Patents

Literature

128results about How to "Increase stirring intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

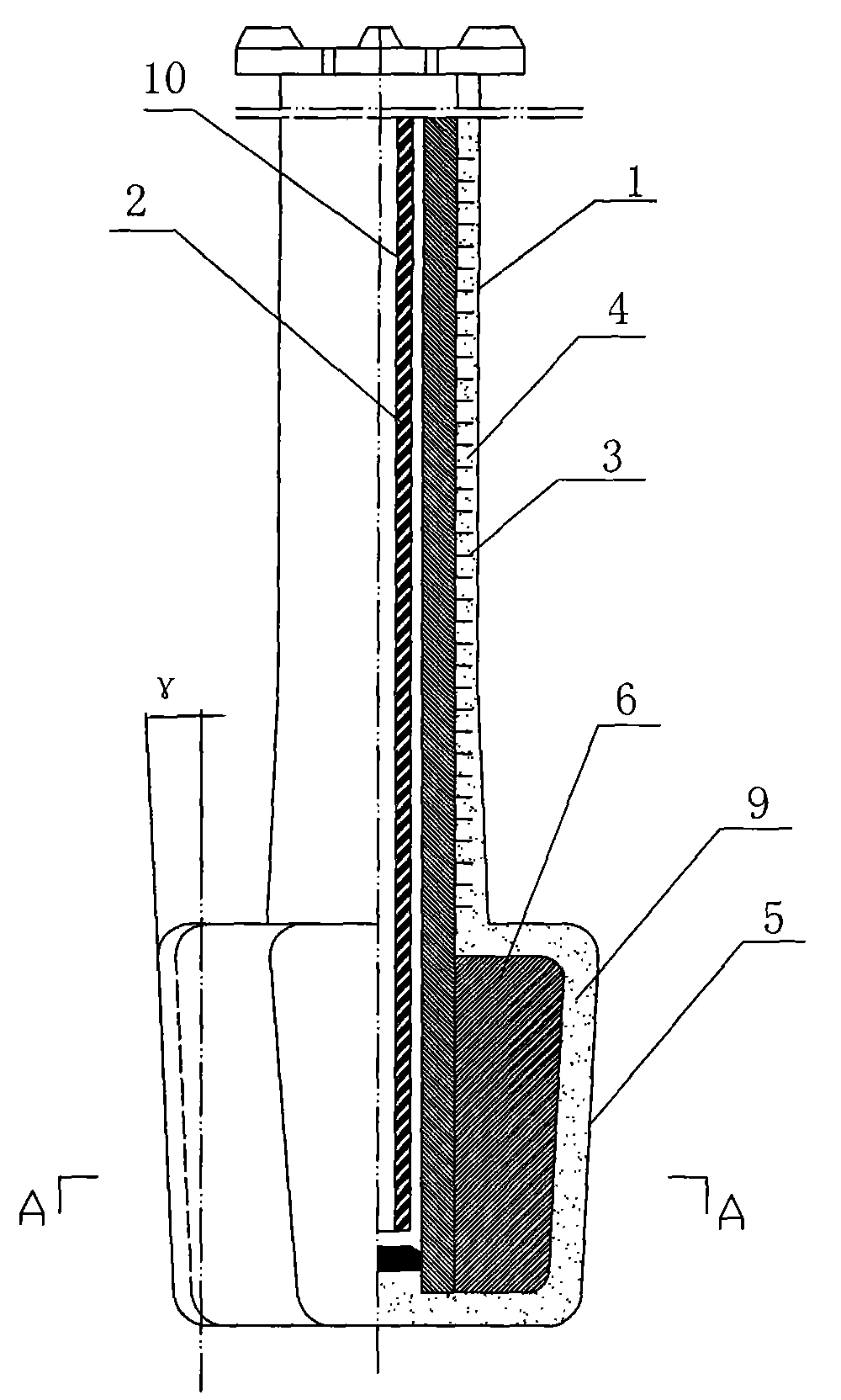

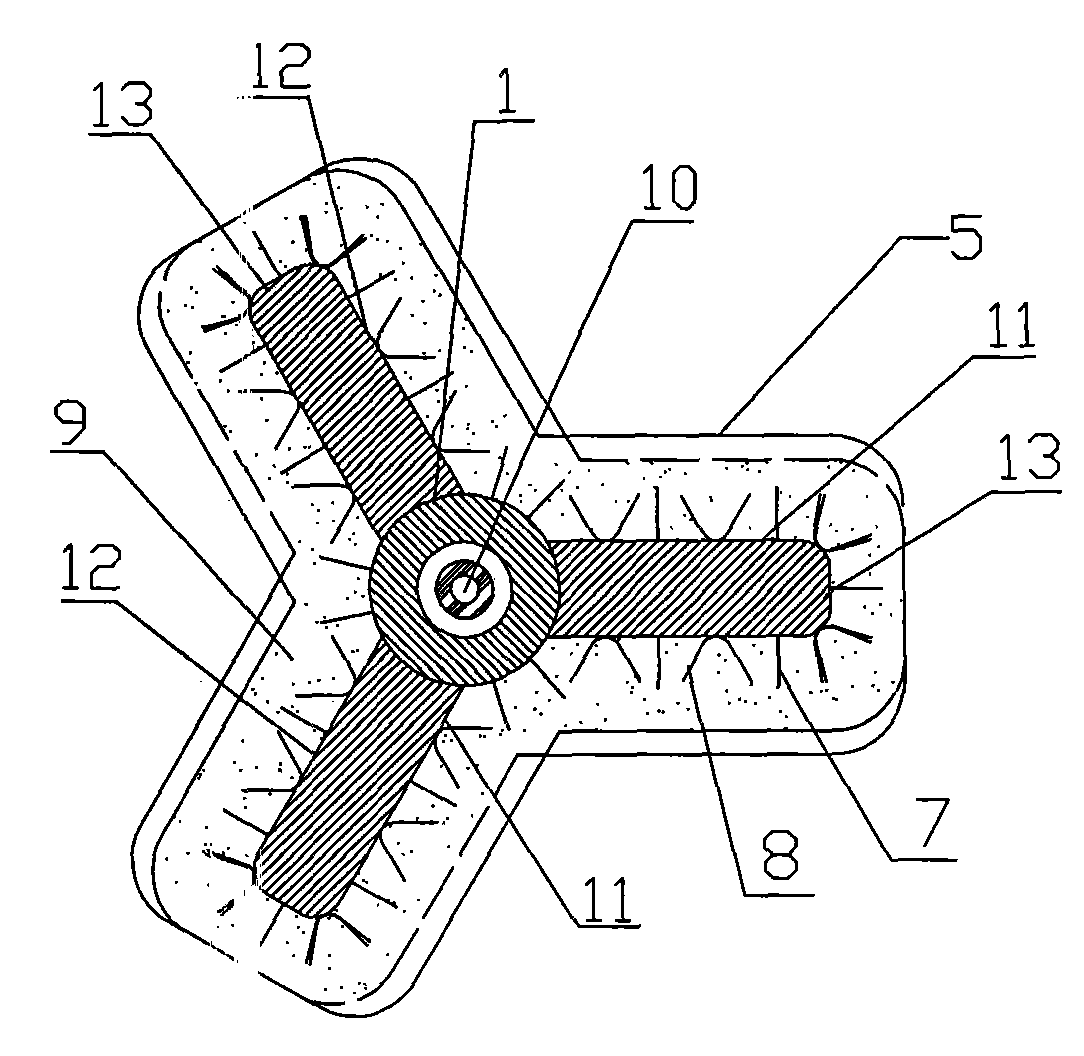

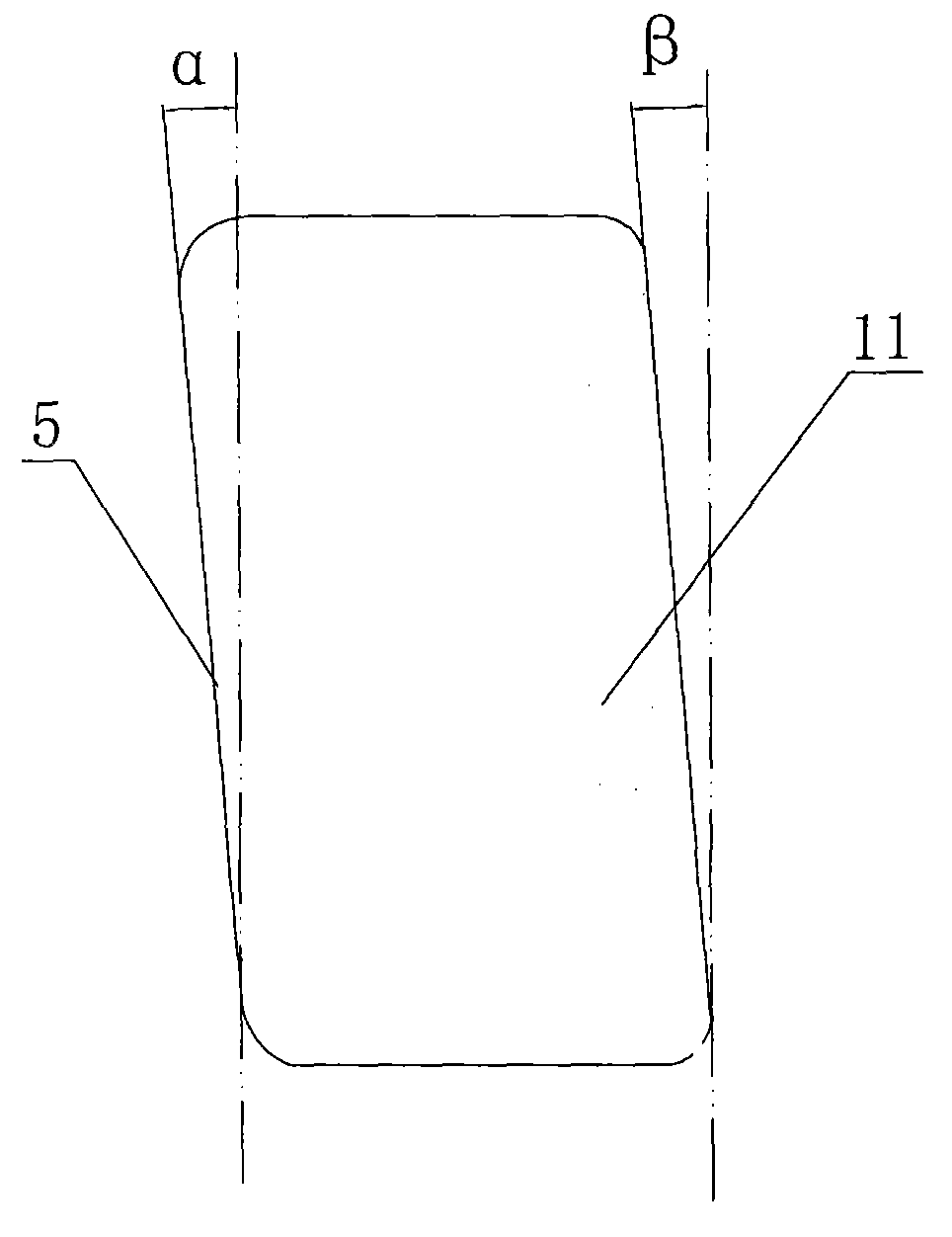

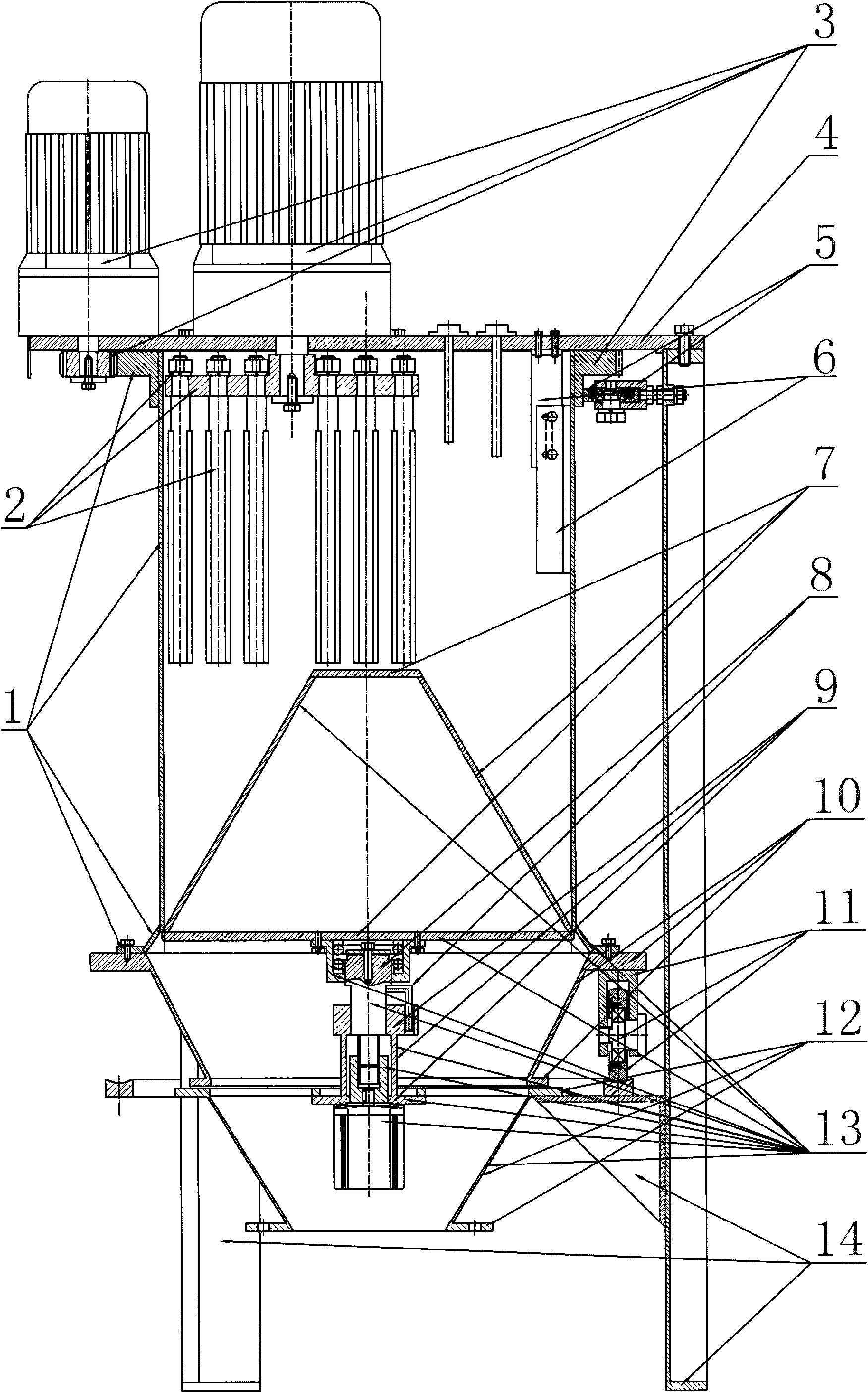

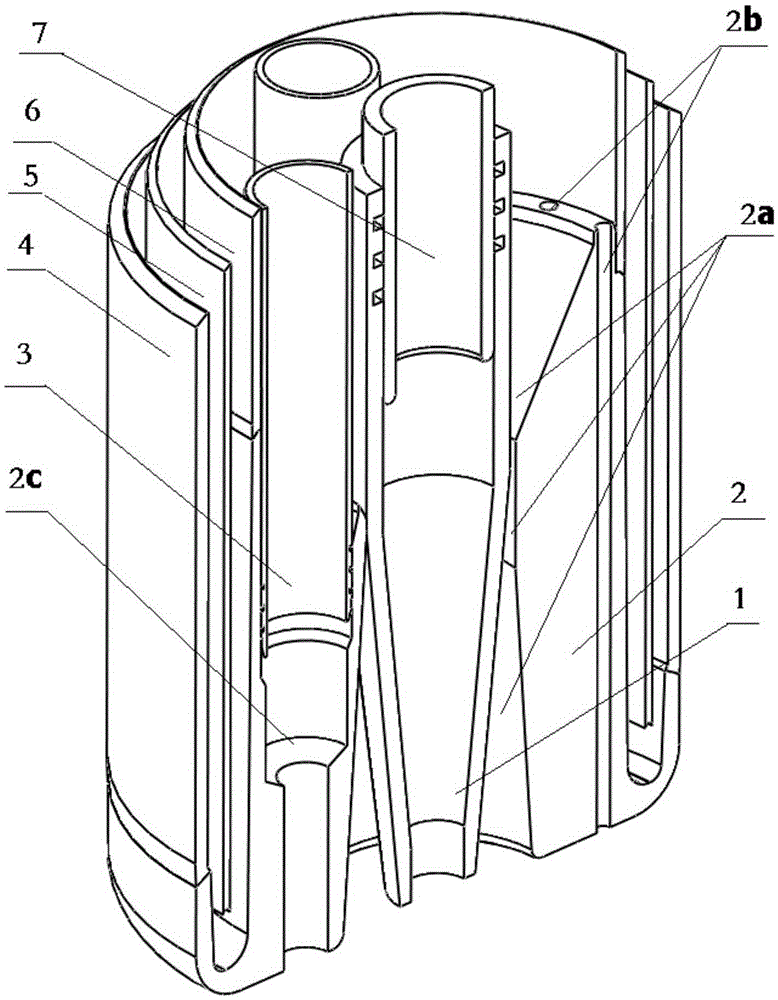

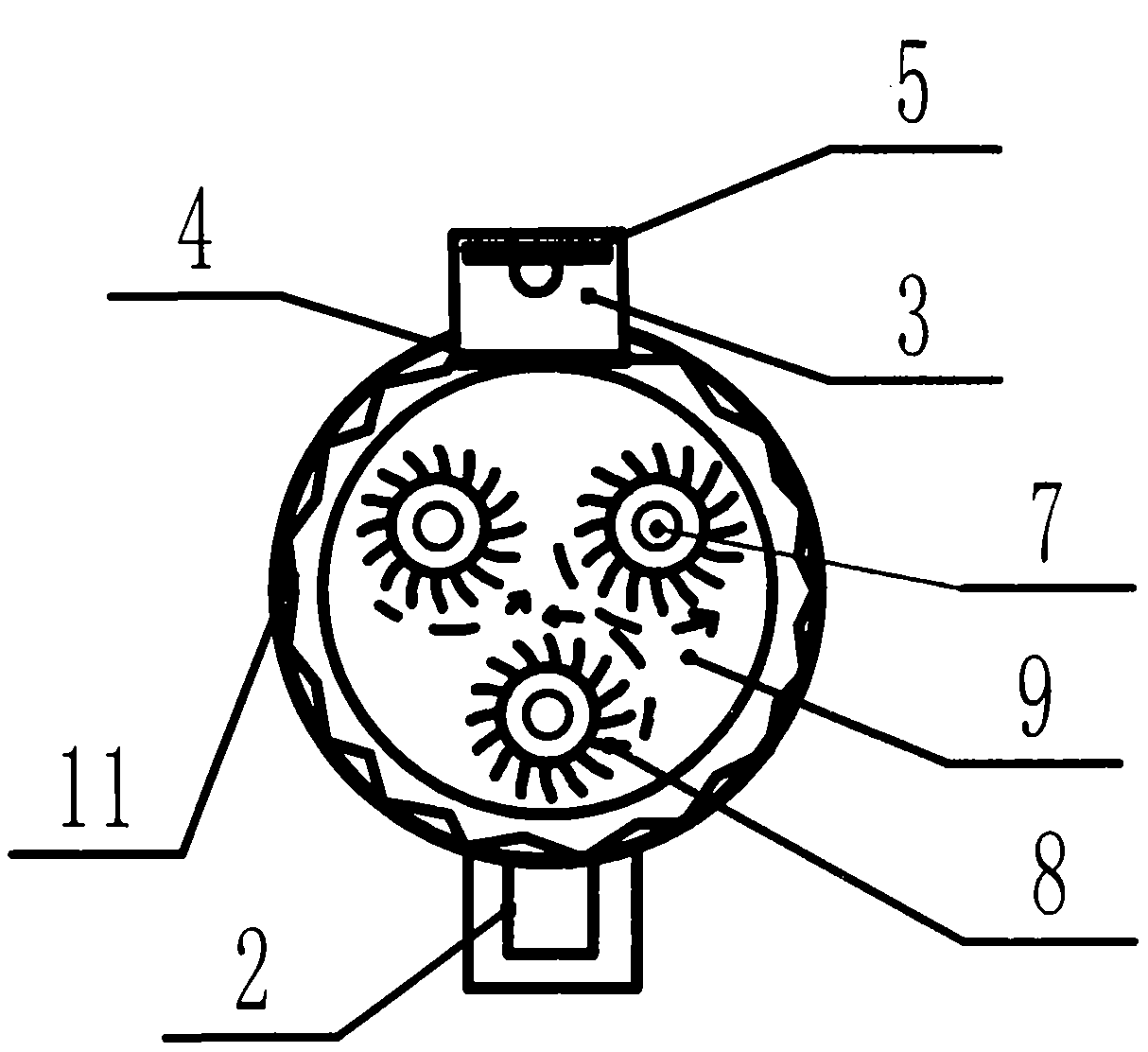

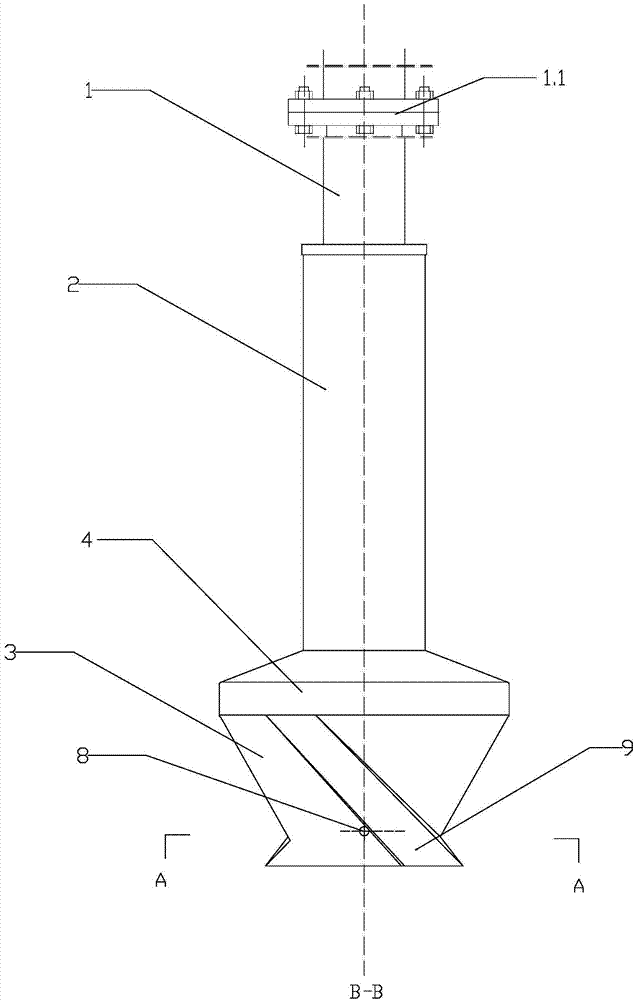

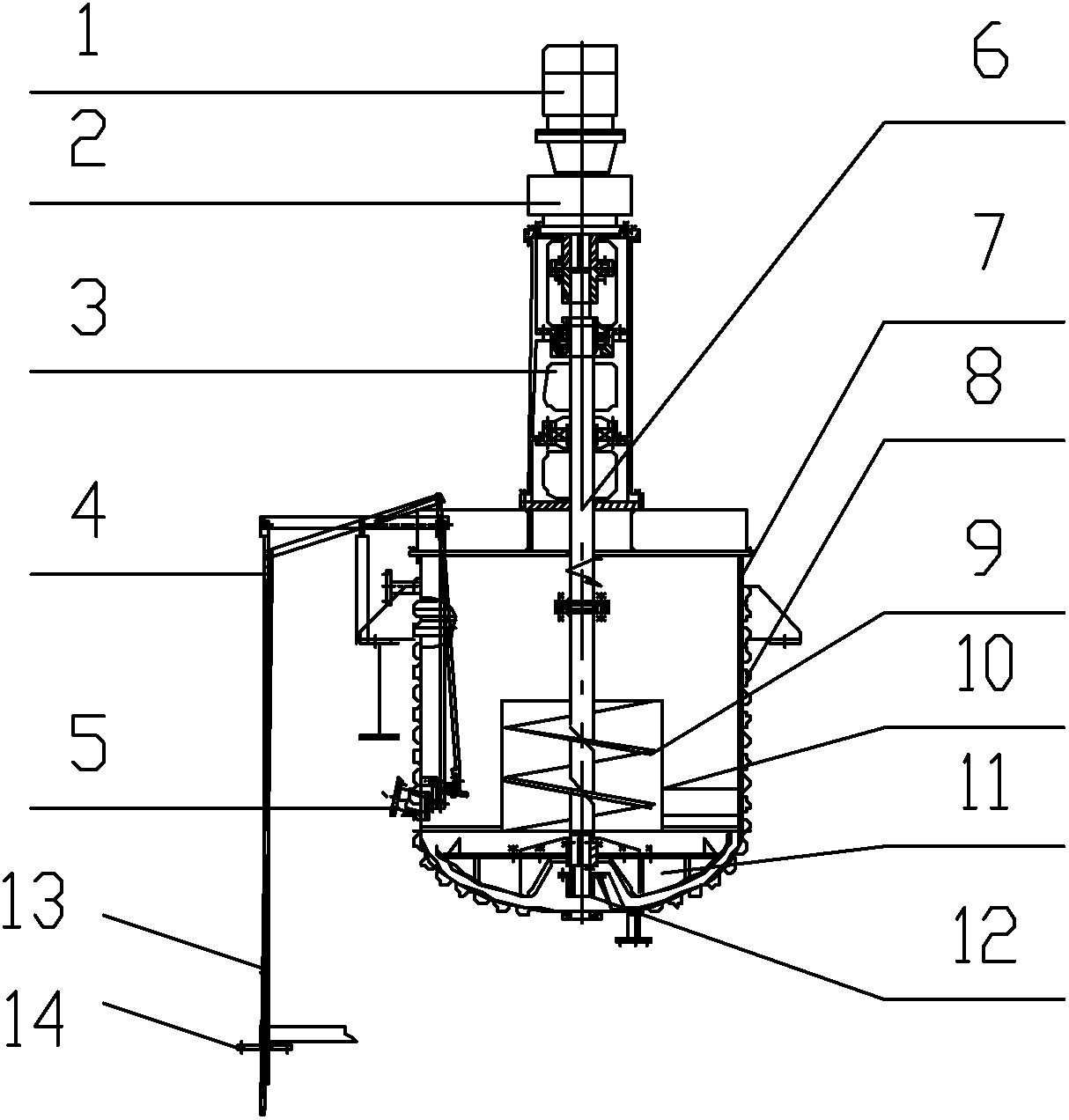

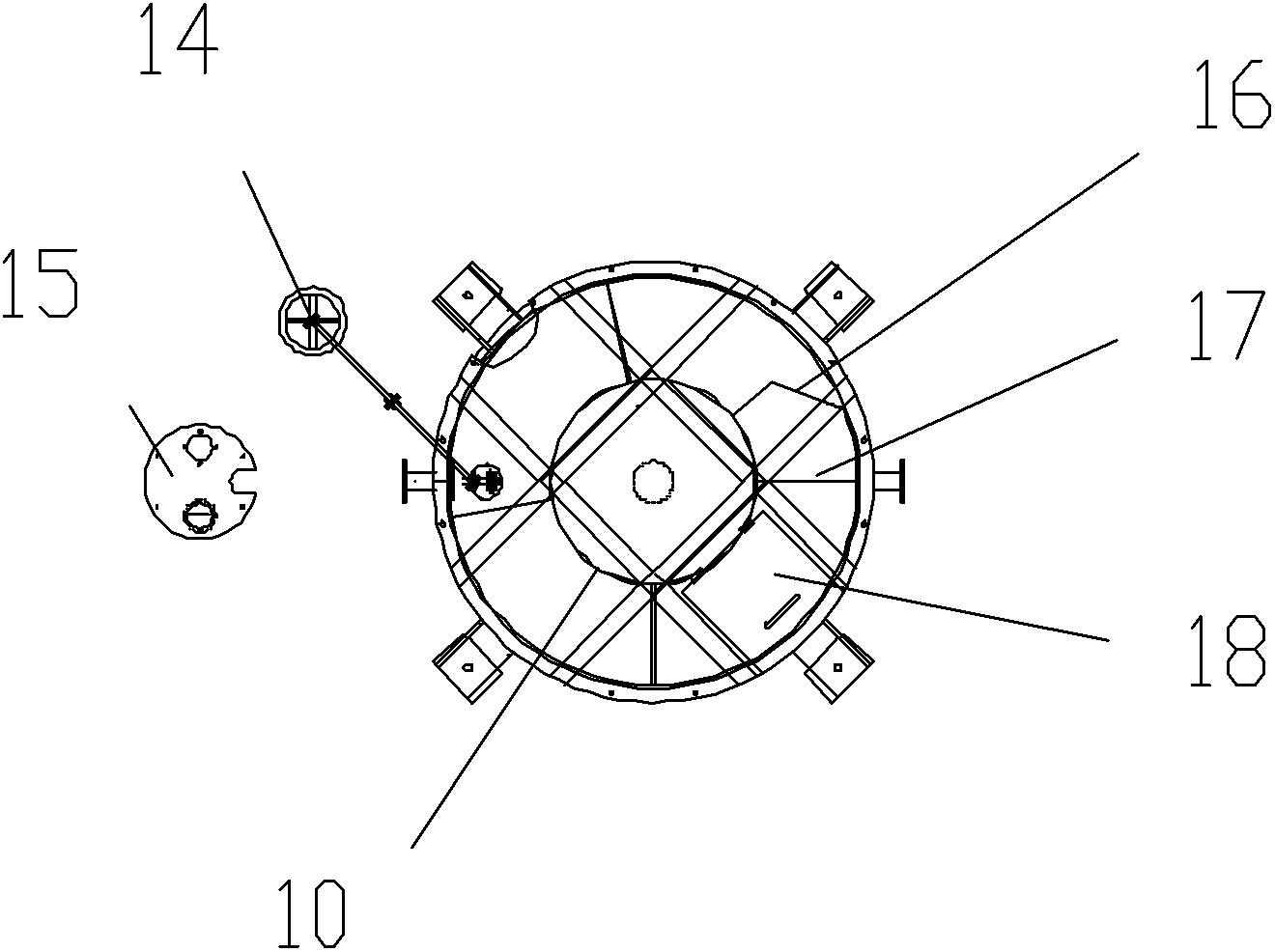

Stirrer for desulphurization of molten iron

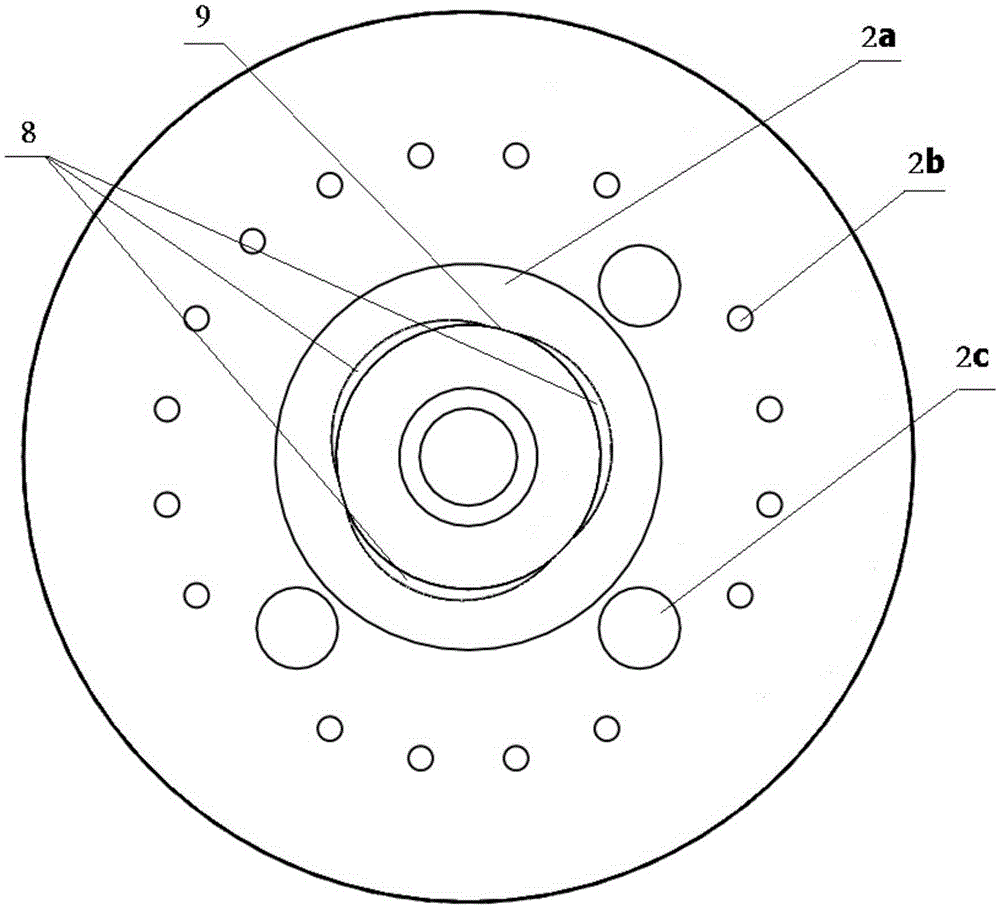

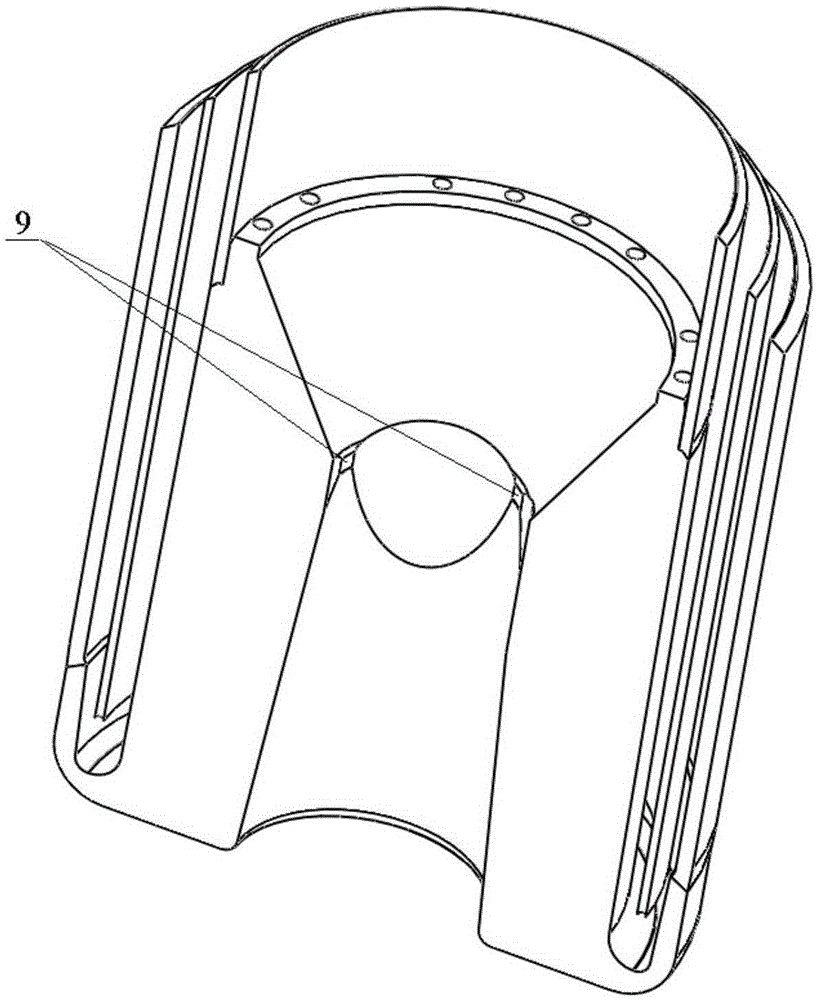

The invention relates to a stirrer for external stirring desulphurization of molten iron before converter steelmaking, aiming at solving the existing deficiencies at present that slags among mixing blades are numerous, large intensity of vortex at the bottom of the metal opposing side of the mixing blades is disadvantageous to the discharging of the involved desulphurization slags. The invention comprises the following measures: the stirrer for desulphurization of molten iron is composed of a metal core 2, a V-shaped rivet firmware 3, a refractory liner 4, a metal chip 6, a V-shaped rivet firmware 7, a double V-shaped rivet firmware 8, a refractory liner 9 and an air cooling tube 10; the metal core 2, the V-shaped rivet firmware 3 and the refractory liner 4 constitute a rotation axis 1; the metal chip 6, the V-shaped rivet firmware 7, the double V-shaped rivet firmware 8, the refractory liner 9 and the air cooling tube 10 constitute mixing blades 5; three mixing blades 5 above the rotation axis 1 are evenly distributed; the front rake angle alpha of the inclined plane from bottom to top of the metal facing water surfaces 11 of the mixing blades 5 is 4.1-30 degrees, the front rake angle beta of the inclined plane from bottom to top of the metal opposing surfaces 12 is 0.1-30 degrees, the camber angle gamma of the inclined plane from bottom to top of the outside surface 13 is 4.1-15 degrees. In the invention, slags among the mixing blades are small, the dynamic condition for stirring desulphurization is excellent, the service life is long and the structure is simple.

Owner:武汉钢铁有限公司 +1

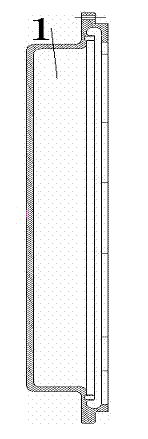

Smelting process of low-grade scrap copper

ActiveCN104131170AFlexible feeding methodFlexible working methodsProcess efficiency improvementScrapSmelting process

The invention discloses a smelting process of low-grade scrap copper. The process comprises the following steps: 1) generation of an initial molten pool; 2) a melting process, namely continuously adding auxiliary materials into a top blowing furnace, inserting a spray gun into melt, spraying oxygen-enriched air and fuel into the melt, carrying out submerged combustion and top-blown smelting, and stopping adding the auxiliary materials when the liquid level of the melt in a to-be-blown furnace is 0.3m to 0.5m higher than a bleed hole, repeatedly