Patents

Literature

375results about How to "Precise clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

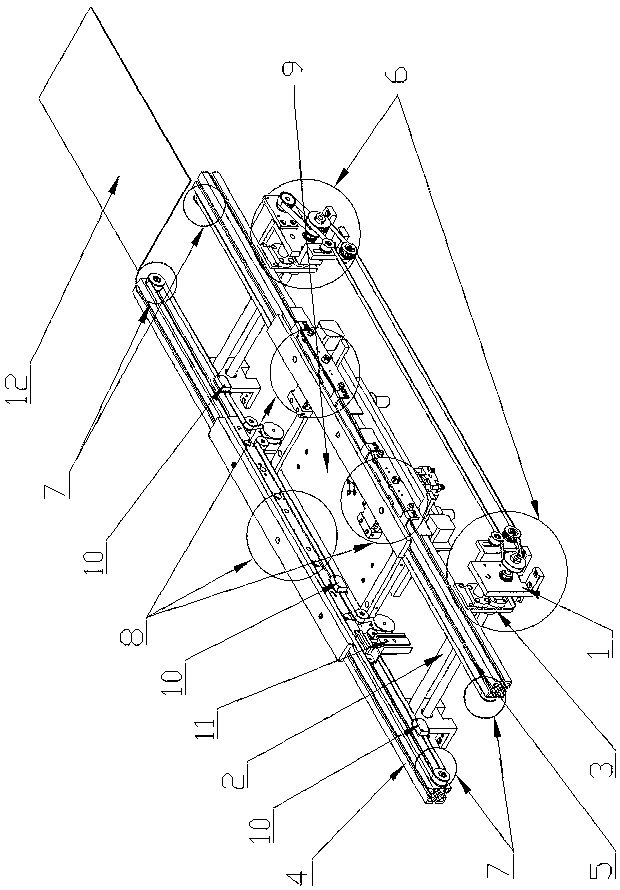

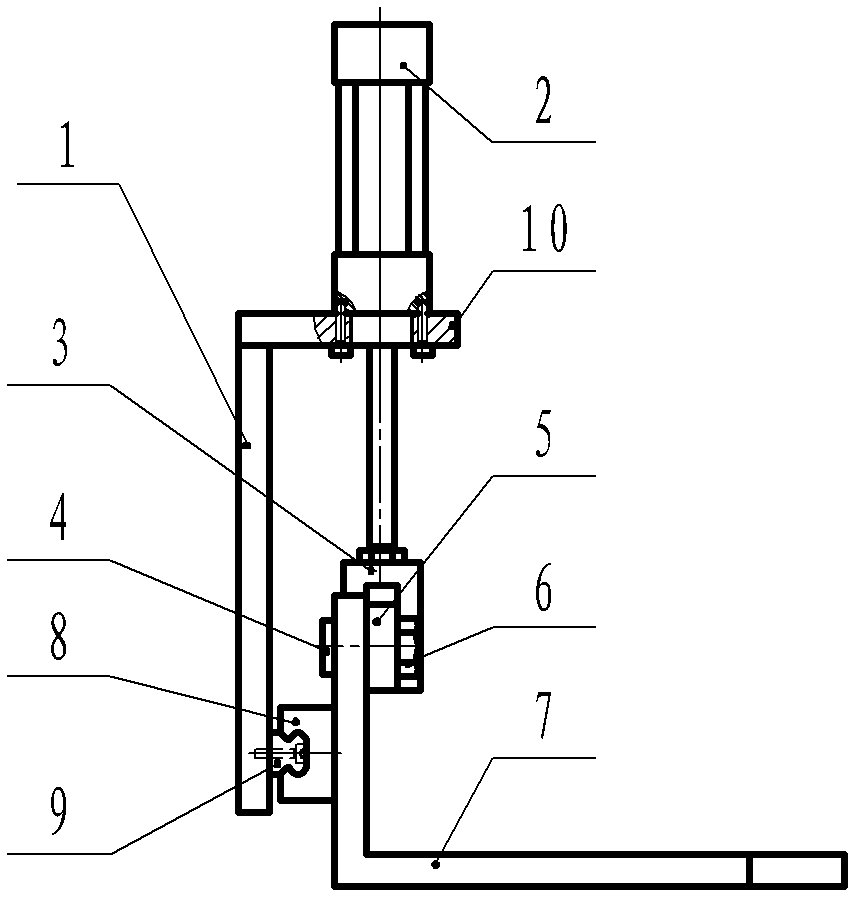

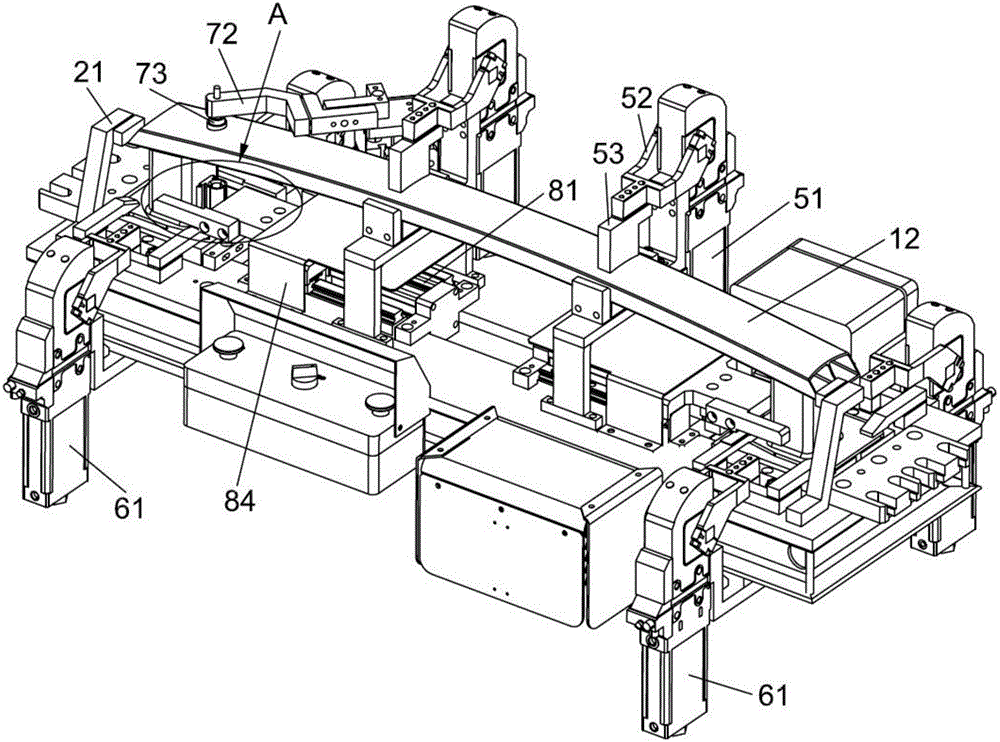

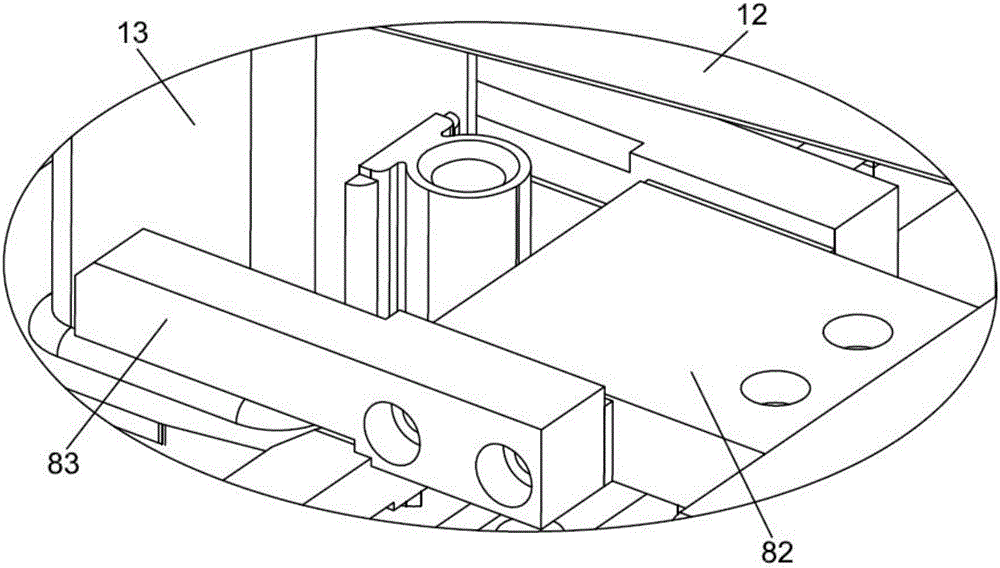

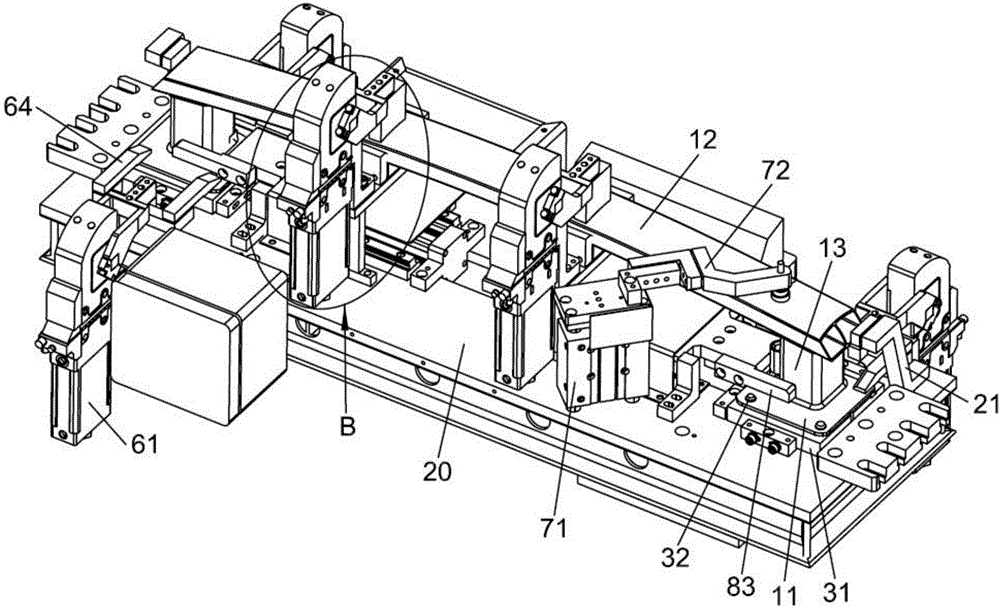

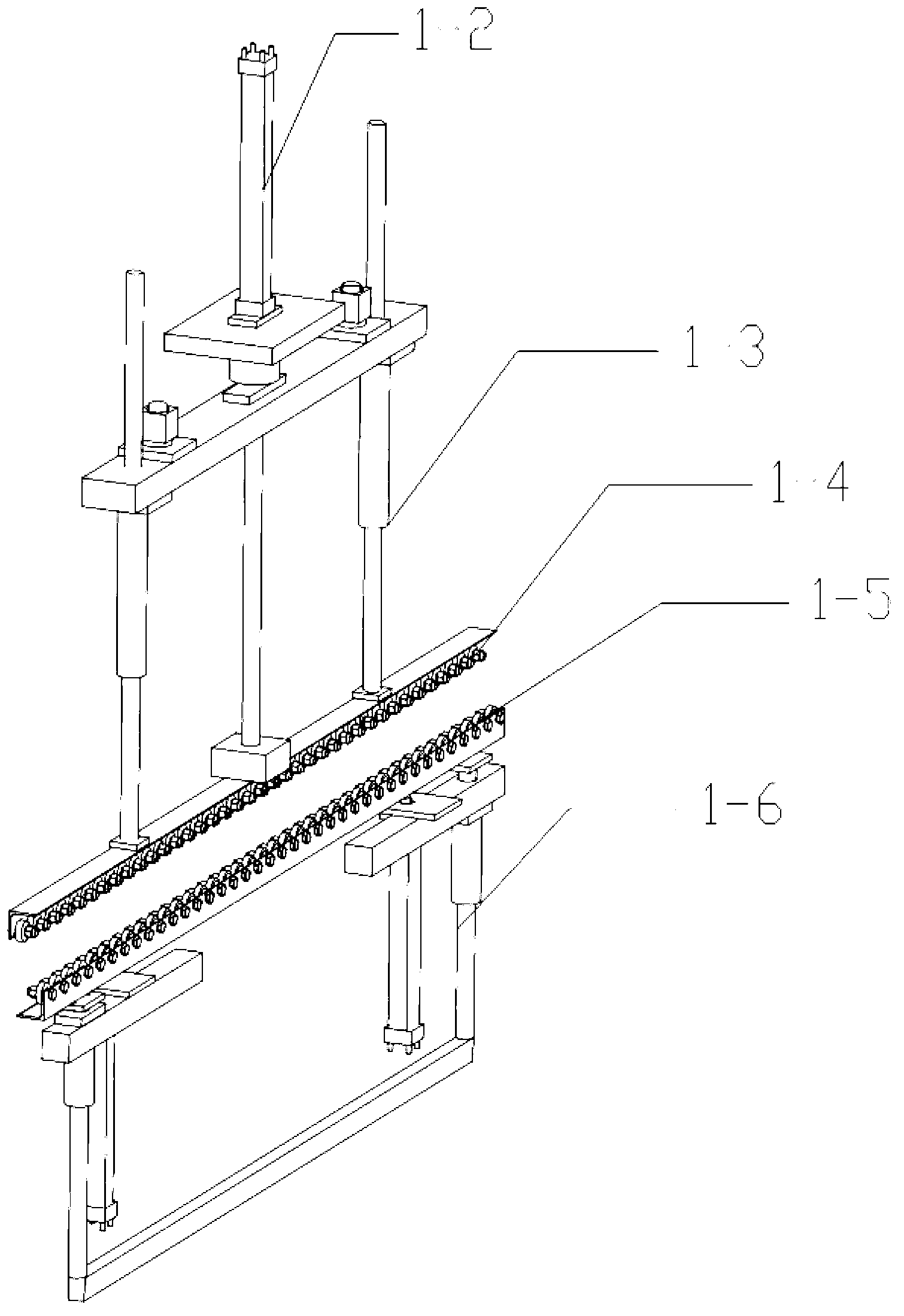

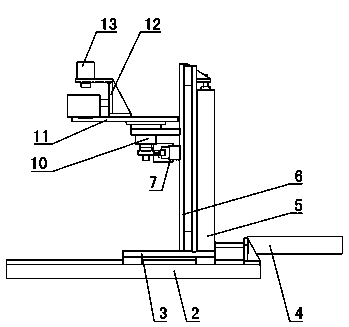

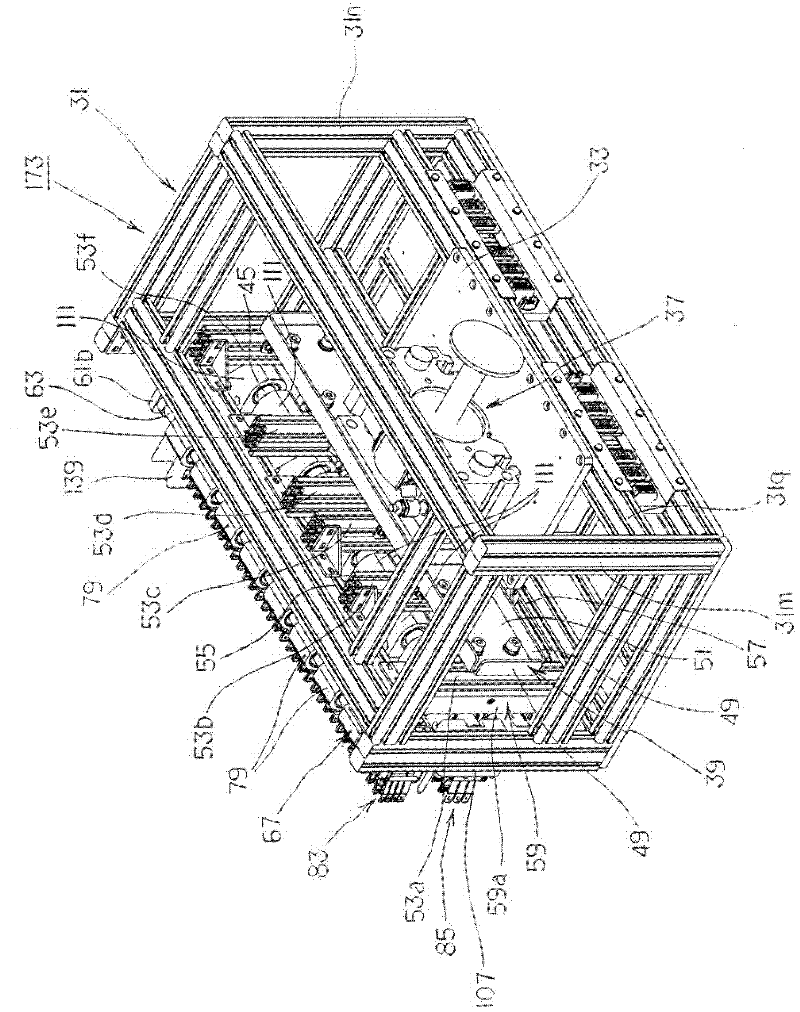

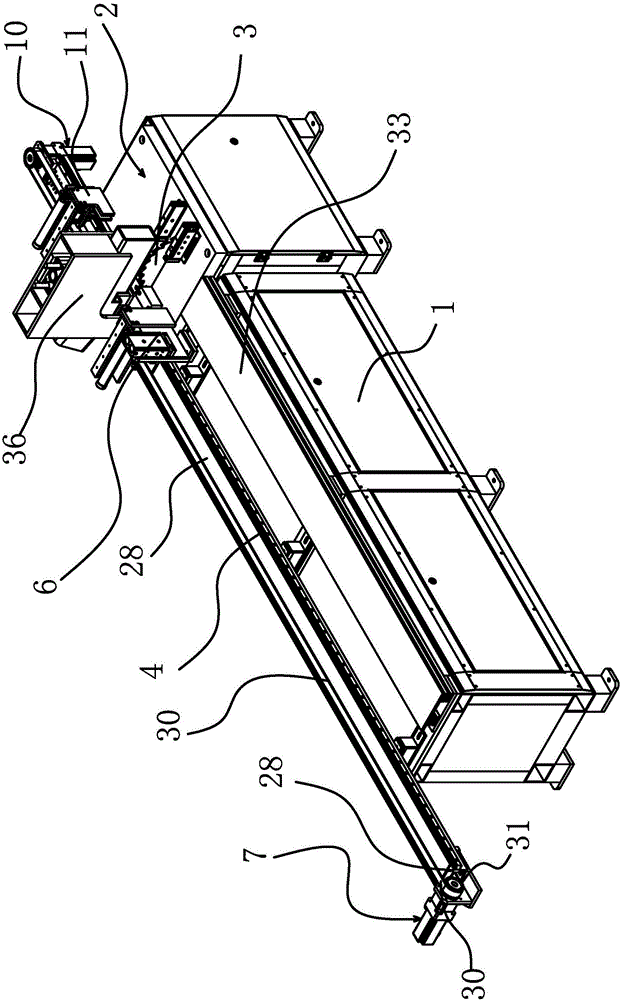

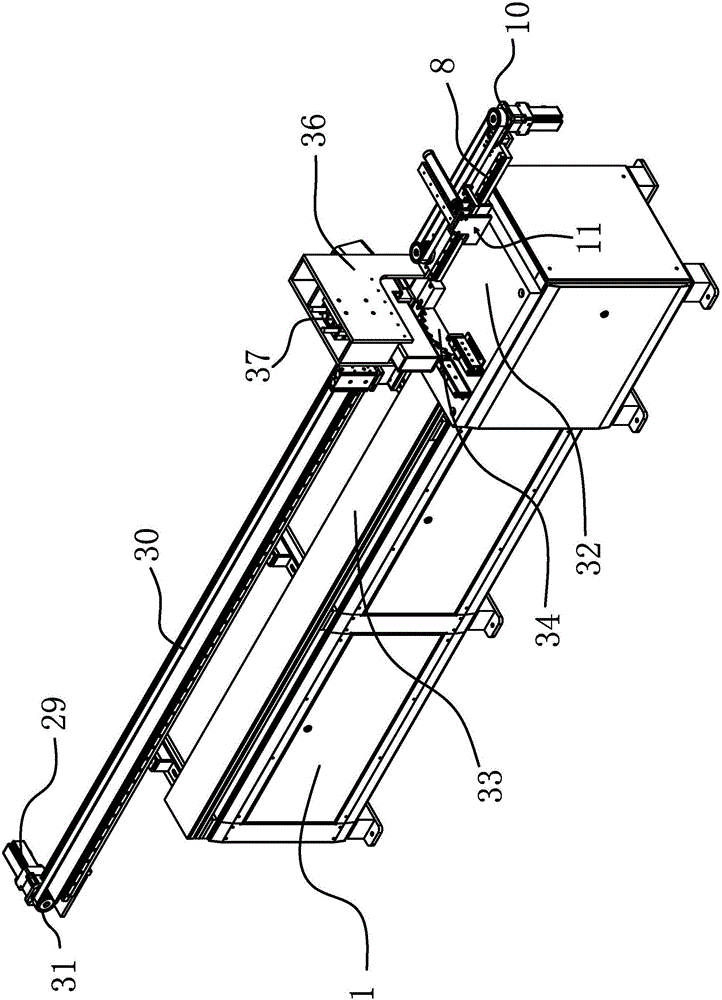

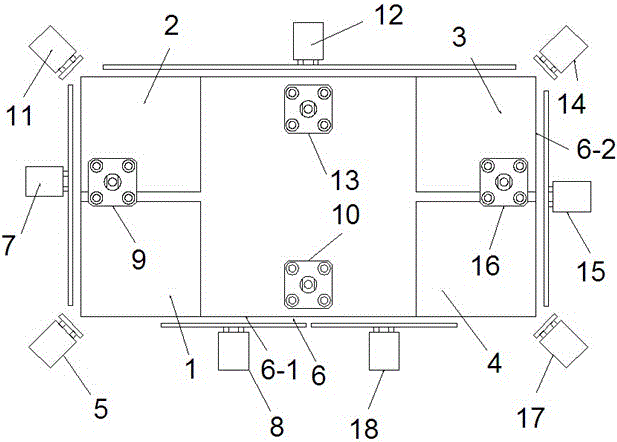

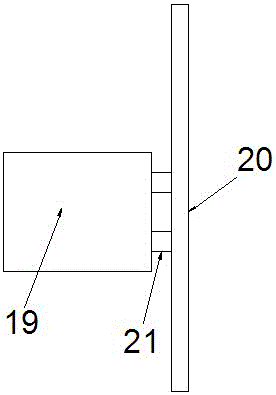

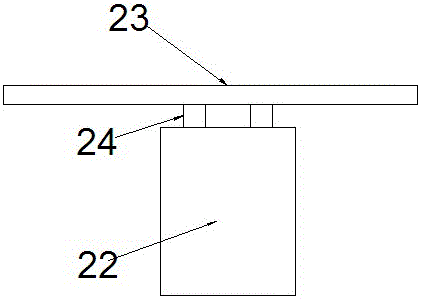

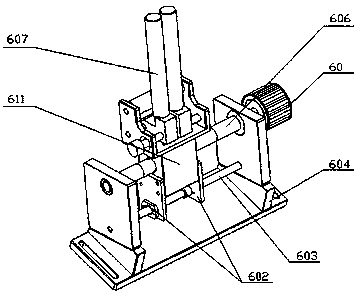

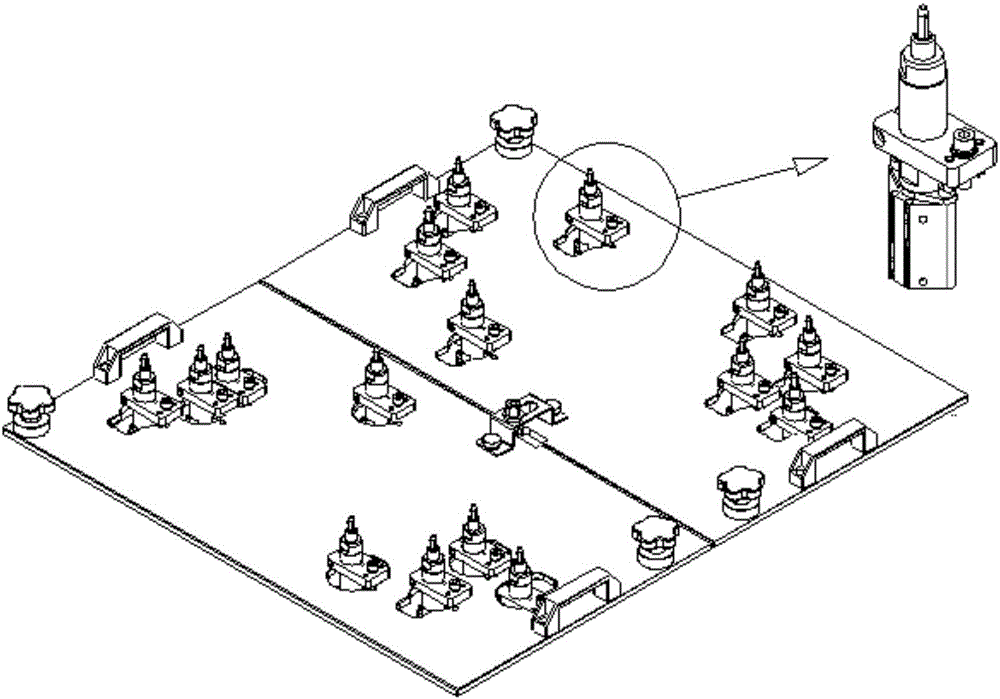

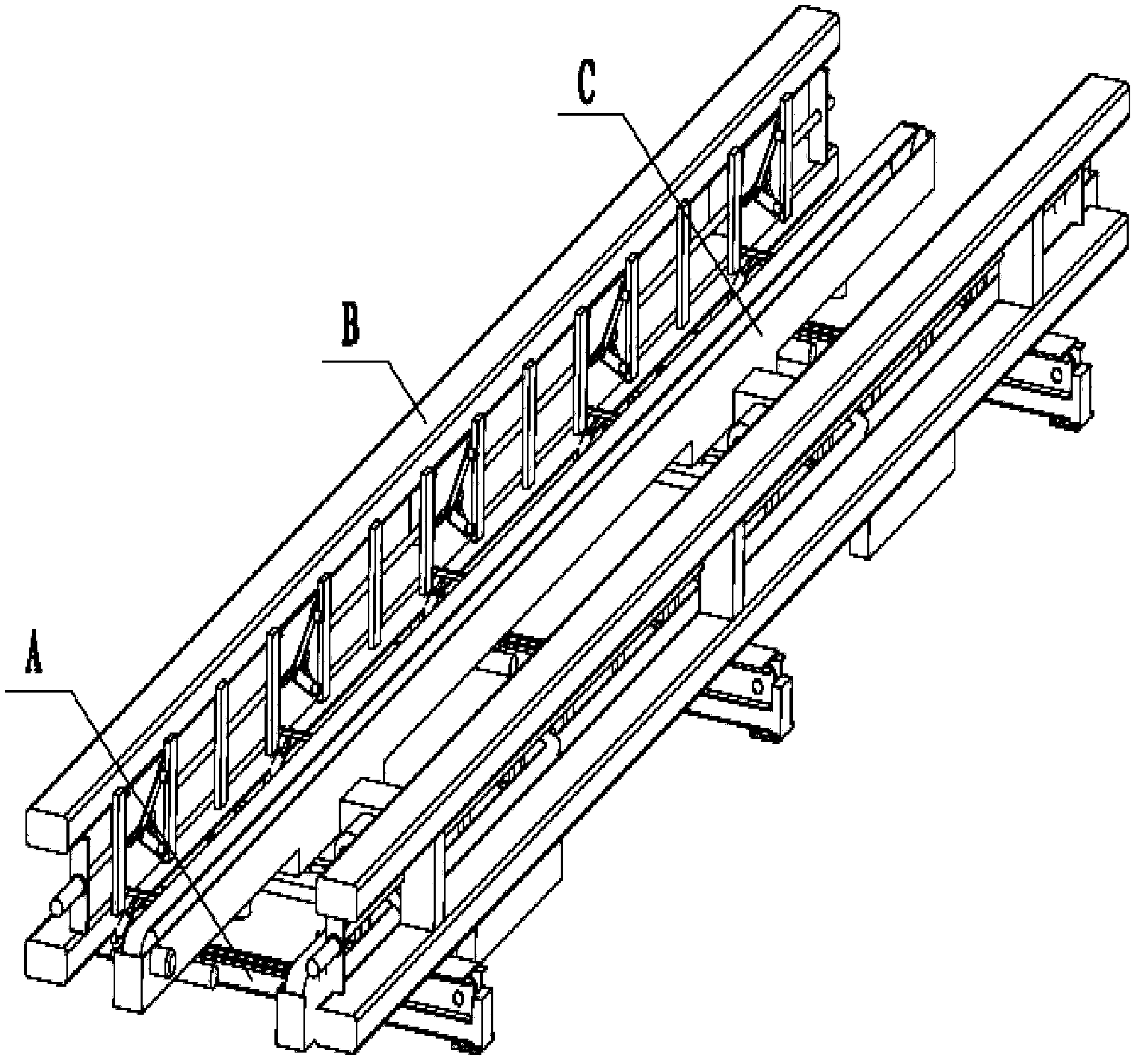

Full-automatic PCB (printed circuit board) positioning clamp

ActiveCN103025077AAccurate positioning and clampingReliable and easy positioning and clampingPrinted circuit assemblingPrinted circuit boardAssembly line

The invention provides a full-automatic PCB (printed circuit board) positioning clamp. The full-automatic PCB positioning clamp comprises a support seat, a support rod, a sliding support plate, a fixed-side railing, a movable-side railing, width adjusting mechanisms, conveying mechanisms, clamping mechanisms, a top plate mechanism, a detecting mechanism and a positioning mechanism, wherein the support rod and the width adjusting mechanisms are assembled on holes reserved on the lateral side of the support seat, the fixed-side railing is fixed on the support seat, the sliding support plate is slidably connected with the support rod, the movable-side railing is fixed on the sliding support plate which is connected with the width adjusting mechanisms, the conveying mechanisms are mounted on the inner sides of the fixed-side railing and the movable-side railing to form a PCB delivery rail, the clamping mechanisms are fixed on the fixed-side railing and the movable-side railing, the detecting mechanism is mounted on the fixed-side railing, and the positioning mechanism used for positioning the PCB when entering is fixed at a positioning position on the fixed-side railing. The full-automatic PCB positioning clamp can quickly automatically deliver the PCB, and can position and clamp the PCB accurately, reliably and conveniently, and production efficiency of an assembly line is improved.

Owner:广州弘高科技股份有限公司

Automatic positioning clamping mechanism for feeding and discharging materials in bell-shaped shell defect-detection/cleaning integrated machine

ActiveCN102608201ASimple structureLow costGripping headsCleaning processes and apparatusEngineeringFour-slide

The invention relates to an automatic positioning clamping mechanism used for feeding and discharging materials in a bell-shaped shell defect-detection / cleaning integrated machine. The mechanism is characterized by fixing a pair of cylinder connecting plates on the top surface of an installing substrate; two pairs of, in other words, four sliding blocks in all, are configured on a straight line guide track at the lower part in front of the installing substrate; a clamping jaw is L-shaped; V-shaped chucks are arranged on the internal side surface at the front parts of a pair of clamping jaw horizontal arms respectively; four clamping jaws are fixed on the four sliding blocks through a perpendicular arm respectively; a cylinder is fixed on the cylinder connecting plate; a movable joint is fixed on a stretching end of a piston rod of the cylinder; the movable joint is U-shaped and the opening thereof faces downwards; each pair of connecting rods are matched in a U-shaped slot of the movable joint rotationally through a hinge pin; and the other ends of each pair of connecting rods are matched on a pair of clamping jaw perpendicular arms rotationally through screws. According to the mechanism, working pieces of different models can be positioned and clamped accurately without adjustment; the adjusting working quantity of the machine can be reduced greatly; the operation is sensitive and reliable; and the production efficiency can be improved greatly.

