Patents

Literature

91results about How to "Adjustable cutting angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

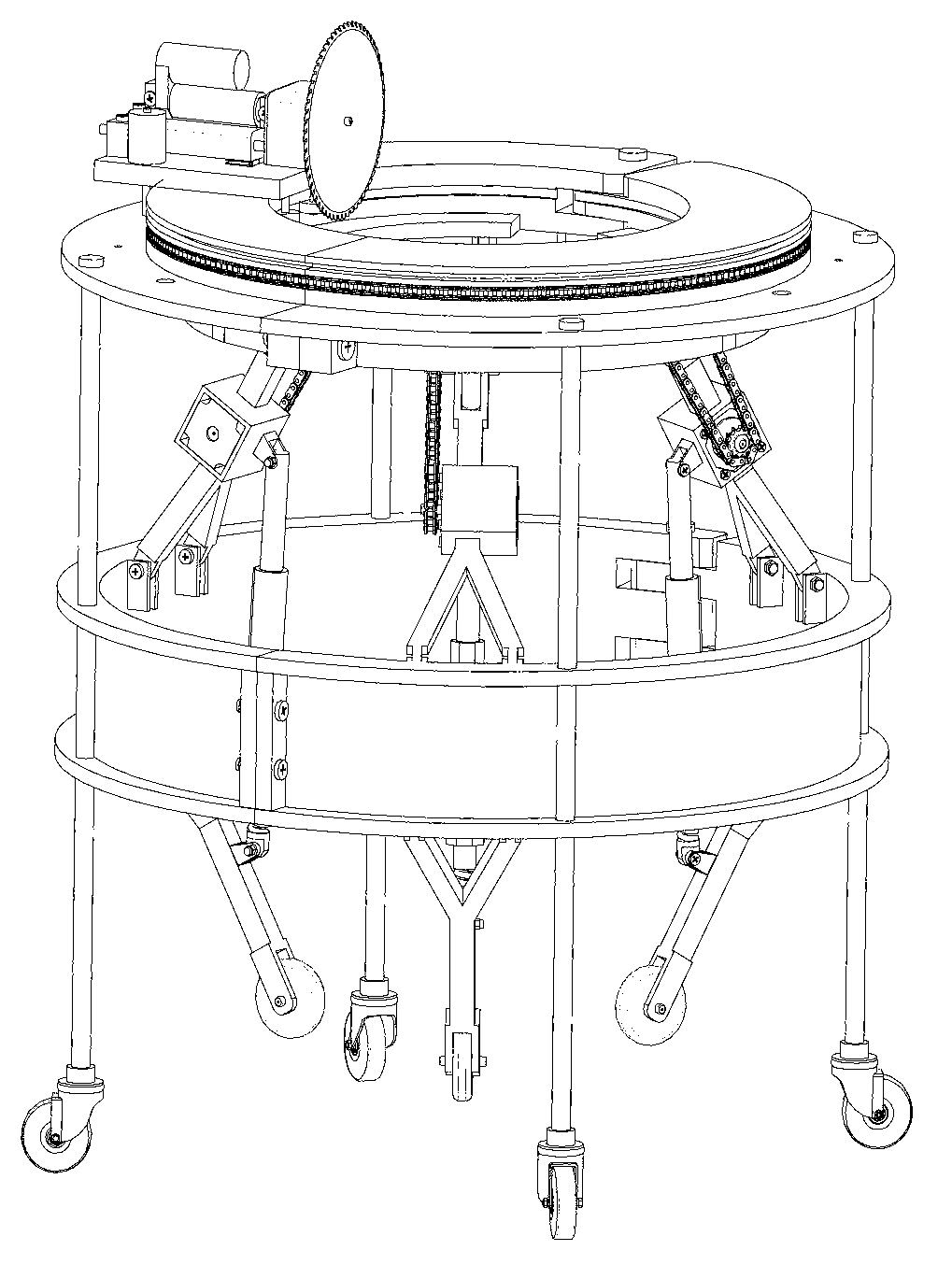

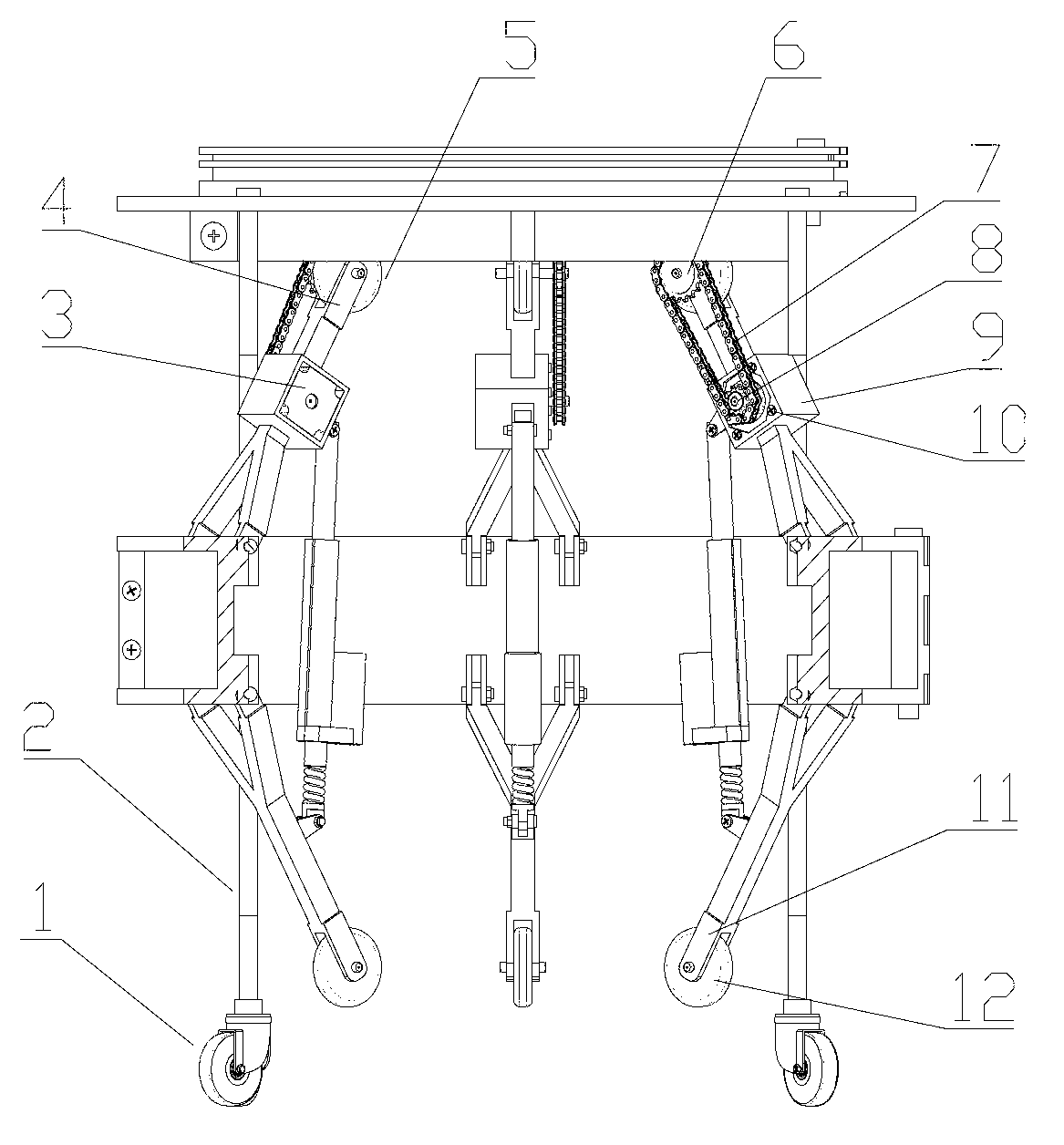

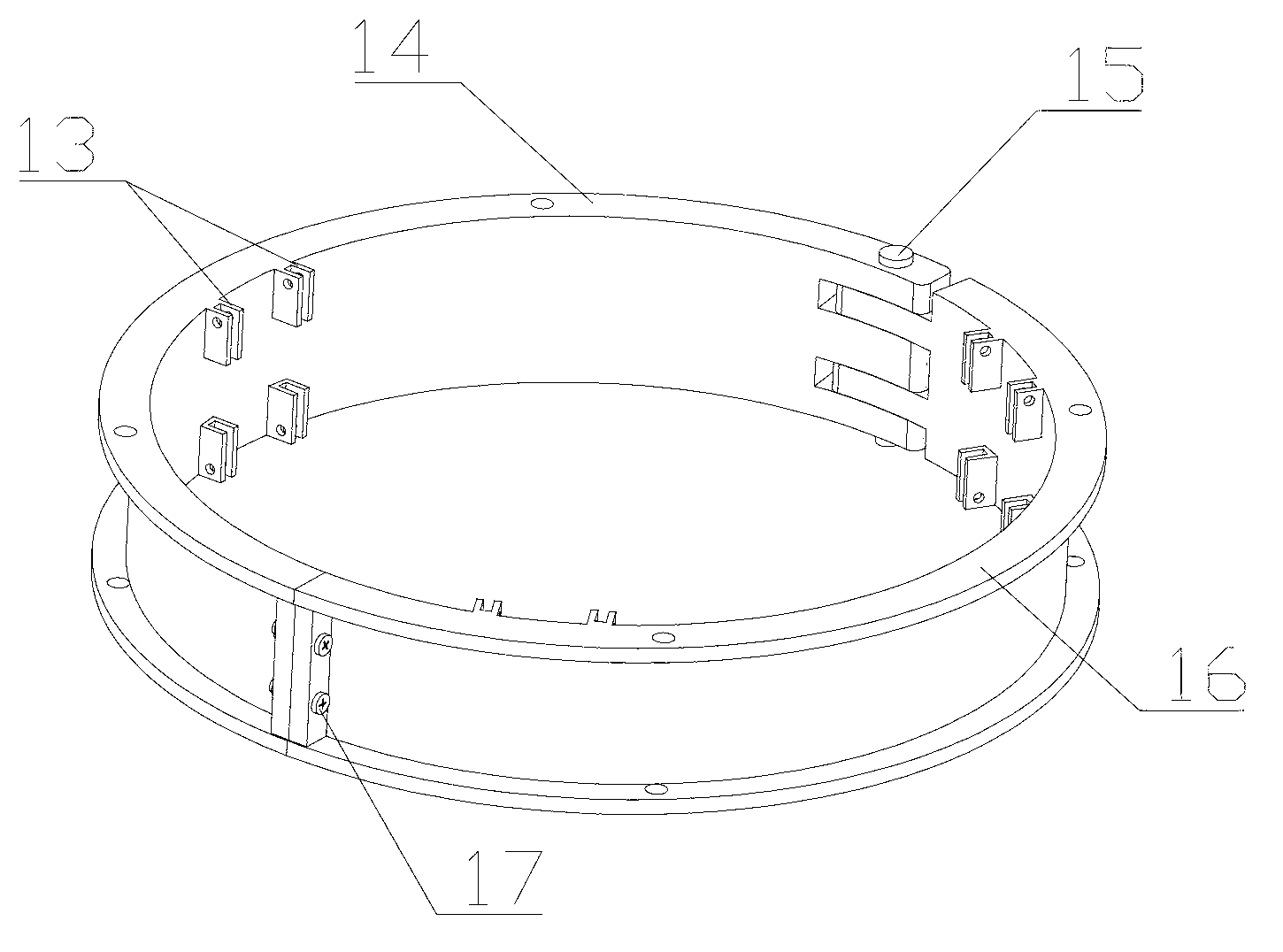

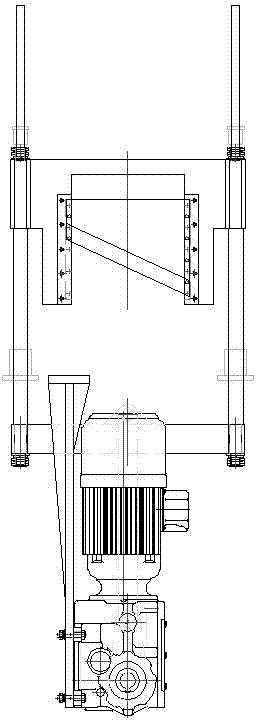

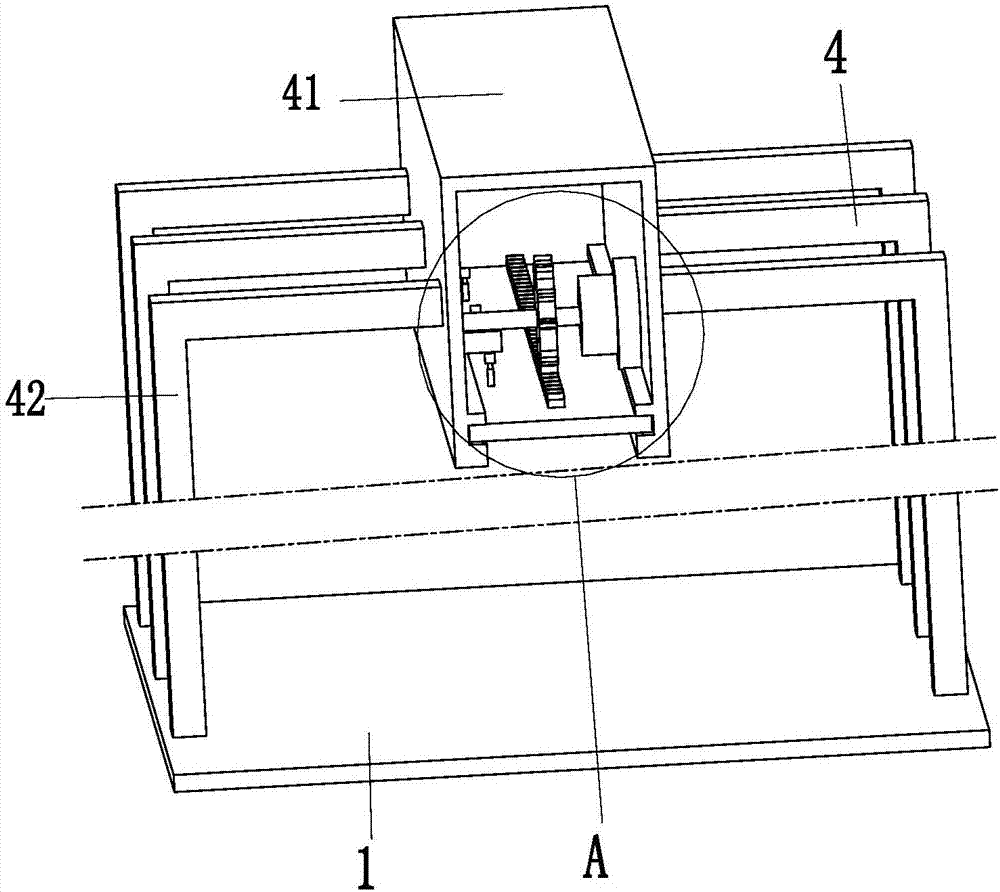

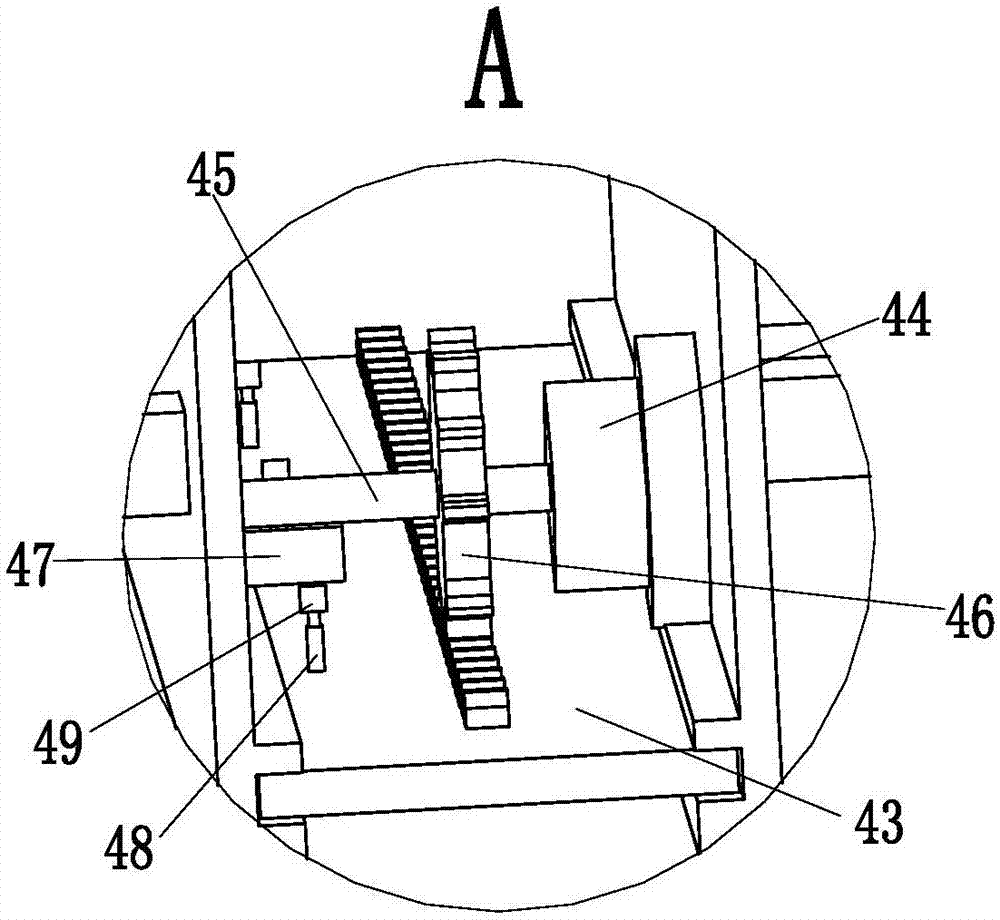

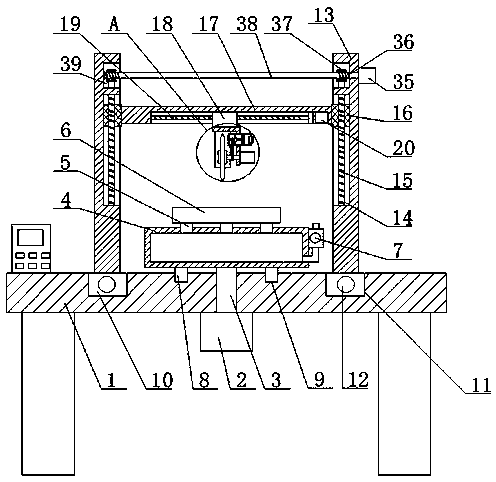

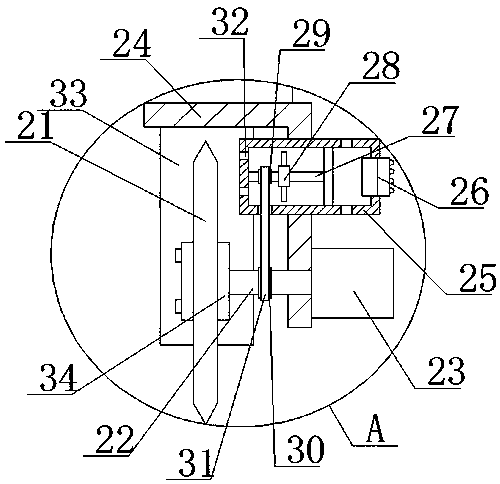

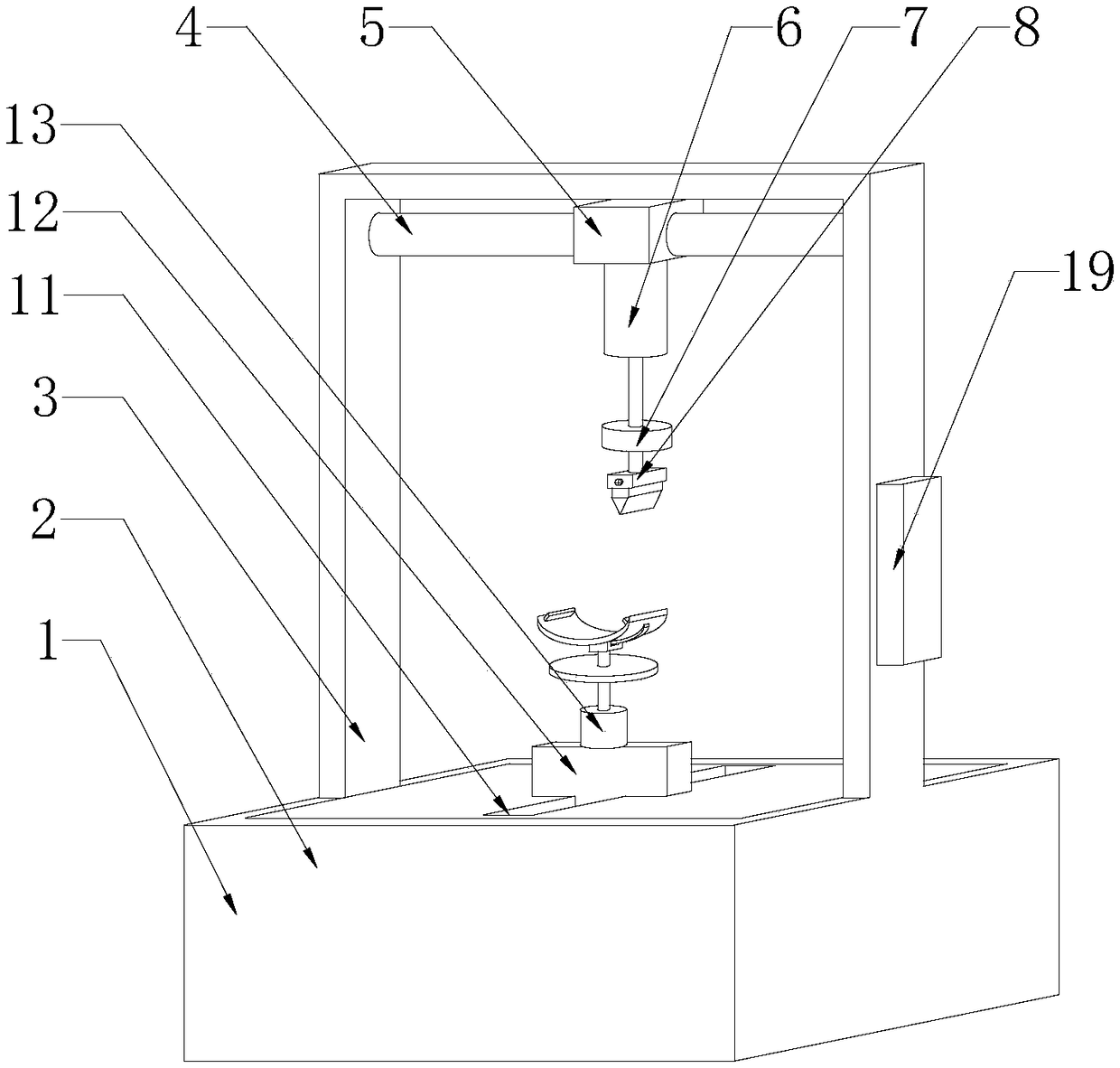

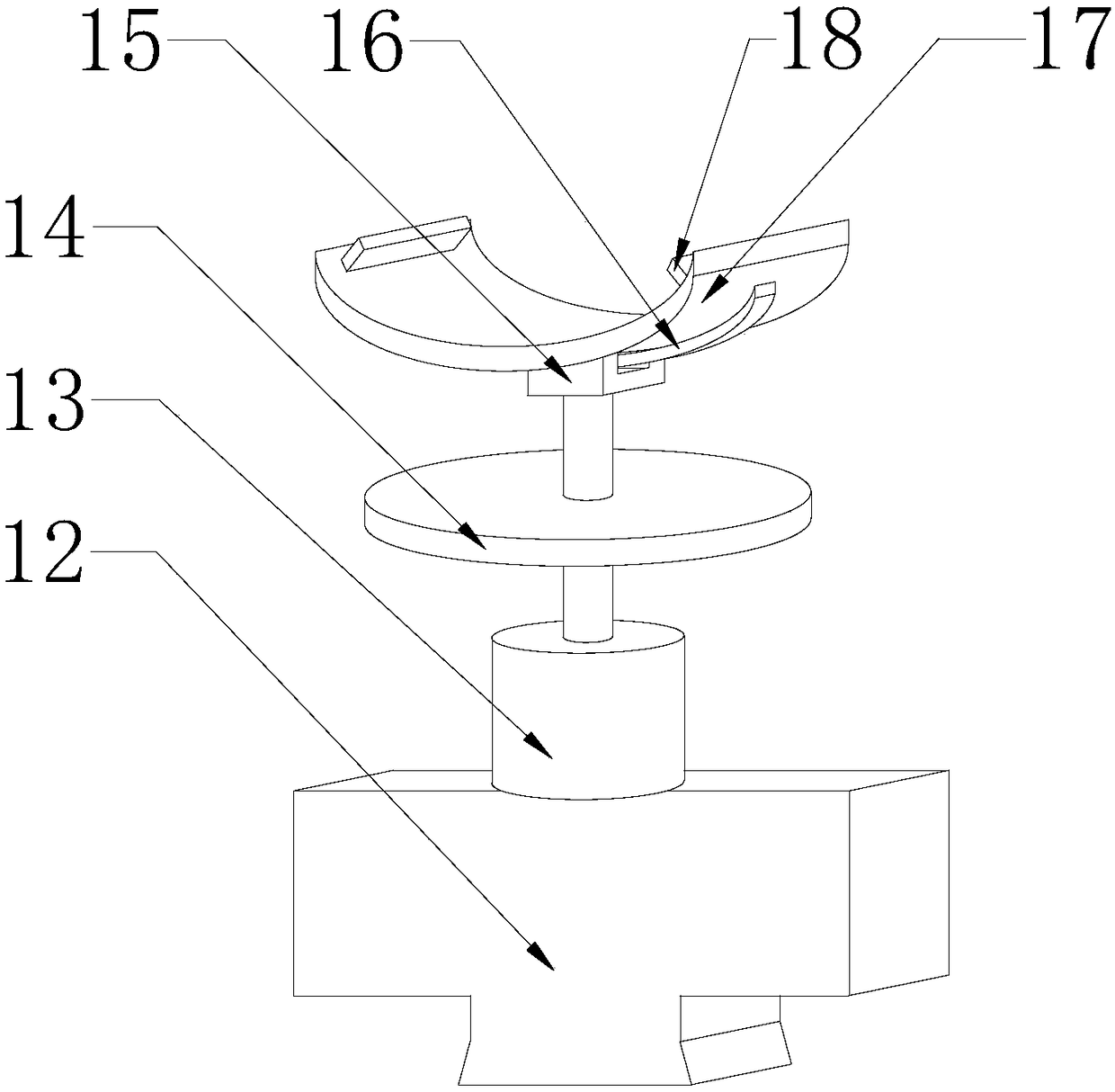

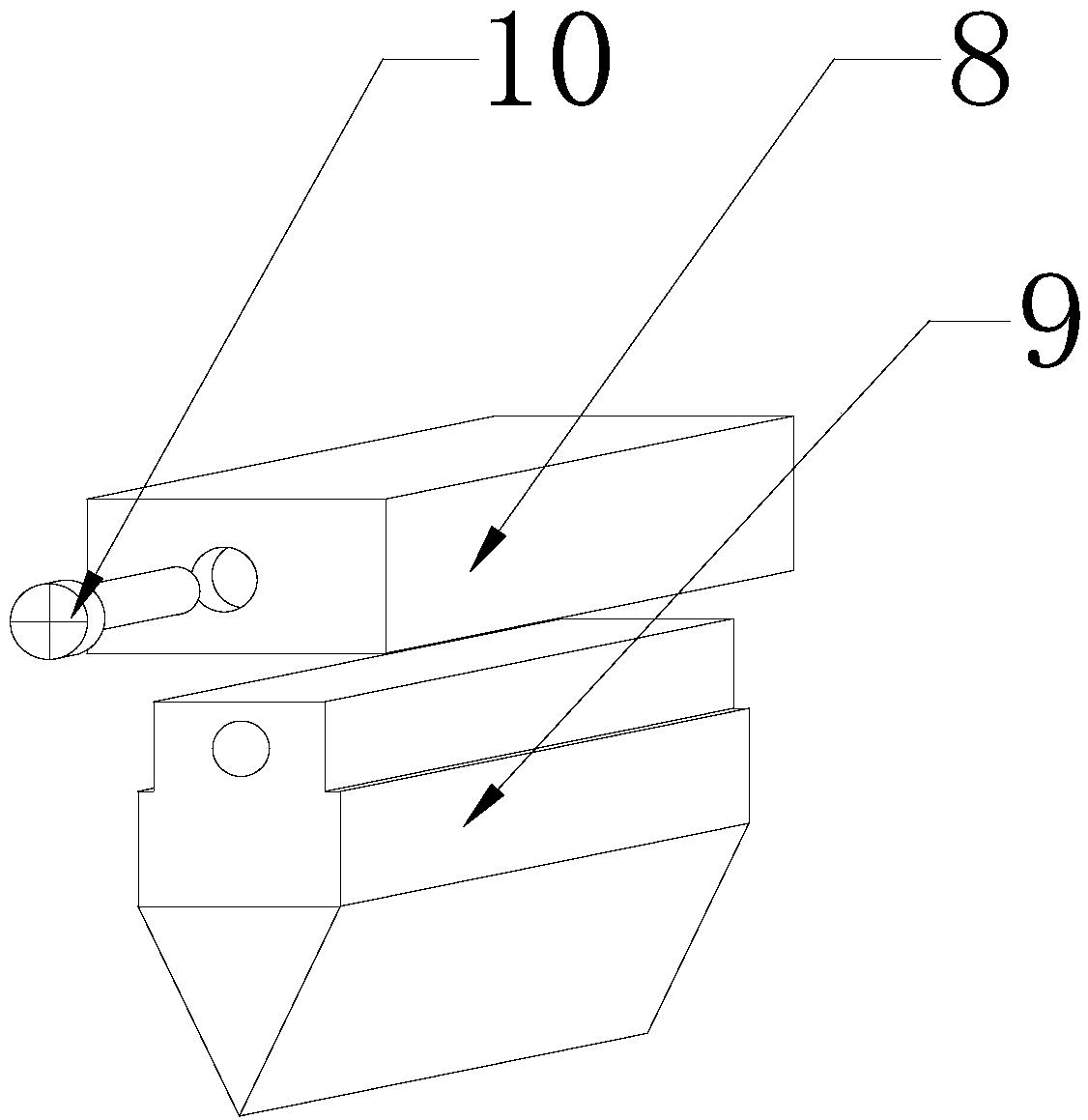

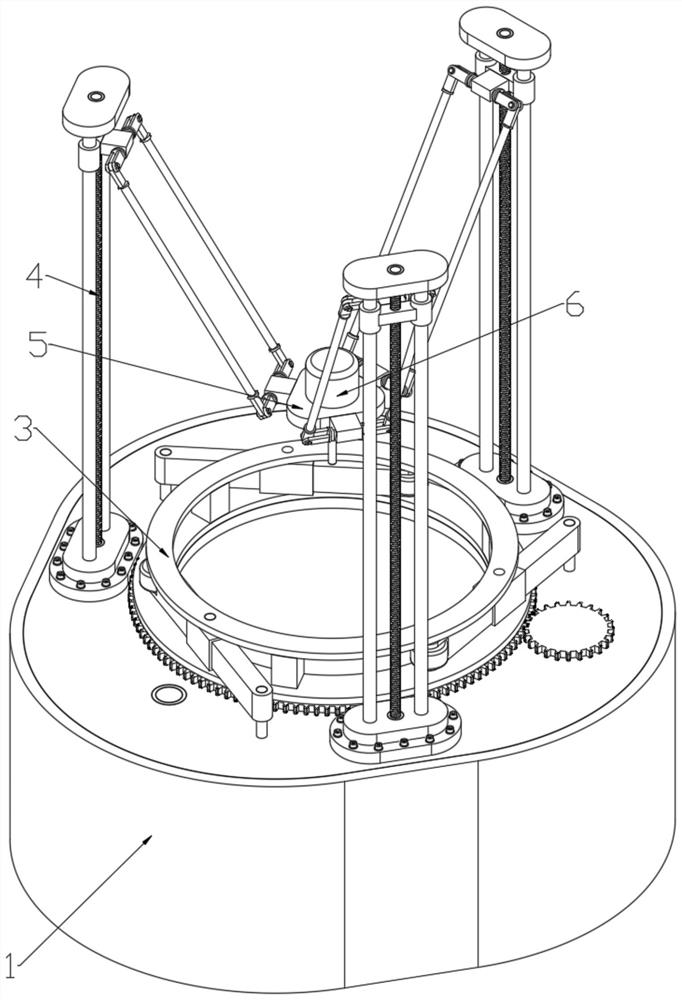

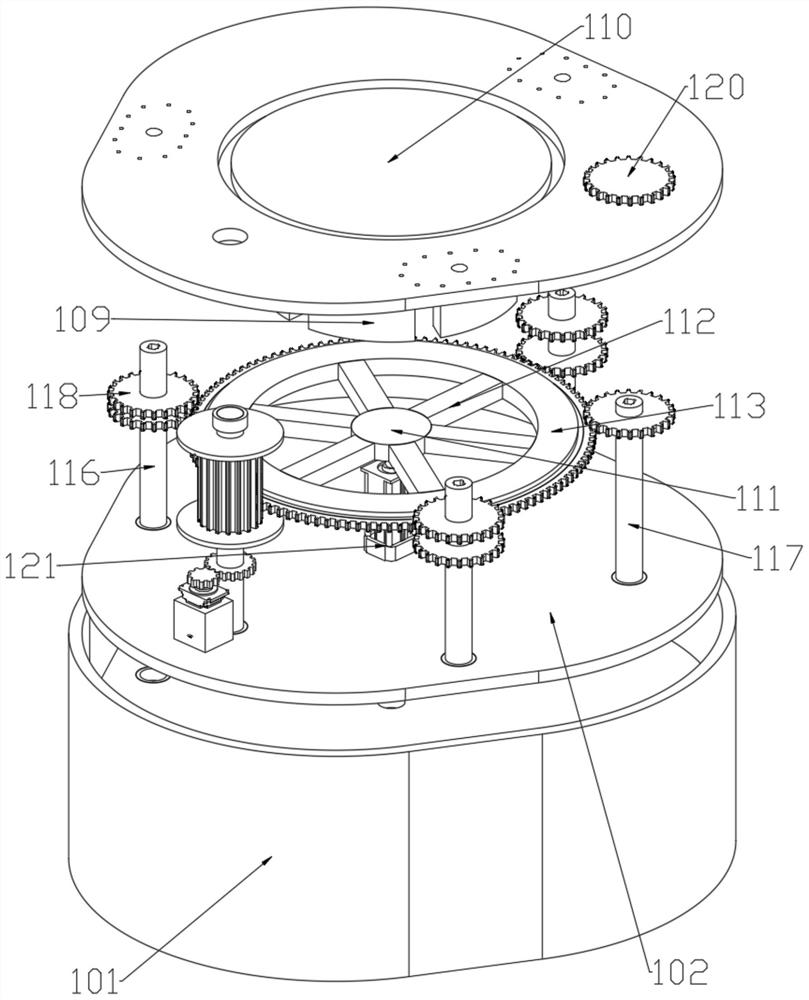

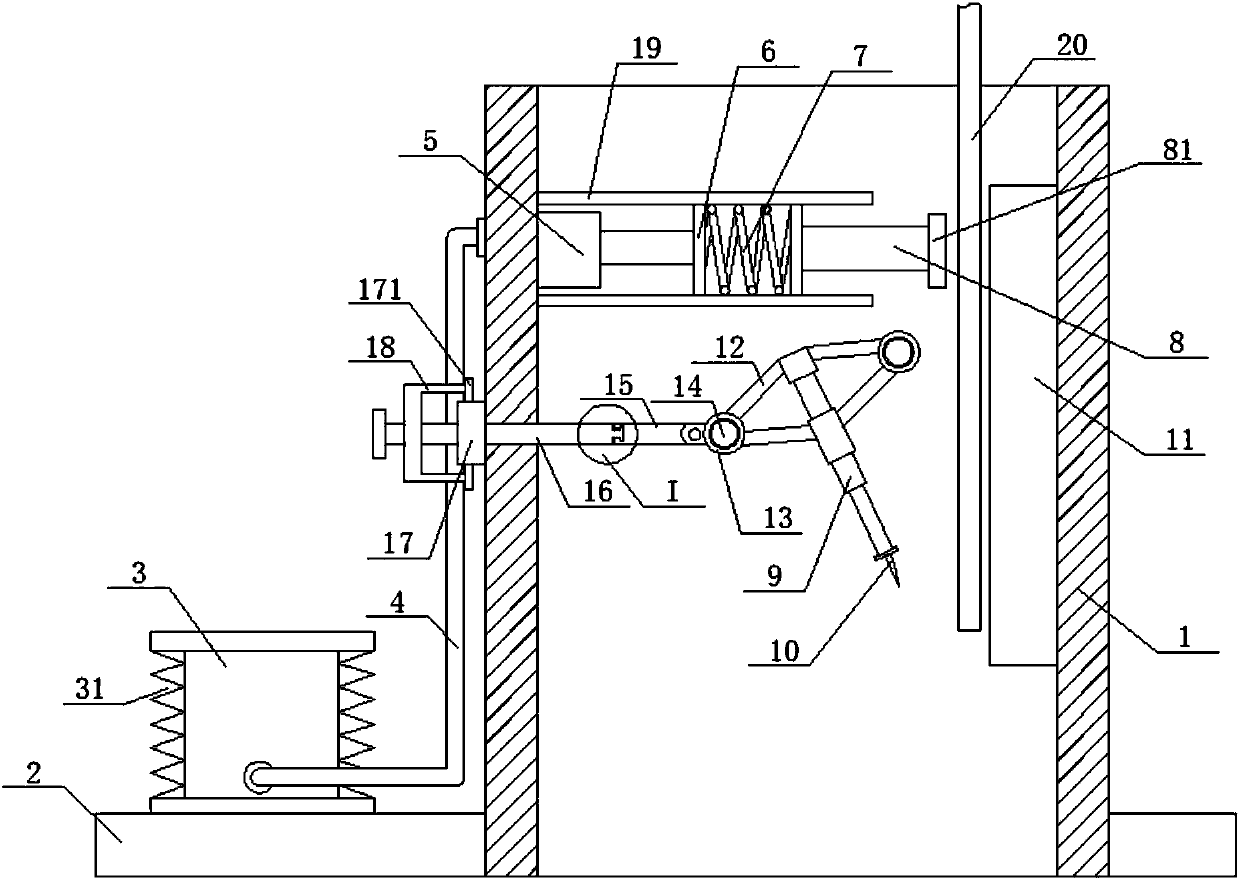

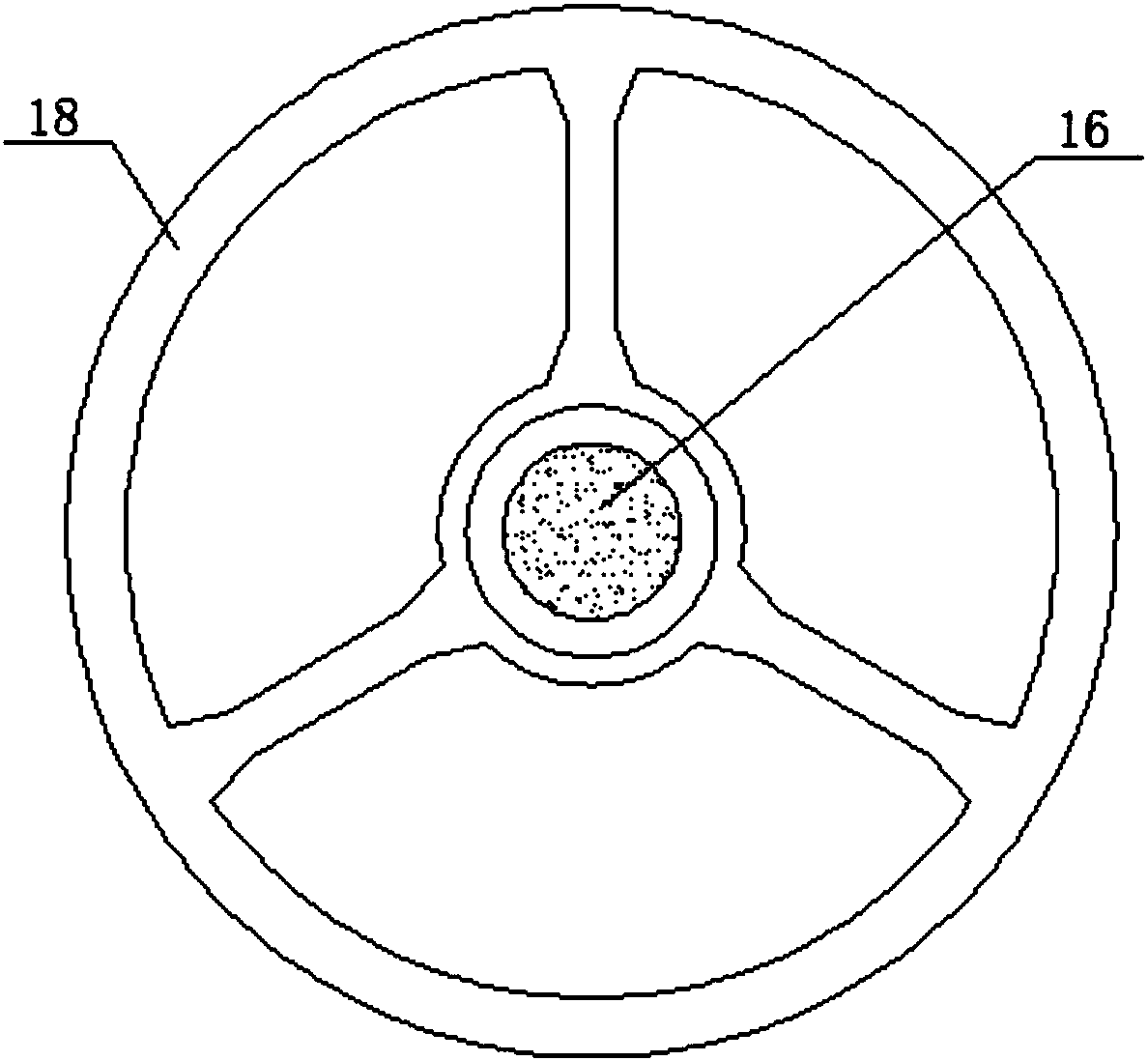

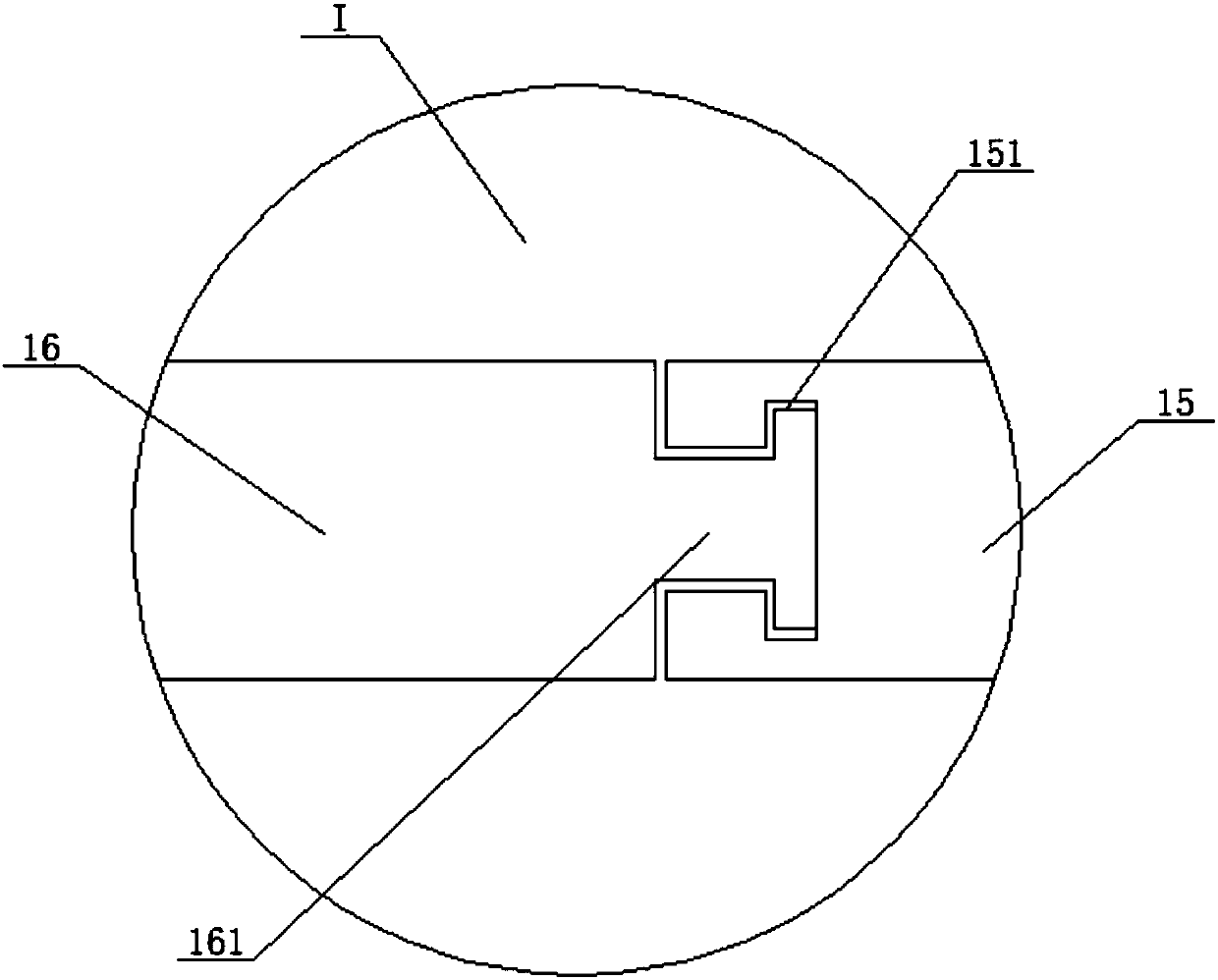

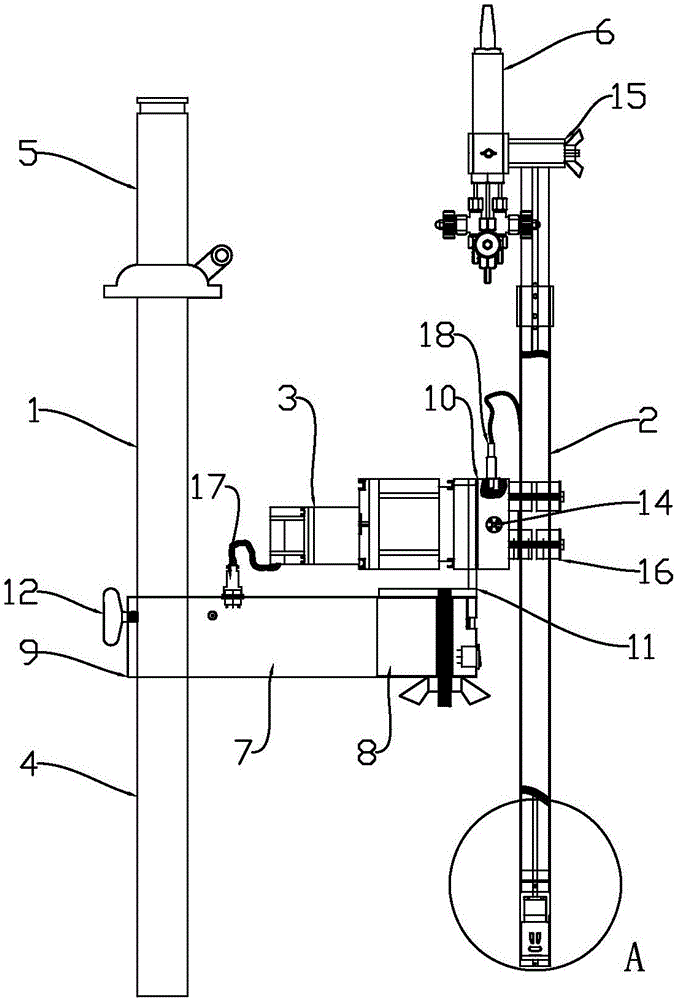

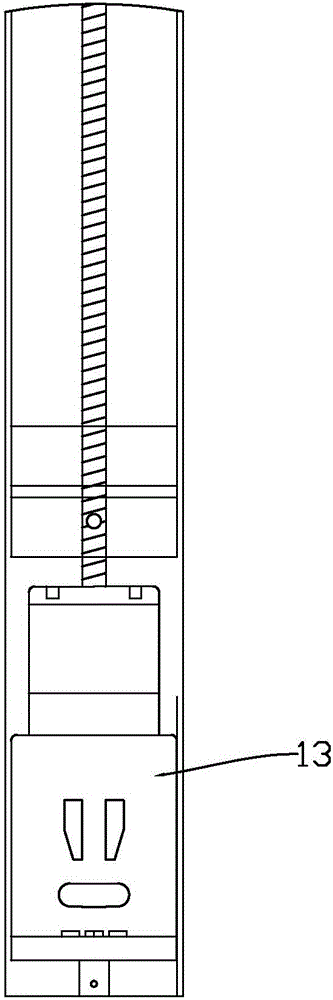

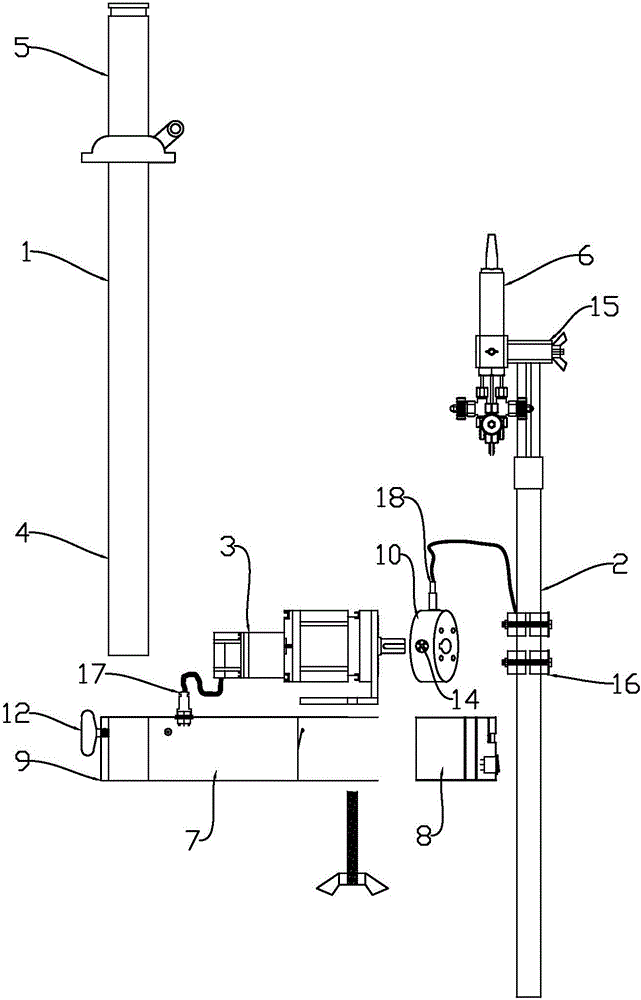

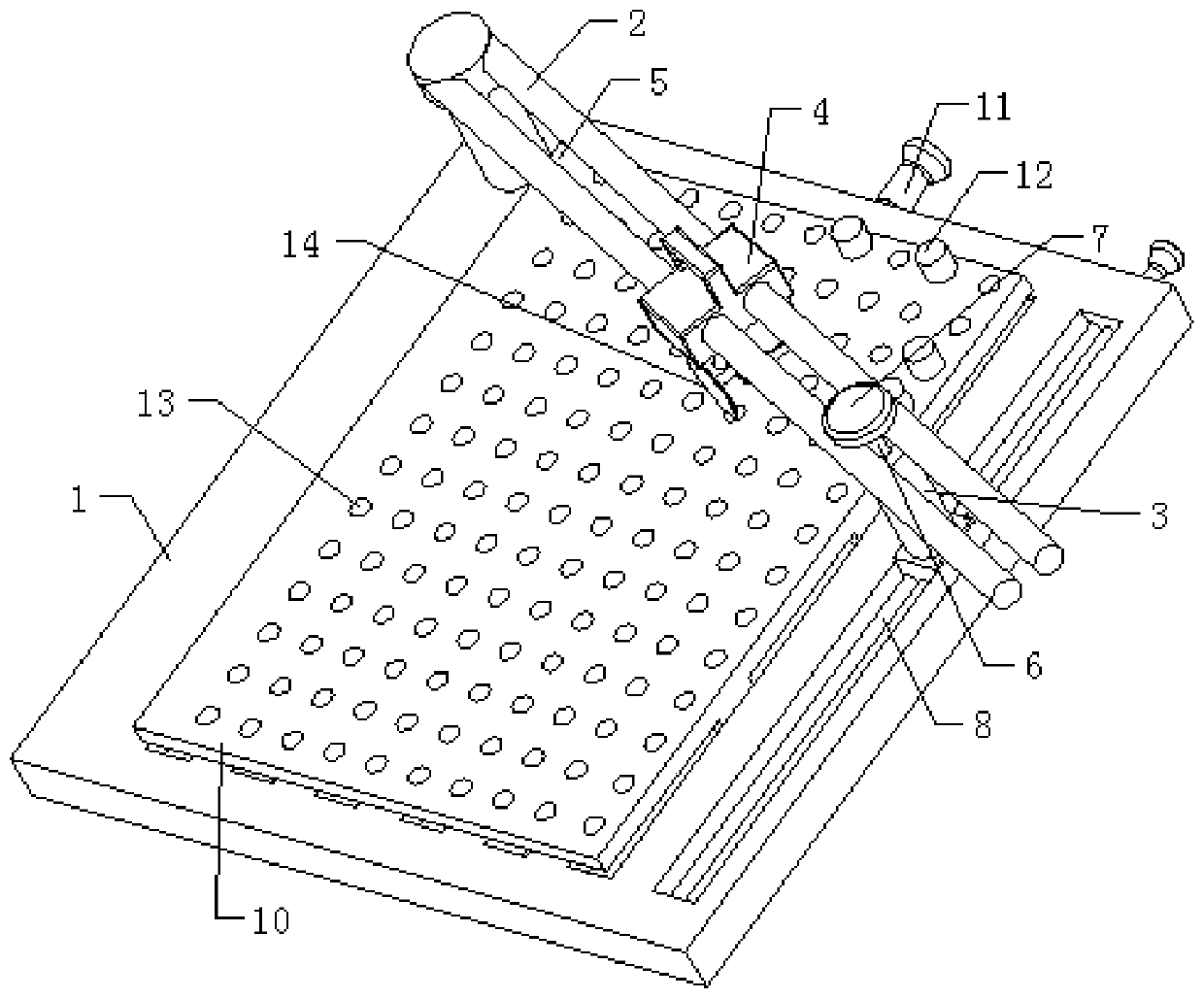

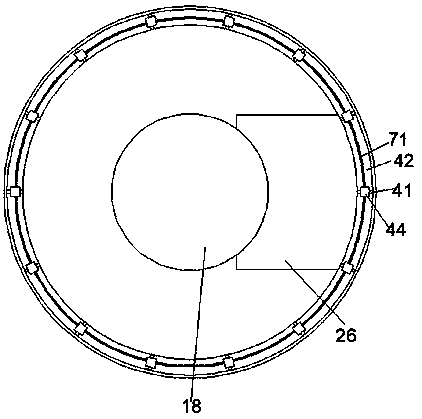

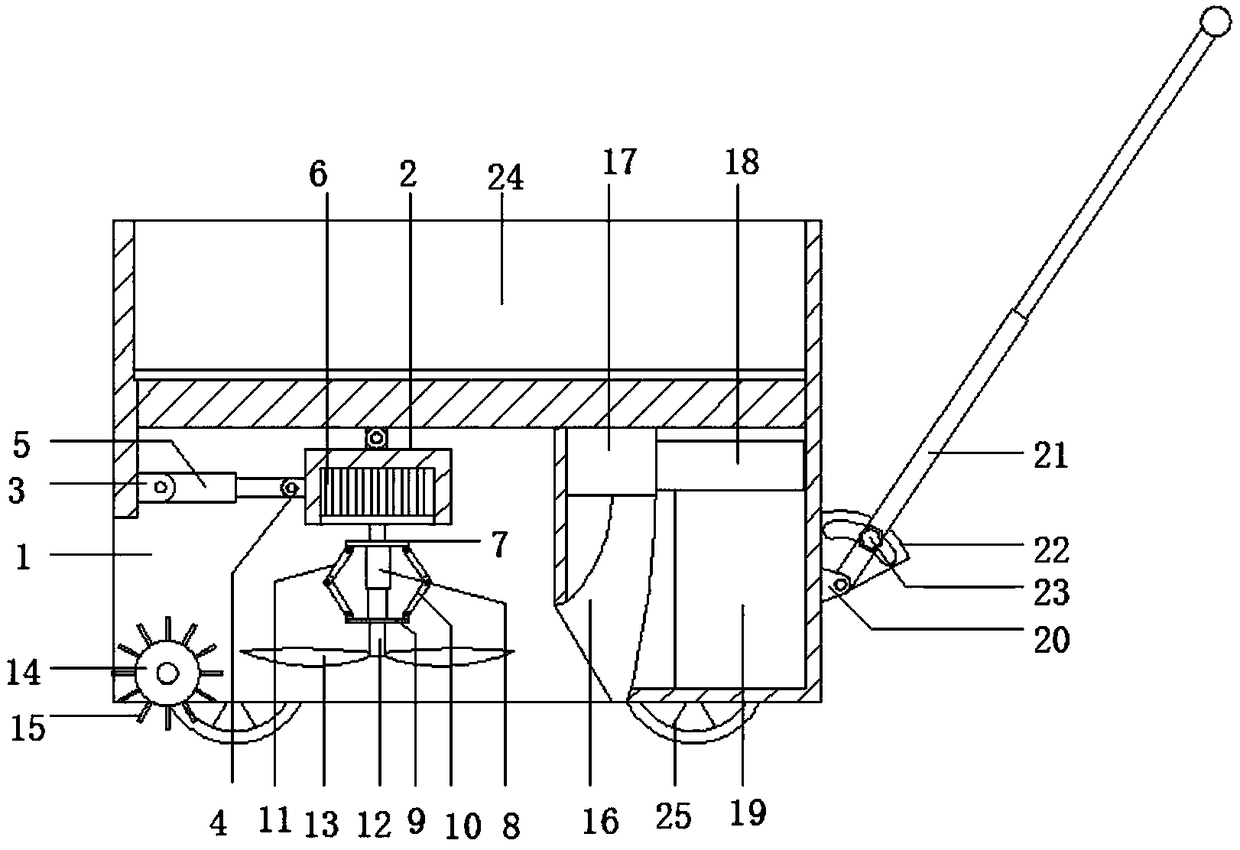

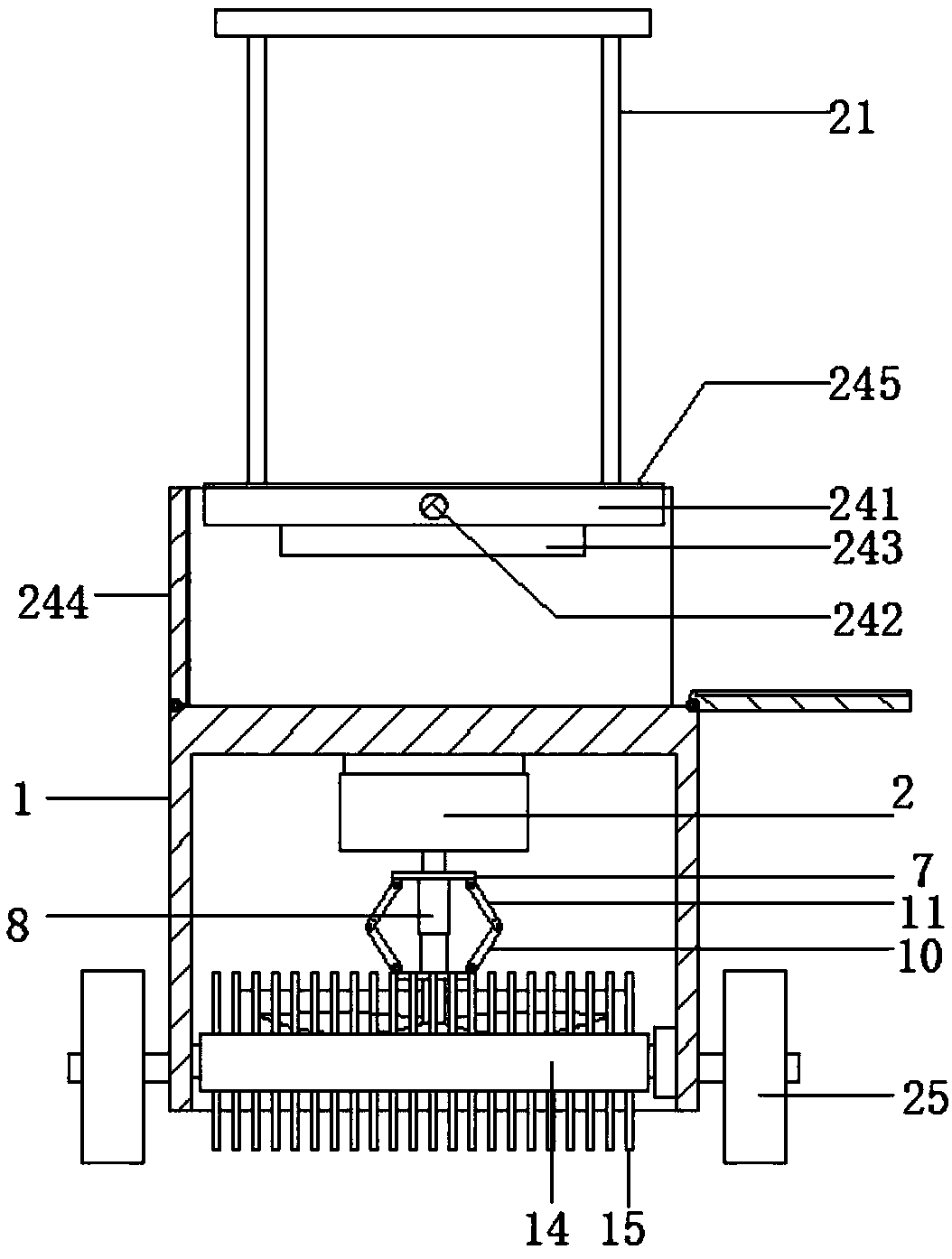

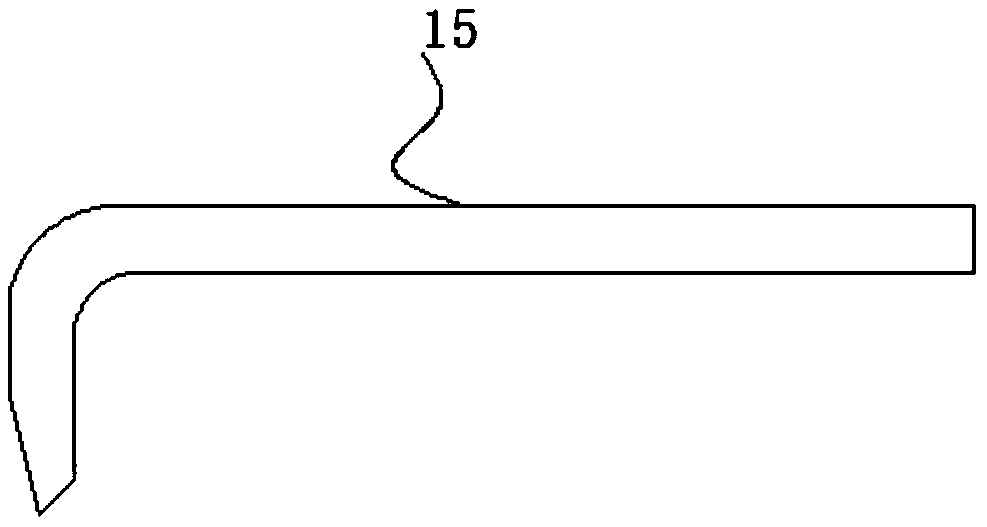

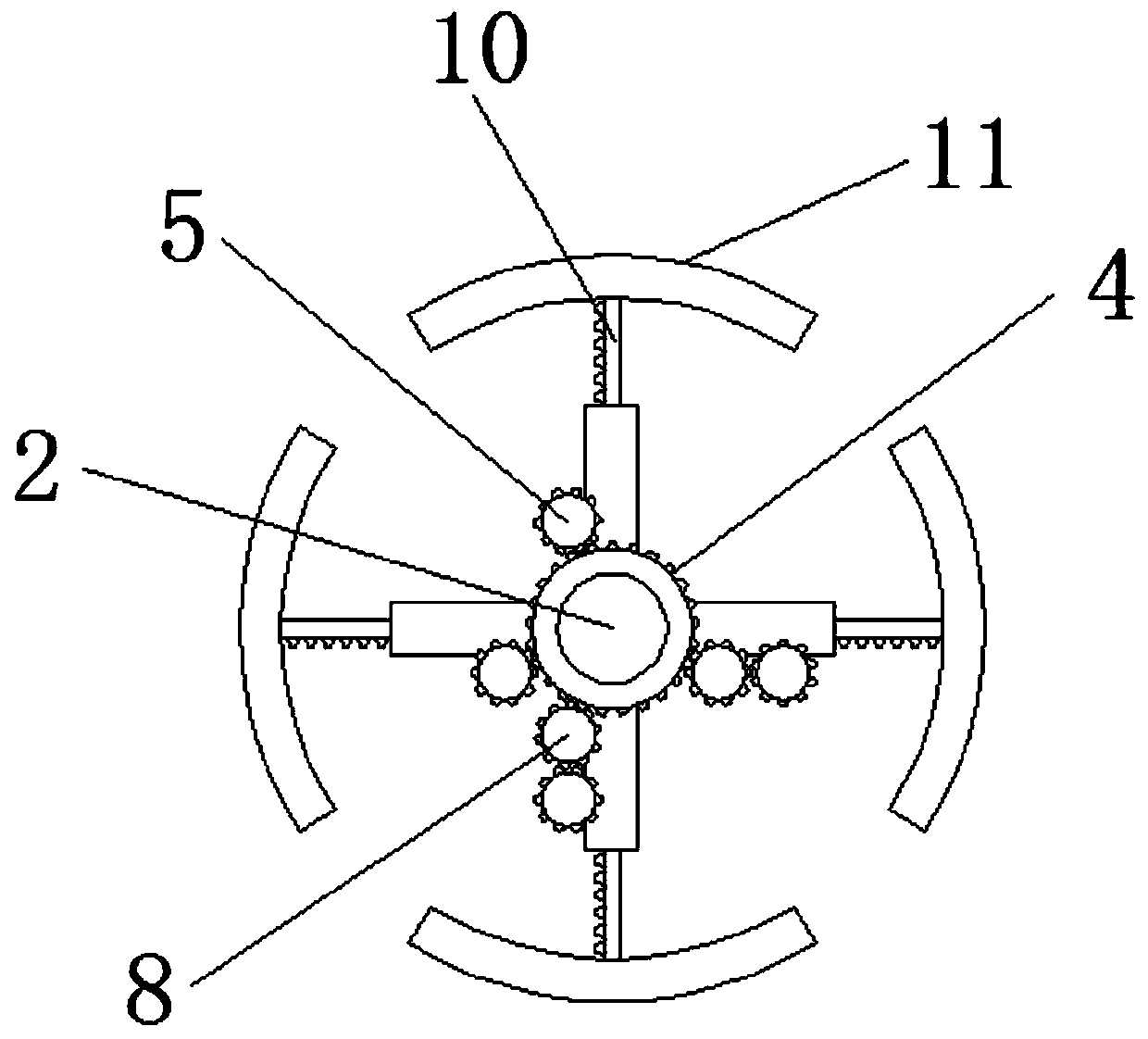

Automatic pruning device for poplars

The invention relates to an automatic pruning device for poplars. The automatic pruning device comprises a climbing mechanism, a rotating mechanism and a pruning saw executing mechanism, wherein the climbing mechanism integrates a driving function and a compression function, wheels are enabled to tightly press the tree trunk, meanwhile, the required motive power is provided for the machine climbing, the rotating mechanism is fixedly arranged at the upper part of the climbing mechanism through a connection support rod, the whole cycle of rotation around the tree trunk is realized, the pruning saw executing mechanism is fixedly arranged on the rotating mechanism, a pruning saw motor and a disk saw realize the feeding in the radial direction under the effect of an electric push rod, the required pruning position is reached, a pruning saw rotates at high speed to realize the sawing along the lateral direction of branches, and