Improved structure of industrial mechanical arms

A technology of industrial machinery and arms, which is applied in the field of improved structure of industrial mechanical arms, can solve problems such as easy falling off of the clamped object, increase the friction force between the clamping end of the robot hand and the clamped object, etc., and achieve increased friction and control precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

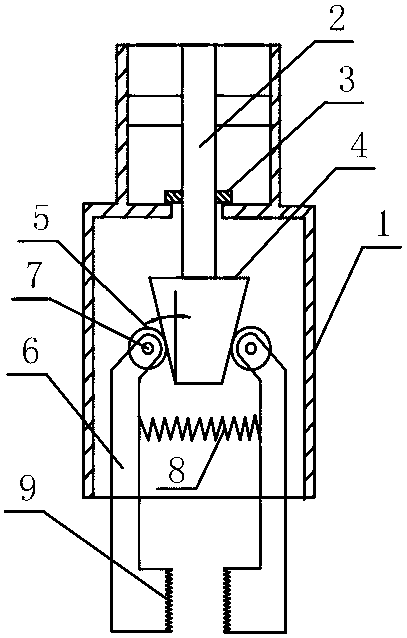

[0021] Such as figure 1 As shown, the improved structure of the industrial robot arm of this embodiment includes a clamping mechanism body 1, a control rod 2, a limit block 3, a wedge 4, a rotating roller 5, a clamping arm 6, and the rotating roller 5 is installed in the clamping mechanism The body 1 is inside and can rotate along the mounting axis. The clamping mechanism body 1 is also provided with a through hole. One end of the control rod 2 passes through the through hole and is fixedly connected to the wedge 4, and the other end is connected to the drive mechanism. The drive mechanism constitutes a control wedge. The inclined surface of 4 is far away from the rotating roller 5 or close to and holding the control mechanism of the rotating roller 5, and the outer wall of the control rod has a protruding limit block 3, one end of the clamping arm 6 is fixedly connected with the rotating roller 5, and the clamping arm The other end of 6 constitutes the clamping end, and the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com