carrying out smelting and slagging operations after opening the bleed hole for slagging, and stopping charging and melting when the black copper melt surface inside the top blowing furnace ascends to the position which is 100mm to 200mm below the bleed hole; (3) a blowing process, namely exhausting slag inside the top blowing furnace, inserting the spray gun into black copper, and spraying the oxygen-enriched air and fuel to carry out submerged combustion and blowing, and respectively discharging the produced raw copper and blowing slag from a copper discharge hole and the bleed hole; and 4) repeating of the smelting and blowing processes. According to the technical scheme disclosed by the invention, the operation for smelting scrap copper is flexible, and the smelting process is strong in adaptability on raw materials, high in safety, and high in recovery rate of copper and valuable metal.

Owner:TONGLING NON FERROUS METAL GROUP CORP

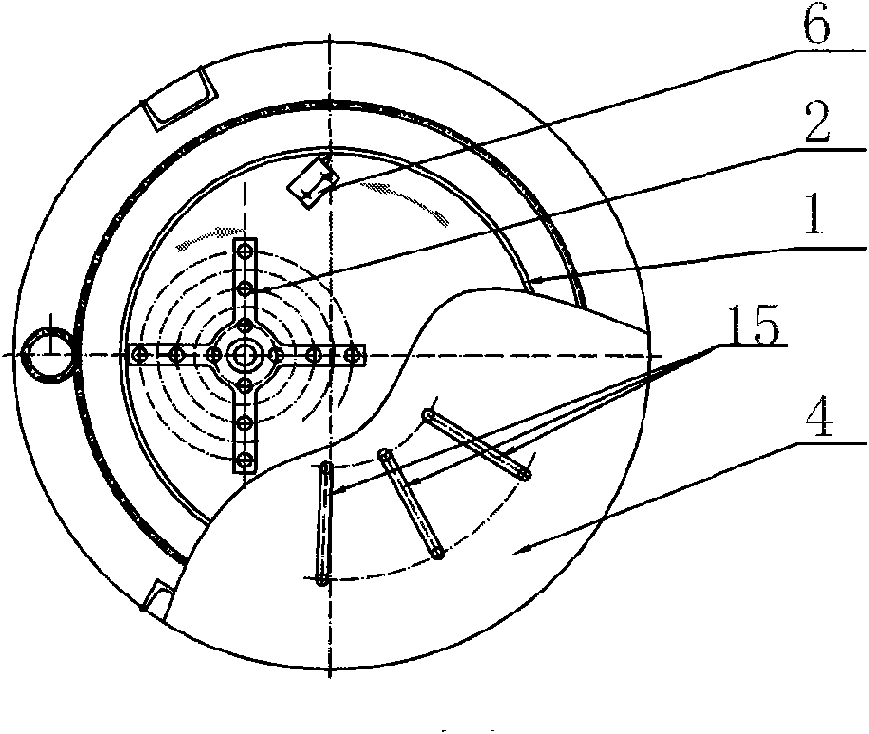

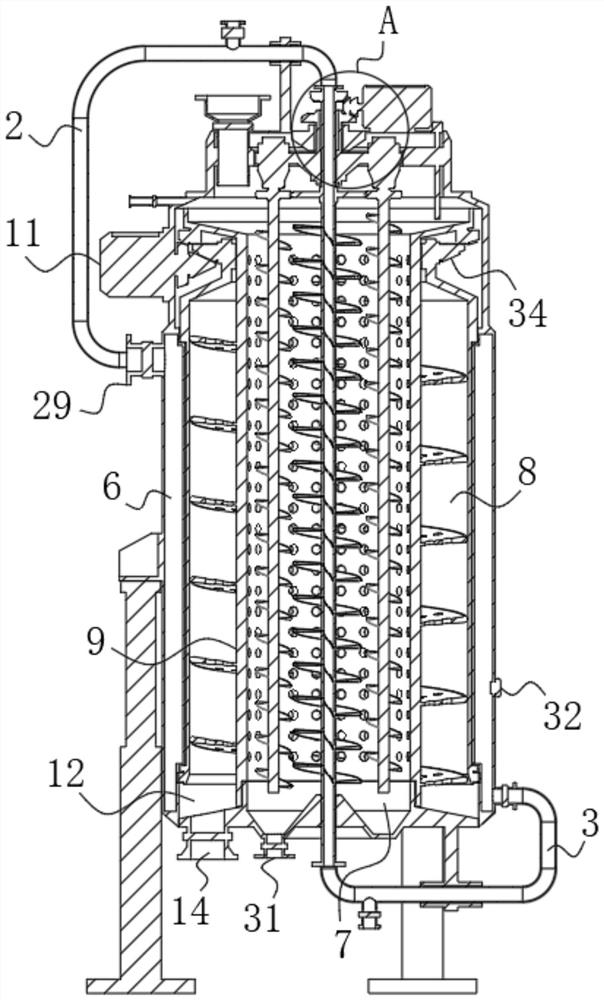

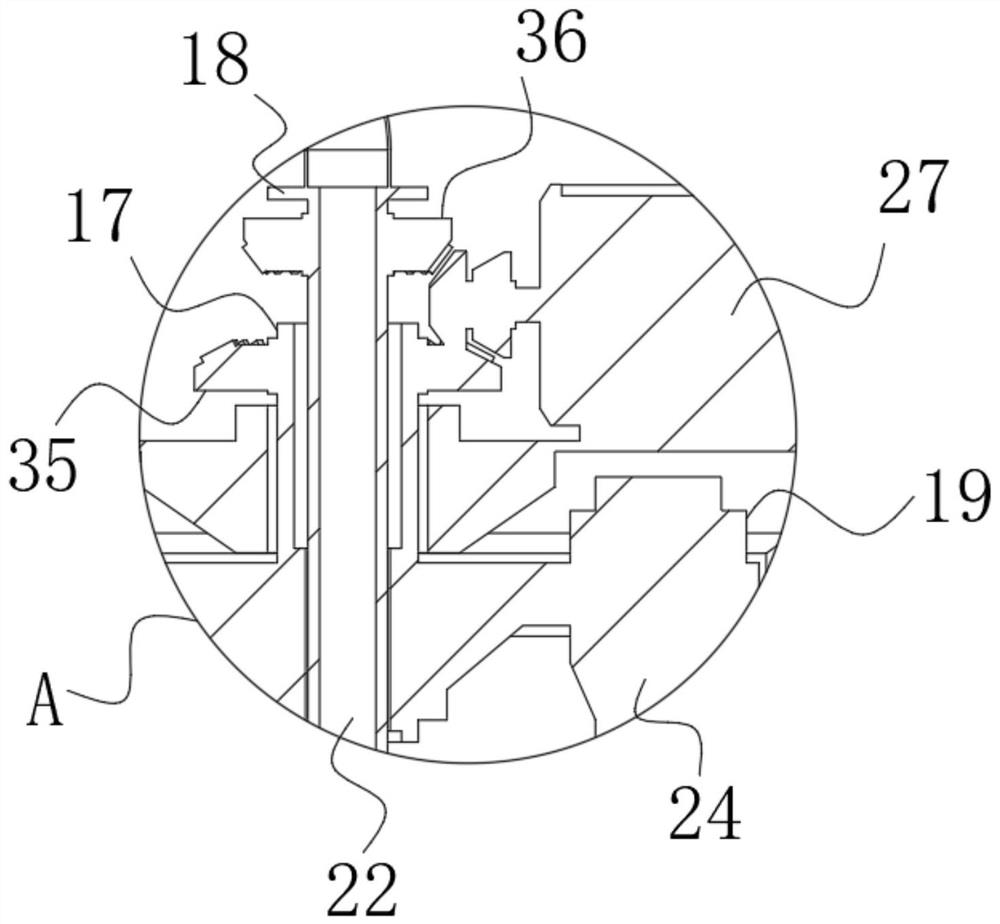

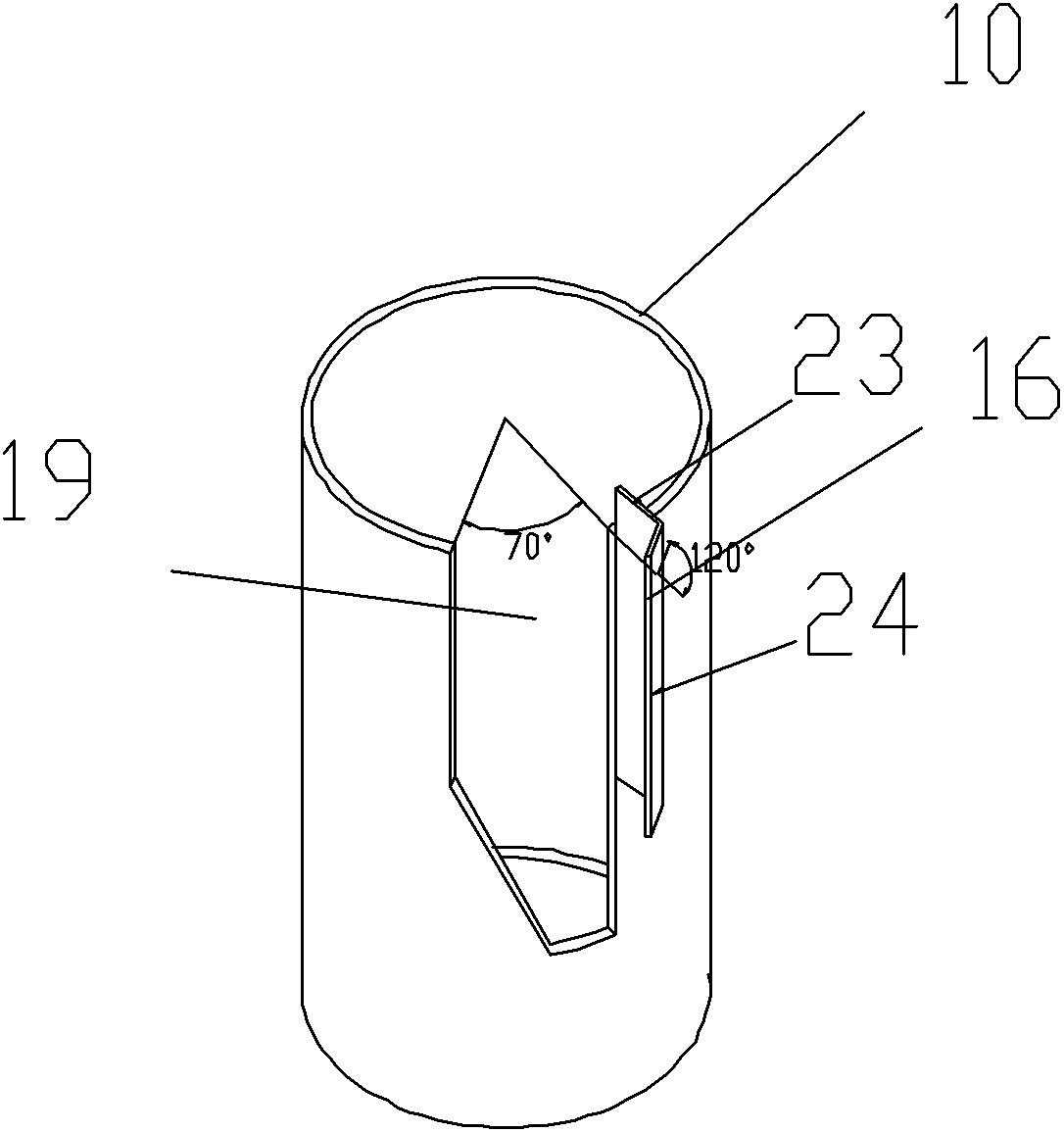

Multifunctional stirring machine

InactiveCN101658771AImprove work efficiencyImprove the quality of workRotating receptacle mixersTransportation and packagingAutomatic controlPulp and paper industry

The invention relates to a multifunctional stirring machine which consists of a rotatable vertical cylindrical container and a stirrer capable of rotating in reverse direction in the container. The structural design that a rotating shaft center of the container and the rotating shaft center of the stirrer are eccentric and a scraper mechanism which is specially arranged can ensure that the multifunctional stirring machine has no stirring dead angles during the work, and an electrical material level automatic control device can ensure the discharge flow of materials by relying on the self-gravity and simultaneously maintain the stable material level in the container. The multifunctional stirring machine can have a plurality of functions of mixing, peeling, clearing, polishing, dampening andthe like by being matched with stirring rods with different structures. When the multifunctional stirring machine is used as a mixing machine, the multifunctional stirring machine has the advantagesof simple structure, low cost, fast mixing speed, high mixing uniformity, small segregation tendency, low energy consumption, simple use and maintenance, long service life and the like. When the multifunctional stirring machine is used as a peeling machine, a clearing machine or a polishing machine, the multifunctional stirring machine has the advantages of high peeling efficiency or good clearingeffect, no production of crushed particles, low energy consumption and the like. When the multifunctional stirring machine is used as a dampening machine, the multifunctional stirring machine has theadvantages of uniform dampening, low energy consumption and the like.

