Patents

Literature

186results about "Meshed-ring wire network" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

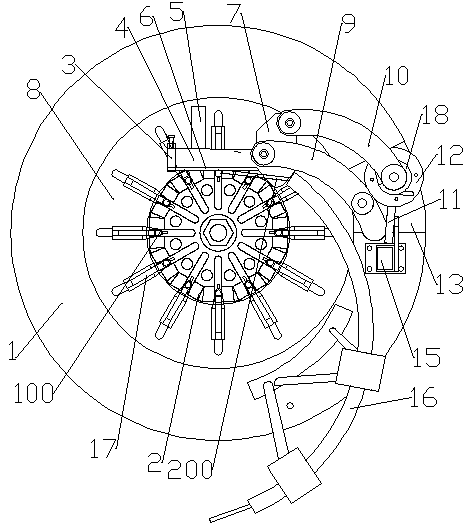

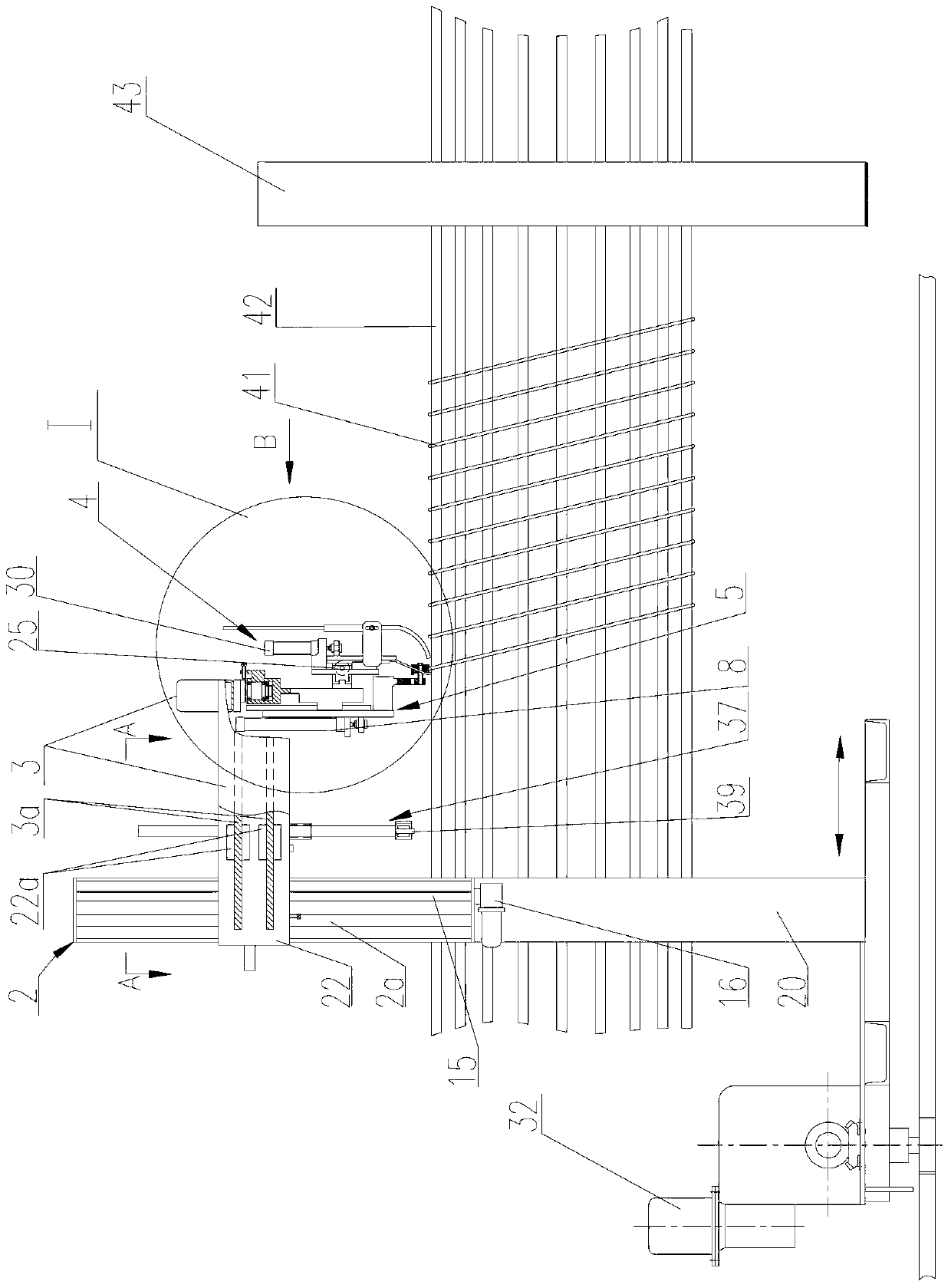

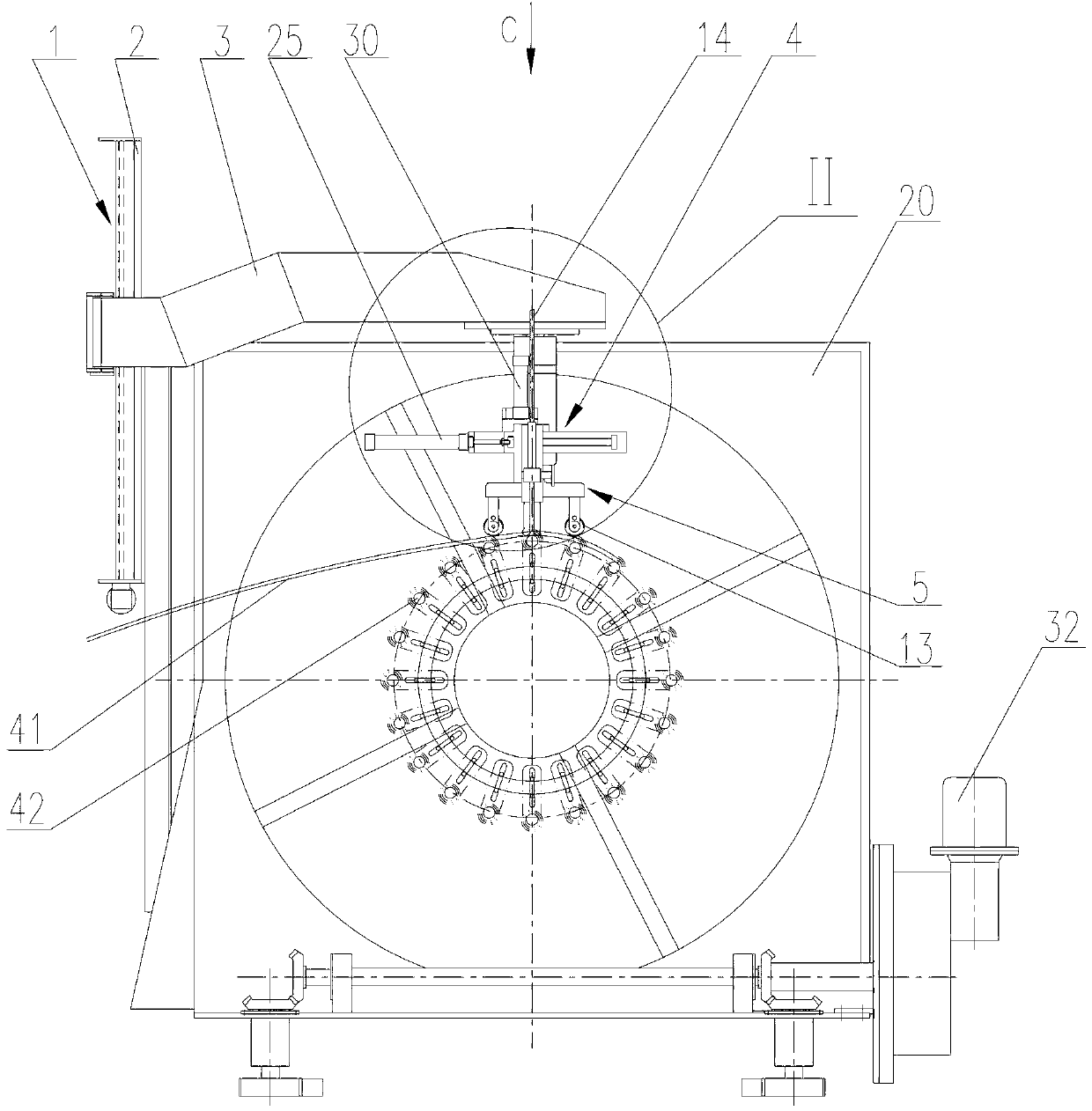

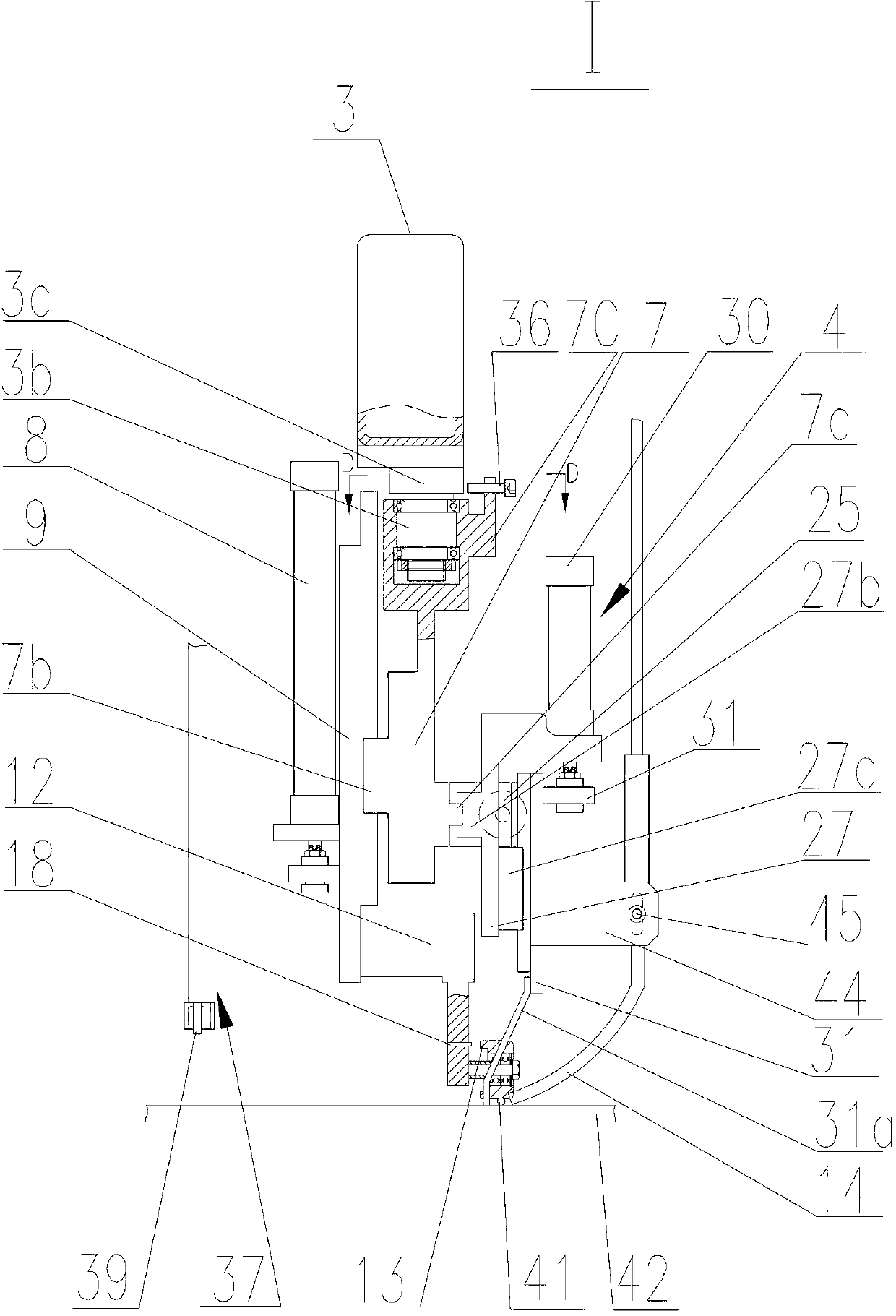

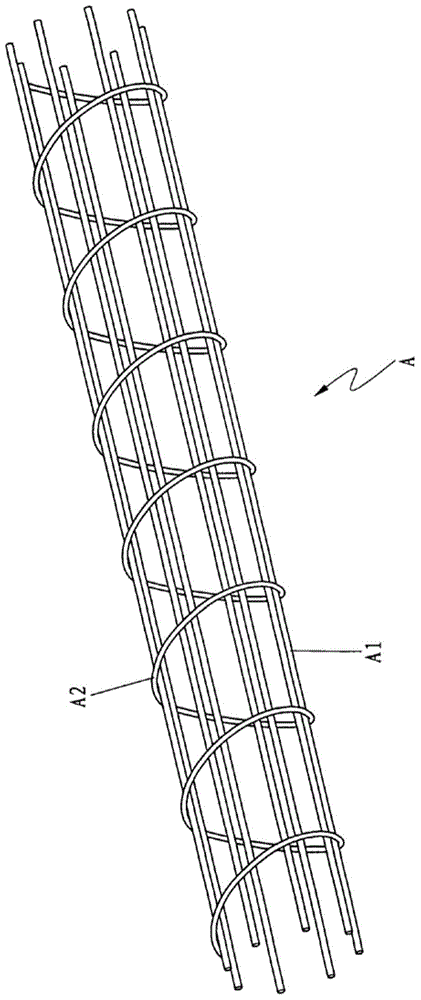

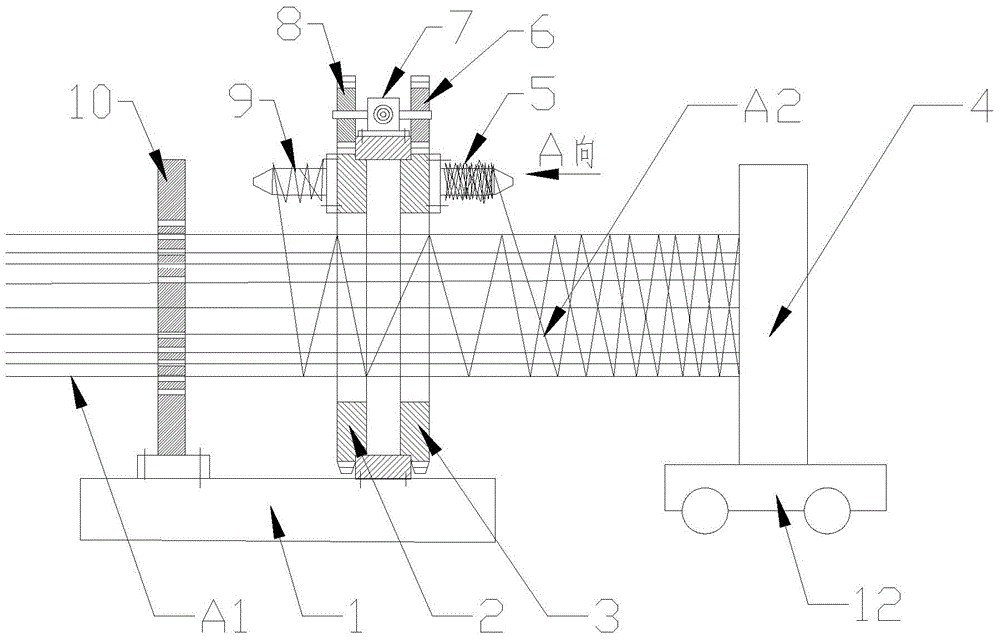

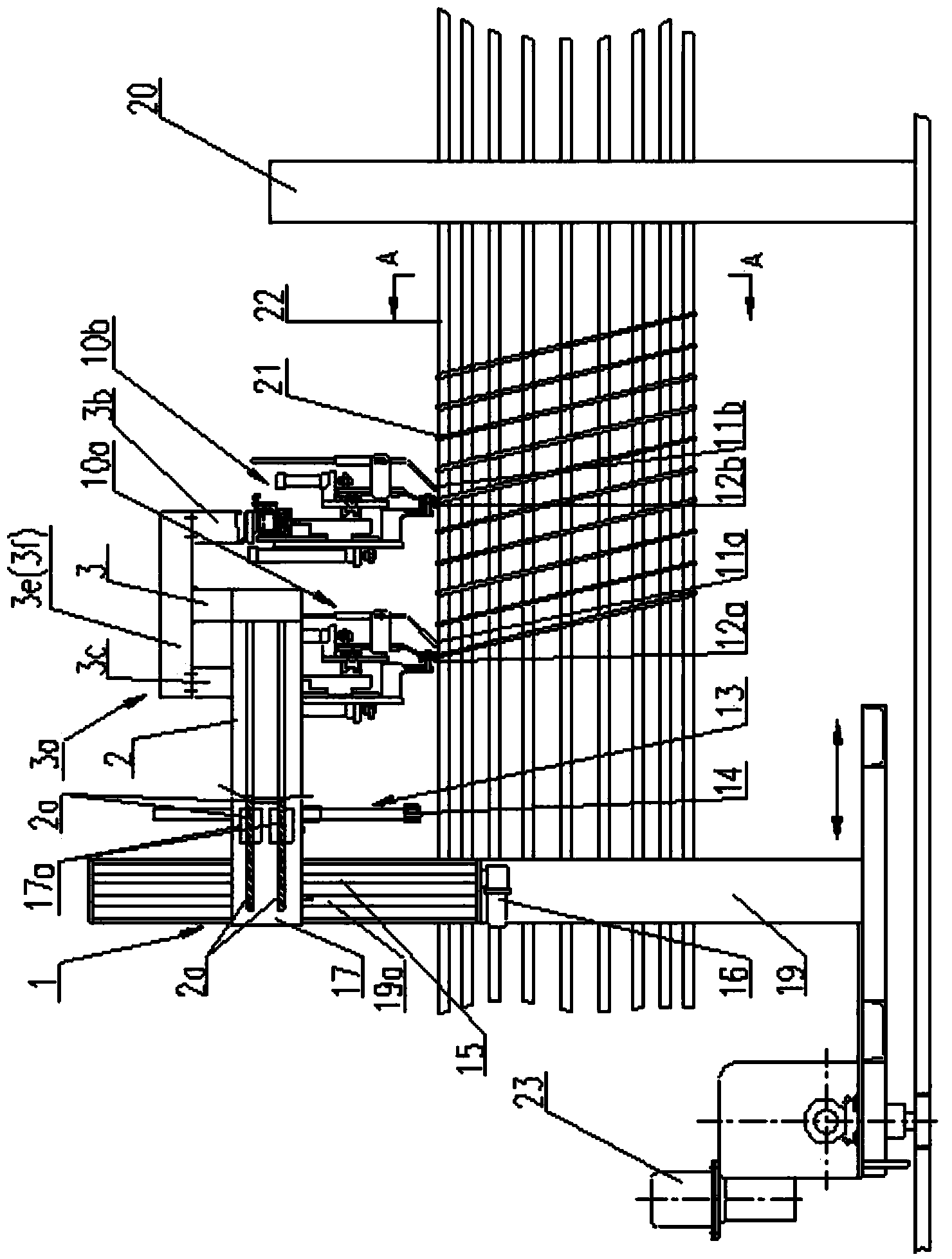

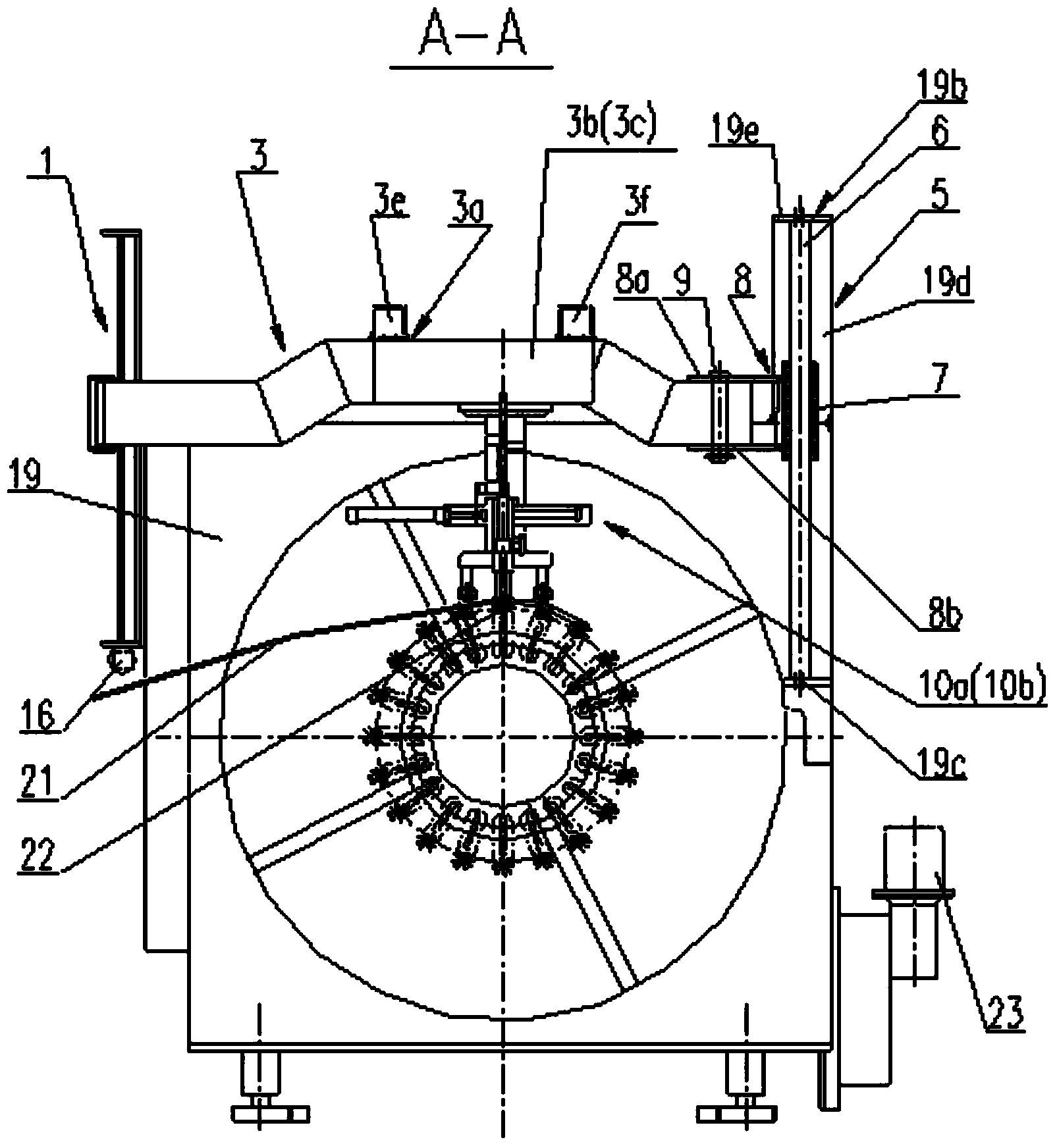

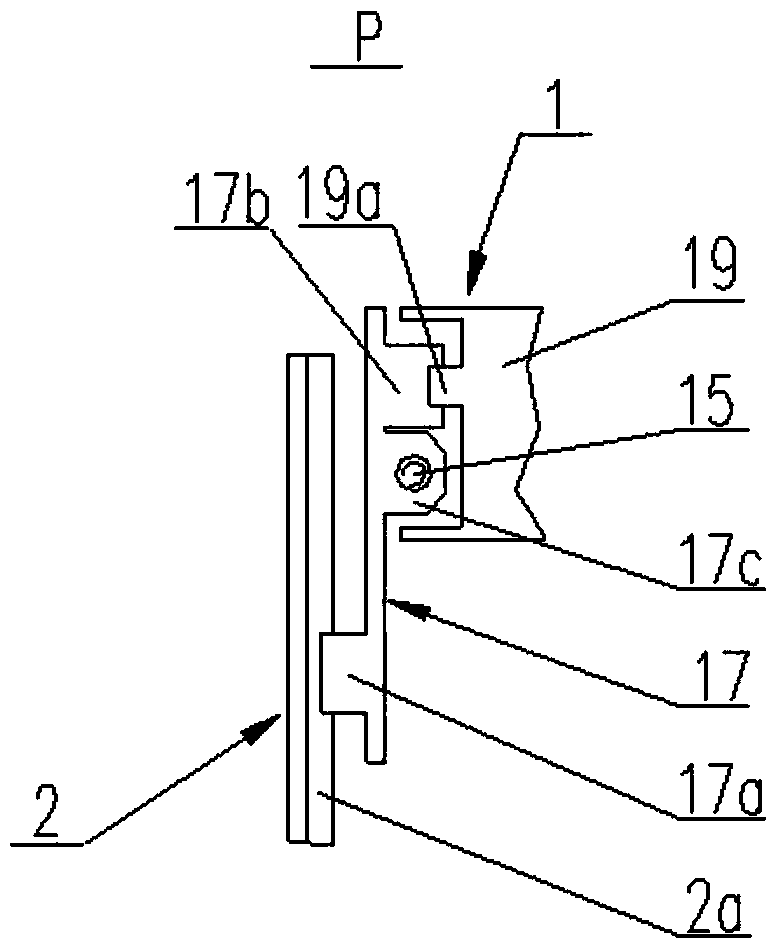

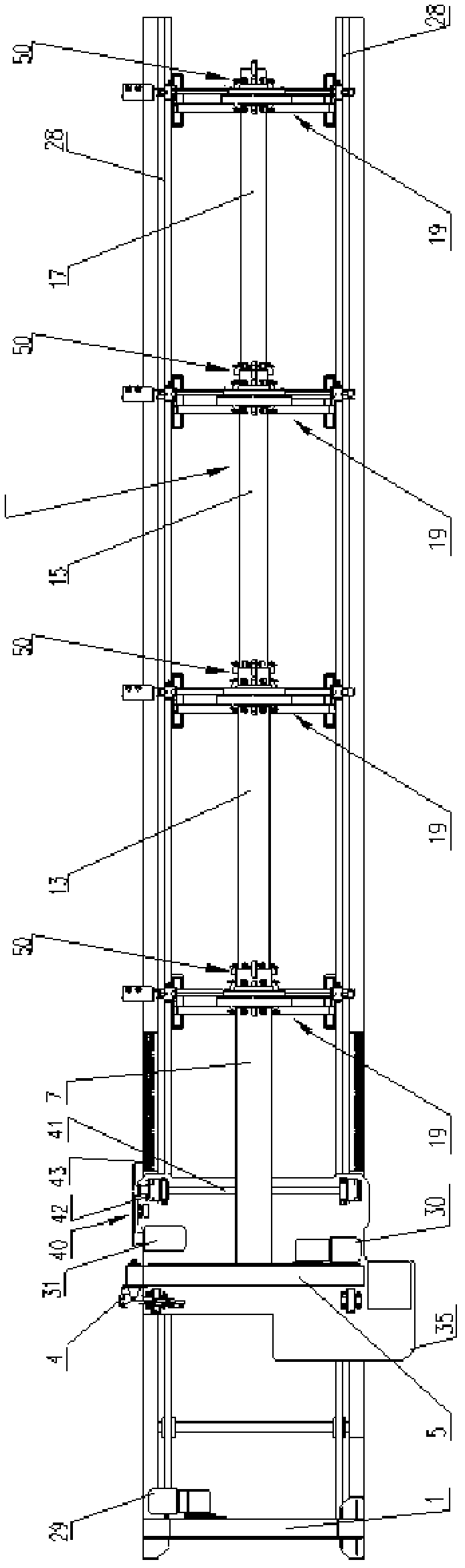

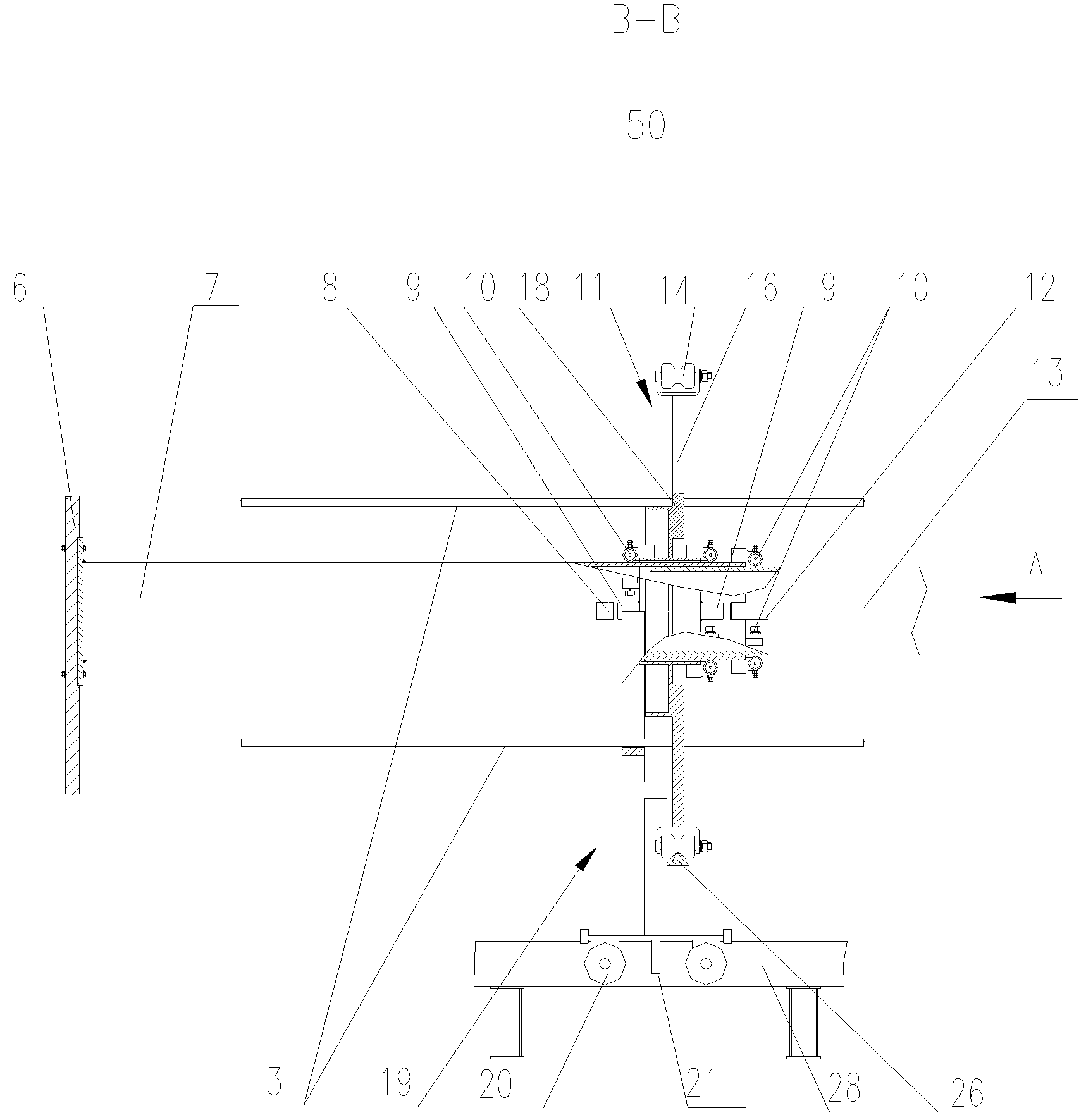

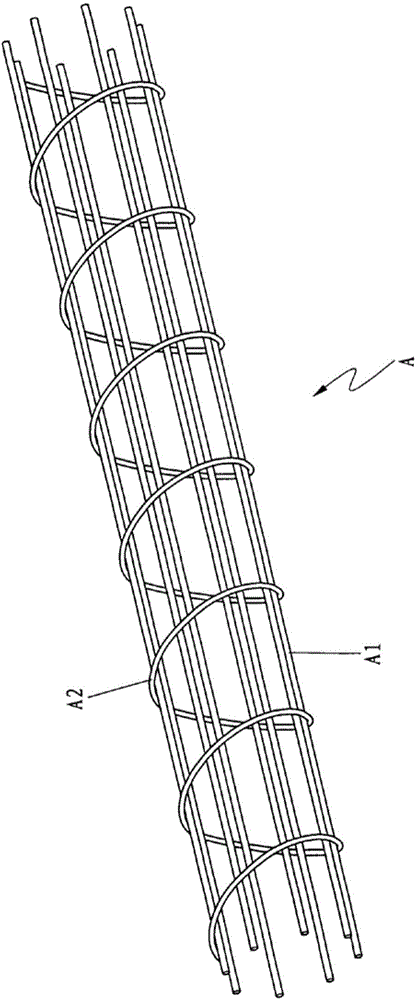

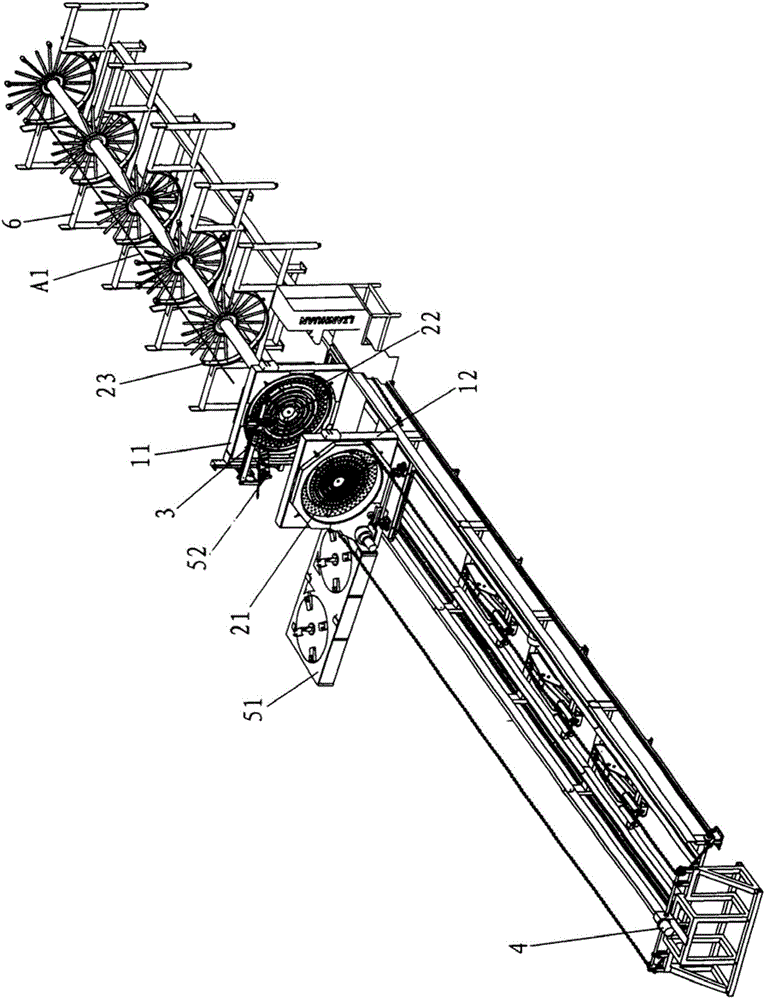

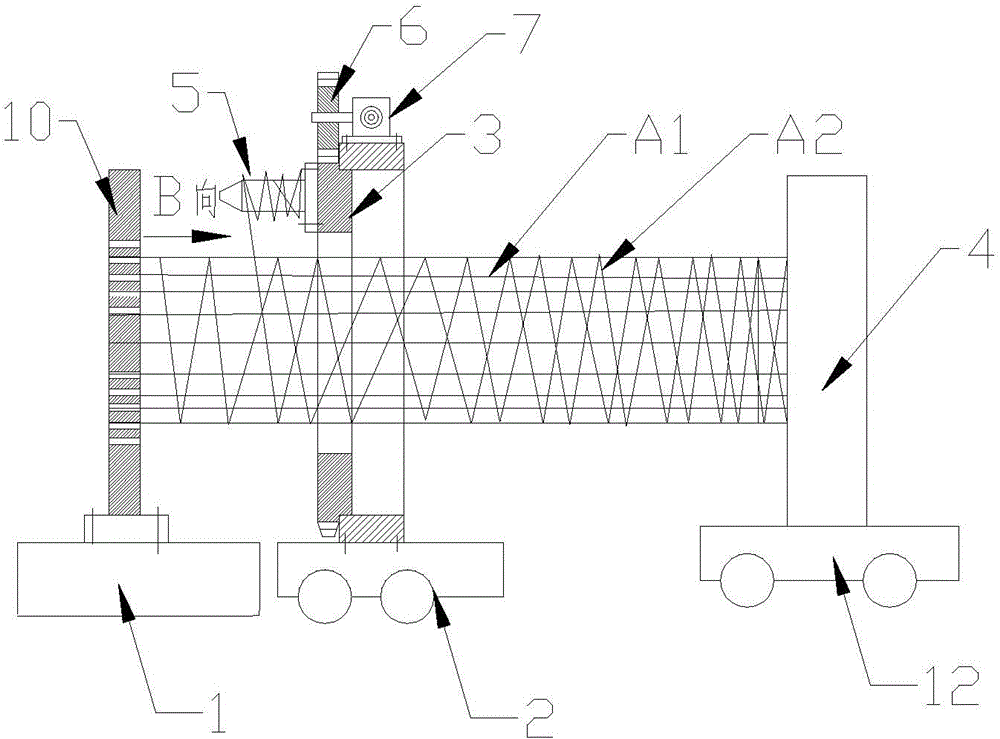

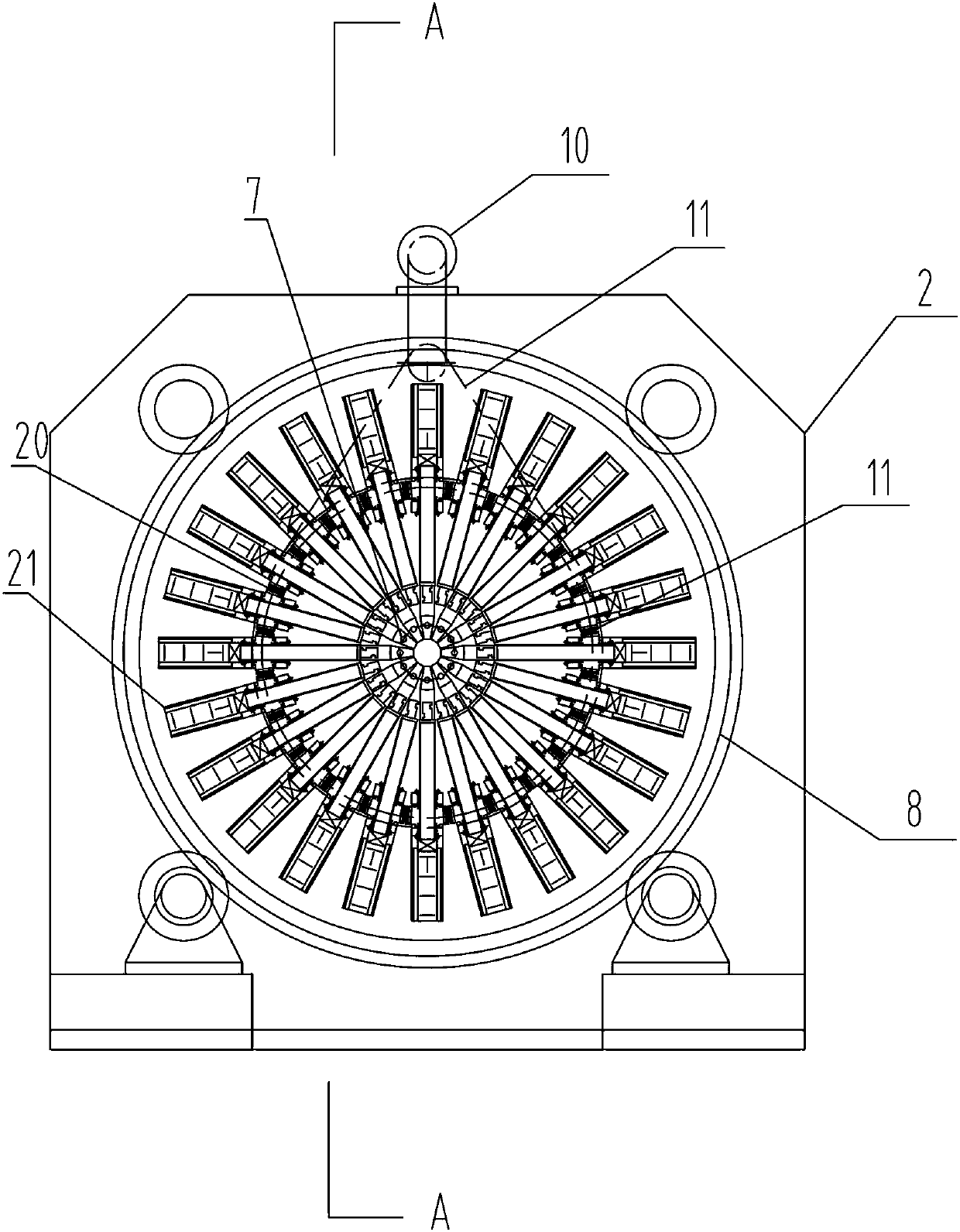

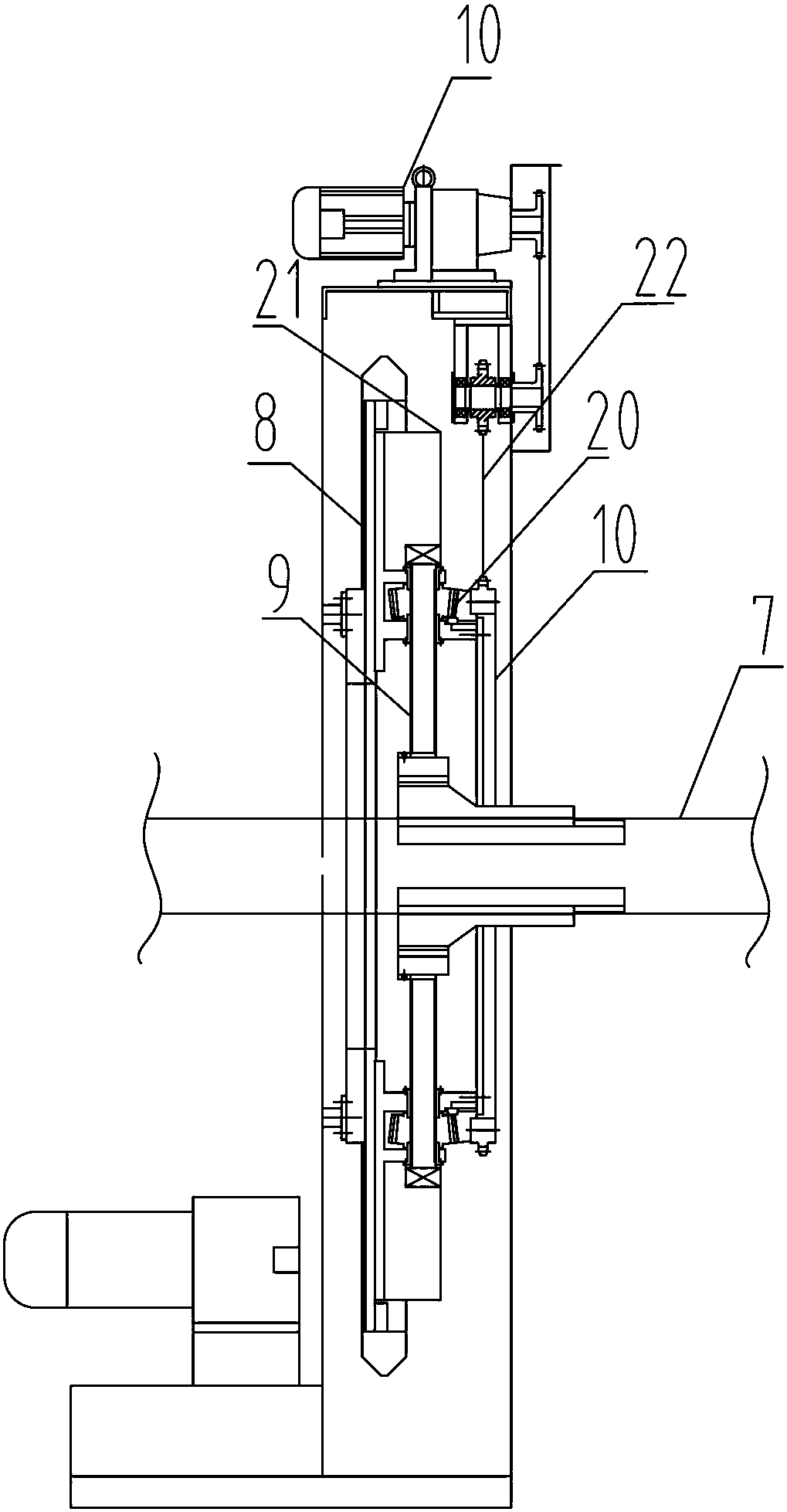

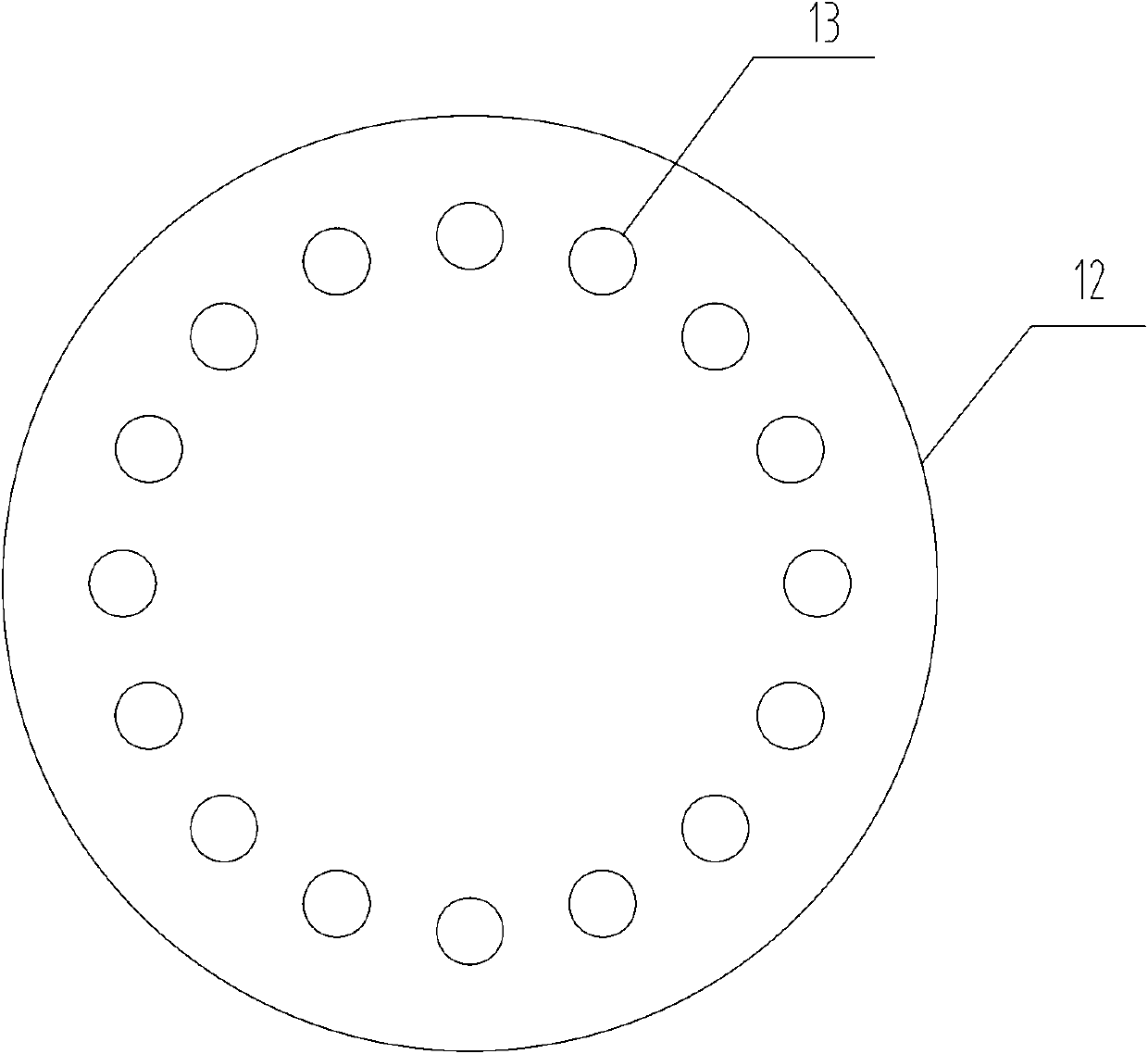

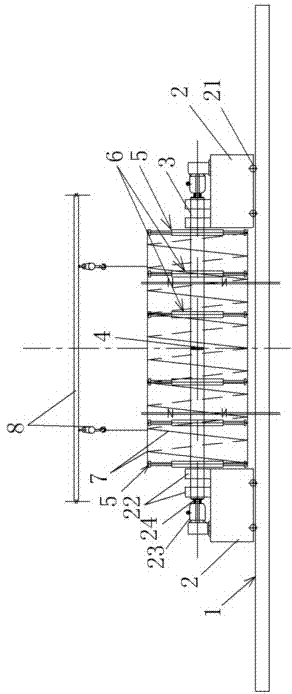

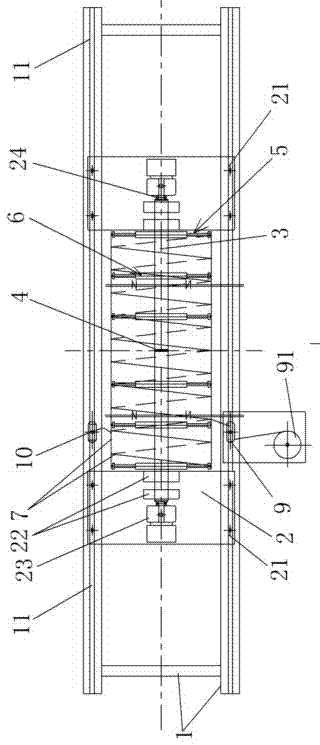

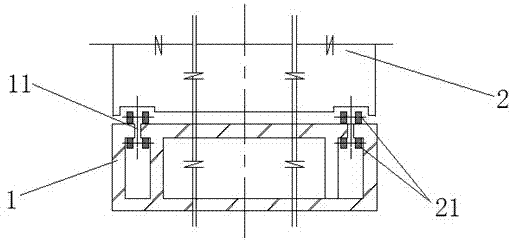

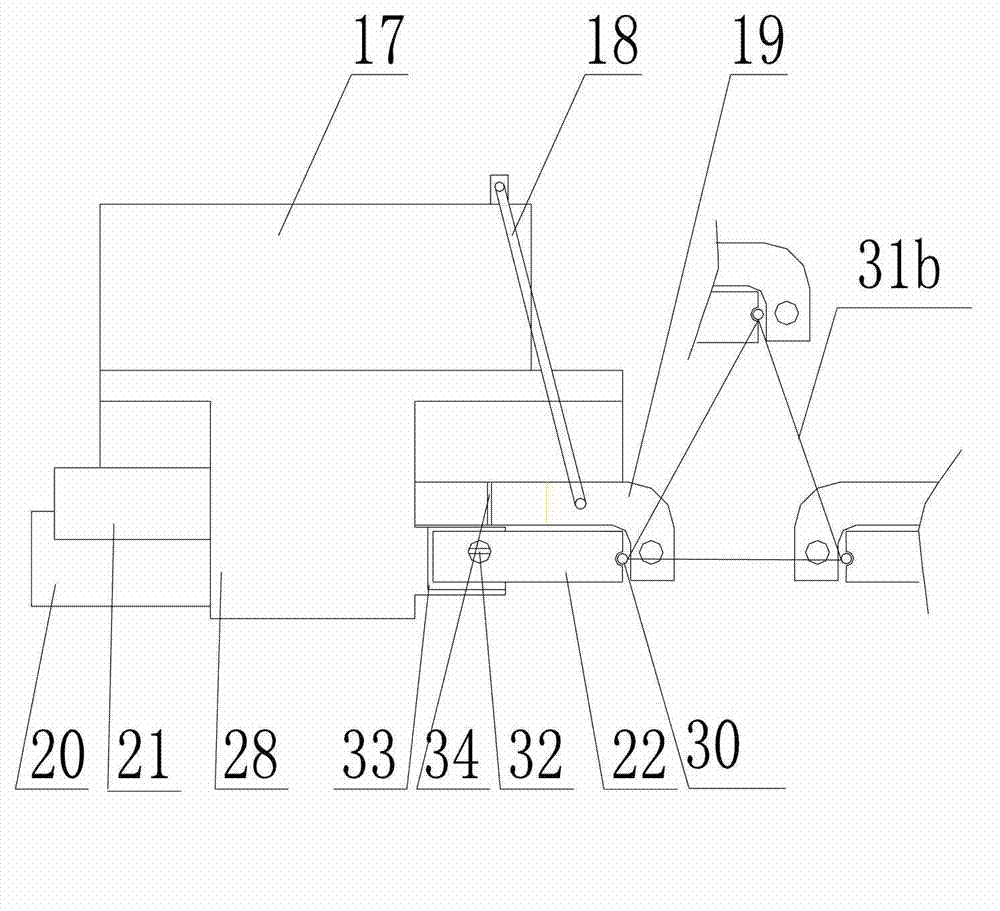

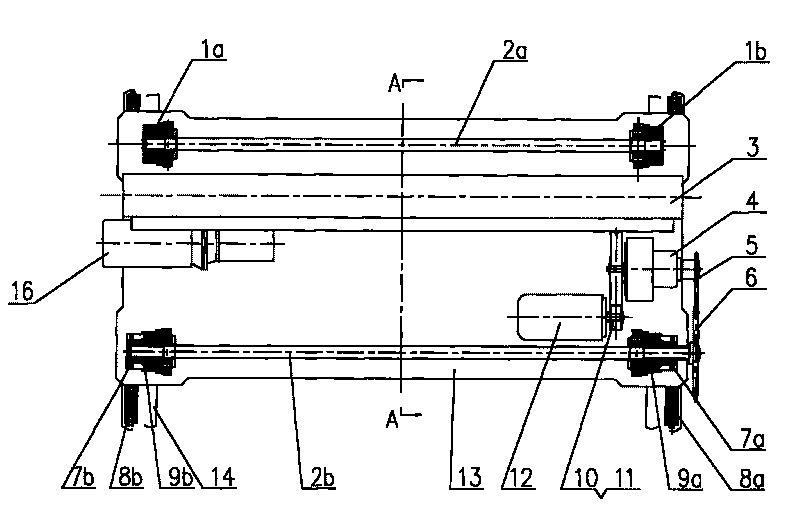

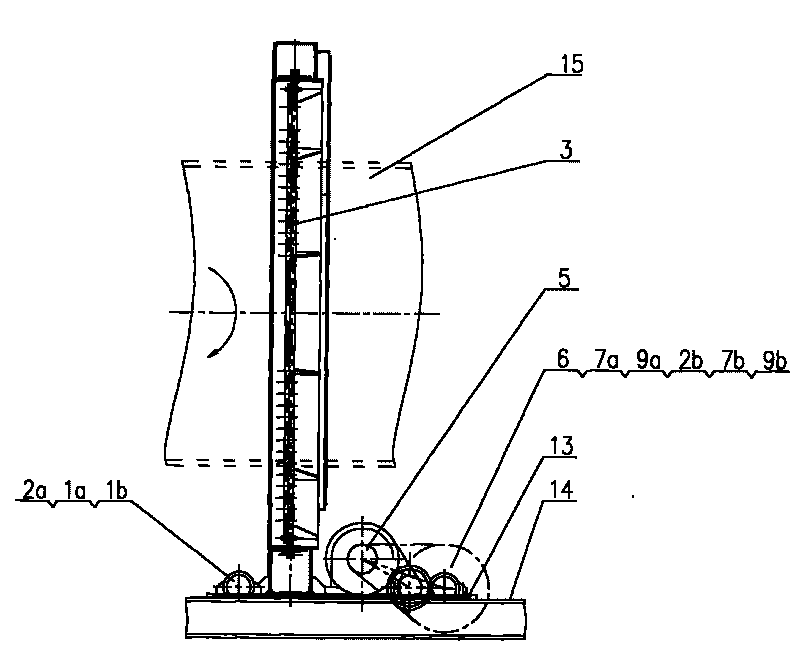

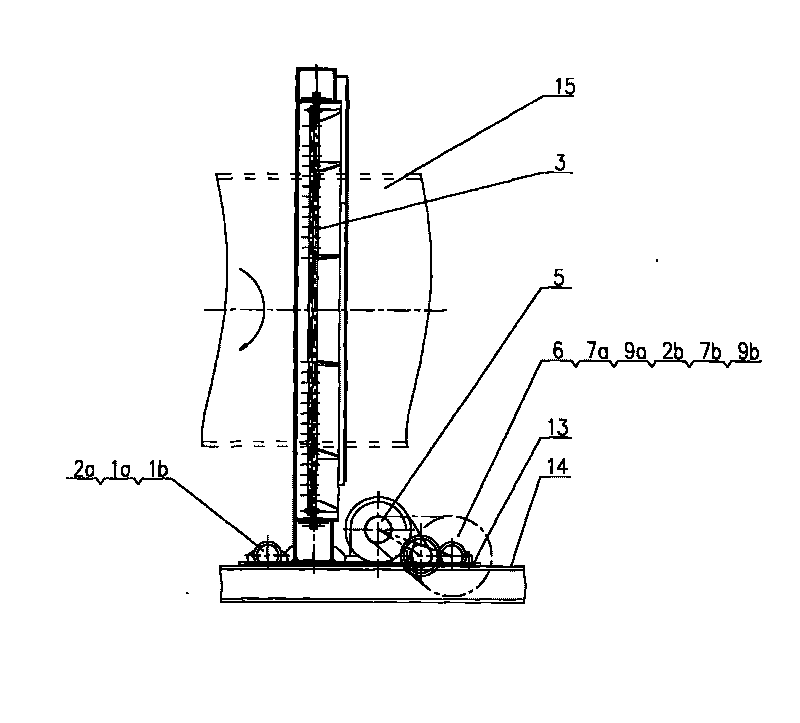

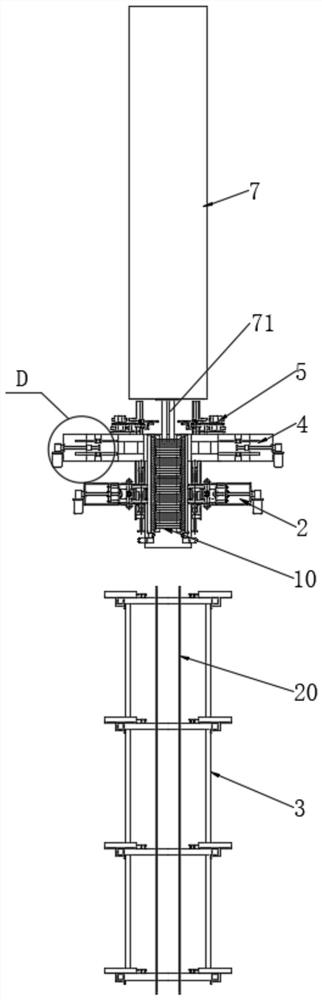

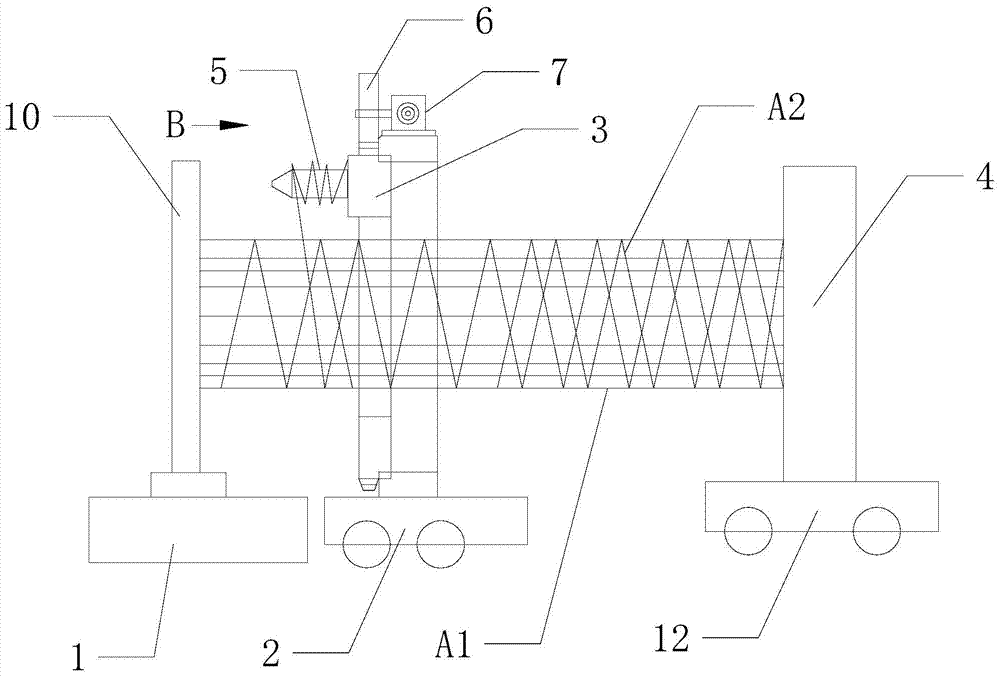

Spiral welding device of conic electric pole reinforcement cage seam welder

ActiveCN104128701AThe pressure is guaranteed to be constantGuarantee welding qualityResistance electrode holdersMeshed-ring wire networkEngineeringRebar

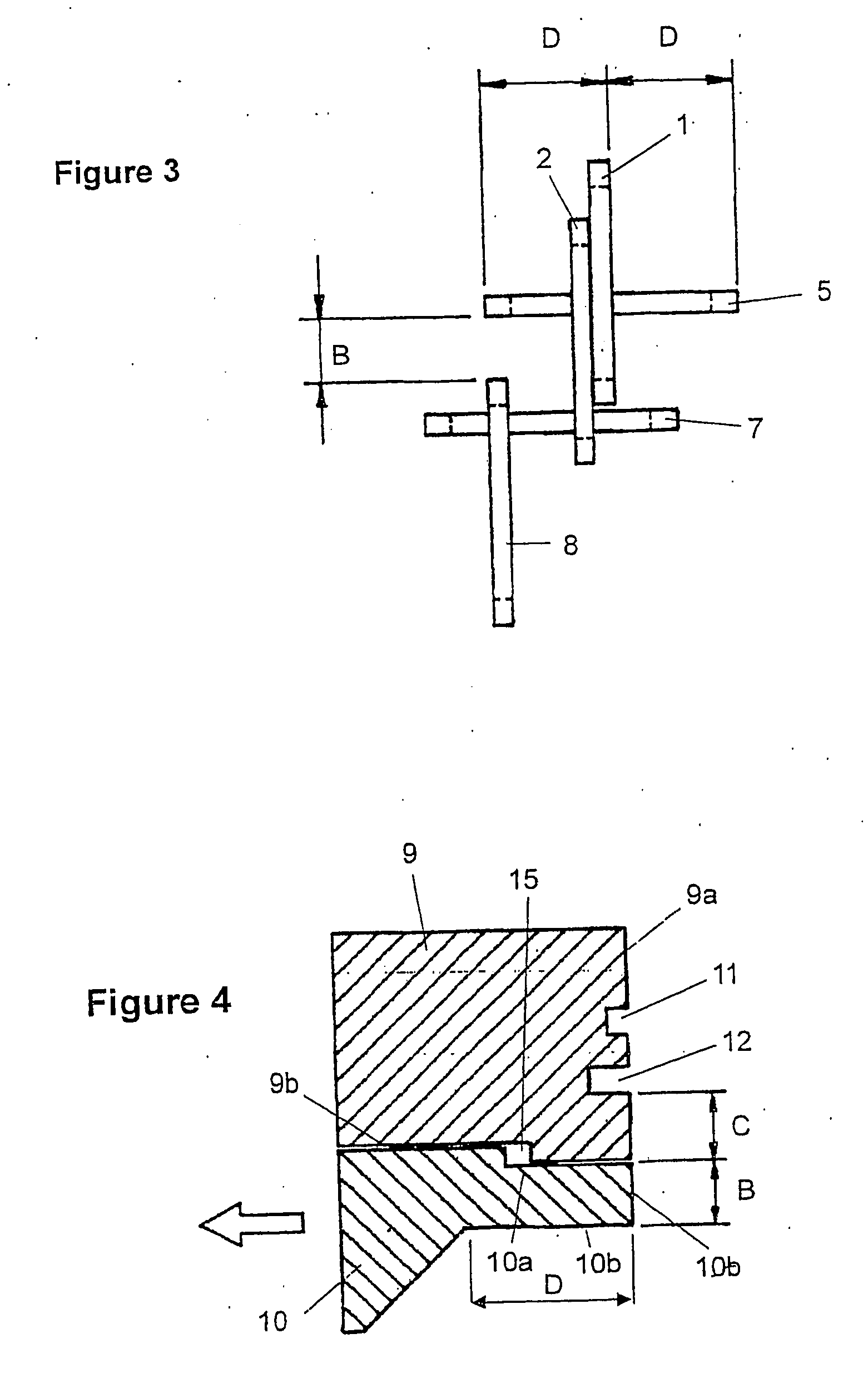

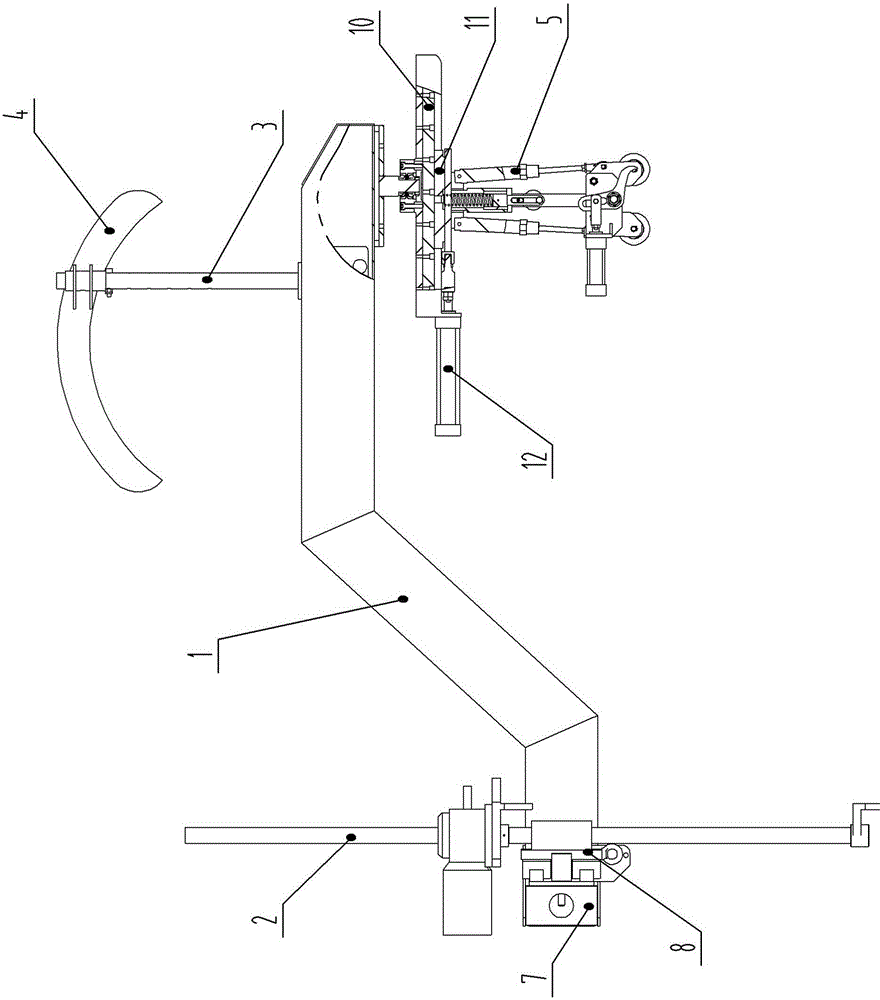

