Patents

Literature

44results about How to "High tin content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

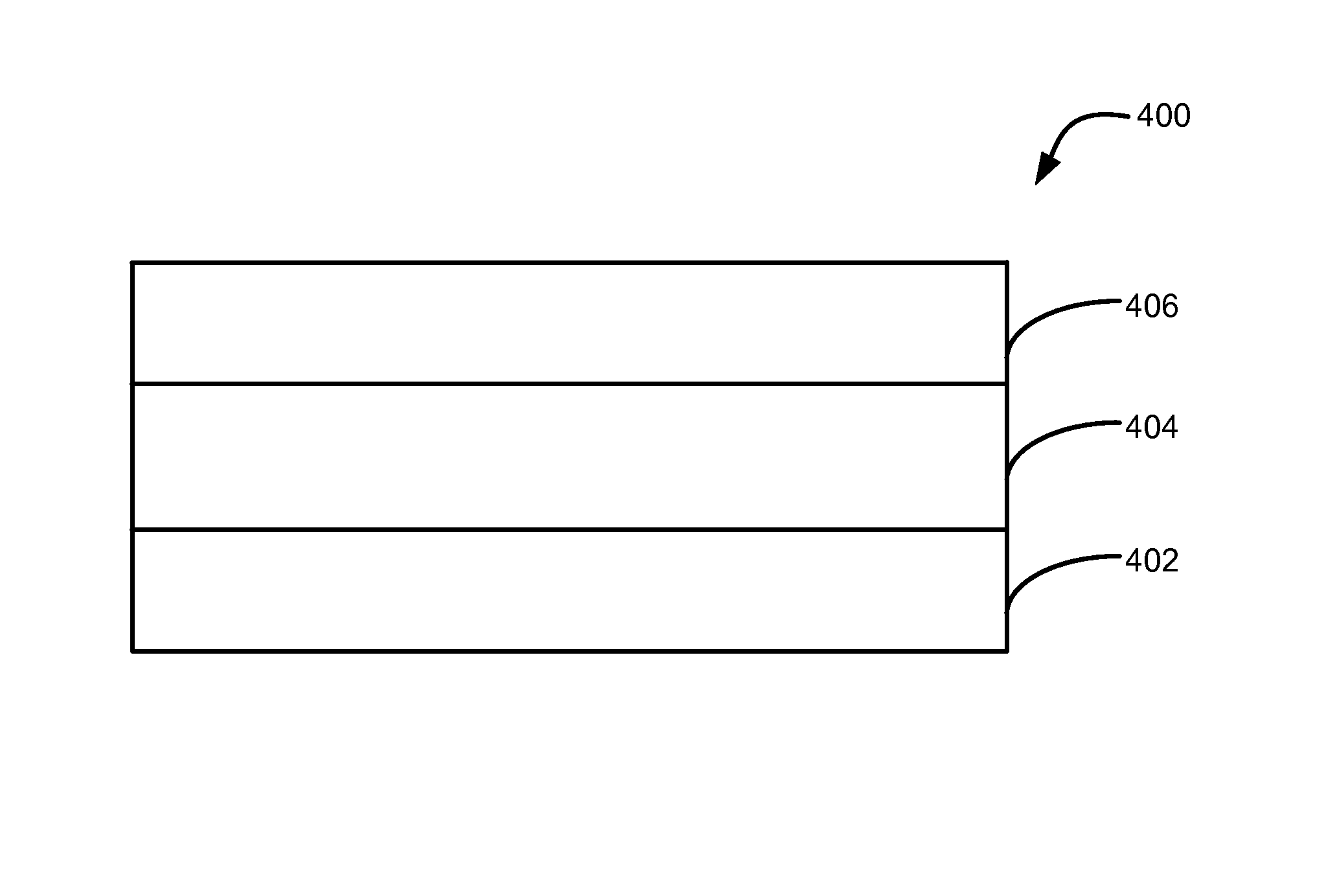

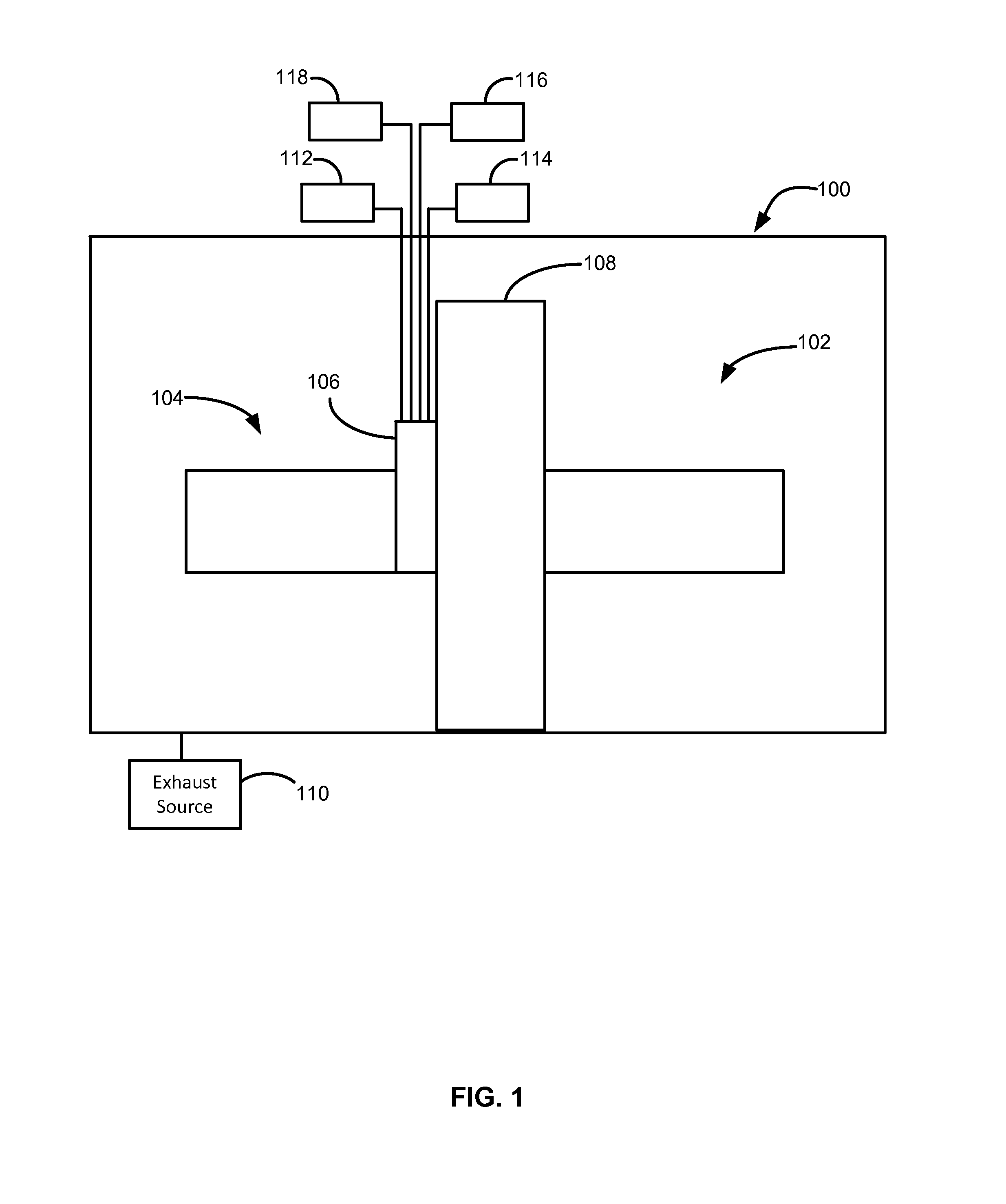

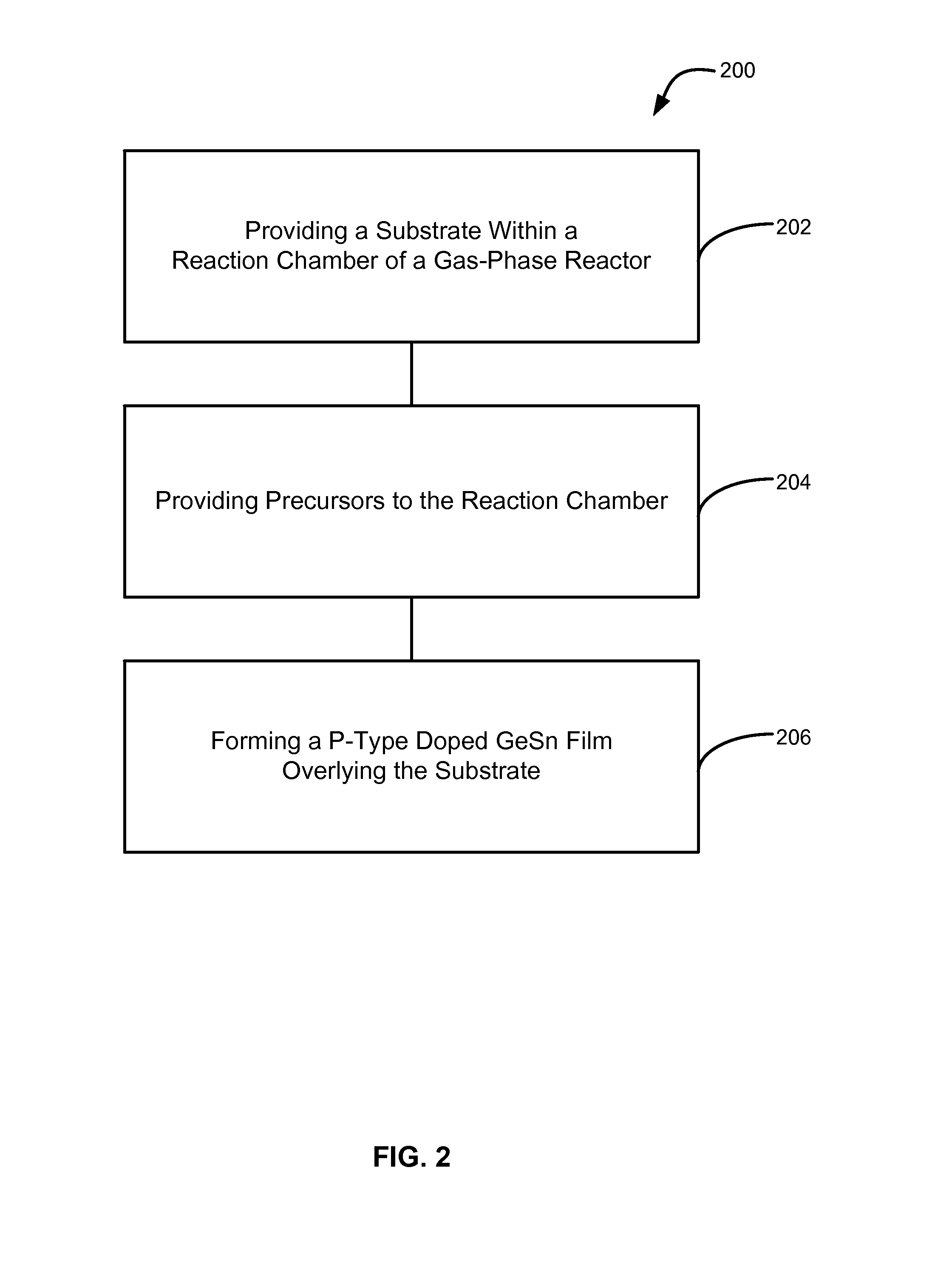

Methods of forming highly p-type doped germanium tin films and structures and devices including the films

ActiveUS20170047446A1High tin contentSuitable for applicationPolycrystalline material growthSemiconductor/solid-state device manufacturingDopantP type doping

Methods of forming p-type doped germanium-tin layers, systems for forming the p-type doped germanium-tin layers, and structures including the p-type doped germanium-tin layers are disclosed. The p-type doped germanium-tin layers include an n-type dopant, which allows relatively high levels of tin and / or p-type dopant to be included into the p-type doped germanium-tin layers.