Owner:SHEYANG HUATONG DETECTOR EQUIP

Welding tool of anti-collision beam and mounting plate

InactiveCN106670709AClamp firmlyQuick clampingWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringEnergy absorbing

The invention discloses a welding tool of an anti-collision beam and a mounting plate. The welding tool comprises a mounting plate body, the anti-collision beam and an energy absorbing box, wherein the anti-collision beam is welded to the energy absorbing box. Positioning holes are formed in the mounting plate body. The mounting plate body comprises a mounting platform. The mounting platform is provided with a supporting platform, a supporting assembly, a first pressing assembly, a second pressing assembly, a transverse pushing positioning assembly and end part positioning blocks. A positioning column is arranged on the supporting platform. The supporting platform and the positioning column position the mounting plate body. The second pressing assembly compresses the mounting plate body and the supporting platform. A positioning circular hole is formed in the anti-collision beam. A circular hole positioning assembly are arranged on the mounting platform. The supporting assembly, the end part positioning blocks and the circular hole positioning assembly position the anti-collision beam. The first pressing assembly compresses the anti-collision beam. The transverse pushing positioning assembly positions the energy absorbing box, so that the welding positions of the energy absorbing box and the mounting plate body are determined. Clamping is reliable, rapid and accurate, and efficiency is improved greatly.

Owner:成都凌云汽车零部件有限公司

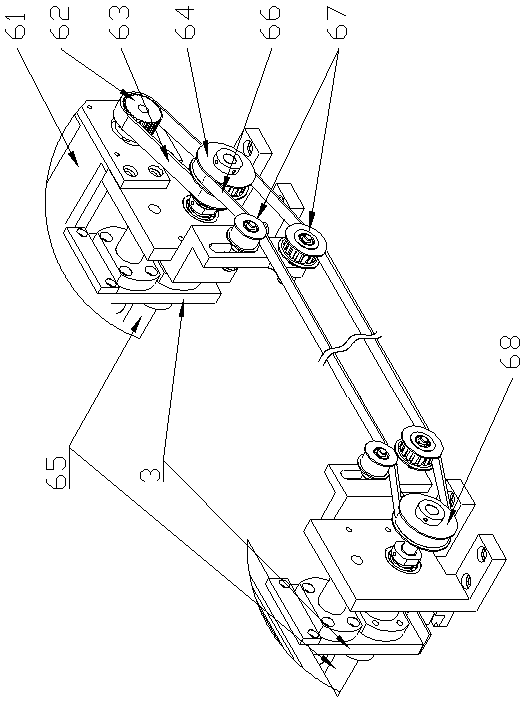

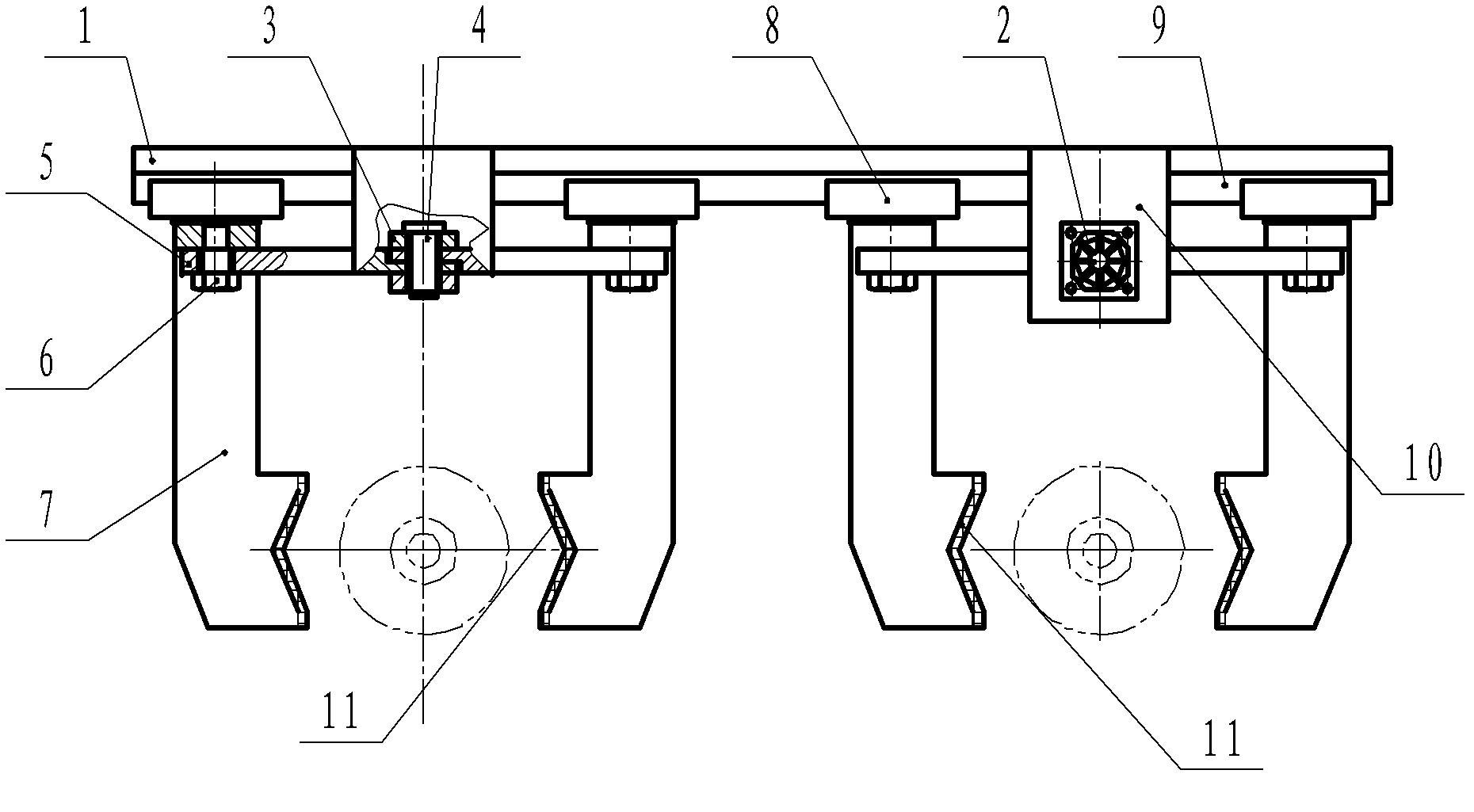

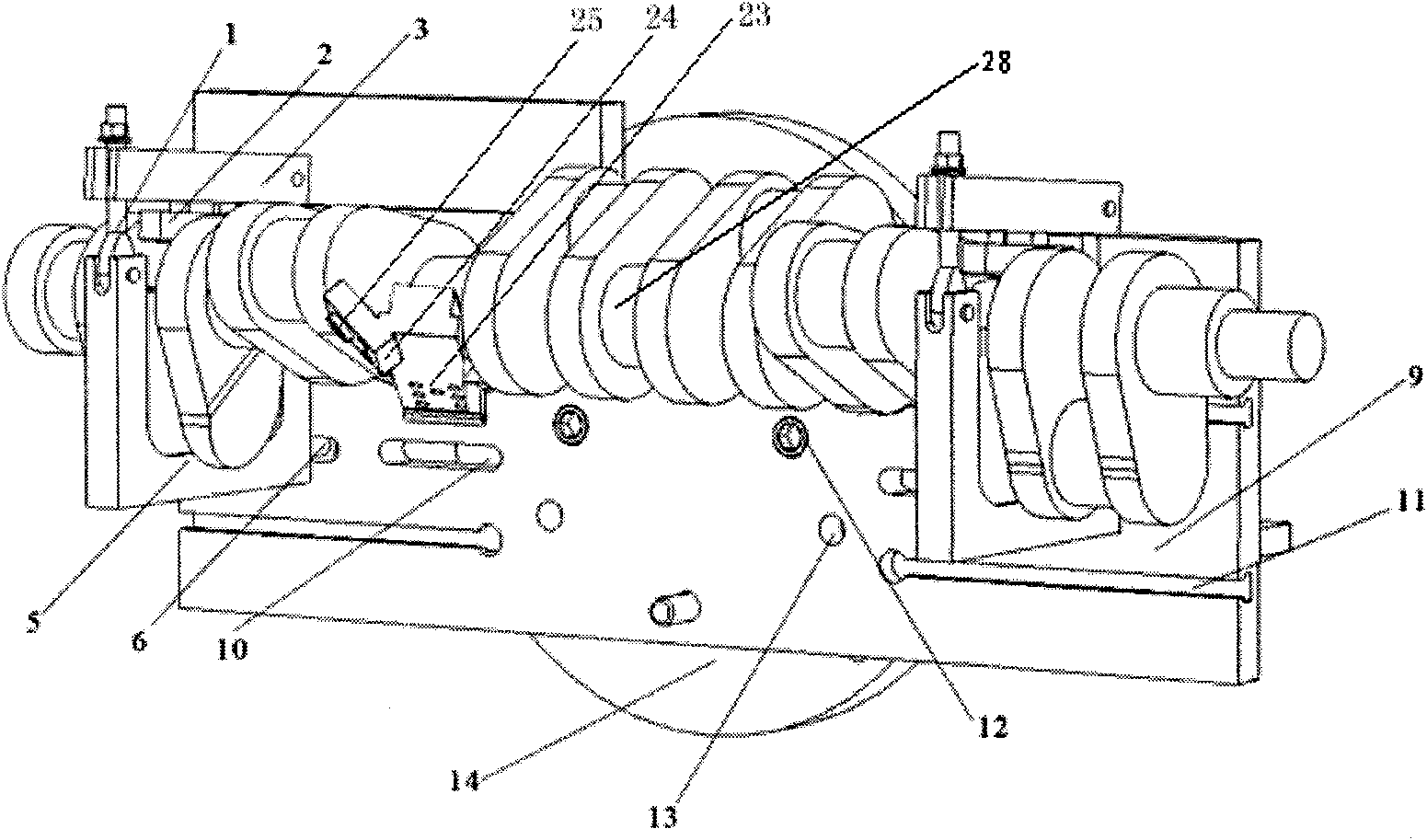

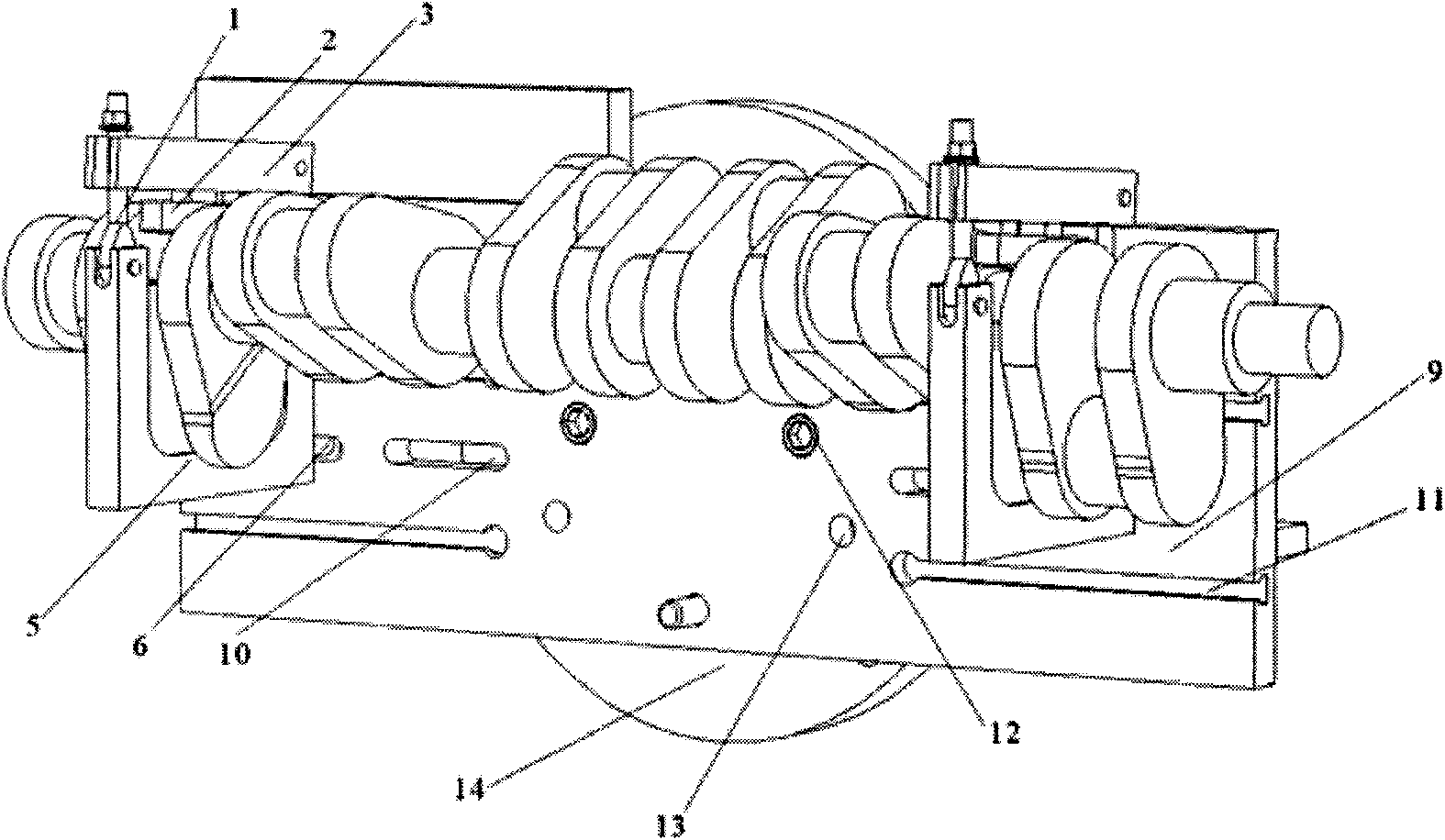

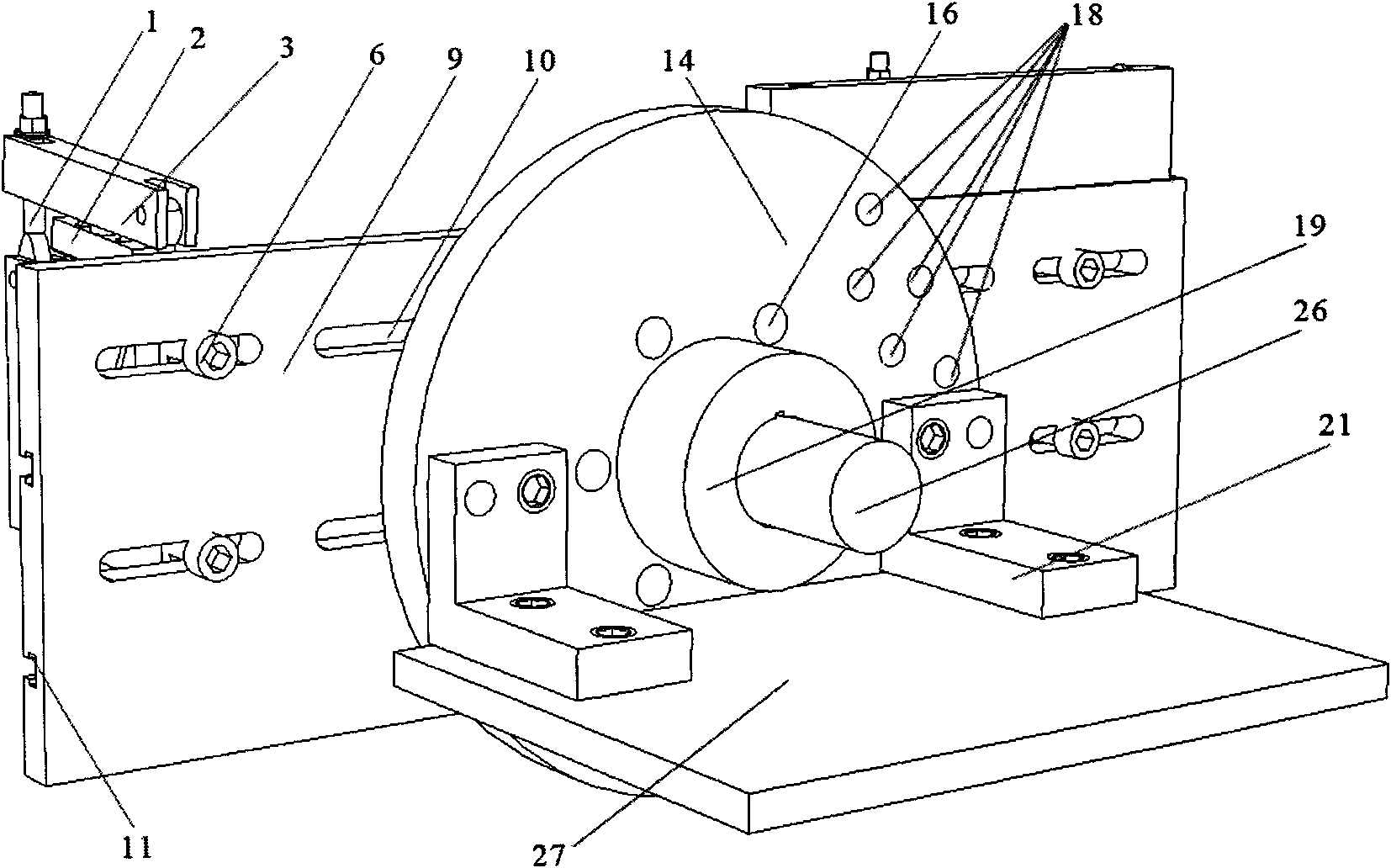

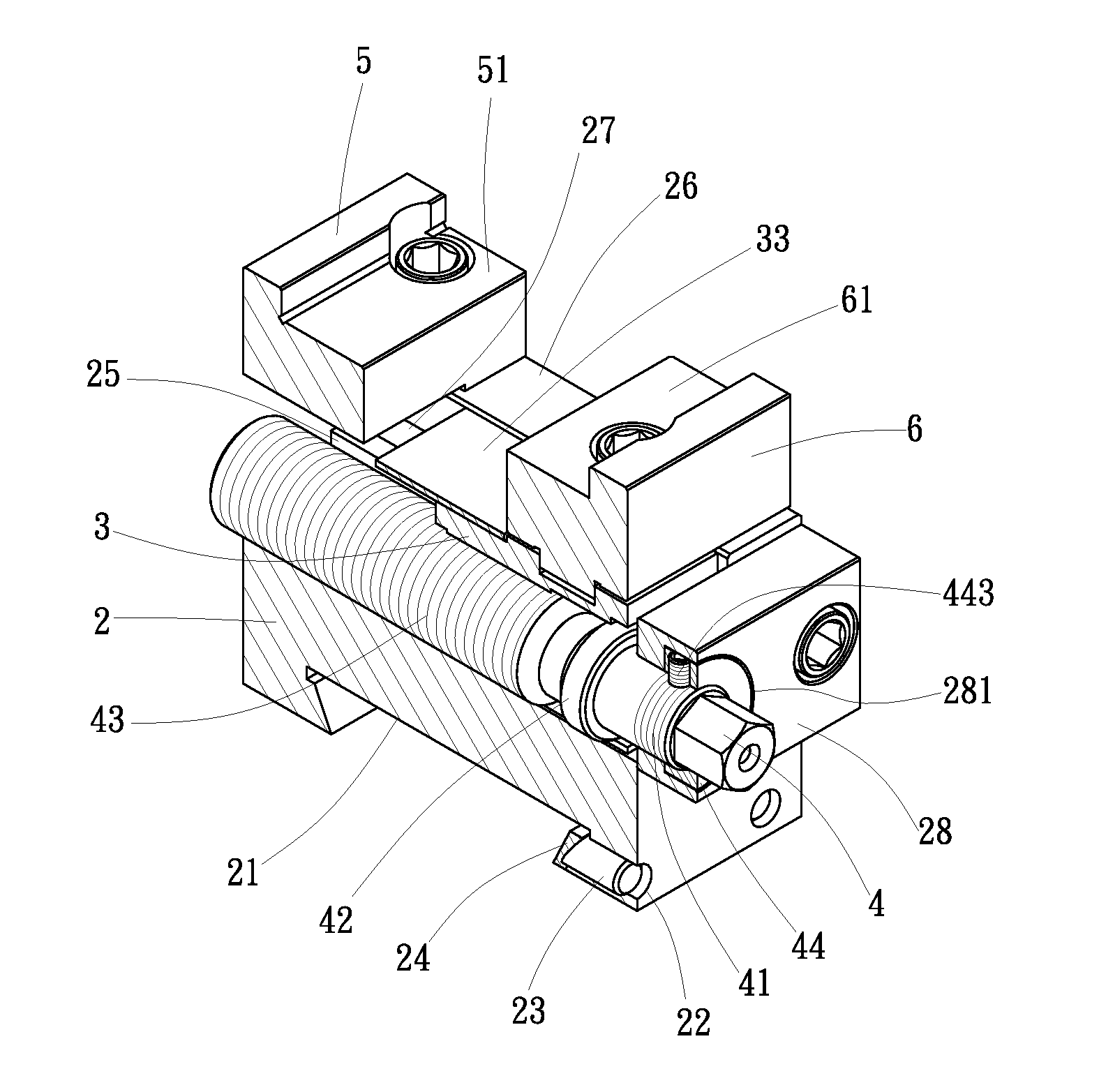

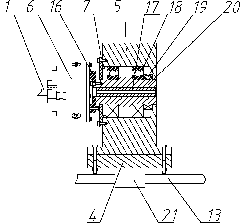

Crankshaft multi-angle oil hole drilling clamp

ActiveCN101786241AAchieve clampingPrecise clampingPositioning apparatusBoring/drilling componentsCrankshaftMechanical engineering

The invention discloses a crankshaft multi-angle oil hole drilling clamp. A crankshaft supporting seat of each crankshaft clamping mechanism is provided with a groove; a gland is arranged above the groove; two ends of the gland are movably connected with the crankshaft supporting seat respectively; a clamp body is uniformly and circumferentially provided with six rotating pin holes and two rotating screw holes taking a bearing hole of the clamp body as a center; six screw holes corresponding to the rotating screw holes, pin holes corresponding to the rotating pin holes and small-angle adjustment screw holes are arranged around a spindle hole of an angle adjustment disc; a circle center-connecting line of two mutually symmetric small-angle adjustment screw holes passes through the circle center of the spindle hole, and adjacent circle center-connecting lines form an included angle; an orthogonal surface of an orthogonal positioning block is provided with two holes of which the circle center-connecting line is a horizontal line; the orthogonal positioning block is arranged together with the angle adjustment disc and a supporting base; the angle adjustment disc is between a positioning supporting seat and one side of the clamp body; the crankshaft clamping mechanisms are symmetrically arranged at two ends of the other side of the clamp body; and an orthogonal slider positioning mechanism is arranged between two crankshaft clamping mechanisms.

Owner:ZHEJIANG WEILIN MECHANICAL

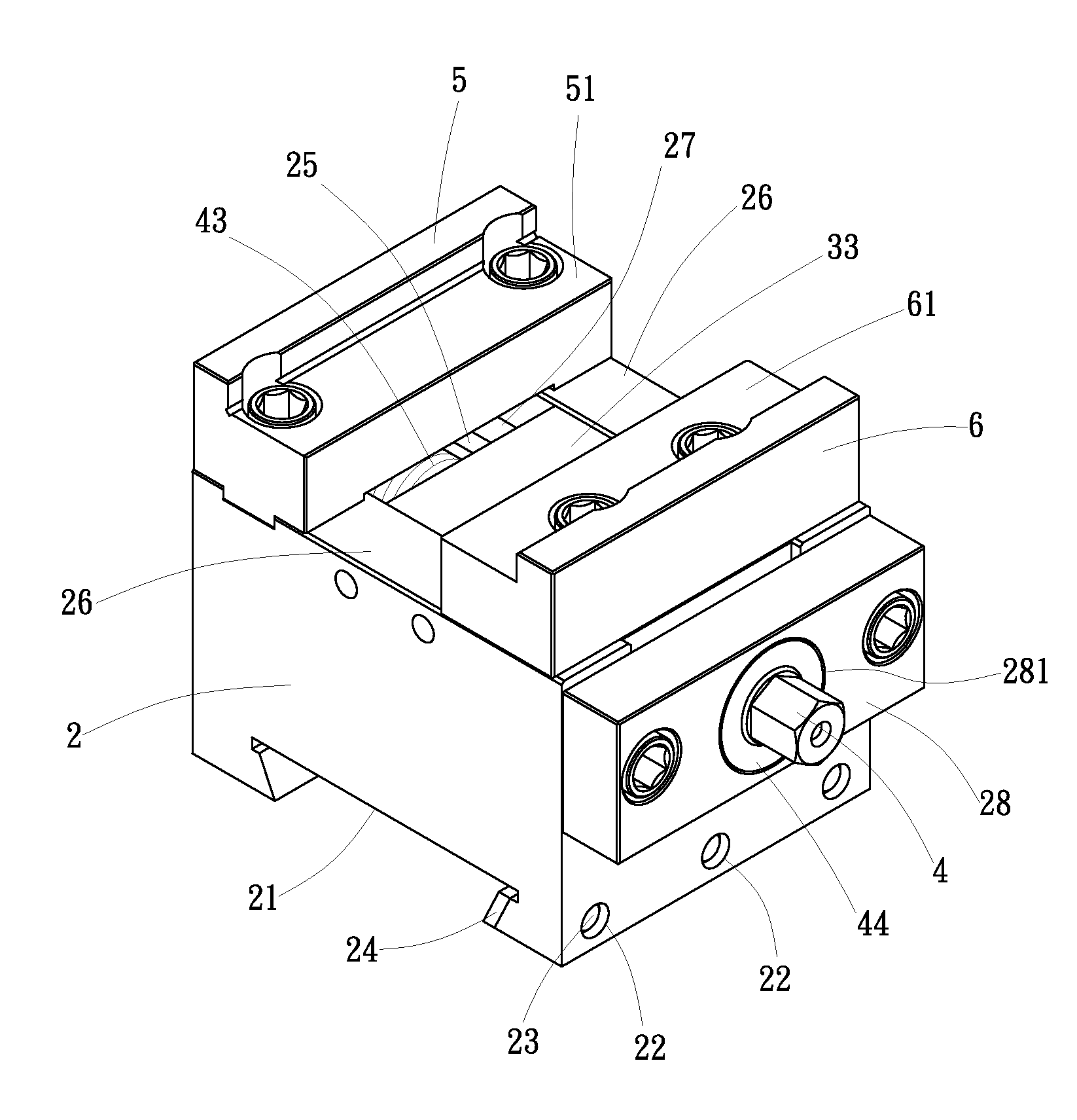

Micro-adjustable parallel bench vise

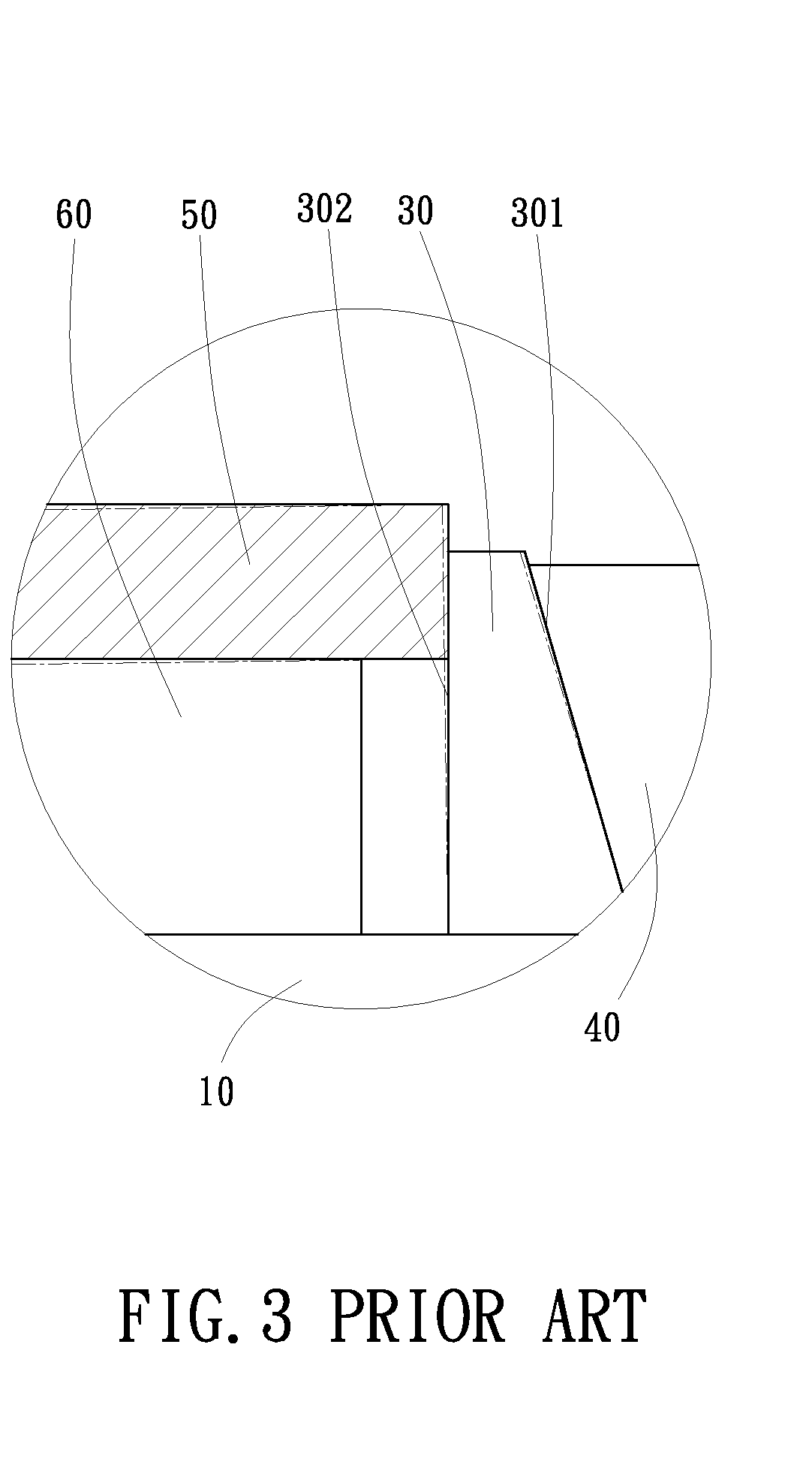

InactiveUS8181949B2Precise clampingDrawback can be obviatedPositioning apparatusVicesEngineeringMechanical engineering

A micro-adjustable parallel bench vise includes a slide holder having a top dovetail rail, a vise body having a bottom dovetail groove coupled to the dovetail rail of the slide holder and holding a fixed jaw member, a screw holder slidably mounted in the top side of the vise body, a screw rod threaded into the screw holder and rotatable to move the screw holder relative to the vise body. When multiple vise bodies are mounted on the slide holder in parallel, they are micro-adjustable to hold a workpiece or multiple workpieces precisely in position.

