Patents

Literature

38results about How to "Meet different cutting needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

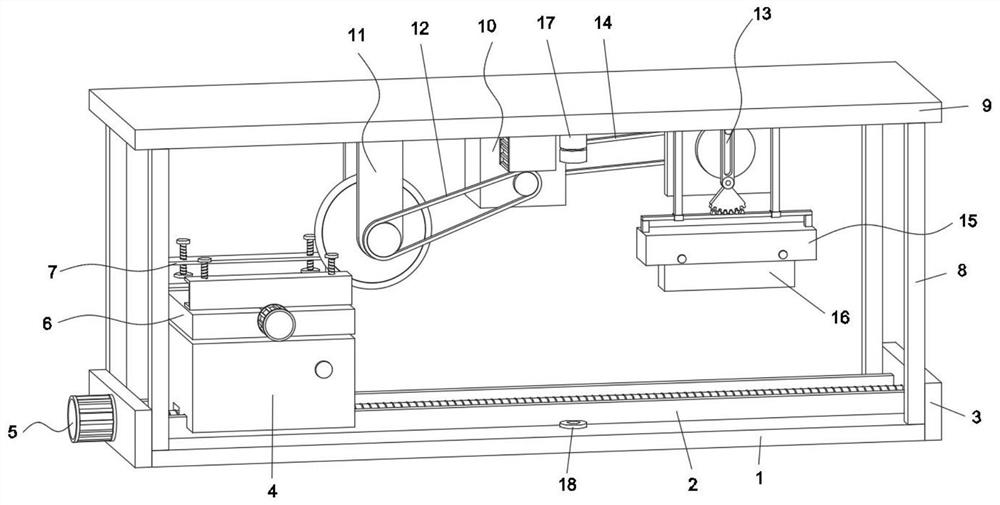

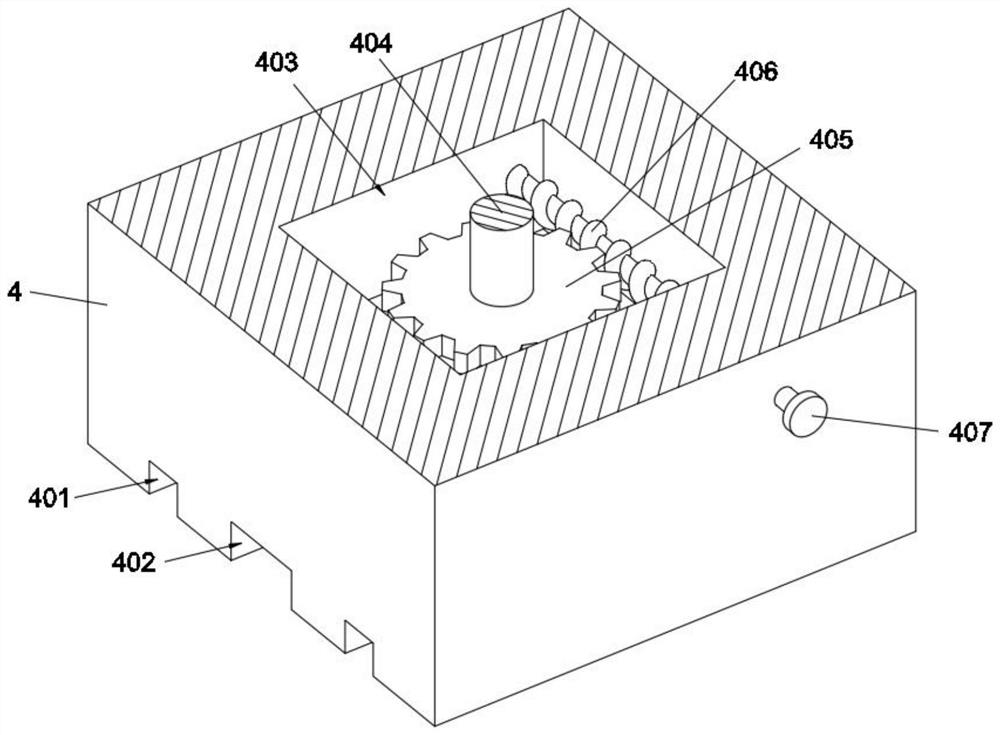

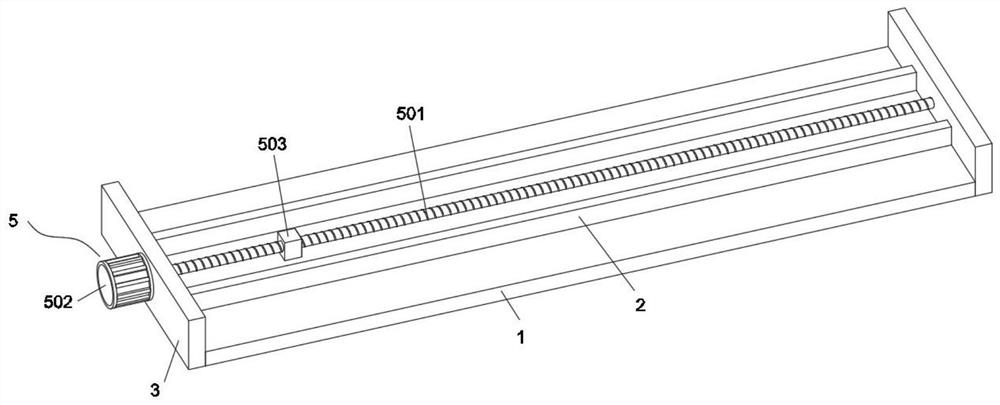

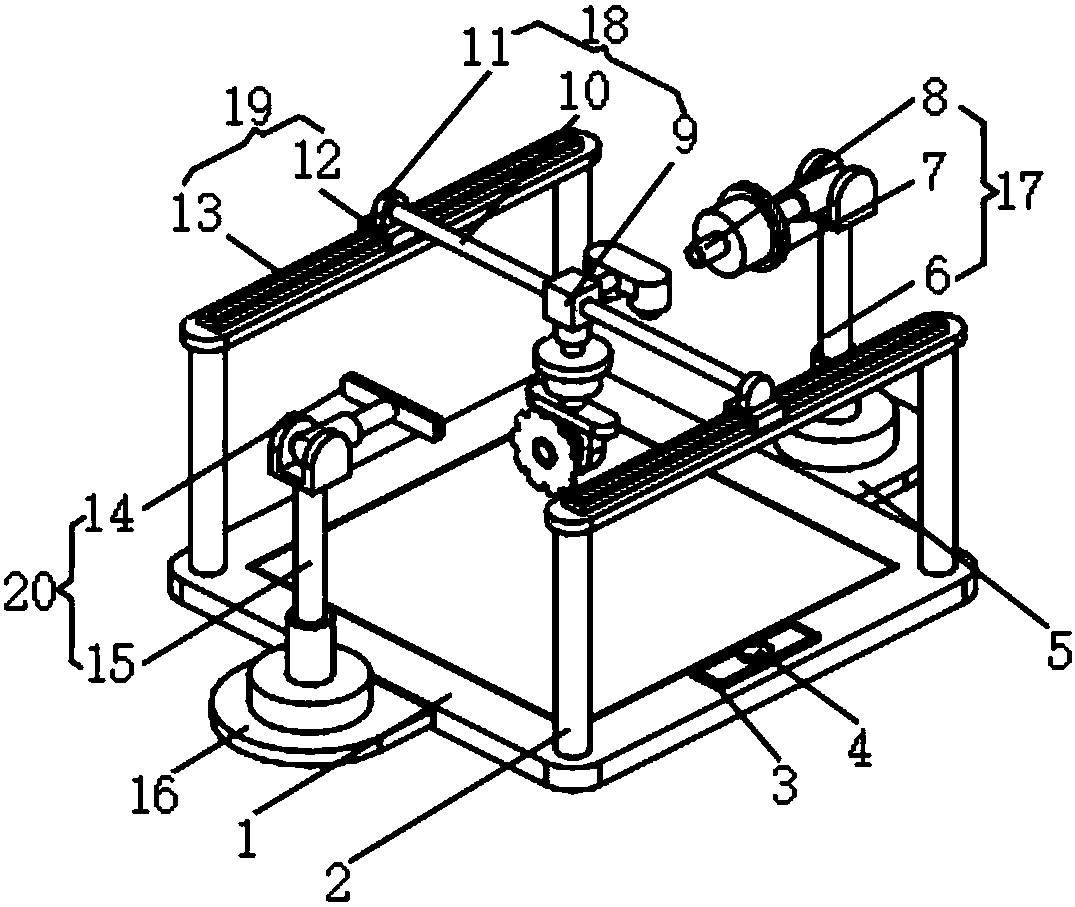

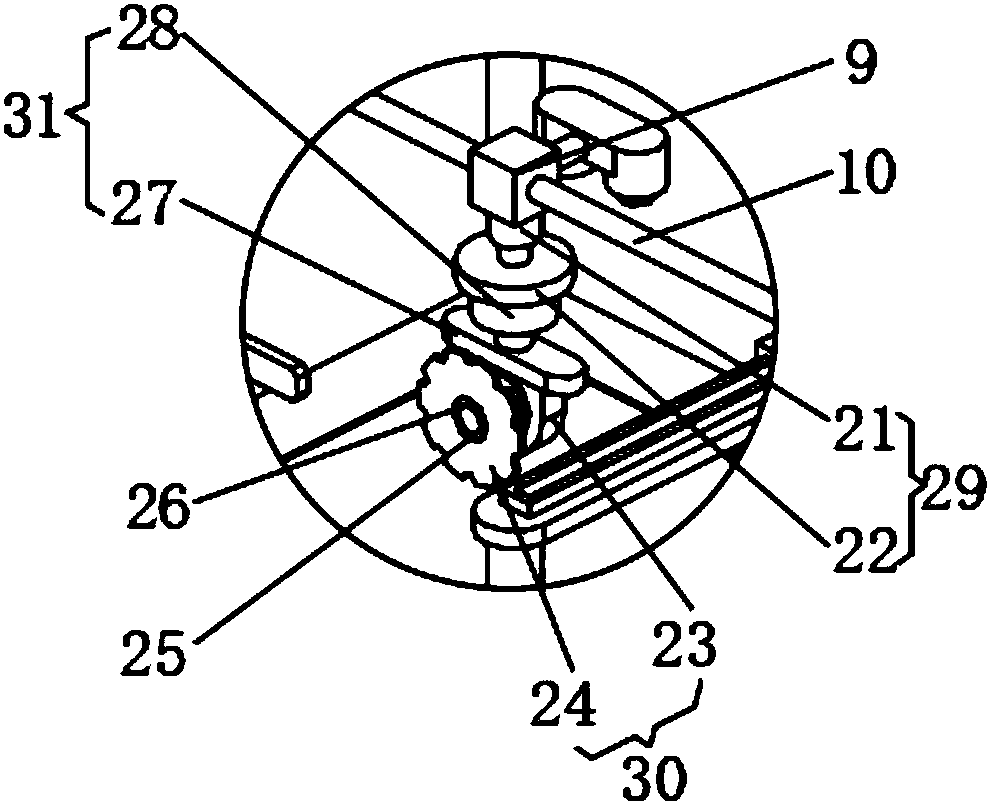

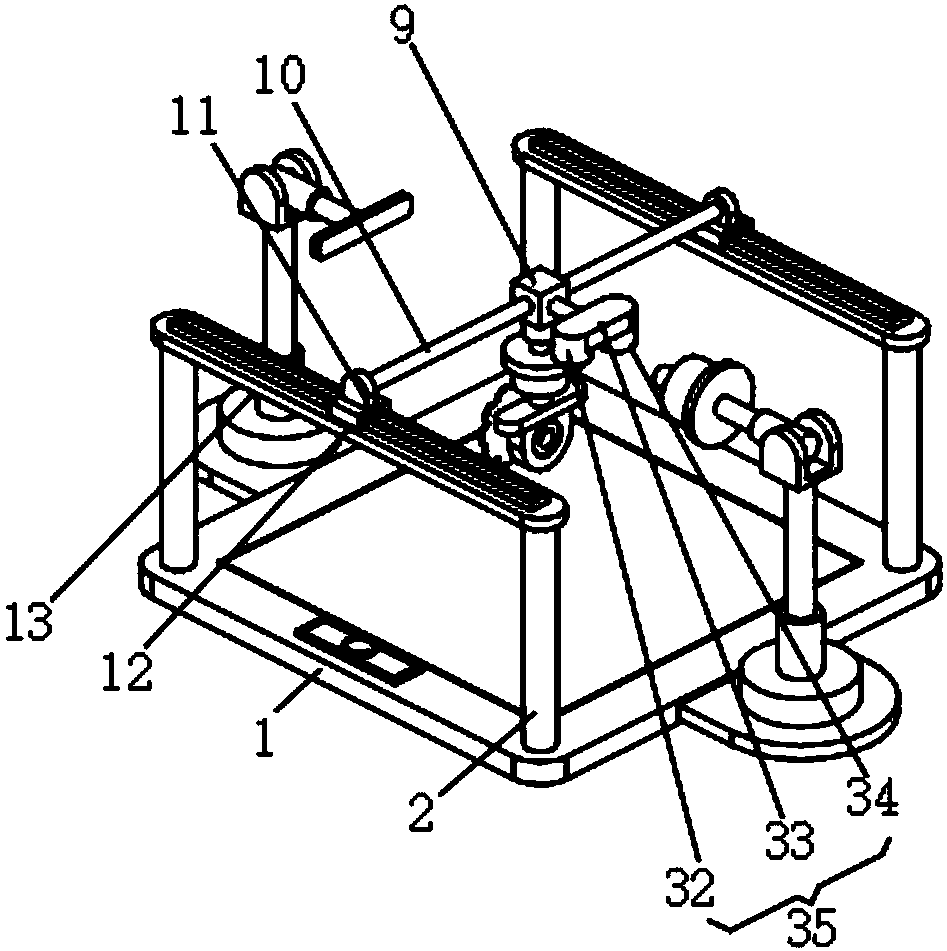

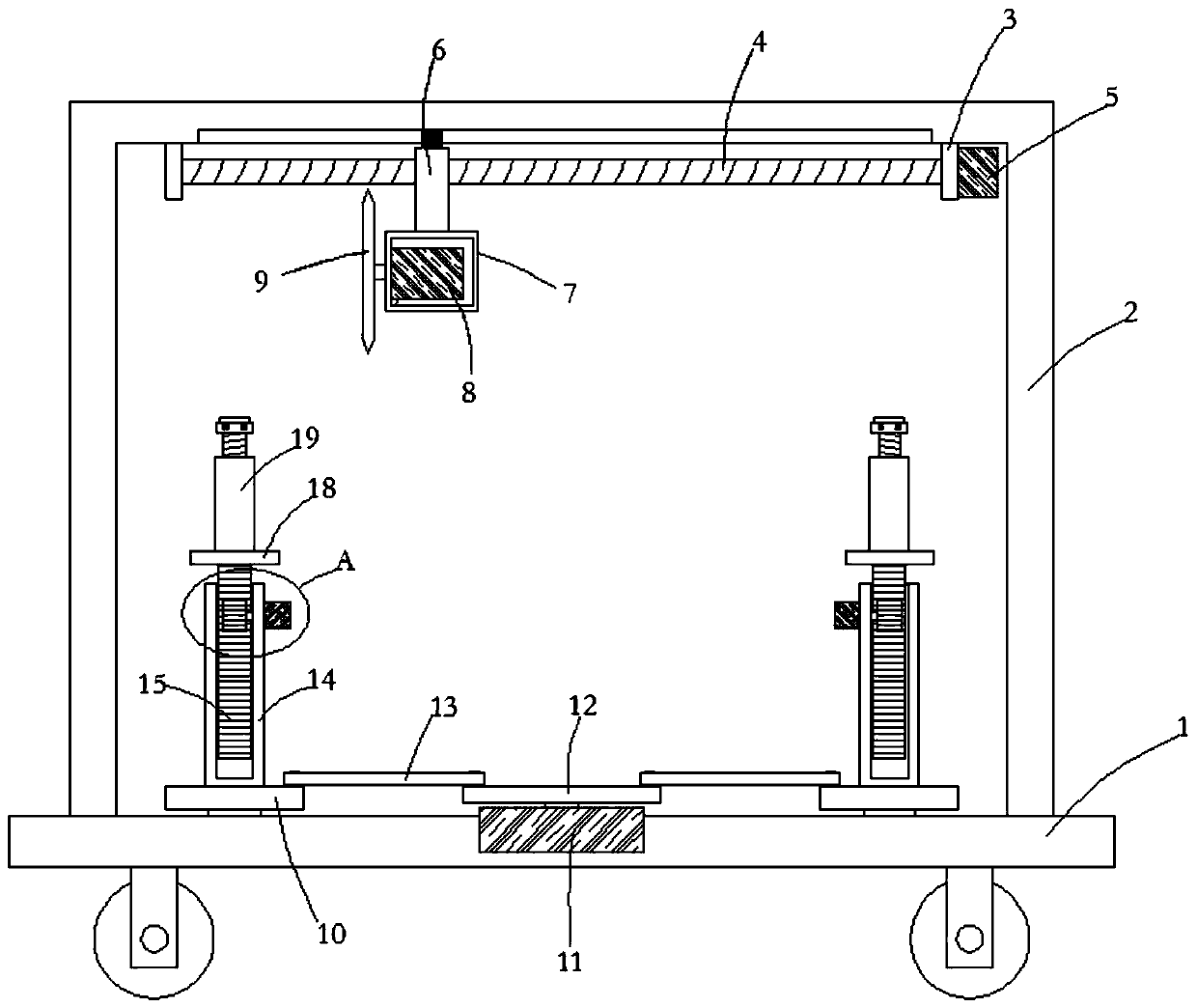

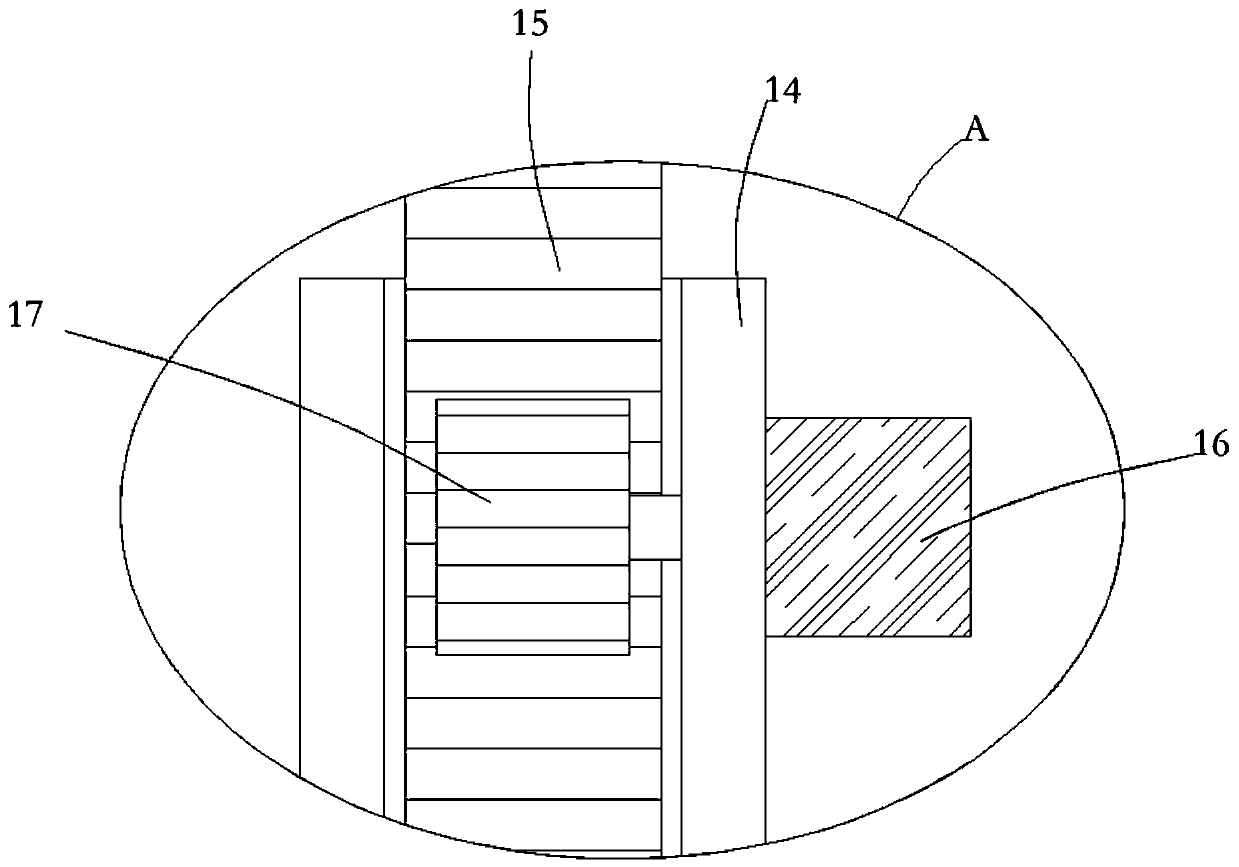

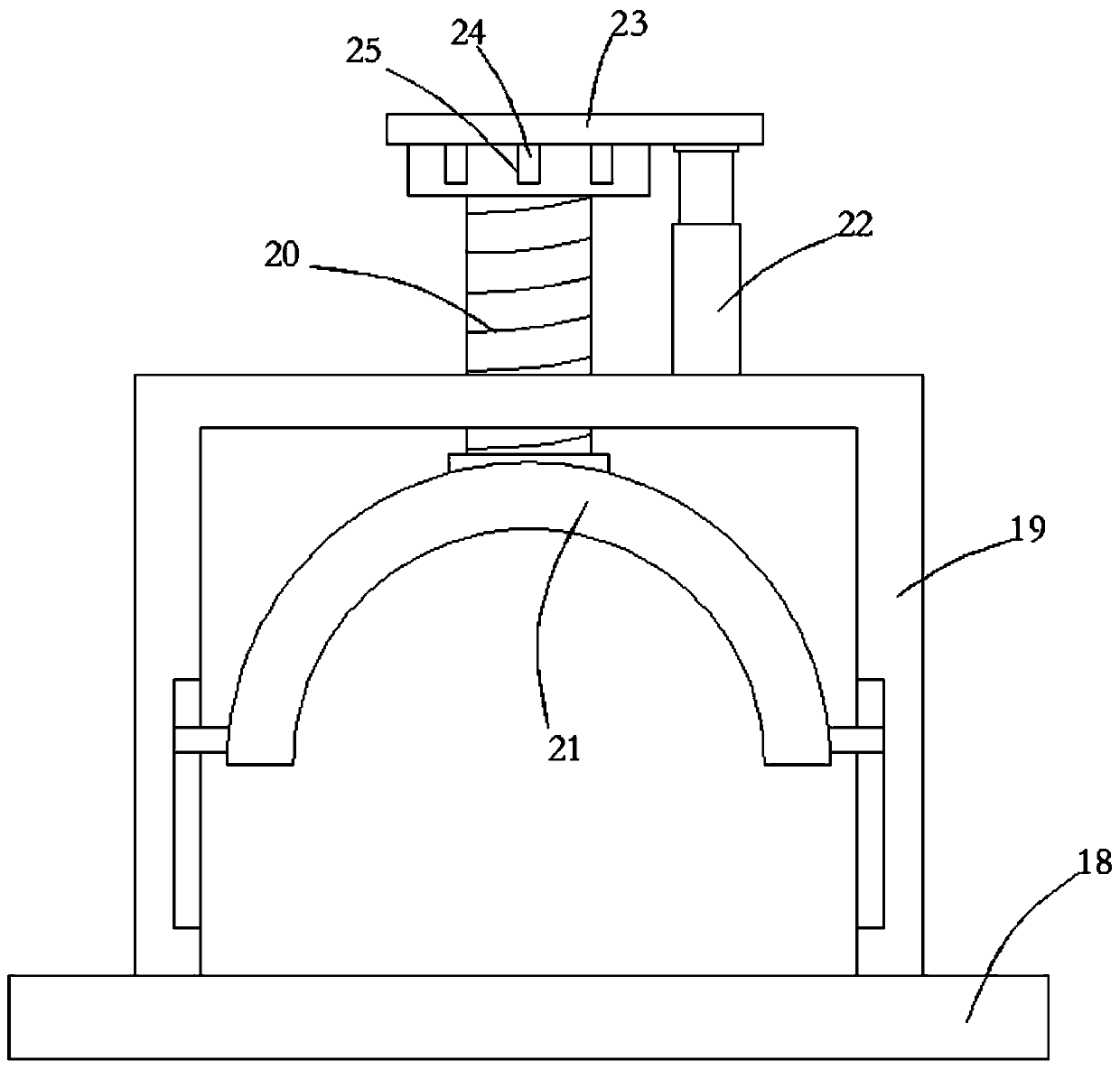