Owner:ASM IP HLDG BV

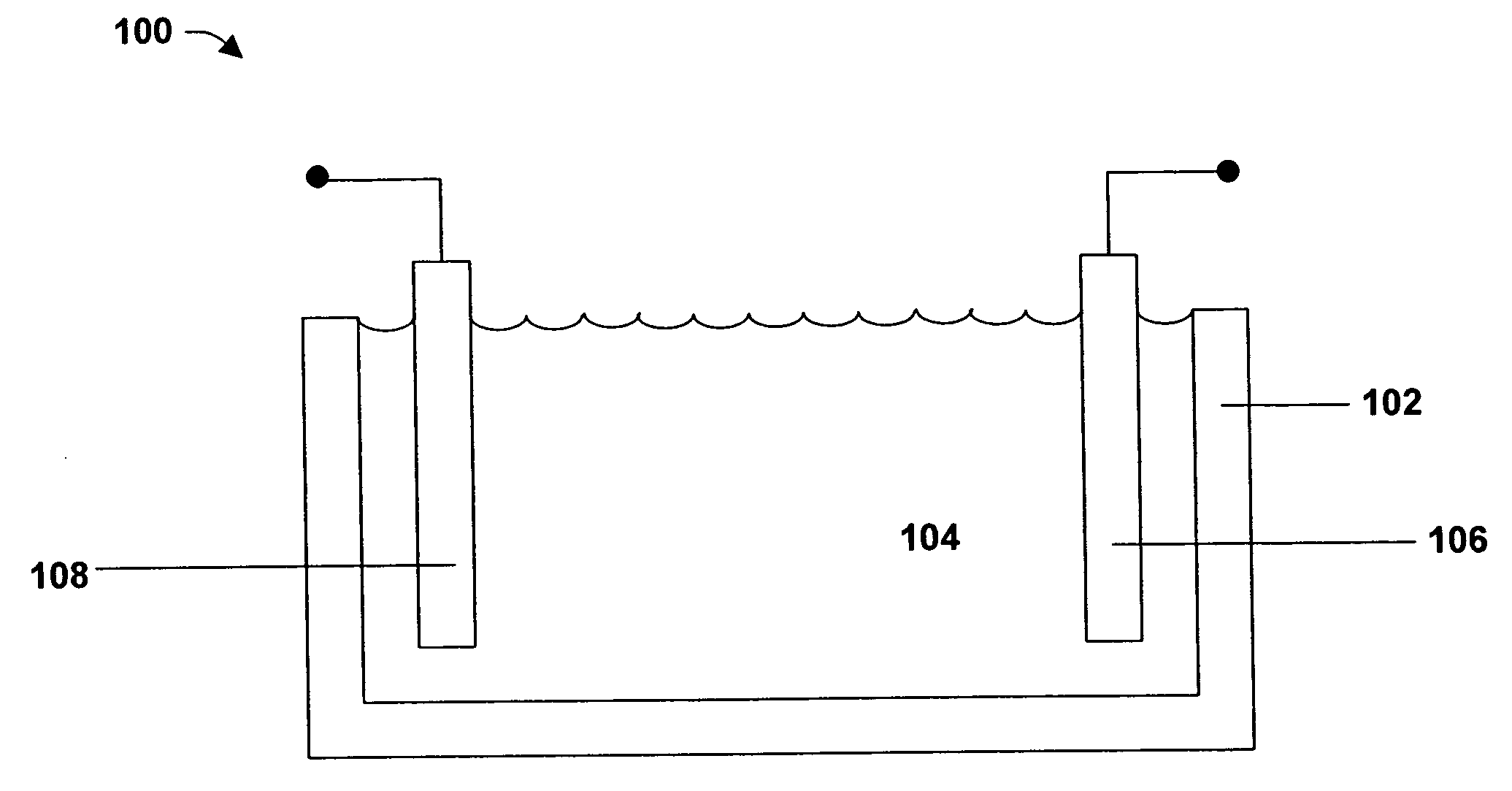

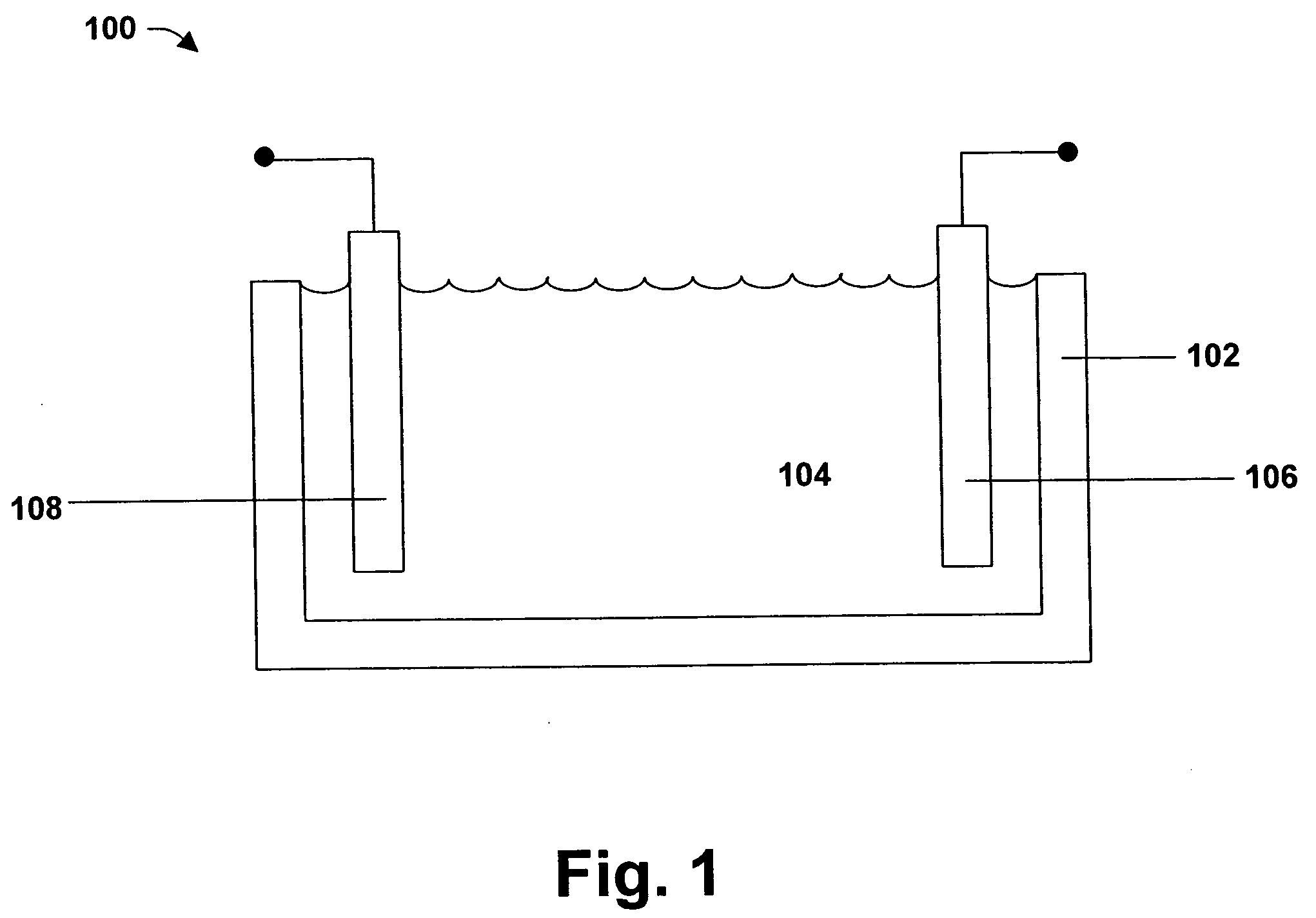

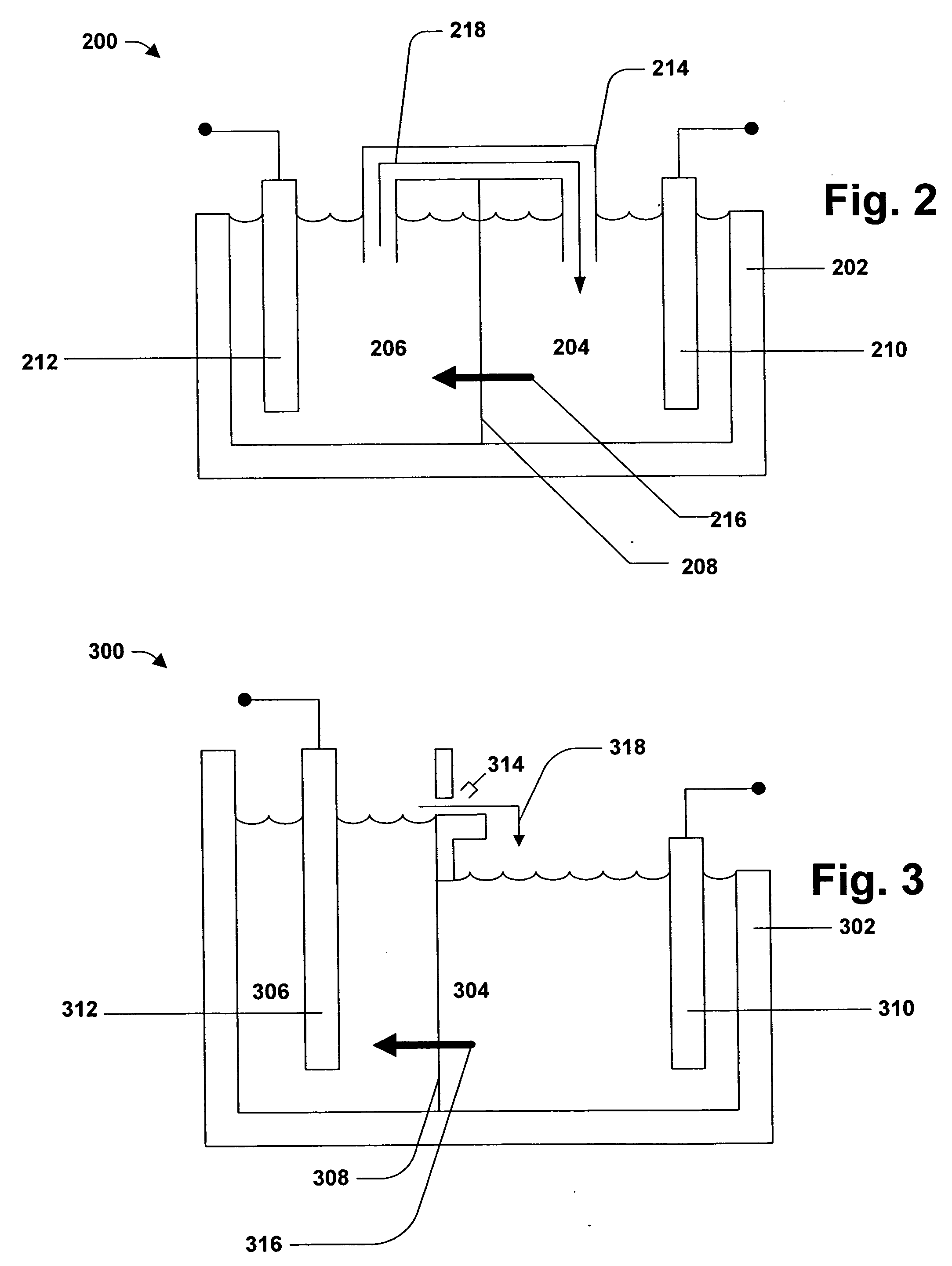

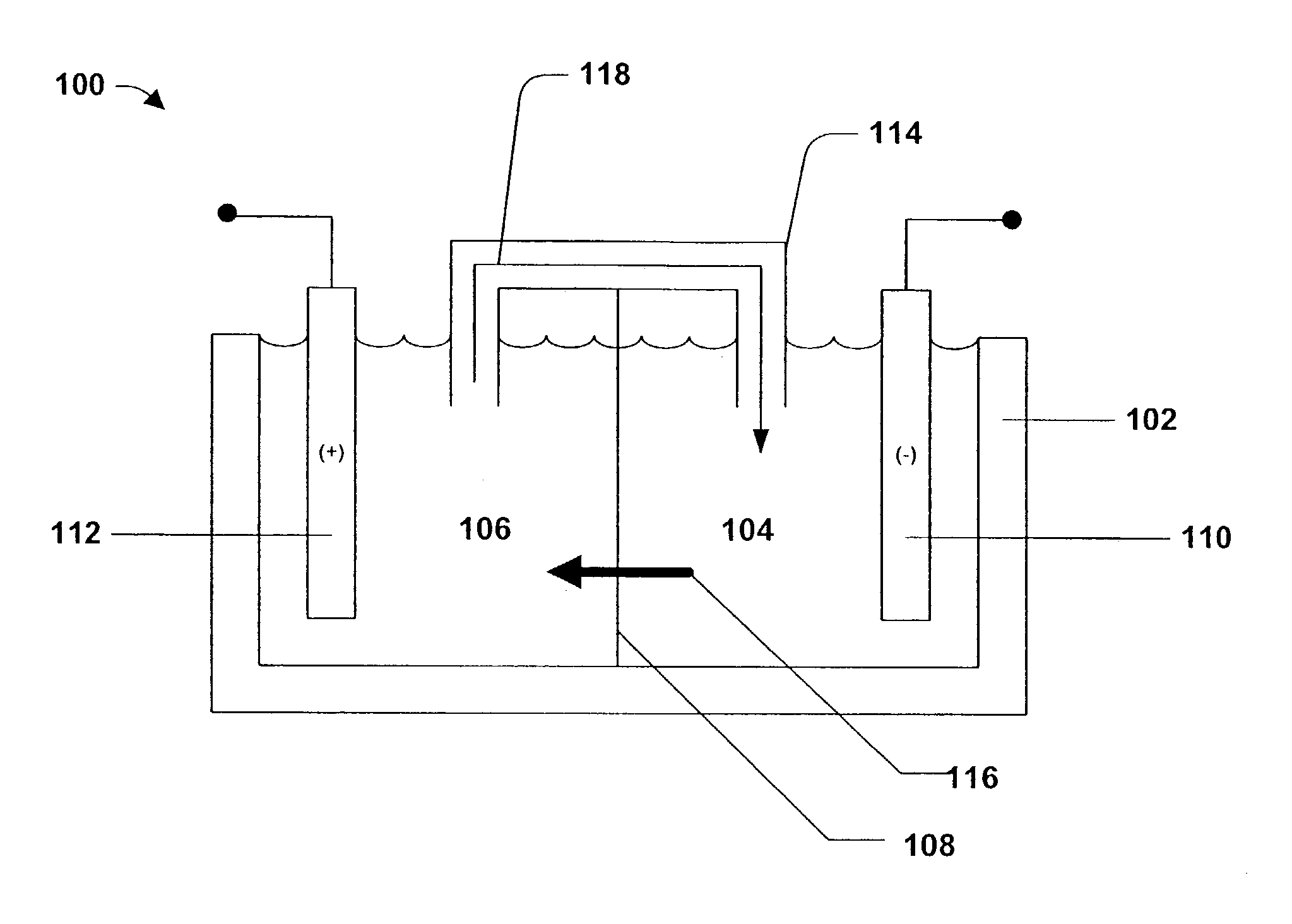

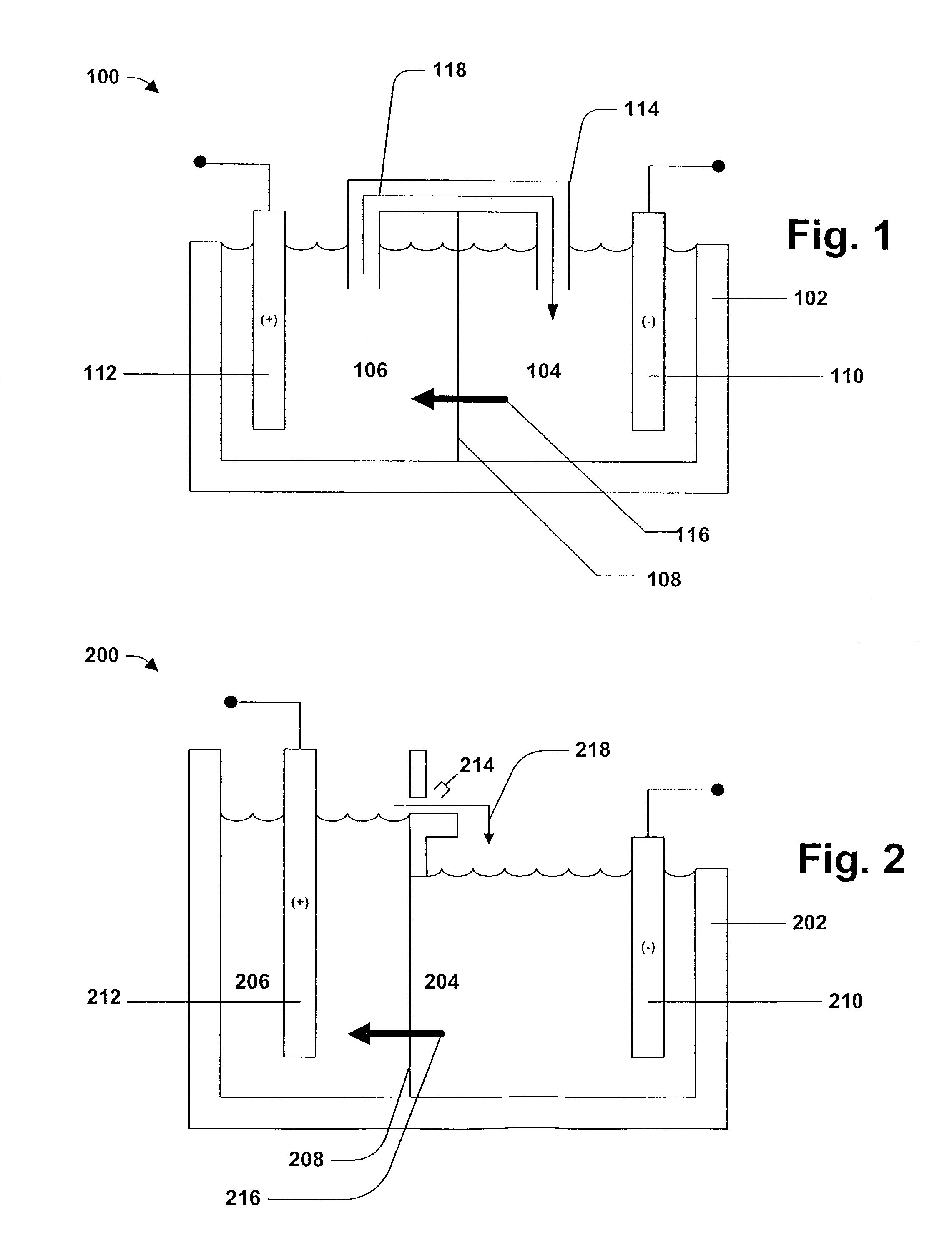

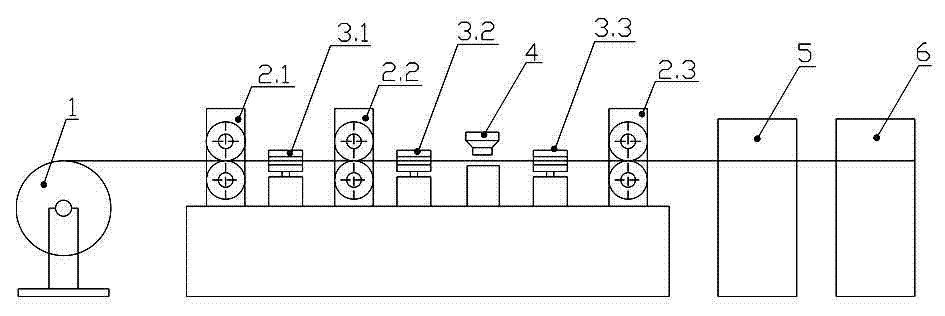

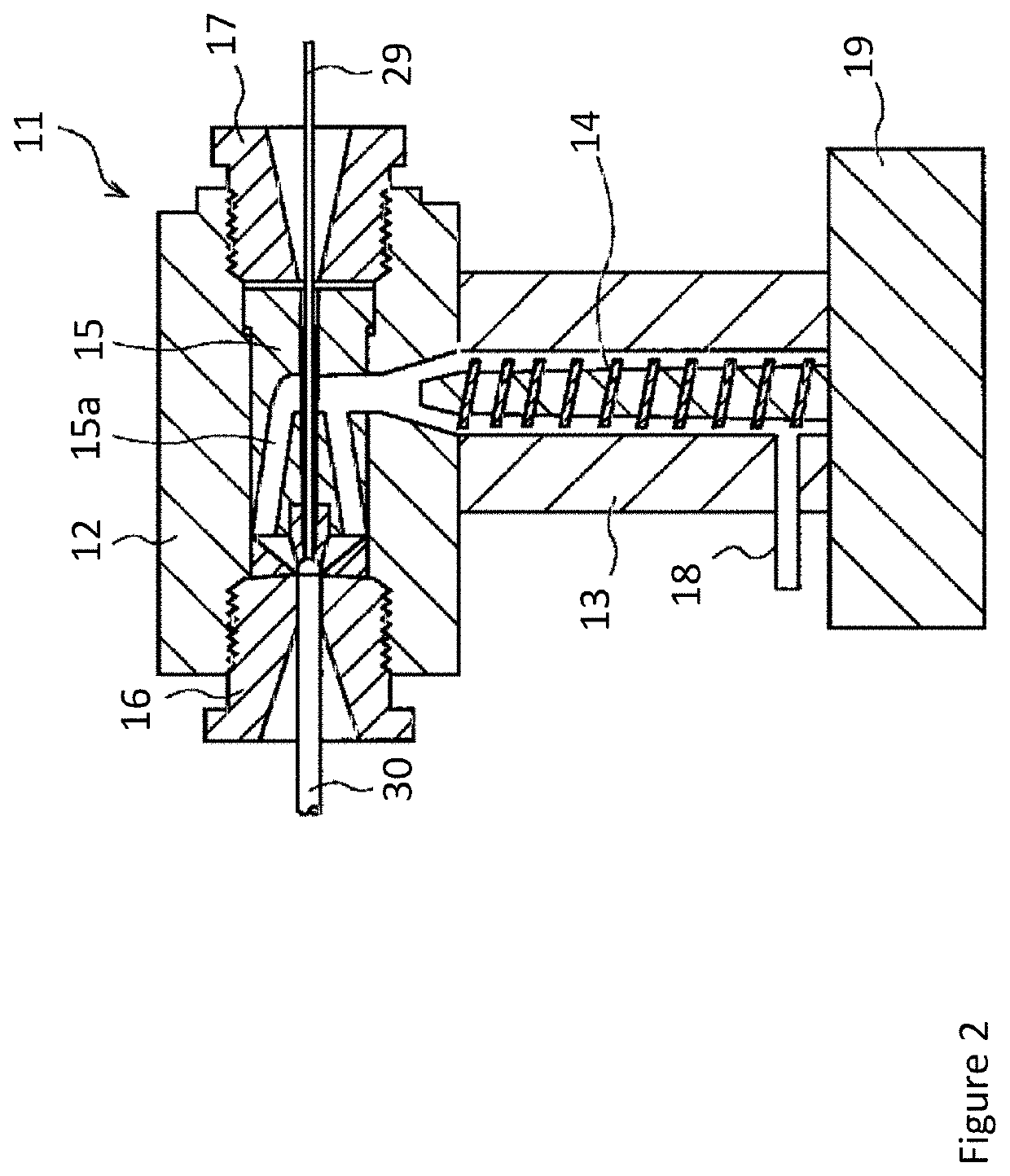

Tin alloy electroplating system

Disclosed are systems and methods of plating a tin alloy in an efficient, economical, and environmentally friendly manner. The system for plating a tin alloy contains an electrochemical cell containing an anode, the cathode, and an electroplating bath. The electroplating bath contains water, an acid, at least one nitrogen-containing heterocyclic complexing agent, an ionic alloy metal, and ionic tin. The methods involve applying a current to the electroplating bath whereby a tin alloy forms on the cathode.

Owner:TASKEM

Tin alloy electroplating system

ActiveUS7195702B2Minimizing and eliminating latent whiskeringReduce disposalCellsAlloyElectrochemical cell

Disclosed are systems and methods of plating a tin alloy in an efficient, economical, and environmentally friendly manner. An electrochemical cell containing an anolyte compartment and a catholyte compartment separated by a selective membrane is employed. The selective membrane prevents ionic metals from migrating from the catholyte compartment to the anolyte compartment. A conduit may be employed in the electrochemical cell to permit one way flow of anolyte to the catholyte compartment thereby replenishing tin to the catholyte compartment.

Owner:COVENTYA INC

Preparation method of tin oxide fiber precursor and tin oxide crystal fibers

ActiveCN103556303AUniform diameterGood whitenessInorganic material artificial filamentsTin oxidesElectrospinningPhotocatalysis

The invention relates to a preparation method of a tin oxide fiber precursor and tin oxide crystal fibers. The preparation method comprises the following steps: carrying out a replacement reaction on halides of tin and potassium (sodium) acetate to synthesize the tin oxide fiber precursor which takes acetic acid as a ligand; concentrating a precursor solution to obtain a spinning solution and carrying out centrifugal silk spinning to obtain tin oxide precursor fibers; and carrying out procedures of special atmosphere pre-treatment, high-temperature heat treatment and the like on the precursor fibers to obtain the tin oxide crystal fibers. According to the preparation method, the long-diameter ratio of the tin oxide crystal fibers is greater than 1000, the tensile strength of the fibers is 0.8GPa-1.1GPa, the whiteness of the fibers is good and the color and luster of the fibers are soft. The preparation method is simple in preparation process, moderate in condition and stable in quality of fibers in batches; spinning sol does not go bad after being placed for a long time. The tin oxide crystal fibers can be applied to the fields of photocatalysis, air sensitivity, humidity sensitivity and the like. The tin oxide fiber precursor can also be used for preparing oxide thin films, nano powder and nano wires or preparing tin-containing functional materials including nano tin oxide fibers and the like by an electrostatic spinning method.

