Patents

Literature

30results about How to "Adjustable cutting length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

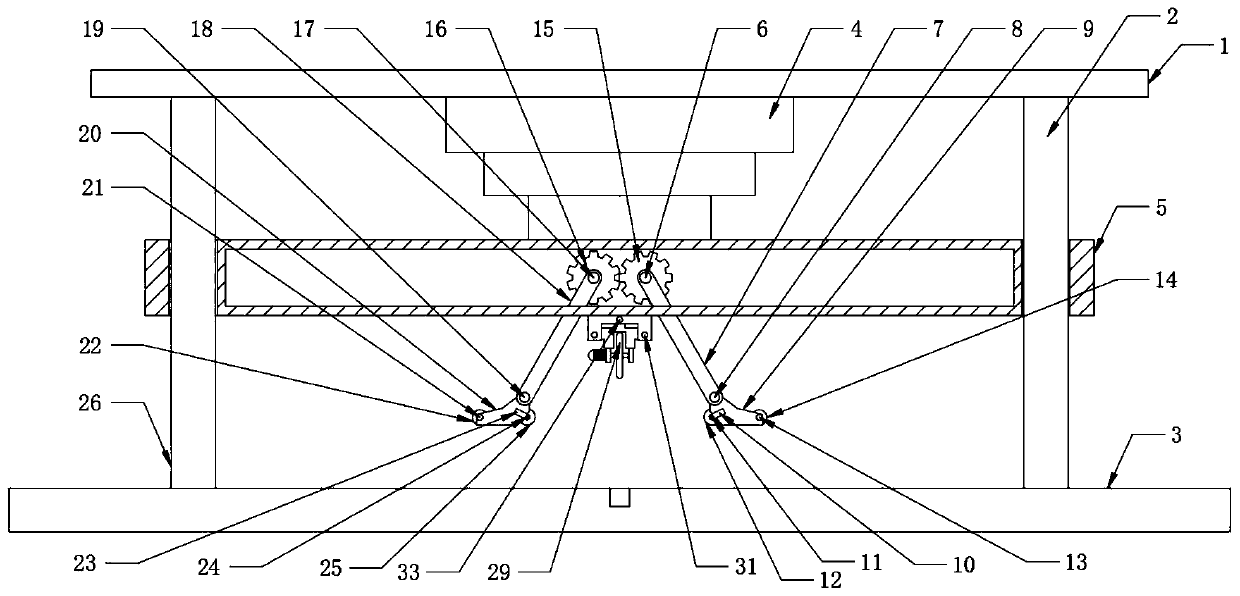

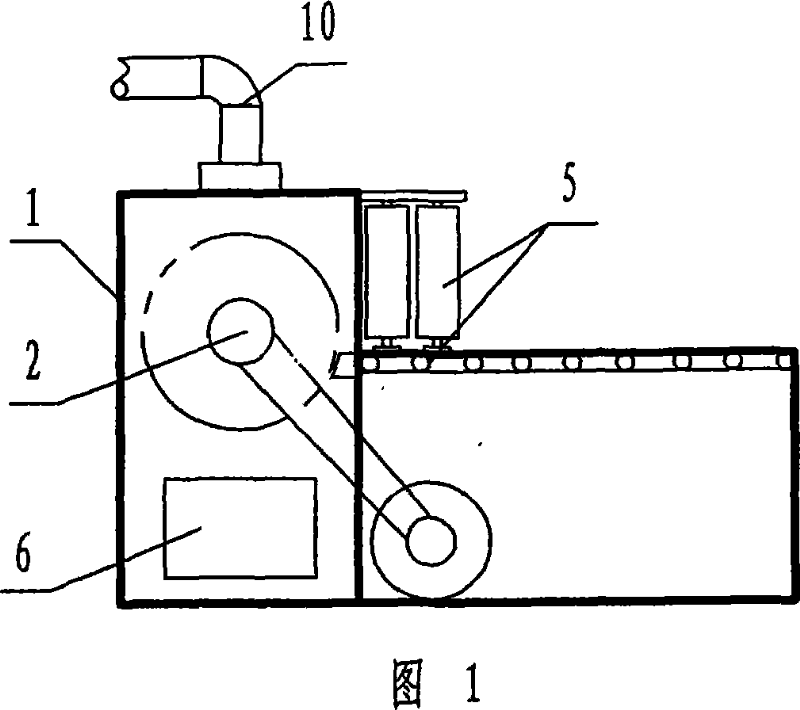

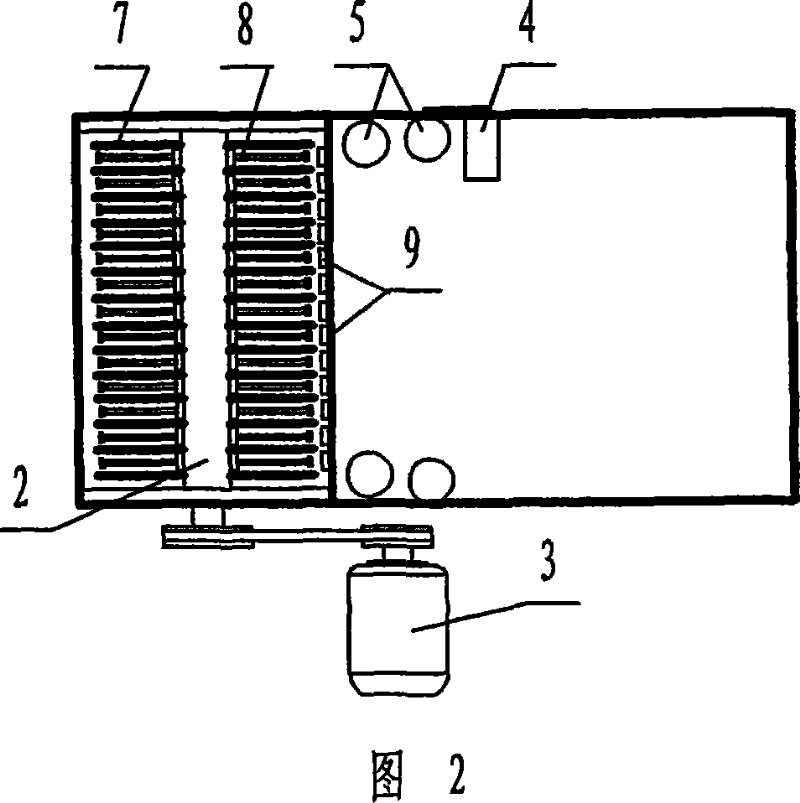

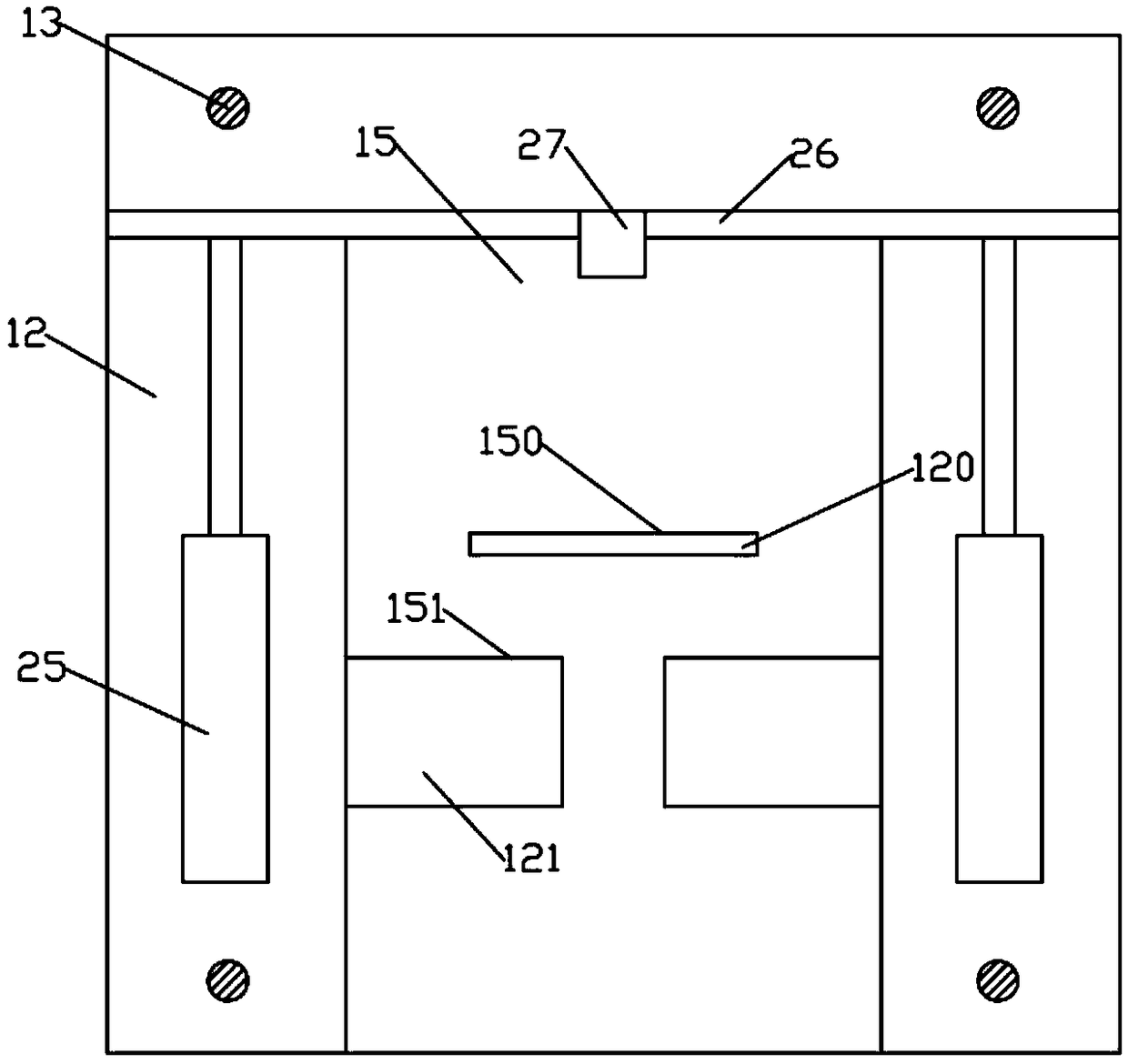

Double-cutter flat cutting machine for sponge cutting

ActiveCN106945096AEasy to storeImprove continuityMetal working apparatusHydraulic cylinderEngineering

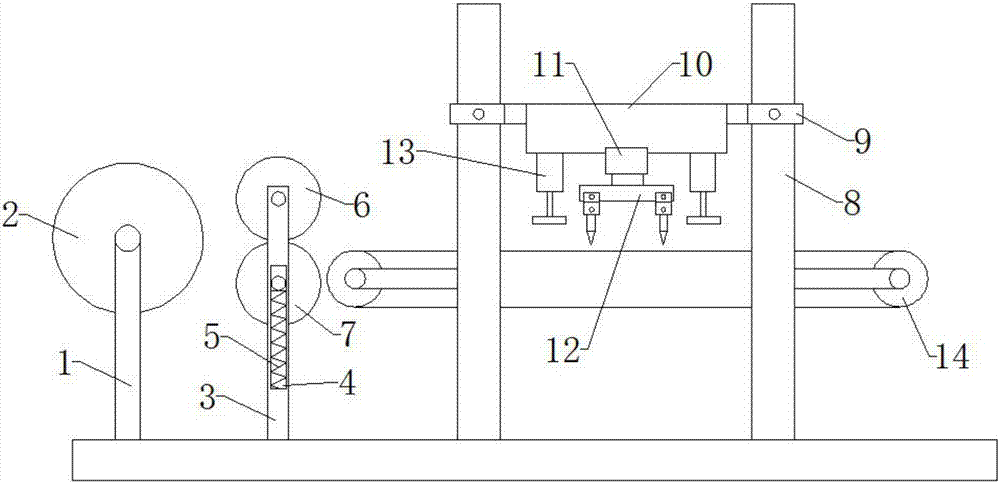

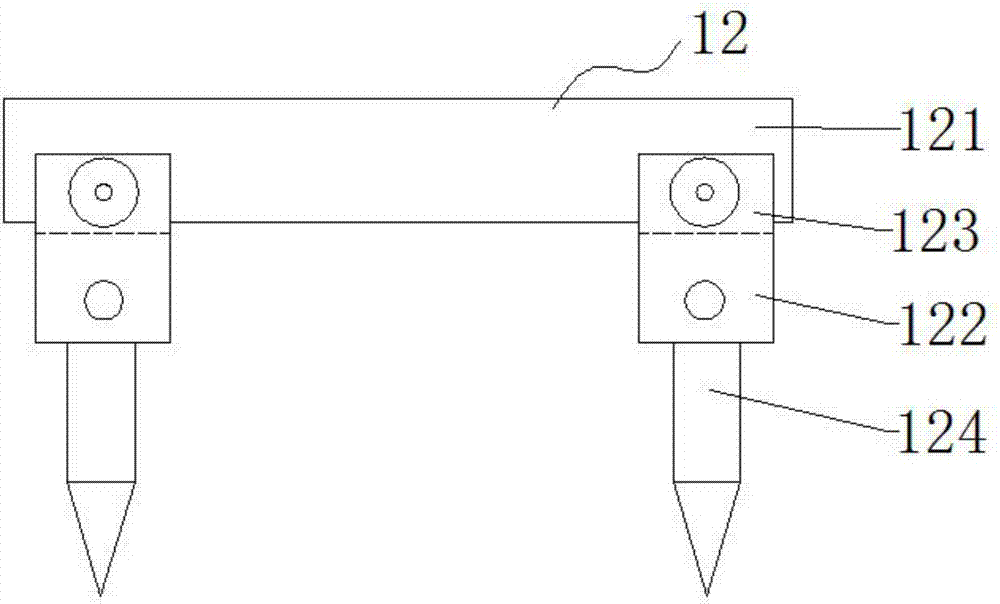

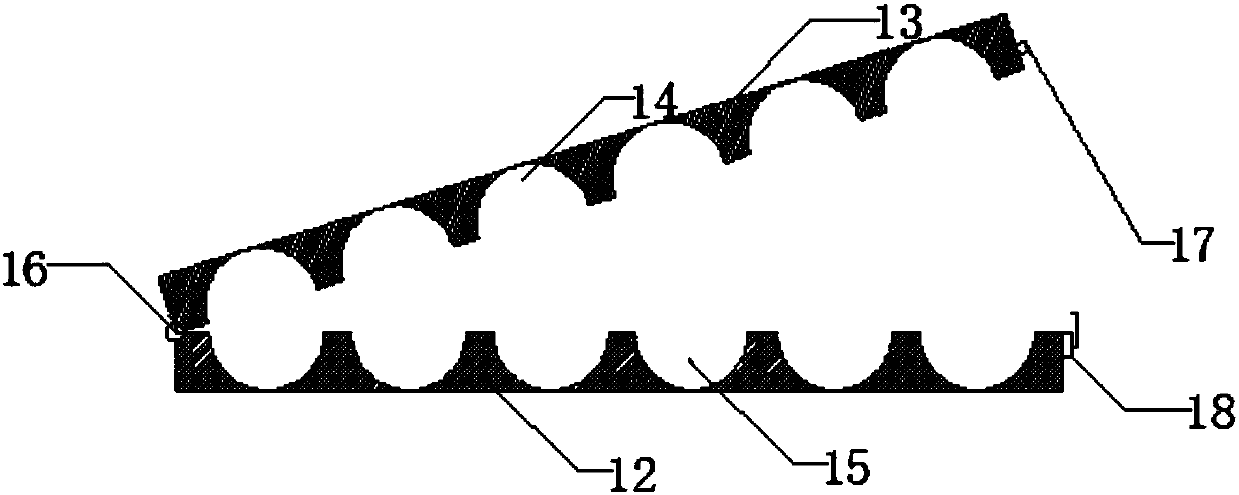

The invention discloses a double-cutter flat cutting machine for sponge cutting in the technical field of flat cutting machines. The machine comprises a first support rod, a second support rod and a bracket arranged in sequence from left to right; the first support rod is connected with a material roller; the second support rod is provided with a chute; a spring is arranged in the chute; a lower leveling roller is inserted in the chute; a rotating shaft end of the lower leveling roller is arranged at the top of the spring; an upper leveling roller is arranged at the top end of the second support rod; the bracket is sleeved with a slide sleeve; the slide sleeve is connected with the bracket through a locking knob; and one side of the slide sleeve is connected with a fixed base. The machine is convenient in raw material storage and continuous cutting for sponges, prelevels the sponges through the upper leveling roller and the lower leveling roller, uses a hydraulic cylinder for leveling during cutting of the sponges to prevent incisions from generating radians, improves the cutting efficiency through settings of double cutters, can adjust the distance between the cutters, and can adjust the cutting length according to specifications of needed materials.

Owner:中山市吉安海棉制品有限公司

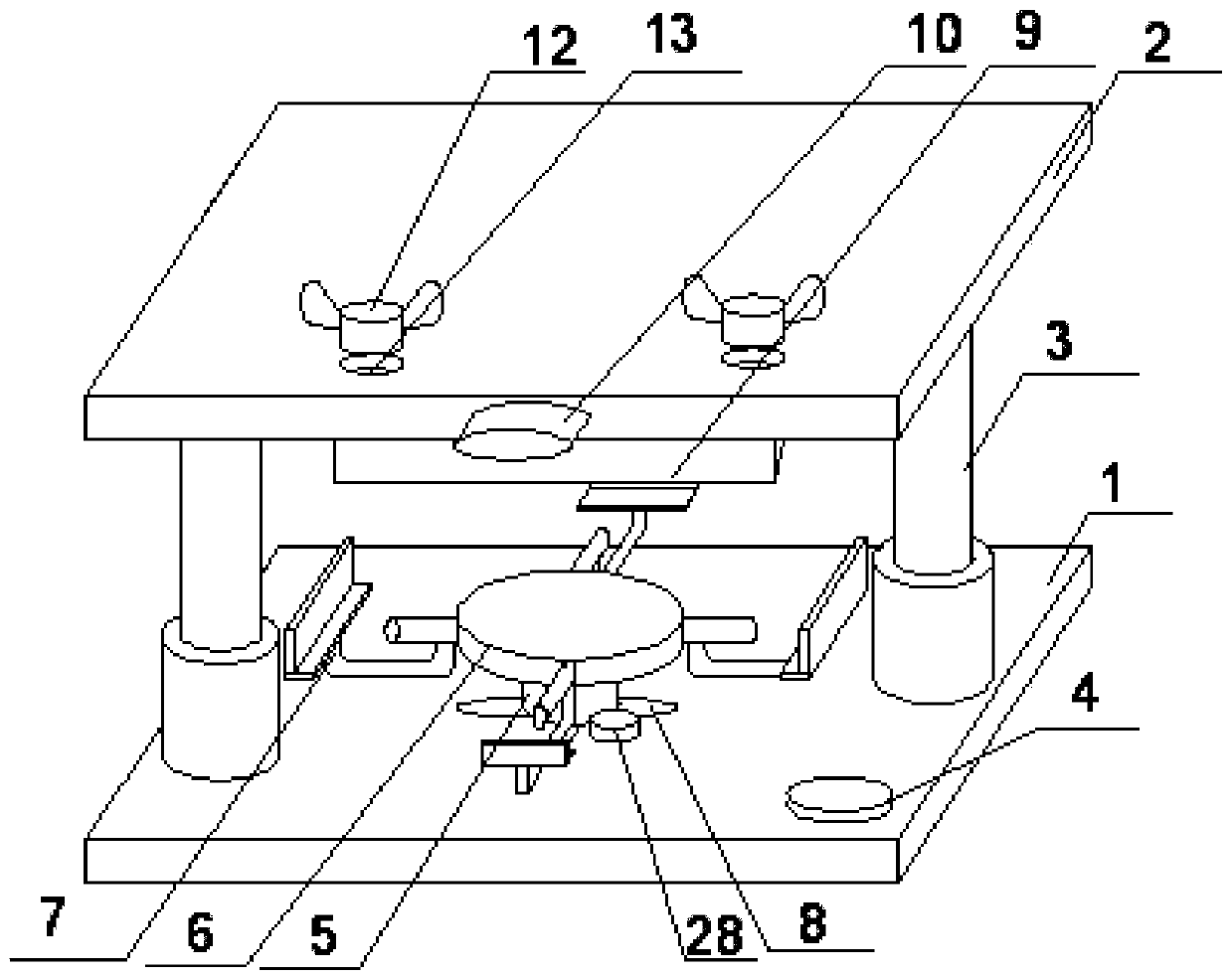

Pipeline cutting machine

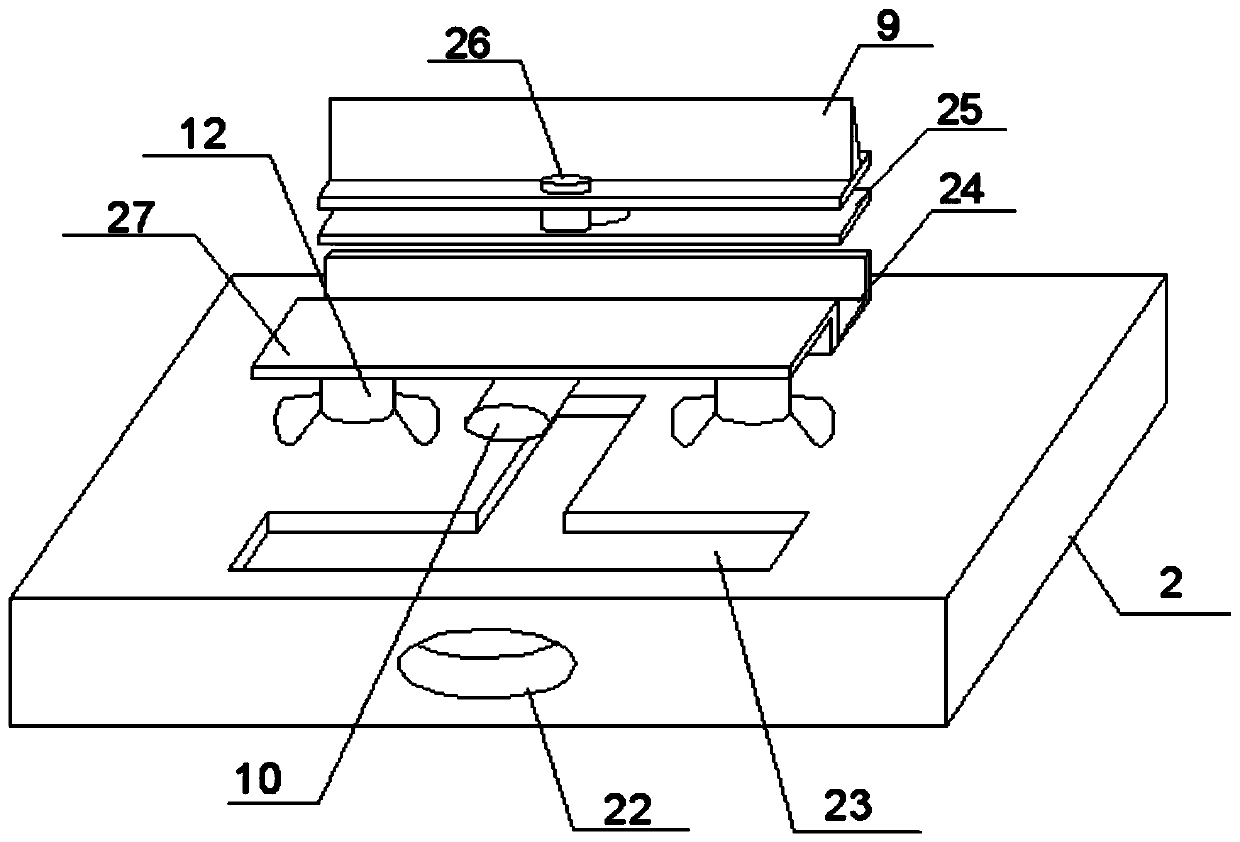

InactiveCN111250776AGood for collectionImprove securityTube shearing machinesPositioning apparatusManufacturing engineeringWorkbench

The invention relates to a cutting machine, in particular to a pipeline cutting machine. The pipeline cutting machine is high in safety and low in manufacturing cost and integrates clamping and cutting. The pipeline cutting machine comprises a base, a supporting plate, a workbench, a first fixing block, a second fixing block, guide rods, a fixed clamping block, a movable clamping block, a first elastic piece, a rotating rod, a handle and the like; and the supporting plate is arranged at the top of the base, the workbench is arranged at the top of the supporting plate, the first fixing block and the second fixing block are symmetrically arranged on two sides of the top of the workbench, the guide rods are symmetrically arranged between the first fixing block and the second fixing block, andthe fixed clamping block is arranged at the top of the second fixing block. The pipeline cutting machine achieves the effects of high safety, low manufacturing cost and integration of clamping and cutting.

Owner:仪征市金银无纺包装材料有限公司

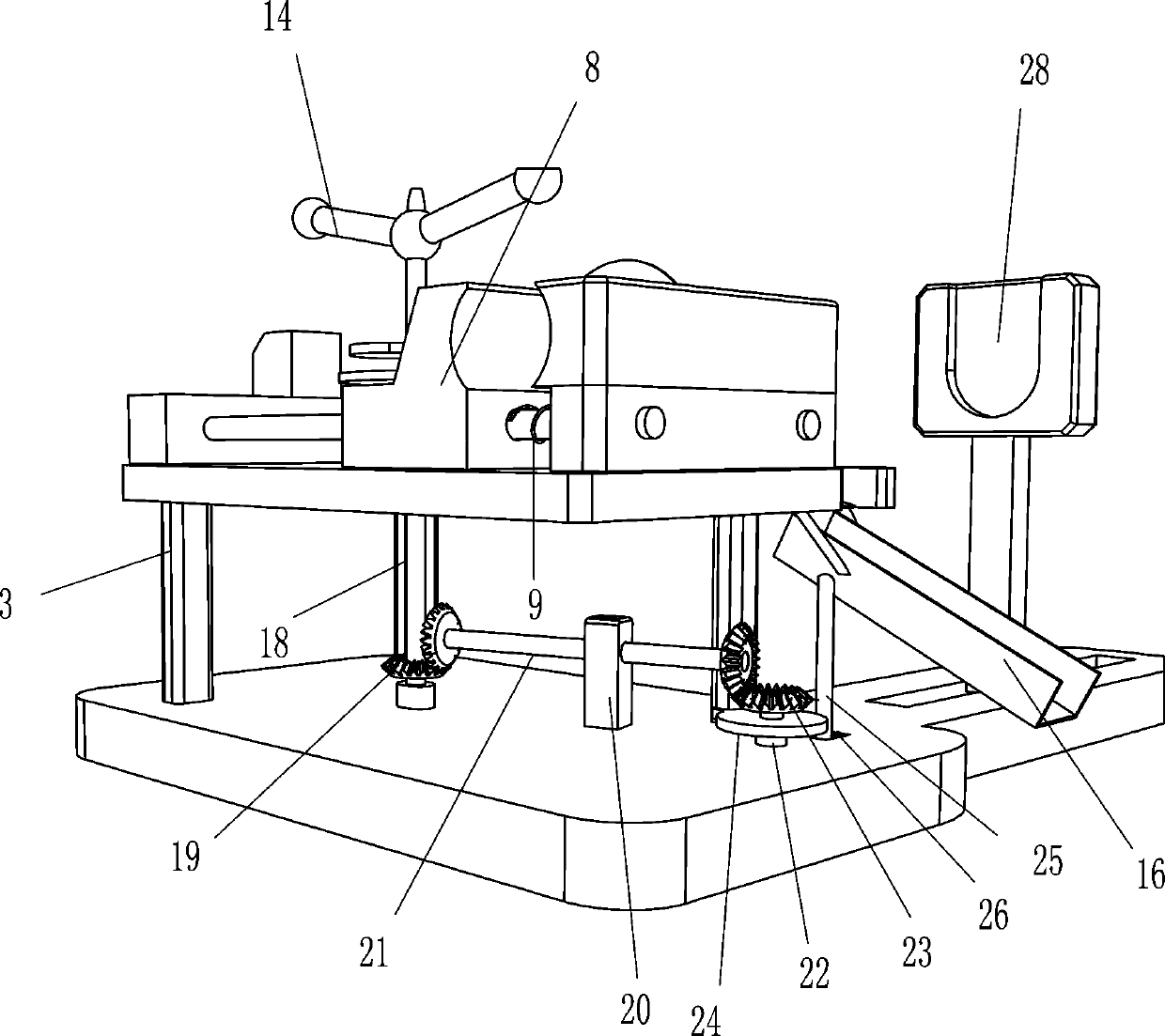

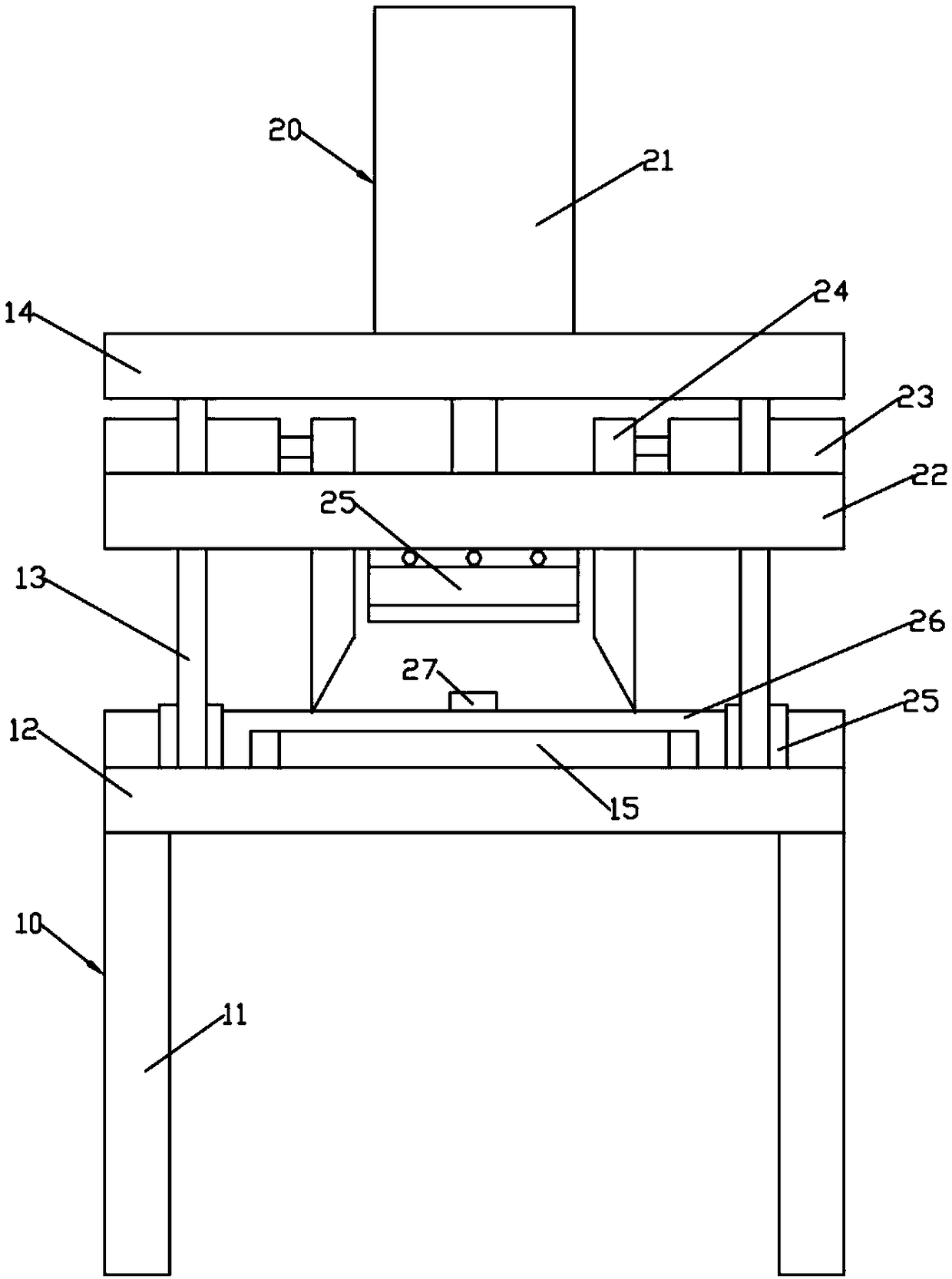

Fixed-length cutting-off device for sealwort

The invention discloses a fixed-length cutting-off device for sealwort. The fixed-length cutting-off device comprises a rack, a support seat, guiders, a blocking mechanism, a support, a servo motor, afirst gear, a feeding nut, a second gear, a lead screw, a guiding plate, limiting rods, a sucking mechanism, a tray, an air bellow, a cover plate, a draught fan, a photoelectric sensor, a stand column, a base plate, a speed adjustment motor, a rotating shaft, a cam, guiding wheels, a connecting plate, first guiding rods, a guiding block, a C-shaped bracket, a cutting-off mechanism and first springs. The fixed-length cutting-off device is simple in structure; fixed-length cutting-off can be automatically conducted on the sealwort; in addition, the cutting-off length can be adjusted; safety achieved in the sealwort cutting process is effectively improved; meanwhile, chippings can be removed automatically; the production process is simplified; and production efficiency is improved.

