Combined multifunctional steel bar cage manufacturing framework and manufacturing method

A production method and steel cage technology, which are applied in the formwork and production fields of combined multi-functional steel cages, can solve the problems of unrealistic transportation of finished steel cages, large factory-like processing workshops, and processing foundation pile steel cages, etc. Achieve the effect of reducing project cost, quick disassembly and assembly, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

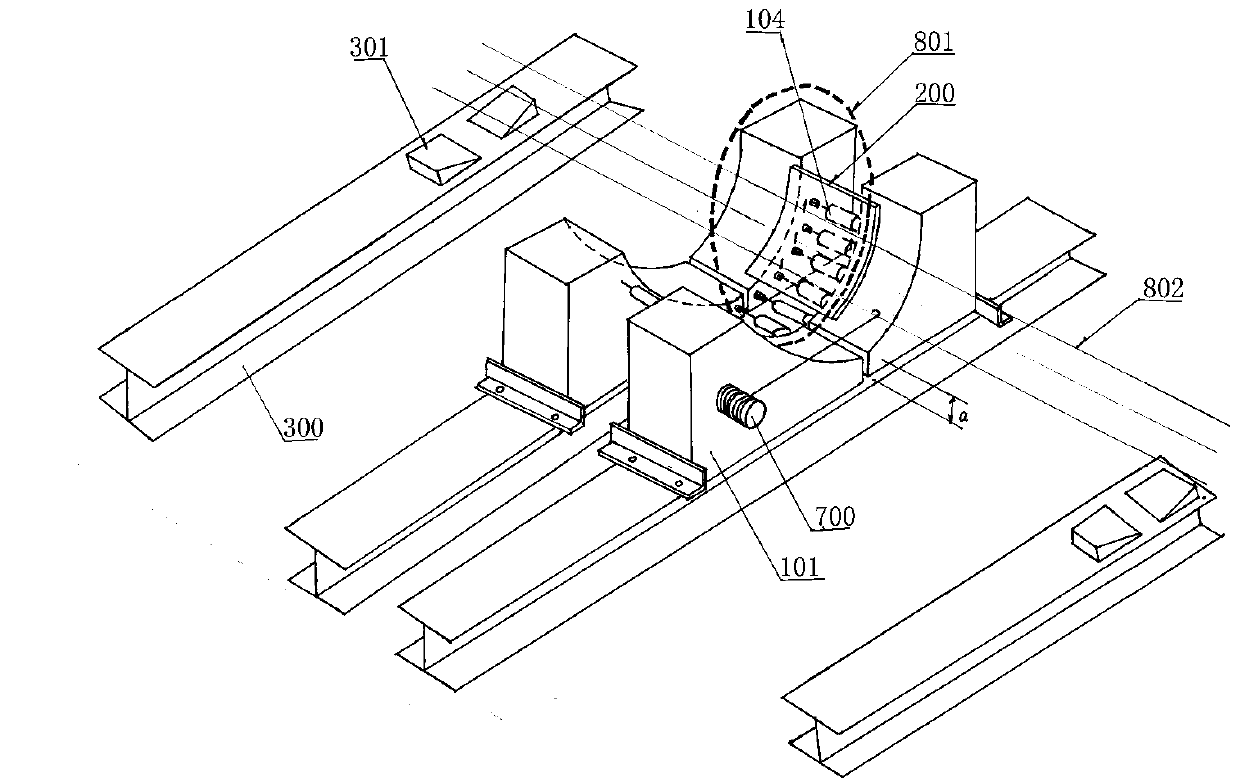

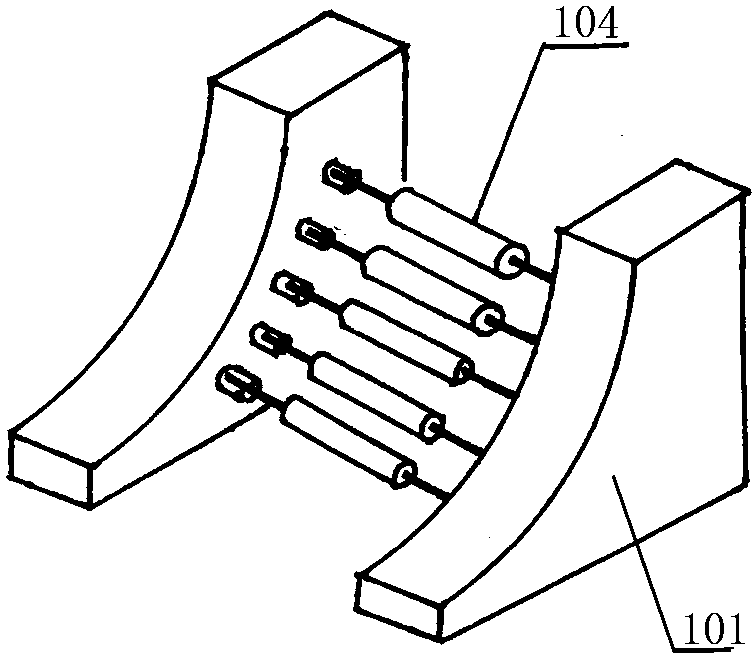

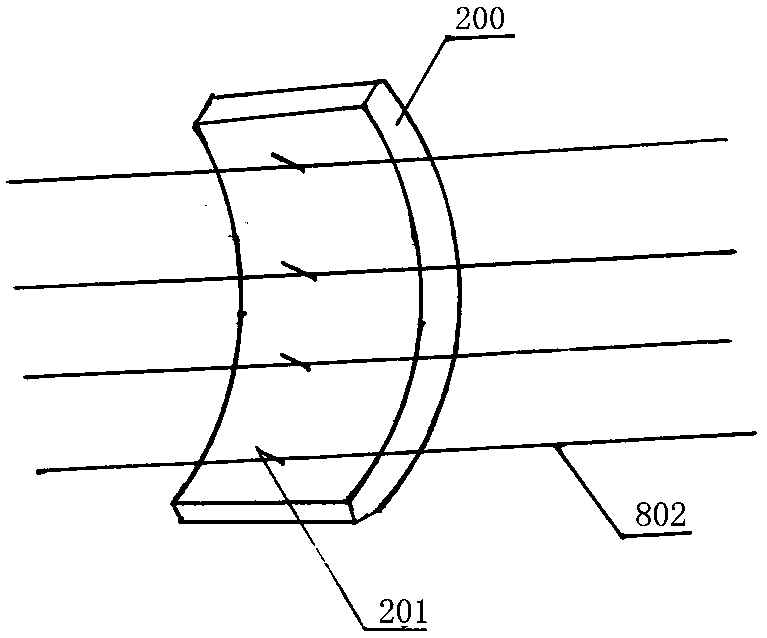

[0047] see Figure 1-Figure 3, a combined multi-functional reinforcement cage manufacturing formwork, including a formwork body 100, a main reinforcement positioning plate 200 and a pad beam 300, the 100 formwork body is provided with an arc-shaped tire mold 101 that matches the reinforcement cage to be made; the main reinforcement The positioning plate 200 is matched with rolling or sliding support on the tire mold 101, and the main reinforcement positioning plate 200 is provided with a main reinforcement placement groove, and the main reinforcement 802 of the reinforcement cage is matched and arranged in the main reinforcement placement groove; the pad beam 300 is used for supporting during the welding process To stabilize the reinforcement cage, wedges 301 can be set on the pad beam to adjust the height and limit, and can als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com