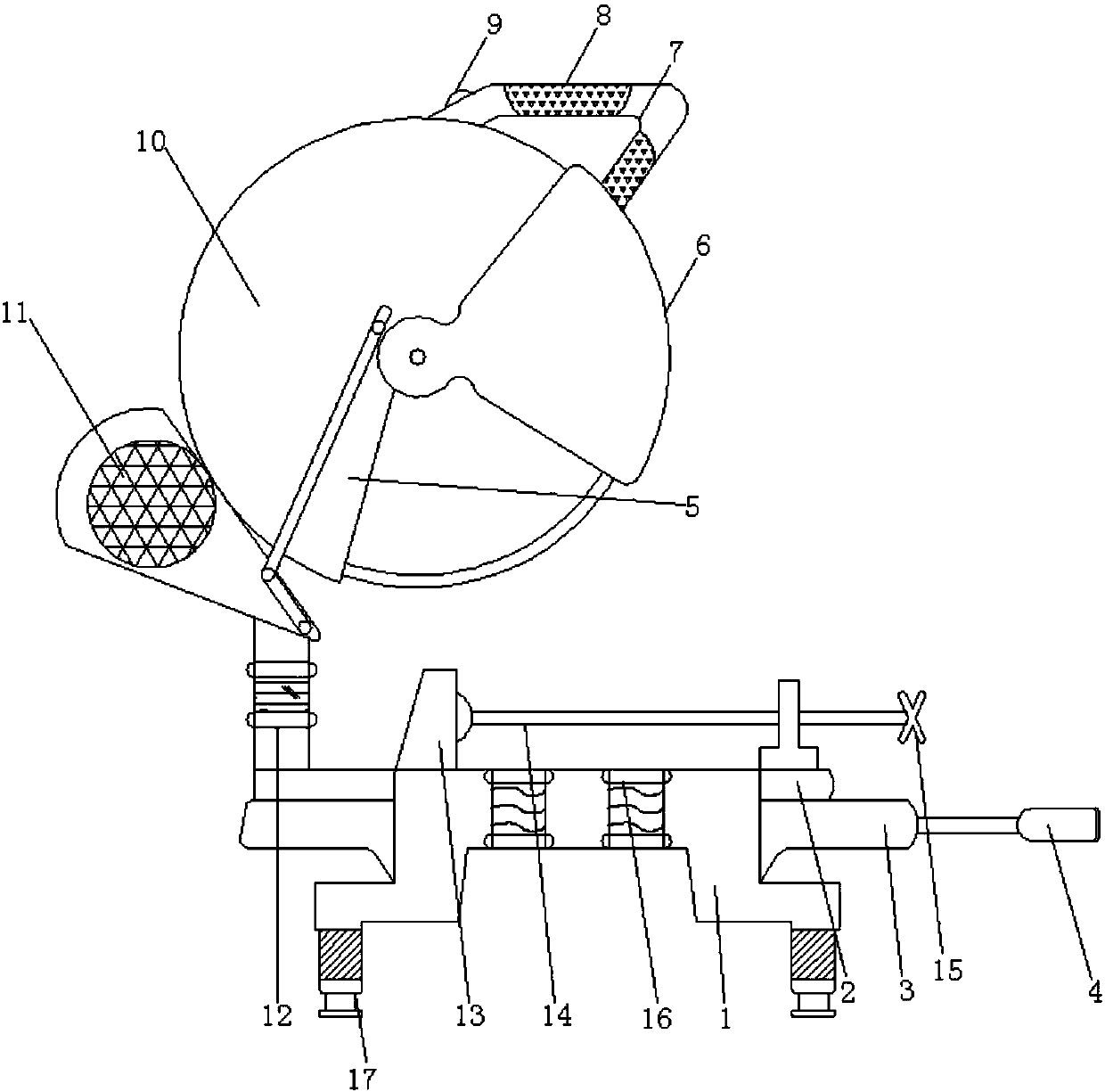

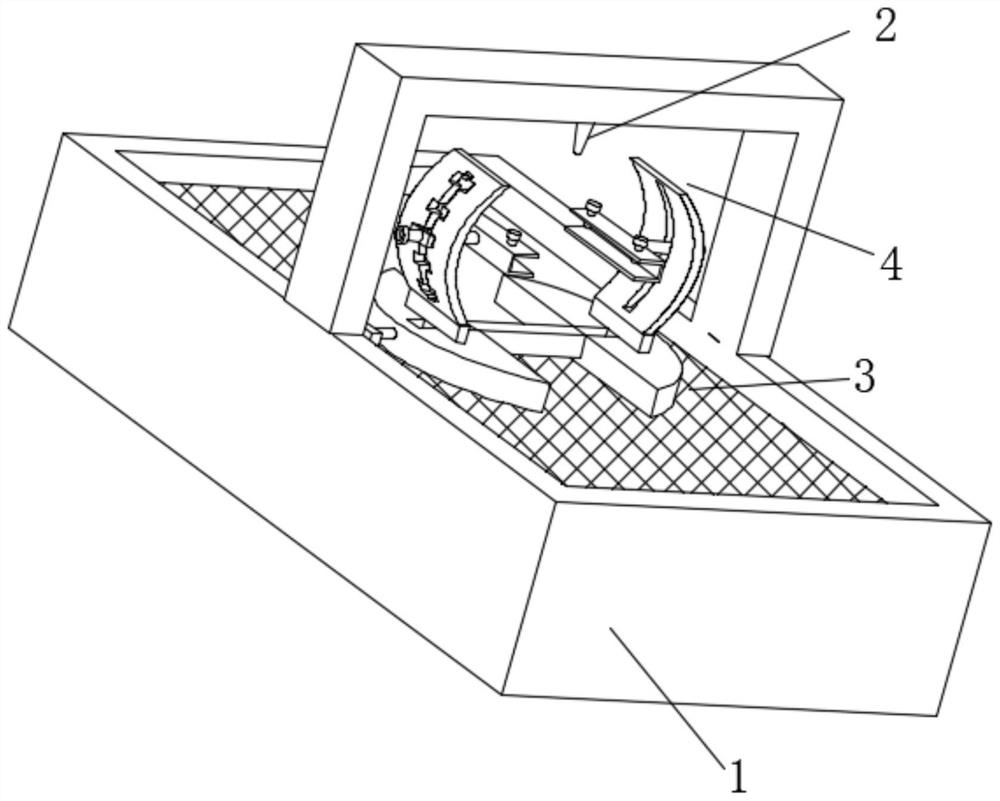

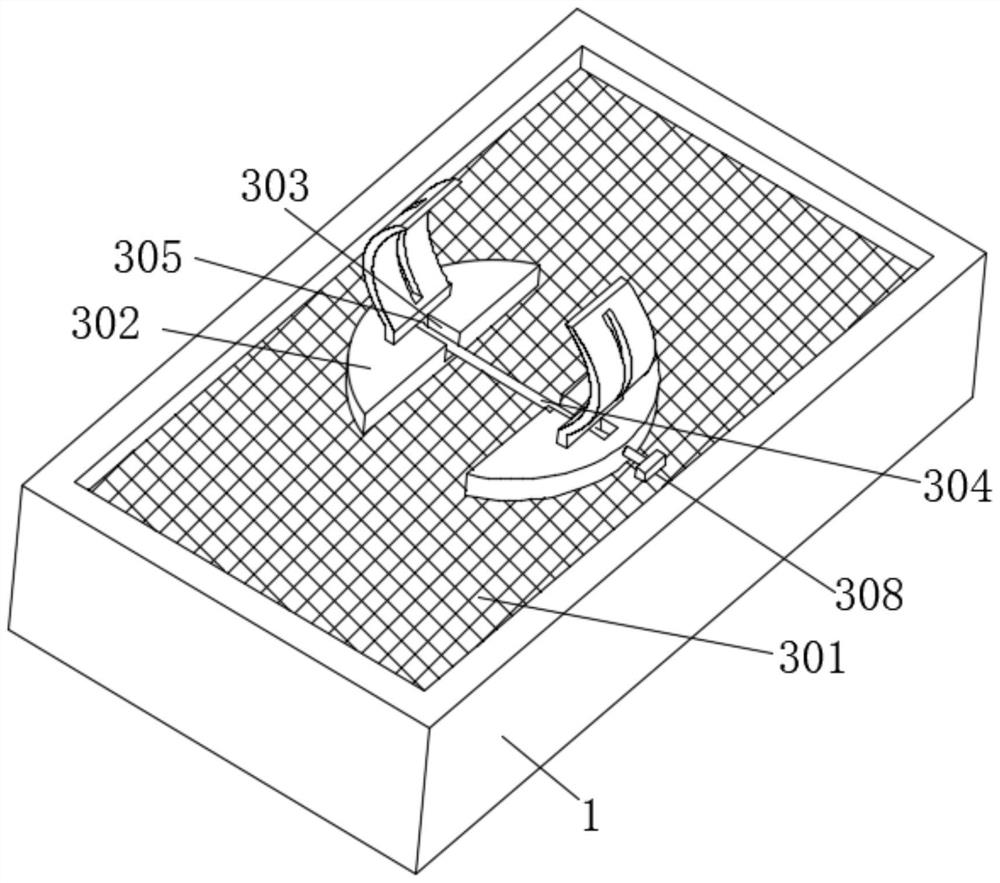

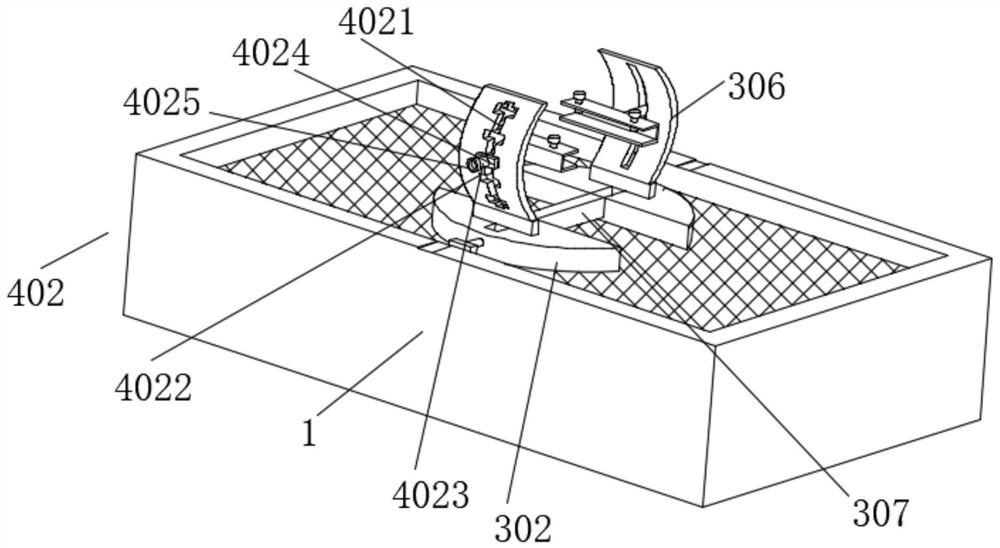

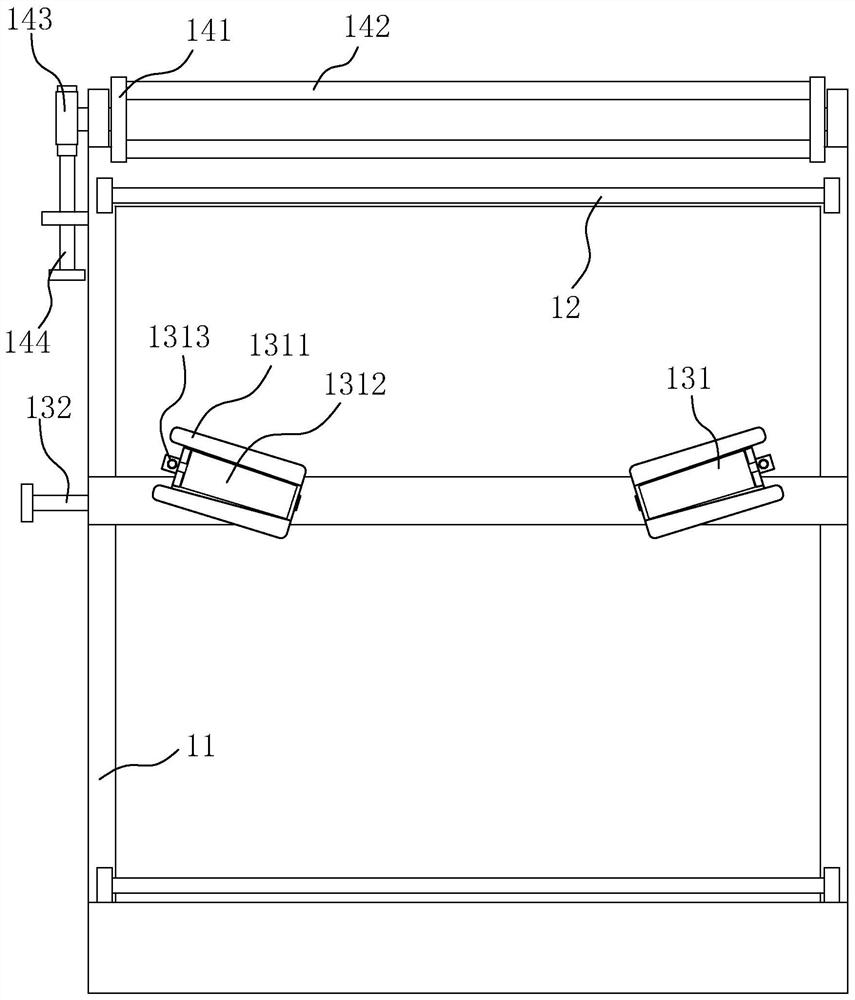

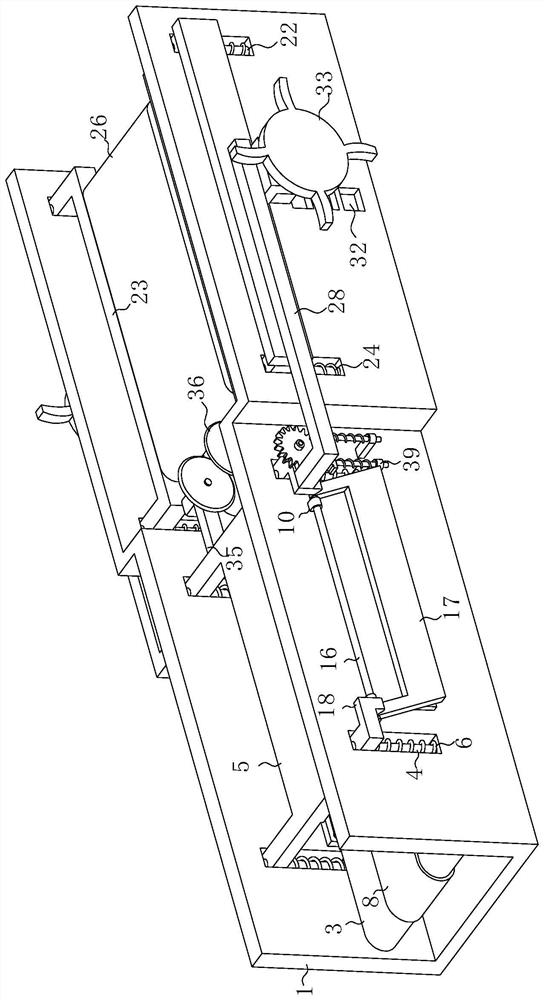

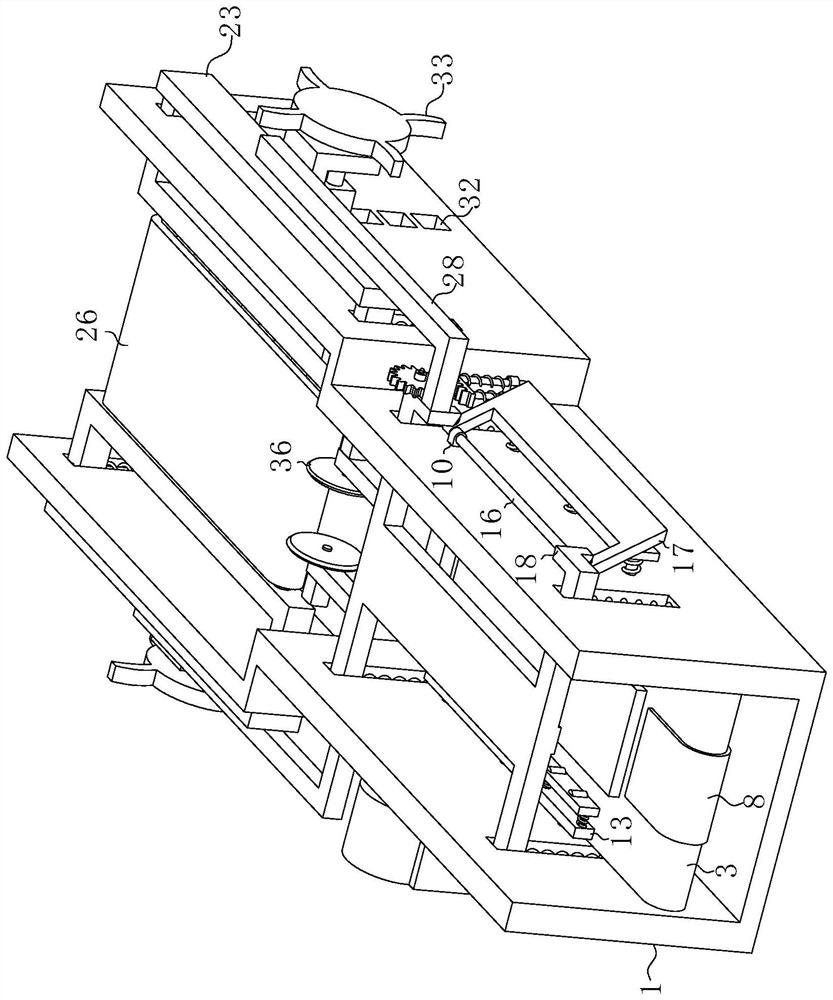

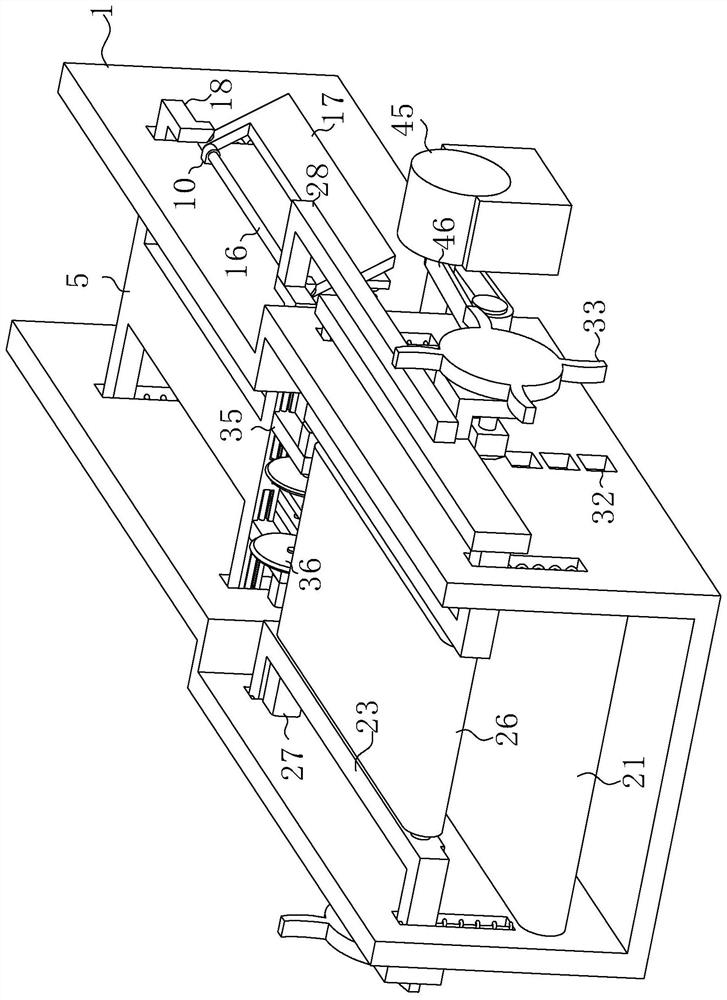

Plate cutting machine and cutting method

InactiveCN111843502AAdjustable cutting angleMeet different cutting needsOther manufacturing equipments/toolsLaser transmitterElectric machinery