the pruning operation is completed. The automatic pruning device for poplars has the advantages that the structure is simple, the operation is convenient, the positioning is accurate, in addition, the automation degree of the pruning is high, the manual direct participation is not needed, and the safety is good. The pruning near the trunk can be realized, the length of small branch piles is favorably reduced, the dead knot is reduced, and the wood quality is improved.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

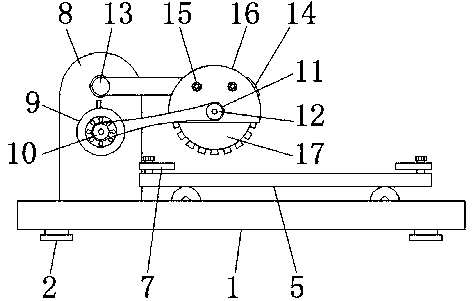

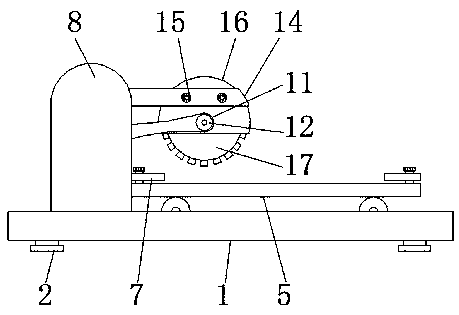

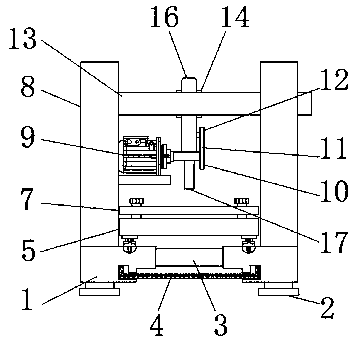

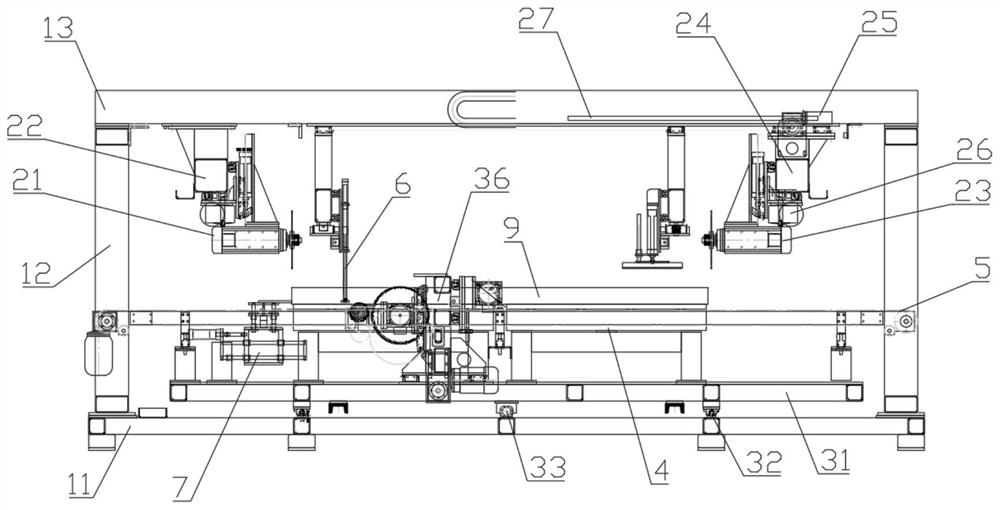

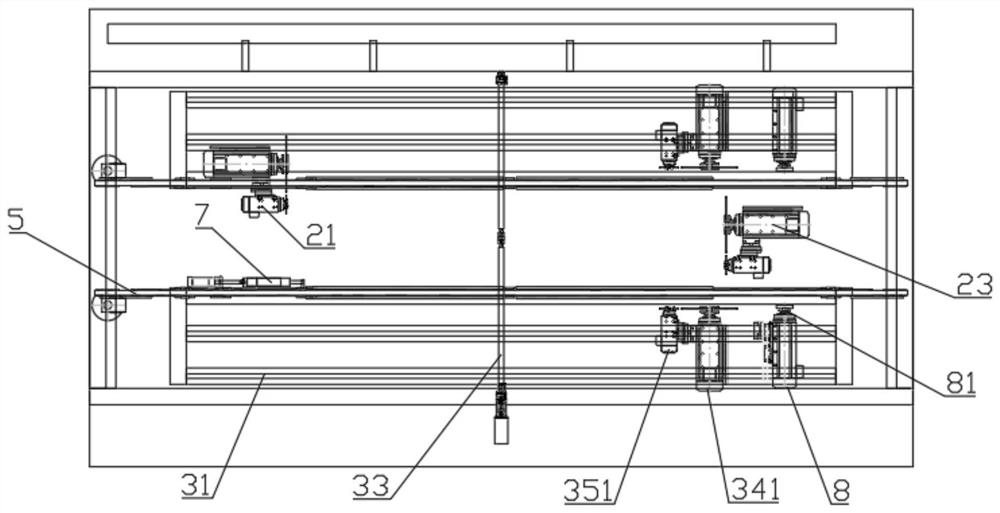

Dual-cutter dual-angle fixed-length crank cutting device

InactiveCN103568061AContinuously adjustable cutting lengthReduce wasteMetal working apparatusCrankControl cell

A dual-cutter dual-angle fixed-length crank cutting device is formed by two groups of cutting units, two groups of compacting units, two synchronous moving worktables, two groups of cutter heating units, a preheating heat, a conveying unit, a rack and a control unit; angles of cutting blades of the cutting units and the intervals of the moving worktables are adjustable; the cutting units, the compacting units and the cutter heating units are respectively mounted at table surfaces of the two synchronous moving worktables; the moving table surfaces are connected with the rack by linear guide tracks. The preheating unit is fixed on one synchronous worktable and moves along with the worktable. The conveying unit is fixedly connected onto the other synchronous moving worktable and moves together along with the worktable. The preheating unit and the conveying unit are fixedly connected with the rack. Cooperative actions of all the units are controlled by the control unit, the dual-cutter dual-angle fixed-length crank cutting device realizes the online automatic cutting of plastic linear section bars with the fixed length at 45-90 degrees, and the cutting length ranges from 600mm to 3100mm.

Owner:上海海弋机电科技有限公司

