Patents

Literature

121results about How to "Achieve shift" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

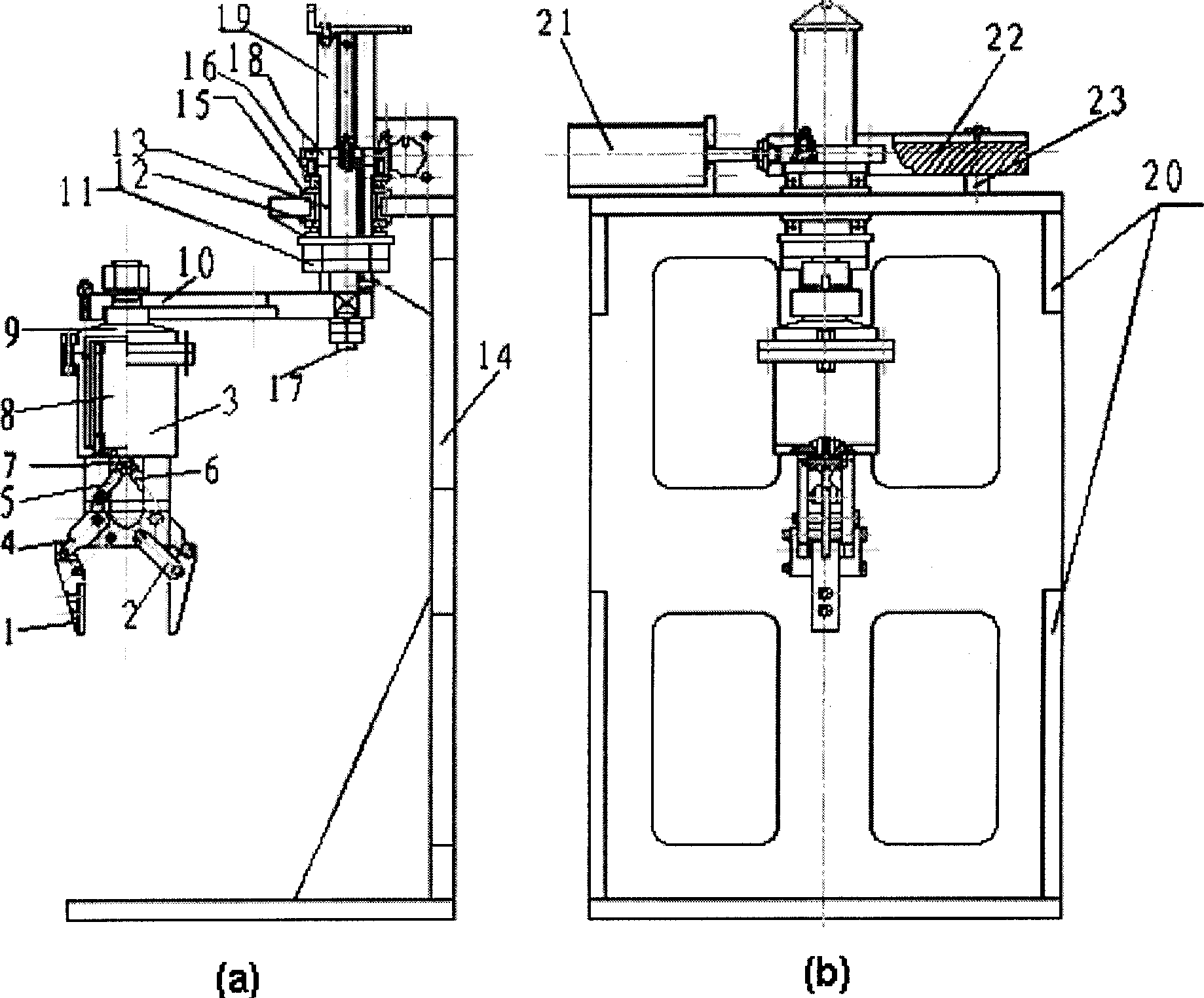

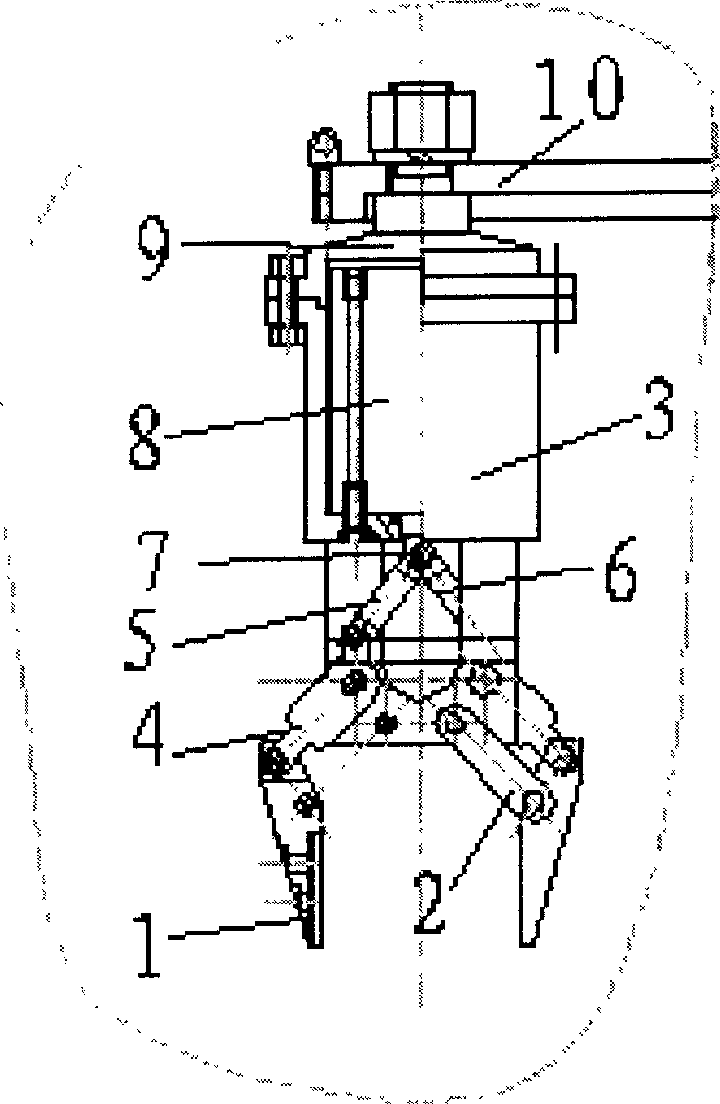

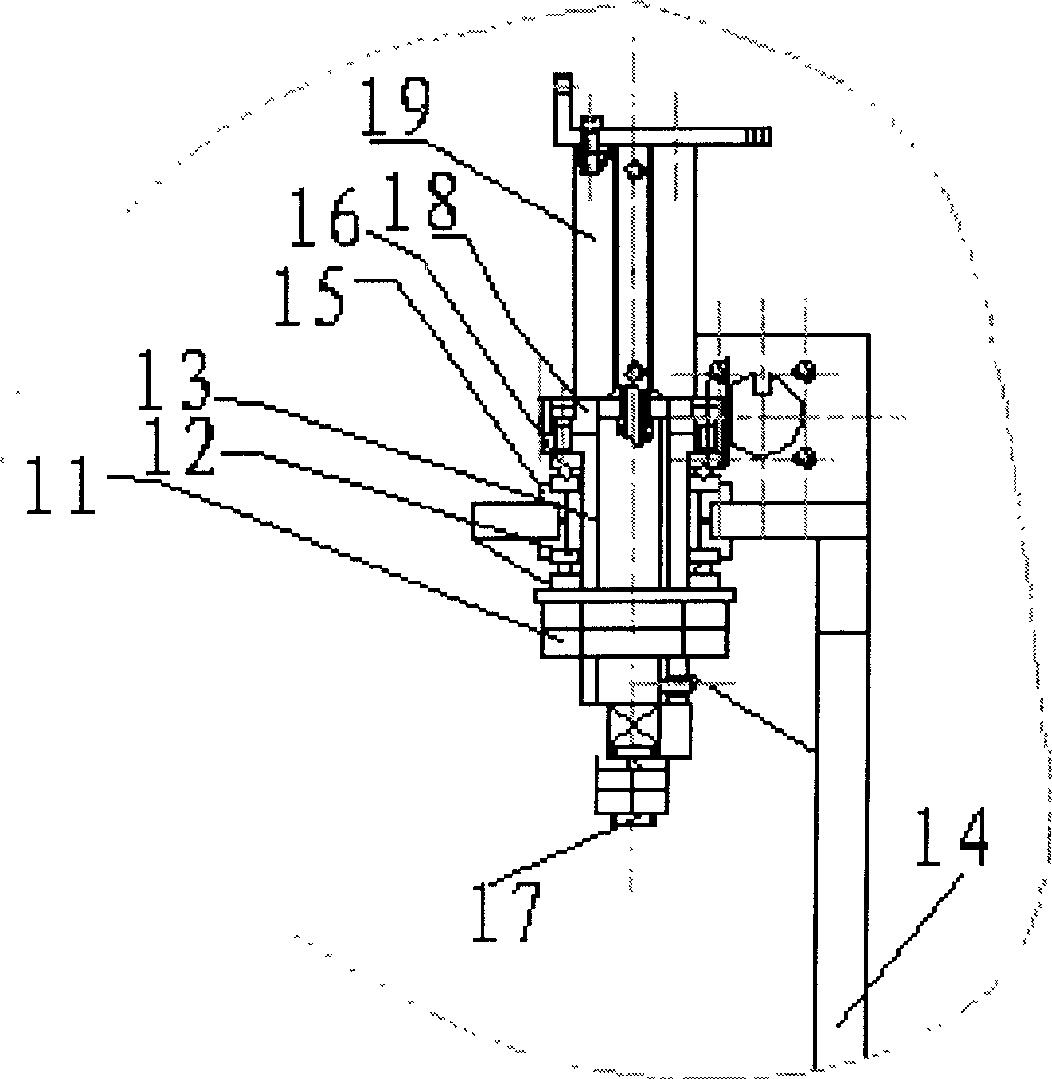

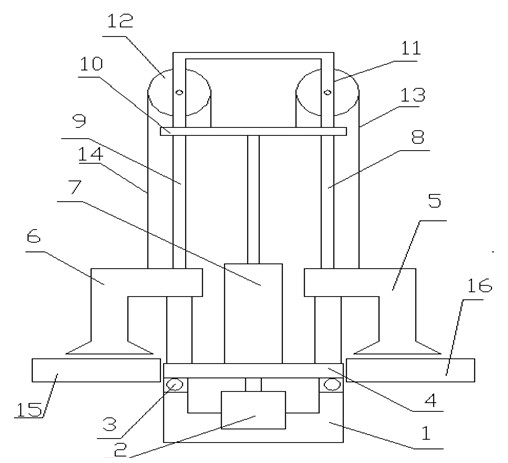

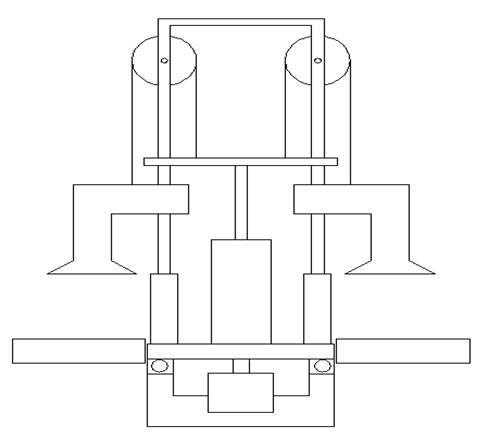

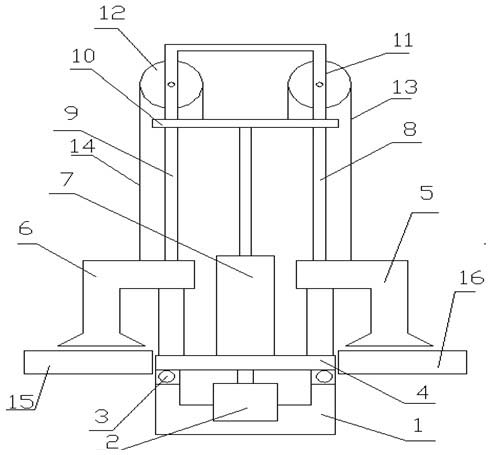

Full pneumatic combined multifunctional industrial manipulator

InactiveCN1701928ARealize the clamping effectAchieve shiftProgramme-controlled manipulatorGripping headsEngineeringActuator

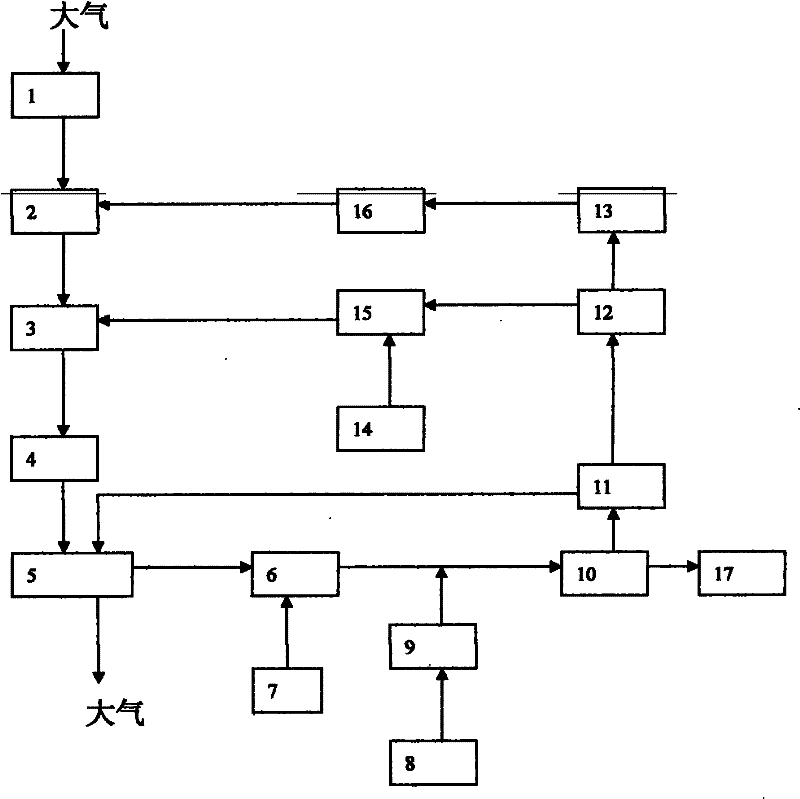

The invention discloses total aerodynamic composite type multifunctional industrial manipulator comprised interchangeable end effector set on suspension arm to clamp workpiece, and aerodynamic system comprised air supply, processor for air supply, two two-position three-way electromagnetic valves, one two-position five-way electromagnetic directional selecting valve, two precompression cylinders, a reciprocating cylinder, and PLC predetermined control program for cylinders to control displacement, mechanical clamp and up-down motion of interchangeable end effector. This invention uses totally gas to drive, selects corresponding mechanical clamper, vacuum absorb hand and gas pocket expand hand for different works to complete work quickly, and increases its application area and utilization rate.