Owner:SHANDONG UNIV

High tin and silver base welding rod and preparation method thereof

ActiveCN103480988ASolve the problem that is difficult to process into welding rodHigh tin contentWelding/cutting media/materialsSoldering mediaIngot castingZinc

The invention discloses a high tin and silver base welding rod and a preparation method thereof. The high tin and silver base welding rod is made of raw materials of 24-61% of silver, 20-41% of copper, 12-35% zinc and 6-12% tin. The preparation method includes atomizing copper and zinc in proportion into powdered alloy, melting copper, adding silver at a certain temperature, covering with compound salt after fully melting, lowering the temperature of metallic solution, adding zin to continue melting, stilling the metallic solution after the zinc is melted fully, pouring the metallic solution into ingot casting, transfer the ingot casting into a resistance furnace to homogenize and anneal after being rough turned, squeezing the ingot casting into a 3.5mm plate and strip, rolling into 0.2mm ribbons by multi passes and small turns ratio after being annealed online, and combing with, drawing and cutting off with the atomized powdered alloy via a flux-cored wire machine to acquire finished product welding rods 1.0-2.5mm in diameter. The preparation method is simple in operation, has good stability and low in production cost, and solves the problem that high tin and silver base brazing filler metal is hard to be processed into welding rods.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

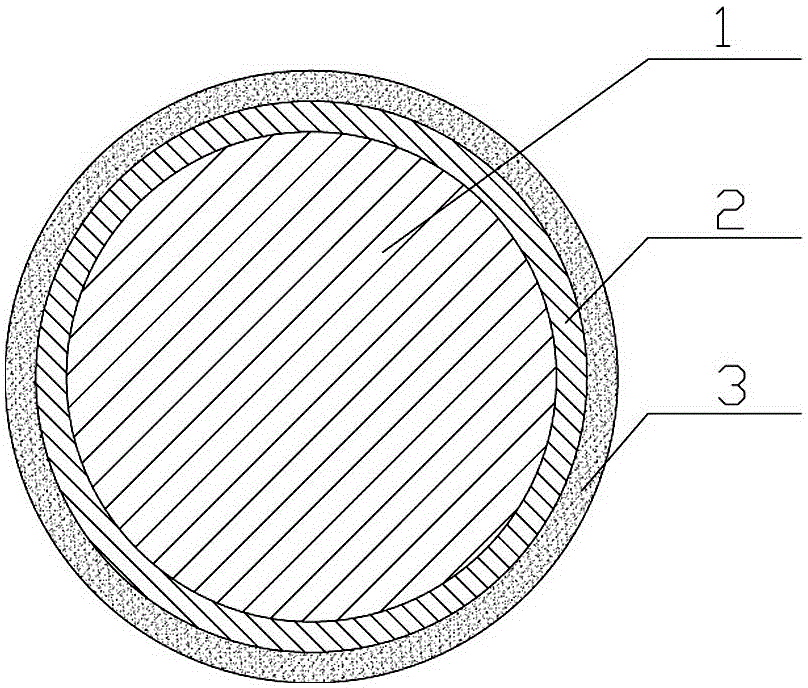

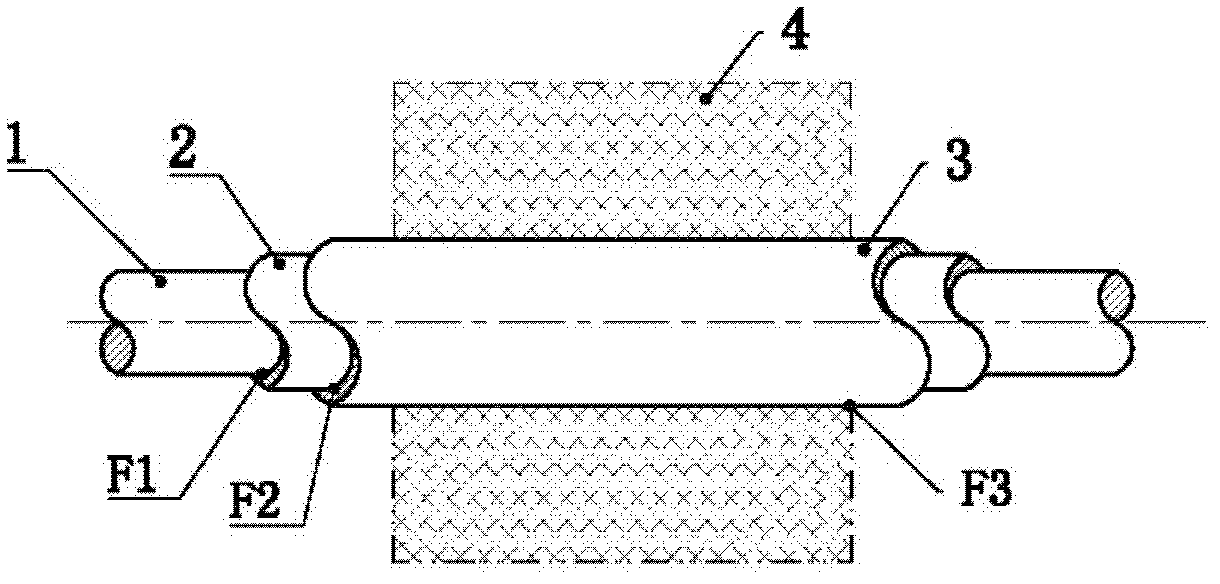

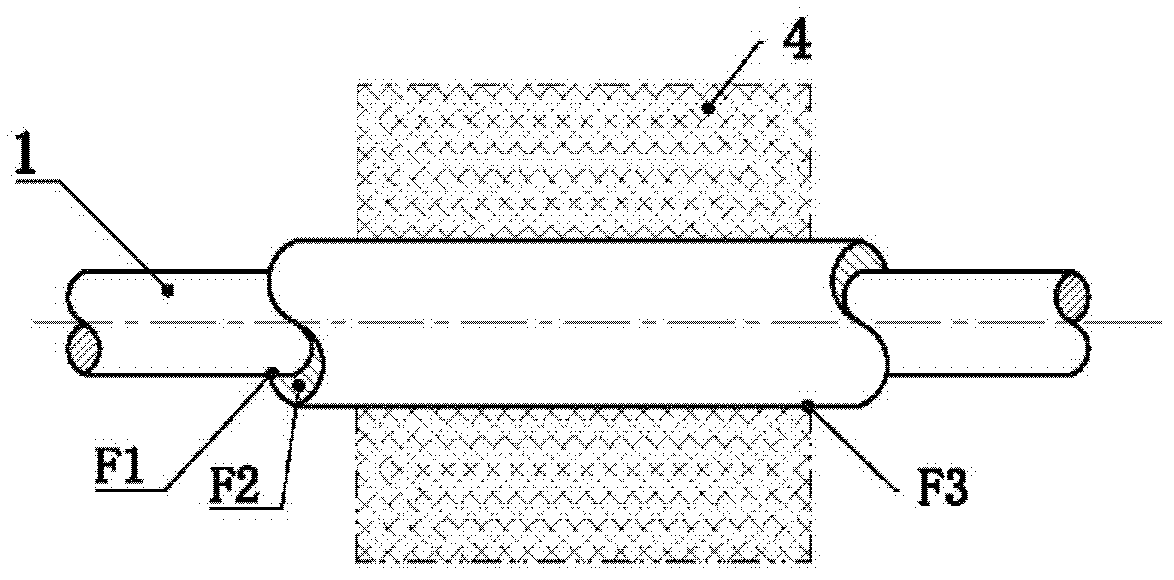

Wetting pilot strip-shaped brazing filler metal and preparation method thereof

InactiveCN106181106AHigh tin contentPrecise control of tin contentWelding/cutting media/materialsSoldering mediaAlloyFiller metal

The invention discloses wetting pilot strip-shaped brazing filler metal. The wetting pilot strip-shaped brazing filler metal comprises a brazing filler metal alloy inner core. A tin layer and a coating brazing flux layer sequentially wrap the brazing filler metal alloy inner core. The cross section of the formed strip-shaped brazing filler metal is in a circular or polygonal shape. The diameter of the brazing filler metal alloy inner core is determined according to the size of a brazing filler metal filling seam, the thickness of the tin layer is determined according to the brazing filler metal seam filling ability, and the thickness of the coating brazing flux layer is determined according to the difficulty of removing an oxidation film from the surface of a workpiece. During preparation, firstly, a brazing filler metal alloy is machined to be in the shape of a wire with the diameter meeting the requirement; after deoiling and acid pickling are conducted, the wire-shaped brazing filler metal alloy is placed in a tinning machine to be subjected to hot-dipping wire plating and then prepared to be in a strip shape after being straightened and cut off; and then, the surface of the tin layer is coated with a brazing flux in a press smearing manner, and a finished product of the pilot strip-shaped brazing filler metal is formed. A preparation method is simple, the tin content can be accurately controlled, and compared with traditional brazing filler metal, the wetting and seam filling performance of the brazing filler metal is greatly improved.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

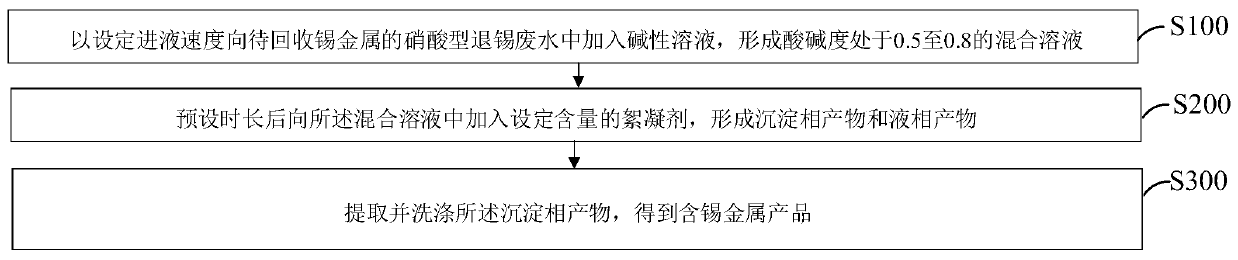

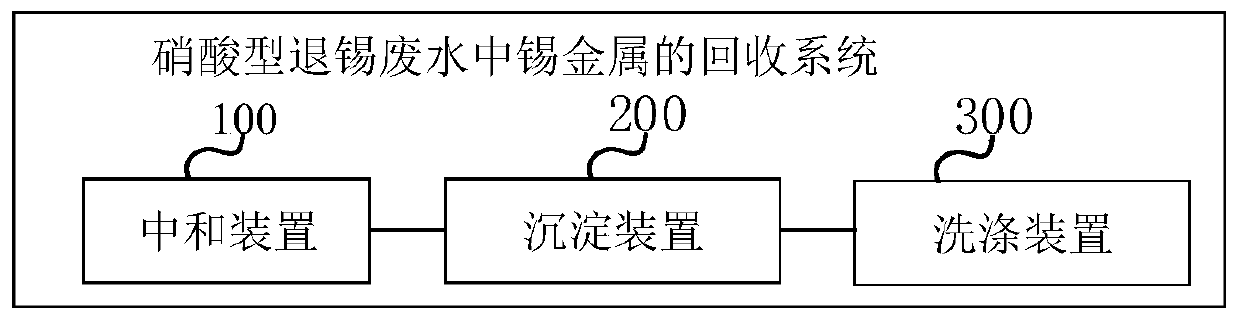

Recycling method and system for tin metal in nitric acid type tin returning waste water

ActiveCN110241308AShort processing cycleHigh tin contentWater contaminantsMultistage water/sewage treatmentRecovery methodLiquid waste

The invention provides a recycling method and system for tin metal in nitric acid type tin returning waste water. Through combination of a neutralizing method and a flocculence method, the system pH value is controlled within a certain range, then, metal ions are deposited through adding of a macromolecule flocculant, and the tin content in tin hydroxide products can be higher than 50%. Compared with the situation that only one method is adopted for conducting the tin returning waste liquid tin recycling treatment process, the usage amount of a needed alkaline solution and the usage amount of the needed flocculant are greatly reduced, the alkaline solution usage amount is about 1 / 2 of the traditional alkaline solution usage amount, and the flocculant usage amount is about 1 / 3 of the traditional flocculant usage amount.

Owner:无锡市安盛再生资源有限公司 +1

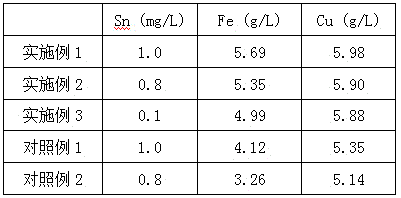

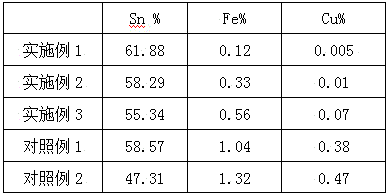

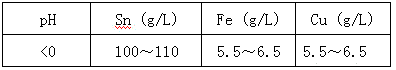

Recycling method of circuit board solder stripping waste liquid

ActiveCN105460972AReduce dosageLower pHTin compoundsAlkali metal nitrate preparationResource recoveryPhysical chemistry

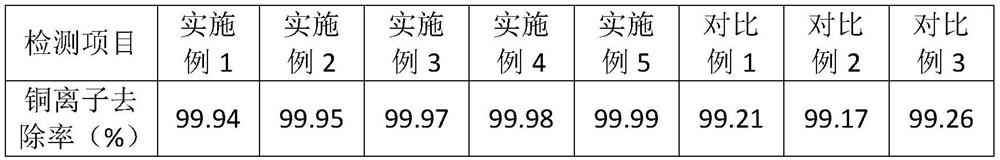

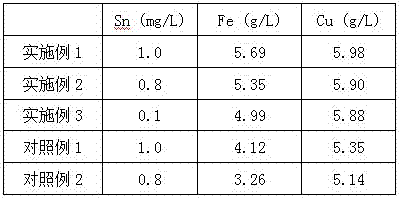

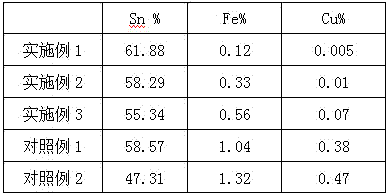

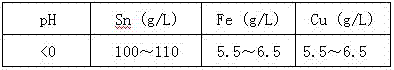

The invention relates to a recycling method of a circuit board solder stripping waste liquid, which comprises the following steps: S1: dropwisely adding an alkaline solution with the hydroxy molar concentration of 0.25-6.00 mol / L into the circuit board solder stripping waste liquid to regulate the pH value of the system to 0.5-1.0, and carrying out solid-liquid separation to obtain precipitated tin; S2: continuing adding the alkaline solution into the filtrate obtained in the step S1 to regulate the pH value of the system to 1.5-4.0, and carrying out solid-liquid separation to obtain precipitated iron; and S3: continuing adding the alkaline solution into the filtrate obtained in the step S2 to regulate the pH value of the system to 6.0-8.0, and carrying out solid-liquid separation to obtain precipitated copper. The method provided by the invention implements step-by-step recycling on heavy metals in the solder stripping waste liquid, and implements zero discharge of the heavy metal waste liquid. The method provided by the invention is more environment-friendly, and has higher popularization and application value.