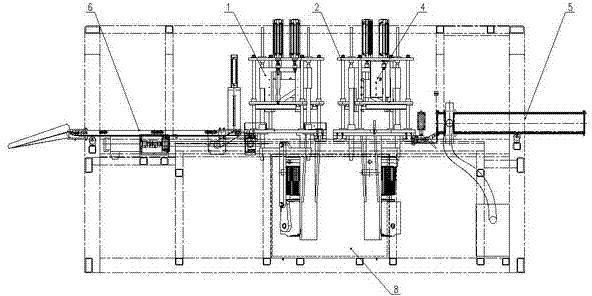

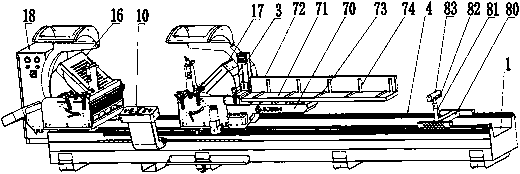

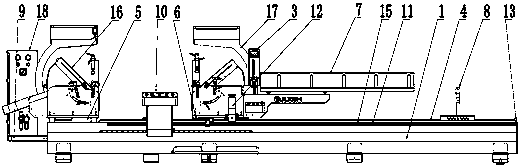

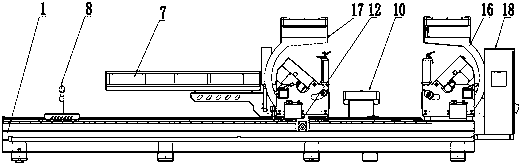

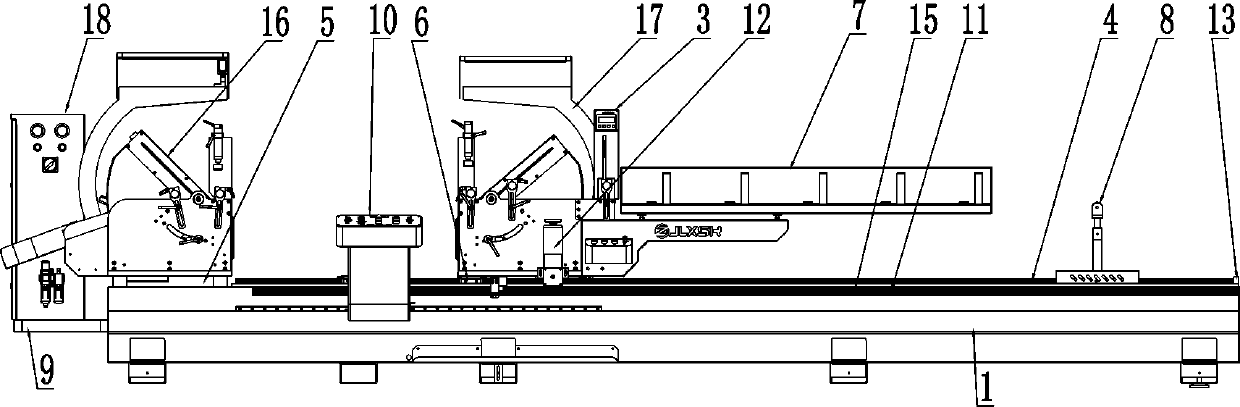

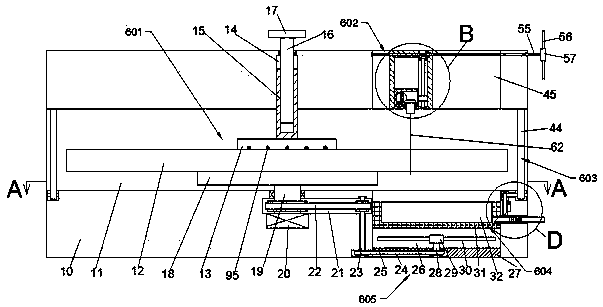

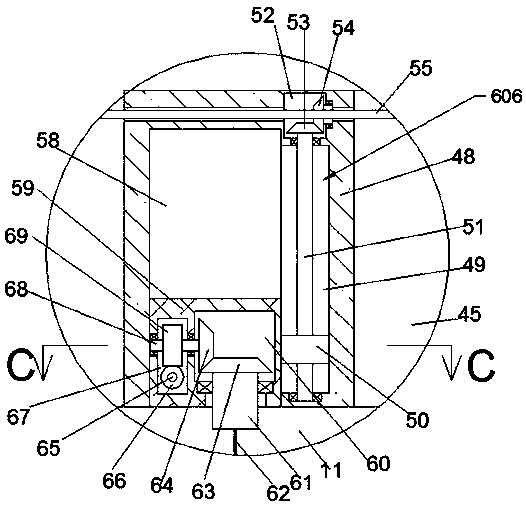

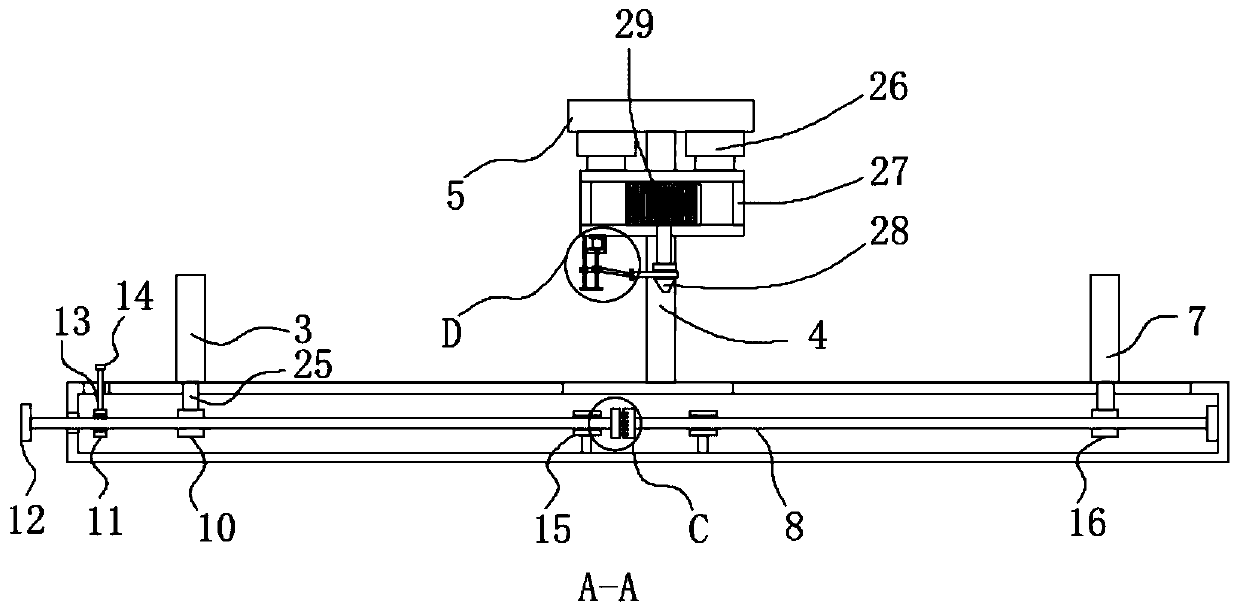

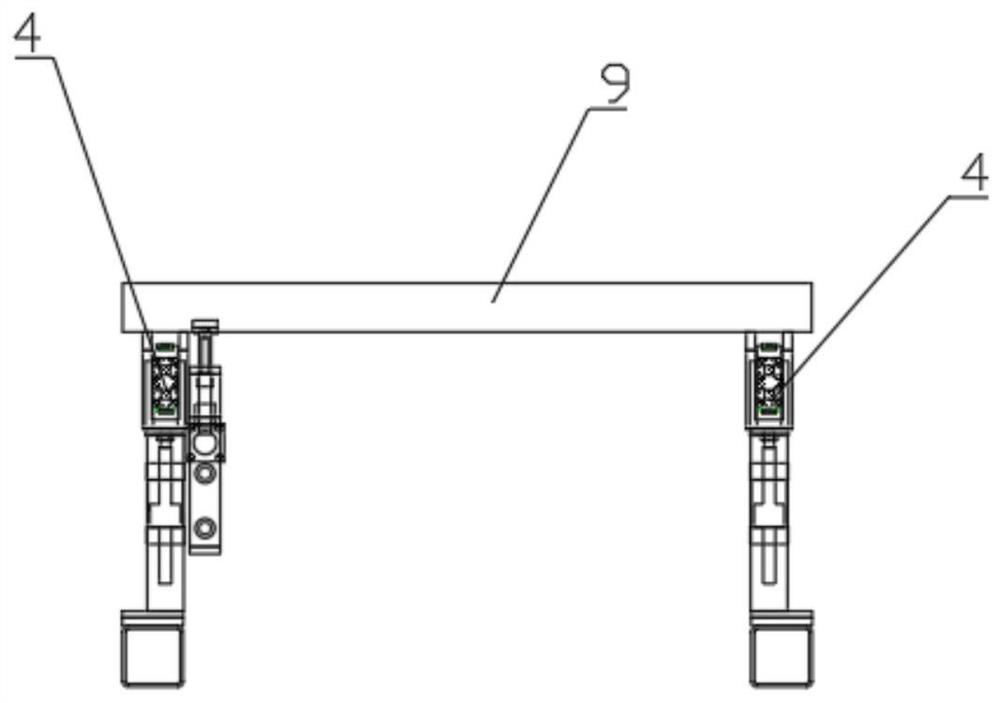

Double-ended saw cutter

InactiveCN110434396AAdjustable cutting angleChange cutting lengthMetal sawing devicesMetal sawing accessoriesEngineeringMechanical engineering

The invention discloses a double-ended saw cutter. The double-ended saw cutter comprises a horizontal type lathe rack, wherein a linear horizontal rail is arranged on the top of the horizontal type lathe rack; a slide base is arranged on the linear horizontal rail in a sliding mode; a fixed base is fixedly arranged at the left end of the horizontal type lathe rack; a transmission frame is jointedto the outer side of the horizontal type lathe rack; a transmission rack is arranged in the transmission frame; two groups of saw blade cutting units are oppositely arranged on the horizontal type lathe rack left and right; a height measuring device and a supporting frame are arranged at the right side of the slide base; a movable rack can be arranged on the right part of the linear horizontal rail in a sliding mode, and is opposite to the supporting frame horizontally; a drive device is arranged at the outer side of the slide base; and the transmission rack drives the slide base to slide leftand right on the linear horizontal rail. The double-ended saw cutter has the characteristics of being compact and scientific in structure, being adjustable in cutting angle of a saw blade cutting assembly, being capable of supporting relatively long section bar workpieces, being adjustable in cutting length of section bar workpieces, and being capable of measuring top side length parameters of the section bar workpieces on line; and the saw blade cutting assembly does not have intermediate transmission link, is high in transmission efficiency, and facilitates energy conservation and environment protection.