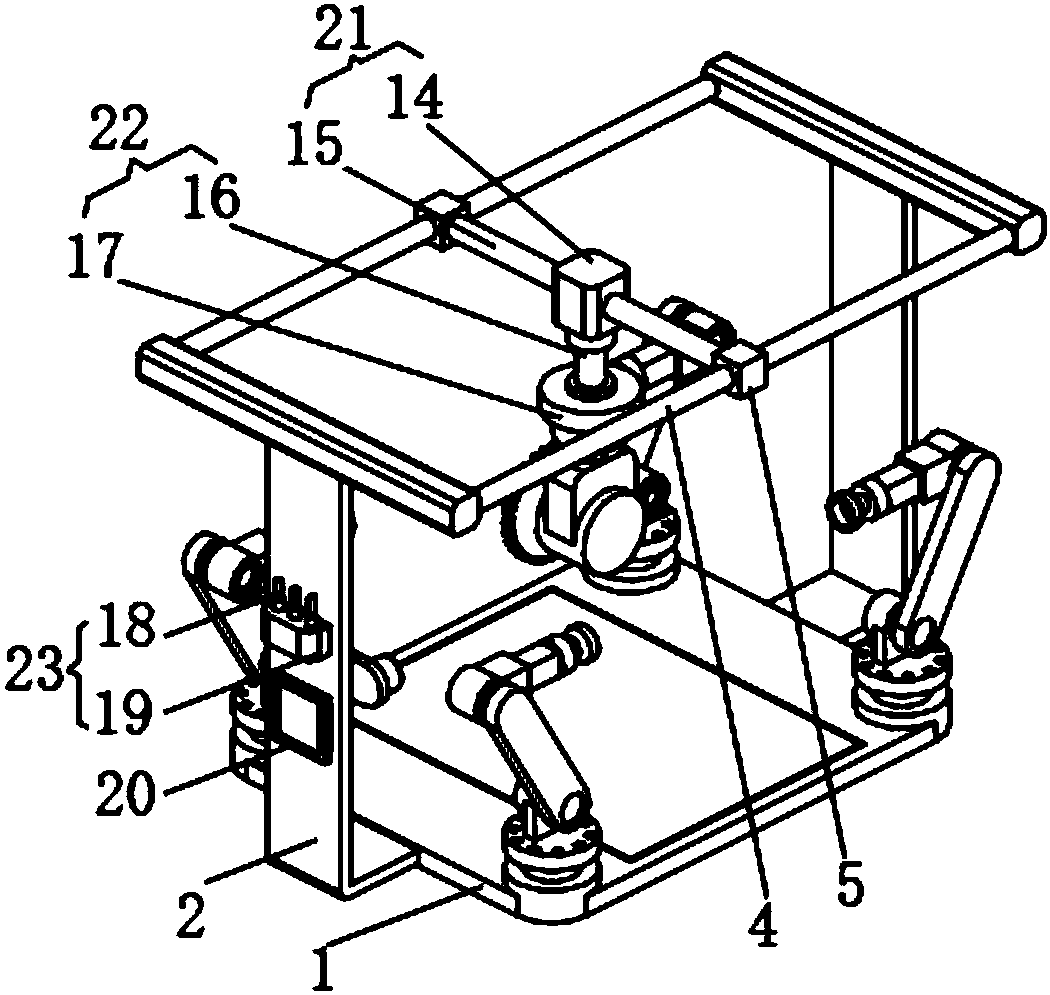

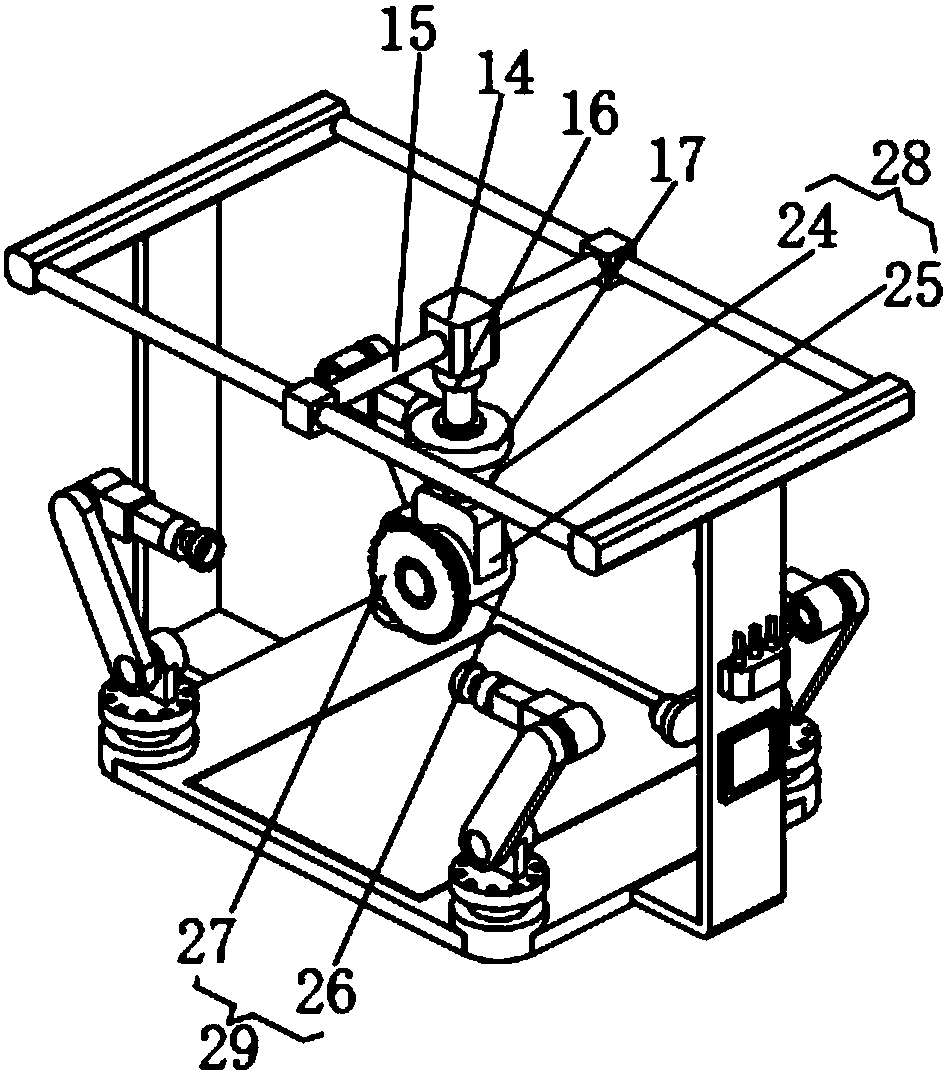

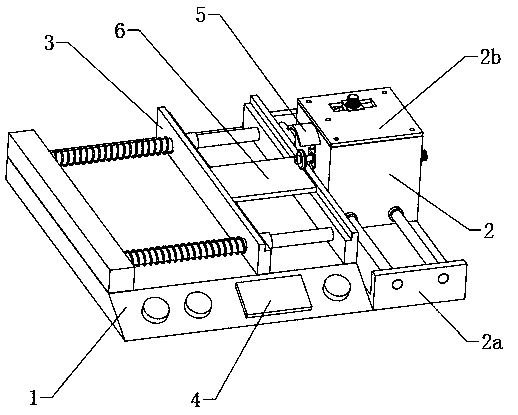

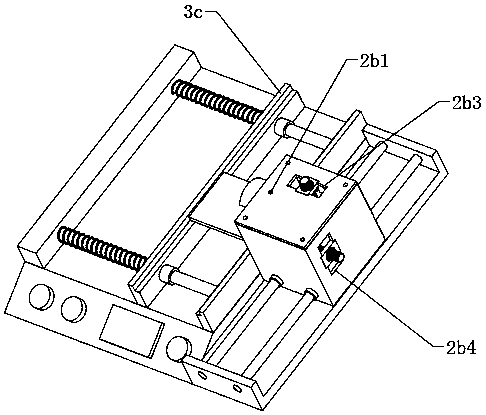

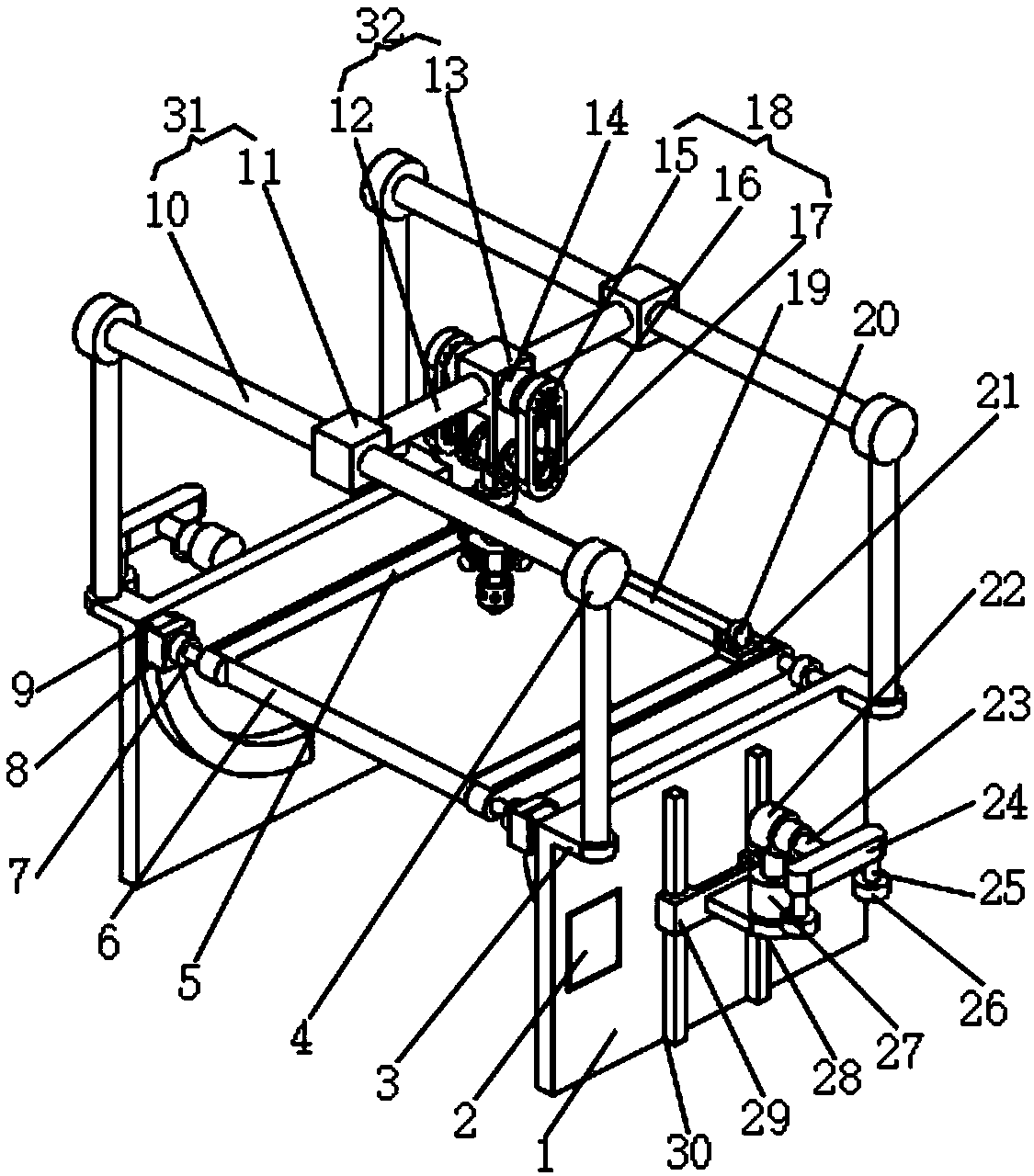

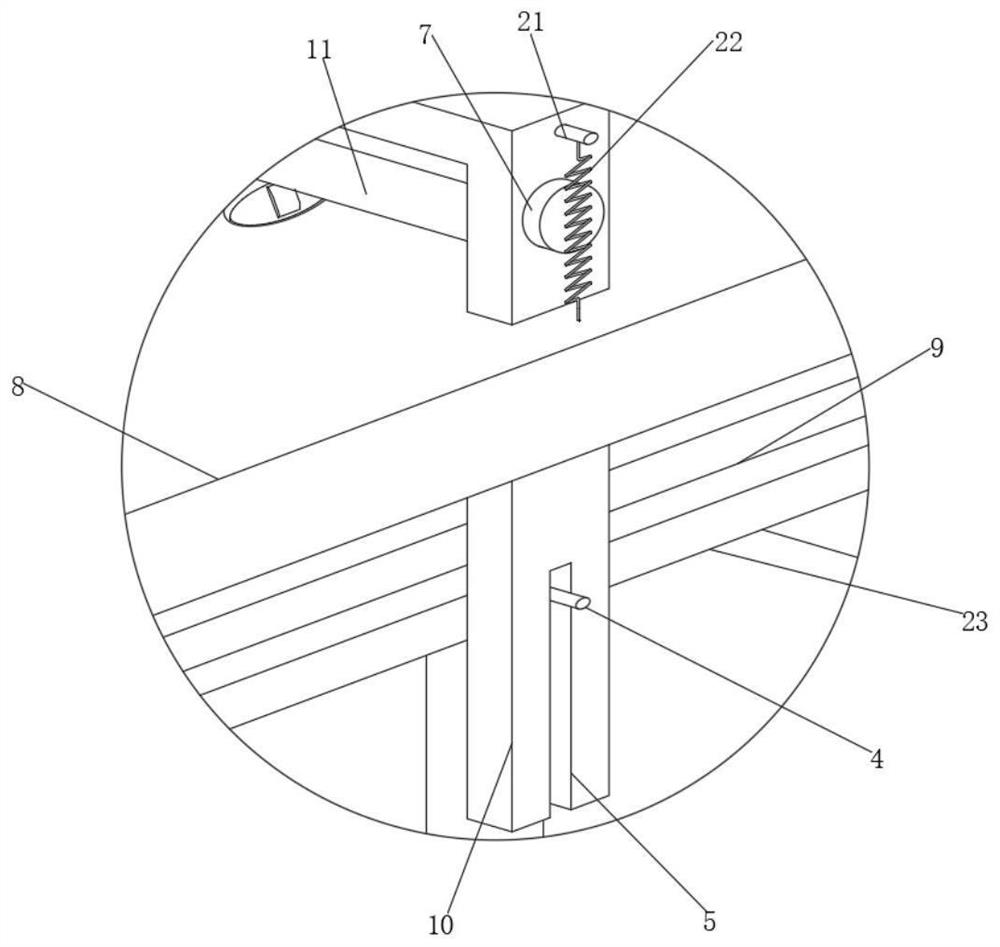

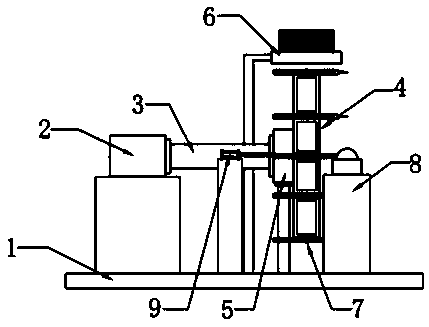

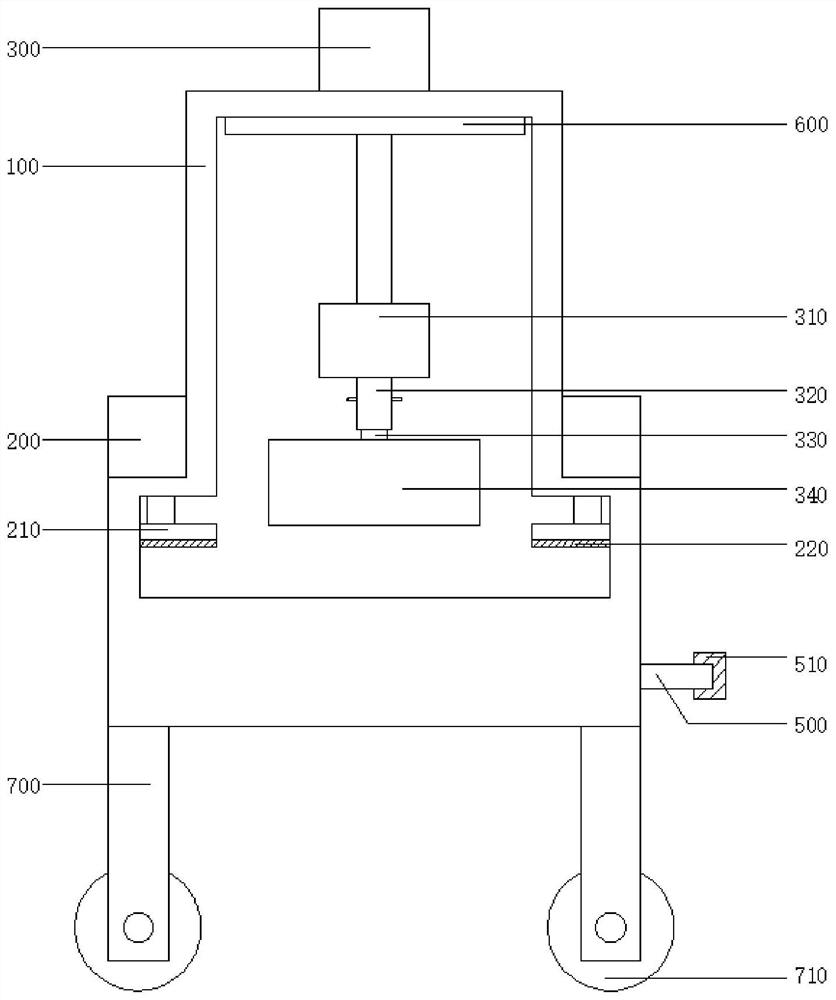

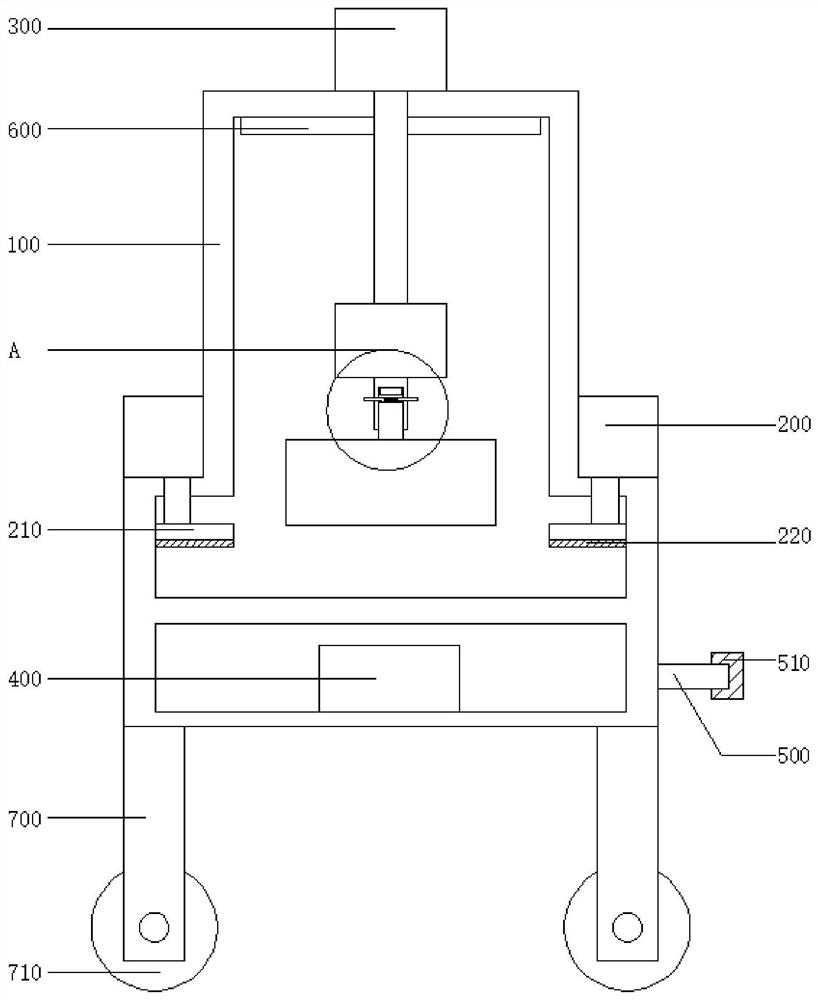

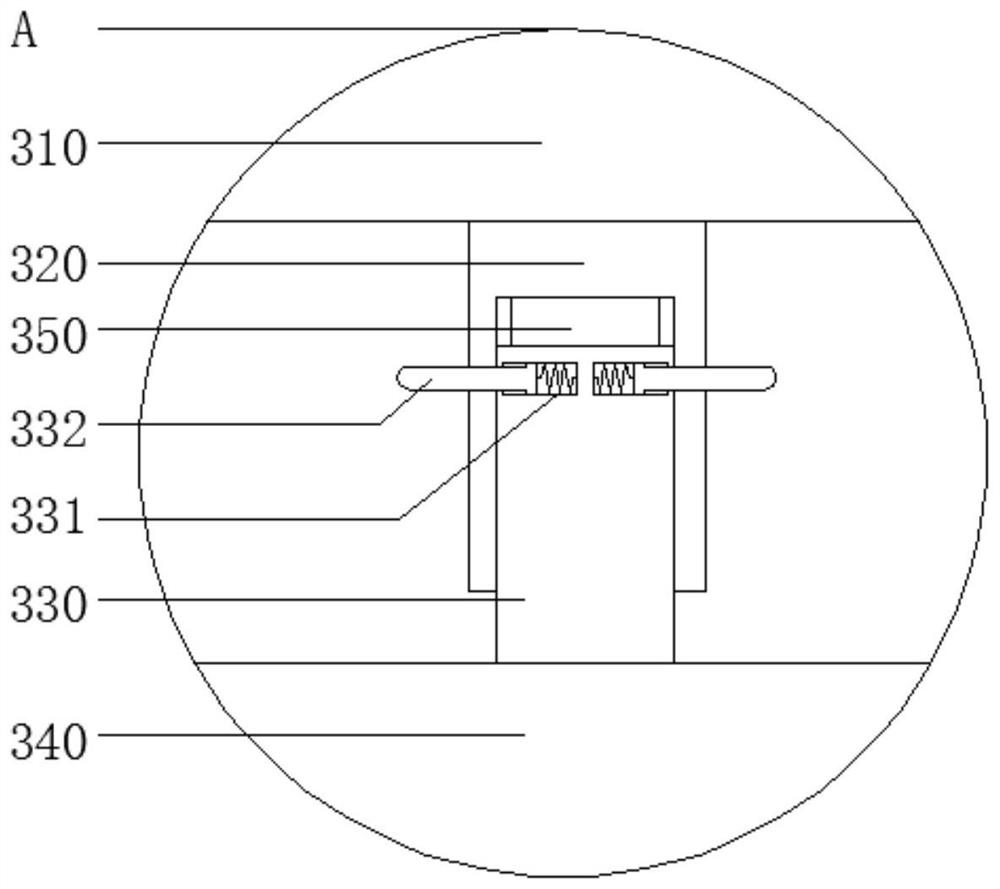

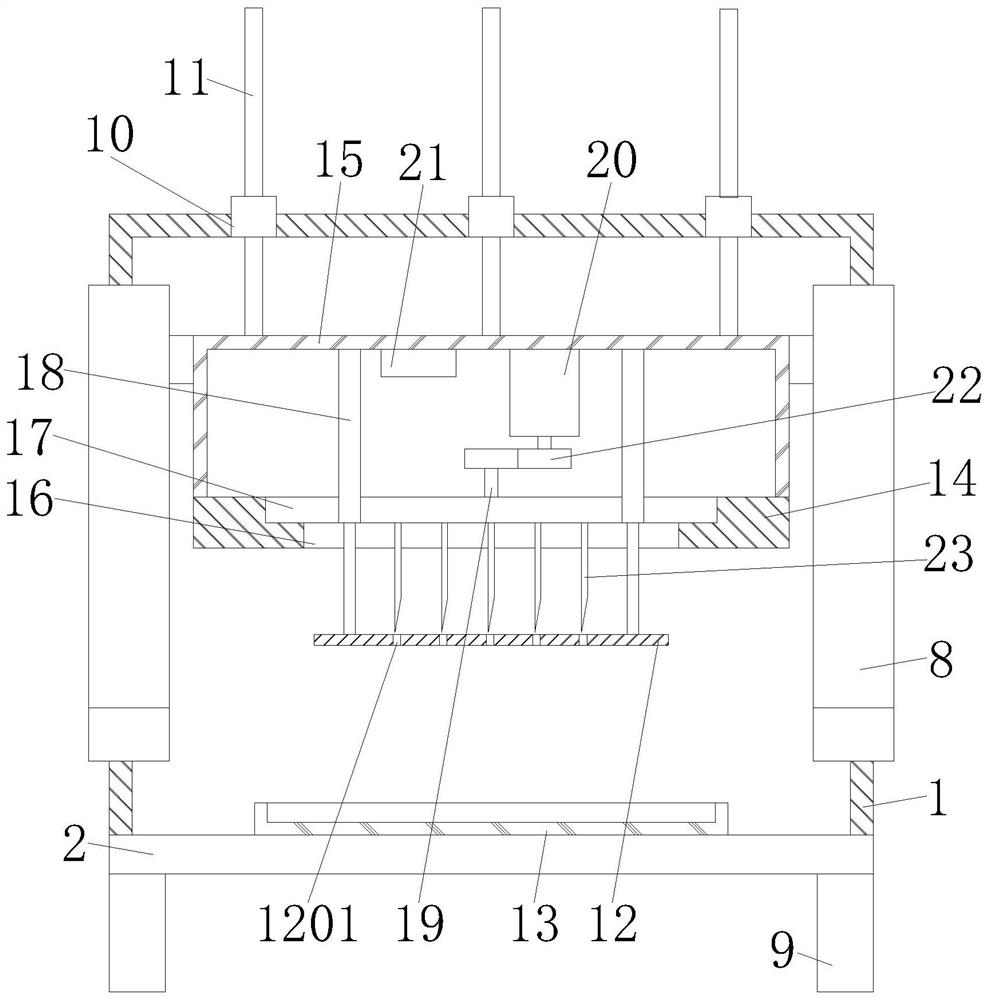

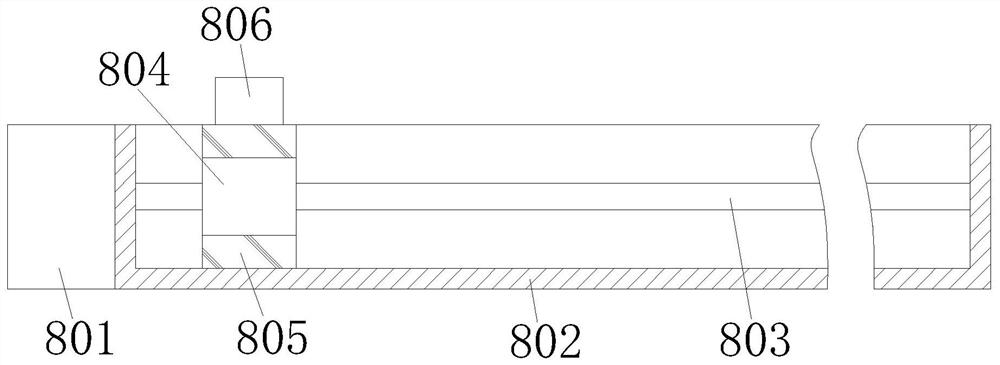

The invention relates to the technical field of plate machining equipment, in particular to a plate cutting machine and a cutting method. The plate cutting machine comprises a bottom plate, wherein aguide rail is arranged on the top wall of the bottom plate, side plates are fixed to the two sides of the bottom plate, a workbench slidably is arranged on the guide rail, a driving assembly is arranged at the bottom of the workbench, a rotating table is arranged at the top of the workbench, a clamping assembly is arranged at the top of the rotating table, stand columns are fixed to the four corners of the top wall of the bottom plate, a top plate is fixed to the tops of the stand columns, a cutting assembly, a power assembly and a reciprocating assembly are sequentially arranged on the bottomwall of the top plate, a mounting block is fixed to the bottom of the reciprocating assembly, a grinding block is clamped to the bottom of the mounting block, a laser transmitter is fixed to the bottom wall of the top plate, and a laser receiver is fixed to the upper wall of the bottom plate. When the plate cutting device is used, the cutting angle of plates can be adjusted, the plates of different sizes can be clamped within a certain range, the application range is wide, the arranged power assembly can drive the cutting assembly and the reciprocating assembly to work, the use number of motors is reduced, energy consumption is reduced, and meanwhile the grinding block is convenient to replace.