Owner:西安思源职业学院

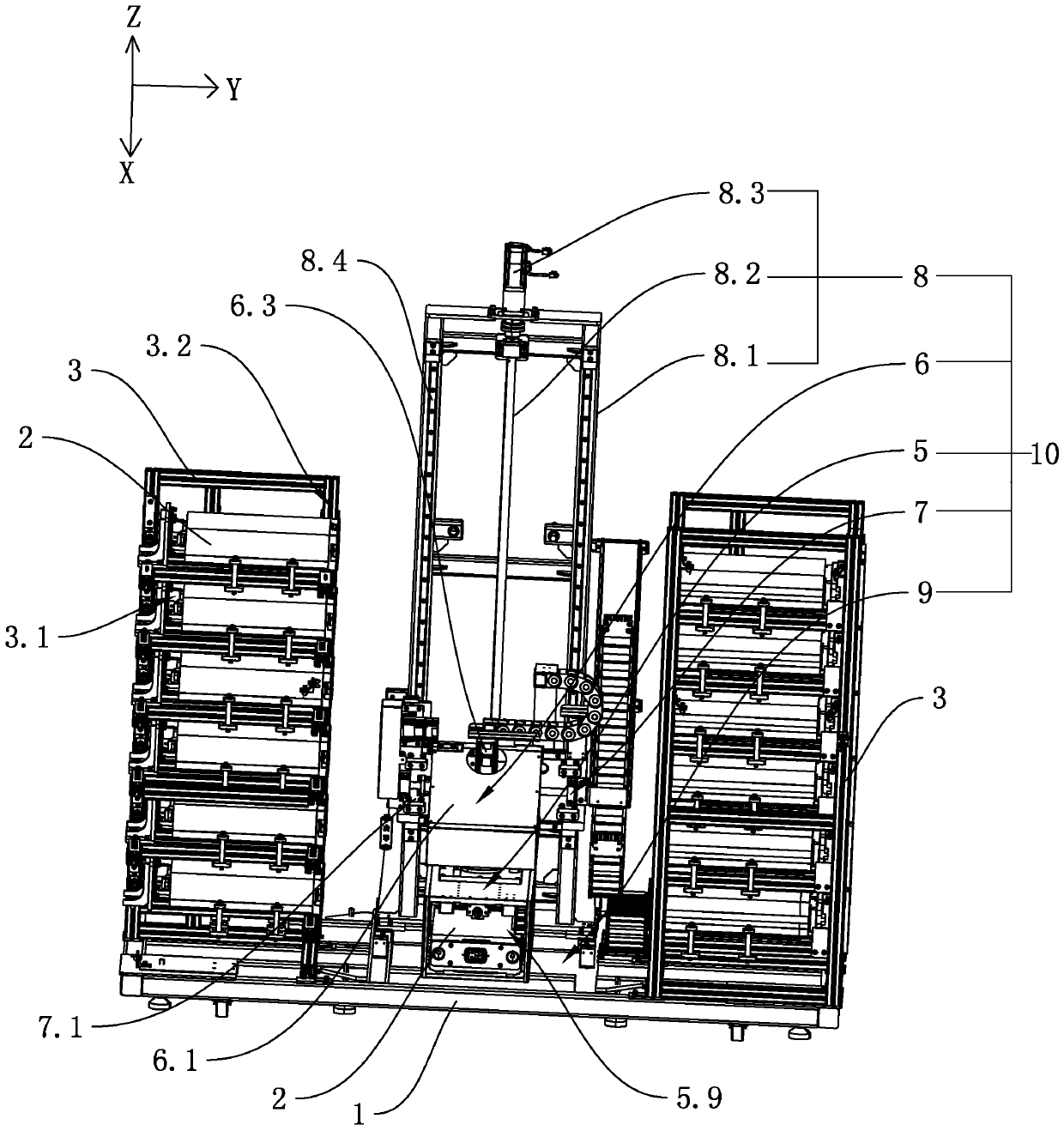

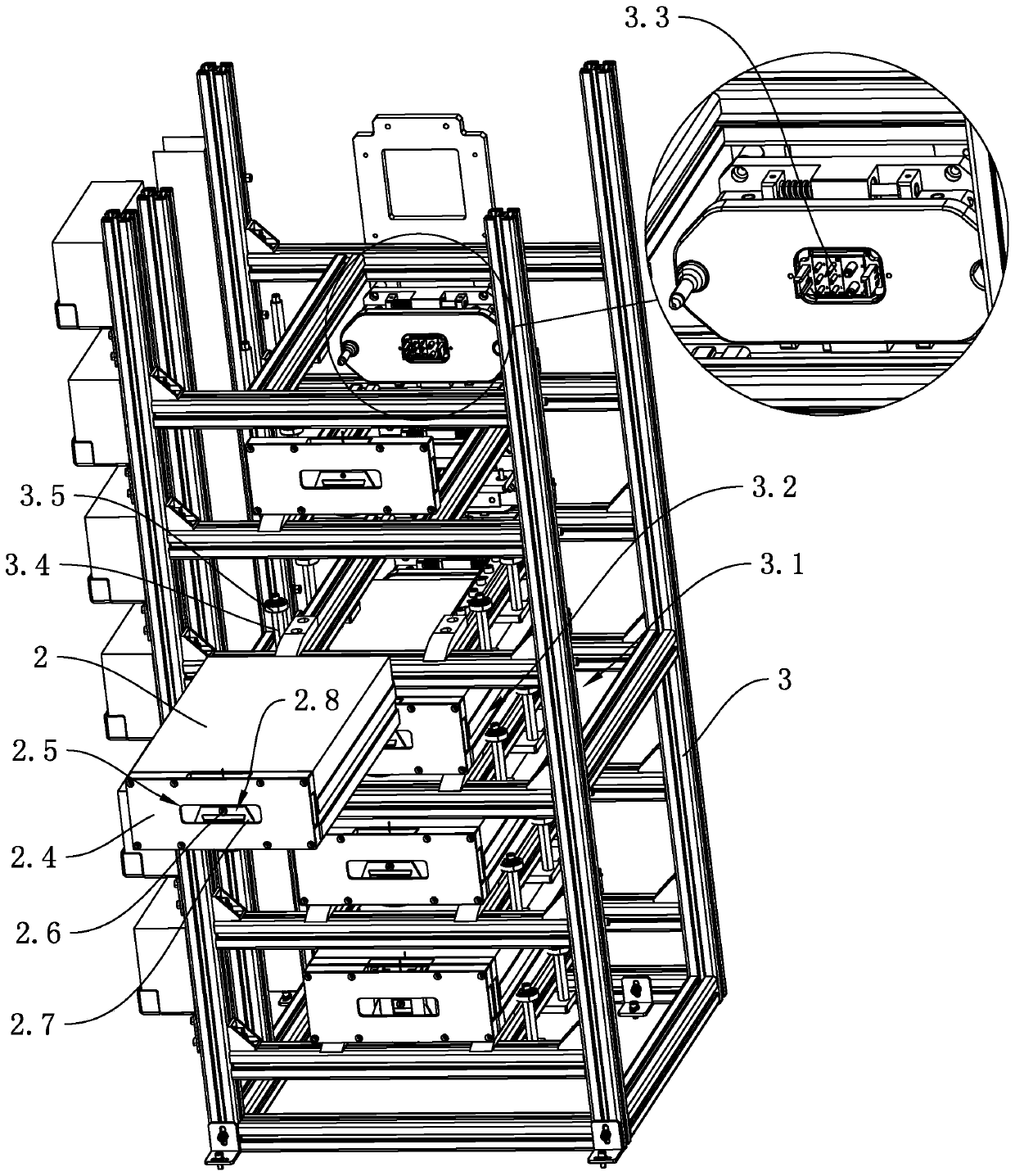

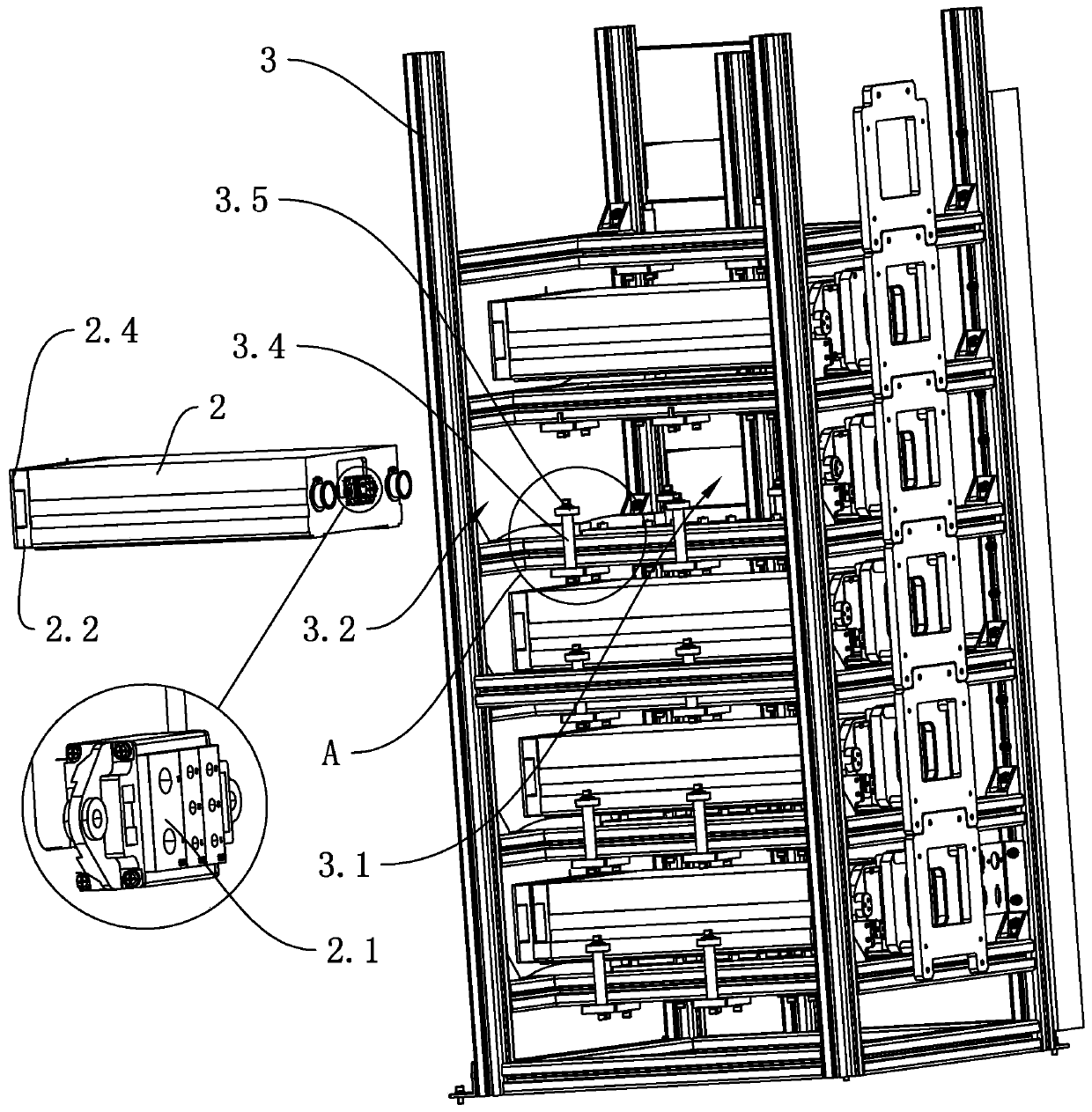

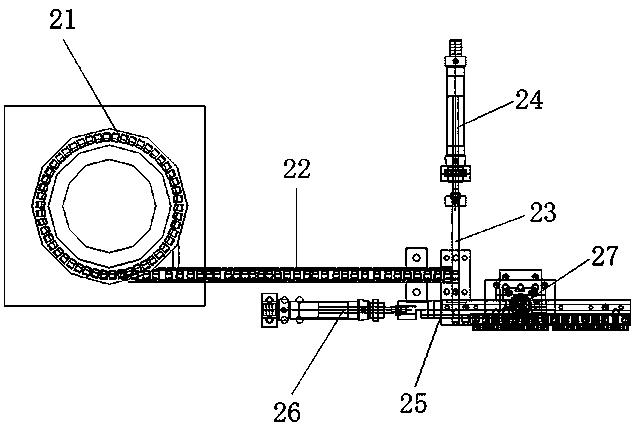

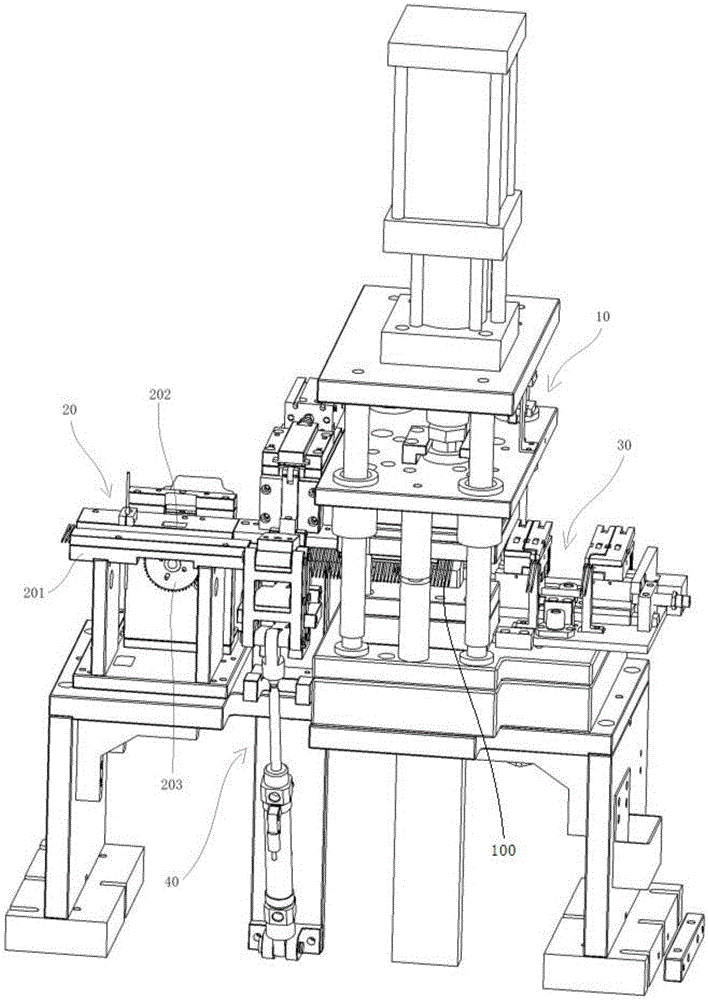

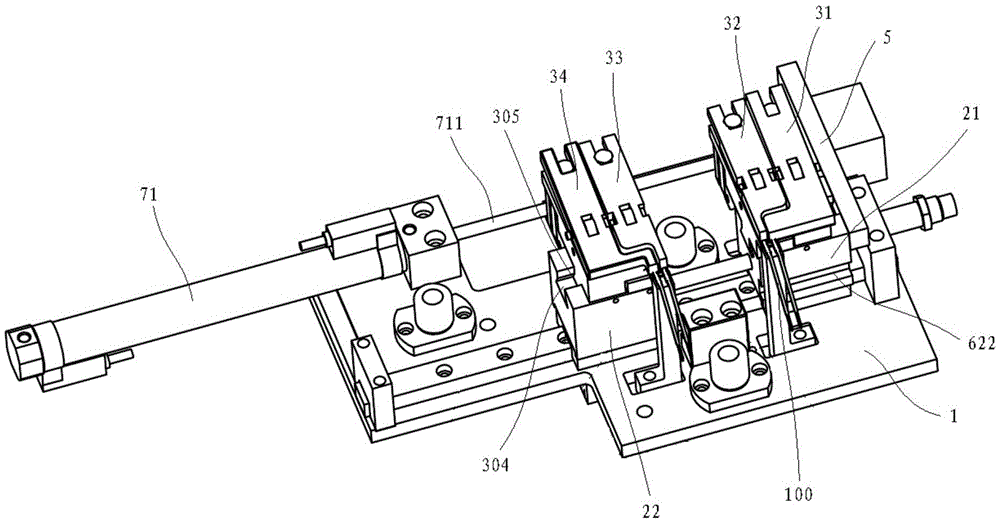

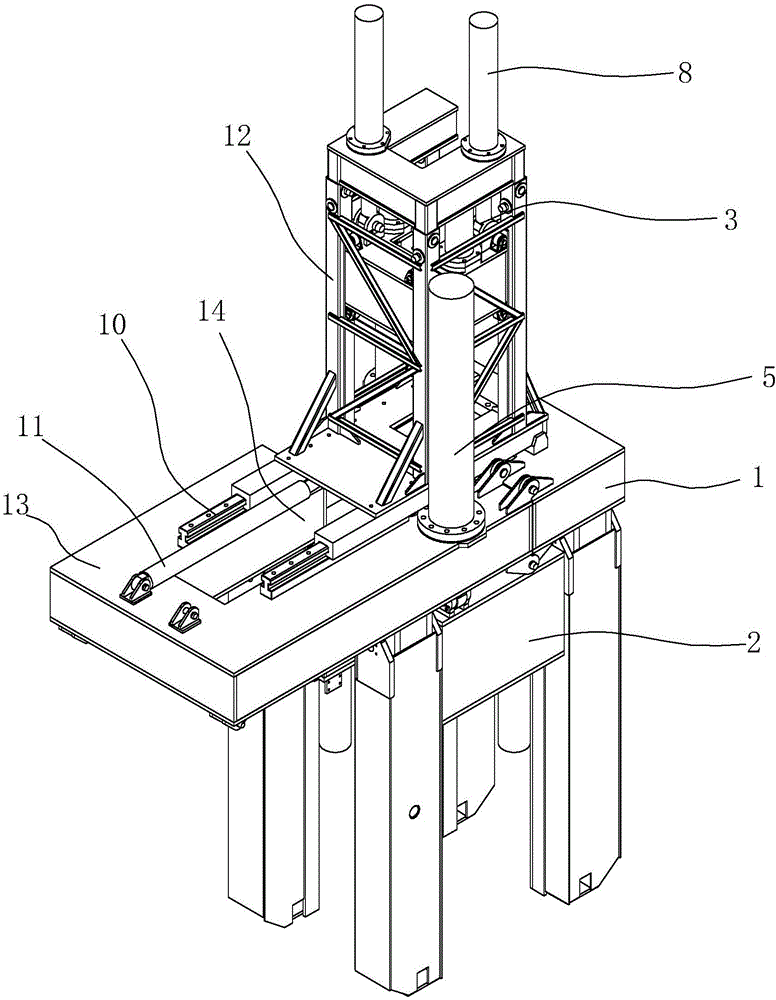

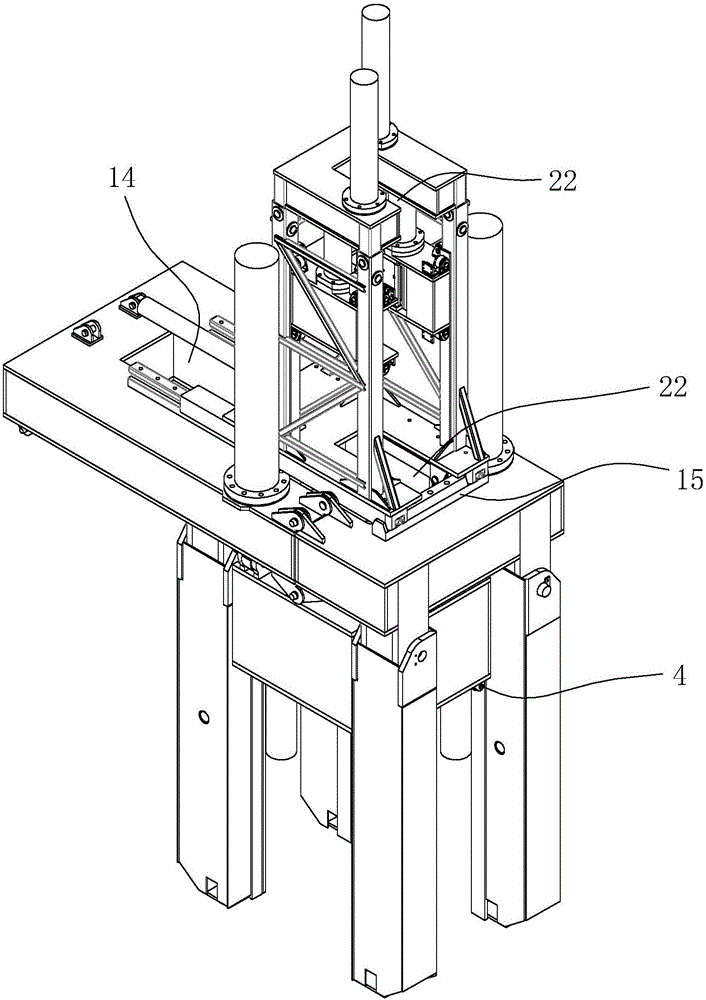

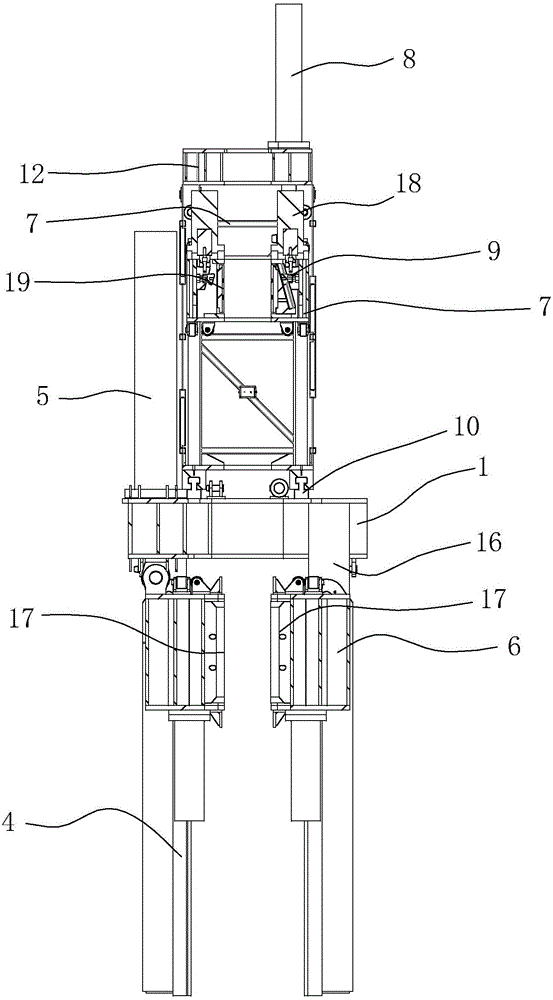

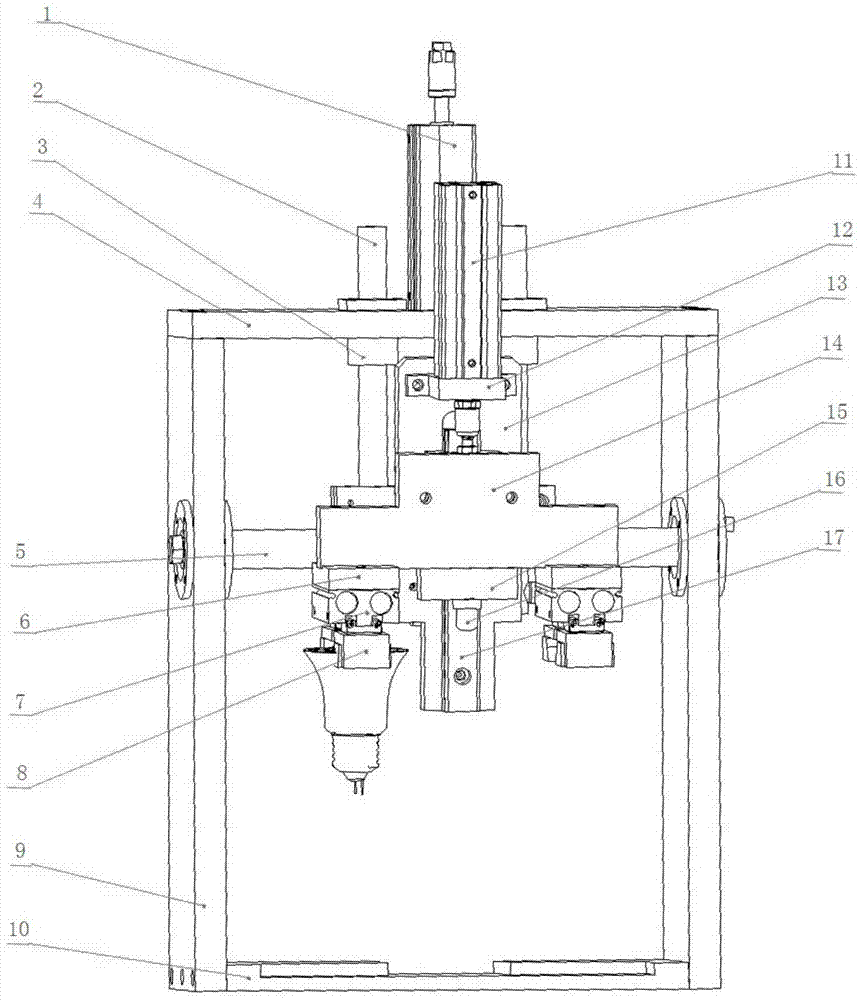

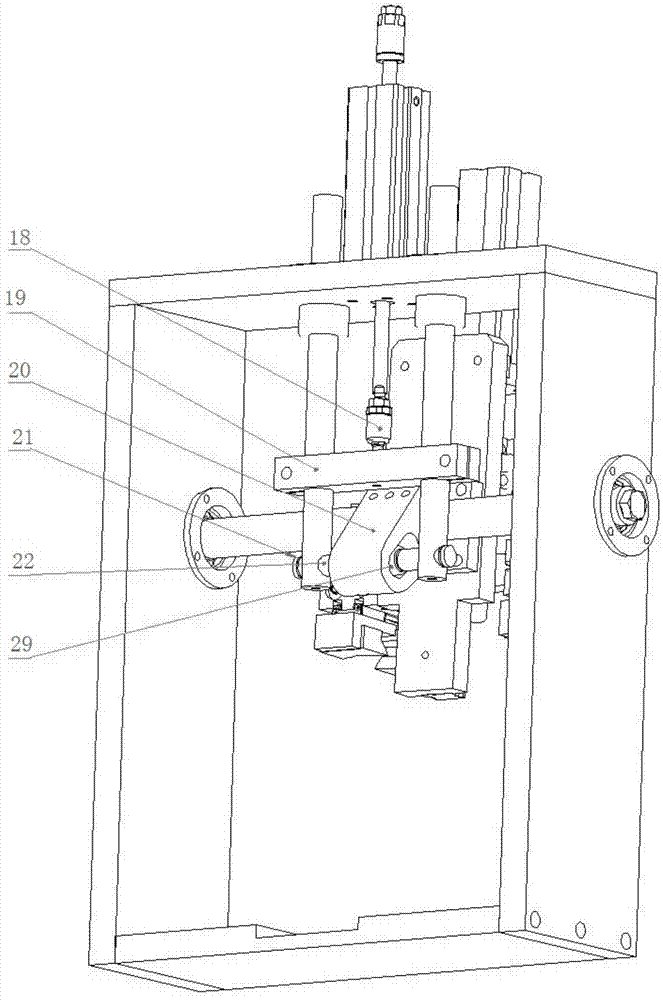

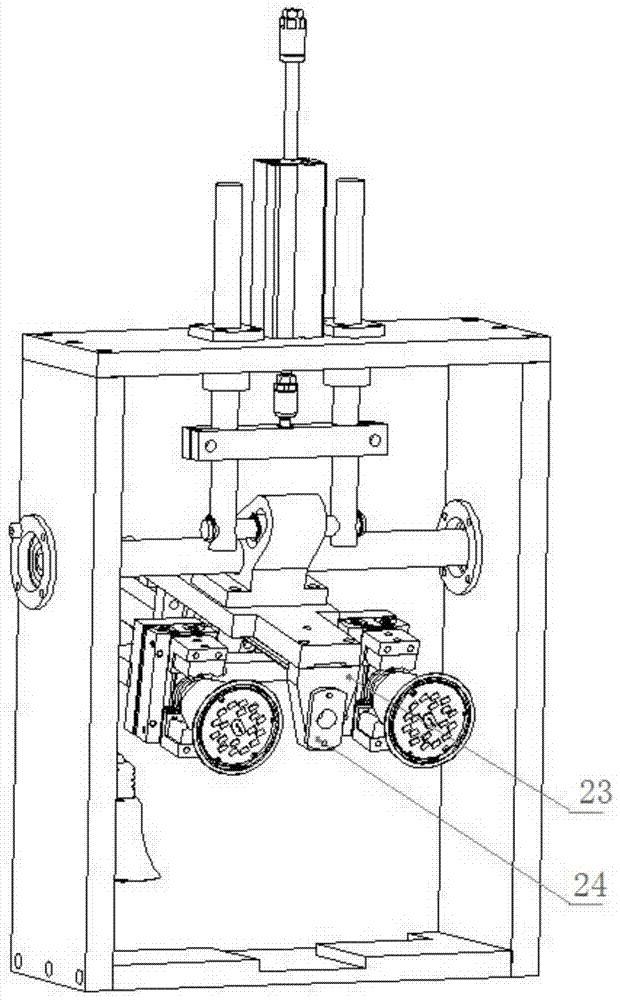

AGV charging station

ActiveCN110901601ALow costGood value for moneyCharging stationsElectric propulsion mountingEngineeringStructural engineering

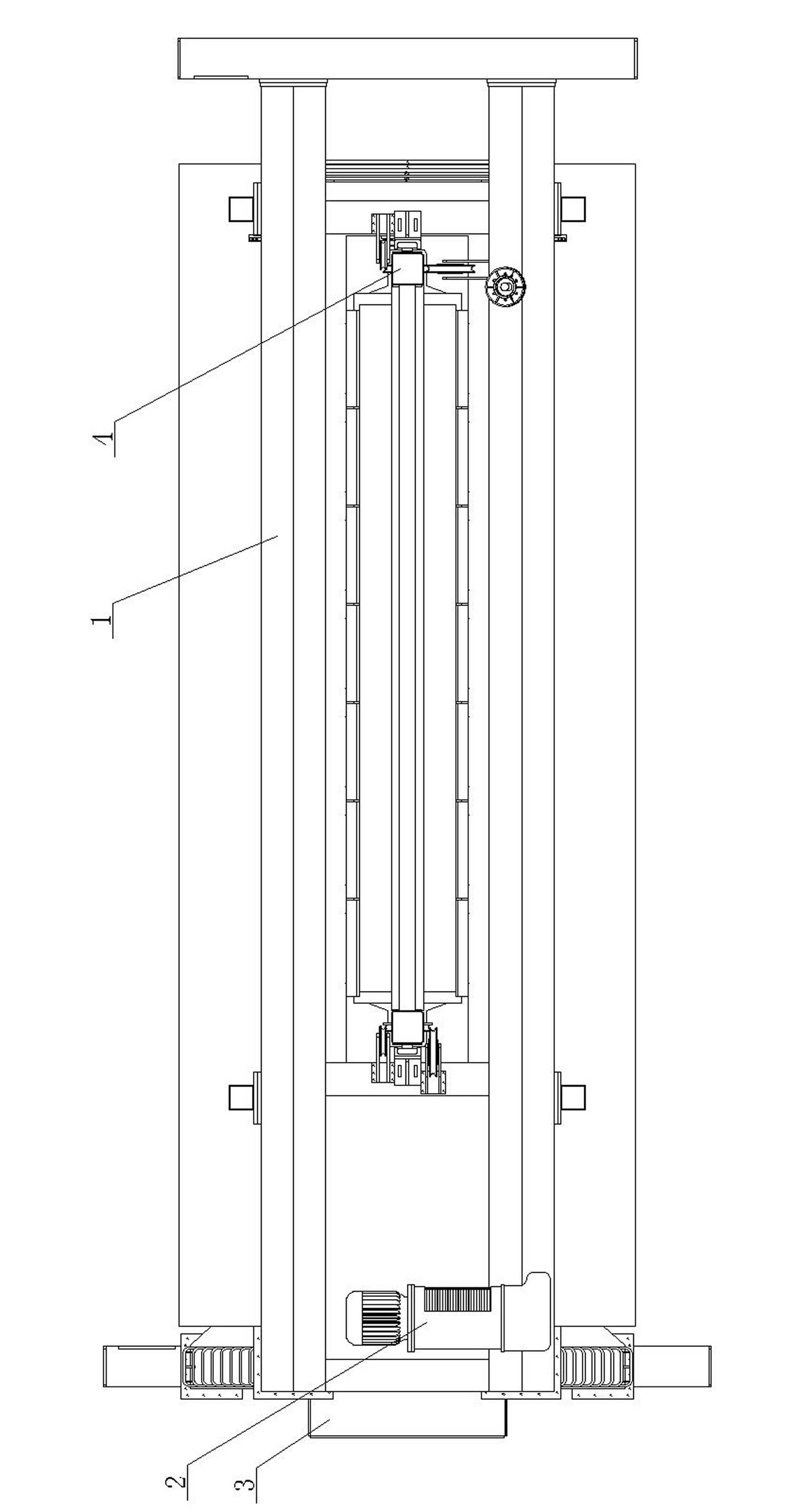

The invention relates to an AGV charging station which comprises a bearing frame for placing a storage battery and a battery assembling, disassembling and replacing device positioned on one side of the bearing frame, the battery assembling, disassembling and replacing device comprises a battery locking mechanism, a pulling and pushing mechanism, a reversing butt joint mechanism, a Y-axis translation mechanism, a Z-axis lifting mechanism and an X-axis sliding mechanism. Multi-axis linkage is adopted, the battery is replaced and charged, the storage battery is automatically taken out of the AGVor fed into the bearing frame to be charged, and the whole process is accurate and stable.

Owner:SHANGHAI FORTREND TECH CO LTD

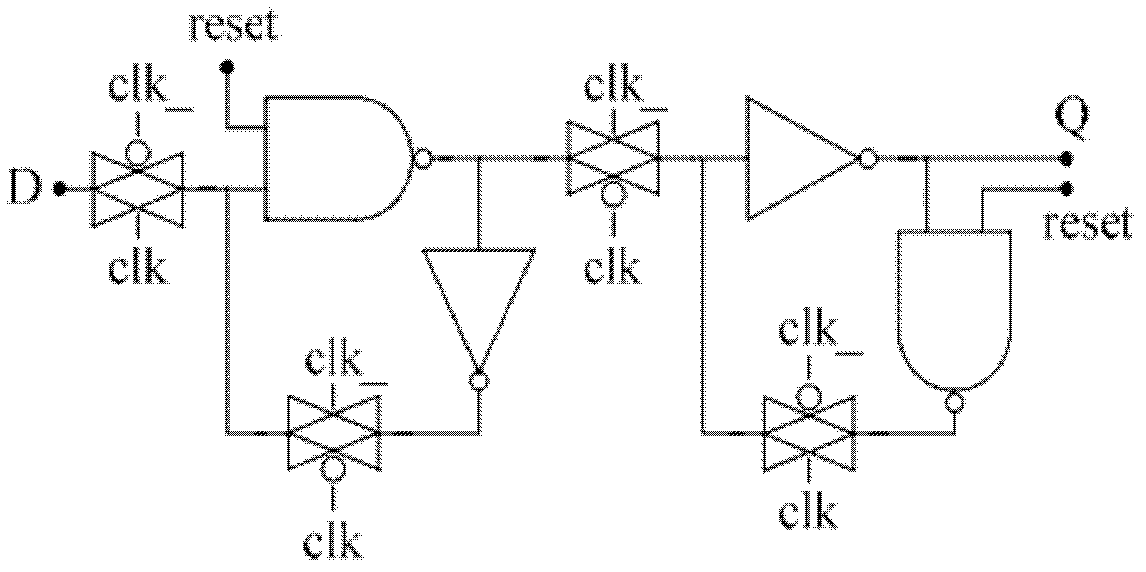

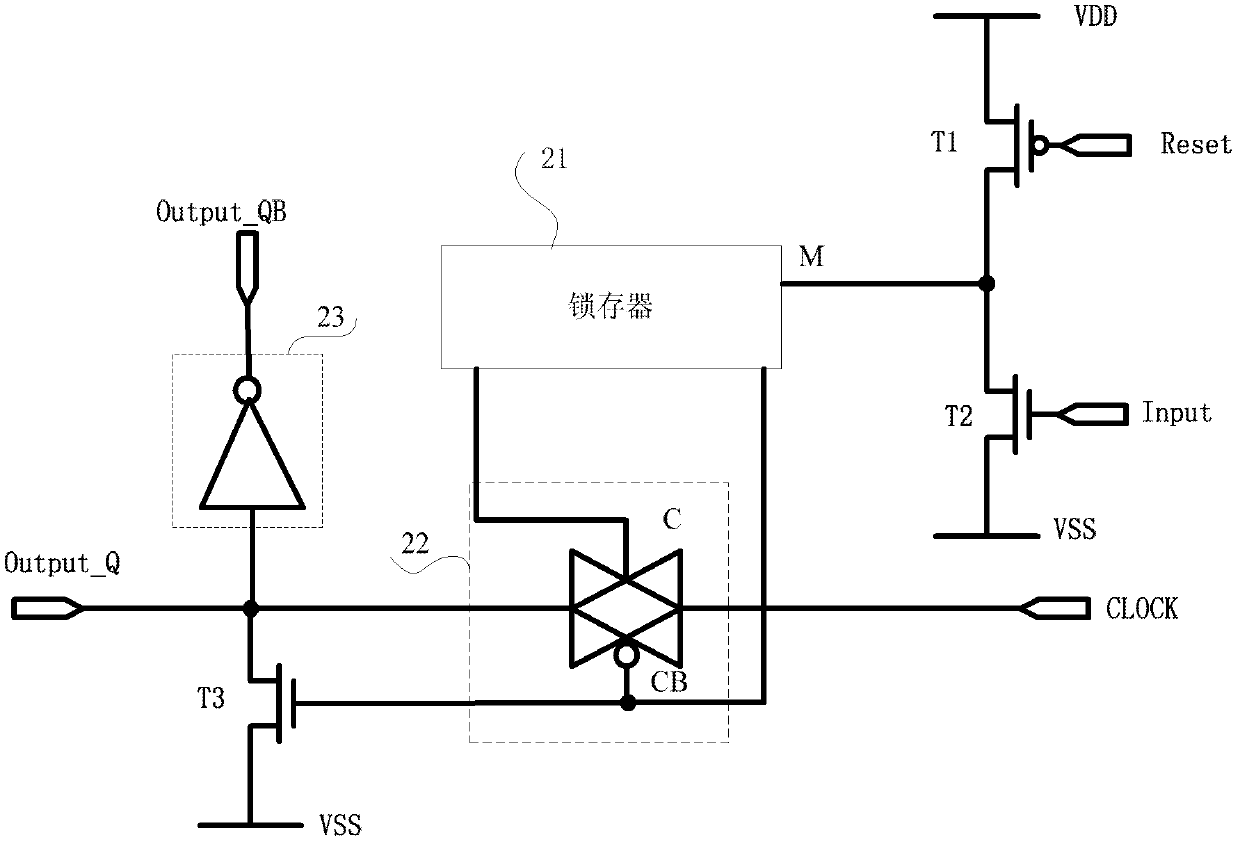

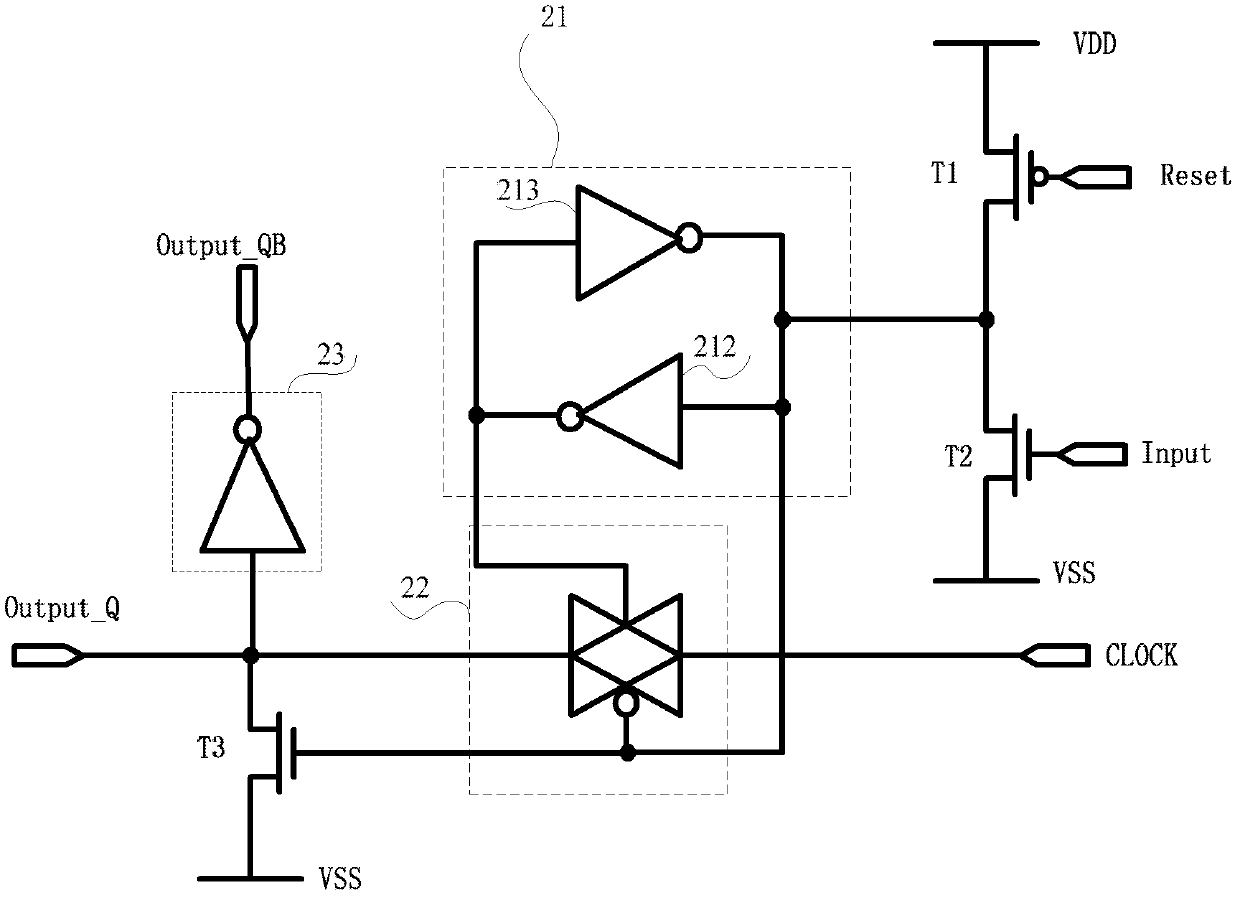

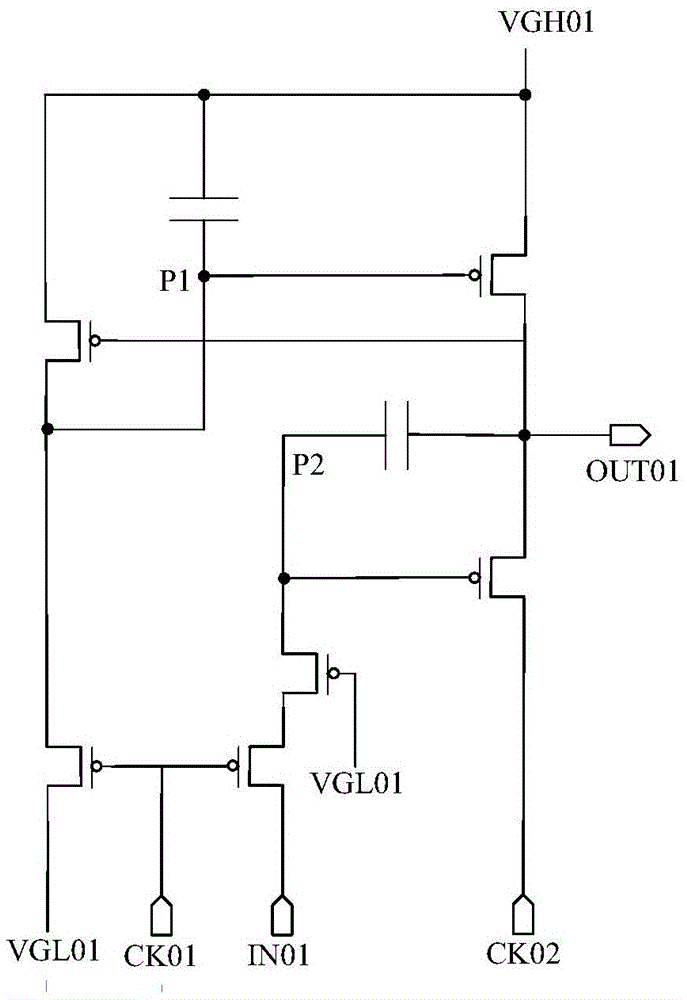

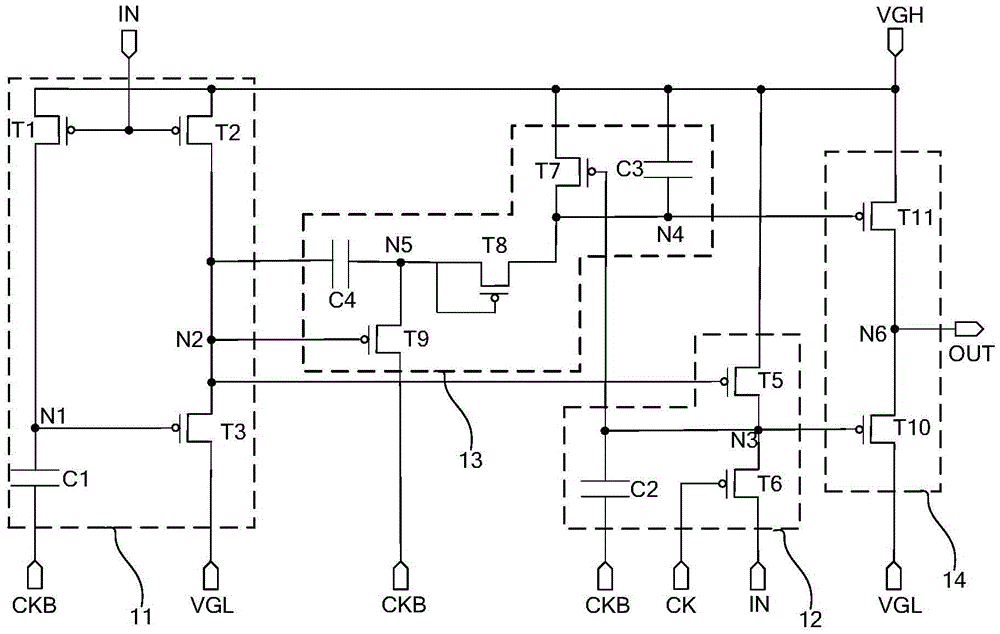

Shift register, grid driving device and display device

ActiveCN102708816AAchieve shiftStatic indicating devicesDigital storageShift registerTransmission gate

The invention provides a shift register, a grid driving device and a display device. The shift register comprises a latch, a transmission gate, a first thin film transistor, a second thin film transistor, a third thin film transistor and a first inverter, wherein a grid of the first thin film transistor is connected with a reset terminal of the shift register, a drain of the first thin film transistor is respectively connected with a drain of the second thin film transistor and an input terminal of the latch, a grid of the second thin film transistor is connected with an input terminal of theshift register, a grid of the third thin film transistor is connected with an inverted output terminal of the latch, a drain of the third thin film transistor is connected with an input terminal of the first inverter, an output terminal of the transmission gate is connected with the drain of the third thin film transistor, an input terminal of the transmission gate is connected with a clock signal input terminal, the drain of the third thin film transistor is connected with a normal phase output terminal of the shift register, and an output terminal of the first inverter is connected with an inverted output terminal of the shift register. The shift register can realize signal shift by the aid of one latch.

