Patents

Literature

513results about How to "Fast melting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Smelting process of low-grade scrap copper

ActiveCN104131170AFlexible feeding methodFlexible working methodsProcess efficiency improvementScrapSmelting process

The invention discloses a smelting process of low-grade scrap copper. The process comprises the following steps: 1) generation of an initial molten pool; 2) a melting process, namely continuously adding auxiliary materials into a top blowing furnace, inserting a spray gun into melt, spraying oxygen-enriched air and fuel into the melt, carrying out submerged combustion and top-blown smelting, and stopping adding the auxiliary materials when the liquid level of the melt in a to-be-blown furnace is 0.3m to 0.5m higher than a bleed hole, repeatedly carrying out smelting and slagging operations after opening the bleed hole for slagging, and stopping charging and melting when the black copper melt surface inside the top blowing furnace ascends to the position which is 100mm to 200mm below the bleed hole; (3) a blowing process, namely exhausting slag inside the top blowing furnace, inserting the spray gun into black copper, and spraying the oxygen-enriched air and fuel to carry out submerged combustion and blowing, and respectively discharging the produced raw copper and blowing slag from a copper discharge hole and the bleed hole; and 4) repeating of the smelting and blowing processes. According to the technical scheme disclosed by the invention, the operation for smelting scrap copper is flexible, and the smelting process is strong in adaptability on raw materials, high in safety, and high in recovery rate of copper and valuable metal.

Owner:TONGLING NON FERROUS METAL GROUP CORP

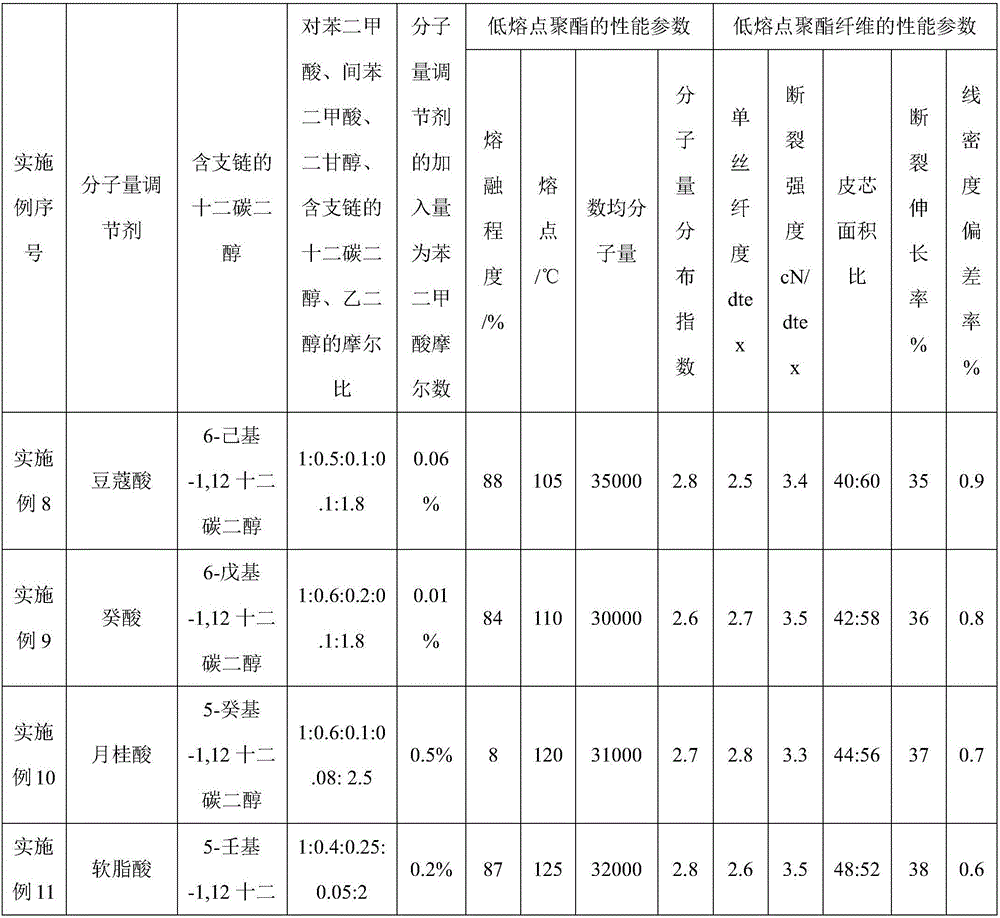

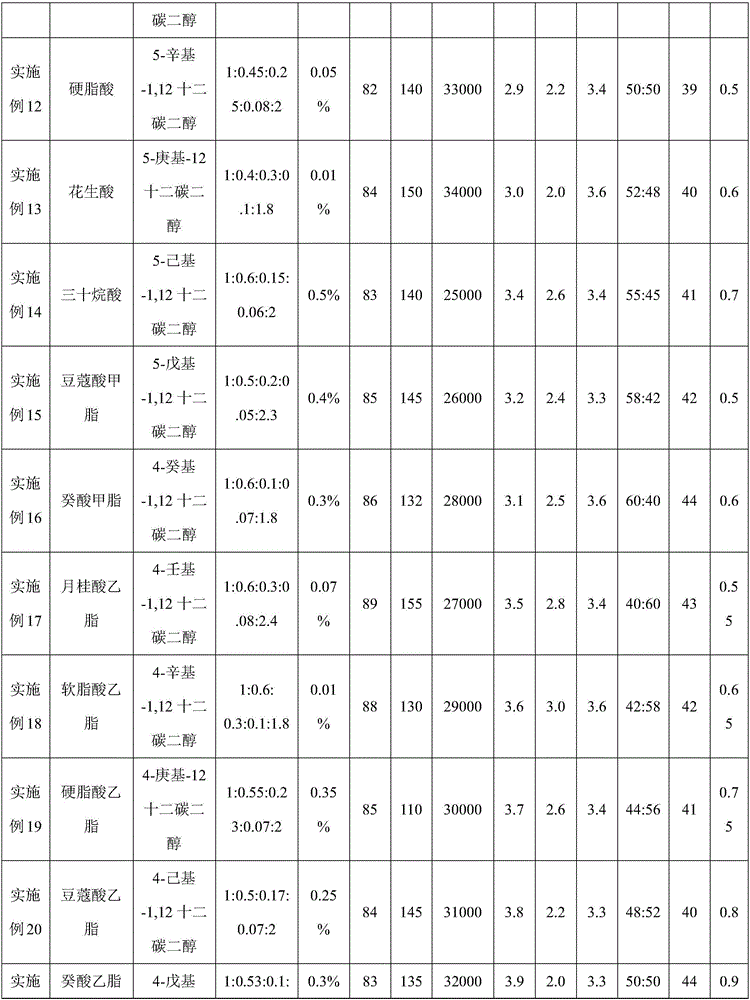

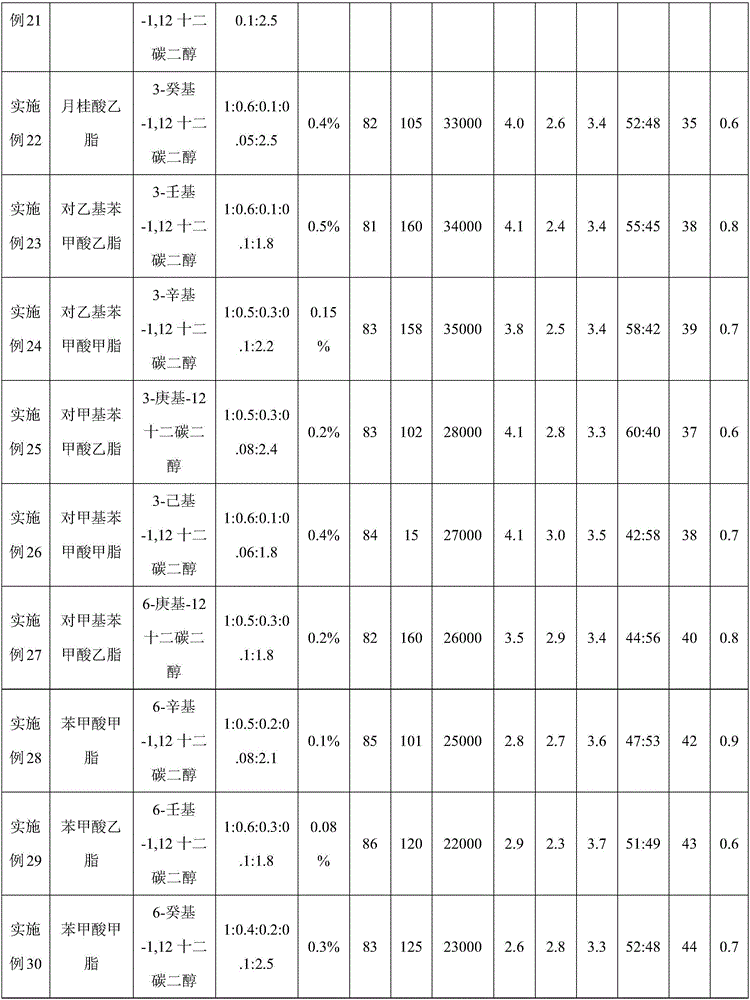

Filament low-melting-point polyester fiber and preparation method thereof

ActiveCN106757518AImprove fitImprove stabilityFilament/thread formingConjugated synthetic polymer artificial filamentsPolymer sciencePolyethylene terephthalate

The invention relates to a filament low-melting-point polyester fiber and a preparation method thereof. The filament low-melting-point polyester fiber is in a skin-core structure, a skin layer is made of low-melting-point polyester; a core layer is made of PET (polyethylene terephthalate); the low-melting-point polyester consists of a terephthalic acid chain segment, an isophthalic acid chain segment, an ethylene glycol chain segment, a diethylene glycol chain segment, a molecular weight modifier chain segment and a 1, 12-Dodecanediol chain segment containing branched chains; a molecular weight modifier corresponding to the molecular weight modifier chain segment is specifically a monoacid series or a diacid series; the preparation method of the filament low-melting-point polyester fiber comprises the following steps: polymerization of the low-melting-point polyester and skin-core composite spinning, so as to obtain the filament low-melting-point polyester fiber. The prepared filament low-melting-point polyester fiber has the advantages that the initial melting point is reduced, the melting speed is increased, the polyester fiber is immediately melted at the corresponding temperature, and the melting effect is good.

Owner:扬州富威尔复合材料有限公司

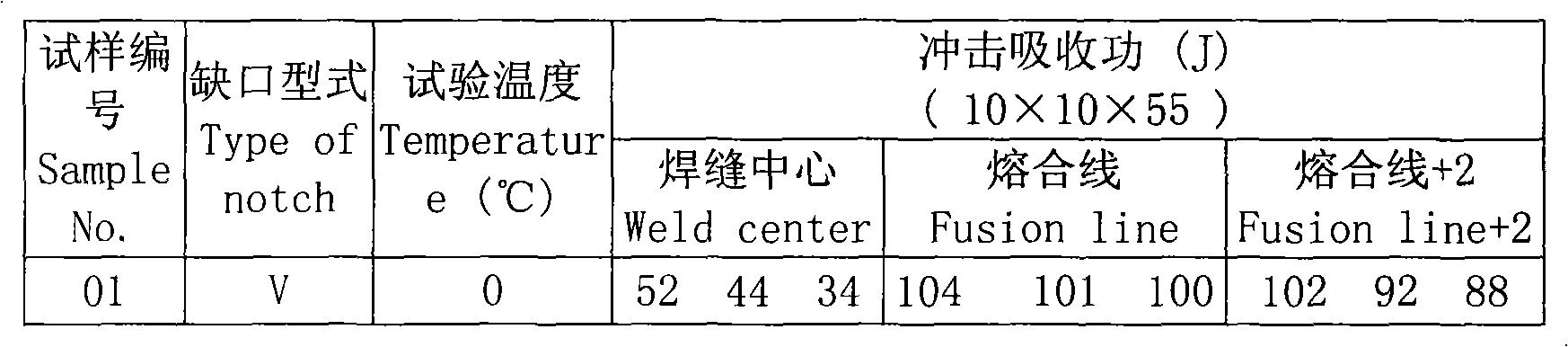

Welding process for carbon steel process pipeline

The invention discloses a welding process for a carbon steel process pipeline. In the welding process, manual argon arc welding is adopted to process a backing weld; flux-cored wire CO2 gas shielded welding is adopted on a filling cover surface; CO2 adsorbs heat in the process of protecting a weld pool, can reduce the temperature on the periphery of the weld pool and take the effect of constricting electric arc, so that the heat input is low and the weld quality is high; the manual arc welding is replaced; no rod stub is generated; few welding slags are generated; little smoke dust is generated; the welding production efficiency is high; and an attractive weld joint is formed.

Owner:江苏利柏特股份有限公司

Environment friendly low-gas-content aluminum alloy ingot and production method thereof

The invention discloses an environment friendly low-gas-content aluminum alloy ingot which comprises the following components in percentage by weight: 1.6-3.3 percent of Cu, 9.8-11.8 percent of Si, 0-0.29 percent of Mg, 0-0.08 percent of Zn, 0-0.8 percent of Fe, 0-0.48 percent of Mn, 0-0.48 percent of Ni, 0-0.1 percent of Ti, 0-0.1 percent of Pb, 0-0.2 percent of Sn, 0-0.25 percent of other trace elements and the balance of aluminum. Meanwhile, the invention also discloses a production method of the environment friendly low-gas-content aluminum alloy ingot. The environment friendly low-gas-content aluminum alloy ingot has the advantages of low gas and dreg content, high aluminum liquid cleanness and good mechanical and machining properties. The production method has the advantages of low production cost and high efficiency and effectively solves the pollution problem of the secondary aluminum industry.

