Abrasive articles, rotationally reciprocating tools, and methods

a technology of rotating reciprocating tools and abrasives, which is applied in the field of abrasive articles, rotationally reciprocating tools, and methods, can solve the problems of affecting the appearance affecting the quality of the orange-peel finish, and flat spots in the characteristic orange-peel appearance, so as to reduce the disturbance of the orange-peel texture around the defect, and the effect of repairing surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

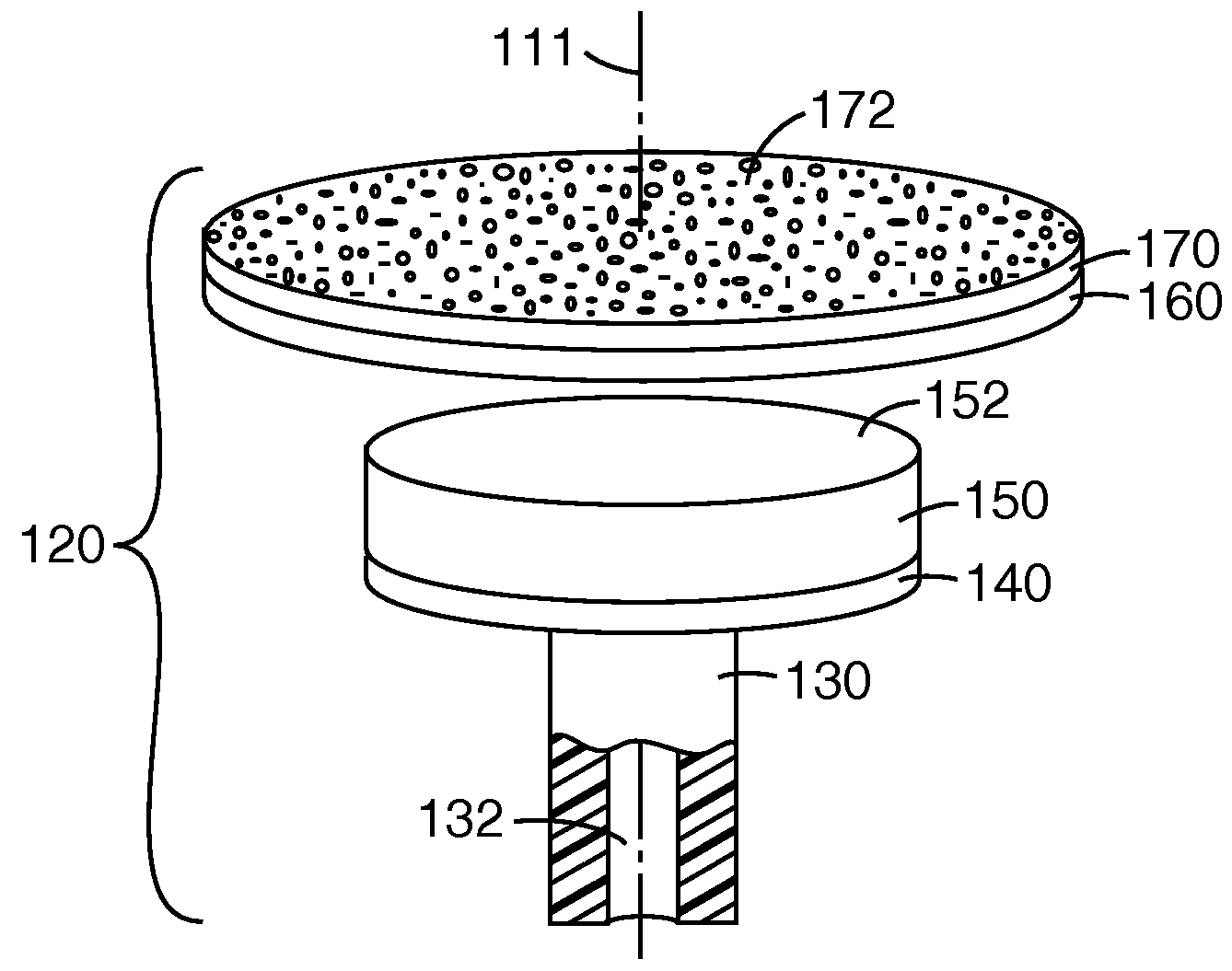

[0145]An abrasive article was manufactured using transfer adhesive (commercially available under the trade designation “9453LE” from 3M Company) that was applied to the non-abrasive face of a 0.5 inch (1.27 cm) diameter structured abrasive member (manufactured as described above). The larger 0.5 inch diameter abrasive member was centered over and attached to the smaller 0.25 inch diameter mounting surface of the base plate assembly. The abrasive article of Example 1 thus included the following components depicted in FIG. 4: the base plate 140 and abrasive member 170 attached directly to the base plate 140. The abrasive article was then used as described in Sanding Test No. 1 below.

example 2

[0146]An abrasive article was manufactured by die-cutting a 0.5 inch (1.27 cm) diameter polyvinyl foam disc, 0.027 inch (0.69 mm) thick from an adhesive bandage commercially available under the trade designation NEXCARE ADHESIVE STRIP BANDAGE from 3M Company. The adhesive liner was removed and the adhesive face of the foam disc was attached to the non-abrasive major surface of a 0.5 inch diameter structured abrasive member (manufactured as described above). The transfer adhesive of Example 1 was then applied to the non-adhesive face of the foam disc. The transfer adhesive-coated major surface of the larger 0.5 inch diameter polyvinyl foam disc (with its attached structured abrasive member) was then centered over and attached to the smaller 0.25 inch diameter mounting surface of the base plate assembly. The abrasive article of Example 2 thus included the following components depicted in FIG. 4: the base plate 140, support layer 160 (polyvinyl foam disc), and abrasive member 170. The ...

example 3

[0147]An abrasive article was made according to the method described in Example 2, except that the 0.5 inch (1.27 cm) diameter polyvinyl foam was replaced by a 5 / 16 inch (7.9 mm), 0.090 inch (2.29 mm) thick disc of polyurethane foam, commercially available under the trade designation “R600U-090” from Illbruck Company, Minneapolis, Minn. The larger 0.5 inch diameter structured abrasive member was centered over the smaller 5 / 16 inch diameter polyurethane foam disc. The 5 / 16 inch diameter polyurethane foam disc was centered on the 0.25 inch diameter mounting surface of the base plate assembly. The abrasive article of Example 3 thus included the following components depicted in FIG. 4: the base plate 140, compressible member 150 (polyurethane foam disc), and abrasive member 170. The abrasive member 170 was attached directly to the compressible member 150. The abrasive article was then used as described in Sanding Test No. 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com