The invention relates to welding devices, in particular to a spiral welding device of a conic electric pole reinforcement cage seam welder. The spiral welding device comprises a longitudinal reinforcement fixing device, a welding device body and a circumferential reinforcement fixing device. The circumferential reinforcement fixing device and the welding device body rotate around the longitudinal reinforcement fixing device. Circumferential reinforcements are welded to longitudinal reinforcements in a wound mode through the welding device body. The welding device body comprises a welding electrode and a pressure mechanism. The pressure mechanism exerts constant pressure to the welding electrode, so that constant pressure of a welding point is kept by the welding electrode. According to the spiral welding device of the conic electric pole reinforcement cage seam welder, the longitudinal reinforcements do not rotate, the circumferential reinforcements are welded in the wound mode, it is guaranteed that the longitudinal reinforcements are not twisted, high noise generated by rotation of the longitudinal reinforcements is avoided as well, the welding speed can be increased by over two times, it can be guaranteed that pressure of the welding electrode is constant all the time along with change of the diameter of a reinforcement cage in the welding process, and therefore welding quality is guaranteed.

Owner:TANGSHAN TIANZE SPECIAL WELDING EQUIP

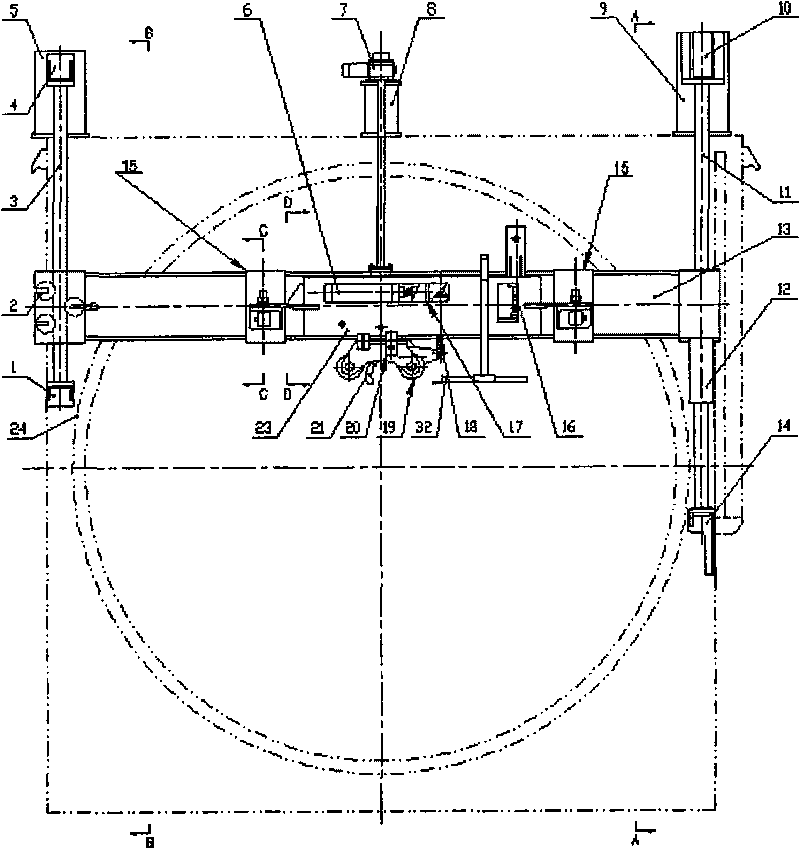

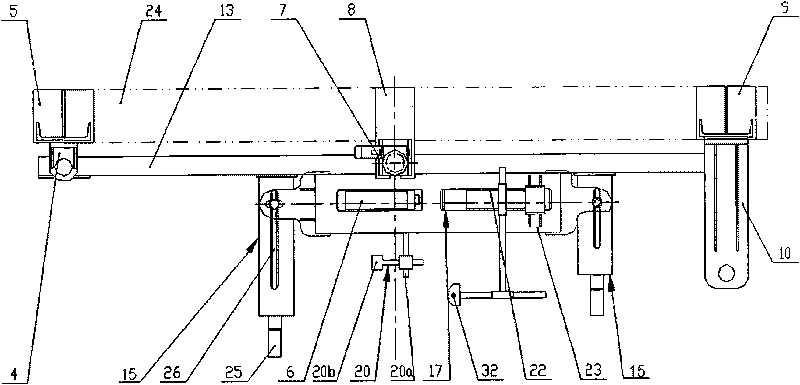

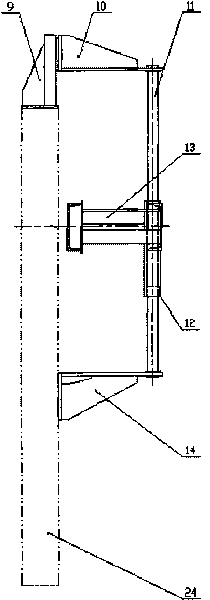

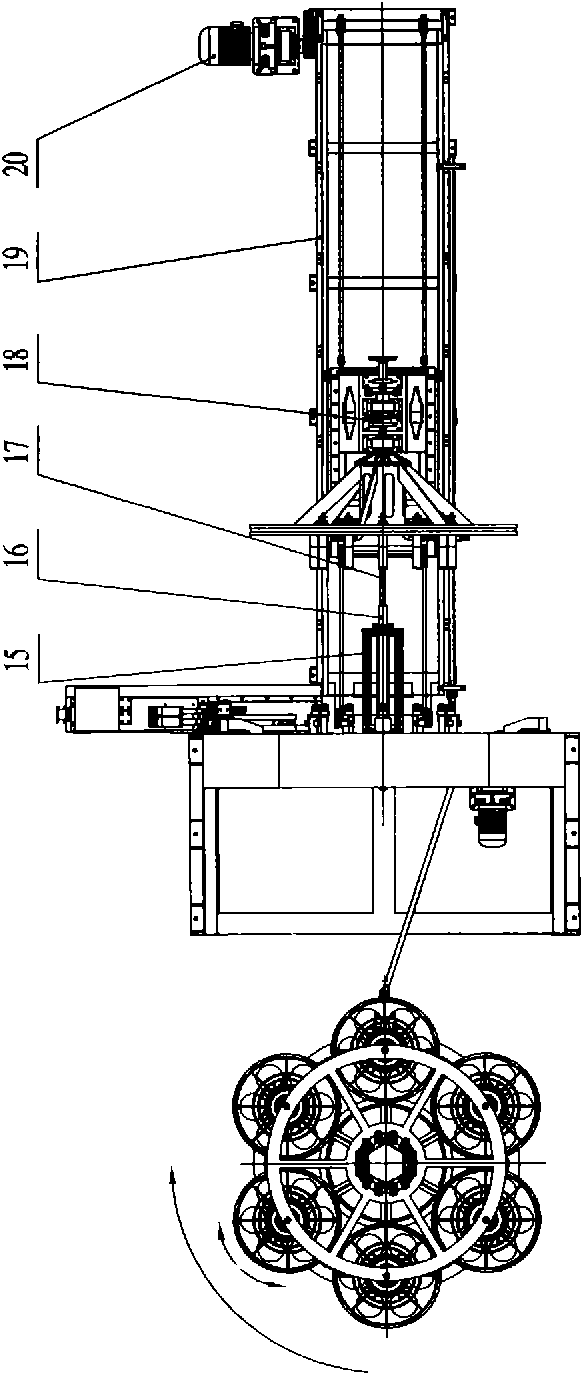

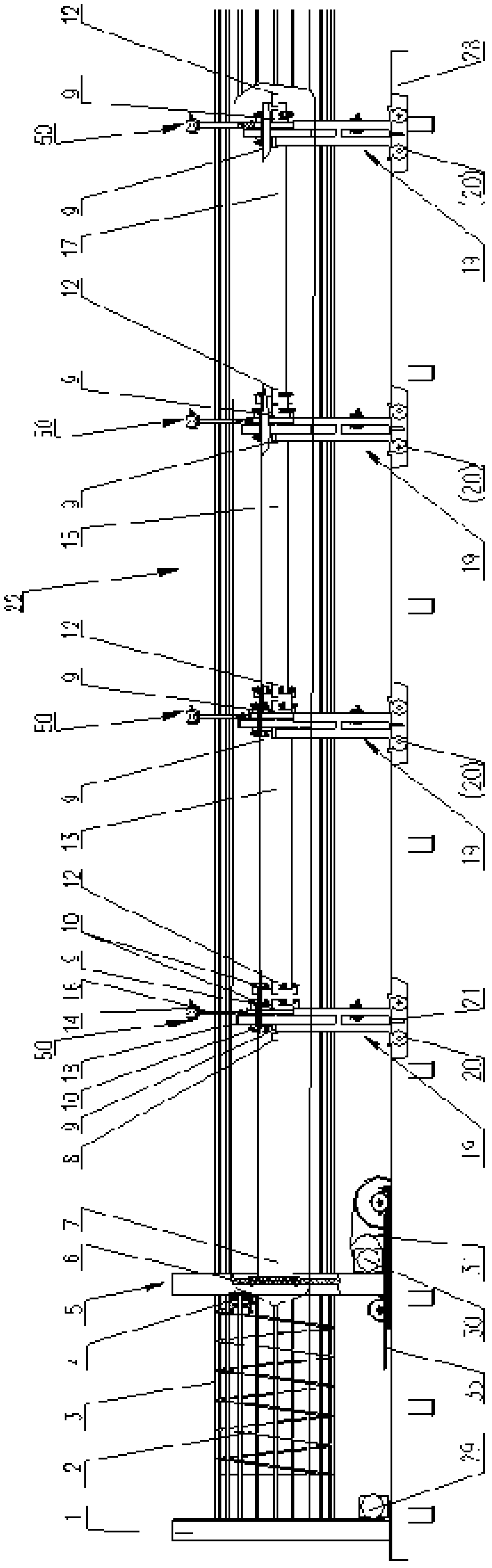

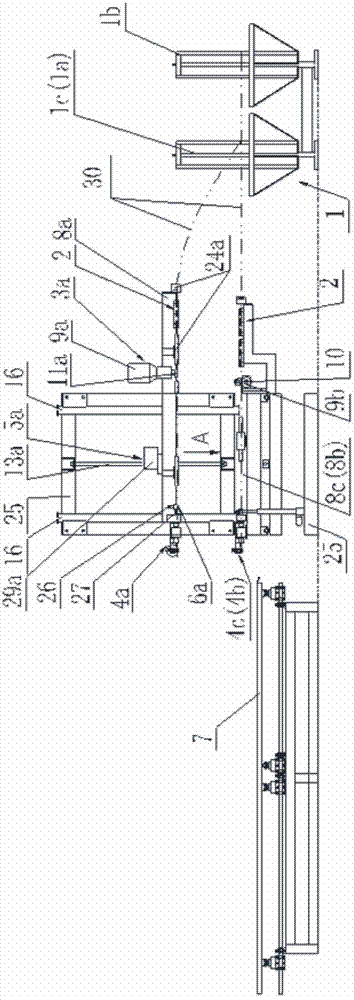

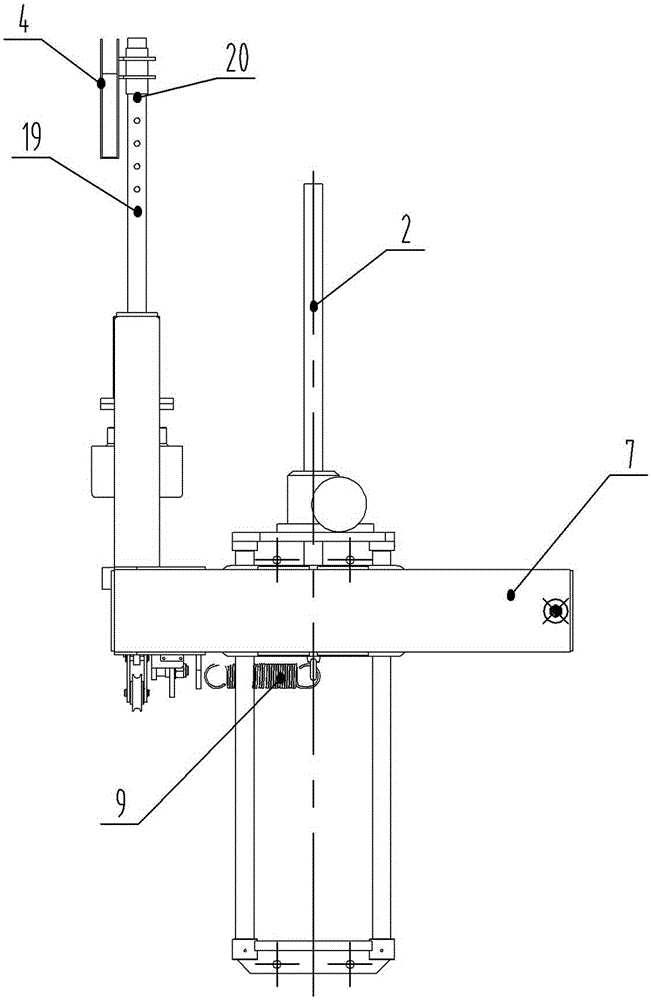

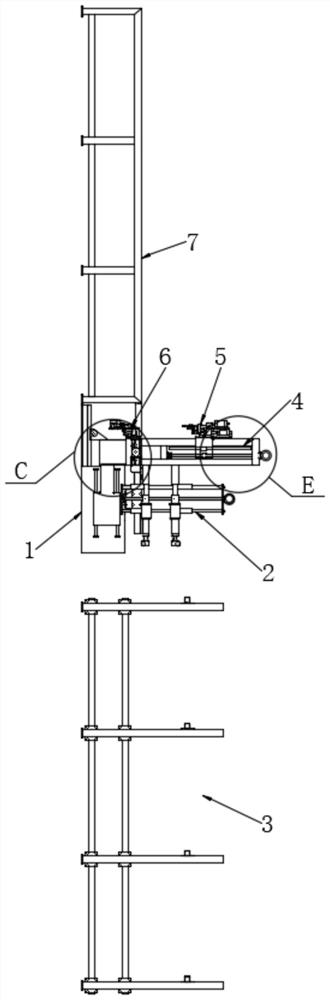

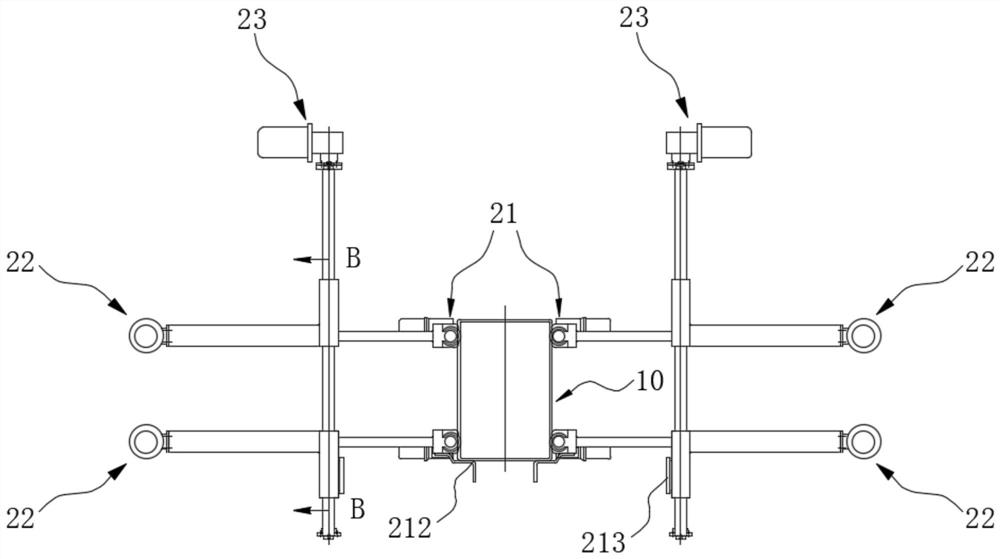

Automatic wielding mechanical device for forming machine of numerical control reinforcing cage

