Patents

Literature

186results about How to "Reduce transshipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rise and fall artificial floating floor of plants for biological treating sewage, preparation method and method of application

InactiveCN101003408AInhibit algae growthPrevent eutrophicationSustainable biological treatmentBiological water/sewage treatmentSurvival periodRoot system

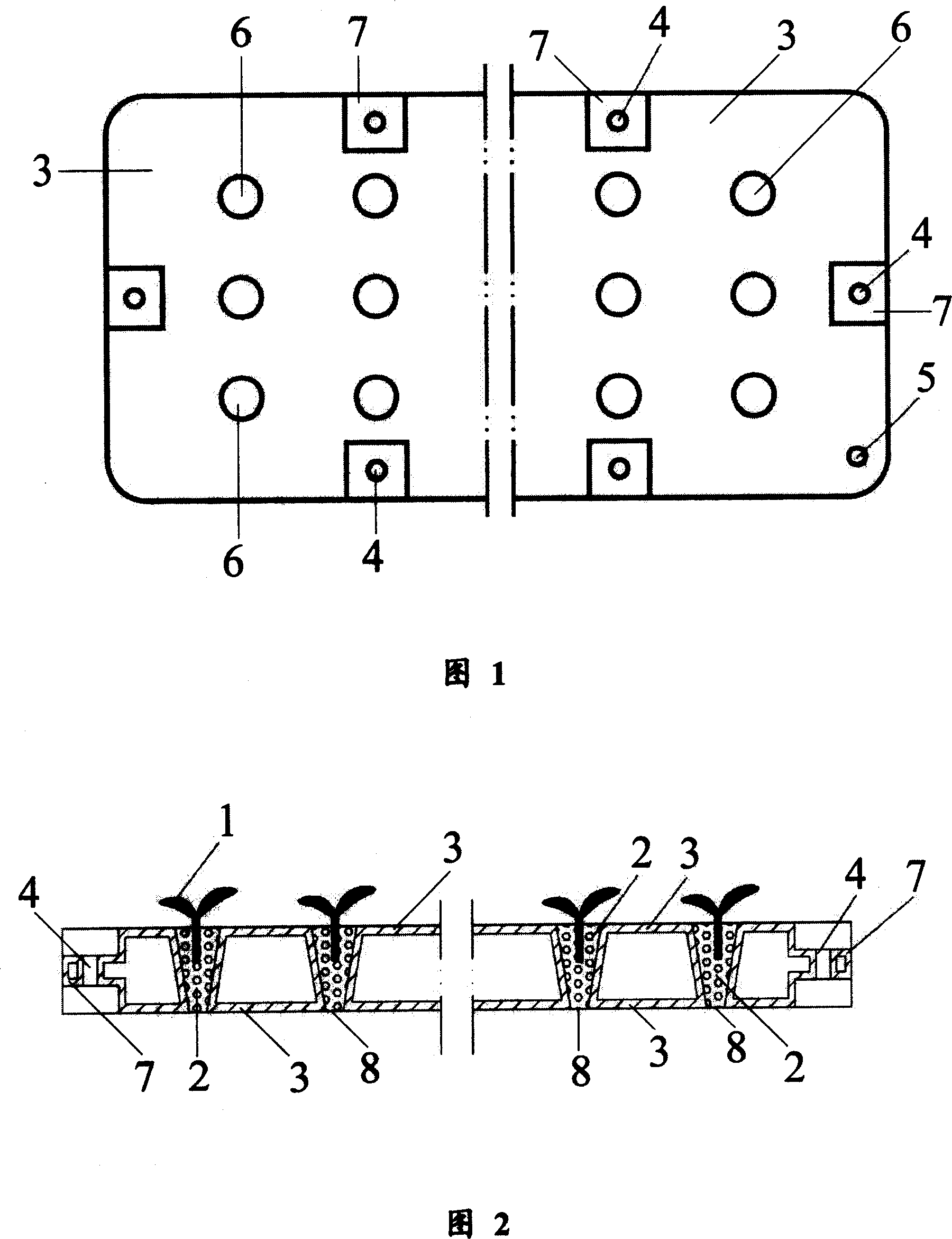

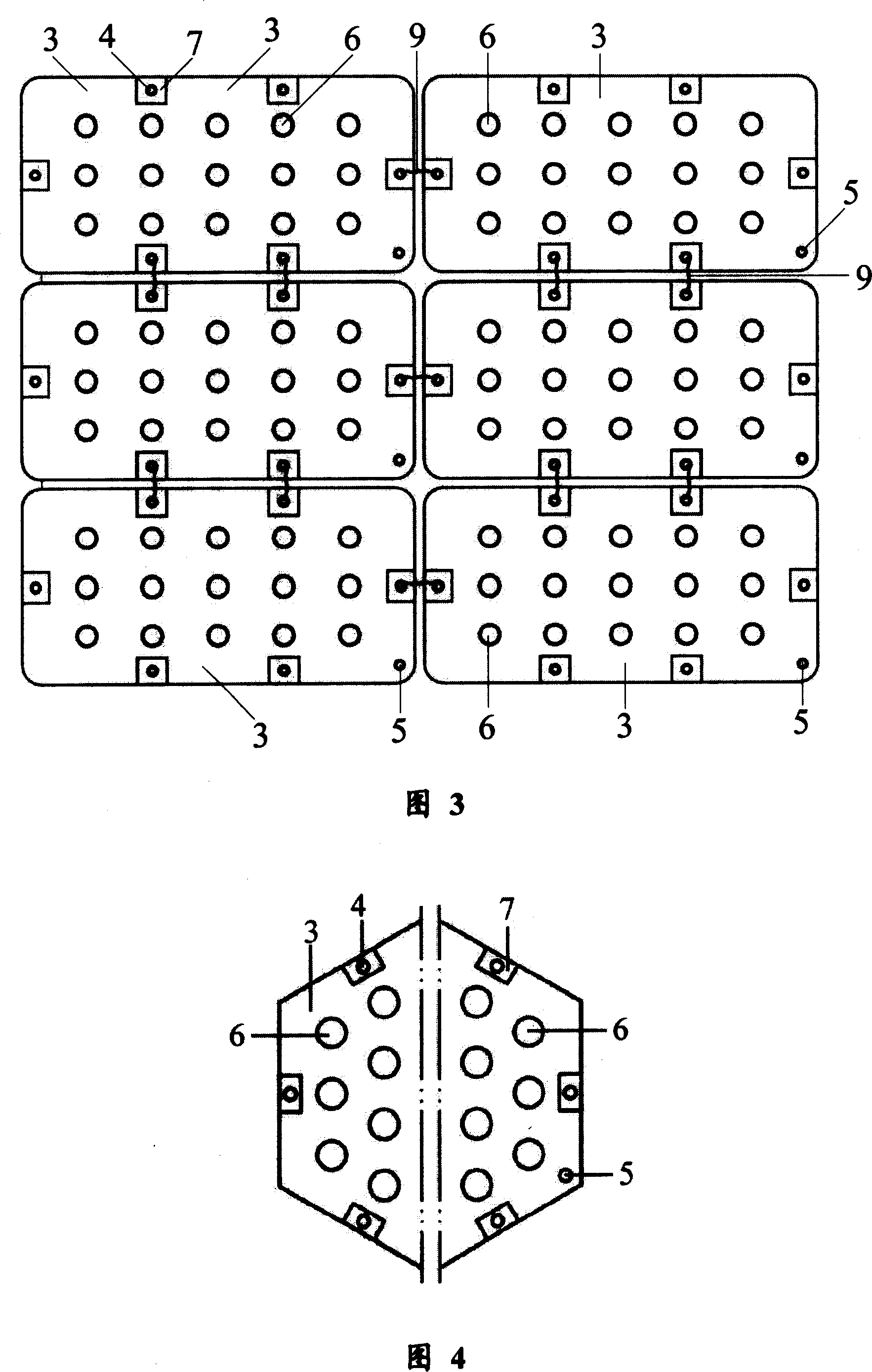

This invention discloses a method for producing rise-fall artificial plant floating bed for wastewater biological treatment. The main body of the floating bed is hollow and sealed, and a planting groove is set on the main body. Filler and plants are placed in the planting groove. A support is set in the planting groove, which is connected with water body. Bed connectors are placed surrounding the main body of the floating bed. At least two main bodies are combined to form the floating bed, which is placed on the water surface. The roots of the plants on the floating bed can realize filtration, absorption and adsorption of pollutive substances in wastewater. The floating bed is sinked into the non-frozen layer below water surface in winter, and taken out of water surface inspring. The plants are left for further filtration, absorption and adsorption of pollutive substances in wastewater. This invention has such advantages as short project period, and rapid acting. Plants of the floating bed have a survival period of more than 8 months / year. The planting can match city landscape, thus are good for city afforestation, and can reduce secondary assembly cost. The floating bed just needs replanting in spring.

Owner:TIANJIN WATER CONSERVANCY INST

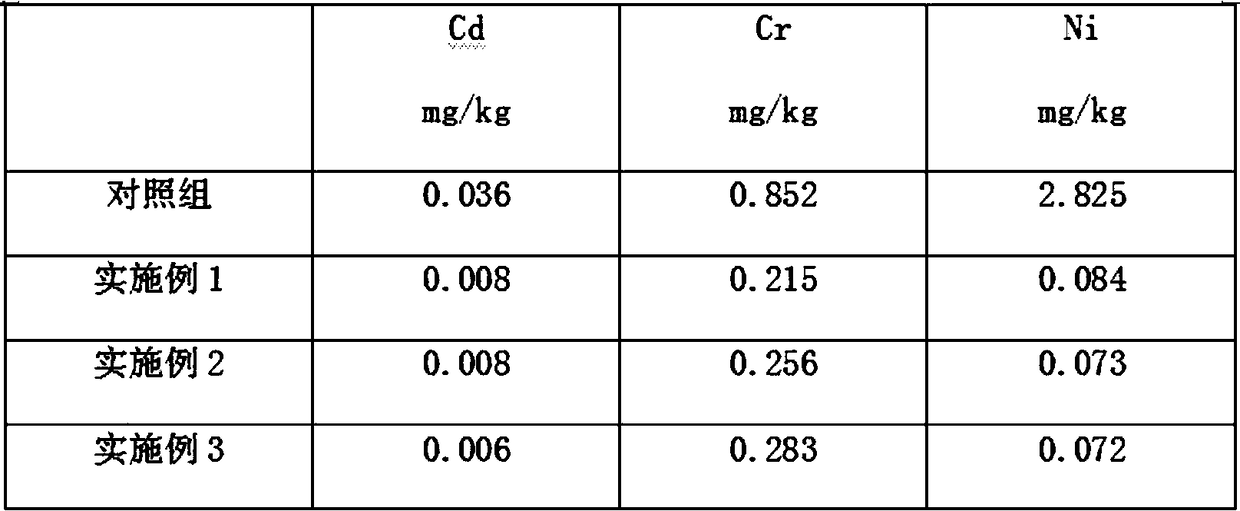

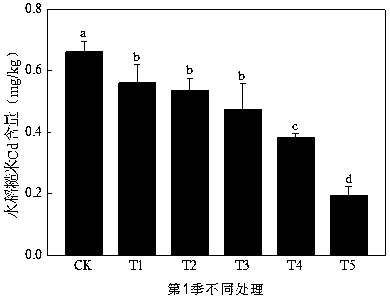

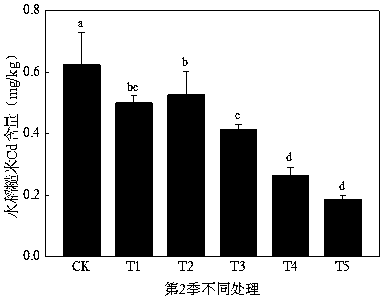

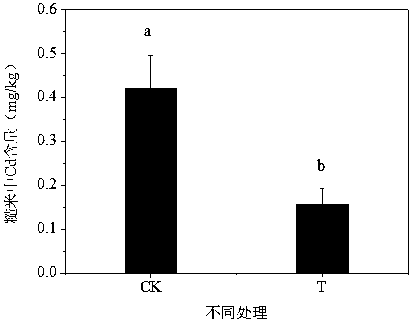

Cadmium-nickel contaminated soil remediator and preparation method

InactiveCN108949180AReduced phytoavailabilityReduced effectivenessCalcareous fertilisersAgriculture tools and machinesPhosphateSoil heavy metals

The invention discloses a cadmium-nickel contaminated soil remediator, relating to the technical field of remediating soil heavy metal pollution. The cadmium-nickel contaminated soil remediator comprises the following components in parts by weight: 70-90 parts of bio-charcoal, 5-8 parts of oxalic acid activated ground phosphate rock, 2-4 parts of zinc fertilizer, 4-6 parts of lime, and 10-15 partsof pulverized fuel ash. The bio-charcoal and oxalic acid activated ground phosphate rock can promote the conversion of weak-acid extractable Cd and Ni to reduction-state Cd and Ni and residue-state Cd and Ni, the effect of combined use is superior to that of single use.

Owner:盐城英贝吉环保科技有限公司

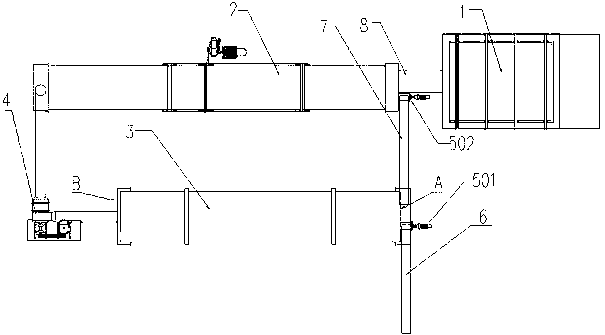

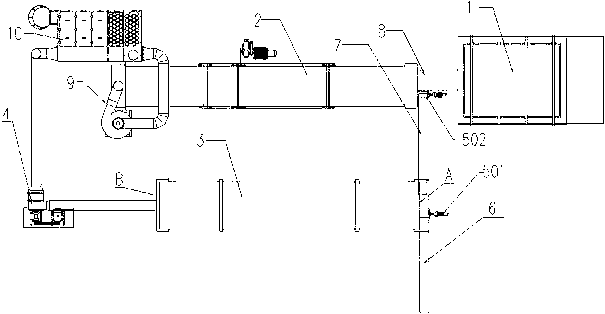

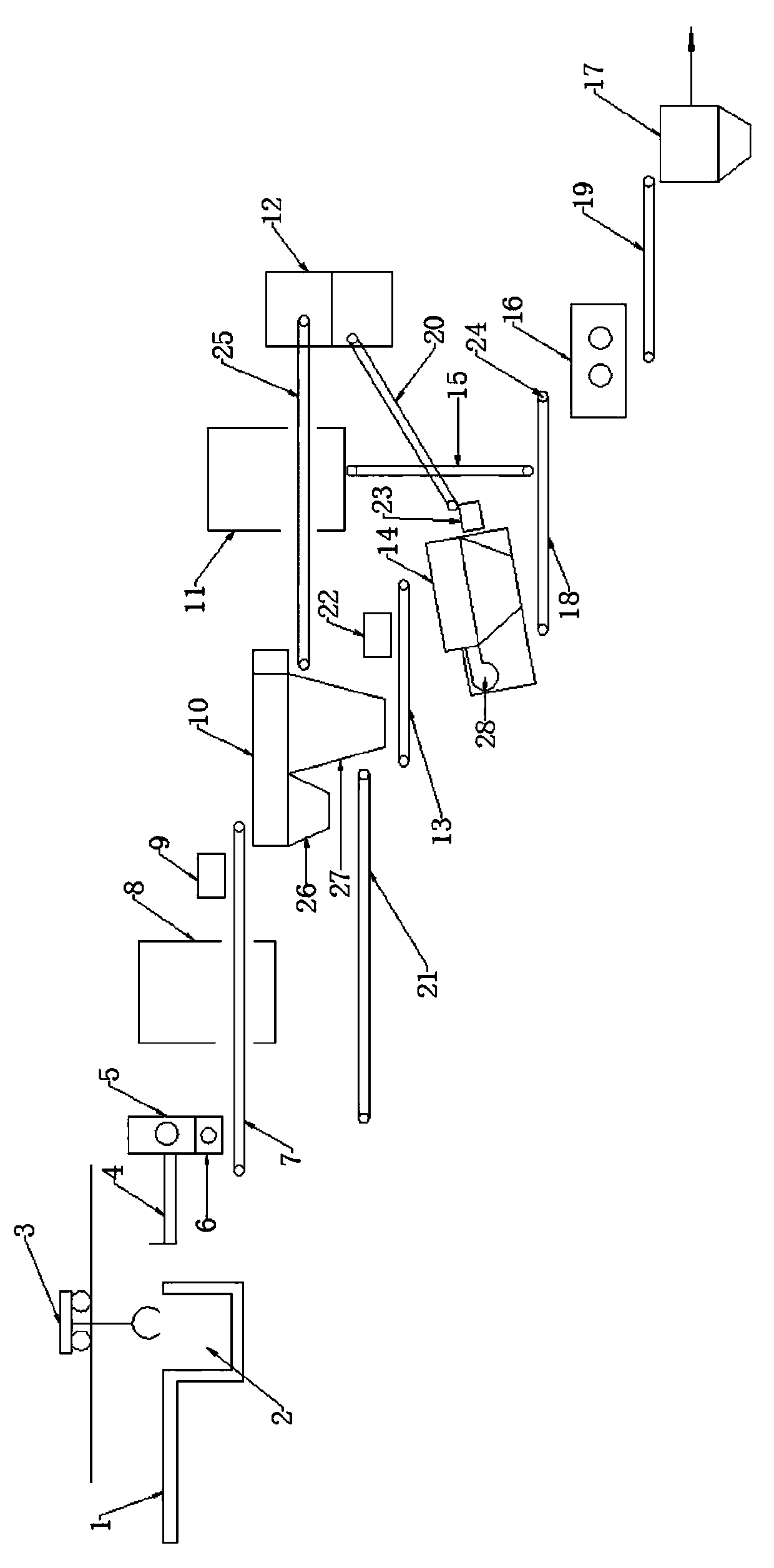

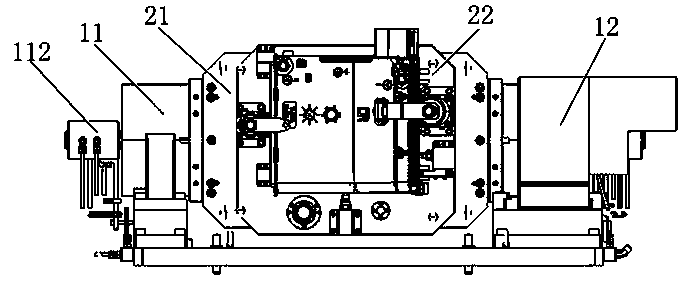

Desulfurization gypsum drying and calcining equipment, and production process

The invention relates to desulfurization gypsum drying and calcining equipment for drying and calcining the desulfurization gypsum to obtain high-quality beta hemihydrate gypsum, and a production process. The equipment comprises a drying drum, a calcining drum and an induced draft fan, wherein an air inlet of the induced draft fan is communicated with the calcining drum; an air outlet of the induced draft fan is communicated with the tail end of the drying drum; the front end of the drying drum is in butt joint with a first feeder and a second conveyor; the first feeder is in butt joint with a first conveyor; the second conveyor is in butt joint with a second feeder; the second feeder is in butt joint with the calcining drum; and a heat source supply furnace is communicated with the calcining drum through a hot air pipe. Two pieces of equipment of a drying process and a calcining process are combined, so the problems about transfer and storage of intermediate products are solved, space is saved, and environmental pollution caused by the intermediate products is avoided; and meanwhile, the induced draft fan is used for leading calcining waste gas in the calcining drum to the drying drum to serve as a heat source for drying the desulfurization gypsum, so the waste gas is reutilized and resources are saved.

