Lithium battery clamping and transportation device and lithium battery production line

A technology of transfer device and lithium battery, which is applied in the direction of lithium storage battery, assembled battery machine, secondary battery manufacturing, etc., can solve the problems of heavy weight, difficult automatic transfer and large volume, so as to improve transfer efficiency, improve automation degree, and ensure consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

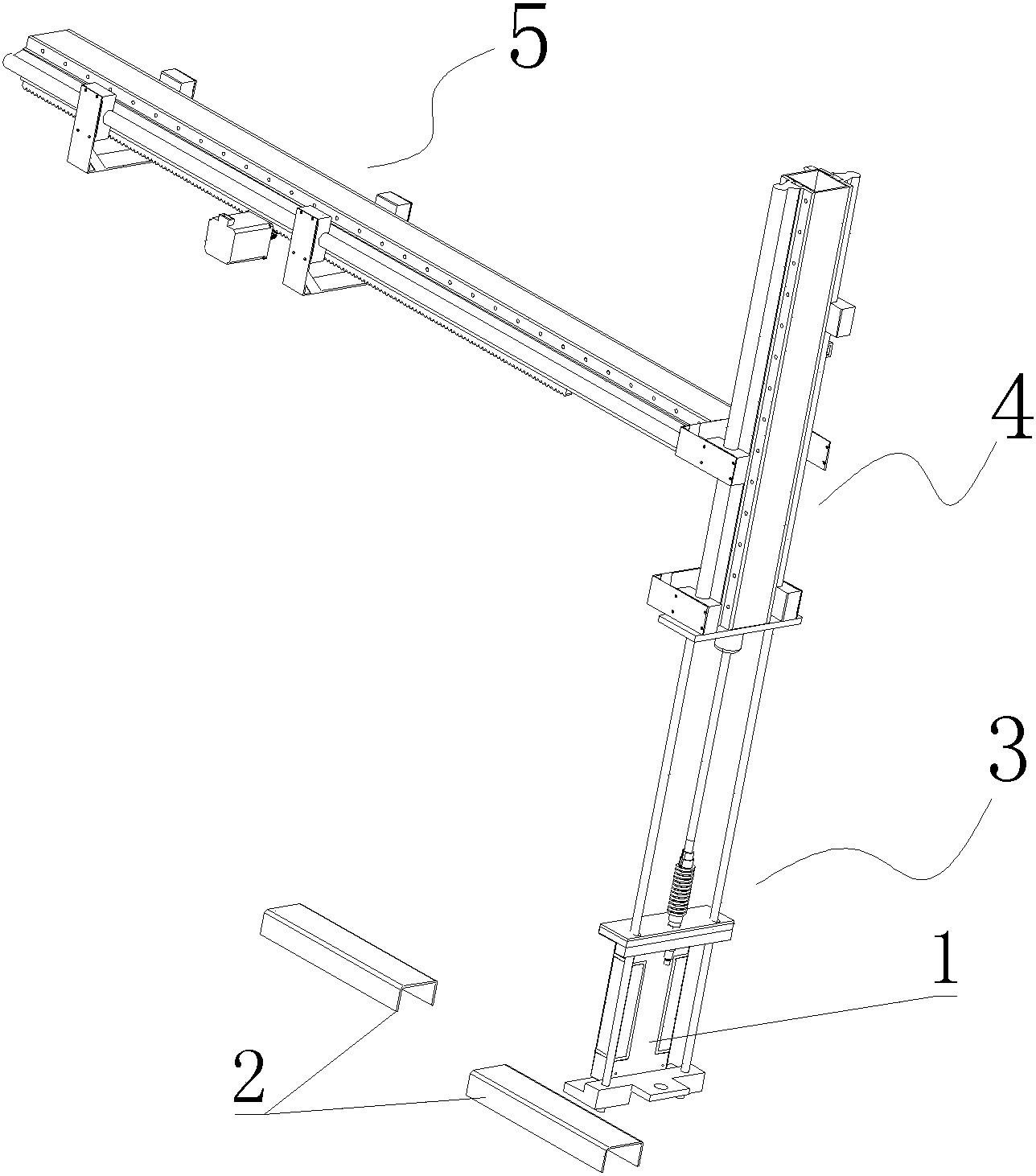

