Method for programming or setting movements or sequences of industrial robot

An industrial manipulator and movement technology, applied in the direction of manipulators, program control manipulators, manufacturing tools, etc., can solve unfavorable problems and achieve high-level security effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

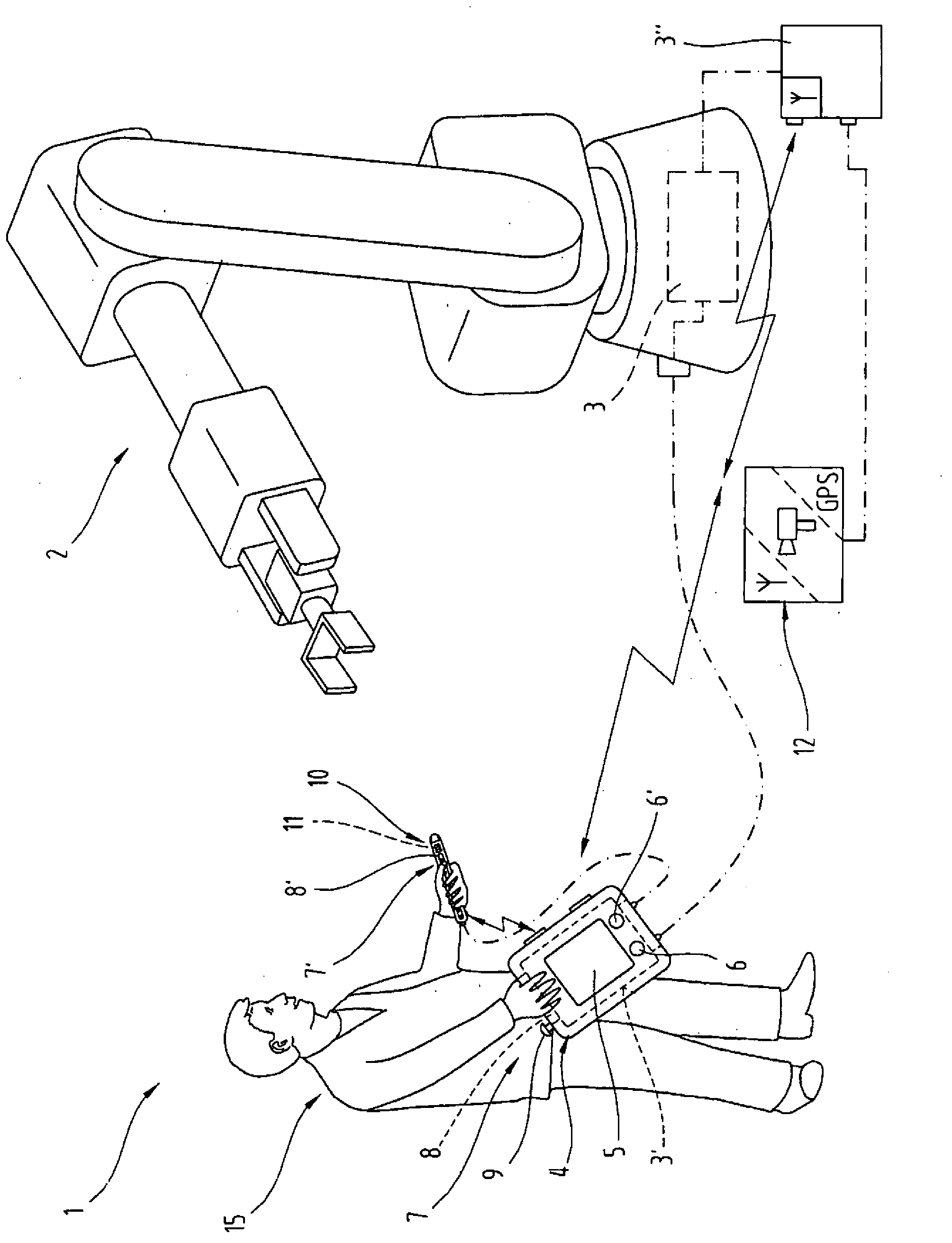

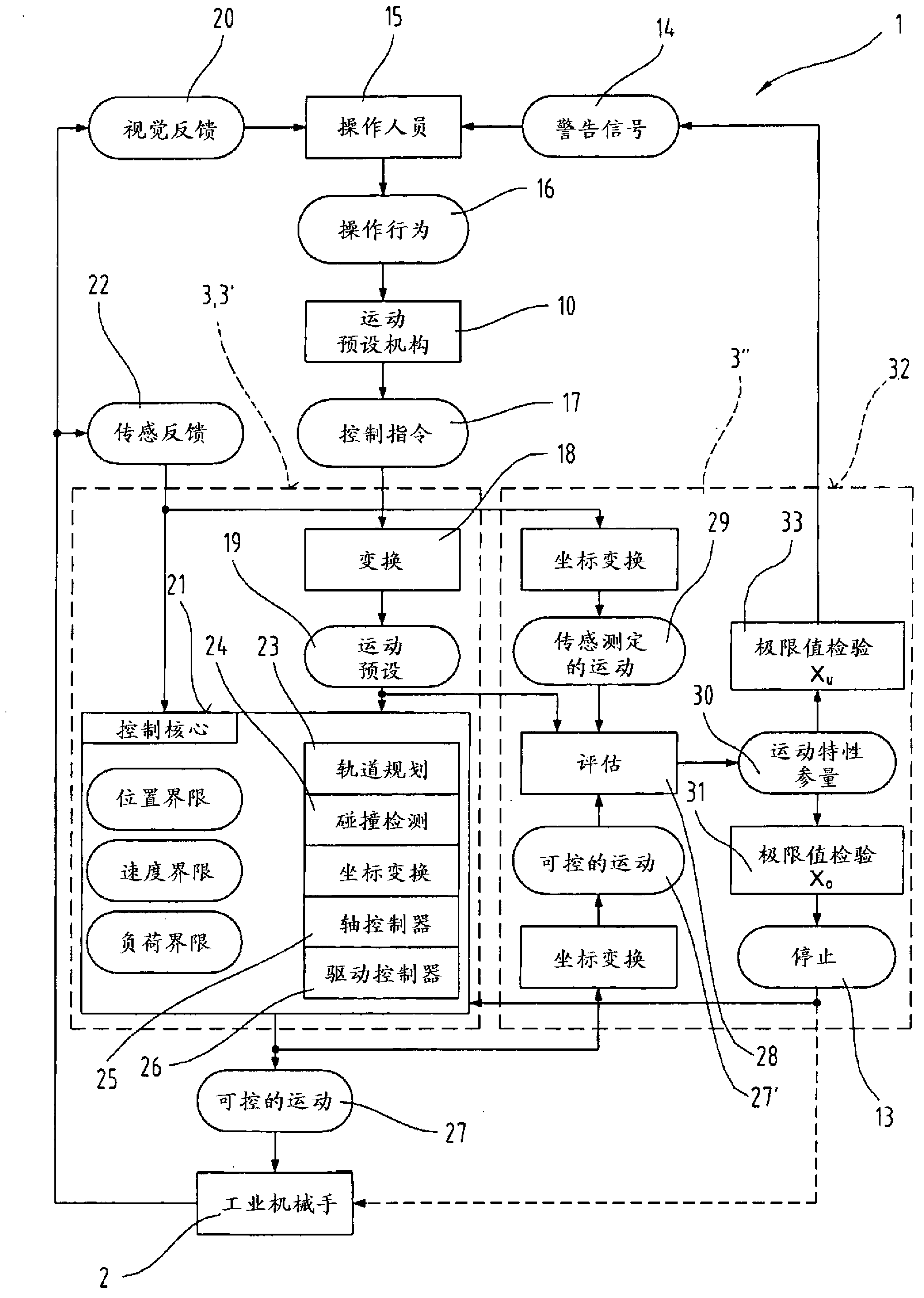

[0029] figure 1 Schematically and by way of example, a control system 1 is shown schematically and by means of which a movement or sequence of an industrial robot 2 can be programmed or preset. The industrial manipulator 2 can be formed by a multi-axis manipulator unit known from the prior art or by other manipulator units, with which technical processes for workpieces, such as welding, can be carried out automatically or partially automatically. Process or paint process or operating process.

[0030]At least one industrial robot 2 in the control system 1 is equipped with at least one built-in and / or external control device 3, 3', 3". The control system 1 can be controlled by any electronic technology known from the prior art. The control devices 3, 3', 3" are formed, wherein a central and / or a decentralized control architecture can be applied according to technical requirements. In particular, the distributed control system 1 can be configured through the cooperation of a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com