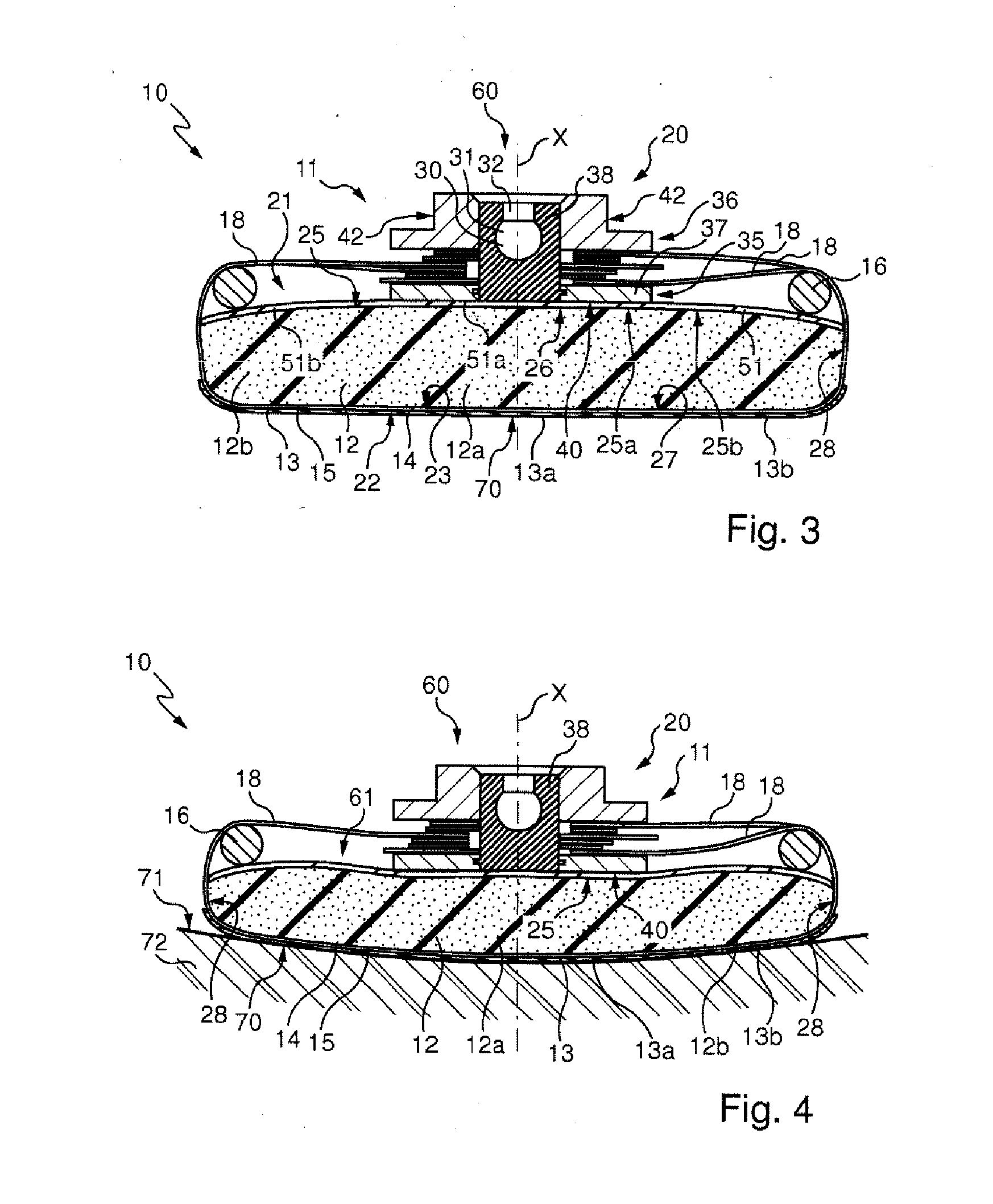

An optical-grade surfacing tool includes: a rigid holder (60); an elastically compressible interface (12) secured to the rigid holder (60); and a flexible pad (13) that can be applied against a surface to be machined (71) and secured to the interface (12) opposite the rigid holder (60). The pad (13) is carried by an elastically extensible membrane (14) including: a central plate (15); and a plurality of straps (18) each radially protruding from the periphery of the plate (15) and each having a distal portion engaged with a fastening element (38), each strap (18) rotating about the side surface (28) of the interface (12) and extending up to the fastening element, each strap (18) being taut.