Owner:HUNG YI PO

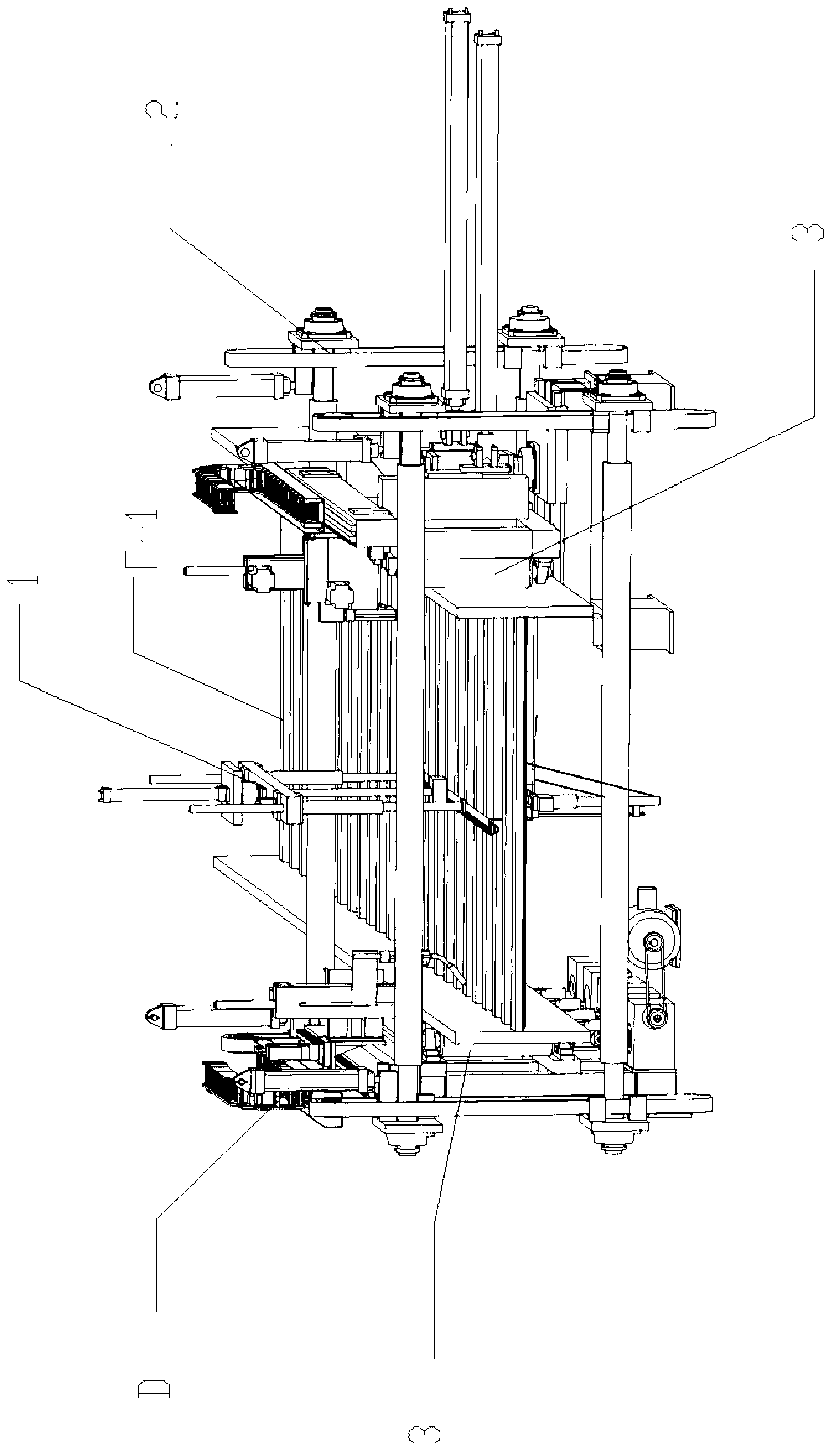

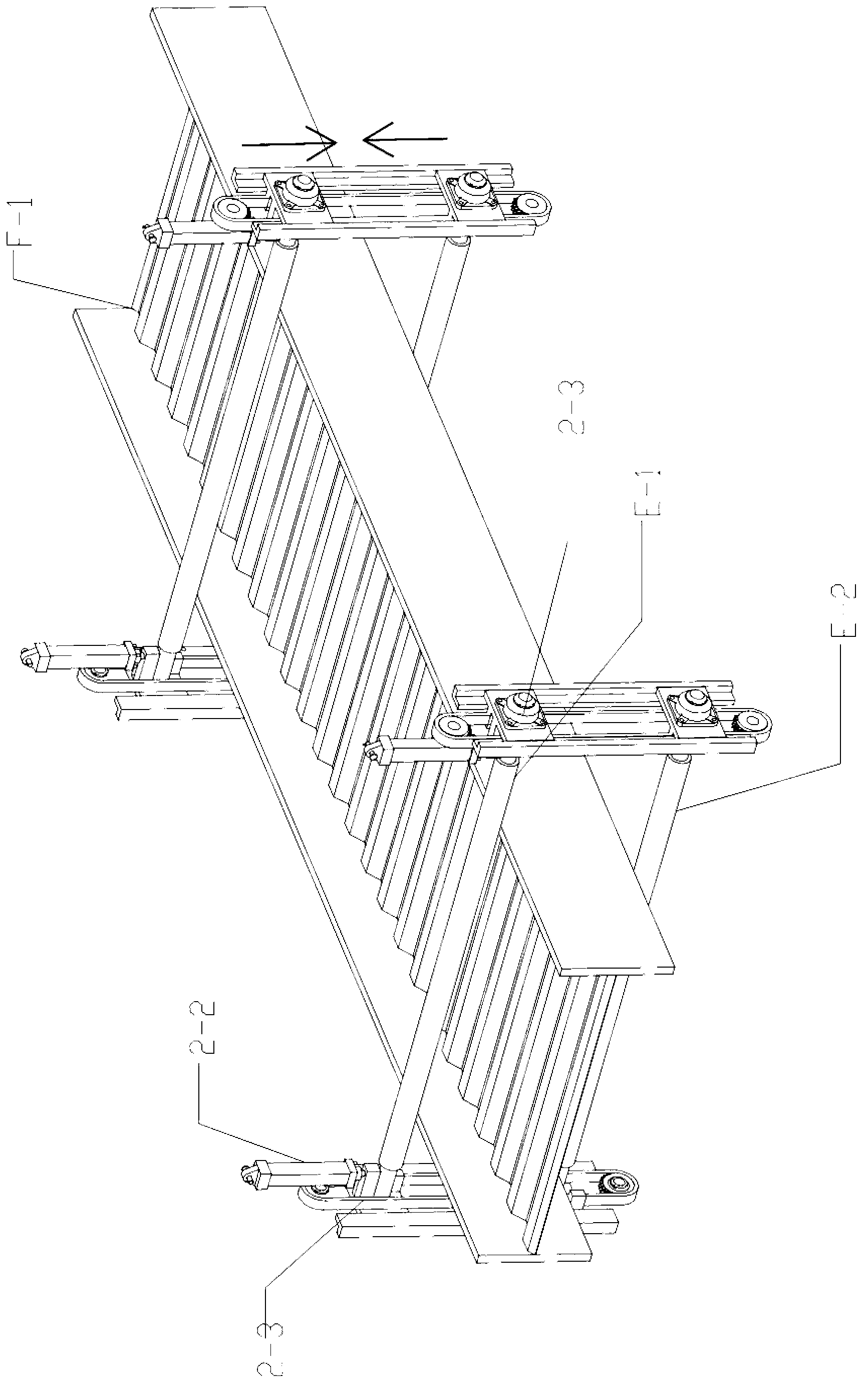

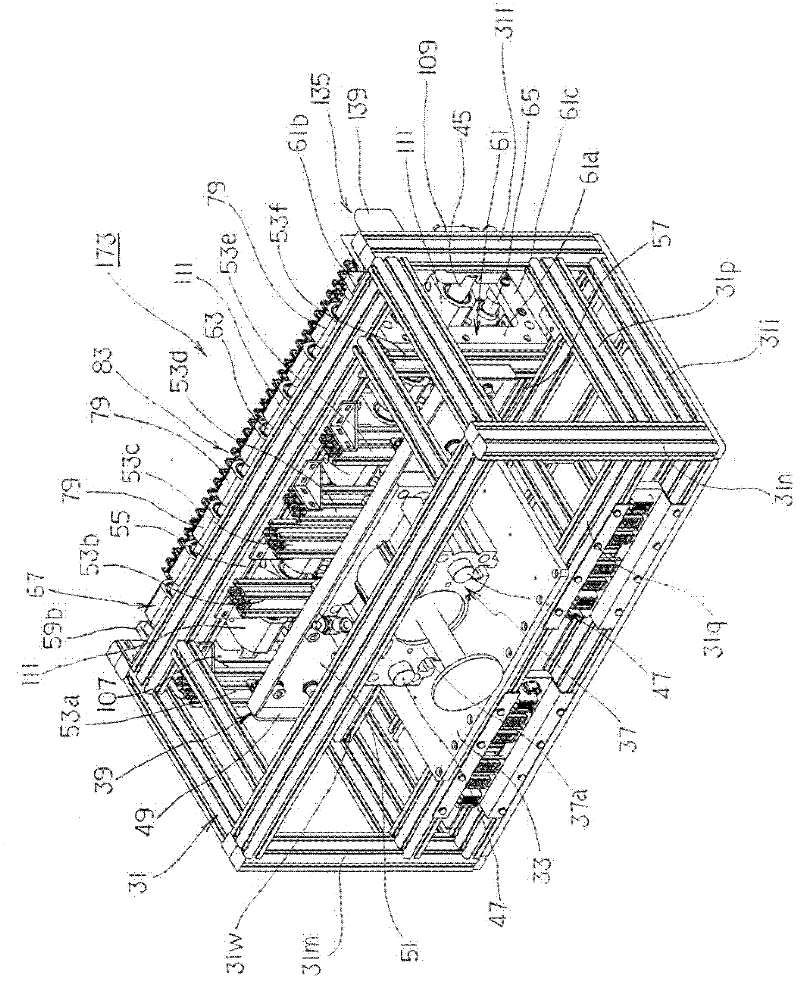

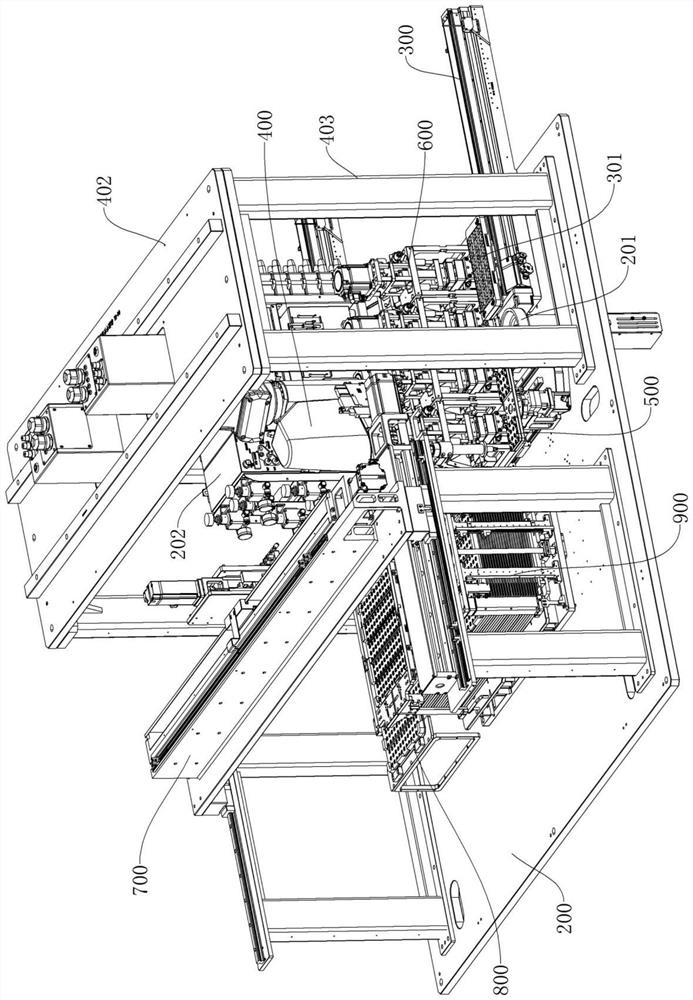

On-line automatic assembly device for H-shaped steel with corrugated web

InactiveCN102848108APrecise clampingDesign scienceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention relates to an on-line automatic assembly device for an H-shaped steel with a corrugated web and belongs to the field of mechanical equipment. The device disclosed by the invention comprises a portal, a runoff table, a hydraulic clamping system, an automatic spot welding machine, hydraulic power and a control system, wherein the hydraulic drive clamping system consists of a corrugated web, flange plates and an assembled H-shaped steel clamping device, the corrugated web and the flange plates are clamped in an up and down corresponding mode, the assembled H-shaped steel is clamped from two sides in a left and right corresponding mode, after clamping and assembly, spot welding is carried out with the automatic spot welding machine, and the spot-welded H-shaped steel is output from the station along with the runoff table of the H-shaped steel with the corrugated web. The on-line automatic assembly device disclosed by the invention has the outstanding characteristics that the hydraulic clamping device and the runoff table are matched concertedly and operated in balance, for example, a hydraulic clamping roller row and a non-started state transmission roller row constitute the H-shaped steel clamping device, a transmission roller row and a non-started state hydraulic clamping roller row constitute the runoff table, and double functions and two effects are realized, so that the purpose of the on-line automatic assembly device is successfully achieved by accurate and balanced coordination.

Owner:HUBEI HONGYI STEEL CONSTR ENG

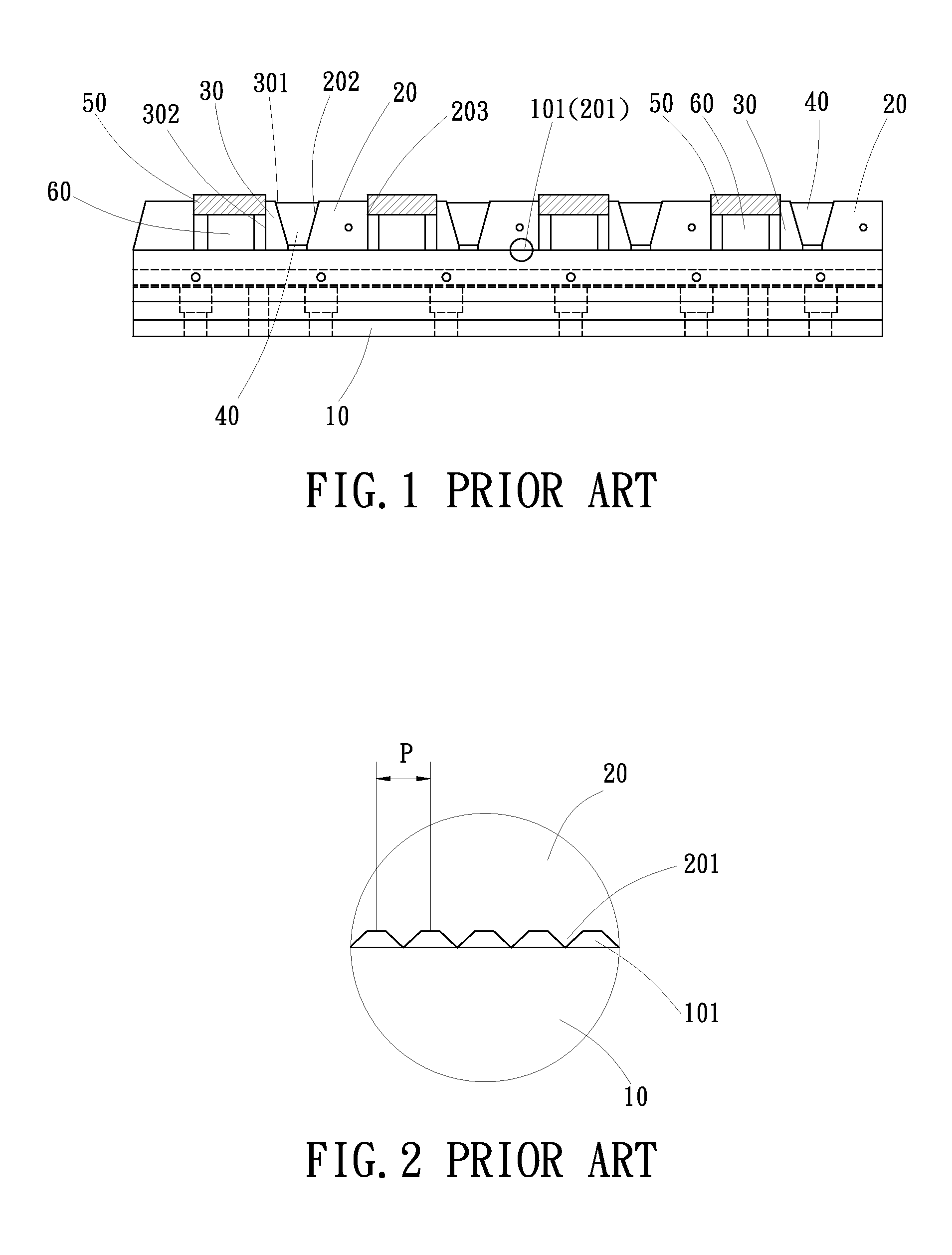

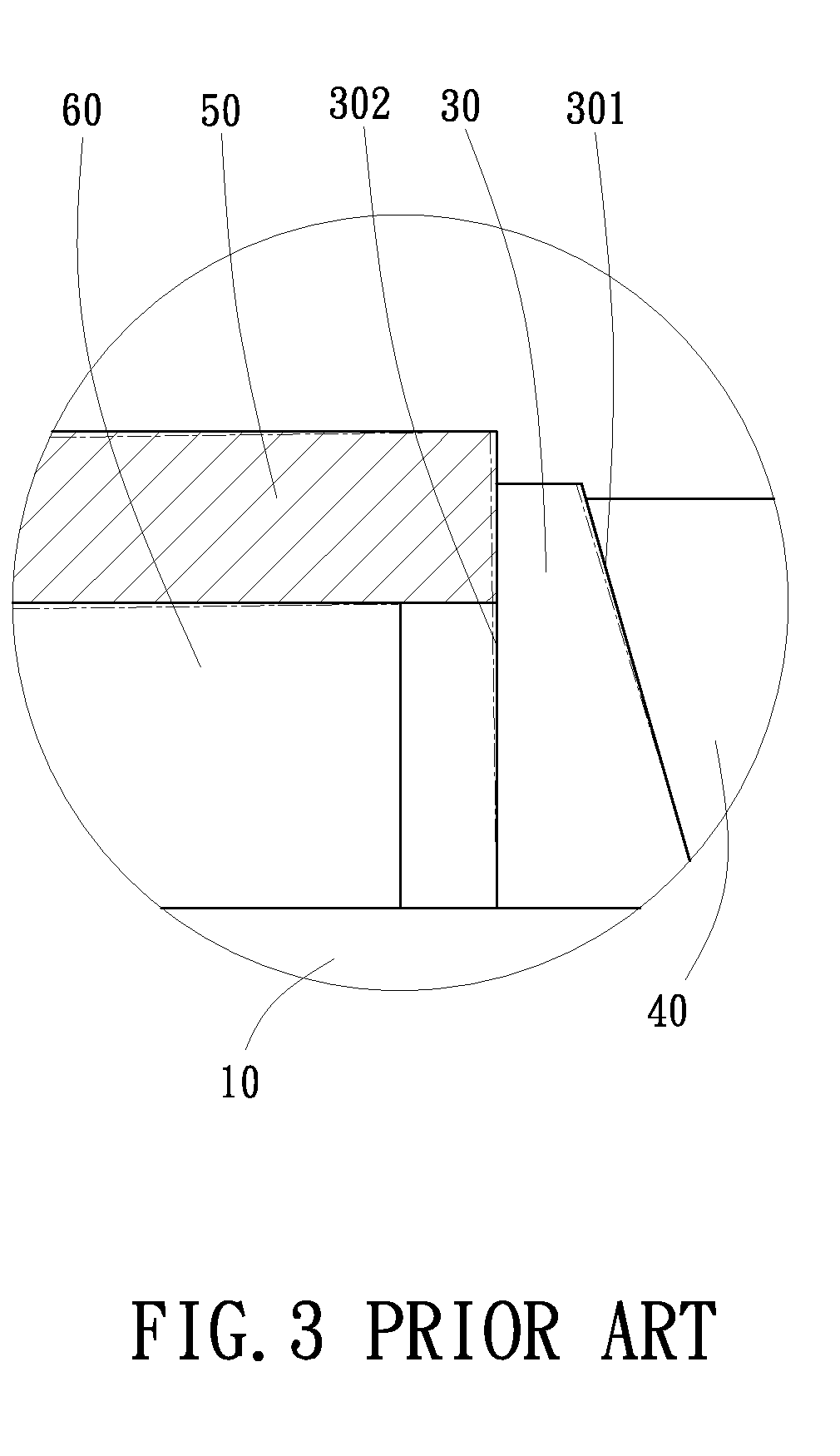

Micro-adjustable parallel bench vise

InactiveUS20100295227A1Precision clampLow clamping forcePositioning apparatusVicesMechanical engineering

A micro-adjustable parallel bench vise includes a slide holder having a top dovetail rail, a vise body having a bottom dovetail groove coupled to the dovetail rail of the slide holder and holding a fixed jaw member, a screw holder slidably mounted in the top side of the vise body, a screw rod threaded into the screw holder and rotatable to move the screw holder relative to the vise body. When multiple vise bodies are mounted on the slide holder in parallel, they are micro-adjustable to hold a workpiece or multiple workpieces precisely in position.

Owner:HUNG YI PO

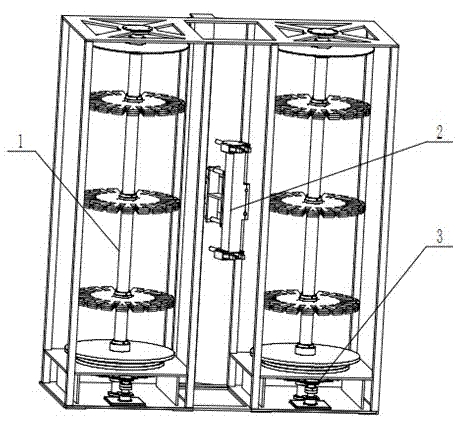

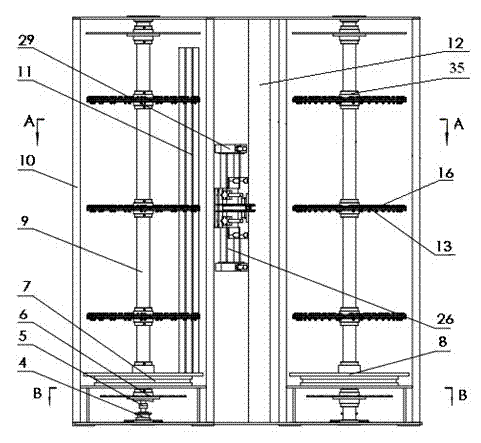

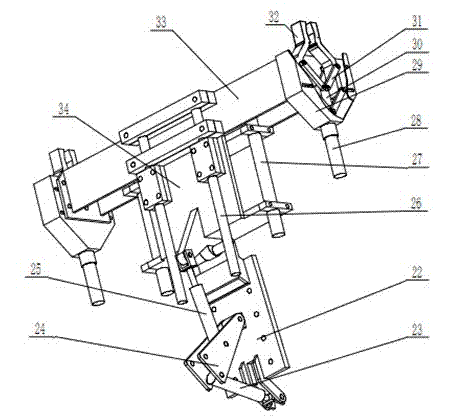

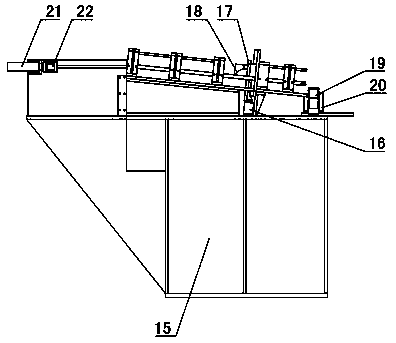

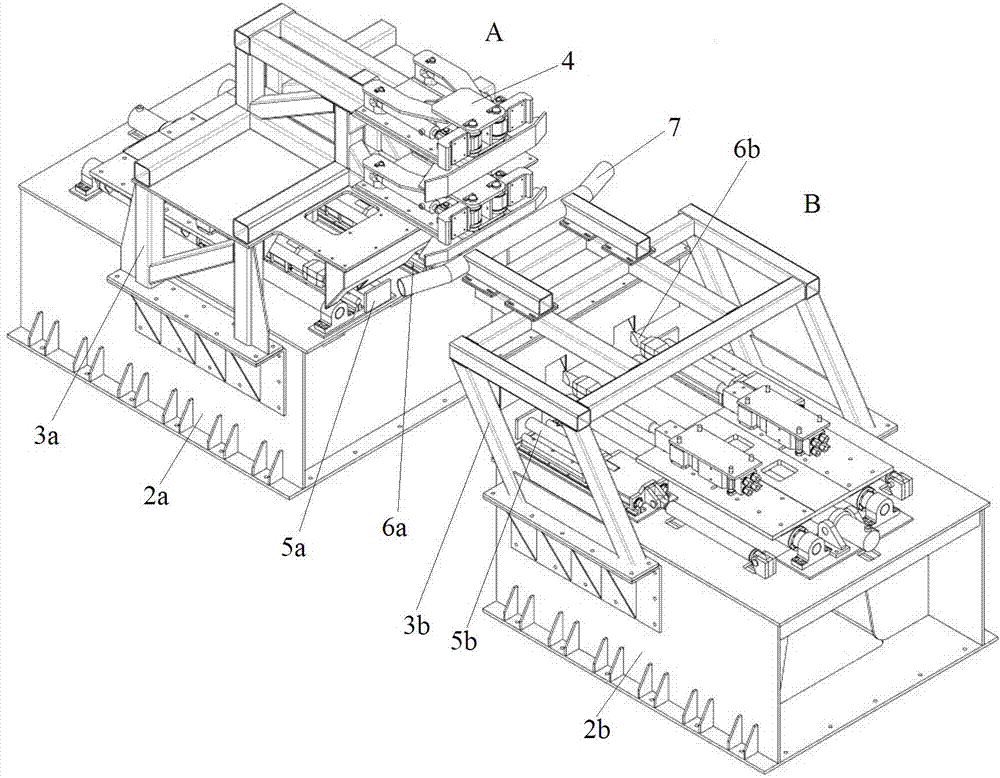

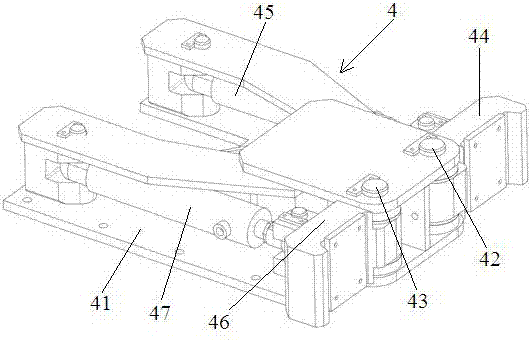

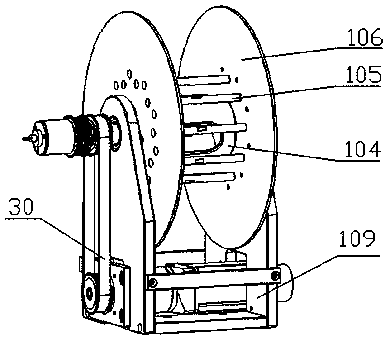

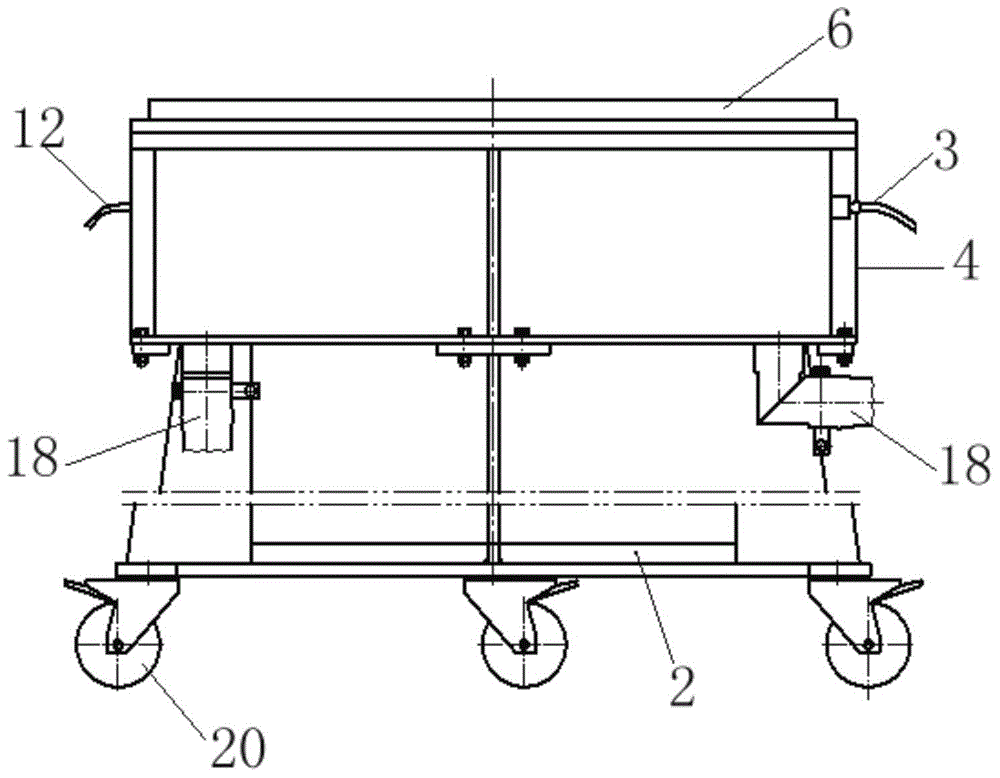

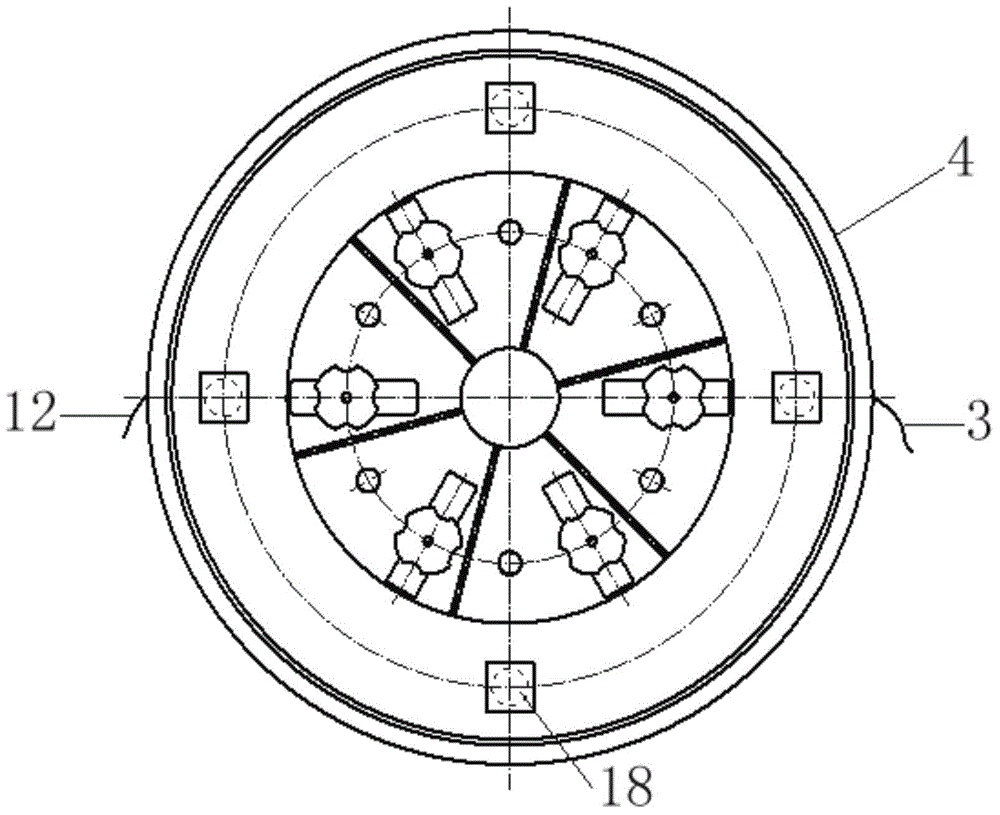

Automatic storage system for drill stem

InactiveCN102242612ALarge capacityAdjustable spacingDrilling rodsDrilling casingsWorking environmentPetroleum engineering

The invention relates to an automatic storage system for a drill stem. The automatic storage system comprises drill stem storerooms, a grab mechanism and a driving mechanism, wherein the drill stem storerooms are two and are mainly used for storing various drill stems, and each drill stem storeroom can store 60 drill stems; the driving mechanism is mainly used for driving the drill stems in the drill stem storerooms to rotate intermittently to ensure that the drill stems in the drill stem storerooms can rotate a certain angle each time; the grab mechanism is used for storing the drill stems and realizing the assembly and disassembly of the drill stems, so that a drilling tool moves among three positions, namely the left drill stem storeroom, the right drill stem storeroom and a power head; and actions such as the storage, take-off, clamping, assembly and disassembly and the like of the drill stems can be completed accurately by the matching among the drill stem storerooms, the grab mechanism and the driving mechanism. The storage system has a simple structure, is large in capacity, convenient to operate and high maintainability, and offers a reliable performance; and when the storage system is used, unmanned operation is realized, the work efficiency is high, and the automatic storage or remote control of the drill stems can be realized in special severe work environment.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

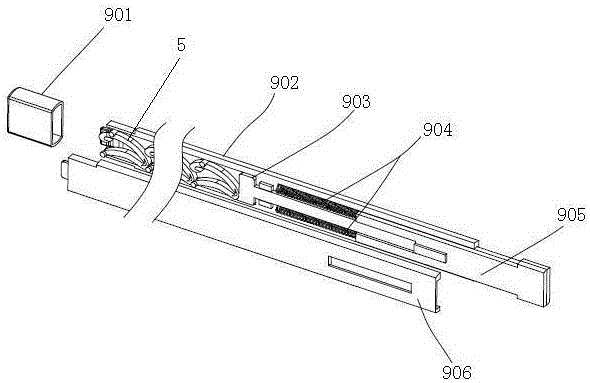

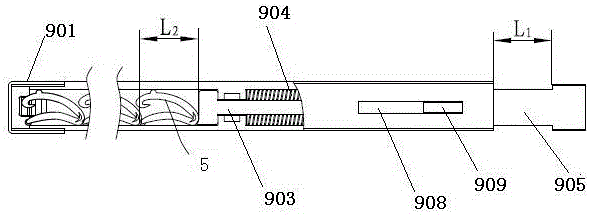

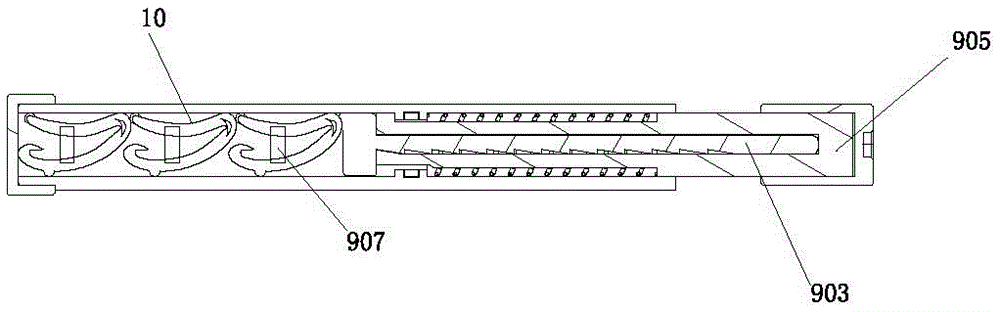

Medical biological clamping box for hair connecting

ActiveCN105997183APrecise clampingRealize the clinical function of ligationWound clampsEngineeringBlood vessel

A medical biological clamping box for hair connecting is characterized by comprising a box cap (901), a box bottom (902), a biological clamping and pushing head (903), a push piece reset spring (904), a reciprocating push piece (905), a box cover (906), and a box body formed by buckling the box bottom (902) and the box cover (906), one end of the box body is provided with biological blood vessel clamps (5), the outlet end of the box body is sleeved with the box cap (901) so that the biological blood vessel clamps (5) can be guided between an upper jaw and a lower jaw, the last biological blood vessel clamp (5), away from the outlet end, in the box body abuts against one end of the biological clamping and pushing head (903), the other end of the biological clamping and pushing head (903) is provided with ratchet teeth which abut against pushing teeth on the reciprocating push piece (905), the force exerting end of the reciprocating push piece (905) extends out of the box body to abut against a push rod (4), one end of the push piece reset spring (904) abuts against the reciprocating push piece (905), and the other end of the push piece reset spring (904) abuts against a boss in the box body. The medical biological clamping box is simple in structure, safe and reliable.

