A resource recovery method for circuit board tin stripping waste liquid

A resource recovery and circuit board technology, applied in chemical instruments and methods, tin compounds, copper sulfate and other directions, can solve the problems of human and environmental hazards, high impurity content, low separation efficiency, etc. The effect of emission and consumption saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

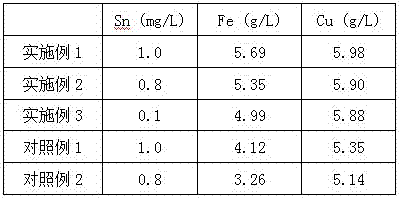

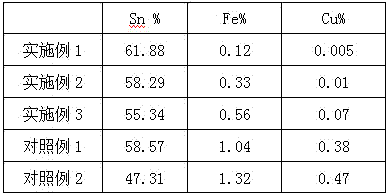

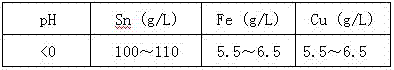

[0025] (1) Take 1L of tin stripping waste liquid whose composition is shown in Table 1, add 3000mL of sodium hydroxide solution with a molar concentration of hydroxide radicals of 0.25mol / L to it, adjust the pH to 0.5, stir for 30min, and perform solid-liquid Separate to obtain the filter cake A1 with components as shown in Table 2 and the filtrate B1 with components as shown in Table 3;

[0026] (2) Take the filtrate B1, add 100 mL of sodium hydroxide solution with a molar concentration of 2.78 mol / L to it, adjust the pH value to 1.5, and carry out solid-liquid separation to obtain the filter cake A2 with the components shown in Table 4 and the components shown in Table 4 Filtrate B2 shown in 5;

[0027] (3) Take the filtrate B2, add 20 mL of sodium hydroxide solution with a molar concentration of 6.00 mol / L to it, adjust the pH value to 6.0, and carry out solid-liquid separation to obtain the filter cake A3 with the components shown in Table 6 and the components shown in Tab...

Embodiment 2

[0031] (1) Take 1L of tin stripping waste liquid whose composition is shown in Table 1, add 320mL of sodium hydroxide solution with a molar concentration of hydroxide radicals of 3.20mol / L to it, adjust the pH to 0.8, stir for 30min, and perform solid-liquid Separate to obtain the filter cake A1 with components as shown in Table 2 and the filtrate B1 with components as shown in Table 3;

[0032] (2) Take the filtrate B1, add 70 mL of sodium bicarbonate solution with a hydroxide molar concentration of 4.35 mol / L to it, adjust the pH value to 2.5, carry out solid-liquid separation, and obtain the filter cake A2 whose composition is shown in Table 4 With composition as the filtrate B2 shown in table 5;

[0033] (3) Take the filtrate B2, add 17mL of sodium carbonate solution with a molar concentration of hydroxide of 7.94mol / L to it, adjust the pH value to 7.0, and carry out solid-liquid separation to obtain the filter cake A3 and Components are filtrate B3 as shown in table 7; ...

Embodiment 3

[0037] (1) Take 1 L of the tin stripping waste liquid whose composition is shown in Table 1, add 165 mL of sodium hydroxide solution with a molar concentration of hydroxide radicals of 6.00 mol / L to it, adjust the pH to 1.0, stir for 30 minutes, and perform solid-liquid separation , to obtain the filter cake A1 with composition as shown in table 2 and the filtrate B1 with composition as shown in table 3;

[0038] (2) Take the filtrate B1, add 55 mL of sodium bicarbonate solution with a hydroxide molar concentration of 6.00 mol / L to it, adjust the pH value to 4.0, and perform solid-liquid separation to obtain the filter cake A2 with the components shown in Table 4 With composition as the filtrate B2 shown in table 5;

[0039](3) Take the filtrate B2, add 15 mL of sodium carbonate solution with a hydroxide molar concentration of 10.0 mol / L to it, adjust the pH value to 8.0, and carry out solid-liquid separation to obtain the filter cake A3 and Components are filtrate B3 as show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com