Owner:ESSILOR INT CIE GEN DOPTIQUE

Method and apparatus for releasably attaching a polishing pad to a chemical-mechanical planarization machine

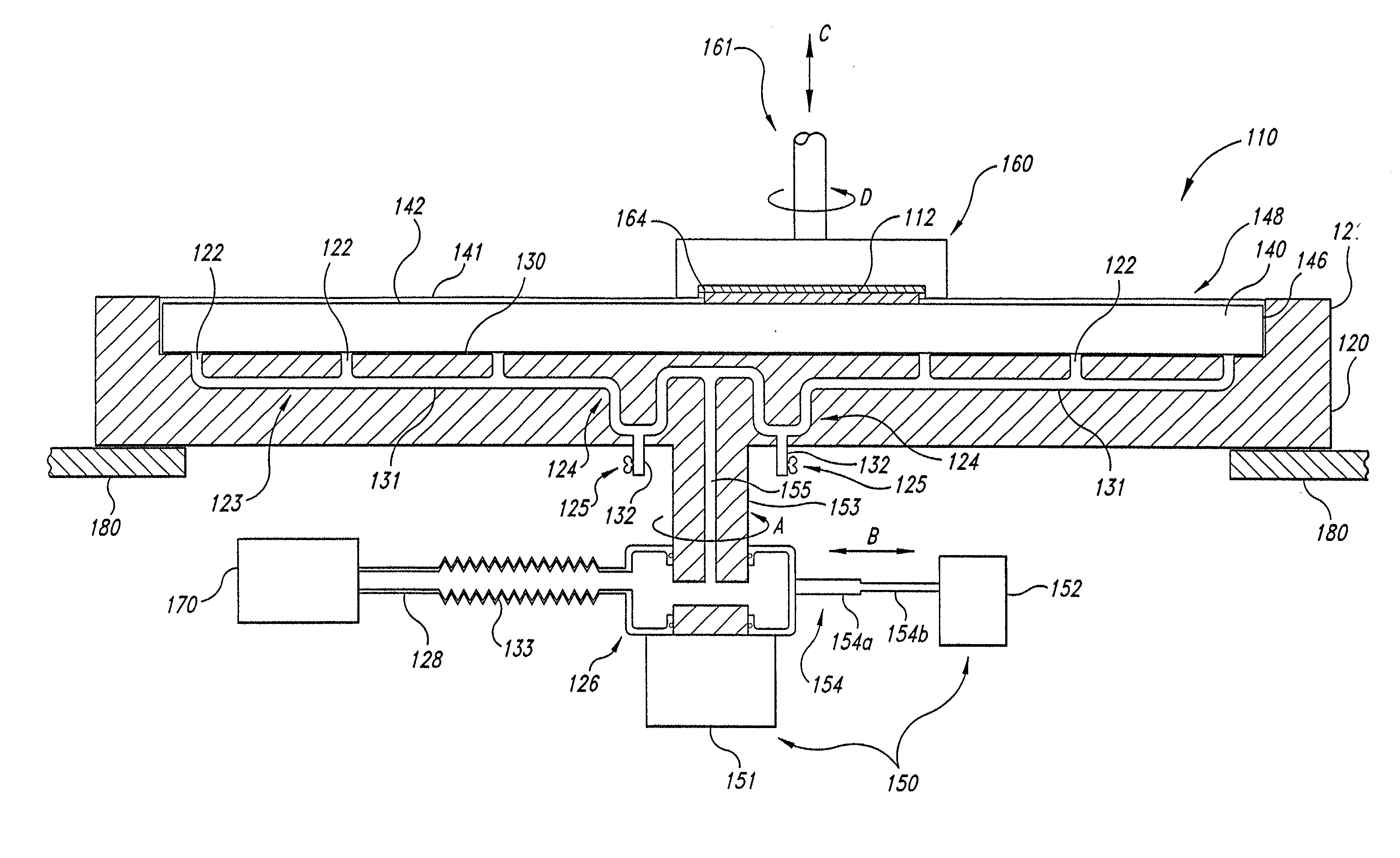

InactiveUS20020127953A1Avoid separationSupport wheelsWork holdersSemiconductorChemical-mechanical planarization

A method and apparatus for releasably attaching a planarizing medium, such as a polishing pad, to the platen of a chemical-mechanical planarization machine. In one embodiment, the apparatus can include several apertures in the upper surface of the platen that are coupled to a vacuum source. When a vacuum is drawn through the apertures in the platen, the polishing pad is drawn tightly against the platen and may therefore be less likely to wrinkle when a semiconductor substrate is engaged with the polishing pad during planarization. When the vacuum is released, the polishing pad can be easily separated from the platen. The apparatus can further include a liquid trap to separate liquid from the fluid drawn by the vacuum source through the apertures, and can also include a releasable stop to prevent the polishing pad from separating from the platen should the vacuum source be deactivated while the platen is in motion. In another embodiment, a signal can be applied to the platen to draw the polishing pad toward the platen via electrostatic or electromagnetic forces. In still another embodiment, the polishing pad can be attached to a pad support and conditioned on a separate jig.

Owner:MICRON TECH INC

Rigid plate assembly with polishing pad and method of using

InactiveUS6835118B2Polishing machinesRevolution surface grinding machinesEngineeringMechanical engineering

An apparatus according to the principles of the present invention includes a rotatable platen, a rigid plate member with a top surface and a bottom surface, includes pin members coupled to the rigid plate member which can be inserted into guide openings positioned within the rotatable platen, and a vacuum channel formed within the platen that enables removable mounting the rigid plate member to a top surface of the rotatable platen. The vacuum channel includes a cavity in the top surface of the platen. The rigid plate member adhesively holds the polishing pad to form a rigid plate assembly. A vacuum source coupled to the vacuum channel can be activated to create a vacuum within the vacuum channel to attract the rigid plate member to the platen. The platen can then used to polish work pieces contacting the polishing pad on the top surface of the rigid plate member.

Owner:ORIOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com