Owner:佛山市金立星机械设备有限公司

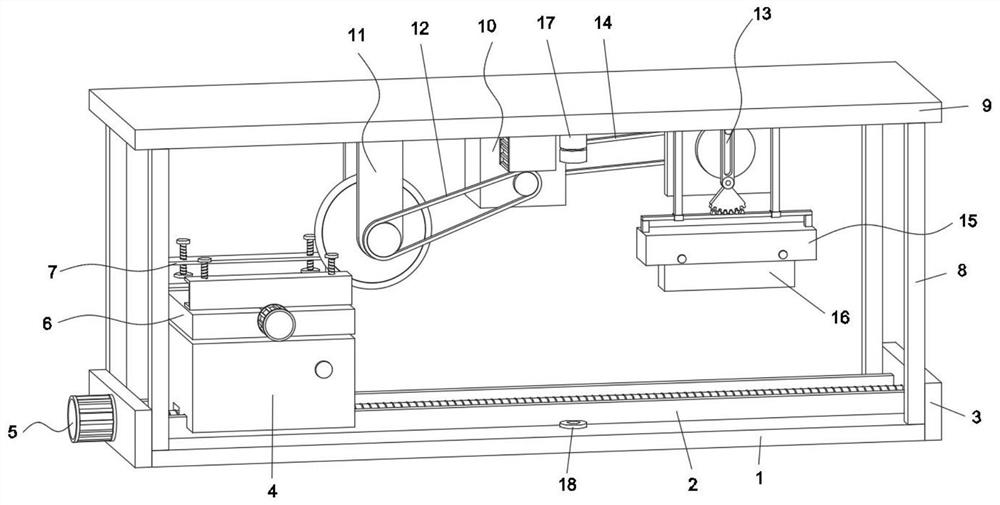

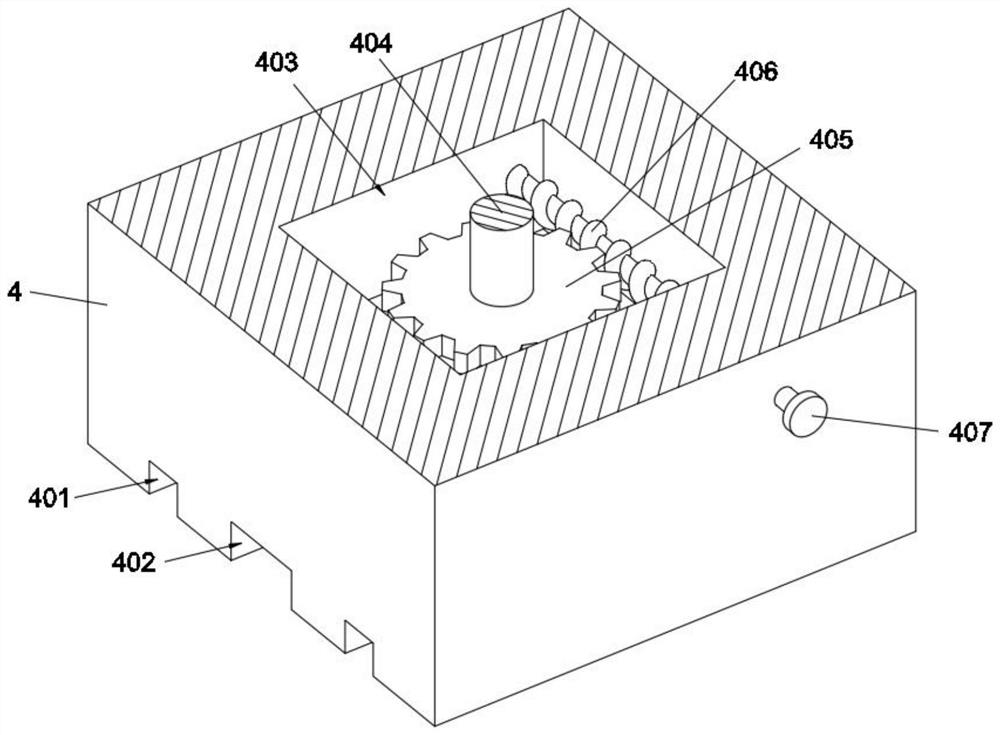

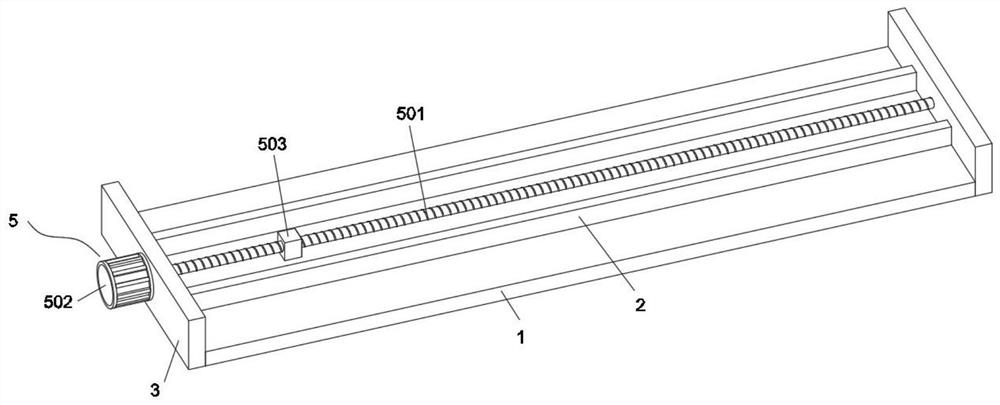

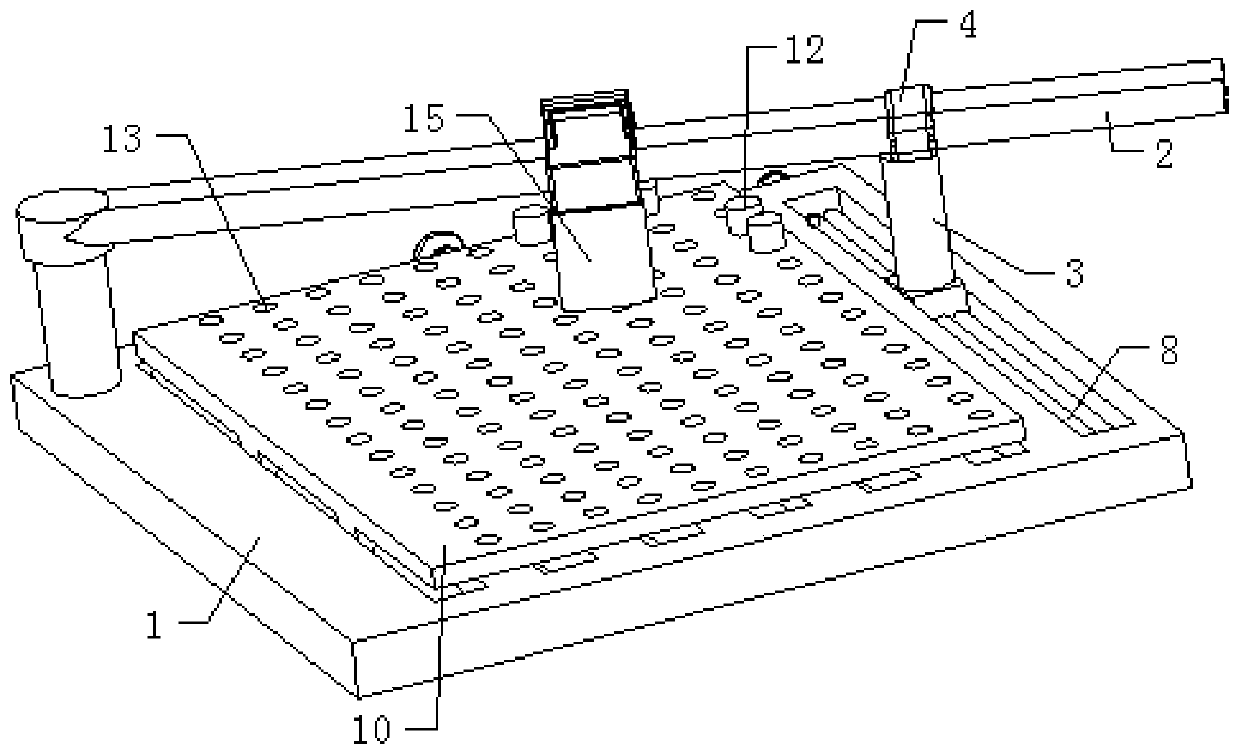

Plate cutting machine and cutting method

InactiveCN111843502AAdjustable cutting angleMeet different cutting needsOther manufacturing equipments/toolsLaser transmitterElectric machinery

The invention relates to the technical field of plate machining equipment, in particular to a plate cutting machine and a cutting method. The plate cutting machine comprises a bottom plate, wherein aguide rail is arranged on the top wall of the bottom plate, side plates are fixed to the two sides of the bottom plate, a workbench slidably is arranged on the guide rail, a driving assembly is arranged at the bottom of the workbench, a rotating table is arranged at the top of the workbench, a clamping assembly is arranged at the top of the rotating table, stand columns are fixed to the four corners of the top wall of the bottom plate, a top plate is fixed to the tops of the stand columns, a cutting assembly, a power assembly and a reciprocating assembly are sequentially arranged on the bottomwall of the top plate, a mounting block is fixed to the bottom of the reciprocating assembly, a grinding block is clamped to the bottom of the mounting block, a laser transmitter is fixed to the bottom wall of the top plate, and a laser receiver is fixed to the upper wall of the bottom plate. When the plate cutting device is used, the cutting angle of plates can be adjusted, the plates of different sizes can be clamped within a certain range, the application range is wide, the arranged power assembly can drive the cutting assembly and the reciprocating assembly to work, the use number of motors is reduced, energy consumption is reduced, and meanwhile the grinding block is convenient to replace.

Owner:成都毅莘瑞科技有限公司

Steel structure fabricated building material machining machine capable of cutting and grinding welding balls

InactiveCN108032087AAvoid the danger of injuryAdjustable cutting angleOther manufacturing equipments/toolsPositioning apparatusSteel platesBuilding material

The invention relates to a steel structure fabricated building material machining machine capable of cutting and grinding welding balls. The steel structure fabricated building material machining machine comprises a supporting bottom plate, a cutting device and a supporting grinding device. The cutting device is mounted at the top of the right end of the supporting bottom plate. The supporting grinding device is connected with the upper end face of the left side of the supporting bottom plate. The cutting device comprises a cutting supporting plate, a cutting electric sliding rail, cutting electric sliding blocks, a cutting supporting telescopic rod, a cutting angle push rod, a cutting mechanism, a supporting mechanism, a rotary motor, a rotary supporting plate, four rotary supporting rods, a rotary sliding groove and a cutting supporting spring. According to the steel structure fabricated building material machining machine, the problems that during existing welding ball machining, the cutting angle cannot be adjusted for cut and extruded steel plates, effective fixing cannot be achieved during cutting, the cutting effect is poor, and cut ball bodies need to be manually ground canbe solved; and the functions of carrying out multi-fixing during steel plate cutting and cutting and grinding the steel plates can be achieved.

Owner:吴丹

Steel structure assembly type building material producing and processing processor

InactiveCN108000161ASupport fixed and stableAutomatic grindingOther manufacturing equipments/toolsSteel platesBuilding material

The invention relates to a steel structure assembly type building material producing and processing processor. The steel structure assembly type building material producing and processing processor comprises a supporting bottom plate, a fixed device, an extruding device, a conversion device, a correcting device, a carrying device, a cutting device and a supporting grinding device, wherein the fixed device is mounted at the right end of the supporting bottom plate; the extruding device is connected with the right end of the conversion device; the conversion device is mounted on the supporting bottom plate; both the correcting device and the carrying device are mounted on the conversion device; the correcting device is positioned at the right side of the carrying device; the cutting device is mounted on the middle part of the supporting bottom plate; and the supporting grinding device is connected with the upper end surface of the left side of the supporting bottom plate. The steel structure assembly type building material producing and processing processor can solve the problems that all-around leveling cannot be performed when a steel plate is extruded, the extruded steel plate cannot be corrected, a cutting angle of the cut and extruded steel plate cannot be regulated, the cutting effect is poor, a cut ball body needs to manually grind, and the like during welding ball processing in the prior art.

Owner:黄远明

Cutting equipment for processing mechanical accessories

InactiveCN111570892AEasy to processImprove cooling effectShearing machinesMaintainance and safety accessoriesEngineeringKnife blades

The invention belongs to the technical field of cutting equipment, and particularly relates to cutting equipment for processing mechanical accessories. In allusion to the problems that an existing cutting device is bulky and extremely inconvenient to use, a blade is inconvenient to cool, and the service life of the blade is shortened, a solution is proposed as follows. The cutting equipment comprises a processing plate, two longitudinal drive mechanisms are arranged at the top of the processing plate, vertical plates are arranged on the two longitudinal drive mechanisms, and a same lifting plate is slidably installed between the two vertical plates; a horizontal drive structure is arranged at the bottom of the lifting plate, the horizontal drive structure is connected with a fixed frame, and a cutting structure and a cooling structure are arranged on the fixed frame; a dust board is arranged on the fixed frame, a rotating structure is arranged at the top of the processing plate, the rotating structure is connected with a placement box, and a plurality of negative pressure pipes communicate with the top of the placement box. The cutting equipment is convenient to operate and small in size, the blade is convenient to cool, and the service life of the blade is prolonged.

Owner:杨明清

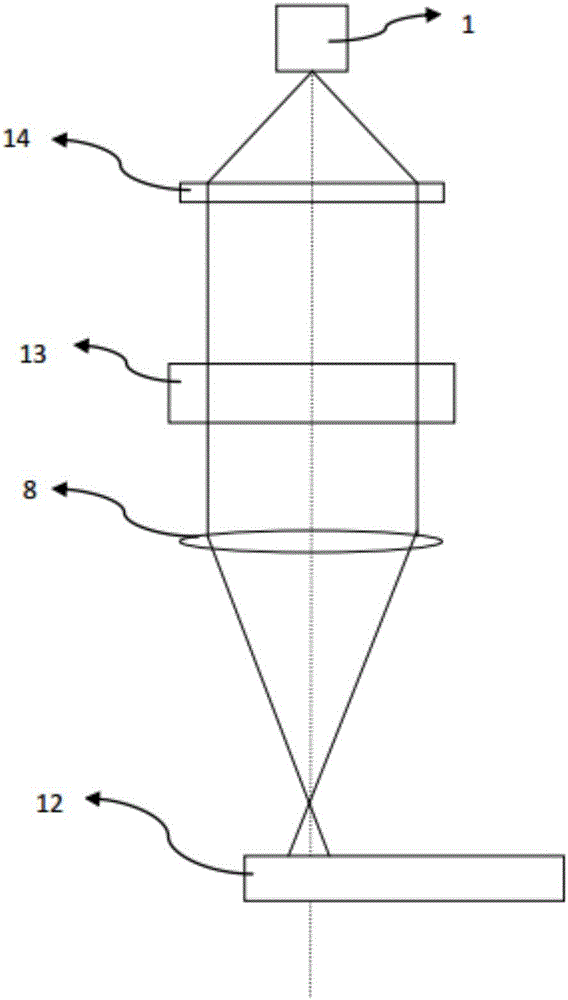

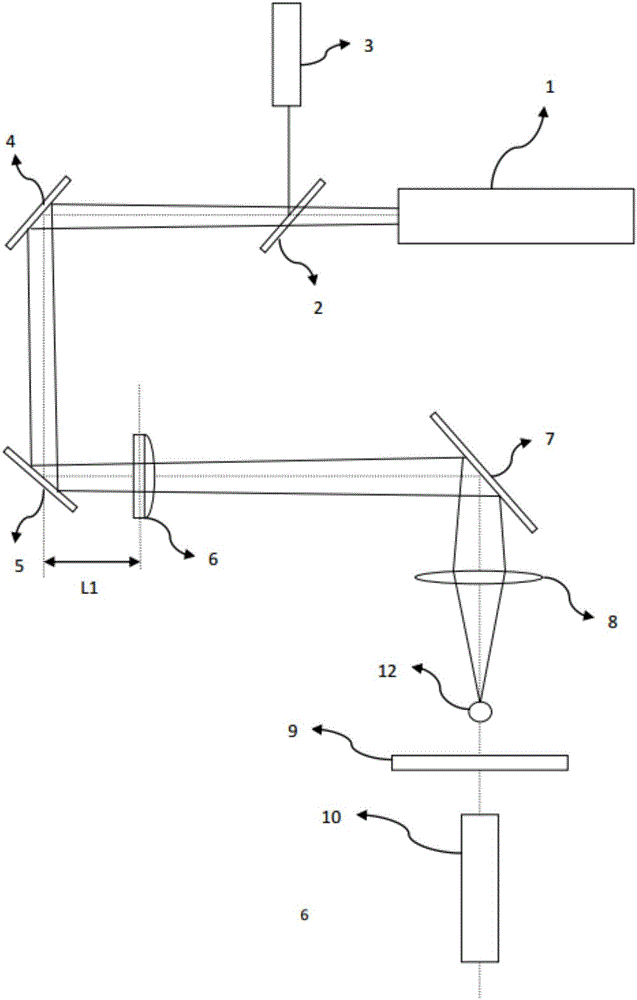

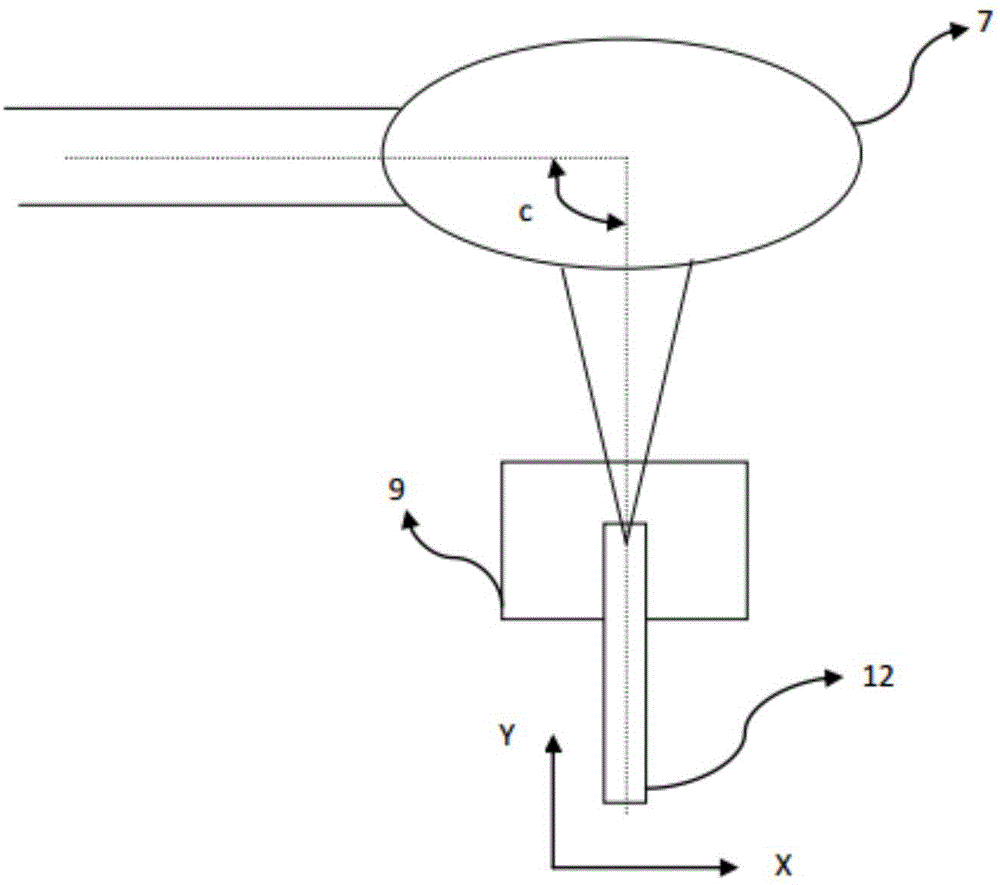

Device and method for cutting optical fiber through laser

InactiveCN106563881AReduce pollutionAvoid pollutionLaser beam welding apparatusOptical axisLight beam

The invention relates to the technical field of laser cutting, in particular to a device and method for cutting an optical fiber through a laser. The device comprises a working laser source, a first reflecting mirror, a second reflecting mirror, a third reflecting mirror and a focusing mirror. A 45-degree included angle is formed between the optical axis of the laser output through the working laser source and the first reflecting mirror. The first reflecting mirror is perpendicular to the second reflecting mirror, and the reflecting surface of the first reflecting mirror and the reflecting surface of the second reflecting mirror correspond to each other. The third reflecting mirror is located at the backward stage of the second reflecting mirror. After being subjected to transition beam expanding through the first reflecting mirror and the second reflecting mirror, the laser output through the working laser source is reflected through the third reflecting mirror and focused to the to-be-processed optical fiber through the focusing mirror. Laser beam shaping and precise processing angle control are achieved through the combination of the first reflecting mirror, the second reflecting mirror, the third reflecting mirror, a shaping cylindrical mirror and the focusing mirror, and the end surface shape of the optical fiber is precisely controlled by adjusting the included angle b of the third reflecting mirror as well as the distance L2 between the focusing mirror and the third reflecting mirror, so that the end surface notch angle of the optical fiber is adjustable.

Owner:WUHAN LINGYUN PHOTOELECTRONICS SYST

Numerical control cutting machine capable of rapidly changing cutter

InactiveCN108340022AAdjustable cutting anglePrevent affecting cutting accuracyLarge fixed membersPositioning apparatusNumerical controlPulp and paper industry

The invention discloses a numerical control cutting machine capable of rapidly changing a cutter. The numerical control cutting machine comprises a main body and a motor, wherein a base is fixed at the lower end of the main body, a portal frame is fixed on the two sides of the upper surface of the base, a transverse driving lead screw is connected to the upper end of the inner side of the portal frame, a movable block sleeves the surface of the transverse driving lead screw, a lifting air cylinder is fixedly arranged at the lower end of the movable block, the lower end of the lifting air cylinder is connected with a cutting motor, a cutting head is fixedly arranged below the cutting motor, a cutting knife is embedded in the bottom surface of the cutting head, a fixing screw rod is insertedinto the cutting head, and a longitudinal sliding rail penetrates through the upper surface of the base. According to the numerical control cutting machine capable of rapidly changing the cutter, thecutting knife can be randomly replaced according to the cutting requirements of a workpiece, the cutting knife which meets the requirements is replaced, the fixing screw rod is inserted into the cutting knife, and the cutting knife and the cutting head are fixed, so that the flexibility and the application range are improved; and the numerical control cutting machine is suitable for production and use of the numerical control cutting machine capable of rapidly changing the cutter, and has a good development prospect.

Owner:宁波和丰人力资源服务有限公司

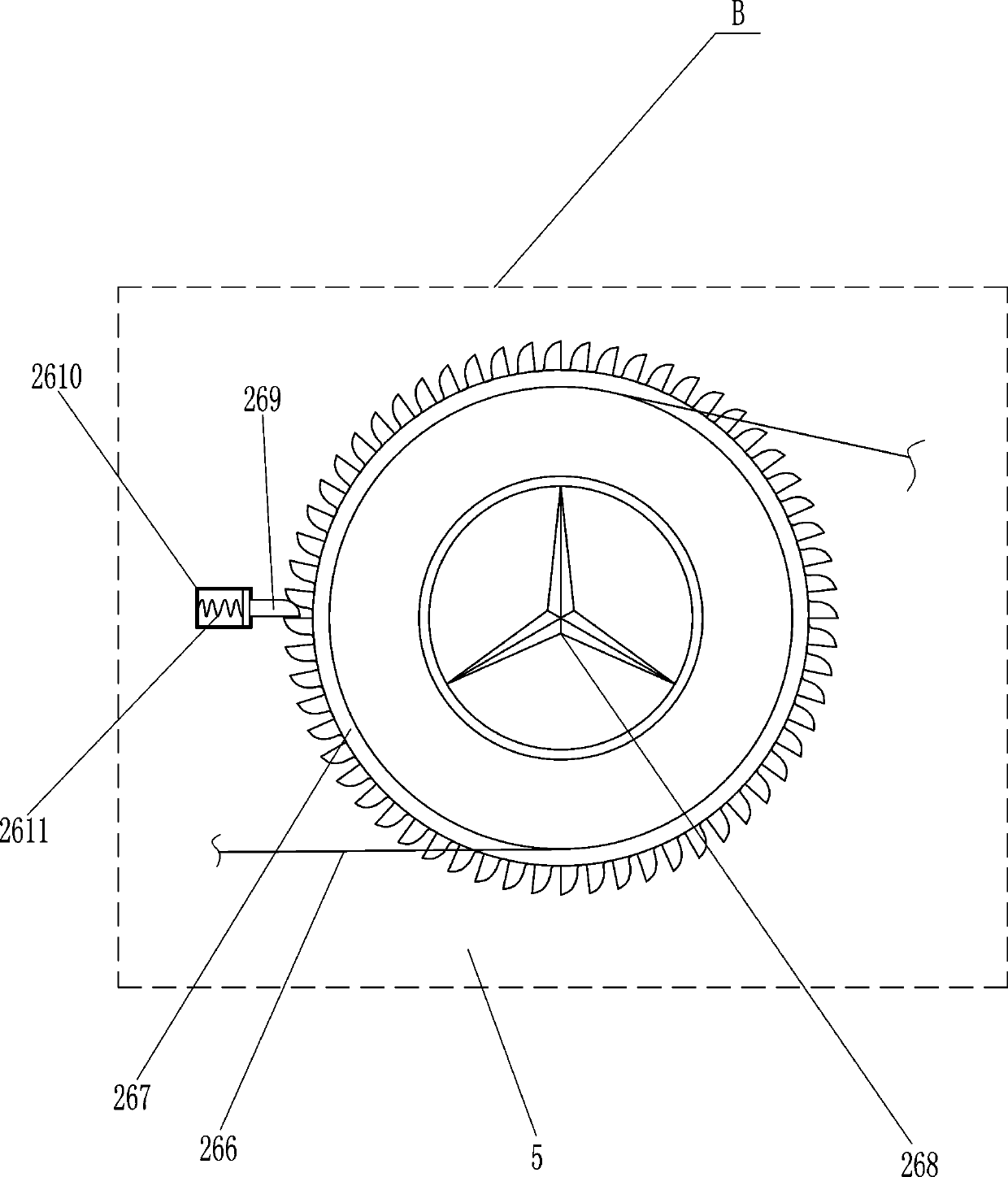

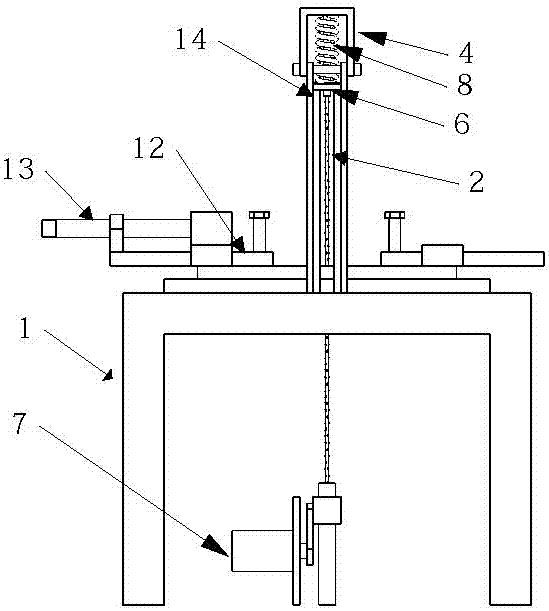

Cutting device for rectifier bridge support mold machining

InactiveCN114734140AHeight adjustableAdjustable distanceLaser beam welding apparatusStructural engineeringLaser cutting

The invention discloses a cutting device for rectifier bridge support mold machining, and particularly relates to the technical field of rectifier mold machining, the cutting device comprises a driving mechanism, four limiting mechanisms are arranged in the driving mechanism, a clamping mechanism is arranged at the center of the top end of the driving mechanism, and three adjusting mechanisms are annularly distributed on the outer ring of the clamping mechanism; the three adjusting mechanisms are all fixedly installed at the top end of the driving mechanism, the base is installed among the three adjusting mechanisms, the laser cutting device is installed in the center of the base, the driving mechanism is used for driving the clamping mechanism or the adjusting mechanisms to work, and the clamping mechanism is used for clamping and limiting a rectifier bridge support mold. The adjusting mechanism is used for adjusting the distance between the laser cutting device and the rectifier bridge support mold and adjusting the cutting angle of the laser cutting device, so that multi-angle cutting can be conducted on the rectifier bridge support mold.