Owner:GUANGZHOU KECHENG ENVIRONMENTAL PROTECTION TECH

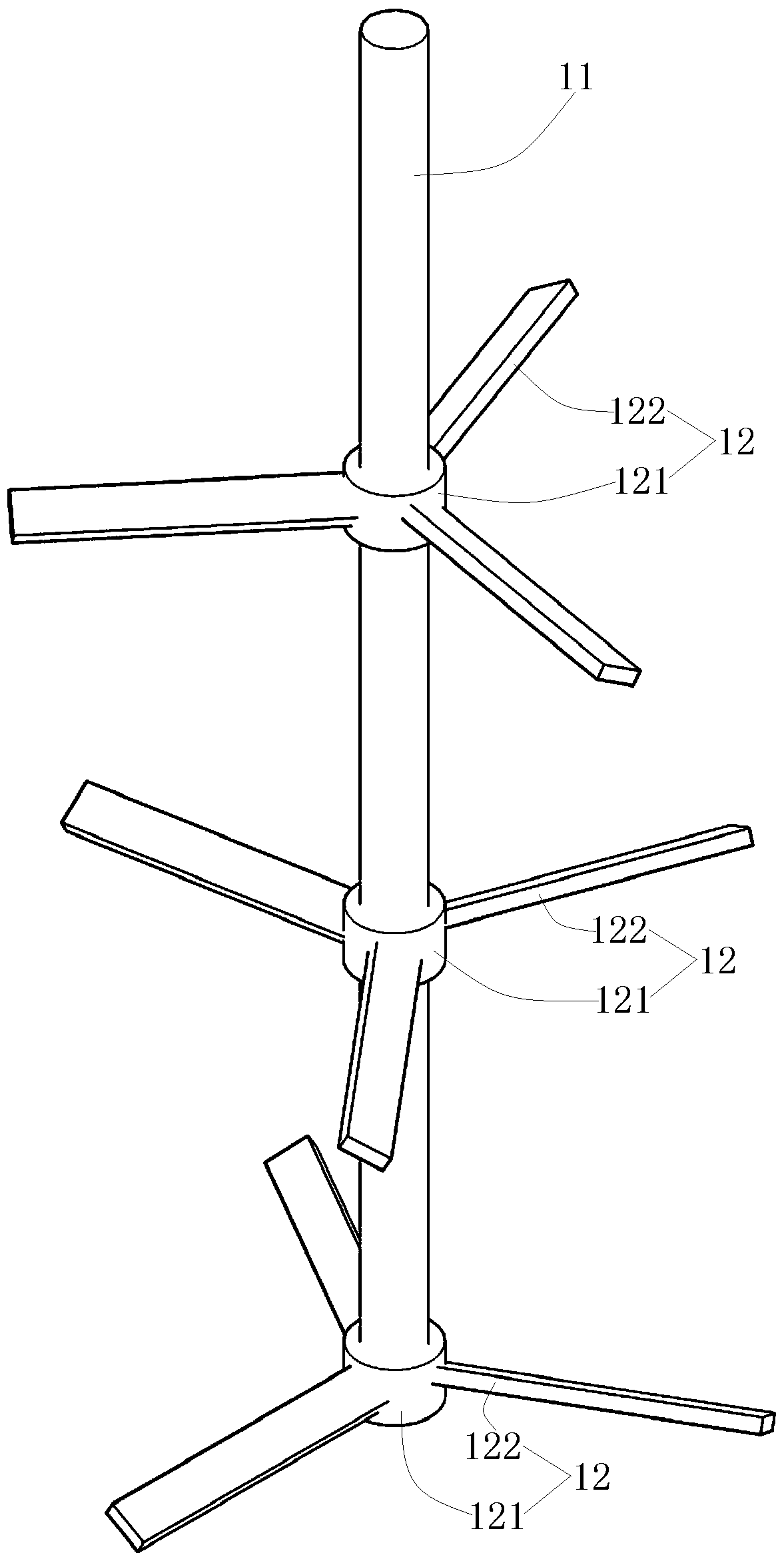

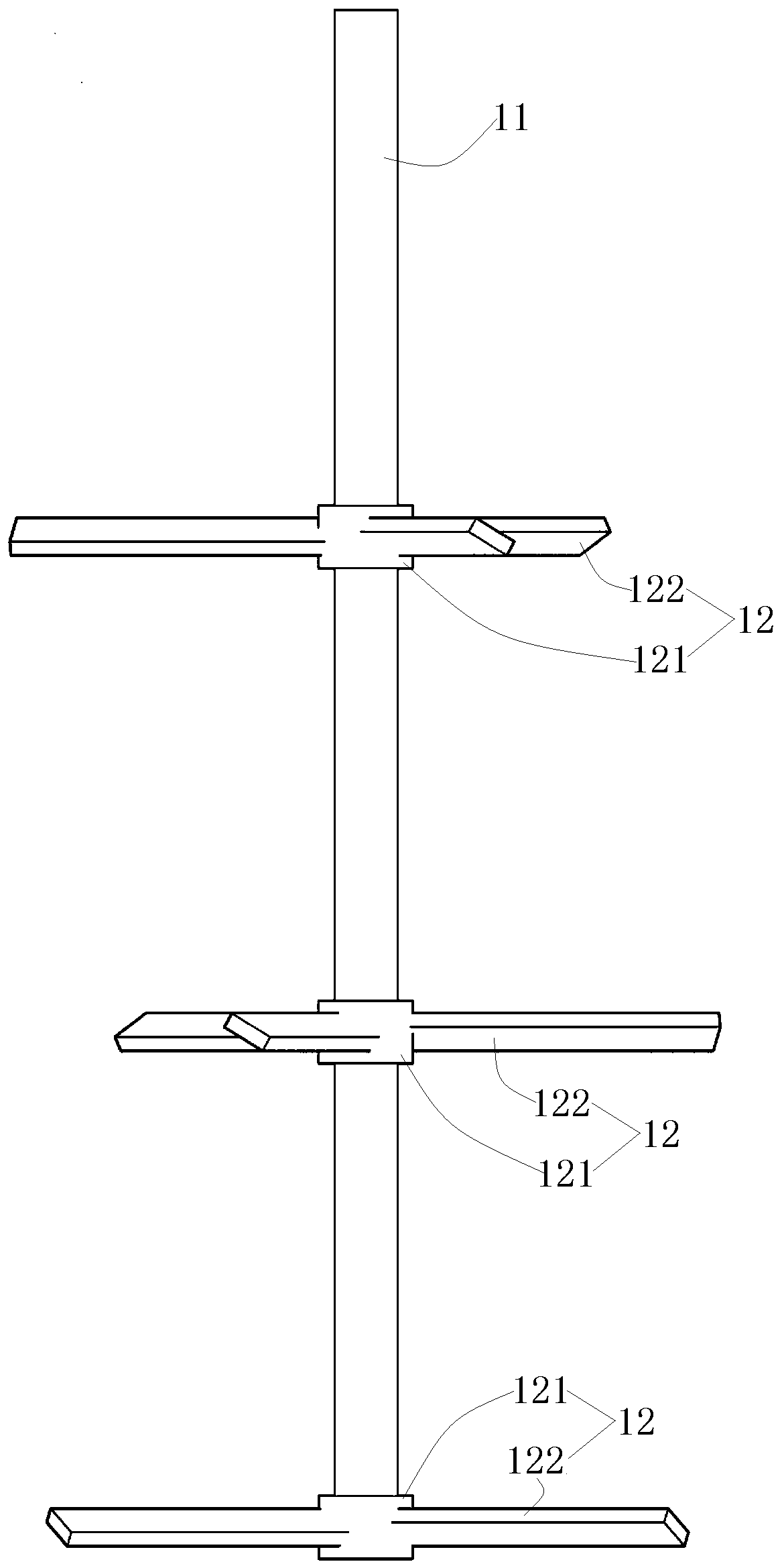

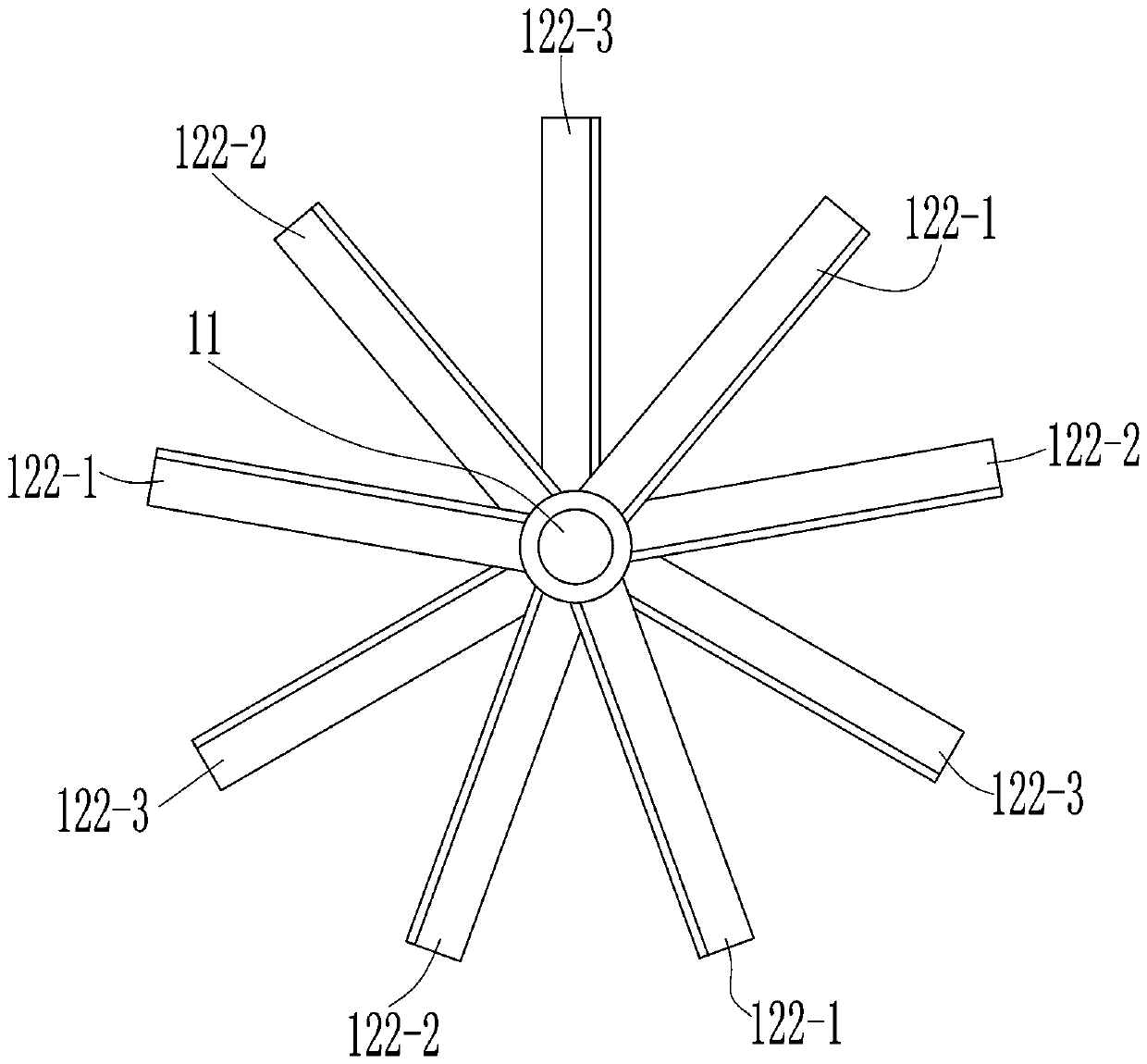

Stirring device

PendingCN107670522AStir wellHigh tin contentTransportation and packagingRotary stirring mixersVertical projectionWastewater

The invention relates to a stirring device. The stirring device comprises a main shaft and at least two stirring paddles. The stirring paddle comprises a cylindrical part provided with a central through hole and three blades. The three blades are uniformly fixed to the outer circumferential surface of the cylindrical part. The stirring paddles respectively pass through the central through holes ofthe cylindrical parts and are fixed to the main shaft. The two adjacent stirring paddles are arranged on the main shaft at a certain interval. The overlooking projections (vertical projections) of the three blades of the stirring paddle along the main shaft central axis are not coincident. The stirring device can fully stir de-tinning waste water materials in a reactor, improves product tin content and production efficiency and has the advantages of simple structure, high production efficiency and good quality.

Owner:深圳市宝安东江环保技术有限公司 +1

High-strength tin-plated bronze tire bead steel wire and preparation method thereof

InactiveCN102517581AProtect against rustImprove adhesionLiquid/solution decomposition chemical coatingSuperimposed coating processTinningCentrifugation

The invention discloses a high-strength tin-plated bronze tire bead steel wire which comprises a steel wire base body. The surface of the steel wire base body is provided with at least two plating layers, tin content of the plating layers is reduced layer by layer from inside to outside, tin content of the plating layer closely attached to the surface of the steel wire base body is high, the adhesive force between the plating layer and the steel wire base body is high, and the plating layer which is high in tin content can effectively prevent the steel wire base body from being rusted. The plating layers with the tin content gradually reduced from inside to outside are closely combined with each other, and a high adhesive force exists between the outermost plating layer with the relatively lowest tin content and tire rubber. Accordingly, the tire bead steel wire in the technical scheme can guarantee that the steel wire base body in the plating layers is not rusted, the high adhesive force between the tire bead steel wire and the tire rubber can be guaranteed, a tire can bear acting force such as high-strength stretching, compression, twisting and centrifugation during the automobile running process, and safety of automobile running is guaranteed.

Owner:SHANDONG DAYE

Hard disk drive spindle motor component of composite coating and composite coating method thereof

ActiveCN101114775AIncrease contentImprove bindingMagnetic circuit rotating partsReflex reflectorsHard disc driveMagnetic storage

The invention discloses a hard disk drive main shaft motor part with a composite coating and a method of the composite coating, which belongs to the technical field of motor parts with surface coating. The hard disk drive main shaft motor part comprises a motor part body and the composite coating which is coated on the motor part body, wherein, the composite coating consists of an inner electrophoretic coating and an outer spraying coating. The composite coating method of the invention comprises that: the motor part body is coated with the electrophoretic coating, and then the spraying coating is coated on the electrophoretic coating. Because of the increase of the tin content in the electrophoretic coating in the invention, the purity requirement for the electrophoretic coating is lowered, and no harm is generated to a magnetic storage media. Also, the composite coating of the invention can eliminate the naked hanging points at the surface of the motor parts and completely cover the motor part, thus having good integral anticorrosion property.