Owner:成都毅莘瑞科技有限公司

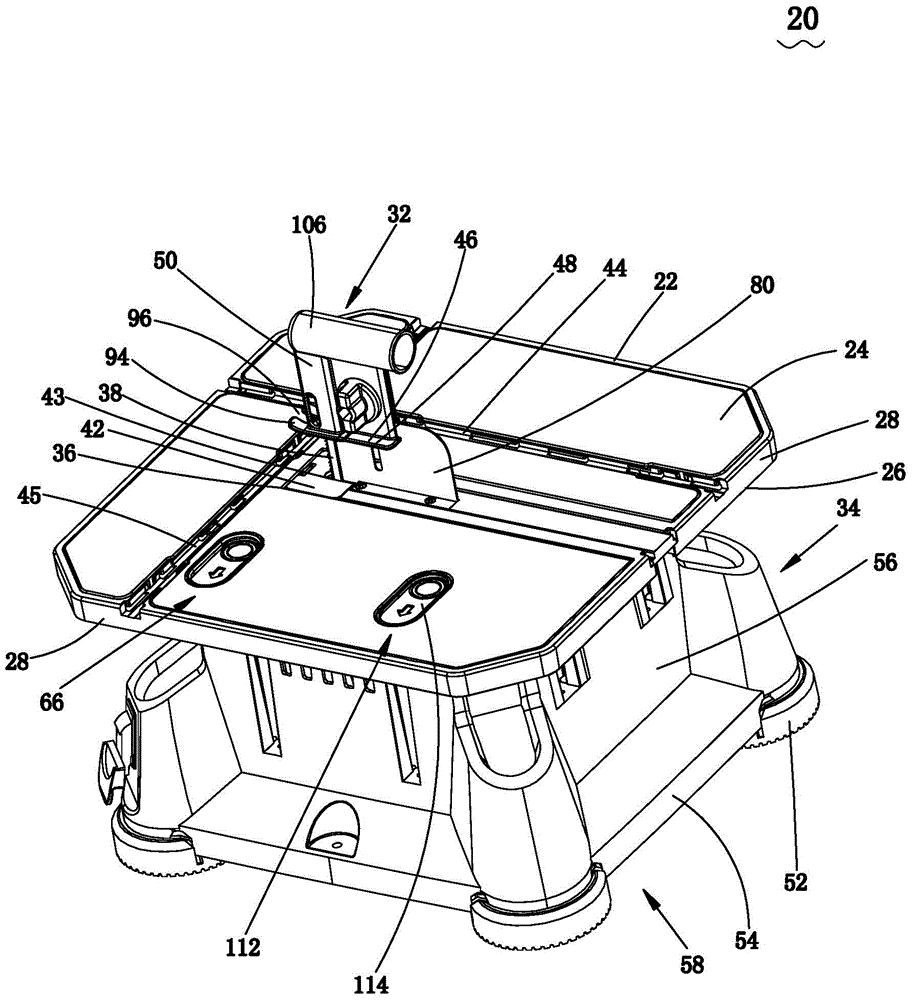

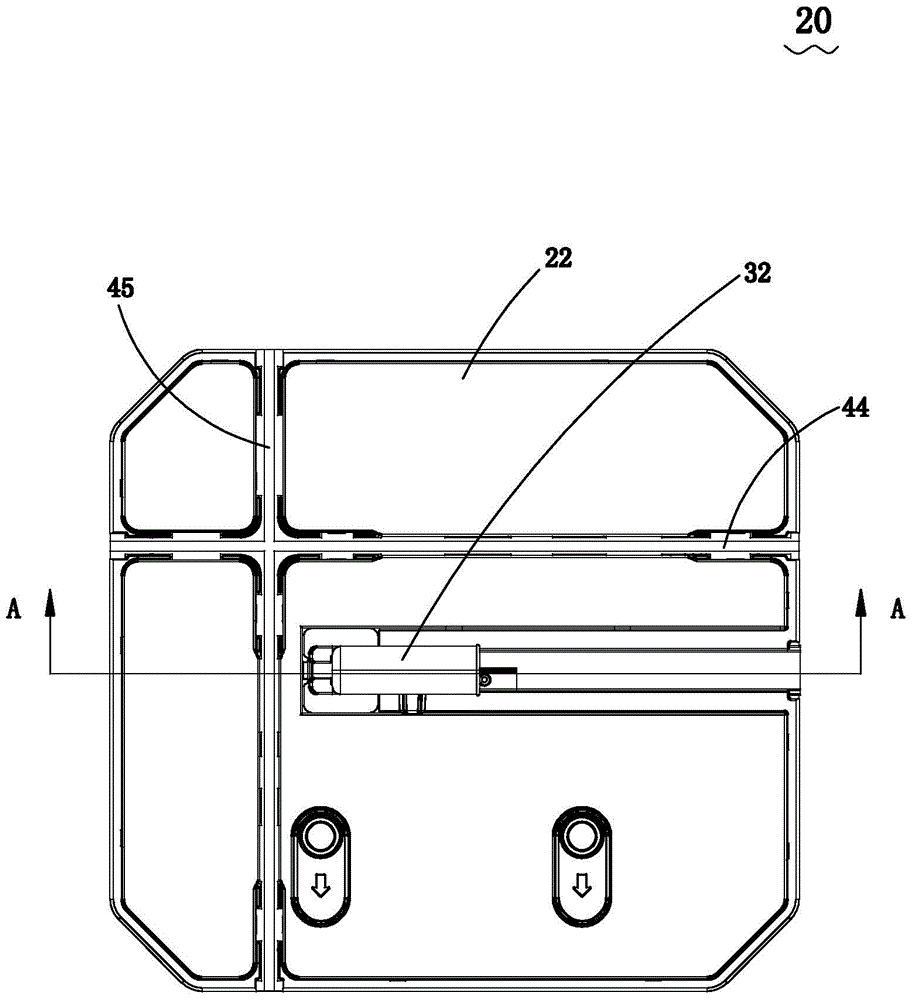

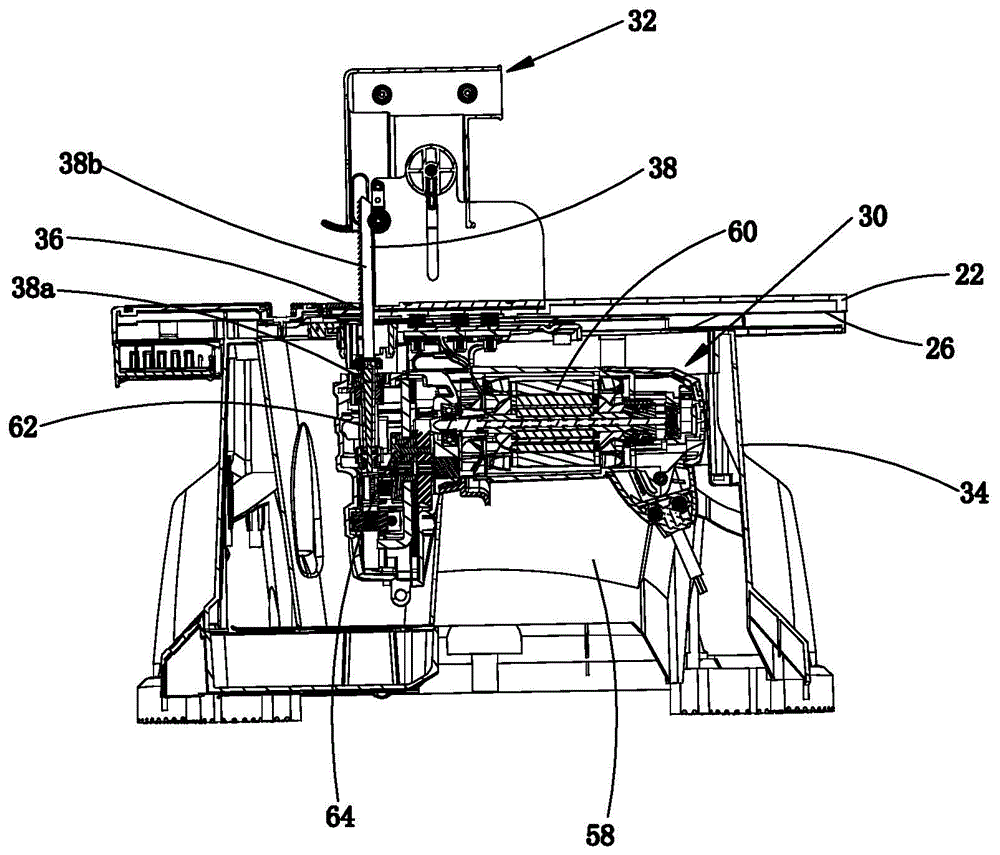

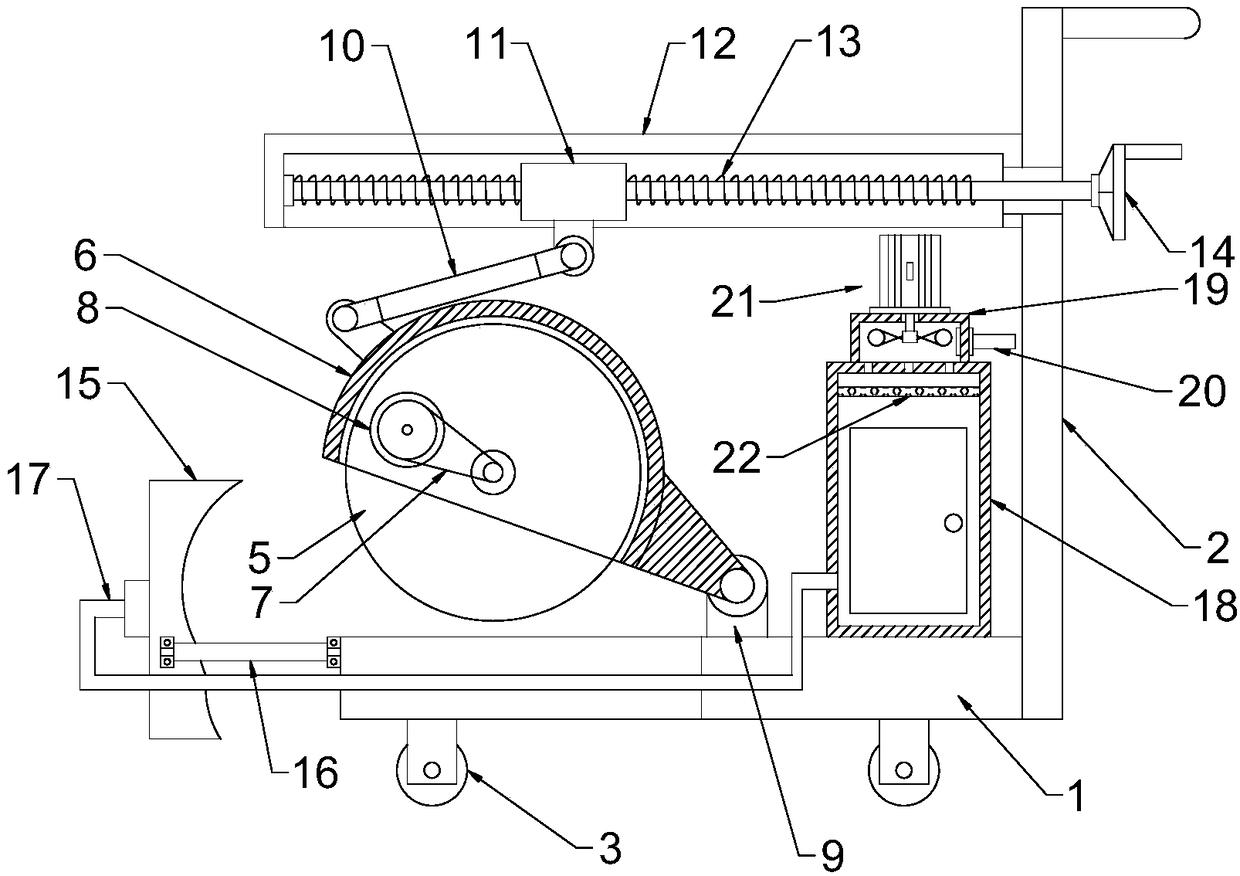

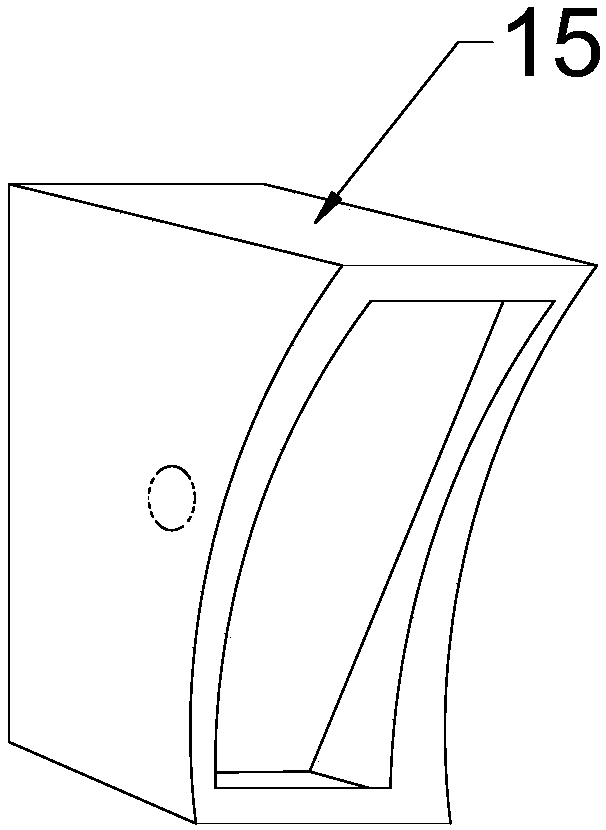

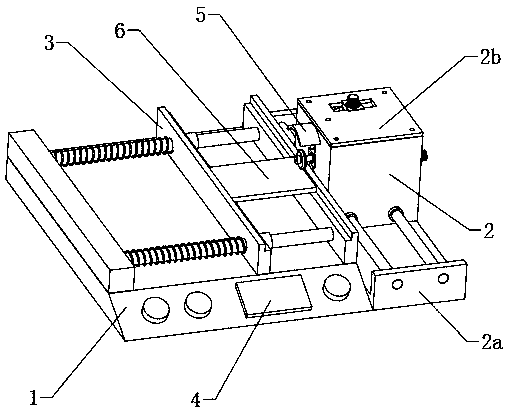

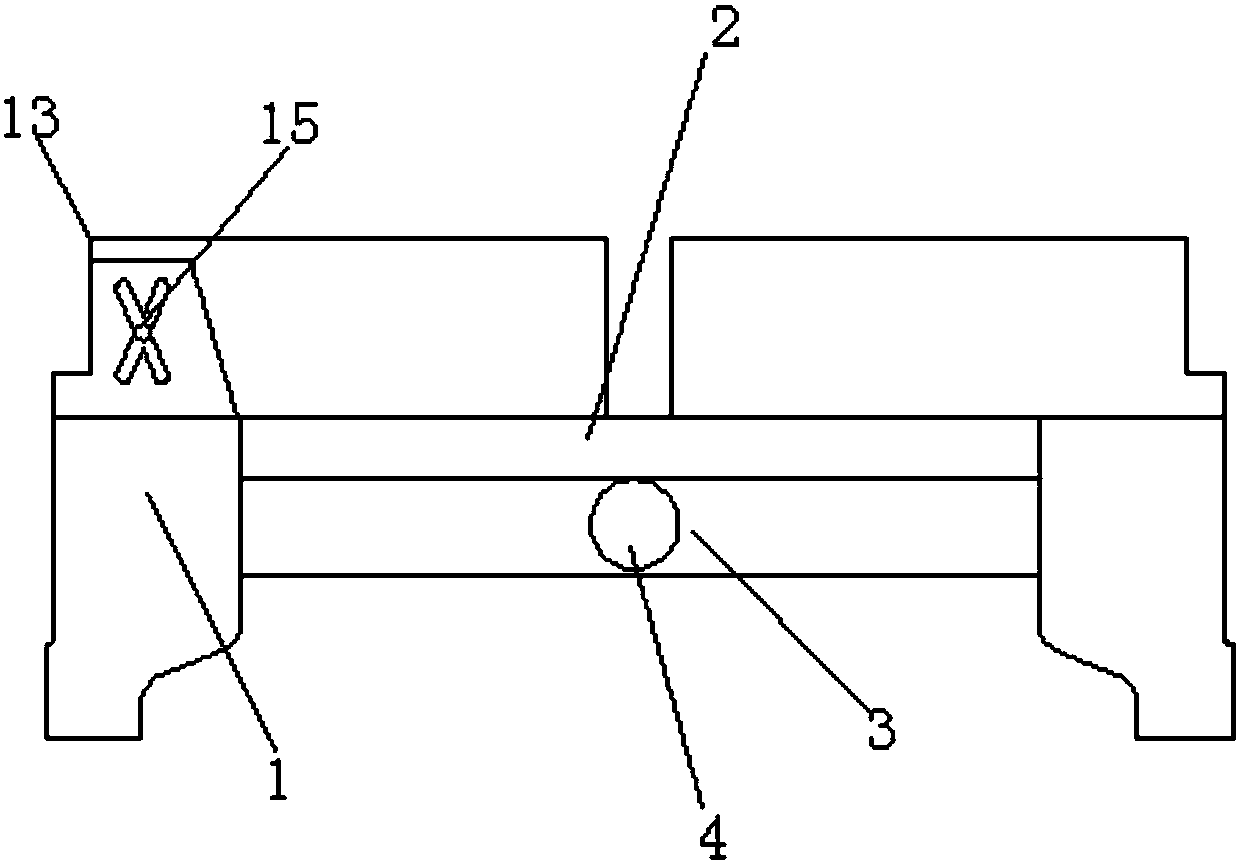

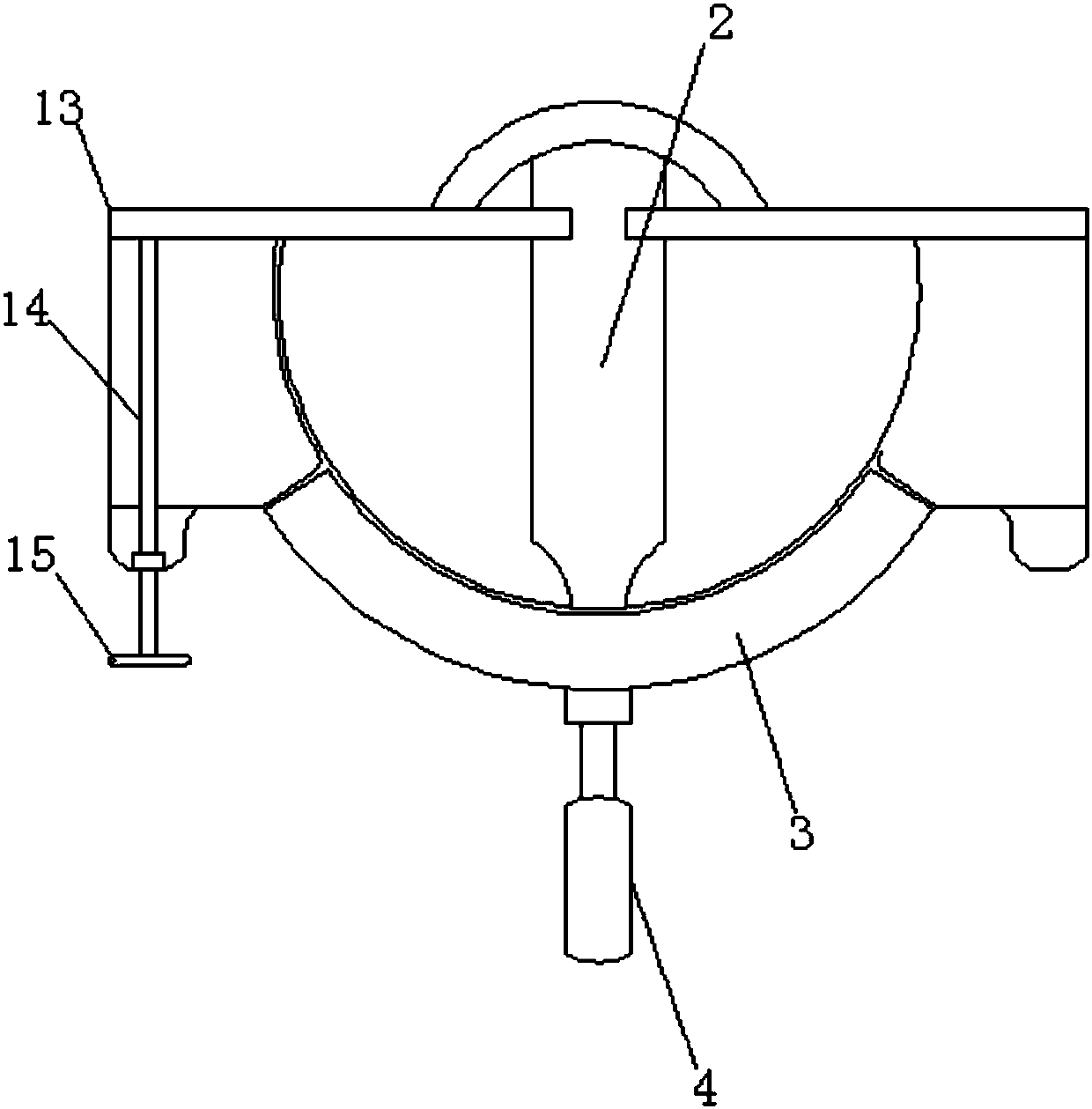

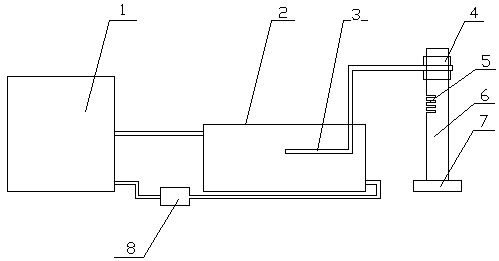

Cutting machine

The invention relates to a cutting machine. The cutting machine comprises a worktable with an opening, a cutting mechanism fixed to a lower surface of the worktable and pressing plate components detachably arranged on the worktable, wherein the worktable comprises an upper surface used for supporting workpieces; the cutting mechanism comprises a motor used for outputting rotary motion, a reciprocating rod used for driving a saw to go through the opening to do reciprocating motion and a motion transformation mechanism used for transforming rotary driving of the motor into reciprocating motion of the reciprocating rod; and each pressing plate component comprises a workpiece pressing plate, and the workpiece pressing plate is provided with a pressing plate plane which is perpendicular to the upper surface and used for pressing the workpieces. According to the cutting machine, different pressing plate components can be conveniently and quickly replaced or dismounted according to different specifications of the cut workpieces or different cutting requirements.

Owner:POSITEC MACHINERY ZHANGJIAGANG

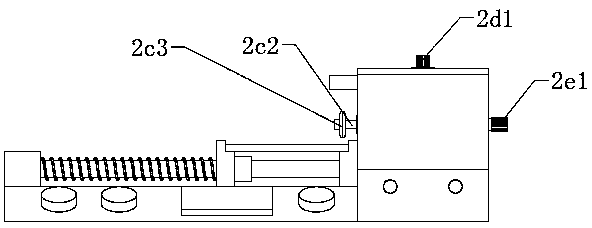

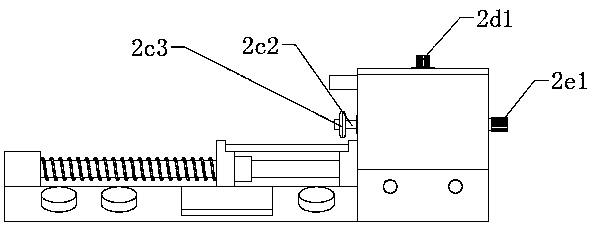

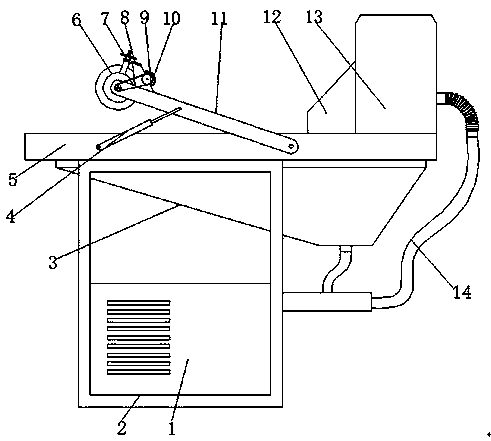

Wet tissue edge cutting and edge material collecting device for wet tissue production

InactiveCN107696111AImprove the level of intelligenceIncrease the level of automationMetal working apparatusWet wipeEngineering

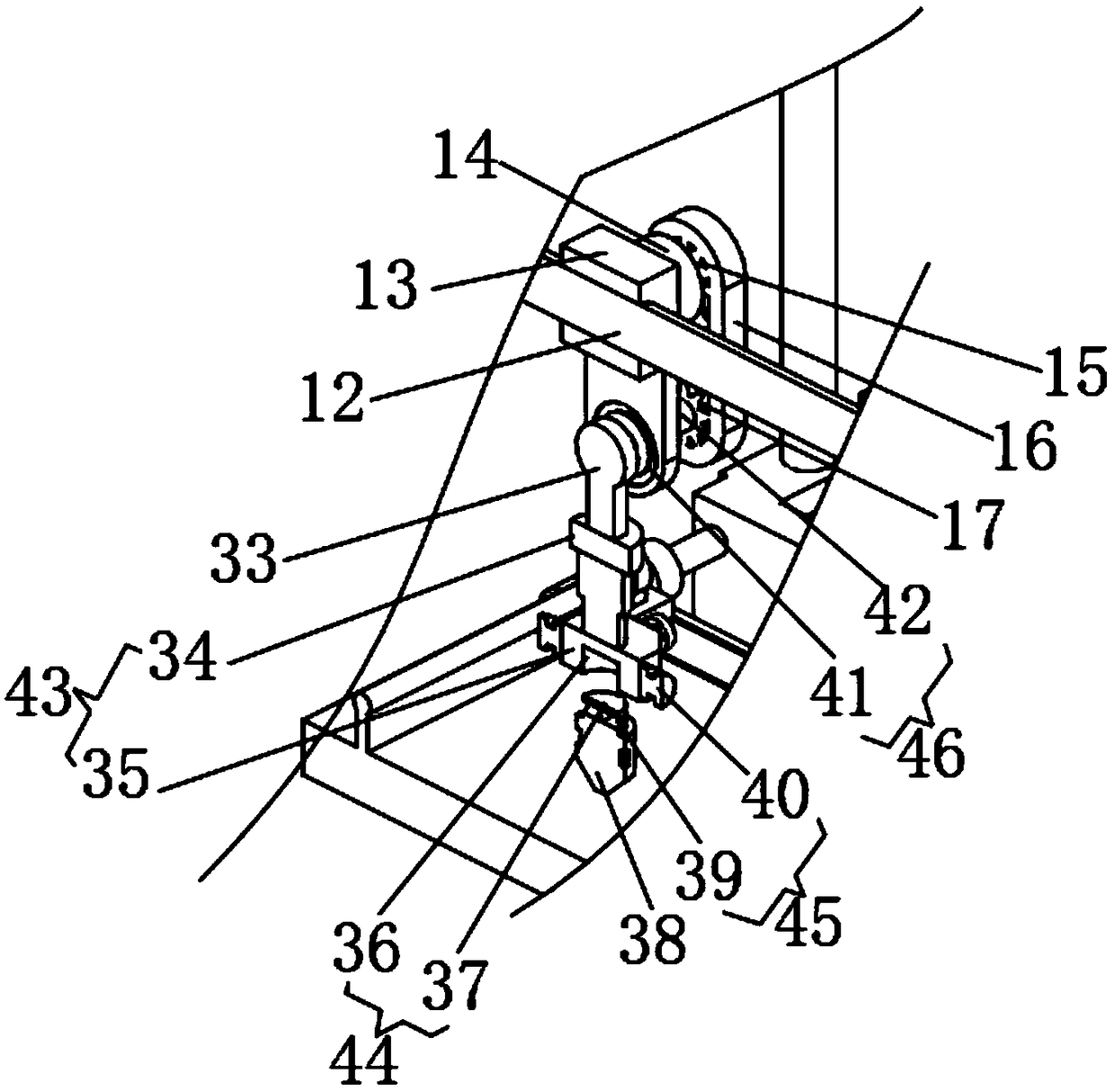

The invention discloses a device for trimming and collecting side materials of wet wipes used in the production of wet wipes. A horizontal adjustment mechanism is installed on the vertical adjustment mechanism, a positioning device is installed on the side of the horizontal adjustment mechanism, and a lifting mechanism is installed at the bottom of the horizontal adjustment mechanism. The cutting position of the cutting device is positioned through the positioning device, which has a high level of intelligence and precise positioning, which greatly improves the cutting accuracy. The cutting position of the cutting device is adjusted through the horizontal adjustment structure, vertical adjustment mechanism and angle adjustment device. It has good flexibility and can meet different cutting needs. The side material is collected by the side material collection device. It has good mobility and high automation level, which greatly improves the production efficiency.

Owner:张渝晨

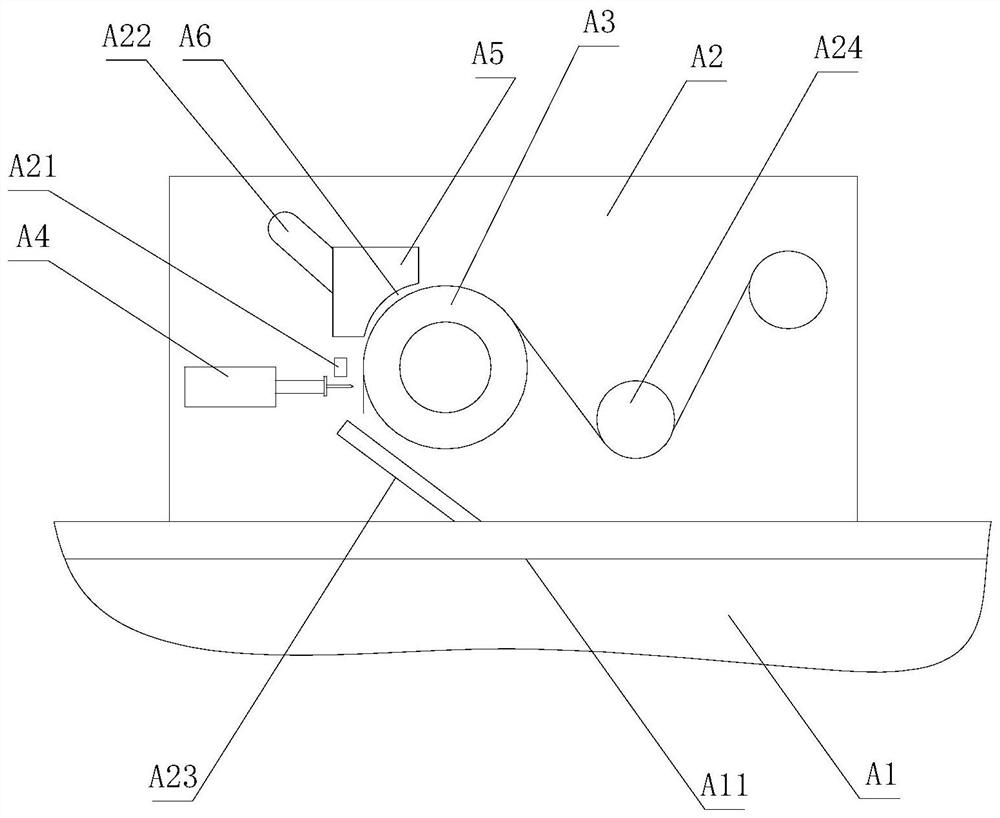

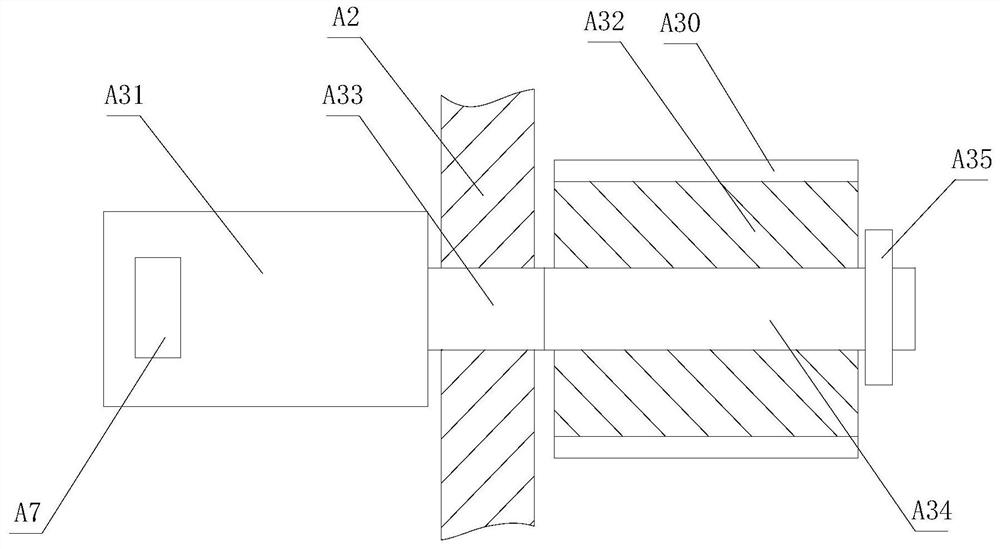

Road joint cutting machine capable of manually regulating cutting depth

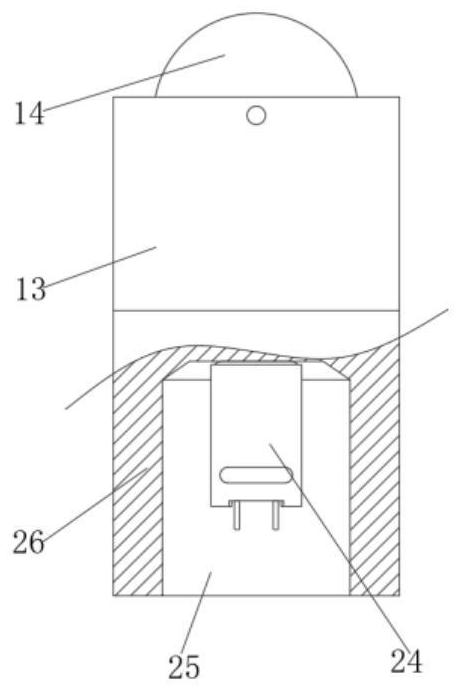

The invention discloses a road joint cutting machine capable of manually regulating cutting depth. The road joint cutting machine comprises a vehicle bottom plate, a cutting mechanism, a regulating mechanism and a dust collecting mechanism, wherein a cutting through groove is formed in the middle position of the left side of the vehicle bottom plate; the cutting mechanism is arranged above the cutting through groove, and comprises a cutting wheel, a protection cover and a cutting motor; the protection cover is connected with the regulating mechanism; the regulating mechanism comprises a connecting rod, a moving block, a slide groove frame, a screw rod and a rotating handle; the top of the protection cover is hinged to the connecting rod; the upper end of the connecting rod is hinged to themoving block; the slide groove frame is nested in the moving block; the dust collecting mechanism is arranged at the left side of the cutting wheel. Through the arrangement of the connecting rod, themoving block, the screw rod, the slide groove frame and the rotating handle, the cutting depth of the cutting wheel is manually regulated; the regulation is convenient; different cutting requirementsare met; through the arrangement of a negative pressure dust collecting box and a dust collecting cover, dust generated by cutting is sucked; sewage overflowing and operation environment pollution caused by watering for dust falling are avoided.

