Crankshaft multi-angle oil hole drilling clamp

A drilling fixture, multi-angle technology, applied in drilling/drilling equipment, clamping, manufacturing tools, etc., can solve the problems of many fixtures and clamping replacements, poor universality of fixtures, and high manufacturing costs, and achieve adjustment methods. Convenience and flexibility, fewer replacements, and lower manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

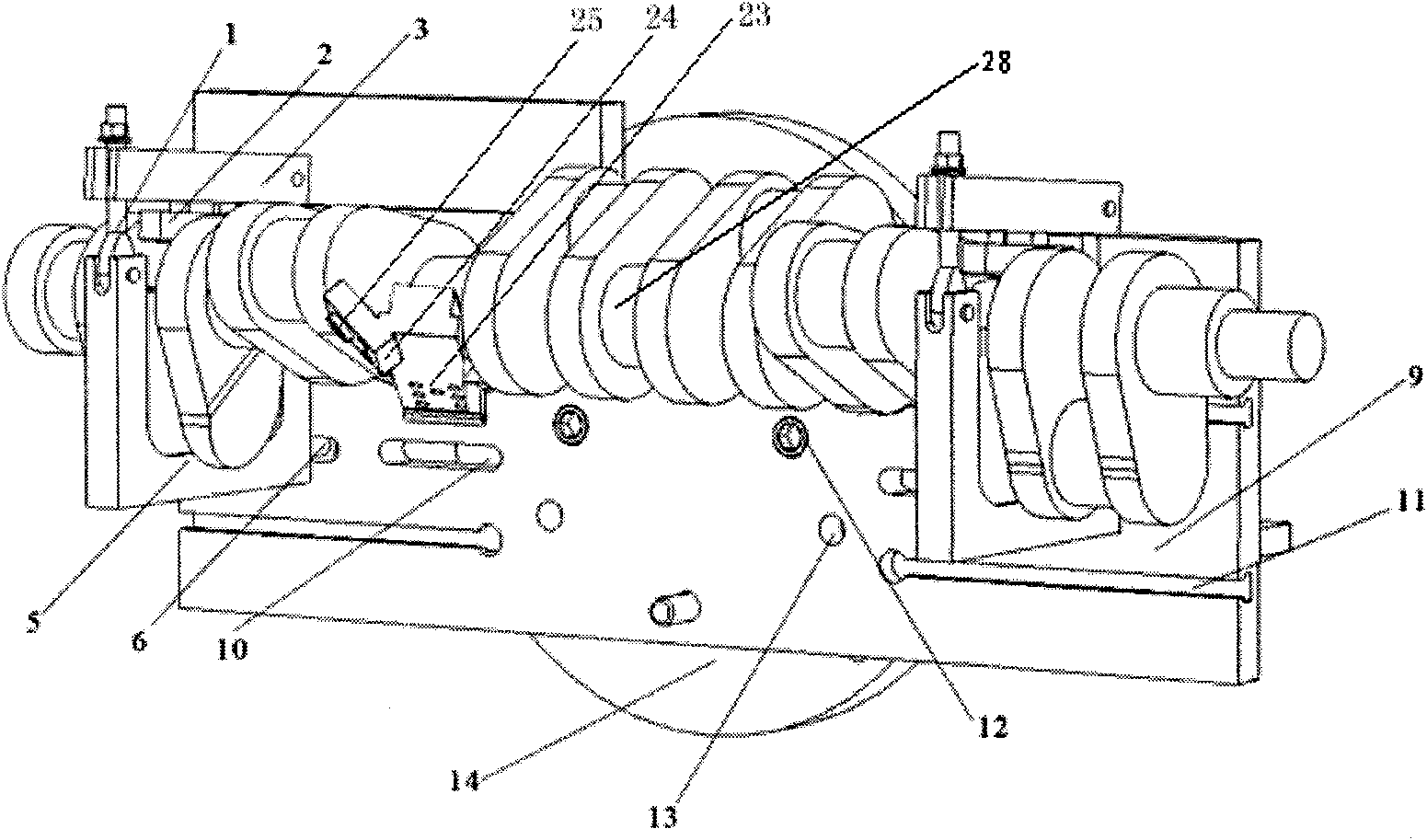