Owner:江苏众联祥博新能源科技有限公司

Angle-adjustable marble cutting device

ActiveCN111015971AAdjustable angleAvoid displacementWorking accessoriesStone-like material working toolsClassical mechanicsElectric machinery

The invention relates to a cutting device, in particular to an angle-adjustable marble cutting device. Therefore, the angle-adjustable marble cutting device aims to achieve the technical effects of being capable of adjusting the cutting angle, firmly fixing marble and preventing the marble from shifting during cutting. According to the technical scheme, the angle-adjustable marble cutting device comprises a bottom plate, first supports, a second support, a conical plate and the like, the first supports are symmetrically arranged on the right side of the top of the bottom plate, and the secondsupport is arranged on the left side of the top of the bottom plate. The angles of a motor and a cutting blade can be adjusted by rotating a first hand rotating wheel, so that the cutting angle of themarble is adjusted, the angle can be adjusted when the marble is cut, the operation of adjusting the angle is simple, the adjusted angle is wide, the adjustment can be carried out according to the cutting requirement, subsequent secondary cutting by using a hand grinder is avoided, the working efficiency is improved, and the operation complexity is reduced.

Owner:济南森华精密机械有限公司

Method for cutting and discharging of box column web

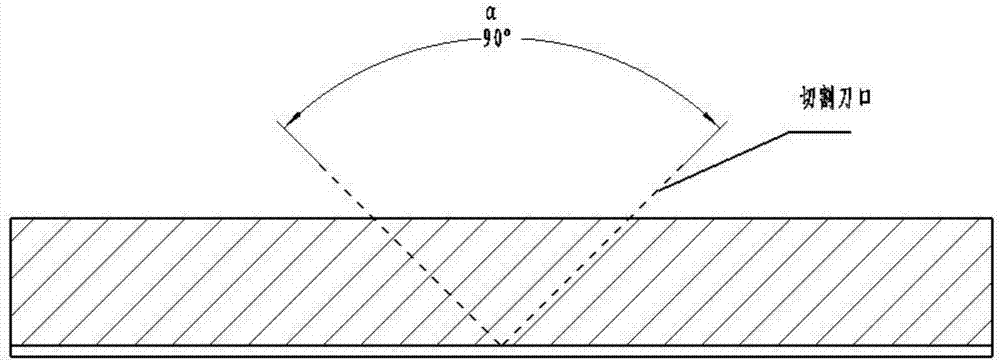

InactiveCN105562882AAdjustable cutting angleGas flame welding apparatusNumerical controlMechanical engineering

The invention provides a method for cutting and discharging of a box column web. A common steel structure machining device is mainly ingeniously used for manufacturing, the box column web is commonly required to be grooved, and a groove is in the form of a 45-degree unilateral groove. According to the method for cutting and discharging of the box column web, a numerical control discharging machine is used for performing one-time cutting and grooving forming, and grooving does not need to be additionally conducted. The method is characterized in that a cutting gun of a numerical control cutting machine needs to be flexibly used; the cutting angle of the cutting gun needs to be well adjusted; the groove of the web is formed through one inclined kerf, and the web and a cover plate are assembled and welded after being formed. According to the method, when cutting and discharging are conducted on a box column web in the prior art, the process of grooving in two edges can be omitted, time and cost are saved, and thermal cutting deformation possibly generated during grooving of the web can also be avoided.

Owner:湖北浩南钢结构工程有限公司

Grafting auxiliary equipment used for fruit tree planting

The invention discloses grafting auxiliary equipment used for fruit tree planting. The equipment includes a shell, a base plate, an inflation shell, pre-folding grooves, a gas pipe, a supporting rod,spring fixing disks, a spring, push rods, a fixing plate, an electric push rod, a cutting knife, a cutting board, support rods, a shaft sleeve, a fixing shaft, a connecting rod, a clamping groove, a screw rod, a clamping convex, a nut, a disc, a rotating disc, a casing pipe and a scion. The equipment is reasonable in structural design; workers can adopt sitting postures to complete operation in awhole course during the whole cutting, so that convenience can be brought for the workers, and work intensity can be reduced; through mechanized structural scion cutting means, all scion cutting angles can be guaranteed to be the same, a large batch of grafting work can be conveniently performed, and the success rates of grafting can be effectively enhanced; and through the adjusting of the anglesof tail end cutting of the scion, cutting can be conveniently performed on the scions with different diameters and kinds.

Owner:闽清县盛旺佳食用菌农业专业合作社

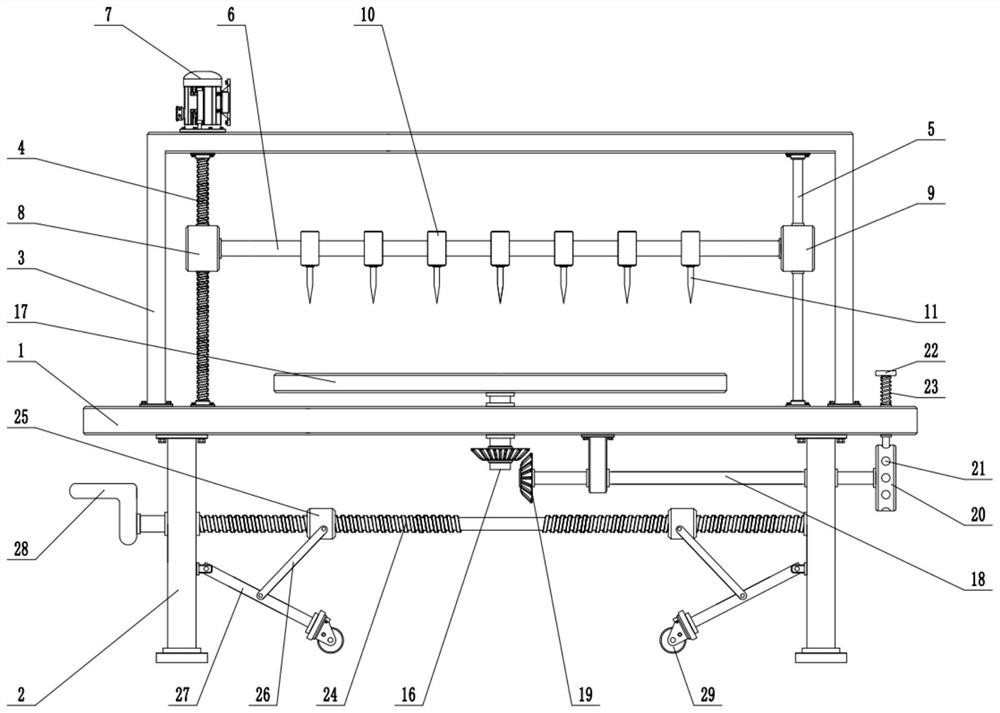

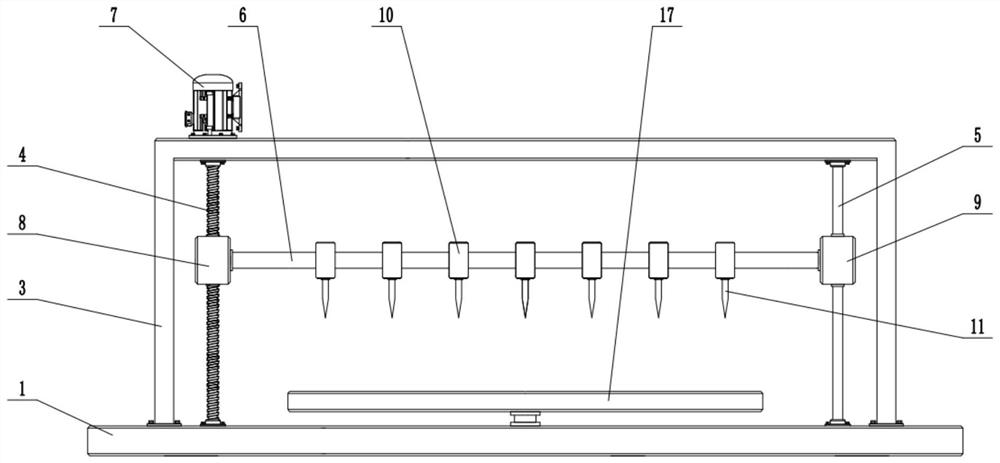

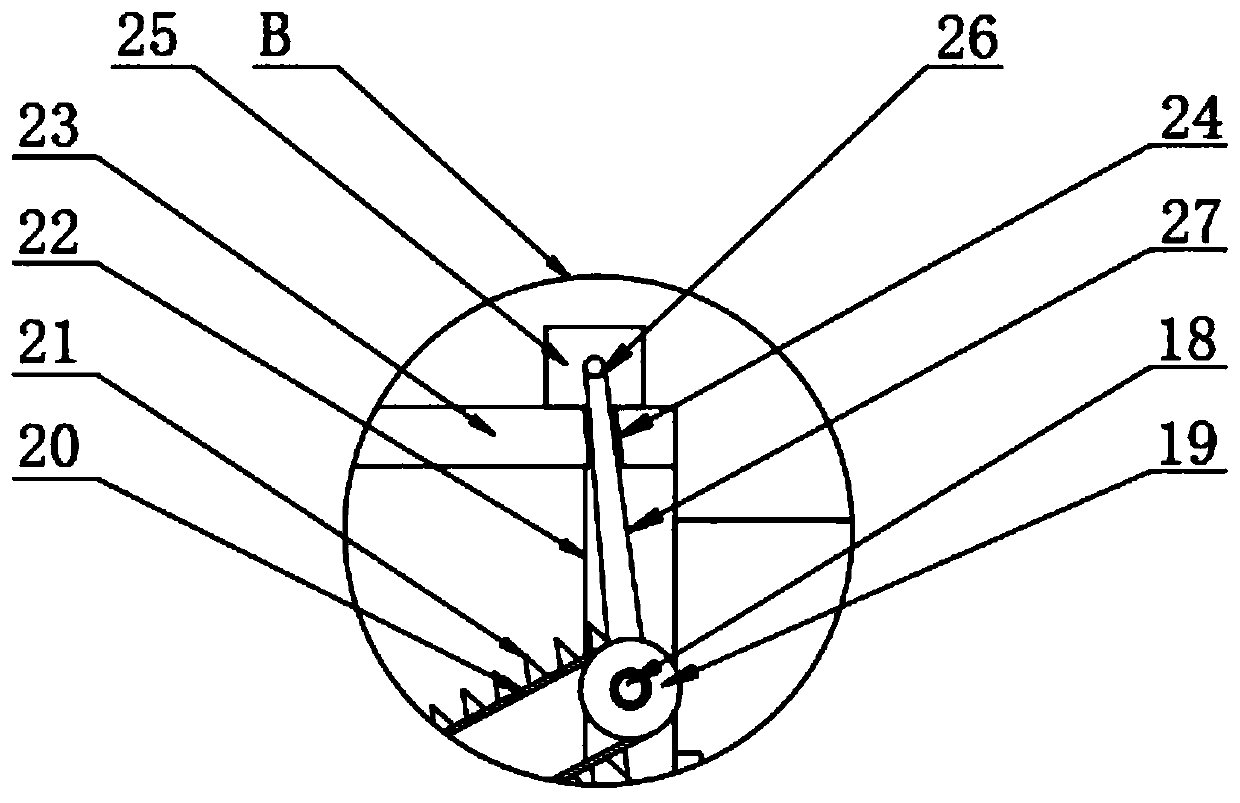

Equidistant cutting structure and automatic dicing device for soya bean product processing

PendingCN113084887AAdjustable spacingAdjustable cutting angleMetal working apparatusSoybean productAgricultural engineering

The invention relates to the technical field of food processing, in particular to an equidistant cutting structure and an automatic dicing device for soya bean product processing. The equidistant cutting structure comprises a workbench, wherein a fixing frame is fixedly installed on the upper surface of the workbench, a lifting assembly is installed inside the fixing frame, a fixing rod is installed on the lifting assembly, adjusting blocks are equidistantly distributed on the fixing rod, and cutting tools are fixedly installed on the lower surfaces of the adjusting blocks. Soya bean products to be cut are placed on a rotating assembly, hydraulic cylinders are controlled to stretch, and the distance between a guide rod and the fixing rod can be adjusted, so that the distance between the cutting tools is adjusted, the rotating assembly is operated to drive the soya bean products to rotate, the cutting angle is adjusted, the lifting assembly is controlled to work, the cutting tools are driven to move up and down, the soya bean products are cut into blocks through the cutting tools, the whole process is automatically carried out, and the cutting efficiency is greatly improved by arranging the plurality of cutting tools.

Owner:付宸羲

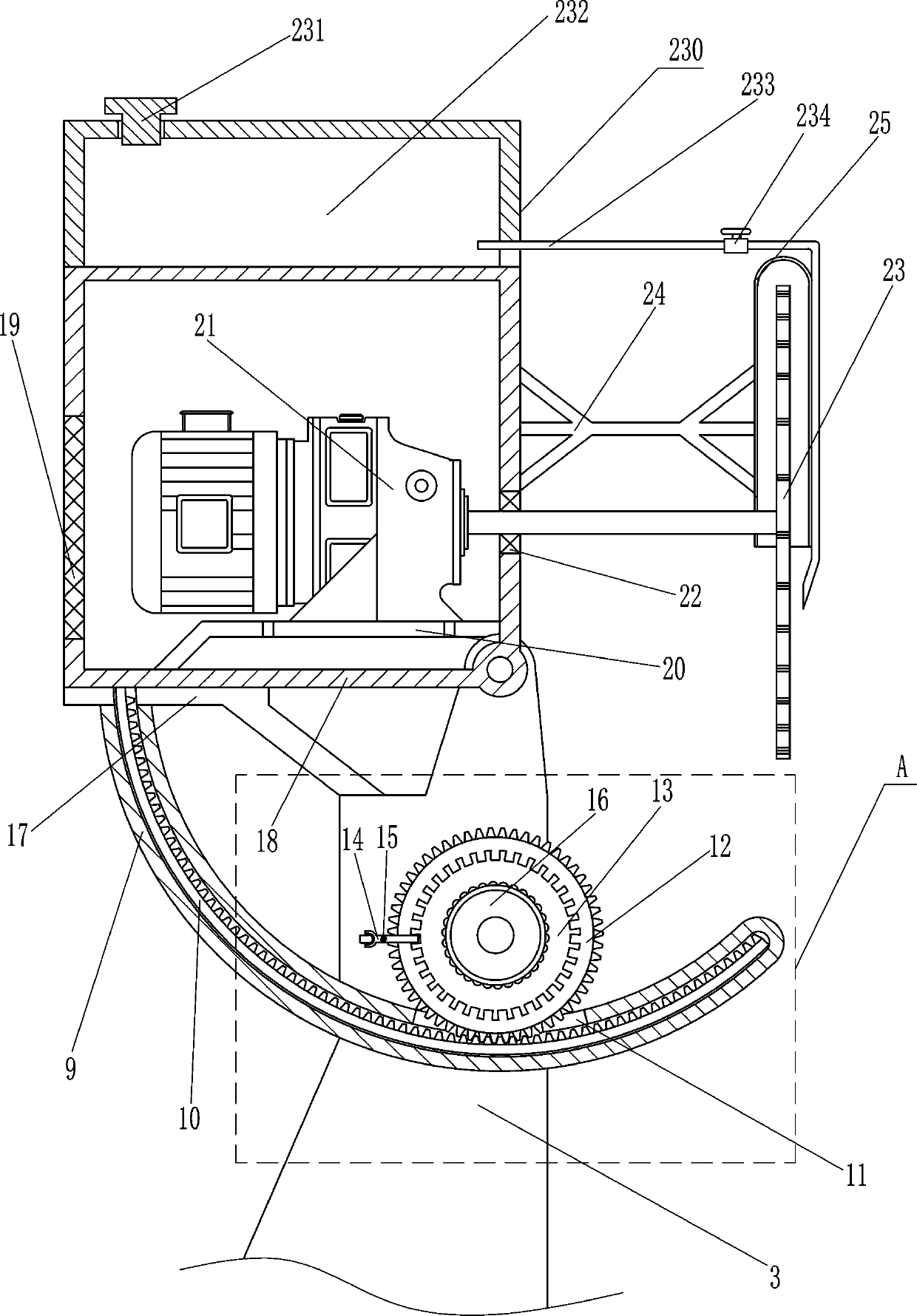

Internal cutting type pipeline cutting machine

InactiveCN106041250ACompact structureSave operating spaceGas flame welding apparatusEngineeringTorch

The invention discloses an internal cutting type pipeline cutting machine. The internal cutting type pipeline cutting machine comprises a static support, a movable support and a stepping motor; the static support comprises a support body and a telescopic fastening device arranged at the end of the support body; a cutting torch is arranged at the end of the movable support; and the stepping motor is fixed to the static support, can drive the movable support to rotate and is connected to a controller, and the stepping motor and the controller are connected to a power source. According to the internal cutting type pipeline cutting machine, the internal cutting mode is adopted, and the operation space needed by work is reduced; the cutting angle is adjustable, and bevels can be formed through cutting; installation is convenient, and the labor intensity is lowered; the circuit structure is compact and does not influence the cutting work; the size is small, and movement is easy; the work efficiency can be effectively improved, and the energy can be saved.

Owner:孟祥生

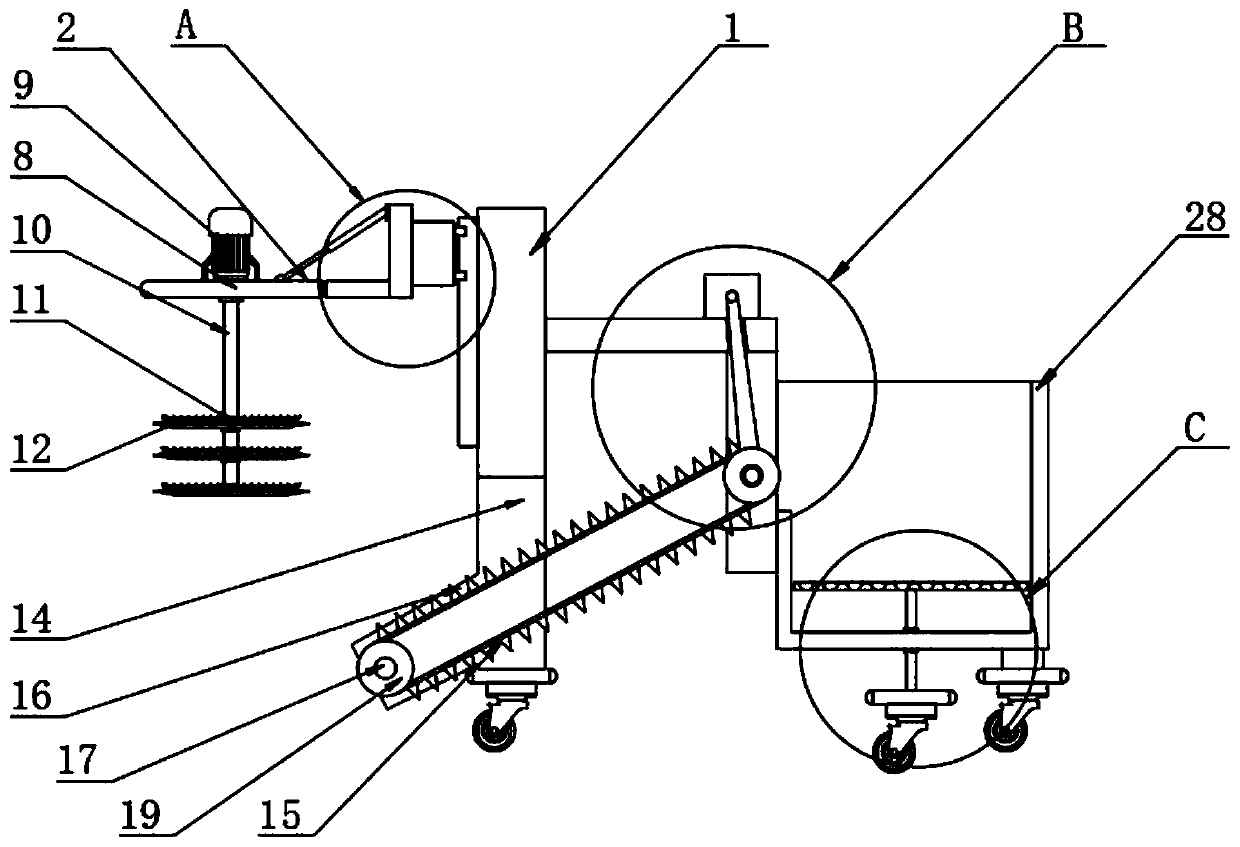

Agricultural weed collecting device

ActiveCN111357477AHeight adjustableAdjustable cutting angleMowersCleaning processes and apparatusAgricultural engineeringControl theory

The invention discloses an agricultural weed collecting device, and particularly relates to the field of weed treatment. The agricultural weed collecting device comprises a fixed shell, wherein a weeding mechanism is arranged on one side of the fixed shell; the weeding mechanism comprises an electric sliding rail, the electric sliding rail is fixedly connected with the fixed shell, a movable sliding block is fixedly arranged on one side of the electric sliding rail, a lifting block is fixedly arranged on one side of the movable sliding block, an adjusting plate is fixedly arranged on one sideof the lifting block, a positioning plate is fixedly arranged on one side of the adjusting plate, an overturning plate is arranged on one side of the positioning plate, one end of the overturning plate is hinged to one end of the positioning plate, a first servo motor is fixedly arranged at the top of the overturning plate, and a first rotating shaft is fixedly arranged at the bottom of the firstservo motor. By arranging the weeding mechanism, the height and the cutting angle of a cutting fluted disc cutter can be effectively adjusted according to the positions of weeds, the cutting quality of weeds is improved through an arranged auxiliary fluted ring cutter, and the situation that the weeds are turned over outwards is prevented.

Owner:SICHUAN INFORMATION TECH COLLEGE

Building wear-resistant material cutting device with polishing function

InactiveCN109318304AWith grinding functionAdjustable cutting angleEdge grinding machinesProfiling/shaping machinesWear resistantArchitectural engineering

The invention discloses a building wear-resistant material cutting device with a polishing function. The building wear-resistant material cutting device comprises a bottom plate, a processing plate, arotating rod and a cutting piece, wherein the left and right ends of the lower surface of the bottom plate are fixedly provided with cushion blocks, a gathering groove is formed below a pawl lever, the processing plate is located above the bottom plate, the left and right sides of the upper portion of the processing plate are in threaded connection with a fixing clamping plate, a motor is fixedlyarranged in the middle of the surface of the inner side of a side plate, the outer side of a first gear plate is connected with a conveyor chain in an engaged manner, the rotating rod is connected tothe interior of the inner surface of the upper end of the side plate in a penetrating manner, the right end of a fixing rod is symmetrically provided with fixing bolts, and the fixing bolts are in threaded connection with an outer shell, and the cutting piece is located on the inner side of the lower end of the outer shell. The building wear-resistant material cutting device with the polishing function can adjust the cutting angle, does not need repeated lifting operation, improves the processing efficiency, and is convenient to install and disassemble. The device is movably installed, and awaste collecting device is arranged.