Owner:BOE TECH GRP CO LTD +1

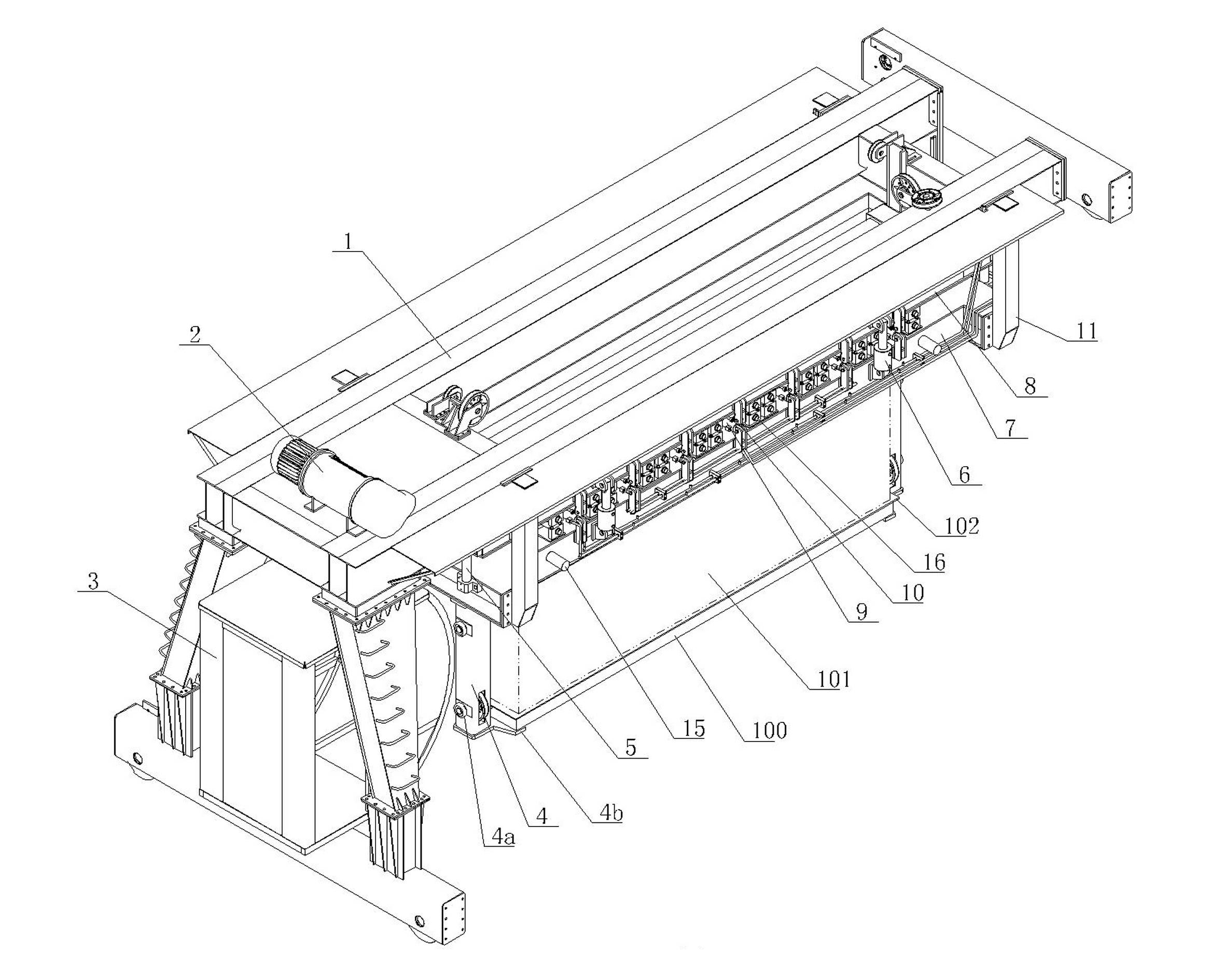

Bridge big-height lifting displacement equipment based on vehicle set and construction method thereof

ActiveCN110528405ASimple structureEasy to assembleBuilding repairsBridge erection/assemblyStructural engineeringMulti beam

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

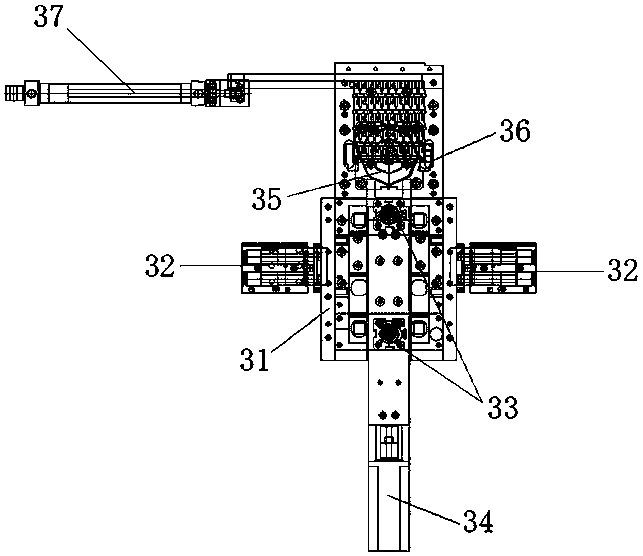

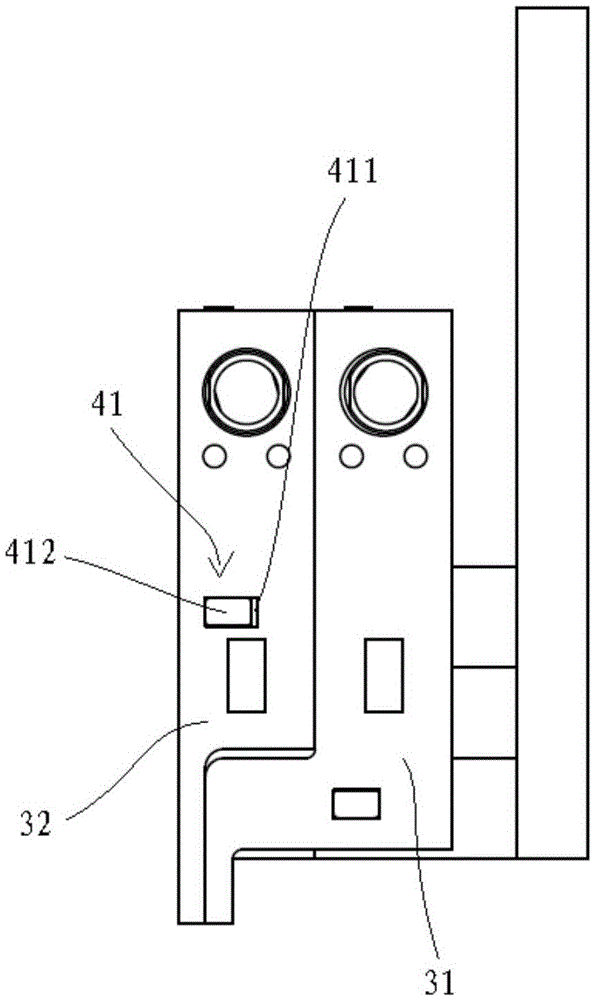

Workpiece turnover and correction mechanism based on image identification

InactiveCN109592365AImprove work efficiencyLow costConveyor partsHydraulic cylinderImaging processing

The invention provides a workpiece turnover and correction mechanism based on image identification, and the workpiece turnover and correction mechanism is used for an industrial production line. The workpiece turnover and correction mechanism based on image identification comprises a conveyor belt, wherein a turnover mechanism is arranged on one side of the conveyor belt; intracavity type storagespaces are arranged on the two sides of the turnover mechanism; two transition platforms are arranged on the sides, close to the conveyor belt, of the outer parts of the storage spaces; the transitionplatforms are provided with workpiece inlets aligning at the conveyor belt; the rear parts of the two transition platforms continuously extend into the turnover mechanism; two rectangular cavities are arranged for holding workpieces; the turnover mechanism and the storage spaces are driven by a servo motor so as to intermittently turn over at 90 degrees; the servo motor is connected with a rotaryshaft of the turnover mechanism through a coupler; a first push rod and a second push rod are arranged on the two sides of the conveyor belt and are driven by an air cylinder or a hydraulic cylinder;the two push rods align at the transition platforms according to the opposite direction from two sides of the conveyor belt in the rears of the transition platforms; and an image processing unit directly facing the conveyor belt is arranged in front of the first push rod. According to the workpiece turnover and correction mechanism based on image identification provided by the invention, the costcan be greatly reduced, and the efficiency is improved.

Owner:NANCHANG UNIV

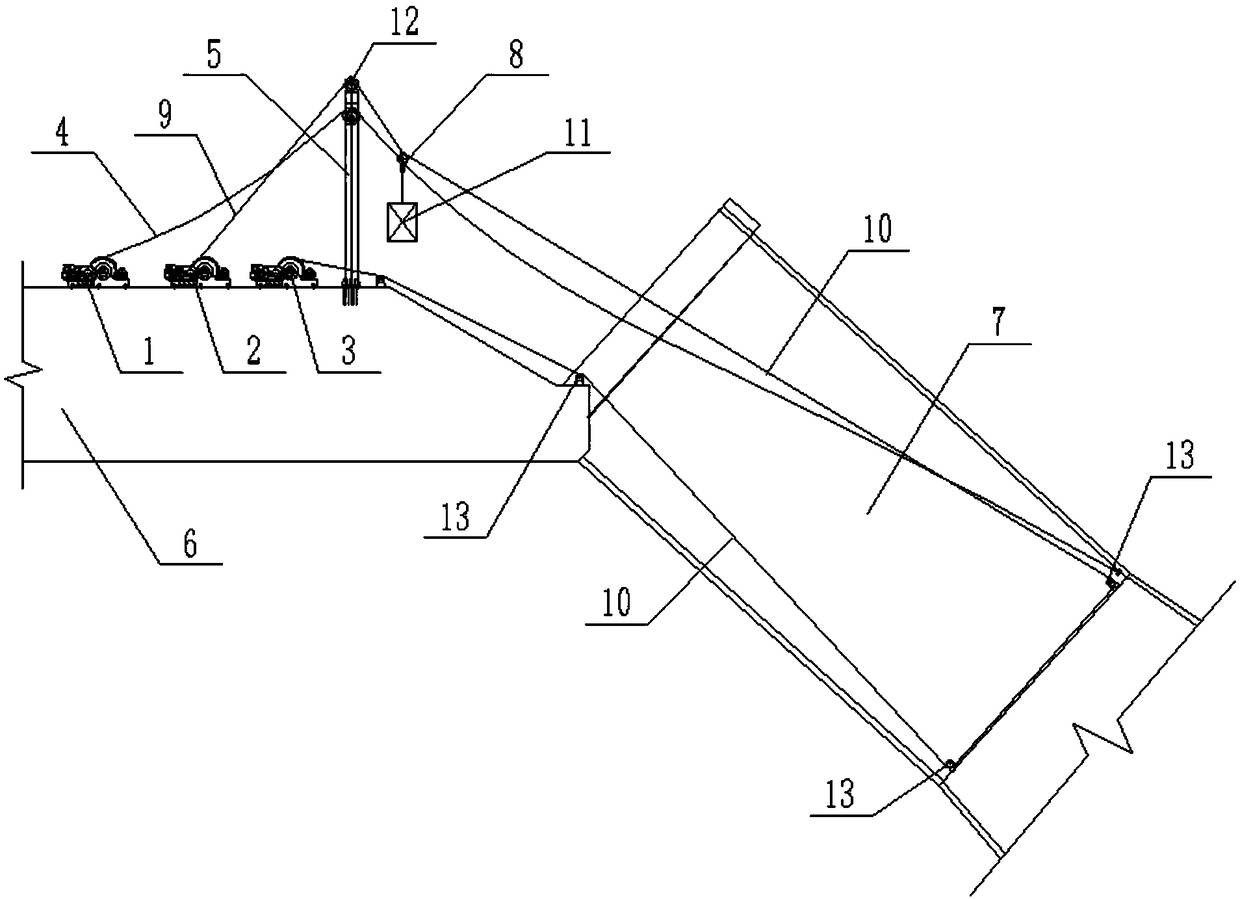

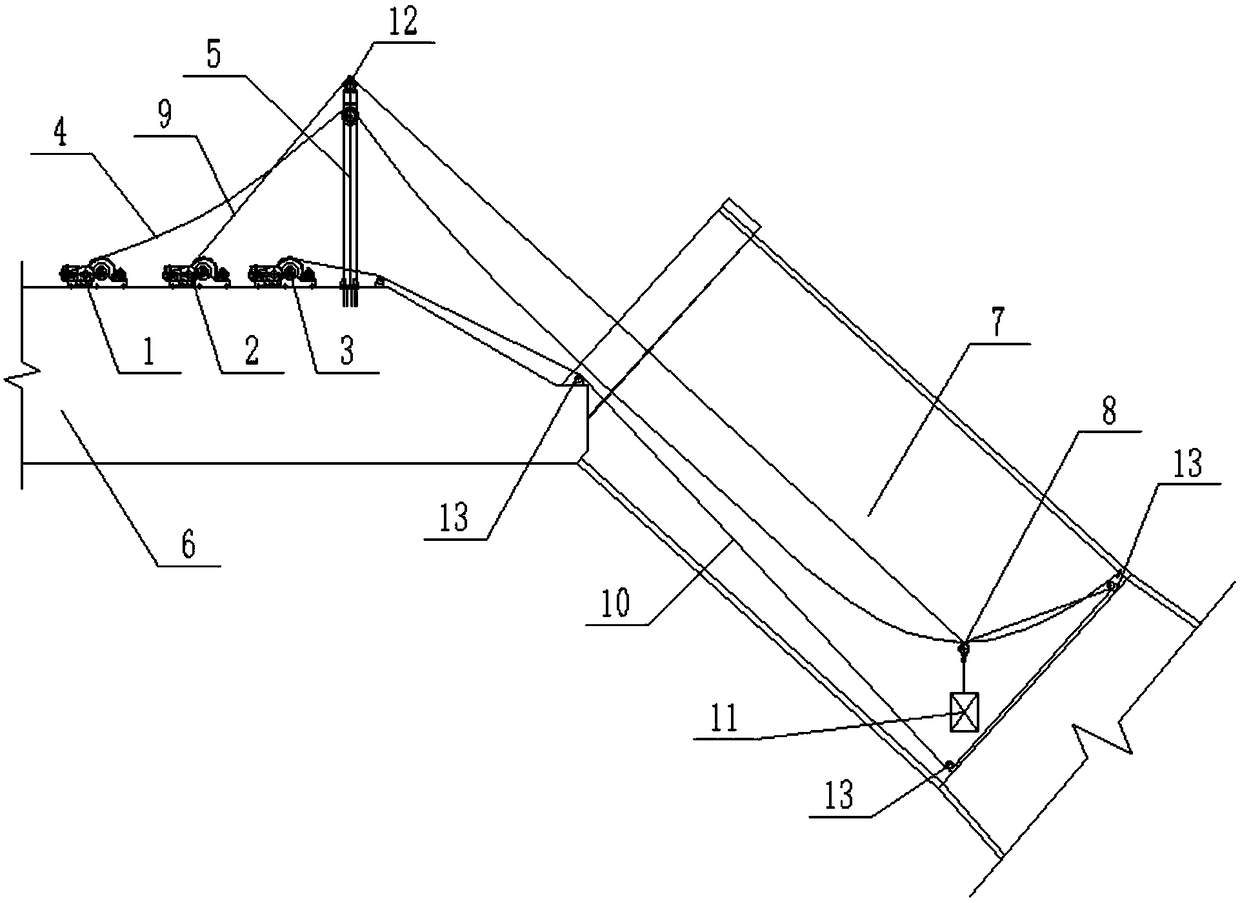

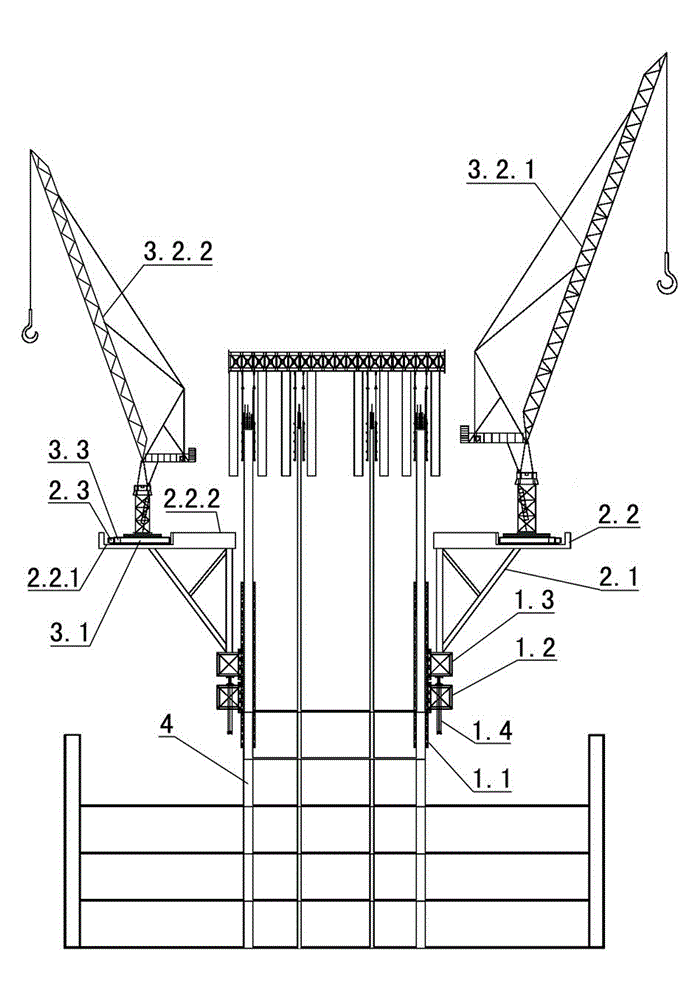

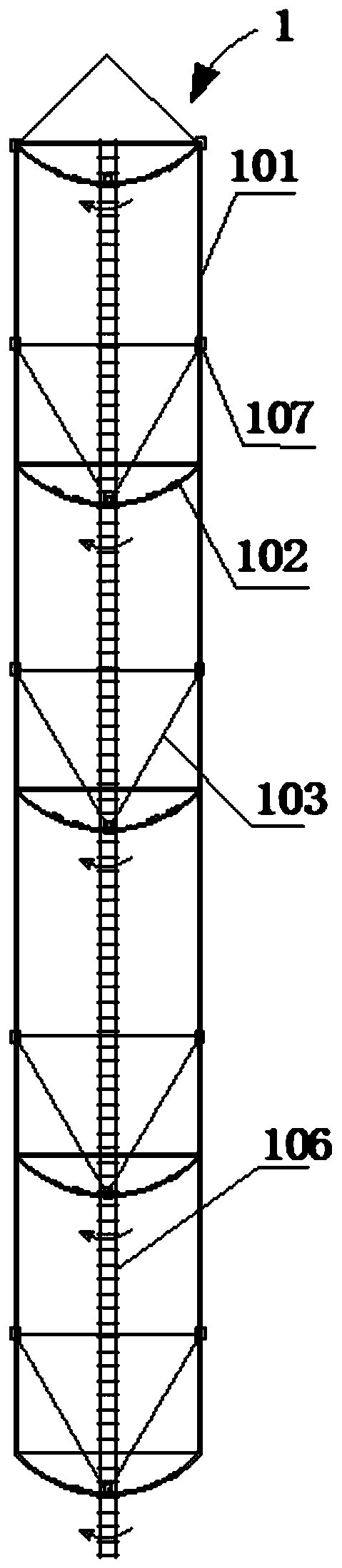

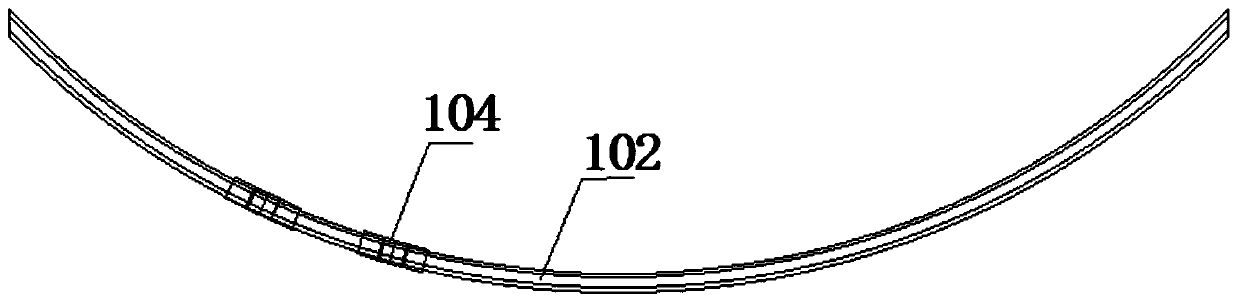

Circulation traction anchoring system

PendingCN108797347AAchieve shiftAchieve installationBridge structural detailsBridge erection/assemblyTraction systemEngineering

The invention discloses a circulation traction anchoring system. The circulation traction anchoring system is arranged between a tunnel anchor and a ground platform of a tunnel portal, and a tunnel has a large slope. The circulation traction anchoring system comprises a supporting frame vertically fixed to the ground platform, a load-bearing system and a traction system. The load-bearing system comprises a first winch, a load-bearing cable and a load-bearing pulley, the first winch is fixed on the ground platform, and the load-bearing cable slides around the supporting frame and anchored at the top end of the anchor surface of the tunnel anchor after being released from a reel of the first winch, the load-bearing pulley is arranged on the load-bearing cable in the tunnel, and building materials are hoisted in the load-bearing pulley. The traction system comprises a second winch and a first traction rope, wherein the second winch is fixed on the ground platform, and the first traction rope slides around the supporting frame after being released from a reel of the second winch and then fixed on the load-bearing pulley. Based on the principle of variable sag cable crane, the circulation traction anchoring system realizes the installation of the building materials at any point in the vertical and horizontal range of the anchor surface, the construction of the tunnel anchor is greatly facilitated, and the construction cost is reduced.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES +1