Owner:CHENGDU GALAXY MAGNETAB

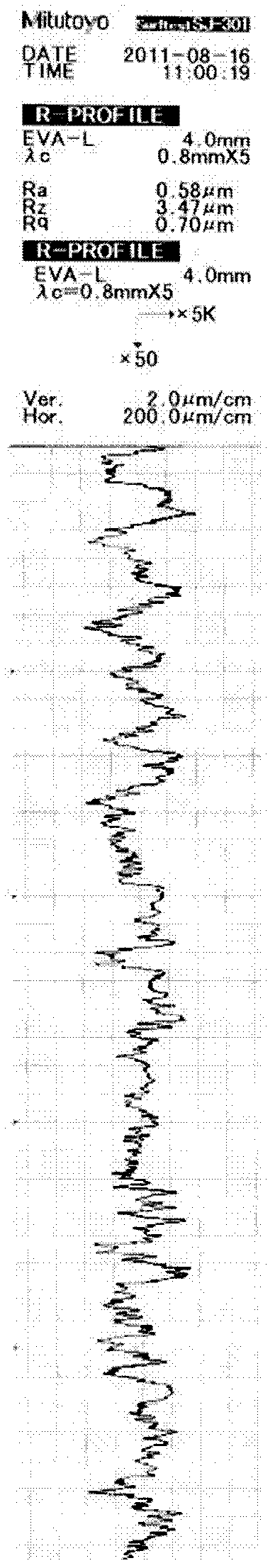

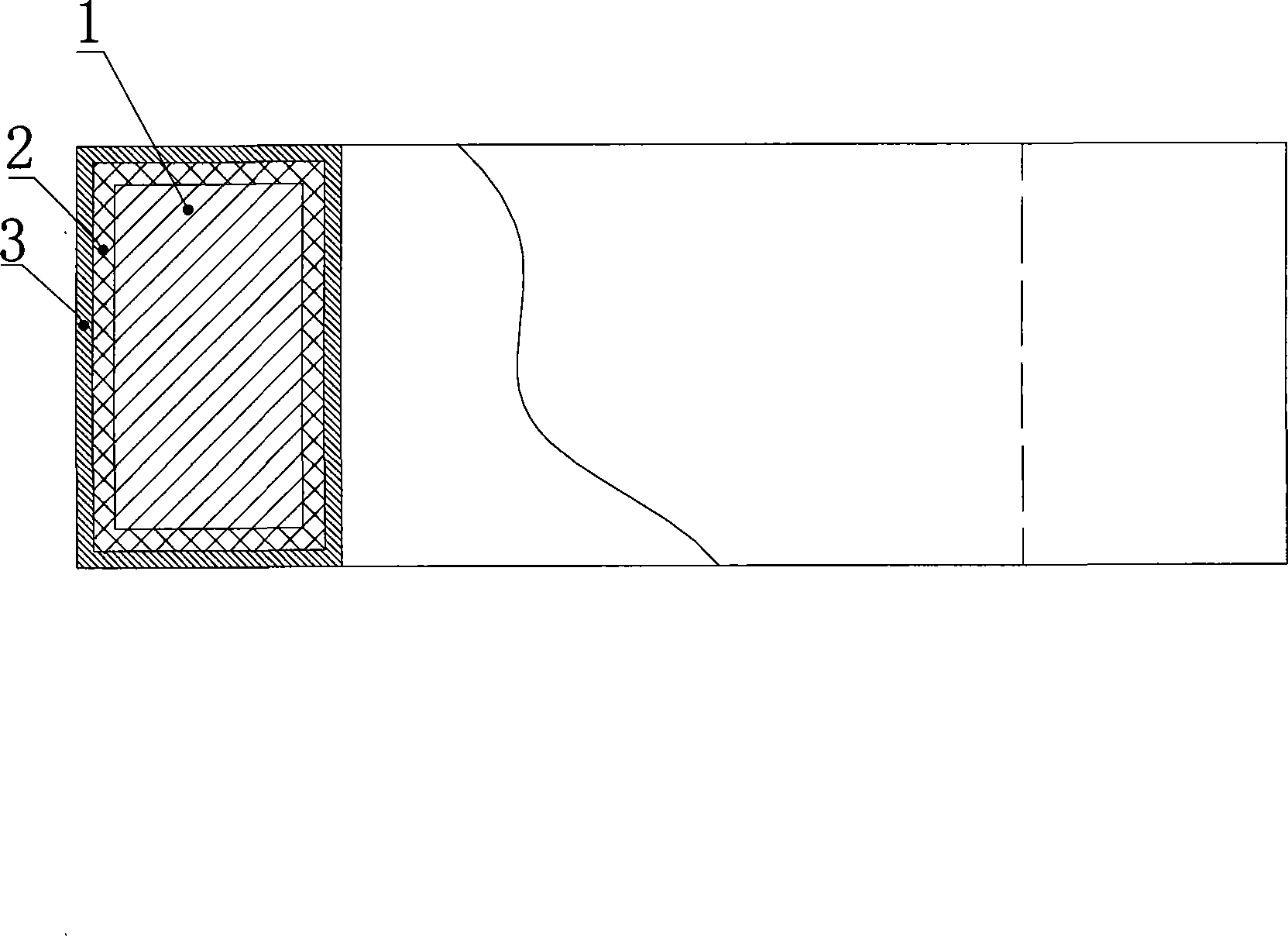

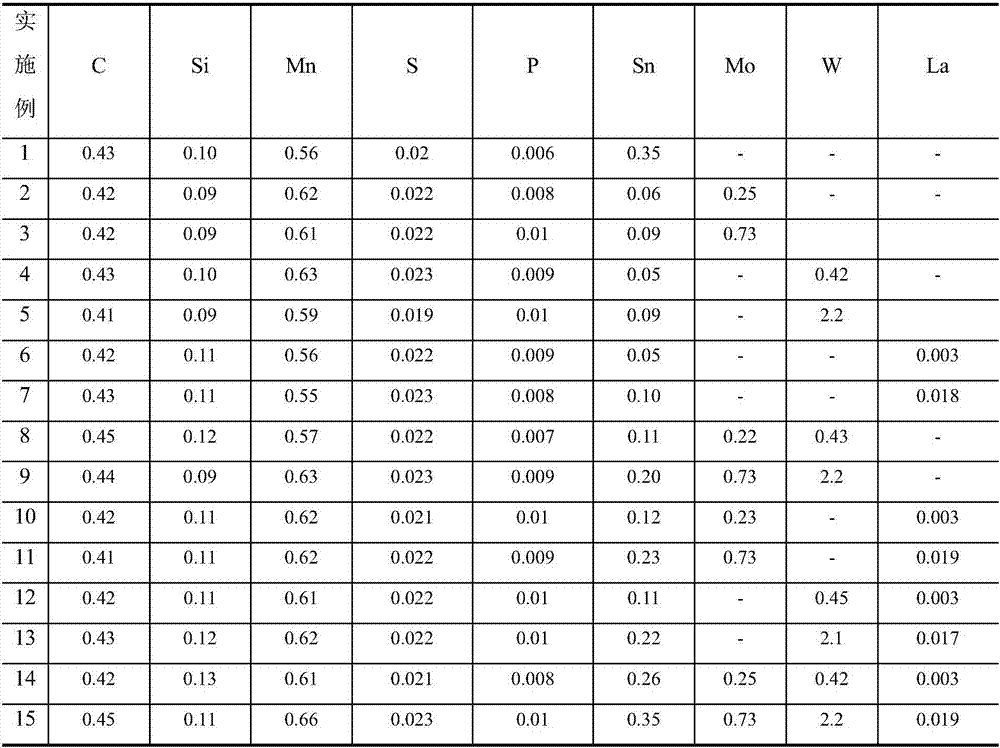

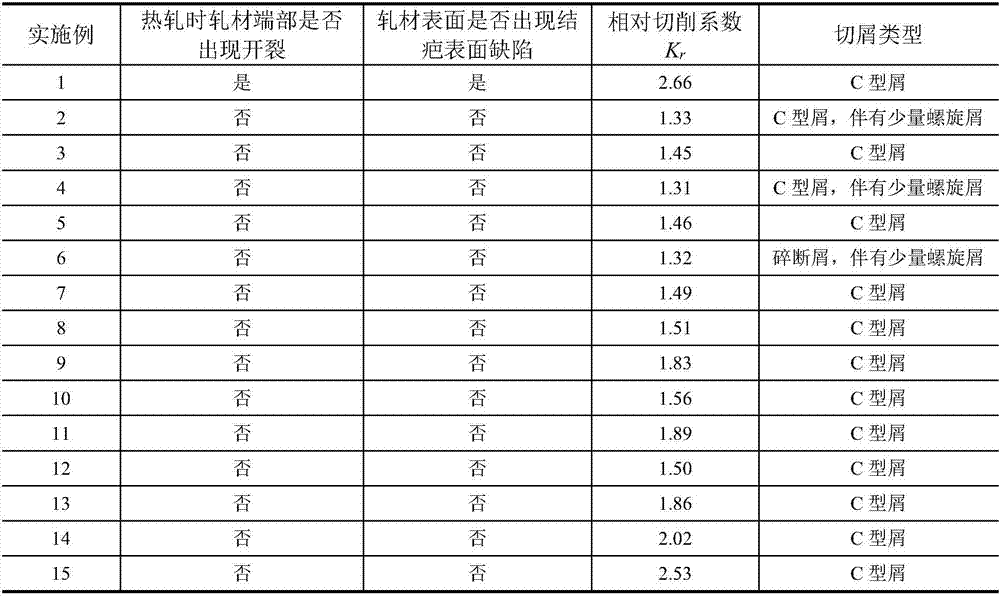

Free-cutting steel containing relatively high content tin and preparation method

Owner:UNIV OF SCI & TECH BEIJING

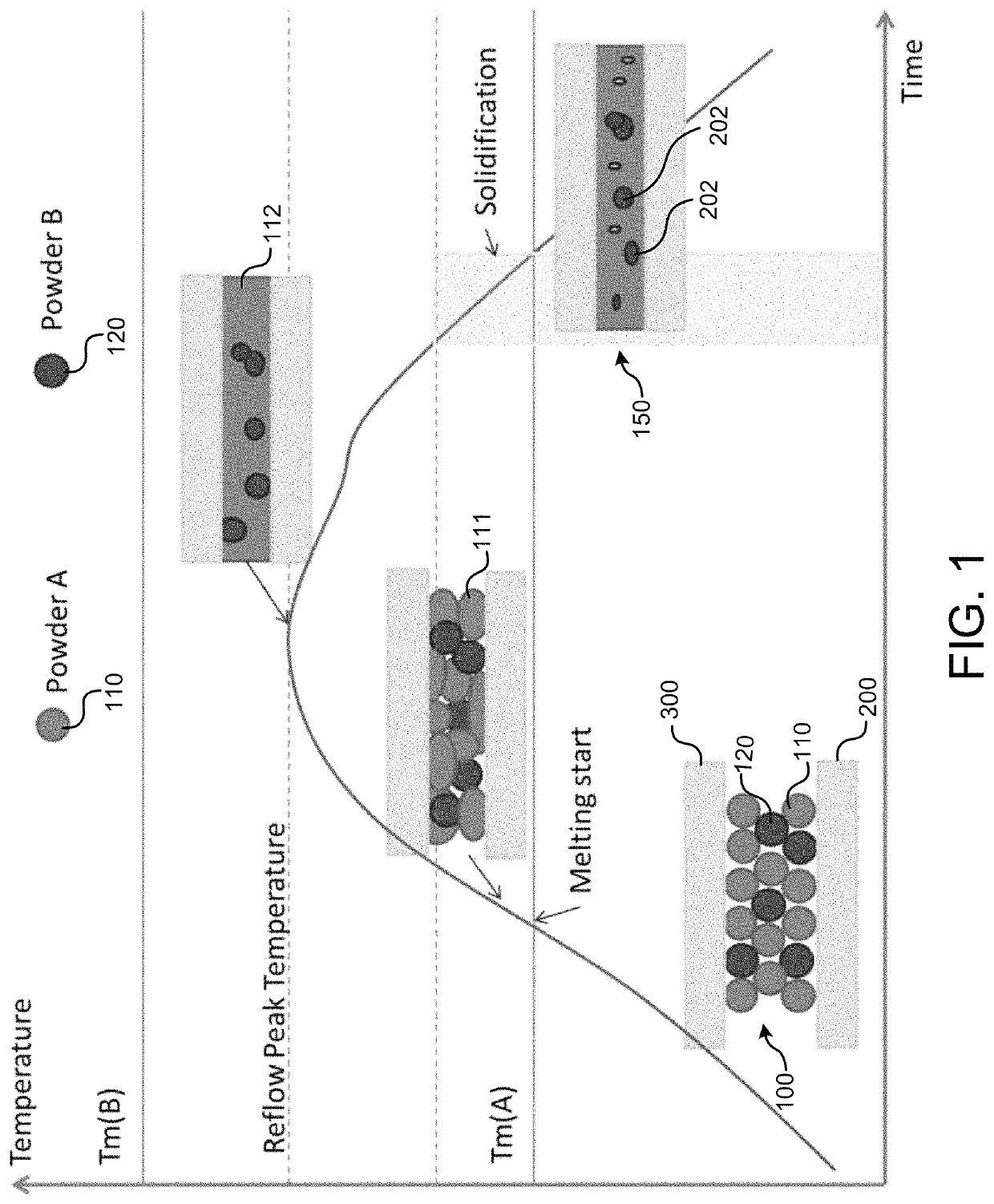

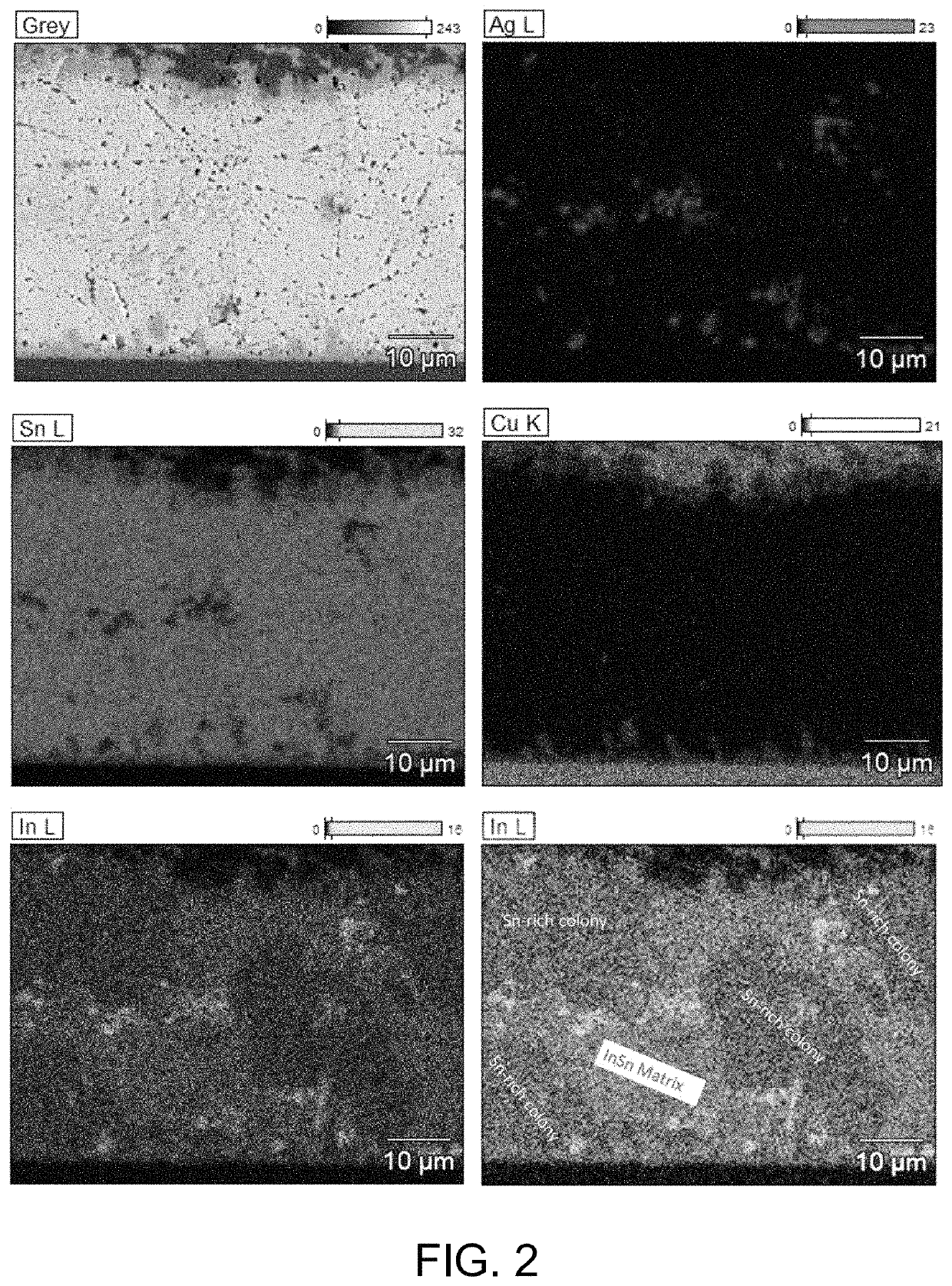

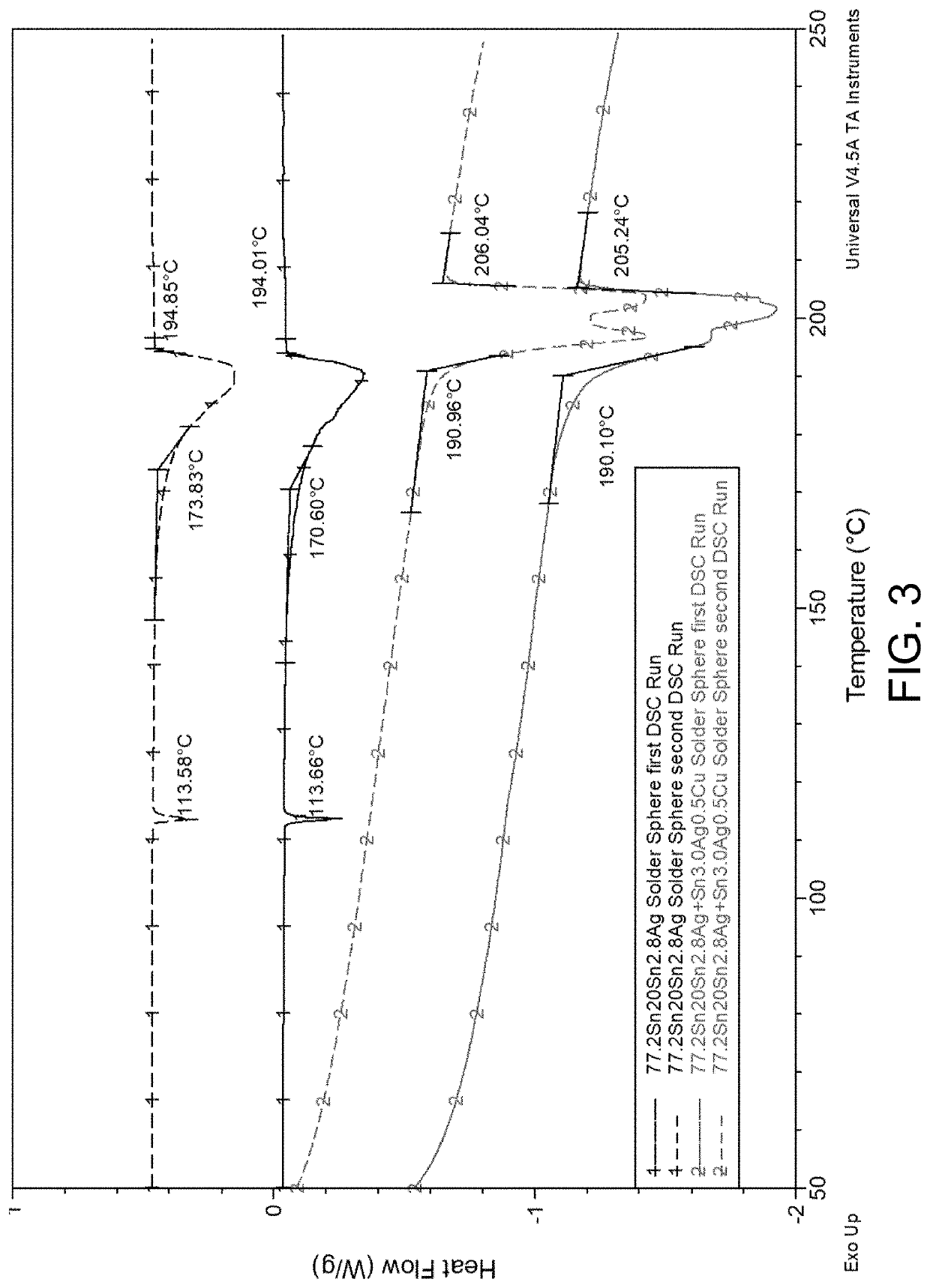

Low temperature melting and mid temperature melting lead-free solder paste with mixed solder alloy powders

ActiveUS11267080B2Increase contentHigh tin contentPrinted circuit aspectsPrinted circuit manufactureSolder pasteLiquidus

Implementations of the disclosure are directed to a lead-free mixed solder powder paste suitable for low temperature to middle temperature soldering applications. The lead-free solder paste may consist of: an amount of a first solder alloy powder between 44 wt % and 83 wt %, the first solder alloy powder comprising Sn; an amount of a second solder alloy powder between 5 wt % to 44 wt %, the second alloy powder comprising Sn, where the first solder alloy powder has a liquidus temperature lower than a solidus temperature of the second solder alloy powder; and a remainder of flux. The solder paste may be used for reflow at a peak temperature below the solidus temperature of the higher solidus temperature solder powder but above the melting temperature of the lower solidus temperature one.

Owner:INDIUM CORP

Preparation method of tin oxide fiber precursor and tin oxide crystal fibers

ActiveCN103556303BUniform diameterSoft lusterInorganic material artificial filamentsTin oxidesFiberLongest Diameter

