Retention of a polishing pad on a platen

a technology for polishing pads and platens, which is applied in the direction of grinding machines, edge grinding machines, manufacturing tools, etc., can solve the problems of bulging bulges, raised areas or bulges in the polishing surface of the polishing pad, and air bubbles that tend to get trapped between the adhesive and the platen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

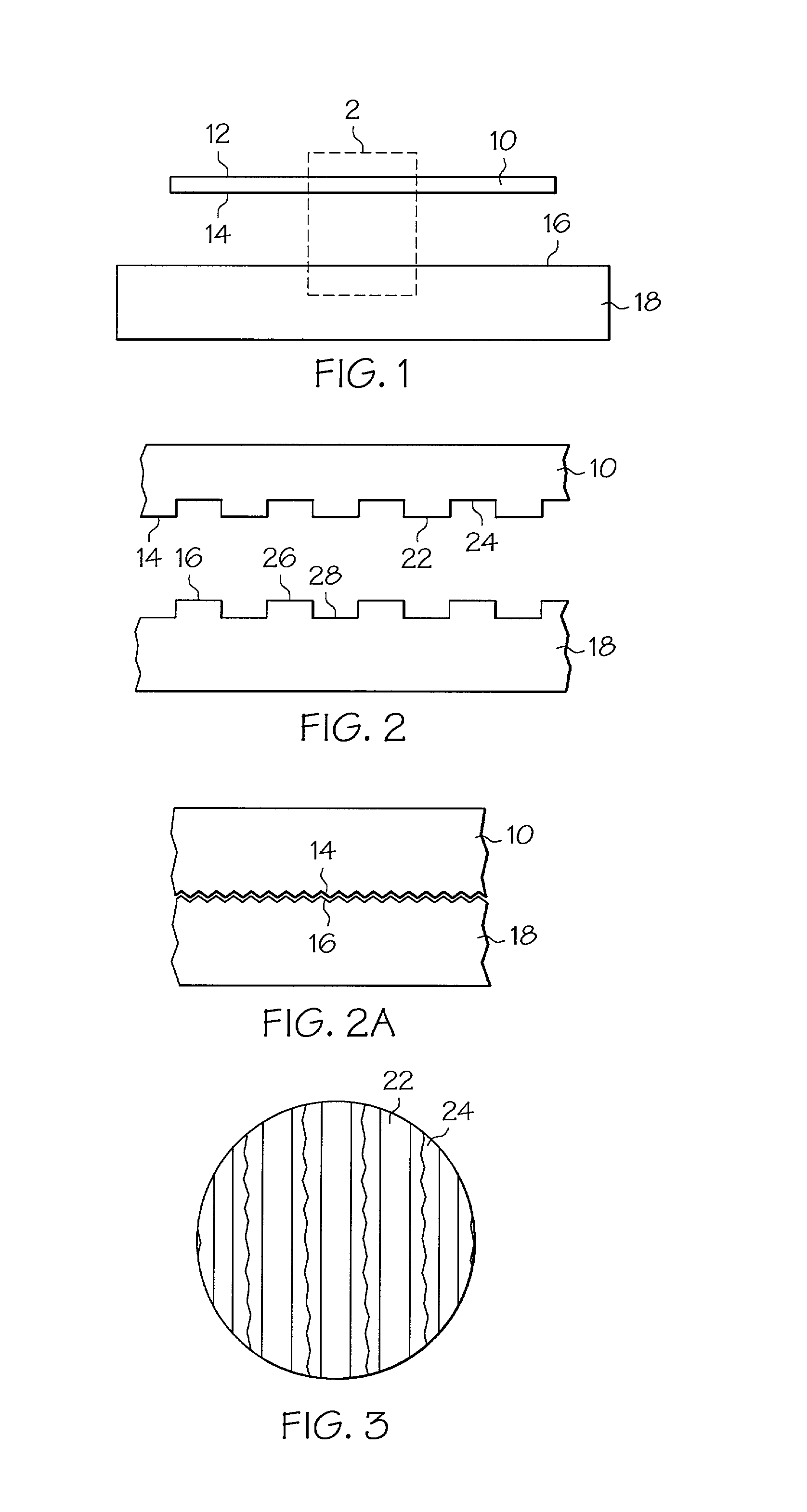

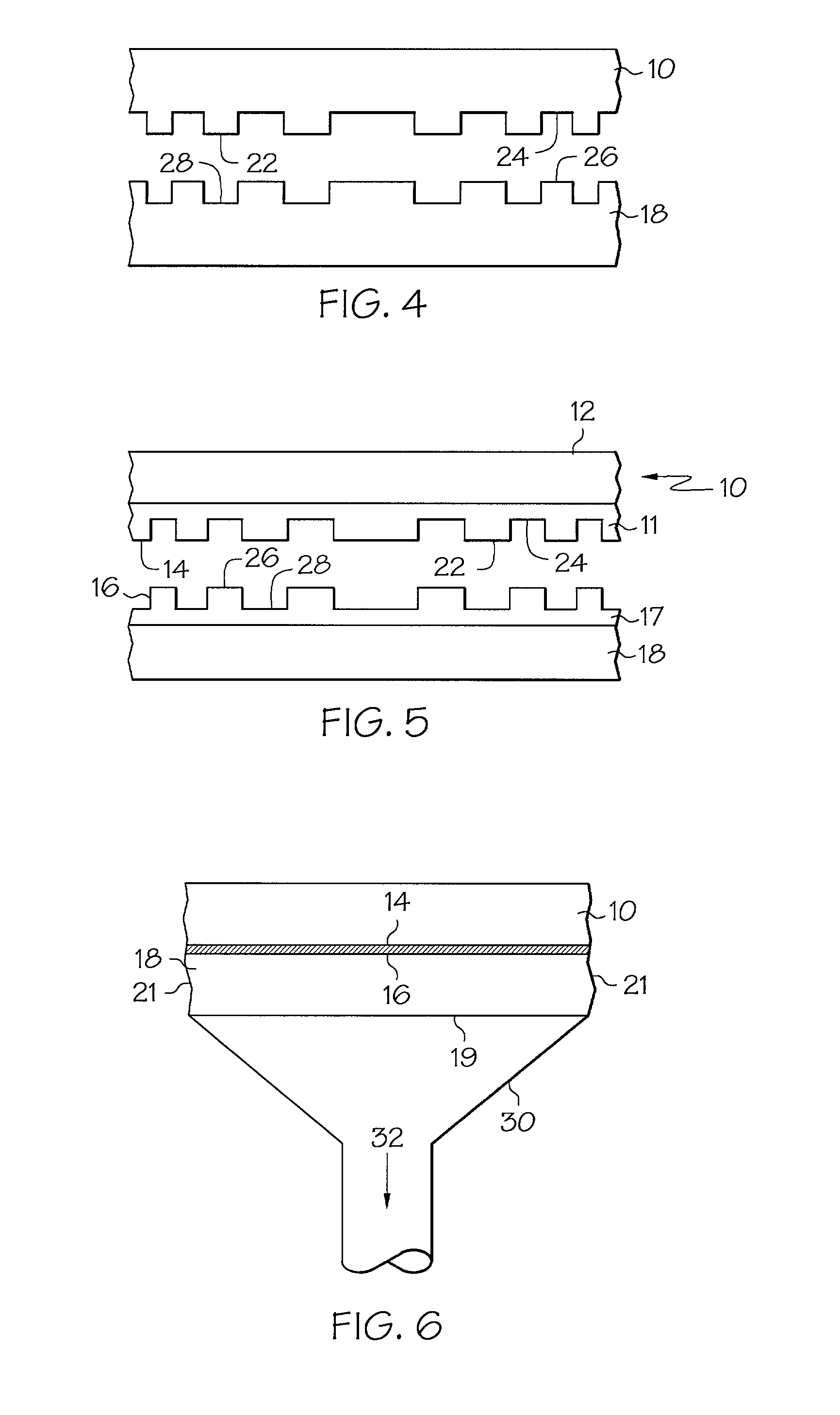