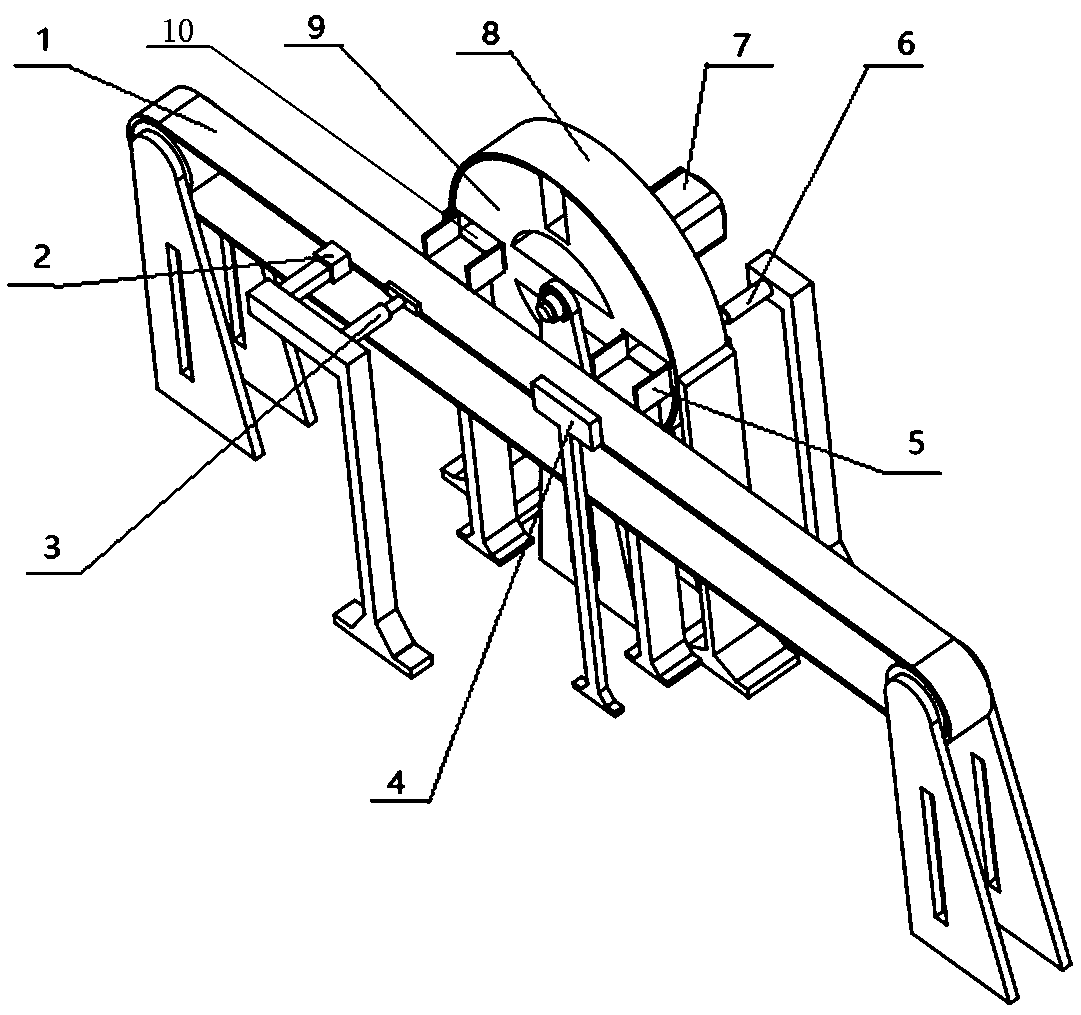

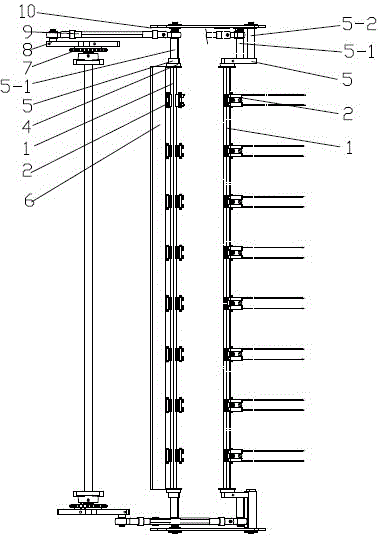

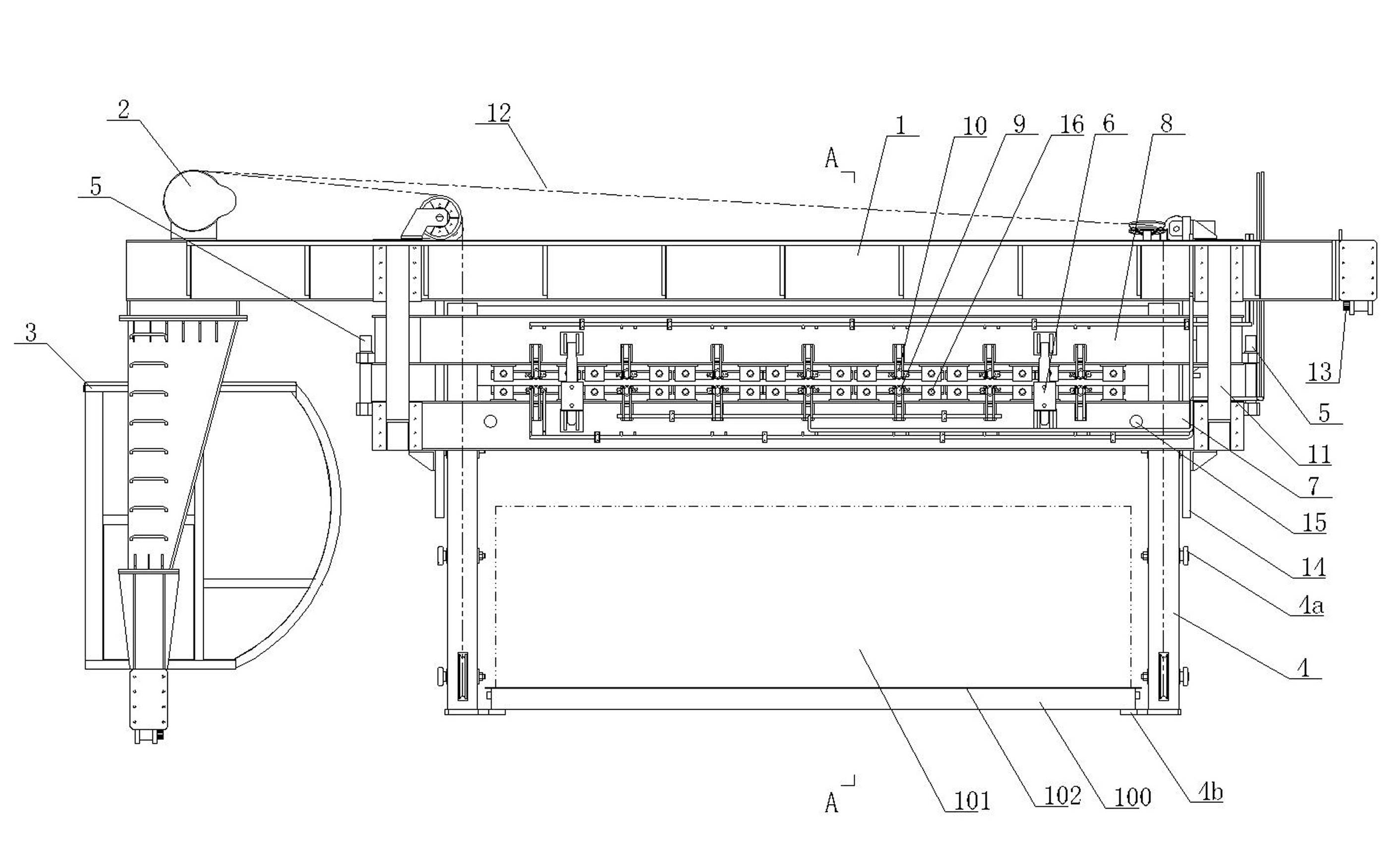

Seedling picking mechanism of vegetable transplanting machine

The invention relates to a seedling picking mechanism of a vegetable transplanting machine, and belongs to the agricultural and forestry machinery technology field. The seedling picking mechanism contains a seedling picking clamp, and the rear end of the seedling picking clamp is fixed on a seedling clamp shaft. Two ends of the seedling clamp shaft form a moving pair with an inner guide groove on an inner rack plate respectively, and are fixedly connected with one end of a transposition toggle with a first limit position and a second limit position. The other end of the transposition toggle and an outer guide groove on an outer rack plate form a moving pair. The middle part of the transposition toggle is hinged to one end of a connection rod. The other end of the connection rod is hinged to a crank driven by a transmission mechanism. The inner guide groove and the outer guide groove have smooth transition profiles respectively, through the transition profiles, the seedling picking clamp is located in a seedling picking position in the horizontal direction when the transposition toggle is located in the first limit position, and the seedling picking clamp is located in a seedling arrangement position in the vertical direction when the transposition toggle is located in the second limit position. The seedling picking mechanism achieves shifting and transposition movement of the seedling picking clamp between the seedling picking position and the seedling arrangement position, and well solves the bottleneck problem of design and manufacturing of a vegetable transplanting machine picking seedling automatically.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

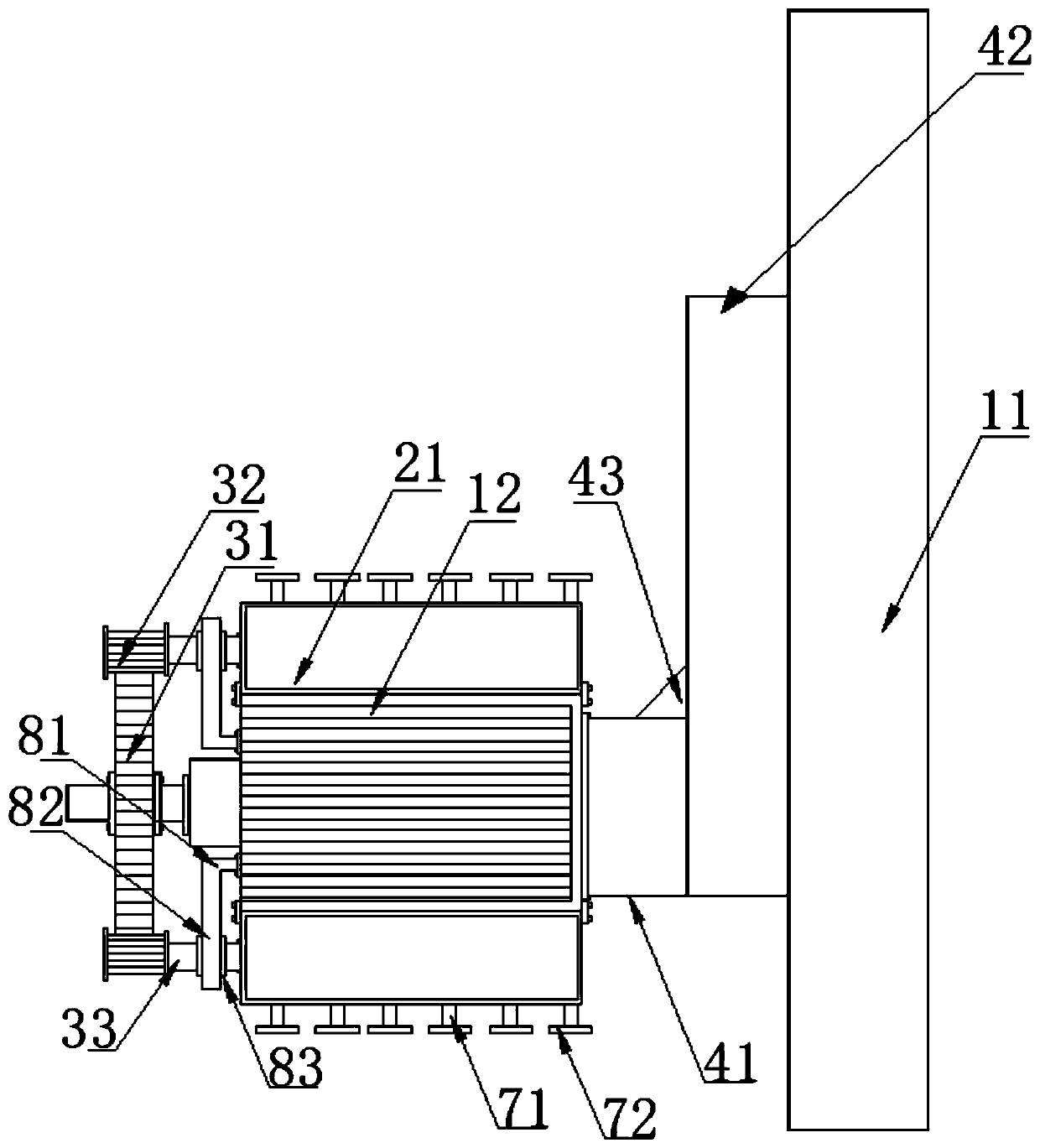

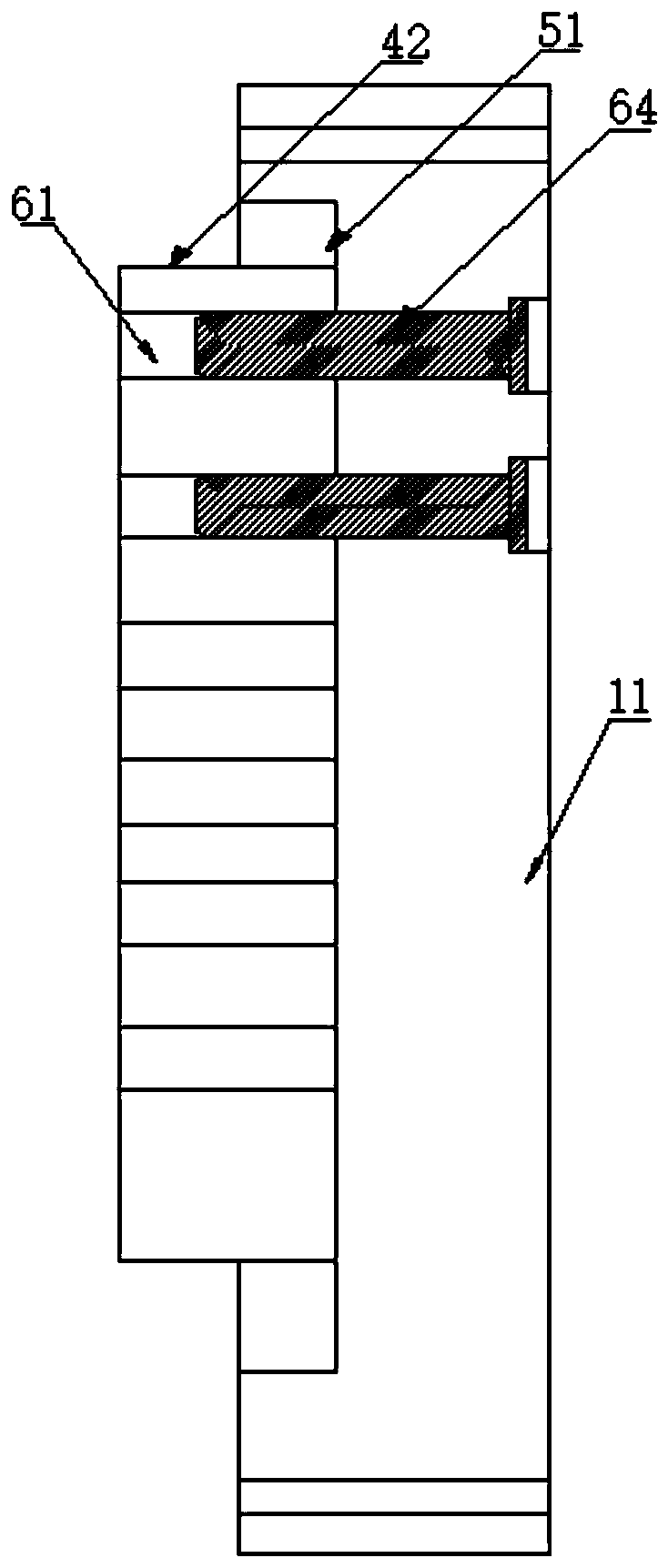

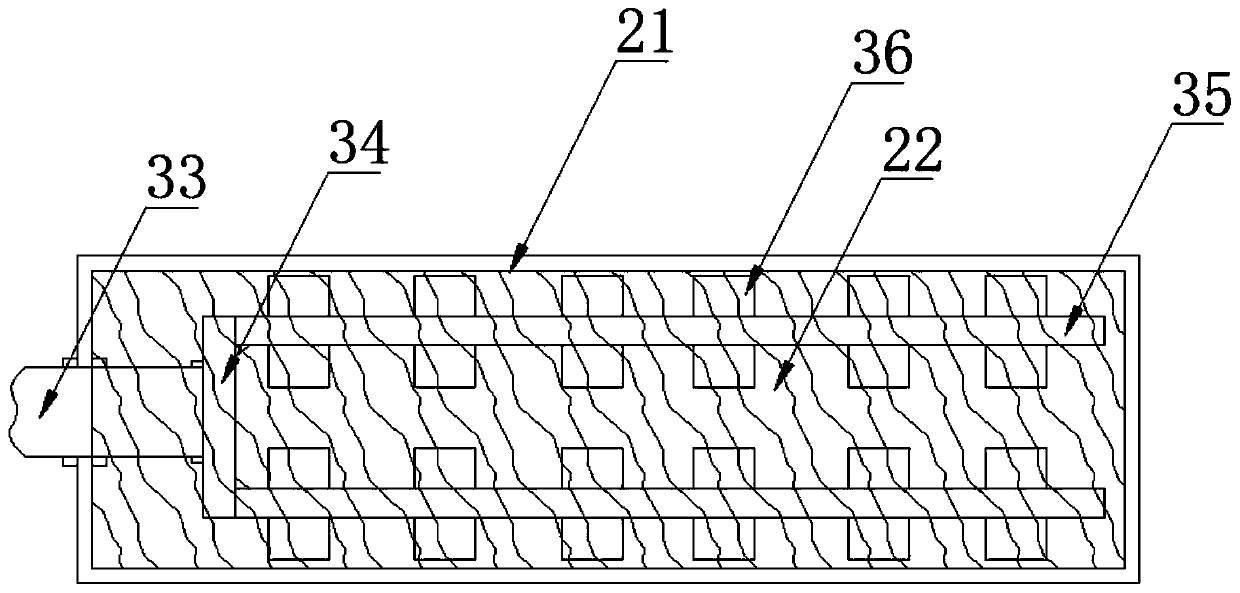

Novel permanent magnet motor

InactiveCN111106714AImprove cooling effectExchangeMechanical energy handlingCooling/ventillation arrangementRotational axisElectric machine

The invention discloses a novel permanent magnet motor. The motor comprises a mounting base and a permanent magnet motor body. The top and the bottom of the permanent magnet motor body are respectively and fixedly provided with a heat dissipation box body. The heat dissipation box body is filled with heat dissipation liquid. A driving gear is fixed on an output shaft of the permanent magnet motorbody. The top and the bottom of the driving gear are each engaged with a driven gear. A rotating shaft is fixed to the circle center of each driven gear. The rotating shafts and the heat dissipation box bodies are arranged in a one-to-one correspondence mode. The rotating shafts extend into the corresponding heat dissipation box bodies. A rotating plate is fixed to the end, located in the corresponding heat dissipation box body, of each rotating shaft. At least two stirring shafts are arranged on each rotating plate, and a plurality of stirring blades are arranged on each stirring shaft. The novel permanent magnet motor has the advantage of being high in heat dissipation performance.

Owner:YANGZHOU POLYTECHNIC INST

Multifunctional building block separator

ActiveCN102514094AMeet transshipment requirementsRealize automatic separationAuxillary shaping apparatusSocial benefitsArchitectural engineering

Owner:浙江瑞港机械有限公司

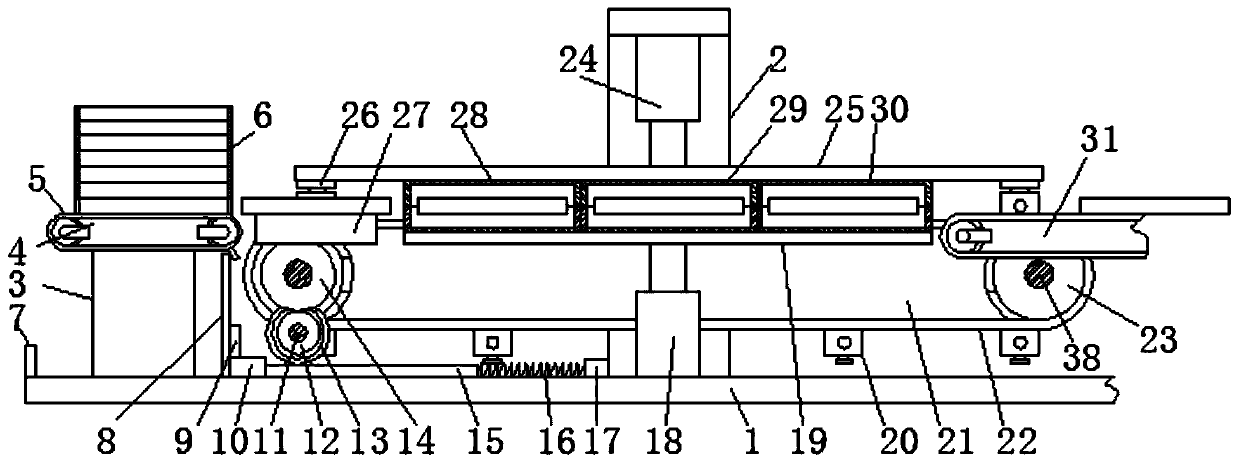

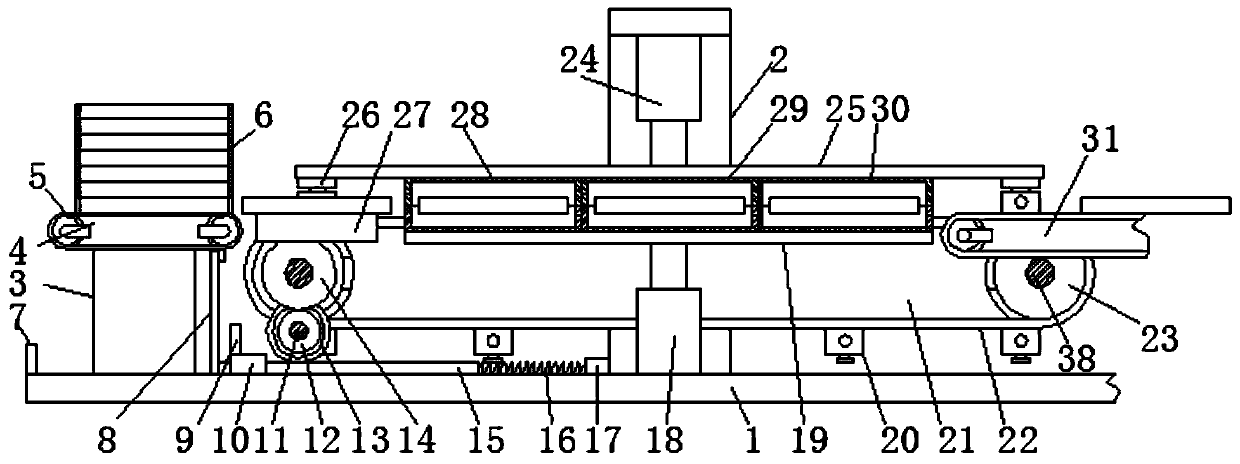

Integrated spraying device used for surfaces of door leaves and using method of integrated spraying device

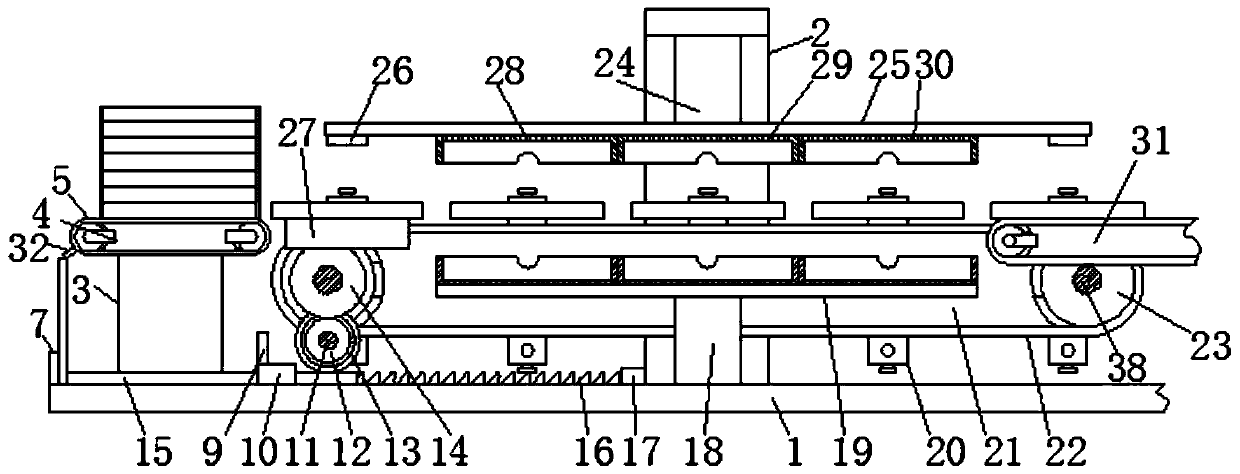

ActiveCN111330775AAchieve shiftReduce labor intensitySpray boothsStructural engineeringMechanical engineering

The invention relates to the field of spraying equipment for surfaces of door leaves, in particular to an integrated spraying device used for surfaces of door leaves and a using method of the integrated spraying device. The integrated spraying device comprises a base, wherein a vertical frame is fixed to the base, a wooden door moving mechanism used for transferring wooden doors is arranged on thebase, a feeding mechanism used for automatically feeding the wooden doors is arranged on the base, is located at the left side of the wooden door moving mechanism and is in transmission connection with the wooden door moving mechanism, and clamping mechanisms used for clamping the wooden doors are arranged on the wooden door moving mechanism. According to the integrated spraying device used for the surfaces of the door leaves and the using method of the integrated spraying device, the feeding mechanism automatically and circularly conducts feeding on the wooden door moving mechanism, and drives the wooden door moving mechanism to move the wooden doors in sequence in the process of feeding the wooden doors, and therefore, sequential moving of the wooden doors is achieved, then the wooden doors are sequentially subjected to cleaning, paint spraying and drying, repeated transferring is not required, the labor intensity is lowered, and the production efficiency is improved.

Owner:胡鸿韬

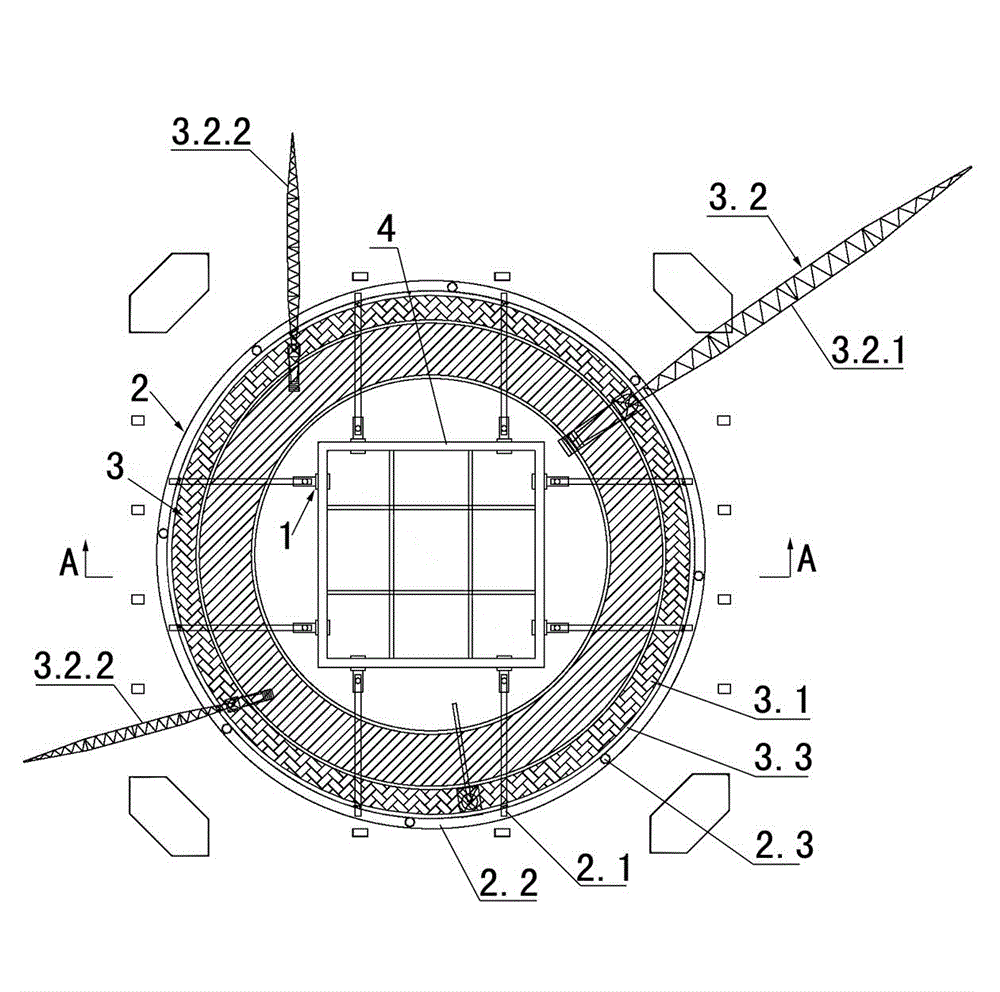

Rotating multi-crane integrated operation platform with integral automatic lifting function

A rotating multi-crane integrated operation platform with an integrated automatic lifting function comprises a wall-climbing automatic lifting system arranged on a core tube shear wall, an annular bracket surrounding the periphery of the core tube shear wall and connected on the wall-climbing automatic lifting system, and an annular rotating platform surrounding the periphery of the core tube shear wall and supported on the annular bracket, wherein the annular bracket includes a support truss group, an annular support platform and a driving system; the annular rotating platform includes an annular base, cranes, and a driven system; and the cranes include a large boom-type tower crane and at least one small-medium crane. The operation platform provided by the invention optimizes the crane configuration in construction of super high-rise buildings, reduces the number of the large boom-type tower crane, and reduces the cost of vertical transportation equipment.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

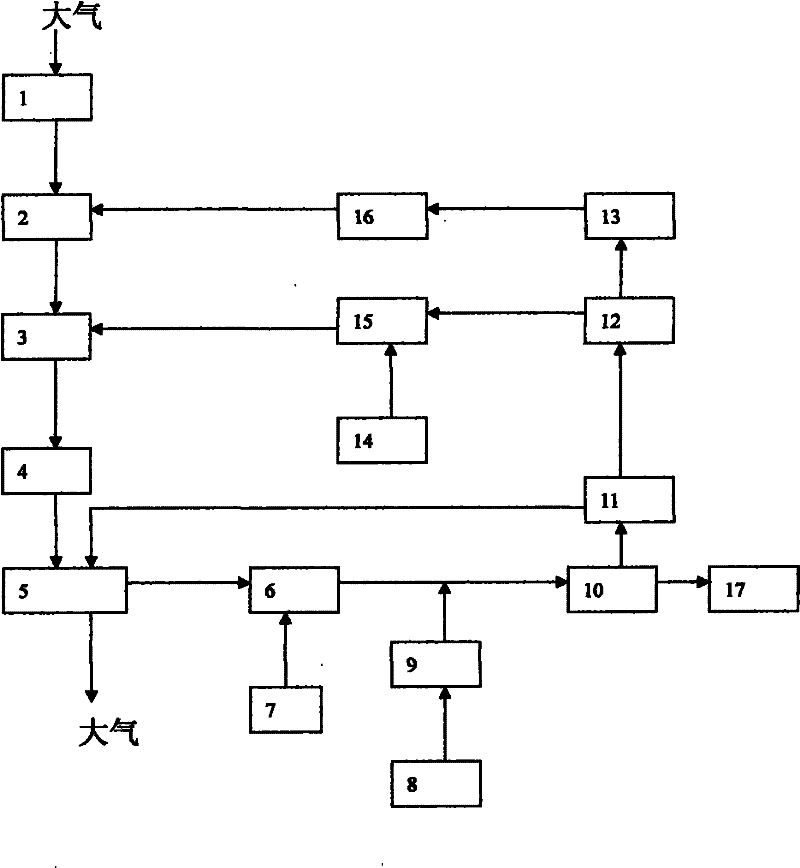

Connection method and device of compressed-air vehicle engine

InactiveCN102200051AWide variety of sourcesLow costValve arrangementsCasingsCompressed-air vehicleCombustion

The invention discloses a connection method and device of a compressed-air vehicle engine as well as a two-process boxer engine by optimizing a method and device for reducing energy consumption of vehicles. Due to the scientific connection method in combination with components with relevant functions, various technical effects of the entire compressed-air vehicle engine are obtained as follows: large-capacity storage battery is not needed, the fuel resources are widely available, sufficient combustion can be realized in ultra-rare air, the energy-saving and environment-protection function is enhanced, the output torque is large, a water cooling system is canceled, frequent air leakage is avoided, air supply is guaranteed, the safety performance is high, electronic air distribution and electronic gear shift are realized, the engine is easy to start, light and durable and has a simple structure, the problem of short continuation is avoided, and the like so that the compressed-air vehicle engine approaches to an ideal state and is more outstanding in reducing energy consumption of vehicles.