Owner:王洪福

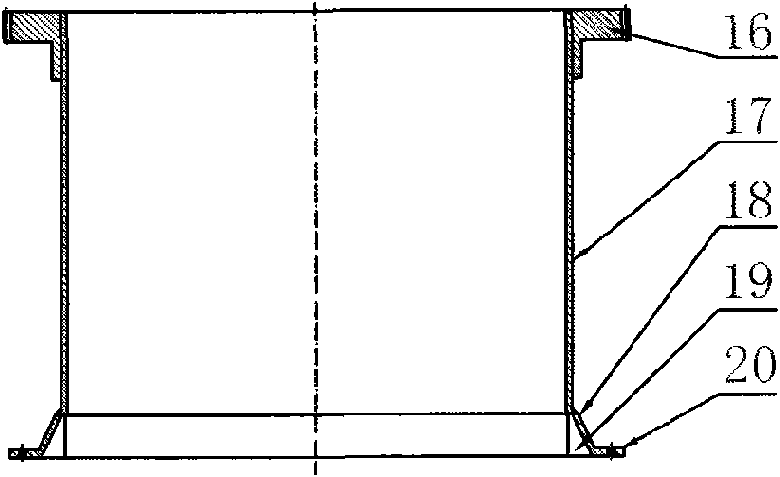

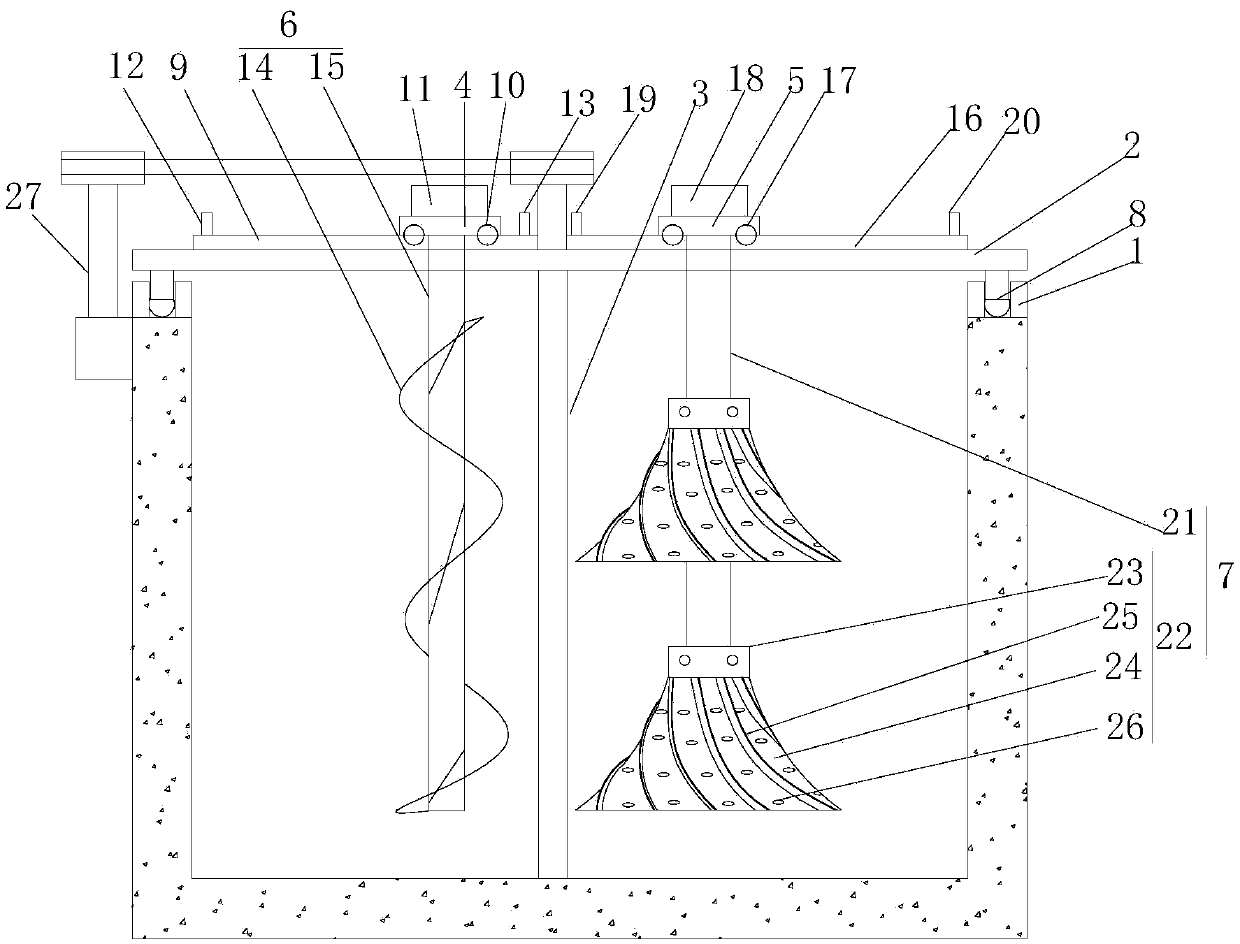

Sewage treatment mixing device and assembling and disassembling methods thereof

ActiveCN103112936AQuick changeExtend working lifeRotary stirring mixersMixer accessoriesStructural engineeringSewage treatment

The invention belongs to the field of sewage treatment equipment, and relates to a sewage treatment mixing device and assembling and disassembling methods thereof, which aims at solving the problems of the prior art that the structure is complicated, the angle and the agitating diameter of an agitating blade are difficultly adjusted and the blade is not easily disassembled and replaced quickly. According to the technical scheme adopted, an upper shell and a lower shell are rotatably connected in a buckling manner, the blade is connected with an impeller sleeve by a positioning rod, to be capable of relatively rotating so as to adjust the inclination angle of the agitating blade, and the agitating diameter of the extended blade can be adjusted through small holes in the blade sleeve and spring ejector pins in a trapezoidal slot of the positioning rod. According to the sewage treatment mixing device and assembling and disassembling methods thereof, the structure is simple, the angle and agitating diameter of the agitating blade are conveniently adjusted and the blade can be disassembled and replaced quickly.

Owner:XIAN TECHNOLOGICAL UNIV

Rapid desulfurization refining method for ladle furnace

The invention discloses a rapid desulfurization refining method for a ladle furnace (LF). The method comprises the following steps of: 1) performing desulfurization refining in the LF, wherein the LF treatment starting temperature is between 1,570 and 1,605 DEG C; 2) after a ladle argon blowing device of the LF is turned on, blowing argon from the bottom of the ladle; 3) after finishing adjusting the temperature, inserting a desulfurization powder spraying gun into a molten steel liquid for spraying a desulfurizing agent; 4) after finishing spraying powder, switching the spraying gun to a functional stage of blowing the argon, blowing the argon from the top, simultaneously blowing the argon from the bottom of the ladle, and performing strong stirring desulfurization operation; 5) alloying, namely after desulfurization is finished, lifting the desulfurization powder spraying gun, adjusting a ladle bottom blowing flow, and performing alloy configuration to meet a target requirement on final components of a steel grade; and 6) after finishing adjusting components, performing soft stirring operation, measuring the temperature, sampling, and turning off the ladle argon blowing device to finish treating. The method realizes rapid desulfurization of the LF, and can shorten an overall melting cycle and improve the number of continuous casting furnaces and production efficiency.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for slagging steelmaking by side blowing of powder particle limestone in top-bottom combined blown converter

InactiveCN102796841ATake away decreaseIncrease profitManufacturing convertersSteelmakingMelting tank

The invention belongs to the technical field of metallurgy, and particularly relates to a method for slagging steelmaking by side blowing of powder particle limestone in a top-bottom combined blown converter. The method of the invention comprises the following steps: arranging at least one side blowing spray gun at one side of a converter trunnion center line, wherein the installation site of the side blowing spray gun is located between a molten pool liquid level and a level 500 mm below the liquid level, an angle between the installation range of the side blowing spray gun and the installation site tangent plane is 10 degrees-75 degrees, the side blowing direction of the spray gun is that the included angle between the side blowing spray gun center line and a horizontal line is 10 degrees-60 degrees, the spray gun faces the bottom of the molten pool, the insertion depth of the side blowing spray gun is 0.1-0.6 times larger than the radius of the molten pool; blowing powder particle limestone with carrier gas through a center pipe of the spray gun by using the side blowing spray gun, blowing protective gas around the circular seam. The method of the invention directly sprays powder particle limestone into the molten pool through the side blowing spray gun; the limestone rapidly decomposes and rapidly participates in slagging reactions; limestone taken away by converter furnace gas is reduced; dust is minimized; and the utilization rate of limestone is improved.

Owner:NORTHEASTERN UNIV

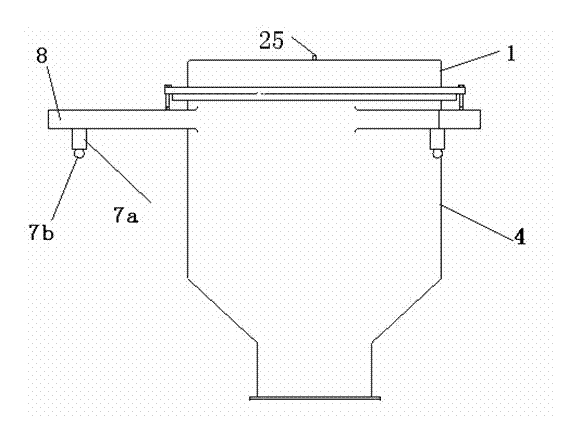

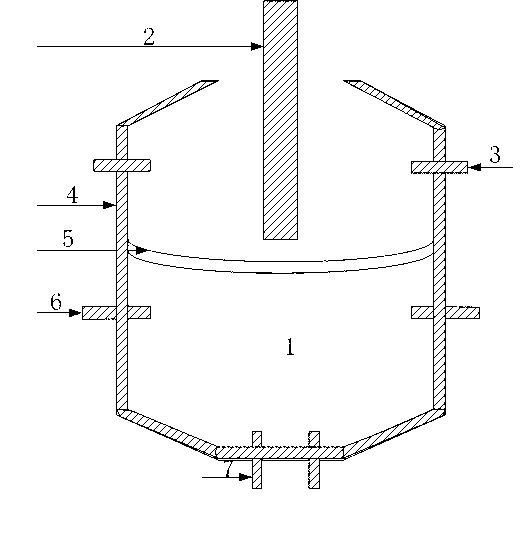

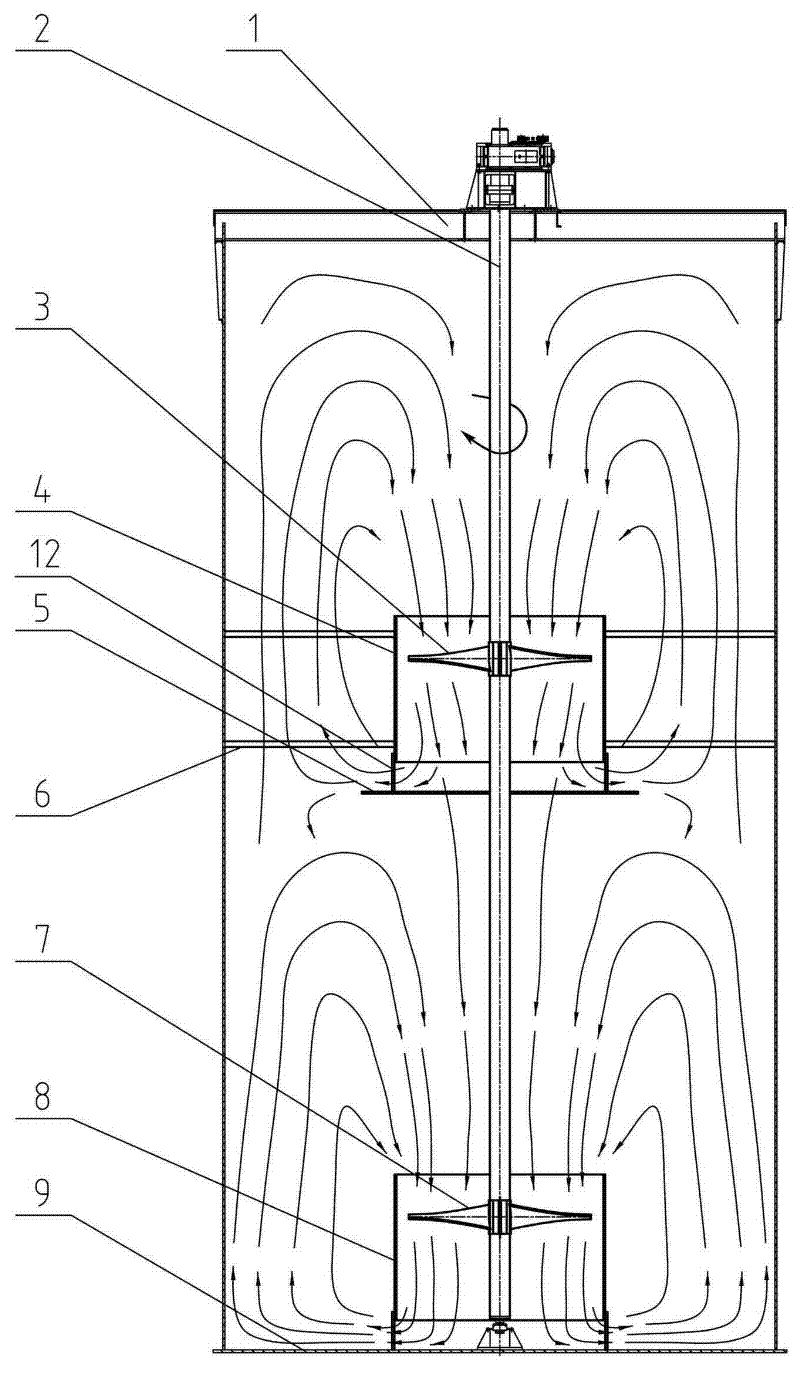

Sewage stirrer

ActiveCN105363374ARich circulating waterIncrease stirring intensityRotary stirring mixersEngineeringSewage

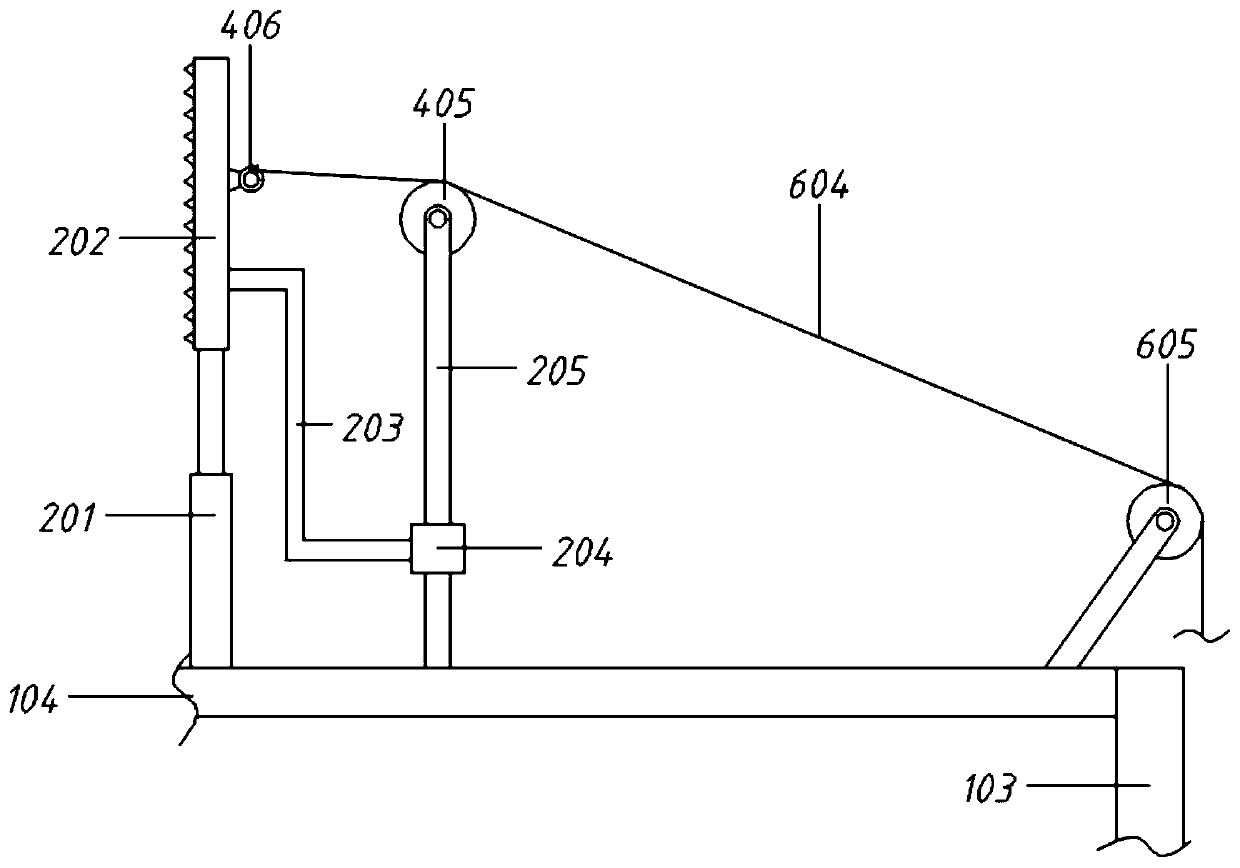

The present invention provides a sewage stirrer including a work guide rail, a work frame, a central support frame, a first traveling mechanism, a second traveling mechanism, a lifting mechanism and a stirring mechanism; the annular work guide rail is mounted on the edge of a sewage tank, a driving mechanism drives the work frame to rotate, the work frame is provided with a first guide rail, the first guide rail extends from the first end of the work frame to the central support frame, a first guide roller is mounted below the first traveling mechanism, the first guide roller is mounted in the first guide rail, the upper end of the lifting mechanism is in rotatable connection with the first traveling mechanism, and is driven by a first drive device, the work frame is provided with a second guide rail, the second guide rail extends from the second end of the work frame to the central support frame, a second guide roller is mounted below the second traveling mechanism, the second guide roller is mounted in the second guide rail, the upper end of the stirring mechanism is in rotatable connection with the second traveling mechanism, and is driven by a second drive device. The sewage stirrer is large in stirring range, good in stirring effect, and high in efficiency.

Owner:ASIA PACIFIC WATER TREATMENT TIANCHANG

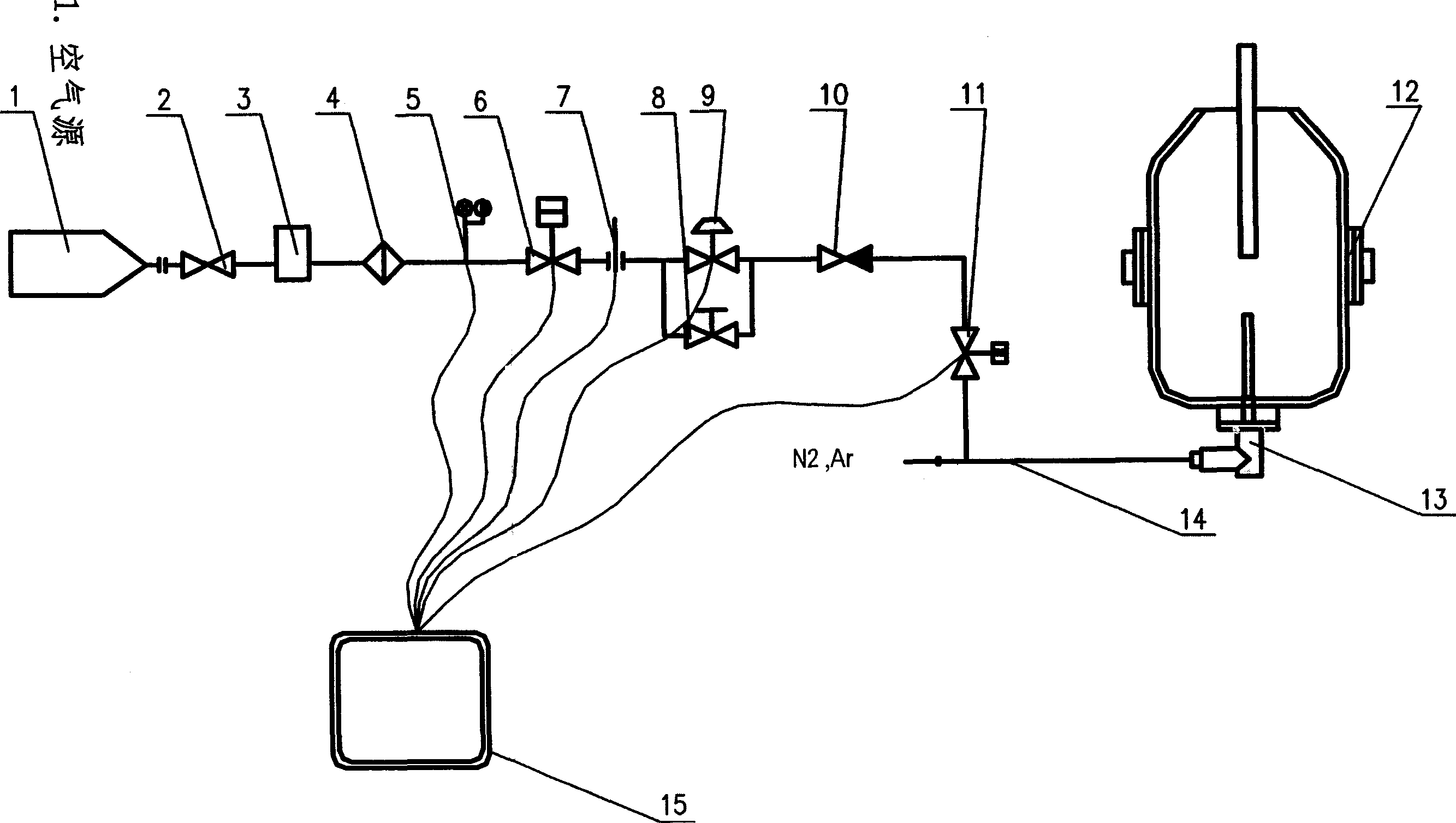

Combined-blowing converter bottom gas supply element blocking-preventing device and method

ActiveCN1743466AGuaranteed metallurgical effectExtend your lifeManufacturing convertersComputer control systemSlag

This invention blow-stop ventilation device of a bottom blow gas supply element of a multi-blow converter is composed of an air dehydrator, a pneumatic fast cut valve, a pneumatic regulation valve, a gas flowmeter, a pressure tester, a computer control system, a blow-step gas source and gas transportation pipe lines interconnected by the gas transportation pipe lines. Said method takes air as the gas supply element and utilizes 20% oxygen in the air to oxidize the blockage-slag-metal mushroom head continuously to keep it at reasonable state to ensure the life time of the supply element the same with the converter lining.

Owner:CENT IRON & STEEL RES INST

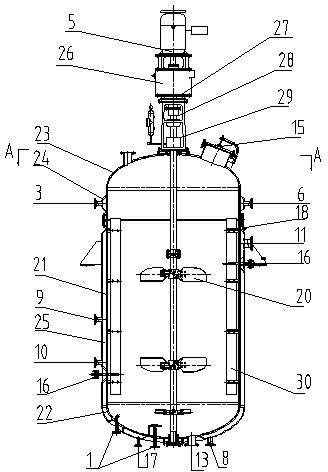

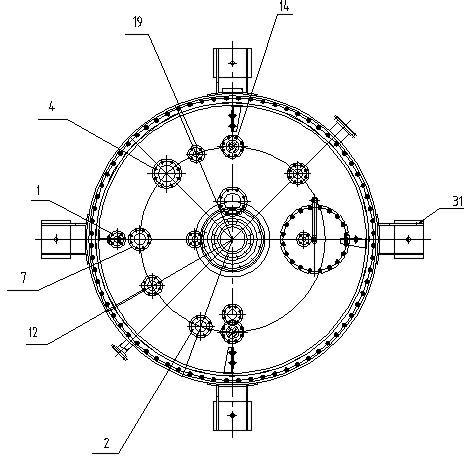

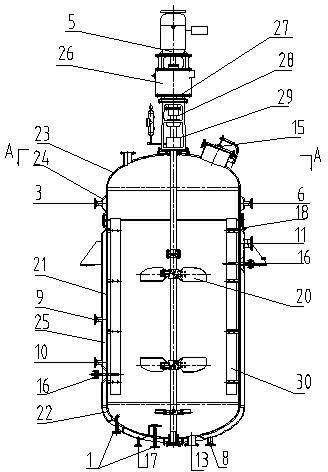

Alloy chlorination reaction kettle for production of chlorinated polyethylene

InactiveCN102633916AIncrease volumeIncrease productivityChemical/physical/physico-chemical stationary reactorsReaction temperatureWater chlorination

The invention provides an alloy chlorination reaction kettle for production of chlorinated polyethylene, which is capable of effectively eliminating reaction temperature delay during synthesis of the chlorinated polyethylene, and is short in production cycle, high in efficiency, low in labor intensity and energy consumption and easy in implementation of automated operation.