Owner:FOSHAN XINLAI ENG TECH CO LTD

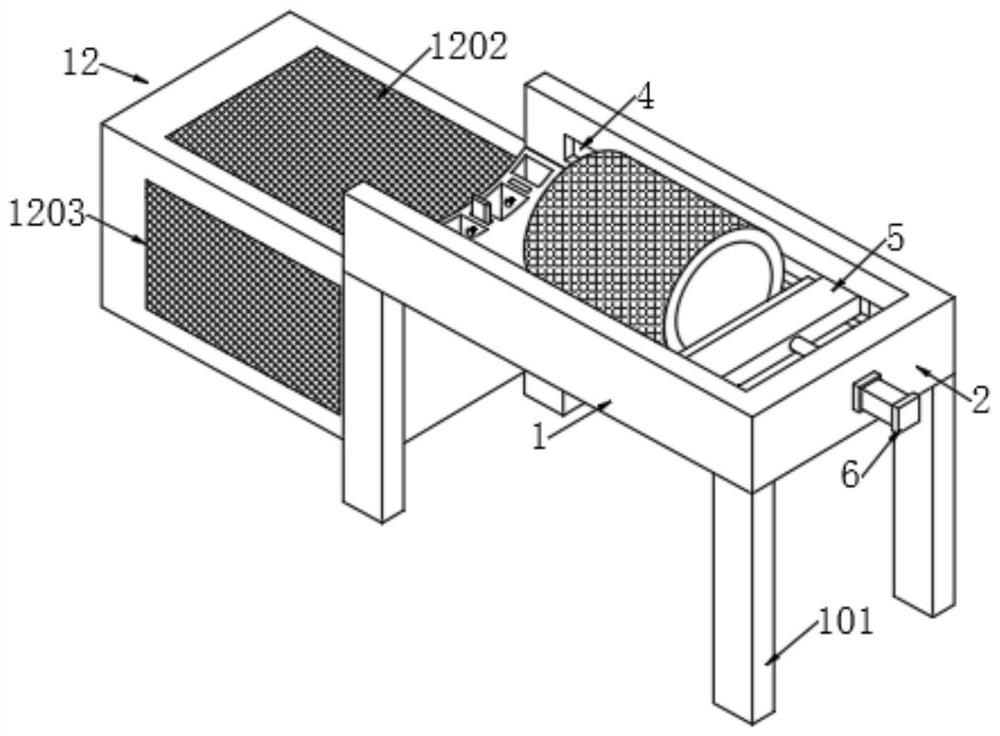

Cutting equipment for producing MBR membrane lining pipe

The invention relates to the technical field of lining pipe production, and further discloses cutting equipment for producing an MBR membrane lining pipe. The equipment comprises a base; the upper endof the base is fixedly connected with a U-shaped supporting plate; two vertical plates are symmetrically and fixedly connected to the lower end of the horizontal part of the U-shaped supporting plate; the same adjusting screw rod is rotationally connected between the two vertical plates; the outer wall of the vertical plate on the right side is fixedly connected with a driving motor; an output shaft of the driving motor penetrates through the side wall of the vertical plate and is fixedly connected with one end of the adjusting screw rod; the rod wall of the adjusting screw rod is in threadedconnection with a moving block; the lower end of the moving block is fixedly connected with a motor shell; a cutting motor is fixedly connected into the motor shell; an output shaft of the cutting motor penetrates through the side wall of the motor shell and is fixedly connected with a cutting blade; and two supporting plates are symmetrically and slidably connected to the upper end of the base.The cutting equipment for producing the MBR membrane lining pipe has the advantages of being capable of achieving rapid cutting of the lining pipe, convenient to operate and use and capable of greatlyimproving the cutting efficiency of the lining pipe.

Owner:江苏吉隆环保科技有限公司

Glassware cutting device

InactiveCN108675623AEasy to useGreat practicabilityGlass severing apparatusNumerical controlDrive shaft

The invention relates to the field of glass cutting devices and in particular to a glassware cutting device. The glassware cutting device comprises a machine body, a cutting control device, a glassware jig and a numerical control device, wherein the cutting control device is installed beside the machine body, the glassware jig and the numerical control device are installed on the machine body, thecutting control device comprises a cutting sliding table, a cutting machine case, a cutting component, a lifting adjusting component and a transverse adjusting component, the glassware jig comprisesa first fixing clamping plate, a second fixing clamping plate and a moveable clamping plate. In use, a cutting blade is firstly fixed on a transmission shaft, an object is fixed by the glassware jig,and the lifting adjusting component and the transverse adjusting component are used for adjusting a height and a position of the cutting component, then a cutting motor is started through the numerical control device, so the transmission shaft drives the cutting blade to be rotated, the object is held by one hand of a worker, and the other hand pushes the cutting control device to be moved on thecutting sliding table, so the cutting machining is completed. The device is skillful in structure, simple in operation, and strong in practicability.

Owner:胡志会

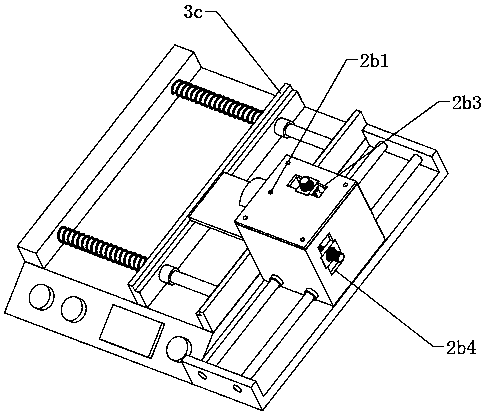

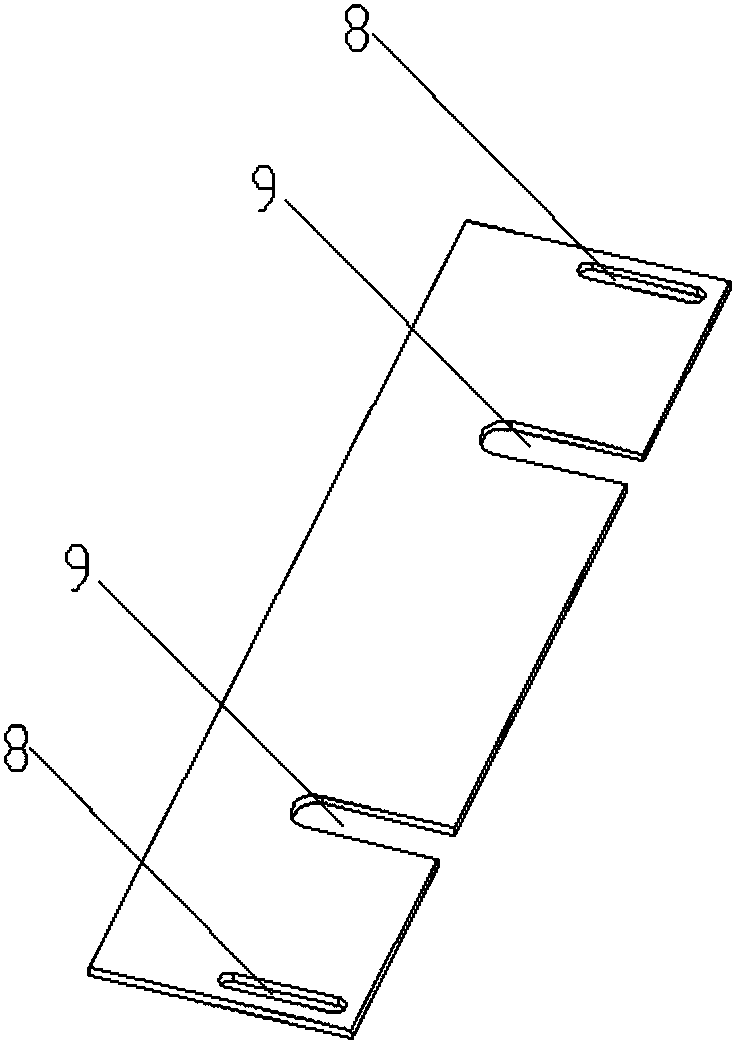

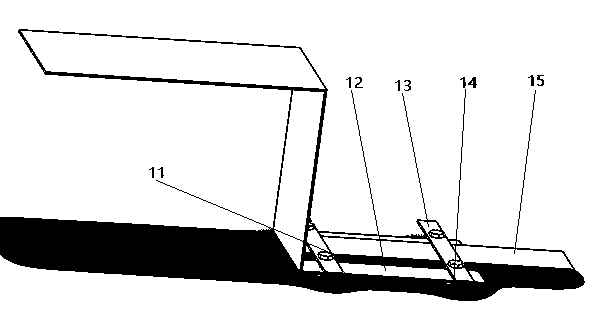

Cutting blanking assisting device for thin and long plates

PendingCN108481038ASimple structureReasonable designPositioning apparatusMaintainance and safety accessoriesEngineeringMechanical engineering

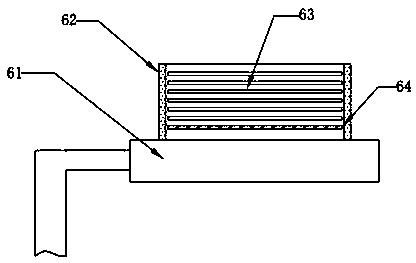

The invention relates to a cutting blanking assisting device for thin and long plates. The cutting blanking assisting device for thin and long plates comprises a supporting plate, a positioning plateand a pressing plate. A cutting groove is formed in the supporting plate, the positioning plate is arranged in the position, close to the cutting groove, of the supporting plate, the positioning plateis provided with two arc-shaped long holes used for adjusting the position of the positioning plate, and two U-shaped grooves are further formed in the positioning plate. The pressing plate is arranged on the positioning plate through the two U-shaped grooves, the position of the pressing plate on the positioning plate is adjusted through the two U-shaped grooves, lug plates are arranged at the left end and the right end of the supporting plate, and a first base, a second base and a third base are arranged at the lower end of the supporting plate. The cutting blanking assisting device for thin and long plates is simple in structure, reasonable in design and convenient to use; thin and long metal plates are tightly pressed through the pressing plate, so that deformation occurring in the cutting process is avoided, and plate cutting quality is further improved; and moreover, the positioning plate is adjusted through the arc-shaped long holes, so that different width cutting requirementscan be met, and the application range of the device is further widened.

Owner:CSSC XIJIANG SHIPBUILDING

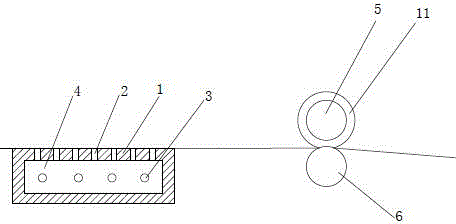

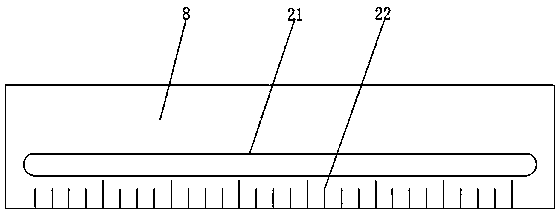

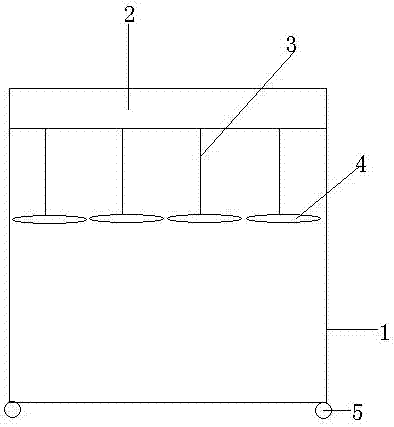

Adsorption type cutting device for paper of multiple specifications

InactiveCN104786260AAvoid breakingReduce tensionMetal working apparatusPulp and paper industryVacuum pump

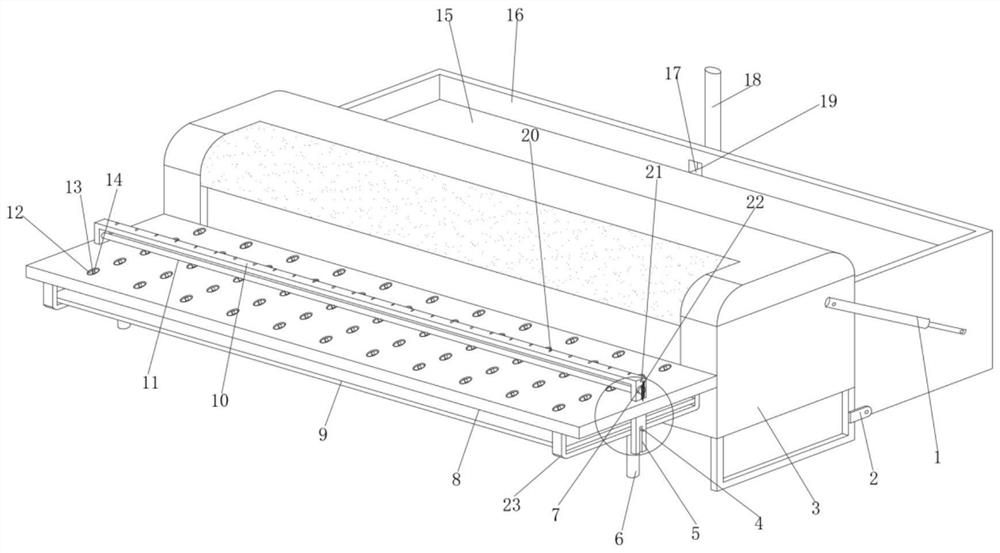

The invention discloses an adsorption type cutting device for paper of multiple specifications, and belongs to the field of papermaking devices. The adsorption type cutting device comprises a paper pressing mechanism and a paper cutting mechanism which are arranged in the paper feed direction. The paper pressing mechanism comprises a vacuum pump and an adsorption plate internally provided with a cavity. A plurality of adsorption holes communicated with the cavity are formed in the upper plate face of the adsorption plate. Through holes communicated with the cavity are formed in the side face of the adsorption plate and are connected with the vacuum pipe through pipelines. The paper cutting mechanism comprises a paper cutting roller and an anvil roller located below the paper cutting roller. The paper cutting roller and the anvil roller each comprise a roller body and a plurality of sleeves axially arranged outside the roller body in a sleeving mode. Annular grooves which are formed in the axial direction at intervals are formed in the outer circle face of each roller body, wherein sections of the annular grooves are each in an arc shape. Positioning structures are arranged in inner circle faces of the sleeves. Cutters are fixed to the sleeves of the paper cutting roller. Paper of multiple specifications can be cut at the same time, different cutting requirements are met, adjustment is easy, convenient and reliable, cutting specifications are diversified, and the work efficiency is improved.

Owner:何再友

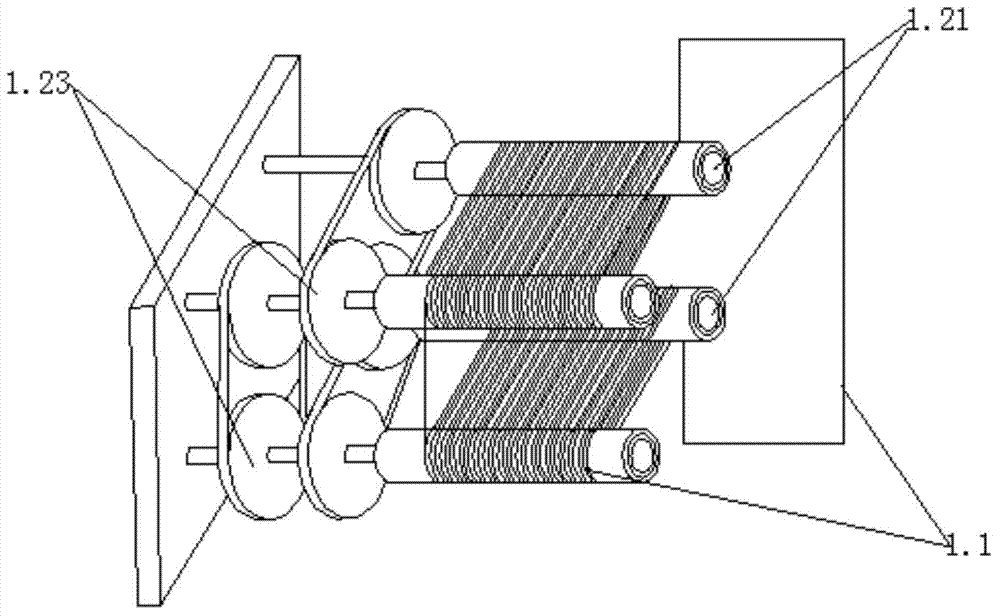

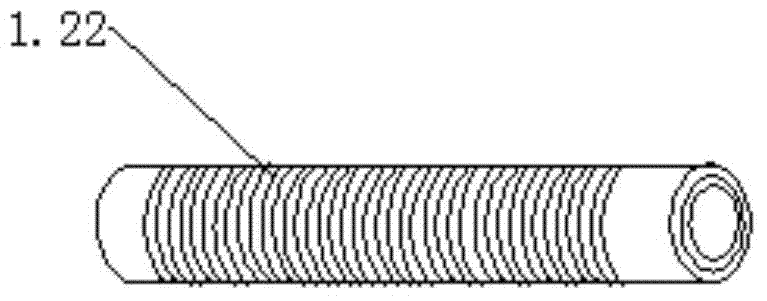

Automatic material collecting equipment for slitting large-opening-diameter thick-wall pipe and working method thereof

InactiveCN113618144APrevent disengagementExtended service lifeTube shearing machinesPositioning apparatusSlide plateThick wall

The invention relates to automatic material collecting equipment for slitting a large-opening-diameter thick-wall pipe and a working method of the automatic material collecting equipment. The automatic material collecting equipment for slitting the large-opening-diameter thick-wall pipe comprises two first supporting plates which are symmetrically distributed. A second supporting plate is fixed between the same ends of the two first supporting plates. A placing table is fixed between the bottom ends of the two first supporting plates, a first annular placing groove is formed in the upper surface of the placing table, and the large-opening-diameter thick-wall pipe is placed in the first placing groove. According to the equipment, limiting blocks are arranged and used for limiting sliding movement of a buffering plate in a buffering groove and preventing the buffering plate from being separated from the buffering groove; and buffering springs are arranged, and therefore when a sliding plate is pushed by a first telescopic air cylinder to collide with the large-opening-diameter thick-wall pipe, the large-opening-diameter thick-wall pipe can make contact with the buffering plate, the buffering plate slides in the buffering groove to extrude the buffering springs, the buffering springs can extrude the large-opening-diameter thick-wall pipe, the buffering effect is achieved, the large-opening-diameter thick-wall pipe is protected, and the service life of the sliding plate is prolonged.

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

Panel glass fixing device capable of adjusting cutting position quickly

InactiveCN108017269AHigh degree of intelligencePrecise positioningGlass severing apparatusEngineeringMechanical engineering

The invention discloses a panel glass fixing device capable of adjusting the cutting position quickly. The device comprises a cutting platform, wherein fixing equipment is mounted on the top of the cutting platform; supporting racks are welded to the left and right sides of the cutting platform; a cross beam is fixed to the end part of each supporting rack; a transverse adjusting device is mountedon the inner side of the cross beam; a longitudinal adjusting device is mounted on the transverse adjusting device; and a height adjusting device is mounted in the bottom of the longitudinal adjusting device. The panel glass fixing device capable of adjusting the cutting position quickly positions the fixing point and the cutting position of panel glass through the positioning device, so that thepanel glass fixing device capable of adjusting the cutting position quickly is high in intelligent level and precise to position, and the work precision of the panel glass fixing device is increasedgreatly; the cutting position of the cutting device is adjusted through the transverse adjusting device, the longitudinal adjusting device, the height adjusting device and an angle adjusting device, so that the panel glass fixing device is good in flexibility and high in adjusting capacity and can meet different cutting demands.

Owner:董怡君

Glass product cutting equipment

InactiveCN110217977AEasy to useGreat practicabilityGlass severing apparatusNumerical controlDrive shaft

The invention relates to the field of glass cutting equipment and in particular to glass product cutting equipment which comprises a machine body, a cutting regulating and control device, a glass product jig and a numerical control device, wherein the cutting regulating and control device is arranged beside the machine body; the glass product jig and the numerical control device are arranged on the machine body; the cutting regulating and control device comprises a cutting sliding platform, a cutting tank, a cutting component, a lifting adjusting component and a transverse adjusting component;and the glass product jig comprises a first fixed clamping plate, a second fixed clamping plate and a moveable clamping plate. When the equipment is used, a cutter is firstly fixed on a transmissionshaft, the article is fixed by using the glass product jig, heights and positions of the cutting component are adjusted through the lifting adjusting component and the transverse adjusting component,a cutting motor is powered on through the numerical control device, the transmission shaft is enabled to drive the cutter to rotate, the article is held by one hand of an operator, the cutting regulating and control device is pushed by the other hand to move on the cutting sliding platform, and then cutting processing can be completed. The equipment is exquisite in structure, simple to operate andgood in practicability.

Owner:胡志会

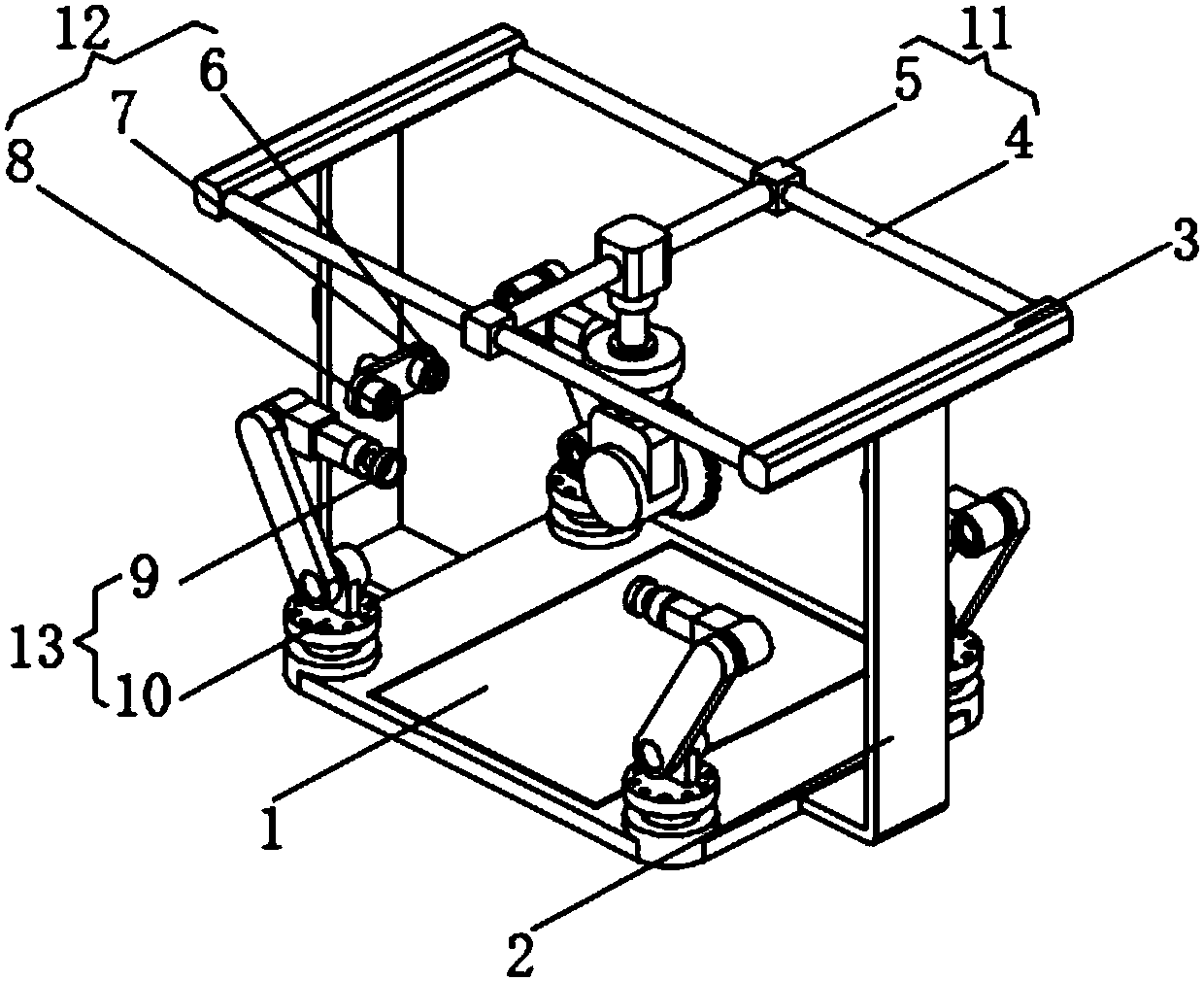

Dust-proof shock-proof type wood cutting machine

InactiveCN108032380APrevent sweating and slippingEasy to useProfiling/shaping machinesBark-zones/chip/dust/waste removalHigh densityEngineering

The invention discloses a dust-proof shock-proof type wood cutting machine. The dust-proof shock-proof type wood cutting machine comprises a base plate, a dust-proof cover, a cutting knife and a scalefixing clamp; a knife disc is mounted above the base plate; a dial scale is mounted on the right side of the knife disc; a handle is mounted at the upper part of the dust-proof cover; a master switchis mounted on the outer side of the handle; a motor is mounted below the cutting knife; a folding rod is mounted below the motor; a pushing rod is mounted on the right side of the scale fixing clamp;a rotating clamp is mounted at the right end of the pushing rod; spring posts are mounted in the base plate. The dust-proof shock-proof type wood cutting machine saves one fifth of space and is convenient to carry and move; the conventional straight open type handle is abandoned, and a sealed annular surface granular rubber layer is adopted to prevent a hand from sweating and skidding; a disc-shaped high-precision dial scale meets different cutting requirements; a thickened high-density aluminium alloy reinforces cutting without shaking, so that a shock-proof effect is achieved better.