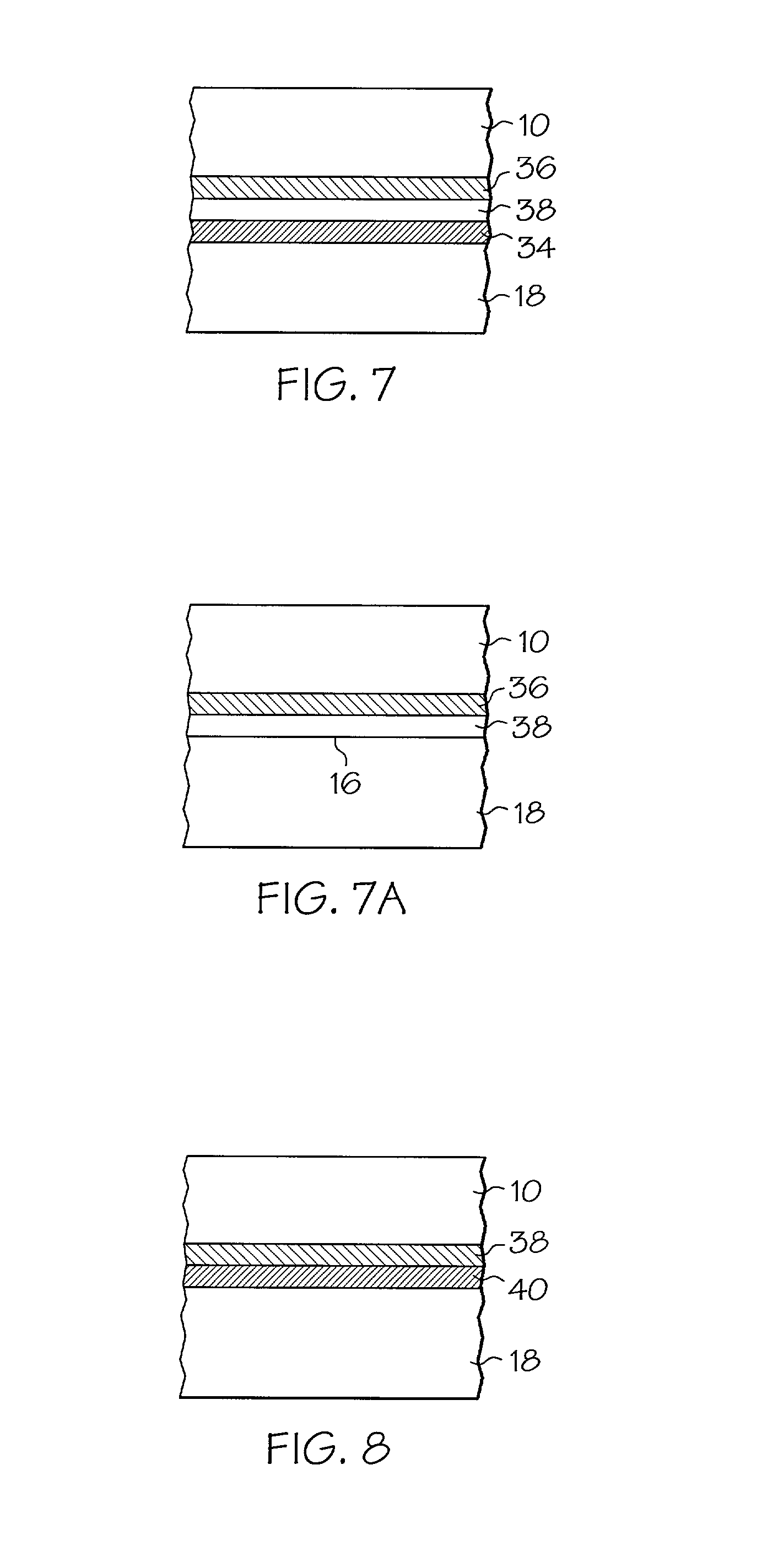

[0029] There is shown in FIG. 1 a polishing pad 10 comprising a top polishing surface 12 and an undersurface 14 that is adapted to be mounted on a front face 16 of a platen 18. The undersurface 14 has a profiled surface which is configured to interfit with a complementary profiled surface on the front face 16 of the platen.

[0030] In a preferred embodiment as shown in FIGS. 2 and 3, the undersurface 14 has a surface profile which includes an array of parallel ridges 22 and grooves 24, and the front face 16 has a surface profile which includes a complementary array of parallel ridges 26 and grooves 28. The ridges 22 and the grooves 24 are configured to interfit with the grooves 28 and the ridges 26, respectively, when the polishing pad is mounted on the platen.

[0031] The ridges 22, 26 are dimensioned for a close slip fit in respective ones of the grooves 24, 28. Preferably, the width of ridges 22, 26 differs slightly from the width of grooves 24, 28 in order to provide room for the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com