Owner:YE CHIU METAL RECYCLINGCHINALTD

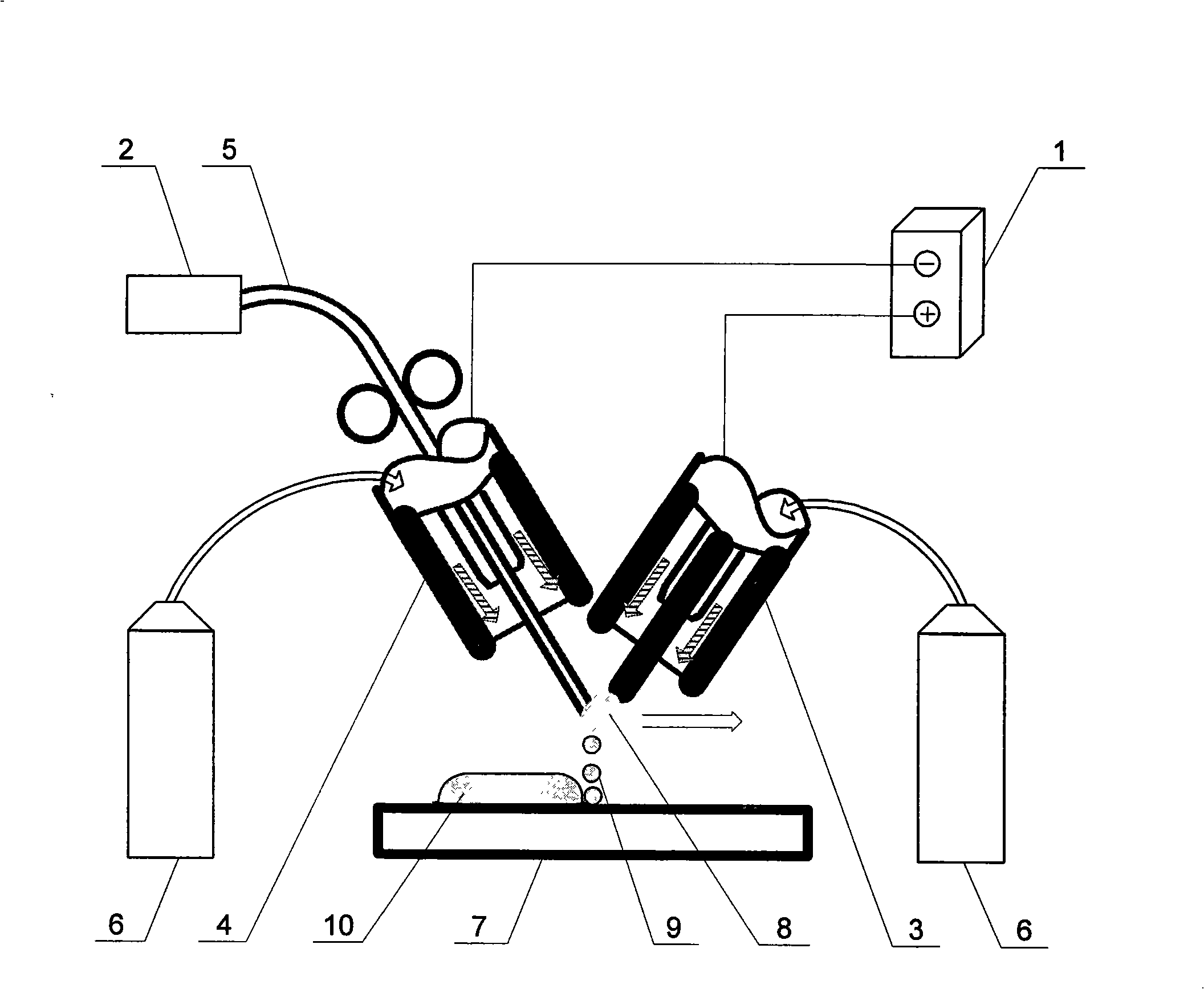

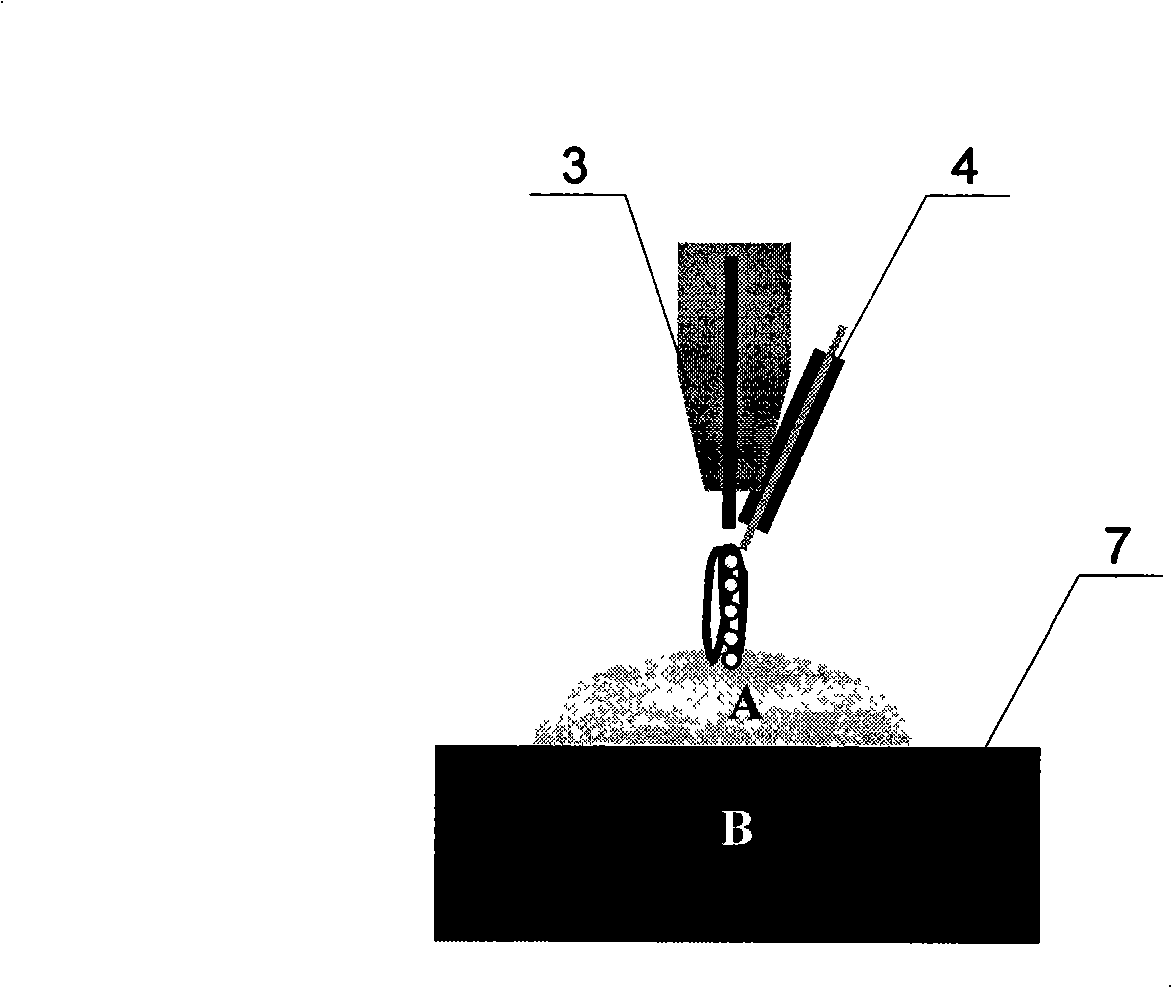

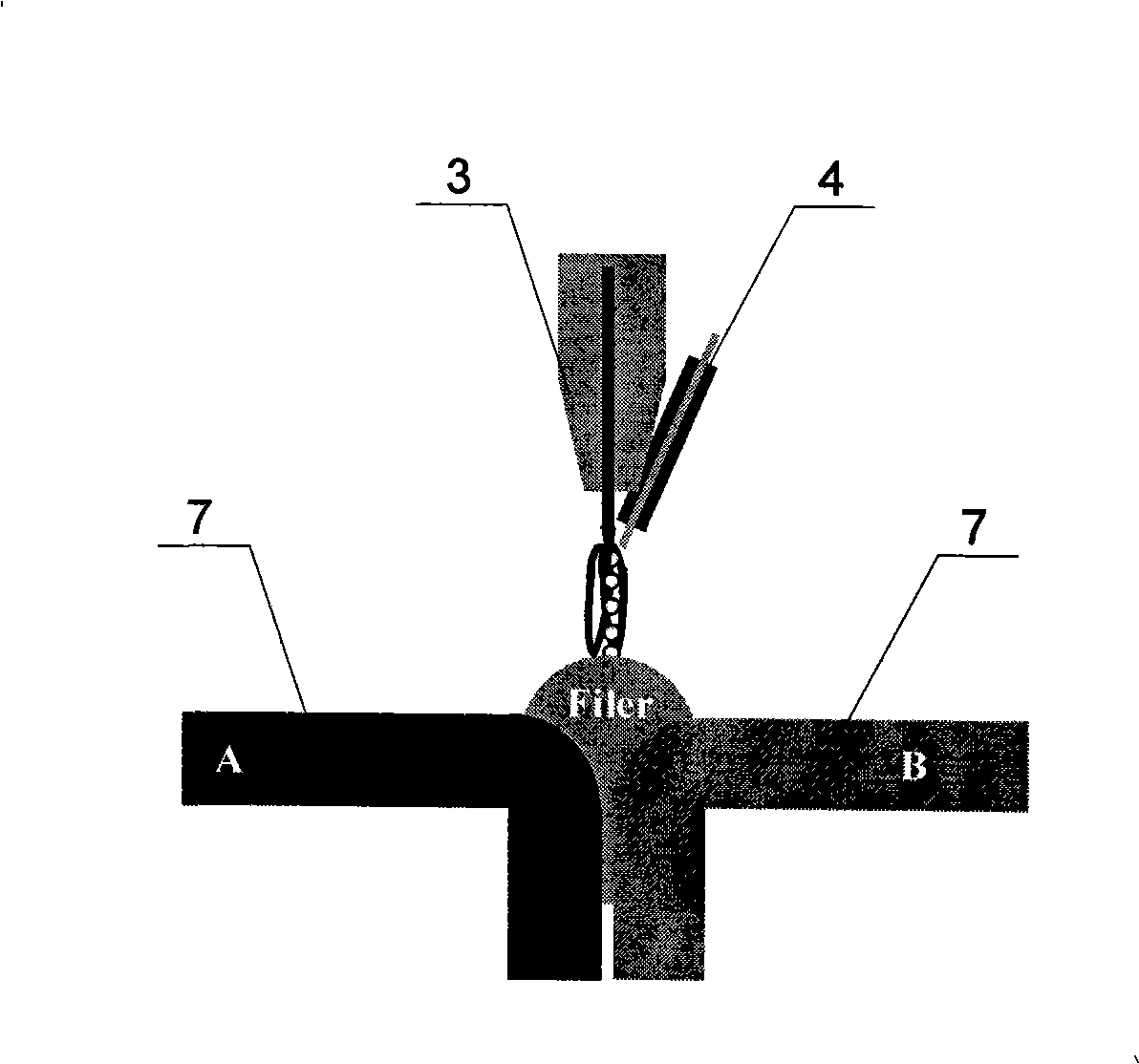

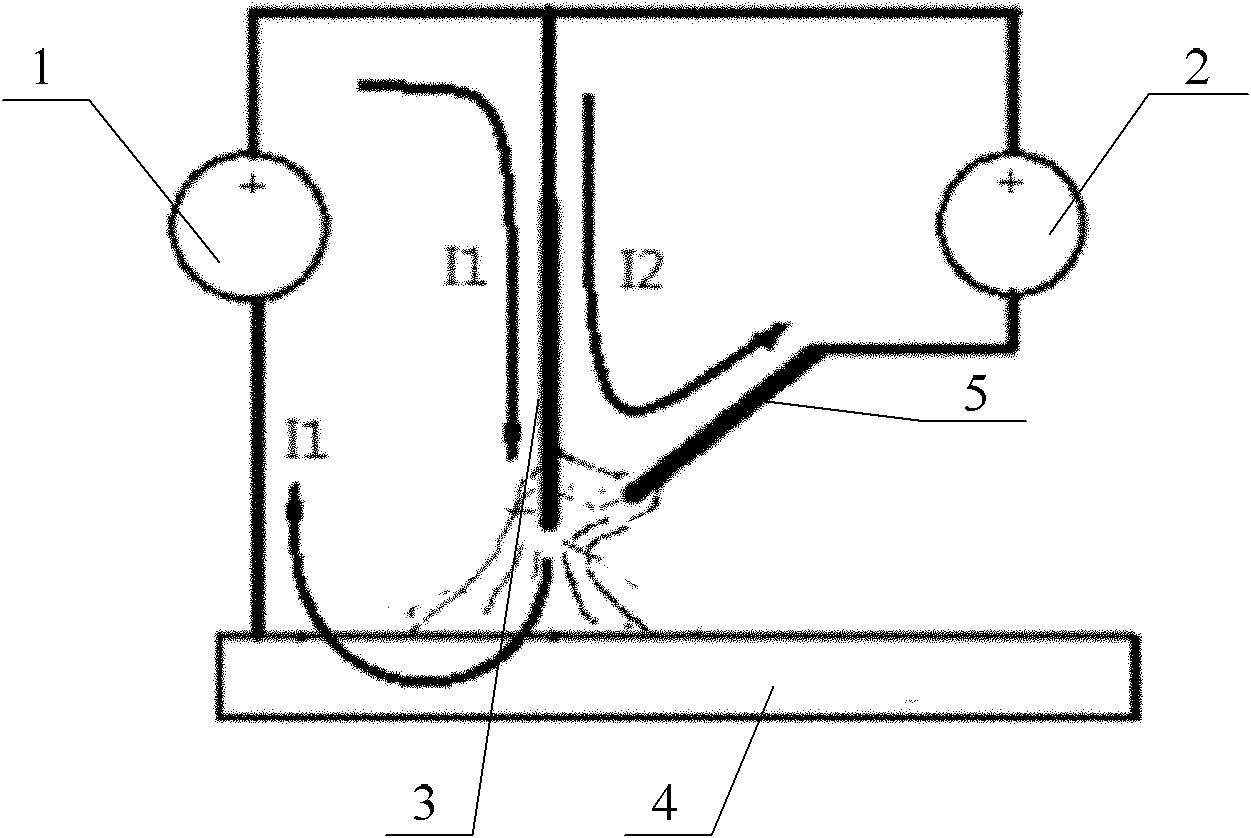

Tungsten electrode-consuming electrode indirect electric arc welding device and its welding method

The invention relates to an indirect arc welding device between tungsten electrode and melting electrode and a welding method thereof, belonging to the technical field of material welding device and welding method, which is used to solve the problems in the prior arc welding devices, such as high hot input, low weld joint deposited ratio and high dilution ratio. The two ends of the welding wire are respectively connected with a wire feeder and a melting electrode welding torch, and exposed outside of the conductive mouth of the melting electrode welding torch. The welding wire is connected with a power supply, and the tungsten electrode welding torch and the melting electrode welding torch are connected respectively with the positive and negative electrodes of GTAW, and the axial point of the two welding torches is on the top of the weldment to be welded, and two protection gas cylinders are connected respectively with the protection gas inlets. Based on the device to weld in a certain welding process, turning on the arc generating switch, and using arc only generated between the tungsten electrode and melting electrode to quickly heat to melt the welding wire, and the droplet of the melted welding wire with heat heats the device indirectly and welds. The welding method has the advantages that the weld joint deposited ratio is increased up to 50g / min and the dilution ratio is controlled within 5%.

Owner:HARBIN INST OF TECH

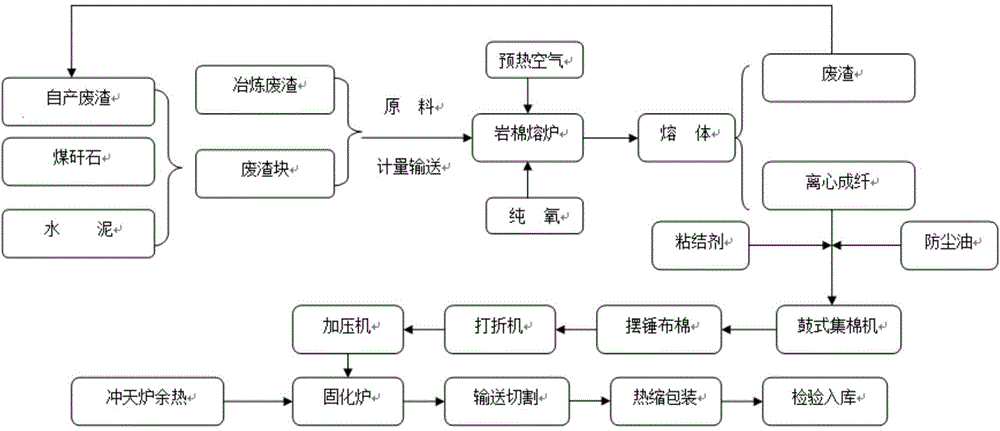

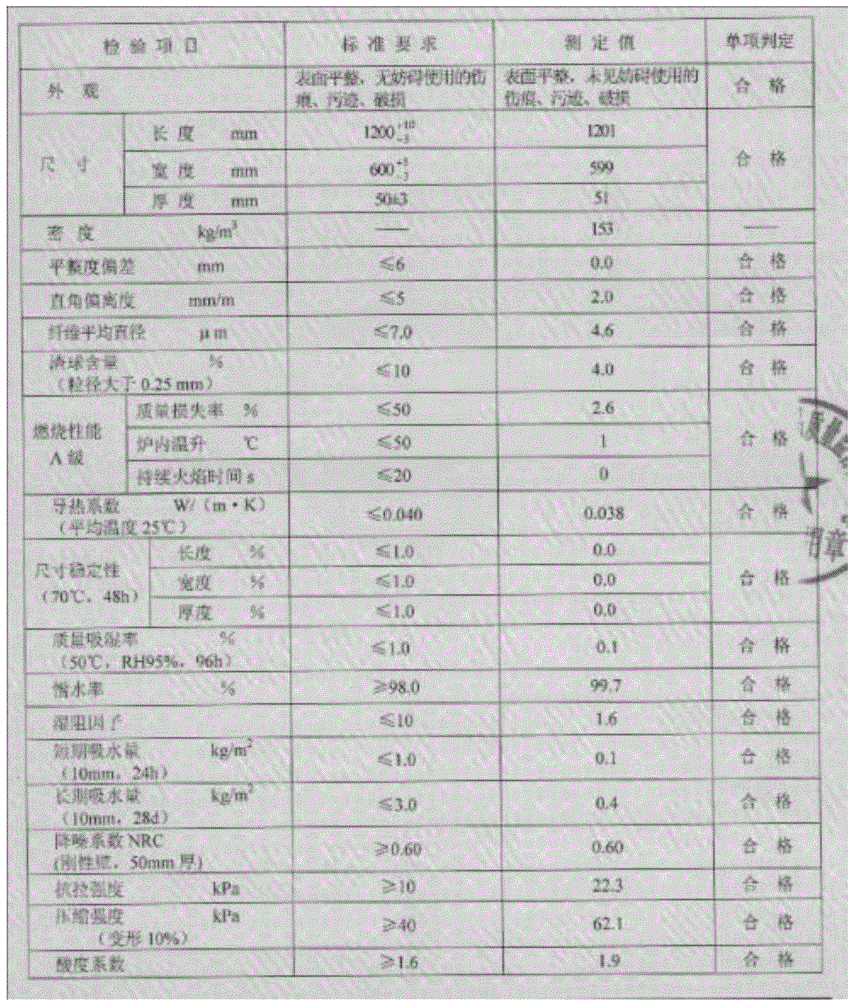

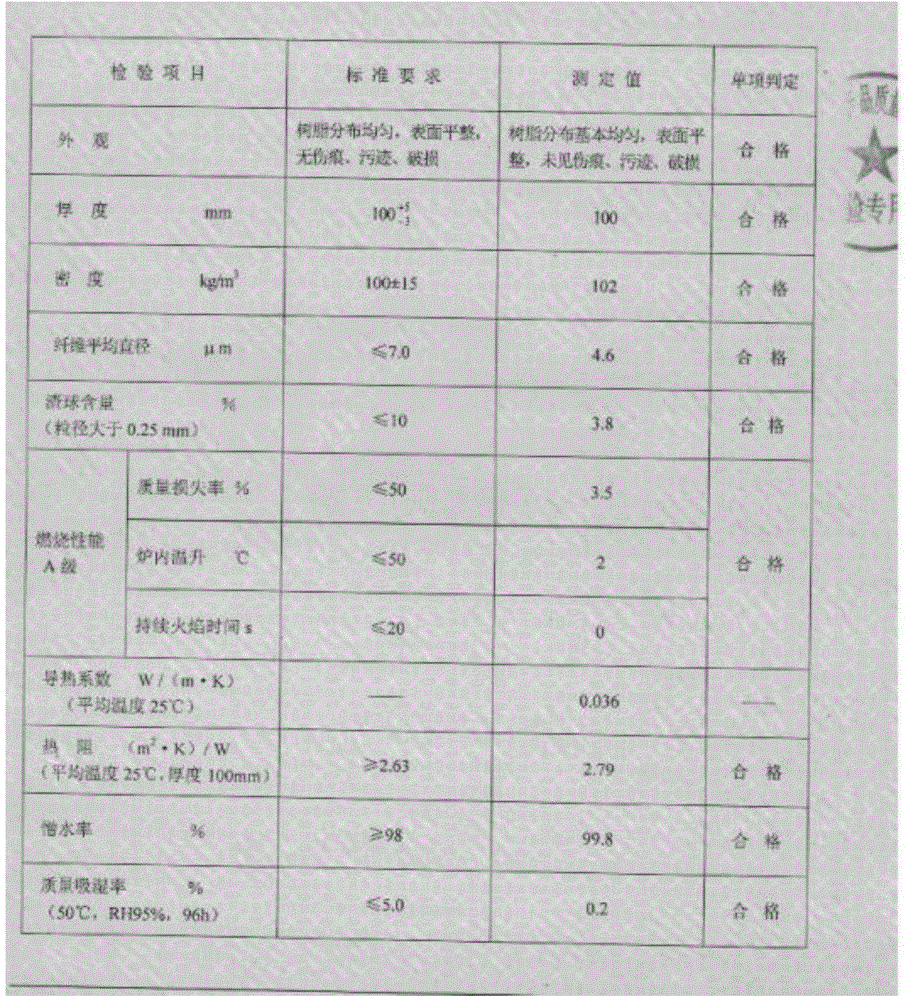

Method and system for producing rock wool by comprehensively utilizing solid wastes

ActiveCN104692648AReduce consumptionLower melting temperatureGlass making apparatusGlass productionFiberAdhesive

The invention discloses a method and system for producing rock wool by comprehensively utilizing solid wastes. The method comprises the following steps: a) uniformly mixing rock wool waste residue, coal gangue and cement in a mass ratio of (50-70):(20-35):(10-20) to prepare an autoclaved waste residue block; b) uniformly mixing the autoclaved waste residue block and smelting waste residue in a mass ratio of (60-80):(20-40) to obtain a mixture; c) melting the mixture at high temperature, and centrifuging at high speed for fiber formation, thereby obtaining fibers; and d) spraying an adhesive, a water repellent and a coupling agent on the fibers, and carrying out wool accumulation, solidification and cutting to obtain the rock wool plate. The method has the advantages of simple technological equipment, low energy consumption and recoverable heat source, is convenient to operate, comprehensively utilizes the solid wastes instead of the traditional basalt and dolomite to produce the rock wool product, and thoroughly solves the problem of solid wastes in the rock wool enterprise.

Owner:TAISHI ROCK WOOL

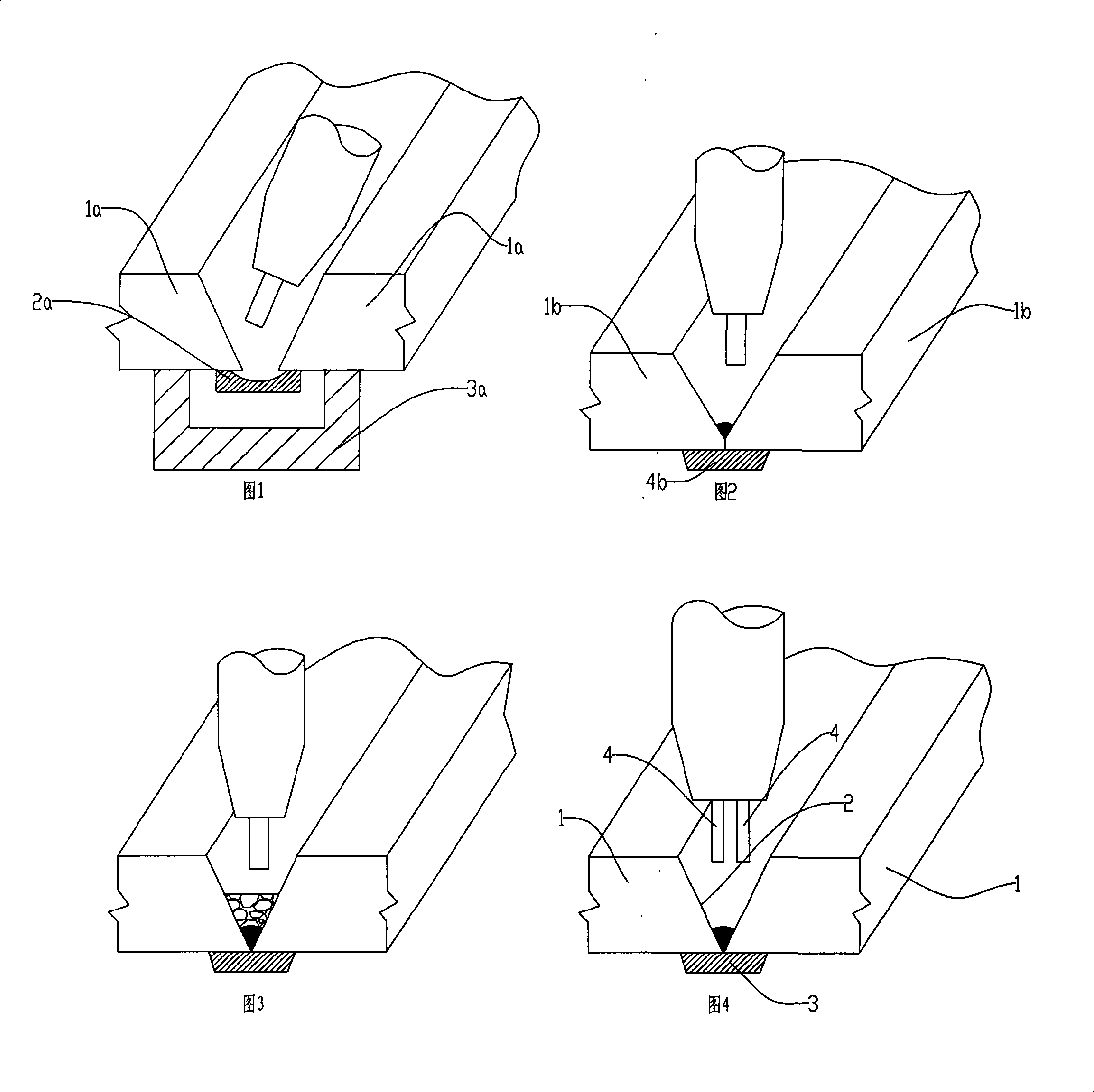

Main plate opposing connection welding method

InactiveCN101342629AFast meltingImprove deposition efficiencyArc welding apparatusButt jointActive force

The invention discloses a butt-jointing and welding method of plates. The bases of the grooves of two plates which need to be welded are butt-jointed closely and are fixed in the groove through spot welding. A ceramic pad is stuck at the bottom of the butt-jointing place by an aluminum foil. Two parallel and separated thin welding wires are used to treat welding seam by submerged arc-welding. The butt-jointing and welding method effectively shunts the welding current to the two thin welding wires, not only improves the melting efficiency of the welding wire, but also avoids the excessive concentration of the active force of electric arc, not only has high welding efficiency, but also is easier to achieve a balance state to form the welding seam under the support of surface tension and the ceramic pad.

