Plate cutting machine and cutting method

A cutting machine and plate technology, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of inconvenient plate angle adjustment, touching the cutting wheel, potential safety hazards, etc., to protect the service life and work efficiency, dismantling Easy installation and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

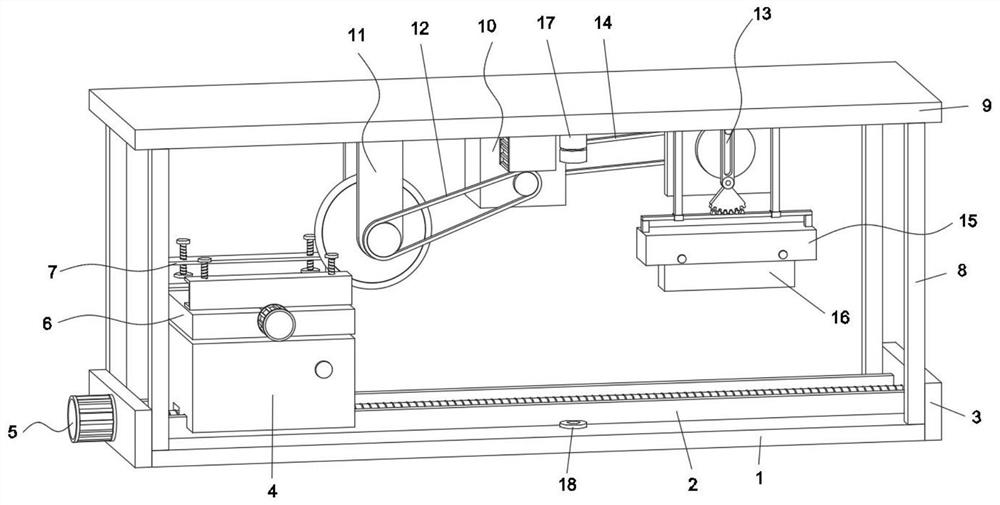

[0044] see figure 1 and Figure 9 , the present embodiment is a plate cutting machine, including a bottom plate 1, two guide rails 2 are symmetrically arranged on the top wall of the bottom plate 1, side plates 3 are fixed on both sides of the bottom plate 1, and a workbench 4 is slidably arranged on the guide rail 2, and the workbench 4 The bottom is provided with a driving assembly 5, the top of the workbench 4 is provided with a turntable 6, and the top of the turntable 6 is symmetrically provided with two clamping assemblies 7, the four corners of the top wall of the bottom plate 1 are fixed with columns 8, and the top of the column 8 is fixed with a top plate 9, Top plate 9 bottom wall is provided with cutting assembly 11, power assembly 10 and reciprocating assembly 13 successively, and power assembly 10 is connected cutting assembly 11 by first transmission belt 12, and power assembly 10 is connected reciprocating assembly 13 by second transmission belt 14, and reciproc...