ActiveCN101700555AReduce labor intensityLow costMeshed-ring wire networkWelding/cutting auxillary devicesNumerical controlHooping

The invention discloses an automatic wielding mechanical device for a forming machine of a numerical control reinforcing cage. The structure thereof comprises a turnplate rack, a first guide post, a second guide post, a movable bracket, a hoist, a case shell, a hook, a rolling mechanism, a welding-gun supporting mechanism and a screw pitch regulating mechanism; the left side and right side of the movable bracket are mounted on the first guide post and the second guide post in a sliding way; the top of the movable bracket is provided with the hoist driving the movable bracket to move up and down; the case shell is arranged at one side of the movable bracket and provided with the hook, the rolling mechanism, the welding-gun supporting mechanism and the screw pitch regulating mechanism; and the screw pitch regulating mechanism is used for regulating the position and angle of the case shell. The invention has the beneficial effects that: the automatic wielding mechanical device can automatically and coordinately complete welding operation of the reinforcing cage under the control of a control system, the regulation of different positions and angles of the case shell can be realized; with the rotation of the reinforcing cage, the hook can automatically hook the longitudinal steel bars, the welding-gun supporting mechanism and the reinforcing cage rotate synchronously and are always aligned with the intersection point of the hooping and the main reinforcement of the reinforcing cage, so as to perform automatic wielding in replacement of man power; the labor intensity is lowered, man power is saved, production efficiency is improved, and welding quality is bettered.