Owner:安徽九华峰生物科技有限公司

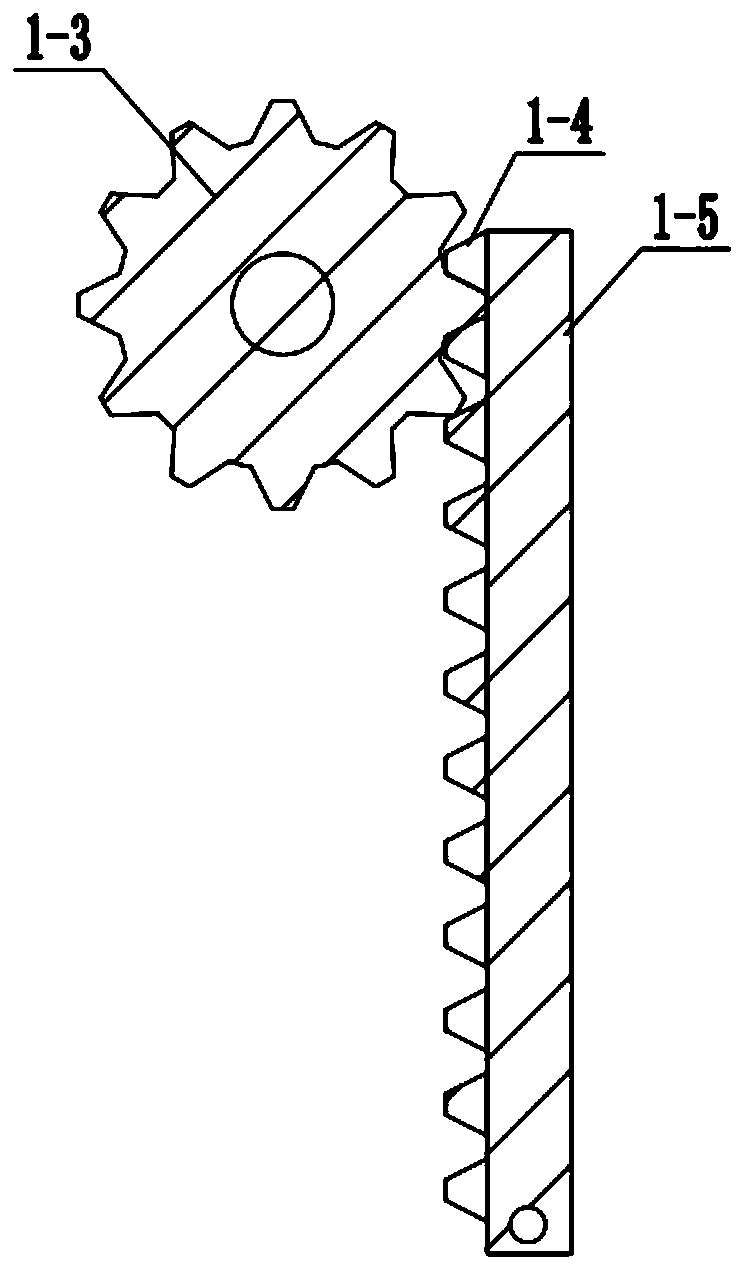

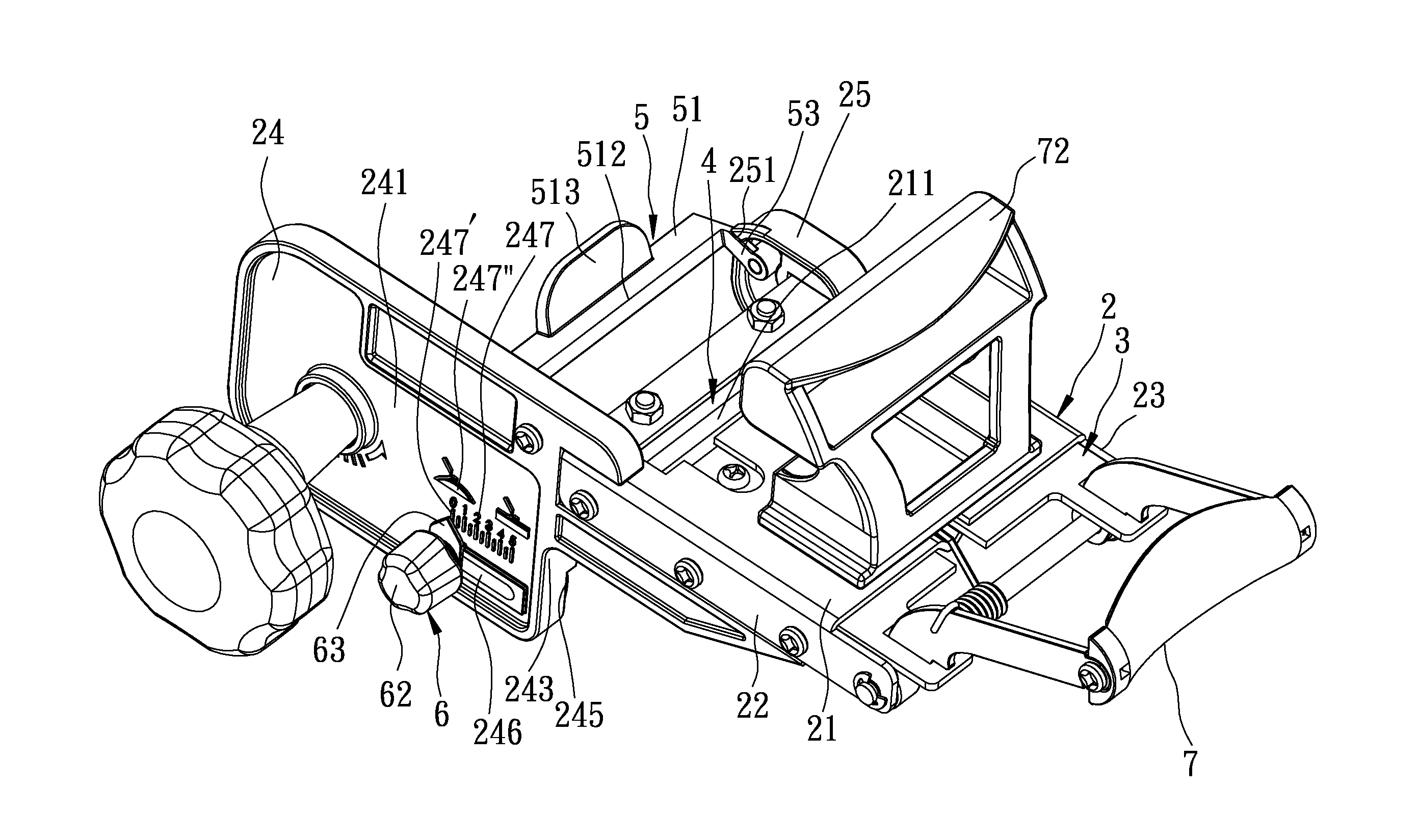

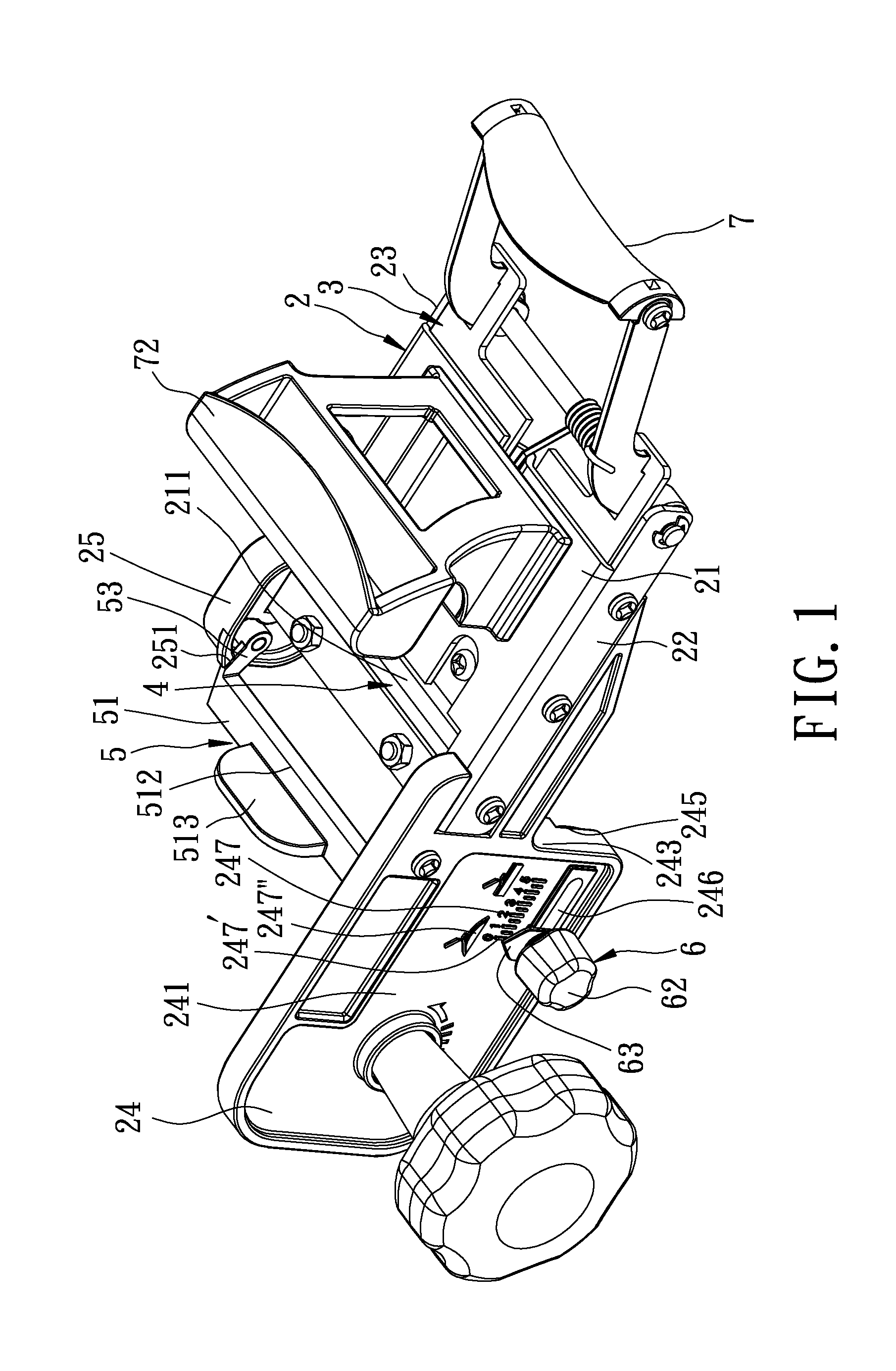

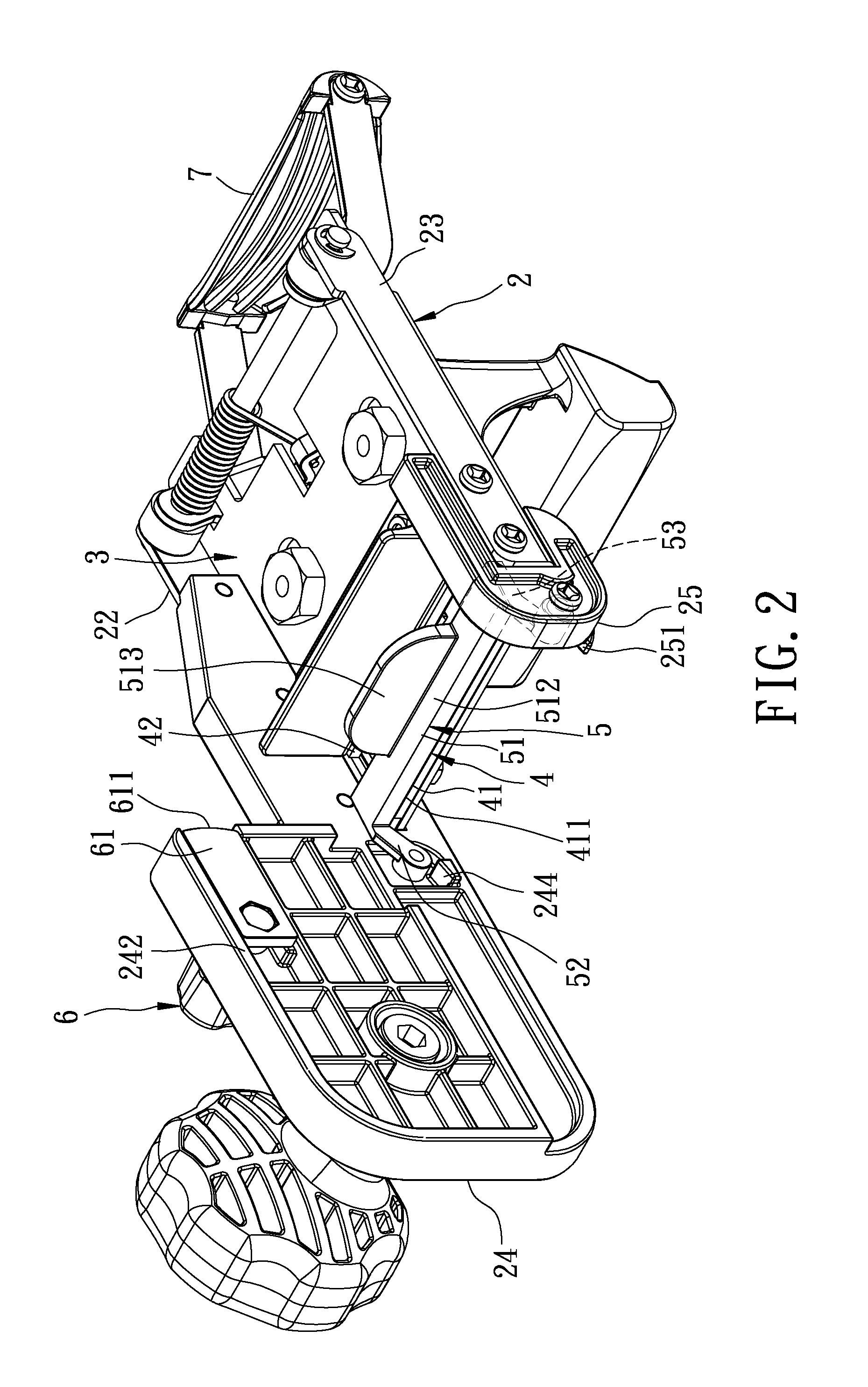

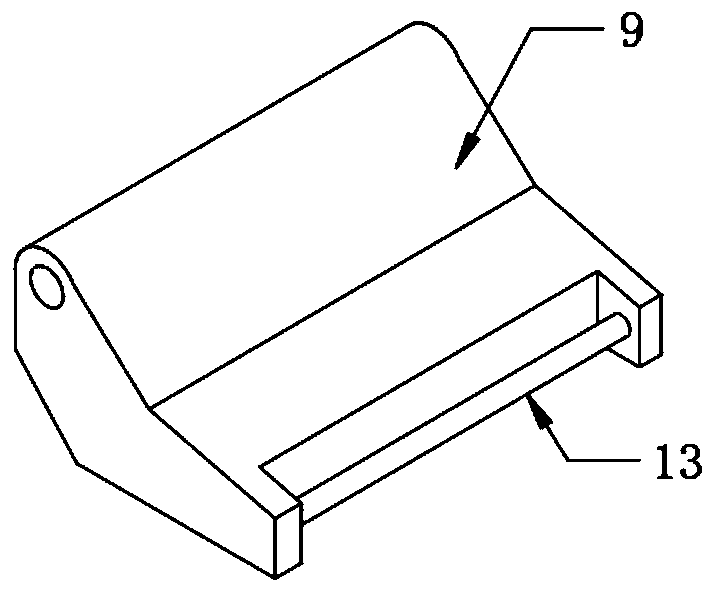

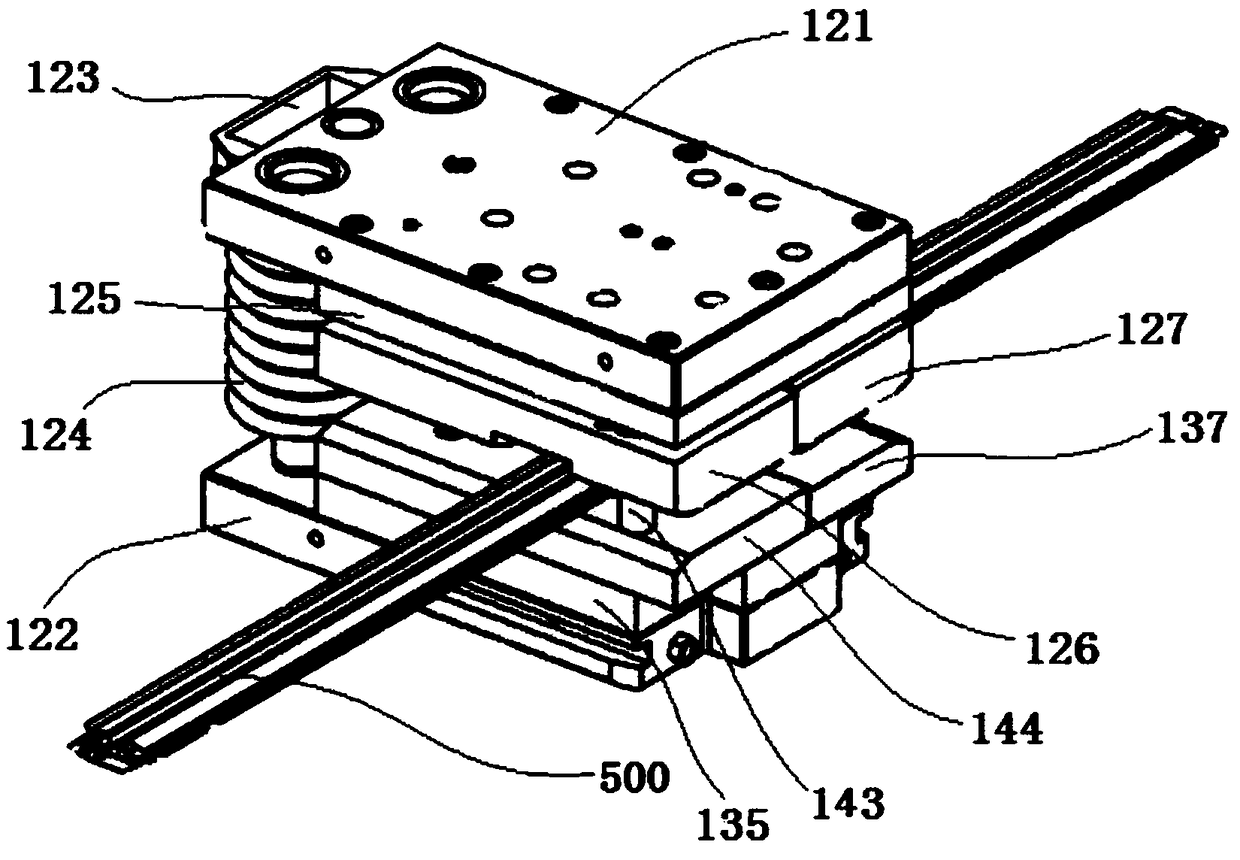

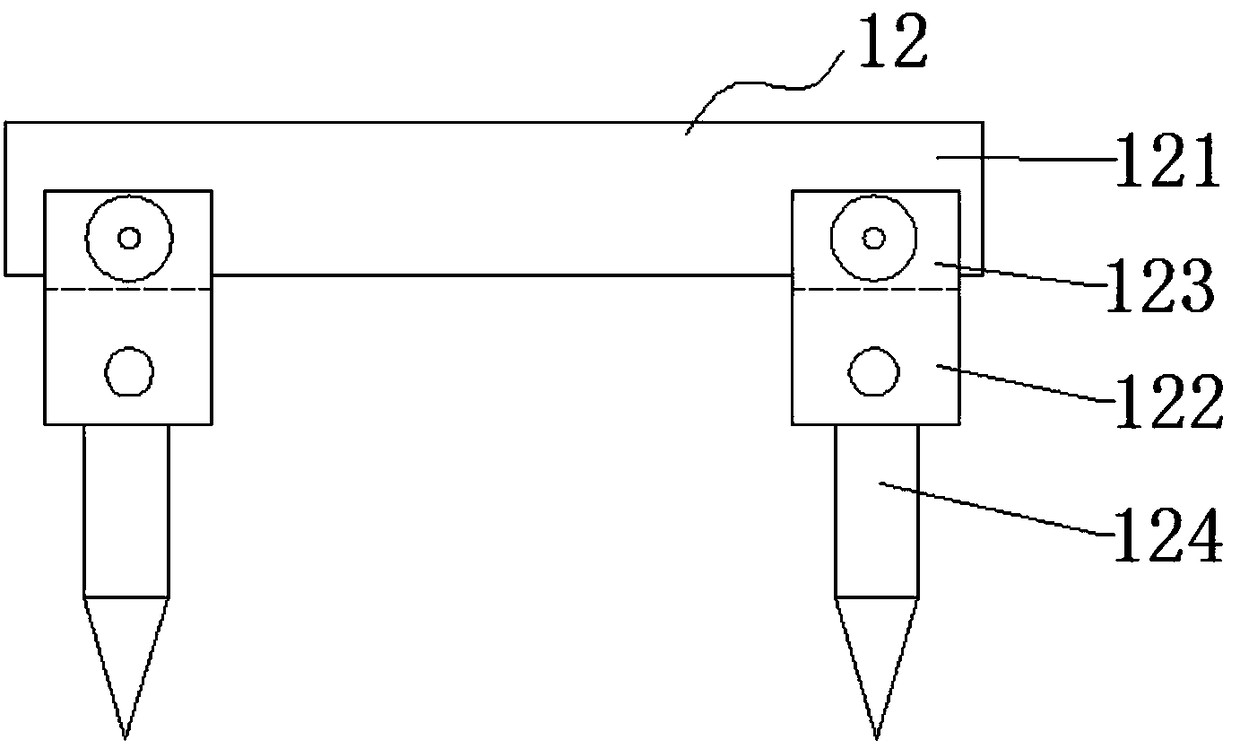

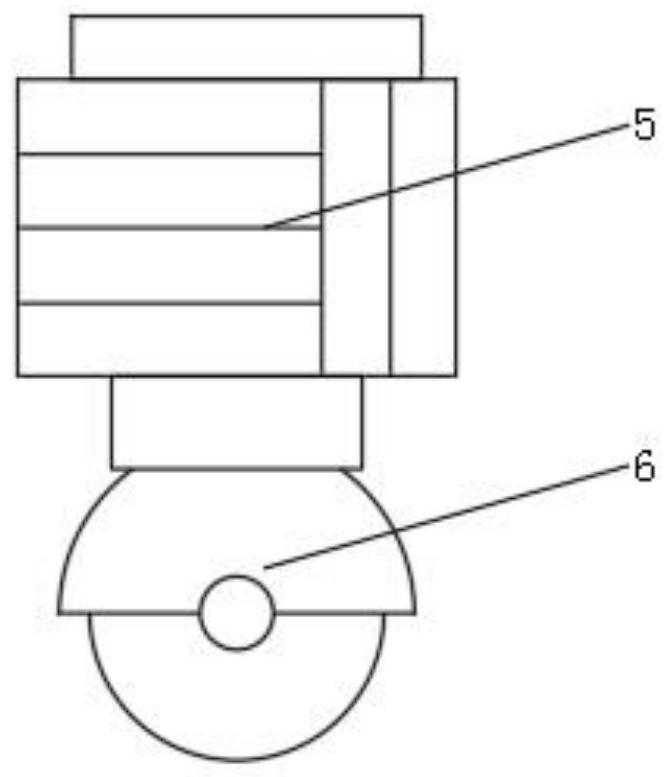

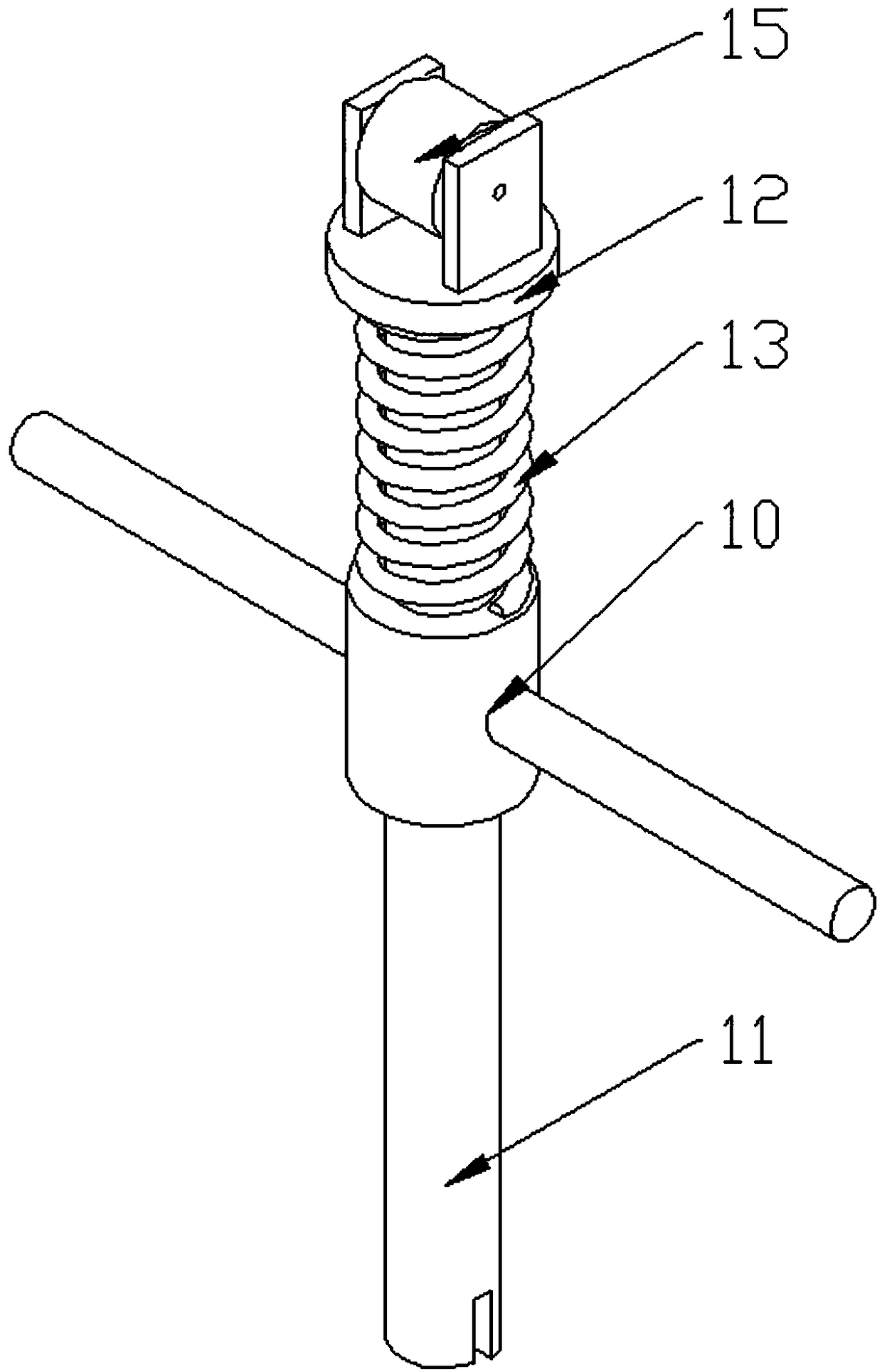

Adjustable cutting knife

PendingCN107932575APrevent movementAdjustable cutting lengthMetal working apparatusEngineeringSlide plate

The invention discloses an adjustable cutting knife, which comprises a sliding plate, a knife mechanism, a guide rod, a spring, and a pressure plate. The adjustment screw is loosened, and the distance between the knife mechanisms is manually adjusted. The distance between the two cutter mechanisms can be intuitively obtained. When the set distance is reached, just lock the adjusting screw. When working, connect the device with the driving mechanism. When the driving mechanism operates, the pressing plate first contacts the material to be cut. With the further action of the driving mechanism, the spring is compressed, the sliding plate moves down along the guide rod, and the cutter passes through the pressing plate The adjustment groove on the upper cuts off the material to be cut. The structure of the device is simple, not only the cutting length is uniform, but also the cutting length is adjustable. At the same time, through the pre-pressing of the over-pressing plate, the movement of the material to be cut is effectively prevented and the cutting accuracy is improved.