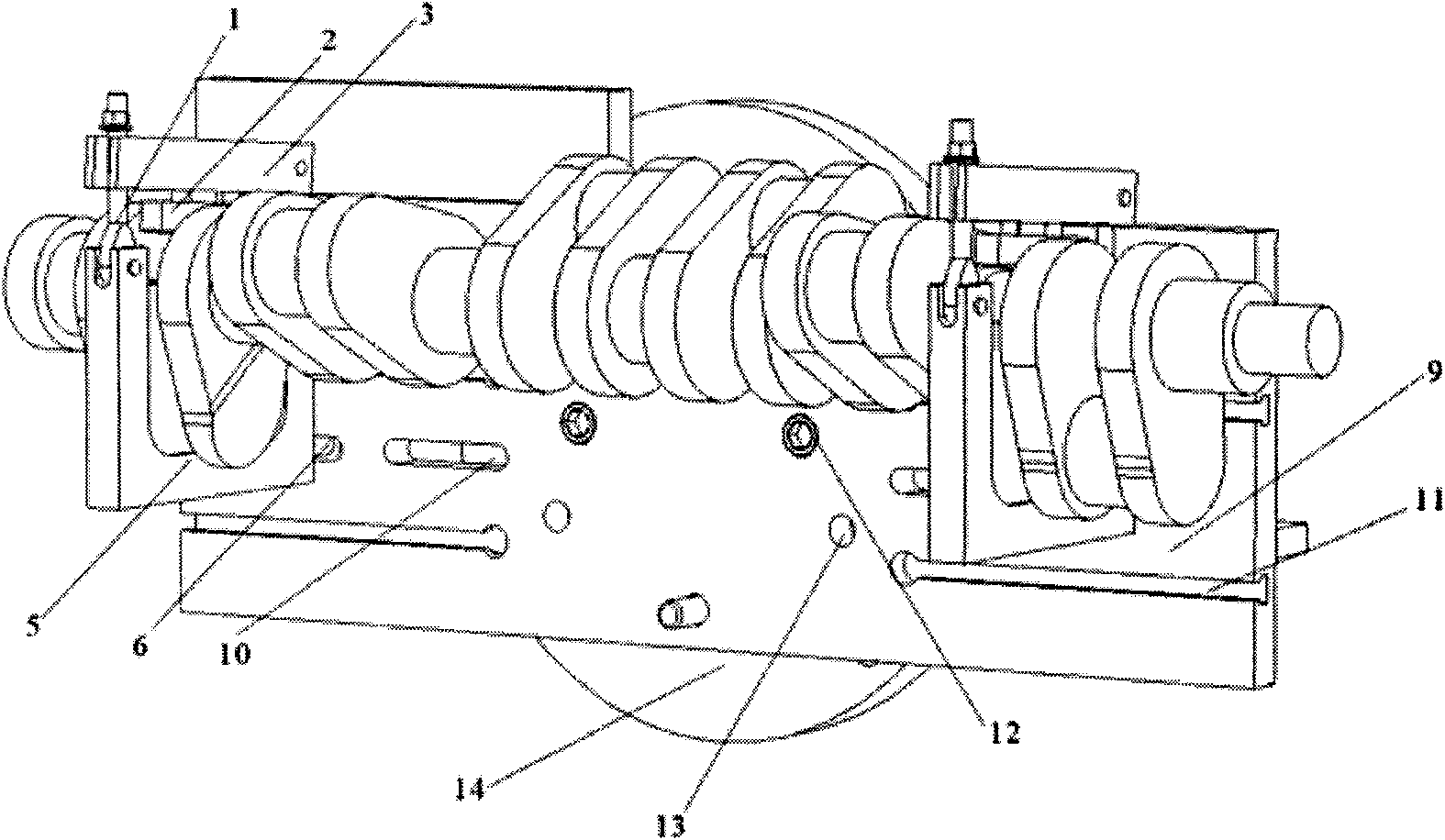

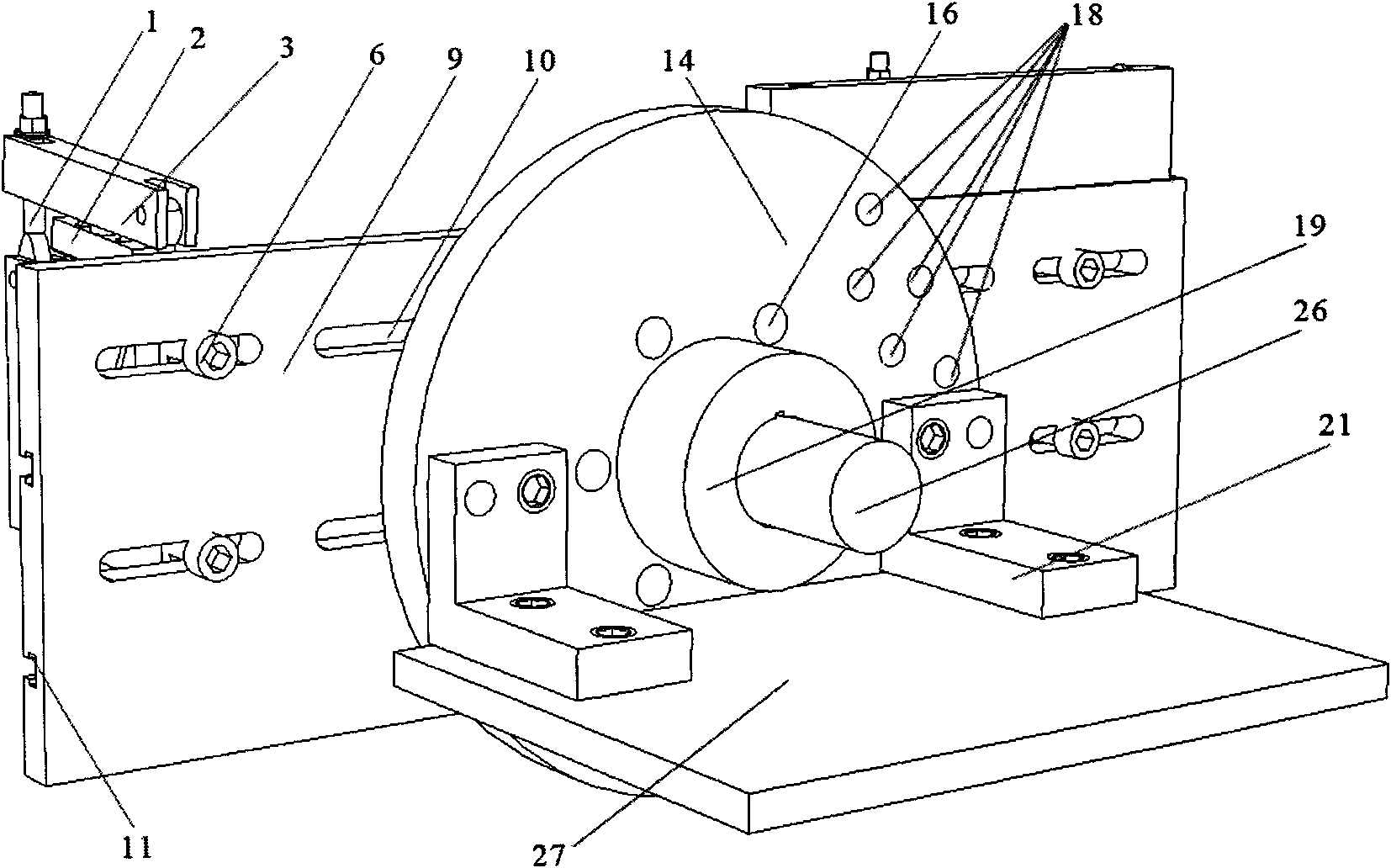

[0022] Such as figure 1 As shown, the crankshaft multi-angle oil hole drilling jig of the present invention includes a crankshaft clamping mechanism, a clamp body 9, an angle adjustment disc 14, a positioning support seat 19, a right-angle positioning block 21 and a right-angle slider positioning mechanism.

[0023] When machining the crankshaft, the crankshaft clamping mechanism is mainly used to clamp and fix the crankshaft. Figure 4 The crankshaft clamping mechanism shown includes swing bolt 1, replaceable pad 2, gland 3, hinge pin 4, V-shaped support seat 5, clamping mechanism fixing screw 6, replaceable support block 7 and T-shaped projection 8 . Figure 4 The V-shaped support seat 5 in the middle is the crankshaft support seat. exist Figure 4 Among them, there is an open V-shaped groove in the center of the V-shaped support seat 5 . The gland 3 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com