Owner:ZHENGZHOU DINGLI DRYING EQUIP

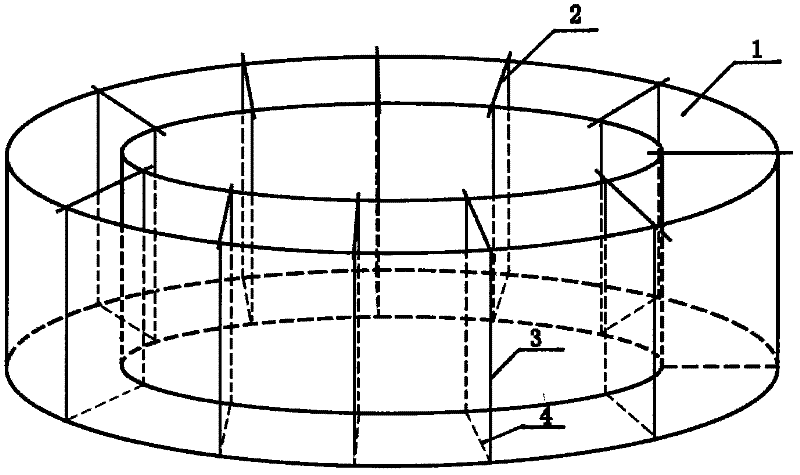

Ring-duct net cage for breeding of oriental weatherfish

InactiveCN102379256AEvenly distributedGuaranteed oxygen supplyClimate change adaptationPisciculture and aquariaWeatherfishAphrodisiac

The invention belongs to the technical field of aquaculture, in particular to the technique enabling weatherfish to reproduce and lay eggs in a net cage disposed in a hatching ring duct and leads fertilized eggs to fall into the hatching ring duct from the net cage to be hatched directly in the hatching ring duct. A large net cage or a plurality of independent large net cages are disposed in the hatching ring duct to serve as a place for aphrodisiac injected parent weatherfish to mate and lay eggs, the net cages are removed while the parent weatherfish having laid eggs are removed after eggs are laid, and the eggs fall into the ring duct from meshes prior to directly being hatched. The large net cages of the hatching ring duct can effectively prevent the parent weatherfish from eating the eggs, the parent weatherfish is not easy to be hurt, loss of the eggs is low, and breeding effect is better. The method omits the egg transferring process, so that labor intensity is reduced greatly, and work efficiency is improved.

Owner:ANHUI SCI & TECH UNIV

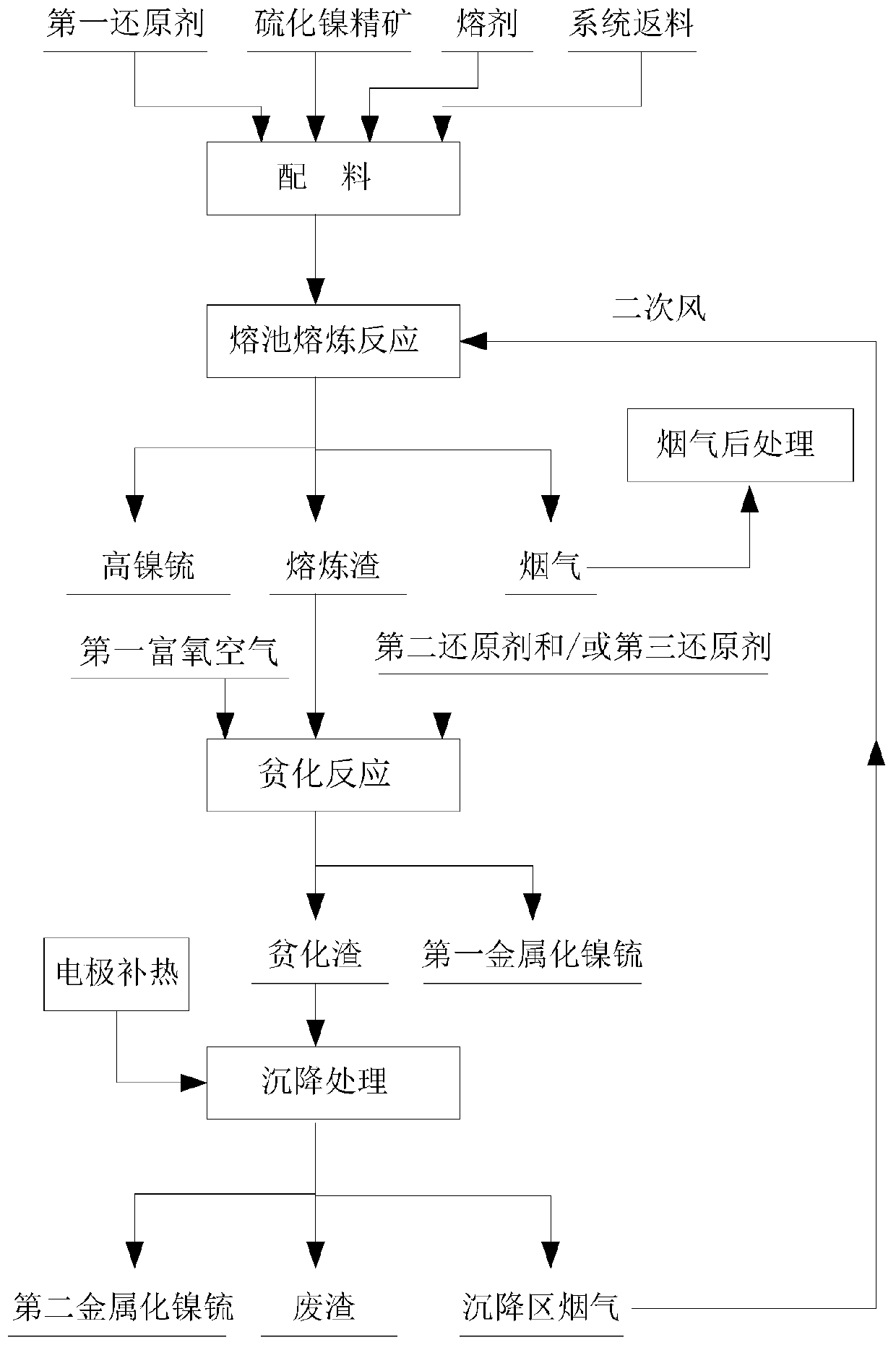

One-step nickel smelting system and one-step nickel smelting method

ActiveCN111101001ASolution conditionsSolve the problem of high nickel content in smelting slagProcess efficiency improvementSlagFlue gas

The invention provides a one-step nickel smelting system and a one-step nickel smelting method. The one-step nickel smelting system comprises a raw material conveying device, a one-step nickel smelting device and a flue gas treatment device; the one-step nickel smelting device is an integrated device and comprises a furnace body, and a molten pool smelting area and a reduction depletion area are sequentially arranged inside the furnace body; a first feeding inlet and a first blower nozzle are formed in the molten pool smelting area, the first feeding inlet is connected with the raw material conveying device, and the molten pool smelting area is used for performing molten pool smelting on nickel sulfide concentrates to produce high nickel matte containing 35-65 wt% nickel, smelting slag andflue gas; the reduction depletion area communicates with the molten pool smelting area, a second feeding inlet, a second blower nozzle and a flue gas outlet are formed in the reduction depletion area, and the reduction depletion area is used for enabling the smelting slag to be subjected to the depletion reaction to produce depleted slag and first metallized nickel matte; the flue gas treatment device is connected with the flue gas outlet. The problems such as high raw material feeding-into-furnace conditions of the DON process, high nickel content in the smelting slag, large load and high energy consumption when an electric furnace separately treats the smelting slag are effectively solved.

Owner:CHINA ENFI ENGINEERING CORPORATION

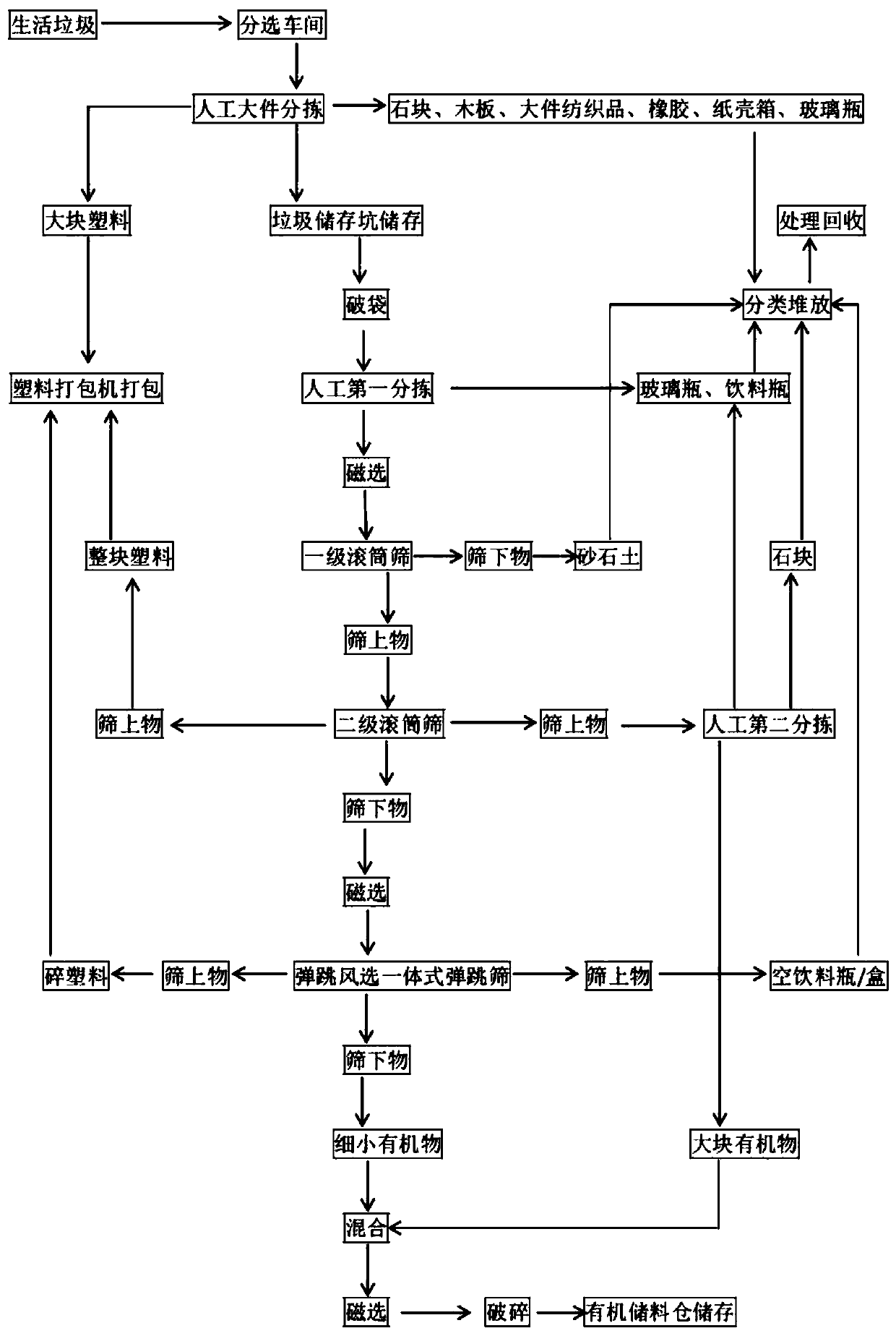

Household garbage sorting process and household garbage sorting system

PendingCN110170377AIncrease productivityConducive to utilization of fermentation resourcesSievingGas current separationPlastic packagingLitter

The invention discloses a household garbage sorting process. The household garbage sorting process comprises the steps of sequentially carrying out household garbage large piece sorting, household garbage bag breaking treatment, garbage primary sorting, garbage fine sorting, organic matter fine sorting and the like. The invention further discloses a household garbage sorting system, wherein the household garbage sorting system comprises a large piece sorting table, a garbage storage pit, a bag breaking machine, a first manual sorting chamber, a first magnetic separation device, a second-stagerotary screen, a second manual sorting chamber, an organic matter fine sorting system and a plastic packaging machine which are sequentially connected through a conveying device. According to the process and the system disclosed by the invention, the household garbage is separated according to the respective differences through the combination of a screening device and the manual sorting, so thatthe effective separation of the whole components of the garbage is realized; and meanwhile, the sorted organic matters are further subjected to fine sorting, the obtained organic matter raw materialsare high in purity, the organic matter productivity is increased, the subsequent organic matter fermentation resource utilization is facilitated, and the recyclable resources in the waste can be fullyrecycled.