Owner:安徽九华峰生物科技有限公司

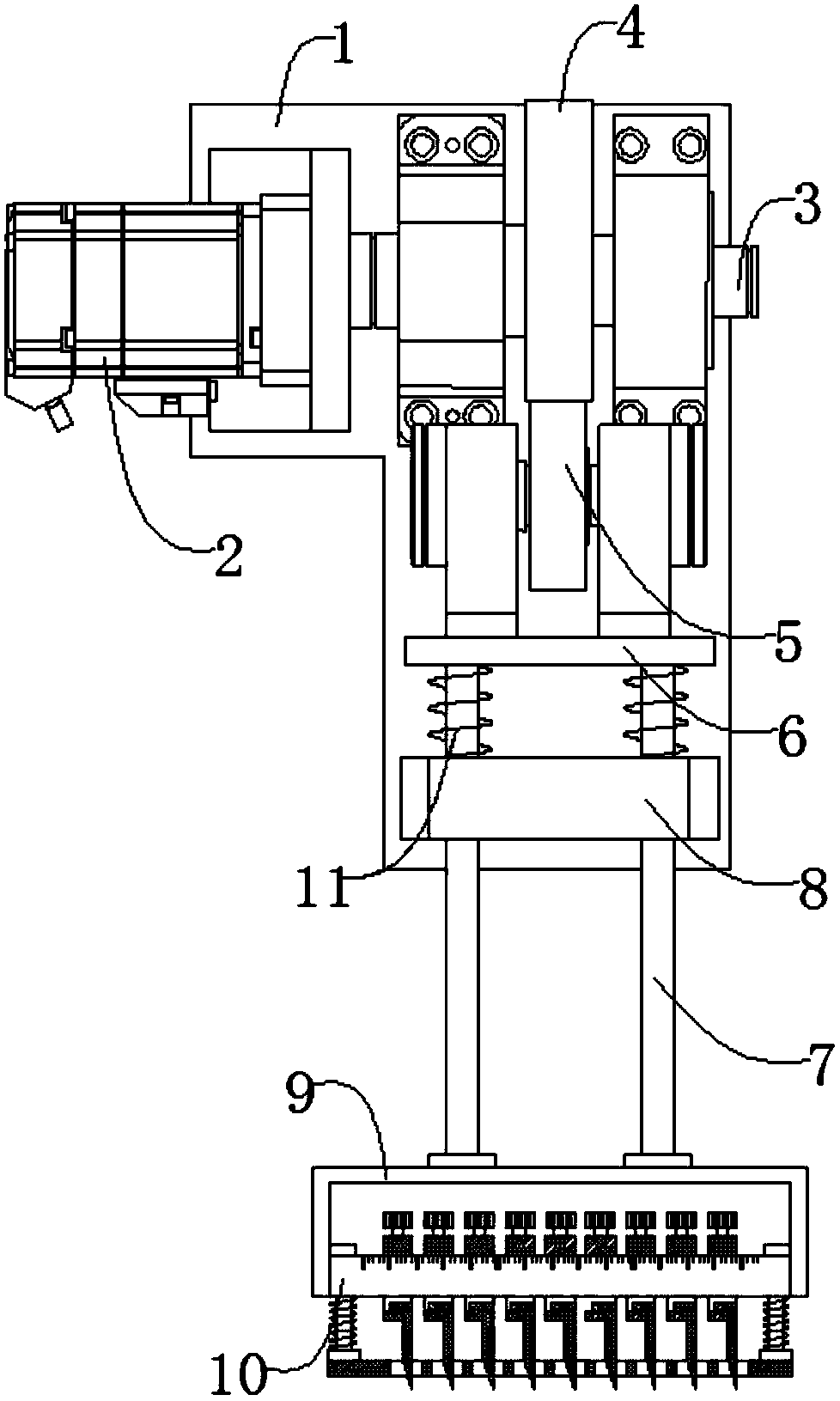

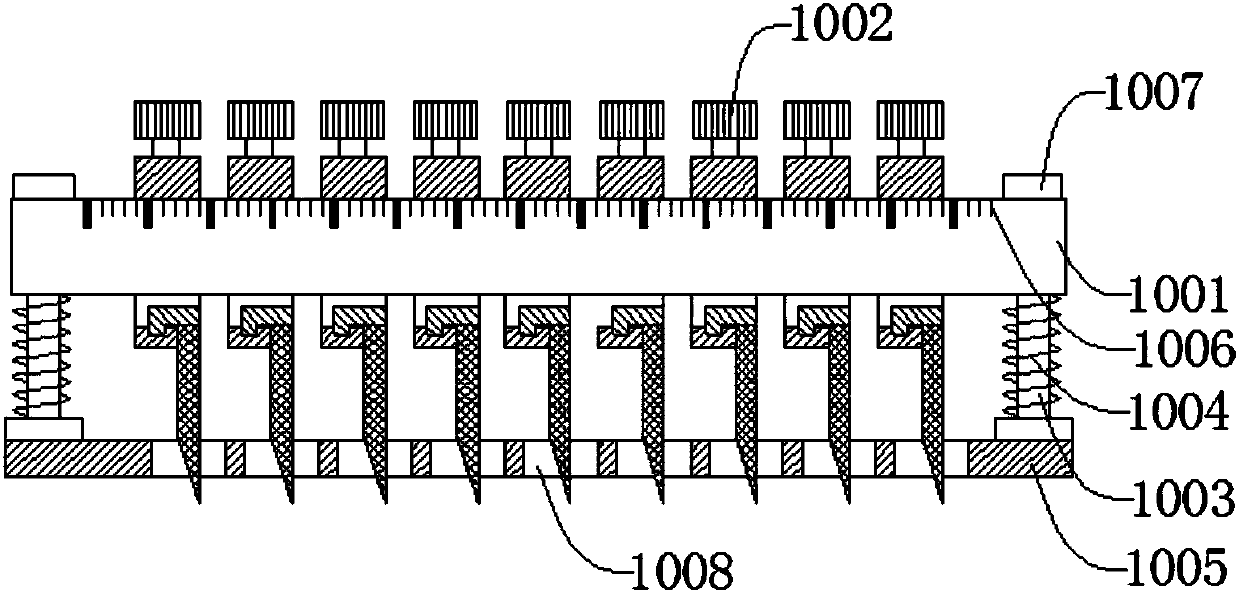

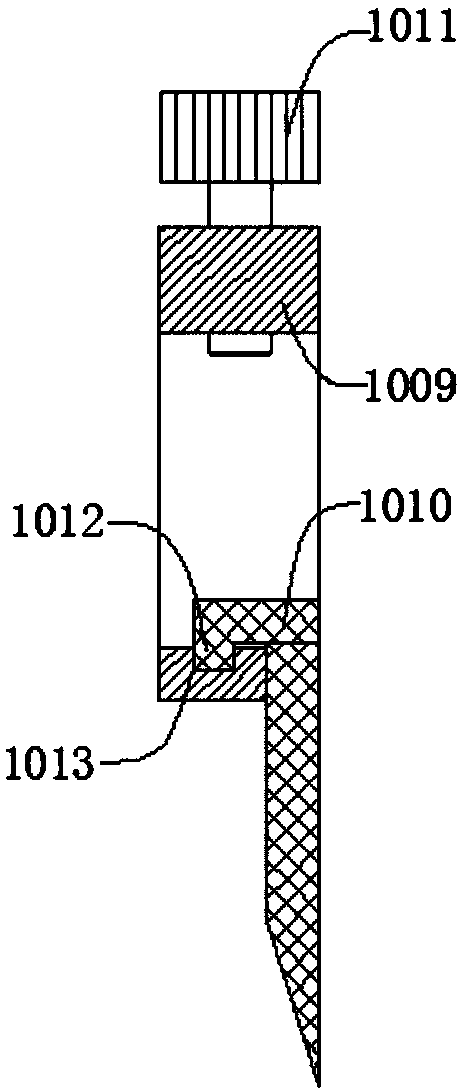

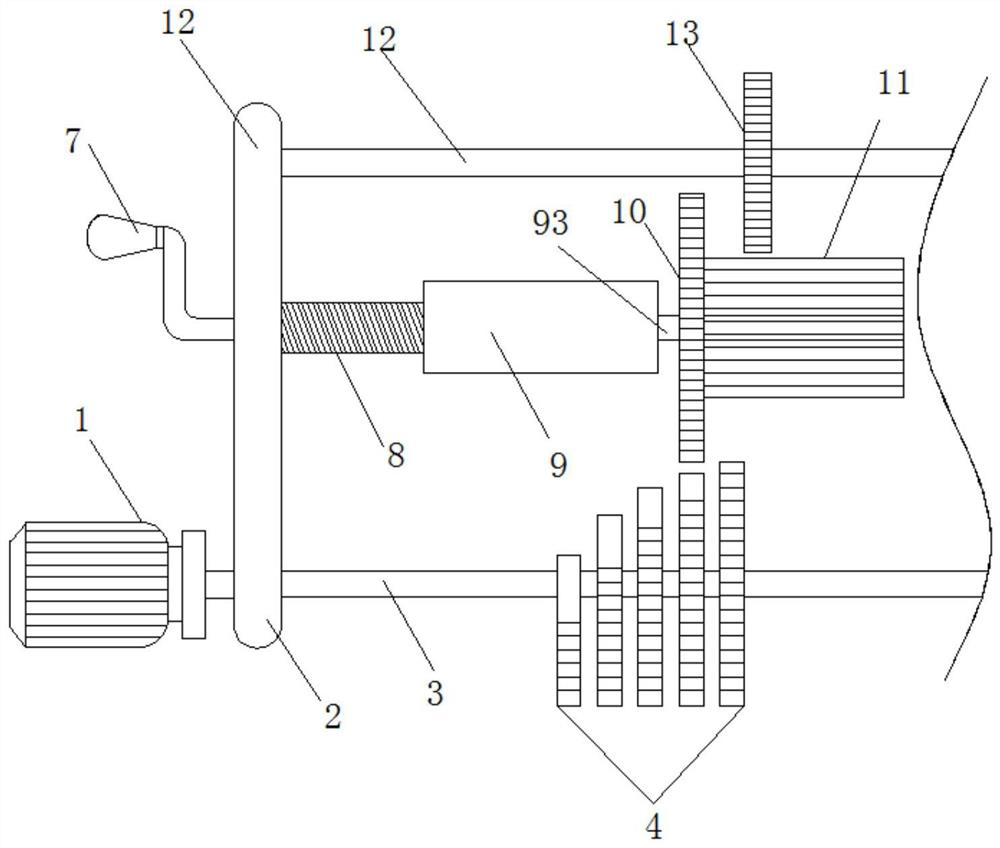

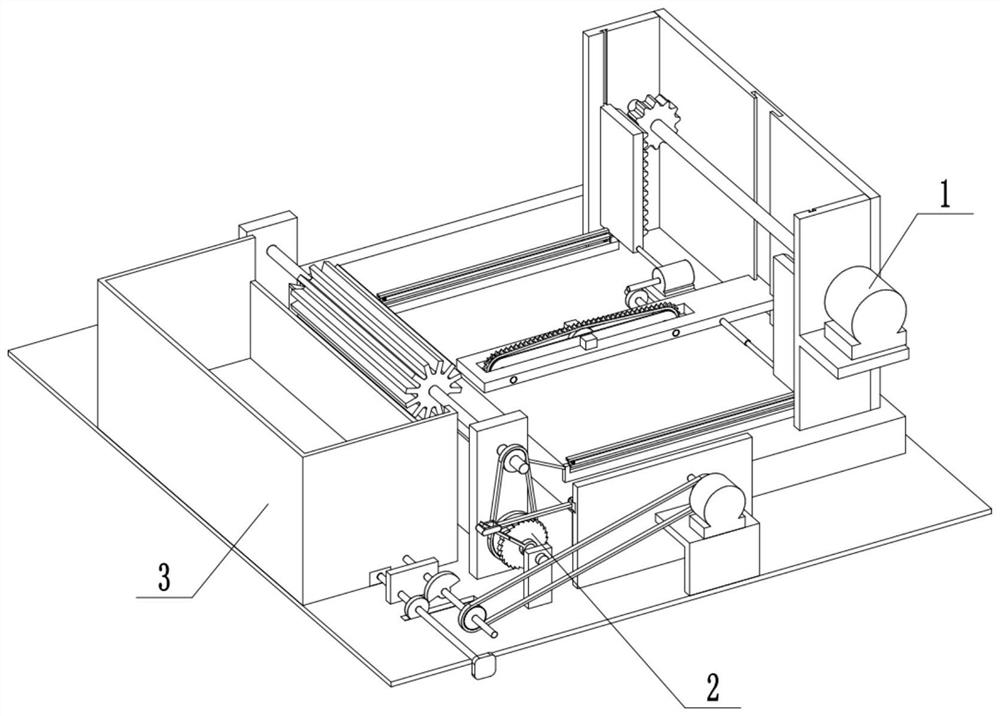

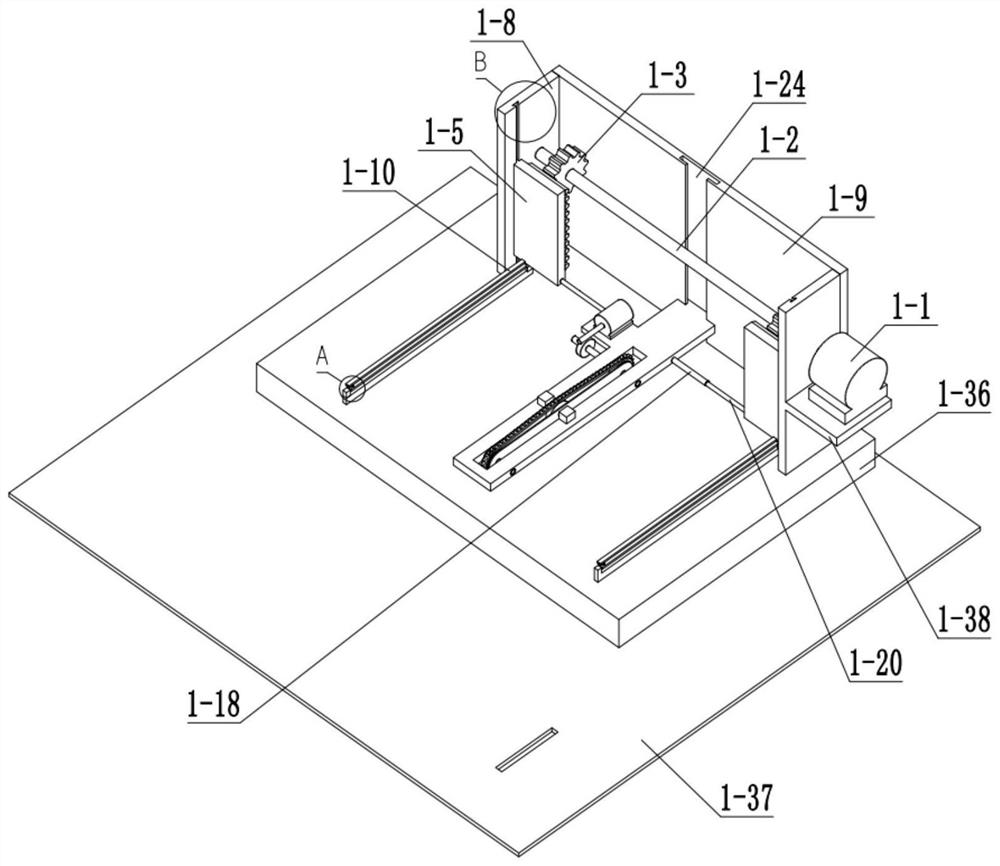

Steel bar cutting equipment

The invention relates to the field of bridges, in particular to steel bar cutting equipment. The steel bar cutting equipment comprises a cutting combined body, a feeding combined body and a material box combined body. By means of the steel bar cutting equipment, the problems frequently encountered when a bridge is built that the automation degree of programs for cutting steel bars in batches is low, and danger is generated to human bodies by too much manual operation are solved. To-be-cut steel bars are put into a material box, a threaded sliding barrel is adjusted, a cutter blade slides in the axial direction of a supporting shaft, and the cutting length of the steel bars can be adjusted. The cutter blade moves reciprocatingly up and down so that the steel bars are cut. When the cutting blade moves upwards, a rotary frame is opened, a feeding rotary barrel rotates and the steel bars in the material box are taken out and fall into the space between the rotary frame and a fixing frame through a slant plate, and a lifting plate of the material box does not move. When the cutting blade moves downwards, the rotary frame is closed, the feeding rotary barrel stops rotating, the steel bars are stacked flush and clamped by the rotary frame and the fixing frame and are convenient for the cutting blade to cut, the lifting plate of the material box rises, and uncut steel bars in the material box are lifted and wait to be taken out by rotation of the feeding rotary barrel.

Owner:王学凤

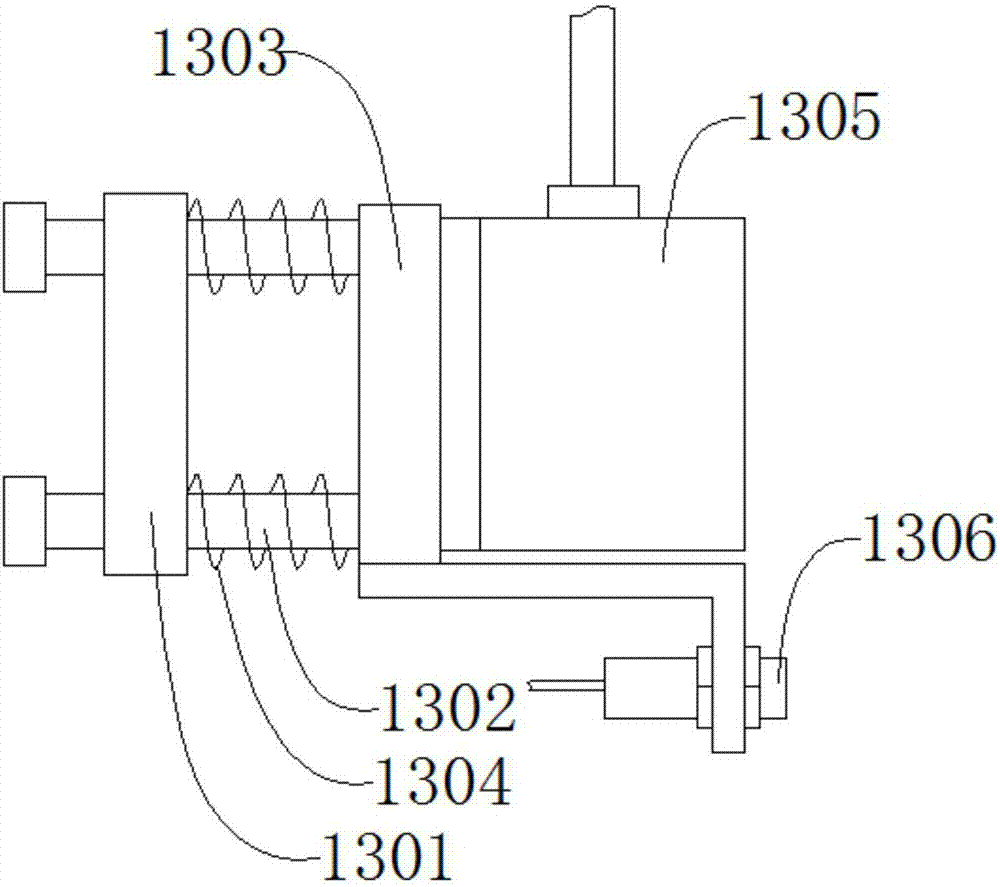

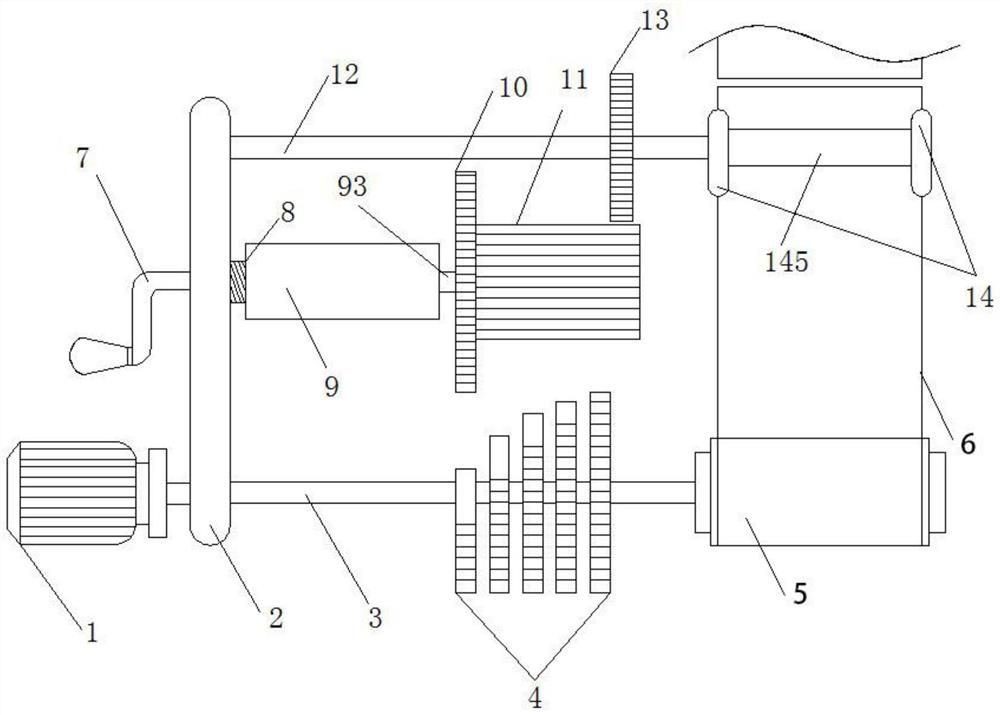

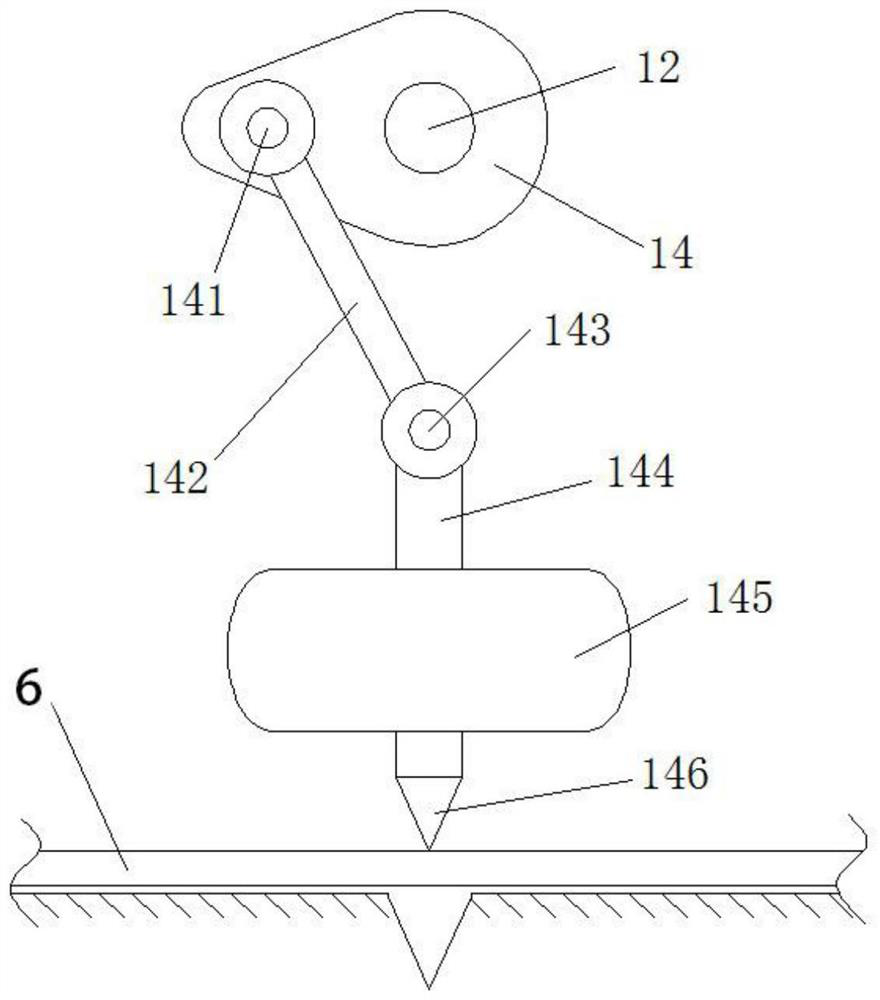

Continuous cutting-off mechanism

The invention discloses a continuous cutting-off mechanism. The continuous cutting-off mechanism comprises a bottom plate, a speed-regulating motor, a rotating shaft, a cam, a guide wheel, a connecting plate, first guiding rods, a guiding block, a C-shaped frame, a cutting-off mechanism body and first springs. The speed-regulating motor drives the cam through the rotating shaft to rotate, and thecam pushes the guide wheel to move downwards, so that the first guiding rods move downwards along the guiding block and accordingly drive the cutting-off mechanism body fixedly connected with C-shapedframe to move downwards; at the moment, the first springs are compressed, a pressing plate makes contact with a to-be-cut material firstly and rotates continuously along with the cam, second springsare compressed, a sliding plate moves downwards along second guiding rods, and cutters penetrate through regulating grooves formed in the pressing plate to cut off the to-be-cut material; and when thecam returns, the first springs return to drive the cutting-off mechanism body to reset, and the actions are repeated till cutting-off operation is completed. The continuous cutting-off mechanism is simple in structure and can conduct cutting-off operation continuously; not only is the efficiency high, but also the cutting-off length is adjustable and uniform; and meanwhile, through pre-pressing of the pressing plate, moving of the to-be-cut material is prevented effectively, and thus the cutting-off precision is improved.

Owner:安徽九华峰生物科技有限公司

Edge band cutting device

InactiveUS20140165809A1Simple structureAdd supportOther plywood/veneer working apparatusWithdrawing sample devicesEngineeringSide band

An edge band cutting device includes a fixed unit, a movable plate movable on a base plate of the fixed unit, a cutter unit including a main cutter and an auxiliary cutter, an adjustable positioning unit abutting removably against the main cutter, and an adjustable supporting unit disposed on the fixed unit. The base plate has an opening. A space between the main cutter and the auxiliary cutter is aligned with the opening. The adjustable supporting unit includes an adjustable supporting member disposed movably on a pressing plate of the fixed unit, and a locking member for locking the adjustable supporting member on the pressing plate to allow the adjustable supporting member to be retracted into or extended from the pressing plate.

Owner:LIN CHIN CHI

Textile fabric cutting device

The invention relates to the technical field of textile equipment, and discloses a textile fabric cutting device. The textile fabric cutting device comprises a top seat, a first guide rod and a base,wherein the bottom of the top seat is fixedly connected with the top end of the first guide rod; the bottom end of the first guide rod is fixedly connected with the top end of the base; and the bottomend of the top seat is fixedly connected with an air cylinder. According to the textile fabric cutting device, a transmission gear, a driven gear, a first transmission arm, a second transmission arm,a first pressing plate, a second pressing plate, a first right press roller, a second right press roller, a first left press roller, a second left press roller and the like are arranged; and after atransmission seat performs descending, and when the first pressing plate and the second pressing plate are in contact with the surface of cloth, the first pressing plate and the second pressing plateare pushed by the first transmission arm and the second transmission arm to simultaneously move towards the two ends of the cloth, and the cloth is straightened while the cloth is pressed, so that thecloth is prevented from wrinkling, the problem that the cloth needs to be pressed and fixed separately when the cloth is cut is solved, and the problem that the cutting area of the cloth is prone towrinkling is avoided.

