Pipeline cutting machine

A technology of pipe cutting machine and slideway, which is applied to pipe shearing devices, shearing devices, metal processing machinery parts, etc., can solve the problems of low safety and inaccurate cutting, and achieve high safety, good collection, and cost of construction. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

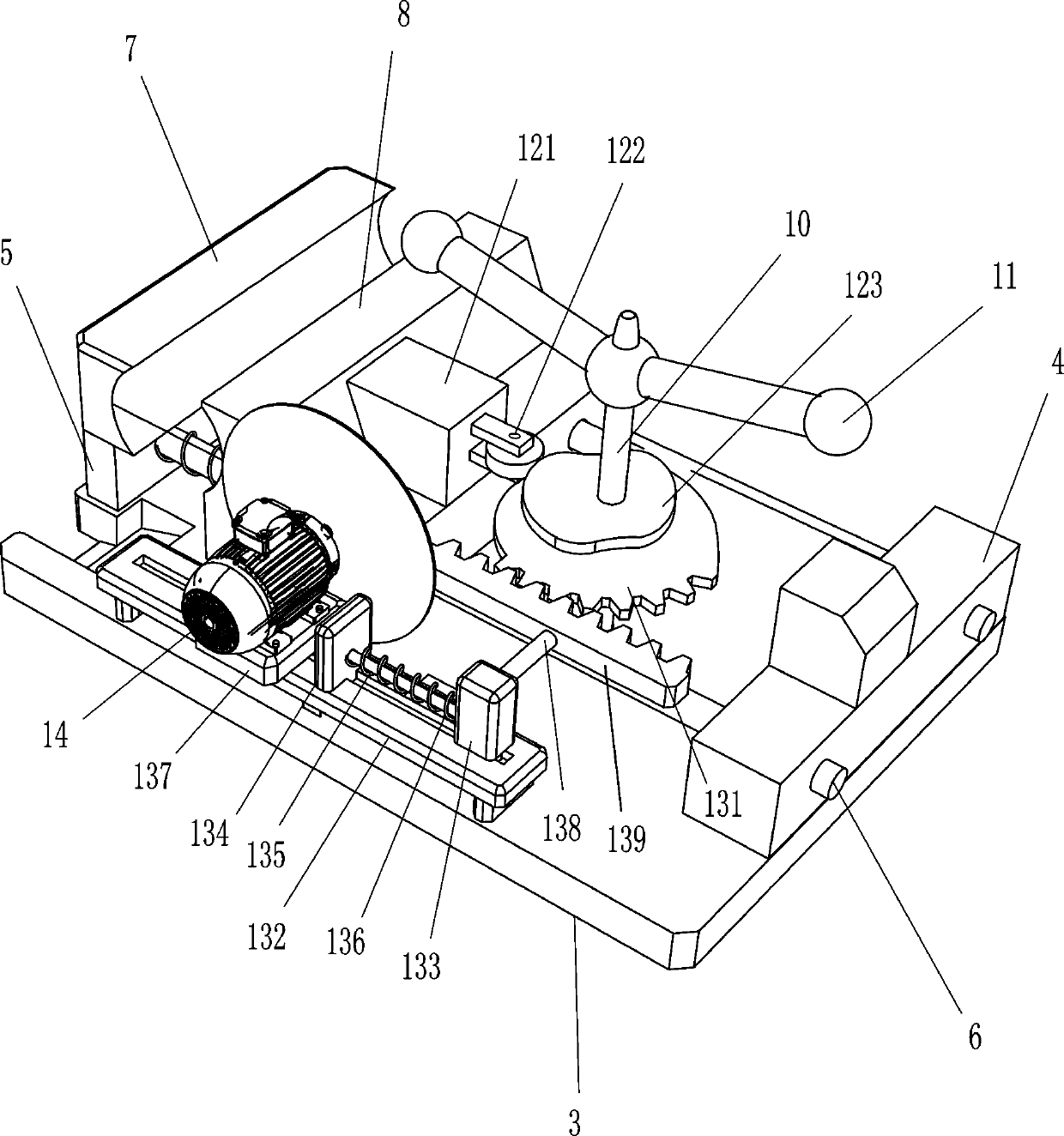

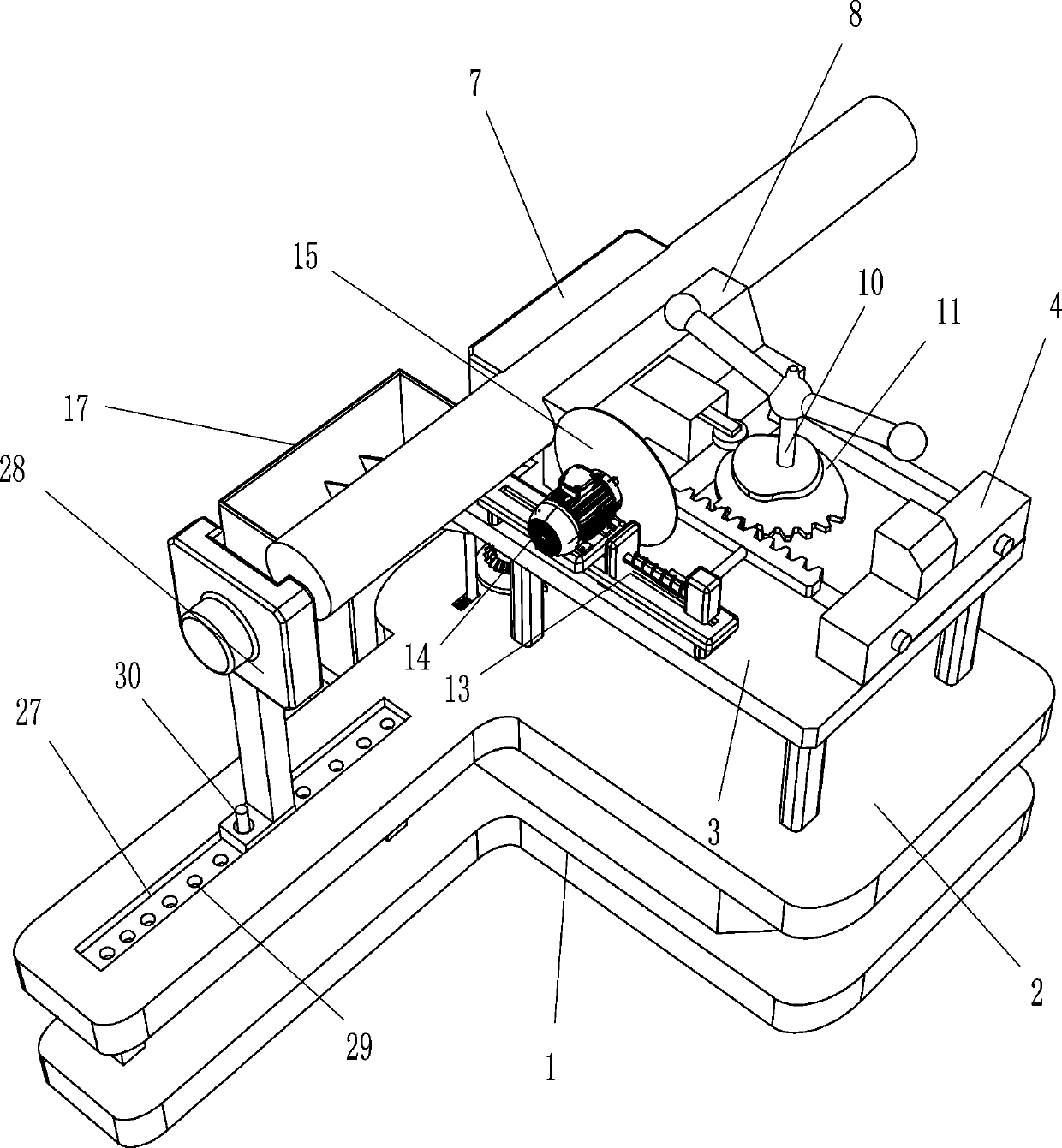

[0022] Such as Figure 1-3 As shown, a pipe cutting machine includes a base 1, a support plate 2, a workbench 3, a first fixed block 4, a second fixed block 5, a guide rod 6, a fixed clamp block 7, a movable clamp block 8, a first Elastic part 9, rotating rod 10, handle 11, extruding mechanism 12, moving device 13, rotating motor 14, circular cutter 15, slideway 16 and collection frame 17, base 1 top is provided with support plate 2, support plate 2 The top is provided with a workbench 3, and the second fixed block 5 and the first fixed block 4 are symmetrically arranged on the left and right sides of the top of the workbench 3, and a guide rod 6 is arranged front and back symmetrically between the first fixed block 4 and the second fixed block 5, The top of the second fixed block 5 is provided with a fixed clip 7, and the two guide rods 6 are slidably provided with a movable clip 8, and a first elastic member 9 is arranged symmetrically between the movable clip 8 and the fixe...