Owner:WUHU HUANGSHANSONG IND FLOOR NEW MATERIAL CO LTD

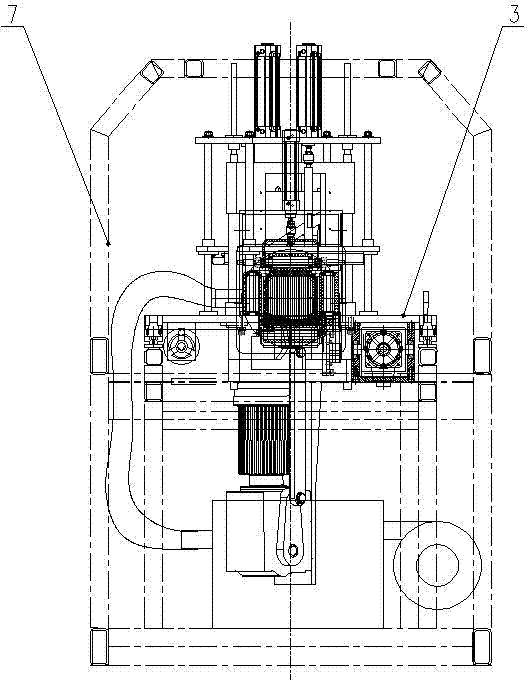

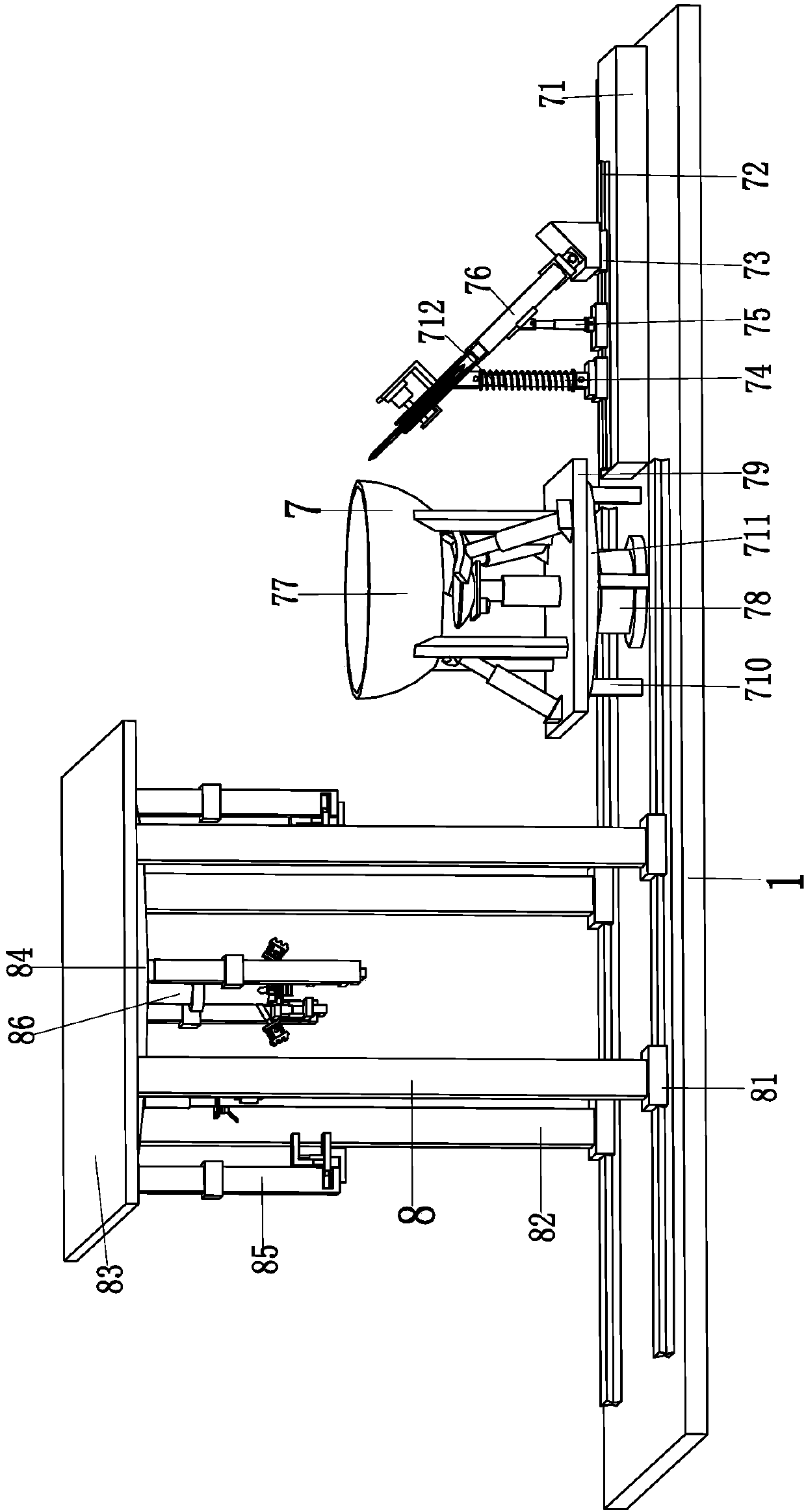

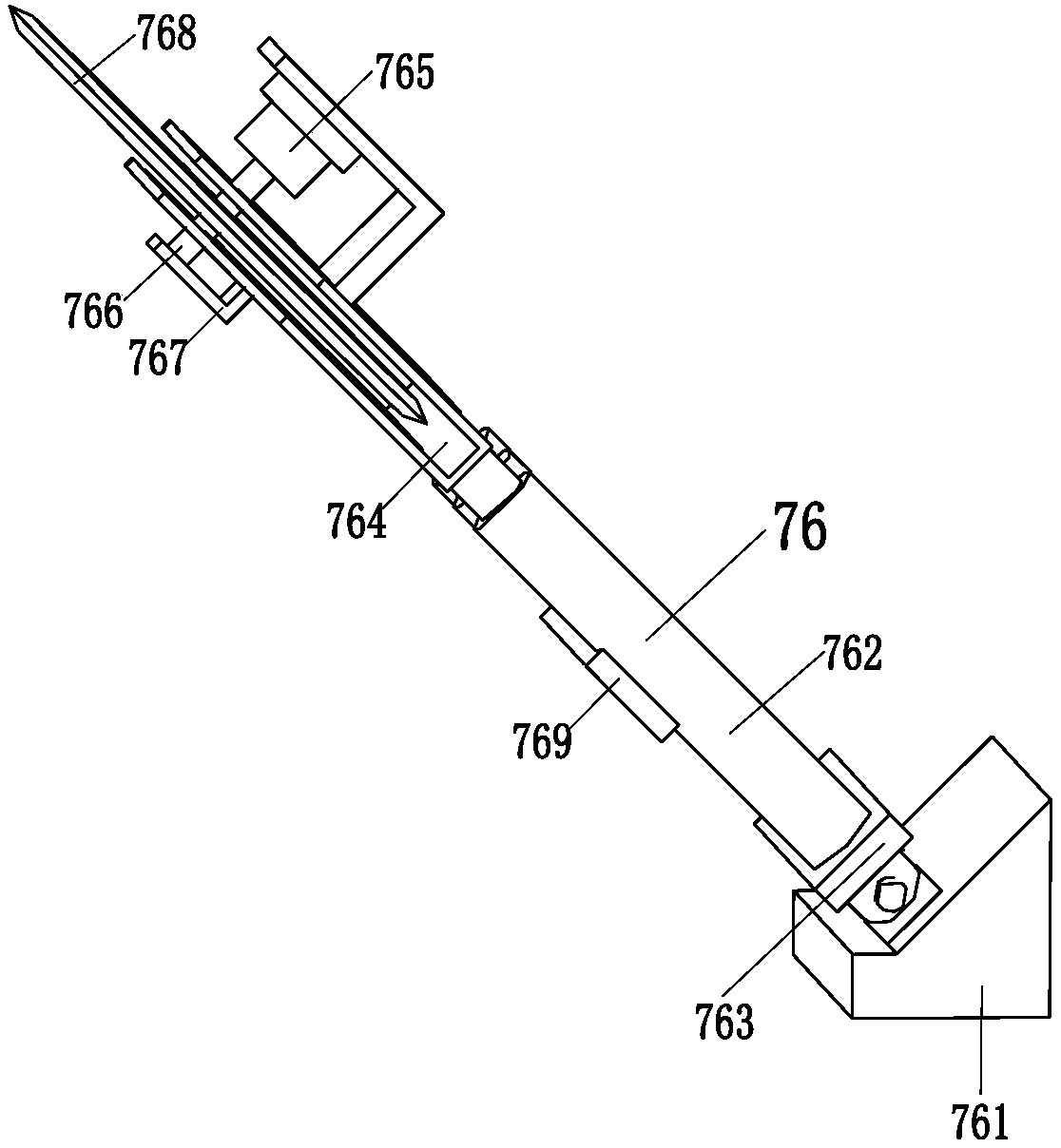

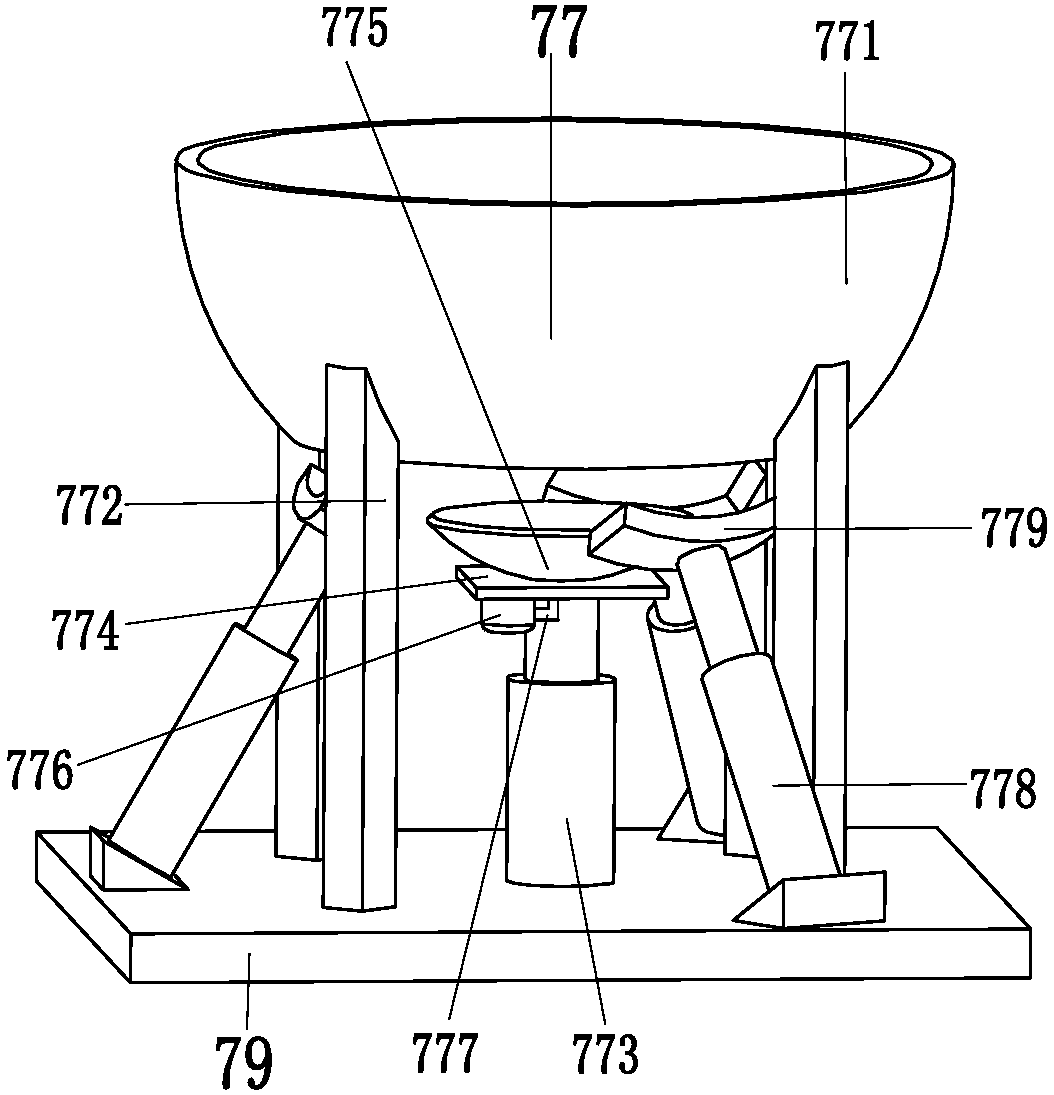

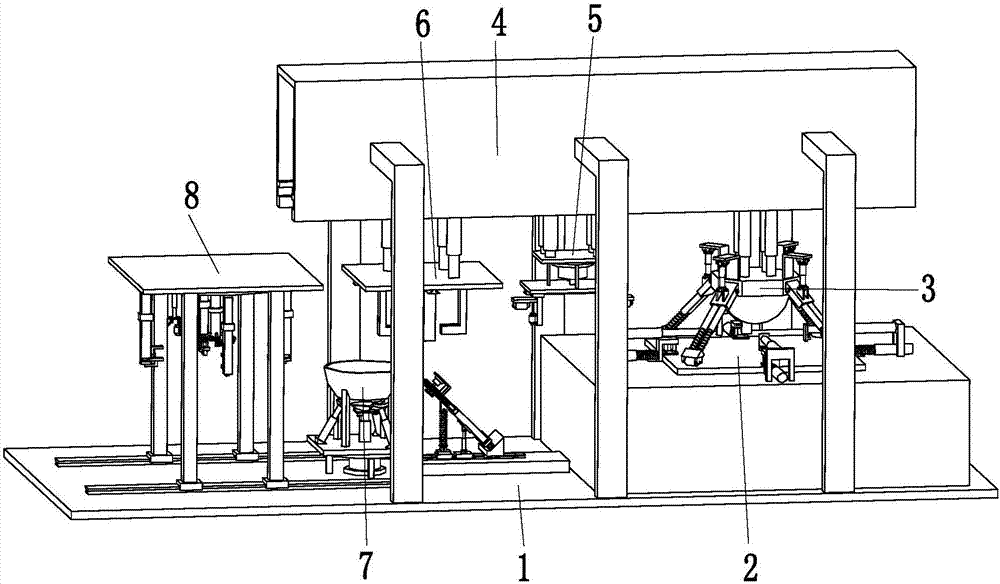

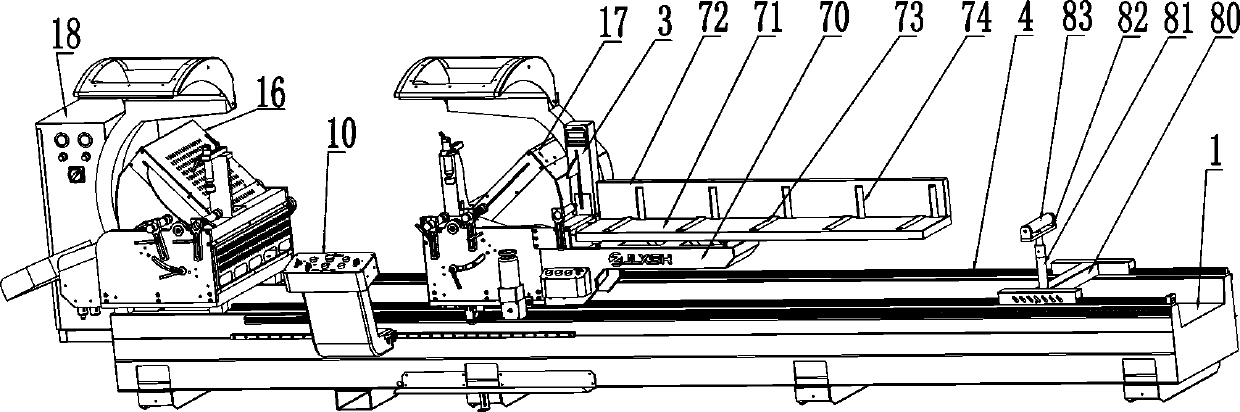

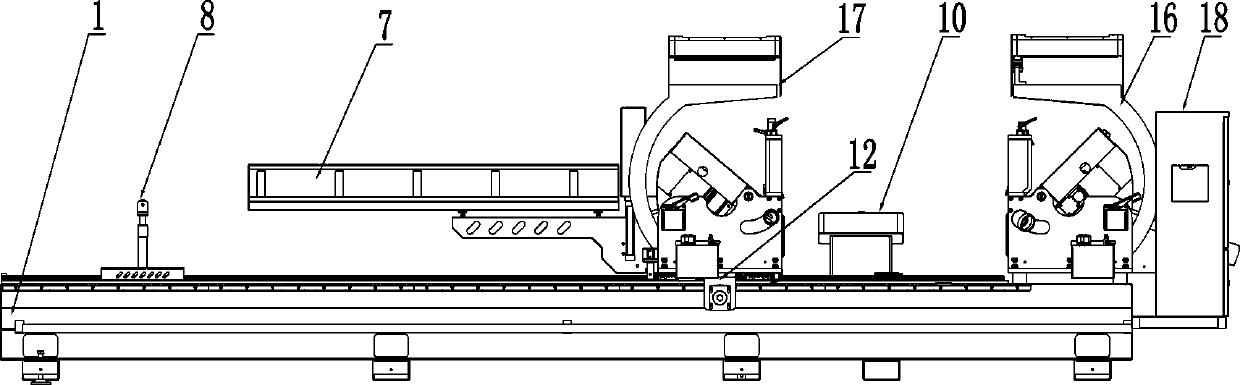

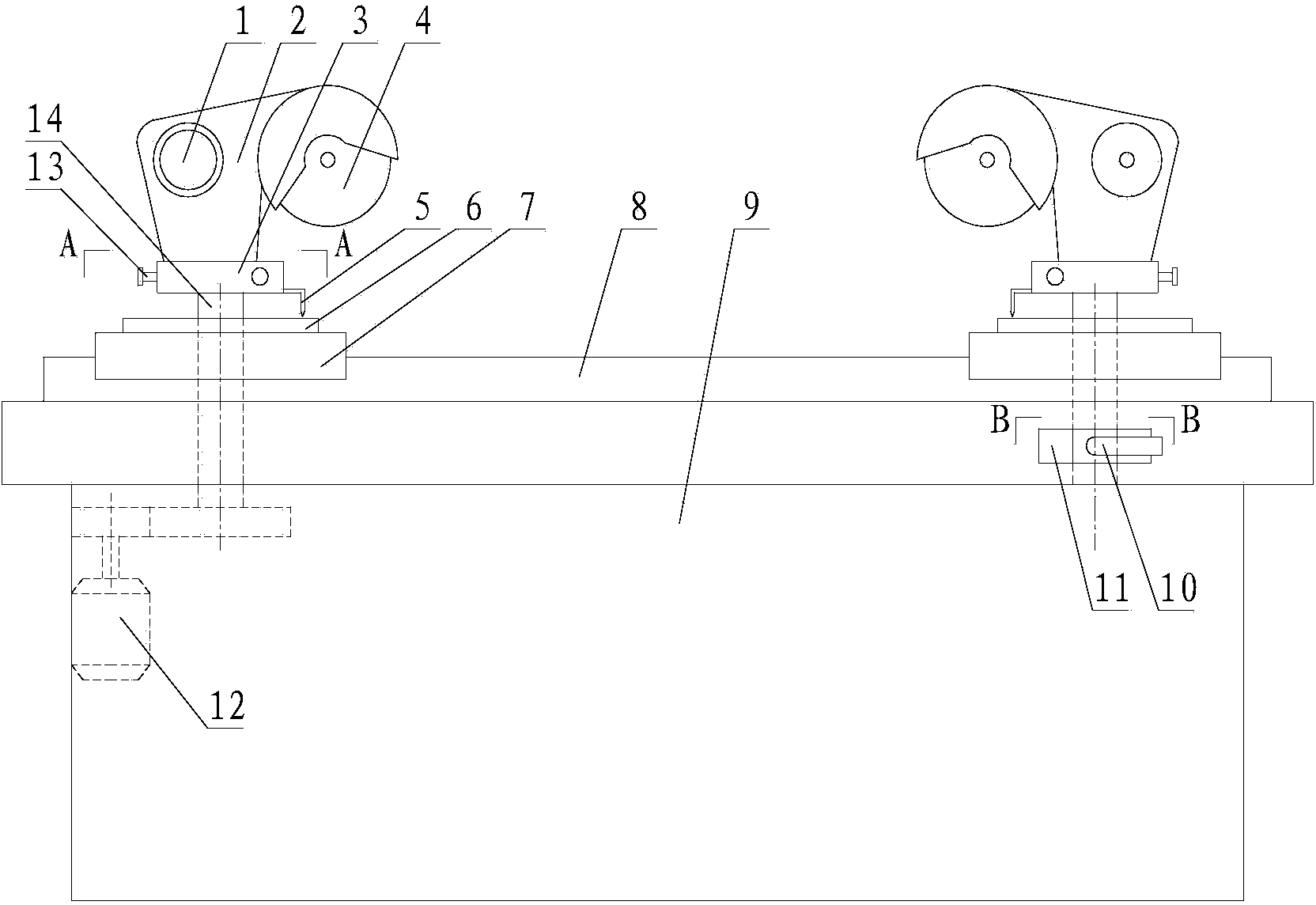

Double-headed saw cutting machine assembly

PendingCN111390272AEasy to installStable jobMetal sawing devicesMetal sawing accessoriesCircular sawMachine

The invention discloses a double-headed saw cutting machine assembly. The double-headed saw cutting machine assembly comprises a horizontal rack extending in the left-right longitudinal direction, anda linear horizontal rail is arranged on the horizontal rack; the cutting machine assembly is characterized by further comprising a fixed cutting unit, a movable cutting unit, a material height measuring device, a control box and an automatic controller, wherein the fixed cutting unit is fixedly arranged on a left side of the horizontal rack and used for cutting one end of a profile through a metal circular saw blade installed on the fixed cutting unit; the movable cutting unit is located on a right side of the fixed cutting unit and is movably arranged on the linear horizontal rail of the horizontal rack in the left-right longitudinal direction; and the material height measuring device is in signal connection with the automatic controller and is used for detecting the cutting height of the cut profile in the cutting direction and transmitting detection data to the automatic controller. The double-headed saw cutting machine assembly has the advantages that the height data of the cut profile can be automatically measured by using the material height measuring device, and the cutting process of the double-headed saw cutting machine assembly is automatically controlled in combinationwith related processing data obtained by implementing man-machine conversation through the control box.

Owner:HUNAN JINLIXING MASCH TECH CO LTD

Building board machining device for construction site

PendingCN109968424AIngenious structureReasonable designDirt cleaningWorking accessoriesBuilding constructionChassis

The invention relates to the field of building equipment, in particular to building board machining device for a construction site. The device comprises a bottom frame, a sliding rail assembly, a cutting assembly and a positioning assembly. The sliding rail assembly comprises a sliding rail on the upper side of the bottom frame, and a sliding supporting column; the end, away from the sliding supporting column, of the sliding rail is rotatably connected with the bottom frame, the other end penetrates through the upper side of the sliding supporting column, a slippage connection structure is arranged between the sliding supporting column and the sliding rail, through arrangement of the slippage connection structure, when the sliding supporting column slides, the sliding rail is crossed withthe axis of the sliding supporting column, and a locking structure is arranged between the sliding supporting column and the bottom frame. The cutting assembly is arranged on the sliding rail in a sliding manner, the positioning assembly comprises a board supporting part arranged on the bottom frame, and a board positioning part arranged on the top of the board supporting part, the board supporting part is consistent with the sliding direction of the sliding supporting column relative to the sliding direction of the bottom frame, the device is ingenious in design, reasonable in design, and capable of conveniently adjusting the board cutting angle and cutting position, and obviously, the production needs can be effectively met.

Owner:SHANDONG UNIV OF TECH

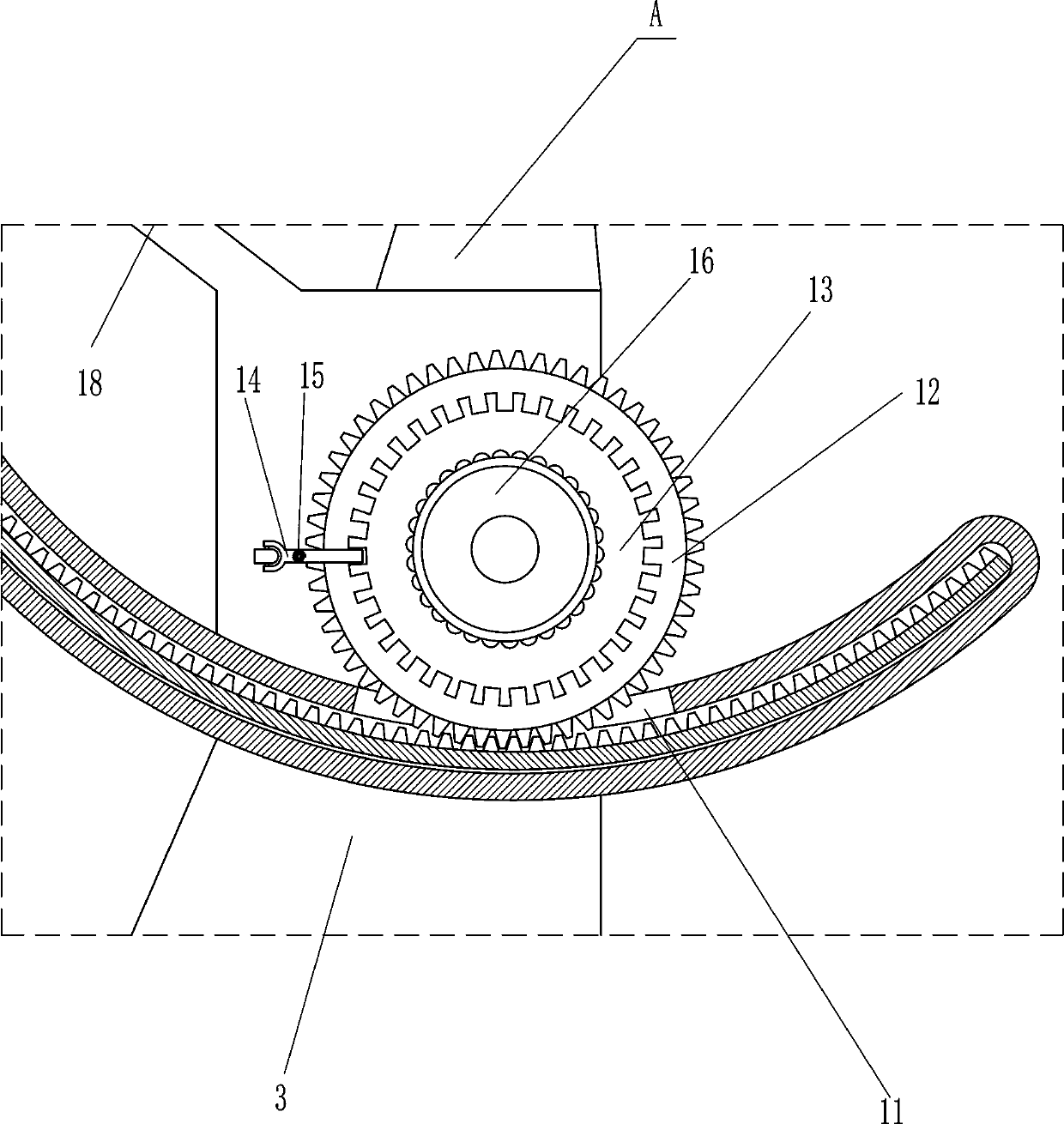

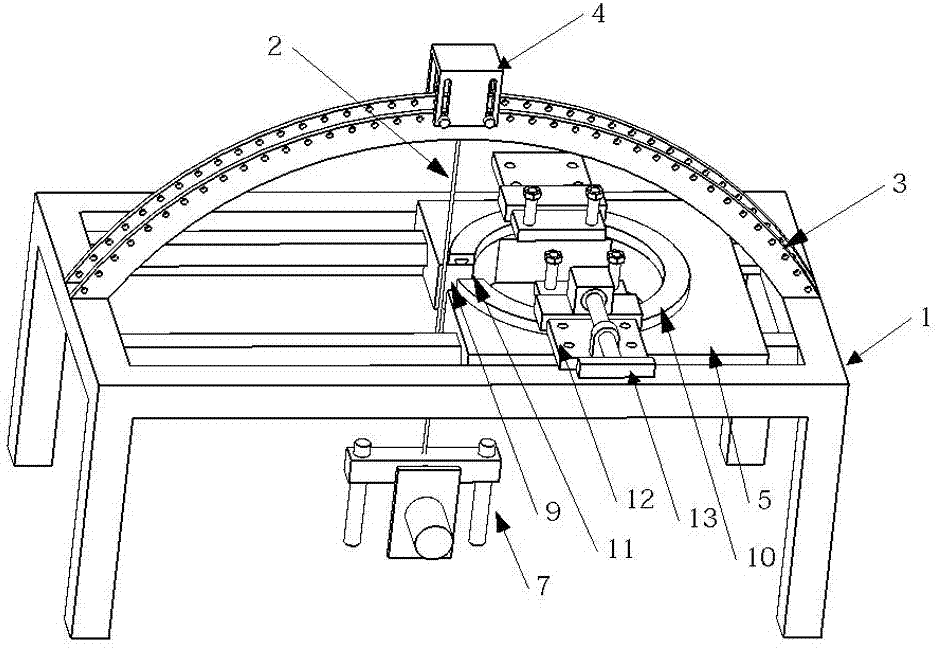

Cutting machine

ActiveCN107442876ASimple structureLow costElectrical-based machining electrodesLarge fixed membersShaped beamComputer engineering

The invention discloses a cutting machine. The cutting machine comprises a rack and a cutting rope. The cutting machine is characterized in that two abreast arc-shaped beam frames are arranged at the left part and the right part of the rack in a spanning mode, the two arc-shaped beam frames are provided with a sliding frame, the position of the sliding frame on the beam fames can be adjusted, the sliding frame can move on the beam frames in the radial direction, the inner sides of the beam frames are provided with convex tables, the convex tables are provided with sliding blocks, the upper end of the sliding frame is connected with one end of the cutting rope, the other end of the cutting rope penetrates through the sliding blocks and is connected with a lifting driving device, the cutting rope between the sliding frame and the sliding blocks is provided with an elastic reset part in a sleeved mode, the rack is provided with a horizontally-moving sliding table, a round hole is formed in the sliding table, a cutting groove which communicates with the round hole is further formed in the sliding table, acircular rotating table is arranged the position, corresponding to the periphery of the round hole, of the sliding table, an opening is formed in thecircular rotating table, the circular rotating table is further provided with a left clamping part and a right clamping part, wherein the clamping width of the left clamping part and the right clamping part can be adjusted, and the left clamping part and / or the right clamping part is provided with a driving handle. The cutting machine is simple in structure, andcutting is convenient to cut.

Owner:瑞安市嘉盛机械有限公司

Novel plastic profile cutting equipment

InactiveCN108568848AReduce the probability of misuse injuryPrecise positioningMetal working apparatusLaser transmitterReciprocating motion

The invention discloses novel plastic profile cutting equipment. The equipment comprises a machine, a fixture module, a cutting module and a traction module; a rail is formed in the middle of the fixture module, and the middle of the rail sinks to form a groove; a clamping part is arranged in the groove; cylindrical clamping platforms are formed on the two sides of the machine, and vertical limiting holes and oblique limiting holes are formed in the side walls of the clamping platforms; the cutting module comprises a horizontal arm arranged on the upper portion of the machine, a laser emitterindicating the cutting position is arranged on the lower portion of the horizontal arm, and a saw blade is arranged at the bottom of a second vertical arm formed in the middle of the horizontal arm downwards; first vertical arms formed on the two sides of the horizontal arm downwards are connected with the clamping platform through sliding rods of nested springs and clamping columns, and the traction module drives the horizontal wall and the saw blade to do reciprocating motion in the vertical direction. According to the cutting equipment, a fixture is adjustable, and the cutting angle is adjustable; cutting position indication is accurate, the cutting action is electrically controlled, and safety and reliability are achieved; a user operates the equipment conveniently, trouble and labor are saved, and the equipment has a wide application prospect.