Owner:南通市联缘染业有限公司

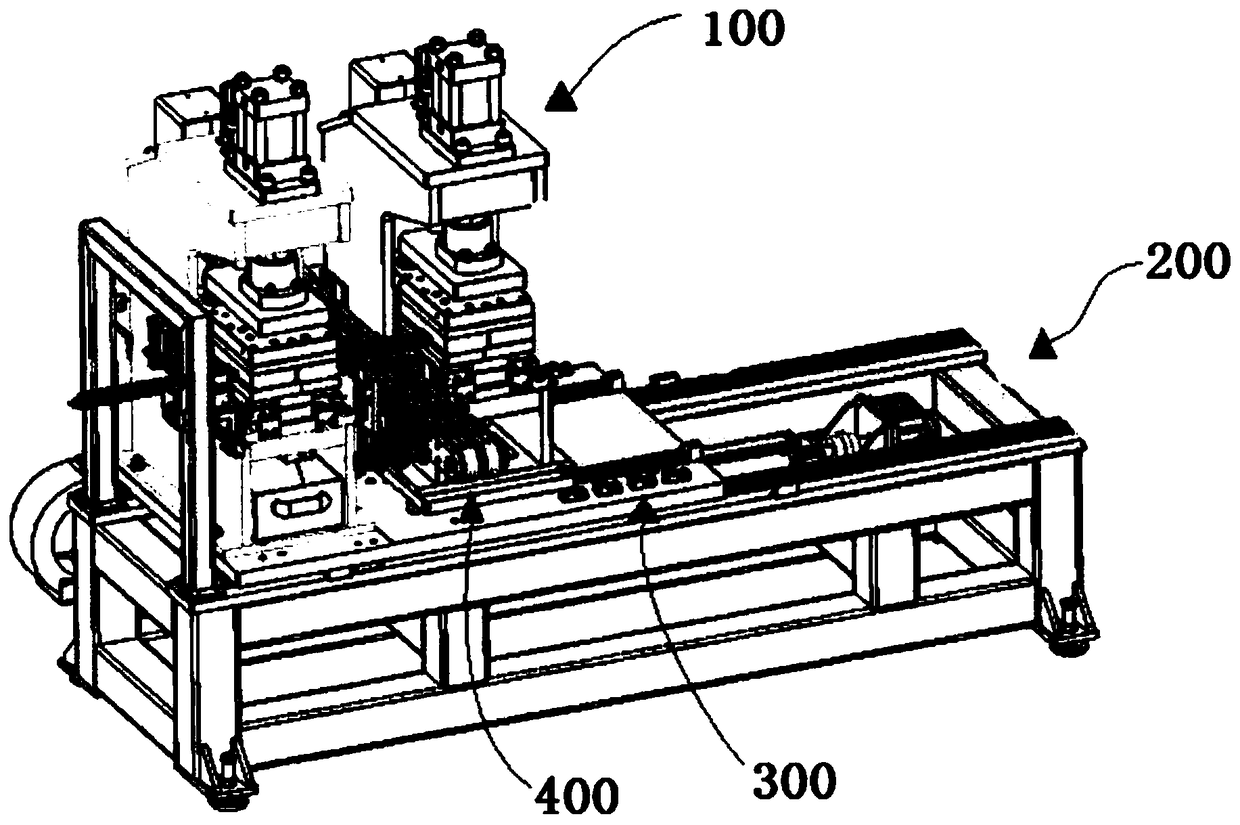

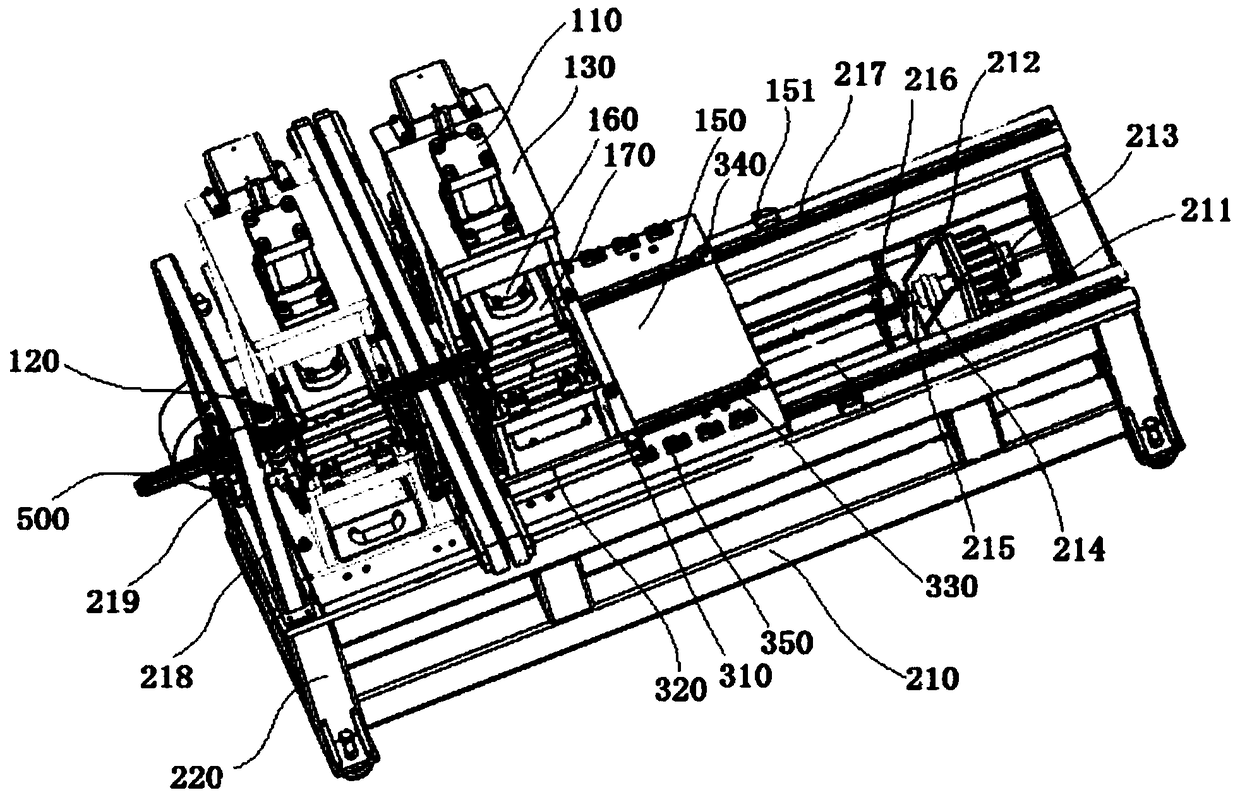

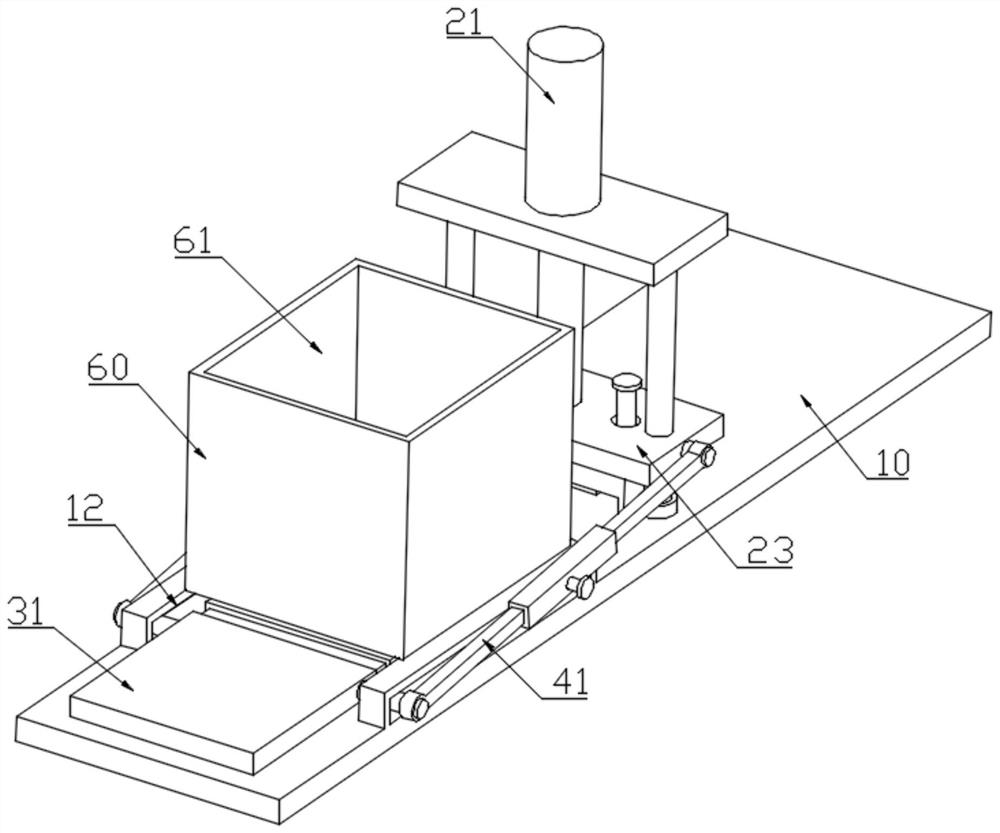

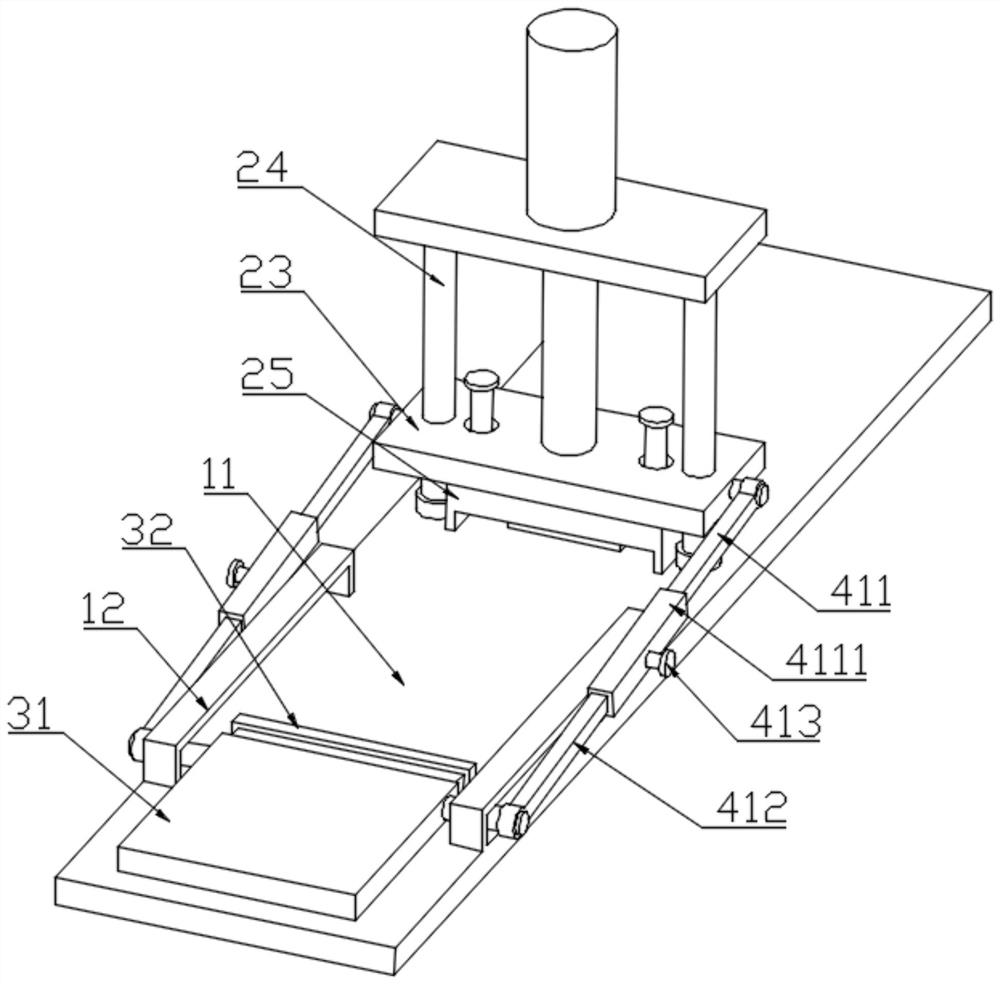

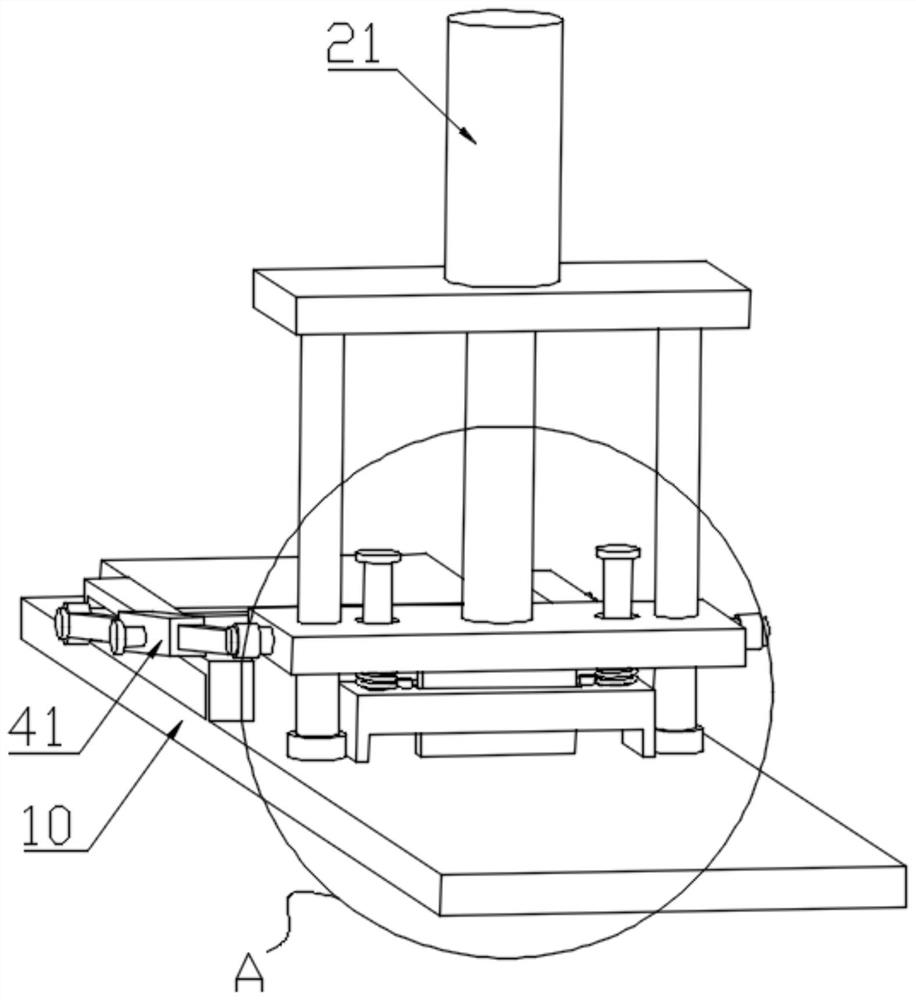

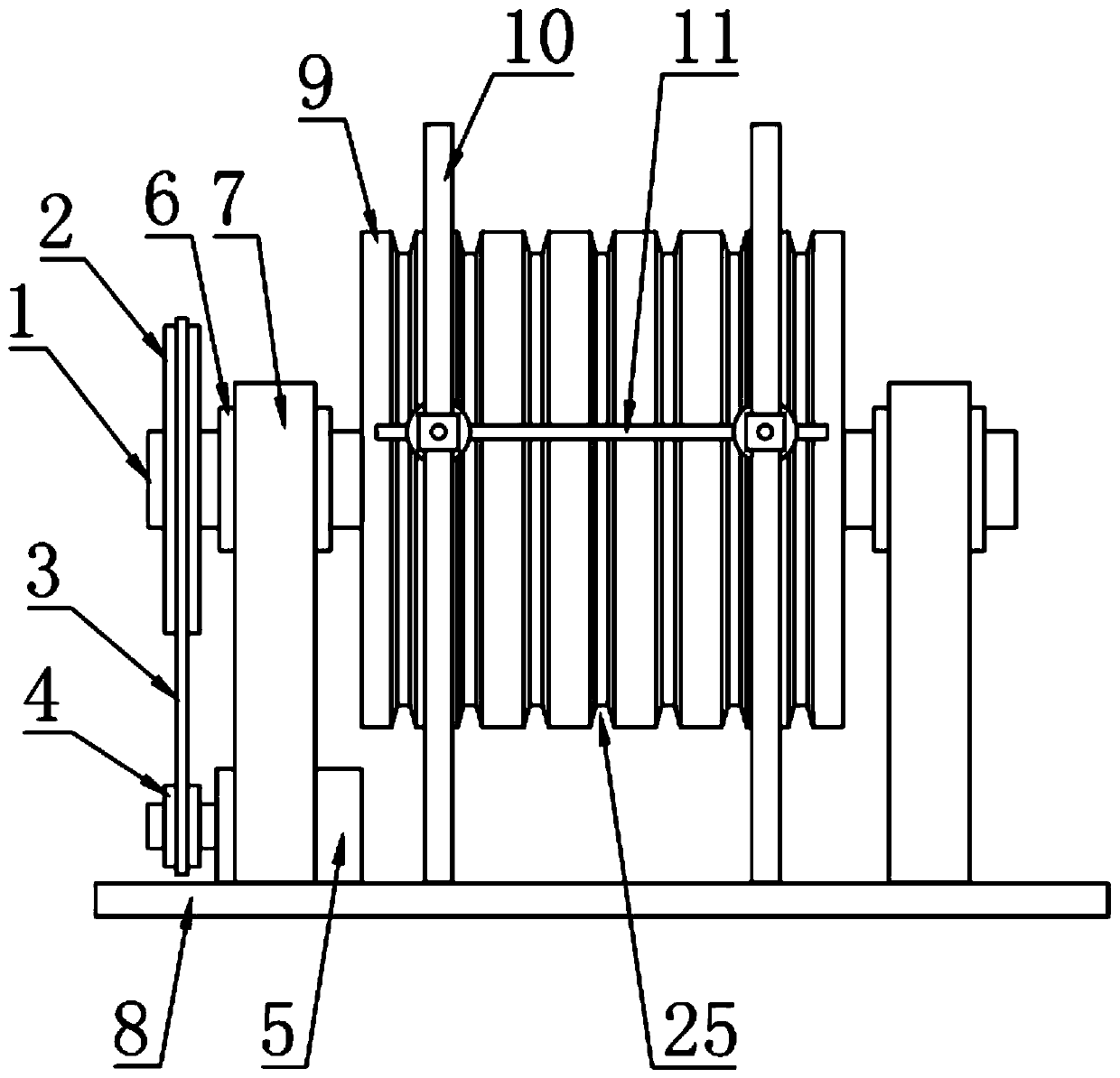

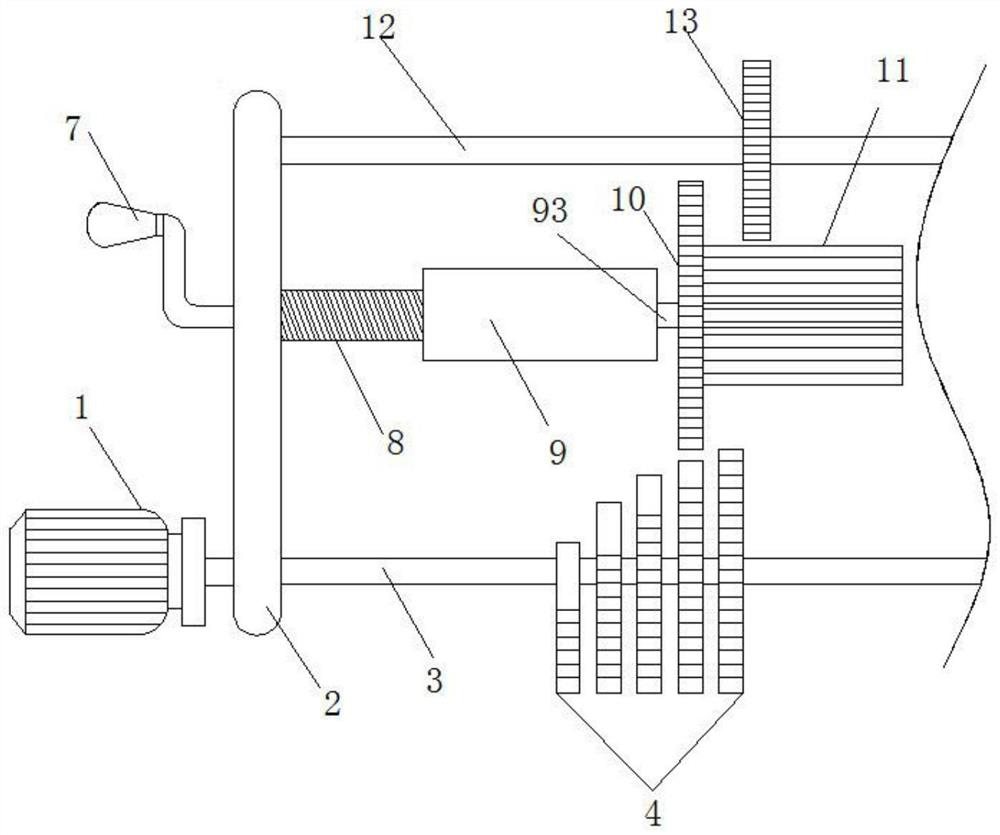

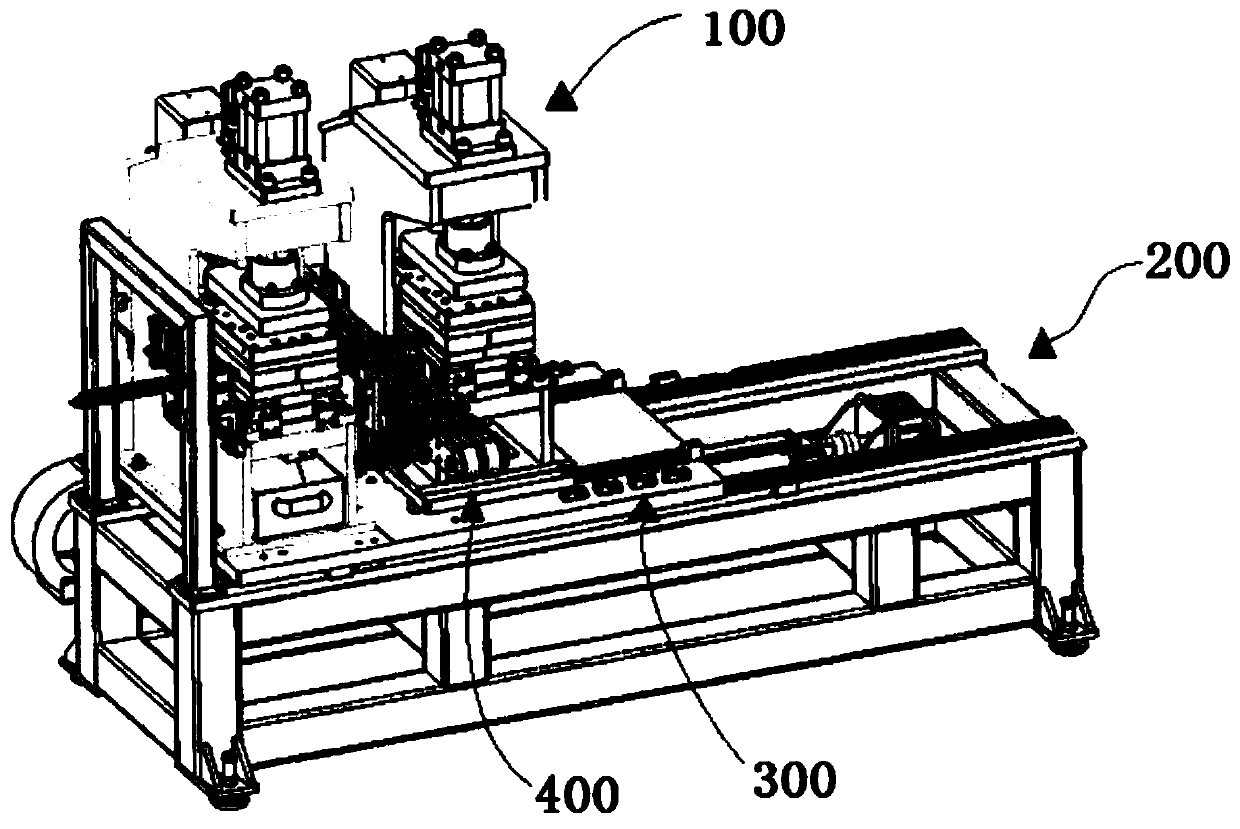

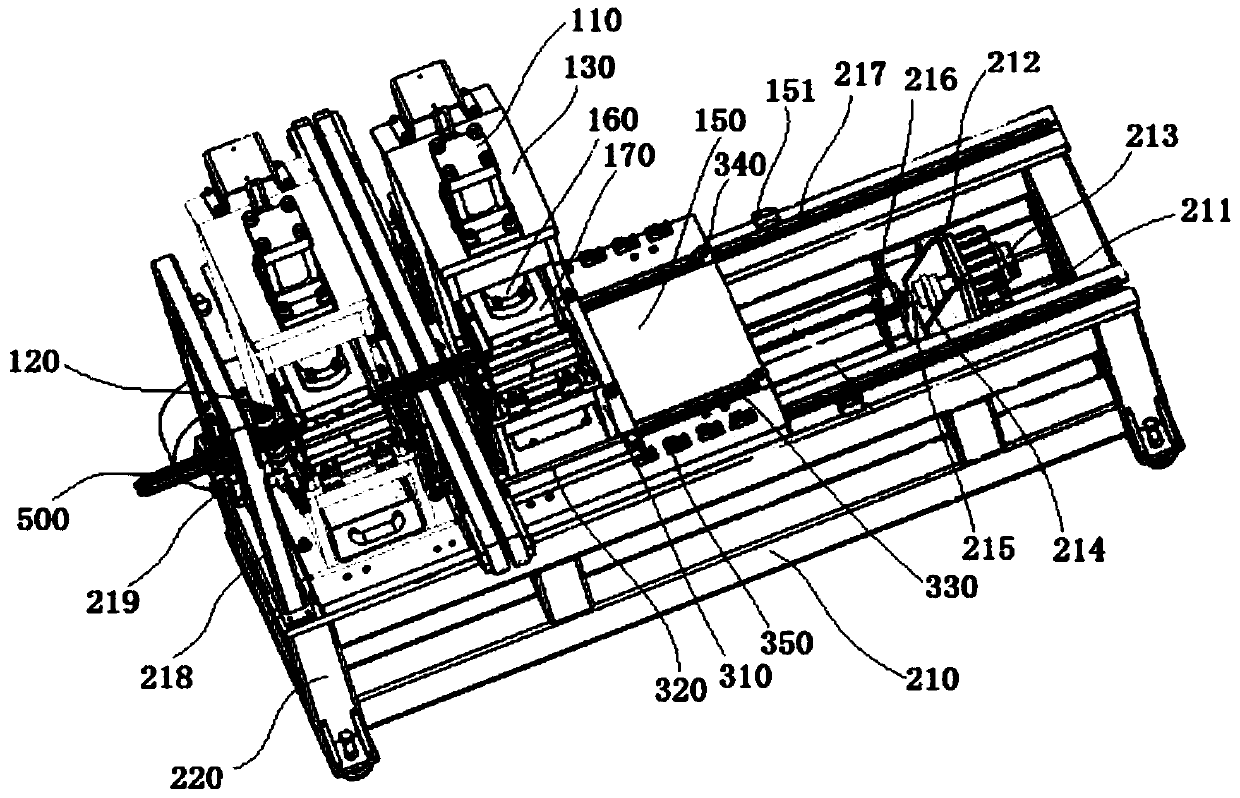

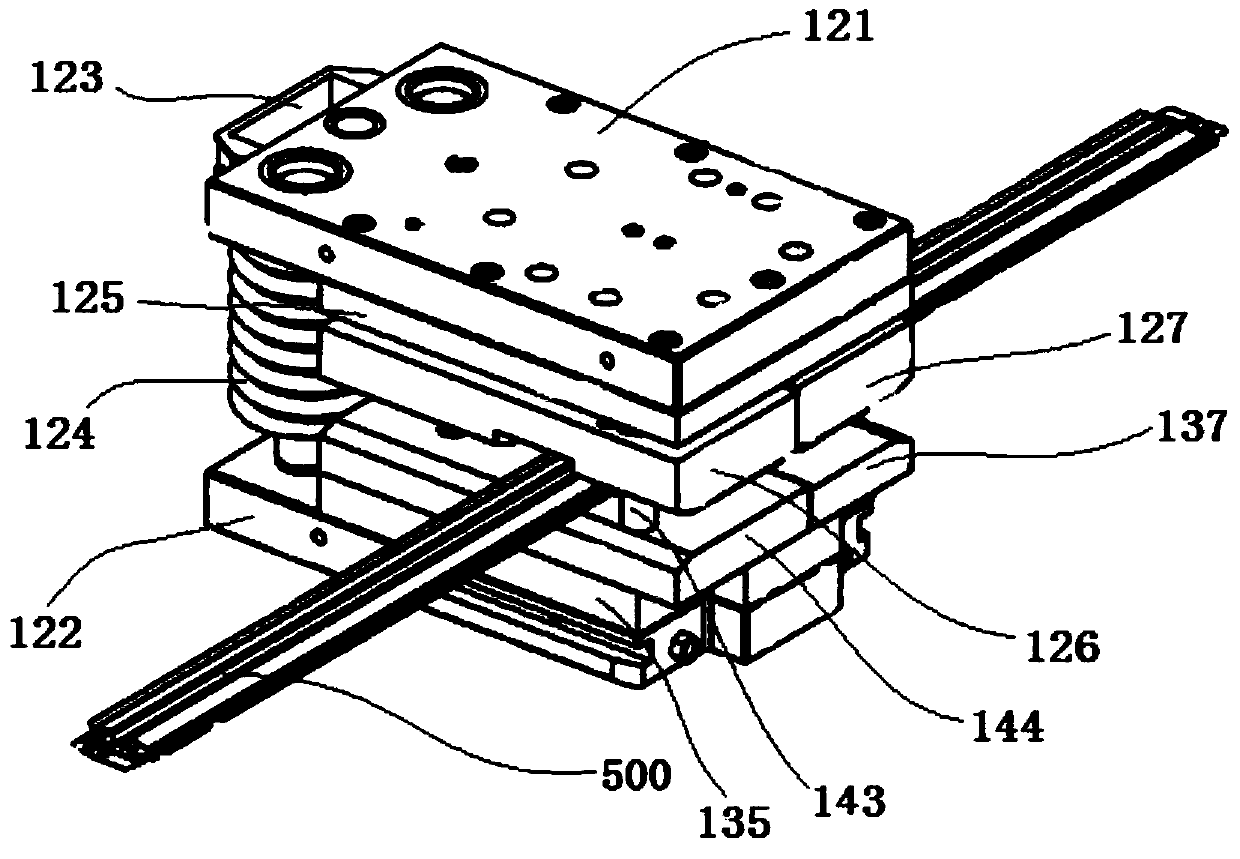

Novel continuous pressing and cutting machine

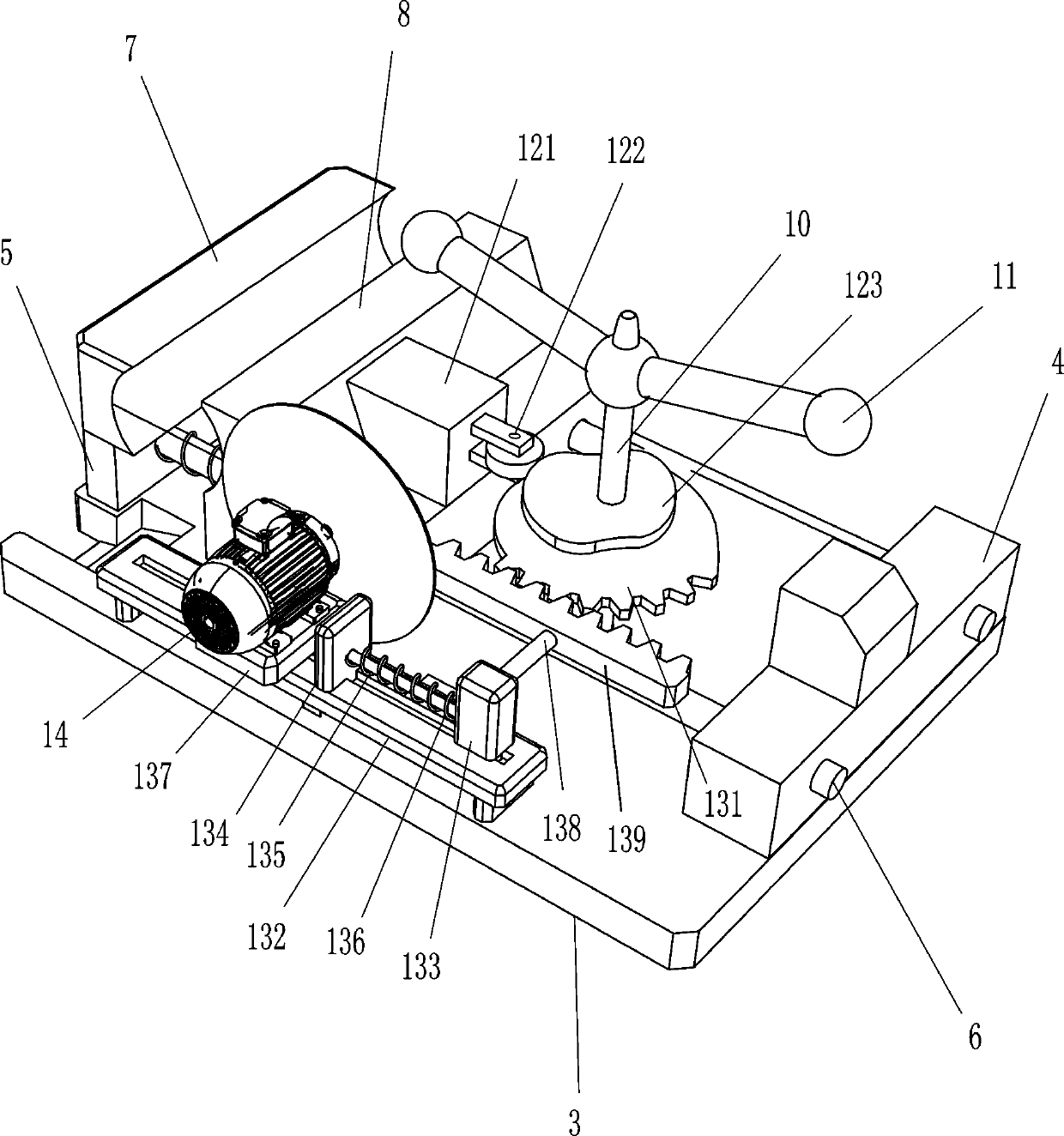

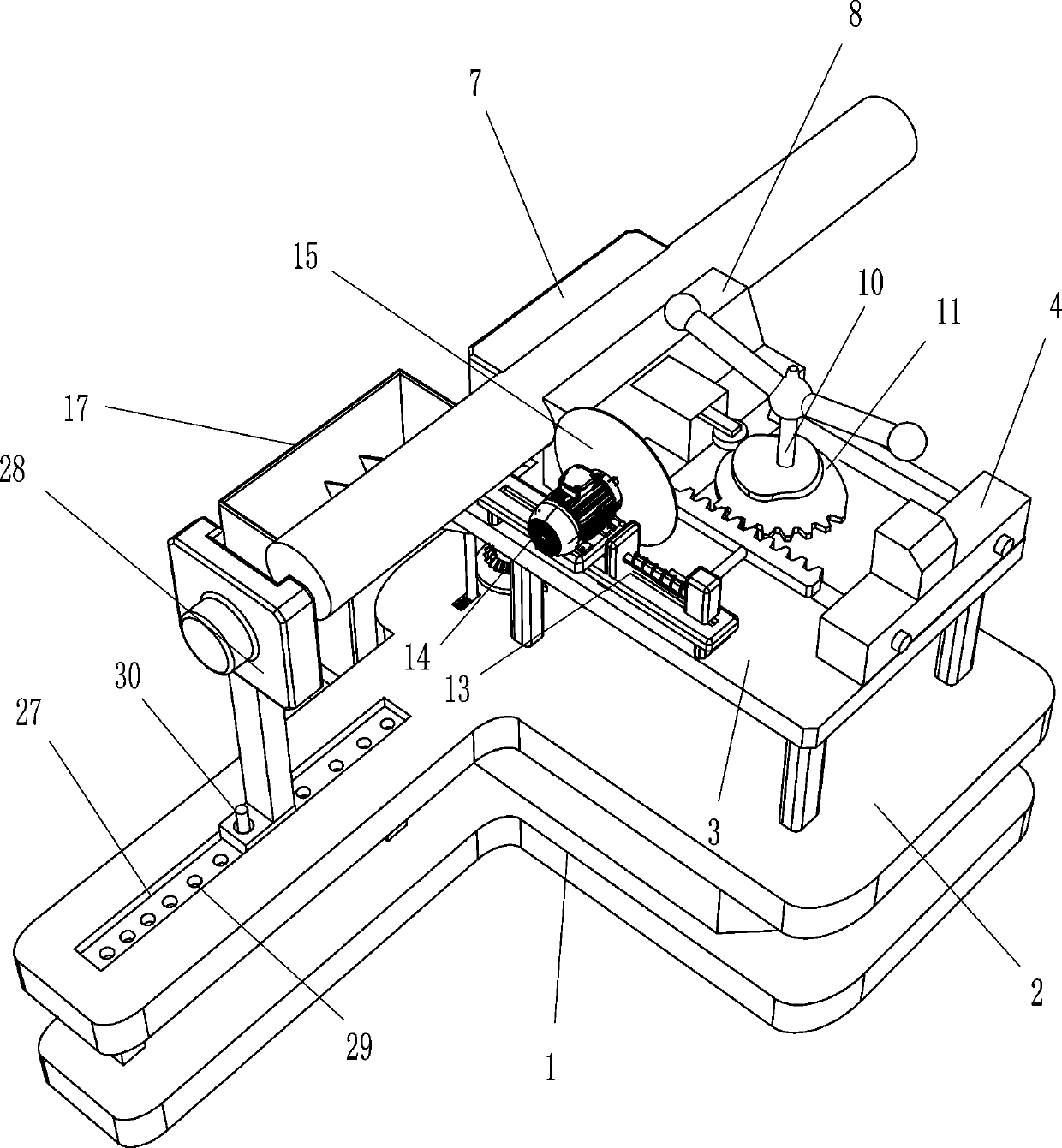

ActiveCN109290805AAdjustable lengthAdjustable cutting lengthShaping toolsShearing machinesPunchingBall screw

The invention discloses a novel continuous pressing and cutting machine which comprises a pressing and cutting assembly, a base assembly, a sliding and positioning assembly and a discharging belt assembly. The pressing and cutting assembly comprises an upper stamping oil cylinder, a pressing, cutting and punching die, an outer installation frame, a lower stamping oil cylinder and a lower sliding installation plate; the base assembly comprises a support base and support legs; a servo motor is connected with a ball screw pair through a coupler; a screw rod bearing seat is arranged on one side, close to the coupler, on the ball screw pair; the far end of the ball screw pair is connected with a nut seat in the middle of the back surface of the lower sliding installation plate; the sliding andpositioning assembly comprises a side support plate, a sliding support plate and a sliding and positioning guide rail; and the side support plate is arranged on the bottom part of a lower die plate. The novel continuous pressing and cutting machine provided by the invention can be used for accurately and continuously pressing, cutting and punching a plate with a folding edge, and the cutting distance of the pressing and cutting assembly can be adjusted, so that the cost of the continuous pressing and cutting machine is greatly reduced, and the production efficiency is improved.