Owner:TJK MACHINERY TIANJIN

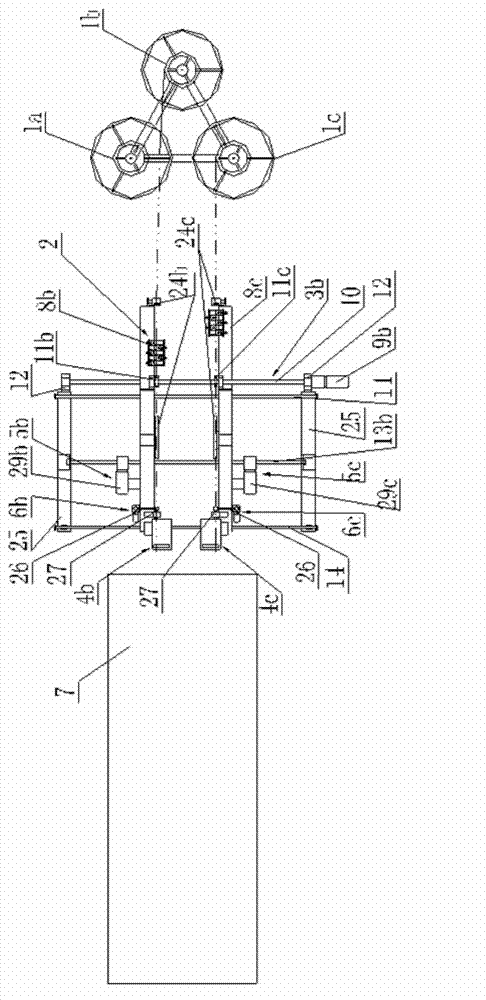

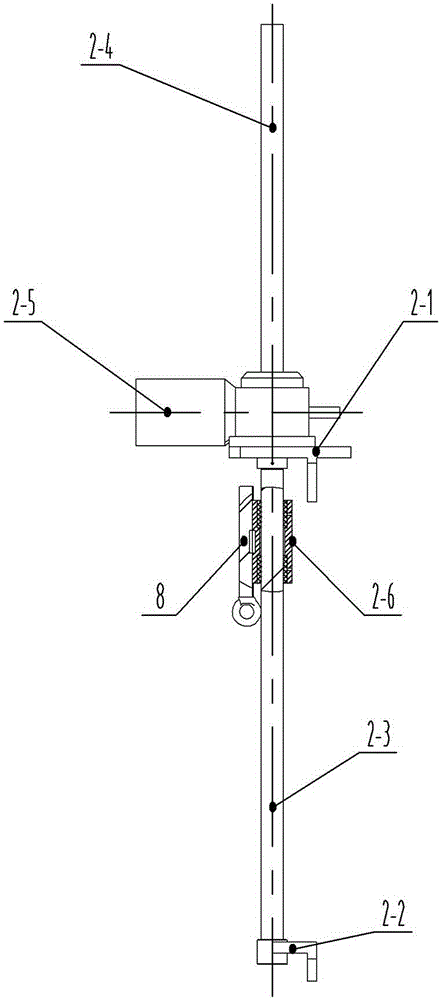

Novel automatic welding device of reinforcing cage forming machine

ActiveCN103273232AIncrease productivityImprove welding qualityMeshed-ring wire networkWelding/cutting auxillary devicesRebarWelding

The invention discloses a novel automatic welding device of a reinforcing cage forming machine. The automatic welding device comprises a movable rotating disk rack provided with longitudinal ribs, a mounting arm, and a welding position regulating mechanism driving the mounting arm to move vertically and horizontally, wherein one end of the mounting arm is installed on one lateral face of the movable rotating disk rack in a sliding mode, the other end of the mounting arm is located on one side of the front face of the movable rotating disk rack and provided with a mounting shaft, a mounting seat is hinged to the mounting shaft, and a press plate, a welding gun, idler wheels, a press plate and welding gun position regulating mechanism, an idler wheel regulating mechanism and a mounting seat rotating regulating mechanism are installed on the mounting seat. The novel automatic welding device of the reinforcing cage forming machine has the advantages that the idler wheel regulating device can achieve regulating of different positions and different angles; the press plate and the welding gun synchronously rotate along with rotating of a reinforcing cage and direct at the intersection point of stirrups and longitudinal ribs of the reinforcing cage, and automatic welding is performed; the novel automatic welding device of the reinforcing cage forming machine has the advantages of being high in production efficiency and welding quality, simple in structure, convenient to maintain, stable in work and low in cost.

Owner:TJK MACHINERY TIANJIN

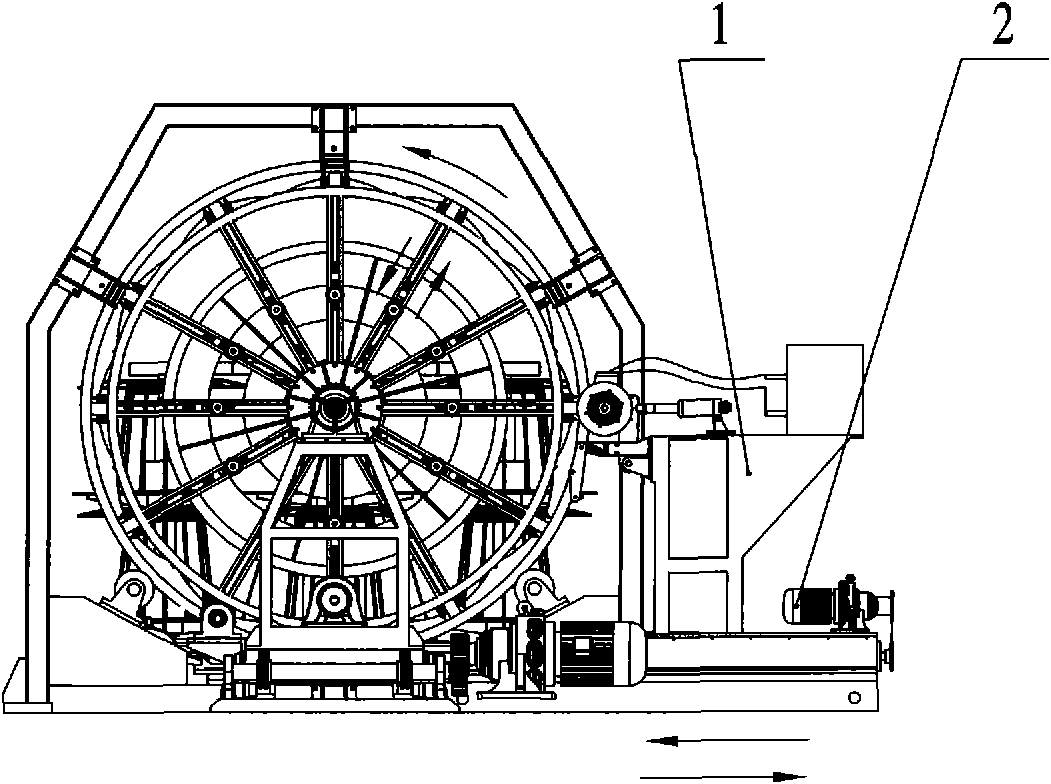

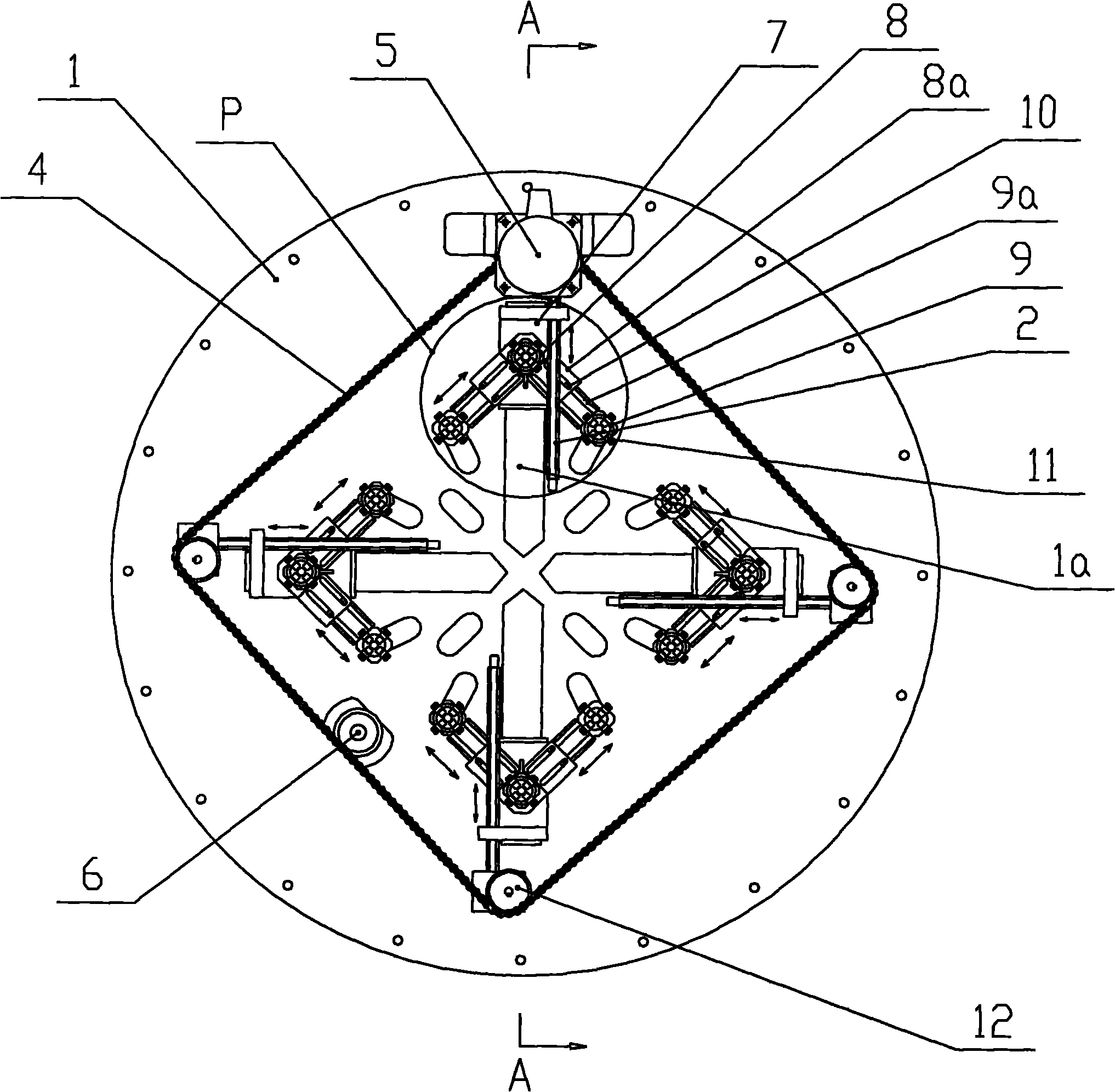

Wire-releasing type automatic reducing seam welder

InactiveCN102009296AEasy dischargeAvoid cutting wasteMeshed-ring wire networkWelding/cutting auxillary devicesRebarRotating disc

A wire-releasing type automatic reducing seam welder relates to automation scheme of reducing seam welder. Longitudinal bar feed can be realized continuously. The automatic reducing seam welder comprises a main disc, a welding station mechanism and a lacing wire disc; the automatic reducing seam welder further comprises a wire releasing disc pack for releasing longitudinal bar continuously, and a synchronization mechanism for driving the wire releasing disc pack and the lacing wire disc to run synchronously with the main disc; the wire releasing disc is disposed at the bar feeding side of the main disc and disposed on ground movably; the wire releasing disc comprises a rotating disc with an axis vertical to the horizontal plane, a plurality of wire releasing drums evenly distributed on a same circumference of the rotating disc and capable of rotating freely relative to the rotating disc, and a wire releasing disc driving mechanism connected to the synchronization mechanism. Compared with the prior technology, a wire releasing device is added in the present invention for realizing the continuous feed of longitudinal bar; after a reinforcement cage is formed, the longitudinal bars and annular bars are cut off; compared with the prior technology, two processes are saved; the waste of a lot of rest materials is avoided. In order to realize material discharging conveniently, the reducing mechanism is separable; the whole occupied space of the equipment is reduced.

Owner:江苏江桥机械制造有限公司

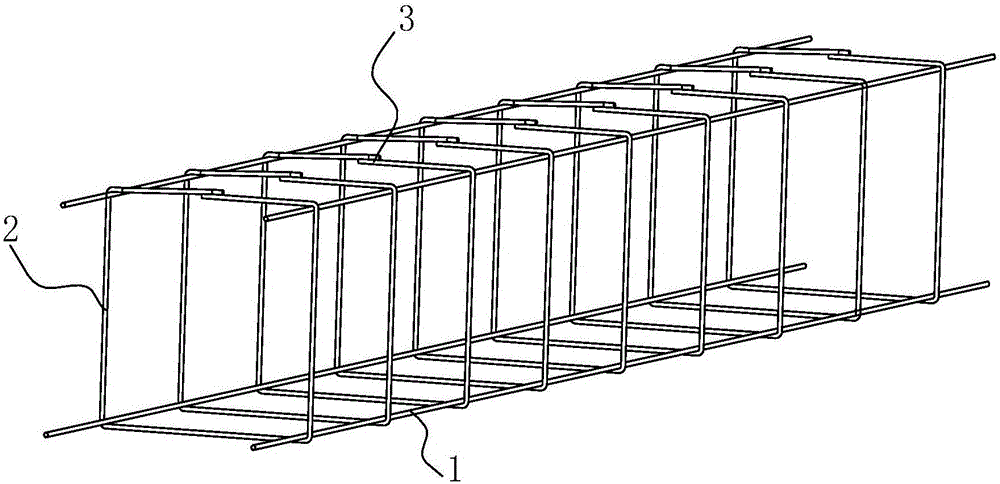

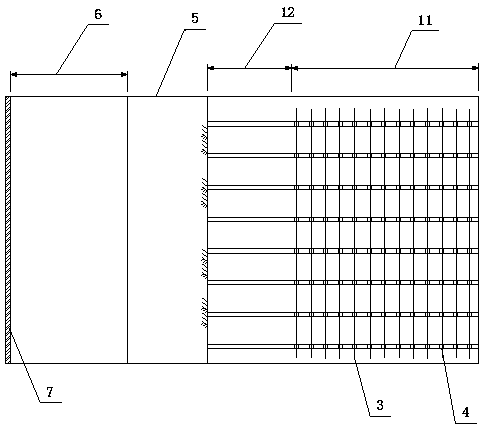

Rebar cage former

InactiveCN104096786ALow costSmall footprintMeshed-ring wire networkWire networkFixed frameEngineering

The invention discloses a rebar cage former which comprises a moving frame, two rotating frames, a fixing frame, two stirrup pay-off devices, a moving mechanism, a rotating mechanism and a welding manipulator. A first fixing disc plate is mounted on the moving frame, the moving frame driven by the moving mechanism can linearly move along the X-axis direction, a second fixing disc plate is mounted on the fixing frame, the rotating frames are mounted on the fixing frame and positioned between the first fixing disc plate and the second fixing disc plate, the stirrup pay-off devices are mounted on the rotating frames respectively and rotate along with the rotating frames, the rotating mechanism can drive the rotating frames to rotate in opposite directions respectively, and the welding manipulator is mounted on the fixing frame. By the rebar cage former, rebar cages with netty spiral stirrups can be manufactured, load-bearing capacity of concrete columns can be improved. The rebar cage former is low in manufacturing cost, small in occupied area and high in manufacturing efficiency.

Owner:武汉侨志科技有限公司

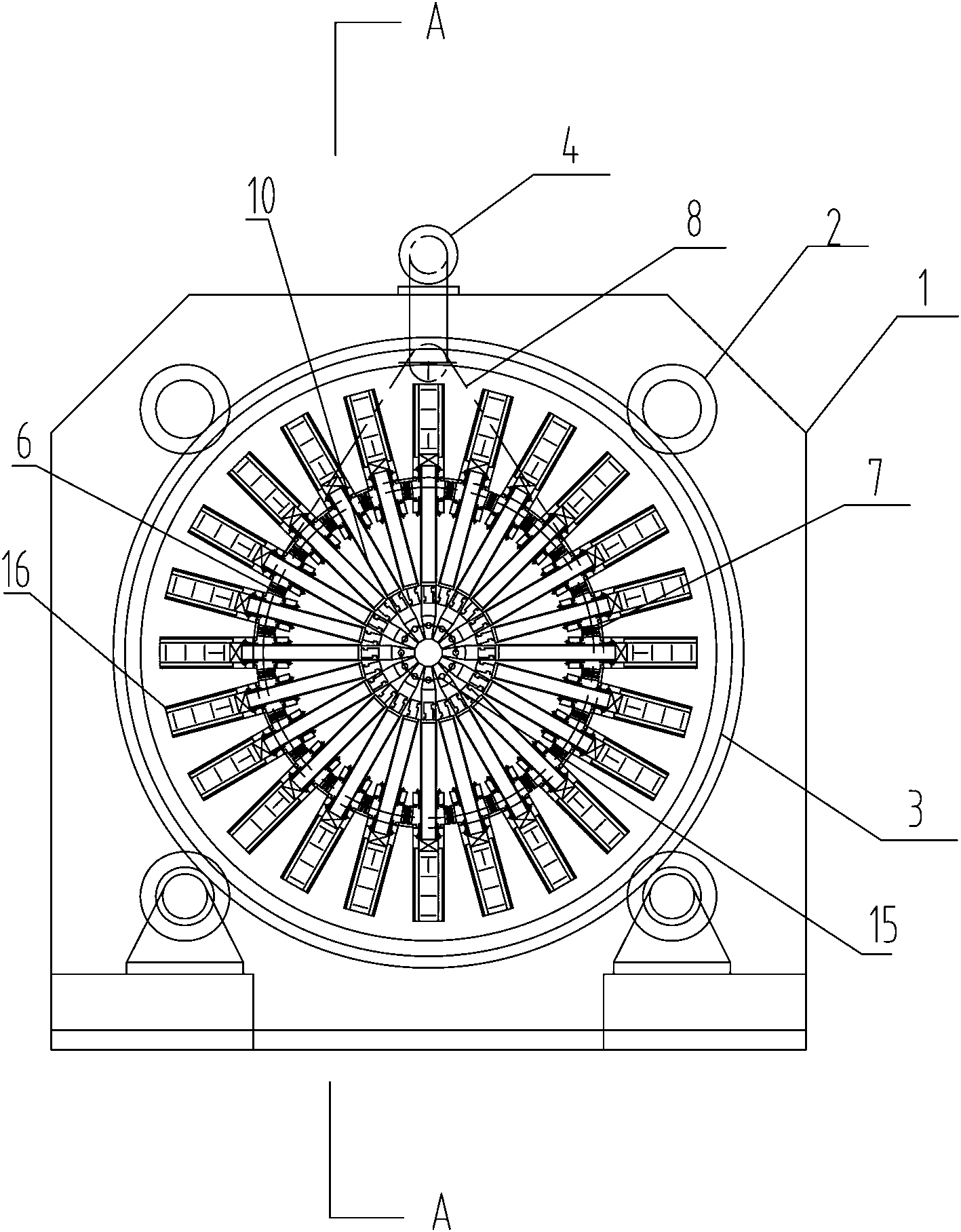

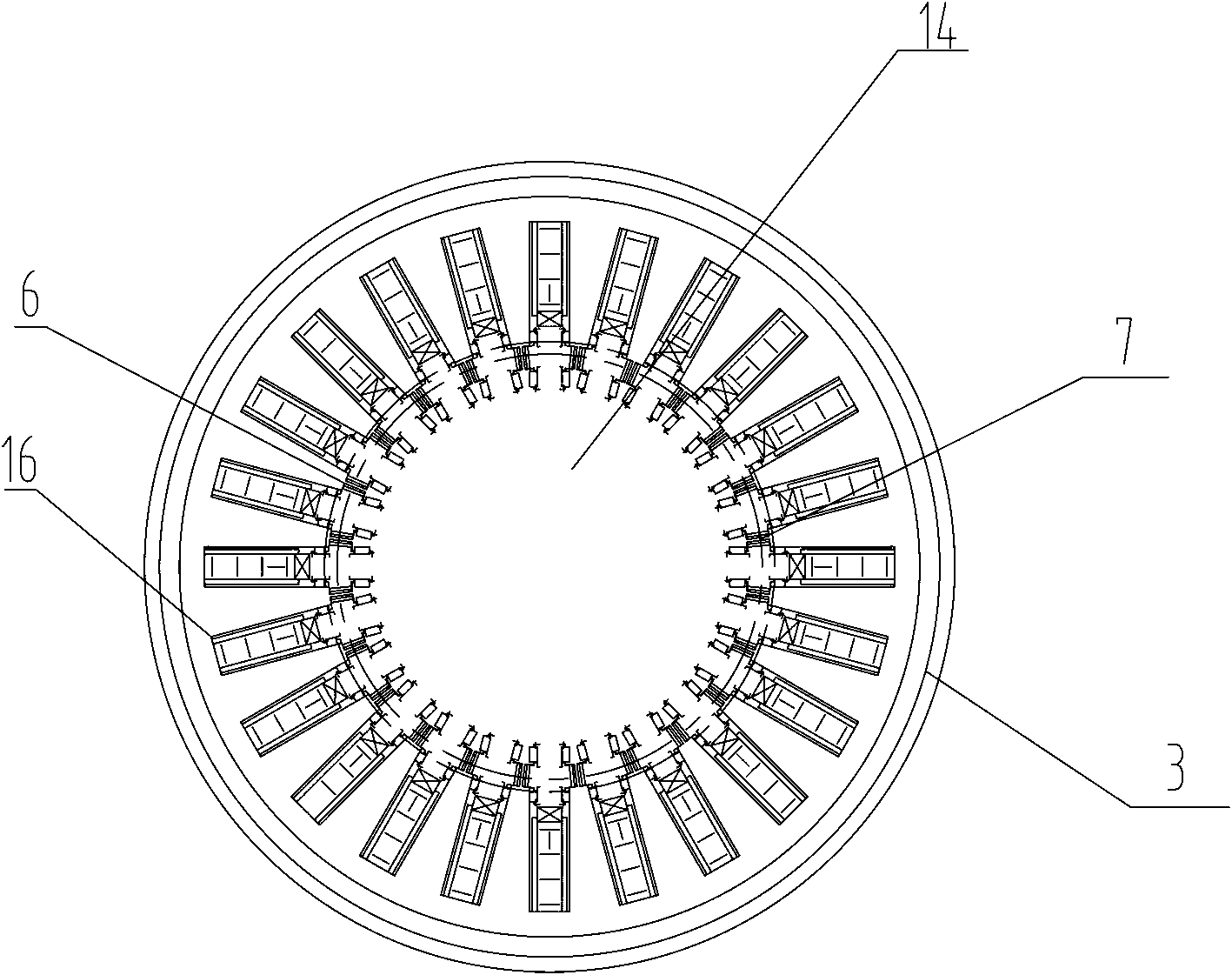

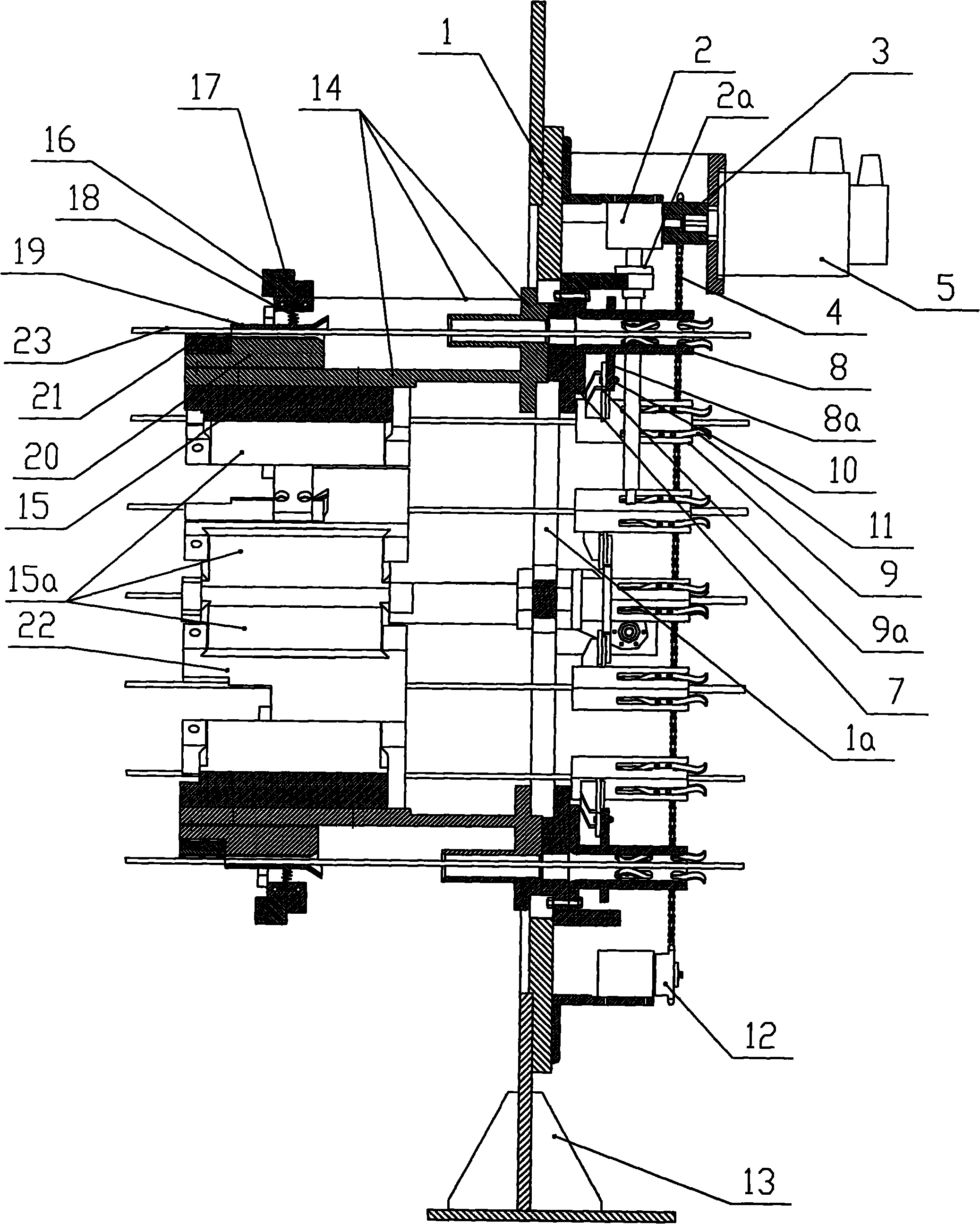

Diameter reducing device for electric pole reinforcing cage forming machine

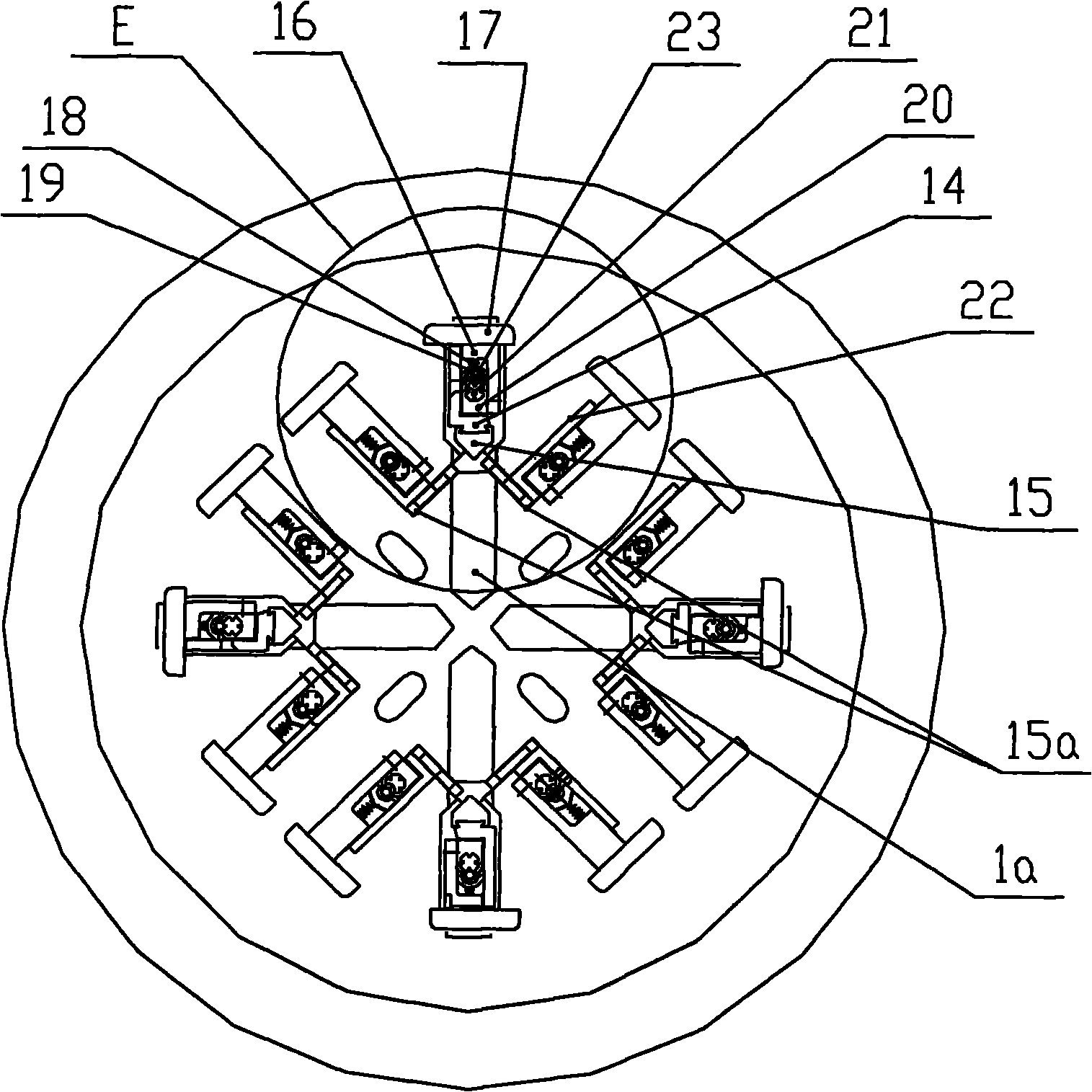

InactiveCN103008509ARealize synchronized movementAutomatically shrinkMeshed-ring wire networkMolding machineSprocket