Owner:罗显平

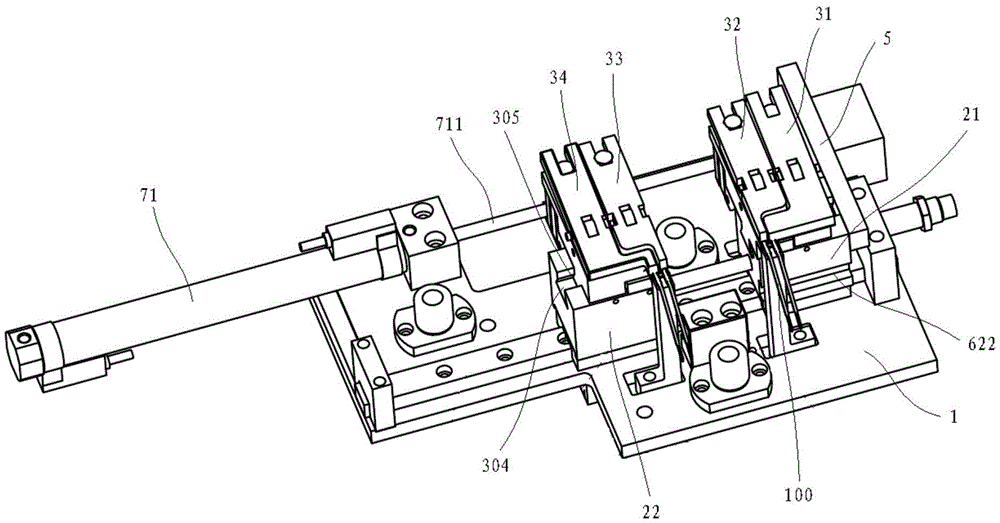

PIN separating mechanism

ActiveCN105633767AConstant spacingGuaranteed PIN effectContact member assembly/disassemblyEngineeringMechanical engineering

The invention discloses a PIN separating mechanism. The PIN separating mechanism comprises a base, a power plant, a moving mechanism, a clamp structure, an elastic element and a limiting structure, wherein the moving mechanism comprises a first sliding block and a second sliding block; the clamp structure comprises multiple clamps capable of clamping PINs arranged side by side, including a first clamp, a second clamp, a third clamp and a fourth clamp in sequence; the elastic element comprises a first elastic element and a second elastic element for enabling the adjacent two clamps on the first sliding block and the second sliding block to generate relative distances respectively; the limiting structure comprises a first limiting structure and a second limiting structure for limiting predetermined displacements between the adjacent two clamps on the first sliding block and the second sliding block respectively; a first connecting part drives the first sliding block to slide close to or far from the second sliding block under the drive of the power plant; when the first sliding block is tightly adhered to the second sliding blocks, the clamps are gathered together; and when the first sliding block performs the predetermined displacement in a direction far from the second sliding block, the clamps are separated. The PIN separating mechanism is high in efficiency, low in error, and capable of realizing automatic preparation process for electronic parts and components.

Owner:CWB AUTOMOTIVE ELECTRONICS

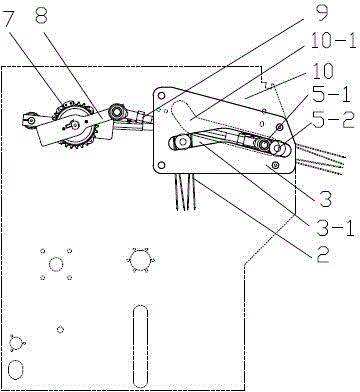

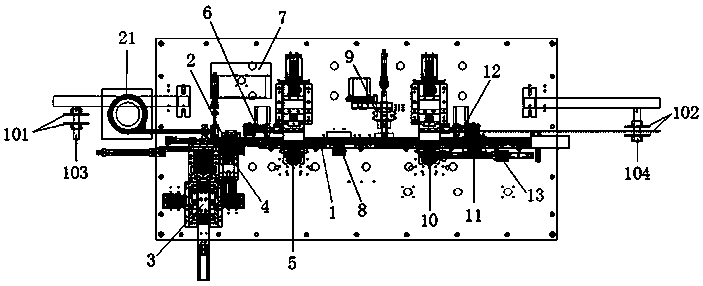

Board insertion type automatic assembly welding machine of mobile phone connector

PendingCN107611746AAchieve shiftPrecise shiftContact member assembly/disassemblyDie castingFully automatic

The invention relates to a board insertion type automatic assembly welding machine of a mobile phone connector. The board insertion type automatic assembly welding machine comprises a product conveying rail, an automatic die casting shell transmission mechanism, an automatic PCB transmission mechanism, a PCB and die casting shell assembly mechanism, a PCB and front face terminal welding mechanism,an automatic front face terminal transmission mechanism, a control display screen, a front face terminal material strap folding mechanism, a motor rotating mechanism, a PCB and back face terminal welding mechanism, a back face terminal material strap folding mechanism, an automatic back face terminal transmission mechanism and an automatic PCB displacement mechanism. The board insertion type automatic assembly welding machine provided by the invention can not only integrate fully automatic feeding, conveying, locating, assembling, welding, 180-degree overturning, discharging and recycling ofdie casting shells and PCBs, but also can integrate fully automatic uncoiling, conveying, locating, cutting, welding and waste material recycling of front and back face terminal material straps, the operation process is fully automatic, the board insertion type automatic assembly welding machine is suitable for producing connectors with different terminals, and is low in cost, high in efficiency,high in productivity and high in yield.

Owner:东莞欧宇自动化设备有限公司

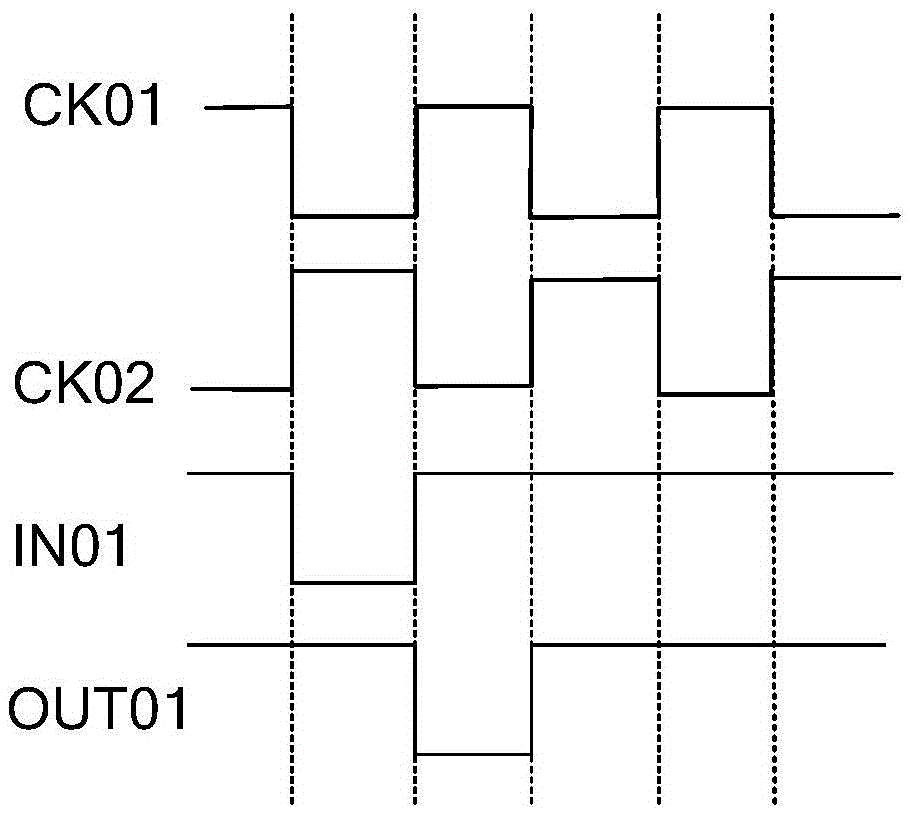

Shift register and drive method thereof

ActiveCN105551420AAchieve shiftImplement overlap shiftStatic indicating devicesDigital storageShift registerLevel trigger

The invention discloses a shift register and a drive method thereof. The potential changes of input signals of the shift register can be controlled by a first control signal and a second control signal respectively, so that high level trigger type signal shift and low level trigger type signal shift can be realized by the shift register. Besides, the first control signal and the second control signal are clock signals with the same frequency, integral shift of the signals on the timing sequence can be realized and overlapping shift of the signals on the timing sequence and at different proportions can be realized by setting the different triggering time of the first control signal and the second control signal, that is shift of different manners is realized, so that the shift register can be suitable for various drive modes of flat panel display devices.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +1

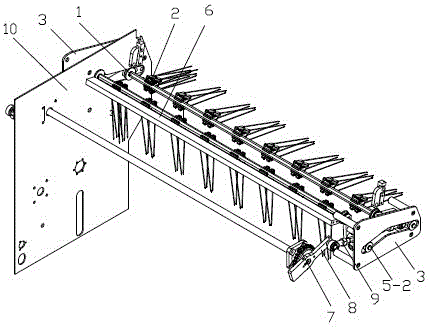

Cropping working station for PIN material strap

ActiveCN105598524AFully automatedIncrease productivityShearing machinesShearing machine accessoriesEngineeringAutomation

The invention provides a cropping working station for a PIN material strap. The cropping working station comprises a cropping mechanism cropping the PIN material strap into separated PINs, a feeding mechanism feeding the PIN material strap to the cropping mechanism, and a PIN distributing mechanism. The PIN distributing mechanism is used for clamping a set number of PINs from the cropping mechanism and distributing the clamped PINs so as to enable the PINs to be distributed according to preset intervals. According to the cropping working station for the PIN material strap, the PIN material strap can be cropped into the separated PINs, the set number of PINs can be distributed so that the PINs can be distributed according to the preset intervals, full automation of the PIN cropping and distributing technology can be achieved, production efficiency is high, the interval accuracy of the PINs is high, and manpower cost is reduced.

Owner:CWB AUTOMOTIVE ELECTRONICS

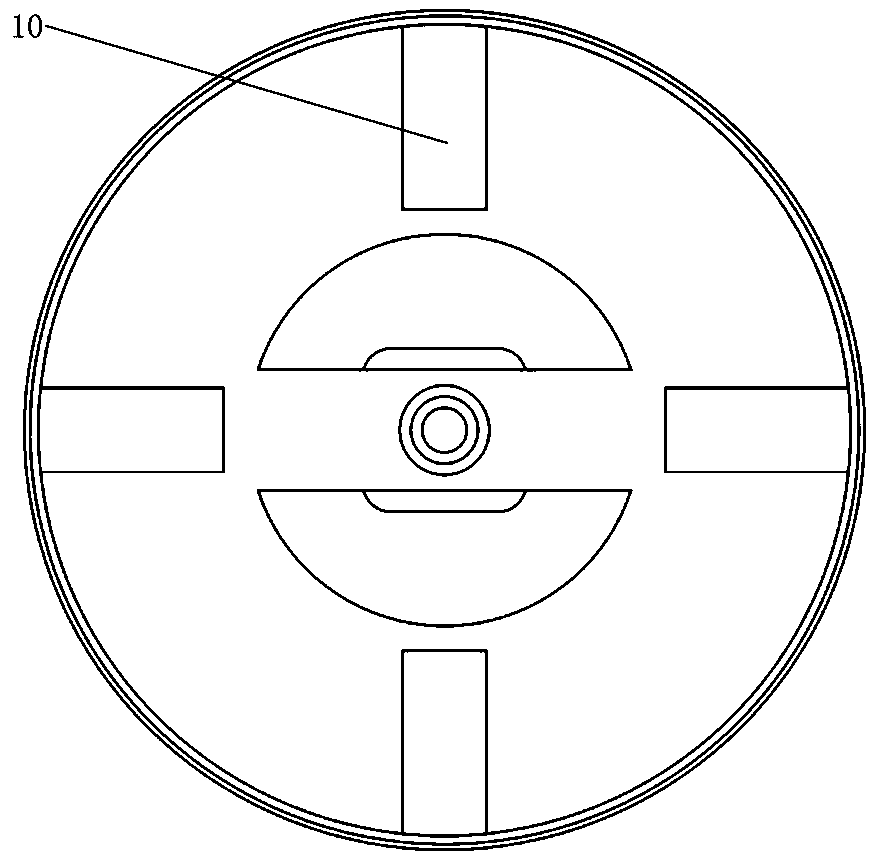

Workpiece shifting device

InactiveCN102672521AAchieve shiftImplement temporary storageMetal working apparatusThrust bearingEngineering

A workpiece shifting device comprises a fixed base, a servo motor, a thrust bearing, a rotating disc, a left workpiece gripping device, a right workpiece gripping device, a cylinder, left guide pillars, right guide pillars, a lifting plate, a left pulley, a right pulley, a left flexible portion and a right flexible portion. The servo motor and the thrust bearing are fixed on the fixed base, the rotating disc is installed on the thrust bearing and is in power connection with the output shaft of the servo motor, the two left guide pillars and the two right guide pillars are arranged on the rotating disc, two holes are arranged on the left workpiece gripping device and the right workpiece gripping device respectively, the left workpiece gripping device and the right workpiece gripping device are in slit fit with the guide pillars, and two holes are arranged on the left side and the right side of the lifting plate which is in slit fit with the guide pillars. The pulleys are respectively installed between the two guide pillars, one end of the left flexible portion is connected with the workpiece gripping devices, and the other end of the left flexible portion is connected with the lifting plate.

Owner:周兰兰

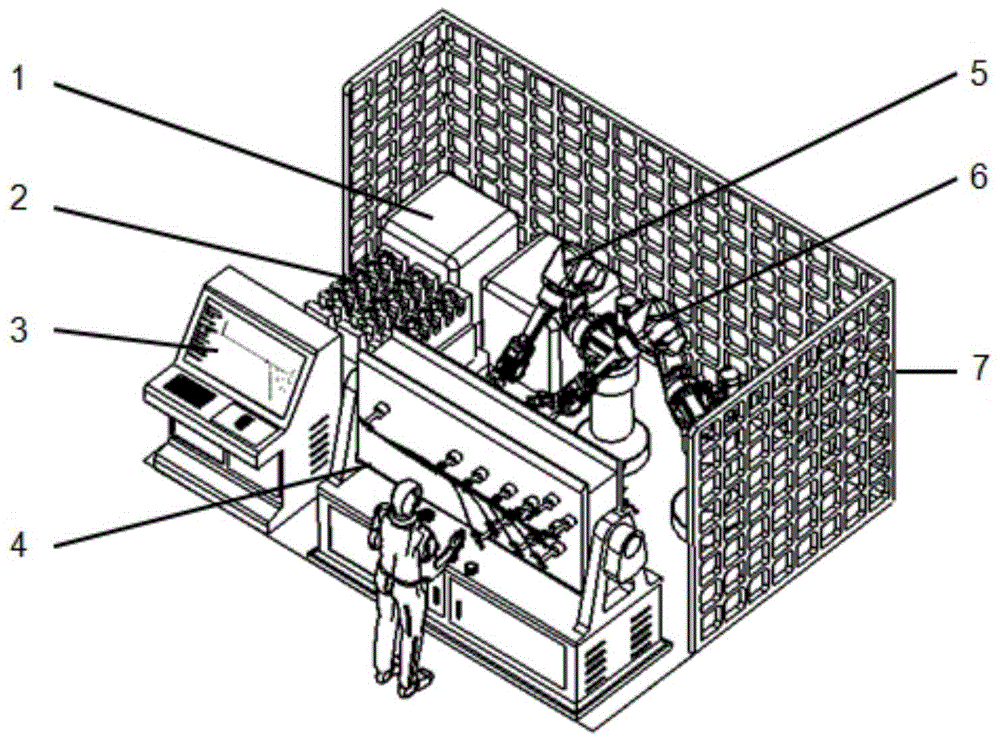

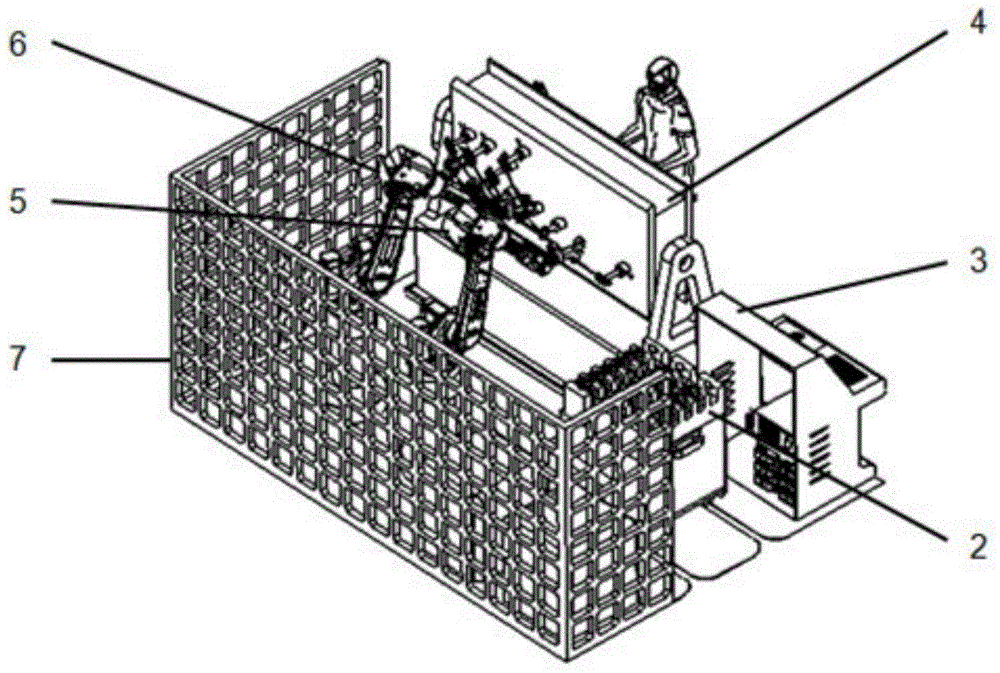

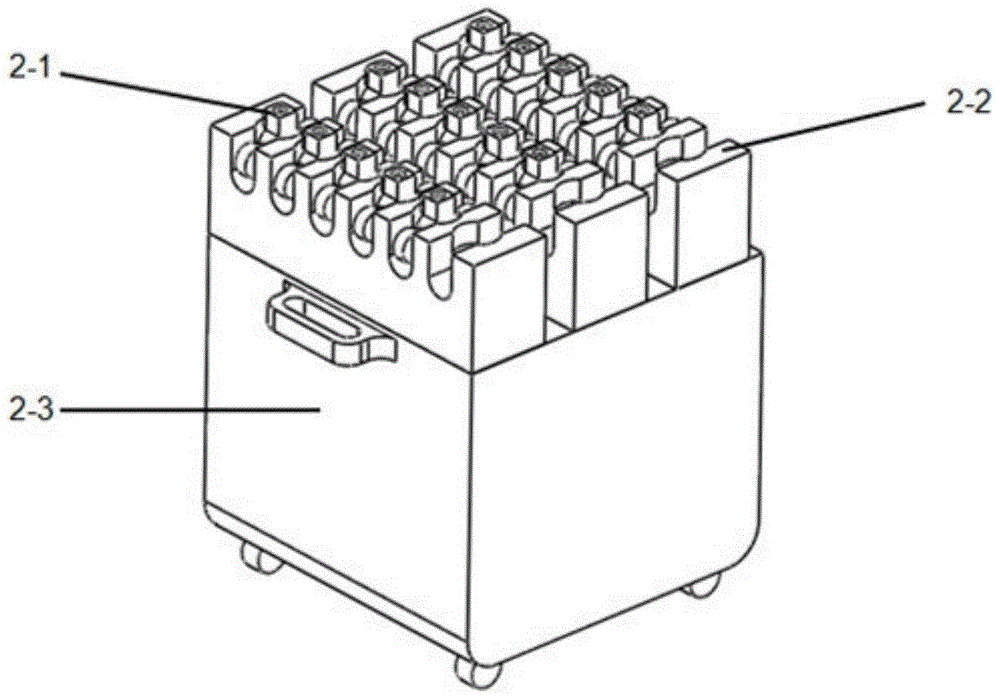

Full-automatic pre-locking, rubber coating and electrical detection platform equipment and usage method

ActiveCN104950790ASmall footprintImprove efficiencyProgramme control in sequence/logic controllersElectricityRobot control

The invention discloses full-automatic pre-locking, rubber coating and electrical detection platform equipment and a usage method. The equipment comprises robot control cabinets, a rubber coating machine tool magazine, a master control console, an intelligent working platform, a rubber coating robot, an auxiliary robot and a protective fence, wherein the intelligent working platform and the master control console are arranged in a same horizontal line; the protective fence is arranged behind the intelligent working platform and the master control console; the two robot control cabinets, one rubber coating robot, one auxiliary robot and the rubber coating machine tool magazine are arranged in space defined by the intelligent working platform, the master control console and the protective fence. According to the full-automatic pre-locking, rubber coating and electrical detection platform equipment and the usage method, scattered and different stations are organically integrated, so that operation of multiple procedures can be realized at one station. Hands of workers can be liberated to the maximum extent, and the efficiency of a harness factory is greatly improved. Meanwhile, the pre-locking, rubber coating and electrical detection quality difference caused by human factors such as sex, proficiency and the like of the workers can be effectively avoided, and the harness quality is improved.

Owner:ZHUJI CANU AUTOMATION EQUIP CO LTD

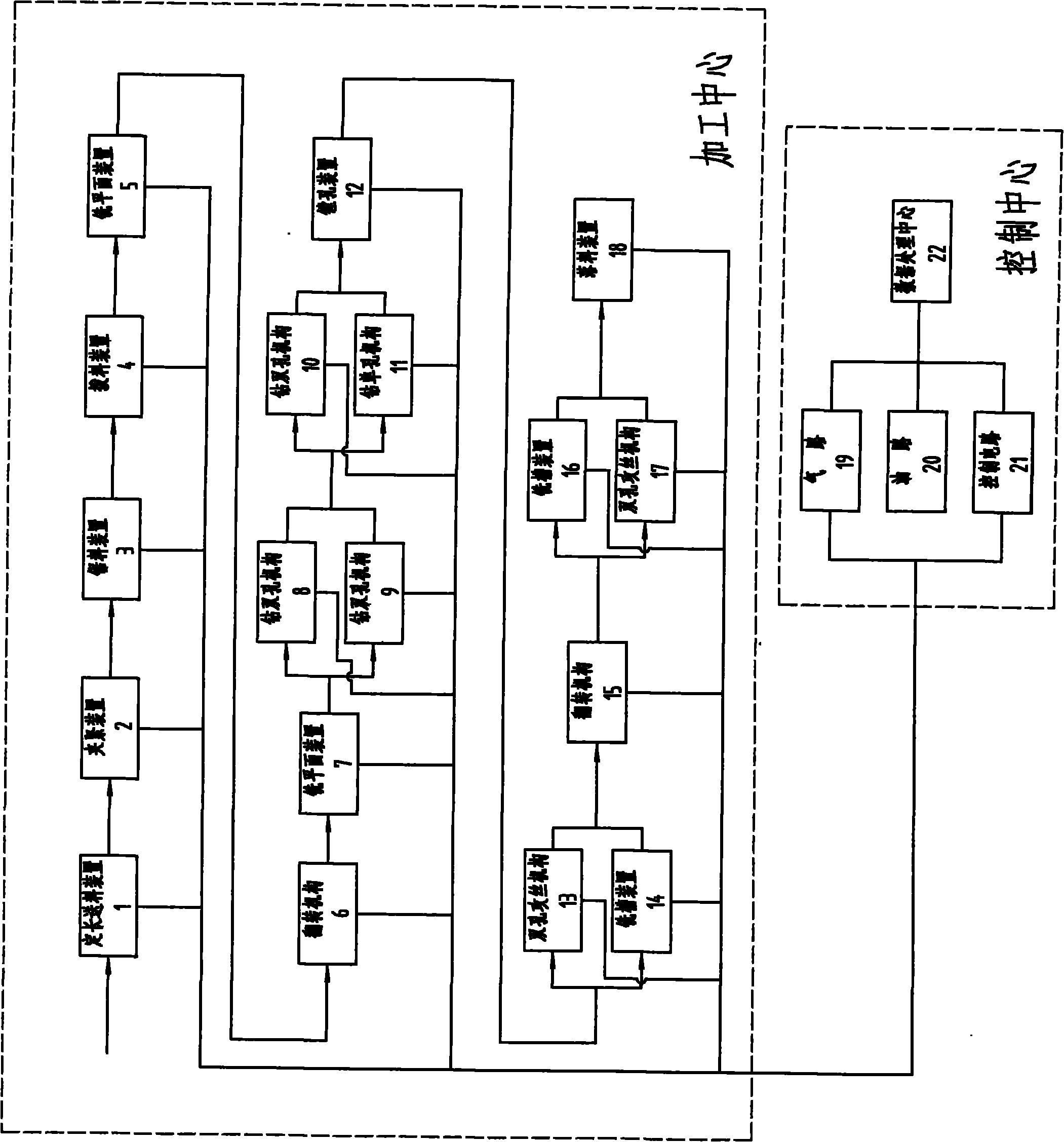

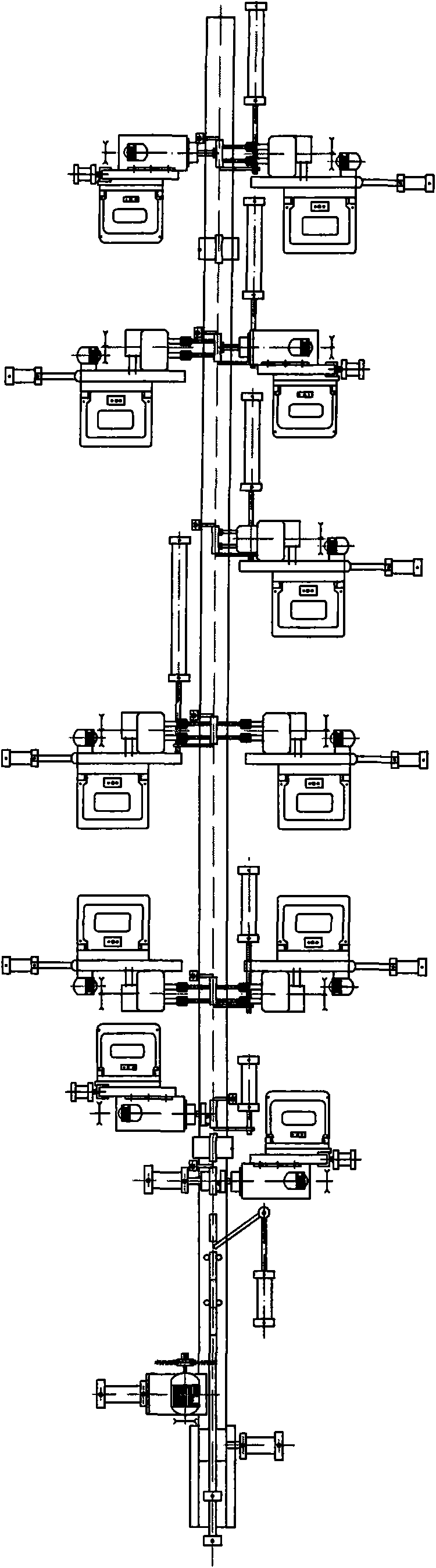

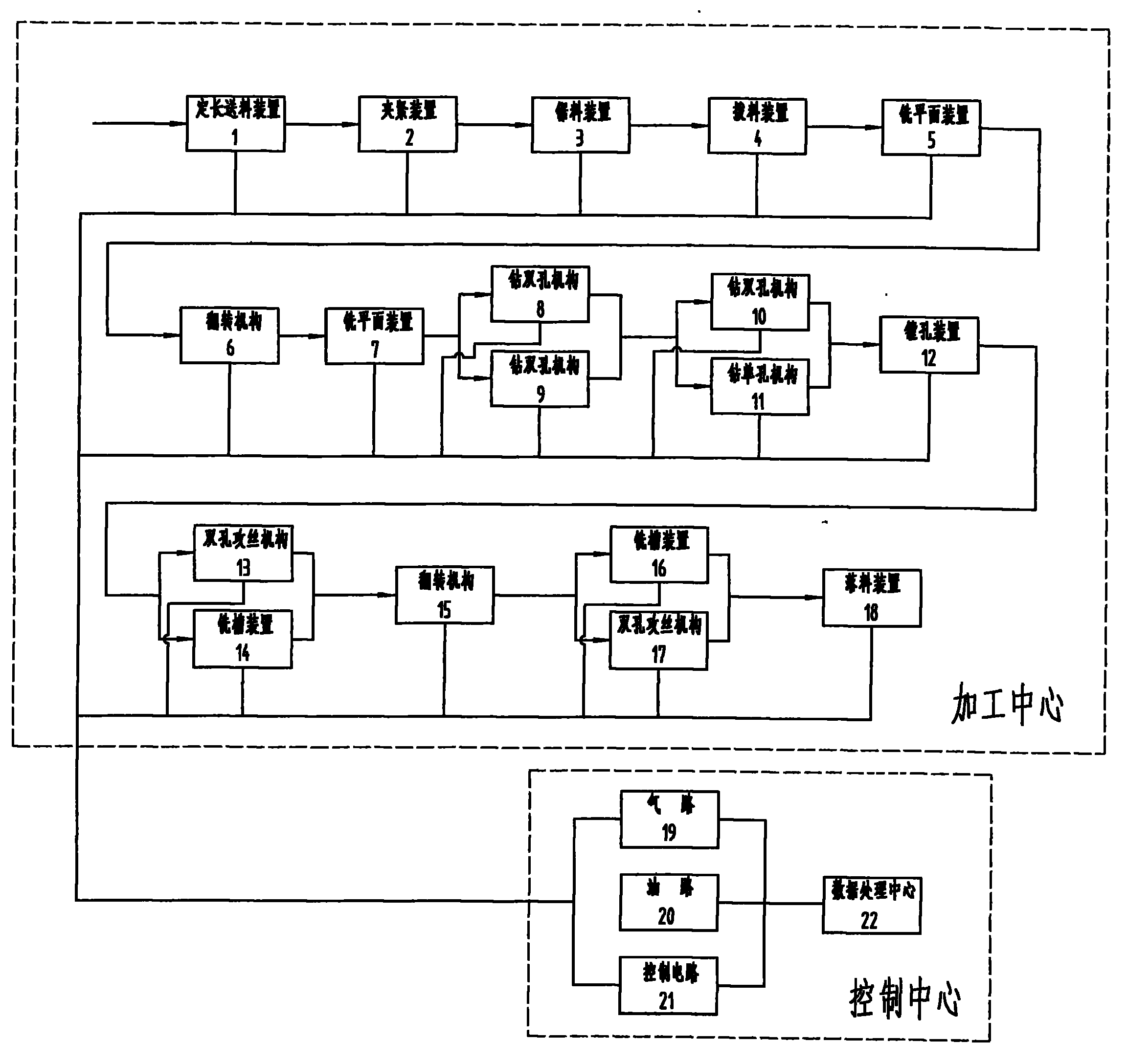

Elastomer program-controlled combined machine tool

InactiveCN101817144ARealize automatic positioningAchieve shiftOther manufacturing equipments/toolsElastomerMulti dimensional

The invention discloses an elastomer program-controlled combined machine tool, which is characterized by comprising a control centre and a processing centre, wherein the control center comprises a data processing center, and a gas circuit, an oil circuit and a control circuit which are connected with the data processing center; a clamping device, a sawing device, an ejecting device, milling equipment, boring equipment, drilling equipment, tapping equipment and the like are arranged on a machine base and an V-type guide rail according to a process procedure in the processing centre, and all the devices and equipment are controlled by the control centre to perform automatic flow line processing. Compared with the prior art, the elastomer program-controlled combined machine tool is characterized in that: automatic positioning, displacement and turning of the elastomer part processing are realized, multi-dimensional processing from section feeding and product finishing is completed at onetime and the automation degree is high; and a great amount of operators and processing equipment are saved, the production efficiency and the finished product yield are improved and the elastomer processing cost is reduced. The program-controlled combined machine tool has a wide market prospect in weighing sensor industry.