Owner:ANHUI KINGPOWER EQUIP & MOLD MFR

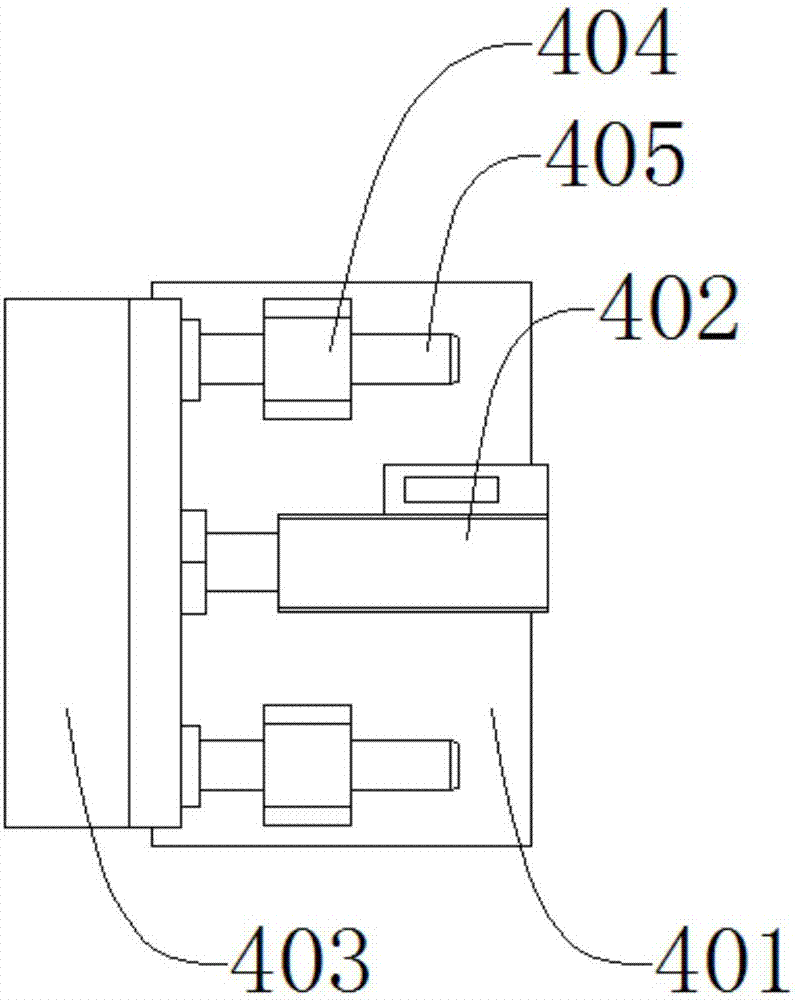

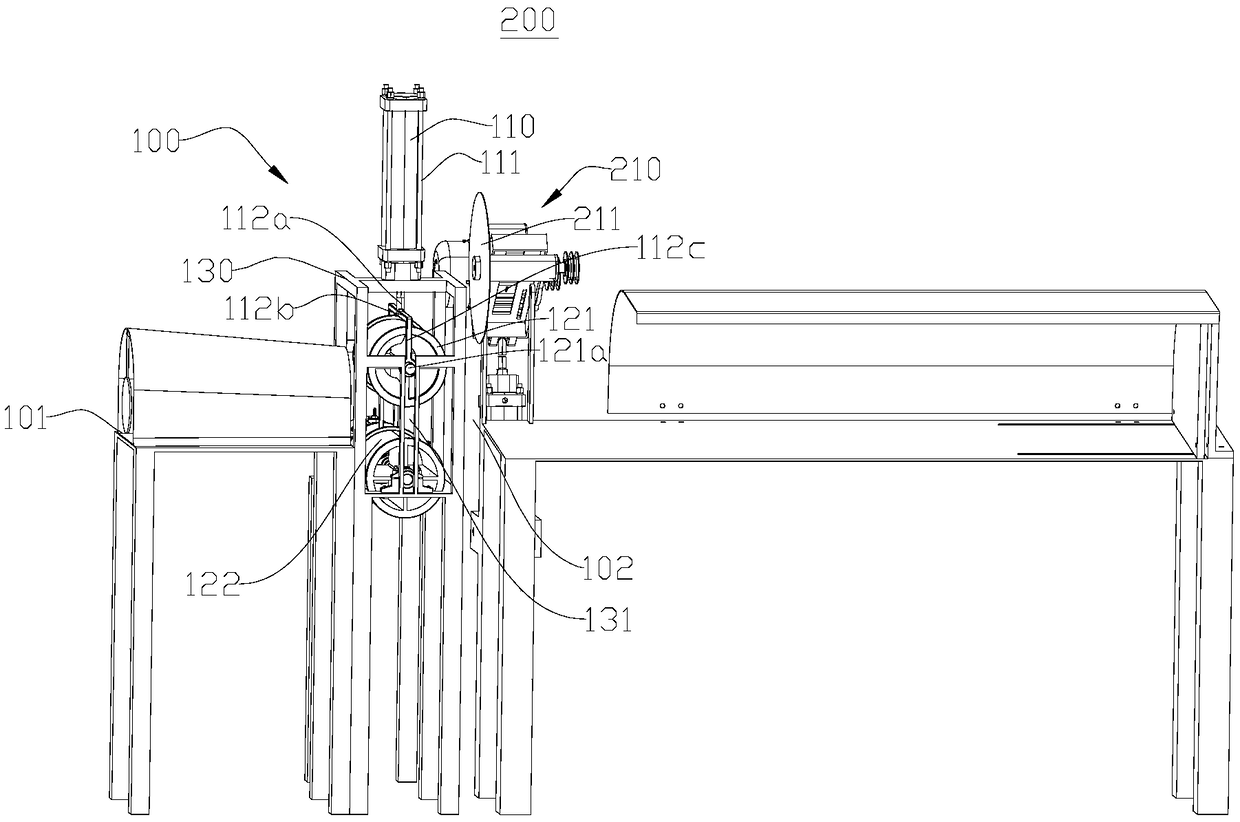

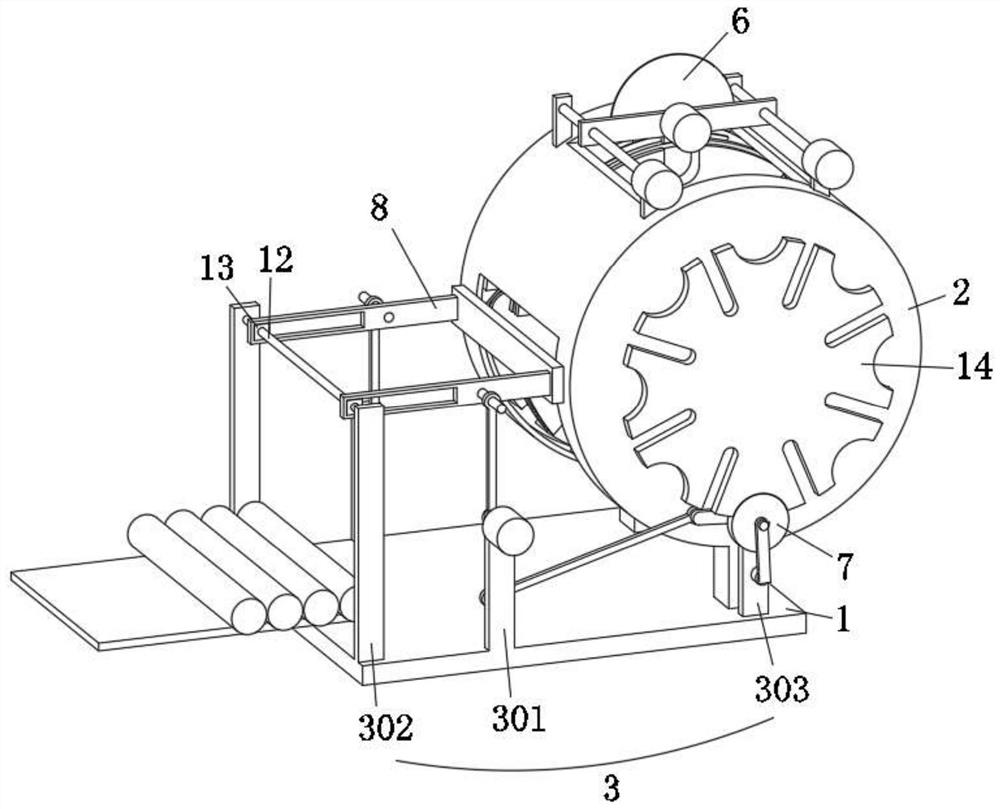

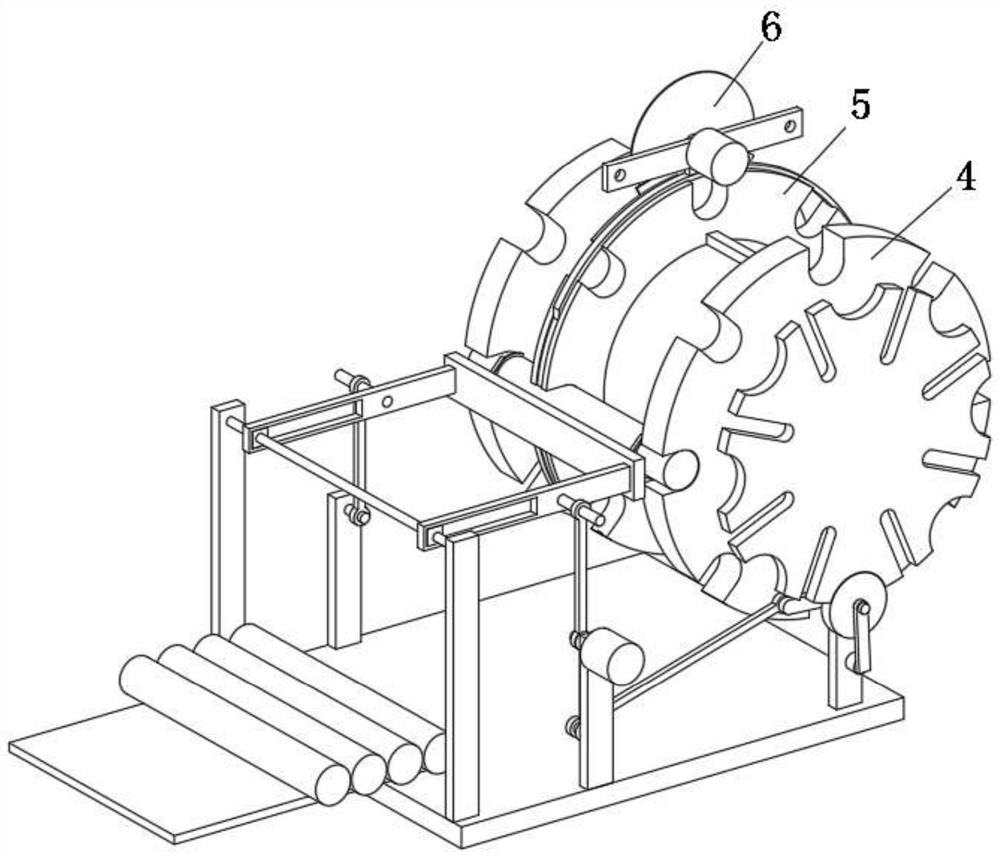

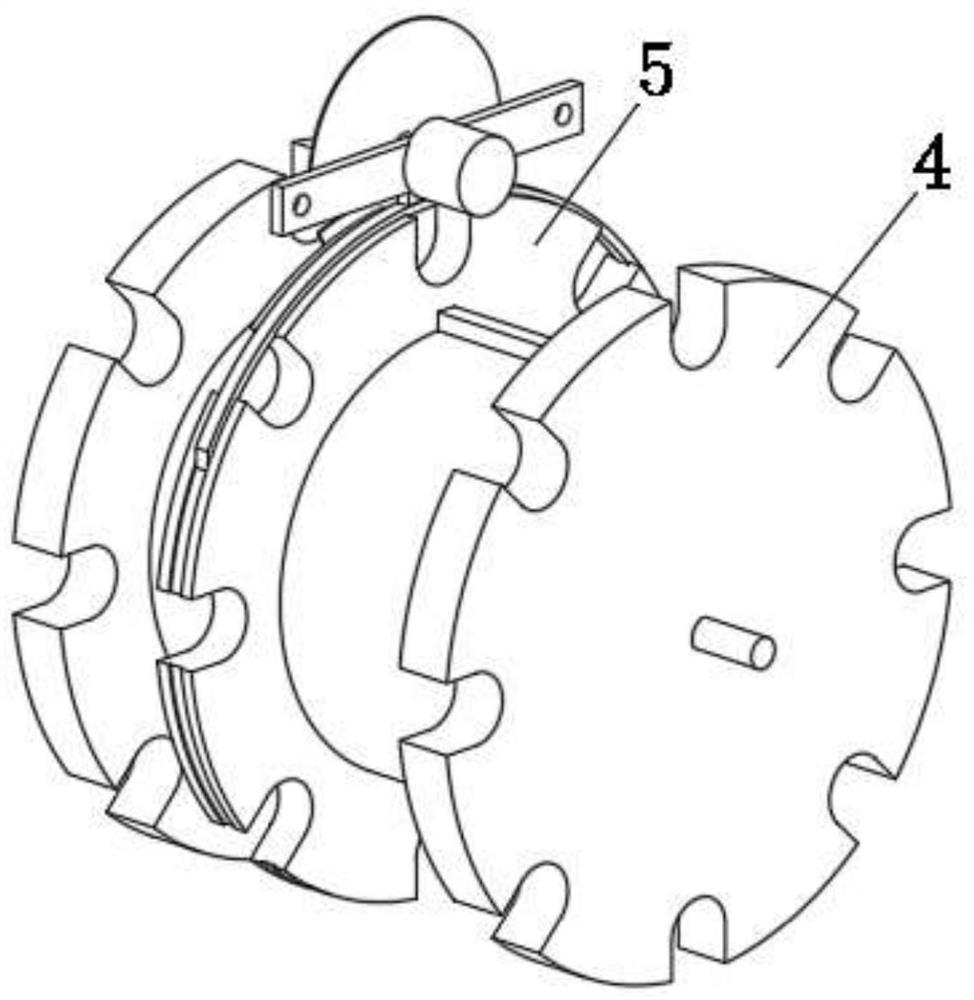

Clamping and feeding device for moso bamboo cutting machine, moso bamboo cutting machine and moso bamboo cutting system

PendingCN109129771AHigh degree of automationSave manpower and material resourcesFeeding devicesCane mechanical workingMaterial resourcesEngineering

The invention provides a clamping and feeding device for a moso bamboo cutting machine, the moso bamboo cutting machine and a moso bamboo cutting system. The clamping and feeding device comprises a moving assembly and a clamping assembly; the clamping assembly comprises a first roller and a second roller which are arranged in the vertical direction, and the first roller and the second roller are mutually matched for use; the moving assembly is connected with the first roller and drives the first roller to get close to or get away from the second roller in the vertical direction; a moso bamboois placed between the first roller and the second roller, thus the moso bamboo is clamped by the first roller and the second roller; and meanwhile, when the first roller and the second roller rotate relatively, the moso bamboo is pushed to move forwards. According to the clamping and feeding device, automatic clamping and feeding of the moso bamboo is achieved, the automatic degree is high, manpower and material resources are greatly saved, and meanwhile, the danger brought by manual operation is also avoided. The moso bamboo cutting machine comprises a cutting device and the clamping and feeding device used for the moso bamboo cutting machine. The moso bamboo cutting system comprises the moso bamboo cutting machine and is convenient to use and high in working efficiency.

Owner:SANMING UNIV

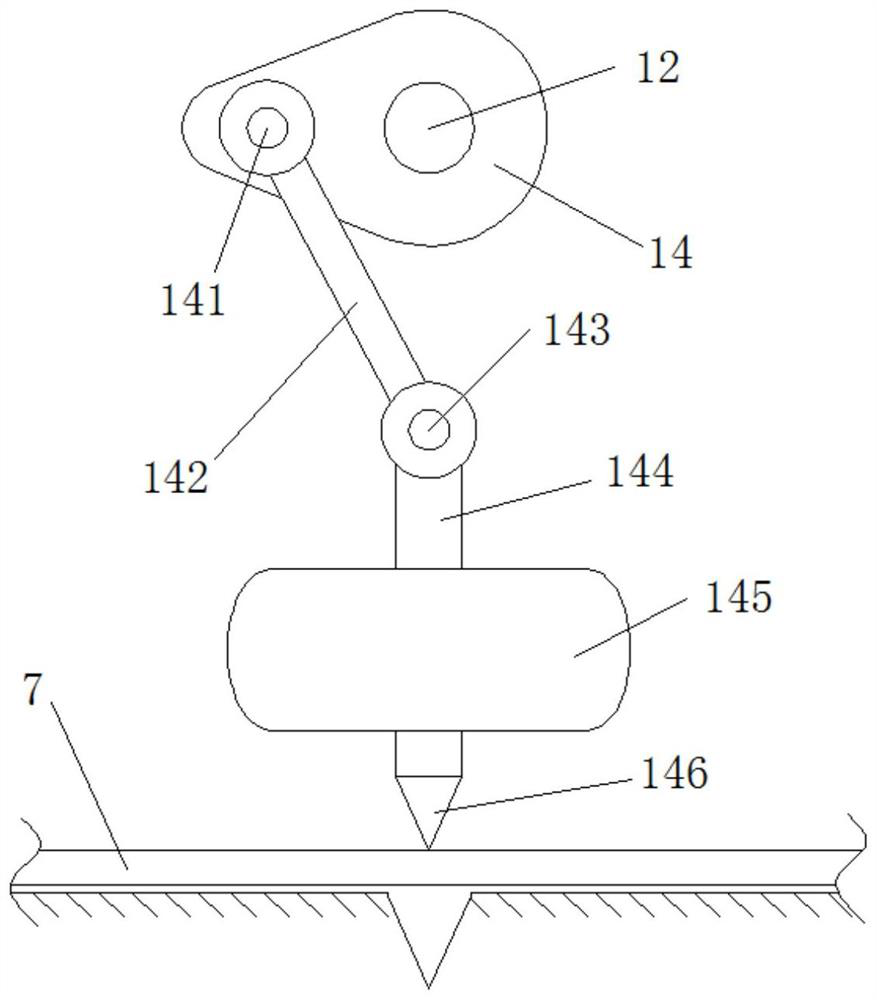

Automatic non-woven fabric cutting equipment with freely adjustable intervals

ActiveCN111663319AAdjustable cutting lengthAchieve cutting automationSevering textilesTool bitGear wheel

The invention relates to the technical field of non-woven fabrics, and discloses automatic non-woven fabric cutting equipment with freely adjustable intervals. The equipment comprises a motor, the right end of the motor is fixedly connected with a baffle, the right side output end of the motor is fixedly connected with a main shaft, the outer ring of the main shaft is fixedly connected with a gearset, the right end of the main shaft is fixedly provided with a roller in a sleeving mode, the left end of the baffle is movably connected with a crank handle, the right end of the crank handle is fixedly connected with a threaded rod, the outer ring of the threaded rod is movably provided with a threaded cylinder in a sleeving mode, the right end of the upper part of the baffle is movably connected with an auxiliary shaft, the right end of the auxiliary shaft is fixedly connected with a cam, a convex end of the cam is movably connected with a movable rod, the lower end of the movable rod ismovably connected with a cutting knife, the outer ring of the cutting knife is movably arranged with a limiting block in a sleeving mode, and the lower end of the cutting knife is fixedly connected with a tool bit. According to the automatic non-woven fabric cutting equipment with the freely adjustable intervals, the gear set, the cutting knife, the threaded rod, the threaded cylinder and a secondgear are matched for use, so that the effect of adjustable cutting length is achieved.

Owner:海宁市米奥服饰有限公司

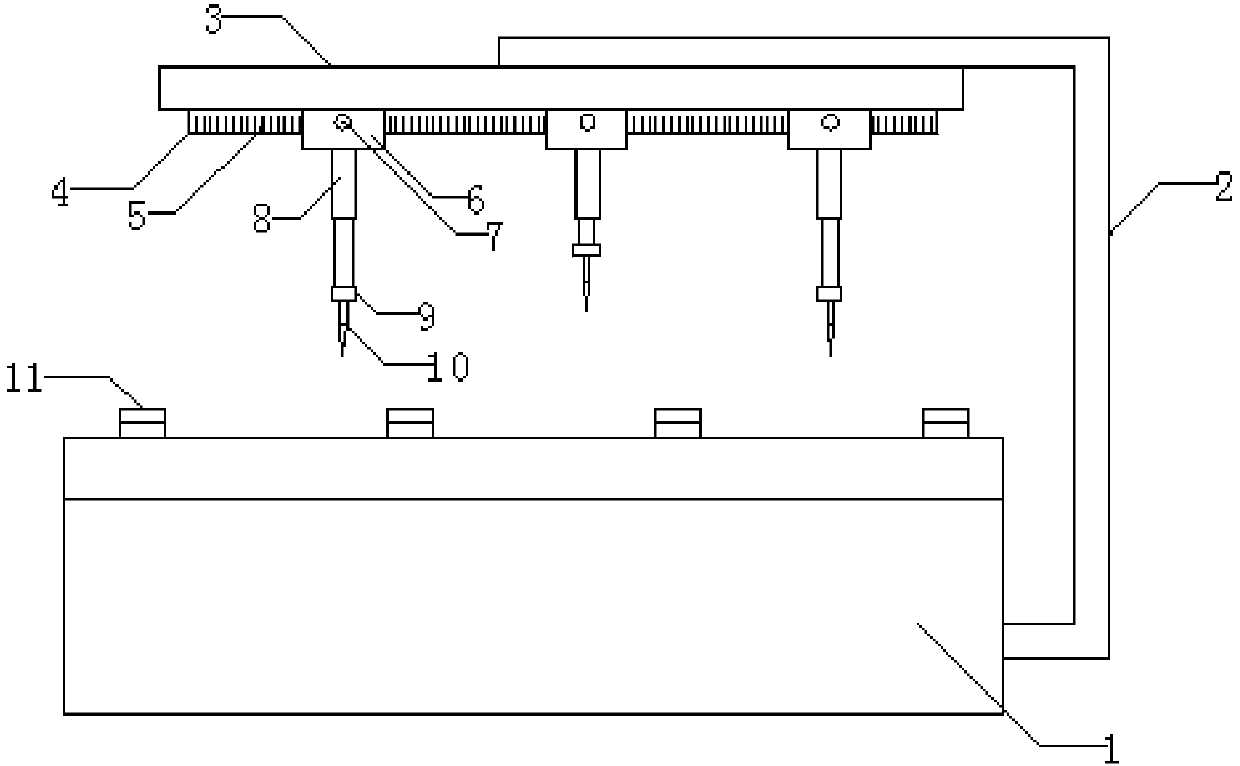

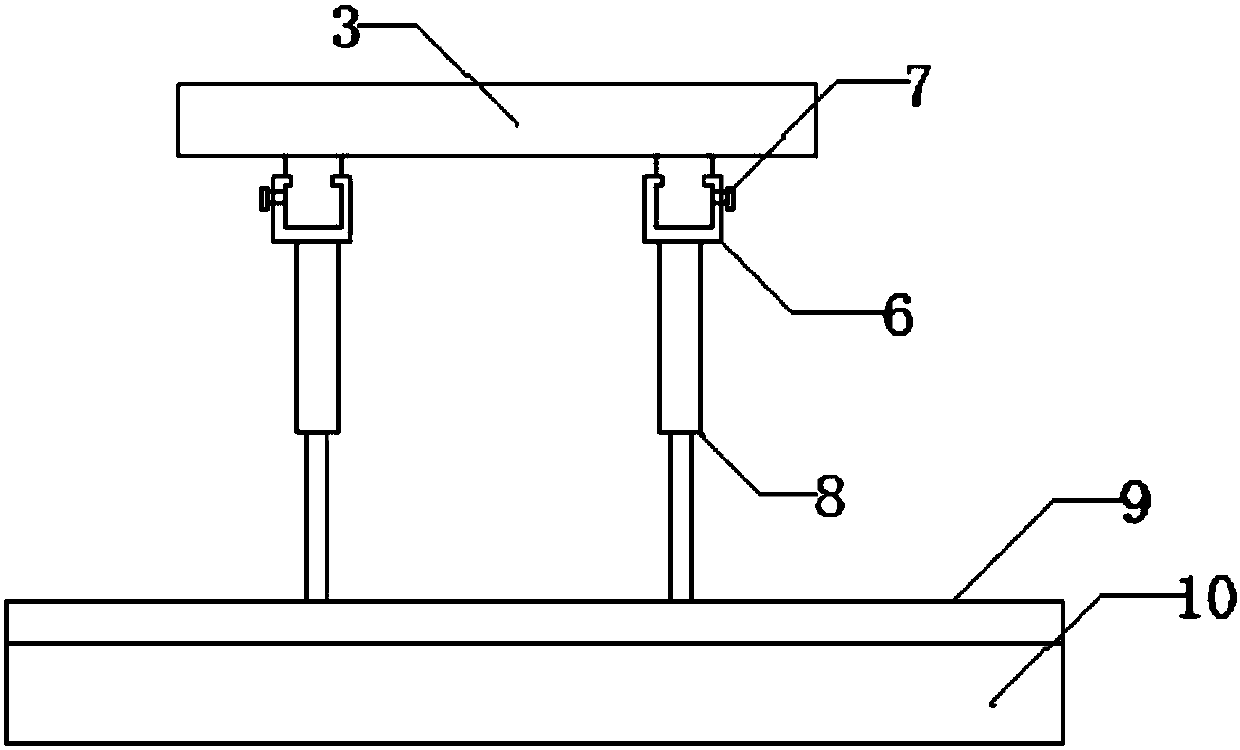

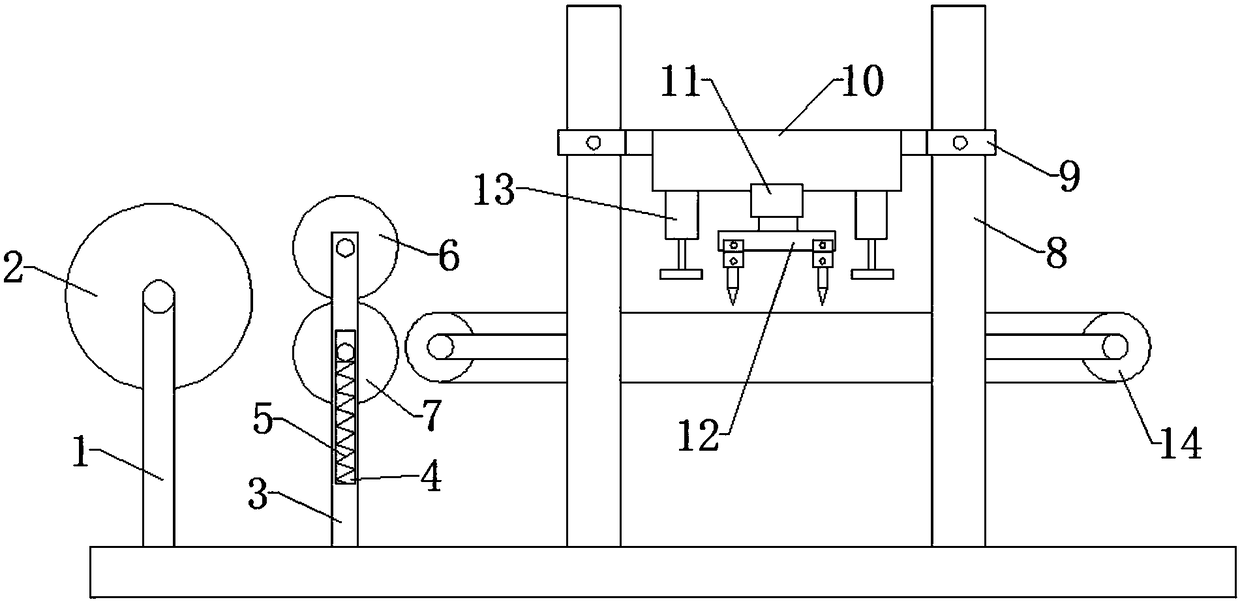

Novel data line cutting device

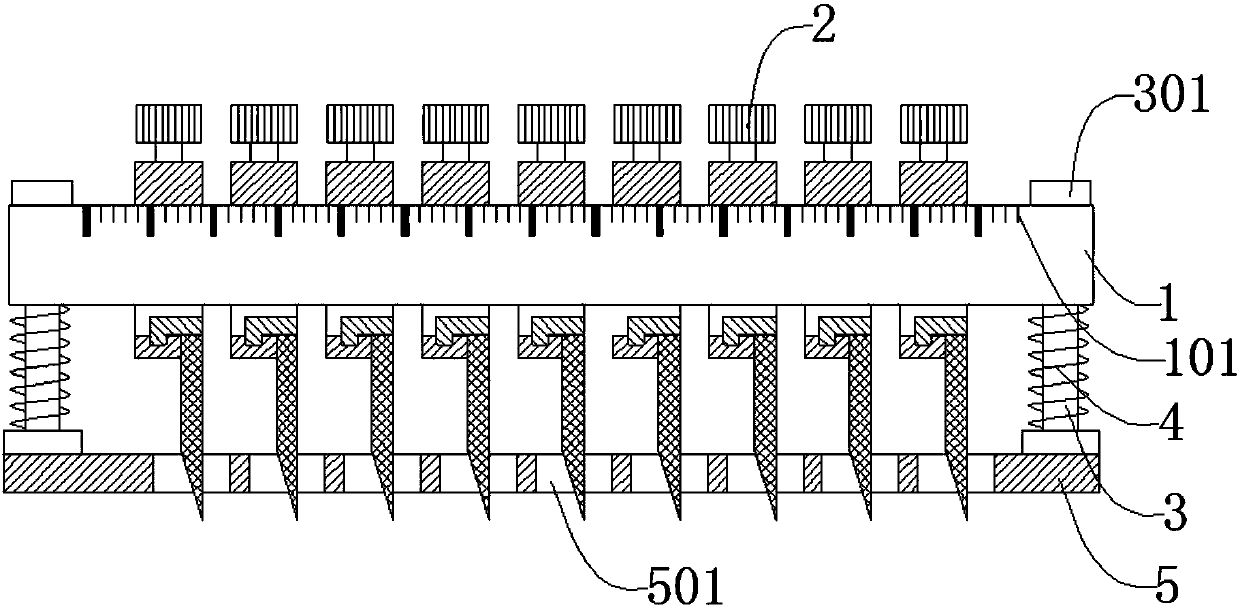

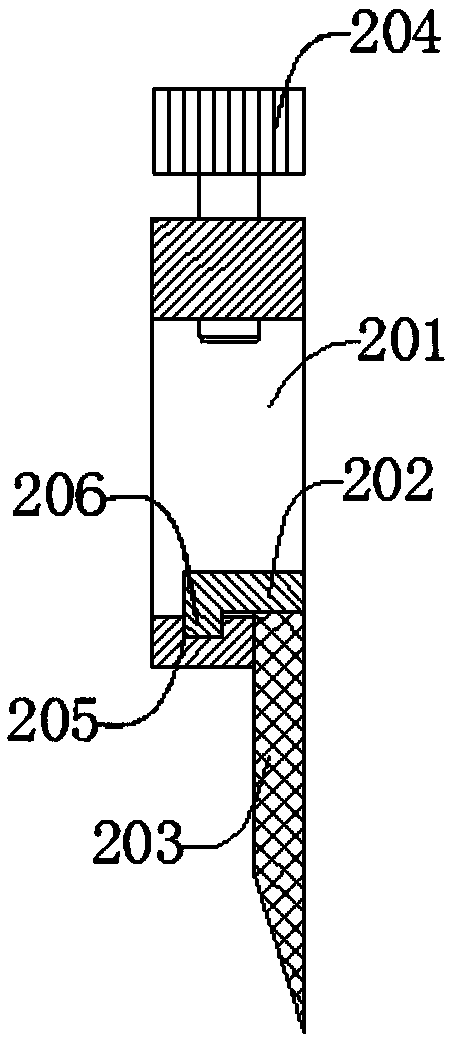

The invention provides a novel data line cutting device. A top plate is arranged over a cutting table through a support, a sliding rail is arranged at the bottom end of the top plate, length scales are marked on the sliding rail, at least two sliding blocks are arranged on the sliding rail, and aer in sliding connection with the sliding rail, a fastening bolt used for positioning is arranged on each sliding block, an air cylinder is arranged at the bottom end of each sliding block, a cutter holder is fixed to the tail end of an air cylinder piston rod, a cutting cutter plate is assembled on each cutter holder, multiple clamps are arranged at the top end of a cutting table, each clamp comprises a lower clamping base on the lower and an upper clamping plate arranged on the upper, one end ofeach lower clamping base and one end of the corresponding upper clamping plate are hinged through a hinge part, a buckle fixing structure and a buckle structure are arranged at the corresponding positions of the other ends of each lower clamping base and the corresponding upper clamping plate, multiple lower containing grooves are formed in the lower clamping bases, multiple upper containing grooves are formed in the upper clamping plate, and holes capable of containing data lines to penetrate are formed by the upper containing grooves and the lower containing grooves. The device has the beneficial effects of being high in work efficiency and high in use flexibility.