The invention provides a diameter reducing device for an electric pole reinforcing cage forming machine. The diameter reducing device comprises a main bracket, a guide wheel mechanism, a main rotating disk, a diameter reducing driving mechanism, a diameter reducing mechanism and a main rotating driving mechanism, wherein the guide wheel mechanism is arranged on the main bracket, the main rotating disk is arranged on the guide wheel mechanism, the diameter reducing mechanism and the diameter reducing driving mechanism are arranged on the main rotating disk, the main rotating driving mechanism can drive the main rotating disk to rotate, the diameter reducing mechanism consists of a pinion and a bevel gear wheel, the diameter reducing driving mechanism drives the bevel gear wheel to rotate by a chain wheel mechanism, the bevel gear wheel rotates to drive the pinion to rotate, a hole is arranged in the middle of the pinion, a thread is arranged in the inner wall of the hole, a thread is arranged at the outer surface of a lead screw mechanism, and the lead screw mechanism penetrates through the hole of the pinion and is connected with a reinforcement penetration mechanism. The diameter reducing device has the advantages that by adjusting the differential value of the rotating speed of the main rotating disk and the bevel gear wheel and automatically changing the diameter of an electric pole reinforcing cage, the forming device not only is applicable to equal-diameter electric pole reinforcing cages, but also is applicable to tapered electric pole reinforcing cages.

Owner:YICHANG HAITIAN ULTRASONIC TECH

Double-welding mechanism of reinforcement cage seam welder

ActiveCN104002034AGuaranteed uptimeRealize weldingResistance electrode holdersMeshed-ring wire networkControl systemEngineering

The invention discloses a double-welding mechanism of a reinforcement cage seam welder. The double-welding mechanism structurally comprises a movable rotary table and an installing arm. A first set of welding gun device and a second set of welding gun device which are arranged in a spaced mode in parallel are installed on the installing arm in the direction of a longitudinal rib. The two ends of the installing arm are arranged on the two sides of the movable rotary table in a sliding fit mode respectively, one side of the movable rotary table is provided with a welding gun position adjusting mechanism driving the installing arm to move vertically and move horizontally, and the other side of the movable rotary table is provided with an auxiliary position adjusting mechanism moving along with the installing arm. The double-welding mechanism has the advantages that the two sets of welding gun devices are used for welding a reinforcement cage in a dot interlace mode under the control of a control system, the two ends of the installing arm are arranged on the two sides of the movable rotary table in the sliding fit mode respectively, the two sets of welding gun devices can operate stably through the welding gun position adjusting mechanism at one end of the installing arm and the auxiliary position adjusting mechanism at the other end of the installing arm, and welding is achieved at the accurate welding position. The double-welding mechanism has the advantages of being suitable for welding reinforcement cages with different specifications, wide in welding type and standard range, high in welding efficiency, good in quality and stable in working.

Owner:TJK MACHINERY TIANJIN

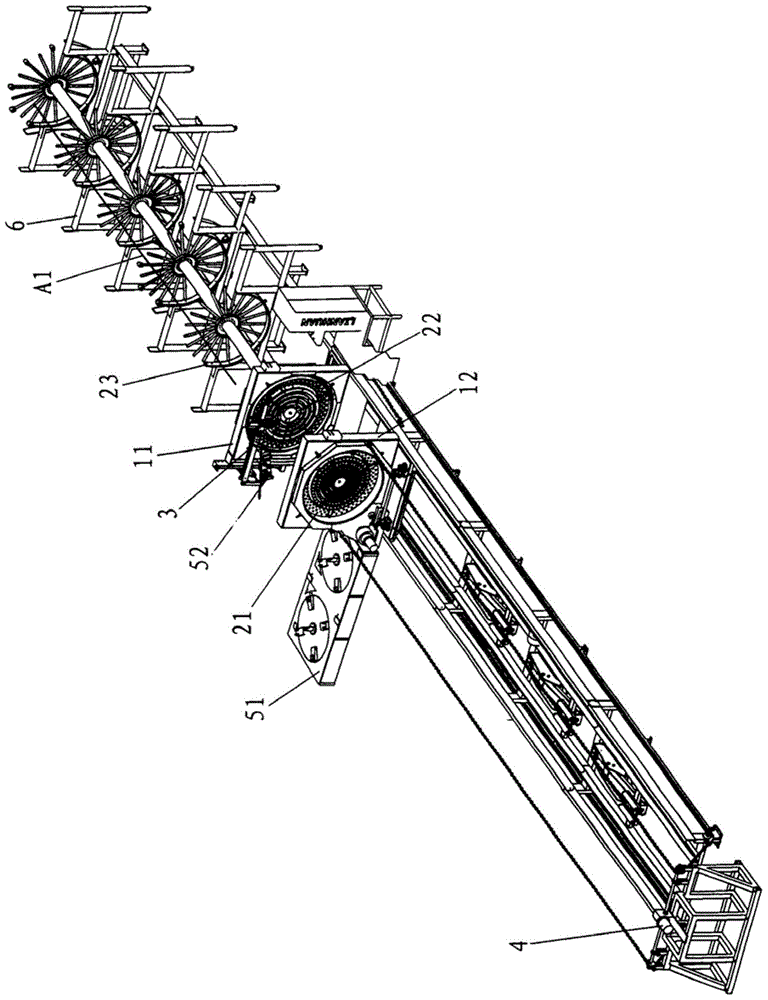

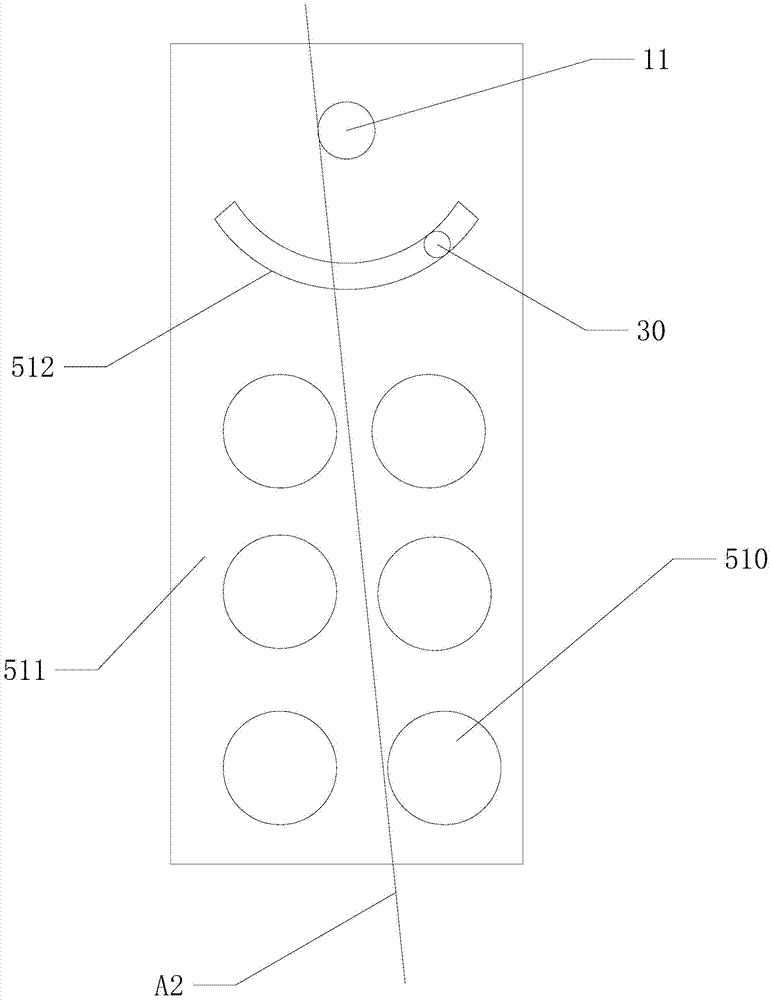

Telescopic bar distribution device for steel bar cage molding machine

ActiveCN102489634ASmall footprintEasy maintenanceMeshed-ring wire networkDistribution frameMolding machine

The invention discloses a telescopic bar distribution device for a steel bar cage molding machine. The telescopic bar distribution device comprises a turntable arranged in a mobile disk, a fixed connection pipe, a plurality of insertion pipes and a plurality of bar distribution frames, wherein one end of the fixed connection pipe is connected with the turntable; the plurality of insertion pipes which are rotated and moved along with the fixed connection pipe are sleeved and inserted into the other end of the fixed connection pipe in a sliding manner; the upper parts of the bar distribution frames are rotated along with the fixed connection pipe and the insertion pipes, and are used for supporting a main bar, and the lower parts of the bar distribution frames are supported on a floor beam in a rolling manner; and the length of the telescopic bar distribution device is gradually compressed when the mobile disk moves. The telescopic bar distribution device has the advantages that: the plurality of bar distribution rotary frames are rotated respectively along with the fixed connection pipe and the insertion pipes; a fixed stop block on the fixed connection pipe or main push stop blocks on the insertion pipes pushes or push each bar distribution frame to move along the floor beam, so that the mobile disk is rotated and welded, and compresses the length of the telescopic bar distribution device at the same time of moving along the floor beam; therefore, a steel bar cage occupies a small area, has a compact structure, is convenient to maintain, saves energy consumption, and is low in cost.

Owner:TJK MACHINERY TIANJIN

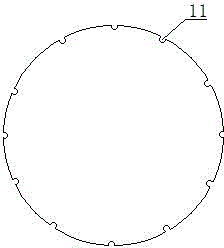

Processing device and method capable of manufacturing reinforcement cages with different diameters

ActiveCN103350165AThe conversion method is simpleImprove butt installation accuracyMeshed-ring wire networkRebarSupport surface

The invention discloses a processing device and method capable of manufacturing reinforcing cages with different diameters. The processing device comprises a base, wherein an arc supporting surface is formed at the upper end of the base, and a plurality of grooves are uniformly formed in the arc supporting surface; a plurality of mounting holes are formed in the lower part of the arc supporting surface; and different models of bases can be fixedly connected through the mounting holes. When the reinforcing cages with different diameters are manufactured by the device and the method, a base changing method is simple, the operation is convenient, the manufacturing and mounting quality can be guaranteed, and the processing device and method capable of manufacturing the reinforcing cages with different diameters are suitable for manufacturing the reinforcing cages of various pile foundations.

Owner:CHINA FIRST METALLURGICAL GROUP

Concrete reinforcing cage forming machine

InactiveCN104096787ALow costSmall footprintMeshed-ring wire networkWire networkManipulatorSmall footprint

The invention discloses a concrete reinforcing cage forming machine. The concrete reinforcing cage forming machine comprises a movable frame, a rotary frame, a fixed frame, a stirrup unreeling device, a first movable mechanism, a second movable mechanism, a rotary mechanism and a welding manipulator. A first fixed plate is arranged on the movable frame, and the movable frame is driven by the second movable mechanism to do linear movement along an X-axial direction; and a second fixed plate is arranged on the fixed frame, the rotary frame is arranged on the first movable mechanism and further arranged between the first fixed plate and the second fixed plate, the rotary frame is driven by the first movable mechanism to do linear movement along the X-axial direction, the stirrup unreeling device is arranged on the rotary frame and rotates along with the rotary frame, the rotary mechanism drives the rotary frame to rotate, and the welding manipulator is mounted on the first movable mechanism. By the concrete reinforcing cage forming machine with low cost and small occupying space, the reinforcing cage with mesh spiral stirrups is produced, bearing capacity of a concrete column is improved, and production efficiency is high.

Owner:武汉侨志科技有限公司

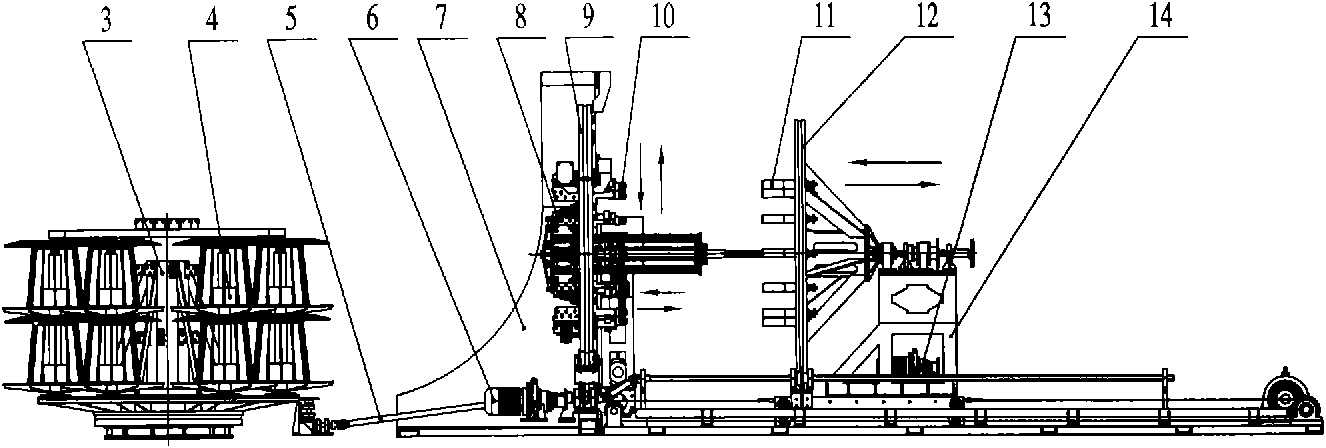

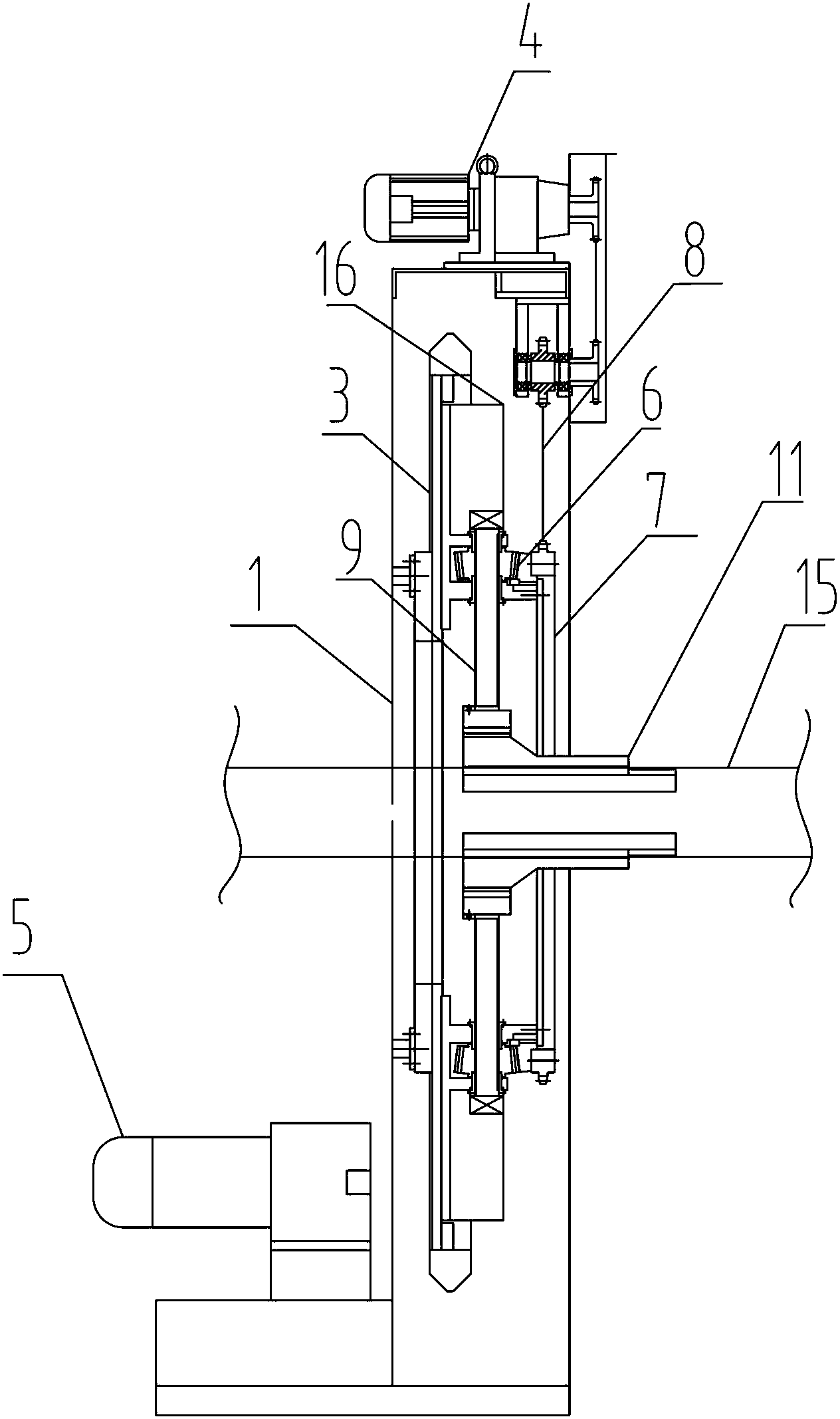

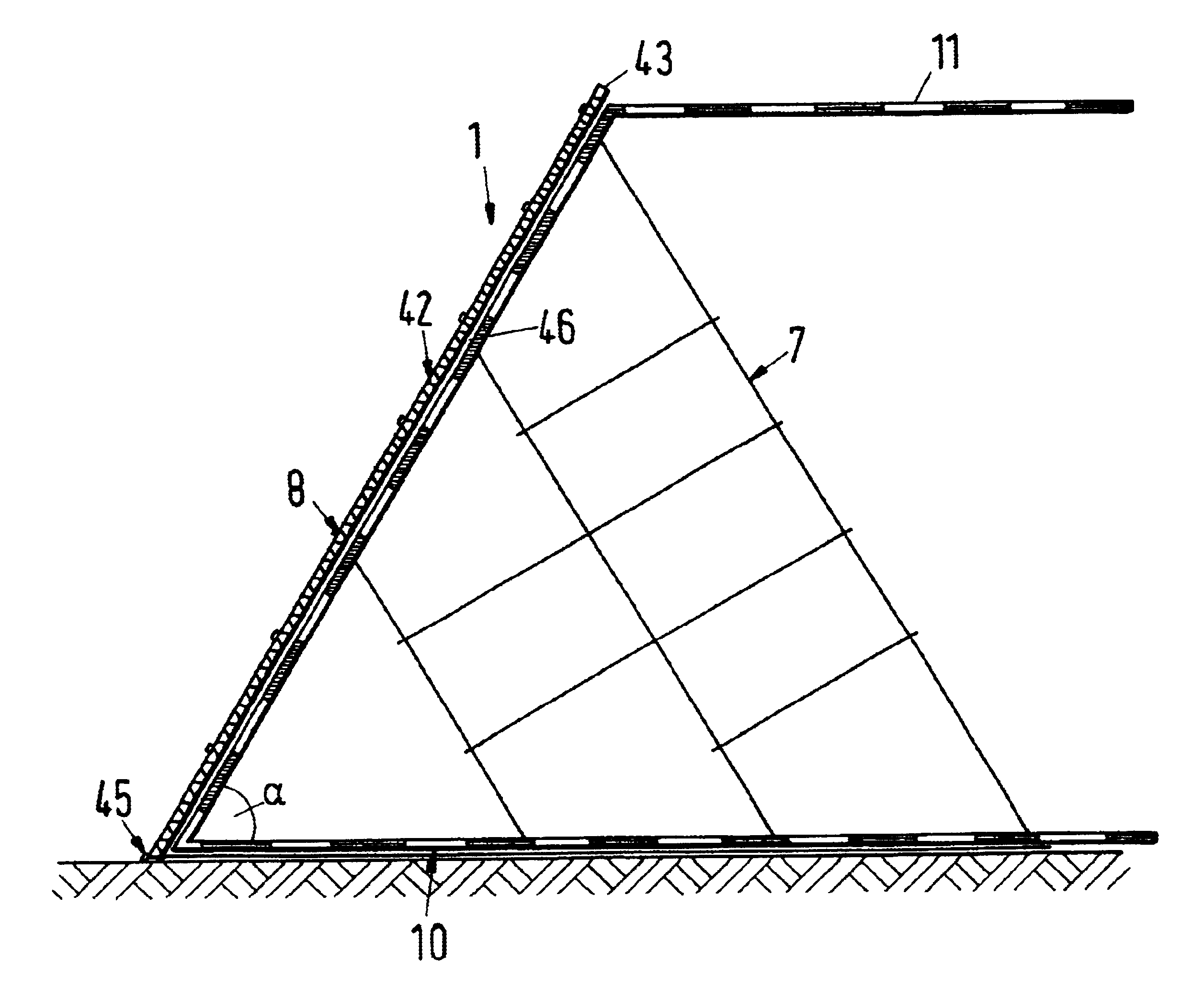

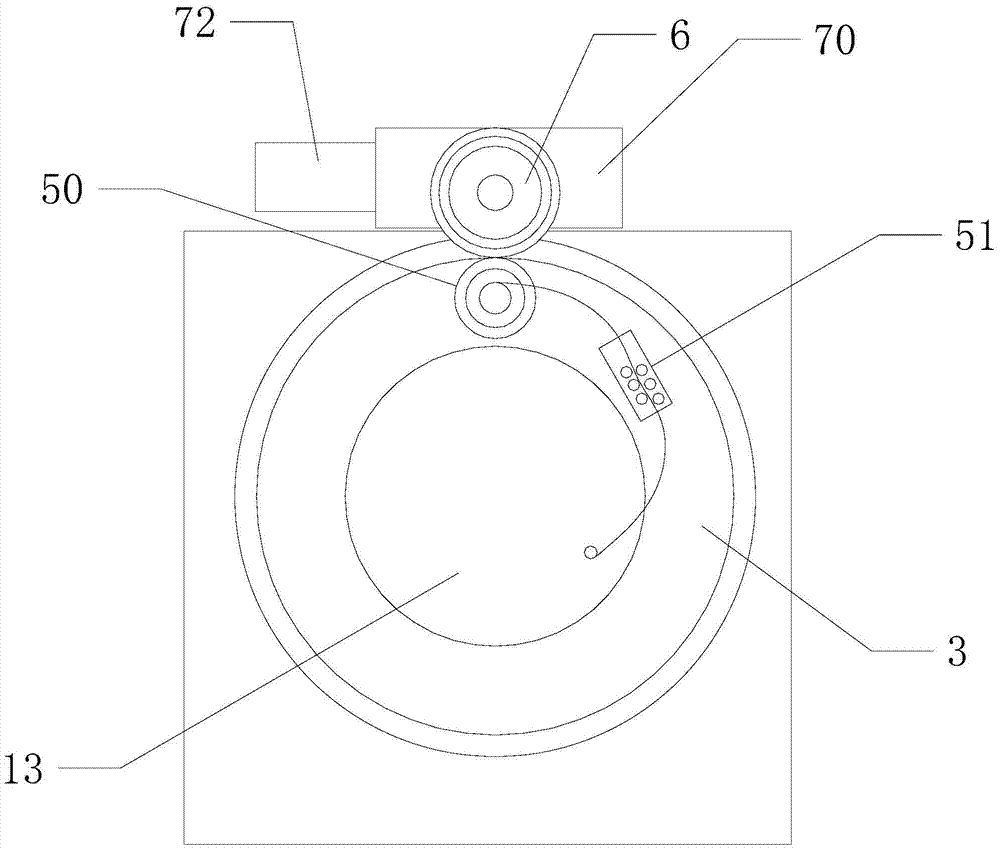

Automatic welding and forming machine of tapered pole reinforcing cage

InactiveCN102989934ARealize automatic weldingStable supportMeshed-ring wire networkResistance welding apparatusMolding machineStructural engineering

The invention relates to an automatic welding and forming machine of a tapered pole reinforcing cage. The automatic welding and forming machine comprises a material frame, a reinforcing cage forming mechanism and a movable rotary mechanism, which are arranged on a bottom bracket, wherein the movable rotary mechanism comprises a first driving device and a locating disc driven by the first driving device, and a main reinforcement locating hole capable of passing through the reinforcing cage is formed in the locating disc; the reinforcing cage forming mechanism comprises a second driving device and a rotary disc driven by the second driving device, a main reinforcement locating device capable of passing through the reinforcing cage is formed in the rotary disc, and the rotary disc and the locating disc rotate synchronously; and a welding device is arranged on one side of the reinforcing cage forming mechanism. The forming machine of the tapered pole reinforcing cage disclosed by the invention has the advantages of being capable of implementing automatic welding and improving the working efficiency.