Owner:JIANGSU YIJIN ENVIRONMENTAL PROTECTION TECH CO LTD

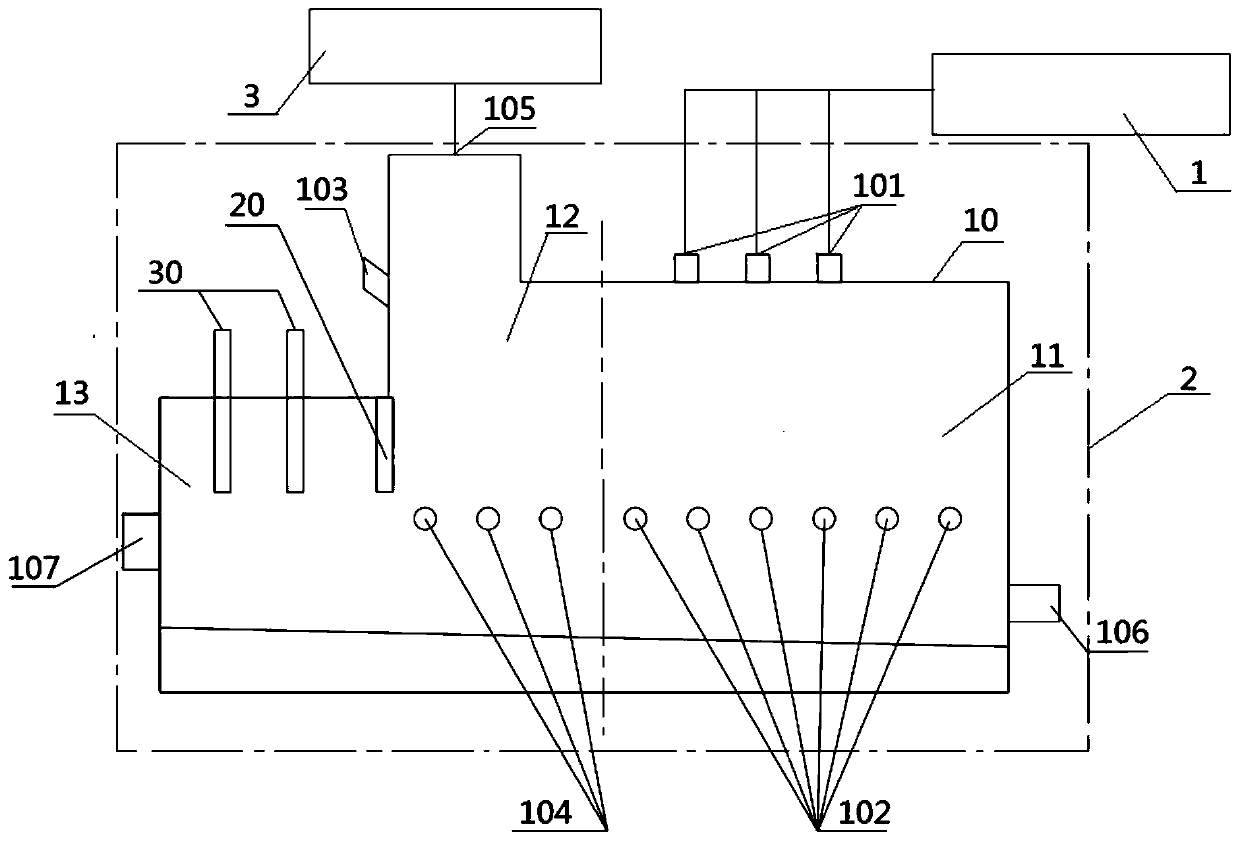

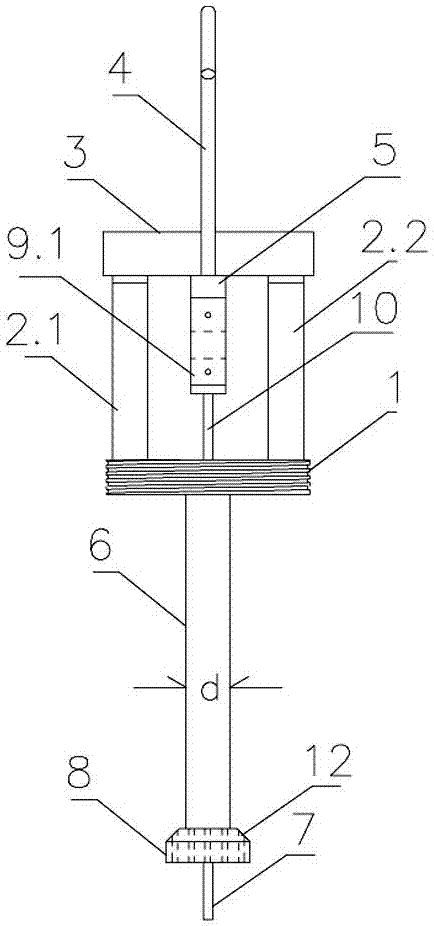

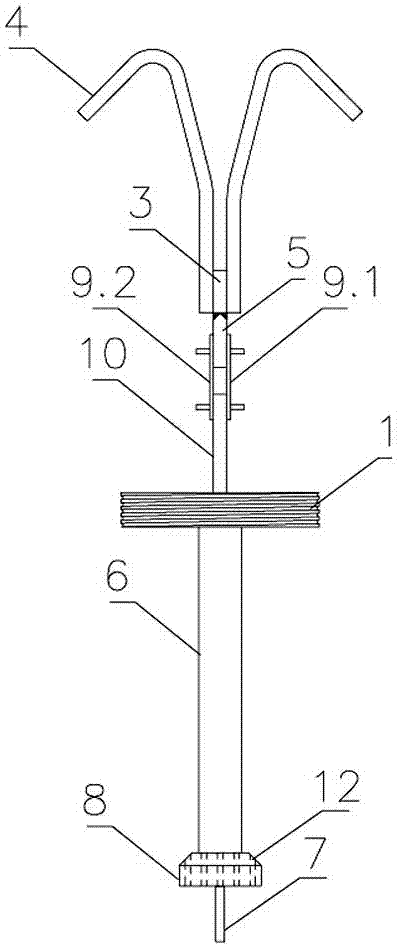

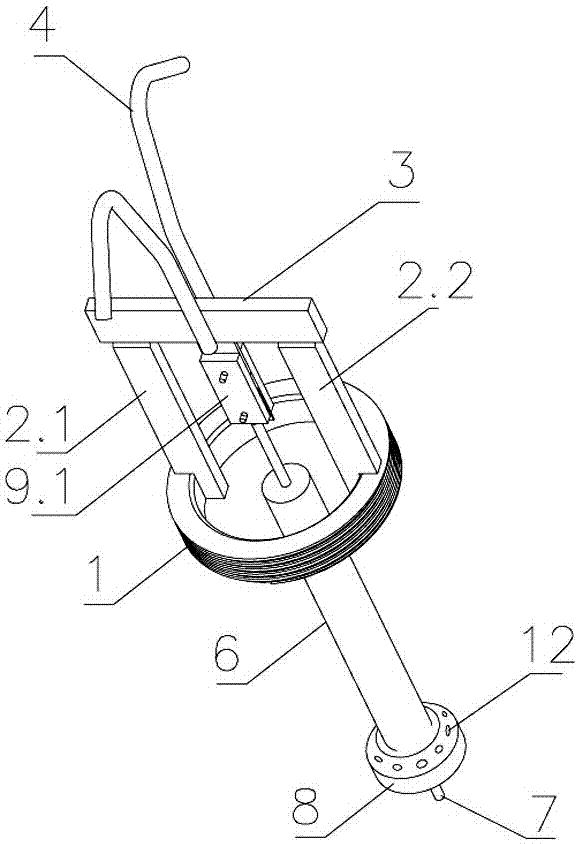

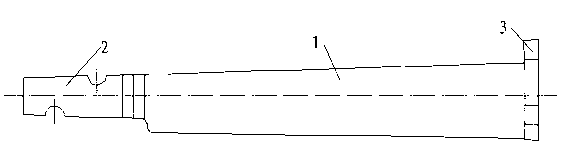

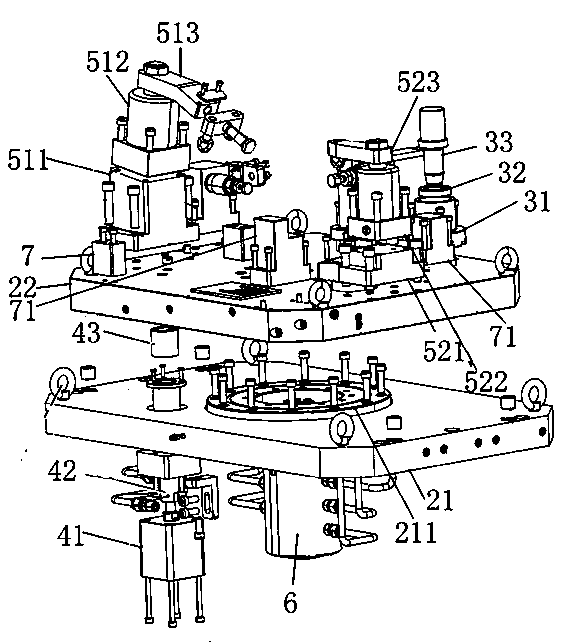

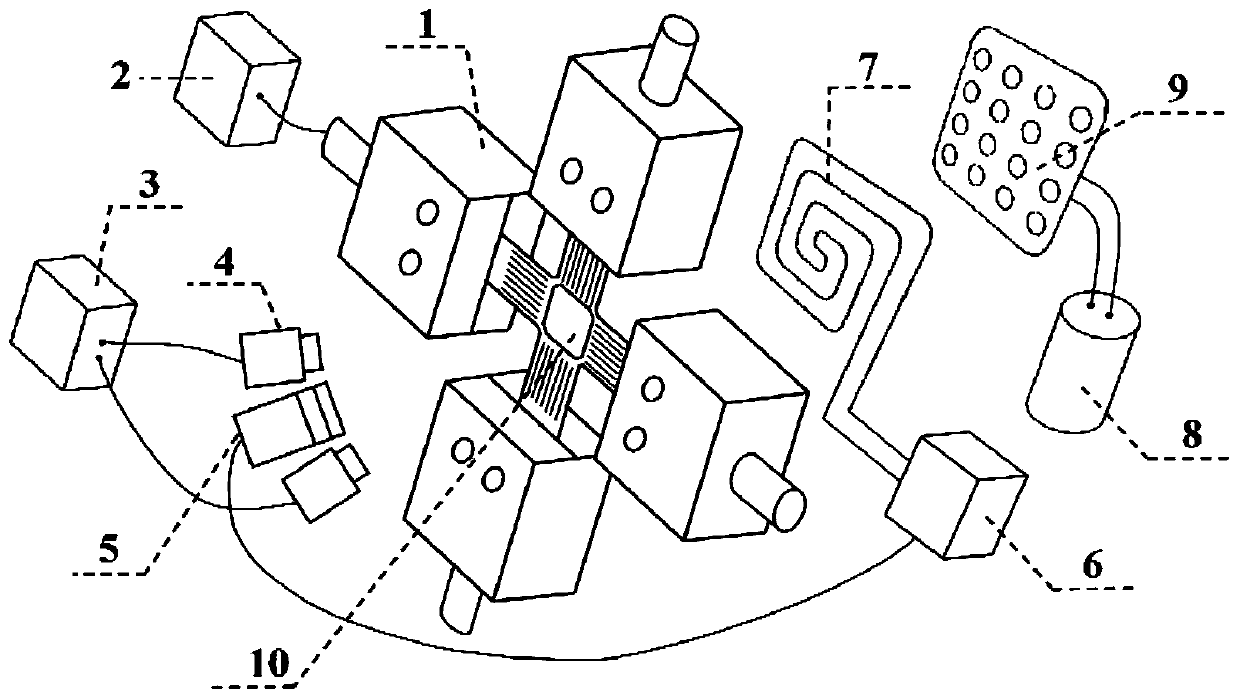

Tooling for simultaneously electroplating inner and outer surfaces of hydraulic oil cylinder and use method

ActiveCN107022787AReduce transshipmentReduce frequent transfersElectrolysis componentsProduction lineHydraulic cylinder

The invention discloses a use method of a tooling for simultaneously electroplating the inner and outer surfaces of a hydraulic oil cylinder. The use method comprises the following steps: first, a conducting column is put in the cylinder body of the hydraulic oil cylinder, and a bolt arranged on the lower end surface of the conducting column penetrates through a valve hole formed in the cylinder bottom of the hydraulic oil cylinder; then, an external thread ring sleeve is connected with an internal thread formed on the cylinder mouth of the hydraulic oil cylinder, and an insulating sleeve is connected onto the bolt; and finally, a lifting hook is hung on a cathode bar of an electroplating bath, the cylinder body of the hydraulic oil cylinder is placed in the electroplating bath, and the conducting column is connected with the anode of the electroplating bath through a lead wire. The use method disclosed by the invention has the advantages that a conventional process for electroplating a hydraulic oil cylinder with a copper-tin alloy is changed, so that the hydraulic oil cylinder machining frequency and transfer frequency can be reduced, the hydraulic oil cylinder can be electroplated with the copper-tin alloy through one-step operation in an electroplating production line, the hydraulic oil cylinder electroplating efficiency and transfer efficiency can be improved by 50% or above, and the production cost can be reduced by about 30%; and meanwhile, the defect that the valve hole formed in the cylinder bottom of the hydraulic oil cylinder cannot be electroplated with the copper-tin alloy is overcome, and the product service life is prolonged.

Owner:ZHENGZHOU COAL MINING MACHINERY GRP +1

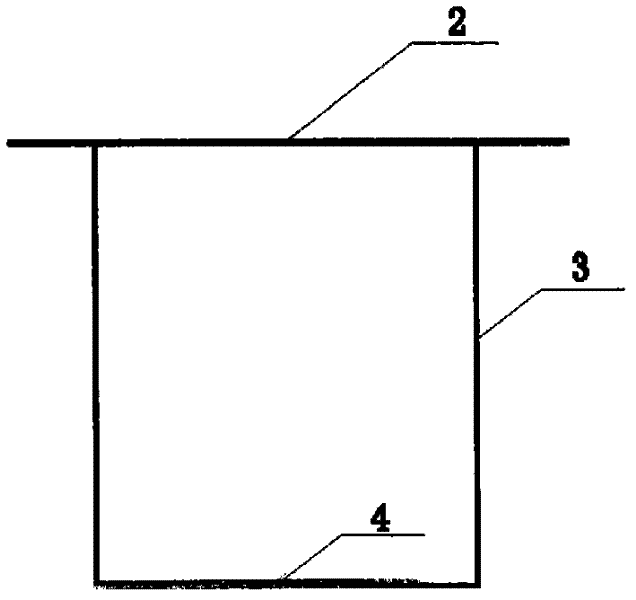

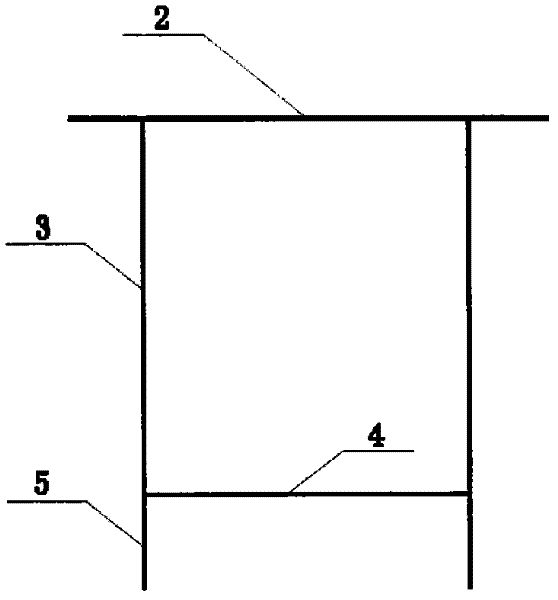

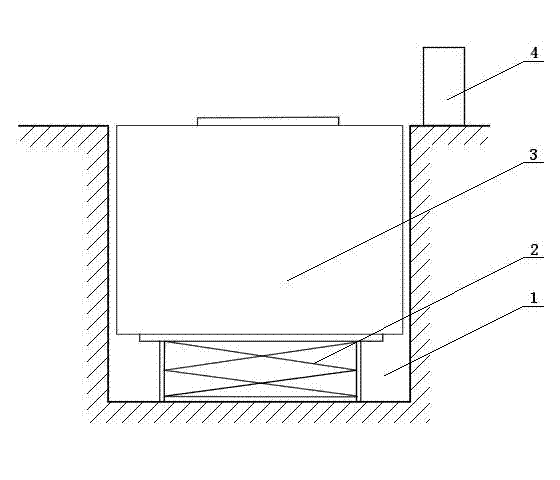

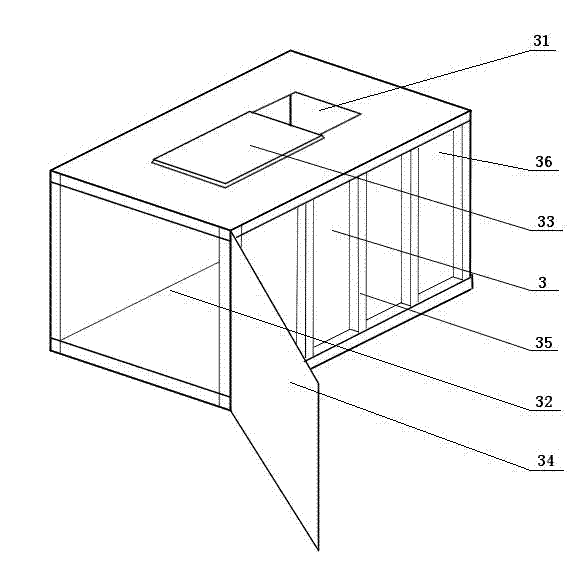

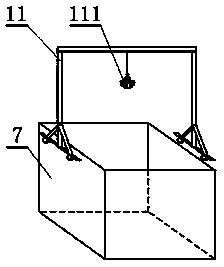

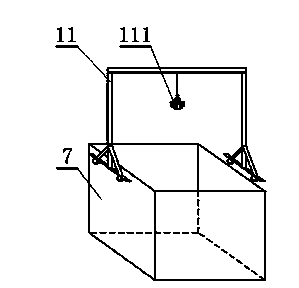

Large-sized underground sealing-type garbage collection device

InactiveCN102951398AFix the messReduce transshipmentRefuse receptaclesRefuse transferringWaste collectionCompression device

The invention discloses a large-sized underground sealing-type garbage collection device, which comprises a pool, a dustbin, an elevation platform and a controller; the elevation platform and the dustbin are arranged in the pool, and the dustbin is arranged on an elevation table-board of the elevation platform; the controller is used for controlling the elevation of the elevation platform so as to lift the dustbin; the dustbin comprises a garbage throw-in port and a garbage discharging outlet; the garbage discharging outlet comprises a sealing door; and the capacity of the dustbin is more than or equal to 3cm3. An embedded compression device, a box body transferring device and a sewage discharging system are additionally designed on the basis. The large-sized underground sealing-type garbage collection device has good sealing performance and is arranged under the ground, so that the community environment can be well improved. Meanwhile, the garbage collection device is large, so that daily domestic garbage accumulated in multiple days can be born and held, the garbage transportation times can be reduced, the work intensity of the sanitation worker can be alleviated, and the pollution caused by the garbage transportation can be reduced.