Embodiment 2

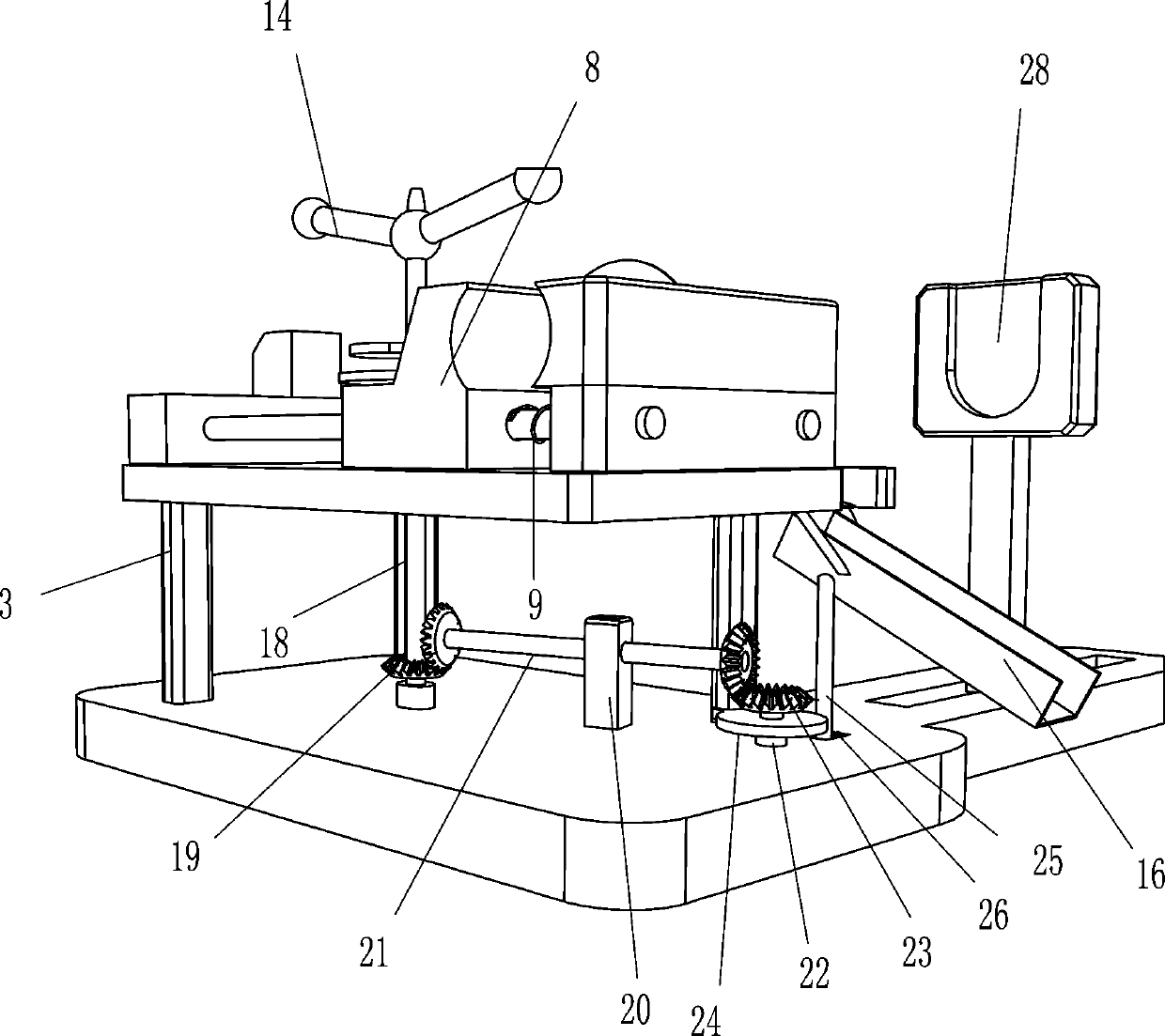

[0027] On the basis of Example 1, such as figure 1 and 3Shown, also include rotating rod 18, first bevel gear 19, bearing block 20, rotating shaft 21, rotating shaft 22, second bevel gear 23, beat wheel 24, ejector rod 25 and the 3rd elastic member 26, rotating rod The lower end of the 10 is connected with a rotating rod 18 through a coupling, the rotating rod 18 is provided with a first bevel gear 19, the top of the base 1 is provided with a bearing seat 20, the bearing seat 20 is provided with a rotating shaft 21, and the right end of the rotating shaft 21 is provided with a first cone Gear 19, two first bevel gears 19 are meshed with each other, base 1 is provided with rotating shaft 22 in the left side rotation type, the left end of rotating shaft 21 and the middle part of rotating shaft 22 are all provided with second bevel gear 23, and two second bevel gears 23 are meshed with each other, The lower part of the rotating shaft 22 is provided with a beating wheel 24 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com