Coal slime sample preparation divider with cutting function

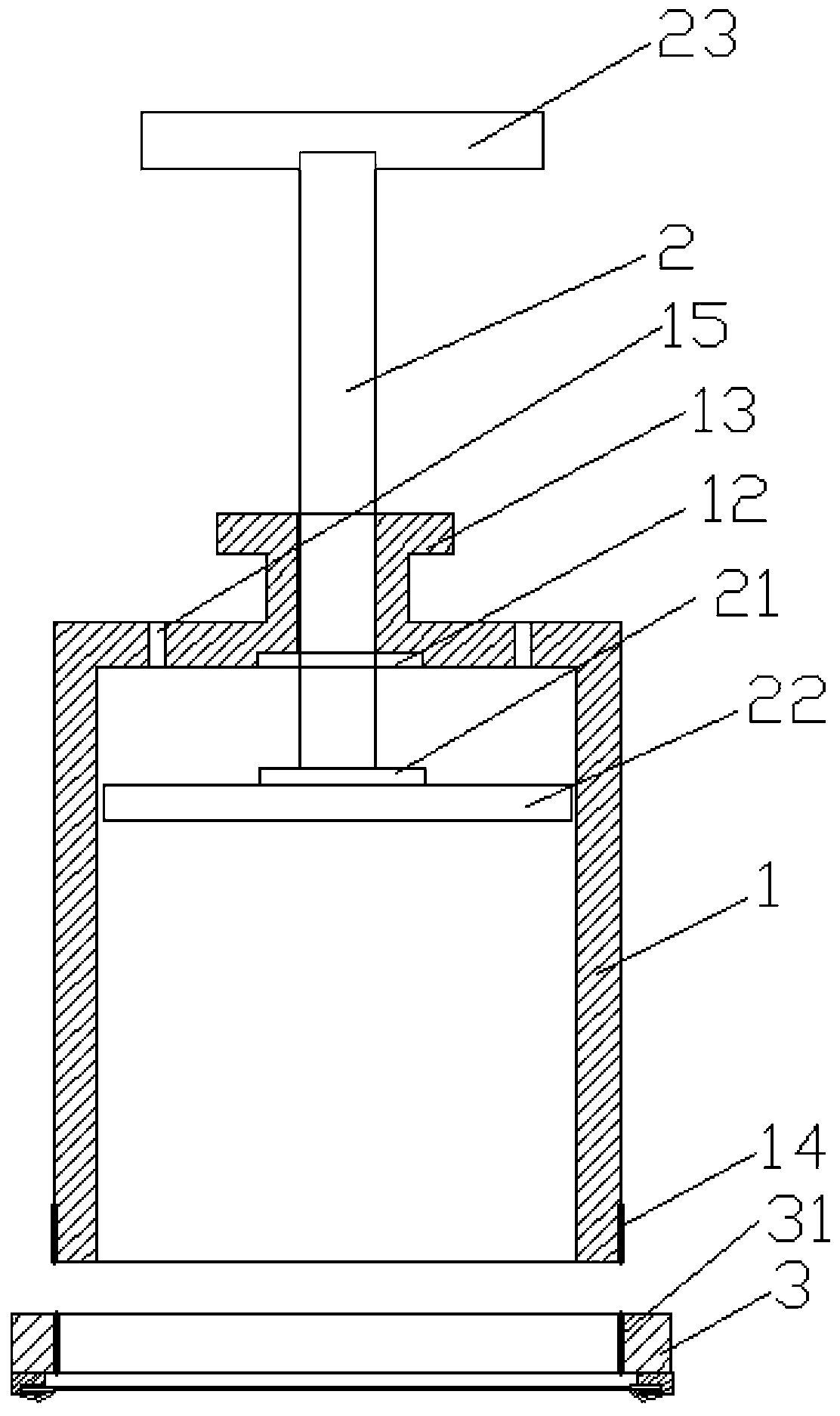

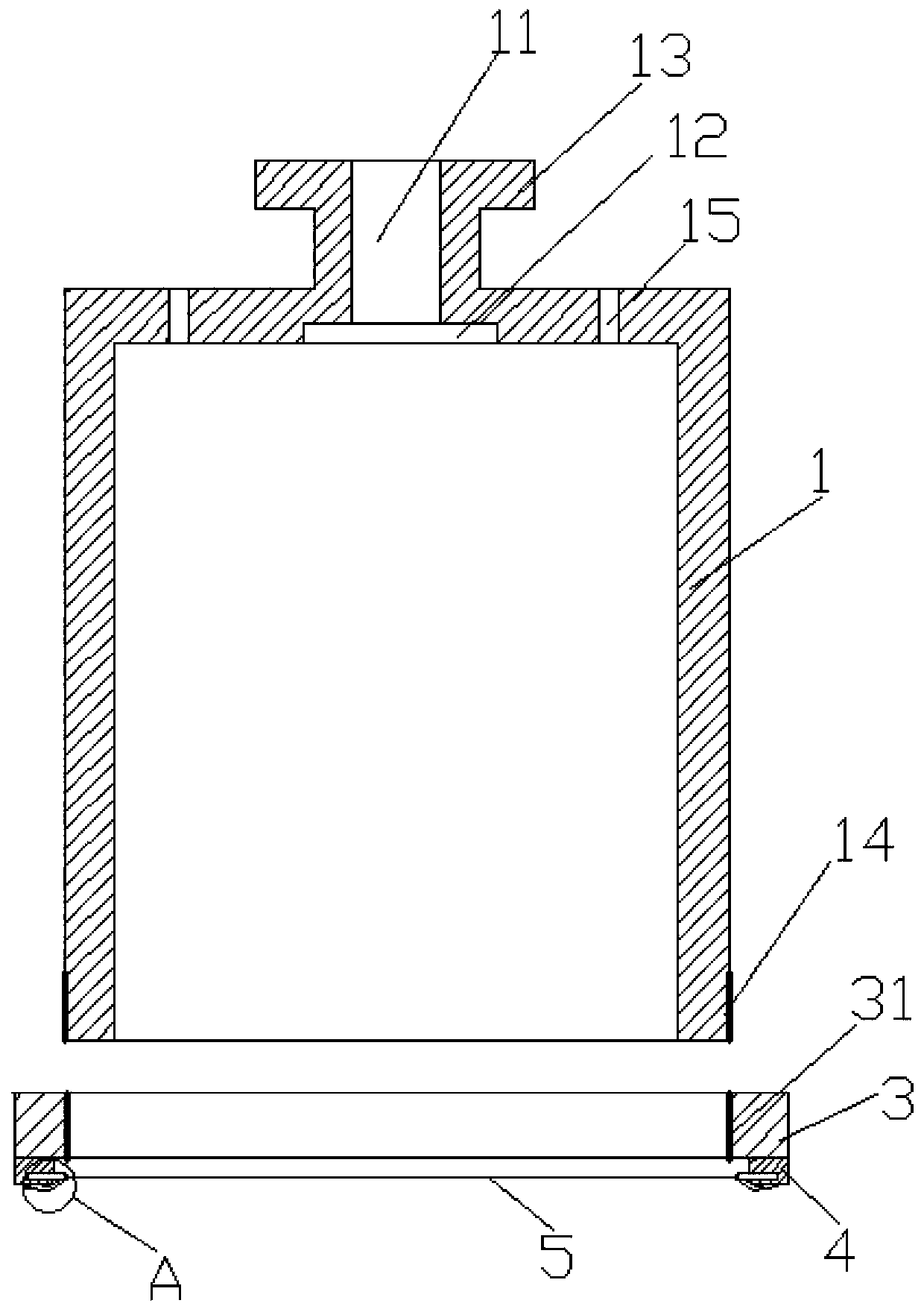

The utility model relates to a technology of reducing device and function, which is applied in the field of coal slime sample preparation and reducing device, which can solve the problems such as complicated process and achieve the effects of simple device structure, convenient disassembly and cleaning, and simplified production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