Owner:中船海洋与防务装备股份有限公司

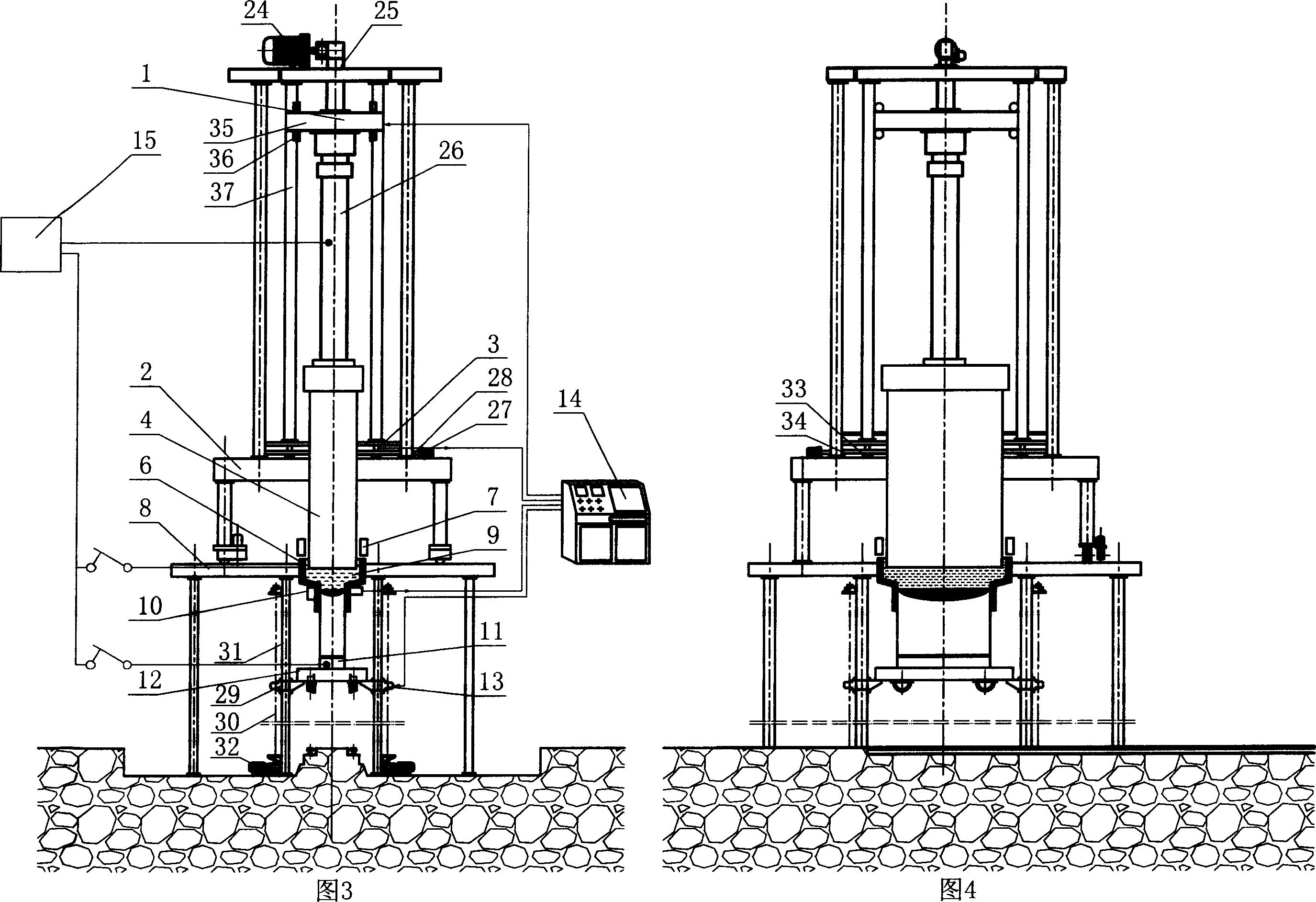

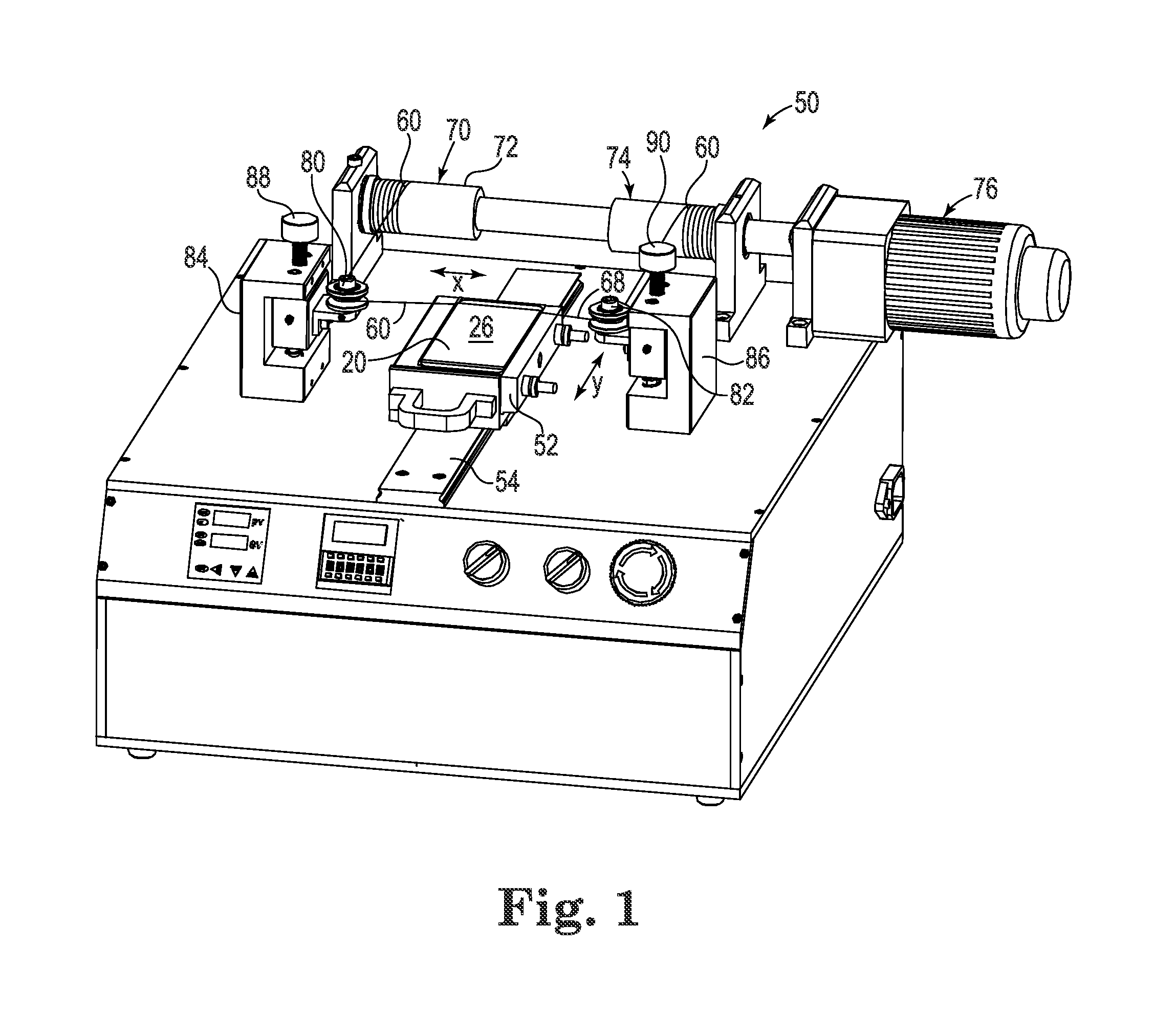

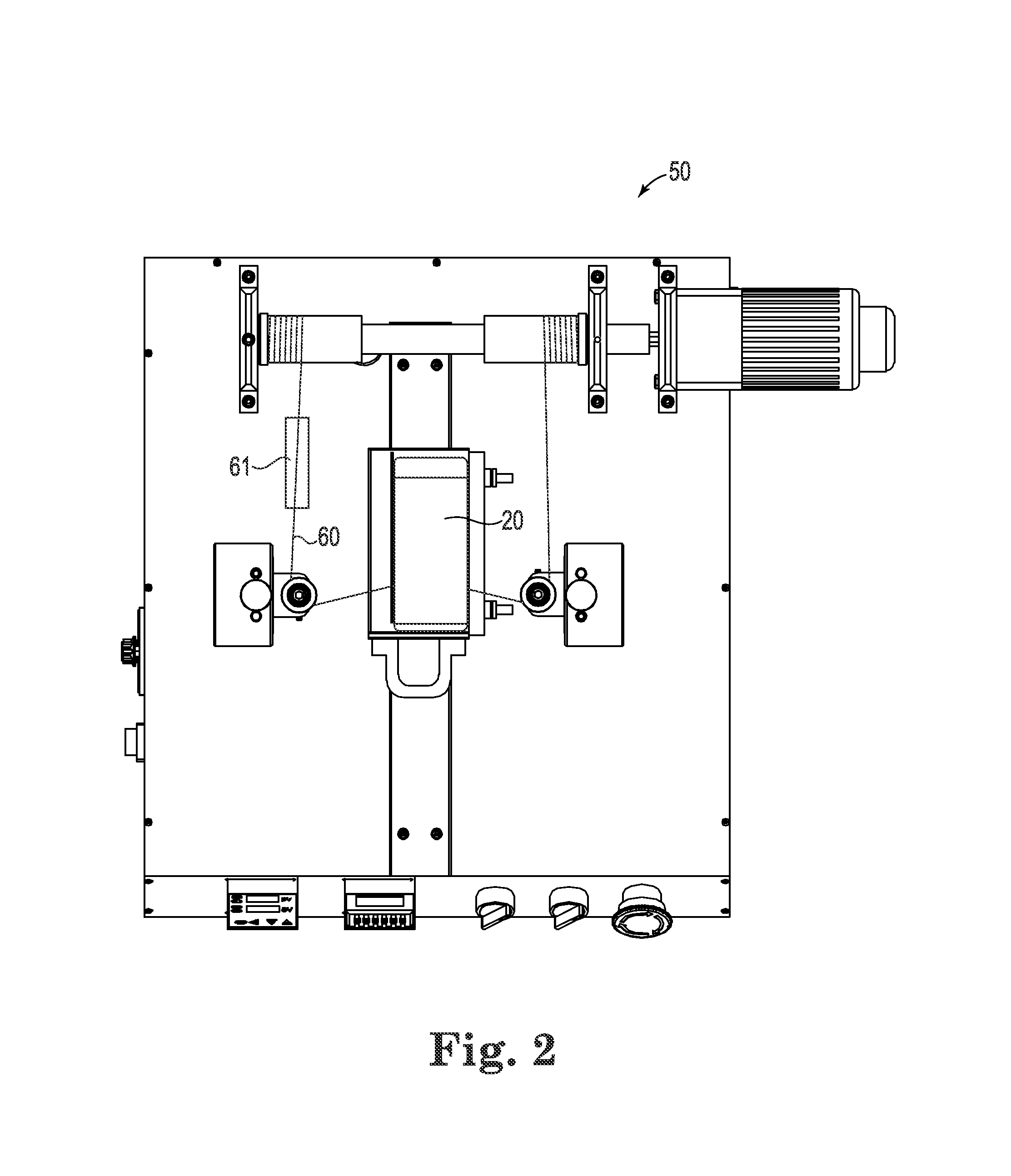

Ultrasonic plasticizing capillary rheometer and viscosity test method

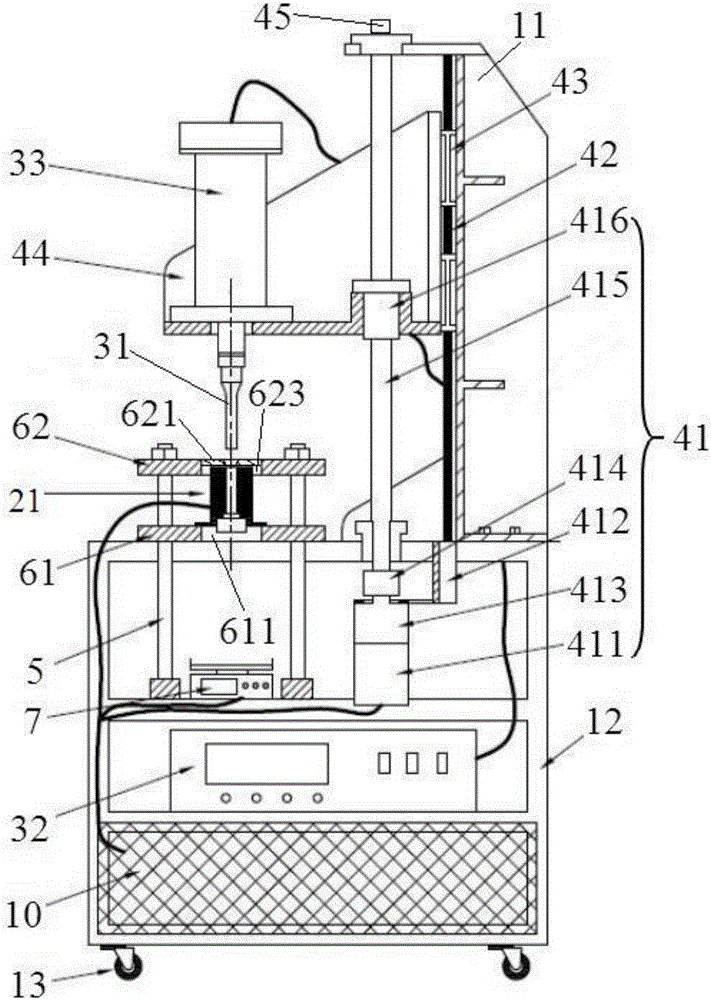

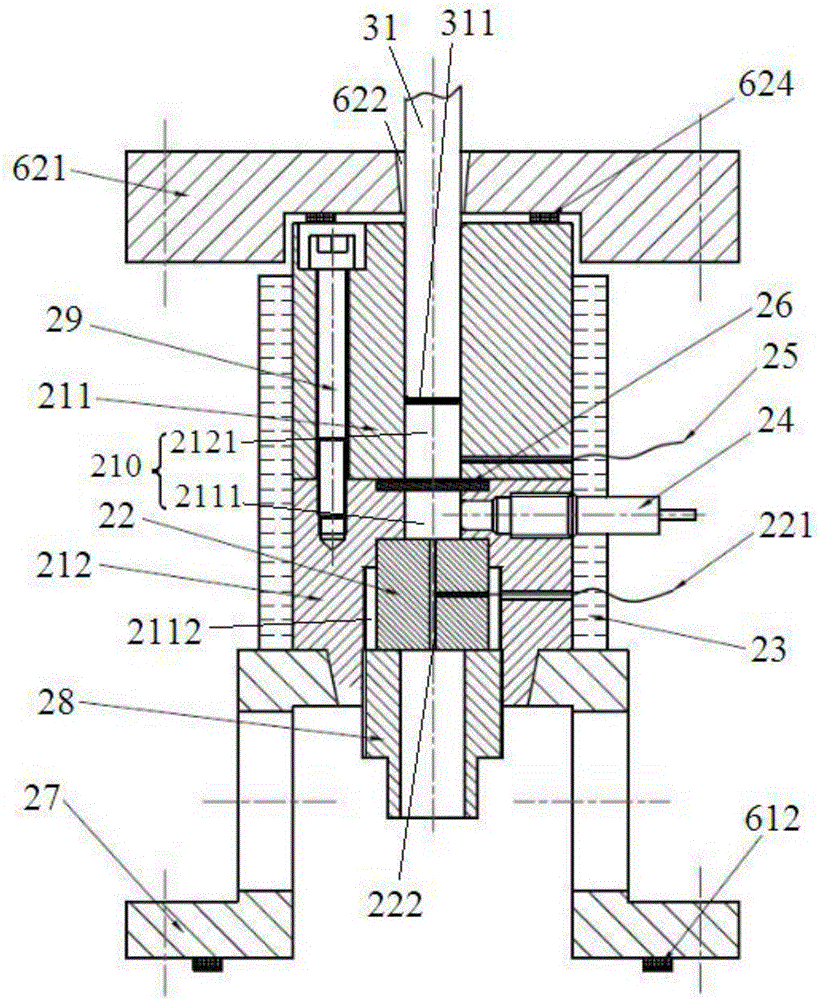

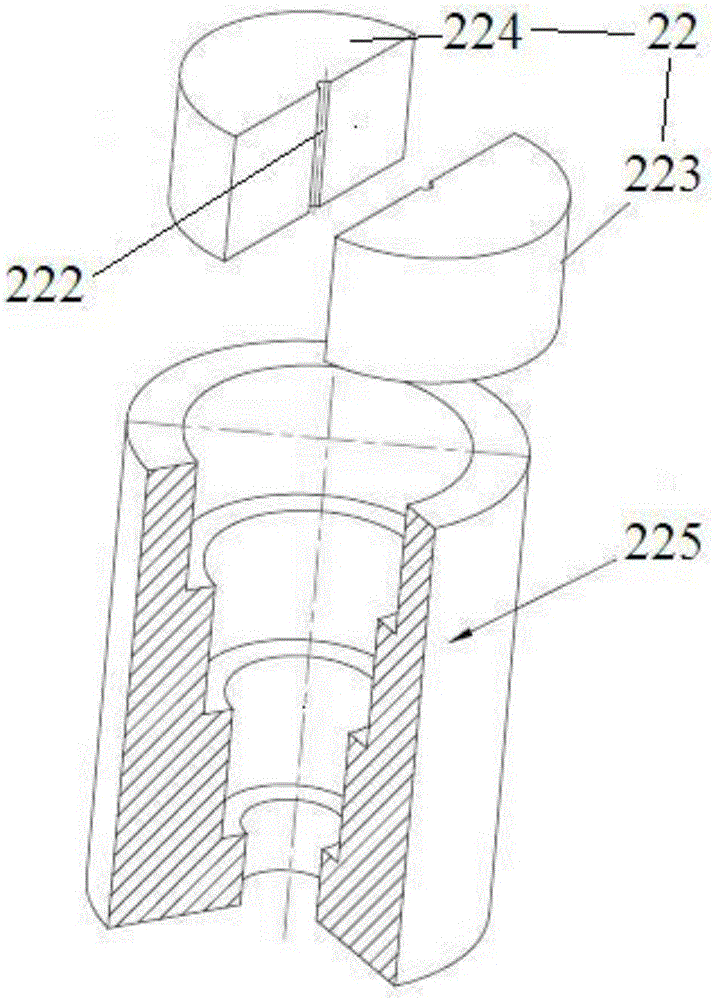

ActiveCN106124362AImprove liquiditySimplify the delivery pathIndirect flow property measurementEngineeringPolymer

An ultrasonic plasticizing capillary rheometer comprises a frame, a rheological test unit, an ultrasonic vibration apparatus, and a tool head moving and loading unit. The ultrasonic vibration apparatus is provided with an ultrasonic tool head capable of extending into a plasticizing chamber along an axial direction, providing extrusion force for polymer in the plasticizing chamber, and providing ultrasonic wave energy required by the polymer for fusion from a solid state to a liquid state. In the ultrasonic plasticizing capillary rheometer, three steps including heating fusion, ultrasonic vibration for fluidity increase, and material extrusion are completed through the ultrasonic tool head and in the plasticizing chamber, thereby simplifying the conveying path. A heating ring providing the required initial temperature for the plasticizing process sleeves a material canister, provides a constant material canister temperature for the rheometer, and reduces the test error. A filter screen is arranged in the material canister, centralizes fused polymer, and improves the test accuracy. During a test process, a viscosity test method is accurate in heating, short in fusion time, and wide in application range, is slightly affected by the external environment, and can provide viscosity data high in accuracy.