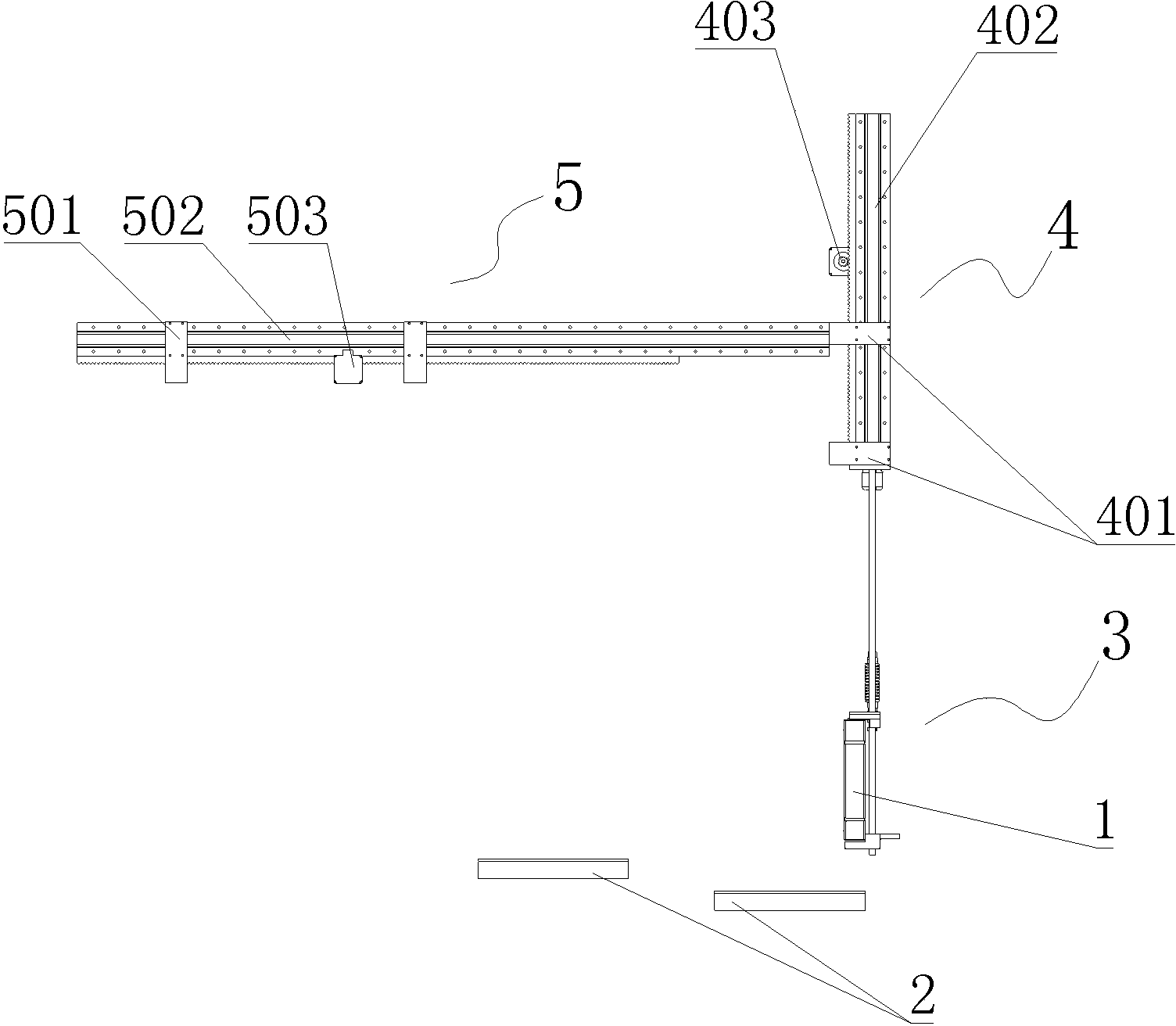

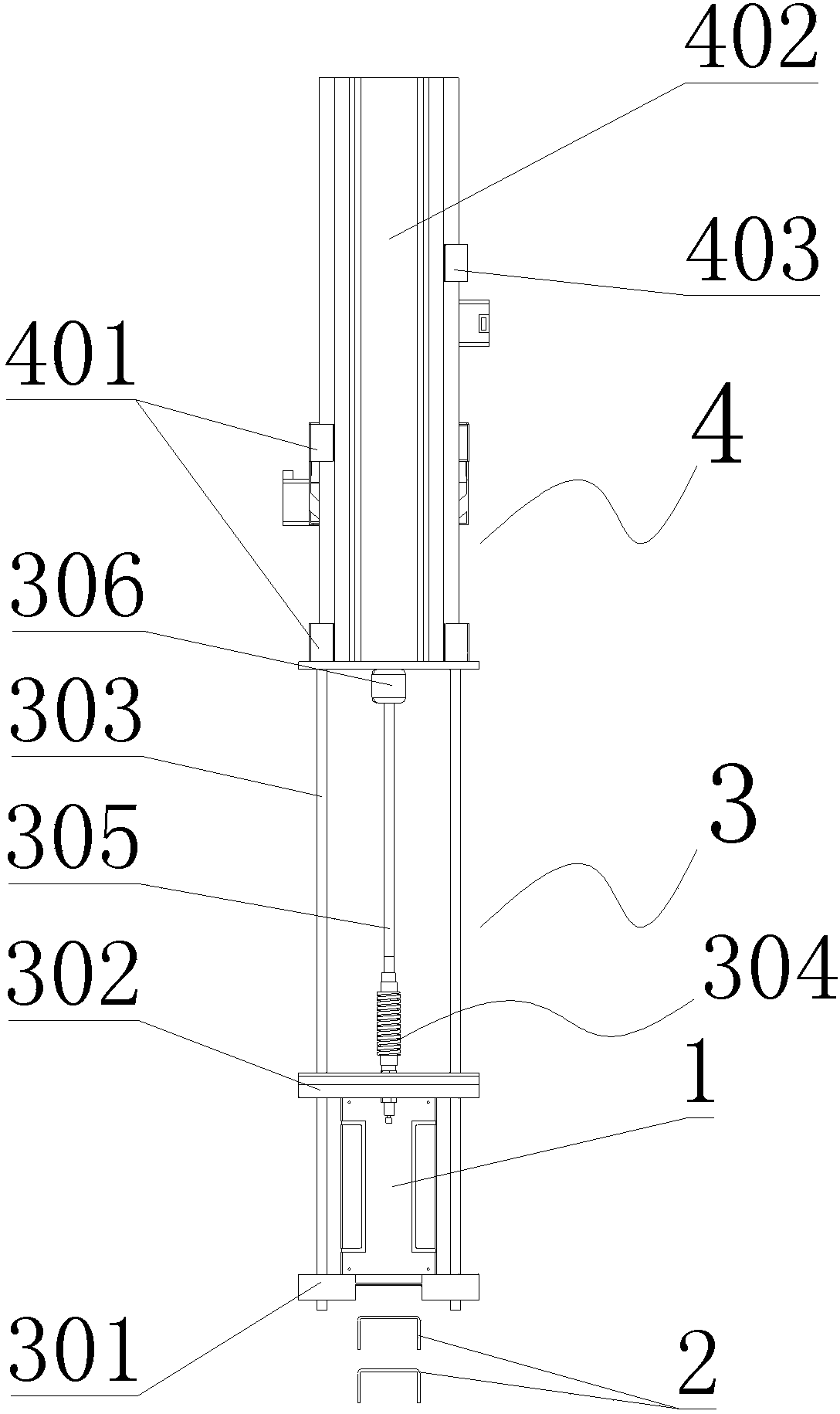

[0025] Embodiment 1 of lithium battery production line among the present invention: as Figure 1 to Figure 7 As shown, the lithium battery production line is a square lithium battery production line, and the battery transfer device on it is a lithium battery clamping transfer device. The transfer device is mainly composed of a horizontal moving device 5, a lifting device 4, and a battery grabbing device 3 It is constituted with the battery support 2, wherein the lifting device 4 is fixed on the horizontal moving device 5, and the battery grasps and fixes the bottom of the lifting device 4.

[0026] The battery grabbing device 3 includes a grabbing bracket 303, a first clamping claw 301, a second clamping claw 302, and a clamping drive mechanism 304, wherein the grabbing bracket 303 is composed of two vertical guide rods spaced before and after, and the two The top of the vertical guide rod is fixed on the bottom of the lifting device 4 and overhangs downwards, and the bottoms ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com