Solar battery cell and fabrication method thereof

A technology for solar cells and silicon wafers, applied in the field of solar cells and its preparation, can solve the problems of aluminum back field height difference and influence on ribbon welding, etc., achieve the goals of reducing height difference, convenient welding process, and improving infrared welding process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

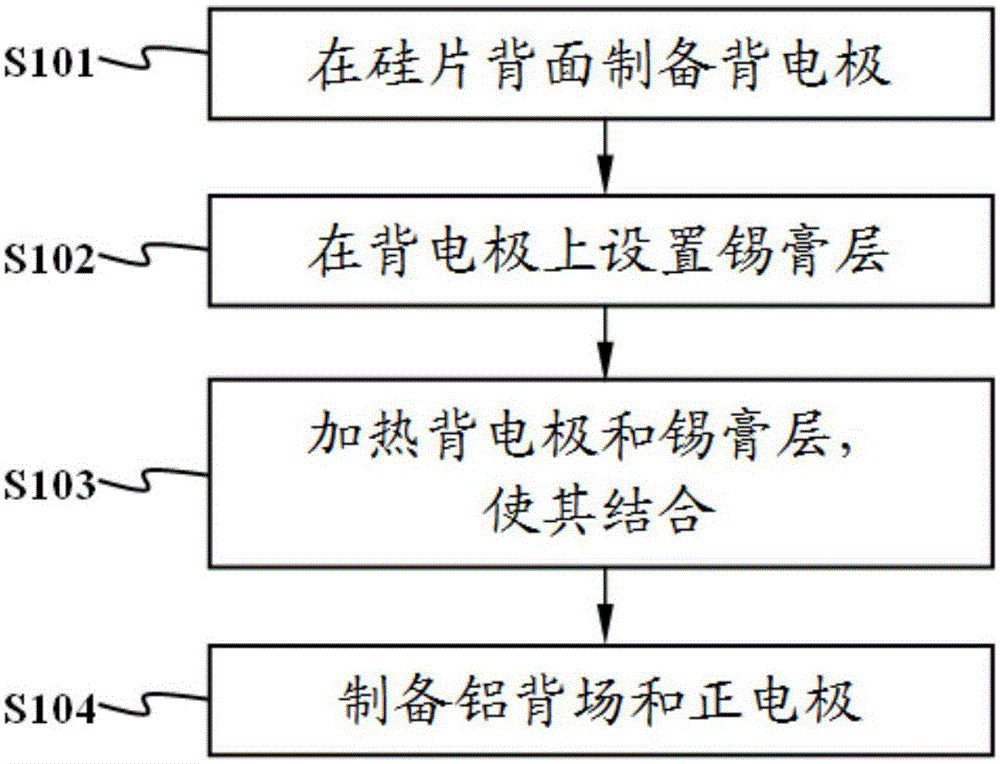

[0031] see figure 1 Shown, the present invention provides a kind of preparation method of solar cell, comprising:

[0032] S101: preparing a back electrode on the back of the silicon wafer;

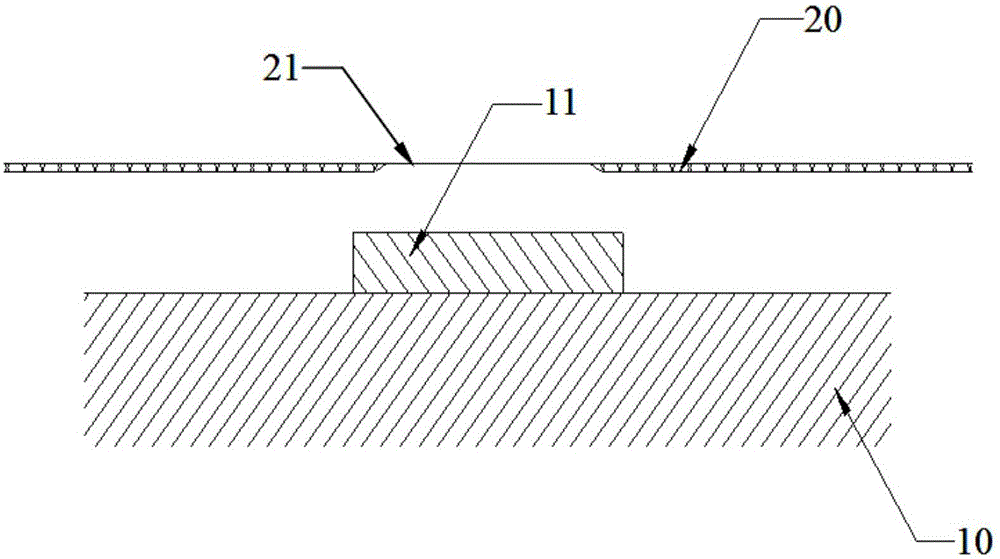

[0033] In this application, the back electrode 11 is produced by screen printing, and the silver paste (Ag) is printed on the back side of the silicon wafer 10 through a steel mesh 20, and then dried to form a figure 2 structure shown.

[0034] S102: setting a solder paste layer on the back electrode;

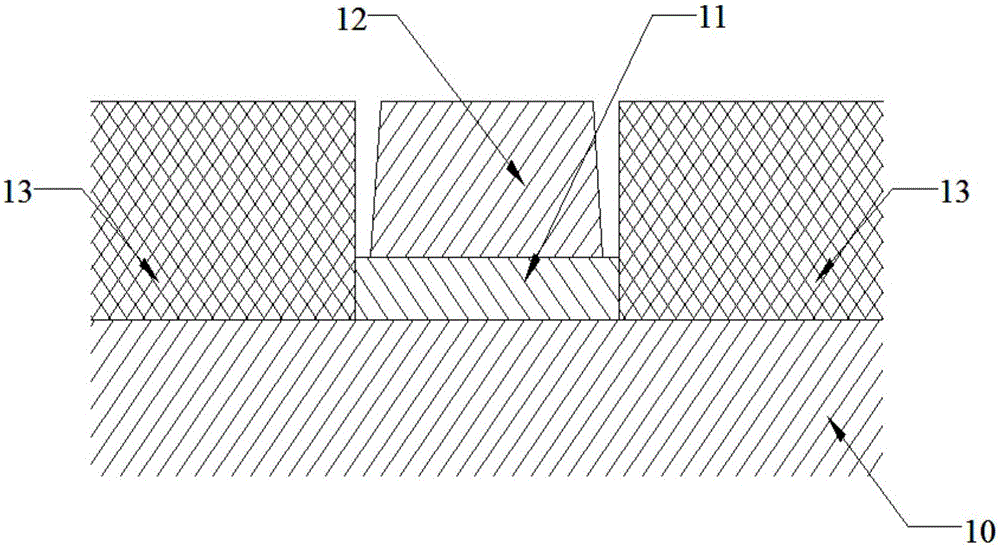

[0035] In a preferred embodiment of the present application, the solder paste layer 12 is printed on the surface of the back electrode 11 through the opening 21 on the steel mesh 20, which can be referred to image 3 As shown, wherein, the thickness of the steel mesh 20≦0.10mm, and the size of the opening 21 corresponding to the back electrode 11 on the steel mesh 20 is 40% to 90% of the size of the back electrode 11, which refers to the size of the area , that is, the solder paste la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com