Patents

Literature

222 results about "Industrial manipulator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

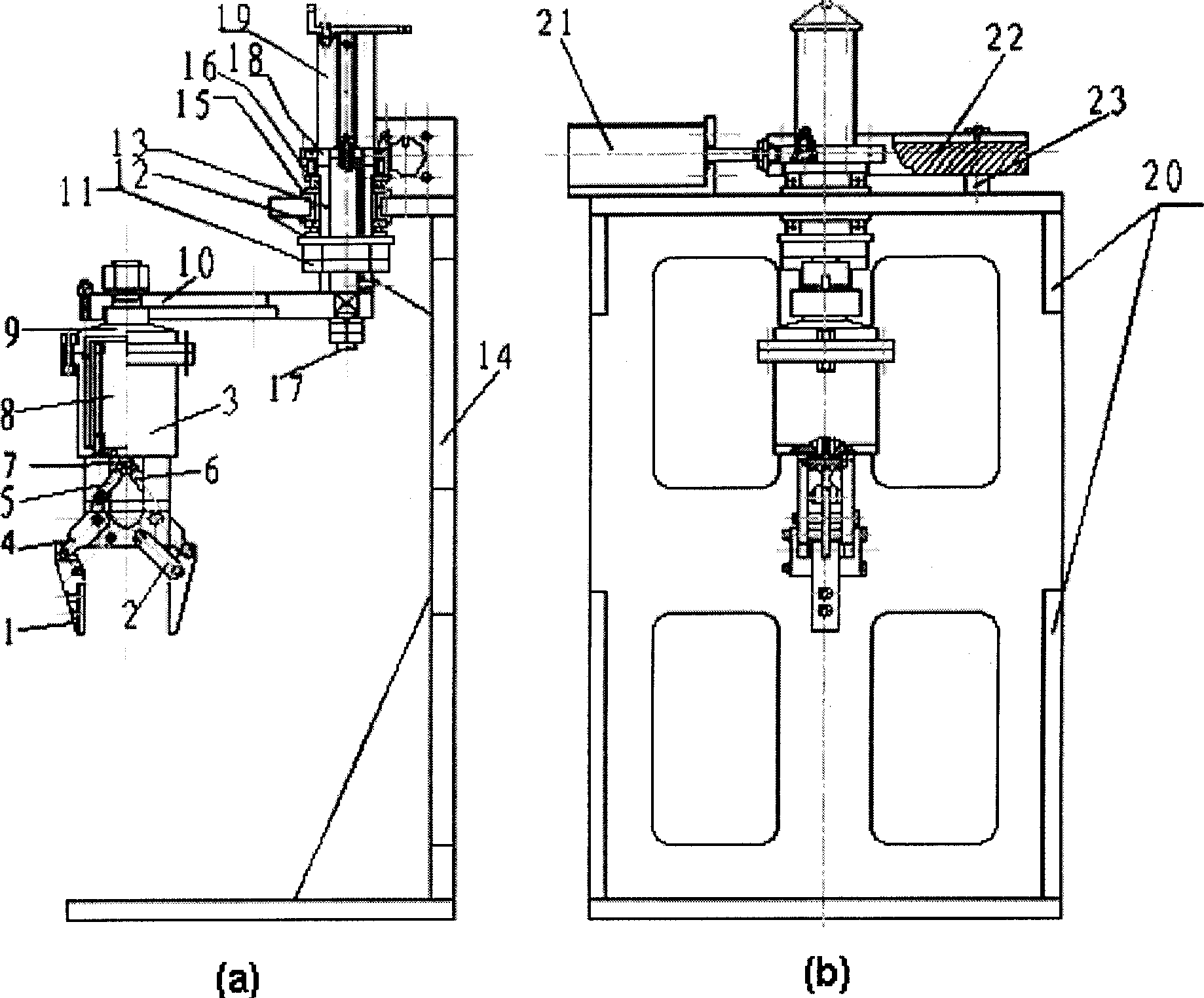

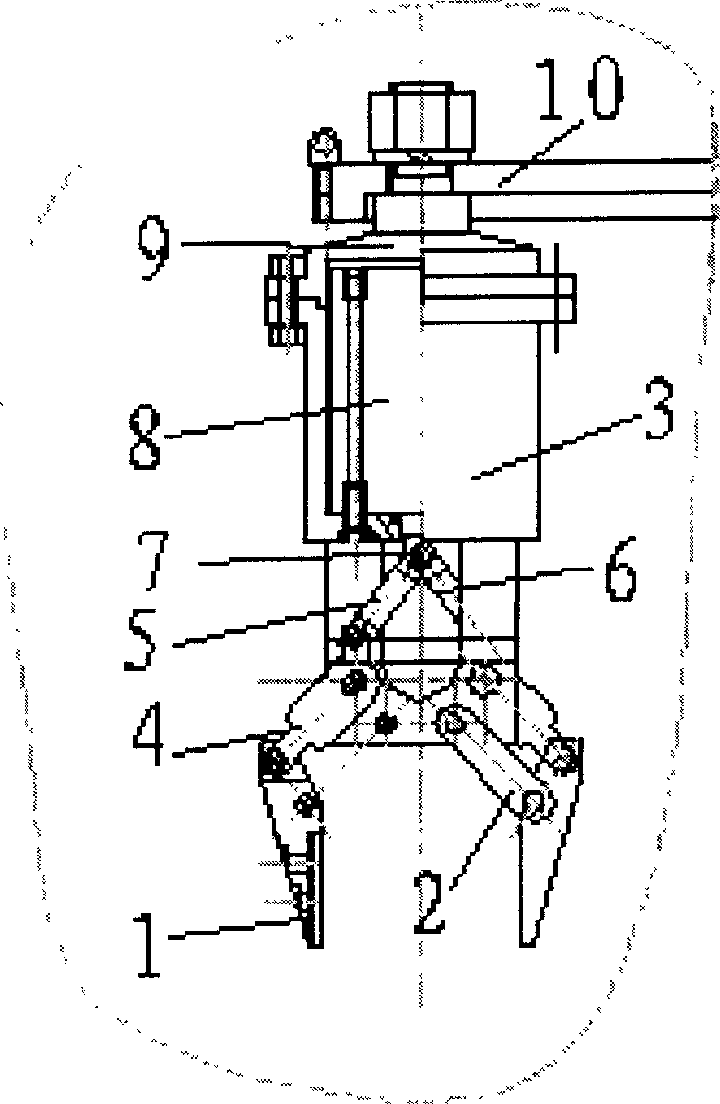

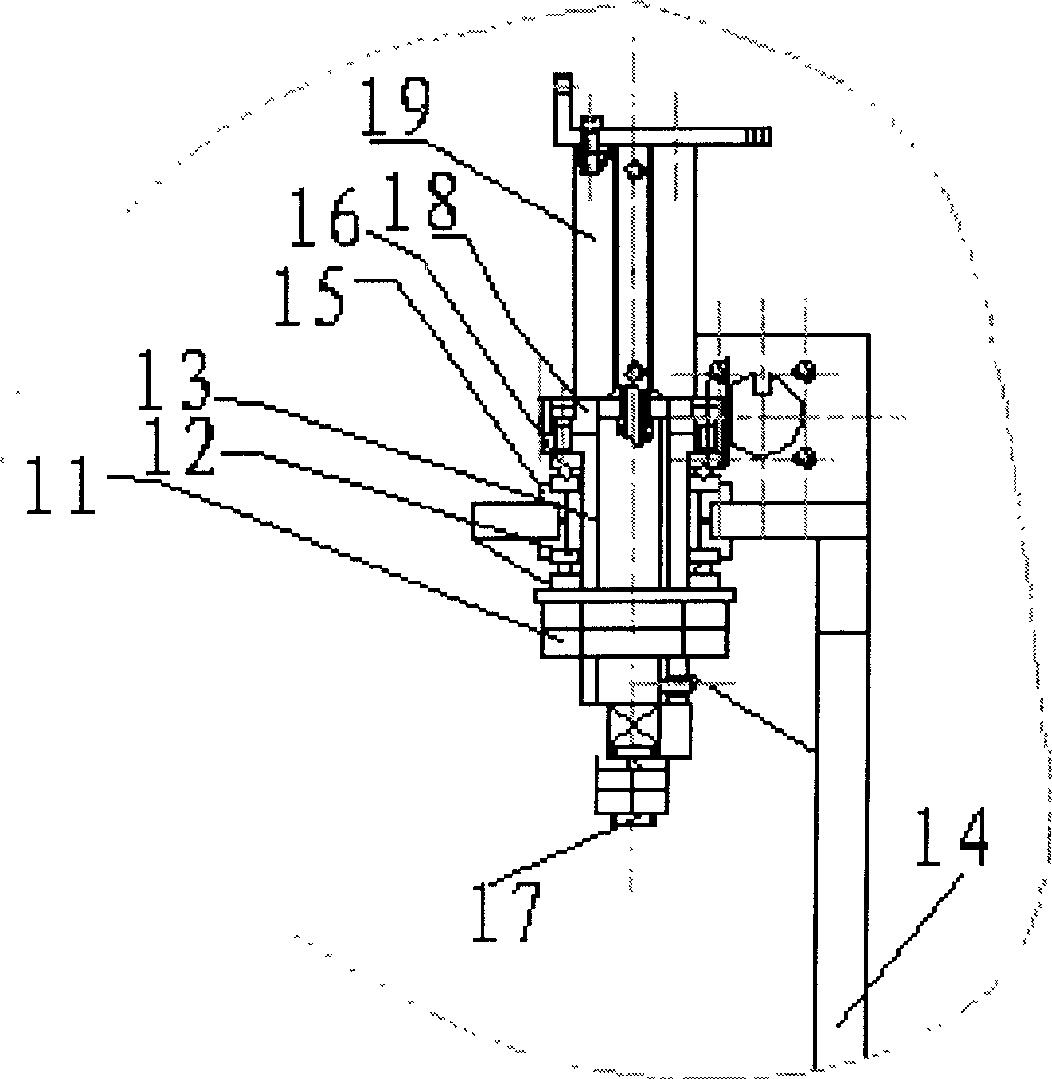

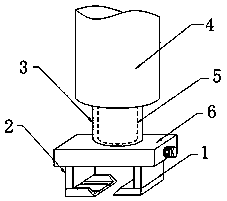

Full pneumatic combined multifunctional industrial manipulator

InactiveCN1701928ARealize the clamping effectAchieve shiftProgramme-controlled manipulatorGripping headsEngineeringActuator

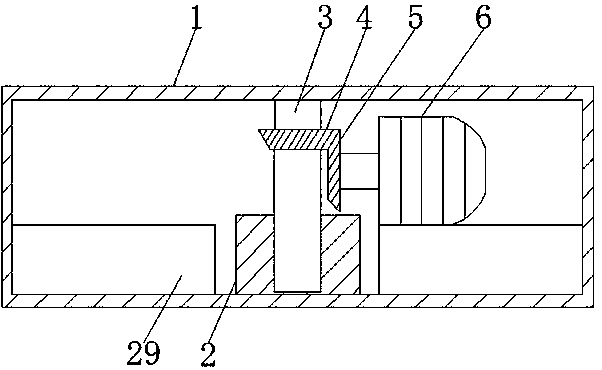

The invention discloses total aerodynamic composite type multifunctional industrial manipulator comprised interchangeable end effector set on suspension arm to clamp workpiece, and aerodynamic system comprised air supply, processor for air supply, two two-position three-way electromagnetic valves, one two-position five-way electromagnetic directional selecting valve, two precompression cylinders, a reciprocating cylinder, and PLC predetermined control program for cylinders to control displacement, mechanical clamp and up-down motion of interchangeable end effector. This invention uses totally gas to drive, selects corresponding mechanical clamper, vacuum absorb hand and gas pocket expand hand for different works to complete work quickly, and increases its application area and utilization rate.

Owner:西安思源职业学院

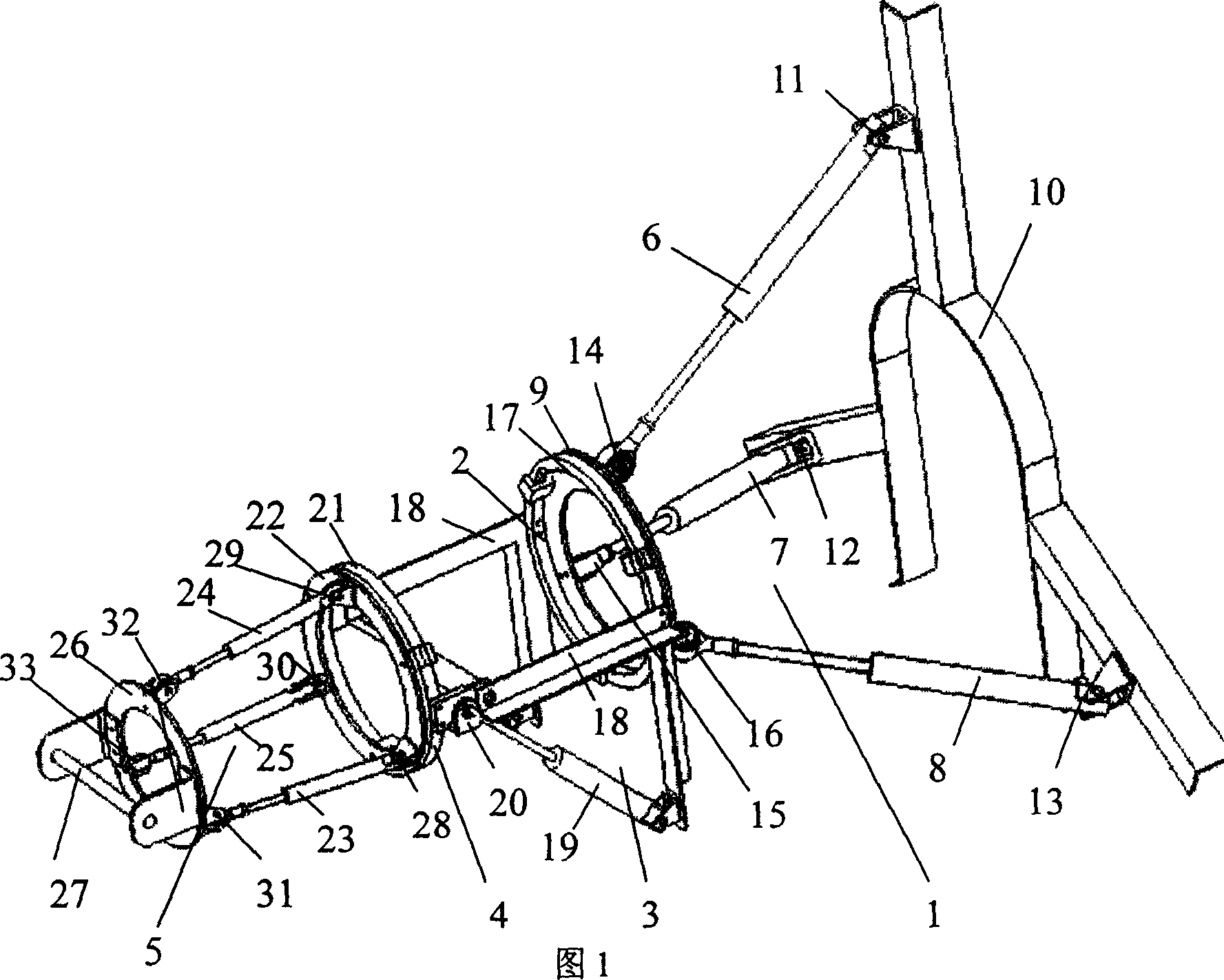

Dress-able type flexible exoskeleton manipulator

InactiveCN1593861AImprove toughnessLarge range of motionProgramme-controlled manipulatorRange of motionBionics

The invention relates to a soft wearable mechanic skeleton arm. It consists of big 3PRS shoulder shunt-wound unit, the shoulder sliding ring units, two elbow sliding ring units, wrist sliding ring unit and little 3PRS wrist shunt-wound in order. It can move freely in nine directions to go with people arms' omnidirectional move. The invention uses cylinder to drive and imitates muscle moving. So it has better tenacity and bionics character, and improves the convenient and comfort of the device, enlarges the move sphere of the manipulator's arm, delimits the present device's limitation on the moving. The moving information of the wearer's arm can be collected easily by the move sensor that is matched with the cylinder. Control the mechanic arm with appreciable force by computer. The mechanic arm can be used to cure as assistant facility for the patients whose arm is atrophied.

Owner:ZHEJIANG UNIV

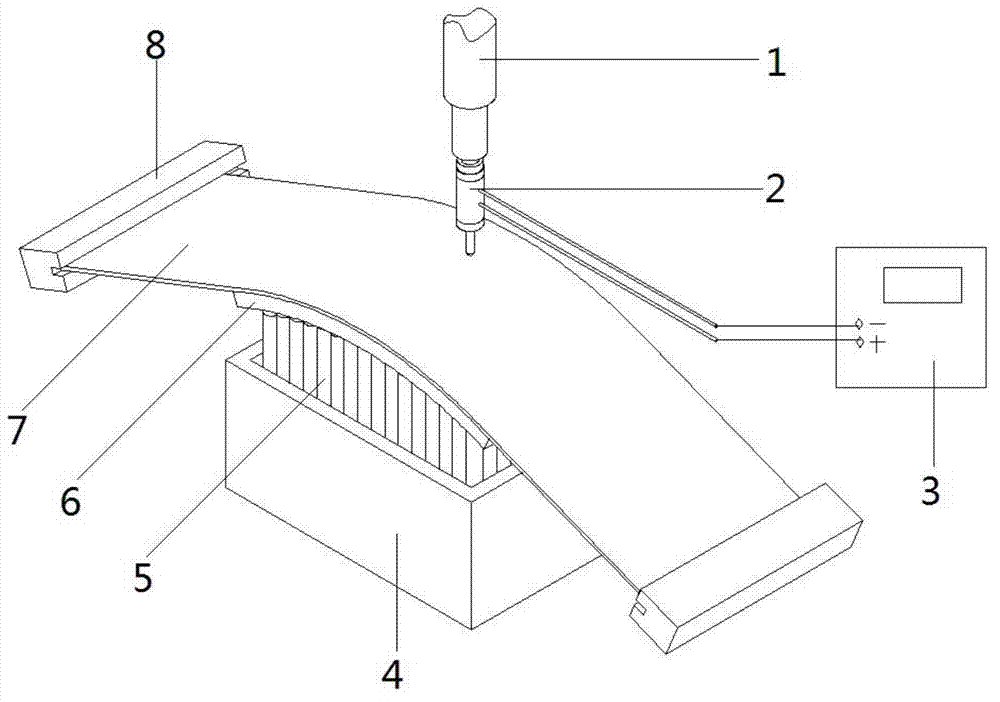

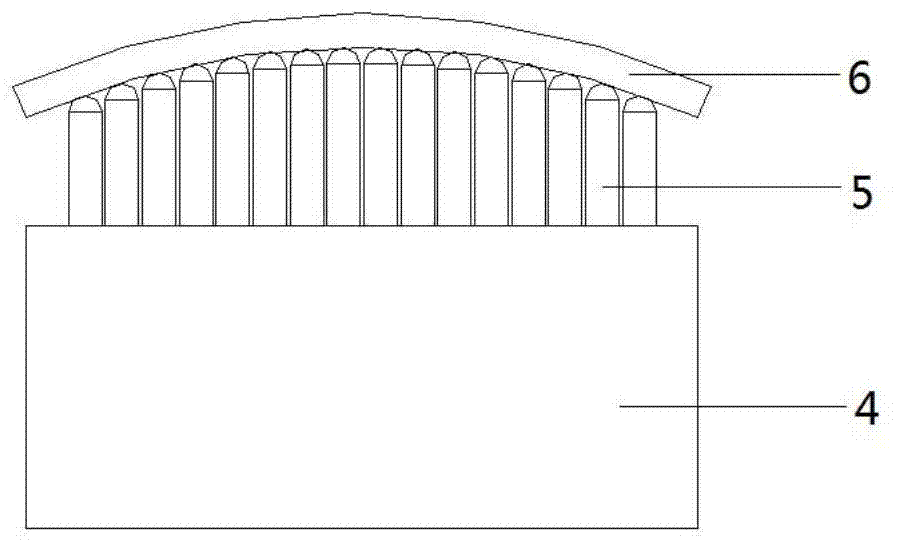

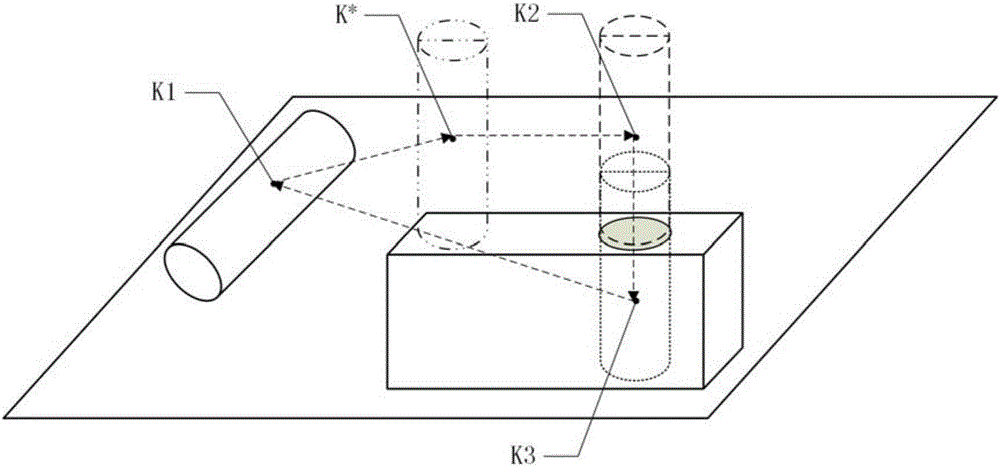

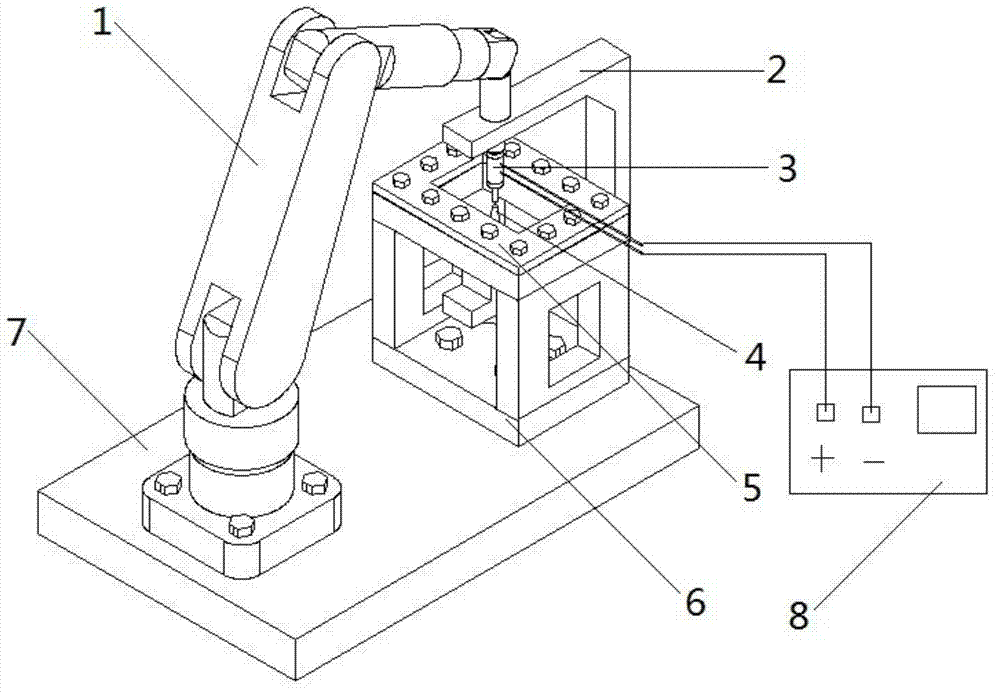

Flexible stretch-forming device and method for carrying out stretch-forming on plate by utilizing same

InactiveCN103480713AReduce deformation resistanceHigh forming precisionShaping toolsIndustrial machineIndustrial manipulator

The invention discloses a flexible stretch-forming device and a method for carrying out stretch-forming on a plate by utilizing the flexible stretch-forming device and solves the technical problem that the stretch-forming accuracy of a flexible stretch-forming device for the molded surface of a reconfigurable unidirectional continuous die is low. The technical scheme includes that the flexible stretch-forming device comprises an industrial manipulator, a heating forming head, a power supply, a multipoint die, a nail post and a polyurethane elastic cushion. The nail post is mounted on the base of the multipoint die, the polyurethane elastic cushion is positioned above the nail post, the lower surface of the polyurethane elastic cushion is attached to the discrete surface formed by the nail head of the nail post, the plate is positioned above the polyurethane elastic cushion, the lower surface of the plate is attached to the upper surface of the polyurethane elastic cushion, the heating forming head is positioned above the plate, and the spherical head surface of the heating forming head is contacted with the upper surface of the plate. According to the flexible stretch-forming device and the method for carrying out stretch-forming on the plate by utilizing the flexible stretch-forming device, the electromagnetic induction heating forming head is adopted to locally heat the plate in the stretch-forming process, the local heat effect of the region can reduce the deformation resistance of the plate, the plasticity is improved, the resilience value is reduced, and the forming accuracy of the plate is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

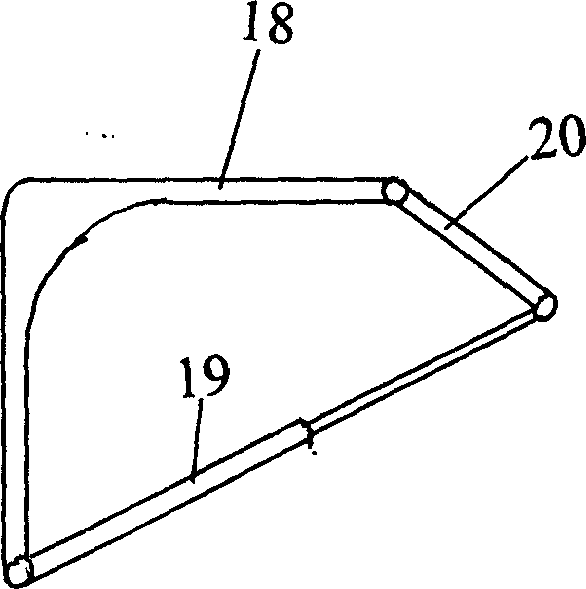

Flexible exoskeleton elbow joint based on pneumatic muscles

InactiveCN1961848ASimple structureAdaptableChiropractic devicesManipulatorMotion parameterUpper limb

The invention relates to a flexible external skeleton elbow joint based on aerated muscle, which is formed by two aerated muscles and one single-freedom rotation couple, to realize the single-freedom rotation of elbow joint. The invention uses aerated muscle as the element of joint to simulate the motion of muscle; the operator can wear said device, via the torque sensor mounted on the rotation couple to obtain the motion parameters, to operate the industrial mechanical hand. And it can control the air pressure of muscle chamber of joint to realize the force feedback. The invention has wide application, as the healthy return device of patient.