Owner:威海金泓高分子有限公司

Process method for smelting high purity steel through VD vacuum treatment device

ActiveCN111378811AReduce slaggingGood removal effectManufacturing convertersSlagNon-metallic inclusions

The invention provides a process method for smelting high purity steel through a VD vacuum treatment device. The method comprises the following steps of KR molten iron desulfuration, wherein it is ensured that before putting into a furnace, S in molten iron is smaller than or equal to 30 ppm; top and bottom combined blowing converter blowing, wherein the mass percent omega [C] of converter tappingC is larger than or equal to 0.08%; external refining and argon refining, wherein in the full process, weak stirring is carried out, and calcium aluminum silicon series slag with the basicity being 2.0 to 4.5 is adopted; and VD treatment, wherein 20 to 35 min VD treatment is adopted, high-vacuum holding of strength is achieved, in the treatment process, according to the strong-weak-strong mode, the bottom stirring argon strength is controlled in a time interval manner, after VD vacuum breaking, a manner that soft blowing is adopted, large-particle inclusions are removed, molten steel is subjected to standing, and small particle inclusions are removed is adopted for further improving the molten steel purity. It is known that through the particular VD treatment process stirring control modeis adopted for assisting with a proper refining slag system and a soft blowing operation method, molten steel slag entrapment can be effectively reduced, the removing effect of non metal inclusions can be improved, and the method is suitable for production of various low, middle and high carbon steel with the carbon content being 0.15 to 1.05%.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

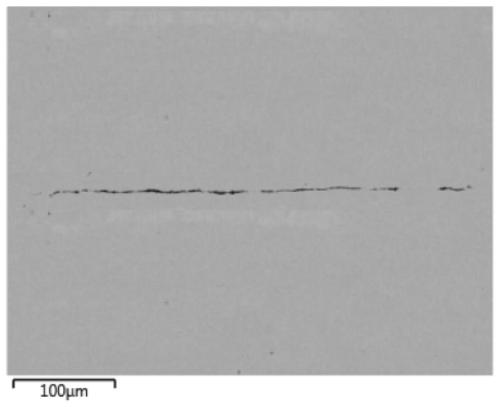

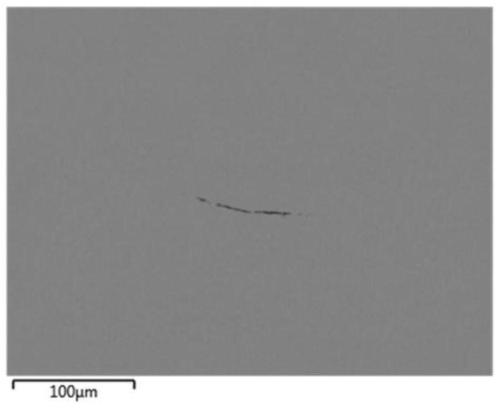

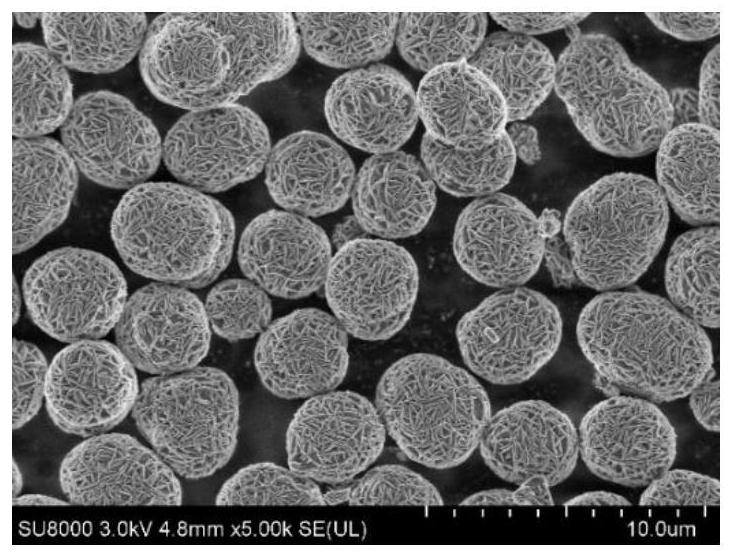

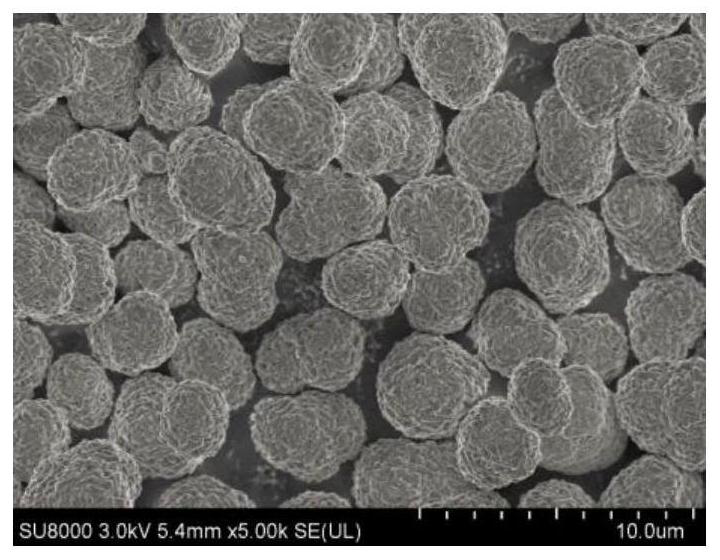

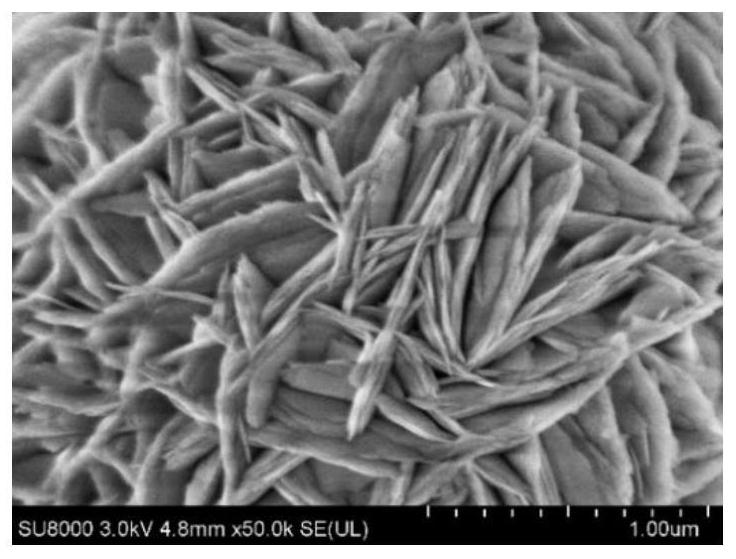

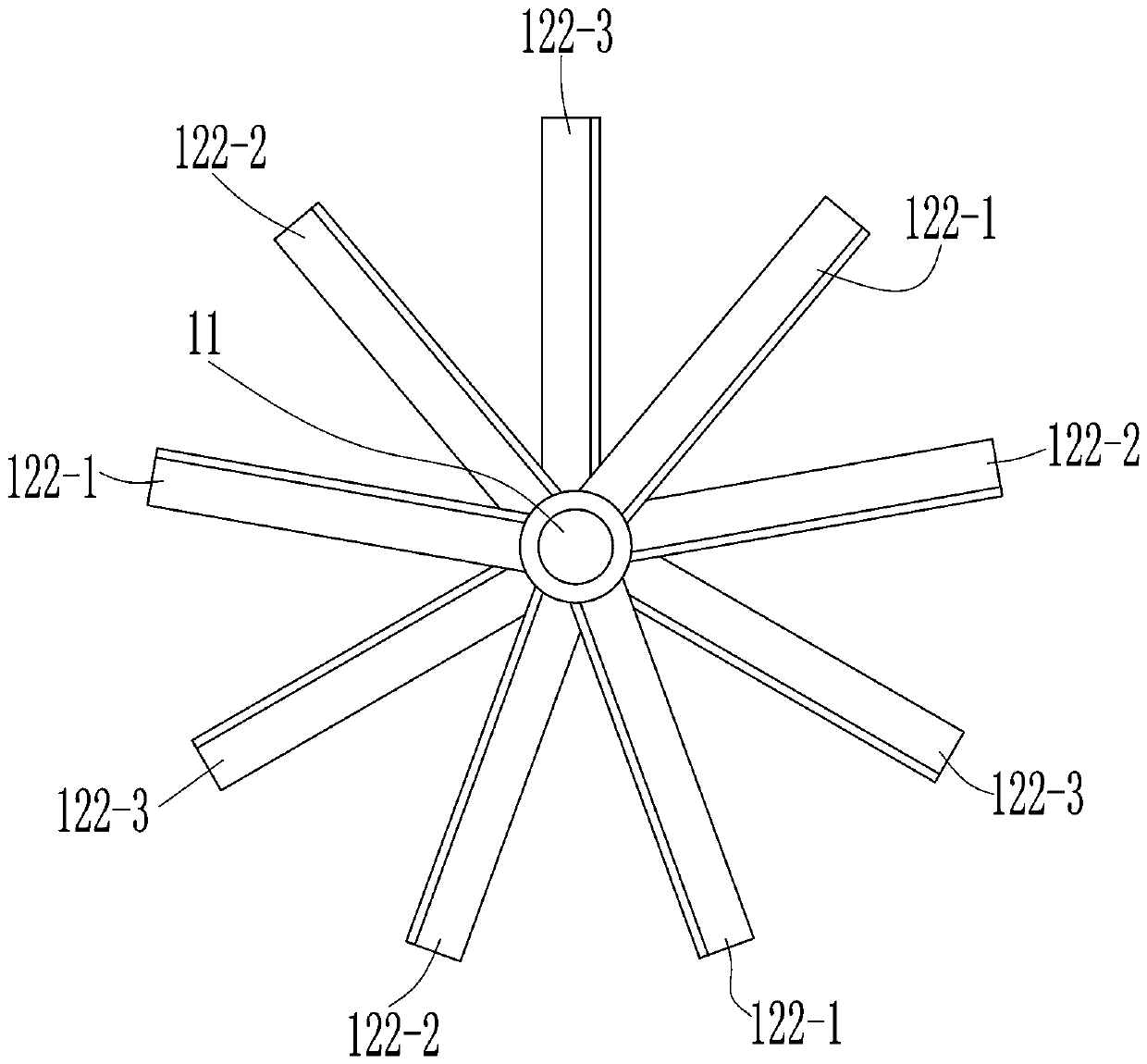

Spherical high-nickel cobalt-free single crystal precursor and preparation method thereof

ActiveCN112939095AGood dispersionReduce DC resistanceCell electrodesSecondary cellsPhysical chemistryReaction temperature

The invention discloses a spherical high-nickel cobalt-free single crystal precursor and a preparation method thereof, a low coprecipitation reaction temperature of 20-40 DEG C is adopted, the crystallinity of the precursor is effectively reduced and the specific surface of the precursor is improved by increasing the feeding speed section by section, changing the pH value and the like, in addition, a long-diameter paddle is adopted, the paddle diameter / kettle diameter is 0.50-0.65, the stirring strength is improved, and the dispersity and sphericity of the single crystal precursor are improved. The process is simple, the process is easy to control, the method is suitable for large-scale production, the prepared high-nickel cobalt-free single crystal precursor is good in dispersity and sphericity, the specific surface area is larger than or equal to 20 m < 2 > / g, the crystallinity is low, the half-peak width FWHM101 of the precursor obtained through XRD testing is larger than or equal to 0.8, and sintering single crystallization is obvious.

Owner:SHAANXI COAL & CHEM TECH INST

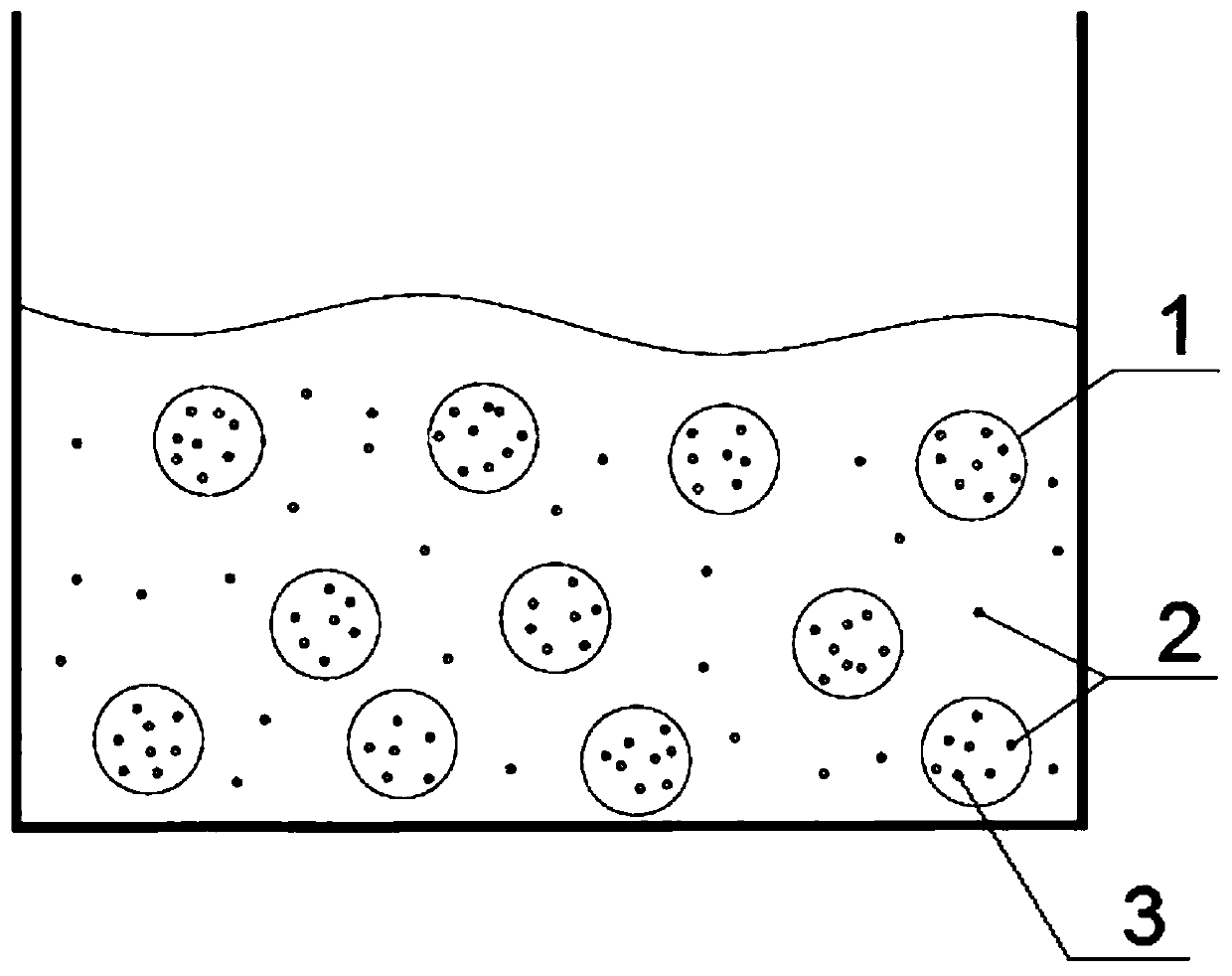

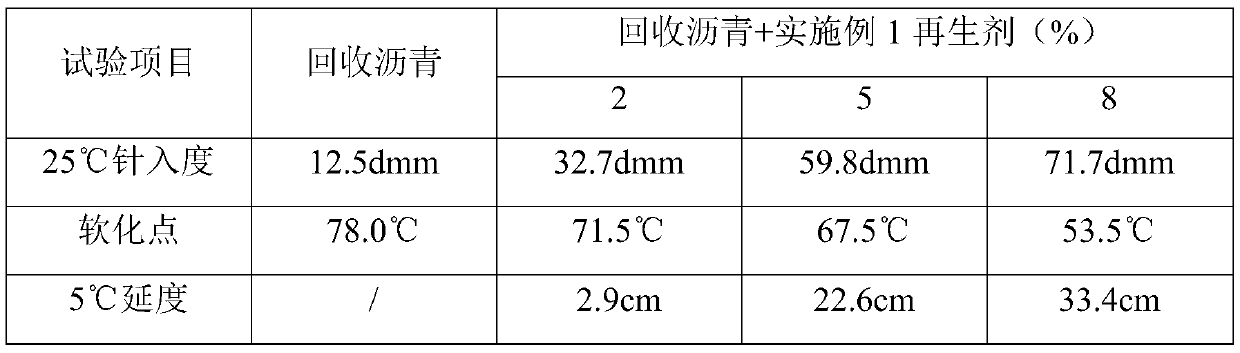

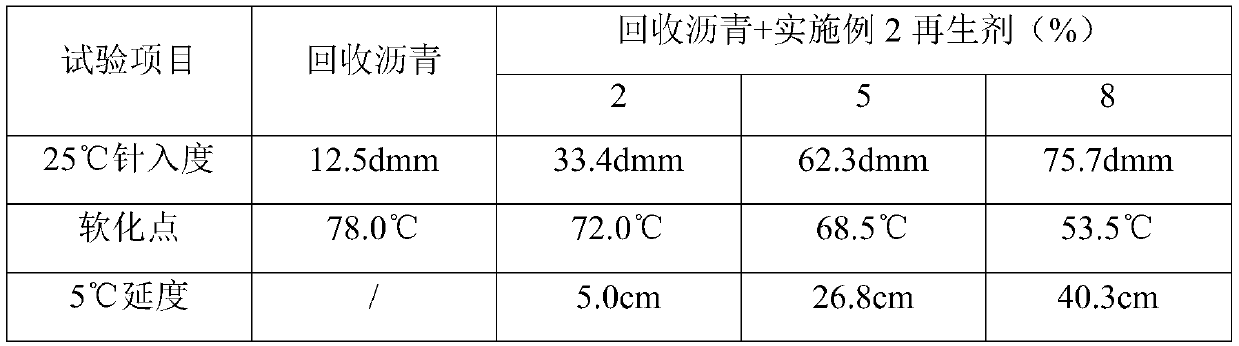

Slow-release asphalt modified regenerant and preparation method thereof

ActiveCN110669345AImprove performanceStrong environmental protectionBuilding insulationsPlasticizerProcess engineering

The invention discloses a slow-release asphalt modified regenerant and a preparation method thereof. The regenerant comprises the following components in parts by mass: 30-80 parts of modified base oil, 30-50 parts of matrix asphalt, 10-30 parts of an added oil, 1-5 parts of a plasticizer, 1-5 parts of an anti-aging agent, 1-5 parts of a modifier and 1-10 parts of a capsule modifier. The regenerant provided by the invention is capable of adjusting the viscosity of new and old asphalt and mixture systems, enhancing the anti-stripping performance of systems, slowly releasing light components, realizing lasting regeneration, saving the dosage of new asphalt, increasing the compatibility of the new and old asphalt through active points, improving the performance of the asphalt, resisting agingand the like. In addition, the regenerant provided by the invention can realize waste recycling, and solve the problems of single performance and poor long-term regeneration effect of traditional regenerants. In addition, the regenerant is simple in preparation process and convenient for industrial production.

Owner:山西交通科学研究院集团有限公司 +1

Enzyme detergent and raw material extraction process

ActiveCN113355170AImprove mixing efficiencyImprove dissolution efficiencyInorganic/elemental detergent compounding agentsDispersed particle filtrationMentha spicataActive agent

The invention discloses an enzyme detergent and a raw material extraction process, and relates to the technical field of enzyme detergent extraction, in particular to the enzyme detergent and the raw material extraction process. The enzyme detergent is prepared from the following raw materials in parts by weight: 20-30 parts of saponin, 10-20 parts of ferment, 7-11 parts of a mint extracting agent, 3-5 parts of glycerinum, 1-3 parts of edible essence, 3-6 parts of dietary alkali, 6-9 parts of an active agent, 6-9 parts of a thickening foam stabilizer and the balance of deionized water. According to the enzyme detergent and the raw material extraction process, an auxiliary stirring mechanism is arranged, a high-pressure air pump guides high-pressure air into a main shaft through a high-pressure pipe, the main shaft is communicated with a supporting rod, the high-pressure air can be sprayed out through a spraying hole of the supporting rod, and the stirring strength of the supporting rod is improved under the action of a driving gear, a driven gear and a driving motor; therefore, the mixing effect of the raw materials can be effectively enhanced, and the raw materials are stirred in cooperation with the flow dividing rod.

Owner:浙江永金生物科技有限公司

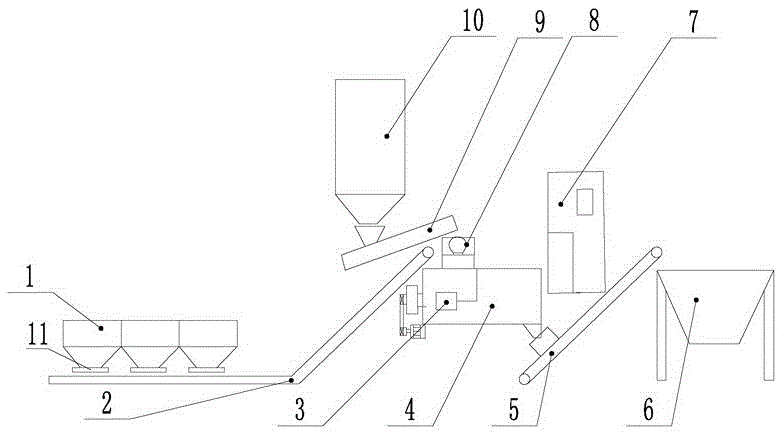

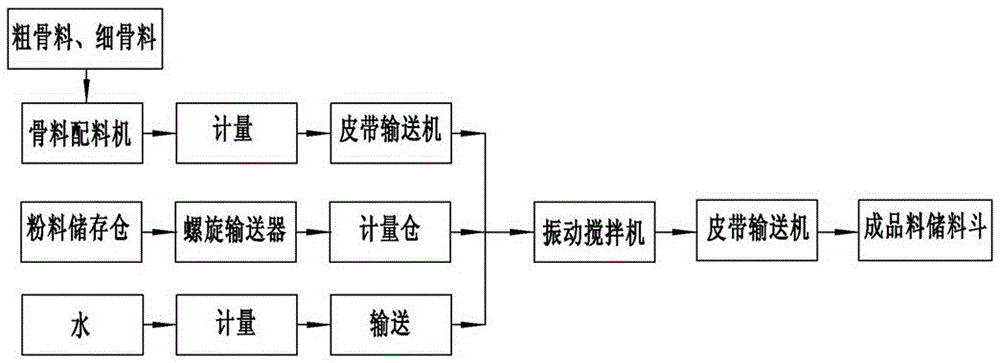

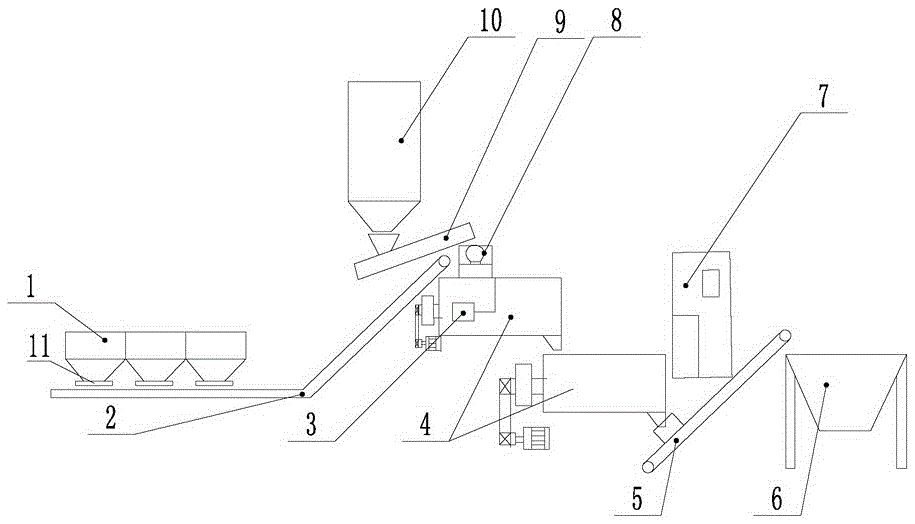

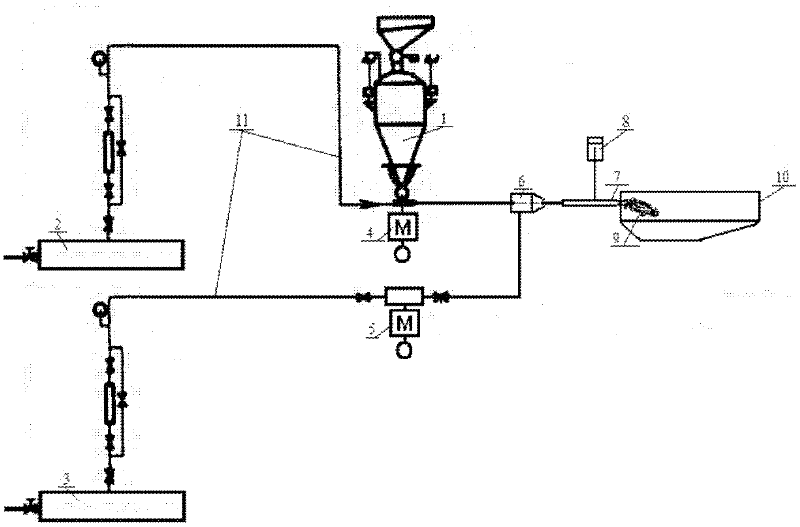

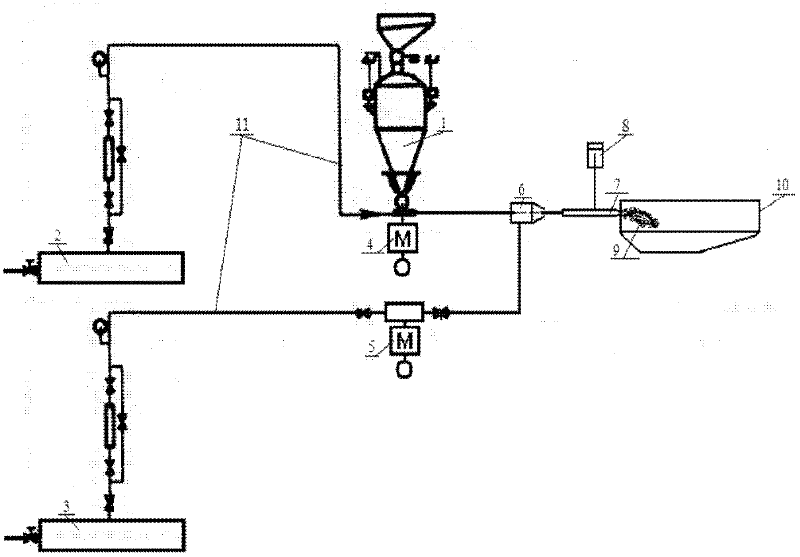

Plant mixing device and method for continuous vibratory stir processing of stabilized soil

InactiveCN106113278AWell mixedImprove micro homogeneityMixing operation control apparatusIngredients proportioning apparatusDual actionMixed materials

The invention relates to the field of stabilized soil stir processing, in particular to a plant mixing device and a method for continuous vibratory stir processing of stabilized soil, and aims to achieve not only t macroscopic uniformity but also better microcosmic uniformity of a stabilized material within a short time. According to the plant mixing device and the method, aggregate is measured and conveyed by aggregate batchers according to gradation requirements; through a belt conveyor arranged below the aggregate batchers, the aggregate is continuously conveyed to a continuous double horizontal shaft vibratory stirrer; meanwhile, powder in a powder storage bin is continuously conveyed to a measuring bin through a spiral conveyor, the measured powder is conveyed to the continuous double horizontal shaft vibratory stirrer, and measured water is continuously pumped by a water supply system into the continuous double horizontal shaft vibratory stirrer at the same time; and in the continuous double horizontal shaft vibratory stirrer, a mixed material is continuously subjected to the double action of stirring and vibrating from a feeding port to a discharging port, and then a finished material is conveyed to a finished material storage hopper through the discharging port. For cement concrete and other materials being difficult to stir and mix, a common stirrer can be added to the upstream of the continuous double horizontal shaft vibratory stirrer, thereby achieving two-stage stirring.