Owner:SHANDONG UNIV

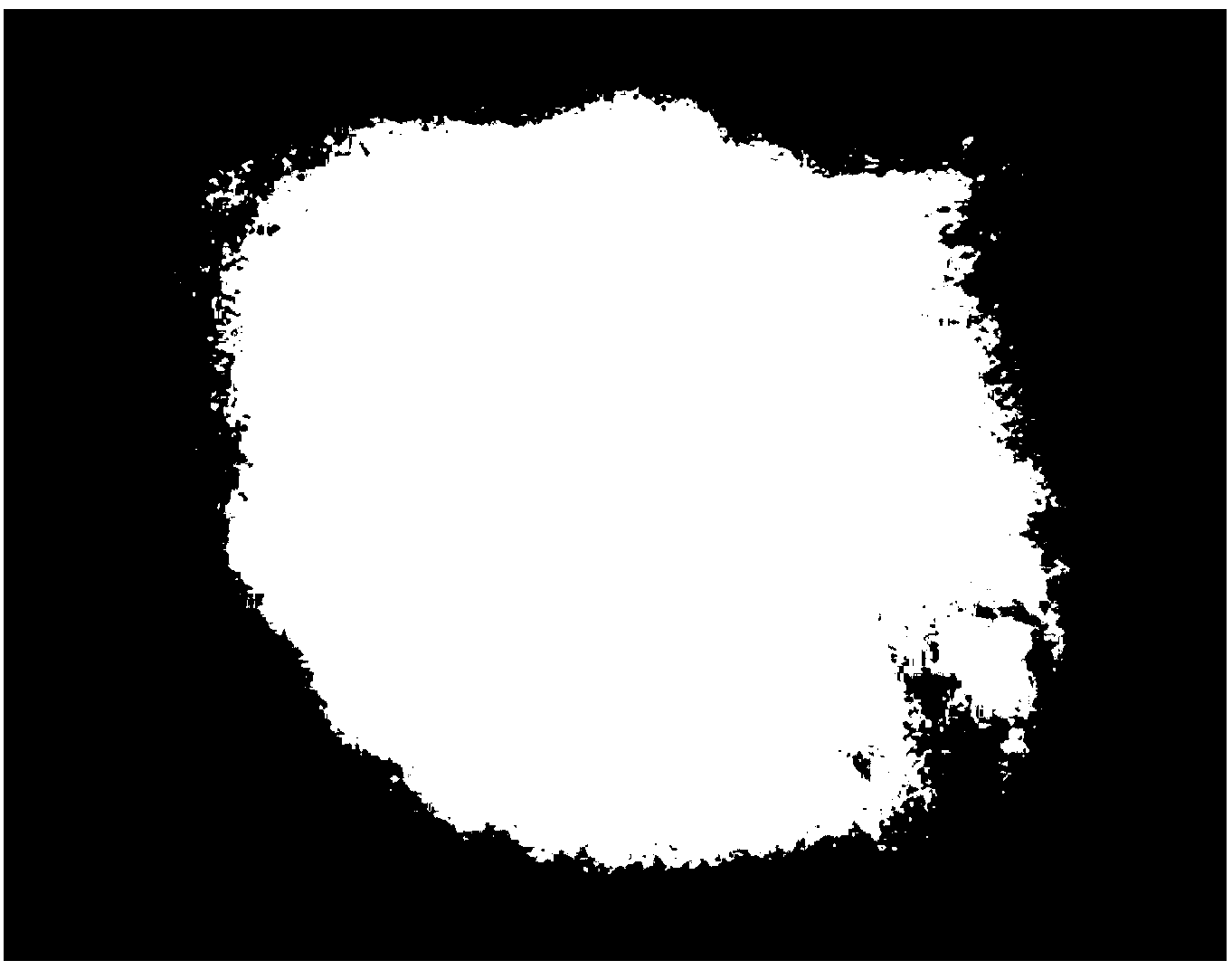

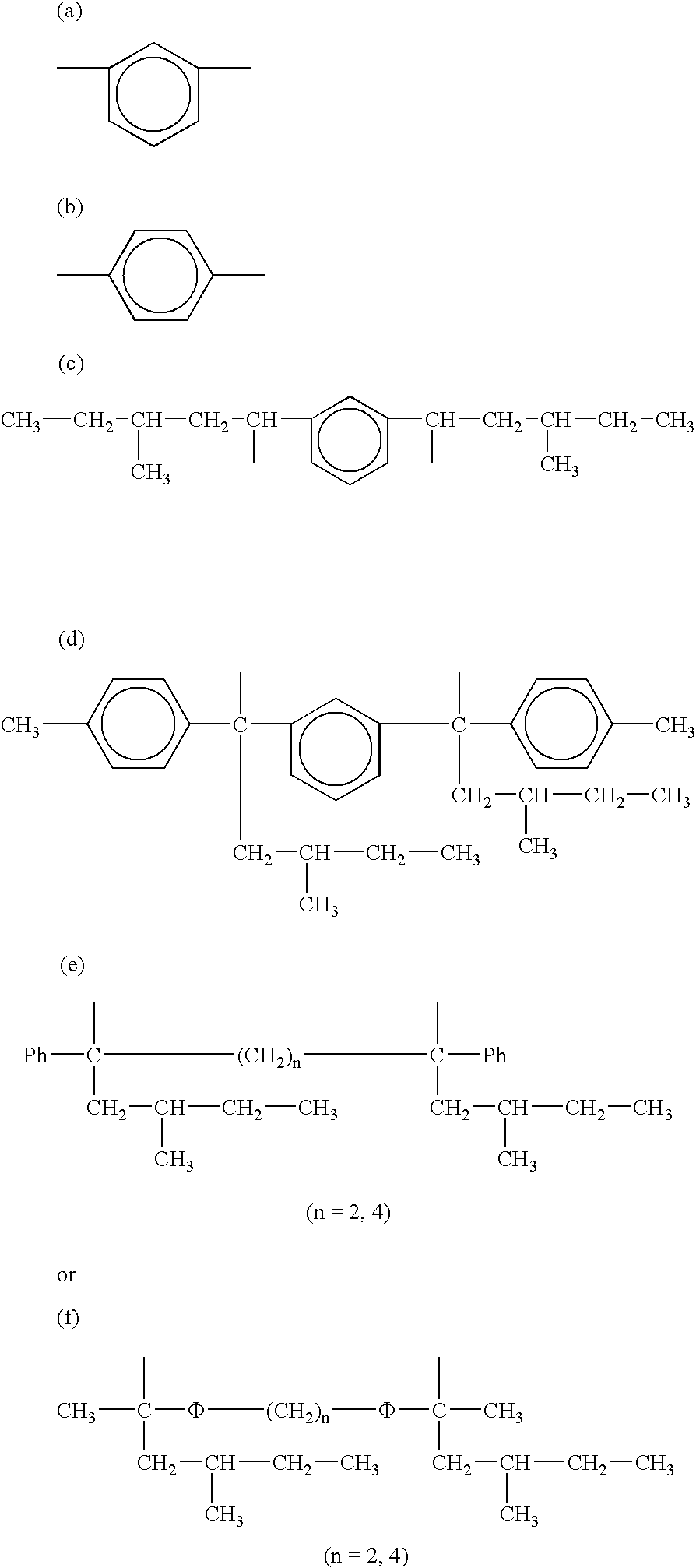

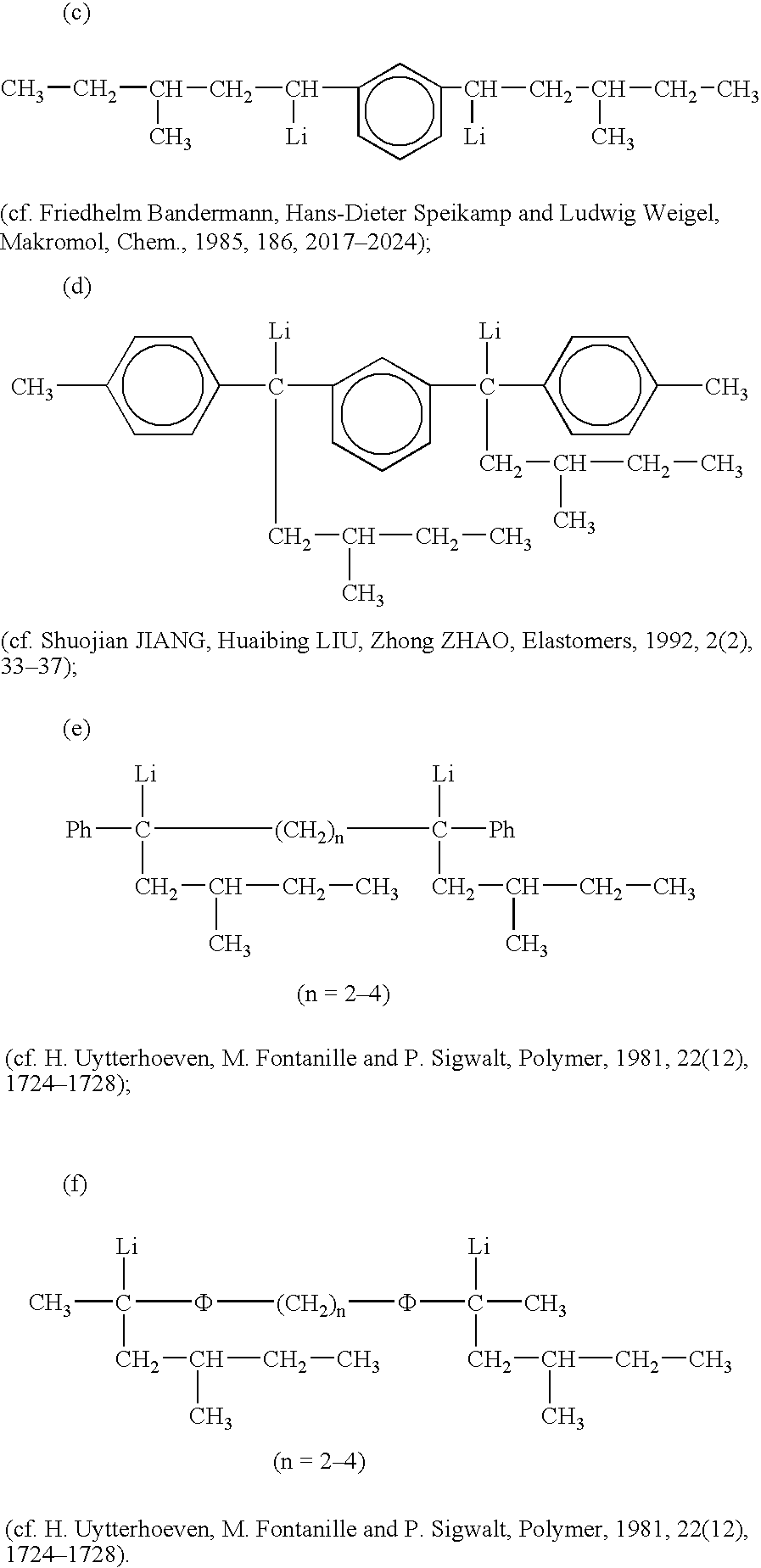

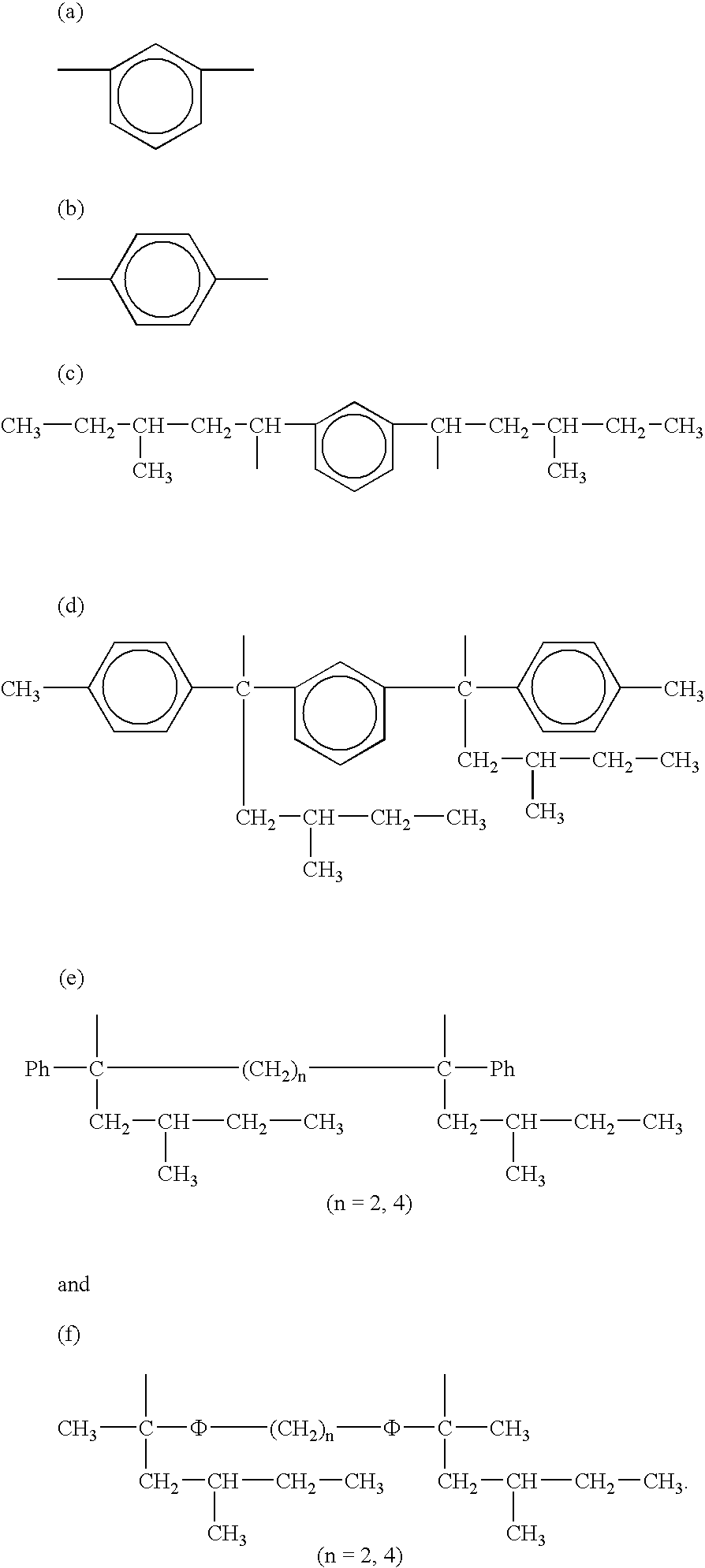

Tin-containing organolithium compounds and preparation thereof

InactiveUS6787661B2Good solubilityReduce hysteresisTin organic compoundsLithium organic compoundsLithium compoundConjugated diene

The present invention relates to a tin-containing organolithium compound which can be used as anionic polymerization initiators, represented by the following formula (1): Wherein R, Z and Y are defined as in the specification; x represents a value of 1 or 2; m represents a value of 0 or 1; a represents a value of 0 to 6, b represents a value of 0 to 6, a+b is from 0 to 6, provided that m=1 when x=1. The tin-containing organolithium compounds according to the present invention can be used as initiators to initiate the polymerization of conjugated dienes and / or monovinyl aromatic hydrocarbons, thereby synthesizing various linear, star or telechelic polymers. The present invention also relates to a method for preparing the tin-containing organolithium compounds according to the present invention.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparing method for brazing filler metal high in tin content

InactiveCN106271182AHigh tin contentUniform shapeWelding/cutting media/materialsSoldering mediaCopperFiller metal

The invention discloses a preparing method for brazing filler metal high in tin content. A tin belt with a certain thickness and a brazing filler metal alloy belt with a certain thickness are put into a precise rolling mill together to be subjected to compound rolling, the tin belt is extended, and a tin layer with the uniform thickness is formed on the surface of a brazing filler metal alloy layer, wherein the thickness of the brazing filler metal alloy layer ranges from 0.01 mm to 20 mm, and the thickness of the tin layer ranges from 0.01 mm to 20 mm. The size of the diameter of an inner core of a brazing filler metal alloy is determined according to the size of a filling joint of brazing filler metal, the thickness of the tin layer is determined according to the joint filling property of the brazing filler metal, and the thickness of a coating brazing flux layer is determined according to the difficulty level of removing an oxidization film from the surface of a workpiece. The preparing method is simple, energy conservation and environment friendliness are achieved, the tin content of the prepared brazing filler metal is high, and the thickness of the tin layer is uniform and consistent. Compared with silver-based or copper-based tin-containing brazing filler metal produced in a traditional method, the tin content is high and can be accurately controlled, the forming property is good, and the brazing filler metal can be wound to be in a disc shape or subjected to the next step of machining; and in the brazing process, the low-melting-point tin in the brazing filler metal is melted firstly, and the joint filling property is good.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

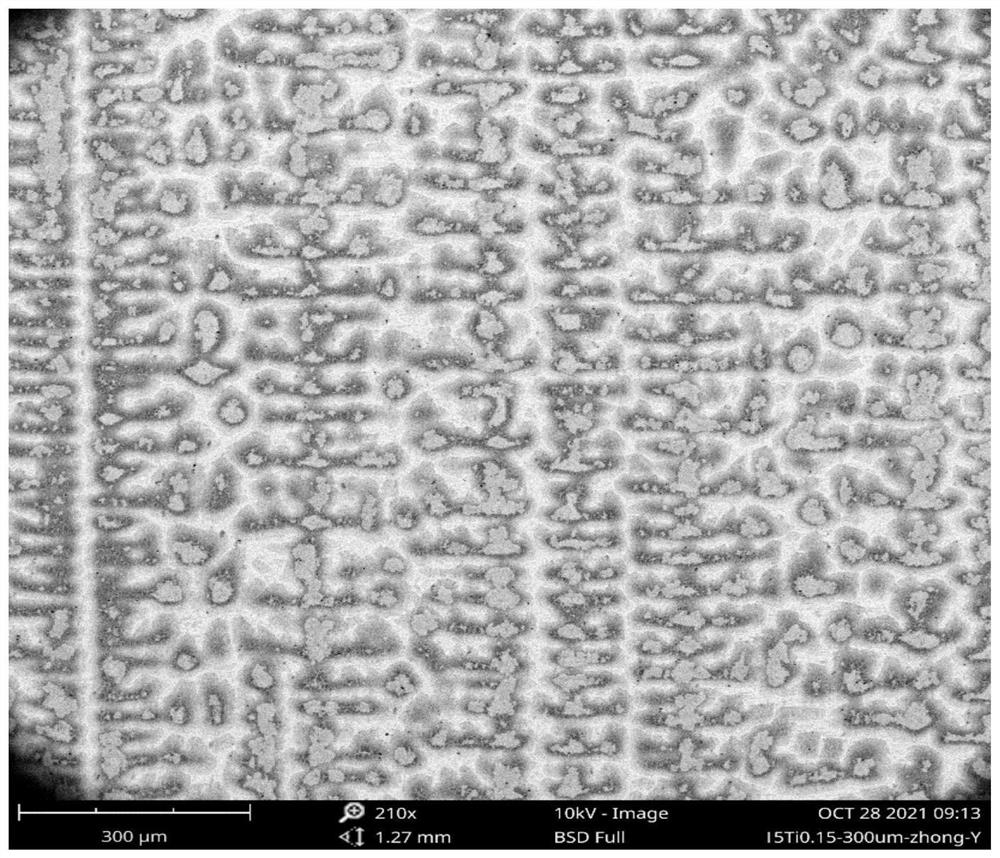

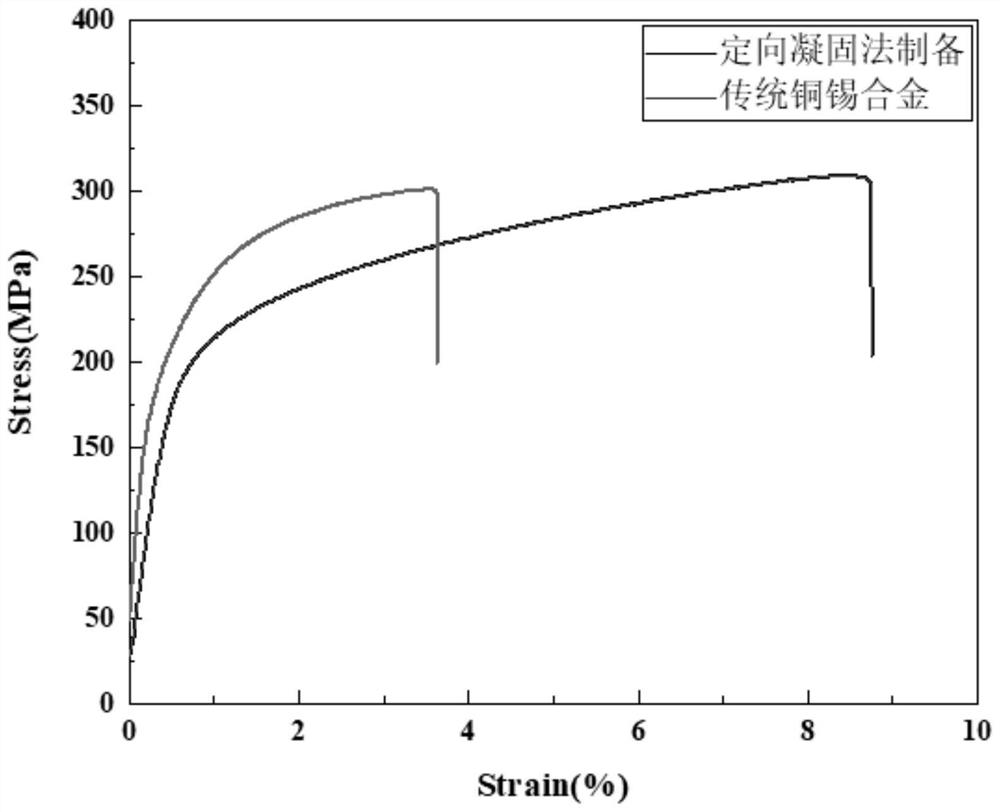

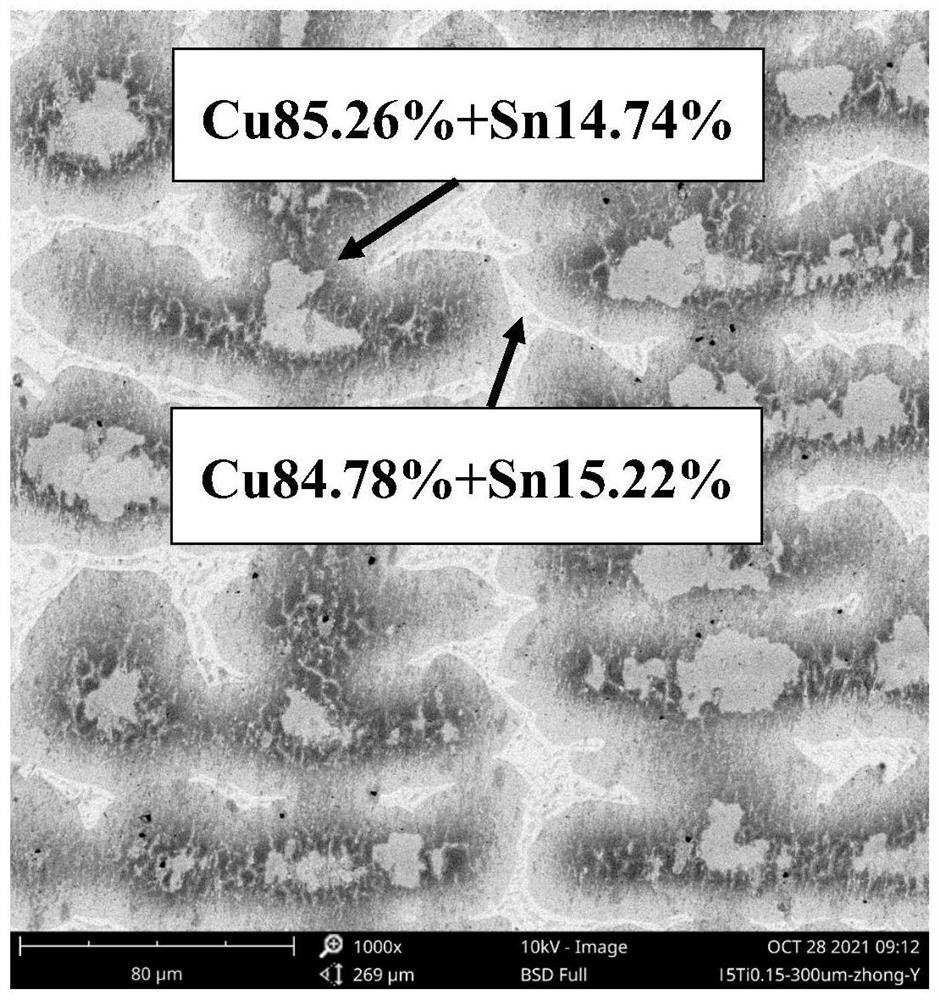

Directional solidification preparation method of high-tin-content and high-plasticity copper-tin alloy

The invention discloses a directional solidification preparation method of a high-tin-content and high-plasticity copper-tin alloy, which comprises the following steps of: 1, weighing a Cu block, Sn and Ti, and pretreating; 2, materials obtained in the step 1 are sequentially put into a magnesia crucible, Ti is put into a feeding hopper for standby application, and a furnace door of a directional solidification furnace is closed; 3, the furnace is vacuumized, then induction melting heating is adopted, molten copper-tin alloy is obtained, a trace titanium element is added into a melt, and heat preservation is conducted to achieve melt homogenization; 4, the molten metal is poured into a constant-temperature cylindrical graphite crucible below for drawing, and a directionally solidified copper-tin alloy cast ingot is obtained after drawing is finished; the problems of low tin solid solubility caused by solute segregation in the existing copper-tin alloy preparation process and poor material plasticity and toughness caused by high intermetallic compound content are solved, meanwhile, the alloy structure is improved, and fine orientation lt is obtained; 001gt, 001gt; and the growing crystal grains synchronously realize directional solidification preparation of the high-solid-solubility and high-plasticity copper-tin alloy.

