Cutting blanking assisting device for thin and long plates

An auxiliary device, slender technology, applied in the direction of positioning device, clamping, support, etc., can solve the problems of inability to obtain long strip materials, inability to meet processing requirements, slender metal curling, etc., to improve the application range, structure Simple and effective to improve the quality of blanking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

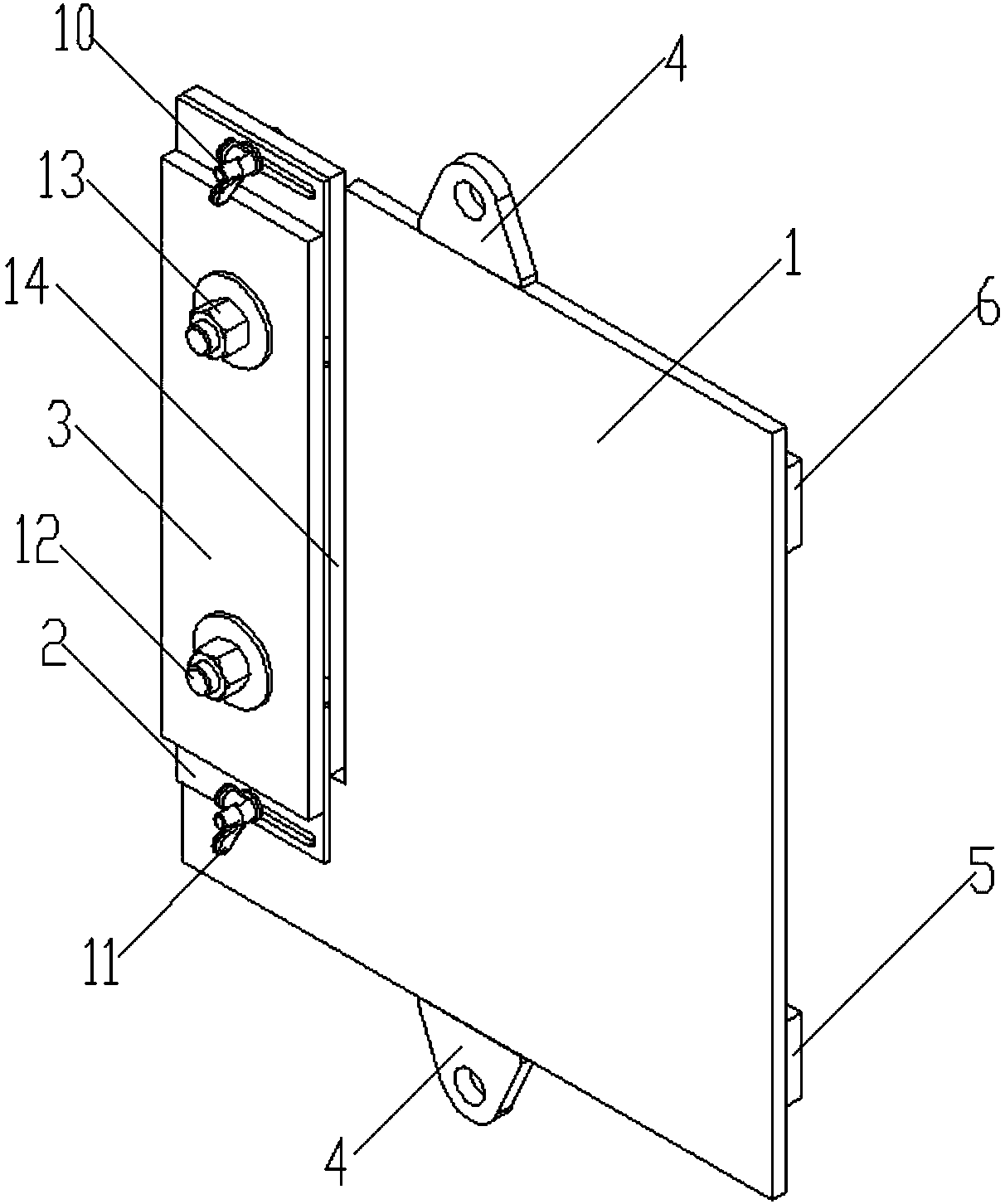

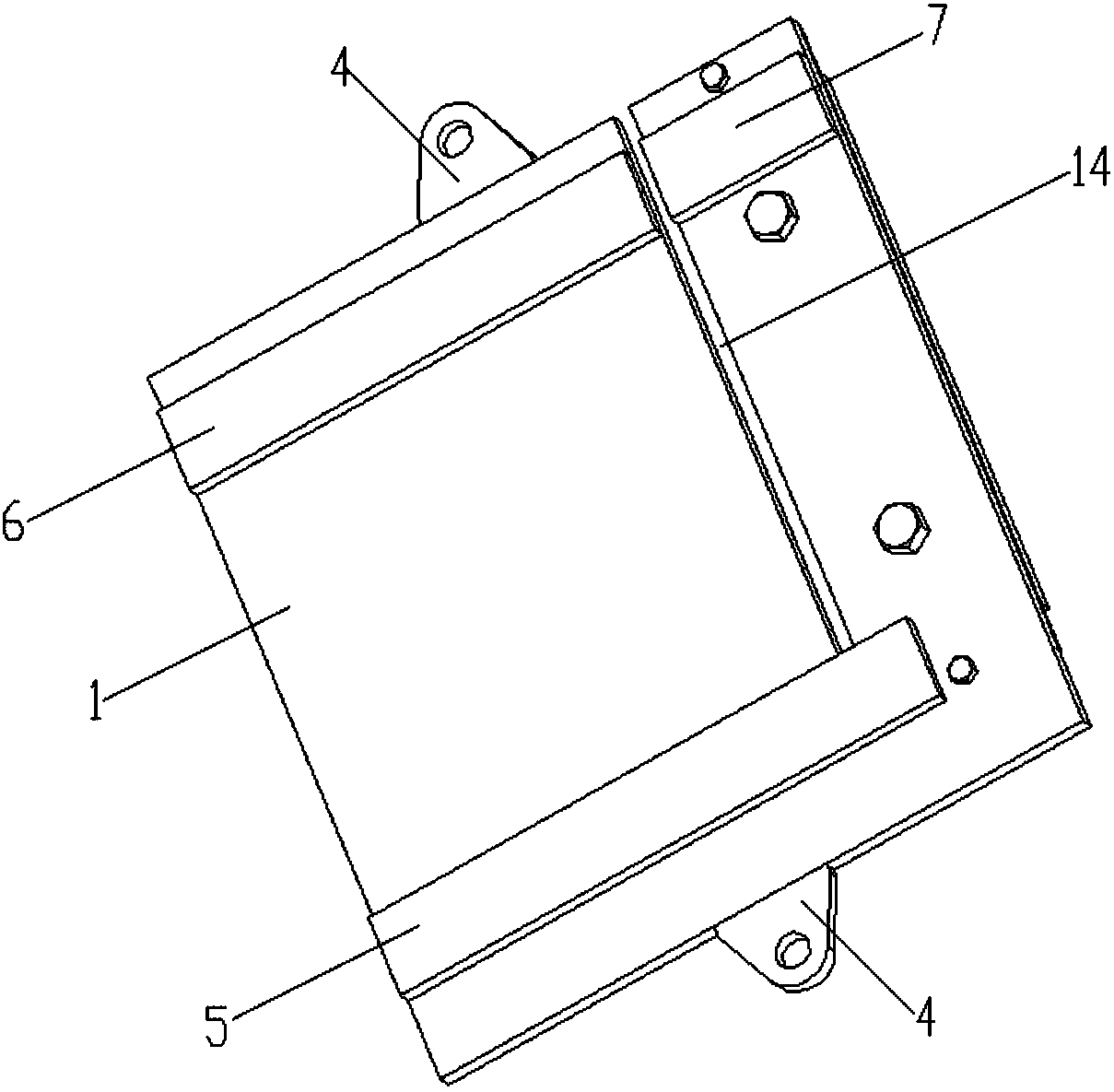

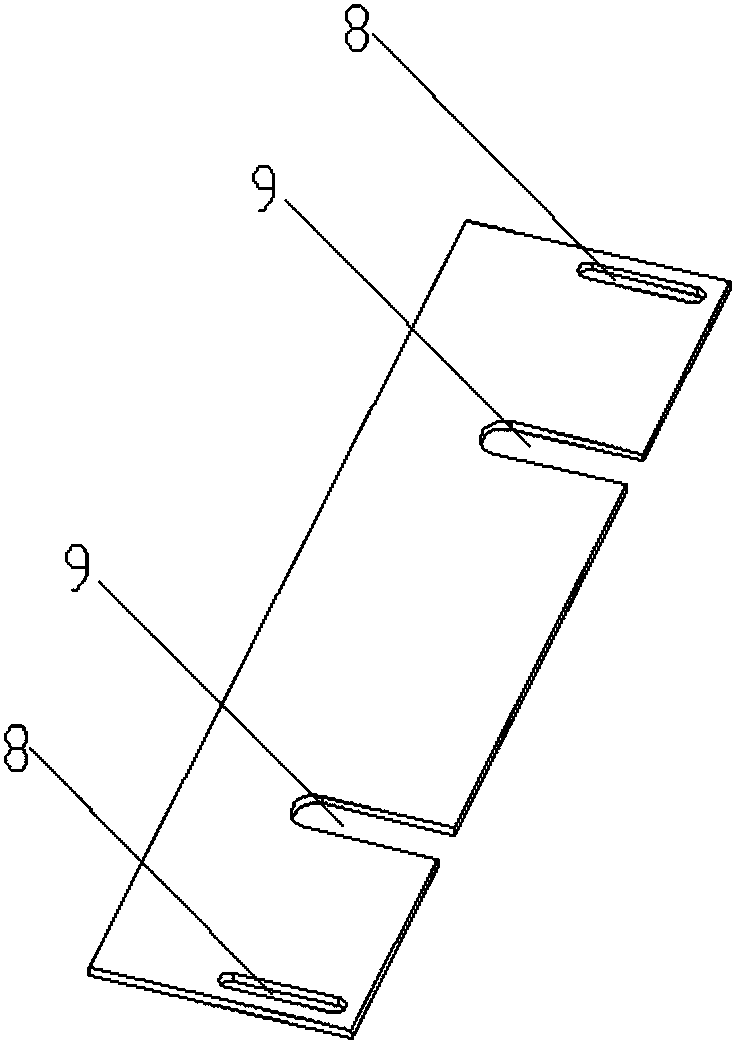

[0017] Such as figure 1 , figure 2 , image 3 As shown, an auxiliary device for cutting and blanking of slender plates includes a support plate 1, a positioning plate 2, and a pressing plate 3. The support plate 1 is provided with a cutting groove 14 with a length of 350 mm and a width of 10 mm. , the support plate 1 near the cutting groove 14 is provided with a positioning plate 2, and the positioning plate 2 is provided with two arc-shaped long holes 8 for adjusting the position of the positioning plate 2, so that by adjusting the positioning plate 2 and the distance from the cutting groove 14, so as to meet the cutting requirements of different plates. The positioning plate 2 is also provided with two U-shaped grooves 9, and the pressure plate 3 is arranged on the positioning plate 2 through the two U-shaped grooves 9. , and adjust the posi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com