Tool

a tool and tool body technology, applied in the field of tools, can solve the problems of not being suitable for tools of the above type, requiring very accurate implementation, and regularly difficult supporting parts, and achieve the effect of easy and rapid implementation of the connection between the supporting part and the working par

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

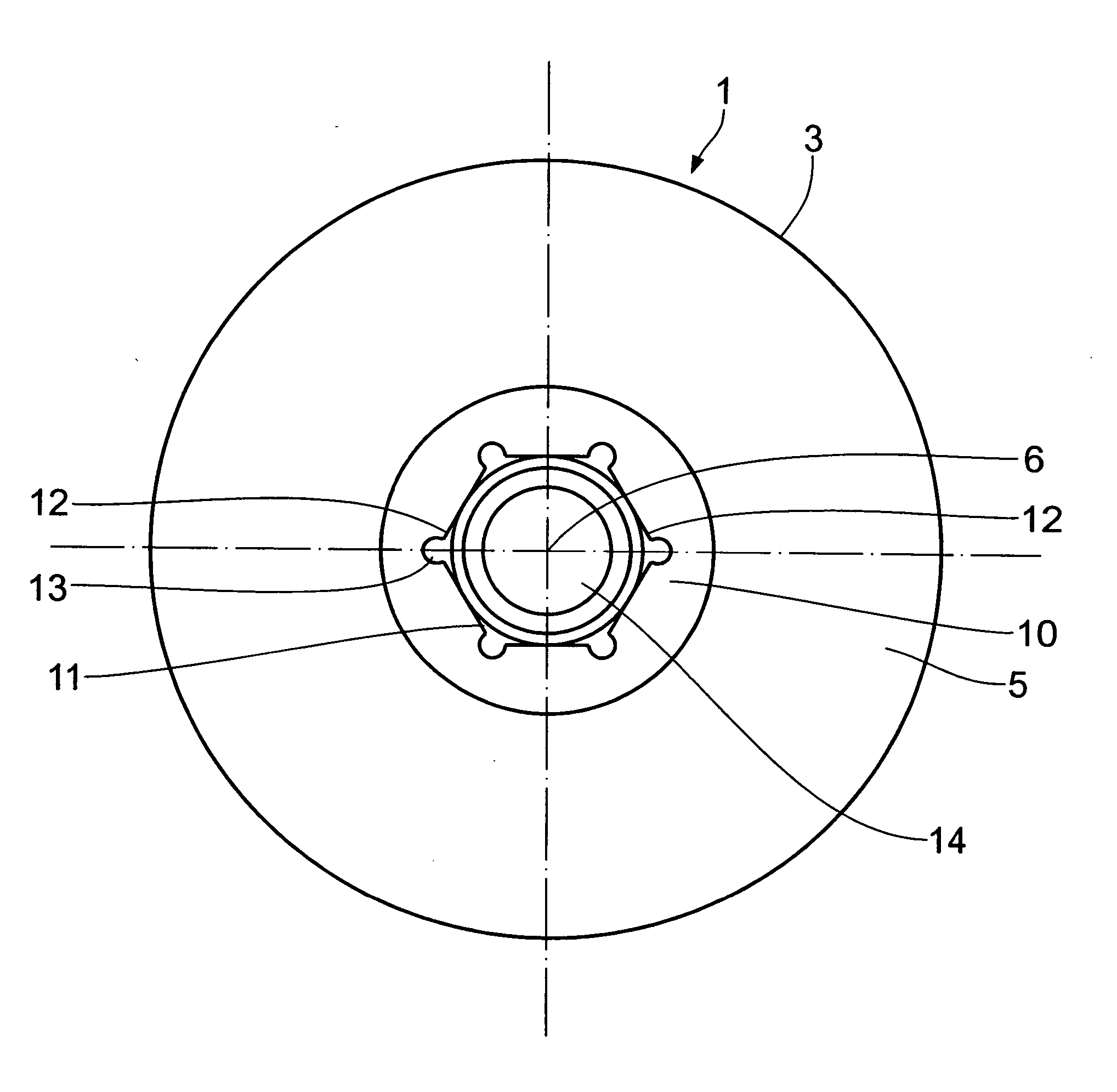

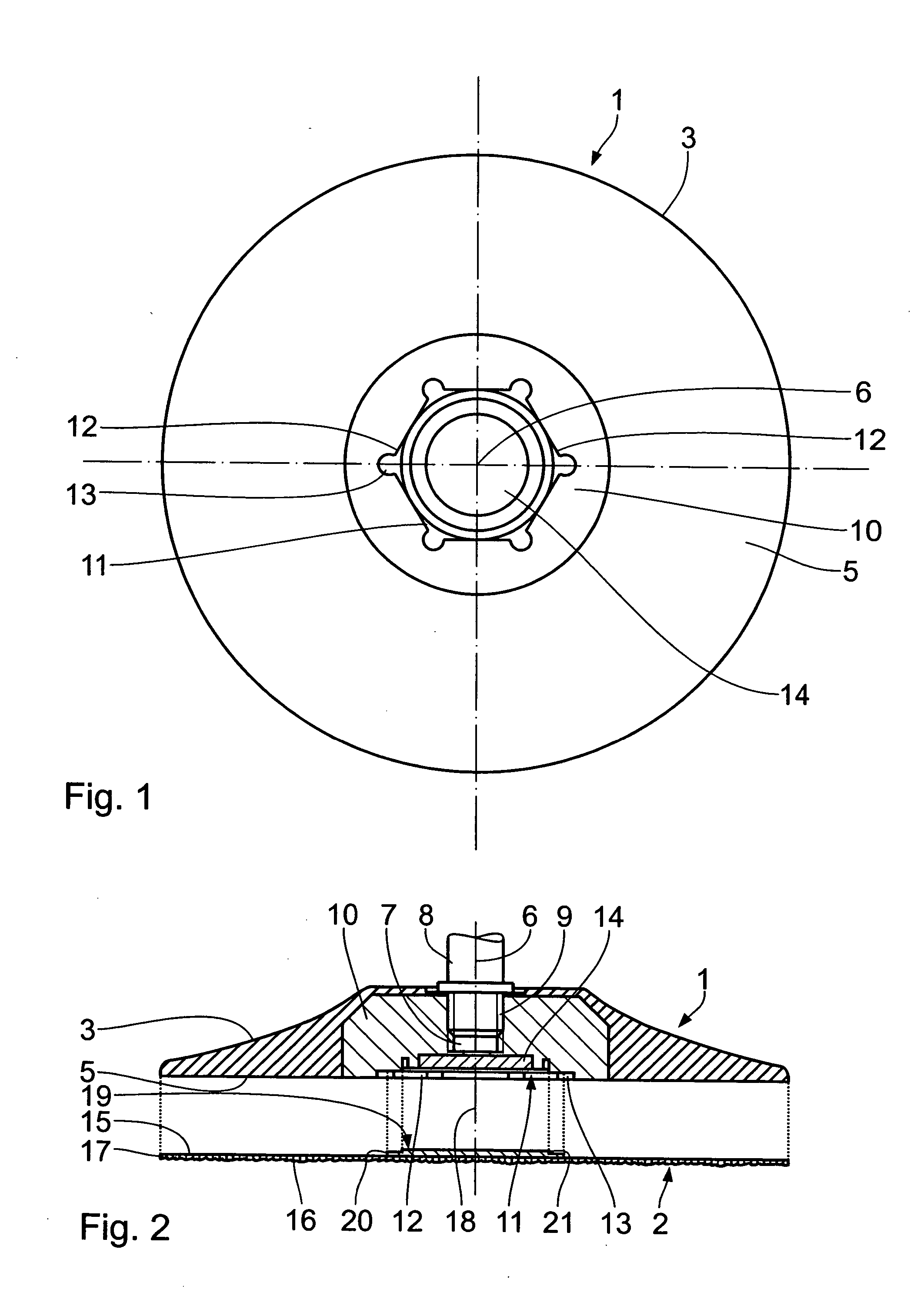

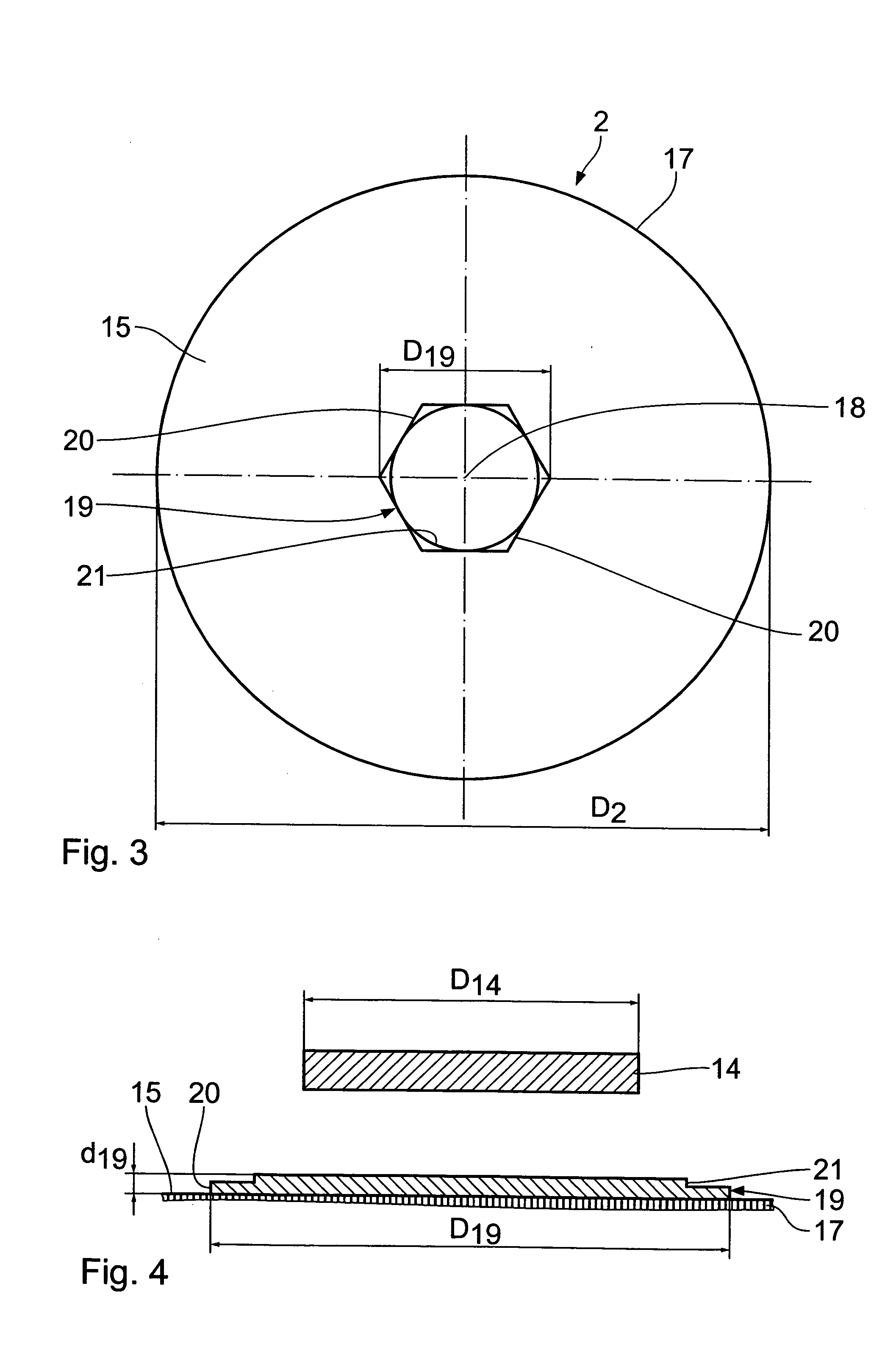

[0018] As seen in the drawing, the tool in its fundamental structure comprises a supporting part 1 in the form of a supporting plate, and a working part 2. The supporting part 1 has a supporting casing 3 of flexible plastics which includes an annular supporting face 5. On the side turned away from the supporting face 5, the supporting part 1 comprises a threaded hole 7 which is concentric of the center line 6 and into which to insert a drive shaft 8 of a tool-actuating unit (not shown) by a corresponding external thread 9. These kinds of tool drive units can be so-called right angle grinders or spur wheel grinders.

[0019] In the supporting casing 3 on the side of the supporting face 5, provision is made for a retainer 10 which includes the threaded hole 7 and, concentrically of the center line 6, a flat recess 11 of polygonal cross-sectional shape. In the present case, the recess 11 is formed by flanks 12 of an equilateral and equiangular polygon, for example a hexagon. A cutout 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com