Owner:CENT SOUTH UNIV

Abrasive surface electrode of efficient high-hardness

InactiveCN101073861AImprove melting efficiencyImprove deposition efficiencyWelding/cutting media/materialsSoldering mediaHigh carbonBoron carbide

The invention is concerned with wear-resisting build up deposited electrode with high efficiency and high rigidity. It relates to Phi4 H08A cored wire, covering with Phi9 outer diameter. The compose of covering is 3 to 5 percent of silver-graphite, 2 to 6 percent of Boron carbide, 2 to 3 percent of carborundum, 3 to 5 percent of ferromolybdenum, 3 to 5 percent of ferrovanadium, 5 to 10 percent of tungsten carbide, 8 to 16 percent of high carbon ferrochrome, 2 to 3 percent of manganese and 72 percent of iron powder. It changes the existing covering structure by adding lots of iron powder, some kinds of alloy element without adding any ore powder. This method increases the melting efficiency and deposition efficiency with buildup deposited metal rigidity of HRC65 to 68 and certain obdurability and without knocking the sediment in the middle of the multi-pathway and multi-layer to continuous build up deposited welding. This is fit for carbon construct ional steel, the buildup deposited welding to low alloy steel and some middle, high alloy steels, and the wear-resisting situation to the abrasion of milling grain.

Owner:XIANGTAN UNIV

Pre-melted slag for refining ultra-low aluminum steel and preparation method and using method thereof

InactiveCN103642991AControl oxygen contentControl restoreProcess efficiency improvementSocial benefitsReduction treatment

The invention relates to pre-melted slag for refining ultra-low aluminum steel and a preparation method and a using method thereof. The preparation method comprises the steps of firstly burdening BaO, CaO, MgO, B2O3, CaC2 and SiO2 according to a proportion, pre-melting at the temperature of 1450-1500 DEG C, cooling, then breaking into blocky materials, and packaging in a moisture-proof mode. The pre-melted slag is used for secondary refining and slagging by a ladle furnace, after pre-deoxidization of molten steel, slag pulling of a ladle and reduction treatment of residual slag, the ladle is added when the ladle is allocated and transported to a refining bay, and the pre-melted slag can be put into the ladle in the LF (ladle furnace) refining or the ladle argon blowing process. Compared with alkaline refined slag adopted in the prior art, the pre-melted slag has the advantages of absorbing Al2O3 in the steel to the greatest extent and promoting the reaction of O and Al in the steel so as to control the Al content below 0.004%; in addition, the pre-melted slag provided by the invention has the advantages of wide raw material sources, simple method and significant economic benefits and social benefits, and is favorable for reducing the cost and protecting the environment.

Owner:JIANGSU UNIV

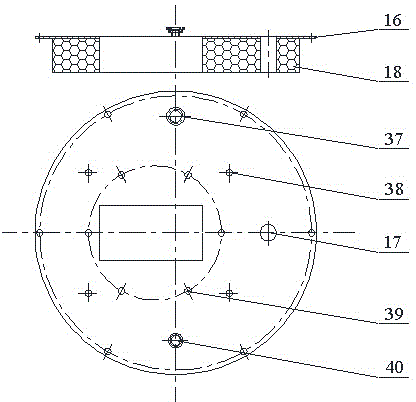

Plate blank electroslag furnace

This invention discloses a slab electroslag furnace, which comprises: an AC power supply, an electrode elevator, an electrode, a crystallizer, a support platform, an ingot feeder, a liquid level detector of molten steel, a rotary frame, a weight sensor, an ingot discharger, and a control system. The crystallizer is fixed in the support platform. The rotary frame is fixed on the support platform, and can move along a fixed track. The electrode elevator is set on the platform of the rotary frame, and can be horizontally adjusted. The weight sensor is set at the contact surface of the electrode elevator and the platform of the rotary frame. One end of the electrode (monopolar or bipolar) is fixed with the electrode elevator, and the other one is set in the crystallizer. The liquid level detector of molten steel is set on the sidewall of the crystallizer. The ingot discharger is set on a frame below the support platform. A wagon is fixed on the ingot discharger. The ingot feeder is fixed in the wagon. The control system, elevator, weight sensor, ingot discharger and wagon are electrically connected.

Owner:NORTHEASTERN UNIV LIAONING

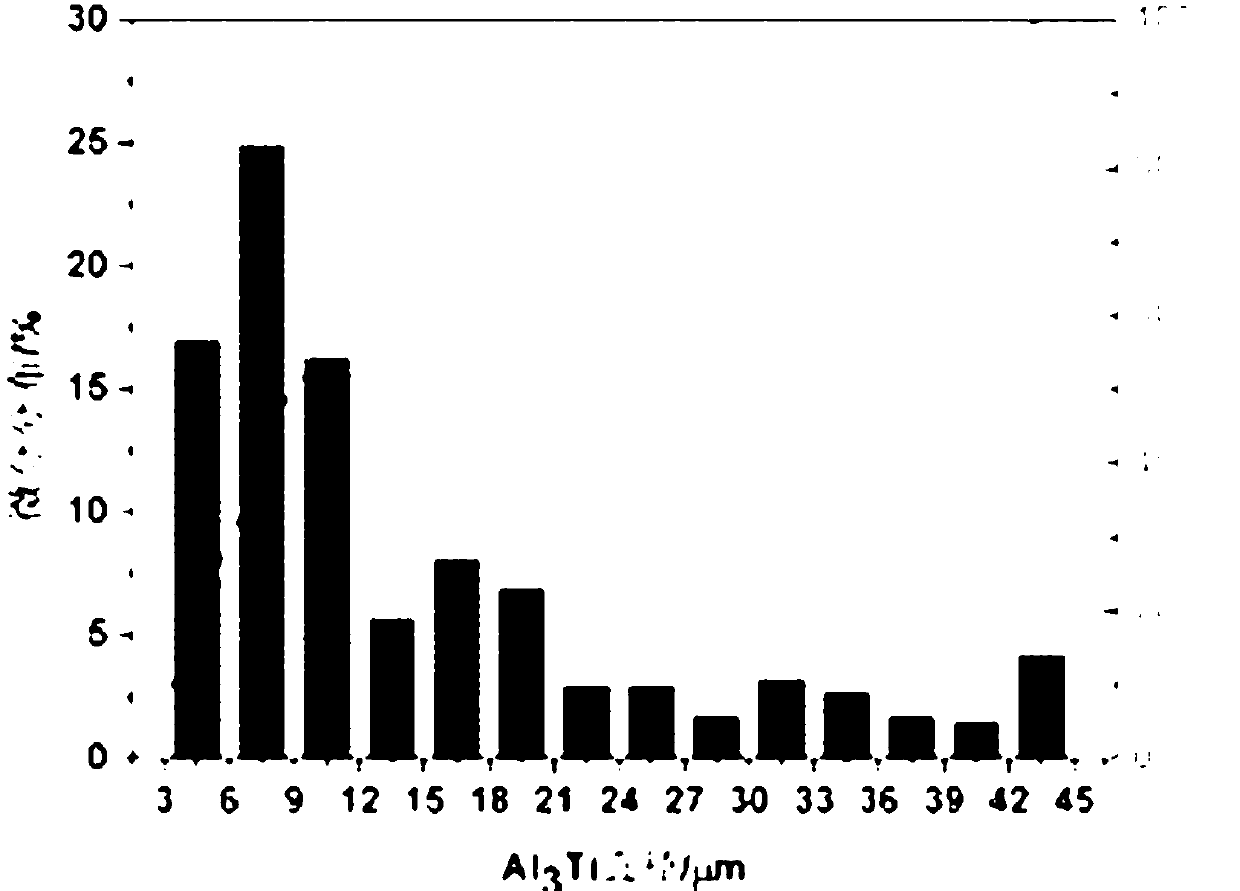

Preparation method of high-quality Al-Ti-B-Sr master alloy composite refining modifier

The invention relates to a preparation method of a high-quality Al-Ti-B-Sr master alloy composite refining modifier. The preparation method comprises the following steps: firstly melting a pure aluminum ingot in an aluminum melting furnace, and then pouring into a medium-frequency induction furnace to be ready for alloying; then weighing K2TiF6 and KBF4 raw materials, uniformly mixing, and pouring into the molten aluminum to be alloyed in the medium-frequency furnace; performing reaction for a certain period of time, then pouring the remaining mixture of K2TiF6 and KBF4 into an aluminum melt, and pouring away water granulated slag after the end of the reaction; performing degassing and re-deslagging treatment, and then gradually adding a certain weight of Al-20Sr alloy wires; performing stirring, re-deslagging and degassing treatment, and directly pouring to form Al-Ti-B-Sr alloy rods; and then sending the alloy rods onto an extruding machine to perform sectional area large-deformation thermal extrusion treatment and finally obtaining the Al-Ti-B-Sr master alloy composite refining modifier wires with the diameter of 9.5mm. The preparation method is characterized by combining a three-step charging method and a thermal extrusion molding process.

Owner:HUNAN JINLIANXING SPECIAL MATERIALS CO LTD

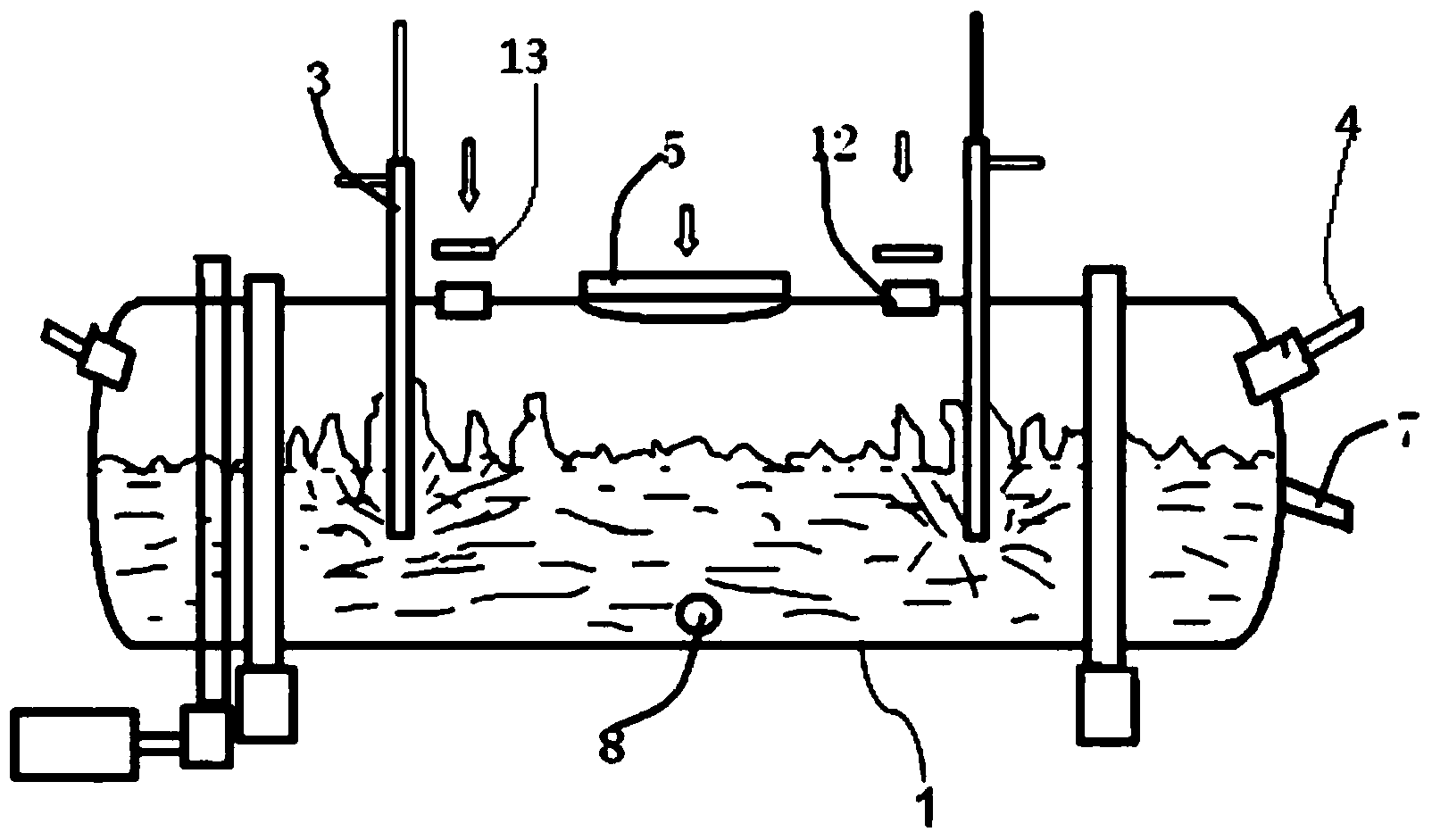

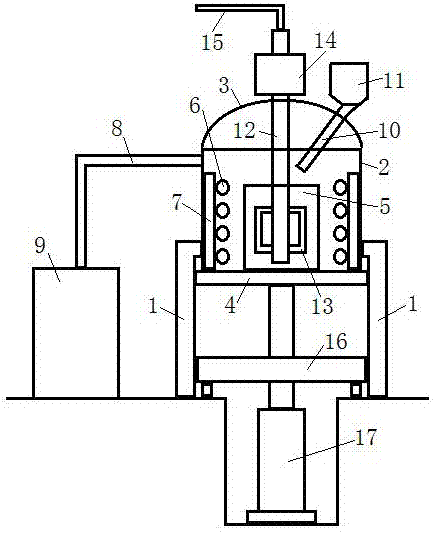

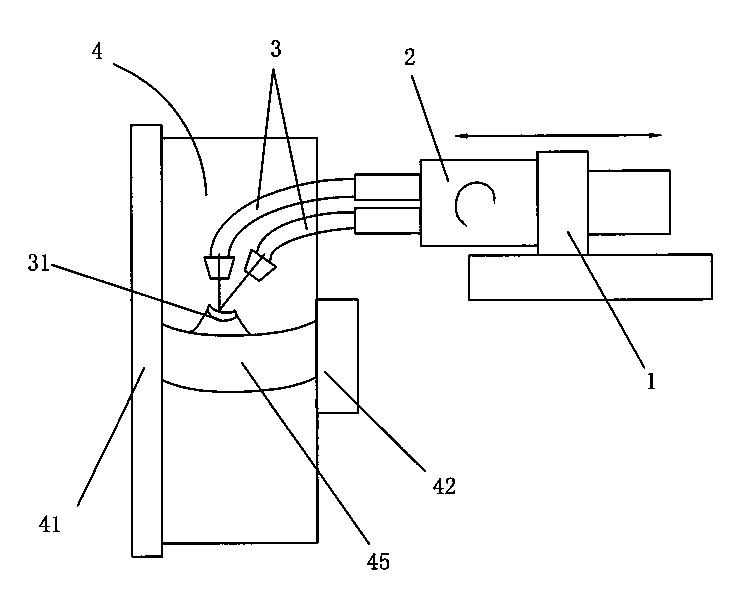

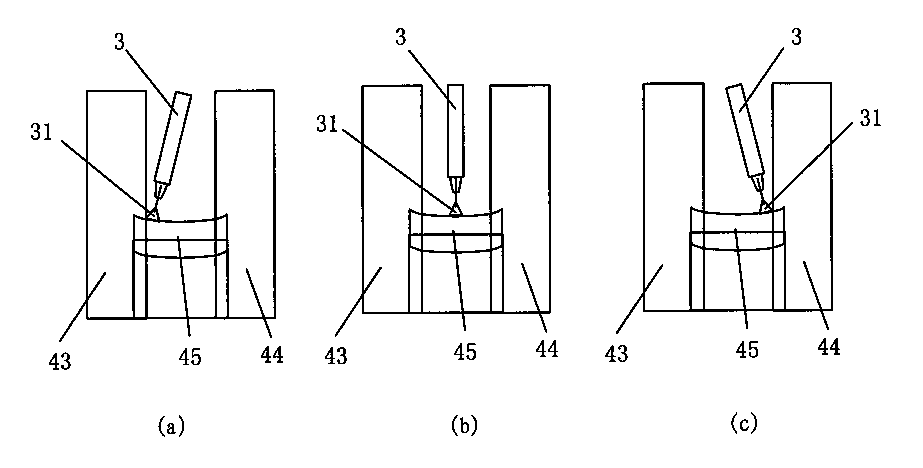

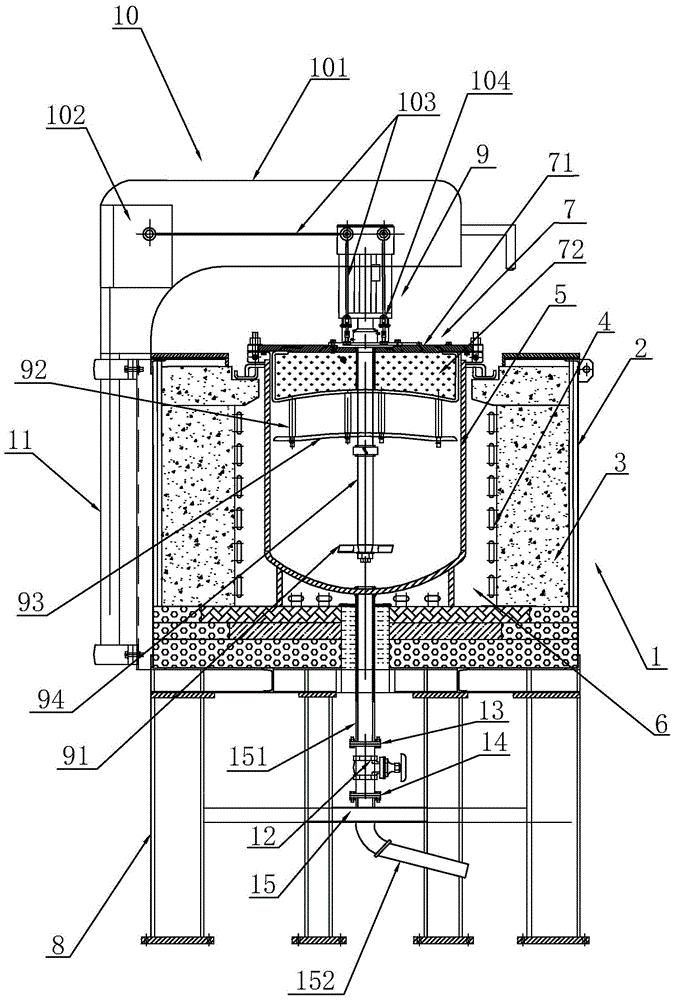

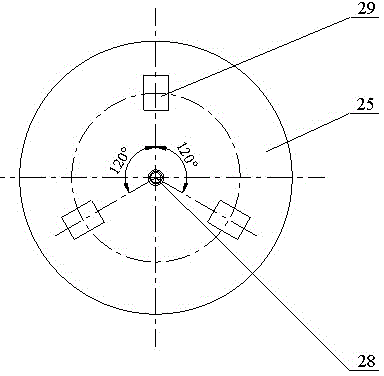

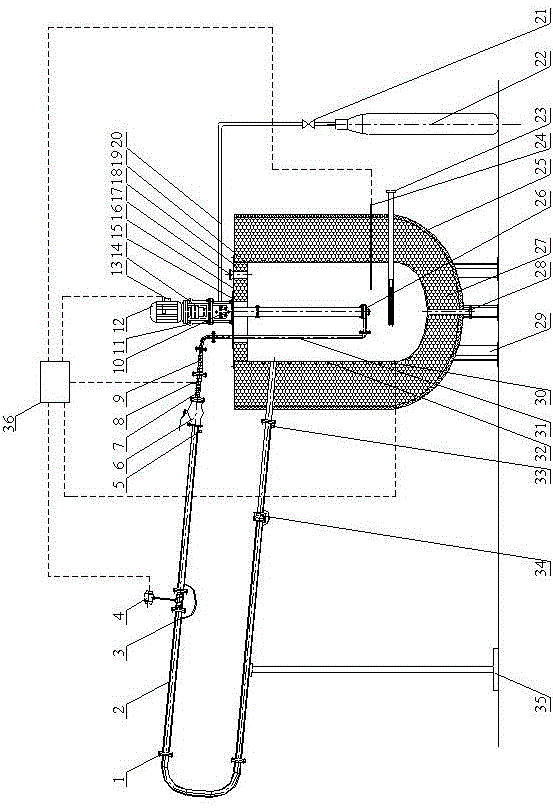

Vacuum induction furnace capable of smelting aluminum and aluminum alloy

PendingCN106871638AEasy to moveFast meltingStirring devicesCharge composition/stateAluminiumVacuum induction furnace

The invention discloses a vacuum induction furnace capable of smelting aluminum and aluminum alloy. The vacuum induction furnace comprises a furnace body erected at the top of a furnace frame, a liftable furnace bottom plate arranged at the bottom end of the furnace body and bearing a graphite crucible, an induction coil arranged in the furnace body, an air suction pipe arranged on the side wall of the furnace body, a charging pipe penetrating through a furnace cover, a stirring shaft penetrating through the furnace cover, a stirring frame arranged at the bottom of the stirring shaft, a through hole formed in the stirring shaft, an argon blowing pipe penetrating through the through hole and extending to the bottom of an inner cavity of the graphite crucible, an argon supply device connected with the argon blowing pipe, a trolley arranged under the furnace body and capable of bearing the furnace bottom plate, and a lifting driving mechanism used for driving the furnace bottom plate to rise and fall vertically. The graphite crucible of the vacuum induction furnace is borne by the liftable furnace bottom plate, thereby entering and going out of the furnace body conveniently. The furnace bottom plate and the graphite crucible can be transported by the trolley, and moving is convenient. The stirring mechanism can conduct stirring during smelting of the aluminum and the aluminum alloy, argon can be led into aluminum liquid during stirring, and a purification effect can be achieved.