Owner:TIANJIN OULIN ELECTRONICS

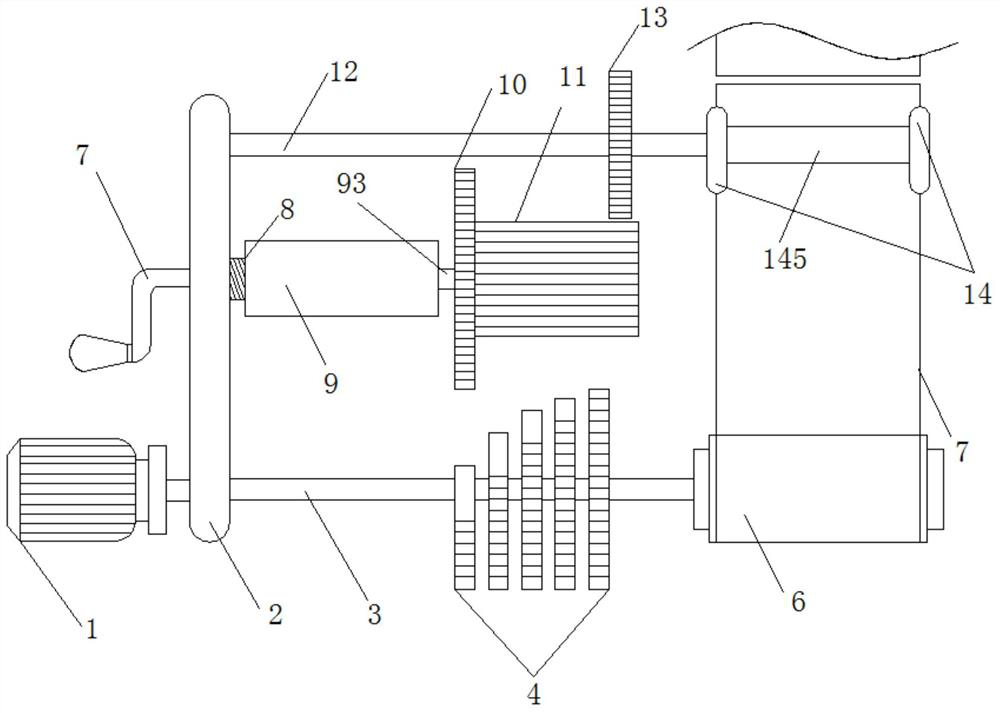

Knife assembly sheet disintegrator

The invention relates to disc sheet combined knife crusher and belongs to crop crushing machine technical field which comprise frame shell, cutting tool and main axle, feeding device and reducing machine drive device. The main axle is fixed at two ends of frame shell and driven by motor out of the frame shell. The cutting tool is composed of a set of disc sheet type moving knife, a set of fixed knife and a set of cutting knife. The disc sheet type moving knife is mounted on main axle in parallel. Several cutting knives mounted on main axle are positioned between the adjacent disc sheet type moving knives. The fixed knife is fixed in parallel at corresponding frame shell separating from disc sheet moving knife and cutting knife. The disc sheet type moving knife and fixed knife is zigzag mounted which endow the device high crushing efficiency and adjustable cutting length. The inventive crusher has simple structure, and is conveniently charged or discharged. The inventive crusher is suitable for cutting and crushing of the rice straw, wheat straw, corn stalk, cotton stalk or fruit tree branch etc.

Owner:范建华

A double-knife flat cutting machine for cutting sponge

ActiveCN106945096BEasy to storeImprove continuityMetal working apparatusHydraulic cylinderEngineering

The invention discloses a double-cutter flat cutting machine for sponge cutting in the technical field of flat cutting machines. The machine comprises a first support rod, a second support rod and a bracket arranged in sequence from left to right; the first support rod is connected with a material roller; the second support rod is provided with a chute; a spring is arranged in the chute; a lower leveling roller is inserted in the chute; a rotating shaft end of the lower leveling roller is arranged at the top of the spring; an upper leveling roller is arranged at the top end of the second support rod; the bracket is sleeved with a slide sleeve; the slide sleeve is connected with the bracket through a locking knob; and one side of the slide sleeve is connected with a fixed base. The machine is convenient in raw material storage and continuous cutting for sponges, prelevels the sponges through the upper leveling roller and the lower leveling roller, uses a hydraulic cylinder for leveling during cutting of the sponges to prevent incisions from generating radians, improves the cutting efficiency through settings of double cutters, can adjust the distance between the cutters, and can adjust the cutting length according to specifications of needed materials.

Owner:中山市吉安海棉制品有限公司

A solid wood furniture manufacturing and processing cutting machine and its use method

ActiveCN112792927BAdjustable cutting lengthIncrease flexibilityMulti-purpose machinesSolid woodProcess engineering

The invention relates to a solid wood furniture manufacturing and processing cutting machine and its use method, comprising a placing board, a receiving device, a conveying device and a cutting device, a receiving device is installed on the top of the placing board, and a The conveying device is installed on the placing plate. The present invention can solve the problem that the existing equipment cannot realize arbitrary adjustment of the cutting length within a certain range when cutting solid wood furniture boards, thereby reducing the flexibility of the equipment, and the boards cannot be neatly processed. The wooden boards tend to be tilted, which reduces the cutting effect of the boards and reduces the use of the equipment. At the same time, the clamping and limiting of the cutting parts of the boards cannot be performed, and the boards will warp during cutting, thus The success rate of plank cutting is reduced, and manual continuous feeding is required, thereby increasing problems such as manpower consumption.

Owner:山东栎舒雅木业股份有限公司

Paperboard cutting device

The invention relates to a paperboard cutting device which comprises a conveying platform, a cutting assembly, a pushing assembly and a linkage assembly. The first end of the conveying platform is provided with an accommodating space for accommodating paperboards; the cutting assembly is arranged on the conveying platform; the cutting assembly comprises a power source and a cutting die, and the power source can drive the cutting die to move vertically; the pushing assembly is arranged at the first end of the conveying platform, and the containing space is located between the pushing assembly and the cutting assembly; the pushing assembly is used for pushing the paperboards in the containing space to the position below the cutting assembly. The linkage assembly is connected with the cutting assembly and the pushing assembly. The linkage assembly drives the pushing assembly to move in a linkage mode when the cutting assembly moves. When the cutting die moves upwards, the pushing assembly pushes the paperboard to the position below the cutting assembly. The working efficiency of paperboard cutting is greatly improved; a user only needs to place the paperboard into the containing space, and accidents are avoided.

Owner:台山市金利达印刷包装有限公司

Fixed-length rapid cutting device for data line production and processing

ActiveCN110459936BPrevent affecting cutting efficiencyStable deliveryLine/current collector detailsComputer periphery connectorsWire wrapIndustrial engineering

The invention relates to the field of data line processing equipment, in particular to a fixed-length fast cutting device for data line production and processing. The fixed-length fast cutting devicecomprises a driving mechanism, support frames, a support shaft and a base. The two support frames are fixedly arranged on the base. The support shaft is rotationally installed across the two support frames through bearings. A winding reel is installed on the support shaft between the two support frames, and the winding reel is provided with at least one annular winding slot. The support shaft is driven to rotate by the driving mechanism. At least one cutting support rod is also installed outside the winding reel, and the two ends of the cutting support rod are fixed on the base. At least one cutting assembly capable of carrying out adjustment and movement along the cutting support rod is installed on the cutting support rod. Fixed-length cutting can be performed on a data line according tothe requirements, the cutting efficiency can be improved, time-consuming and laborious manual cutting is avoided, and the work intensity of employees is reduced.

Owner:郴州市伟强科技有限公司

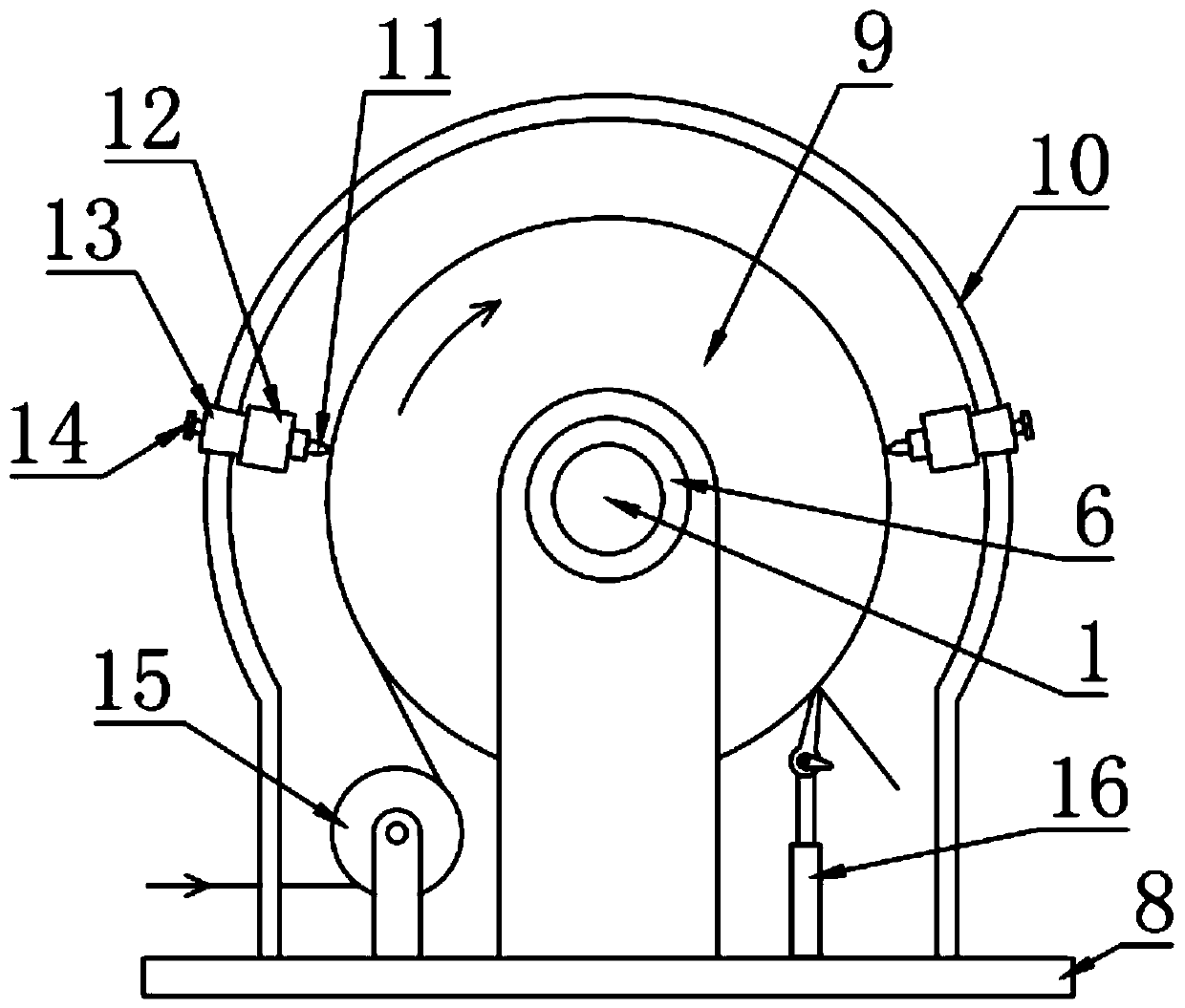

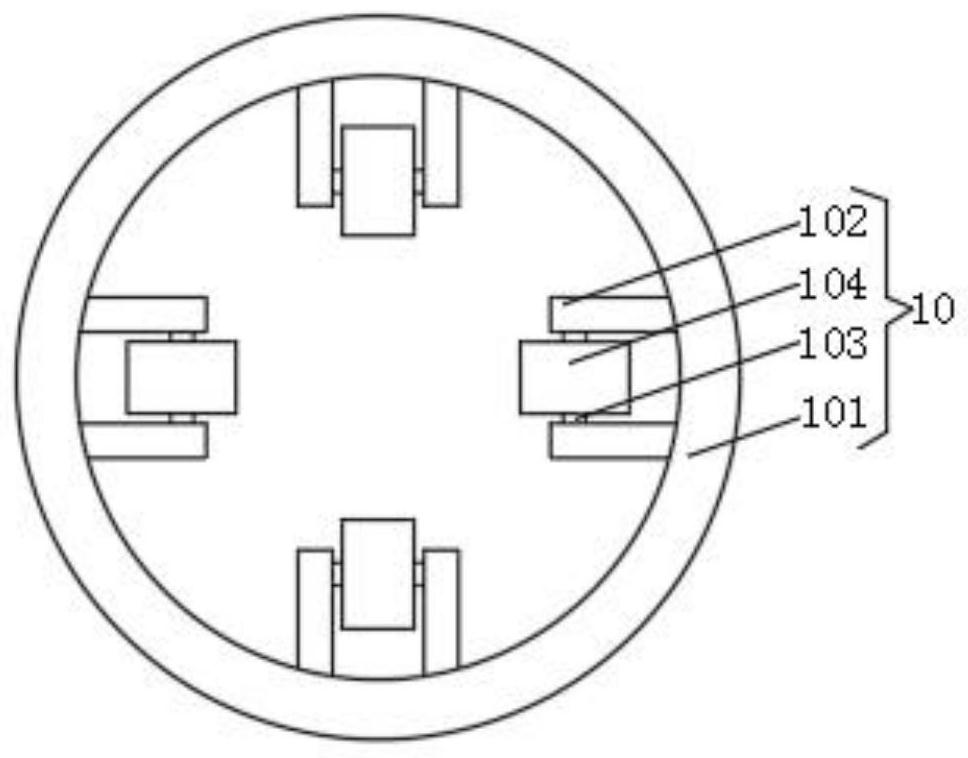

Easy-to-adjust refrigerator backplane blanking device

InactiveCN111299400AExpand the scope of workAdjustable cutting lengthShaping toolsHydraulic cylinderPunching

The invention discloses an easy-to-adjust refrigerator backplane blanking device. The easy-to-adjust refrigerator backplane blanking device comprises a base and a punching plate, a hydraulic cylinderis connected between the base and the punching plate, a hydraulic switch and a rotating shaft are arranged on the base, a fixed disc is welded to the rotating shaft, four pairwise symmetrical fixed devices are fixed to the side wall of the fixed disc, and a movable blade is arranged at the bottom of the punching plate. According to the easy-to-adjust refrigerator backplane blanking device, the movable blade is additionally arranged, the purpose of adjustable cutting length is realized, the blanking die model is variable, and is suitable for different types of blanking workpieces; and in addition, the fixed disc is rotatably arranged, the blanking position can be rotated, and the working range of a blanking die is expanded.

Owner:滁州市永达机械科技有限公司

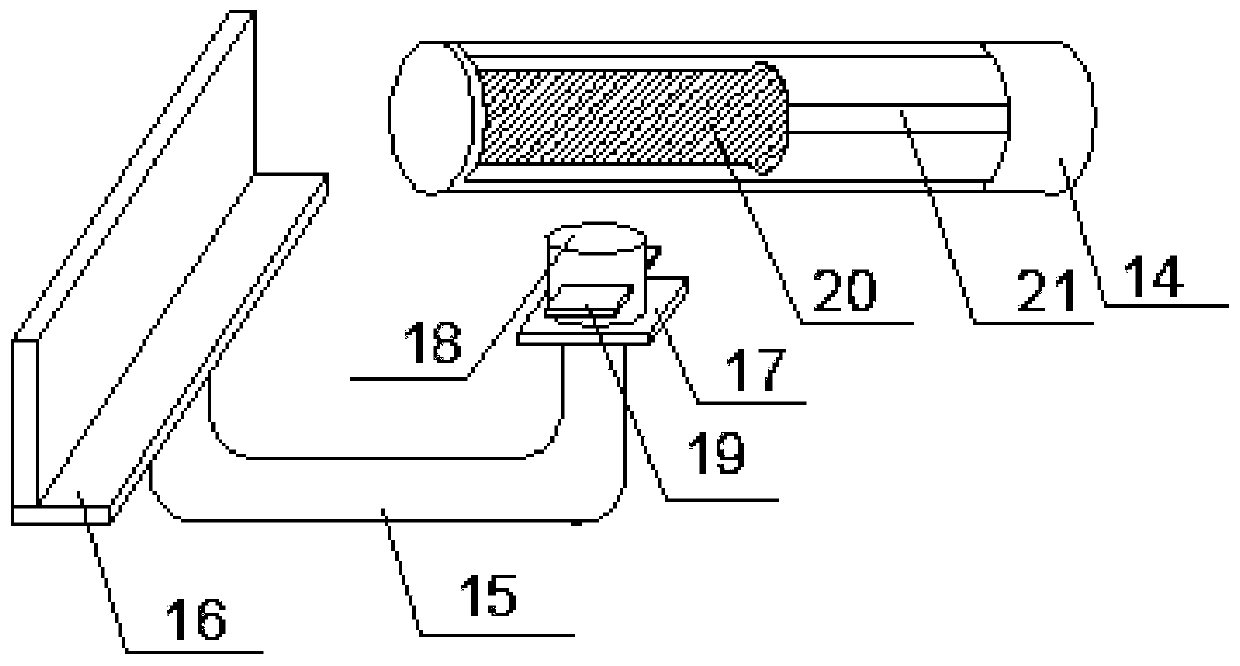

Pipe cutting device for constructional engineering

The invention discloses a pipe cutting device for constructional engineering. The pipe cutting device comprises a fixing table, a supporting mechanism is fixed to the fixing table, and the supportingmechanism comprises a first fixing plate, a second fixing plate and a third fixing plate; a box body is further arranged on the fixing table, a fixing rod is transversely inserted into the box body ina penetrating mode, the fixing rod is sleeved with a limiting disc, the limiting disc is sleeved with a limiting ring, and a special-shaped disc is arranged at one end of the fixing rod; a threaded rod is arranged on the outer surface of the upper end of the box body, a third motor is arranged at one end of the threaded rod, a cutting mechanism is arranged on the box body, and the cutting mechanism comprises a moving frame, a cutting blade, a first motor and an arc-shaped ring; and a rotating mechanism is arranged on the fixed table. The third motor can drive the moving frame to move transversely through the threaded rod, so that when the moving frame moves, the limiting ring is driven by the arc-shaped ring to move on the limiting disc, and the cutting length of the pipe cut by the cutting blade can be adjusted.

Owner:汪旺

A pipe cutting machine

InactiveCN111250776BAchieve clampingAdjustable cutting lengthTube shearing machinesPositioning apparatusStructural engineeringWorkbench

The invention relates to a cutting machine, in particular to a pipe cutting machine. The technical problem of the present invention is how to provide a pipe cutting machine with high safety, low cost and integrated clamping and cutting. A pipe cutting machine, including a base, a support plate, a workbench, a first fixed block, a second fixed block, a guide rod, a fixed clamp block, a movable clamp block, a first elastic member, a rotating rod, a handle, etc.; the top of the base A support plate is provided, a workbench is arranged on the top of the support plate, the first fixed block and the second fixed block are symmetrically arranged on both sides of the top of the workbench, and guide rods are symmetrically arranged between the first fixed block and the second fixed block, and the second A fixed clip block is arranged on the top of the fixed block. The invention achieves the effects of high safety, low manufacturing cost and integrated clamping and cutting.

Owner:仪征市金银无纺包装材料有限公司

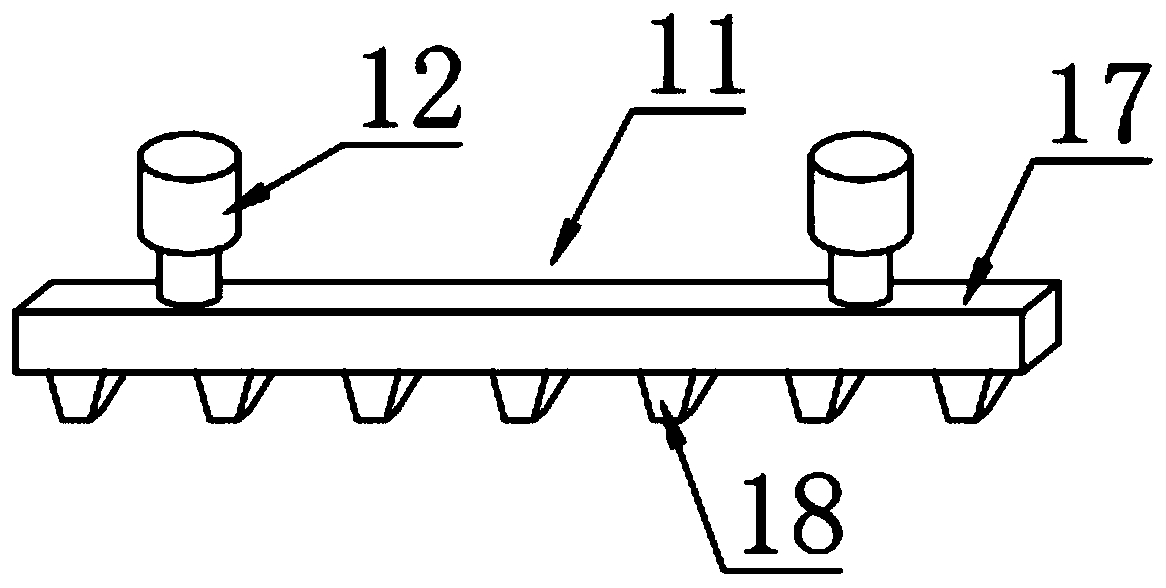

Automatic centered cutting mechanism for electric wire penetrating groove plates

ActiveCN109013823AAdjustable cutting lengthSimple structureMetal-working feeding devicesPositioning devicesElectric wireEngineering

The invention discloses an automatic centered cutting mechanism for electric wire penetrating groove plates. The mechanism comprises a frame and a cutting device; a cutting support plate is arranged in the center of the upper end surface of a lower support plate; a lifting support plate is arranged between the lower support plate and an upper support plate in a lifting mode; a cutter is detachablymounted in the center of the lower end surface of the lifting support plate; a pair of centered driving blocks is arranged on the lifting support plate in a left-right moving mode; the lower edge lines of the approaching end surfaces of the pair of centered driving blocks are formed as chamfering angles; a pair of upper centered avoiding grooves for enabling the centered driving blocks to insertin is formed in the front part of the cutting support plate; the lower support plate is provided with lower centered avoiding grooves, same with the upper centered avoiding grooves, right under the upper centered avoiding grooves; length adjusting blocks are arranged at the back part of the upper end surface of the lower support plate in a front-back sliding mode; and upper stop plates are moldedat the middle parts of the upper end surfaces of the length adjusting blocks. The mechanism is simple in structure and adjustable in cutting length of the electric wire penetrating groove plates, andcan automatically center the electric wire penetrating groove plates.

Owner:扬州高新电缆材料有限公司

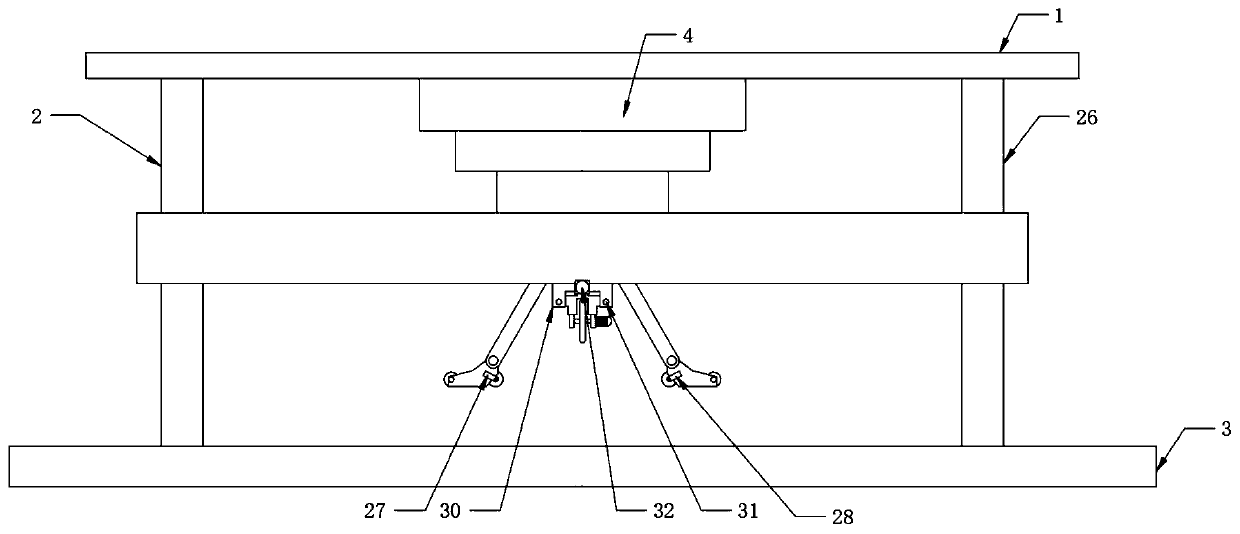

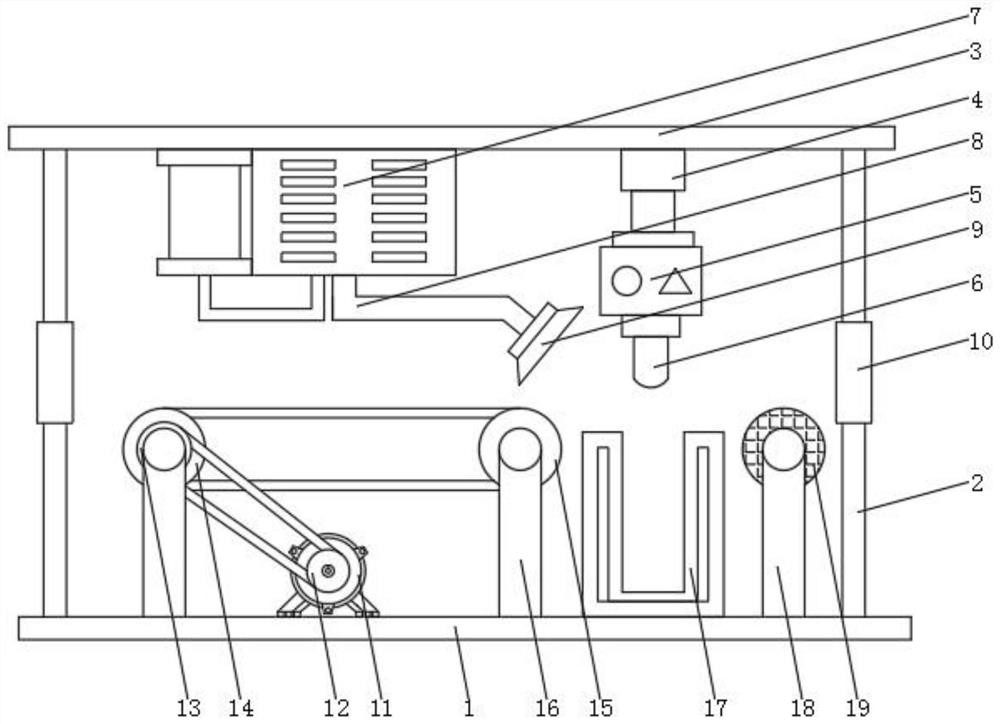

Cutting-off platform capable of adjusting cutting-off length of raw materials

PendingCN112296434AHigh precisionImprove work efficiencyShearing machinesMaintainance and safety accessoriesStructural engineeringIndustrial engineering

The invention discloses a cutting-off platform capable of adjusting the cutting-off length of raw materials. The cutting-off platform comprises a bottom plate, a vertical plate is arranged on one sideof the top of the bottom plate, a top plate is fixedly connected to the top of the vertical plate, a hydraulic telescopic rod is fixedly connected to the bottom of the top plate, a cutting machine isarranged at the bottom of the hydraulic telescopic rod, a cutting wheel is arranged at the bottom of the cutting machine, a dust suction mechanism is arranged at the bottom of the top plate and located on one side of the hydraulic telescopic rod, a dust suction pipe is arranged on one side of the bottom of the dust suction mechanism, a dust suction hopper is arranged at the bottom end of the dustsuction pipe, and a sliding device is arranged inside the vertical plate. According to the cutting-off platform capable of adjusting the cutting-off length of the raw materials, a motor and the dustsuction mechanism are arranged, so that the cutting accuracy can be improved, the cost is reduced, the cutting working efficiency is improved, the environmental pollution can be further reduced, the use effect is good, and the cutting-off platform is suitable for application and popularization and brings a better use prospect.