Owner:郝玲

Novel environment-friendly electric ceramic tile cutter

PendingCN108818976AHigh degree of mechanizationEasy loading and unloadingWorking accessoriesStone-like material working toolsCeramic tilesHinge angle

The invention discloses a novel environment-friendly electric ceramic tile cutter which comprises two base plates which are symmetrically arranged left and right. The base plates are hinged to a cutting platform through rotary hinges; an arc-shaped guide rail is fixed to the inner side of each base plate; a first linear motor is movably hinged to each arc-shaped guide rail; the first linear motoris rotatably connected to the cutting platform through a rotary connecting part; a horizontal guide rail is fixed to the top of the cutting platform; a second linear motor is movably connected to thehorizontal guide rail; a row brush is fixed to the side face of the second linear motor; and brush hairs of the row brush are in contact with the table board of the cutting platform. According to thenovel environment-friendly electric ceramic tile cutter disclosed by the invention, an electric vacuum sucking disc is controlled by means of a control switch to adsorb and fix ceramic tiles, and a third linear motor is controlled by means of the control switch to more linearly on a vertical guide rail, so that the working height of the electric vacuum sucking disc is adjusted.

Owner:浙江润土城乡规划设计有限公司

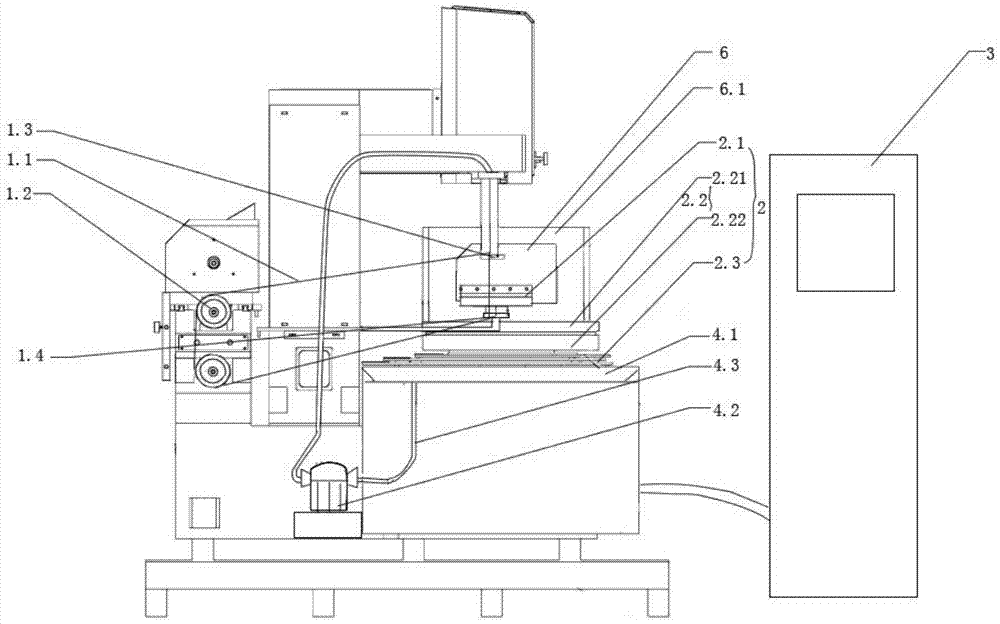

A cardboard cutting machine for paper product production

ActiveCN111299858BRealize the collectionEasy accessLaser beam welding apparatusCardboardIndustrial engineering

The invention discloses a cardboard cutting machine for the production of paper products, which includes a laser cardboard cutting machine, a supporting plate arranged horizontally at the position of the feeding port of the laser cardboard cutting machine, and a supporting plate for adjusting Cardboard direction adjustment mechanism, the top of the pallet is provided with a feeding assembly for driving cardboard feeding, and a collection basket is hinged at the outlet of the laser cardboard cutting machine, and both sides of the collection basket are hinged There are damping telescopic rods, and the ends of the two damping telescopic rods away from the collection basket are respectively hinged with the two ends of the laser cardboard cutting machine. The inner wall of the collection basket is provided with a partition, and the side wall of the collection basket is provided with a partition for adjustment High lifting mechanism. The present invention can adjust the direction of the cardboard through the provided adjusting unit, and can conveniently rotate and adjust the angle of the collection basket through the provided damping telescopic rod, so as to facilitate the cleaning of the collection basket.

Owner:滁州远达彩印包装有限公司

Laser cutting device

InactiveCN100531998CMeet different cutting needsWelding/cutting auxillary devicesAuxillary welding devicesThermal expansionOptoelectronics

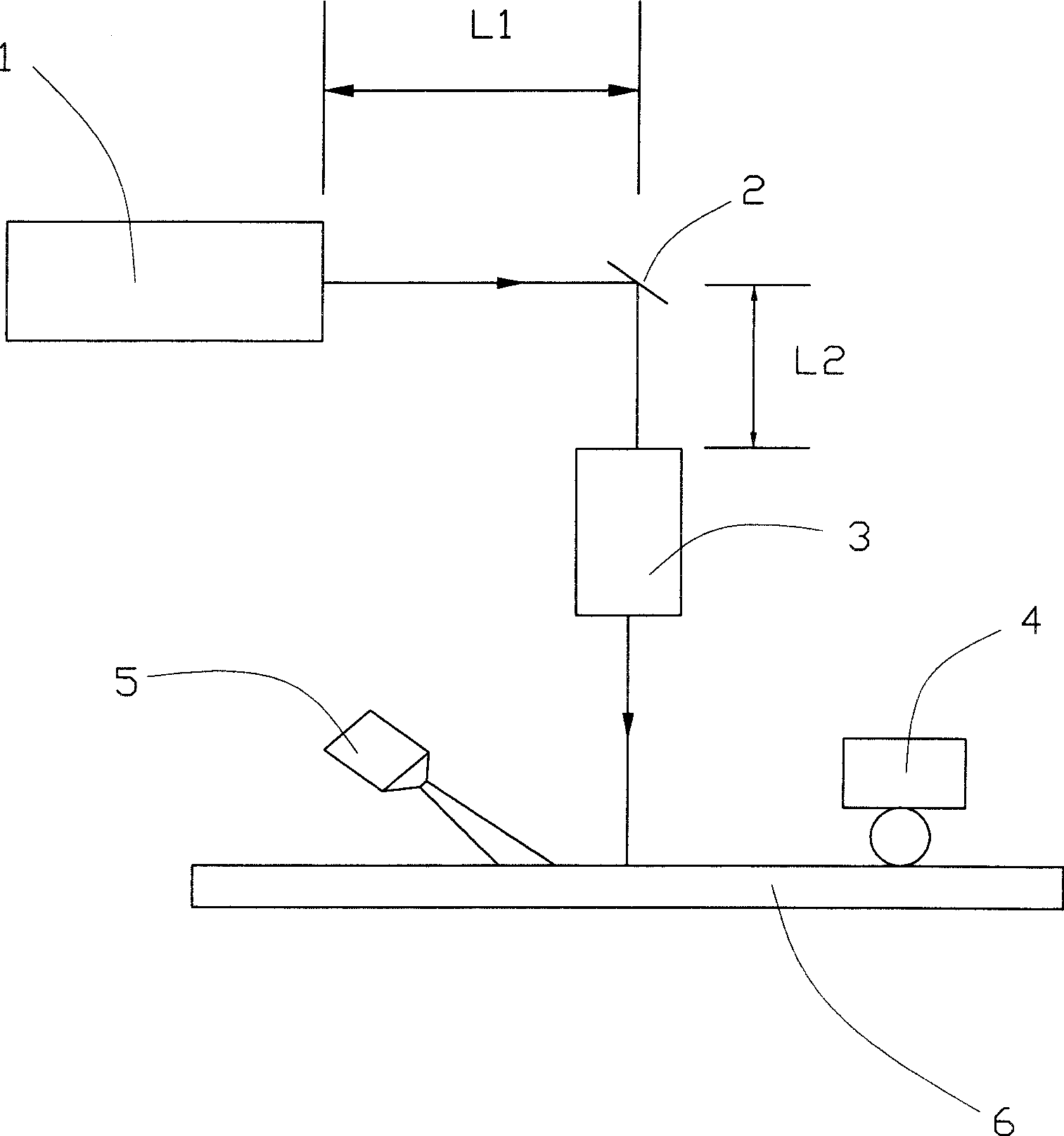

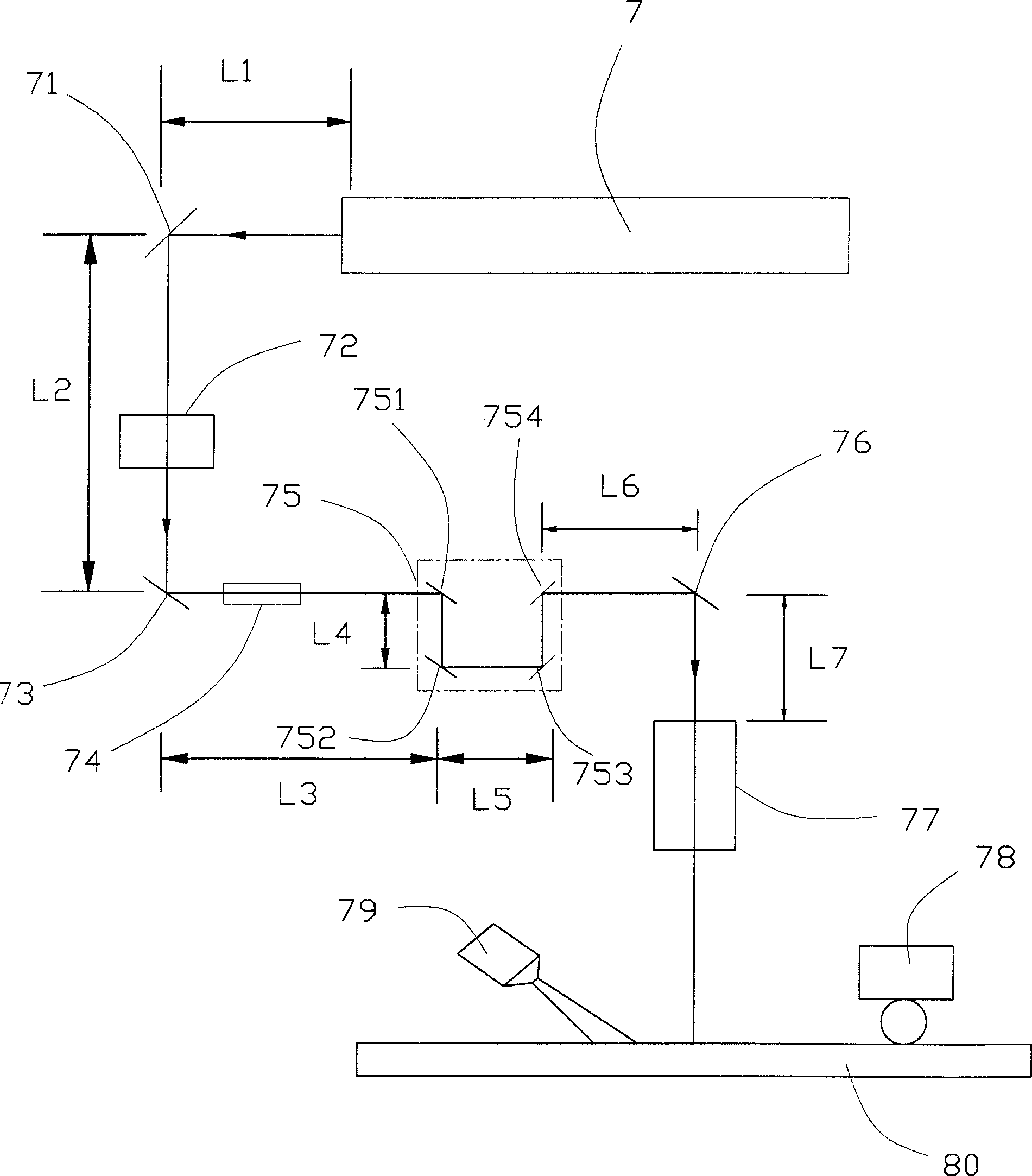

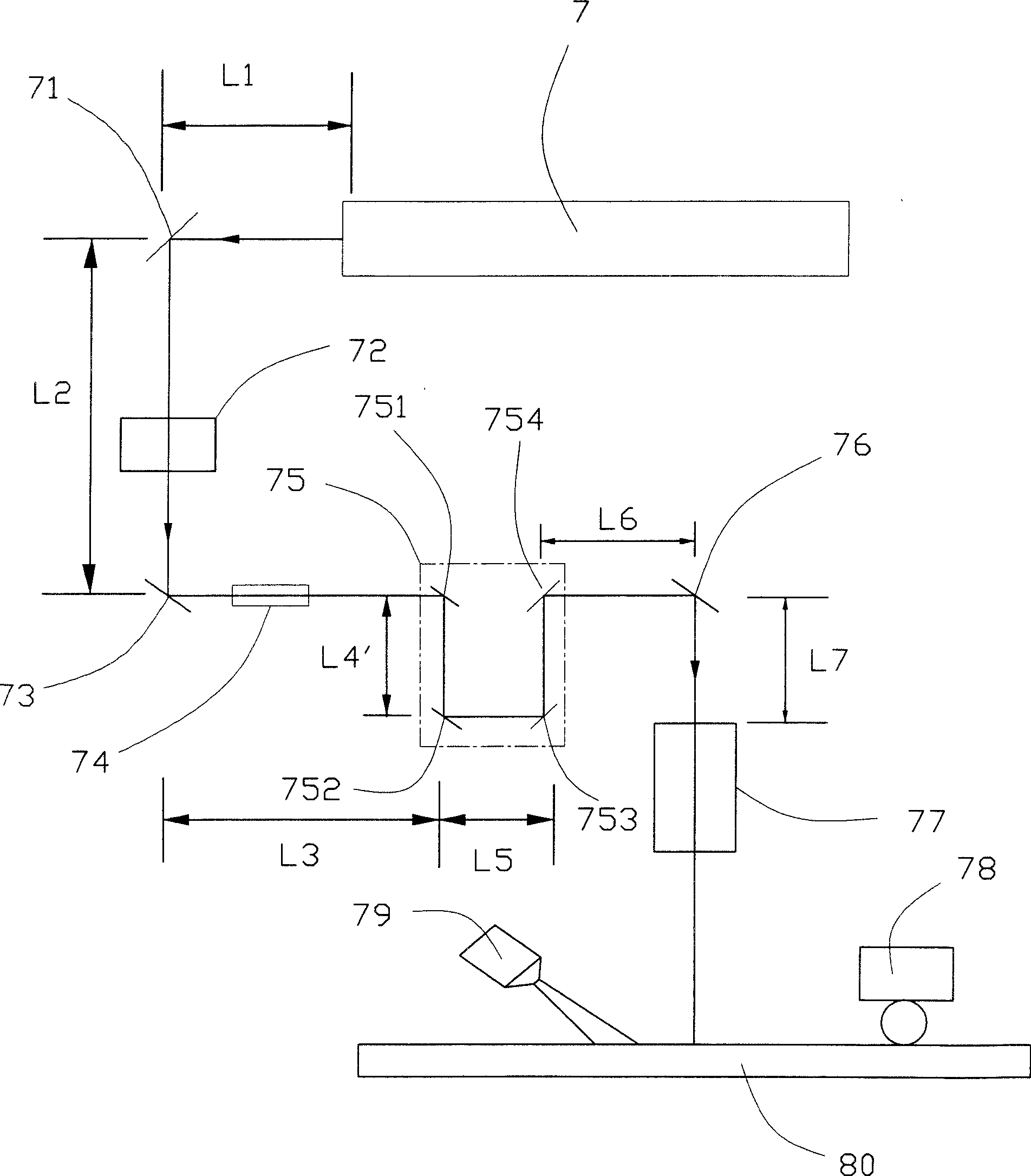

A laser-cutting device for cutting brittle basilar plates includes pre-cutting systems, laser optical system and cooling system, said pre-cutting system is used for forming pre-cutting line on the basilar plates; said laser optical system is used for producing laser light, and the laser light heats the basilar plates along the pre-cutting line to making the basilar plates thermal expansion; said cooling system is used for cooling said thermal expanding basilar plates; said laser optical system includes laser cavity generating said laser light and optical path adjustment system, the optical path adjustment system is equipped on the optical path on the basilar plates and illuminated by said laser light to adjusting the length of the optical path, so it can adjust the size of laser light point to meet different cutting needs.

Owner:FOXSEMICON INTEGRATED TECHNOLOGY (SHANGHAI) INC +1

Efficient sensor base lead cutting-off device and using method thereof

InactiveCN110976703AReduce manual labor intensityImprove work efficiencyElectric machineWire cutting

The invention discloses an efficient sensor base lead cutting-off device in the technical field of sensors. The efficient sensor base lead cutting-off device comprises a base; a driving motor mountedon a fixing table is arranged above the base; the output end of the driving motor is fixedly connected with a rotating column; the end part of the rotating column is fixedly connected with a turntable; the side wall of the turntable is rotationally embedded in a fixing support; a feeding mechanism is arranged above the turntable; fixing mechanisms are embedded in the outer disc edge of the turntable at equal intervals; a cutting mechanism is arranged on one side of the turntable; an adjusting mechanism is arranged on the other side of the cutting mechanism; a waste material collecting box is arranged below the turntable; and the waste material collecting box is mounted at the top of the base through a pulling structure. The integrated functions of feeding, fixing, cutting, collecting and adjusting during lead cutting are achieved, traditional manual cutting is replaced, the labor intensity is reduced, and the working efficiency is improved.

Owner:BENGBU XINGCHUANG ELECTRONICS TECH CO LTD

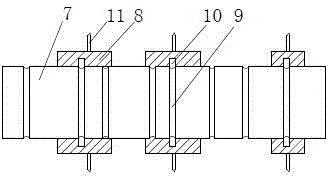

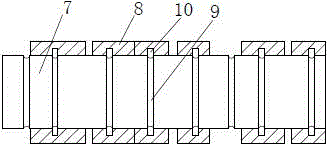

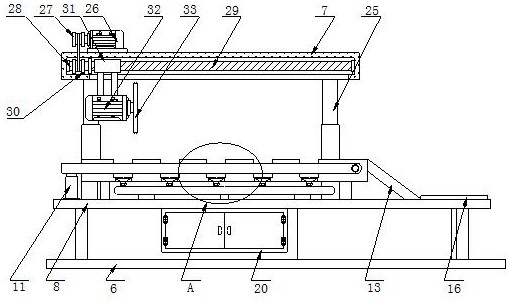

Numerical control wire saw processing machine

InactiveCN104493982AAchieve one-way movementReduce pauseMetal sawing devicesMetal sawing accessoriesNumerical controlControl system

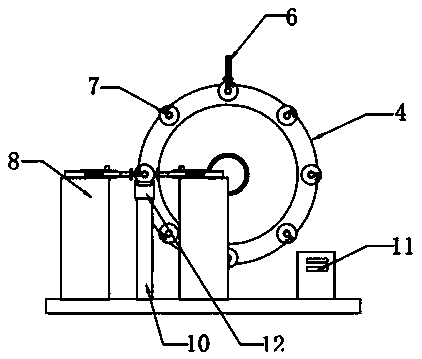

The invention provides a numerical control wire saw processing machine. The numerical control wire saw processing machine comprises a wire storage system, a workbench, a control system and a cutting fluid lubricating system, wherein the control system is connected with the cutting fluid lubricating system; the workbench comprises a revolving platform, a linear moving platform and a base; the linear moving platform is connected with the base in a sliding way; the revolving platform is arranged above the linear moving platform; the wire storage system comprises a cutting wire, a wire storage guide-wheel group, an upper wire rack and a lower wire rack; the upper wire rack and the lower wire rack are arranged above and below the outer side of the revolving platform respectively; the cutting wire is connected end to end, passes through the upper wire rack and the lower wire rack, and is wound on the outer side of the wire storage guide-wheel group; the control system is connected with the wire storage guide-wheel group, the revolving platform and the linear moving platform. An enclosed annular cutting wire is formed through end-to-end connection, so that one-way motion of the cutting wire is realized, and pause of the cutting wire is reduced; 360-degree rotation of a processed part can be realized through the revolving platform, and the motion direction of the workbench is consistent with the profile cutting direction of a workpiece, so that the smoothness of a processing face is ensured.

Owner:NANTONG HENGLONG MACHINERY MFG

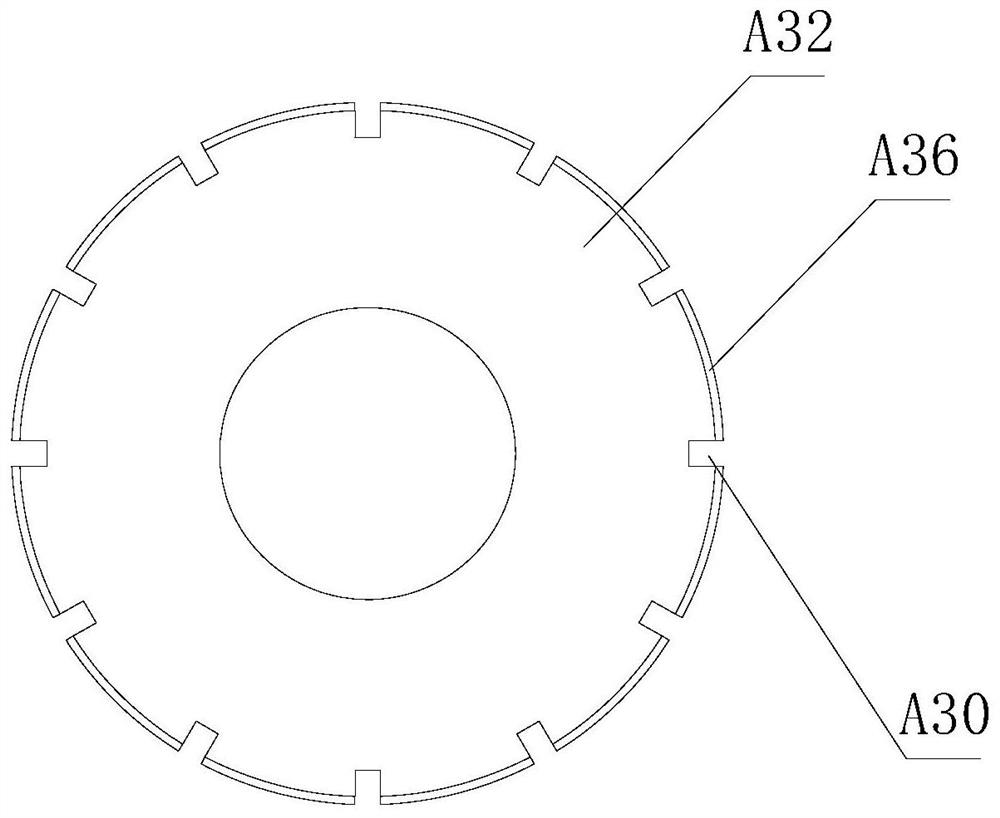

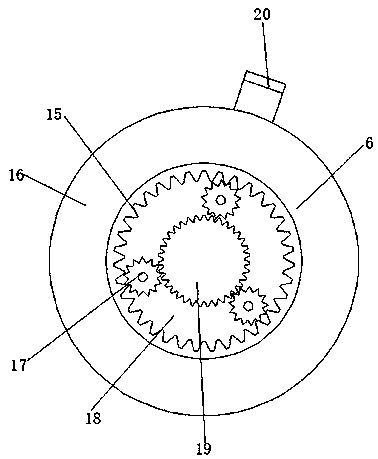

Spoon separating device for spoon counting machine

InactiveCN112265703AGuaranteed stabilityGuaranteed cutting efficiencyPackagingEngineeringMechanical engineering

The invention relates to a spoon separating device for a spoon counting machine. The spoon separating device comprises a rack, a support, a rotating body and a cutting mechanism; the rotating body isarranged on the support; a groove is formed on the outer circumferential side wall of the rotating body; and the support is also movably connected with a guide pressing block. The spoon separating device has the advantages that rotary feeding of a raw material is implemented through rotation of the rotating body on the support, cutting of the raw material is implemented by the cutting mechanism, and the rotating body is provided with the groove matched with the cutting mechanism, a certain limiting function can be achieved on the cutting mechanism so as to ensure the cutting stability of the cutting mechanism, ensure that every two adjacent spoons in raw material can be accurately and rapidly cut off and separated; and secondly, a certain pressing effect can be taken on the raw material onthe rotating body through the guide pressing block, so that the raw material is always attached to the outer circumferential side wall of the rotating body in the cutting process, cutting efficiencyis guaranteed, and breakage of the cutting mechanism is also prevented.

