Spiral welding device of conic electric pole reinforcement cage seam welder

A technology of spin welding and welding equipment, applied in auxiliary equipment, welding equipment, welding equipment, etc., can solve the problems of difficult quality assurance, high production cost, complicated operation, etc., and achieve the effect of ensuring welding quality and avoiding noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

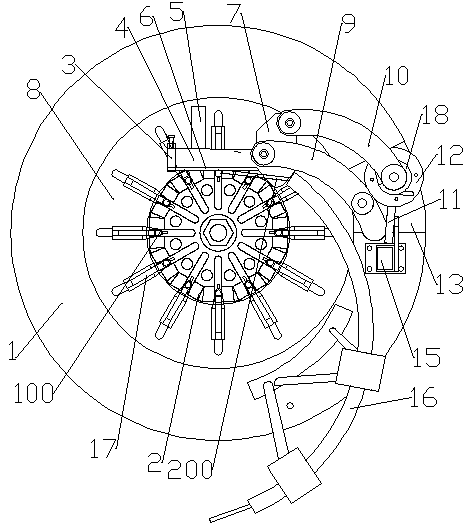

[0010] The specific embodiment of the present invention is illustrated in conjunction with the accompanying drawings, such as figure 1 As shown, the rotary welding device of the conical pole reinforcement cage roll welding machine includes a longitudinal reinforcement fixing device, a welding device and a circumferential reinforcement fixing device; The hoop reinforcement fixing device is used to fix the hoop reinforcement 200, and the hoop reinforcement 200 is vertically fixed on the longitudinal reinforcement 100. The reinforcement bars 200 are wound and welded to the longitudinal reinforcement bars 100 .

[0011] The longitudinal reinforcing bar fixing device comprises a fixed plate 8, and the center of the fixed plate 8 is equipped with a tapered ring-shaped variable diameter die 2, and the variable diameter die 2 is concentric with the fixed plate 8; Diameter slide block 17, the diameter reduction slide block 17 slides radially on the surface of the fixed disk 8 under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com