Embodiment 2

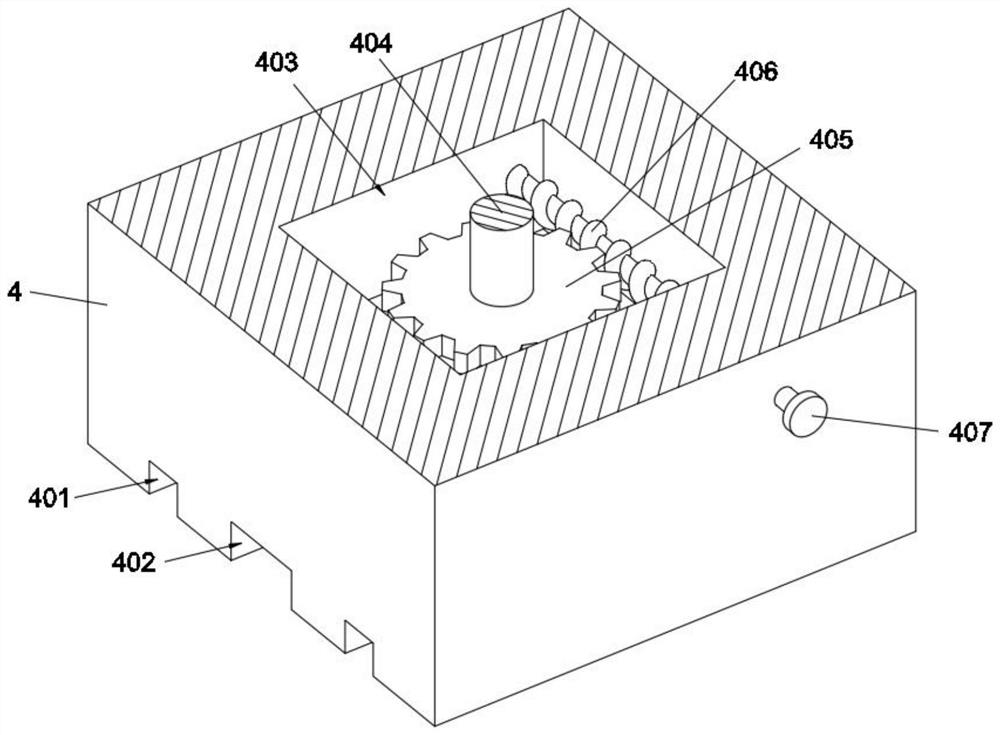

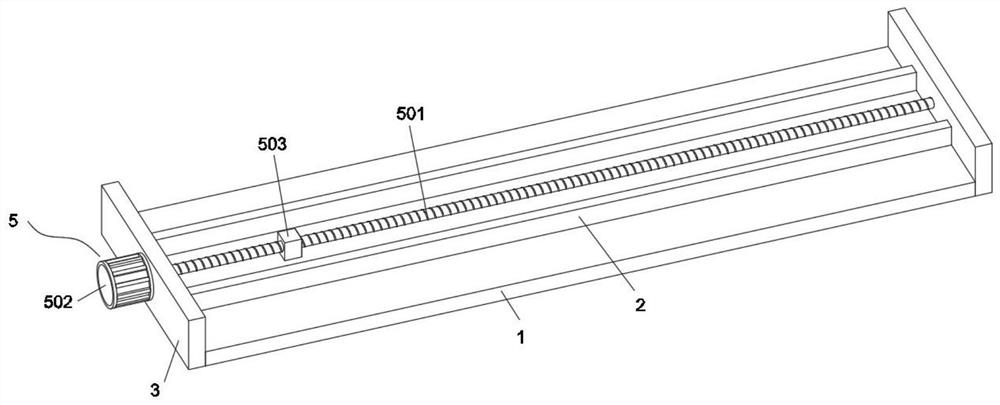

[0046] see Figure 2-3 , the bottom of the workbench 4 is provided with a guide groove 401 corresponding to the position of the guide rail 2, and the bottom of the workbench 4 is provided with a rectangular through groove 402 between the guide grooves 401, and a cavity 403 is provided in the workbench 4, and the cavity 403 is vertically rotated. There is a rotating shaft 404, a worm wheel 405 is fixed on the rotating shaft 404, and the worm wheel 405 is meshed with a worm 406, and the worm 406 is horizontally rotated and arranged in the cavity 403, and one end of the worm 406 passes through the side wall of the workbench 4 through a bearing and is fixed with a rotating knob 407. The top of the rotating shaft 404 runs through the top wall of the workbench 4 through bearings and is fixedly connected to the center of the bottom end of the turntable 6. The driving assembly 5 includes a screw 501, a first servo motor 502 and a screw block 503. The screw 501 is rotatably arranged bet...

Embodiment 3

[0048] see Figure 4 , the turntable 6 includes a platform body 601, a limit chute 602 is provided in the center of the top of the platform body 601, a bidirectional lead screw 603 is arranged for rotation in the limit chute 602, a second servo motor 604 is fixed on one side of the platform body 601, and the second The power output shaft of the servo motor 604 runs through the side wall of the table body 601 through bearings and is fixedly connected to one end of the two-way lead screw 603. The two ends of the two-way lead screw 603 are symmetrically screwed with two lead screw nuts 605, and the top of the lead screw nut 605 is fixed with a connecting clamp. Component7. The set turntable 6 can adapt to plates of different sizes within a certain range, and has strong practicability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com