Resilient abrasive article and method of manufacture

a technology of abrasives and abrasives, applied in the field of abrasive articles, can solve the problems of premature degradation of sheet-like substrates, slippery opposite sides of sanding sponges which are gripped by the hand, and difficulty in obtaining the effect of sanding sponges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0109]While the invention is amenable to various modifications and alternative forms, specifics thereof are shown by way of example in the drawings and described in detail herein. It should be understood, however, that the intention is not to limit the invention to the particular embodiments described. On the contrary, the intention is to cover all modifications, equivalents, and alternatives falling within the spirit and scope of the invention.

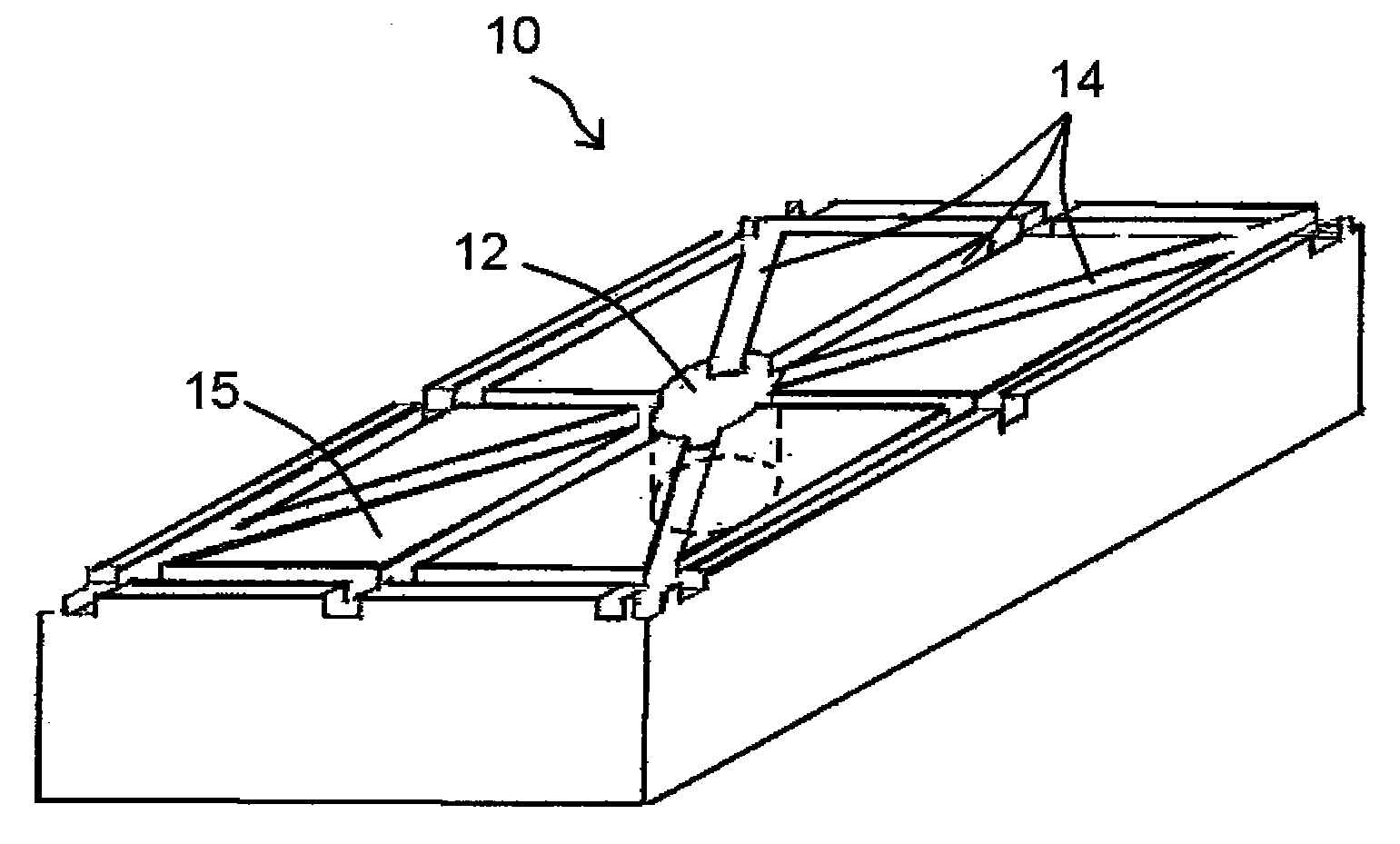

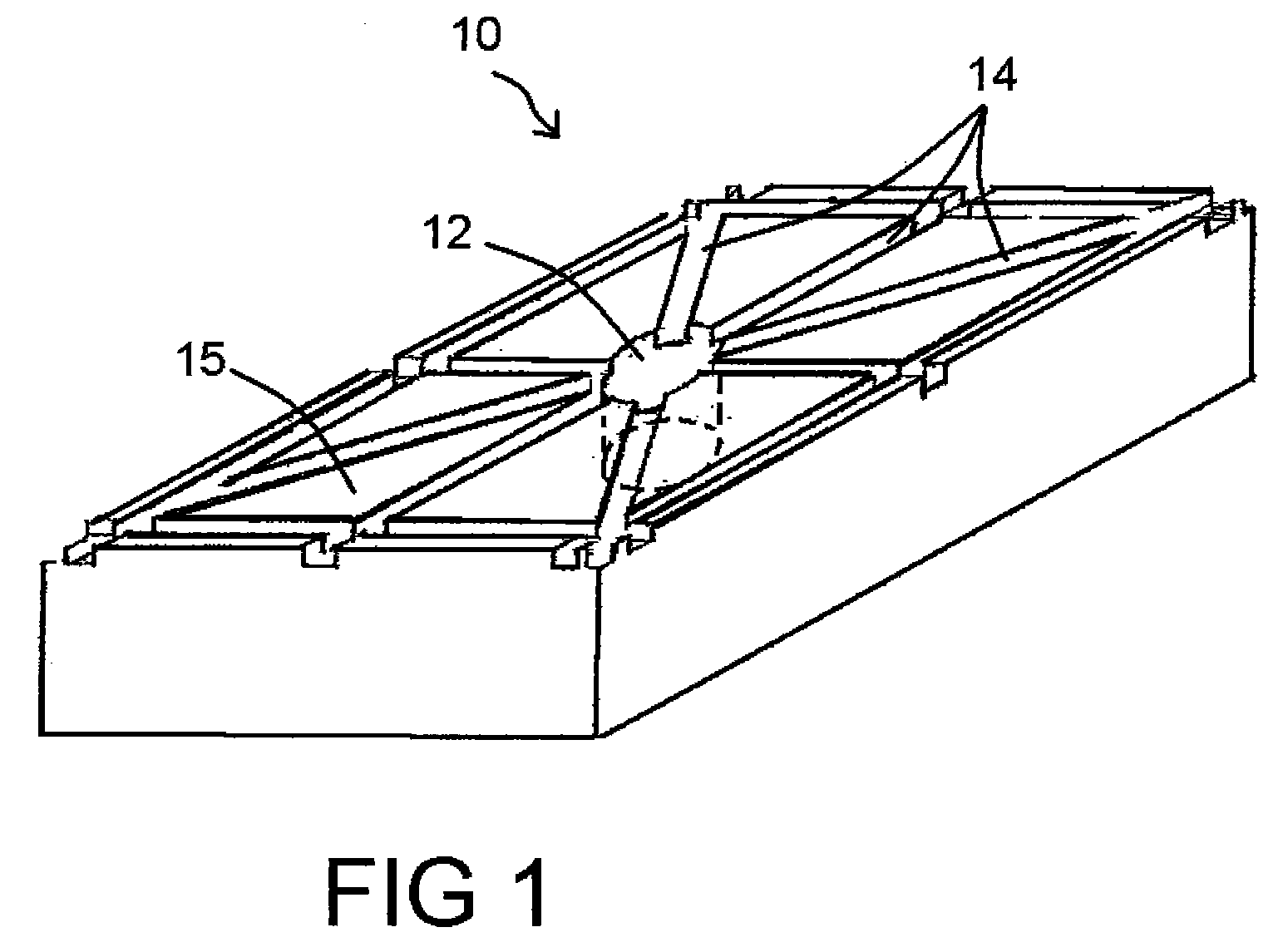

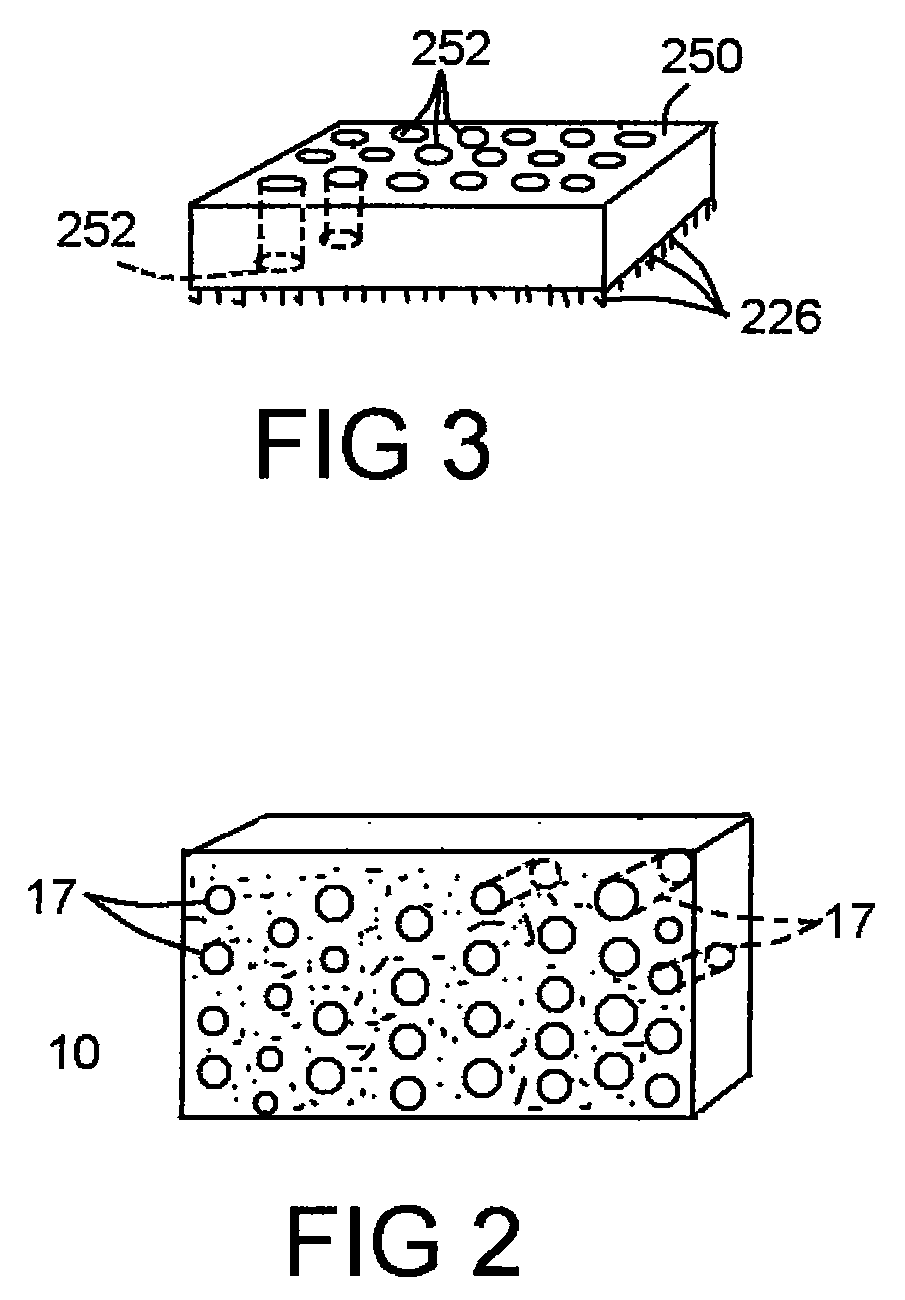

[0110]FIG. 1 illustrates a tool comprising a sanding sponge 10 having vacuum channels 14 in a grid form recessed into the large flat surface 15 or surfaces of the sanding sponge. The sponge 10 is of a type known to the skilled artisan and is commonly used for sanding wood or drywall. The sponge is typically made of a resilient material such as urethane foam or foam rubber or sponge but should not be limited to only these materials and should include all materials having a resilience including, e.g., rubber and plastic. The sponge has an abras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com