Owner:上海友声衡器有限公司

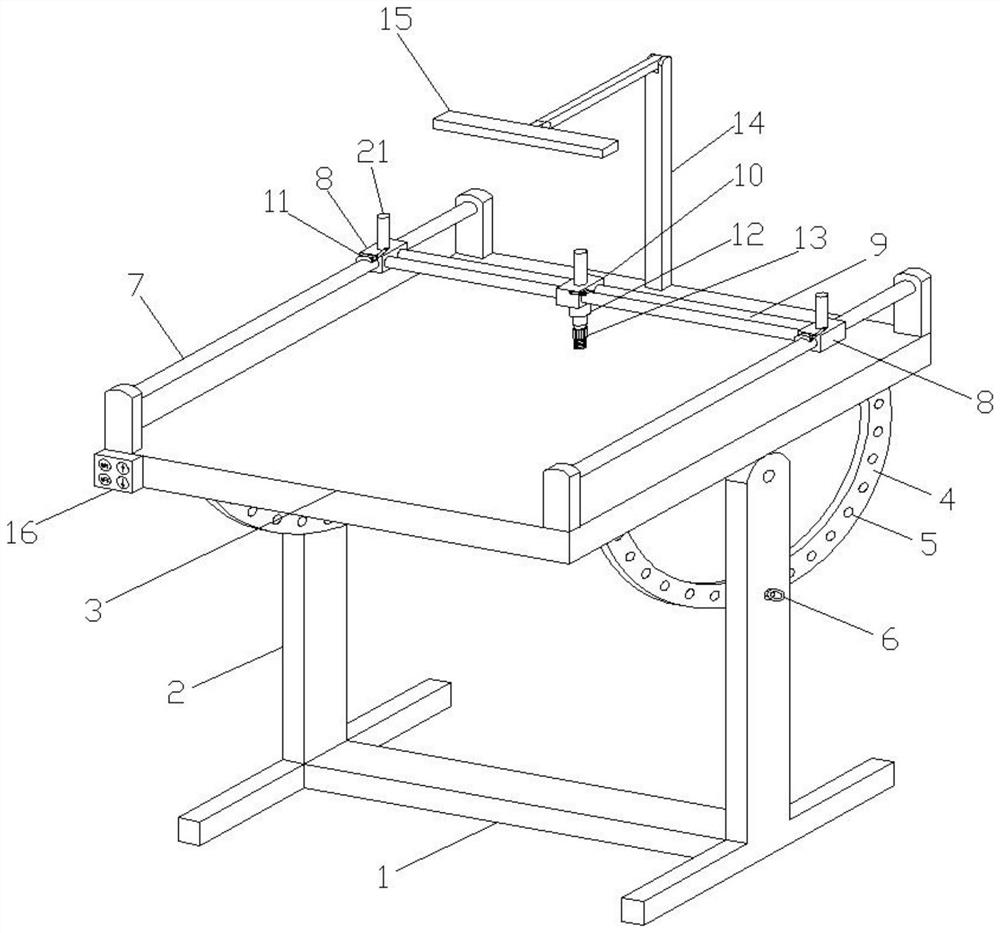

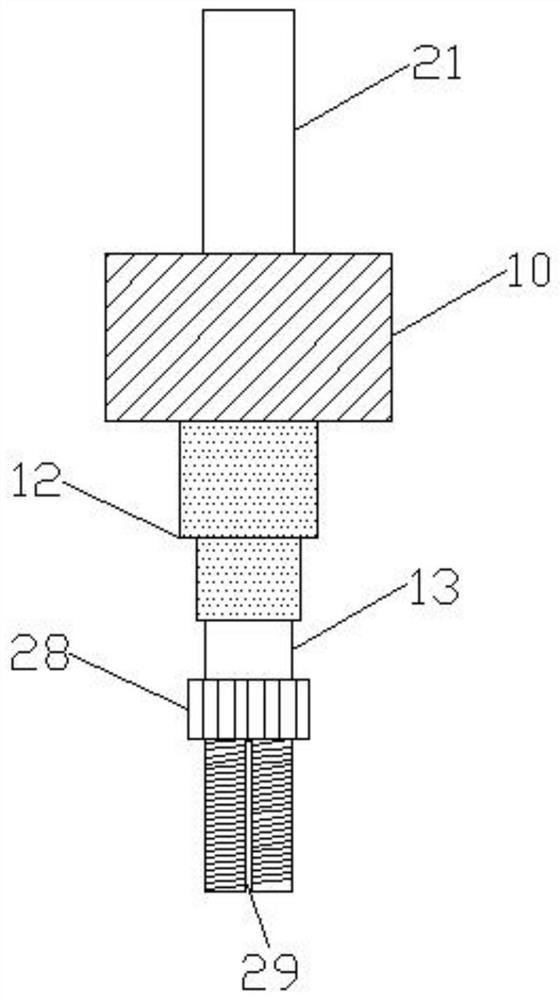

Rotatable costume designing workbench with line drawing and cutting functions and using method thereof

InactiveCN111789388AFree and easy switchingEasy to operateLighting support devicesElectric circuit arrangementsEngineeringWorkbench

The invention discloses a rotatable costume designing workbench with line drawing and cutting functions and a using method thereof, and belongs to the technical field of costume designing workbenches.The workbench includes a base, supporting arms are perpendicularly fixed to the two ends of the base, a workbench face is rotationally hinged between the top ends of the two supporting arms; semicircular angle adjusting plates are fixedly mounted at the bottoms of the two ends of the workbench face correspondingly. Adjusting lock pins are arranged on the supporting arms; longitudinal sliding rodsare fixedly mounted at the two ends of the upper surface of the workbench face correspondingly. Longitudinal sliding blocks are slidably connected to the longitudinal sliding rods in a sleeving mode,a transverse sliding rod is fixedly connected between the longitudinal sliding blocks at the two ends, a transverse sliding block is slidably connected to the transverse sliding rod in a sleeving mode, an electric telescopic rod is installed at the bottom of the transverse sliding block, and a four-jaw clamping cylinder is connected to the bottom of the electric telescopic rod. The rotatable costume designing workbench integrates line drawing and cutting, further has the size assisting and lighting functions and is convenient to use, in addition, the workbench face can incline by a certain angle, and the effect and the size of drawings or cloth can be observed conveniently.

Owner:黄海龙

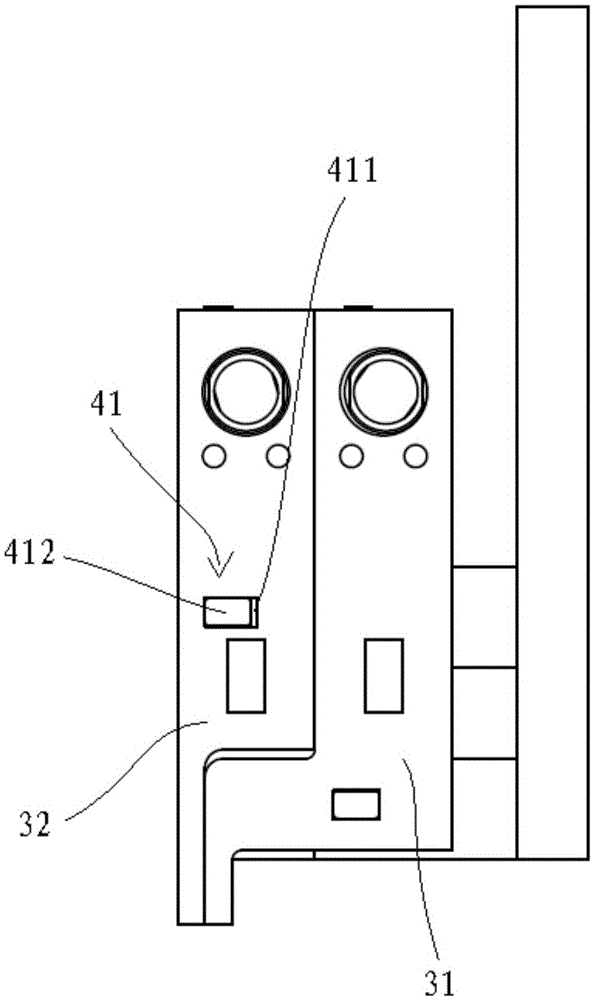

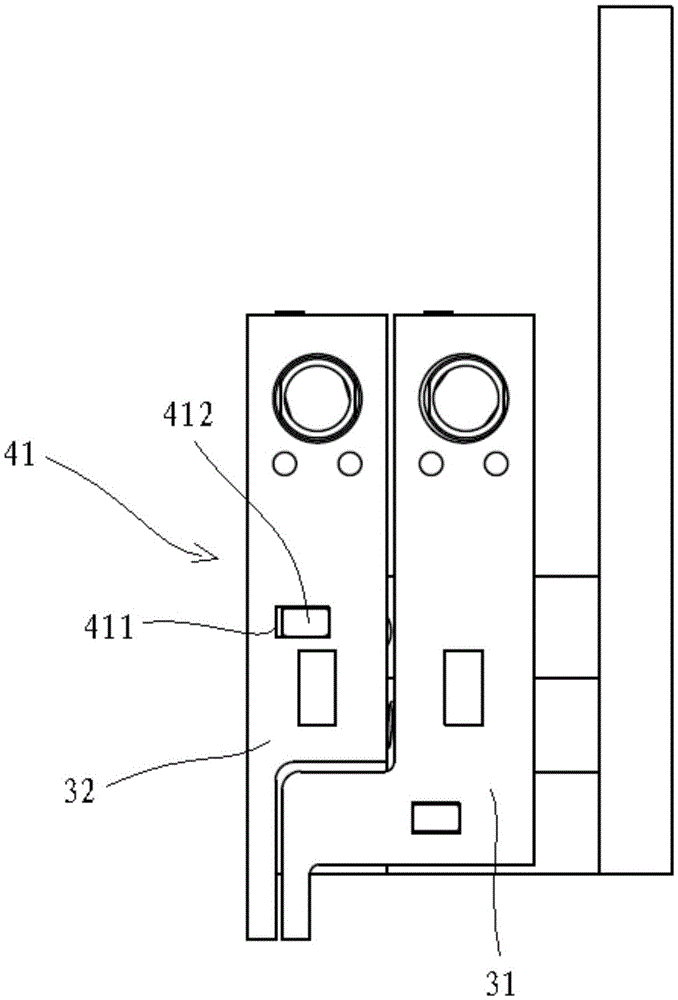

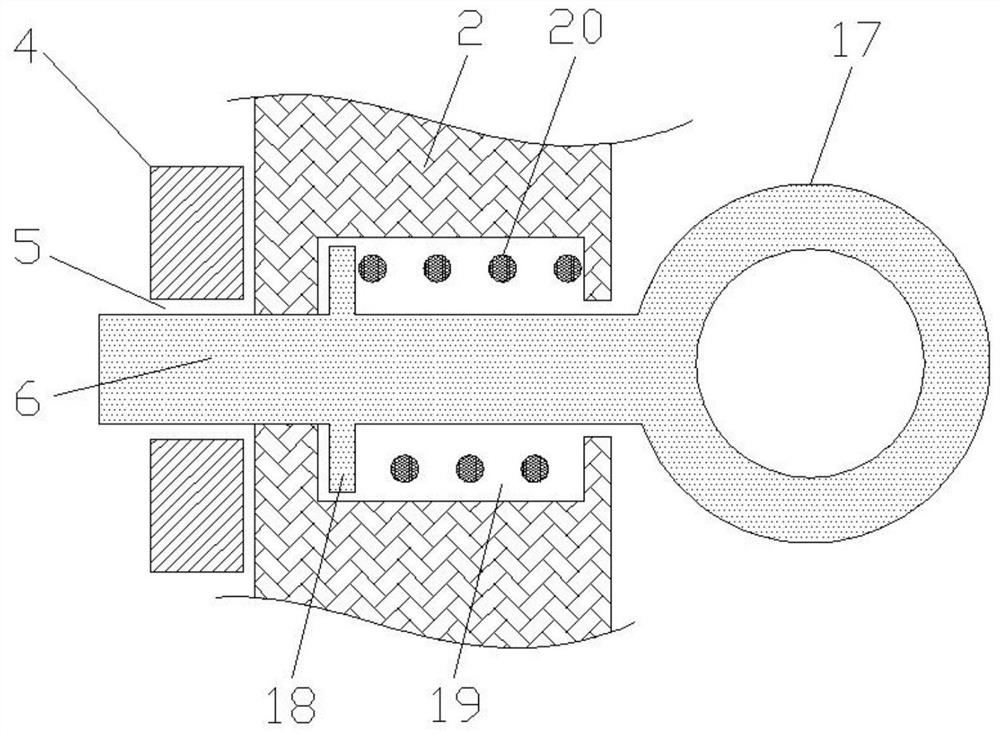

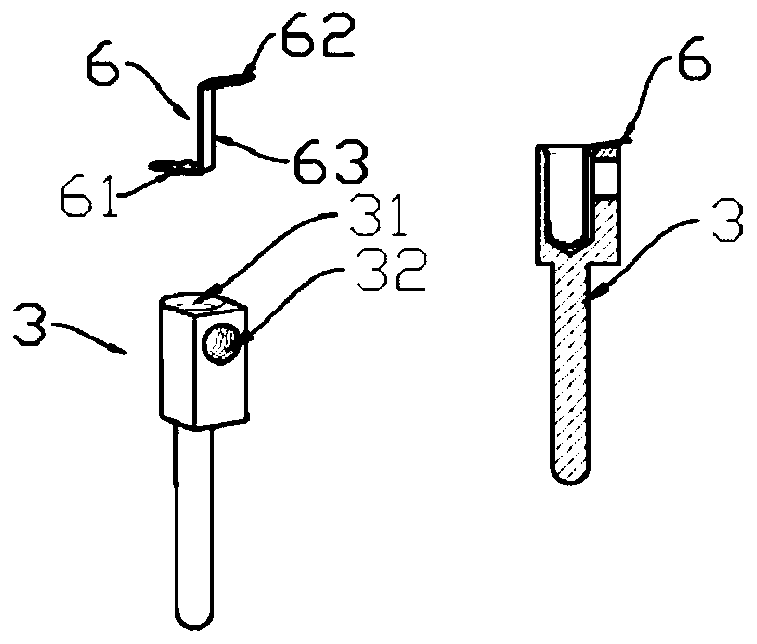

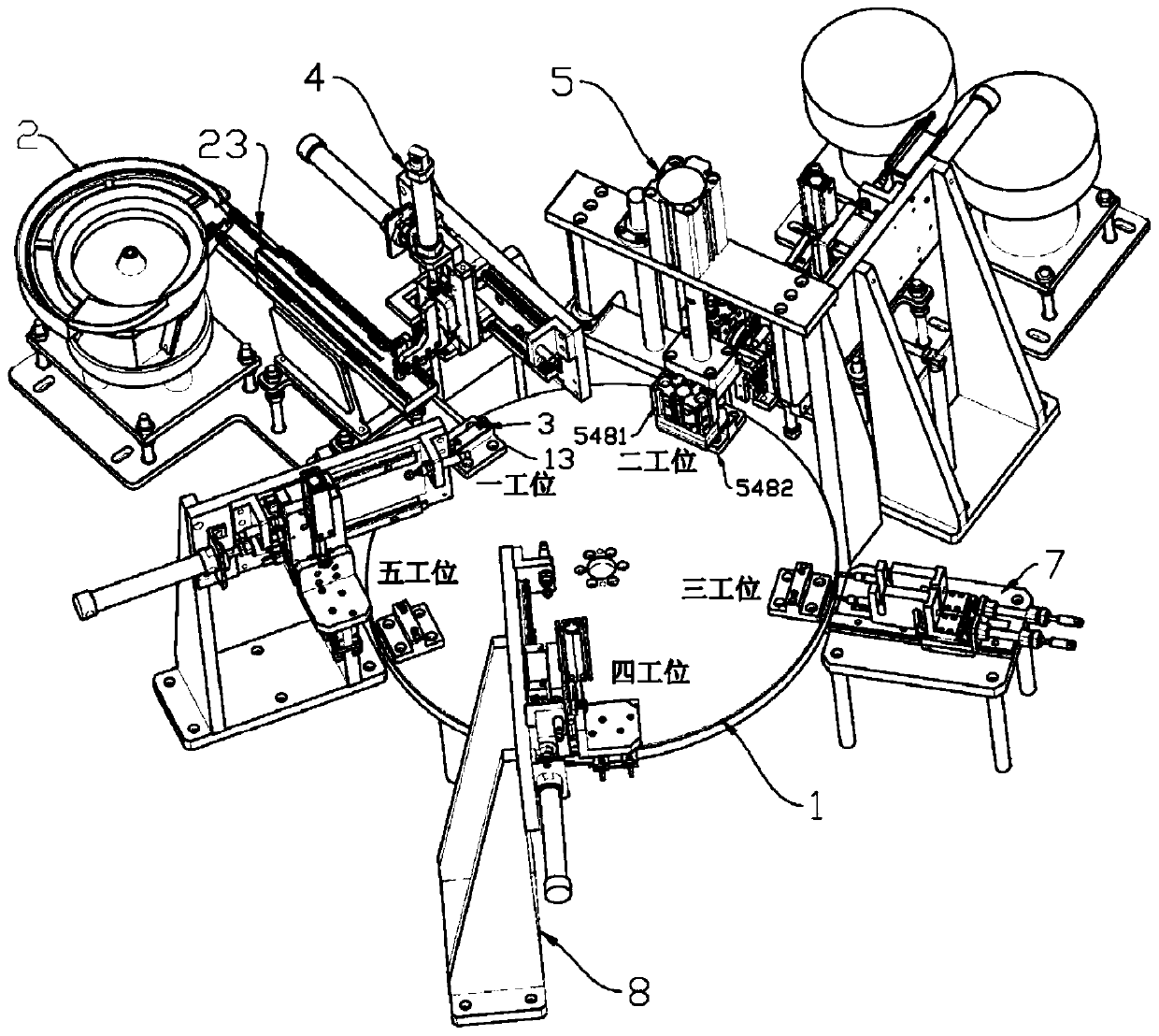

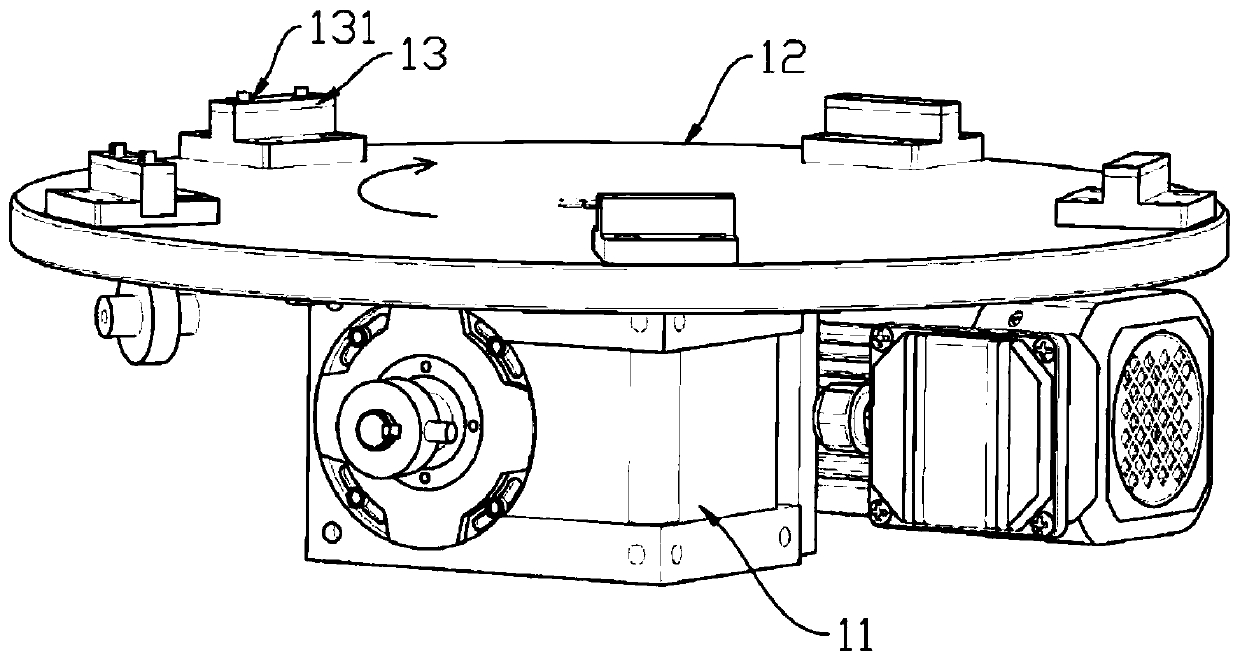

Numerical control full-automatic assembling machine for built-in contact reed of rectangular heavy-load electric connector

PendingCN110890684AAchieve shiftSimple structureContact member assembly/disassemblyNumerical controlControl system

The invention relates to a numerical control full-automatic assembling machine for a built-in contact reed of a rectangular heavy-load electric connector. The numerical control full-automatic assembling machine comprises a rotary workbench, five stations are arranged clockwise along the circumference of the rotary workbench, and a workpiece conveying device, a feeding mechanism, a reed press-fitting mechanism, a detection mechanism, a qualified product discharging mechanism, an unqualified product discharging mechanism and an electrical control system are separately arranged beside each station. A reed switching mechanism and a reed positioning mechanism in the reed press-fitting mechanism jointly achieve the displacement and turnover of a reed, when the reed press-fitting mechanism works,the reed positioning mechanism clamps the reed to play a role in positioning the reed and replace a special clamp, and the detection mechanism and the two discharging mechanisms achieve an automaticsorting function. According to the numerical control full-automatic assembling machine for the built-in contact reed of the rectangular heavy-load electric connector, the labor cost of reed assembly is greatly reduced, the structure of the machine is simple and compact, the cost is low, and meanwhile because of the high automation degree, the working efficiency and precision are high, the workingis reliable, and the fault rate is low.

