Multifunctional building block separator

A separator and multi-functional technology, applied in the direction of ceramic molding machines, auxiliary molding equipment, manufacturing tools, etc., can solve the problems of low production efficiency, complicated supporting equipment, backward production technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

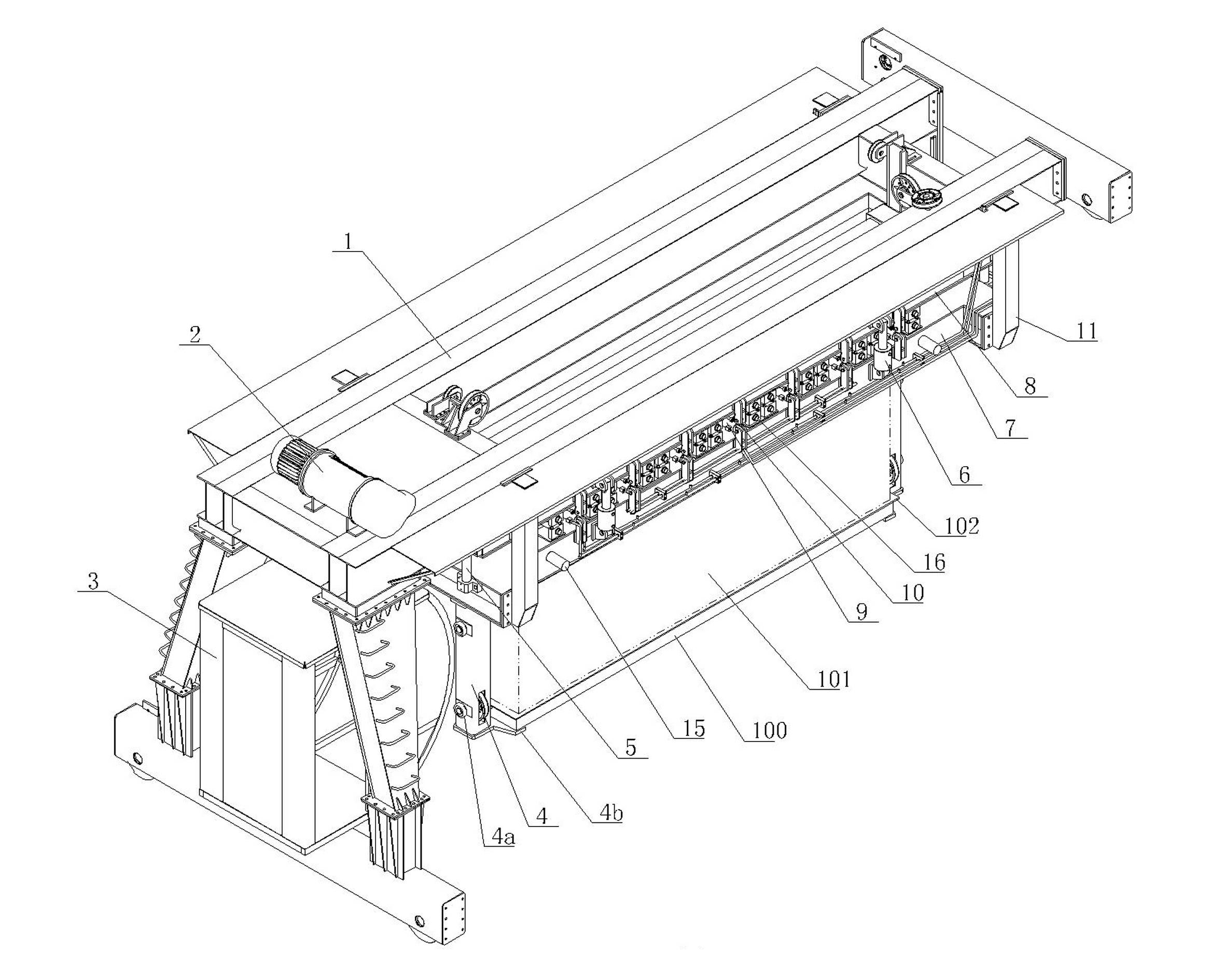

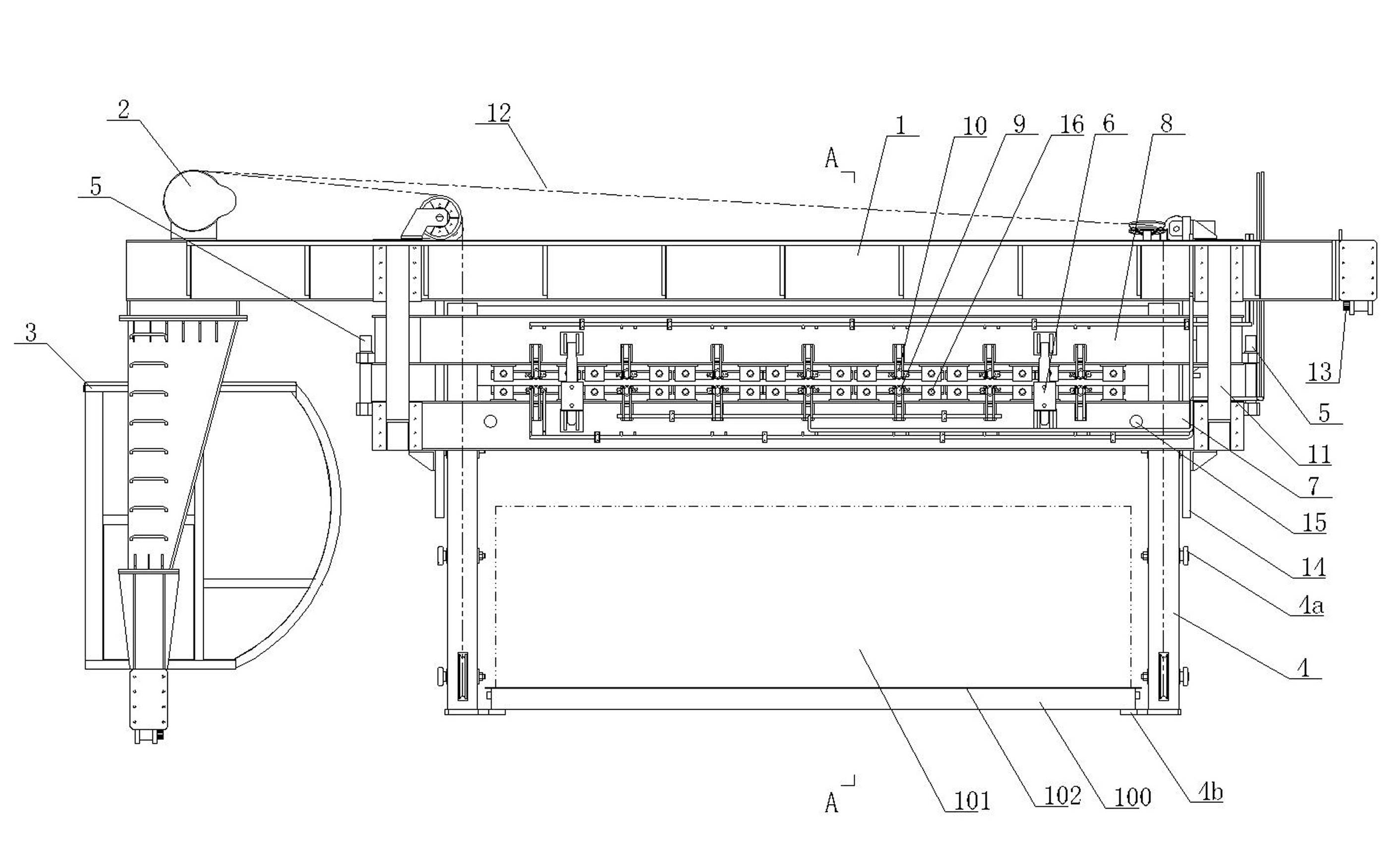

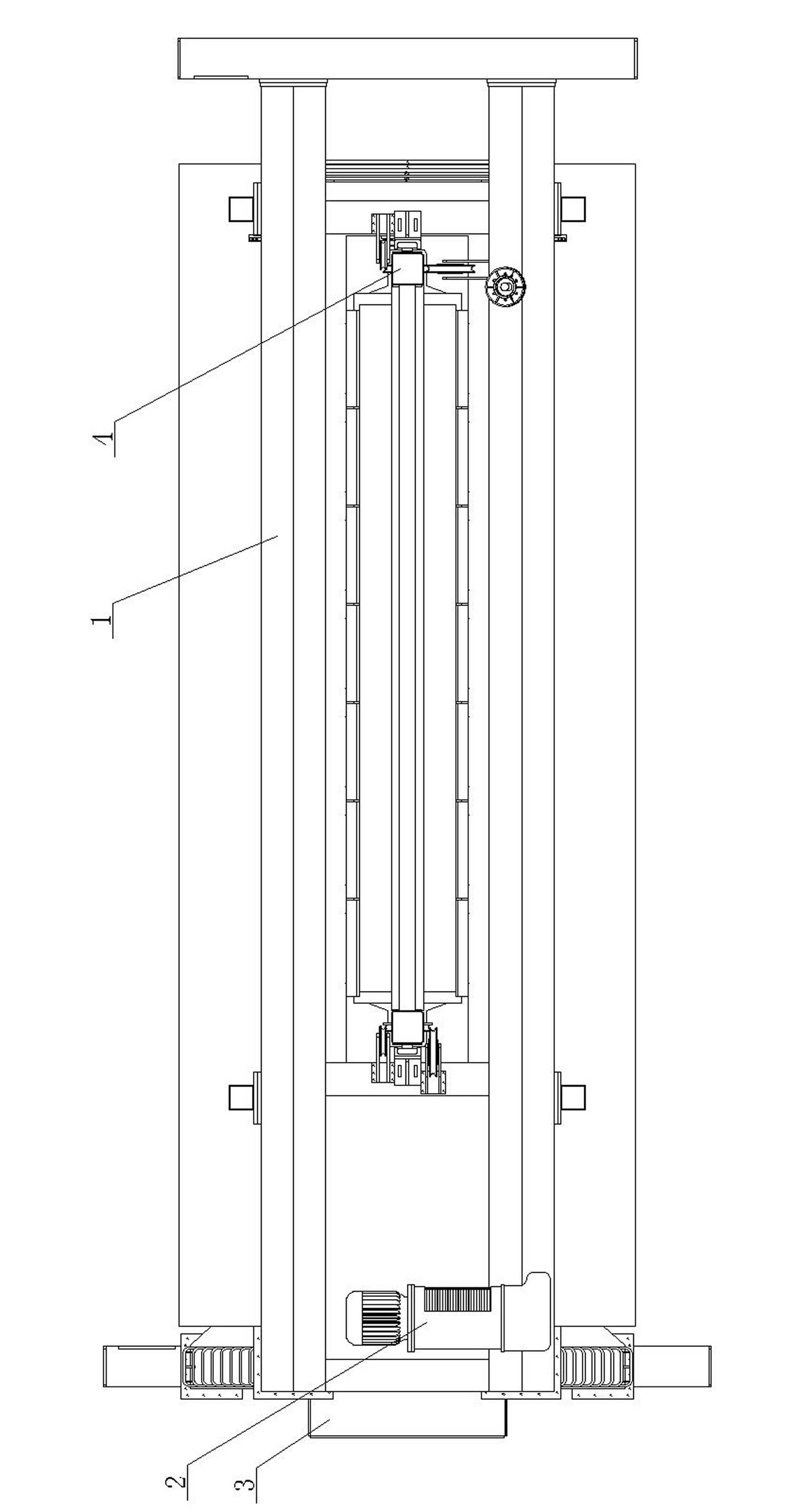

[0019] The accompanying drawings show the technical solution of the present invention and its embodiments, and the relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings.

[0020] Refer to attached Figure 1-6 , this kind of multi-functional block separator includes a steel crane 1, a lifting frame 4, a fixed beam 7 and a movable beam 8, the fixed beam 7 is fixedly installed under the beam of the steel crane 1 through a cantilever 11, and the fixed beam 7 includes a connected front beam. The fixed beam 7a and the rear fixed beam 7b, the distance between the front and rear fixed beams is greater than the front and rear width of the concrete block 101; Separation device promotes, and described separation device is the oil cylinder 6 that is vertically arranged, and the cylinder body of vertical oil cylinder 6 is connected on the described fixed crossbeam 7, and the piston rod of vertical oil cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com