Owner:JIANGSU HAIZE MEDICAL TECH DEV

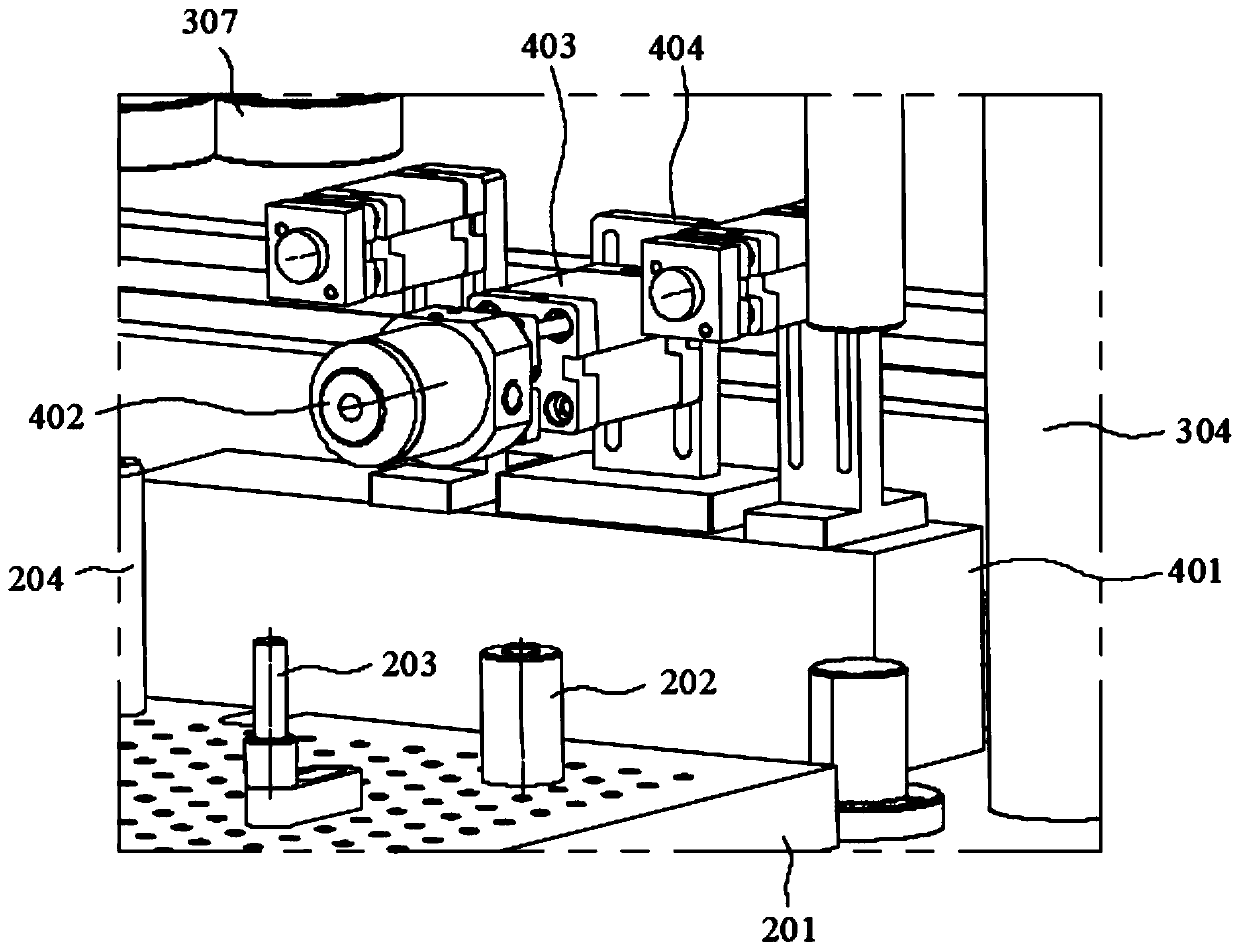

Axis part machining center

PendingCN108817970AImprove processing qualitySmall sizeFeeding apparatusOther manufacturing equipments/toolsDrillMachining

The invention relates to an axis part machining center, and belongs to the technical field of single hydraulic prop machining equipment. The axis part machining center comprises a drilling device anda lathe; and the axis part machining center is characterized in that the drilling device comprises a drilling clamp and a plurality of drilling main shafts (26) arranged around the drilling clamp, themultiple drilling main shafts (26) are arranged in one plane, the drill ends of the drilling main shafts (26) face the drilling clamp, each drilling main shaft (26) is connected with a drilling motor(27) driving the drilling main shaft (26) to rotate, each drilling main shaft (26) is connected with a drilling feeding device, and a drilling device drilling cutter (28) on each drilling main shaft(26) faces the drilling clamp. According to the drilling device of the axis part machining center, machining of multiple holes in workpieces can be completed, synchronization machining of the multipleholes in the workpieces is achieved through one time of feeding, the sizes and positions of the holes in the workpieces are accurate, the machining quality is stable, the machined workpiece quality is good, the accuracy is high, and efficiency is improved.

Owner:SHANDONG HANYE MACHINERY CO LTD +1

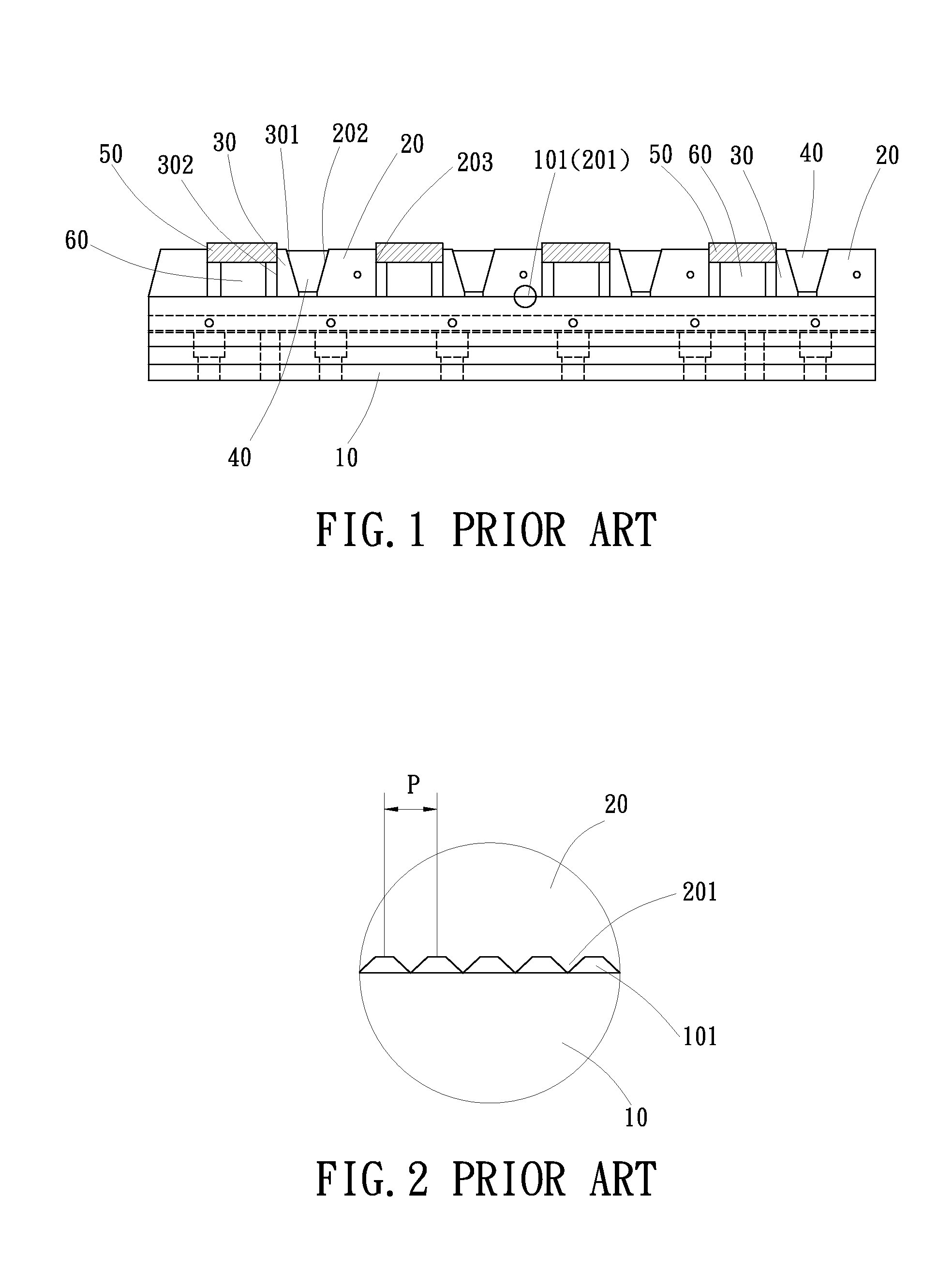

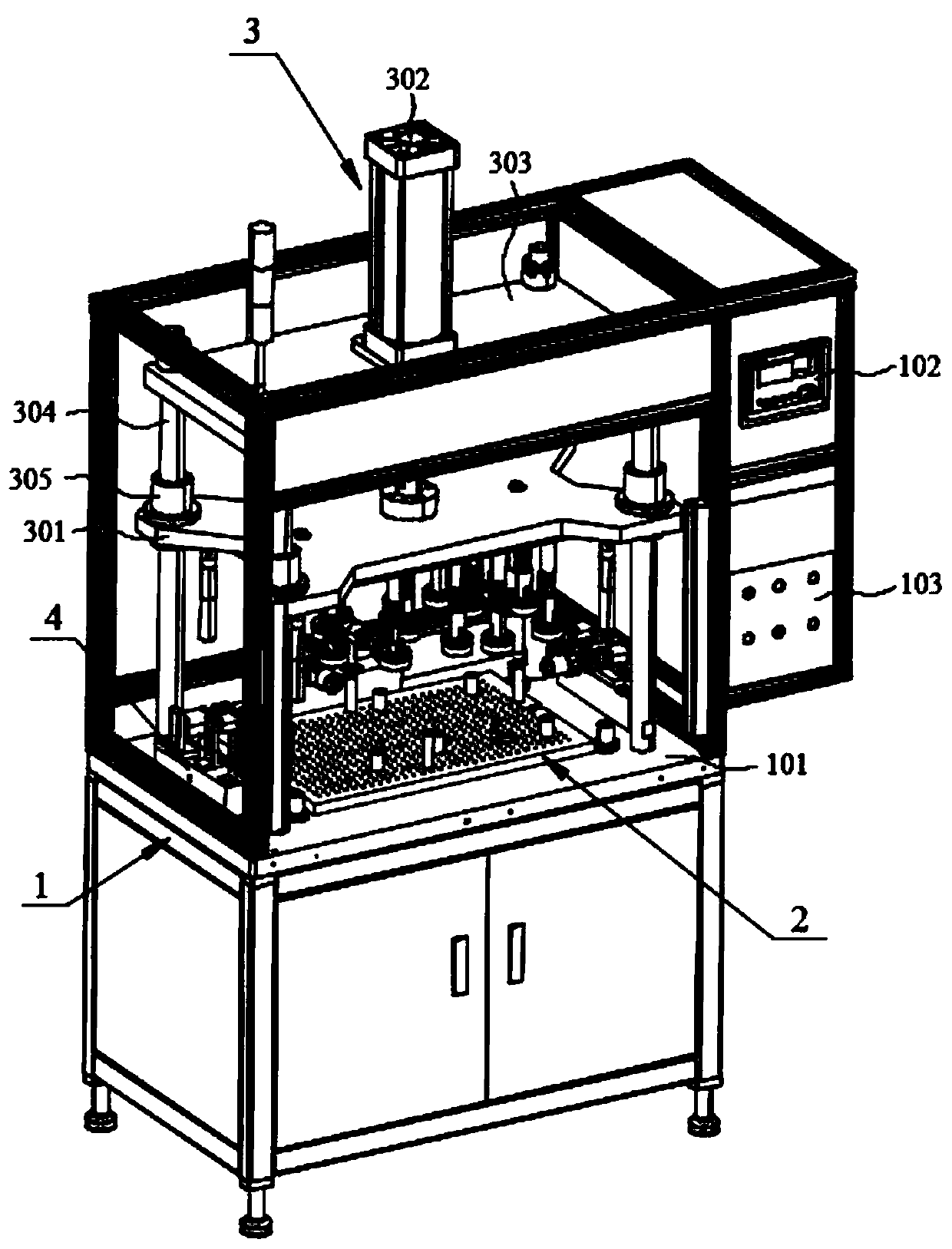

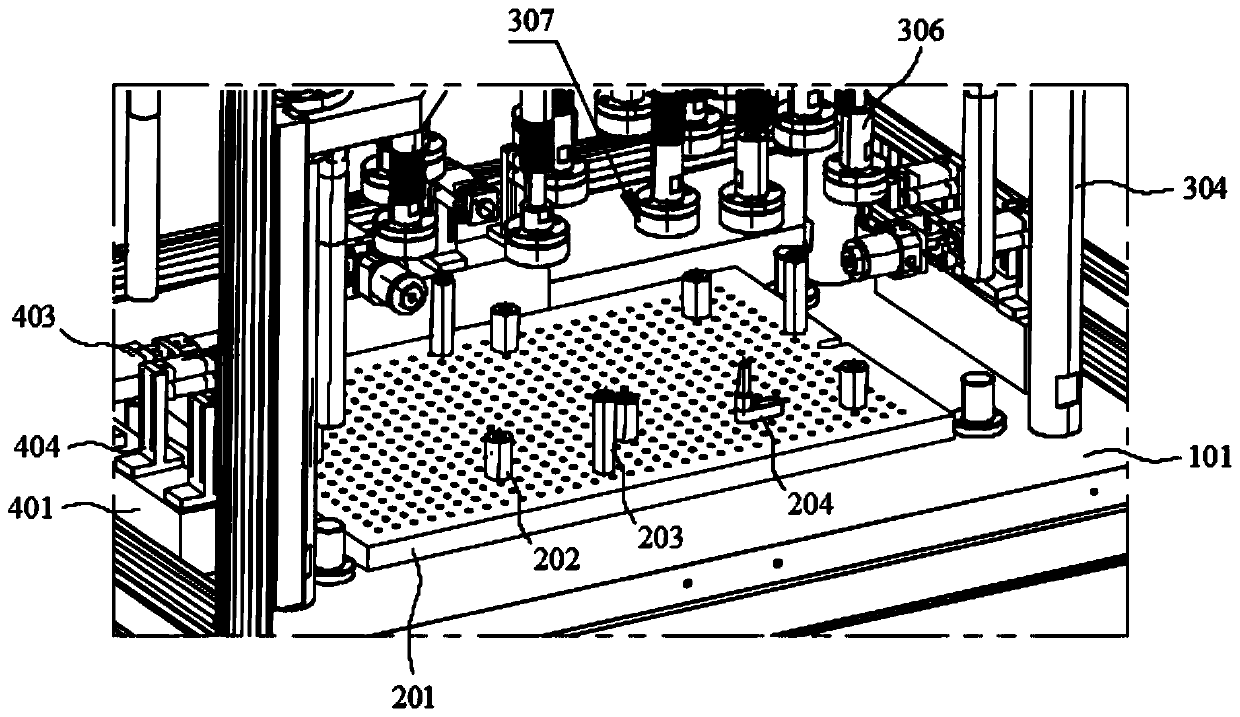

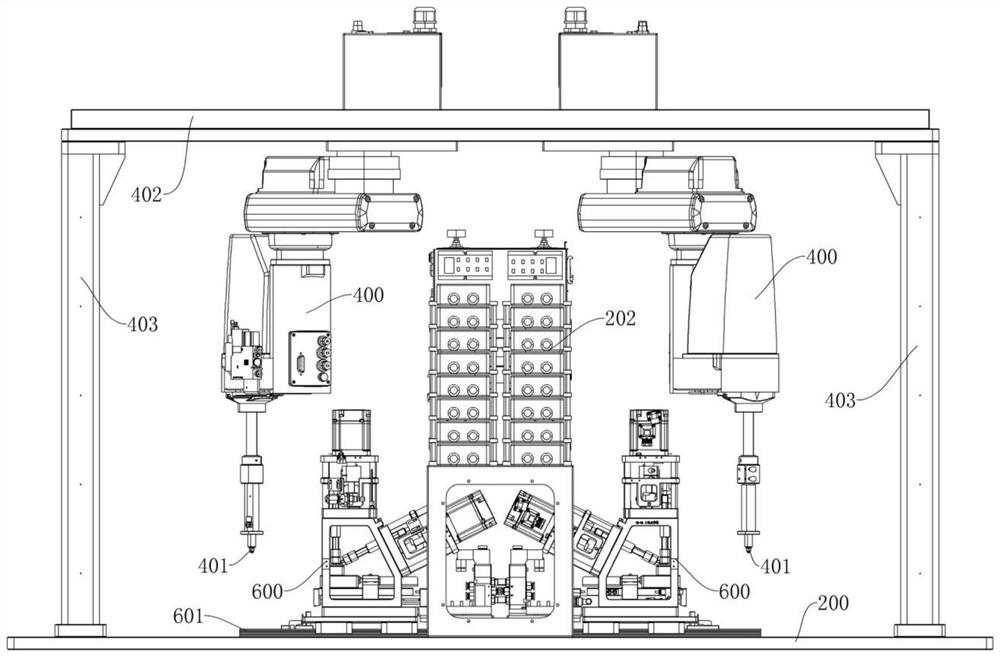

Clamping mechanism of charge-discharge test device for thin secondary battery

ActiveCN102290615APrecise clampingCorrectly and well clampedFinal product manufactureCurrent conducting connectionsBattery chargeElectrical battery

The present invention relates to a chuck mechanism of a charge / discharge testing device for flat-rechargeable batteries and has a proposition to provide a chuck mechanism that makes it possible to lighten conventionally needed troublesome works, that is, for example, works of storing and fixing a large number of flat-rechargeable batteries in a container, and that is capable of surely chucking the flat-rechargeable batteries (electrodes). The chuck mechanism includes a first guide couplable with a battery storage retaining a plurality of flat-rechargeable batteries arranged in parallel, and a plurality of chuck units continuously joined with the first guide and resiliently arranged in parallel, wherein the chuck units each have a second guide resiliently positioning each of the chuck units with a predetermined number of corresponding flat-rechargeable batteries in the battery storage.

Owner:TOKYO SEIMITSU +1

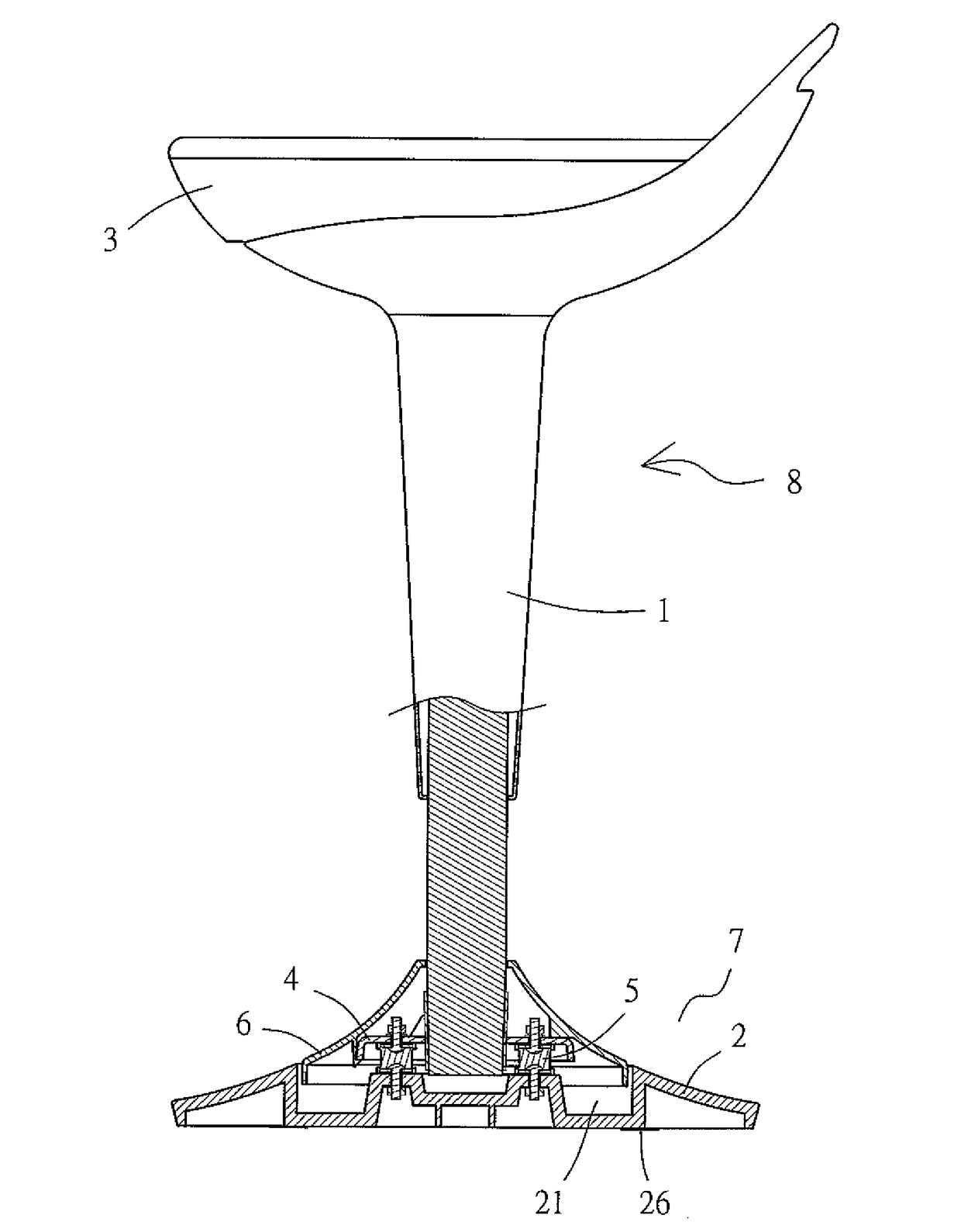

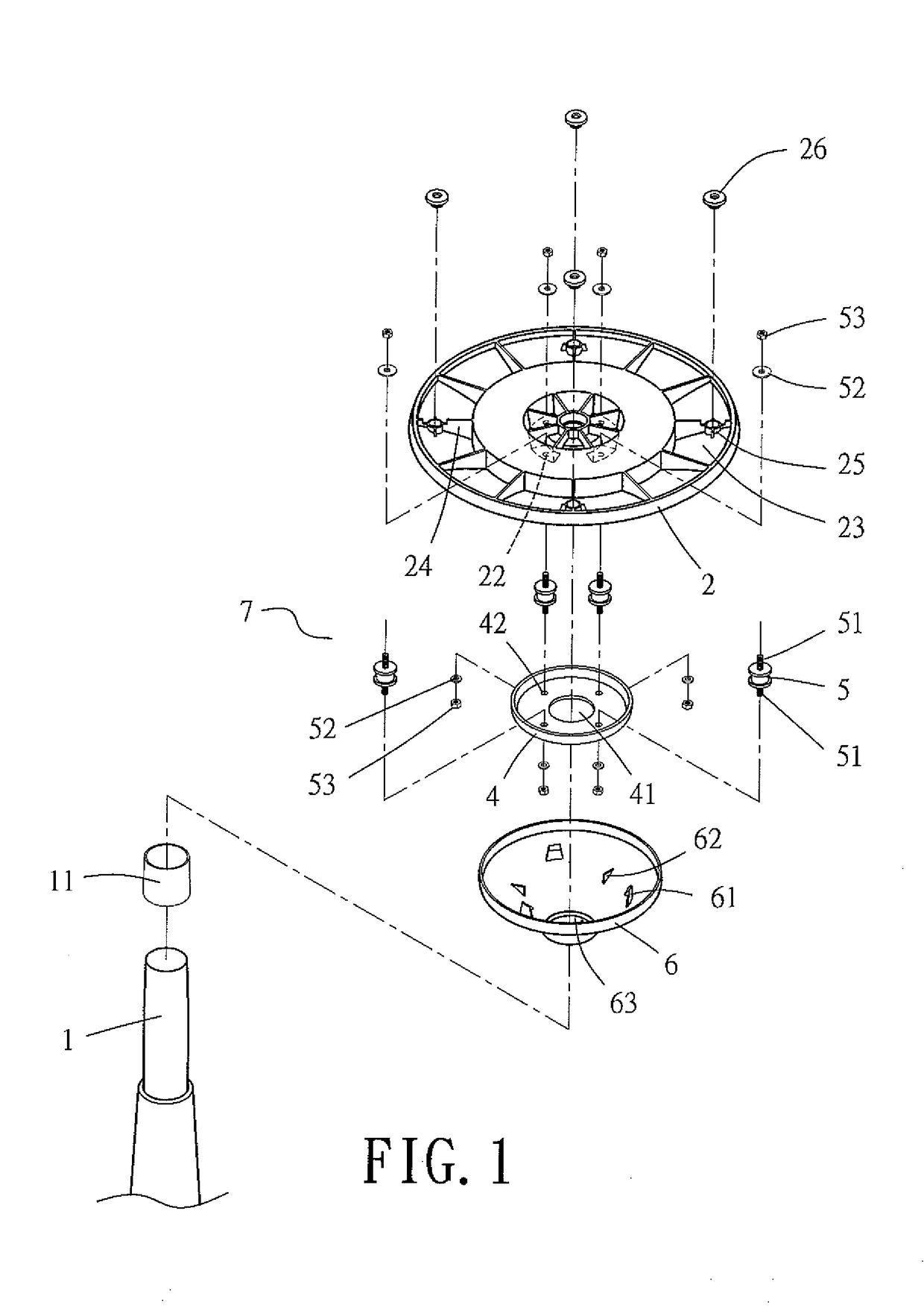

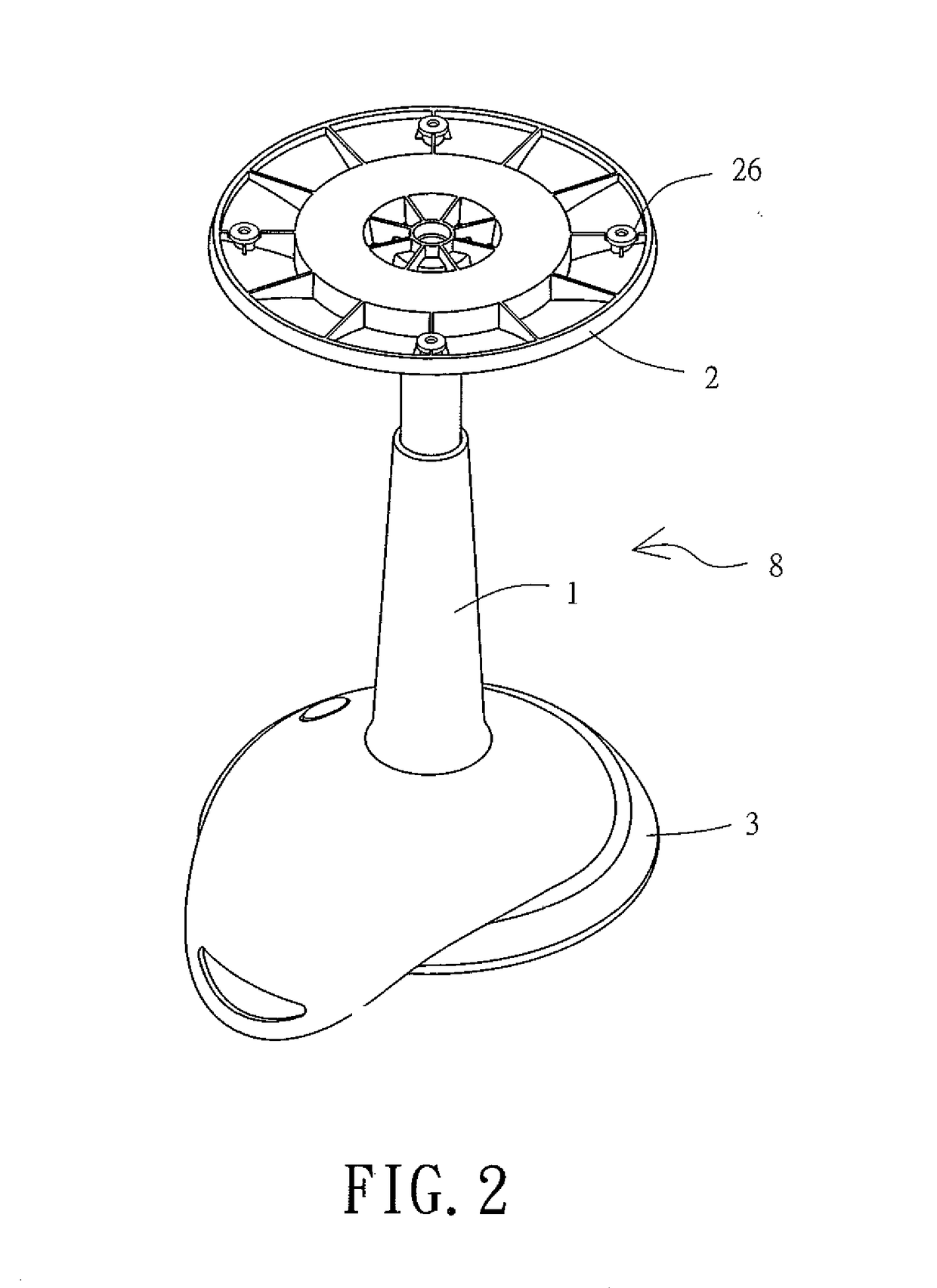

Reclinable office chair

ActiveUS9763520B1Lose directional stabilityComfortable seatOffice stoolsRocking chairsOffice chairForward backward

A reclinable office chair includes a reclination adjustment unit disposed at the bottom of the office chair. The reclination adjustment unit balances itself on the floor properly, resiliently and steadily. The office chair tilted in a forward-backward direction and / or a left-right direction displays directional stability relative to the floor in a manner not to lose the directional stability even when a sitter tilts in any direction, thereby allowing the office chair to provide a comfortable seat for the sitter to sit on, regardless of whether the office chair is upright or tilted in any direction.