Owner:ZHEJIANG UNIV

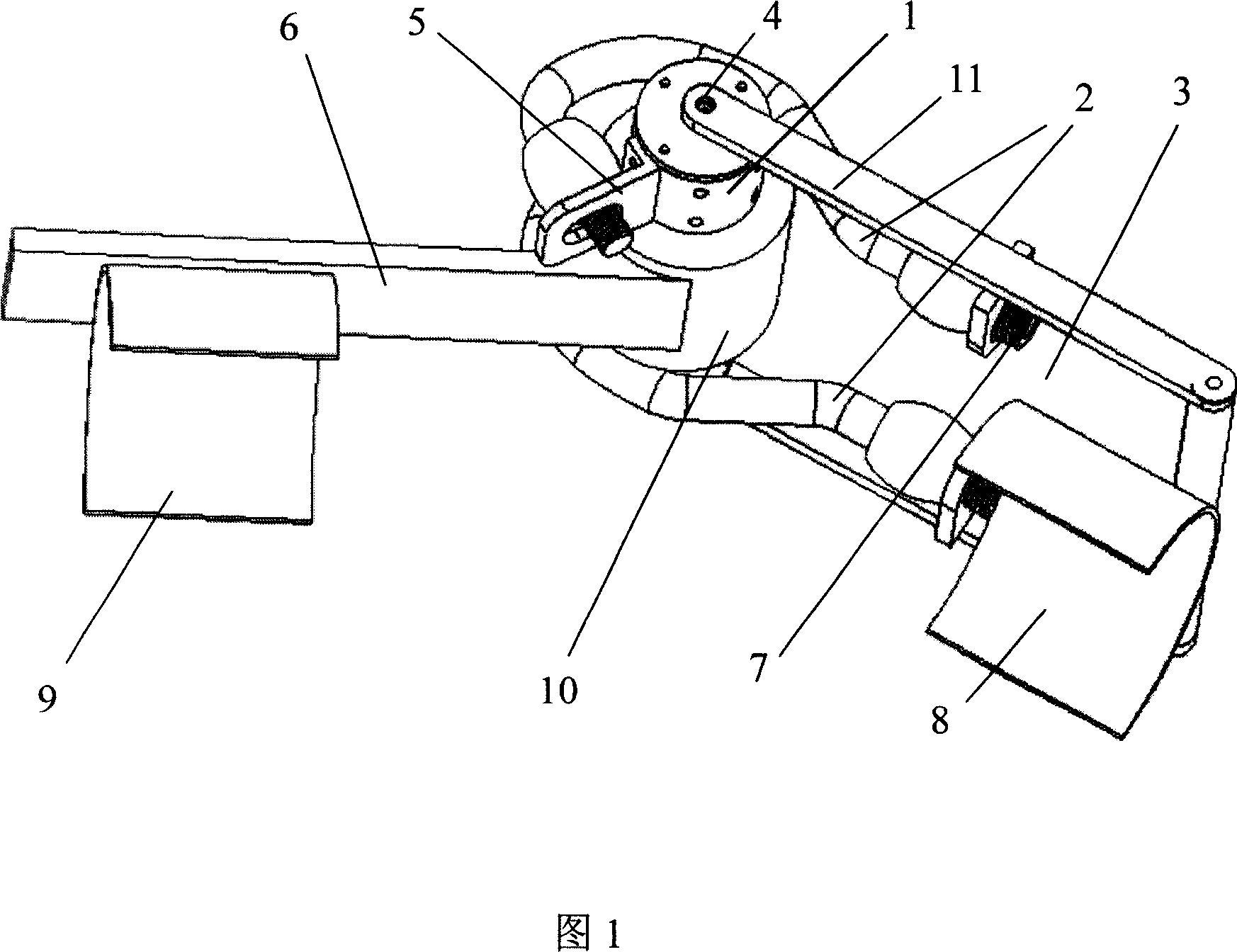

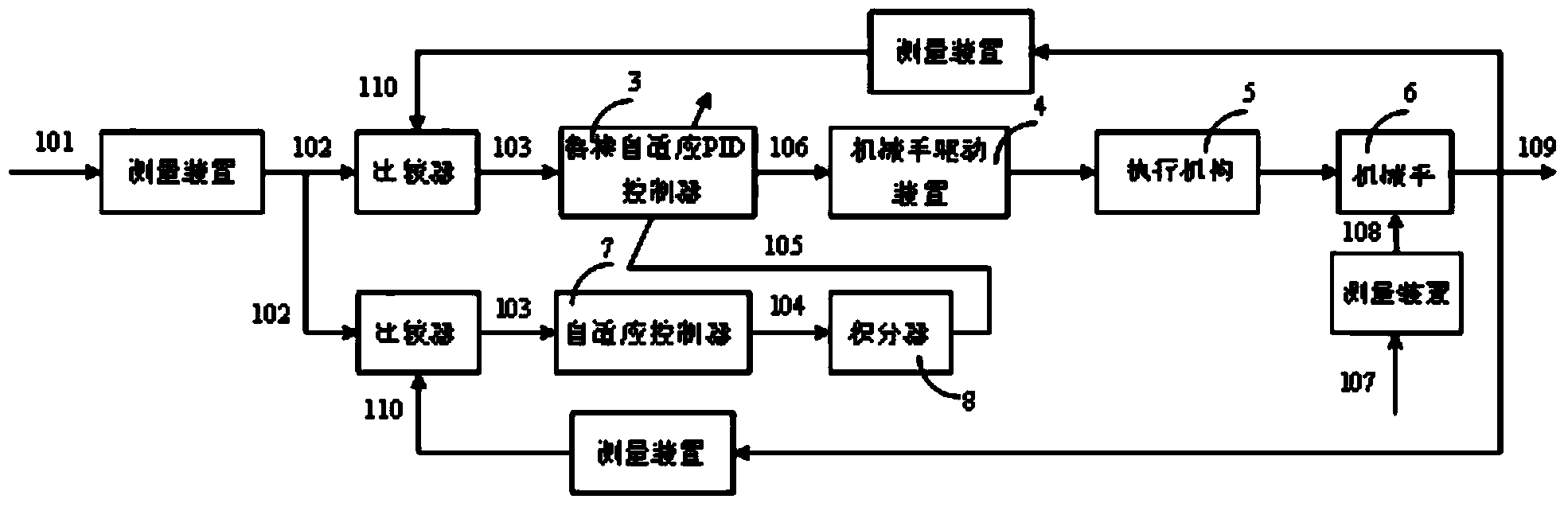

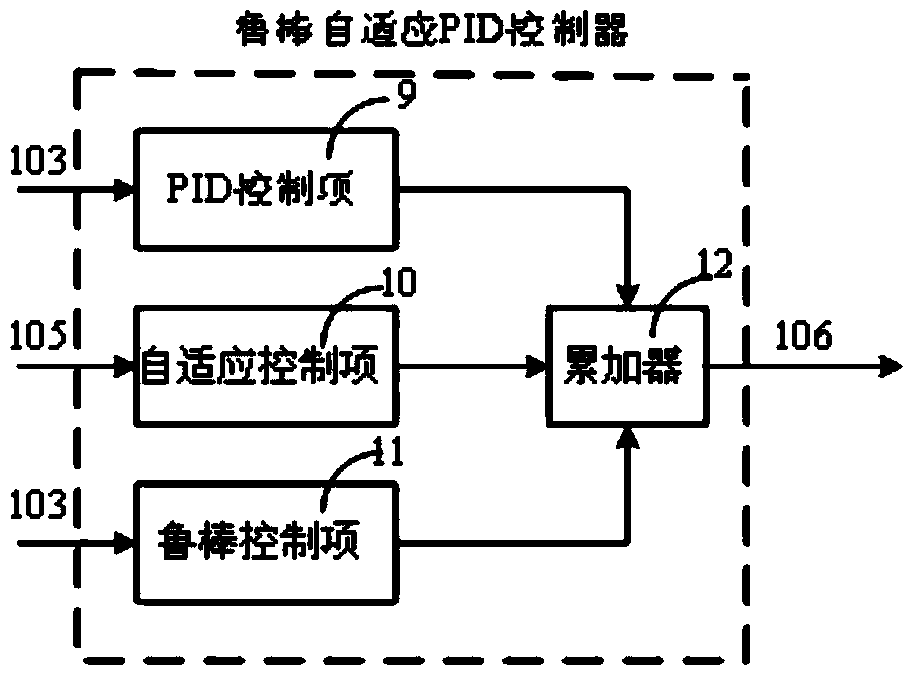

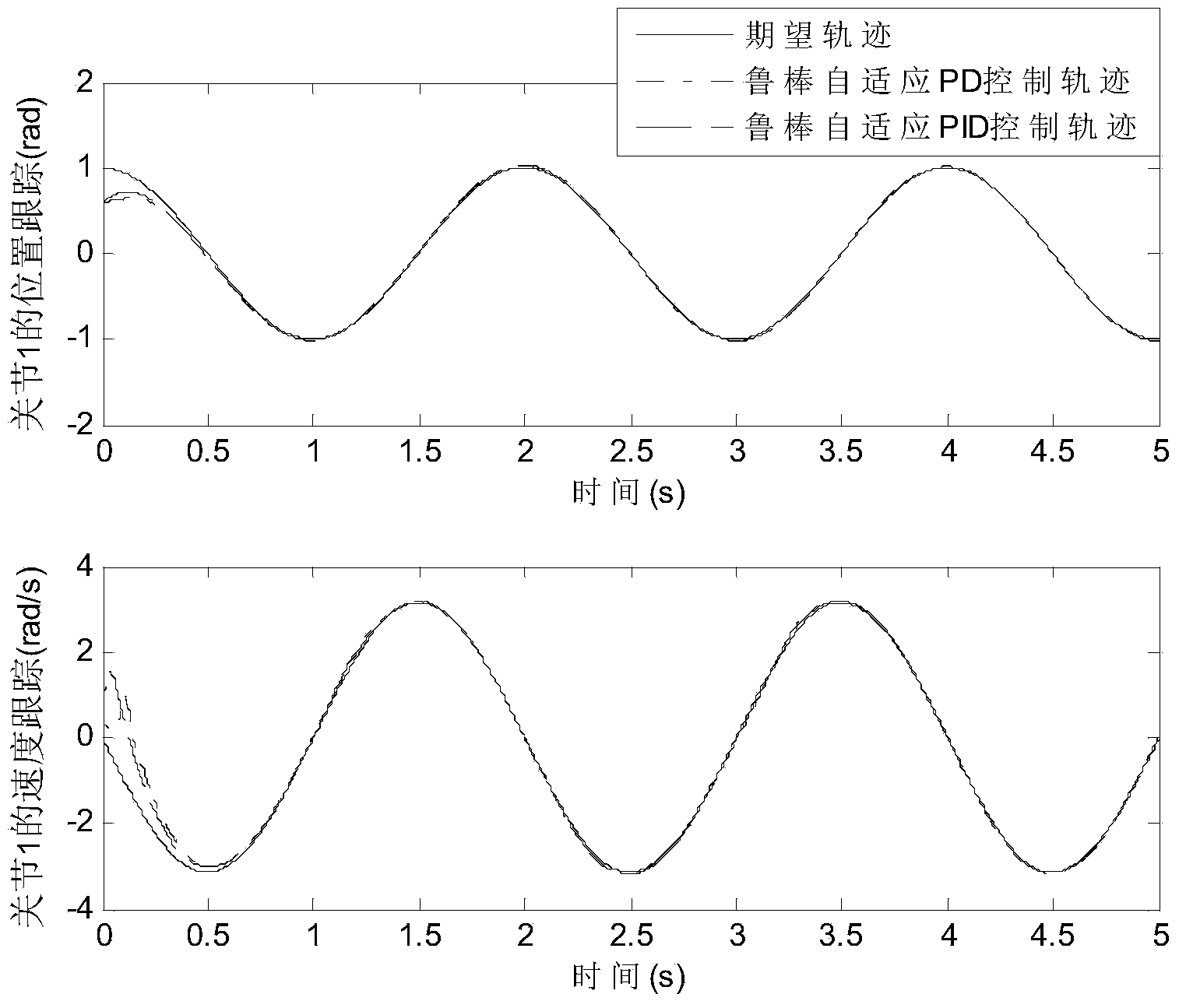

Industrial mechanical arm anti-interference robustness self-adaptation PID control method

InactiveCN103901776AIncreased external disturbanceIncreased tracking errorProgramme-controlled manipulatorAdaptive controlIndustrial manipulatorSelf adaptive

The invention relates to an industrial mechanical arm anti-interference robustness self-adaptation PID control method. The industrial mechanical arm anti-interference robustness self-adaptation PID control method is characterized in that a robustness self-adaptation PID controller comprises a PID control item, a self-adaptation control item and a robustness control item, the input of the PID control item and the input of the robustness control item are the errors of the position and the speed of a mechanical arm, the input of the self-adaptation control item is the estimation value of indefinite kinetic parameters of the mechanical arm, and the robustness self-adaptation PID control is achieved by carrying out the superposition on the PID control item, the self-adaptation control item and the robustness control item.

Owner:HARBIN ENG UNIV

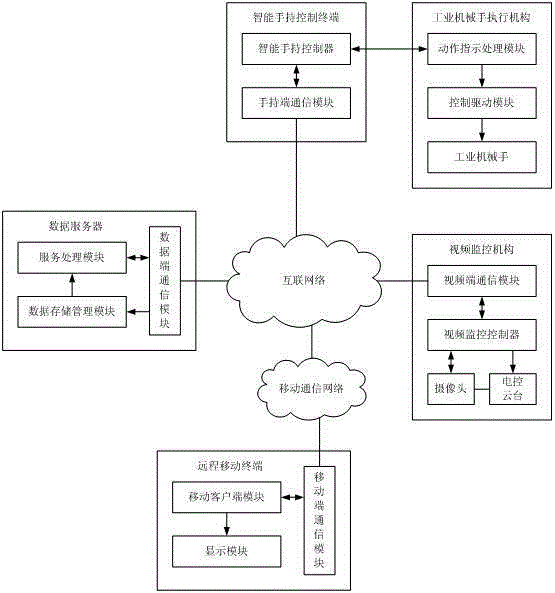

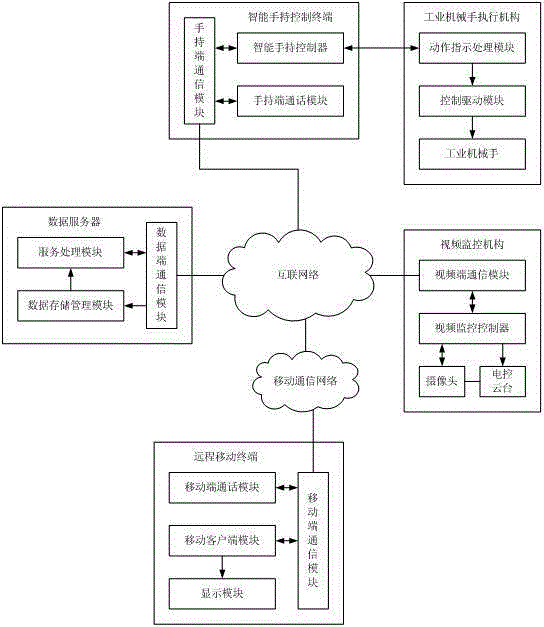

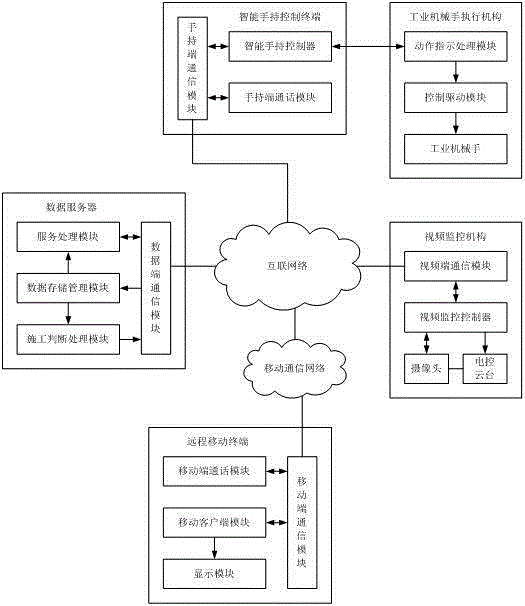

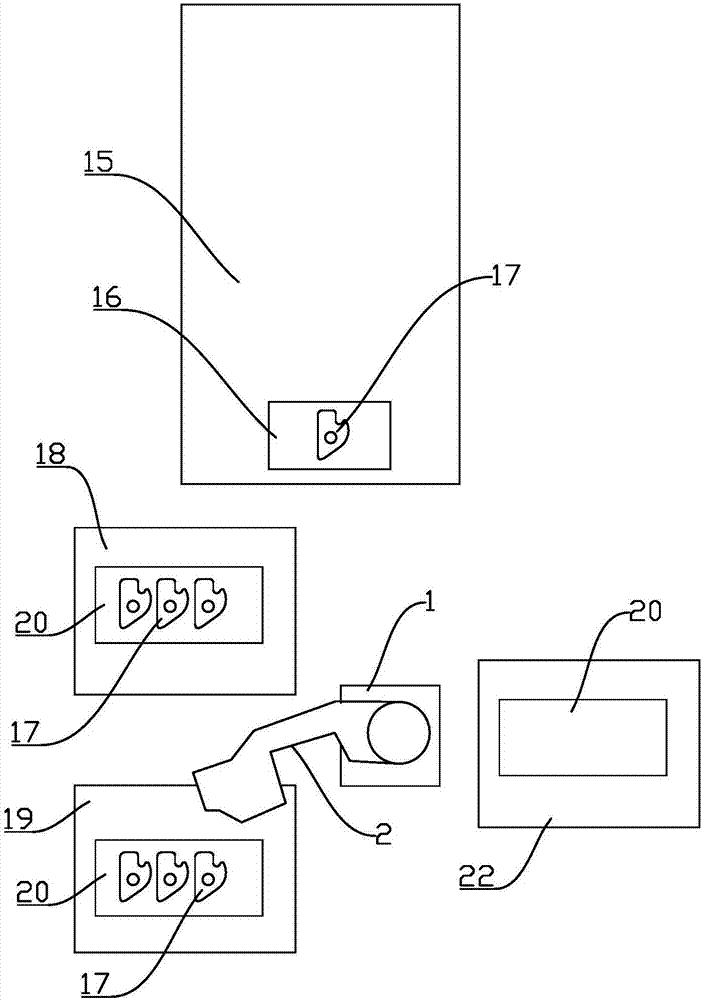

Remote monitoring and control system for industrial manipulator based on Internet

ActiveCN105137860ARealize IoTWork in timeProgramme controlComputer controlVideo monitoringVoice communication

The invention provides a remote monitoring and control system for an industrial manipulator based on the Internet, and the system controls an industrial manipulator executing mechanism to execute construction operation through an intelligent hand-held control terminal, takes a data server as an interconnecting center for building the remote internet communication channel among the intelligent hand-held control terminal, a video monitoring mechanism, and a remote mobile terminal, achieves the operation of the industrial manipulator through the Internet of Things, achieves the multi-aspect information interaction between a remote place and the industrial manipulator construction site, and provides a favorable system technical conditions for the inspection and maintenance of the industrial manipulator. Meanwhile, the system also can achieve the miniaturization and light weight of the intelligent hand-held control terminal based on the embedded system technology, reduces the faults and accidents because of the misoperation of the industrial manipulator, also can integrate a function of voice communication and functions of abnormality detection, alarm and emergent braking and control of the industrial manipulator executing mechanism, facilitates the improvement of the production and efficiency of the industrial manipulator, reduces the economic loss caused by a fault.

