Transfer trailer with adjustable traction mechanism and damping device

A technology of traction mechanism and shock absorbing device, which is applied in the direction of motor vehicles, traction connectors, vehicle parts, etc., can solve the problems of inability to ensure the smooth and safe transfer process, lack of height adjustable function, and structural deformation of transfer trailers, etc., to achieve buffering The shock absorption effect is obvious, the cushioning effect is improved, and the safety and stability are high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

[0027] This embodiment provides a transfer trailer with an adjustable traction mechanism and a shock absorption device. The traction height of the traction mechanism is adjustable, and a shock absorption device is provided inside the transfer trailer, which can effectively adapt to the harsh environment and traction on the transfer site. time requirement.

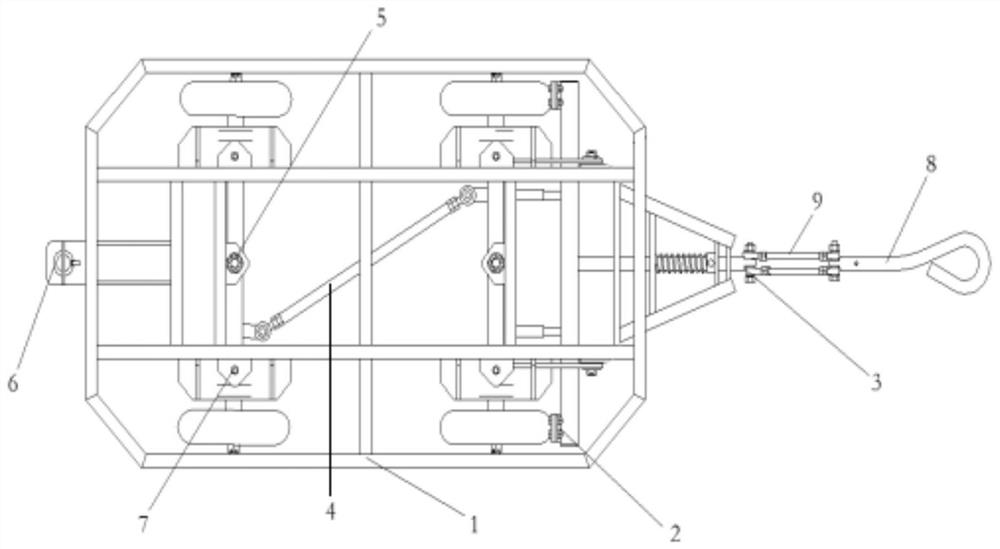

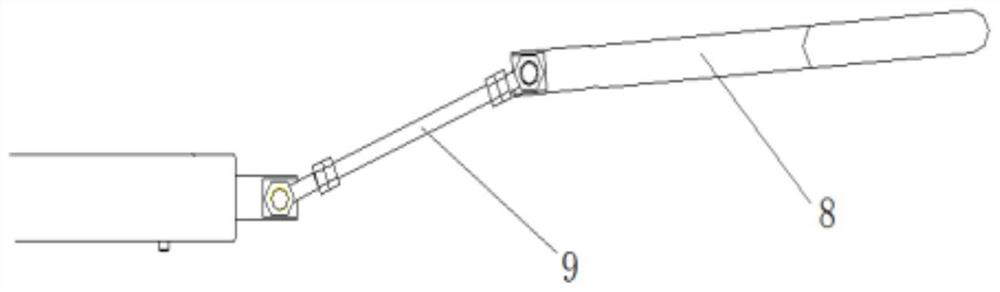

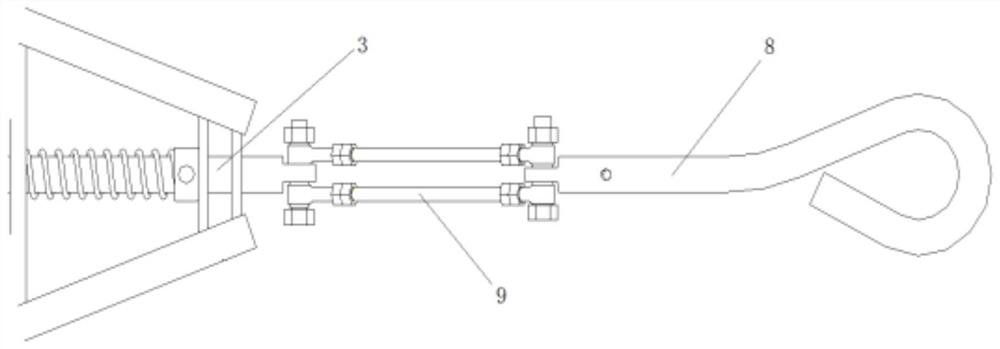

[0028] like figure 1 As shown, the transfer trailer includes: a trailer frame, a cargo platform 1, a braking mechanism 2, a traction mechanism 3, a steering mechanism 4, a shock absorber, a brake front support frame and a rear lift pin 6;

[0029] The steering mechanism 4 is rotatably connected to the bottom of the cargo platform 1 to realize four-wheel steering; the brake front support frame is fixed on the trailer frame and is located at the front end of the cargo platform 1, and the brake front s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com