Owner:TIANJIN HUANGJIA LEHONG PLASTIC PROFILES MFG

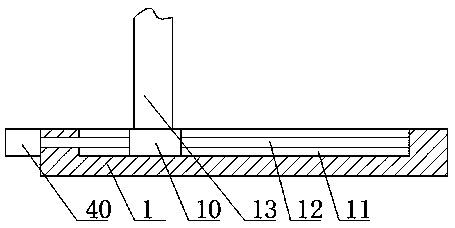

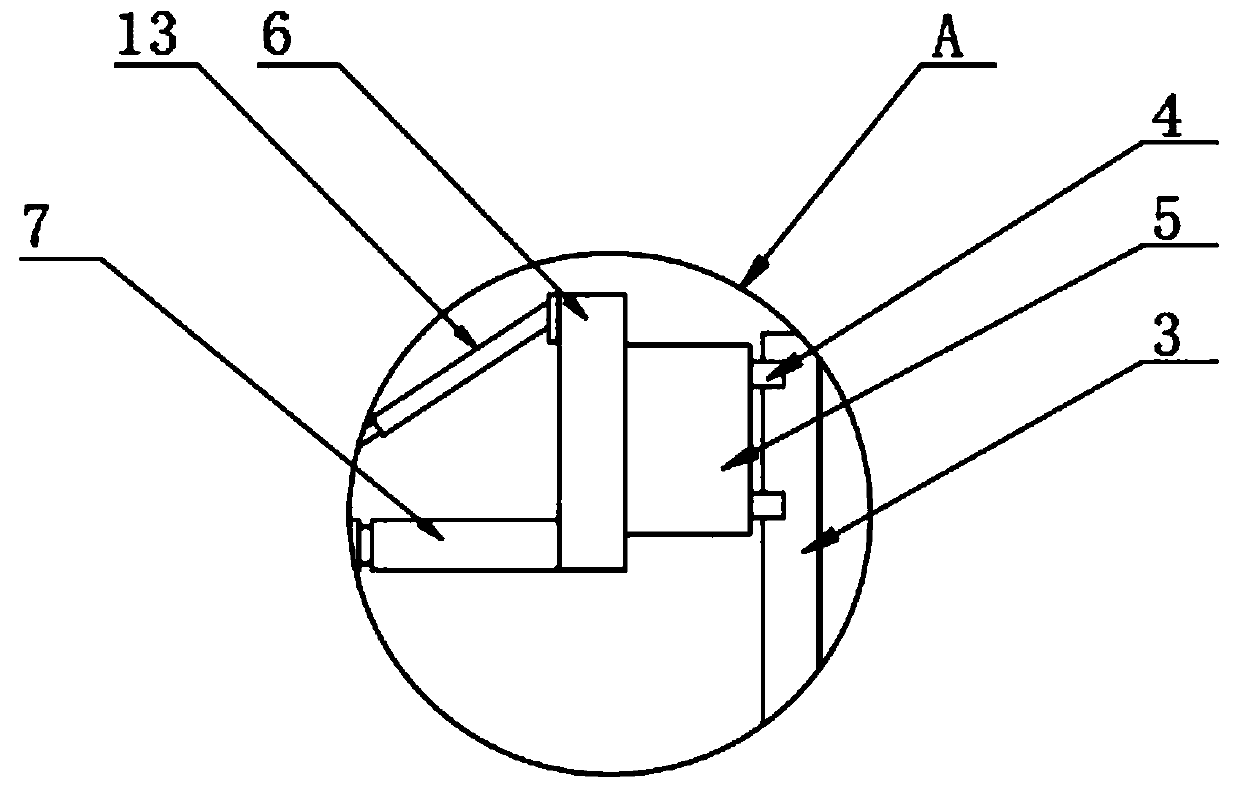

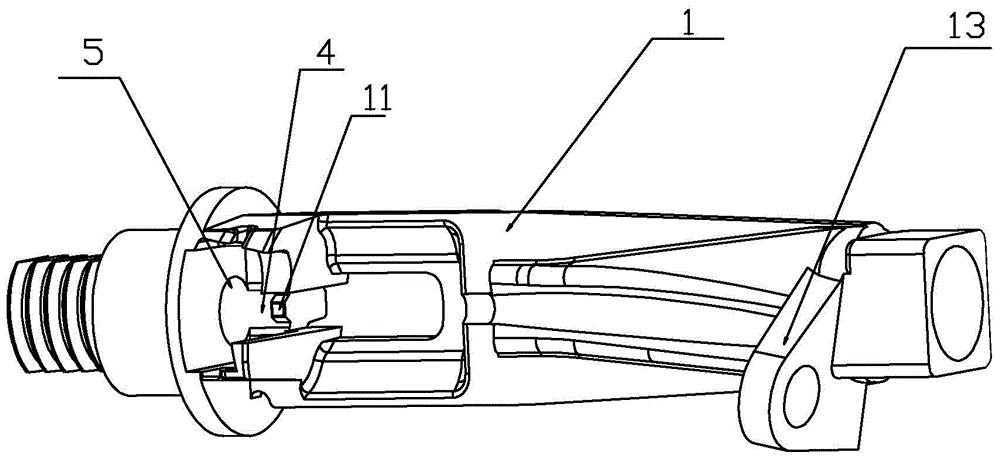

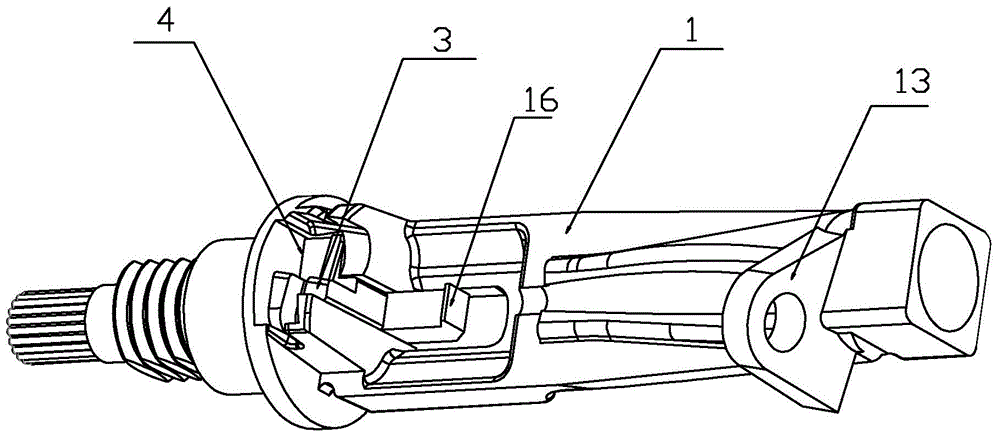

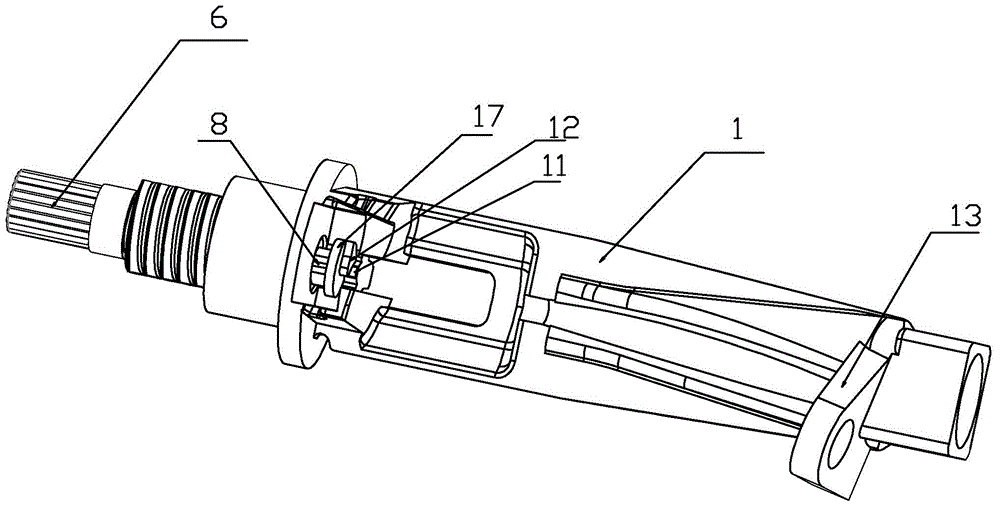

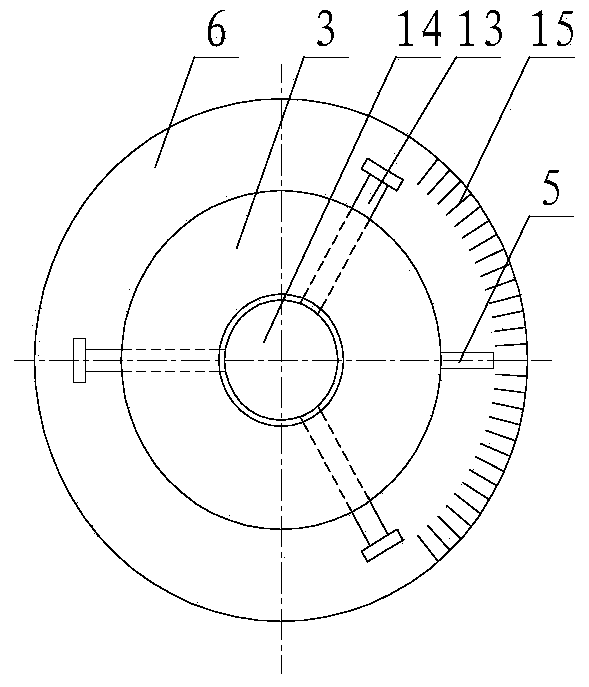

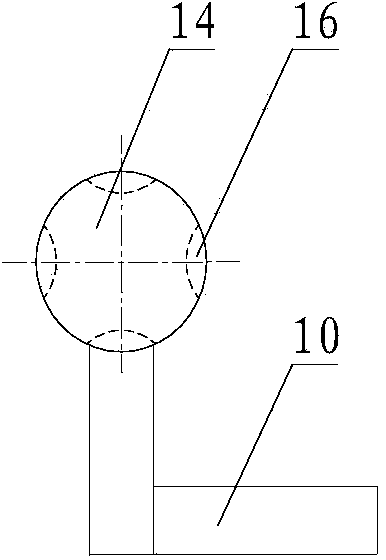

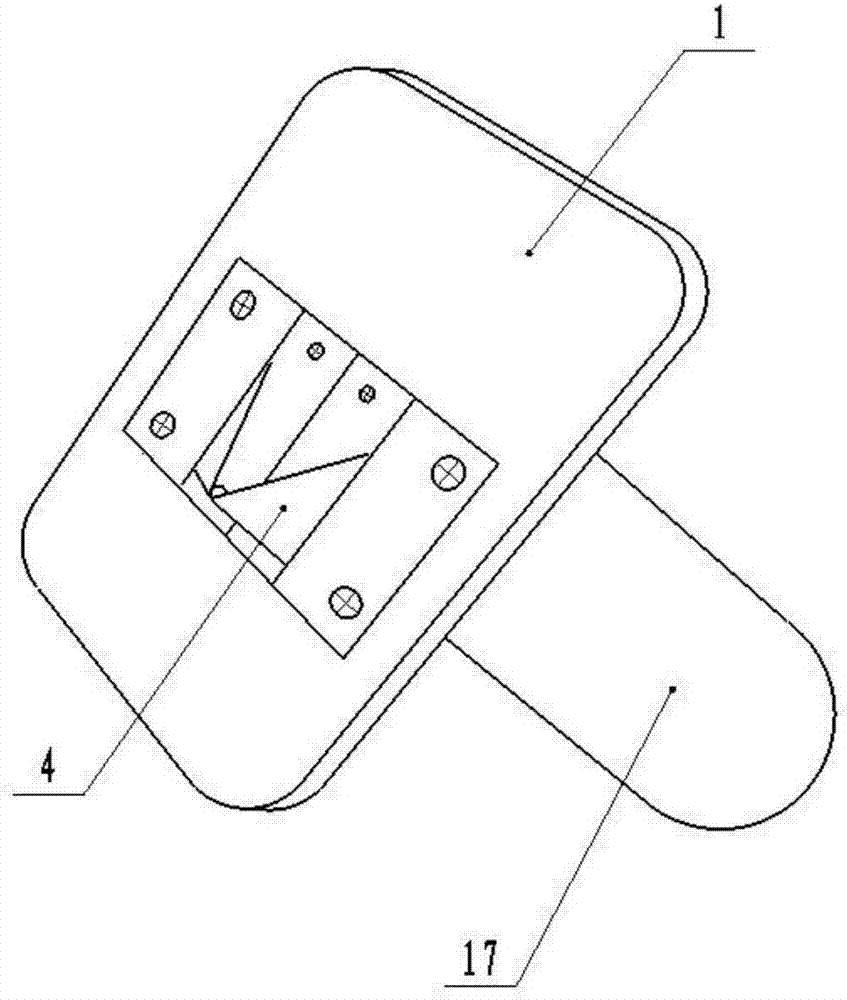

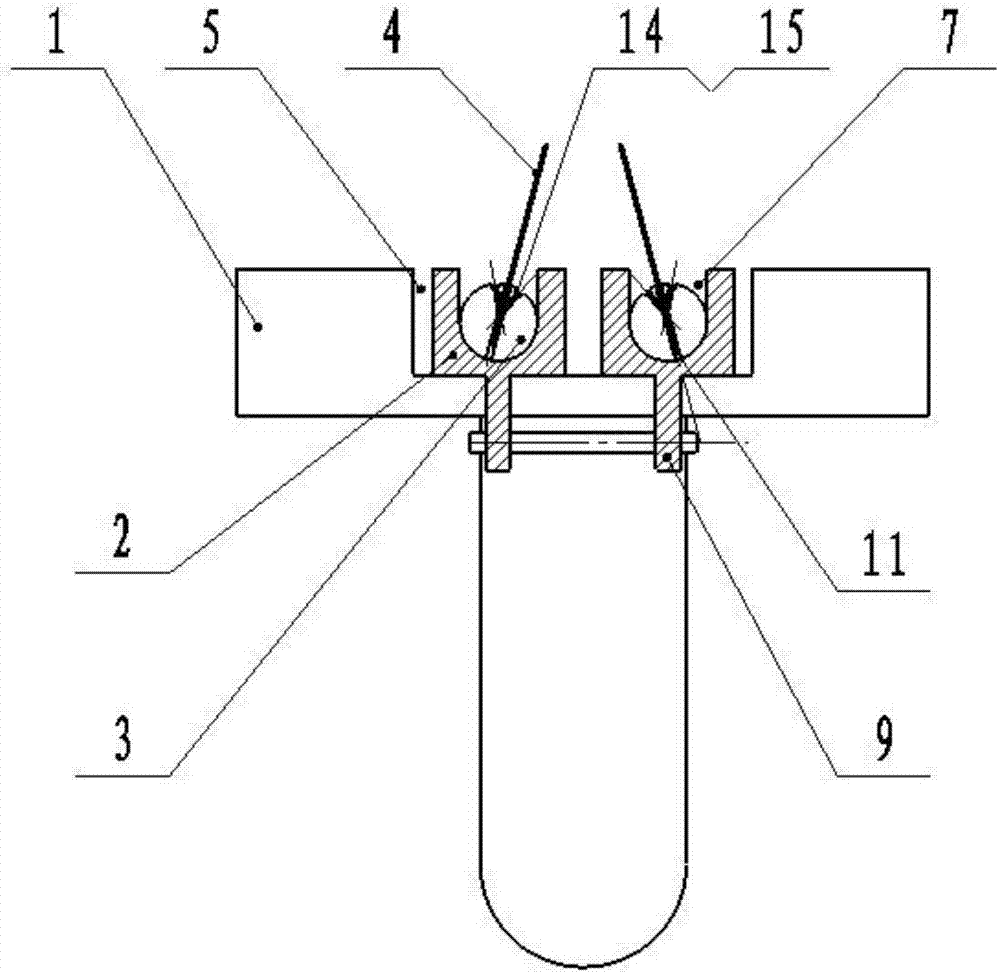

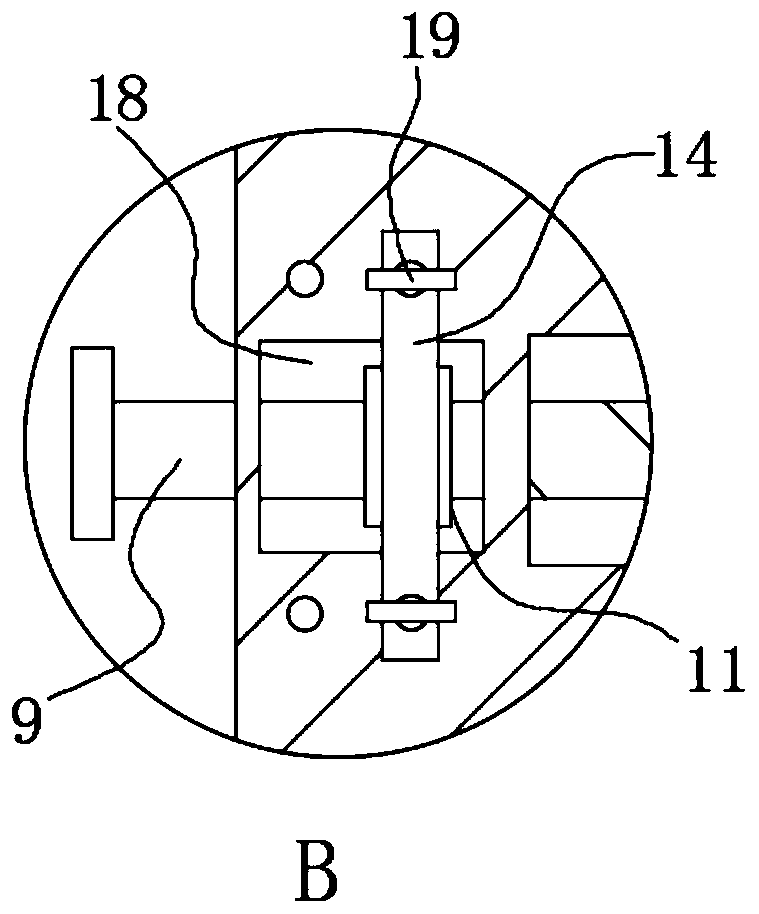

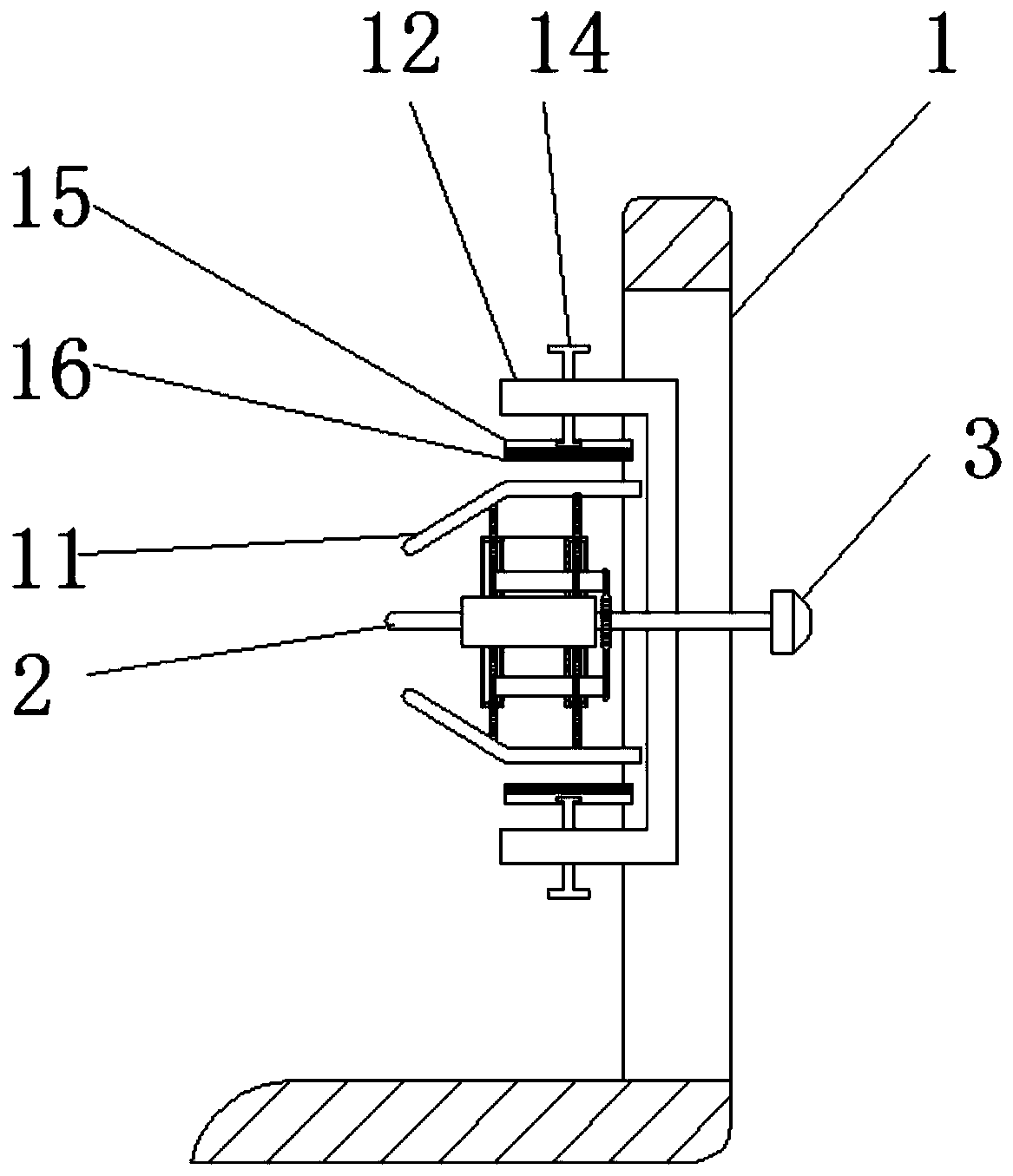

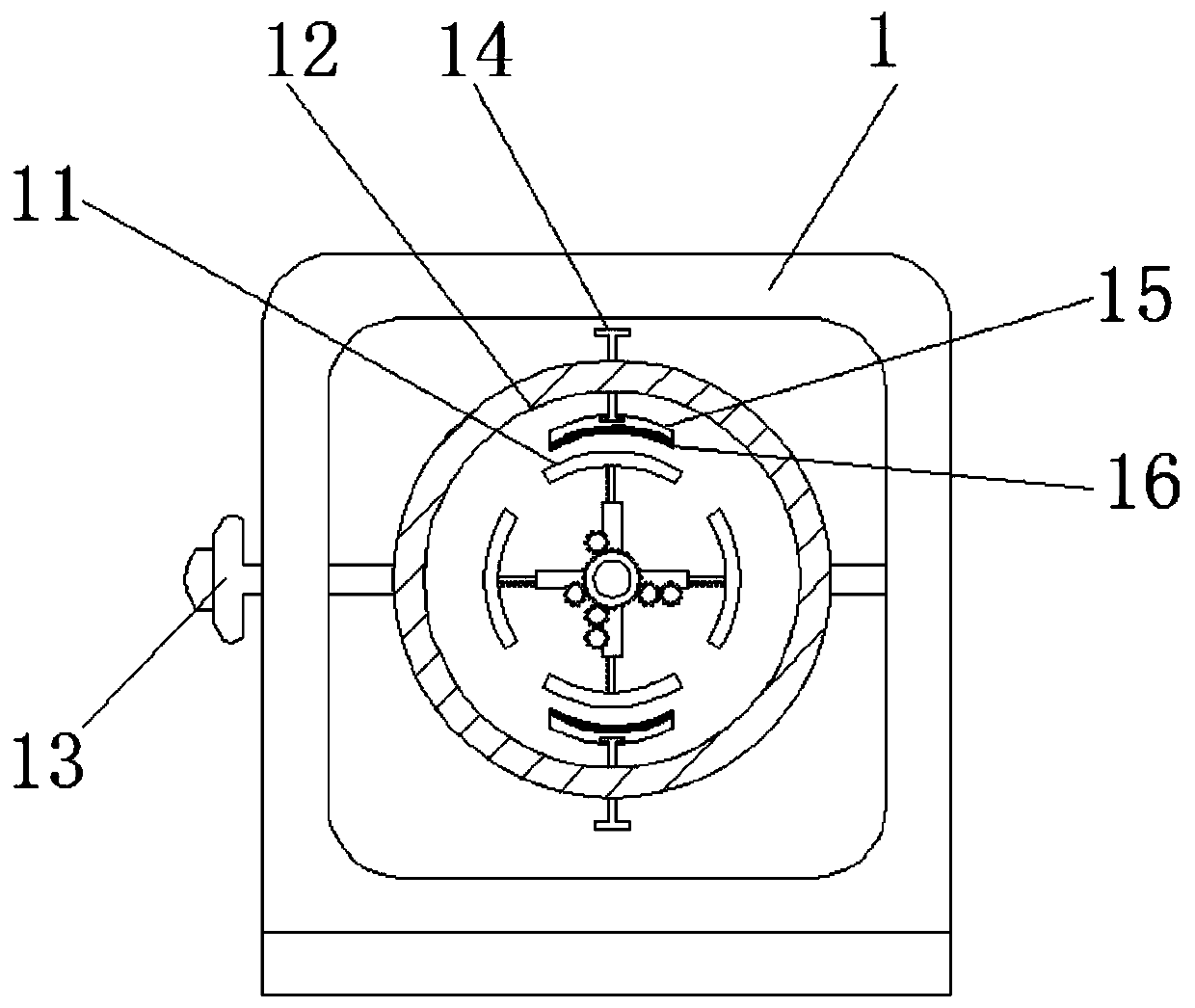

Knife rest of pencil sharpener

The invention discloses a knife rest of a pencil sharpener. The knife rest of the pencil sharpener comprises a knife rest (1) and a hob shaft (2) equipped with a hob (14), wherein a shaft support seat (3) is arranged at one end of the knife rest (1), a shaft support (13) is arranged at the other end of the knife rest (1), two ends of the hob shaft (2) are mounted on the shaft support seat (3) and the shaft support (13) respectively, an angle adjusting device for adjusting the angle of the hob shaft (2) is arranged on the knife rest (1) and specially adopts a chute (4) arranged on the knife rest (1), and the shaft support seat (3) is in sliding fit in the chute (4). The knife rest of the pencil sharpener has the advantages of simple structure, simplicity in operation, low cost, high reliability and good cutting quality and can change the thickness of a pencil lead under the condition that the pencil lead cutting length is not changed.

Owner:雪松

Material breaking cutting device

InactiveCN104384613AThe method is simplePrecise and intuitive rotation angleLarge fixed membersEngineeringEnergy conservation

The invention relates to a material breaking cutting device, which comprises a work platform, a base, a cutter blade, a cutter blade motor and a cutter blade displacement driving device, wherein a slide sleeve is arranged on a guide rail of the work platform, an angle display panel is arranged on the slide sleeve, angle scales are made on the angle display panel, a through hole is formed in an axis part of the angle display panel and the slide sleeve, a rotating shaft is coaxially arranged in the through hole in a penetrating way, the lower end of the rotating shaft is arranged in the work platform, a rotating shaft driving device is arranged on the rotating shaft, the upper end of the rotating shaft is fixedly arranged at the lower bottom surface of the base, the lower part of the base is provided with a pointer, and the pointer is positioned above the scales of the angle display panel. The material breaking cutting device has the advantages that the cutting angle can be adjusted, after the cutting device is used, the occupied space of equipment can be reduced, energy sources can be saved, the work efficiency and the processing precision can be improved, the qualified rate of products can be guaranteed, and in addition, great convenience is provided for workers.