Owner:JIAXING YANDANG PACKAGING

Environment-friendly high-pressure water cutting machine for automobile parts

PendingCN114871949AChange cutting angleMeet different cutting needsAbrasive machine appurtenancesMotor vehicle partStructural engineering

The invention relates to the technical field of water cutting, and discloses an environment-friendly automobile part high-pressure water cutting machine which comprises a cutting table and a water jet cutter body, the water jet cutter body is arranged at the top of the cutting table, an adjusting mechanism is arranged at the top of the cutting table, a fixing mechanism is installed in the adjusting mechanism, and the adjusting mechanism comprises a grating table. Two half-moon-shaped plates are installed at the top of the grating table, sliding grooves are formed in the tops of the two half-moon-shaped plates, a two-way lead screw is movably connected between the two sliding grooves, sliding blocks are installed at the positions, close to the two sliding grooves, of the outer side wall of the two-way lead screw, and arc-shaped surrounding plates are fixedly connected to the tops of the two sliding blocks. The environment-friendly high-pressure water cutting machine for the automobile parts has the advantages that the horizontal cutting face can be adjusted, and special-shaped parts can be conveniently cut, and the problem that an existing horizontal water cutting platform cannot meet the cutting requirements of some special-shaped automobile parts is solved.

Owner:陈平辉

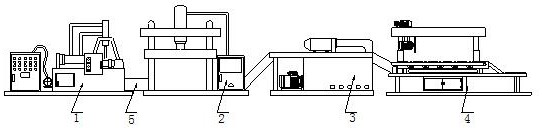

Aluminum alloy plate production line and cutting device

InactiveCN111745419AEasy to unloadPlay a protective effectDirt cleaningFeeding apparatusProduction lineSupport plane

The invention discloses an aluminum alloy plate production line, and belongs to the technical filed of aluminum alloy plates. The aluminum alloy plate production line comprises a casting machine, a die-casting machine, a straightening machine and a cutting device, wherein every two of the casting machine, the die-casting machine, the straightening machine and the cutting device form the aluminum alloy plate production line through a conveying mechanism; and the cutting device of the aluminum alloy plate production line comprises a bottom plate, a top frame and a fixing plate, the bottom of thefixing plate is fixedly connected with the top of the bottom plate through supporting legs, the top of the fixing plate is fixedly connected with an operation table through a supporting frame, and one side of the front face of the operation table is rotationally connected with a movable frame. According to the aluminum alloy plate production line and the cutting device, aluminum alloy plates cuton the operation table can be conveniently discharged, a certain protection effect is achieved on the plates in the discharging process, manual taking from the operation table is not needed, the cutting efficiency of the plates is improved, and meanwhile certain potential safety hazards are reduced.

Owner:东莞市群和五金制品有限公司

Cutting device for high-abrasion-resistance antistatic dampproof reconstituted bamboo floor processing

ActiveCN110341020AEasy to absorbEasy to adjust the angleCane mechanical workingProfiling/shaping machinesEngineeringDust collector

The invention discloses a cutting device for high-abrasion-resistance antistatic dampproof reconstituted bamboo floor processing. The cutting device comprises a support frame, the outer wall of the top end of the support frame is fixedly provided with a transversely-arranged support frame through bolts, a horizontally-arranged porous screen is welded to the inner wall of the support frame, a metalhopper is fixed to the outer wall of the bottom end of the support frame through bolts, a dust collector is fixed to the inner wall of the support frame through bolts, an air suction cover is fixed to one side of the top end of the support frame through bolts, air suction hoses are connected to the side walls of the air suction cover and the metal hopper, air suction holes are formed in the sidewall of the air suction cover, baffles are welded to the positions, close to the two edges of the air suction hole, of the side wall of the air suction cover, the two air suction hoses are connected with an air inlet of the dust collector, and a door-shaped support is hinged to the side wall of the support frame. By means of the cutting device, the angle of the door-shaped support is convenientlyadjusted, the position of a cutting unit is conveniently adjusted, the cutting depth is conveniently adjusted, adjustment is facilitated, different cutting needs are met, and waste debris in the cutting process are conveniently absorbed.

Owner:安徽尧龙竹木制品有限公司

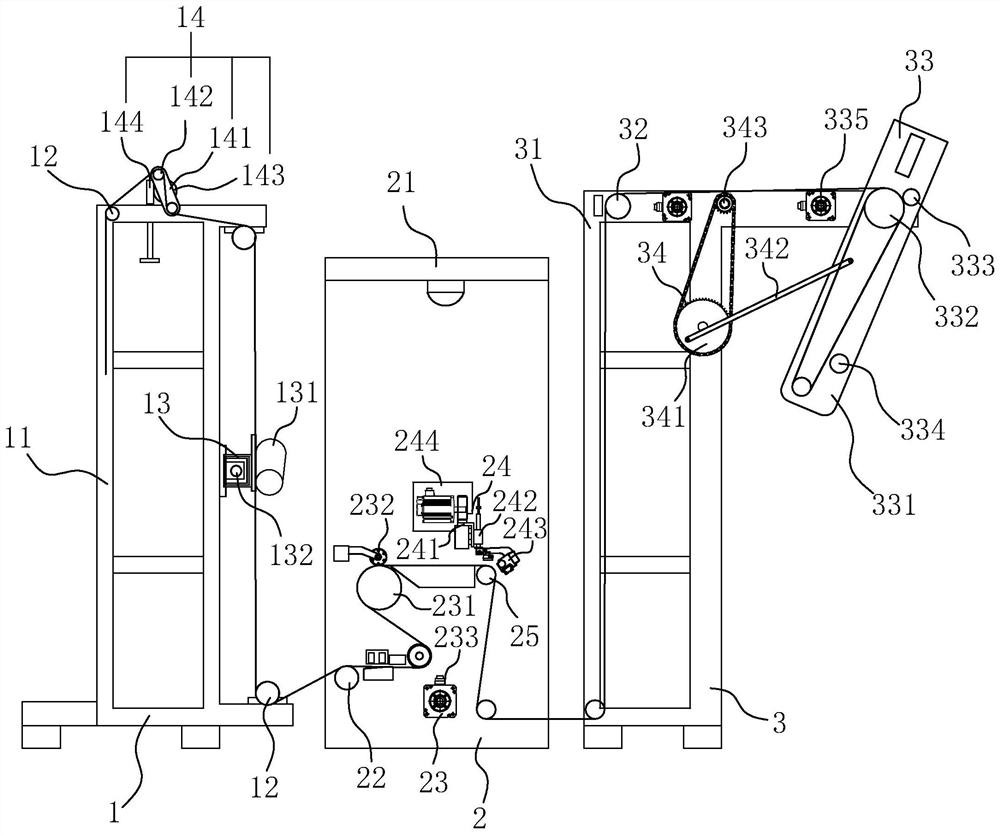

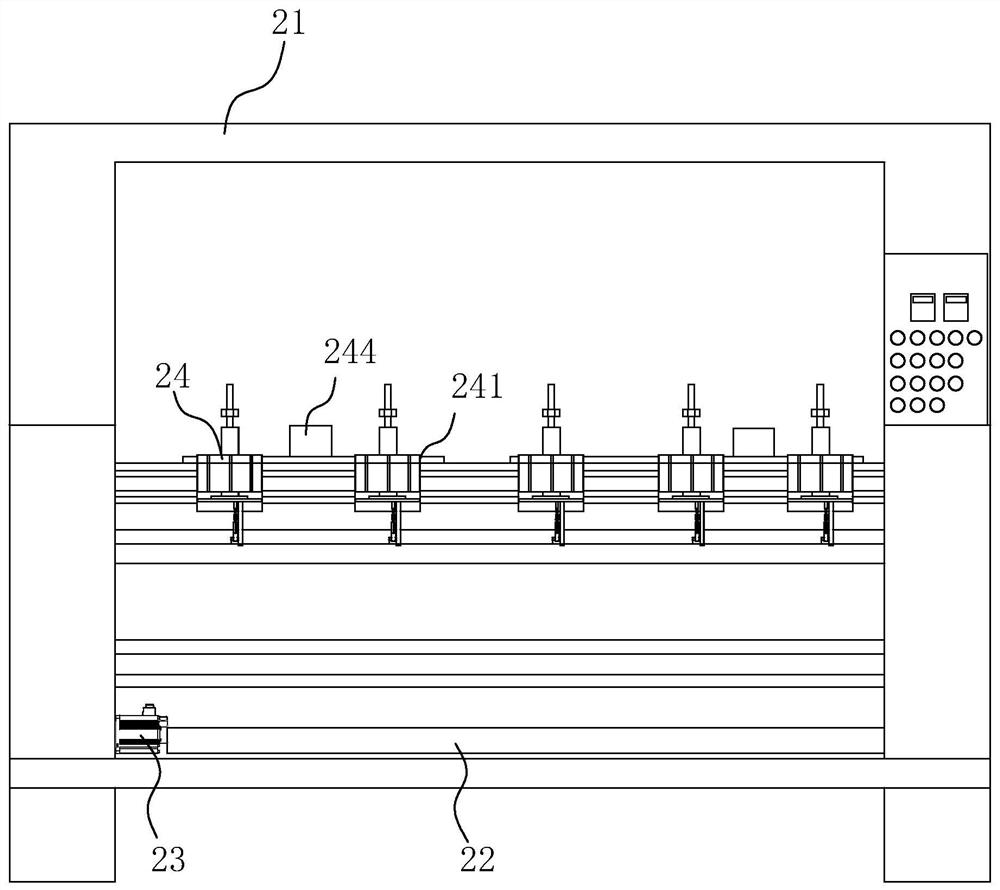

Automatic cloth cutting system

PendingCN112207882AEasy to collectMeet different cutting needsSevering textilesMetal working apparatusEngineeringMechanical engineering

The invention relates to an automatic cloth cutting system, the automatic cloth cutting system comprises a cloth conveying device, a cloth slitting device and a cloth swinging and collecting device which are arranged in sequence, the cloth conveying device comprises a cloth feeding frame, a plurality of cloth guide rods and a cloth spreading mechanism, the cloth slitting device comprises a rack, aplurality of tensioning rollers, a conveying driving mechanism, a cutter bar and a plurality of cutter mechanisms, the cloth swinging and collecting device comprises a cloth swinging frame, a plurality of reversing rollers, a cloth swinging mechanism and a swinging driving mechanism, and each cutter mechanism comprises a cutter base, a plurality of hot cutter assemblies, a plurality of cold cutter assemblies and a cutter adjusting driving mechanism. According to the automatic cloth cutting system, the cloth spreading mechanism spreads and flattens cloth in the conveying process, meanwhile, the cloth is in a tensioned state under the action of the cloth swinging mechanism, the cutter adjusting driving mechanisms drive the cutter bases to move, the positions of the cutter mechanisms are adjusted, the hot cutter assemblies or the cold cutter assemblies are selected and controlled to cut the cloth according to needs, and therefore different cutting requirements are met, and the adjustingprocess is more convenient and faster.

Owner:苏州市立刚机械制造有限公司

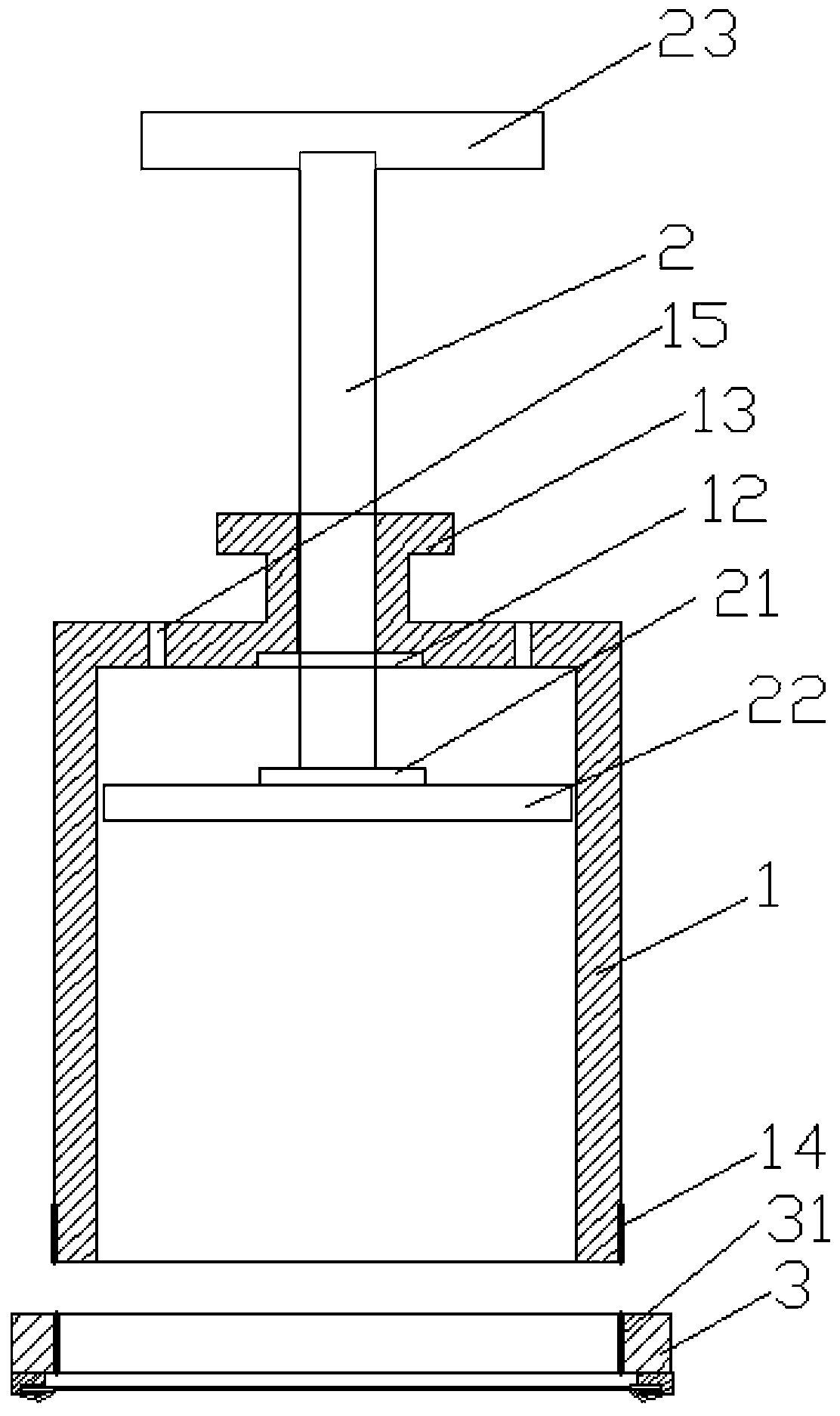

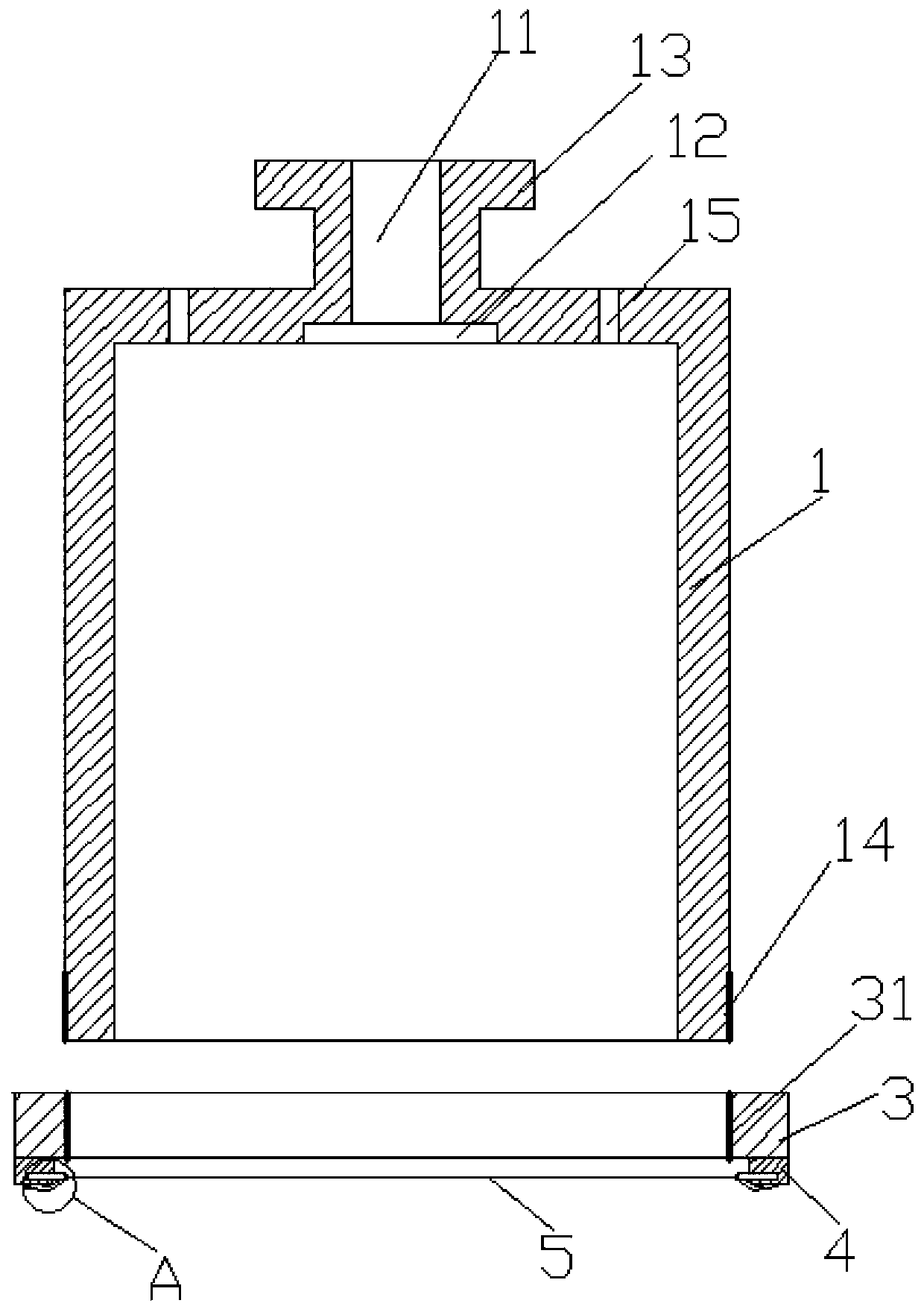

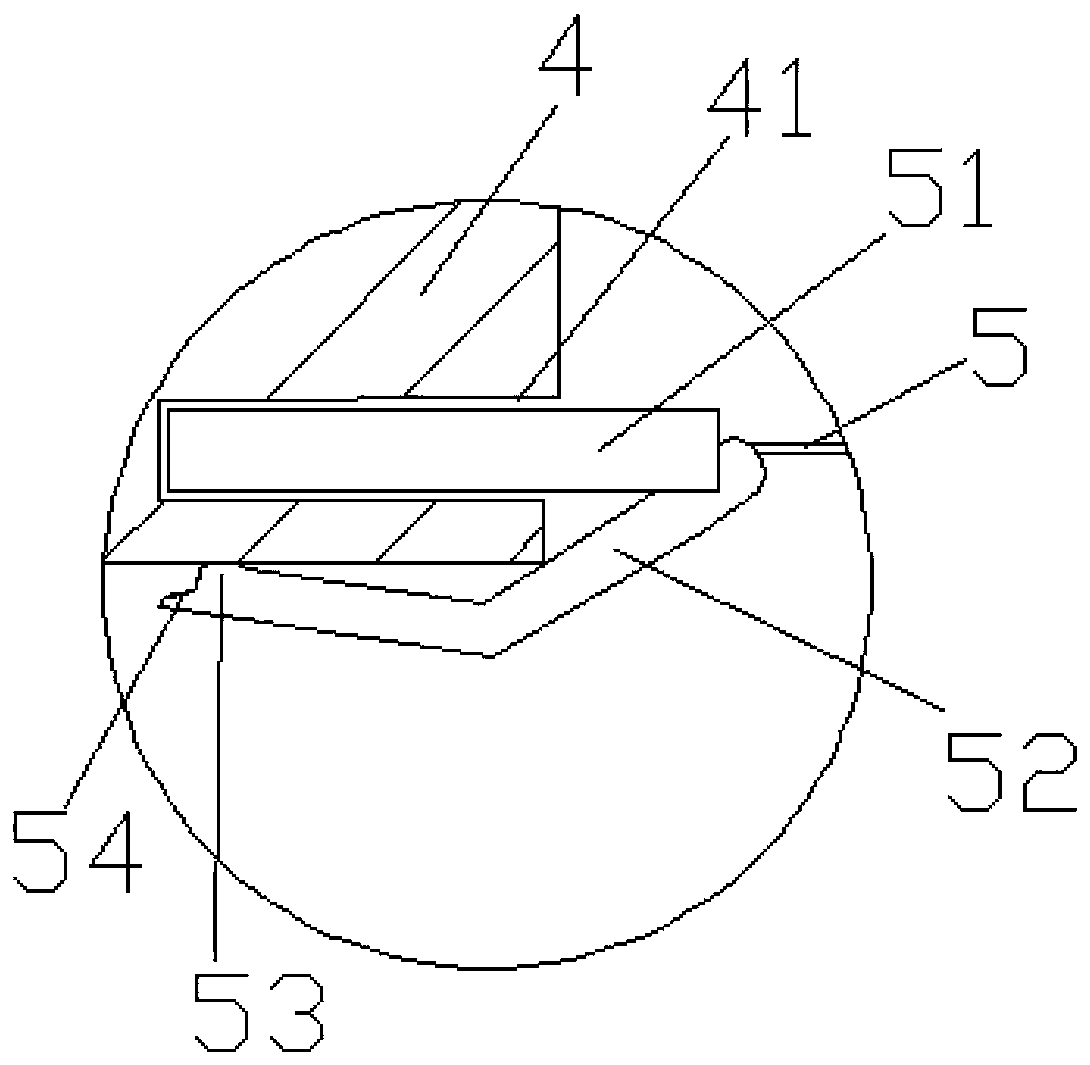

Coal slime sample preparation divider with cutting function

InactiveCN110346191ASimple structureEasy to assemble and disassemblePreparing sample for investigationEngineeringCoal

The invention belongs to the technical field of coal slime sample preparation, and particularly relates to a coal slime sample preparation divider with a cutting function; the coal slime sample preparation divider comprises a cylinder body, an extrusion part and a cutting part; the top of the cylinder body is provided with a columnar bulge, and the top of the columnar bulge is provided with a clamping strip; the extrusion part comprises a push rod, the upper end of the push rod is detachably connected with a pressing plate, and the lower end of the push rod is connected with a pressing block through a connecting block. The cutting part comprises a connecting cylinder, fixed blocks are evenly distributed on an annular face of the bottom of the connecting cylinder, and limiting grooves are formed in the fixed blocks. A limiting piece is detachably installed in the limiting groove, and the end, close to the center line of the connecting cylinder, of the limiting piece is connected with ametal wire. Compared with the prior art, the divider has the following advantages that collected coal slime blocks can be shrunk with one hand, blocking can be completed in an extrusion process, and the separated coal slime can be used for sampling or using again; the whole divider is simple in structure and convenient to disassemble, assemble and clean, different cutting requirements can be met,the step of cutting with a knife again is omitted, and the production process is simplified.