Owner:德通智能科技股份有限公司

High-lance-position vacuum refining method based on coherent jet top lance

The invention provides a high-lance-position vacuum refining method based on a coherent jet top lance. The coherent jet top lance is provided with a powder passage located at the center, a main oxygen passage located on the periphery of the powder passage and an auxiliary oxygen passage located on the periphery of the main oxygen passage; and during RH vacuum refining, oxygen enters from the main oxygen passage and the auxiliary oxygen passage to form a main oxygen flow and an auxiliary oxygen flow respectively, powder is injected into molten steel together with the main oxygen flow under the sweeping and protection of the main oxygen flow, the main oxygen flow impacts the molten steel and reacts with carbon in the molten steel to generate carbon monoxide, and carbon monoxide escaping from the molten steel is subjected to secondary combustion with the coherent surrounding accompanying auxiliary oxygen flow to heat a vacuum tank so as to reduce temperature drop of the molten steel. According to the invention, the auxiliary oxygen flow forms the surrounding accompanying flow outside the central supersonic jet flow, so that the expansion and attenuation of the central supersonic jet flow are smaller, the supersonic jet flow is longer, the penetration depth and stirring strength of the oxygen jet flow to a molten bath are increased, a lance position is raised to reduce splashing of the molten steel and slag sticking to a lance head, and the service life is prolonged.

Owner:CISDI ENG CO LTD +1

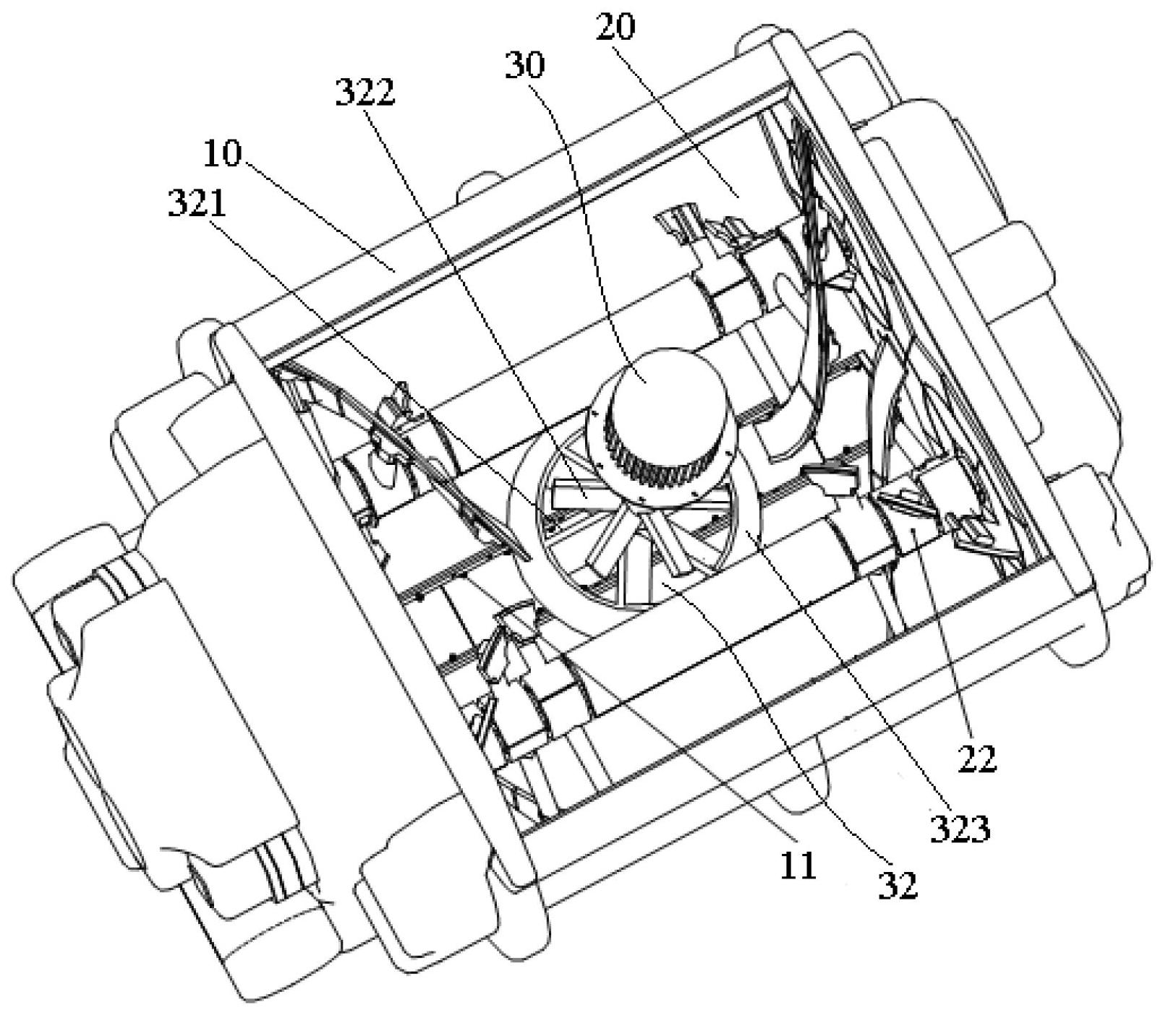

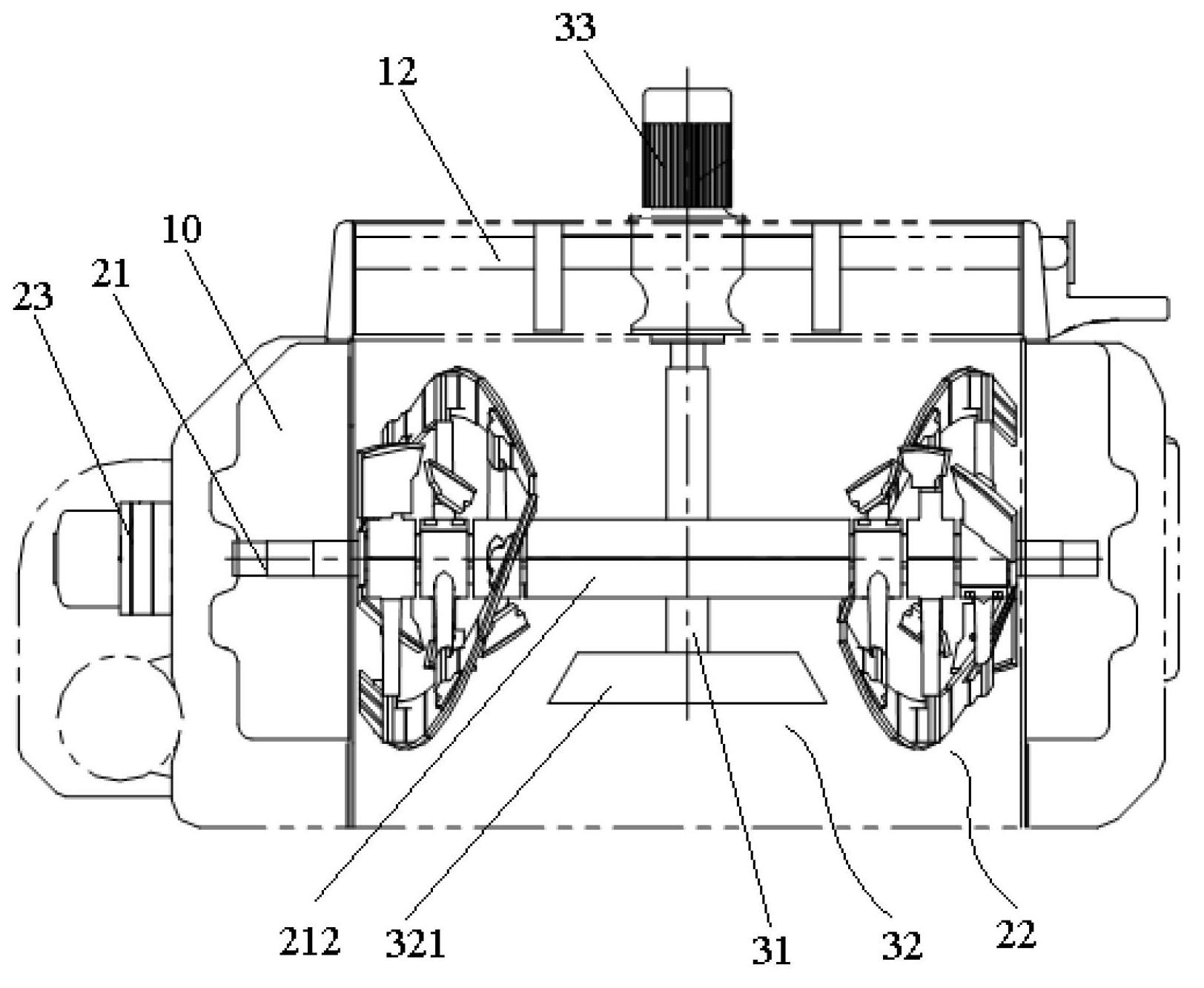

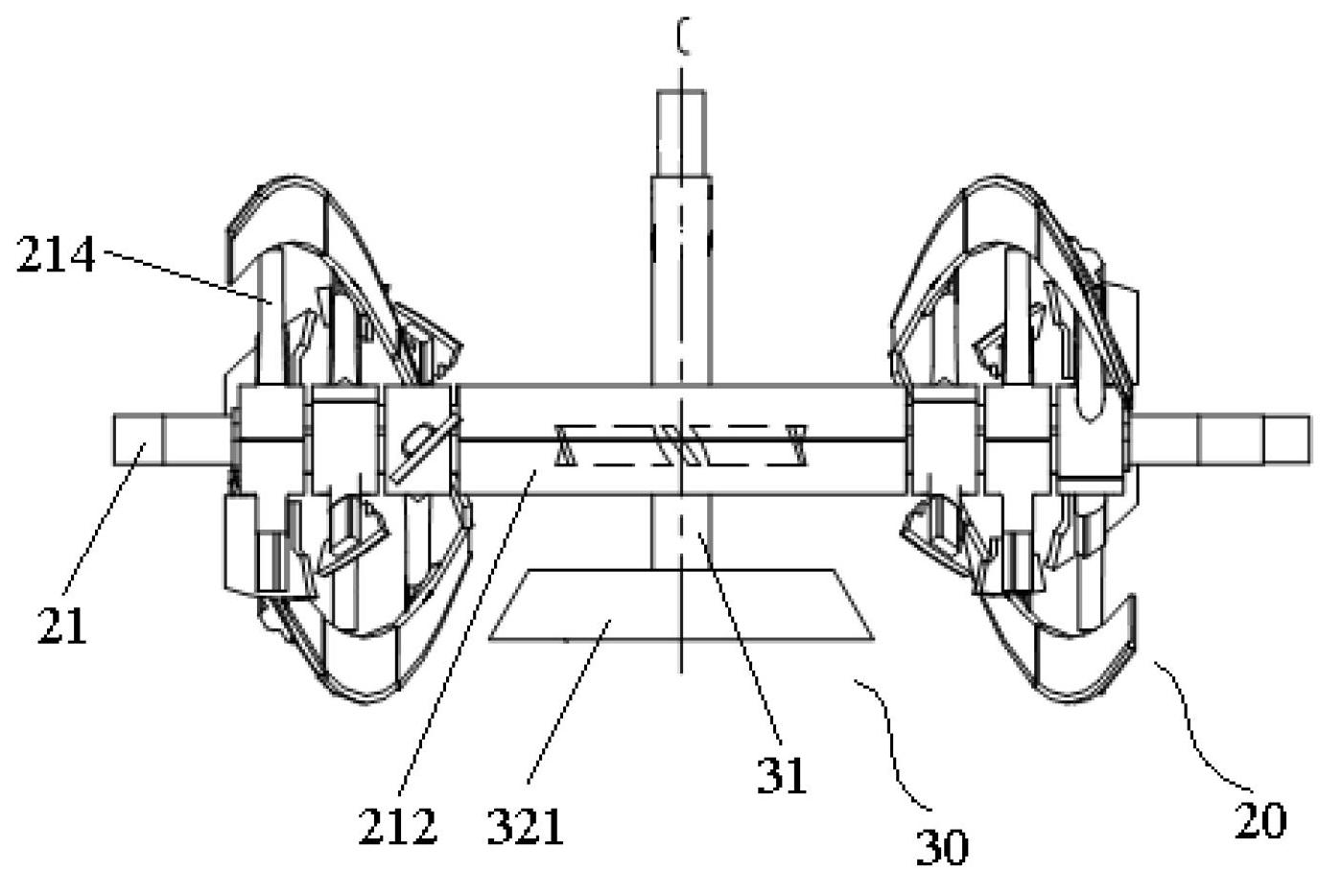

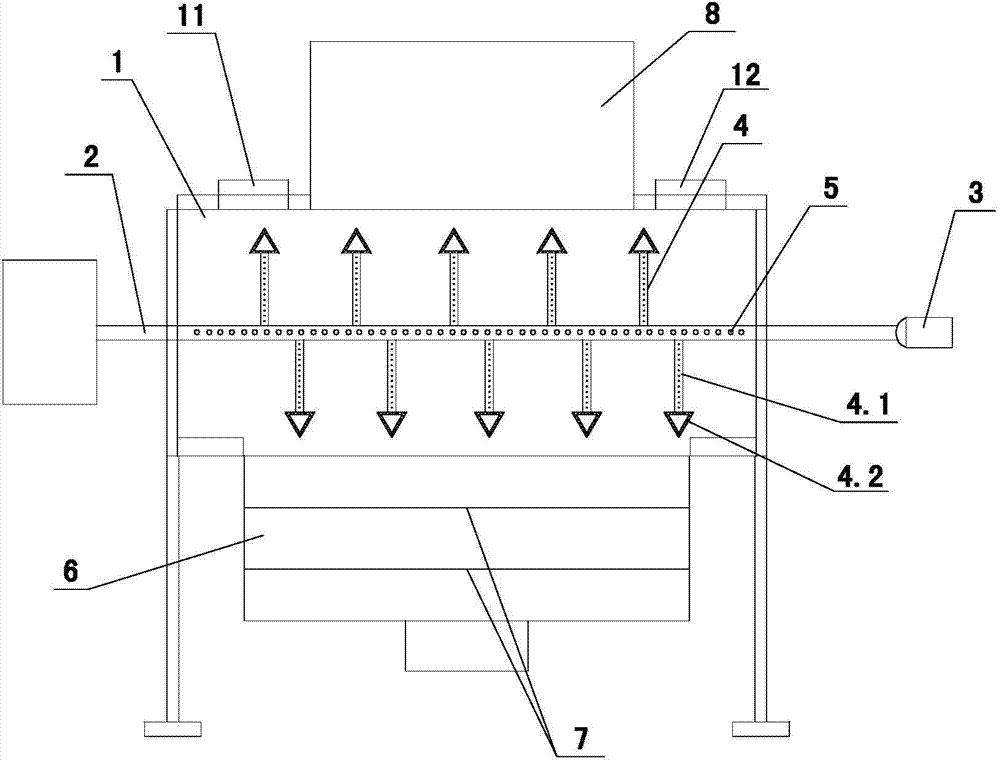

Mixing equipment

ActiveCN102658598AIncrease stirring intensityStirring speed is fastCement mixing apparatusEngineeringUltimate tensile strength

The invention provides mixing equipment. The mixing equipment comprises a body (10), a first mixing system (20) and a second mixing system (30), wherein the first mixing system (20) comprises two first rotating shafts (21) which are parallel to each other and are horizontally arranged in the body (10) and first mixing components (22) which are respectively arranged on the two first rotating shafts (21); and the second mixing system (30) is arranged between the two first rotating shafts (21) and comprises a second rotating shaft (31) perpendicular to a plane formed by the two first rotating shafts (21) and a second mixing component (32) which is arranged on the second rotating shaft (31). By the mixing equipment, the material mixing strength is high, the mixing speed is high, the material flow speed is high, the materials are fully mixed, and the efficiency is high.

Owner:ZOOMLION HEAVY IND CO LTD

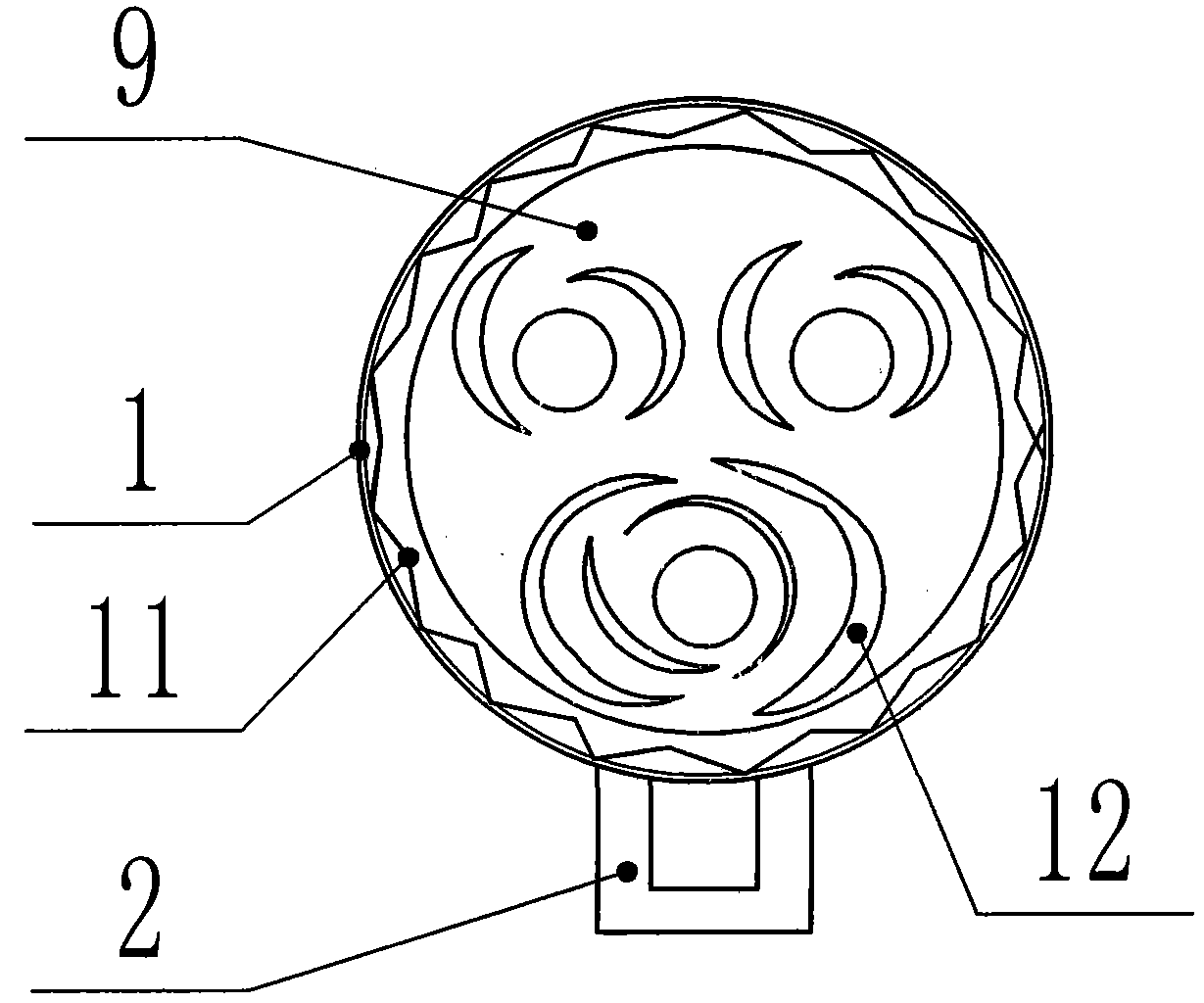

Three-shaft scattering device of viscous slurry

InactiveCN103521111AReduce the effect of negative pressureNegative pressure effect guaranteeRotary stirring mixersImpellerSlurry

The invention relates to a three-shaft scattering device of viscous slurry. The three-shaft scattering device comprises a round cylinder, a master stirring apparatus, a slave stirring apparatus, a guide blade, a pressure stabilizing plate, a waveform shear plate, a feeding hole, a discharge hole, a round hole sieve plate, a high-pressure water pipe and the like. According to the scattering device of the viscous slurry, the pressure stabilizing plate is arranged at the bottom and can automatically suck ore slurry into the round cylinder by pressure difference; a cylindrical rotary zone in the cylinder is eliminated by the shear plate arranged at the inner wall; the shear performance of the material is also improved; the stirring intensity of each stirring apparatus is effectively increased by the guide plate and three groups of mixing impellers arranged on stirring bearings; namely, the kinematic velocity of the material in the round cylinder is increased. Thus, effective dispersing of a viscous material is achieved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

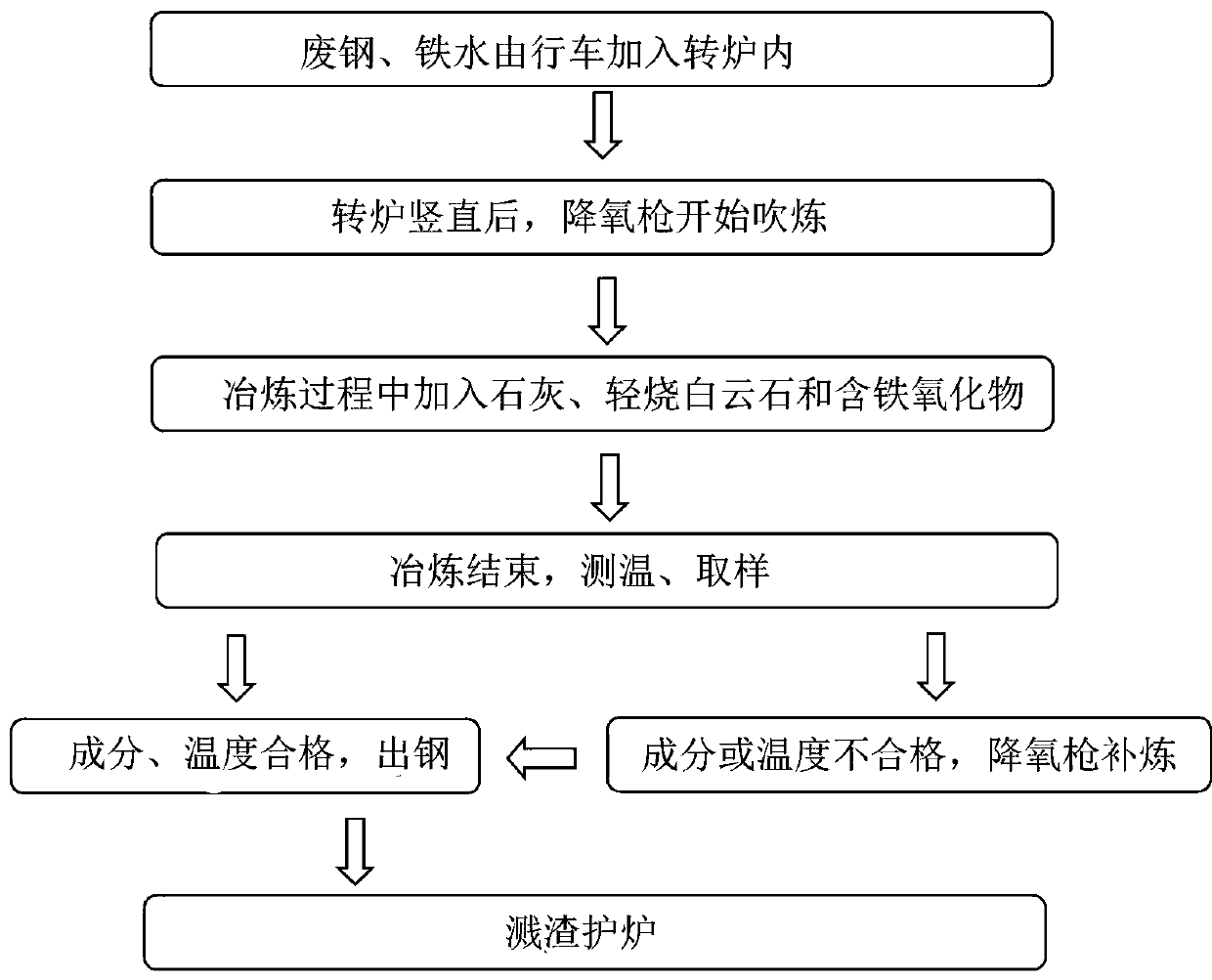

Fast smelting method of blast furnace in-service converter

InactiveCN109666775AShorten the smelting cycleImprove converter productivityManufacturing convertersProcess efficiency improvementSlagDolomite

The invention relates to the technical field of smelting, in particular to a fast smelting method of a blast furnace in-service converter. The fast smelting method is characterized by comprising the following steps: S1, adding molten iron and steel scrap in the converter according to certain proportion; S2, after slag splashing of the converter, not pouring the slag, and after adding the molten iron and steel scrap in the converter, adopting an oxygen lance for oxygen blowing smelting; S3, after adopting the oxygen lance in the converter, quickly adding quick lime and light roasted dolomite weighed in advance in the converter; and S4, enabling the position level of the oxygen lance to be 800-900 mm, after carbon and oxygen reaction, raising the position level of the smelting lance to be 1200-1500 mm, and adding quick lime in batches, and adding the rest of the quick lime eight minutes before smelting. With adoption of the fast smelting method, rapid dephosphorization and temperature rise of the converter are realized, the entire smelting period can be shortened, the production efficiency of the converter is improved, and the purpose of realizing the scale benefit of the iron and steel industry is realized.