Owner:YANCHENG ZHONGYE HYDRAULIC COMPONENT

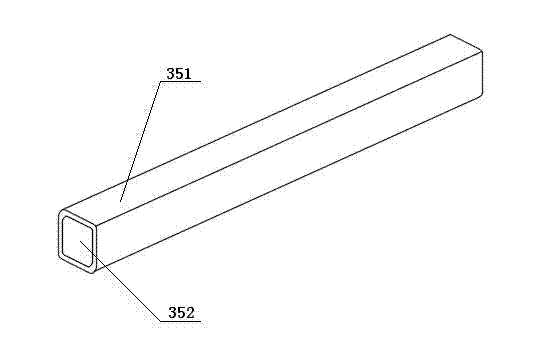

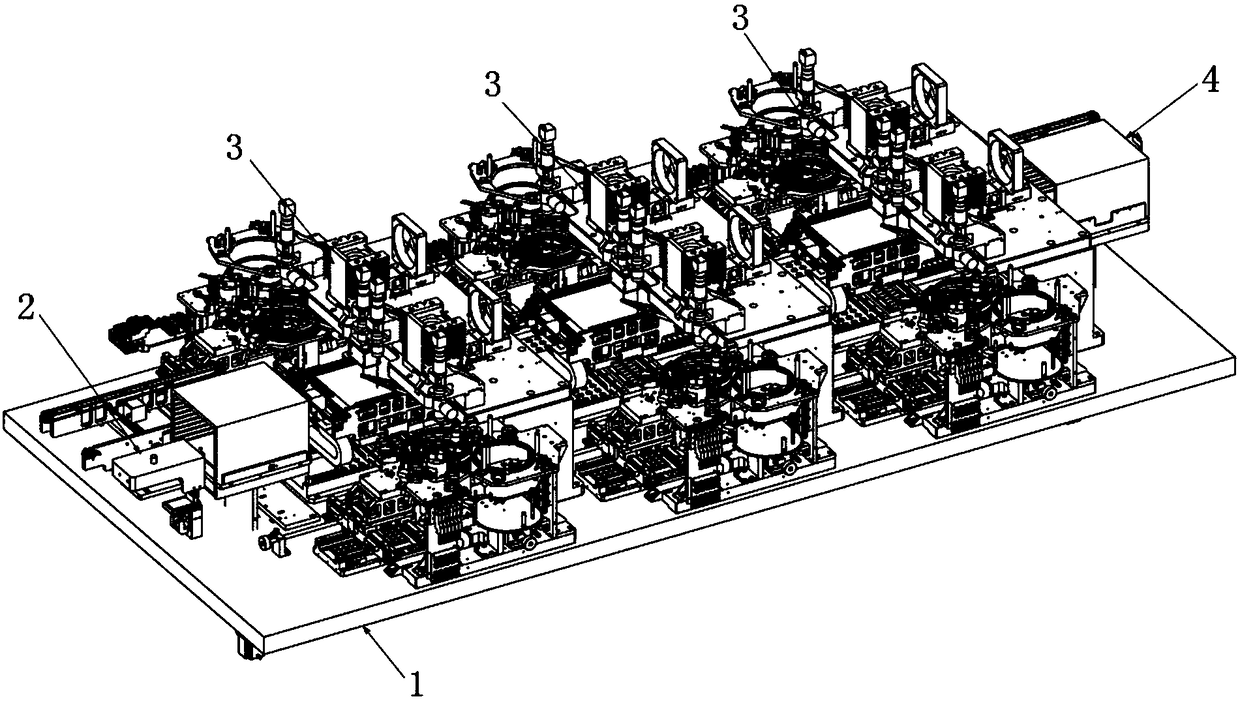

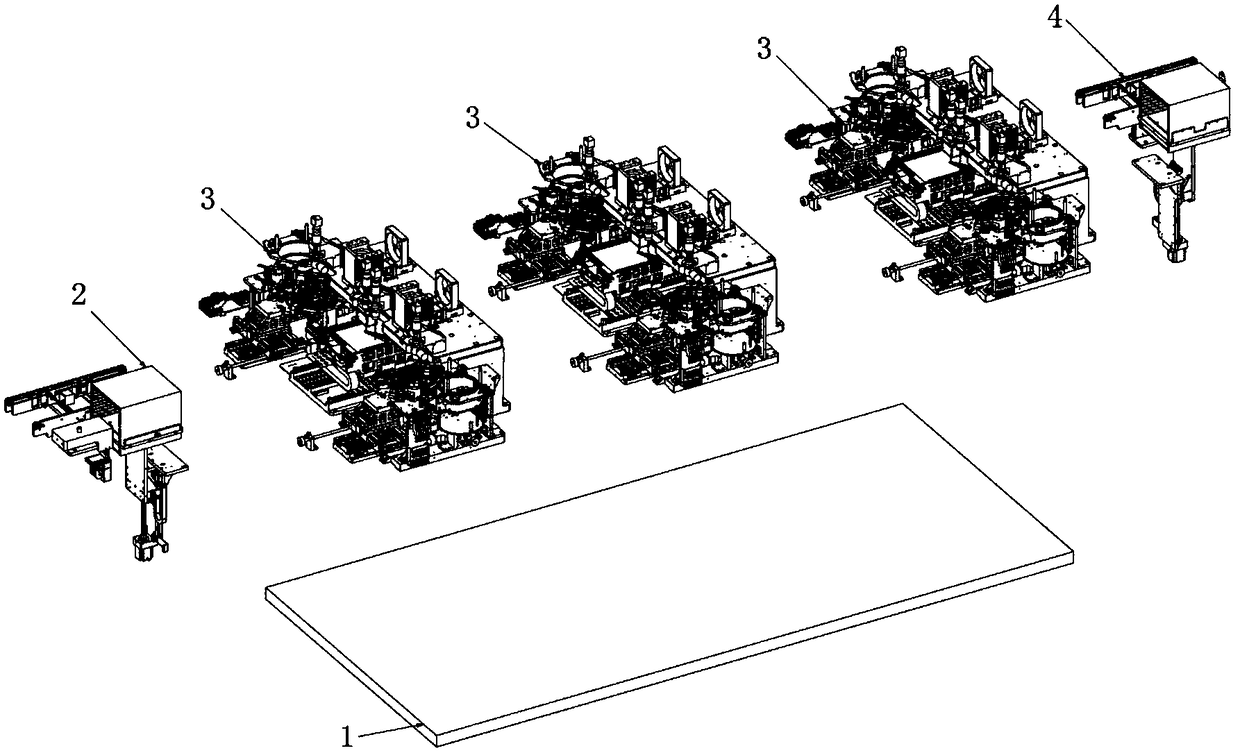

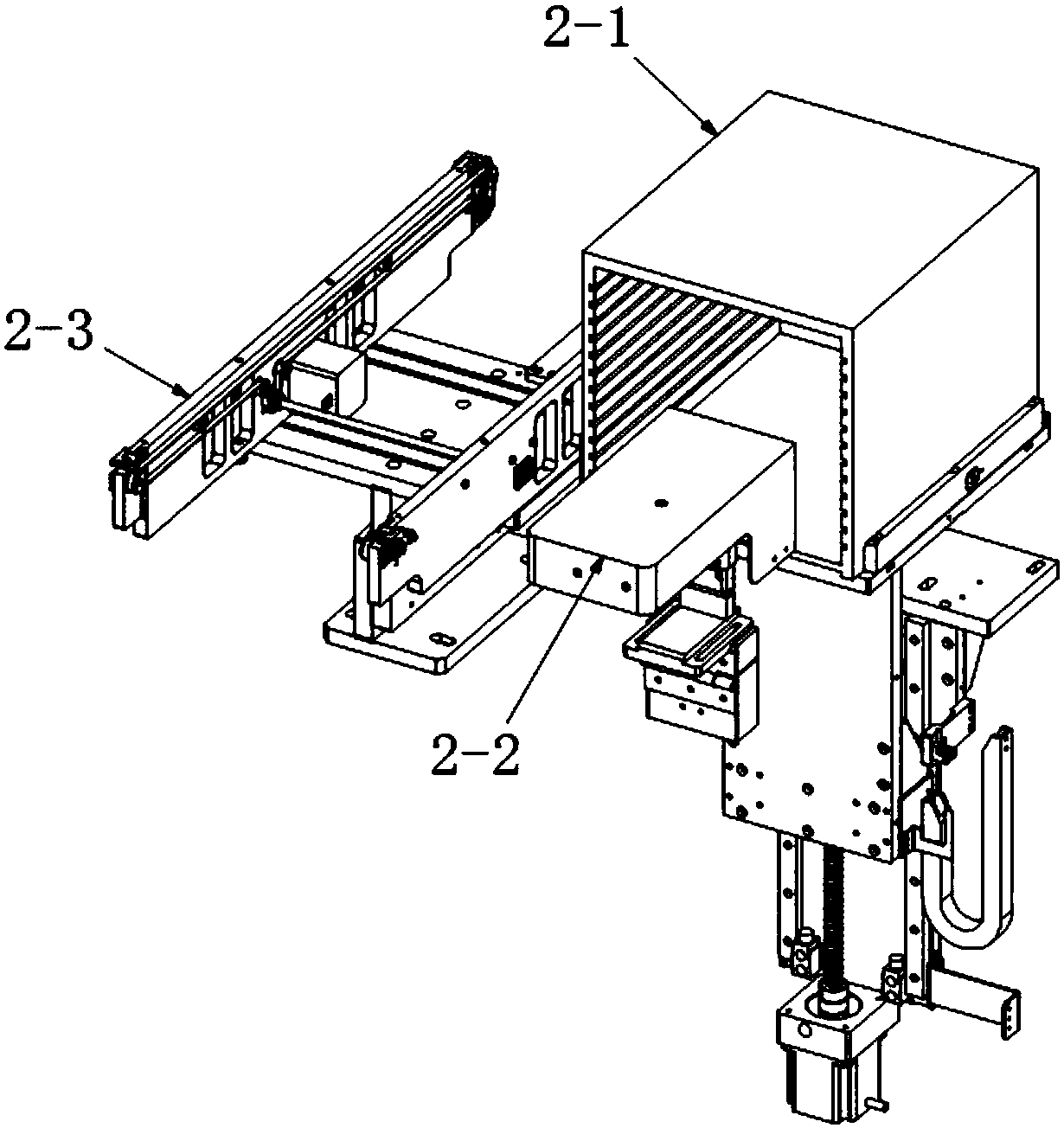

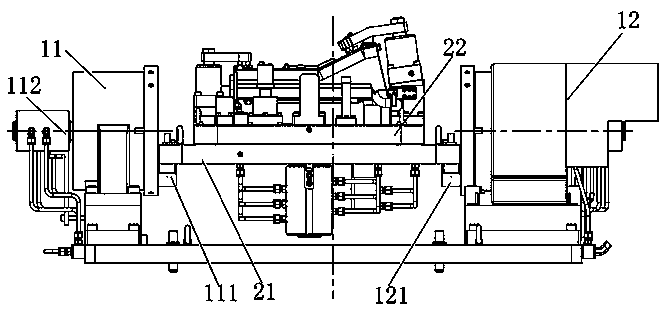

Mini-LED full-automatic die bonder and a die bonding method thereof

ActiveCN108615804ARealize in-line die bonding operationReduce transit linksSemiconductor/solid-state device manufacturingConveyor partsEngineeringDie bonding

The invention discloses a mini-LED full-automatic die bonder and a die bonding method thereof. The full-automatic die bonder comprises a platen and a feeding mechanism and a receiving mechanism respectively arranged at two ends of the platen; and multiple die bonding units are arranged between the feeding mechanism and the receiving mechanism. An LED bracket is conveyed to the adjacent die bondingunit through the feeding mechanism, each die bonding unit performs twice die bonding on the LED bracket, and then conveys the same to the next die bonding unit until the die bonding of the LED bracket is finished; the receiving mechanism receives the LED bracket after the die bonding is finished. For the die bonding way of the LED bracket needing to perform the die bonding of multiple LED chips,the die bonder disclosed by the invention reduces the transit loops of multiple die bonding in comparison with the traditional die bonding way, the production efficiency is greatly improved, the reject ratio is reduced; and the die bonder is compact in structure and small in floor area.

Owner:中山市新益昌自动化设备有限公司

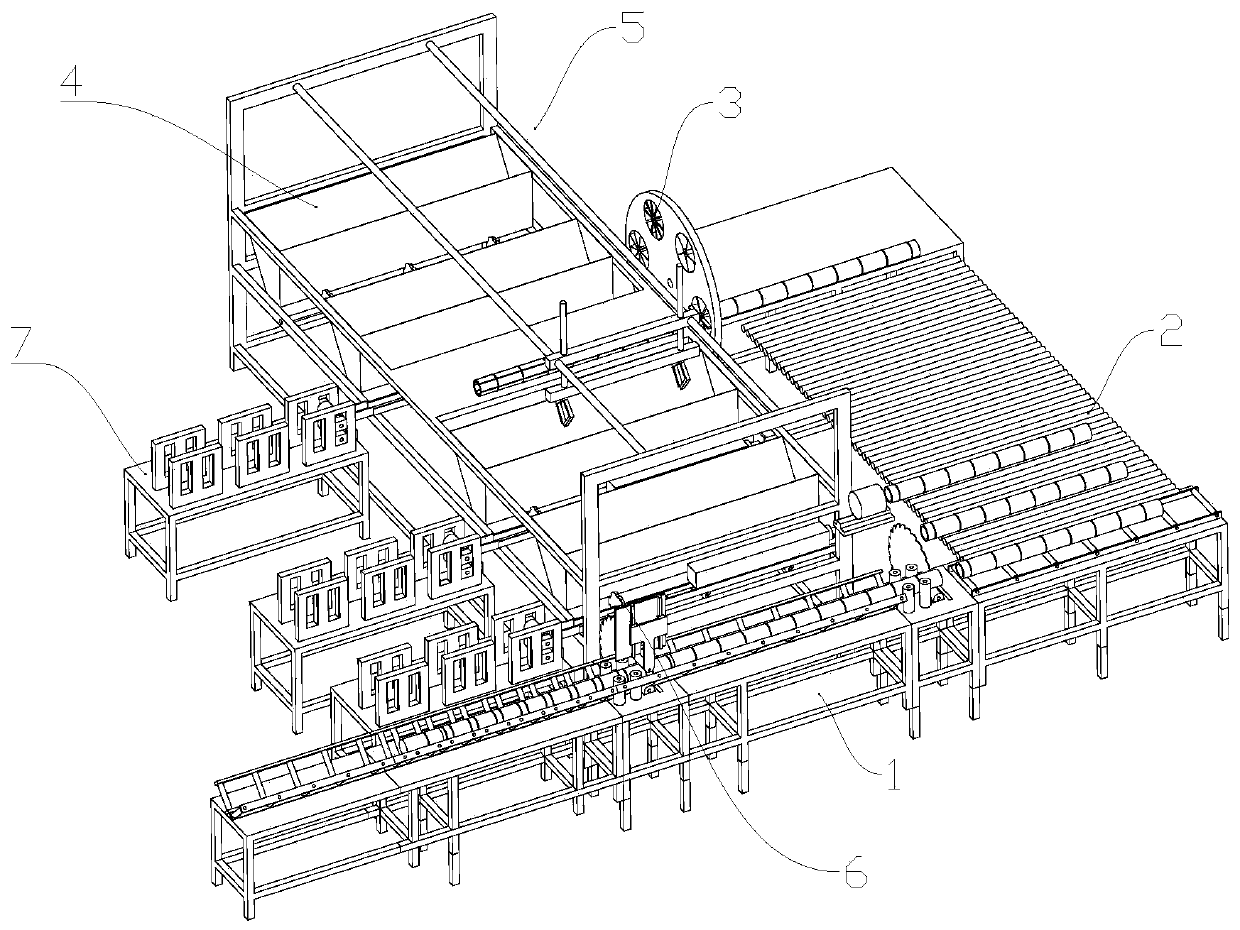

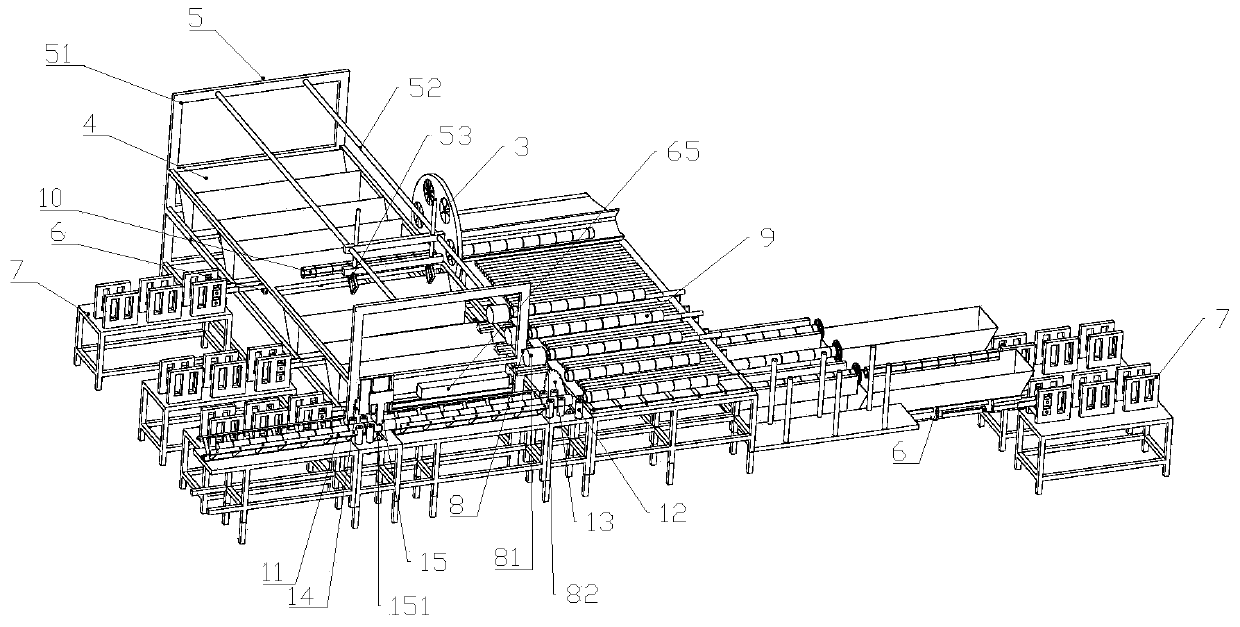

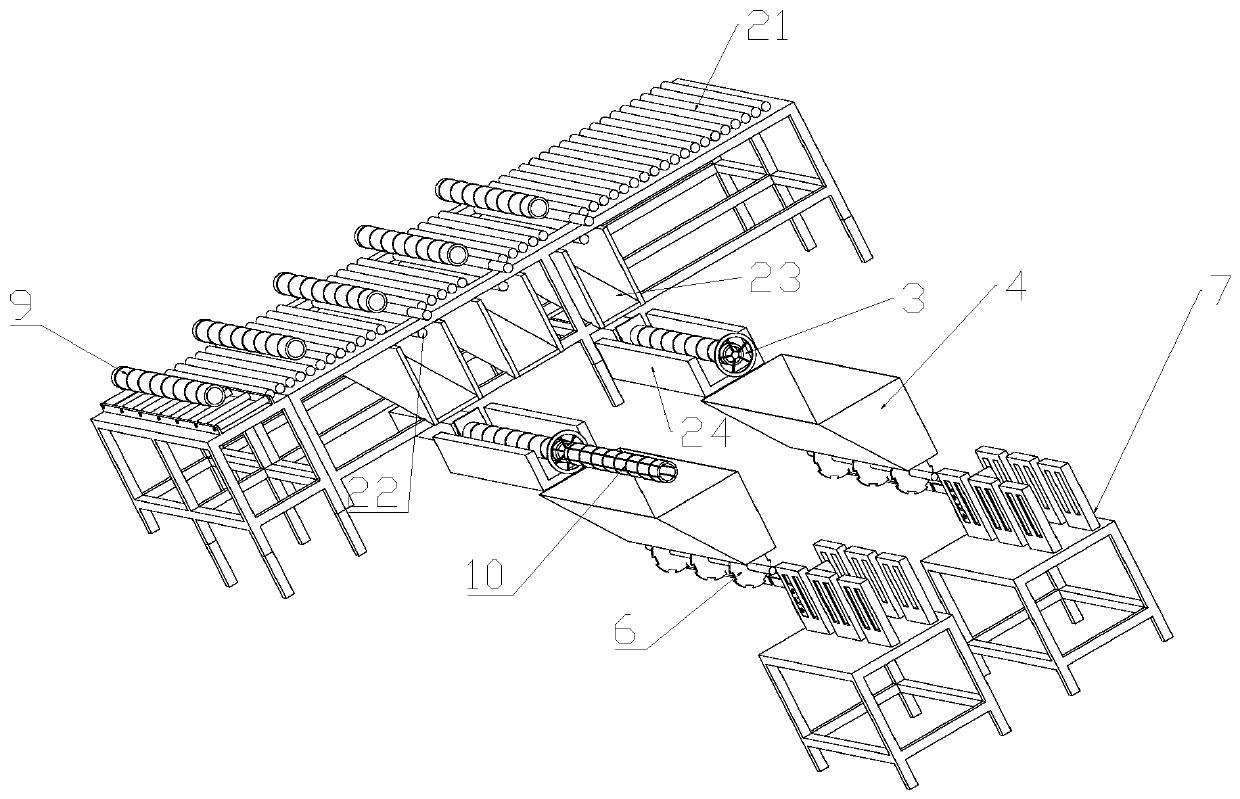

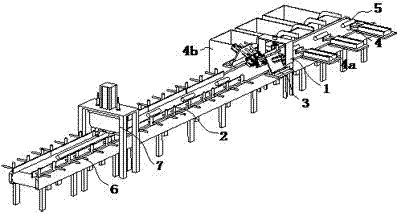

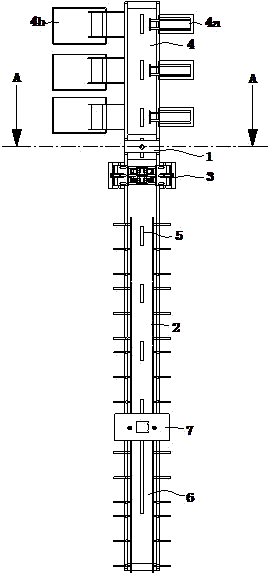

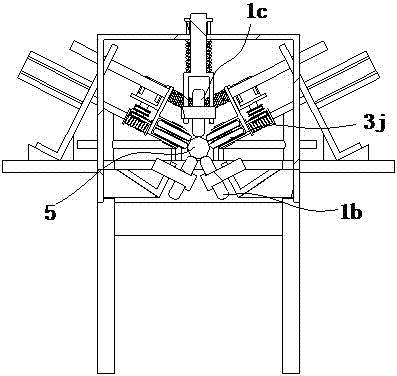

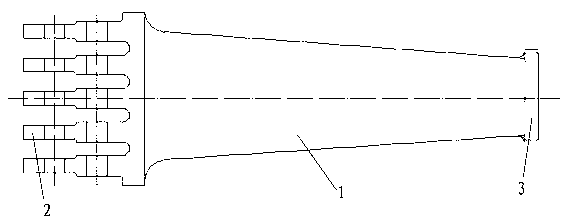

Intelligent bamboo fixed-section bamboo breaking and rough milling integrated equipment

PendingCN109773915AReduce utilizationContinuous processingMulti-purpose machinesCane mechanical workingContinuous operationMechanical engineering

The invention relates to intelligent bamboo fixed-section bamboo breaking and rough milling integrated equipment. The intelligent bamboo fixed-section bamboo breaking and rough milling integrated equipment is characterized in that the intelligent bamboo fixed-section bamboo breaking and rough milling integrated equipment comprises a length fixing device, a first conveying device, a cutter disc, amaterial bin and a milling device, wherein the length fixing device is used for processing raw bamboos into fixed-length bamboo tubes; the first conveying device is used for conveying the fixed-lengthbamboo tubes and connected with the length fixing device; the cutter disc is used for equivalently dividing the fixed-length bamboo tubes into a plurality of bamboo pieces; the material bin is positioned at one side, far away from the conveying device, of the cutter disc and is used for containing the bamboo pieces; a carrying mechanism is arranged on the material bin and is used for conveying the bamboo pieces into the material bin; a stirring mechanism is arranged close to a discharge opening of the material bin; a milling device is connected with the stirring mechanism; the stirring mechanism is used for conveying the bamboo pieces to the milling device one by one; and the milling device is used for milling the bamboo pieces. The intelligent bamboo fixed-section bamboo breaking and rough milling integrated equipment realizes the continuous operation of processing the raw bamboos into the bamboo pieces, thereby being high in processing efficiency.