Owner:TIANJIN XINTAI LIANFENG DOOR & WINDOW CO LTD

Material cutting device for producing bamboo-wood furniture

InactiveCN110605763AAdjustable cutting angleImprove comprehensivenessCane mechanical workingProfiling/shaping machinesMechanical engineeringEngineering

The invention discloses a material cutting device for producing bamboo-wood furniture. The device comprises a device main body; a cutting cavity is formed in the device main body; a clamping device isarranged in the cutting cavity, and comprises an upper clamping plate and a lower clamping plate; bamboo-wood plates are clamped between the upper clamping plate and the lower clamping plate; five balls are rotationally mounted on the lower end surface of the upper clamping plate; the clamping device can drive the bamboo-wood plates to rotate; the bamboo-wood plates are clamped through the upperclamping plate and the lower clamping plate, and are rotated for cutting; secondly, in the cutting process, a cutter can be adjusted in the horizontal direction and the vertical direction to improve the cutting direction comprehensiveness; the cutting angle of the cutter can be adjusted for cutting of the bamboo-wood plates according to different paths and different shapes; and in addition, a dustsucking device is arranged in the device for downwards collecting wood chips and dust generated in the cutting process without influencing the cutting vision, so that the size of the device is reduced, and the operation is convenient.

Owner:东阳潘辰竹木工艺品有限公司

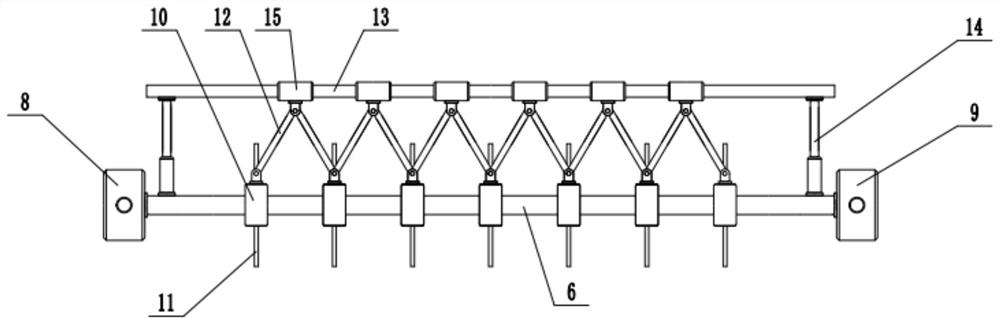

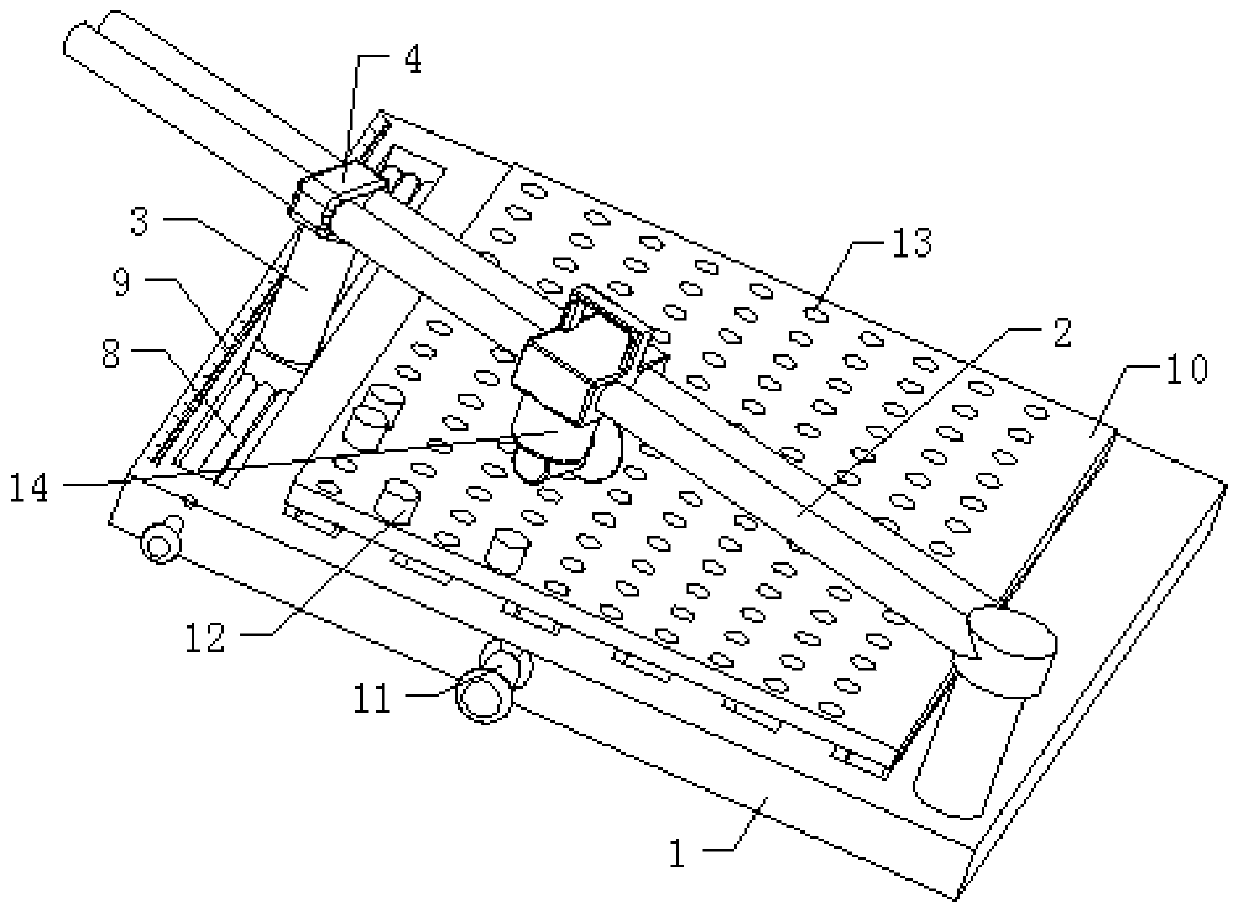

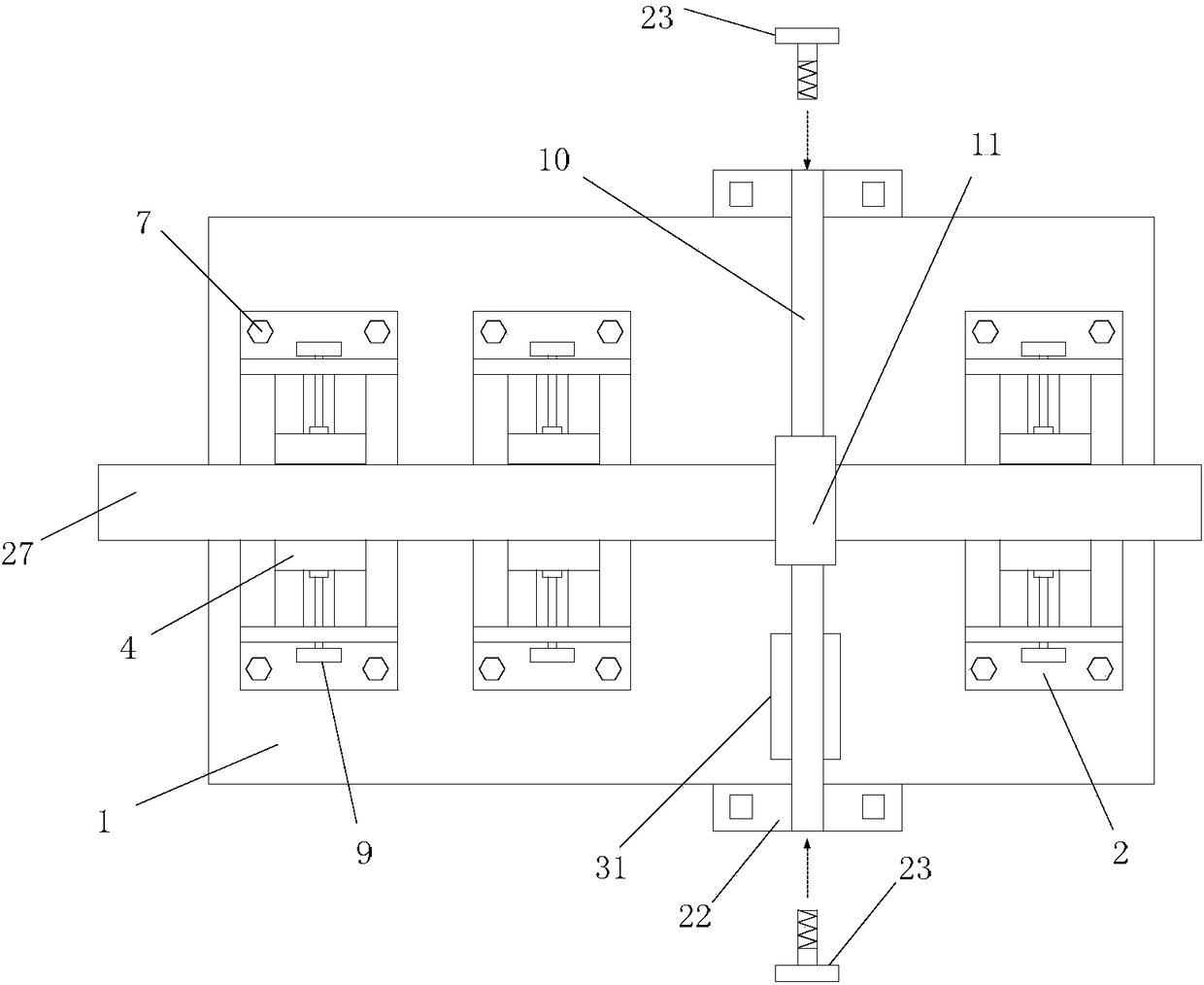

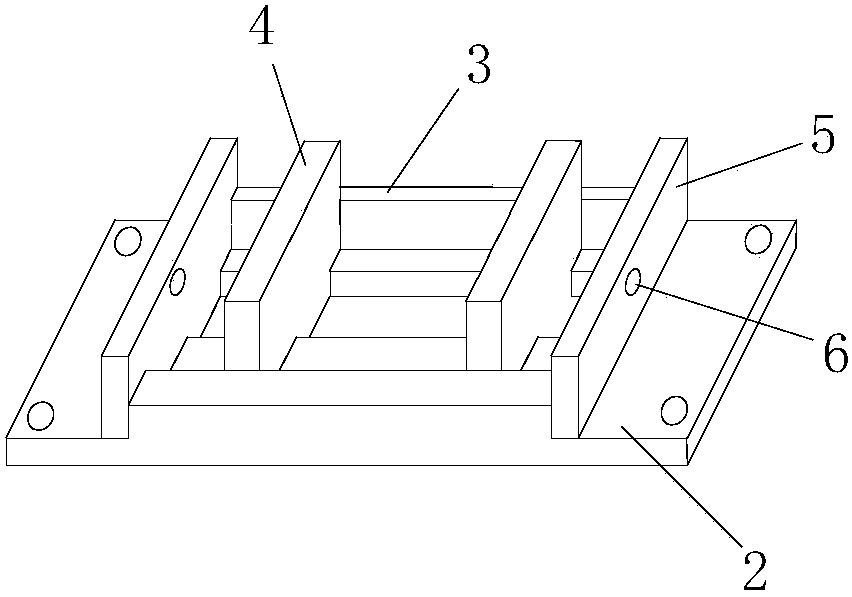

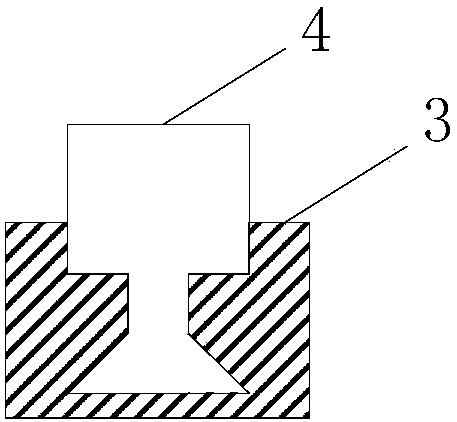

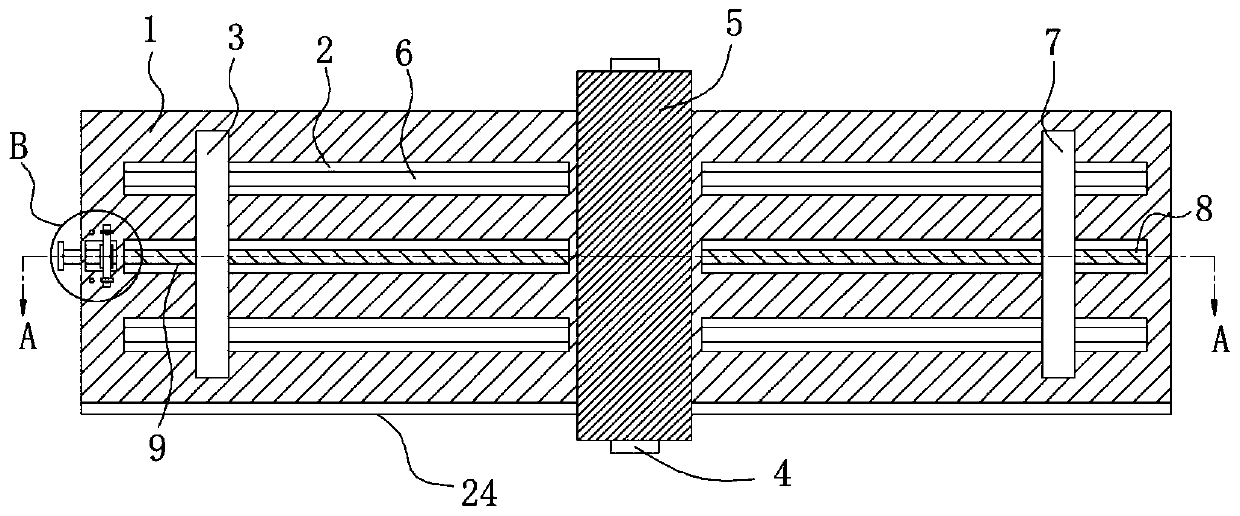

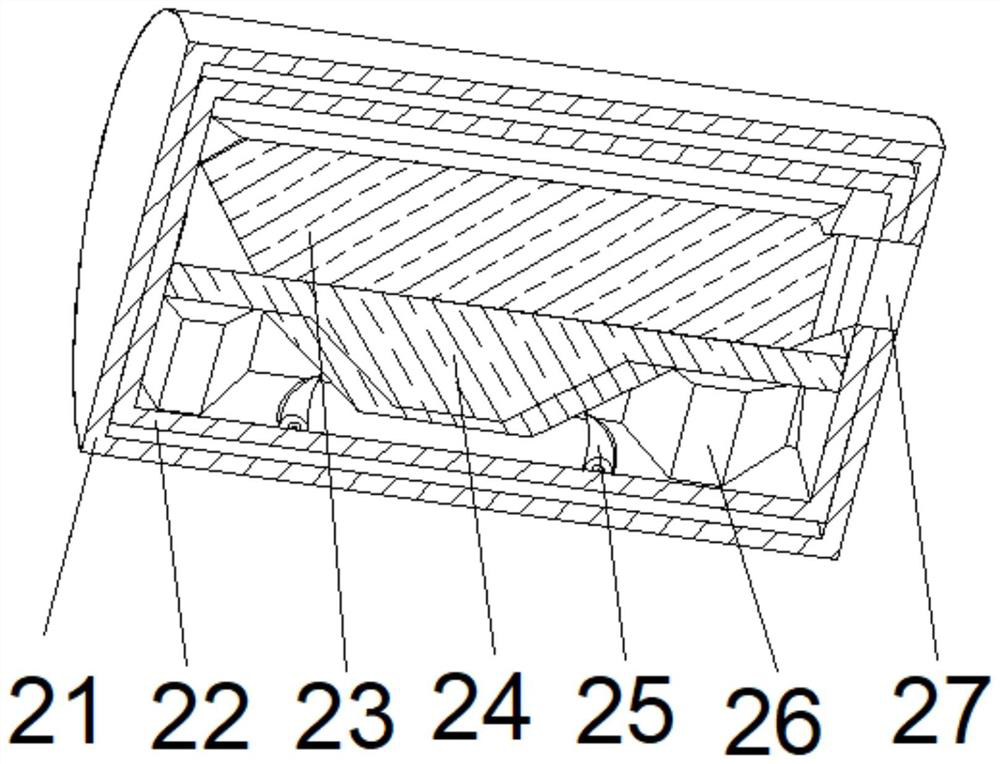

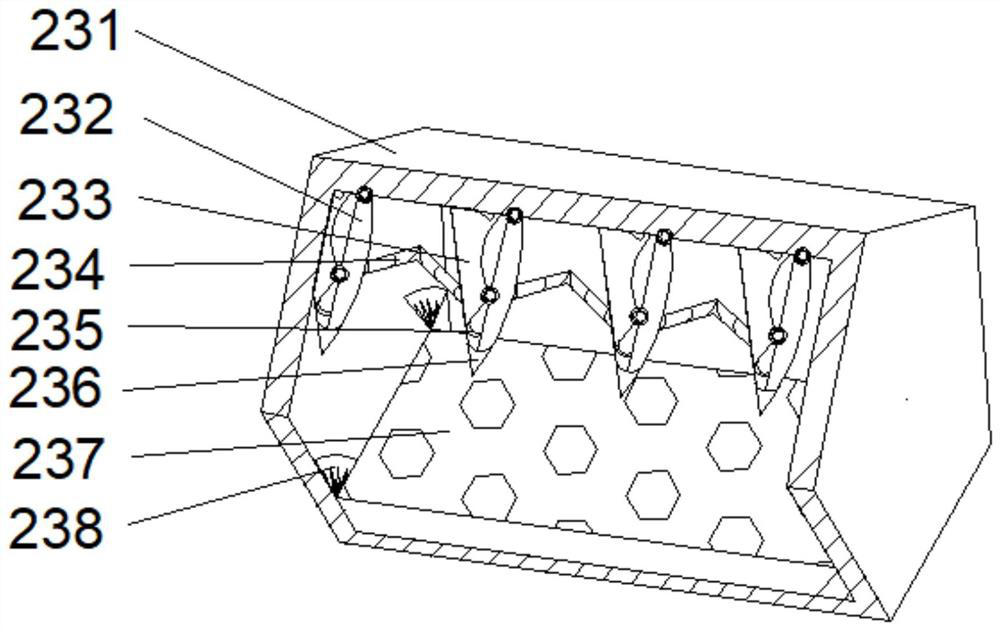

Adjustable double-knife head cutter device and adjustment method for making phenolic air duct

ActiveCN106584585BAdjustable distanceAdjustable spacingMetal working apparatusEngineeringMechanical engineering

The invention discloses an adjustable double cutting head cutter device used for manufacturing a phenolic aldehyde air duct and an adjusting method. The adjustable double cutting head cutter device comprises a cutter mounting block, cutter adjusting blocks, cutter adjusting frames and cutting heads. Cutter adjusting block mounting grooves are formed in the cutter mounting block, and cutter adjusting grooves are formed in the bottom of a cutter frame mounting groove. Adjusting frame mounting grooves are formed in the cutter adjusting blocks. Adjusting holes are formed at the two ends of each adjusting frame mounting groove, and adjusting blocks mounted in the cutter adjusting grooves are arranged at the bottoms of the cutter adjusting blocks. The cutter adjusting blocks are used for, on one hand, adjusting the cutting distance between two blades on one hand, and on the other hand, mounting the cutter adjusting frames. Each cutter adjusting frame is of a shaft structure convenient to rotate and adjust. Fastening threaded end heads are arranged at the two ends of each cutter adjusting frame, and a cutting head mounting groove is arranged in the middle of each cutter adjusting frame. The two cutter adjusting blocks are mounted in the cutter adjusting block mounting grooves, and adjusting blocks of the two cutter adjusting blocks are connected through an adjusting screw rod. The cutter adjusting frames are mounted in the adjusting frame mounting grooves. The two ends of each cutter adjusting frame are adjusted and fixed by locking nuts. The cutting heads are mounted in the cutting head mounting grooves.

Owner:CHINA MCC5 GROUP CORP

Multi-angle adjusting type laser cutting machine

The invention discloses a multi-angle adjusting type laser cutting machine, and relates to the field of laser cutting machines. The machine is reasonable in structure, a to-be-machined workpiece can be conveniently fixed, movement of two workpiece fixing plates can be achieved only by rotating a handle at one place, the laser cutting angle can be adjusted, the structure is ingenious, and the lasercutting machine is suitable for being used and popularized. According to the technical scheme, the l machine is characterized by comprising a cutting machine workbench and a laser device supporting column arranged in the middle of the side face of the cutting machine workbench, wherein a longitudinal mounting top base is arranged on the laser device supporting column; a linear sliding table is fixed to the bottom of the longitudinal mounting top base; a laser device mounting base is arranged at the sliding end of the linear sliding table; a laser generator is arranged on the laser device mounting base; the transmitting end of the laser generator is connected with a laser head through an optical fiber; the laser head is arranged on the laser device mounting base through an angle adjustingmechanism; and the angle adjusting mechanism is used for controlling the laser head to swing left and right.

Owner:江苏觅科激光设备有限公司

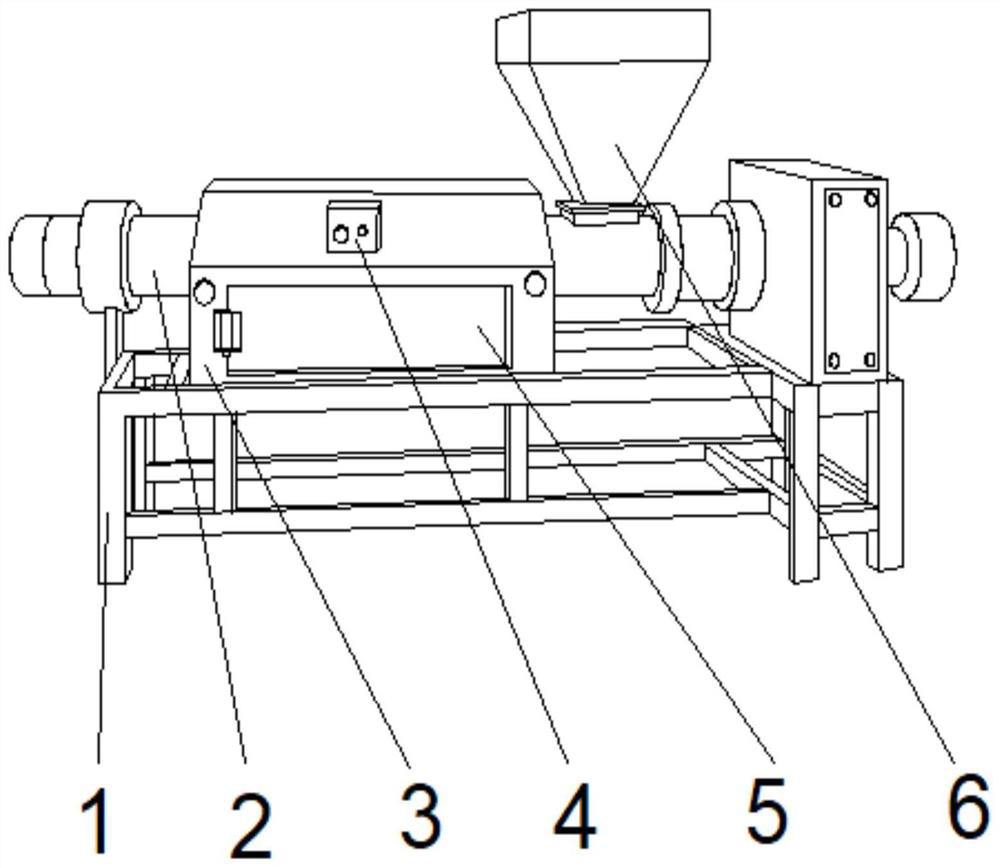

Granulator

PendingCN112693021AIncrease extrusion areaSave internal spaceSievingScreeningInterior spaceEngineering

The invention discloses a granulator. The granulator comprises a base, a cooling box is fixedly connected to the middle of the top of the base, a box door is arranged in the middle of the bottom of the front face of the cooling box, a controller is fixedly connected to the middle of the top of the front face of the cooling box, an extrusion device is arranged on the outer walls of the two sides of the cooling box, the middle of the extrusion device penetrates through the cooling box, and a heating hopper is arranged at the position, located on the right side of the cooling box, of the middle of the extrusion device. The granulator relates to the technical field of granulation equipment. The granulator is provided with the heating hopper, the extrusion device and the cooling box, rubber is heated and melted in the heating hopper and then enters the extrusion device, and manufactured rubber particles are uniform; during extrusion, the extrusion device makes contact with the rubber at first, shrinking is conducted, the internal space is reduced, and therefore the extrusion area of the rubber is increased, and unqualified rubber particles are treated; and the working efficiency is improved, the cutting efficiency is improved, and the situation of cutting omission is avoided.

Owner:李会娟

Multifunctional new energy lawn mower

InactiveCN109496534AProtection from damageAdjustable cutting angleMowersRenewable energy machinesNew energyEngineering

The invention discloses a multifunctional new energy lawn mower in the technical field of new energy. The multifunctional new energy lawn mower comprises a lawn mower frame, a motor mounting frame isarranged at the middle part of the lower cavity of the lawn mower frame, the motor mounting frame is hinged to the top of the lower cavity of the lawn mower frame, the left sidewall of the lower cavity of the lawn mower frame is provided with a first engaging lug, the left sidewall of the motor mounting frame is provided with a second engaging lug, an electric push rod is hinged between the firstengaging lug and the second engaging lug, and a motor is fixedly mounted in the inner cavity of the motor mounting frame. A solar panel assembly converts solar energy into electrical energy and storesthe electric energy in a storage battery, the rotation of a rotating mounting plate and a sidewall mounting plate protects the solar panel assembly from being damaged when not in use, grass is cut bycutting blades, and a height between the cutting blades and the ground is adjusted through a second electric push rod to easily cut lawns having different heights.

Owner:合肥众建翔新能源有限公司

Wooden door four-side saw with groove-shaped workbenches and sawing method of wooden door four-side saw

ActiveCN112677244ASuitable for processingConsistent thicknessCircular sawsStructural engineeringWorkbench

The invention provides a wooden door four-edge saw with groove-shaped workbenches and a sawing method of the wooden door four-edge saw. The wooden door four-edge saw comprises a rack, a door length sawing group, a door width sawing group and the two groove-shaped workbenches which are arranged on two bases; each groove-shaped workbench comprises two narrow-edge workbench surfaces; the workbench surfaces are arranged on the bases; a lifting type conveying belt is arranged between the two workbench surfaces of each groove-shaped workbench; and the lifting type conveying belts are arranged on the bases. According to the wooden door four-edge saw with the groove-shaped workbenches and the saw cutting method of the wooden door four-edge saw, the groove-shaped workbenches are adopted, the lifting type conveying belts are arranged between the two workbench surfaces of each groove-shaped workbench, when a narrow door is machined, the two groove-shaped workbenches are driven by a left threaded lead screw and a right threaded lead screw to get close to the middle at the same time, blocking of the lifting type conveying belts is avoided, and the limiting distance can be achieved, so that the width of the narrow door capable of being machined can reach the minimum value, and the saw is suitable for machining of a child door of a child-mother door.

Owner:JIANGSU GUOQUAN AUTOMATION TECH CO LTD

Clamping device with angle convenient to adjust used during cutting of special-diameter pipe inclined end part

The invention discloses a clamping device with an angle convenient to adjust used during cutting of a special-diameter pipe inclined end part. The clamping device comprises a device fixing seat and aprotective shell, wherein the middle position of the device fixing seat is provided with a first rotating rod in a penetrated mode, the right end of the first rotating rod is provided with a grip, themiddle position of the first rotating rod is provided with a main gear, a fixing sleeve is mounted on the left side of the main gear, and a first transmission gear is mounted above the main gear; andthe first transmission gear is connected with a second transmission gear through a transmission shaft, the inner side of the second transmission gear is provided with a telescopic rod in a meshing mode, the upper end of the telescopic rod is connected with an abutting plate, the protective shell is connected to the device fixing seat through a second rotating rod, a threaded rod is arranged in the upper portion of the protective shell in a penetrating mode, a pressing plate is mounted at the lower end of the threaded rod, and a rubber pad is bonded to the lower surface of the pressing plate.According to the clamping device, the requirement of clamping of a special-diameter pipe in the cutting process can ne well met, and angle adjustment can be carried out in the cutting process, so thatthe cutting process is more convenient and faster.

Owner:徐州标特福数控科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com