Automatic truss cutting equipment

A technology of cutting equipment and truss, which is applied in the field of automatic truss cutting equipment, can solve the problems of unguaranteed size, low production efficiency, high labor intensity, etc., and achieve the effects of arbitrary adjustable cutting length, precise cutting size and high production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

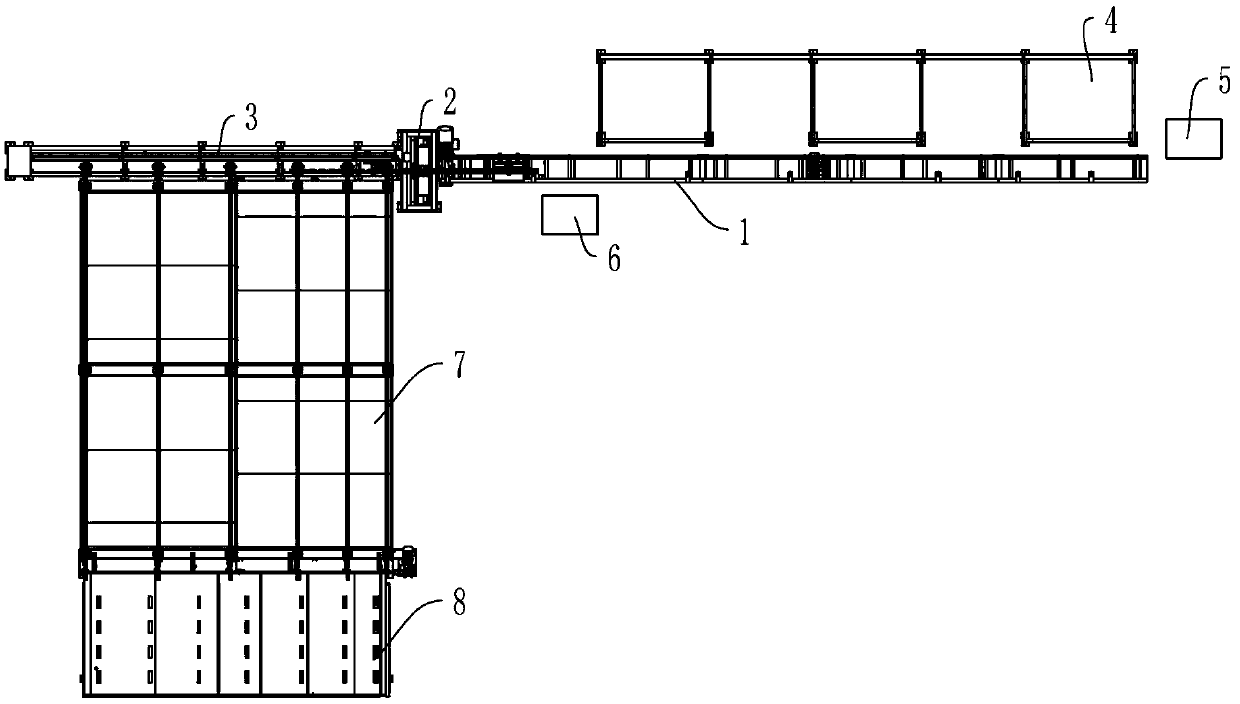

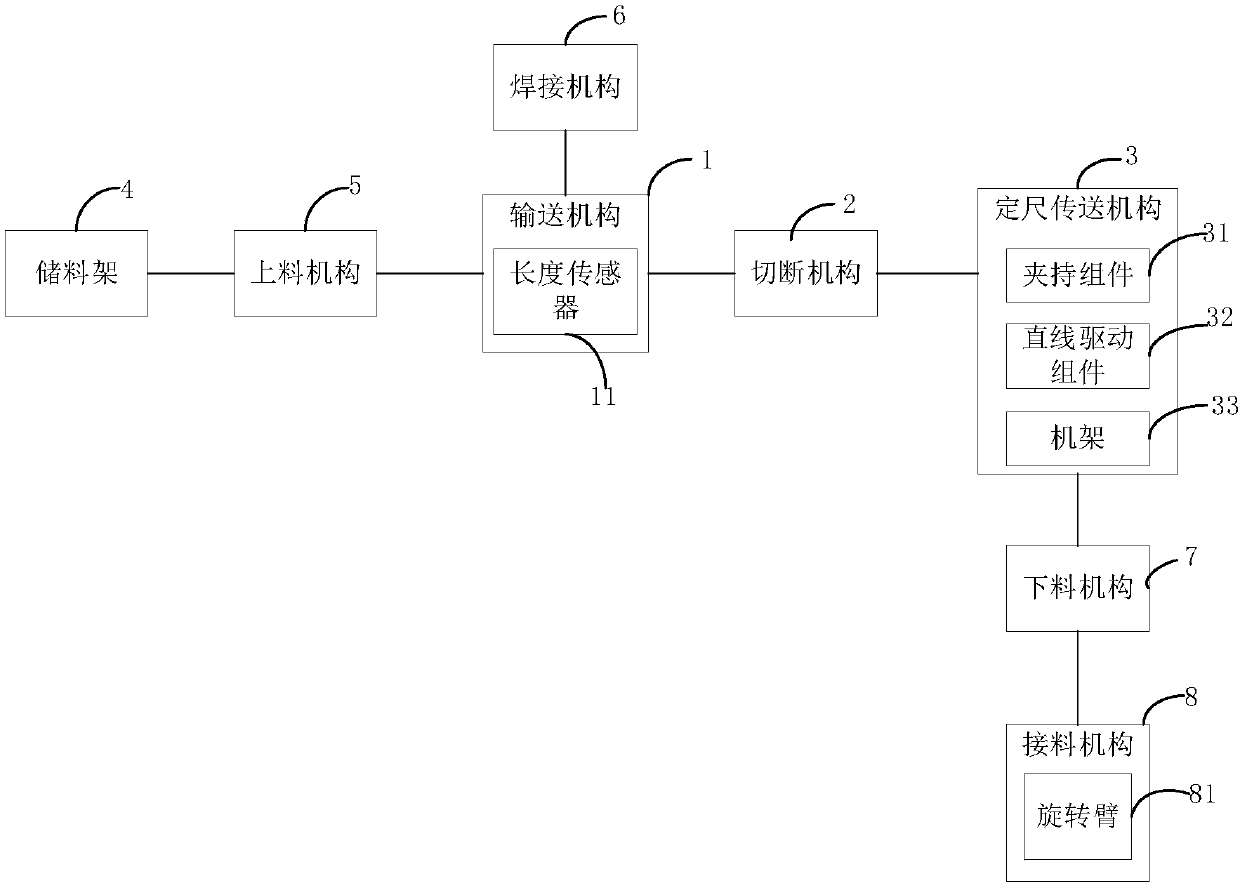

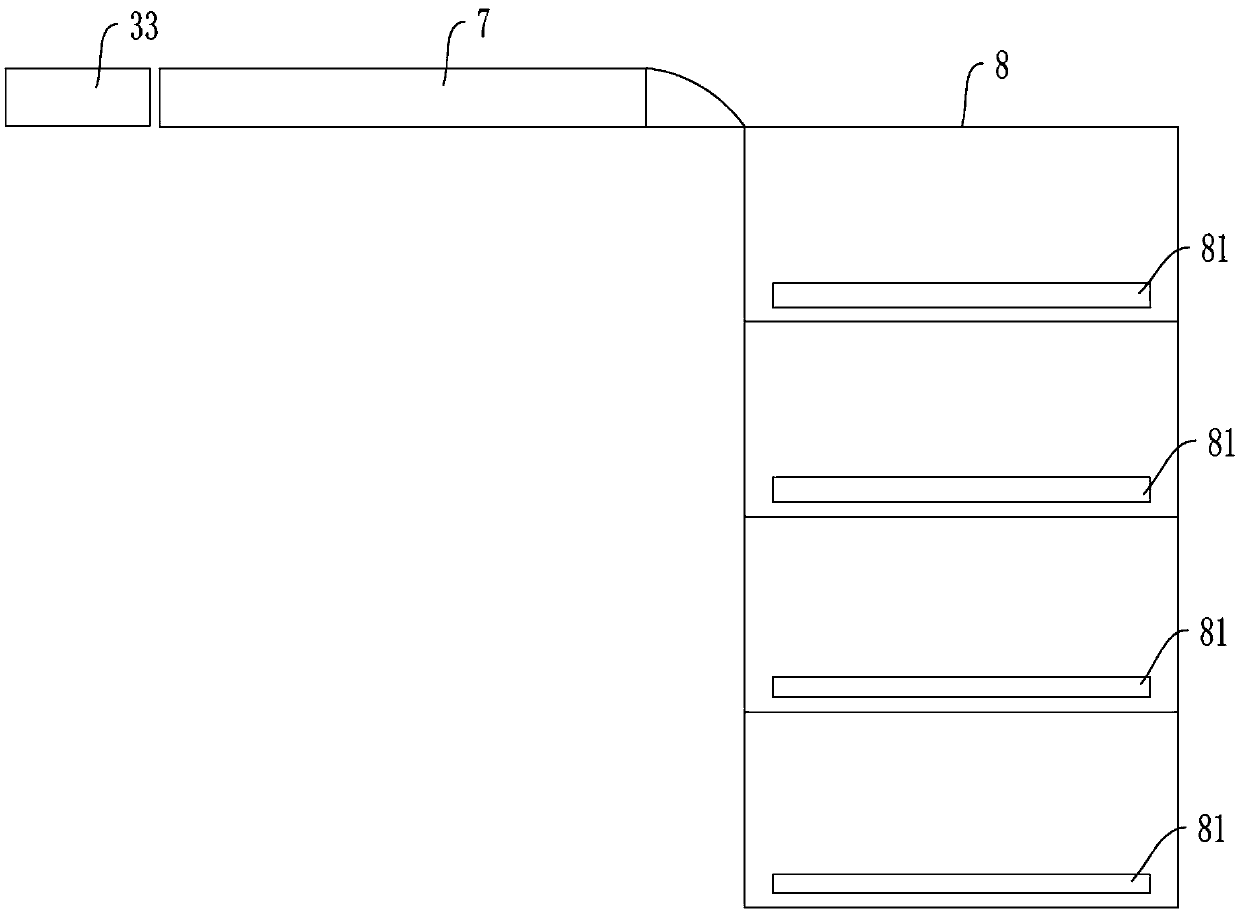

[0036] Please also refer to figure 1 and figure 2 , the present embodiment provides an automatic truss cutting device, including a conveying mechanism 1 , a cutting mechanism 2 and a length-defining conveying mechanism 3 . The cutting mechanism 2 is located between the conveying mechanism 1 and the fixed length conveying mechanism 3. The cutting mechanism 2 is used to cut off the truss. When the conveying mechanism 1 transports the truss to the fixed-length conveying mechanism 3, the fixed-length conveying mechanism 3 stops after conveying the truss according to a preset conveying distance, and the cutting mechanism 2 cuts off the truss.

[0037] As mentioned above, the conveying mechanism 1 is a kind of conveying device, which can drive / drive the truss to continuously move to the cutting mechanism 2, eliminating the need for manual material pushing. The cutting mechanism 2 can be an existing cutting device, and its cutting execution part is a cutter, which is driven to mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com