Owner:上海华伦仪表电子有限公司

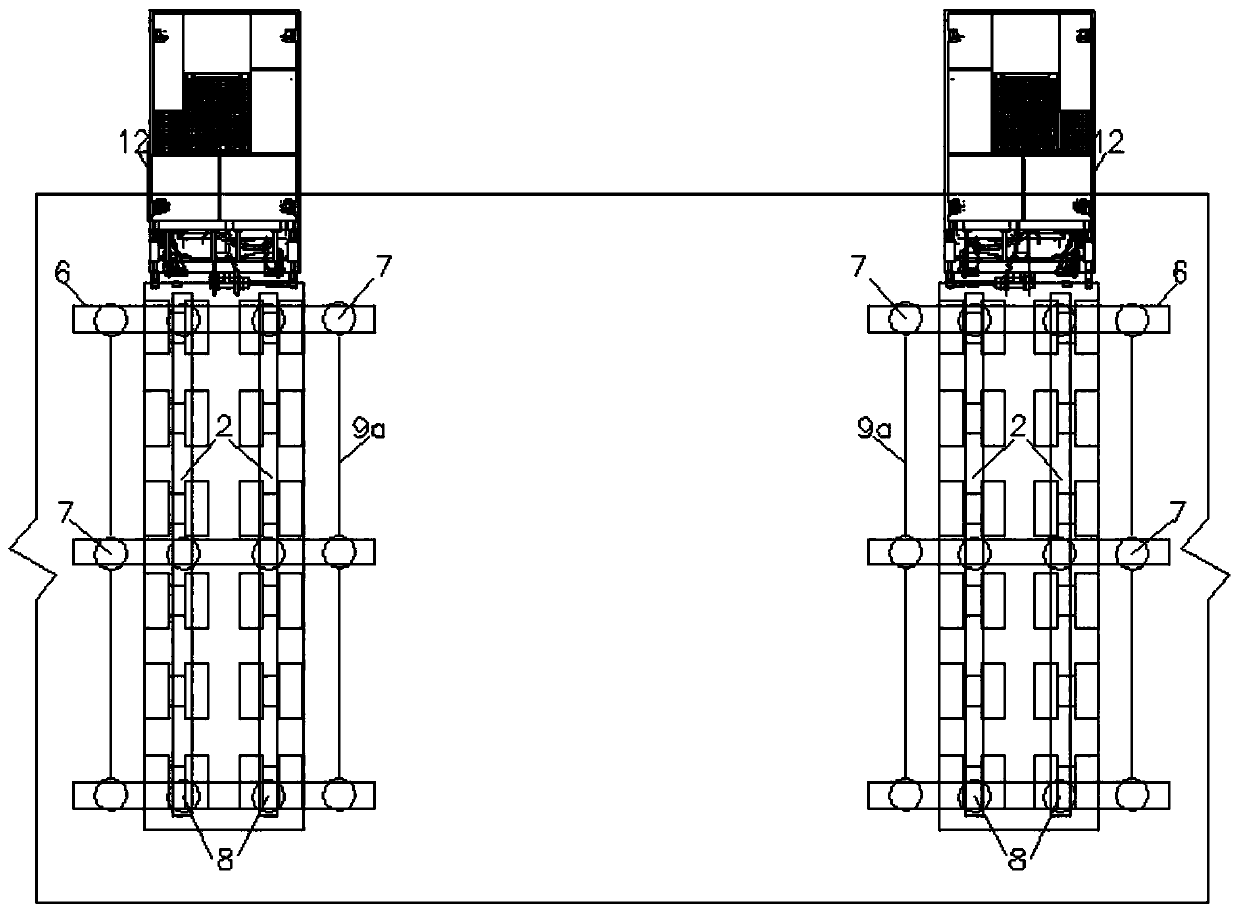

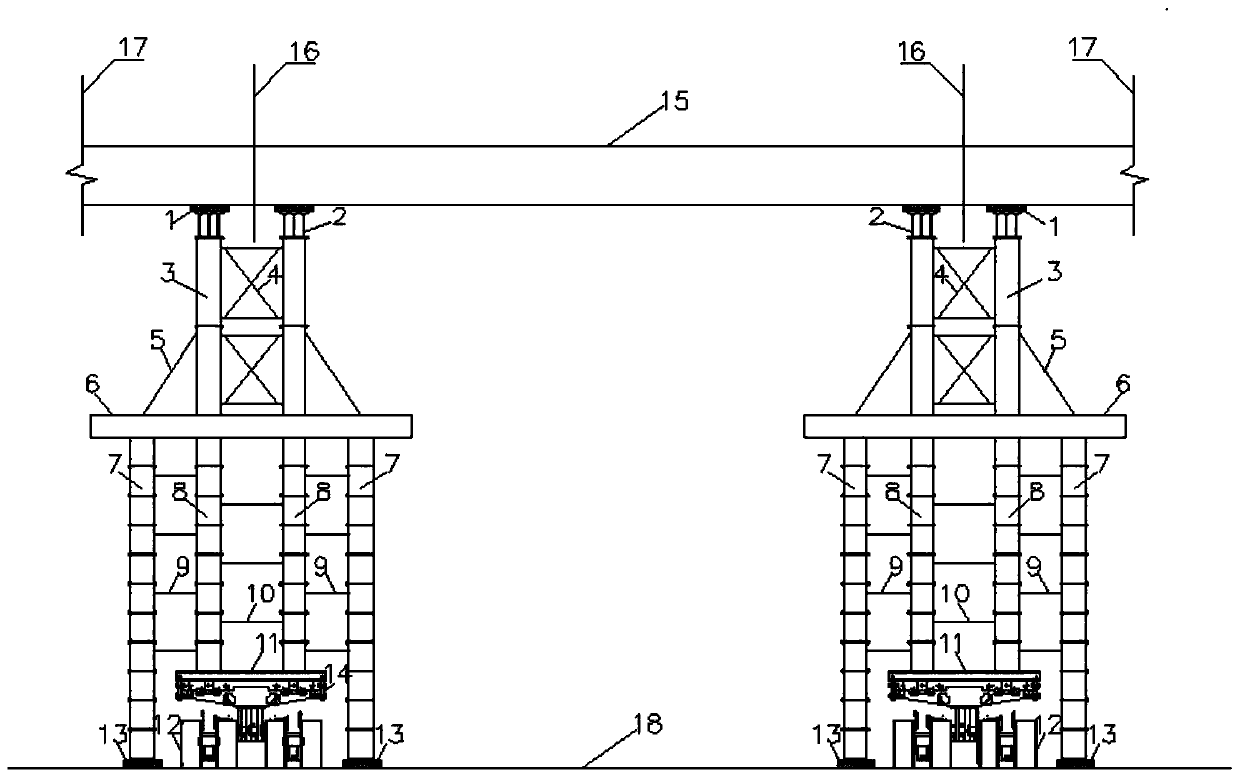

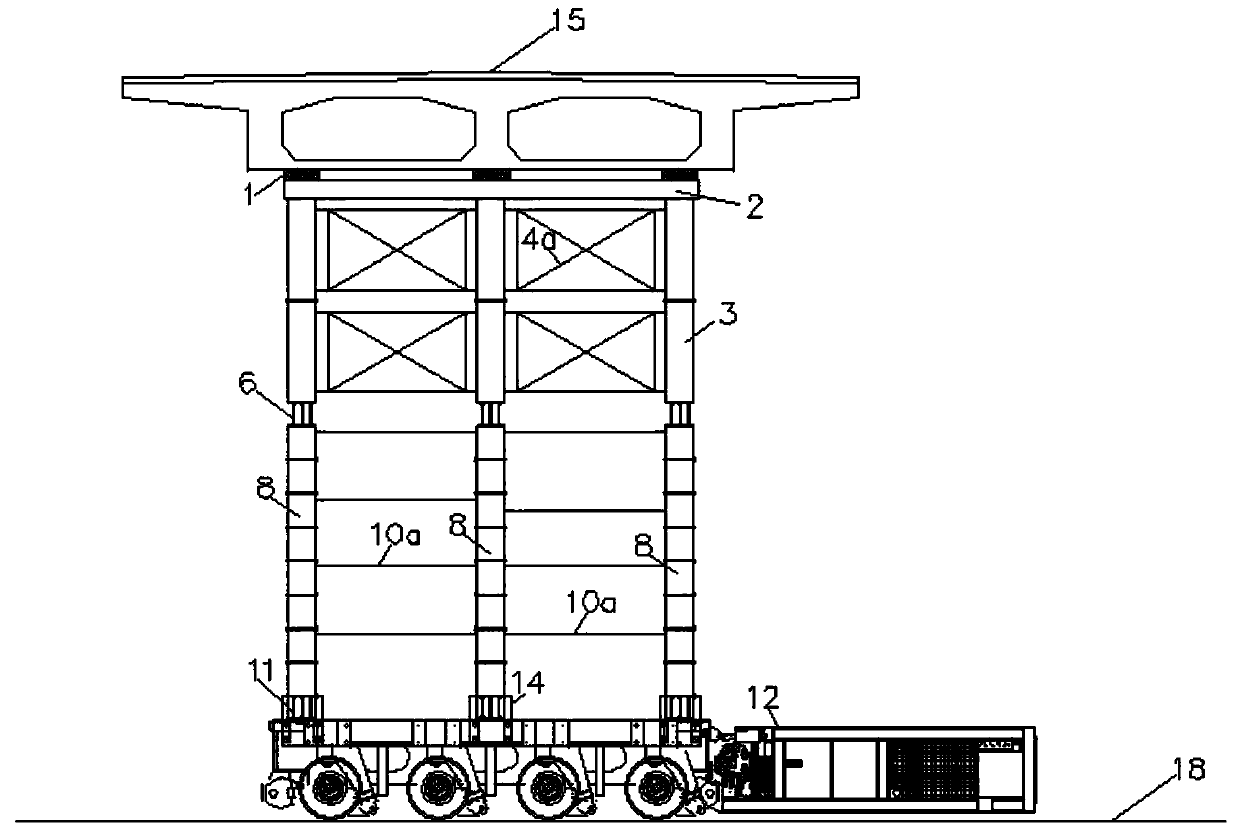

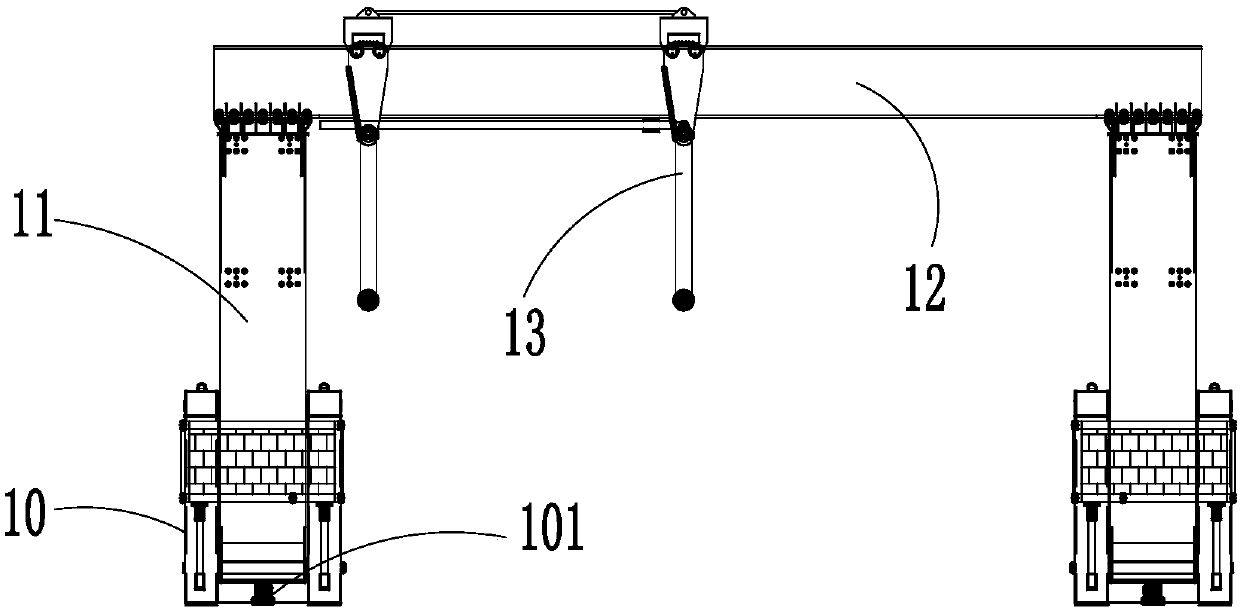

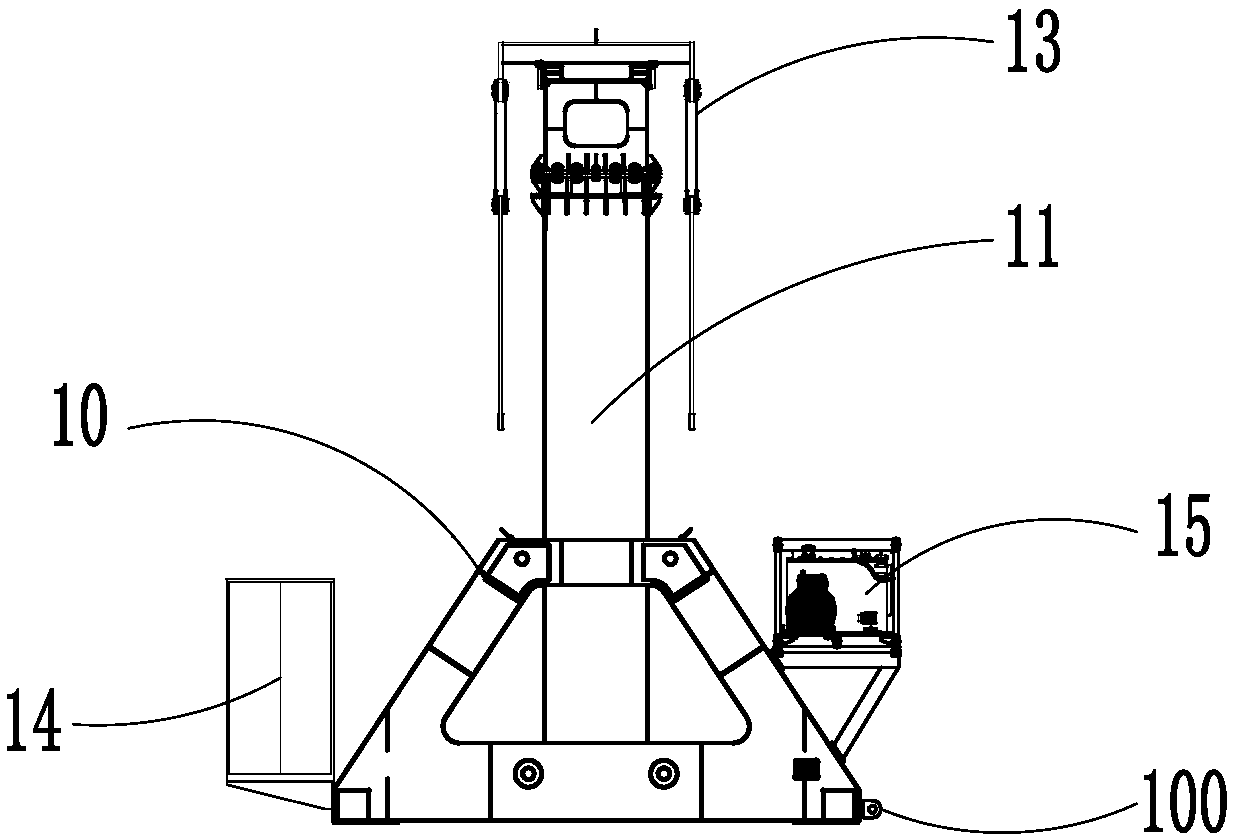

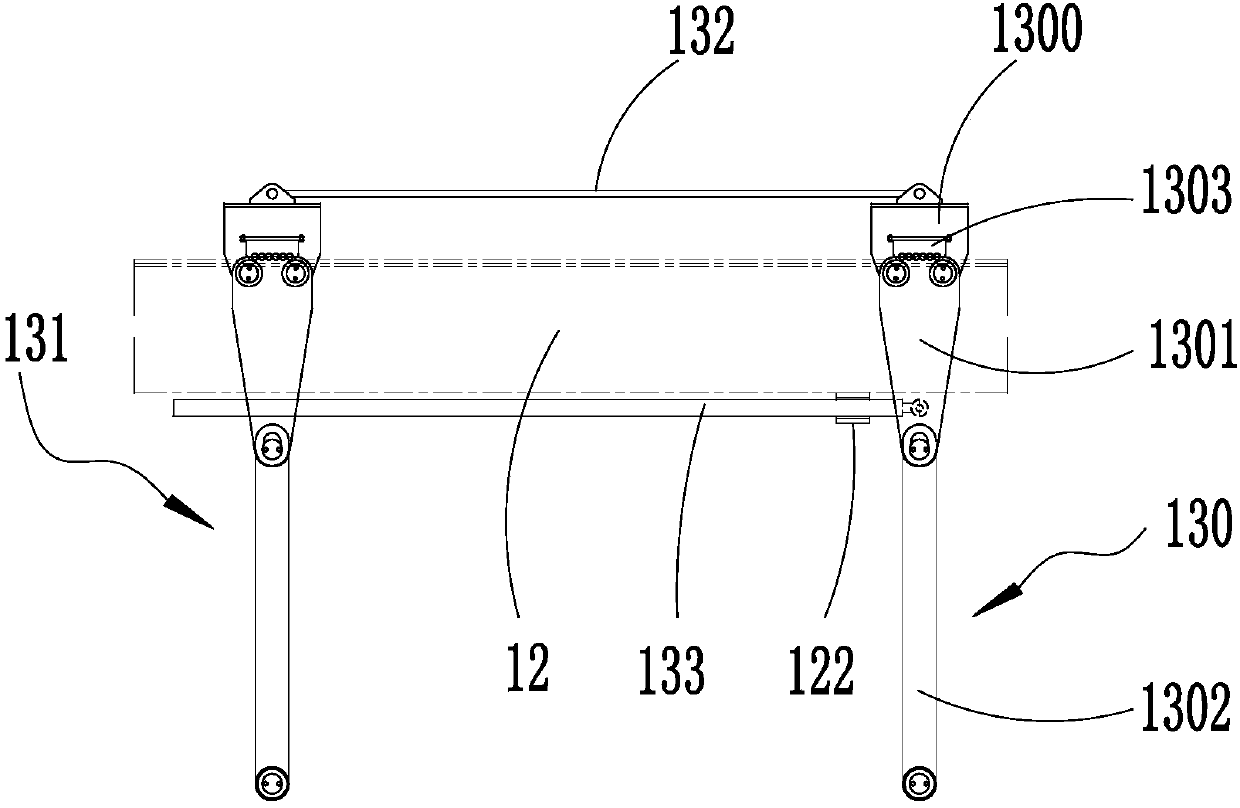

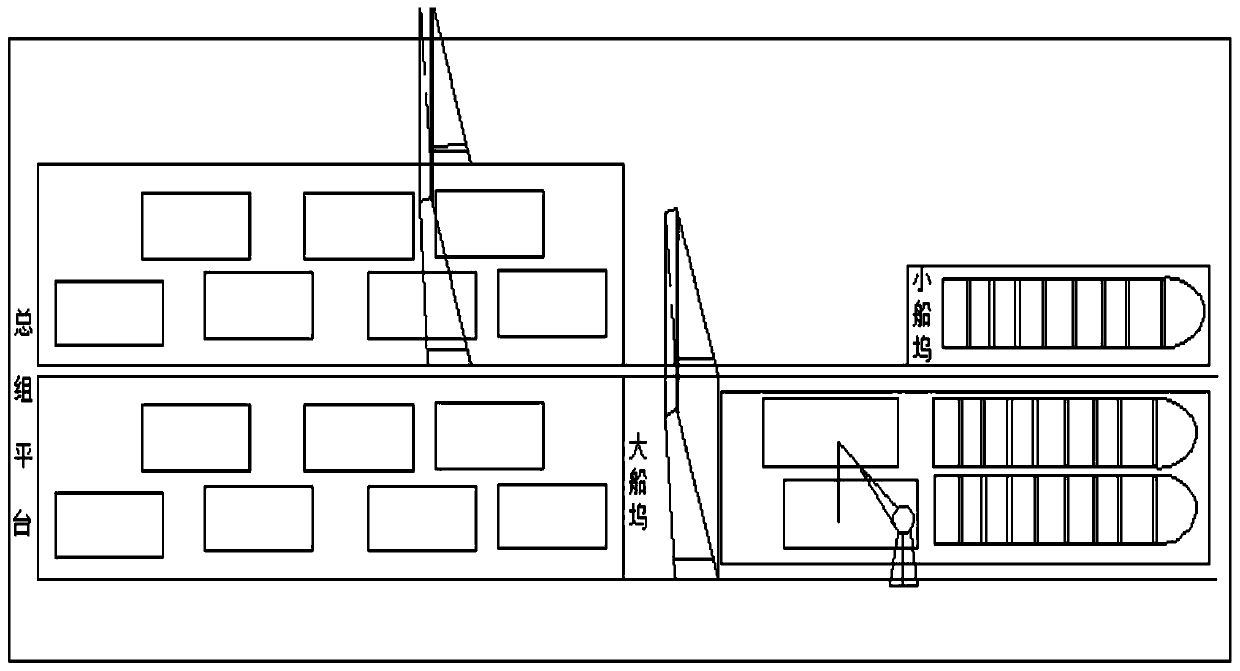

Portal crane

PendingCN107601268AAchieve shiftAchieve regulationBase supporting structuresBraking devices for hoisting equipmentsEngineeringGantry crane

Owner:SUZHOU DAFANG SPECIAL VEHICLE

Corner guide rail bracket shifting device and corner guide rail bracket shifting mounting method

Owner:JIANGNAN SHIPYARD GRP CO LTD

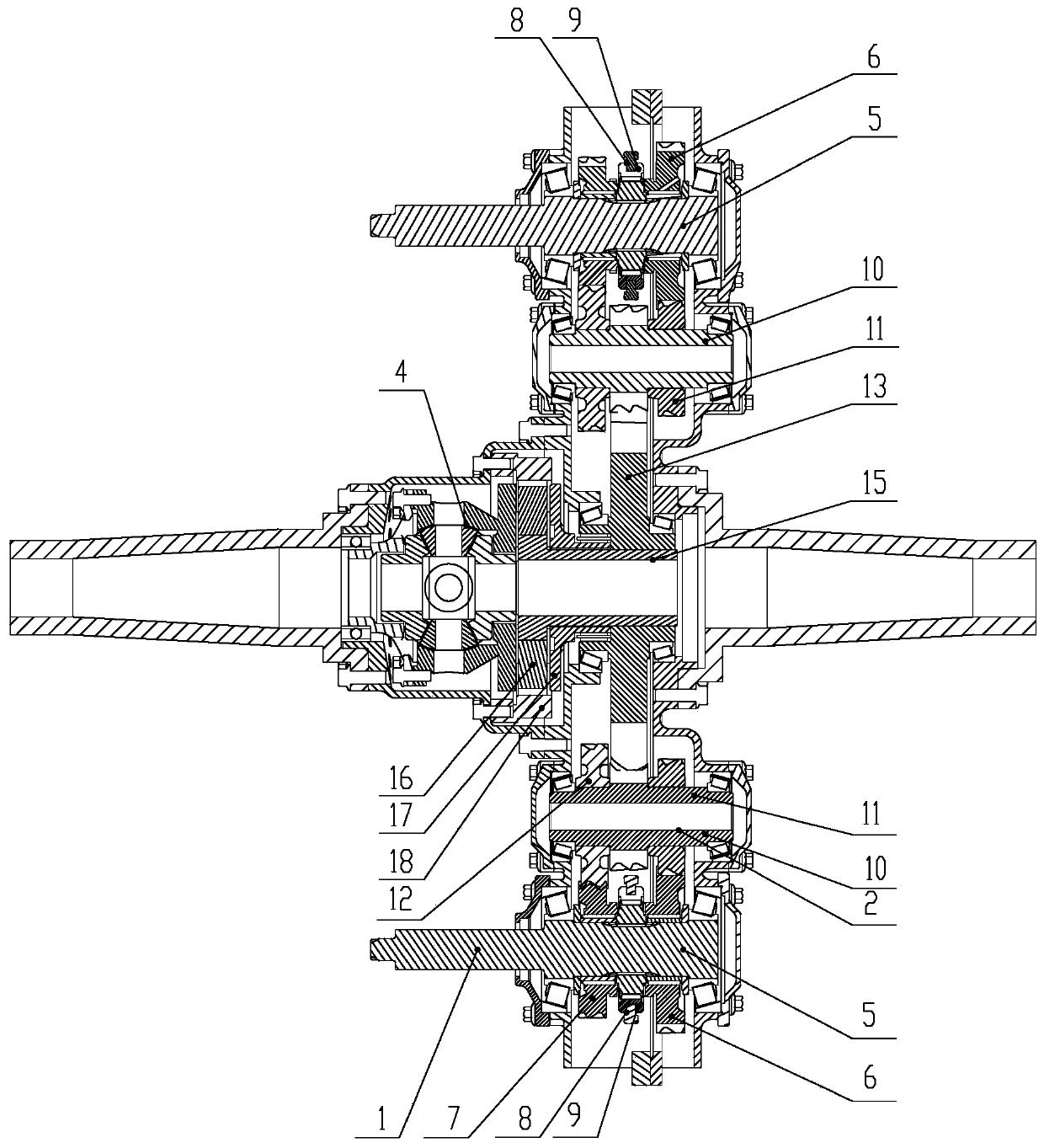

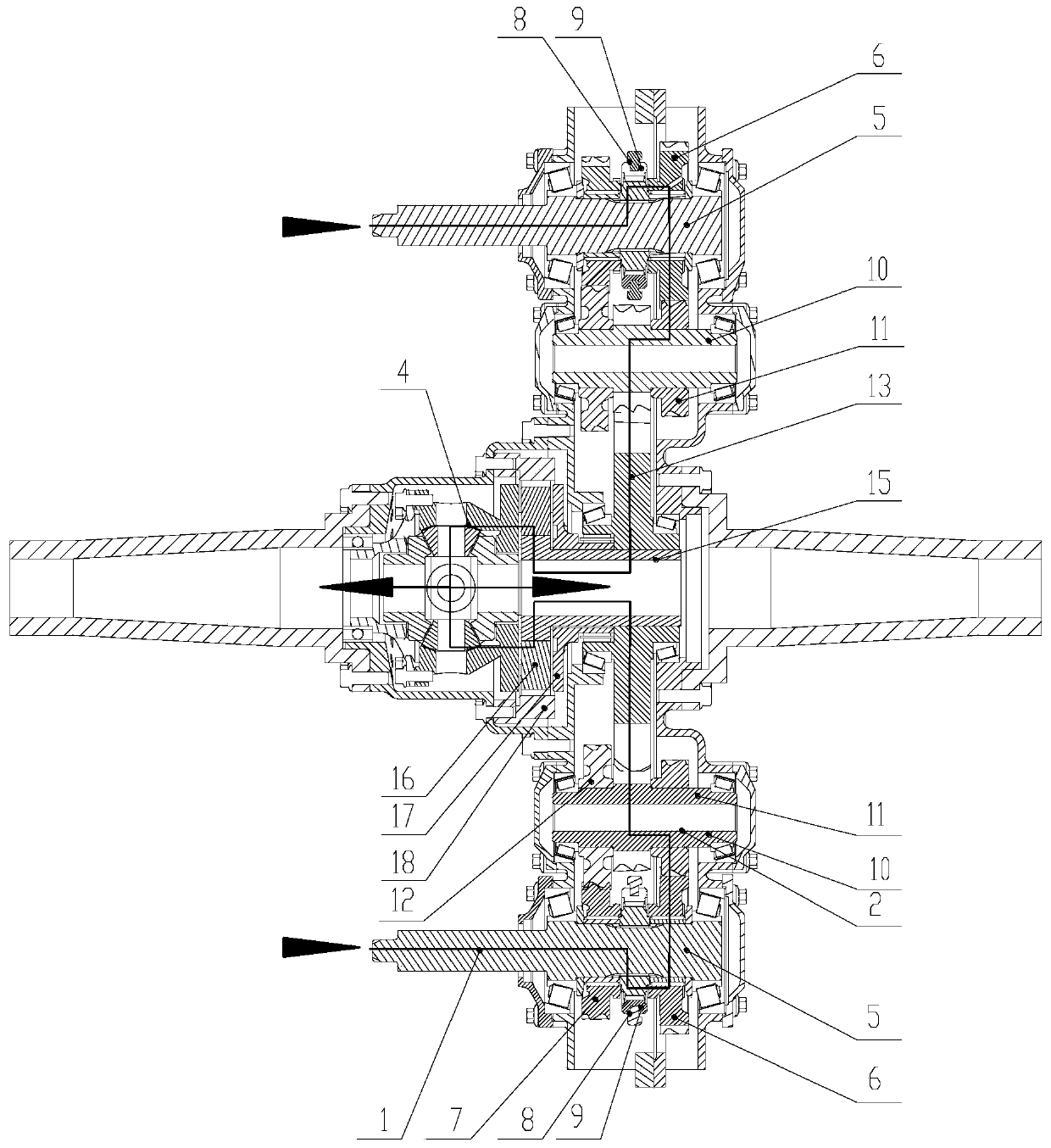

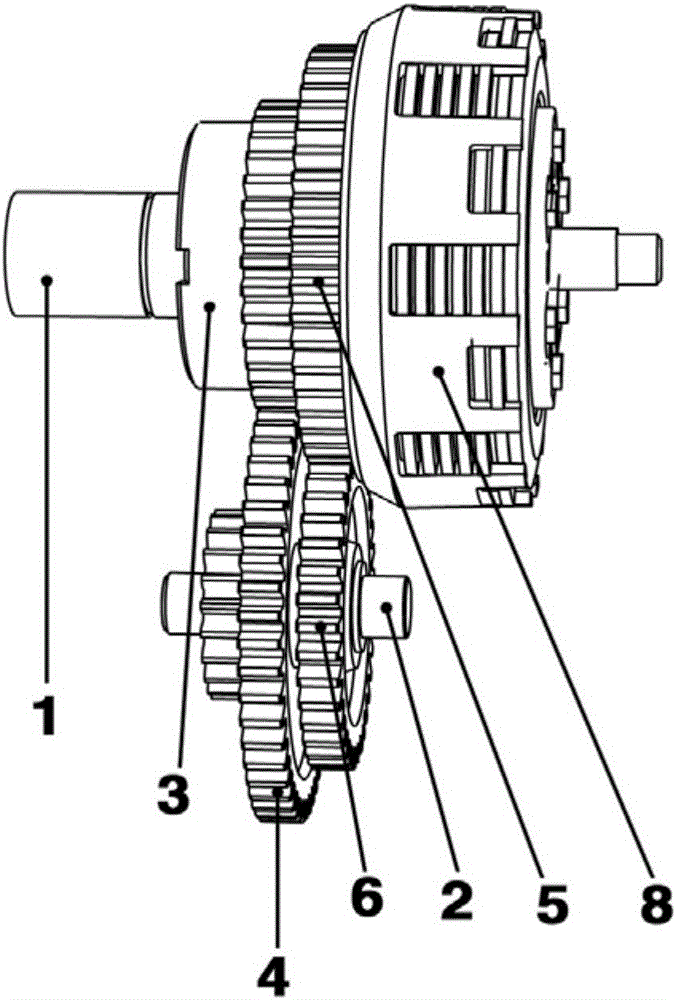

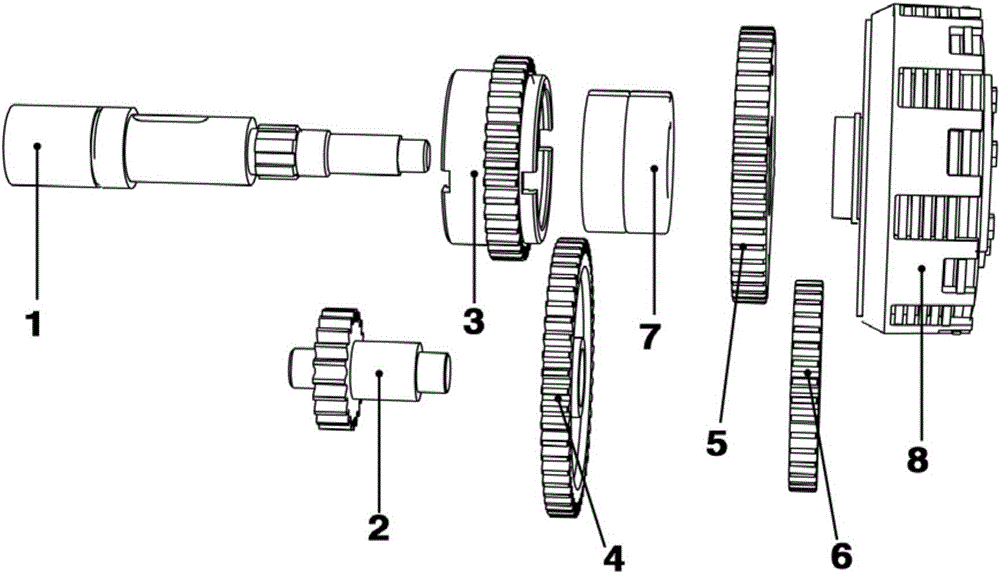

Dual-motor transverse gear-shiftable electric drive axle speed reducer assembly

PendingCN110848346AAchieve shiftSave layout spaceToothed gearingsGearing detailsReduction driveGear wheel

The invention discloses a dual-motor transverse gear-shiftable electric drive axle speed reducer assembly which comprises two motors, two gear-shifting assemblies, a planetary reduction gear assemblyand a differential mechanism assembly. The gear-shifting assemblies include a first shaft assembly and a second shaft assembly. The motors are connected with the first shaft assembly. High-speed and low-speed two-gear speed regulation is realized through a sliding meshing assembly on the first shaft assembly. The second shaft assembly is in transmission with a sun wheel axle of the planetary reduction gear assembly through a long meshing gear set. A planet carrier of the planetary reduction gear assembly is connected with a differential mechanism inner shell of the differential mechanism assembly through a planet pinion shaft. A gear ring is connected with a differential mechanism shell. The dual-motor transverse gear-shiftable electric drive axle speed reducer assembly is compact in structure, high in integrity, low in machining difficulty and light in weight.