Owner:XIAN UNIV OF TECH

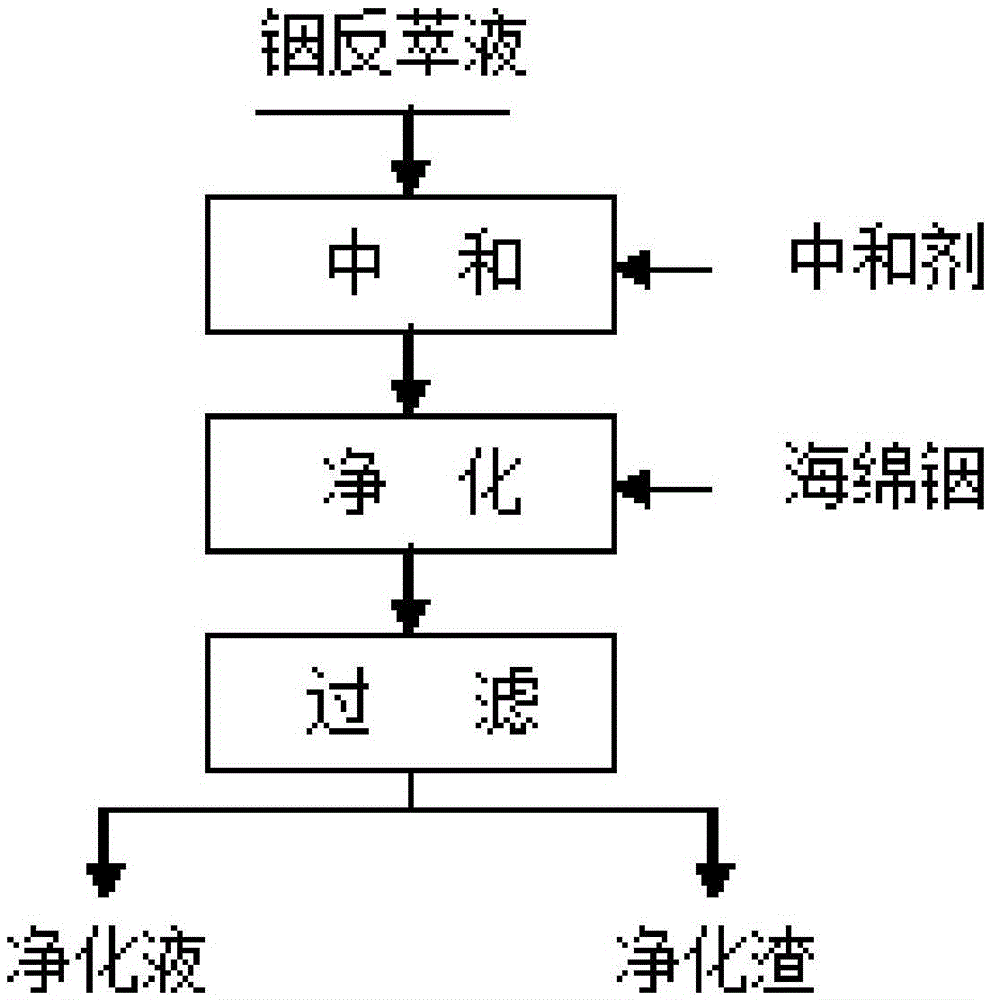

Method for refining indium reverse extraction liquid and gathering valuable metal and application

InactiveCN105483377AReduce acidityRegular replacement went wellProcess efficiency improvementIndiumElectrolysis

The invention provides a method for refining indium reverse extraction liquid and gathering valuable metal. The method for refining the indium reverse extraction liquid and gathering the valuable metal includes the steps that A, a neutralizing agent is added to the indium reverse extraction liquid and stirred so as to be dissolved; B, a reducing agent is added to a neutralized solution, and AsO33-, Bi3+, Cu2+, Sn4+ and Sn2+ in the solution are reduced into As, Bi, Cu, Sn and other valuable metal; and C, filtration is performed, so that purified liquid and purified residues are obtained. By the adoption of the method for separating and gathering the valuable metal existing in the indium reverse extraction liquid in the form of the impurity element and refining the indium reverse extraction liquid, the impurities such as arsenic, copper, bismuth and tin in the indium reverse extraction liquid can be separated and gathered into the metal so as to be recycled conveniently, consumption of zinc sheets in a replacement process is reduced, and conditions are provided for one-time qualification of the precipitated indium impurity generated by following electrolysis refinement. Meanwhile, the method for refining the indium reverse extraction liquid and gathering the valuable metal is simple in process, convenient to operate and low in production cost.

Owner:ZHUZHOU SMELTER GRP

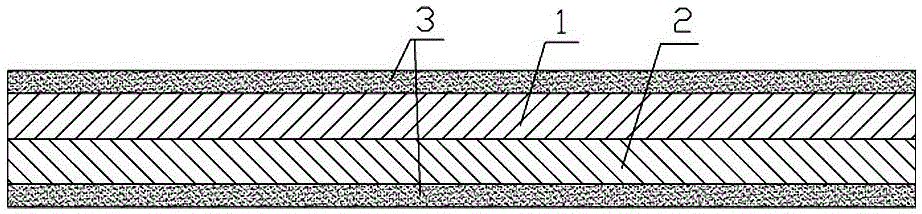

Wetting-piloted composite solder and preparation method thereof

InactiveCN106181124ABeautiful shapeHigh tin contentMolten spray coatingWelding/cutting media/materialsComposite solderMaterials science

The invention discloses wetting-piloted composite solder which comprises a tin layer and a solder alloy layer, which are compositely rolled, wherein soldering flux layers are sprayed and deposited on the outer surfaces of the tin layer and the solder alloy layer respectively to form a finished composite solder product with a four-layer structure; the thicknesses of the tin layer and the solder alloy layer can be adjusted within 0.01-20 mm according to the clearance filling property of the solder and the size of a clearance; and the thicknesses of the soldering flux layers are adjusted within 0.01-10 mm according to the level of difficulty in removing an oxide film of a workpiece. During preparation of the composite solder, a tin belt and a solder alloy belt are put into a precision rolling machine to be compositely rolled so that the uniform-thickness tin layer is formed on the surface of the solder alloy layer, and then the uniform thickness soldering flux layers are deposited on the outer surfaces of the tin layer and the solder alloy layer in a hot spraying way to form the finished composite solder product with the four-layer structure. A preparation method provided by the invention saves energy and protects the environment, the composite solder is high in tin content and uniform in thickness and beautiful in forming, and since the composite solder has soldering flux, automatic, accurate and quantified addition of the soldering flux is realized during soldering.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

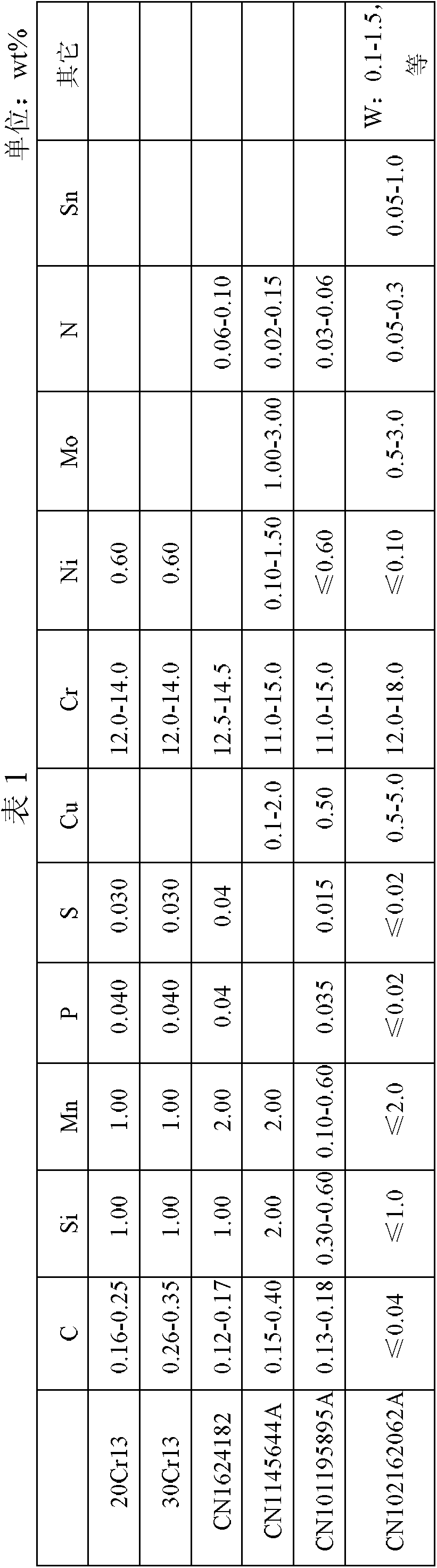

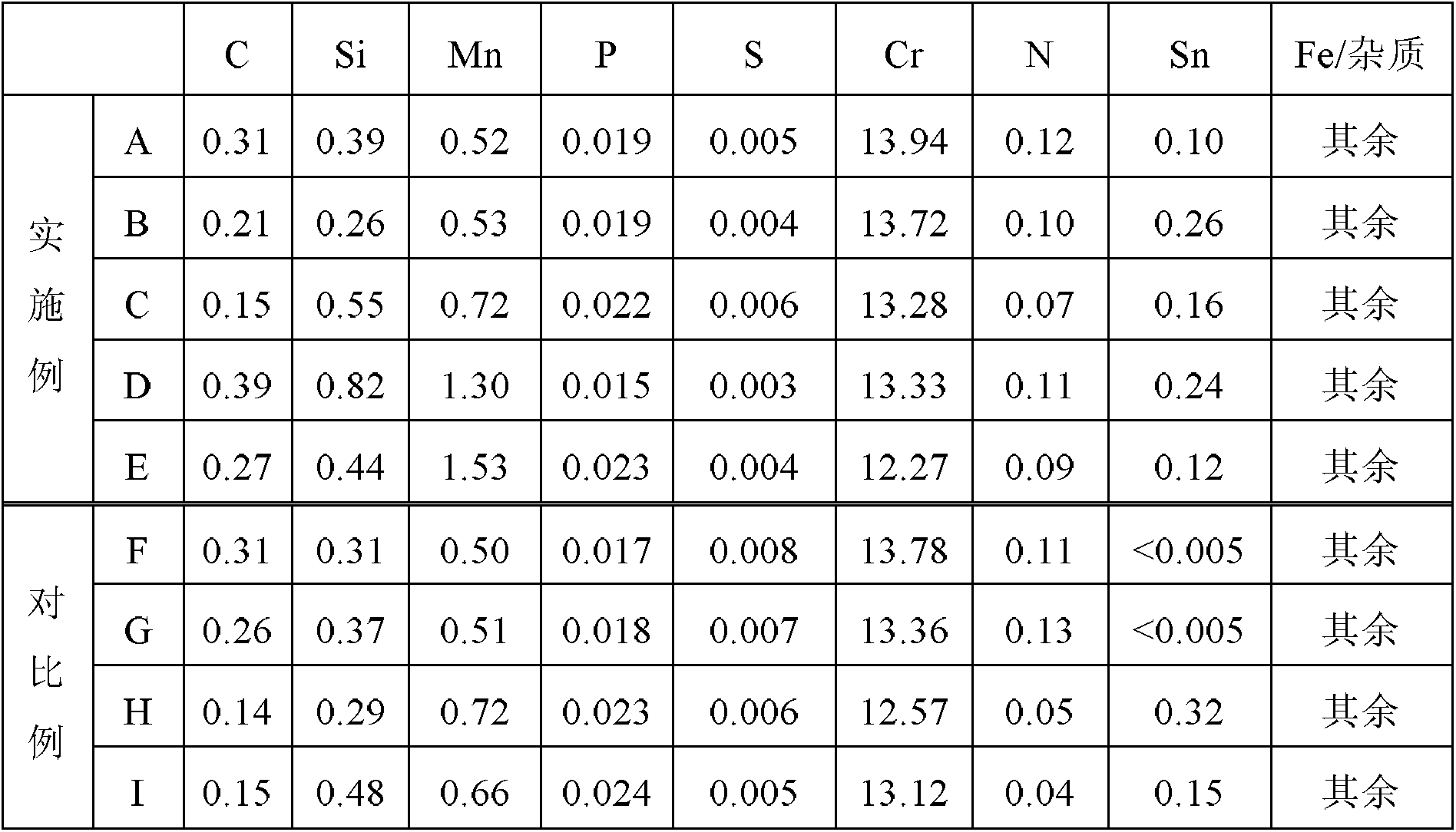

Stanniferous martensitic stainless steel with excellent performance and manufacturing method thereof

The invention discloses stanniferous martensitic stainless steel with excellent performance and a manufacturing method thereof. The steel comprises the following chemical components in percentage by weight: 0.15-0.40% of C, less than or equal to 1.0% of Si, less than or equal to 2.0% of Mn, less than or equal to 0.04% of P, less than or equal to 0.010% of S, 12.0-14.0% of Cr, 0.05-0.12% of N, 0.10-0.30% of Sn, and the balance of Fe and inevitable impurities. Tinned waste steel is added to control the content of Sn and then stanniferous martensitic stainless steel with excellent performance is melted. After being quenched at 1050 DEG C, the stanniferous martensitic stainless steel has the advantages that tensile strength of the steel is greater than or equal to 1500MPa, the Rockwell hardness is greater than or equal to 48HRC and the pitting potential is greater than or equal to 105mV. The steel has high strength and hardness as well as excellent corrosion resistance, and is suitable for manufacturing top-grade cutters, measuring implements and other parts requiring high hardness and corrosion resistance.