Owner:BEIJING FORESTRY MACHINERY RES INST OF STATE FORESTRY ADMINISTRATION

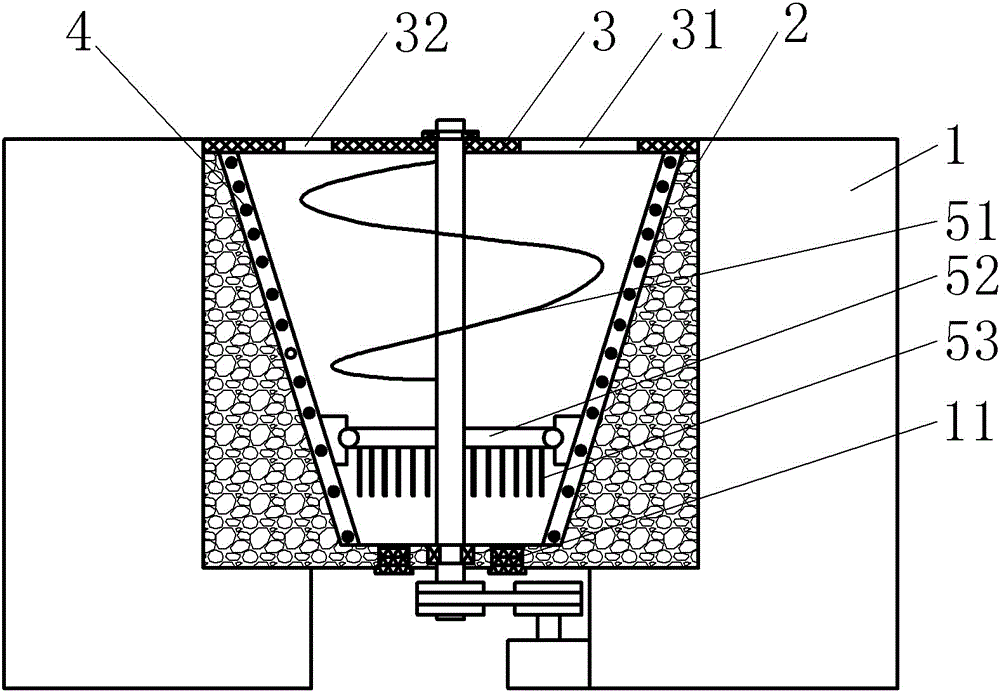

Device for producing and processing spicy hot sauce

InactiveCN104998574AReduce transshipmentLow costRotary stirring mixersMixer accessoriesSpiral bladeEngineering

The invention discloses a device for producing and processing spicy hot sauce. The device comprises a rack and a processing furnace which is fixed on the rack. An inner cavity of the processing furnace is in an inverted cone shape. An upper cover is fixedly connected to the top of the processing furnace and is provided with a feeding opening. An electric heating wire is embedded in the side wall of the processing furnace from top to bottom. A stirring roller is rotatably connected to the center of the bottom of the processing furnace, and a plurality of discharging openings are circumferentially formed in the bottom of the processing furnace. The stirring roller comprises an upper section and a lower section. A spatially-spiral blade is arranged on the upper section, and a plurality of supporting rods are circumferentially and evenly distributed on the lower section. Scrapers tangent to the side wall of the inner cavity of the processing cavity are hinged to the outer ends of the supporting rods. According to the device for producing and processing spicy hot sauce, the process of heating and the process of mixed stirring are combined into one, the transport process and transport equipment in the prior art are omitted, hence, cost is greatly lowered, and efficiency is improved.

Owner:重庆酱人调味品有限公司

Graded-sorting conveying belt

ActiveCN106927082AProtect your healthGuaranteed uniform diameterPackaging automatic controlSortingEngineeringMechanical engineering

The invention relates to the field of conveying belts, in particular to a graded-sorting conveying belt. The graded-sorting conveying belt comprises a detection device and a main conveying belt body. The detection device is connected with the main conveying belt body. A feed conveying belt body is arranged at the front end of the main conveying belt body. A cutting-off device is arranged between the feed conveying belt body and the main conveying belt body. A boosting device is further arranged on the portion, adjacent to the detection device, of the main conveying belt body. An auxiliary conveying belt body connected with the detection device is arranged at the rear end of the detection device, and a plurality of pushing cylinders are arranged on the side edge of the auxiliary conveying belt body. Boxes corresponding to the pushing cylinders are arranged on the other side of the auxiliary conveying belt body. According to the graded-sorting conveying belt, a whole piece of sugarcane is cut off and then directly conveyed onto the main conveying belt body through cooperation between the feed conveying belt body and the cutting-off device, so that the transferring process is shortened, and the production efficiency is improved accordingly; and sugarcane pieces with different diameters can be sorted in a graded mode through the detection device, the manual sorting procedure is omitted, the health of people is guaranteed while the working efficiency is improved, and errors caused by manual sorting are avoided.

Owner:优尼斯工业服务建湖有限公司

Processing method of five-fork blade-root moving blades with own shrouds

ActiveCN103203490AAvoid deformationLess effective cuttingMilling equipment detailsProcess engineeringMachine tool

The invention discloses a processing method of five-fork blade-root moving blades with own shrouds, belonging to the technical field of blade processing. The processing method comprises: step 1, clamping blades, step 2, roughing, step 3, semi-refining, step 4, refining, step 5, positioning a steam-out side of a shoulder of the blade root, a steam-out side of a shroud and a back radial surface of the blade root, selecting a cutter with cutting edges matching with five-fork blade root lines, with a rotating speed being 25-30 r / min, a feeding speed being 12.5 mm / min, a feed amount being 0.5-0.8 mm, and performing fine milling for the five-fork blade root lines of the blade along a linear direction. According characteristics of the five-fork blade-root moving blades with own shrouds, positioning reference surface during processing is unified, a one-time clamping is used to complete processing of each part, thereby effectively preventing accumulative errors, increasing processing precision, optimizing integration processing, shortening processing periods of products, reducing required amount of machine tool, and reducing production cost.

Owner:SICHUAN MIANZHU XINKUN MACHINERY MAKING

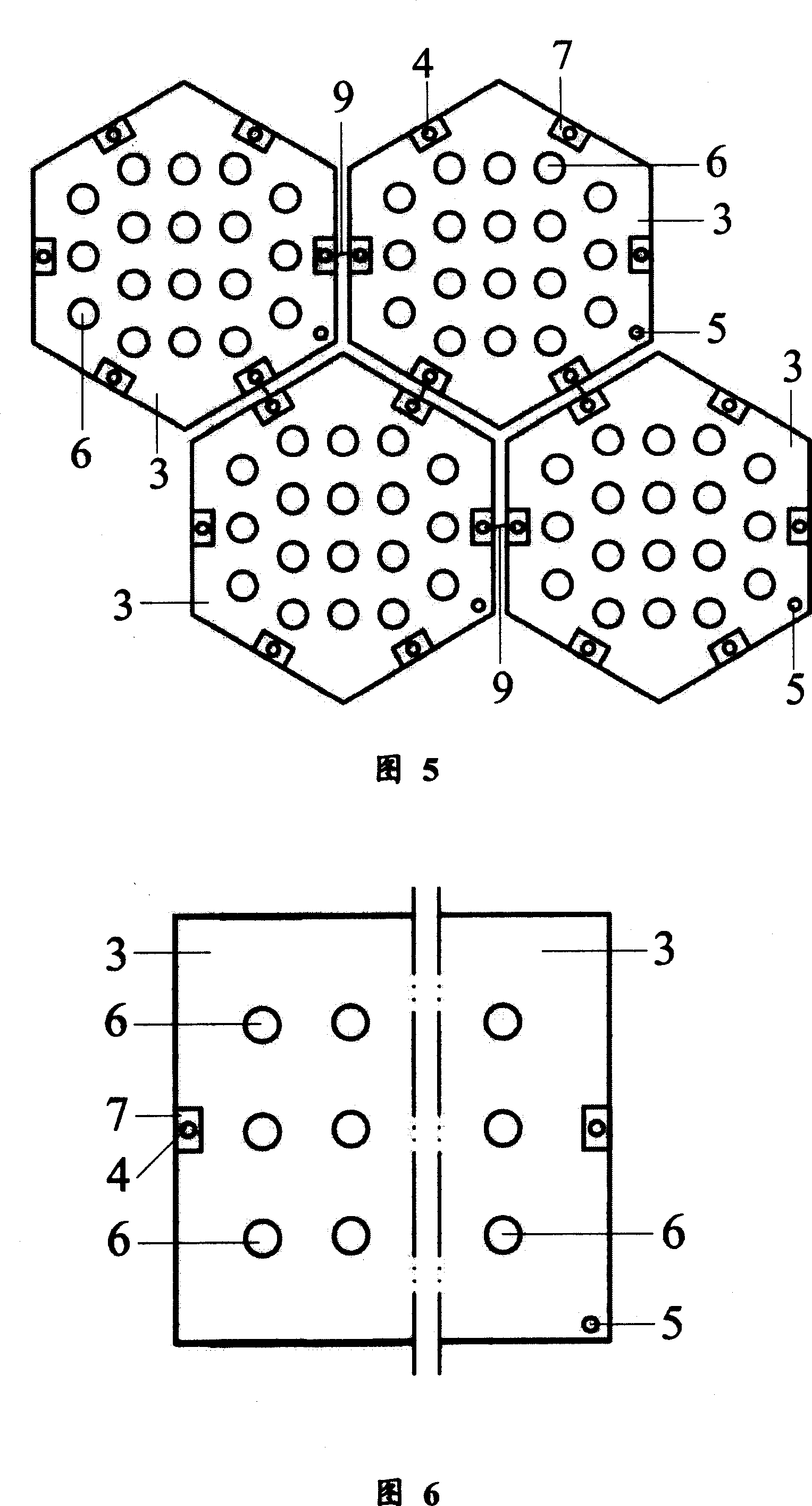

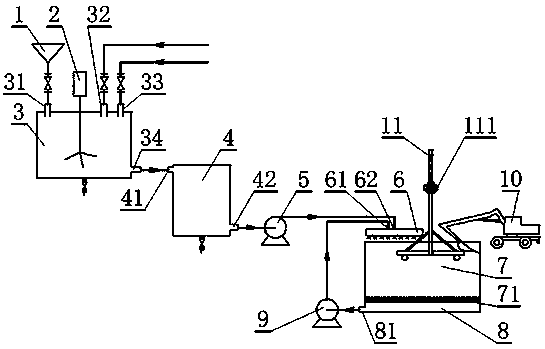

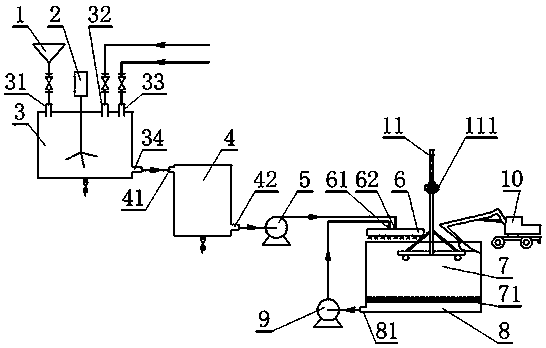

Stable curing repair system for polluted soil

InactiveCN103894409AQuick fixAccelerates the curing reactionContaminated soil reclamationCentrifugal pumpCirculating pump

The invention relates to a stable curing repair system for polluted soil. The system consists of a dispensing tank, a chemical storage box, a centrifugal pump, a spraying device, a reaction tank, a recovery tank, a circulating pump, a backhoe excavator and a movable gantry mixer; the system can be used for rapidly repairing the polluted soil by adopting repair chemicals with different forms, types and concentrations at different temperatures according to the characteristics of the different polluted soil; the system is mainly suitable for the soil polluted by heavy metals such as Cr, Cd, Pb, Zn and Cu. The stable curing repair system is reasonable in arrangement, wide in application scope, rapid in reaction speed, short in repair period, good in flexibility, safe and stable in operation and economically feasible, and can be used for heterotopic or in-situ repair of the polluted soil; the repaired soil can meet the relevant standard, and comprehensive resource utilization of the polluted soil can be realized, so that the system has good environmental protection benefit and social benefit.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