Owner:重庆世纪精信机械制造有限公司

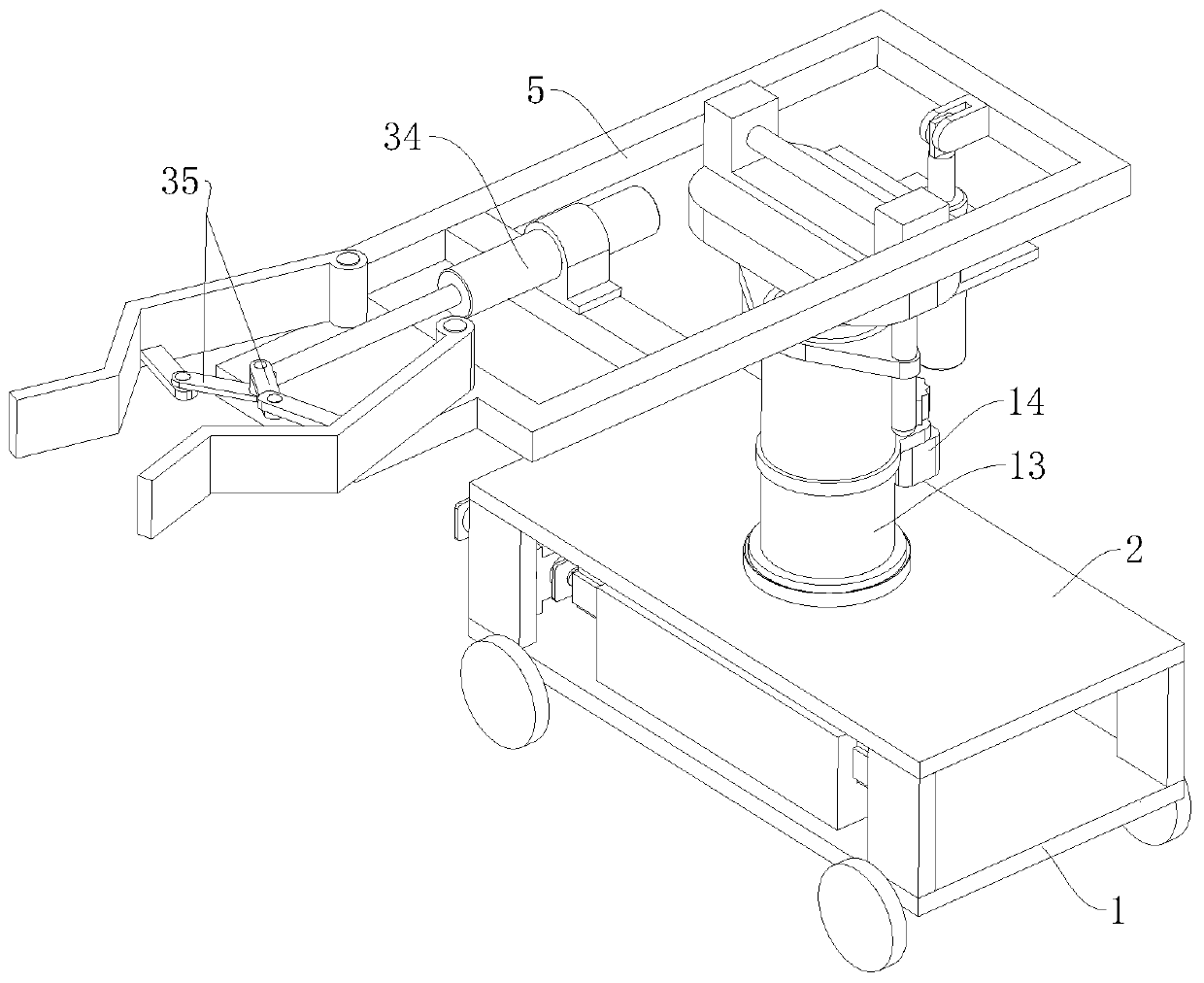

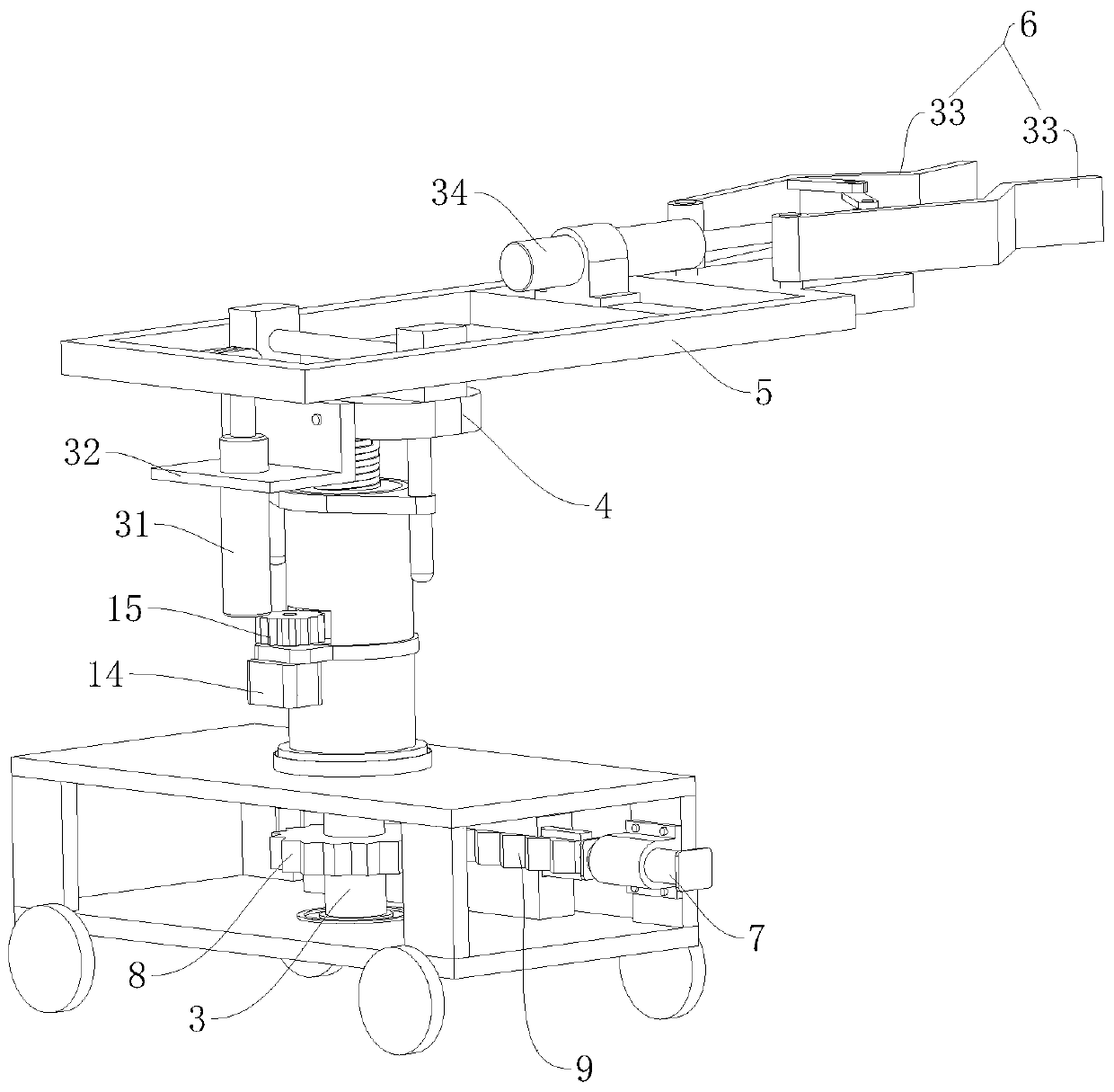

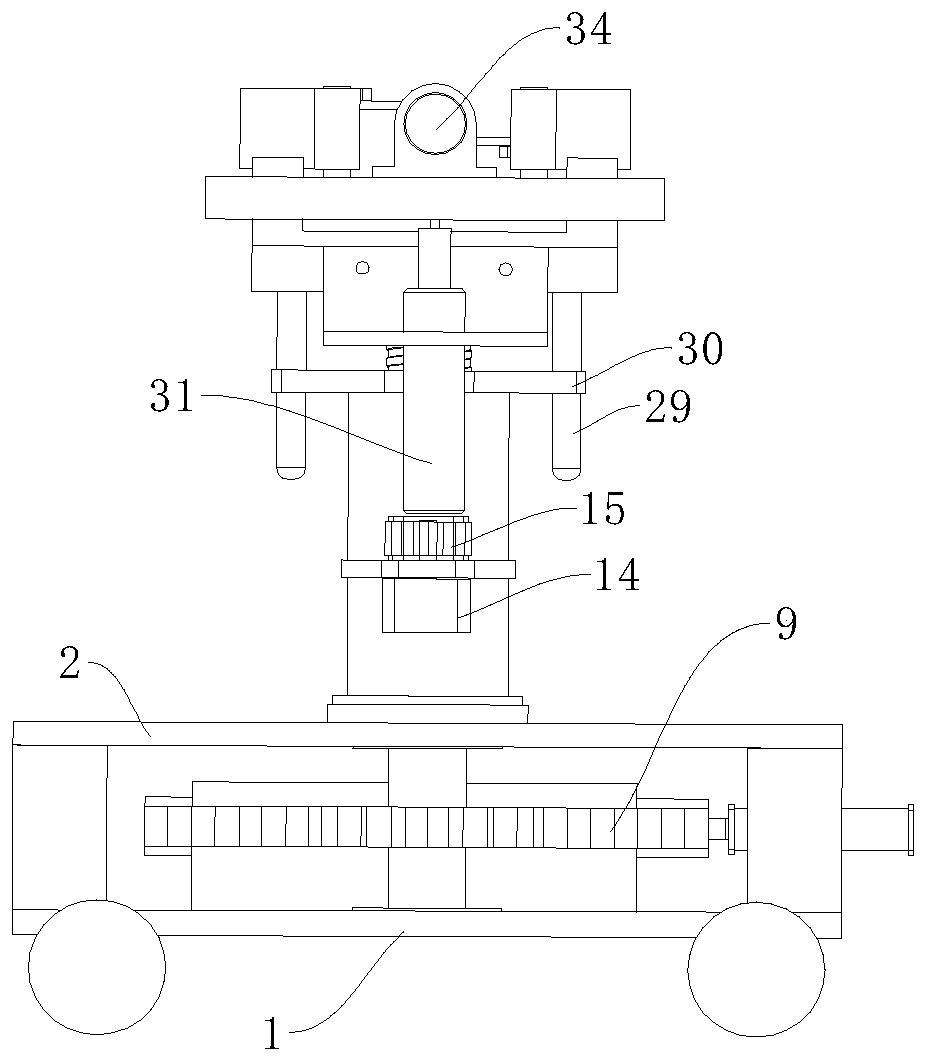

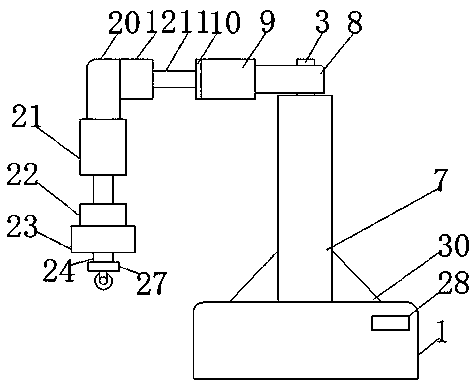

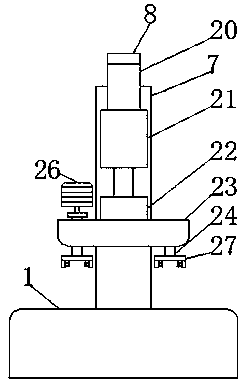

Movable industrial manipulator

InactiveCN109986532APlay a guiding roleLow costProgramme-controlled manipulatorIndustrial manipulatorIndustrial engineering

The invention relates to the field of industrial machinery, in particular to a movable industrial manipulator. The movable industrial manipulator comprises a flat car, and further comprises a rotatingcomponent, a lifting component, a swing component and a clamping component mounted on the flat car. The upper part of the flat car is provided with a supporting plate; the supporting plate is fixedlyconnected to the top of the flat car through a fixed bracket; the rotating component comprises a guiding shaft capable of rotating and a rotating driving component for driving the rotating shaft to rotate; the lifting component comprises a lifting plate capable of lifting and a lifting driving component for driving the lifting plate to lift; the swing component comprises a swing frame capable ofswinging and a swing driving component for driving the swing frame to swing; the clamping component comprises a clamping plate capable of clamping a workpiece; and the clamping plate is arranged at one end, away from the swing driving component, of the swing frame. By means of the movable industrial manipulator, the clamping can be carried out according to the height of different goods, so that the cost is reduced, and the efficiency is improved.

Owner:丽水奇异果信息技术有限公司

Automatic assembling system based on three-dimensional vision

InactiveCN106228563ALower barriers to useReduced commissioning timeImage enhancementProgramme-controlled manipulatorSimulationIndustrial manipulator

The invention provides an automatic assembling system based on three-dimensional vision. The automatic assembling system comprises a machine frame, an industrial mechanical hand, a mechanical hand controller and a three-dimensional camera, wherein the industrial mechanical hand is fixedly arranged on the machine frame; the three-dimensional camera obtains two-dimensional pictures and depth information of the industrial mechanical hand at the current work moment; after the industrial mechanical hand is subjected to teaching training, the automatic assembling task is completed according to the teaching process; in the teaching process, a workpiece is held by the hand of a person, and the migration of the workpiece from the original posture, assembly initial posture and assembly termination posture is completed. The automatic assembling system has the advantages that the plan can be completed on the movement of the mechanical hand according to the one-step manual assembly teaching training, so that the mechanical hand can independently and repeatedly complete the artificial demonstration.

Owner:杭州鹰睿科技有限公司

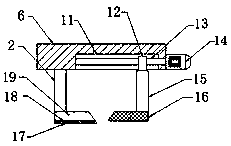

Device for carrying and testing bill

ActiveCN101515381AAdd dynamic weighing functionSimple structureGripping headsCharacter and pattern recognitionEngineeringIndustrial manipulator

The invention relates to a device for carrying and testing bill, which comprises a horizontal linear guide rail; wherein, the horizontal linear guide rail is provided with a horizontal slide rod which is connected with a vertical linear guide rail which is provided with a vertical slide rod, the lower end of the vertical slide rod is provided with a pull pressure pickup which is connected with a weighting circuit wafer, the lower end of the pull pressure pickup is provided with a sucker bracket, one side of the horizontal linear guide rail is provided with a belt delivery mechanism, and a pick-up device is arranged above the belt delivery mechanism. The invention perfectly combines the existing industrial manipulator technique, the vacuum carrying and the image recognition system to cause that cash money realizes the non-touch delivery between two commercial banks or two cashboxes; meanwhile, the device also can realize the automatic acquisition function of delivery information such as the weight of the bill, the hanks of the bill, the stamp counting, the stamp identification, etc.

Owner:BEIJING C&W ELECTRONICS GRP +1

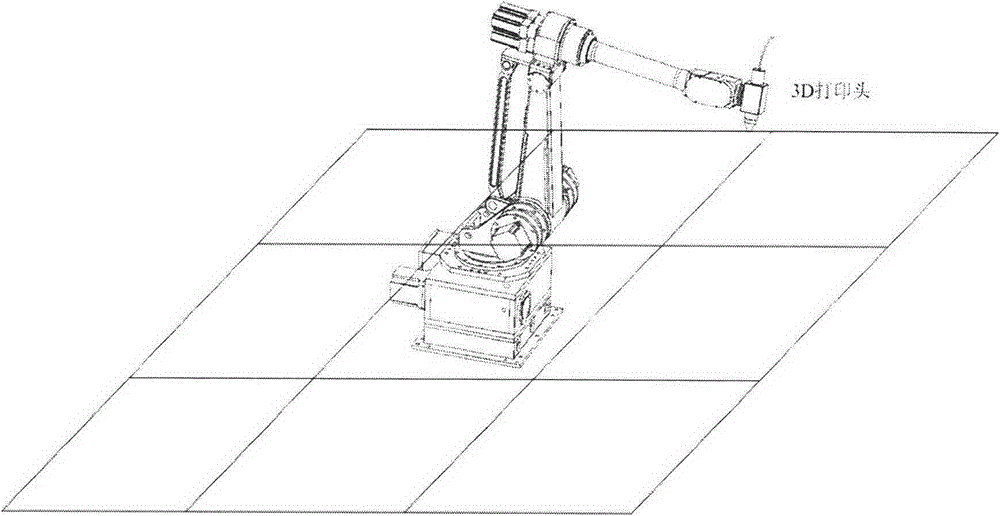

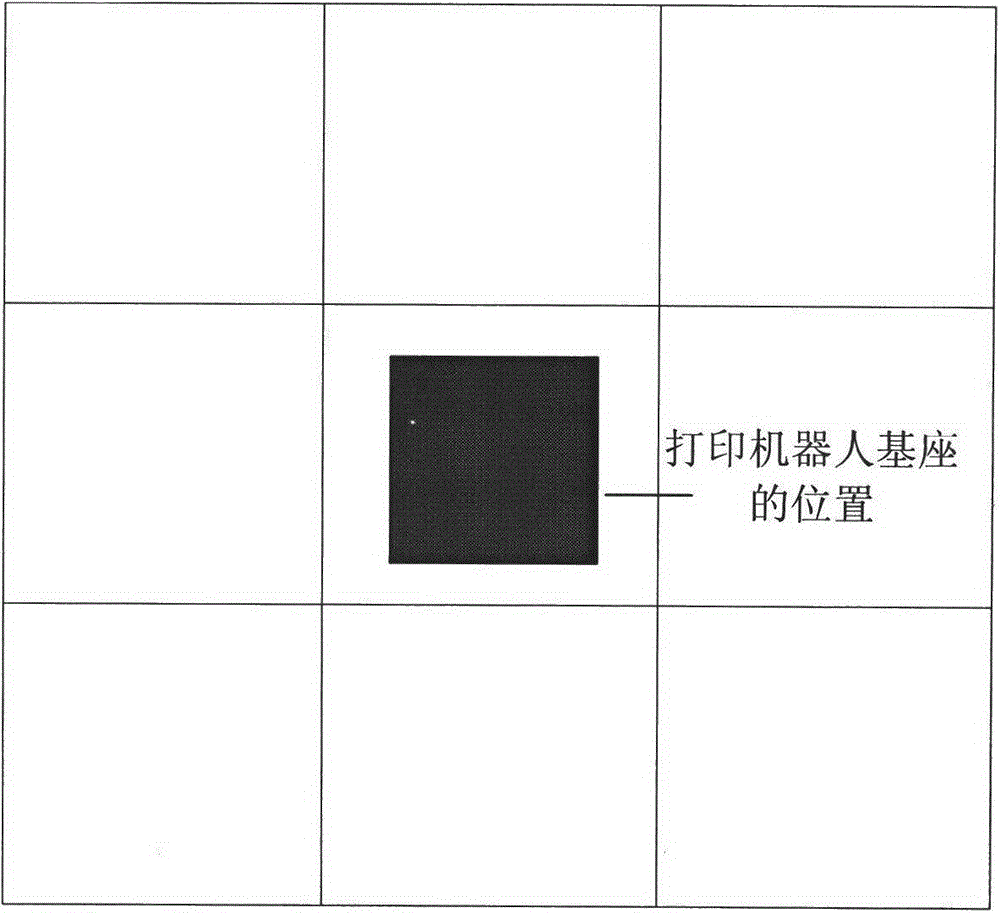

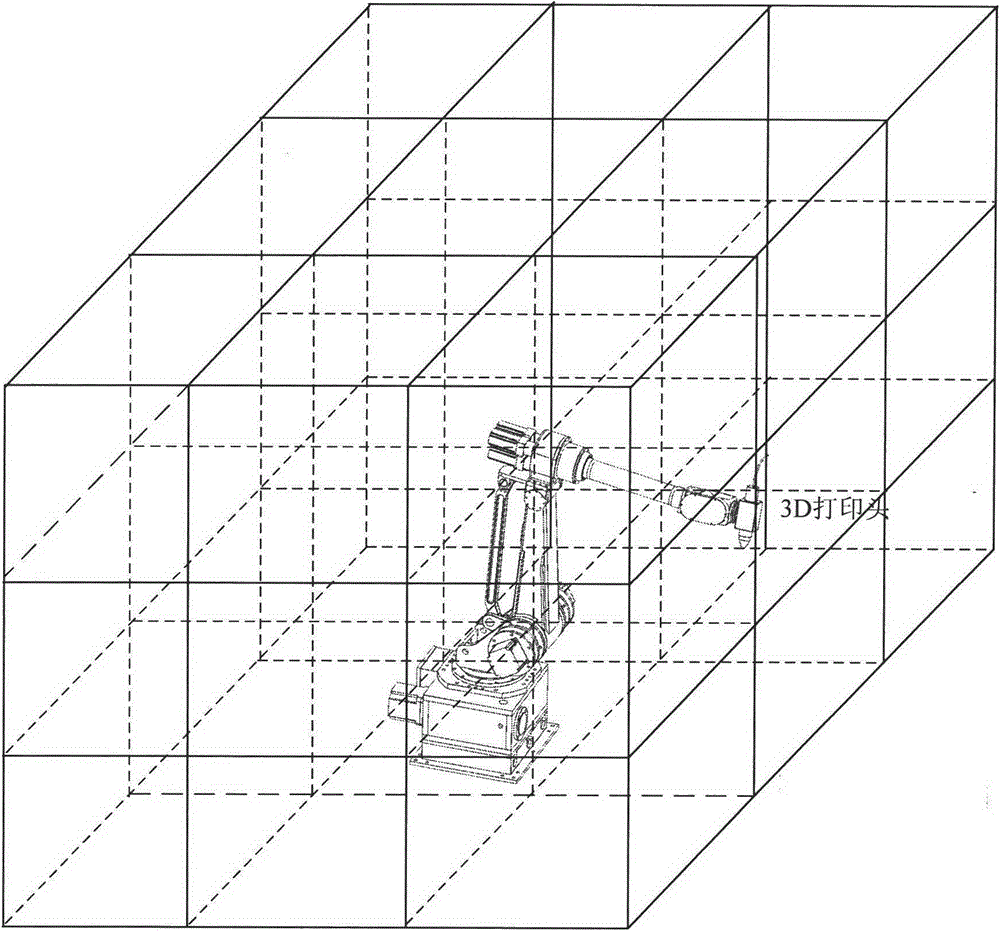

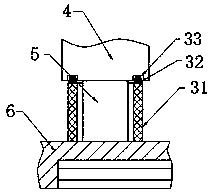

3D printing robot based on industry manipulator

The invention discloses a 3D printing robot based on an industry manipulator, is the combination of the conventional 3D printing technology and the industry robot and is characterized in that a printing head is mounted at the end of a multi-shaft manipulator of a robot, the printing repeated positioning accuracy is high, and the printing mode is not limited by the space. The size of the object to be printed is limited by the size of the conventional 3D printer and the printing speed is slow. The repeated positioning accuracy of the existing 3D printing robot is poor and the printing head cannot be mounted at the end of the manipulator, the robot is separated from the 3D printer for batch processing and assembling the printed pieces. The printing material is not limited, the size and shape of the printed object are not limited while the printing speed is faster than the conventional 3D printer.

Owner:郑西涛

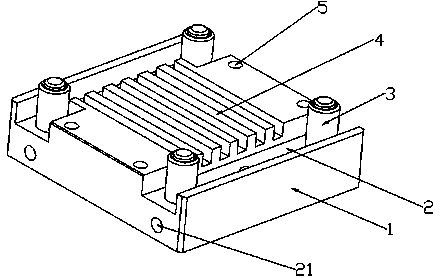

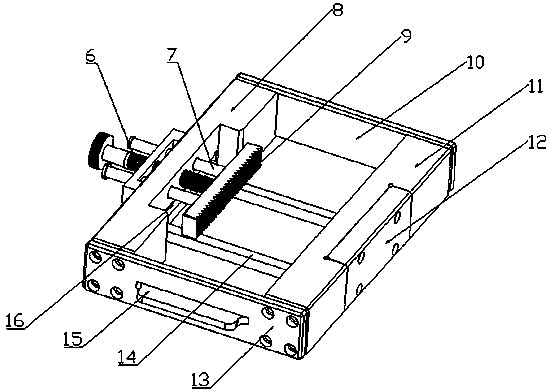

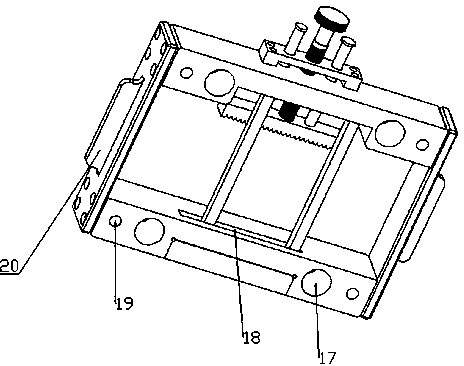

Universal clamp applicable to clamping plastic molds on various processing units

ActiveCN103894853AImprove efficiencySimple structureWork holdersPositioning apparatusProduction lineMeasuring instrument

The invention provides a universal clamp applicable to clamping plastic molds on various processing units. The universal clamp comprises a bas and a clamping device. The base comprises a foundation bed, a grooved electromagnetic chuck, a pneumatic device and the like, quick positioning between the base and the clamping device is realized via the pneumatic device, and a workpiece to be machined is supported and fixed by the grooved electromagnetic chuck. The clamping device comprises a push plate, a screw, a support piece, bar-shaped pieces and the like, and the push plate can be translated via the screw so as to lock an end face of the workpiece to be machined. The universal clamp is mainly applicable to continuous machining and measuring processes of mold parts of a numerically controlled machining center, an electric spark machine tool, a line cutting machine tool, a tri-linear coordinates measuring instrument and the like, and automatic continuous production of mold manufacturing in a mold manufacturing automatic production line can be realized by an industrial manipulator or a robot.

Owner:ZHUHAI CPT PRECISION MOLD

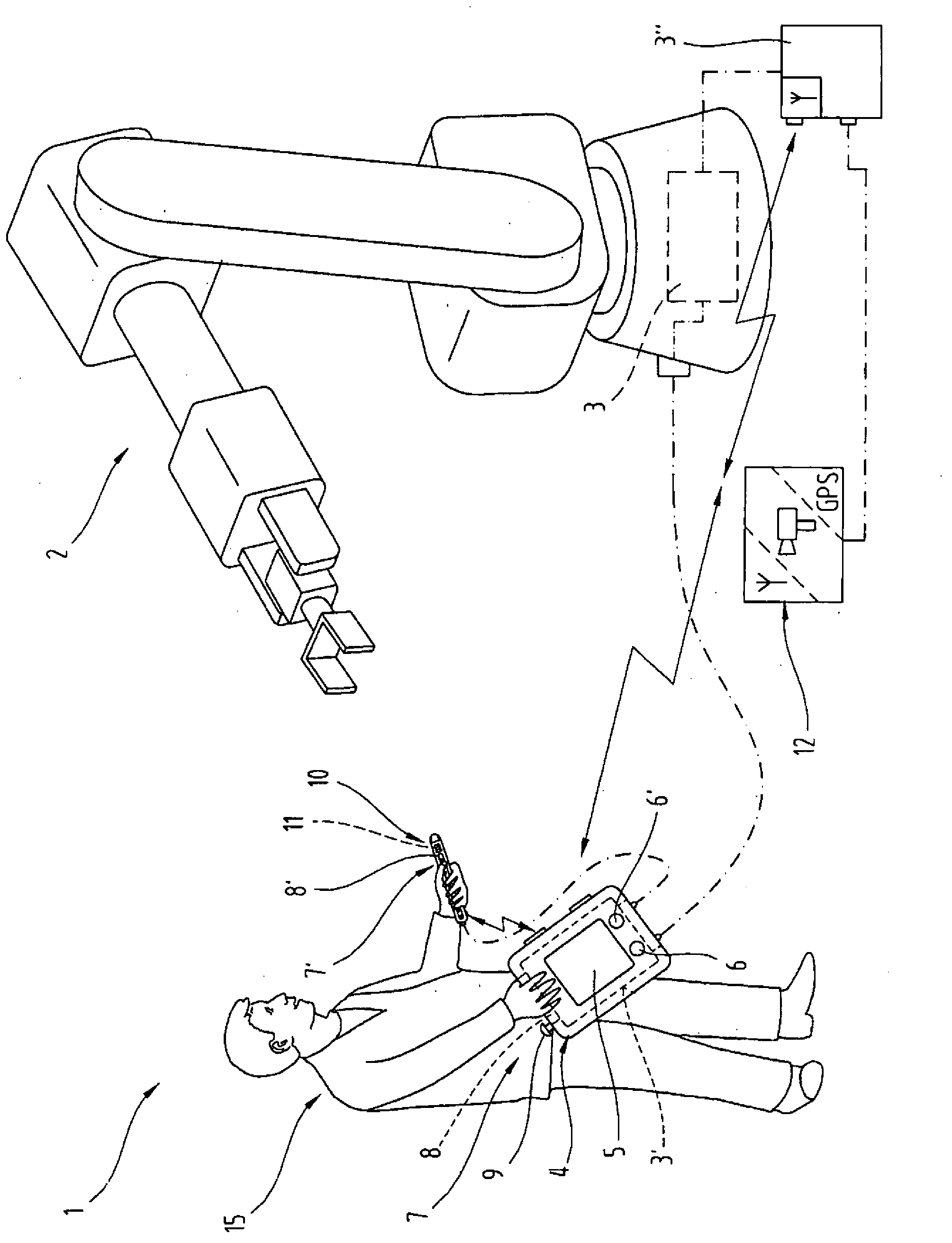

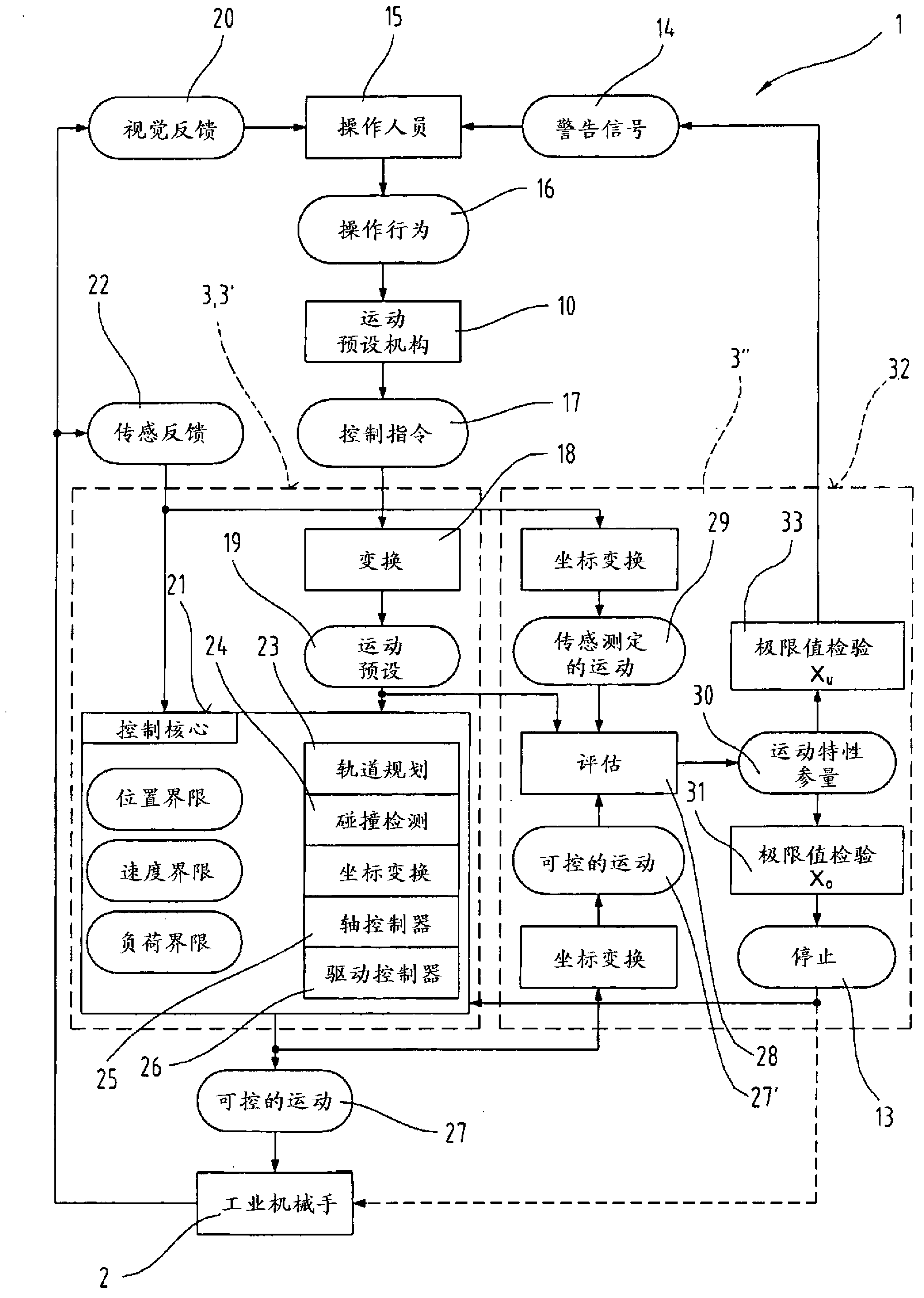

Method for programming or setting movements or sequences of industrial robot

ActiveCN102939188AImprove security levelCut off in timeProgramme controlProgramme-controlled manipulatorControl systemIndustrial manipulator