Owner:OASYSCHAIR

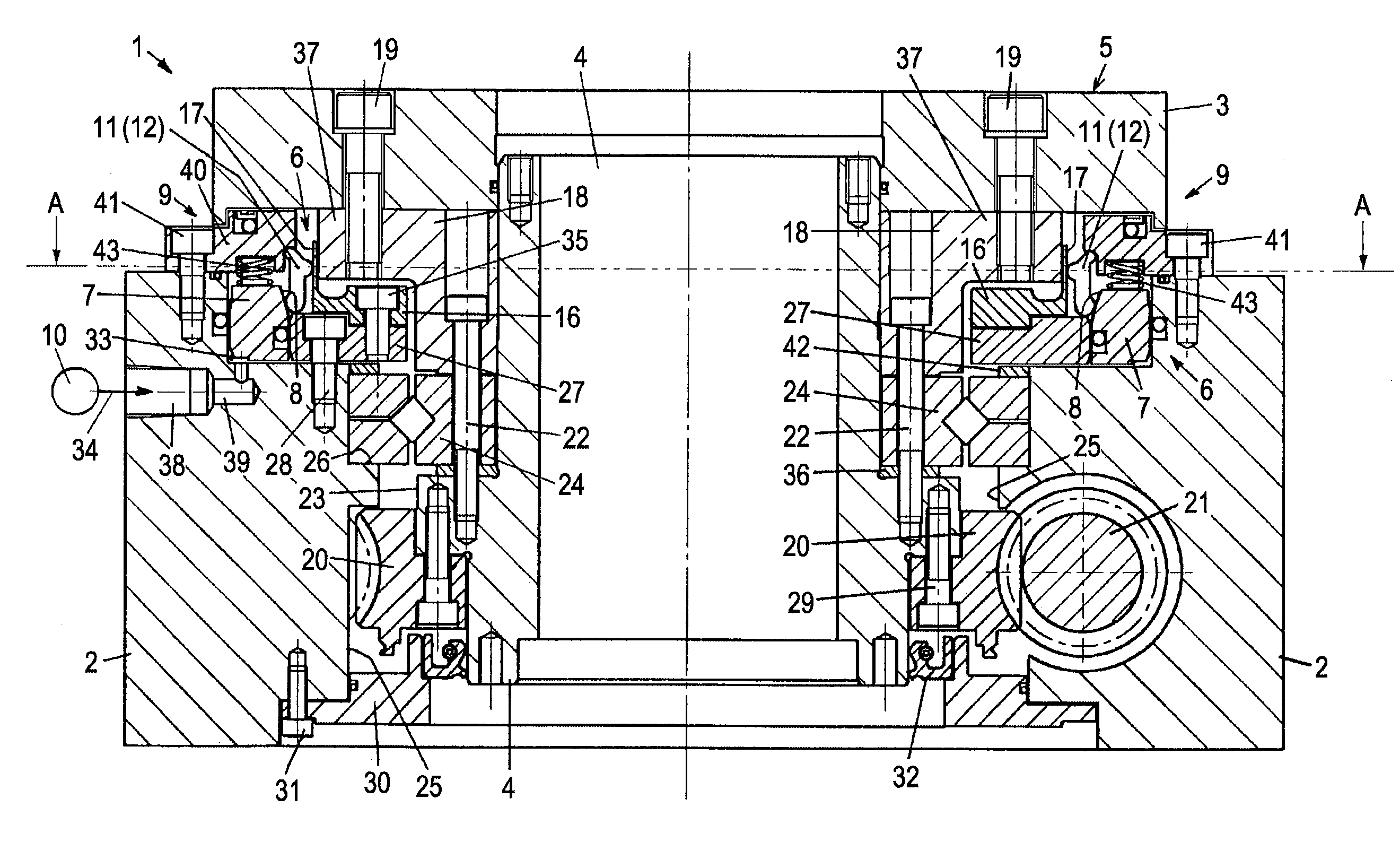

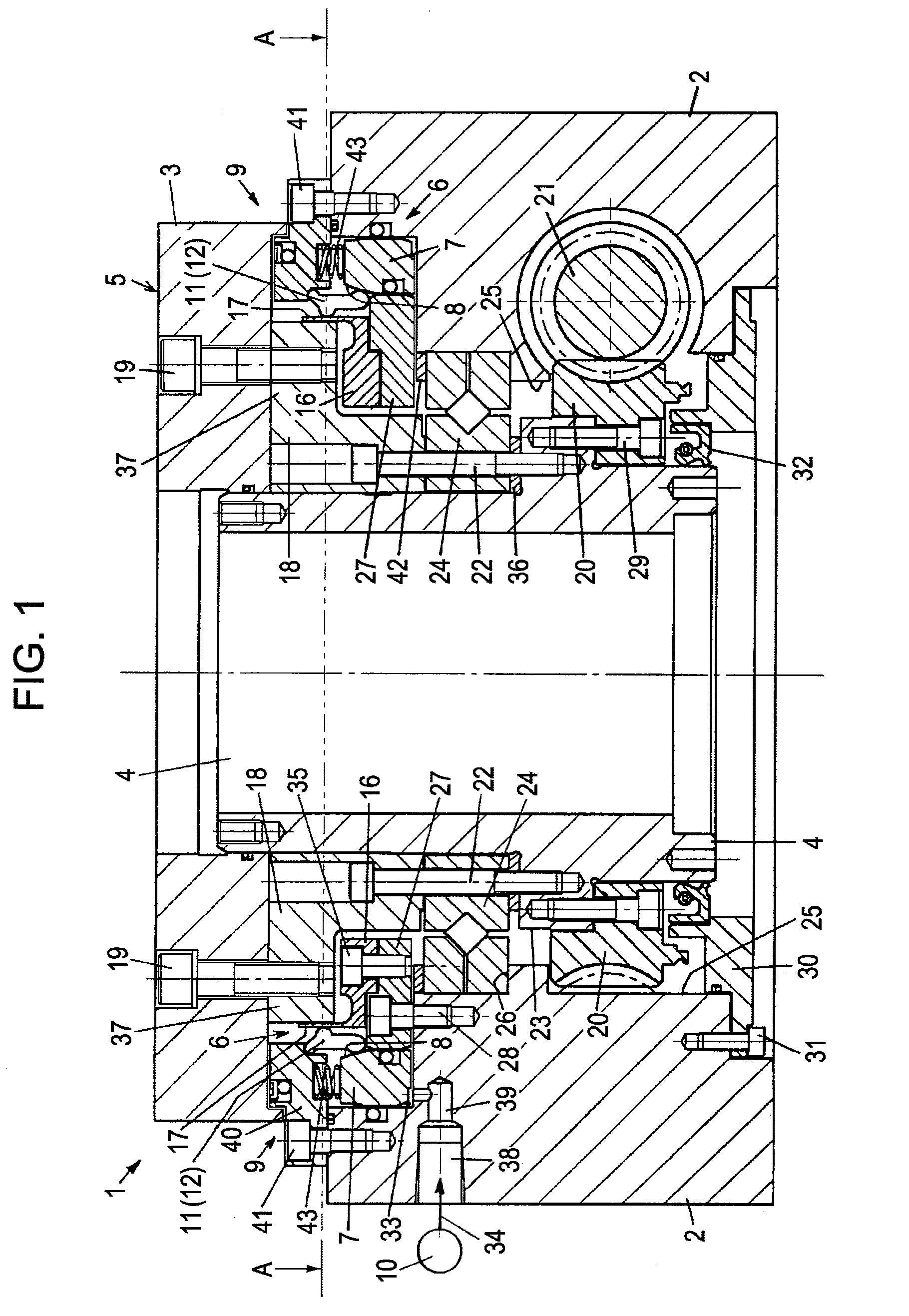

Rotary index device in machine tool

InactiveUS20100199804A1Improve accuracyPrecise clampingMechanical apparatusPrecision positioning equipmentRotational axisEngineering

A rotary index device in a machine tool includes a rotating shaft; and a clamp device. The clamp device includes a piston member provided displaceably in a direction along a rotational axis of the rotating shaft and having a tapered surface formed on a side surface thereof on a clamp position side, pressing force conversion means, for receiving a pressing force from the piston member when the piston member is displaced, converting the pressing force into a force in the radial direction of the rotating shaft, and causing the converted force to act on the rotational body, and urging means for urging the piston member in a direction in which the pressing force conversion means generates the pressing force in the radial direction of the rotating shaft.

Owner:TSUDAKOMA KOGYO KK

Timber discharging machine with tailing material dragging function

ActiveCN106078931AReduce wasteAvoid the defect of excessive marginFeeding devicesCircular sawsEngineeringMechanical engineering

The invention provides a timber discharging machine with a tailing dragging function and belongs to the technical field of machines. The technical problem that a last section of tailing material is seriously wasted when an existing discharging sawing machine is used for cutting a batten is solved. The timber discharging machine comprises a rack. A horizontal worktable is arranged on the rack. An electric saw is arranged on the rack. A first horizontal guide rail is further fixed to the rack. A first sliding block is connected to the first horizontal guide rail in a sliding manner. The rack is provided with a first driving source used for driving the first sliding block to move along the first horizontal guide rail. A first clamping claw is fixed to the first sliding block. A second horizontal guide rail is further fixed to the rack. A second sliding block is connected to the second horizontal guide rail in a sliding manner. The rack is provided with a second driving source used for driving the second sliding block to move along the second horizontal guide rail. A second clamping claw is fixed to the second sliding block. The first clamping claw and the second clamping claw are located on the two sides of the electric saw correspondingly and can clamp the same piece of timber at the same time. According to the timber discharging machine with the tailing material dragging function, the waste of the tailing material of the timber can be reduced, and the utilization rate of the last section of tailing material of the timber is increased when the batten is cut.

Owner:TAIZHOU EVOK MASCH CO LTD

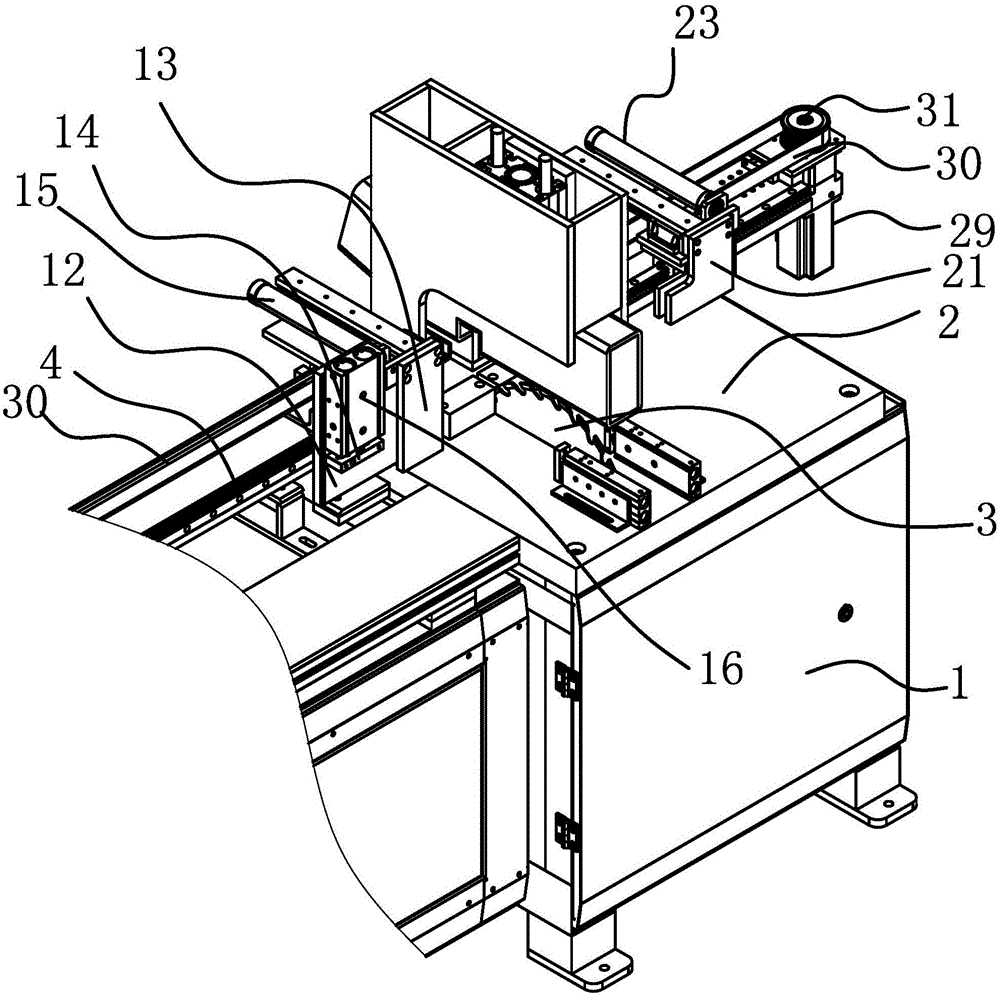

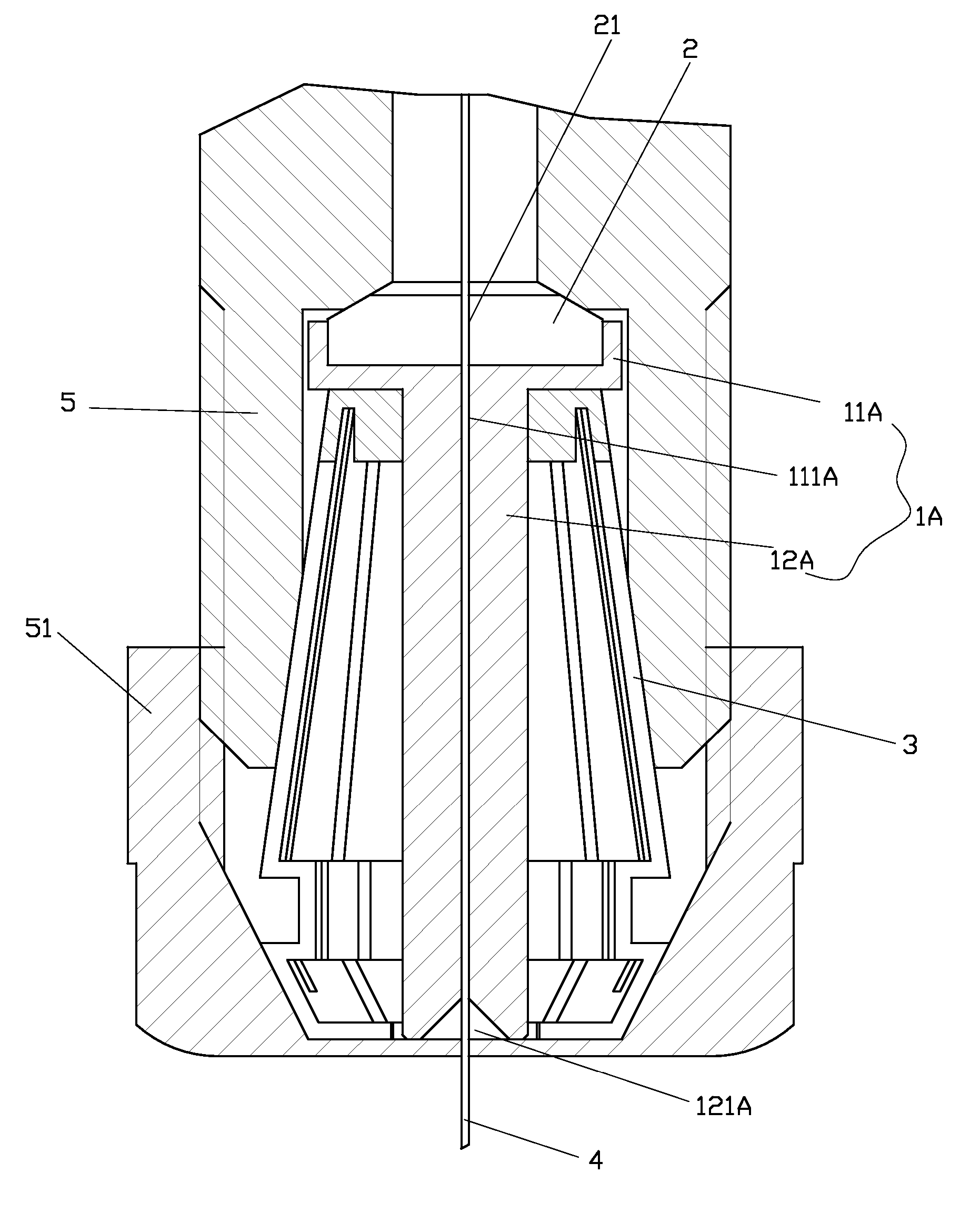

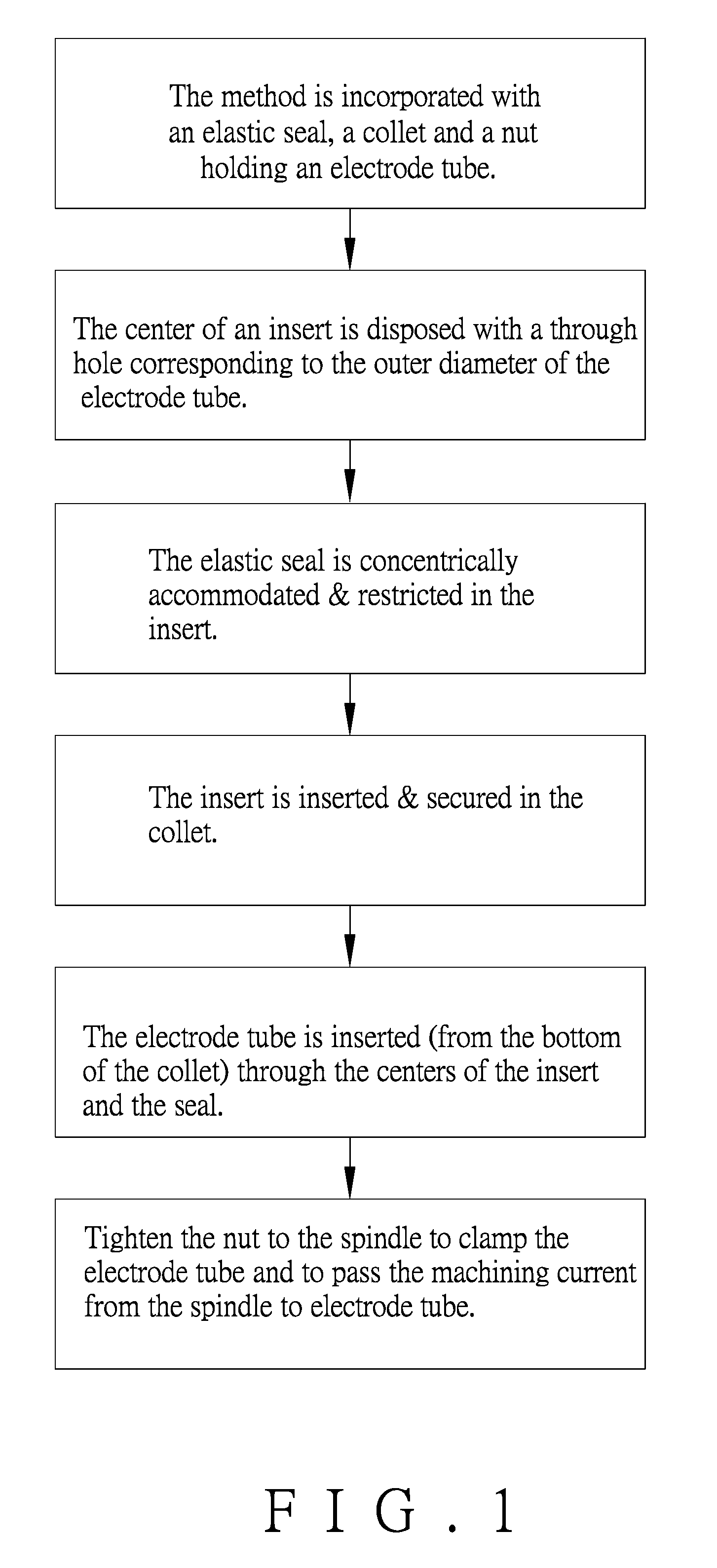

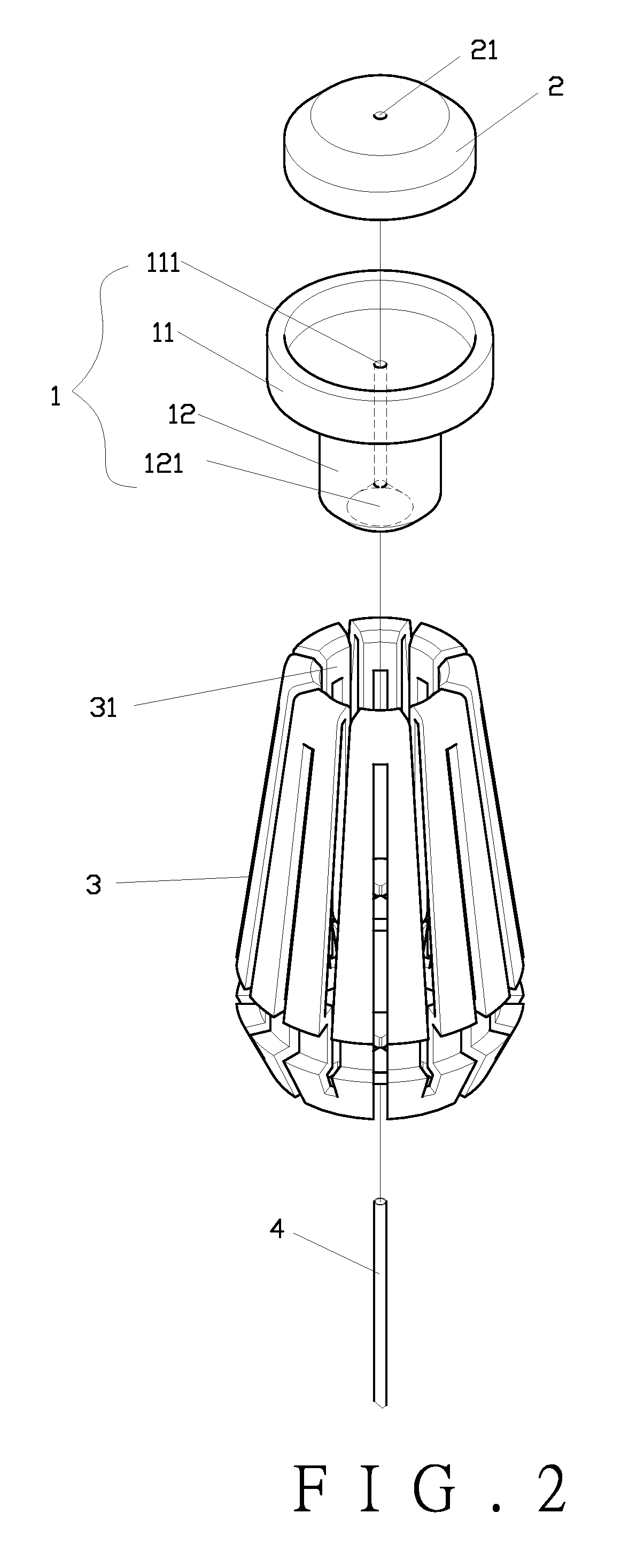

Method and Apparatus for Clamping an Electrode Tube in EDM Drill Equipment

InactiveUS20060289392A1Accurately heldPrecise clampingElectrical-based machining electrodesRetaining ringEngineering

A method and apparatus for clamping an electrode tube in an EDM drill equipment is incorporated with an elastic seal and a collet. The method providing an insert having a through hole disposed at the center to concentrically accommodate and restrict the elastic seal, placing the insert into the collet, and inserting the electrode tube in the insert and the elastic seal, tightening the nut to the spindle to clamp the electrode tube and passing the EDM machining current from the spindle to electrode tube. The apparatus includes an insert having a retaining ring to restrict an elastic seal, a through hole to admit insertion by the electrode tube. The insert of the above method and apparatus comprises a guiding pipe to be secured in the collet, and a tapered guide hole interconnecting with the through hole to facilitate insertion of the electrode tube. Optional slots are provided at the lower portion of the guiding pipe.

Owner:TAI I ELECTRON MACHINING

Intelligent steel coil clamp

ActiveCN105819329AQuality improvementPrecise clampingLoad-engaging elementsRolling resistanceCrane scheduling

The invention relates to an intelligent steel coil clamp in the technical field of intelligent unmanned crane scheduling systems for steel coil yards. The intelligent steel coil clamp comprises a clamp body and swing mechanisms, wherein a width detection limit switch and a planar linear bearing are installed on one clamping arm of the clamp body; each swing mechanism is connected with the corresponding clamping arm through a pin shaft; a slide plate is installed in each swing mechanism; each slide plate is located between a steel coil and the corresponding planar linear bearing; and when the steel coil is clamped by the clamping arms to enable the swing mechanisms to rotate around the pin shafts to trigger the width detection limit switches, one end part of the steel coil jacks the slide plates, and the steel coil moves downwards along the planar linear bearings with the slide plates until the clamping arms hook an inner ring wall of the steel coil. The intelligent steel coil clamp disclosed by the invention has the following beneficial effects: the stability of the clamp is improved through connection between hanging shafts and a double-end hook, and rolling friction is formed through the slide plates and the planar linear bearings to ensure the quality of the end part of the steel coil; and the clamp is simple in structure, fast and convenient to operate, and low in cost, and thereof is capable of accurately clamping the steel coil and avoiding damage to the steel coil.