Owner:YICHANG HAITIAN ULTRASONIC TECH

Half-shaft separation-type reinforcement cage making equipment and use method

ActiveCN105436360AEasy to useSimple structureMeshed-ring wire networkBulkheads/pilesSocial benefitsEconomic benefits

The invention discloses half-shaft separation-type reinforcement cage making equipment and a use method. The half-shaft separation-type reinforcement cage making equipment can be used for making a reinforcement cage which is shaped like a cylinder or square tube. According to the making equipment, two mobile stations which support the reinforcement cage are each provided with a rotatable and integrally connected half shaft, each mobile station is further provided with a motor and a clutch converter which converts the output power of the motor to drive the corresponding half shaft to rotate or drive the corresponding mobile station to move axially, and multiple positioning supports which have the same numbers and positions as those of reinforcing rings of the reinforcement cage and are used for supporting main reinforcement of the reinforcement cage are additionally arranged between two positioning plates; meanwhile, corresponding improvement is conducted on positioning plate structures for supporting the main reinforcement of the reinforcement cage, the improved reinforcement cage making equipment has the advantages of being simple in structure, convenient to use, reliable in quality, economical, reasonable, high in degree of mechanization and automation, high in universality and the like, a better using effect can be achieved by matching with a corresponding use method, and higher economic benefit and social benefit are achieved.

Owner:NINGBO COMM ENG CONSTR GRP

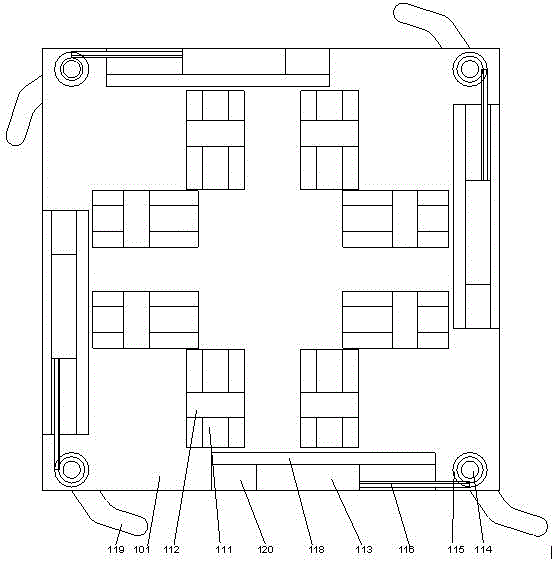

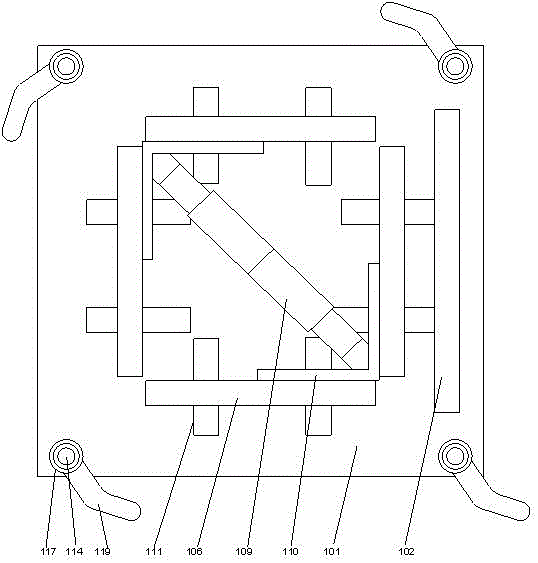

Automatic adjustment mechanism for main bar position of numerical control square reinforcement cage forming machine

ActiveCN101982250AReduce mistakesRapid positioningMeshed-ring wire networkNumerical controlEngineering

The invention discloses an automatic adjustment mechanism for the main bar position of a numerical control square reinforcement cage forming machine. The automatic adjustment mechanism for the main bar position comprises an adjustment plate; a sliding seat is arranged in the slide way of the adjustment plate; a spiral lift driving unit is fixed on the adjustment plate; the drive end of the spiral lift driving unit is connected with the sliding seat and drives the sliding seat to move back and forth along the slide way of the adjustment plate; a main bar penetration pipe is fixed on the sliding seat on one side of the adjustment plate; a conductive sliding seat is fixed on the sliding seat on the other side of the adjustment plate; and a main bar through hole and a conductive electrode are arranged on the conductive sliding seat. The invention has the beneficial effects that: a servo motor controls the positioning; the main bars at four corners can be quickly positioned at a time; the size can be accurately adjusted; and the error of the finished product is low. The side reinforcement can realize fast manual adjustment in place and the adjustment range is large; a numerical control square reinforcement cage forming machine can produce cages of various specifications, realizes multiple functions of one machine and saves the cost. Moreover, the roll welding speed and production efficiency are greatly improved, and the invention has the advantages of simple structure, energy conservation and low cost.

Owner:TJK MACHINERY TIANJIN

Equipment capable of manufacturing reinforcing cages with various section shapes

ActiveCN103042137AQuality improvementHigh degree of automationMeshed-ring wire networkHoopingEngineering

The invention discloses equipment capable of manufacturing reinforcing cages with various section shapes. The equipment comprises a pay-off reel and a frame. A straightening mechanism, a traction mechanism and a welding mechanism are arranged on the frame, the welding mechanism comprises multiple groups of welding joints which are respectively connected with a position adjusting mechanism and an angle adjusting mechanism, the position adjusting mechanism comprises a supporting frame, the welding joints and a movable driving device are arranged on the supporting frame, one group of welding joints moves along with the supporting frame, the angle adjusting mechanism comprises an electric push rod, a movable end of the electric push rod is hinged at one end of a rotating shaft, the other end of the rotating shaft is connected with the welding joints, the rotating shaft is supported on the supporting frame by means of hinging, and under drive of the electric push rod, the rotating shaft rotates to drive the welding joints to perform angle adjustment. The equipment has the advantages that hoopings pre-processed to various section shapes are placed in the equipment, and the equipment is capable of automatically welding the hoopings into reinforcing cages with various section shapes; and the equipment has the advantages of high automation degree, compact structure, stability in operation, low cost and high production efficiency.

Owner:TJK MACHINERY TIANJIN

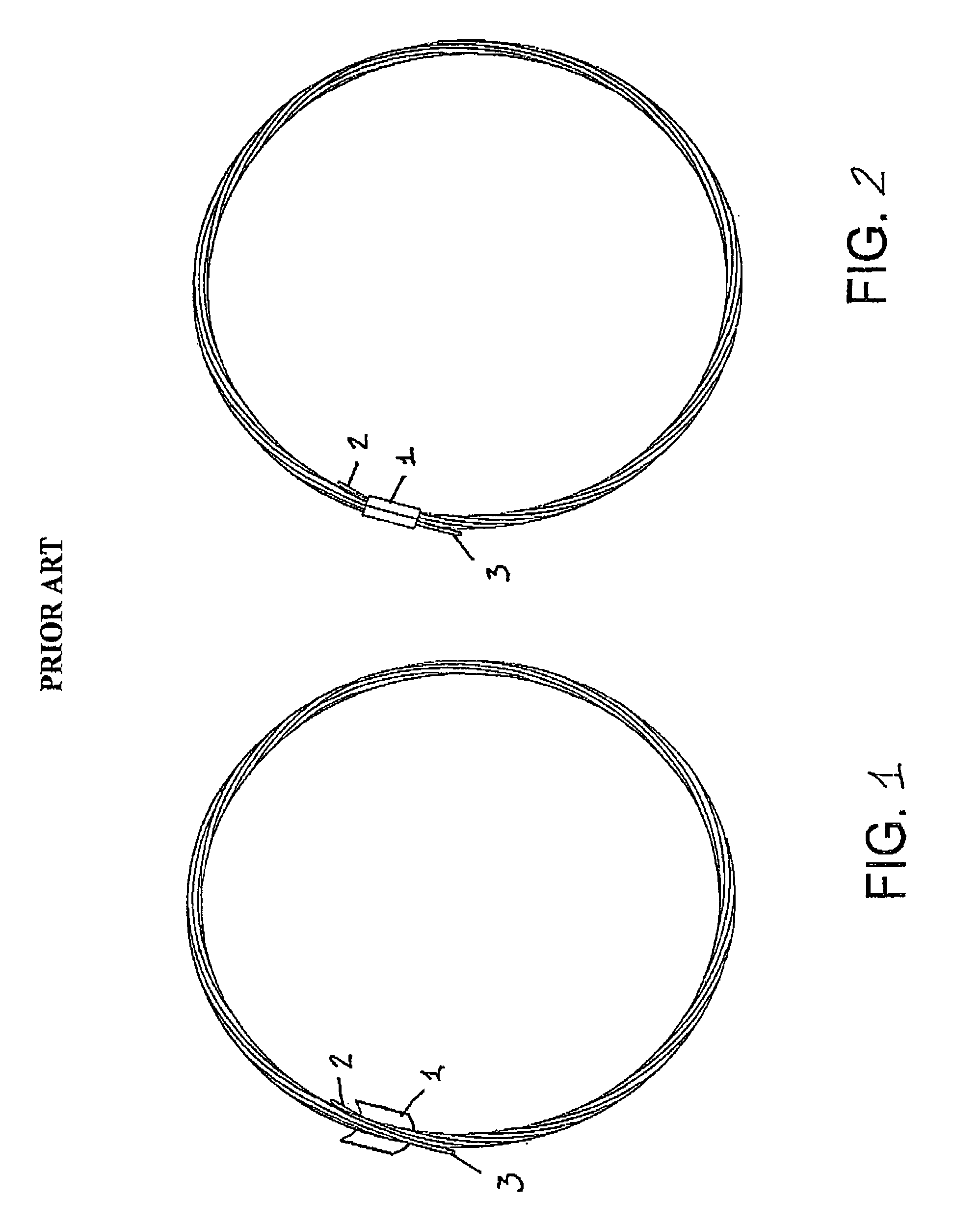

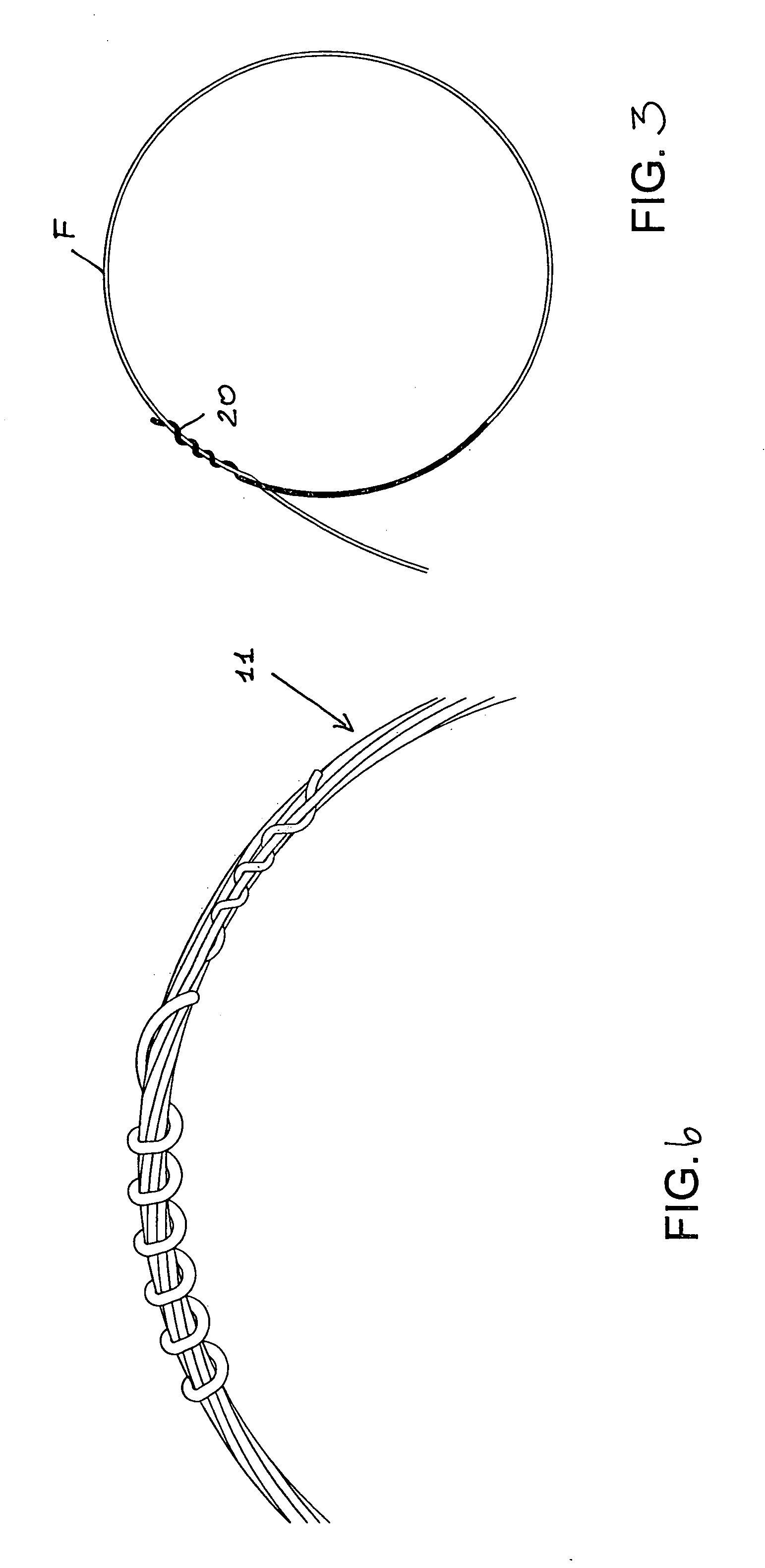

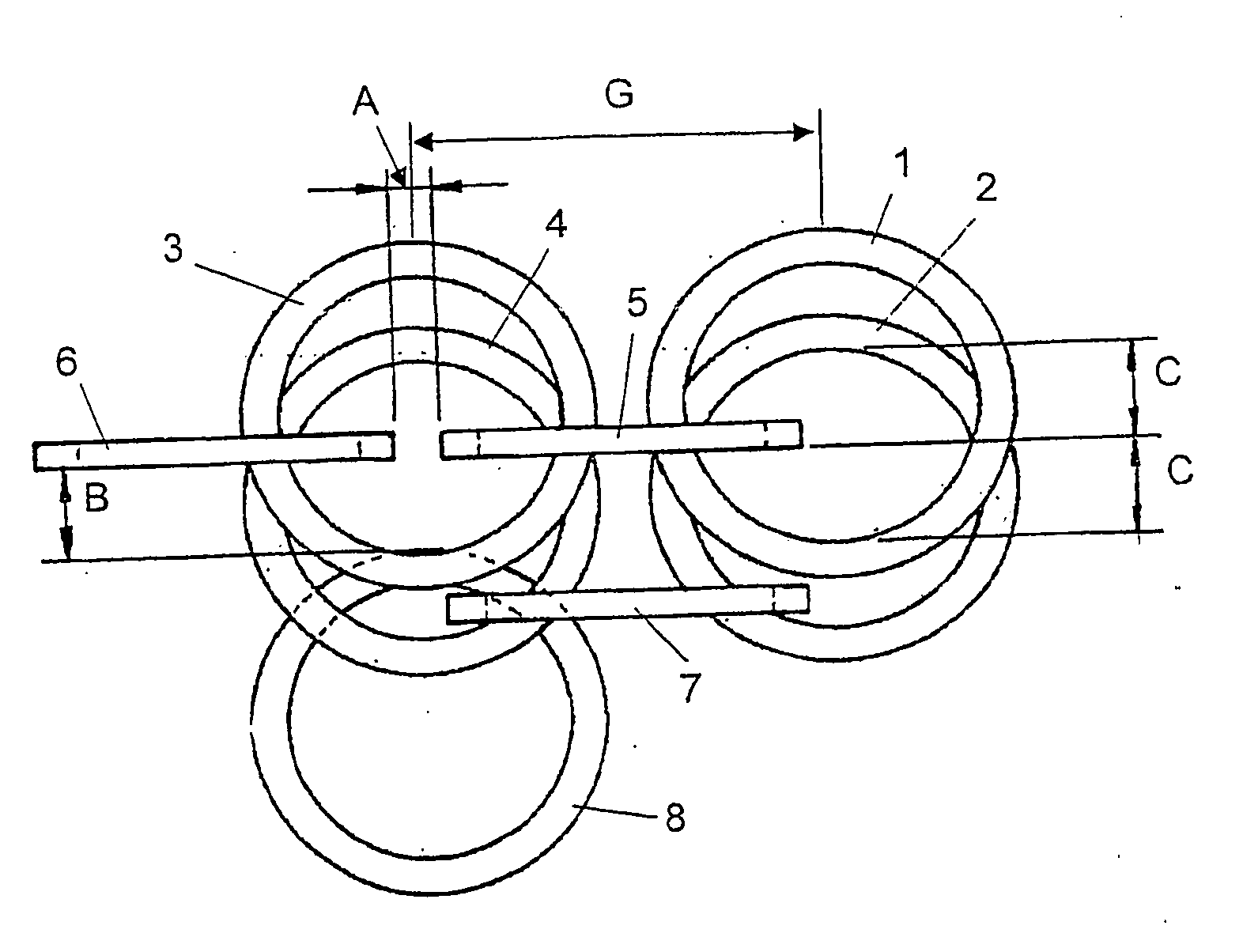

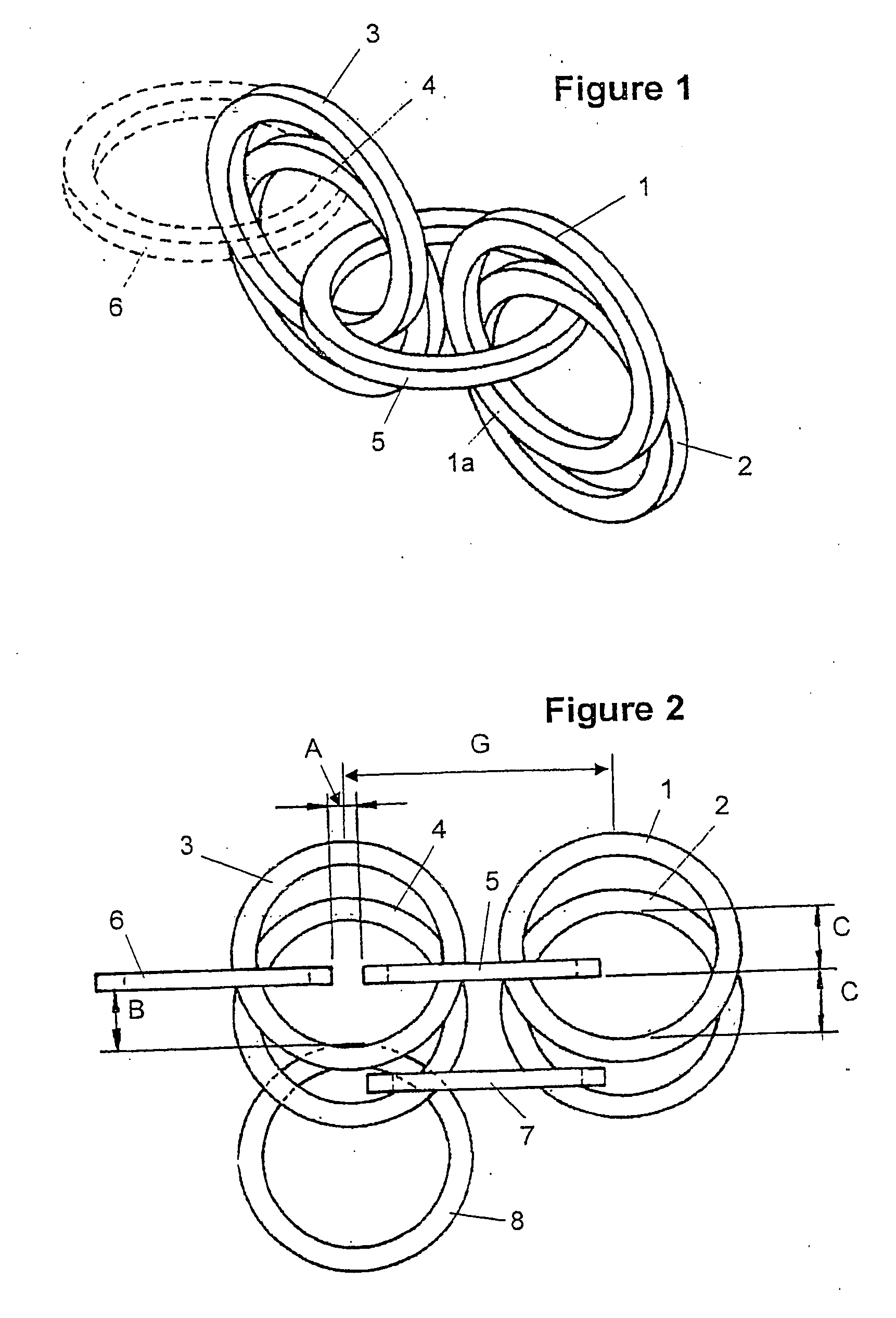

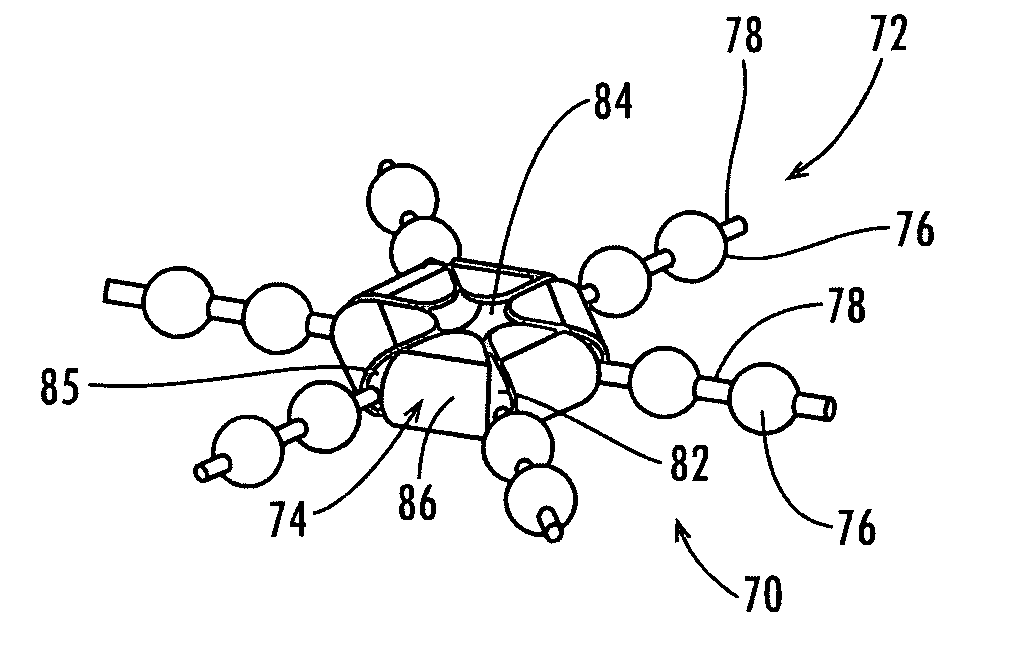

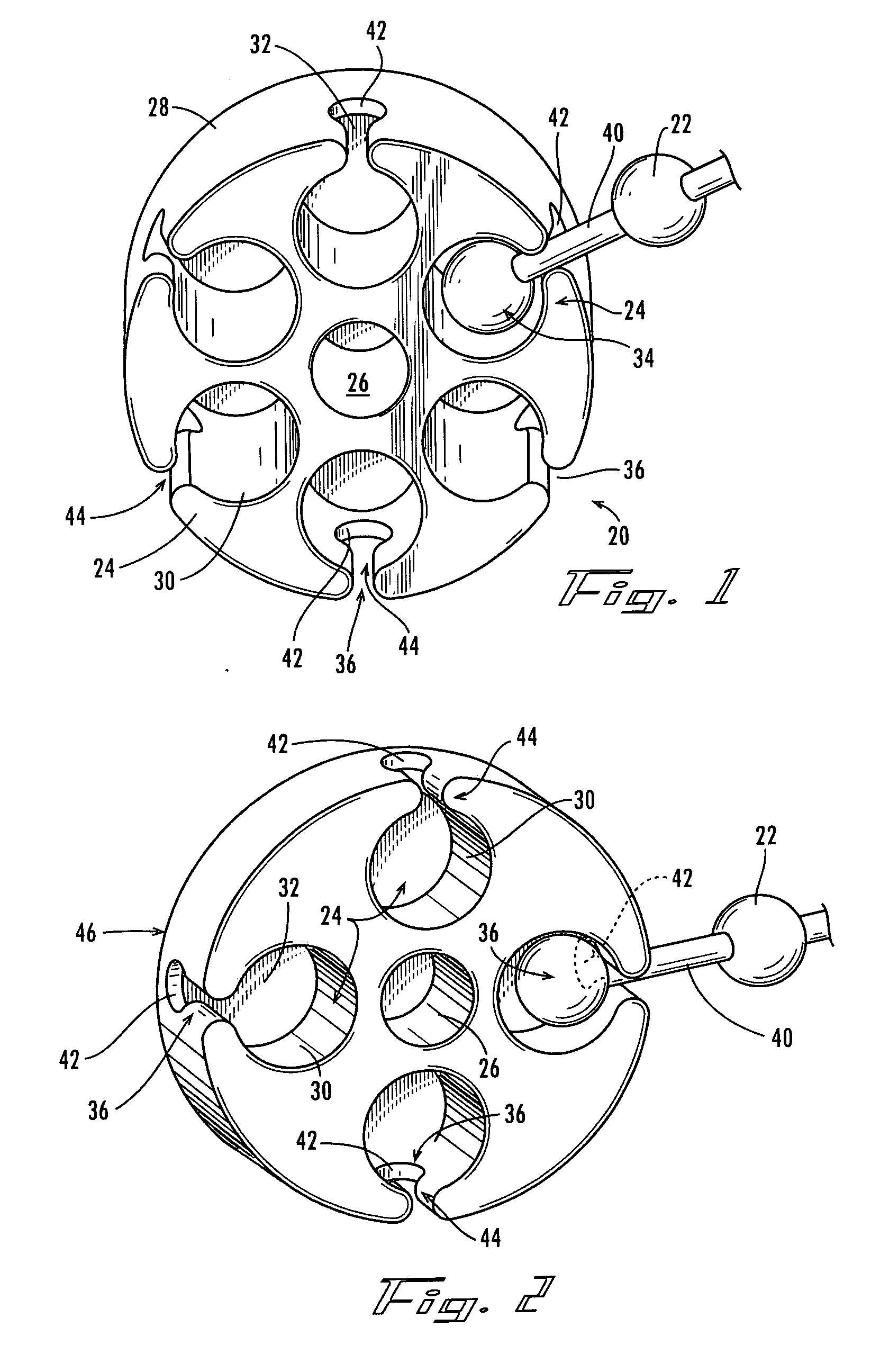

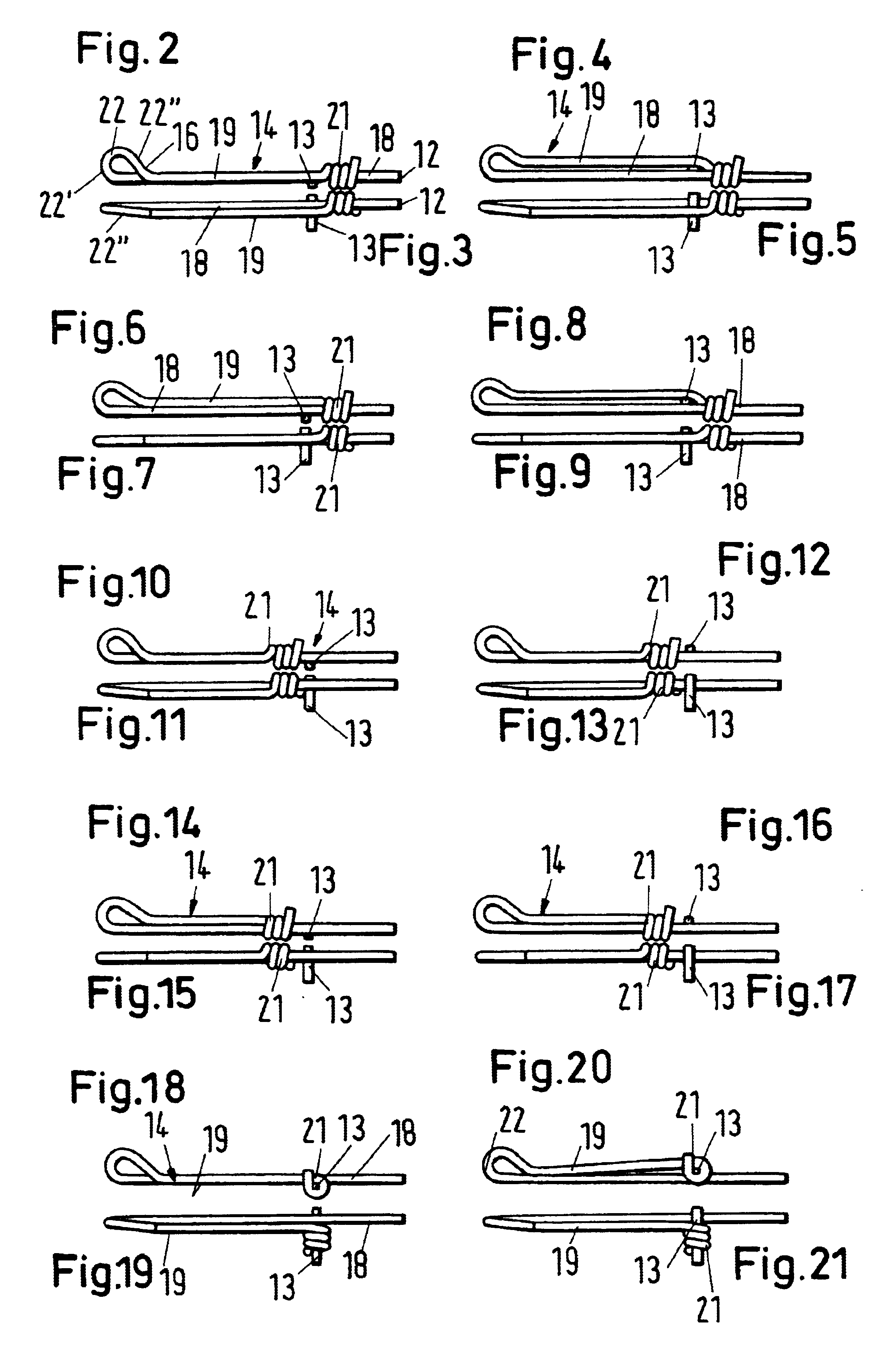

Ball chain and connector for tessellated patterns

A ball chain assembly may be used to form tessellated patterns of ball chains. The ball chains include a series of balls and intermediate links of a breadth less than the breadth of said balls. A chain connector of one-piece construction defines a circular array of ball-receiving sockets. Each of the sockets are sized to receive a ball of one of said chains. A ball of the chain can be inserted into one of the sockets of the chain connector where a link of the inserted ball passes through the slot extending from the socket, such that a chain can be connected to each of the sockets.