Owner:DONGFENG COMML VEHICLE CO LTD

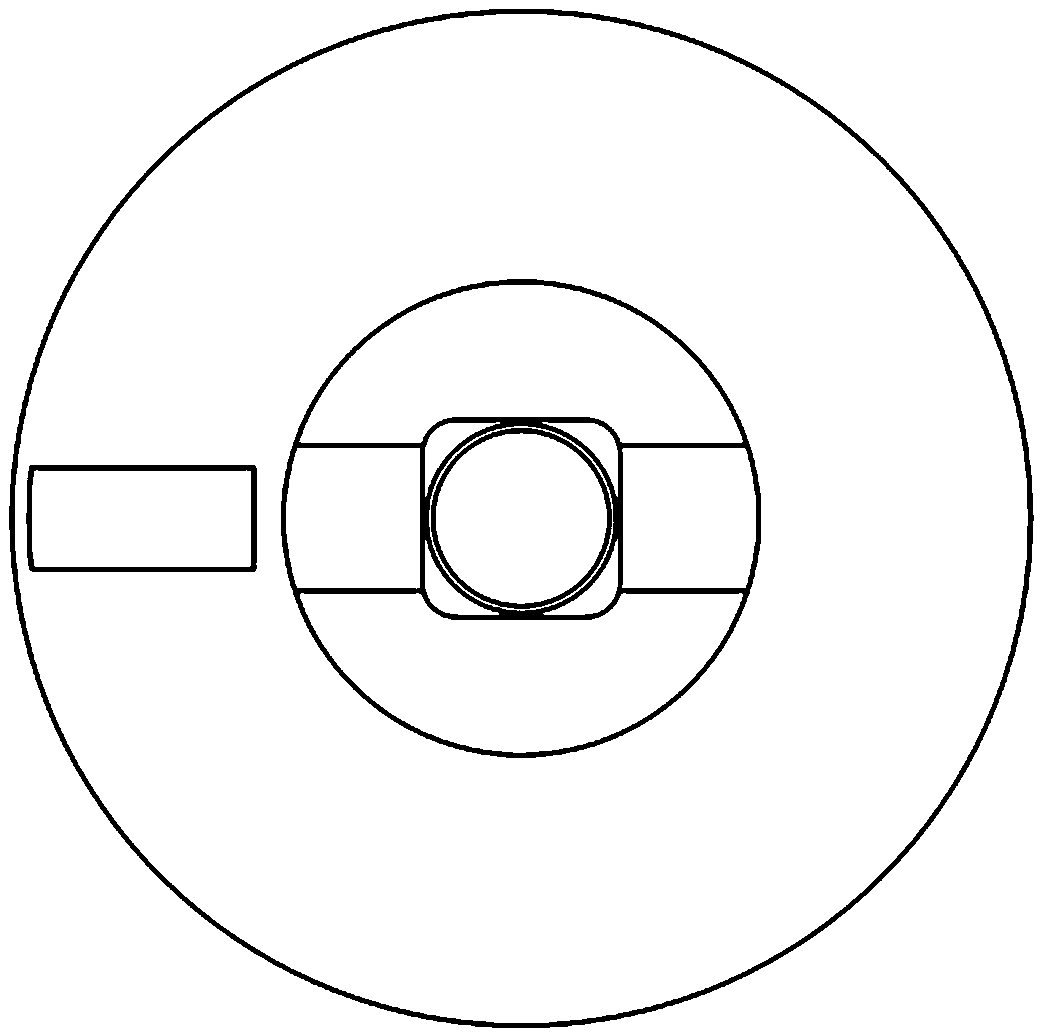

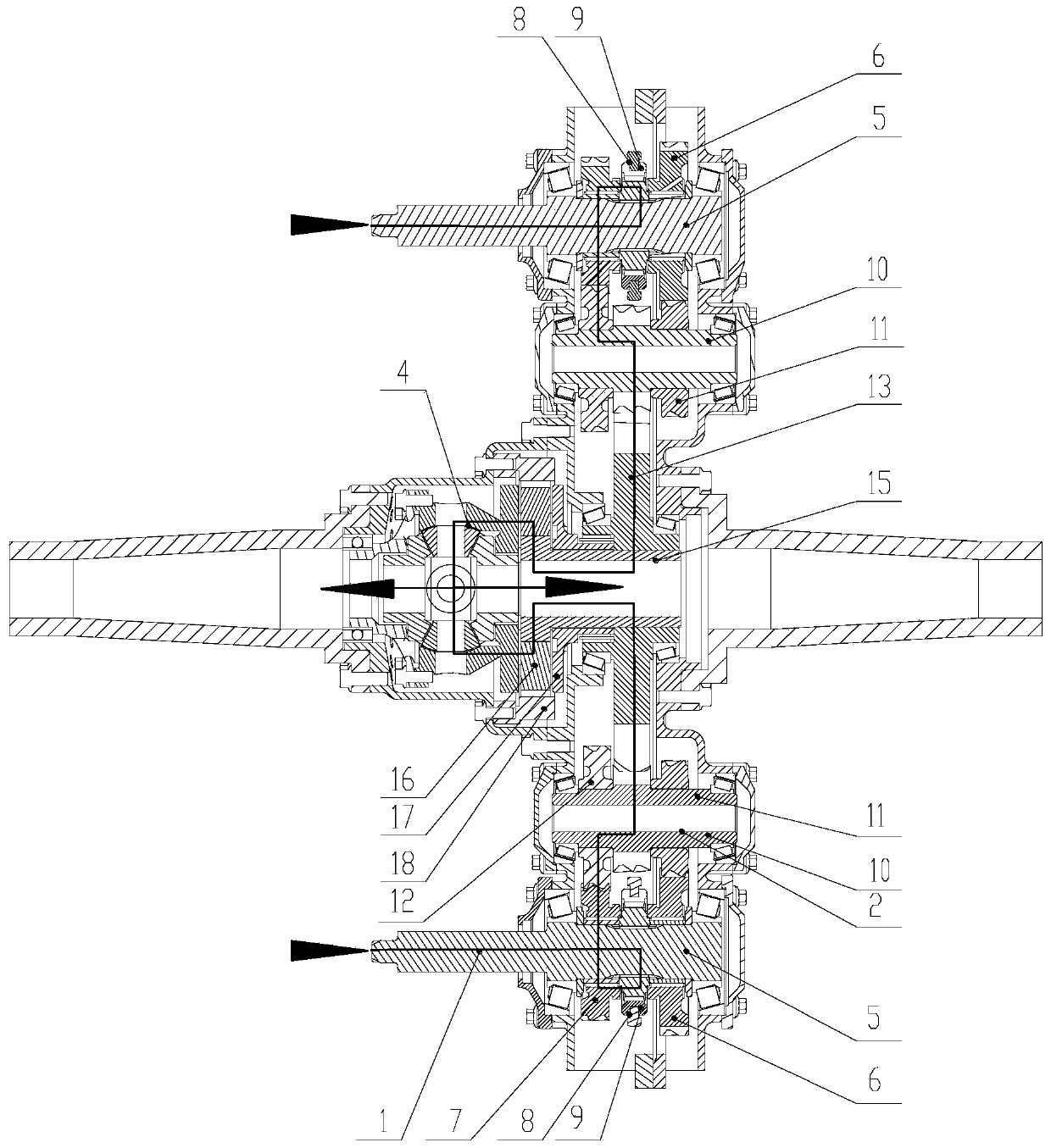

Drill pipe double-clamping system for pile driver

ActiveCN106320996AGuaranteed verticalityImprove work efficiencyDrilling rodsDrilling casingsEngineeringPile driver

The invention belongs to the technical field of buildings and relates to a drill pipe double-clamping system for a pile driver. The system comprises a clamping table, wherein a primary clamping mechanism which is used for clamping a drill pipe and can drive the drill pipe to move vertically is arranged on the clamping table, a secondary clamping mechanism which can hold the drill pipe and can drive the drill pipe to move vertically is arranged on the clamping table, and when the secondary clamping mechanism holds the drill pipe, the axis of the second clamping mechanism coincides with that of the primary clamping mechanism. The system adopts two clamping mechanisms and can realize continuous drilling operation, the operation efficiency is improved, the axes of the two clamping mechanisms coincide during working, the drill pipe is always supported by force during drilling, so that the perpendicularity of the drill pipe is guaranteed, and the engineering quality is guaranteed.

Owner:浙江兆弟技术有限公司

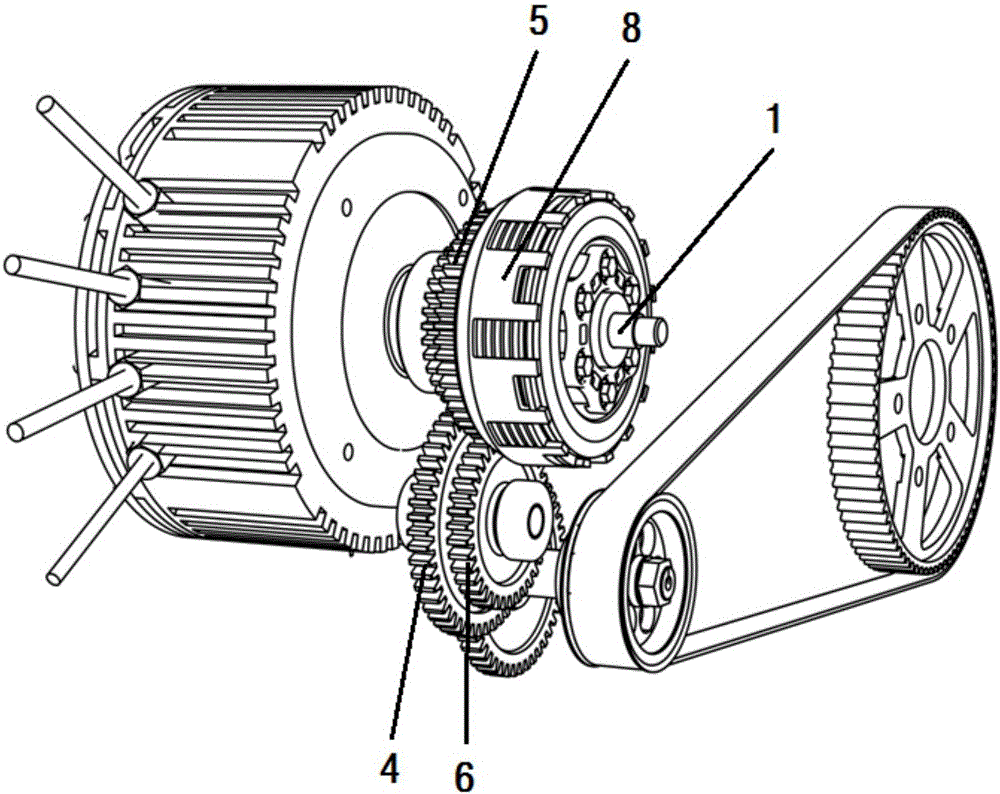

Multi-clutch gear-shifting system and using method thereof

InactiveCN105889429AThe overall structure is simpleEase of production implementationToothed gearingsTransmission elementsElectrical controlClutch

The invention discloses a multi-clutch gear-shifting system and a using method thereof. The multi-clutch gear-shifting system comprises an input shaft, an output shaft, a plurality of groups of mutually meshed gear pairs, a controllable clutch and a plurality of one-way clutches, wherein gears of the gear pairs at highest-speed gears in the groups of gear pairs are installed on the input shaft through the controllable clutch in a sleeving mode, and gears of the gear pairs at low-speed gears in the groups of gear pairs except the highest-speed gears are installed on the input shaft through the one-way clutches in a sleeving mode. When the multi-clutch gear-shifting system is used, the whole structure is simple, the gear-shifting system is small in size and light in weight, can be used for motorcycles and mopeds and is easy to produce and implement. Gapless gear shifting can be achieved through the clutches, and the multi-clutch gear-shifting system does not require an operator to have technical experiences and can achieve automatic gear shifting and manual electrical control gear shifting. In addition, no gear impact is produced in gear shifting, the gear shifting is achieved through engagement of the clutches, the engagement is smooth, and the service life is prolonged. Furthermore, energy loss and heat quantity are small in work.

Owner:杭州虬龙科技有限公司

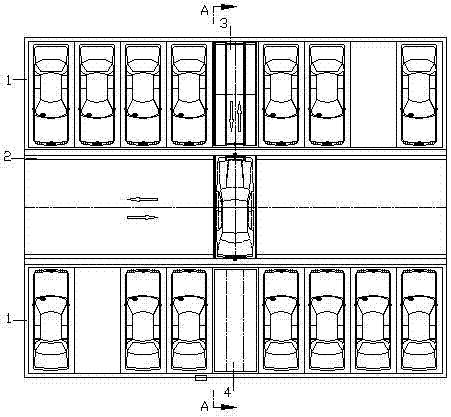

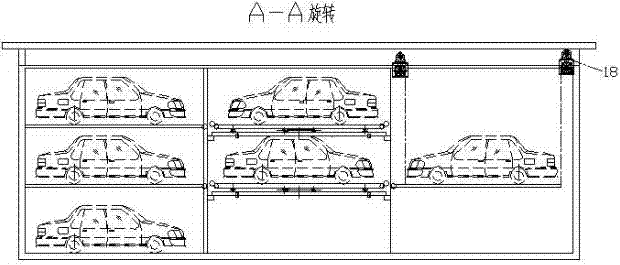

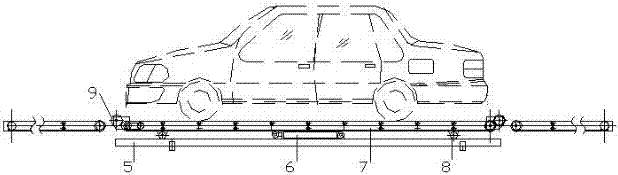

Plane mobile stereo garage

The invention relates to a plane mobile stereo garage. A transverse-moving trolley is driven to move transversely along a trolley rail through a driving motor. When the transverse-moving trolley moves to parking positions, a belt-type conveyor II is driven to run through a positive and negative rotation motor. Through the meshing of a driving gear and a driven gear, power is transmitted to a conveyor at the parking positions, access of vehicles from the parking positions is achieved, a power source is not needed to be installed at each parking position, a garage structure is simplified, the plane mobile stereo garage is convenient to install and maintain, and the using and maintenance cost is reduced greatly; and vehicle parking and taking are achieved by utilizing relay of the belt-type conveyor, the structure is more simple, operation is convenient, and the problem of faults of interchanging caused by using vehicle loading plates is avoided.

Owner:山东恒升智能停车系统有限公司

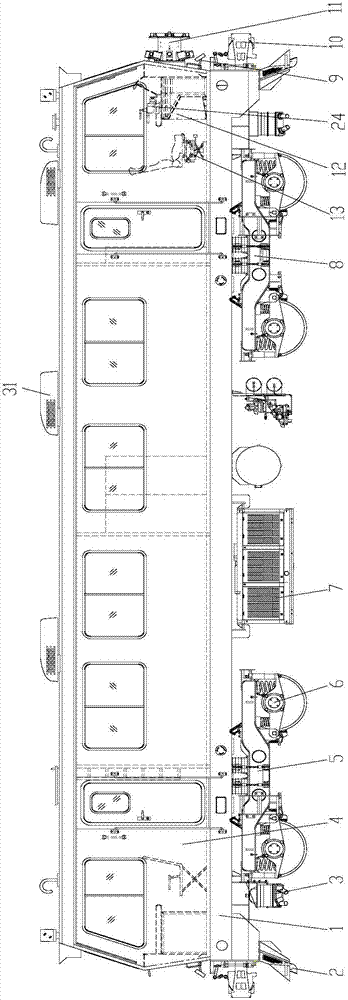

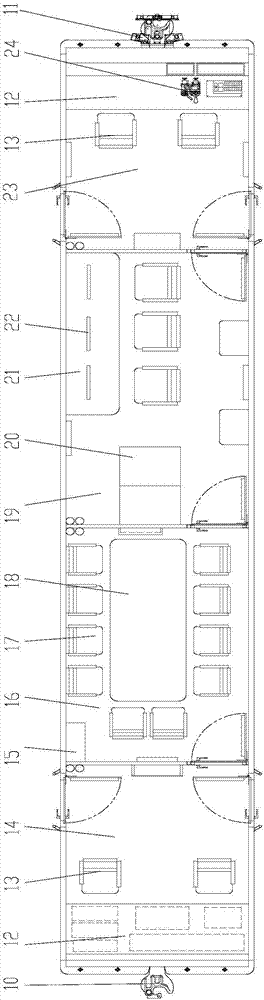

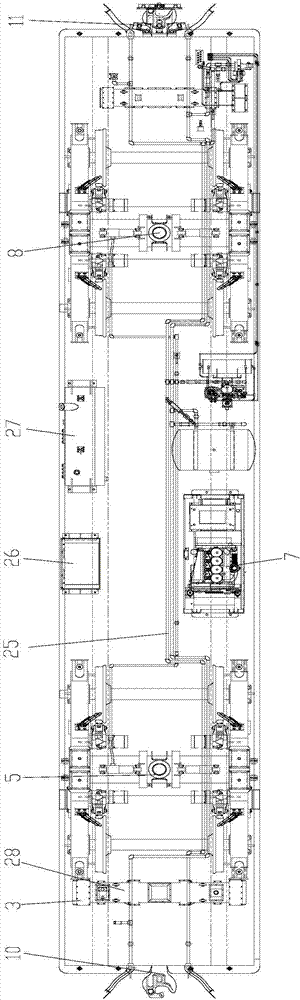

Subway track inspection vehicle

ActiveCN104925086BMeet detectionMeet operational technical requirementsRailway auxillary equipmentRailway profile gaugesBogieVideo monitoring

The invention provides a subway rail inspection vehicle which comprises a vehicle frame. A front bogie and a rear bogie are arranged at the front end and the rear end of the lower portion of the vehicle frame respectively. A generator set, an electrical system and a diesel box are arranged in the middle of the lower end face of the vehicle frame. A vehicle body is arranged on the upper end face of the vehicle frame. Rail detection devices are arranged at the two ends of the lower portion of the vehicle frame. A limit detection device is arranged at one end of the vehicle body. Video monitoring systems are arranged at the two ends of the vehicle body. A front cab, a meeting room, a detection room and a rear cab are arranged in the vehicle body in sequence. A detection cabinet and a detection table are arranged in the detection room. The generator set is electrically connected with the rail detection devices, the limit detection device and the video monitoring devices and provides detection electric power for the rail detection devices, the limit detection device and the video monitoring systems. All the detection devices are electrically connected with the detection cabinet, and detection results are displayed through a displayer on the detection table. According to the subway rail inspection vehicle, the rail detection devices and the limit detection device are integrally installed on one vehicle; the requirement for detection of subway lines and national railway line is met; the subway rail inspection vehicle has the advantages of being high in detection efficiency and accurate in detection.

Owner:BAOJI CSR TIMES ENG MACHINERY

Automatic lamp holder turnover and transportation machine for LED (light-emitting diode) lamp

The invention discloses an automatic lamp holder turnover and transpiration machine for an LED (light-emitting diode) lamp, belonging to the mechanical field. The turnover and transpiration machine comprises a first turnover mechanism and a second turnover mechanism which are in mirror symmetry; each turnover mechanism comprises a turnover gas cylinder, a guide pillar, a linear bearing, a top plate, a rotary shaft, a gas cylinder base, a clamping jaw gas cylinder, clamping jaw fingers, a stand column plate, upper and lower gas cylinders, a panel, a movable plate, a movable joint, a connecting plate, a rotary base and a rotary shaft. By adopting a mode of respectively turning over left and right parts by 90 degrees, the automatic lamp holder turnover and transportation machine can be used for realizing the turnover and shifting of the lamp, and can be used for realizing the automation turnover of a lamp body. Meanwhile, the automatic lamp holder turnover and transpiration machine is simple in structure and low in manufacturing cost. A grabbing step and a putting-down step of the lamp body are respectively completed by two turnover mechanisms without mutual interference, so that the working efficiency is high. The clamping jaw fingers in the automatic lamp holder turnover and transpiration machine are simple, and the proper clamping jaw fingers can be designed according to the specific grabbing position of the lamp body.

Owner:MAANSHAN LIANBANG INTELLIGENT EQUIP

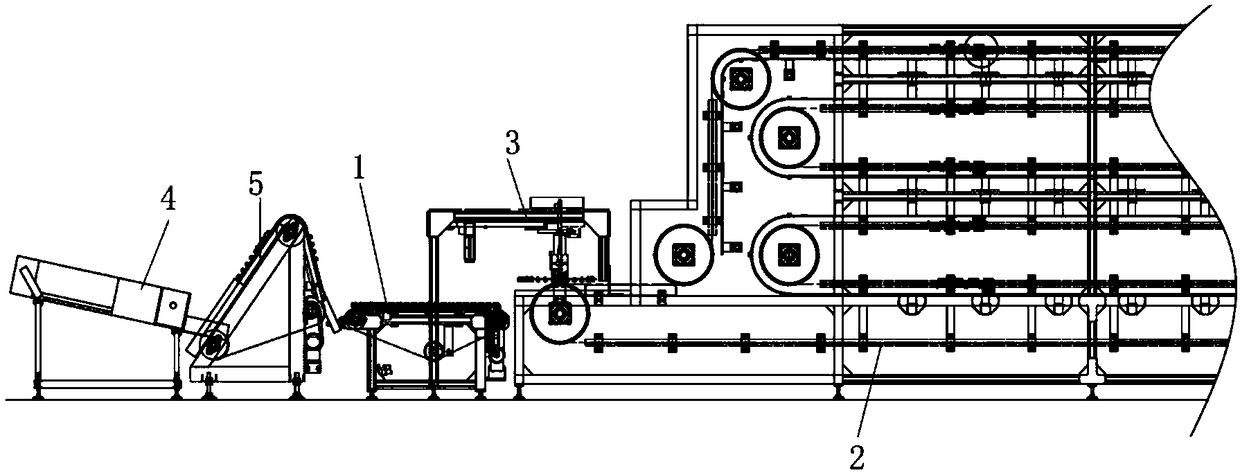

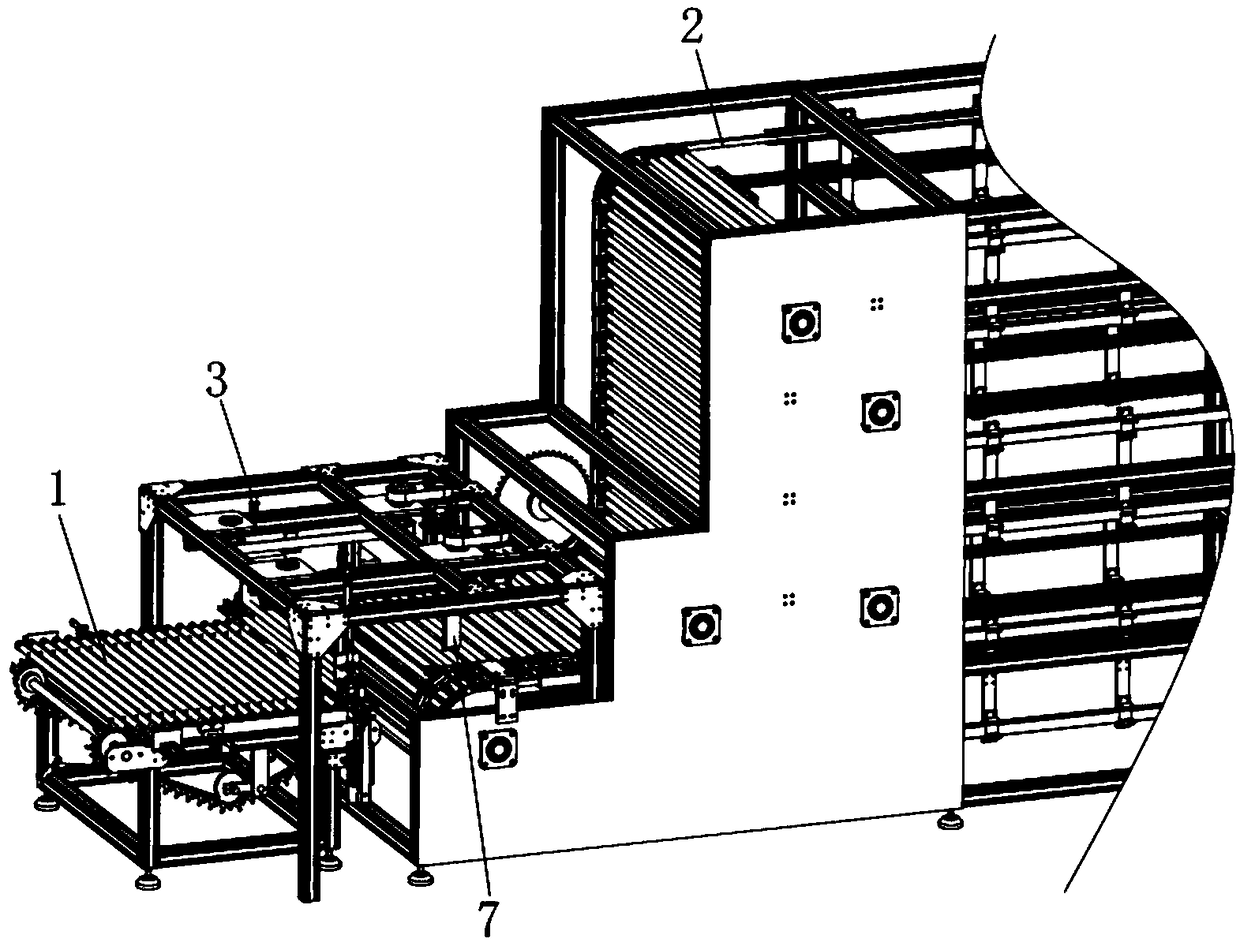

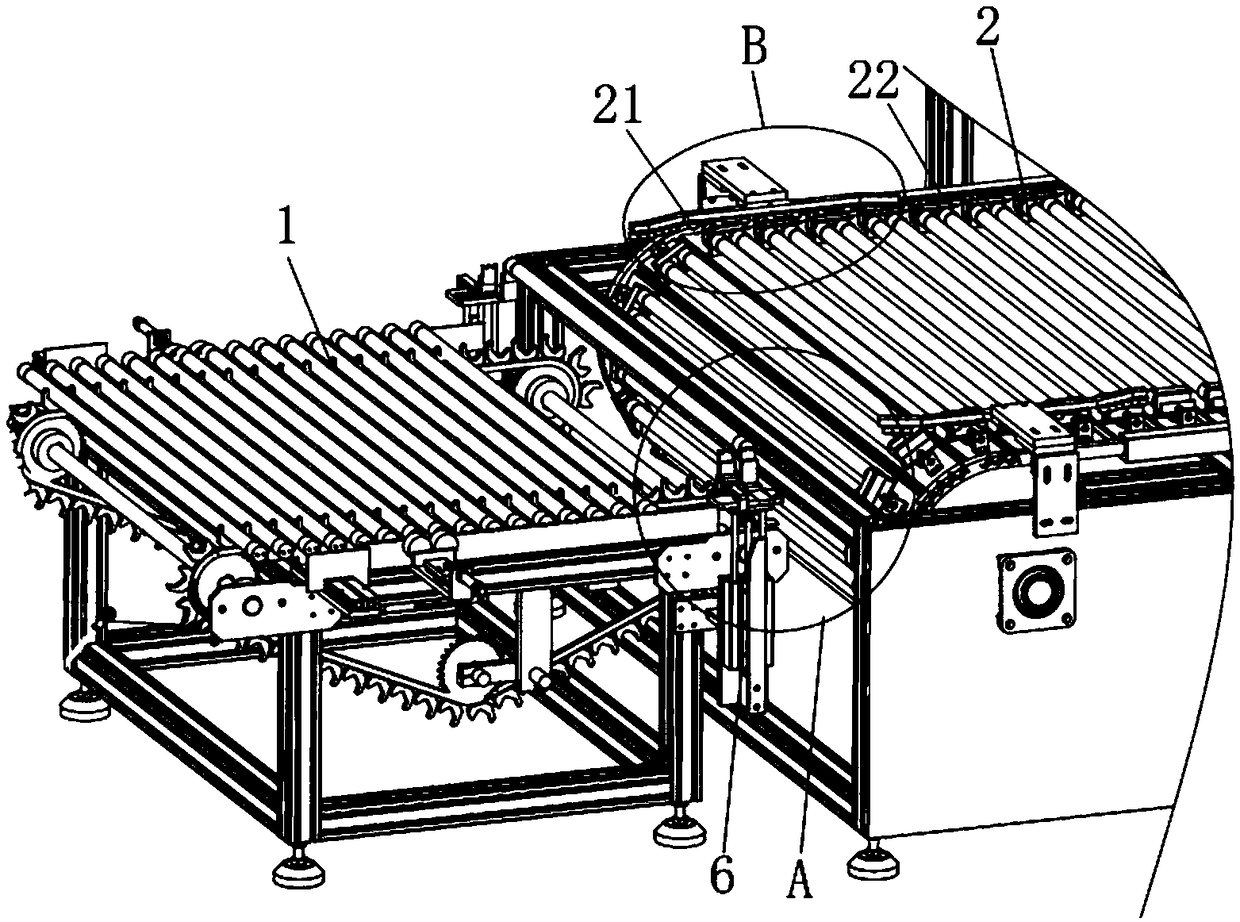

Ageing machine convenient for automatic loading

The invention discloses an ageing machine convenient for automatic loading. The ageing machine convenient for automatic loading comprises a feeding conveyor line, an ageing conveyor line and a lamp tube transfer mechanism, wherein the feeding conveyor line is used for conveying lamp tubes in an equally spaced manner to the direction of the ageing conveyor line; the ageing conveyor line comprises aguiding mechanism and conveying chains; a positioning assembly for positioning the lamp tubes is arranged on the conveying chains; the positioning assembly comprises clamping seats for positioning lamp holders of the lamp tubes and anti-falling parts for preventing the lamp tubes from falling; the guiding mechanism is used for driving the anti-falling parts to move, so that the anti-falling partsare far away from the clamping seats or at least parts of the anti-falling parts lean against the lamp tubes on the positioning assembly; and the lamp tube transfer mechanism is used for transferringthe lamp tubes on the feeding conveyor line to the clamping seats of the ageing conveyor line. The ageing machine disclosed by the invention transfers the lamp tubes automatically to the ageing conveyor line conveniently.

Owner:FOSHAN ELECTRICAL & LIGHTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com