Owner:CISDI ENG CO LTD

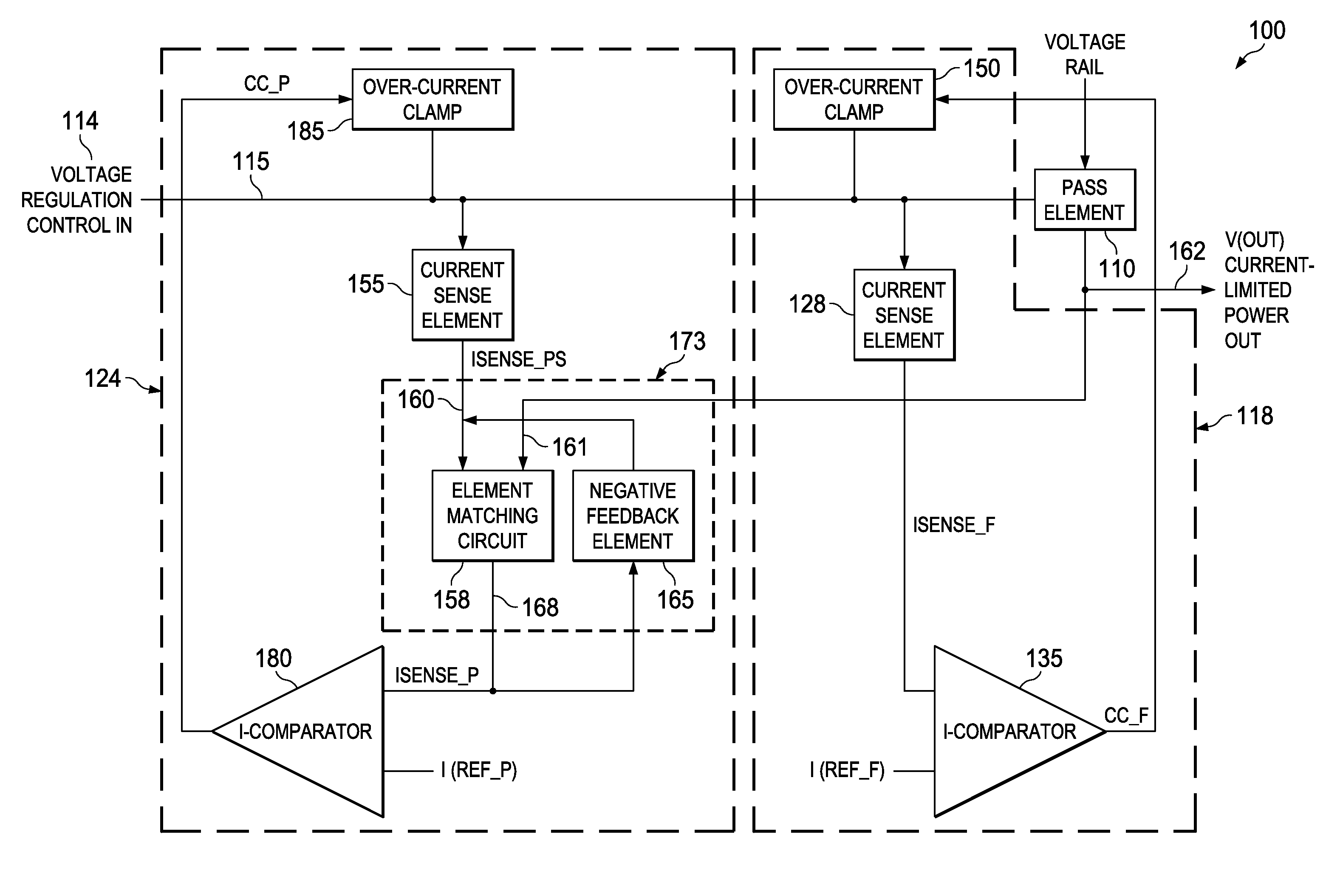

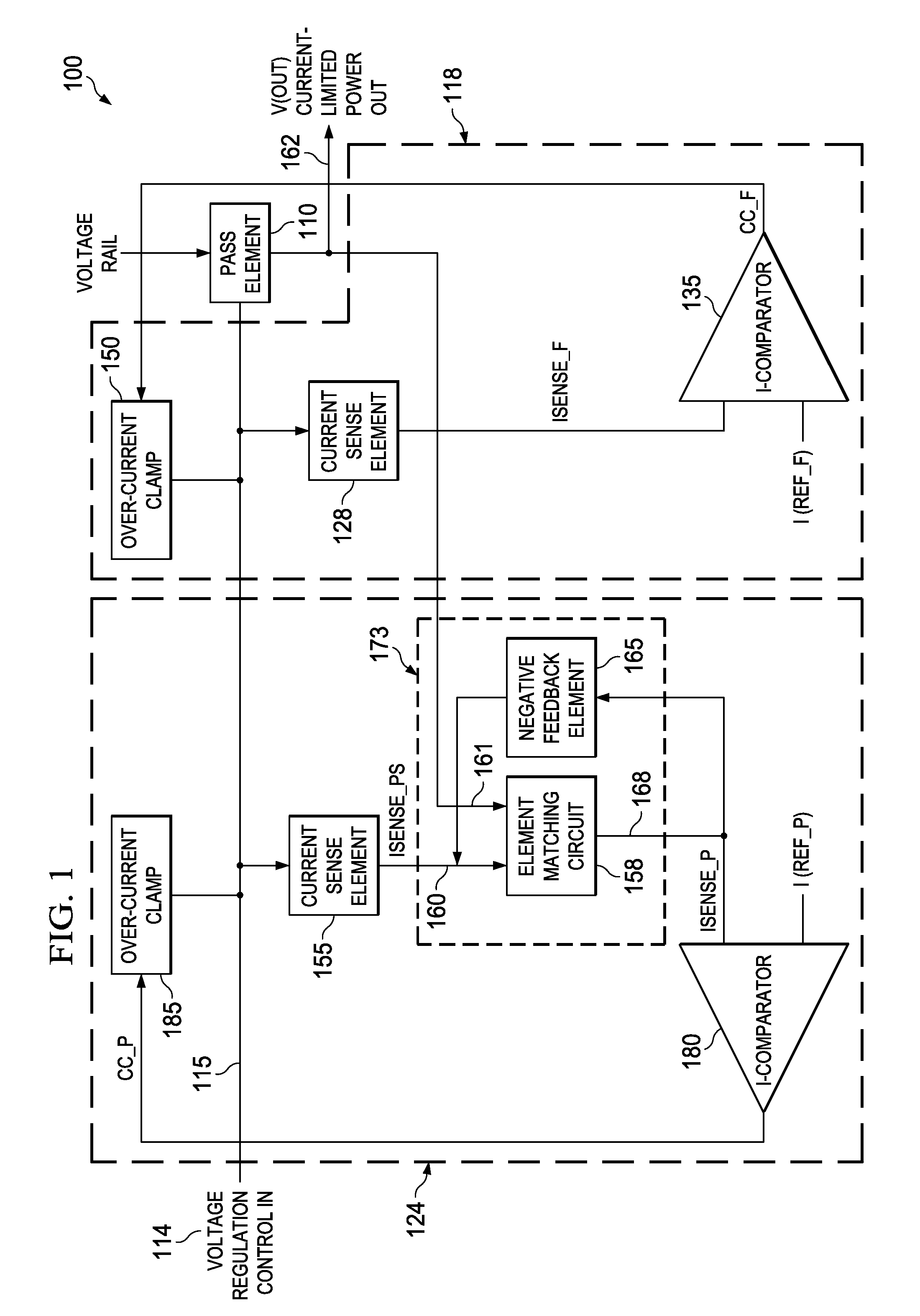

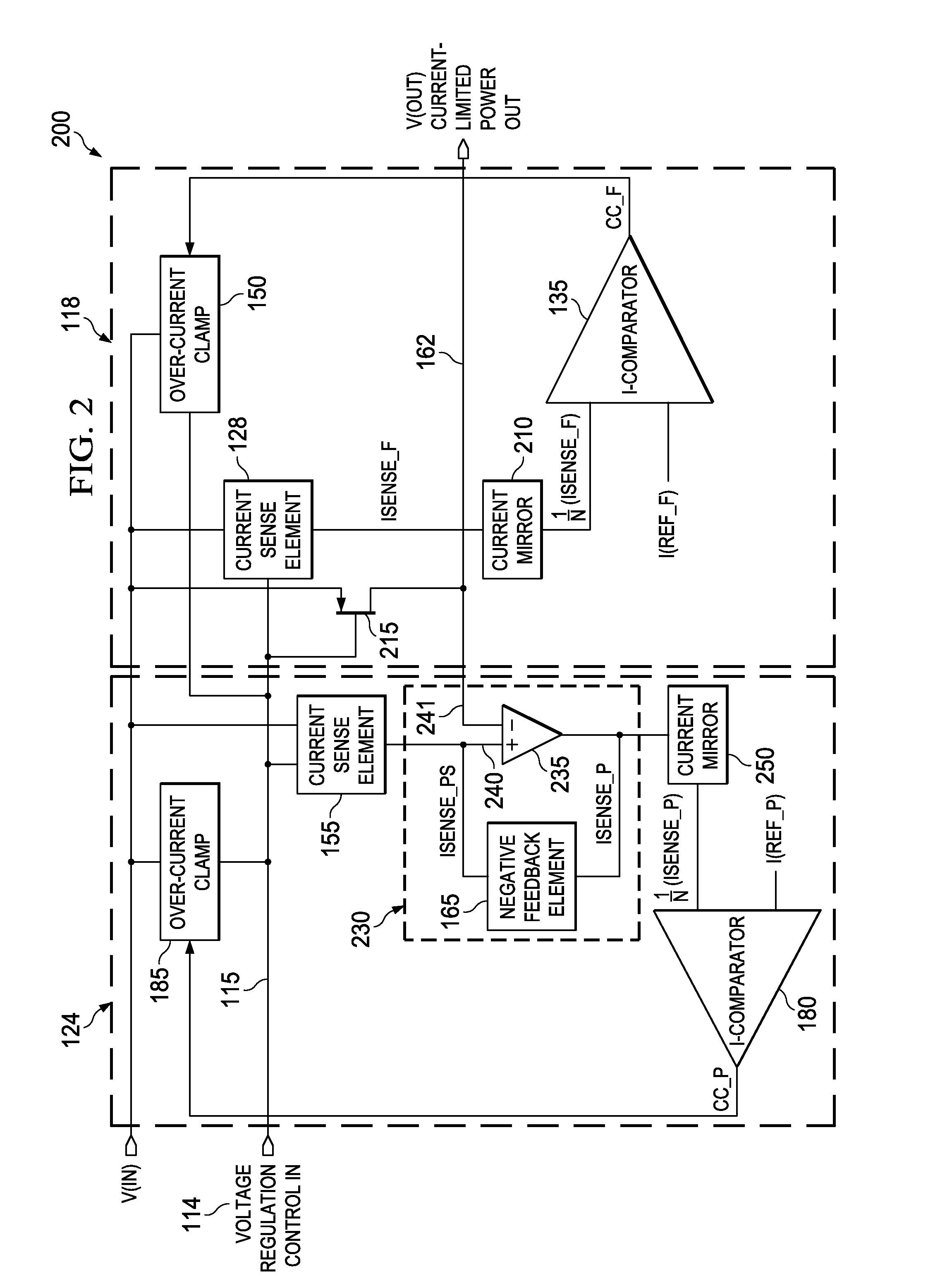

Fast transient precision power regulation apparatus

ActiveUS20140355161A1Precise clampingAccurate signalEmergency protective arrangements for limiting excess voltage/currentInner loopLinearization

Apparatus disclosed herein implement a fast transient precision current limiter such as may be included in an electronic voltage regulator. The current limiter includes two current sense element / current clamp control loops. A fast response time control loop first engages and clamps a current spike. A precision control loop then engages to more accurately clamp the output current to a programmed set point. The precision clamping loop includes an inner loop to linearize the precision current sense element. The inner loop forces the drain-to-source voltage (VDS) of the precision sense element to track the VDS of the regulator pass element. A more precise clamping operation results. Overall speed is not sacrificed as the fast response time clamping loop operates in parallel to protect circuitry while the precision clamping loop engages.

Owner:TEXAS INSTR INC

Electrolyte cleaning device

The invention relates to an electrolyte cleaning device. When the electrolyte cleaning device disclosed by the invention is used, two groups of guide rod clamping mechanisms which are arranged up and down at intervals are respectively clamped on different rod sections of an aluminum guide rod to preliminarily limit the motion of an anode guide rod group; and the displacement of carbon blocks is limited through a carbon block clamping mechanism. According to the electrolyte cleaning device disclosed by the invention, the anode guide rod group of higher level is sectionally fixed in an up-down direction, so that the improvement on a fixing effect is facilitated; further, after the anode guide rod group is preliminarily limited by the guide rod clamping mechanism, the carbon block clamping mechanism is driven to do a clamping action so that the carbon blocks can be accurately clamped and positioned by a clamping surface. Meanwhile, by adopting clamping claws of the guide rod clamping mechanism, an aluminum guide rod is clamped and fixed from a front side surface and a rear side surface of the aluminum guide rod; and the carbon blocks are clamped and fixed by the carbon block clamping mechanism from left sides and right sides of the carbon blocks. According to the application, the anode guide rod group can be accurately fixed on a set position, so that the improvement on a crushing effect is facilitated.

Owner:HTC METALLURGICAL EQUIP CO LTD XINXIANG VIBRATION

Clamping and machining method capable of guaranteeing machining accuracy of aluminum profile frame

The invention discloses a clamping and machining method capable of guaranteeing the machining accuracy of an aluminum profile frame. One right angle of the rectangular aluminum profile frame is clamped firstly, a half length of an X-direction aluminum profile frame bar and a half length of a Y-direction aluminum profile frame bar at the right angle are cut, then the other three right angles of the rectangular aluminum profile frame are respectively clamped and cut, and finally cutting of the whole rectangular aluminum profile frame is completed. According to the method, the mode of clamping the whole rectangular aluminum profile frame and then cutting the rectangular aluminum profile frame in the past is changed into the clamping and machining mode of separately clamping the four angles and cutting the clamped angles after the angles are clamped, rectangular aluminum profile frames of different tolerance can be machined, frames of different dimensional tolerance can be accurately clamped and completely attached to the standard, and the yield can be greatly increased.

Owner:豆秀梅

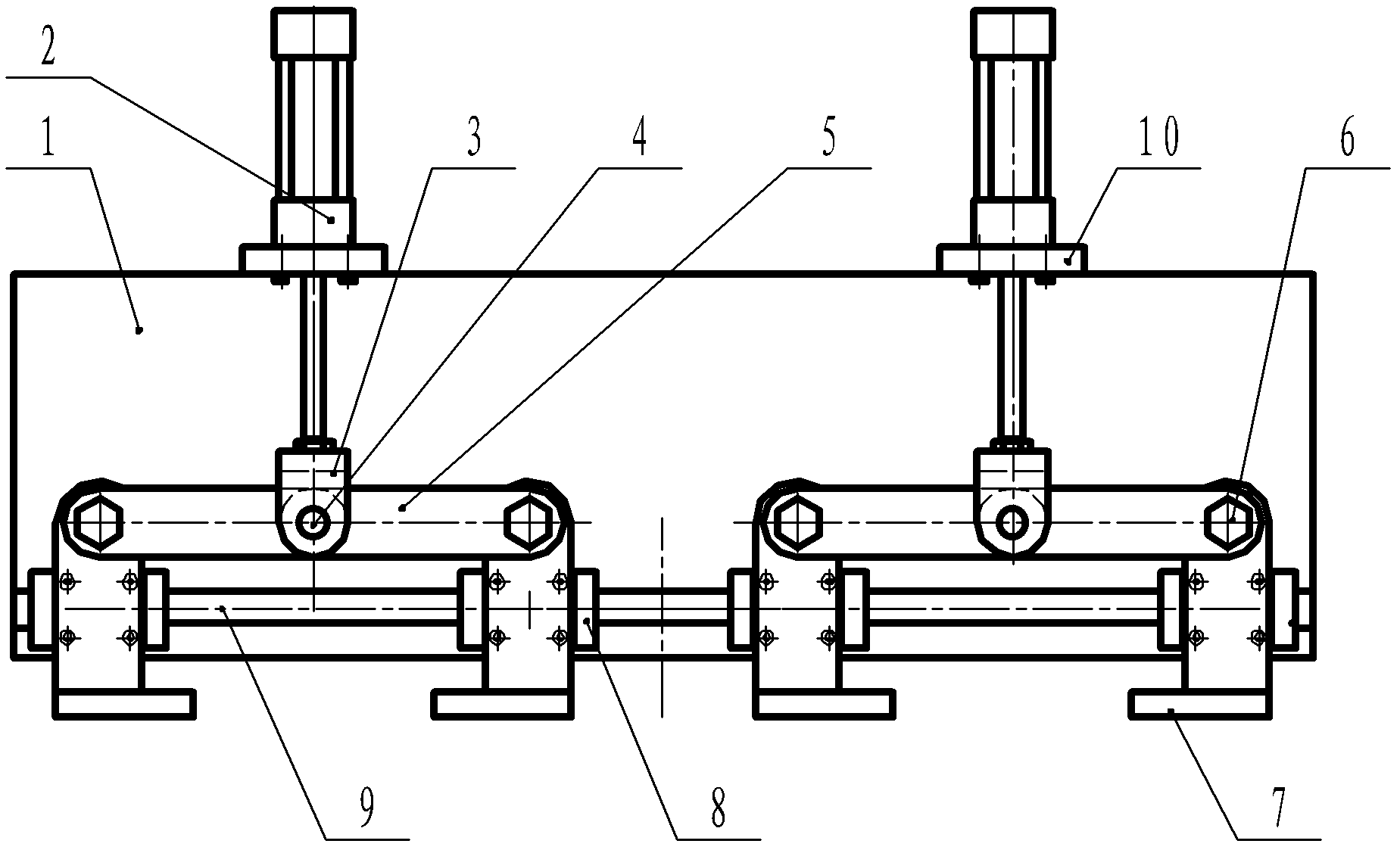

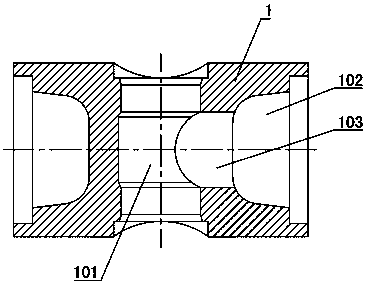

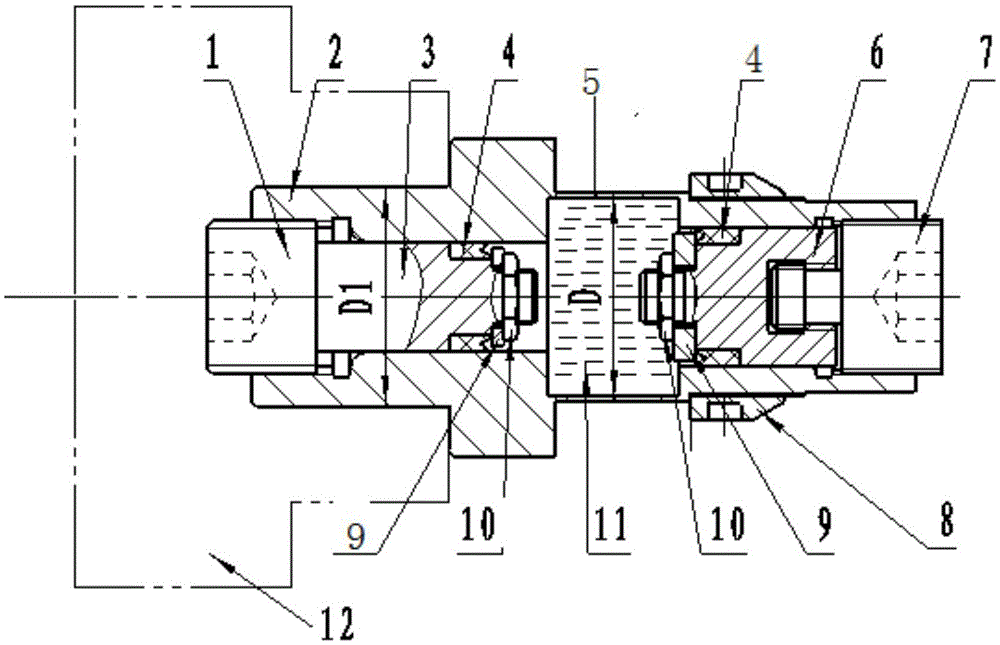

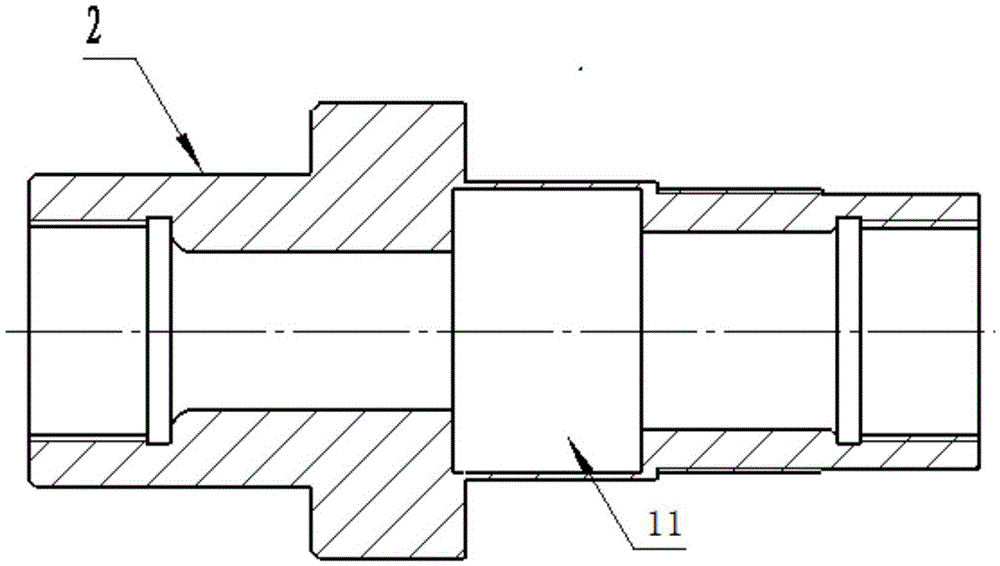

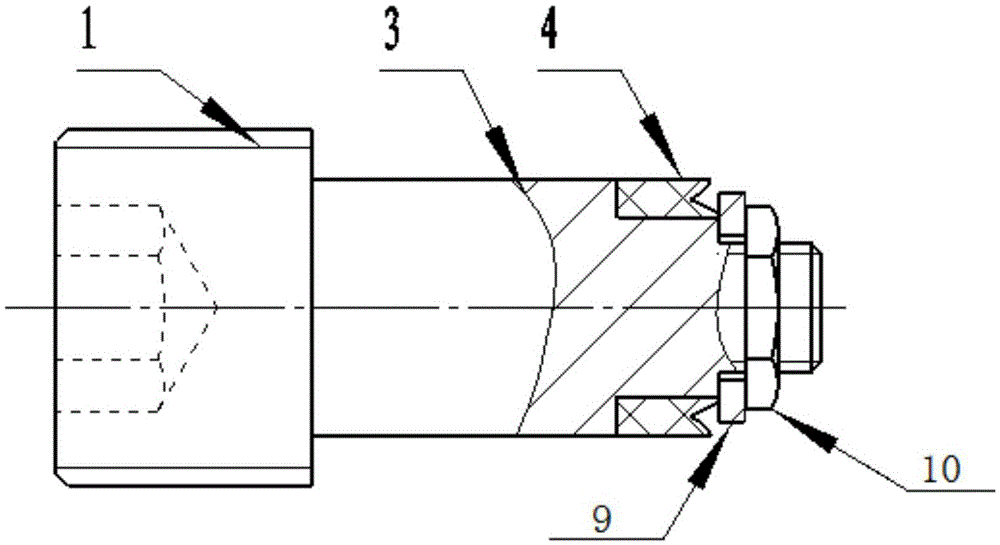

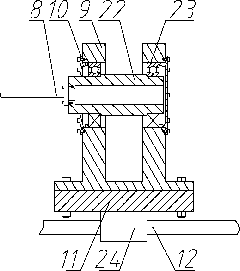

Hydraulic tensioning clamping mandrel for thin-wall shaft sleeve

InactiveCN105458317AReliable positioning and clampingSimple structureExpansion mandrelsEngineeringMachine tool

The invention discloses a hydraulic tensioning clamping mandrel for a thin-wall shaft sleeve. The hydraulic tensioning clamping mandrel is provided with a mandrel body located to the end face of a machine tool chuck or a spring sleeve. A step shaft table for locating the end face of a part to be machined is manufactured on the mandrel body, and step holes for assembling of plungers and a hydraulic oil cavity communicated with the step holes are formed in the two ends. The left pressure adjusting plunger (3) is sealed at the left end of the hydraulic oil cavity from the leftward step hole of the mandrel body (2), the right pressure adjusting plunger (6) is sealed at the right end of the hydraulic oil cavity from the rightward step hole of the mandrel body, and a closed container is formed. The to-be-machined part assembled on a rightward barrel of the mandrel body is clamped between the end face of the step shaft table of the mandrel body and a compressing nut (10) through the compressing nut (10). Sealing screws (7) are screwed down to drive the plungers to move and compress hydraulic oil in the hydraulic oil cavity, and the to-be-machined part clamped on the external circle tensioning mandrel body on the thin wall of the hydraulic oil cavity is expanded through pressure generated by the hydraulic oil cavity under the action of oil pressure. The hydraulic tensioning clamping mandrel is easy to manufacture and high in clamping precision, and a clamping area is stable and reliable in clamping.