The invention relates to a method for programming or setting movements or sequences of an industrial robot (2) or another handling device having multiaxis control. To this end, at least some of the data and control commands for controlling the movement, or programming the sequence, of the industrial robot (2) are generated via a movement setting means (10) to be operated manually by an operator. Said control commands are then implemented by the industrial robot (2) substantially without delay. It is essential that, on the basis of the movement setting by means of the movement setting means (10) to be operated manually and / or on the basis of the measured values, acquired by sensors, of the movement carried out by the industrial robot (2) and / or on the basis of the control commands generated by the control system (1), a characteristic movement variable is determined and compared to an upper limiting value, and that, if the upper limiting value is exceeded, the movement or sequence change of the industrial robot (2) is stopped immediately or after an overrun phase limited in a defined manner, and / or that, if the characteristic movement variable approaches the upper limiting value in a defined manner, or if a lower limiting value, which is lower than the upper limiting value, is exceeded, the closeness to or approach of the upper limiting value is signaled to the operator by outputting a warning signal.

Owner:KEBA GMBH & CO

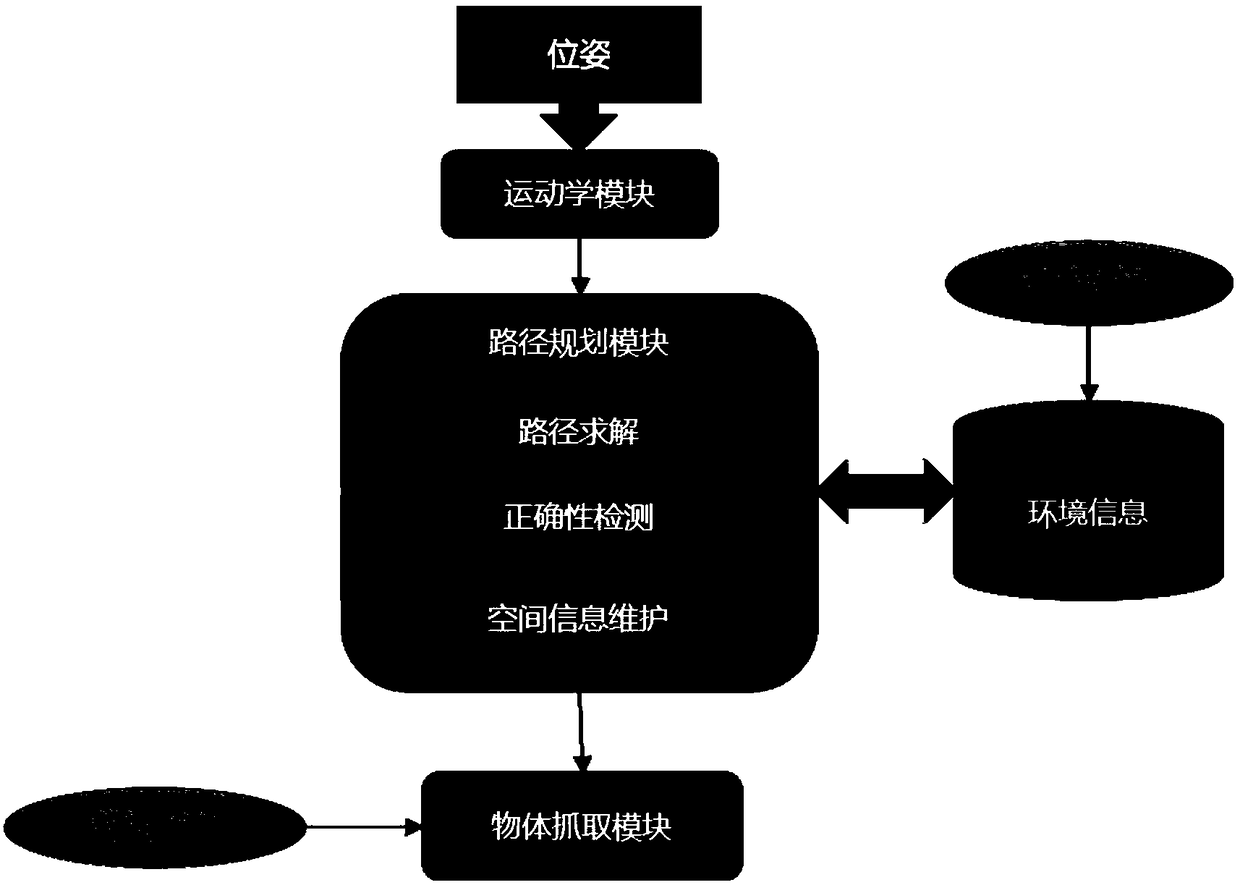

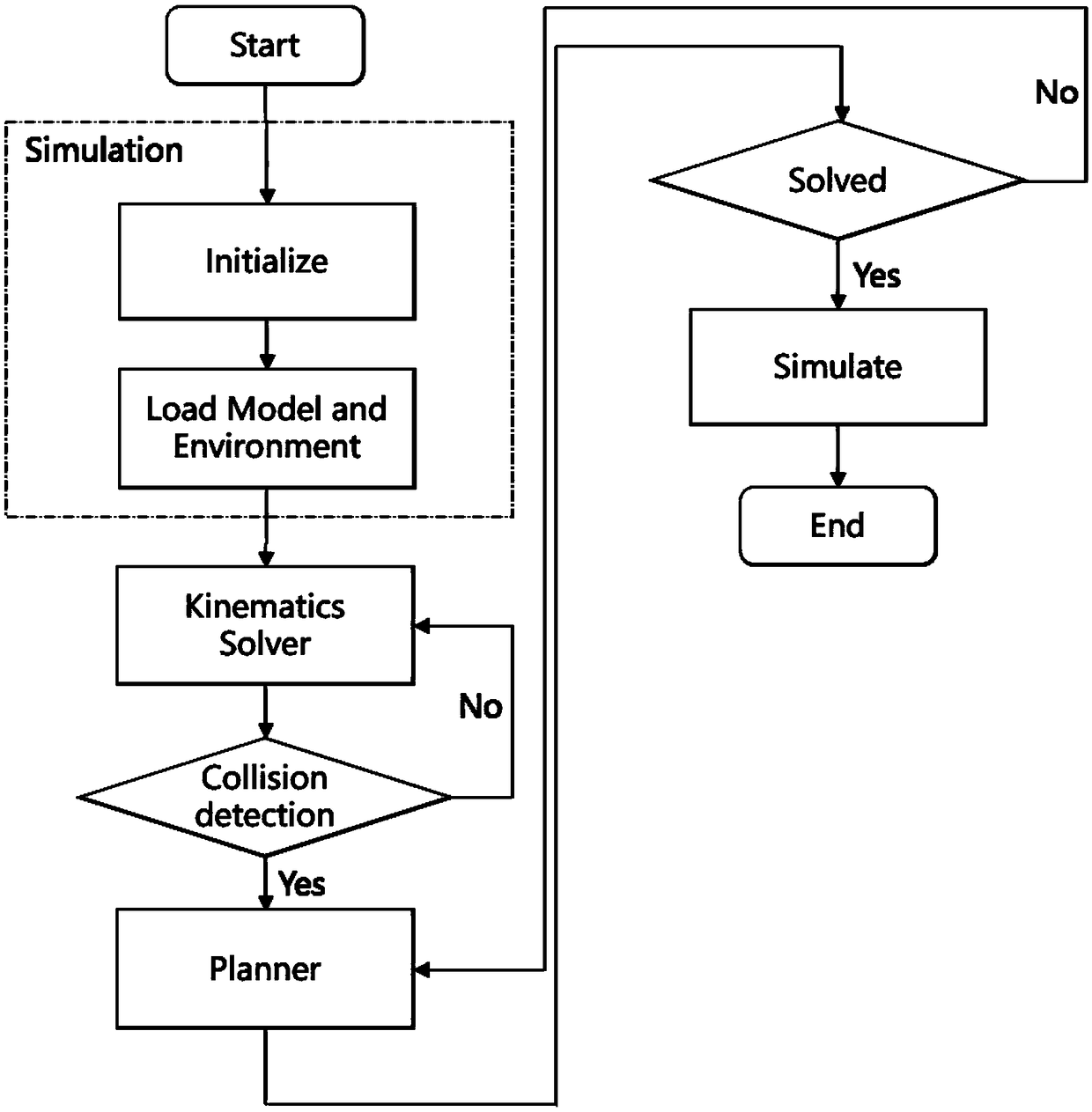

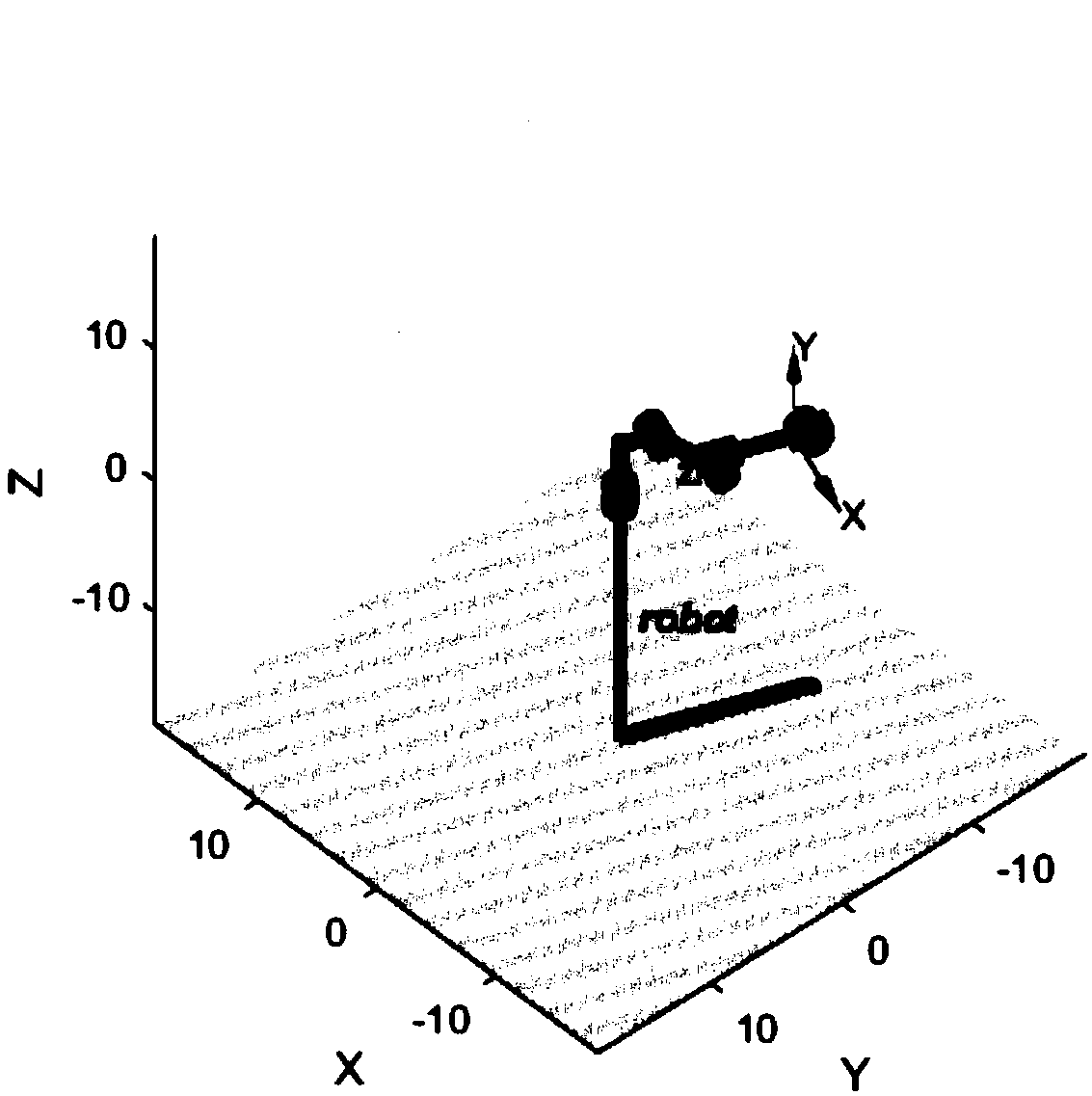

Real-time obstacle-avoiding planning and grabbing system for industrial manipulators based on Kinect depth camera

ActiveCN108972549AImplement obstacle avoidance planningImprove securityProgramme-controlled manipulatorVisual technologyInterconnection

The invention discloses a real-time obstacle-avoiding planning and grabbing system for industrial manipulators based on Kinect depth camera. A Kinect depth camera is used with the computer vision technology to dynamically sense a production environment around an industrial manipulator, thereby detecting and tracking a dynamic obstacle in the environment; boundary information of the dynamic obstacle is acquired through a boundary detection algorithm. A bounding box of the dynamic obstacle is updated; LazyPRM algorithm is used to provide dynamic obstacle-avoiding planning and object grabbing. The system herein has the advantages that an industrial manipulator is given the capacity to more intelligently sense changes in the production environment, production safety is effectively improved, intelligence level of industrial manipulator operation is effectively increased, and a feasible scheme is provided for substantially implementing intelligence and interconnection of future intelligent factories.

Owner:SOUTH CHINA UNIV OF TECH

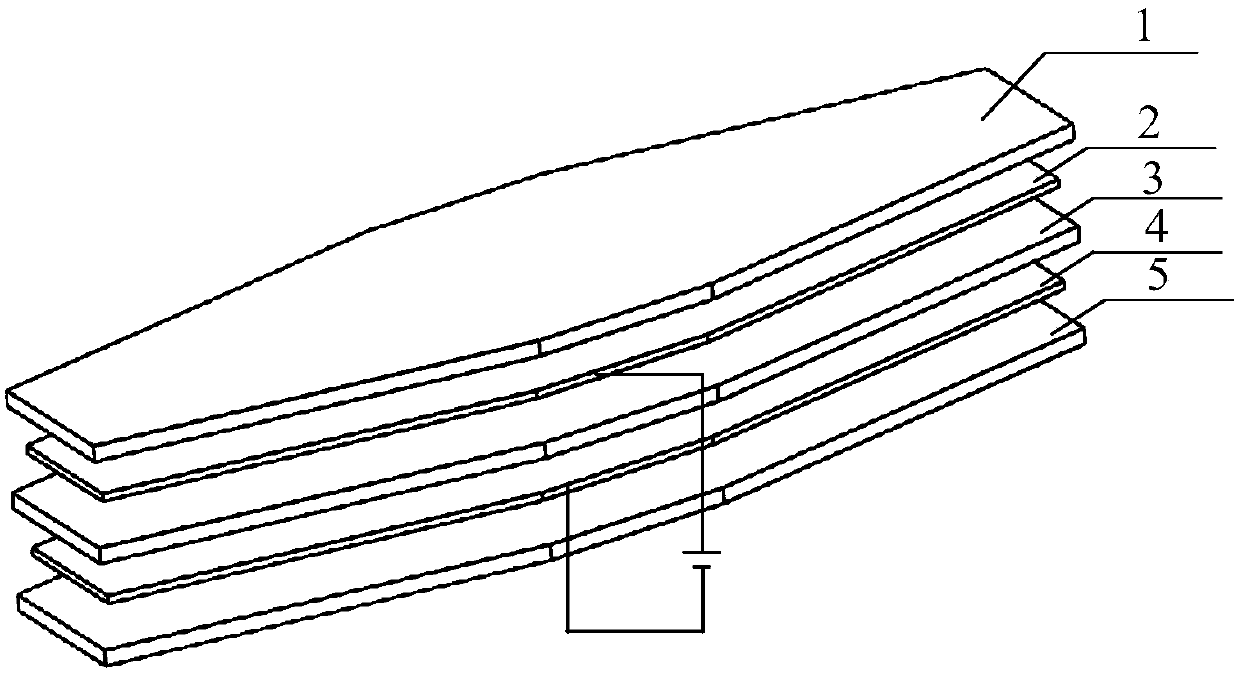

Variable stiffness dielectric elastomer actuator based on magnetorheological elastomer

InactiveCN109571453AQuick responseEasy to controlProgramme-controlled manipulatorVariable stiffnessDielectric elastomer actuator

The invention provides a variable stiffness dielectric elastomer actuator based on a magnetorheological elastomer. The variable stiffness dielectric elastomer actuator comprises a dielectric elastomeractuator of a minimum energy structure, a magnetorheological elastomer film and a flexible electrode. According to the magnetorheological elastomer film, the film has lower stiffness when an externalmagnetic field is absent, and the stiffness is increased by 10 times or more once the film is under the action of the external magnetic field, so that the stiffness of the dielectric elastomer actuator is changed. The dielectric elastomer actuator is of a strip-shaped multilayer minimum energy structure and comprises an acrylic frame, a first flexible electrode layer, an electroactive polymer layer, a second flexible electrode layer and a magnetorheological elastomer film from top to bottom. The variable stiffness dielectric elastomer actuator is simple in structure, convenient to manufactureand light, the stiffness of the actuator can be quickly changed under the action of the magnetic field, so that the actuator has strong load capacity and can be applied to the fields of industrial manipulators, satellite grabbing, space garbage recycling and the like.