Owner:JIUJIANG PINGGANG STEEL

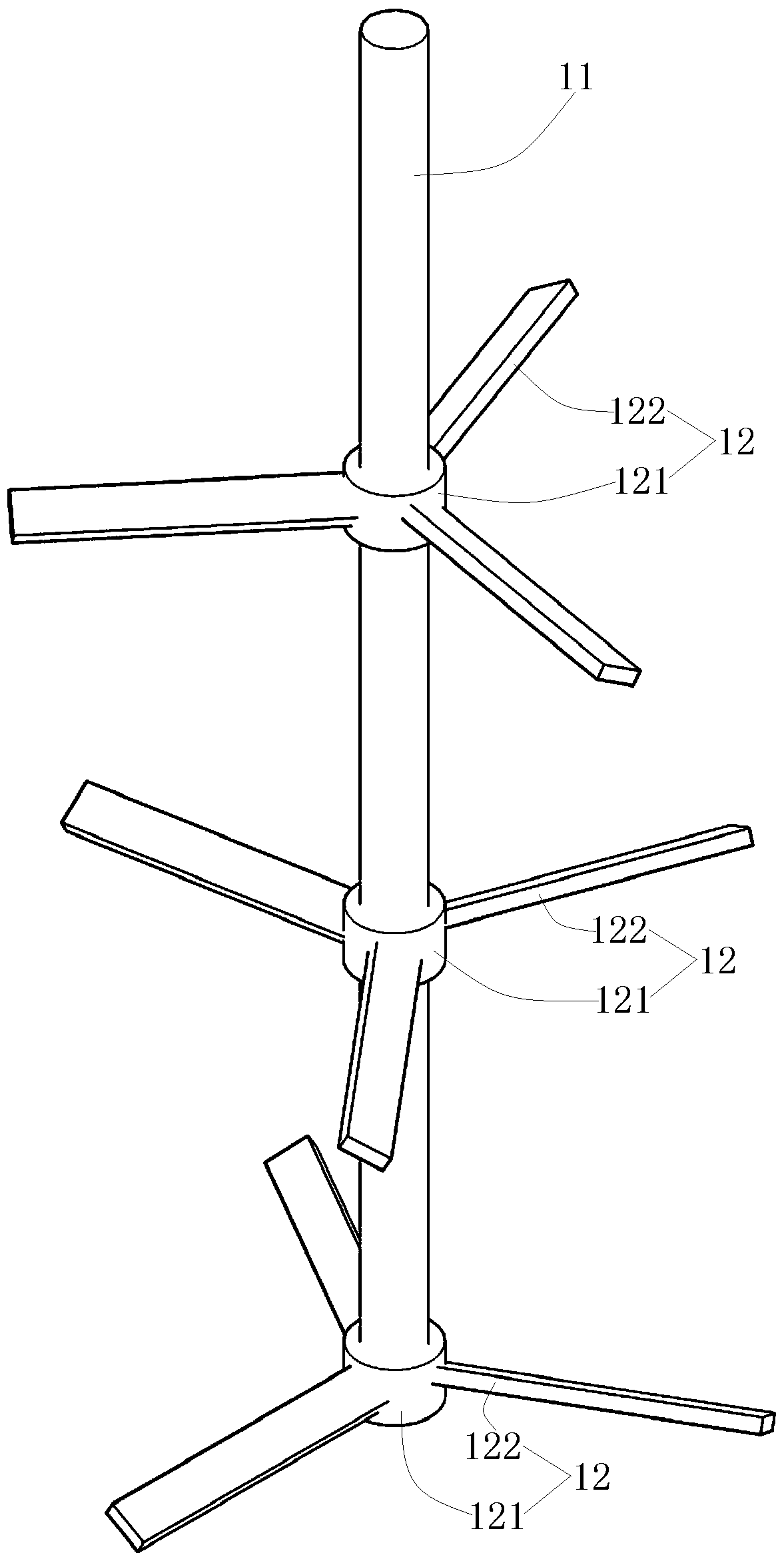

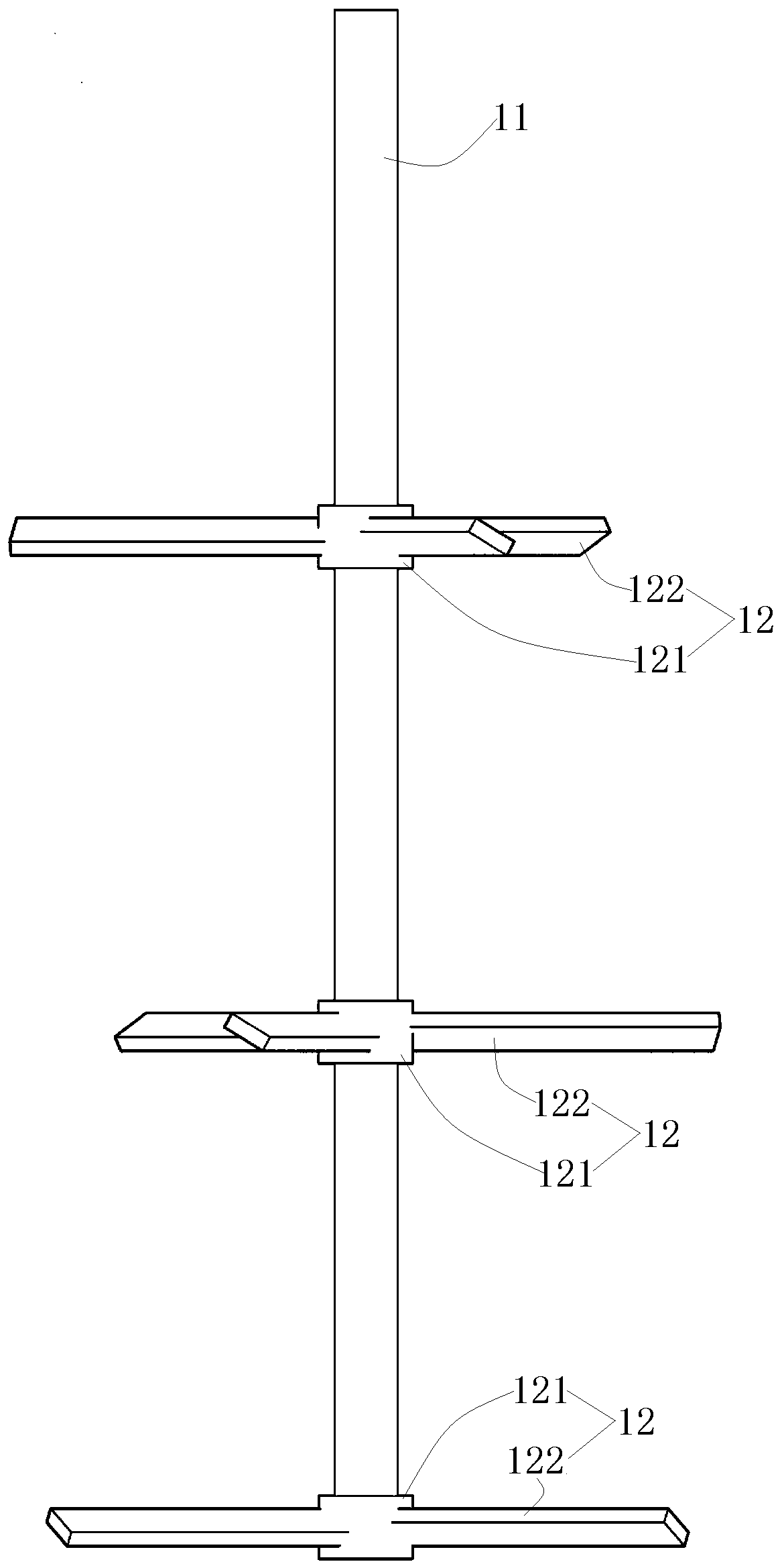

Stirring device

PendingCN107670522AStir wellHigh tin contentTransportation and packagingRotary stirring mixersVertical projectionWastewater

The invention relates to a stirring device. The stirring device comprises a main shaft and at least two stirring paddles. The stirring paddle comprises a cylindrical part provided with a central through hole and three blades. The three blades are uniformly fixed to the outer circumferential surface of the cylindrical part. The stirring paddles respectively pass through the central through holes ofthe cylindrical parts and are fixed to the main shaft. The two adjacent stirring paddles are arranged on the main shaft at a certain interval. The overlooking projections (vertical projections) of the three blades of the stirring paddle along the main shaft central axis are not coincident. The stirring device can fully stir de-tinning waste water materials in a reactor, improves product tin content and production efficiency and has the advantages of simple structure, high production efficiency and good quality.

Owner:深圳市宝安东江环保技术有限公司 +1

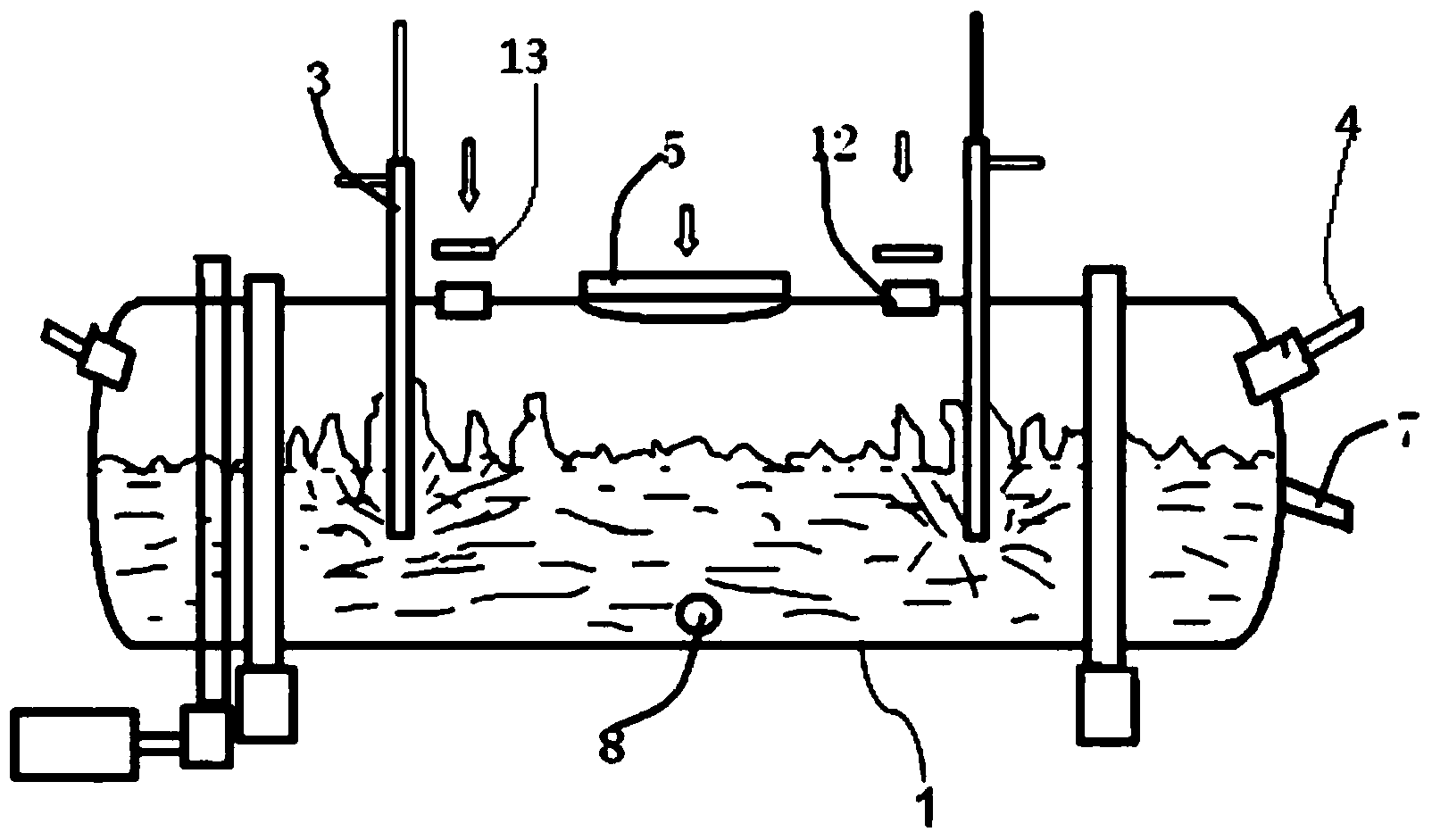

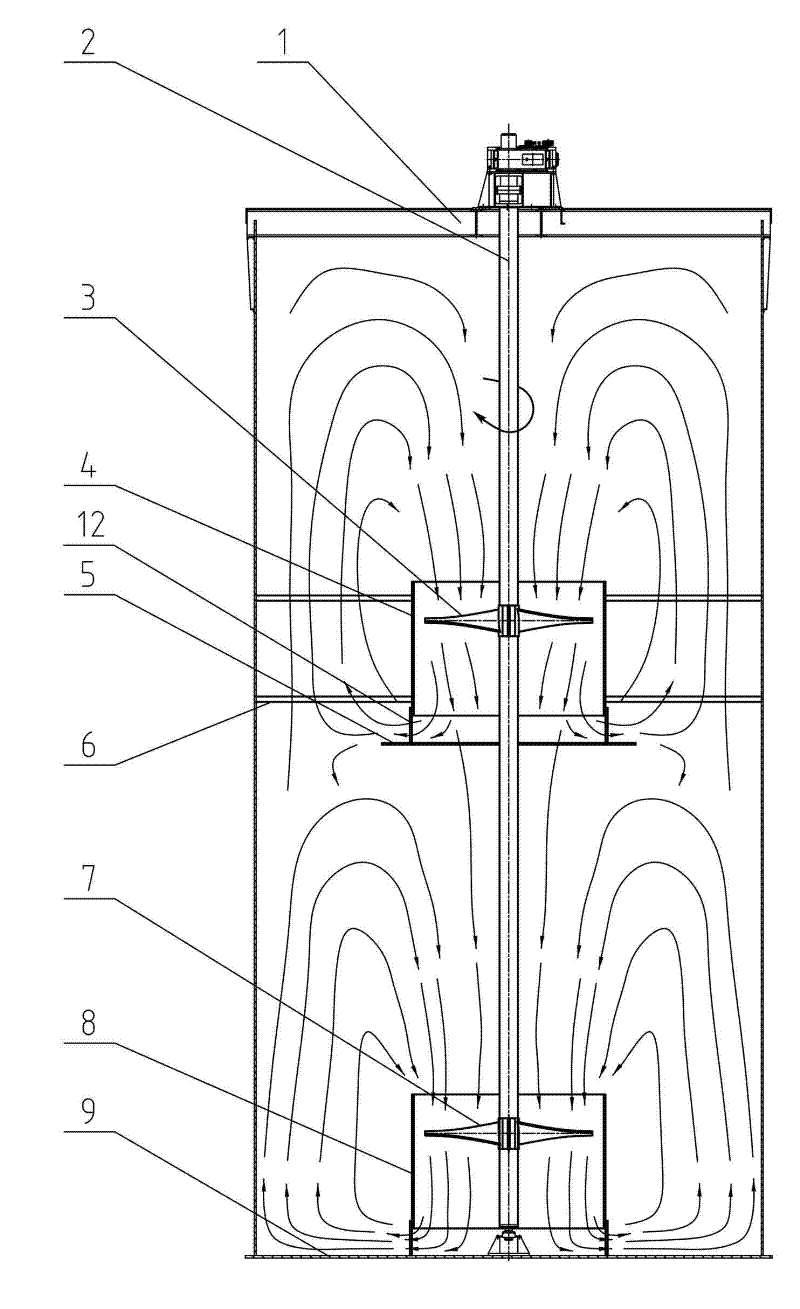

Continuous mixing reaction device

InactiveCN102247791AQuality improvementRealize all-round mixingRotary stirring mixersChemical/physical/physico-chemical stationary reactorsEngineeringContinuous mixing

The invention discloses a continuous mixing reaction device and aims to provide a continuous mixing reaction device which can realize continuous production, shorten process time and guarantee product quality. A horizontal hollow stirring shaft is arranged in a kettle body and is connected with a stirring motor through a transmission mechanism after passing through the kettle body; the internal space of the kettle body is partitioned into a plurality of mixing reaction chambers by a plurality of baffle plates; a material passage is formed between the top of each baffle plate and the inner wall of the kettle body; the horizontal hollow stirring shaft corresponding to each mixing reaction chamber is fixedly connected with a stirring blade fixture respectively; a plurality of stirring blades are fixed on each stirring blade fixture respectively; and the height of the stirring blades is greater than that of the baffle plates. In the device, the internal space of the kettle body is partitioned into a plurality of mixing reaction chambers, so that continuous production can be realized, the process time can be shortened, and the energy can be saved; meanwhile, the height of the stirring blades is greater than that of the material, so that omnibearing stirring is realized, a stirring dead zone is not formed, and stable quality is guaranteed.

Owner:TIANJIN HENGSHITONG ENG TECH DEV

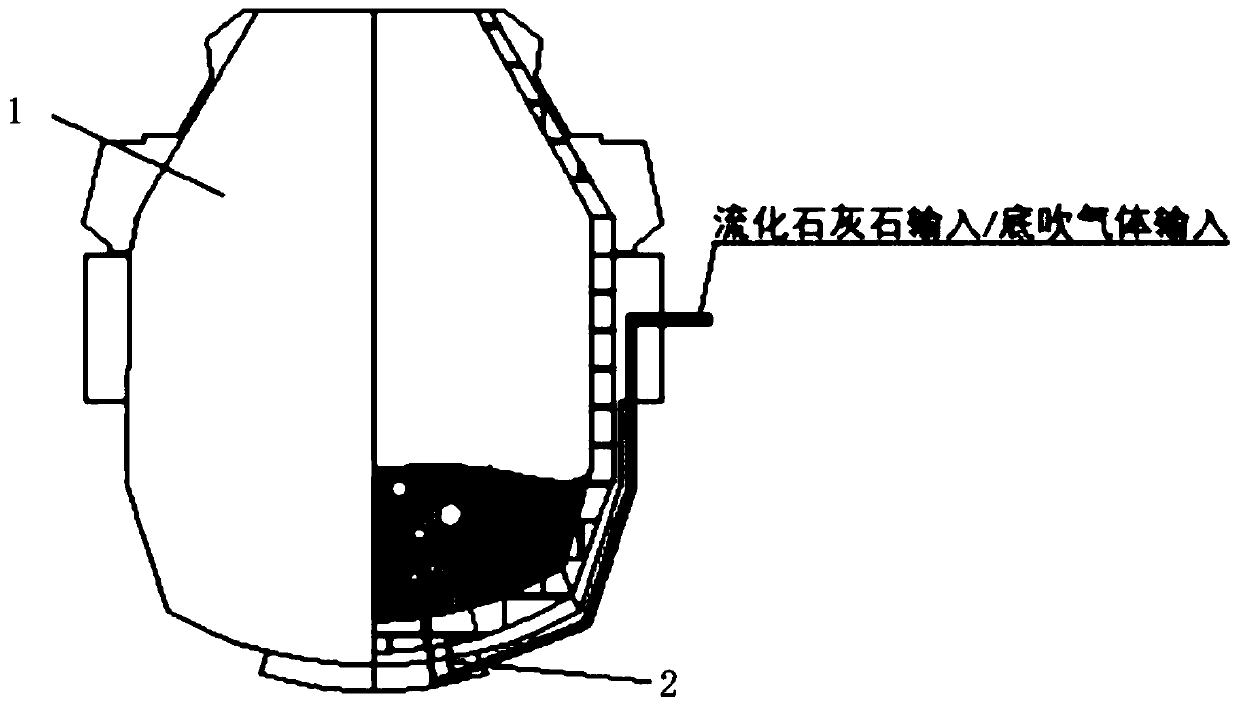

Bottom spraying type limestone smelting method of combined top-bottom combined blowing converter

InactiveCN109852762AImprove the mixing effectStir wellManufacturing convertersProcess efficiency improvementSteelmakingMelting tank

The invention provides a bottom spraying type limestone smelting method of a combined top-bottom combined blowing converter. According to the technical scheme, the method is characterized in that limestone is crushed into powder with certain particle size; the limestone powder is directly sprayed into molten steel in a smelting pool of the converter through a bottom blowing pipeline and a ventilating spraying arranged at the bottom of the combined blowing converter and blowing element under the effect of high-pressure carrier gas; the limestone powder is directly sprayed into the bottom of theconverter through the high-pressure carrier gas on the basis of continuing to blow oxygen from the top, so that the specific surface of the limestone and inner elements of the molten steel in reaction can be expanded without limitation; CO2 and CaO are generated by heating and decomposing the limestone and are used for supplying an oxidizing atmosphere and an alkaline environment for inner smelting of the converter; the limestone is decomposed through surplus energy in smelting of the converter; the limestone is sprayed and blown through the high-temperature carrier gas, and materials in thesmelting pool can be fully stirred, so that the steel slag reaction is further promoted. With the adoption of the method, the energy is effectively saved; the smelting cost is decreased; the smeltingprogress is improved; and the quality of the smelting molten steel of the converter is improved.