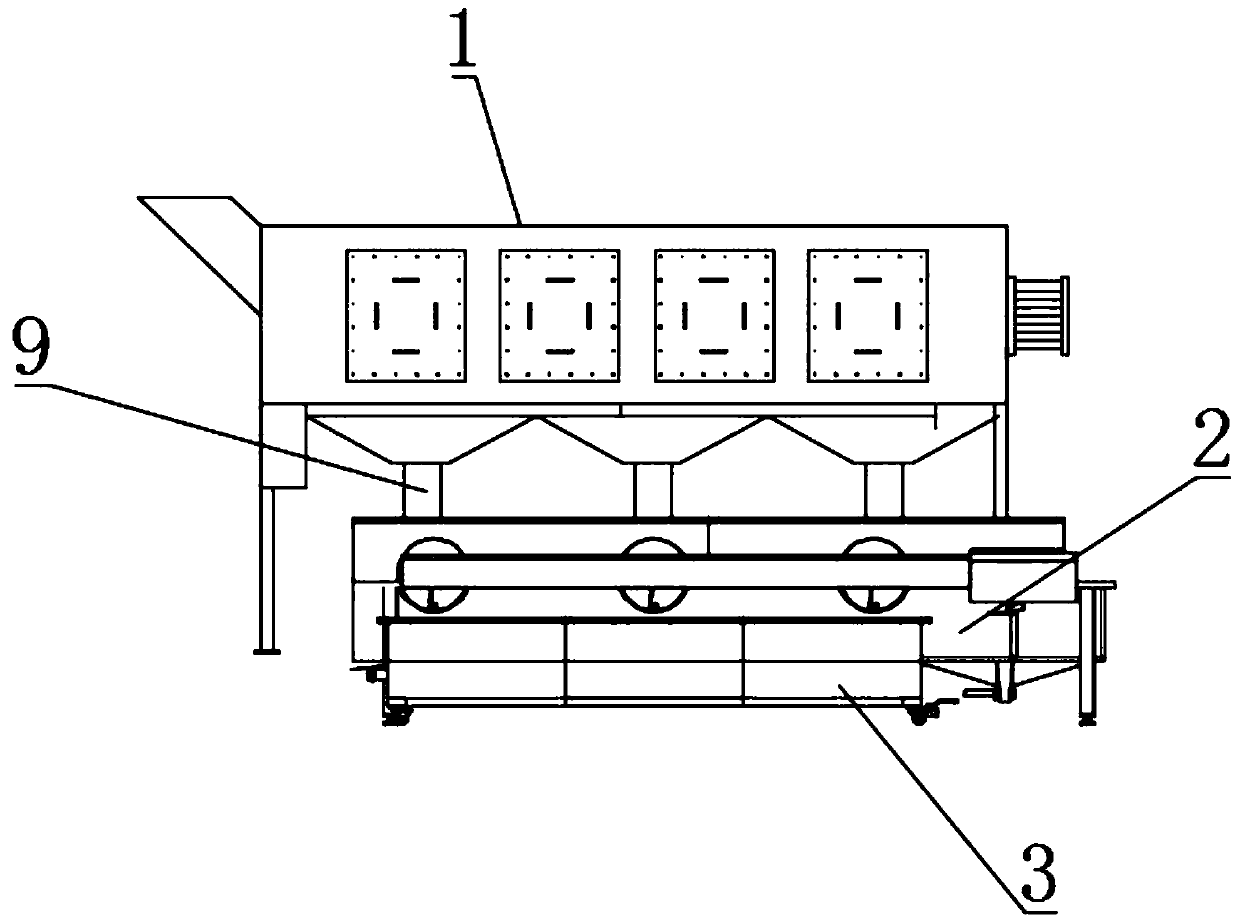

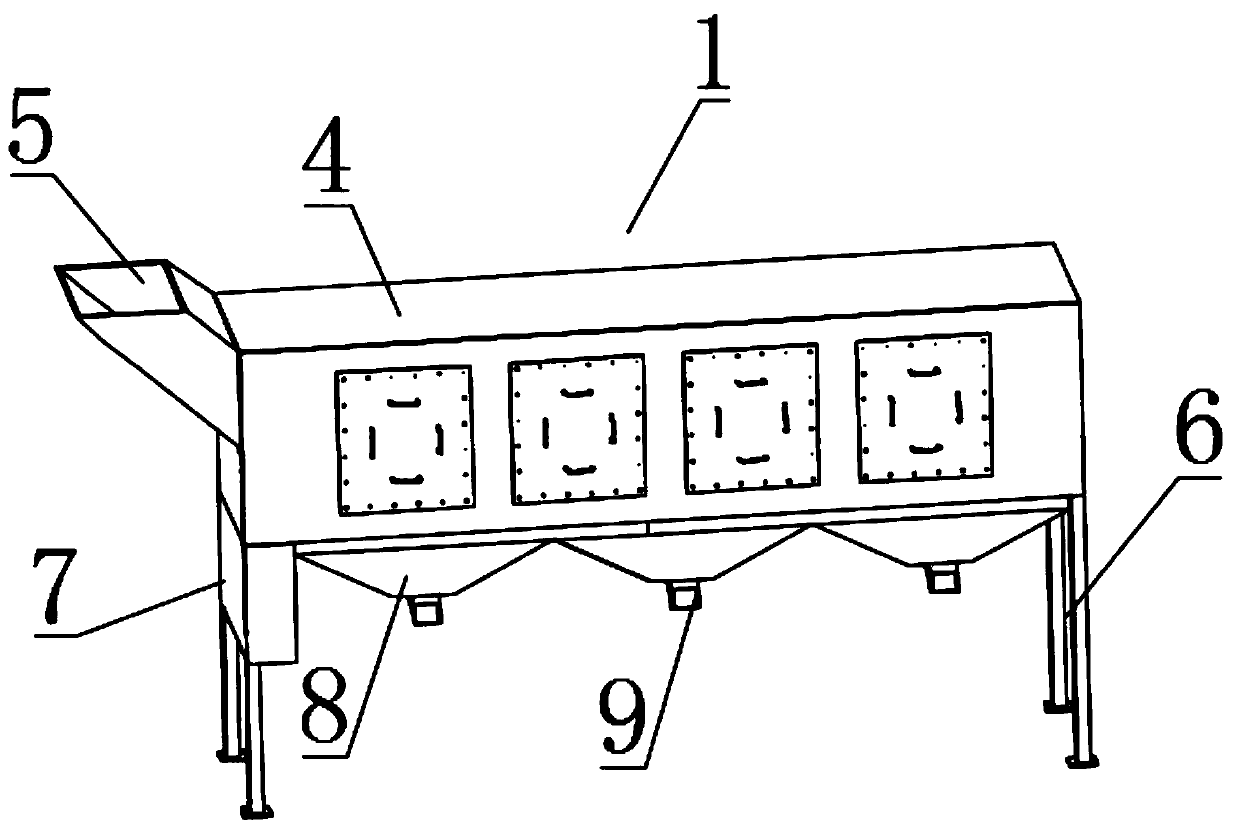

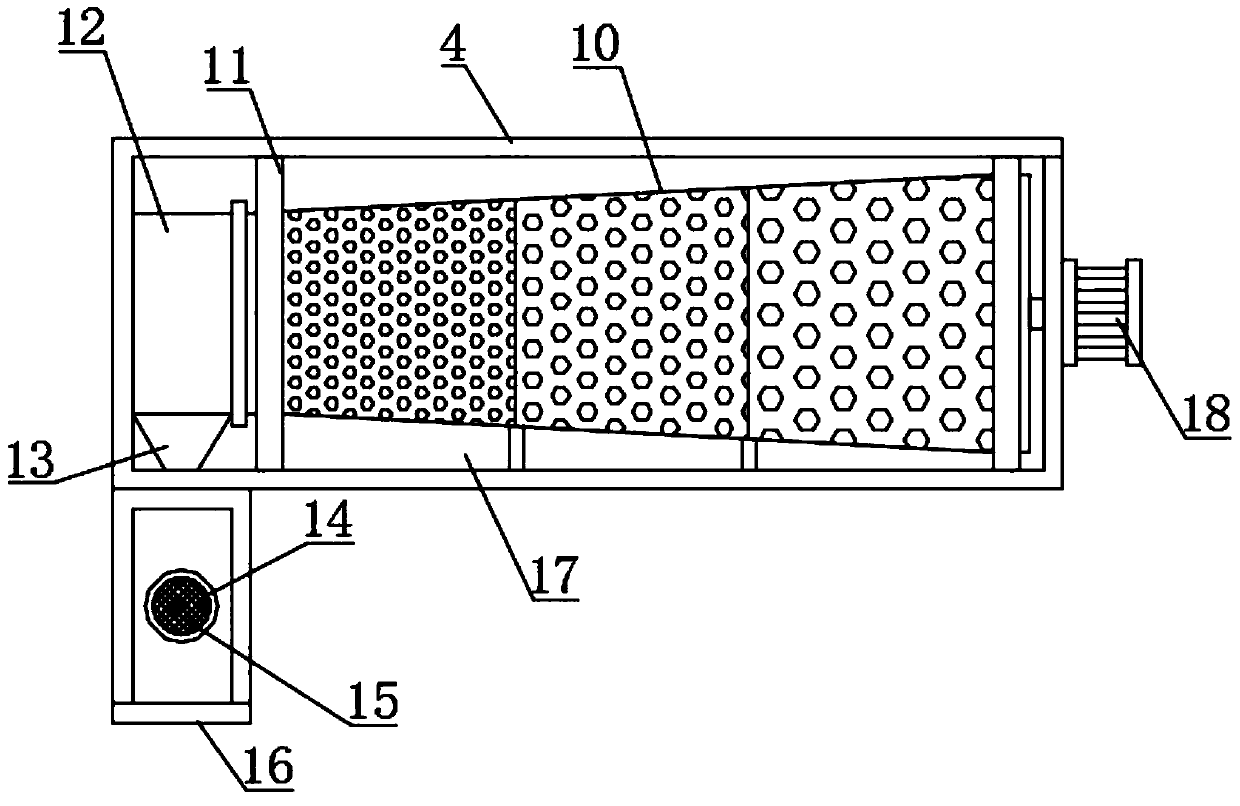

Screening and cleaning device for food processing and application method thereof

InactiveCN111266286ALess cleaning and handlingSimple structureSievingScreeningProcess engineeringFood material

The invention discloses a screening and cleaning device for food processing. The screening and cleaning device comprises a screening mechanism, a cleaning mechanism and a material receiving mechanism.The screening mechanism is mounted on a supporting frame. The cleaning mechanism is mounted on a supporting seat. The cleaning mechanism is located in front of the screening mechanism. The discharging end of the screening mechanism communicates with the feeding end of the cleaning mechanism through a communicating pipe. The material receiving mechanism is located in front of the cleaning mechanism. The screening mechanism comprises a screening box, a feed pipe, a dust suction pipe, a dust suction assembly and a screening assembly. The screening box is mounted on the supporting frame, and thefeed pipe is arranged on one side of the screening box and is arranged obliquely. The screening assembly is mounted in the screening box. The dust suction box is arranged at the bottom of the side, close to the feed pipe, of the screening box. The dust suction assembly is mounted in the dust suction box. According to the screening and cleaning device, screening, graded cleaning, graded collectionand drying are integrated, and the efficiency of processing food raw materials is greatly improved.

Owner:耿言华

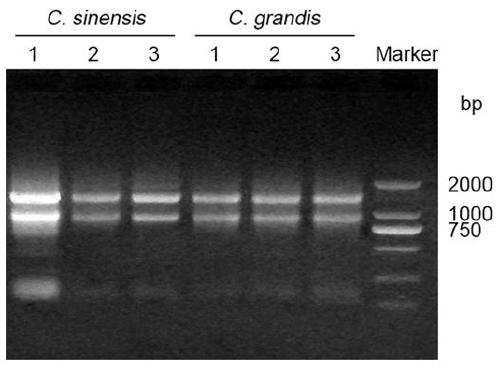

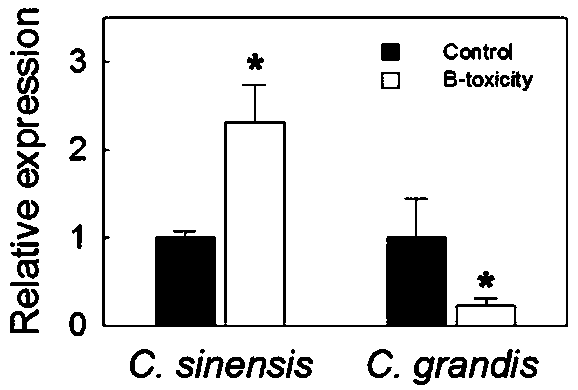

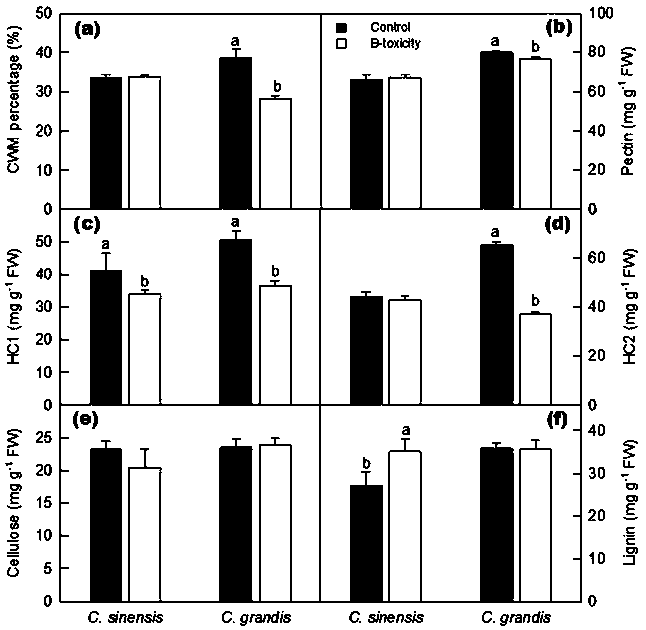

Citrus laccase family gene CsiLAC4 and application thereof

InactiveCN109468333AImprove boron toxicity resistanceIncreased resistance to boron toxicityOxidoreductasesFermentationForward primerTotal rna

The invention discloses a citrus laccase family gene CsiLAC4 and application thereof and belongs to the technical field of plant genetic engineering. A method for obtaining the citrus laccase family gene CsiLAC4 comprises the following steps: extracting total RNA (Ribonucleic Acid) from citrus leaves; (2) carrying out reverse transcription on the RNA obtained in the step (1) so as to obtain cDNA (Complementary Deoxyribonucleic Acid); (3) by taking the obtained cDNA as a template, carrying out a first round of PCR (Polymerase Chain Reaction) amplification by using a forward primer F1 and a reverse primer R1; (4) by taking an amplification product of the first round as a template, carrying out nest type PCR amplification by using the forward primer F1 and a reverse primer R2, thereby obtaining the citrus laccase family gene CsiLAC4. The citrus laccase family gene CsiLAC4 is adopted to improve the boron toxin resistance of plants, and provides new gene resources for abiotic stress resistant molecule breeding of plants.

Owner:POMOLOGY RES INST FUJIAN ACAD OF AGRI SCI

Method for wet composting of bio-organic fertilizer from rural garbage

InactiveCN105000924AOvercome limitationsSolve pollutionBio-organic fraction processingOrganic fertiliser preparationInsect pestBiological activation

The invention provides a method for wet composting of bio-organic fertilizer from rural garbage. The method includes: conducting efficient classification on rural garbage at source, for the classified organic domestic garbage and corn straw, taking household as the unit, and carrying out microbial fermentation, deodorization and complete decomposing to make the bio-organic fertilizer. The bio-organic fertilizer fermented by the method provided by the invention has the characteristics of no pollution, no nuisance, scientific formula, complete nutrient, soil activation, fertilizer efficiency increase, low cost, high yield, product quality improvement, harmful accumulation reduction, farmland fertility enhancement, soil fertility supply environment improvement, diseases and insect pest inhibition, and crop prematurity promotion. The method has the advantages of simple operation, convenient use and strong practicability, and can be popularized and applied on a large scale in rural areas.

Owner:张小平

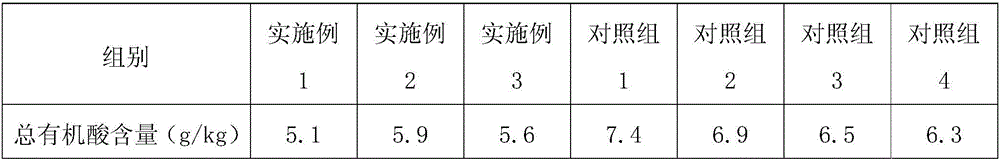

Cultivating method reducing content of organic acid in winter fruit of grape

ActiveCN106577157AIncrease contentReduce contentCalcareous fertilisersExcrement fertilisersOrganic acidTemperature control

The invention relates to the grape cultivating technology field, and especially relates to a cultivating method reducing the content of organic acids in winter fruits of grapes. The cultivating method comprises the following steps: (1) pruning; (2) accelerating germination; (3) erasing redundant buds; (4) pinching; (5) managing flowers and fruits; (6) and managing fertilization. After flowering 6-10 weeks, temperature control, light supplement by energy-saving lamps, strict control over the proportion of leaves to fruits of grapes, and other flower and fruit management measures are adopted to promote catabolism of organic acids and reduce the frequency of transport of organic acid synthesized substrates.

Owner:GRAPE & WINE RES INST GUANGXI ACADEMY OF AGRI SCI

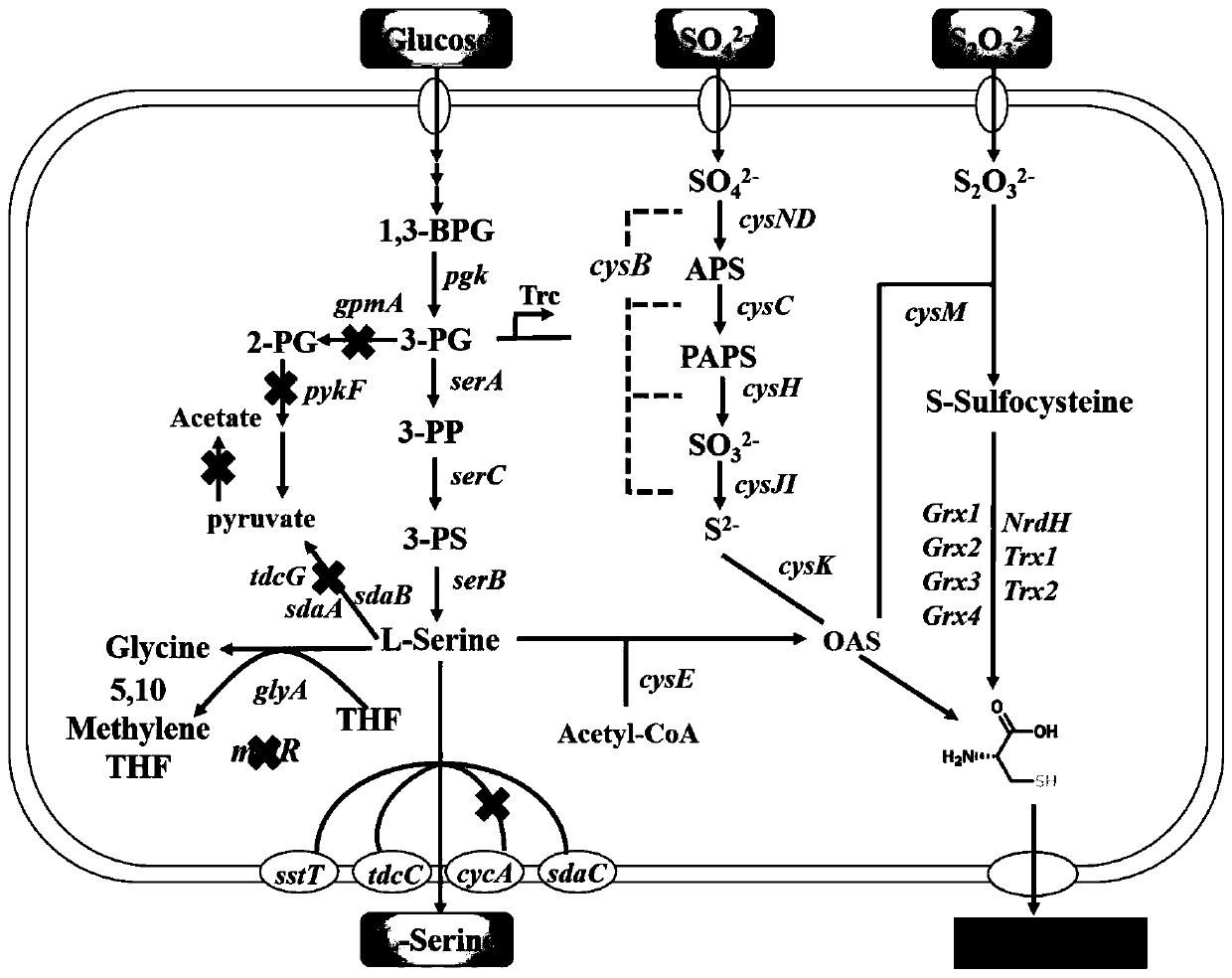

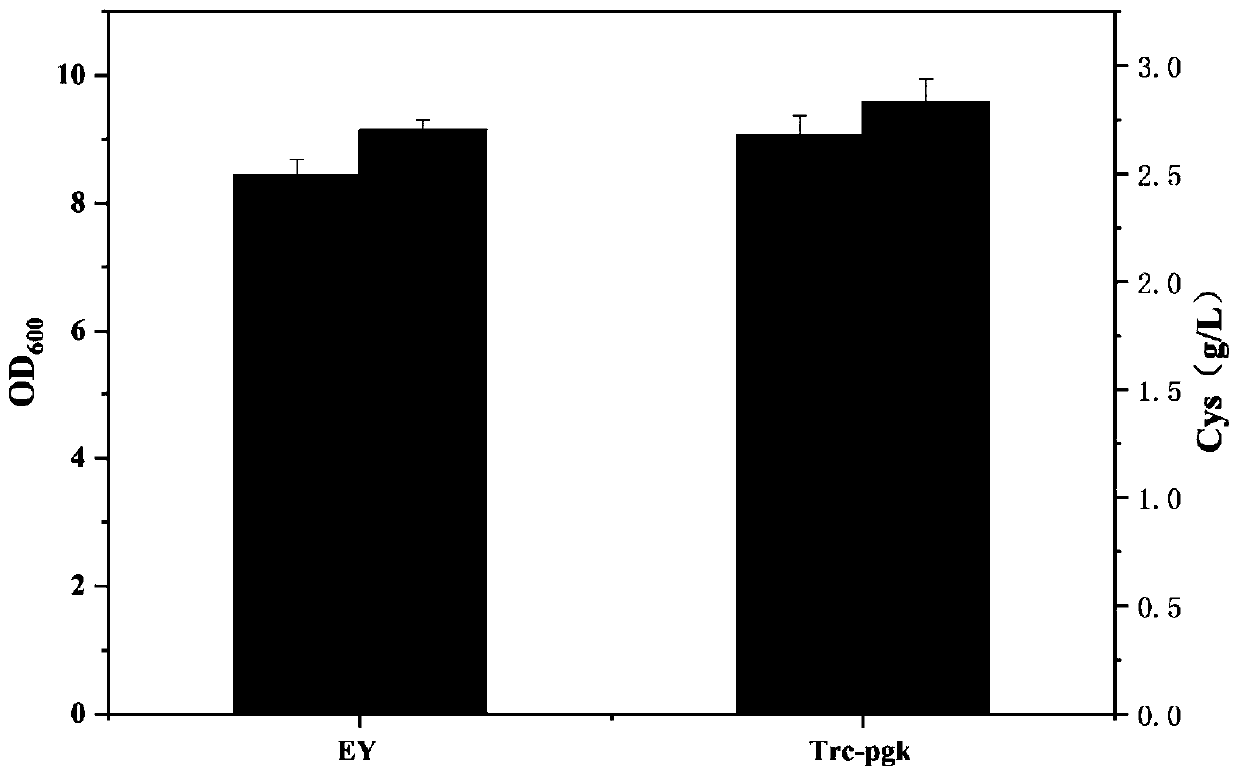

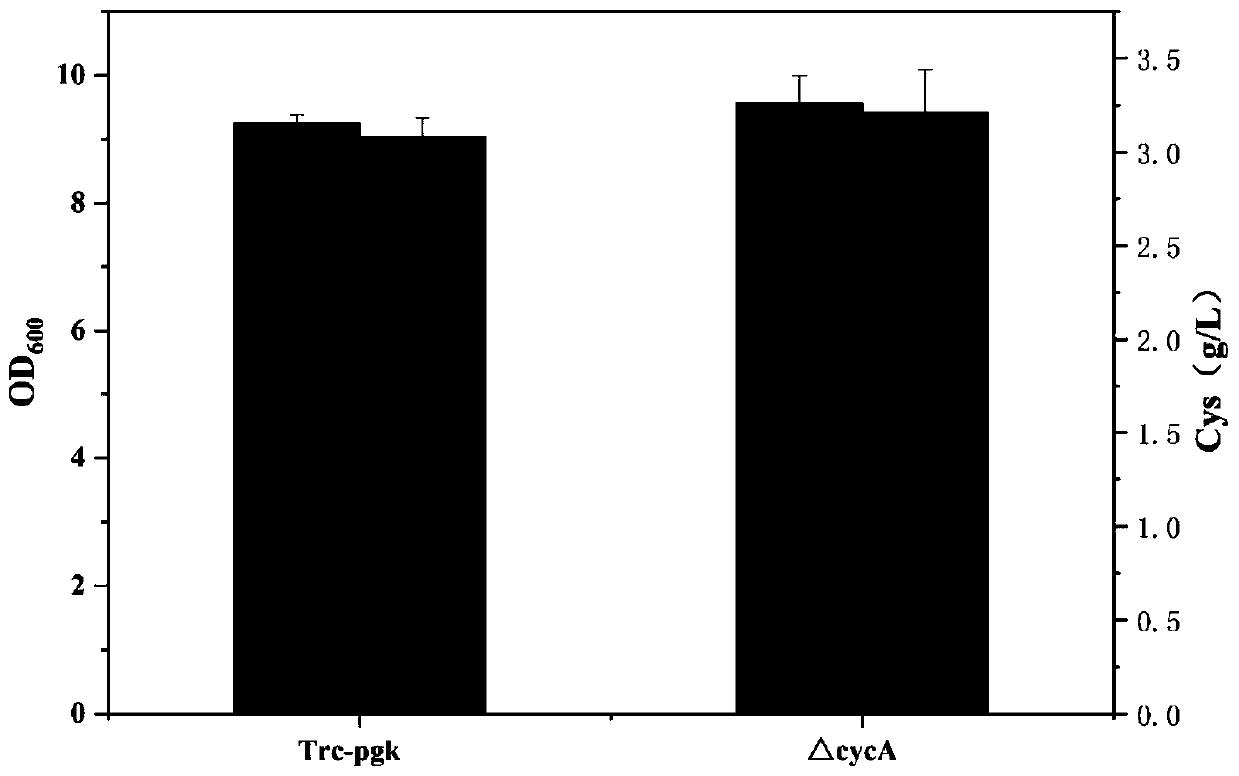

Genetically engineered bacterium for high yield of L-cysteine, construction method and application

ActiveCN111019877AReduce the effect of synthesisImprove utilizationBacteriaStable introduction of DNAHeterologousMicrobacterium

The invention discloses a genetically engineered bacterium of L-cysteine, a construction method of the genetically engineered bacterium and application of the genetically engineered bacterium in preparation of L-cysteine through microbial fermentation. The construction method comprises the following steps: (1) strengthening a serine module of an escherichia coli L-cysteine synthetic route, so thatthe serine utilization capability of escherichia coli is enhanced; (2) weakening the transfer of serine, so that the influence of byproducts on the L-cysteine synthesis is weakened; (3) increasing the expression of a sulfur module synthesis gene; and (4) heterologously expressing serC gene of Cornebacterium glutarum on a plasmid to obtain an escherichia coli genetically engineered bacterial strain with high L-cysteine yield, wherein the L-cysteine yield is increased from 2.7 g / L to 3.83 g / L.