Owner:SHANGHAI JIAO TONG UNIV

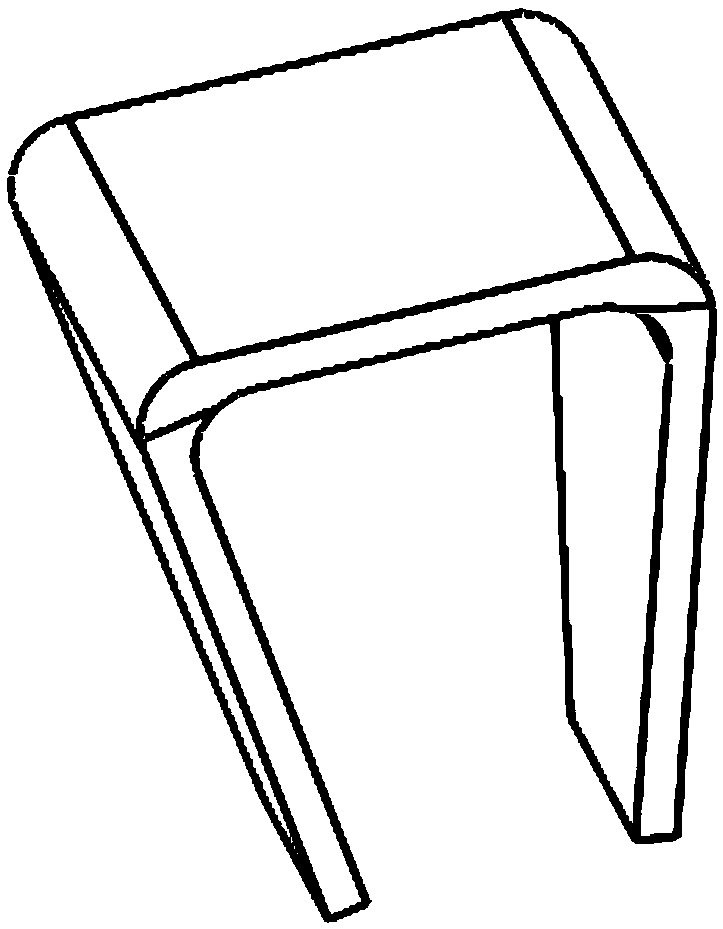

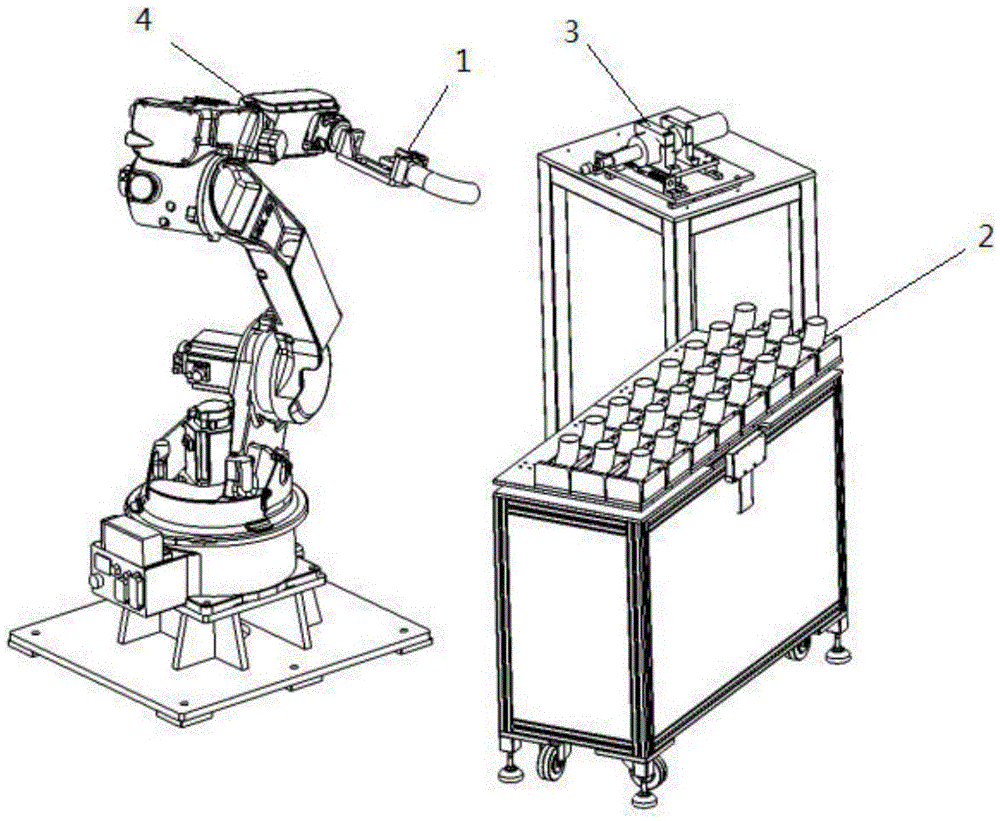

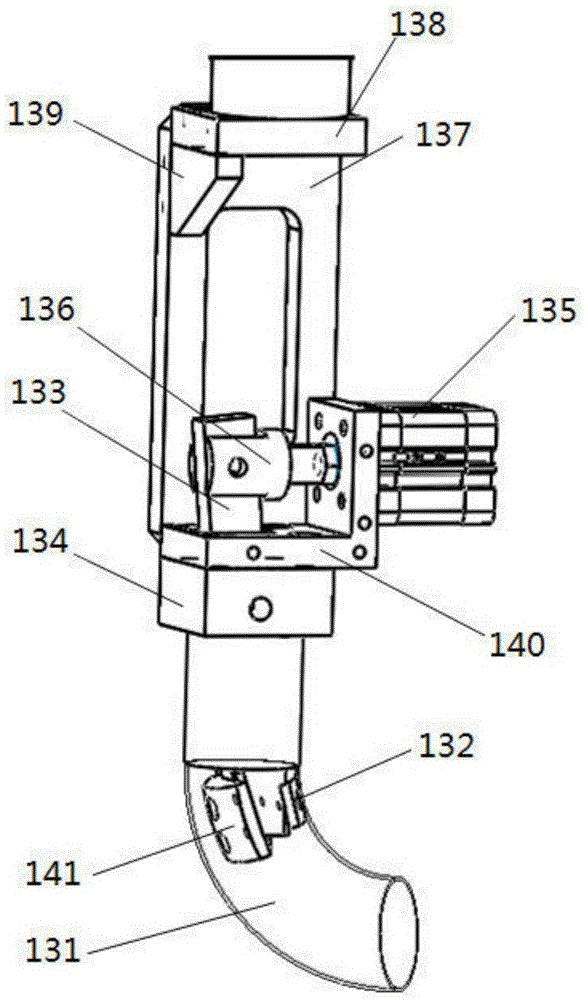

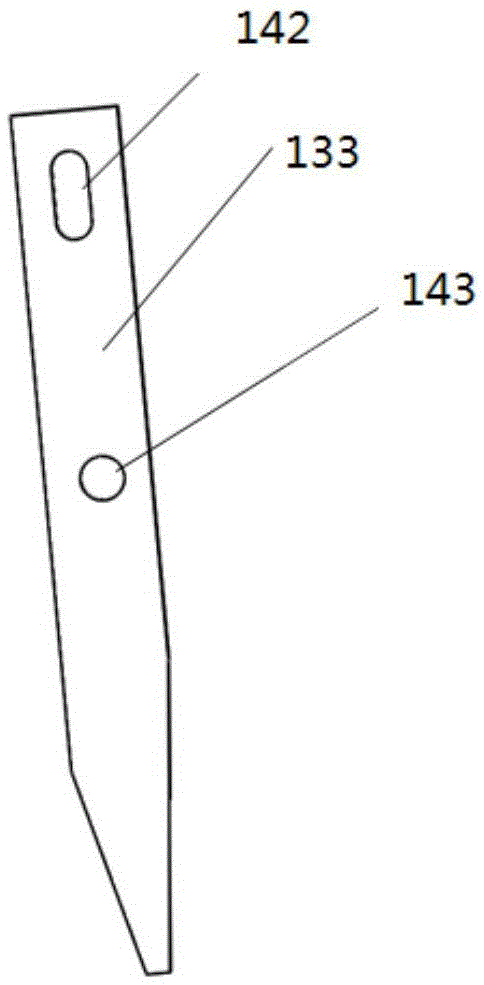

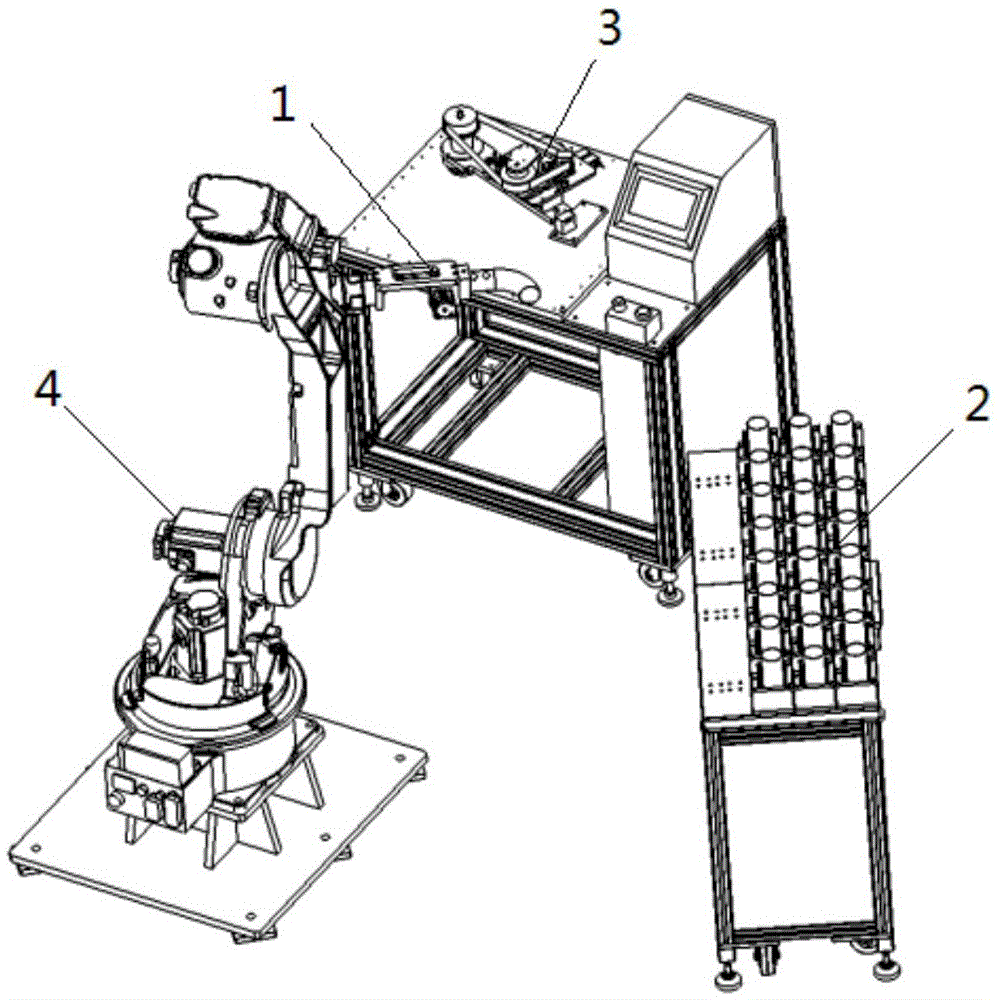

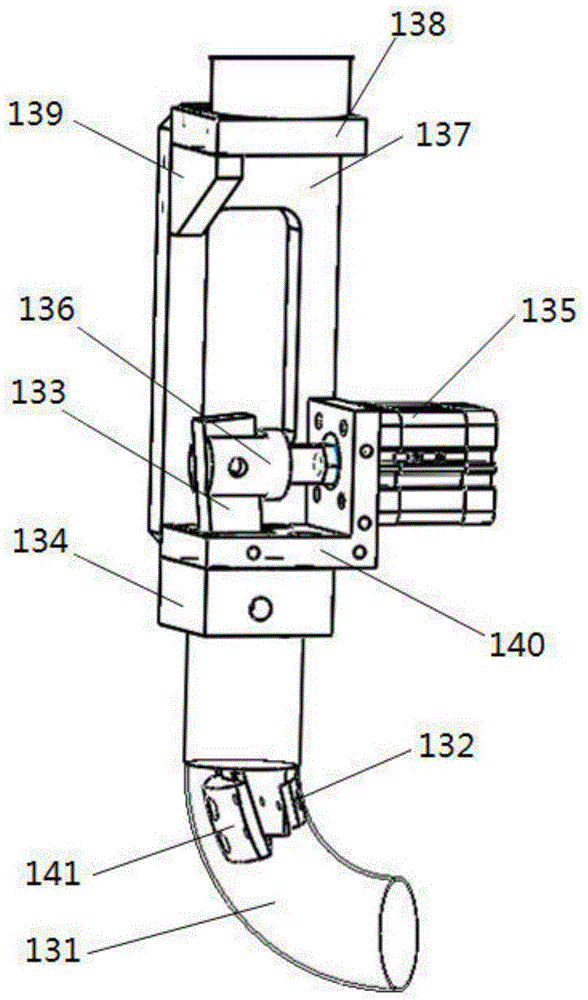

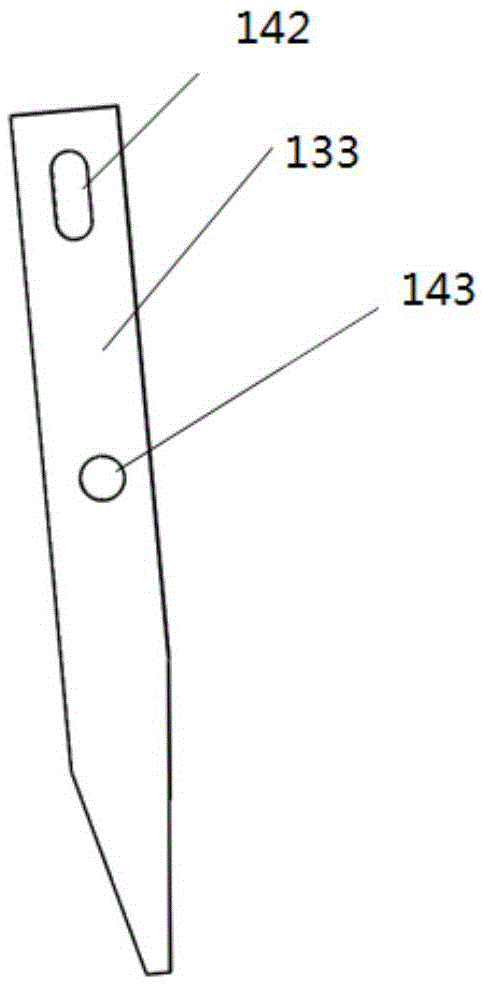

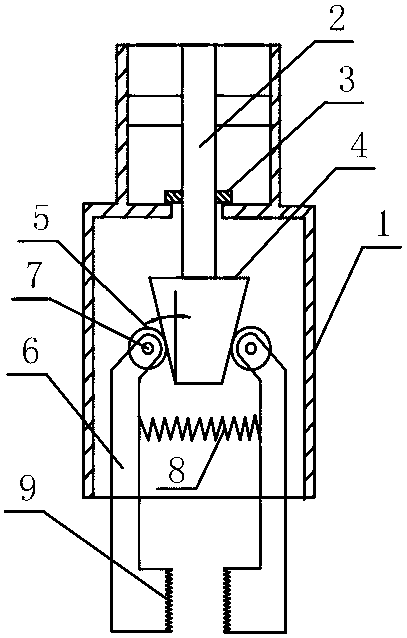

Industry-manipulator-based in-pipe polishing system of stainless steel elbow pipe

ActiveCN105598819AClamp firmlyEasy to controlGrinding wheel securing apparatusGrinding carriagesEngineeringIndustrial manipulator

The invention provides an industry-manipulator-based in-pipe polishing system of a stainless steel elbow pipe. The industry-manipulator-based in-pipe polishing system comprises an industrial manipulator, a clamping mechanism, a feeding cart and an in-pipe polishing mechanism; the clamping mechanism is mounted at the tail end of the industrial manipulator; the clamping mechanism comprises a mechanical supporting unit and a clamping action unit; the mechanical supporting unit comprises a manipulator connection piece, a reinforcing rib, a main connection plate and a right-angled fixing block; the feeding cart comprises a profile rack, four conveying guide rails, four conveying sliding blocks, a material placement plate and a feeding and conveying unit; the in-pipe polishing mechanism comprises a polishing rack and a buffering unit and a polishing unit which are mounted on the polishing rack. The in-pipe polishing system of the stainless steel elbow pipe can completely achieve automatic polishing of the interior of the stainless steel elbow pip, manual operation can be completely replaced, work efficiency is remarkably improved, manpower cost is lowered, and the automated level of an enterprise is raised.

Owner:LYNCWELL INNOVATION INTELLIGENT SYST ZHEJIANG CO LTD

Stainless steel elbow pipe outer circle polishing system based on industrial manipulator

ActiveCN105643402AClamp firmlyEasy to controlGrinding carriagesBelt grinding machinesEngineeringIndustrial manipulator

The invention provides a stainless steel elbow pipe outer circle polishing system based on an industrial manipulator. The stainless steel elbow pipe outer circle polishing system based on the industrial manipulator comprises the industrial manipulator, a clamping mechanism, a feeding trolley and an outer circle polishing mechanism. The clamping mechanism is installed at the tail end of the industrial manipulator and comprises a mechanical supporting unit and a clamping action unit. The feeding trolley comprises a profile machine frame, four conveying guide rails, four conveying sliding blocks, a storage plate and a feeding conveying unit. The feeding conveying unit is installed in the middle of the top of the profile machine frame and located between the two corresponding conveying guide rails. The outer circle polishing mechanism comprises a polishing machine frame and a movement unit installed on the polishing machine frame. By the adoption of the stainless steel elbow pipe outer circle polishing system based on the industrial manipulator, automatic polishing of stainless steel elbow pipes can be achieved completely, manual operation can be completely replaced, the working efficiency is remarkably improved, the labor cost is reduced, and the automation degree of enterprises is improved.

Owner:LYNCWELL INNOVATION INTELLIGENT SYST ZHEJIANG CO LTD

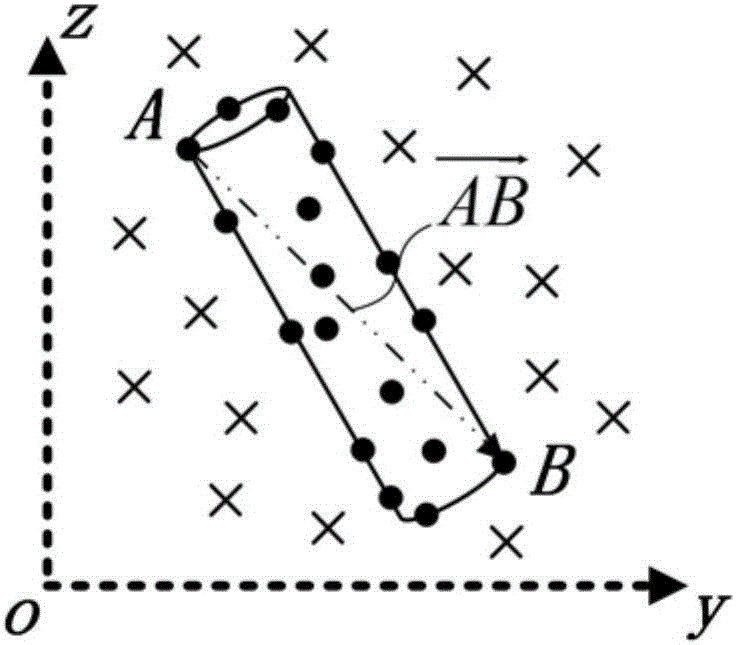

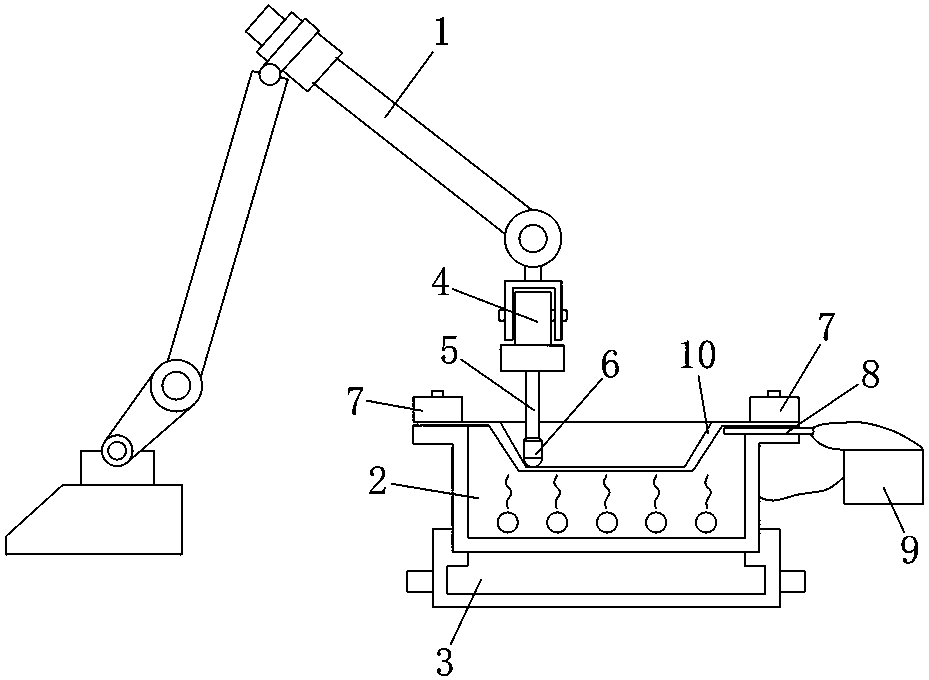

Increment forming device and method for performing increment forming by utilizing increment forming device

InactiveCN103480751AAchieve stretch deformationImprove surface qualityShaping toolsHigh energyControl system

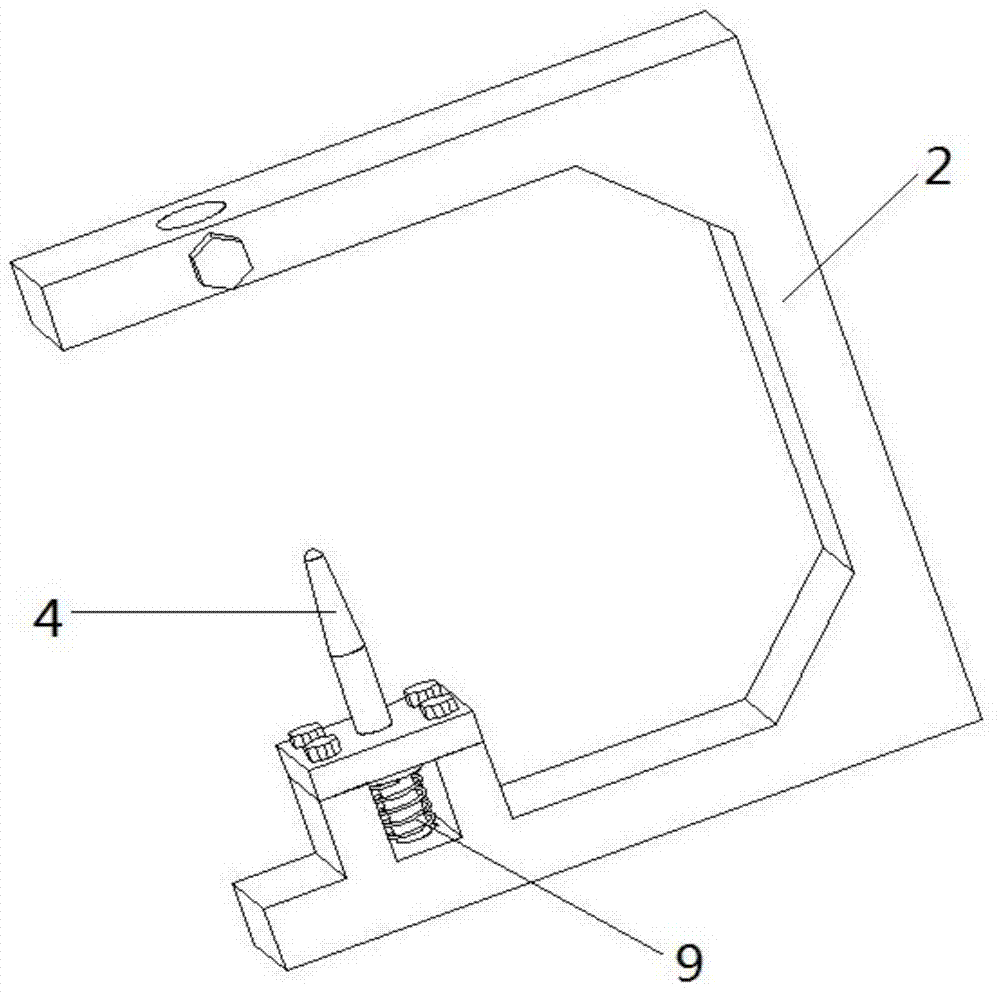

The invention discloses an increment forming device and a method for performing increment forming by utilizing the increment forming device and solves the technical problem of poorer forming precision of the existing panel movable ring electromagnetic incremental forming device. The technical scheme is that an industrial manipulator and a C-shaped frame are respectively fixed two ends of a base; a clamping frame is positioned at the opening of the C-shaped frame; a heating forming head is mounted at the clamping end of the industrial manipulator; a control system for the heating forming head is connected with a high-energy pulse power supply. During heating forming, a panel is placed on the clamping frame to be clamped, then the C-shaped frame is mounted on the industrial manipulator and the heating forming head is well mounted, the panel is subjected to an extruding force by a compression spring, and meanwhile, the heating forming head is enabled to be consistent and harmonious in moving due to the C-shaped frame. As the heating forming head adopts electromagnetic induction for heating, the deforming resistance of a material is reduced by the local heat effect of the contacting deforming area between the heating forming head and the panel, the plasticity is improved and the forming precision is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