Owner:SICHUAN LINGFENG AVIATION HYDRAULIC MACHINERY

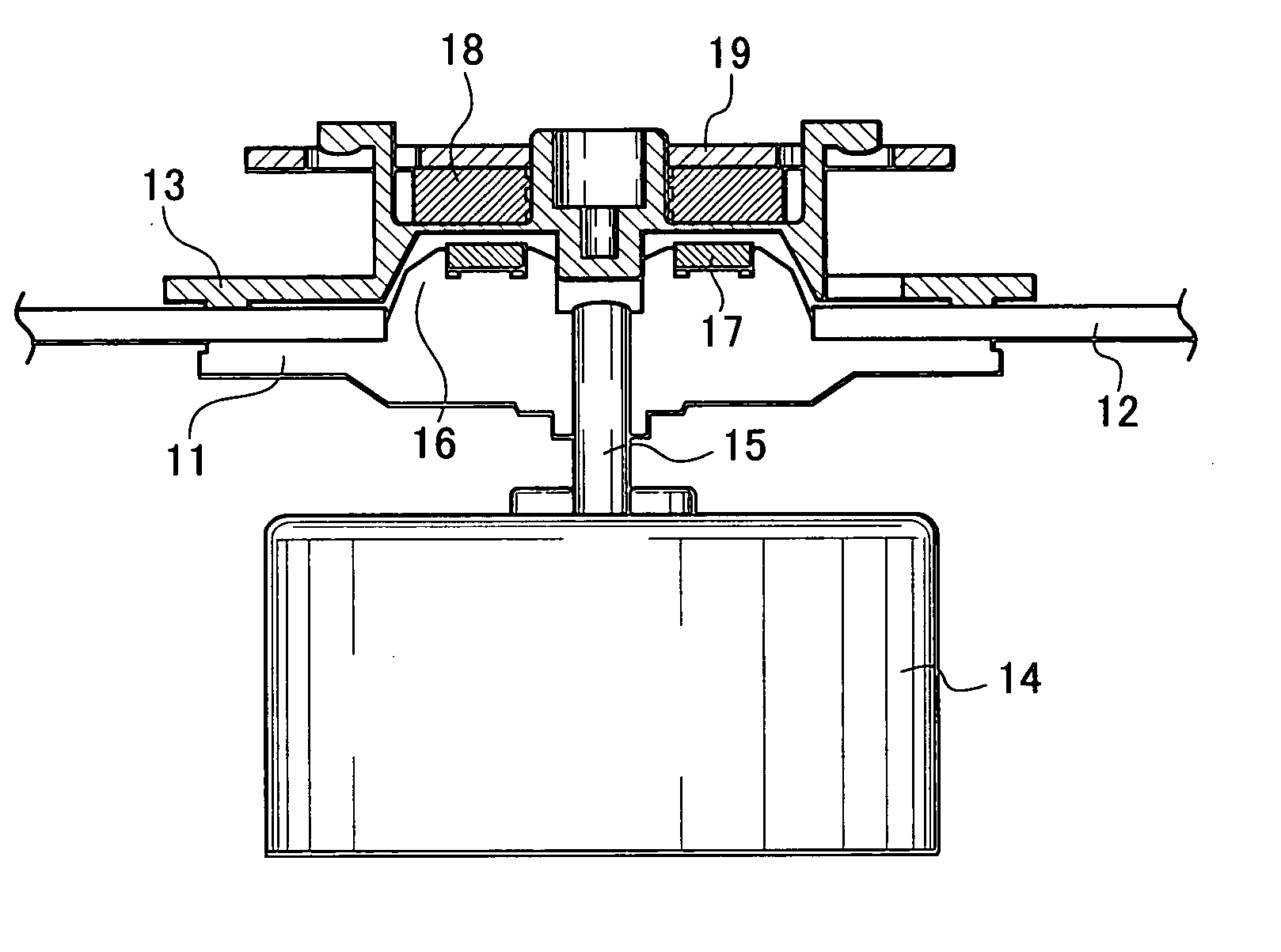

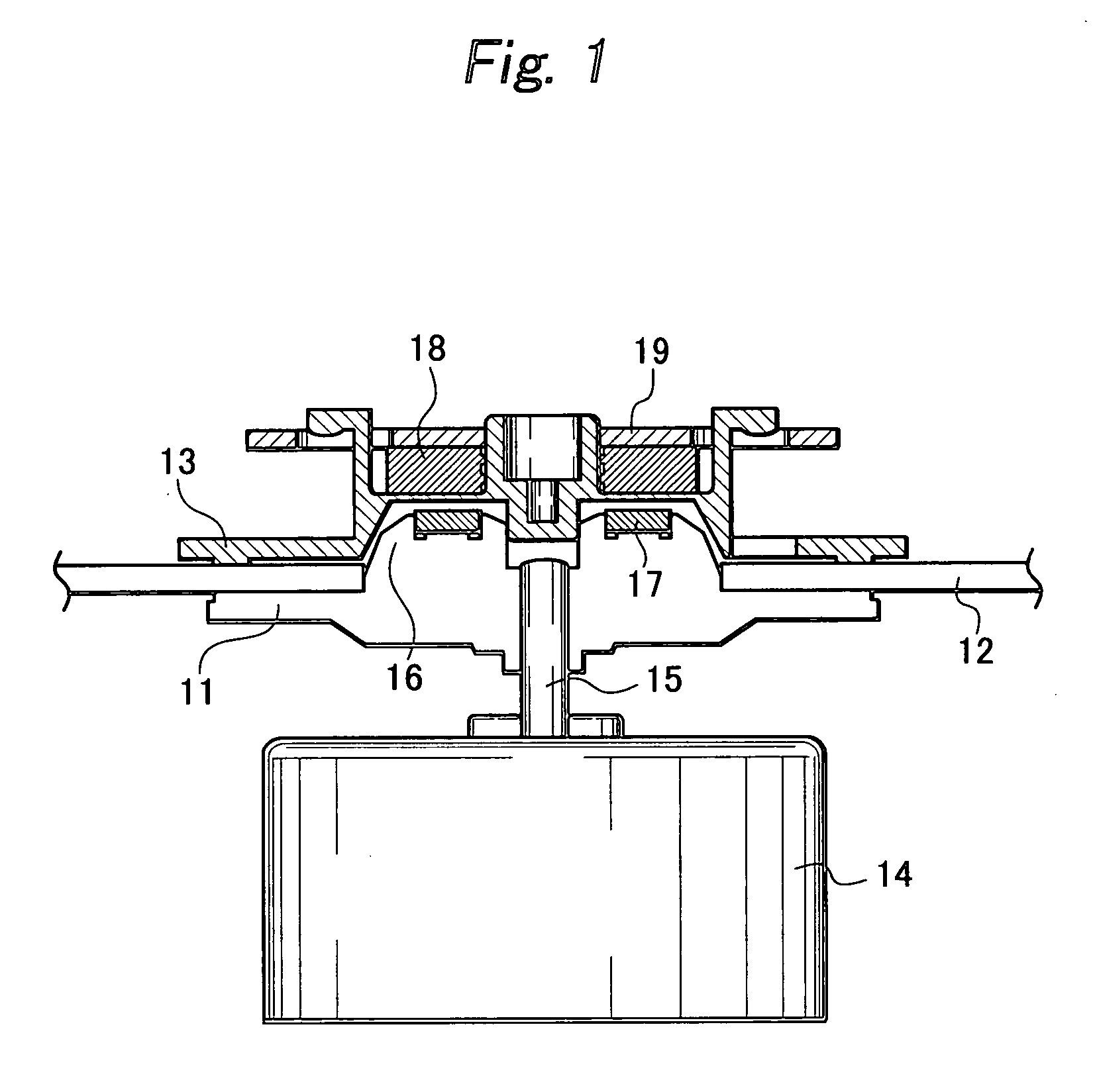

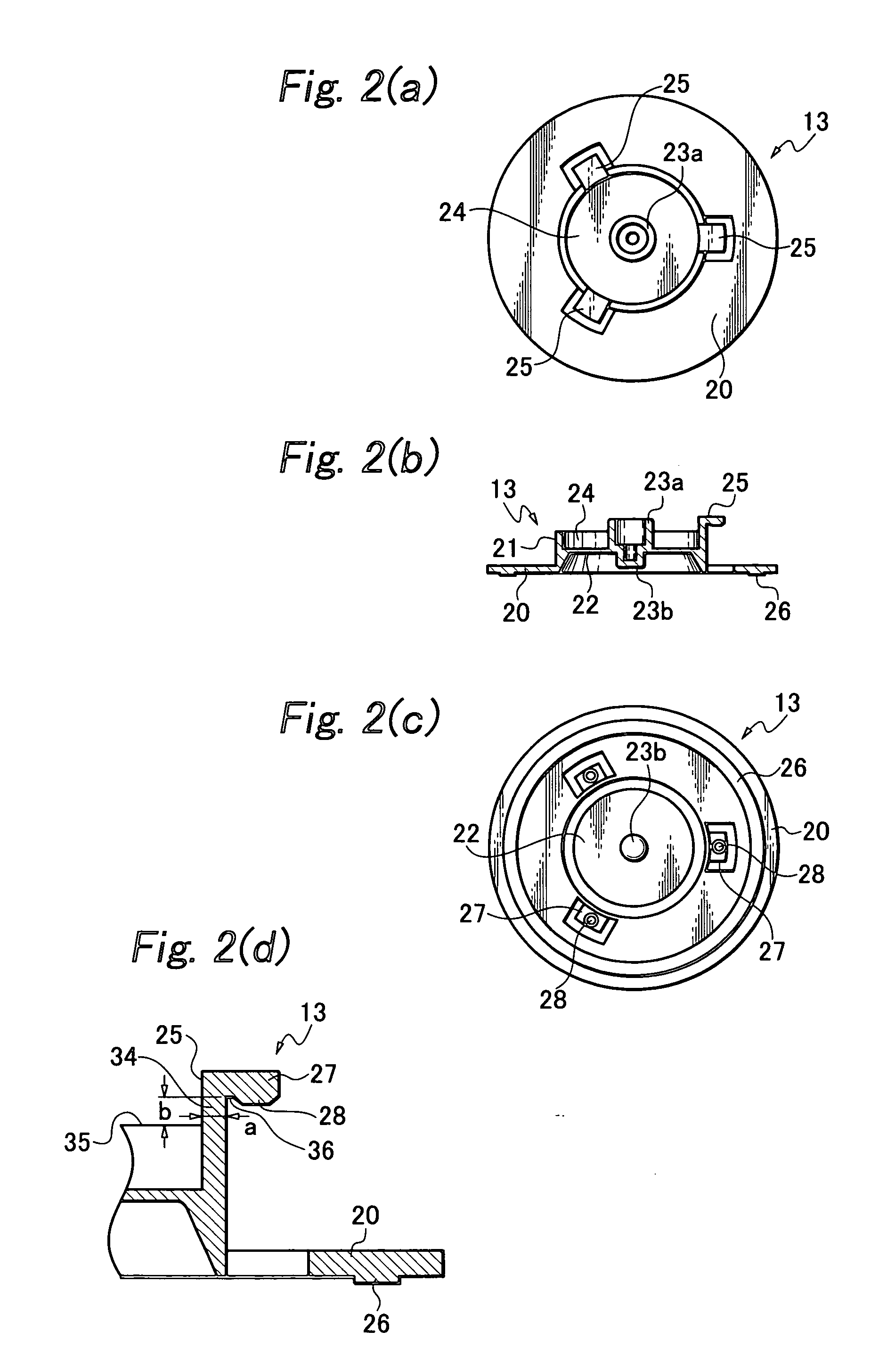

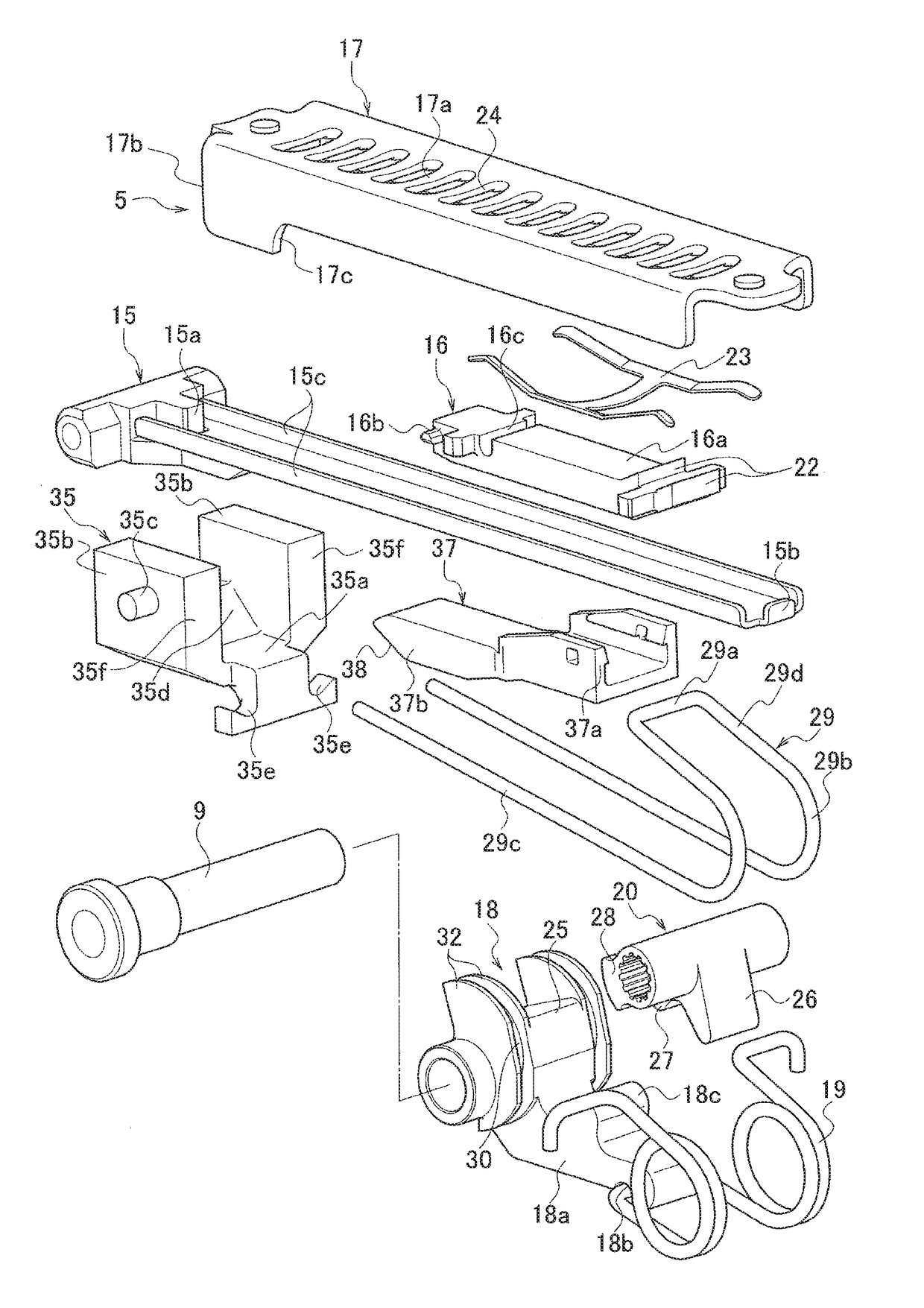

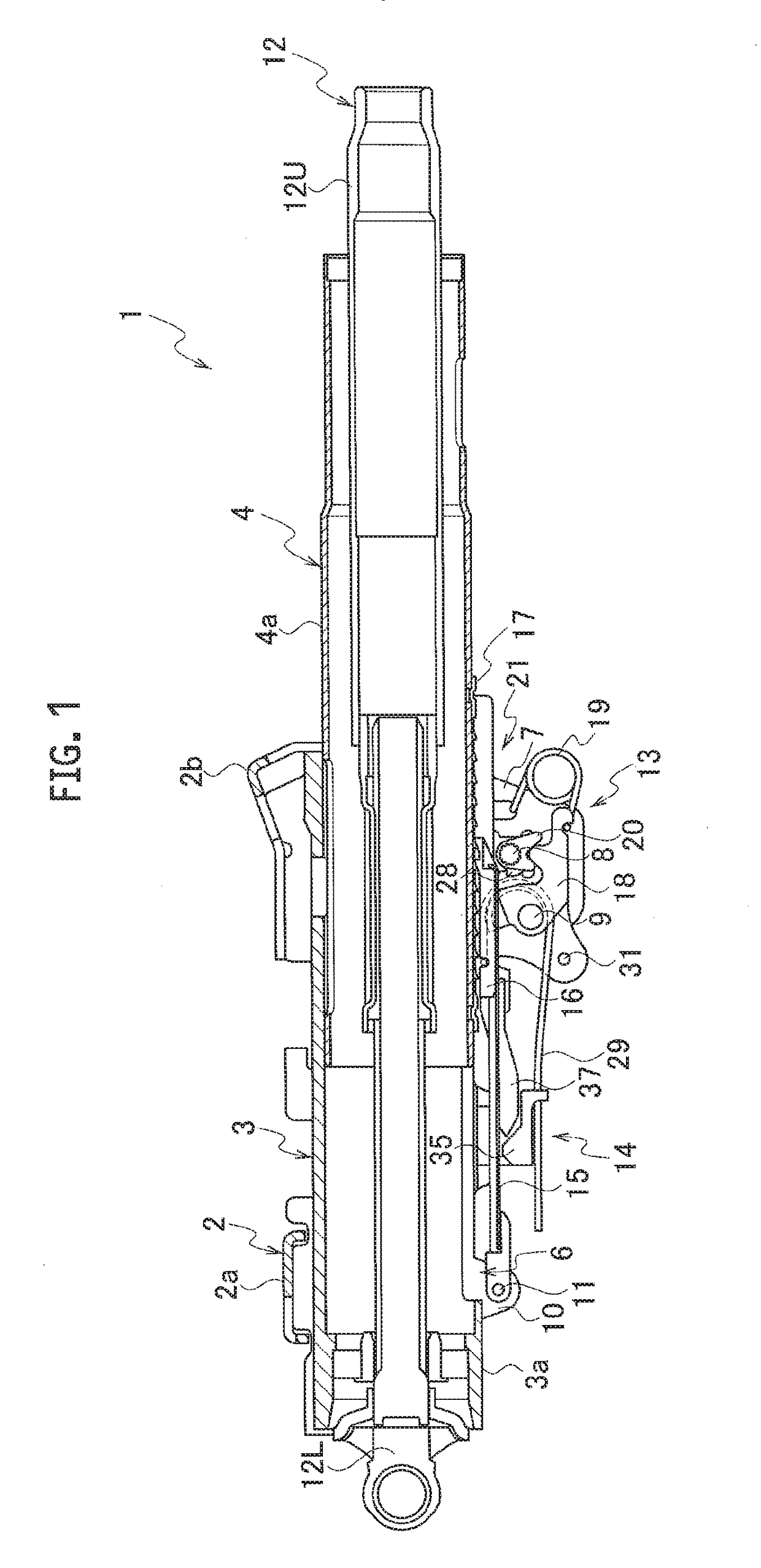

Disk device having clamp mechanism

InactiveUS20050071862A1Avoid vibrationPrecise clampingRecord information storageRecord carrier contruction detailsLower faceMagnet

To provide a disk device having a clamp mechanism, which can correctly clamp a disk mounted on a turntable, which can regulate eccentricity at the turning time and can prevent slips and facial vibrations, and which can prevent a clamper from becoming loose during the turning motions, the clamp mechanism comprises a clamper integrally formed of a resin material, a magnet and a cover. The clamper includes a disk-shaped clamp unit, a cylindrical rib formed at the central portion of the clamp unit, a bottom plate formed a housing space to house the magnet in the rib and to be covered by the cover, a boss projected from the lower face side of the center of the bottom plate and adapted to be fitted and positioned in a recess of the upper face of a turntable. The cylindrical rib is provided on its upper edge with at least two such L-shaped hook portions at equal intervals as each includes a connection member extended vertically and having a bulge on its lower face, and a retention member extended horizontally outward from the leading end of the connection member. The cover is provided in its outer circumference with engagement holes at positions individually corresponding to the hook portions. Each of the engagement holes includes a communication portion for allowing the connection member of the corresponding hook portion to pass therethrough, an insertion portion formed to communicate with one end side of the communication portion for inserting the corresponding hook portion, and an engagement portion formed to communicate with the other end side of the communication portion and made smaller than the retention member of the corresponding hook portion, for fitting the bulge on the lower face of the retention member of the corresponding hook portion.

Owner:ORION ELECTRIC CO LTD

Rotary-forging forming and feeding device for internal thread pipe

ActiveCN102189213AImprove forming qualityImprove efficiencyForging/hammering/pressing machinesFree rotationPull force

The invention discloses a rotary-forging forming and feeding device for an internal thread pipe. The device comprises a feeding mechanism and a central spindle actuating mechanism, wherein a lower guide rail surface of a feeding table in the feeding mechanism is matched with an upper guide rail surface of a guide rail; the main shaft of the feeding table is axially supported by a thrust bearing; a lower guide rail surface of a central spindle feeding table in the central spindle actuating mechanism is matched with the upper guide rail surface of the guide rail; the guide rail is mounted on a device body; a workpiece and the central spindle are both axially driven by a servo motor and a ball screw nut pair and both can freely rotate in circumferential direction; the thread of an internal thread pipe is formed by the rotary forging under the self-guiding action of the thread on the central spindle; the central spindle is in threaded connection with a pull rod through a core mold, and bears axial tension in the forging process and bending and deformation can be avoided. By the adoption of the device disclosed by the invention, distortion and deformation caused by the torque effect onthe workpiece during rotary forging can be avoided, and the workpiece forming precision is improved; in addition, the device has advantages of simple structure, high control precision, good stability, strong applicability and the like, and is convenient to operate.

Owner:XI AN JIAOTONG UNIV

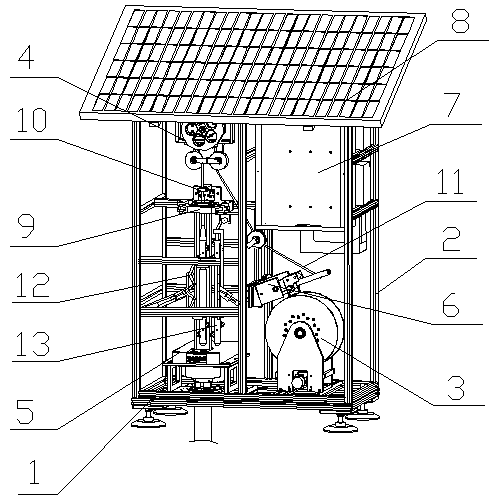

Intelligent inclination measuring system and monitoring method thereof

ActiveCN110359440AImprove human-computer interactionRegression is accurateIn situ soil foundationData acquisitionDeformation monitoring

The invention provides an intelligent inclination measuring system and a monitoring thereof method. The intelligent inclination measuring system comprises an automatic inclination measuring machine, adata acquisition terminal, a cloud monitoring management system and a power supply system. The automatic inclination measuring machine comprises a machine frame, an unwinding device, a cable arranging device, a meter counting device, a reversing device, a correcting device, an in-place detecting device, an electric control system, a gripping device and a trial winding device; the intelligent inclination measuring system is simple in structure and convenient to maintain, assemble and disassemble, and does not have a safety hazard; an inclination measuring pipe is detected by simulating automatic trial winding of an inclination measuring device; the damage of an inclination measuring sensor, inaccurate data and the like are avoided; the operating state of equipment can be monitored in realtime by arranging a tension sensor; automatic measurement is realized in the overall process; measuring point data are automatically acquired through the data acquisition terminal and are transmittedto the cloud monitoring management system in real time; event information in the operating process of the equipment is displayed through the cloud monitoring management system; the intelligent inclination measuring system processes and gives an alarm when an abnormity appears; the measurement precision is high; and the equipment is stable and reliable, and can be applied to deformation monitoringon a sliding surface in a soil body of a landslide mass, dangerous rock, high side slope and the like.

Owner:广州日昇岩土科技有限公司

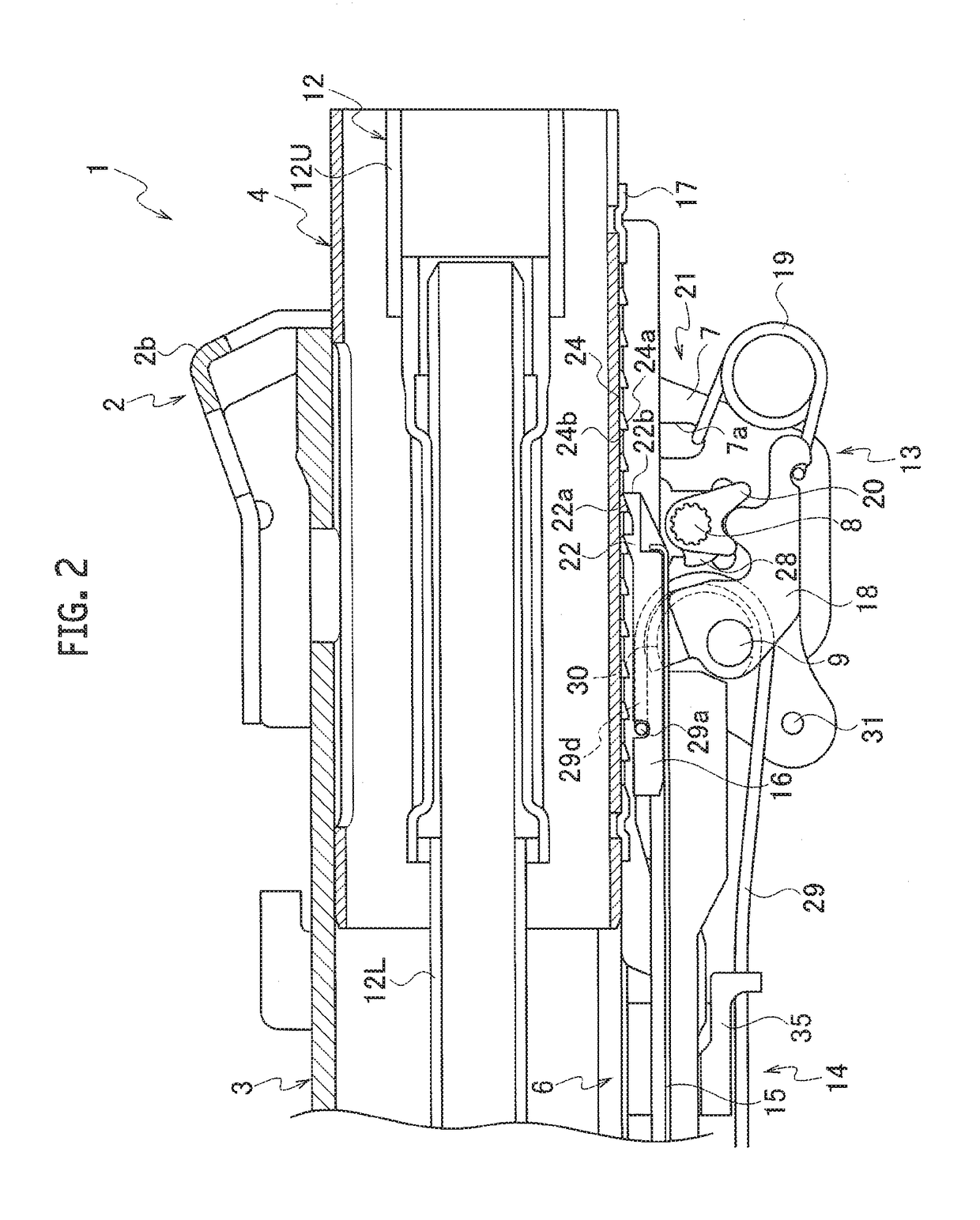

Steering column device

In a steering column device, a locking shaft is disposed on a vehicle front side relative to an operating shaft for an operating lever in parallel to the operating shaft. On the locking shaft, a cam member is disposed which is configured to press a locking member against a locked member via a guiderail in such a direction as to engage the locking member with the locked member. On the other hand, on the operating shaft, a linking member is disposed which is configured to bring the cam member into a state where the locking member and the locked member are disengaged from each other when the operating shaft is moved to an unlock position.

Owner:FUJI KIKO CO LTD

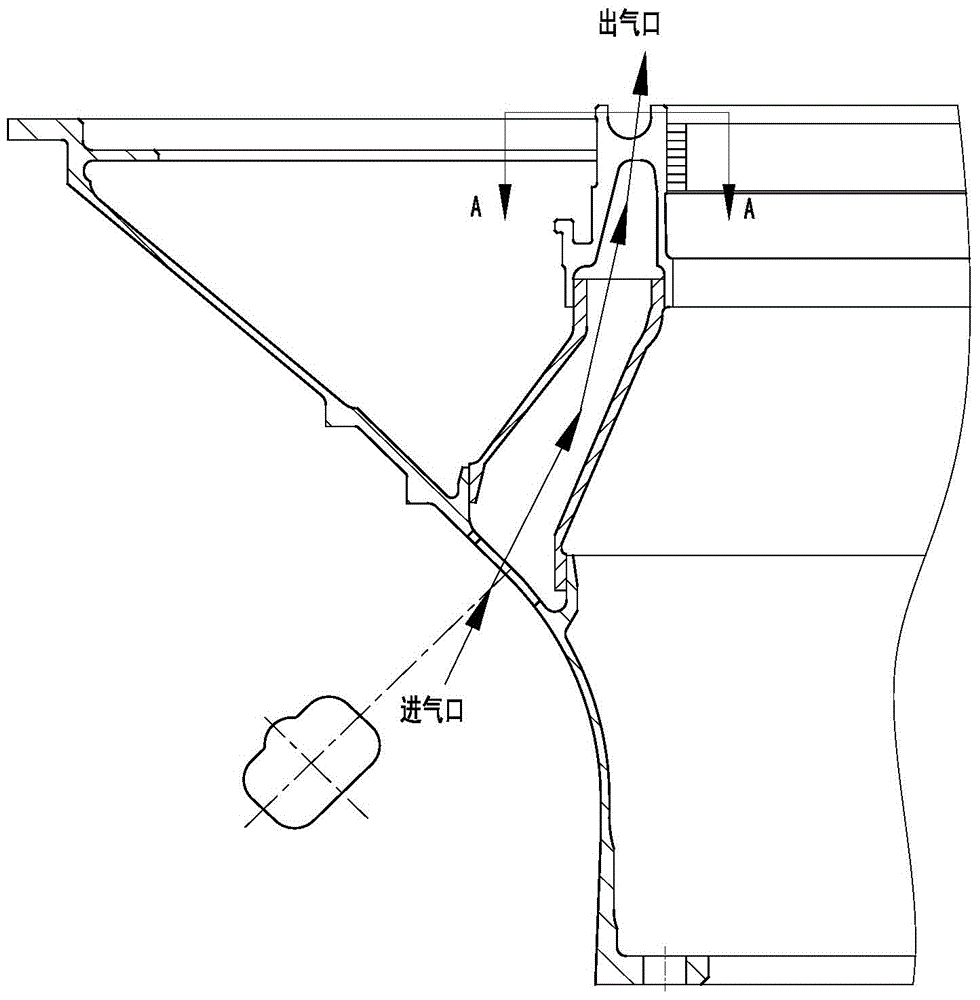

Experimental device for detecting aeroengine guider

ActiveCN104406794APrevent leakagePrecise positioningGas-turbine engine testingJet-propulsion engine testingAviationPressure sensor

The invention discloses an experimental device for detecting an aeroengine guider. The experimental device comprises a device bracket, a barrel cavity which is formed in the bracket and used for mounting the guider to be detected, a first annular cavity A formed in the barrel cavity, a second annular cavity B formed above the first annular cavity A, a seal assembly for sealing the flow channel outlet of the guider, a measurement airflow distribution device, a pressure sensor and a temperature sensor which are arranged on the second annular cavity B, and a flow sensor arranged on an air inlet pipeline, wherein the barrel cavity comprises a barrel cavity bottom plate and an outer barrel body airtightly connected with the barrel cavity bottom plate; the first annular cavity A comprises an annular plate airtightly connected with the lower part of the outer barrel body and an inner barrel body airtightly connected with the barrel cavity bottom plate and the annular plate, a plurality of holes communicated with the second annular cavity B are formed in the annular plate, and an air inlet pipe hole is formed in the barrel cavity bottom plate forming the first annular cavity A; the second annular cavity B comprises the annular plate of the first annular cavity A, the outer barrel body and the outer wall surface of the guider to be detected.

Owner:AECC AERO SCI & TECH CO LTD

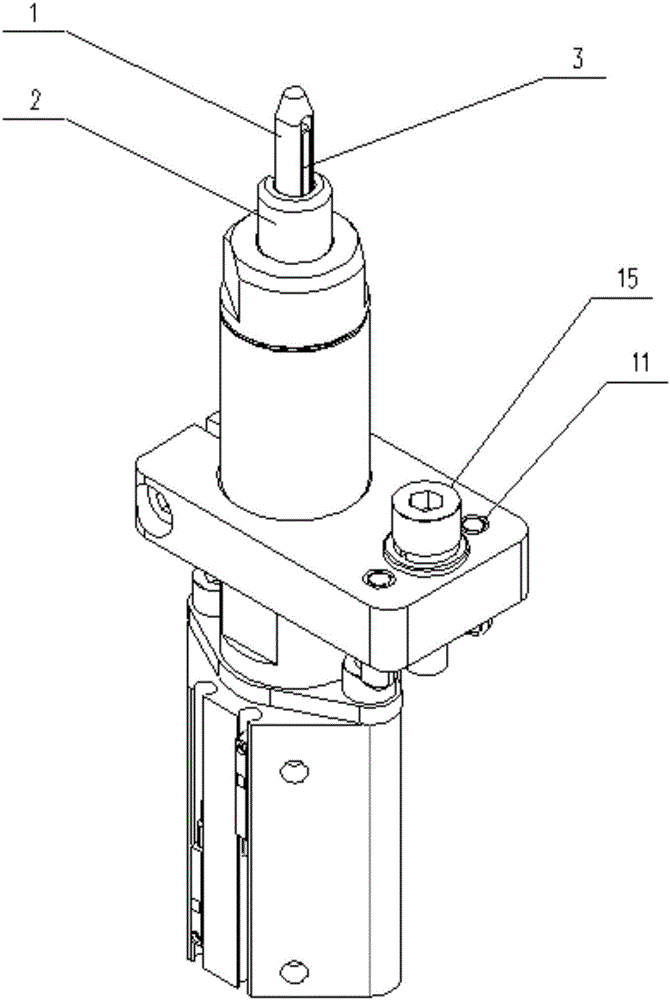

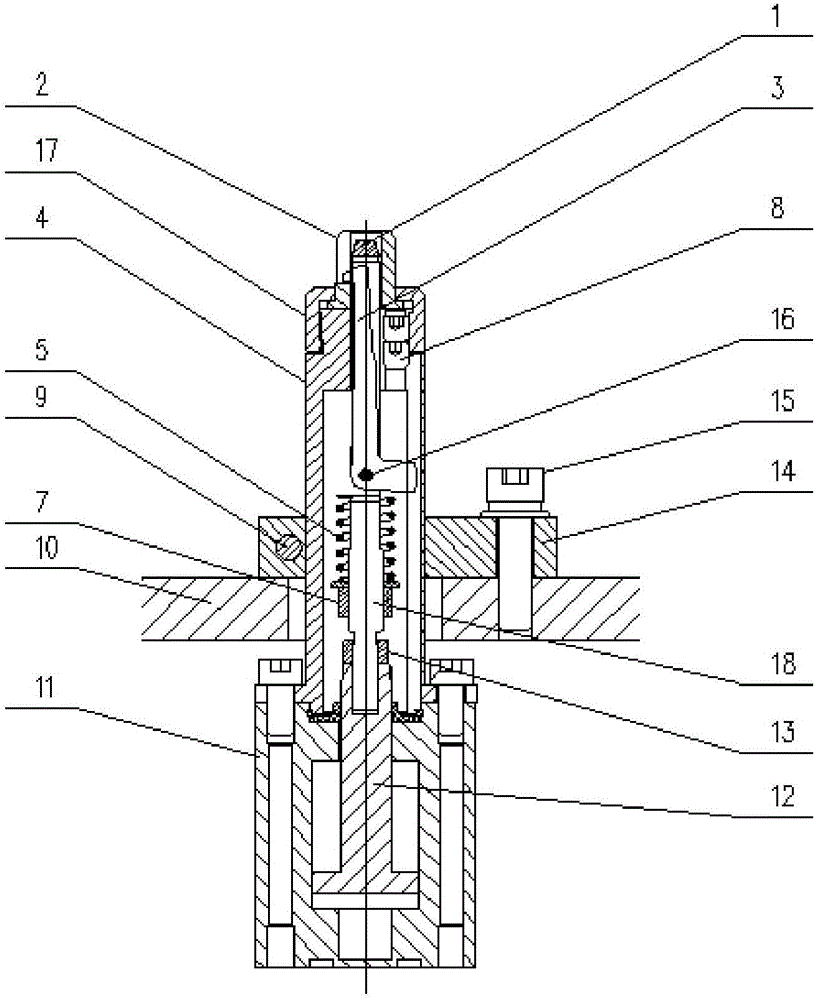

Pneumatic positioning and locking pin hook mechanism.

ActiveCN106392440APrecise positioningPrecise clampingLiquid surface applicatorsWelding/cutting auxillary devicesAutomatic controlJackscrew

The invention provides a device facilitating achievement of clamping and positioning of various parts. The device can achieve automatic control easily, and fast switching and positioning locking between various to-be-machined parts can be performed conveniently. The production efficiency can be improved, the product quality can be improved, and the mechanism has the beneficial effects of being easy to operate, convenient to maintain, safe in production and the like and is broad in application prospect. The mechanism comprises a pin 1, a supporting ring 2, a hook 3, a pin body 4, springs 5, spring pre-tightening nuts 7, a jackscrew 8, a pin body locking bolt 9, a clamping fixture installing plate 10, a cylinder 11, a cylinder rod 12, a pin locking nut 13, a pin body fixing plate 14, a pin body fixing plate bolt 15, a cylinder pin 16, a supporting ring gland 17 and a connecting rod 18.

Owner:江西清研扬天科技有限公司

Air impermeability detection device and detection method applicable to communication box assembly

InactiveCN110160717AImprove the efficiency of air tightness testingSave the cost of air tightness testingMeasurement of fluid loss/gain rateEngineeringAir tightness

The invention discloses an air impermeability detection device and detection method applicable to a communication box assembly, and belongs to the field of box air impermeability detection. A supportcomponent, a pressing component and a lateral blocking component are correspondingly arranged on a rack; due to the corresponding match of the support component and the pressing component, the communication box assembly can be reliably fixed on a workbench, and due to the arrangement and adjustment of the lateral blocking component, the accurate blockage of holes in side surfaces during a box airimpermeability detection process can be achieved, and thus the air impermeability detection of the box can be accurately achieved. The air impermeability detection device provided by the invention issimple in structure, simple and convenient to control; via corresponding match of the components, the communication box assemblies with different appearances and different specifications can be reliably mounted and clamped on the fixture base plate; the air impermeability detection device is good in box adaptability and high in reliability; the air impermeability detection cost of the communication box assemblies is reduced, the air impermeability detection efficiency and accuracy are enhanced, and the relatively good application prospect and popularization value are achieved.