Owner:BAOSTEEL STAINLESS STEEL

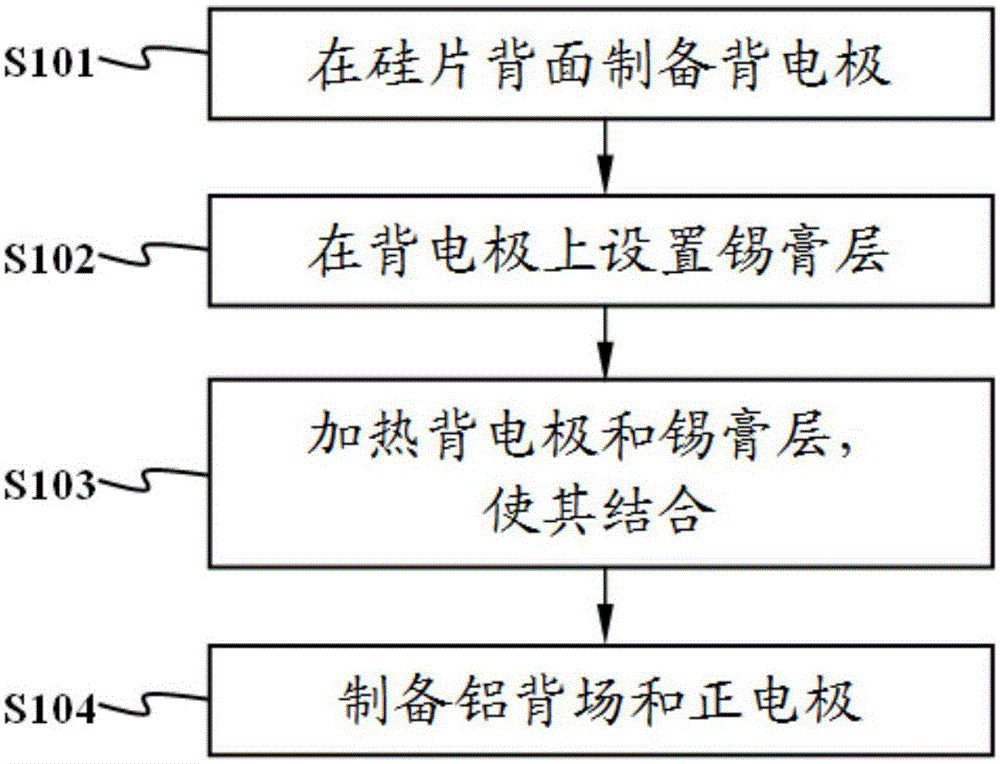

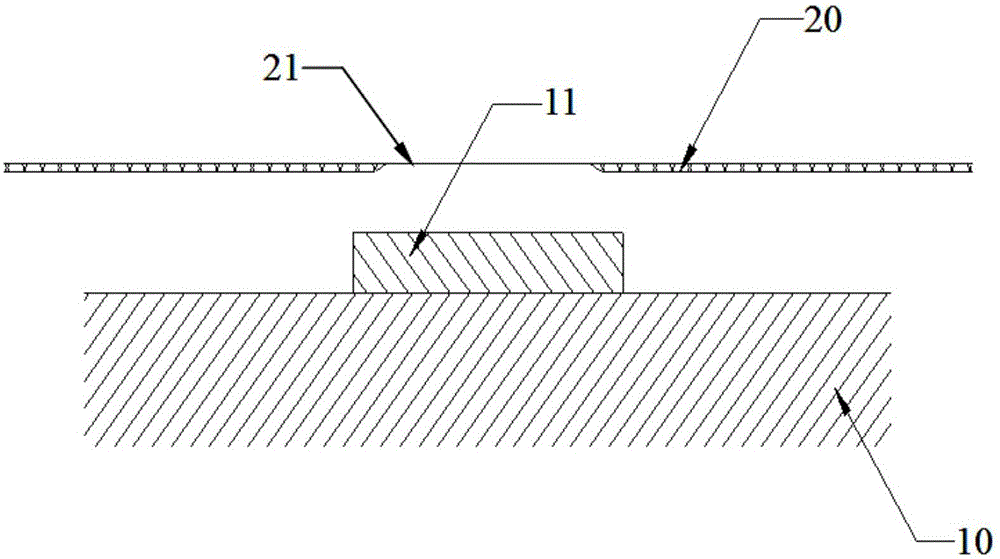

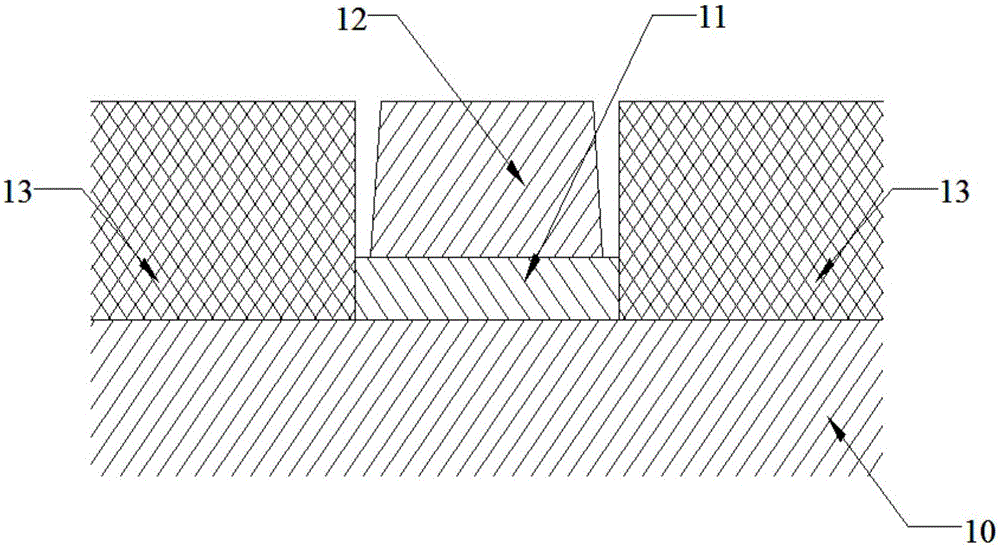

Solar battery cell and fabrication method thereof

InactiveCN106328725AImprove welding processHigh tin contentFinal product manufacturePhotovoltaic energy generationAluminiumHeight difference

The invention provides a solar battery cell and a fabrication method thereof. The fabrication method comprises the steps of fabricating a back electrode on a back surface of a silicon wafer; arranging a tin paste layer on the back electrode; heating the back electrode and the tin paste layer to make the back electrode and the tin paste layer combined; and fabricating an aluminum back field and a positive electrode. The tin paste layer is additionally arranged on the surface of the back electrode, thus, the height difference between the back electrode and the aluminum back field is greatly eliminated, the problem of unfavorable contact of a welding strip and the back electrode caused by the height difference is prevented, and the welding process of the back electrode and the welding strip is more convenient; and meanwhile, with the arrangement of the tin paste layer, the tin content between the welding strip and the back electrode is increased, and an infrared welding process of a fine welding strip can be improved.

Owner:CSI CELLS CO LTD +1

Cable sheathing of a Pb-Ca-Sn alloy and method of manufacture thereof

ActiveUS20200254498A1Rapid extrusionImprove mechanical propertiesClimate change adaptationSubmarine cablesManufacturing engineeringElectric cables

Owner:NEXANS

Method for recycling tin and copper from PCB (Printed Circuit Board) tin waste liquid in cyclic regeneration manner

PendingCN114317969AHigh tin contentHigh recycling valueRotary drum furnacesCrucible furnacesOXALIC ACID DIHYDRATEProcess engineering

The invention provides a method for recycling tin and copper from PCB (Printed Circuit Board) tin waste liquid in a cyclic regeneration manner, which comprises the following steps of: adding sulfuric acid and a filter aid into the PCB tin waste liquid to precipitate tin ions, and separating tin sulfate precipitate from supernate; adding the supernatant as a circulating separating agent into a new PCB tin waste liquid for precipitation separation of tin sulfate, and entering the next step until the copper content of the supernatant meets the requirement; oxalic acid and a filter aid are added into the supernate with the copper content reaching the standard, and copper ions are precipitated; and then the filtrate is subjected to regeneration liquid blending, and tin-stripping regeneration sub-liquid is obtained and returned to a production line for use. According to the method, metal ions tin and copper in the waste liquid can be selectively precipitated and separated, the tin content in the tin sludge and the copper content in the copper sludge are increased, the tin stripping liquid medicine can be regenerated and recycled, in the whole production process, no waste water is generated, the method is green and environmentally friendly, and the production cost is greatly reduced.

Owner:江西瑞亿电子科技有限公司

Preparation technique of dibutyl tin diacetate

InactiveCN104497036AGuaranteed overdoseGuaranteed responseTin organic compoundsAcetic acidBoiling point

The invention belongs to the technical field of catalyst preparation, and particularly relates to a preparation technique of dibutyl tin diacetate. The technique comprises the following steps: (1) weighing excessive glacial acetic acid for reaction, and adding into reaction kettle; (2) starting a stirring device, and adding dibutyl tin oxide while stirring; (3) heating to 60-80 DEG C, and keeping the temperature to react for 1-2 hours until the dibutyl tin oxide is completely dissolved; (4) vacuumizing, heating to 105 DEG C, stopping heating, and keeping the temperature for 20-30 minutes; (5) continuing heating to 110 DEG C, keeping the temperature, and vacuumizing for 2-3.5 hours until no low-boiling-point substance is distilled off; and (6) discharging, and weighing to obtain the required dibutyl tin diacetate. The technique has the advantages of complete reaction, low production cost and good product quality.

Owner:CHANGSHA LUOSI TECH

Treatment method for recycling tin, copper and waste gas from PCB (Printed Circuit Board) tin waste liquid in cyclic regeneration manner

PendingCN114277249AHigh tin contentHigh recycling valueDispersed particle separationOXALIC ACID DIHYDRATEProduction line

The invention provides a treatment method for recycling tin, copper and waste gas from PCB (Printed Circuit Board) tin waste liquid in a cyclic regeneration manner, which comprises the following steps of: adding sulfuric acid and a filter aid into the PCB tin waste liquid to precipitate tin ions, and separating tin sulfate precipitate from supernate; adding the supernatant as a circulating separating agent into a new PCB tin waste liquid for precipitation separation of tin sulfate, and entering the next step until the copper content of the supernatant meets the requirement; oxalic acid and a filter aid are added into the supernate with the copper content reaching the standard, and copper ions are precipitated; then, the filtrate is subjected to regeneration liquid blending, and tin-stripping regeneration sub-liquid is obtained and returned to a production line for use; and finally, spraying the generated tail gas with hydrogen peroxide, and discharging the tail gas after the tail gas is detected to meet the standard. According to the method, metal ions tin and copper in the waste liquid can be selectively precipitated and separated, the tin content in the tin sludge and the copper content in the copper sludge are increased, the tin stripping liquid medicine can be regenerated and recycled, in the whole production process, no waste water or dangerous waste gas is generated, the method is green and environmentally friendly, and the production cost is greatly reduced.

Owner:江西瑞亿电子科技有限公司

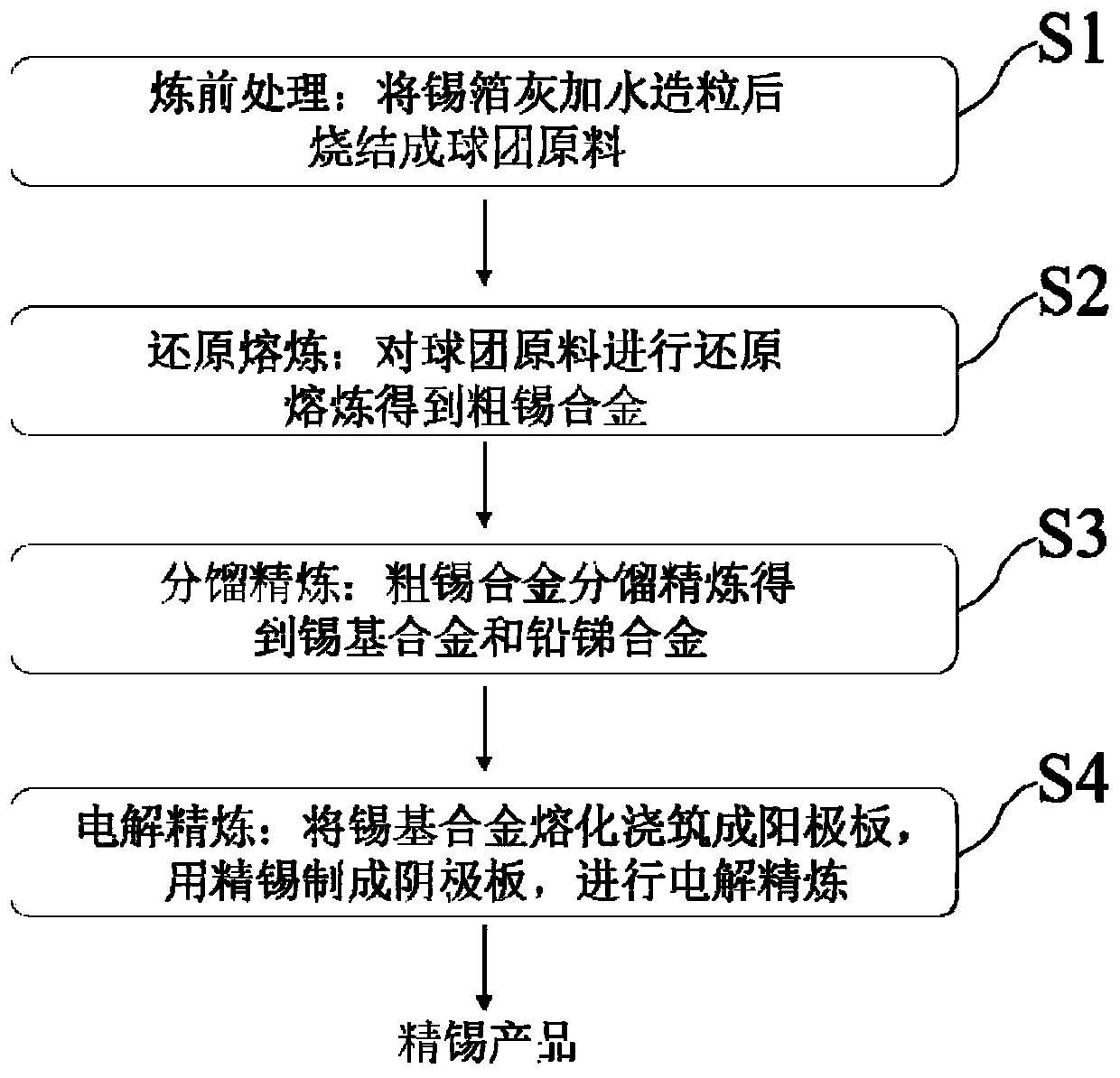

Method for recovering and regenerating refined tin from tin foil ash

InactiveCN111235394AReduce flyingHigh recovery ratePhotography auxillary processesProcess efficiency improvementElectrolysisAlloy

The invention discloses a method for recovering and regenerating refined tin from tin foil ash, and belongs to the field of metal resource regeneration. The method comprises the following steps of S1,smelting pre-treatment, specifically, after water is added into the tin foil ash, granulating and sintering are conducted to form a pellet raw material; S2, reduction smelting, specifically, the pellet raw material obtained in the S1 is subjected to the reduction smelting, and crude tin alloy is obtained; S3, fractionating and refining, specifically, the fractionating and refining are conducted on the crude tin alloy of the S2 to obtain a tin-based alloy and a lead-antimony alloy; and S4, electrolytic refining, specifically, the tin-based alloy obtained in the S3 is melted and cast into an anode plate, the refined tin is used for manufacturing a cathode plate, electrolytic refining is conducted, and a refined tin product is obtained. According to the method for recovering and regeneratingthe refined tin from the tin foil ash, through the smelting pre-treatment, the reduction smelting, the fractionating and refining and the electrolytic refining, the recovery method which is high in recovery rate and capable of reducing pollution and cost is provided for the incinerated tin foil ash, and the recovery effect is far superior to that of a traditional tin foil ash recovery method.

Owner:马鞍山市伟泰锡业有限公司 +1

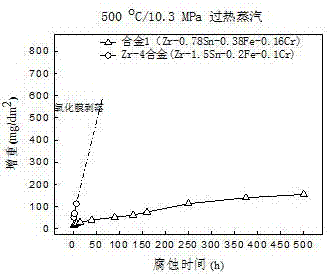

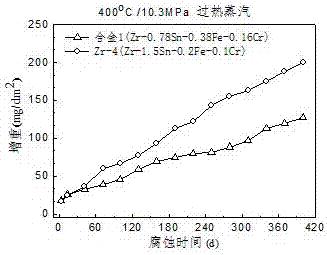

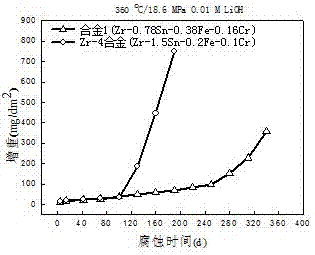

Zirconium alloy for cladding material of nuclear fuel element in non-hydrogenated deoxidization pressurized water reactor

InactiveCN107034385AImprove corrosion resistanceExcellent boil-like corrosion resistanceOptical rangefindersNuclear energy generationPressurized water reactorNiobium

The invention relates to zirconium alloy for a cladding material of a nuclear fuel element in a non-hydrogenated deoxidization pressurized water reactor, and belongs to the technical field of zirconium alloy materials. The zirconium alloy comprises, by weight, 0.73%-1.1% of Sn, 0.25%-0.6% of Fe, 0.1%-0.25% of Cr and the balance Zr and inevitable impurities. The zirconium alloy does not contain niobium and thus is insensitive to dissolved oxygen in corrosive media, and meanwhile, the alloy has extremely excellent corrosion resistance and is obviously superior to Zr-4 alloy under the corrosive condition of superheated steam at the temperature of 500 DEG C and under the pressure of 10.3 Mpa, the corrosive condition of superheated steam at the temperature of 400 DEG C and under the pressure of 10.3 Mpa, the corrosive condition of a LiOH water solution at the temperature of 360 DEG C and under the pressure of 18.6 Mpa / 0.01 M and the corrosive condition of deionized water at the temperature of 360 DEG C and under the pressure of 18.6 Mpa. The zirconium alloy is used for the cladding material of the nuclear fuel element in the non-hydrogenated deoxidization pressurized water reactor.

Owner:SHANGHAI UNIV

Preparation method for high-transmittance diffuser plate

InactiveCN109054069AReduce surface tensionImprove controlDiffusing elementsCoatingsCross-linkDiaminodiphenyl ether

The invention discloses a preparation method for a high-transmittance diffuser plate and belongs to the technical field of diffuser plate preparation. In the invention, polyvinylpyrrolidone powder isdissolved in a light-transmitting solution and the nucleation rate thereof is increased during the process of generating stannic oxide grains by oxidizing stannous mono-sulphate; a transparent homogeneous sol in the invention contains zinc oxide and is doped with aluminum nitrate nonahydrate; band gap and exciton binding energy of zinc oxide are higher; a polyamide acid sol is prepared by taking 4,4'-diaminodiphenyl ether and pyromellitic dianhydride as raw materials; a hybrid membrane at molecular level is acquired under the cross-linking effect of the polyamide acid sol and the transparent adhesive solution through hydrogen bonds; superfine indium tin oxide powder is adopted for reducing an inductive dipole moment, reducing the diffusing in the diffuser plate and increasing the light diffusion rate; the compound of the superfine indium tin oxide powder and the transparent homogeneous sol can increase the stability of the adhesive solution, can narrow the size distribution of nano-particles in the hybrid membrane and can increase the light transmissivity of the diffuser plate; the high-transmittance diffuser plate has a wide application prospect.

Owner:FOSHAN TENGLI NEW ENERGY TECH CO LTD

Method for recovering tin in PCB production process

ActiveCN112573698AHigh recovery rateImprove efficiencyMultistage water/sewage treatmentProcess efficiency improvementWastewaterProcess engineering

The invention discloses a method for recovering tin in a PCB production process, wherein the method is characterized by comprising the following steps: S1, carrying out alkali pretreatment; S2, treating with a heavy metal treating agent; S3, carrying out cation exchange resin treatment; and S4, carrying out inverse capture. According to the method for recovering tin in the PCB production process,tin stripping wastewater generated in the PCB production process can be treated rapidly, efficiently and safely, tin is recycled, waste is turned into wealth, the environment is protected, and the purpose of saving energy is achieved. In addition, the recovery method is high in recovery rate and efficiency, high in product tin content, free of secondary pollution, low in recovery cost, small in equipment investment, low in energy consumption and high in application and popularization value.

Owner:KUNSHAN MEIYUANDA ENVIRONMENTAL PROTECTION TECH

A resource recovery method for circuit board tin stripping waste liquid

ActiveCN105460972BReduce dosageLower pHTin compoundsMultistage water/sewage treatmentResource recoveryCopper

The invention relates to a recycling method of a circuit board solder stripping waste liquid, which comprises the following steps: S1: dropwisely adding an alkaline solution with the hydroxy molar concentration of 0.25-6.00 mol / L into the circuit board solder stripping waste liquid to regulate the pH value of the system to 0.5-1.0, and carrying out solid-liquid separation to obtain precipitated tin; S2: continuing adding the alkaline solution into the filtrate obtained in the step S1 to regulate the pH value of the system to 1.5-4.0, and carrying out solid-liquid separation to obtain precipitated iron; and S3: continuing adding the alkaline solution into the filtrate obtained in the step S2 to regulate the pH value of the system to 6.0-8.0, and carrying out solid-liquid separation to obtain precipitated copper. The method provided by the invention implements step-by-step recycling on heavy metals in the solder stripping waste liquid, and implements zero discharge of the heavy metal waste liquid. The method provided by the invention is more environment-friendly, and has higher popularization and application value.

Owner:GUANGZHOU KECHENG ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com