Spoon separating device for spoon counting machine

The technology of a spoon counting machine and rack, which is applied in the field of spoon dividing devices for spoon counting machines, can solve the problems that the spoons are easily infected with dust or other sundries, manual separation is time-consuming and laborious, and the packaging bags of the spoons are damaged, etc., so as to achieve good practical performance, Guarantee cutting quality and prevent breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

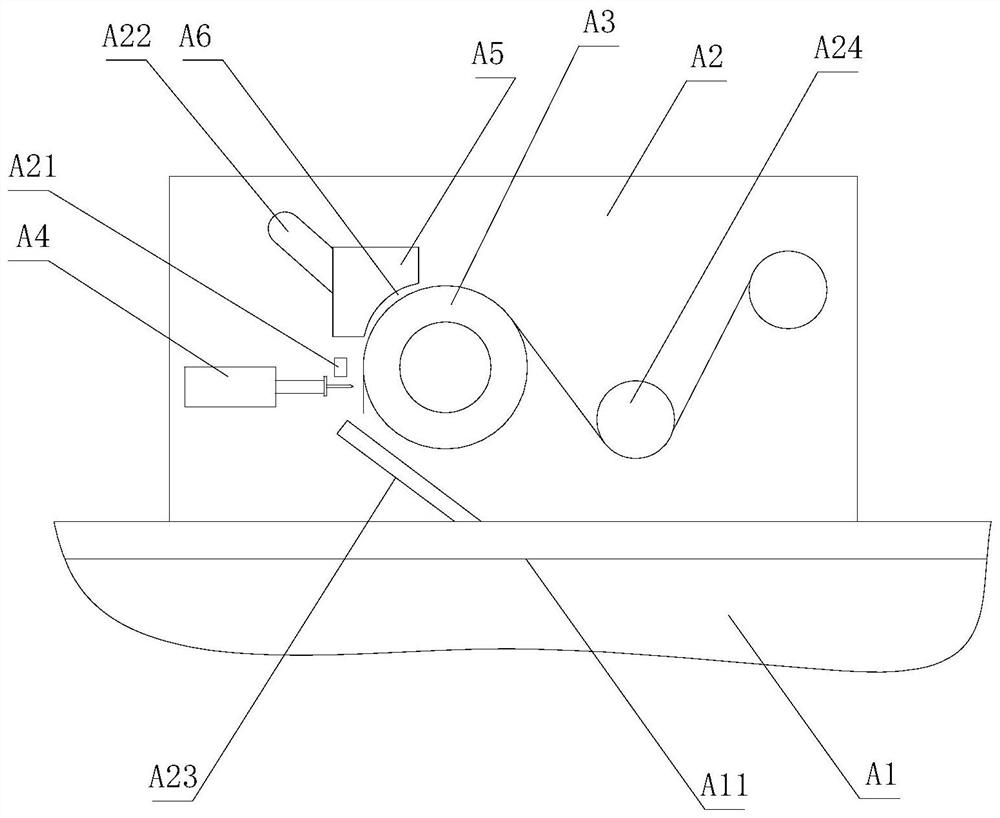

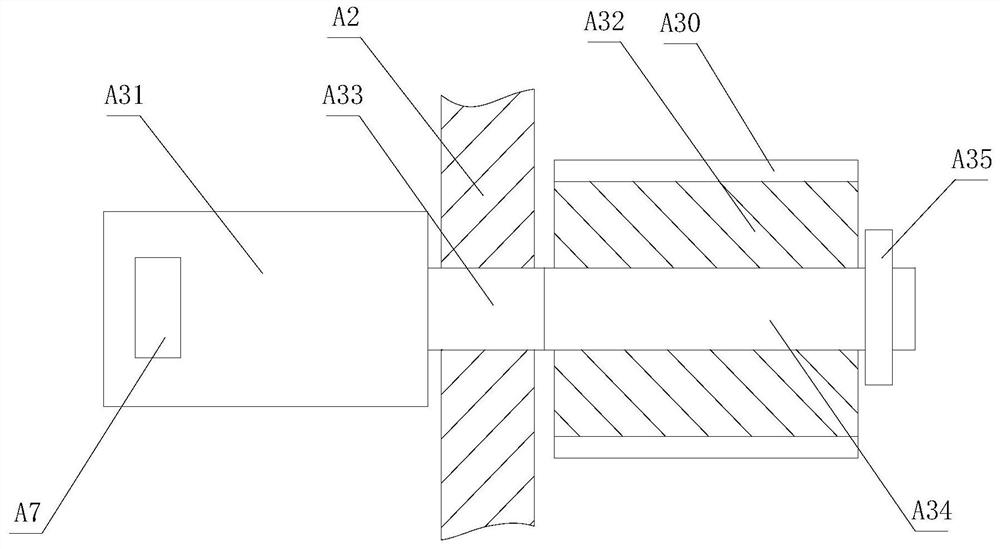

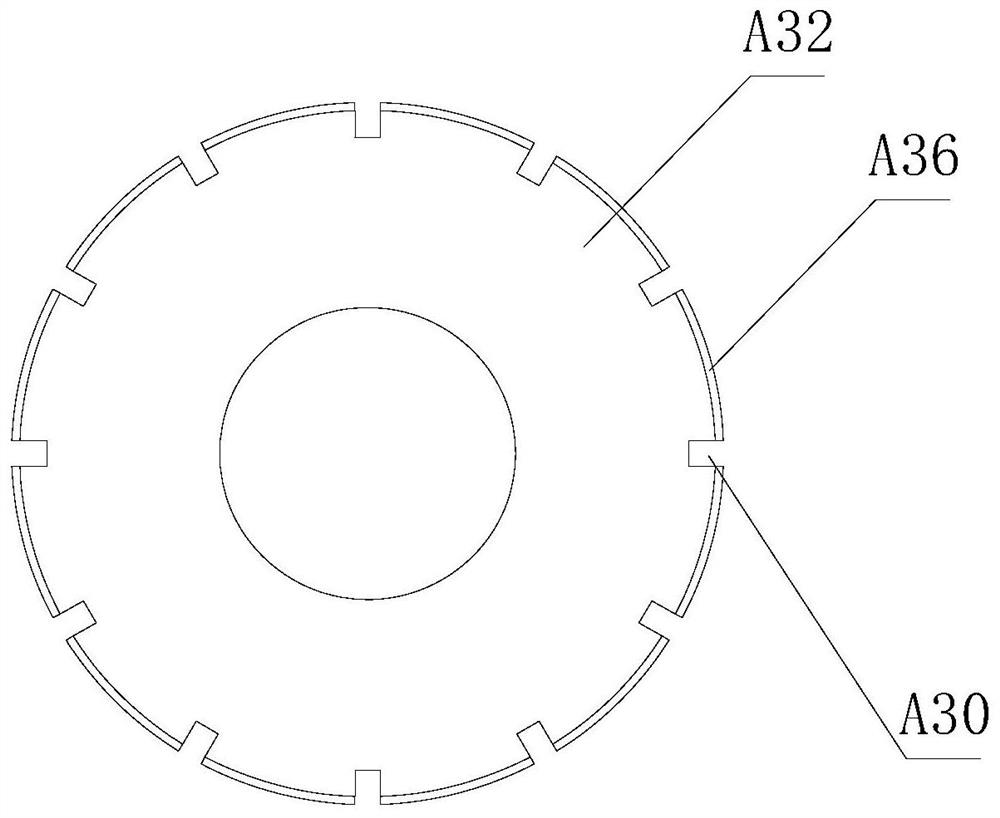

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a scooping device for a scoop pointing machine includes a frame A1, a support A2, a rotating body A3 and a cutting mechanism A4, the support A2 is arranged on the frame A1, and the rotating body A3 is arranged on the support A2 , the cutting mechanism A4 is arranged on the bracket A2 and is located in front of the rotating body A3, the outer peripheral side wall of the rotating body A3 is provided with a groove A30 suitable for the cutting assembly, and the bracket A2 is also movable A guide block A5 is connected, and a channel A6 for raw materials is formed between the guide block A5 and the rotating body A3. The first magnetic switch A7 is provided on the rotating body A3, and a magnetic switch A7 is provided on the cutting mechanism A4. The second magnetic switch A8, the first magnetic switch A7 and the second magnetic switch A8 are a pair of linkage switches.

[0024] The rotation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com