Owner:GUANGDONG HONGTU TECHNOLOGY (HOLDINGS) CO LTD

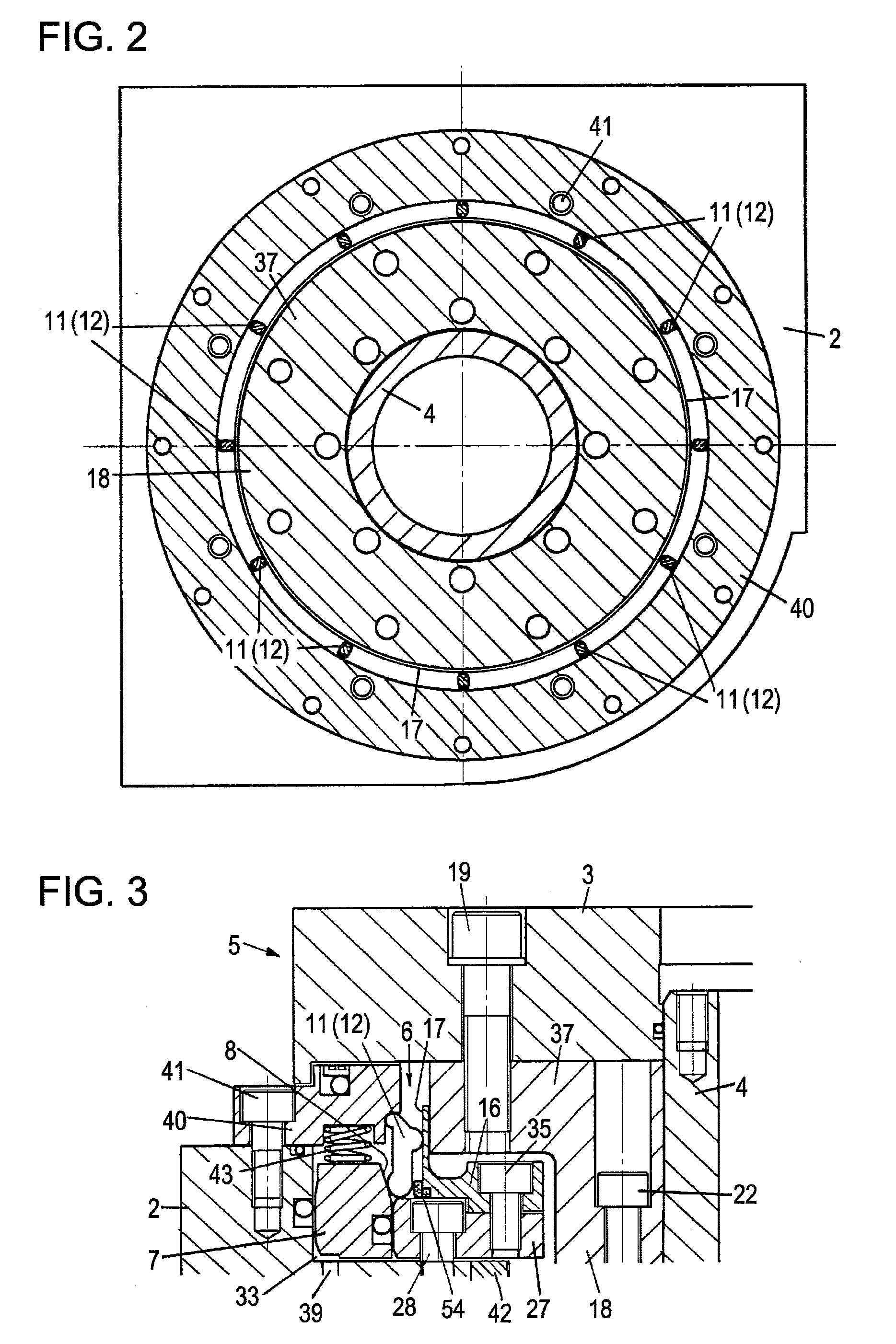

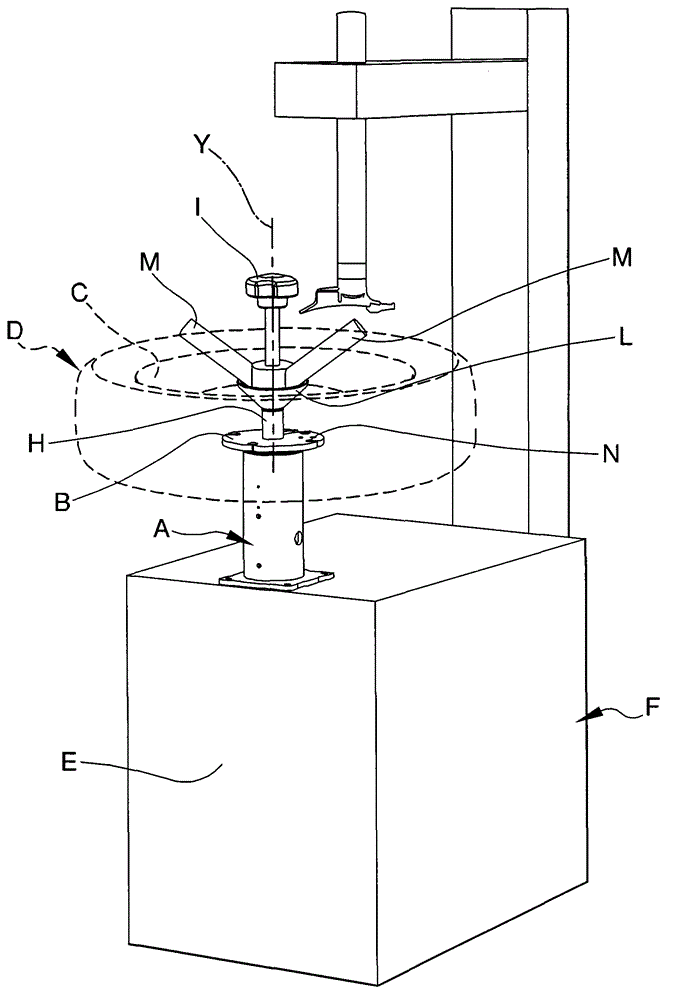

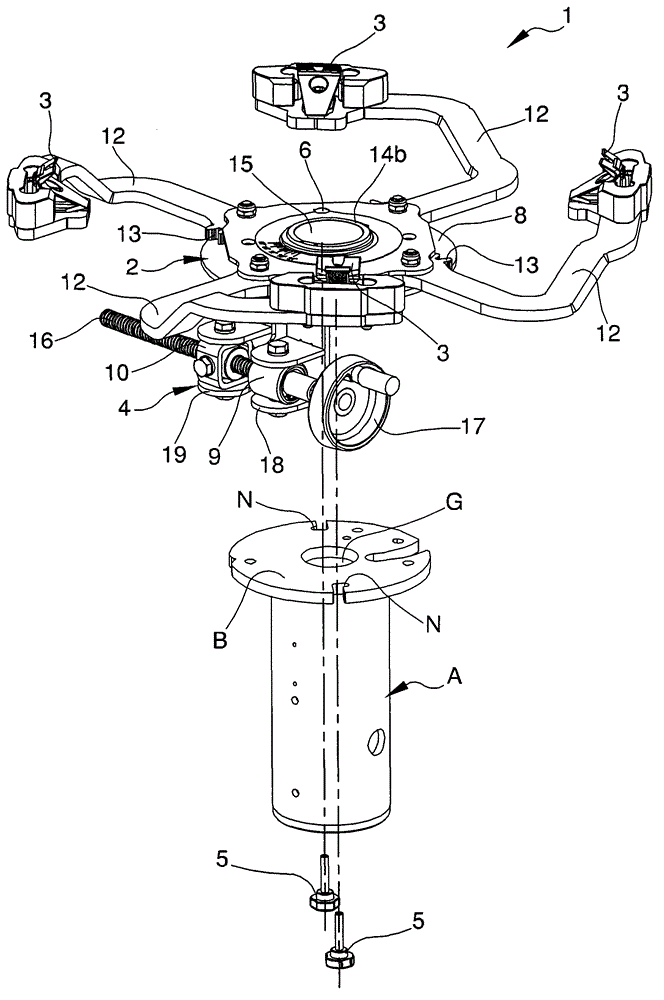

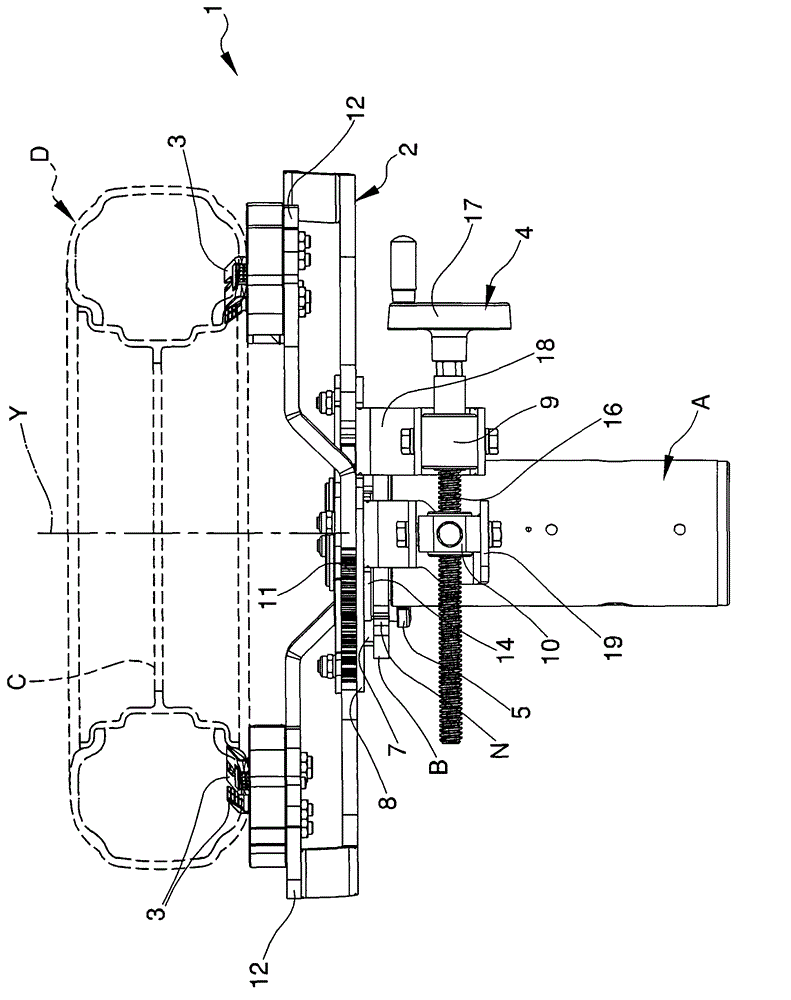

Accessory for tyre-changing machines, particularly for the locking of wheel rims for vehicles

InactiveCN103144505APrecise clampingImprove efficiencyTyre repairingMechanical engineeringMinimum distance

The accessory (1) for tyre-changing machines, particularly for the locking of wheel rims for vehicles, comprises supporting means (2) associable in a removable way with a revolving portion (B) of gripping means of the hub of the rim on a tyre-changing machine, at least two gripping jaws (3) of the rim of a wheel associated with the supporting means (2) and moving along a reciprocal approach and away direction between a position of maximum opening, wherein the gripping jaws (3) are arranged at a preset maximum distance, and a position of minimum opening, wherein the gripping jaws (3) are arranged at a preset minimum distance, and movement means (4) associated with the supporting means (2) and with the gripping jaws (3), suitable for moving the gripping jaws (3) between the position of maximum opening and the position of minimum opening.

Owner:GIULIANO GROUP

Air tightness test device

The invention discloses an air tightness test device. The device comprises a feeding assembly which is installed on a bottom plate, and is provided with a feeding carrier used for conveying a product to be subjected to air tightness detection, a detection assembly which is mounted on the bottom plate, and a discharging assembly, wherein the product on the feeding carrier is carried into a detection station of the detection assembly through a carrying manipulator moving in space so as to carry out air tightness detection on the product; and the discharging assembly is installed on the bottom plate, the discharging assembly comprises a qualified product recycling assembly and an NG product recycling assembly, and the carrying manipulator carries products subjected to air tightness detection to the transfer carrier. The carrying module moving in the space carries products with qualified airtightness detection on the transfer carrier to the qualified product recovery assembly, and the carrying module carries products with unqualified airtightness detection on the transfer carrier to the NG product recovery assembly. According to the invention, batch testing can be carried out and the testing efficiency is high.

Owner:BOZHON PRECISION IND TECH CO LTD

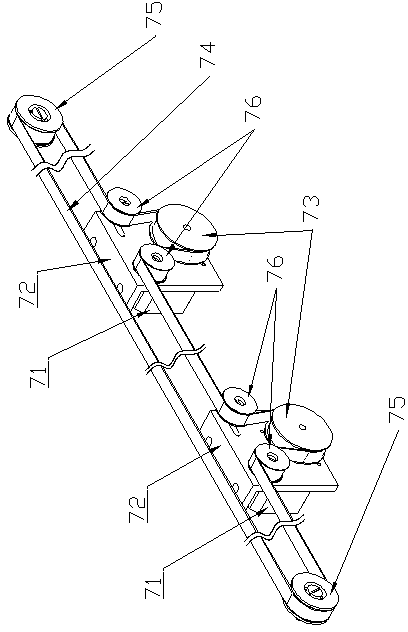

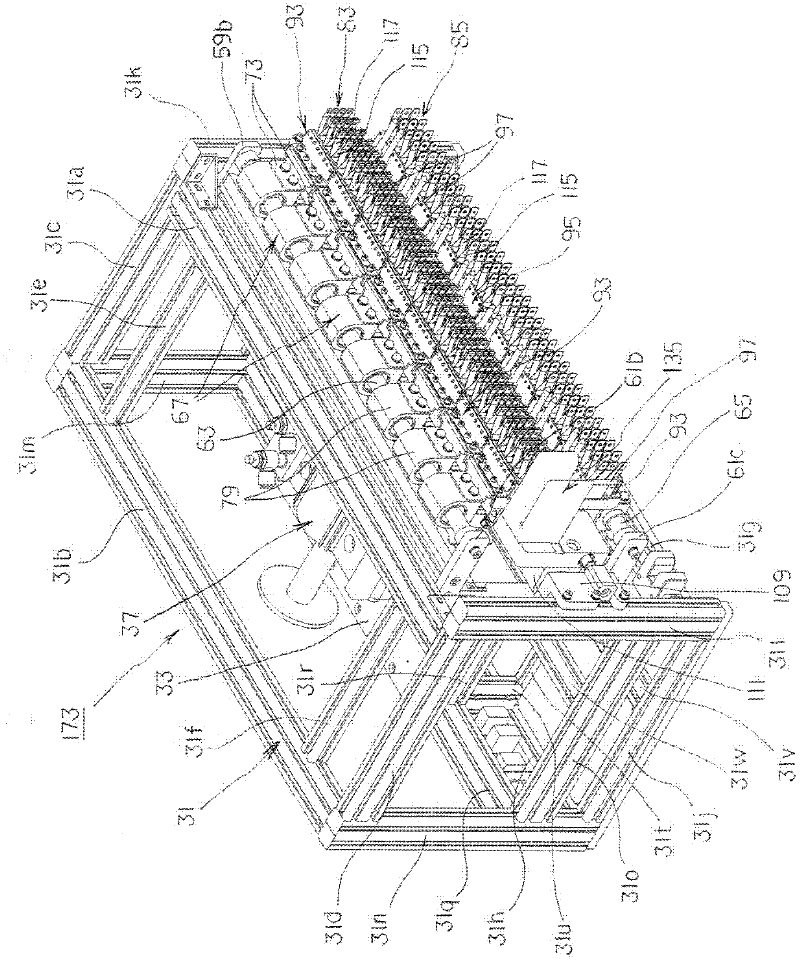

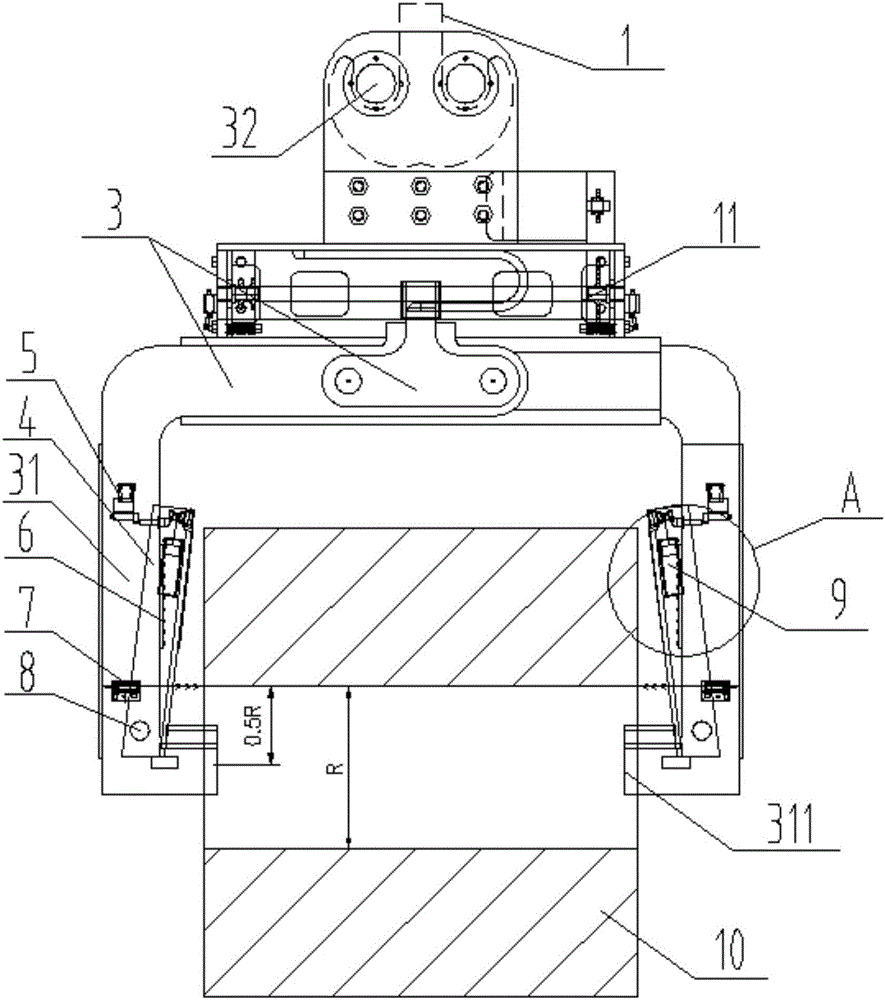

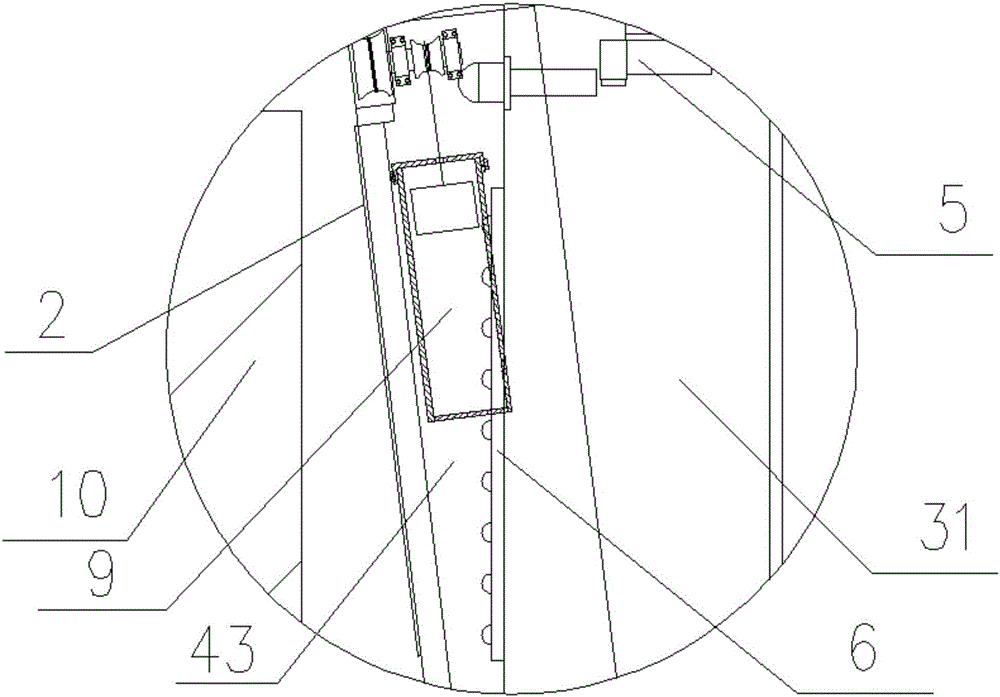

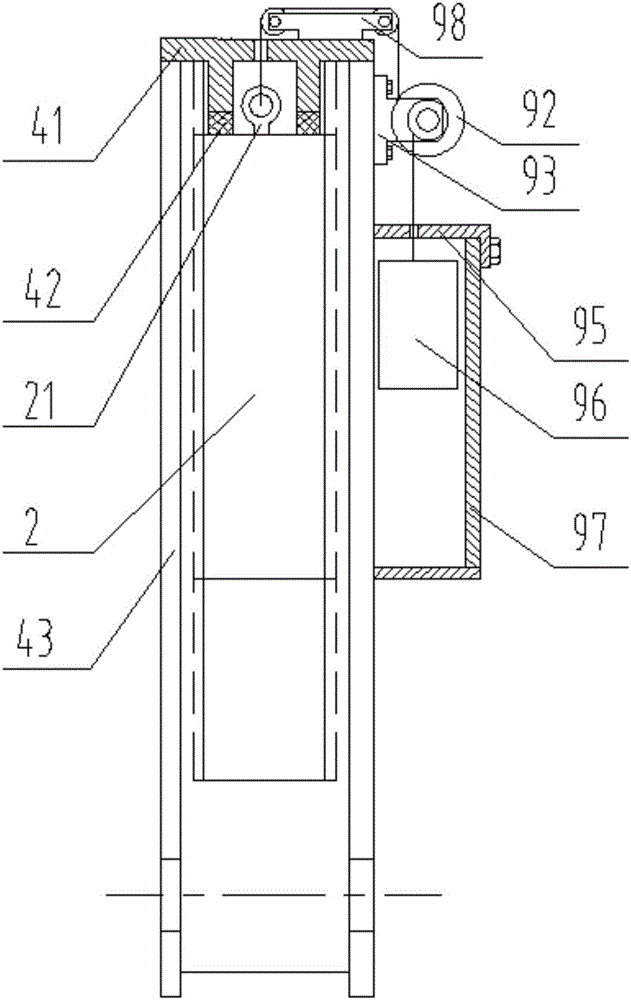

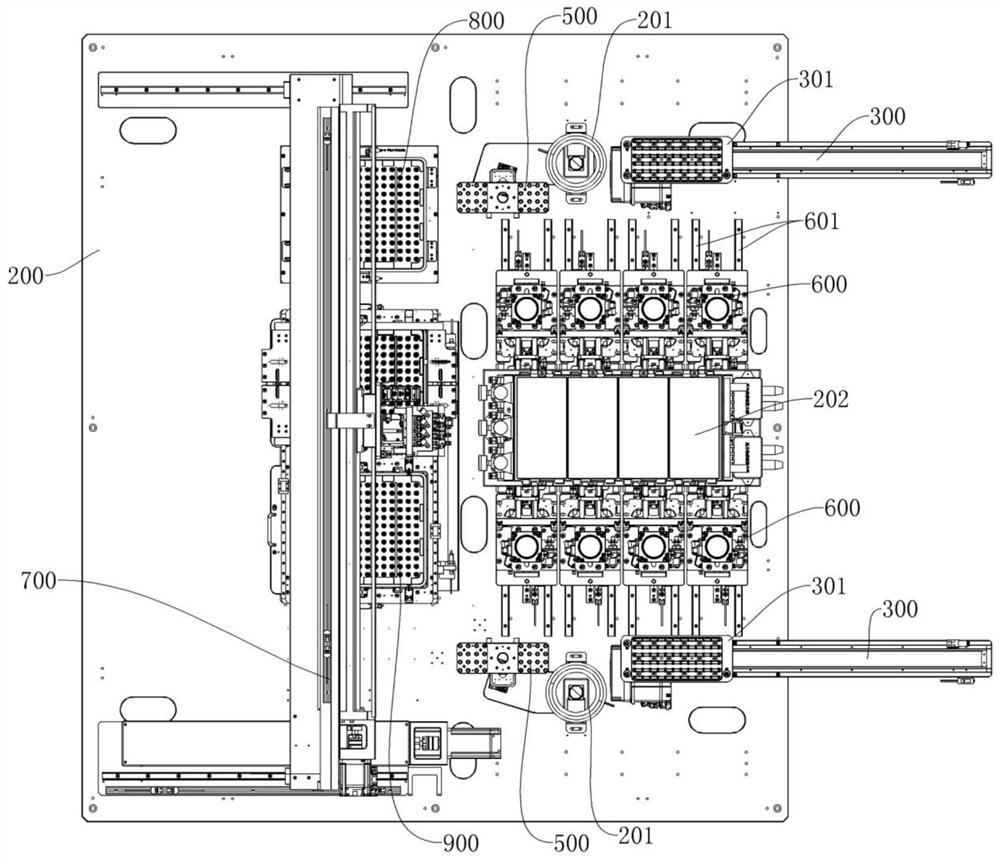

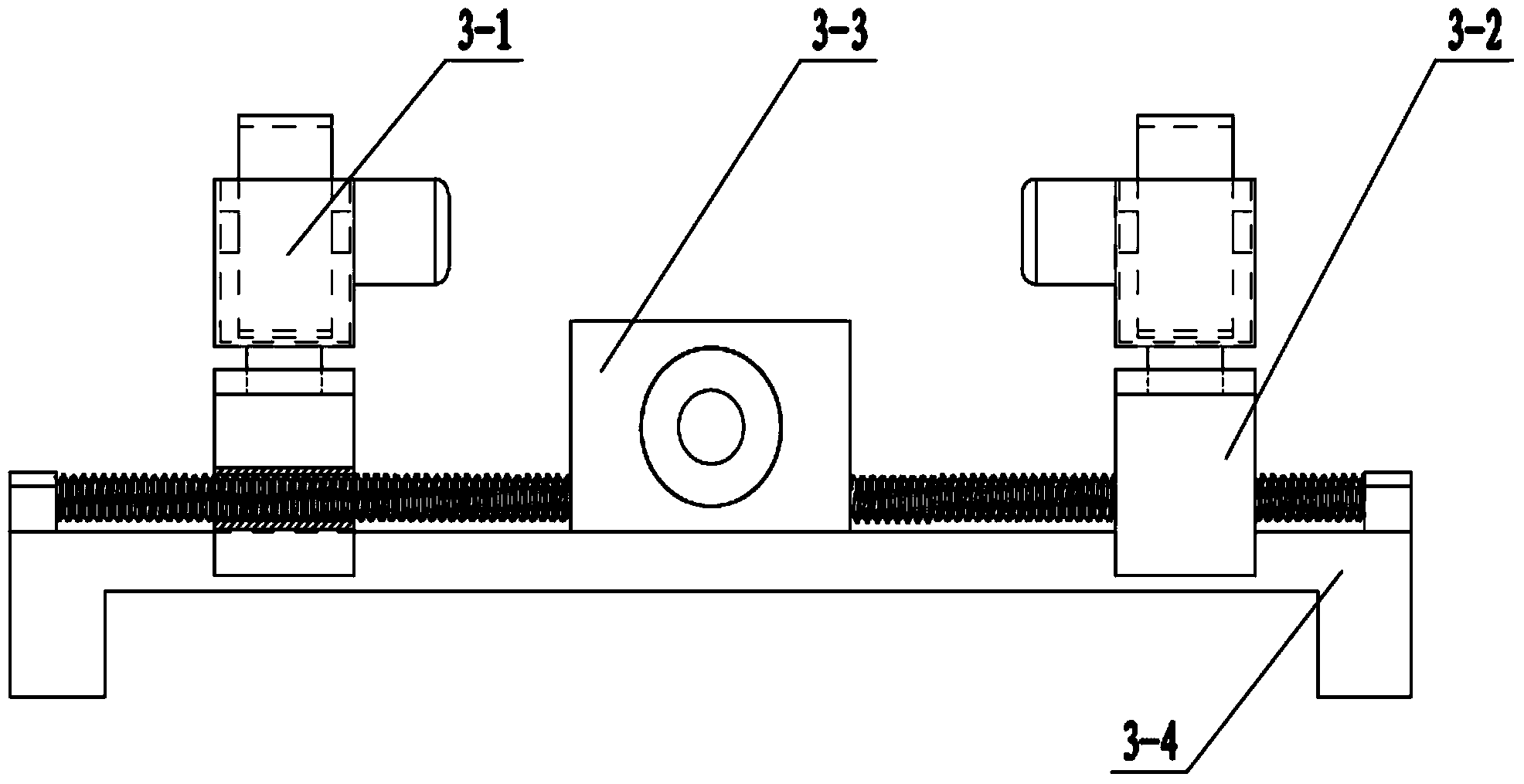

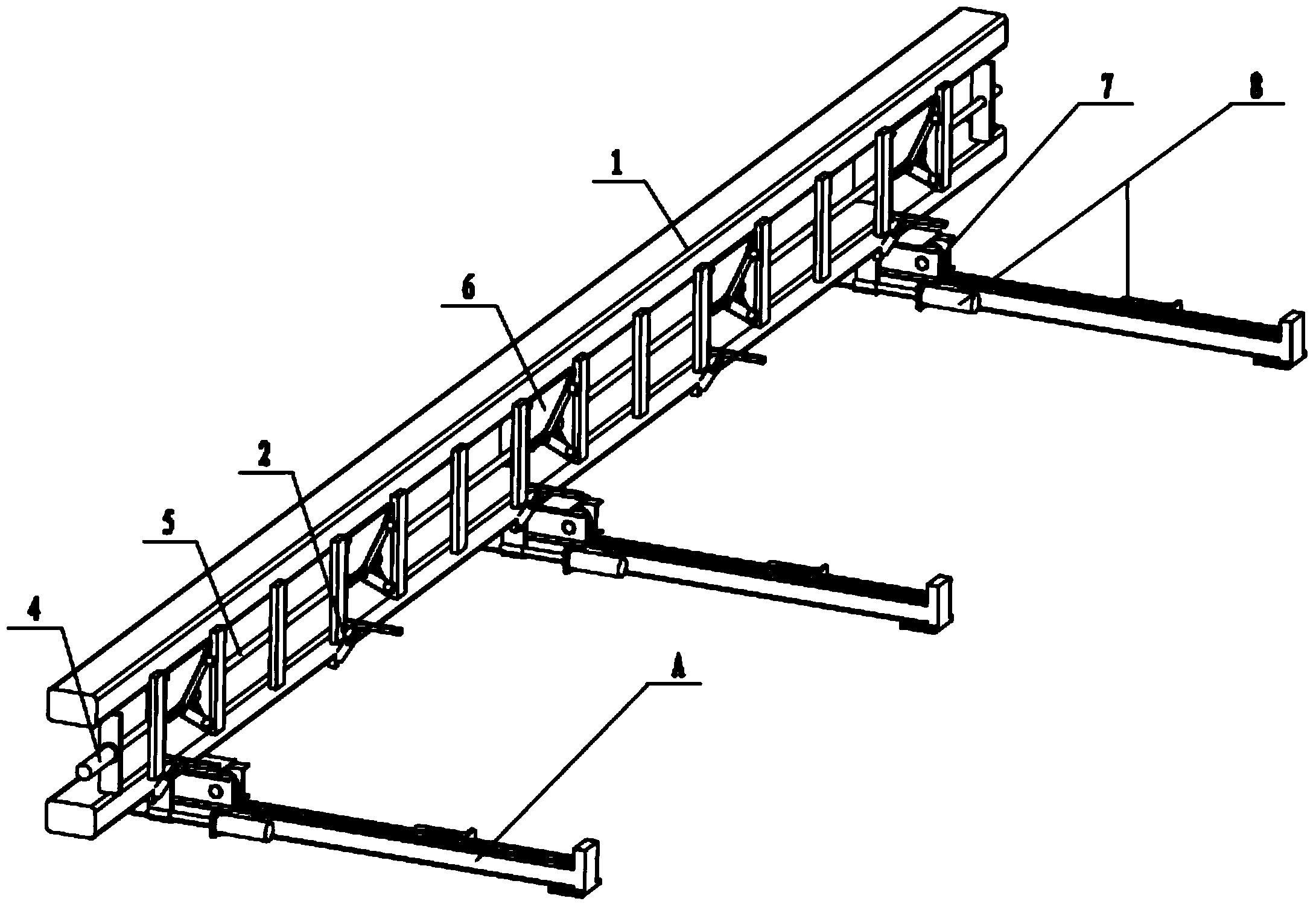

Centering and clamping assembling machine for H-shaped steel of corrugated web plates

InactiveCN103878519APrecise clampingClamp firmlyWelding/cutting auxillary devicesAuxillary welding devicesClassical mechanicsEngineering

The invention relates to a centering and clamping assembling machine for H-shaped steel of corrugated web plates, and belongs to the field of machining equipment. A flange plate centering and clamping mechanism of each centering and assembling device consists of a linkage long shaft, a connecting rod clamping mechanism and a longitudinal oil cylinder, wherein the linkage long shafts longitudinally penetrate in a clamping rack; the connecting rod clamping mechanisms are connected to the inner side of the clamping rack at intervals through a bottom plate; center shafts of the connecting rod clamping mechanisms are correspondingly connected with the linkage long shafts; the longitudinal oil cylinders are arranged at the head end of the clamping rack; flexible ends of the longitudinal oil cylinders are connected with the linkage long shafts; flange plates which are turned upwards in the connecting rod clamping mechanisms via a turning-up device are clamped by driving the linkage long shafts to longitudinally move in the clamping rack; and the two centering and clamping devices move relative to a web plate conveying device, so that the flange plates and the corrugated web plates are centered and clamped. The centering and clamping assembling machine for the H-shaped steel of the corrugated web plates is simple in structure and easy to operate, and is applicable to centering and clamping assembly on the corrugated plates with different sizes; stable centering and clamping on the flange plates in an assembling process is effectively guaranteed; and the assembling quality and the production efficiency on the H-shaped steel of the corrugated web plates are improved.

Owner:HUBEI HONGYI BUILDING DECORATION ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com