Owner:SUZHOU ZHENHU ELECTRIC FURNACE

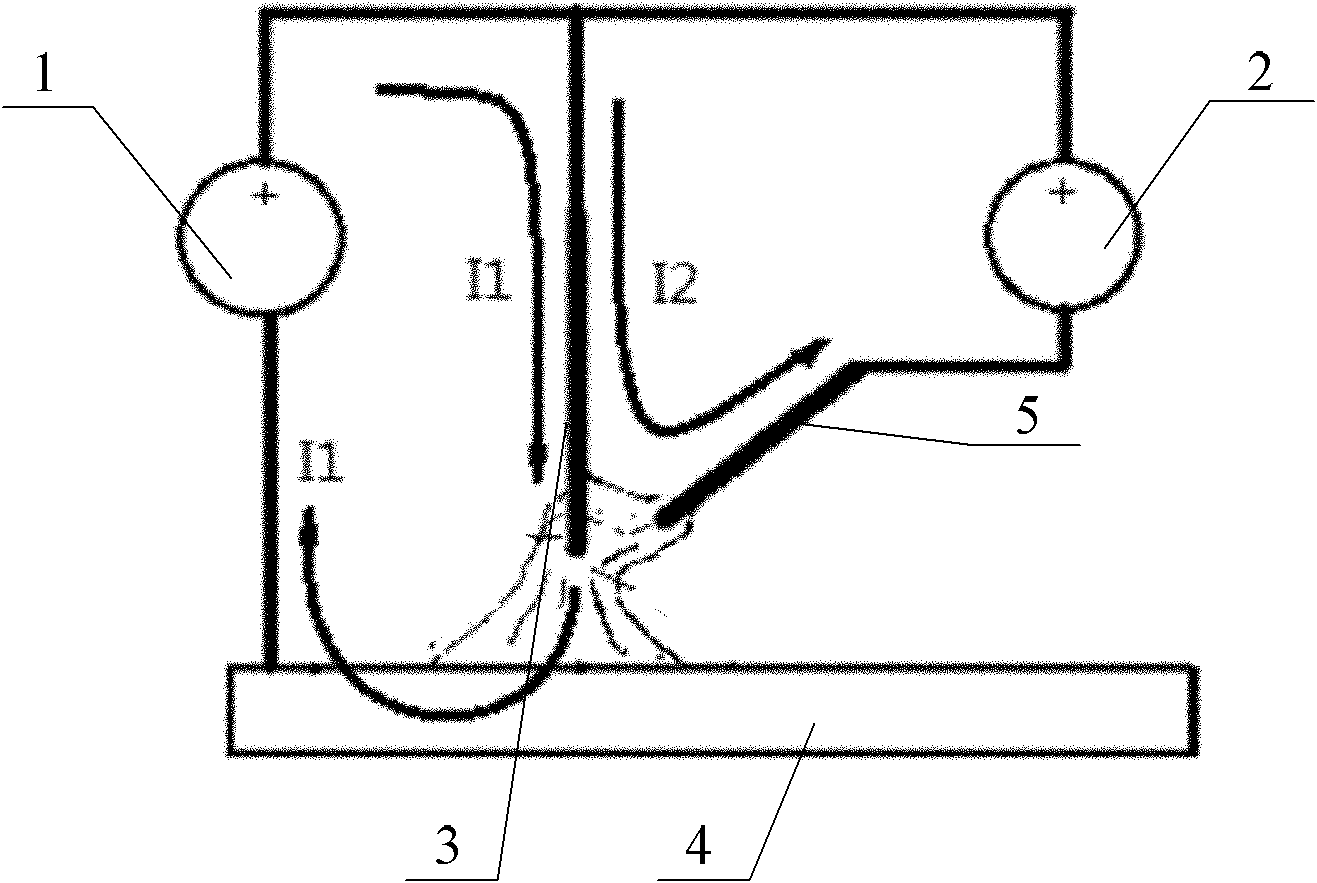

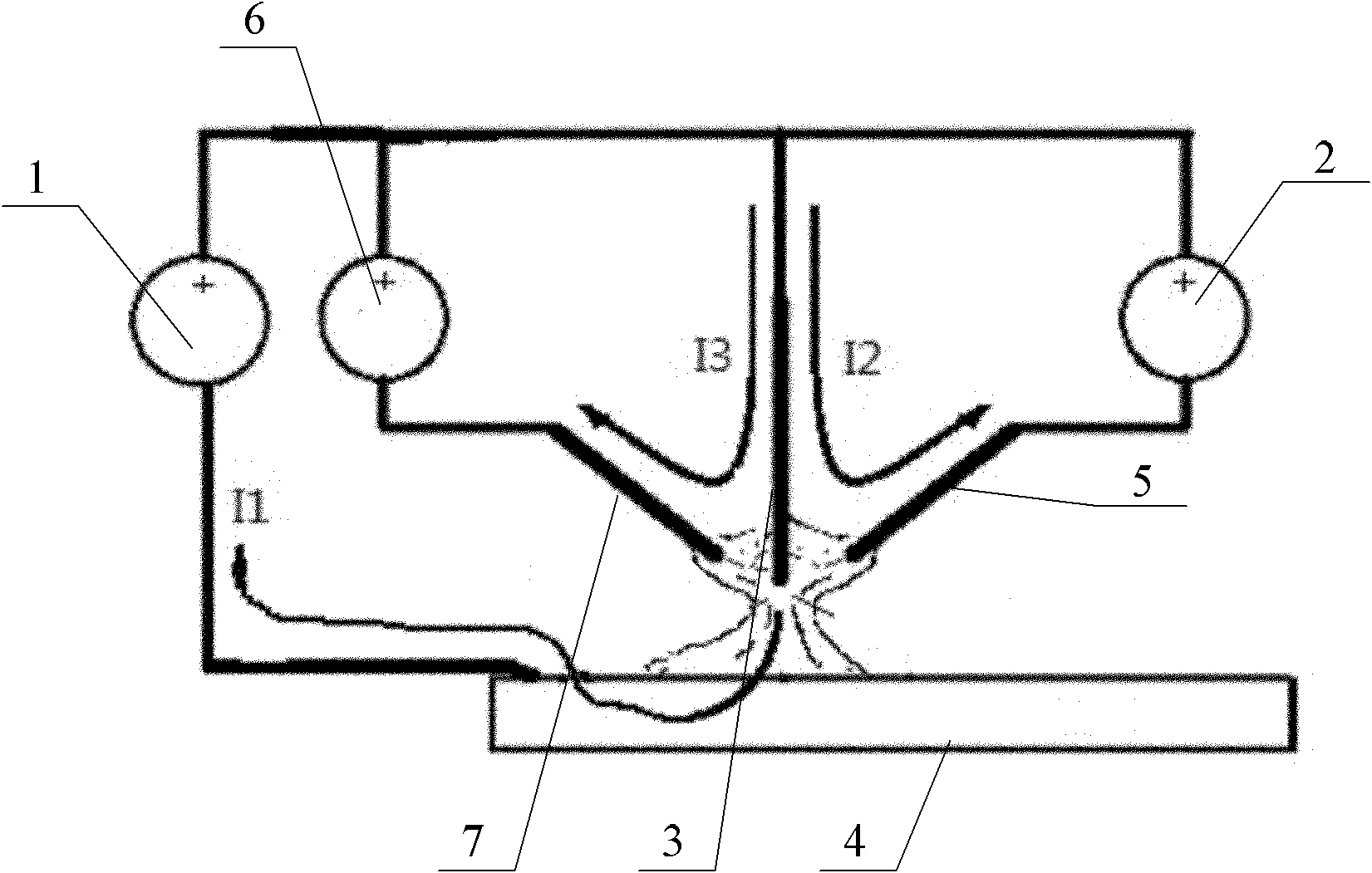

Electric arc welding method with high welding wire melting speed and low welding heat input

ActiveCN101972879AFast meltingReduce welding heat inputArc welding apparatusEngineeringAuxiliary electrode

The invention relates to an electric arc welding method with high welding wire melting speed and low welding heat input, belonging to the technical field of welding. The electric arc welding method solves the problem of the mutual contradiction between improving the melting speed of a welding wire and reducing the welding heat input in the consumable electrode electric arc welding method. The electric arc welding method is characterized in that: the homopolar output ends of a main power supply and an auxiliary power supply are connected with the head end of a main consumable electrode, and the other electrode output end of the main power supply is connected with a workpiece to be welded, and the other electrode output end of the auxiliary power supply is connected with the head end of an auxiliary electrode. The welding method comprises the following steps of: enabling the tail end of the main consumable electrode to be close to the part to be welded, of the workpiece to be welded, and forming a main electric arc between the tail end of the main consumable electrode and the surface to be welded, of the workpiece to be welded under the action of the main power supply; enabling the tail end of the auxiliary electrode to be close to the tail end of the main consumable electrode, forming an auxiliary electrode arc between the tail end of the main consumable electrode and the tail end of the auxiliary electrode under the action of the auxiliary power supply, and forming a composite electric arc between the main electric arc and the auxiliary electric arc so as to realize the welding. The invention is used as an electric arc welding method.

Owner:HARBIN INST OF TECH

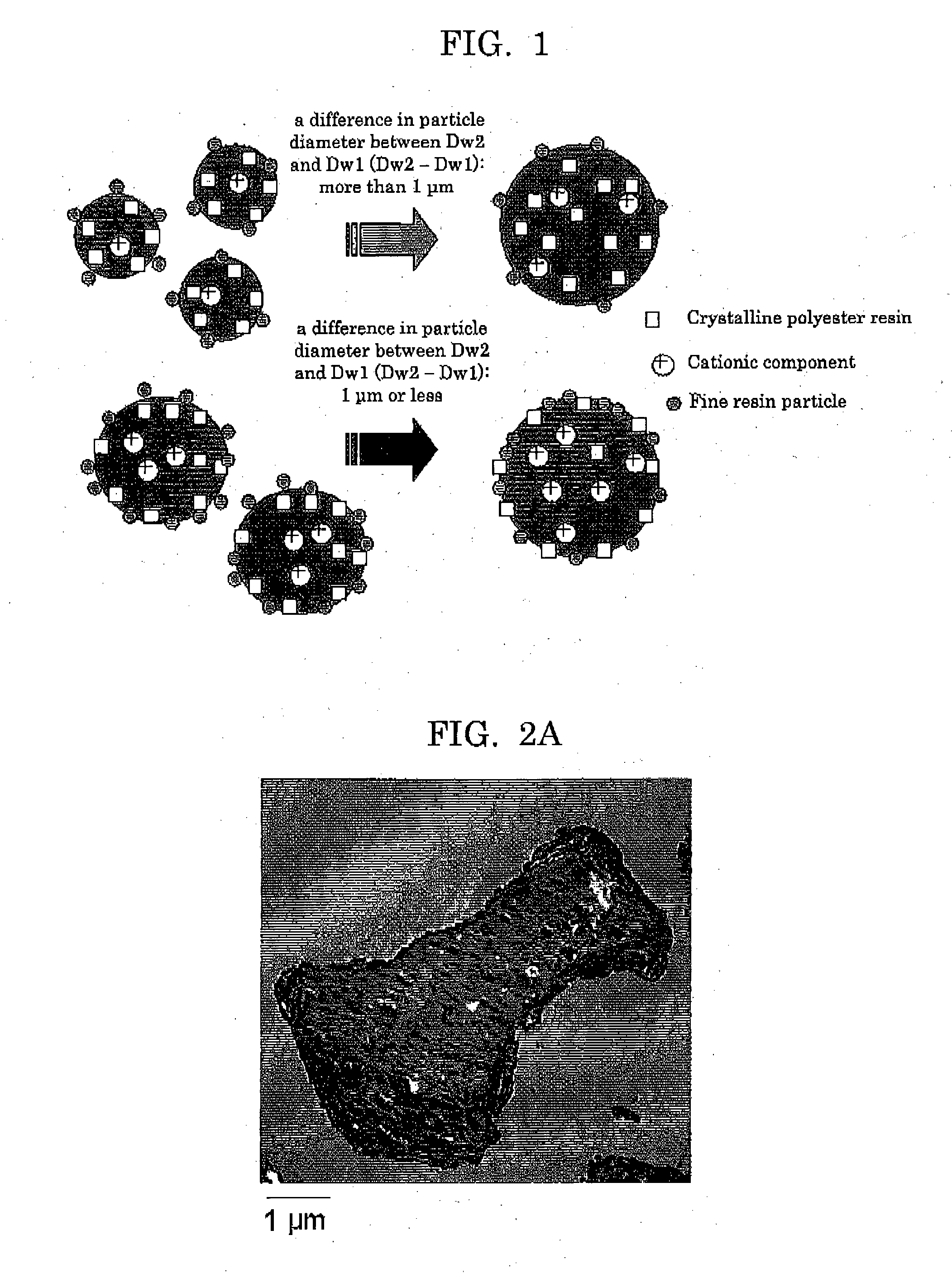

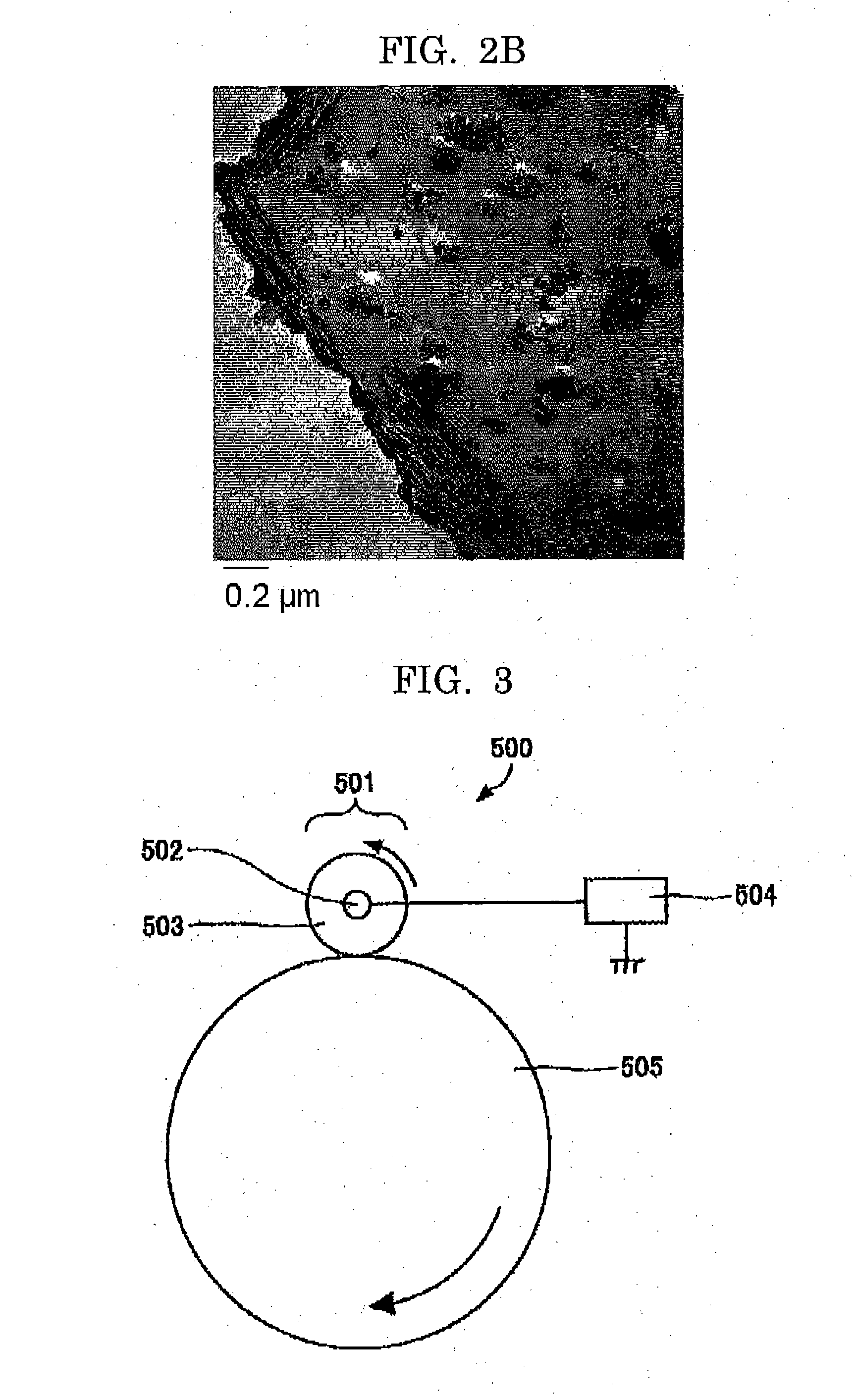

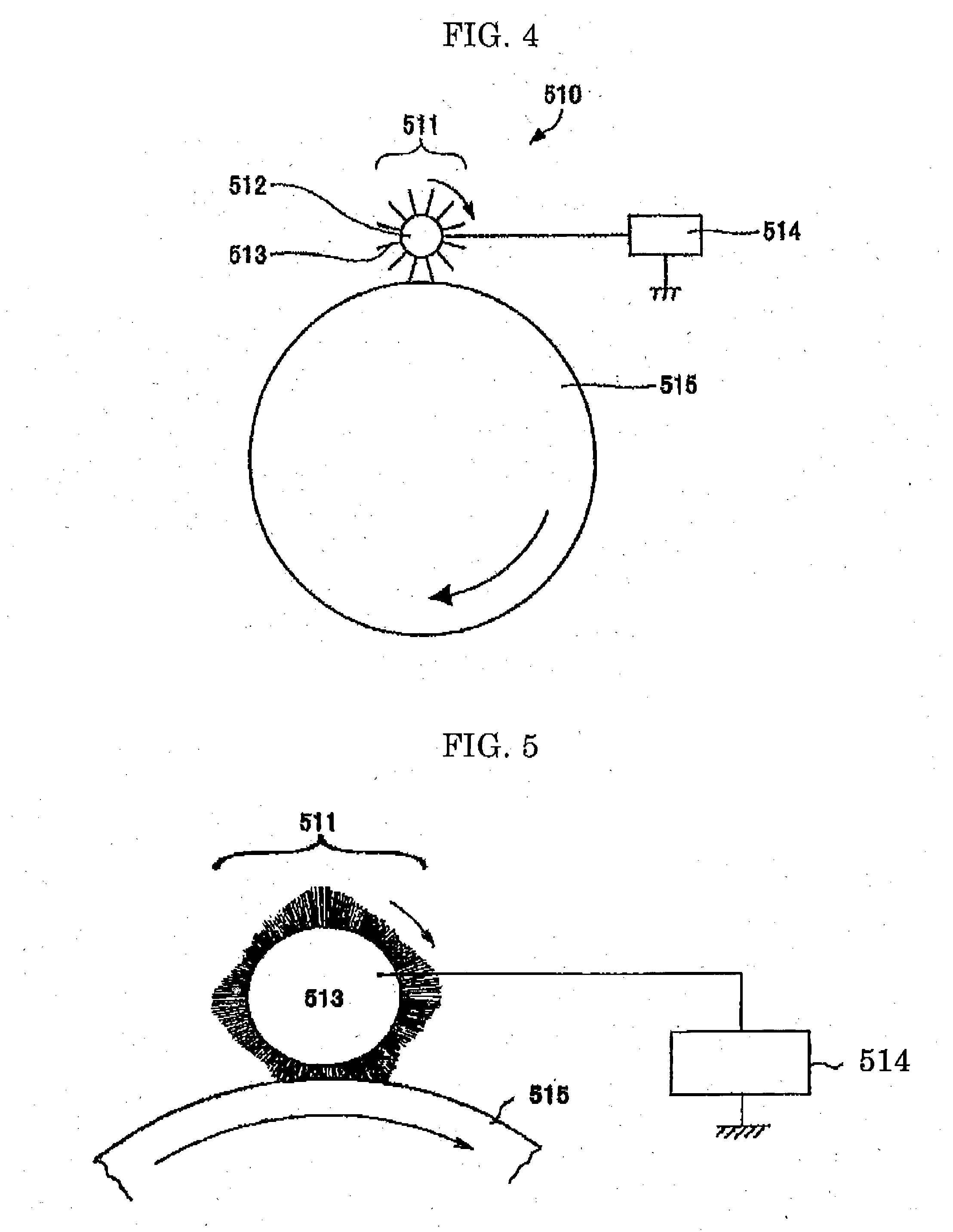

Toner, developer, process cartridge, image forming method, and image forming apparatus

InactiveUS20130011779A1Excellent low temperature fixabilityExcellent offset resistanceMaterial nanotechnologyDevelopersOrganic solventEmulsion

A toner obtained by a method for producing a toner, which includes dissolving or dispersing in an organic solvent a toner material containing at least a binder resin, and a dispersion liquid of a crystalline polyester resin, so as to prepare a solution or dispersion liquid of the toner material, emulsifying or dispersing the solution or dispersion liquid of the toner material in an aqueous medium, so as to prepare an emulsion or dispersion liquid, and removing the organic solvent from the emulsion or dispersion liquid, wherein the crystalline polyester resin is localized near a surface of the toner.