Owner:BOLAND PAUL E

Processing method of steel bar cage

InactiveCN104690194ASave human effortEvenly spacedMeshed-ring wire networkNumerical controlEngineering

The invention discloses a processing method of a steel bar cage, which comprises the steps of main bar positioning, wire rod straightening, stirrup winding, carbon-dioxide arc welding, integral forming and numerical control operation. A main bar of the steel bar cage manually penetrates through a corresponding template round hole of a fixed rotary disk into a corresponding hole of a movable rotary disk for fixing; the end of a stirrup is welded on the main bar and then wound on the main bar via rotation of the fixed rotary disk and the movable rotary disk; welding is performed; and then the steel bar cage is formed. The prepared steel bar cage is uniform in spacing and high in accuracy; mechanical rotation, bar coiling and main bar winding are tight; and forming is performed and then an internal reinforcing rib is adopted, so that the concentricity of the steel bar cage is ensured.

Owner:青岛昊河水泥制品有限责任公司

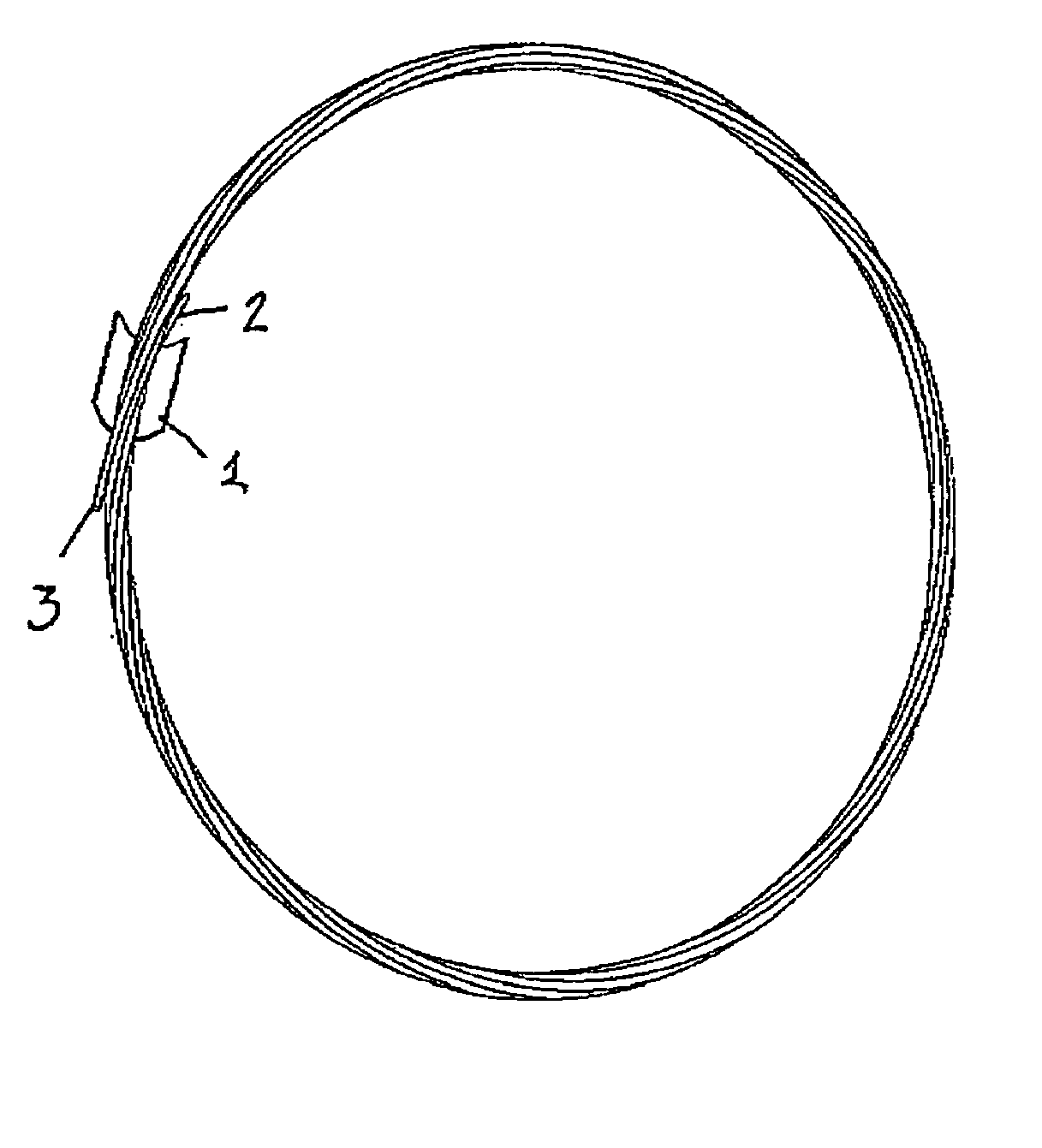

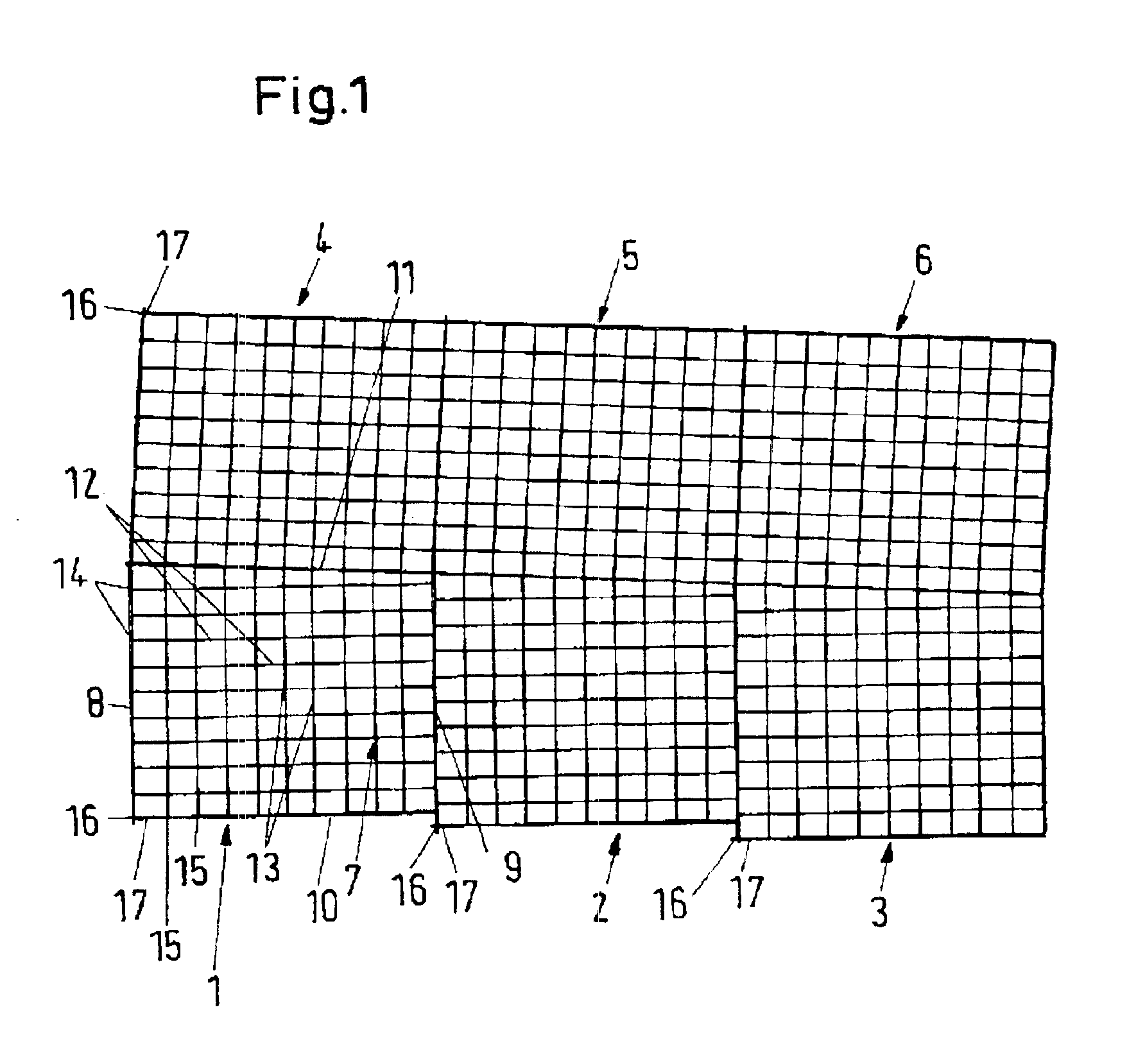

Wire ring net for rocky wall barriers and method for making it

InactiveUS7108233B2Optimum strength and constructional characteristicIncrease clamping forceMeshed-ring wire networkProtective constructionElectric wireEngineering

A wire ring net, particularly for providing barriers for rocky walls and the like comprises a plurality of braided wire rings, each wire ring comprising, at a starting end of its wire, a first curled portion wound about the wire of the first turn and, at the terminal, end of the wire, a second curled portion wound about the rope forming the wire ring.

Owner:IGOR

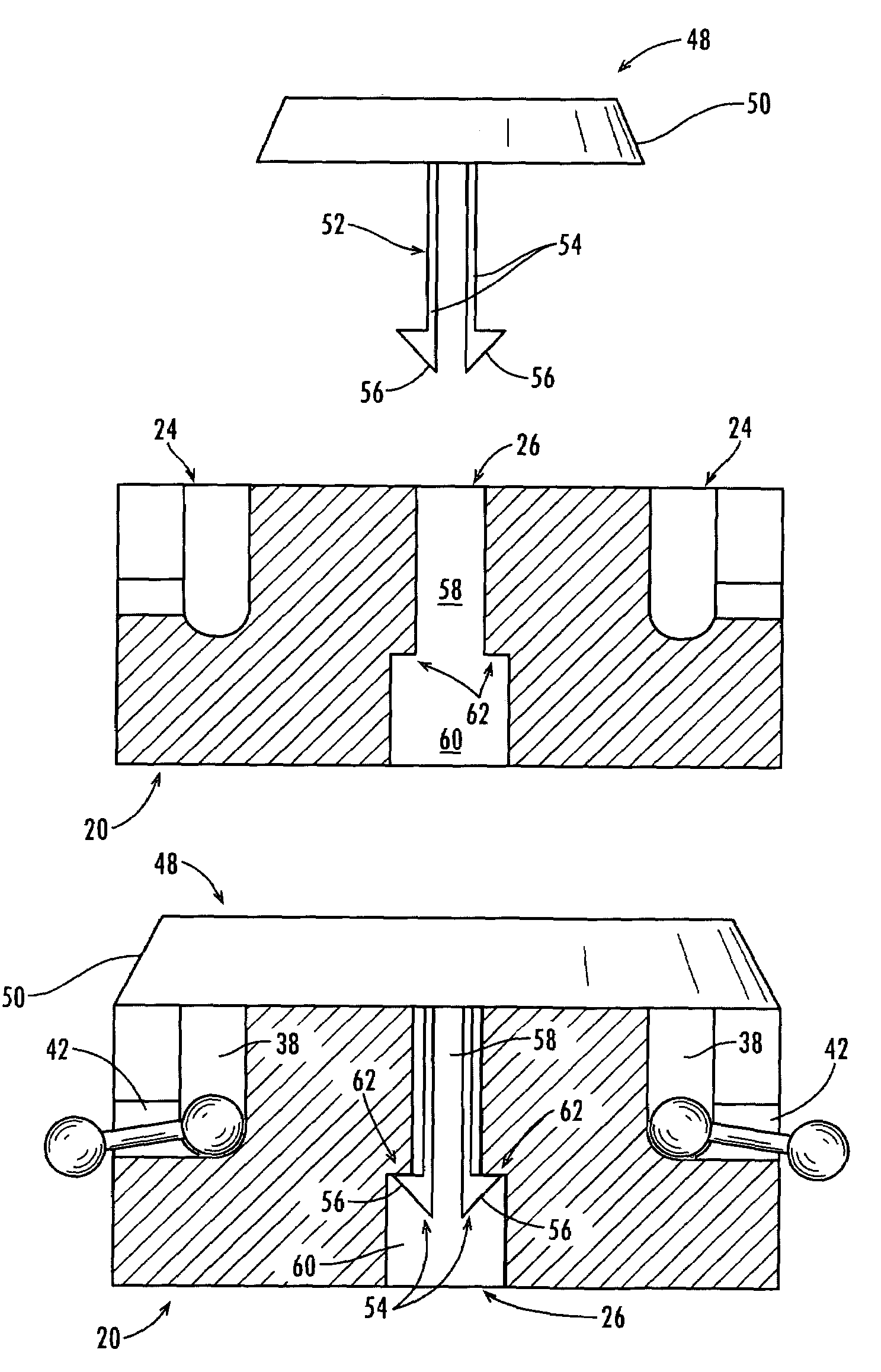

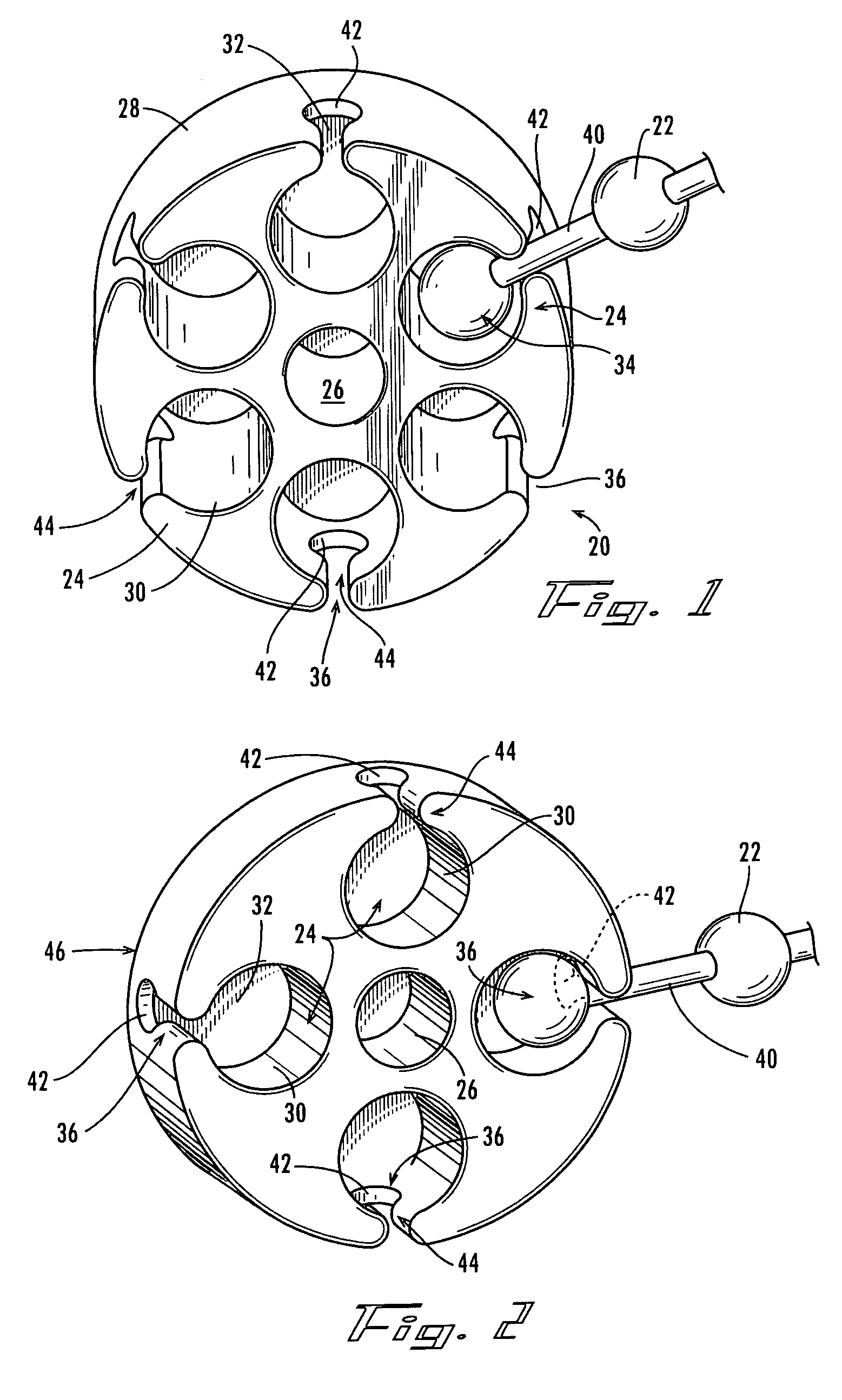

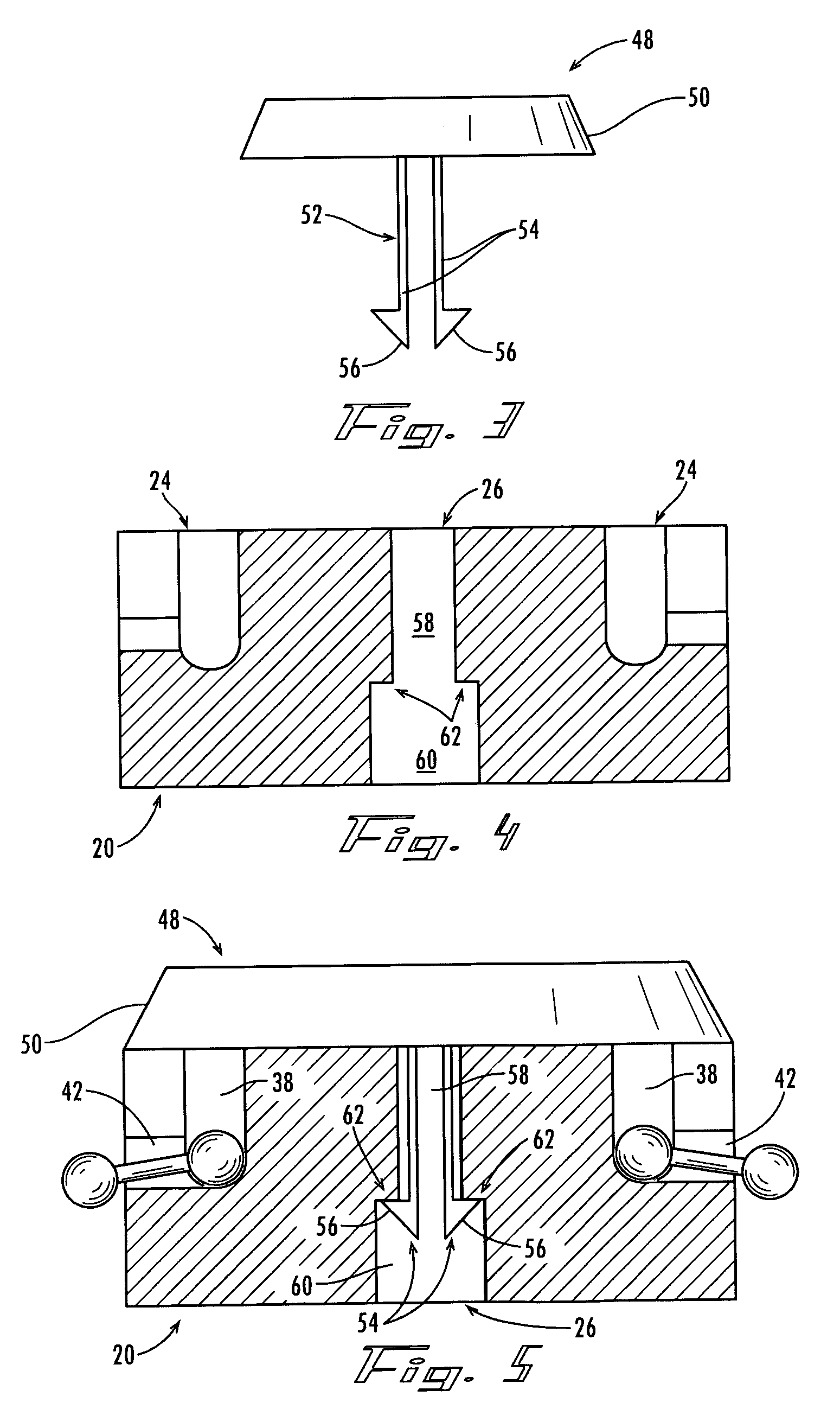

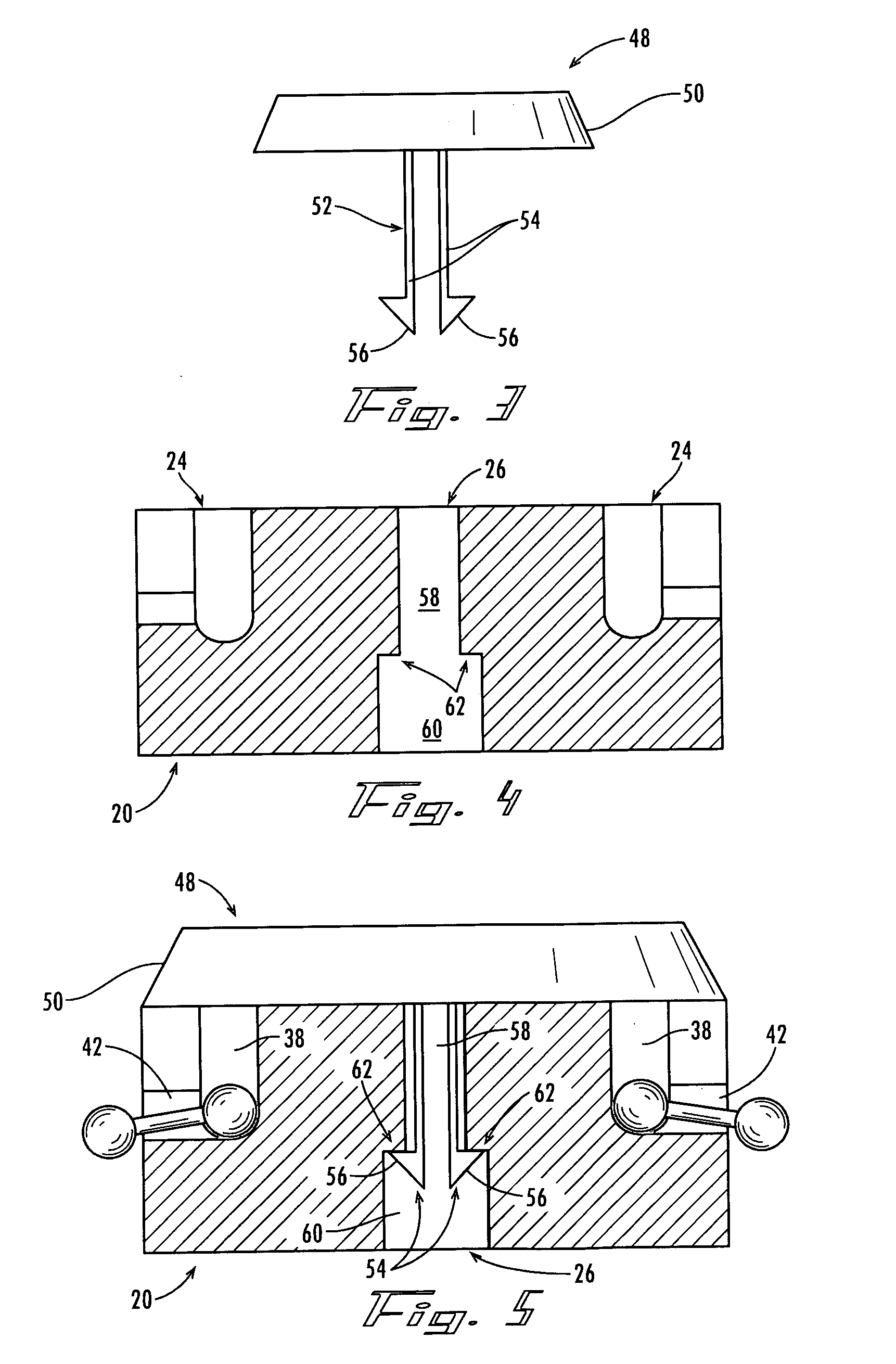

Mesh and methods and apparatus for forming and using mesh

ActiveUS20070042210A1Improves Structural IntegrityAttractive appearancePig casting plantsLayered productsMulti materialPlastic materials

A method of forming a mesh by a moulding a link element around other link elements to form a mesh in which the interlinking link elements are formed as continuous unjoined loops by a moulding process. An apparatus for forming a mesh including a plurality of first cavities for accommodating first link elements and a plurality of second cavities for forming interlinking link elements. The method and apparatus allow the continuous production of mesh formed of a range of materials including plastics materials.