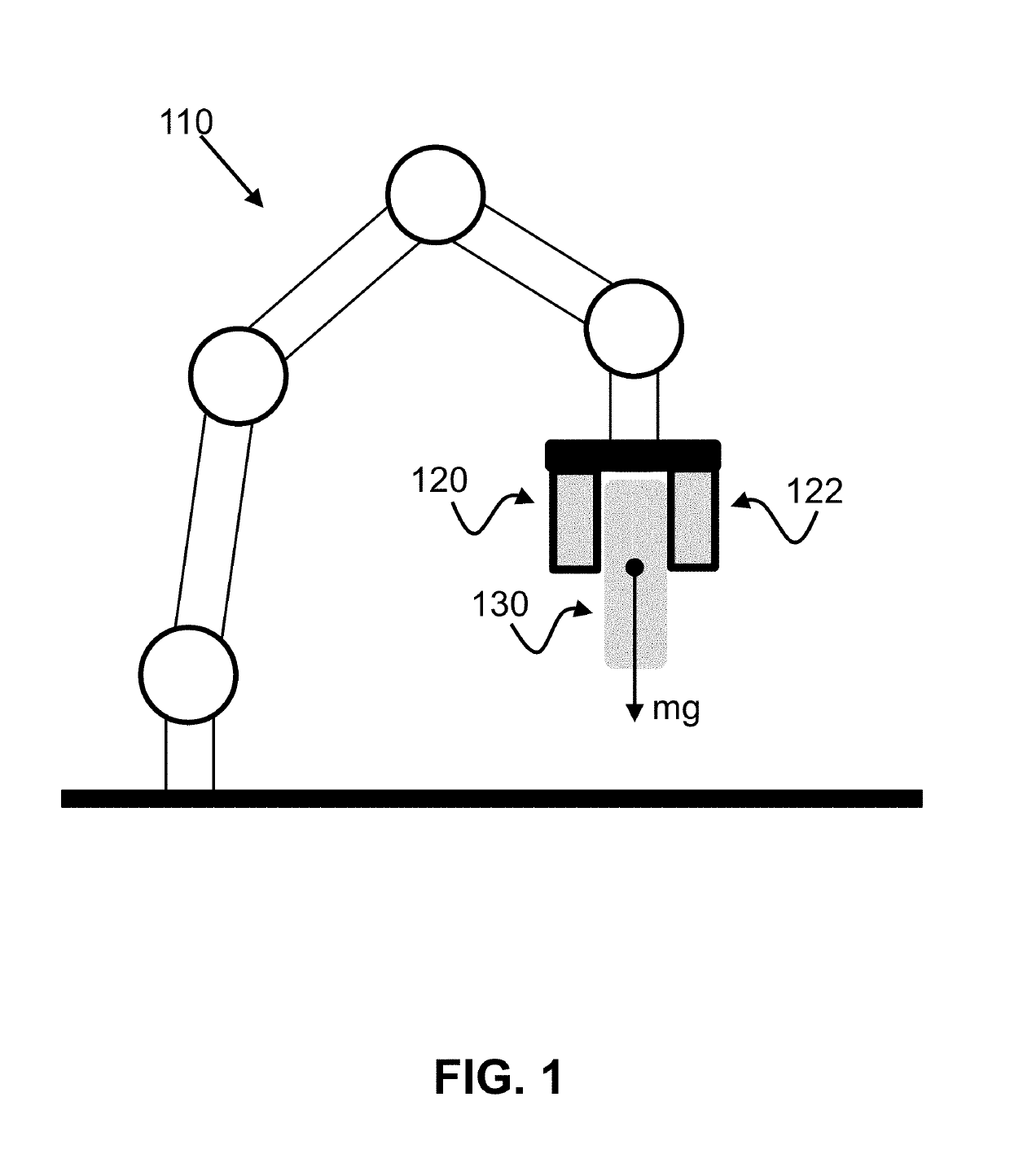

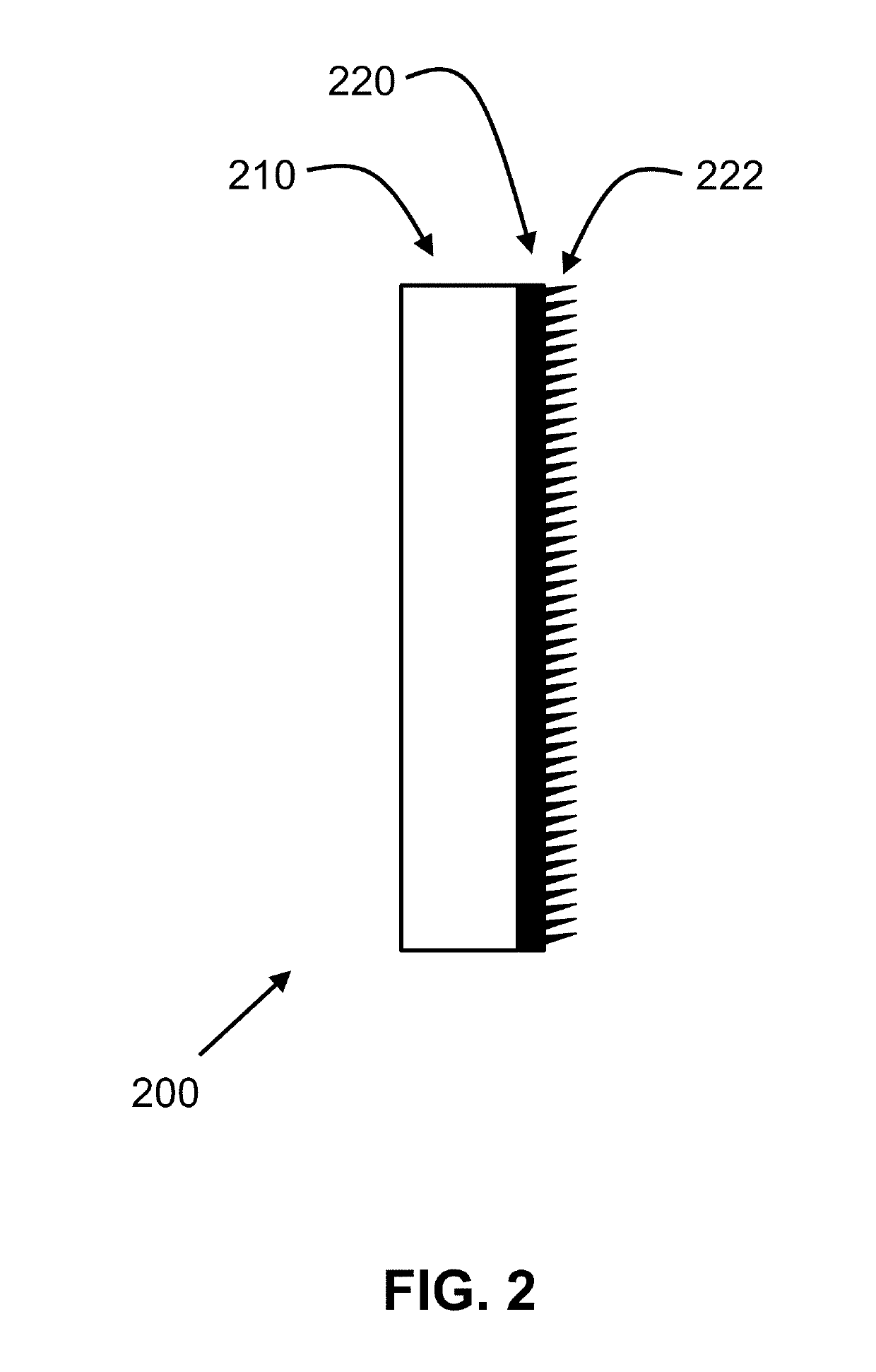

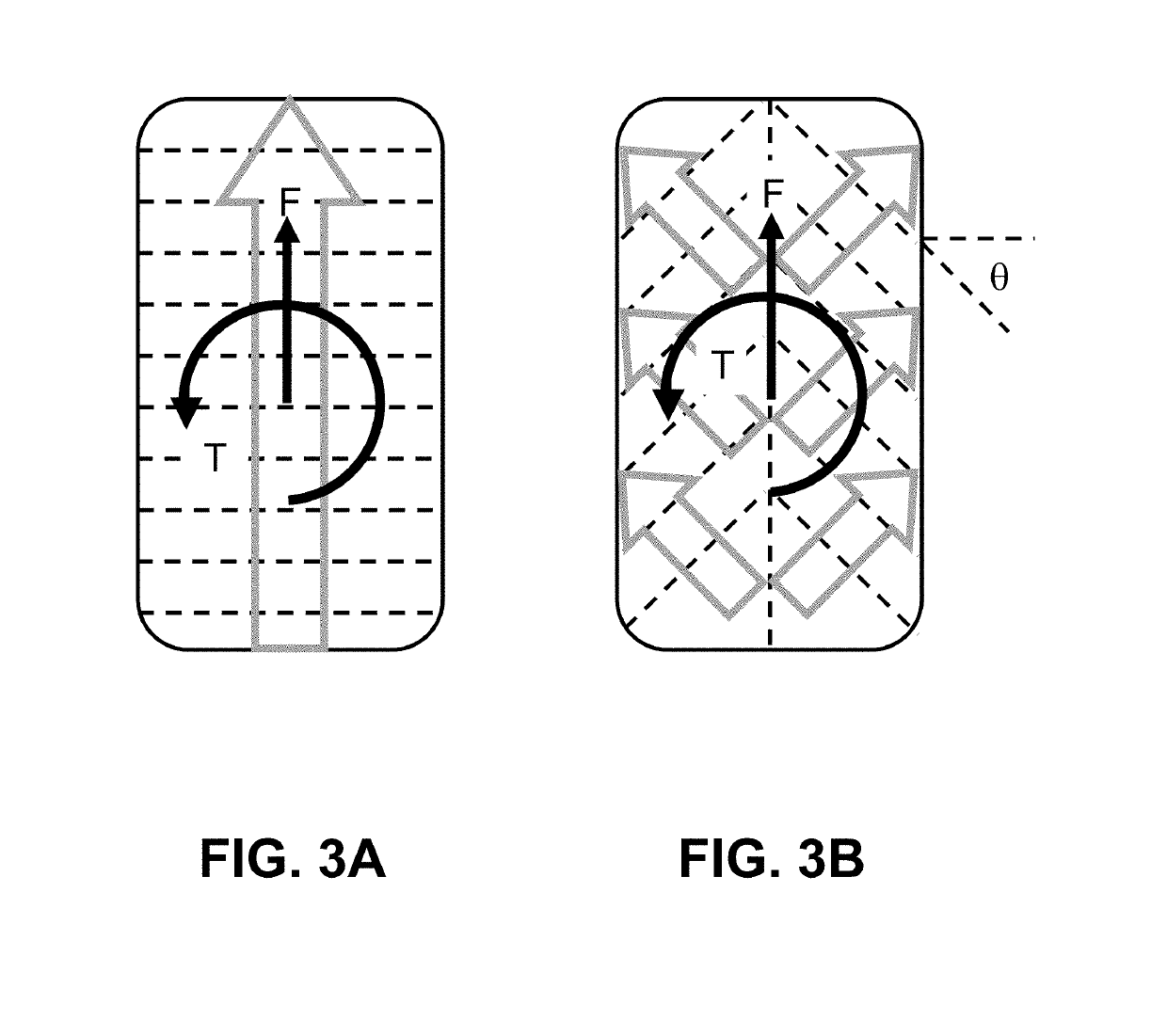

Patterned and instrumented directional adhesives for enhanced gripping with industrial manipulators

Gripper pads are provided for use, augmentation or retrofitting in a robot manipulator. The gripper pads distinguish a dry adhesive layer with dry adhesive wedges that would interface with an object that is desired to be manipulated. The plurality of dry adhesive wedges is organized in a pattern such that the pattern has at least two different orientations for the direction of the plurality of wedges. The gripper pads further distinguish a sensor array underneath the dry adhesive layer. The data obtained from the sensor array provides an estimate of the shape and size of the contact between the gripper pad and the object when the dry adhesive layer is in contact with the object.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

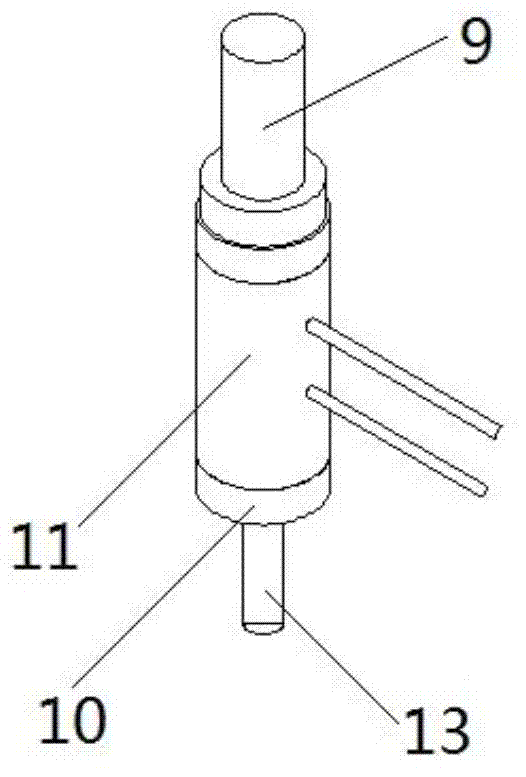

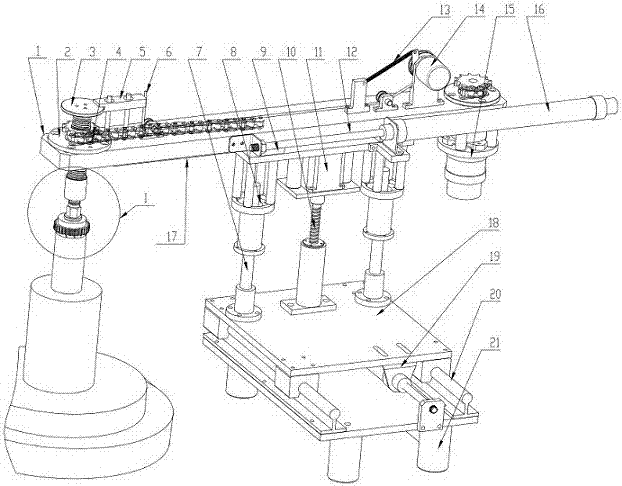

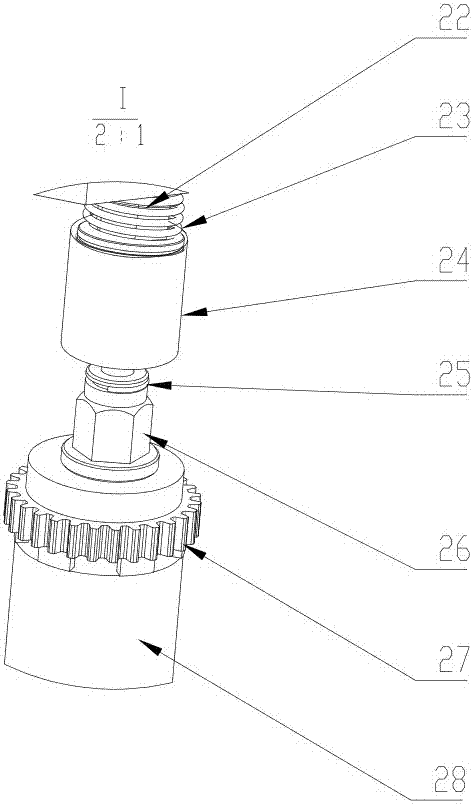

Automatic locking and disassembling device for work piece clamping and locking nut of gear manufacturing equipment

InactiveCN106914749AImprove processing efficiencyReduce labor costsMetal working apparatusGear-cutting machinesEngineeringIndustrial manipulator

The invention discloses an automatic locking and disassembling device for a work piece clamping and locking nut of gear manufacturing equipment. The automatic locking and disassembling device comprises a mechanical arm, a rotary transmission mechanism, a sleeve spring mechanism, a sleeve displacement sensor, an elastic clamping nut and a control circuit, wherein the mechanical arm is driven by an air cylinder to move a sleeve towards to or away from a tooling screw, the sleeve is driven by a motor to rotate to drive the nut to be locked or disassembled, elastic force of a retainer ring spring of the elastic clamping nut can keep the disassembled nut in the sleeve, the displacement sensor can detect longitudinal displacement of the sleeve and reports the displacement to the control circuit, and the control circuit can control action course according to the displacement. The device can be used together with an industrial manipulator to finish automatic work piece feeding and discharging of the gear manufacturing equipment.

Owner:李倩 +1

Thermal vibrating integrated incremental forming device for magnesium alloy thin-wall part and forming technology thereof

InactiveCN108435903AReduce tangential frictionImprove deformation internal microstructureShaping toolsIndustrial manipulatorThin walled

The invention relates to a thermal vibrating integrated incremental forming device for a magnesium alloy thin-wall part and a forming technology thereof. The device comprises an industrial manipulator, a heating box, a cooling box, a vibration generator, an amplitude-change pole, a tool head and a blank pressing block, wherein the blank pressing block for pressing the magnesium alloy thin-wall part is screwed to the side edge of a heating port in the upper end of the heating box; the cooling box is mounted at the lower end of the heating box; the vibration generator is mounted at the tail endof the industrial manipulator; the upper end of the amplitude-change pole is fixedly connected to the output end of the vibration generator, and the lower end of the amplitude-change pole is connectedto the tool head which acts on the magnesium alloy thin-wall part. The device is simple and reasonable in structure; the thermal assisted and vibrating assisted plastic processing modes are combined;the low-amplitude vibrating point pressing formation of the magnesium alloy thin-wall part can be realized through a frequency-adjustable and amplitude-adjustable vibration generator. Therefore, theformation limit and the formation quality of a magnesium alloy material can be improved; and moreover, the formation technology chain of the magnesium alloy thin-wall part is shortened, and as a result, the short plastic processing process is achieved.

Owner:FUZHOU UNIV

Improved structure of industrial mechanical arms

InactiveCN103317525AIncrease frictionSolve the problem of easy falling offArmsEngineeringIndustrial manipulator

Owner:四川海普工控技术有限公司

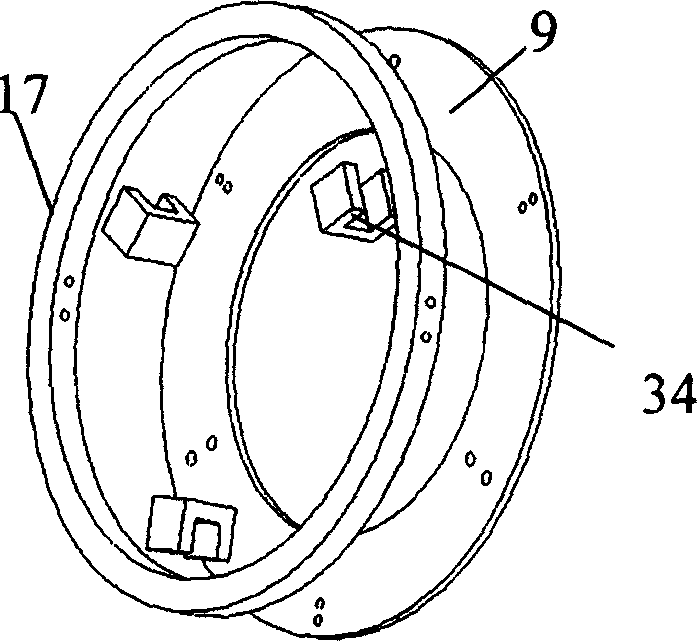

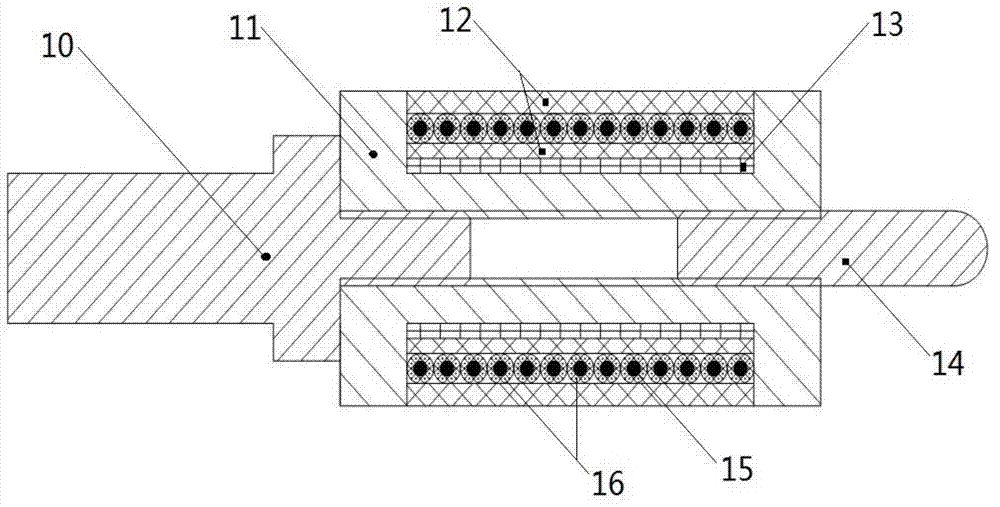

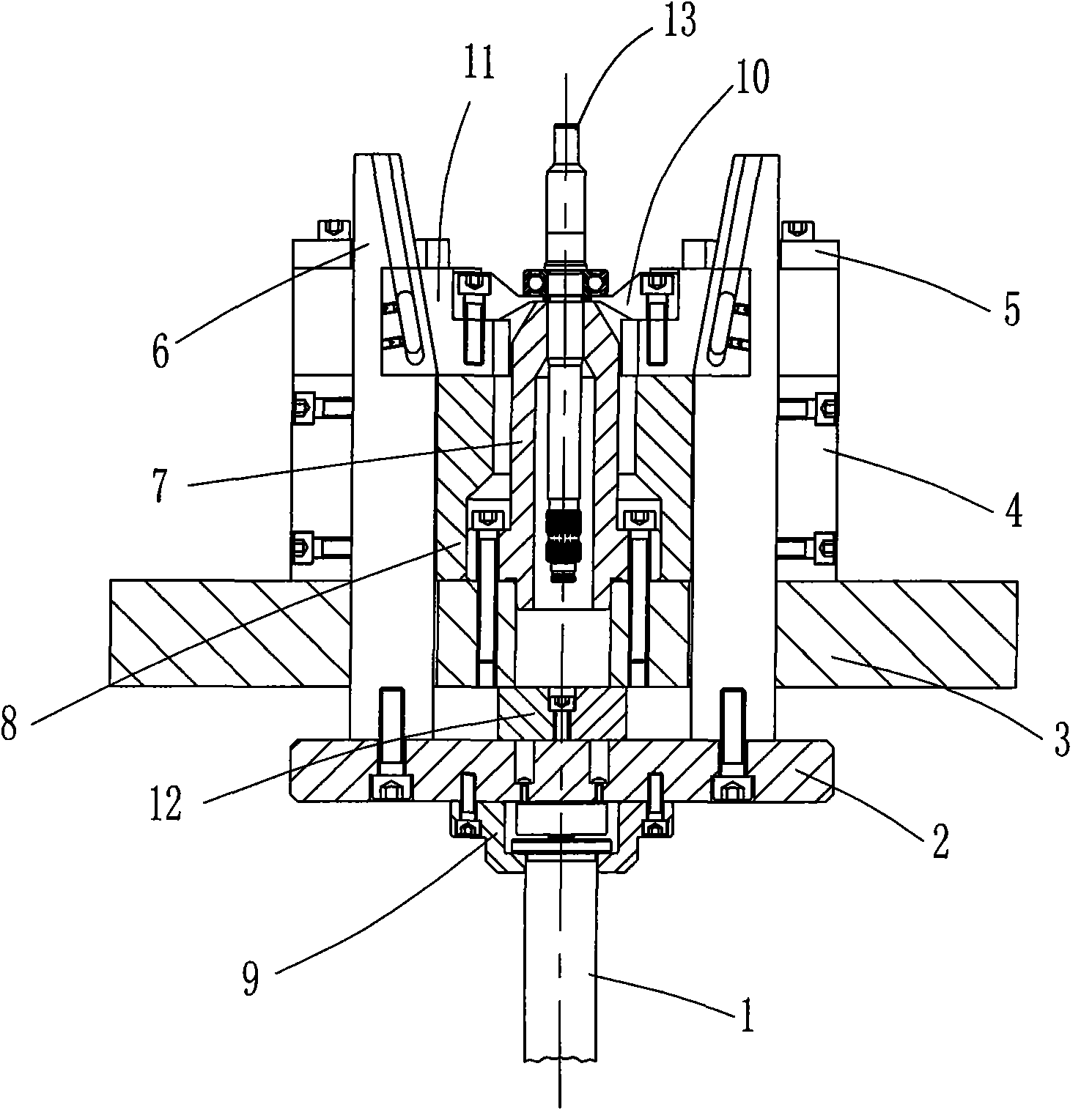

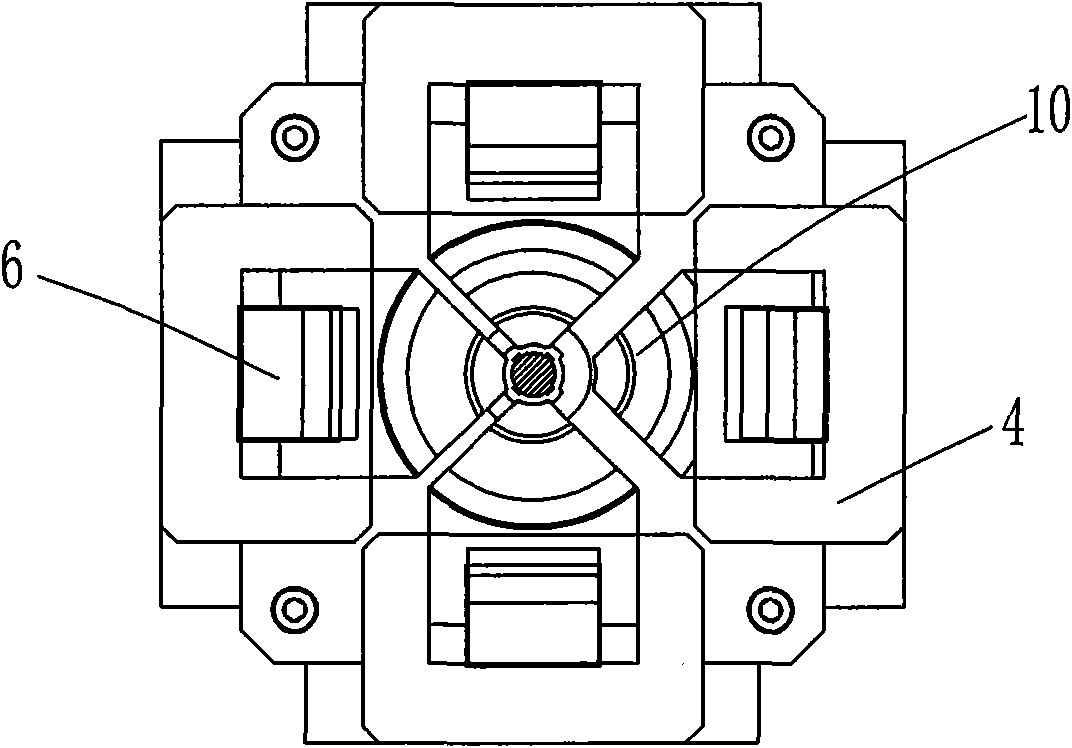

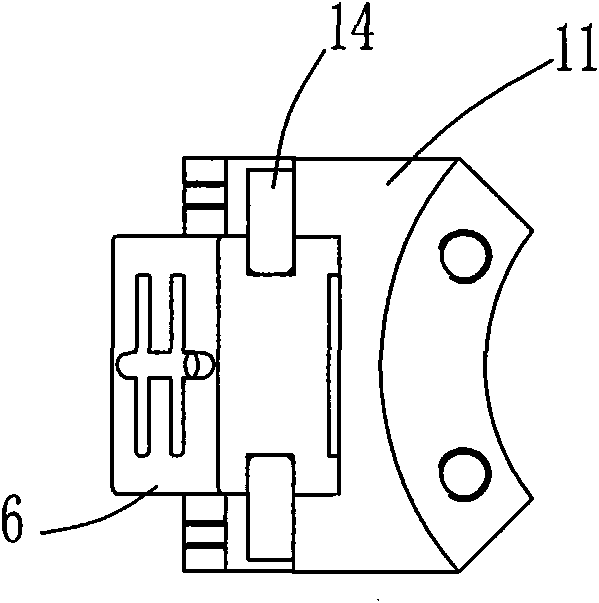

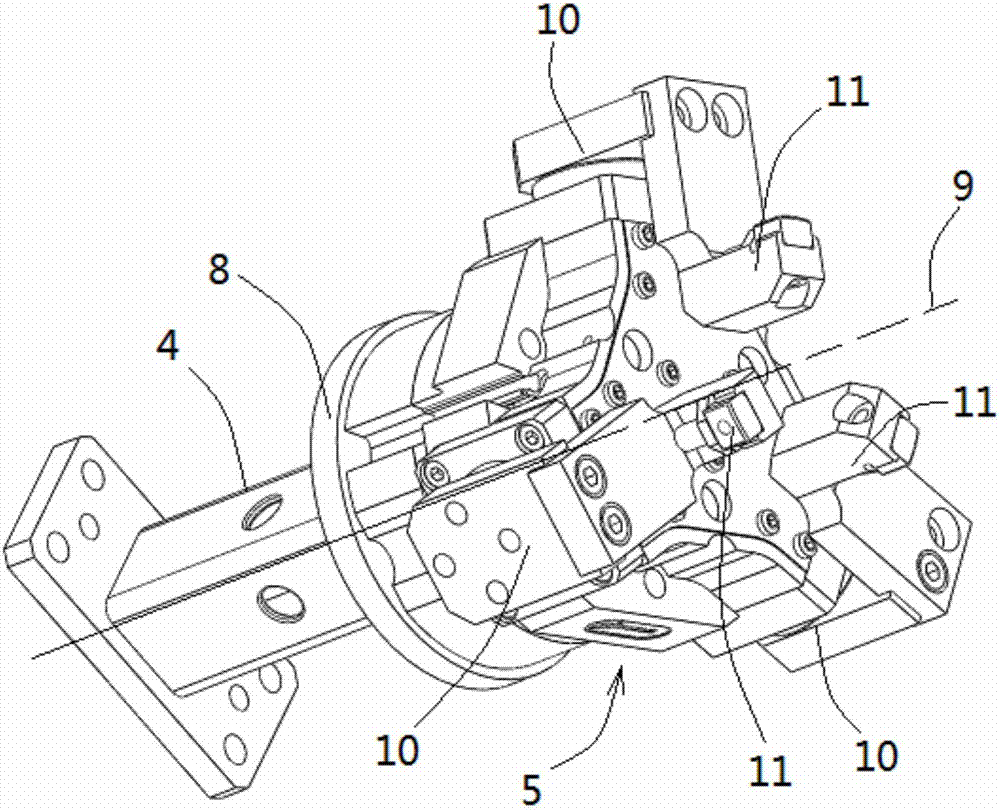

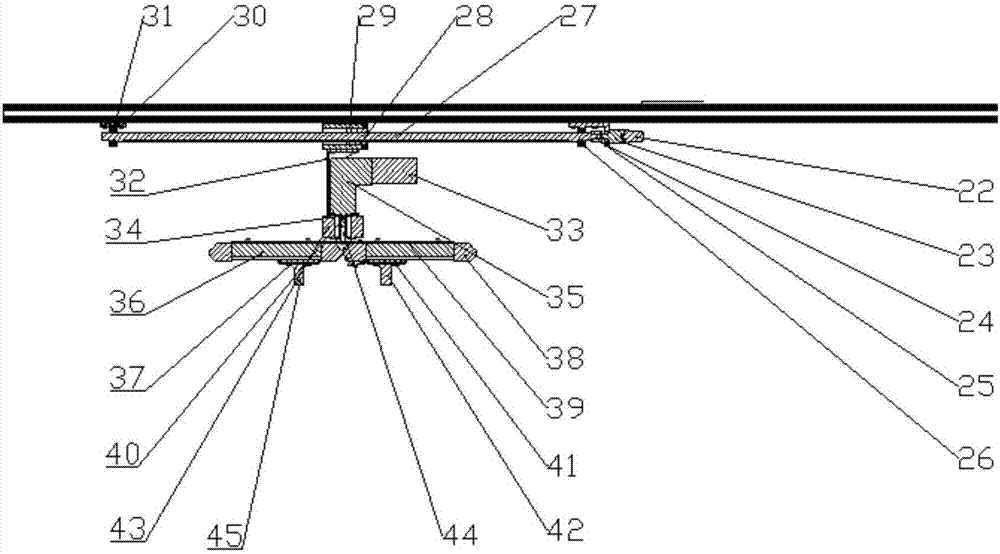

Self-centering radial synchronous clamping and riveting device

InactiveCN101791764ASolve multi-directional motion problemsAdjustable clamping forcePositioning apparatusMetal-working holdersRadial motionEngineering

The invention discloses a self-centering radial synchronous clamping and riveting device, which can convert the axial motion of guide plates arranged on a drive rod pushed by a single drive source into the synchronous radial motion of a plurality of clamping block-mounting plates in order to achieve the purpose of accurately clamping and riveting shaft workpieces. The invention can be widely used for workpiece clamping in mechanical machining and automatic centering and clamping in automobile part assembly, and can be used as an industrial manipulator execution mechanism to clamp workpieces, and if clamping blocks are substituted by riveting tools, the invention can be used in cases requiring high centering, clamping and riveting precision, such as radial workpiece riveting.