Owner:RICOH KK

Method and Apparatus for Display Screen Shield Replacement

A method and apparatus for replacement of damages display shield (typically glass) covering a display screen on a device, typically a mobile phone. Mobile phones have an electronic display protected by a glass shield. Between the glass and the display is often a plastic polarizing or other intermediary sheet. Removal of a damage glass can be accomplished by cutting thru the polarizer with a moving wire or blade. This separates the glass from the sensitive display and allows replacement of the glass without damaging the more expensive display.

Owner:VIKING TECH L C

Mold powder capable of effectively controlling peritectic steel thick slab narrow face depression defect

The invention relates to a mold powder capable of effectively controlling peritectic steel thick slab narrow face depression defect. The mold powder comprises the following elements by weight percent: 38.02 to 40.1 percent of Cao, 28.8 to 30.02 percent of SiO2, 9.9 to 10.5 percent of CaF2, 9.06 to 9.5 percent of Na2O, 1.55 to 1.93 percent of MgO, 1.5 to 1.93 percent of AL203, 0.01 to 0.037 percent of Li2O and 0.035 to 0.053 percent of MnO. The mold powder has good lubricating property and spreadability. Because of the high melting speed, the invention can complement the quick consumption of liquid slag in time; because of the high alkalinity, the invention has strong absorbing and mixing capability; and because of the proper viscosity and the reasonable crystallization temperature, the invention plays an important role in uniformity. When the mold powder is applied to the casting of peritectic steel thick slab, the slag entrapment defect caused by crystallizer liquid level fluctuation is reduced greatly, the heat transmission uniformity is improved greatly and the surface quality of casting blank is good.

Owner:SHOUGANG CORPORATION

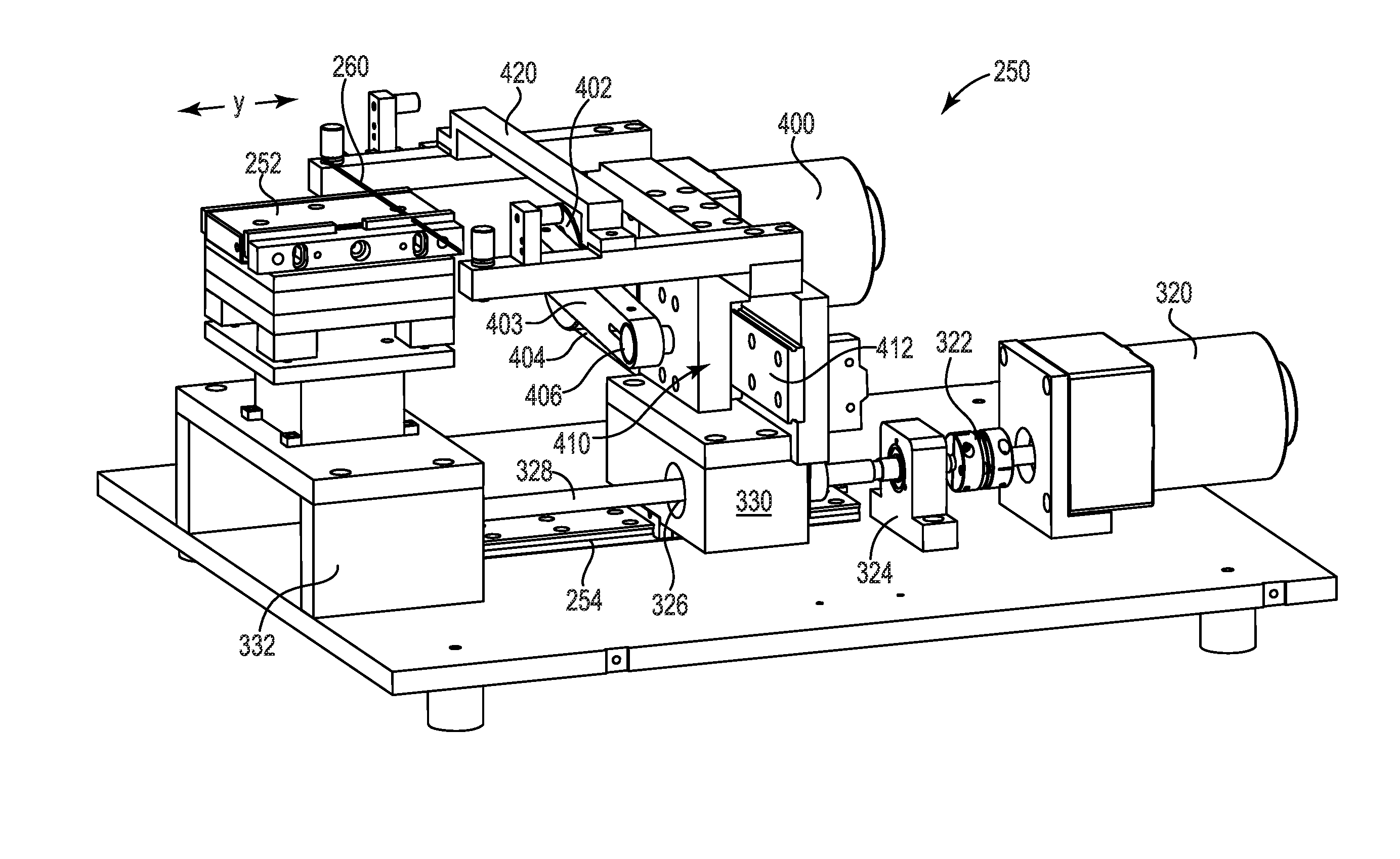

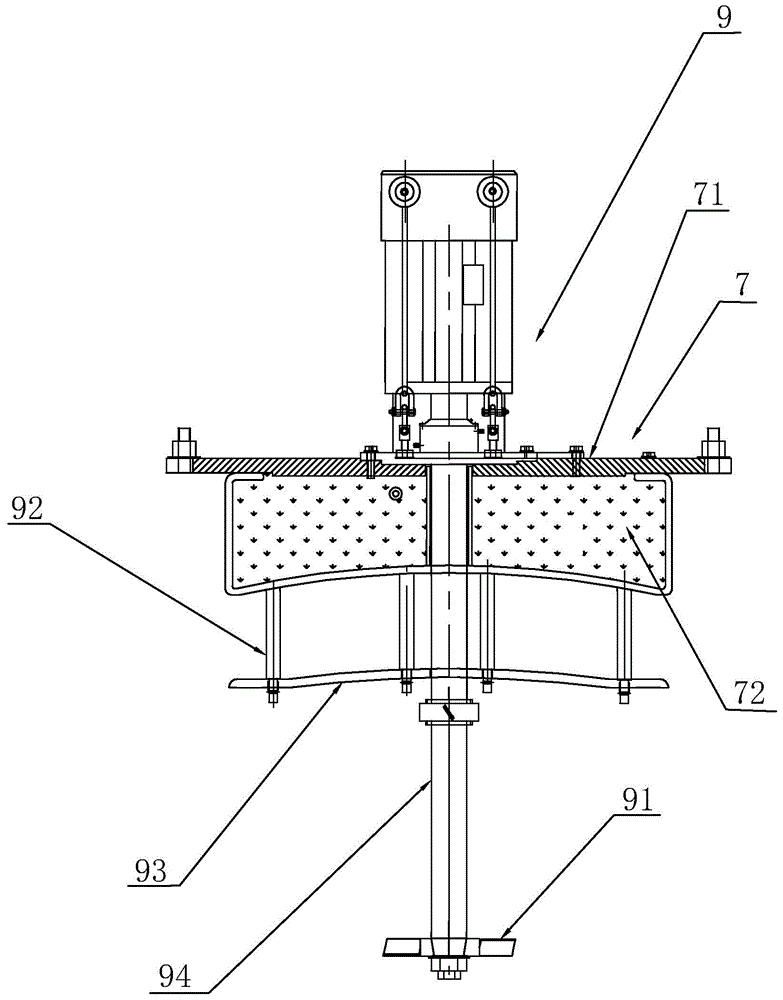

Welding gun swinging device for vertical electrogas welder

ActiveCN102423827AStrong penetrating powerImprove mechanical propertiesArc welding apparatusLinear motionReciprocating motion

The invention provides a welding gun swinging device for a vertical electrogas welder, which comprises a horizontal sliding mechanism for leading a welding gun to carry out linear motion along the direction of a vertical weld seam and a serrated swinging mechanism for leading the welding gun to swing in a groove clearance of the vertical electrogas welder, wherein the serrated swinging mechanism on which the welding gun is mounted is arranged on the horizontal sliding mechanism. Thus, the invention has the beneficial effects that a welding electric arc can move back and forth and be welded between a forming cushion plate on the back surface of the weld seam and a water-cooled forming slide block on the front surface of the weld seam as well as between a left side plate and a right side plate of a groove of the vertical electrogas welder; the side wall of the weld seam can be effectively ensured to be fully fused with a welding pool; the depth of a weld penetration can be remarkably increased, so that the mechanical property of the weld seam can be remarkably improved; and even if the melting speed of a welding wire is improved and the welding heat input is reduced, the side wall of the weld seam can still be fully fused with the welding pool to avoid interruption or mutation, even crack.

Owner:SHENZHEN RILAND IND

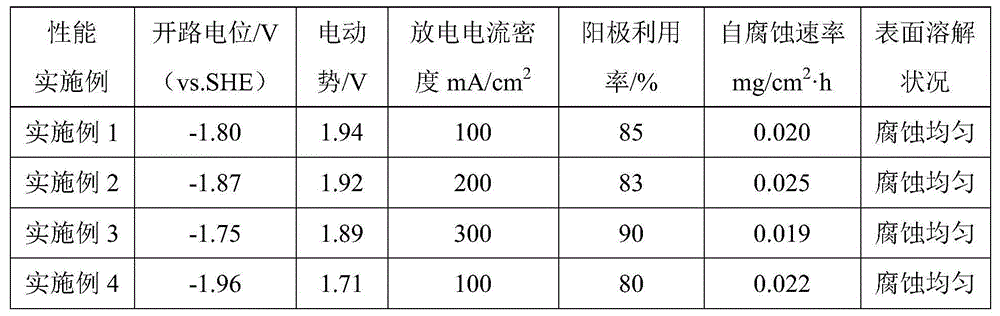

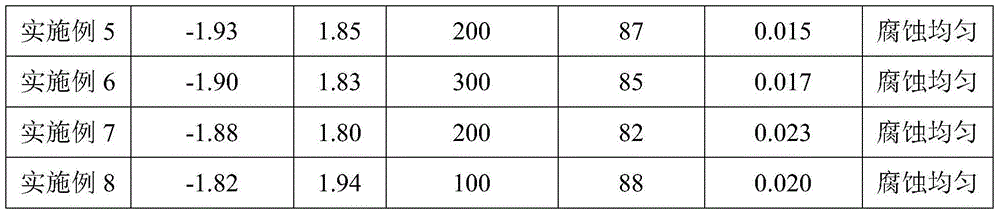

Rare earth-containing amorphous/nanocrystal aluminum anode composite material, preparation method and aluminum air battery

InactiveCN104372206AImprove electrochemical performanceAbundant resourcesFuel and primary cellsCell electrodesRare-earth elementDissolution

The present invention discloses a rare earth-containing amorphous / nanocrystal aluminum anode composite material, a preparation method and an aluminum air battery, and belongs to the techncial field of air batteries. The aluminum anode composite material comprises, by weight, 0.5-5% of Mg, 0.02-2% of Sn, 0.02-2% of Ga, 0.1-5% of La or Ce, and the balance of Al. According to the present invention, aluminum with the purity of more than or equal to 99.8% is adopted as the base, the trae amounts of Mg, Sn, Ga and the rare earth element La or Ce are added so as to reduce the self-corrosion rate and improve the electrochemical property and the surface dissolution uniformity of the alloy, especially the trae amount of the rare earth element is added to the aluminum alloy, and the addition of the rare earth element to the aluminum has effects of oxygen removing, hydrogen removing, desulfuration, melting rate accelerating, metal burning loss reducing, change of species distribution and refinement modification of iron and other harmful impurities, and the like so as to slow down the self-corrosion of the aluminum alloy, such that the anode utilization rate is improved.

Owner:HENAN UNIV OF SCI & TECH

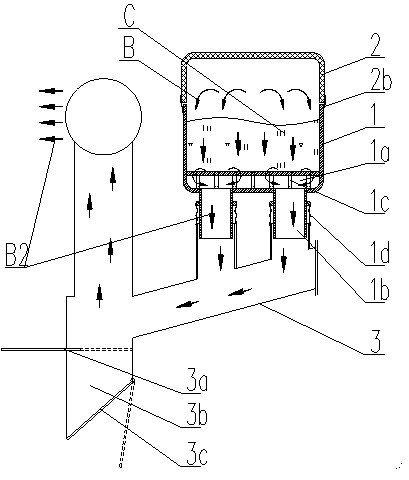

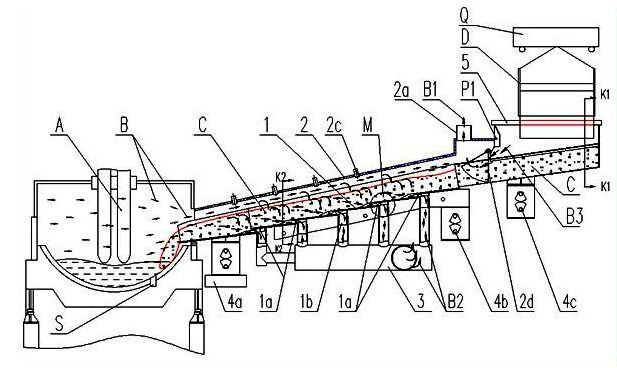

Scrap steel pre-heating conveyor with short process

InactiveCN101907401AExtend your lifeReduce wearCharge manipulationPreheating chargesNew energyEngineering

The invention discloses a scrap steel pre-heating conveyor with a short process, comprising a conveying trough (1) which is provided with a fume guiding hood (2) and is inclined relative to the horizontal plane. The lower end of the conveying trough (1) extends into an electric furnace (A) via an opening on the sidewall of the electric furnace (A); a bottom-opened long distributing trough (D) is arranged above the other end of the conveying trough (1), is arranged above a material receiving section of the conveying trough (1) by a swing device (Q), and is arranged in the downward projection of the material receiving section of the conveying trough (1) longitudinally; and scrap steels (C) are longitudinally arranged at the bottom of the material receiving section of the conveying trough (1) in a strip shape, and then the conveying trough (1) conveys the scrap steels (C) into the electric furnace (A). The scrap steel pre-heating conveyor with a short process is short, has high heat exchange efficiency, low operation rate of a crane, small abrasion, less maintenance, energy conservation, environment protection and reduces investment and operation cost, thus the invention is a new energy-saving and environment-friendly technology with promotional value in smelting technique, such as electric furnaces and the like.

Owner:CISDI ENG CO LTD

High-aluminum steel die casting protective slag

The invention relates to a protective slag, in particular to a high-aluminum steel die casting protective slag comprising the chemical components in percentage by weight: 22-28% of SiO2, 2-7% of Al2O3, 16-22% of CaO, 2-5% of Fe2O3, 2-5% of MgO, 2-6% of MnO, 5-10% of BaO, 4-6% of B2O3, 5-10% of R2O, 7-12% of F and 2-4% of C; the summation of the weight percentage of all the components is 100%, and R2O consists of Na2O and Li2O. With the adoption of the protective slag, the quality problems of longitudinal cracks, pits and slag bonding on the surface of the cast high-aluminum steel are solved, the slag degeneration caused by the fact that a reducing element enters the slag after being oxidized is inhibited, the stability of the property of the protective slag is ensured, and meanwhile, the Al2O3 absorbing rate of the slag is increased.