Owner:HAMMOCK IP LTD

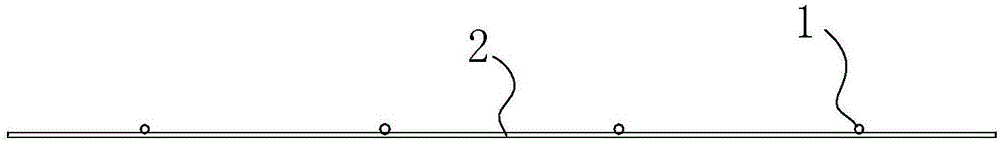

Pile foundation steel bar cage manufacturing method

ActiveCN104532829AReduce assembly positioning problemsImprove construction qualityMeshed-ring wire networkBulkheads/pilesCircular discSteel bar

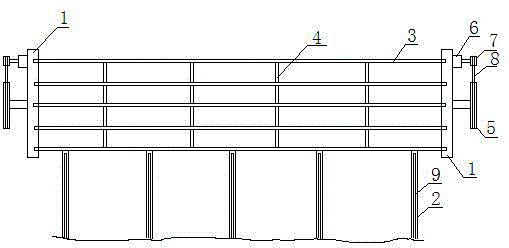

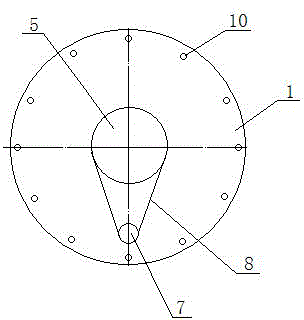

The invention discloses a pile foundation steel bar cage manufacturing method which includes the following operation steps that grooves are formed in the ground, location discs are arranged on two sides of a first groove and a last groove, planes of the two location discs face each other, through holes for vertical steel bars to rotate are evenly formed in the edge of the location discs, a chain wheel A is arranged on one side of each location disc, a motor is arranged adjacent to the chain wheel A, and a chain wheel B is arranged on an output shaft of the motor. A support disc is evenly arranged between the location discs, two ends of the vertical steel bars are fixed in the through holes, and the middles of the vertical steel bars are fixed in location grooves of the support disc. The starting ends of stirrups are fixedly welded with the vertical steel bars, the location discs are rotated to fasten the stirrups to the surface of the vertical steel bars, then the tail ends of the stirrups are fixedly welded, spot welding is conducted on the other contact parts, and manufacture of a basic steel bar cage is finished. The method solves the problem that the vertical steel bar is inaccurate in position during welding, and construction quality and working efficiency are improved.

Owner:GUIZHOU XINLIAN BLAST ENG GRP

Automatic welding device of reinforcement cage seam welder

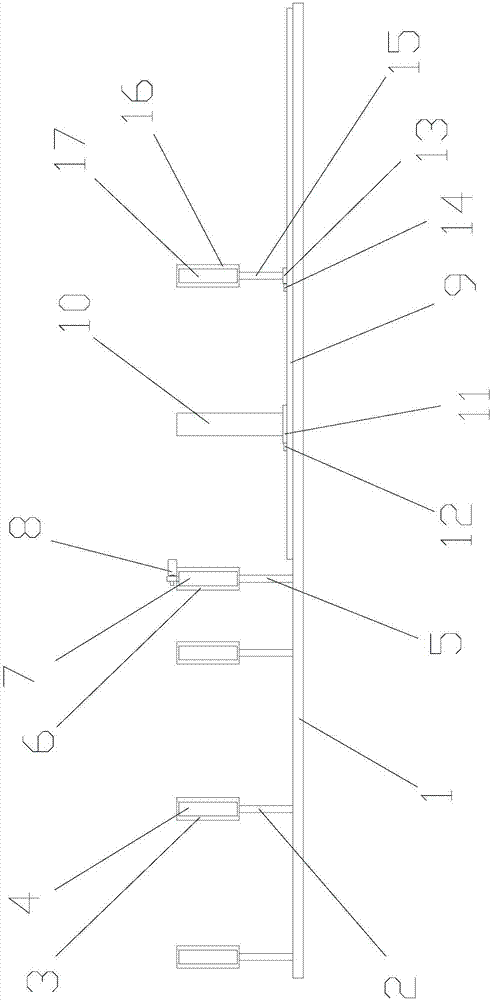

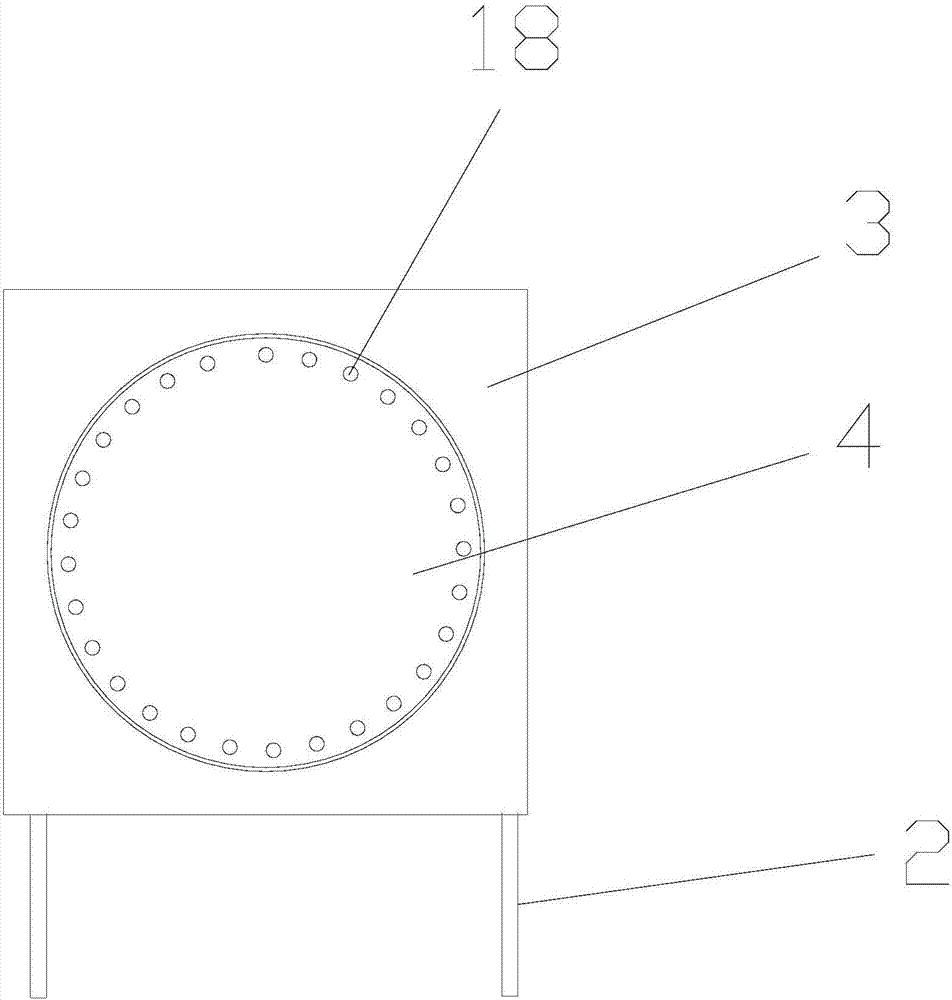

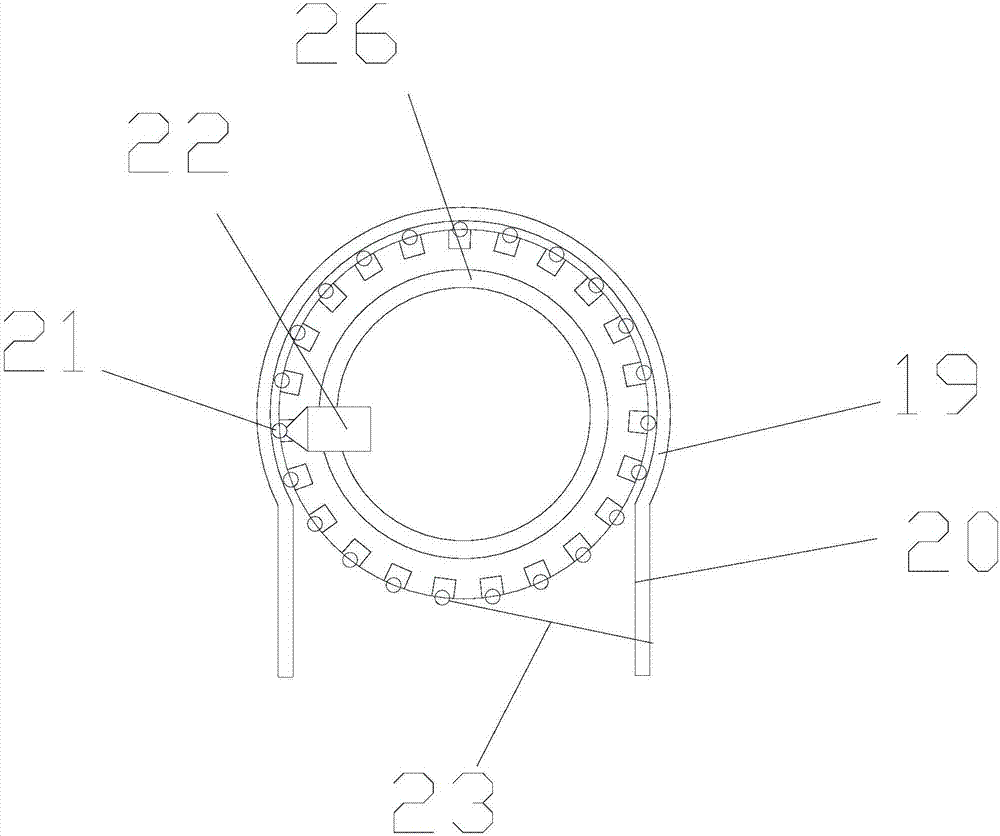

ActiveCN105171294AMeet verticalMeet the needs of lateral displacementMeshed-ring wire networkWelding/cutting auxillary devicesSlide plateEngineering

The invention belongs to the technical field of reinforcement cage seam welding equipment and particularly relates to an automatic welding device of a reinforcement cage seam welder. The automatic welding device comprises a welding support arm, a lifting mechanism of the welding support arm, a welding wire support rod, an arc-shaped bracket of the welding wire support rod, a welding hand mechanism and a welding handle clamping mechanism. The welding support arm is of a horizontal Z shape. A linear rail I and a slide plate connected to the linear rail I in a sliding and matching mode are arranged at the lower end of the welding support arm in the longitudinal direction, and the slide plate is fixedly connected to the lifting mechanism. A tension spring is arranged between a slide block I and the linear rail I in the longitudinal direction. The welding wire support rod and the arc-shaped bracket of the welding wire support rod are arranged on the top of the upper end of the welding support arm. A linear rail II and a slide block II connected to the linear rail II in a sliding and matching mode are arranged on the bottom of the upper end of the welding support arm. An air cylinder I is arranged between the slide block II and the linear rail II, and the slide block II is fixedly connected to the welding hand mechanism. The automatic welding device can replace manual welding to improve the welding efficiency, lower the labor intensity of workers and improve the welding quality.

Owner:郑州市聚能建筑机械有限公司

Ball chain and connector for tessellated patterns

InactiveUS20050199008A1Meshed-ring wire networkBuilding locksMechanical engineeringBuilding construction

A ball chain assembly may be used to form tessellated patterns of ball chains. The ball chains include a series of balls and intermediate links of a breadth less than the breadth of said balls. A chain connector of one-piece construction defines a circular array of ball-receiving sockets. Each of the sockets are sized to receive a ball of one of said chains. A ball of the chain can be inserted into one of the sockets of the chain connector where a link of the inserted ball passes through the slot extending from the socket, such that a chain can be connected to each of the sockets.

Owner:BOLAND PAUL E

Processing equipment of reinforcing steel bar frame for electric power construction

The invention discloses processing equipment of a reinforcing steel bar frame for electric power construction. The processing equipment comprises a bearing plate and a supporting seat arranged under the bearing plate, wherein the cross section of the supporting seat is quadrangular; at least two grooves for clamping reinforcing steel bars are formed in the inner wall of the bearing plate; the grooves are formed at an equal interval in the height direction of the bearing plate; positioning plates are arranged above the supporting seat; the number of the positioning plates is four, and a quadrangular structure is formed by the four positioning plates; clamping slots of which the positions correspond with those of the grooves are formed in the four positioning plates; two air cylinders are arranged in the middle part of a position above the supporting seat, are positioned at a diagonal line of the supporting seat, and are oppositely arranged; a pressure plate is arranged on a telescopic rod of each of the two air cylinders. According to the processing equipment disclosed by the invention, a method for fixing by using the inner positioning plates and extruding by using external reinforcing steel bar pressed buckles is adopted, so that bending the reinforcing steel bars is realized, and processing the reinforcing steel bar frame is facilitated.

Owner:中国电建集团河北工程有限公司

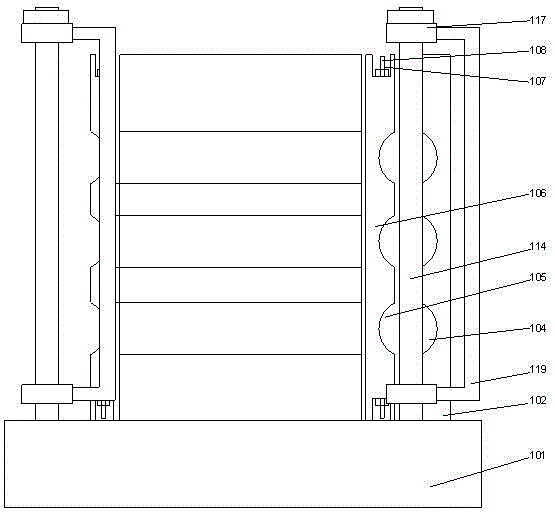

Turntable movement and transmission mechanism of numerical control steel reinforcement cage forming machine

The invention discloses a turntable movement and transmission mechanism of a numerical control steel reinforcement cage forming machine. The turntable movement and transmission mechanism comprises a frame base, a movable base and a turntable. A transmission device for dragging the movable base to move comprises a first chain, a second chain, a transmission driving mechanism, a second shaft, a first driven chain wheel and a second driven chain wheel, wherein the first chain and the second chain are parallel; the transmission driving mechanism is fixed at one end of the movable base; the second shaft is connected with the transmission driving mechanism and can rotate; and the first driven chain wheel and the second driven chain wheel are fixed at both ends of the second shaft and respectively engaged on the first chain and the second chain. The turntable movement and transmission mechanism has the advantages of simple structure, convenient maintenance and stable work and realizes that the turntable moves while rotating so as to wind stirrups on a main rib. Synchronous belt wheels and the chain wheels are used for transmission, thereby guaranteeing that two rollers are synchronous, avoiding the turntable from deflecting in the process of moving, guaranteeing the quality of a steel reinforcement cage, lightening the labor intensity of workers and improving the production efficiency.

Owner:TJK MACHINERY TIANJIN

Concrete pole reinforcement cage manufacturing device

ActiveCN106938308AQuality improvementEasy to processMeshed-ring wire networkWire networkDrive motorEngineering

The invention discloses a concrete pole reinforcement cage manufacturing device. The device comprises a loading positioning device, a rotating device, a welding forming device and a traction device correspondingly matched and connected to fixed plates; the loading positioning device includes a first turntable rotationally matched and connected in a first fixed plate; the first turntable is provided with a first positioning hole; the rotating device includes a second turntable and a driving motor arranged on a second fixed plate; the second turntable is provided with a second positioning hole; the welding forming device includes a winding rib arrangement plate; the winding rib arrangement plate is connected with a third turntable provided with a third positioning hole; the third turntable is connected with a welder corresponding to the third positioning hole; the traction device includes an annular plate connected with the third fixed plate; and a locking screw is arranged on the annular plate. The concrete pole reinforcement cage manufacturing device has the following advantages: the device is provided with the loading positioning device, the traction device and the welding forming device matched with each other, realizes automatic welding formation, is convenient to machine and fast in speed, forms a circle by main ribs, uniformly distributes winding ribs, and is excellent in quality of a formed reinforcement cage.

Owner:永立杆塔股份公司

Numerical control reinforcement cage forming machine

PendingCN112605564ARealize automatic processingReduce labor intensityMeshed-ring wire networkWelding/cutting auxillary devicesNumerical controlMolding machine

The invention belongs to the technical field of reinforcement cage machining, and discloses a numerical control reinforcement cage forming machine. The numerical control reinforcement cage forming machine comprises a welding box, a stirrup feeding mechanism, a main reinforcement storage mechanism, a traction mechanism and a welding mechanism, wherein the stirrup feeding mechanism is mounted on the welding box; the main reinforcement storage mechanism is located on one side of the welding box; the traction mechanism is arranged at the downstream position of the stirrup feeding mechanism and can move relative to the welding box in the first horizontal direction; the welding mechanism comprises a first welding mechanism body and a second welding mechanism body, the first welding mechanism body and the second welding mechanism body are both mounted on the traction mechanism and can move in the first horizontal direction along with the traction mechanism, the first welding mechanism body can be driven by the traction mechanism to move in the vertical direction and the second horizontal direction, the second horizontal direction is perpendicular to the first horizontal direction, and the first welding mechanism body and the second welding mechanism body are configured to clamp main reinforcements and weld the contact positions between the main reinforcements and stirrups. According to the numerical control reinforcement cage forming machine, the reinforcement cage can be automatically machined, the automation degree is high, the labor intensity of workers and potential safety hazards are reduced, and the machining efficiency is improved.

Owner:TJK MACHINERY TIANJIN

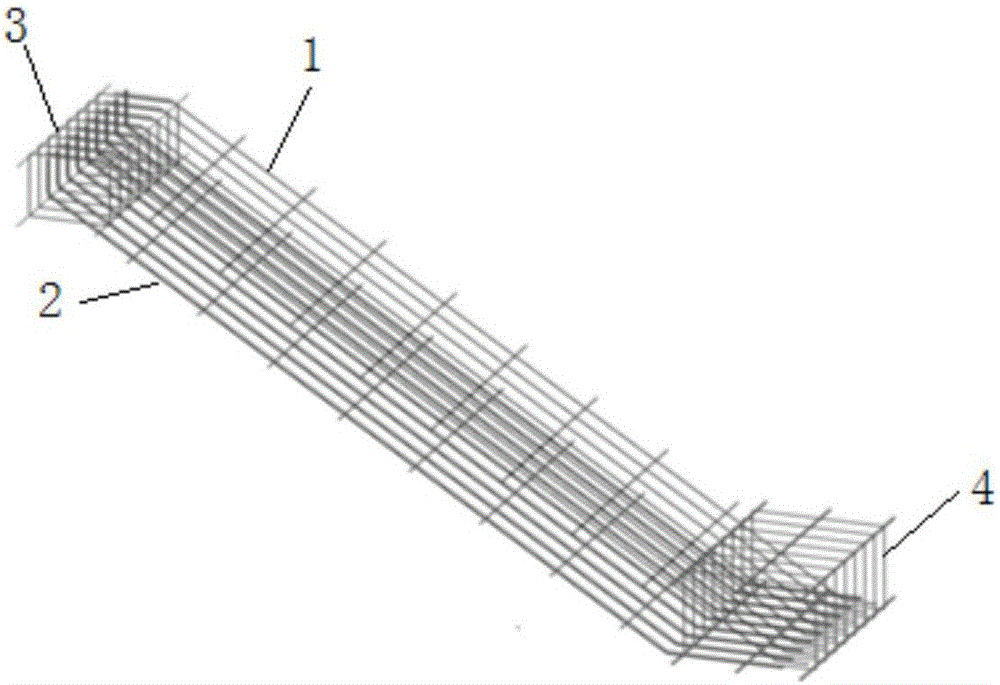

Machining method of cylindrical reinforcement cage

ActiveCN106238630AImprove processing efficiencyStrapping is stable and reliableMeshed-ring wire networkLow latitudeKeel

The invention relates to machining methods and devices of a cylindrical reinforcement cage. The machining method of the cylindrical reinforcement cage comprises the steps that sheet-shaped reinforcement meshes are machined; the sheet-shaped reinforcement meshes are bent into deep U shapes or shallow U shapes; then, the middle portions of the shallow-U-shaped reinforcement meshes are bent again to form U-shaped structures, the reinforcement meshes are made to form cylinders in a surrounding manner, the folded portions of bent reinforcing steel bars are connected, and then the reinforcement cage is formed; or, the two sides of each deep-U-shaped reinforcement mesh is bent oppositely to form a cylinder, the folded portions of the bent reinforcing steel bars are connected, and then the reinforcement cage is formed. The machining method of the cylindrical reinforcement cage has the beneficial effects that the sheet-shaped reinforcement meshes are obtained through a mesh welding machine, the reinforcement meshes are bent, and then the cylindrical reinforcement cage is formed; and the upper latitude reinforcing steel bars and the lower latitude reinforcing steel bars of the cylindrical reinforcement cages are connected correspondingly, and then continuous reinforcement cages can be rapidly machined, and then the continuous reinforcement cages are cut into needed steel reinforcing bar keels or are cut and then connected into the needed steel reinforcing bar keels. The machining method of the cylindrical reinforcement cage solves the bottleneck problem that in a prefabricated wall module, the machining efficiency of the steel reinforcing bar keels is low and creates conditions for wide application of the prefabricated wall module.

Owner:赵光林

Wire mesh mat, in particular, for Gabion baskets

InactiveUS6857817B2Simple configurationAvoid risk of breakageMetal-working apparatusRigid containersEngineeringGabion

A wire mesh mat for Gabion baskets for securing slopes has longitudinal wires and transverse wires connected to one another and having wire ends, respectively. At least some of the wire ends have an eye, respectively. The wire ends provided with the eye have a compensation section configured to compensate expansions and compressions occurring in a longitudinal direction of the wires. The compensation section has two legs and the eye is positioned between the two legs of the compensation section.

Owner:ROTHFUSS THOMAS

Reinforcement cage forming machine

InactiveCN104759564AReasonable structureLow costMeshed-ring wire networkSmall footprintMachining process

The invention relates to the technical field of building material construction machinery and discloses a reinforcement cage forming machine. The reinforcement cage forming machine comprises a movable rack, rotating racks, a fixed rack, a stirrup pay-off device, a second moving mechanism and a rotating mechanism, a first fixed disc plate is installed on the movable rack, the movable rack can be driven by the second moving mechanism to move in the X-axis direction straightly, and a second fixed disc plate is installed on the fixed rack. According to the reinforcement cage forming machine, the structure is reasonable, a main steel bar is fixed in the machining process, so that a stirrup is wound on the main steel bar spirally, rotating equipment which is large in size is not needed to be used, the fabrication cost of the reinforcement cage forming machine is reduced, the floor area is reduced, so that the reinforcement cage forming machine is low in fabrication cost, small in floor area and high in fabrication efficiency, meanwhile, the two rotating racks are adopted, so that the reinforcement cage forming machine can drive two stirrups to rotate in the positive direction and in the negative direction respectively, the net-shaped stirrups of a spiral structure are formed on the main steel bar, and the external pressure bearing capacity of a finished reinforcement cage is greatly improved.

Owner:海盐海潮水泥制管股份有限公司

Processing technology for production of precast stair reinforcement cage

ActiveCN106825337AImprove machining accuracySave human effortMeshed-ring wire networkEngineeringRebar

The invention discloses a processing technology for production of a precast stair reinforcement cage. The processing technology comprises the steps that (1) according to the structure of the precast stair reinforcement cage to be machined, the precast stair reinforcement cage to be machined is divided into a plurality of reinforcement cage components to be machined, the reinforcement cage components to be machined include the upper hidden beam reinforcement cage component, the lower hidden beam reinforcement cage component, an upper iron net and a lower iron net, and the upper iron net and the lower iron net correspond to the slope of a stair; (2) reinforcement welded nets are machined for the reinforcement cage components through welded net production equipment; and (4) the upper hidden beam reinforcement cage component, the lower hidden beam reinforcement cage component, the upper iron net and the lower iron net are assembled together. By means of the processing technology, the stair reinforcement cage is not tied manually any longer, the processing efficiency is improved, and the processing precision of the stair reinforcement cage is improved as well.

Owner:CHINA CONSTR SCI & TECH CO LTD

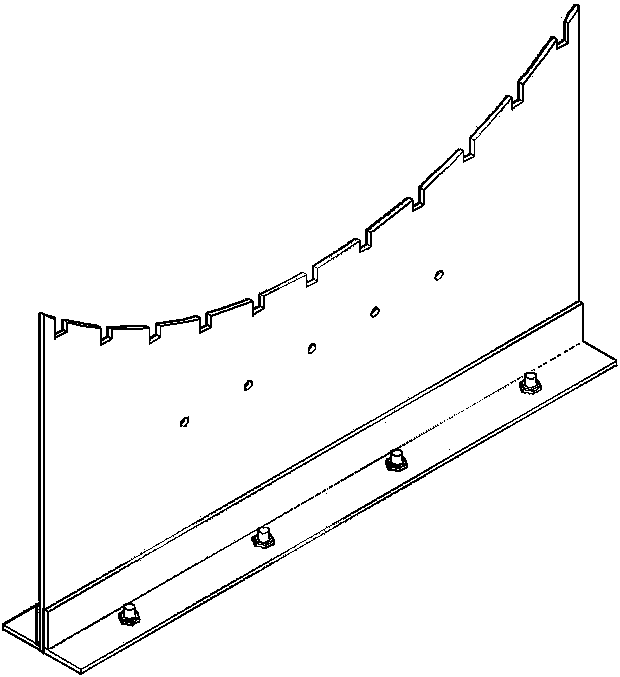

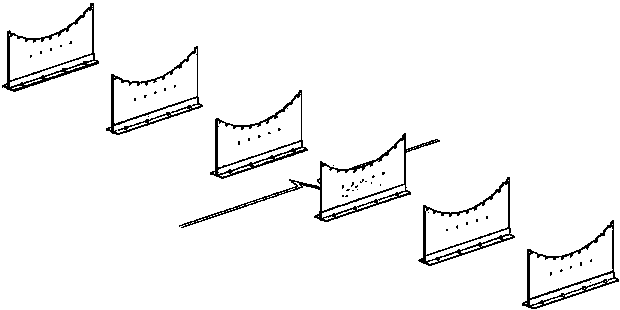

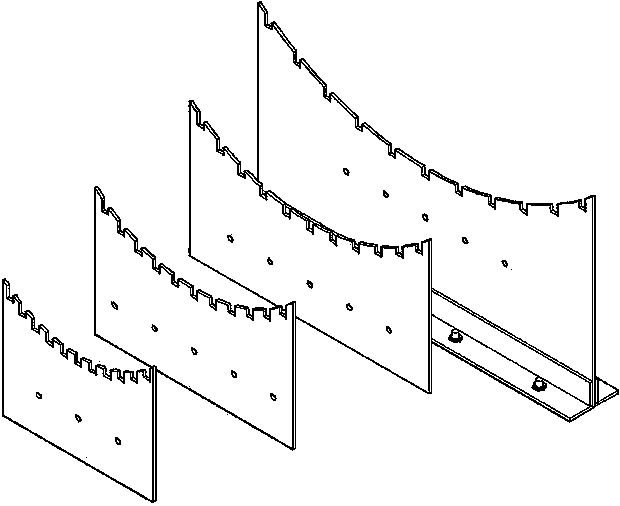

Serration-type steel reinforcement cage machining jig frame and construction method thereof

ActiveCN103586374AImprove processing qualityImprove processing progressMeshed-ring wire networkRebarMachining

The invention discloses a serration-type steel reinforcement cage machining jig frame, and belongs to the field of steel reinforcement cage machining. The jig frame is divided into a main rib welding and forming area and a spiral rib bonding area, wherein the tail portion of the main rib welding and forming area is an arc section, and the upper surface of the main rib welding and forming area is provided with a plurality of notches matched with intervals and diameters of main ribs at equal intervals. The construction method sequentially includes the following steps that the main ribs needing to be welded are placed in the notches of the main rib welding and forming area of each jig frame one by one, firstly, the main ribs on the arc section of each jig frame are welded and roll towards the spiral rib bonding area of the corresponding jig frame after welding, the main ribs sequentially roll, are sequentially welded and ultimately roll to the spiral rib bonding area, and spiral stirrups are bound. According to the jig frame and a construction method of the jig frame, all the main ribs of a machined steel reinforcement cage are evenly distributed, machining quality of the steel reinforcement cage is higher, function requirements can be met on the condition that the machining progress of the steel reinforcement cage is accelerated, construction operators and equipment investment are reduced, and machining cost of the steel reinforcement cage is reduced.

Owner:CCCC SHEC FOURTH ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com