Owner:HEFEI PRESSURE MACHINERY

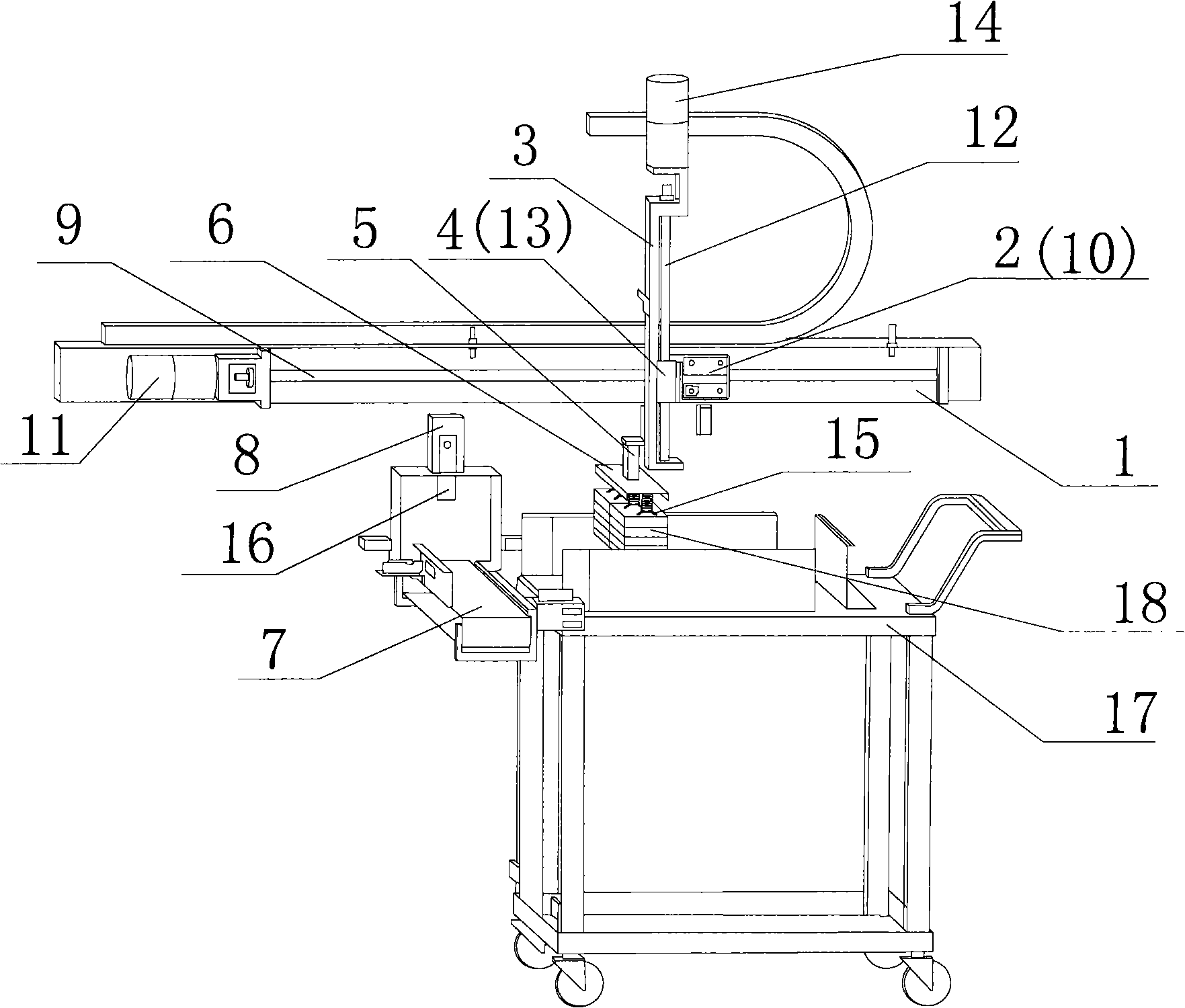

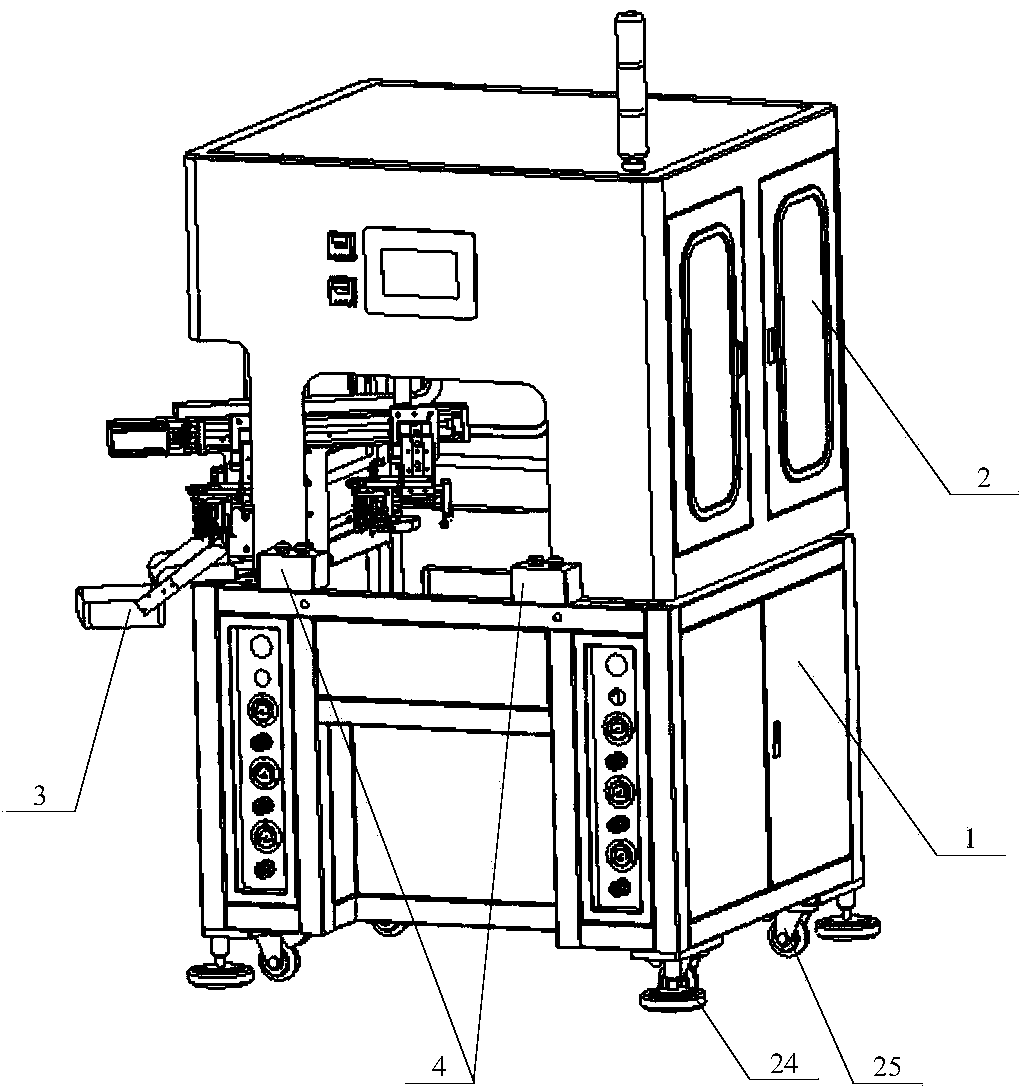

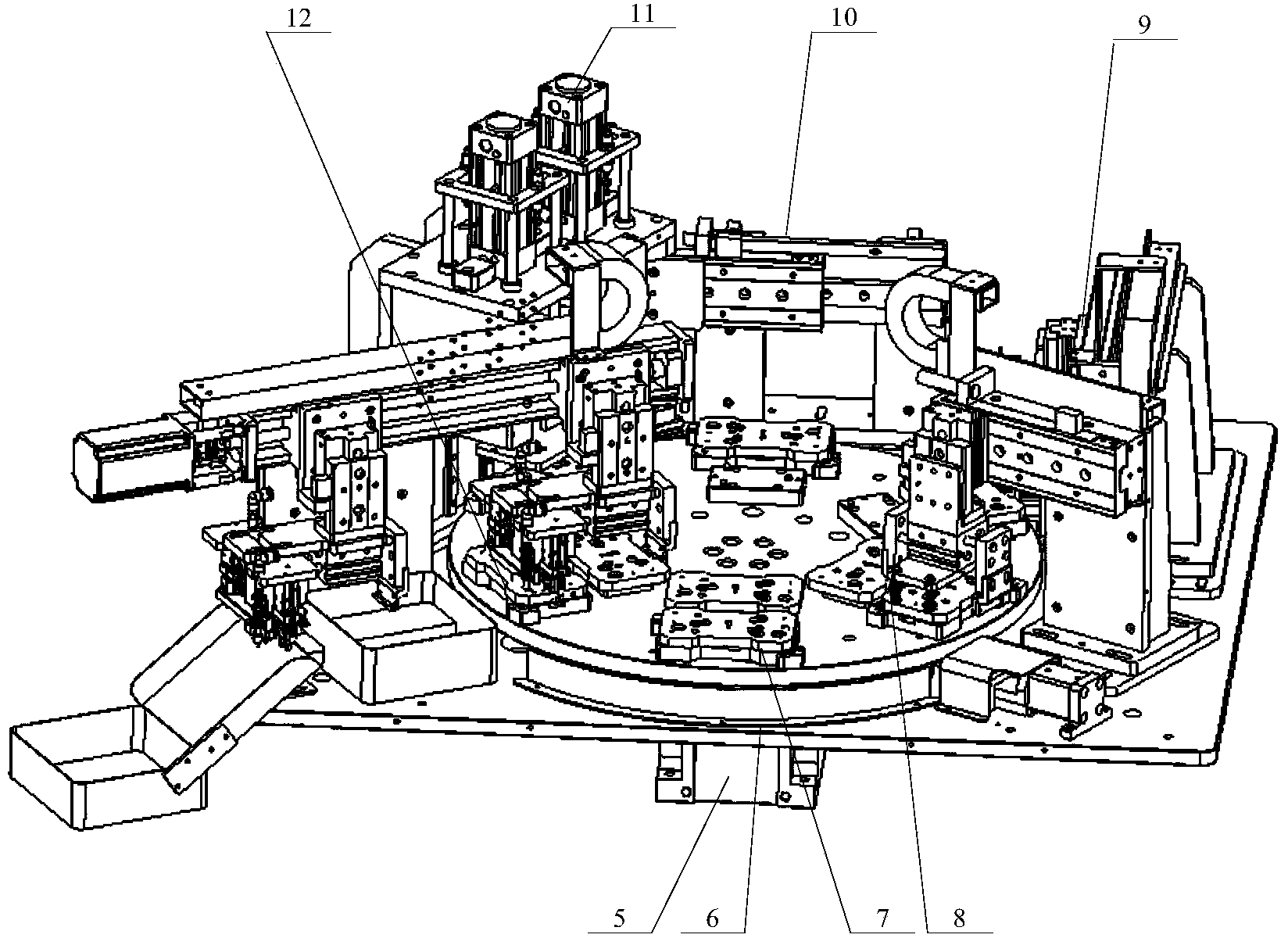

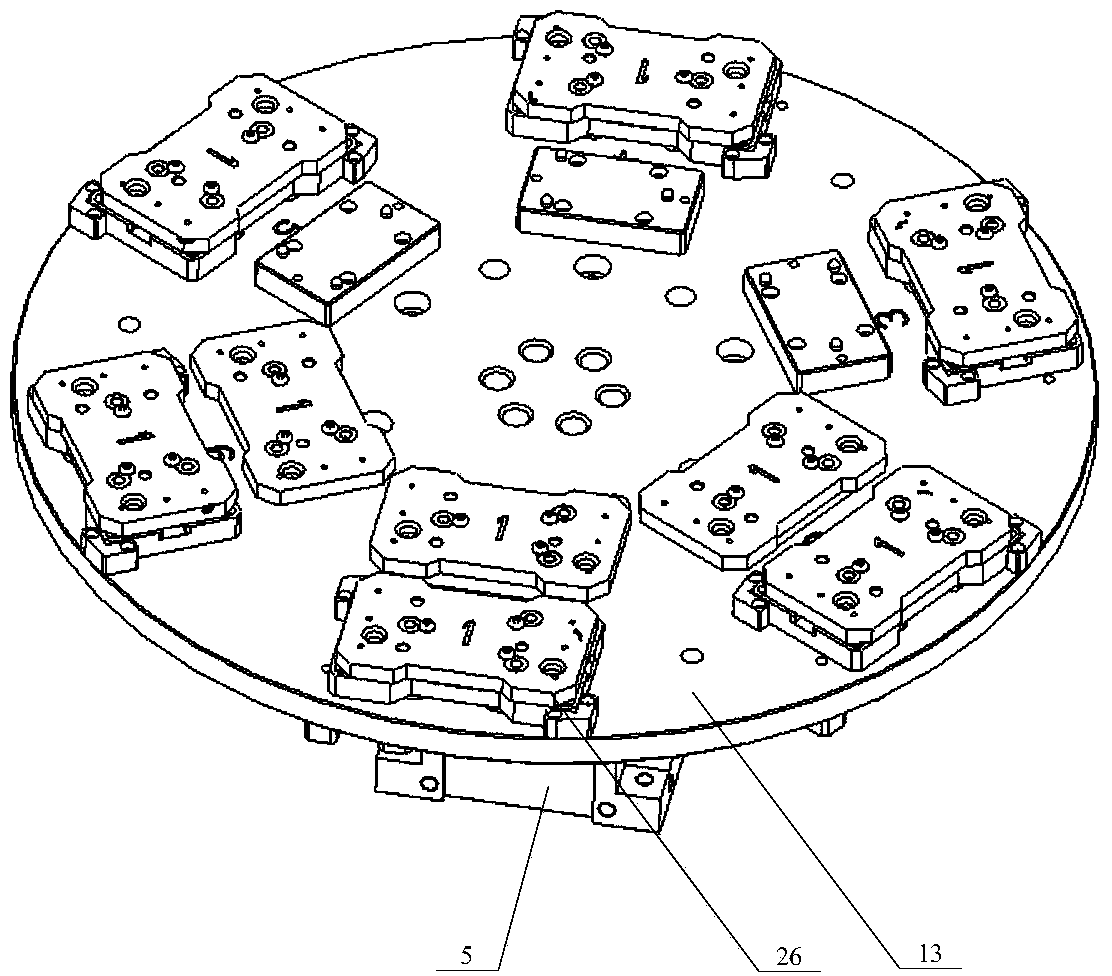

Full-automatic brass nail hot-melting assembly and detection machine based on industrial manipulator

The invention discloses a full-automatic brass nail hot-melting assembly and detection machine based on an industrial manipulator. The assembly and detection machine comprises a rack, a six-station divider rotationally mounted on the rack, a rotary table fixedly connected onto the six-station divider and a servomotor used for driving the six-station divider to rotate on the rack, wherein six product positioning jigs which are uniformly distributed in the circumferential direction are arranged on the rotary table; a product placing station, a product cover plate placing station, a first brass nail pick-and-place station, a second brass nail pick-and-place station, a brass nail hot-melting station and a finished product pick-and-place station which are located at the periphery of the rotary table and sequentially distributed in the circumferential direction of the rotary table are arranged on the rack; and the servomotor, the product cover plate placing station, the first brass nail pick-and-place station, the second brass nail pick-and-place station, the brass nail hot-melting station and the finished product pick-and-place station are electrically connected with a programmable logic controller. The full-automatic brass nail hot-melting assembly and detection machine is small in size and compact in structure,multifunctional, and can achieve full-automatic fast assembly and detection of two different specifications of brass nails and improve the automation degree and operational efficiency of brass nail assembly.

Owner:SUZHOU YIMEIDE TECH CO LTD

Simple industrial mechanical arm for teaching

InactiveCN108015757AImprove scalabilitySimple structureProgramme-controlled manipulatorEducational modelsGear wheelDrive shaft

The invention discloses a simple industrial mechanical arm for teaching, and relates to the technical field of teaching tools. The simple industrial mechanical arm for teaching comprises a base box; abearing block is arranged at the bottom of the inner wall of the base box; a transmission shaft matched with the bearing block is arranged in the bearing block; the end, close to the bearing block, of the transmission shaft is sleeved with a first bevel gear; weighting blocks are symmetrically and fixedly connected to the bottom of the inner wall of the base box and are located on the two sides of the bearing block; a rotating shaft motor is fixedly connected to the top of the weighing block on the right side of the bearing block; and an output shaft of the rotating shaft motor is fixedly connected with a second bevel gear. According to the simple industrial mechanical arm for teaching, the overall structure of the mechanical arm can be simplified through an electromagnetic telescopic device, use can be more convenient, the size is small, carrying by teachers and explaining to students can be facilitated so that the students can better understand and master related knowledge, and therefore the learning interests of the students can be increased, and the classroom life can be enriched.

Owner:黄静

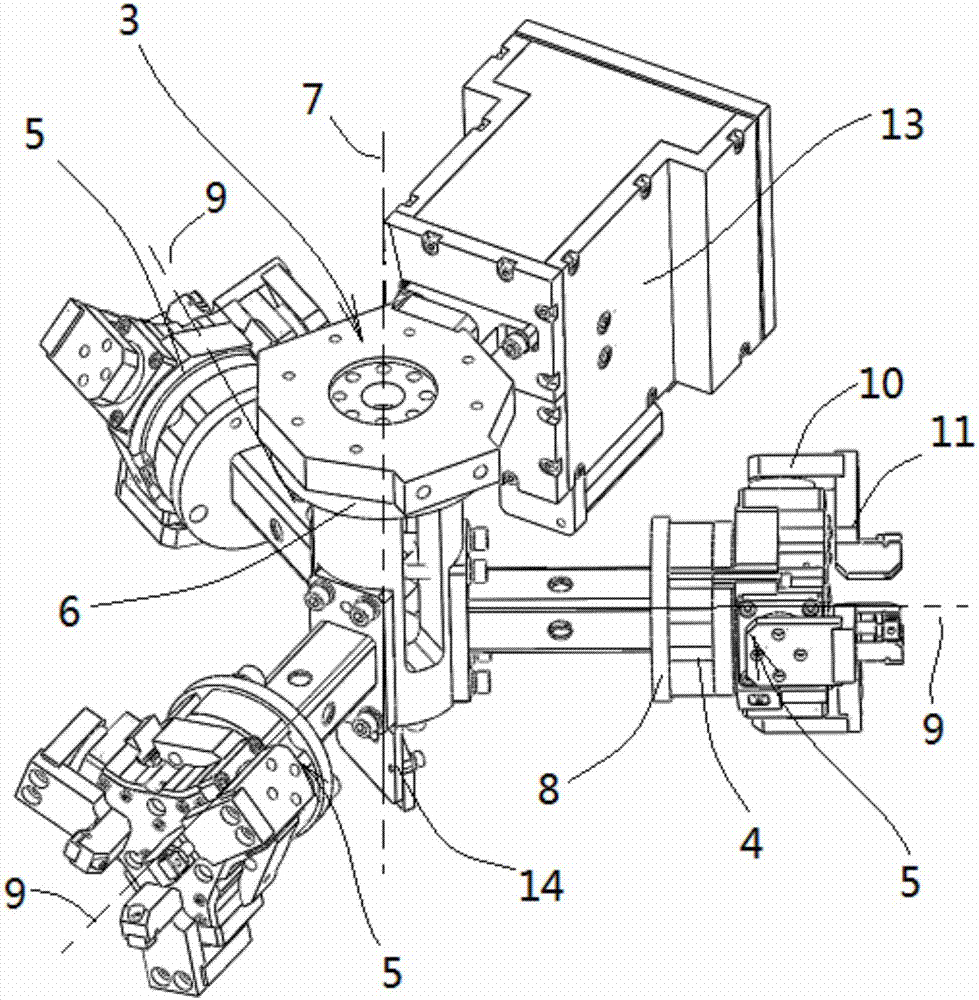

Device for dieless progressive molding of metal plate

InactiveCN101829722AHigh processing flexibilityRealize formingShaping toolsIndustrial machineEngineering