Owner:ZHEJIANG UNIV OF TECH

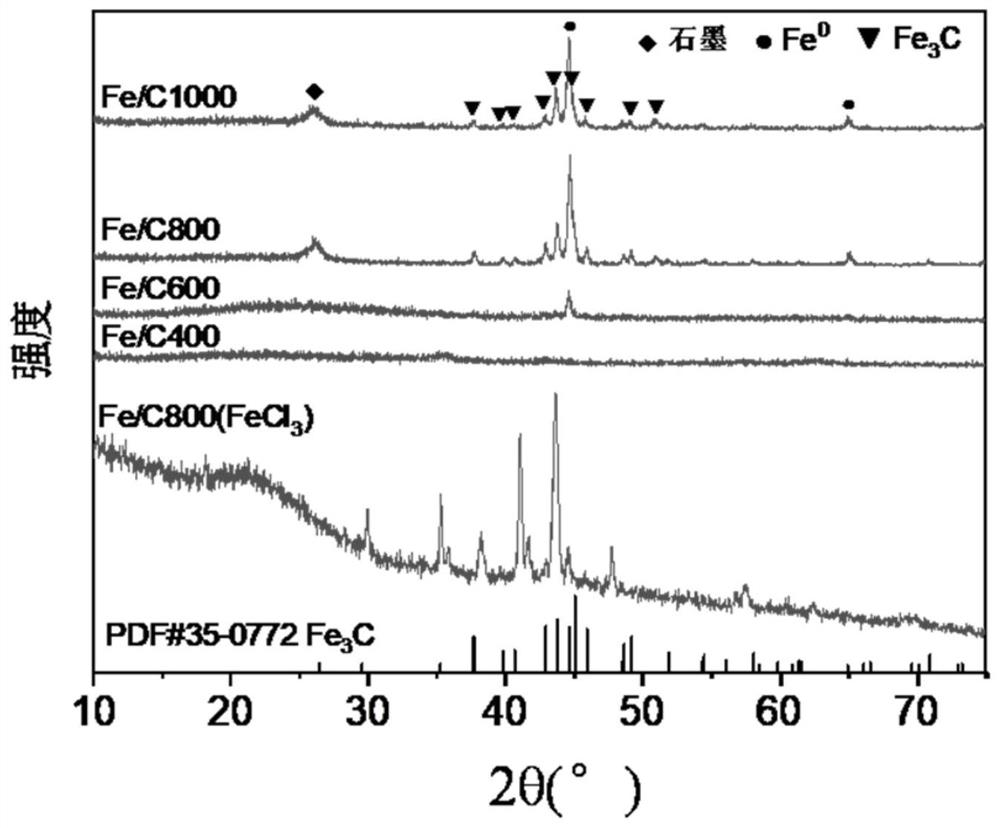

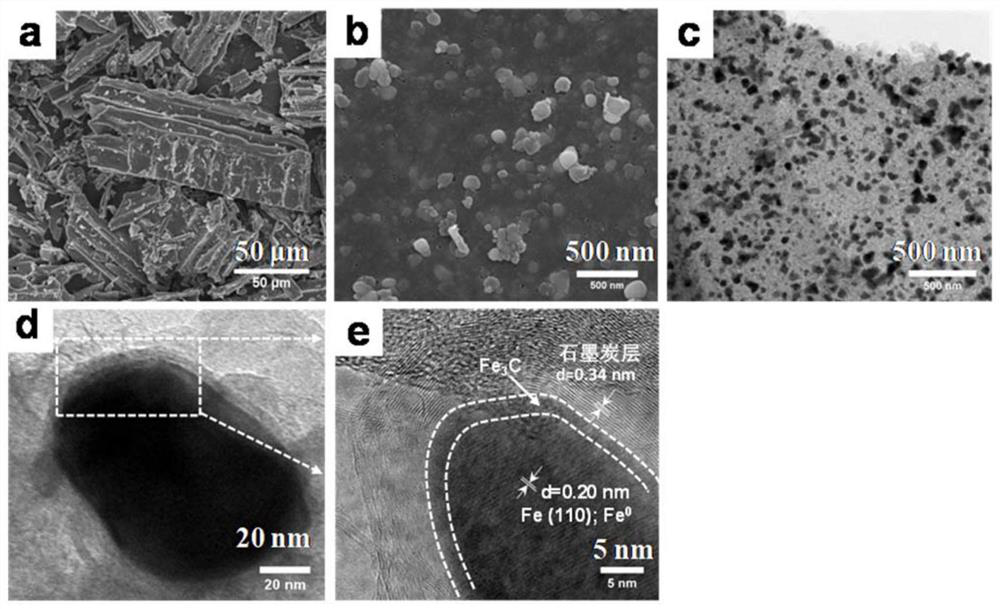

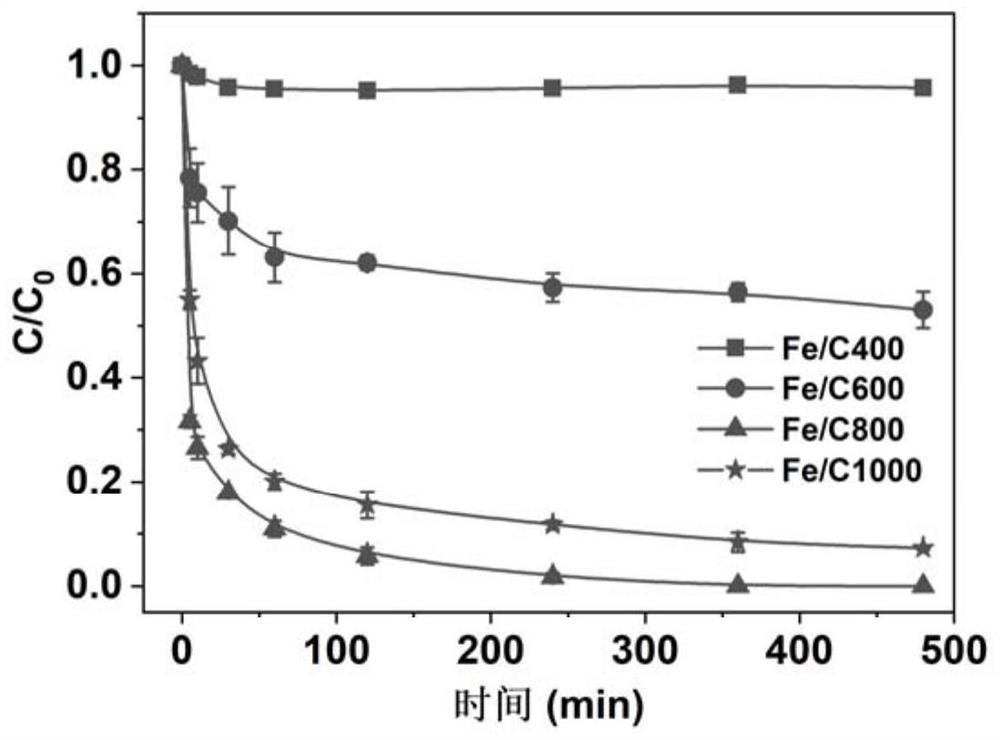

Iron-carbon composite material as well as preparation method and application thereof

ActiveCN113070028ALow toxicityReduced ability to migrateOther chemical processesWater treatment compoundsCarbon compositesGraphite carbon

The invention discloses an iron-carbon composite material and a preparation method and application thereof. The iron-carbon composite material has a three-layer core-shell structure, and the three-layer core-shell structure sequentially comprises a porous graphite carbon outer layer, an iron carbide middle layer and a nanoscale zero-valent iron inner core from outside to inside. The nano zero-valent iron is coated in the porous graphite carbon and the iron carbide so that the nano zero-valent iron can be prevented from being oxidized, the existence of the iron carbide effectively improves the arsenic fixing capability, the efficient and long-term utilization of the nano zero-valent iron is realized, very strong adsorption and fixing capability on the arsenic is achieved, and particularly, As (III) can be efficiently oxidized and converted into As (V) with relatively low toxicity.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

Stable solidification treatment and sanitary landfill disposal method for polluted soil

InactiveCN103846275AReduce transshipmentHarm reductionContaminated soil reclamationMedicinePollution soil

The invention relates to a stable solidification treatment and sanitary landfill disposal method for polluted soil. According to the stable solidification treatment and sanitary landfill disposal method, a corresponding medicament solution is prepared by adopting a solid medicament or a liquid medicament through a stable solidification treatment system of the polluted soil according to pollution properties of different types of heavy-metal polluted soil; the soil which is severely polluted by heavy metals including Pb, Zn, Cu and the like is rapidly treated; the medicament solution and the heavy metals in the polluted soil are subjected to a series of physical and chemical processes by agitating, so that free-state heavy metals which can move easily in the polluted soil are changed into an insoluble state or an indissolvable state. The treated soil reaches sanitary landfill entrance standards and is conveyed into a sanitary landfill to be filled; the soil is filled by layers, is compacted layer by layer and is subjected to daily covering treatment, so as to realize sanitary treatment disposal of the polluted soil. The stable solidification treatment and sanitary landfill disposal method for the polluted soil is wide in applicable range, rapid in reaction speed, short in repairing period, good in flexibility, safe and stable to operate and is economically feasible.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

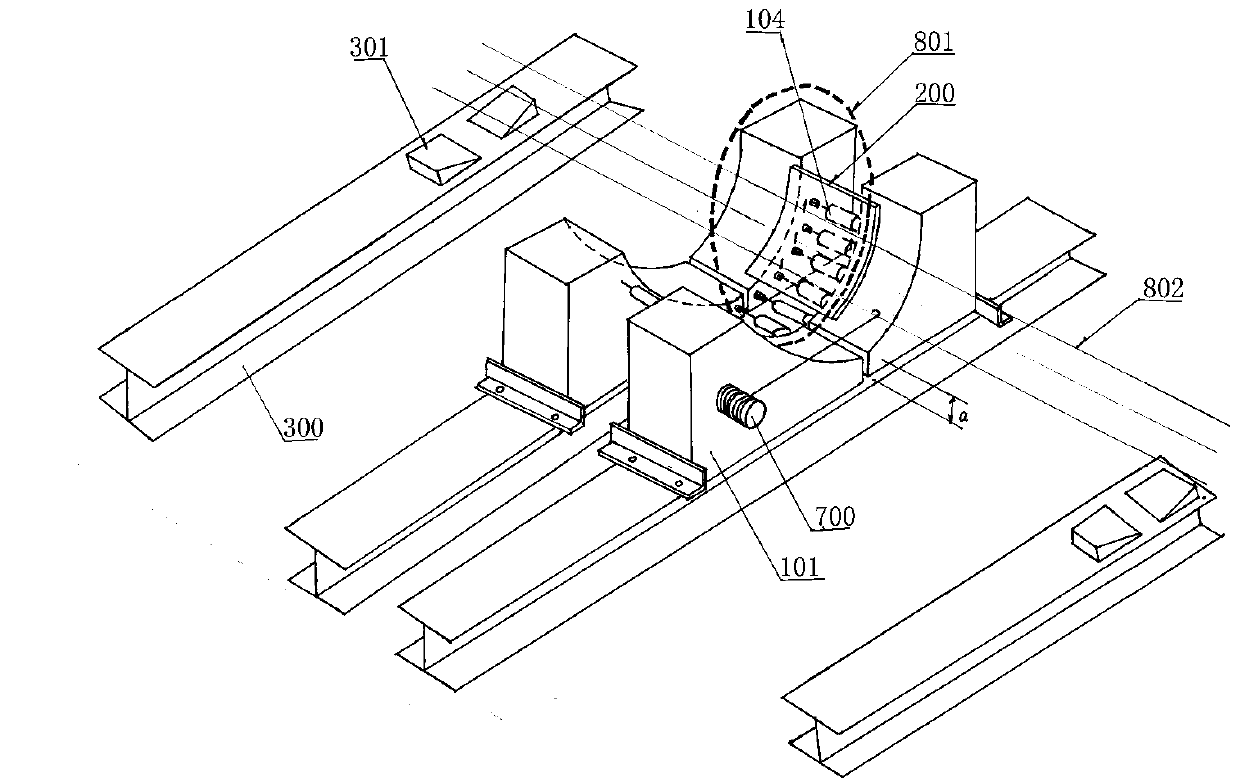

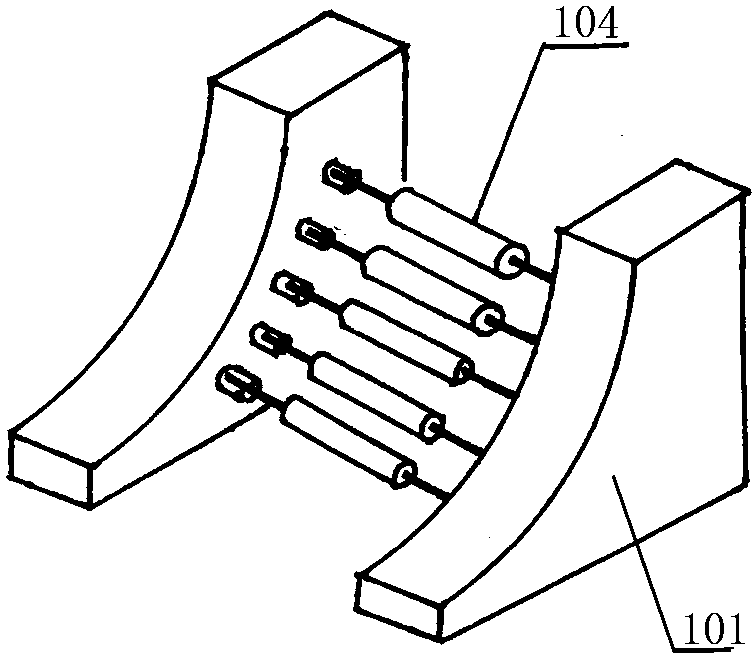

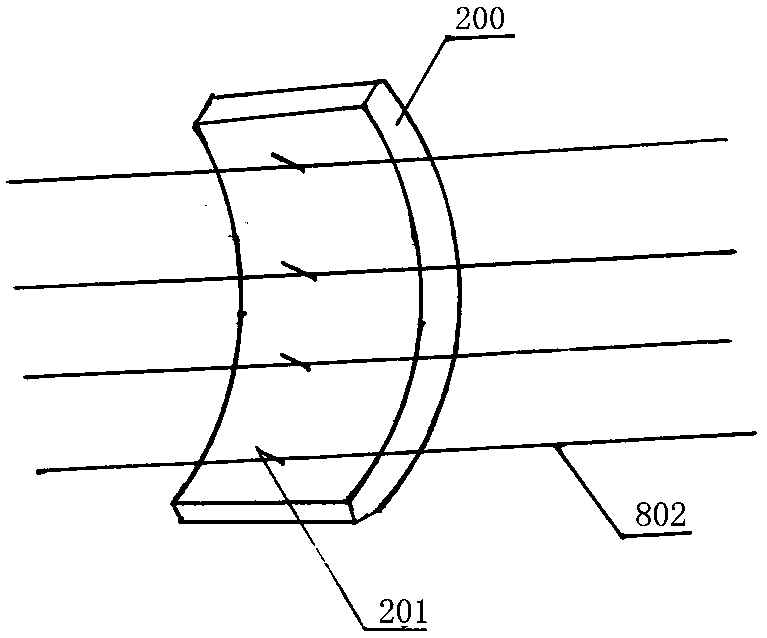

Quasi-five-axis machining centre and machining method thereof

ActiveCN104097072AGuaranteed rotation accuracyGuaranteed rigidityLarge fixed membersPositioning apparatusMachine toolMachining

The invention discloses a quasi-five-axis machining centre and a machining method thereof. The quasi-five-axis machining centre comprises an AC rotary table structure, wherein the AC rotary table structure comprises a C-axis rotary table, the C-axis rotary table comprises a bridge frame plate with one end which is supported and connected to a first support table, and the other end which is supported and connected to a second support table, and a crossing shaft ring capable of freely rotating around a C-axis is further assembled on the bridge frame plate; a rotary plate is arranged by being parallel to the axis direction of an A-axis, and supported and connected to the rotary end surface of the crossing shaft ring, a shaft sleeve is further arranged on the rotary plate, and a rotary bearing capable of freely rotating around the C-axis is arranged in the shaft sleeve; a machining main shaft is detachably connected with a drive pin, and when the rotary bearing moves to be below the drive pin, the drive pin is inserted in the middle hole of the rotary bearing. According to the quasi-five-axis machining centre and the machining method thereof disclosed by the invention, the rotary power source of the C-axis is from the machining main shaft of a common vertical machine, and the existing common vertical XYZ three-axis machine can be utilized, thus furthest reducing the machining cost of polyhedral components; moreover, the machining accuracy is high and the equipment structure is simple.