Owner:NANJING IRON & STEEL CO LTD

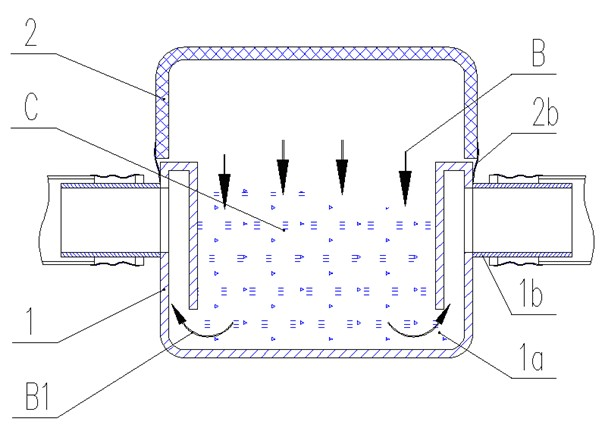

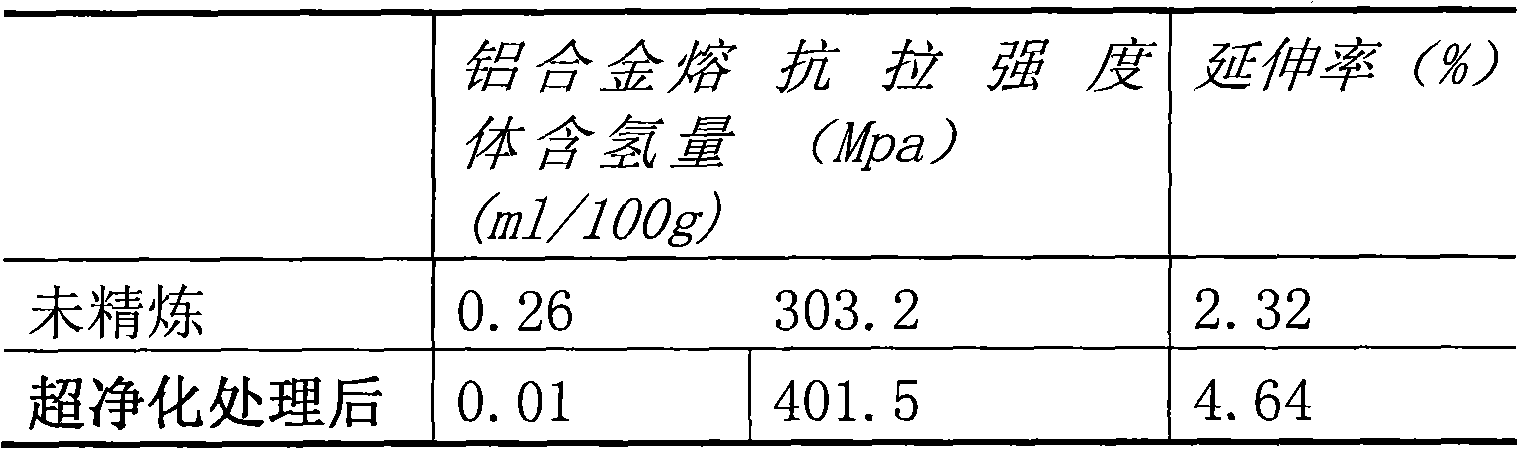

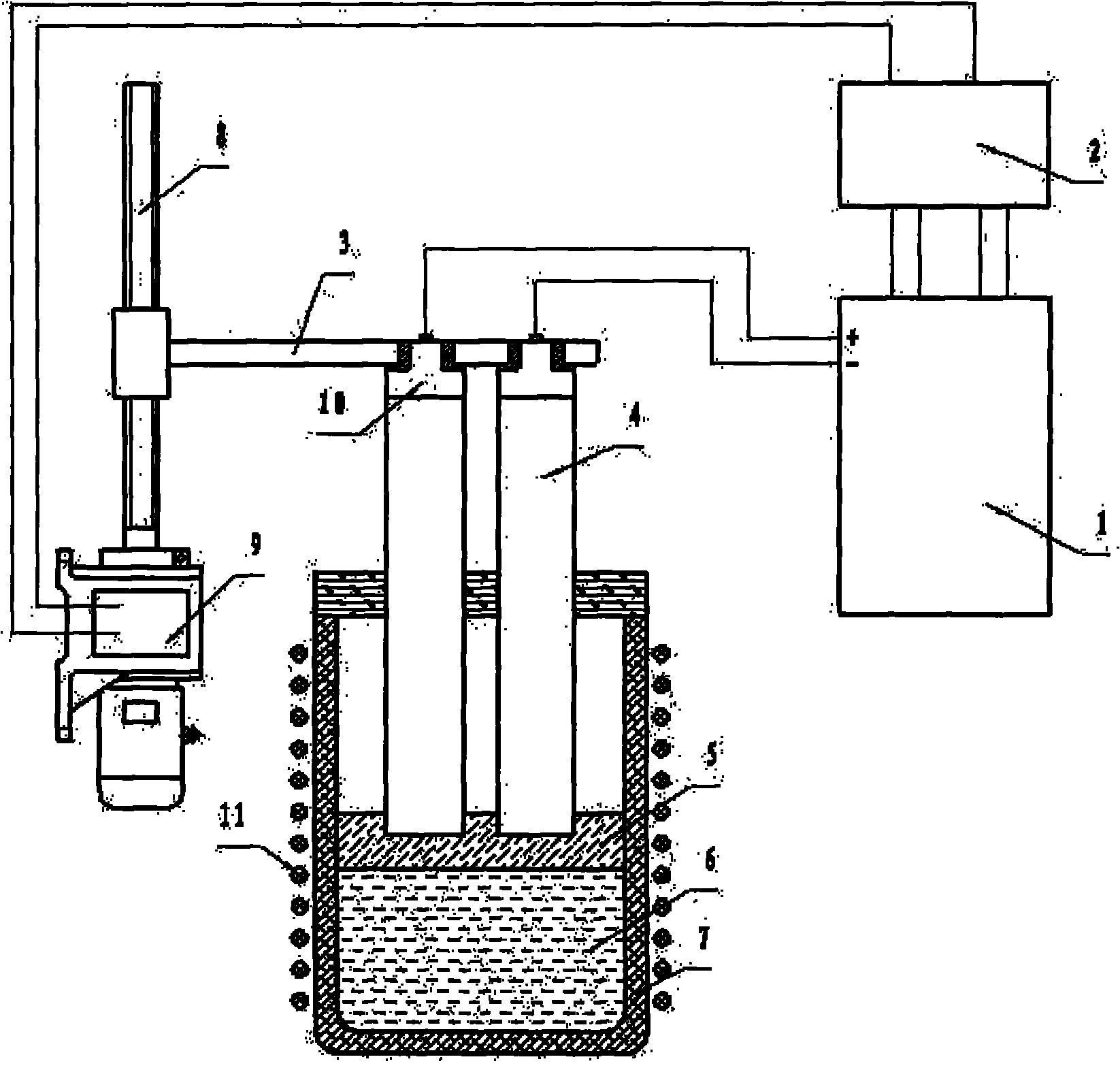

Aluminum alloy super-purification refining method

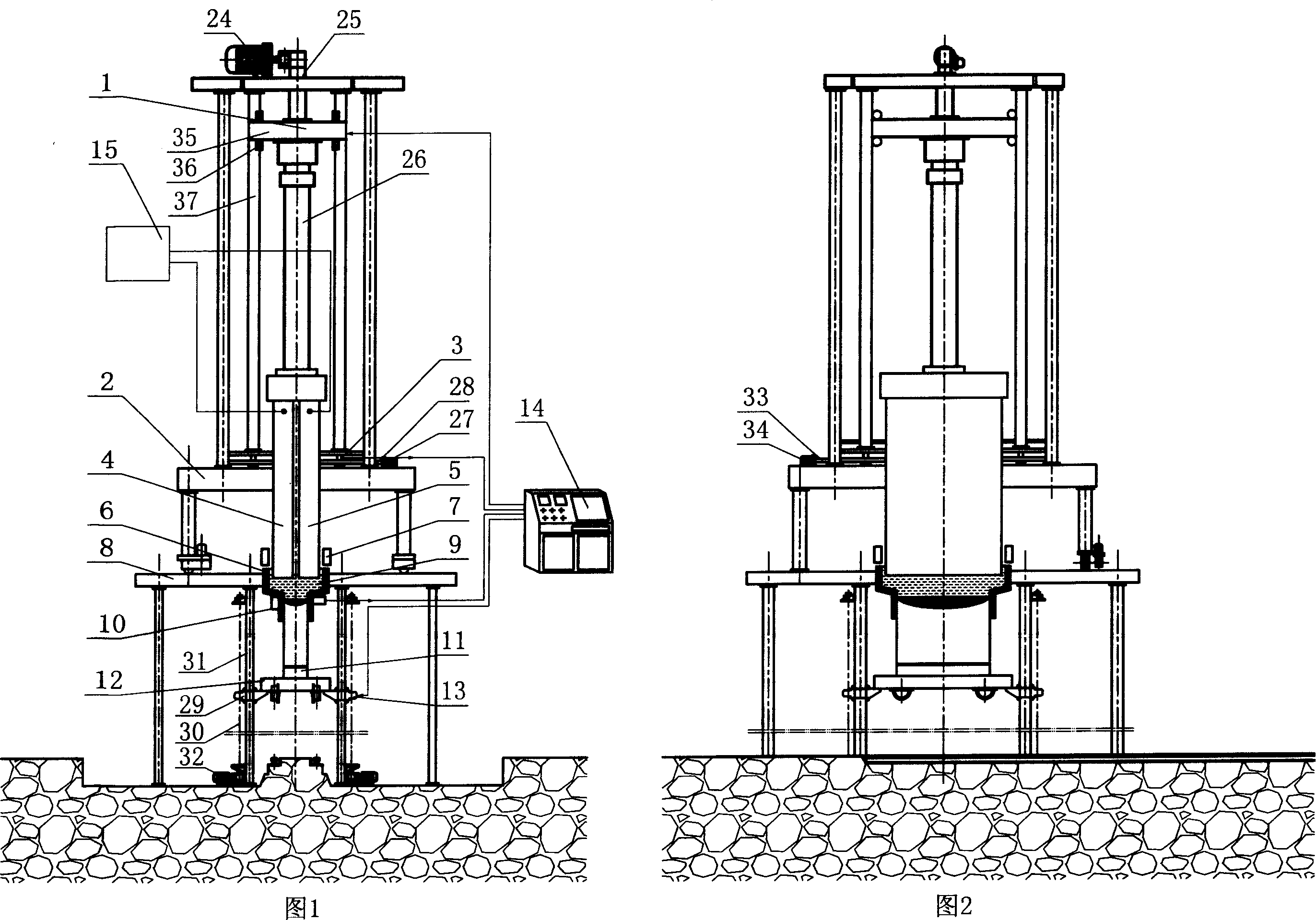

The invention discloses an aluminum alloy super-purification refining method, and aims to reduce the hydrogen content, oxide inclusion content and harmful alloy element content in the aluminum alloy. The method comprises the following steps of: arranging two aluminum alloy blanks to be melted on a lifting mechanism and connecting the two aluminum alloy blanks to the positive electrode and the negative electrode of a melting power supply respectively; arranging a non-metal crucible under the aluminum alloy blanks, placing the slag in the crucible and heating the slag to the working temperature of between 630 and 700 DEG C to change the slag into a liquid state; starting the lifting mechanism to drop the aluminum alloy blank and extend the lower end into the liquid-state slag, wherein the immersion depth is 10mm, and opening cooling water; preserving heat for a certain time and switching on the melting power supply after the slag in contact with the aluminum alloy blank is remelted, wherein the current is 250 to 280A and the voltage is 8 to 9V; automatically feeding by the lifting mechanism according to a voltage value and feeding downwards when the voltage value is more than 9V; stopping the feeding when the voltage value is less than 8V; when the feeding is stopped, increasing the voltage value along with the continuous melting of the aluminum alloy blank; automatically adjusting the feeding process by the lifting mechanism until all the aluminum alloy blanks are fed into the melting crucible by a feeding mechanism; ending the melting and closing the melting power supply when the feeding mechanism feeds the aluminum alloy blanks to the bottommost part and the voltage is more than 9V; and lifting the lifting mechanism, scratching the slag in the crucible out and casting an ingot with the refined aluminum alloy liquid or directly pouring a cast.

Owner:ZHONGBEI UNIV

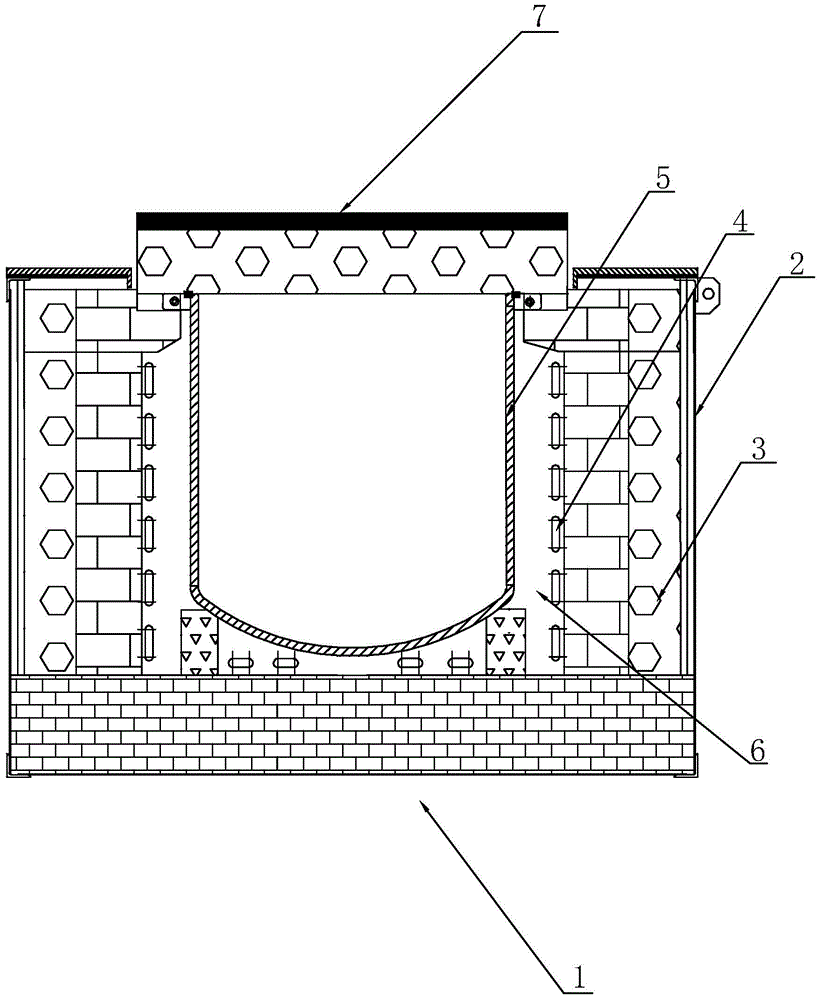

Metal homogenizing melting furnace

InactiveCN104390457AWith lossOxidation resistantStirring devicesCrucible furnacesCrucibleMolten metal

The invention relates to a metal homogenizing melting furnace. The metal homogenizing melting furnace comprises a furnace body and a support used to fix the furnace body, wherein the furnace body comprises a furnace shell, a furnace lining, a heating element and a crucible, which are sequentially arranged from outside to inside, the heating element is arranged around the outer surface of the crucible, the crucible is provided with a furnace cover, a stirrer is arranged on the furnace cover, and a stirring shaft of the stirrer is stretched into the crucible, and stirs molten liquid in the crucible through stirring impellers arranged at the bottom of the stirring shaft. The metal homogenizing melting furnace stirs molten metal through the stirrer, uniforms constituents of the molten metal obtained after melting metal, and greatly improves product quality.

Owner:贵州鑫凯达金属电源有限责任公司

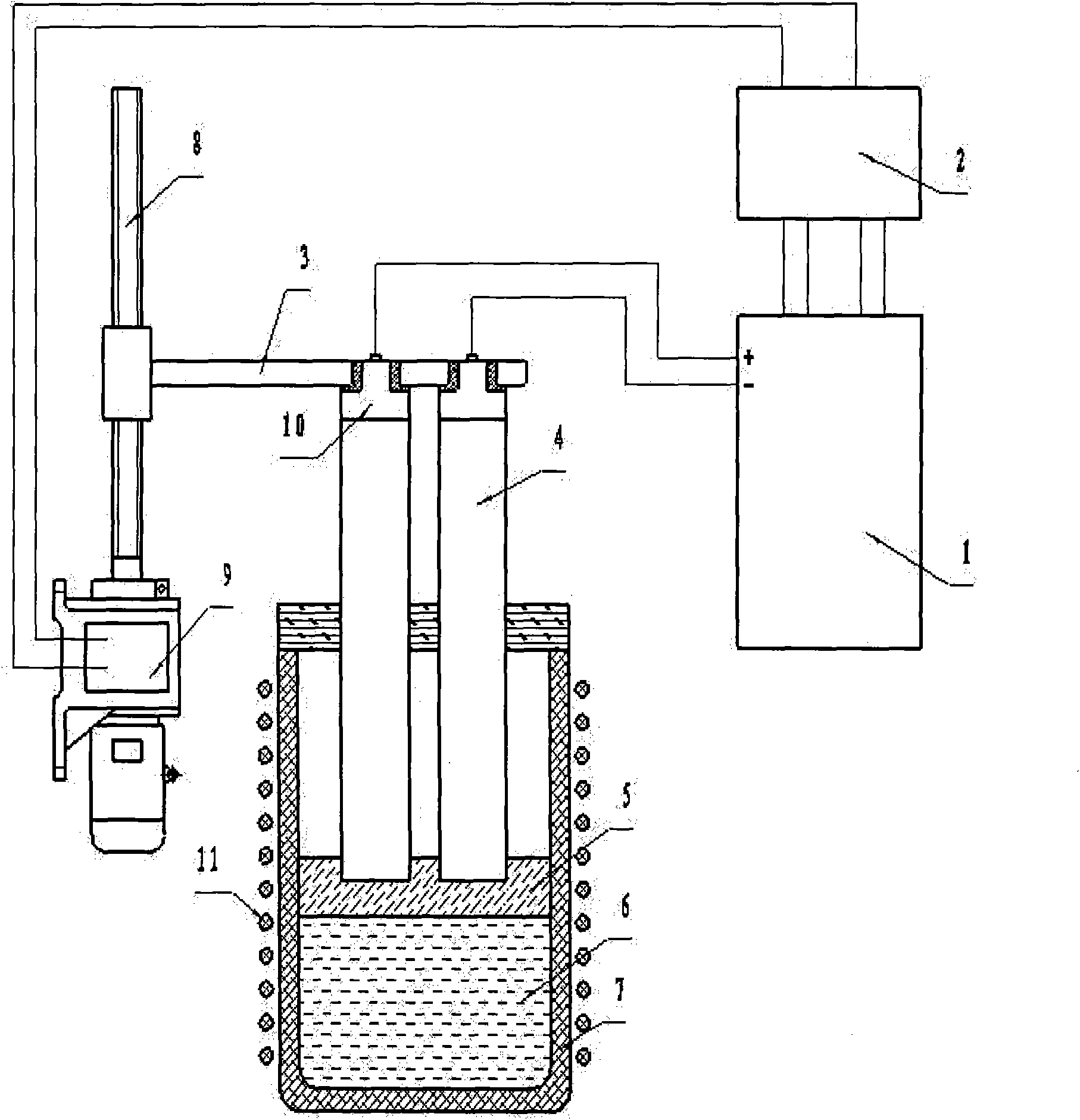

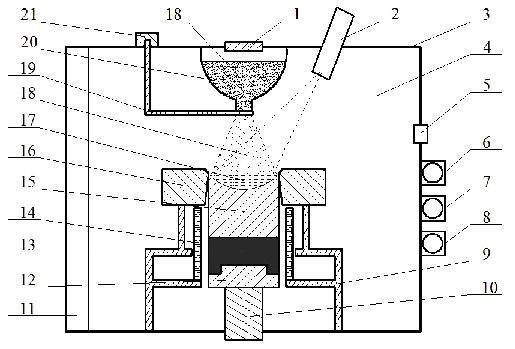

Method and device for coupling and purifying polysilicon and removing phosphorus and metal with electron beams

InactiveCN102120578AEvenly distributedReduce distributionChemical industrySilicon compoundsMelting tankMetal impurities

The invention belongs to the technical field of polysilicon purification with a physical metallurgy technology and particularly relates to a method for coupling and purifying polysilicon and removing phosphorus and metal with electron beams. The method comprises the following steps of: forming a stable melting pool on the top of a low-phosphorous low-metal high-purity silicon ingot with the electron beams; putting silicon powder to be purified into the melting pool and melting to realize the rapid melting of the powder body to remove volatile phosphorous impurity in the silicon powder; simultaneously carrying out directional ingot pulling so that the low-phosphorus polysilicon grows in a directional solidification way; and removing metal impurities in the polysilicon by utilizing a segregation effect. The invention has the remarkable effects that: because ways of melting silicon powder with the electron beams and carrying out directional solidification are simultaneously adopted, the phosphorus impurity is rapidly removed with the electron beams, and the metal impurities with lower segregation coefficient are removed by the directional solidification way, the purity of the polysilicon is effectively improved, and the using requirement of solar grade silicon is achieved. The invention has the advantages of good purification effect, stable technology, simple process, high production efficiency, energy saving, low cost and suitability for batch production.