Owner:TIANJIN SHENGFA IND & TRADE

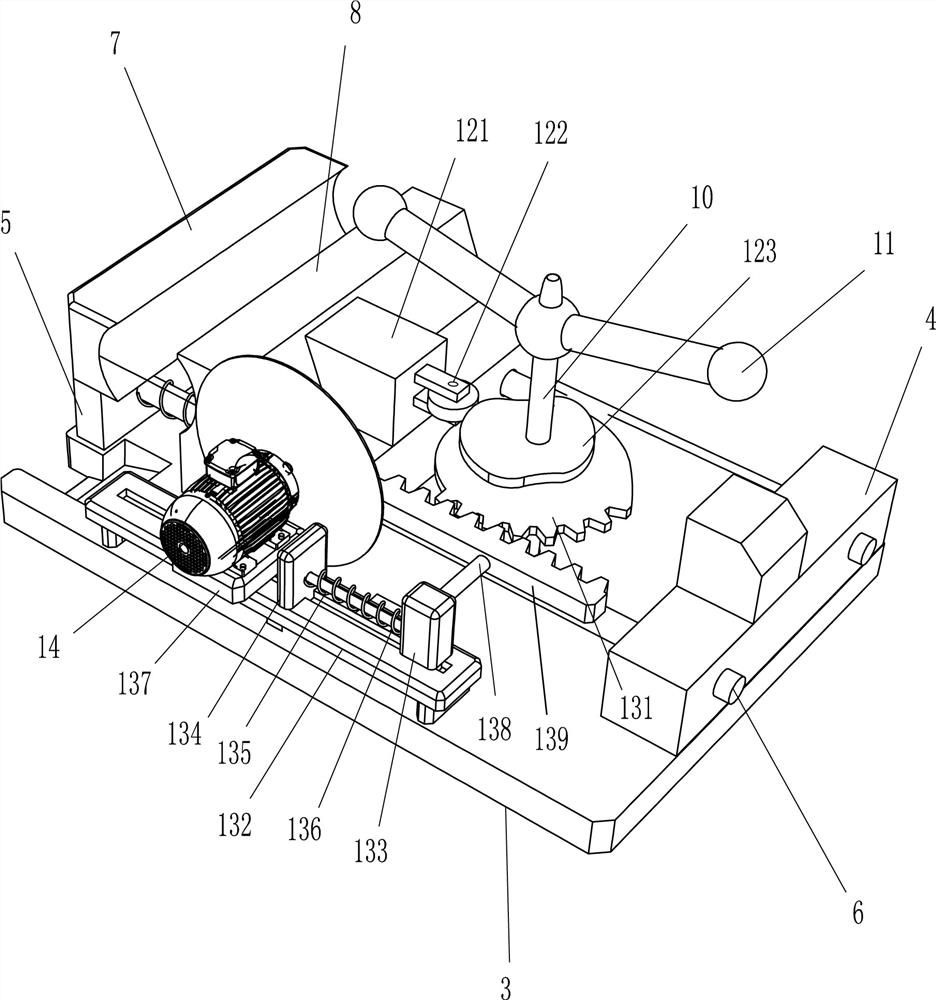

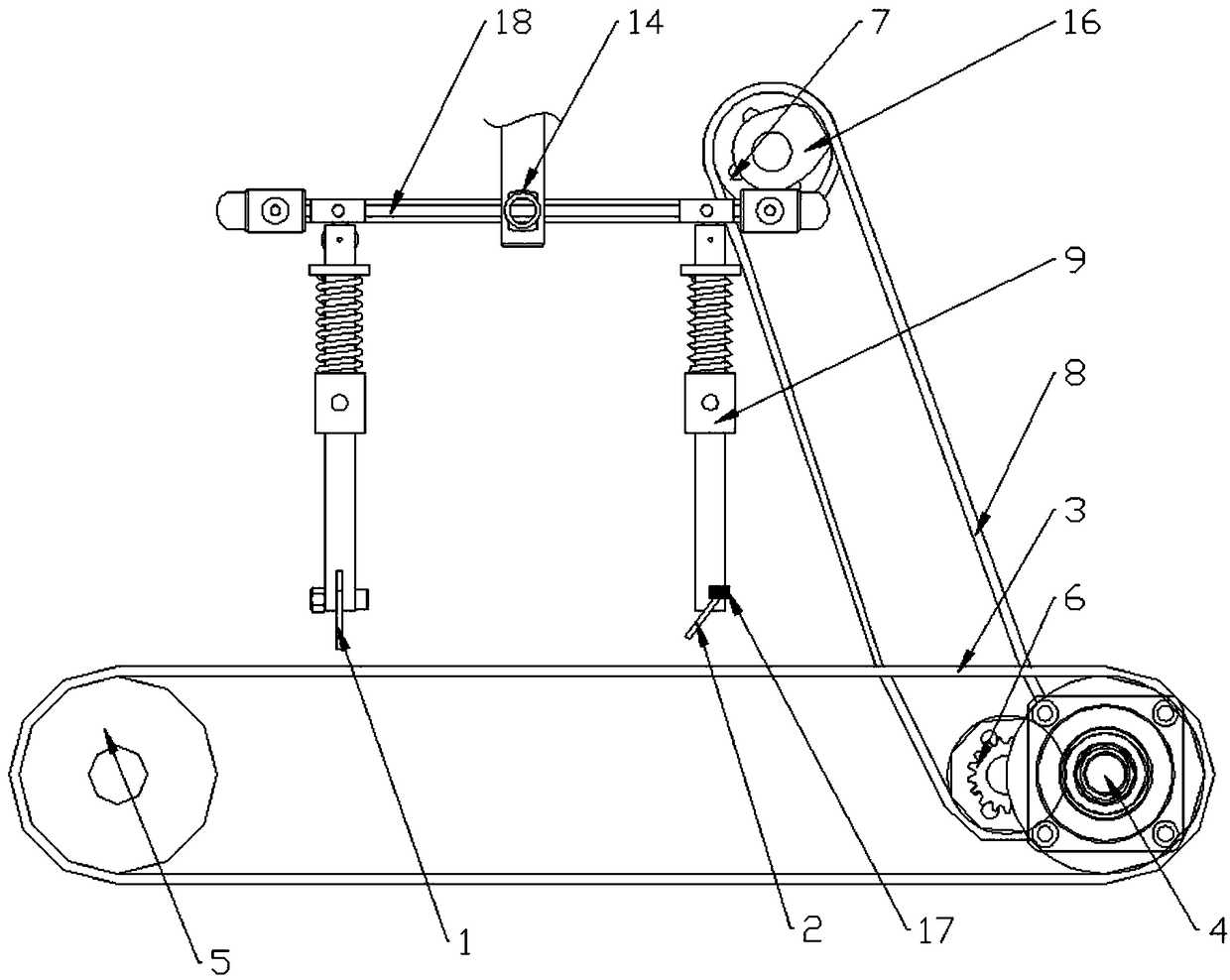

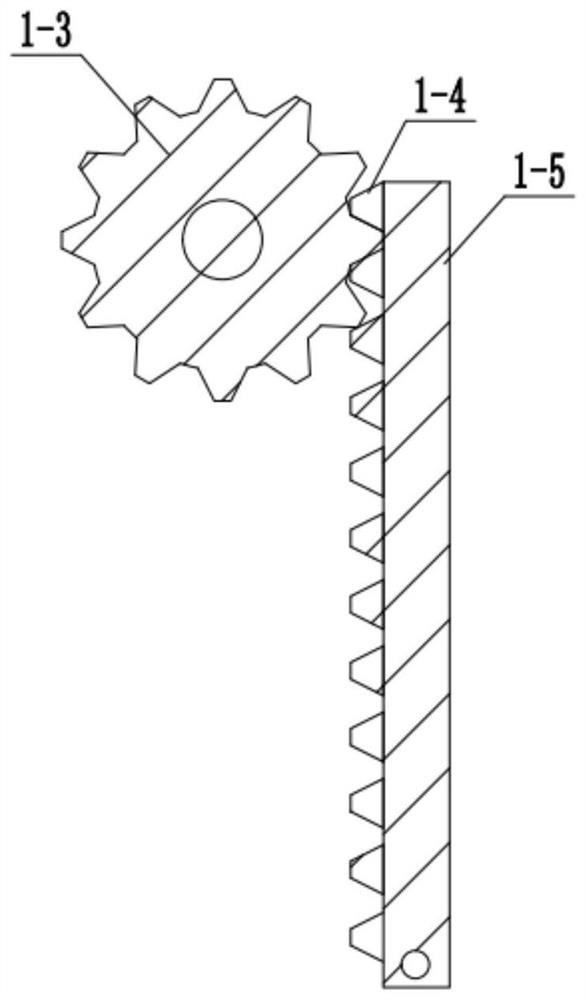

Adjustable single-drive tapered tooth cutting device

InactiveCN108326379AGuarantee processing qualityAdjustable cutting lengthGear teeth manufacturing toolsGear teethEngineeringDrive motor

An adjustable single-drive tapered tooth cutting device comprises a perpendicular cutter, an inclined cutter and a conveyer belt. The perpendicular cutter, the inclined cutter and the conveyer belt are driven by a drive motor. The drive motor and a belt pulley of the conveyer belt are in transmission connection in a meshed manner through a transmission gear. The perpendicular cutter and the inclined cutter are both installed on linkage assemblies. The linkage assemblies of the perpendicular cutter and the inclined cutter are connected through a transmission connection rod. The transmission connection rod is driven through transmission wheels. The transmission wheels and the belt pulleys are in transmission through a transmission belt. The transmission wheels comprise a driving transmissionwheel and a driven transmission wheel. The adjustable single-drive tapered tooth cutting device has the beneficial effects that tapered tooth cutting in the perpendicular direction of a workpiece canbe achieved, lateral deformation is avoided, the machining quality of the workpiece is guaranteed, the cutting length, the cutting depth and the cutting interval can be adjusted, the use cost of thedevice is reduced, and the universality of the adjustable single-drive tapered tooth cutting device is improved.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

A non-woven automatic cutting equipment with freely adjustable spacing

ActiveCN111663319BAdjustable cutting lengthAchieve cutting automationSevering textilesTool bitGear wheel

The invention relates to the technical field of non-woven fabrics, and discloses an automatic non-woven fabric cutting device whose spacing can be adjusted freely. The outer ring of the main shaft is fixedly connected with a gear set, the right end of the main shaft is fixedly sleeved with a roller, the left end of the baffle is movably connected with a rocker, the right end of the rocker is fixedly connected with a threaded rod, the outer ring of the threaded rod is movably socketed with a threaded barrel, and the baffle The upper right end of the upper part is movably connected with a sub-shaft, the right end of the sub-shaft is fixedly connected with a cam, the protruding end of the cam is movably connected with a movable rod, the lower end of the movable rod is movably connected with a cutting knife, and the outer ring of the cutting knife is movably socketed with a limit block , the lower end of the cutting knife is fixedly connected with a knife head. The non-woven fabric automatic cutting equipment with freely adjustable spacing achieves the effect of adjustable cutting length through the cooperative use of gear sets, cutting knives, threaded rods, threaded barrels and gear two.

Owner:海宁市米奥服饰有限公司

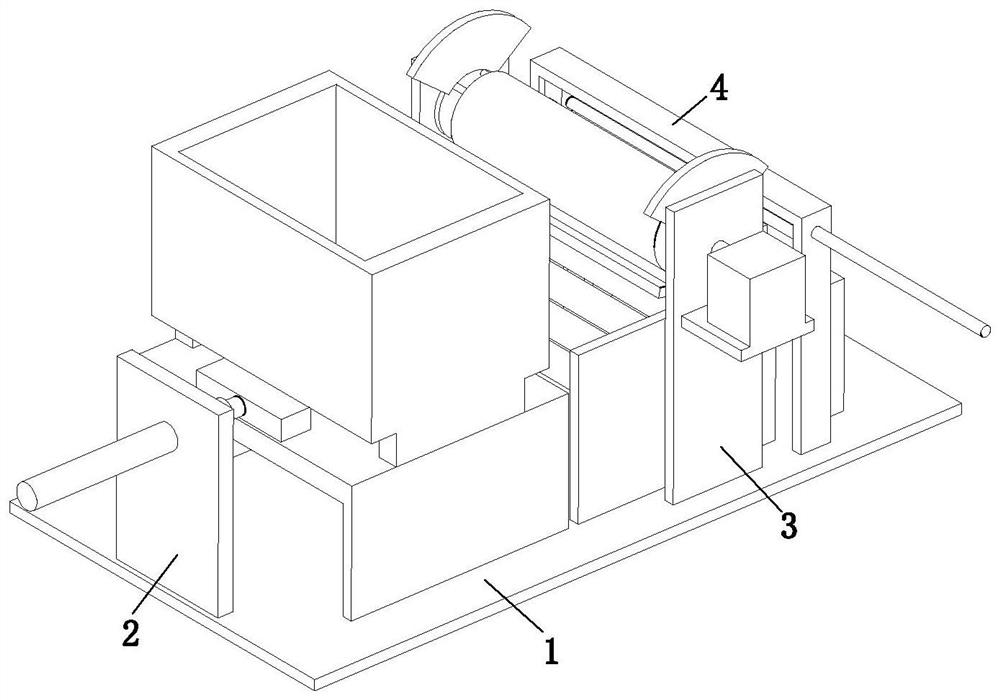

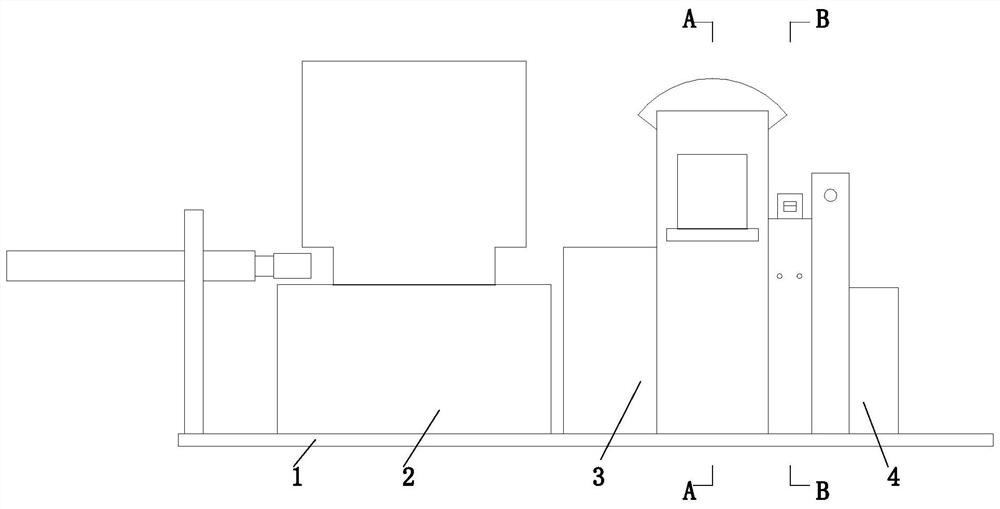

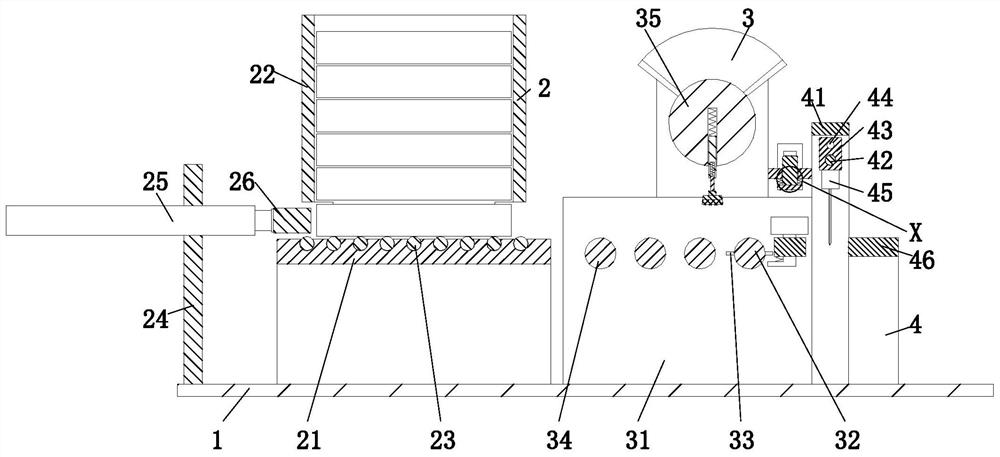

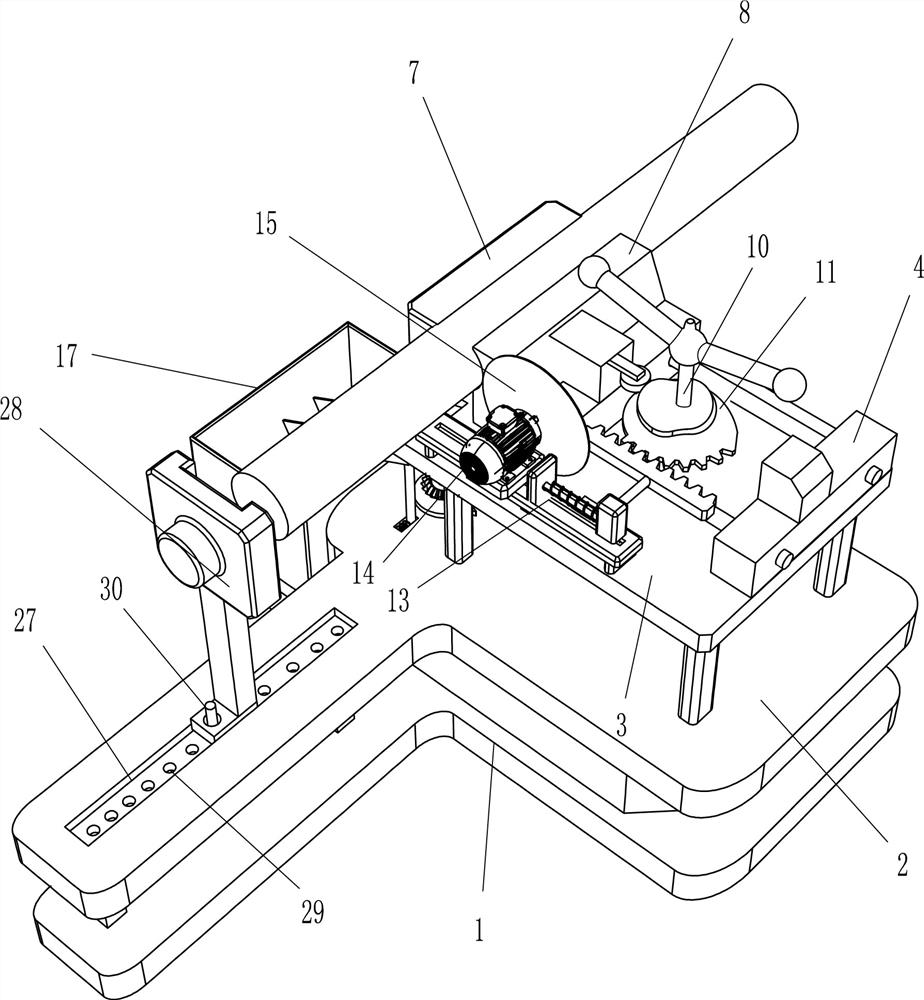

A new type of continuous pressing cutting machine

ActiveCN109290805BAdjustable lengthAdjustable cutting lengthShaping toolsShearing machinesPunchingBall screw

The invention discloses a novel continuous profile cutting machine, which comprises a profile cutting assembly, a base assembly, a sliding positioning assembly, and a feeding belt assembly; the profile cutting assembly includes: an upper stamping oil cylinder, a profile cutting punching die, an outer The installation frame, the lower stamping cylinder, and the lower sliding installation plate; the base assembly includes a support base and a support foot, and the servo motor is connected with a ball screw pair through a coupling, and a wire is provided on the side of the ball screw pair near the coupling. The rod bearing seat and the far end of the ball screw pair are connected with the screw nut seat in the middle of the back of the lower sliding mounting plate; the sliding positioning assembly includes a side support plate, a sliding support plate, and a sliding positioning guide rail, and the side support plate is located at the bottom of the lower formwork. The present invention can accurately and continuously carry out the pressing, cutting and punching of the end of the plate with the bending edge, and the cutting distance between the pressing and cutting components can be adjusted, which greatly reduces the cost of the continuous pressing and cutting equipment and improves the production efficiency. efficiency.

Owner:ANHUI KINGPOWER EQUIP & MOLD MFR

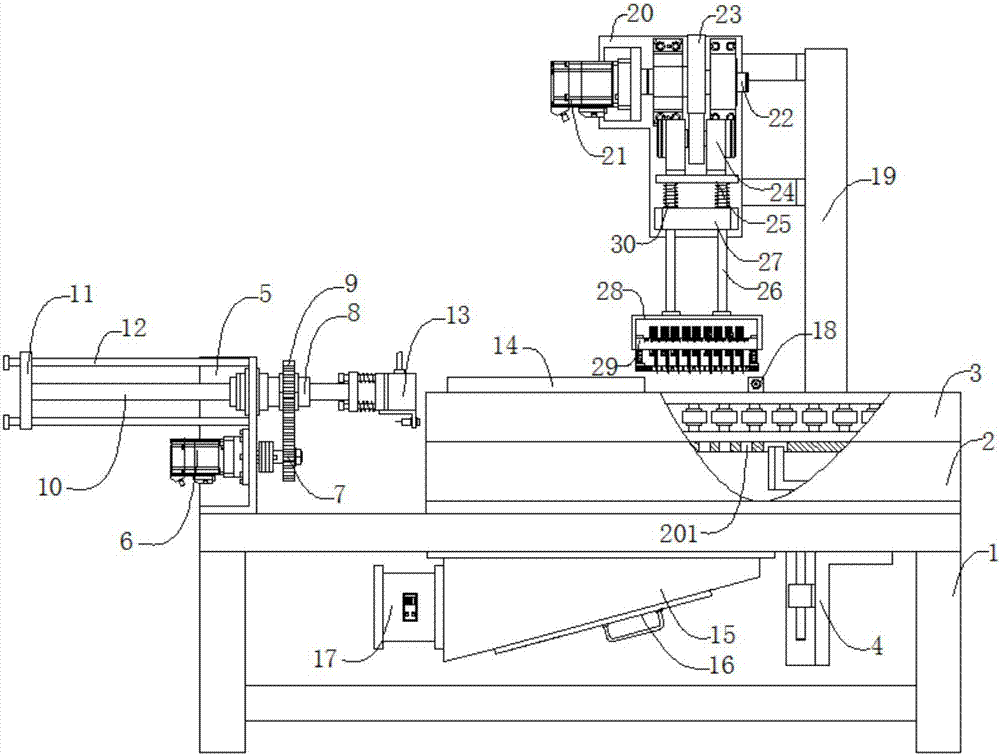

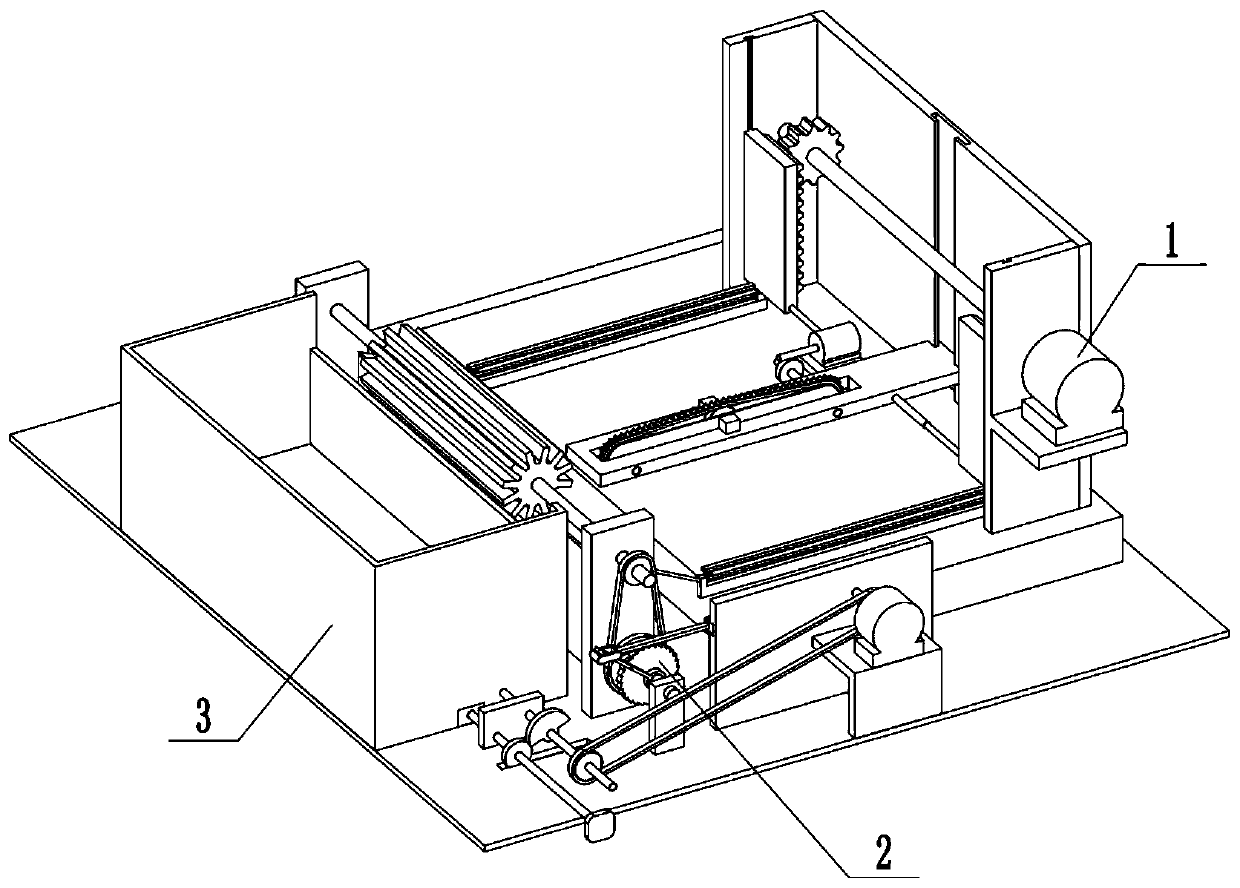

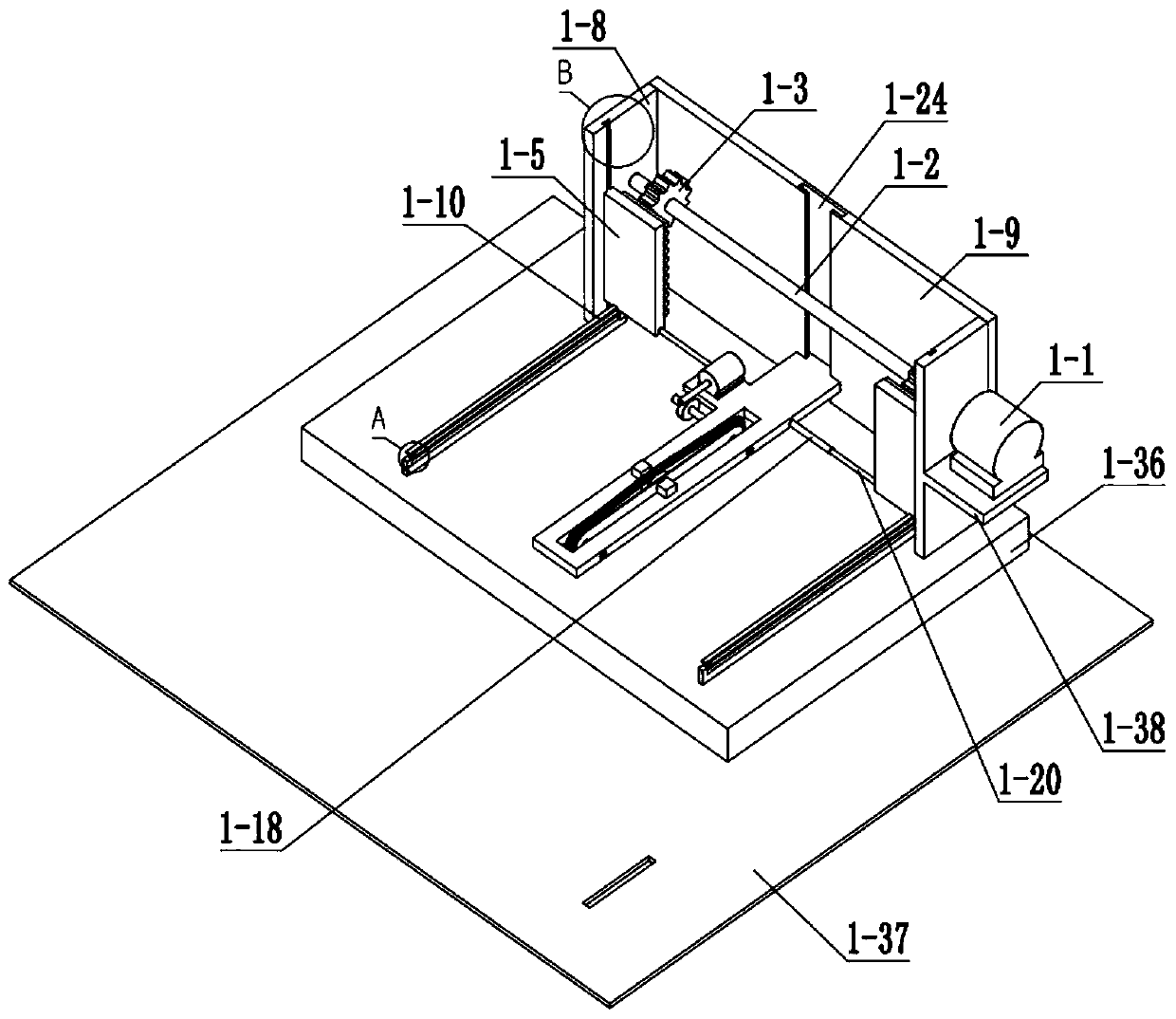

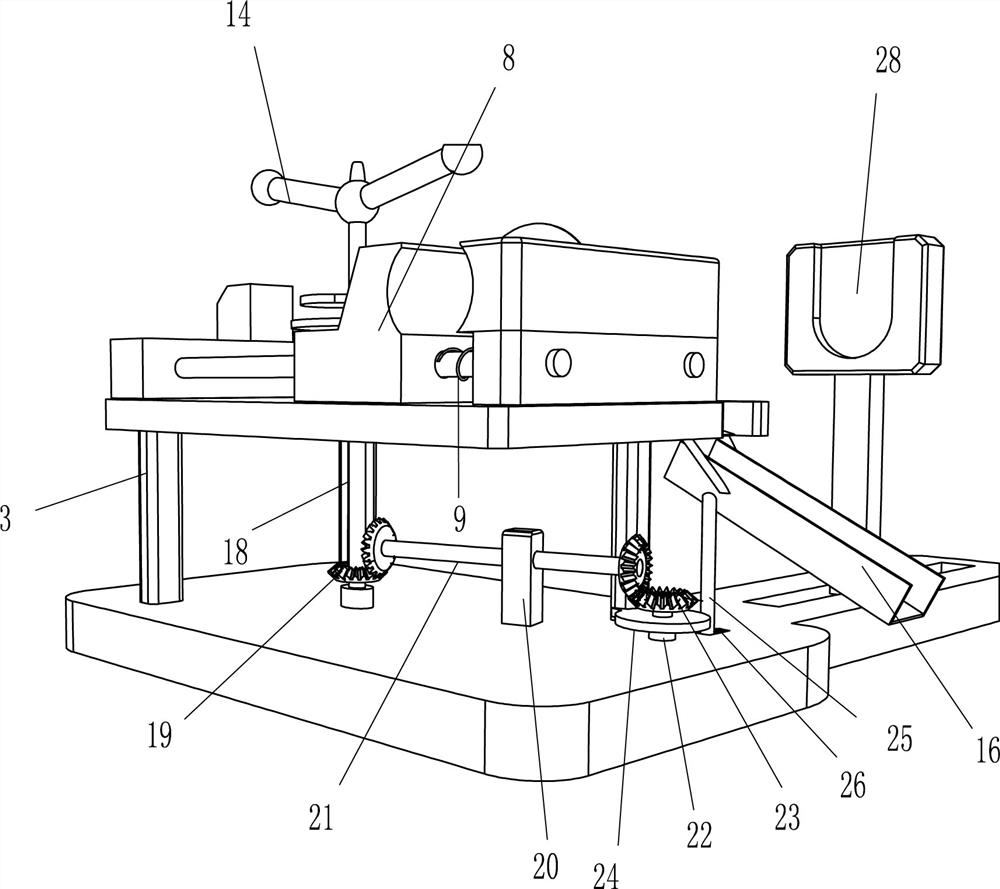

A steel bar cutting device

The invention relates to the field of bridges, in particular to steel bar cutting equipment. The steel bar cutting equipment comprises a cutting combined body, a feeding combined body and a material box combined body. By means of the steel bar cutting equipment, the problems frequently encountered when a bridge is built that the automation degree of programs for cutting steel bars in batches is low, and danger is generated to human bodies by too much manual operation are solved. To-be-cut steel bars are put into a material box, a threaded sliding barrel is adjusted, a cutter blade slides in the axial direction of a supporting shaft, and the cutting length of the steel bars can be adjusted. The cutter blade moves reciprocatingly up and down so that the steel bars are cut. When the cutting blade moves upwards, a rotary frame is opened, a feeding rotary barrel rotates and the steel bars in the material box are taken out and fall into the space between the rotary frame and a fixing frame through a slant plate, and a lifting plate of the material box does not move. When the cutting blade moves downwards, the rotary frame is closed, the feeding rotary barrel stops rotating, the steel bars are stacked flush and clamped by the rotary frame and the fixing frame and are convenient for the cutting blade to cut, the lifting plate of the material box rises, and uncut steel bars in the material box are lifted and wait to be taken out by rotation of the feeding rotary barrel.

Owner:王学凤

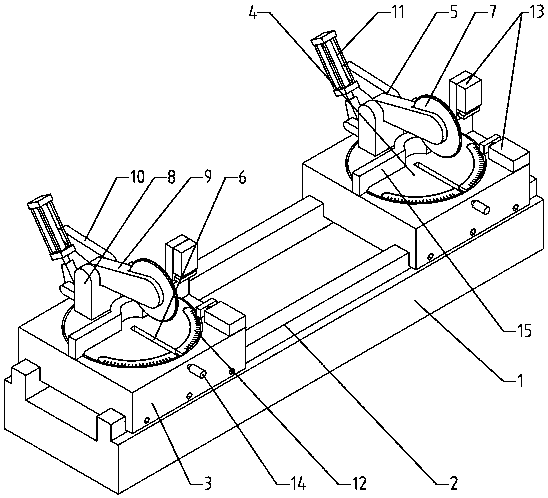

Multi-angle steering cutting device for profiles

ActiveCN105750618BAdjustable cutting lengthAdjustable cutting angleShearing machinesShearing machine accessoriesEngineeringSteering angle

The invention discloses a multi-angle steering cutting device for a sectional material. The multi-angle steering cutting device comprises a worktable, and sliding rails fixed to the worktable; two cutting devices are mounted on the sliding rails; each cutting device comprises a base; a rotatable cutting turntable is arranged at the center of each base; a cutting arm is fixed to one side of each cutting turntable; a cutting groove is formed in each cutting turntable radially; a cutting hobbing cutter is mounted above each cutting groove through the corresponding cutting arm; a sectional fixing tool is arranged on each base. According to the multi-angle steering cutting device for the sectional material, the two cutting devices with adjustable distance is arranged on the worktable, and the rotatable cutting turntables are arranged on the cutting devices, so that the cutting length and angle of the sectional material can be adjusted when the multi-angle steering cutting device is used; the cutting efficiency is greatly improved; the cutting precision is high.