Owner:SD STEEL RIZHAO CO LTD

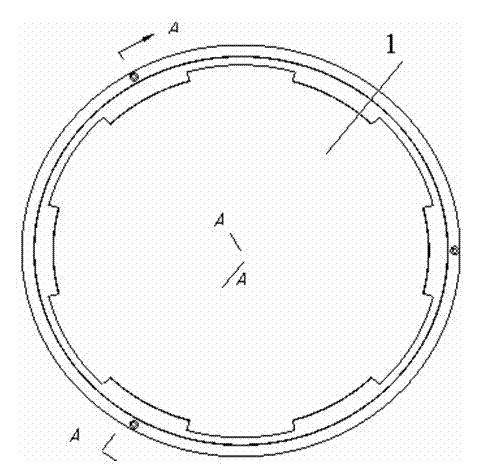

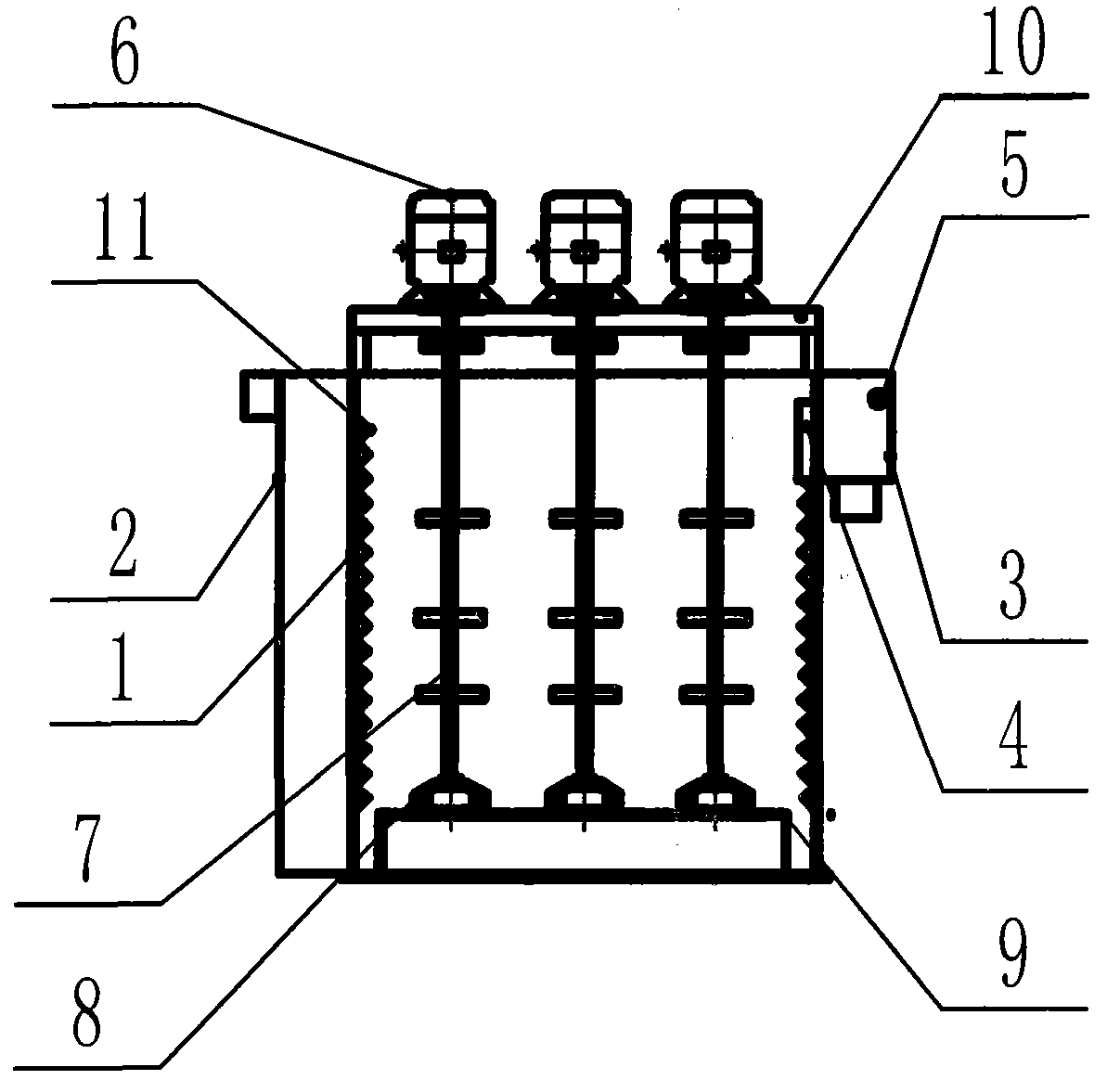

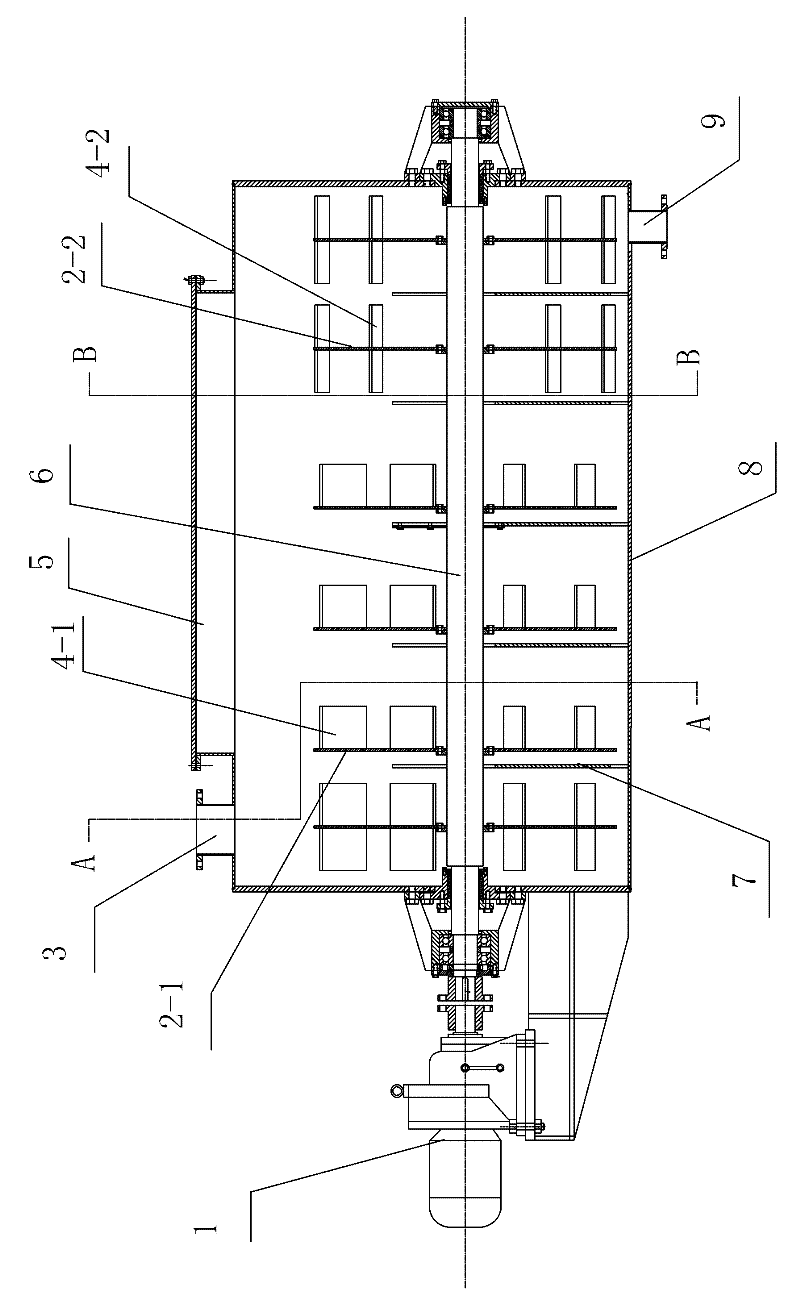

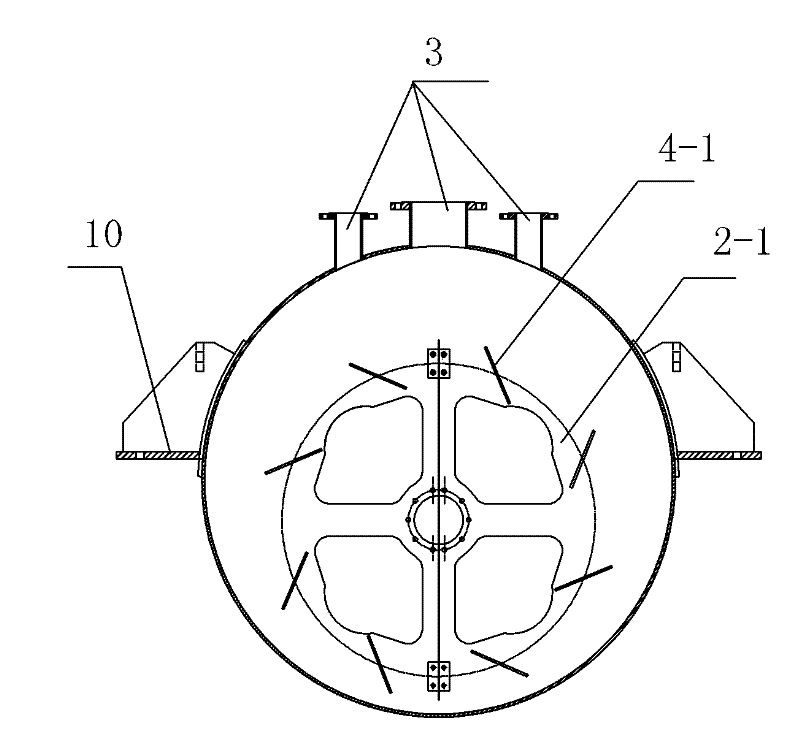

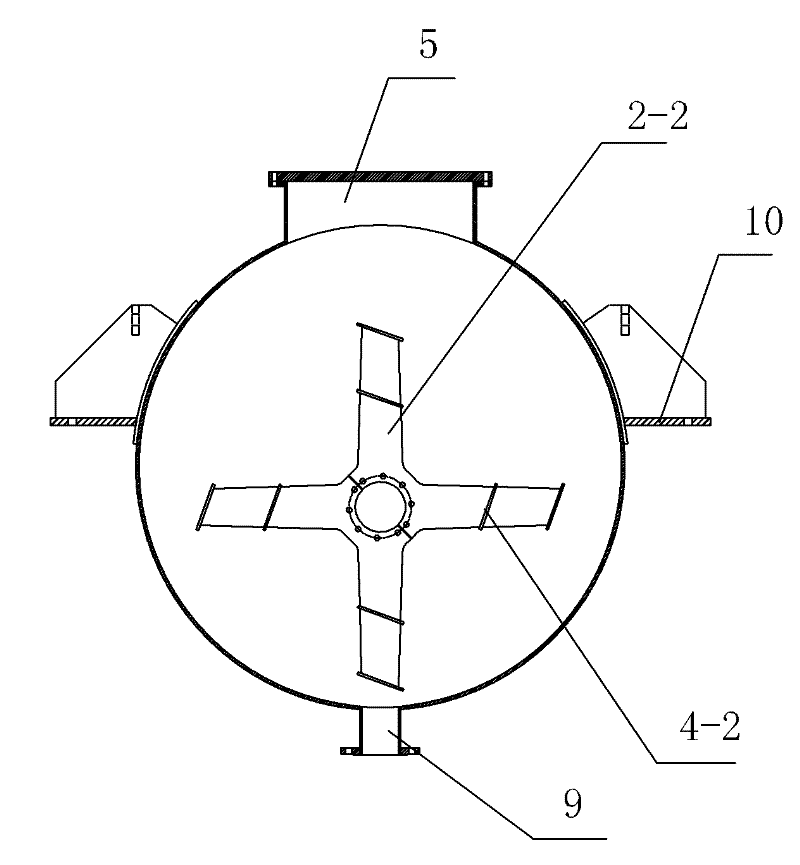

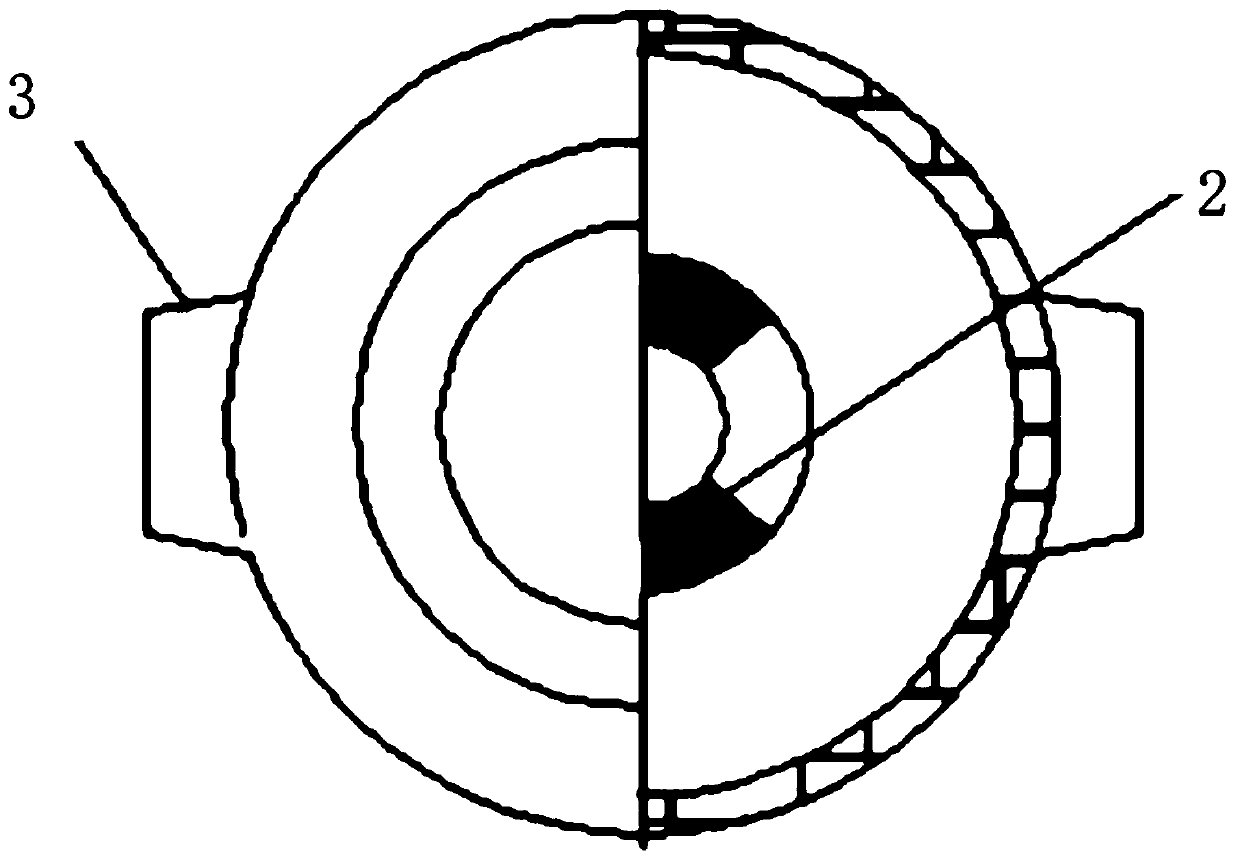

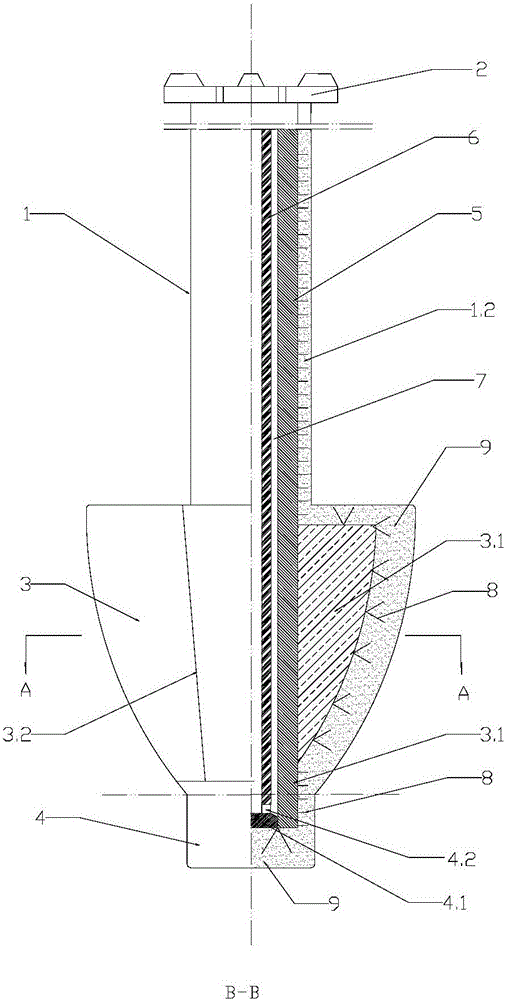

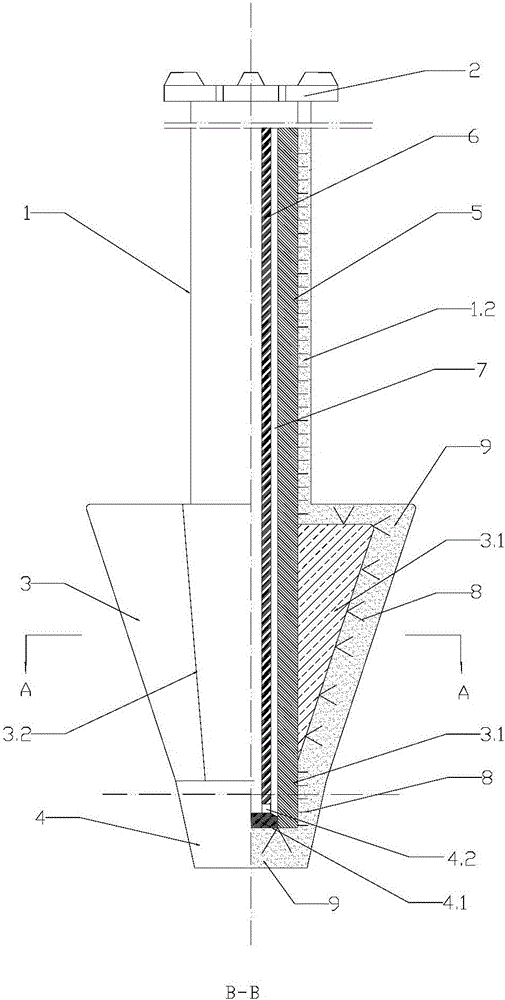

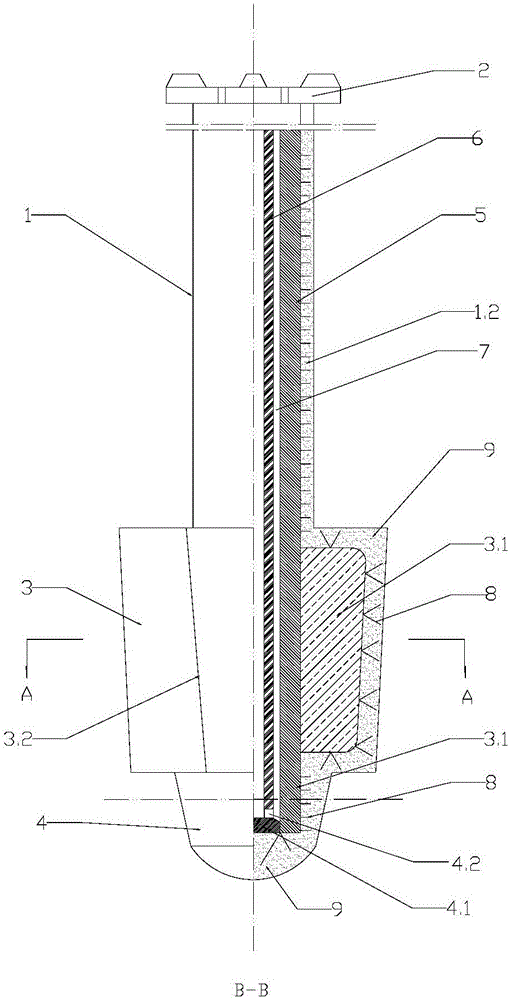

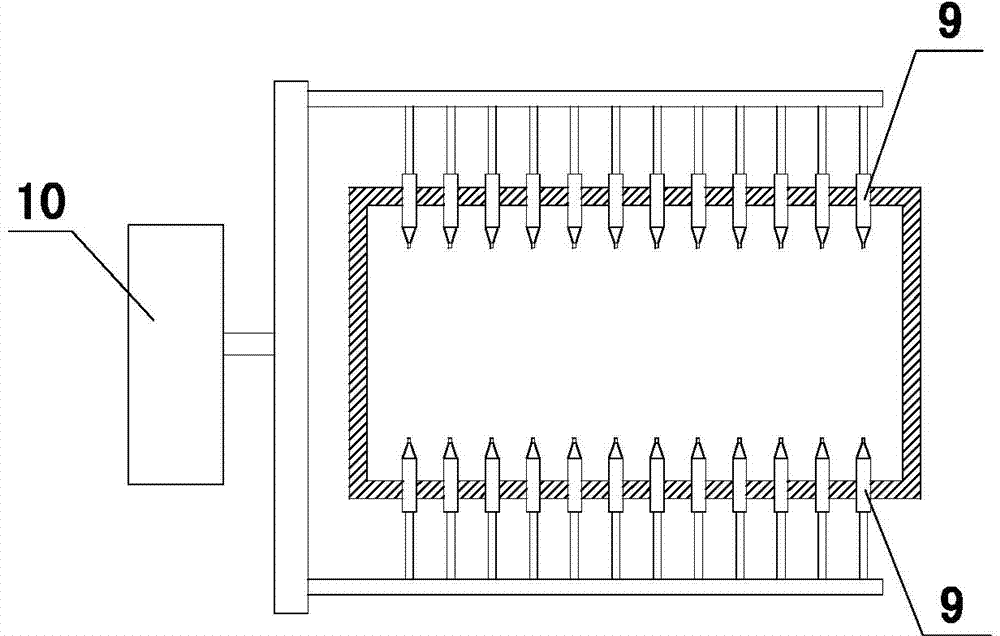

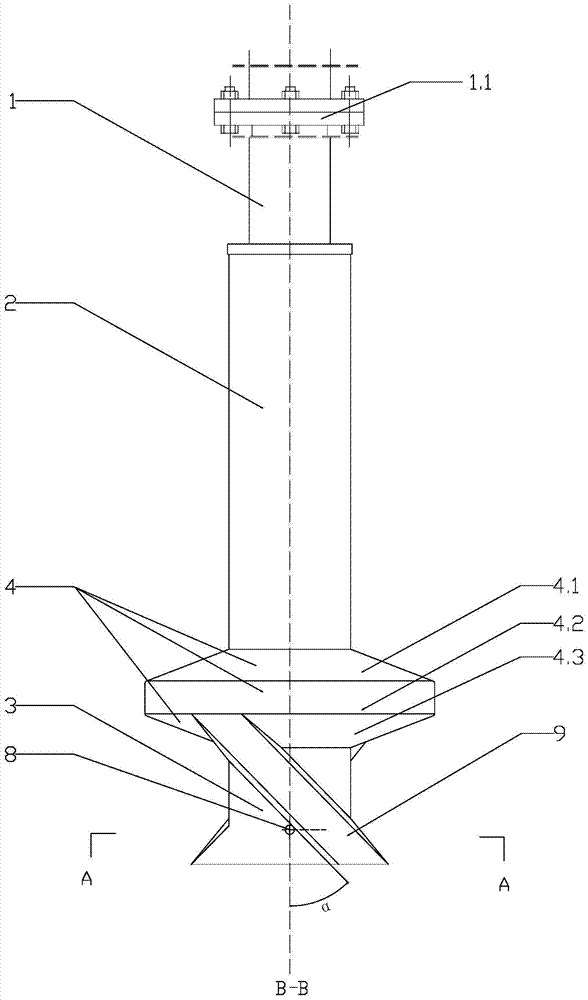

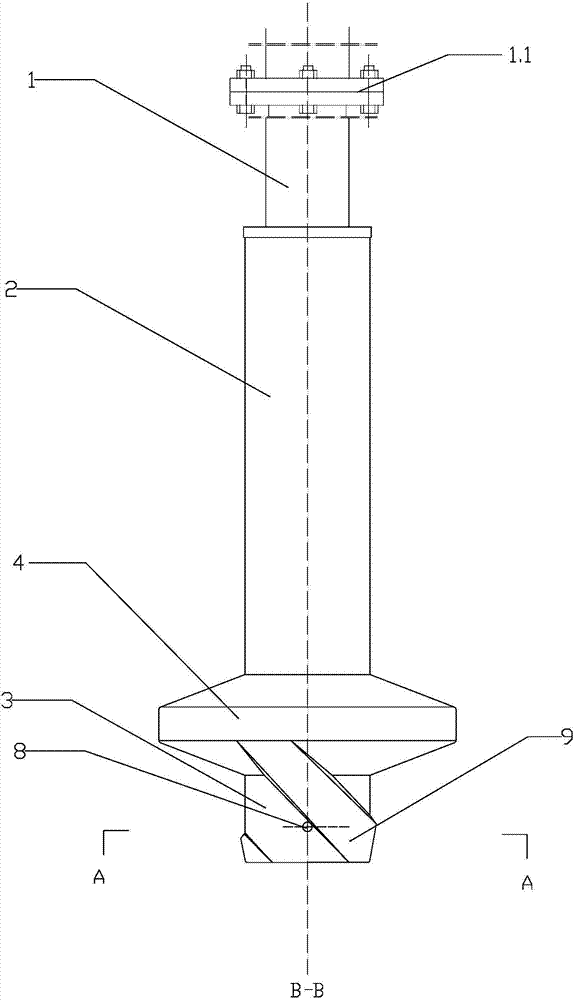

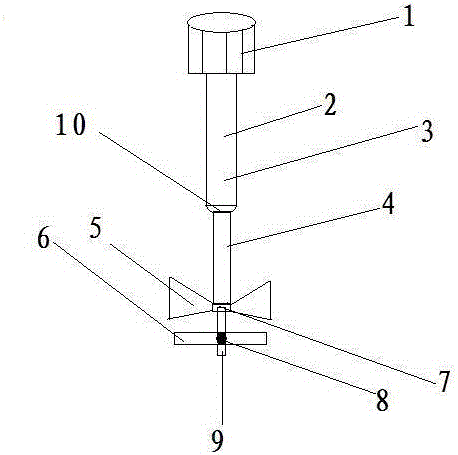

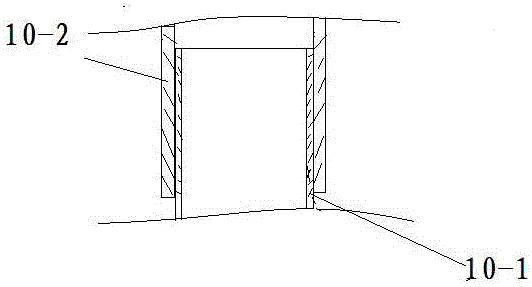

Stirrer for realizing desulfurization by using mechanical stirring

ActiveCN106399621AReduce the intensity of the swirling eddy current of molten ironDelay the breakage processEngineeringAir cooling

The invention discloses a stirrer for realizing desulfurization by using mechanical stirring. The stirrer comprises a stirring shaft and a connecting flange, wherein the connecting flange is arranged at the upper portion of the stirring shaft; stirring blades and a stabilizer are sequentially arranged at the lower end of the stirring shaft; each of the stirring shaft, the stirring blades and the inner layer of the stabilizer is a hollow metal pipe core; the top of each hollow metal pipe core is connected with the connecting flange; a metal blocking head is arranged on the inner wall of the lower end of the hollow metal pipe core; an air cooling pipe is inserted into each hollow metal pipe core; the top end of each air cooling pipe is connected with the connecting flange; the pipe orifice at the lower end of each air cooling pipe forms an air outlet with the corresponding metal blocking head. The stirrer disclosed by the invention has the advantages of reducing the intensity of rotating vortex of liquid iron below the bottom center of the stirrer, delaying the damage progress of the stirrer, improving the comprehensive application performances of the stirrer, effectively relieving the shortcoming of short long service life of a large stirrer and realizing the comprehensive aims of prolonging the service life of the stirrer, reducing the consumption of the stirrer, improving the economical efficiency and the direct-selling property of a large liquid iron KR stirring desulfurization technology and the like.

Owner:武汉钢铁有限公司

Device and method for improving jet flow impact effect by utilizing injecting powder in electric arc furnace steelmaking

ActiveCN102643951AIncrease profitReduce consumptionElectric furnaceProcess efficiency improvementSteelmakingElectric arc furnace

The invention belongs to the technical field of ferrous metallurgy and particularly relates to a method for supplying oxygen and injecting powder in electric arc furnace steelmaking, which can be used for solving the problems that the oxygen supply and jet attenuation speed is rapid in the current electric arc furnace steelmaking, the impact force is insufficient and the powder yield is low; the oxygen and powder particles are mixed into a gas-solid mixed phase to generate a high-speed mixed jet flow; the kinetic energy of powder particles is utilized to improve the impact force of the electric-arc furnace oxygen supply jet flow; stirring in the molten pool is strengthened; and the efficient transportation of the powder particles is realized. The powder flow range is 5-60kg / min, the oxygen flow is 500-3500Nm3 / h, gas-solid mixed phase flow is 500-4000Nm3 / h, the gas-solid ratio is 0.5-5kg / kg; and the high-speed mixed jet flow velocity is 50-700m / s. The method is suitable for 5-300t of electric-arc furnace steelmaking of wall furnace oxygen supply and powder injection; the stirring strength in the electric-arc furnace molten pool is strengthened by over 20%; the utilization rate of the oxygen and power is improved; the oxygen consumption is lowered to be larger than 15%; and the blowing powder consumption is lowered to be larger than 30%.