Owner:谭毅

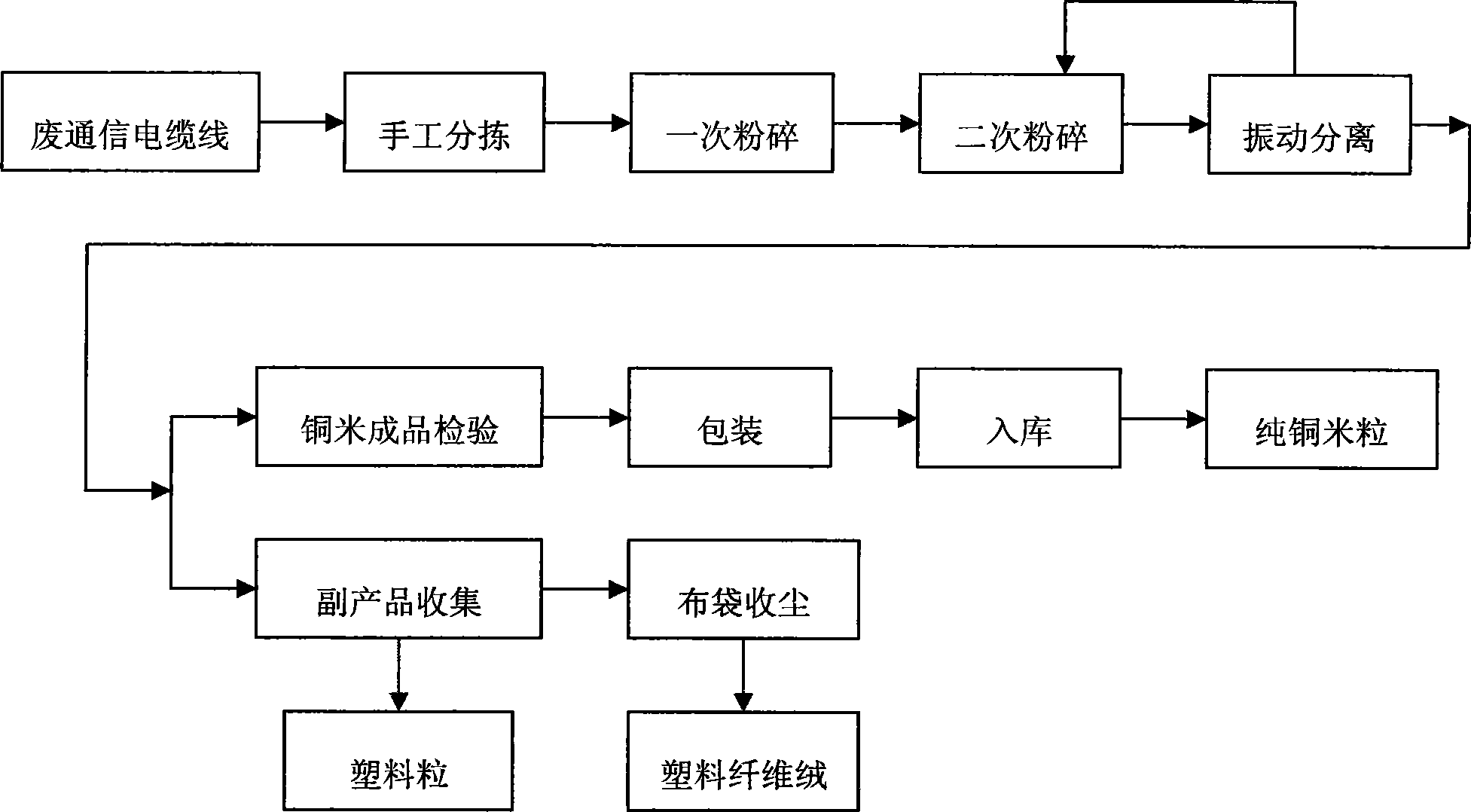

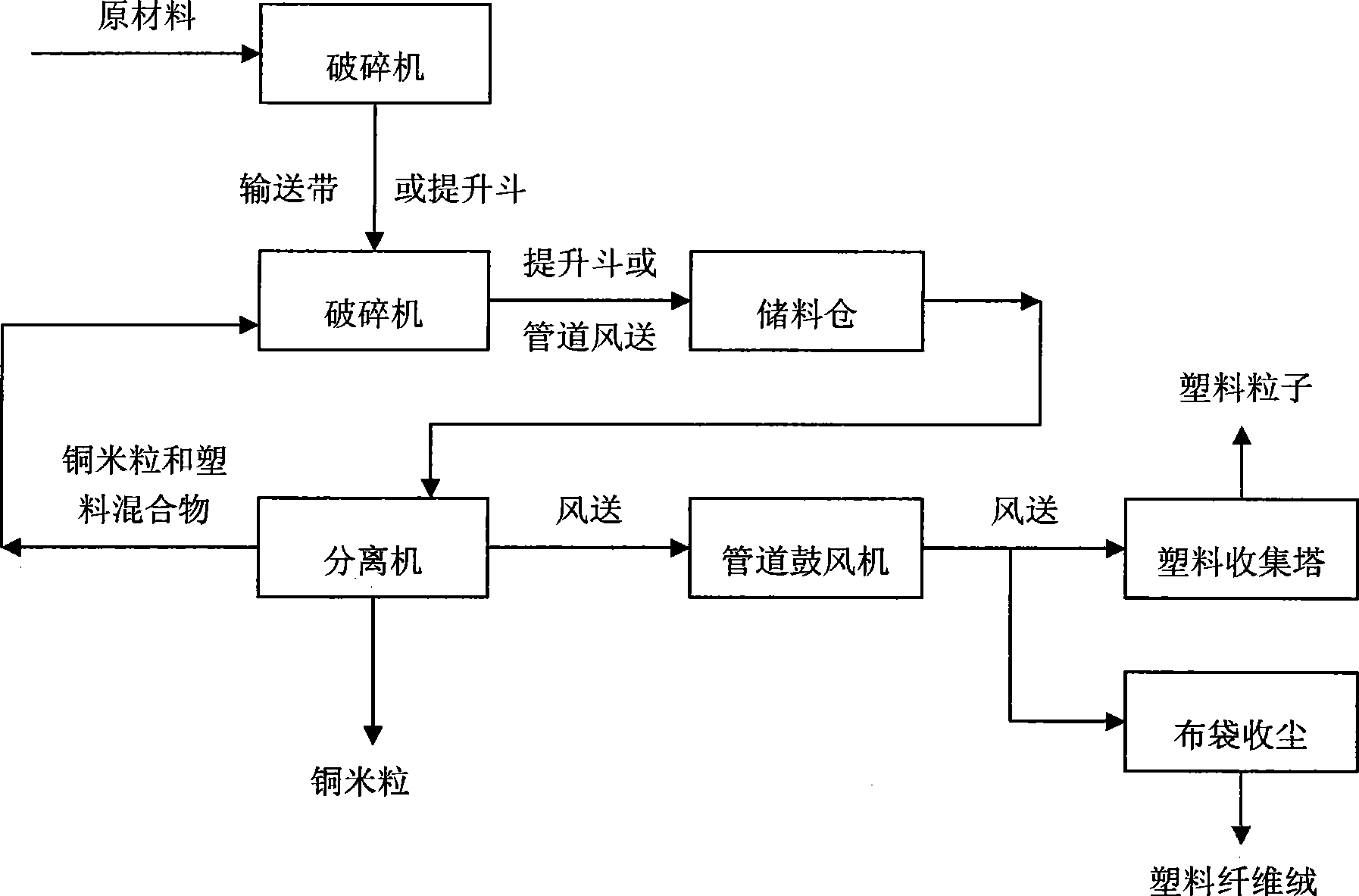

Process for recycling and manufacturing copper granule from waste and old electric wire and cable

InactiveCN101367084ALow costReduce energy consumptionSievingSolid waste disposalEngineeringMixed materials

The invention discloses a technological method for producing copper rice grains by recovering waste wires and cables based on an improvement of the prior production mode that the waste wires and cables recover copper raw materials. The technological method has low cost, small energy consumption, less discharge and no waste pollution, meets the requirement of circular economy development, and can obtain a copper rice grain product the purity of which reaches 99.9 percent. The technological process comprises the steps of classification inspection, loading, primary crushing, secondary crushing, and vibration separation; the angle of a vibration sieve is adjusted according to the content of copper and the wire diameter, and the copper rice grains and plastic are subjected to optional separation through vibration sieving; a material from a mixed material port flows into an air suction pipe, and is sent for secondary crushing through a circulating air pipe; the air suction pipe above the vibration sieve sucks plastic fibers and other dust in the space of the vibration sieve to a dust collector for treatment; the qualified copper rice grains obtained at a copper outlet flow into a packing bag; and the finished product inspection is performed, namely the obtained copper rice grains enter a warehouse through the inspection.

Owner:南京东南铜业有限公司

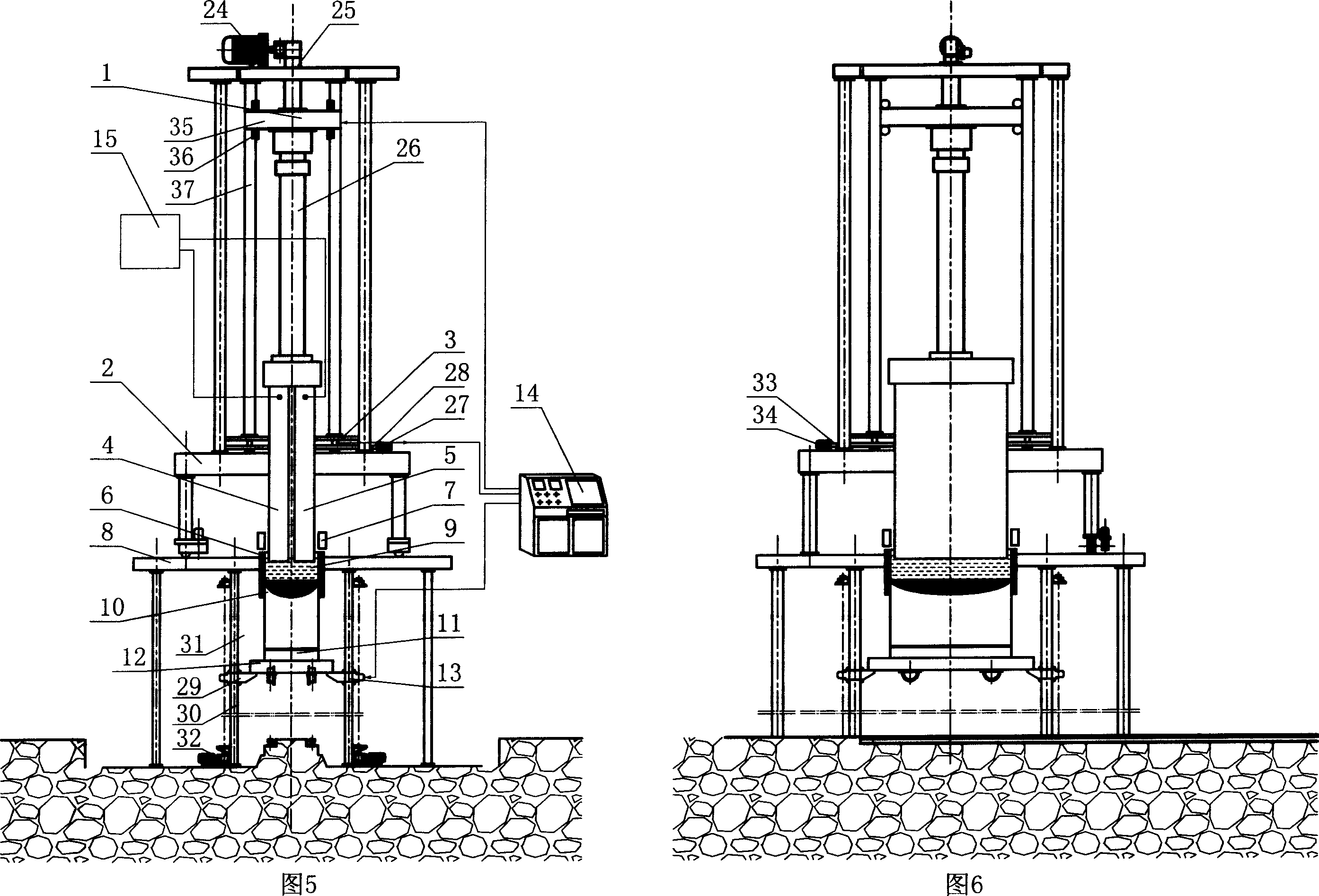

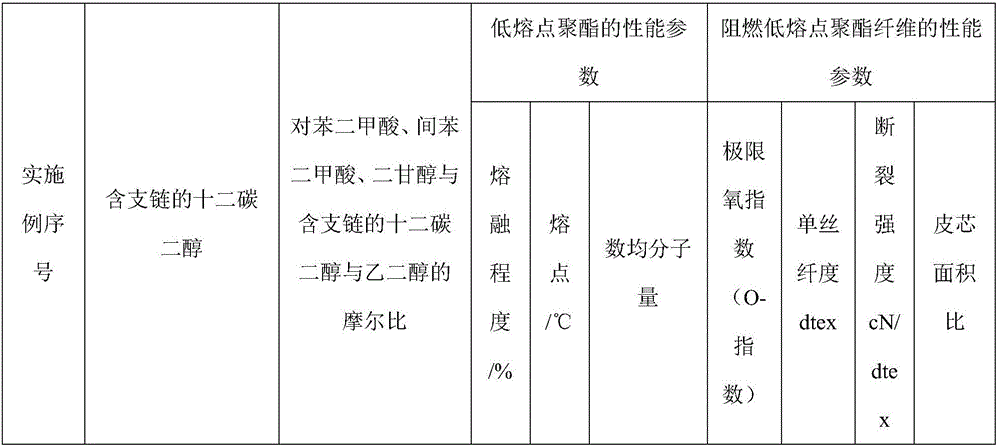

Flame-retarding low-melting-point polyester fiber and preparation method thereof

ActiveCN106811830ALow melting point temperatureFast meltingFilament/thread formingConjugated synthetic polymer artificial filamentsFiberDiethylene glycol

The invention discloses a flame-retarding low-melting-point polyester fiber and preparation method thereof, wherein the flame-retarding low-melting-point polyester fiber is a belt core structure, wherein the belt layer is low-melting-point polyester, and the core layer is flame-retarding polyester; the low-melting-point polyester is formed by terephthalic acid chain section, isophthalic acid chain section, glycol chain section, diglycol chain section and branch-chain-contained dodecynoic glycol chain section; the flame-retarding polyester consists of terephthalic acid chain section, glycol chain section, and flame retardant 2- ethoxy phenyl hypophosphorous acid chain section. The preparation method includes low-melting-point polyether polymerization and belt core composite spinning; the post spinning adopts drafting technique; the flame-retarding low-melting-point polyester fiber is acquired through rolling, cutting and drying. The flame-retarding low-melting-point polyester fiber is low in melting point and good in flame retarding effect.

Owner:扬州富威尔复合材料有限公司

Preparing method of TiAl alloy turbine blade

ActiveCN107931609ASmall internal thermal stressAvoid deformationTurbinesAdditive manufacturing apparatusVacuum pumpingTurbine blade

The invention discloses a preparing method of a TiAl alloy turbine blade. The method comprises the steps that a three-dimensional model of the turbine blade is built, slicing treatment is carried out,and layer cutting data are obtained; secondly, secondly, a forming cavity of an electronic beam area selection rapid forming device is subject to vacuum pumping, and a forming substrate is preheated;thirdly, TiAl alloy powder is laid on the preheated forming substrate, and preheating is carried out; fourthly, the preheated TiAl alloy powder is subject to area selection melting scanning, and a single-layer solid piece layer is formed; fifthly, the third step and the fourth step are repeated, and an electronic beam area selection melting forming part is formed; sixthly, after cooling, the TiAlalloy turbine blade is obtained. The TiAl alloy turbine blade is prepared through the electronic beam area selecting rapid forming method, preheating of the forming substrate and the TiAl alloy powder is achieved, forming temperature of the TiAl alloy turbine blade is controlled, internal heat stress of the TiAl alloy turbine blade is reduced, deforming and breaking of the TiAl alloy turbine blade are avoided, and matching of strength and plasticity of the TiAl alloy turbine blade is enhanced.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

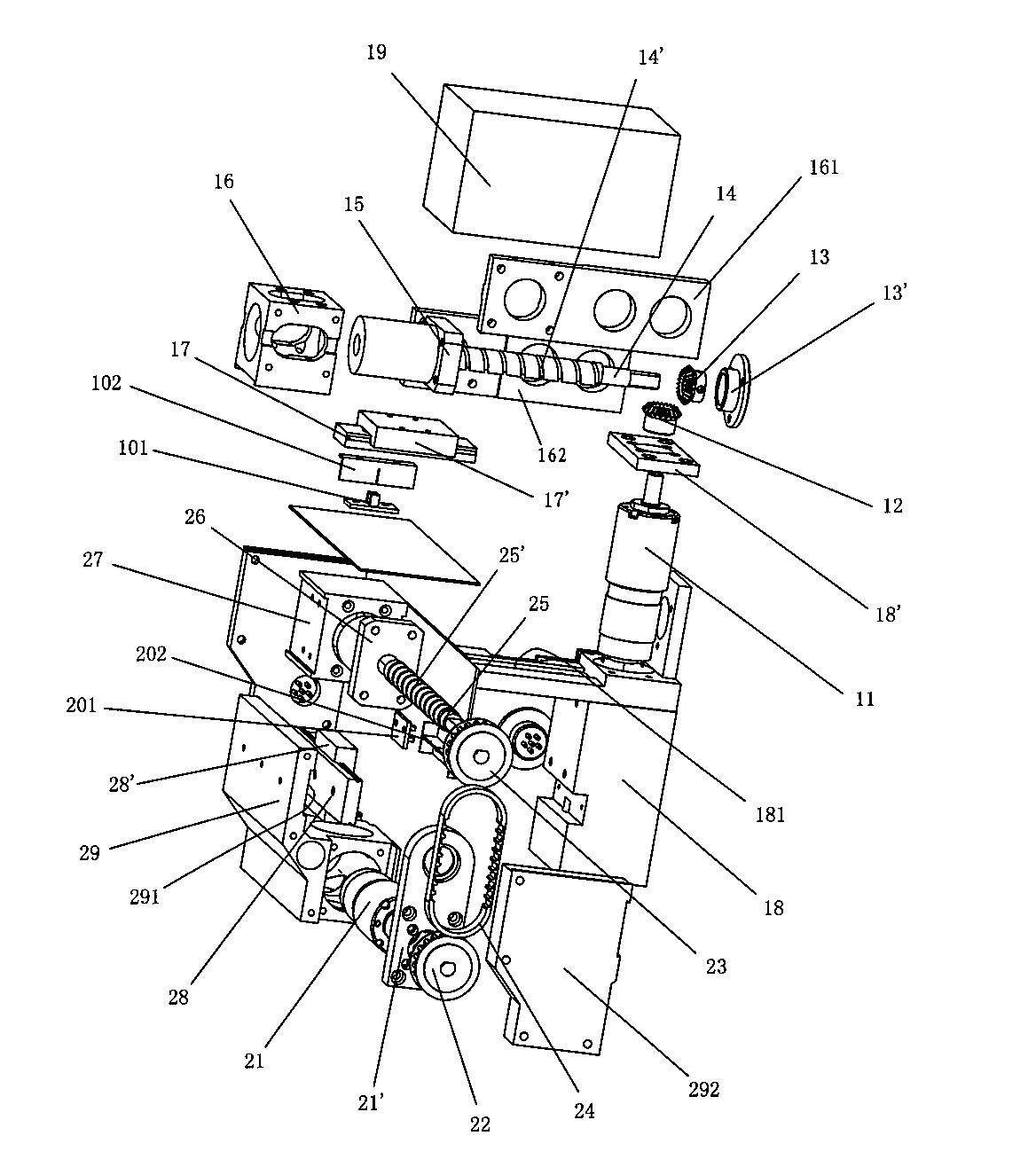

Testing device for external characteristics of high-temperature molten salt pump

InactiveCN104373339AImprove efficiencyHigh precisionPump testingPositive-displacement liquid enginesFiberDrivetrain

The invention provides a testing device for the external characteristics of a high-temperature molten salt pump. The testing device is mainly used for measuring the external characteristics of the molten salt pump when the molten salt pump conveys high-temperature molten salt. The testing device mainly comprises a power transmission system, a liquid path system, a gas path system, a heating system, a heat insulation heat tracing system and a data collection and analysis system. The power transmission system provides power for stable operation of the molten salt pump. The liquid path system forms a molten salt circulation loop and guarantees that the testing device has high measurement precision and operates safely. The gas path system provides protective gas for the molten salt. The heating system heats the molten salt directly and has the advantage of being efficient. The heat insulation heat tracing system carries out heat insulation through alumina silicate fibers in the mode of combining steam heat tracing and electric heat tracing so as to prevent the molten salt from solidifying. The data collection and analysis system is used for collecting pressure signals, rotation speed signals, flow rate signals, temperature signals, current signals, voltage signals and other signals and analyzing the collected data to obtain the external characteristics of the molten salt pump.

Owner:NANJING UNIV OF TECH

Finegrained aluminium-chromium composite fireproof materials

The invention relates to a novel fire-resistant raw material for preparing periclasite magnesium aluminate spinel fireproof material and high grade fusion-cast AZS fireproof material whose formulation is, desiliconisation zirconium 30-73%, commercial alumina 27%-70%, magnesite 0-10%, wherein the content of zirconium dioxide in desiliconisation zirconium is 85-92%, the content of magnesium oxide in magnesite is 97%, the total content of magnesium oxide in the formulation is 0.2-10%, the total content of silicon oxide is 0.5-1.5%, the total content of zirconium oxide is 30-60%, the total content of alumina is 30-65%. The raw material can be used to prepare periclasite-magnesium aluminate spinel material with substantial improvement on heat and shock resistance, thermal conductivity.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

Deep desulfurizer for refining ultra-low-carbon steel and manufacturing method thereof

The invention discloses an ultralow carbon steel refining deep-desulfurizer and making method, which comprises the following parts: 60%-69% CaO, 11%-20% Al, 5%-10% MgO, 5%-10% SiO2, 1%-5% Al2O3, 0.5%-1.2% Fe2O3, 1%-3% CaF2, 1%-3% B2O3, 1%-3% BaO and impurity. The making technique comprises the following steps: blending; grinding the material with grain size not more than 1mm; inactivating the material; drying; draining the trace element of water; packing.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com