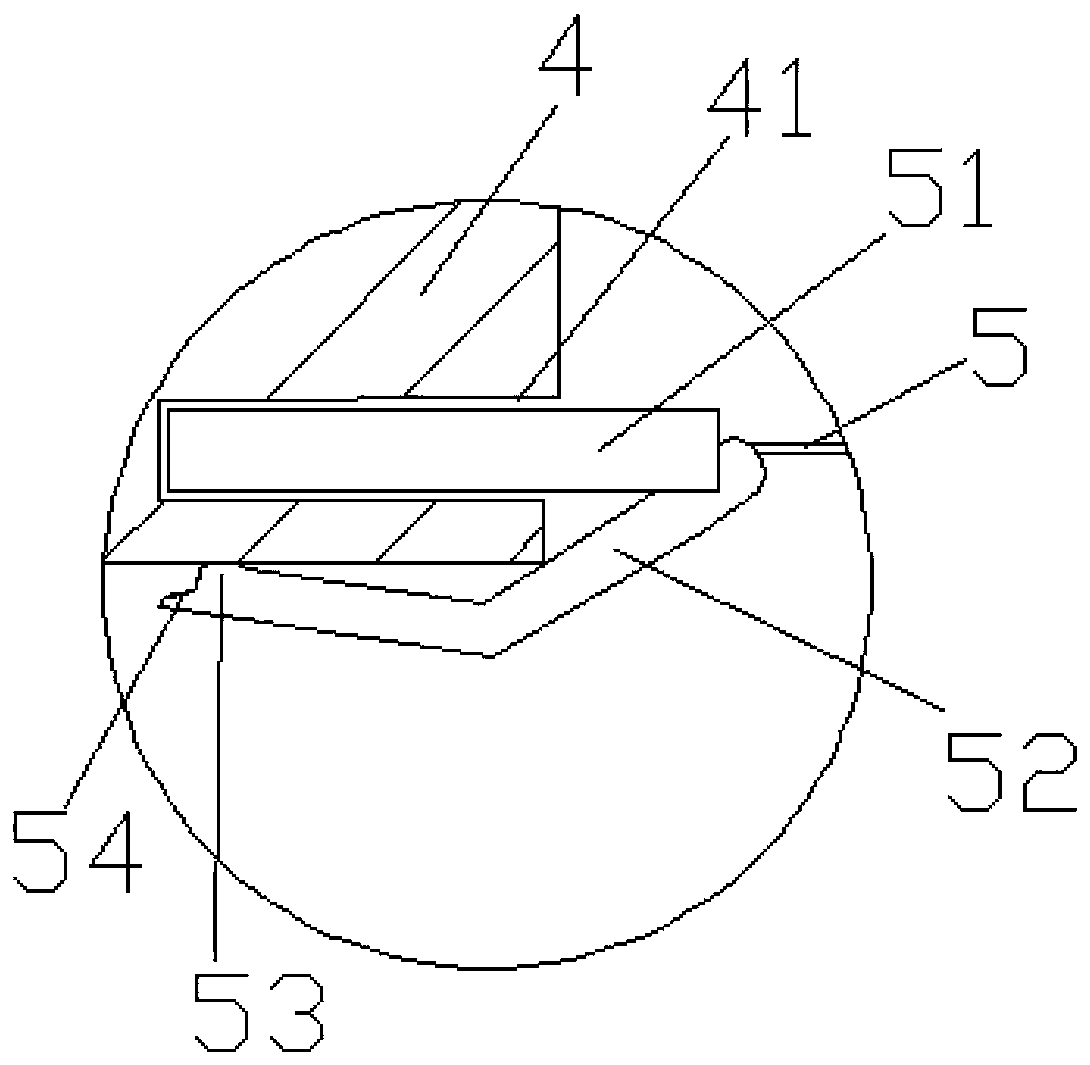

[0028] Such as Figure 5 As shown in , 12 fixed blocks 4 are evenly distributed on the circular surface at the bottom of the connecting cylinder 3, and two sets of fixed blocks 4 are selected to set limit pieces, each group includes two symmetrical fixed blocks 4, and each set of fixed blocks 4 corresponds to The limit piece is connected with the same metal wire 5, which can evenly divide the coal slime block in the cylinder body 1 into four fan-shaped cylinder structures.

Embodiment 2

[0030] Such as Figure 6 As shown in , 12 fixed blocks 4 are evenly distributed on the circular surface at the bottom of the connecting cylinder 3, and three fixed blocks 4 are selected to set limit pieces respectively. Each limit piece is connected to a metal wire 5, and the three metal wires 5 are in the The centers of the circles are connected, and the slime blocks in the cylinder body 1 can be evenly divided into three fan-shaped cylinder structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com