Owner:HUAIBEI MINING IND +1

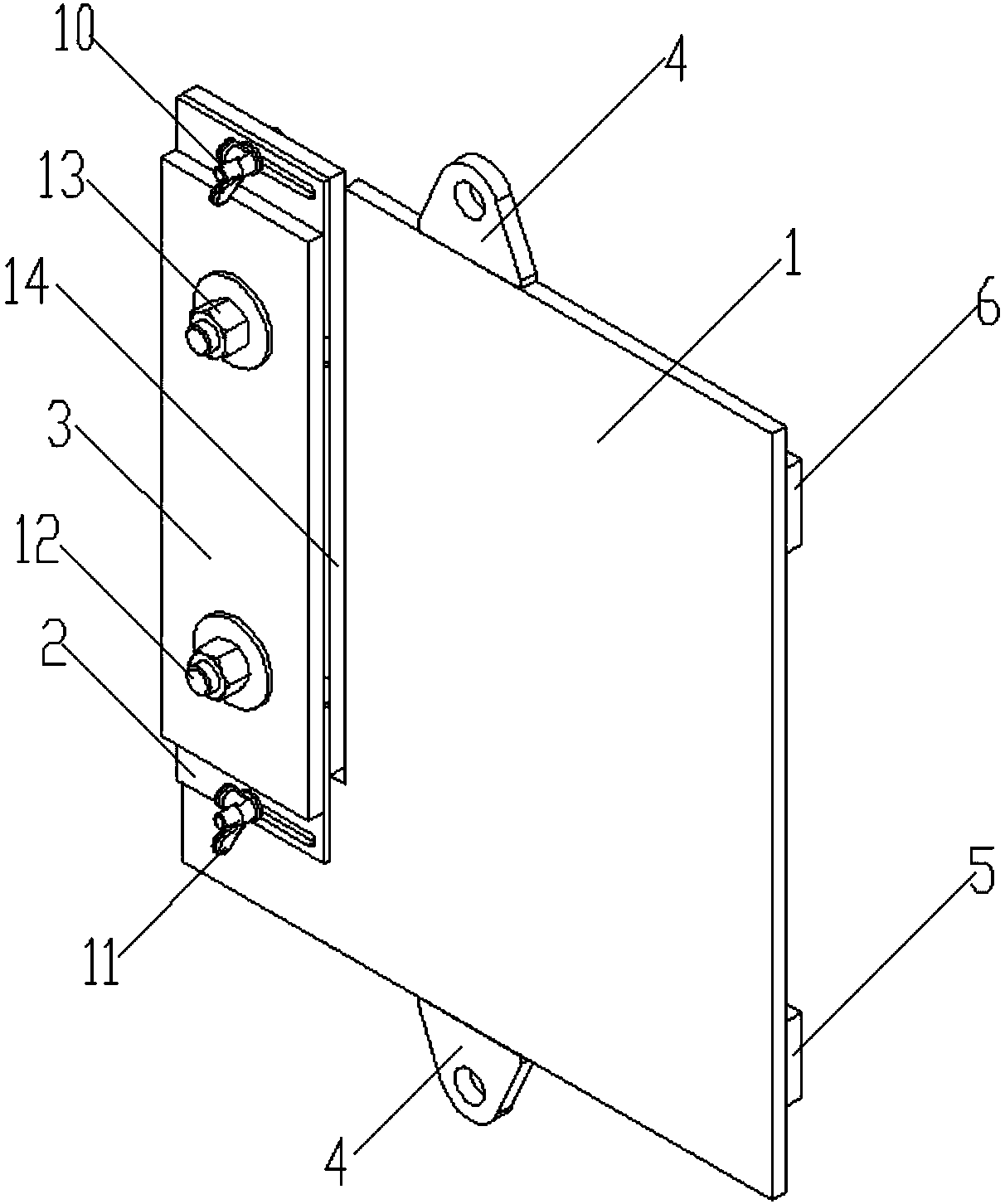

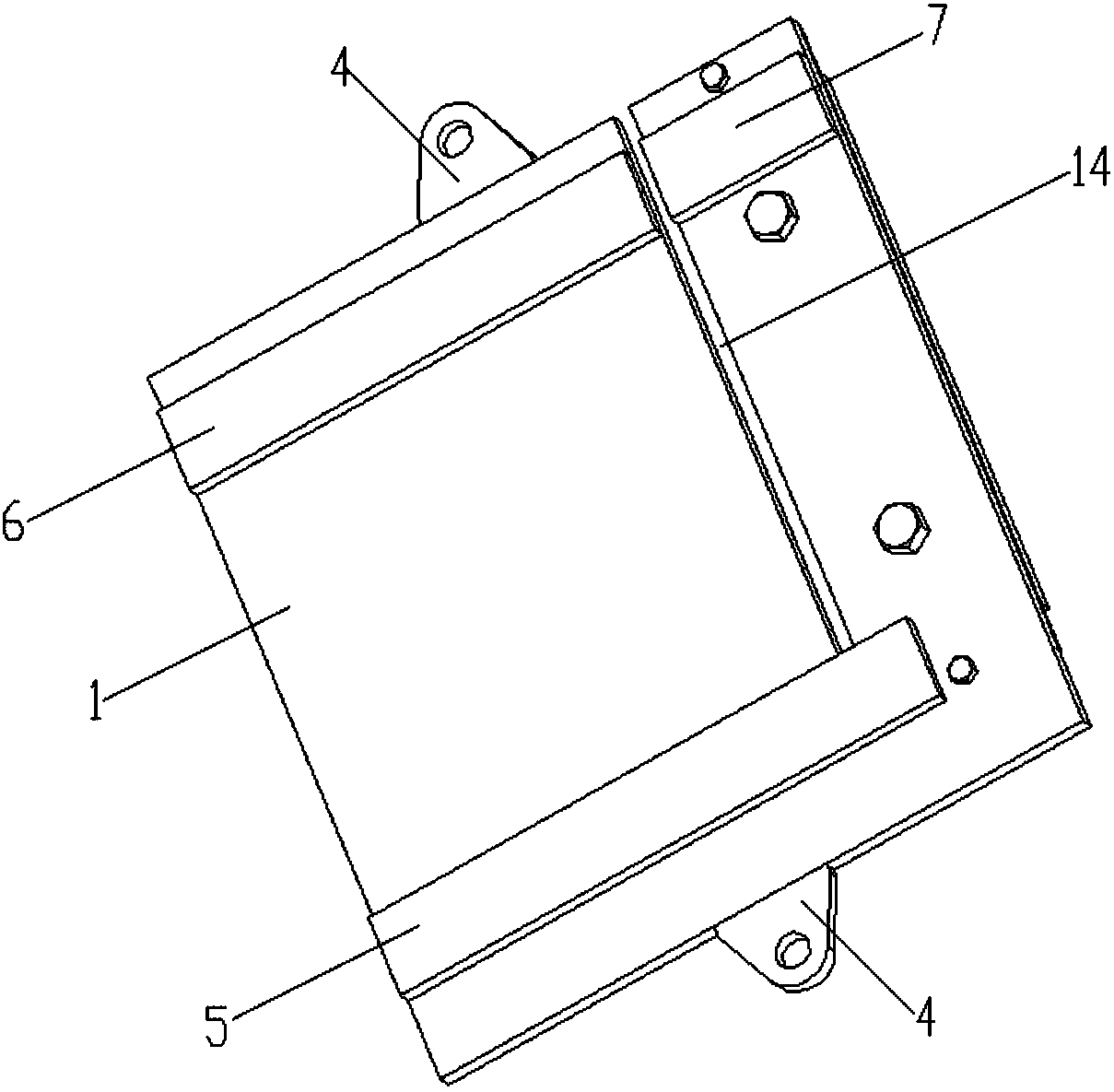

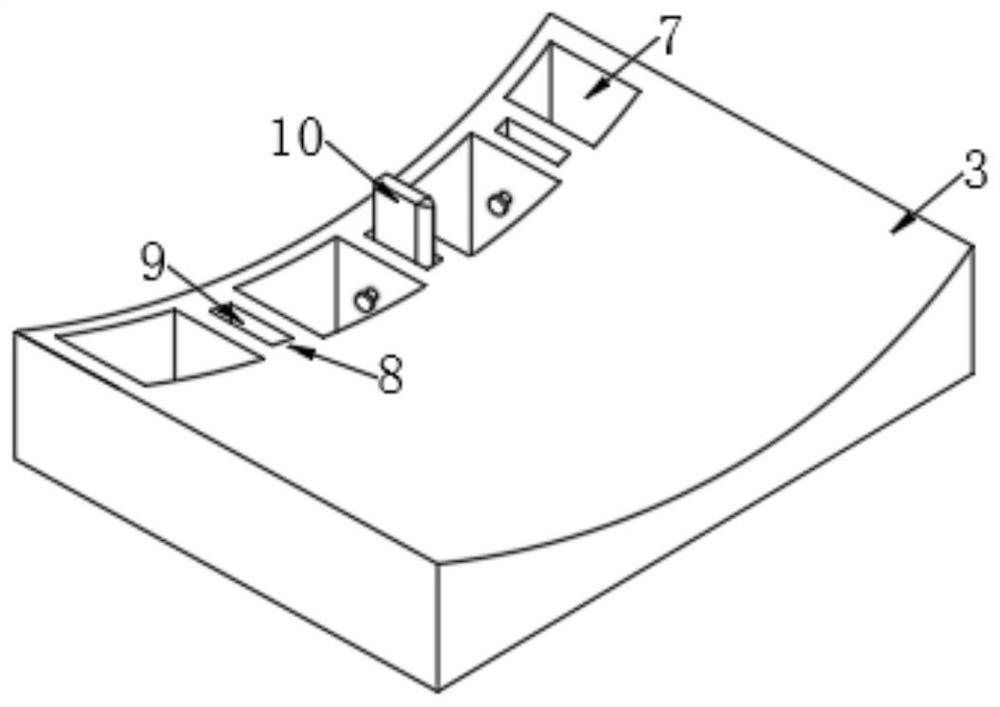

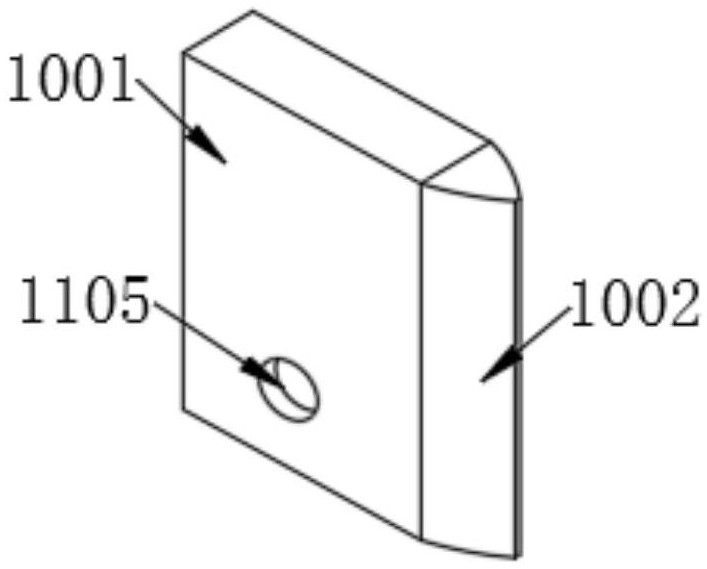

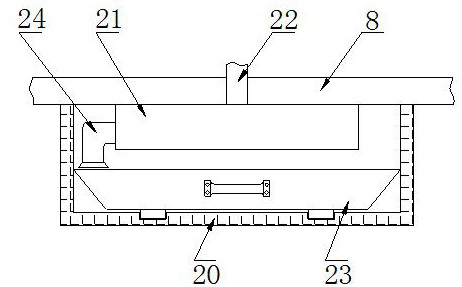

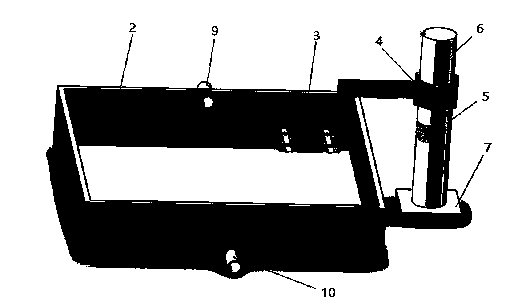

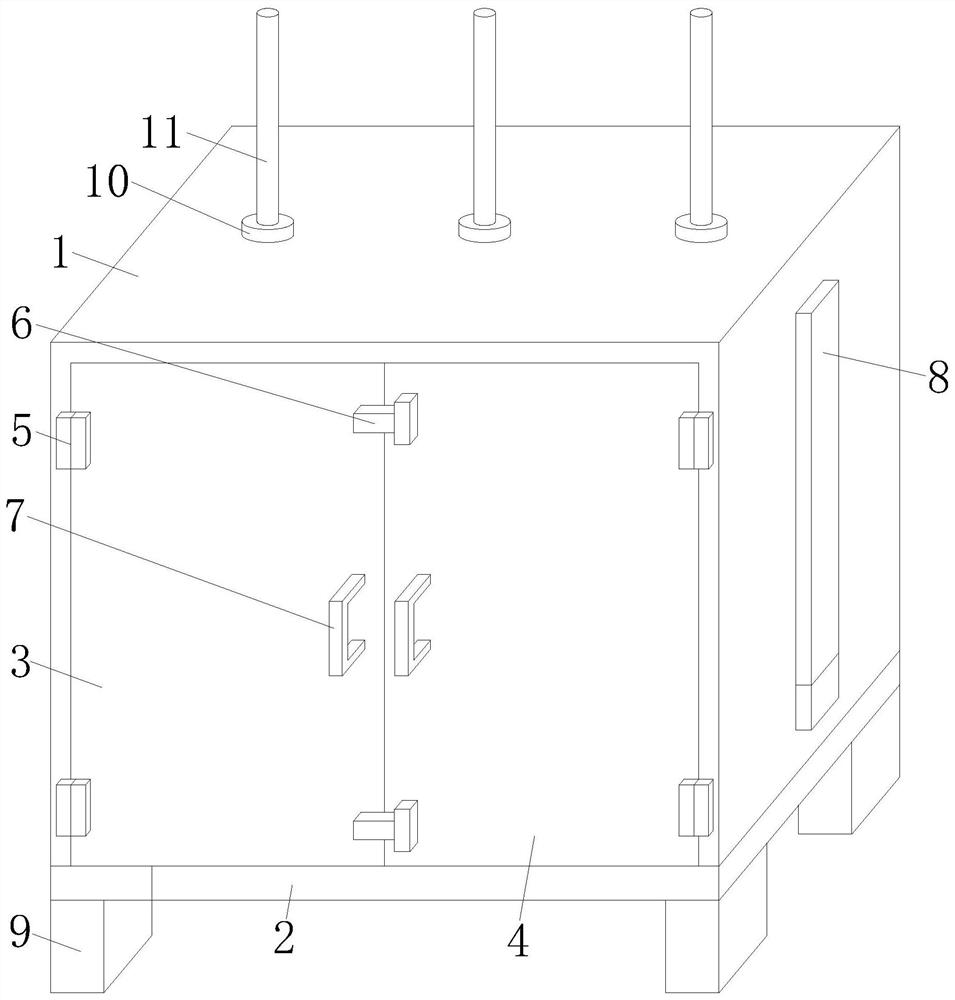

High-speed aircraft empennage underwater laser processing device

InactiveCN109885119AImprove cut qualityMeet different cutting requirementsSimultaneous control of multiple variablesLaser beam welding apparatusLaser processingFlight vehicle

The invention discloses a high-speed aircraft empennage underwater laser processing device. The device comprises a cold water machine 1, a liquid tank 2, a clamp 3, fixing nuts 4, clamping grooves 5,a fixed rod 6, a fixed base 7 and a filter 8, wherein the two ends of the liquid tank 2 are provided with a water inlet and a water outlet respectively; the water inlet and the water outlet are connected with the filter 8 and the cold water machine 1 through pipelines to form a circulation system; the temperature and the flow speed of the whole system are controlled by the cold water machine 1; residues in a working solution are filtered by the filter 8, so that the cleanness of the working solution is guaranteed; the fixed rod 6 is provided with the clamping grooves 5 for positioning the clamp 3; and the two fixing nuts 4 are matched with the clamping grooves 5 to enable the clamp 3 to be fixed more firmly. Under the coupling action of multiple energy fields such as light, temperature, flow field and the like, efficient and high-quality cutting of an empennage sample piece is realized. The empennage sample piece is controllable in immersion depth, flow field speed and temperature; andthe device is simple in structure and simple and convenient to operate.

Owner:SHANDONG UNIV OF TECH +1

Multifunctional automatic cutting device

InactiveCN107199469AAdjustable positionMeet different cutting needsLarge fixed membersMetal working apparatusPush pullPulley

The invention discloses a multifunctional automatic cutting device, which comprises: a frame body, a motor, a push-pull rod, a bearing, a rotating cutter body, and a pulley. The pulley is arranged at the bottom of the frame body, and the motor is arranged at the bottom of the frame body. The top of the frame body, one end of the push-pull rod is connected with the motor, the other end of the push-pull rod is connected with the bearing, the bearing is connected with the rotary cutter body, and the push-pull rod It is a retractable structure up and down. Through the above method, the multifunctional automatic cutting device of the present invention can adjust the position and cutting direction of the knife holder in time, can meet different cutting requirements, and has a simple structure and is convenient to use.

Owner:TAICANG SIPUNING PRECISION MACHINERY

Rapid cloth cutting machine for textile cloth production

InactiveCN113123113AAvoid replacementEasy to replaceSevering textilesMechanical engineeringIndustrial engineering

The invention discloses a rapid cloth cutting machine for textile cloth production. The rapid cloth cutting machine comprises a workbench, first electric push rods, a second electric push rod and a controller; the first electric push rods are fixedly mounted on the two sides of the workbench, and the bottom ends of the two first electric push rods penetrate through the workbench and are fixedly connected with clamping plates; the second electric push rod is fixedly installed at the top end of the workbench; a servo motor is fixedly connected to the bottom end of the second electric push rod; a fixing rod is fixedly connected to the bottom end of the servo motor; and a connecting rod is movably connected to the bottom end of the fixing rod. According to the rapid cloth cutting machine for textile cloth production, cloth can be clamped, the angle of a cutting head can be adjusted, the cutting effect is better, the cutting head is convenient to replace, different cutting requirements are met, and meanwhile the cutting head can be prevented from being damaged.

Owner:江苏添时利纺织品有限公司

A rotary cutting device for meat processing

ActiveCN110900673BImprove hygieneImprove cutting efficiencyMetal working apparatusCircular discElectric machinery

The invention discloses a rotary cutting device for meat processing, which comprises a box body, a bottom plate, a first box door, a second box door, a hinge, a hasp lock, a handle, a lifting structure, a driving motor, a casing, a screw rod, and a nut , jacket, connection block, support foot, guide ring, guide rod, plate body, knife slot, bearing plate, flat plate, fixed cover, bottom groove, disc, elastic rod, fixed tube, movable rod, spring, short rod, Servo motors, servo motor controllers, gears, cutters and germicidal UV lamps. The invention has a reasonable structure and can automatically cut processed meat pieces. Through the setting of multiple cutting knives, it can cut into multiple pieces at one time, and the cutting efficiency is high. When cutting, the meat pieces are carried by the carrying plate to carry out meat When picking and placing, the carrying plate is also replaced accordingly, and the manual does not directly contact the meat, which improves the hygiene of the meat.

Owner:湖南现代资源农业科技有限公司

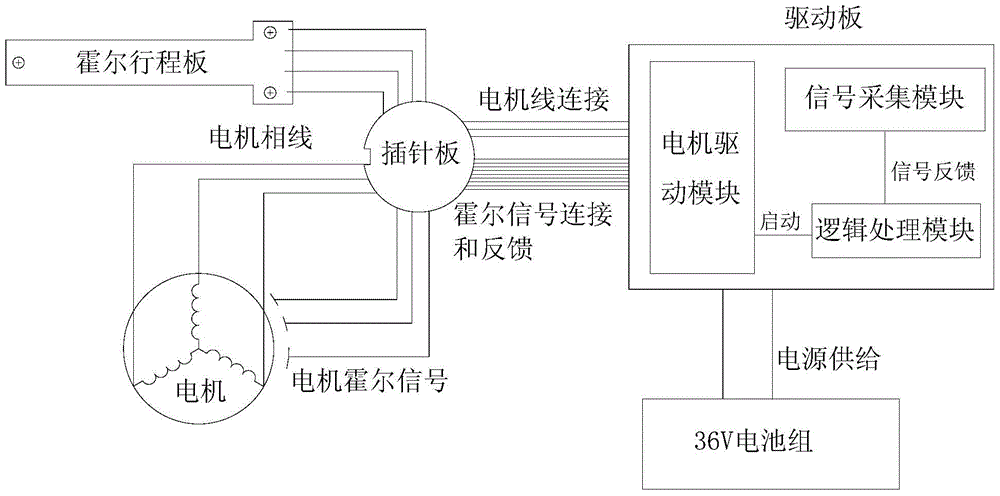

A control system for electric scissors

InactiveCN104516358BMeet different cutting needsWith current limiting protectionControl using feedbackBrushless motorsElectricity

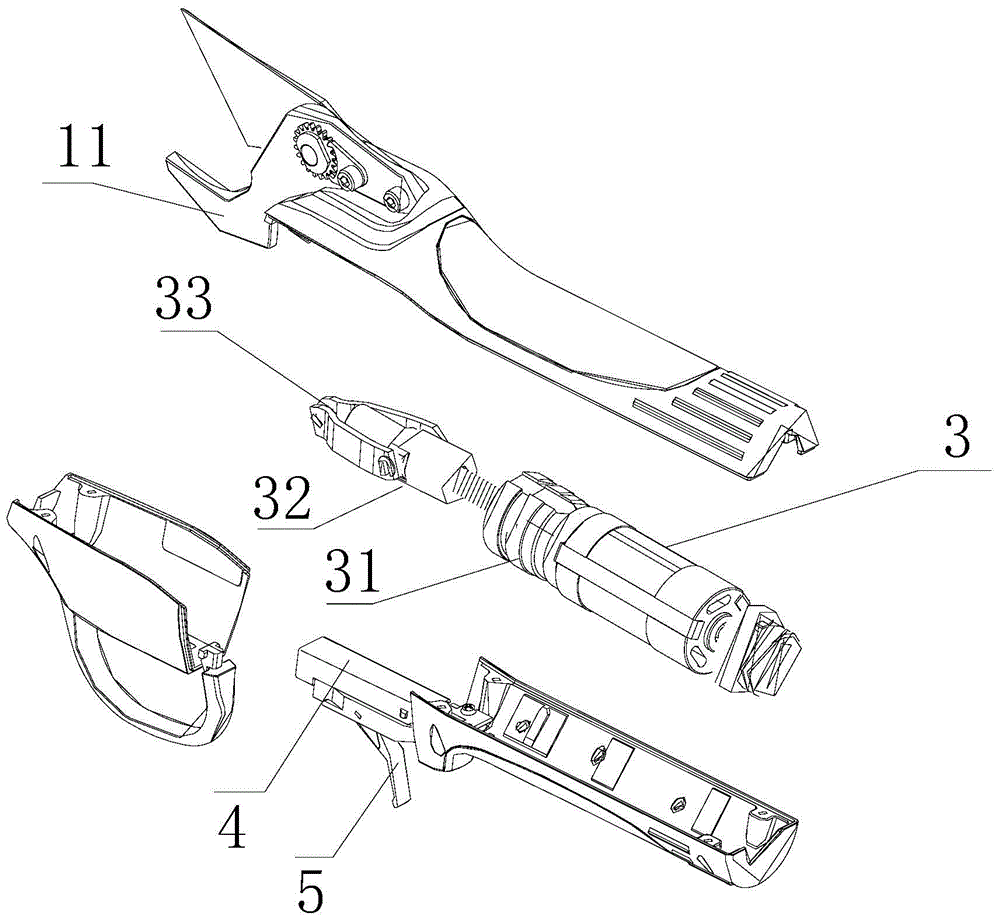

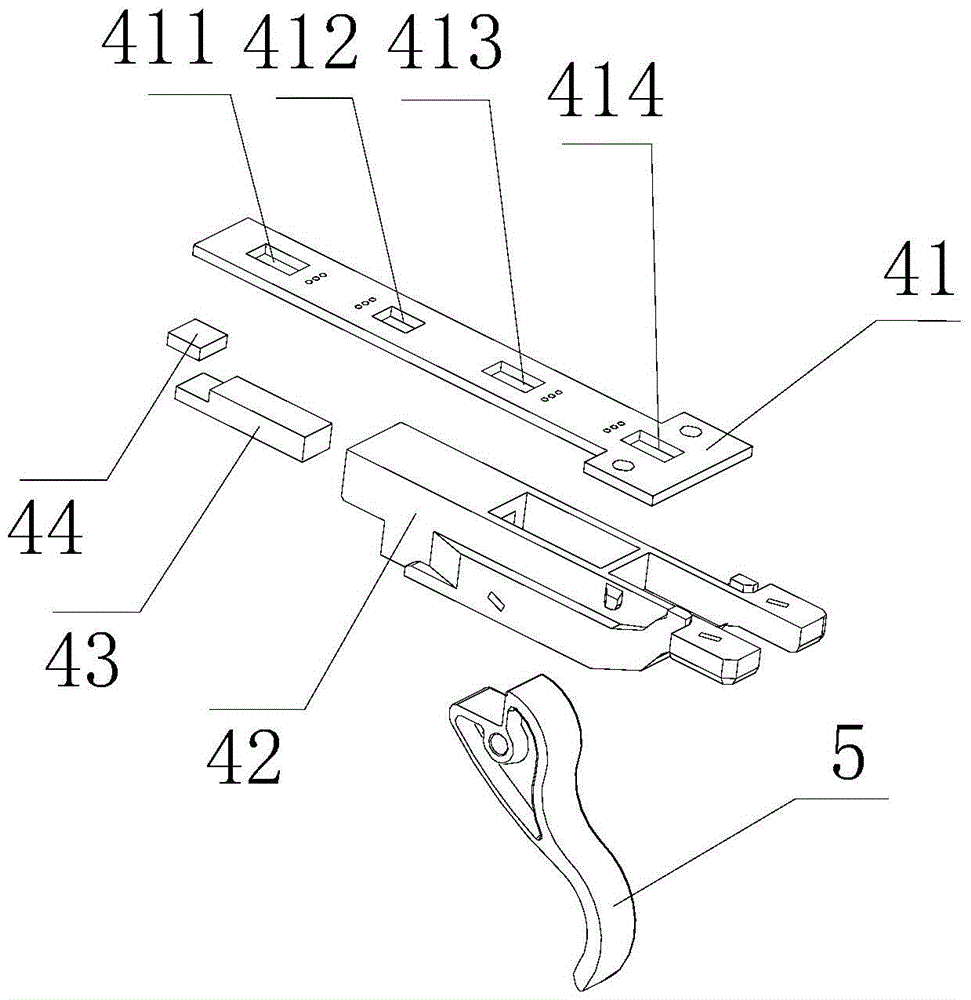

The invention discloses a control system for electric scissors, relates to the field of industrial control, and solves the problems of single cutting mode and relatively large potential safety hazards in the prior art. The control system includes a Hall sensor device for sensing the position of the trigger and a controller receiving the Hall signal of the Hall sensor device. The Hall sensor device includes a Hall travel plate with multiple positions and With the matching magnet, when the trigger drives the magnet to be in different positions, the Hall stroke plate senses the corresponding Hall signal, and inputs the Hall signal to the controller, and the controller outputs the corresponding control signal to control the rotation angle of the brushless motor And the direction of rotation, and then control the shearing action of the scissors head. This control system can realize the full range and half range opening of the cutter head of the electric scissors. It has the function of current limiting protection and pulls the trigger twice after the power is turned on. , the scissor head will be fully opened, reminding the user to start cutting work, avoiding potential safety hazards and making it safer to use.

Owner:宁波市镇海长城汽车摩托车部件厂

Ship steel plate cutting device

PendingCN114734096AImprove stabilityImprove uniformityFeeding apparatusMetal working apparatusMarine engineeringStructural engineering

The invention discloses a ship steel plate cutting device in the field of ship steel plate cutting, which comprises a mounting seat, a first transportation mechanism is arranged on the inner side wall of the mounting seat, the first transportation mechanism comprises a plurality of first transmission rollers, and the first transmission rollers are rotationally connected to the inner side wall of the left end of the mounting seat in an array manner; a driving mechanism is arranged at the end of one first transmission roller, the surfaces of the first transmission rollers are jointly in transmission connection with a first conveying belt, and the first conveying belt and the mounting base are jointly provided with a pressing mechanism. By arranging the pressing mechanism and the positioning mechanism, steel plates with different widths and thicknesses can be automatically positioned and pressed in time, the cutting stability and uniformity are improved, manual adjustment is not needed, the labor intensity is reduced, and the cutting efficiency is improved.

Owner:天长市蓝天船舶设备制造有限公司

Frequency control system and method using type detection

ActiveCN112606083BMeet different cutting needsCompact structureImage enhancementCharacter and pattern recognitionAgricultural engineeringControl theory

The invention relates to a frequency control system using type detection, comprising: a uniform transmission mechanism, which is composed of a single transmission motor and a plurality of rolling shafts, and the transmission motor is respectively connected with the plurality of rolling shafts for driving the multiple The two rolling shafts drive the vegetables above to be conveyed at a constant speed in the horizontal direction according to the set speed; the cutting actuator is used to perform uniform cutting operations on the conveyed vegetables according to the adjusted cutting frequency of the frequency adjustment device; the vegetable storage box is used for Receives and holds vegetable bodies after performing a constant speed cutting operation on vegetables. The invention also relates to a frequency regulation method using type detection. The frequency control system and method using type detection of the present invention are compact in structure, convenient and practical. Since different vegetable cutting frequencies can be adaptively selected based on the types of vegetables detected on site, different cutting demands of people for vegetables with different lengths of leaves or stems are met.

Owner:平邑现代中药产业园有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com