Owner:SUZHOU MINGZHI TECH

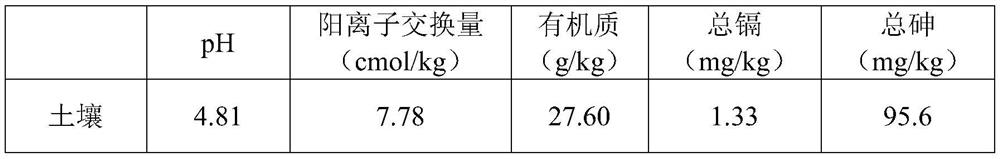

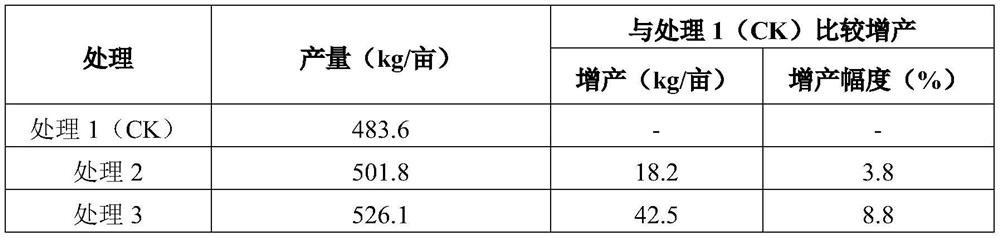

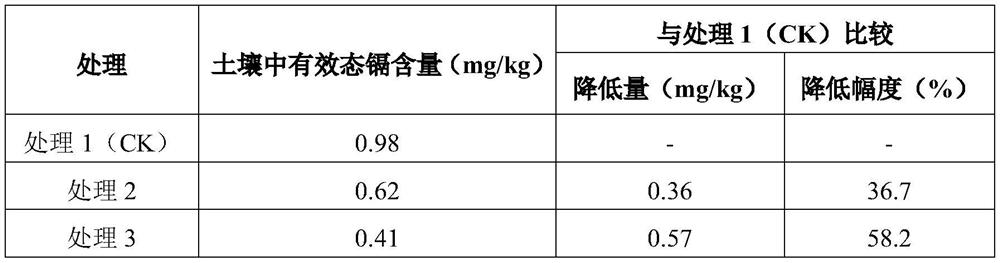

Soil conditioner for treating cadmium and arsenic combined pollution of farmland and application method of soil conditioner

PendingCN112939696AReduced bioavailabilityLarge specific surface areaAgriculture tools and machinesFertilising methodsSoil scienceSoil remediation

The invention relates to the field of farmland soil remediation, in particular to a soil conditioner for treating farmland cadmium and arsenic combined pollution and an application method of the soil conditioner. The soil conditioner is prepared from the following components in percentage by mass: 50%-60% of modified charcoal, 10%-30% of reduced iron powder, 10%-30% of calcium magnesium phosphate fertilizer and 10%-30% of sepiolite. When the soil conditioner is applied, the soil conditioner is uniformly mixed with water through a stirring box to form slurry, then the slurry is sprayed into a rice field through slurry spraying equipment, and then the soil conditioner is fully mixed with soil through ploughing. The soil conditioner provided by the invention can effectively reduce the bioavailability of cadmium and arsenic in farmland soil, reduce the content of cadmium and arsenic in agricultural products produced in a cadmium and arsenic combined pollution farmland, and avoid secondary pollution in the use process.

Owner:湖南中米环保科技有限公司

Corn straw stack retting fermentation ecological organic fertilizer returned to field and production method thereof

PendingCN109879707AReduce transshipmentReturn to fieldBio-organic fraction processingOrganic fertiliser preparationPoultry manureOrganic fertilizer

The invention discloses a corn straw stack retting fermentation ecological organic fertilizer returned to a field and a production method thereof, and relates to the technical field of microbial organic fertilizer preparation. The corn straw stack retting fermentation ecological organic fertilizer consists of the following raw materials: a fermentation raw material and a composite strain, the fermentation raw material comprises fresh livestock and poultry manure and corn straw. The raw materials are taken according to a certain ratio and processed according to the production method for the corn straw stack retting fermented ecological organic fertilizer returned to the field, so that the preparation can be completed. After the technical scheme is adopted, the invention has the beneficial effects that centralized on-site stack retting and on-site field returning treatment are carried out in the center of a large planting field, so that costs for transferring, crushing and field returning of straw are greatly saved. The straw returning cost per mu can be controlled within 150 yuan.

Owner:吉林省智联农业科技有限公司

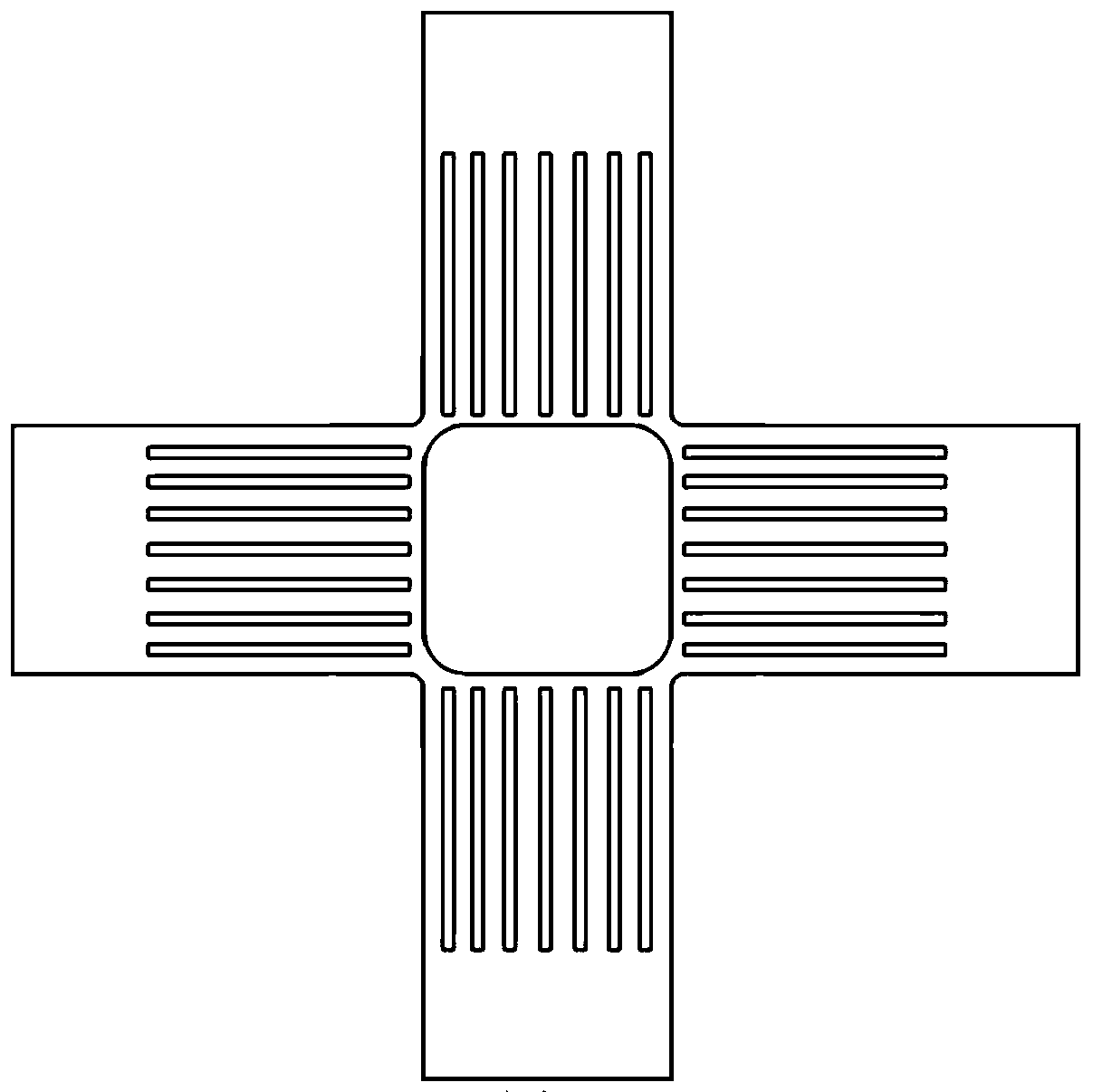

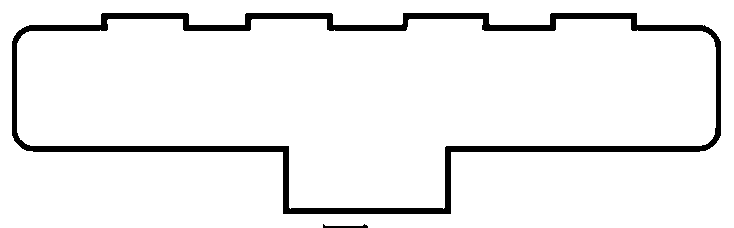

Device and method for testing transient hot forming limit of metal sheet

PendingCN109916735AEasily brokenSolve the problem of high temperature frictionPreparing sample for investigationMaterial strength using tensile/compressive forcesHot stampingForming limit diagram

The invention provides a device and method for testing the transient hot forming limit of a metal sheet. The test device comprises: a two-way stretching experimental device, a computer control system,an optical strain measurement system, an infrared thermometer, an electromagnetic induction heating device, a cooling device, wherein the optical strain measurement system photographs the surface deformation of a cross-shaped sample by a CCD camera; the electromagnetic induction heating device heats and maintains the temperature of the central portion of the cross-shaped sample through a mosquito-coil induction coil; and the cooling device cools the high-temperature cross-shaped sample by a high-pressure air nozzle. The device can cool the high-temperature cross-shaped sample during a stretching process at a specified cooling rate so as to accurately obtain the transient ultimate strain of the material and establish a transient hot forming limit diagram, is consistent with the continuoustemperature change characteristic of an actual hot stamping metal sheet, can achieve reliable sheet formability prediction, guides process optimization, and improves production efficiency and productquality.

Owner:CIVIL AVIATION UNIV OF CHINA

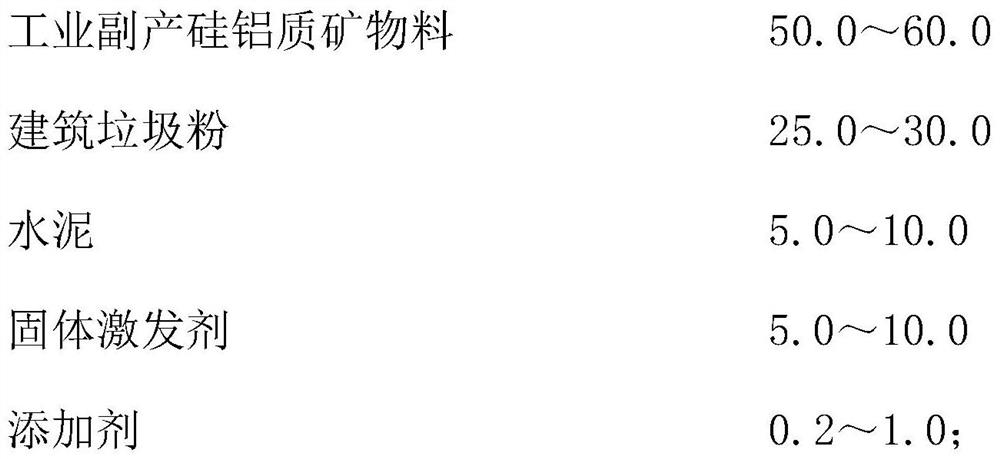

Single-component modified geopolymer and application thereof

InactiveCN112174554AEasy to transportSlow curingSolid waste managementCement productionCrushed stoneGeopolymer

The invention discloses a single-component modified geopolymer and an application thereof. The single-component modified geopolymer is prepared from 50.0 to 60.0 parts of an industrial byproduct silicon-aluminum mineral material, 25.0 to 30.0 parts of construction waste powder, 5.0 to 10.0 parts of cement, 5.0 to 10.0 parts of a solid excitant and 0.2 to 1.0 part of an additive. The prepared single-component modified geopolymer adopts the solid excitant, the solid excitant is a salt substance, and the prepared single-component modified geopolymer is in a solid state, convenient to transport, low in curing speed and long in operable time, and can be directly constructed after water is added and stirred on site, the single-component modified geopolymer is applied to a lime-fly ash gravel cold regeneration treatment process, and a base material obtained through cold regeneration treatment is high in strength and good in stability. According to the lime-fly ash gravel cold regeneration treatment process, lime-fly ash gravel base course milling material field treatment can be achieved, the transferring and stacking cost is reduced, and environmental pollution is reduced.

Owner:JIANGSU NIGAO SCI & TECH +2

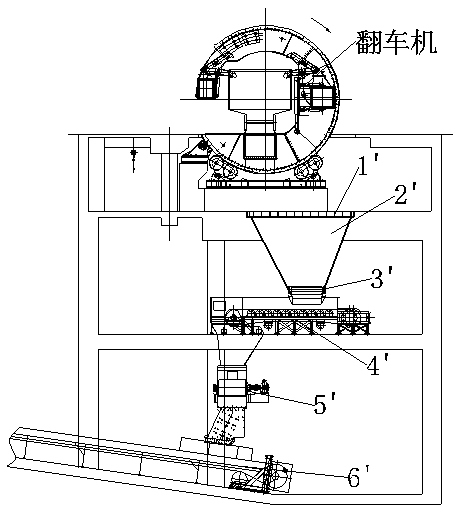

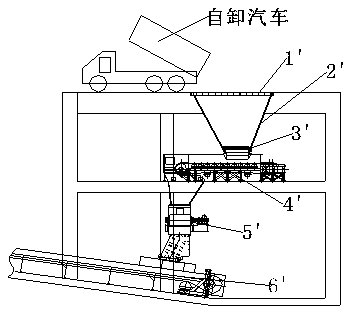

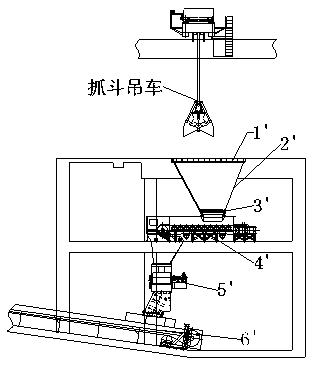

Bulk material conveying, transfer and loading method and system

The invention provides a bulk material conveying, transfer and loading method and a system; and the system comprises a grid net, a receiving hopper, a feeding crusher and a downstream belt conveyor. Compared with the prior art, the material conveying system has less equipment used, the transfer and loading technological process of bulk materials from unloading to the belt conveyor is shortened, the conveying distance is shortened, the vertical height from the unloading place to the receiving place of the belt conveyor is reduced, the capital construction cost and the daily use cost are reduced, and the efficiency of the conveying system is improved. An insertion plate door in a feed port of the feeding crusher can control the conveying volumeof the downstream belt conveyor. A crushing tooth roller of the feeding crusher is positioned above a scraper conveyor for crushing materials with particle sizes larger than a gap between the crushing tooth roller and the scraper conveyor and not indirectly crushing materials with particle sizes smaller than the gap; and the selective crushing largely saves the crushing power consumption, saves the cost, improves the efficiency and accords with the targets of energy conservation and emission reduction.

Owner:长沙贤正益祥机械科技有限公司

Sandy-spoil-based C30 slope-protection brick mixture ratio and preparation method of slope-protection brick

InactiveCN104310933AReduce transshipmentReduce adverse effectsSolid waste managementSoil scienceBrick

The invention discloses a C30 slope-protection brick mixture ratio based on sandy spoil in navigation projects and a preparation method of the slope-protection brick. The C30 slope-protection brick comprises the following raw materials in parts by mass: 9-18 parts of cement, 55-70 parts of sandy spoil, 7-13 parts of mineral powder, 0.8-3.5 parts of plaster, 0.4-2 parts of an enhancer and 9-12 parts of water. The preparation method comprises the following steps: after the raw materials are fully and evenly mixed according to the ratio, injecting the mixture into a prefabricated mold, molding under the working pressure of 20MPa, enabling a molded test specimen to be demolded immediately, and placing the demolded test specimen indoors for natural watering maintenance to obtain the sandy-spoil-based slope-protection brick. The cube test specimen strength of the sandy-spoil-based slope-protection brick can reach C30, and the cube test specimen can replace a concrete material to be used for preparing the slope-protection brick and other hydraulic engineering materials. The sandy spoil is reasonably utilized, so that the transferring and ground pressing of spoil and the adverse effects on the environment in channel improvement are reduced, and the field of resource utilization of sandy spoil curing products is expanded.

Owner:HOHAI UNIV +1

Combined multifunctional steel bar cage manufacturing framework and manufacturing method

The invention belongs to the technical field of civil engineering and discloses a combined multifunctional steel bar cage manufacturing framework and manufacturing method. The combined multifunctionalsteel bar cage manufacturing framework comprises a framework body, a main rib positioning plate and bearing beams. The framework body is provided with arc moulding beds matched with a steel bar cageto be manufactured; the main rib positioning plate rolls in a matching manner or is slidably supported on the moulding beds, main rib placing grooves are distributed in the main rib positioning plate,and main ribs of the steel bar cage are matched in the main rib placing grooves; and the bearing beams are used for supporting and steadying the steel bar cage in a welding process. The combined multifunctional steel cage manufacturing framework is reasonable in design, steady in support, convenient for machining and rapid in disassembly and assembly, not only can be used in a machining shed, butalso can be used nearby a construction site and a pile site for directly hoisting the steel bar cage or steel bar framework to be directly in position.

Owner:HENAN HIGHWAY ENG GROUP

Paddy safety production method for paddy field soil with moderate-severe cadmium pollution

PendingCN111436340AReduce cadmium content in brown riceRaise soil pHPlant growth regulatorsBiocideEnvironmental chemistryBiology

The present invention discloses a paddy safety production method for paddy field soil with the moderate-severe cadmium pollution. The method comprises the steps of (1) throwing a passivation agent onthe surface of the paddy field soil, performing turnover until the passivation agent is uniformly mixed with the soil, keeping the water content of the paddy field soil at 60% or above after application of the passivation agent, and performing balance culture for 3-7 days; (2) applying a silicon compound-containing antagonistic element by a method of performing basal application of the half amountbefore paddy planting and performing additional application of the rest half amount in a paddy booting stage; and (3) spraying a leaf surface blocking control agent once in each of the paddy bootingearly stage and filling stage, wherein the leaf surface blocking control agent is prepared by mixing a silicon compound, a surfactant and water. The paddy safety production method can obviously reducethe content of cadmium in paddy rice, the operation method is simple and convenient, and the effect is stable.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com