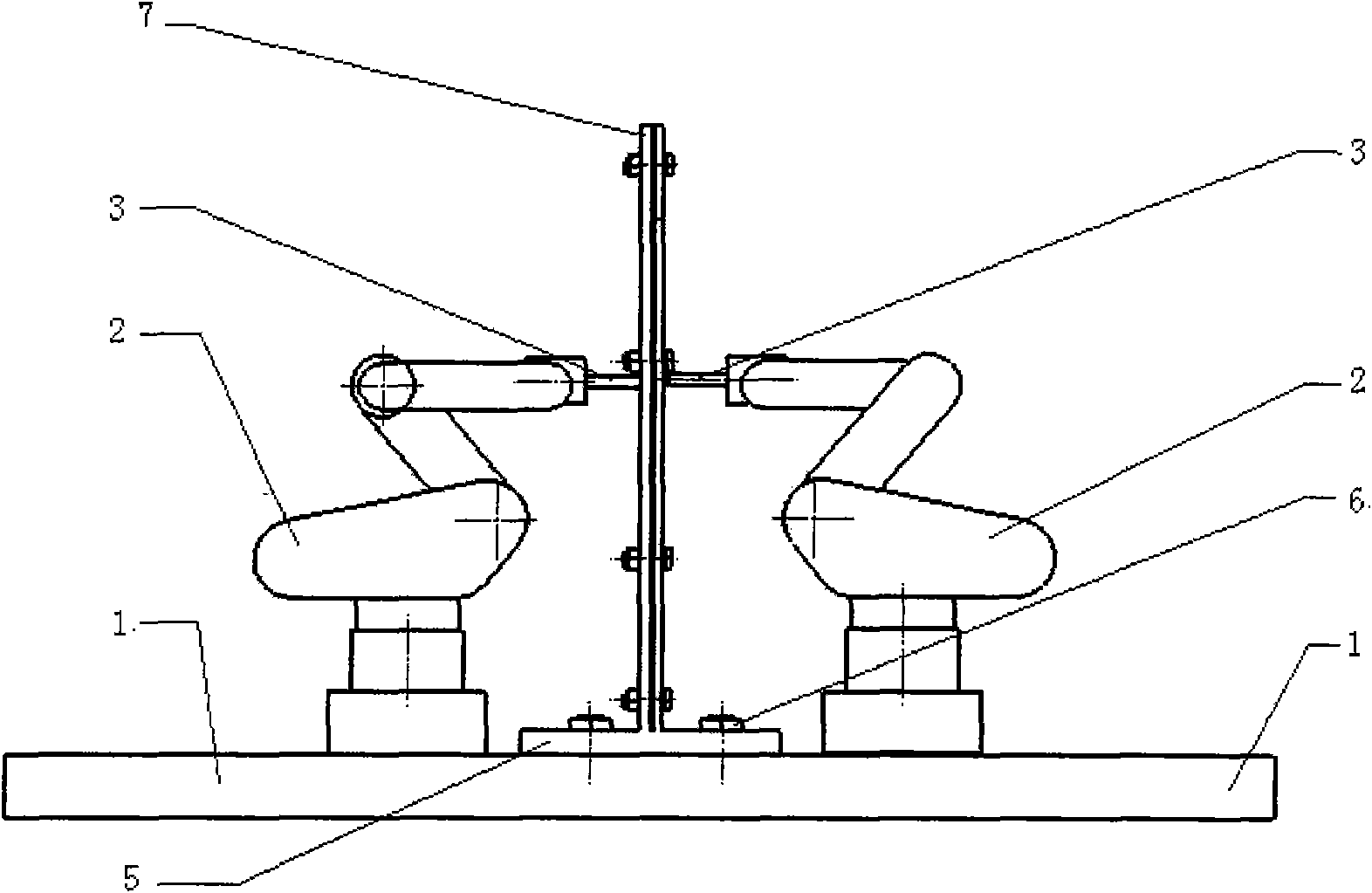

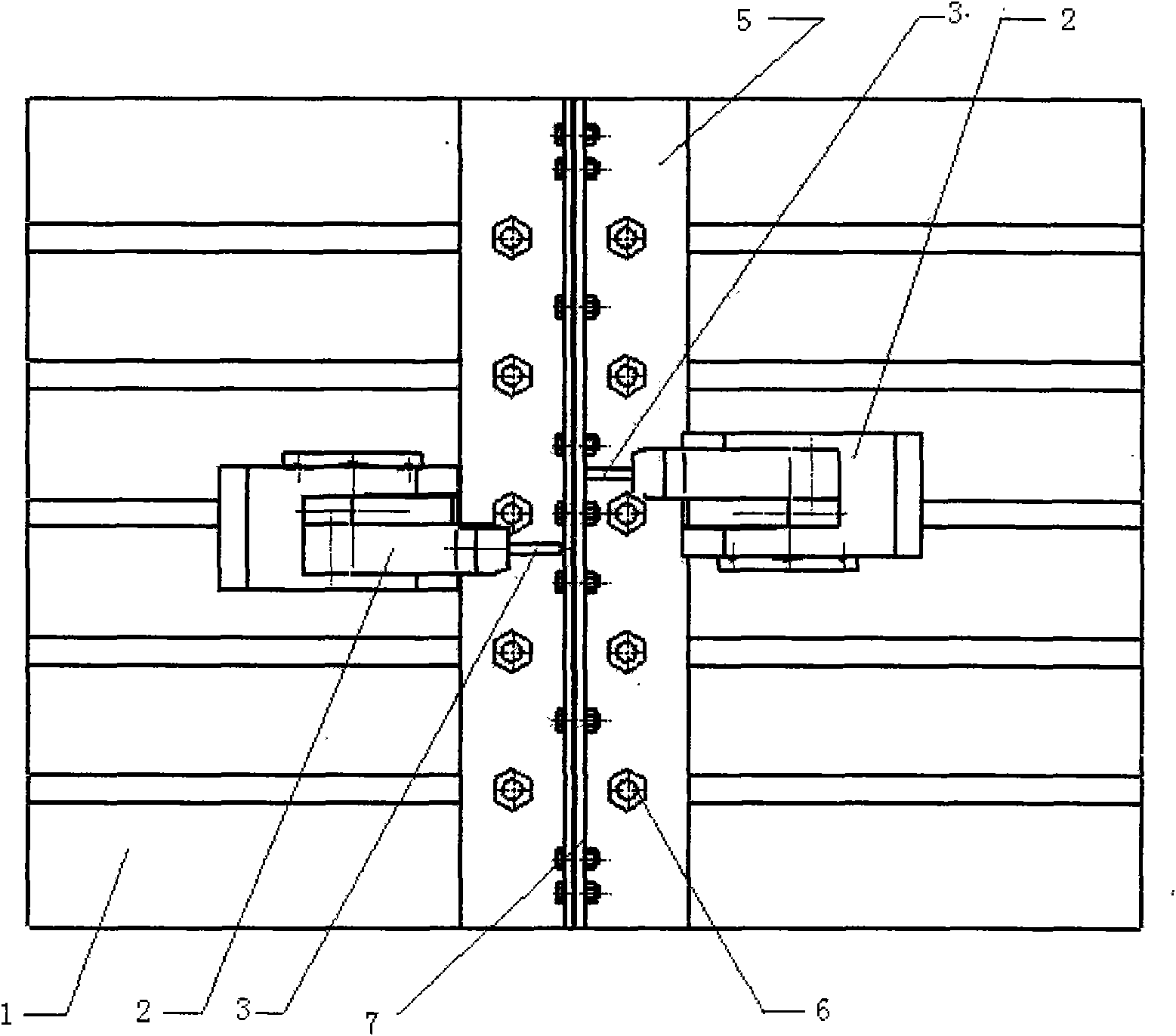

The invention relates to a device for dieless progressive molding of a metal plate, which comprises two industrial manipulators (2), molding tool heads (3), a plate clamping frame (7) and a platform (1), wherein the plate clamping frame is fixed in the middle of the platform; the two industrial manipulators are respectively distributed at both sides of the plate clamping frame (7); and one ends of the two molding tool heads are connected with the industrial manipulators (2), and the other ends are in contact with a plate on the plate clamping frame (7). At work, the industrial manipulators (2) drive the molding tool heads (3) to move to respectively exert both sides of the plate, the molding on the whole plate can be realized, the molding or correction of a small local area on the plate can be also realized, and various metal plate parts meanwhile containing convex and concave curved surfaces are molded without a die and have larger processing flexibility. The invention has simple structure and low use cost and is suitable for the molding processing of parts in small batch with various complicated curved surfaces, such as automobile covering element, aerospace aircraft shell, and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Industrial mechanical arm

InactiveCN106272370AAvoid affecting work efficiencyGuaranteed stabilityProgramme-controlled manipulatorEngineeringIndustrial manipulator

Owner:WUXI XINGUANG COMP INSTALLATION

Industrial manipulator and working method thereof

ActiveCN107030721AReduce waiting timeReduce cycle timesProgramme controlProgramme-controlled manipulatorRobot handIndustrial manipulator

The invention relates to an industrial manipulator and a working method thereof. The industrial manipulator is characterized in that two manipulator grippers can be controlled by a control device to pre-grip two workpieces to be processed and move the workpieces to be processed to a processing machine tool; an idle manipulator gripper is used for gripping a finished workpiece product from a processing clamp and positioning one of the two pre-gripped workpieces to be processed on the processing clamp for processing; after the workpiece to be processed is processed to be the finished workpiece product, the industrial manipulator is operated to position another pre-gripped workpiece to be processed on the processing clamp; two griped finished workpiece products are positioned to a finished product area through the industrial manipulator while the workpiece to be processed on the processing clamp is processed through the processing machine tool, and then two workpieces to be processed are griped from a charging area and moved to the processing machine tool through the industrial manipulator. Therefore, the circling strokes of the mechanical arm can be reduced, and as a result, the production efficiency is increased, and the cycle time can be saved.

Owner:华域皮尔博格泵技术有限公司

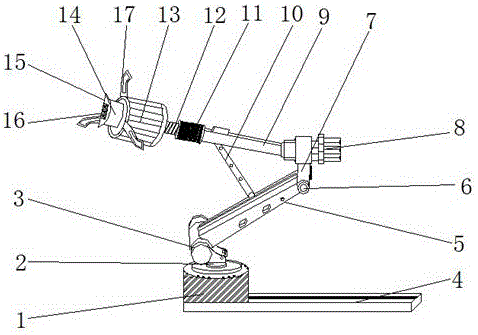

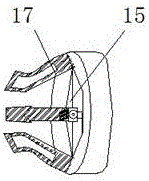

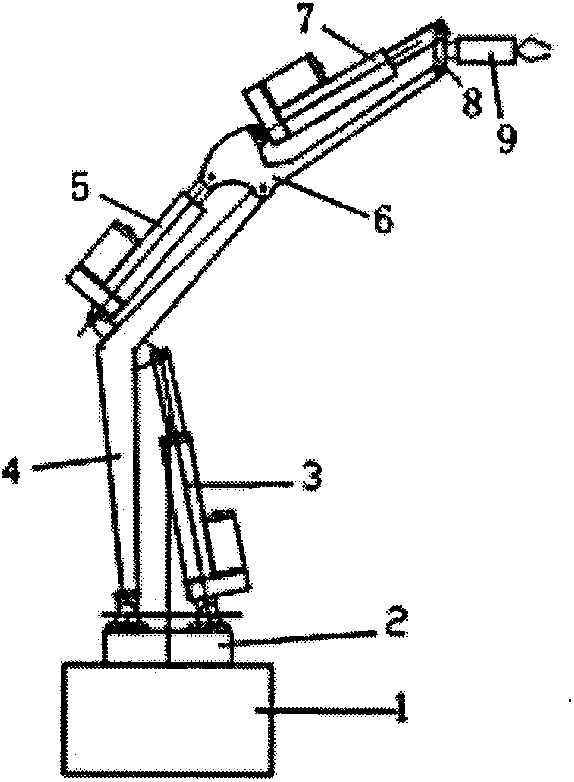

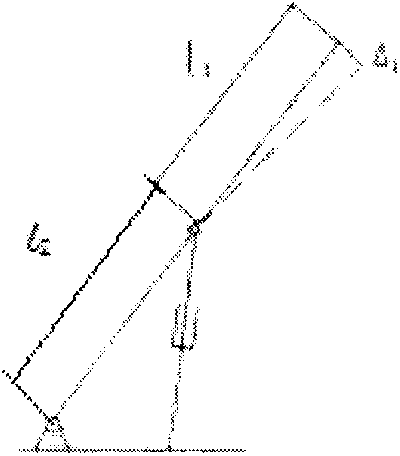

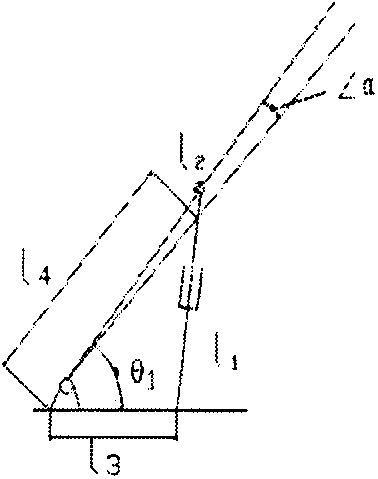

Four-degree-of freedom electrically driven multi-joint industrial manipulator of closed-chain structure

InactiveCN104723331AImprove rigidityHigh precisionProgramme-controlled manipulatorElectricityRobotic arm

The invention relates to the technical field of manipulators and in particular relates to a four-degree-of freedom electrically driven multi-joint industrial manipulator of a closed-chain structure. The manipulator is composed of a base, a rotary table, a large arm, an electric large arm push rod, a small arm, an electric small arm push rod, a wrist oscillating bar, an electric wrist push rod and a gripper; the large arm is mounted on the rotary table; the electric large arm push rod is connected with the large arm and the rotary table by use of hinges; the electric small arm push rod is connected with the large arm and the small arm by use of hinges; the electric wrist push rod is connected with the wrist oscillating bar and the small arm by use of hinges; the gripper is mounted on the wrist oscillating bar. According to the four-degree-of freedom electrically driven multi-joint industrial manipulator of the closed-chain structure, the electric push rods and the arms are combined into the triangular closed-chain manipulator, and compared with the existing manipulator of an open-chain structure, the rigidity of the mechanical arm is improved, the mass of the mechanical arm is reduced and the precision is improved; as a result, the manipulator has the characteristics of low cost, simple structure, good rigidity, high precision and high modularization degree.

Owner:GUANGXI UNIV

Rotatable simple industrial mechanical hand

InactiveCN107696057ARealize the function of anti-fallAvoid crash situationsGripping headsBall screwEngineering

The invention provides a rotatable simple industrial mechanical hand which comprises a ball screw, a moving clamping plate, a supporting block, an auxiliary bearing table, a guiding groove, a guide-incavity, a transparent protection sleeve, a guide wheel and an annular sliding groove. The ball screw is assembled to the middle position of the interior of the groove. The moving clamping plate is installed on the lower end face of a nut seat. The supporting block is fixed to the lower end face of the moving clamping plate. The auxiliary bearing table is installed on the lower end face of a fixedclamping plate. The guiding groove is formed in the lower end face of the interior of the guide-in cavity. The guide-in cavity is formed in the middle position of the auxiliary bearing table. By means of the design, the anti-falling function of goods clamping is achieved, the transparent protection sleeve is arranged on the annular side face of a rotating shaft in a sleeving manner, the guide wheel is installed on the upper end face of the transparent protection sleeve, and the annular sliding groove is formed in the lower end of a mechanical arm. By means of the design, the protection function of the rotating shaft is achieved, the service life of the rotating shaft is prolonged, and the rotatable simple industrial mechanical hand is reasonable in structure, good in protection performance, long in service life, good in stability and high in reliability.

Owner:董杰

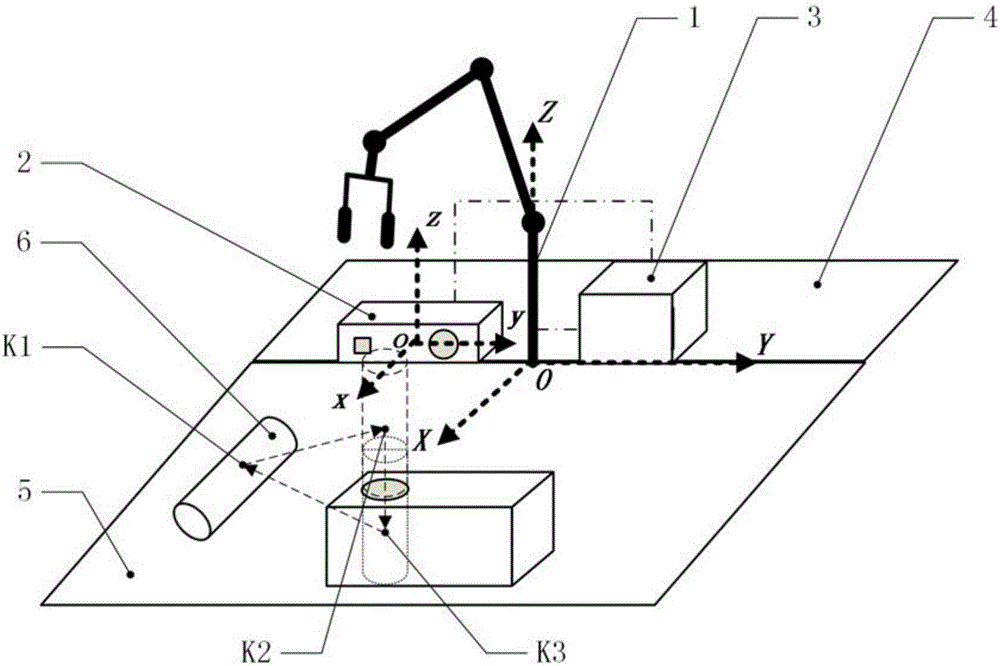

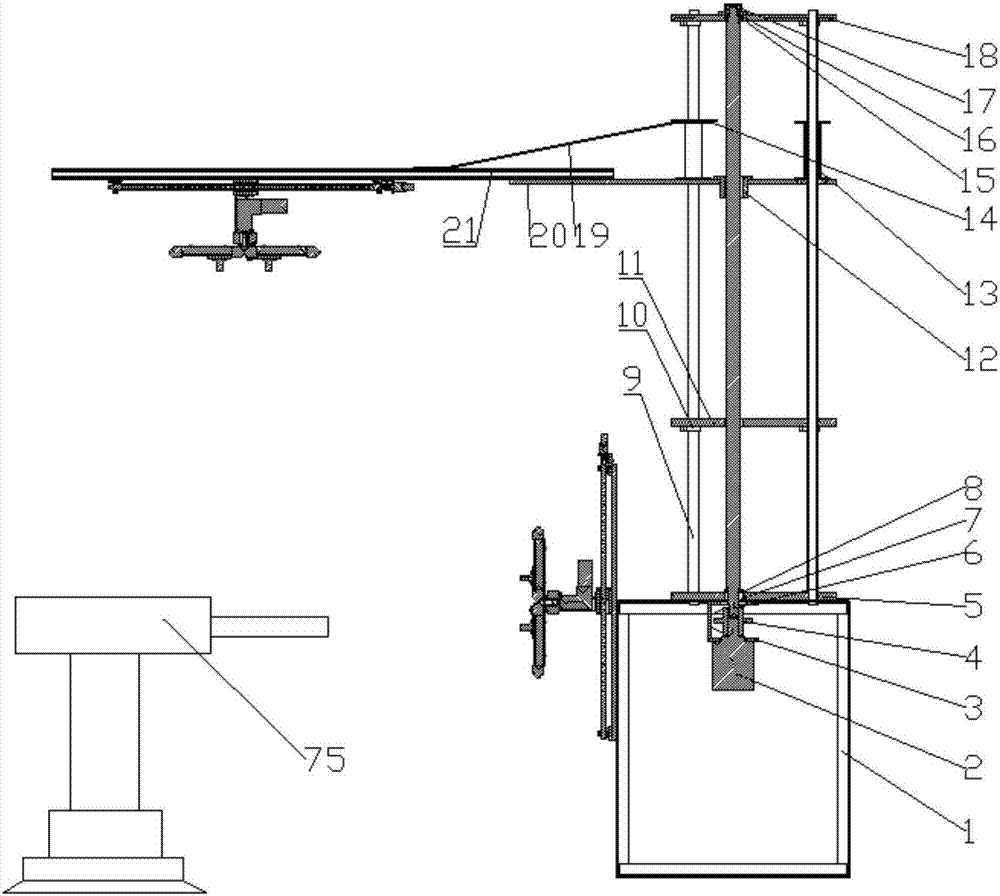

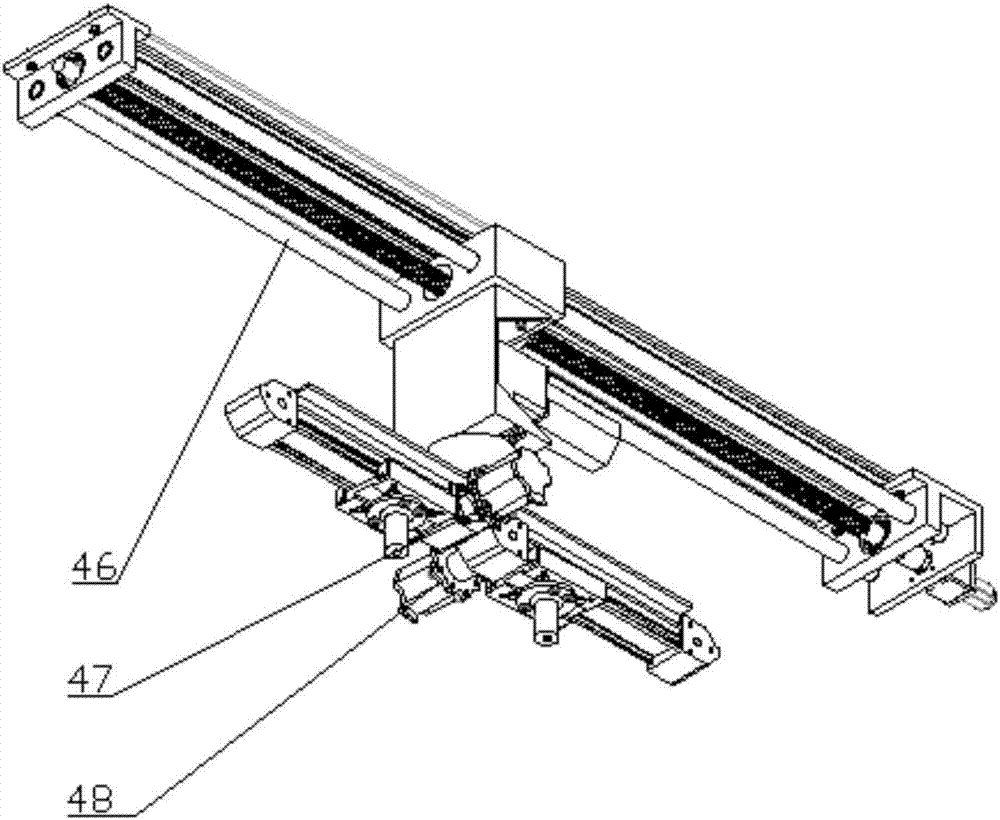

Three-dimensional positioning device for position calibration of industrial manipulator

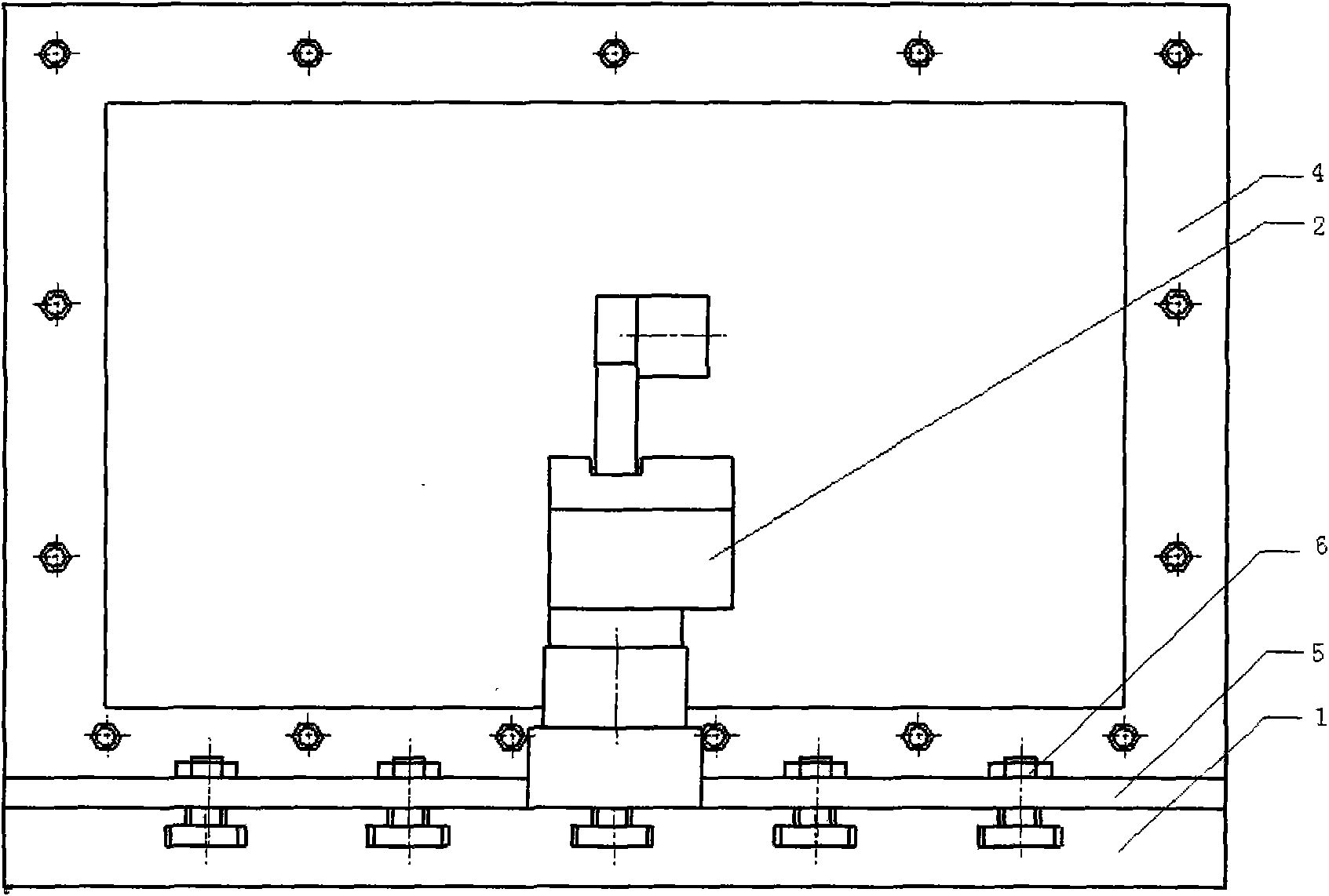

The invention provides a three-dimensional positioning device for position calibration of an industrial manipulator. The three-dimensional positioning device comprises a stand column base, a stand column lead screw component, an X-axis component, a Y-axis component and the like, wherein the X-axis component is fixed on the stand column lead screw component; the Y-axis component is fixed on the stand column base; and red and green laser transmitters on Z-axis straight line sliding table modules on the X-axis and the Z-axis transmit laser so as to realize coordinate calibration of the designated location of the manipulator. Compared with the traditional method, an additional device is not needed to be arranged at the tail end of the manipulator during the positioning process, and the three-dimensional positioning device is visual, simple to operate, low in cost, and convenient to mount.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com