Owner:UNIV OF SCI & TECH BEIJING

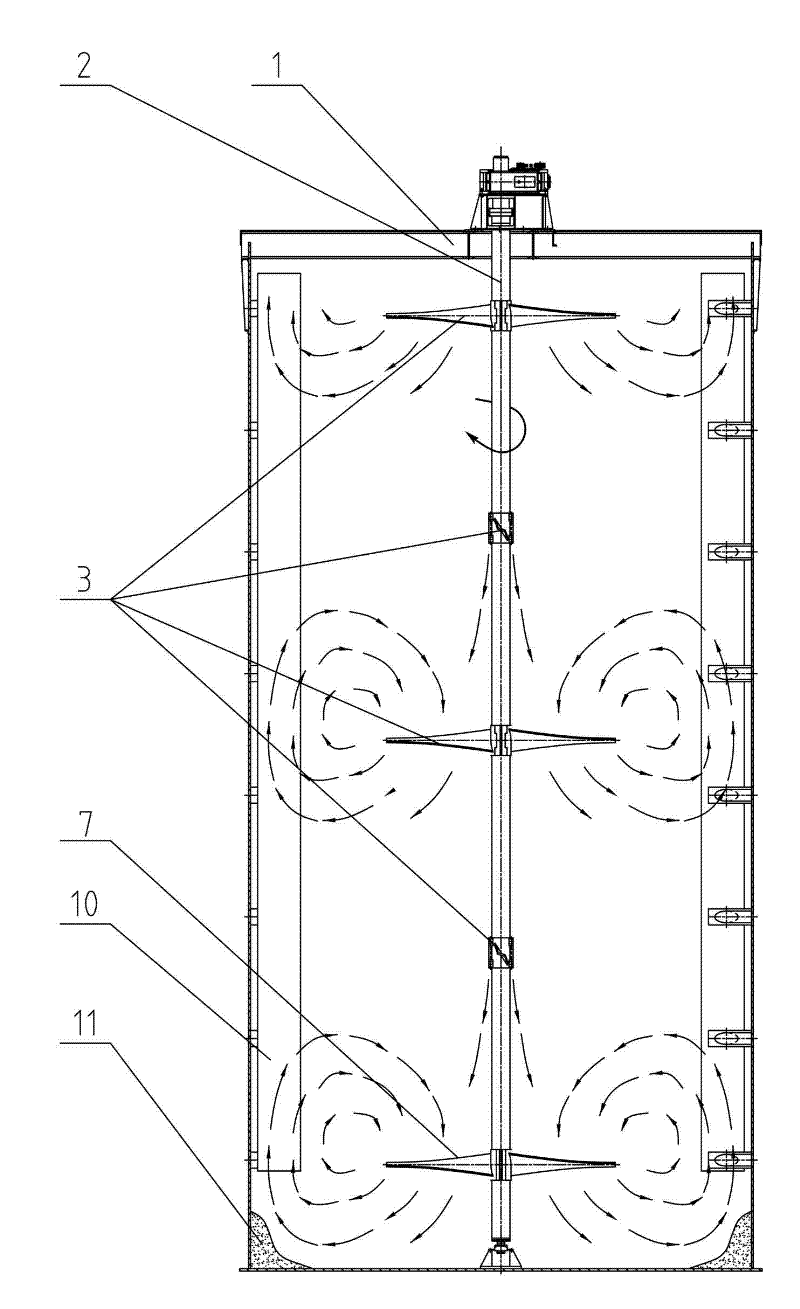

Agitating device of high-performance agitating tank

InactiveCN102527275ASignificant effective stirring rangeReduce shearRotary stirring mixersTransportation and packagingSheet steelEngineering

The invention relates to an agitating device, in particular to an agitating device of a high-performance agitating tank. The agitating device comprises an agitating paddle, wherein the agitating paddle is divided into an upper-layer paddle and a bottom-layer paddle; the outer circle of the upper-layer paddle is provided with a circle of upper-layer steel plate cylinder; a ring baffle is arranged below the upper-layer steel plate cylinder; the upper-layer steel plate cylinder is connected with the side wall of the agitating tank through a support plate; the outer circle of the bottom-layer paddle is provided with a circle of lower-layer steel plate cylinder; and the lower-layer steel plate cylinder is fixed on a bottom plate of the tank through the support plate. The invention has the following advantages: the agitating effect is better, the flow rate is accelerated, the scouring force is greatly increased, and the agitating strength is enhanced; compared with a common paddle, the energy is saved by about 40-60%; the effect on eliminating precipitates and scabs is obvious; and a common vertical baffle is canceled, so that energy consumption is reduced, and shear on liquid flows is reduced, thereby being beneficial to the growth of crystal grains in a seed precipitation tank.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

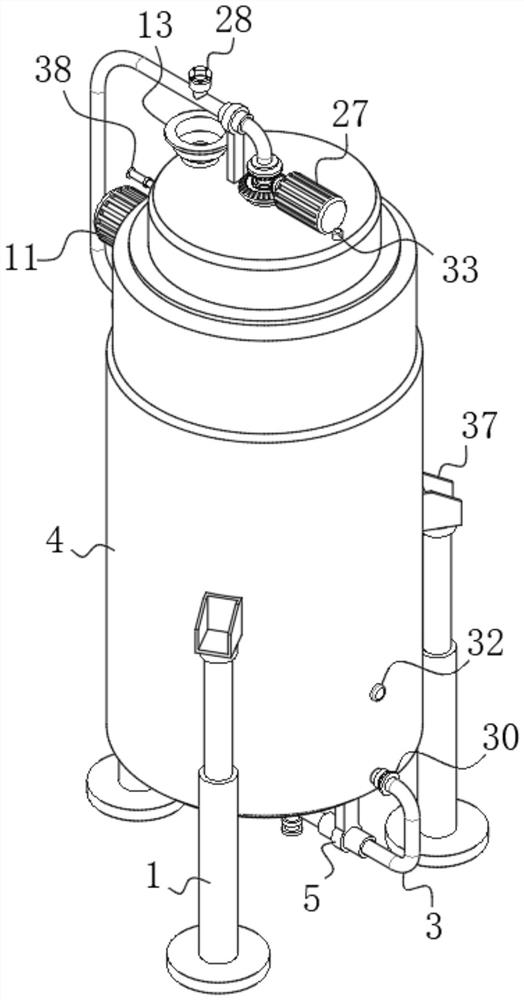

Preparation device of calcium 2-hydroxy-4-methylthio-butyrate

ActiveCN104725290AIncrease touch pointsIncrease contact surfaceOrganic compound preparationRotary stirring mixersAgricultural engineeringN-Butyrate

The invention discloses a preparation device of calcium 2-hydroxy-4-methylthio-butyrate, which comprises a drying device, a mixing device with a liquid spray device, a screening device and a control device, wherein the mixing device is arranged in the drying device; the liquid spray device is connected to the mixing device; the screening device is arranged on the lower side of the drying device; and the control device controls the operation of the drying device, liquid spray device, mixing device and screening device. The preparation device has the advantages of quick and thorough reaction, high product yield, high drying speed and efficiency, low energy consumption, fewer product impurities, high purity, low waste / exhaust emission, high safety and environment friendliness, is convenient and easy to operate, and shortens the technical process.

Owner:宁波它世界生物科技有限公司

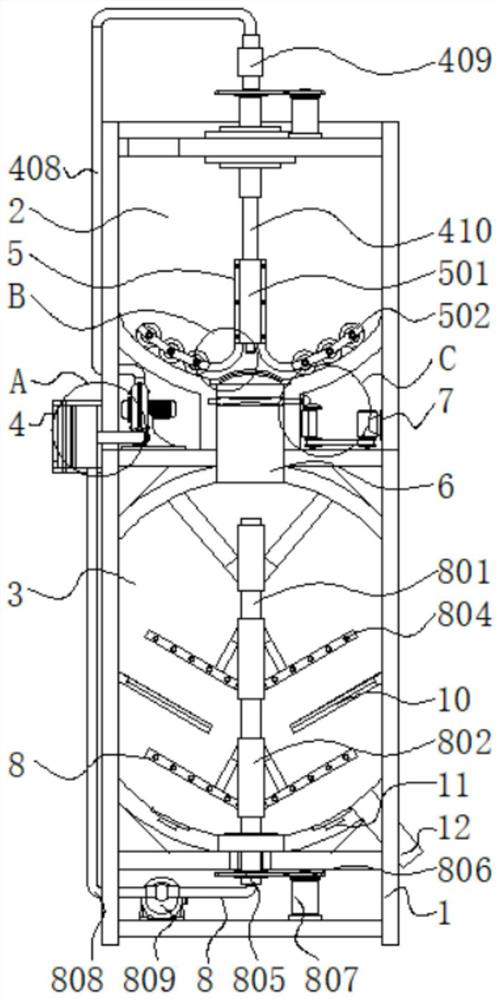

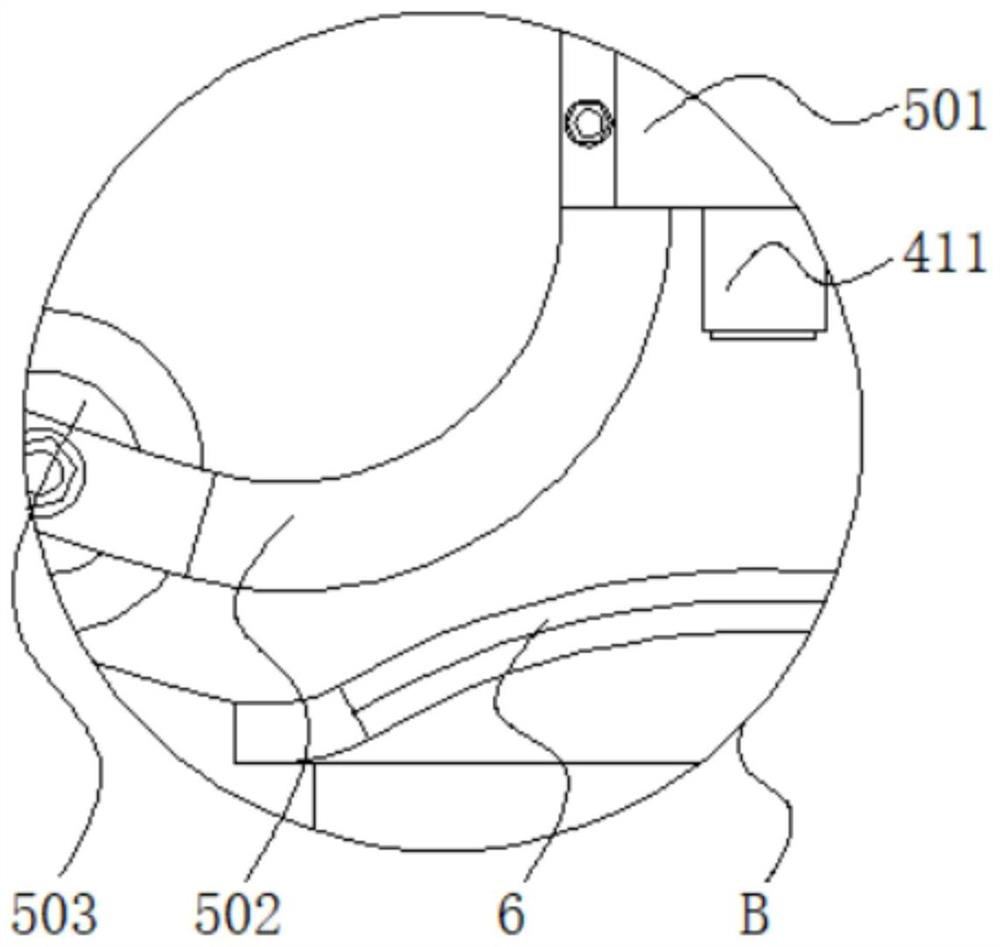

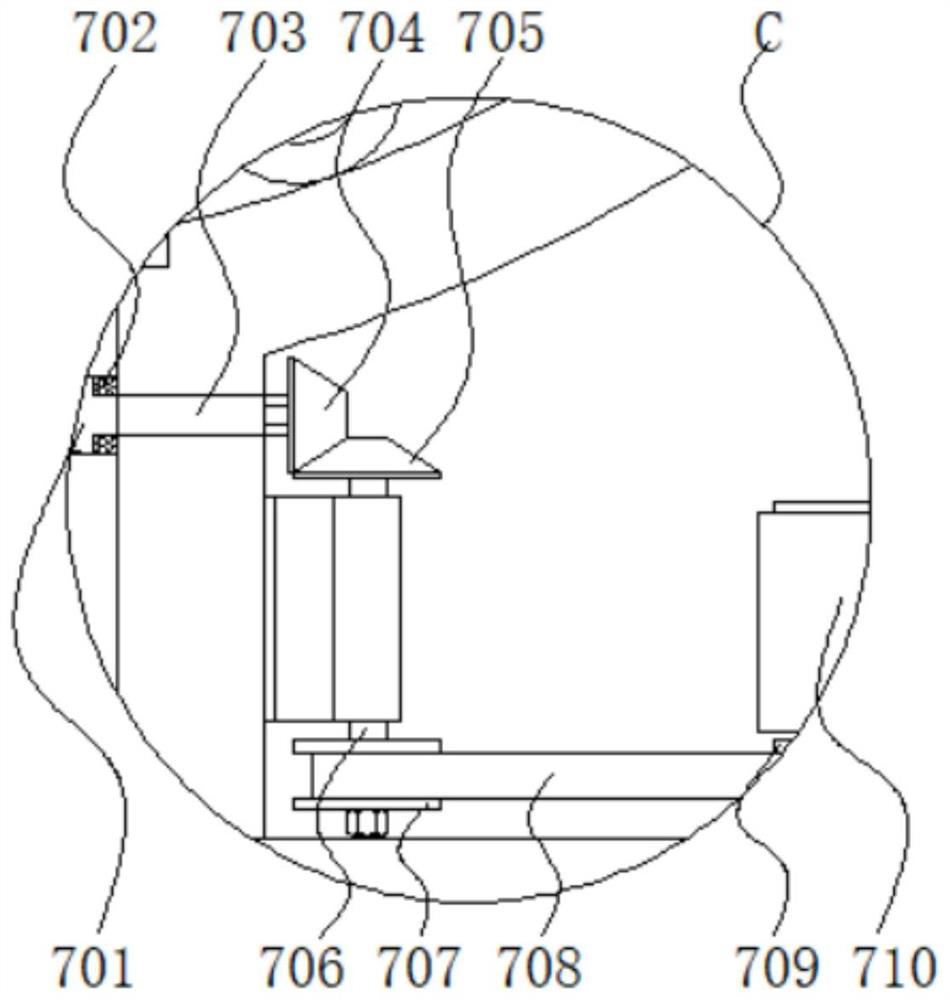

Multi-rotation-type asphalt material storage equipment

InactiveCN112878141AIncrease stirring intensityImprove stirring efficiencyRoads maintainenceEngineeringAsphalt

The invention discloses multi-rotation-type asphalt material storage equipment, and belongs to the technical field of asphalt processing. The equipment comprises a group of supporting vertical rods which are distributed in a circumferential array, and further comprises a heat exchange liquid inlet pipe and a heat exchange liquid outlet pipe; the top ends of the supporting vertical rods are fixedly connected with an outer tank, the top face of the outer tank is fixedly connected with the heat exchange liquid inlet pipe through a connecting plate, and the bottom face of the outer tank is fixedly connected with the heat exchange liquid outlet pipe through a connecting plate; and a heating outer cavity and a storage cavity which are isolated from each other are formed in the outer tank from outside to inside, an inner container is rotationally connected to the inner wall of the storage cavity through a bearing, a screen drum communicated with the storage cavity is rotationally connected to the inner wall of the inner container through a bearing, and the circumferential side face of the screen drum is rotationally connected with the outer tank. Through the design of a driven shaft rod, a heat exchange inner shaft pipe, a driven gear and a driving main gear, a one-way stirring structure of a stirring mechanism of a transmission asphalt storage device is changed into a multi-rotation-direction stirring structure, and through the implementation of the multi-rotation-direction stirring structure, the material stirring strength and stirring efficiency of the equipment can be effectively improved.

Owner:余冬标

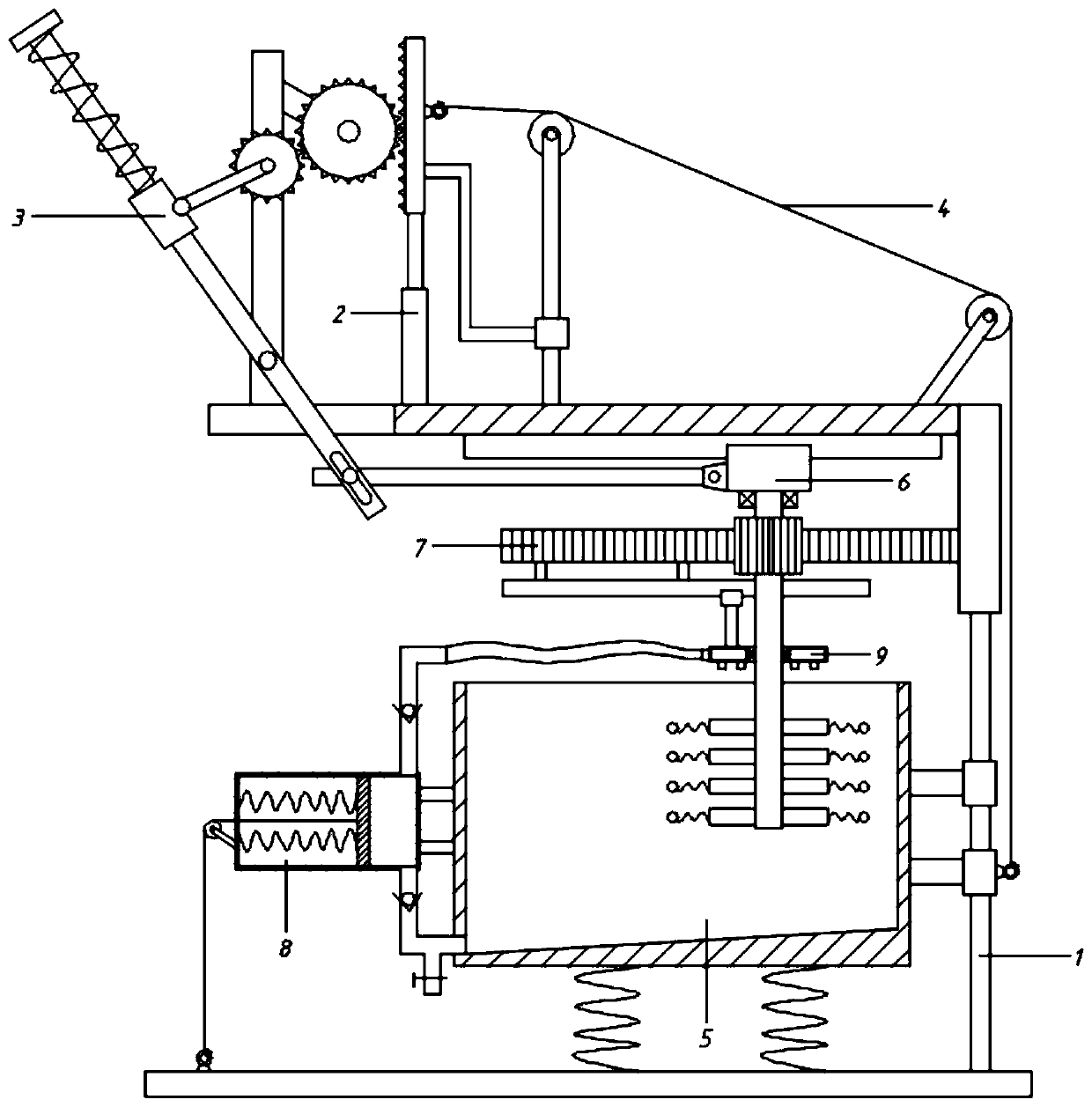

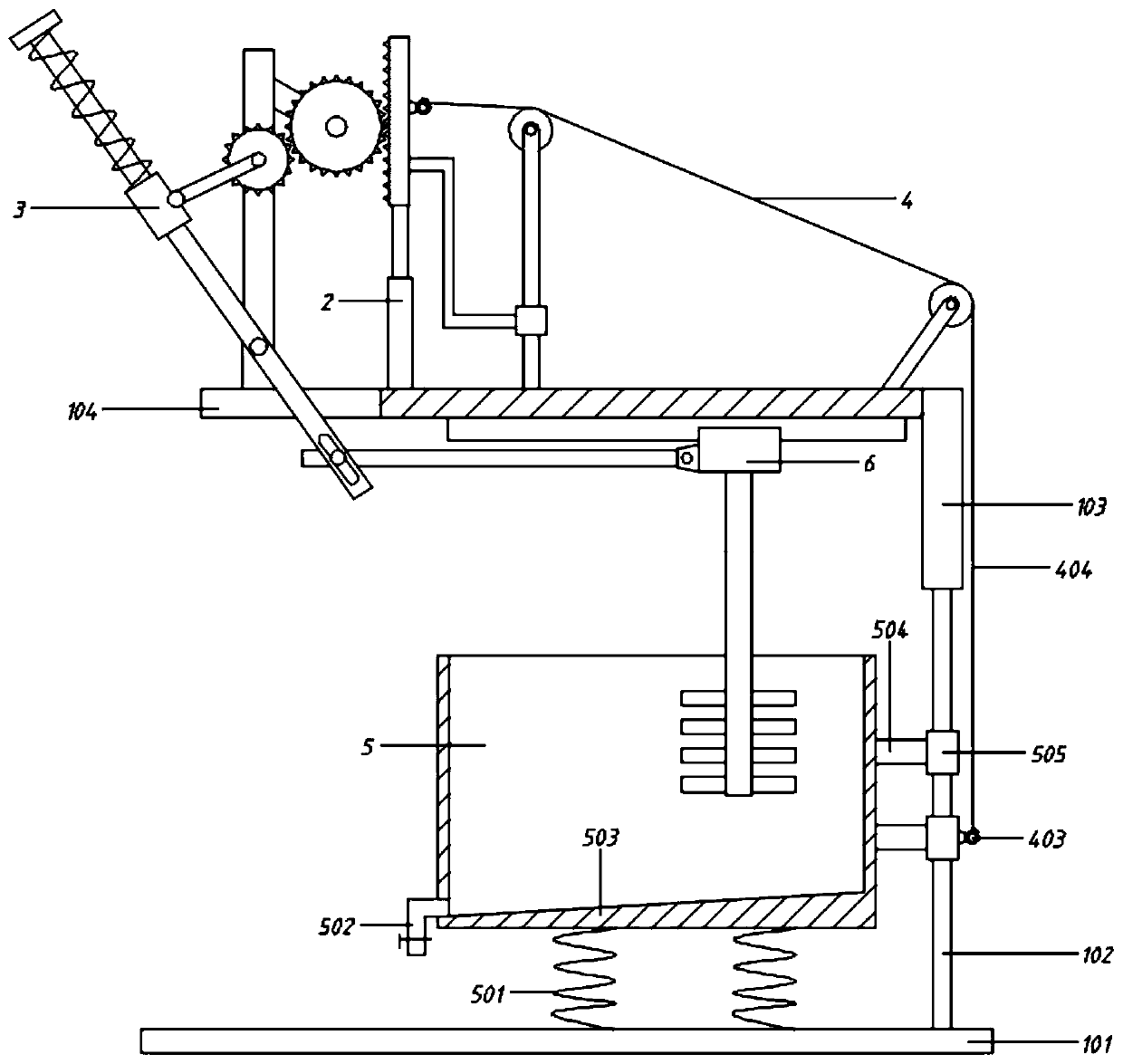

High-uniformity blending device for enzyme milk tea production

InactiveCN111001320AImprove uniformityIncrease stirring intensityShaking/oscillating/vibrating mixersTransportation and packagingMechanical engineeringRack and pinion

The invention relates to the technical field of enzyme beverage production and preparation, in particular to a high-uniformity blending device for enzyme milk tea production. An electric push rod telescopically drives a first rack to move up and down; the first rack drives a large gear to rotate. The large gear enables a small gear to rotate through the meshing effect; a pinion drives a short rocker to rotate, so that a second sliding sleeve moves along a long rocker and drives the long rocker to swing left and right, a push-pull rod drives a first sliding block to move left and right along afirst sliding rail through the cooperation of a linear hole and a sliding shaft, then a stirring shaft moves along with the push-pull rod, and therefore the stirring area ofa stirring rod in the left-right direction is changed; when the first rack moves up and down, a first pull rope acts on a first tether ring, so that the first tether ring moves up and down along the sliding rod, a preparation box moves up and down, and the stirring area of the stirring rod in the up-down direction is changed.

Owner:安徽易码数据科技有限公司

High-performance spray gun for molten iron injection pretreatment

The invention discloses a high-performance spray gun for molten iron injection pretreatment. The high-performance spray gun comprises a connection segment, a gun body segment and an injection segment, which are sequentially communicated, wherein a swirling diffuser is arranged between the gun body segment and the injection segment and comprises an upper cone, a cylinder and a lower reversed cone, which are sequentially communicated; 2-4 nozzles are uniformly formed between a main pipe of the spray gun and a seal head in the circumferential direction of the spray gun and positioned in the side wall of the injection segment; swirling pieces obliquely arranged on the outer wall from the top end of the lower reversed cone to the bottom end surface of the injection segment and positioned above the nozzles. By strengthening three key kinetic parameters of molten iron injection pretreatment, the spray gun significantly improves the kinetic conditions of molten iron injection pretreatment and achieves the comprehensive purposes of improving the sulfur removal efficiency of injection pretreatment and the utilization rate of desulfurizer reaction, shortening the injection time and increasing the production capacity of desulfurization equipment.

Owner:武汉钢铁有限公司

Telescopic household stirrer

InactiveCN105879741ASimple structureIncrease stirring intensityRotary stirring mixersTransportation and packagingPulp and paper industry

The invention discloses a telescopic household stirrer, which comprises a stirring rod, wherein a motor is arranged at the top end of the stirring rod; a stirring paddle is arranged at the bottom end of the stirring rod; the telescopic household stirrer is characterized in that the stirring rod comprises a sleeve and an extension rod connected through an extension end; an inner thread is formed at the bottom end of the sleeve; an outer thread matched with the inner thread of the sleeve is formed at the top end of the extension rod; the stirring paddle comprises a first stirring paddle and a second stirring paddle; the first stirring paddle is movably connected to the bottom of the extension rod through a bolt; the second stirring paddle comprises a stirring blade and a connecting rod; the stirring blade is fixed on the connecting rod through a bolt; and the connecting rod sleeves on the bottom end of the extension rod. Compared with the prior art, the structure is simple; the stirring rod can be pulled out through the arrangement of the extension end on the stirring rod when the stirring rod is used and a stirring vessel is too deep; the stirring rod can be folded when being carried; meanwhile, the stirring paddle is movably connected to the bottom of the stirring rod, and can be dismantled when being carried; the stirring paddle is designed into two types; and different objects can be relatively effectively stirred, so that the stirring strength is improved and the stirring efficiency is improved.

Owner:韩彦荣

Fusing and mixing device

The invention discloses a fusing and mixing device for producing a compound fertilizer by performing tower granulation. The fusing and mixing device comprises a transmission device, a pot cover, a discharging valve assembly, a discharging pipe, a stirring shaft, a pot body, an outer heat insulating device, a stirring device and a shaft sleeve, wherein the stirring device comprises a spiral stirring blade and a diversion cylinder; the diversion cylinder is a hollow cylindrical body which is sleeved outside the spiral stirring blade and is opened on the top and at the bottom; the cylinder wall of the diversion cylinder is provided with a gap extending downwards from the upper edge of the diversion cylinder; included angles between lines of the two end points of the gap on the upper edge of the diversion cylinder and the central point of the upper edge of the diversion cylinder are 60-80 degrees; the gap is three fourth to four fifth of the height of the diversion cylinder; and a baffle plate is arranged between one side of the gap along the downstream direction of the slurry flowing direction and a pot wall. In the fusing and mixing device, a stirring device with small heat loss is adopted, so that the use of an inner coil is reduced, the manufacturing cost is saved, the energy is saved, and the stirring efficiency is increased simultaneously.

Owner:拉多美科技集团股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com