Owner:ZHE JIANG ZHONGYI BUILDING MATERIALS TECH CO LTD

An automatic centering cutting mechanism for wire threading trough plate

ActiveCN109013823BAdjustable cutting lengthSimple structureMetal-working feeding devicesPositioning devicesElectric wireEngineering

The invention discloses an automatic centered cutting mechanism for electric wire penetrating groove plates. The mechanism comprises a frame and a cutting device; a cutting support plate is arranged in the center of the upper end surface of a lower support plate; a lifting support plate is arranged between the lower support plate and an upper support plate in a lifting mode; a cutter is detachablymounted in the center of the lower end surface of the lifting support plate; a pair of centered driving blocks is arranged on the lifting support plate in a left-right moving mode; the lower edge lines of the approaching end surfaces of the pair of centered driving blocks are formed as chamfering angles; a pair of upper centered avoiding grooves for enabling the centered driving blocks to insertin is formed in the front part of the cutting support plate; the lower support plate is provided with lower centered avoiding grooves, same with the upper centered avoiding grooves, right under the upper centered avoiding grooves; length adjusting blocks are arranged at the back part of the upper end surface of the lower support plate in a front-back sliding mode; and upper stop plates are moldedat the middle parts of the upper end surfaces of the length adjusting blocks. The mechanism is simple in structure and adjustable in cutting length of the electric wire penetrating groove plates, andcan automatically center the electric wire penetrating groove plates.

Owner:扬州高新电缆材料有限公司

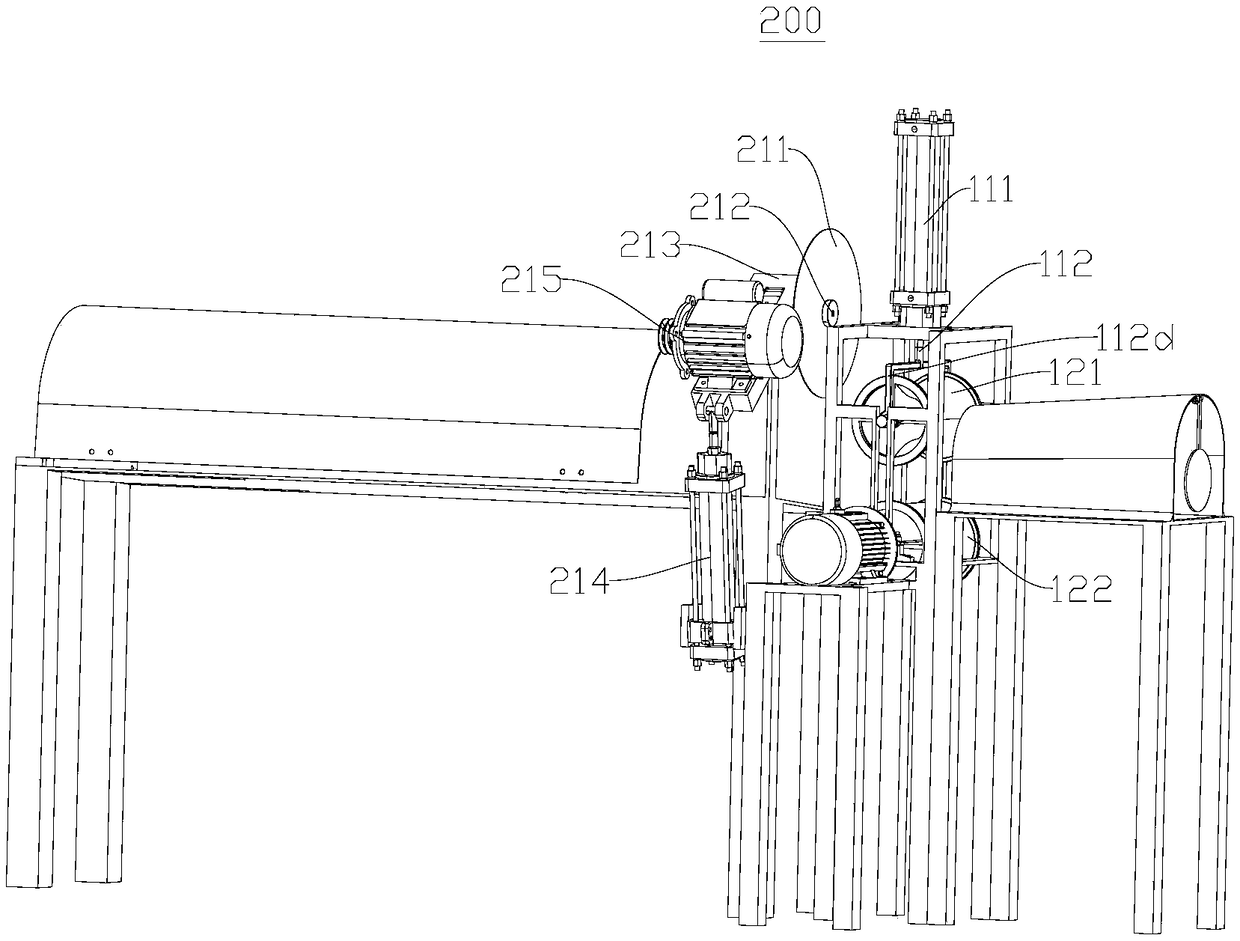

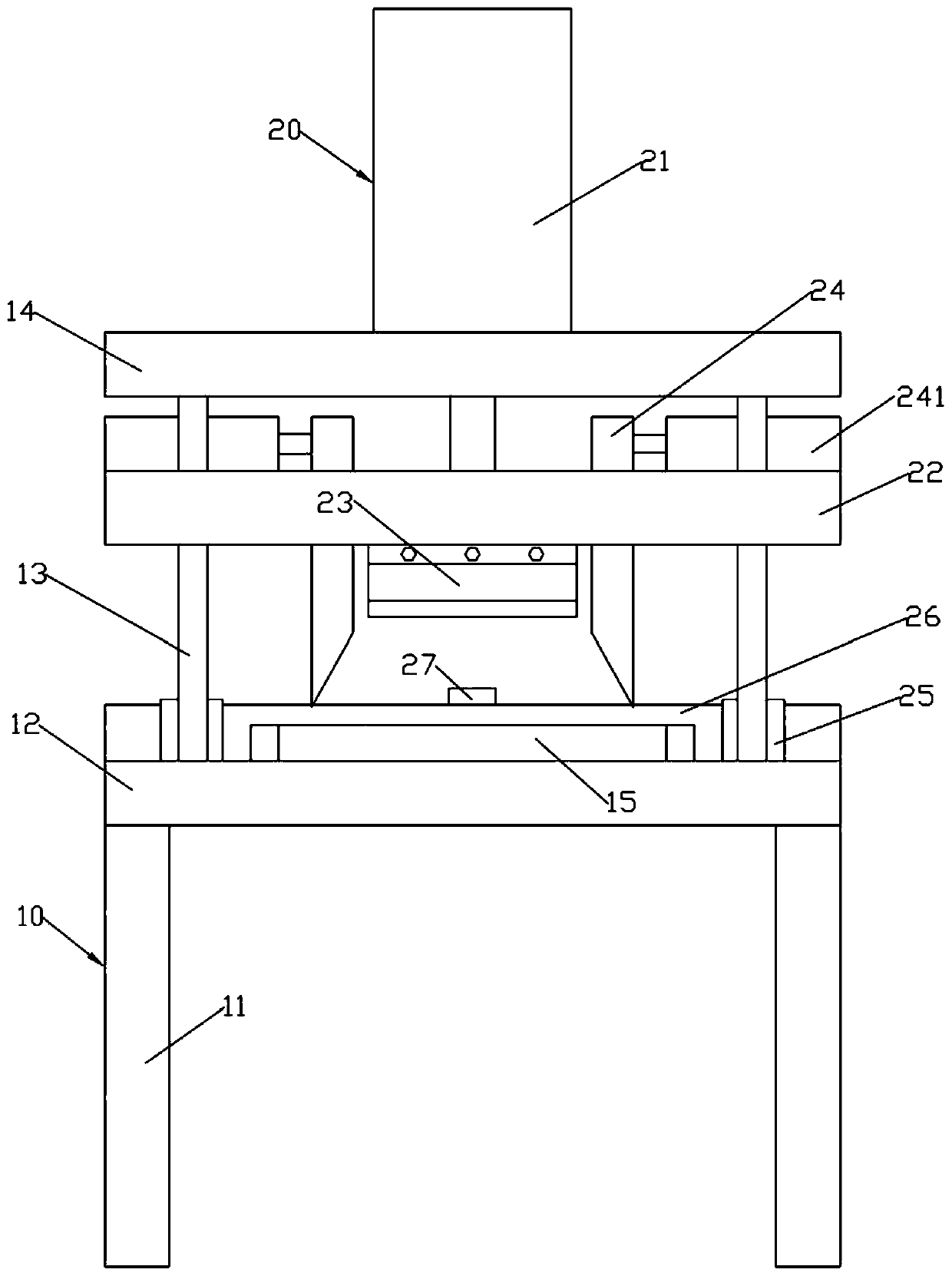

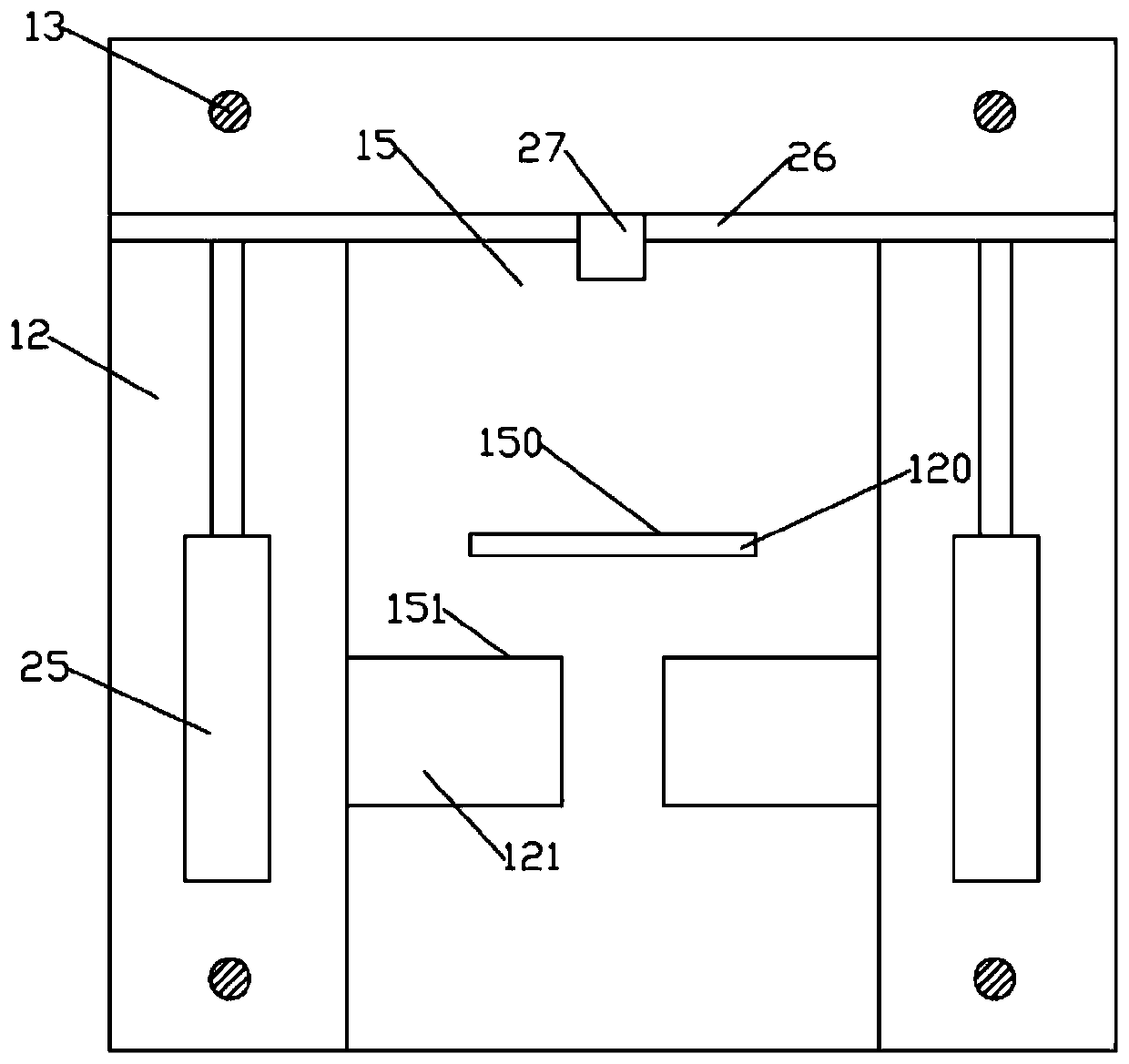

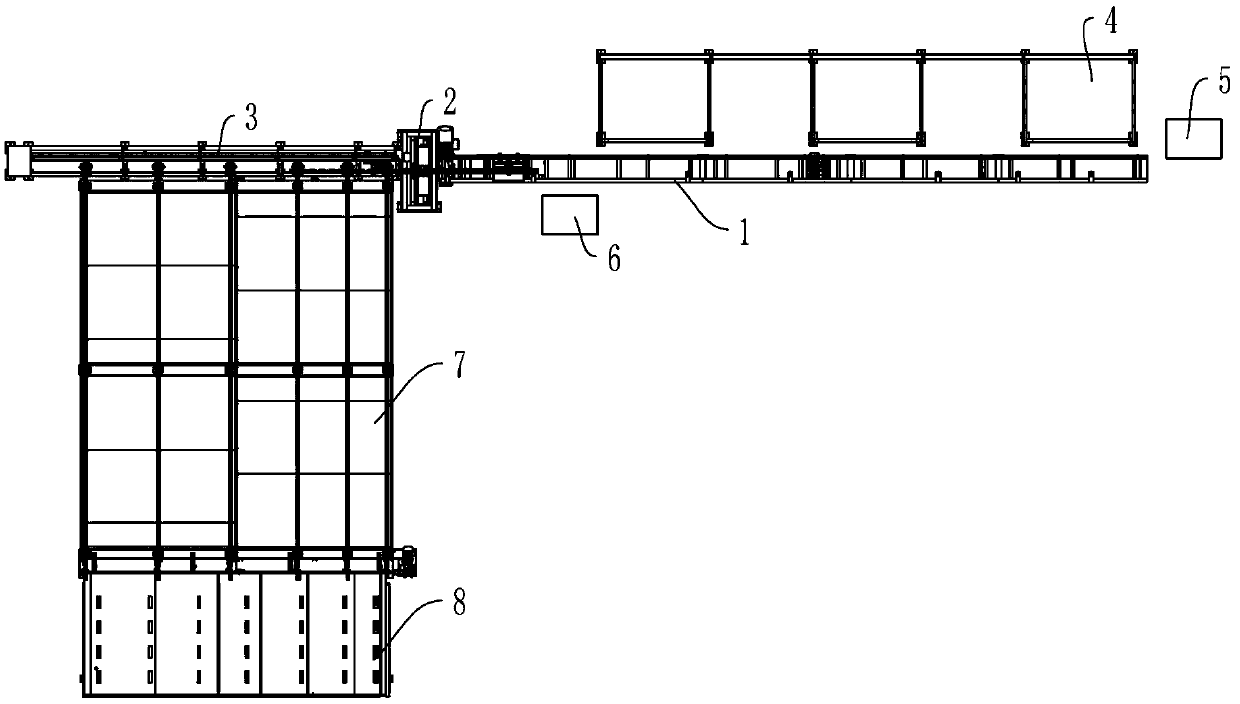

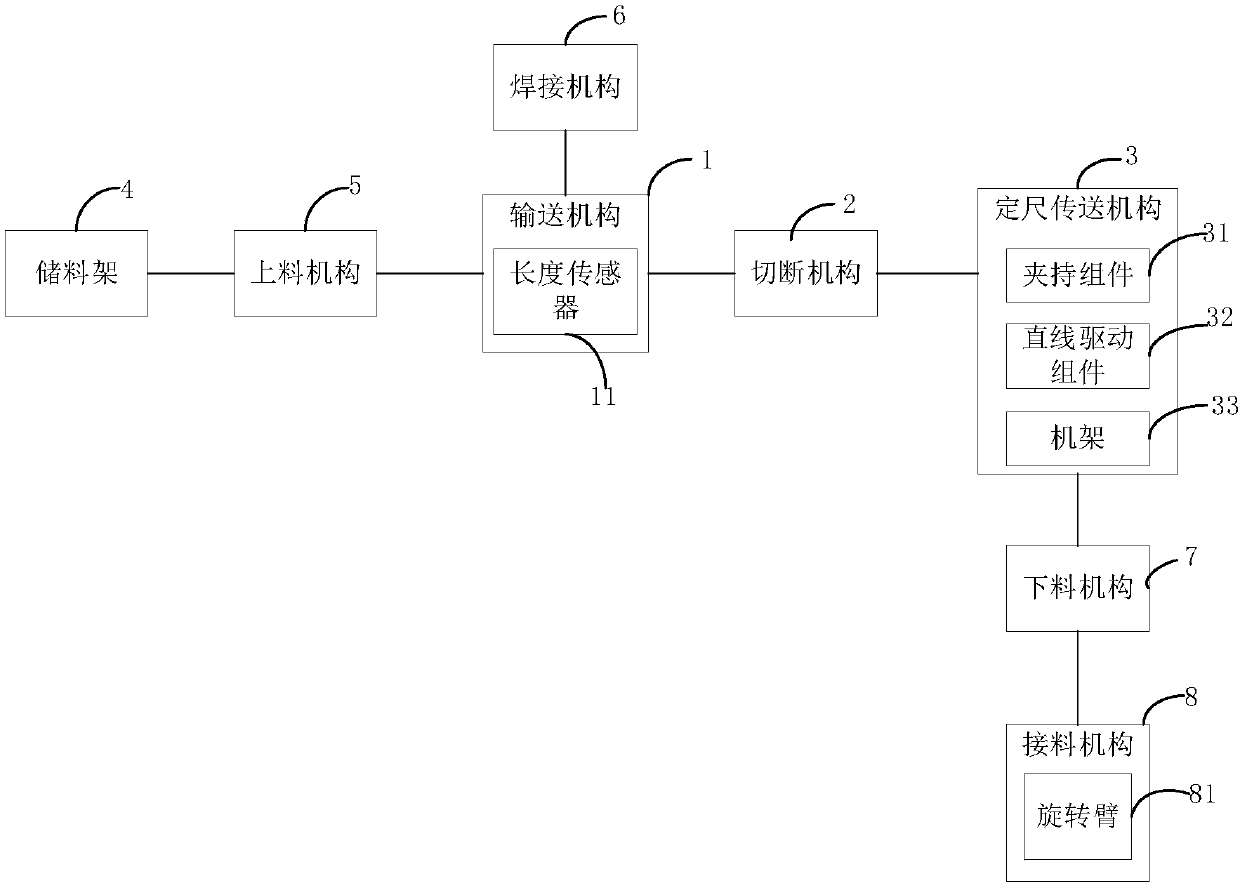

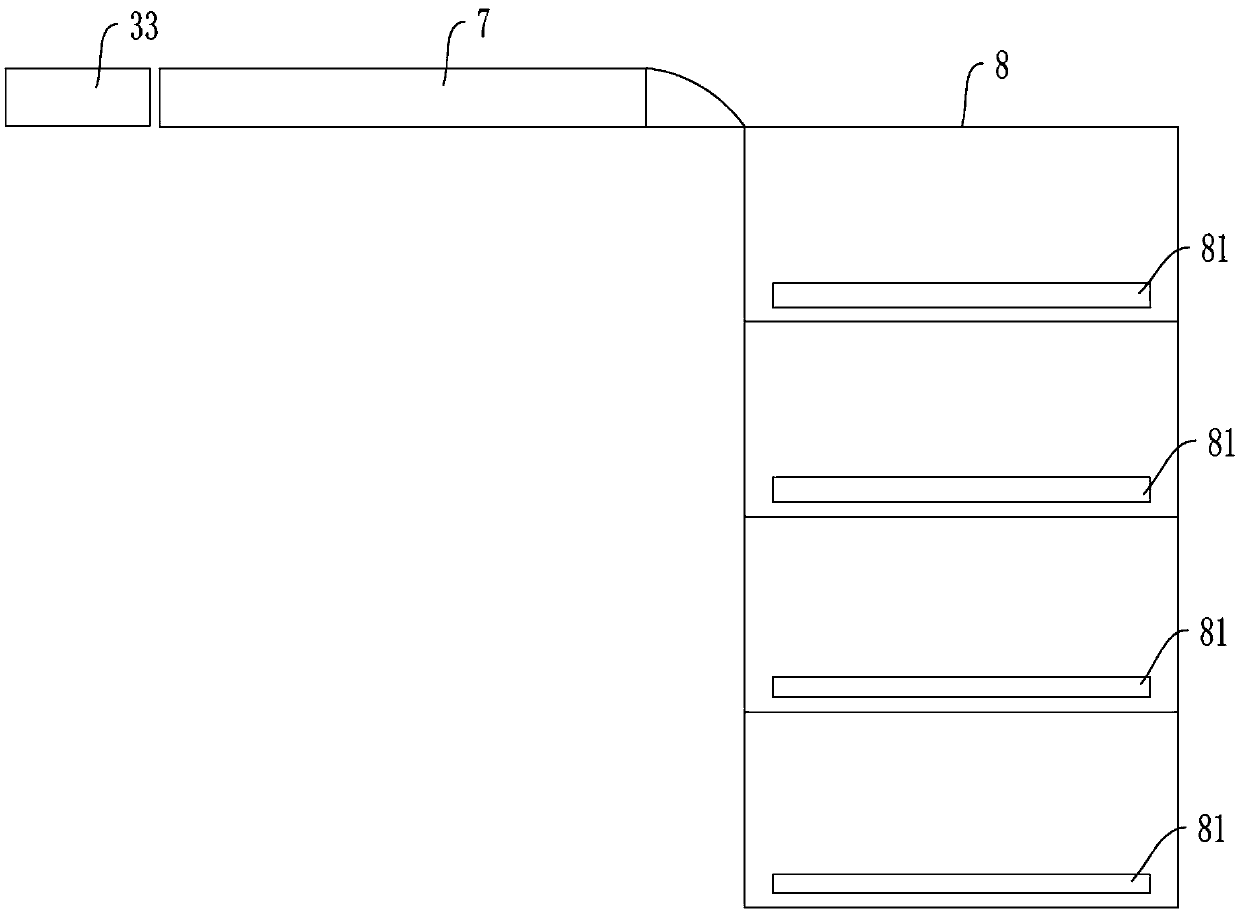

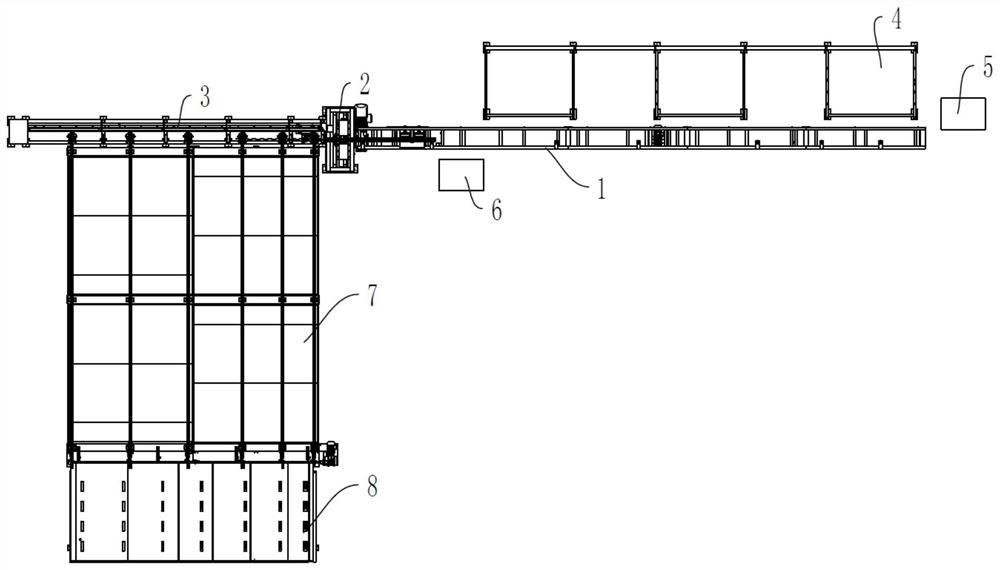

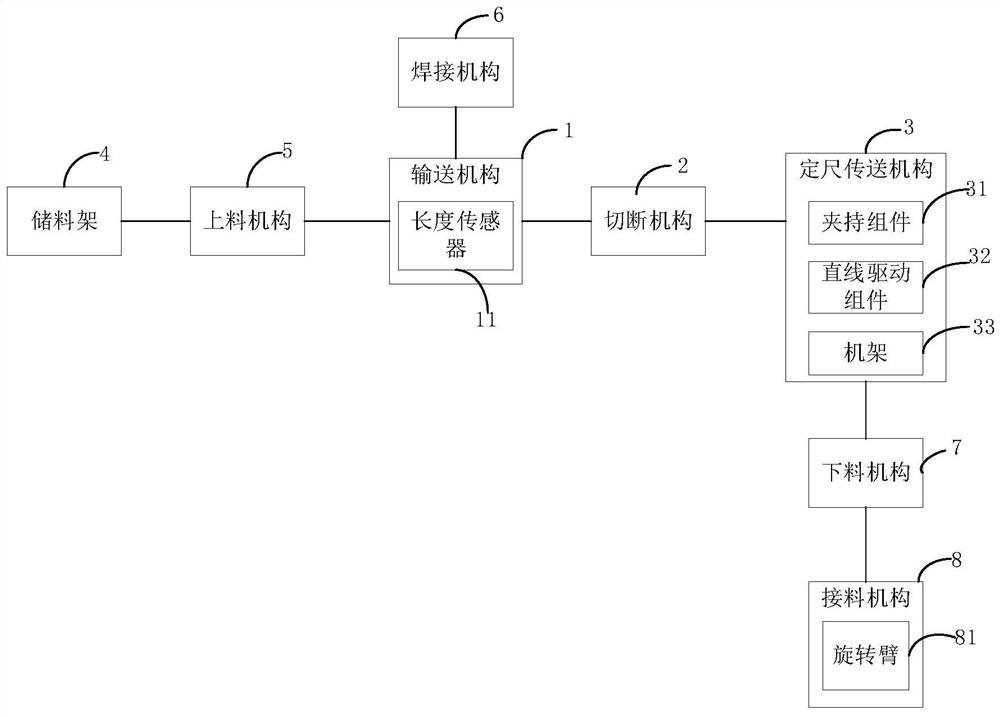

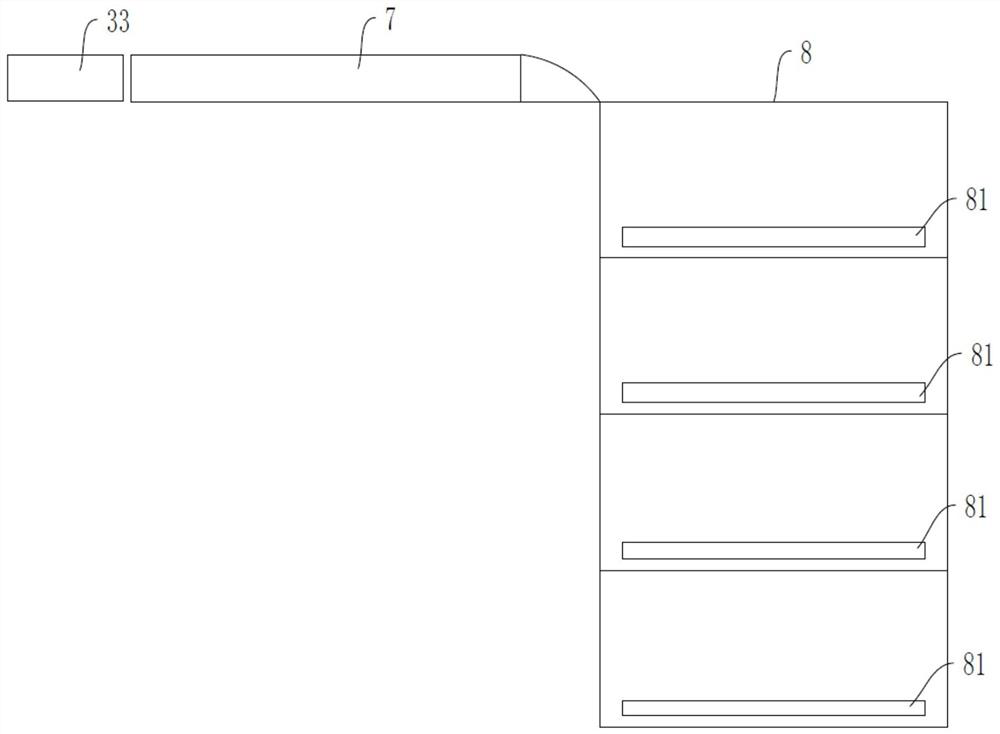

Automatic truss cutting equipment

ActiveCN109571029AThe cutting length can be adjusted at willAdjustable cutting lengthShearing machinesOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention discloses automatic truss cutting equipment. The automatic truss cutting equipment comprises a conveying mechanism, a cutting mechanism and a fixed-length conveying mechanism. The cutting mechanism is arranged between the conveying mechanism and the fixed-length conveying mechanism, the cutting mechanism is used for cutting off trusses, the conveying direction of the conveying mechanism is the same as the conveying direction of the fixed-length conveying mechanism, and the conveying mechanism conveys the trusses to the cutting mechanism. When the conveying mechanism conveys the trusses to the fixed-length conveying mechanism, the fixed-length conveying mechanism stops after the trusses are conveyed according to a preset conveying distance, and the cutting mechanism cuts the trusses. The fixed-length conveying mechanism drives the trusses to move, and the distance from the cutting mechanism to the trusses is controlled by controlling the moving distance of the fixed-lengthconveying mechanism to drive the trusses, so that the cutting length of the trusses is controlled. The conveying distance of the fixed-length conveying mechanism can be adjusted and controlled at will, so that the cutting length of the trusses is adjusted and controlled at will, the trusses can be automatically conveyed, the cutting length of the trusses can be adjusted at will, the cutting sizeis more accurate, the production safety is high, and the efficiency is high.

Owner:HUNAN SANY KUAIERJU RESIDENTIAL IND CO LTD

An automatic truss cutting device

ActiveCN109571029BThe cutting length can be adjusted at willAdjustable cutting lengthShearing machinesOther manufacturing equipments/toolsStructural engineeringTransfer mechanism

The automatic truss cutting device of the present invention includes a conveying mechanism, a cutting mechanism and a fixed-length conveying mechanism; the cutting mechanism is arranged between the conveying mechanism and the fixed-length conveying mechanism, and the cutting mechanism is used for cutting the truss, the transmission mechanism and the fixed-length conveying mechanism. The direction is the same and the conveying mechanism conveys the truss to the cutting mechanism; when the conveying mechanism conveys the truss to the fixed-length conveying mechanism, the fixed-length conveying mechanism stops after transmitting the truss according to the preset transmission distance, and the cutting mechanism cuts the truss. The fixed-length conveying mechanism drives the truss to move, and the distance that the truss is transmitted from the cutting mechanism is controlled by controlling the moving distance of the fixed-length conveying mechanism to drive the truss, thereby controlling the cutting length of the truss. Since the transmission distance of the fixed-length conveying mechanism can be adjusted arbitrarily, Therefore, the cutting length of the truss can be adjusted arbitrarily, and it is a truss cutting that can automatically convey the truss, the cutting length of the truss can be adjusted arbitrarily, the cutting size is more accurate, the production safety is high, and the efficiency is high.

Owner:HUNAN SANY KUAIERJU RESIDENTIAL IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com